Page 1

Model 195T

System Temperature DMM

Instruction Manual Supplement

Document Number: 195T-90%OIA

Publication Date: February 1993

.

Page 2

WARRANTY

We warrant each of our products to be free from defects in material

and workmanship. Our obligation under this warranty is to repair

or replace any instrument or part thereof which, within a year after

shipment, proves defective upcn examination. We will pay local

domestic surface freight costs.

To exercise this warranty, write or call your local Keithley repre-

sentative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and shipping instructions.

REPAIRS AND

CALIBRATION

Keithley Instruments maintains a complete repair and calibration

service as well as a standards laboratory in Cleveland, Ohio.

A Keithley service facility at our Munich, Germany office is

available for our customers throughout Europe. Service in the

United Kingdom can be handled at our office in Reading. Additionally, Keithley representatives in most countries maintain service

and calibration facilities.

To insure prompt repair or recalibration service, please contact

your local field representative or Keithley headquarters directly

before returning the instrument. Estimates for repairs, normal

recalibrations and calibrations traceable to the National Bureau of

Standards are available upon request.

Keithley Instruments, Inc.128775 Aurora Road/Cleveland, Ohio 44139/U.S.A./(216) 246-0400/Telex: 965469

WEST GERMANY: Ksithley Instruments GmbHlHeiglhofstrasse 5/O-8000 MUnchen 7O/lO691 7144&65/Telex: 521 21 60

GREAT BRITAIN: Keithley Instruments. Ltd./l, Boulton Road/Reading, Berkshire RG2 ONL/i07341 66 12 B7lTelex: 647047

FRANCE: Kefthley Instrumenta SAALl2 Bis, Rue Ldon Blum1B.P. 60/91121 Palaiseau Cedex/~61011.51.55/Telex: 600933F

NETHERLANDS: Keithley Instrument8 BVlArkelsedijk 4/NL-4206 AC Gorinchem/i016301 25577/T&x: 24 664

SWITZERLAND: Kelthley Instruments SAIKriasbachstr. 4/CH-6600 OUbendorf/Ol 621 94 44/T&x: 57 536

AUSTRIA: Kslthley instruments Ges.m.b.H./OOblinger Hauptstr. 32/A-1190 Wien/0222 314 2BS/Telex: 13 45 00

Page 3

Model 195T

System Temperature DMM

Instruction Manual Supplement

01983, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

Page 4

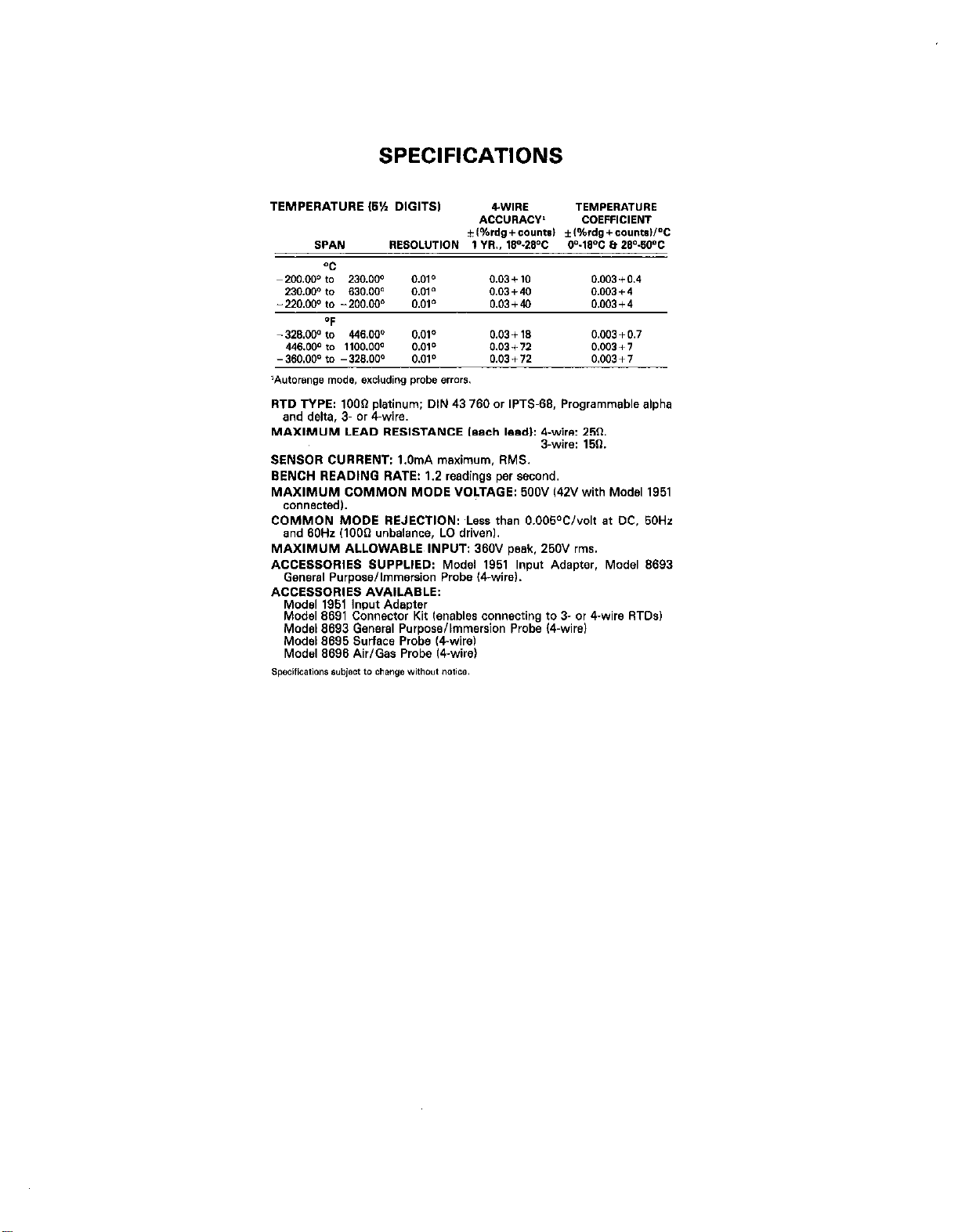

SPECIFICATIONS

RTD TYPE: lOO* platinum; DIN 43 760 or IPTS-SB, Programmable alpha

and delta, 3. or 4.wire.

MAXIMUM LEAD REBlBTANCE leach lead): 4.wire: 250.

SENSOR CURRENT: l.OmA maximum. RMS.

BENCH READING RATE: 1.2 readings per second.

MAXIMUM COMMON MODE VOLTAGE: 500V 142V with Mod81 1951

connected,.

COMMON MODE REJECTION: ,Less than 0.005°C/volt at DC, 50Hz

and 60Hz (1000 unbalance, LO drivenl.

MAXIMUM ALLOWABLE INPUT: 360V peak. 250V rms.

ACCESSORIES SUPPLIED: Model 1951’ lnp~t Adapter. Model 9693

General Purpose/Immersion Probe l4wire).

ACCESSORIES AVAILABLE:

Model 1961 Input Adapter

Model 8991 Connector Kit (enables connecting to 3. or 4.wire RTDs)

Model 9993 Gensral Purpose/Immersion Probe ICwirel

Model 9695 Surface Probe kvirel

Model 9696 Air/Gas Probe ICwirel

S-wire: 150.

Page 5

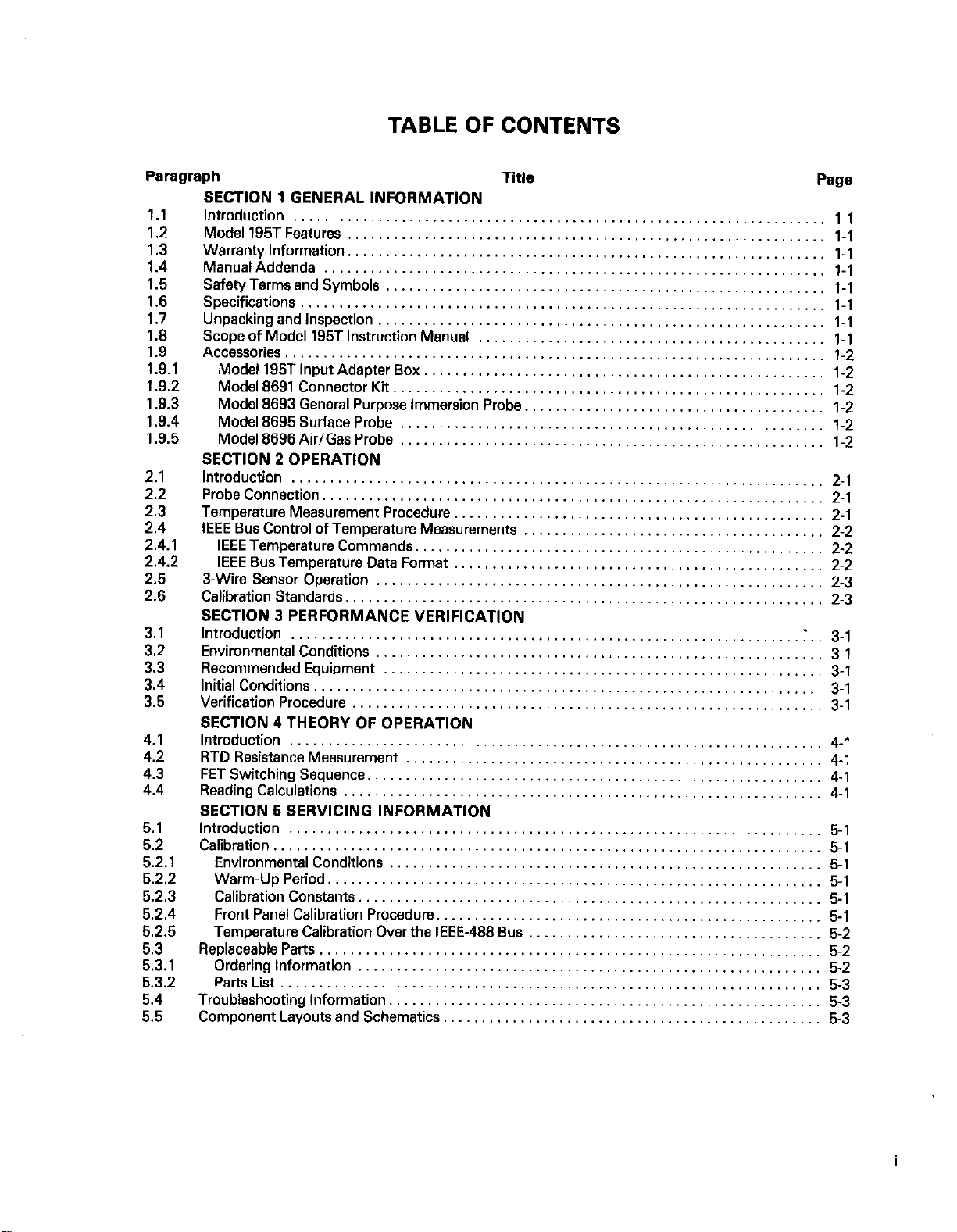

TABLE OF CONTENTS

Paragraph

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.9.1

1.9.2

1 Al.3

1.9.4

1.9.5

2.1

2.2

2.3

2.4

2.4.1

2.4.2

2.5

2.6

3.1

3.2

3.3

3.4

3.5

4.1

4.2

4.3

4.4

5.1

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.3

5.3.1

5.3.2

5.4

5.5

Title

SECTION 1 GENERAL INFORMATION

Introduction .....................................................................

Modell95TFeatures ..............................................................

Warranty Information.

.............................................................

ManualAddenda .................................................................

Safety Terms and Symbols

..................

......................................

PalIe

l-l

l-l

1-l

1-l

l-l

Specifications .................................................................... l-l

Unpackingandlnspection

..........................................................

Scope of Model 195T Instruction Manual

.............................................

l-l

l-l

Accessories ...................................................................... l-2

Model 195T Input Adapter Box.

...................................................

Model669lConnectorKit ........................................................

Model 8693 General Purpose Immersion Probe.

......................................

Modal6695SurfaceProbe .......................................................

Model 6696 Air/Gas Probe

SECTION 2 OPERATION

.......................................................

l-2

1-2

1.2

1-2

l-2

Introduction ..................................................................... 2-l

ProbeConnection .................................................................

Temperature Measurement Procedure.

IEEE Bus Control of Temperature Measurements

IEEE Temperature Commands.

IEEE Bus Temperature Data Format

3-Wire Sensor Operation

..........................................................

...............................................

.......................................

....................................................

................................................

2-1

2-l

2.2

2-2

2-2

2-3

Calibrationstandards .............................................................. 2-3

SECTION 3 PERFORMANCE VERIFICATION

Introduction

Environmental Conditions

RecommendedEquipment

Initial Conditions

Verification Procedure

SECTION 4 THEORY OF OPERATION

..................................................................

..........................................................

.........................................................

..................................................................

.............................................................

Introduction .....................................................................

RTD Resistance Measurement

......................................................

:. 3-l

3-l

3-l

3-l

3-l

4-l

4-l

FETSwitching Sequence ........................................................... 4-l

ReadingCalculations.. ............................................................

SECTION 5 SERVICING INFORMATION

Introduction .....................................................................

Canbra6on .......................................................................

Environmental Conditions

........................................................

Warm-UpPeriod ................................................................

Calibration Constants.

Front Panel Calibration Prqcedure.

Temperature Calibration Over the IEEE-466 Bus

...........................................................

.................................................

...................................... 5-2

ReplaceableParts .................................................................

Ordering Information

Parts List

......................................................................

Troubleshooting Information

Component Layouts and Schematics.

............................................................

........................................................

................................................

4-l

5-l

5-l

5-l

5-l

5-1

5-l

5-2

5-2

5-3

5-3

5-3

Page 6

LIST OF FIGURES

Figure

2-l Model 195T Front Panel Showing Model 1951 Input Adapter Box

2-2

2-3

3-1

4-l

4-2

4-3

5-1

5-2

5-3

Model195TProbeWiring

3-Wire Sensor Connections.

Connections for Performance Verification

Simplified Circuit of RTD Resistance Measurement

FETSwitchingSequence

FET Switching Sequence for RTD Resistance Measurements

Remote Box, Schematic Diagram, Drawing Number 1951-106

Mother Board, Component Layout, Drawing Number 195T-100

Mother Board. Schematic Diagram, Drawing Number 195T-106

..........................................................

........................................................ 2-3

..........................................................

Title

.............................................

.....................................

.............................

............................

...........................

................... : ...... 5-9

LIST OF TABLES

Table Title

2-1 Calibration Standards.,

3-1 Performance Verification Summary

5-1

5-2

Calibration Procedure Messages,

Model 195T Replaceable Parts List

............................................................

..................................................

.................................................... 5-1

...................................................

Page

........................ 2-l

2-l

3-1

41

4-1

4-2

5-4

5-5

Page

2-3

3-1

5-3

Page 7

SECTION 1

GENERAL INFORMATION

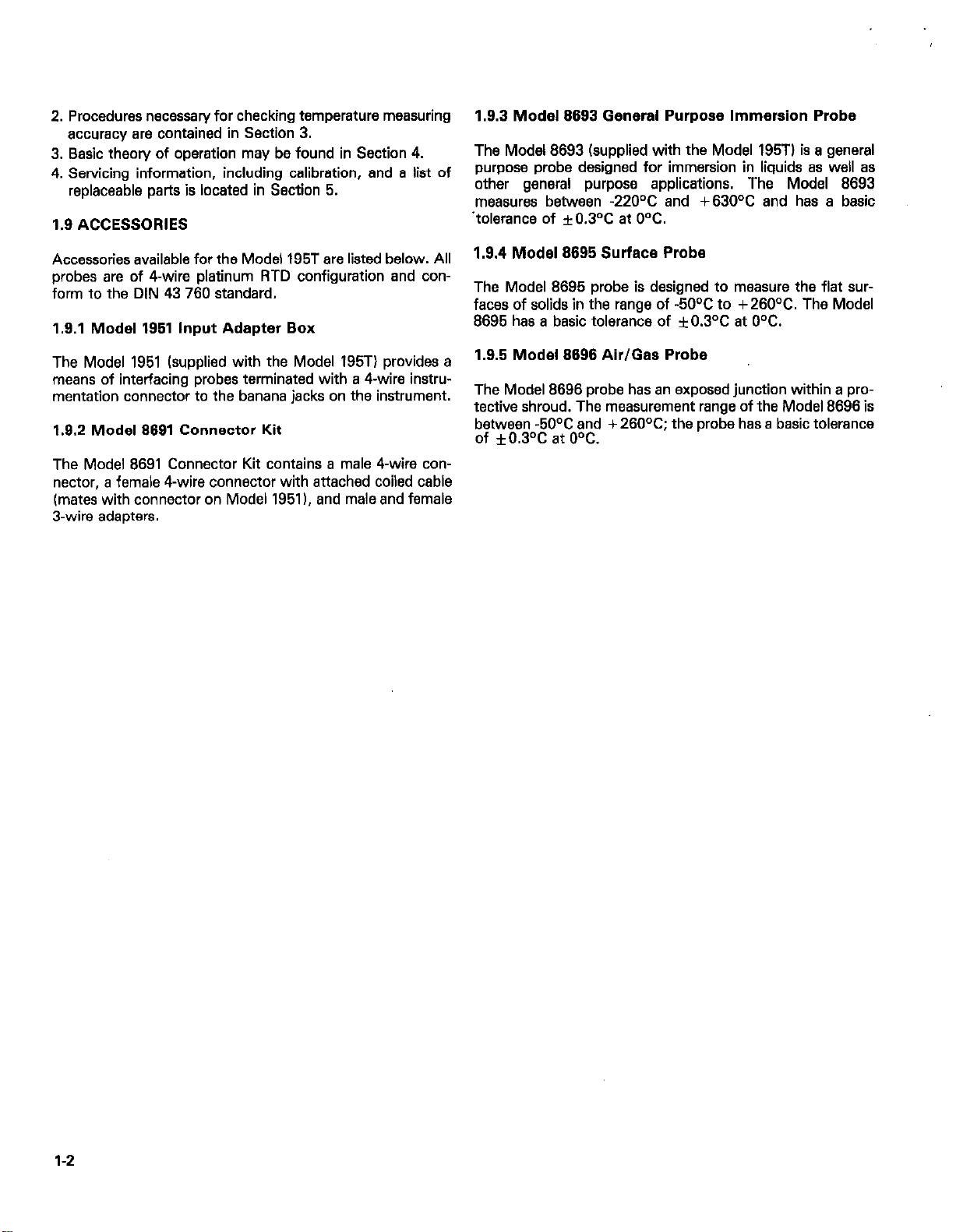

1.1 INTRODUCTION

The Model 195T is an enhanced version of the Model 195 that

includes temperature measuring capabilities. The Model 195T

is capable of temperature measurements in the range of

-220°C and +630°C and between -360°F and +llOO°F.

The instrument is designed to work with platinum RTD

probes, a factor which contributes to high accuracy. Temperature readings may be read directly from the front panel

display or transmitted over the IEEE bus to a central controller

or other instrumentation.

1.2 MODEL 195T FEATURES

Some kev Model 195T features include:

High Accuracy. Because platinum RTD probes have

1.

predictable resistance change with temperature and are

highly linear, temperature measurements are made with a

greater degree of accuracy than is possible with thermistor or thermocouple type probes.

Ease of Use. The temperature measuring mods is easily

2.

entered from the front panel or over the IEEE bus. Sophis-

ticated software automatically measures the probe

resistance and calculates the reading.

3.

Dual Scale Temperature Measurements. Temperature

readout may be obtained in either OC or OF. Readings are

available on the display and over the IEEE bus.

Front Panel Calibration. Temperature calibration may be

4.

performed from the front panel. Probe errors can be

minimized with the calibration procedure.

Four Wire Resistance Measurements. Resistance msas-

5.

urements with the supplied probe are performed using the

4-wire method to minimize the effects of lead resistance.

6.

Selectable 3-wire or 4.wire Operation. The instrument

may be used with either 3-wire or 4-wire probes; the mods

of operation is easily changed from the front panel.

1.3 WARRANTY INFORMATION

Warranty information may be found inside the front cover of

this manual. Should it become necessary to use the warranTV, contact Your nearest Keithley representative or the factory

to determine the correct course of action. Keithlsy Instruments, Inc. maintains service facilities in the United States,

West Germany, Great Britain, France, the Netherlands, Switzerland and Austria. Information regarding the application,

operation, or service of Your instrument may be directed to

the applications engineer at any of these locations. Check inside the front covsr of this manual for addresses.

1.4 MANUAL ADDENDA

Information pertaining to improvements or changes to the in-

strument which occur after the printing of this manual will be

found on an addendum sheet included with the unit. Be sure

to note any changes before attempting to operate or service

the instrument.

1.5 SAFETY TERMS AND SYMBOLS

The following safety terms are used in this manual or found

on the instrument:

The&symbol on the instrument indicates that a poten-

tial of 1OOOV or more may be present on the terminal(s).

The A symbol on the instrument indicates that the user

should refer to the operating instructions.

The WARNING heading used in this manual explains

dangers that could result in personal injury or death.

The CAUTION heading used in this manual explains hazards

that could damage the instrument.

1.6 SPECIFICATIONS

Detailed specifications pertaining to Model 195T temperature

measurements are located at the front of this manual.All

other specifications are located at the front of the Model 195

Instruction Manual.

1.7 UNPACKING AND INSPECTION

The Model 195T was carefully inspected before shipment.

Upon receiving the unit, carefully unpack all items from the

shipping carton and check for any obvious signs of physical

damage. Report any damage to the shipping agent at once.

Retain the original packing materials in case reshipment

becomes necessary.

The following items are included with every Model 195T shipment:

-Model 195T System Temperature DMM

*Model 1951 Input Adapter Box

*Model 8693 General Purpose Immersion Probe (Cwire

platinum RTD, DIN 43 760 standard)

*Model 195 Instruction Manual

*Model 195T Instruction Manual Supplement

1.8 SCOPE OF MODEL 195T INSTRUCTION MANUAL

This manual provides information pertaining to Model 195T

temperature measuring capabilities and is supplied as a supplement to the Model 195 Instruction Manual, which contains

information on all other operating aspects of the instrument.

The Model 195T manual is divided into the following sections:

1. Section 2 contains information necessary to connect

temperature probes and program the Model 195T to make

temperature measurements. Additional IEEE bus commands are also included in this section.

l-l

Page 8

2. Procedures necessary for checking temperature measuring

accuracy are contained in Section 3.

3. Basic theory of operation may be found in Section 4.

4. Servicing information, including calibration, and a list of

replaceable parts is located in Section 5.

1.9 ACCESSORIES

1.9.3 Modal 8693 General Purpose Immersion Probe

The Model 8693 (supplied with the Model 195Tl is a general

purpose probe designed for immersion in liquids as well as

other general purpose applications. The Model 8693

measures between -22OOC and +630°C and has a basic

.tolerance of f0.3OC at 0%.

Accessories available for the Model 195T are listed below. All

probes are of 4-wire platinum RTD configuration and con-

form to the DIN 43 760 standard.

1.9.1 Model 1951 Input Adapter Box

The Model 1951 (supplied with the Model 195Tj provides a

means of interfacing probes terminated with a 4-wire instrumentation connector to the banana jacks on the instrument.

1.9.2 Model 9691 Connector Kit

The Model 8691 Connector Kit contains a male 4-wire con-

nector, a female 4-wire connector with attached coiled cable

(mates with connector on Model 1951). and male and female

3-wire adapters.

1.9.4 Modal 8695 Surface Probe

The Model 8695 probe is designed to measure the flat surfaces of solids in the range of -5OOC to +260°C. The Model

8695 has a basic tolerance of f0.3Y at 0%.

1.9.5 Modal 8696 Air/Gas Probe

The Model 8696 probe has an exposed junction within a protective shroud. The measurement range of the Model 8696 is

between -50°C and + 260°C; the probe has a basic tolerance

of *0.3°C at OOC.

1-2

Page 9

SECTION 2

OPERATION

2.1 INTRODUCTION

This section contains information necessary to connect the

temperature probe to the Model 195T and program the unit

for temperature measurements. Also included is information

on additional IEEE-488 bus commands and data formats.

2.2 PROBE CONNECTION

The Model 195T is supplied with the Model 1951 Input Adapter Box, designed to interface the unit with a standard 4-wire

instrumentation connector. To connect the temperature

probe to the instrument, proceed as follows:

WARNING

To avoid

nect all test leads from the Model 196T

before connecting the adapter box or tampsrsture probe.

1. Connect the Model 1951 to the VOLTS OHMS and OHMS

SENSE terminals on the front or rear panel of the Model

195T as desired. The input box is designed with suitable

banana plugs designed to connect with the Model 195T

banana jacks and includes a 4-wire connector, as shown in

Figure 2-l. The box is designed to connect only one way.

2. Check to see that the rear panel INPUTS switch is in the

correct position.

3. Connect the temperature probe to the jack on the front of

the adapter. If desired, a probe may be wired using the

connections shown in Figure 2-2.

possible

shock hazards, discon-

NOTE

As shipped, the Model 195T is calibrated to use

platinum probes conforming to the DIN 43 760

standard tapha =0.00385). Instrument calibration may be changed for other standards as

described in Section 5.

2

2

m

m

~SENSOR .SENSOR

Figure 2-2. Model 195T Probe Wiring Figure 2-2. Model 195T Probe Wiring

2.3 TEMPERATURE MEASUREMENT PROCEDURE

Using the instrument to measure temperature is simply a mat-

ter of entering front panel Program 6, es described below.

1. Connect a suitable probe to the instrument as described in

the last paragraph.

(SST SYSTEM TEMPERATURE DMM

Figure 2-l. Model 196T Front Penal Showing Model 1961 input Adapter Box

2-1

Page 10

2. Turn on the power to the instrument and allow it to warm

up for at least one hour to achieve rated accuracy. Upon

power-up, the instrument will display the programmed line

freauencv and software revision level similar to the example ‘below.

l=l5llt

S

The Model 195Tzp message differs from the Model

195 message in that the “t” in the software revision level

indicates the instrument is configured for temperature

measurements.

3. Press PRGM. The instrument will prompt for a program

number as follows:

turs mode. See Section 3 of the Model 195 Instruction

Manual for front panel program details.

3. The instrument may be placed in the one-shot mode when

making temperature measurements by using Program 9.

See Section 3 of the Model 195 Instruction Manual for

details.

4. As with other Model 195T msasurements, the final, filtered

temperature reading is not displayed until the FILTER light

ceases flashing.

5. Program 0 doss not cancel the temperature mode.

2.4 IEEE BUS CONTROL OF TEMPERATURE MEASUREMENTS

pFF7

4. Press 6. The instrument will briefly display the program

number as follows:

-1

5. Following the program number, the unit will enter the

temperature measuring mods; each time the PRGM, 6 key

stroke sequence is performed, the instrument will toggle

between the OC and “F temperature modes. The flashing

decimal point shows the conversion rate.

6. In the “C mode, a typical reading might be:

jl

For a typical reading in the OF mods, the display might appsarasfollows~ D 7~icIcI F I

7. If the temperature is outside the measuring range of the instrument, or if the probe is open, the following message

will be disolaved:

8. Place the probe on or in the material to be measured and

take the temperature reading. Allow sufficient time for the

reading to stabilize.

WARNING

Do not

potential more than 30V RMS, 42.4V peak

above earth ground, or a shock hazard may

result.

subject

the temperature probe to a

9. To cancel the temperature mode, press a valid FUNCTION

button, such as VOLTS,

NOTES:

1. The instrument may be operated in either the 4% digit or

5’/i digit resolution mode while in the temperature mods.

The RESOLN button on the front panel controls display

resolution. When in the 5’h digit mods, the o character is

replaced by the least significant digit of the temperature

reading.

2. Temperature measurements may be stored in the internal

buffer by entering Program 7 after entering the tempera-

The instrument may be placed in the temperature measuring

mods with commands given over the IEEE bus, and temperature data may be read over the bus as described in the following paragraphs.

2.4.1 IEEE Temperature Commands

The following commands control the Model 195T over the

IEEE bus:

F5 Places the instrument in the OF mode.

F6 Places the instrument in the OC mode.

Sl Default rats mods from front panel hates must be pro-

grammed with appropriate rats commands).

NOTES:

1. A DCL or SDC command transmitted over the bus to the

instrument will cancel the temperature mode.

2. As with other device-dependent commands, the instrument must be in the remote mode before it will respond to

temperature commands. See Section 4 of the Model 195

Instruction Manual for complete details on using the unit

over the IEEE-488 bus.

Programming Example-To

program the instrument for

temperature measursmsnts in “C, enter the following

statements into the HP-85:

REMOTE 716 (END LINE)

OUTPUT 716; “F8X” (END LINE1

When the END LINE is pressed the second time, the instrument will enter the OC temperature mode.

2.4.2 IEEE Bus Temperature Data Format

Temperature data sent over the IEEE bus has a format similar

to other instrument data. Formats for the two temperature

modes are:

DEGFnnnn.nnE+n “F Mods

DEGCnnnn.nnE+ n OC Mode

NOTES

1. The data prefix is not present in the Gl, G3 or G5 data

modes.

2. The bus reading rate may be increased by sending the

following command string: SlPOX. However, noisier

readings will result.

2-2

Page 11

3. Turning the multiplex mode off with the Al command will

also increase the reading rate, but probe heating may increase, possibly affecting accuracy.

Programming Example-Connect a suitable probe to the

instrument and enter the following statements into the HP-85

keyboard:

REMOTE 716 (END LINE1

OUTPUT 716; “F5X” (END LINE)

ENTER 716; A$ (END LINE)

DISP AS (END LINE)

After the last statement is executed, the temperature data

string will be displayed on the CRT.

different calibration parameters, as summarized in Table 2-l.

Note that it is imperative that the instrument be calibrated for

the standard for which the probe is designed, or inaccurate

temperature readings will result. Instrument calibration is

covered in detail in paragraph 5.2.

2.5 3-WIRE

SENSOR OPERATION

As supplied, the Model 195T is designed for operation with

4-wire probes, such as the supplied Modal 6693 probe.

However, the unit may be used with an appropriate 3.wire

platinum RTD probe by using the connections shown in

Figure 2-3. Before using a 3-wire probe, the instrument must

be properly programmed as described in the calibration pro-

cedure in Section 5 of this manual.

WARNING

To avoid possible shock hazards, discon-

nect all test leads from the Model 196T

before connecting the temperature probe.

NOTE

Model 195T temperature accuracy figures given

in the specifications are based on 4-wire operation.

2.6 CALIBRATION STANDARDS

As shipped, the Model 195T is calibrated for use with probes

conforming to the DIN 43 760 standard. Another popular

temperature standard is the IPTS-66 standard, which uses

Figure 2-3. 3-Wire Sensor Connections

Table 2-1. Calibration Standards

DIN 43 760 IPTS-68

Parameter Standard Standard

R, (Probe resis- 100.000

100.003

tance at O°C)

Alpha 0.00385

Delta 1.502

A4, C4

l l

0.00392

1.49633

*Not directly programmable; automatically programmed by

selection of DIN 43 760 or IPTS-66 standard during calibration.

2-312-4

Page 12

Page 13

SECTION 3

PERFORMANCE VERIFICATION

3.1 INTRODUCTION

This section contains information necessary to verify that

Model 195T temperature measurements are made within

specified accuracy. Model 195T temperature specifications

are located at the front of this manual. Performance verification may be performed when the instrument is first received

to ensure that no damage or change in calibration has occur-

red during shipment. The verification procedure may also be

performed following calibration. If performance is substandard, use the calibration procedure in Section 5 to bring the

unit back within specifications. If that procedure does not

bring the unit within specifications, complete calibration may

be required; see Section 7 of the Model 195 Instruction

Manual.

NOTE

If the instrument does not meet specifications,

and it is still under warranty, (less than 12

months since the date of shipment) contact your

Keithley representative or the factory to deter-

mine the correct coursa of action.

3.2 ENVIRONMENTAL CONDITIONS

Verification measurements should be made with the instru-

ment at an ambient temperature between 18O and 28OC (65e

to 82°F) at a relative humidity of less than 80%.

3.3 RECOMMENDED EQUIPMENT

The following equipment is recommended for performing the

verification procedure:

Gen Rad precision decade resistance box Model 1433T. or

equivalent 1 fO.Ol% tolerance). Other equipment may be

used as long as the above accuracy figure is met or exceeded.

and seeing that the displayed reading falls within the required

range.

NOTE

The following procedure assumes the instrument is calibrated for the DIN 43 780 standard

Iapha =0.00385). Other standards will require

different resistor values. See Section 5 for information on calibration.

WARNING

To avoid possible shock hazards, discon-

nect all other test leads from the unit before

connecting the decade box.

I. Connect the precision decade resistance box to the Model

195T as shown in Figure 3-l. Four wire connections must

be used as shown on the diagram. Make sure the INPUTS

switch is in the front panel position and that the instrument is programmed for 4-wire operation (paragraph

5.2.4).

2. Enter the OC temperature mode by pressing the PRGM

and 6 buttons in sequence. If the display shows unit is in

the “F mode, press PRGM and 6 in sequence again. Make

sure the display is in the 5% digit resolution mode; also

see that

ZERO

is disabled.

3. Refer to Table 3-1, which summarizes the verification

resistance values. To check Model 195T accuracy at each

of the points, set the decade box to the indicated resistance value and see that the displayed Model 195T

reading falls within the required range.

3.4 INITIAL CONDITIONS

Before performing the verification procedure, make sure the

Model 195T meets the following conditions:

1. If the instrument has been subjected to temperatures

below 18°C (65°F) or above 28OC (82”F), allow sufficient

time for it to reach a temperature within this range. Typically, it takes one hour to stabilize an instrument 10°C

118°F) outside the normal range.

2. Turn on the power to the Model 195T and allow it to warm

up for at least one hour before beginning the verification

procedure.

3.5 VERIFICATION PROCEDURE

Model 195T temperature verification is based on substituting

precise, known resistance values for the temperature probe

Figure 3-l. Connections for Performance Verification

Table 3-1. Performance Verification Summary

Allowable Reading

(18O to 2E°Cl

-200.12 to - 199.8OT

-100.13 to - 99.87OC

0.10 to + O.lOT

+ 99.87 to + 100.13”C

+199.84 to +200.16°C

+399.48 to +400.58°C

+599.42 to +600.58T

3-l 13-2

Page 14

Page 15

SECTION 4

THEORY OF OPERATION

4.1 INTRODUCTION

Model 195T temperature readings are based on the 4-wire

resistance measurements of a platinum RTD (resistance

temperature detector). As the probe temperature rises, its

resistance increases as well, although not in a precisely linear

manner.

In the Model 195T, these resistance measurements are made

in the normal manner, but, during the measurement process,

thermal voltages generated by dissimilar electrical contacts

are cancelled cut. This cancellation is achieved by making

two measurements: the first is the voltage across the OHMS

SENSE HI and LO terminals with current flowing through the

RTD probe; the second measurement is made with no our-

rent flowing through the probe. These voltage measurements

are then used bv the microcomputer to calculate the temperature. Because the RTD current has a 25% duty cycle, probe

heating is reduced; also, the off cycle allows thermal voltages

to be measured.

4.2 RTD RESISTANCE MEASUREMENT

Figure 4-l shows a simplified schematic of the Model 195T

and RTD probe during temperature measurements. V,

through V, represent thermal contact voltages generated by

dissimilar metals. VRTp is the voltage developed across the

probe when current I IS flowing. The remaining circuitry to

the right is the normal Model 195 input and multiplexer cir-

cuitly.

v,,-v,, = v, t v, t v,

Since the voltage is measured at the OHMS SENSE terminals, V, and V, are insignificant.

The resistance value of the probe can then be calculated as

follows:

RRTO = Rr,V,T,‘(Vr~fHt-Vr,fLO)

4.3 FET SWITCHING SEQUENCE

As with all other Model 195T measurements, RTD resistance

measurements are performed by switching various input

FETs on and off. Figure 4-2 shows the general switching

sequence for RTD measurements. Figure 4-3 shows the flow

char-i for the switching sequence. Each FET is assumed to be

on when a positive pulse occurs.

Flgura 4-2. FET Switching Sequence

During the first phase of the measurement cycle, 0121 is

turned on, causing current to flow through the RTD. Qlll,

QIIO, Ql09 and Q108 are then turned on in sequence to

measure the voltage across the RTD with current flowing

through it. During the second phase, Ql21 is turned off, and

Qlll and 0110 are turned on in sequence to perform the

necessary measurements for the last phase. This last phase is

repeated three times to provide the necessary duty cycle.

4.4 READING CALCULATIONS

Figure

When current is flowing through the RTD probe, the voltage,

as seen at the OHMS SENSE HI and LO terminals, is:

With no current flowing, the voltage between these two terminals is:

4-I. Simplified Circuit of RTD Resistance Meas-

urements

VH,-VLO = v, + VRTD + v, + v,

Once the measurements are stored within. the microcomputer, it is a simple matter to calculate the final reading.

Above O°C, these calculations era performed using the

following relationships:

-A+JAz-4B[l-RJR01

T,=

Where:

A=fl+d/lOO)

B = -cSflO-41

01 and 6 are given constants

Ro is the probe resistance at 0°C

Rt is the probe resistance at the measured temperature

T, = 9/5T, t 32

28

4-1

Page 16

Example:

Assume the Model 195T is used with a probe conforming to

the DIN 43 760 standard and is measuring a temperature of

2.10°C. At this temperature with this probe, the values are:

R. = 100.000

R,=179.510

OL = 0.00385

S=l.502

A=0.00385[1+ (I .502/100)1=0.0039078

B=-(10-4)10.00385)(1.502)=-5.7827x lO-7

0.0039079+J(0.0039078l*-4~ -5.7827X lO~')[l-(I-79.51/100)1

T,-

Zl-5.7927x10-7)

T,=210°C

Below OOC, two additional constants, A4 and C4, are used in

a fourth order polynomial to calculate the temperature

reading. These constants are not directly programmable, but

their values will change in accordance with the selected standard (DIN 43 760 or IPTS-68). which can be programmed

during the calibration procedure as described in paragraph

5.2.4.

Figure 43. FET Switching Sequence for RTD Resis-

tance Measurements

42

Page 17

SECTION 5

SERVICING INFORMATION

5.1 INTRODUCTION

This section contains temperature calibration procedures.

Also included is a list of replaceable parts for the Model 195T.

5.2 CALIBRATION

Temperature calibration is performed by using front panel

Program 5. The basic procedure is similar to that used for

calibrating other instrument functions. The following paragraphs describe the basic calibration procedure.

NOTE

Proper temperature calibration requires that all

other functions be properly calibrated fespecial-

ly the 2000 and 2kD ranges). See paragraph 7.5

of the Model 195 Instruction Manual for those

calibration procedures.

5.2.1 Environmental Conditions

Calibration should be performed under laboratory conditions

having an ambient temperature of 23 f 1°C and e relative

humidity of less than 80%. If the instrument has been sub-

jected to temperatures outside this range, or to higher

humidity, allow at least one additional hour for operating con-

ditions to stabilize.

5.2.2 Warm-Up Period

Before beginning the calibration procedure, turn on the

power to the Model 195T and allow the unit to warm up for at

least one hour.

5.2.3 Calibration Constants

During the calibration procedure, the instrument will prompt

for a number of constants. Table 5-I summarizes prompt

messages. Along with each prompting message, the display

will show either the factory default value or the previously

programmed value for each constant. The inputs required for

calibration include:

1. Alpha-Used for reading calculations above O°C (for DIN

43 760 standard, alpha =0.00385; for IPTS-68 standard,

alpha=0.003921.

2. Delta-Also used for reading calculations above O°C (for

DIN 43 760, delta = 1.502; for IPTS-68, delta = 1.496331.

3. t=OV-the probe resistance at O°C.

4. DIN or NBS (IPTS-68) standard-Used to select appro-

priate A4 and C4 constants for better conformity below

OT.

5. 3- or 4-terminal operating mode selection.

5.2.4 Front Panel Calibration Procedure

The Model 195T is factory calibrated to conform to the DIN

43 760 standard. The following calibration procedure may be

used to change instrument calibration to another standard, or

to optimize instrument performance for use with a specific

probe. Proceed as follows:

NOTE

Program 0 may be used at any time during the

calibration procedure to return the instrument to

the normal mode. Simply press PRGM and 0 in

seauence.

Remarks

$*] Fzz;:,“for alpha constant.

I

r-2m-rj

ln standard.

m ;roro&~r 3- or4-wire Probe ~,~~~~~mpt,

I progress.

Prompts for delta constant. Default delta value displayed after

Prompts for probe resistance at Default probe resistance value

Prompts for DIN or NBS IPTS-68

Shows temperature calibration in

Default alpha value displayed after

prompt (DIN 43 760=0.00385

IPTS-68=0.003921

prompt. (DIN 43 760= 1.502

IPTS-68 = 1.49633)

displayed after prompt.

Programmed standard displayed with

Programmed operating mode displayer

5-1

Page 18

I. Press PRGM. The instrument will prompt for a program

number as follows:

I

,

2. Press 6. The instrument will briefly display the

number:

rFzTProj

.._ -

/

1

3. Following the program number, the unit will enter the

temperature mode. To continue with calibration, press

PRGM. The Model 195T will again prompt for a program

number:

4. Press 5. The instrument will then display the program

number followed bv a prompt for the alpha parameter as

follows:

ILLPH

5. Following the prompt, the default alpha value (for the

DIN 43 760 standard) will be displayed:

6. If the displayed value of alpha is to be used, press ENT. if

a new value of alpha is to be used, key in the digits and

press ENT (the allowable range of alpha is

0.00360~alpha~0.00420). For example, for the

IPTS-68 standard, key in a value of 0.00392.

7. The unit will now prompt for the delta constant with the

followina messaae:

8. After the oromot. the default value (for the DIN 43 760

standard) ‘will be displayed:

9. To use the displayed value, simply press ENT. To change

the value, key in the digits and press ENT (the allowable

range for delta is 1.4cdelta ‘1.61. For example, for the

IPTS-68 standard, a value of 1.49633 would be used.

10. The instrument will now display a message prompting for

the nominal probe resistance value et 0% as follows:

pJjoc_l

11. Following the prompt, the default probe resistance at O°C

lfor the DIN 43 760 standard) will be displayed:

13. The unit will now prompt for operation on either the DIN

or,NBS (IPTS-68) standard. The importance of thisselection lies in proper conformity for temperatures below 0%

With the NBS standard, the display will appear as

follows:

14. For the DIN standard, the display will show:

15. To select the DIN standard, press the 1 button. To select

the NBS standard: Dress the 2 button. Once the desired

standard is displaieb, press ENT.

16. The instrument will now prompt for selection of 3-wire or

4-wire operation. For 4wire operation, the display will appear as follows:

130r rt~~~~~ 4 ,

L.x-~r

17. Press 3 or 4 to select the desired mod:, then press ENT.

The unit will then display the following message to in-

dicate that calibration is being performed.

(1

After a few seconds, the unit will return to the normal

temperature measurement mode.

NOTE

The following steps must be performed to permanently store temperature calibration constants in NVRAM.

18. Press PRGM. The instrument will prompt for a program

number as follows:

/I

19. Press I. The instrument will briefly display the program

number and then ask if NVRAM storage is desired:

r!FGTF

20. Press ENT. If NV storage is successful, the instrument will

return to normal operation after storing the temperature

calibration values. Momentarily power down the unit

before using the new calibration values.

NOTE

If the calibration jumper has been removed, NV

storage will not be performed. Under these conditions, the following message will be displayed:

12. To use the present value, press ENT. To change the

value, key in the digits and press ENT. Instrument perfor-

mance is guaranteed for values between 850 and 1203,

but the user may experiment with a wider range of values.

NOTE

If the precise probe resistance at 0°C is known,

key in that value instead of the nominal value for

better overall accuracy.

5-2

L no5tr_i

See Section 7 of the Model 195 Instruction Manual for

calibration jumper details.

5.2.5 Temperature Calibration Over the IEEE-488 Bus

The Model 195T temperature calibration sequence may be

performed by sending commands over the IEEE bus with one

of two methods.

Page 19

I. Emulate the front panel control sequence with the H (hit

button) command. (HIOX, H5X. HOX, etc.)

2. Use the V command along with the calibration parameters

after the instrument is in the temperature mode. For example, the following command string might be used:

VO.OO385X VI .49436X VlOO.OOX VIX V4X

Note that it is not necessary to enter Program 5 before

calibrating the instrument with the V command. See Section 4 of the Model 195 Instruction Manual for complete

details on IEEE-488 bus programming.

Programming Example: Enter the following program into

the HP-85 keyboard; be sure to press the END LINE key after

each statement.

Program

10 REMOTE 716

Comments

Set up 195T for remote

operation.

20 CLEAR 716

Return 195T to default

conditions.

30 OUTPUT 716;“F6X”

Program for OC tempera-

turcmode.

40 OUTPUT 716;“VO.OO392X” Program alpha value.

50 OUTPUT 716;“V1.49633X” Program delta value.

60 OUTPUT 716:“V101.00X” Program probe resistance

at 0%.

70 OUTPUT 716;“V2X” Program for NBS stan-

dard.

80 OUTPUT 716;“V3X” Program for 3-wire opera-

tion.

90 END

5.3.2

Parts List

Table 5-2 lists only those parts used by the Model 195T which

are not used in the Model 195. For other Model 195 and

Model 195T parts, refer to Section 8 of the Model 195 Instruction Manual.

Table 5-2. Model 19BT Replaceable Parts List

Keithley

Description

PROM (U112)

Front Panel Overlay

RTD Probe

Box, Adapter

Cover, Adapter Box

Overlay, Adapter Box

Connector, 4 Pin (Male)

Banana Plug

Terminal

Standoff

*Order sami

5.4 TROUBLESHOOTING INFORMATION

sl

ast two digits as present sof

Part Number

195T-800.XX*

195T-301

8693-300

1951-301

1951-302

1951-303

CS-458

EG-15-1

TE-55

ST-137-7

fare revision levf

The Model 195T differs from the Model 195 only in ROM con-

figuration. In the Model 195, software is contained in two

ROMs (one 8k and one 4kl, Ulll and U112. In the Model

195T, these two ROMs are replaced by a single 16k ROM

(U1121. Since this is the only difference between the two instruments, troubleshooting information located in the Model

195 Instruction Manual is also applicable to the Model 195T.

After entering the program, press the HP-85 RUN key. As

each parameter is sent to the Model 195T. the value will appear on the display. Once all parameters have been programmed, the instrument will display the usual “CAL” message

and then return to the normal temperature mode.

5.3 REPLACEABLE PARTS

The following paragraphs contain parts ordering information

and a list of replaceable parts for the Model 195T.

5.3.1 Ordering Information

Keithley Instruments, Inc. maintains a complete inventory of

all normal replacement parts. To place an order, or to obtain

information concerning replacement parts, contact your

Keithley representative or the factory. When ordering parts,

be sure to include the following information:

I. Instrument Model Number

2. Instrument Serial Number

3. Part Description

4. Circuit designation, including schematic and component

layout numbers, if applicable.

5. Keithley Part Number

5.5 COMPONENT LAYOUTS AND SCHEMATICS

Component layouts and schematics for the Model 195T are

located at the end of this section. Only those items associated

with the Model 195T which differ from the Model 195 are

contained in this supplement. For all other component layouts and schematics, refer to the Model 195 Instruction

Manual.

5-3

Page 20

II

1

PRTD

(PROBE1

L,oo~ - - - 7 (SEE SCHEMATIC 195106

1951

14 PINI

I I

PI002 1 JIOl9

>

Jl”‘e VOLTS OHMS HI

I

I

I

JK20 OHMS SENSE LO

I

195T

PAGE 3 OF4 ,ZONE A4+5)

OHMS SENSE HI

2

4-

3

4

A

d

I

B

Figure 5-l. Remote Box, Schematic Diagram, Drawing Number 1951.106

I

C

4

D

I

E I

F

Page 21

I,

5

Y II/ --

Page 22

-

-

-

z

-

-

E

Figure 52. Mother Board, Component Layout, Drawing

Number 19!X-100 (Sheet 2 of 21

Page 23

.l

1

2

3

JF

e

4

5

“,Y C”*I*I”N

IEEE-

-6

Figure 5-3. Mother Board, Schematic Diagram, Draw-

ing Number 195T-106

59/510

Page 24

Page 25

Keithley Inetrumente, Inc./28775 Aurora Road/Cleveland, Ohio 44139/U.S.A./(218) 24&0400/Telex: SE5469

WEST QERMANY: Keithlsy Instruments QmbHlHeiglhofstrasse 5/D-6COO Monchen 70/106917144065/Telex: 521 21 60

GREAT BRITAIN: Keithley Instruments, Ltd./l, Boulton Road/Reading, Berkshire RGZ ONL/107341 66 12 67/T&x: 647047

FRANCE: Kelthley Intirumants SARLlZ Eis, Rue Ldon Bluml6.P. 60/91121 Palaiiu Cedex/(GI 011.51.55/Telex: 600933F

NETHERLANDS: Keithley Instruments SVlArkelsedijk 4/NL-4206 AC Goriyhem/(01830) 25577/Telex: 24 664

SWITZERLAND: Keithlsy In&umsntr SAIKriesbachstr. 4/CH8600 Dubendo!f/Ol 621 94 M/Telex: 57 536

AUSTRIA: Keithley lnst~msnm Gss.m.b.H./DOMingw Hauptstr. 32/A-1190 Wien10222 314 269/Telex: 13 45 Mf

Loading...

Loading...