Page 1

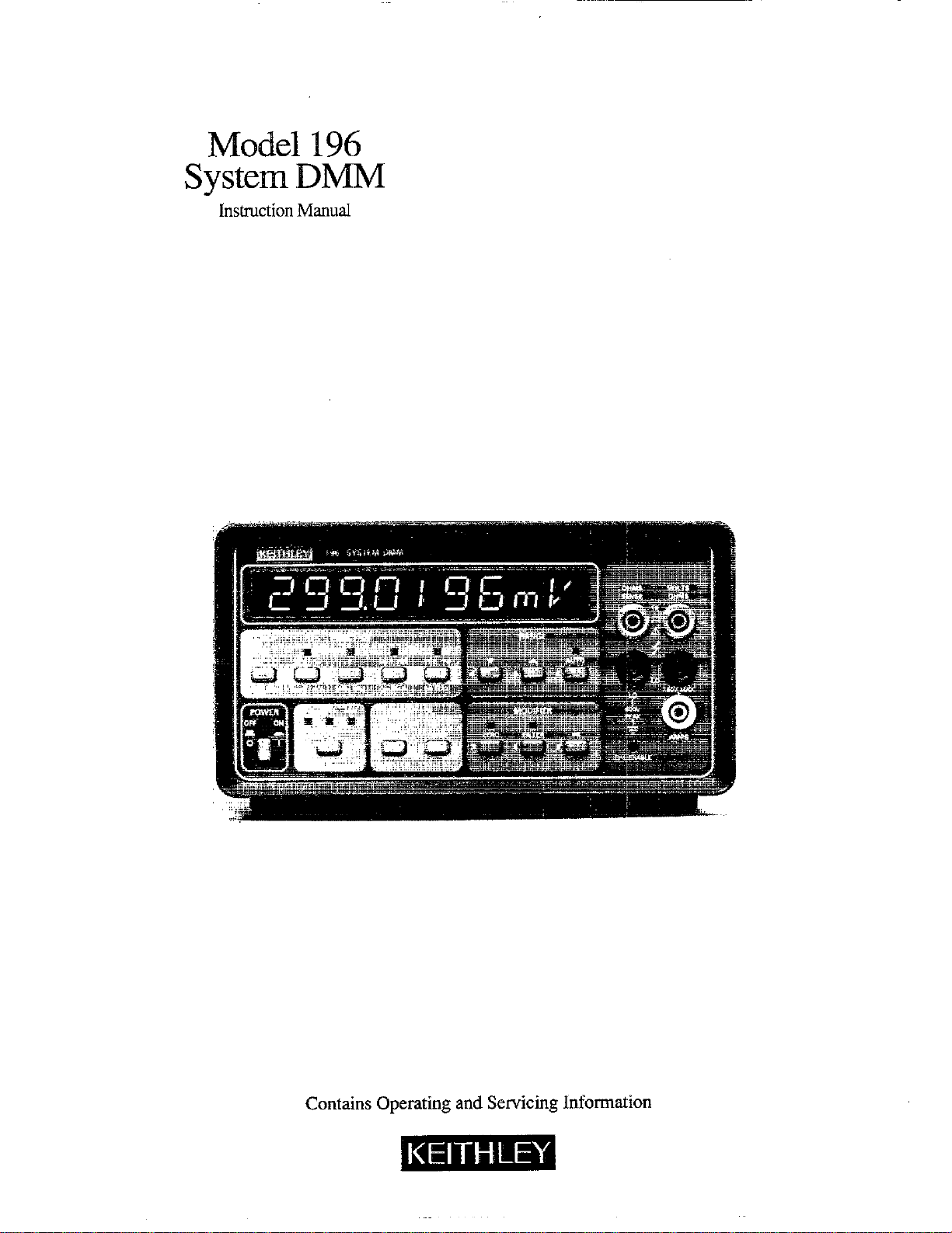

Model 196

System DMM

instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and tiorkmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at OUT option, either repair or replace any product that proves to be defective.~~ :

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Ct&e.land, Ohio. YOU will

be given Prompt assistance and return instruciions. Send the product, transport&~ prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least PO days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses,~software, non-rechargeable batteries, damage from battery leakage,~or

problems arising~55Zi-i ncmii~l wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTtiERWARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PRO\IIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, JNDIRECT, SPECIAL, INCIDENTALOR CONsE:QUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS JNSTRIJM.ENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED To: COSTS OFT REMOVAL

AND INSTALLATION, Lossm SUSTAINED As THE RESULT OF IN3URY TO ANY PERSON, OR DAMAGETO PROPERTY.

Page 3

Model 196~ System DMM

Instruction Manual

01986, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

Fourth PrintingJanuary 1992

Document Number: 196-901-01 Rev. 0

Page 4

Safety Precautions

The following safety precautions should be observed befoE

using this product and any associated inshvmentation. Although some instruments and accessories would normally be

used with non-hazardousvoltages, therearesituatio~iis where

hazardous conditions may be present

This product is intended for use by qualiied personnel who

iecognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating

information carefully before using the product.

Exercise extreme caution when a shock hazard is present. Lethal voittige may be present on cable connector jacks or test

f?xtures. The American National Standards Instih~te (ANSI)

states that a shock hazard exists when voltage levels greater

than 30V RMS, 42.4V peak, or 60VDC are present. A good

safety practice is to expect that hazardous voltage is present

in any unknown circuit before measuring.

Before operating an inskutient, make sure the line cord is

connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible

wear, cracks, or breaks before each use.

For maximum safety, do not touch the product, test cables, or

any other instruments while power is applied to the circuit

under test. ALWAYS remove power from the entire test systern and discharge any capacitors before: connecting or disconnecting cables or jumpers, installing or removing

switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to

the common side of the circuit under test or power lie

(earth) ground. Always make measurements with dry hands

while standing on a ~JY, insulated surface capable of withstanding the voltage being measured.

Do not exceed the maximum signal levels of the instruments

and accessories, as defined in the specifications and operating

inform&ion, and a~ shown on the instrument or test fixture

rear panel, or switchiig card.

Do not connect switching cards directly to unlimited power

circuits. They are intended to be used with impedance limited sources. NEVER cbnnect switching cards directly to AC

tin. When connecting sources to switching cards, install

$~~tive devices to lit fault current and voltage to the

card.

When fuses are used in a product, replace with same type and

rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections

for measuring circuits, NOT as safety earth ground connections.

If you are using a test fxtwe, keep the lid closed while power

is applied to the device under test. Safe operation requires the

u.s$of a lid interlock.

Ifa @saew ispresenton~hetest tixhm?,connectit tbsafety

earth ground using #18 AWG or larger wire.

The $ symbol on an instrument or accessory indicates that

1oOOV or more may be present on the terminals. Refer to the

product manual for detailed operahlng information.

Instrumentation and accessories should not be connected to

humans.

Maintenance should be performed by qualified service personnel. Before perfo&ng any maintenance, disconnect the

line cord~and all test cables.

Page 5

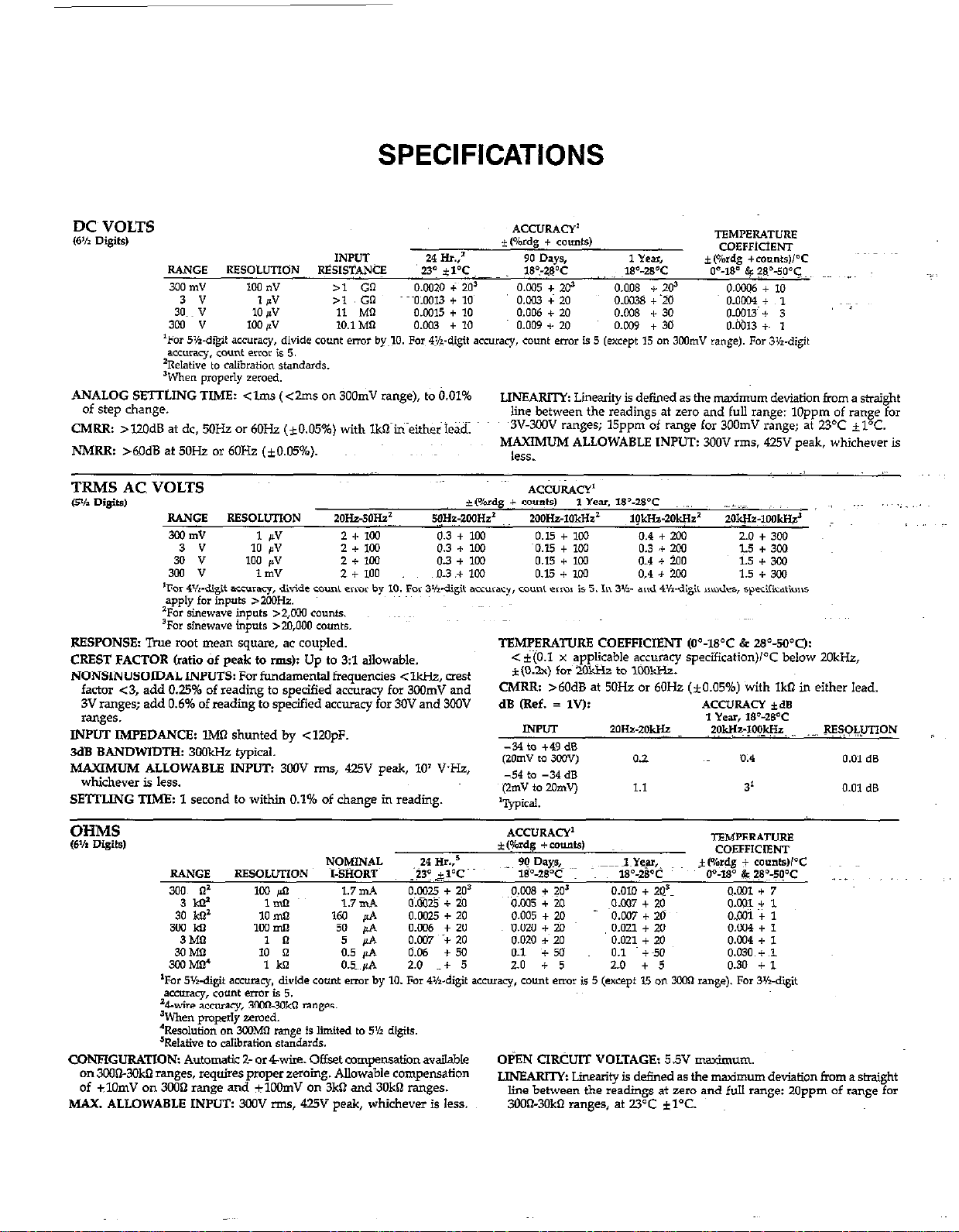

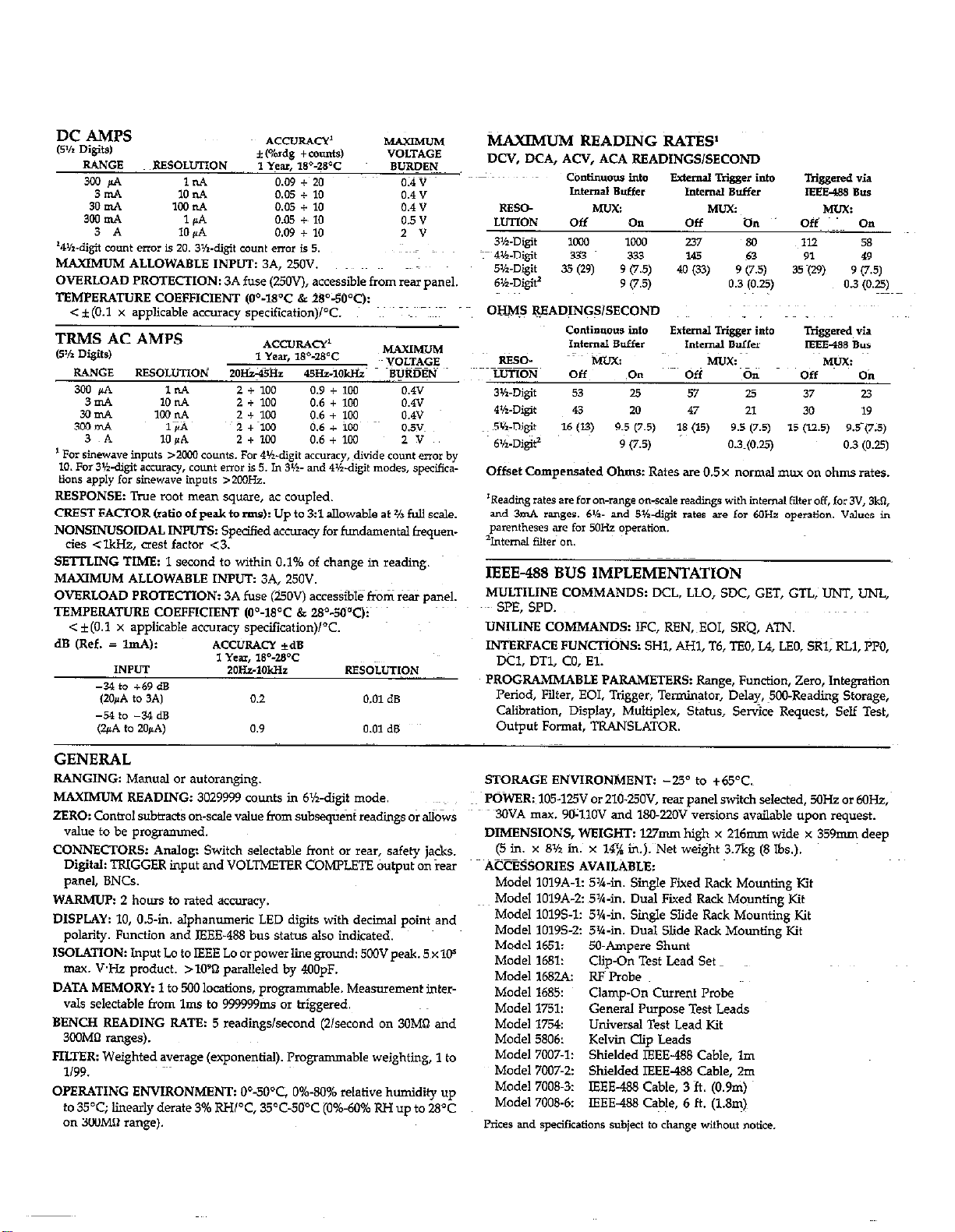

DC~ VOLTS

6% Digits,

SPECIFICATIONS

ANALOG SETTLING TIME: <lm.s (<2ms on 300mV range), to 0.01%

of step change.

CMRR: >lZOdB at dc, MHz or 6OHz (iO.O5%) with lkQ in either lead.

NMRR: >M)dB at50Hz or60Hz (iO.0546). ~~

RESPONSE: Tiue root mean square, ac coupled.

CREST FACTOR (ratio of peak to rms)z Up to 3:l allowable.

NONSINUSOIDAL INPUTS: For fundamental frequencies < -, mest

factor ~3, add 0.25% of reading to specified accuracy for 3oomV and

3V ranges; add 0.6% of reading to specified accuracy for 30V and 3fXlV

ranges.

INPUT IMPEDANCE: lMlI shunted bv <12OoF.

3dBBANDWIDTHz 3WkHzfypical. ’ ’

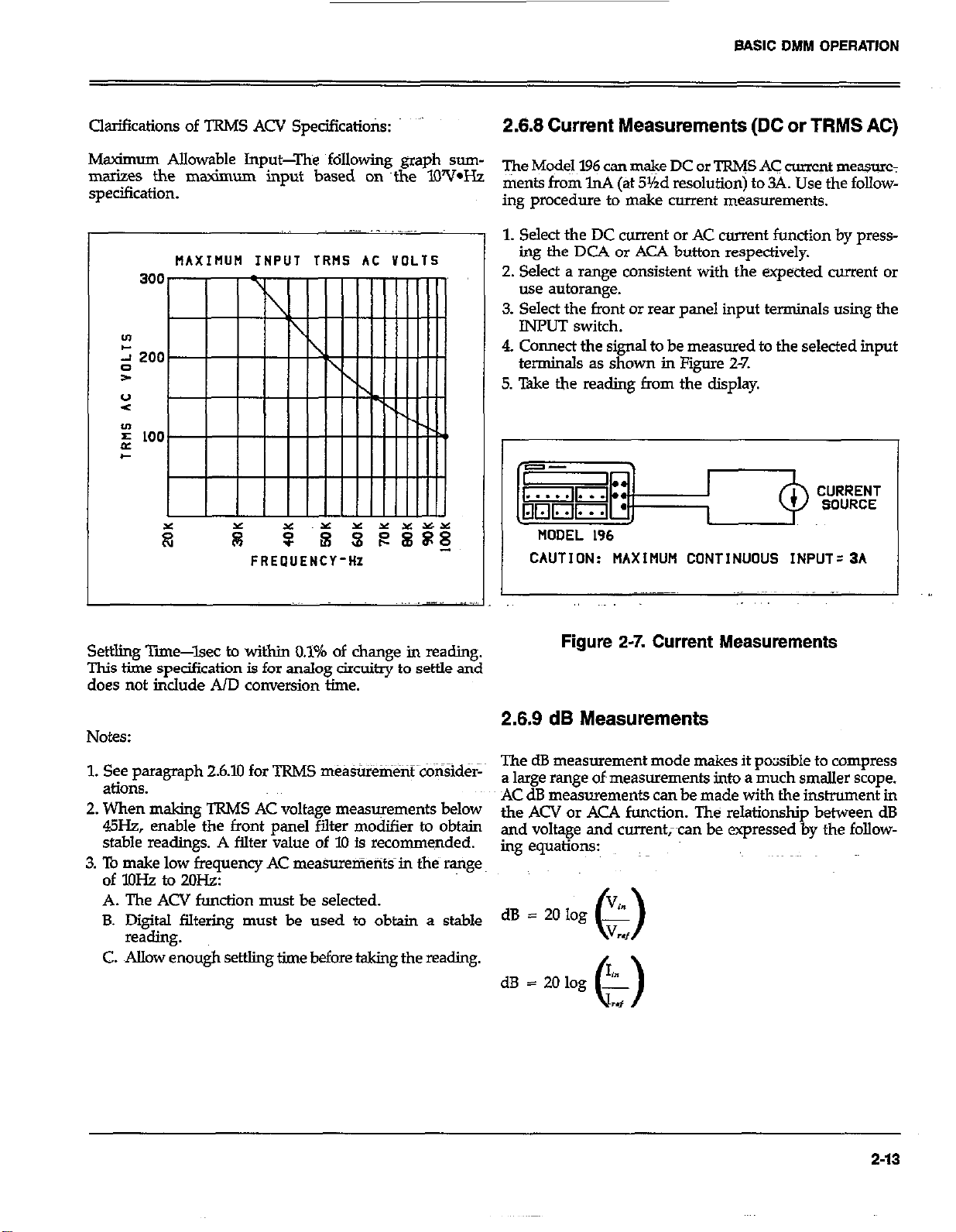

MAXIMUM ALLOWABLE INPUT: 3oOV -, 425” peak, 10’ VHz,

whichever is less.

SETTLING TIME: 1 second to within 0.1% of change in reading.

LINEARI’IY Linearity is defined as the timurn deviation from a straight

line between the readings at zero and full range: 1Oppm of range for

~3V-3ooV ranges; 15ppm of range for 3OOmV range; at 23OC il°C.

MAXIMUM ALLOWABLE INPUT: 300V rms. 425” peak, whichever is

less.

TBMF’ERATURE COEFFICI@‘JT (0=18”C & 28Y?,*C):

< i(O.l x app!icable accuracy specification)K below 2OkHz,

f(0.2.x) for 2okHz to 1ook?iz.

CMRR: >6OdB at 5OHz or 6OHz (*0.05%) with IkR in either lead.

dB (Ref. = 1”):

INPUT *OHa-~0gz

.4CC”RAcY *a

1 Year, IP-WC

?OW-?c!

-. P??LUnoN

WNETGURATION: Automatic 2- or&,ire. Offset compensationavai!ab~e OBN CIRCUIT VOLTAGE: 5.5V maxinwm.

on 3wiXOkO ranges, requires proper zeroing. Allowable compensation

of ilOmV on 3OilQ range and ilWmV on 3ktl and 3OkO ranges.

MAX, ALLOWABLE INPIJZ 3wV rms, 425V peak, whichever is less.

JJNEARIlY Linetity is defined as the madmum deviation from a &might

line between the readings at zero and full range: 20ppm of range for

SCO@3OkO ranges, at 23°C iYC.

Page 6

3mA

3iE

3 A

‘4wigit count error is 20. 3K-digit CO”“t error is 5.

MAXIMUMALLOWABLHINPUT: 3A, 250”.

OVERLOAD PROTECTION: 3A fuse (25OV), accessible from reii~ panel.

TEMPERATURE COEFFICIENT (O”-18’C & 2S”-500C):

c iCO.1 x applicable accumw svecification)PC.

1 For Sinewave inputs >x.m EOuntS. For 4Vdigit accuracy, divide cou*t error by

10. .%3lidigit accuracy, count errOI b 5. Jn 3vl- and 4K.digit modes, specificati‘J”d apply for stnew.we inputs ,200Hz.

RESPONSE: True mot mean square, ac coupled.

CREST FACTOR (ratio of peak to rms): Up to 3:l allowable at % full scale.

NONSINUSOIDAL INPUTS: Spe&d accwacy for fundamental fquen-

ctes <lkJ&, CI& factor <3.

SEmING TIME: 1 second to within 0.1% of change in reading.

MAXIMUM ALLOWABLE INPUT: 3A, 250V.

OVERLOAD PROTECTION: 3A fuse (UOV) accessibl&fiom rear panel.

TEMPERATURE COEFFICIENT (O’-18’C & 28%d”Qi~ ~’

< f(O.l x applicable accuracy specification)i°C.

dB (Ref. = ImA): ‘4CC”RAcY *a

INPUT

-34 to +69 dB

(ZOJ4.4 to 3.4) 0.2 0.01 dB

-54 to -34 dB

@!A to 20PA)

10 n.4 0.05 + 10

1ooP.A

1d

10 K.4 0.09 + 10

1 Year, 1S%B’C

2oH51okHz

0.05 0.05 + +~ 10 10

0.9 0.01 dB

* v

~~~

RE8OLuTION ~~~~

tiAXIMUM READING RAT&

DCV, DCA, ACV, ACA READINGS/SECOND

conttn”ovs into Extemal Rigger into Triggered via

Internal Buffer I”temd Buffer

IEEE488 Bus

IEEE-488 BUS IMPLEMENTATION

MULTILINE COMMANDS: DCL, LLO, SDC, GET, GTL; UNT, UNL,

.~- SPE, SPD.

UNILINE COMMANDS: IFC, REN,~EOI, SKQ, ATN.

INTERFACE FUNCTIONS: SHl. AHl, T6, TBO, L4, LEO, SRl, RLl, ?PO,

DCI. DTl, CO, El.

PROGRAMMABLE PARAMETERS: Range, Function, zero, Integration

Period, Filter. EOI. Trigger, Terminator, Delay, ?OO-Reading storage,

Calibration. Display, Multiplex, Status, Service Request, Self Test,

Output Format. TRANSLATOR.

GENERAL

RANGING: Manual or autoranging.

MAXIMUM READING: 3029999 counts in 6%.digit mode.

ZERO: Control subtract: on-scale value from subseqtient readings or allows

value to be prog&nmed.

CONNECTORS: Analog: Switch selectable front or rear, safety j&s.

Digital: TRIGGER input tid VOLTMETER COMPLETE &put on iear

panel, BNCs.

WARMUP: 2 hours to rated accuracy.

DISPLAY: 10, 0.5-in. alphanumeric LED digits with decimal point and

polarity. Function and IEEE-488 bus status also indicated.

ISOLATION: Input Lo to IEEE Lo orpower line ground: 5oOVpeak. 5~xlC+

max. VI+ product. >lO’D paralleled by 4OOpF.

DATA MEMORY: 1 to 500 locations, programmable. Measurement inter-

vals selectable from lms to 999999,&s or triggered.

BENCH READING RATE: 5 readings/second (2lsecond on 30M8 and

3COMtl ranges).

FILTER: Weighted average (exponential). Programmable weighting, 1 to

l/99.

OPERATING ENVIRONMENT: O”-500$ 0%.80% relative humidity up

to 35T; linearly derate 3% RH/“C, 35’C-5Ci’C (0%.60% RH up to 28OC

on 3oOMB range).

STORAGE ENVIRONMENT: -25” to +65OC.

POWER: 105.125V or 210.UOV, rex panel switch selected, 5OHz or 6OHz,

30VA max. YO-1lOV and 18022OV versions available upon request.

DIMENSIONS, WEIGHT: l27mm high x 216mm wide x 359mm deep

(5 in. x 8% in. x 14% in.). Net weight 3.7kg (8 Ibs.).

ACCBSSORIES AVAILABLE:

Model lOlYA-1: 5%.in. Single Fixed Rack Mounting Kit

Model lOlYA-2: 5’%-in. Dual Fixed Rack Mounting Kit

Model 10195-1: 5’%-in. Single Slide Rack Mounting Kit

Model 10195-2: 5X-b,. Dual Slide Rack Mounting Kit

Model 1651: 5&Ampere Shunt

Model 1681:

Model 168s RFPmbe

Model 1685:

Model 1751:

Model 1754:

Model 5806:

Model 7W7-I: Shielded IEEE-488 Cable, lm

Model 7007-2: Shielded IEEE-488 Cable, 20,

Model 7008.3: IEEE-488 Cable, 3 ft. (O.Ym)

Model 7008-6: IEEE488 Cable, 6 ft. (1.8m)

Prices and specifications Subject to change without notice.

Clip-On Test Lead Set

Clamp-On Current Pmbe

General Purpose Test Leads

Universal Test Lead Kit

Kelvin clip Leads

Page 7

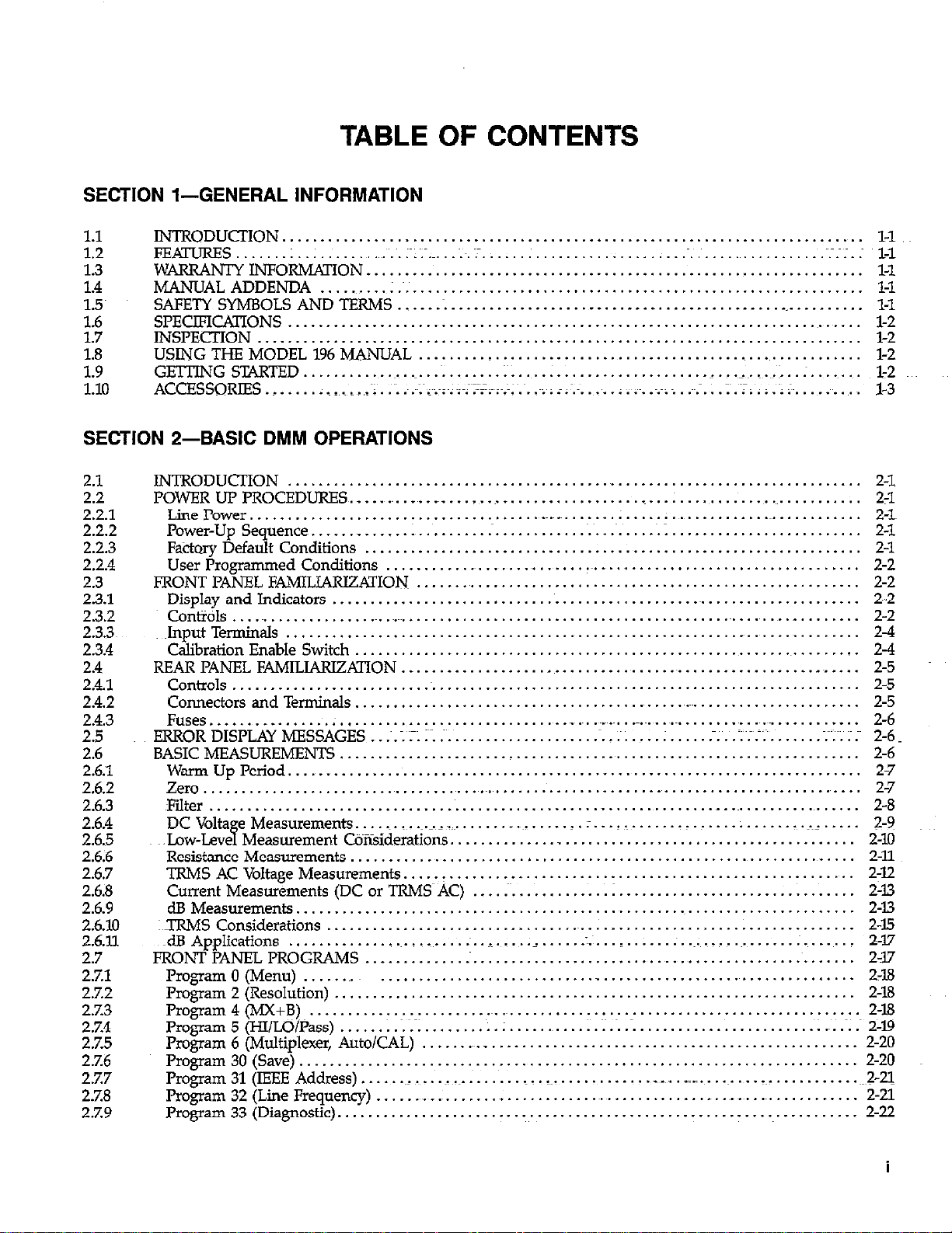

TABLE OF CONTENT!3

SECTION l-GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5~

:p7

1.8

1.9

1.10

INTRODUCTION. ...........................................................................

FEAI-URES ...... .;. ................

WARRANTY INFORMATION .................................................................

MANUAL ADDENDA ..........

SAFETY SYMBOLS AND TFRMS

SPECIFICATIONS

INSPECTION ..............................................

USING THE MODEL 196 MANUAL

GE’JTMG STARED .............................

ACCESSORIES .................... .~: .~.~;~.~..~;~..~~.~;-;;~.‘;~.~. .~;~; ;:~.~.

............................................................................

;~:~.~ .... .;.e:.;. .. .;. .......................................

; ..............................................................

............................................................... l-l

SECTION 2-BASIC DMM OPERATIONS

2.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.3

23.1

2.3.2

2.33~

2.3.4

2.4

2.4.1

2.4.2

2.4.3

2.5

2.6

2.6.1

2.6.2

2.6.3

2.6.4

2.65

2.6;6

2.6.7

2.68

2.6.9

2.6.10

2.6.u.

2.7

27.1

2.7.2

2.7.3

2.%4

2.75

2.7.6

2.7.7

2.7.8

2.7.9

INTRODUCTION ...........................................................................

POWER UP PROCEDURES .........

Line rower ...................................................

Power-Up sequence.

Factory Default Conditions

User Programmed Conditions .................................................................

FRONT PANEL FAMILIARIZATION

DisplayandIndicators

controls..

~1nputTermine.k

Calibration Enable Switch

REAR PANEL FAMILIARIZATION

Controls

Connectors and Terminals

Fuses..

ERROR DISPLAY MESSAGES. ..~.;Z:..;

BASIC MEASUREMENTS

WarmUpPeriod

Zero.........................~............~.~.......~

Filter

DCVolta eMeasurements..

.Low-Leve Measurement Coiisiderations

Resistan& Measurements ...................................................................

TRMS ACVoltageMeasurements

Current Measurements (DC or TRMS~~AC)

dBMeasurements

:TRMS Considerations

~~dBApplications .......................

FRONT PANEL PROGRAMS

Program 0 (Menu)

Program2(Resolution)

Program4(MX+B)~.

Program5~/LO/Pass).....................;

Program 6 (Multiplexer, Auto/CAL)

Program30(Save)..................~.....~

Program 31 (IEEE Address).

Program 32 (Lie Frequency) .......................................................

Program 33 (Diagnostic).

........................................................................................

................................................................................... 2-5

.....

_. ....... .

.......................................................................................

H

............................................................................

......................................................................

.............................................................................

...................................................................

....................................................................

.............................................................................

.....................................................................

...........................................................................

.........................................................................

...................................................................... 2-15

........................................................................

....................................................................

........................................................................... 2-18

.....................................................................

_._.~ .............................. ..I..

.................................................................

....................................................... __

...

~.~~..~...=_

...........................................................

................................................................... 2-17

.......................................................................... ~2-21

l-1 ..

.~.-.~:.: l-l

l-1

l-l

l-2

....

....

l-2

2-l

2-1

2-l

2-l

2-2

2-2

2-2

2-4

2-4

2-5

2-5

Z-6

2-6

2-7

2-8

2-9 ~~~

2-11

2-12

2-13

2-13

2-17

2-18

2-18

2-20

2-22

. ....................................

.......................................................... l-2

.; .........................

.... : .... .;~;;

: .................................

.......................................................... 2-2

.....................

......................................... 2-7

.................

..................................................... 2-10

.... ;. ........... .I ...............................

................

.:

.............................................. 2-19

..........................................................

.................................................. 2-20

~...~;. ... .

..: . ..*-.

..........

:.~

....................... .~.

..~~...._~. ..~..: .. .;. ....... 1-2

.~~.-.: . :~.-;~; : .~: ;~. ........ l-3

....................... 2-l

...... ........

.;...:~;.=;

:..~: .............. .

_. ........... 2-21

;~~;~;::~ 2-6.

........

i

Page 8

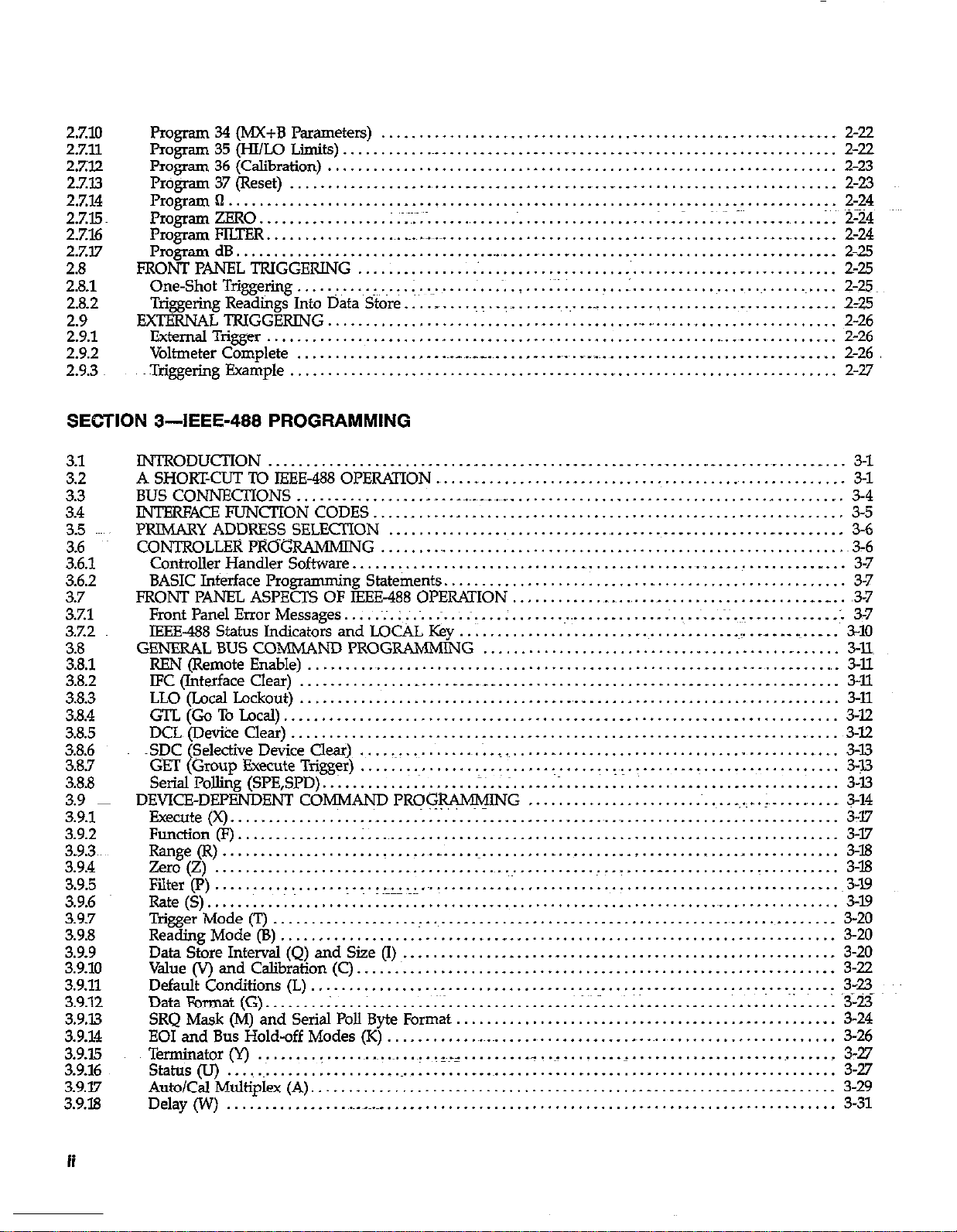

2.7.10

2.7.11

2.%x?

27.13

2.7.14

2.7.15

2.7.16

2.7x7

2.8

2.8.1

2.8.2

2.9

2.9.1

2.9.2

2.9.3

Program 34 (MX+B Pammeters) ............................................

Program 35 (HI/LO Limits) ..............................

Program36(Calibration) ...................................................................

mgram 37 (Reset) ..................

Programn ................................................................................

Program ZERO.. .............. .: .~;:.~.~.

Program FILTER

................. ..~.._~~

Program dB .................................

FRONT PANEL TRIGGERING .................................................................

One-ShotTrigge~ring.. ........ I.~...;..~

Triggering Readings Into Data Store.

EXTEEWAL TRIGGERING ...........................................

ExternalTrigger.. ..........................................................................

Voltmeter Complete ...................

~Trigering Example..

......................................................................

SECTION 3-IEEE-488 PROGRAMMING

., ..... _~. ... _ _ .... 2-22

., ...... ., ............................

., .... __. ................. -. ............................

.............................. .I. ..

. ... I~.~:.-. .......... .l~. 2-24

................................................... .._. 2-24

_,_,_ ............................................

.................. .;..... T . ..I. .............................

..................... ., .... __ .............................

., .. Z-25

_. ........................

.~._ .. .._. ............. ___~. ........................

._ .... 2-26

2-22

2-23

2-23

2-24

2-25

2-25

2-25

2-26

2-26

2-27

3.1

3.2

3.3

3.4

3.5 ~~~,

3.6

3.6.1

3.6.2

3.7

3.7.1

3.%2

3.8

3.8.1

3.8.2

3.8.3

3.8.4

3.8.5

3.8.6

3.8.7

3.8.8

3.9 ~

3.9.1

3.9.2

3.9.3~

3.9.4

3.9.5

3.9.6

3.9.7

3.9.8

3.9.9

3.9.10

3.9.11

3.9.32

3.9.13

3.9.14

3.9.15

3.9.16

3.9.17

3.9.18

INTRODUCTION.. ........................................................

A SHORTCUT TO IEEE-488 OPERATION

BUS CONNECTIONS..

...................

........................................................ 3-l

. . ..~.~_~..~_ ............................................

INTERFACE FUNCTION CODES ..............................................................

PRJMARY ADDRESS SELECTION ......................................

CONTROLLER PRO%

RAMMING

........ _.

................................................... ~3-6

Controller Handler Softwae ..................................................................

BASIC Interface Programming Statements.

FRONT PANEL ASPECTS OF IEEE-488 OPERATION

FrontPanelErrorMessages.. ... ~;.;~.~..:...:~~ ...

IEEE-488 Status Indicators and LOCAL Key

GENERAL BUS COMMAND PROGRAMMIN

....................................................

..........................................

. ....................... ~..~..~...~;.~ ..............

....................................

G ................................................

REN (Remote Enable) .....................................................................

IFC (Tnterface Clear) .......................

__ _., .............................................

LLO (LocalLockout).......................................................~

GTL(GoToLocal). ........................................................................

DCL(Devi?e Clear) ........................................................................

~SDC t Selective De& Clear), ..................

1. _.~. .... -. ........... ._ ..........................

GET Group Execute Trigger) ..................................

Se&d Polling (SPE,SPD). .1.. ................

DEVICE-DEPENDENT COMMAND PRWWNG

Execute(x).

Fur&on (F) ................

Range(R). ......................

................................................. .._.

;

..............................................................

.._ ......................................................

.-;. ........ .: ....................................

............................. _..:. . ;,

zero(Z). .........................................................

Filter(P).......................~~............................................................3-

Rate (S).

........

......................................................................... 3-19

.;.

Trigger Mode Q ............................................................................

Reading Mode (B) .............................

Data Store Interval (Q) and Size (I)

Value (V) and Calibration (C)

...............................................................

..........................................................

__ ..........................................

Default Conditions (L) ..............................................................

DataFormat(G). .... .

............. ;~:.

SRQ Mask (M) and Serial Poll Byte Format

...............

:I;.....; .:.

..................................................

EOI and Bus Hold-off Modes (K) ................................................................

Terminator(Y) .............. ~..~..~...~...l~.~ _.

........ _ ..........................................

status (u) ...................................................................................

Auto/Cal Multiplex (A).

Delay (W)

.................................................................................... 331

....................................................................

...................

_ ........... _ ......... 3-6

__ __ ,3-7

.~I. .... ._ ....... 3-10

................ 3-11

-~.~. ........

t. ................. 3-n

....

....

.,

........................... 3-17

..- .......................

.~: .... : 3-23

........................ 3-23

3-l

3-4

3-5

3-7

3-7

. 57

3-n

., . 3-ll

3Xl

3-12

3-12

3-13

3-13

3-14

3-17

3-18

3-18

.

3-20

3-20

3-20

3-22

3-24

3-26

:I!

3-29

ii

Page 9

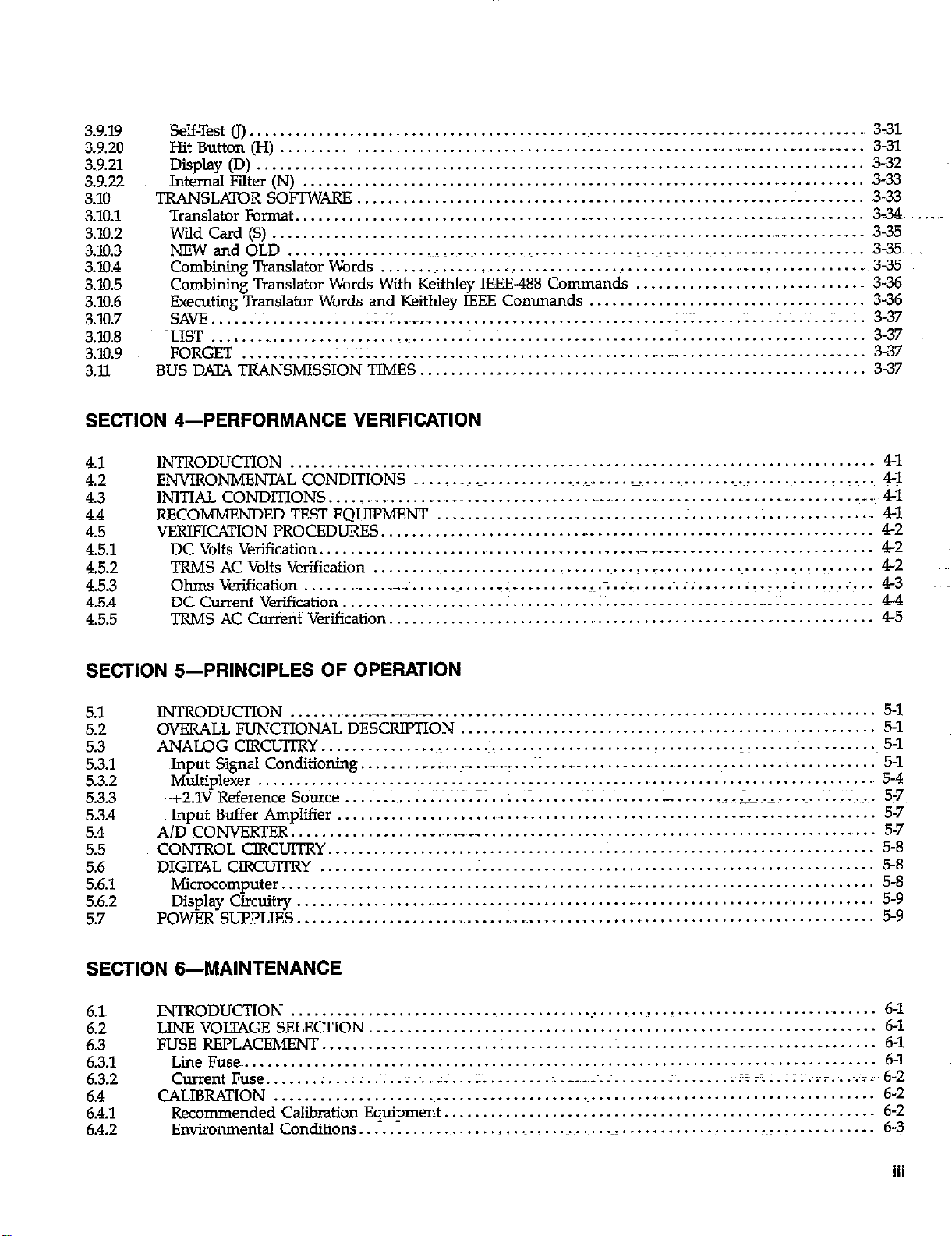

3.9.19 ~Sem&~).

3.9.20

whit Button (H)

3.9.21 Display (D)

3.9.22

3.10

3.10.1

3.10.2

3.10.3

3.108

3.10.5

3.10.6

3.10.7

3.10.8

3.10.9

3.11

lntemalFilter(N) .........................................................................

TRANSLATOR SOFIWARE

Translator Format.

WildCard($).

NEW and OLD ................. .;~,..~..~.~.

Combining Translator Words

Combining Translator Words With Keithley IEEE-488 Commands

Executing Translator Words and Keithley IEEE Commands

SAVE.. ..................... ~;~.~...~v ................................

~LIST

FORGET ............. :.I;

BUS DKC.4 TRANSMISSION TIMES

...................................................

...................................................................... ~...~.~.~__ .. 3-31

...............................................................................

..................................................

.............................................................

...............................................

..............

.........................

.......

_.~.

......

.._

.....................

..........................................................

SECTION 4-PERFORMANCE VERIFICATION

.._. . .._. . .- ................. 331

....

._.

-~

.........

.......

_.,_~ ., . .,

. . c____. ... .._

.............. 335

....

...................... I. ... ,:~. ......................... 3-35~

..................

.

..............

_

................

.,_

..............................

....................................

.

.........................

1;:.

..........

.: ........................ 3-37

;.~.

;...;. 3-37

....

..~ ...................................

332

3-33

3-33

~3-34

3-35

3-36

3-36

3-37

3-37

...

4.1

4.2

4.3

4.4

4.5

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

INTRODUCTION

ENVIRONMENTAL CONDITIONS

INITIAL CONDITIONS. ..... -

RECOMMENDEDTESTEQUIPMENT..

VERIFICAXION PROCEDURES.

DC Volts Verification ........................................ __ __ _._ ___ __

TRMS AC Volts Verification ......

Ohms Verification

DCCurrentVerification.. .... ;I;. ....... ;~ ................

TRMS AC Current Verification

..............................................................................

............................

_*_..._..__._ ................ ~.~_~. ................... ..--

.................................................................

..~.~......................~...I..~...........~.......~ ..........

.........

..~.._~:.

............

..............................

SECTION 5-PRINCIPLES OF OPERATION

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.4

5.5

5.6

5.61

5.6.2

5.7

INTRODUCTION

OVERALL FUNCTIONAL DESCRIPTION

ANALOG CIRCUITRY..

Input Signal Conditioning.

Multiplexer

~+2.1V Reference Source ...........

Input Buffer Amplifier

A/D CONVERTER ...............

CONTROL CIRCUITRY

DIGITAL CIRCUITRY

Microcomputer.

Display Circuitry ................

POWER SUPPLIES ....................

...........

.___ ~.~_~.~.~._.

............................................

....................

.................................................................................

.............

.........................................................

.._..~~.~_~_..................................~......_....._~ ...

.......................................................................

........................................................................................................................................................

..~._.......................~....................~ ...........

..

..................................

_.

.

......

~.;;.

~...~.;~;.

...............

................................

.........

. ._

_.

. .m .,._

~:

.....

~_-_.

........................................................

...........................................................

. .......... _:~ ................. 5-l

.~.~.~~-. . .~; _.

................................

. .................... -. .... ~~~.~~:.~~. .................

..~.~...._..~ .............................................

......

...............

.........

.

......................

..... ;..~; ..:.

.~;~.~.-;.-;.......;. 4-4

......

................

...........

;

.:

............

..

..-- ...

.~..;

...

....

41

4-1

41

41

42

4-2

4-2

4-3

4-5

5-l

5-l

5-l

5-4

5-7

.55

5-8

;

5-9

5-9

SECTION B-MAINTENANCE

6.1

6.2

6.3

6.3.1

6.3.2

6.4

6.4.1

6.4.2

INTRODUCTION

LINE VOITAGE SELECTION

FUSE REPLACEMENT

Line Fuses

CurrentFuse

CALIBRKION .....

RecommendedCalibrationEquipment

Environmental Conditions.

..............................................................................

..................................................................................

....................... . ................

..................................................................

....................................................

..,

____.:

...

.......................

.........

.._....................~

..................

.)

..~~.~...~..-*~~

. .._

__:.:

..

........

-;~

..................

I,;;...;..;;.~....;.~~~:

...................

.................................................................................

.~_.

6-l

....

6-l

2;;

iii

Page 10

6.4.3

6.4.4

6.4.5

6.4.6

6.4.7

Warn-UpPeriod..

............

CALENABLE Switch.. .................

Front Panel Calibration ...............

IEEE-488Bus~CaIibration.. ..............

Calibration Sequence .... ! ........ ,.._._

DC V&s CaI’b 1 *alon.. t’ ............................

t%

6.4.10

6.4.11

6.4.72

6.5

6.6

6.7

6.7.1

6.7.2

67.3

6.7.4

6.7.5

6.7.6

Resistance Calibration. .......... .I

TRMS~ACVtiltsCalibration.. ...................

DC Current Calibration .............

TRMS AC Currefit Calibration ................................................................

DISASSEMBLYINSi-RUCTIONS ..........

SPECIAL HANDLING OF STATIC-SENSI’?IVE DEVICES

TROUBLESHOOTING ............. .~I,~_.

Recommended Test Equipment .........

Power Up Self Test ..................

Program 33 - Self Diagnostic Program

Power Supplies ...................

Signal COnditioning Check .-. .. .:.:~~.

Digital and Display Circuitry Checks

SECTION 74iEPLACEABLE PAFITS

... I......,: ..:. .... ..:.~:..:...~ ..;

..I...

...........

........................................................

_.-.

_

.......................

......

.,

.....

_.

.......................................

.._. __.__ _...................,

.. :&.-. _. ...... ‘~-. ,_. ... .~_ .............................

.._ ..........................................

.... _, .......................................................

;~. .._ .. :.:~:.~ ... . ...............................

_. . __ ......... ... ._. .....................................

~...__._ . ,........I_ .......... ...............................

........

.................... .~:.

- ..l..: ..........

... ., .........................

-., .. ..I. ................ ._,_ _~. .,..__.

.-~- ._.~_._. .......... ._~.~.~.~.~.~.~. ., . ___.,

................ ._ ....... . _, ...............

.~.~_.__-. ..... .___“.,_. ............. _. .........................

....... .~-.:~. ....... _. ....... ._. ........................

........................................................

. ............. 6-3

6-3

6-3

.. ~.~6-4

__ . _ .. ,6,-4

6-5

6-6

6-7

., . 6-9

6-10

6-11

_I...~ ............ ~&lZ

: ......

., ... 6-12

...................... 6-14

. ., ...................... 6-14

__. ............. 6-14

6-15

_. .. 6-15

6-15

7.1

Z2

z3

%4

7.5

INTRODUCTION...~.~..~:~...;..;~..~.~..; .._.....I.... _......_......................_.._......_ _..

PARTS UST..............................................~....................~..~......-.... 7-1

ORDFRINGINFORMATION ..,................,. _.._ __........... ~-~ . . . . ~~.-- _..... ~-...1.~...~...-~~1~3~

FACTORY SERVICE . . . . . . . . ;..;.;....;...;;~-__.~.~-;; ._.. ~..__ . . . . . . . . . . . . . . I_ . . . . . . . . f . . . _ . . . . . . . . . . . .

SCHEMp;TIC DIAGRAMS ps;rrj: COMPG&T LOC&TIOti DRAWINGS . . . . : .~ .~. ; _ _ . . .~. __ . 7-l

APPENDIX A

ASCII CHARACTER CODES AND IEEE-488 MULTILINE INTERFACE COMMAND MESSAGES.. 1. A-1~

APPENDIX B

IBM PC/XT and MODEL 8573A PROGRAMMING . _ _. . . . . . _. . . _ _ _ _. _. . _ . _ __. . . k-1

APPENDIX C

CONTROLLER PROGRAMS. .‘, . .‘:. . ., . . . ::. .~. . __ . . . _ . .~. . . . _ . . . . . . , . . . . . :. . . _. .

APPENDIX D

IEEE-488 BUS OVERVIEW . . . . ._ . . . . . . . . . . . . . . . . _ . . . _ . , . _ . . _ __ _. . . _ . . . . . . _ . _ _.

7-1

;rl

C-l

D-l

iv

Page 11

LIST OF TABLES

SECTION 2-BASIC DMM OPERATION

2-l

2-2

23

Et

2-6

2-7

2-8

Factory Default Conditions ......

ErrorMessages

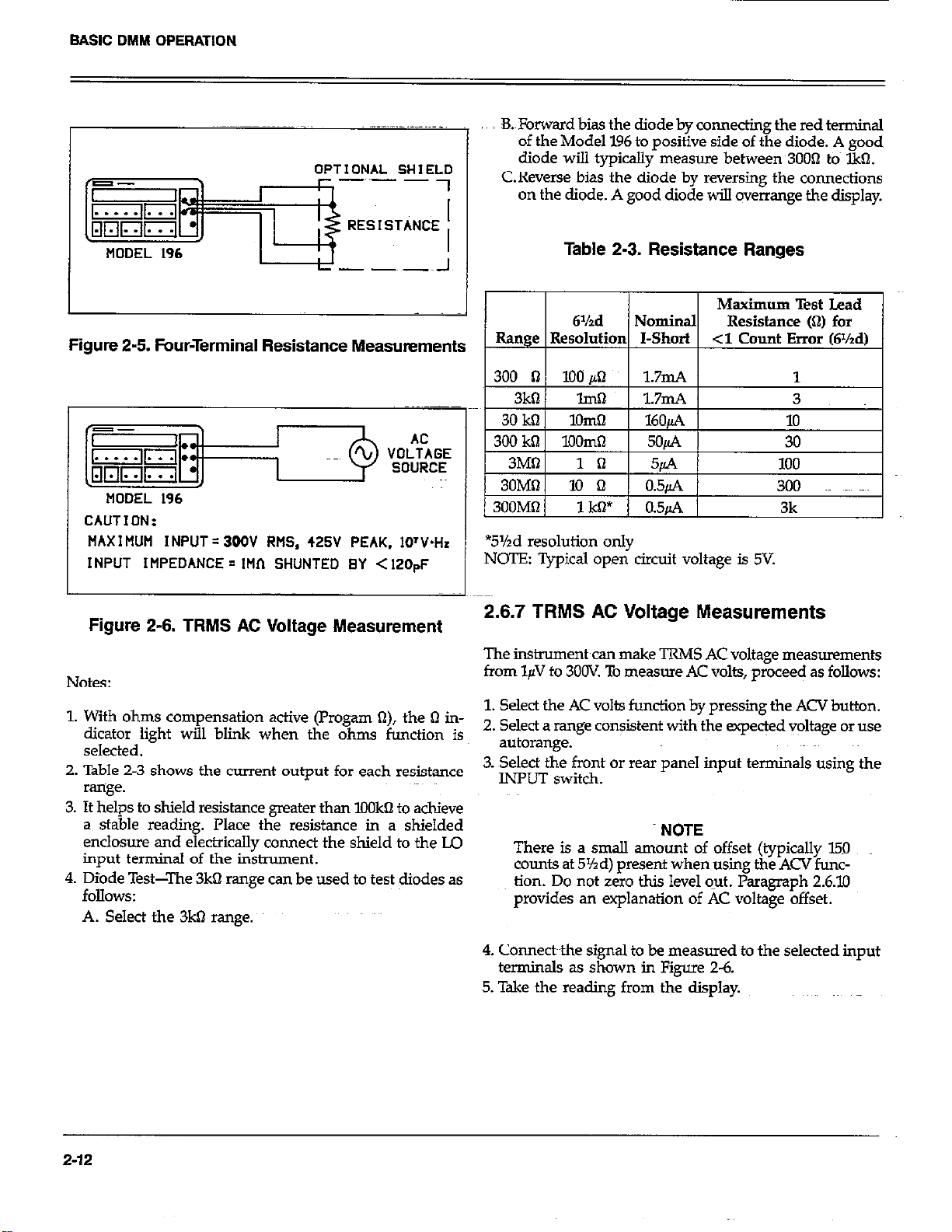

ResistanceRanges..

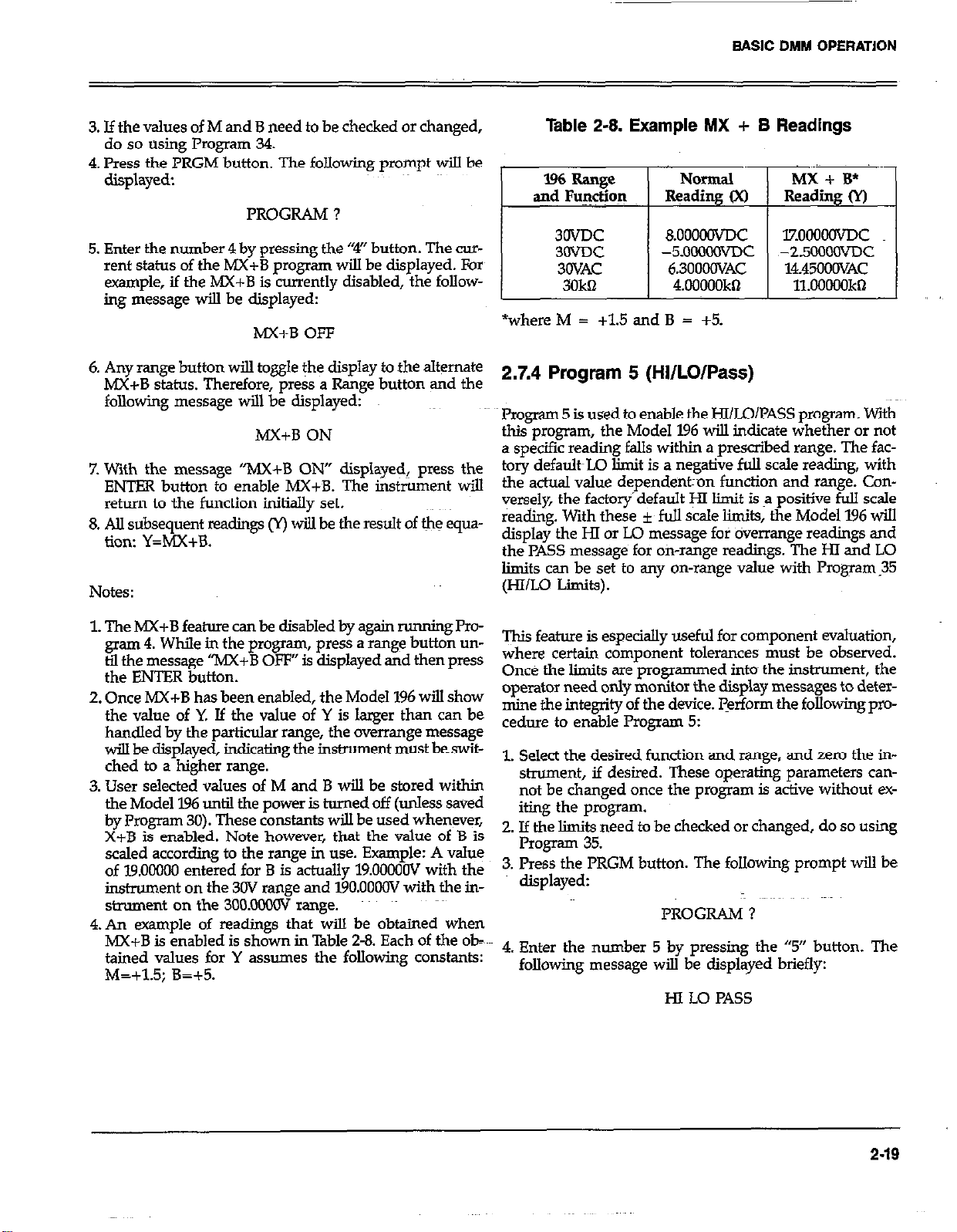

Corresponding Voltage +ferenceJev$@for Impedance !7eference.

Comparison of Average and TRMS Meter Readings .............................................

FrontPanelPrograms..

Display Resolution ........................... .............

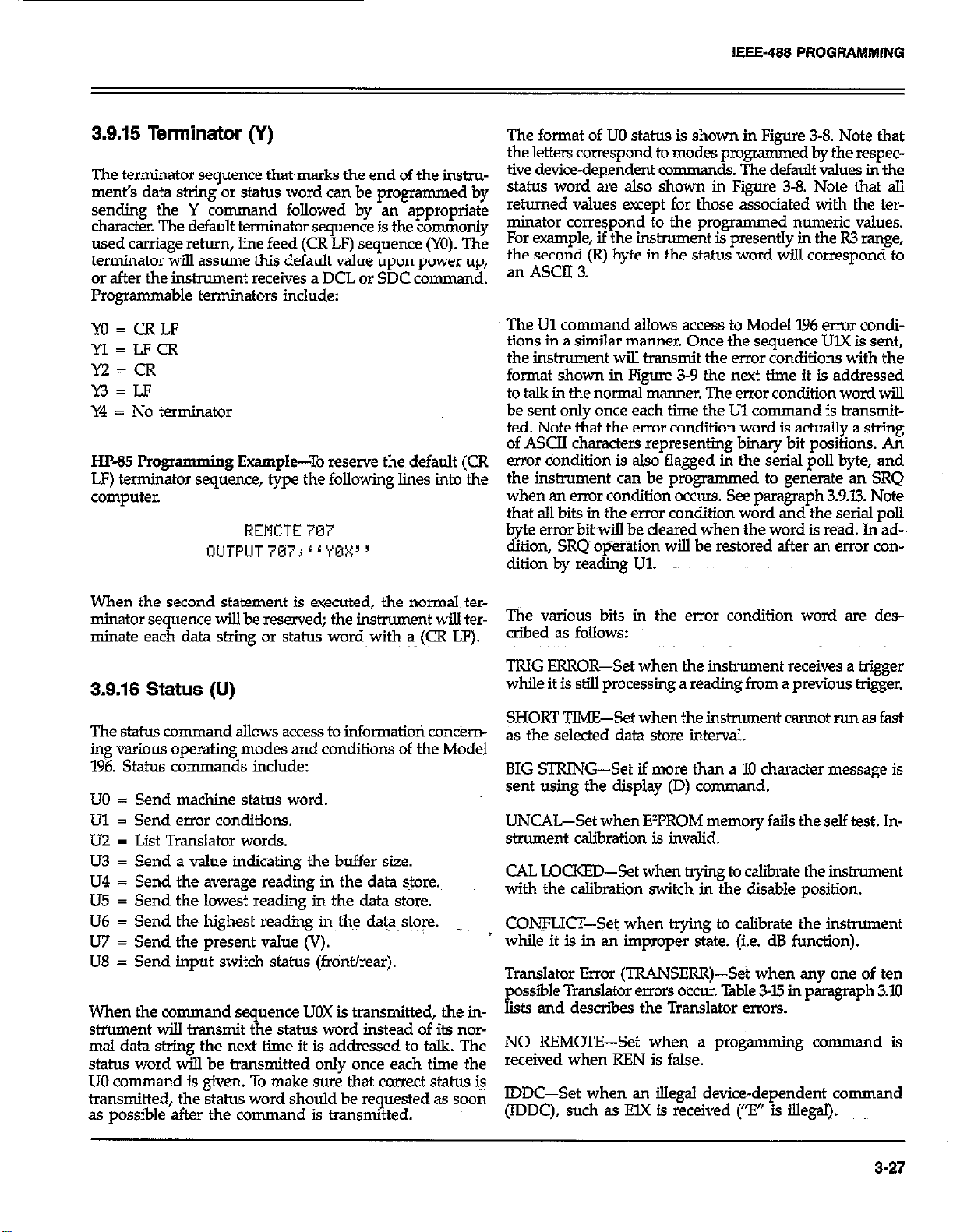

ExampleMX+BReadings.:.

.......... ..~.......;-.....................,......................;

............................

...... ~.:.

.~I. :. . : .;

.... . ..... :z.:. ... ~.:. ...

......

SECTION 3-IEEE-488 PROGRAMMING

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-ll

3-12

3-13

3-14

3-35

3-16

IEEE-488 Commands Used to Select Function and Range ........................................

~lEEE Contact Designation. ..............................

Model 196 Interface Function Codes ............................................

BASIC Statements Necessary to Send Bus Commands ...............................

FrontPanelIEEE488Messages..

General Bus Commands and Associated BASIC Statements ;~.

FactoryDefaultConditiotis

Device-Dependent Command Summary ............................................

Range Co~andSummary...~..,,:.

Rate Command Summary

High Speed Data Store

SRQ Command Parameters

Bus Hold-off Ties

Translator Reserved Words and Chxacter ....................................

Translator Error Messages ... z

Trigger To Reading-Ready Times (DCV Funct&~n) ...............................................

........................................

..........................................................................

............................................

..

~~;I.~;.~~...;.;.~~; ....... ;;...~.J:.:..~..: ...

.......

..................................................

....................................................................

:~.

...

.................................................

. ............................................

.:~. ............... . .......

........

I...;

......................

:I............... l............

.....................

.z.:..~ .:. .................

.__

.,

..

.... _ .............................

. ............. ~;;.;;~;;.

i ......................................

.................

:r:..~-..~.~ ~..~i: ..%.

._.

.......

. .... -..I~;~.~ 1..

..... ...........

_

... _ .. _ ................

.~.~.:.

......

.............. 2-6

.: ...... ;~. ..... 2-15

:.~. .......... 2-l7

... i...;;. 2-19~

_.

_.

...

........

1..

...........

..................

.~;.

...............

............ 3-12

._

..........

_

_.

..........

:.

............

_

................

-.!L. 3-l$

......

3-22

_

__ 3-25

.

__ 3-26

3-33

3-34

3-37

2-2

2-12

2-16

2-18

3-3

35

3-6

3-7

3-8~

3-10

3-E

3-19

SECTION 4-PERFORMANCE VERIFICATION

41

4-2

22

45

46

RecommendedTest Equipment

Limits for DCV Volts Verification

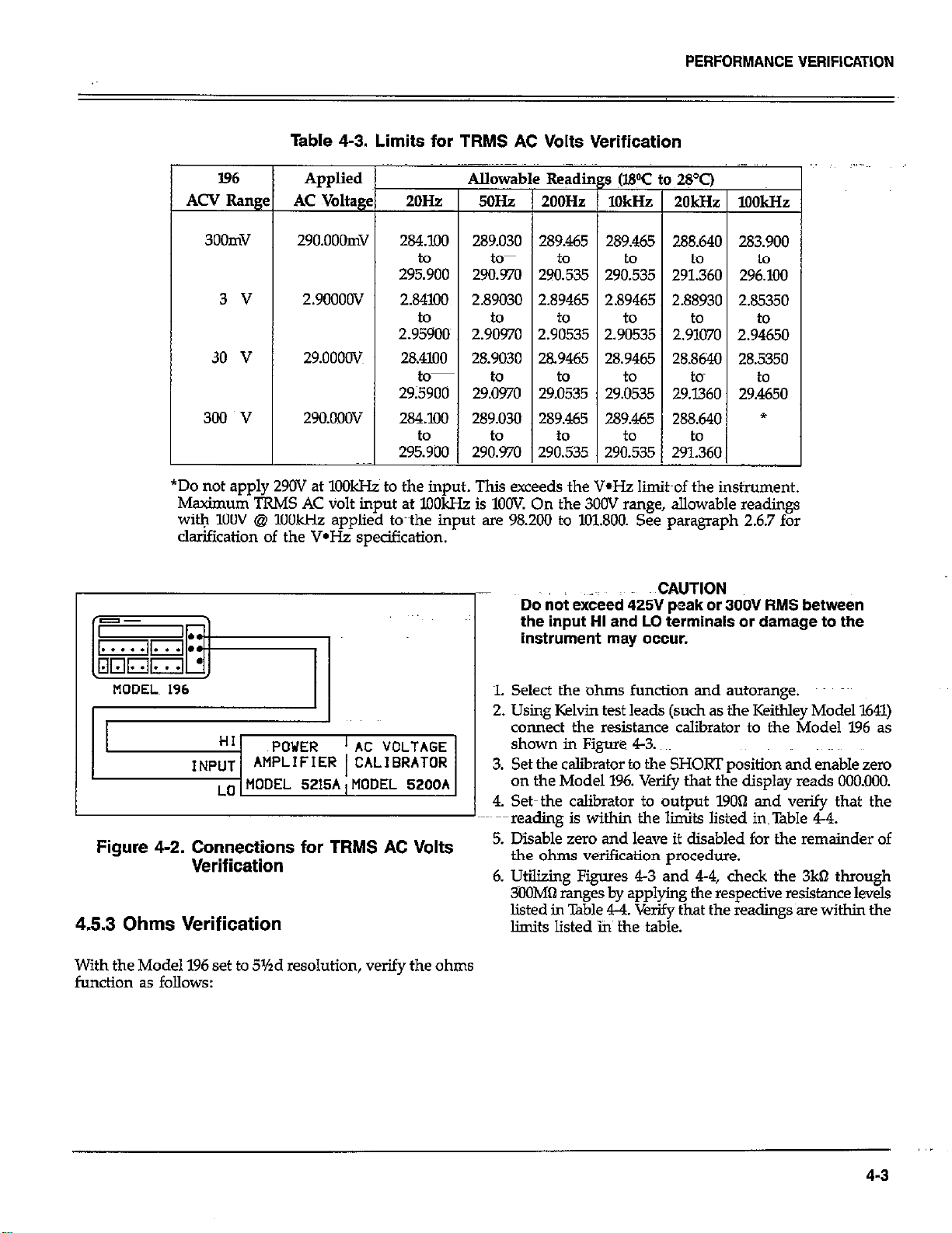

LimitsforTRMSACVoltsVerifibation..

Limits for Ohms Verification ... .:~. ;~.~.~. ....... ;...~

Limits for DC Current Verification

Limits for AC CurretifVerification

................................................................

................................................................

........ .

.............................................................

.......................

SECTION 5-PRINCIPLES OF OPERATION

5-1

Input Buffer Amplifier (U35) Gain Co*gt&ation . . . . . . ‘. . . . . .‘; i . . . . ~ . . . . . _~. _ . _ . 5-7

.......

....................

.....................................

MY..;

....

t..

~.I;

......................

41

42

i-3

.:. ...................... 4-4

4-4

........

.

4-5

V

Page 12

SECTION 6-MAINTENANCE

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-J.0

6-12

6-12

6-13

6-14

LineVoltage Selection

LineFuseReplacement

Current~Fuse Replacement

Recommended Calibration Equipment

DCVoltsCalibration......................~.....-

ResistanceCalibration

TRMS AC Volts Calibration.

DC Current Calibration

TRMS AC Currefit calibration

Recommended Troubleshooting Equipment

Model I.96 Troubleshooting Mode

Power Stipply Checks.

Digital Circuitry Checks.

Display Circuitry Checks

............ ..L

.......................................................................

...................................

........................................................................

.................

............ .~.....................

.......................................

................................................

........................................................................

.....................

.........................................................

..........................................................

..............................................................

_. ....... __. ......................

..............................................

_, .. _._ ...............................................

.......................................

....................................................

., .. __ .............

_. ............................

.........................

_.

_ ............ _

..... ., .. ., ., 6-18

6-l

6-2

6-2

6-2

6-5

6-6

6-7

6-10

6-11

6-14

6-15

6-18

6-19

SECTION 7-REPLACEABLE PAFKS

7-1 Display Board, Parts List.. . . . . . . . . . . , . . . . _ _ .-. .: . _ . _ :. . . . _:. . . . . _. . . . . . :. . . . .‘. . ._ _. 7-3

7-2

7-3 AnalogBoard,Parts List . . . . . . . . . . . . . . . . . . . . ..~.............................................. 719

7-4 Model196MiscellaneousParts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._........................

DigitalBoard,PartsList........................-~.............................................. 7-S

7-33

APPENDIX B

B-1 BASIC Statements Necessary to Send Btis

APPENDIX D

D-l lEEE488Bus Command So

D-2

D-3 Typical Addressed Command Sequence.

;;

Hexadecimal and Decimal Command Codes

Typical Device-Dependent Commiind Sequence

IBEE Co

mmaid

Group ................

............................................................

Co

mmands........................................... B-1

...................................................

.......... D-7

.............................................

.. ;~. ...................

_ ..... ; ....................................

.; ..... . .. .;~..~ ............

_

., .......

D-3

D-7

D-7

., .... D-7

Vi

Page 13

LIST OF ILLUSTRATIONS

SECTION 2-BASIC DMM OPERATION

2-l

2-2

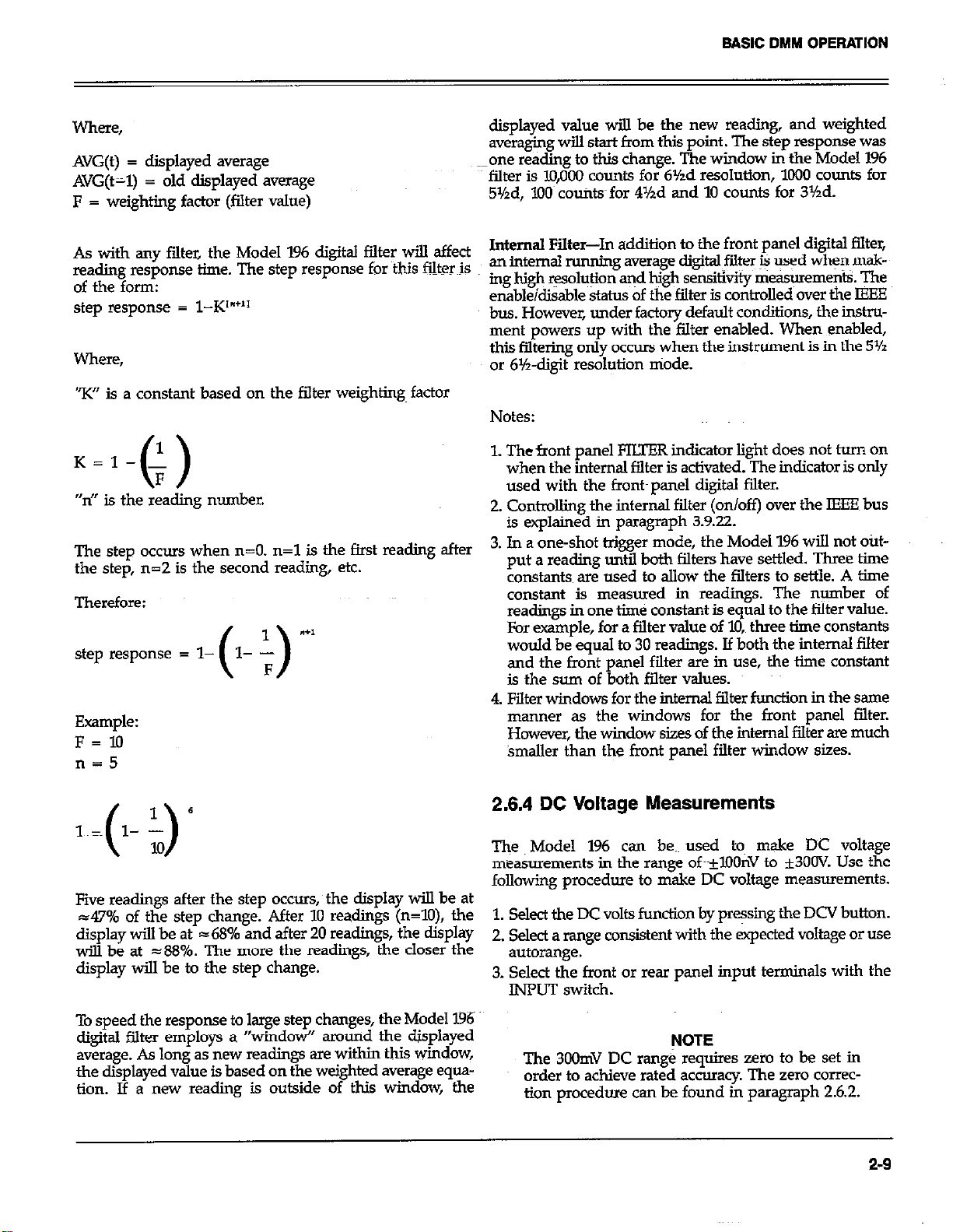

2-3

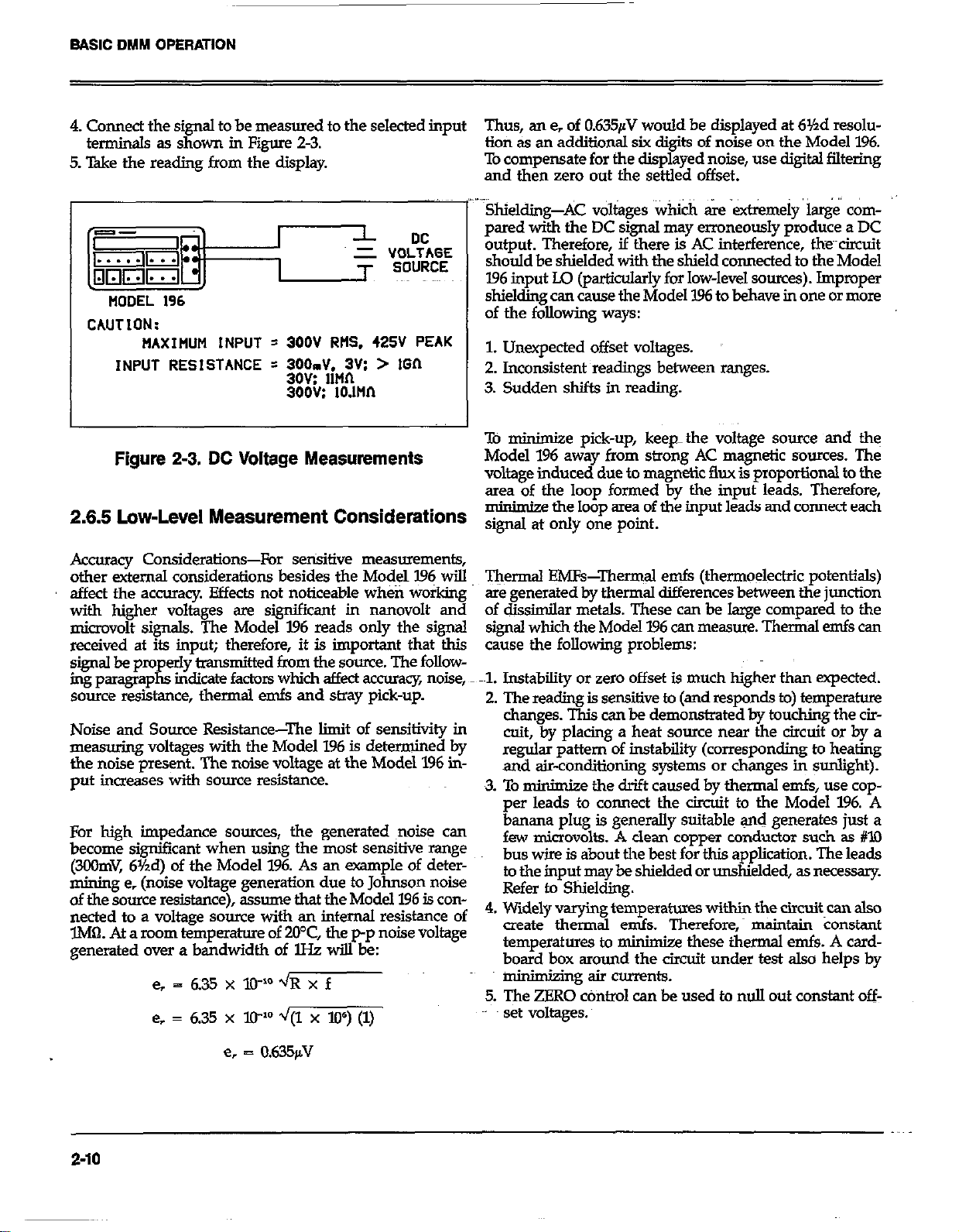

2-4

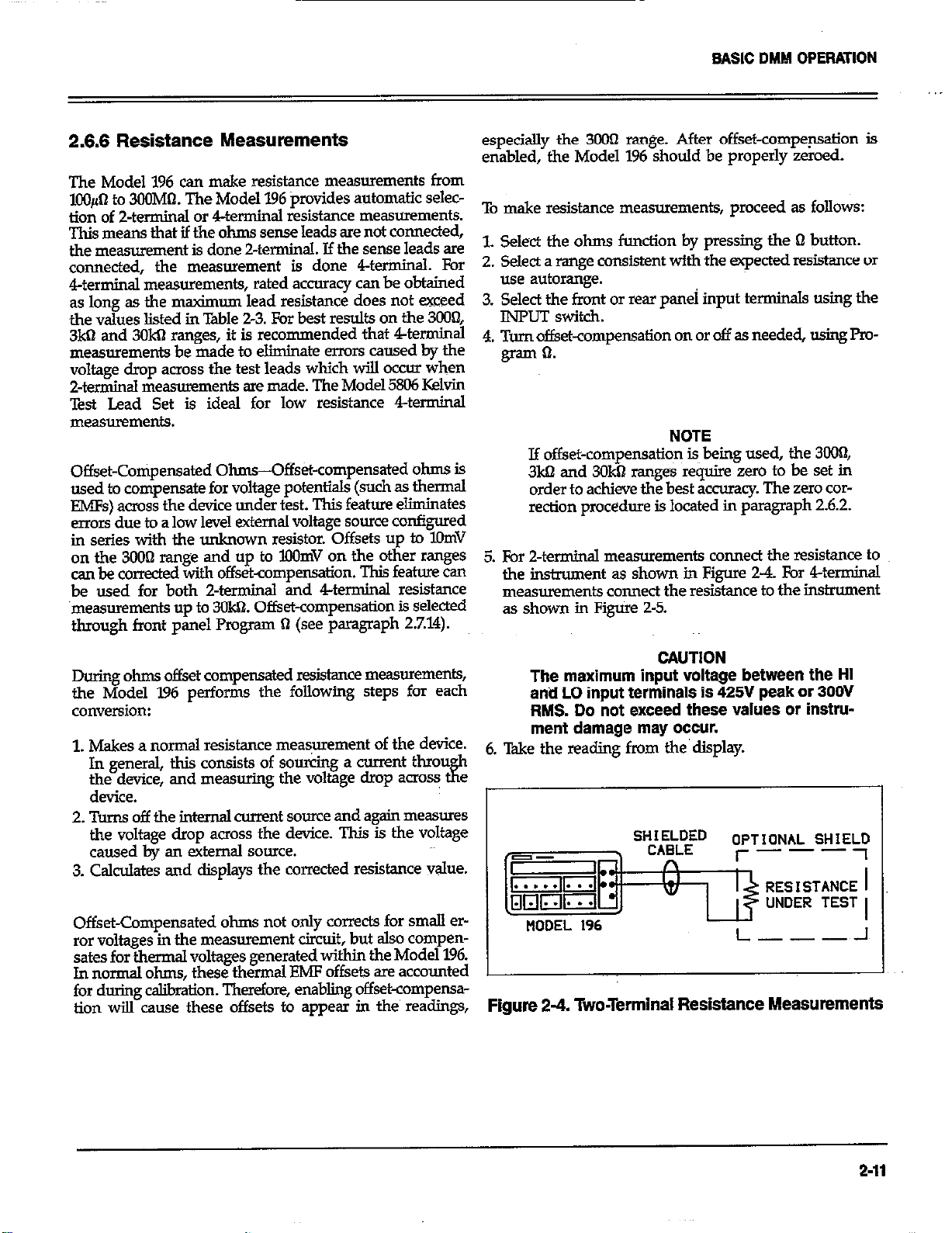

2-5

2-6

2-7

2-8

2-9

2-10

Model196FrontPanel................................................~.......~.......~-

Model 196 Rear Panel

DCVoltageMeasurements ........................... ..~....~.....-...............~.-...~-

Two-Terminal Resistance Measurements

Four-Terminal Resistance Measurements

TRMSACVoltageMeasuremement

Current Measurements.

External Trigger Pulse Specifications

Voltmeter Complete Pulse Specifications

External Triggering Example

.............................................................

....................................................................................................................................

.........

SECTION 3-IEEE-466 PROGRAMMING

3-l

3-2

2

3-5

3-6

37

3-8

3-9

3-10

TypicalProgramFlo~ Chart..

IEEE-488 Connector .. ................ .......

IEEE-488Connections~.

IEEE-488 Connector Location ...

Contact Assignments

~Generd Data Format

SRQMask and Serial Poll Byte Fo~at.........................................~.....-...-..-

UO Machine Status Word and Default V&es

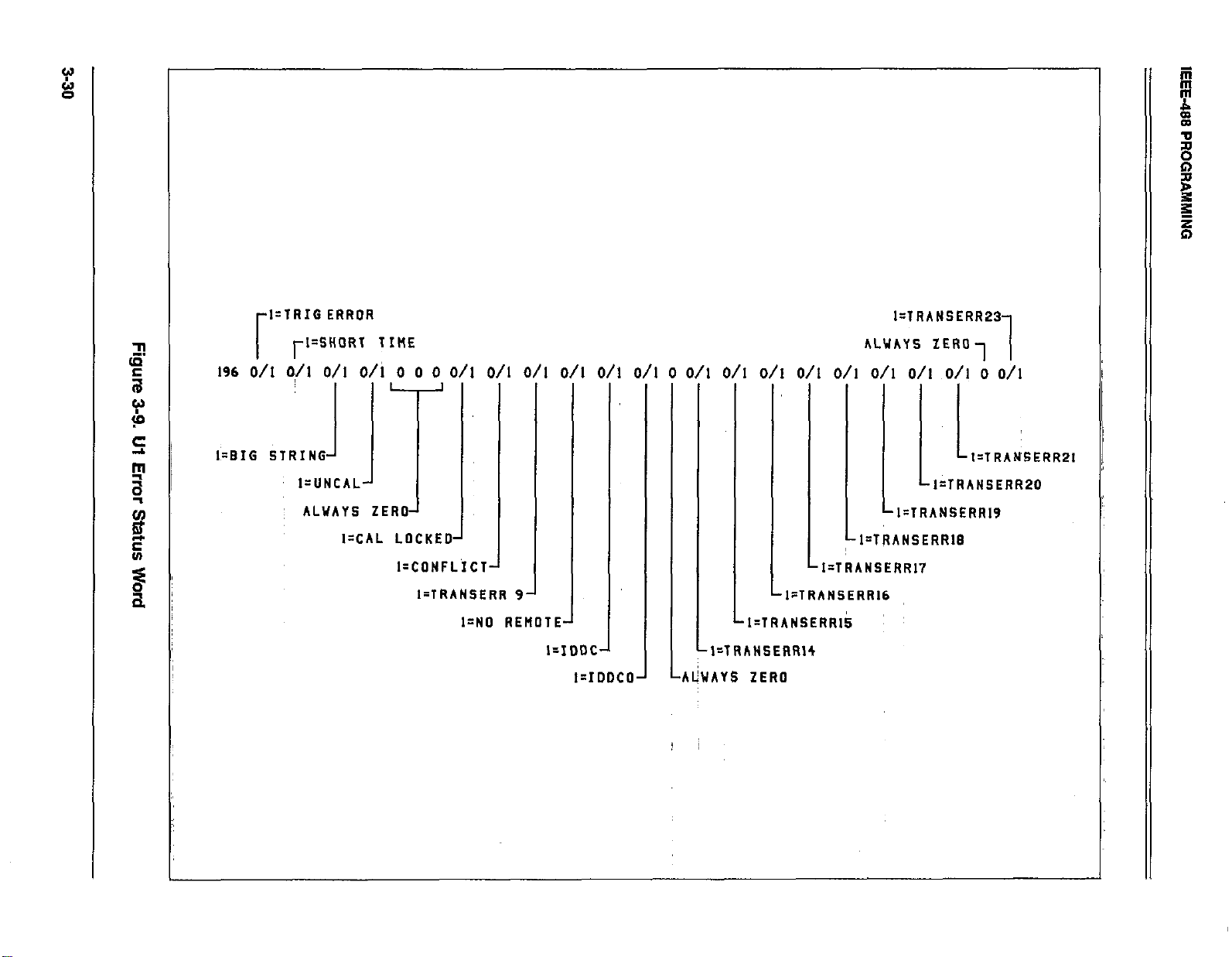

Ul Error Status Word .... .... ........

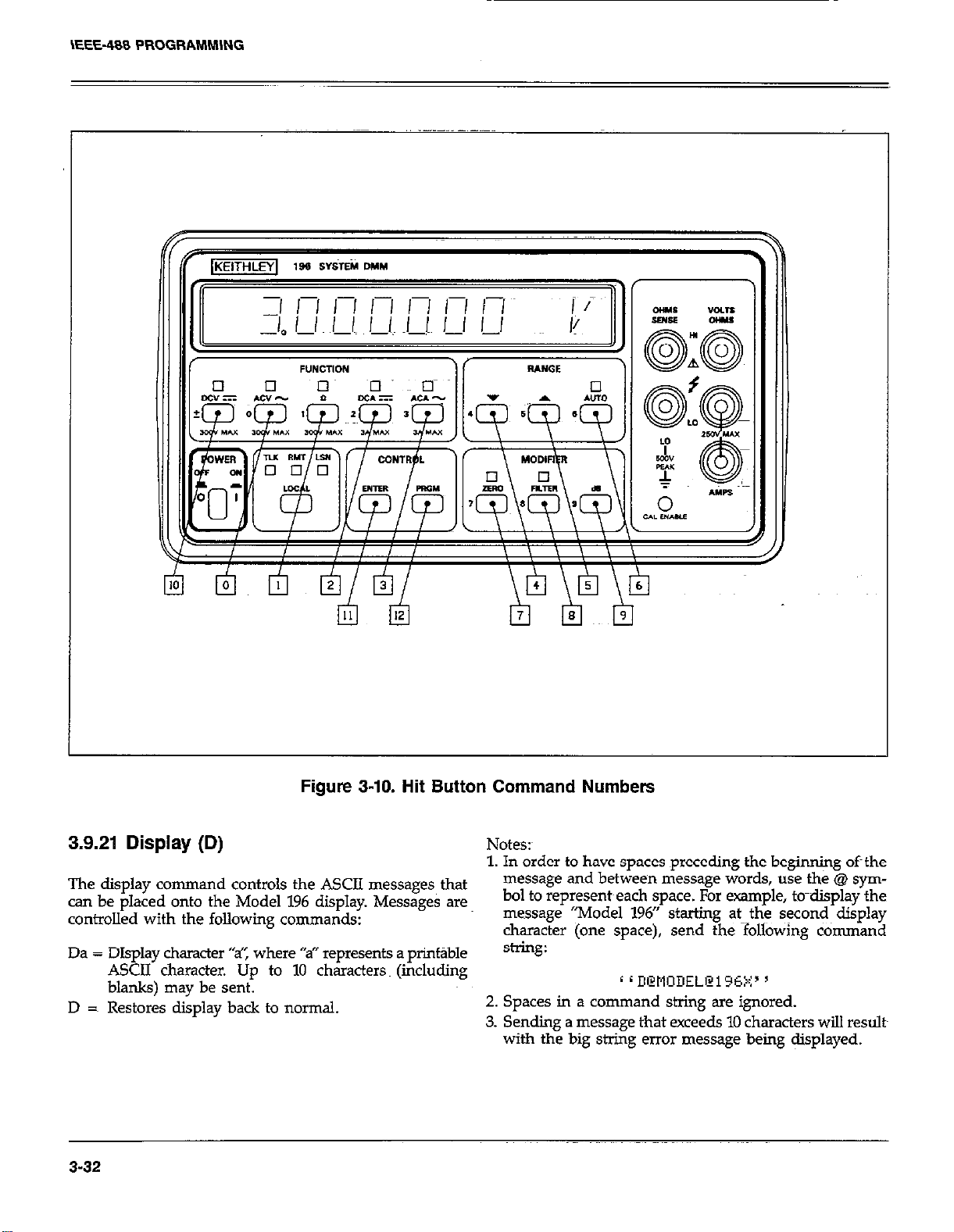

Hit Button Command Numbers

...................................

.........................................................................

........................

..............................................................

.._ ........

.................................................

........................

..........................................................

.._..............._ .................

.....................................

~.y.:~I.T ._ ~.~--.~:~.~.~.

....................

~.:.~ ..;

.......................

......................................................

_

.............................................................................................................

................................

.~.- .. . _~_.~_ _,_

I

......................................

;:

.

............................ .

.......

.....

..-

........

..*........~

...... _ .

_,__

r

........................

.

.................

.,

.,

.......

...

......

...

.~_.

-.:-~. :;4j

.....

;;.~:3:

...

.

2-3

2-5

2-10

2-11

2-p

$E

2-26

i;g

3-5

3-23

3-24

i;;:

3-32

SECTION 4-PERFORMANCE VERIFICATION

41

42

43

E

4-6

Conmctions ‘for DC Volts Verification

CoMectionsforTRMSACVoltsVeriCication~

Connections for Ohms Verification (300%#$! Range)

Connections for Ohms Verification (3OOkn--3OOMQ Ranges)

Connections for DC Current Verification

Connections for TRMS AC Cur&t Verification ._.

..........................................................

........................................................ 45

SECTION &PRINCIPLES OF OPERATION

5-l

5-2

5-3

S-4

5-5

5-6

Overall Block Diagram.

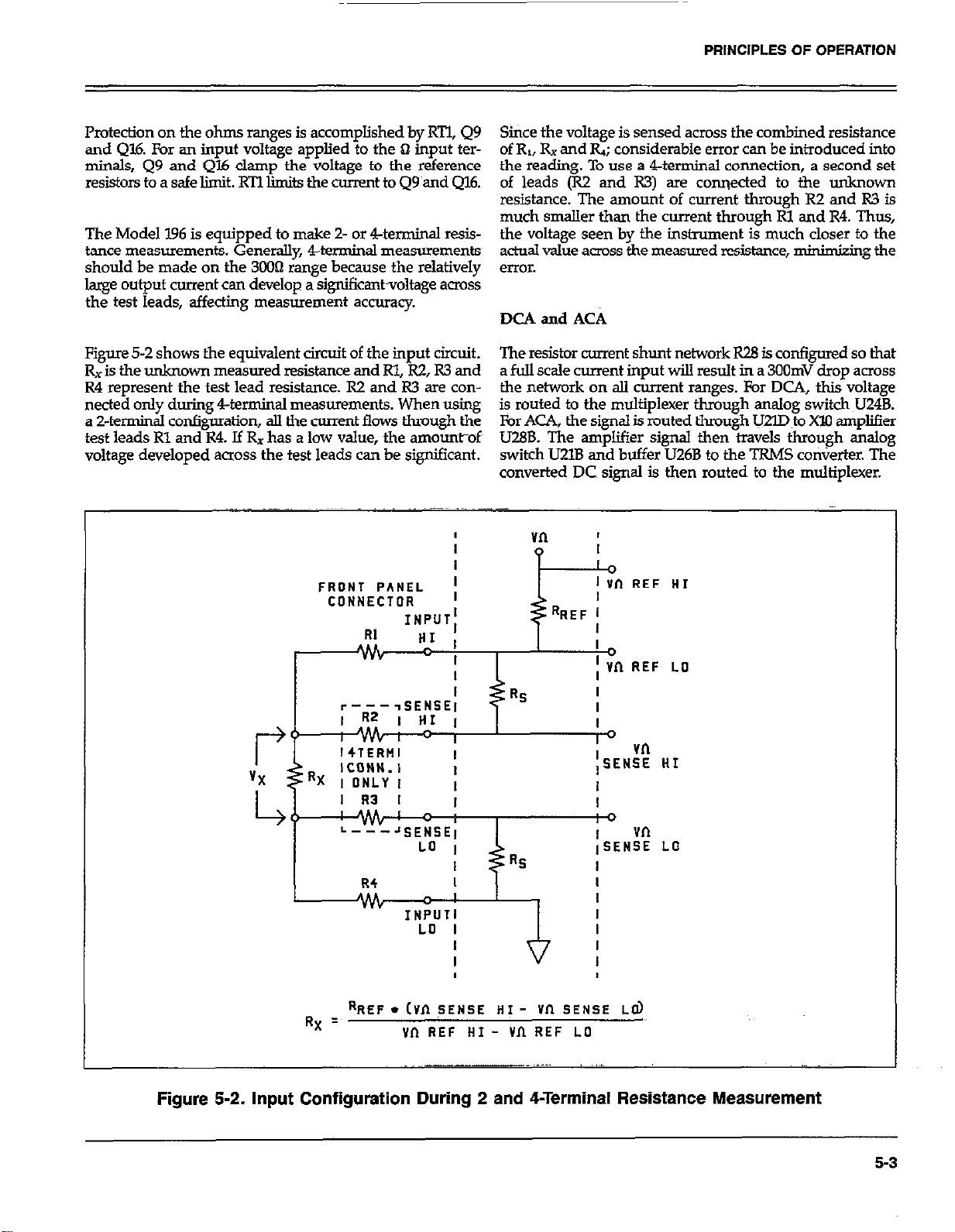

Input Configuration During 2 and 4Terminal Resistance Measurement.

Resistance Measurement Simplified Circi&y

JFET Multiplexer

Multiplexer Phases

A/D Converter Simplified Schematic

.......................................................................

.........................................................................................................

...........................................................

.

......

.....

....................................................

...................................................

_:.

.........

...............

......................................

..!.

.......

.........................

_.

........................... 5-3

.,

...............................................

.

...................

42

43

44

44

4-5

5-2

5-4

;:

5-8

Vii

Page 14

SECTION 6-MAINTENANCE

DC Volts Calibration Confii&on (300mV ani ,y @nges)

DC Volts Calibration Confi~atio~ (3OV-300V Ranges) ...........................................

Four-Wire Resistance Calibration Configuration (3000-3OkQ Ranges)

Two-Wire Resistance Calibration Configuration (300kO3OOMQ Ranges).

Flowchart of AC Volts Calibration Procedure

TRMS AC Volts Calibration Configuration :.I

TRMS~ AC Volts Calibration Adjustments .......................................................

DC Current Calibration Configuration., .......................................................

ACCurrent CalibrationConfiguration

Analog Board Conne~ors~. ..........

Model196ExplodedViav

....................................................................

SECTION 7-REPLACEABLE PARTS

7-1

7-2

7-3

z

7-6

Display Board, Comporient Location Drawing, Dwg. No. 196-110.

Display Board, Schematic Diagram, Dwg. No. 196.XL6

Digital Board, Component Location Drawing, Dwg. No. 196-100

Digital Board, Schematic Diagram, Dwg. No. 196-106.

Analog Board, Component Location Drawing, Dwg. No. 196.120

Analog Board, Schematic Diagram, Dwg. No. 196-126

APPENDIX D

D-l

D-2

D-3

tEEEBusCon@ration

IEEE Handshake Sequence .......

CommandCodes

............................................................................

......................................................................

......................................

....................................................

.. ;

..................................................

.........................................................

(.

.........................................

..............................................

...............................

...........................................

;Y;~;

..............................................

...............................

............................

.~.-i..

..............

..................................

.................... ;. .. ; . ~; ;

‘.‘~.

.........

..................................

.;.

.............

6-5

6-5

6-6

6-7

6-8

1. ... 6-8

6-9

6-10

6-U.

6-12~

6-l3

~7-4

7-5

....... ; . 7-12

:

7-13

..

7-24

7-25

D-l

D-3

D-6

viii

Page 15

SECTION 1

GENERAL INFORMATION

1.1 INTRODU~ION

The Keithley Model 196 System DMM is a five function

autoranging~ digital multimeter. At 6% digit resolution, the

LED display can display ~*3,@0,1lOO coo@s. The ran@ of

this analog-to-digital (A/D) converter is greater t+q the nor:

mal *l,999,999&tit~AAID converter used in many 6% &St

DMMs. The built-in IEEE-488~ interface makes the instrument fully programmable over the IEEE-488 bus. The Model

196 can make the following basic measurements:

1. DC voltage measurements from lOOnV to 3OOV.

2. Resistance measurements from lOOpI tb’3OOM62.

3. TRMS AC voltage measurements from 1pV to 300V.

4. DC current me&urements from lnA to 3A.

5. TRMS AC current measurements from lnA to 3A.

In addition to the above~ mentioned measurement

capabilities, the Model 196 can make:AC dB voltage and

current measurements.

1.2 FEATURES

1.3 WARRANTY INFORMATION

Warranty information may be found on the inside front

cover of this manual. Should it become necessary to exq

c@e the warranty, contact your Keithley represent&e or

the ~factory to determine the proper course of action.

Keithley Instruments maintains service facilities in the

United States, United Kingdom and throughout Europe.

Information concerning the application, operation or service of your instrument may be directed to the applications

engineer at any of these locations. Check the inside front

cover for addresses.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

will be found on an addendum sheet included with the

manual. Be sure to review these changes before attempting to operate or service the instrument.

1.5 SAFETY SYMBOLS AND TERMS

Some important Model 196 features include:

l 10 Character Alphanumeric Display-Easy to read 14seg-

ment LEDs used for readings and front panel messages.

*High Speed Measurement Rate-l000 readings per

second.

l Zero-Used to cancel offsets or establish baselines. A zero

value can be programmed from the front panel or over

the IEEE-488 bus.

l Filter-The weighted average digital filter can be set from

the front panel or over the bus.

l Data Store-Can stoti tip to 500 readings and is accessl%le

only over the bus.

l Digital Calibration-The instrument may be digitally

calibrated from either the front panel or over the bus.

l User Programmable Default Condition&&y inshument

measurement configuration can be established as the

power-up default conditions.

l Translator Softwze-User defined words (stored in non-

volatile memory) can be used to replace standard command strings over the IEEE-488 bus.

l Offset Compensated Ohms-Used to correct for small er-

ror voltages in the measurement circuit.

The following safety symbols and terms are used in this

manual or found on the Model 196.

The A

symbol on the instrument denotes that the user

should refer tom the -operating instruction iq this manual.

The I/y on the instrument denotes that a potential of

300V or more may be present on the terminal(s). Standard

safety practices should be observed when such dangerous

levels are encomitered.

The WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains hazards that

could damage the instrument:

1.6 SPECIFICATIONS

Detailed Model 196 specifications may be found preceding

the 7hble of Contents oft &is manual. ~. ~~~~

l-l

Page 16

1.7 INSPECTION

1.9 GETTING STARTED

The Model 196 System DMM was carefully inspected, both

electrically and mechanically before shipment. After unpacking all items from the shipping carton, check for any

obvious signs of physical damage that may have occurred

during transit. Report any damage to the shipping~agent.

Retain and use the original packing materials in case reshipment is necessary. The following items are shipped with

every Model 196 order:

Model 196 System DMM

Model 196 Instruction Manual

Safety Test Leads (Model 3751)

Additional accessories as ordered.

Jf an additional instruction manual is required, order the

manual package (Keithley Part Number 196-901-00). The

manual package includes an instruction manual and any

applicable addenda.

1.8 USING THE MODEL 196 MANUAL

This manual contains information necessrny for operating

and servicing the Model 196 System DMM. The information is divided into the following sections:

l Section 1 contains general information about the Model

396 includiig that necessary to inspect the instrument and

get it operating as quickly as possl%le.

l Section 2 contains detailed operating information on

using the front panel controls and programs, making connections and basic measuring techniques for each of the

available measuring functions.

l Section 3 contains the information necessary to connect

the Model 196 to the IEEE488 bus and program operating

modes and functions from a controller.

l Se&on 4 contains performance verification procedures

for the instrument. This information will be helpful if you

wish to verify that the instrument is operating in compliance with its stated specifications.

l Section 5 contains a description of operating theory.

Analog, digital, power supply, and IEEE-488 interface

operation is included.

0 Section 6 contains information for servicing the instru-

ment. This section includes information on fuse replacement, line voltage selection, calibration and

troubleshooting.

l Section 7 contains replaceable parts information.

The Model 196 System DMM is a highly sophisticated instrument with many capabilities. To get the instrument up

&id running quickly use the following procedure. For complete information on operating the Model 196 consult the

appropriate section of this manual.

Power up

1. Plug the line cord intom~the rear anel power jack and

plug the other end of the cordpinto an appropriate,

grounded power source. See paragraph 2.2.1 for more

complete information.

2. Press in the POWER switch to apply power to the in-

shument. The instrument will power up in the 3CW DC

*ange.

Making Measurements

‘L Connect safety~shrouded testy leads to the front panel

VOLTS H.I and LO input terminals. Make sore the INPUT switch on the rear panel is in the in (FRONT)

position.

2. To make a voltage measurement, simply connect the in-

put leads to a DC voltage source (up to 3OOV) and take

the reading from the display.

3. To change to a different measuring function, simply

press the desired function button. For -pie, to

measure resistance, press the OHMS button.

Using Front P.&e1 Programs

Program selection is accomplished by pressing the PRGM

button followed by the button(s) eat corresponds to the

program number or name. For example, to select Program

31 (IEEE), press the PRGM button and then the 3 and 1

buttons. ‘Ihble 2-7 lists and briefly describes the available

front panel programs. Once a program is selected the

following general rules will apply:

1. A displayed program condition can be entered by pressi”p the ENTER button.

2. Program conditions that prompt the user with a flashing

digit can be modified using the data buttons (0 through

9 and i).

3. Programs that contain alternate conditions can be

displayed by pressing one ofthe range buttons. Each

press of one of these buttons toggles the display between

the two available conditions.

1-2

Page 17

GENERAL INFORMATION

4. A program will be executed when the ENTER button is

pressed.

5. A program can be exited at any time and thus not eyecuted, by pressing the PRGM button.

Paragraph 2.7 provides the detailed information for using

the front panel programs.

1.10 ACCESSORIES

The following accessories are available to enhance the

Model l96s, capabilities.

Models lOl9A and 1019s Rack Mounting Kits-The Model

~1019A is a stationary rack mounting kit with two front

panels provided to enable either single or dual side-by-side

mounting of the Model 196 or other similar Wthley instruments. The Model 10195 is a similar rack mounting kit

with a sliding mount configuration.

Model X301 Temperature Probe-The Model 1301 is a rUgged low cost temperature probe designed to allow temperature measurements from -55 to I5O’C.

Model 16008 High Voltage Probe-The Model 16008 extends

DMM measurements to 40kV.

Model 165150Ampere Current Shunt-The Model 1651 is

an external 0.00161 +J% 4terminal shunt, which permits

current measurements from 0 to 50A AC or DC.

Model l&31 Clip-On Test Lead Set-The Model l68l’con

tains two leads, 1.2m (4 ft.) long terminated with banana

plugs and spring action clip probes.

Model 1754 Universal Test Lead Kit--The Model 1754 is a

12 piece test lead kit, with interchangeable plug-in accessories. Included in the kit is one set of test leads (l-red,

l-black), two spade lugs, two standard b-a plugs, two

phone tips (0.06 DIA.), two hooks and miniature alligator

clips (with boots).

Model 5804 Test Lead Set-The Model 5804, used for

4terminal measurements, includes: two test probes with

spring-loaded plunger clip adapters to fit test probes, two

spring-loaded plunger test clips with in-line banana jacks,

and four solid copper alligator clips with insulator boots.

Model 5805 Kelvin Probes-The Model 5805 includes two

spring-loaded Kelvin test probes (one red, one black), with

48-inch banana plug cable assemblies. A set of eight replacement contacts for the Model 5805 Kelvin test probes

is also available (Keithley PIN CS-551).

Model 5806 Kelvin Clip Lead Set-The Model 5806 includes

~two I+in clip test lead assemblies with banana plug ter-

mination (one red, one black). A set of eight replacement

rubber bands for the lviode1~5806 is also available (Keithkey

PIN GA-22).

Model 7087 IEEE-&3 Shielded Cables-The Model 7007 connects the Model 196 to the IEEE-488 bus using shielded

cables to reduce electromagnetic interference (EMI). The

Model 7Ow-1 is one meter in length and has a EMI shielded IEEE-488 connector at: each end. The Model 7007-2 is

identical to the Model 7007-1, but is two meters in length.

Model 7088 IEEE488 Cables-The Model 7008~connects the

Model 196 to the IEEE-488 bus. The Model 7008-3 is D.9m

(3 ft.) in length and has a~standard IEEE488 connector at

each end. The Model 7008-6 cable is identical to the Model

7008-3, but~is 1.8m (6 ft.) in length.

Model 1682A RF Probe-The Model 1682A permits voltage

measurements from lOOkHa to 25OMHz. AC to DC transfer

accuracy is *ldB from lOOkFIr to 25OhJH.z at IV, peak

responding, calibrated in RMS of a sine wave.

Model 1685 Clamp-On AC Probe-The Model 1685

measures AC current by clamping on to a single conductor. Interruption of the circuit is unnecessary. The Model

1685 detects currents by sensing the chsnglng magnetic field

produced by the current~flow.

Model I751 Safety Test Leads-Finger gu$.s and shrouded

banana plugs help minimize the chance of making contact

with live circuitry.

Model 8573A IEEE488 Interface--The Model 8573A is an

IEEE1188 standard interface designed to interface the IBM

PC or XT computers to Keithley instrumentation over the

~IEEE-488 bus. The interface system contains two distinc-

tive parts an interface board containing logic~ to perform

the necessary hardware functions and the handler software

(supplied on disk) to perform the required control func-

tions. These two important facets of the Model 857ZA join

together to give the IBM advanced capabilities over

lXE-488 interfaceable instrumentation.

l-311-4

Page 18

SECTION 2

BASIC DMM OPERATION

2.1 INTRODUCTION

Operation of the Model 196 can be divided into two general

categories: front panel operation and IEEE-488 bus~operation. This section contains information necesssay to use the

instrument from the front panel. Theses functions can also

be programmed over the lEFE-488 bus, as described in Section 3.

2.2 POWER UP PROCEDURE

2.2.1 Line Power

Use the following procedure to connect the Model 196 to

line power and power up the instrument.

1. Check that the instrument is set to correspond to the

available line power. When the instrument leaves the factov, the internally selected line voltage is marked on the

rear panel. Ranges are 105W25V or 2kW!5OV 5016OHz

AC. If the line voltage setting of the instrument needs

to be changed, refer to Section 6, paragraph 6.2 for the

procedure. If the line frequency setting of the instrument

needs to be checked and/or changed, utilize front panel

Program 32 (see paragraph 2.7.8) after the instrument

completes the power up sequence.

2. Connect the female end of the power cord to the AC

receptacle on the rear panel of the instrument.~ Connect

the other end of the cord to a grounded AC outlet.

WARNING

The Model 196 is equipped with a 3-wire power

cord that contains a separate ground wire and

is designed to be used with grounded outlets,

When proper connections are made, instrument

chassis is connected to power line ground.

Failure to use a gmunded outlet may result in

personal injury or death because of electric

shock.

CAUTION

Be sure that the power line voltage agrees with

the indicated range on the rear panel of the instrument. Failure to obsenre this precaution

may result in instrument damage.

2.2.2 Power Up Sequence

The instrument can be turned on by pressing in the front

panel POWER switch. The switch will be at the inner most

position when the instrument is turned on. Upon ower

up, the instrument will do a number of tests on itse 9 Tests

are performed on memory (ROM, RAM and ETROM). If

RAM or ROM fails, the instrument will lo& up. If ETROM

FAILS, the message ‘TINCAL!’ will be displayed. See paragraph 67.2 for a complete description of the power up self

test and recommendations to resolve failures.

2.2.3 Default Conditions

Default conditions can be defined as setup conditions that

the instrument will return to when a particular feature or

command is asserted. The Model 196 will return to either

factory default conditions or user saved default conditions.

Factory Default Conditions

Ate the factory, the Model 196 is set up so that the instru-

ment is configured to certain setup conditions on the

initial power up. These factory default conditions are listed

in Tables 2-l and 37 (located in Section 3). If alternate setup

conditions are saved (see User Saved Default Conditions),

the instrument can be returned to the factory default con-

ditions by running Program 37 (Reset). To retain the fac-

tory default condihons as power-up default conditions, run

Program 30 (Save} immediately after executing kograrn 37

(Reset).

Sending device-dependent comman d I.0 over the IEEE-488

bus is equivalent to running Program 37 (Reset) and then

Program 30 (Save).

2-l

Page 19

Table 2-1. Factory Default Conditions

2.3 FRONT PANEL FAMILIARIZATION

Control/kahw

Zero value (rrogram ZERO)

dB

dB Reference Value

(program dB)

Filter

Filter Value (Program FILTER)

MX+B Status (Program 4)

MX+B Parameters (Program 34)

Multi

NOTE: The Model 196 is initially set for an IEEE address

of 7. The line frequency is set to 50 nor 6OHz.

User Saved Default Conditions

Each function oft the Model 196 “remembers”~ the last

measurement configuration that it was set up for (such as

range, zero value, filter value, et+ Switching back and forth

between functions will not affect the unique tonfiguratioq

of each function. However, the instrument will “forget” the

configurations on power-down unless they are saved.

Unique setup conditions can be saved by running front

panel Program 30 (Save) or by sending device-dependent

command Ll aver the IEBE-488 bus. These~tiser saved

default conditions will prevsjl over the factory default conditions on power-up, or when a DCL or SDC is asserted

over the bus.

IEEE Address and Lie Frequency

Any IEEE address and line frequency setting can be saved

as default conditions by running Program 30 (Save) or by

sending Ll over the bus. See paragraph 2.7 for complete

information on Programs 31 (IEEE Address) and 32 (Line

Frequency).

lexer (Program 6) ‘-’

HI/ LB

/l’ASS~~(l’rogrsm 5)

HI/Lo Limits (Program 35)

Ohms Compensation (Program R

kfault Condition

DCV

3cQV

6% Di ‘ts

Diiabgd

000.0000

Disabled

1.000000

Disabled

lo

Disabled

M=1.0OWOO~ ;~~

3=000.0000

Enabled

Disabled

+3.030000,

-3.o3clooo

1)

Disabled

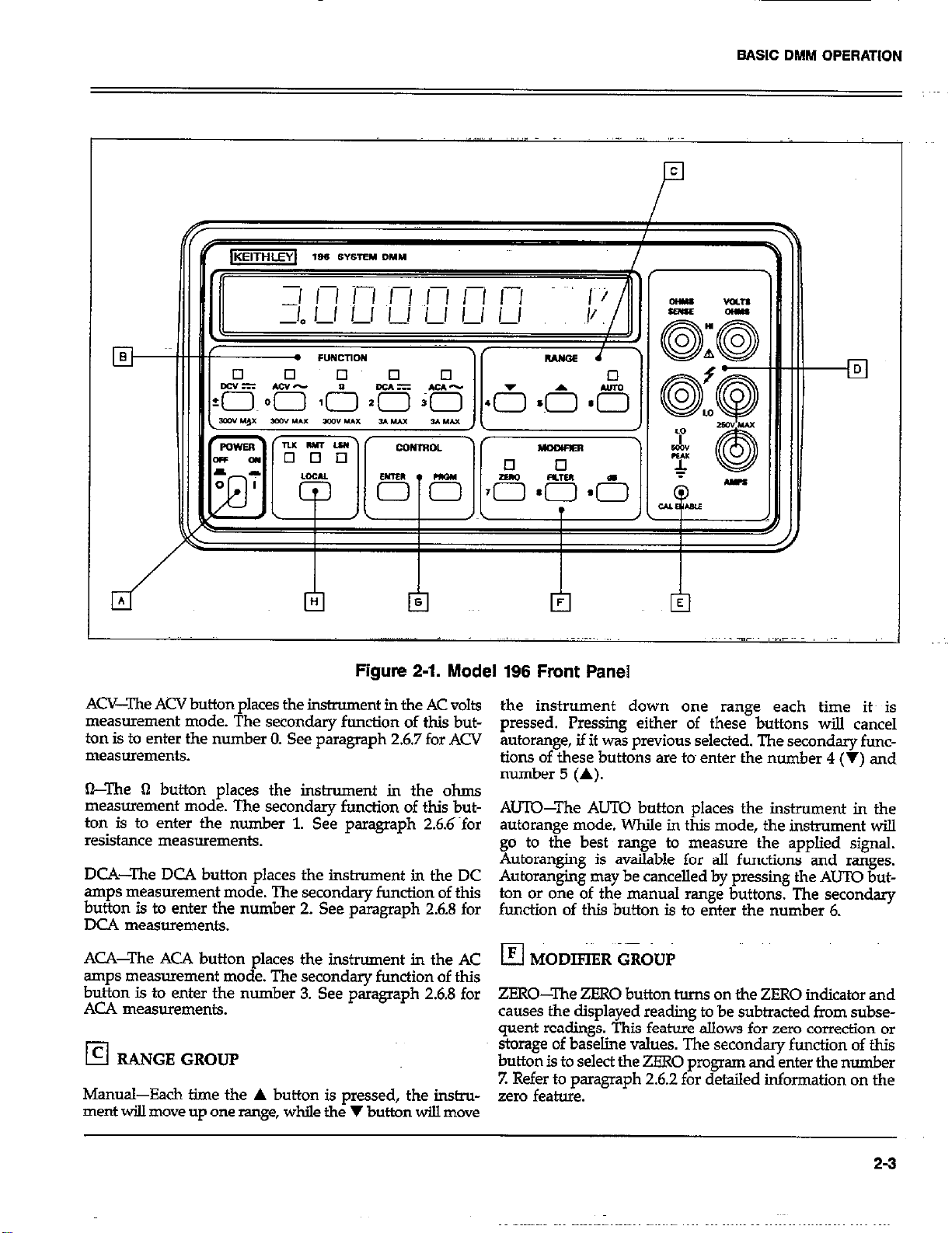

The front panel layout of the Model 196 is shown in Fiie

Z-l. The following paragraphs describe the various components of the front panel in detail.

2.3.1 Display and Indicators

Display-The 10 character, alphanumeric, LED display is

used to display numeric conversion data, range and function mnemonics (i.e. mv) and messages.

Function Indicators-The indicator that is on identifies

which of the five operating functions is currently selected.

Rsnge Jndicator-When the instrument is in autorange the

AUTO indicator light will be on.

Modifier Indicators-When the zero feature is enabled, the

ZERO indicator will torn on. When filter is enabled, the

FKTER indicator will turn on.

IEEE Status Indicators-These three indicators apply to instrument operation over the IEEE-488 bus. The RMT indicator shows when the instrument is in the IEEE-488

remote state. The TLK and LSN indicators show when the

instrument is in the talk and listen states respectively. See

Section 3 for detailed information on oueration over the

bus.

2.3.2 Controls

.&lI front panel co&ols, except the POWER and C%L

ENABLE switches, are momentary contact switches. Indicaton are located above certain buttons to show that they

are enabled. Some buttons have secondary functions that

are associated with front panel program operation. See

paragraph 2-7 for detailed information on front panel

prOg.3lllS.

El

POWER-The POWER switch controls AC power to

the insbxment . Depressing and releasing the switch once

tams the power on. Depressing and releasing the switch

a second time turns the power off. The correct positions

footi\and off are marked on the front panel by the POWER

El FUNCTION GROUP

NOTE

An ‘TJNCAI!’ error will set the IEEE address to 7

and the line frequency to 6OHz.

2-2

DCV-The DCV button places the instrument in the DC

volts measurement mode. The secondary function of this

button is to enter the i sign. See paragraph 2.6.4 for DCV

measurements.

Page 20

BASIC DMM OPERATION

El

Figure 2-1. Model 196 Front Panel

ACV-The ACV button places the instrument in the AC volts

measurement mode. The secondary function of this button is to enter the number 0. See paragraph 26.7 for ACV

measurements.

&The fl button places the instrument in the ohms

measurement mode. The secondary function of this button is to enter the number 1. See paragraph 2.6.6~for

resistance measurements.

DCA-The DCA button places the instrument in the DC

amps measurement mode. The secondary function of this

button is to enter the number 2. See paragraph 26.8 for

DC4 measurements.

ACA-The ACA button places the instrument in the AC

amps measurement mode. The secondary function of this

button is to enter the number 3. See paragraph 2.6.8 for

ACA measurements.

RANGE GROUP

!zl

Manual-Each time the A button is pressed, the instrument will move up one range, while the V button will move

the instrument down one range each time its is

pressed. Pressing either of these buttons will cancel

autorange, if it was previous selected. The secondary functions of these buttons are tom enter the number 4 (V) and

number 5 (A).

AUTO-The AUTO button places the instrument in the

autorange mode. While in this mode, the instrument will

go to the best range to measure the applied signal.

Autoranging is available for all functions and ranges.

Autoranging may be cancelled by pressing the AUTO button or one of the manual range buttons. The secondary

function of this button is to enter the number 6.

ZERO-The ZERO button turns on the ZERO indicator and

causes the displayed reading to be subtracted from subsequent readings. This feature allows for zero correction or

storage of baseline values. The secondary function of this

button is to select the ZERO program and enter the number

Z Refer to paragraph 2.62 for detailed information on the

zero feature.

2-3

Page 21

SAS\C DMM OPERATION

FIUER-The FIWER button turns on the FIUEl7 indicator

and causes the instrument to start weighted averaging (1

to l/99) fhe readings. The factory default weighted average

is l/10, but may be changed using the PIITER program (see

paragraph 2.7.16). See paragraph 2.6.3 for filter operation.

Selectin the PILTEK rogiam is one of the secondary functionsof&isbutton.&eothersecondaryfunctionisto~nter

the number 8.

dB-The dB button places the inshument~~in the dB

measurement mode and may be used with the ACV and

ACA functions. Under factory default conditions, measure-

ments are referenced to 1V or lmA. However, the dB program may be used to change the referqce @ell. ‘JTh$ seconY

day function of this button is to select the dB program and

enter the number 9. See paragriph 2.6.9 for dB measurements.

El

CONTROL GROUP

PRGM-This button is used tom enter the fronts panel pro-

gram mode.

ENTER-This button is used to enter program parameters.

This button will also trigger a reading when the instruments

is in a one-shot trigger mode.

the LOCAL button will be inoperative. See Section 3 for

informa$on on operating the instnunent-over the IEEE488

bus.

2.3.3 Input Terminals q

The ~input terminals are intended to be used with safety

shrouded test leads to help minimize the possibility of contact with live cikuits. Note that the terminals sre duplicated

sideways on the rear panel and that the INPUT switch (also

located on the rear panel) determines which set of termin&

is Bctive.

VOLTS 0HMS~i-J.I akd LQ-l’he VOLTS OHMS Hl atid LO

terminals are used for making DC volts, AC volts and two-

wire resistance measurements.

AMPS and LO-The AMPS and LO terminals are used for

making DC current and AC cUrrent measurem&s.

OHMS SENSE HI and LO--The OHMS SENSE HI and LO

terminals are used with the VOJXS OHMS HI and LO terminals to make four-wire resistance measurements.

El LQCA&When the instrument is in the IEEE-488

remote state (RM’I indicator on), the LOCAL button will

return the instrument to front panel operation. However,

if local lockout (LLO) was asserted over the IEEE-488 bus,

2.3.4 Calibration Enable Switch q

Calibration of the Model 196 can only be done if the CAL

ENABLE switch is in the enable position. See paragraph

6.4 for details.

2-4

Page 22

BASIC DMM OPERATION

2.4 REAR PANEL FAMILIARIZATION

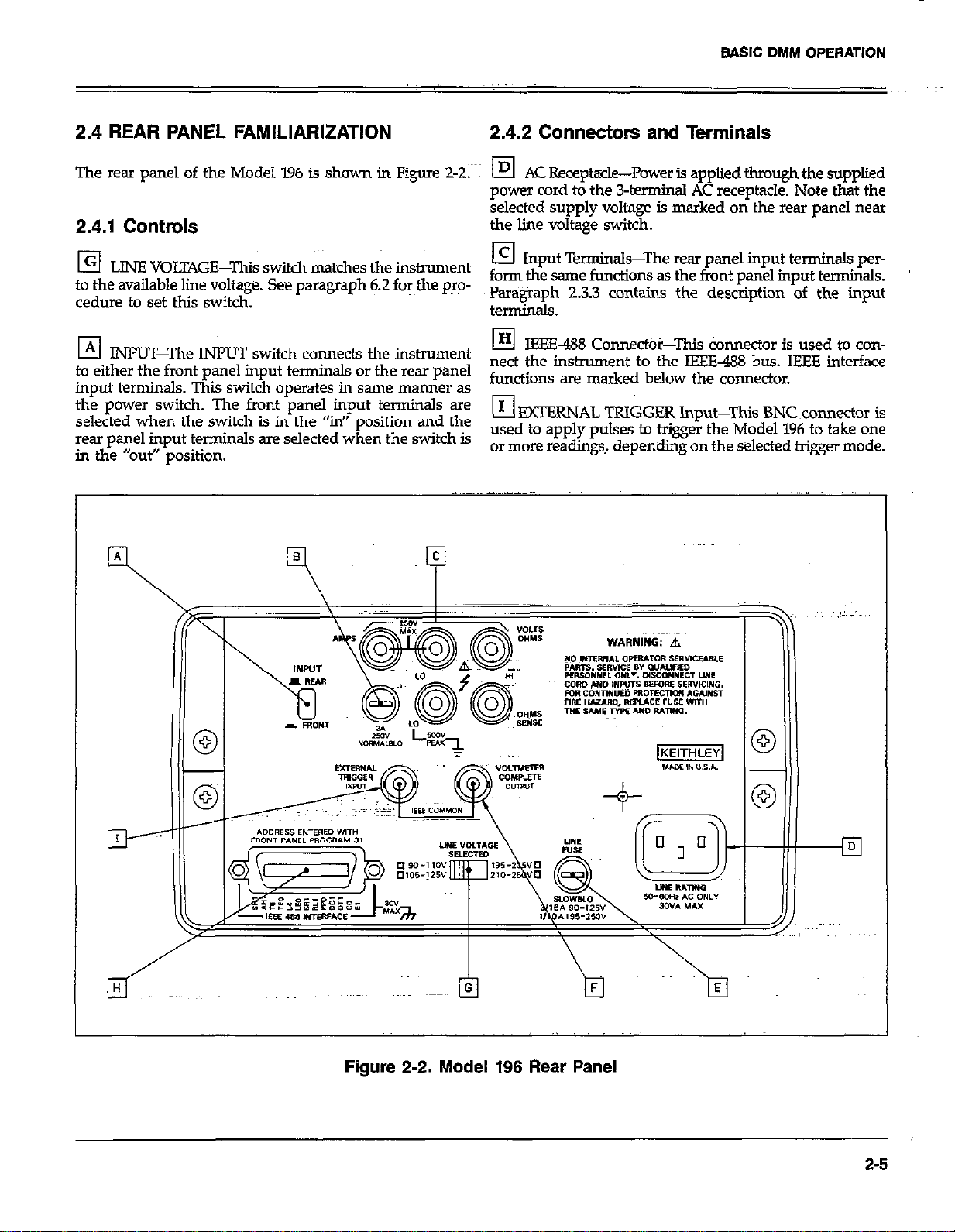

The reax panel of the Model 196 is shown in Figure 2-2.

2.4.1 Controls

ra T TkTc TIC%TTA,-C -t-L:- a.r.2~L -A,-~ the hment

Iable lme voltage. see paragrapn 6.2 for the proset this switch.

L4

INPUT-The INPUT switch connects the instrument

to either the front panel input terminals or the rear panel

input terminals. This switch operates in same manner as

the power switch. The front panel input terminals are

selected when the switch is in the “in’ position and the

rear panel input terminals are selected when the switch is

in the “0uV position.

2.4.2 Connectors and Terminals

~~~ pJ

AC Receptacle-Power is applied through the supplied

power cord to the 3-terminal AC receptacle. Note that the

selected supply voltage is marked on the rear panel near

the line voltage switch.

El Input Terminals-The rear panel input terminals per-

form the same functions as the front panel input terminals.

Paragraph 2.3.3 contains the description of the input

terminals.

mu IEEE-488 Car

nect the ins,e

functions ym -rl-l

q

used to apply pulses to trigger the Model 196 to take one

or more readings, depending on the selected trigger mode.

x5 14,&ed below the connector.

EXTERNAL TRIGGER Input-This BNC~connector is

mector-This connector is used to connt to the IEEE-483 bus. IEEE interface

Figure 2-2. Model 196 Rear Panel

2-5

Page 23

BASIC DMf.4 OPERATION

I3

VOITMFXER COMPLETE Output-T% BNC output

connector provides a TTLcompatible negative-going pulse

when the Model 196 has completed a reading. It is useful

for triggering other inshumentation.

2.4.3. Fuses

El

LINE FUSE-The line fuse provides protection for the

AC power line input. Refer to paragraph 6.3.1 for the line

fuse replacement procedure.

El

CURRENT FUSkhe 3A current fuse provides protection for the current measurement circoits of the instrument. Refer to paragraph 63.2 for the cwr$nt fuse replacement procedure.

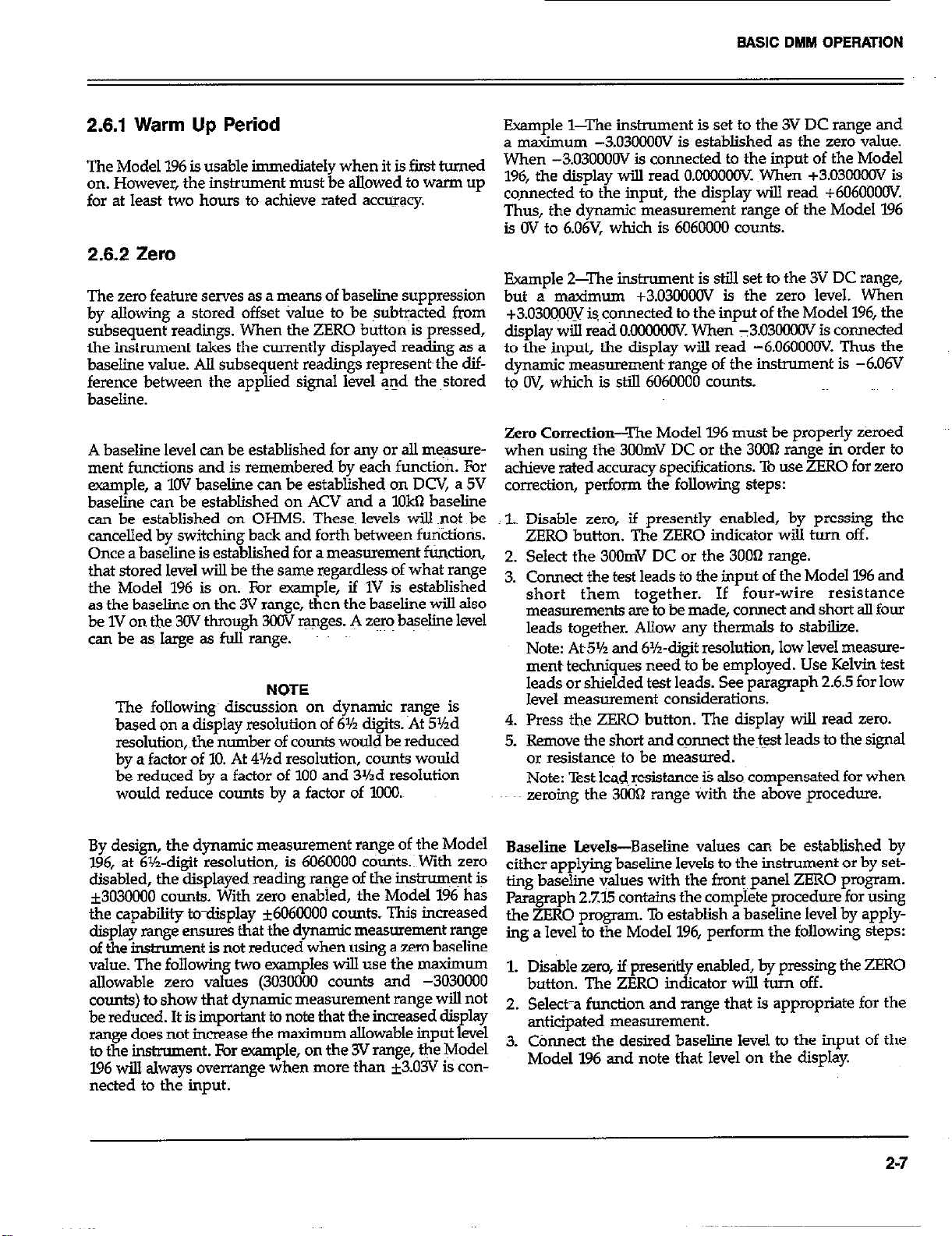

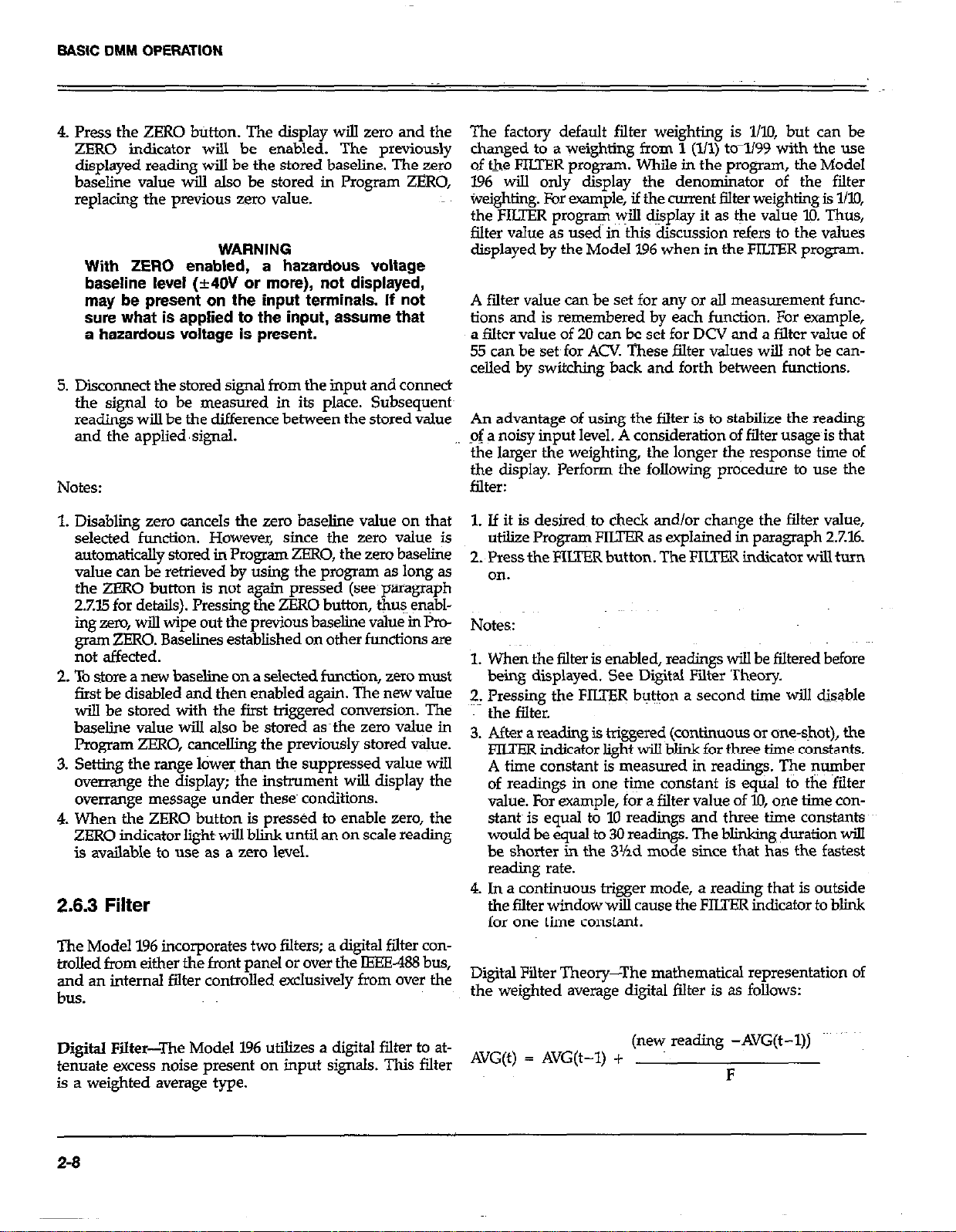

To optimize safety when measuring voltage in high energy

distribution circuits, read and use the directions in the

following warning.

WARNING

Dangerous arcs of an explosive nature in a high

energy circuit can cause severe personal injury

or death. If the meter is connected to a high

energy circuit when set to a current range, low

resistance range or any other low impedance

range, the circuit is virtually shorted. Dangerous

arcing can also result when the meter is set to

a voltage range if the minimum voltage spacing

is reduced.

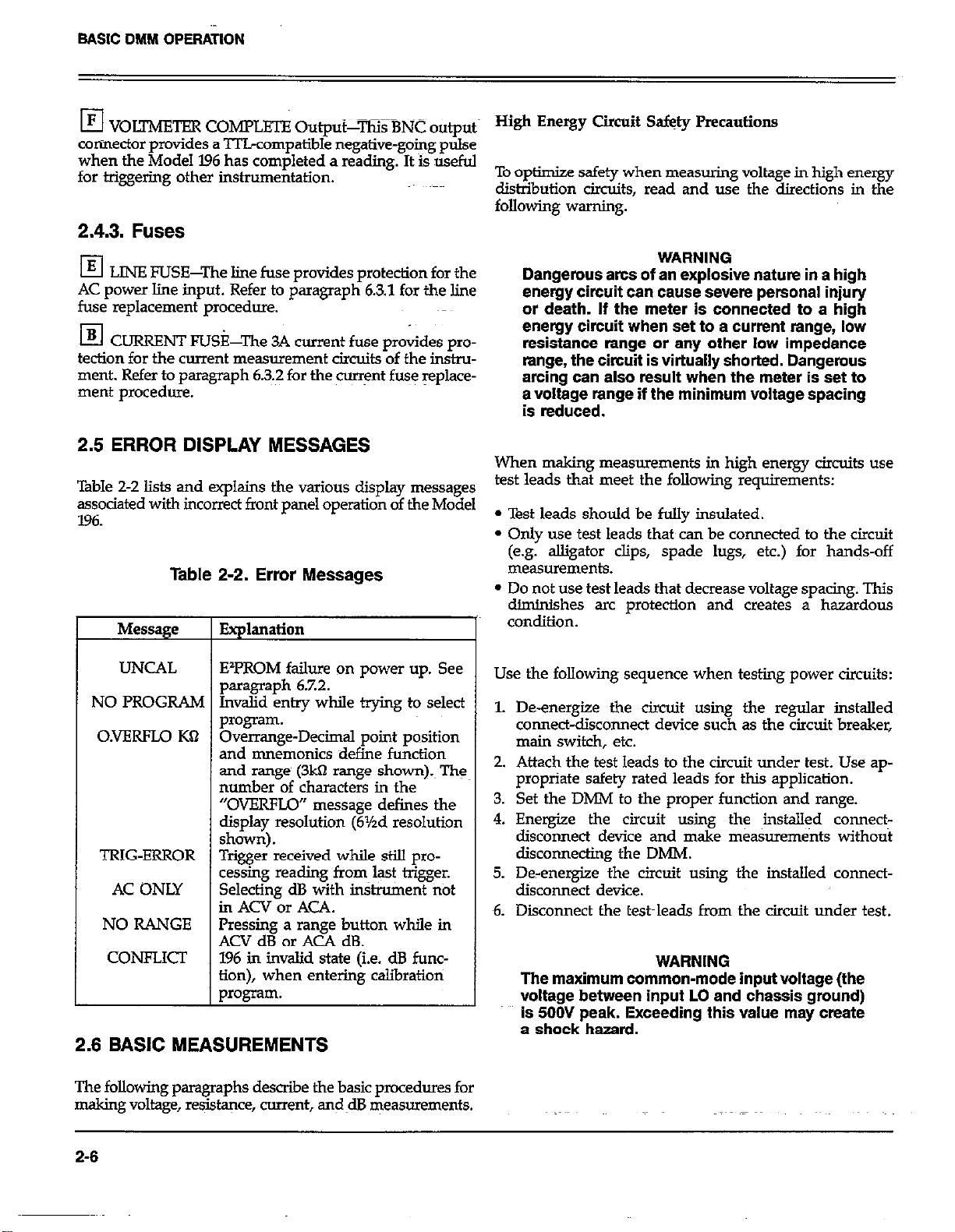

2.5 ERROR DISPLAY MESSAGES

Table 2-2 lists and explains the various display messages

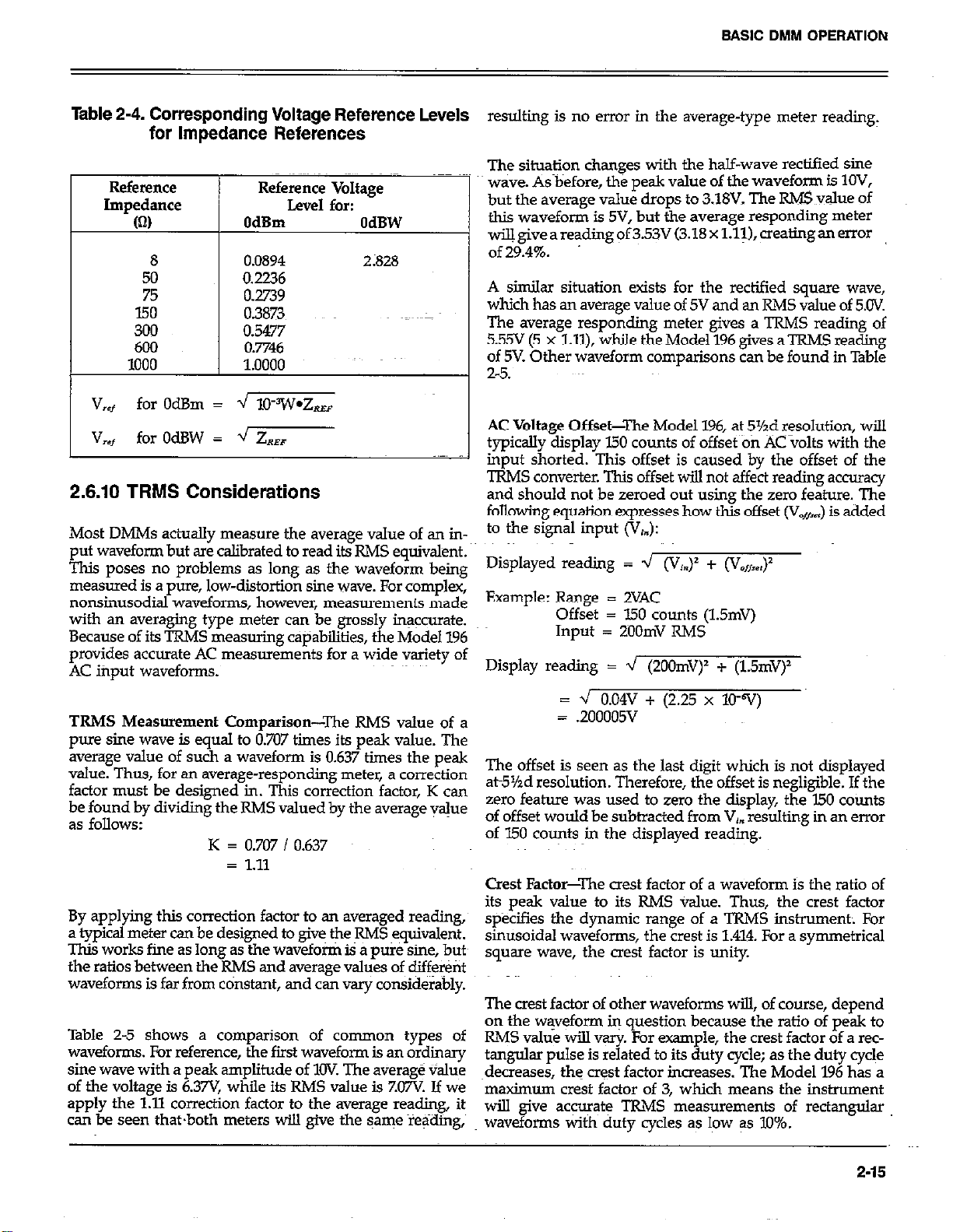

assodated with incorrect front panel operation of the Model