Keating Of Chicago Hands Free User Manual

A. FILTER-DRAWER

WARNING!

WATER + HOT OIL = DON'T MIX!

1. Operator should be outfitted with proper protective

attire: safety goggles, oil and heat resistant gloves,

apron and footwear

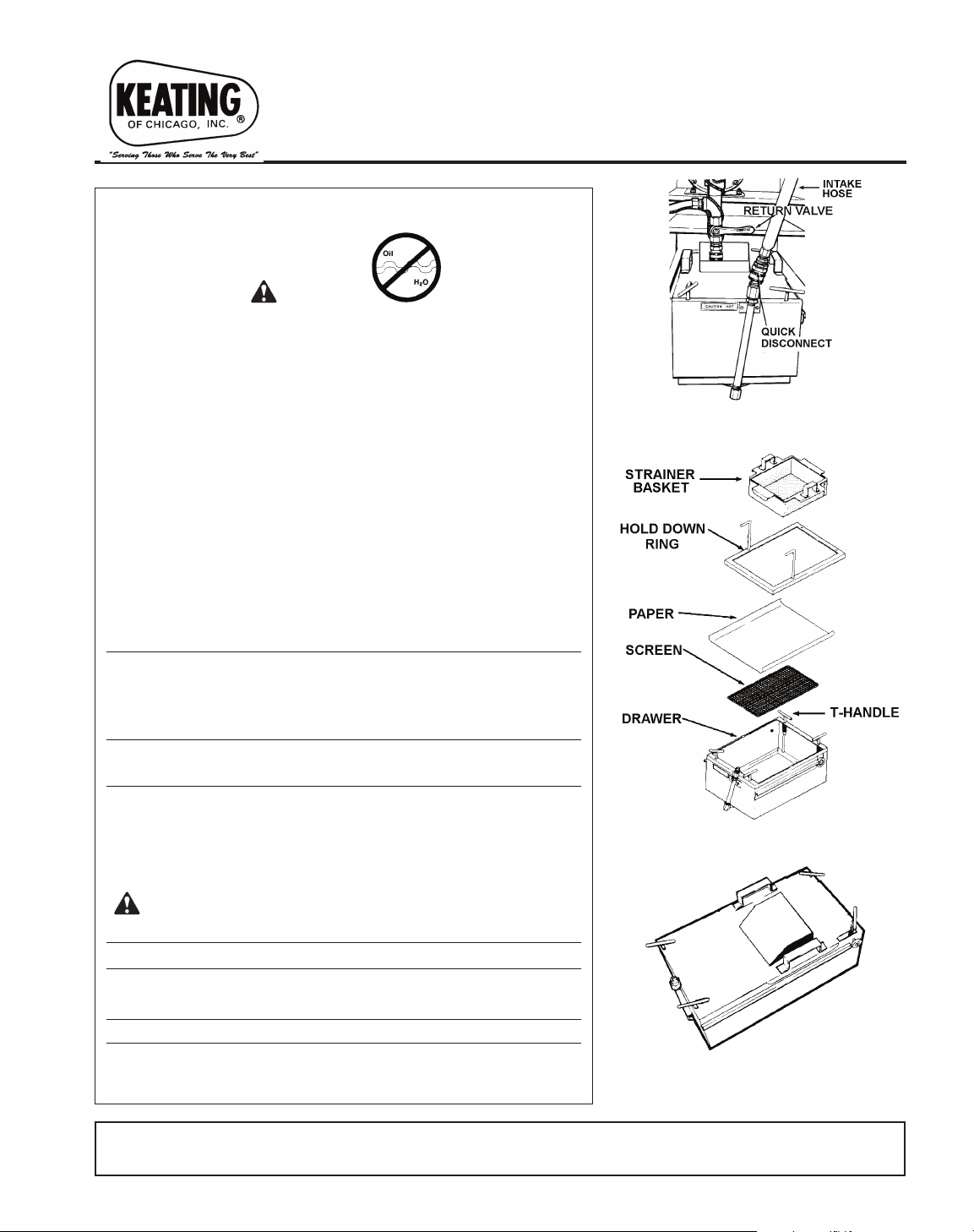

2. Release intake hose from filter drawer using the quick

disconnect. Refer to Figure 1.

3. Pull filter drawer forward and remove the cover and

strainer basket. Refer to Figure 2.

4. Release the spring loaded T-Arms located in the corners

of the filter drawer and remove the hold down ring. Refer

to Figure 2.

5. Filter screen should be in bottom of drawer. Place filter

paper on top of screen.

6. Position hold down ring on top of paper and secure with

T-Arms. Refer to Figure 3.

NOTE: Hold down ring makes a gasket-like seal on filter

paper. Filter paper must be placed edge to edge from front to

back, overlapping on sides. Filter Paper must be smooth and

flat under hold down ring to get a proper seal.

NOTE: One package of Acidox is needed for every 40 pounds

of oil.

7. Sprinkle Keating Acidox Powder evenly over the paper.

8. Replace strainer basket and cover, push drawer fully into

cabinet and reconnect intake hose and pull up on hose to

check connection.

CAUTION

Pull up on hose to check connection.

NOTE: Cabinet door should be closed during filtration.

NOTE: For best results, new filter paper and Acidox Powder

should be used for each fryer.

B. PREPARING OIL FOR FILTRATION

NOTE: Oil in fryer must be between 250° - 350°F.

1. Turn fryer completely off.

FIGURE 2. FILTER DRAWER ASSEMBLY

FIGURE 3. FILTER DRAWER COMPLETE WITH

SCREEN, FILTER PAPER, HOLD DOWN RING,

ACIDOX, STRAINER BASKET AND COVER.

HANDS FREE CENTRAL FILTER

OPERATING INSTRUCTIONS

KEEP THIS MANUAL FOR TRAINING NEW PERSONNEL

FIGURE 1. QUICK DISCONNECT

– 1 –

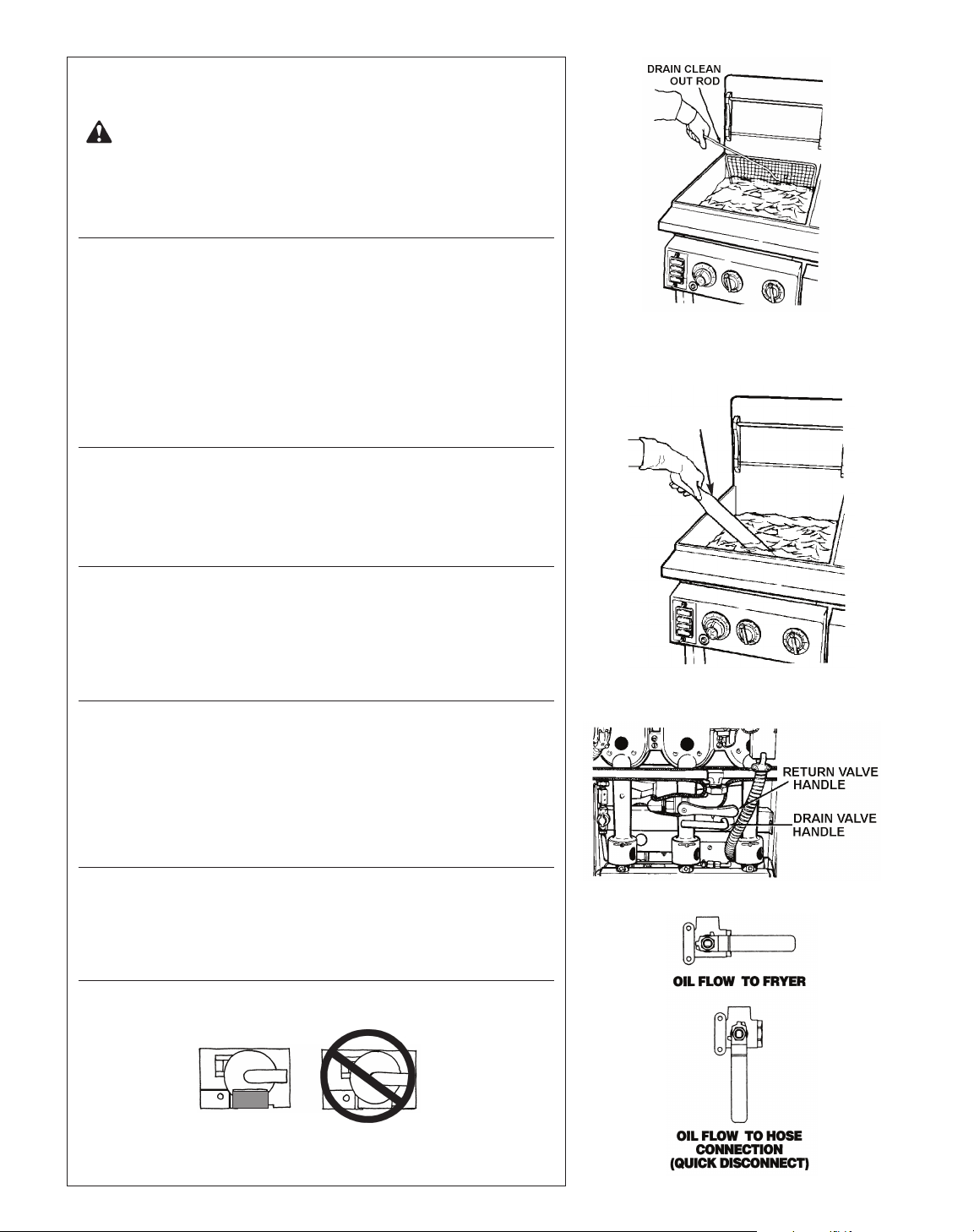

2. Remove screen from over tubes/element with tongs or a

Drain Clean Out Rod. Refer to Figure 4.

CAUTION

Screen over tubes will be very hot and should be moved

to a safe place.

3. Use spoon provided to stir oil. Bubbling will occur until all

water is removed. Refer to Figure 5.

NOTE: Water settles in the cooler oil in the Cold Zone. If the

water is not removed, the filter paper absorbs the water

preventing the oil from passing through it.

C. FILTRATION

1. In fryer cabinet, have return valve handle located directly

above the drain valve set to oil flow to fryer. Refer to

Figure 6.

2. Open the drain valve by lifting and then pulling the drain

valve handle and drain fryer.

NOTE: A Drain Clean Out Rod may be needed to loosen any

solid residue. Use it only when valve is fully open.

3. Wipe crumbs from splashdeck while fryer is empty.

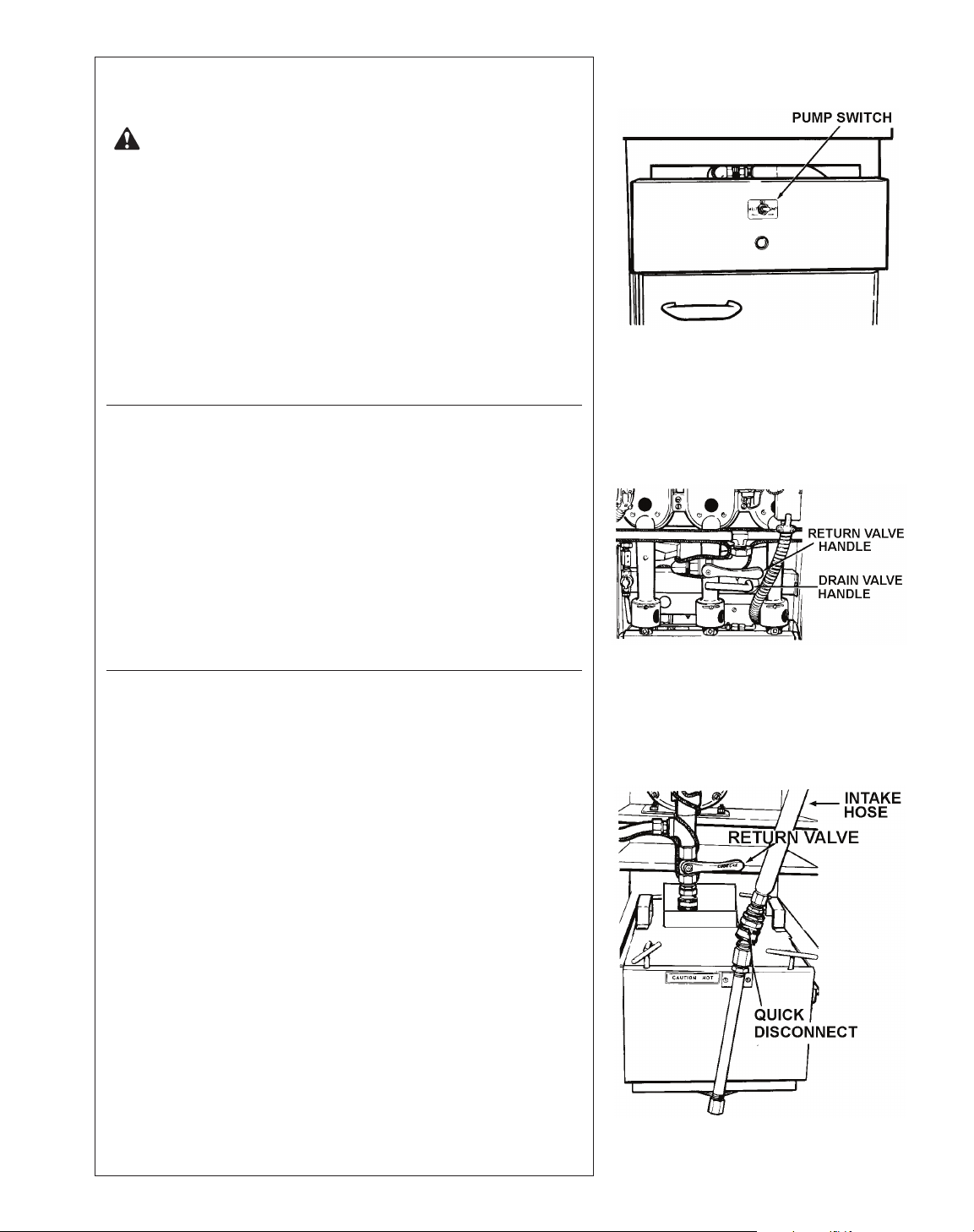

4. On the filter panel, turn the pump switch to the “Pump” or

“ON” position. Refer to Figure 8.

NOTE: If oil does not return to fryer, set pump switch to

“MELT” position for ten minutes to melt any solidified

shortening in the return pipe (only on models with melt cycle.)

5. Let the pump run with drain valve open to remove crumbs

and residue from the bottom of fryer and the drain lines.

Failure to do so may cause the drain lines to clog up.

NOTE: If the pump shuts down, turn it off and let the motor

cool.Then pull motor reset lever located in filter cabinet.

Check filtering procedure or clean pump if needed.

6. Partially close drain valve to allow fryer to fill above

tubes/elements.

7. Let swirling action rinse down fryer.

8. Fully drain fryer.

NOTE: Pump should be run for at least 30 seconds after

crumbs are removed from fryer. This will help prevent

blockage in the drain lines.

9. Close drain valve and completely refill fryer. Refer to

Figure 9.

NOTE: The drain valve handle activates fryer’s Main Power

Switch. If drain valve is not fully closed and locked, fryer will

not operate.

10. Turn pump switch to the “OFF” position and close return

valve.

FIGURE 4. REMOVE SCREEN OVER

TUBES/ELEMENTS

FIGURE 5. STIR WITH SPOON PROVIDED

TO REMOVE WATER

FIGURE 6. FRYER VALVE HANDLES

FIGURE 7

FIGURE 9

– 2 –

SPOON

D. CLEAN UP

CAUTION: Filter drawer and pipes will remain hot

following filtration. Allow the unit to cool down before

clean up. Failure to do so may result in serious injury to

the operator.

1. Release intake hose from filter drawer using the quick

disconnect. Refer to Figure 10.

2. Pull filter drawer forward and remove the cover and

strainer basket. Refer to Figure 2.

3. Release the spring loaded T-Arms located in the corners

of the filter drawer and remove the hold down ring. Refer

to Figure 2.

4. Thoroughly clean and dry the filter drawer.

NOTE: Tilt the drawer towards the back to fully drain sump.

This will prevent solidified oil from blocking the pipe.

5. Replace filter screen after cleaning.

6. Place filter paper on top of screen.

7. Position hold down ring on top of paper and secure with TArms. Refer to Figure 3.

8. Sprinkle Keating Acidox powder over the paper.

9. Replace strainer basket and cover, push drawer fully into

cabinet and reconnect intake hose. Check to ensure

proper connection.

10. Close the cabinet door.

NOTE: Instructions for cleaning the fryer are in the Operating

Section of the fryer Service Manual.

E. CLEANING AND BOIL-OUT

When cleaning and boiling out your fryer use Keating Sea

Powder and Keating Klenzer to keep your fryer in top

condition.

Operator should be outfitted with proper protective attire:

- safety goggles

- oil and heat resistant gloves, apron and footwear

Turn the fryer off.

A cleaning hose and wand have been provided for cleaning

the fryer and discarding the oil.

Attach cleaning hose to quick disconnect located below the

valve handle in filter cabinet.

Remove fry baskets and screen. Drain fryer into the central

filter drawer.

Set the return valve to “oil flow to hose.” See Figure 6 & 7.

The hose may now be used to rinse the tubes/elements and

fry pot and to pump the oil into the shortening handling

system and discard properly.

FIGURE 8. FILTER CONTROL PANEL

FIGURE 9. DRAIN VALVE HANDLE

FIGURE 10. QUICK DISCONNECT

– 3 –

Loading...

Loading...