Page 1

USING THIS GUIDE

This reference and programming guide contains condensed

specifications, a summary of front panel operating controls.

and IEEE-488 programming commands and examples for

the Models 194A. 1941, and 1944A. It is intended to provide a quick reference to the many available features of your

instrument as well as the many programming commands

available to control the instrument over the IEEE-488 bus.

Because of the limited amount space available in this guide.

many details abourinstrument operation will not be found

here. Refer to the Model 194A Instwction Manual for

aspects of instrument operation not covered in this guide.

This guide describes the following aspects of the Model

194A:

l Front panel operation including XY mode.

l A description of mathematical functions.

* Input and output signal connections.

l IEEE-488 programming information, including commands,

data and status formats. and exampkprograms for typical

COntrOllers.

01989, Keithley Instruments. Inc.

28775 Aurora Road

Cleveland, Ohio 44139

Document Number: 194A-900-01 Rev. A

1

Page 2

CONTENTS

CONDENSED SPECIFICATIONS .~. . . 4

ENGlNEERlNG “NITS CONVERSION . .~. .~.~. ~.._5

SAFElYPRECAUTIONS...................... 6

FRONT PANEL FEATURES AND OPERATlON.. . 7

Display

Annunciators

Genera, Display Messages

Shift Functions

Mathematical Functions

Ratio and Difference Modes

Range

Data Entry

Programmable Parameters

Rate and Samples Programming

Recalling Data

Trigger

Channel Selection

Input Coupling

Zero

Filter

FRONT PANEL PROGRAMS., _~_ _~_ 25

SetUPstatus

Reset

XY Mode

INPUT AND OUTPUT CONNECTIONS . 3,

A/D Module InpuffOutput Connections

Analog Output Connections

Enernal Clock

IEEE-466 PROGRAMMING. _, 36

Device-dependent Commands

TRANSLATOR MODE.. _. _ .~__ _ _~~ 56

CONTROLLER PROGRAMS t t __ _ __ 56

IBM XT or PC (with CEC Interface1

Hewlett-Pock& 300 Series Compac

ASCII CHARACTER CODES AND IEEE-466

MULTILINE INTERFACE COMMAND MESSAGES 62

3

Page 3

CONDENSED SPECIFICATIONS

,

I

INPUT IMPEDANCE: 1MO in parallel with less than 47pF.

MAXIMUM ALLOWABLE INPUT: 260” peak, 2 x 10’” Hz.

MAXIMUM SAMPLING RATE: lMHz et 6.bit resolution;

100kHz et 16.bit resolution.

MATH FUNCTIONS: Average, Peak, Peak-to-Peak, TRMS,

Standard Deviation, Integral, Waveform.

FRONT PANEL PROGRAMS: IEEE-466 Address, Self Test,

Digital Calibration, Calibration Storage, X Output Full Scale,

Y Output Full Scale, Z Output Blanking Level,

DISPLAY Fourteen digit alphanumeric LED display.

RANGING: Manual or autoranging.

CONNECTORS: All I/O connectors are BNC except Real

Trme Output IDS-261 and IEEE-466 connectors.

4

Page 4

ENGINEERING UNITS AND

SCIENTIFIC NOTATION

CONVERSION

Prefix

pico“anOmicromilli-

kilomegagigaterapeta-

Engineering

Symbol

Scientific Notation

I

5

Page 5

SAFETY PRECAUTIONS

The following safety precautions should be observed before

using the Model 194A:

1. Before operation. ground the instrument through-a properly earth grounded power receptacle

2. Do not exceed 30” rms between input low and earth

ground.

3. Do not exceed the maximum allowable input 8s defined

in the condensed specifications section of this guide

4. Before servicing. disconnect the Model lg4A from the

power line and all other equipment.

5. Do not touch any terminals while the instrument is turn-

ed on or connected to any other equipment or sources.

Page 6

FRONT PANEL FEATURES

AND OPERATION

DISPLAY

DESCRIPTION

The Model lg4A display consists of fourteen 14.segment

LED units which display both instrument readings as well

as many messages to augment the variow operational

modes. The basic display format for readings includes the

voltage value, units ImV or VI. mathematical function (for

example AVG for average) and channel number (1 or 2).

Channel 2 is available only for those units equipped with

a Model lg44A AID module in the CARD 2 location.

The display can be operated singlechannel or dualchannel,

as selected with the CHANNEL button. The selected thannel also dictates which channel is affected by pressing other

buttons. Most other modes cannot be changed when the

display is in the dual-channel mode

DISPLAY EXAMPLES

Typical examples for the display modes include:

Channel 1 Average Reading: -1.2500 V AVG 1.

Channel 2 TRMS Reading: 0.3450 mV RMS 2.

Dual Channel Reading: -1.2500 0.3450

Page 7

ANNUNCIATORS

Front panel annunciators indicate when a number of front

panel modes are selected as described below:

IEEE-488 STATUS: The TALK, LISTEN, and REMOTE indicators show when the instrument has been placed in

those respective modes via programming commands sent

wer the IEEE-488 bus. These indicators are not operational

during front panel operation.

ZERO: Indicates when a baseline measurement is being subtracted from subsequent measurements.

FILTER: Shows when either the 5OkHz or 5OOkHr analog

filters are enabled.

SGUCONT: Indicates when the instrument is in the single

or ccmtinuou* trigger.

SLOPE: Shows whether the instrument will be triggered on

the rising or falling edge of an input signal waveform.

‘CPLG: Indicates BC or dc input coupling. Ground coupling

is selected when both indicators are off.

AUTO: Shows when the instrument is in the autorange

mode.

SHW Shows when the shift mode has been enabled by

pressing the shift key. Shifted modes are marked below the

respective control buttons.

RECALL: Indicates when the recall mode is in effect. This

mode allows access to individual samples in the measurement buffer.

8

Page 8

GENERAL DISPLAY MESSAGES

Display messages that may occur during general front panel

cpererlcn are summarimzi below. The unit also has a number

of specific messages associated with the various operating

modes, as described in the instruction manual.

MESSAGE DESCRIPTION

OFLO

SHIFTLESS KEY

NMSR TOO SMALL

iwmi7 mo LARGE

Overrange input applied for at

least one sample.

Shift function invoked for key

not having one.

Too small a value keyed in during data entry.

Too big a value keyed in during

data entry.

SHIFT FUNCTIONS

Page 9

DESCRIPTION

Many of the front panel keys have a secondary function

which is placed intoaffect by pressing theSHIFT key before

pressing that particular button. Each shifted function is

listed below the key in question. For example, pressing

SHIFT ZERO VAL allows a baseline value to be keyed in from

the front panel. While the shift function is enabled. the

associated indicator will be on. Pressing a key which does

not have a~shifted function will result in the following display

message:

SHIFTLESS KEY

MATHEMATICAL FUNCTIONS

DESCRIPTION

The Model 1g4A has a number of mathematical functions

that can be applied to the measurement. If the instrument

10

Page 10

is in a continuous trigger mode. a single math function, Once

selected, can be applied to successive measurements. In

a single trigger mode, a variety of different math functions

can be applied to a single measurement. Each mathematical

function can be enabled by pressing SHIFT followed by the

corresponding key.

OPERATION

WAVEFORM: Displays the individual sample occurring at

the trigger point, or thesample as close as possible to the

trigger point. Example: 1.2345 V DC 1.

PK TO PK: Displays the peak--to-peak value of the measurement, which is calculated by subtracting the most negative

sample from the most positive samples

Eample: 2.3410 V P-P 1.

STD DEW Displays the standard deviation of the measurement, which shows how far the samples deviate from the

average of the measurement. Example: -12.341 V STD 1.

INTEGRAL Displays the integral of the measurement, which

is the area under a curve bounded by the measurement

amplitude and the measurement duration.

Example: 800.23 VS 2.

AVG: Shows the average of the measurement, which is

calculated by dividing the sum of all the samples ~bv the

number of sample. Example: -16.225 V AVG 1.

TRMS: Displays the true rms value of the meas~rment. Ex-

ample: 31.800 V RMS 1.

PEAK: Shows the most positive or mrxt negative sample

in the measurement. Example: 1.1220 V PK+ 1. Press

repeatedly to alternate between positive and negative peak.

Page 11

RATIO AND DIFFERENCE

MODES

(

0 0~0

00000

DESCRIPTION

The ratio and difference modes allow you to divide the chatnel 1 reading by the channel 2 reading or to subtract the

channel 2 reading fmm the channel 1 reading. In order to

use either of these modes, the optional Model 1944A A/D

Module must be installed in the CARD 2 location. If there

is no second channel installed, pressing either CHl-CHZ or

CHl+CHZ module installed will result in the following

message:

NOAiDINCH2

OPERATION

CHlrCH2 IRatio): To display the ratio between the two

channels, press SHIFT CHltCH2. The instrument will then

display the ratio as in this example: 1.2367 V l/2.

12

Page 12

CHI-CH2 (Differencel: To display the difference between

the two channekpress SHIFT CHl-CHZ. The instrument

will then display the difference between the two channels.

as in this examole: 2.4000 V 1-2.

RANGE

DESCRIPTION

The ranging controls give you control over sensitivity of the

measurement The range may be selected either on an

automatic or manual basis. When using manual ranging,

the lowest rangepossible without overranging the instru-

ment should be used to maximize accuracy and resolution.

13

Page 13

OPERATION

AUTO: The AUTO button toggles the instrument between

auto and manual ranging. The AUTO indicator will be on

when in autoranging.

Uprange: Pressing uprange moves the instrument to the

next higher range until the highest (2OOVl range is reached, Uprange also cancels autorange if that mode is presently

enabled. Uprange is also used with various other functions

such as data entry and recall.

Downrange: This key moves the instrument to the next

lower range when pressed until the lowest I32OmVl range

is reached. Downrange also cancels autorange if enabled.

and it is used with various other functions such as data entry and recall.

14

Page 14

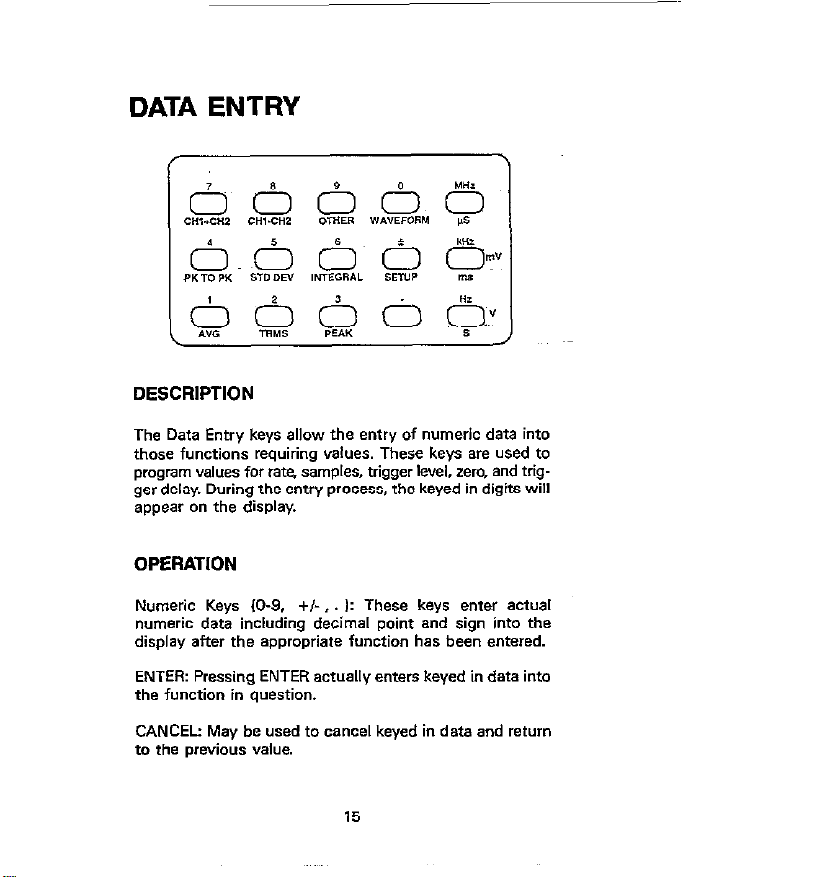

The Data Entry keys allow the entry of numeric data into

those functions requiring values. These keys are used to

program values for rate. samples, trigger kvel. zero, and trig

get delay. During the entry process, the keyed in digits will

appear on the display.

OPERATION

Numeric Keys (O-9. +/-,. I: These keys enter actual

numeric data including decimal point and sign into the

display after the appropriate function has been entered.

ENTER: Pressing ENTER actually enters keyed in data into

the function in question.

CANCEL: May be used to cancel keyed in data and return

to the previous value.

15

Page 15

Units Keys (MHz, kHz, Hzl: Determines the type of units

to be keyed in. Voltage or time or frequency units are

automatically chosen by the selected function. Pressing a

units key automatically enters the displayed data.

FRED/TIME: This key toggles the instrument between time

t@ec, msec, sl and frequency (MHz, kHz, Hz1 units. For example, sampling rate may be entered either as time interval or sampling frequency units.

Cursor Control: During the data entry process. the digit affected by pressing a numeric keey will be indicated by a

flashing segment or digit. This cursor can be moved left or

right with the downrange or uprange buttons. respectively.

PROGRAMMABLE

PARAMETERS

Perameten to be programmed with the Date Entry keys are

summarized below, along with limits and resolution of each

parameter.

16

Page 16

FUllCtkJ~

Limits

bsohJtion

RATE

SAMPLES

DELAY

LEVEL

ZERO “AL

x output

Full Scale*’

Y Output*~

Full Scale

Time Irsec-lsec

Frequency lHz-1MHz

No: l-65.535*

lime: Opsec-65,534sec’

NO Samples: -65,536 to

10’

‘lime: -65,536 to 10’sec

*20CW

*2ocw

l-1OV nominal

l-1OV nominal

RATE AND SAMPLES

PROGRAMMING

0.1 rrjec

HZ

Samples

0.1 *ec

Samples

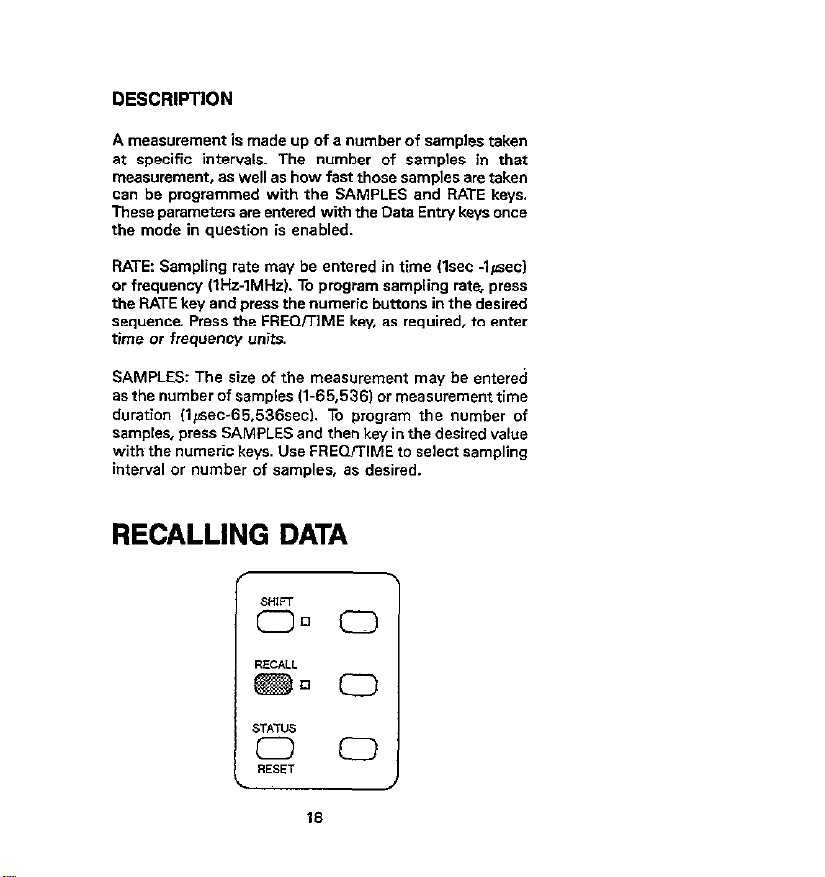

Page 17

DESCRIPTION

A measurement is made up of a number of samples taken

at specific intervals. The number of samples in that

measurement, as well as how fast those samples are taken

can be programmed with the SAMPLES and RATE keys.

These parameters are entered with the Data Entry keeys O~CB

the mode in question is enabled.

RATE: Sampling rate may be entered in time (Isec -lpecl

or frequency (IHI-1MHr). To program sampling rate, press

the RATE key and press the numeric buttons in the desired

sequence. Press the FRECUTIME key, as required, to enter

time or frequency units.

SAMPLES: The size of the measurement may be entered

as the number of samples 11-65.536) or measurement time

duration il#ec-65,536secl. To program the number of

samples, press SAMPLES and then key in the desired value

withy the numeric keys. Use FREQiTlME to select sampling

interval or number of samples, as desired.

RECALLING DATA

Page 18

DESCRIPTION

Recall allcw you tc display individual samples within the

measurement. This mode is entered by using the RECALL

button. Once in the recall mode, individual samples may be

accessed on a sequenr,al or random basics.

OPERATION

To enter recall, simply press the RECALL button. While in

this mode, the RECALL indicator button will be on. To access individual samples, either use the uprange or

downrange keys to access individual samples, or key in a

specific sample number and press the ENTER key.

TRIGGER

DESCRIPTION

The Model 194A may be triggered in a variety of different

ways: with the TRIGGER button. with an input ~pulse ap-

plied to the TRIGGER IN jack, from the other channel, or

from the input signal. When triggering from the input signal,

the slope and trigger level can be programmed.

19

Page 19

OPERATION

SOURCE: To select the trigger scum?, press SOURCE

repeatedly until the desired mode is displayed: front panel

(TRIGGER), input signal, external. or other channel. Press

CHANNEL to save the selected source.

SGUCONI A measurement sequence can beperformed on

a continuous or single basis. In a continuous mode, the in-

strument repeatedly arms the A/D for the next trigger

measurement without requiring additional triggers. In the

single mode, B separate arm stimulus is required for each

measurement. SGLICONT toggles the instrument between

these two modes, as indicated by the respectiwindicator.

TRIGGER: When selected with the SOURCE key,pressing

this keey will initiate a continuous or single measurement,

depending on the selected mode

SLOPE: Rising or falling edge triggering may be selected with

the SLOPE key only when input signal triggering is selected.

The annunciator next to the key indicates the selected mode

LEVEL: When triggering from the input signal, the actual

voltage level et which the unit is triggered may be selected

with the LEVEL key. Once this mode is entered, the voltage

is keyed in with the Data Entry keys.

DELAY Delay selects the number of samples between the

trigger and the first sample A positive or negative delay

may be selected. Delay may be entered in number of

samples or actual time by using the FREOrrlME key.

20

Page 20

CHANNEL SELECTION

DESCRIPTION

For dualchannel units, the CHANNEL button allows you to

select one of three display modes: channel 1, channel 2,

or dual-channel display. For the two single-channel modes,

the displayed channel also determines which channel will

be affected by pressing other keys. In the dual channel

mode, most other buttons are inoperative

INPUT COUPLING

21

Page 21

DESCRIPTION

The Model 194A has three available forms of input cowl-

ing: ac, de, and ground. The selected mode of coupling is

selected with the CPLG key and indicated by the respec-

tiw indicaton. When ground coupling is selected. both ac

and dc will be off.

OPERATION

The input circuit is configured as follows for the three

modes:

DC: A straight-through dc signal path is established.

AC: Instrument response is down 3dB at 2Hz.

Ground: The high and low terminals of the input amplifier

are shorted together.

ZERO

Page 22

DESCRIPTION

Zero allows a baseline measurement to be subtracted from

subsequent measurements. The baseline can be obtained

either from an applied signal, or keyed in with the data entry keys. Once a baseline is established, it will be subtracted

from measurements until disabled. Any such zero will be

subtracted from the from the number to be displayed.

OPERATION

Zeroing an Applied Signal. Connect the signal to act as a

zero baseline with zero disabled and press the ZERO key.

Apply the measured signal and take readings es usual. The

displayed velue will be the difference between the applied

signal and the stored baseline value.

Keying in the Zero Value. To key in the baseline from the

front~panel,~press SHIFT ZERO VAL key in the desired value

then press O\lTER. The baseline will remain in effect as long

as the ZERO indicator is on.

FILTER

23

Page 23

DESCRIPTION

The Model 194A has two available low-pass analog filters

with -3dB points of 5OkHHr and 5OOkHz. These filters are

selected with the FILTER buttton. When either the 5OkHz

or SOOkHz filters are enabled, the FILTER indicator will be on.

OPERATION

To select one of the filters. simply press the FILTER button

until the correct display message is shown 60kHz SOOkHz,

or off). When the desired filter is shown, press the CHANNEL key to return to the previous mode.

24

Page 24

FRONT PANEL PROGRAMS

0 0~0.0 0

00000

DESCRIPTION

The OTHER key allows selection of a number of front panel

program modes as follows: IEEE-488 address; self test;

digital calibration: NVRAM storage; X output full scale ahe;

Y output full scale value; and Z output blanking level. These

programs are numbered O-S, and are entered by pressing

the OTHER key. Once this mode has been entered. you can

either key in the appropriate digit, or use the uprange and

downrange keys to scroll through available programs.

OPERATION

IEEE-488 Address (SHIFT, OTHER, Ok Once entered. you

can program a valid primary address (O-301 by using the

Data Entry or oursOr keys and then pressing enter.

Self Test (SHIFT. OTHERV: Performs a self test on internal

instrument circuitry and will return appropriate error

messages.

25

Page 25

Digital Calibretion (SHIFT. OTHER, 21: Digital calibration,

which requires specialized test equipment. is performed by

this program.

NVRAM Storage ISHIFT.OTHER.3): Stores calibration con-

stants in NVRAM once the unit is calibrated.

X Output Full Scale (SHIFT.OTHER,4): Programs the maximun voltage at the X analog output jack.

Y Output Full Scale (SHIFT. OTHER, 51: Sets the maximum

voltage of the Y analog 0utpuL

2 Output Blanking Level (SHIFT. OTHER.6): Determines the

blanking level at the 2 analog output.

SETUP

ooo@o

I’

DESCRIPTION

Setup allows you to store up to two different instrument

configurations in NVRAM. These setups can then be later

26

Page 26

recalled. thus simplifying instrument configuration for a

variety of different test procedures.

OPERATION

Saving Setups: Select the channel !or scanner) to be configured and program the desired modes. Press the SETUP

button twice followed by the desired setup number W2).

Press ENTER to store the selected configuration. Setup 0

contains the fectoly defaults and Cannot be reprogrammed.

Recalling Setups: Press SETUP followed by the desire setup

number. Press the ENTER key to recall the desired setup

STATUS

DESCRIPTION

The current instrument status for both channels. ten be

determined by recalling instrument status with STATUS key.

27

Page 27

The returned status velues will depend on the jxesent

selected operating modes.

OPERATION

To access instrument status, simply press the STATUS key

once, the unit will display the following stetos parameters

in the following order, moving through the list et about one

item per second:

Zero value

Filter status (50kHz or SOOkHzj

Trigger *cum*

Wgger mode

Trigger delay

migger level

Sample rate

Measurement size

Maximum semple rate for each resolution

RESET

DESCRIPTION

The RESET key allows wu to quickly return the instrument

to the power-on default configuration (setup 1). Both A/D

channels will be effected by this key.

OPERATION

lb simulate a power on reset, simply press SHIFT RESET.

28

Page 28

XY MODE

DESCRIPTION

The XY mode allows you to plot your data on a display

device such es a CRT, o*cilloscope, or plotter. Connections

to these plotting devices is made through* the X, Y, end

2 analog output jsck on the rear panel. Various scaling factom cm be applied to the data before being plotted.

OPERATION

XY MODE: Enters the XY mode and ellows the *election

of the type of plotting device: CRT, oscilloxopa or plotter.

XY DATA: Allows you to select the source of data to be

displayed. individual samples from the measurement buffer, or readings from the display buffer for either channel

1 or channel 2.

XY TRIG: Used to *tart and stop the analog output

sequence.

29

Page 29

XY ZOOM: Provides a methad of scaling data located in the

buffer to the display window.

XY PAN: Controls which data point is the first displayed

in the window.

30

Page 30

INPUT AND OUTPUT

CONNECTIONS

A/D MODULE INPUT/OUTPUT

CONNECTIONS

DESCRIPTION

Each A/D module has several input D, output connectors

on the rear panel for voltage signal input, real time output,

and trigger input and output. Each of these connectors is

briefly described below.

OPERATION

VOLTAGE INPUT: All voltage input signals are applied to this

SNC jack for processing and AID conversion. Note that the

maximum input voltage is 25OVps~ak, 2 x 10,‘V Hz. The

maximum cmnmon mode voltage is 30%

REAL TIME OUTPUT A/D data at the sampling rate may

be read via this output. Data can be transmitted in S-bit

or %-bit format This connector is also used to select between internal and external sample rate clocks.

TRIGGER IN: A negative*oing pulse at TTL levels llO$c+ec

minimum) can be applied to this jack to one trigger a

measurement. External triggering must be selected with the

SOURCE key before this connector is active

31

Page 31

TRIGGER OUT A negative going lO#sec pulee et TTL levels

will appear et this jack when a valid meaeurement trigger

occurs. The pulse will occur regardless of the selected trig-

ANALOG OUTPUT

CONNECTIONS

DESCRlPTlON

The analog output includes three jacks located on the rear

panel. labeled X, Y, and 2. Signals appearing at these jacks

are controlled by the XY mode. Each jack is a standard BNC

m”“eCtOL

X OUTPUTr This signal, which provides time information,

should be used as en X-axis signal for a plotter or CRT.

Y OUTPUT The Y output provides amplitude about the

verlo~s samples, and should be used as a Y-axis signal for

the CRT and plotter, and vertical input information for an

oscilloscope.

Z OUTPUT: The Z output provides a blanking pulse for a

CRT. en external triggerpulse for an oeoillosoope, of a pen

up signal for e plotter.

32

Page 32

EXTERNAL CLOCK

DESCRIPTION

The external clock jacks provide methods of synchronir-

ing two or more Model 194s together to a common time

base. as described below.

OPERATION

CLK IN: An externally generated 1OMHz clock et TTL levels

can be applied to this input to synchronize sample taking

to an external time base. Detection and switching is

a”tOmatic

CLK OUT: Normally. the internal 1OMHz clock (TTL levels1

of the Model lg4A will appear et this output. If the unit

Is operating with en external time base, the external clock

rate will appear et CLK OUT instead.

Synchronizing units: To synchronize units, connect the CLK

OUT of the master unit to the CLK in of the dave unit. Other

unite may be daisy chained in a similer manner.

33

Page 33

IEEE-488 PROGRAMMING

DEVICE-DEPENDENT COMMANDS

FUNCTION

FO

Fl

F2

F3

F4

FS

FS

F7

F20

F21

Waveform bmple at trigger

point)

Average

TRMS

+ Peak

- Peek

Peak-to-oeak

Standard deviation

Integral

CHI-CHZ

CHlICH2

Auto

320mV

3.2V

32v

2oov

Cancel auto lst*y on present

range)

Page 34

TRIGGER

TO

n

T2

T3

T4

T5

T6

T7

T20.m

T21.m

T22.m

T23.m

124

T26

T26

T27

T30

T31

Continuous, talk

Single, talk

Continuous. GET

Single, GET

Continuous, X

Single, X

Continuous, external

Single, external

Continuous, + slope. level m

i-ZOOrmr+2OOV)

Single, + slope, level m

(-200~ms+200Vl

Continuous, - slope, level m

(-200sm~+200Vl

Single, - *lope, level m

I-200~m~+ZOOV)

Continuous, other channel

Single, other channel

Continuous, immediate

Single, immediate

Start plotter

Stop plotter

36

Page 35

De& in set ~-65.536~m_clE71

‘. ,,I, .,,, 2 ‘i,

( DATA FORMAT

GO

Gl

G2

G3

G4

ii:

G7

I

~,,. ,“...Y.. .,.,., :~ :~ ,~,,. ,,

‘ASCII; 1 rdg. prefix on, suffix off

ASCII. 1 rdg, prefix off, suffix off

ASCII, 1 rdg, prefix an. suffix on

*SC11. n rdgs. prefix on. suffix off

ASCII. n rdgs. prefix 0% suffix ofl

ASCII, n rdgs. prefix oh suffix on

Binary, n rdgs. prefix off, suffir

Off

Binary, n rdgs Ibyte countI. p~refix

off. suffix off

37

Page 36

02.2

02.3

02.4

02.5

03.0

03.1

03.2

03;3

04.m

05.m

06.m

07.m

06.m

09

scope mode

Future expansion

Slow plot (XY analog plotters

Strip chart

Measurement buffer

64k RAM buffer

Display readings

IEEE-488 reading ~buffer

m-X output full *tale voltage

(1 smsl0)

m=Y output full scale voltage

(1 smrlo)

m=Z output blanking level

U=high, O=loW

m=XY zoom Yal”e

(0.1 rmslooo)

m=XY pan value

I-65.536ams65.5361

start plotter

B3.m

I

pointer to m.

Set reading buffer start pointer to

tn.

36

I

Page 37

READING BUFFER

QO

Ql

Q2

flLTEi7

PO

F

F1

F2

Reading buffer off.

Linear reading buffer on.

Circular reading buffer on.~

Filter off

500kHz filter

50kHz filter

Z3.m

24

Z5.m

INPUT COUPLING

IO

I1

12

Use value m as baseline value

(-200~ms+200V)

22 + Zl

23 +~Zl (-ZOOsms+ZOOVI

DC coupling

AC coupling

Ground coupling

39

Page 38

STATUS

uo

Ul

u2

u3

u4

u5

U6

U8

us

UlO

Ull

u12

Error status

Data *muus

Zero IZ) parameter

Delay (WI parameter

Number samples (NI parameter

Sample rate 61 parameter

Trigger levsl

Measurement buffer start pointer

Measurement buffer end pointer

Reading buffer start pointer

Get Translator list

M32

Error

40

Page 39

TERMINATOR

Ylll

Yn,m

Y (DELI

RECALL

A0

Al

A2

Program m as single terminator

Program mn as dual terminator

No terminator

Recall factory setup

Recall setup 1

Recall setup 2

41

Page 40

HIT SUTTDN

Hi7 Act as if button n (l-381 has been

DISPLAY

DaaaaX

DX

SELF TEST

Jl Ul self test byte =1: fail

EXECUTE

X Execute other devicedependent

pressed

Display ASCII characters aaaa 114

maximum)

Return to normal display mode

commands

42

Page 41

Figure 1. SRQ Mask and Status Byte Format

Figure 2. ASCII Data Format (GO to G5)

43

Page 42

Page 43

45

Figure 3. Binary Data Format (Cont.)

Page 44

FUNCTION (FM)

OO=WAVEFORM

Ol=AVERAGE*

OZ=TRMS

03=+PEAK

04=-PEAK

06=PEAK TO PEAK

06=STANDARD DEVlATlON

07=INTEGRAL

20=CHl-CH2

21=CHl/CH2

RANGE (Ann)

O=AUTO’

1=32OmV

2=3.2V

3=32V

4=2OOV

TRIGGER (mn)

OO=CONTINUOUS, TALK

Ol=SINGLE. TALK

OZ=CONTINUOUS, GET

03=SINGLE, GET

04=CONTINUOUS, X

05=SINGLE, X

OB=CONTINUOUS, EXTERNAL

07=SINGLE, EXTERNAL

ZO=CONTINUOUS, +SLOPE

21=SINGLE, +SLDPE

Figure 4. UO Status Word Format

46

Page 45

22=CONTINUOUS, -SLOPE

23=SINGLE, -SLOPE

24=CONTINUOUS, OTHER CHANNEL

25=SINGLE, OTHER CHANNEL

26=CONTINUOUS,~ IMMEDIATE*

27=SlNGLE, IMMEDIATE

3O=START PLOTTING

31=STOP PLOTTING

FILTER (Pn)

O=OFF’

1=600kHr

2=50kHz

ZERO (Zn)

O=DISABLED*

1 =ENABLED

2=SAVE MEAS

S=USE VAL.

4=Zl + 22

5=Zl f-Z3

EOI, BUS HOLD OFF (Kn)

O=EOI, HOLD OFF’

l=NO EOI, HOLD OFFS

2=EOI, NO HOLD OFF

3=NO EOI, NO HOLD OFF

BUTTON PRESSED (Hnn)

OO=NONE

01 =ZERO

OZ=FILTER

03=TRIGGER

04=SGL/CONT

05=SOURCE

06=DELAY

Figure 4. UO Status Word Format (Cont.)

47

Page 46

07=SLOPE

OII=LEVEL

09=SCAN

lO=CPLG

ll=SAMPLES

lZ=RATE

13=LOCAL

14=CHANNEL

15=AUTO

16=%

l7=.,

18=SHIFT

lS=RECALL

2O=sTATUS

Zl=ENTER

ZZ=CANCEL

ZB=FREQ/TIME

24=7

25=4

26=1

27=8

28=5

29=2

3O=S

31=6

32=3

33=6

34=*

35=*

36=MHz

37=kHr

38~Hr

Figure 4. UO Status Word Format (Cont.)

48

Page 47

INPUT COUPLING (In)

O=DC COUPLING’

,=AC COUPLING

Z=GROUND COUPLING

RECALL SETUP (A”)

O=FACTORY SETUP’

l=SETUP 1’

Z=SETUP~ 2

SAVE (Ln)

l=SAVE SETUP I*

2=SAVE SETUP 2

4=CALlBRATE USING VALUE

5=STORE CAL IN NVRAM

READING BUFFER (Qn)

O=DISABLED*

l=LINEAR BUFFER

2=CIRCULAR BUFFER, OVERWRITE

DATA FORM&T IGn,

O=ASCII. PREFIX ON, SUFFIX OFF, ,RDG

l=ASCII, PREFIX OFF, SUFFlX OFF, ,RDG

2=ASCII, PREFIX ON, SUFFlX ON, IRDG’

3=ASCIL PREFIX ON. SUFFIX OFF. n RDGS

4=ASCII. PREFIX OFF, SUFFIX OF+, n RDGS

5=ASCII. PREFIX ON, SUFFIX ON, n RDGS

B=BINARY, PREFIX OFF, SUFFIX OFF

7=8INARY, PREFIX OFF, SUFFIX 0FF;BYTE COUNT

SELF TEST (Jnn)

CODE/MEANING

OO=NO ERROR

Ol=SELFTEST COMPLETE, NO ERROR

(GOES TO 00 IJO READ]

Flgure 4. UO Status Word Format (Cont.)

49

Page 48

02=NOT USED

03=NOT USED

04=NOT USED

05=NOT YSED

06=NOT USED

07=NOT USED

OB=RAM ERROR ON MOTHERBOARD

09=ROM ERROR ON MOTHERBOARD

lX=A/D ERROR ON CHl

(SEE TABLE BELOW FOR X MEANING)

2X=A/D ERROR ON CH2

ISEE TABLE BELOW FOR X MEANING)

A/D ERROR CODES

O=NOISY AID

l=NOT USED

2=INOPERATIVE CAL

3=NOT USED

4=NOT USED

5=TIMEBASE ERROR

fi=NOT USED

7=RAM ERROR

CHANNEL (Cm)

Ol=CHANNEL I*

02=CHANNEL 2

12=COMPOSiTE CHANNEL

SRQ (Mnnn)

OOO=DlSABLED’

OOl=OVERFLOW

002=DATA

004=HIT BUTTON

OOB=READING DONE

O,S=~READY

032=ERROR

ADJUSTMENT

Figure 4. UO Status Word Format (Cont.)

50

Page 49

TERMINATOR (Ynnnnnn)

nnnnnn=YlASCII)

000000=No TERMINATOR

O,SOlO=CR LF*

TERMINATOR

DEFAULT CR LF

Figure 4. UO Status Word Format (Cont.)

Page 50

BUTTON NUMBERS USED BY HIT COMMAND

AND RETURNED IN UO STATUS

0 NOW

1 ZERO 22

2 Flu-m

3 TRIGGER

: SGL/CONT SOURCE

6 DELAY

7 SLOP&

8 EE

9

10 CPLG

11 SAMPLES

12 RAT?2

I3 LOCAL

14 ChxNNEL

I5 Au-r0 E

16 uP=JW

I7 DOwnrange

18 SHFl

RECALL

I9

20 STATUS

21

28

24

25 26

27

28

29

80

31

32

33

84

37

38

52

Page 51

53

Figure 5. Ul Status Word Format

Page 52

54

Page 53

Figure 7. U3-Ull Status Word Formats

55

Page 54

TRANSLATOR MODE

DESCRIPTION

The Translator mode allows you to substitute English-like

words in place of device-dependent commands or commands strings. For example the word SAMPLES could take

the place of the command NlOOOX, which programs the

instrument to take 1000 samples. A single word can also

replace a group of commands at one time For example. the

word SETUP1 could be used to replace the following cornmand string: FlS+lOON250W+-25Z1P2X.

RESERVED WORDS AND SYMBOL

Tmnslator resewed words and symbol are listed~below, along

with a brief description of each word.

Reserved Word Description

ALIAS

NEW

OLD

LIST

FORGET

Define Translator words. enable

Translator.

Enable Translator, combine words.

Disable Translator.

Get list of Tmnslator words from

instrument.

Purge Translator words.

Terminate Translator command

string.

56

Page 55

EXAMPLES

“ALIAS SETUP1 ROFlX ;* - Defines the word SETUP! in

place of ROFlX.

“ALIAS TE’34 N1000S+1010X ;* - Defines TEST4 in place

of N1000S+1010X.

57

Page 56

CONTROLLER PROGRAMS

The following programs have been supplied as a simple aid

to demonstrate basic programming techniques and are not

intended to suit specific needs. Each program allows you

send a device-dependent command string to the instrument

and obtain Andy display an instrument reading string. The

returned data is an ASCII string variable of the form:

NAVG+1.2345 CR LF

Here, CR LF represents the default carriage return, line feed

terminator and will not normally be displayed.

A note included with each program indicates modifications

necessary to provide a numeric variable of the form:

11.2345

Programs for the following contmllers are included:

IBM PC or Xl (with CEC IEEE-488 interface).

Hewlett-Packard 300 series computer running BASIC,

58

Page 57

IBM XT or PC (with CEC Interface)

Page 58

HEWLETFPACKARD SERIES 300

The following program sends a command string to the

Model 194A from a Hewlett-Packard Model 310 computer

and displays the instrumsnf reading string on the computer

CRT. The computer must be equipped with the HP82937

GPIB Interface and HP BASIC 4.0

DIRECTIONS

1. Using the front panel program feature, set the primary

address of the Model 194A to 9.

2. With the power off. connect the Model 194A to the

~HP82937A GPIB interface installed in the 9816 computer.

3. Type EDIT and press the EXEC key.

4. Enter the lines in the program below, using the ENTER

key after each line

6. Press the 9816 RUN key and type in the desired command string at the command prompt. For example, to

place the instrument in the autorange and average modes,

type in ROFIX and press the ENTER key.

6. The instrument reading string will then appear on the

CRT. A typical display is: DAVG+1.2345.

60

Page 59

PROGRAM COMMENTS

IBRE”OTE789 Place 194A in remote

20 INPUT“ COFiMClND Prompt for and input command.

STRING”;A*

30 OUTPU*09;** Address 194A to listen, send

40 ENTER 709; BB Address 194A to talk, input

string.

readina.

Display reading string.

Repeat.

Page 60

ASCII Character Codes and

IEEE-488 Multiline Interface

Command Messaaes

Decimal Hexadecimal ASCII I

0 00 NUL

1 01 SOH GTL

2 02 8Tx

3 03

4 04

6 05

ETX

EOT

ENQ

SDC

PPC

; 06 07

8 08

9 09

10 OA

11 08

12 oc FF13 OD CR

14 OE so

15 OF SI

16 10 DLE

17 DC1

24 18 CAN

26 19

26 IA

28 1c

27 18

29 ID GS

30 lE RS

ACK 8EL

8S

HT

LF

VT

Z

GET

TCT

LLO

DCL

PPU

SPE

SPD

Page 61

hAmal Hexadecimal ASCII IEEE-488 Message’

32 20 ASP MLAO

33 21 I MLAl

34 22 ” MLA 2

ii ii

39 ~27

40 28

41 29

42 2A

43 43 26 26

44 44 2c 2c

46 46 2D 2D

46 46

47 47 2F 2F

48 48 30 30

49 49 31 31

50 50 32 32

z: z:

53 53 35 35

54 54 36 36

66 66

56 56

57 57 39 39

58 58 3A 3A

59 59 38 38

60

61

62 3E > MLA 30

63

2E 2E

33 33

34 34

,“;: ,“;:

;;

3F

# MIA3

?i MLA MLA 4 5

& MLA 6

i

1 MLA 9

’ _ MLA10

+ MIA 11

i MLA MLA 14 15

0 MLA16

1 MLA 17

2 MLA 18

3 MLAIS

4 MLA 20

5 MLA 21

6 MLA 22

~7 MLA 23

8 MLA 24

9 MLA 26

;

= MLA 29

? UNL

MLA7

MLA 8

MLA 12

MLA 13

MLA 26

MLA 27

MLA 28

Page 62

Decimal Hexadecimal ASCII IEEE-468 Message*

64 40 f MTA 0

65 41 MTA 1

66 42 B MTA 2

67 43 C MTA 3

68

69 45

70 46

71 47

74 4A

75 48

76 4c

77 4D

78 4E

2

81

62 52

63

84 64

87 57

88 5*

44

48

49

4F

~~ 50

51

53

D MTA 4

E MTA 5

F MTA 6

ii MTA MTA 7 8

I MTA 9

J MTA 10

K MTA 11

L MTA 12

M MTA 13

N MTA 14

0 MTA 15

P MTA 16

Q MTA 17

R MTA 18

S MTA 19

T MTA 20

U MTA 21

V MTA 22

W MTA 23

X MTA 24

Y MTA 25

2 MTA 26

i MTA MTA MTA 28 29 27

A MTA 30

UNT 95 5F

Page 63

leclmal Hexadecimal ASCII IEEE-488 Message’

96 60

97 61

98 62

99 63

100 64

101 65

102 68

103 67

104 68

105 69

106

107 66 :

108 6C I

109 6D m

110 6E n MSA 14,PPE

111

112

113

114

115

116

117

118

119

120

12,

122

123

124

125

126

127

ETA

6F

70

71

72

::

76

76

:;

79

7A

76

7c

7D

7E

7F DEL

MSA O.PPE

MSA 1,PPE

MSA 2,PPE

MSA 3,PPE

MSA 4,PPE

MSA 5,PPE

MSA 6,PPE

MSA 7,PPE

MSA 8,PPE

MSA 9.PPE

MSA 10,PPE

MSA ll,PPE

MSA 12,PPE

MSA 13,PPE

MSA 15;PPE

MSA 16,PPD

MSA 17,PPD

MSA ILPPD

MSA 19,PPD

MSA 20,PPD

MSA 21,PPD

MSA 22,PPD

MSA 23,PPD

MSA 24,PPD

MSA 25,PPD

MSA 26,PPD

MSA 27,PPD

MSA 28,PPD

MSA 29,PPD

MSA 30,PPD

Loading...

Loading...