Page 1

IEEE-488 Programming Guide

Model 194A

High Speed Voltmeter

Ql.987, Keithley Instruments, Inc.

Instrument Division

Cleveland, Ohio, U.S.A.

Document Number: l94A-903-01 Rev. A

Page 2

TABLE OF CONTENTS

......

....

..

1

7

37

41

47

About This Programming Guide .............................................................. .,

Computer Programming Syntax ................................. .: .. ., ............ ; .............. 3

Single Channel Programming ...................................

Dual Channel Programming ................. -~__ __ ................................................ 11

Single and Continuous Trigger Arming .............................................. ., .......... 17

SRQ~andErrorHandling.. ................... ;...:~ ........... .: .... .._..... .... ..I ...... .._ ....... 21

Binary DataTransfer .......................................................................... 29

Reading Buffer Operation ...................................

Using Translator ...................................................

Using External Sample Triggering ................................

Generating Bus Time Information ............................................... _ ............... 55

Appendix A - Device-Dependent Commands~ ...................... .~~.;. :, .I. : ........... ., ......... ~A-1

Appendix B - Data Formats ................................................................... B-l

...............................

I

_.

.,

..

.............................

._._.

................

_

.......................

._.~.

., _ .,

Appendix C - Status Words and SRQ Format I .................................. .I .............. C-l

Appendix D - Front Panel Modes and Equivalents IEEE-488 Commands ........................... D-l

Appendix E - Data~ Transmission and NRFD Hold-off Times ...... ; .............................. E-l

Page 3

ABOUT THIS PROGRAMMING GUIDE

This programming guide is intended as a tt.&xial on a number of programming conceptss

associated with the Model 194A. It is not intended to replace the IEEE-488 programming

section of the Instruction Manual, which should be consulted for detailed programming

information.

Programming concepts discussed in this guide include:

l Programming a single-channel unit and obtaining data.

l Programming a dual-channel unit and requesting data.

l Single/continuous arming and~triggering.

l Using binary data transfer to optimize speed.

l Using SRQ and error word to minimize controller overhead.

l Buffer operation, including use of buffer pointers.

l Using Translator to increase readability and emulate-other instrumentation.

In addition to these fundamental concepts, applications programs for external sample tiggering, plotting data, and trigger performance and timing are also included. Fmally, reference

information such as device-dependent commands, data formats, and error words is also

supplied.

l/2

Page 4

COMPUTER PROGRAMMING

SYNTAX

All the example programs in this guide are written in Hewlett=Packard BASIC 4.0, which

is used on the Series 200 and 300 computers. This programming language was chosen for

these examples because of its ease of understanding, as well as its powerful subset of commands and statements controlling the IEEE-488 bus.

Most BASIC 4.0 statements are very similar to those used~.in other BASIC languages; however,

there are some statements associated with IEEE-488 bus Ii0 that require discussion. The

following provides a brief overview of some of the statements you will encounter in the various

programs in this guide. Refer to the BASIC 4.0 Reference for more detailed information.

OUTPUT

OUTPUT allows you to send a variable or string over the bus, and it may take on one c$

several forms. A typical syntax is:

In this instance, 7 specifies the interface select code, while 09 is the primary address of the

instrument. FlX is a literal string that will be transmitted to the instruments when the statement~ is executed.

ENTER

ENTER performs the opposite-function,~ allowing the transmission of data from the instru-

ment to the computer. Typical syntax for this statement is;

Again, 7 specifies the interface select code, while 09 represents the primary address of the

instrument. .A$ is a string variable into which incoming data is placed. Keep in mind that

A$ must be dimensioned large enough to hold all Rpected characters. As an alternative,

the ENTER statement-can directly input the data into a numeric variable, assuming that the

proper instrument data format is used.

SPOLL

SPOLL serial polls the instrumentand places its status byte in a numeric variable as follows:

Here again, 709 represents the interface select code and primary address of the instrument.

S is a numeric variable which will contain the decimal value of the status byte after the state-

3

Page 5

ment is executed. The status byte-can then be checked by ANDing or BIXng S to determine

the status of the required bits. These bits can yield certain information such as reading,overflow

and ready for a new command.

BIT

BIT can be used to detetie the bit status of numeric variables:

In this example, the status of bit 5 of the variable S is placed into A.

TRIGGER

TRIGGER sends a GET (Group Execute Trigger) to a device as follows:

A GET is one of many methods that can be used~& initiate a~ Model 194A +?v+urement~

In order to~~use~~ this form of triggering, the GET t$ger mode must be programmed, and

the A/D converter must be armed. Note that programming a trigger mode over the bus

automatically arms the A/D converter.

ASSIGN

ASSIGN is used to assign an I/O path, as in the following example:

Following ASSIGN execution, the attribute D194 will be associated with the interface code

and primary address. Another form of ASSIGN is used to-define the IiO~buffer:

ASSIGM IZufTU BUFFER k8 ‘~

TRANSFER TRANSFER

TRANSFER is used to perform a rapld I/O data transfer sequence. Usualli, TRANSFER is TRANSFER is used to perform a rapld I/O data transfer sequence. Usualli, TRANSFER is

used with the binary dump feature oft the Model 194A for most~rapid data transfer. Using used with the binary dump feature oft the Model 194A for most~rapid data transfer. Using

this combination, data can be transferred at a rate as high as 90K bytes per second. this combination, data can be transferred at a rate as high as 90K bytes per second.

Typical syntax for TRANSFER is:

TRAHSFER I?11194 TO WUF; COU~KT-i00B,W~Il

In this instance, a total of 1000 bytes will be tr~mitted from the Model 194A to~~the~internal

buffer.

4

Page 6

STATUS

SX4TUS allows access to certain computer status registers. Most often, this statement is used

to either determine if aii SRQ has occurred, or dear an SRQ interrupt. Typical syntax is:

Here, 7 is the interface select code, and the second 7 is the status register being accessed.

The value of the status register is placed in the variable S when the statement is executed.

ON INTR and ENABLE INTR

These two statements work together to enable interrupts and to tell the computer where to

go for next line execution. A typical ON INTR statement is:

In this case, when the computer detects an IEEE-488 interrupt, it-begins executing the

subroutine at line 4000.

SRQ is the most often used type of interrupt for the IEEE-488 bus. Using BASIC 4.0, SRQ

interrupts are enabled as follows:

Once enabled, an SRQ Wi cause the computer to branch to the line number specified by

the ON INTR statement. Typically, an error handling subroutine will be incorporated at that

point to determine the reason for the SRQ and to handle any other required tasks.

5/6

Page 7

SINGLE CHANNEL PROGRAMMING

PROGRAMMING CONCEPTS

l Sending command strings to the Model 194A.

l Obtaining data and displaying iton the computer CRT

PROGRAMMING CONSIDERATIONS

At the very least, it will be necessary to send commands to the instrument to set it up as

desired, and to request data back from the unit. The program below demonstrates~ the basic

recess for doing so. Note that if you have a dual-channel unit, you should proceed to

F

rogTam 2.

PROGRAM OPERATION

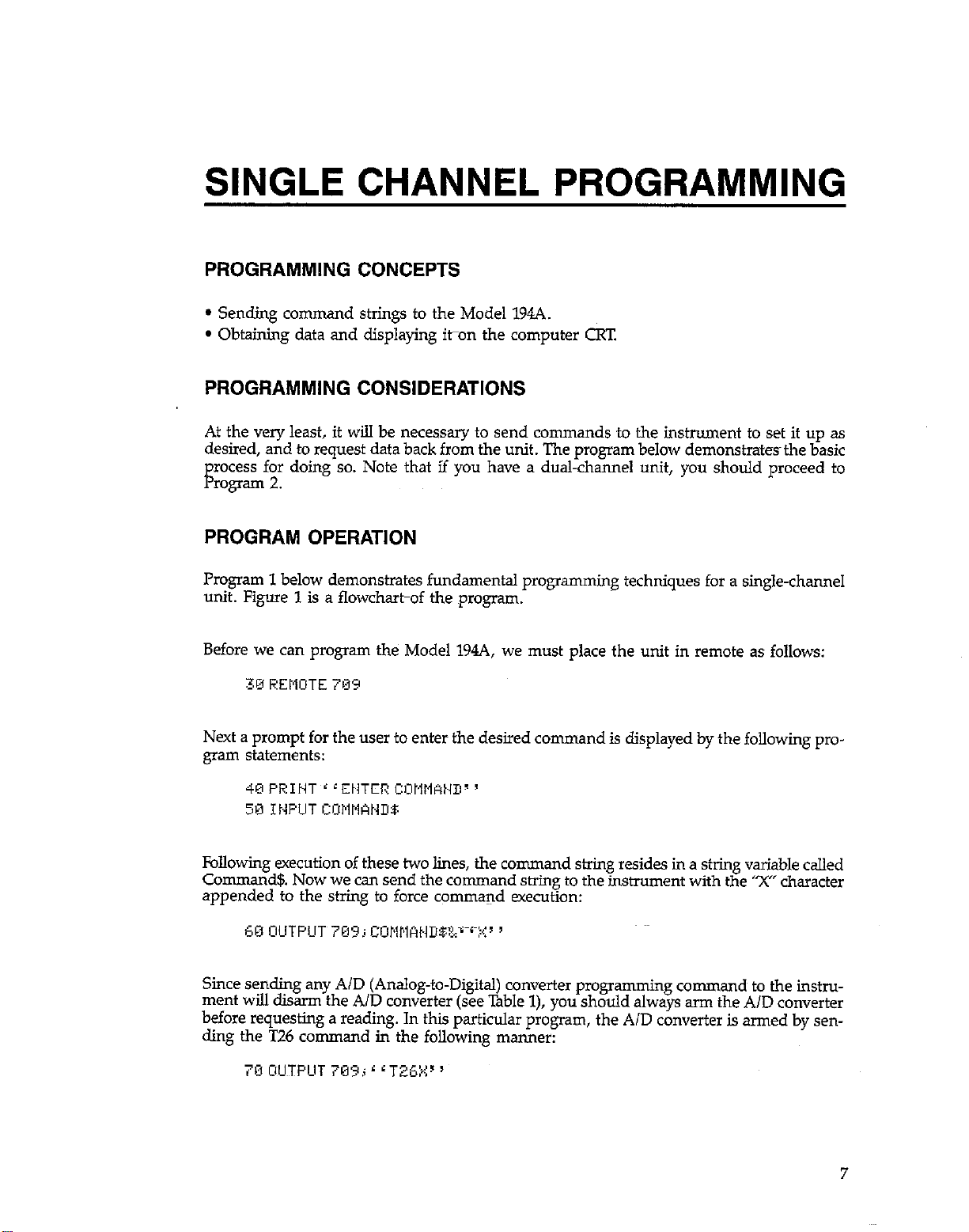

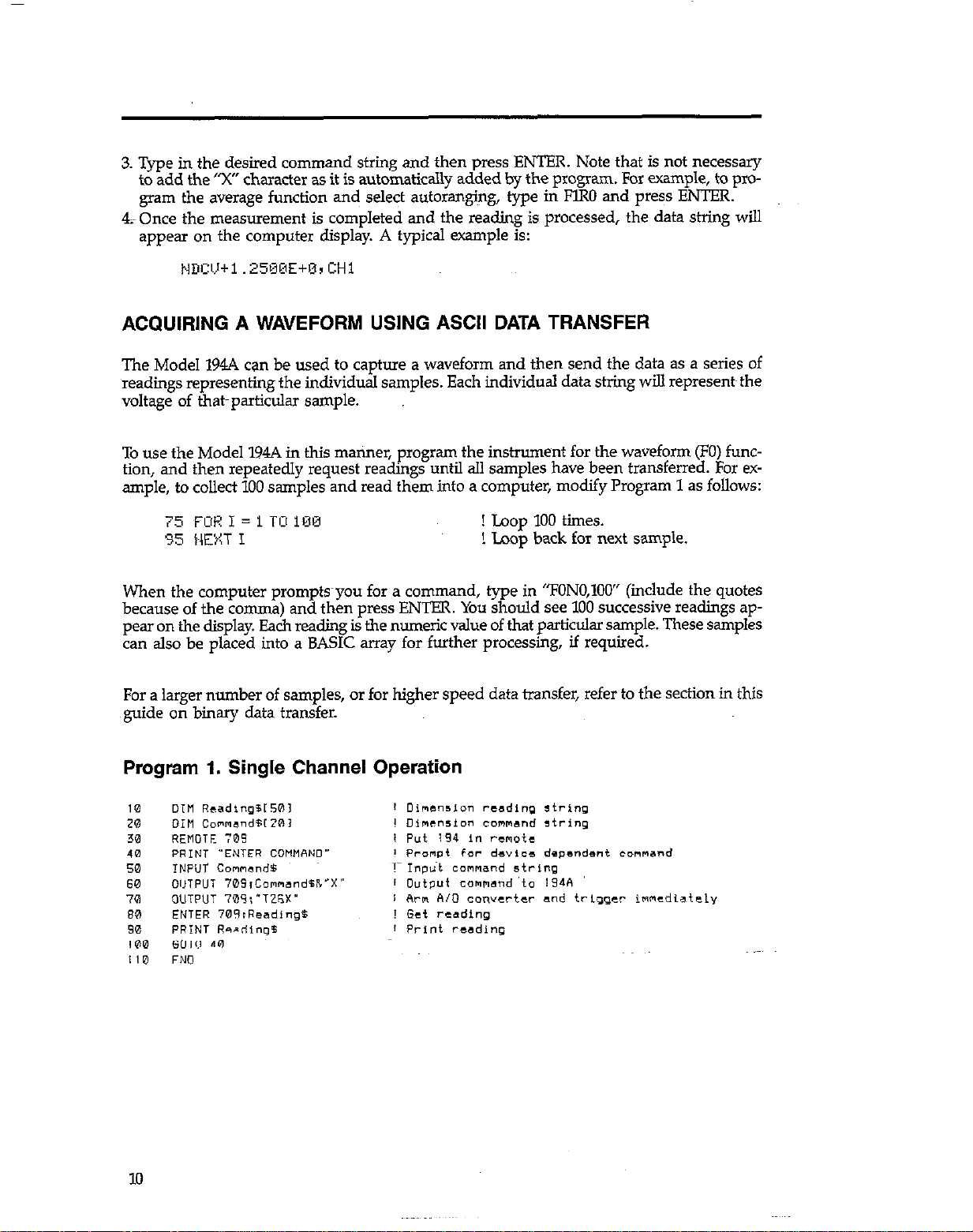

Program 1 below demonstrates fundamental programming

unit. Figure 1 is a flowchartof the program.

Before we can program the Model 194A, we must place the unit in remote as follows:

Next a prompt for the user to enter the desired command is displayed by the following program statements:

Following execution of these two lines, the command suing resides in a string variable called

Command!& Now we can send the command string to the instrument with the ‘X” character

appended to the string to force command execution:

Since sending any AID (Analog-to-Digital) converter programming command to the instrument will disarm the AID converter (see Table 1), you should always arm the AID converter

before requesting a reading. In this particular program, the AID converter is armed by sen-

ding the T26 command in the following manner:

techniques for a single-channel

7

Page 8

PUT ,944

I

IN REM3T.E

INPUT COMMAND

STRING

c

OUTPUT COMMAND

STRING TO 194.4

c

ARM AND TRIGGER

/vD CONVERTER

I

r

c

I

Figure 1. Single Channel Operation Flowchart

Note that the immediate trigger mode is used in this instance, so it is not necessary to~~trigger the unit to process a measurement; however, with other tri

to trigger the unit before the unit will collect samples. Once t

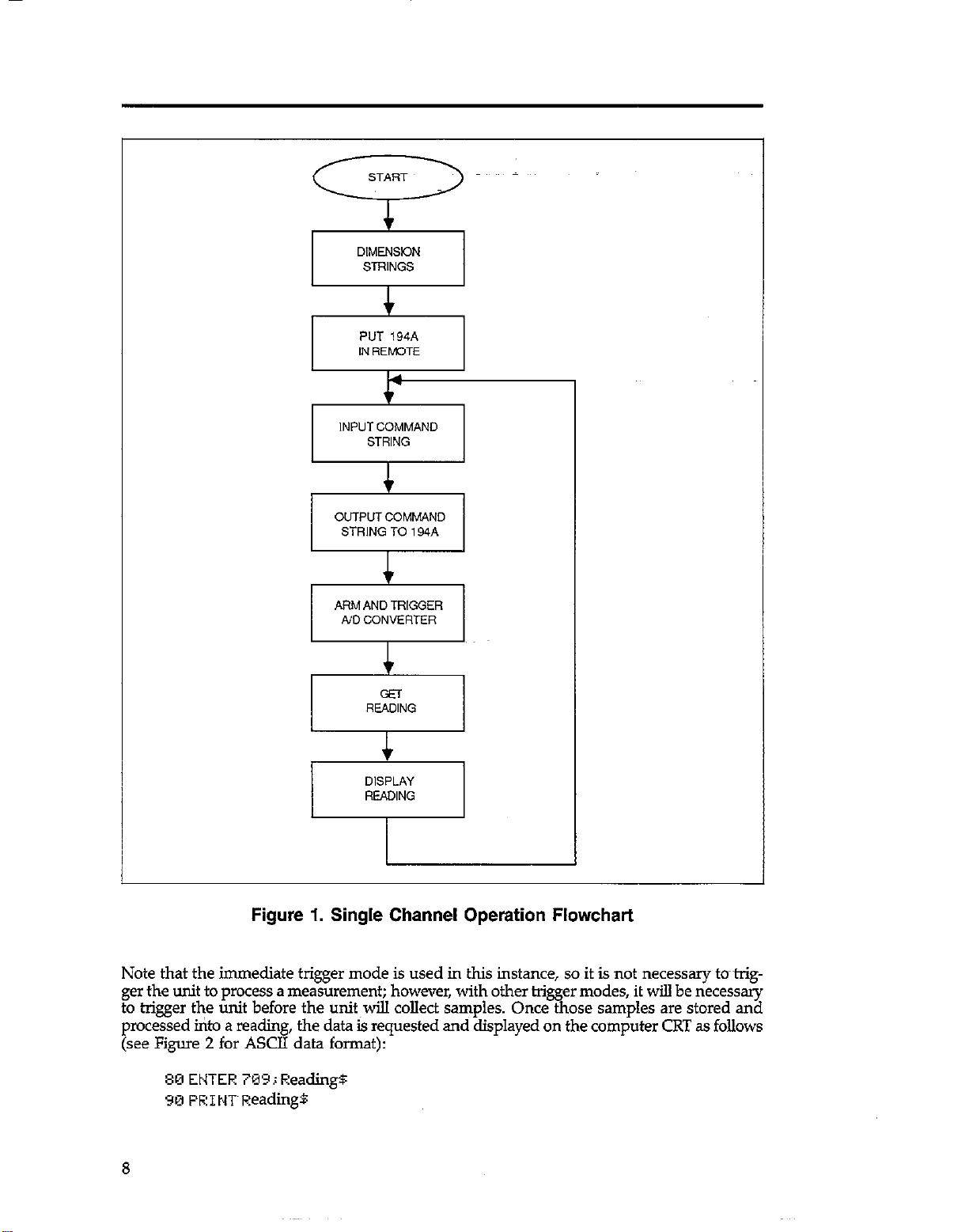

processed into a reading, the data is requested and displayed on the computer CRT as follows

(see Figure 2 for ASCII data format):

80 ENTER 70’3; Readings

YM PEItKReading8

er modes, it will be necessary

ose samples are stored and

PB

Page 9

PREFIX

(GO G-2, G3. GS)

BUFFER

SUFFIX (G2, GS) WITH CF

EOIASSERTED~

N=NORMAL A

0 = OVERFLOW

Z=ZEROED

READING

I = INVALID

MEASUREMENT

RMS = TRMS

A”G = AVERAGE

+PK = +PEAK

-PK = -PEAK

DIF = CHI CH2

RAT = CH1ICH2

DEV I STANDARD DE”,AT,ON

P.P = PEAK TO PEAK

INT= INlEGRAL

DC” = WAVEFORM

RCL = RECALL

+-I

N DCV * 1.2345 E + 0. CH2, 80050 TERMlNATOR

kdST TM,, &&;ToRicRLF

EXFCNENl

~ ~~~

NOTE: SUFFER LCCATDN SHOWS

A I

NUMBER

SAMPLE nnnni, IN WAVE

FORM MODE

Figure 2. ASCII Data Format

Table 1. Commands That Disarm the A/D Converter

Command

Description

I

Recall setup

Function

$P~z?

Number of samples

Filter

Range

Rate

Trigger

w

Z

Delay

7mv-l

RUNNING THE PROGRAM

1. Enter the program into the computer.

2. Run the program by pressing the RUN key. The computer wti promptyou to type in your

command:

9

Page 10

3. Type in the desired command string and then press ENTER. Note that is not necessary

to add the “X” character as it is automatically added by the program. For example, to program the average function and select autoranging, type in FlRO and press ENTER.

4; Once the measurement is completed and the reading is processed, the data string will

appear on the computer display. A typical example is:

ACQUIRING A WAVEFORM USING ASCII DATA TRANSFER

The Model 194A can be used to capture a waveform and then send the data as a series of

readings representing the individual samples. Each individual data string will represents the

voltage of that-particular sample.

To use the Model 194A in this manner, program the instrument for the waveform (FO) function, and then repeatedly request readmgs until all samples have been transferred. For example, to collect 100 samples and read them into a computer, modify Program 1 as follows:

75 FUR I = 1 TU i0EI

35 HEYT I c ,

! Loop 100 times.

! Loop back for next sample.

When the computer prompts~you for a command, type in ‘~ONO,lOO” (include the quotes

because of the comma) and then press ENTER. You should see 100 successive readings appear on the display. Each reading is the numeric value of that particular sample. These samples

can also be placed into a BASIC array for further processing, if required.

For a larger number of samples, or for higher speed data transfer, refer to the section in this

guide on binary data transfer.

Program 1. Single Channel Operation

10

20

30

40

50

60

70

80

90

100

$10

10

Page 11

DUAL-CHANNEL PROGRAMMING

PROGRAMMING CONCEPTS

l Basic command programming of a dual-channel Model 194A.

l Obtaining data fmn a dual-channel Model 194A.

l Demonstrating that both channels share a single IEEE-488 output.

l How to turn off an unused channel for maximum speed and to ensure that data comes

only from the desired channel.

PROGRAMMING CONSIDERATIONS

Programming a dual-channel unit is somewhat more complex than a single-channel unit,

even for the most basic measurements. In particular, there are several important aspects~~tokeep in mind:

1. Before sending programming commands to the instrument, select the desired channel

by sending ClX for channel 1, or C2X for channel 2. Doing so will ensure that the com-

mands you send will affect the desired channel. Note that sOme commands such as data

format (G), SRQ (M), and terminator (Y) affect both channels, so it is not necessary to

select the channel before using them.

2. The two channels share a common IEEE-488 output and reading buffer. As a result, there

is no way to dictate which channel has the currentoutput when both channels are running simultaneously. Thus, it will be necessary~for~you use the channel suffii in the data

string (Figure 2) to determine the source of the data. Alternatively, you can use the reading

buffer for storage and request data later.

3. If one channel is not being used, it should be disabled by sending a trigger command

for a tri

ing, se* the co 9 rnmand string CXI7X to disarm channel 1, or send C2XM( to disable

channel 2. Turning off an unused channel will accomplish two things: (1) maximize

throughput for the channel being used, and (2) make sure that data comes only from the

channel in use.

4. Another way to keep the reading from both channels separated is to use the F command

to re-calculate a reading. Even If a reading has already been calculated, you can force

another calculation for the desired channel to place the result in the reading buffer. For

example, send C2FlX to compute the average of the channel 2 measurement and place

the results in the reading buffer. Keep in mind that the other channel must not be running fast enough to overwrite this data between the time it is calculated and the time it

is requested.

er stimulus that will not occur. For example, if you are not using external trigger-

PROGRAM OPERATION

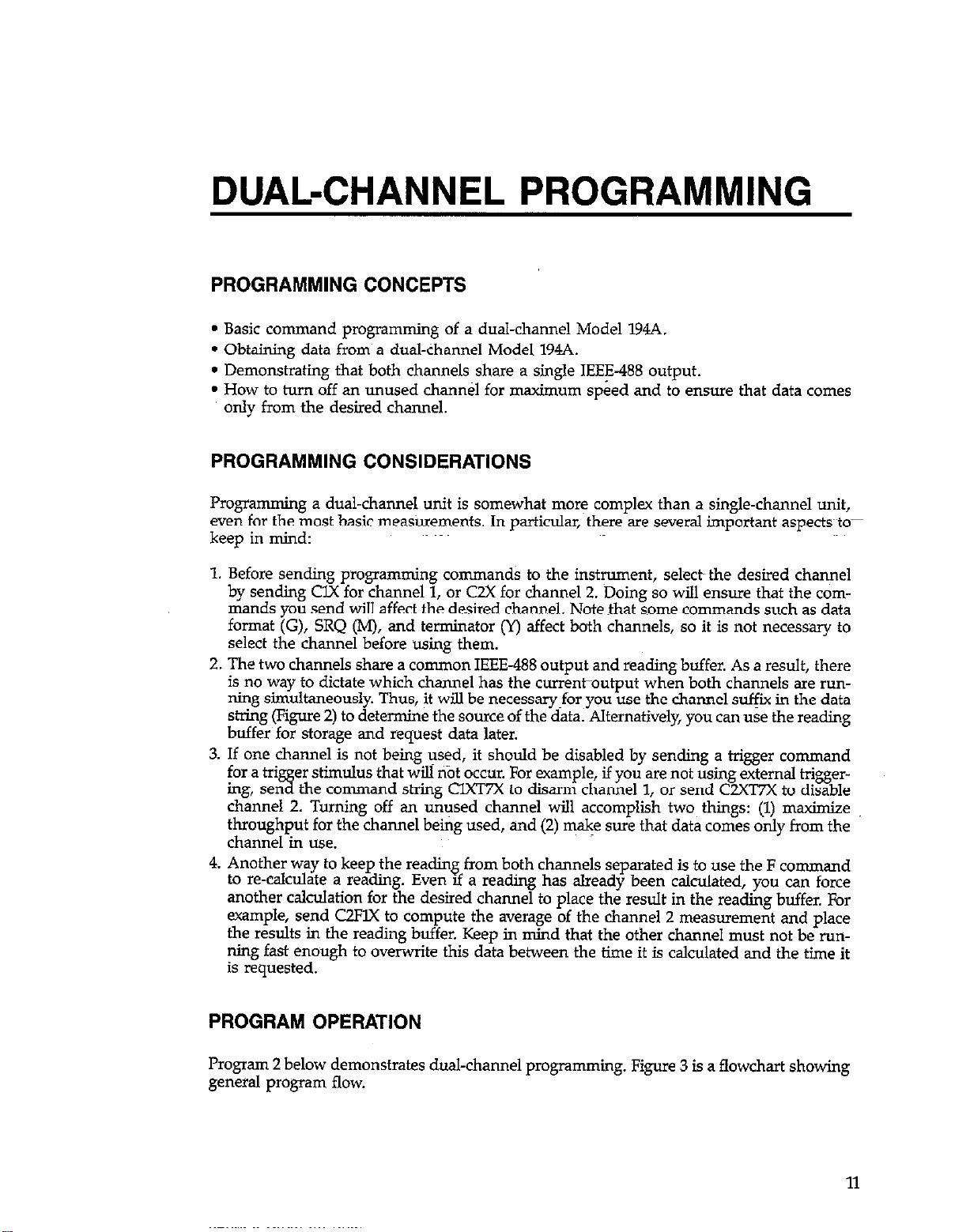

Program 2 below demonstrates dual-channel programming. Figure 3 is a flowchart showing

general program flow.

11

Page 12

I I

t

ARM AND TRIGGER

CHANNEL 2

READING

I_!

Figure 3. Dual Channel Operation Flowchart

Page 13

Usually, an instrument is sent a command at the start of a program to return it to some default

state. In the program below, this operation is performed by sending an SDC (Stile&d Device

Clear) as follows:

This statement instructs the Model 194A to assume its power-up (setup 1) configuration.

Next, we must make certain that the instrument is in remote before sending programming

commands as follows:

3M REMOTE 76’3

Now we can program channel 1 and channel 2 as required. For channel 1, we will select

the 32OmV range (Rl) and TRMS function (F2) as follows:

In a similar manner, channel 2 is programmed for the ZOOV range (R4) using the average

function (Fl):

In both cases, you will note that the channel select (C) command is included at the fronts

of the command string containing range and function commands, followed by an execute

(X) character to assure proper channel selection. (Note that the X immediately after the C

command is not required, but it does no harm).

At this point, we have programmed both channels; however, since the range and function

were changed, we must arm both A/D converters. First, for channel 1, we have:

Again, each command string includes the channel selection command prior to the trigger

command that arms the AID converter. Here again, the immediate trigger mode vZ6) is used

so that no further triggering is necessary to start the AID converters. With other trigger sources,

you will be required to apply the necessary trigger stimuli to start the A/D converters after

arming them.

Now that both A/D converters are running and readings are being processed, it is a simple

matter to set up a loop to request and display readings:

Page 14

This loop repeats indefinitely, with one reading per loop accessed and displayed.

RUNNING THE PROGRAM

1. Enter the program into the computer.

2. Press the computer RUN key tostart the program.

3. The program will send the commands to the instrument and then request readings from

the Model 194A. Note that data will alternate between channel 1 and channel 2 depending on which channel has the most current reading.

USING ONE CHANNEL

In order to use only one channel, program the other channel for an unused trigger source.

For example, to turn off channel 1, modify line 60 as follows:

6’3 OUTPUT 7B9j 6 g tCl:XTTK’ 3

Similarly, to disable channel 2, modify line 70 to read:

In both instances, the disabled channel is programmed for the external trigger mode. Thus,

in order for that~channel to remain disabled, no trigger signal can be applied to the trigger

input~for that channel. Another way to disable a channel is to use T27 which causes only

one trigger; no further triggers will oCcur even with external triter input noise.

SELECTING CHANNEL OUTPUT

As discussed previously, you can dictate which channel has the current-output by programming the desired channel for a particular function (so&as average), and then immediately

requesting a reading. In order to demonstrate this process, eliminate lines 80-110 from Program 2, and add the following lines:

20 OIJTPUT 789; L dCIFiX”

90 ENTER 7B9; ReadingB

1BW PEIMT &adiigB

110 OUTPUT70’3; 6 GCZFlX””

12’3 EMTEE 7W3; Readings

130 PEIMT Readings

i4k3 GOTO 80

159 END

! Compute channel 1 reading.

! Get channel 1 reading.

! Display channel 1 reading.

! Corn ute channel 2 reading.

! Get jtl annel2 reading.

! Display channel 2 reading.

! Repeat

14

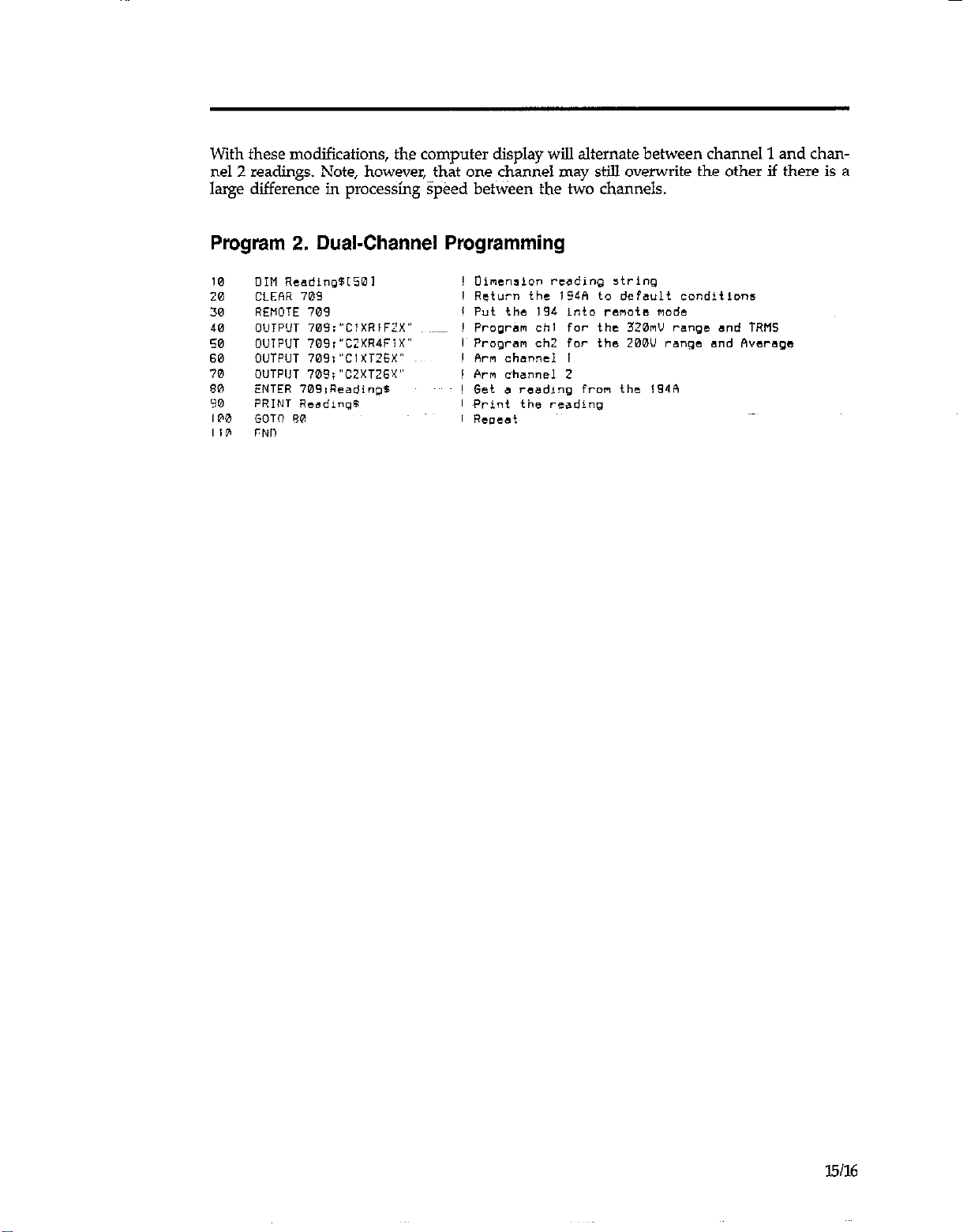

Page 15

With these modifications, the computer display will alternate between channel 1 and channel 2 readings. Note, however, that one channel may still overwrite the other if there is a

large difference in processing speed between the two channels.

Program 2. Dual-Channel Programming

10

OIM ReadlngBlSOl

20

CLEAR 709

30

RErlOTE 709

40

0UiP”T 709;“CIXRIF:X-

50

0”iP”T 709i”C:XR4FiX”

60

OUTPUT 709i”CIXT?fiX’

70

OUTPlJT 709; ~CZXT26X”

ENTER 709,Readimp

PRINT Reading*

GOT” 80

TN,,

oincnalo” reading string

Return the 194.4 to default conditions

Put the 134 into renotc mode

Program chl far the 320mU range and TRMS

Program ch2 for the 200” range and Rverags

Am channci I

Am channel 2

Get a reading fron the !94A

Print the rcadlng

ReDeat

I5116

Page 16

SINGLE AND CONTINUOUS

TRIGGER ARMING

PROGRAMMING CONCEPTS

l Sending the arming command ~once with continuous arming.

l Sending the arming command before each trigger with single arming.

l Triggering the measurement with single and continuous arming.

PROGRAMMING CONSIDERATIONS

Before the Model 194A will take a measurement, it must be triggered with the stimulus determined by the selected trigger source: immediate, input signal, external, other channel, or

an IEEE-488 GET, X, or t& command. However, it will notrespond to a trigger unless the

A/D converter is first-armed and ready for a trrgger.

Basically, there are two A/D arming modes: single and continuous. With single arming, the

A/D converter must be re-armed before each trigger. However, in continuous, the A/D converter need be armed only once, as the converter is automatically rearmed after each

measurement.

Over the IEEE-488 bus, arming takes place when the programming command for that particular trigger mode is received. For example, sending l3X (single arm, trigger on GET), arms

the A/D converter. Once armed, the measurement will be initiated when GET (Group Execute Trigger) is received. In this instance, the T3X~command must be sent before each trigger to arm the A/D converter. In contrast, if using continuous GET (TUC), you need send

the command only once before the first trigger, after which the A/D converter will automatical-

ly rearm itself after each measurement.

To summarize, there are several steps to programming and using triggers:

1. Fit select the channel to be armed and triggered. For example, to select channel 1, send

ax.

2. Send the command to select the trigger source and arm the A/D converter. For example,

toselect single, GET, send ‘l’3X.

3. Repeat steps 1 and 2 for the other channel, if desired.

4. Apply the necessary trigger stimulus to initiate the measurement. For example, issue the

GET command to initiate the measurement.

5. If you have selected a single arming mode, remember to re-arm the converter before each

trigger by sending the appropriate command over the bus.

Page 17

PROGRAM OPERATION

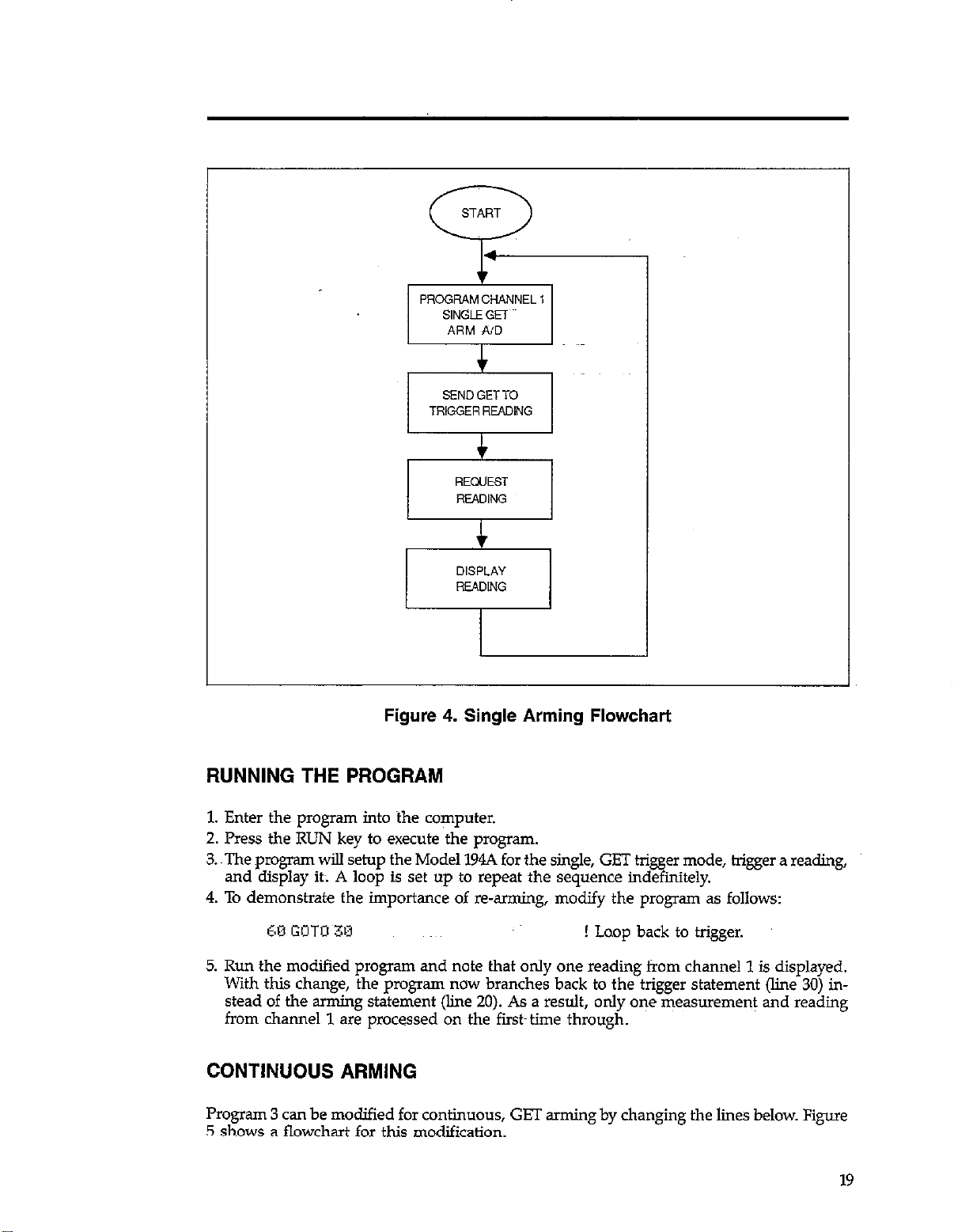

Program 3 below demonstrates single arming using the GET trigger source. Figure 4 is a

flowchart of the program.

Once the unit is in remote, we can program the trigger source and arm the channel 1 A/D

converter as follows:

In this particular instance we have selected the single arm, GET trigger mode (T3X); after

the command is sent, the A/D converter will be armed.

Now that the A/D converters is armed, we can trigger a measurement by sending GET:

The next two lines request a reading from the Model 194A and display a reading on the CRT:

40 ENTER 709;EeadingS

5W PR I t.IT Readings

Here the incoming data string is stored in Readmg$.

One final line necessary to complete the loop is:

Note that this branch goes back to the line containing the re-arm (T3X) command because

a single-arm trigger mode is jn effect. If instead we had branched back only to line 30, only

one reading would be taken the first time through the loop.

18

Page 18

SENDGETTO

TRIGGER READING

Figure 4. Single Arming Flowchart

RUNNING THE PROGRAM

1. Enter the program into the computer.

2. Press the RUN key to execute the program.

3. The prc~gram will setup the Model 194A for the single, GET trigger mode, bigger a reading,

and display it; A loop is set up to repeat the sequence indefinitely.

4. To demonstrate the importance of reaming, modify the pmgram as follows:

60 GOTO 38 ! Laop back to trigger.

5. Run the modified program and note that only one reading from channel 1 is displayed.

With this change, the program now branches back to the trigger statement (line 30) in-

stead of the arming statement (line 20). As a result, only one measurement and reading

from channel 1 are processed on the fiist~ time through.

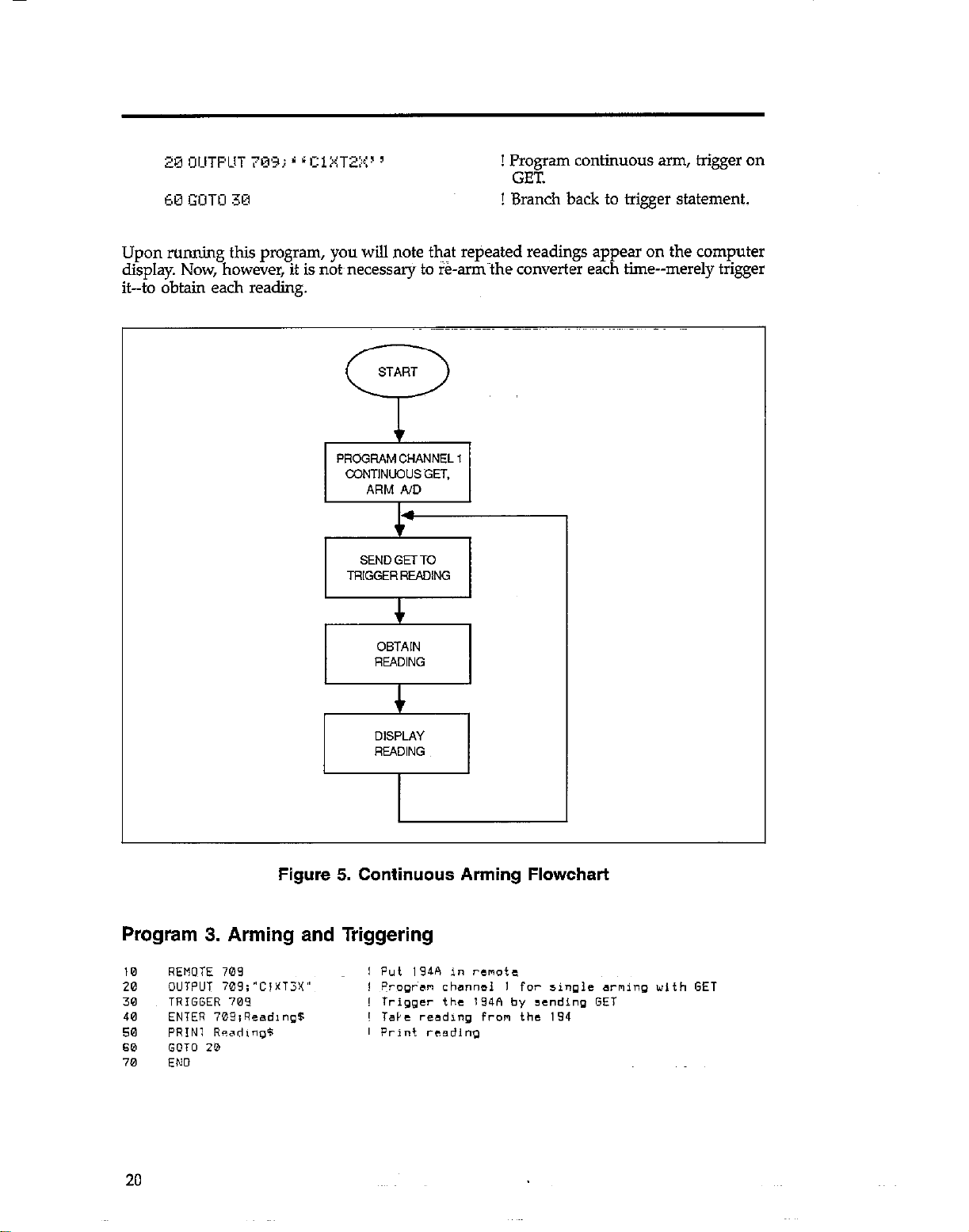

CONTINUOUS ARMING

Program 3 can be modified for continuous, GET arming by changing the lines below. Figure

5 shows a flowchart for this modification.

19

Page 19

20 O,JTPClT 70’3; 6 ~I:l:<T;?)<’ J ! Program continuous arm, trigger on

GET.

co GOT0 30

Upon running this program, you will note that repeated readings appear on the computer

display. Now, however, it is n&necessary to %rmthe converter each time--merely trigger

it--to obtain each reading.

PROGRAM CHANNEL 1

CONTINUOUSGET.

ARM A/D

! Branch back to trigger statement.

SEND GETTO

TRlGGERREADlNG

Figure 5. Continuous Arming Flowchart

Program 3. Arming and Triggering

10 REMOTE 709

20 OUTPUT 709;‘C,XT3X~

30 TRIGGER 709

40 ENTER 709,4ead,ng5

50 PRINI RPsdlng*

60 FOTO 20

70 END

20

Page 20

SRQ AND ERROR HANDLING

PROGRAMMING CONCEPTS

l Programming the h@ument to generate an SRQ on reading done and error conditions.

l Servicing the SRQ and determining the exact condition that caused it.

l Taking appropriate action tin the SRQ condition.

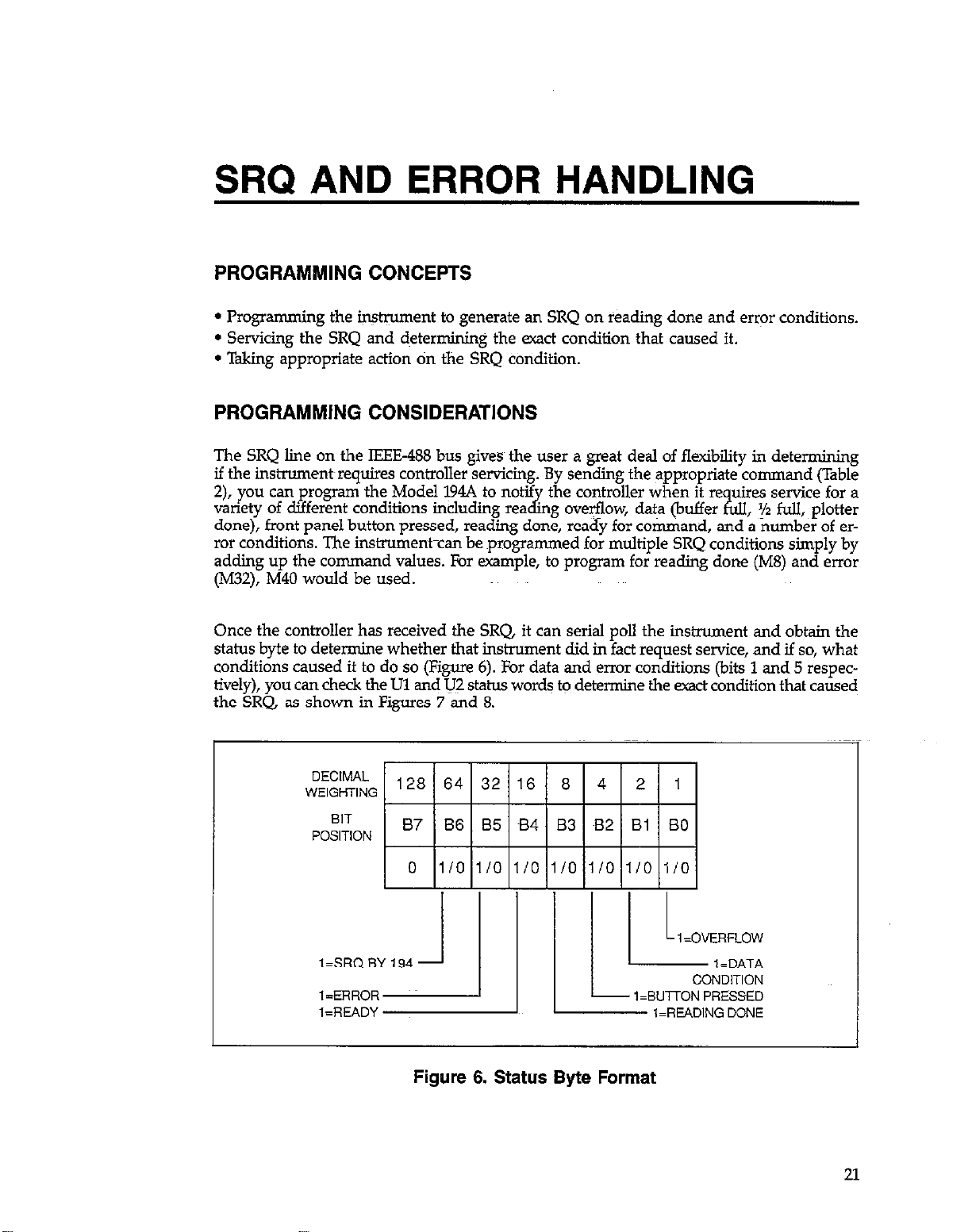

PROGRAMMING CONSIDERATIONS

The SRQ line on the IEEE488 bus gives the user a great deal of flexibility in determining

if the instrument~requires controller servicing. By sending the appropriate command (Table

2), you can program the Model p4A to notif

variety of different conditions including rea

done), front panel button pressed, reading done, ready for cotiand, and a number of er-

ror conditions. The instrument-can be programmed for multiple SRQ conditions simply by

adding up the command values. For example, to program for reading done (M8) and error

(M32), M40 would be used.

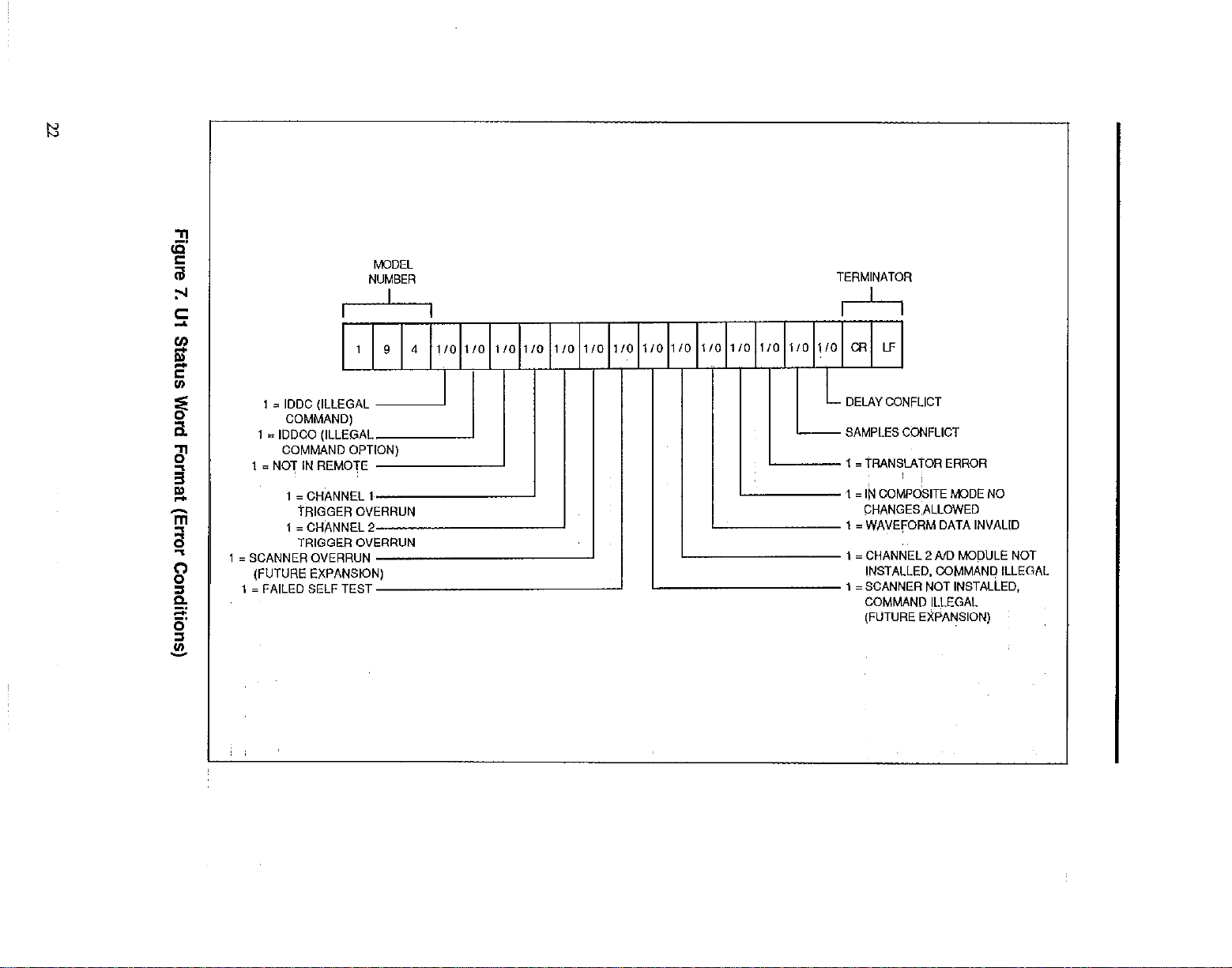

Once the controller has received the SRQ, it can serial poll the instxument and obtain the

status byte to determine whether that instrument did in fact request service, and if so, what

conditions caused it to do so (Figure 6). For data and error conditions (bits 1 and 5 respectively), you can check the Ul and U;? status words to determine the exact condition that caused

the SRQ, as shown in Figures 7 and 8.

the controller when it re uires service for a

kg oveflow, data (buffer ?i.zll, ‘/2 full, plotter

DECIMAL

WEIGHTING

BIT

POSITION

Figure 6. Status Byte Format

21

Page 21

I

I I I I I I I

I119141~ I I I I I I I I I I I I I, I I

1 = IDDC (ILLEGAL -

COMMAND)

1 = IDDCO (ILLEGAL

COMMAND OPTION)

M3DEL

NUMBER

I

TERMINATOR

I I ’

I I I I I I I I I I I I

1/o 110 110 l/O 110 l/O 110 1/o l/O 1/o 110 l/O 110 110 CR LF

SAMPLES CONFLICT

I= iRANSLATWi ERROR

COMMAND ILLEGAL

[FUTURE EXPANSION)

I

I

I

Page 22

Basically, there are two different methods the controller can use to detect the SRQ: interrupt

and po!.ling. The interrupt~method is by far the more versatile, since it is possible for the

controller to perform other tasks until the instrument requests service. With the polling

method, the controller must periodically check the status of the SRQ line to determine if

the instrument requires service.

Table 2. SRQ Commands

Description

SRQ disabled

Reading overflow

Data (Buffer full, Yz full, plotier done)

Front panel button pressed

Reading done

Ready for new command

Error (IDDC, IDDCO, tiot in remote, trigger overrun, channel 2

not installed waveform invalid, composite mode, translator,

samples 07 delay conflict.

*Pro am multi

M4 X for SR

f cf

le SRQ conditions by ad&g individual command values. For example, send

on error, and when reading is done.

KXEL

NUMBER

BUFFER HALF FULL

1 = PLOTTER

DONE

Figure 8. U2 Status Word Format (Data Conditions)

PROGRAM OPERATION

TERMINATOR

CONVERTER ARMED

1 i CHANNEL 1AX?

CONVERTER ARMED

Program 4 below demonstrates interrupt SRQ handling and error status checking. The pro-

gram can be broken into two sections: initialization and main task, and error handling. Figure

9 gives a flowchart of key sections of the first part of the program, while Figure 10 outlines

the error handling routmes.

23

Page 23

Highlights of the first part of the program include:

1. The Model 194A is returned to default by sending an SDC (line 20).

2. The unit is serial polled in order to clear a peiiding SRQ (line 30).

3. The service routine that will detect andservice the SRQ on an interrupt basis is then defined

(lines 70-100).

4. Channel 2 of the instrument is disabled by sending czT7X (line 120).

5. The user command string is requested and sent to the instrument (lines 130-150).

6. The instrument is programmed to generate~an SRQ on reading done or error conditions

by sending the command M40X (line 160).

7. The unit is programmed for continuous, GET trigger by sending T2X (line 770). Note that

the channel 1 A/D converter will continuously arm in this mode; it-will not be necessary

to re-arm the converter before every trigger.

8. Since the A/D converter will be armed at this point, it is only necessary to send a GET

command to trigger the unit and initiate the measurement (lie 180).

9. The user’s main task then begins execution. In thjs instance, the “main task” is a simple

incremental counter to indicate that the propam is looping (lines 200-220).

When executing, the program will stay in the main task until an SRQ is detected. When

an SRQ occurs, the program will service the SRQ as follows:

1. The Model 194A is first serial polled to obtain the status byte (line 250).

2. Next, the state of bit 6 in the status byte is tested to determine if the SRQ was, in fact,

generated by the Model 194A (line 270). Jf this bit is set, the program will continue checking other bits in the states byte. Otherwise, the program returns tu the main task. This

steps is essential only when more than one instrument is on the bus.

3. Bit 5 of the status byte is then checked (line 290) to determine if an error condition occured. Jf so, the program branches to a subroutine (beginning at line 350) which requests

the Ul error word and then tests appropriate bits in the error word to determine the nature

of the error. A suitable message is then displayed if an error is found, and the program

then halts.

4. If no error is found, the program tests the state of bit 3 in the status byte (line 310). Jf

this bit is set, a reading is ready tom be processed, and the program branches to a subroutine

to request and display a reading, and trigger a new one (liies 530-570). The subroutine

then returns to the use& main task.

RUNNING THE PROGRAM

1. Enter the program into the computer.

2. Execute the program by pressing the RUN key.

3. At theco mmand prompt; type in the desired string command. The command string should

contain only A/D programming commands (range, function, filter, coupling, sample, and

rate). In order to allow sufficient time for the main task to run, choose a sampling rate

and number of samples resulting in a measurement duration of several seconds. For example, to program a sampling interval of lmsec and 3ooO samples, enter “SOJE-3NOJOCOX”

(quotes must be used because of the commas).

4. The computer will then display the incremental counter to show that the main task is

running.

24

Page 24

5. Once the Model 194Abas taken its measwmnent~and processed the reading, the unit will

generate an SRQ, and the read&g will be displayed.

6. To demonstrate an SRQ-generated error message, type in an illegal command at the command prompt. For example, type in ElX; note that the computer displays the IDD~C ERROR

because E is an illegal device-dependent command letter.

START

i>

SEND DNW

DEFINE BRANCH AND

ENABLE INTERRUPT

Figure 9. Program 4 Flowchart (Initialization and Main Task Section)

25

Page 25

RE(xIEST ERROR

r-2-l

SERlAL POLL

Figure 10. Program 4 Flowchart (SRQ and Error Handling Section)

26

Page 26

USING POLLED SRQ

The program can be modified for polled SRQ by making the modifications below:

1. Remove lines 70, SO, 90, lOO,- and 550.

2. Add the following lines to the program:

211 STATILlS 717; Bus-lines

212 IF BIT IEusJines)=l

THEN GOSUH Service_routine

! Read bus lines.

I Check SRQ~ bit status.

With this modification, the controller must check the status of the SRQ line each time it goes

through its main task loop. Although from a user’s standpoint the program may appear to

operate the same, the additional controller overhead necessary for p4led SRQ uv3y becomq

restrictive in larger applications.

Iii0 OUTPUT 7091 -M40X”

(

Page 27

Program 4. SRQ and Error Handling (Cont.)

28

Page 28

BINARY DATA TRANSFER

PROGRAMMING CONCEPTS

l Data transfer speed considerations.

l Transferring binary data from the Model 194A to the computer.

l Converting binary data into displayable form.

PROGRAMMING CONSIDERATIONS

When a relatively large number ofsamples must be transferred from the Model 194A to the

computer, speed becomes an important consideration. The binary transfer mode of the instrument can significantly reduce the amount of time it takes to send 8 given amount of data

from the iwtrurnent to the computer. Binary transfer speeds up this operation for two reasons:

(1) the Model 194.4 is not required to process the data before s&ding it out, and (2) fewer

bytes are transferred per sample in the binary mode.

In order to take full advantage of binary transfer speed, the computer must be ca able of

transferring at a rate at least as high as that of the Model 194A--approximately 9 I& bytes

per second in binary mode. The HP9816 used for the example program below can operate

at rates as high as l30K bytes per second using fast handshake transfer, but other controllers

may require use of DMA transfer to operate with sufficientspeed. In any event, the advan-

tage to using binary transfer can be seen by comparing the time necessary to~transfer 1000

samples. In binary mode using fast handshake, these

65msec as opposed to 15 seconds required when using ASC

ment. (using an HP9816 computer).

sam les

can be transmitted in only

E

transfer and the ENTER state-

The general binary formats for the G6 and G7 modes +we shown in Figure 11. In addition

to the one or two bytes for each sample, a~~&byte status word and byte count (G7 only) is

added to the front of each byte sequence. The statis word contains unportant information

such as range, channel, function, as well as the exponent for the data. In order to display

the data, it must first be converted into ASCII form, as demonstrated in Program 5 below.

PROGRAM OPERATION

Program 5 below demonstrates fundamental concepts for obtaining bii data and converting

it into displayable form. Figure I2 shows a general flowchart of the program.

Program highlights include:

1. The program first initializes variables and Ii0 paths (liies 10-70).

2. The instrument is then programmed for the waveform mode (FO), number of samples (NO),

sampling rate (SO), binary data format (G7), and reading buffer disabled (lines 80-140).

29

Page 29

A. GS

STATUS WORD 4 wn3

SEE BELOW

B. G7

MSB LSS I

5-5-+ww5----LT-l

BYTE STATUS WORD SAMPLE SAfvwLE~ SAMPLE SAMPLE

COUNT (CBYTES) 1 2

(I-64K) SEESELOW

2 3 4 MSS LSB MSB LSS MS8 LSS MSS LSS I..+$q

1 j ; j j / j j 1 RANGE

’ ’ ! ! ! ! ! sEESELOwl

1 = 1 S-BIT MODE

0 -8.SIT MODE

1 =ZERCED

RANGE CHPlNNEL

*-Em MODE: EACH BYTE IS A SEPARATE SAMPLE.

lS.S,T MODE: BYTE 1 IS MOST SIGNIFICANWYTE, BYTE 2 LEAST

SIGNIFICANT.

3 N

(BYTE PER SAMPLE IN 8.SIT MODE;

CHANNEL 1 ~TusED 1 FUNCT0N 1 EXPONENT

,sEEBELow SEE BELOW 125 COMPLEMENTl

I I

I

S!MJLE

F”NCTlON

EOI

1

IWTF ,

lN”ALlD NUMERIC: 1 = READING IS lN”ALlO

SUFFER IN”ALID: 1 = MEASUREMENT SUFFER CONTAINS lN”ALlD SAMPLE

OVERFLOW: I= READING SAMPLEO”~RFLOWED

WAVE FORM IN SUFFER: 1= MEASUREMENT SUFFER CONTAlPJSAWA”EFORM

8HG SIT MODE: 1 = <S-SIT: 0 E S-SIT

ZEROED: 1 =zERO IS ENABLED

Figure 11. Binary Data Formats

30

6

7 0111 INTEGRAL

~8 1000 RECALL

0110 STANDARD DEVlATlON

Page 30

3. Next, the program performs a test to see if the reading is done (lines 160 and 170). This

test is performed by serial polling the unit and testing the state of bit 3 in the status byte

(the reading done bit). If the bit is cleared, the reading (and thus the measurement) has

not been completed, and the program remains in the loop until bit 3 is set, indicating

that a reading is available.

4. Once it-has been determined that the reading is complete, the fast handshake transfer

is performed tom read the binary data into a computer I/O buffer (lines X30-221). In order

to properly terminate the transfer, it is necessary to know how many bytes are to be transferred. This value is determined from the number of samples programmed, as well as

whether the data is in eight or 16-bit format. A value of six is added to the total byte count

to account for the count and status bytes.

5. Next, the byte count and status are read from then I/O buffer and placed into numeric

variables (line 240). In this case, the firsts two bytes represent the byte count; while the

last four bytes contain Model 194A status information, as shown in Figure 11(c).

6. Binary data is then read from the I/O buffer into-a numeric array, (line 770 or 280). The

transfer is in byte @-bit) or word (X-bit) format,

strument stores S-bit-data at rates above lMlk&).

ending on the sam

R

ote that the end o P

ling rate (the inthe data for this

de

transfer is determined by EOI.

7 The binary data is then converted into displayable form (lines 350-410). This subroutine

must take into account the weight of each bit. In the g-bit mode, the bit weight is 256,

while in the 16-bit mode, the bit weight is 1.

8. The data is then scaled according to range by using~ the range information located in byte

2 of the status word..Since this range information is located in the most significant nibble,

it must be converted by ANDing with 48 and then dividing by 16. Figure 13 outlines this

conversion process.

~~.

9. Once final test is made to determine the status of the overflow bit located in byte 1 (lines

520-570). A normal or overflow reading message is determined by the status of this bit.

31

Page 31

PROGRAM AND

TRlGGER 194.4

GEM GEM

SAMPLE SAMPLE

1 1

CONVERT CONVERT

SAMPLE SAMPLE

1 1

DWLAY DWLAY

SAMPLE SAMPLE

32

Figure 12. Flowchart of Binary Transfer Program

Page 32

I

AND

RANGES

r-l

CHANNEL

0 0 ~1 1 0 0 0 1 ~BME 2

0011 0 0 0 0~ ~(~~4810)

0011

i

A. ANDing WITH 48, o TO MASK OFF UNWANTED BITS

000000E

--a

~8. DIVIDING BY 16 SHIFTS RANGE BITS ~FOIJR PLACES

TO RIGHT.

0 0 0.0

RANGE

Figure 13. Converting Byte 2 Range Bits

RUNNING THE PROGRAM

1. Enter the program into the computer.

2. Execute the program by pressing the RUN key.

3. Apply a DC voltage oft less tbti 32OmV.

4. When the prompt for number of samples is displayed, type in the desired value. For example, for 100 samples type in 100 and press the ENTER key.

5. When the computer prompts for the reading rate, type in the desired value. For example,

to program a lpec rate interval, type in ll?-6 and press ENTER.~

6. The Model l94A will now process a measurement and then display the individual samples,

including sample number and a message as to whether the sample is normal or overflowed.

With less than 32OmV applied, the reading should always be normal.

7. Increase the applied voltage to 5oOmV and NIX the program again. Note that the overflow

message is now displayed because the 500mV applied signal is above the maximum input

voltage of the 320mV range.

8. Change the Rl range command in line 130 of the program to RO. This change will program

the Model 194A for autorange. Ream the program several times with different applied

voltages between 200mV and 200V and note that displayed data is automatically scaled

according to range.

33

Page 33

Program 5. Binary Data Transfer

10 Initializegrog: !

30 INTEGER 8( 32000)

40 REAL A

41 OIM A$[320001 SUFFER

50

60

70 OUTPUT KBOICHR$( 2% )&CHR8(75 )i

30 I”li ielize~1~S4: I

35

90

100

110

120

121

130

140

150 Test_reading:l

160

170

1B0 setup-tranefei: !

190

200

210 Perfarn-transf: I

211

212

220

ZZ,

230 Rend-statue:!

240

260 Read-data:!

250

270

271

280

281

290

300

310

320

330 STOP

340 convert: I

3G0

360

361

370

371

330

390

400

410

420

430

440

450

4G1

460

470

480

490

ASSIGN 80194 TO 703

WiGIGN @Suf TO BUFFER A$

REMOTE 703

PRINT “ENTER NUMBER OF SAPIPLES’

INPUT Samples

PRINT “ENTER RE&OING RRTE IN US <e.g IE-6)”

INPUT Pate

! Progren 194

OUTPUT 709;“F0R,NB,“&“ALs(S~~~~~,~~“S0.”6VALO(Rete~~.G7O0~.

OUT~PUT 709, ‘T27X”

S=SPOLLC 709 1

IF SIT<S,3)=0 THEN GOTO 160

IF Rate/l.OE-5 THEN Numb&r-bytes-l

IF Rate:,, .0E-5 THEN Nunhcr-bytes-2

! Transfer 194pI Data us‘ng fast hand,haks. Te~ll how maw

bytes are ta be tranafered.

TRANSFER 00134 TO WufiCOUNT ~(Nunber_bytes+Sanpis.)t6,WnTT

: Read 194A status fran buffer

ENTER Wuf USING ~X.W,B.B.R.B~;Count,Statual ,Stat~.Z.Statu.3,Statu.4

FOR Data=, TO Sample5

IF Ratei,.0E-5 THEN ENTER R&f USING ‘%.B”r3(0ata) I Read 8 bit word

IF Rate:,.0E-5 rHEN ENTER B&f USING ‘%.W*iE(Data) 1 Rea~d 16 bit word

GDS”9 canvert

PRTNT Oat a .Reading .Hessaoes

NEXT Data

SENO 7,UN1

A=BtOata)

IF Rate:, .“E-5 THEN Rij+weight-256

IF Rate,,.OE-5 THEN Bit-weight-1

IF Range-0 THEN Reading-R*i.OE-5

IF Range=, THEN Reeding=R*I.OE-4

IF Range-2 THEN Readlng=R*I.OE-3

IF Range-3 THEN Read,ng=R.i.BE-2

I Reserves storage for floatiig mint variable

I Goaub ta ravtina that converta raw binary

I DiFlenei0n tntcrxr

I Dlnaneio” buffar

~! *seign I/D path n*ne to 1946

I Rsalgn I/O path name to BUFFER

I Clear em-can

! Put 194R in renote

! ~PrOFlpt for tt w&npl+a

! Input * sanplea

! J+*np_t for rate

I Input rate

I Arm the 194A

I Perforn serial poll

1 Teat far reading done

( Oeterninc X bytea PCP aanele

! Detern~ne P bytes per ~anple

! fro,, buffer.

! from buffer.

! Dsteinlne bit we,pht for 8

! bit mode.

I Deternlne bit weight for 16~

1 bit node.

! et.tu.

1 Scale reading for.320V range

/ Scale reading for 3.~2” range

! Scale readying for 32V range

! Scale reading for 200” range

34

Page 34

Program 5. Binary Data Transfer (Cont.)

35136

Page 35

READING BUFFER OPERATION

PROGRAMMING CONCEPTS

l Fundamental operation of the reading buffer.

l Disabling the unused channel so that only desired readings are stored in the reading buffer.

l Triggering each stored reading indiyidually.

l Operation of the reading buffer pointer.

l Dumping entire buffer contents in one string.

PROGRAMMING CONSIDERATIONS

The reading buffer is a 100 location buffer into which processed readings can be stored as

they become available. By sending the appropriate command, you can operate the reading

buffer in a linear configuration (Qi) or a circular mode (QZ). With a linear buffer, the instrument will continue to store readings until all 100 locations are full and then stop storing until

the buffer is completely emptied. With the circular buffer, the instrument will store 100

readings and then stop. As old readings are taken from the buffer (in oldest to newest order),

new readings will be stored in the empty locations.

Since a single lOO-location reading buffer is shared by both channels (dual-channel units),

care must be taken when reading the buffer to determix the source of the dataIf both channels are running, data will be stored in the buffer on an as-available basis. Thus, to determine which channel is the data source, you should check the channel suffii (Figure 2) on

the reading string. Of course, you can also turn off an unused channel by programming

for a trigger condition that~will note be met. For example, to turn off channel 2, send C2XT7X

over the bus. Doing so will make certain that data comes only from the desired channel.

The way the buffer fills will depend on the programmed trigger mode. In the immediate

mode, the instrument will fill the buffer without requiring additional triggers. However, in

the remaining trigger modes, yen ,must supply one trigger per measurement in order to fill

the buffer.

Once your data is stored in the buffer, there am several ways to access it. with the GO through

GZ data formats, one buffer location will be sent with each request. However, you can also

dump the complete buffer in one operation by using G4 or G5. Remember, however, that~

the computer input buffer or string must be dimensioned large enough to handle all the

bytes in the data string.

By using the B3 command, you can dictate how many oft the reading buffer locations will

be sent. Simply use B3,nX, where n represents the last location that will be transmitted.

For example, if you send the command B3,2OX, locations 1 through 20 will be transmitted

when requested.

37

Page 36

It~is important to clarify the operation of the buffer location suffix, which is shown in Figure

2. This value does not represent the buffer location number; rather, it shoti the number

of readings left in the reading buffer after accessing this particular location. For example,

assume you send B3,2OX to set an end pointer of 20. The~first location to be sent will be number

1, but the suffix will show 0019, meaning that there are still 19 locations left to access. This

value will decrement once per buffer location until it shows a value of 0000 with the access

of the last buffer location.

PROGRAM OPERATION

Program 6 below demonstrates fundamental operation of the reading buffer. Figure 14 is a

flowchart of the program.

Basically, the program operates as follows:

1. The string called Readi& is dimensioned to hold 2,KlO bytes (line lo), and the unit is

placed in remote (line 20).

2. Both channel 1 and channel 2 are disarmed by sending T7x to then appropriate channel

(Iines 30 and 40). Channel 1 is disarmed to ensure that no readings are being processed

when the reading buffer is turned on; othqise, undesired readings will be stored. Channel 2 is turned off to avoid storing channel 2 readings at ail.

3. Channel 1 is programmed to take 10 samples (NO,lO) per measurement at the maximum

rate of l* (SOJE-6) by line 50.

4. The reading buffer is then enabled for the~linear configuration by sending QlX (line 70).

5. Next, a lOO- point loop is set up to arm the A/D converter and trigger each measurement

(lines 80-I.&. Each t rme through the loop, the A/D converter is armed by sending ‘I3X,

and a measurement is then triggered by GET. As each reading is processed, it is stored

in the reading buffer in the next sequential location.

6. After the loop is complete, the unit is programmed to dump the fast 20 readings of the

reading buffer in one long string (line l30)Jhe G5 command tells the instrument to output all available buffer locations at once, while the B3,20 command limits the output to

the fast 20 locations only (Iocations l-20).

7. Finally, the reading string is requested and displayed on the computer screen (lines l6O-170).

RUNNING THE PROGRAM

1. Enter the program into the computer.

2. Press the RUN key to execute the program.

3. The program will send commands to the Model 194A, and 100 readings will be stored

in the reading buffer.

4. Once storage is complete, the complete reading string will be displayed on the computer

display. Note that the reading number suf@es decrement ram 19 down to 0 throughout

the reading string. As pointed out earlier, this number represents the number of readings

left to access at that~point--not the buffer location number.

38

Page 37

Figure 14. Flowchart for Reading Buffer Program

39

Page 38

Program 6. Reading Buffer Operation

I0

OIM RaadlnQG~20001

20

REMOTE 703

30

OUTPUT 709:‘CIT7X”

40

OUTPUT 709i”CZT,X’

50

OUTPUT 703i”CIN0.,050,iE-6X”

60

70

OUTPUT 703:“QIX”

80

FOR I-1 TO 100

OUTPUT 709i”T3X”

30

I00

TRIGGER 703

110

120

NEXT I

OUTPUT 7a3,‘GSB3.:0X”

130

140

150

160

ENTER 709iReadrngB

170

PRINT Readings

160

END

I oinanaion readings

! Put the 1948 in rcnotc

! Turn off channel 1

f Turn off channel 2

! Program rats and * sanplca for

! channa, 1.

! Enable linear bvffer

1 Take I00 readinps

.I Program trfpper mode and arm AI0

! charm*, I.

! Trrwer the 1348

! Triggsr another reading

! Program 194R to ,end

! readings 1-20

!

! Read buffer Iocatlons I-20

lKPFi”i rcading$

40

Page 39

USING TRANSLATOR

PROGRAMMING CONCEPTS

l Using Translator tom make programs easier to read.

l Instrument emulation using Translator.

PROGRAMMING CONSIDERATIONS

The Translator feature allows you to substitute a group of ASCII characters for a device-

dependent command string. Basically, there are two chief reasons for using this feature: (1)

to make programs more readable, and (2) to emulate the operation of other instruments.

Translator words are defined with the ALIAS command by including the defied word along

with the associated device-dependent-comaqd string. For example, to define the word

SAMPLES to prograti 1000 samples, the ftiiiowing would be used:

Note that spaces are included to delimit the ALIAS command, the defined word (SAMPLES),

and the device-dependent command (NO,lOOOX). Also, the definition string must be terminated with a semicolon.

Once Translator words are defined, using them is simply a matter of sending them in place

of device-dependent commands, for example:

In this case, the word SAMPLES would program 1000 samples because SAMPLES was

previously defied as NO,lOOOX.

MAKING PROGRAMS READABLE

Program 7 below gives an example of how Translator can be used to make programs more

readable. Figure 15 is a flowchart of the program.

Page 40

SEND SELECTIVE

DEVICE CLEAR

Figure 15. Flowchart for Program 7

Program Operation

Key points of the program include:

1. The variable Voltmeter is defined as 709 for use in subsequent OUTPUT statements (line 20).

2. The inshument is then returned to default conditions tid placed in remote (lines 30 and 40).

3. Next, the Translator words are defined by using the ALIAS command (lines 50-100).

4. Test 1 is then executed by sending the appropriate Trkslator words to program the various

operating modes (lines 120-170).

5. In a similar manner, Test 2 is performed by programming the &trument (lmes 190-240).

42

Page 41

Running the Program

1. Enter the &xogmm into the computer.

2. Press RUN to execute the program.

3. The program wi!.l then send Translator words to the inshument to be defined. Two different readings should appear on the computer CRT, one each for Test 1 and Test 2.

INSTRUMENT EMULATION

Program 8 demonstrates the use of Tran$a@’ to emulate the TRMS measurement of an AC

waveform. Notes that TCR4? is the command string that is to be emulated by the Model 194%.

This command selects RMS, 1OVAC range, and DC coupling of the DVM being emulated.

Figure 16 gives a flowchart of the program.

Program Operation

1. The Translator word is first defined (line ~3).

2. The instrument is placed in remote (line 10).

3. The defined Translator word (TCR4?) is then sent to the instrument (line 20).

4. Finally, a loop is set up to request and display 10 readings (lines 40-70).

Running the Program

1. Enter the program into the computer.

2. Apply an AC signal of approximately 1OV RMS to the instrument INPUT jack.

3. Press the RUN key to execute the program.

4. The program will send the necessary Translator definition command to the instrument;

program the instrument accordingly, and then request and display 10 readings.

43

Page 42

DEFINE TRANSLATOR

bm=a~

4

PUT 1~94A

INTOREMOTE

4

PROGRAM ~194A TO

EMULATE D”M

USING TR4NSLATOR

GET READING

c

DISPLAWEADING

44

Figure 16. Program 8 Flowchart

Page 43

Program 7. Using Translator for Program Readability

10 ProQram-aetupL

“a,tneter=709

20

CLERR Voltmeter

30

40 REMOTE “altmcter

OUTPUT Voltneteri”RLIA5 ZERO CIZ4X :” 1 Define trans1a+or word

50

OUTPUT “oltneteri’ALIA5 SETUP1 CIXF3R311X :” I 0efine translator word

60

OUTPUT “oltnetcrr”RLIAS SETUP2 ClXFiXRZX i- I 0efinc irans,ator ward

70

OUTPUT “o,tneter,“ALIAS 1000SAMPLES N0.1000X i-

80

DUTPU, “oitneter;‘ALIRS ARIl T2GX /-

90

OUTPUT “oiineier;“ALIRS OISPIBLECHZ CZXT7X i’l I Define translator word

I00

II0 Test-l:,

OUTPUT Uoitnettr;‘OISABLECHZ”

120

OUTPUT “altnetsr,“SET”PI’

130

OUTPVT “oIincter:‘ZERO‘

140

OUTPUT “01tmcteri’etR”‘

150

ENTER Uoltmetcr;ReadlnaB

I60

PRINT RcadlngB

170

180 rest-z: 1

DUTPUT Uoitmeterr”SETU~2”

190

OUTPUT Uoitneteri’l000SAMPLES

260

OUTPUT “oiinctcri “ARM”

210

ENTER U~ltmeter~Rc~din~S

220

230 PRINT r?.adinq%

END

240

!~Oaflne 194.A~ address

!LReiclrn to default

I Pui 194A rn rcmoic

I Define trans1atar word

I Define translator ward

Program 8. Using Translator for Instrument Emulation

I I Line 3 translates the DVM commands to 134A cmnanda.

O”TP!,T 709,‘ALIAS TCR47 C2TiXC1F:R3G11050,i66.7E-6N0.l000T26X 8”

3

10 REMOTE 709

20 OUTPUT 709i”TCR4?*

30

40 FOR I-i TO 10 1 LOOP~~~l0 tines

50 ENTER 709;ReadinuB 1 Get readinp

60 PRINT Readiny)% 1 Print rcad,ms

70 NEXT i

S0 EN”

1 Put ovn I” rcnote

~~‘1 ~irooran D”M for cont‘nuaus node.

I

Rk *c ,DC coueled and Irn’J ranOC

45146

Page 44

USING EXTERNAL SAMPLE

TRIGGERING

l Using external sample triggering~ to test potentiometers.

l Fundamental graphing techniques.

l Combining two instruments on the bus.

PROGRAMMING CONSIDERATIONS

The external sample trigger feature of the Model 194A allows you to synchronize sample

collection to external events. By applying appropriate TTLcompatible pulses to the sample

trigger input, you can trigger each sample individually.

One possible external sample~tigger application involves testing for potentiometer linearity

using the basic setup shown in Figure 17. In addition to the Model 194A, additional equip-

ment is necessary: (1) a Model 220 current source, and (2) an optical encoder. The Model

220 sources current through the potentiometer, developing a voltage to be measured by the

Model 194.A. The optical encoder develops- the sample trigger pulses necessary to trigger

individual samples.

To run the test, the current source is Seth to the desired value, and the potentiometer shaft

is rotated, either manually, or by a motor. As the shaft rotates, the encoder develops sample

trigger pulses at precise increments of rotation (typically 1 to 2 degrees per trigger pulse).

At each rotational increment, the Model 194A measures the voltage across the potentiometer

and stores that value asp a single sample.

Once all samples are taken, it is a simple matter to compute the resistance at each point

from the measured voltage and the source current. Computed data can then be further

analyzed or graphed, as required. Program 9 below demonstrates basic techniques for

graphing such data.

PROGRAM OPERATION

Program 9 is written to perform the potentiometer test described above. Figure 18 shows

a flowchart outlining key sections of~the program.

Important program sections are described below.

1. The program is first initialized by clearing the screen and assign&I/Q paths (lines 20-70).

2. Next, prompts are given for the user to input degree increments, degrees of span, and

maximum potentiometer resistance (Iines 8030). From this information, the total number

of samples required is calculated based on the degrees of span and degree increments

(line 140).

47

Page 45

3. The Model 220 current and voltage compliance are then programmed, and the output

is turned on (lines ‘I70 and 180). In this instance, we are programming a current of 100/A

(l.OOE-4); to program a different current value, simply change the current variable in line

170 to the required value.

4. The Model 194A is programmed for the number of samples (based on the required number

computed), samplmg rate (166.7@ec), range (32v), function (waveform), data format (no

prefix) by lines 230-260. In this case, we ” using channel 2~with channel 1 disabled. To

use channel 1 instead of channel 2, reverse the Cl ax-d C2 commands in these three lines.

5. Now that the instrument is ready, the program prompts the operator to turn the potentiometer and then inputs all samples into an may called Reading (lines 310-360).

6. The plot routines are then initialiied (lines 380530).

Z The graph is labelled (lines 550-740).

8. Finally the resistance is calculated fmm the stored samples, and the deviation from nominal

is then plotted (lines 760-860).

HP9816

COMPCrrER

IEEE - 488 BUS

POTENTIOMETER

UNDER TEST

MODEL 220

MODEL 194A

EXTERNAL

SAMPLE

TRIGGER

INPUT

4

VOLTAGE

INPUT

A

SAMPLES

TRIGGERPULSES

3 4~

; _ _ _ _ - - - - q-,

OPTICAL

ENcorn

OUTPUT

MOTOR

CURRENT

SOURCE

Figure 17. Potentiometer Test Configuration (Set up for Program 9)

48

Page 46

POTENTIONETER

CALCULATE RESlSTANCE

AND DE”lATlON

PLOT

POINT

ALL

POlNTS ?

0’

Figure 18. Potentiometer Test Program Flowchart

N3

YES

49

Page 47

RUNNING THE PROGRAM

1. Connect the Model 220 OUTPUT and Model 194A VQJ-T&X INPUT t0 the potentiometer

being tested. Both lows should be connected twone end of the potentiometer, and both

highs should be connected to the wiper.

2. Mount the optical encoder on the potentiometer shaft, and connect the encoder output

to the SAMPLE TRIGGER inputs of the Model 1944 through the Model 1942 or similar

sample cable. Remember that the encoder must supply JTLcompatible pulses with a

duration of greater than 1OOnsec (samples trigger on the rising edge).

3. Connect the instruments to the IEEE-488 bus of the controller using suitable cables.

4. Be sure that the primary address of the Model 194A is set to 9, and that the Model 220

address is programmed for a value of 12.

5. Enter the program into the computer, and check it for errors. If a different current value

than 1004 is desired, modii line 170 accordingly.

6. Rotate the potentiometer to one end~of-its rotation.

7. Make sure the ABORT line on the Model 194A is set low (connect the black and white

wires on the Model 1942 Sample Cable together).

8. Execute the program by pressing the RUN, key.

9. At the prompts, enter the degree increments (the resolution in degrees of the encoder),

the total span of the pot in degrees, and the maximum potentiometer value.

10. When prompted to do so, smoothly rotate the potentiometer to- the opposite end of rotation. The instrument will collect samples as the potentiometer is rotated.

11. Once data is taken, the readings will be read into the computer array, and the graph will

be generated using the voltage data and current source value to compute the resistance.

The plot generated shows deviation from nominal (

as shown in the example of Figure 19. Note that a

this example, yielding a total possible rotatidn in excess of 6,000 degrees.

percent) versus degrees of rotation,

i

O-turn potentiometer was used for

50

Page 48

Figure 19. Potentiometer Test Example

51

Page 49

Program 9. Potentiometer Test

10 InltallzcJr~m:!

20

30

40

50

60

70

80

30 INPUT Oewee

I00

110

I20

130

140

150

160 Set-“p-z20:l

$70

I80

190

200

210 setup-i94a: !

*20

230

240

250

260

270

280

290

300 Buffer-fill:!

310

320

330

340

350 ENTER 709IRsadi”g(Cou”t)

360 NEXT Count

370 Smtlmoiot:~

380

390

400

4,0

420

430

440

450

460

470

480

490

500

510

520

530

540 Lcocl~dxIs: r

550

560

570

580 SIZE 3

590

GCLERR

OUTPUT KYD,CHR6(255)BCHR5(75)

ASSIGN @fl220 TO 712

ASSIGN 811194 TO 709

CLEAR 0Mi94

DIM RCCdi”Q( 10000)

PRINT “ENTER THE NUMBER OF DEGREES BETWEEN EACH REROiNG’

PRINT ‘“ENTER THE TOTAL NUMBER OF OEGREES OF SPAN”

INPUT Oegree~total

PRINT “ENTER MAX REYIYTRNCE OFPOT IN OHMS’

INPUT Rcsistencc

Sam~le.-Depree_totallDepres

0”TP”T KEO;CHRL(25~S)&CHRb(75)

Current-l.00E-4

REMOTE BUZZ0

OUTPUT @M220,“l”W,L5(Curre”t )&“V60FIX” ! Program 220 for voltage,

REMOTE 0N194

OUiPUT @rl194~;“clT7x’

OUTPUT 0M194; ‘C2SB.I .667E-4N0.‘&UAL$~Samples)L’X”! ~Progran channsi 2 for

OUTPUT ~~194:“CZXGlR3F0B0T27X‘

PRINT “TURN POT”

FOR Count-1 TO 5amples

GRAPHICS ON

OUTPUT KBO:CHRS<255 >&CHR$(75)

GiNiT

PLOTTER IS 702 ,“HPGL’ PLOTTER IS 702 ,“HPGL’

CSIZE 7 CSIZE 7

NO”E 5.90 NO”E 5.90

LRBEL~” nodal 194A Potentiometer LRBEL~” nodal 194A Potentiometer

CSIZE 4 CSIZE 4

WOVE 40,10 WOVE 40,10

LABEL -Degrees of Rotation’ LABEL -Degrees of Rotation’

MOVE 5.15 MOVE 5.15DEG DEG

LOW 90

LABEL v): Ocviatic” From Non~nal’

“IEWPORT 20,100.20,70

GRID i0,10,0,5R,l,,,I

VIEWPORT 20, l00.20,70

WINDOW 0,oe~rcs~total,-200,2~0~0

CLIPS OFF

FOR Label-x-0 TO Degree-iota1 STEP-1000

!~Clear praphics display

! C1s.v screen

I AsciQn II0 path “ame to 220

! Resign I/O path name to 194A

! Return ,946 to 8 know” state

! Dinension reading

! In,mt degree

1 Inpl&Dcpree-total

! Input rcsiatanct

/ Calculate ““nber of sanelss

! Clear ccrecn

1 Ocfinc test cwrent value

!~Put 220 in remote node

!

currant and operate nods.

! Put 194A in renots nods

! Turn off channsi 1

I

! Program channel 2 for orefix and

I

suffxx off.3Z” ra”Qc. wavefor”

I~ .nodc. clear uavcform output and

I

cinglc arming co”ti”“ous trtgger.

! Pronpt to start turning pot

! Define number of readings

! Controller wtll Wait for buffer to

I fill

I Get ,946 readlno and wt into array

! Repeat fir next reading

!~ Turn graehics dlaolay on

! ClsG sCre.5”

/ ‘Set grap~hic varrables to default

! Select plotting device

! set character CfLC

1 nave pen

Test’

! Set character size

1 “0”s pen

I Draw label

!KMova pan

! Select deprees c5 unit of FlCCS”CC

I Defin* mole at which-i&al is’drawn

! O-fin& arca

1 Draw grid

! Oefine area

! Define current unit of rnCI3U?-C

! Oisable soft c’lip l‘nit

! set character CITC

I Draw label

I Draw label

! Label X axis at 1000 degree

rata and ~anplcs

52

Page 50

Program 9. Potentiometer Test (Cont.)

600 I incrcncnt~

610

620 LOIR 0 1 Set angle at which label is draw”

630 NO”E Lehcl-r ,-240 ! Move pen

640 LABEL USING ~t.K”iLnbsl-x 1 Oraw label

650 NEXT Label-x

660

670 DEG

680 LDIR 360 1 Set angle St uh,ch lnbcl i$ drru”

690 NO”6 -700 .Lobsl~-y 1 nave pen

700 LRYEL USING “t,K”;Label-y

710 NEXT Label-y

720 VIEWPORT 20.100.20.70 I Define area

730 WlNDOW 1 ,$*nDles,-:00.:00 1 Oefinc current unit of Flea~uTe

740 FRPlME 1 b-au frant

750 CalcuI.tc:l

760

770

780

790 Ohns=RFading(Count,,Current 1 Ca!c”latc actual

800 ! rca‘atanse

010 Nom,“Ci~(Cou”t/SanpiCC~*~CCiC,~“~C 1 Calculate ideal

820 / rcaiatoncc

830

840 Plot:,

850

860

870

OEG

FOR Label-y=-200~~ TO 200i STEP 50 1 Label Y e.xi, at 50% increncnts

FOR Count-l TO Samplas*Oegrce 1 Define read,“* al-ray size

IF Read‘ng~Count~.0 THEN Rcoding~Count,=.0000, ! Prevent undefined math

Error=~Noninal-Ohnc~,oh~c*~00 1 colc”!ctc % of w-t-or

PLOT Gaunt .Error

NEXT count

EN”

! Set degrees as unit of measure

1 @peat for next label

1 Set degrees ns unit of rn~esu~ve

I “raw label

I Rc~eat for “r-t iabal

I

error condition

1 Plot point

I Re”“Ct for ncrt pnint

53154

Page 51

GENERATING BUS TIME

INFORMATION

PROGRAMMING CONCEPTS

l Factors that affect trigger to SRQ times.

l Denionstrating measurement of trigger to SRQ times.

l Summarizing typical GET trigger to SRQ times.

PROGRAMMING CONSIDERATIONS

The time it takes for a reading to be completed after the instrument is triggered is an important consideration, especially in time-critical situations. A common yardstick used to measure

this time eriod is the duration between the tri

generated%

trigger is the sum of the measurement time and the reading processing time, as we will now

discuss.

the mstrument, as shown in Figure

er stimulus and a readin done SRQ

0. Note that the duration % etween the

53

Figure 20. Basic Time Interval Between Trigger and SRQ

The measurement time depends solely on the programmed number of samples and the

sampling rate. For example, with a sampling interval of l@ec and lOo0 sample, the measure-

ment time is -Irnsec (ij&?c X NUU = i+ec). The reading processing time is primarily due

to software overhead, and it depends on the selected math function as well as the number

ofsamples in the measurement; Other time periods such as trigger response times do enter

into the equation, but they are u@ly sm$ enough to be negligible, and can be ignored

for all practical purposes.

55

Page 52

A common operational condition is to trigger the Model l!34A with GET (Group F&cute Trig-

ger), and then wait until the instrument generates an SRQ as shown in Figure 21. (For simpler

situations, the controller can simply wait until the SRQ occurs; but more complex situations

require interrupt SRQ proceiGig:j Here, the time interval is defined as the period from when

the GET trigger is completed ~until the time thatSRQ~ is set~low by the instrument when

the reading is completed.

DATA

TRiGGER

CNGET

u

TRIGGER TO SRcl 4

lb-

ON READNG DONE

I

TIME

I

Figure 21. Simplified GET-to-SRQ Interval

In order to accurately measure GET-to-SRQ times, it is necessary to monitor the ATN, DAV,

and SRQ lines with a logic analyzer. Figure 22 shows tygical waveforms for tr&egni;

unit with GET and waiting for a reading done SRQ. Note at the presence of G

by monitoring the DAV line, as activity on this line indicates that bytes are being sent-over

the data lines (one byte per spike). In this case, three spikes are evident: one each for the

listen address, GET command byte, and UNL command.

Once the instrument receives the GET, it will initiate a measurement, take all samples in

that measurement, process the reading, and then generate the SRQ. Typically, the instrument will also be serial polled (to verify the reason for the SRQ), tid this activity is also

shown on the ATN and DAV lines in Figure 22.

56

Page 53

Figure 22. GEFto-SRQ Times Showing Serial Poll and Data Transfer

PROGRAM OPERATION

Program 10 is a typical program that can be used to generate GET to reading done SRQ times.

Figure 23 is a flowchart of the program. Typical times for various sampling rates, measurement-durations, and math functions are summarized in Table 3..

Program 10 operates as follows:

1. The program first dimensions variables, assigns I/O paths, and places the instrument in

remote (lines 20-50).

2. Next, the Model l&A is serial polled in order to dear out any pending SRQ (line 60).

3. The user is then prompted to enter the desired command, and the instrument is then

programmed accordin

programmed for the 3

GET mode (T2).

4. The instrument is then triggered by sending GET (line X30), and the program enters a

loop to wait for the SRQ to occu (lines 150 and 160).

5. Once the SRQ is detected,~ the Model 194A is serial

is requested and displayed along with the serial po

6. The program then loops back (line 210) to repeat the trigger,~SRQ serial, data display process. The loop repeats indefinitely to allow the bus lines to be analyzed properly.

ly (lines 80-U). Note that channel 2 is disabled, and channel 1 is

5 OmV range (Rl), SRQ on reading done (MS), and the continuous,

oiled (line l70), and a data string

l!

byte (lines 190 and 200).

57

Page 54

58

Figure 23. Program 10 Flowchart

Page 55

Table 3. Typical GET to SRQ on Reading Done Times

# of

iample!

1000

KOO

1000

1000

1030

1000

1000

E

100

E

100

100

1000

1000

1000

1000

1000

1000

1000

Math

Function

AVERAGI

TRms

+PEAK

-PEAK

P-P

STD DEV

IN-r

AVERAGE

TRms

+PEAK

-PEAK

P-P

STD DEV

lNT

AVERAGE

TRms

+l’EAK

-PEAK

r-r

STD DEV

INT

Trigger to

SRQ on

Reading

Done

l36ms

255ms

59.5ms

59.5ms

595ms

337ms

l56ms

23m.s

145ms

14UlS

1hS

14ms

l53ms

44ms

l39ms

2.58~~

65m.s

65ms

65ms

335rns

l57ms

# of

;amples

100

z

100

100

100

100

1000 .

1000

1000

1000

E

xx0

100

100

loo

100

ii

100

Math

Function

AVERAGE

TRms

+PFAK

-PEAK

P-l?

STD DEV

INT

WERAGE

TRms

+PEAK

-PEAK

P-P

STD DEV

INT

WERAGE

‘TRms

+PEAK

-PEAK

P-P

STD DEV

INT

iigger to

SRQ on

Reading

Done

1Ei

15ms

l5ms

lzz

444m.s

248ms

347ms

l54IllS

mms

l54ms

425ms

2.49l-m

32.8m.s

?E::

238ms

23.8m.s

161.5ms

53.4ms

RUNNING THE PROGRAM

1. Connect a logic analyzer to the ATN, DAY and SRQ lines, and se up the analyzer to view

bus information.

2. Enter the program into the computer.

3. Execute the program by pressing the RUN key.

4. Ate the prompt, enter the desired sample rate, number of samples, and math function in

command form. For example, to program a rate of l@ec,’ uxx) satiples, and the average

math function enter the following: “SOJE-6NO,lOOO,Fl” Note that it is not necessary to in-

clude the X character as the program will add it to the string when it is sat to the instrument~ (you must use quotes, however because of the commas).

5. A reading will then be triggered, and the program will wait for the SRQ on reading done

to occur The instrument will be serial polled and asked to send a reading, after which

both will be displayed on the computer CRT. The loop will be repeated indefinitely, allowing you to use the logic analyzer-to measure @igger tom SRQ tiriies.

59

Page 56

Program 10. Test Program for Measuring Trigger to SRQ on Reading Done

10 systcn-init: 1

IJIM ConnandP~G01

20

30 DIM Detasi ,001

ASSIGN BM194 TO 709

40

REMOTE PM, 94

50

Ger_paII=SFOLL~BMI94 1

60

61

70 Progran-inat: !

INPUT “ENTER COMMAND :” ,CamnandB

90

OUTPUT IMi94;‘C,“gConnands&“~,~G~~~’

110

OUTPUT @Mi94~*CZT7X-

III

I20 Trig-inst: I

TRIGGER @Ml94

130

60

Page 57

APPENDIX A

Tb~7i~0,lhn0nA0n+ Cnmmanrlc

FUNCTION

RANGE

RATE

NUMBER SAMPLES

TRIGGER

DELAY

f

Fa Waveform

Average

ii TRMS

F3 +Peak

-Peak

Eg

FZO CHl-cH2

F2l CHl/CH2

RO Auto

E

Iz3

R4 2oOV

RI2 Cancel auto (stay on present range)

SO,m m=sampling rate in sec. (lE-69n~Qsec)

Sl,m

NO,m m=number of samples (1 cm ~65,535, g-bit,

mm

To continuous, talk

Tl Single, talk

T2~

T3

T4

T5 Single, X

T6 Continuous, external

l-7

T20,lll

T21,m

T22,m Continuous, -slope, level m (-200 9n c +2OOV)

T23,m

T24

T25 Single, other channel

T26 cOntinuous, immediate

T27 Single, immediate

T30 Start plotter

T31

WOim Delay in number of samples (65,536 smslE7)

Peak-to-peak

Standard deviation

Integral

32omv

3.2V

32V

m=sampliig rate in Hz (19nslE6Hz)

l~ms32,767, l6-bit)

m=measurement duration in set

(O<m~65.534E3, g-bit; 0 <m<32,766, 16-bit)

Continuous, GET

Single, GET

continuous, x

Single, external

Continuous, +slope, level m (-200 5-M s +2OOV)

Single, +slope, level m (-2OO-cm_c+20W)

Single, -slope, level m (-2OO_cmc+20OV)

Continuous, other channel

Stop plotter

NOTE: The following characters may be used as a delimiter in place of comma: ! @ # $ %

A&() = \ I < >?:; <space>

A-l

Page 58

Device-Dependent Command Summary (Cont.)

Slow Plot (XY Analog Plotter)

64k RAM Buffer

IEEE-488 Reading Buffer

m=X Output Full Scale Voltage (lcmd0)

m=Y Output Full Scale Voltage (1 <rn 510)

m=Z Output Blanking Level (l=High, O=Low)

m=XY Zoom Value (0.1911 dOO0)

m=XY Pan Value (-65,536_cm_c65,536)

et measurement buffer start