Page 1

Model 2000Multimeter

Calibration Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 3 years from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility . Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL O THER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE

REMEDIES PROVIDED HEREIN ARE B UYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OF ITS INSTRUMENTS AND SOFTW ARE EVEN IF KEITHLEY INSTR UMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY .

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.k eithley.com

BELGIUM: Keithley Instruments B.V. Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

CHINA: Keithley Instruments China Y uan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

FRANCE: Keithley Instruments Sarl 3, allée des Garays • 91127 Palaiseau Cedex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Keithley Instruments GmbH Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Keithley Instruments Ltd The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 0118-9 57 56 66 • Fax: 0118-9 59 64 69

INDIA: Keithley Instruments GmbH Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Keithley Instruments s.r.l. Viale S. Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

NETHERLANDS: Keithley Instruments B.V. Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWITZERLAND: Keithley Instruments SA Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: Keithley Instruments Taiwan 1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077• Fax: 886-3572-903

9/00

Page 3

Model 2000 Multimeter

Calibration Manual

©1994, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Third Printing January 2001

Document Number: 2000-905-01 Rev. C

Page 4

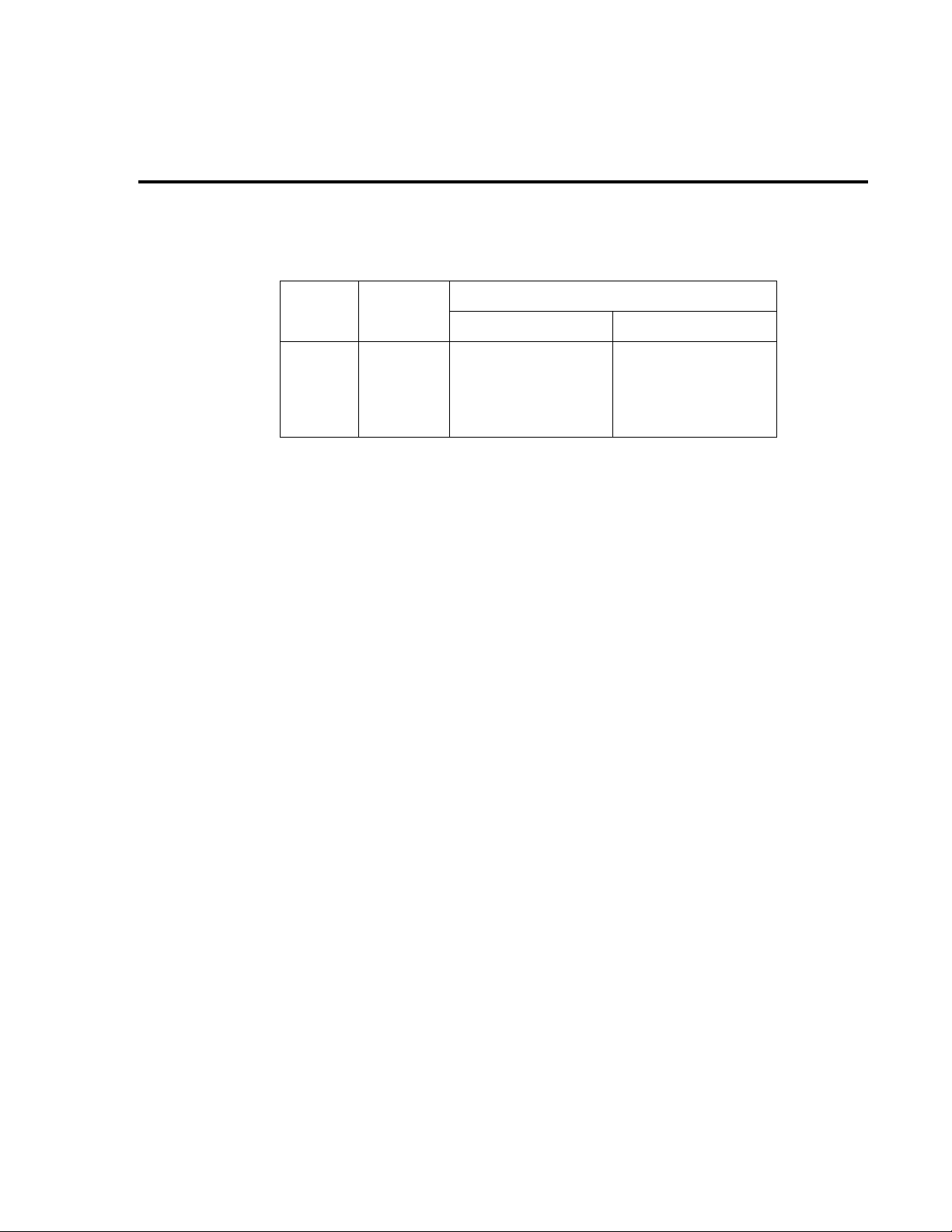

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Le vel letter increases alphabetically as the manual under goes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered

sequentially . When a new Re vision is created, all Addenda associated with the previous Re vision

of the manual are incorporated into the new Revision of the manual. Each ne w Revision includes

a revised copy of this print history page.

Revision A (Document Number 2000-905-01)........................................................November 1994

Addendum A (Document Number 2000-905-02)..............................................................June 1995

Revision B (Document Number 2000-905-01)................................................................. June 2000

Revision C (Document Number 2000-905-01)............................................................ January 2001

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous

voltages, there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read the operating information carefully

before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for

ensuring that the equipment is operated within its specifications and operating limits, and for ensuring

that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures

and proper use of the instrument. They must be protected from electric shock and contact with hazardous

live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating, for example,

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the

manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of prod-

ucts. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable con-

nector jacks or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage lev els greater than 30V RMS, 42.4V peak, or 60VDC are present.

practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Users of this product must be protected from electric shock at all times. The responsible body must ensure that users are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product users in these circumstances must be

trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or

above 1000 volts,

As described in the International Electrotechnical Commission (IEC) Standard IEC 664, digital multimeter measuring circuits (e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are Installation

Category II. All other instruments’ signal terminals are Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with

impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting

sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any

capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching

cards, or making internal changes, such as installing or removing jumpers.

no conductive part of the circuit may be exposed.

A good safety

Page 6

Do not touch any object that could provide a current path to the common side of the circuit under test or power

line (earth) ground. Alw ays make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions

or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications

and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth

ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in

the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to av oid personal contact

with these voltages.

The

WARNING heading in a manual explains dangers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

The

CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the

power transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses,

with applicable national safety approvals, may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as long as they are equivalent to the original

component. (Note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a replacement component,

call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument

only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Rev. 10/99

Page 7

T able of Contents

1

Performance Verification

Introduction..........................................................................................1-2

Verification test requirements ..............................................................1-3

Performing the verification test procedures.........................................1-6

Verifying DC voltage...........................................................................1-7

V erifying A C voltage ...........................................................................1-8

Verifying DC current .........................................................................1-10

V erifying A C current..........................................................................1-11

Verifying resistance ...........................................................................1-12

Calibration

2

Introduction..........................................................................................2-2

Environmental conditions....................................................................2-3

Calibration considerations...................................................................2-4

Calibration code...................................................................................2-5

Comprehensive calibration..................................................................2-6

Front panel calibration.........................................................................2-7

SCPI command calibration................................................................2-14

3

Calibration Command Reference

Introduction..........................................................................................3-2

Command summary.............................................................................3-4

Miscellaneous calibration commands..................................................3-6

DC calibration commands .................................................................3-10

AC calibration commands .................................................................3-16

Manufacturing calibration .................................................................3-18

Bus error reporting.............................................................................3-19

Detecting calibration step completion...............................................3-20

A

Specifications

Accuracy calculations.........................................................................A-7

Optimizing measurement accuracy...................................................A-10

Optimizing measurement speed........................................................A-11

B

Error Messages

Calibration Program

C

Page 8

List of Illustrations

1

Performance Verification

Connections for DC volts verification.................................................1-7

Connections for AC volts verification.................................................1-8

Connections for DC current verification...........................................1-10

Connections for AC current verification............................................1-11

Connections for resistance verification (100 Ω -10M Ω ranges).........1-12

Connections for resistance verification (100M Ω range)...................1-13

Calibration

2

Low-thermal short connections...........................................................2-8

Calibrator connections for DC volts and ohms portion of

comprehensive calibration ..............................................................2-9

Connections for DC and AC amps comprehensive calibration.........2-11

Connections for AC volts calibration................................................2-12

Synthesizer connections for manufacturing calibration....................2-21

Page 9

List of T ables

1

Performance Verification

Recommended verification equipment................................................1-4

DCV reading limits..............................................................................1-7

ACV reading limits..............................................................................1-9

DCI limits ..........................................................................................1-10

ACI limits ..........................................................................................1-11

Limits for resistance verification.......................................................1-13

Calibration

2

Recommended equipment for comprehensive, DC only, or

Comprehensive calibration procedures................................................2-7

DC volts calibration summary...........................................................2-10

Ohms calibration summary................................................................2-10

DC current calibration summary .......................................................2-11

Connections for AC volts calibration.................................................2-12

AC current calibration summary........................................................2-13

DC voltage calibration programming steps.......................................2-16

Resistance calibration programming steps ........................................2-16

DC current calibration programming steps........................................2-17

AC voltage calibration programming steps.......................................2-18

AC current calibration programming steps........................................2-19

Recommended equipment for manufacturing calibration .................2-20

AC only calibration.........................................................................2-6

3

Calibration Command Reference

Calibration command summary...........................................................3-4

DC calibration commands .................................................................3-10

AC calibration commands .................................................................3-16

B

Error Messages

Error summary....................................................................................B-2

Page 10

1

Performance

V erification

Page 11

1-2 Performance Verification

Introduction

Use the procedures in this section to verify that the Model 2000 Multimeter accuracy is within

the limits stated in the instrument’s one-year accuracy specifications. You can perform verification procedures:

W ARNING The information in this section is intended only for qualified service person-

• When you first receiv e the instrument to mak e sure that it w as not damaged during shipment, and that the unit meets factory specifications.

• When a question exists about the instrument’s accuracy.

• Following calibration.

nel. Do not attempt these procedures unless you are qualified to do so.

NOTE

If the instrument is still under warranty and its performance is outside specified limits, contact your Keithle y repr esentative or the factory to determine the corr ect course

of action.

This section includes the following information:

•

Verification test requirements: Explains the test requirements.

•

Performing the verification procedures: Provides general information about the test

procedures.

•

Verifying DC voltage: Provides the procedure to verify that the instrument meets its

DC voltage accuracy specifications.

•

V erifying AC voltage: Provides the procedure to verify AC v oltage measurement accu-

racy.

•

Verifying DC current: Outlines the procedure to test DC current measurement accura-

cy.

•

V erifying AC current: Provides the procedure to verify AC current measurement accu-

racy.

•

Verifying resistance: Provides the procedure to test resistance measurement accuracy.

Page 12

V erification test requirements

Be sure that you perform the verification tests:

• Under the proper environmental conditions.

• After the specified warm-up period.

• Using the correct line voltage.

• Using the proper calibration equipment.

• Using the specified reading limits.

Environmental conditions

Performance Verification 1-3

Conduct your performance verification procedures in a test environment that has:

• An ambient temperature of 18-28°C (65-82°F).

• A relative humidity of less than 80% unless otherwise noted.

Line power

The Model 2000 Multimeter requires a line voltage of 100V/120V/220V/240V, ±10% and a

line frequency of 45Hz to 66Hz, or 360Hz to 440Hz.

W arm-up period

Allow the Model 2000 Multimeter to warm up for at least one hour before conducting the v er-

ification procedures.

If the instrument has been subjected to temperature extremes (those outside the ranges stated

above), allow additional time for the instrument’s internal temperature to stabilize. Typically,

allow one extra hour to stabilize a unit that is 10°C (18°F) outside the specified temperature

range.

Also, allow the test equipment to warm up for the minimum time specified by the manufacturer.

Page 13

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1-4 Performance Verification

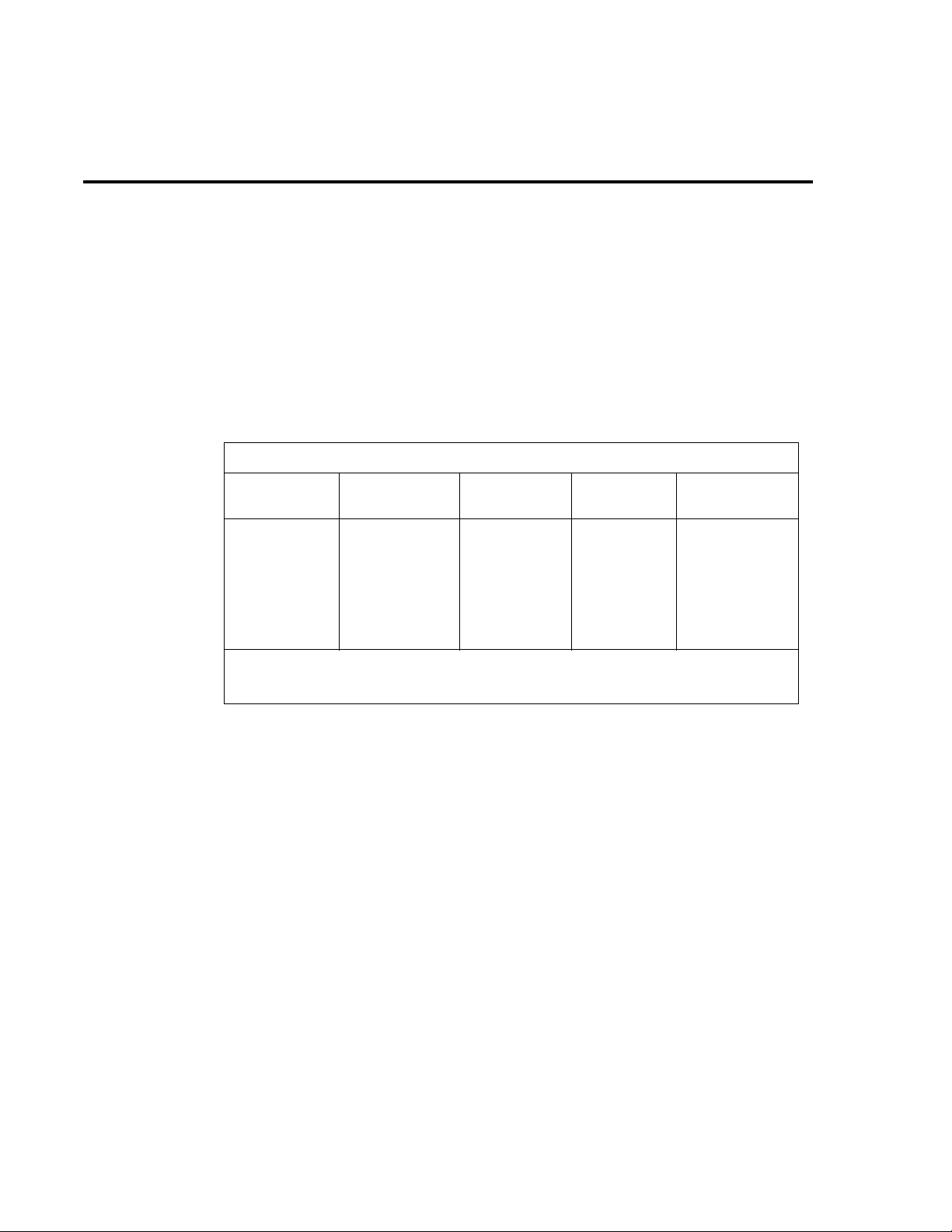

Recommended test equipment

Table 1-1 summarizes recommended verification equipment. Use the Fluke Model 5700A

Calibrator (or the equivalent) to verify Model 2000 Multimeter measurement accuracy.

You can use alternate equipment as long as that equipment has specifications at least as good

as those listed in T able 1-1. K eep in mind, howe ver , that the calibrator will add to the uncertainty

of each measurement. T able 1-1 lists the uncertainties of the recommended Fluk e 5700A at each

source value.

Table 1-1

Recommended verification equipment

Fluke 5700A Calibrator:

DC voltage

100mV: ±14ppm

1.0V: ±7ppm

10V: ±5ppm

100V: ±7ppm

1000V: ±9ppm

Fluke 5725A Amplifier:

AC Voltage, 50kHz: 700V, ±375ppm

*1kHz specifications shown. 5725A amplifier required to source 700V @ 50kHz.

90-day, 23°C ±5°C specifications shown.

NOTE: The Fluke 5725A amplifier is necessary only if you wish to verify the 750V AC range at 50kHz. Verification at 220V, 50kHz using only the 5700A calibrator is adequate for most applications.

AC voltage

(1kHz, 50kHz)*

100mV: ±200ppm

1.0V: ±82ppm

10V: ±82ppm

100V: ±90ppm

700V: ±85ppm

DC current

10mA: ±60ppm

100mA: ±70ppm

1A: ±110ppm

2.2A: ±94ppm

AC current

(1kHz)

1A: ±690ppm

2.2A: ±682ppm

Resistance

100

1k

: ±12ppm

10k

100k

1M

10M

100M

: ±17ppm

: ±11ppm

: ±13ppm

: ±18ppm

: ±37ppm

: ±120ppm

Page 14

×

V erification limits

The verification limits stated in this section have been calculated using only the Model 2000

one-year accuracy specifications, and they do not include test equipment uncertainty. If a particular measurement falls slightly outside the allowable range, recalculate new limits based on

both Model 2000 specifications and pertinent calibration equipment specifications.

Example reading limit calculation

The following is an example of how reading limits have been calculated:

Assume you are testing the 10V DC range using a 10V input value. Using the Model 2000

one-year accuracy specification for 10V DC of ± (30ppm of reading + 5ppm of range), the calculated limits are:

Performance Verification 1-5

Reading limits = 10V ± [(10V

Reading limits = 10V ± (.0003 + .00005)

Reading limits = 10V ± .00035V

Reading limits = 9.99965V to 10.00035V

Restoring factory defaults

Before performing the verification procedures, restore the instrument to its factory defaults

as follows:

1. Press SHIFT and then SETUP. The instrument will display the following prompt:

RESTORE: FACT

NOTE Pressing either range key toggles the RESTORE selection between USER and FACT.

2. Restore the factory default conditions by pressing ENTER.

3. Factory defaults will be set as follows:

Speed: medium

Filter: 10 readings

30ppm) + (10V × 5ppm)]

Page 15

1-6 Performance Verification

Performing the verification test procedures

T est summary

Verification test procedures include:

• DC volts

• AC volts

• DC current

• AC current

• Resistance

If the Model 2000 is not within specifications and not under warranty , see the calibration pro-

cedures in Section 2.

T est considerations

When performing the verification procedures:

• Be sure to restore factory defaults as outlined above.

• Make sure that the equipment is properly warmed up and connected to the front panel

input jacks. Also mak e sure that the front panel input jacks are selected with the INPUTS

switch.

• Do not use autoranging for any v erification tests because autorange hysteresis may cause

the Model 2000 to be on an incorrect range. For each test signal, you must manually set

the correct range for the Model 2000 using the range keys.

• Make sure the calibrator is in operate before you verify each measurement.

• Always let the source signal settle before taking a reading.

• Do not connect test equipment to the Model 2000 through a scanner or other switching

equipment.

W ARNING The maximum common-mode voltage (voltage between INPUT LO and chas-

sis ground is 500 V peak. Exceeding this value may cause a breakdown in

insulation, creating a shock hazard. Some of the procedures in this section

may expose you to dangerous voltages. Use standard safety precautions

when such dangerous voltages are encountered to avoid personal injury

caused by electric shock.

Page 16

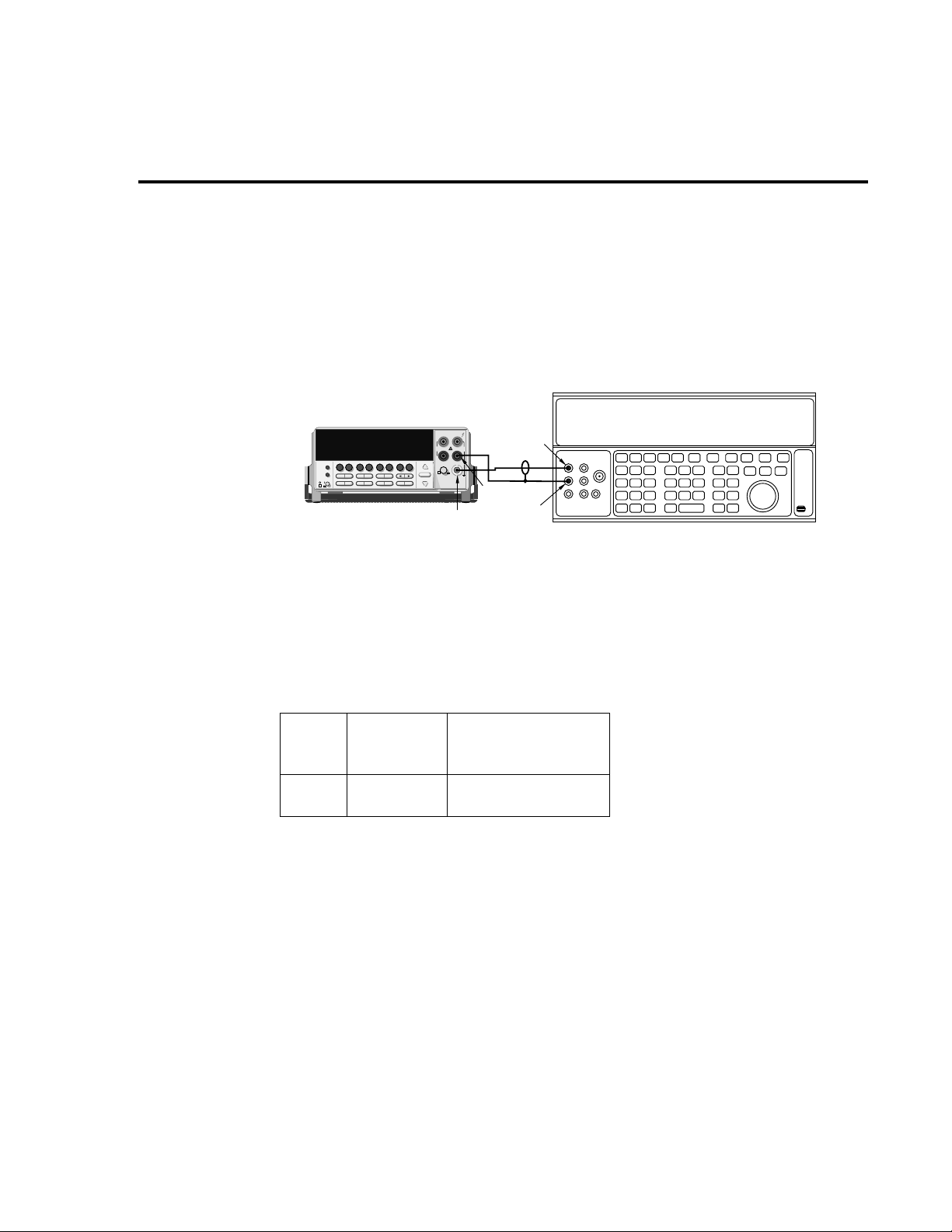

V erifying DC voltage

Check DC voltage accuracy by applying accurate DC v oltages from the calibrator to the Model 2000 INPUT jacks and verifying that the display reads within specified limits. Follow these

steps to verify the DC voltage:

1. Connect the Model 2000 HI and LO INPUT jacks to the DC v oltage calibrator as sho wn

in Figure 1-1.

NOTE Use shielded, low-thermal connections when testing the 100mV and 1V ranges to

avoid errors caused by noise or thermal ef fects. Connect the shield to the calibrator’ s

output LO terminal.

Performance Verification 1-7

Figure 1-1

Connections for

DC volts verification

5700A Calibrator (Output DC Voltage)

Model 2000

2000 MULTIMETER

Input HI

Output HI

!

R

Input

LO

Output

LO

Note : Use shielded, low-thermal cables

for 100mV and 1V ranges.

2. Select the DC volts function by pressing the DCV key, and set the Model 2000 to the

100mV range.

3. Set the calibrator output to 0.00000mV DC, and allow the reading to settle.

4. Enable the Model 2000 REL mode. Leave REL enabled for the remainder of the DC

volts verification tests.

5. Source positive and negative full-scale voltages for each of the ranges listed in Table 1-

2. For each voltage setting, be sure that the reading is within stated limits.

Table 1-2

DCV reading limits

DCV

Range

Applied DC

voltage*

Reading limit

(1 year, 18°C-28°C)

99.9915 to 100.0085mV

0.999963 to 1.000037V

9.99965 to 10.00035V

99.9949 to 100.0051V

999.939 to 1000.061V

1V

100.0000mV

1.000000V

10.00000V

100.0000V

1000.000V

100mV

10V

100V

1000V

* Source positive and negative values for each range.

Page 17

1-8 Performance Verification

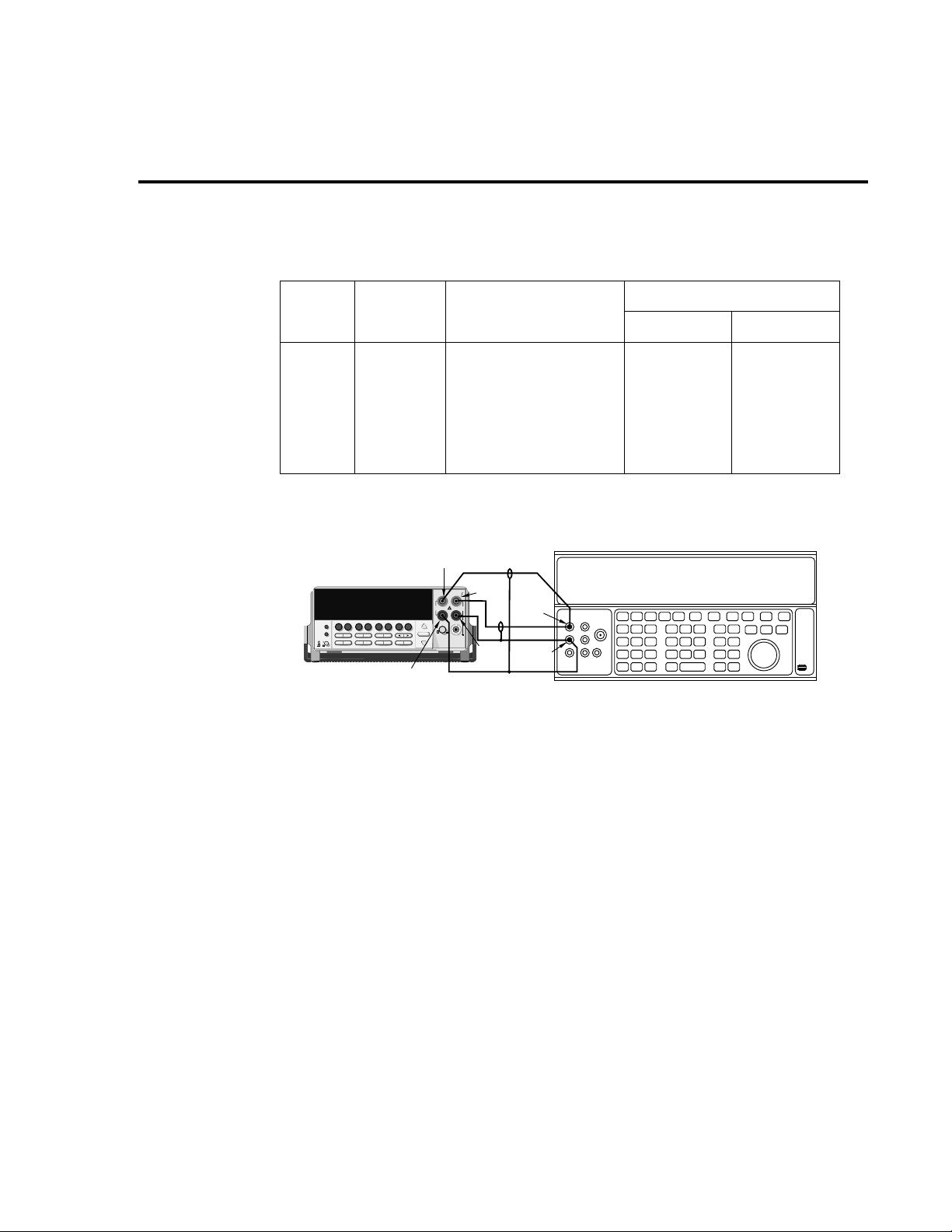

V erifying AC voltage

Check AC voltage accuracy by applying accurate AC voltages at specific frequencies from

the calibrator to the Model 2000 inputs and verifying that the display reads within specified limits.

CAUTION Do not exceed 1000 V peak between INPUT HI and INPUT LO, or 8

V•Hz input, because instrument damage may occur.

Follow these steps to verify AC voltage accuracy:

1. Connect the Model 2000 HI and LO INPUT jacks to the AC voltage calibrator as shown

in Figure 1-2.

7

×

10

Figure 1-2

Connections for

AC volts verification

5725 Amplifier (Connect to calibrator)

Note: Amplifier required only

for 700V, 50kHz output.

Model 2000

2000 MULTIMETER

Input HI

Output HI

!

R

Input

LO

Shielded cable

Output

LO

5700A Calibrator (Output AC Voltage)

2. Select the AC volts function by pressing the ACV key.

3. Set the Model 2000 for the 100mV range; make sure that REL is disabled.

4. Source 1kHz and 50kHz AC voltages for each of the ranges summarized in Table 1-3,

and make sure that the respective Model 2000 readings fall within stated limits.

Page 18

Table 1-3

ACV reading limits

Performance Verification 1-9

ACV

Range

100mV

10V

100V

750V

*If the 5725A amplifier is not available, change the 700V @ 50kHz step to 219V @ 50kHz.

(Reading limits for 219V @ 50kHz = 218.362 to 219.638V.)

1V

Applied AC

voltage

100.0000mV

1.000000V

10.00000V

100.0000V

700.000V*

Reading limits (1 year, 18°C-28°C)

1kHz 50kHz

99.9100 to 100.0900mV

0.999100 to 1.000900V

9.99100 to 10.00900V

99.9100 to 100.0900V

699.355 to 700.645V

99.8300 to 100.1700mV

0.998300 to 1.001700V

9.98300 to 10.01700V

99.8300 to 100.1700V

698.785 to 701.215V

Page 19

1-10 Performance Verification

V erifying DC current

Check DC current accuracy by applying accurate DC currents from the calibrator to the

AMPS input of the Model 2000 and verifying that the display reads within specified limits. Follow these steps to verify DC current accuracy:

1. Connect the Model 2000 AMPS and INPUT LO jacks to the calibrator as shown in Figure 1-3.

2. Select the DC current measurement function by pressing the DCI key.

3. Set the Model 2000 for the 10mA range.

4. Source positive and negative full-scale currents for each of the ranges listed in Table 14, and verify that the readings for each range are within stated limits.

Figure 1-3

Connections for

DC current verification

Model 2000

2000 MULTIMETER

Input

LO

!

R

Output HI

Amps

Output

LO

Table 1-4

DCI limits

DCI

Range

10mA

100mA

* Source positive and negative currents with values shown.

1A

3A

Applied DC

current*

10.0000mA

100.0000mA

1.000000A

2.20000A

Reading limits

(1 year, 18°C-28°C)

9.99460 to 10.00540mA

99.9100 to 100.0900mA

0.999160 to 1.000840A

2.19732 to 2.20268A

5700A Calibrator (Output DC Current)

Note: Be sure calibrator is set for

normal current output.

Page 20

V erifying AC current

Check A C current accurac y by applying accurate AC current at specific frequencies from the

calibrator to the Model 2000 input and verifying that the display reads within specified limits.

Follow these steps to verify the AC current:

1. Connect the Model 2000 AMPS and INPUT LO jacks to the calibrator as shown in Figure 1-4.

Figure 1-4

Connections for

AC current verification

Model 2000

Performance Verification 1-11

Output HI

!

2000

MULTIMETER

R

Input

LO

Amps

Output

LO

5700A Calibrator (Output AC Current)

2. Select the AC current function by pressing the ACI key.

3. Set the Model 2000 for the 1A range.

4. Source 1A and 2.2A, 1kHz AC currents as summarized in T able 1-5, and verify that the

readings are within stated limits.

Table 1-5

ACI limits

ACI

Range

1A

3A

Applied AC

current

1.000000A

2.20000A

Reading limits

(1 year, 18°C-28°C)

1kHz

0.998600 to 1.001400A

2.19490 to 2.20510A

Page 21

1-12 Performance Verification

V erifying resistance

Check resistance by connecting accurate resistance values from the calibrator to the Model

2000 and verifying that its resistance readings are within the specified limits.

Follow these steps to verify resistance accuracy:

1. Using shielded 4-wire connections, connect the Model 2000 INPUT and SENSE jacks

to the calibrator as shown in Figure 1-5.

2. Set the calibrator for 4-wire resistance with external sense on.

3. Select the Model 2000 4-wire resistance function by pressing the

4. Set the Model 2000 for the 100

5. Recalculate the limits in Table 1-6 based on actual calibrator resistance values.

6. Source the nominal full-scale resistance values for 100

Table 1-6, and verify that the readings are within stated limits.

4 key.

range, and make sure the FILTER is on.

-10M Ω ranges summarized in

Ω

Ω

Ω

Ω

Ω

Ω

Figure 1-5

Connections for

resistance verification (100

10M

Ω

ranges)

Ω

-

5700A Calibrator

Sense LO

Model 2000

2000

Sense LO

Sense HI

MULTIMETER

!

R

Sense HI

Input

HI

Output

HI

InputLOOutput

LO

Note : Use shielded low-thermal cables to

minimize noise. Enable or disable

calibrator external sense as indicated

in procedure.

7. Connect the Model 2000 INPUT and SENSE jacks to the calibrator as shown in Figure

1-6.

8. Disable external sense on the calibrator.

9. Set the Model 2000 to the 100M

10. Source a nominal 100M

the 100M

range listed in Table 1-6.

resistance value, and verify the reading is within the limits for

range.

Page 22

Table 1-6

Limits for resistance verification

Ω

1k Ω

Performance Verification 1-13

1M Ω

1k Ω

1M Ω

Figure 1-6

Connections for

resistance verification (100M

Ω

range)

Range

100 Ω

10k Ω

100k Ω

10M Ω

100M Ω

Nominal

applied

resistance

100 Ω

10k Ω

100k Ω

10M Ω

100M Ω

Model 2000

Sense LO

Sense HI

2000

MULTIMETER

Nominal reading limits

(1 year, 18°C-28°C)

99.9860 to 100.0140Ω

0.999890 to 1.000110kΩ

9.99890 to 10.00110kΩ

99.9890 to 100.0110kΩ

0.999890 to 1.000110MΩ

9.99590 to 10.00410MΩ

99.8470 to 100.1530MΩ

5700A Calibrator (Output 2-wire Resistance)

Input

HI

!

R

Output

HI

InputLOOutput

LO

Note : Use shielded cables to minimize noise.

Disable calibrator external sense mode.

Recalculated limits

Low limit High limit

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

Page 23

2

Calibration

Page 24

2-2 Calibration

Introduction

Use the procedures in this section to calibrate the Model 2000. Calibration procedures in-

clude:

•

Comprehensive calibration: Calibrate DC and AC voltages, DC and AC currents, and

resistance values.

•

Manufacturing calibration: Usually only performed at the factory.

W ARNING This information in this section is intended only for qualified service person-

nel. Do not attempt these procedures unless you are qualified to do so.

All the procedures require accurate calibration equipment to supply precise DC and AC voltages, DC and A C currents, and resistance v alues. Comprehensiv e A C and DC calibration can be

performed any time by a technician either from the front panel, or by using the SCPI commands

sent either over the IEEE-488 bus or the RS-232 link.

NOTE Manufacturing calibration is required in the field only if the Model 2000 has been re-

paired.

This section includes the following information:

Environmental conditions: Explains the type of environment needed for calibration.

Calibration considerations: Summarizes test conditions to observe when performing cali-

bration.

Calibration code: Explains how to enter the calibration code to unlock Model 2000 calibra-

tion.

Comprehensive calibration: Summarizes the calibration cycle and also lists recommended

comprehensive calibration equipment.

Front panel calibration: Provides the calibration procedures using the front panel.

SCPI command calibration: Provides the detailed procedures for calibrating the Model

2000 using SCPI commands.

Manufacturing calibration: Explains the manufacturing calibration procedure using both

the front panel and SCPI commands.

Page 25

Environmental conditions

Conduct the calibration procedures in a location that has:

• An ambient temperature of 23°C ±5°C

• A relative humidity of less than 80% unless otherwise noted

W arm-up period

Allow the Model 2000 Multimeter to warm up for at least one hour before performing cali-

bration.

If the instrument has been subjected to temperature extremes (those outside the ranges stated

in the above section) allow e xtra time for the instrument’ s internal temperature to stabilize. Typically, allow one extra hour to stabilize a unit that is 10°C (18°F) outside the specified temperature range.

Calibration 2-3

Also, allow the test equipment to warm up for the minimum time specified by the manufacturer.

Line power

The Model 2000 Multimeter requires a line voltage of 100V/120V/220V/240V, ±10% and a

line frequency of 45Hz to 66Hz or 360Hz to 440Hz.

Page 26

2-4 Calibration

Calibration considerations

When performing the calibration procedures:

• Make sure that the equipment is properly warmed up and connected to the appropriate

input jacks. Also make sure that the correct input jacks are selected with the INPUTS

switch.

• Make sure the calibrator is in operate before you complete each calibration step.

• Always let the source signal settle before calibrating each point.

• Do not connect test equipment to the Model 2000 through a scanner or other switching

equipment.

• If an error occurs during calibration, the Model 2000 will generate an appropriate error

message. See Section 3 and Appendix B for more information.

W ARNING The maximum common-mode voltage (voltage between INPUT LO and chas-

sis ground) is 500 V peak. Exceeding this value may cause a breakdown in

insulation, creating a shock hazard. Some of the procedures in this section

may expose you to dangerous voltages. Use standard safety precautions

when such dangerous voltages are encountered to avoid personal injury

caused by electric shock.

Page 27

Calibration code

Comprehensive calibration code

Before performing comprehensive (user) calibration, you must first unlock calibration by en-

tering the appropriate calibration code.

Front panel calibration code

For front panel calibration, follow these steps:

1. Access the calibration menu by pressing SHIFT then CAL, and note that the instrument

displays the following:

CAL: DATES

2. Use the up or do wn range keys to scroll through the av ailable calibration parameters until

the unit displays RUN, then press ENTER.

3. The Model 2000 then prompts you to enter a code. (The f actory default code is 002000.)

Use the left and right arrow keys to move among the digits; use the up range key to increment numbers, and press the down range key to specify alphabetic letters. Confirm

the code by pressing ENTER.

4. The Model 2000 allo ws you to define a new calibration code. Use the up and do wn range

keys to toggle between yes and no. Choose N if you do not want to change the code.

Choose Y if you want to change the code. The unit then prompts you to enter a ne w code.

Enter the code, and press ENTER.

Calibration 2-5

Programming the calibration code

If you are performing calibration over the IEEE-488 bus or the RS-232 link, send this com-

mand to unlock the calibration lock:

:CAL:PROT:CODE <up to 8-character string>

The default code command is:

:CAL:PROT:CODE 'KI002000'

Manufacturing calibration lock

T o unlock manufacturing calibration, press and hold the front panel OPEN k ey while turning

on the power. See Manufacturing calibration at the end of this section for procedures.

Page 28

2-6 Calibration

Comprehensive calibration

The comprehensive calibration procedure calibrates the DCV, DCI, ACV, ACI, and ohms

functions You can also choose to calibrate only DCV/DCI and resistance, or the A CV/A CI functions.

These procedures are usually the only ones required in the field. Manufacturing calibration is

done at the factory and should be done if the unit has been repaired in the field. See the Manufacturing calibration paragraph at the end of this section for more information.

Calibration cycle

Perform comprehensive calibration at least once a year, or every 90 days to ensure the unit

meets the corresponding specifications.

Recommended equipment

Table 2-1 lists the recommended equipment you need for comprehensive, DC only, and AC

only calibration procedures. You can use alternate equipment, such as a DC transfer standard

and characterized resistors, as long that equipment has specifications at least as good as those

listed in the table.

Table 2-1

Recommended equipment for comprehensive, DC only, or AC only calibration

Fluke 5700A Calibrator

DC voltage

10V: ±5ppm

100V: ±7ppm

Keithley 8610 Low-thermal shorting plug

*1kHz specifications. 10mV and 700V points require 1kHz only.

All calibration specifications are 90-day, 23° ±5°C specifications.

AC voltage

(1kHz, 50kHz)*

10mV: ±710ppm

100mV: ±200ppm

1.0V: ±82ppm

10V: ±82ppm

100V: ±90ppm

700V: ±85ppm

DC current

10mA: ±60ppm

100mA: ±70ppm

1A: ±110ppm

AC current

(1kHz)

100mA: ±190ppm

1A: ±690ppm

2A: ±670ppm

Resistance

1k

Ω : ±12ppm

10k

Ω : ±11ppm

100k

Ω : ±13ppm

1M

Ω : ±18ppm

Canceling calibration

You can cancel the calibration process at any time by pressing EXIT.

Page 29

Front panel calibration

Follow the steps in the following paragraphs for comprehensive, DC only, and AC only cali-

bration procedures.

The procedures for front panel calibration include:

• Preparing the Model 2000 for calibration

• Front panel short and open calibration

• DC voltage calibration

• Resistance calibration

• DC current calibration

• AC voltage calibration

• AC current calibration

• Setting calibration dates

Calibration 2-7

Preparing the Model 2000 for calibration

1. T urn on the Model 2000, and allo w it to warm up for at least one hour before performing

the calibration procedure.

2. Select the DCV function and choose SLOW as the RATE (integration time = 10 PLC).

3. Start the calibration process as follows:

A. Access the calibration menu by pressing SHIFT then CAL.

B. Use the up and down range keys to scroll through the available calibration menu

items until the unit displays RUN, then press ENTER.

C. At the prompt, enter the calibration code. (The default code is 002000.) Use the left

and right arrow keys to move among the digits; use the up range key to increment

numbers, and press the down range key to specify alphabetic letters. Confirm the

code by pressing ENTER.

D. Choose N at the prompt to proceed without changing the code, then press ENTER.

4. Choose which of the the calibration tests summarized in T able 2-2 you w ant to run at the

CAL: RUN prompt. Use the up and do wn range keys to scroll through the options; select

your choice by pressing ENTER.

Table 2-2

Comprehensive calibration procedures

Procedure Menu choice Procedures

Full calibration

DCV, DCI, and ohms

ACV and ACI

ALL

DC

AC

All comprehensive calibration steps.

DC voltage, DC current, and resistance calibration.

AC voltage and AC current calibration.

Page 30

2-8 Calibration

Front panel short and open calibration

Figure 2-1

Low-thermal

short connections

At the Model 2000 prompt for a front panel short, do the following:

1. Connect the Model 8610 low-thermal short to the instrument front panel INPUT and

SENSE terminals as shown in Figure 2-1. Make sure the INPUTS b utton is not pressed

in so that the front inputs are selected. Wait at least three minutes before proceeding to

allow for thermal equilibrium.

NOTE Be sure to connect the low-thermal short properly to the HI, LO, and SENSE termi-

nals. Keep drafts away from low-thermal connections to avoid thermal drift, which

could affect calibration accuracy.

Model 2000

S+ HI

2000 MULTIMETER

!

R

Model 8610

Low-thermal

short

LOS-

2. Press ENTER to start short-circuit calibration. While the unit is calibrating, the unit will

display:

CALIBRATING

3. When the unit is done calibrating, it will display the following prompt:

OPEN CIRCUIT

4. Remove the calibration short, and press ENTER. During this phase, the CALIBRATING message will be displayed.

Page 31

DC voltage calibration

After the front panel short and open procedure, the unit will prompt you for the first DC volt-

age: +10V. Do the following:

1. Connect the calibrator to the Model 2000 as sho wn in Figure 2-2. Wait three minutes to

allow for thermal equilibrium before proceeding.

NOTE Although 4-wire connections are shown, the sense leads are connected and discon-

nected at various points in this procedure by turning calibrator external sense on or

off as appropriate. If your calibrator does not have provisions for turning external

sense on and off, disconnect the sense leads when external sensing is to be turned of f ,

and connect the sense leads when external sensing is to be turned on.

Calibration 2-9

Figure 2-2

Calibrator connections for DC

volts and ohms

portion of comprehensive calibration

5700A Calibrator

Sense LO

Model 2000

2000 MULTIMETER

Sense LO

Sense HI

!

R

Sense HI

Input

HI

Output

HI

InputLOOutput

LO

Note : Use shielded low-thermal cables to

minimize noise. Enable or disable

calibrator external sense as indicated

in procedure.

2. Set the calibrator to output DC volts, and turn external sense off.

3. Perform the steps listed in Table 2-3 to complete DC volts calibration. For each calibration step:

• Set the calibrator to the indicated value, and make sure it is in operate.

• Press the ENTER key to calibrate that step.

• Wait until the Model 2000 finishes each step. (The unit will display the CALIBRAT-

ING message while calibrating.)

Page 32

2-10 Calibration

NOTE If your calibrator cannot output the values recommended in T able 2-3, use the left and

right arrow ke ys, and the up and down rang e keys to set the Model 2000 display value

to match the calibrator output voltage.

Table 2-3

DC volts calibration summary

Calibration step

+10V

-10V

100V

Resistance calibration

Completing the 100V DC calibration step ends the DC voltage calibration procedure. The

Model 2000 will then prompt you to connect 1 k

1. Set the calibrator output for resistance, and turn on external sense.

NOTE Use external sense (4-wire

the calibrator external sense mode is turned on.

2. Perform the calibration steps summarized in Table 2-4. For each step:

• Set the calibrator to the indicated value, and place the unit in operate. (If the calibrator

cannot output the exact resistance value, use the Model 2000 left and right arro w ke ys

and the range keys to adjust the Model 2000 display to agree with the calibrator resistance.)

• Press the ENTER key to calibrate each point.

• Wait for the Model 2000 to complete each step before continuing.

Calibrator

voltage

+10.00000V

-10.00000V

+100.0000V

Allowable range

+9V to +11V

-9V to -11V

+90V to +110V

Ω . Follow these steps for resistance calibration:

Ω

) when calibrating all resistance ranges. Be sure that

Table 2-4

Ohms calibration summary

Calibration step

1k Ω

10k Ω

100k Ω

1M Ω

* Nominal resistance. Adjust Model 2000 calibration parameter to

agree with actual value.

Calibrator

resistance*

1k Ω

10k Ω

100k Ω

1M Ω

Allowable range

0.9k Ω to 1.1k Ω

9k Ω to 11k Ω

90k Ω to 110k Ω

0.9M Ω to 1.1M Ω

Page 33

DC current calibration

After the 1M Ω resistance point has been calibrated, the unit will prompt you for 10mA. Fol-

low these steps for DC current calibration:

1. Connect the calibrator to the AMPS and INPUT LO terminals of the Model 2000 as

shown in Figure 2-3.

Calibration 2-11

Figure 2-3

Connections for

DC and AC amps

comprehensive

calibration

5700A Calibrator

Model 2000

2000 MULTIMETER

Input

LO

Output HI

!

R

Amps

Output

LO

Note: Be sure calibrator is set for

normal current output.

2. Calibrate each current step summarized in Table 2-5. For each step:

• Set the calibrator to the indicated DC current, and make sure the unit is in operate.

• Make sure the Model 2000 display indicates the correct calibration current.

• Press ENTER to complete each step.

• Allow the Model 2000 to finish each step.

NOTE If you are performing DC-only calibrator, proceed to the “Setting calibr ation dates”

paragraph.

Table 2-5

DC current calibration summary

Calibration step

Calibrator

current

Allowable range

10mA

100mA

1A

10.00000mA

100.0000mA

1.00000A

9mA to 11mA

90mA to 110mA

0.9A to 1.1A

Page 34

2-12 Calibration

AC voltage calibration

Figure 2-4

Connections for

AC volts calibration

Follow these steps for AC voltage calibration:

1. Connect the calibrator to the Model 2000 INPUT HI and LO terminals as shown in Figure 2-4.

5700A Calibrator

Model 2000

2000 MULTIMETER

Input HI

Output HI

!

R

Input LO

Output LO

2. Perform the calibration steps summarized in Table 2-6. For each step:

• Set the calibrator to the indicated value, and make sure the calibrator is in operate.

• Press ENTER to complete each step.

• Wait until the Model 2000 completes each step.

Table 2-6

AC voltage calibration summary

Calibration step Calibrator voltage, frequency

10mV AC at 1kHz

100mV AC at 1kHz

100mV AC at 50kHz

1V AC at 1kHz

1V AC at 50kHz

10V AC at 1kHz

10V AC at 50kHz

100V AC at 1kHz

100V AC at 50kHz

700V AC at 1kHz

10.00000mV, 1kHz

100.0000mV, 1kHz

100.0000mV, 50kHz

1.000000V, 1kHz

1.000000V, 50kHz

10.00000V, 1kHz

10.00000V, 50kHz

100.0000V, 1kHz

100.0000V, 50kHz

700.000V, 1kHz

Page 35

AC current calibration

After the 700VAC at 1kHz point has been calibrated, the unit will prompt you for 100mA at

1kHz. Follow these steps for AC current calibration:

1. Connect the calibrator to the AMPS and INPUT LO terminals of the Model 2000 as

shown in Figure 2-3.

2. Perform the calibration steps summarized in Table 2-7. For each step:

• Set the calibrator to the indicated current and frequency, and make sure the unit is in

operate.

• Press ENTER to complete each calibration step.

• Allow the unit to complete each step before continuing.

Table 2-7

AC current calibration summary

Calibration 2-13

Calibration step Calibrator voltage, frequency

100mA at 1kHz

1A at 1kHz

2A at 1kHz

Setting calibration dates

At the end of the calibration procedure, the instrument will display the CALIBRATION

COMPLETE message. Press ENTER to continue, and the the Model 2000 will prompt you to

enter the calibration date and the calibration due date. Set these dates as follows:

1. At the CAL DATE: mm/dd/yy prompt, use the left and right arrow keys, and the range

keys to set the calibration date, then press ENTER.

2. The unit will then prompt you to enter the next calibration due date with this prompt:

CAL NDUE: mm/dd/yy . Use the left and right arrow keys, and the range ke ys to set the

calibration due date, then press ENTER.

3. The unit will prompt you to save new calibration constants with this message: SAVE

CAL? YES. To save the new constants, press ENTER. If you do not want to save the

new constants, press the down range key to toggle to NO, then press ENTER.

NOTE Calibration constants calculated during the curr ent calibration pr ocedur e will not be

saved unless you choose the YES option. Previous calibration constants will be retained if you select NO.

100.0000mA, 1kHz

1.000000A, 1kHz

2.000000A, 1kHz

Page 36

2-14 Calibration

SCPI command calibration

Follow the steps in this section to use SCPI commands to perform comprehensive, DC only,

and A C only calibration procedures. See Section 3 for a detailed list and description of SCPI calibration commands.

When sending calibration commands, be sure that the Model 2000 completes each step before

sending the next command. You can do so either by observing the front panel CALIBRATING

message, or by Detecting the completion of each step over the b us. (See “Detecting calibration

step completion” at the end of Section 3.)

The procedures for calibrating the Model 2000 using SCPI commands include:

• Preparing the Model 2000 for calibration

• Front panel short and open calibration

• DC voltage calibration

• Resistance calibration

• DC current calibration

• AC voltage calibration

• AC current calibration

• Programming calibration dates

• Saving calibration constants

• Locking out calibration

NOTE As with front panel calibration, you can choose to perform complete, DC-only , or A C-

only calibration. When sending calibration commands, be sure to include a space

character between each command and parameter.

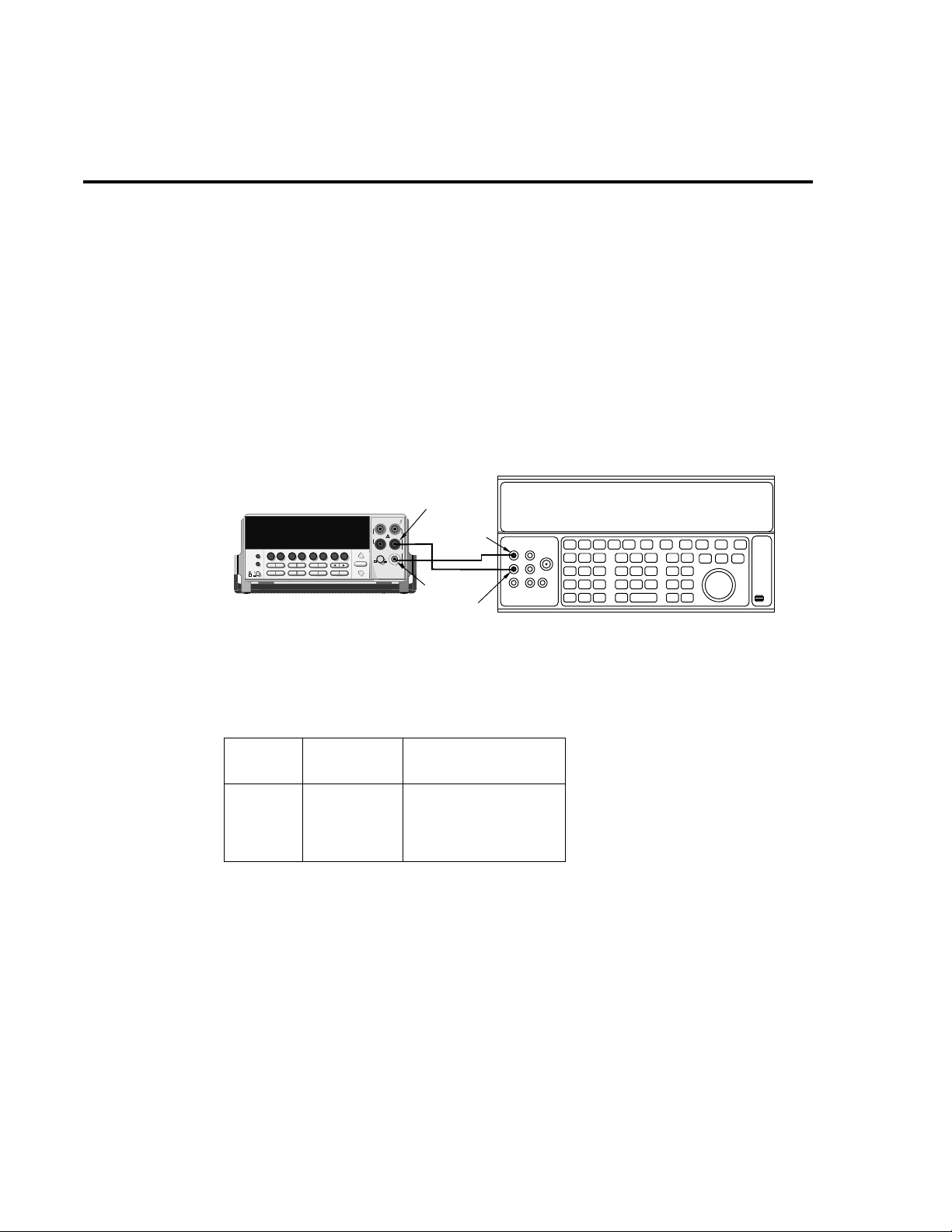

Preparing the Model 2000 for calibration

1. Connect the Model 2000 to the IEEE-488 bus of the computer using a shielded IEEE488 cable, such as the Keithley Model 7007, or connect the unit to a computer through

an RS-232 port using a straight-through 9-pin to 9-pin cable (use a 9-25-pin adapter if

necessary).

2. T urn on the Model 2000, and allow it to warm up for an hour before performing calibration.

3. Select the DCV function and choose SLOW as the RATE (integration time = 10 PLC).

4. Make sure the primary address of the Model 2000 is the same as the address specifi ed in

the program that you will be using to send commands. (Use the GPIB key.)

5. Unlock the calibration function by sending this command:

:CAL:PROT:CODE 'KI002000'

(The above command shows the default code, KI002000. Substitute the correct code if

changed.)

6. Send the following command to initiate calibration:

:CAL:PROT:INIT

Page 37

Front panel short and open calibration

1. Connect the Model 8610 lo w-thermal short to the instrument INPUT and SENSE terminals as shown in Figure 2-1. Make sure the INPUTS b utton is not pressed in so that the

front inputs are active. W ait at least three minutes before proceeding to allo w for thermal

equilibrium.

NOTE Be sure to connect the low-thermal short properly to the HI, LO, and SENSE termi-

nals. Keep drafts away from low-thermal connections to avoid thermal drift, which

could affect calibration accuracy.

2. Send the following command:

:CAL:PROT:DC:STEP1

3. After the Model 2000 completes this step, remove the short, and send this command:

:CAL:PROT:DC:STEP2

DC voltage calibration

After front panel short and open steps, do the following:

1. Connect the calibrator to the Model 2000 as shown in Figure 2-2. Allow three minutes

for thermal equilibrium.

Calibration 2-15

NOTE Although 4-wire connections are shown, the sense leads are connected and discon-

nected at various points in this procedure by turning calibrator external sense on or

off as appropriate. If your calibrator does not have provisions for turning external

sense on and off, disconnect the sense leads when external sensing is to be turned of f ,

and connect the sense leads when external sensing is to be turned on.

2. Perform the calibration steps summarized in Table 2-8. For each step:

• Set the calibrator to the indicated voltage, and make sure the unit is in operate. (Use

the recommended voltage if possible.)

• Send the indicated programming command.

• Wait until the Model 2000 completes each step before continuing.

Page 38

2-16 Calibration

Table 2-8

DC voltage calibration programming steps

Calibration

step

+10V

-10V

100V

* Change parameter accordingly if using a different calibrator voltage.

Calibrator

voltage

+10.00000V

-10.00000V

100.0000V

Resistance calibration

Follow these steps for resistance calibration:

1. Set the calibrator to the resistance mode, and turn on external sensing.

NOTE Use external sense (4-wire

the calibrator external sense mode is turned on.

2. Perform the calibration steps summarized in Table 2-9. For each step:

• Set the calibrator to the indicated resistance, and make sure the unit is in operate. (Use

the recommended resistance or the closest available value.)

• Send the indicated programming command. (Change the command parameter if you

are using a different calibration resistance than that shown.)

• Wait until the Model 2000 completes each step before continuing.

Table 2-9

Resistance calibration programming steps

Calibration command*

:CAL:PROT:DC:STEP3 10

:CAL:PROT:DC:STEP4 -10

:CAL:PROT:DC:STEP5 100

Ω

) when calibrating all resistance ranges. Be sure that

Parameter

range

9 to 11

-9 to -11

90 to 110

Calibration

step

1kΩ

10kΩ

100kΩ

1MΩ

* Use exact calibrator resistance value for parameter.

Calibrator

resistance

1kΩ

10kΩ

100kΩ

1MΩ

Calibration command*

:CAL:PROT:DC:STEP6 1E3

:CAL:PROT:DC:STEP7 10E3

:CAL:PROT:DC:STEP8 100E3

:CAL:PROT:DC:STEP9 1E6

Parameter

range

900 to 1.1E3

9E3 to 11E3

90E3 to 110E3

900E3 to 1.1E6

Page 39

DC current calibration

After the 1MΩ resistance point has been calibrated, follow these steps for DC current cali-

bration:

1. Connect the calibrator to the AMPS and INPUT LO terminals of the Model 2000 as

shown in Figure 2-3.

2. Perform the calibration steps listed in Table 2-10. For each step:

• Set the calibrator to the indicated current, and make sure the unit is in operate. (Use

the recommended current if possible.)

• Send the indicated programming command. (Change the current parameter if you are

using a different calibration current.)

• Wait until the Model 2000 completes each step before continuing.

NOTE If you are performing DC-only calibration, proceed to the “Pr ogr amming calibration

dates” paragraph.

Table 2-10

DC current calibration programming steps

Calibration 2-17

Calibration

step

10mA

100mA

1A

* Change parameter if using a different current.

Calibrator

current

10.00000mA

100.00000mA

1.000000A

Calibration command*

:CAL:PROT:DC:STEP10 10E-3

:CAL:PROT:DC:STEP11 100E-3

:CAL:PROT:DC:STEP12 1

Parameter

range

9E-3 to 11E-3

90E-3 to 110E-3

0.9 to 1.1

Page 40

2-18 Calibration

AC voltage calibration

Follow these steps for AC voltage calibration:

1. Connect the calibrator to the Model 2000 INPUT HI and LO terminals as shown in Figure 2-4.

2. Perform the calibration steps summarized in Table 2-11. For each step:

• Set the calibrator to the indicated voltage and frequency, and make sure the unit is in

operate. (You must use the stated voltage and frequency.)

• Send the indicated programming command.

• Wait until the Model 2000 completes each step before continuing.

Table 2-11

AC voltage calibration programming steps

Calibration step

10mV AC at 1kHz

100mV AC at 1kHz

100mV AC at 50kHz

1VAC at 1kHz

1VAC at 50kHz

10VAC at 1kHz

10VAC at 50kHz

100VAC at 1kHz

100VAC at 50kHz

700VAC at 1kHz

AC current calibration

Follow these steps for AC current calibration:

1. Connect the calibrator to the AMPS and INPUT LO terminals of the Model 2000 as

shown in Figure 2-3.

2. Perform the calibration steps summarized in Table 2-12. For each step:

• Set the calibrator to the indicated current and frequency, and make sure the unit is in

operate. (You must use the stated current and frequency.)

• Send the indicated programming command.

• Wait until the Model 2000 completes each step before continuing.

Calibrator voltage,

frequency

10.00000mV, 1kHz

100.0000mV, 1kHz

100.0000mV, 50kHz

1.000000V, 1kHz

1.000000V, 50kHz

10.00000V, 1kHz

10.00000V, 50kHz

100.0000V, 1kHz

100.0000V, 50kHz

700.000V, 1kHz

Calibration command

:CAL:PROT:AC:STEP1

:CAL:PROT:AC:STEP2

:CAL:PROT:AC:STEP3

:CAL:PROT:AC:STEP4

:CAL:PROT:AC:STEP5

:CAL:PROT:AC:STEP6

:CAL:PROT:AC:STEP7

:CAL:PROT:AC:STEP8

:CAL:PROT:AC:STEP9

:CAL:PROT:AC:STEP10

Page 41

Table 2-12

AC current calibration programming steps

Calibration 2-19

Calibration step

100mA at 1kHz

1A at 1kHz

2A at 1kHz

Calibrator current,

frequency

100.0000mA, 1kHz

1.000000A, 1kHz

2.000000A, 1kHz

Programming calibration dates

Program the present calibration date and calibration due date by sending the following com-

mands:

:CAL:PROT:DATE <year>, <month>, <day>

:CAL:PROT:NDUE <year>, <month>, <day>

For example, the following commands assume calibration dates of 12/15/95 and 3/14/96 re-

spectively:

:CAL:PROT:DATE 1995, 12, 15

:CAL:PROT:NDUE 1996, 3, 14

Saving calibration constants

After completing the entire calibration procedure, send the following command to save the

new calibration constants:

Calibration command

:CAL:PROT:AC:STEP11

:CAL:PROT:AC:STEP12

:CAL:PROT:AC:STEP13

:CAL:PROT:SAVE

NOTE Calibration constants will not be saved unless the :SAVE command is sent.

Locking out calibration

After saving calibration, send the following command to lock out calibration:

:CAL:PROT:LOCK

Page 42

2-20 Calibration

Manufacturing calibration

The manufacturing procedure is normally performed only at the factory, but the necessary

steps are included here in case the unit is repaired, and the unit requires these calibration procedures.

NOTE If the unit has been repaired, the entire comprehensive calibration procedure should

also be performed in addition to the manufacturing calibration procedure.

Recommended test equipment

T able 2-13 summarizes the test equipment required for the manufacuring calibration steps. In

addition, you will need the Fluke 5700A Calibrator (see Table 2-1) to complete the comprehensive calibration steps.

Table 2-13

Recommended equipment for manufacturing calibration

Keithley 3930A or 3940 Frequency Synthesizer:

1V RMS, 3Hz: ±5ppm

1V RMS, 1kHz: ±5ppm

Keithley Model 2001 or 2002 DMM:

1V, 3Hz AC, ±0.13%

Keithley Model 8610 Low-thermal shorting plug

Unlocking manufacturing calibration

To unlock manufacturing calibration, press and hold in the OPEN key while turning on the

power.

Measuring the synthesizer voltage

The 3Hz synthesizer signal amplitude must be accurately measured using the digital multimeter listed in Table 2-13. Proceed as follows:

1. Connect the synthesizer output to the digital multimeter input jacks (see Figure 2-5).

2. Turn on the synthesizer and multimeter, and allow a one-hour warm-up period before

measuring.

3. Set the synthesizer to output a 1V RMS sine wa ve at 3Hz; measure and record the signal

amplitude.

Page 43

Front panel calibration

1. Connect the low-thermal short to the rear panel input jacks, and select the rear inputs

with the INPUTS switch. Allow three minutes for thermal equilibrium.

2. Press in and hold the OPEN key while turning on the power.

3. Press SHIFT then CAL, select R UN, then enter the appropriate calibration code (default:

002000).

4. Select ALL at the CAL:RUN prompt.

5. Press ENTER.

6. Perform the entire front panel comprehensi v e calibration procedure discussed earlier in

this section.

7. Connect the synthesizer to the Model 2000 INPUT jacks as sho wn in Figure 2-5. Select

the front input jacks with the INPUTS switch.

8. After the last A C current calibration step, the instrument will prompt you to enter 3Hz at

1V RMS and 1kHz. For each prompt:

• Low frequency cal: Set the synthesizer to output a 1V RMS, 3Hz sine wa v e. Use the

left and right arrow keys, and the range keys to adjust the displayed voltage v alue to

the value you measured and recorded earlier. Press Enter.

• Frequency cal: Set the synthesizer to output a 1V RMS sine wave at 1kHz. Enter

1.000000kHz, then press ENTER.

9. Set the calibration dates, then save calibration constants to complete the process.

Calibration 2-21

Figure 2-5

Synthesizer connections for manufacturing

calibration

Model 2000

2000 MULTIMETER

!

R

BNC-to-Dual

Banana Plug

Adapter

50Ω BNC Coaxial Cable

Note: Synthesizer output voltage

must be accurately measured.

(See text).

Model 3930A or 3940 Synthesizer

Main

Function

Output

Page 44

2-22 Calibration

SCPI command calibration

1. Connect the low-thermal short to the rear panel input jacks, and select the rear inputs

with the INPUTS switch. Allow three minutes for thermal equilibrium.

2. Press in and hold the OPEN key while turning on the power.

3. Enable calibration by sending the :CODE command. F or example, the default command

is:

:CAL:PROT:CODE 'KI002000'

4. Initiate calibration by sending the following command:

:CAL:PROT:INIT

5. Calibrate step 0 with the following command:

:CAL:PROT:AC:STEP0

6. Perform the entire SCPI command comprehensive calibration procedure discussed earlier in this section.

7. Connect the synthesizer to the Model 2000 INPUT jacks as sho wn in Figure 2-5. Select

the front input jacks with the INPUTS switch.

8. Set the synthesizer output to 1V RMS at 3Hz, then send the following command:

:CAL:PROT:AC:STEP14 <Cal_voltage>

Here <Cal_voltage> is the actual 3Hz synthesizer signal amplitude you recorded earlier.

9. Set the synthesizer output to 1V RMS at 1kHz, then send the following command:

:CAL:PROT:AC:STEP15 1E3

10. Send the following commands to set calibration dates, save calibration constants, and

lock out calibration:

:CAL:PROT:DATE <year>, <month>, <day>

:CAL:PROT:NDUE <year>, <month>,<day>

:CAL:PROT:SAVE

:CAL:PROT:LOCK

NOTE After manufacturing calibration is unlocked, you have the option of performing com-

prehensive, DC-only, or AC-only calibration. If you calibrate DC-only and then lock

out calibration, manufacturing calibration is then locked, and you cannot then perform AC calibration. You must then unlock manufacturing calibration by holding in

the OPEN key and cycling power.

Page 45

3

Calibration

Command Reference

Page 46

3-2 Calibration Command Reference

Introduction

This section contains detailed information about the various Model 2000 SCPI bus calibration commands. Section 2 of this manual covers detailed calibration procedures. F or information

about additional commands to control other instrument functions, refer to the Model 2000 User's

Manual.

Page 47

Calibration Command Reference 3-3

Information in this section includes:

Command summary: Summarizes all commands necessary to perform comprehensive and

factory calibration.

Miscellaneous calibration commands: Gives detailed explanations of the various com-

mands used for miscellaneous functions such as programming the calibration code and date.

DC calibration commands: Details those commands required to calibrate the DCV, DCA,

and ohms functions.

AC calibration commands: Covers commands that calibrate Model 2000 ACV and ACI

functions.

Manufacturing calibration commands: Summarizes the commands necessary to perform

the manufacturing calibration steps.

Bus error reporting: Discusses bus calibration errors and discusses how to obtain error in-

formation.

Detecting calibration step completion: Covers how to determine when each calibration step

is completed by using the *OPC and *OPC? commands.

Page 48

Ω

Ω

Ω

Ω

3-4 Calibration Command Reference

Command summary

Table 3-1 summarizes Model 2000 calibration commands.

Table 3-1

Calibration command summary

Command Description

:CALibration

:PROTected

:CODE ‘<up to 8 char. string>’

:COUNt?

:INITiate

:LOCK

:LOCK?

:SAVE

:DATE <year>, <month>, <day>

:DATE?

:NDUE <year>, <month>, <day>

:NDUE?

:DC

:STEP0

:STEP1

:STEP2 <NRf>

:STEP3 <NRf>

:STEP4 <NRf>

:STEP5 <NRf>

:STEP6 <NRf>

:STEP7 <NRf>

:STEP8 <NRf>

:STEP9 <NRf>

:STEP10 <NRf>

:STEP11 <NRf>

:STEP12 <NRf>

Calibration root command.

All commands in this subsystem are protected

by the calibration lock (except queries and

:CODE).

Calibration code or password (default:

KI002000).

Request the number of times the unit has been

calibrated.

Initiate calibration.

Lock out calibration (opposite of enabling cal

with :CODE command).

Request comprehensive cal lock state.

(0 = locked; 1 = unlocked)

Save cal constants to EEROM.

Send cal date to 2000.

Request cal date from 2000.

Send next due cal date to 2000.

Request next due cal date from 2000.

DC cal steps.

Rear terminal short step.

Front terminal short circuit.

Open circuit.

10V DC step.

-10V DC step.

100V DC step.

1k

4-wire step.

10k

4-wire step.

100k

4-wire step.

1M

4-wire step.

10mA DC step.

100mA DC step.

1A DC step.

1

Page 49

Calibration Command Reference 3-5

Table 3-1 (cont.)

Calibration command summary

Command Description

:CALibration

Calibration root command.

:PROTected

:AC

:STEP1

:STEP2

:STEP3

:STEP4

:STEP5

:STEP6

:STEP7

:STEP8

:STEP9

:STEP10

:STEP11

:STEP12

:STEP13

:STEP14

:STEP15

NOTES:

1. DC:STEP0, AC:STEP14, and AC:STEP15 are one-time factory calibration points and are only valid in

manufacturing calibration mode.

2. Upper case letters indicated short form of each command. For example, instead of sending ":CALibration:PROTected:INITiate," you can send":CAL:PROT:INIT."

AC cal steps.

10mV AC at 1kHz step.

100mV AC at 1kHz step.

100mV AC at 50kHz step.

1V AC at 1 kHz step.

1V AC at 50kHz step.

10V AC at 1kHz step.

10V AC at 50kHz step.

100V AC at 1kHz step.

100V AC at 50kHz step.

700V AC at 1kHz step.

100mA AC at 1kHz step.

1A AC at 1kHz step.

2A AC at 1kHz step.

1V AC at 3Hz step.

1V AC at 1kHz step.

1

1

Page 50

3-6 Calibration Command Reference

Miscellaneous calibration commands

Miscellaneous commands perform calibration functions such as programming the calibration

code and date. These commands are discussed in detail in the following paragraphs.

:CODE

(:CALibration:PROT ected:CODE)

Purpose

Format

Parameter

Description

Notes

Example

:COUNt?

Purpose

Format

Response

T o program the calibration code or password so that you can perform the calibration procedures.

:cal:prot:code '<char_string>'

Up to an 8-character string including letters and numbers.

The :CODE command enables the Model 2000 calibration procedures when

performing these procedures over the bus. In general, this command must be

sent to the unit before sending any other comprehensive or manufacturing

calibration command. The default calibration code is KI002000.

• The :CODE command should be sent only once before performing either

the comprehensive or factory calibration. Do not send :CODE before each

calibration step.

• To change the code, first send the current code, then send the new code.

:CAL:PROT:CODE 'KI002000' Send default code of KI002000.

(:CALibration:PROT ected:COUNt?)

To determine how many times the Model 2000 has been calibrated.

:cal:prot:coun?

<n> Calibration count.

Description

Note

Example

The :COUNt? command allows you to determine how man y times the Model

2000 has been calibrated.

Use the COUNt? command to help you monitor for unauthorized calibration

procedures.

:CAL:PRO T:COUN? Request number of times the unit has been

calibrated.

Page 51

:INIT (:CALibration:PROT ected:INITiate)

Calibration Command Reference 3-7

:LOCK

Purpose

Format

Parameter

Description

Note

Example

(:CALibration:PROT ected:LOCK)

Purpose

Format

Parameter

Description

To initiate comprehensive and factory calibration procedures.

:cal:prot:init

None

The :INIT command enables Model 2000 calibration when performing these

procedures over the bus. This command must be sent to the unit after sending

the :CODE command, but before sending any other DC, AC, or manufacturing calibration command.

The :INIT command should be sent only once before performing either comprehensive, DC, AC, or factory calibration. Do not send :INIT before each

calibration step.

:CAL:PROT:INIT Initiate calibration.

To lock out comprehensive or manufacturing calibration.

:cal:prot:lock

None

The :LOCK command allows you to lock out both comprehensi ve and man-

ufacturing calibration after completing those procedures. Thus, :LOCK perfoms the opposite of enabling calibration with the :CODE command.

Note

Example

:LOCK?

Purpose

Format

Response