Page 1

Instruction Manual

Model 193A

System DMM

01985, Keithley Instruments, Inc.

Instrument Division

Cleveland, Ohio, U.S.A.

Document Number 193A-901-01

Page 2

Page 3

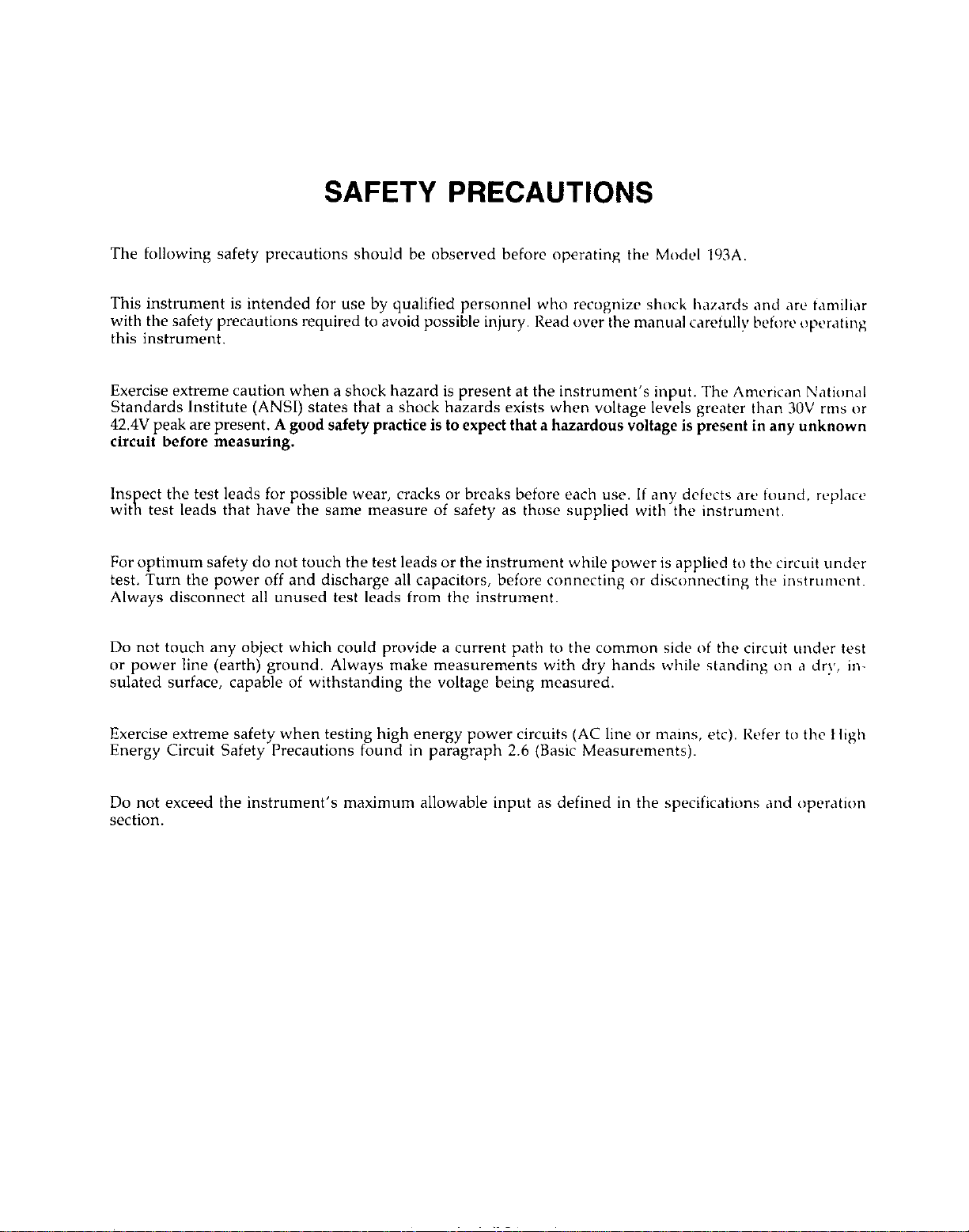

SAFETY PRECAUTIONS

The following safety precautions should be observed before operating the Model ~193A

This instrument is intended for use by qualified personnel who recognize shock huxds .~nd are i,lmiliar

with the safety precautions required to avoid possible injury. Read WET the manual carefully before operating

this instrument.

Exercise extreme caution when a shock hazard is present at the instrument’s input. The American National

Standards Institute (ANSI) states that a shock hazards exists when voltage levels greater than 3OV rms or

42.4V peak are present. A good safety practice is to expect that a hazardous voltage is present in any unknown

circuit before measuring.

ect the test leads for possible wear, cracks or breaks before each use. If any defects are found, replxe

Ins

.R

test leads that have the same measure of safety as those supplied with the instrument.

wt

For optimum safety do not touch the test leads or the instrument while power is applied to the circuit under

test. Turn the power off and discharge all capacitors, before connecting or disconnecting the instrunwnt.

Always disconnect all unused test leads from the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under lest

or power line (earth) ground. Always make measurements with dry hands while standing on ‘1 dry, ills&ted surface, capable of withstanding the voltage being measured.

Exercise extreme safety when testing high energy power circuits (AC line or mains, etc). Refer to the t ligh

Energy Circuit Safety Precautions found in paragraph 2.6 (Basic Measurements).

Do not exceed the instrument’s maximum allowable input as defined in the specifications and operation

section.

Page 4

Page 5

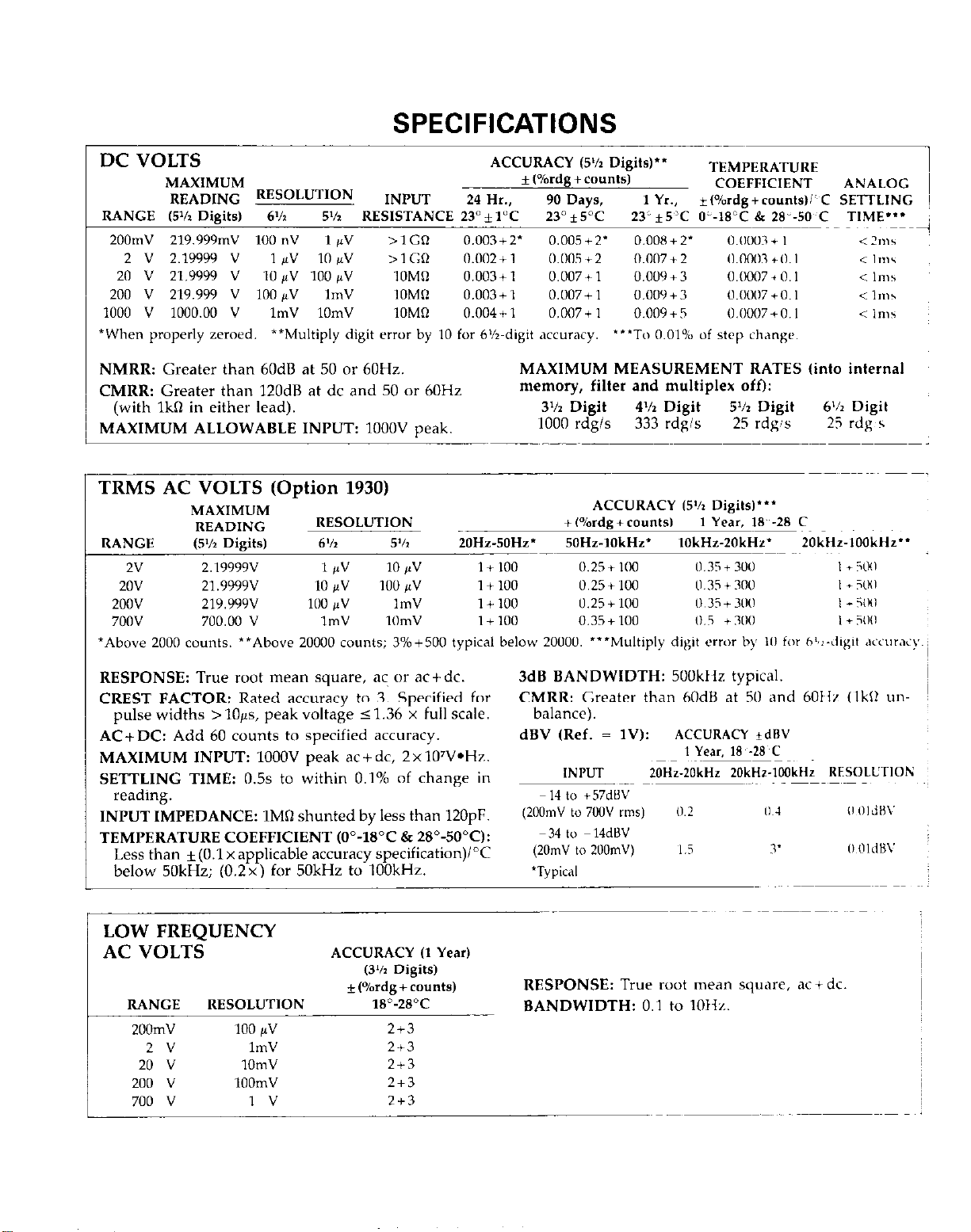

SPECIFICATIONS

DC VOLTS

MAXIMUM

READING RESOLUTION

RANGE (5% Digits) 6% 5%

200mV 219.999mV 10” n” 1 IrV

2 V 2.19999 V 1 $V lop”

20 V 21.9999 V

200 V 219.999 V 100 ,,V

1000 v 1000.00 v

*When properly zeroed. **Multiply digit error by 10 for h%~digit accuracy.

10 &V 100 &V

lm”

1mV 1OmV

INPUT 24

RESISTANCE 23O+l”C 23’*5T

>lCX

>lCx 0.002+

1OMCl 0.003+

1OMR 0.003+1 O.O07+l

1OMR 0.004+1

ACCURACY (5% Digits)”

* t%rdg +

Hr.,

0.003+2* 0.005+2’

1

1

counts)

90 Days,

0.005+2

0.007+1

0.007+1

TEMPERATURE

COEFFICIENT

1 Yr.,

23’f5”C O”-18’C & 28--5O~C TIME”*

0.00x+2* o.wK? in 1

0.007+2

0.009+3 (1.lx)O7+O.l

0.009+3 O.WO7

0.009+5 0.0007+0.1

“‘To (1.01% of step ch.qe.

it%rdg+countsli~~ C SETTLING ~

(l.WOS +~ 0. I

+o. I

ANALOG 1

< zms

i

< 1,115

< I”,>

< lms

< I”,5

NMRR: Greater than 60dB at 50 or 60Hr. MAXIMUM MEASUREMENT RATES (into internal

CMRR: Greater than

(with lk0 in either lead).

120dB at dc and 50 or 6OHz

MAXIMUM ALLOWABLE INPUT: 1OOOV peak.

memory, filter and multiplex off):

3% Digit

1000 rdgis

4% Digit 5% Digit

333 rdgls 25 rdg:s

6’12 Digit

25

rdg s

TRMS AC VOLTS (Option 1930)

MAXIMUM

READING

RANGE

2" 2.19999"

2ov

2oov 219.999"

700" 700.00

*Above 2000 COUPES. **Above 20000 counts; 3%+500 typical below 20000. “‘Multiply digit erwr by ill for 6’.:-digit .~cur.xy. ~

(5% Digits)

21.9999"

v

RESOLUTION + t%rdg + counts, 1 Year, 18’.28 c

6% 5%

1 Ir”

10 /Lv

100 PV

1mV

100 flv

10 pv

1mV 1+ 100 0.25+

lOmV 1+100

20Hz-50Hz’

1 + 100

1+ 100

ACCURACY (5% Digits)‘*’

50Hz-IOkHz’

0.25+

I(10

0.25+100

100

0.35+100

IOkHz-20kHz’ ZOkHz-100kHz”

11.35 + 300

L1.35

13.31+ 3Nl

0.5 4~ SW

+ SW

I f so0

I f xx1

I _ 3ki

I + SiHl

RESPONSE:

CREST FACTOR: Rated accuracy to 3.

pulse widths > lops, peak voltage 5 1.36 x full scale.

True root mean square, ac or

ac+dc.

Specified for

AC+DC: Add 60 counts to specified accuracy.

MAXIMUM INPUT: 1OOOV peak ac + dc, 2 x lO’V*Hr.

SETTLING TIME: 0.5s to within 0.1% of change

reading.

INPUT IMPEDANCE: 1Mfi shunted

by

less than 120pF.

TEMPERATURE COEFFICIENT CO’=-18°C & 28’-50°C):

Less than *(0.1x applicable accuracy specification)i”C

below 50kH.z; (0.2x) for 50kHz to 100kHr.

200mv

2"

20

200

700

100 pv

ImV 2+3

v

v

v

1OmV 2+3

100mV 2+3

1 v

2+3

2+3

3dB BANDWIDTH:

CMRR: Greater than

balance).

dBV (Ref. = 1V):

in

INPUT ZOHz-ZOkHz ZOkHz-1WkHr RESOLUTION

14 to +57dHV

(2OOmV t* 7WV rms) 0.2

-34 to 14dUV

(20mV t0 2OOmV) I .s S’

‘Typical

500kHr typical.

6OdB at 50 and 6OHr (Ikl2 1111. ~

ACCURACY +dBV

1 Year. In~-zn c

11.4

,J OldH\’

i)~illdH\

!

Page 6

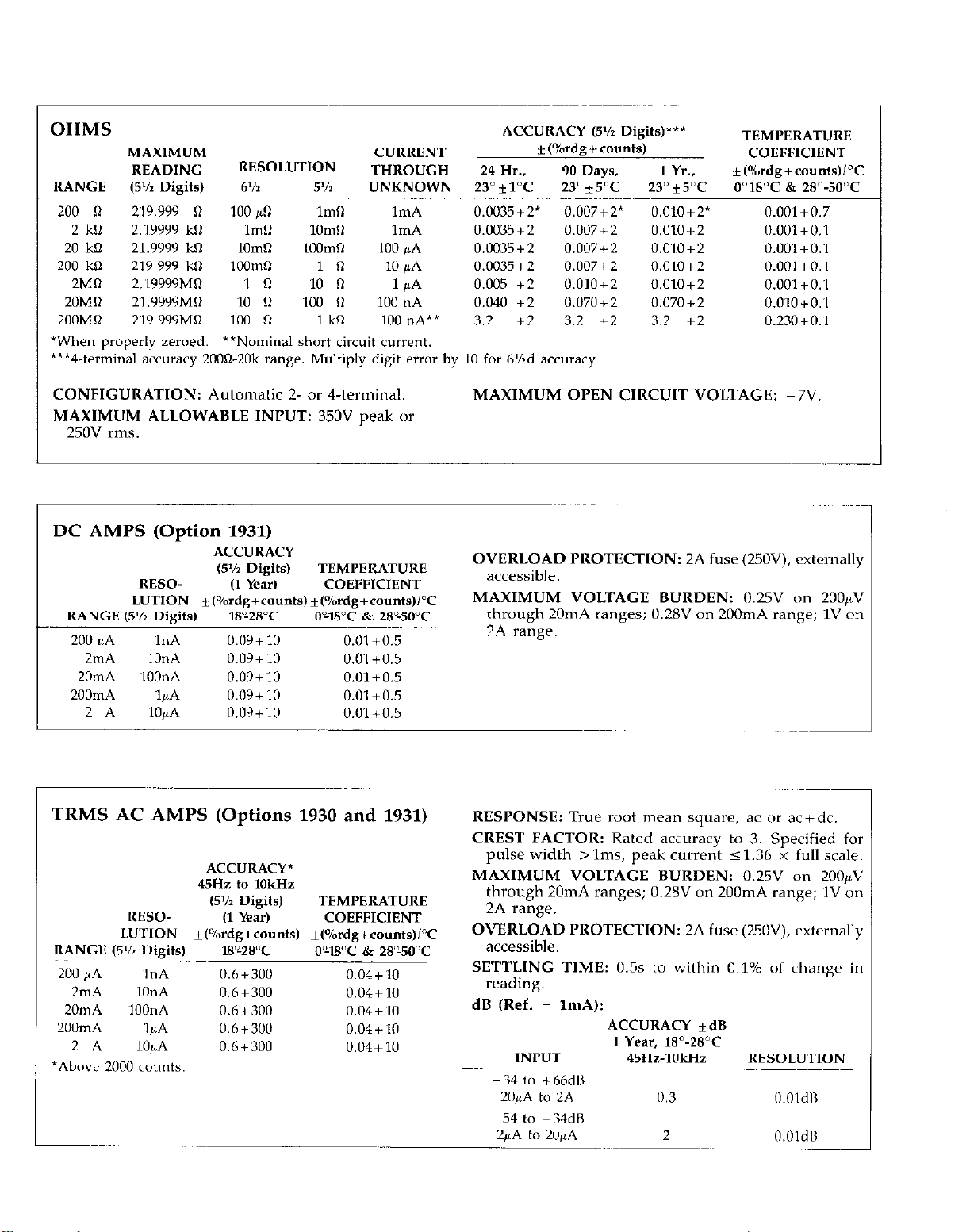

OHMS

MAXIMUM CURRENT

READING RESOLUTION THROUGH

RANGE (5% Digits) 6% 5’,2

200 n 219.999 n 100 po lmfl ImA

2 kO 2.19999 k!I ImIl 1Omfl ImA

20 kn 21.YYYY k0 Nllll~

200 kR 219.999 kll 1OOmR 1 n 10 I”A

2Mfl 2:19999Mn 1 R ‘IO n 14

20Mll 21.9999MQ 10 n 100 a 100 nA

200Mn 21Y.YY9Mn 100 R 1 kn 100 nA**

*When properly zeroed.

***4-terminal accuracy 200S20k range. Multiply digit error by 10 for 6’/zd accuracy.

**Nominal short circuit current.

1oomn 100 &A

UNKNOWN

ACCURACY (5% Digits)***

-t (%rdg + counts)

24

Hr.,

230

* 1°C

0.0035+2* 0.007+2* 0.010+2*

0.0035+2 0.007+2 0.010+2

0.0035+2 0.007+2 0.010+2

0.0035+2 0.007+2 0.010+2

0.005 +2 0.010+2 Ll.o10+2

0.040 +2 0.070+2 0.070~2

3.2 +2 3.2 +2 3.2 +2

90 Days, 1 Yr.,

23’ i ST 230 i5T

TEMPERATURE

COEFFICIENT

*(%rdg+counts)/“C

O”lBoC & 28’-5O’C

0.001+0.7

0.001+ 0.1

0.001+0.1

0.001+0.1

0.001+0:1

0.010+0:1

0.230+0.1

CONFIGURATION:

MAXIMUM ALLOWABLE INPUT: 350V

250V rms.

Automatic 2. or 4.terminal.

peak or

DC AMPS (Option 1931)

ACCURACY

(5% Digits)

(S/2 v,ges, 1

RESO- RESO- (1 Year) (1 Year) COEFFICIENT

LUTION *(%rdg+counts)*(

RANGE 15% Dieits)

RANGE (5% Digits)

200 pA InA 0.09+10

20mA lOOnA

200mA l@A

LUTION *(%rdg+counts) -t(%rdg+counts)i”C

2mA 10nA 0.09+10

2 A lo+4

18*28”C

18*28”C

0.091-10 0.01+0.5

0.09+10 0.01+0.5

o.o9+1O 0.01+0.5

TEMPERATURE

0’

00-18T & 280-SOT

0.01+0.5

0.01+0.5

TRMS AC AMPS (Options 1930 and 1931)

ACCURACY*

RESO-

LUTION +(%rdg+counts) -t(%rdg+counts)/“C

RANGE (5% Digits)

GO fill

2mA 1OnA

20mA IOOnA

200mA

2 A 10fiA

*Abwc 2000 counts.

‘InA

‘IpA

45Hz to

1OkHz

(5% Digits) TEMPERATURE

(1 Year) COEFFICIENT

180-28°C

0.6+300 0.04+10

0.6+300

0.6+300

0.6+300

0.6+300

0”-18”C & 28%5O’C

0.04+10

0.04+10

0.04+10

0.04+10

MAXIMUM OPEN CIRCUIT VOLTAGE: 7V

OVERLOAD PROTECTION: 2A

accessible.

fuse (25OV), externally

MAXIMUM VOLTAGE BURDEN: 0.25V on 200pV

through 20mA ranges; 0.28V on 200mA range; 1V on

2A range.

RESPONSE:

CREST FACTOR:

pulse width > lms, peak current 5 1.36 x full scale.

True root mean square, ac or ac+dc.

Rated accuracy to 3. Specified for

MAXIMUM VOLTAGE BURDEN: 0.25V on 2OOpV

through 20mA ranges; 0.28V on 200mA range; 1V on

2A range.

OVERLOAD PROTECTION: 2A

accessible.

SETTLING TIME: 0.5s

reading.

to within 0.1% of change in

fuse (25OV), externally

dB (Ref. = ImA):

ACCURACY + dB

1 Year, 18O-28°C

INPUT

-34 to +66dB

20pA to 2A

-54 to -34dB

2pA t” 20/~/I

45Hz-10kHz

0.3

2

RESOLUTION

O.O~ldB

O.OldU

Page 7

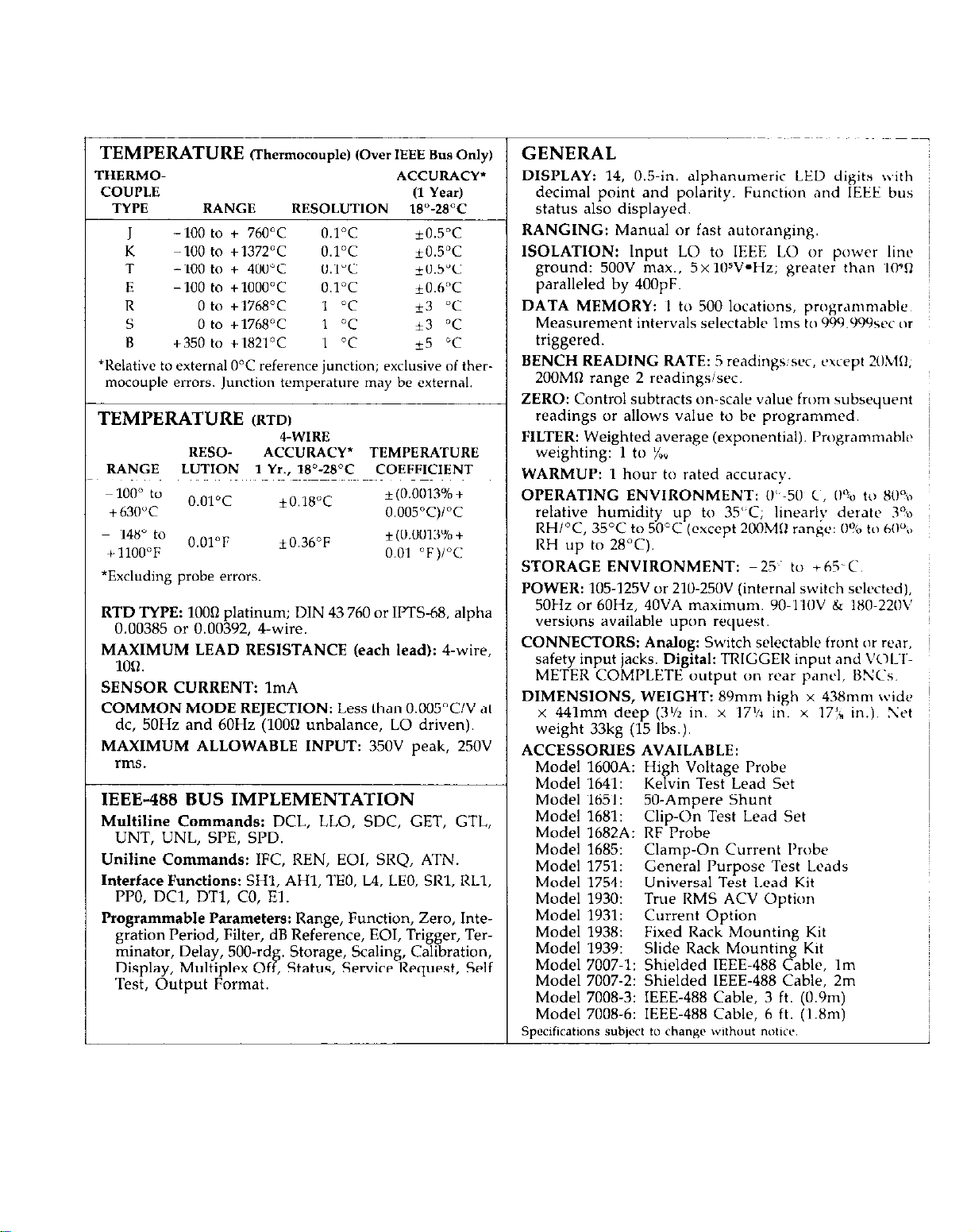

TEMPERATURE

THERMO-

COUPLE

TYPE RANGE

-100 to + 760°C O.l”C

J

K -100 t” +1372”C O.l”C

T

R 0 to +1768”C 1 “C

-100 to + 400°C O.l”C

E - 100 to + 1000°C O.l”C kO.h”C

s 0 to c176PC 1 “C *3 “C

B

c350 t” +1821”C 1 “C

(Thermocouple) (over IEEE Blrs only)

ACCURACY=

(1 Year)

RESOLUTION 113°-28”C

10.5”C

+0.5”C

+0.5oc

*3 “C

1-5 “C

‘Relative to external 0°C reference junction; exclusive of ther-

mocouple errors. Junction temperature may be external.

TEMPERATURE

(RTD)

4-WIRE

RESO- ACCURACY* TEMPERATURE

RANGE LUTION 1 Yr.,

1000 to

+63O”C O.O05~C)/~C

148O to

+llOO”F 0.01 ‘F)PC

*Excluding probe errors.

O.Ol"C

O.Ol”F 10.36OF

18°-2~oC

*o.lt?"c

COEFFICIENT

* (0.0013% +

*(0.0013%+

RTD TYPE: 1000 platinum; DIN 43 760 or IPTS-68, alpha

0.00385 or 0.00392, 4.wire.

MAXIMUM LEAD RESISTANCE (each lead): 4.wire,

10R.

SENSOR CURRENT: 1mA

COMMON MODE REJECTION: Less than 0.005”CIV at

dc, 50Hz and 60Hz (lOOn unbalance, LO driven).

MAXIMUM ALLOWABLE INPUT: 350V peak, 250V

*Ins.

IEEE-488 BUS IMPLEMENTATION

Multiline Commands: DCL, LLO, SDC, GET, GTL,

UNT, UNL, SI’E, SI’D.

Uniline Commands: IFC, REN, EOI, SRQ, ATN.

Interface Functions: SHl, AHl, TEO, LA, LEO, SRl, RLZ,

PPO, DCl, DTl, CO, El.

I’rogrammable Parameters: Range, Function, Zero, Inte-

gration Period, Filter, dB Reference, EOI, Trigger, Ter-

minator, Delay, 500-rd P Storage, Scaling, Calibration,

Display, Multiplex Of, Status, Service Request, Self

Test, Output Format.

GENERAL

DISPLAY: 14, 0.5.in. alphanumeric LED digits \vith

decimal point and polarity. Function and IEEE bus

status also displayed.

RANGING: Manual or fast autoranging.

ISOLATION: Input LO to IEEE LO or power line

ground: 500V max., 5xlOSV.Hz; greater than ~10%

paralleled by 400pF.

DATA MEMORY: I to 500 locations, progrumwble,

Measurement intervals selectablr lms to 999.999x-c or

triggered.

BENCH READING RATE: 5 readingswr, vwpt 2O~lIl;

ZOOMR range 2 rcadingsisec.

ZERO: Control subtracts on-scale value from subsequent

readings or allows value to bc programmed.

FILTER: Weighted average (exponential). Programmable

weighting: 1 to &

WARMUP: 1 hour to rated accuracy.

OPERATING ENVIRONMENT: [I’,-50 C’, 0% to 809,

relative humidity up to 35’C; linearly derate 3%

RH/“C, 35°C to 50°C (except 2OOMII range: 0% TV, M1”,>

RH up to 28°C).

STORAGE ENVIRONMENT: -25~~ to +65-C.

POWER: 105.725V or 210.250V (internal switch selected),

50Hz or 6OHz, 40VA maximum 90.I~ItlV & 180.22O\’

versions available upon request.

CONNECTORS: Analog: Switch selectable front (lr rear,

safety input jacks. Digital: TRIGGER input and \‘(>I-.I-

METER COMPLETE output on rear panel, BSCs.

DIMENSIONS, WEIGHT: 89mm high x 43Hmm wide

x 441mm deep (3% in. x ~17% in. x 171% in.). Set

weight 33kg (15 Ibs.).

ACCESSORlES AVAILABLE:

Model 1600A: Hi h Voltage Probe

Model 1641: K&n Test Lead Set

Model 1651: 50.Ampere Shunt

Model 1681: Clip-On Test Lead Set

Model 1682A: RF Probe

Model 1685: Clamp-On Current Probe

Model 1751: General Purpose Test Leads

Model 1754: Universal Test Lead Kit

Model 1930: True RMS ACV Option

Model 1931: Current Option

Model 1938: Fixed Rack Mounting Kit

Model 1939: Slide Rack Mounting Kit

Model 7007-l: Shielded IEEE-488 Cable, lm

Model 7007-2: Shielded IEEE-488 Cable, 2m

Model 7008.3: IEEE-488 Cable, 3 ft. (0.9m)

Model 7008.6: IEEE-488 Cable, 6 ft. (1.8m)

Specifications subject to change without notice,

Page 8

Page 9

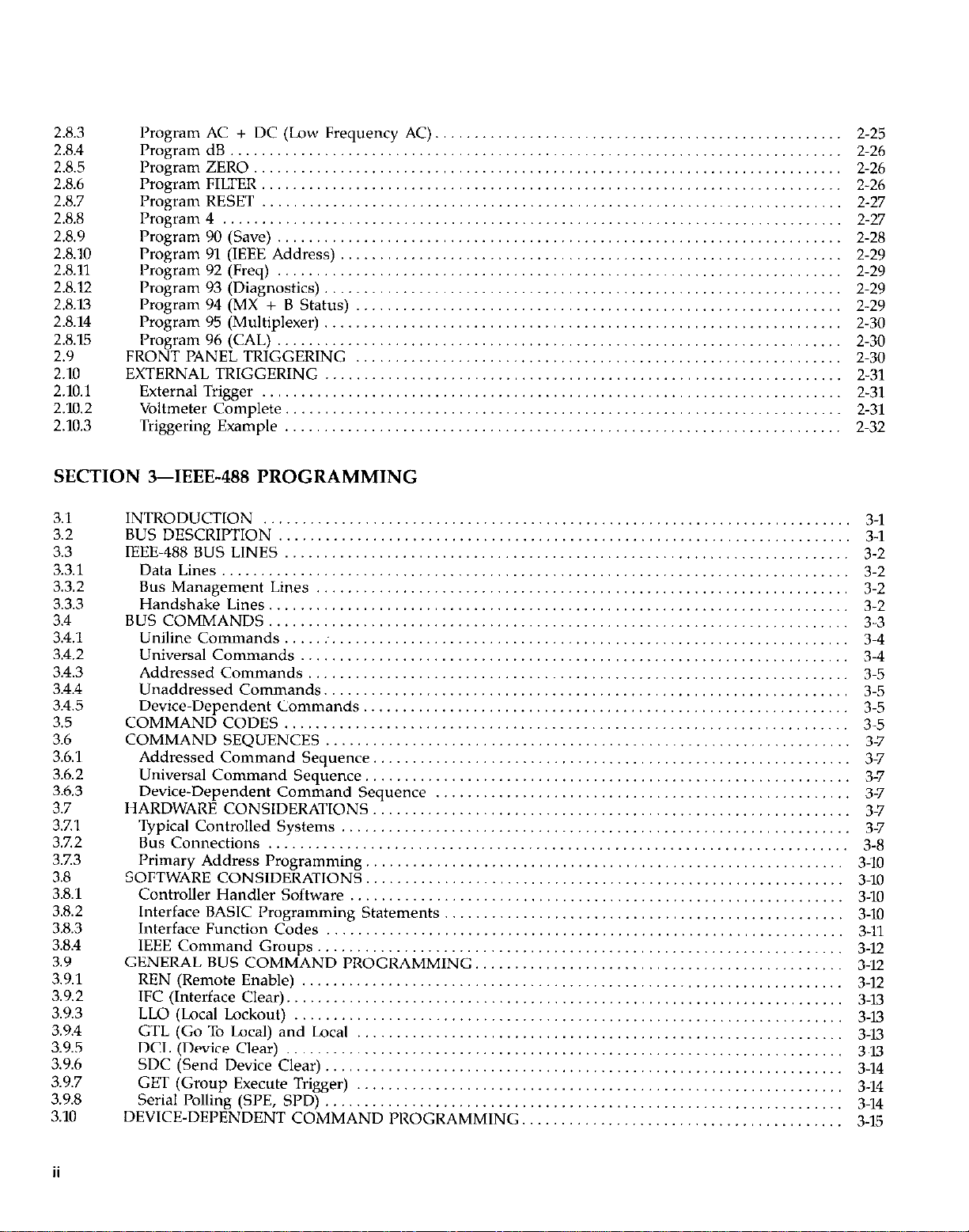

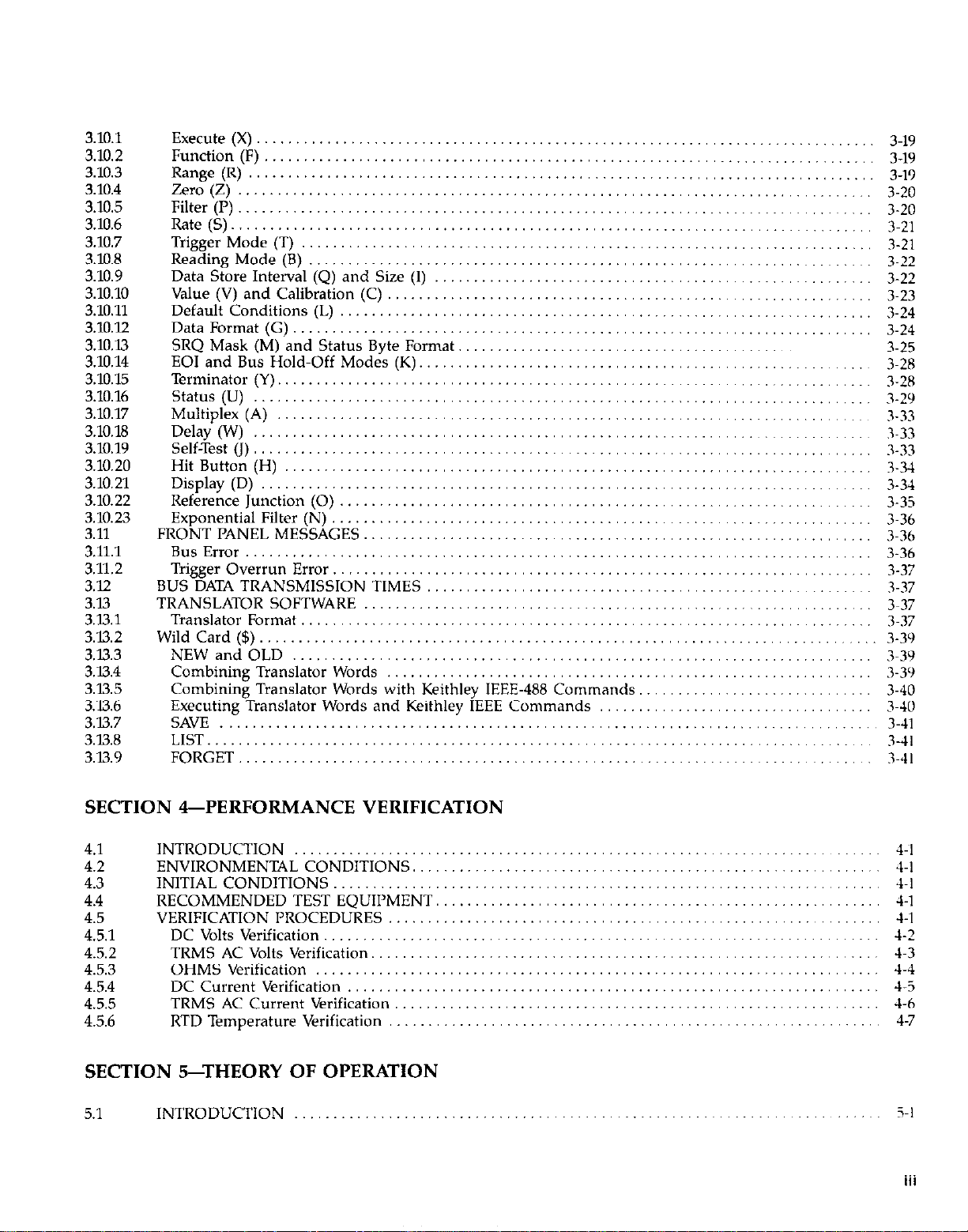

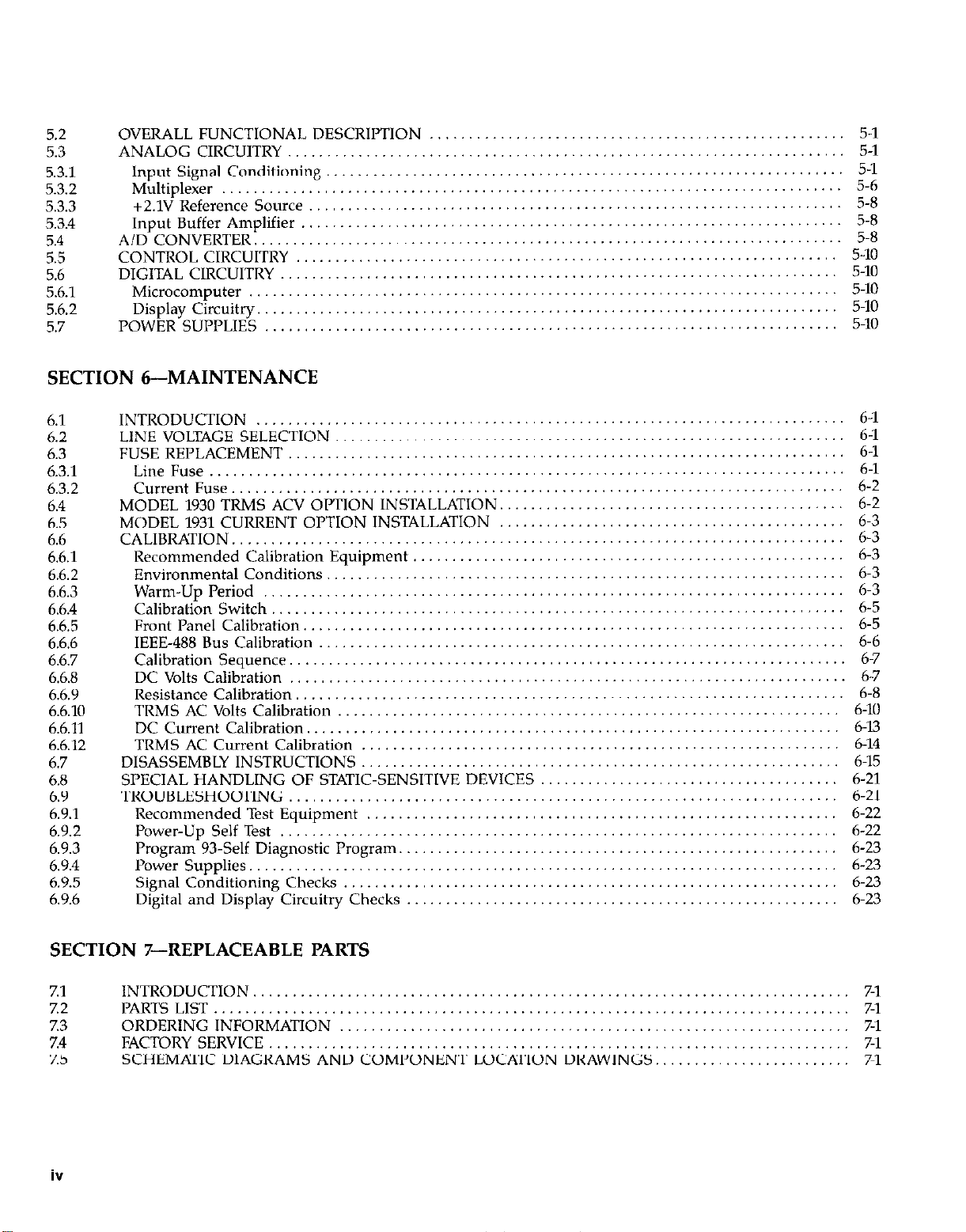

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

INTRODUCTION

FEATURES

..................................................................................

WARRANTY INFORMATION

MANUAL ADDENDA

SAFETY SYMBOLS AND TERMS

SPECIFICATIONS

INSPECTION

USING THE MODEL 193A MANUAL,

GETTING STARTED

ACCESSORIES

............................................................................

.................................................................

.......................................................................

.............................................................

...........................................................................

...............................................................................

........................................................

.........................................................................

..............................................................................

SECTION 2-BASIC DMM OPERATIONS

2.1

2.2

22.1

2.2.2

2.2.3

2.2.4

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.4

2.4.1

2.4.2

2.4.3

2.5

2.6

2.6.1

2.6.2

2.6.3

2.6.4

2.6.5

2.6.6

2.6.7

2.6.8

2.6.9

2.6.10

2.6.11

2.6.12

2.6.13

2.7

2.7.1

2.7.2

2.8

2.8.1

2.82

INTRODUCTION ...........................................................................

POWER UPPROCEDURES ...................................................................

Line Power ................................................................................

rower-up Sequence ........................................................................

Factory Default Conditions

User Programmed Conditions

FRONT PANEL FAMILIARIZATION

.................................................................

..............................................................

..........................................................

DisplayandIndicators .....................................................................

Controls..

................................................................................

Input Terminals ...........................................................................

Current Fuse ..............................................................................

REAR PANEL FAMILIARIZATION

Connectors and Terminals

.................................................................. 2-4

............................................................

Calibration Switch .........................................................................

Line Fuse .................................................................................

ERROR AND WARNING DISPLAY MESSAGES

BASICMEASUREMENTS ....................................................................

Warm Up Period

Zero ......................................................................................

.....................................................................................

Filter

DC Voltage Measurements

..........................................................................

.................................................................

Low-Level Measurement Considerations.,

TRMS AC Voltage Measurements.

..........................................................

Resistance Measurements ..................................................................

Current Measurements (DC or TRMS AC)

RTD Temperature Measurements

dBMeasurements

......................................................................... 2.17

...........................................................

dB Measurement Considerations and Applications,,

TRMS AC + DC Measurements

TRMS Conslderatmns

DATA STORE

Storing Data

Recalling Data

.......................................................................

.............................................................................. 2-22

............................................................................. 2-22

............................................................................

............................................................

FRONT PANEL PROGRAMS ................................................................

Cursor and Data Entry,

ProgramTEMP

...........................................................................

...................................................................

............................................... 2-5

...................................................

..................................................

......................................... 2-19

1-l

1-l

I-1

l-l

l-1

1-2

l-2

l-2

1-2

1-3

2-l

2-l

2-l

2-I

2-I

2.2

2-2

2-2

2.2

2-4

2-4

2-3

2-5

2-S

2-Y

2-Y

2-Y

2-11

2-12

Z-13

2.14

2-15

2-16

2.17

2-19

Z-20

2-23

2.25

2-25

2-25

i

Page 10

2.8.3

2.8.4

2.8.5

2.8.6

2.8.7

2.8.8

2.8.9

2.8.10

2.8.11

2.8.12

2.8.13

2.8.14

2.8.15

2.9

2.10

2.10.1

2.10.2

2.10.3

Program AC + DC (Low Frequency AC).

Program dB

Program ZERO

Program FILTER

Program RESET

Program4

Program 90 (Save)

Program

Program 92 (Freq)

Program 93 (Diagnostics).

Program 94 (MX + B Status)

Program 95 (Multiplexer)

Program 96

FRONT PANEL TRIGGERING

EXTERNAL TRIGGERING

External Trigger

Voltmeter Complete.

Triggering Example

...........................

........................

.......................

.......................

............................

.....................

91 (IEEE Address)

.....................

(CAL)

.....................

.......................

...................

....................

.............

..............

...........

...............

...........

...............

SECTION 3-IEEE-488 PROGRAMMING

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

............................

............................

......

......

......

......

......

......

......

......

.............

.............

............. 2-26

............. Z-26

......

......

......

......

......

......

...... 2.29

...... 2.29

......

...... 2.29

......

......

......

......

......

......

...... 2-31

......

......

...... 2.32

2-25

Z-26

2-27

2-27

2.28

2-29

Z-30

2-30

2-30

2-31

2-31

3.1

3.2

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.5

3.6

3.6.1

3.6.2

3.6.3

3.7

3.7.1

3.7.2

3.7.3

3.8

3.8.1

3.8.2

3.8.3

3.8.4

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

3.9.6

3.9.7

3.9.8

3.10

INTRODUCTION

BUS DESCRIPTION..

IEEE-488 BUS LINES

Data Lines

Bus Management Lines

Handshake Lines

BUS COMMANDS

Uniline Commands..

Universal Commands..

AddressedCommands

Unaddressedcommands

Device-Dependent Commands

COMMAND CODES

COMMAND SEQUENCES

Addressed Command Sequence

Universal Command Sequence

...........................................................................

....................................................................... 3-l

........................................................................

................................................................................

....................................................................

..........................................................................

..........................................................................

... . ..................................................................

....................................................................

.....................................................................

...................................................................

..............................................................

........................................................................

................................................................... 3-7

.............................................................

..............................................................

Device-Dependent Command Sequence .....................................................

HARDWARE CONSIDERATIONS

Typical Controlled Systems

BusConnections

..........................................................................

Primary Address Programming.

SOFTWARE CONSIDERATIONS

Controller Handler Software

Interface BASIC Programming Statements

Interface Function Codes

IEEE Command Groups

...................................................................

GENERAL BUS COMMAND PROGRAMMING.

.............................................................

.................................................................

............................................................

.............................................................

...............................................................

...................................................

..................................................................

..............................................

REN(RemoteEnable) .....................................................................

IFC(InterfaceClear)

LLO(IocalLockout)

GTL (Go To Local) and Local

DCL(DeviceClear)

.......................................................................

......................................................................

..............................................................

.......................................................................

SDC(Send Device Clear) ..................................................................

GET (Group Execute Trigger)

..............................................................

Serial Polling (SPE, SPD) ..................................................................

DEVICE-DEPENDENT COMMAND PROGRAMMING

.........................................

3-l

3-2

3-2

3-2

3-2

3-3

3-4

3-4

3-5

3-5

3-5

3-5

3-7

3-7

3-7

3-7

3-7

3-8

3.10

3.10

3-10

3.10

3-11

3.12

3-12

3.1~2

3.13

3.13

3.13

3-n

3-14

3-14

3.14

3-15

ii

Page 11

3.10.1

3.10.2

3.10.3

3.10.4

3.10.5

3.10.6

3.10.7

3.10.8

3.10.9

3.10.10

3.10.11

3.10.12

3.10.13

3.10.14

3.10.15

3.10.16

3.10.17

3.10.18

3.10.19

3.10.20

3.10.21

3.10.22

3.10.23

3.11

3.11.1

3.11.2

3.12

3.13

3.x3.1

3.X3.2

3.13.3

3.w.4

3.x3.5

3.X3.6

3.w.7

3.13.8

3.x3.9

Execute(X) ...............................................................................

Function(F) ..............................................................................

Range(R) ................................................................................

Zero(Z) .................................................................................

Filter(P)............................................................................~

Rate(S) ..................................................................................

Trigger Mode (T) .........................................................................

Reading Mode(B) ........................................................................

Data Store Interval (Q) and Size (1) ........................................................

Value (V) and Calibration (C)

Default Conditions (L)

Data Format(G) ..........................................................................

SRQ Mask (M) and Status Byte Format. ....................................................

EOI and Bus Hold-Off Modes (K) ..........................................................

Terminator (Y)

Status(U) ...............................................................................

Multiplex (A)

Delay(W) ...............................................................................

Self-Test(J)

Hit Button(H) ...........................................................................

Display(D) ..............................................................................

Reference Junction (0) ....................................................................

Exponential Filter (N)

FRONT PANEL MESSAGES .................................................................

Bus Error ................................................................................

Trigger Overrun Error .....................................................................

BUS DATA TRANSMISSION TIMES ......................................................... 3.37

TRANSLATOR SOFTWARE

Translator Format

Wild Card($)

NEW and OLD ..........................................................................

Combining Translator Words

Combining Translator Words with Keithley IEEE-488 Commands .............................. 3-40

Executing Translator Words and Keithley IEEE Commands

SAVE

LIST

FORGET

.................................................................................... 3-41

..................................................................................... 3-41

............................................................................

.....................................................................

...............................................................................

............................................................................... 3-3’)

.................................................................................

....................................................................

.....................................................................

.........................................................................

..............................................................

... ~, 3.33

................................................................. 3-37

..............................................................

.........................

.........

3.19

3-1~

3-19

3-20

.... 3.20

3.21

3.21

3.22

3.22

3.23

3.24

3-24

3.25

3.28

3.28

3.2’)

3.33

R-33

3-3-1

3-W

3-35

3.36

3.36

3-36

3.37

3.37

3-39

3-3’)

3-40

3.41

SECTION 4-PERFORMANCE VERIFICATION

4.1

4.2

4.3

4.4

4.5

4.5.1

4.5.2

4.5.3

4.5.4

4.55

4.5.6

INTRODUCTION ...........................................................................

ENVIRONMENTALCONDITIONS

INITIAL CONDITIONS.. ....................................................................

RECOMMENDED TEST EQUIPMENT.

VERIFICATION PROCEDURES ......................................................

DC Volts Verification.. .....................................................................

TRMS AC Volts Verification

OHMS Verification

DC Current Verification

TRMS AC Current Verification

RTD Temperature Verification .............................................................

........................................................................

....................................................................

............................................................

........................................................

.................................................................

..............................................................

SECTION 5-THEORY OF OPERATION

5.1

INTRODUCTION ..,,...........,......,....,.,,.,...................................~....~. 5-l

4-l

1-1

4-l

4-I

........ 4-I

1-2

4-3

4-4

4-5

4-h

4-7

iii

Page 12

5.2 OVERALL FUNCTIONAL DESCRIIJTION

5.3 ANALOG CIRCUITRY .......................................................................

5.3.1

5.3.2

5.3.3

5.3.4

5.4

5.5

5.6

5.6.1

5.6.2

5.7

Input Signal Conditioning

Multiplexer

+Z.lV Reference Source

Input Buffer Amplifier

AIDCONVERTER ...........................................................................

CONTROLCIRCUITRY.. ...................................................................

DIGITAL CIRCUITRY .......................................................................

Microcomputer ...........................................................................

Display Circuitry

POWER SUPPLIES

............................................................................... 5-6

..........................................................................

.........................................................................

..................................................................

.................................................................... 5-8

.....................................................................

.....................................................

SECTION 6-MAINTENANCE

5-l

5-l

5-l

5-8

5-8

5-10

5-10

5-10

5-10

5-10

6.1

6.2

6.3

6.3.1 Line Fuse

6.3.2

6.4

6.5

6.6

6.6.1

6.6.2

6.6.3

6.6.4

6.6.5

6.6.6

6.6.7

6.68

6.6.9

6.6.10

6.6.11

6.6.12

6.7

6.8

6.9 TROUBLESHOOTING

6.9.1 Recommended Test Equipment

6.9.2 Power-Up Self Test .......................................................................

6.9.3 Program 93.Self Diagnostic Program.

6.9.4 Iowa Supplies ...........................................................................

6.9.5 Signal Conditioning Checks

6.9.6 Digital and Display Circuitry Checks

INTRODUCTION

LINE VOLTAGE SELECTION

FUSEREPLACEMENT

Current Fuse.

MODEL 1930 TRMS ACV OPTION INSTALLATION

MODEL 1931 CURRENT OPTION INSTALLATION

CALIBRATION

Recommended Calibration Equipment

Environmental Conditions

Warm-Up Period ..........................................................................

Calibration Switch ......................................................................... 6-5

Front Panel Calibration.

IEEE-488 Bus Calibration

Calibration Sequence .......................................................................

DC Volts Calibration

Resistance Calibration

TRMS AC Volts Calibration

DC Current Calibration.

TRMS AC Current Calibration

DISASSEMBLYINSTRUCTIONS .............................................................

SPECIAL HANDLING OF STATIC-SENSITIVE DEVICES

...........................................................................

.................................................................

.......................................................................

.................................................................................

.............................................................................

............................................

............................................

..............................................................................

.......................................................

..................................................................

....................................................................

...................................................................

....................................................................... 6-7

...................................................................... 6-8

................................................................

...................................................................

............................................................. 6-14

...................................... 6-21

...................................................................... 6-21

............................................................ 6-22

.......................................................

...............................................................

.......................................................

6-l

6-l

6-l

6-l

6-2

6-2

6-3

6-3

6-3

6-3

6-3

6-5

6-6

6-7

6-10

6-13

6-15

6-22

6-23

6-23

6.23

6.23

SECTION 7-REPLACEABLE PARTS

7.1 INTRODUCTION ............................................................................ 7-l

7.2

7.3 ORDERING INFORMATION ................................................................. 7-l

7.4 FACTORY SERVICE.. ........................................................................ 7-l

7.5

iv

PARTS LIST ................................................................................. 7-l

SCHEMATIC DIAGRAMS AND COMPONENT LOCATION DRAWINGS ......................... 7-l

Page 13

LIST OF ILLUSTRATIONS

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

Z-10

2-11

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

4-l

4-2

4-3

4-4

4-5

4-6

4-7

4-8

Model193A Front Panel

Model193ARearPanel

DC Voltage Measurements

TRMS AC Voltage Measurements

Two-Terminal Resistance Measurements

Four-Terminal Resistance Measurements.

Current Measurements..

RTD Temperature Measurements.. ........................................................... 2-17

External Pulse Specifications

Meter Complete Pulse Specifications

External Triggering Example..

IEEE-488 Bus Configuration

IEEE-488 Handshake Sequence

Command Groups

System Types

Typical Bus Connections

IEEE-488 Connections.

Model 193A IEEE-488 Connector ........

Contact Assignments.

General Data Format

SRQ Mask and Status Byte Format .....

UO Status Word and Default Values

Ul Error Status Word.

Hit Button Command Numbers

Connections for DC Volts Verlflcation .......................................................... 4-2

Connections for TRMS AC Volts Verification

Maximum Input TRMS AC Voltage

Connections for Ohms Verification (200%20kn) Range

Connections for Ohms Verifications (200k0-200MR Ranges).

Connections for DC Current Verification.

Connections for TRMS AC Current Verification

Connections for RTD Temperature Verification. .................................................

........................... ...... ...... 3-8

......................................................................

.......................................................................

...................................................................

............................................................

.......................................................

......................................................

....................................................................

................................................................

.........................................................

...............................................................

.............. ...... ...... ......

...........

......................

.................

...................

...................

................... ...... ...... ...... 3-26

...... ...... ...... ...... 3-30

..................

......... ...... ...... 3-34

............................................................

...... 3-3

...... ...... 3-6

...... 3-x

......

......

...... ...... 3-10

...... ......

...... ......

...................................................

..........................................

.....................................

......................................................

.................................................

...... 3-26

2-7

2-7

2.13

2.14

2-16

2-16

2-16

2-31

2-32

2-33

3-2

3-Y

3-Y

3-32

4-3

4-4

4-4

4-S

4-h

1-7

-1-7

5-l

5-2 Input Configuration During 2 and 4-Terminal Resistance Measurements

5-3 Ohms Source (2k12 Range Shown)

s-4

5-5

5-6

5-7

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

Overall Block Diagram ...............................................

....................................

Resistance Measurement Simplified Circuitry

JFET Multiplexer

Multiplexerl’hases .................................................

A/D Converter Simplified Schematic

Models 1930 and 1931 Installation.

DC Volts Calibration Configuration (2OOmV and 2V Ranges)

DC Volts Calibration Configuration (ZOV-1OOOV Ranges),

Four-Wire Resistance Configuration (200%20kO Ranges)

Two-Wire Resistance Calibration Configuration (200k0-ZOOM0 Ranges).

Flowchart of AC Volts Calibration Procedure

TRMS AC Volts Calibration Adjustments.

TRMS AC Volts Calibration Configuration

DC Current Calibration Configuration

TRMS AC Current Calibration Configuration

....................................................

..................................

...........................................................

........................................................

..........................

.....................................

.........................................

.........................................

..................................................

.....................................................

.....................................................

..................................................

...........................

5.2

5.3

i-4

5-j

S-6

j-7

5-9

h-4

b-7

6-S

6-Y

6-9

6-11

6-12

h-l3

6.14

h-15

Page 14

6-11

6-12

Co”“ectors.....................................................

........................... 6-17

Model 193A Exploded View. ........................... 6-19

7-1 Jumper Board, Component Location Drawing, Dwg. No. 193.160.

7-2 Display Board, Component Location Drawing, Dwg. No. 193.110

7-3

7-4

7-5

7-6

7-7

7-8

Display Board, Schematic Diagram, Dwg. No. 193.116

Digital Board, Component Location Drawing, Dwg. No. 193.100

Digital Board, Schematic Diagram, Dwg. No. 193-106

Analog Board, Component Location Drawing, Dwg. No. 193.120

Analog Board, Schematic Diagram, Dwg. No. 193.126

Model 1,930, Component Location Drawing, Dwg. No. 1930.100

7-9 Model 1930, Schematic Diagram, Dwg. No. 1930.106

710 Model 1931, Component Location Drawing, Dwg. No. 1931-100

7-11 Model 1931, Schematic Location Drawing, Dwg. No. 1931.106

......

......

......

......

......

......

......

......

......

......

......

..............

..............

..............

..............

7-3

7-4

7-5

7-10

.............. 7-11

............. 7.22

.............

7-23

............. 7.34

.............

7-35

............. 7-38

............. 7-39

vi

Page 15

LIST OF TABLES

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-n

3-14

3-15

3-16

3-17

3-18

Factory Default Conditions

Front PanelPrograms ........................................................................

Error and Warning Messages .................................................................

Internal Filter ...............................................................................

Resistance Ranges ..........................................................................

Corresponding Voltage Reference Levels for Impedance References

Comparison of Average and TRMS Meter Readings.

High Speed Data Store

Example MX + B Readings .................................................................

IEEE-488 Bus Command Summary.

Hexadecimal and Decimal Command Codes

Typical Addressed Command Sequence

Typical Device-Dependent Command Sequence

IEEE Contact Designation

BASIC Statements Necessary to Send Bus Commands

Model 193A Interface Function Codes

IEEE Command Groups.

General Bus Commands and Associated BASIC Statements

Factory Default Conditions

Device-Dependent Command Summary

Range Command Summary

High Speed Data Store

SRQ Command Parameters

Bus Hold-Off Times ........................................................................

Trigger to Reading-Ready Times (DCV Function)

Translator Reserved Words and Character.

Translator Error Messages .................................................................... 3-38

................................................................... 2-l

2.12

2.15

..............................

...........................................

.....................................................................

..........................................................

................................................... 3-5

...................................... ................ 3-7

................................................ 3-7

....................................................................

......................................... 3-11

........................................................ 3.11

.................................................................... 3.12

.................................... 3-12

..................................................................

...................................................... 3-16

.................................................................

....................................................................

..................................................................

..............................................

....................................................

2.19

2-21

2.22

Z-28

3-14

3-20

2-23

3-27

3-28

3-37

3-38

2-4

2-9

3-4

3-9

4-l

4-2

4-3

4-4 Limits for Ohms Verification

4-5

4-6

4-7

5-l

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

6-11

6-12

6-13

Recommeded Test Equipment ..............

Limits for DC Volts Verification .............

Limits for TRMS AC Volts Verification. ......

Limits for DC Current Verification

Limits for AC Current Verification

Limits for RTD Temperature Verification ....

Ranging Information .........................................................................

Line Voltage Selection ........................................................................

Line Fuse Replacement

Current Fuse Replacement

Recommended Calibration Equipment

DC,Volts Calibratiqn .........................................................................

Resistance Calibration .......................................................................

TRMS AC Volts (Model 1930) Calibration

DC Current Cahbratmn

TRMS AC Current Calibration

Static-Sensltwe Devzes

Recommended Troubleshooting Mode

Model 193A Troubleshooting Mode

Power Supply Checks

.......................................................................

......................................................................

.....................................................................

......................................................................

......

......

...............

..........

..........

...................................................................

.........................................................

..................................................... 6-13

...............................................................

........................................................

..........................................................

......

......

......

......

......

......

......

......

......

5.3

6-l

6-2

6-2

6;

6-10

6-14

6-15

6.21

6;:

h-28

vii

Page 16

6.14

6-15

Digital Circuitry Checks

Display Circuitry Checks

...............................................................

..............................................................

6-28

6-29

7-l

7-2

7-3

7-4

7-5

7-6

Display Board, Parts List

Digital Board, Parts List

Analog Board, Parts List,,

Model 1930, Parts List

Model 1931, Parts List.

..............................................................

..............................................................

............................................................

.................................................................

................................................................

Model 193A Mechanical Parts List

......................................................

......

......

7-2

7-7

715

7-31

7-37

7-41

vttt

Page 17

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Keithley Model 193A System DMM, with the TRMS

AC Volt and Current options installed, is a six function autoranging digital multimeter. At 6% digit resolution, the LED

display can display ~2,200,OOO counts. The range of this

analog-to-digital (A/D) converter is greater than the normal *1,999,999 count AID converter used in many 6% digit

DMMs. The built-in IEEE-488 interface makes the instrument fully programmable over the IEEE-488 bus. With the

TRMS ACV option and the Current option installed, the

Model 193A can make the following basic measurements:

1. DC voltage measurements from 1OOnV to lOOOV.

2. Resistance measurements from 1OOpfl to ZOOMR.

3. RTD temperature measurements from -1OOOC to 63O’C.

4. TRMS AC voltage measurements from I$/ to 700V.

5. DC current measurements from 1nA to 2A.

6. TRMS AC current measurements from 1nA to 2A.

In addition to the above mentioned measurement capabilities, the Model 193A can make dB and TRMS AC + DC

measurements.

1.2 FEATURES

Some important Model 193A features include:

the power-up default conditions.

l Translator Software-User defined words can be used to

replace standard command strings over the IEEE488 bus.

l Thermocouple (TC) temperature measurements con be

made over the IEEE-488 bus.

1.3 WARRANTY INFORMATION

Warranty information may be found on the inside front

cover of this manual. Should it become necessary to exercise the warranty, contact your Keithley representative or

the factory to determine the pmper course of action.

Keithley Instruments maintains service facilities in the

United States, United Kingdom and throughout Europe.

Information concerning the application, operation or ser.

vice of your instrument may be directed to the applications

engineer at any of these locations. Check the inside front

cover for addresses.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

will be found on an addendum sheet included with this

manual. Be sure to review these changes before attempting to operate or service the instrument.

l 14 Character Alphanumeric Display-Easy to read 14 seg-

ment LEDs used for readings and front panel messages.

l High Speed Measurement Rate-1000 readings per

second.

l Zero-Used to cancel offsets or establish baselines. A zero

value can be rogrammed from the front panel or over

the IEEE-488 & us.

l Filter-The weighted average digital filter can be set for

1 to 99 readings from the front panel or over the bus.

l Data Store-An internal buffer that can store up to 500

readings is accessible from either the front panel or over

the bus.

l Digital Calibration-The instrument may be digitally

calibrated from either the front panel or over the bus.

l User Programmable Default Conditions-Any instrument

measurement configuration can be established as

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual or found on the Model 193A.

The A

should refer to the operating instructions in this manual.

The M

1OOW or more may be present on the terminal(s). Standard safety practices should be observed when such

dangerous levels are encountered.

The WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains haz.ards that

could damage the instrument.

symbol on the instrument denotes that the user

on the Instrument denotes that a potential of

l-l

Page 18

GENERAL INFORMATION

1.6 SPECIFICATIONS

Detailed Model 193A specifications may be found preceding

the Table of Contents of

this

manual.

1.7 INSPECTION

The Model 193A System DMM was carefully inspected,

both electrically and mechanically before shipment. After

unpacking all items from the shipping carton, check for any

obvious signs of physical damage that may have occurred

during transit. Report any damage to

Retain and use the original packing materials in case reshipment is necessary. The following items are shipped with

every Model 193A order:

Model 193A System DMM

Model 193A Instruction Manual

Additional accessories as ordered.

If an additional instruction manual is required, order the

manual package (Keithley Part Number 193-901-00). The

manual package includes an instruction manual and any

applicable addenda.

the

shipping agent.

l Section 6 contains information for servicing the instru-

ment, This section includes information on fuse replacement, line voltage selection, calibration and

troubleshooting.

l Section 7 contains replaceable parts information.

1.9 GETTING STARTED

The Model 193A System DMM is a highly sophisticated in-

strument

and running quickly use the following procedure. For complete information on operating the Model 193A consult the

appropriate section of this manual.

POWW-Up

1. Plug the line cord into the rear panel power jack and

plug

grounded power source. See paragraph 2.2.1 for more

complete information.

2. Press in the POWER switch to apply power to the instrument. The

range.

with many capabilities. To get the instrument up

the

other end of the cord into an appropriate,

instrument

will power up to the 1OOOVDC

1.6 USING THE MODEL 193A MANUAL

This manual contains information necessary for operating

and servicing the Model 193A System DMM, TRMS ACV

option and the Current option. The information is divided

into the following sections:

l Section 1 contains general information about the Model

193A including that necessary to inspect the instrument

and get it operating as quickly as possible.

l Section 2 contains detailed operating information on us-

ing the front panel controls and programs, making connections and basic measuring techniques for each of the

available measuring functions.

l Section 3 contains the information necessary to connect

the Model 193A to the IEEE-488 bus and program

operating modes and functions from a controller.

l Section 4 contains performance verification procedures

for

the

instrument. This information will be helpful if you

wish to verify that the instrument is operating in compliance with its stated specifications.

l Section 5 contains a description of operating theory.

Analog, digital, power supply, and IEEE-488 interface

operation is included.

Making Measurements

1. Connect the supplied safety shrouded test leads to the

front panel VOLTS HI and LO input terminals. Make

sure the INPUT switch is in the out (FRONT) position.

2. To make a voltage measurement, simply connect the input leads to a DC voltage surge (up to 1OOOV) and take

the reading from the display.

3. To change to a different measuring function, simply

press the desired function button. For example, to

measure resistance, press the OHMS button.

Using Data

Store

Storing Data:

1. Press the DATA STORE button. The DATA STORE indicator will turn on and a storage rate (in seconds) will

be displayed.

2. Select an interval, other than 000.000, using the 4 and

w, and data buttons.

3. Press the ENTER button. The buffer size will be

displayed. Size 000 indicates that data will overwrite after

500 readings have been stored.

4. If a different buffer size is desired, enter the value using the number buttons (0 through 9).

5. Press the ENTER button to start the storage process.

1-2

-

Page 19

GENERAL INFORMATION

The data store mode can be exited at any time before the

start of the storage process by pressing the RESET button.

Once storage has commenced, the storage process can be

stopped by pressing any function button. See paragraph

2.7.1 for complete information on storing data.

Recalling Data:

1. Press the RECALL button. The buffer location of last

stored reading will be displayed.

2. To read the data at a different manor location, enter

the value using the number buttons O-9).

3. Press the ENTER button. The reading and the memory

location will be displayed.

4. The A and 7 buttons can be used to read the data in

all filled memory locations.

5. To read the highest, lowest and average reading stored

in the buffer, press the number 1,2 and 3 buttons respectively. Note that the memory location of the highest and

lowest reading is also displayed. The average reading is

displayed along with the number of readings averaged.

The recall mode can be exited by pressing the RESET but-

ton. See paragraph 2.7.2 for complete information on data

recall.

Y

Paragraph 2.8 provides the detailed information for using

the front panel programs.

1.10 ACCESSORIES

The following accessories are available to enhance the

Model 193As, capabilities.

Model 1301 Temperature Probe-The Model Uol is a rugged low cost temperature probe designed to allo\v temperature measureme”ts from -55 to 150°C.

Model 16008 High Voltage Probe-The Model 1booB extends

DMM measurements to 40kV.

Model 1641 Kelvin Test Lead Set-The Model 1641 has

special clip leads that allow 4-terminal measurements to be

made while making “nly two c”nnectims.

Model 165150.Ampere Current Shunt-The Model 1651 is

an external O.OOlR *l% 4.terminal shunt, which permits

current measurements from 0 to 50A AC or DC.

Model 1681 Clip-On Test Lead Set-The Model 1681 contains two leads, 1.2m (48’) long terminated with banana

plugs and spring action clip probes.

Using Front Panel Programs

Program selection is accomplished by pressing the PRGM

button followed by the button(s) that corresponds to the

program number or name. For example, to select Program

91 (IEEE status), press the PRGM button and then 9 and

1 buttons. Table 2-2 lists and briefly describes the available

front panel programs. Once a

following general rules will

1. A displayed program condition can be entered by pressing the ENTER button.

2. Program conditions that prompt the user with a flashin

digit can be modified usmg the data buttons (0 throug

9 and +) and the cursor control buttons (manual range

buttons).

3. Programs that contain alternate conditions can be

dis K layed by ressin one of the manual range buttons.

Eat press o

between the two available conditions.

4. A program will be executed when the pressed ENTER

button causes the instrument to exit the program mode.

5. A pro ram can be exited at an time and thus not execute 1 , by pressing the RESE

P P

one o these buttons toggles the display

rogram is selected the

P

app y:

if

button.

a

Model 1682A RF Probe-The Model 1682A permits voltage

measurements from 1OOkHz to 250MHz. AC to DC transfer

accuracy is +ldB from 1OOkHr to 250MHz at IV, peak

responding, calibrated in RMS of a sine wave.

Model 1685 Clamp-On AC Probe-The .Model 1685

measures AC current by clamping on to a single conductor. Interruption of the circuit is unnecessary. The Model

1685 detects currents by sensing the changing magnetic field

produced by the current flow.

Model 1751 Safety Test Leads-Finger guards and shroud-

ed banana plugs help minimize the chance “1 making con-

tact with live circuitry.

Model 1754 Universal Test Lead Kit-The Model 1754 is rl

12 piece test lead kit, with interchangeable plug-in accessories. Included in the kit is one set of test leads (l-red,

l-black), two spade lugs, two standard banana plugs, two

phone tips (0.06 DIA.), two hooks and miniature alligator

clips (with boots).

Model 1930 TRMS AC Volt 0

True Root Mean Square (TRM

Model 193A. This option allows the instrument to measure

the TRMS value of an AC signal. When the Model 1Y30

tion-The Model 1930 is d

! ) AC plug-in option for the

1-3

Page 20

is installed, AC + DC voltage measurements can be made.

Field installation or removal/replacement of the Model 1930

will require recalibration of the Model 193A and the Model

1930.

Model 1931 Current 0

current option for the R

tion-The Model 1931 is a plug-in

ode1 193A. This option allows the

instrument to measure DC current up to 2A. When both

Models 1930 and 1931 are installed, the instrument can

make TRMS AC current measurements and TRMS AC +

DC current measurements. Field installation requires

recalibration of the Model 193A.

Model 7007 IEEE488 Shielded Cables-The Model 7007 connects the Model lY3A to the IEEE-488 bus using shielded

cables to reduce electromagnetic interference (EMI). The

Model 7007-l is one meter in length and has a EMI shielded IEEE-488 connector at each end. The Model 7007-Z is

identical to the Model 70071, but is two meters in length.

Model 7008 IEEE-488 Cables-The Model 7008 connects the

Model 193A to the IEEE-488 bus. The Model 7008-3 is 0.9m

(3 ft.) in length and has a standard IEEE-488 connector at

each end. The Model 7008-6 cable is identical to the Model

7008.3, but is 1.8m (6 ft.) in length.

Model 1938 Fixed Rack Mount-The Model 1938 is a stationary mount kit that allows the Model 193A to be

mounted in a standard 19 inch rack.

Model 1939 Slide Rack Mount-The Model lY39 is a sliding

mount kit that allows the Model 193A to be rack mounted

with the added feature of sliding the instrument forward

for easy access to the rear panel and top cover.

Model 8573 IEEE-488 Interface-The Model 8573 is an

IEEE-488 standard interface designed to interface the IBM

PC or XT computers to Keithley instrumentation over the

IEEE-488 bus. The interface system contains two distinctive parts: an interface board containing logic to perform

the necessary hardware functions and the handler software

(supplied on disk) to perform the required control functions. These two important facets of the Model 8573 join

together to give the IBM advanced capabilities over

IEEE-488 interfaceable instrumentation.

1-4

Page 21

SECTION 2

BASIC DMM OPERATION

2.1 INTRODUCTION

Operation of the Model 193A may be divided into two The instrument can be turned on by pressing in the front

general categories: front panel operation and IEEE-488 bus panel POWER switch. The switch will be at the inner most

operation. This section contains information necessary to

use the instrument from the front panel. These functions

can also be programmed over the IEEE-488 bus, as described in Section 3.

2.2 POWER UP PROCEDURE

2.2.1 Line Power

Use the following procedure to connect the Model 193A to

line power and power up the instrument.

1. Check that the instrument is set to correspond to the

available line oower. When the instrument leaves the factory, the internally selected line voltage is marked on the

rear panel near the AC power receptacle. Ranges are

105Vl25V or ZloV-250V 50160Hz AC. If the line voltage

setting of the instrument needs to be changed, refer to

Section 6, paragraph 6.2 for the procedure. If the line

frequency setting of the instrument needs to be checked

and/or changed, utilize front panel Program 92 (see

paragraph 2.8.11) after the instrument completes the

power-up sequence.

2. Connect the female end of the power cord to the AC

receptacle on the rear panel of the instrument. Connect

the other end of the cord to a grounded AC outlet.

WARNING

The Model 193A is equipped with a 3-win? power

cord that contains a separate ground wire and

is designed to be used with grounded outlets.

When proper connections are made, instrument

chassis is connected to power line ground.

Failure to use a grounded outlet may result in

personal injury or death because of electric

2.2.2 Power-Up Sequence

position when the instrument is turned on. Upon P owerup, the instrument will do a number of tests on itse f. Tests

are performed on memory (ROM, RAM and NVRAM). If

RAM or ROM fails, the instrument will lock up. If EYROM

FAILS, the message “UNCALIBRATED” will be

See paragraph 6.92 for a complete description of the pw~erup self test and recommendations to resolve failures.

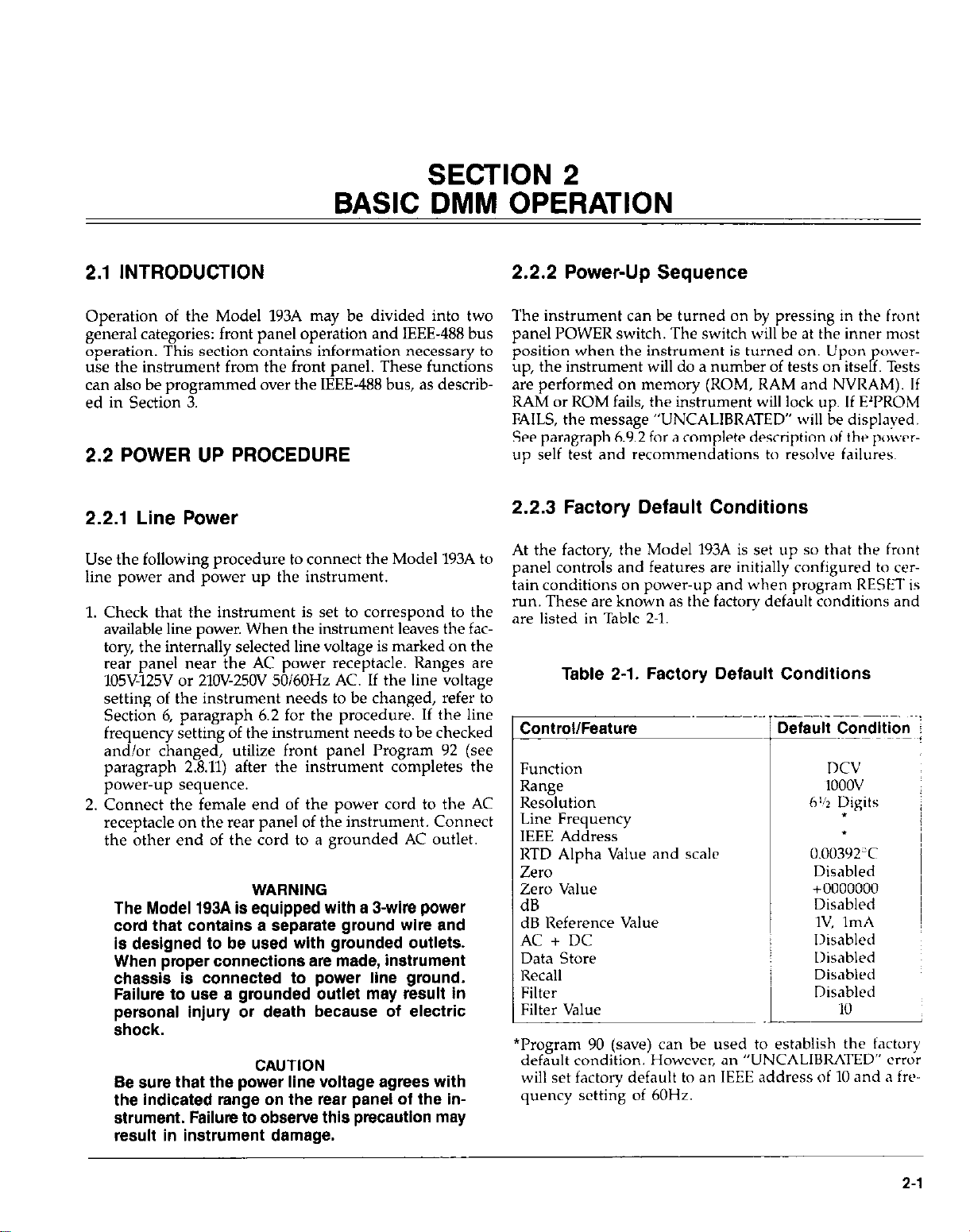

2.2.3 Factory

At the factory, the Model 193A is set up so that the front

panel controls and features are initially configured to certain conditions on power-up and when program RESET is

run. These are known as the factory default conditions and

are Iisted in Table 2.l,

Default Conditions

displayed.

Table 2-1. Factory Default Conditions

Function

Range

Resolution

Line Frequency

IEEE Address

RTD Alpha Value and scale

ZW”

Zero Value

dR

dB Reference Value

AC + DC

Data Store

Recall

Filter

Filter Value

DCV

1ooov

6% Digits

1

f

0.00392LC

Disabled

+ooooooo

Disabled

IV, 1mA

Disabled

Disabled

Disabled

Disabled

10

shock.

‘Program 90 (save) can be used to establish the factory

CAUTION

Be sure that the power line voltage agrees with

the indicated range on the rear panel of the instrument. Failure to

ObSSNS

this

pmCautiOfl

may

default condition. However, an “UNCALIBRATED” error

will set factory default to an IEEE address of 10 and a irequency setting of 60Hz.

result in instrument damage.

2-1

Page 22

2.2.4 User Programmed Conditions

A unique feature of the Model 193A is that each function

“remembers” the last measurement configuration that it

was set up for (such as range, zero value, filter value, etc).

Switching back and forth between functions will not affect

the unique configuration of each function. However, the

instrument will “forget” the configurations on power-down.

Certain confi urations can be saved by utilizing front panel

Program 90. % n power-up, these user saved default condi-

tions will prevail over the factory default conditions. Also,

a DCL or SDC asserted over the IEEE-488 bus will set the

instrument to the user saved default conditions. For more

information, see paragraph 2.8.9 (Program 90).

NOTE

Keep in mind that power-up default conditions can

be either factory default conditions or user saved

default conditions.

2.3 FRONT PANEL FAMILIARIZATION

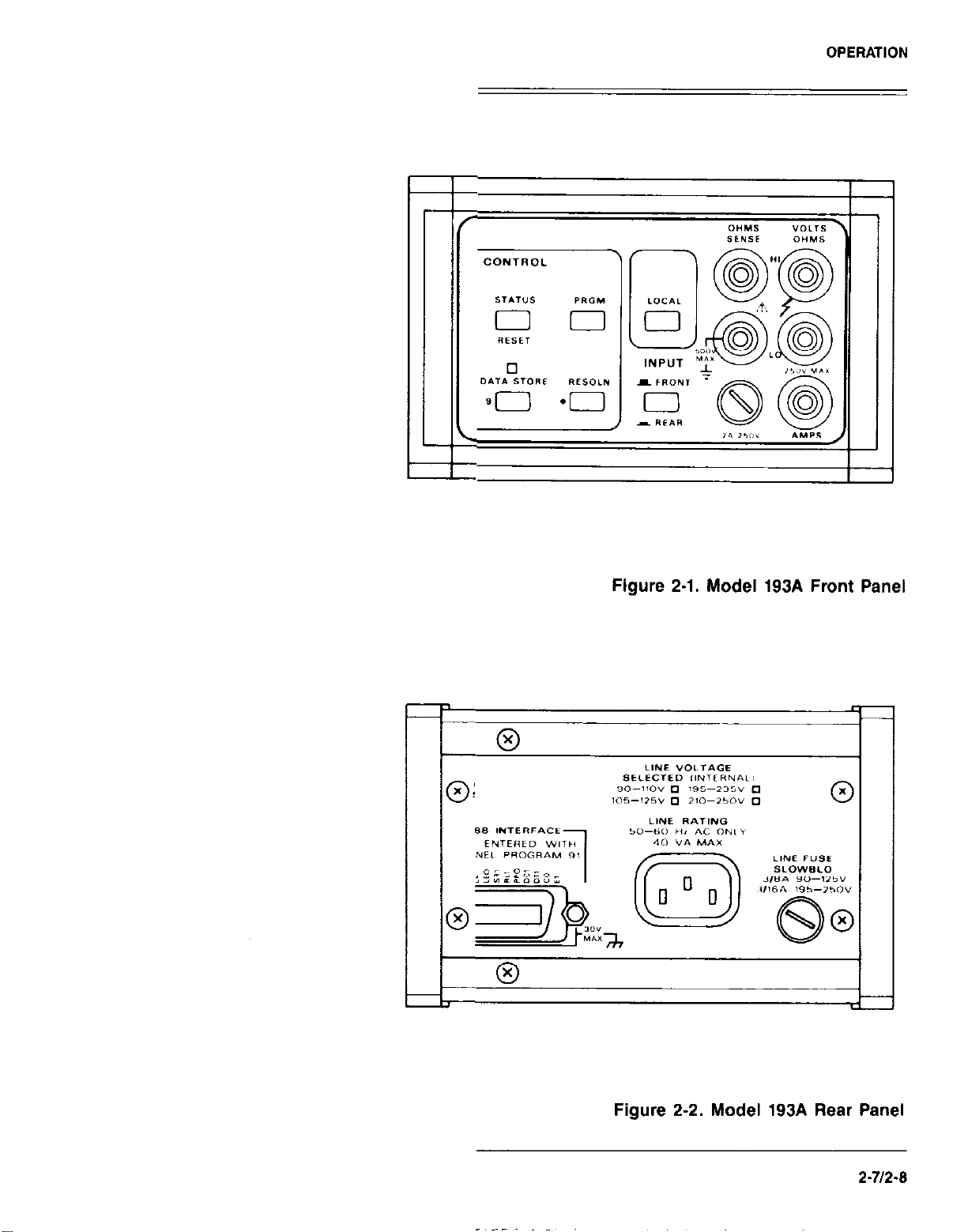

The front panel layout of the Model 193A is shown in Figure

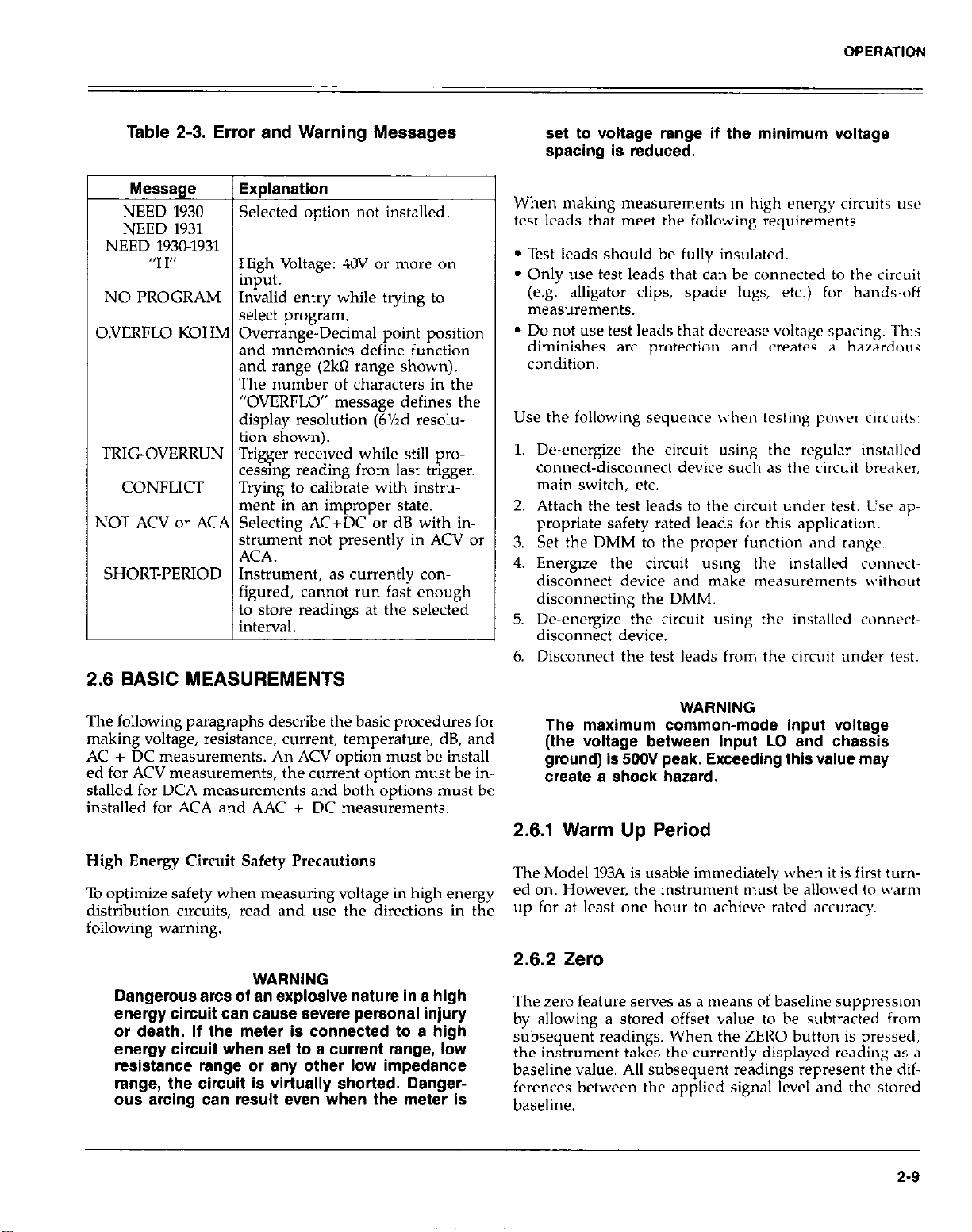

2-l. The following paragraphs describe the various components of the front panel in detail.

POWER-The POWER switch controls AC power to the in-

strument. Depressing and releasing the switch once turns

the power on. Depressing and releasing the switch a second time turns the power off. The correct positions for

on and off are marked on the front panel by the POWER

switch.

INPUT-The INPUT switch connects the instrument to

either the front panel input terminals or the rear panel in-

put terminals. This switch operates in same manner as the

power switch. The front panel input terminals are selected

when the switch is in the “out” position and the rear panel

input terminals are selected when the switch is in the “in”

position.

FUNCTION GROUP-The FUNCTION buttons are used

to select the primaly measurement functions of the instru-

ment. These buttons also have secondary functions.

DCV-The DCV button places the instrument in the DC

volts measurement mode. The secondary function of this

button is to enter the number 0. See paragraph 2.6.4 for

DCV measurements.

Am-With the ACV option installed, the ACV button places

the instrument in the AC volts measurement mode. The

secondary function of this button is to enter the number

1. See paragraph 2.6.6 for ACV measurements.

2.3.1 Display and Indicators

Display-The 14 character, alphanumeric, LED display is

used to display numeric conversion data, range and function mnemonics (i.e. mV) and messages.

Status Indicators-These three indicators apply to instrument operation over the IEEE-488 bus. The REMOTE indi-

cator shows when the instrument is in the IEEE-488 remote

state. The TALK and LISTEN indicators show when the in-

strument is in the talk and listen states respectively. See

Section 3 for detailed information on operation over the

bus.

2.3.2 Controls

All front panel controls, except the POWER and INPUT

switches, are momentary contact switches. Indicators are

located above certain feature buttons to show that they are

enabled. Included are AUTO (autorange), ZERO, FILTER,

RECALL and DATA STORE. Some buttons have secondary

functions that are associated with front panel program

operation. See paragraph 2-8 for detailed Information on

front panel programs.

OHMS-The OHMS button places the instrument in the

ohms measurement mode. The secondary function of this

button is to enter the number 2. See paragraph 2.6.7 for

resistance measurements.

ACA-With the ACV option and current option installed,

the ACA button places the instrument in the AC amps

measurement mode. The secondary function of this but-

ton is to enter the number 3. See paragraph 26.8 for ACA

measurements.

DCA-With the current option installed, the DCA button

places the instrument in the DC amps measurement mode.

The secondary function of this button is to enter the

number 4. See paragraph 2.6.8 for DCA measurements.

TEMP-The TEMP button places the instrument in the RTD

temperature measurement mode. The secondary functions

of this button are to select the TEMP program (select alter-

nate alpha value and thermometric scale) and to enter the

number 5. See paragraph 2.6.9 for RTD temperature

measurements.

RANGE GROUP-The Aand vbuttons are used for

manual ran

ing. These %

ing and the AUTO button is used for autorang-

uttons also have secondary functiolw.

2-2

Page 23

OPERATION

Manual-Each time the A button is pressed, the instrument will move up one range, while the v button will move

the instrument down one range each time it is pressed.

Pressing either of these buttons will cancel autorange, if

it was previous selected. The secondary functions of these

buttons are associated with front panel program operation.

AUTO-The AUTO button places the instrument in the

autorange mode and turns on the AUTO indicator. While

in this mode, the instrument will go to the best range to

measure the applied signal. Autoranging is available for all

functions and ranges. Autoranging may be cancelled by

pressin f the AUTO button or one of the manual range buttons. T e secondary function of this button is to enter the

* sign.

MODIFIER GROUP-The MODIFIER buttons activate

features that are used to enhance the measurement ca

bilities of the Model 193A. These features in effect ma Ify

a-

1

the selected function. In addition to their primary tasks,

these buttons have secondary functions.

ZERO-The ZERO button turns on the ZERO indicator and

causes the displa ed reading to be subtracted from subsequent readings. -F, his feature allows for zero correction or

storage of baseline values. The secondary function of this

button is to select the ZERO program. Refer to paragraph

2.6.2 for detailed information on the zero feature.

dB-The dB button places the instrument in the dB

measurement mode and may be used with the ACV and

ACA functions. Under factory default conditions, measurements are referenced to 1V or ImA. However, the dB program may be used to change the reference level. The secondary function of this button is to select the dB program.

See paragraph 2.6.10 for dB measurements.

FILTER-The FILTER button turns on the FILTER indicator

and causes the instrument to start weighted averaging a

number (l-99) of readings. The factory default value is 10,

but may be changed using the FILTER program (see

paragraph 2.8.6). See paragraph 2.6.3 for filter operation.

Selecting the FILTER

tions of this button. TK

rogram is one of the secondary func-

e other secondary function is to enter

the number 6.

AC + DC-With the appropriate options installed, the AC

+ DC button (with ACV selected) places the instrument in

the AC + DC measurement mode. With the ACV o

installed, VAC + DC measurements can be made.

tion

%ith

both the ACV and current option installed, AAC + DC

measurements can be made. See paragraph 2.6.12 for AC

+ DC measurements. The secondary functions of this button are to select the AC + DC program (low frequency

TRMS measurements) and to enter the number 7.

CONTROL GROUP-The CONTROL buttons are features

that allow for the control and manipulation of various

aspects of instrument operation. All of these buttons, except PRGM, have a secondary function.

RESOLN-The RESOLN button allows for the selection of

the number of digits of display resolution. Each press of

the RESOLN button increases resolution by one digit.

Pressing the RESOLN button after the maximum resolu-

tion is reached will revert the display back to the lowest

resolution. Dis

can be selecte B

lay resolution of 3%, 4’12, 5% or 6% digits

for DCV and ACV. Display resolution of

4% or 5’/2 digits can be selected for DCA and ACA. On

OHMS, Y/z, 4% 5% and 6% digit resolution is available on

the ZOOR through 200kfl ranges. On the 2MQ and 20MR

ranges, 5% and 6% digits can be selected. On the 200MR

ran e, only 5%d resolution is available. The RESOLN button a as no effect on low frequency AC + DC (Program AC

+ DC), TEMP or dB measurements. The secondary func-

tion of this button is to enter the decimal point (.).

TRIGGER/ENTER-The TRIGGER/ENTER button is used

as a terminator for data entry when the instrument is in

the front panel program mode and as a front panel trigger

when the data store is active.

STATUS/RESET

STATUS-Instrument status can be displayed when the in-

strument is in the normal measurement mode or logRing

readings. When the STATUS button is first pressed, the

following current instrument conditions can be displayed

with the use of the A and v buttons:

Software revision level

IEEE address

Line frequency setting

Multiplexer status (on/off)

MX+B status (on/off)

MX+B values

dB reference value

Filter value (OO=filter disabled)

Zero status (on/off)

Zero value

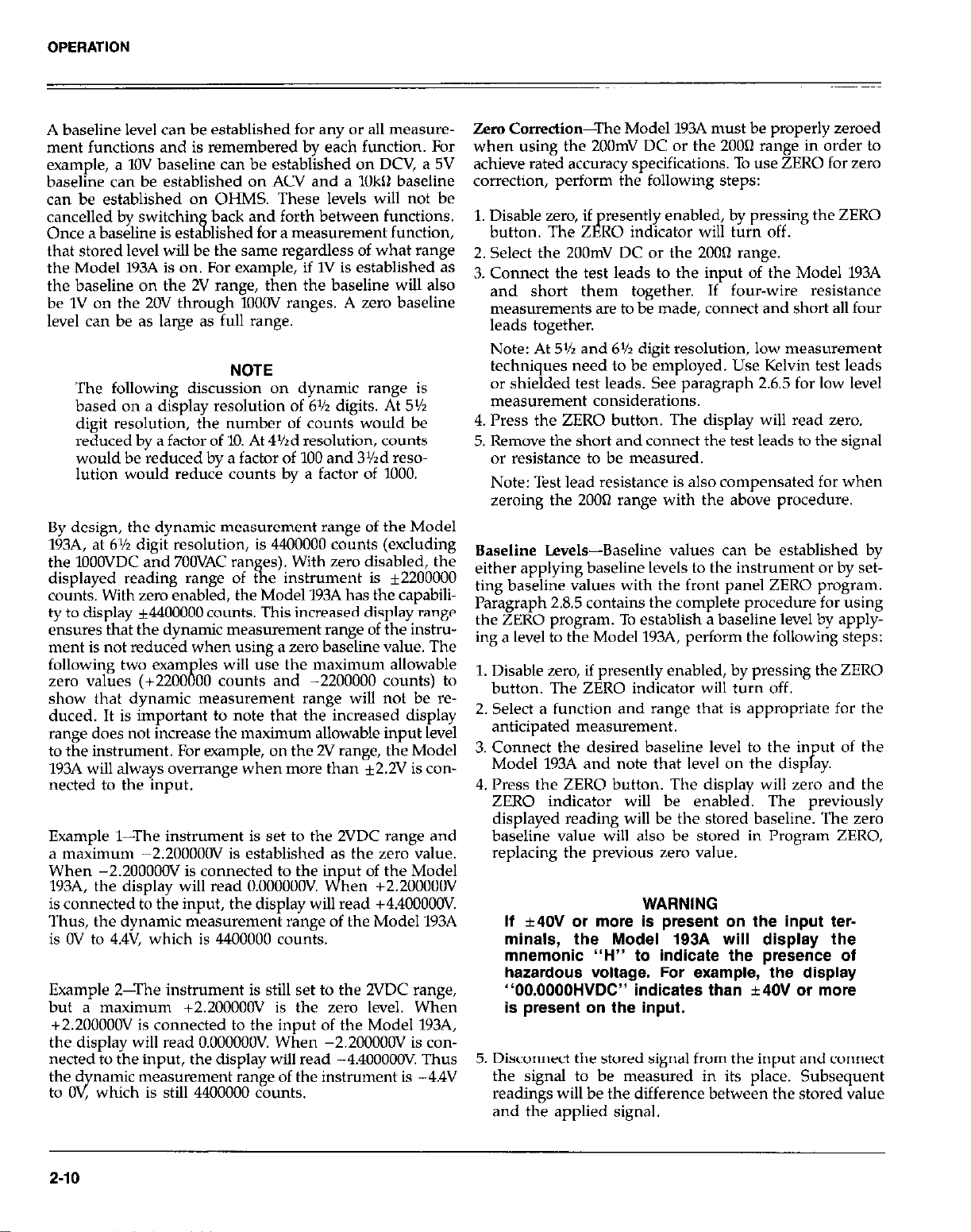

Pressing the STATUS button a second time takes the in-