Page 1

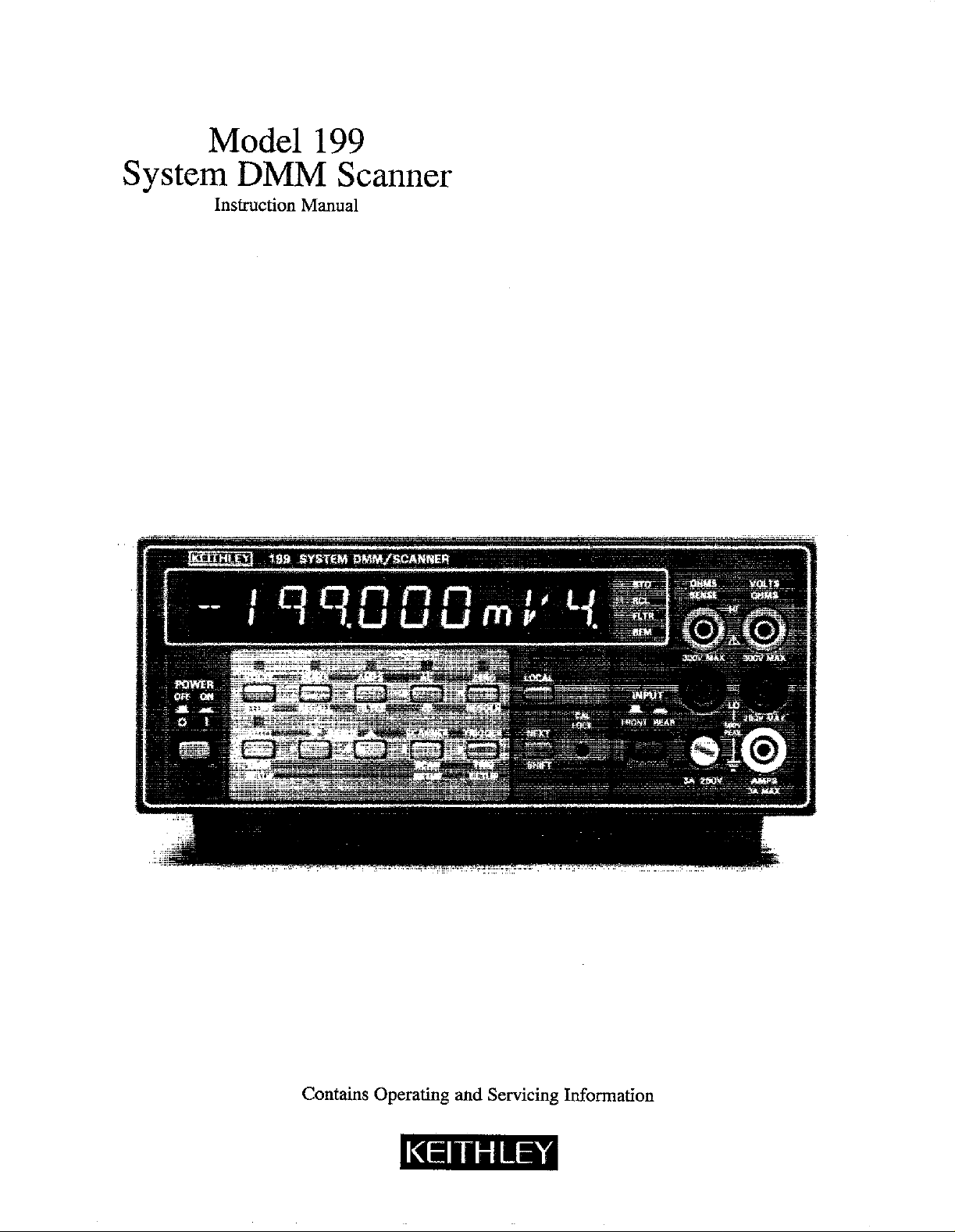

Model 199

System DMM Scanner

Instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants tbis product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting froti~product modification without Keitbley’s express written consent, or misuse of

any product ox- part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from batteIy leakage, or

problems arising from normal wear or failure to follow instmctions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIE S, EXPRESSED OR IMPLIED. INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KZITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRBCT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT AR!? NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

REMEDIES PROVIDED HEREIN ARE

Page 3

Model 199 System DMM Scanner

Instruction Manual

0 1988, Keith& Instruments, Inc

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

July 1987, Fourth Printing

Document Number: 199-901-01 Rev. D

Page 4

SAFETY PRECAUTIONS

The following safety precautions should be observed before operating the Model 199.

This instrument is intended for use by qualified ~personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read over the manual carefully before operating

this instrument.

Exercise extreme caution when a shock hazard is present at the instrument’s input. The American National

Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 3OV rms or

42.4V peak are present. A good safety practice is to expect that a hazardous voltage is present in any unknown

circuit before measuring.

Inspect the test leads for possible wear, cracks or breaks before each use. If any defects are found, replace

the test leads.

For optimum safety do not touch the test leads or the instrument while power is applied to the circuit under

test. Turn the power off and discharge all capacitors, before connecting or disconnecting the instrument.

Always disconnect all unused test leads from the instrument.

Do not touch any object which could provide a current path to the common side of the ,+cuit under test

or power line (earth) ground. Always make measurements with dry hands while standmg on a dry, insulated surface, capable of withstanding the voltage being measured.

Exercise extreme safety when~ testing high energy power circuits (AC line or mains, etc). Refer to the High

Energy Circuit Safety Precautions found in paragraph 2.6 (Basic Measurements).

Do not exceed the instrument’s maximum allowable input as defined in the~specifications and operation

section.

Page 5

cw%a wi) sdw 3a

;., ,,

Page 6

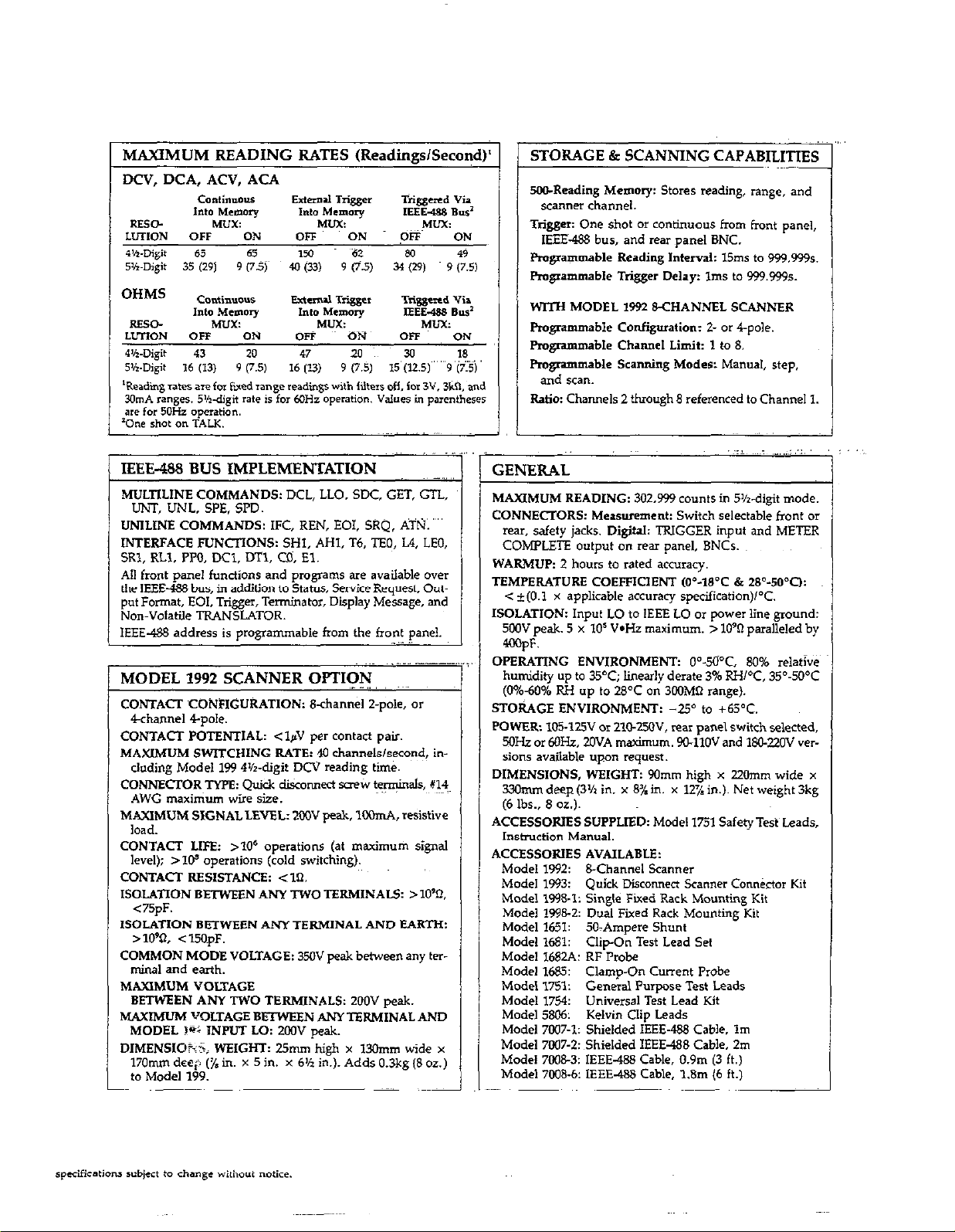

MAXIMUM READING RATES (Readings/Second)’

STORAGE & SCANNING CAPABILITIES

SO&Reading Memory: Stores reading, range, and

scanner channel.

Trigger: One shot or continuous from front pane,,

IEEE.488 bus. and rear panel BNC.

Programmable Reading Interval: 15ms to 999.999s.

Programmable Trigger Delay: Ims to 999.9995.

WITH MODEL 1992 &CHANNEL SCANNER

Pmgmmmable Configuration: t or 4-pole.

Fmgrammable Channel Limit: 1 to 8.

Pmgnmmable Scanning Moder: Manual, step,

and scan.

Ratio: Channels 2 thmugh 8 referenced to Channel 1.

IEEE-488 BUS IMPLEMENTATION

MULTILINE COMMANDS: DCL, LLO. SDC, GET, GTL,

UNT, UNL, SPE. SPD.

UNlLiNE COMMANDS: IFC, REN, EOI, SRQ. ATN.

INTERFACE FUNCIlONS: SHl, AHI, T6, TFQ, L4, LEO,

SRl, RLI. PPO, DCl, DTl, CD. El.

All front pane, functions and programs are available over

the IEEE-488 bus, in addition to Status, Swice Request, Output Format, EOI, Trigger, Terminator, Display Message, and

Non-Volatile TRANSLATOR.

IEEE-488 address is programmable from the front panel.

_ ,I

MODEL 1992 SCANNER OPTION

CONTACT CONFIGURATION: 8-channel 2-p&, or

4channel 4pole.

CONTACT POTENTIAL: <lpV per contact pair.

MAXIMUM SWITCHING RATE: 40 channels/second, in-

cluding Model 199 4’/r-digit DCV reading time.

CONNECTOR TWE: Quick disconnect screw ~y$inaIS, X’?~

AWG maximum wire size.

MAXIMUM SIGNAL LEVEL: 200” peak, lM)mA, resistive

load.

CONTACT LIFE: 210’ operations (at maximum signal

level); >I@ operations (cold switching).

CONTACT RESISTANCE: <Xl.

ISOLATION BETWEEN ANY TWO TERMINAL5 >lO%

<75pF.

lSOLATION BETWEEN ANY TERMlNAL AND EARTH:

> 10% < 15OpF.

COMMON MODE VOLTAGE: 35oV peak between any ter-

mhaf and earth.

MAXIMUM VOLTAGE

BETWEEN ANY TWO TERMINALS: 2OOV peak.

MAXIMUM VOLTAGE BEI’WEEN ANYTERMINAL AND

MODEL 19; INPUT Lo: 2oOV peak.

DIMENSIOhi; WEIGHT: 25mm hieh x 13Omm wide x

170mm deep (% in. x 5 in. x 6% ic). Adds 0.3kg (8 0~)

to Model 199.

GENERAL

MAXIMUM READING: 302,999 cmmts in SK-digit mode.

CONNECTORS: Measurement: Switch selectable front or

rear, safety jacks. DigitaL TRIGGER input and METER

COMPLET!? output on rear panel, BNCr.

WARMUP: 2 hours to rated accuracy.

TEMPERATURE COEFFICIENT ,04-18’C & 28’-50’0:

c t(O.1 x applicable accuracy sp&fication)l°C.

ISOLATION: Input LO to IEEE LO or power line ground:

5wV peak. 5 x IO’ V-Hz maximum. > lo90 paralleled by

4wpF.

OPERATING ENVIRONMENT: O”-5O”C, 80% re,ativ&

humidity up to 35°C; linearly derate 3% RH/‘C, 35”.M”C

(0%40% RH up to 28OC on 300MI-i range).

STORAGE ENVIRONMENT: -2Y to +WC.

POWER: IOS-125V or ZlC-25OV, rear panel switch selected,

5oH.z or MIHz, ZOVA maximum. 9UllOV and 180-ZOV MF

sions available upon request.

DIMENSIONS, WSIGKT: 90mm high x 220mm wide x

33hm deep (3% in. x 81 in. x 12% in.). Net weight 3kg

(6 lbs., 8 oz.).

ACCESSORlES SUPPLIED: Model ,751 Safety Test Leads,

Instruction Manual.

ACCESSORlES AVAILABLE:

Model 1992: B-Channel Scanner

Model 1993:

Model 199&l: Single Fixed Rack Mounting Kit

Model 1998-2: Dual Fixed Rack Mounting Kit

Model 1651: SO>Ampere Shunt

Model 1681:

Model 1682A: RF Probe

Model 1685: Clamp-On Curem Probe

Model 1751:

Model 1754:

Mode, 5806:

Model 7W7-1: Shielded IEEE-488 Cable. Im

Model 7007-2: Shielded IEEE-488 Cable, 2m

Model 7008-3: IEEE-488 Cable, 0.9m (3 ft.)

Model 7008.6: IEEE-488 Cable, 1.8m (6 ft.)

Quick Disconnect Scanner Conn&tor Kit

Clip-On Test Lead Set

General Purwse Test Leads

Universal T&t Lead Kit

Kelvin Clip Leads

specifications +ect to change without “otke.

Page 7

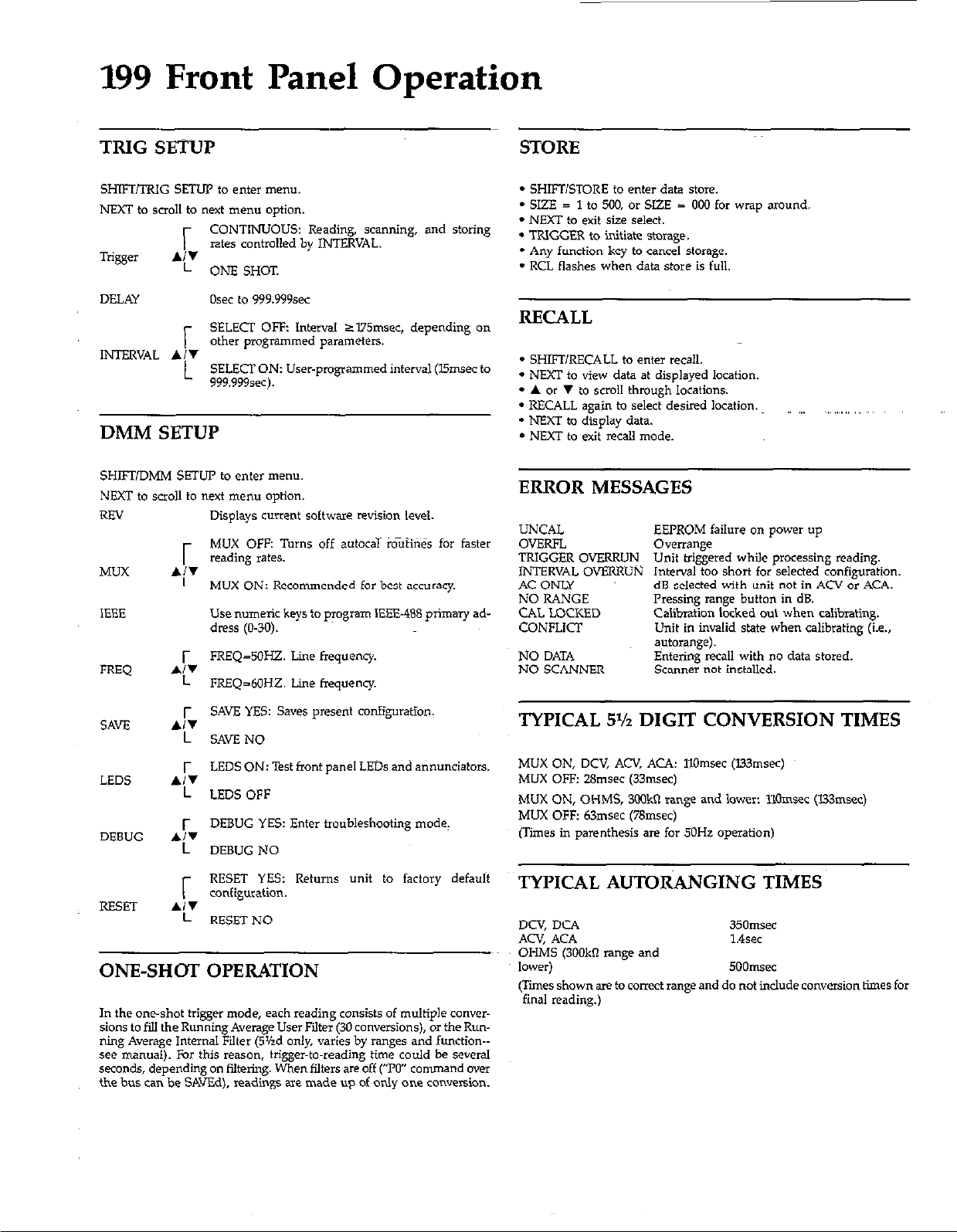

199 Front Panel Operation

TRIG SETUP

SHIFT/TRIG SETUP to enter nwnu.

NEXT to scroll to next menu option.

CONTINUOUS: Reading, scanning, and storing

rates contmlled by INTERVAL.

r

Trigger

DELAY

INTERVAL A/W

A:’

ONE SHcrT.

Osec to 999.999sec

SELECT OFF: Interval 2I75msec. depending on

other programmed parameters.

r

SELECT ON: User-pmgrammed interval (Ismsec to

L

999.9994.

DMM SETUP

SHIFUDMM SETUP to enter menu.

NEXT to scroll to next menu option,

REV

MUX

IEEE

FREQ

Displays current software revision level.

MUX OFF: Turns off autocal mufir% for faster

reading rates.

MUX ON: Recommended for best accuracy.

Use numeric keys to program IEEE-488 ptimary address (O-30).

FREQ=SOHZ. Line Frequency.

FREQ=60HZ. Line frequency.

STORE

- SHIFT/STORE to enter data store.

* SIZE = 1 to 500, or SIZE = 000 for wrap around.

* NEXT to exit size select.

- TRIGGER to initiate storage.

* Any function key to cancel storage.

- RCL flashes when data store is full.

RECALL

* SHIFURECALL to enter recall.

* NEXT to view data at displayed location.

* A or V to scroll through locations.

* RECALL again to select desired location.

- NEXT to display data.

- NEXT to exit recall mode.

ERROR MESSAGES

UNCAL

OVERFL

TRIGGER OVERRUN

INTERVAL OVERRUN

AC OI’KY

NO RANGE

CAL LOCKED

CONFIiCT

NO DATA

NO SCANNER

EEPROM failure on power up

OWTa”ge

Unit triggered while processing reading.

Interval too short for selected configuration.

dB selected with unit not in ACV or ACA.

Pressing range button in dB.

Calibration locked out when calibmtine

Unit in invalid state when calibrating &.,

autorange).

Entering recall with no data stored

Scanner not installed.

~,, ,,,, ,,

,,,

SAW

SAVE YES: Saves present configuration.

SAVE NO

LEDS ON: Test front panel LEDs and annunciators.

LEDS

LEDS OFF

DEBUG YES: Enter troubleshooting mode.

DEBUG

DEBUG NO

RESET YES: Returns unit to factory default

configuration.

NSET

RESET NO

ONE-SH(TT OPERATION

In the oneshot trigger mode, each reading consists of multiple conversions to fill the Running Average User Filter (30 canvenions), or the Running Average Internal Filter (5%d only, varies by ranges and function-see manual). For this reason, trigger-to-reading time could be several

seconds, depending on iiltering. When filters are off (‘TO” command wer

the bus can be SAvEd), readings are made up of only one conversion.

TYPICAL 5% DIGIT CONVERSION TIMES

MUX ON, DCV, ACV, AU: 1lOmsec (U3msec)

MUX OFF: Z&nsec (33msec)

MUX ON, OHMS, 3ookn range and lower: 1lOmsec (l33msec)

MUX OFF: 63msec (76msec)

(Times in parenthesis are for 50Hz operation)

TYPICAL AUTORANGING TIMES

DCV, DCA

ACV, ACA

OHMS (3OOkn range and

lower,

(Tffes shown are to coIIeCt range and do not include conversion times for

final reading.)

35amsec

1.4sec

500msec

Page 8

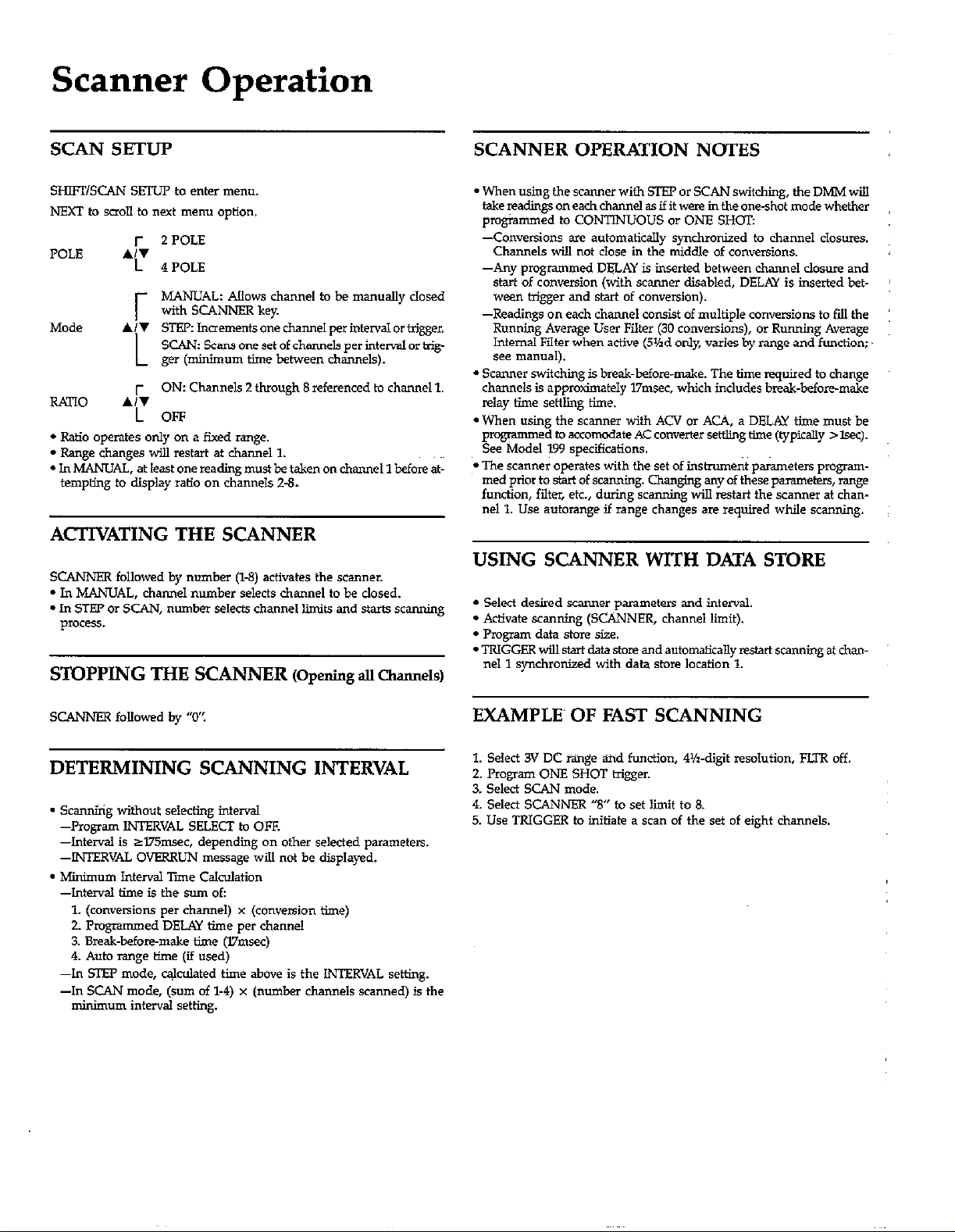

Scanner Operation

2 POLE

POLE A/T

Mode A/V

RATIO

l Ratio operates only on a fixed range.

l Range changes will restart at channel 1.

l In MANUAL, at least one reading must be taken on channel 1 before at-

tempting to display ratio on channels Z-8.

ACTIVATING THE SCANNER

SCANNER followed by number (%3) activates the scanner.

- In MANUAL, channel number selects channel to be dosed.

l In STEP or SCAN, number selects channel limits and starts scanning

process.

STOPPING THE SCANNER (opening au aam&)

r

4 POLE

MANUAL: A!lows channel to be manuaJly closed

with SCANNER key.

;

STEP: lnaements one channel perintenral or trigger,

SCAN: Scans one set of channels per interval or trig-

ger (minimum time between channels).

L

ON: Channels 2 through 8 referenced to channel 1.

*L

OFF

L

SCANNER OPERATION NOTES

l When using the sc.mner with STEP or SCAN switching, the DMM wi!J

takereading~oneachcharmel ssifit were in&one-shot mode whether

pmgmmmed to CONTlNUOUS or ONE SHOT:

-Conversions are automatically synchronized to channel closures.

Channels will not close in the middle of conversions.

-Any programmed DELAY is inserted between channel closure and

start of conversion (with scanner disabled, DELAY is inserted between trigger and start of conversion).

-Readings on each channel consist of multiple conversions to fill the

Running Average User Filter (30 conversions), 01 Running Average

Internal Filter when active (51hd only, varies by range and function;

see manual).

* Scanner switching is break-before-make. The time required to change

channels is approximately 17rwc. which includes break-before-make

relay time settling time.

l When using the scanner with ACV or ACA, a DELAY time must be

programmed to accomcdate AC converter settling time (typically >lsec).

See Model 199 sp&fications.

*The scanner operates with the set of insirument parameters program-

med prior to stat of scanning. Chanpinp any of these parameters, range

function, filter, etc., during scanning will restart the scanner at than~11. Use autorange if range changes are required while scanning.

USING SCANNER WITH DATA STORE

l Select desired scanner parameters and interval.

l Activate scanning (SCANNER, channel limit).

- Program data store size.

. TRIGGER vd, start data store and automatically restart scanning at than-

nel 1 synchronized with data store location 1.

SCANNER followed by “0’:

DETERMINING SCANNING INTERVAL

- scanning without s&ding interval

--Program INTERVAL SELECT to OFF.

-Interval is sl75msec. depending on other selected parameters.

--INTERVAL OVERRUN message wi!J not be displayed.

l Mienurn Interval Tiie Calculation

-Interval time is the sum oE

1. (conversions per channel) x (conversion time)

2. Programmed DELAY time per channel

3. Break-before-make time (17msec)

4. Auto range time (if used)

--In !XEP mode, c&l&d time above is the INTERVAL setting.

-In SCAN mode, (sum of l-4) x (number channels scanned) is the

minimum interval setting.

EXAMPLE’ OF FAST SCANNING

1. Select 3V DC range and function, 4%-d@ resolution, FLTR off.

2. Program ONE SHOT trigger.

3. Select SCAN mode.

4. Select SCANNER ‘8” to set limit to 8.

5. Use TRIGGER to initiate a scan of the set of eight channels.

Page 9

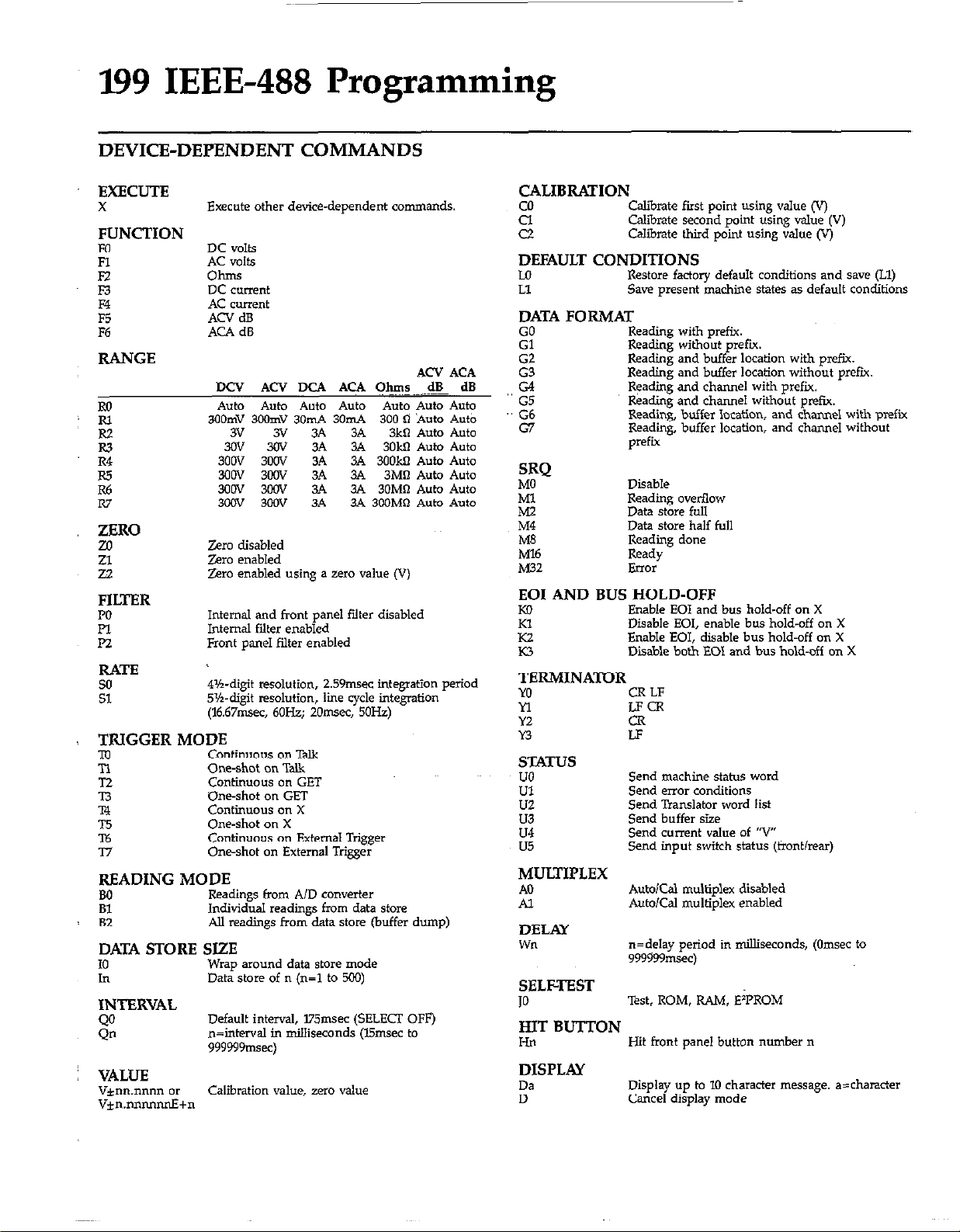

199 IEEE-488 Programming

DEVICE-DEPENDENT COMMANDS

EXECUTE

X

Execute other device-dependent commands

FUNCTION

Fo

R

F2 Ohms

53

E

F6

DC volts

AC volts

DC current

AC current

ACV dB

ACA dB

RANGE

DCV ACV DCA ACA Ohms dB dB

Ro

Auto Auto Auto Auto Auto Auto Auto

3OOmV 3WmV 3OmA 3OmA

s

R3

R4

z

R7

3V 3V 3A 3A

306’ 3OV 3A 3.4 3Okn Auto Auto

300V 300V 3A 3.4 3OOM Auto Auto

3oOV 30%’ 3A 3.4 3Mn Auto Auto

3mv 3wv 3A 3A 30MR Auto Auto

3OOV 3wV 3A

3A 3OOMO Auto Auto

ZERO

Zero disabled

Zero enabled

Zero enabled using a zero value (V)

FILTER

PO

Pl

P2

Internal and front panel filter disabled

Internal filter enabled

Front panel filter enabled

RATE

so

Sl

4%digit resolution, 2.59msec integration period

5%digit resolution, lie cycle integration

(16.67msec. 6OHz; 2Omsec, 50Hz)

TRIGGER MODE

m Continuous on Talk

n

T2

T3

T4

T5

T6

T7

READING

BO

z

One-shot on Talk

Continuous on GET

One-shot on GE?

co”tin”o”s on x

One-shot on X

Continuous on External Trigger

One-shot on External Trigger

MODE

Readings from AID converter

Individual readings from data store

All readings from data stwe (buffer dump)

DATA STORE SIZE

IO

h

Wrap around data store mode

Data store of n (n=I to 500)

INTERVAL

Q’J

Qn

Default interval, l75msec (SELECT OFF)

n=intwval in milliseconds (l5msec to

999999msec)

VALUE

v*nn.nnnn or Calibration value, zzo value

v*n.nnnnnrtE+n

A’3 ACA

300 d ‘Auto A&

3kl-i Auto Auto

CALIBRATION

co Calibrate first point using value (V)

2

Calibrate second point using r&e (V)

Cd&rate third point using value (V)

DEFAULT CONDITIONS

Lo Restore factory default conditions and save (Ll)

L* Saw present machine states as default conditions

DATA FORMAT

GO Reading with prefix.

Gl Reading without prefu.

G2 Reading and buffer location with prefix.

G3

G4

G5

G6

G7

SRQ

MO Disable

Ml Reading overflow

M2

M4 Data store half full

MB Reading done

Ml6 Ready

Reading and buffer I&ion without prefix.

Reading and channel with prefix.

Reading and channel without prefix.

Reading, buffer location, and channel with prefix

Reading, buffer location, and channel without

prefix

Data stcre full

M32 Fmx

EOI AND BUS HOLD-OFF

Ko

E

K3 Disable both EOI and bus hold-off on X

Enable EOI and bus hold-off on X

Disable SO,, enable bus hold-off on X

Enable EOI, disable bus hold-off on X

TERMINATOR

MI

ii

Y2

n

CR LF

LFCR

STATUS

UO

Ul

uz

u3

u4

u5

Send machine status word

Send error conditions

Send Translator word list

Send buffer size

Send current value of ‘?I’

Send input switch status (front/rear)

MULTIPLEX

A0

Al

AukKzd multiplez disabled

Auto/Cal multiplex enabled

DELAY

Wll

n=delay period in milliseconds, (Omsec to

999999msec)

SELFTEST

JO

Test, ROM, RAM, E?‘ROM

HIT BUTTON

HKl

Hit front pane, button number n

DISPLAY

Da Display up to 10 character message. a=character

D Cancel display made

Page 10

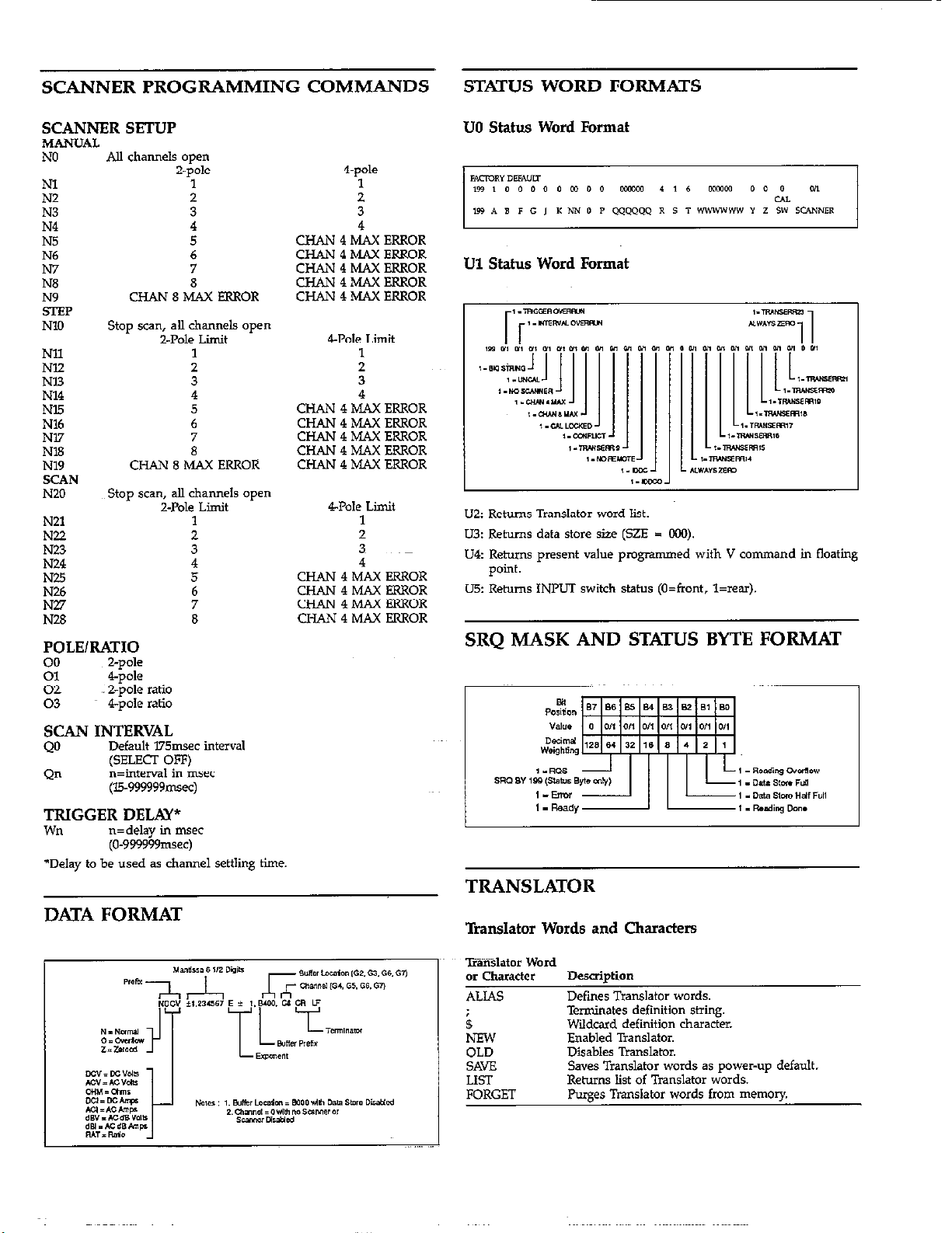

SCANNER PROGRAMMING COMMANDS

STATUS WORD FORMATS

SCANNER SETUP

MANUAL

NO

Nl

NZ

N3

N4

N5

N6

N7

N8

NY

!5lXP

NlO

Nil

NE2

Nl3

N14

Nl.5

N16

Nl7

NT3

N19

SCAN

N20

N21

N22

NW

N24

N25

N26

Au channels open

CHANgMAXERXOR

Stop scan, all channels open

Z-Pole Limit

CHAN 8 MAX ERROR

Stop scan, all channels open

Z-Pole Limit

POLE/RATIO

Z-pole

E

02

03

4-p&

Z-pole ratio

4-p& ratio

Z-pole

1

6

7

8

1

z

4

5

6

i

1

4-p&

:.

3

4

CHAN4MAXERROR

CHAN4MAXERROR

CHAN4MAXERROR

CHAN4MAXFRROR

CHAN4MAXERXOR

4Pole Limit

1

2

:

CHAN4MAXERROR

CHAN 4 MAX ERROR

CHAN 4 MAX ERROR

CHAN 4 MAX ERROR

CHAN 4 MAX ERROR

4Pole Limit

1

2

3

4

CHAN4MAXRRROR

CHAN4MAXERROR

CHAN4MAXERROR

CHAN4MAXERROR

UO Status Word Format

Ul Status Word Format

L

U2: Returns Translator word list.

U3: Returns data store size (SZE = CCQ.

U4: Returns present value programmed with V command in floating

p0illt.

u5: Returns INPLJT switch status (O=fmnt, l=rear).

SRQ MASK AND STATUS BYTE FORMAT

SCAN INTERVAL

QO

Qn

Default 175msec interval

(SELECI OFF)

n=tnterval in msec

(15.999999mxc)

TRIGGER DELAY*

wn

*Delay to be used as channel settling time.

n=delay in msec

(O-999999msec)

DATA FORMAT

TRANSLATOR

Translator Words and Characters

-miis.lator word

or character Description

ALIAS Defmes Translator words.

B

NEW Enabled Translator.

OLD

SAVE Saves Translator words as power-up default.

LIST Returns list of Translator words.

FORGET Purges Translator words from memory

Terminates definition string.

Wildcard definition character.

Disables Translator.

Page 11

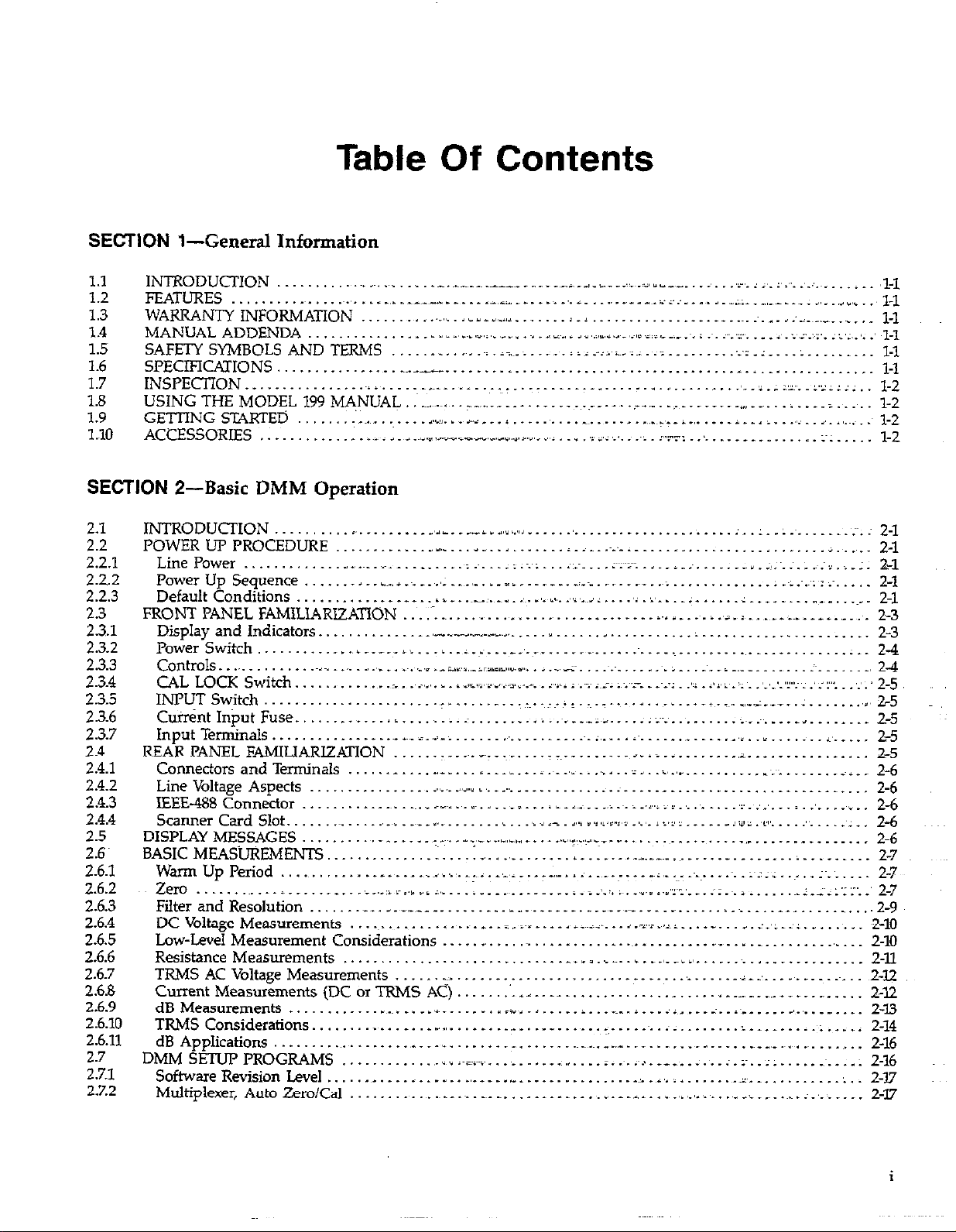

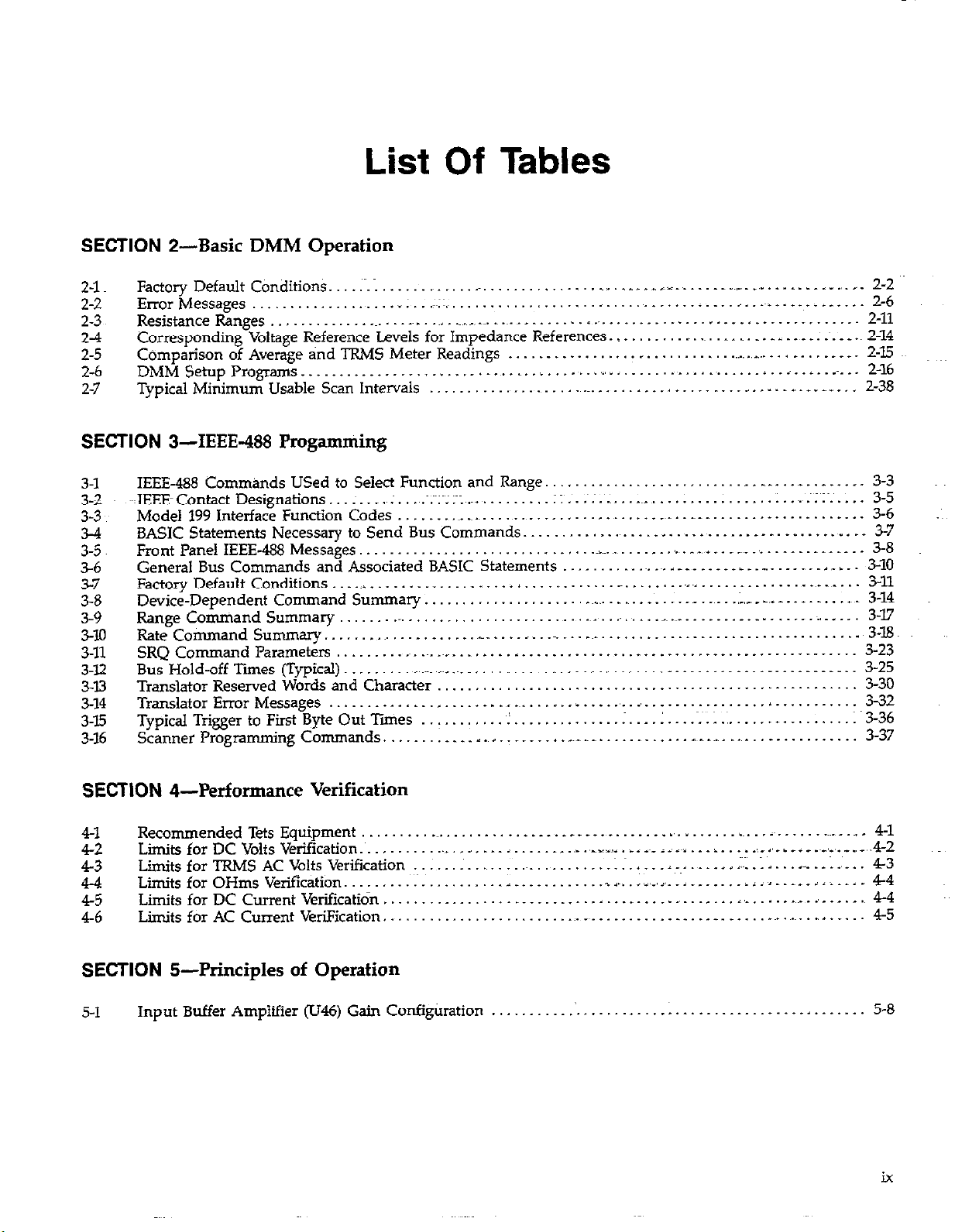

Table Of

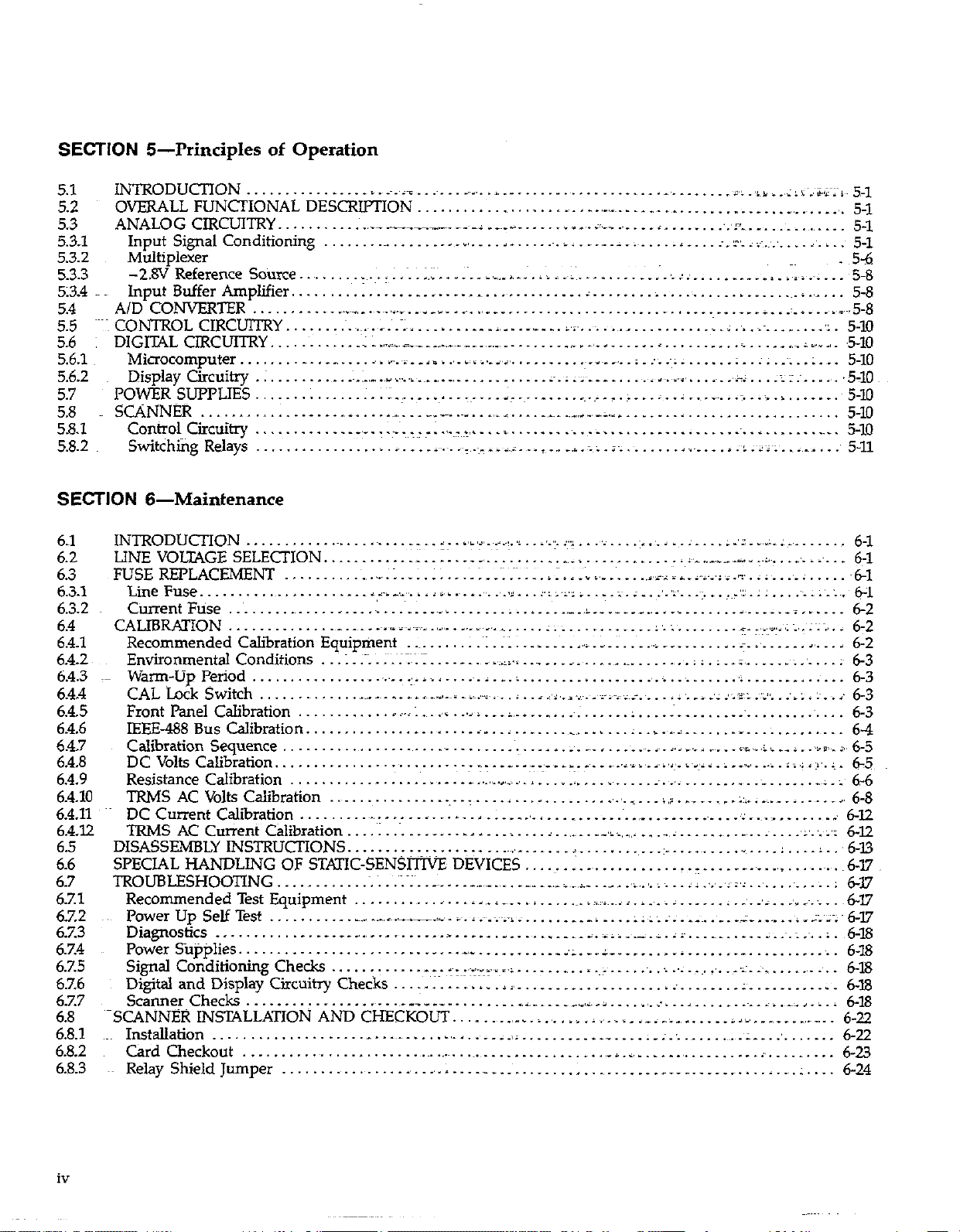

SECTION l-General Information

Contents

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

INT?““-‘^“’

INTRODUCTION ~. _~. . ._.~__~__~

FE.4 FEATURES .~. _~... t . _ _.L _ ___ ~_-. ^ _ _ _

WARRANTY WARRANTY INFORMATION . . ., t..,,. . . I

MANUAL AI MANUAL ADDENDA _. . . _ __ _ .,_,_ ~.,I

SAFETY SYMBOLS AND TEE SAFETY SYMBOLS AND TERMS _ _. .~.

SPECIFICATIONS.. . . t. _ _~.~.-... . . . . . _. . . . . ._. . _. , l-1

INSPECTION ._._........_... ;.._....,.. _.._ . . . ._................... _ . . . . . . ~..;.;:~..:~z::::..

USING THE MODEL 199 MANUAL .~~.~~.~. - _.r.._ . . . . . . . . . ___. -~. . .._I. .: . . --. . -_ . .,. . i . . i

GETTING STARTED .‘:~.~. _:. <,-I.. _ a. _. i .~. . _~. _. _ .,._~_,__ j .,. . . . . i.. , i.. .,,_, I,_ .,_~i : l-2

ACCESSORIES . . . _ __._ _ ._

SECTION 2-Basic DMM Operation

2.1

2.2

2.2.1

2.22

2.2.3

2.3

23.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.3.7

2.4

2.4.1

2.4.2

24.3

2.4.4

2.5

2.6~

2.6.1

2.6.2

2.43

2.6.4

2.6.5

2.6.6

2.6.7

2.68

2.6.9

2.6.10

2.6.11

2.7

2.7.1

2.7.2

INTRODUCTION

..........

POWER UF PROCEDURE

I.

.........

............

LinePower ..................... ._

PowerUpSequence .......... .~.,..~...~.,;

Default Conditions ..............

FRONT PANEL FAMILIARIZAXTON ................................................

Display and Indicators ..............

Power Switch ............. ..___ ......

Controls ................. ._.,_ .., .......

CAL LOCK Switch ...................

INPUTSwitch.. ......................

CutintInjxtFuse.. ...............................

Input Ten&naIs . . ..___.__..._.._ A_,i_i_i___ ___...._..._... ~.i ,..., a. . . .._.~..._._. j ._~__..___ a, __._.

REARPANELFAMILIARIZQION ._._.I ~__.~_____~ _.... ~_~ . . .._.... . ..ii ._._. _ .,..,, - .____.___ L ._.._. 2-5

Connectors and Terminals . ^ t . _ . .._ _ _ . I _ _ _ ,. _ _ i .~. .,i . ,. . : , i, .,I . _ _ . . ~.‘; _ _ _ _ _ ) j _ _ 2-6

Line Voltage Aspects . . __, a,\ ._... ,+ >.. _.... ___. . . . :. . .__. _. __ _. _____ ___. _. 2-6

IEEE-488 Connector _ __ _~. .~. _ r_. . I~. . _ _ s. _. ~ . _ _~_. _ _.i . . i _ .‘,.i ii,. ,_ . . . 2:. _,_,. . ~ .‘. _~i _.

Scanner Card Slot. _~_ t .._~1 _~_ _ I;.~_. . ,~ i __ ,,.i v,i,:v: _,_,. L <.i’: t _ _ _ iri r.t*‘. . . _“. .‘: _. 2-6

DISPLAY MESSAGES . _ _ _ _ _ _ _ .:. . _ ,_,_ _ ..,_,_f _. . . . . I.,.. :a ,c_. _. .~. . . . .,. _ _ _ _ _ _ _ _. . .

BASICMEAS-iJREMENTS .__...__._..._: _.__I _.._..____... :..I _..._..._^ ~__ __...___ __.____I . . . ..I____ 2-7

WarmUpperiod .._..__ __~ ___._, j ..,._ ~_.~.._,e,L _..._,.. *a.~ ._._. - ..__ ~‘,..~~-.~-~ . . ~..:~;;;..~...;~. _____

Zero . . . . .._ __...______ _.__i_._:iil.jv/i ,.__.: ____ _....___ ;.;.‘.:r;~..r.=...“~-.‘....:.~.i ._____ ~.:.:~;:~:;‘..‘2-7

FiIterandResolution .._.. __.r____-_ _______.. _ __._..._..._ _,..~ ._..._ __ _.... __~ ______._______.... 2-9~

DC Voltage Measurements _~. . . . ._ .__~_ _ ____ I_~ .“..__. ~ji~~ii._ j..L,l.~iii_.. ___ _. i.,L-.‘l. _. . :.. 2-10

Low-Level Measurement Considerations _ _ . _ . . . . .~. . . _ _ . .._ . I . _ . _ _,. _ 2-10

Resistance Measurements _ . . . . _ _ _ . _ . _. . _ _,_ _i .,. . . . . . _ _ _ _ _ . . _ .

TRMS AC Voltage Measurements . . _~. . . . _ . . . . _. . .,. _.A-_‘. _ . . .~_ _ _~. ~2-12

Current Measurements (DC OT TRMS AC) :. ., _. __ _ . _ . . _ . _ _- _ _ _.. _ _ _ _ _ _ . . . 2-I2

dBMeasurements .._._...____ I.~__._._ ____. _.“_+, ,.L...._____ c_.j __... in ..__ ;__l~ __.____~....__,____

TRMSConsiderations . .._......__._ t_ ~_..._..__,._..__...._. r.-...~..i ___...... ,I ______.__; ._._ ~

dB Applications . .~. . . _ _. . . .,__ __,_. . . . . _ _. _. _ _~_~_~. _-__ __ . _ ._ _ _ ___ _. . .~__,_ _~. . .~_ . ,. . 2-16

DMM SETUp PROGRAMS _ . ,_.~1 l~=I~~f~. _ _ _. . _.:.I. _. i. .~. .~>_ ____. _. . _: :~. . ;. _ . . _~. _ _; 2-16

SoftwareRevisionLeveI ._...._.___ __._~ _._,____ I,_ _......_._._.... i_i,.i ._...... 1 .__...____._ :..

Multiplexer, AutoZeroiCal ..______ ~..~._____~ __.._._.. _ __.._ L .__- L...~ _,.,_ ,., . . ..__ i ___. ~...~_.. ____.

,.,_” I . 1. AU._ a i”..?/V,“7,,_.i

.l” ,asic _:_ _~;~i _:_ :‘.,?. _ _ . “ ‘.‘.;.:~:‘. I :‘;..I; .’ ,1-l

_zx~_~ . . iij.~.;ii~.i~i__i .__...-.. :.:.; _...: ..__.__._ l-1

l-2

l-2

_) _r,1513~1--11111111~1*.“,_ ..,i I ,i #i ,:. _~L z”1_: :. . ., . _ _. . . ~. .I . l-2 _

,A_..-ia..,u..,,

^

....................................................... .;

......

.‘.

...................

.:

..

1. .:.~.

......

~;~. ; 2-l

.......

2-l

........ i.~. ... :...~;...i ...... rr;:. ............. . “.*.~.;...~.;.;.;: 2-l

... .... _ ..... . ___I____. .._- .................. ;.~;.~.:::;~ ..... 2-l

_ _ ...... .~.-...~.~. .,~. .‘.~.,, .,,&,.~~. i .... ‘: L’ .... I. ..... I ........... ., ...... 2-l

_,-_-l __..--

...........................

...

..i. 2

:

......................

___~__ __ ____

...

23

2-3

__,_.i_.~ _____’ .__.. ....................................... :__ 2-4

,_.=_ lsIx “,,_ irl_ .. . .. v.r j __._ ;_ ........................ .__. .. ., .. .:~.~ .. ____, 2-4

..... j_~i~~~w~~iJ.. .. .. Ibjl ; ..:;~;~. . ..~_ . .~-,; _I~ ..l’l.:~:~. . ‘.‘.‘.‘:: . ..::“. . :::: 2-5

_.

..........

~.._~..l

..................

+.-~...- .: ____.:

........

.,2-5 I,

i_.~,__~_:~>. :~~ ..... .......... i~__~ .. .._ ......... 2-5

2-5

2-6

2-6

2-7

2-11

2-13

2-14

2-17

2-17

i

Page 12

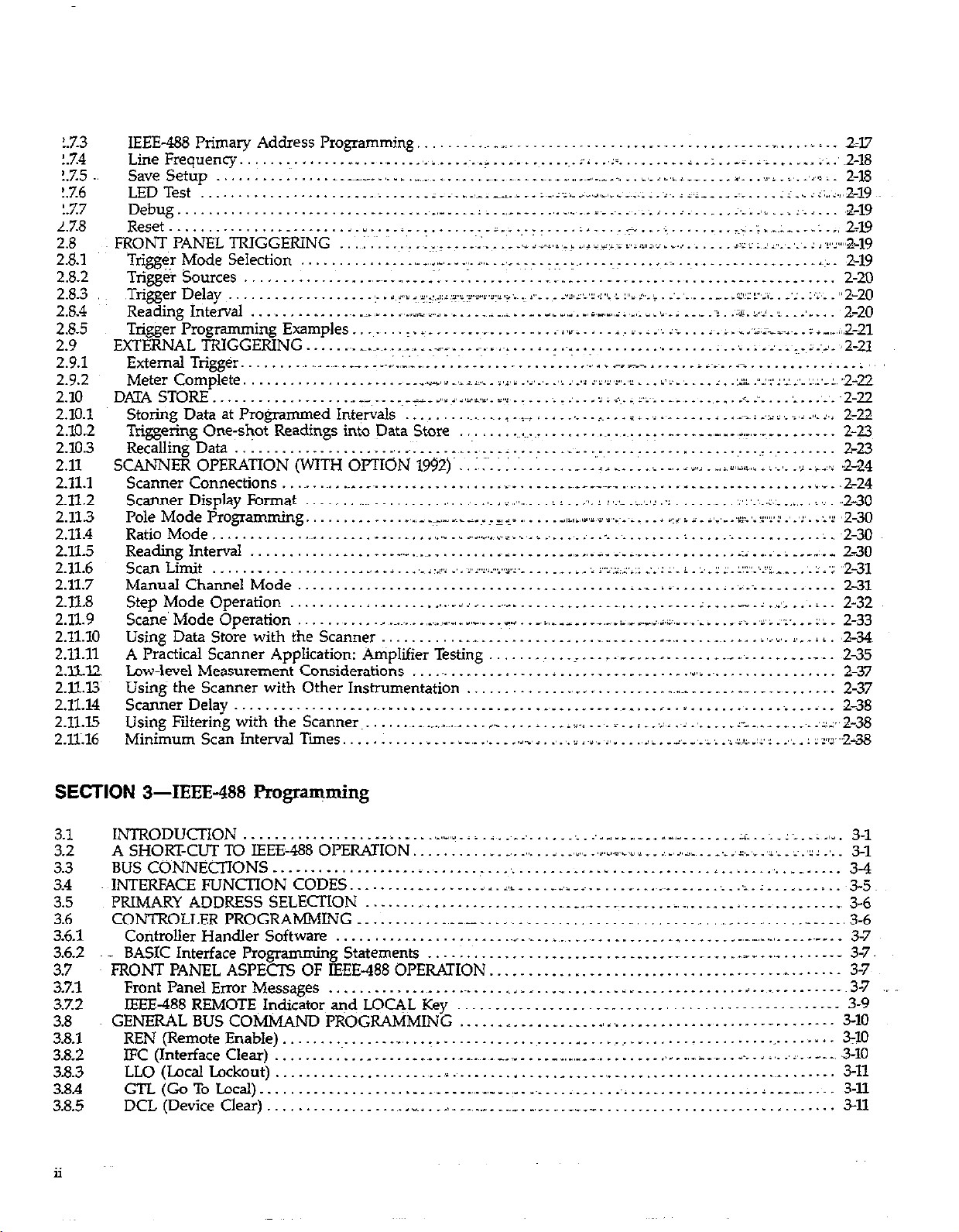

1.7.3

!.7.4

!.%5

!.7.6

!.7.7

L.7.8

2.8

2.8.1

2.8.2

2.8.3

2.8.4

2.8.5

2.9

2.9.1

2.9.2

2.10

2.10.1

2.102

2.10.3

2.11

2.11.1

2.11.2

2.113

2.11.4

2X.5

2.11.6

2.11.7

2X.8

2.11.9

2.11.10

2.11.11

2.xi2

2.ll.13~

2.11.14

2.11.15

2.X16

IEEE-488 Primary Address Programming. ............................................... . .... ._ . .. 2-17

LineFrequency.. ....... ~:.: . ..< .......... ,_, ......... . ............. ;- ... z= ......... ;..:.r-x.;; ...... ;;.,~2-18

save Setup ................ ._~_ .... ... ._~_, ........ _~. . _. . * .~._ “_.~ ..,..^ ..... i,_ > ., . ,.___ ... I,. . .i#i . -,. _‘,,.l i 2-18

LEDTest ............................... i__~__ .,-.I_ .. .._.~..z.< . ,r_., d ., ......... i~.J<.i __ . ..!. ..... ;...;L..,2-19

Debug.. ............................... .._..._~ ___.___.__, . .,._ ~..r..~...; ...... i ..... .;.....;..ii. .A___ .a-19

Reset.. ....................... I .... L ........... i.~. ... r- ___.; .... -~+ . ..< .........

FRONT PANELTRIGGERING ..‘.~:~..:......~.-.t..~..~.....~~~.~;,.,

Trigger Mode Selection .............. _,__,,L ,.,__ _,,_ ., .......... --. .............. ._. .................. _j~:__ 2-19

TriggeT Sources ....... : ........ .,_~. ..... .~:. .; ......... __~_, ..... _ ................ __ ........... 2-20

,Trigger Delay

Reading Interval ......... ., ...... _f __ .. _._, _ ..i. ..... _.,i _,,i .. _ . _, . .,, ... I, i ,-,I,, ;. ,_,_ ,, . w_ ; .. ,_ 7: .I. :‘.I ,I .. .‘. ... 2-20

Trigger Programming Examples ....... I. .................. .~j.r .. . .. &. ;_ : .., ii ... >~.,; . ~..i.;~~~-.~. .; ._,_, 11,2-21

EXTERNAL TRIGGERING. ..... ~__~.~.~t~__~_ .___ _~ .... ~.https://manualmachine.com/~ .... ....... ....... ;..i.:..‘..~_~.i.~i. ‘2-U

External Trigger. .................

Meter Complete .....................

D.QA STORE .................... __ .... _ ii_ ..,I i <,w,tis. i,.: ..... : _ ..... > i .+. i p.~i .......... .i :_ ... ,A. . .,., .. 2-22

StoringDataatProgrammedIntervals ......... ~.~..~rl._~ _ ......... ~~...i~.__~. ..... ,.t_.-i.,:i:,.,_,j....i .l 2-22

Triggeri?g One-s&t Readings into Data Store _~_~_, .t. _,_ . __ ‘,....,‘-...~ -. ....... Z-3

Recalling Data

SCz4NNE.R OPERATION (WITH OrrION 1942)’ :~;. : : .... 1

ScannerConnections...~ ............................. _~ .. .._...._. ~_~~ ........... _._ .............. b,d.,2-24

Scanner Display Format ....... ^~_ .......... ., .. _, ., . ; .,,_ ... j : .. :‘. I :,.‘~. .:.~‘.‘. :I .... _,_ .. :I’.‘,..:.:. .., .. _;;_ ..2- 30

Pole Mode Programming. ............ .,.,__ ~,IL.~.I-z,~~ ., .... ..~jli,Y~j,_lY,....~. ... i CL/, i :_ -~-,-.‘~:.‘.Y::~ .‘.‘:. :X 2-30

RatioMode.. ............. ................~ ....... _,I.II,_ ., . -I .,..., ;_.,._~ ........ . .................. :.;2-30

Reading Interval ..................................... .~L ........ ,_,,._ .............. .___I.: ..... ~_:____~._ 2-30

Scan Limit .................... I .. j ... ,_ i zii; ., . .pYYi..rpz,, ..... _ . 1 . ‘~ r~.:.:;:.r:: .:_‘: 1’. i :. . I I . L:‘:‘.‘.:L. ... ‘_ ?~ I ‘1: ,,2-31

Manual Channel Mode.. ........ .._. ~__~ ........................... i .... L:~ ...... :_~_,_~ .... ....... 2-31

Step Mode Operation .......... I ......... ...~.ii. ... .._. ....................... ;_ . _.- _: ..‘: ... i .. 2-32

Sane’ Mode Operation .......... ., ........ _,l.il_,_ _,-._ _ . I .... _i,.~-__, . _.-~.i_,L1._,j,i,_,__~.~_ .... i_ _,:> .‘.: .... 2: . 2-33

Using Data Store with the Scanner.. .......... ................. I~__L .... A~_ ...... ~..I..j..,I..i,...ij. ,2-34

A Practical Scanner Application: Amplifier Testing .......... __ .... .~- __ .......... __

Lw+level Measurement Considerations ............. _ ..... , ................. ,*,, ................... 2-37

Using the Scanner with Other Instrumentation ............. .,_. _ ................................ ., . 2-37

Scanner Delay.. ......................................................... ~__* ..................... 2-38

Using Filtering with the Scam-w

Minimum Scan Interval Ties. ...

...................

.................... ., ........ _, .............. __ ..

:_ . e ‘v, ,‘:~:,‘:*~‘s~:~,“‘.~:u.)

__ .. .~.:.,I:.:,.~. _:

.......................

,._.__.” ... ._.. ‘ ,.__., i.,il_ ,., i‘~“~_~~~” ___, 1L.-‘,--,-IL.,i,~~~~..~~:..,...111’--.-2~ .

.... ................

~____iY_~.iii.i_j~i~i_~i~_~__~jj_~iii~~~:I~_~~._.L~i_~

..........................

.. .... _ .. 11 _~_ ... i .... i ,>.> _,/u,./j,/ . j .., .. ,> . i_: .. ,224

.....

, ......... ii~ .... i .. ‘. _, ..; .~. ., ..... ;- _._,__ ....... :;,:.2-38

* -8, ; -,A 1_ rj ,>,,>,,i . _ ......... 2% :: ;~_I L.,., . ,.‘. : J -!.‘&-lg

.

...

i,._ ,_ ..~.LI’::.z

‘.l.~l...‘.

.,.., .... _ ........... ._ . _: _,_ ....... 2-23

1 :‘.u~/

...............

,

... i ....

‘.,

....

:l-.‘;.~-~: ____ :..,% l9

......

.zz. :‘,.i_ :I :‘Y,

......

i

i .................

I,.--.~-~,~:-~r,.‘.:.l,~r.,2-22

.......

_ . ._ .. 235

...

“2-20

SECTION 3-IEEE-488 Programming

3.1

3.2

3.3

3.4 INTERFACEFUNCTIONCODES

3.5 PRIMARY ADDRESS SELECTION ....... _ ................... _.,_ . _ ... __ ... 1, _,_ .................. ., 3-6

3.6 CONTROLLERPROGRAh4MING.. .......

3.61

3.6.2 ... BASIC Interface Programming Statements ............................... __ .. _ .... .__ ......... _._ 31

3.7 FRONT PANEL ASPECTS OF IEEE-488 OPERATION. ..................................... -. ...... 3-7

3.7.1 FrontPanelEnorMessages ..........................................................

3.7.2 IEEE-488 REMOTE Indicator and LOCAL Key .................................................. 3-9

3.8 GENERAL BUS COMMAND PROGRAMMING

3.8.1 REN(RemoteEnabIe) ............... _, ..........................................................

3.8.2

3.8.3

3.8.4

3.8.5 DCL (Device Clear) ..................

ii

INTRODUCTION ............... .._ .......... L,l_ii_i ............ :_:__/ ..__...__._ ..... :i..:..:.e..;-.r. 3-l

A SHORTCUT TO IEEE-488 OPERATION. ........... _ .......... _,I.,_ .... ..e..u .. .,_ < ... ..A. .. _._ ..L.....~ ... >~.‘:z .... 3-l

BUSCO~NNECTIONS ............................... .............................. ___., ......... 3-4

.........

CotitroIIer Handler Software ........ ..,

IFC (InterfaceClear) .................. . ........... ____ _______,_,___

LLO (Local Lockout)

GTL(GoToLxaI) .......................... ._,,__, 1.~ _,___ ____: ...... pi ............... ;.:A.-.~. ..... 3-11

......................

_ __I__._

~.I.~.~____

............................................. ..~_~_~._~._

..c ... , . ._,

..... . . _

................................

..................

..............

i

.....

....

-__ _,__ . ______

......

~v.__.~

....

_

~._.~,~__ _._.r ..... . . . ........ ..~3- 5

...

_._,____(_ . .__, 3-6

i...~

.........

...................

_, i,.

.............. _&_~

.............................

., . _

..............................

........

.......

-.

_,._,i, ..... . 3-10

.... - ...

3-7

~3-7

3-10

3~10

3-11

3-11

Page 13

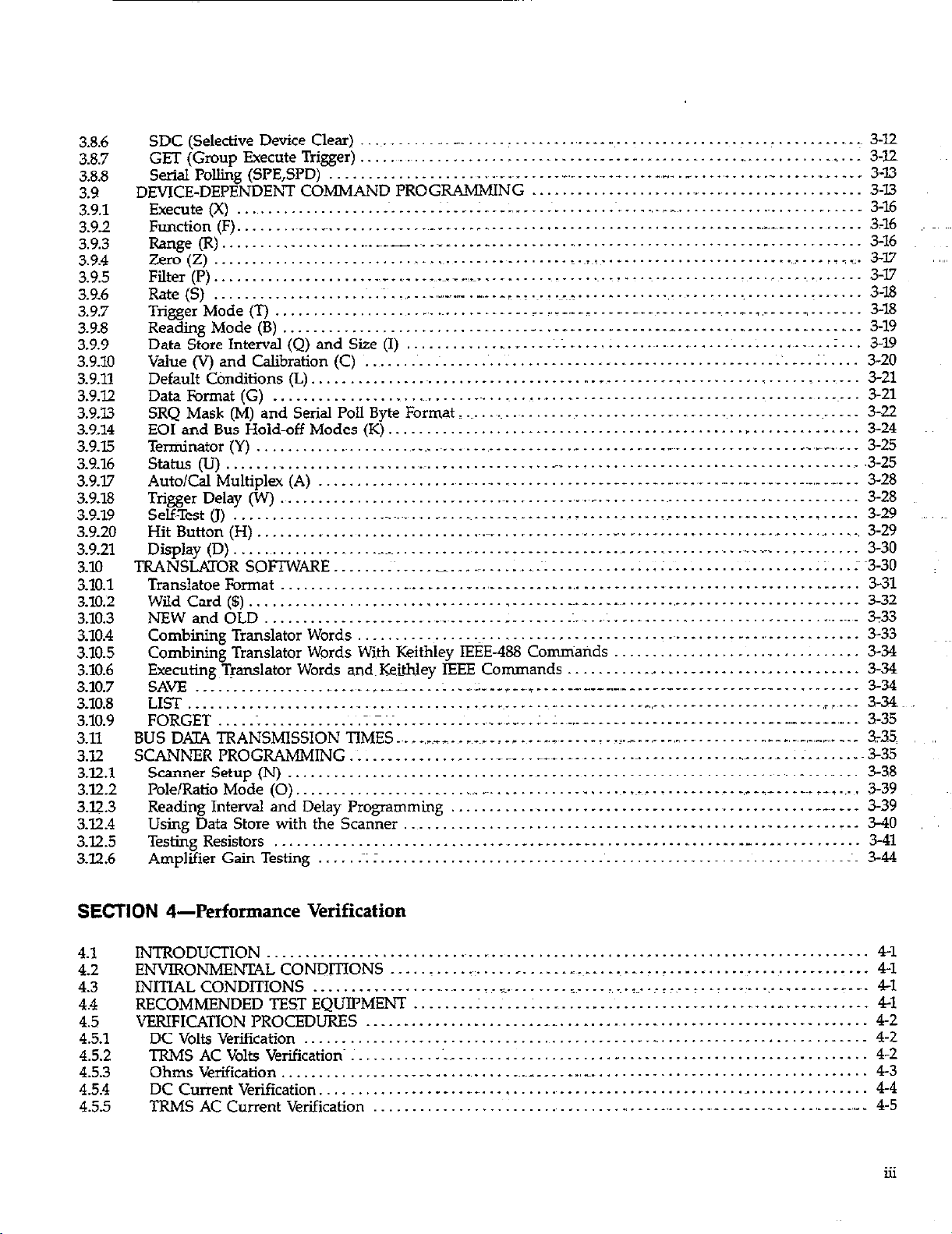

3.8.6

~~1

,,,,

3.8.7

3.88

3.9

3.9.1

3.92

3.9.3

3.9.4

3.9.5

3.%6

3.9.7

3.9.8

3.9.9

3.9.10

29.11

3.922

3.9.u

3.9.14

3.9.15

3.9.16

3.9.17

3.9.18

3.9.19

3.9.20

3.9.21

3.10

3.10.1

3.10.2

3.10.3

110.4

3.10.5

3.10.6

3.10.7

3.10.8

3.10.9

3.11

3.12

3x.1

3.12.2

3.12.3

3.12.4

3.12.5

3.12.6

SDC (Selective Device Clear)

GET (Group Execute Trigger)

...........

_ _

.......

.................................

...........

:

_,

..

...................

_,_

..

............

_

_.

SerialPoJIiig(SPE,SPD) ...................... .._. ______ I .._._.._ ... _ ._._.._ ...........

DEVICE-DEPENDE&T COMMAND PROGRAMMING

Exe&e(X) ........................... ::...: .... .................. ,_____

Fumtion (F). ..... ..~_.._

......

I..._

...

~___

.....................................

....................

._

_.

........................

Range(R). .................. ~..~_-.~...~_ .... _ ................................................

Zero(Z) .............................. ~_. ..............

Filter (I’).

Rate (S)

TriggerMode(T

Reading Mode (B)

Data Store Interval(Q) and Size (I)

Value (V) and Calibration (C)

DefaultC&ditions(L).

Data Format (G)

SRQ Mask (M) and Serial Poll Byte Format _

EOI and Bus Hold-off Modes (K)

Terminator (Y)

...................

.....................

.....

................................

._~__ .~_ ._~.~..~_...._. _.

..; ~,_,-

.............................

................................

.................................

...................................

......................................

,

.......

.._._ .._ I._.~

.

............

............................. _. ................ _

..............................................

_,_ . _

.......

.._. r ..

.._..._ _:.

..... _ ..............

__~:~<

................................

.............................

_

..

.~..~~_.

...........

...................

,__^_ _ .__________.__ ___ ____,,__ _____._____ 3-18

...

_

...

__ _

...

_._.

.....................................

^_

...

_ _

...........................

........................

_

........

____

-.

__._

...............

Status(U). ......................... ~_~___. ....................................................

Auto/Cal Multiplex (A)

Trigger Delay (W)

Self-Test(J)

Hit Button (H)

Display(D).

..................................

............................................

...................................................

..........................

..........................................

TRANSLATORSOFTWARE ......... ._______ _.~

Translatoe Format

Wild Card ($)

NEW and OLD

................

..................................

................................. _ ...... ..:.

CombiningTranslator Words

.........................................

_~.

........

...........

_:

................... _~.

.

.._

...

.........................

..................................

..__.

________.______._______,_ _,_______._____._______ 3-32

Combining Translator Words With Keithley IEEE-488 Comniarids

Executing Translator Words a& Keithley IEEE Commands

SAVE

LIST..

.......................

....................

_.

FORGET .................... ~;..~

BUS DATA TRANSMISSION TIMES ...

SCANNER PROGRAMMING

Scanner Setup (N)

Pole/Ratio Mode (0).

..........................................

.........................

: ................

Reading Interval and Delay Programming

Using Data Store with the Scanner

Testing Resistors

.............................

Amplifier Gain Testing ..... _~~; :,

....

..____

:..-:...,.e~, _._____ ___I_ .~~..-._--..-.-.-----

............ _._._~ ........ - .... .._

.._ ........ ~..~.w..:..: ..

...

,_ _ ,_r T_ . _~_~_ _ I _ _

., .._. _. . _ _ . .z._

..

__~__ .. __~_. __ ...........................

..................

_~.

............... ., ...............................

..............................................

...

..

_

_. _

.............................................................

~_.

,_

..

..........

_.__._._. __.

__ __

_ . __.

..

__

.. _ ..

.._

..

..................................

........

...

................

_.

..............

_

.

...................

.................................. 3-33

.:

__~

.......

...................... , ......... 3-34

..........................

_~

.............................

_ _.._......._...___ _ _ __._

...

...

_.

_

._ . __

......

.,

............

_

...........

.........

_~.

_.

..........

......................

.._ .._ _

......

.......

__

......

.,

_.l..

..............

,

.....

.._ .. _.

.___

............

_.

__.

...............

........

.......

_. _,T _i__. _ _~. i_.

......

_“. . _.

..... _ ... _ ..

:

...

,

_ .._ _

~..__. 3-W

...

..........

:?_

...

............

,

.......

_

......

_ _.

..

: ;

-...~

....

...

...

3-20

3-21

~..~...:

_

...

3-21

.......

3-22

3-24

..

__,L_,_,_

3-25

_ .3-25

_~_ . __._,_

....

., . 3-28

3-28

. ... _. 3-29

....

.........

>.

.... _ ..

_ ., 3-29

3-30

::...;~3-3 0

...........

_.

3-31

3-33

3-34

............ 3-34

*?

3-34~.

...

3-35

..

.....

.. _ .

_ 335~

_ 3-35

__- ., _,_, _._m

.~_. :.

__ _ ___. ._ _. 3-38

.....

3-39

__~_ __ _ 3-39

...........

._

..........

3-40

3-41

:_ 3-44

3-12

3-12

3-13

3-16

3-16

3-16 ~‘~

3-17

3-17

3-J.8

3-19

3-19

......

...

SECTION 4-Performance Verification

4.1

4.2

INTRODUCTION ...............

ENVIRONMENTAL CONDITIONS

4.3 INITIALCONDITIONS ....................... .1._

4.4

4.5

4.5.1

4.5.2

4.5.3

4.5.4

4.55

RECOMMENDED TEST EQUIPMENT ........ :

VERIFICATION PROCEDURES

DC Volts Verification

.............................................................

TRMS AC Volts Verifications ........... .‘.~_

Ohms Verification .............................. _~_~___

DC Current Verification, ............... _.

TRMS AC Current Verification

...............................................................

..... _ ..........

......

...................................................................

......................................................

.......................................

............................................

.....

__

.........

.........................

:

....

_.~__.

....

...

_~

_,

..

.....................................

.,.,_

.. _ ..........................

__

...

I~...J _.

_. ................ .._.

_,_

.....

.,

...............

._

............

...........

_,

............

,

...

.,

4-1

4-l

.....

4-l

4-1

4-2

4-2

4-2

4-3

4-4

_.,_. 4-5

u1

Page 14

SECTION 5-Principles of Operation

5.1

5.2

5.3

5.3-l

5.32 Multiplexer

5.3.3

513.4~~~

5.4

5.5

5.6 : DIGITALCIRCUITRY .__.____tt__ ::w..~.-. _____,_.: ___,_. _ ,_..______,_ ~ .~_.~______ L ._t____...; ____._,,. ;v_._ 5-10

5.6.1

5.6.2

5.7

5.8 SCANNER . . . . . . . . . .._.._.....~..... ~ ,_______. _...,. L . . .._.-__I_.._, _.I ._..._.... 2 .._...._..__..... 5-10

58.1

5.8.2

INTRODUCTION . . . .._......__._ >.,i_<~r...~ ___r..... 1,__ . . . . . . . . . . . . ..____._..~...... a,>_,,y __,. ;:i~;l,:~;~i~5.1

OVERALLFUNCTIONALDESCRII’TION ___......_....._... _ .I-., _,_.._.__.__ .__.._. _ .___.. I,_.~.._.,.

ANALOG CIRCUITRY.. . _. ..__I __-_ __~_~A __~_I_.. _. _ _ ..,. ii,_,. .~_ _ z _. . :.‘I-. _. _ .~.,. _. 5-l

InputSignalConditioning .._.. .._._. _~_I ,._._ 1 . . . . . . ~,I ..-.-. i_i~ . . . . . i _.._ ;.)I’..;~.:.’ _.._ i_i_.

-28V Reference Source . ~. . ~. : .~. : ;.::~. . . . . _ .,-._

InputBufferAmplifier . . . . . . !.~.I ..____..... _ ..,.......... 2 . . . . . . . . i . . . . . ..__....____ ~_i.,_,.. 5-8

A/D CONVERTER

~~~:CONTROLCIRCUITRY ~.~.~.,.<..;z .__....__. > ,...-,.... i.i..~...~._ . . . . . . . . . . :..:..i~ . .._.... ‘1.

Microcomputer . . . .._.._.._..____... ~_~i__,ij .,_. Ijj,__,,j’ . . . . . . . . . . l_-~._..;_;..: . . . . . . . . z..:;..;..;...

Display Circuitry . ; _ _ -1-i ,“.., I . . . .._. _ ___,_ _ , . . :-.: .;~.-- _. .~_~_ j~l~_l, ;. .~_ .‘+z.. .:: :. . . .,. &lO

POWERSUI’I’LIES _.,__..; .__.__ :..~:.. ._...___ __.. I).~ .._._._ -~.~.-..I...:..;..~ __._.I :._.i _,,.._.__ ~5-IC

c0ntr01cicnilTy . . . . . . . . . ..___. _... -.~..~~-;.~.~-~~,~...~ ,........ ~_.~.i ~....___.....____.. ..,_ _ . . . . . . . .

Switching Relays . . . . I. _ . _ a~.~. .z: __. i,. i.i. ._ _ . _.i .~:; . i: . . . . I._. _ ) ;~: .~xr:~. . _. . S-11

.._.....,_. __._,_,_. _~_.~._._~______~..,_ _~.......___....._.___. ..__ ____ ____ i...:.....1=~~5-8

/ . . . . iii _........__ r.‘.;. ______^___ ~_iii_~ ____

5.1

5-1

. ~5-6

~5.8

5-10

5-10

5-10

SECTION 6-Maintenance

6.1

6.2

6.3

6.3.1

6.3.2

6.4

6.4.1

6.4.2

6.4.3 ..

6.4.4

6.4.5

6.4.6

6.41

6.4.8

6.4.9

6.4.10

6.& DCC

6.5.

6.6 SPECIAL HANDLING

6.7 TROUBLESHOOTING

67.1

6.7.2 ..

6.7.3

6.%4

6.7.5

6.76

6.7.7

6.8 ~SCANNERINSTALLATIONANDCHECKOUT.

6.8.1

6.8.2

6.8.3

INTRODUCTION

LINEVOLTAGESELECTION

FUSEREPLACEMENT

LineFuse ....................... . ..-L......i.~~..............~:~~~:

Current FU

CALIBRATION

Recommended Calibration Equipment

Environmental Conditions

Warm-UpPeriod.. ......................

CAL Lock Switch .............. ,.,_ _, _ L ., _

Front Panel Calibration ............ ...._:

IEEE-488 Bus Calibration

Calibration Sequence .....................

DCVoltsCalibration..

Resistance C&&ration ....................

TRMSACVoltsCalibration ...... ........

unrent Calibration ......... ~.,~“~.-~ ........

TRMS AC Current Calibration ...........

DISASSEMBLY INSTRUCTIONS..

Recommended Test Equipment ..................

I’owerUpSeIfTest ............. _.._. _._--,.L~.i.~~__~~i,.~

Diagnostics ............ .._.__ .....................

PowerStipplies.. ....................

Signal Conditioning Checks ............ _ _ ....... . .-

DigitalandDisplayCircuitryChecks..

Scanner Checks.. .............. .~...~__.__ _ _

Installation .......................... _ ............

Card Checkout .....................................................

Relay Shield Jumper ..................

................ .t......_

.............

.......... ~.,.-.; ._ 1.;

se ..................... L .......................

............. _^__ .. .~.I;~._.~

...

: . .~; :~.~:::~I.

...........................

........................

.............................

................

... __., i ,a,_ :i..> .: ..i.:.;; .. _‘i .... ._I’., ..:.... L.‘:.-,:,-:-~

..I: ... . ............ ._ .............

..... ;...:.~..:..A:.1 ............ l,i~irl_ii_,i,i.~.ii_._‘_1.

..... ;~_; .,._ ... . ..

.._ .. i ._.__ f.. ... _ ...............

........ _._ _ ......... ;: : ........... I..:.

...........

..

:_ili.. .. ~.i. ... . ................................

... _yy_~I _ jmj.i .... i .. j i~i ..* :.. _ ....~..~.L~...~. ... i

......... . . ... .

._ ................. _. ..... .,,_ ,, .... _ ..

L.. .. l.. ................ ....t...ii ..__ _. ..;: ....... _ ....... _ 2,

_ .............. i _.__ .._._. _,.,_ .. _~.,:

.......

.~:~I

_.____.^ .~.........._. .: .__, L___ .... __I

..... _._ .... ji,. .............................

.

............

;. : ... __ ........ . ........ _,.;, ___

._ _ .~i,l.Lj.l .

_ . .._

_ ............ . pi .~i i.

. .................. __,_._______

....

._I,, _

,_.,_ ............

....

~=.;. ..... _

..... ____., i _.___ __w,i_~/.

........

.___ ,i .......... .._.

_.

......................

._

..... . ..

.

...............

.....

._,__ _._i~_.i_.

_. ... ..___ _ i.__._-__.iz~

_..i.....l.i.....l.._i_ i .....

............

::.

..... I ..............................

,__L.__~. ..... ..~.....‘....‘~~~.i.‘.~.......‘.:.’.:’.~..l. 6-5

i:.

..

......................

+ ........... . ..................

............................

....

Il~_~_~.~i

.... ..^ ._ i ........ ;..e_

............................

_,_ ...... .__ ___ .

:.

..i

................

.....

_._& ..................

i;. .,_,_, -.----T.i~...-..L~~ ..- 6-1

..~~....~..~..11.... ........... 6-1

....... c. -.-:.‘:a; .... 1~: .... 6-2

........................ 6-2

; :. ; __:

.. _ _ -‘: ;.r: .z: : . : . ; ..... 6-3

.~.+ ;.. ....

..

......... .,_ ...... ..; .... 1’: 6-12

.... L ... ii :..::z:.:

.....

..... i ....

i_

. ..__ .. -..;..~.:.~..:. 6-l8

..... .._ ............ 6-18

;.: ._. ......

.......

.: ............. 6-3

.*.

, _._ .. _,_ .; L __ : .. ‘L #,,., jl, 6-5

., _:_ ...... _~; . ; 6-6

..... .:..~ ........... 6-12

__._ ......... ~.~..6-17.

.._._; _ ...... ~;.;....~6- 17

..L. _._

. ___._._.__._ 6-18

.___.__ ii._i,_i_i 6-18

.._. izi,.__ ...... .._

.;-

_._.

........

....... 6-l

.... ~61

_i ....... 6-2

......

:

............

L.. .. ~...6- I3

.............

_‘*._ _‘wr~_:_ ~6-17

...........

...........

i ......... 6-23

:~ 6-3

I 6-v

6-18

..

6-22

6-22

; .... 6-24

6-3

6-4

6-8

iv

Page 15

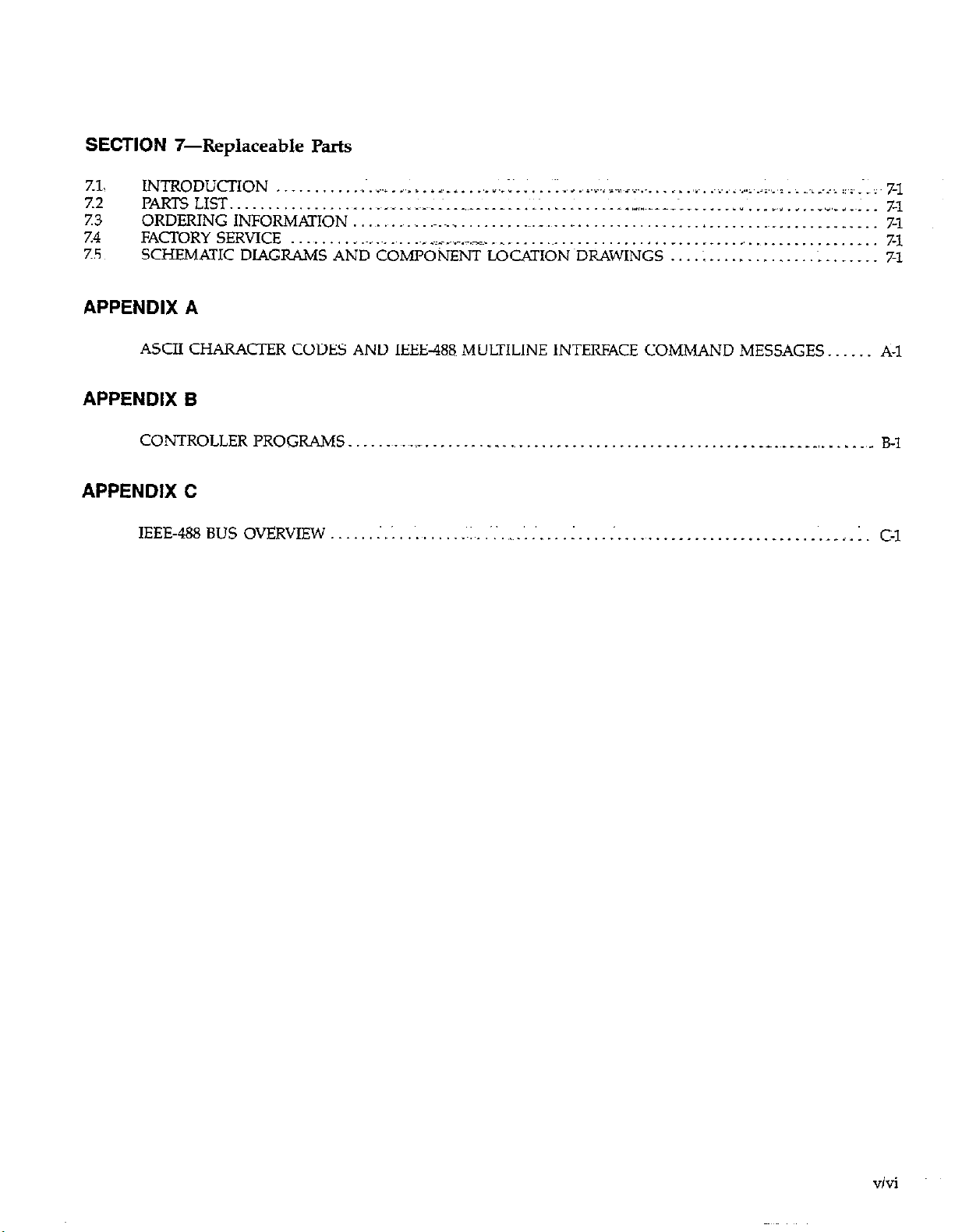

SECTION 7-Replaceable Parts

7.1.

7.2

7.3

7.4

7.5

INTRODUCTION ..........................

PARTS LIST

ORDERING INFORMATION

FACTORY SERVICE

SCHEMATIC DIAGRAMS AND COMPONENT LOCATION ~DRKWINGS

APPENDIX A

ASCII CHARACTER CODES AND TEEE-188~ MULTILINE INTERFACE COMMAND MESSAGES _ . . A-l

APPENDIX B

CONTROLLER PROGRAMS _~. ~._ . . . . . _ . _ . t . . . . . _ _ ___ _ _ _ _ _,. L . _,_ B-l

APPENDIX C

IEEE-488 BUS OVERVIEW :. : .:: :: ,. .: .‘. : :. r . . . . . . . _ . . _~. _ _ , . :

................... ~.~.~...:~..~:

..........................................................................

.................................

l,_ ....... ..1~.

..... ,,--..-.-. .:. ........ _.-._ .---- . .

_ .................................

....

., L.II II~,.~.

: .,

.

.......

.... : ..............

.,.~. ..... ,.“i _I: ,, .1

.........

..I,

.................

.._,“.

i _., _.ii i: i _~_;~ 7-1

... . “....~L

;. ...... 7-1

7-l

..

7-1

7-1

C-l

Page 16

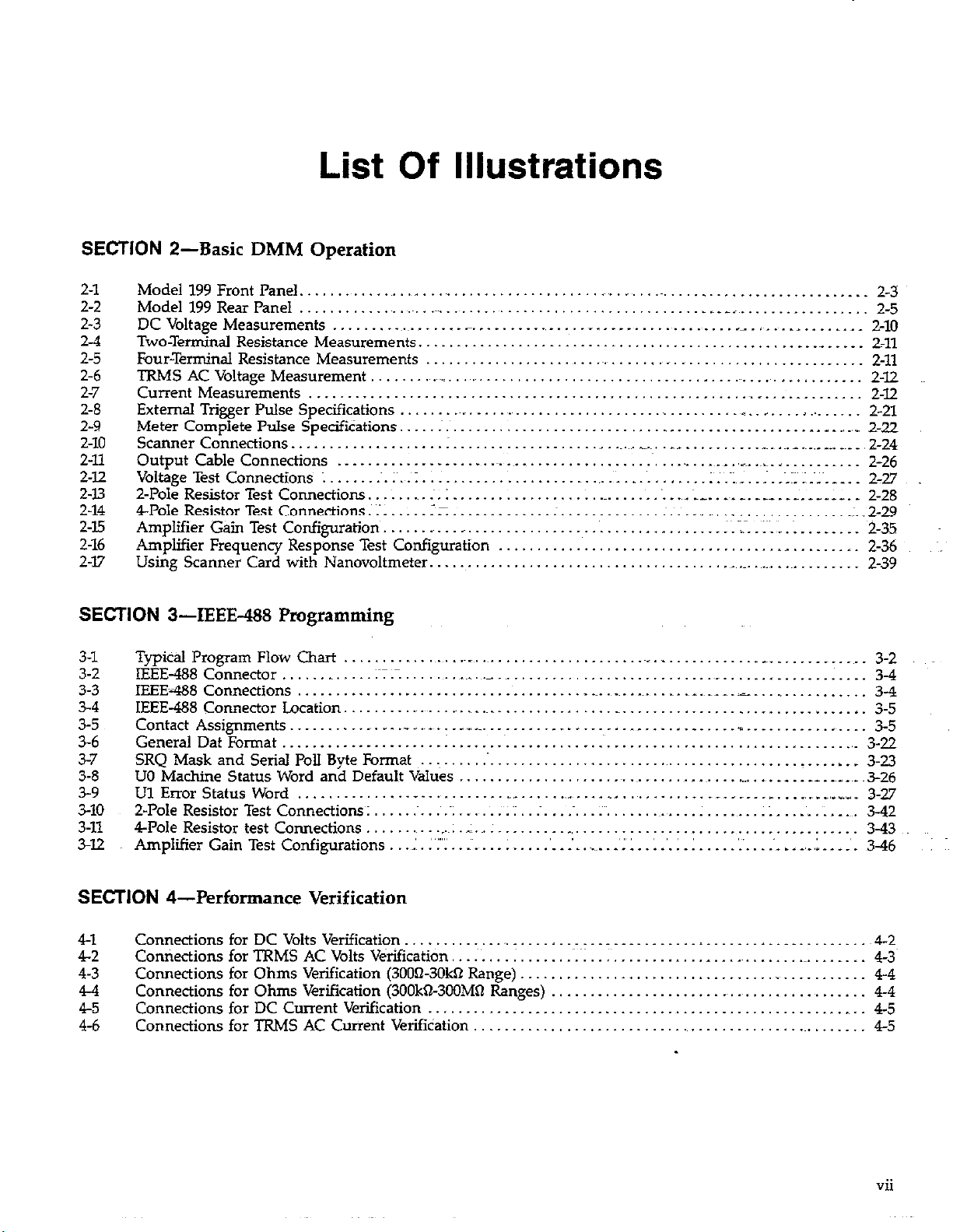

List Of Illustrations

SECTION 2-Basic DMM Operation

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-u

2-12

2-13

2-14

2-15

2-16

2-w

Model 199 Front Panel. ...........................................................................

Model 199 Rear Panel ........................................................

DCVoltageMeasurements

Two-Terminal Resistance Measurements.

Four-Terminal Resistance Measurements

TRh4S AC Voltage Measurement .........................................................

Current Measurements..

External Trigger Pulse Specifications

Meter Complete Pulse SpecifZations.

Scanner Connections

Output Cable Connections ........................................................

Voltage Test Connections ;

2-l’& Resistor Test Connections

4-P&? Resistor Test Connections.

Amplifier Gain Test Configuration.

Amplifier Frequency Response Test Configuration

Using Scanner Card with Nanovoltmeter

...................

.......................................................................

.............................................

.... (.

....................

............

.I.

............

.......

...............................................

_ .................

................................................

..........................................................

...................................................

:

................................

....................................

: .................

.Lz

.............

....................................

............................................................

:.

_

. ............... _ _,__ ~__ ...

...

__

:

................

.................................

,~ _ __

.........

_:: _~:L_

L

..

.................

.._ .._ 2-10

_

....... _ .

.

........

,

_

.............

..

__~_ .~._.~_._ _- _~__, 2-24

..~. .~.~_, ..... _ ....

..L. L.~.~

.....

_~_ __ ___

___ _____. _ 2-28

L .;

L_

...

__

__ __

........

.........

......

..

2-3

2-s

2-11

2-11

2-12

2.12

2-21

_,_ ,,., Z-22

2-26

2-27

..:-..2-2 9

2-35

2-36

2-39

SECTION 3-IEEE-488 Programming

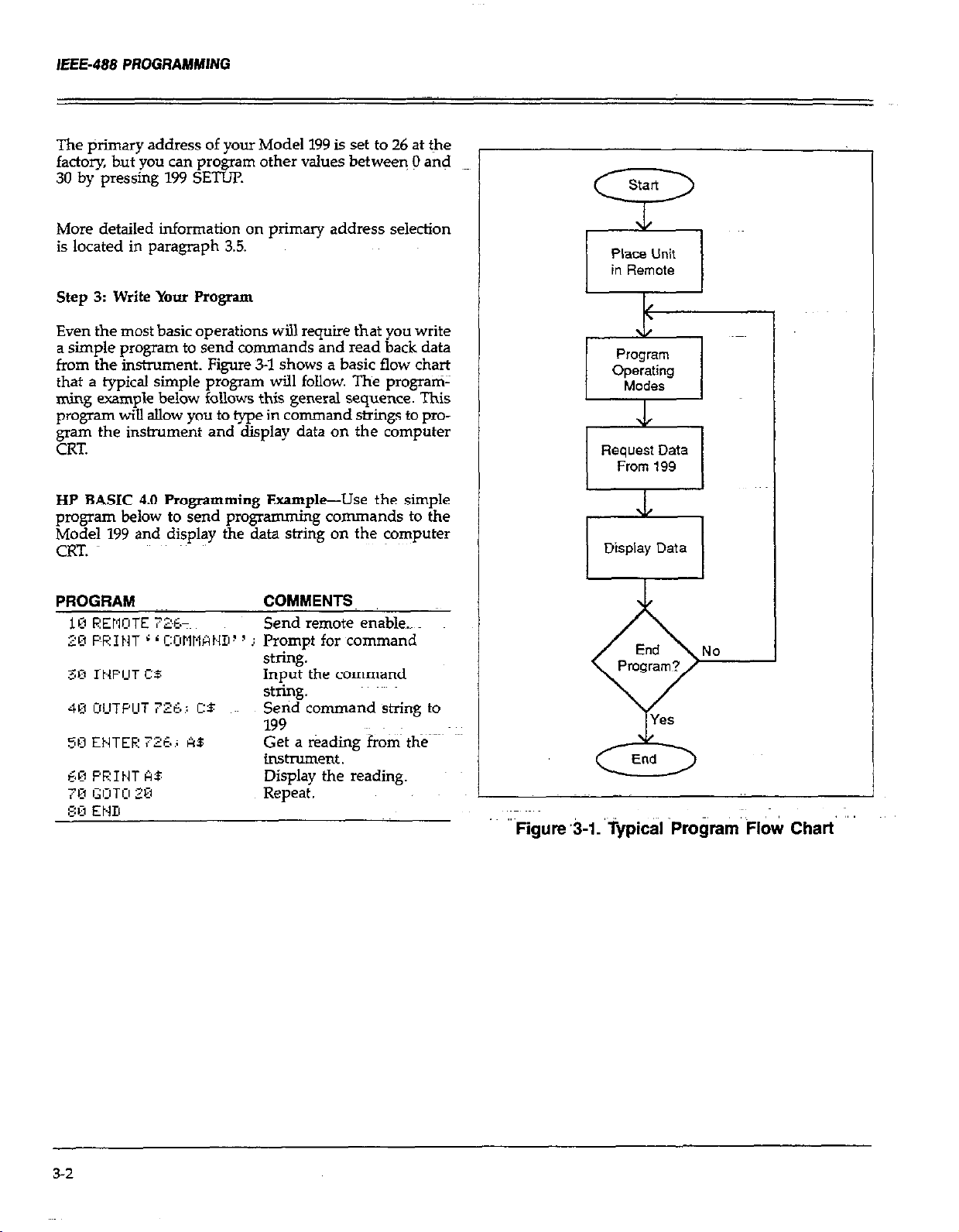

3-l Typical Program Flow Chart _. .~.~. . .~_. .~. . .~. . _ _. _ _ ___ _ 3-2

3-2 IEEE-488 Connector _ :Y: .: .~. ._ . .~. . _ :

3-3 IEEE-488 Connections . . . . . . . . . _ . . . _. . .~. _. .~_.~_~_ __- _ _. _ . . _ _ 3-4

3-4

3-5 ContactAssignments _____._._r.~.__...~ _.._ _.__ _ I______ ~ _.__. _ . . . . . . ^ _.... I._ .___. _L _________..,___. 3-5

3-6 General Dat Format . . . _ . . . . . . . . t _ .._ 3-22

37 SRQ Mask and Serial Poll Byte Format .~. :_ . ~ _. _. . . 3-23

3-8 UO Machine Status Word and Default Values . ..__. . .,.... ~..~ .,.,.. . . . . . . . . . . __ ________ ~-~3-26

3-9 UlErrorStatusWord . . . . ..___......_._........... ^ . .._... ^_I..~ . . . . . . . _._____ ____..___.. ~,_-I_ 3-27

3-10 2-l’& Resistor Test Connections : . . .~. .~; : .~. . .~. .~. . : . ; .~. 1 _.~~.

3-n 4-P& Resistor test Connections .+; .;. _ ., . . . 3-43

3-12 Amplifier Gain Test Configurations I 1’:. _~_ 1 . .‘. _ _‘. ._~. .‘I 1. 1.‘. 1 _ I _ 1.. _‘_ . _ _,_, 1. _ _ _‘_ 346

IEEE-488 Connector Location. .~. . . .~.. _. . . ,. . .~. . . _. _. . _. . 3-5

3-4

3-42

SECTION 4-Performance Verification

4-l Connections for DC VoltsVerification . . . . . . . . . ..___ I __________.___._._ 1 _____ _ ..___-._ ~_~ ._.,_ ~...~4-2

4-2 Connections for TRMS AC Volts Verification.. :‘. :. , . _. . I~. . . . .~. . . __ _. 4-3

4-3 Connections for Ohms Verification (300%3Ok0 Range). . . . 4-4

44

4-5 Connections for DC Current Verification _ . _ . . _. . . , 4-5

4-6 Connections for TRMS AC Current Verification .~. . . 4-5

Connections for Ohms Verification (300kil-3OOM0 Ranges) . .~. .~. . 4-4

vii

Page 17

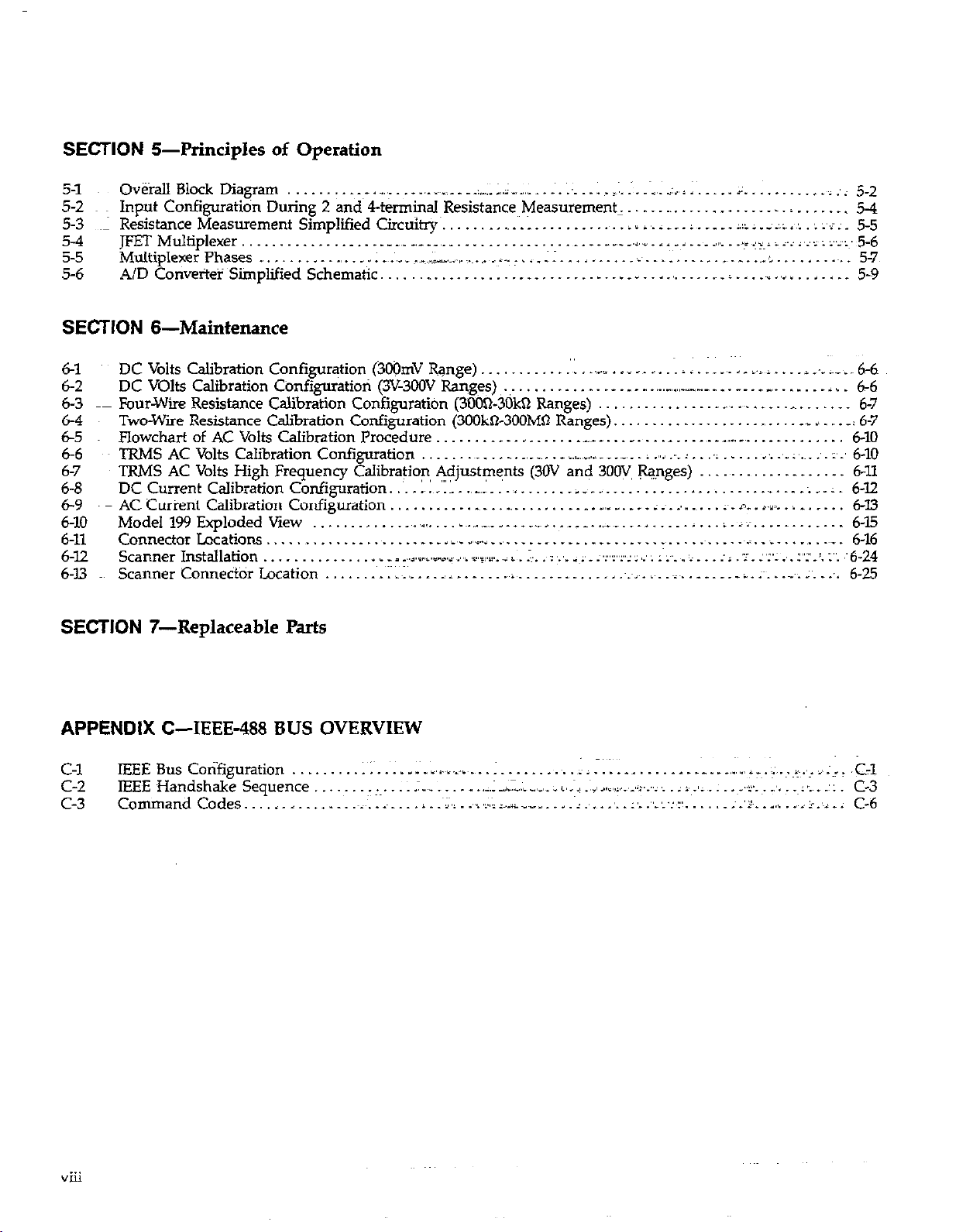

SECTION t&-Principles of Operation

5-l &&all Block Diagram . _ _ _. ~.,,- _ _ .._ .~~II_ _ _. _:*,. I;-.,. _ . :. . . . *.. ., .,_ <:I, i i _ . . i:. . . . _ _ . _; :; 5-2

5-2 Input Configurati& During 2 and 4-terminal Resistance~Measurement, . _ _.. . . _ _ . _ _ _ _. I _ . . . _. S-4

5-3 ~: ResistanceMeasurementSimplIfiedCircuitry _....._, _ _.__....__..... Lji,.i__.j .___. ii:....i~rl.‘.l’,~;. 5-5

5-4 JFET MuliipIexer . . . . . . _ . . . _ _, _,_ _,_ __ ,_ _ . . . . .~.~. . _. _. _ _,_ <.<,,I * .~_ 2 . _ _ i,,. .’ .:;: i ii i ‘2% : :‘i:~. 5-6

5-5 MultiplexerPhases _........._,._ _ ,.__. ___~_~.~~,ll~.~.__~I.._..__ _._. j _...._ \~..> . . . . . . . ..____. . . . . . . . . ~.. 5-7

5-6 A/D Conveitei Simplified Schematic. _ . . . . _ _ _ . . . _ . . . _ . . . ,. _ _ ;. . . _~~. ,, I . , . _ _

5-9

SECTION 6-Maintenance

DCVoltsCalibrationConfiguration(3CQmV~nge) __..____..._ ‘I.... ,.=. . . ...1.-.* __,. L_i.l~i .___ -.~.;....6-6~

t-i

6-3 ~~ Four-wire Resistance Calibration Configuration (300%3OkQ Ranges) . . . _ .~. . _ _ .~. _ _ 6-7

6-4 Two-Wire Resistance Calibration Configuration (300kQ-300MQ Ranges). . . . . . _ . __ I _ . . _: 6-7

6-5 Flowchart of AC Volts Calibration Procedure . _ . . . , . _I_ _ . . _. _ . . ,. _..,..” _. . _ . . . . .

6-6

6-7

6-B

6-9 ~~ACCur?entCalibrationConfiguration .._... _ __.._ ________,..__ _.l~l_____i_~__.l_~._.;~.j~~_.j~.yl~..j_ ._... 6-13

6-10

6-n Connector Locations.. . . . . . ..~. ...__.i,. e,m..i ..,.._. ..~.__. . _.. . ._... . ..~ . . . . .~*..i.. . . . .~_.

6-12 Scanner Installation . . . . _ = _..I.DI, i._m.v~_,,L ,Y,18.=.. I L Z:. : ‘_‘. i~i _ ;‘:‘YYI: ,: ‘. ; :. . zi I; .‘:. I’:‘: .., :“.‘.r. 1”. :6-24

6-13 Scanner ConneCtor Location _ _ YL.. _ ij ._ . _ .~( _ _ _. _ _ _. . , _~.~*. =_ _.z~. _ __ ___&. ;~. . ._.. __ . :.

DC Volts Calibration Cbnfiguratioti (3V-300V Ranges) ,. ,. . . . . _ . _. . . ..._..,, _..__,_ _ . . __. _ _,. _ _ . i i _

TRMS AC Volts Call&ration Configuration . ~_ _ , _. _,_ _. _ _ ..,_,, I,. _ _ __,_ i .,,. _,,. : . .i . . .,.. .‘. Y. : I .’ 6-10

TRMS AC Volts High Frequency Calibration, &ljustments (30V and 3OOv, Ranges) . . . _. . . . 6-11

DCCurrentCalibrationConfiguration..’.. ..__ _..._.___...___.._ *.___ ___....___.._.._...._ -..--;_.:.

Model 199 Exploded View . . _ . . . . ~. . ._._ _ _ _ _ _._ , . _ _ . ._~_ _ . , I . . i. _ ;. . _ . . _ .

6-6

6-10

6-12

6-15

6-16

6-25

SECTION 7-Replaceable parts

APPENDIX C-IEEE-488 BUS OVERVIEW

C-l IEEEBusCoiifiguration .._..... :..L ._._I, .~*..,.~...: ___.__._ ~..; .__..__.__.________._ ~-~.-,.~~-~.,I~;~-I.C~l

c-2 IEEE Handshake Sequence __ ~ ~~. : ;. _ _ _ _ _ _,_,; -.LLu,.,. ,_ /,_~. .I_, + ,,_,. G . . _ _ . i i _,: .~...?. _ _,. _~: ‘-. _: I

c-3 Command Codes. L. L. _ . . _ _ _~i~. . i_ _ . i .~,,A .“L ‘P,:: :_ii___ , _~j _, .~. . ‘r . ;‘. :‘-:: :“. _ ;.‘;.. . .,. <_, ;.‘~A _ .

C-3

C-6

Page 18

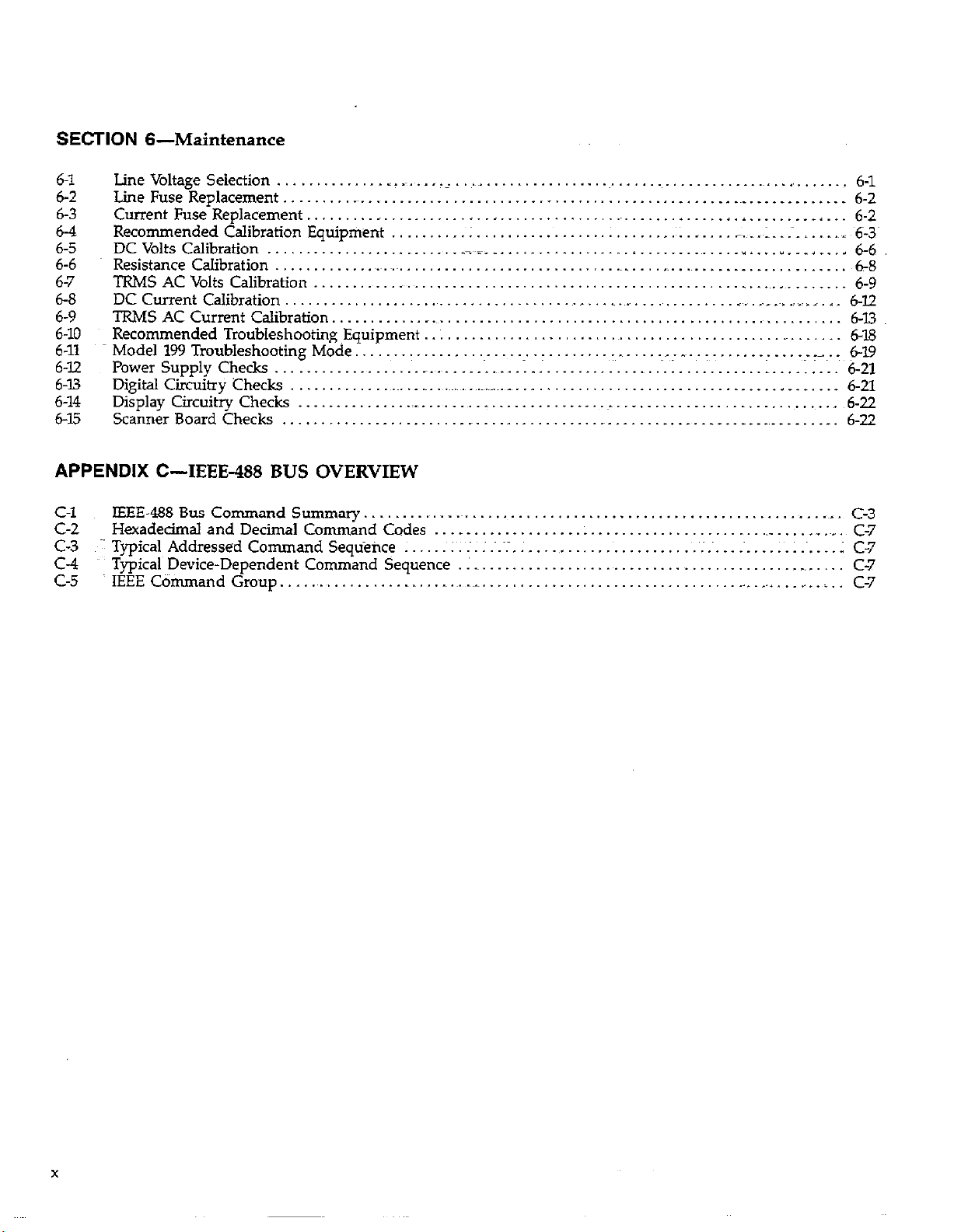

List Of Tables

.~~

SECTION 2-Basic DMM Operation

2-l

2-2

2-3

2-4 Corresponding Voltage Reference Levels for Impedance References.. . ,~. _~. _, . . _. _ _ _ _ _ _ _~. _ _ .~ 2-14

2-5

2-6

2-7

Factory Default Conditions. .~. 1 , _~. . _. _ __ . __:-_ _ _ _ _ _.,__ _._ _ . _ _ _ _ _ _ ., _. 2-2

Error Messages _ : .z.. _ . _ _ _ , ..* _ . . .,. . _ _ _ . 2-6

Resistance Ranges .~_ _~. ~. , _~~,~_, .~. . .~_ . . . . ~ _. . _ . . . . . _ . . _ _ _ _ . 2-11

Comparison of Average and TRMS Meter Readings _ _. _, . .._....... . . _. __ __. 2-15

DMM Setup Programs _ _ _ . . . _ . _ _ _ . ,~. . .~, r ;. _. . _ .~. .~ _ .~_ 2-16

Typical Minimum Usable Scan Intervals .~_ .~.~. . . . . . , _ _ __ .._ . .._.,___ 2-38

SECTION 3-IEEE-488 Progamming

3-l

3-2

3-3

3-4

3-5

56

3-7

3-8

3-9

3-10

3-11

3-Y

3-w

3-14

3-15

3%

IEEE-488 Commknds USed to Select Function and Range. . . , _ . _.. . . _ . . . 3-3

JEEEContact Designations...: . . . . ~; . ~;~:~;::.~ . . . . . . . . :: .~..;..: . . . .._............ . . . ..I . . ~::~ . . . . .

Model 199 Interface Function Codes . . _~_ .~. . . ~. . . . _~_. _ __ _ . . . _ . 3-6

BASIC Statements Necessary to Send Bus Commands. _ . .~. . . . . . _ . _. . . _ . . . .~_. . . 3-7

Front Panel IEEE-488 Messages. . . _~.~~_ ~ ,.~. __, . _. _ __ _.. _ _ _ _ __ __ _ . 3-8

General Bus Commands and Associated BASIC Statements , .,. . . _., , __ _ _ _ _ _ _. _ _. . . . . . , _ . 3-10

FactoryDefaultConditions ____..._._.... .__._..._._ jj ____._......_.._...__ _~ t________....... ~..~ . . . . 3-11

Device-Dependent Command Summary .~_.. _ _ . _ _ _ _ _ .;,. _ _,. _ _ . _ . . _ . .~. 3-14

Range Comniand Summary . _~_ ,. . .,~_~_ _ _ _ __ _ _ _>_. 3-17

Rate Command Summary.. ..~. . _. _.._... .._. ..~ . . . .~.. . _. . . . . . . . 3-li3

SRQ Command Parameters . _~ _~_ .~_, . . . , . _ . . . . . _ _ . _ _ . _ _ _ _ 3-23

Bus Hold-off Times (Typical) . _ _~~_ ~_~L .~. _ , . _ _ _ _ _ _~_ _ _ I . _ _ _ _ . _ . _ _ . _ _ _ . _ _ _ _ _ _ _

Translator Reserved Words and Character . . . . 330

Translator Error Messages . . . _ _ , . _ . .~. .~. . . . . _ . _.. _, . . . . _ . I 3-32

TypicaITriggertoFirstByteOutliies __. . ...,,.. ~1.__...,..__.__ I____ I.... Y;;.:....,. _ ._.__...__ 336

Scanner Programming Commands. _ . _ . I _~ L _ _ _ _ _ . _ .._ _ _ . _ . . . _.. . _, . _ . . _ _

3-5

3-25

3-37

SECTION 4-Performance Verification

4-l

4-2

4-3

4-4

4-5

4-6

Recommended TZ+s Equipment .~, _ _ _ _ _ _ _ _ _ _ _ _ _ . ~ I in. I~ _ _~~_ _ ~. _ 4-1

Liits for DC Volts Verification.~. _. _. _ _ _ , _ _ _ _,. .,_% ,.,.” . _. _~_ iia.l . . . . . .,,. .,_. _i _ _~_,_,. __,_ 4-2

Limits for TRMS AC Volts Verification .~_ .~_ _. _ = _, . . . ,::. .lI.. ,~. . _ .,_. 4-3

LiitsforOHmsVerification _.___.._. _ . . . . . . . . _ ________....SC...~l~ _ ,,,._j___._._ Liil..___l‘L . . . . 44

Limits for DC Current Verificatidn. . . . . . . . . . . . . . . . . . .._. _..,... ~ . . . ,,.. . . . . .._. i_ . . . . . 4-4

Limits for AC Current VeriFication. .~. _~_ _ . . _ _ . . . _. _ . __ ~.~_. _. . _. 4-5

SECTION 5-Principles of Operation

5-l

Input Buffer Ampliiier (U46) Gain Configtiration . .‘. . _ . _ . . _ _ . . . . . . . 5-8

ix

Page 19

SECTION 6-Maintenance

6-l

6-2

6-3 Current Fuse Replacement .........................................................

6-4

6-5

6-6 Resistance Calibration

6-7 TRMS AC Volts Calibration .....................................................................

6-8

6-9

6-10

6-11

6-12

6-13

6-14 Display Circuitry Checks .........................................................................

645

line Voltage Selection

Line Fuse Replacement ............................................................................

Recommended Calibration Equipment

DC Volts Calibration

DC Current Calibration ............................................................

TRMS AC Current Calibration ..................................................................

Recommended Troubleshooting Equipment

~ModelWTroubIeshootingMode

Power Supply Checks

Digital Circuitry .Checks .......................................................................

ScannerBoard Checks

.............. .

.........................

........................................................

...................

......................

...... _, ..........................................................

.......... :

........................................................

........................

_.~.~ ..... .

.......................................

_~~_~_

.................................

.I .........................................

...

..~................~....................~

APPENDIX C-IEEE-488 BUS OVERVIEW

C-l

c-2

c-3

C-4

c-5

IEEE-488 Bus Command Summary _ _~. . . _1_ C-3

Hexadecimal and Decimal Command Codes _ _ . . . _ . . . . .._ . . ~. .~_

Typical Addressed Command Sequence : .~. : .~.~1. . .,. . .~; .~. _~. _~. ; C-7

Typical Device-Dependent Command Sequence I _~ .~. . . _, . C-7

IEEE Command Group.. . . .~ _~_ .~.~, _. . . . . . . L

,~. ......................

_. ....... _~ ...... ~,-^~.

I ...

,

.......

_

...

, ... , 6-6

. . 6-1.2

.. 6-19

1

.........

L.. I.. ...

I

....

L_.

....... .. ...

......... - .... ~.-~.~

.........

6-l

6-2

6-2

.~,_ 6-3~

1 ~6-8

6-9

6-13

6-18

6-21

6-21

6-22

6-22

C-7

C-7

Page 20

i~fl10N I

General Information

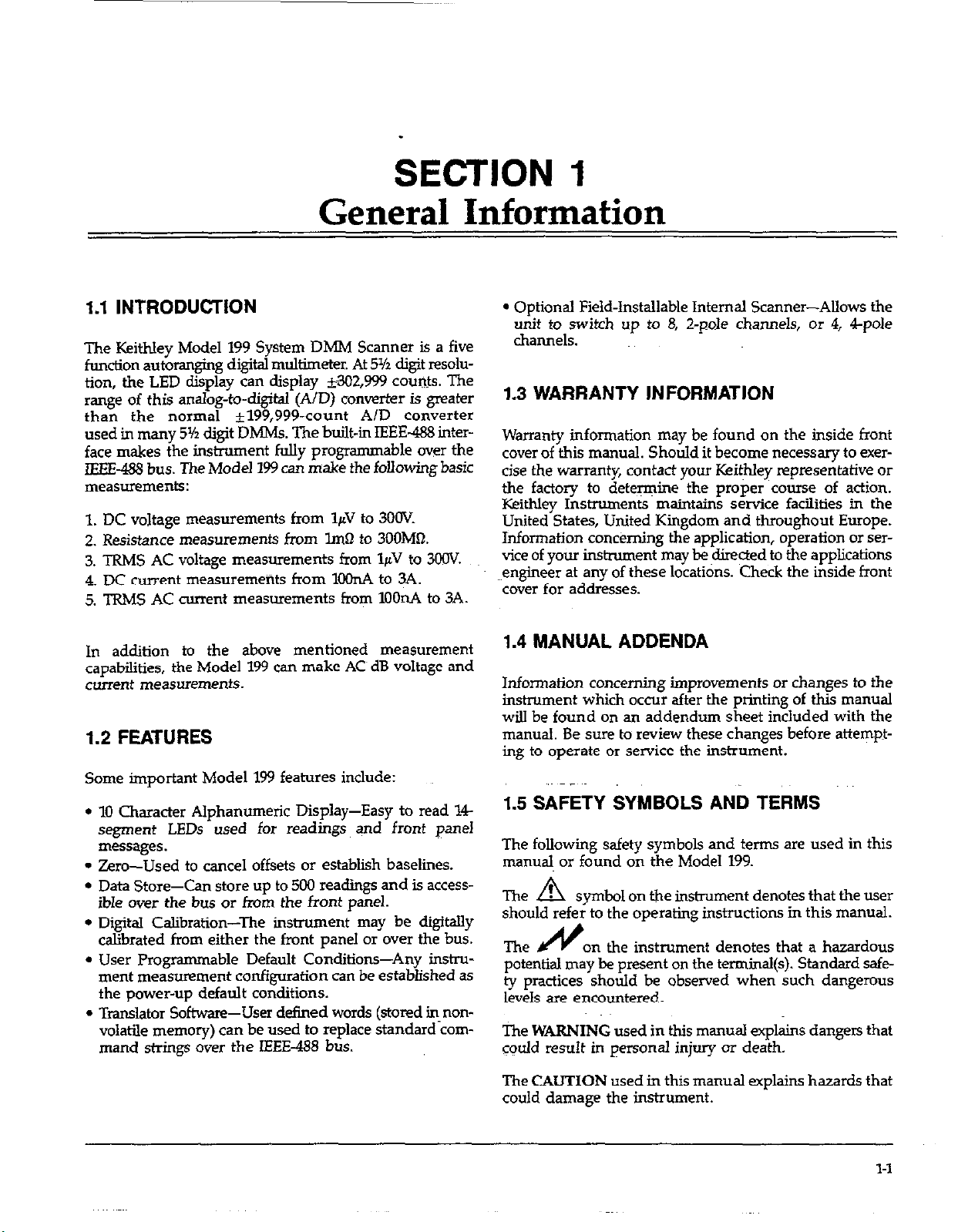

1.1 INTRODUCTION

The Keithley Model 199 System DhJM Scanner is a five

function autoranging digital multimeter. At 5% digit resolu-

tion, the LED display can display &02,999 counts. The

range of this analog-to-digital (A/D) converter is greater

than the normal *199,999-count A/D converter

used in many 5% digit DMMs. The built-in IEEE-488 titerface makes the instrument fully programmable over the

LEEE-488 bus. The Model 199 can make the foBowing basic

measurements:

1. DC voltage measurements from l&V to 3OOV.

2. Resistance measurements from II& to 3OOMR.

3. TRMS AC voltage measurements from 1pV to 309V.

4. DC current measurements from lOOnA to 3A.

5. I’RMS AC current measurements from lOOnA to 3A.

In addition to the above mentioned measurement

capabilities, the Model 199 can make ACT dB voltage and

current measurements.

1.2 FEATURES

l Optional Field-Installable Internal Scanner-Allows the

unit to switch up to 8, 2-pole channels, or 4, 4pole

channels.

1.3 WARRANTY INFORMATION

Warranty information may be found on the inside front

cover of this manual. Should it become necessary to exercise the warranty, contact your KeithIey representative or

the factory to determine the proper course of action.

Keithley Instruments maintains service facilities in the

United States, United Kingdom and throughout Europe.

Information concerning the application, operation or service of your instrument may be directed to the applications

engineer at any of these locations. Check the inside front

cover for addresses.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

will be found on an addendum sheet included with the

manual. Be sure to review these changes before attempting to operate or service the instrument.

Some important Model 199 features include:

l 10 Character Alphanumeric Display-Easy to read 14

segment LEDs used for readings and front panel

messages.

l Zero-Used to cancel offsets or establish baselines.

l Data Store-Can store up to 500 readings and is access-

ible over the bus or from the front panel.

l Digital Calibration-The instrument may be digitally

calibrated from either the front panel or over the bus.

l User Programmable Default Conditions-Any instru-

ment measurement configuration can be established as

the power-up default conditions.

l Translator Software-User defined words (stored innon-

volatile memory) can be used to replace standard command strings over the IEEE-493 bus.

1.5 SAFETY SYMBOLS AN6 TERMS

The following safety symbols and terms are used in this

manual or found on the Model 199.

The A

should refer to the operating instructions in this manual.

The&

potential may be present on the terminal(s). Standard safe-

ty practices should be observed when such dangerous

levels are encountered.

The WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains hazards that

could damage the instrument.

symbol on the instrument denotes that the user

on the mstrument denotes that a hazardous

l-1

Page 21

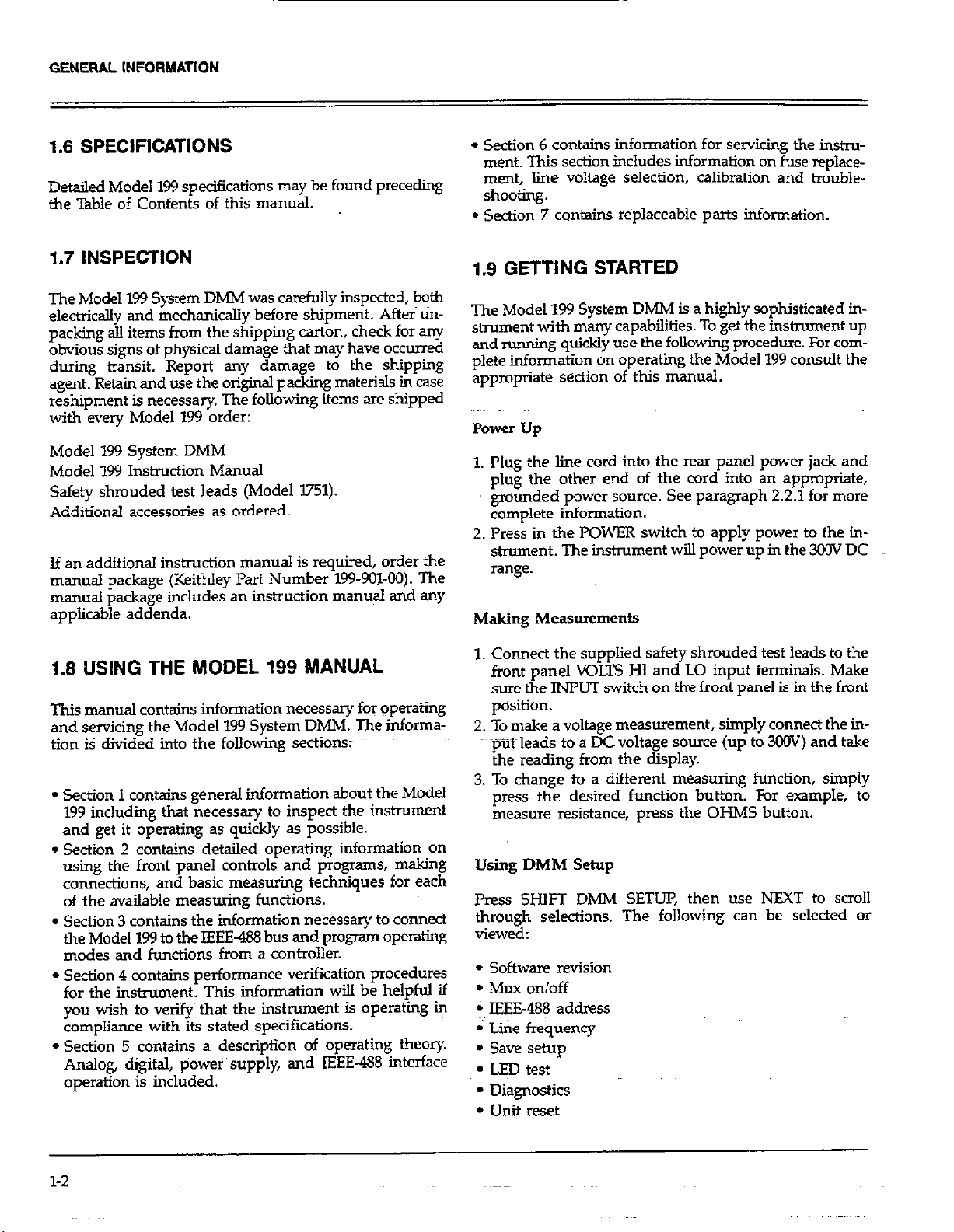

GENERAL INFORMATION

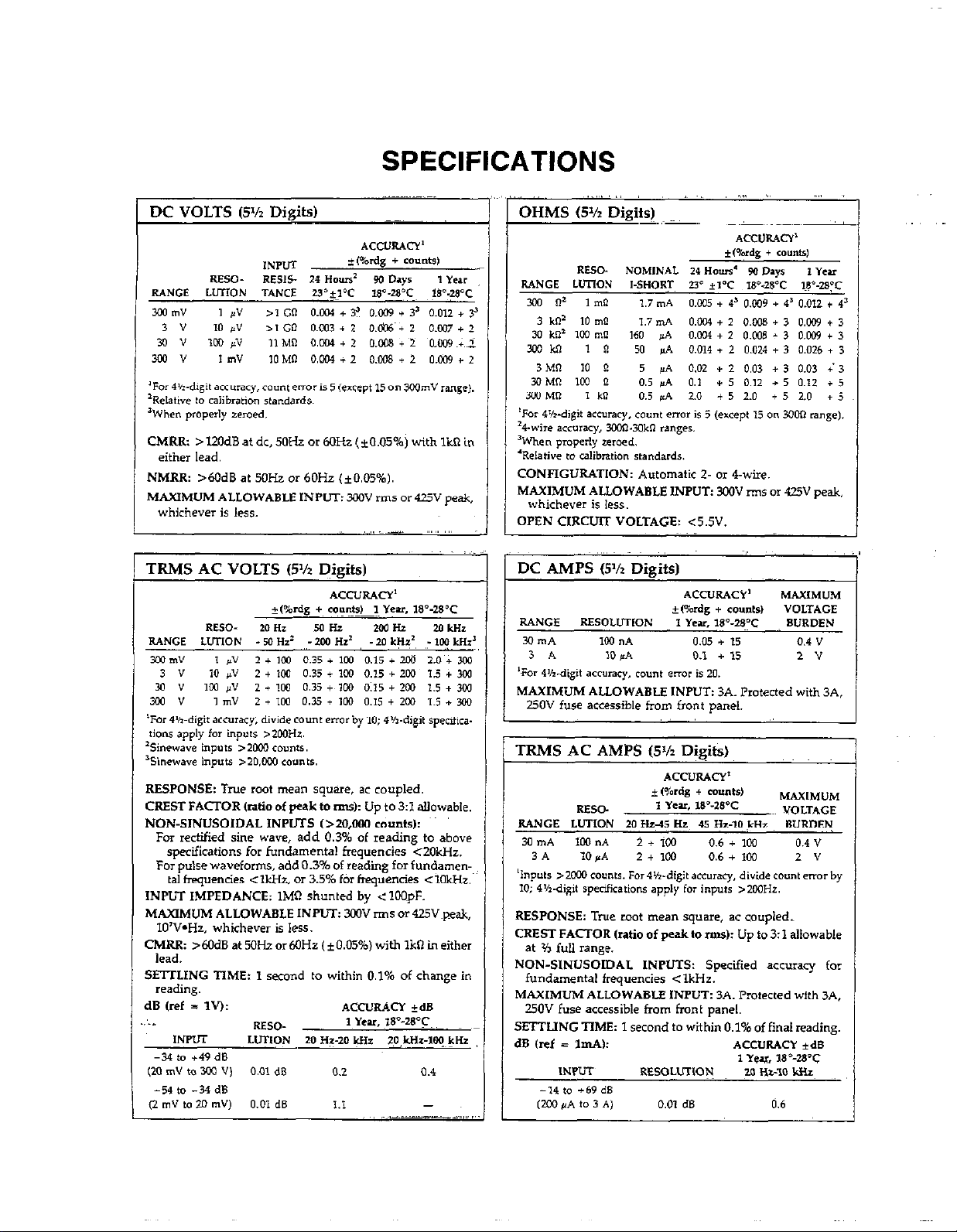

1.6 SPECIFICATIONS

Detailed Model 159 specifications may be found preceding

the Table of Contents of this manual.

1.7 INSPECTION

The Model 199 System DMM was carefully inspected, “th

electricalIy and mechanically before shipment. After Unpacking all items from the shipping carton, check for any

obvious signs of physical damage that may have occurred

during transit. Report any damage to the shipping

agent. Retain and use the original packing materials in case

reshipment is necessary, The following items are shipped

with every Model 159 order:

Model 199 System DMM

Model 199 Instruction Manual

Safety shrouded test leads (Model 1751).

Additional accessories as ordered.

If an additional instruction manual is required, order the

manual package (Keithley Part Number 199-901-00). The

manuai package includes an instruction manual and any~

applicable addenda.

* Section 6 contains information for servicing the instru-

ment. ‘Ihis section includes information on fuse replacement, line voltage selection, calibration and troubleshooting.

l Section 7 contains replaceable pats information.

1.9 GETTING STARTED

The Model 199 System DMM is a highly sophisticated in-

strument with many capabilities. To get the instrument up

and running quickly use the following procedure. For complete information on operating the Model 199 consult the

appropriate section of this manual.

Power up

1. Plug the line cord into the rear panel power jack and

plug the other end of the cord into an appropriate,

grounded power source. See paragraph 22.1 for more

complete information.

2. Press in the POWER switch to apply power to the instrument. The instrument will power up in the 3WV DC

range.

Making Measurements

1.8 USING THE MODEL 199 MANUAL

This manual contains information necessary for operating

and servicing the Model 199 System DMM. The informa-

tion iS divided into the following sections:

l Section 1 contains general information about the Model

199 including that necessary to inspect the instrument

and get it operating as quickly as possible.

l Section 2 contains detailed operating information on

using the front panel controls and programs, making

connections, and basic measuring techniques for each

of the available measuring functions.

l Section 3 contains the information necessary to connect

the Model 199 to the IEEE488 bus and program operating

modes and functions from a controller.

l Section 4 contains performance verification procedures

for the instrument. Thii information will be helpful if

you wish to verify that the instrument is operating in

compliance with its stated specifications.

l Section 5 contains a description of operating theory.

Analog, digital, powei supply, and IEEE-488 interface

operation is included.

1. Connect the supplied safety shrouded test leads to the

front panel VOLTS HI and Lo input terminals. Make

sure the INPUT switch on th-e front panel is in the front

position.

2. To make a voltage measurement, simply connect the in-

~.~rrufleads to a DC voltage source (up to 30OV) and take

ihe reading from the display.

3. To change to a different measuring function, simply

press the desired function button. For example, to

measure resistance, press the OHMS button.

Using DMM Setup

Press SHIFT DMM SETUF, then use NEXT to scroll

through selections. The following can be selected or

viewed:

l Software revision

l MUX on/off

l IEEE-1188 address

l Line frequency

l save setup

l LED test

l Diagnostics

l unit reset

l-2

Page 22

GENERAL INFORMATION

For all selections except software revision and IEEE488 address, use uprangeidownrange to toggle the selection.

Pa’a~;p~~p,provides the detailed information for using

1.10 ACCESSORIES

The~following accessories are available to enhance Mode1

199 capabilities.

Model 1651 SO-Ampere Current Shunt--The Model 1651 is

an external O.oOlQ *l% 4-terminal shunt, which permits

current measurements from 0 to 5OA AC or DC.

Model 1681 Clip-On Test Lead Set-The Model 1681 contains two leads, 1.2m (4 ft.) long terminated with banana

plugs and spring action clip probes.

Model l682A RF Probe-The Model 1682A permits voltage

measurements from 1oOktrz to 25OMH.z. AC to DC t&&r

accuracy is *ldB from 1OOkHz to 25OMHz at IV, peak

responding, calibrated in RMS of a sine wave.

Model 1685 Clamp-On AC Probe-The Model 1685

measures AC current by clamping on to a single conductor. Interruption of the circuit is unnecessary. The Model

1685 detects currents by sensing the changing magnetic

field produced by the current flow.

phone tips (0.06 DIA.), two hooks and miniature alligator

clips (with boots).

Model 1992 4/8 Channel Scanner-The Model 1992 Scan-

ner option allows scanning of four, 4-pole channels, or

eight, 2-pole channels. The Model 1992 installs within the

Model 199 with connections available on the rear panel of

the instrument.

Model 1993 Quick Disconnect Scanner Connector Kit-

The Model 1993 includes two connector blocks, 10 tie

wraps, and two sets of red and black output cables for~the

Model 1992 Scanner Card.

Model 1998 Rack Mounting Kit-The Model 1998-l Single

Fixed Rack Mounting Kit mounts a single Model 199 in a

~~

gandard 19 inch rack. The Model 1998-2 Dual Fied Rack

Mounting Kit mounts two Model 199s side by side in a

standard 19 inch rack.

Model 5806 Kelvin Clip Lead Set-The Model 5806 includes

two Kelvin clip test lead assemblies with banana plug termination (one red, one black). A set of eight replacement

rubber bands for the Model 5806 is also available (Keithley

PIN GA-22).

Model 7007 IEEE-488 Shielded Cables-l-he Model 7007

connects the Model 199 to the IEEE-488 bus using shield-

ed cables to reduce electromagnetic interference @MI). The

Model 7007-1 is one meter in length and has a EMI shielded IEEE-488 connector at each end. The Model 7007-2 is

identical to the Model 7007-1, but is two meters in length.

Model 1751 Safety Test Leads-Finger guards and

shrouded banana plugs help minimize the chance of

making contact with live circuitry.

Model I754 Universal Test Lead Kit-The Model I754 is a

12 piece test lead kit, with interchangeable plug-in accessories. Induded in the kit is one~set Of test leads (l-red,

l-black), two spade lugs, hvo standard banana plugs, two

Model 7008 IEEE488 Cables--The Model 7008 connectsthe

Model 199 to the IEEE-488 bus. The Model 7008-3 is 0.9m

(3 ft.) in length and has a standard IEEE-488 connector at

each end. The Model 7008-6 cable is identical to the Model

7008-3, but is 1.8m (6 ft.) in length.

l-3/1-4

Page 23

SECTION 2

Basic DMM Operation

2.1 INTRODUCTION

Operation of the Model I.99 can be divided into two general

categories: front panel operation and IEEE-188 bus op~ation. This section contains information necessa?y to use

the instrument from the front panel. These functions can

also be programmed over the IEEE-488 bus, as described

in Section 3.

2.2 POWER UP PROCEDURE

2.2.1 Line Power

Use the following procedure to connect the Model 199 to

line power and power up the instrument.

1. Check that the instrument is set to correspond to the

available lie power. When the instrument leaves the

factory, the externally selected line voltage is marked on

the rear panel. Ranges are 105WZ5V or 21OV-25OV

50/6OHz AC (9GllOV, 180~220V with optional transformer). If the line voltage setting of the instrutitint

needs to be changed, set switch as required. If the line

frequency setting of the instrument needs to be checked

and/or changed, utilize front panel DMM SETUP (see

paragraph 2.7) after the instrument completes the power

up sequence (the line frequency is displayed upon

power up).

2. Ctmnect the female end of the power cord to the AC

receptacle on the rear panel of the instrument. Connect

the other end of the cord to a grounded AC outlet.

WARNING

The Model 199 is equipped with a 3-wire power

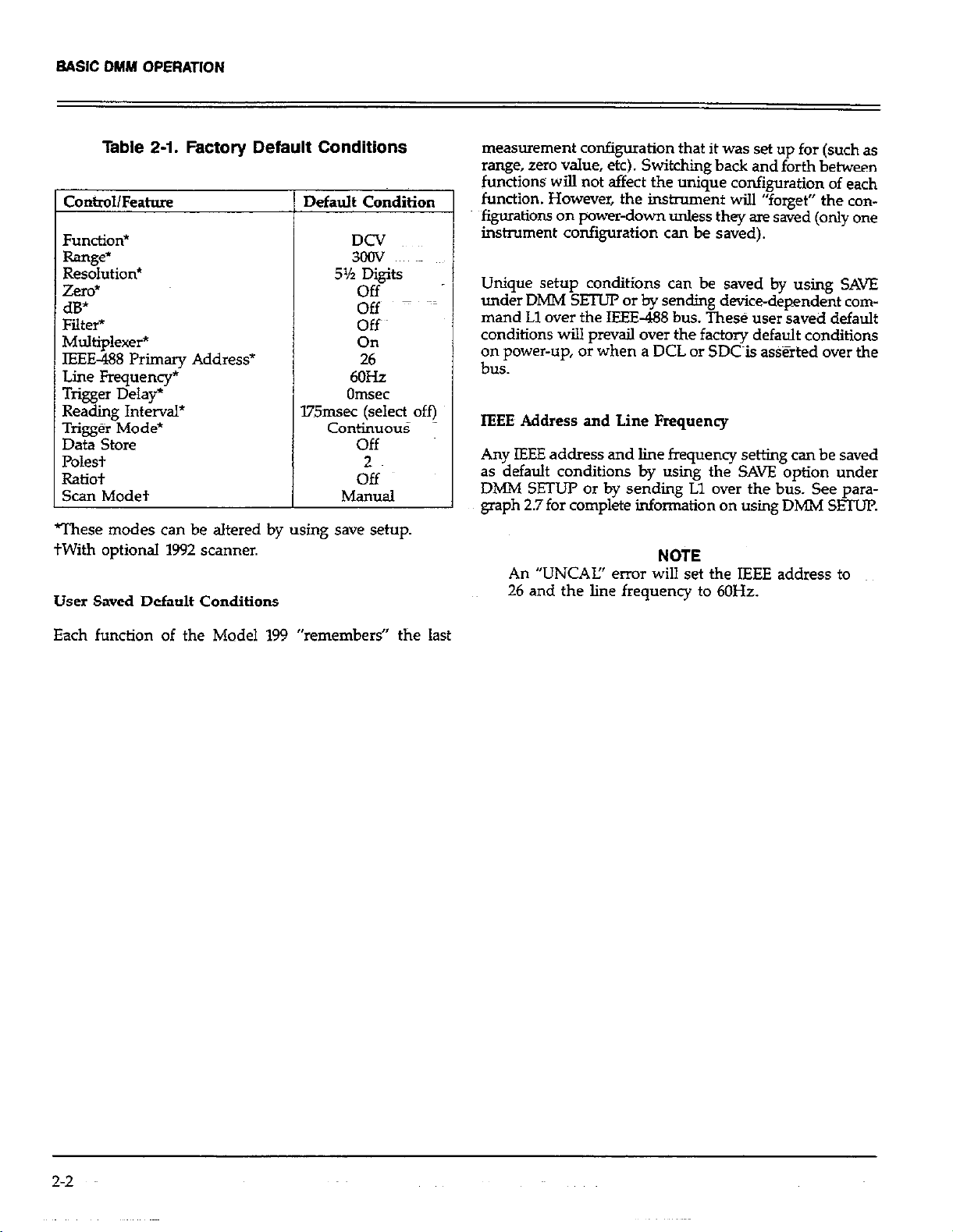

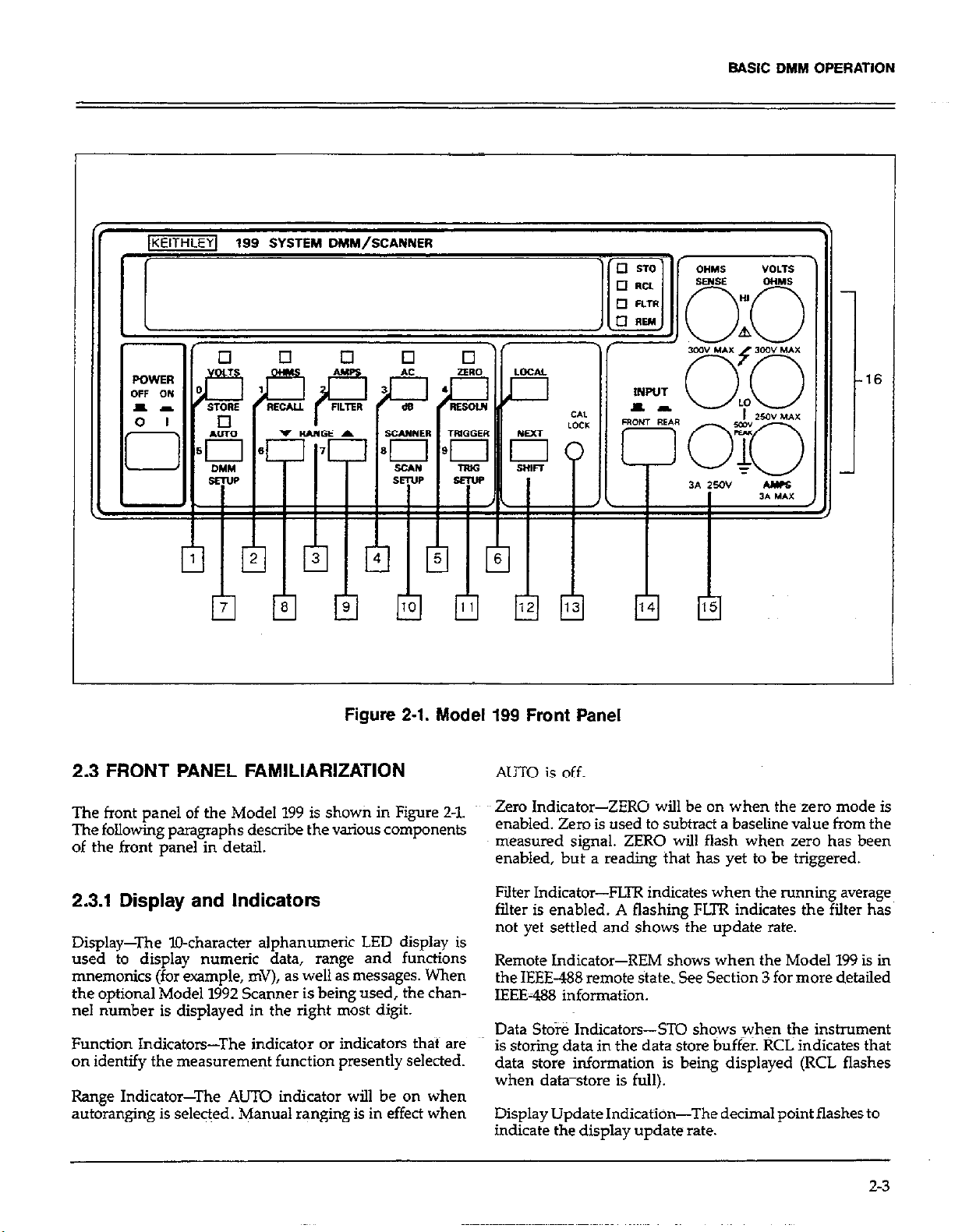

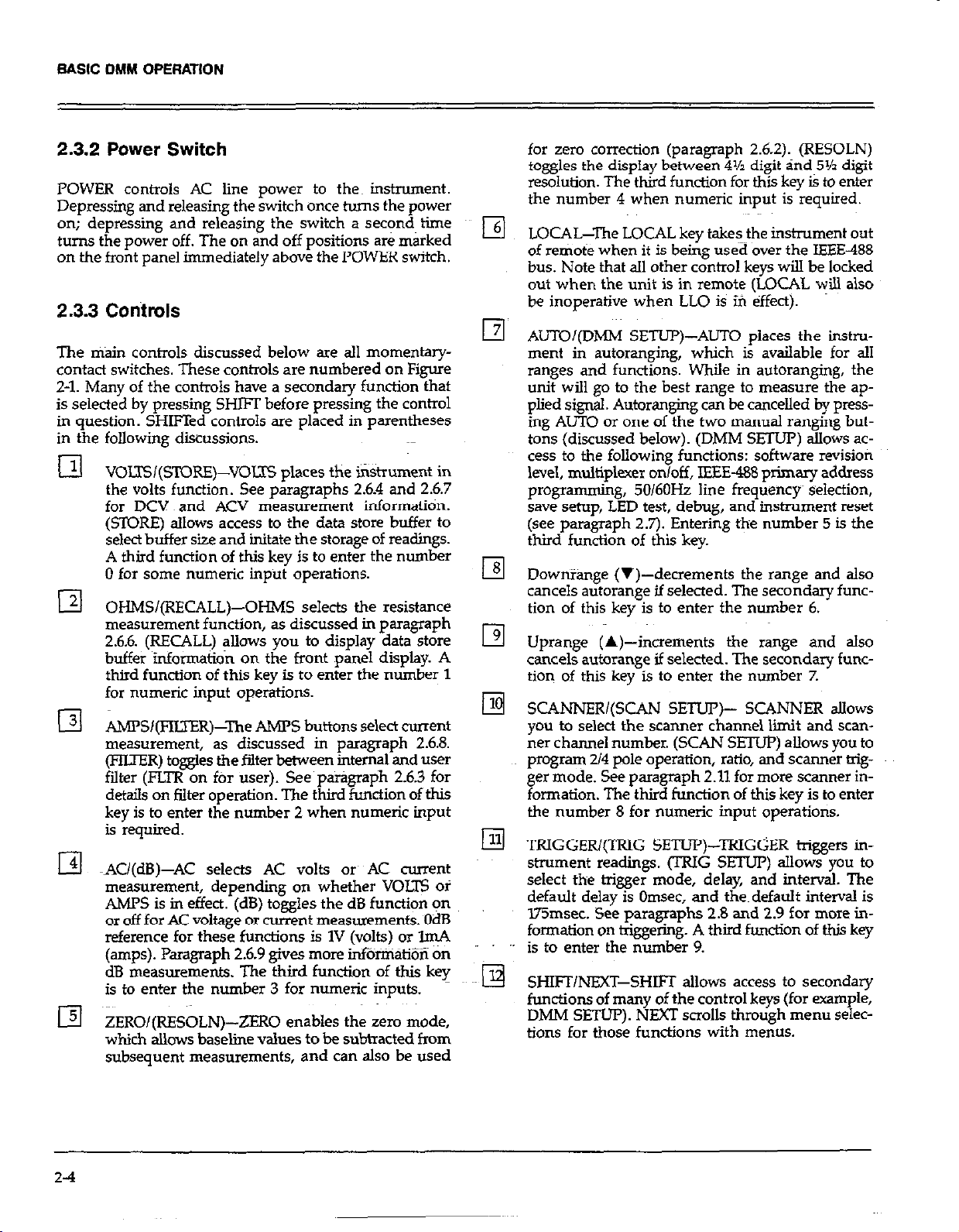

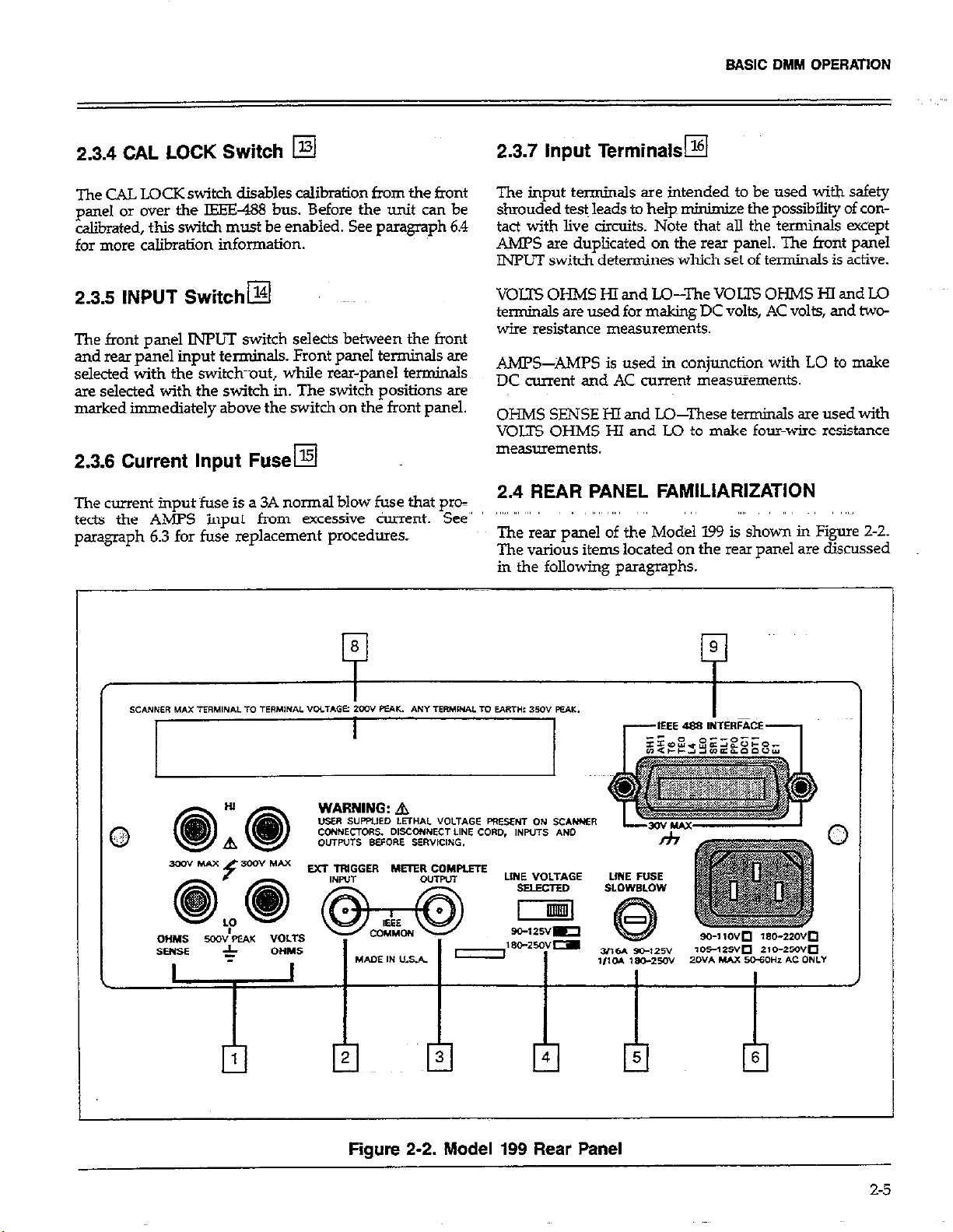

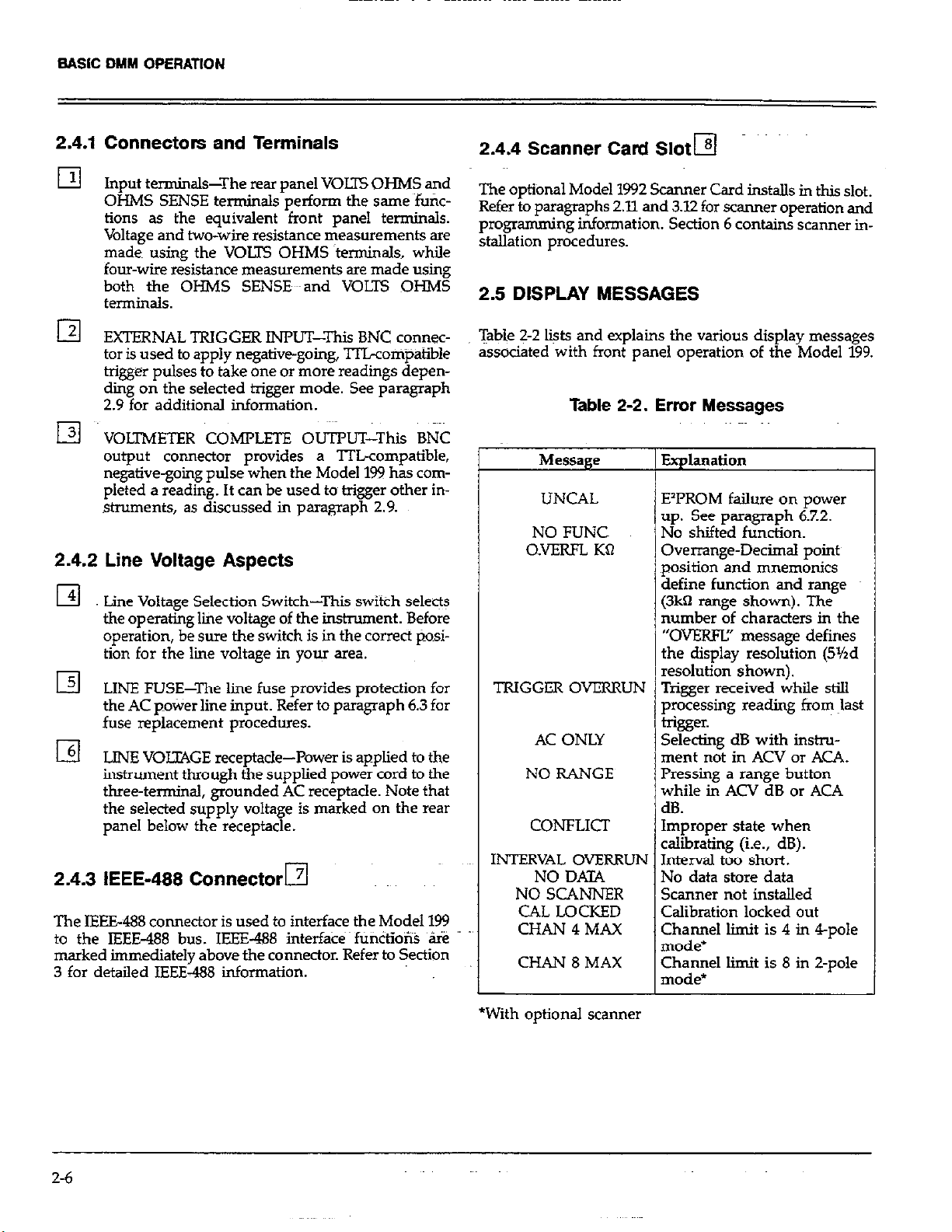

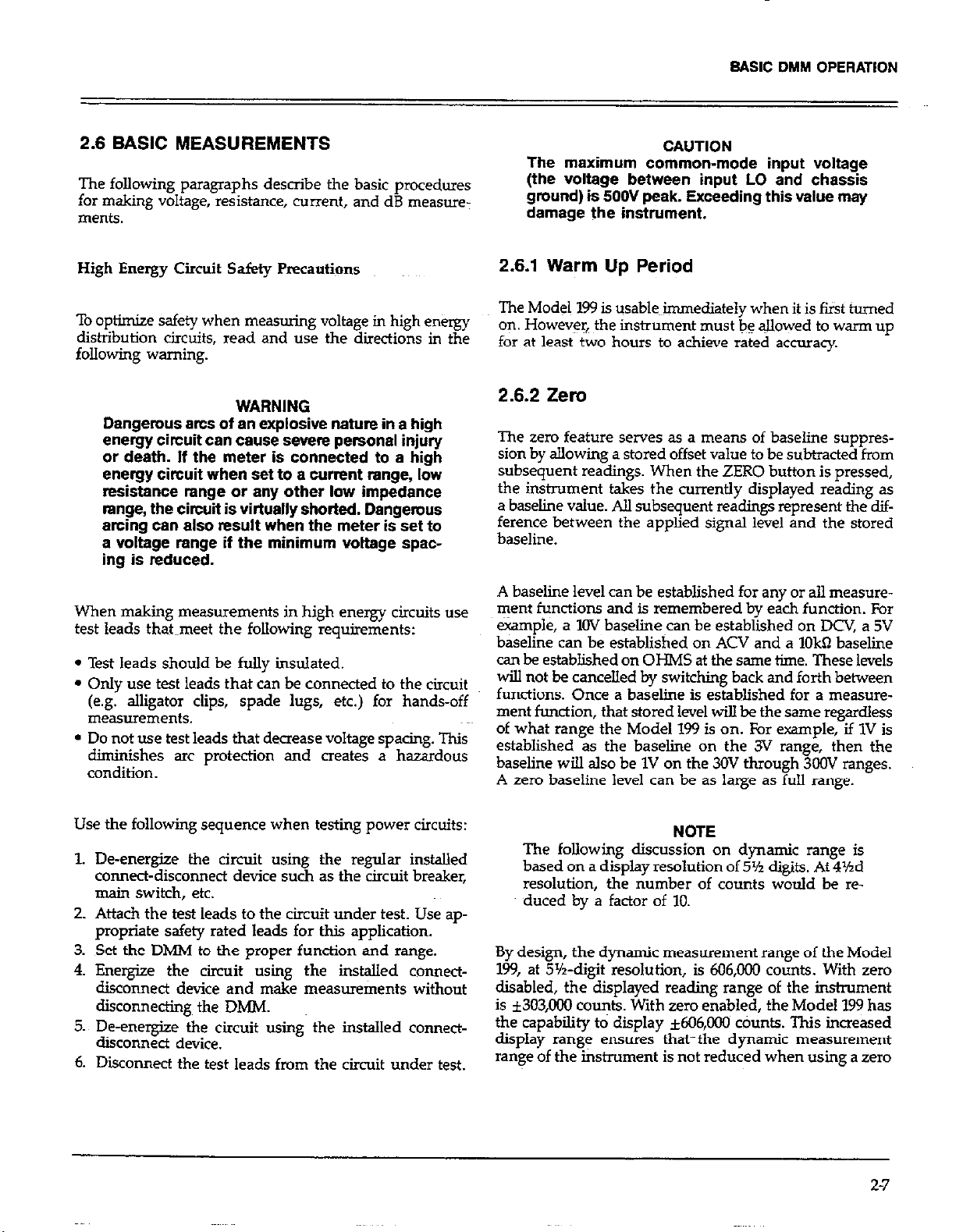

cord that contains a separate ground wire and