Page 1

KBCC-240D

TM

TM

®

CHASSIS MOUNT PENTA-DRIVE

Var iable Speed-Torque SCR DC Motor Control

for Shunt Wound and PM Motors

ONE MODEL COVERS

1/50 – 1 Hp @ 115 VAC – 50/60 Hz

1/25 – 2 Hp @ 230 VAC – 50/60 Hz

TYPICAL APPLICATIONS

• Packaging Machines • Pumps • Feeders

• Exercise Equipment • Conveyors

STANDARD FEATURES

• Electronic Overload Protection

• Built-in Ar mature Fusing

• LED’s for “Power On,” “Overload” and “Stop”

• Electronic Star t-Stop

▲

Fuse supplied separately

JUMPER SELECTABLE FEATURES

• Control Mode: Speed, Torque

• DC Current Output (ADC): 2.5, 5.0, 7.5, 10

• AC Line Voltage (VAC-50/60 Hz):115, 230

• DC Ar mature Voltage (VDC): 90, 180

• Feedback Type: Armature, T achometer

• Tachometer Voltage

• Timed Current Limit: TCL, NTCL

Bold figure indicates factory setting.

TRIMPOT ADJUSTMENTS

• Minimum Speed (MIN) • Maximum Speed (MAX)

• Current Limit (CL) • IR Compensation (IR)

• Acceleration (ACCEL) • Deceleration (DECEL)

• Timed Current Limit (TCL) • Jog Speed (JOG)

▲

Used with Run-Stop-Jog option.

OPTIONAL FEATURES

• Forward-Brake-Reverse Switch (P/N 9339)

• Run-Stop-Jog Switch (P/N 9340)

• Signal Isolator, KBSI-240D (P/N 9431)

• On/Off AC Line Switch (P/N 9341)

• Electronic Pot, KBEP-240D (P/N 9108)

• Anti Plug Reversing Module (P/N 9378)

• Auto/Manual Kit (P/N 9377)

▲

▲

(VDC): 7, 20/30, 50

▲

Per 1,000 RPM

▲

DATA SHEET D-222

*

P/N 9947

DESCRIPTION

The KBPC state-of-the-art electronics include

short circuit and transient protection to provide the

ultimate in reliability. Electronics overload protection is

also provided, which prevents motor burnout and

demagnetization of PM motors. The control can be

operated in either the speed or torque mode via a

jumper selection. The current range, which is also

jumper selectable, eliminates the necessity for

calibration of IR compensation and current limit

for most applications.The KBCC also contains jumper

selections for AC line voltage (115/230), DC armature

voltage (90/180) and feedback type (armature/

tachometer).

Standard features include Armature Fusing,

Electronic Start/Stop and LED Indicator Array for

“Power On,” “Stop” and “Overload.”

Although the KBCC is factory set for most

applications, a variety of trimpots allows adjustment

of the following parameters: MIN and MAX speed,

Acceleration, Deceleration, Current Limit, IR Comp,

and Timed Current Limit. The drive offers the

ultimate in flexibility with the availability of several

customer installed options. These include: ForwardBrake-Reverse, Run-Stop-Jog, On/Off AC Line

Switch, Anti-Plug Reversing Module, Input Signal

Isolation, and Electronic Potentiometer. A complete

instruction manual is included.

* CE Compliance Requires KBRF-200A RFI Filter

16

A Complete Line of Motor Drives

Rev.______(A_______)

Page 2

SPECIFICATIONS

Parameter Specification

AC Line Voltage Regulation (% Base Speed) .............. ±0.5.............. —

Current Ranges (ADC) .......................................... 2.5, 5, 7.5, 10 ...... 10

ACCEL and DECEL Ranges (Seconds) .................... 0.1–15 ............ 1

MIN SPEED Range (% Base Speed) .......................... 0–30 .............. 0

MAX SPEED Range (% Base Speed)........................ 60–140 .......... 100

IR COMP Range at 115 VAC Line (VDC) .................... 0–15 .............. 4

IR COMP Range at 230 VAC Line (VDC) .................... 0–30 .............. 8

CL Range (% Range Setting)...................................... 0–200 .......... 150

TIMED CL Range (Seconds) ...................................... 0.5–15 ............ 7

Voltage Following Linearity (% Base Speed)................ ± 0.5 ............ —

Factory

Setting

Parameter Specification

Horsepower Range at 115 VAC Line (Hp) [KW]...... 1/50–1, [.015-.75] .... —

Horsepower Range at 230 VAC Line (Hp) [KW]...... 1/25–2, [.03–1.5].... —

Armature Voltage Range at 115 VAC Line (VDC)........ 0–130* ............ —

Armature Voltage Range at 230 VAC Line (VDC) ........ 0–220* .......... 180

Field Voltage at 115 VAC Line (VDC) ........................ 100/50** .......... —

Field Voltage at 230 VAC Line (VDC) ...................... 200/100**.......... —

Ambient Temperature Range (°C) ................................ 0–50 ............ —

Speed Range (Ratio) .................................................... 50:1.............. —

Load Regulation, Arm. Feedback(% Base Speed)............ ± 1 .............. —

Load Regulation, Tach. Feedback (% Set Speed)............ ± 1 .............. —

AC Line Voltage (VAC ± 10%, 50/60 Hz) ................ 115 or 230........ 230

NOTES: *Maximum recommended output voltage is 90 VDC for 115 VAC and 180 VDC for 230 VAC.Exceeding these output voltages may cause a reduction in load regulation

performance. **For shunt wound motor with lower voltage field, use L1and F1connection.

Factory

Setting

ELECTRICAL RATINGS

Model

Number

KB Part

Number

KBCC-240D 9947

AC Line Voltage

(VAC) ± 10%

50/60 Hz

115 0 – 130

230

Motor

Voltage

(VDC)

0 – 220

0 – 130*

Max. AC

Load Current

(RMS Amps)

15.0

15.0

Max. DC

Load Current

(DC Amps)

10.2

10.2

Maximum

Horsepower

Hp, (KW)

1, (.75)

2, (1.5)

*Stepdown operation (90 VDC motors with 230 VAC input) can cause a reduction in motor performance.**Shunt motors only

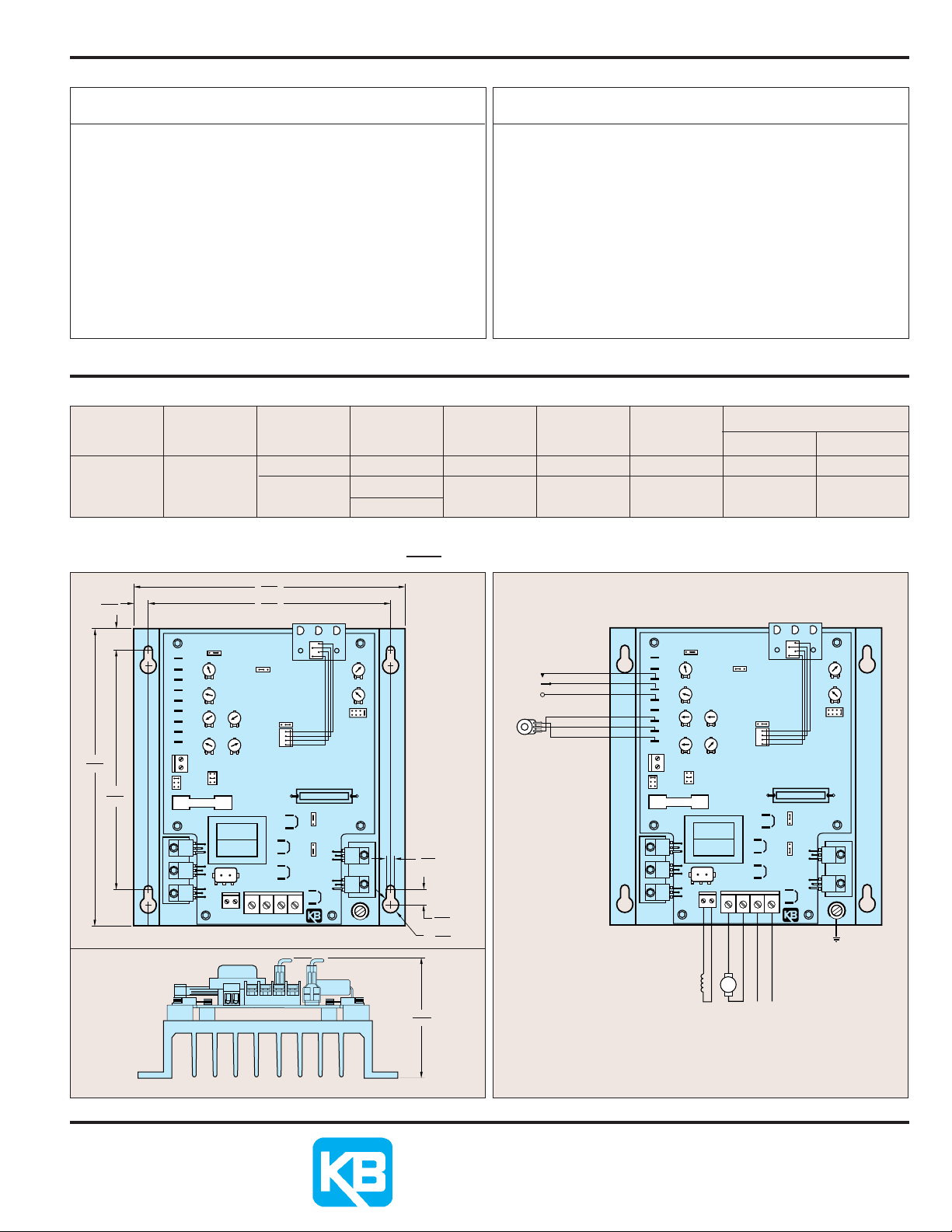

INCHES

[mm]

CONNECTION DIAGRAM

0.340

[8.6]

MECHANICAL SPECIFICATIONS

6.290

[159.8]

5.610

[142.5]

Field Voltage** (Volts DC)

Terminals F

, F2Terminals F1, L

1

100

200

50

100

1

7.000

[177.8]

5.625

[142.9]

STOP OL

10V 5V

ON

YGRB

LED BOARD

TRQ SPD

J1

YGRB

CONN1

L1B

J9A

L1A

A1B

J8A

A1A

T1

A2B

J8B

A2A

A2

L1

L2

AC LINE

INPUT

CL

IR

J4

10A

7.5A5A2.5A

R69

115V

230V

J2A

J2B

230V

115V

L2A

J9B

L2B

GND

(earth)

STOP OL

ON

KBPC

J5

TCL

I1

I2

START

COM

STOP

JOG

P3

P2

P1

50V

20/30V

7V

ARM FUSE

DECEL

TT+

F1

NTCL

TCL

JOG

ACCEL

MIN MAX

180V

90V

T

J3

TB2

F1 F2

CONN2

10V 5V

J7

TB1

A1

GRY

GRY

TB3

J6

YGRB

LED BOARD

TRQ SPD

J1

YGRB

CONN1

L1B

J9A

J2A

L1A

A1B

J2B

J8A

A1A

T1

A2B

J8B

A2A

A2 L1 L2

DWG#: C3000-1-00986

CL

IR

J4

10A

7.5A5A2.5A

MAIN

POTENTIOMETER

R69

115V

230V

230V

115V

L2A

J9B

L2B

3.000

[76.2]

0.200

[5.1]

TYP.

0.365

TYP.

[9.3]

0.386

TYP.

–

[9.8]

START

STOP

START/STOP SWITCH

VLT

ORN

WHT

WHT

BLK

RED

TACH INPUT

KBPC

J5

TCL

I1

I2

START

COM

STOP

JOG

P3

P2

P1

50V

20/30V

7V

ARM FUSE

DECEL

TT+

F1

NTCL

TCL

JOG

ACCEL

MIN MAX

180V

90V

T

J3

TB2

F1

FIELD

J7

CONN2

TB1

F2

A1

M

*

ARMATURE

GRY

GRY

TB3

J6

DWG#: C3000-1-00986

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065-2516

(954) 346-4900 • FAX (954) 346-3377

Outside Florida Call TOLLFREE (800) 221-6570

www.kbelectronics.com

DWG#: A3000-2-00987

© 1998 KB Electronics, Inc.

Rev.______(A_______)

17

Loading...

Loading...