Page 1

Instruction Manual

Model

197

Autoranging Microvolt

DMM

0

Keit hley Instruments, Inc.

Cleveland,

Document Number 197-901-01

Ohio,

U.S.A.

Page 2

DC

VOLTS

RANGE LUTION RESISTANCE 22'-24"C 18"-28'C

-

200mV

2V

20

200

loo0

*Relative to calibration accuracy.

NMRR:

Greater than 6OdB at

MAXIMUM ALLOWABLE INPUT:

minute on the 200mV and 2V ranges; 300V rms continuous).

SETTLING TIME

dB

MODE

0.OldB above

TRMS

RANGE 50Hz* 1OkHz' 20kHz'

200mV

2V - 200V

~ ~~~ ~~ ~ ~ ~ ~~~

750V

'Above

1800

MAXIMUM ALLOWABLE INPUT:

minute on 200mV and 2V ranges, 300V

3dB

BANDWIDTH:

INPUT IMPEDANCE:

1.1MR

paralleled by 75pF on

SETTLING TIME:

dB

MODE

RANGE INPUT lOkHz 20kHz 50kHz 100kHz

2V - 750V 200mV to 750

200mV 20mV to 200mV 0.18

RESOLUTION:

DC

AMPS

RANGE RESOLUTION

200 uA

2mA lOnA 0.3V

20mA 100nA 0.3V

200mA

2000mA

10

"Above 5A derate

*'When properly rereod.

OVERLOAD PROTECTION: mA

10A

Input: 20A for

SETTLING TIME:

TRMS

AC

RANGE BURDEN ZOHz

200pA - 20mA 0.3V

200mA 0.3V

2ooOmA

10

*Above 1800 counts. "1kHz max. Above 5A derate

SETTLING TIME:

RESO- INPUT 24

1

V

V

v

10

100

1

rV

pV

pV

ImV

OmV

>iGR

>

1GR

iiMR

1OMR

1OMR

"When properly zeroed.

50Hz.

60Hz

lO00V

1

second to within 3 counts of final reading

(ref:

ma):

Accuracy: &(0.02dB+I count) above -78dBm. Resolution:

0.5%

of range

"OLTsACCURACY (1

2OHz-

1.00+100

1.00+700

1.25+100

*'Above

counts.

3JOkHr typical.

1MR paralleled by less than 75pF

1

second to within

(ref: 600R):

Yr.)

50Hz-

0.35+100

0.35+100

0.75+100 1.0+200 1.8+250 3+400

18000

counts.

750V

rms,

rms

200mV,

2V and 2OV ranges. Capacitively coupled.

0.1

%

20Hz- 10kHz- 20kHz- 5OkHz-

V

(-

12 to 59.8dBmj

(-32 tn -12dBmj

2mV to 20mV

(-52 to -32dBm)

1mVto 2mV 2.00 3.00

(-58 to -52dBm)

0.OldB above 0.5% of range.

1

nA

1

PA 0.3V 0.2

10

A

pA

100

pA 0.3V 0.75+15'

0.15%

rdg per amp for self-heating.

15s.

unfused.

1

second to within 3 count5 of final reading.

0.18

0.85

MAXIMUM ACCURACY

VOLTAGE 18"-28'C

BURDEN

Input: 2A fuse (250V), externally accessible.

AMPS

MAXIMUM 18'-28"c

VOLTAGE

A 0.3V

0.8V

1

second to within

-

50Hz 50Hz - lOkHz 10kHz - 30kHz

1.0+100

l.O+IOO

1

OflW

1.5+100**

0.1%

*0.1%.

dc

or

18"-28"C

lOkHz

0.6+200

0.6+200

IOOOV

continuous). lO'V*Hr maximum.

of final reading on range.

ACCURACY

0.3V

0.8V

ACCURACY

of final reading.

ACCURACY

*(%rdg+counts)

Hr.,*

0.007+2 0.016+3

0

005+2 0.011+2

0

m6+2 0.015+2

0.006+2 0.015+2

0.007+2 0.015+2

peak ac (less than

on

range.

~~

*(%rdg+counts)

20kHz - 50kHz-

-

50kHz'* 100kHz"

1.5+250 5+400

1.5+250 3+400

peak (less than

on

200V and 750V ranges.

(

+-dBm)

0.18 0.28

0.18

1.10

0.8+100

08+100

08+100

1.0+100'*

0.15%

0.28 0.65

2.00

-

*(%rdg+counts)

0.1

0.1

0.1

0.2 +I5

(1

Yr.)*

+(%rdg+counts)

rdglamp for self-heating.

10

+15'*

+I5

+I5

+I5

**

1 Yr.,

seconds per

10

seconds per

0.50

~

-

(1

Yr.)

2 + 250

-

-

-

OHMS

RANGE

200

n

2 kR*

20 kQ lOOmR 400pA 4.0V 0.014+2 0.026+2

200 kR*

2MR"

20MR"'

200MR**

'When properly zeroed.

CONFIGURATION:

MAXIMUM ALLOWABLE INPUT:

rms

continuous.

OPEN-CIRCUIT VOLTAGE:

DIODE TEST:

nominal.

SETTLING TIME:

RESO- NOMINAL ACROSS 24 HI.. 1

LUTION I-SHORT

1mR

1OmR

1

R

10

n

100

R

10

kR

'*Appropriate range selected automatically in MR.

Automatic 2-

Display reads junction voltage

2 seconds to within 3 counts of final reading on range.

OUTPUT

MAX

v

ACCURACY

~

?(%rdg+counts)

UNKNOWN 22 -24°C 18

2mA

2mA 4.0

40pA 4.0V 0.014+2 0.026+2

4

aA

400nA 4.0V

400

nA

or

4-terminal.

450V dc

+5V.

or

peak ac

05V

4.0V

5.0V

up

001

V

0.01

0.02 +2 0.035+2

0.10

2.00

10

seconds per minute. 350V

to 2.2V Test Current: 1.6mA

+2' 002 +3'

+2 0 018+2

+2 0.12 +2

+1

2.00

Yr.

-28°C

GENERAL

DISPLAY:

RANGING:

RELATIVE:

DATA LOGGER

CONVERSION RATE:

OVERRANGE INDICATION: "OL"

CREST FACTOR

MAXIMUM COMMON MODE VOLTAGE:

COMMON MODE REJECTION RATIO (1kR

TEMPERATURE COEFFICIENT (Oo-lS0C & 28 -50-C):

ENVIRONMENT:

WARMUP:

POWER:

DIMENSIONS, WEIGHT:

ACCESSORIES SUPPLIED:

ACCESSORIES AVAILABLE:

*220,oo0 count LCD.

indication.

dc amps

Model

Model 1017:

Model 1301: Temperature Probe

Model 1600A. High Voltage Probe

Model 1641

Model 1651: 50-Ampere Current Shunt

Model

Model 1682A: RF Probe

Model 1684:

Model

Model 1751: Safety Test Leads

Model 1754:

Model 1972:

Model 1973: IEEE-488 Interface

Model 1978: Rechargeable Battery Pack

Model 7008-3: IEEE-488 Digital Cable (3

Model 7008-6: IEEE-488 Digital Cable

Model 8573.

Auto

or

manual

made with respect to baseline value Front panel annunciator indicates REL mode.

six selectable rates from 3 readingslsecond to

ing. Also detects and stores maximum and minimum readings continuously while

data logger mode.

SOHr, 6OHz

accuracy specification)/'C.

linearily derate 3% RH/"C, 35"-50"c. Storage: -25' to 60-C.

50-60Hz,

in.

I'ushbutton allows zeroing of

and

MIN/MAX:

(ratio

+0.1%.

Operating: O"-5O0C; less than

1

hour to rated accuracy.

105-125V or 210-25OV (external switch selected).

12V.A. Optional 5-hour battery pack, Model 1978.

X

10%

in.). Net weight 1.8kg

Single Rack Mounting Kit

1010:

Dual Rack Mounting Kit

Kelvin Test Lead Set

:

Clip-On Test Lead Set

1681:

Hard Shell Carrying Case

1685:

Clamp-On Ac Probe

Universal Test Lead Kit

IEEE-488 with Analog Output

IEEE-488 Interface for IBM

(use with 1972l3)

0.45

in. height; polarity, function, range. and status

on

dc volts, ac volts, and ohms: manual on ac amps and

on

range readings. Allows readings to be

100

reading storage capacity: records data at one of

1

reading;hour

3 readings/second.

of

Greater than 6OdB in ac volts.

displayed.

peak value to rms value),

89mm high X 235mm wide X 275mm deep (31 2 in.

Model 1751 safety te5t leads, instruction manual.

500V

peak

unbalance): Greater than 12OdB at dc,

80%

(3

Ibs., 14

OL

1.

ft

)

(6

it.)

IT

or

by manual trigger-

AC FUNCTIONS:

*

(0.1

X

applicable one year

relative humidity up to 35'C:

90-llOV

3.

available;

+1

X

in

91

4

Specifications subject to change without notice

Page 3

TABLE

OF

CONTENTS

SECTION 1-GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.5

2.6

2.6.1

2.6.2

2.6.3

2.7

2.7.1

2.7.2

2.7.3

2.7.4

2.7.5

2.7.6

2.7.7

2.7.8

2.7.9

2.7.10

2.7.11

2.7.12

2.8

2.8.1

2.8.2

2.8.3

2.8.4

Introduction

Features

Warranty Information

ManualAddenda

Safety Symbols and Terms.

...

Specifications

Unpacking and Inspection

Using the Model

Initial Operation

Accessories

...........

..............................................

....

......................................

..............................

.........................................

.

197

Manual

... ................................................................

......................

.............................

......................................................

......................................................

......................................................

SECTION 2-BENCH OPERATION

Introduction

High Energy Circuit Safety Precautions

Preparation For Use

LinePower

BatteryPackPower

Battery Charging.

Front Panel Familiarization

Display

Front Panel Controls

Input Terminals

Current Fuse Replace

ErrorMessages

Operating Conditions.

Environmental Conditions

Maximum Allowable Inputs

WarmUp

Basic Bench Measurements

PowerUp

Relative Mode

TRMS

Microvolt Measurement Considerations

Resistance Measurements

Current Measurements (DC or TRMS

AC Plus

dB Measurements

dB Measurements Considerations and Applicatio

MIN/MAX and

Diode Test

TRMS

AC

Voltage Offset

TRMS

CrestFactor

Extended Frequency Response

....................

...............................

.....

.........................................

..................................................................

....................................

....................

..................................

............................................

...

..............................................................

...

.............................

......................................................

...........................................................

................

......................................................

......................................................

................................

..............................

...........................................

................................

ent

..................

AC

Voltage Measurements

..............................

......................

AC)

DC

Measurements

..............

100

Point Data Logger Operatio

....................

Considerations

.............

Measurement Comparison

.........................................

..........

.

......................................................

.......................

..........

..........

.................

.........

.....................

...........................................

......................

.................................

.................

.....................

......

...........

...........................................

...............

..........................................

..........................................

.....................

..................

.....................

..................

.....................

..................

......................

......................

....................

....................

..........

........

..........

..........

..........

.........

......

1-1

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-2

2-1

2-1

2-1

2-1

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-4

2-4

2-4

2-4

2-4

2-4

2-5

2-5

2-6

2-6

2-7

2-8

2-9

2-10

2-13

2-14

2-14

2-14

2-14

i

Page 4

SECTION

3-

PERFORMANCE VERIFICATION

3.1

3.2

3.3

3.4

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

4.1

4.2

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.4

4.4.1

4.4.2

4.4.3

4.4.4

4.5

4.6

4.7

Introduction

Environment itions

Recommended Test Equipment

Initial Conditions

..

Verification Procedure

DC Voltage Accuracy Check

AC Voltage Accuracy Check

Resistance Accuracy Check

DC Current Accuracy Check

AC Current Accuracy Check

........................................................

......

..................

.............................

........

..................... ............................

...........

............

...........

.............

.................................................

..................................................

SECTION 4-THEORY OF OPERATION

Introduction

Overall Functional Description

Analog Circuitry.

Multiplexer

Input Buffer Amplifier

AC Converter

PIA

Display Board

Digital Calibration

Model

..................................................

........................................................

........................

................................................

.......

.....

.................................................

.................................................

.....

......................

1978

Battery Option

. . ......................................................

.................................................

......................................................

.......................................................

...

............................

...................

............................

.....................................

.......................

..................................

.............

.....................................

................

........................

...........................

............................

......

...........................................

........................

.................

3-1

3-1

3-1

3-1

3-2

3-2

3-3

3-5

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-4

4-5

4-5

4-5

4-6

4-6

4-6

4-7

5.1

5.2

5.3

5.4

5.5

5.5.1

5.5.2

5.6

5.6.1

5.6.2

5.6.3

5.6.4

5.6.5

5.6.6

5.6.7

5.6.8

5.7

5.7.1

5.7.2

5.7.3

-___

ii

SECTION 5-MAINTENANCE

Introduction

Top Cover Removal/Installation

Battery Pack (Model

Line Voltage Selection

Fuse Replacement

Line Fuse Replacement

Current Fuse Replacement

Front Panel Calibration

Recommended Calibration Equipment

Environmental Conditions

Calibration Jumper

DC Voltage Calibration

AC Voltage Calibration

Frequency Compensation.

Resistance Calibration

Calibration Storage

Troubleshooting

PowerUpSequence

Self Diagnostic Program

Power Supply and Battery Pack (Model

....................................

1978)

Installation

...................

.................................................

....

....................................

.

.................

...........................................

........................

............................................. ............

.................

.....................................

...............

.......................................

........................

............................... ............................

.............................................

............................

...............

........................................

......................................................

........................................

.....................

...................................

......................................

........................................

.......................................

1978)

Checks

......................................

............................

.............................

....

....................

........................

.......

...............

...................

..........

5-1

5-1

5-1

5-2

5-2

5-2

5-2

5-4

5-4

5-4

5-4

5-5

5-5

5-5

5-7

5-7

5-8

5-8

5-8

5-9

ild

Page 5

5.7.4

5.7.5

5.8

A/D Converter and Display

Signal Conditioning

.......................

Special Handling of Static Sensitive Devices

................

.....

SECTION 6-REPLACEABLE PARTS

.......

.......

.......

......................

......................

......................

...

......

......

...

....

......

5-9

5-9

5-9

6.1

6.2

6.3

6.4

6.5

Introduction

Replaceable Parts

Ordering Information

Factory Service

..............................

..........................

.......................

............................

.......

..

......

..

......

..

......

Schematic Diagrams and Component Location Drawings

......................

..

......................

..

......................

..

......................

..

.........................

...

..

...

...

...

..

........

...

......

......

......

....

6-1

6-1

6-1

6-1

6-1

...

Ill

Page 6

LIST

OF

TABLES

2-1

2-2

2-3

2-4

2-5

2-6

2-7

3-1

3-2

3-3

3-4

3-5

3-6

5-1

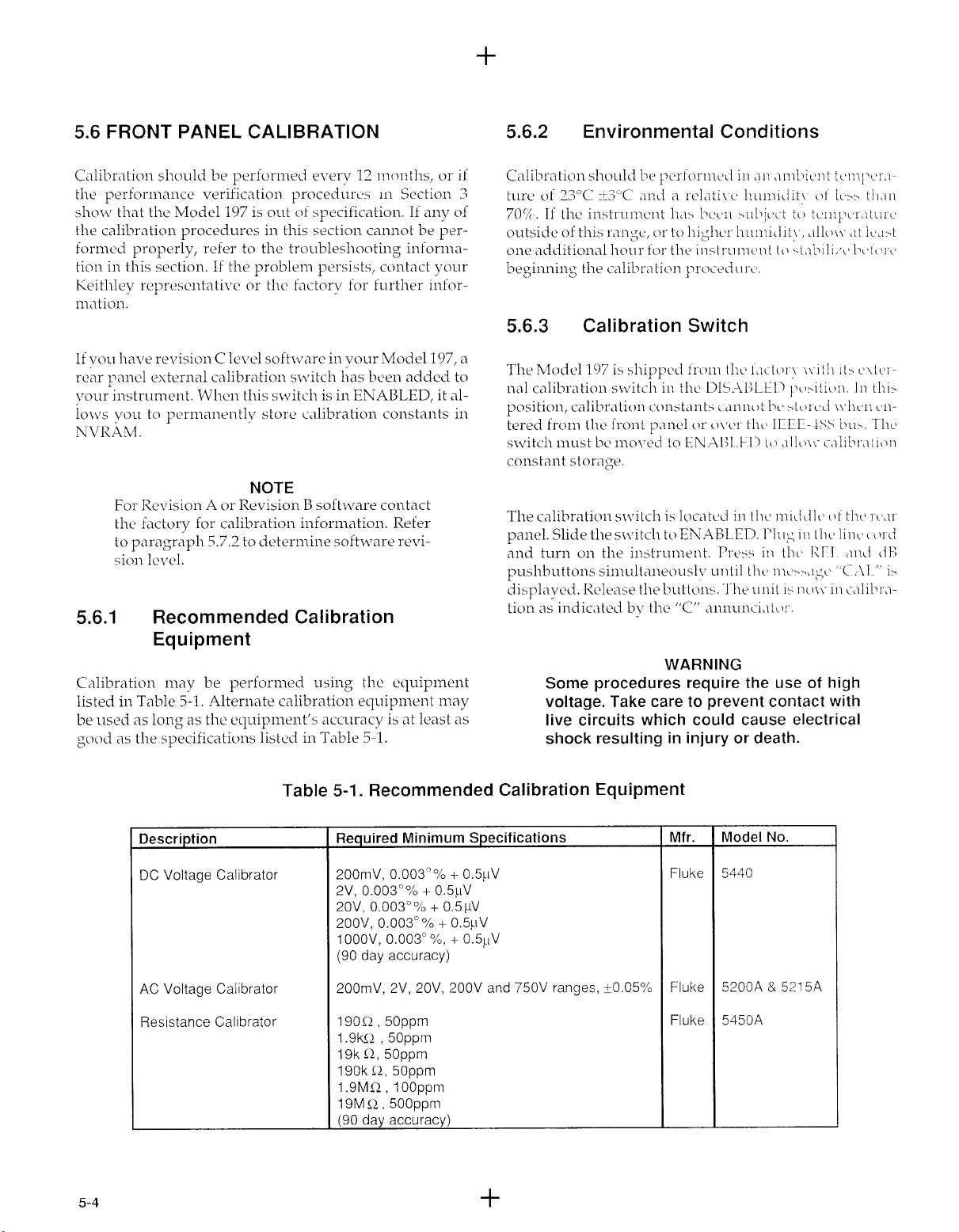

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

ErrorMessages

Model 197 Maximum Allowable Inputs

Resistance Range Output Values

dB Specification for DC Volts (600fl Ref)

dB Specification for AC Volts (600fl Ref)

Levels for Other Reference Impedances

Comparison of Average and

Recommended Test Equipment

Limits for DC Voltage Verification

Limits for AC Voltage Verification

Limits for Resistance Verification

Limits for DC Current Verification

Limits for AC Current Verification

Recommended Calibration Equipment

DC Voltage Calibration

ACVoltageCalibration

Resistance Calibration

Recommended Troubleshooting Equipment

Model 197 Troubleshooting Mode

.........................................................

.......

..........................................................

............................. ................

..................................................

...................................................

TRMS

...............................................

.................................................................

................................................

Meter Readings

...........................................................

..............

........................................................

................................................

............

........................................................

.....................................................

.................................................

.....................................

Power Supply and Battery Pack (Model 1978) Checks

DisplayBoardChecks

A/D Converter Checks

Model 197 Static Sensitive Devices

.................................................................

...............................

.......................................................

.........

.................................

......................................

......................

....

......................

........

..........

........

.......................................

..............

2-4

2-5

2-8

2-10

2-11

2-12

2-15

3-1

3-2

3-3

3-3

3-4

3-6

5-4

5-5

5-6

5-7

5-8

5-10

5-12

5-12

5-13

5-13

6-1

6-2

6-3

Model197PartsList

Display Board. Parts List

....................................................................

................................................................

Model 1978 Battery Pack. Parts List

.......................................................

6-3

6-6

6-6

iv

Page 7

LIST

OF

ILLUSTRATIONS

2-1

2-2

2-3

2 -4

2-5

2-6

2-7

2-8

2-9

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

4-1

4-2

4-3

4-4

4-5

4-6

Model 197 Front Panel

DC Voltage Measurements

TRMS AC Voltage Measurements

Two Terminal Resistance Measurement

Four Terminal Resistance Measurement

Four Terminal Zeroing

Current Measurements Between 2

Current Measurements up to 2000mA

Typical ACV Frequency Response

Connections for

Connections for ACV Verification

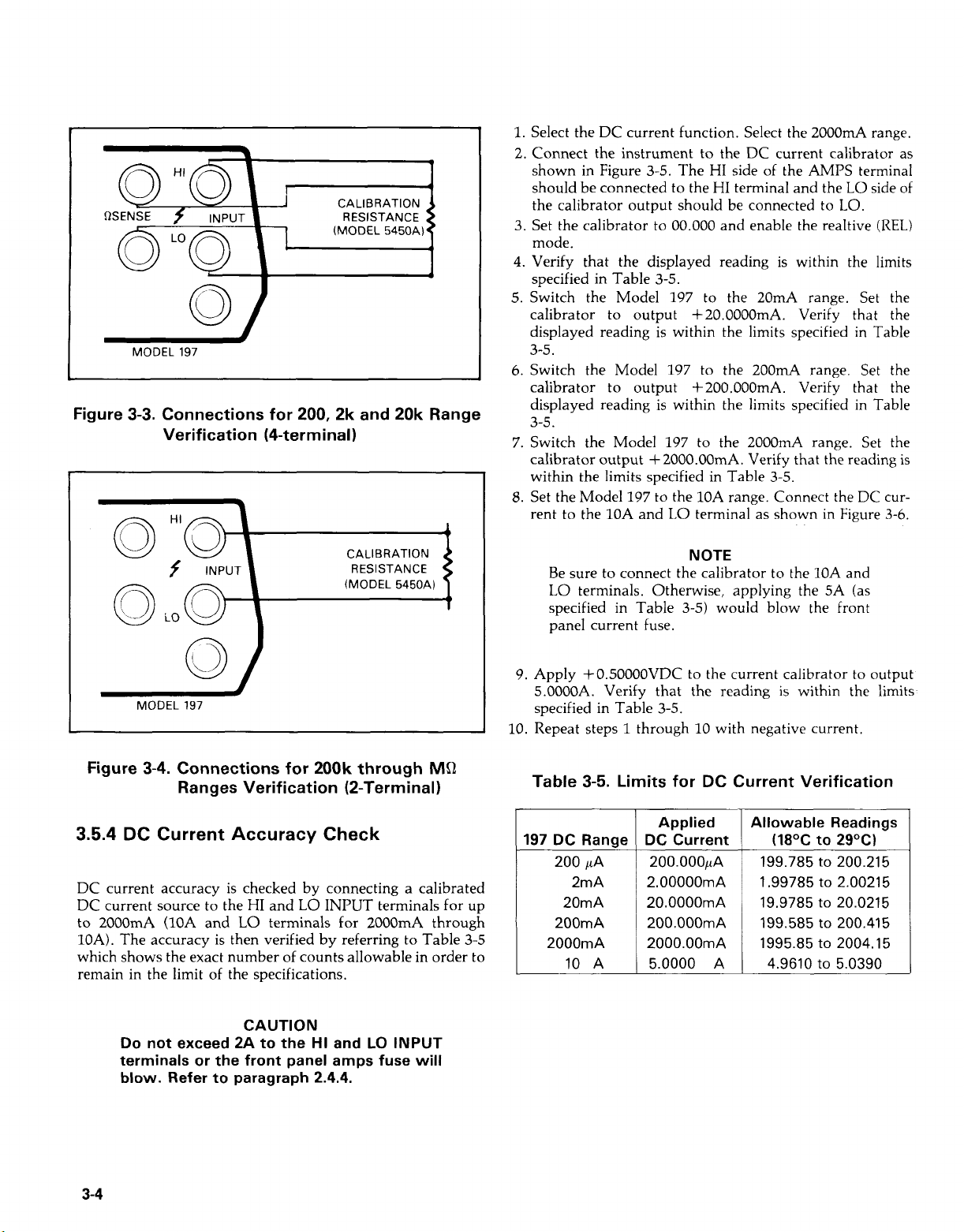

Connections for 200, 2k and 20k Range

Connections

for

Connections for DC Current Verification (200pA to 2000mA)

Connections for DC Current Verification (2000mA to 20A)

Connections for AC Current Verification (200pA to 2000mA)

Connections for AC Current Verification (2OOOmA to 10A)

Simplified Block Diagram

JFET Multiplexer

Simplified Schematic of the Input Buffer Amplifier

.......................

...................

........................................................

.................................

.................................

.... ....................

....

DCV

.........

Verification

.........................................

.........

.......................................................

...

.................................

................................

...

...............................

200k through MU Ranges Verification (2-Terminal)

..................................

...................................

..................................

...................................

....

............

........................................................

........................................................

..........................................

............................

Input Configuration During 2- and 4-Terminal Resistance Measurements

Resistance Measurement Simplified Circuit

A/D Converter

...........

.................................................

................................................

....................

..................

..................

........................

2-2

2-6

2-7

2-9

2-9

2-9

2-10

2-10

2-15

3-2

3-3

3-4

3-4

3-5

3-5

3-6

3-6

4-2

4-3

4-3

4-4

4-5

4-6

5-1

5-2

5-3

5-4

5-5

5-6

5

-7

6-1

6-2

6-3

6-4

6-5

6-6

6-7

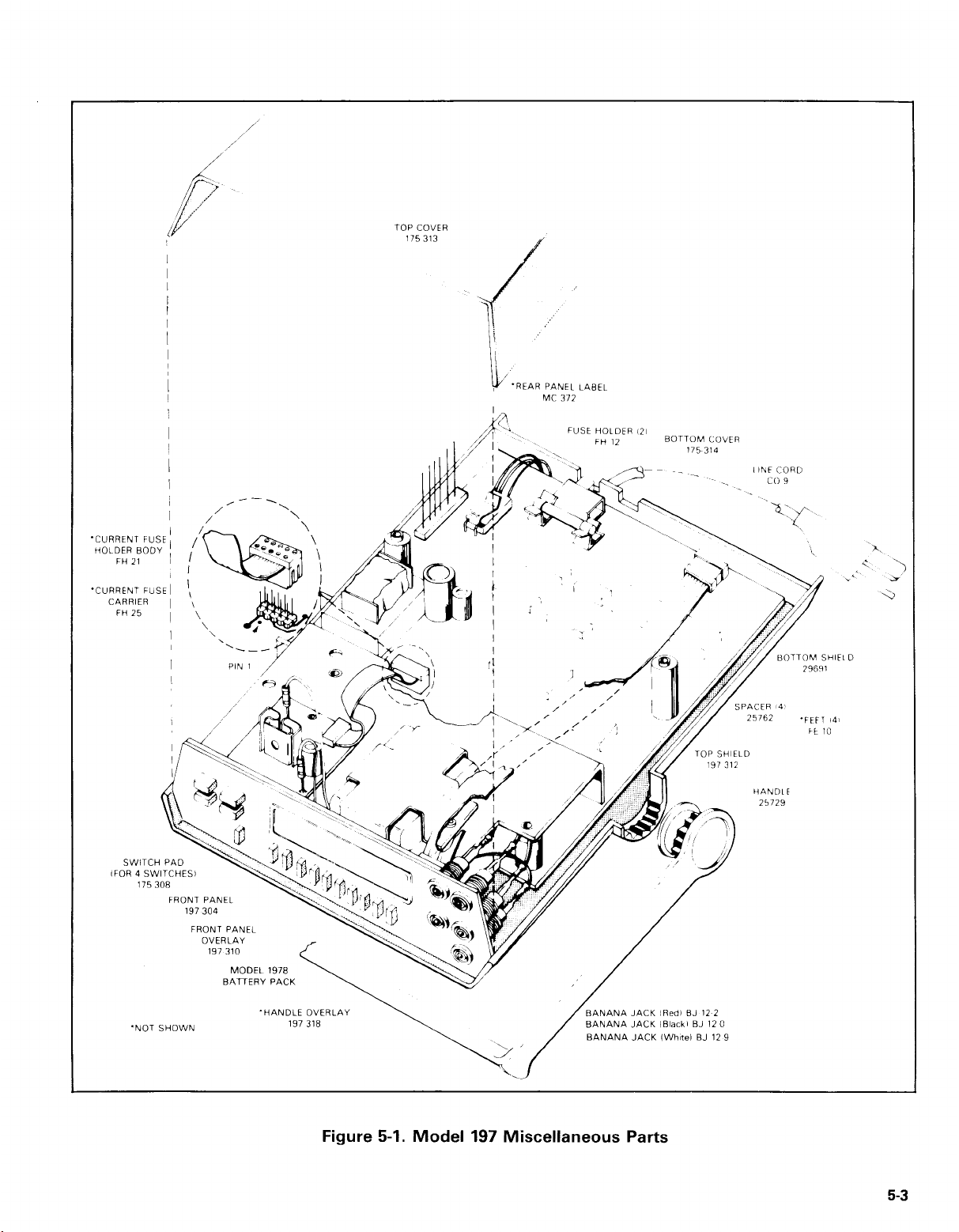

Model

DCI

197

I<TJ~:II

ON

Miscellaneous Parts

REVISION

C

........

....

DC Voltage Calibration Configuration

AC Voltage Calibration Configuration

.................................................

................................................

...................................................

...................................................

200, 2k and 20k Four Wire Resistance Calibration

200k. 2M and 20M

Segment Identification

Display Assembly, Exploded View

Model 1978 Battery Pack, Compone

Two

Wire Resistance Calibratic

...............................

................................................

ion Drawing, Dwg

Mother Board, Component Location Drawing, Dwg

Display Board, Component Location Drawing, Dwg

Mother Board, Schematic Diagram, Dwg

Display Board, Schematic Diagram, Dwg

.

No

.

.

No

197-106

.

197-116

Model 1978 Battery Pack, Schematic Diagram, Dwg

.

.

.

No

No

No

.

197-100

.

197-110

......

.....

.

1978-106

...........

.............................

.

No

.

1978-100

............

.............................

................

.............................

......

..........

...............

. .

.................

...

.........

.......

5-3

5-5

5-5

5-7

5-7

3-7

5-9

6-1

6-7

6-11

6-13

6-15

6-17

vlvi

Page 8

SAFETY

PRECAUTIONS

The following safety precautions should be observed before operating the Model

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar with the

safety precautions required to avoid possible injury. Read over the manual carefully before operating this instrument.

Exercise extreme caution when a shock hazard is present at the instrument's input. The American National Stan-

dards Institue (ANSI) states that a shock hazard exists when voltage levels greater than 30V rms

present.

measuring.

Inspect the test leads for possible wear, cracks or breaks before each use.

leads that have the same measure of safety as those supplied with the instrument.

For optimum safety do not touch the test leads or the instrument while power is applied to the circuit under test.

Turn the power off and discharge all capacitors, before connecting or disconnecting the instrument. Always

disconnect all unused test leads from the instrument.

Do

line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface,

capable

A

good safety practice is to expect that a hazardous voltage

not touch any object which could provide a current path to the common side of the circuit under test or power

of

withstanding the voltage being measured.

is

present in any unknown circuit before

If

any defects are found, replace with test

197.

or

42.4V peak are

Exercise extreme safety when testing high energy power circuits (AC line

tion.

Do

not exceed the instrument's maximum allowable input as defined in the specifications and operation section.

or

mains, etc). Refer to the operation sec-

Page 9

SECTION

GENERAL INFORMATION

1.1

INTRODUCTION

The Model 197 is a six function,

autoranging digital multimeter with a

(Liquid Crystal Display). This

normal +-199,999 count

5%

The

voltage from 1pV/count to

measurements are standard in the Model 197. TRMS ACV

capability ranges from IpVlcount to

measures resistance from 1mQ to 220MQ on seven resistance

ranges. The Model 197 has six current ranges that measure

current from 1nA (lO-9A) to 10A.

digit resolution allows the Model 197 to measure

A/D

A/D

used in many

1OOOV.

5?h

digit resolution

+-220,000

range is greater than the

count LCD

5?h

digit DMMs.

DC

AC

voltage and current

750V.

The Model 197

1

6.

5%

Digit Resolution-The Model 197 has a +220,000

count A/D that surpasses the more common k199,999

count A/D.

Four

7.

8.

1.3

Terminal Ohms-These terminals are used to

eliminate the voltage drop across the current carrying

leads.

Sensitivity-The Model 197 has 1pV, ImQ and 1nA sensitivity. The IpV of sensitivity allows minute levels of offset, temperature etc. A 1nA sensitivity allows low current

measurements without special equipment. Measure

leakage, bias and offset current. A ImQ sensitivity allows

easy low resistance measurements.

WARRANTY INFORMATION

The dB function makes

of readings into a much smaller scope. The Model 197 dBm

measurements are referenced to the standard

but can be modified with the use of relative

The Model 197 has two IEEE-488 interface options: The

Model 1972 and the Model 1973. These optional interfaces

enhance the capabilties of the Model 197 by allowing programmed control over the IEEE-488 bus. The Model 1972 also

includes an analog output. The bus commands are the same

for each interface and respond to IEEE-488 protocol.

1.2

FEATURES

The Model 197 includes the following features:

Six Measurement Functions-DCV, ACV, DCA, ACA,

1.

OHMS

(REL) Relative Mode-The relative mode allows offsets to

2.

be nulled out (e.g. test lead resistance for low resistance

measurements) and selects a variety of reference impedances for dB measurements.

Digital Calibration-A non-volatile

3.

tion constants and can be performed from the front panel

or

Data Logger-A data storage buffer is included to allow

4.

up to

internally stored at a user selectable rate. The buffer may

be read and controlled from the front panel

IEEE-488 bus. In the talk-only mode, the output rate can

also be programmed.

Autoranging-The Model 197 includes a fast autoranging

5.

feature for easier measurements.

and dB all built in.

over the IEEE-488 bus.

100

readings and minimum/maximum readings be

it

possible to compress a large range

600Q

impedance

(REL)

feature.

RAM

stores calibra-

or

over the

Warranty information may be found on the inside front cover

of this manual. Should

warranty, contact your Keithley representative

to determine the proper course of action. Keithley Instruments maintains service facilities in the United States,

United Kingdom and throughout Europe. Information con-

cerning the application, operation

ment may be directed to the applications engineer at any of

these locations. Check the inside front cover for addresses.

1.4

MANUAL ADDENDA

Information concerning improvements or changes to this instrument which occur after the printing

found on an addendum sheet included with this manual. Be

sure to review these changes before attempting to operate

service the instrument.

1.5

SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual or found on the Model 197.

The symbol

refer to the operating instructions in this manual.

The symbol &n the instrument denotes that a potential

1OOOV

of

ard safety practices should be observed when such dangerous

levels are encountered.

A

or

more may be present on the terminal(s). Stand-

it

become necesary to exercise the

or

the factory

or

service of your instru-

of

this manual will be

or

on the instrument denotes the user should

1-1

Page 10

The

WARNING

that could result in personal injury

The

CAUTION

that could damage the instrument.

heading used in this manual explain dangers

heading used in this manual explain hazards

or

death.

NOTE

The Models 1973 and 1972 IEEE-488 interfaces

come supplied with their own instruction

manual.

1.9 INITIAL OPERATION

1.6 SPECIFICATIONS

Detailed Model 197 specifications may be found preceding

the table of contents of this manual.

1.7 UNPACKING AND INSPECTION

The Model 197 Autoranging Microvolt DMM was carefully

inspected, both electrically and mechanically before shipment. Upon receiving the instrument, carefully unpack all

items from the shipping carton and check for any obvious

signs of physical damage that may have occurred during transit. Report any damage to the shipping agent. Retain and use

the original packing materials in case reshipment is necessary.

The following items are shipped with every Model 197 order:

Model 197 Autoranging DMM

Model 197 Instruction Manual

Model 1751 Safety Shrouded Test Leads

Additional accessories as ordered.

If

an additional instruction manual is required, order the

manual package (Keithley Part Number 197-901-00). The

manual package includes an instruction manual and any applicable addenda.

1.8 USING THE MODEL 197 MANUAL

This manual contains information necessary for operating

and servicing the Model 197 Autoranging Microvolt DMM

and the Model 1978 Rechargeable Battery Pack. The informa-

tion is divided into the following sections.

1.

Section 2 contains detailed bench operation information

for the Model 197.

2. Section 3 contains the information needed to verify the accuracy of the Model 197. Performance verification can be

done upon receipt of the unit

curacy of the instrument is in question.

3.

Information concerning theory of operation, maintenance

and servicing is contained in Sections 4 through

or

whenever the basic ac-

6.

Perform the following steps in sequence to acquaint yourself

with the basic operation of the Model 197.

Verify that the instrument was not damaged in transit, (see

paragraph 1.7).

Carefully read over all safety information (see Section

Basic Operation).

Refer to paragraph 2.3 (Line Power) and set the line voltage

switch. Plug the power cord into a properly grounded

receptacle. If the Model 1978 is installed the charging circuit

is activated.

Acquaint yourself with the front panel controls as follows:

1.

Turn on the instrument using the ON/OFF button. All of

the zeroes are briefly displayed.

2. Connect the supplied test leads to the HI and

minals. Connect the red test lead to the HI terminal and

the black test lead to the

together.

3. Select AC volts and autoranging by pressing in the

AC/DC, V and AUTO buttons. The AC, AUTO and mV

annunciators are displayed. Pressing in any of the other

range buttons activates manual ranging. This is indicated

by the absence of the AUTO annunciator.

4. Select DC volts by releasing (out position) the AC/DC

V

button.

5.

Select the autoranging OHMS by pressing in the AUTO,

and

symbol is displayed. Press the AC/DC button in (means

select AC) and note that the "Err" message is displayed.

This indicates an invalid mode.

6.

Select AC or DC current by setting the AC/DC button ac-

cordingly and pressing in the A button. The annunciator

that reflects the selected mode

rent will not autorange. The 10A and

be used on the 10A range.

7. Select dB by selecting AC

button. The dB annunciator is now displayed. Press the dB

button to take the instrument out of the dB mode.

8.

The REL (relative) feature can be used with any measurement function: Volts, Amps, Ohms

select the ohms function and autorange. The display reads

approximately 000.1403, which is the test lead resistance.

Press the REL button. The REL annunciator is turned on

and the display reads 000.0003. The relative level of

000.143 will be subtracted from all subsequent

measurements. Press the REL button a second time to

cancel the REL level.

is still selected. The AC annunciator turns off.

3

buttons. DC must still be selected. The 3 (omega)

LO

terminal. Short the test leads

is

displayed. Note that cur-

or

DC volts and pressing the dB

or

LO

input ter-

LO

terminals must

dB. For example,

2

1-2

Page 11

9. To activate the

minimum/maximum, press and hold in the STO/CLR button. When the reading rate r=O is displayed release the

STO/CLR button. The STO annunciator turns on. Press

the RCL button and the last data point is briefly displayed

followed by the reading (data). Other data points can be

displayed by holding in the RCL button. Turn off the

DATA LOGGER by pressing the STO/CLR button again.

100

point DATA

LOGGER

with

1.10 ACCESSORIES

The following accessories can be used with the Model 197

MODEL

mount one Model 197 in a standard 5%’’

MODEL 1017 DUAL RACK MOUNTING KIT-Use to

mount two Model 197s in a standard

MODEL

temperature probe designed to allow precision temperature

measurements from -55 to 150°C.

MODEL 1600A HIGH

measurements to 40kV.

Model 1641 Kelvin Test Lead Set-Special clip leads allow

4-terminal measurements to be made while making only two

connections.

MODEL 1651 50-AMPERE CURRENT SHUNT-The external

measurements from 0 to 50A

MODEL 1681 CLIP ON TEST LEAD SET-Contains two

leads, 1.2m (48”) long terminated with banana plugs and

spring action clip probes.

1010

SINGLE RACK MOUNTING KIT-Used to

X

19” rack.

5Y4”

X

19” rack.

1301 TEMPERATURE PROBE-A rugged low cost

0.001Q

VOLTAGE

f

1 % 4-terminal shunt, permits current

PROBE-Extends

AC

or DC.

DMM

MODEL 1751 SAFETY TEST LEADS-This test lead set is

supplied with every Model 197. Finger guards and shrouded

of

banana plugs help minimize the chance

with live circuitry.

MODEL 1754 UNIVERSAL TEST LEAD KIT-A 12 piece

test lead kit, with interchangeable plug-in accessories. Included in the

lugs,

two hooks and miniature alligator clips (with boots).

MODEL 1972 ANALOG OUTPUT IEEE-488 INTERFACEThe Model 1972 is an optional IEEE-488 interface that in-

cludes all of the logic necessary to interface the Model 197 to

the IEEE-488 bus. The Model 1972 is similar to the Model

1973 however,

put is a scaled output that follows the display of the Model

197. The Model 1972 is field installable.

MODEL 1973 IEEE-488 INTERFACE-The Model 1973 is an

optional IEEE-488 interface for the Model 197. This interface

adds extra versatility to the Model 197 by allowing the

transmission of data and commands over the IEEE-488 bus.

The interface provides all the logic necessary to interface the

Model 197 to the bus using standard IEEE-488-1978 protocol.

The Model 1973 is field installable.

MODEL 1978 RECHARGEABLE BATTERY PACK-The

rechargeable battery pack allows off line or in the field operation of the Model 197. The pack provides typically five hours

operation from full charge. The battery pack contains its own

charging circuit and can be recharged within

battery pack is field installable.

MODEL 7008 IEEE-488 DIGITAL CABLE-Useful for con-

necting the 1973 to the IEEE-488 bus. The Model 7008-3 is

0.9m (3

at each end. The Model 7008-6 is 1.8m (6

a standard IEEE-488 connector at each end.

kit

is one set of test leads (1-red, 1-black), two spade

two standard banana plugs, two phone tips (.06 DIA.)

it

contains an analog output. The analog out-

ft.)

in length and has a standard IEEE-488 connector

making contact

10

hours. The

ft)

in length and has

MODEL 1682A RF PROBE-Permits voltage measurements

AC

from 100kHz to 250MHz.

+IdB from 1OOkHz to 250MHz at

calibrated in RMS of a sine wave.

MODEL 1684 HARD SHELL CARRYING CASE-Hard

vinyl case, 100mm

has a fitted foam insert with room for the Model 197, an in-

struction manual and small accessories.

MODEL 1685 CLAMP ON

rent by clamping on to a single conductor. Interruption of the

circuit is unnecessary. The Model 1685 detects currents by

sensing the changing magnetic field produced by the current

flow.

X

300mm X 350mm (4”

to DC transfer accuracy is

1V,

peak responding,

X

13”

AC

PROBE-Measures AC cur-

X

14”)

MODEL 8573 IEEE-488 INTERFACE-The Model 8573 is an

IEEE-488 standard interface designed to interface the

or

XT

computers to Keithley instrumentation over the

IEEE-488 bus. The interface system contains two distinct

parts: an interface board containing logic to perform the

necessary hardware functions and the handler software

(supplied on disk) to perform the required control functions.

These two important facets of the Model 8573 join together to

give the IBM advanced capabilities over IEEE-488 interfaceable instrumentation.

IBM

PC

1-311-4

Page 12

SECTION

2

BENCH OPERATION

2.1

INTRODUCTION

This section contains the information needed to prepare and 4. Energize the circuit using the installed connect-disconnect

operate the Model 197 as a bench

consists of using the Model 197 to perform basic voltage, cur- DMM

rent, resistance and

the data logger is covered. The capabilities of the Model 197

can be enhanced with the addition of the Model 1973 or

Model 1972 IEEE-488 interface.

the Model 1973 Instruction Manual. The optional battery

pack (Model 1978) is also covered in this section.

2.2

HIGH ENERGY CIRCUIT SAFETY

dB

measurements. Also, the operation of 5. ~~-~~~~~i~~

DMM.

IEEE

Bench operation

operation is covered in

PRECAUTIONS

To

Optimize safety

distribution circuits, read and use the directions in the following warning.

Dangerous arcs

high energy circuit can cause severe personal injury or death.

nected to a high energy circuit when set to

a current range, low resistance range or any

other low impedance range, the circuit is

virtuallv shorted. Dangerous arcing can

result even when the meter is set

range

reduced.

when

measuring

WARNING

of

an explosive nature in a

If

the meter is con-

if

the minimum voltage spacing is

in

to

voltage

high energy third-wire grounded

2. Attach the test leads to the circuit under test. Use ap-

propriate safety rated test leads for this application.

3.

Set the

device and make measurements without disconnecting the

disconnect

6,

Disconnect the

2.3

2.3.1

The Model 197 has a three-wire line cord which mates with

AC

1.

Set the LINE VOLTAGE switch on the back of the instrument to correspond to line voltage available. Ranges are

105V-125V or 210v-250V 50/60Hz

2. Plug the power cord into a properly grounded outlet.

DMM

to the proper function and range.

~~

.

the

device.

test

circuit

leads

using the installed connect-

from

the

circuit

under

PREPARATION FOR USE

Line

Power

Connect

line

power

as

follows:

CAUTION

Connect only to the line voltage selected.

Application

damage the instrument.

of

incorrect voltage can

AC.

the

instrument

test,

to

When making measurements in high energy circuits use test

leads that meet the following requirements:

Test leads should be fully insulated.

Only use test leads that can be connected to the circuit (e.g.

alligator clips, spade lugs, etc.) for hands-off measurements.

Do not use test leads that decrease voltage spacing. This

diminishes arc protection and creates a hazardous condi-

tion.

Use the following sequence when testing power circuits:

1.

De-energize the circuit using the regular installed connect-

disconnect device such as the circuit breaker, main switch,

etc.

WARNING

Ground the instrument through a properly

grounded receptacle before operation.

Failure to ground the instrument can result

in severe injury or death in event of a short

circuit or malfunction.

NOTE

Although the Model 197 is specified at 50 and

60Hz the instrument may be operated

and 440Hz.

at

400Hz

2-1

Page 13

2.3.2 Battery Pack Power

The Model 197 may be operated from rechargeable sealed

nickel-cadmium batteries contained in the optional Model

1978 Rechargeable Battery Pack. The battery pack will

operate the Model 197 for typically five hours. (NOTE: The

Model 197 uses the most power on the amps function and also

2OOQ,

in the

turns on when the charge is insufficient to maintain accurate

readings. Refer to paragraph 5.3 for installation procedures.

2kQ or 750VAC ranges). The BAT annunciator

2.3.3 Battery Charging

If the battery pack is not maintaining a charge

10

for five hours after a full

following.

A. Disconnect the Model 197 from line power.

B.

Turn on the Model 197 and leave

discharge the battery pack.

C. Connect the Model 197 to line power and charge the

10

battery pack for

D.

Repeat steps A through C three more times. The battery pack should again be good for typically five hours.

3.

When the Model 197 is in use on line power, the battery

charger maintains a trickle charge on the battery pack.

hours with power off.

hour charge cycle, do the

it

on to completely

(BAT

off)

After the Model 1978 is installed in the Model 197

charged and recharged as follows:

1.

Connect the instrument to line power as described in

paragraph 2.3.1.

2.

With the power switch off, the battery charge circuitry is

automatically energized to charge the battery at the max-

imum rate. When the battery pack is first installed, or

is completely discharged, allow

of

10

hours.

For maximum battery efficiency only charge the

battery pack after

charged (BAT annunciator on). Do not make

measurements with BAT annunciator on as the

readings may be erroneous.

it

has become completely dis-

NOTE

it

to charge for a minimum

-1

it

197

AUTORANGING

can be

if

NOTE

The

IEEE

options (Model 1972 and Model 1973)

do not run off of battery power.

2.4

FRONT

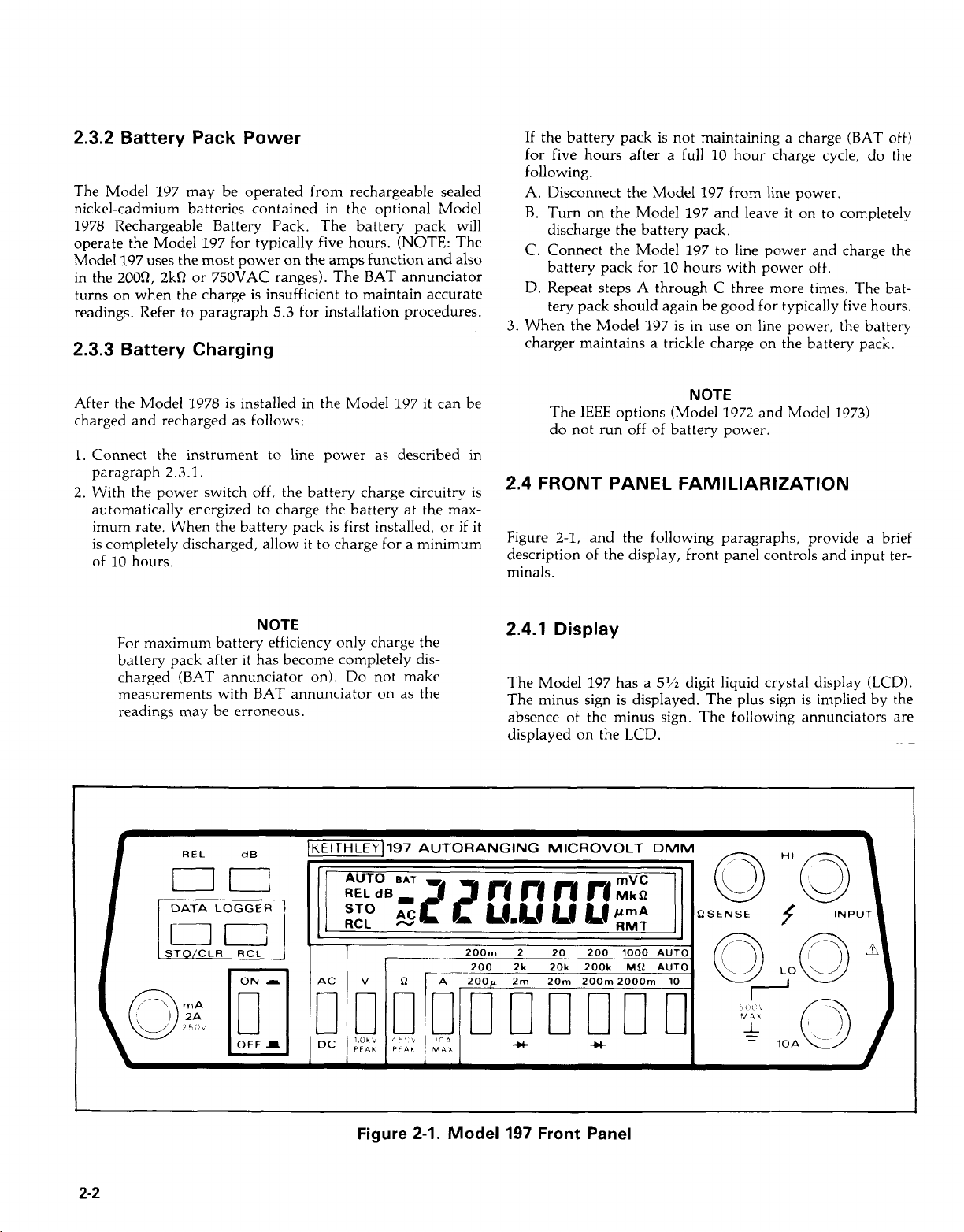

it

Figure

description of the display, front panel controls and input terminals.

2.4.1

The Model 197 has a

The minus sign is displayed. The plus sign is implied by the

absence of the minus sign. The following annunciators are

displayed on the

2-1,

Display

MICROVOLT

PANEL FAMILIARIZATION

and the following paragraphs, provide a brief

5%

digit liquid crystal display (LCD).

LCD.

DMM

~

I

I

2-2

w

200m

*

QSENSE

u

I

Page 14

BAT-Low battery indicator for the Model 1978.

AC-AC selected (DC implied by the absence of the AC annunciator).

AC/DC-This button is used along with the volts

(A),

rent

AC, releasing (out) this button selects

condition. See Table 2-1.

and dB functions. Depressing (in) this button selects

DC.

AC

!2

(V),

cur-

is invalid

or

mV

O,

p,

RMT

IEEE-488 bus (Model 1973

C-Model 197 in calibration mode.

AUTO-Autorange.

REL-Relative.

dB-Decibel measurement mode.

STO-Data being stored.

RCL-Data being recalled. RCL flashes when buffer is full

during logging cycle.

V-Millivolts or volts.

kO or MO-Ohms, kilohms

mA or A-Microamps, milliamps

(REMOTE)-Model 197 being controlled over the

or

megohms.

or

amps.

or

Model 1972 installed).

2.4.2 Front Panel Controls

ON/OFF-Pressing this button turns on the Model 197.

Releasing (out) this button turns the instrument off.

REL-(RELATIVE)-This button allows readings to be made

of

with respect to any baseline value. Also allows zeroing

range readings. See paragraph 2.7.2 for more detailed infor-

mation on

dB-This button selects the dB function and is used along

with the ACV or DCV function. Measurements are made in

dBm referenced to

voltage level the OdB reference point for dB measurements.

DATA LOGGER and MIN/MAX-100 reading storage

capacity; records data at one

reading/second

(r=6).

readings continuously while in the data logger mode.

REL.

600O.

REL

can be used to make any

of

seven selectable rates from

to

1

reading/hour

Also detects and stores maximum and minimum

or

by manual trigger

on

V-Depressing this button selects the volts function.

0-Depressing this button selects the ohms function. The

AC/DC button must be released (out).

A-Depressing (in) this button selects the current function.

Up to 2A on red and black input jacks and up to 10A with the

black and white input jacks. Refer to paragraph 2.4.3.

RANGE BUTTONS

1.

Depressing AUTO button allows volts and ohms to

autorange. In current,

autorange function for current.

2.

Manual ranging

propriate range button.

it

selects the 10A range. There is no

is

accomplished by depressing the ap-

2.4.3 Input Terminals

The input terminals are intended to be used with safety

shrouded test leads to help minimize the possibility

with live circuits. Safety shrouded tests leads (Model

are supplied with the Model 197. Always disconnect all un-

from

used test leads

HI

and

LO

INPUT (Red and Black)-Use this pair of ter-

minals

1OA

measuring current up to 10A (up to 20A

OHMS Sense HI and LO-Use this pair of terminals along

with HI and

3

for

all volt, ohm, milliamp and dB measurements.

and

LO

(White and Black)-Use this pair of terminals for

LO

the instrument.

for

15 seconds).

input for four wire resistance measurements.

2.4.4 Current Fuse Replacement

of

contact

1751)

1.

STO/CLR-Pressing this button initiates the logging se-

a

quence. Pressing this button

data logger. For

reading is desired, press the STO/CLR button.

2. RCL-Pressing and holding in this button scrolls the data

pointer. To read the data at a certain point, simply release

the button. The logged readings are stored in buffer locations

01

to 102. They are depicted on the front panel as

follows: Buffer location

r=6

rate (manual trigger) every time a

#1

second time turns off the

is represented

___

by n=01.

-

-

Tne current fuse protects the 200pA through 2000mA ranges

from an input current greater than 2A. To replace the current

fuse, perform the following steps:

NOTE

The front panel current fuse (F101) is rated at

2A. With a 220,000 count display, the 2A range

Page 15

can momentarily (approx. one minute) read

2.2A before the fuse will blow. This

range will not harm the instrument.

1.

Turn off the power and disconnect the power line and test

leads.

2. Place the end of a flat-blade screwdriver into the slot in the

fuse holder on the front panel. Press in slightly and rotate

the fuse carrier one quarter turn counterclockwise. Release

pressure and remove the fuse carrier and the fuse.

3. Remove the defective fuse and replace

type: 2A, 250v, 3AG, normal-blow (Keithley part number

FU-13)

or

equivalent.

10%

over-

it

with the following

of less than 80% up to

humidity 3% per "C up to 50°C.

subjected to extremes of temperature, allow sufficient time for

internal temperature

Typically,

(18°F) out of the specified temperature range.

it

takes one hour to stabilize a unit that is 10°C

35°C.

For ambient above 35°C derate

If

the instrument has been

to

reach environmental conditions.

2.6.2 Maximum Allowable Inputs

Table 2-2 lists the maximum allowable inputs for the Model

197.

CAUTION

Use only the recommended fuse type. If a

fuse with a higher current rating is installed, instrument damage may occur.

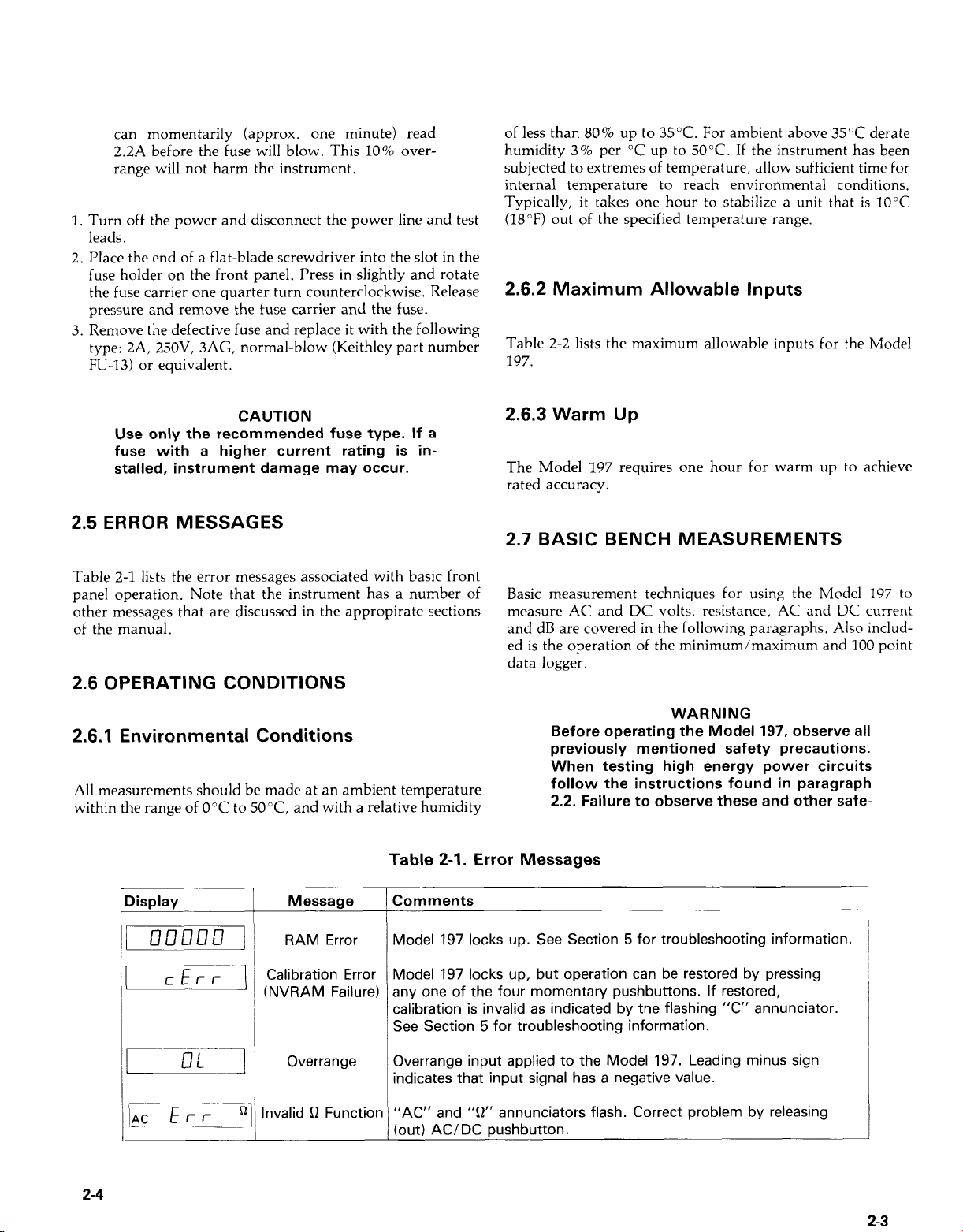

2.5

ERROR MESSAGES

Table 2-1 lists the error messages associated with basic front

panel operation. Note that the instrument has

other messages that are discussed in the appropirate sections

of the manual.

a

number of

2.6 OPERATING CONDlTlONS

2.6.1 Environmental Conditions

All

measurements should be made at an ambient temperature

within the range of 0°C to 50°C, and with a relative humidity

Table

2-1.

2.6.3 Warm Up

The Model 197 requires one hour for warm

rated accuracy.

up

2.7 BASIC BENCH MEASUREMENTS

Basic measurement techniques for using the Model 197 to

measure AC and DC volts, resistance,

and

dB

are covered in the following paragraphs.

ed is the operation of the minimum/maximum and

data logger.

WARNING

Before operating the Model

previously mentioned safety precautions.

When testing high energy power circuits

follow the instructions found in paragraph

2.2.

Failure to observe these and other safe-

Error

Messages

AC

197,

observe all

and

Also

to achieve

DC

current

includ-

100

point

2-4

3isplay

LC

Err

--

~

Message

I

~

Q11(

Invalid D Function

Comments

Model 197 locks up. See Section 5 for troubleshooting information.

Model 197 locks up, but operation can be restored by pressing

any one of the four momentary pushbuttons. If restored,

calibration is invalid as indicated by the flashing "C" annunciator.

See Section

Overrange input applied to the Model 197. Leading minus sign

indicates that input signal has a negative value.

"AC" and

(out) AC/DC Dushbutton.

5

for troubleshooting information.

"Q"

annunciators flash. Correct problem by releasing

2-3

Page 16

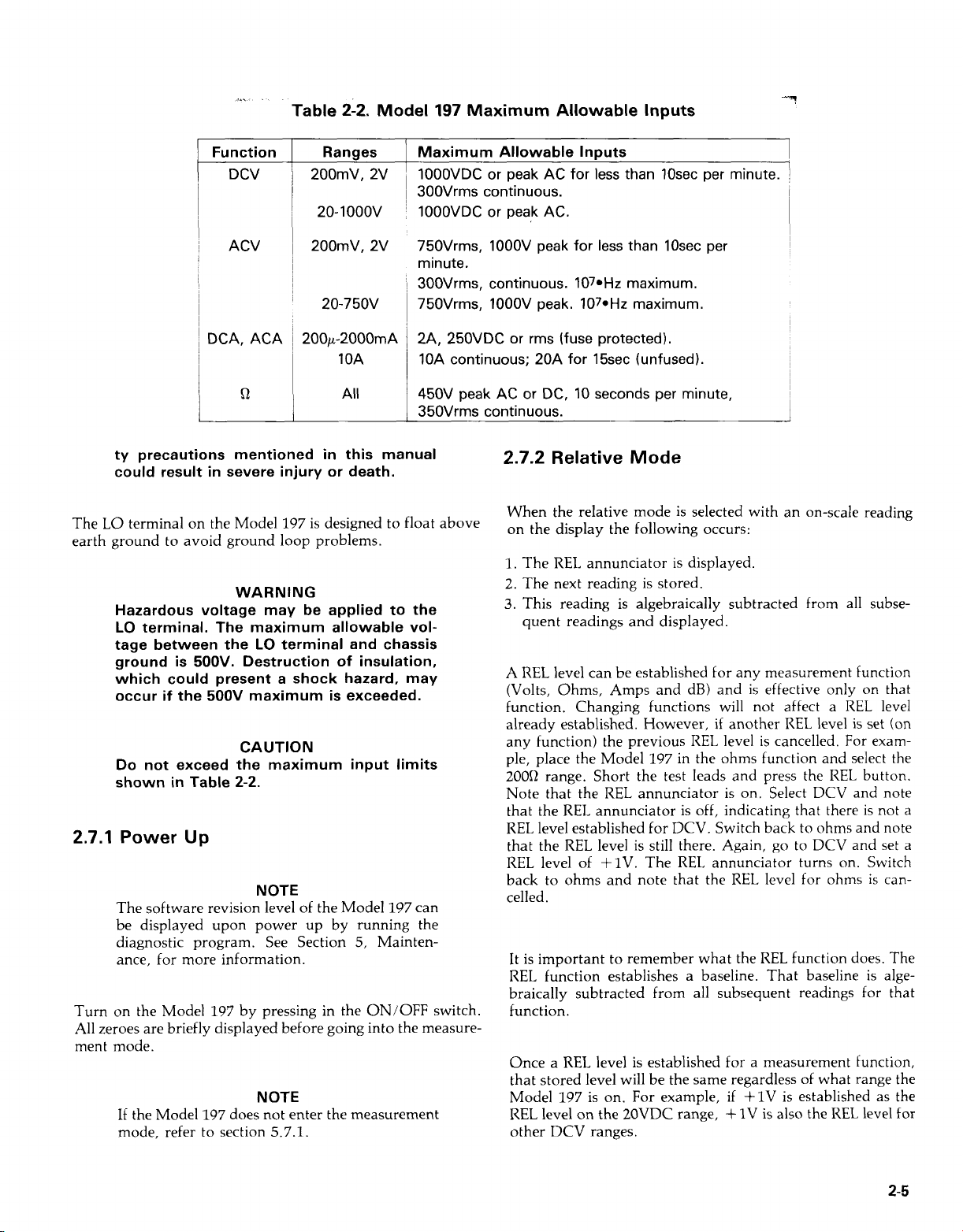

Table

2-2.

Model

197

Maximum Allowable Inputs

-7

Function

DCV

ACV

DCA, ACA

Q

ty precautions mentioned in this manual

could result in severe injury or death.

The

LO

terminal on the Model 197 is designed to float above

earth ground to avoid ground loop problems.

WARN I NG

Hazardous voltage may be applied to the

LO

terminal. The maximum allowable voltage between the

ground is

which could present a shock hazard, may

occur

Do not exceed the maximum input limits

shown in Table

2.7.1

Power

The software revision level of the Model 197 can

be displayed upon power up by running the

diagnostic program. See Section

ance, for more information.

Turn on the Model 197 by pressing in the

All

zeroes are briefly displayed before going into the measure-

ment mode.

If

the Model 197 does not enter the measurement

mode, refer

if

the

Up

500V.

500V

to

LO

Destruction

maximum is exceeded.

CAUTION

2-2.

NOTE

NOTE

section 5.7.1.

Ranges

200mV, 2V

20-1OOOV 1000VDC or peak AC.

i

~OO~V,

'

20-75OV

~

200p-2000mA

I

1 OA

1

terminal and chassis

All

of

5,

1

'

~

2v

insulation,

Mainten-

ON/OFF

Maximum Allowable Inputs

1000VDC or peak AC for less than 10sec per minute.

300~rms continuous.

750Vrms, 1OOOV peak for less than 10sec per

minute.

300Vrms, continuous. lO7*Hz maximum.

750Vrms, IOOOV peak. l07.H~ maximum.

2A, 250VDC or

10A continuous; 20A for 15sec (unfused).

450V peak AC

350Vrms continuous.

switch.

rrns

(fuse protected).

or

DC,

10

seconds per minute,

2.7.2

3.

Relative

When the relative mode is selected with an on-scale reading

on the display the following occurs:

1.

The REL annunciator is displayed.

2.

The next reading is stored.

This reading is algebraically subtracted from all subse-

quent readings and displayed.

A

REL level can be established for any measurement function

(Volts, Ohms, Amps and dB) and

function. Changing functions will not affect a

already established. However,

any function) the previous

ple, place the Model 197 in the ohms function and select the

200Q

range. Short the test leads and press the REL button.

Note that the REL annunciator is on. Select DCV and note

that the

REL

that the

REL

back

celled.

It

REL

braically subtracted from all subsequent readings

function.

Once a

that stored level will be the same regardless of what range the

Model 197 is on.

REL level on the 20VDC range,

other DCV ranges.

REL

level established for DCV. Switch back to ohms and note

REL

level of

to

ohms and note that the

is important to remember what the

function establishes a baseline. That baseline

REL

Mode

is

effective only on that

if

another

REL

level is cancelled.

annunciator is off, indicating that there is not a

level is still there. Again,

+lV.

The REL annunciator turns on. Switch

REL

level for ohms

REL

level is established for a measurement function,

For

example,

if

+1V is established as the

+

1V

is

I

1

I

REL

REL

level is set (on

For

exam-

go

to

DCV and set

is

function does. The

is

for

also the REL level

level

a

can-

alge-

that

for

2-5

Page 17

The dynamic range

means that

applying +1.99999V to the input displays +3.99999V.

Once the REL level is established, that level is algebraically

subtracted from the input signal.

+

1

.OOOOOV

f2.OOOOOV level displays a

if

of

the display is

a

REL

level of -2.OOOOOV is established, then

REL level is established, then applying a

+1.OOOOOV

-+400,000

For

example:

level.

counts. This

if

a

7

The instrument accepts a +220,000 count input before going

(OL).

into the overrange condition

REL

level is established and 1.50000V is applied. The instrument displays +2.500000V. If the input is 2.20000V the instrument overranges.

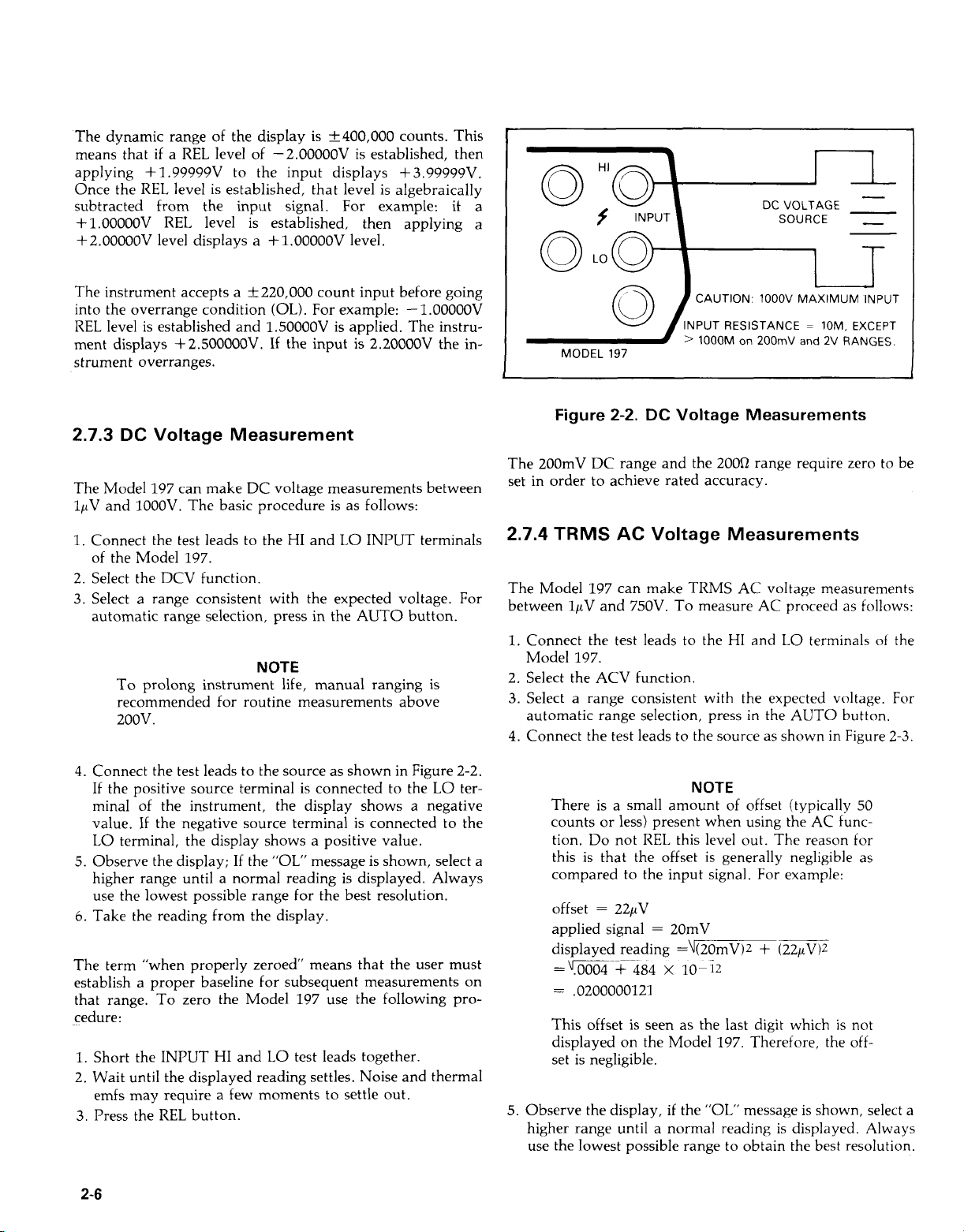

2.7.3

The Model 197 can make DC voltage measurements between

DC

Voltage Measurement

1pV and

1.

2. Select the DCV function.

3. Select a range consistent with the expected voltage. For

IOOOV.

Connect the test leads to the

of the Model 197.

automatic range selection, press in the

To prolong instrument life, manual ranging is

recommended for routine measurements above

200v.

The basic procedure is as follows:

NOTE

For example:

HI

and

LO

AUTO

-1.OOOOOV

INPUT

button.

terminals

CAUTION.

o/

I

The 200mV DC range and the 2000 range require zero to be

set in order to achieve rated accuracy.

2.7.4

The Model

between

1.

2. Select the ACV function.

3.

4.

MODEL

Figure

TRMS

Connect the test leads

Model 197.

Select a range consistent with the expected voltage.

automatic range selection, press in the AUTO button.

Connect the test leads to the source as shown in Figure 2-3.

197

2-2.

AC

197

can make TRMS AC voltage measurements

1pV

and 750V. To measure AC proceed as follows:

INPUT RESISTANCE = 10M. EXCEPT

>

lOOOM

DC

Voltage Measurements

Voltage Measurements

to

the

HI

on

1OOOV

MAXIMUM INPUT

200mV

and

LO

and

2V

terminals

RANGES

of

the

For

4.

Connect the test leads to the source as shown in Figure 2-2.

If

the positive source terminal is connected to the

minal of the instrument, the display shows a negative

If

value.

LO

5. Observe the display;

higher range until a normal reading is displayed. Always

use the lowest possible range for the best resolution.

6.

Take the reading from the display.

The term "when properly zeroed" means that the user must

establish a proper baseline for subsequent measurements on

that range. To zero the Model 197 use the following pro-

cedure:

1.

Short the INPUT

2. Wait until the displayed reading settles. Noise and thermal

emfs may require a few moments

3. Press the

2-6

the negative source terminal is connected to the

terminal, the display shows a positive value.

If

the

"OL"

message is shown, select a

HI

and

LO

test leads together.

to

settle out.

REL

button.

LO

ter-

NOTE

There is a small amount of offset (typically 50

counts

tion.

this is that the offset is generally negligible as

compared to the input signal.

offset

applied signal

displayed reading =\(20mV)2

This offset is seen as the last digit which is not

displayed on the Model 197. Therefore, the offset is negligible.

5.

Observe the display,

higher range until a normal reading is displayed. Always

use the lowest possible range to obtain the best resolution.

or

less) present when using the

Do

not REL this level out. The reason for

=

22pV

=m-+484

=

.0200000121

=

20mV

x

10-iZ

if

the

AC

For

example:

+

(22pV)Z

"OL"

message is shown, select a

func-

Page 18

6. Take the reading from the display

NOTE

See paragraph

When measuring

leads from the OHMS SENSE terminals.

-INPUT

MODEL

197

2.8

for TRMS considerations.

AC

signals disconnect any test

IMPEDANCE

BY

<

75pF

=

IMR

SHUNTED

R,

=

parallel combination of source resistance and input impedance.

e, = Johnson noise of the source resistance.

on

Even

is

Thus, for an R, of

inherent 1.5pV peak to peak. Beyond

to R, becomes a limiting factor in the measurement.

Therefore, it is recommended that

ments R, be kept relatively 10~7,

As

(due to Johnson noise of the source resistance) assume that the

Model 197 is connected to a voltage source with an internal

resistance of

p-p noise voltage generated over a bandwidth

most sensitive range, the noise due to the current

not appreciable until R, reaches approximately

OQ

to

lMQ,

the noise at the input is the

1MQ

the noise due

for

sensitive measure-

if

possible below

an example of determining e, noise voltage generation

1MQ.

At

a

=

e,

e, = 6.35

room temperature

6.35

X

10-10

X

lO-lO\r(lx

\J

R

X

10m

of

20°C

of

f

1MQ.

(293K),

1Hz

will be:

lMQ.

the

Figure

2.7.5

Accuracy Considerations-For sensitive measurements, other

external considerations besides the Model

accuracy. Effects not noticeable when working with higher

voltages are significant in microvolt signals. The Model 197

reads only the signal received at its input; therefore,

portant that this signal be properly transmitted from the

source. The following paragraphs indicate factors which af-

fect accuracy, noise, source resistance, thermal emfs and

stray pick-up.

Noise and Source Resistance-The limit of resolution in

measuring voltages with the Model 197 is determined by the

noise present. The displayed noise of the Model 197 is 1.5pV

peak to peak. This noise is inherent in the Model 197 and is

the minimum amount present in all measurements. The 1.5pV

of noise is due to the instrument voltage noise. The noise at

the Model 197 input increases beyond this minimum when the

noise current passes through a resistor thus generating a

voltage noise. The total noise becomes a function of the

source resistance and is given by the equation:

2-3.

TRMS

AC

Voltage Measurements

Microvolt Measurement Considerations

197

will affect the

it

is im-

=

en2

+

n2

(inRs)2

+

er2

e, = 0.635pV

Thus

it

is clear that optimum microvolt measurements with

the Model 197 are possible with source resistances as high as

1MQ.

However, this resolution will not be realized unless

shielding is employed.

Shielding-The Model 197 is insensitive

DC

superimposed upon a

However,

with the

Therefore,

shielded and the shield connected to the Model 197 ground

(particularly for low-level sources). Improper shielding can

cause the Model 197 to behave in one

ing ways:

1. Unexpected offset voltages.

2.

Inconsistent readings between ranges.

3.

Sudden shifts in reading.

To minimize pick up, keep the voltage source and the Model

197 away from strong

duced due to magnetic flux is proportional to the area

loop formed by the input leads. Therefore, minimize the loop

area of the input leads and connect each signal at only one

point.

AC

voltages which are extremely large compared

DC

signal may erroneously produce

if

there is

AC

signal at the input terminals.

interference, the circuit should be

AC

magnetic sources. The voltage in-

to

AC

voltages

a

DC

output.

or

more of the follow-

of

the

where

n

=

total noise input.

=

input voltage noise of the Model 197.

en

in

=

input current noise.

Thermal EMFs-Thermal emfs (thermoelectric potentials) are

generated by thermal differences between two junction

dissimilar metals. These can be large compared

which the Model 197 can measure. Thermal emfs can cause

the following problems:

to

the signal

of

2-7

Page 19

1.

Instability

2. The reading is sensitive to (and responds to) temperature

changes. This can be demonstrated by touching the circuit,

by placing a heat source near the circuit

pattern of instability (corresponding to heating and airconditioning systems or changes in sunlight).

3. To minimize the drift caused by thermal emfs, use copper

leads to connect the circuit to the Model 197.

plug is generally sufficient and generates just a few

microvolts.

is about the best for the application. The leads to the input

may be shielded

Shielding.

4.

Widely varying temperatures within the circuit can also

create thermal emfs. Therefore, maintain constant temperatures to minimize these thermal emfs.

box around the circuit under test also helps by minimizing

air currents.

5. The REL control can be used to null out constant offset

voltages.

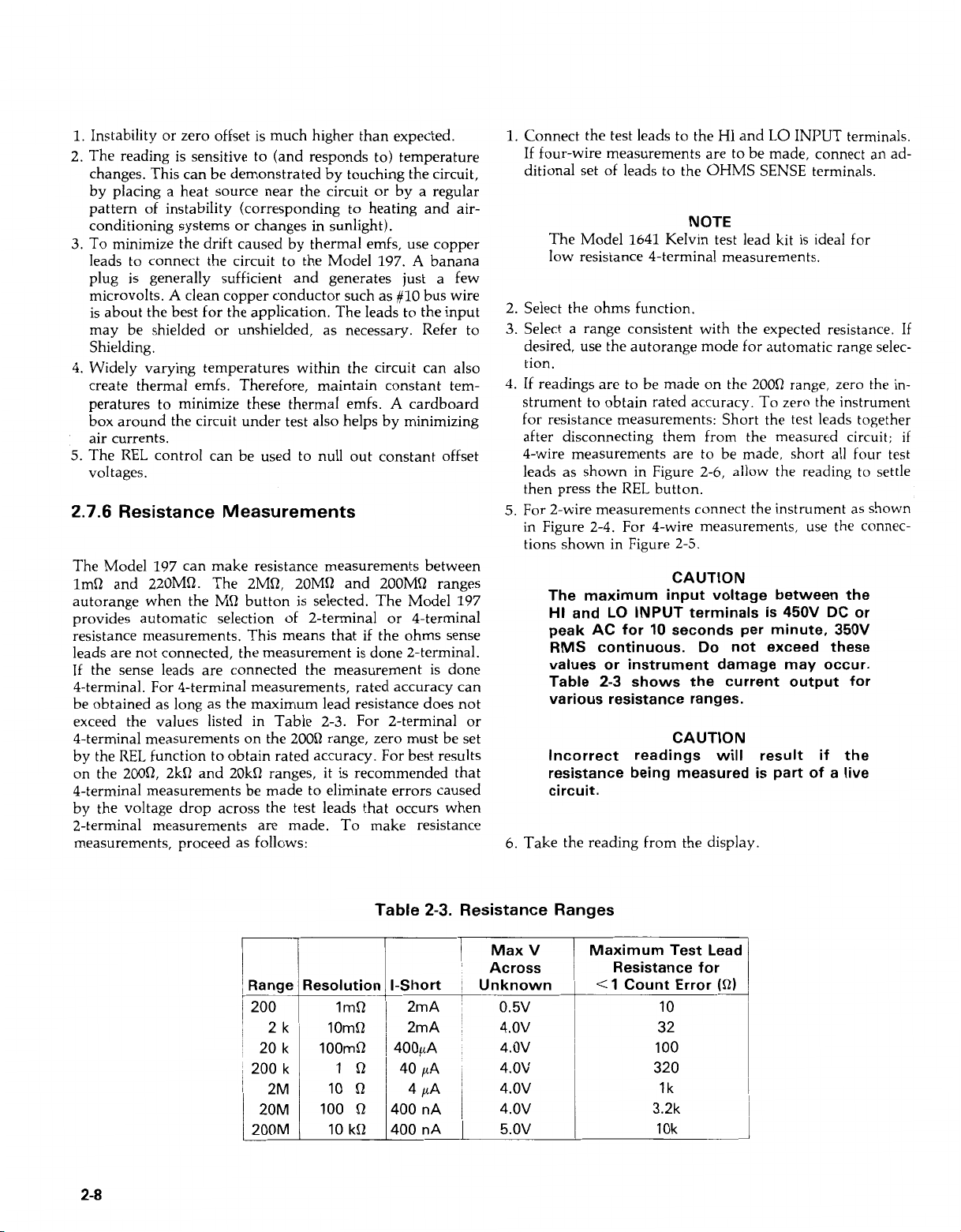

2.7.6

The Model 197 can make resistance measurements between

1m3 and 22OM3. The 2M3, 20MQ and 200MQ ranges

autorange when the

provides automatic selection of 2-terminal

resistance measurements. This means that

leads are not connected, the measurement is done &terminal.

If

the sense leads are connected the measurement is done

4-terminal. For 4-terminal measurements, rated accuracy can

be obtained as long as the maximum lead resistance does not

exceed the values listed in Table 2-3. For 2-terminal

4-terminal measurements on the 2003 range, zero must be set

by the REL function to obtain rated accuracy. For best results

on the 2003, 2k3 and 2Ok3 ranges, it is recommended that

4-terminal measurements be made to eliminate errors caused

by the voltage drop across the test leads that occurs when

2-terminal measurements are made. To make resistance

measurements, proceed as follows:

or

zero offset is much higher than expected.

A

clean copper conductor such as

or

unshielded, as necessary. Refer to

Resistance Measurements

M3

button is selected. The Model 197

or

by a regular

A

banana

#lo

bus wire

A

cardboard

or

4-terminal

if

the ohms sense

or

1.

Connect the test leads to the HI and

If four-wire measurements are to be made, connect an additional set of leads to the OHMS SENSE terminals.

NOTE

The Model 1641 Kelvin test lead kit is ideal for

low resistance 4-terminal measurements.

2. Select the ohms function.

3.

Select a range consistent with the expected resistance.

desired, use the autorange mode for automatic range selection.

4.

If

readings are to be made on the 2OOQ range, zero the instrument to obtain rated accuracy. To zero the instrument

for resistance measurements: Short the test leads together

after disconnecting them from the measured circuit:

4-wire measurements are to be made, short

leads as shown in Figure 2-6, allow the reading to settle

REL

then press the

5.

For 2-wire measurements connect the instrument as shown

in Figure 2-4. For 4-wire measurements, use the connections shown in Figure 2-5.

The maximum input voltage between the

HI

and LO INPUT terminals is

peak AC for

RMS

values or instrument damage may occur.

Table

various resistance ranges.

Incorrect readings will result if the

resistance being measured is part

circuit.

6. Take the reading from the display.

continuous. Do not exceed these

2-3

button.

CAUTION

10

seconds per minute,

shows the current output for

CAUTION

LO

450V

INPUT

all

DC or

350V

of

a live

terminals.

four test

If

if

2-8

Range

200

2k

20 k

,

200 k

200M

tesolutior

lm3

1

OmQ

1

OOmQ

1Q

10

0

100

Q

10

k3

Table

I-S

hort

2mA

2mA

400pA

40 pA

4 PA

400 nA

400 nA

2-3.

Resistance Ranges

Across

Unknown

4.0V

4.0V

5.0V

Maximum Test Lead

Resistance for

(1

Count Error

10

(Q)

32

100

320

Ik

3.2k

10k

Page 20

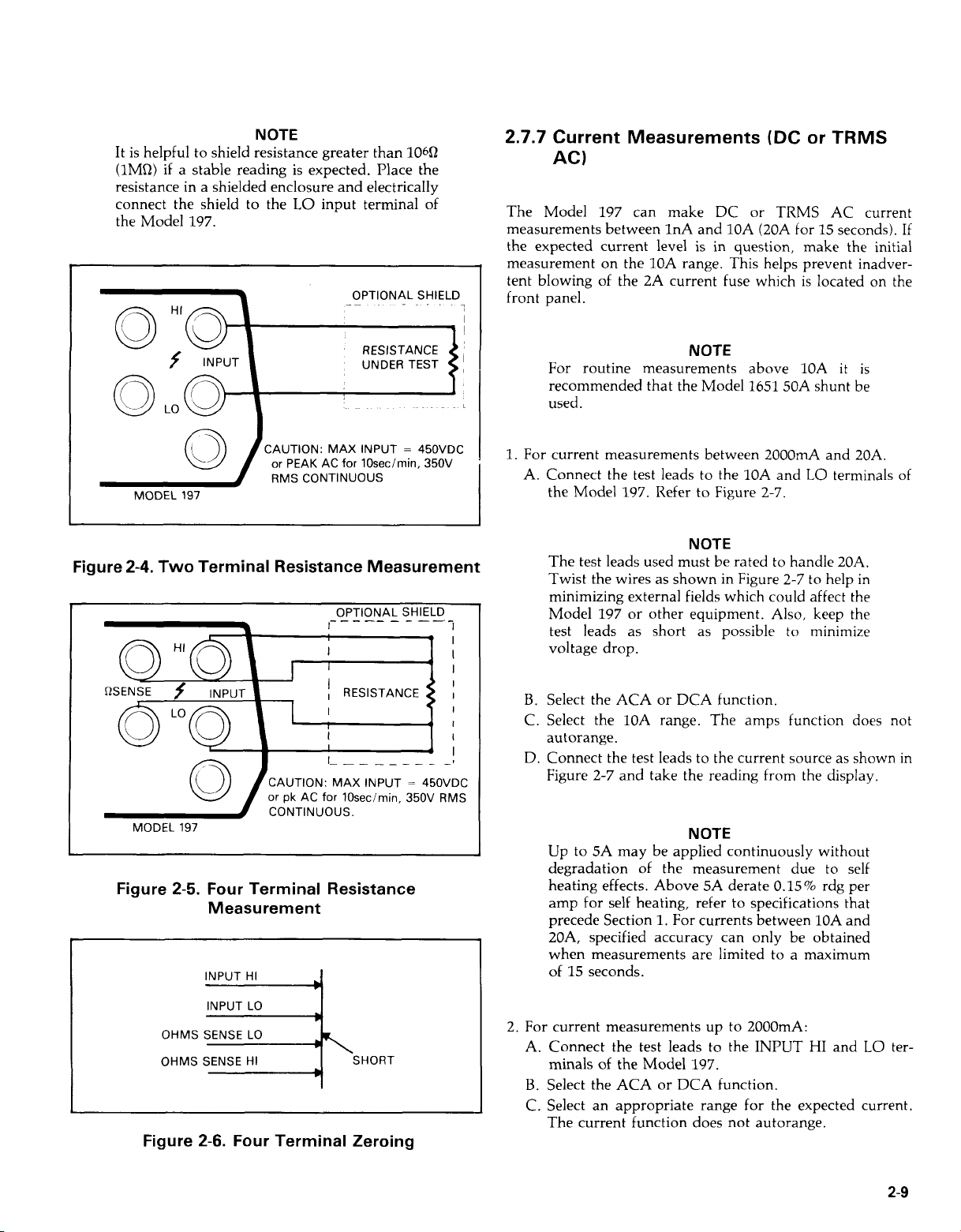

NOTE

It

is helpful to shield resistance greater than 106Q

(1MQ)

resistance in a shielded enclosure and electrically

connect the shield to the

the Model 197.

-

if

a stable reading is expected. Place the

LO

input terminal of

OPTIONAL SHIELD

__

RESISTANCE

2.7.7

Current Measurements

(DC

or TRMS

AC)

The Model 197 can make DC or TRMS AC current

measurements between 1nA and 10A (20A for

the expected current level is in question, make the initial

measurement on the 10A range. This helps prevent inadvertent blowing of the 2A current fuse which is located on the

front panel.

I

I

NOTE

For routine measurements above 10A

recommended that the Model 1651 50A shunt be

used.

15

seconds).

it

If

is

Figure

MODEL 197

2-4.

Two

MODEL 197

Figure

CAUTION: MAX INPUT

or PEAK AC for lOsec/min, 350V

[

RMS CONTINUOUS

=

450VDC

Terminal Resistance Measurement

OPTIONAL SHIELD

I-----

CAUTION: MAX INPUT = 450VDC

or

pk

AC for 10sec/min, 350V RMS

CONTINUOUS.

2-5.

Four Terminal Resistance

-

-

---

Measurement

1.

For current measurements between 2000mA and 20A.

to

A. Connect the test leads

the Model 197. Refer

The test leads used must be rated to handle 20A.

Twist the wires as shown in Figure 2-7

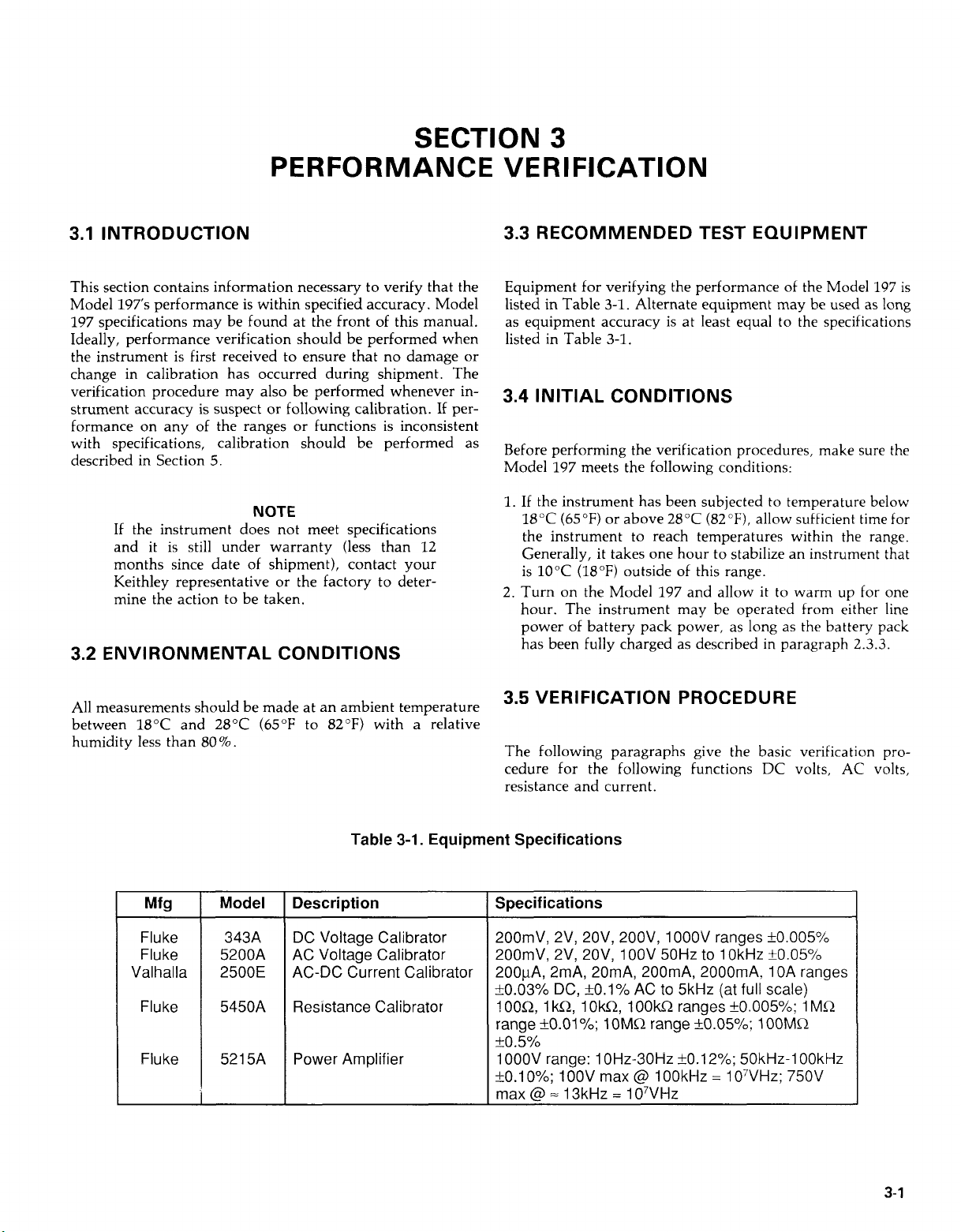

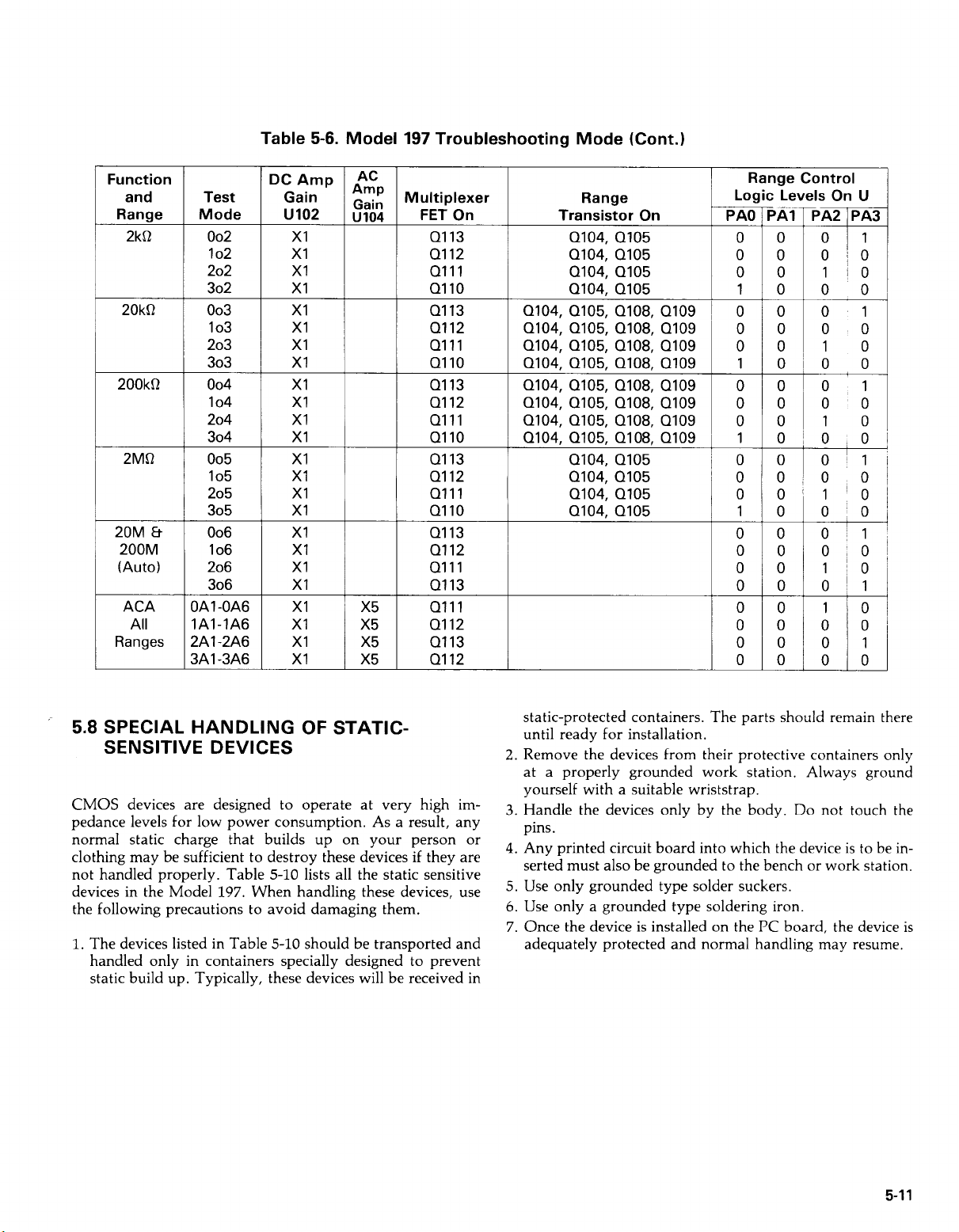

minimizing external fields which could affect the