Keating Of Chicago LB-200, LB-65 User Manual

1-800-KEATING

www.keatingofchicago.com

Keep this manual for training new personnel.

portableFilter

04/10

Part # 018164

*AS CONTINUOUS PRODUCT IMPROVEMENT OCCURS, SPECIFICATIONS MAY BE CHANGED WITHOUT NOTICE.

Users Manual

PORTABLE FILTER

MODELS PC14, LB-100, LB-65, LB-200

READ AND SAVE THIS MANUAL FOR FUTURE REFERENCE.

IMPORTANT:

Keep a copy of your bill of sale. The date on the bill establishes the warranty period should

service be required. If service is performed, it is in your interest to obtain and keep all receipts. Keating

commercial filters are not intended for household use.

The Owner’s Guide provides specific operating instructions for your model. Use the Portable Filter

only as instructed in this Owner’s Guide.

RECORD THE MODEL AND SERIAL

NUMBERS OF THIS PORTABLE FILTER

IN THE SPACES PROVIDED.

SERIAL NO. ______________________________

MODE L NO. _____________________________

KEEP THESE NUMBERS FOR FUTURE REFERENCE.

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . .1-2

A: PREPARING THE PORTABLE FILTER . . . . . . . . . . . . . . . . . . . . .1

B: FILTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

C: CLEAN-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

D: MELTING SOLID SHORTENING . . . . . . . . . . . . . . . . . . . . . . . . .2

E: FILTER FAILURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

WARRANTY REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SELF-HELP GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A: MELT/PUMP INDICATOR LIGHTS . . . . . . . . . . . . . . . . . . . . . . . .4

B: MELT/PUMP ON/OFF SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . .4

C: MELT CYCLE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

D: HEATER ELEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

E: PUMP AND MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

F: HEAT TAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

ORDERING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

WARNING AND OPERATING PLATES . . . . . . . . . . . . . . . . . . . . . . .7

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-13

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . .14

CONTENTS:

PORTABLE FILTER

OPERATING INSTRUCTIONS

1

Figure 1.3: Assemble filter

Figure 1.1: Remove screen over

elements/ tubes

Figure 1.2: Stir with spoon to

remove water

A. PREPARING THE PORTABLE FILTER

1. Remove screen from over tubes/element with tongs or a Drain Clean Out

Rod (See Figure 1.1).

SCREEN OVER TUBES/ ELEMENTS WILL BE VERY HOT AND

SHOULD BE MOVED TO A SAFE PLACE.

2. Heat fryers to 325°F. Stir oil thoroughly until all water is removed and

shut fryer off (including pilot light) before filtering. (Figure 1.2)

NOTE: Water settles in the cooler oil in the Cold Zone. If the water is not

removed, the filter paper absorbs the water preventing the oil from

passing through it.

OIL IS HOT. USE CARE WHEN FILTERING.

3. Place in clean filter tub (See Figure 1.3):

1st: Filter Screen

2nd: Filter Paper (new sheet for each fryer)

3rd: Hold down ring

4th: Secure hold down ring at each corner with “T” rod handles

5th: Acidox filter powder (new powder for each fryer)

6th: Strainer basket

NOTE: Hold down ring makes a gasket-like seal on filter paper. Filter paper

must be placed edge to edge from front to back, overlapping on

sides. Filter Paper must be smooth and flat under hold down ring to

get a proper seal. Lock the two tension arms into place by pushing

down and rotating 90°.

NOTE: One package of Acidox is needed for every 40 pounds of oil.

B. FILTRATION

1. Place filter under fryer drain. Screw drain extension tube in to drain valve

if desired. Open main drain valve and let oil flow completely into filter

(See Figure 2.1).

2. Turn on pump and flush all crumbs from bottom of fryer into filter. Flush

out fryer completely (See Figure 2.2).

3. Close fryer drain valve (See Figure 2.3).

4. Clean fryer vessel with non-abrasive scrub pad & Keating Klenzer.

5. Fill fryer with filtered oil by turning on pump and directing end of wand

into vessel (See Figure 2.4).

NOTE: Filters with two-way pump - do NOT place wand in cold zone

of fryer pot as it may pick up crumbs & other debris and excessively

clog filter paper.

C. CLEAN-UP

FILTER UNIT AND PIPES WILL REMAIN HOT FOLLOWING

FILTRATION. ALLOW THE UNIT TO COOL DOWN BEFORE CLEAN

UP. FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY TO THE

OPERATOR.

1. Turn off filter and disconnect from electrical source.

2. Remove strainer basket and hold down ring for cleaning

3. Remove and discard filter paper and any residue.

4. Clean filter tub thoroughly.

5. Coat inside of pump with oil if water has been running through it.

6. Place hose so that remaining oil will drain out.

D. MELTING SOLID SHORTENING

1. Clean filter tub and remove all accessories.

2. Place a cube of shortening in filter tub.

3. Turn fat melter on. (50 lbs takes 1 hr to melt)

4. Once shortening is melted fill fryer with oil by turning on pump and

directing end of wand into vessel (See Figure 2.4).

DO NOT ALLOW SHORTENING TO SOLIDIFY IN FILTER AS IT WILL

ALSO SOLIDIFY IN PIPES.

DO NOT TURN ON FAT MELTER WITHOUT SHORTENING IN TUB.

E. FILTER FAILURE

If filter will not pump, solidified shortening may have plugged pipes. Turn on

fat melter for 20 minutes. This will heat filter tub and pipes to free system of

solidified shortening. Reset motor before attempting filtering (reset button is

located on rear of pump motor.)

WARRANTY REPAIRS

Keating’s 1 year parts & labor warranty begins with the date of installation.

In the event that your filter, under warranty, needs repairs other than routine

cleaning, you are requested to contact KEATING OF CHICAGO, INC.

(1-800-KEATING) before calling a local service company.

r of pump motor).

Figure 2.3: Close drain valve

Figure 2.4: Fill fryer with filtered

oil

2

Figure 2.1: Drain fryer

Figure 2.2: Flush out fryer

HOT FLUID. DO NOT FILL

BEYOND MAXIM UM FILL LINE

LOCATED IN THE FRYER VESSE L.

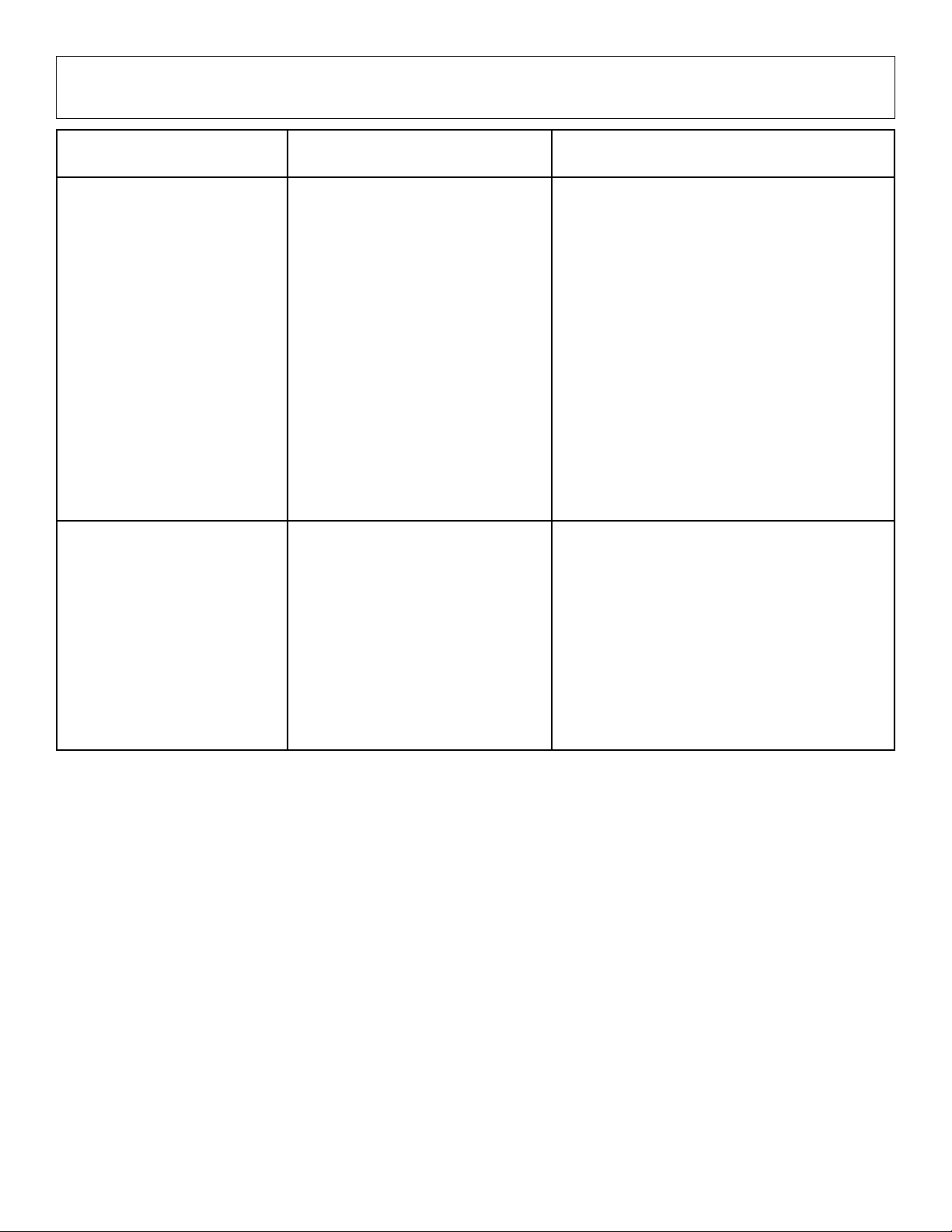

SELF-HELP GUIDE

3

PROBLEM PROBABLE CAUSE SOLUTION (Follow Sequentially)

Motor runs but will not pump oil. A. Solidified shortening may have

plugged pipes.

Turn on fat melter for 20 minutes. This will heat

filter tub and pipes to free system of solidified

shortening. Reset motor before attempting filtering

(reset button is located on rear of pump motor).

B. Tub not set up properly. Place components in tub per the following:

1. Filter screen on the very bottom.

2. Filter paper over filter screen (Lie it flat on the

bottom, creasing the sides).

3. Hold down ring (ensure paper is not folded,

lock hold down ring into place ensuring a tight

seal).

4. Sprinkle Acidox powder evenly over filter

paper (1 bag per 40 lbs. of oil).

5. Strainer basket for large debris.

Motor does not operate. A. Not plugged in.

B. Motor has overheated.

C. Motor pump is clogged.

1. Plug filter into a 120 or 220 Vac electrical

power source.

2. Turn ON/OFF switch to ‘ON’.

1. Allow motor to cool for approximately 10

minutes.

2. Press the motor overload reset button and try

again.

1. Call a qualified service technician to clean

your pump. Clogged motor pumps are not

covered by warranty.

Preventative maintenance should be performed during & after each use of the filter. Following preventative maintenance

procedures will help to keep your filter working efficiently. Proper care & servicing will lead to years of quality performance.

PREVENTIVE MAINTENANCE

Familiarize yourself with the proper filtering procedure prior to attempting to filter:

1. To remove water, stir oil until bubbling stops; water will clog filter paper pores.

2. Use only one sheet of filter paper properly sealed under hold down ring.

3. Do NOT turn on fat melt without oil in filter tub.

4. Use a drain clean out rod if partial or full blockage in fryer drain is suspected.

5. If filter was used for fryer boil out, run oil through filter to lubricate motor/pump.

6. Clean filter and all components after each use. Do not permit oil to remain in filter drawer; it will clog the pump.

7. Verify all lights and controls operate.

8. Adhere to operating instructions in sequence given for proper filtration.

9. Prepare filter for next use by using new filter paper and Acidox Powder for each fryer.

DISASSEMBLY

You will need:

Adjustable wrench “Stubby” screwdriver

Standard pliers Standard screwdriver

Servicing should only be performed by qualified and licensed

service companies. Always disconnect the electrical power

cable before attempting any service

The filter maybe hot; use care while servicing. As a

safety precaution, it is recommended you drain oil from

the filter vessel before performing any servicing.

A. MELT AND/OR PUMP INDICATOR LIGHTS

Removal:

1. Disconnect filter from electrical power source.

2. Feel front end panel from bottom to locate rear of

defective indicator light. Note two tangs that extend

slightly beyond indicator light barrel diameter. Use a

standard pliers to squeeze tangs together and pull

indicator light free from panel. If indicator light doesn’t

release, squeeze tighter and break barrel to release

electrical leads. Discard broken pieces.

Replacement:

1. If necessary, clip off electrical leads as close as

possible to indicator light. If leads were clipped, trim

off insulation 1/8 inch from end.

2. With electrical leads extending through panel front,

press them into recesses at rear of replacement

indicator light to secure them in place. Press

indicator light into panel until tangs engage to secure

indicator light to panel.

B. MELT AND/OR PUMP ON/OFF SWITCH

Removal:

1. Disconnect filter from electrical power source.

2. Unscrew nut securing defective switch to panel.

Push switch in to release from panel. Remove

nameplate from front of panel.

3. Access to rear of switch through bottom hole under

front end panel.

4. Disconnect leads from switch. Tag leads as they are

disconnected to assure, during replacement, they are

reconnected to the proper switch terminals.

Replacement:

1. Connect tagged electrical leads to replacement

switch.

2. Insert replacement switch through panel from which

defective switch was removed. Insert nameplate over

toggle and secure to panel with nut supplied with

switch. Orient switch and tighten nut to secure in

desired position.

3. Plug in filter power cord and operate switch to verify

switch orientation corresponds to nameplate legend.

If not, loosen attaching nut and reorient nameplate

and/or switch as desired and retighten nut.

C. MELT CYCLE SENSOR

Removal:

1. Disconnect filter from electrical power source.

NOTE: Remove all oil from filter vessel. Filter must

be positioned on its end to access melt cycle

sensor.

2. Raise front (power cord) end of filter and rest filter on

oil absorbing rags on its back end.

3. Remove bottom cover attaching screws; remove

bottom cover.

4. Remove electrical leads from defective melt cycle

sensor.

5. Loosen heater element cover attaching nut adjacent

to melt cycle sensor sufficiently to release melt cycle

sensor and its retaining plate. Disengage melt cycle

sensor.

Replacement:

1. Orient replacement melt cycle sensor in its retaining

plate such that the metallic sensing surface will be in

direct contact with filter vessel. If necessary, reverse

orientation of retaining plate.

2. Position retaining plate under heater element and tab

on heater element cover with melt cycle sensor

sensing surface in direct contact with filter vessel.

Tighten loosened heater element attaching nut.

3. Attach removed electrical leads to melt cycle sensor.

Verify terminals are not in contact with any metallic

parts of filter vessel, heater cover or heater.

4. Secure bottom cover with removed attaching screws.

5. Position filter right-side-up and clean up oil absorbing

rags.

SERVICE

4

Loading...

Loading...