Keating Of Chicago 240V User Manual

KEEP THIS MANUAL FOR TRAINING NEW PERSONNEL

1-800-KEATING

www.keatingofchicago.com

Part # 000000 Electric Pasta 0107 09/07

CUSTOM

PASTA

™

SYSTEM

ELECTRIC

SERVICE

MANUAL

i

This operating, installation, and service manual should be given to

the user. The operator of the Custom Pasta

™

System should be

familiar with the functions and operation of the cooker. This manual

must be kept in a prominent, easily reachable location near the Pasta

System.

POST THIS LABEL IN A

PROM INENT LOCATION ON

YOUR UNIT

Using any parts other than genuine, Keating of Chicago, Inc. factory

manufactured part relieves the manufacturer of all warrant and liability.

Keating of Chicago, Inc. (manufacturer reserves the right to change

specifications at any time.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

WARNING

Do not store flammable

liquids near this or any

other appliance.

WARNING

Improper installation

can cause damage,

injury or death.

SECTION I SPECIFICATIONS . . . . . . . . . . . . . . 1

SECTION II INSTALLATION

Shipment and Transit . . . . . . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

A. Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

B. Electrical Connection . . . . . . . . . . . . . . . . . . . . .1

C. Water & Drain Connection . . . . . . . . . . . . . . . . .1

SECTION III OPERATION

Thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . .2

The Auto-Fill System . . . . . . . . . . . . . . . . . . . . . . . .2

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electronic Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SECTION IV MAINTENANCE

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . .4

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A. Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

B. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION V SERVICE AND PARTS INFORMATION

Auto-Fill System . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Cooker Heating Section . . . . . . . . . . . . . . . . . . . . . .5

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SECTION VI SERVICE DIAGNOSIS

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

SECTION VII PARTS LIST

Control Panel Assembly . . . . . . . . . . . . . . . . . . . . .9

14” Drop-In Custom Pasta Parts List . . . . . . . . . . .10

18” Custom Pasta Parts List . . . . . . . . . . . . . . . . .10

SECTION VIII WIRING DIAGRAMS

14" Electric Pasta, 2-Thermostat without timers . .11

14" Electric Pasta with 138 timers . . . . . . . . . . . . .12

18" & 20" Electric Pasta with 138 timers . . . . . . . .13

18" Electric Pasta, 2-Thermostats without timers .14

WARRANTY

Keating Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .15

TABLE OF CONTENTS

1

2

I INTRODUCTION

GENERAL

Keating Electric Custom Pasta™Systems are designed

to give maximum production efficiency, delivering high

quality food products. The following design features are

incorporated in Keating Pasta Electric Systems.

STANDARD FEATURES

• Highly polished stainless steel vessel

• Highly polished stainless steel front

• Highly polished stainless steel elements

• Highly polished stainless steel thermostat bulb

• Highly polished stainless steel Hi-Limit sensor

• Grid screen over elements

• Automatic water fill with manual override

• Water solenoid and indicating light

• Starch overflow

• Two electronic timers

• Low water safety shutoff

• 1" full port front drain valve on 14;

1

1

/4" for 18 and larger

• High temperature limit control with manual reset

• Patented accurate temperature control system

±2°F

• Ideal 35" working height

• One pair of split baskets or one perforated basket

• Patented dual thermostat system

• Indicating lights for pilot and secondary thermostat

on

STANDARD ACCESSORIES

• Keating Klenzer Sample

• Keating Sea Powder Sample

• Drain clean out rod

• Sensor Cleaning Brush

STANDARD PASTA SYSTEMS

• Sizes: 14 to 24

• Water capacity 51/

2 to 17

1

/

2 gallons

• 24 Pasta System can cook 6 lbs. of dry pasta per

load up to 110 lbs. per hour

• NSF certified

• ETL Certified listed

• ETL Sanitation Certified listed

MODEL VARIATIONS

Basket-Lift Model: Basket-Lift Model Pasta Systems

come with all the same features as the standard

models. The Basket-Lift mechanism lowers the baskets

of food into the water when the timer button is pressed

and raises the baskets when the cooking cycle is

complete. Split baskets are required for these models.

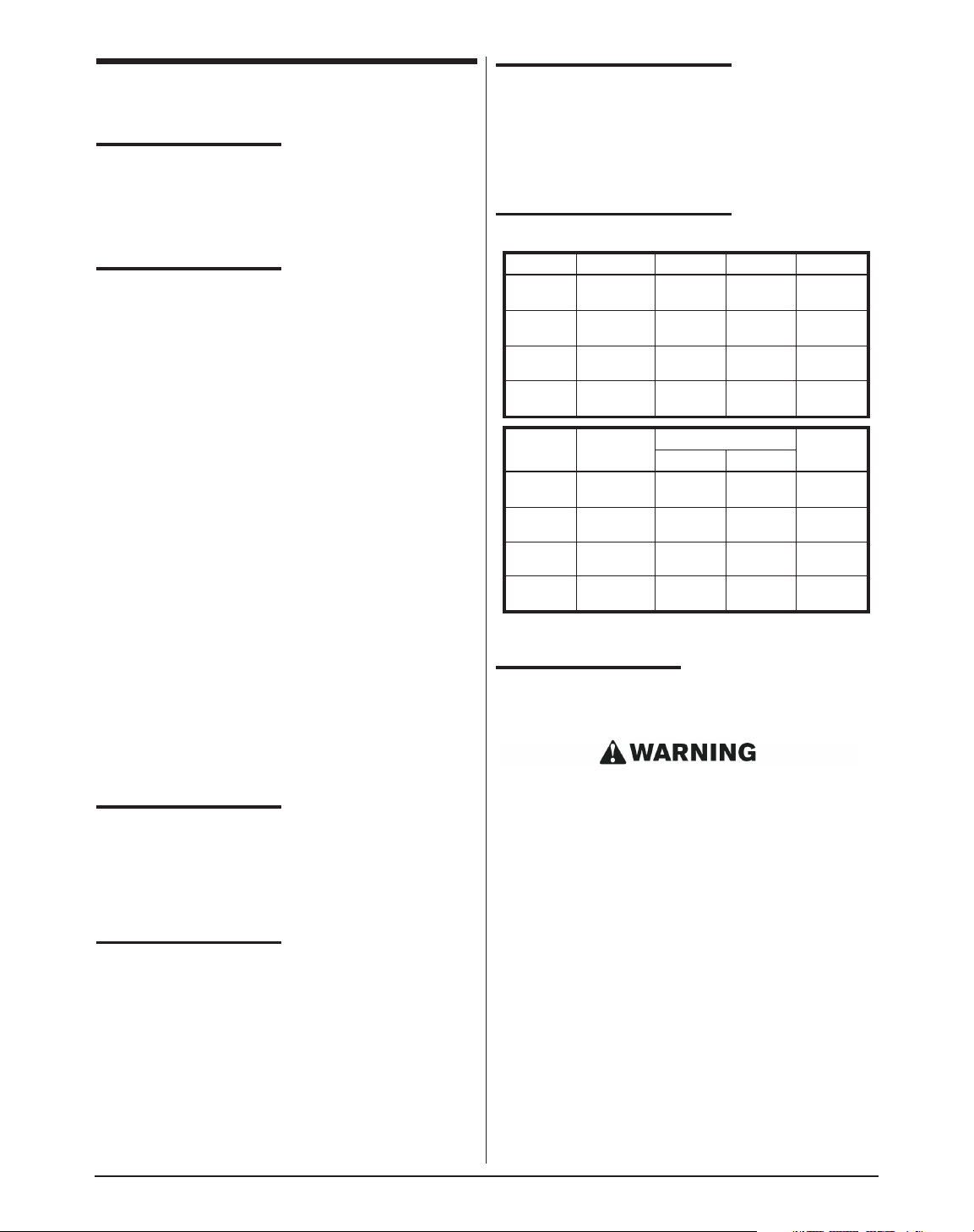

SPECIFICATIONS

SAFETY

PRECAUTIONS

THIS SYMBOL WARNS YOU THAT SERIOUS BURNS

OR OTHER INJURIES MAY RESULT IF SAFETY

INSTRUCTIONS ARE NOT FOLLOWED.

• This service manual should be retained in a safe

place for future reference. The installation of your

new Pasta System must conform to local codes

and with the current National Electrical Codes and

regulations as applicable.

• Your ventilation hood, when installed, must conform

to the current standards.

• No frame or restriction shall be constructed around

the Custom Pasta System that will restrict air

movement into the Pasta System or prevent proper

ventilation.

• You must maintain this appliance free and clear

from combustibles.

• Adequate clearance for servicing and proper

operation must be maintained. Your pasta system

is designed to be serviced from the front.

MODEL kW @ 240V

AMPS

SHIP WT.

3P 1P

14 15.5 32-56-32 65 125 lbs

18 20.7 50-50-50 87 175 lbs.

20 20.7 50-50-50 87 200 lbs.

24 28.6 52-82-82 119 300 lbs.

MODEL CAPACITY HEIGHT DEPTH WIDTH

14 7 gal. 461/2" 311/8" 153/8"

18 10 gal. 461/2" 331/8" 193/8"

20 15 gal. 461/2" 351/8" 213/8"

24 19 gal. 461/2" 391/8" 253/8"

• Keating Custom Pasta™Systems are intended for

other than household use.

• ALWAYS instruct new employees on proper pasta

system operation.

• A Custom Pasta System™should be operated

ONLY by properly trained personnel.

• ALWAYS turn pasta system off each night.

• ALWAYS turn pasta system off at customer power

panel before servicing.

• NEVER leave a pasta system unattended during

operation.

• NEVER move a pasta system when full of hot

water.

• NEVER introduce objects or liquids into pasta

system, while operational, which are not designed

or made for cooking.

• THIS CUSTOM PASTA

™

SYSTEM MAY NOT BE

ALTERED, MODIFIED OR CHANGED IN ANY

WAY.

IF THE EQUIPMENT IS NOT

INSTALLED, OPERATED AND

MAINTAINED IN ACCORDANCE

WITH THE ABOVE,

CONCENTRATIONS OF CARBON

MONOXIDE IN EXCESS OF THE

ESTABLISHED LIMITS COULD BE

PRESENT IN THE KITCHEN

ENVIRONMENT.

ALL PERSONNEL IN THE WORK PLACE WHO MAY

BE SUBJECT TO ANY EXPOSURE OF CARBON

MONOXIDE MUST BE WARNED OF SUCH

POSSIBLE EXPOSURE. THIS WARNING SHOULD

BE CONVEYED IN A MANNER SO THAT IT IS

CLEARLY UNDERSTOOD BY THE EMPLOYEE, AND

THE EMPLOYEE SHOULD BE ASKED IF IN FACT HE

OR SHE UNDERSTANDS THE CORRECT METHOD

OF OPERATION OF THE EQUIPMENT AND THAT A

RISK OF EXPOSURE EXISTS IF THE EQUIPMENT

IS OPERATED IMPROPERLY.

IF NOT INSTALLED, OPERATED AND MAINTAINED

IN ACCORDANCE WITH THE MANUFACTURER’S

INSTRUCTIONS, THIS PRODUCT COULD EXPOSE

YOU TO SUBSTANCES IN FUEL OR IN FUEL

COMBUSTION WHICH CAN CAUSE DEATH OR

SERIOUS ILLNESS AND WHICH ARE KNOWN TO

THE STATE OF CALIFORNIA TO CAUSE CANCER,

BIRTH DEFECTS OR OTHER REPRODUCTIVE

HARM.

II INSTALLATION

This Custom Pasta™System MUST

be installed, inspected, calibrated

and serviced by qualified and/or

certified and/or licensed service

personnel – you may void your

Keating warranty if installation is not

completed per current local, national

and Keating specifications. Contact

your dealer for assistance.

DAMAGE DURING

SHIPMENT

The Custom Pasta™System has been assembled,

tested and inspected at the factory. Upon arrival, the

complete Pasta System should be checked for any

damage that may have occurred during shipment.

The carrier is responsible for all damage in transit

whether visible or concealed. Do not pay for the freight

bill until the Custom Pasta™System has been

thoroughly checked for damage. If concealed damage

is found later, contact the carrier immediately to file a

claim.

WHAT TO DO IF EQUIPMENT

ARRIVES DAMAGED:

VISIBLE LOSS OR DAMAGE — Be certain to

note this on the freight or express receipt and

have it signed by the delivery person.

FILE CLAIM FOR DAMAGES

IMMEDIATELY — Regardless of extent of

damage.

CONCEALED LOSS OR DAMAGE —If

damage is noticed when equipment is

unpacked, notify the freight company

immediately, and file a “concealed damage

claim”. This MUST be done immediately. Be

sure to retain the shipping container for

inspection.

Keating does not assume responsibility for Loss OR

Damage incurred in transit.

NOTE: Interstate commerce regulations require that

the claim must be initiated by the consignee within 10

days from the date it is received.

IT MAY BE NECESSARY TO INSTALL A BACK

FLOW OR CHECK VALVE ON THE WATER SUPPLY

LINE TO THE PASTA COOKER. CHECK WITH

EITHER YOUR LOCAL WATER OR HEALTH

DEPARTMENT TO DETERMINE IF THIS IS

NECESSARY IN YOUR SPECIFIC AREA.

3

WARNING

Improper installation

can cause damage,

injury or death.

WARNING

Improper installation

can cause damage,

injury or death.

4

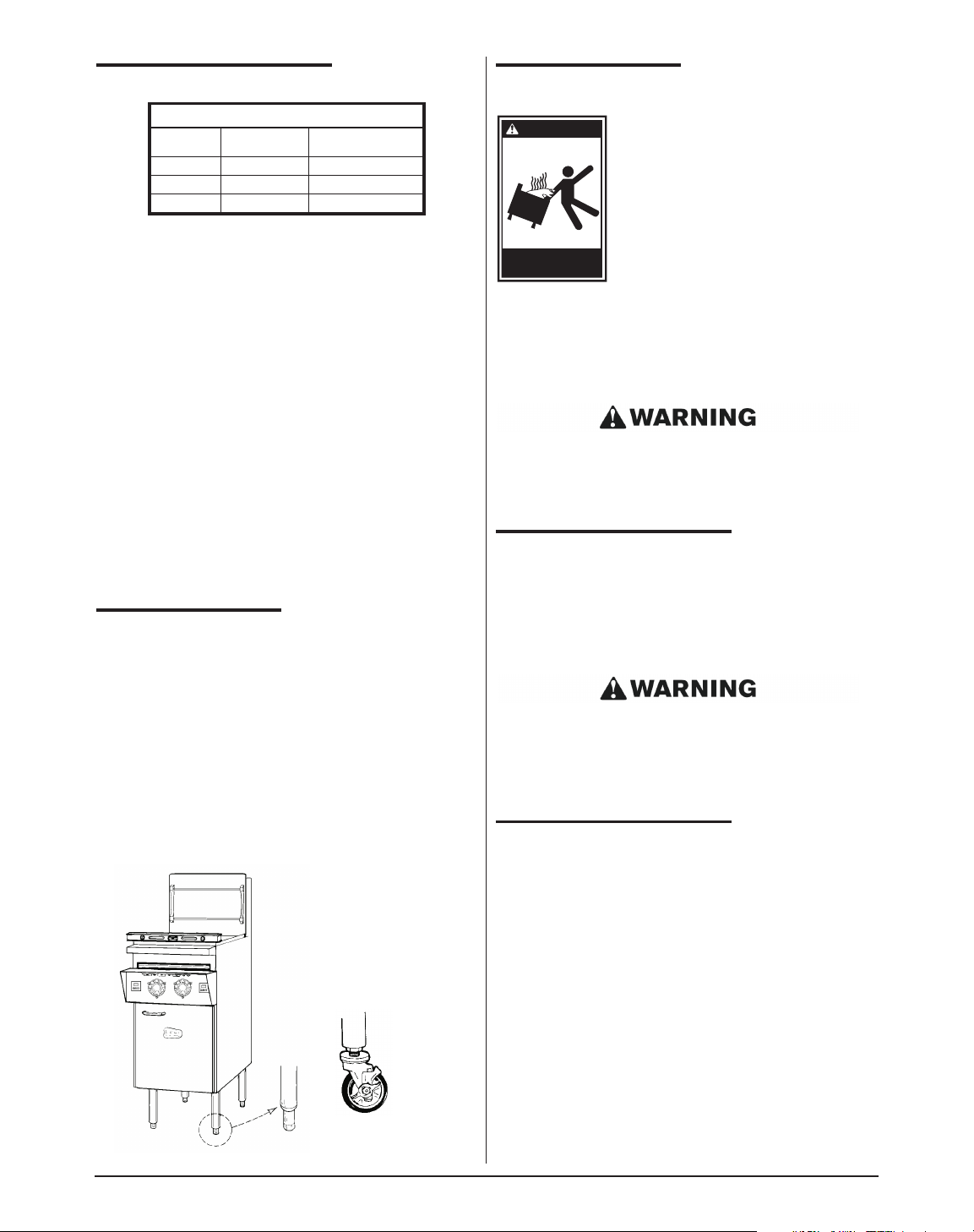

POSITIONING

The pasta cooker must be no closer than 6" from any

combustible material. When placed under an exhaust

hood with a fire retardant system it must comply with

ANSI/UL 507-(Latest Edition) and ANSI/NFPA 96(Latest Edition). No frame or restriction can be

constructed around the lower part of the pasta cooker

that would restrict ventilation or air movement into the

pasta cooker. You must insure adequate air supply to

the pasta cooker.

Adequate clearance for servicing and proper operation

must be maintained. Your pasta cooker is designed to

be serviced from the front. Do not place a pasta cooker

next to a deep fat fryer. Hot oil and water can cause an

unstable condition creating a hazardous situation. The

pasta cooker will operate at highest efficiency when

properly leveled. Place a level across the cooker front

panel from left to right, and then front to rear. Screw the

adjustable bullet feet or casters in or out as necessary

until the cooker is as level as possible. Each leg is

adjustable to 3/4". Do not expose more than three

threads on the stem of the caster.

LEVELING

The Pasta System will operate at its highest efficiency

when properly leveled. Place a level on Pasta System

vessel from side to side. For Pasta Systems on legs, the

bottom foot of the leg is adjustable. Turn counter

clockwise to decrease height or clockwise to increase

height until level. For Pasta Systems on casters, the

casters are adjustable by loosening the jam nut and

turning the caster in or out. When the desired level is

reached, tighten the jam nut. Adjustments of more than

3

/4" are not recommended on any caster. The same

procedure should be followed to level the Pasta System

from front to back.

Figure 2-1

RESTRAINING

DEVICES

On Custom Pasta

™

System

installations with casters, casters and

jam nuts must be completely

tightened. Adequate means must also

be provided to limit the movement of

the appliance without depending on

the connector, the quick-disconnect

device or its associated piping to limit

the appliance movement.

Connectors must comply with ANSI Z21.69/CAN1

CAN/CGA 6.16 (latest edition) for connectors for

movable gas appliances. Quick-disconnect devices

must comply with ANSI Z21.41/CAN 1 6.9 (or latest

edition) standard for quick-disconnect devices for use

with gas fuel as applicable.

IF DISCONNECTION OF THE RESTRAINT IS

NECESSARY, IT MUST BE RECONNECTED WHEN

THE CUSTOM PASTA

™

SYSTEM IS RETURNED TO

ITS ORIGINALLY INSTALLED POSITION.

ELECTRICAL CONNECTION

Your pasta cooker has been ordered in either 1 phase

or 3 phase by your dealer. All electrical connections

should be made by a licensed electrician. If necessary

this unit can be field changed from 1 phase to 3 phase

or from 3 phase to 1 phase. Have a qualified electrician

refer to the wire diagram.

ALL ELECTRICAL WIRING LEADING TO THE PASTA

COOKER MUST CONFORM TO LOCAL CODES. BE

SURE THE ON/OFF SWITCH IS IN THE OFF

POSITION BEFORE TURNING THE POWER ON TO

THE PASTA COOKER.

WATER AND DRAIN CONNECTION

The water is to be connected to the 3/8" female pipe

connection on the cabinet back, for auto-fill and the

optional faucet.

Make sure this and all other connections do not leak.

Check your water pressure. The auto-fill system is not

designed to handle pressure greater than 60 psi. Any

pressure greater than this can damage the auto-fill

solenoid or cause the system to fail. If the pressure is

greater than 60 psi a pressure regulator should be

added. The water temperature must not exceed 150°F

(65.6°C). Hot or warm water is not needed due to the

instant recovery of the Custom Pasta™System.

If during operation the boil is killed when water

automatically enters the pasta cooker, turn the water

pressure down until the water is added without killing

the boil. The drain terminates within inches of the floor

and is designed for the standard dump to drain opening.

CLEARANCES

Combustible

Construction

Non-Combustible

Construction

Back 6" 0"

Right Side 6" 0"

Left Side 6" 0"

Caster

WARNING

Restraining devices

required.

5

In most cases the health department will not allow a

direct connection between the cooker drain and the

floor receptical. Contact your local health department

for specific information in your area.

III OPERATION

FILLING

NOTE: Before filling the Pasta System make certain the

vessel is sanitized, dry and the drain valve is completely

closed.

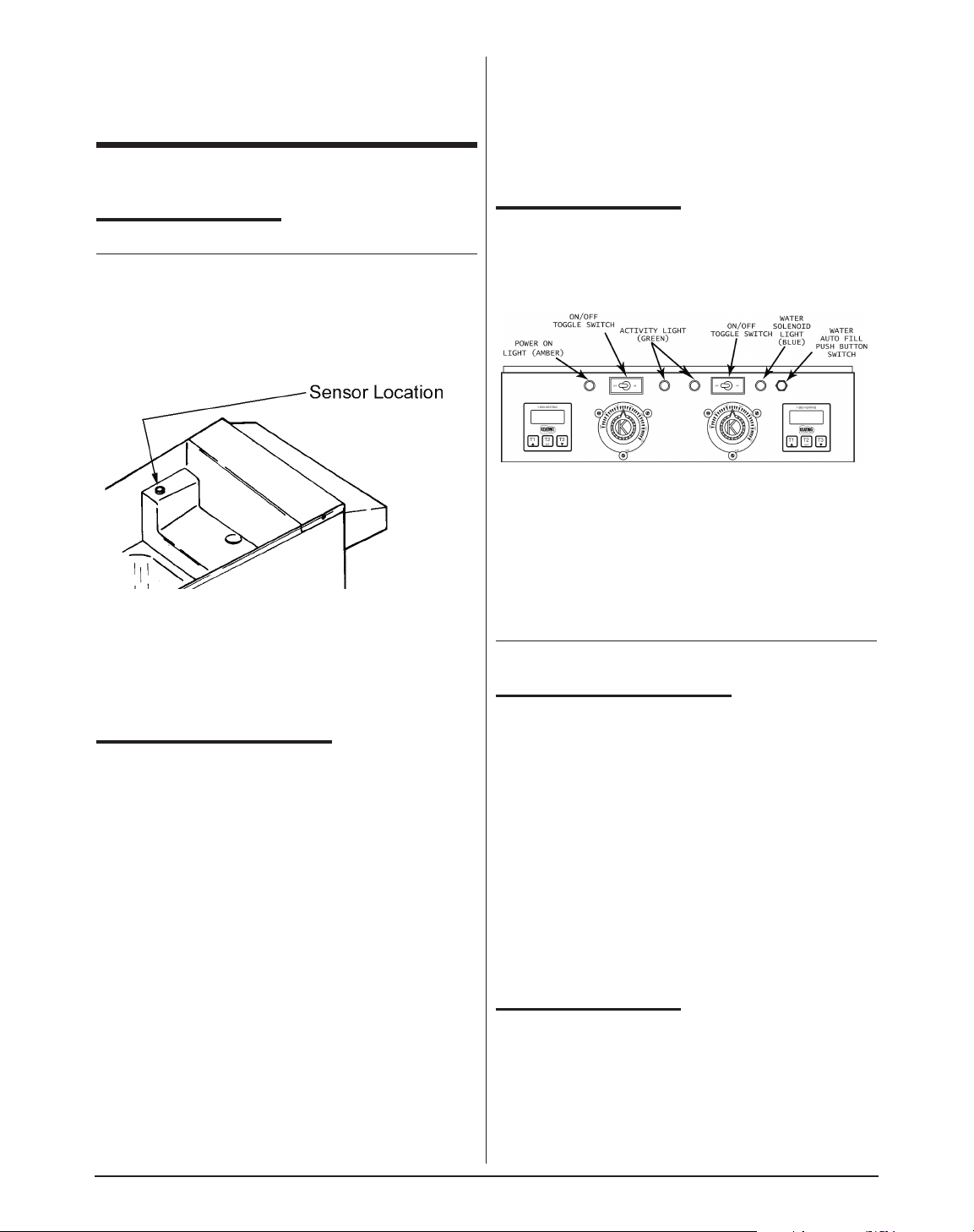

Figure 3-1

Manual Water Fill Level

When the water fill toggle switch (located between the

green and blue indicating lights) is turned on, the Pasta

System vessel automatically will be filled to the proper

level. If the vessel is being manually filled with water

from a faucet or through the manual fill button, fill to just

below the overflow deck. The black manual fill button is

located to the right of the blue water fill indicating light.

THERMOSTATS

The Keating pasta cooker has two thermostats. This is

to allow maximum control of the boil. The system is

designed so that both thermostats will function together

when called for but one thermostat will act as primary

and hold the water at a rolling boil during cooking as

well as idle time. The two thermostats allow the user to

have complete control over the cooking process.

The right side thermostat will only activate if the left side

thermostat is active. From a cold start all elements and

thermostats will be on and heat the water to a rolling

boil. Once the water has reached a rolling boil the right

side (secondary) thermostat will turn off and the left side

thermostat (primary) will hold the water at a rolling boil.

When product to be cooked is dropped into the pasta

cooker the drop in temperature depends on the

temperature spread between the two thermostats as

determined by the user.

If adding product does not turn on the secondary

thermostat and the water falls below a rolling boil,

increase the setting slightly on the secondary

thermostat. It is not recommended that there be less

than a twenty degree difference between the two

thermostats. Having less than a twenty degree

difference will increase the possibility of a boil over and

cause the pasta cooker to short cycle. The

recommended starting temperatures for the cooker are

212°F (98.8°C) for the primary and 190°F (87.8°C) for

the secondary thermostat. Using these settings with the

knowledge of the operation of this system, the user can

fine tune the settings to fit his specific operation.

INDICATING LIGHTS

Figure 3-2

Custom Pasta System Electric Control Panel

AMBER–shows the power is on.

GREEN–shows the secondary (right)

thermostat is calling for heat from the

center element(s).

BLUE–shows water is filling into the

Pasta System vessel through the Pasta

System water solenoid valve.

NOTE: The black manual water fill button is located

to the right of the blue indicating light.

THE AUTO-FILL SYSTEM

The water temperature must not exceed 120°F (48.8°C).

Control of the water level is fully automatic with the auto-fill

system. The water level is controlled by two circuit boards

attached to the two water level sensors located on the front

of the pot below the spashdeck. Once the water switch is

turned to ON, the pasta cooker will start to fill with water.

The heating elements will not turn on until the water level is

above the bottom sensor. This is an automatic water safety

built into every pasta cooker. This safety prevents the pasta

cooker from accidental heat damage due to low or no

water. The bottom sensor is the low water cut off. The top

sensor is the water level control. Both sensors should be

cleaned on a regular basis to prevent water deposits from

interfering with the sensor reaction. Cleaning should be

done with the brush up and down the sensor tube located

on the right side of the splashdeck.

COOKING

Keating Electric Custom Pasta Systems are designed to

provide maximum production efficiency and deliver high

quality food products. Low-temperature cooking and highly

polished stainless steel mean greater energy savings. Two

thermostats are used to provide instant recovery and to

save energy while water is boiling. The secondary (right)

thermostat calls for additional heat at start up or

occasionally when water is added. Follow cooking

Loading...

Loading...