Page 1

HD 3.5/30-4S Ea

HD 3.7/22-4S Eg

www.kaercher.com

5.961-344.0 09/07

Page 2

English

Français

Español

5

14

24

2

Page 3

Page 4

4

Page 5

English

Environmental protection

The packaging material can be

recycled. Please do not place

the packaging into the ordinary

refuse for disposal, but arrange

for the proper recycling.

Old appliances contain valuable

materials that can be recycled.

Please arrange for the proper

recycling of old appliances.

Batteries, oil, and similar

substances must not enter the

environment. Please dispose of

your old appliances using

appropriate collection systems.

Caution!

Follow the maintenance instruc-

tions specified in the manual

This machine has been designed for

use with cleaning detergents by the

manufacturer. The use of other

cleaning detergents may affect the

operation of the machine and void the

warranty.

IMPORTANT SAFETY

INSTRUCTIONS

WARNING!

When using this product basic

precautions should always be

followed, including the following:

Read all the instructions before

using the product.

To reduce the risk of injury, close

supervision is necessary when a

product is used near children.

Know how to stop the product and

bleed pressures quickly. Be

thoroughly familiar with the controls.

Stay alert — watch what you are

doing.

Do not operate the product when

fatigued or under the influence of

alcohol or drugs.

Keep operating area clear of all

persons.

Do not overreach or stand on

unstable support. Keep good footing

and balance at all times.

Follow the maintenance instructions

specified in the manual.

This Product Is Provided With A

Ground Fault Circuit Interrupter

(GFCI) Built Into The Power Cord

Plug. If Replacement Of The Plug Or

Cord Is Needed, Use Only Identical

Replacement Parts.

Risk of Injection or Injury to persons

- Do not direct discharge stream at

persons.

High pressure jets can be dangerous

if subject to misuse. The jet must not

be directed at persons, animals,

electrical devices, or the machine

itself.

Wear safety goggles.

Do not use acids and solvents in this

product. These products can cause

physical injuries to the operator and

irreversible damage to the machine.

To reduce the risk of electrocution,

keep all connections dry and off the

ground. Do not touch plug with wet

hands.

5

Page 6

English

!

!

The Trigger Gun Safety Lock

PREVENTS the trigger from

accidentally being engaged. This

safety feature DOES NOT lock

trigger in the ON position.

Do not use extension cord for this

unit.

Warning!

To reduce the risk of

electrocution, keep all connections dry

and off the ground. Do not touch plug

with wet hands.

Grounding Instructions

This product must be grounded. If it

should malfunction or breakdown,

grounding provides a path of least

resistance for electric current to reduce

the risk of electric shock. This product

is equipped with a cord having an

equipment-grounding conductor and a

grounding plug. The plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and

ordinances.

Danger!

Improper connection of the

equipment-grounding conductor can

result in a risk of electrocution. Check

with a qualified electrician or service

personnel if you are in doubt as to

whether the outlet is properly

grounded. Do not modify the plug

provided with the product - if it will not

fit the outlet, have a proper outlet

installed by a qualified electrician. Do

not use any type of adapter with this

product.

Ground Fault Circuit Interrupter

(GFCI) Protection

This product is supplied with a Ground

Fault Circuit Interrupter (GFCI) built

into the power cord plug. This device

provides additional protection from the

risk of electric shock. If power is

interrupted in the line, the GFCI will

automatically re-close the circuit to the

load after power is restored.

Depending on the GFCI model, it may

be necessary to manually operate the

reset button to restore power to the

GFCI load circuit. If replacement of the

plug or cord is needed use identical

replacement parts.

WATER SUPPLY

Caution!

When connecting the water inlet to

the water supply mains, local regulations

of your water company must be

observed. In some areas the unit must

not be connected directly to the public

drinking water supply. This is to ensure

that there is no feedback of chemicals

into the water supply. Direct connection

via a receiver tank or backflow preventer

for example, is permitted.

Dirt in the feed water will damage the

unit. To avoid this risk, we recommend

fitting a water filter.

Never use the pressure washer to

draw in water contaminated with

solvents, e.g. paint thinners,

gasoline, oil, etc.

Always prevent debris from being

drawn into the unit by using a clean

water source.

SAVE THESE

INSTRUCTIONS!!

6

Page 7

English

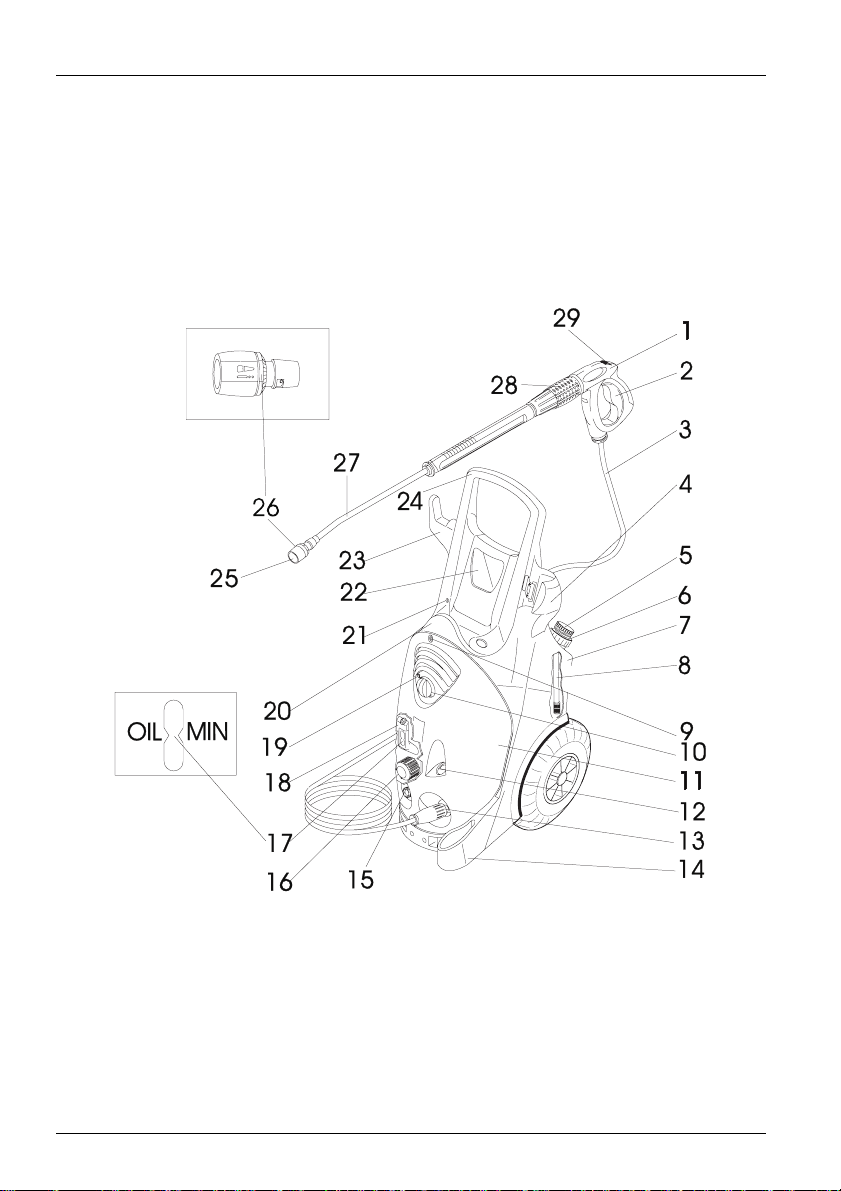

Unit components

Please fold out illustration page at the front

1 Hand-held spray gun

2 Lever of hand-held spray gun

3 High-pressure hose

4 Handgun support

5 Detergent metering valve

6 Cap for detergent reservoir

7 Detergent reservoir

8 Detergent suction-hose with filter

9 Fastening screw for hood

10 Unit switch

11 Hood

12 Pressure gauge

13 High-pressure outlet

14 Nozzle rest

15 Water connection

16 Fine filter

17 Oil level display

18 Oil reservoir

19 Indicator light

20 Hose rest

21 Detergent reservoir vent

22 Accessories box

23 Cable holder

24 Handle

25 Nozzle

26 Marking of the nozzle

27 Spray lance

28 Pressure/flow control

29 Safety catch of hand-held spray gun

For your safety

Before you use the cleaner for the first time,

read these operating instructions and take

special note of the accompanying booklet

"Safety Instructions for High-Pressure Cleaners" No. 5.951-949.

Use of the cleaner

Use this unit exclusively for

– cleaning with high-pressure jet and deter-

gent (e.g. cleaning of machines, vehicles,

buildings, tools),

– cleaning with high-pressure jet without de-

tergent (e.g. cleaning facades, terraces,

gardening equipment).

For stubborn dirt we recommend the dirt

blaster as an optional accessory.

Safety features

Relief valve with pressure

switch

On reducing the flow rate with the pressure

and flow control, the relief valve opens and

part of the water runs back to the suction side

of the pump.

If the lever of the hand-held spray gun is released, the pressure switch switches the

pump off. If the lever is retracted, the pressure

switch switches the pump on again.

The overflow valve and pressure switch have

been set and sealed at the factory.

Adjustments are made only by Customer

Service.

7

Page 8

English

Preparing the unit for use

Unpack the unit

– When unpacking the unit, check the con-

tents of the packaging. If there has been

any damage in transit inform the dealer.

– Do not dispose of the packaging with the

household rubbish, hand it in at the appropriate collection point for recycling.

Check the oil level

Read the oil level displayed while unit is at

a standstill. The oil level must be above the

two indicators.

Activate the oil reservoir vent

Unscrew the fastening screw of the hood

and remove the hood.

Cut off the tip on the cover to the oil reser-

voir.

Fasten the unit cover.

Mount the accessories

Mount nozzle on the spray lance (see

markings on the top of the setting ring).

Fit the spray lance to the hand-held spray

gun with pressure and flow control.

Lock cable clincher into bore lateral to the

handle.

Tighten the high-pressure hose according-

ly.

Switching on the unit

Electrical connection

Caution!

The voltage specified on the model rating plate must correspond to the voltage supplied.

Do not use extension cord for this unit.

For connected loads see model rating plate/

Technical Specifications.

Caution!

It is essential that the unit is connected

to the power supply by means of a plug. An inseparable connection to the power supply is

prohibited. The plug is used to disconnect

from the mains.

Please turn the machine switch off before resetting the GFCI, otherwise, the GFCI will be

damaged

GFCI INSTRUCTIONS

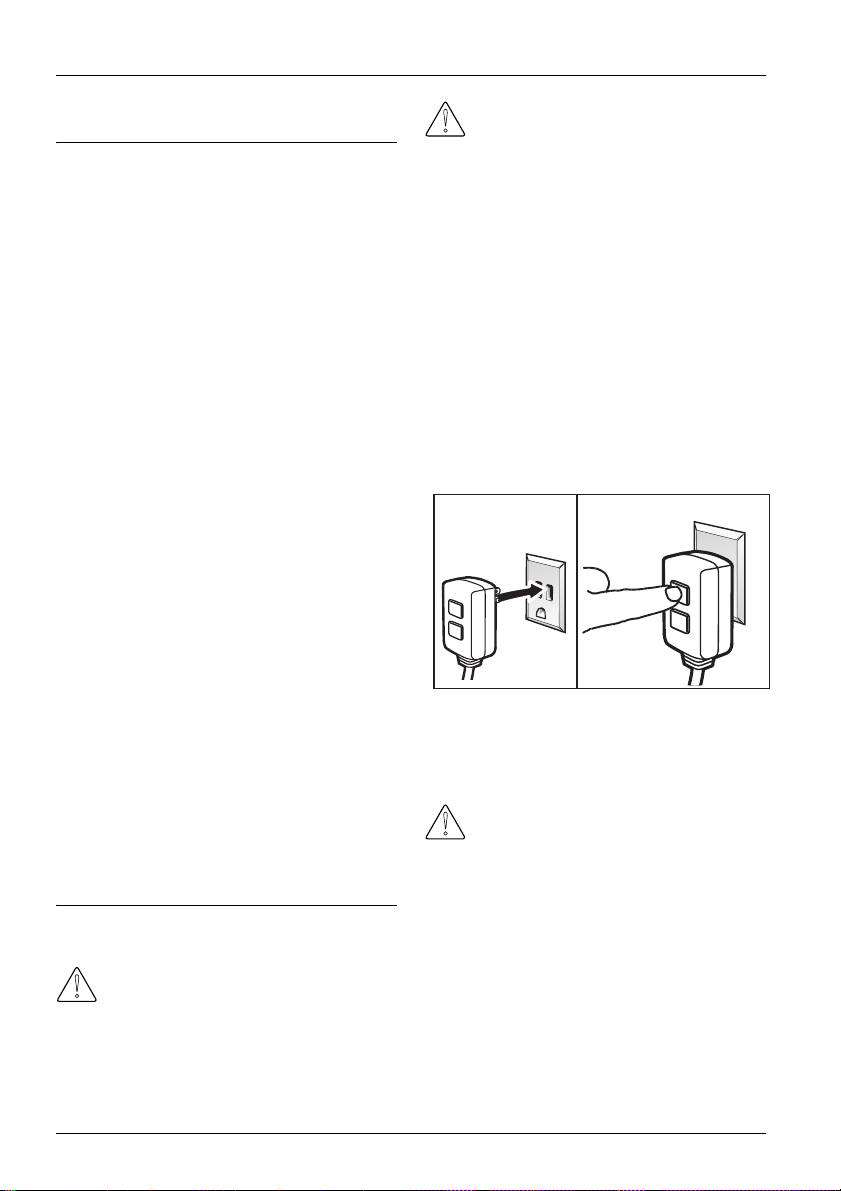

STEP 1: Plug the Ground Fault Circuit

Interrupter (GFCI) into a working outlet.

STEP 2: Press ’’TEST’’, then press

’’RESET’’ to assure proper connection to

power.

Note: The actual appearance of the GFCI

may be different from this illustration.

2

1

Water connection/Suction feed

operation

Connection to water main

Caution!

Pay attention to the regulations of the

water supply company; according to DIN

1988, the unit may not be connected direct to

the public drinking water supply. A short-term

connection via a non-return valve

(Order no. 6.412-578) is allowed.

For connected loads see Technical Specifications.

Connect a supply hose (not supplied) to the

water outlet on the unit and to the water inlet (e.g. water tap).

Open water inlet.

8

Page 9

English

!

Suctioning water from an open container

Screw suction hose with filter

(Order no. 4.440-238) to the water outlet.

Vent the unit before using.

To evacuate air from the unit, unscrew the

nozzle and leave the unit running until water exits with no air bubbles.

Switch off the unit and screw the nozzle

back on.

Operating the unit

Danger!

Observe the relative safety regulations

when using the unit at filling stations or other

high-risk areas.

Caution!

Only clean engines in places which

have appropriate oil separators (protection of

the environment).

Caution!

Only wash animals with the lowpressure fan jet (see "Selecting the type of

spray").

Operating with high pressure

The unit is equipped with a pressure switch.

The motor only starts up when the lever is retracted.

Set the unit switch to "I". The indicator light

will go green.

Unlock the hand-held spray gun and retract

the lever of the gun.

Adjust operating pressure and flow rate

(+/–) by rotating the pressure/flow control

(infinitely variable).

At the lowest flow rate the waste heat from

the motor will heat the water to approx.

15 °C.

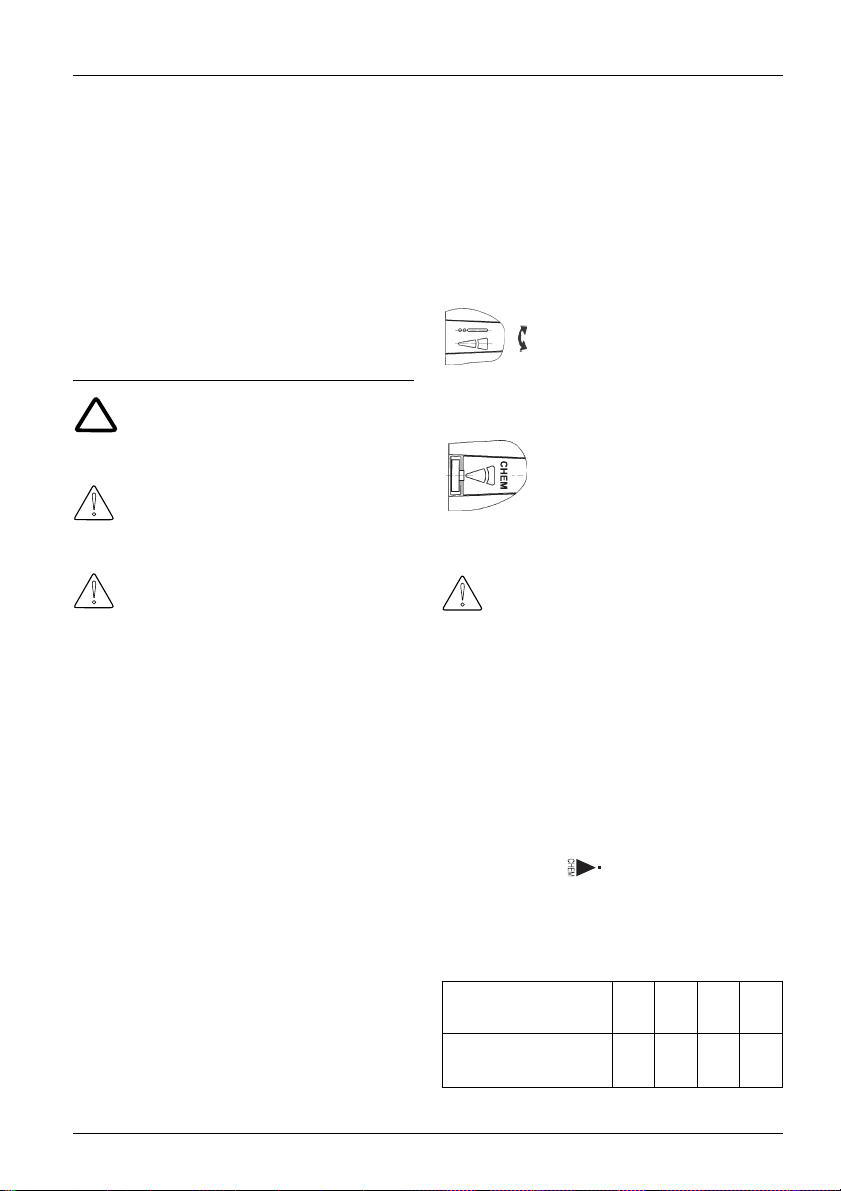

Selecting the type of spray

The handgun must be closed.

Rotate the housing of the nozzle until the

desired symbol corresponds with the marking.

Select pencil jet or fan jet by contactless

changeover:

rotate the spray lance, which is pointing

down at an angle of approx. 45°, to the left

or right.

Explanation of the symbols

High-pressure pencil jet (0°),

for particularly stubborn accumulation of grime.

High-pressure fan jet (25°), for

dirt accumulation over a large

surface.

Low-pressure fan jet (CHEM)

for operation with detergent or for

cleaning at low pressure.

Operating with

detergent

Caution!

Unsuitable detergents can harm the

cleaner and the object which is to be cleaned.

Use only detergents which are released by

Kärcher. Proportions of detergent to be used

and accompanying instructions should be noted carefully. Use detergents sparingly out of

consideration for the environment.

Kärcher cleaning agents guarantee troublefree operation. Please seek advice or ask for

our catalogue of information sheets on cleaning agents.

Fill detergent reservoir.

Set nozzle to .

Set the detergent metering valve to the

desired concentration.

Concentration of detergent when flow at

maximun:

Position of metering

valve

1357

0.5%2.5%5.0%7.0

%

9

Page 10

English

!

!

Recommended cleaning methods

Spray detergent with low pressure jet spar-

ingly over the dry surface to be cleaned and

let it take effect but not dry out.

Spray off (rinse off) the loosened dirt using

the high-pressure spray.

When you have finished the operation, set

detergent metering valve to "0" and switch

the unit on for about 1 minute and rinse it

clear of detergent.

Interrupting the operation

Release lever of the handgun, the unit

switches off. Retract lever again and the

unit switches on again.

Availability time

Within the availability time, the unit starts

when the hand-held spray gun is opened.

The indicator light will go green.

If the spray gun remains closed for

30 minutes, the availability time ends.

The indicator light will flash green.

Reset availability time

Switch off the unit switch.

Wait a moment.

Switch the unit back on again.

Customer Service can change the unit to

permanent operation.

Switching the unit off

Set unit switch to "0" and pull out power

plug.

Close water inlet.

Retract lever until the unit is without pres-

sure.

Push safety catch of the hand-held spray

gun forward to lock the lever of the gun

from being actuated inadvertently.

Danger!

Risk of scalding due to hot water. Residual water contained in the switched off unit

can heat up. When removing the hose from

the water inlet, the heater water can spurt out

and cause scalds. Do not remove the hose

until the unit has cooled down.

Transporting the cleaner

To transport the cleaner over relatively long

stretches, take hold of it by the handle and

pull it along behind you.

Empty the detergent reservoir before trans-

porting it horizontally.

Storing the cleaner

Place the handgun in the support.

Reel in the high-pressure hose and hang it

over the hose rest.

or

Coil the connecting cable round the cable/

hose rest.

Frost protection

Caution!

Frost will destroy a unit that is not completely empty of water! Store the unit where it

will be free of frost.

If storage away from frost is not possible:

Empty the detergent tank (see care and

maintenance/As and when required).

Drain off the water and rinse the unit

through with anti-freeze.

Leave the unit to dry for max. 1 minute.

Use the standard glycol-based anti-freezes

for cars.

Follow the handling instructions of the anti-

freeze manufacturer.

Care and maintenance

Danger!

Before any care and maintenance work

on the unit draw out the mains plug.

Caution!

When changing the oil, dispose of any

waste oil only at authorised collection points.

10

Page 11

English

!

Safety inspection/Maintenance

contract

You can arrange with your dealer to have a

regular safety inspection carried out or to

have a maintenance contract. Please seek

advice.

Before each use

Check connecting cable for damage (risk of

getting an electric shock), have a damaged

connecting cable replaced without delay by

authorised Customer Service personnel or

an electrician.

Check high-pressure hose for damage

(danger of explosion), replace a damaged

high-pressure hose without delay.

Check unit (pump) for any leaks.

Three drops per minute are allowable and

can appear on the underside of the unit.

Seek the help of Customer Service if leaks

are more serious.

Every week

Check oil level in oil reservoir: if the oil is

milky (water in oil), seek the help of Customer Service immediately.

Clean the fine filter.

– Unpressurize unit.

– Unscrew the fastening screw of the hood

and remove the hood.

– Unscrew the cover with filter.

– Clean the filter with clean water or com-

pressed air.

– Reassemble in the reverse order.

Clean the filter at the suction hose for de-

tergent.

Annually or after 500 operating

hours

Change the oil

– For oil quantity and type see Technical

Specifications.

– Undo the fastening screw, remove the

hood, unscrew the front oil drain plug on

the motor housing.

– Drain oil into a suitable container.

– Screw in the oil drain plug.

– Fill slowly with fresh oil; air bubbles have

to escape.

As and when required

Emptying and cleaning the detergent tank

– Pull out the screw cap and hose for the

detergent tank.

– Place the unit on its rear.

– Empty and clean the detergent tank.

Troubleshooting

Danger!

Before any repair work is undertaken,

switch the unit off and pull out the power plug.

Have electrical components checked and repaired only by authorised Customer Service

personnel.

For faults which are not identified in this chapter, or when in doubt or when expressly instructed to do so, consult authorised

Customer Service personnel.

Indicator light

The indicator light shows the operating status

(green) and faults (red).

To reset:

Switch off the unit switch.

Wait a moment.

Switch the unit back on again.

Operating status display

Constant green light:

– Unit is operational.

1 x flashing green:

– Operational readiness expired after

30 minutes.

– The unit switched off after 30 minutes of

permanent operation (safety feature in

the case of a burst high-pressure hose).

11

Page 12

English

Fault display

1 x flashing red:

– High-pressure side leaking. Check high-

pressure hose, hose connections and

hand-held spray gun for leaks.

2 x flashing red:

– Motor too hot. Switch off the unit switch.

Leave unit to cool down. Switch the unit

back on again.

3 x flashing red:

– Fault in the power supply. Check the

mains connection. Check supply fuses.

4 x flashing red:

– Current consumption too high. Consult

Customer Service

Unit does not work

Availability time has run out. The indicator

light will flash green. Switch the unit off and

then on again.

Check connecting cable for damage.

Consult Customer Service if there is an

electrical fault.

Unit does not come up to pressure

Set nozzle to "high pressure".

Clean/replace nozzle.

Clean the fine filter, replace if required.

Evacuate air from the cleaner (see Switch-

ing on the unit).

Check water inlet volume (see Technical

Specifications).

Check all supply lines to the pump for leaks

or obstructions.

Seek the help of Customer Service if nec-

essary.

Pump is leaky

Three drops per minute are allowable and

can appear on the underside of the unit.

Seek the help of Customer Service if leaks

are more serious.

Pump makes a knocking noise

Check all supply lines as well as the deter-

gent system for leaks.

Evacuate air from the cleaner (see Switch-

ing on the unit).

Clean the fine filter.

Seek the help of Customer Service if nec-

essary.

Detergent is not being drawn in

Set nozzle to "Chem".

Check detergent suction hose with filter for

leaks or obstructions and clean it if necessary.

Clean/renew non-return valve in detergent

suction-hose connection.

Open detergent metering valve or check it

for leaks/remove obstruction. Also clean

the venting orifice in the housing.

Seek the help of Customer Service if nec-

essary.

Spare parts

You will find a list of spare parts at the end of

these operating instructions.

Warranty

The warranty terms issued by our authorised

marketing company are valid in every country.

We remedy any fault in the unit free of charge

within the warranty period providing the cause

of the fault proves to be a material or manufacturing error.

The warranty only becomes operative when

your dealer has completed the reply card accompanying the sale of the unit, has stamped

and signed it and you have then sent the reply

card to the marketing company in your country.

Should you wish to call upon the guarantee,

please apply to your dealer or nearest authorised Customer Service centre taking along

also the accessories and bill of sale.

12

Page 13

English

Technical Specifications

HD 3.5/30-4S

Ea

1.286-110.0

Mains connection

Voltage V 220... 240 200...208

Type of current Hz 1 ~ 60

Connected load hp/kW 8.5/6.3 6.9/5.1

Supply fuse (delayed-action, char. C) A 30

Water connection

Supply temperature max. °F/°C 140/60

Supply volume min. gpm / l/min 5.3/20

Supply hose – minimum length m 7.5

Supply hose – minimum diameter inches 3/4

Suction height from an open container 20 °C m 0.5

Supply pressure max. psi/MPa 145/1

Performance data

Operating pressure psi/MPa 435...3000 /

Flow rate

Detergent intake

Recoil force of the handgun N 62

Sound emission

Sound pressure level

(EN 60704-1)

Garanted sound pressure level

(2000/14/EC)

Vibrations of unit / total of vibration (ISO 5349)

Handheld gun m/s

Spray lance m/s

Dimensions

Length mm 560

Width mm 500

Height mm 1090

Weight without accessories kg 62

Reservoir capacity, detergent l 6

Oil quantity, pump l 1.2

Oil type, pump 15W40

gpm / l/min

gpm / l/min

dB (A)

dB (A) 87

2

2

3...20.6

1.8...3.5 /

6.8..13.2.

HD 3.7/22-4S

1.286-115.0

435...2200 /

3...15.2

1.8...3.7 /

6.8...14.0

0...0.3 / 0...1.1

72

2.2

2.0

Eg

13

Page 14

Fran çais

Protection de

l’environnement

Les matériaux constitutifs de

l’emballage sont recyclables.

Ne pas jeter les emballages

dans les ordures ménagères,

mais les remettre à un système de recyclage.

Les appareils usés contiennent des matériaux précieux

recyclables lesquels doivent

être apportés à un système de

recyclage. Il est interdit de jeter les batteries, l'huile et les

substances similaires dans

l'environnement. Pour cette

raison, utiliser des systèmes

de collecte adéquats afin d'éliminer les appareils usés.

ATTENTION !

En utilisant ce produit, toujours observer une certaine prudence élémentaire, incluant notamment :

Lire toutes les instructions avant

d'utiliser le produit.

Afin de réduire le risque de blessu-

res, une surveillance attentive est requise lorsqu'un produit est utilisé à

proximité d'enfants.

Savoir comment arrêter le produit et

réduire la pression rapidement. Etre

parfaitement familiarisé avec les

commandes.

Rester attentif — toujours regarder

ce que l'on fait.

Ne pas utiliser le produit en étant fa-

tigué ou sous l'influence de l'alcool

ou de drogues.

Ne laisser personne approcher la

zone de travail.

Ne pas se pencher ou se tenir sur un

support instable. Toujours rester en

équilibre.

Observer les instructions de mainte-

nance figurant dans le présent manuel.

Ce produit est fourni avec un dis-

joncteur différentiel monté dans la

fiche du cordon d'alimentation. Si le

remplacement de la fiche ou du

cordon d'alimentation s'avère nécessaire, n'utiliser que des pièces de rechange identiques.

Risque d'injection ou de blessures

sur les personnes - ne pas diriger le

jet sur des personnes.

Utilisés abusivement, les jets à hau-

te pression peuvent être dangereux.

Le jet ne doit jamais être dirigé sur

des personnes, des animaux, des

appareils électriques ou la machine

même.

Porter des lunettes de protection.

Ne pas utiliser d'acides, ni de sol-

vants dans la machine. Ces produits

peuvent nuire à la santé de l'opérateur et causer des dégâts matériels

irréversibles à la machine.

Afin de réduire le risque d'électrocu-

tion, garder toutes les connexions au

sec et ne pas les laisser à terre. Ne

pas toucher la fiche avec les mains

mouillées.

Le verrouillage de sécurité de la poi-

gnée-pistolet EMPECHE d'actionner

accidentellement la gâchette. Le dispositif de sécurité NE VERROUILLE

PAS la gâchette en position actionnée.

Ne pas utiliser que des rallonges.

14

Page 15

Français

!

Attention !

Afin de réduire le risque d'électrocution, garder toutes les connexions

au sec et ne pas les laisser à terre. Ne

pas toucher la fiche avec les mains

mouillées.

Instructions de mise à terre

Ce produit doit-être mis à la terre. En

cas de mauvais fonctionnement ou de

panne, la mise à la terre établit un chemin de moindre résistance pour le courant électrique afin de réduire le risque

de décharge électrique. Ce produit est

équipé d'un cordon doté d'un conducteur de mise à la terre de l'équipement

et d'une prise de mise à la terre. La prise doit être branchée dans une prise

appropriée qui est correctement installée et mise à la terre en conformité

avec les codes et ordonnances locaux.

Danger !

Un conducteur de mise à la terre

d'équipement incorrectement branché

peut entraîner un risque d'électrocution. Vérifier avec un électricien ou un

technicien d'entretien qualifié en cas

de doute sur la mise à terre correcte de

la prise. Ne pas modifier la fiche fournie avec le produit - si elle ne peut pas

être branchée, faire installer une prise

appropriée par un électricien qualifié.

Ne pas utiliser n'importe quel type

d'adaptateur avec ce produit.

Protection par disjoncteur différentiel

Ce produit est fourni avec un disjoncteur différentiel intégré dans la

fiche de cordon d'alimentation. Ce dispositif fournit une protection supplémentaire contre les risques de décharges électriques. En cas de coupure de

courant, le disjoncteur différentiel referme automatiquement le circuit lorsque le courant est rétabli. Selon le modèle de disjoncteur différentiel, il peut

s’avérer nécessaire d’actionner manu-

ellement le bouton de réinitialisation

pour rétablir l’alimentation du circuit de

charge. Utiliser des pièces de rechange identiques en cas de remplacement

du cordon ou de la fiche.

ALIMENTATION EN EAU

Attention !

Lors de la connexion de l'entrée

d'eau à la canalisation d'alimentation

en eau, les régulations locales de votre

compagnie d'eau doivent être observées. Dans certaines zones, l'appareil

ne doit pas être connecté directement

à l'alimentation en eau potable publique. Il s'agit de s'assurer qu'il n'y a pas

de retour de produits chimiques dans

l'alimentation en eau. Une connexion

directe par l'intermédiaire d'un réservoir de réception ou d'un disconnecteur hydraulique par exemple est

autorisée.

D'éventuelles impuretés dans l'eau d'alimentation endommagent l'appareil.

Pour prévenir ce risque, nous recommandons d'installer un filtre à eau.

Le tuyau d'eau doit avoir un diamètre

d'au moins 16 mm.

Le débit d'alimentation en eau ne

doit pas être inférieur à 7,6 l/min

(litres par minute).

Le débit peut être déterminé en lais-

sant couler de l'eau pendant une minute dans un bidon vide de 20 litres.

La température de l'eau d'alimentati-

on ne doit pas excéder 40°C/104°F.

Ne jamais utiliser le nettoyeur à hau-

te pression pour aspirer de l'eau

contaminée par des solvants, des diluants, de l'essence, de l'huile, etc.

Toujours utiliser une source d'eau propre pour éviter d'aspirer des débris.

CONSERVER CES

INSTRUCTIONS !

15

Page 16

Fran çais

Composants de l'appareil

Veuillez déplier le volet illustré de la première

page

1 Poignée-pistolet

2 Gâchette de la poignée-pistolet

3 Flexible haute pression

4 Support de la poignée-pistolet

5 Vanne de dosage du détergent

6 Couvercle verrouillant le réservoir de

détergent

7 Réservoir de détergent

8 Flexible d’aspiration du détergent, avec

filtre

9 Vis de fixation du capot

10 Commutateur de l’appareil

11 Capot

12 Manomètre

13 Prise haute pression

14 Porte-buse

15 Prise d'arrivée d'eau

16 Filtre fin

17 Indicateur du niveau d’huile

18 Réservoir à huile

19 Témoin de contrôle

20 Logement du flexible

21 Dégazage du réservoir de détergent

22 Rangement pour accessoires

23 Porte-câble

24 Poignée

25 Buse

26 Repère de la buse

27 Lance

28 Variateur de pression et de débit

29 Blocage de la poignée-pistolet

Pour votre sécurité

Veuillez lire la présente notice d’instructions

avant d’utiliser votre appareil pour la première

fois et respectez en particulier la brochure cijointe « Consignes de sécurité pour nettoyeurs haute pression », n° 5.951-949.

Domaines d’utilisation de

l’appareil

Utilisez cet appareil exclusivement pour

– les nettoyages au jet haute pression avec

détergent (p. ex. pour nettoyer machines,

véhicules, édifices, outils),

– les nettoyages au jet haute pression sans

détergent (p. ex. pour nettoyer façades,

terrasses, appareils de jardinage).

Si les salissures sont tenaces, nous vous recommandons la fraise à salissures, accessoire en option.

Dispositifs de sécurité

Vanne de surpression avec

pressostat

Lorsque vous réduisez le débit de l’eau à l’aide du variateur de pression et de débit, cette

vanne s’ouvre et une partie de l’eau retourne

du côté aspiration de la pompe.

Si vous relâchez complètement la gâchette

de la poignée-pistolet, le pressostat éteint la

pompe. Si vous appuyez sur la gâchette, le

pressostat réenclenche la pompe.

La vanne de surpression et le pressostat ont

été réglés et plombés à la fabrication.

Seul le service après-vente est habilité à en

modifier le réglage.

16

Page 17

Français

Avant la première mise en

service

Déballage de l’appareil

– Lors du déballage, vérifiez le contenu du

carton. Si vous constatez des dégâts dus

au transport, veuillez en informer votre

revendeur par lettre recommandée avec

accusé de réception.

– Ne jetez pas l’emballage dans la poubelle

à déchets domestiques. En vue de son

recyclage, rapportez-le à un point de

collecte approprié.

Contrôle du niveau d’huile

Relevez le niveau d’huile affiché par l’indi-

cateur lorsque l’appareil est à l’arrêt. Le niveau d’huile doit se situer au-dessus des

deux aiguilles.

Activation du dégazage du

réservoir à huile

Dévissez la vis de fixation du capot, puis

retirez le capot.

Coupez le bout pointu du couvercle du ré-

servoir d’huile.

Fixez le capot.

Montage des accessoires

Montez la buse au bout de la lance (les

repères sur la bague de réglage doivent se

trouver en haut).

Raccordez la lance à la poignée-pistolet

munie du variateur de pression et de débit.

Emboitez l’enrouleur de câble dans l’orifice

prévu sur le côté de l’appareil.

Dans ce cas, vissez le flexible haute-pres-

sion à fond.

Mise en service

Branchement électrique

Attention !

La tension mentionnée sur la plaque signalétique doit correspondre à celle du secteur.

Ne pas utiliser que des rallonges.

Données de branchement, voir la plaque si-

gnalétique/la section « Données

techniques ».

Attention !

L’appareil doit absolument être branché

dans la prise secteur avec une fiche mâle. Un

branchement permanent au réseau est interdit. La fiche mâle sert à couper l’alimentation

secteur.

Veuillez mettre l'interrupteur de la machine

sur Arrêt avant de réinitialiser le GFCI car sinon vous endommageriez le GFCI.

DISJONCTEUR DIFFERENTIEL

ETAPE 1 : Brancher le disjoncteur différen-

tiel dans une prise alimentée.

ETAPE 2 : Appuyer d’abord sur « TEST »,

puis sur « RESET » pour assurer le branchement correct au secteur.

Remarque : L’apparence effective du disjoncteur différentiel peut différer de l’illustration.

2

1

Prise d'arrivée d'eau /

Mode Aspiration

Raccordement à la conduite d’eau du

réseau public

17

Page 18

Fran çais

!

Attention !

Respectez les prescriptions de votre

sociétés distributrice des eaux ; selon

DIN 1988, le raccordement direct de l’appareil

au réseau public de distribution d’eau potable

est proscrit. Toutefois, un branchement de

courte durée avec clapet anti-retour intercalé

est admissible (n° réf. 6.412-578).

Données de branchement, voir la section

« Données techniques ».

Raccordez un flexible d’alimentation en

eau (non compris dans les fournitures) à la

prise d’arrivée d’eau de l’appareil et à l’alimentation en eau (par ex. au robinet).

Ouvrez le robinet d’eau.

Aspiration de l’eau contenue dans un

réservoir ouvert

Vissez le flexible d’aspiration avec filtre

(n° réf. 4.440-238) à la prise d’arrivée

d’eau.

Chassez les bulles d'air de l'appareil avant

de le mettre en service.

Pour dégazer l'appareil, dévissez la buse

puis faites marcher l'appareil jusqu'à ce

que l'eau sorte sans bulles.

Eteignez l'appareil puis revissez la buse.

Commande

Danger !

Si vous utilisez l'appareil dans des stations-service ou autres zones dangereuses,

respectez les prescriptions de sécurité appropriées.

Attention !

Ne nettoyez les moteurs qu’à un poste

de nettoyage dûment équipé d’un séparateur

d’huile (protection de l’environnement).

Attention !

Lavez les animaux uniquement avec la

lance plate basse pression (voir la section

« Choix du type de jet »).

Service haute pression

L’appareil est équipé d’un pressostat. Le moteur démarre uniquement si vous appuyez sur

la gâchette.

Amenez le commutateur de l’appareil sur la

position « I ». Le témoin de contrôle s’allume en vert.

Déverrouillez la poignée-pistolet et ap-

puyez sur la gâchette.

Réglez la pression de service et le débit

d’eau en tournant (en continu) le variateur

de pression et de débit (+/–).

Si le débit d'alimentation en eau est très fai-

ble, la chaleur perdue du moteur hausse la

température de l'eau de 15 °C environ.

Choix du type de jet

La poignée-pistolet doit être fermée.

Tournez le boîtier de la buse jusqu’à ce que

le symbole souhaité se trouve en face du

repère.

Sélectionnez soit le jet crayon soit le jet plat

grâce à une commutation sans contact :

tournez vers la gauche ou la droite la lance

inclinée vers le bas d'un angle de 45° env.

Signification des symboles

Jet crayon haute pression (0°),

pour les salissures particulièrement tenaces.

Jet plat haute pression (25°),

pour les salissures occupant une

large surface.

Jet plat basse pression

(CHEM), lors de l'utilisation de

détergent ou dans le cas d'un

nettoyage à faible pression.

Marche avec détergent

Attention !

Des détergents inappropriés pourraient

endommager l’appareil et l’objet à nettoyer.

N’utilisez que des détergents homologués par

Kärcher. Respectez le dosage recommandé

ainsi que les consignes accompagnant les

détergents. Afin de ménager l’environnement,

utilisez les détergents parcimonieusement.

Les détergents Kärcher vous garantissent

des travaux sans incident. Demandez conseil

ou réclamez notre catalogue ou les fiches

d’information sur les détergents.

Remplissez le réservoir de détergent.

Réglez la buse sur .

18

Page 19

Français

!

Réglez la vanne de dosage de détergent

sur la concentration voulue.

Dosage de détergent pour débit de refoulement maximal :

Position de la vanne

de dosage

Méthode de nettoyage recommandée

Avec le jet basse pression pulvérisez parci-

monieusement le détergent sur la surface

sèche puis laissez agir sans laisser sécher.

A l’aide du jet haute pression, chassez les

souillures décollées.

Une fois que vous avez terminé de vous

servir de l’appareil, positionnez la vanne de

dosage du détergent sur « 0 » puis enclenchez l’appareil et rincez-le à l’eau claire

pendant une minute environ.

1357

0,5%2,5%5,0%7,0

%

Interruption du service

L’appareil s’éteint si vous relâchez la

gâchette de la poignée-pistolet. Il se remet

en marche en appuyant à nouveau sur la

gâchette.

Période de veille

Pendant la période de veille, l’appareil se met

en marche lorsque vous ouvrez la poignée-pistolet. Le témoin de contrôle s’allume en vert.

La période de veille se termine si la poignéepistolet reste fermée pendant 30 minutes. Le

témoin de contrôle clignote en vert.

Remise à zéro de la période de

veille

Eteignez l'appareil.

Attendez un court instant

Enclenchez de nouveau l’appareil.

Si l’appareil doit fonctionner en mode continu,

le SAV peut effectuer les modifications nécessaires.

Mise hors service de l’appareil

Amenez le commutateur de l’appareil sur

« 0 » puis débranchez la fiche mâle de la

prise de courant.

Fermez le robinet d’arrivée d’eau.

Appuyez sur la gâchette jusqu’à ce que

l’appareil soit hors pression.

Glissez vers l’avant le levier de sécurité de

la poignée-pistolet pour empêcher d’actionner la gâchette par inadvertance.

Danger !

Risque d'ébouillantage par eau très

chaude. Les résidus d'eau qui se trouvent

dans l'appareil hors circuit peuvent chauffer.

Lors de l'enlèvement du tuyau d'arrivée d'eau,

l'eau chaude peut jaillir et provoquer des

ébouillantages. Retirer le tuyau seulement

quand l'appareil est refroidi.

Transport de l’appareil

Pour transporter l’appareil sur de longues

distances, prenez-le par la poignée puis

tirez-le derrière vous.

Si vous devez le transporter à l’horizontale,

vidangez le réservoir de détergent.

Rangement de l’appareil

Enfoncez la poignée-pistolet dans le sup-

port.

Enroulez le flexible haute pression puis ac-

crochez-le sur le logement de flexible.

Ou

Enroulez le cordon d’alimentation autour

du support de câble/flexible.

Protection antigel

Attention !

Le gel peut endommager l’appareil si

de l’eau se trouve encore à l’intérieur ! Rangez l’appareil à l’abri du gel.

Si vous ne pouvez pas stocker l’appareil à

l’abri du gel :

Videz le réservoir de détergent (voir net-

toyage et entretien/selon besoin).

Videz l’eau et rincez l’appareil avec du pro-

duit antigel.

Faites sécher l’appareil en le laissant

fonctionner pendant 1 min maximum.

19

Page 20

Fran çais

!

!

Utilisez de l’antigel pour voitures à base de

glycol, que l’on trouve dans le commerce.

Respectez les consignes d’utilisation pres-

crites par le fabricant d’antigel.

Nettoyage et entretien

Danger !

Avant d'effectuer tous les travaux de nettoyage et d'entretien sur l'appareil, veuillez débrancher sa fiche mâle de la prise de courant.

Attention !

Lorsque vous vidangez l’huile, remettez

l’huile usagée à un centre de collecte agréé.

Inspection de sécurité / Contrat

d'entretien

Vous pouvez convenir une inspection de sécurité régulière avec votre revendeur ou bien

souscrire un contrat d’entretien. Ce dernier

vous conseillera volontiers.

Avant chaque utilisation

Vérifiez si le câble d’alimentation est en-

dommagé (risque d’électrocution). Faites

remplacer immédiatement un câble endommagé par un électricien ou le service

après-vente agréé.

Vérifiez si le flexible haute pression est en-

dommagé (risque d’éclatement). S’il l’est,

remplacez-le immédiatement.

Vérifiez l’étanchéité de l’appareil (pompe).

3 gouttes par minute sont tolérables. Cette

eau peut s’écouler par le fond de l’appareil.

En cas de fuite plus importante, contactez

le SAV.

Chaque semaine

Vérifiez le niveau d’huile dans le réservoir

à huile : si l’huile est laiteuse (présence

d’eau), contactez immédiatement le SAV.

Nettoyez le filtre fin.

– Enlevez toute pression de l’appareil.

– Dévissez la vis de fixation du capot, puis

retirez le capot.

– Dévissez le couvercle avec le filtre.

– Nettoyez le filtre avec de l’eau propre ou

à l’air comprimé.

– Remontez le filtre en procédant dans

l’ordre inverse.

Nettoyez le filtre du flexible d’aspiration du

détergent.

Une fois par an ou toutes les

500 heures de service

Vidangez l’huile

– Quantité et type d’huile à utiliser : voir la

section « Données techniques ».

– Desserrez la vis de fixation, retirez le

capot, dévissez la vis de vidange de

l'huile se trouvant sur le devant du

boîtier moteur.

– Laissez s’écouler l'huile dans un récipi-

ent approprié.

– Revissez la vis de vidange de l’huile.

– Remplissez lentement le réservoir avec

de l’huile neuve pour laisser s’échapper

les bulles d’air.

Selon le besoin

Vidangez et nettoyez le réservoir de déter-

gent

– Retirez le couvercle du réservoir de dé-

tergent avec le flexible d'aspiration.

– Posez l’appareil sur la face arrière.

– Vidangez et nettoyez le réservoir de dé-

tergent.

Dérangements et remèdes

Danger !

Avant d’effectuer toute réparation sur

l’appareil, débranchez sa fiche mâle de la prise secteur. Les composants électriques

doivent être contrôlés et réparés exclusivement par le SAV agréé.

Lors de dérangements qui ne seraient pas répertoriés dans ce chapitre, en cas de doute ou

bien si vous avez expressément besoin de

conseils, adressez-vous au service aprèsvente agréé.

20

Page 21

Français

Témoin de contrôle

Le témoin de contrôle indique l’état de marche de l’appareil (vert) et la présence de

dérangements (rouge).

Remise à zéro :

Eteignez l'appareil.

Attendez un court instant

Enclenchez de nouveau l’appareil.

Affichage de l’état de marche

Allumé en vert en permanence :

– L’appareil est prêt à fonctionner.

Clignote une fois en vert :

– La période de veille s’est terminée après

30 minutes.

– L’appareil s’est éteint après 30 minutes

de marche continue (mesure de sécurité

en cas d’éclatement du flexible haute

pression).

Affichage de dérangements

Clignote une fois en rouge :

– Le côté haute pression est inétanche.

Contrôlez l’étanchéité du flexible haute

pression, des raccords de flexible et de

la poignée-pistolet.

Clignote deux fois en rouge :

– Surchauffe du moteur. Eteignez l'ap-

pareil. Laissez refroidir l’appareil.

Enclenchez de nouveau l’appareil.

Clignote trois fois en rouge :

– Défaut au niveau de l’alimentation en

tension. Vérifiez le branchement sur

secteur. Vérifiez les fusibles de secteur.

Clignote quatre fois en rouge :

– Consommation de courant trop im-

portante. Contactez le SAV.

L’appareil ne fonctionne pas

La période de veille est terminée. Le té-

moin de contrôle clignote en vert. Eteignez

l’appareil puis enclenchez-le de nouveau.

Vérifiez si le cordon d’alimentation de l’ap-

pareil est abîmé.

En présence de tout dérangement des cir-

cuits électriques, contactez le SAV.

L’appareil ne monte pas en

pression

Réglez la buse sur « Haute pression ».

Nettoyez / remplacez la buse.

Nettoyez le filtre fin, remplacez-le si

nécessaire.

Purgez l’air de l’appareil (voir la section

«Mise en service»).

Vérifiez le débit d’arrivée d’eau (voir la sec-

tion «Données techniques»).

Vérifiez si toutes les conduites aboutissant

à la pompe sont étanches ou si elles sont

bouchées.

Si nécessaire, contactez le SAV.

La pompe n’est pas étanche

3 gouttes par minute sont tolérables. Cette

eau peut s’écouler par le fond de l’appareil.

En cas de fuite plus importante, contactez

le SAV.

La pompe cogne

Vérifiez l’étanchéité de toutes les conduites

d’arrivée ainsi que du circuit de détergent.

Purgez l’air de l’appareil (voir la section

«Mise en service»).

Nettoyez le filtre fin.

Si nécessaire, contactez le SAV.

Pas d’aspiration de détergent

Réglez la buse sur « Chem ».

Vérifiez si le flexible d’aspiration du déter-

gent et son filtre ont des fuites ou s’ils sont

bouchés. Nettoyez si nécessaire.

Nettoyez / remplacez le clapet anti-retour

se trouvant dans le raccord du flexible

d’aspiration du détergent.

Ouvrez la vanne de dosage du détergent

ou vérifiez si elle a des fuites. Si elle est

bouchée, enlevez l’obstruction. Nettoyez

également le trou de dégazage situé dans

le boîtier.

Si nécessaire, contactez le SAV.

21

Page 22

Pièces de rechange

Vous trouverez à la fin de la présente notice

d’instructions un récapitulatif des pièces de

rechange.

Garantie

Dans chaque pays, les conditions de garantie

en vigueur sont celles publiées par notre société de distribution autorisée. Si, pendant la

durée de la garantie, votre appareil présente

des vices de matière ou de fabrication, la réparation est gratuite.

La garantie n’entre en vigueur que si le revendeur remplit intégralement la carte-réponse

ci-jointe lors de la vente, y appose son cachet

et la signe, et que si ensuite vous renvoyez ladite carte-réponse à la société distributrice de

votre pays.

En cas de garantie, veuillez vous adresser

avec les accessoires et la preuve d’achat à

votre revendeur ou au bureau du service

après-vente autorisé le plus proche de chez

vous.

Fran çais

22

Page 23

Français

Données techniques

HD 3.5/30-4S

Ea

1.286-110.0

Branchement électrique

Tension V 220... 240 200...208

Type de courant Hz 1 ~ 60

Puissance raccordée hp/kW 8.5/6.3 6.9/5.1

Fusible secteur (temporisé, char. C) A 30

Prise d'arrivée d'eau

Température d’arrivée d’eau max. °F/°C 140/60

Débit d’arrivée d’eau min. gpm / l/min 5.3/20

Longueur du flexible d’arrivée d’eau min. m 7.5

Diamètre min. inches 3/4

Hauteur d’aspiration dans un réservoir ouvert à 20 °C m 0.5

Pression d’arrivée max. psi/MPa 145/1

Performances

Pression de service psi/MPa 435...3000 /

Débit de refoulement

Débit d’aspiration de détergent

Force de recul au niveau de la poignée-pistolet N 62

Emission de bruit

Niveau de pression acoustique (EN 60704-1)

Pression acoustique garantie (2000/14/EC) dB (A) 87

Vibration de l’appareil / Vibration totale (ISO 5349)

Poignée-pistolet m/s

Lance m/s

Dimensions

Longueur mm 560

Largeur mm 500

Hauteur mm 1090

Poids sans accessoires kg 62

Contenance du réservoir de détergent l 6

Quantité d’huile pour la pompe l 1.2

Type d’huile pour la pompe 15W40

gpm / l/min

gpm / l/min

dB (A)

2

2

3...20.6

1.8...3.5 /

6.8..13.2.

HD 3.7/22-4S

1.286-115.0

435...2200 /

3...15.2

1.8...3.7 /

6.8...14.0

0...0.3 / 0...1.1

72

2.2

2.0

Eg

23

Page 24

Español

Protección del medio

ambiente

Los materiales de embalaje

son reciclables. Po favor, no

tire el embalaje a la basura doméstica; en vez de ello, entréguelo en los puntos oficiales

de recogida para su reciclaje o

recuperación.

Los aparatos viejos contienen

materiales valiosos reciclables

que deberían ser entregados

para su aprovechamiento posterior. Evite el contacto de baterías, aceites y materias

semejantes con el medioambiente. Por este motivo, entregue

los aparatos usados en los

puntos de recogida previstos

para su reciclaje.

INSTRUCCIONES DE

SEGURIDAD

IMPORTANTES

¡ADVERTENCIA!

Al utilizar este producto, tome siempre las

precauciones básicas, incluidas las siguientes:

Lea todas las instrucciones antes de

utilizar el producto.

Para reducir el riesgo de lesiones,

es necesario extremar las

precauciones cuando se utilice el

aparato cerca de niños.

Tiene que saber cómo parar el

aparato y purgar la presión

rápidamente. Familiarícese con los

controles.

Esté alerta; mire lo que esté

haciendo.

No haga funcionar el producto si

está cansado o si está bajo los

efectos del alcohol o las drogas.

Mantenga la zona en la que esté

limpiando libre de personas.

No se alargue demasiado sobre una

base ni se ponga sobre una base

inestable. Mantenga en todo

momento una buena base de apoyo

y un buen equilibrio.

Siga las instrucciones de

mantenimiento especificadas en el

manual.

Este producto se suministra con un

interruptor de circuito de avería por

puesta a tierra, que está montado

en el enchufe del cable de potencia.

Si es necesario reemplazar el

enchufe o el cable, utilice sólo

piezas de repuesto idénticas.

Riesgo de inyección o lesiones a

personas; no dé con el chorro

directamente a personas.

Los chorros de alta presión pueden

ser peligrosos si se utilizan mal. El

chorro no debe ser enfocado a

personas, animales, aparatos

eléctricos ni al aparato mismo.

Póngase gafas protectoras.

No utilice ácidos ni disolventes con

este producto.. Estos productos

pueden causar lesiones físicas al

usuario y daños irreversibles al

aparato.

Para reducir el riesgo de

electrocución, mantenga todas las

conexiones secas y alejadas del

suelo. No toque el enchufe con las

manos mojadas.

El pestillo de seguridad de la pistola

de disparo EVITA que la pistola se

dispare accidentalmente. Esta

característica de seguridad NO

bloquea el disparo en la posición de

encendido.

No se debe usar el cable de

extensión para esta máquina.

24

Page 25

Español

!

¡ADVERTENCIA

Para reducir el riesgo de

electrocución, mantenga todas las

conexiones secas y alejadas del suelo. No

toque el enchufe con las manos mojadas.

Instrucciones de puesta a tierra

Este producto se tiene que poner a

tierra. Si funcionase mal o si se

rompiese, la puesta a tierra

proporcionaría una circuito menos

resistente a la energía eléctrica para

reducir el riesgo de electrochoque.

Este producto está equipado con un

cable que tiene un conductor a tierra y

un enchufe a tierra para el equipo. El

enchufe se tiene que enchufar a un

tomacorriente adecuado, que esté

correctamente instalado y puesto a

tierra conforme a todas las normas y

reglamentos locales.

¡Peligro!

Si la conexión del conductor a

tierra del equipo es incorrecta puede

existir riesgo de electrochoque. En caso

de duda, compruebe con ayuda de un

electricista cualificado o del personal del

servicio técnico que el tomacorriente

está correctamente puesto a tierra. No

modifique el enchufe proporcionado con

el producto; si no encaja en el

tomacorriente, pida a un electricista

cualificado que le instale un

tomacorriente adecuado. No utilice

ningún tipo de adaptador con este

producto.

Protección mediante interruptor de

circuito de avería por puesta a tierra

Este producto se suministra con un

interruptor de circuito de avería por puesta

a tierra montado en el enchufe del cable

de potencia. Este aparato proporciona

una protección adicional contra el riesgo

de electrochoque. Si la corriente se

interrumpe en la línea, el interruptor de

circuito de avería por puesta a tierra

recerrará, automáticamente, el circuito al

circuito de carga una vez restablecida la

corriente. En función del modelo de

interruptor, puede que sea necesario

tener que poner en funcionamiento el

aparato manualmente mediante el botón

de reinicio para restaurar la corriente del

circuito de carga del interruptor de circuito

de avería por puesta a tierra. Si es

necesario reemplazar el enchufe o cable,

utilice piezas idénticas.

SUMINISTRO DE AGUA

¡Atención!

Al conectar la toma de agua a la

red de suministro del agua, es obligatorio

respetar la normativa local establecida

por la compañía del agua. En algunas

zonas, está prohibido conectar la unidad

directamente a la red pública de

suministro de agua potable. Esto es así

para garantizar que no penetren

sustancias químicas en la red de

suministro del agua. Sí se permite

efectuar la conexión directamente por

ejemplo a través de un depósito receptor

o un dispositivo antirretorno.

Si el agua de alimentación está sucia,

la unidad sufrirá daños. Para evitar

este riesgo, le recomendamos que

monte un filtro de agua.

No utilice nunca el limpiador a

presión para aspirar agua

contaminada con disolventes como,

p. ej., diluyentes de pintura,

gasolina, aceite, etc.

Evite siempre que la unidad aspire

residuos utilizando una fuente de

abastecimiento cuya agua esté

limpia.

¡GUARDE ESTAS

INSTRUCCIONES!

25

Page 26

Español

Elementos y componentes

del aparato

Despliegue, por favor, la página con las

ilustraciones

1 Pistola

2 Gatillo de la pistola

3 Manguera de alta presión

4 Soporte para colocar la pistola

5 Válvula dosificadora del detergente

6 Tapa del depósito del detergente

7 Depósito del detergente

8 Manguera de aspiración del detergente,

con filtro

9 Tornillo de sujeción del capó de la

máquina

10 Interruptor para conexión y desconexión

del aparato

11 Capó

12 Manómetro

13 Conexión de alta presión

14 Soporte para guardar las boquillas

15 Toma de agua del aparato

16 Filtro fino

17 Indicador del nivel de aceite

18 Depósito de aceite

19 Indicador luminoso

20 Soporte para guardar la manguera

21 Evacuación de aire del depósito del

detergente

22 Compartimento para accesorios

23 Sujetacables

24 Asa

25 Boquilla

26 Marca de la boquilla

27 Lanza

28 Mando de regulación de la presión y del

caudal de agua

29 Seguro de la pistola

Para su seguridad

Antes de poner en marcha por vez primera su

aparato deberá leer atentamente las

presentes instrucciones de servicio, así

como, especialmente, el cuaderno adjunto

sobre «Consejos e instrucciones de

seguridad para las limpiadoras de alta

presión» Nº 5.951-949.

Campo de aplicación del

aparato

El aparato ha sido diseñado exclusivamente

para

– la limpieza con alta presión y detergentes

de máquinas, vehículos, herramientas,

edificios y objetos similares.

– la limpieza con alta presión, sin

detergentes, de terrazas, edificios,

herramientas y muebles de jardín.

Para eliminar suciedad particularmente

resistente y fuertemente adherida

aconsejamos emplear la boquilla turbo

(«efecto fresadora»), que está disponible

como accesorio opcional.

Dispositivos de seguridad

Válvula de derivación (by-pass)

con presostato

Al reducir el caudal de agua a través del

mando regulador de la presión y el caudal de

agua, se abre la válvula derivación (by-pass),

haciendo retornar la bomba de alta presión

una parte del agua hacia las válvulas de

aspiración de la bomba.

Al dejar de oprimir la palanca de

accionamiento (gatillo) de la pistola, el

presostato desconecta la bomba. Al volver a

oprimir el gatillo, el presostato conecta la

bomba.

La válvula de derivación (by-pass) y el

presostato vienen ajustados y precintados de

fábrica.

Los ajustes sólo podrán ser modificados por

personal especializado del Servicio Técnico

Postventa Oficial.

26

Page 27

Español

Antes de la primera puesta

en marcha del aparato

Desembalar el aparato

– Verificar el contenido del embalaje. Si al

desembalar el aparato comprobara Vd.

algún daño o desperfecto en el mismo

atribuible al transporte, rogamos se dirija

inmediatamente al Distribuidor en donde

adquirió su aparato.

– No tire el embalaje del aparato y sus

elementos al cubo de basura. Entréguelo

en los Puntos o Centros Oficiales de

recogida para su reciclaje o recuperación.

Verificar el nivel del aceite

Controlar el indicador del nivel de aceite

con el aparato de pie. El nivel de aceite

deberá encontrarse por encima de los dos

indicadores.

Activar la evacuación de aire

del depósito de aceite

Desenroscar el tornillo de sujeción del

capó. Retirar el capó.

Cortar la punta de la tapa del depósito de

aceite.

Montar y fijar el capó de la máquina en su

sitio.

Montaje de los accesorios

Montar la boquilla en la lanza (los símbolos

deben coincidir con la marca de referencia

que se encuentra en el anillo de ajuste).

Montar la lanza en la pistola con la

regulación de la presión y el caudal.

Encajar el sujetacable en el orificio lateral

en el asa.

Atornillar correspondientemente la

manguera de alta presión.

Puesta en marcha del

aparato

Conexión a la red eléctrica

¡Atención!

Cerciorarse de que la red eléctrica

coincide con los valores detallados en la

placa de características del aparato.

No se debe usar el cable de extensión para

esta máquina.

Los valores de conexión figuran en la placa

de características del aparato, así como en

las Características Técnicas del mismo.

¡Atención!

Es estrictamente necesario conectar el

aparato con un enchufe a la red eléctrica.

Está terminantemente prohibida una

conexión no separable con la red eléctrica. El

enchufe sirve para la separación de la red.

Antes de resetear el GFCI desconecte el

interruptor de la máquina; de lo contrario el

GFCI podría resultar dañado

INSTRUCCIONES DEL INTERRUPTOR DE

CIRCUITO DE AVERÍA POR PUESTA A

TIERRA

PASO 1: Enchufe el interruptor de circuito

de avería por puesta a tierra a un

tomacorriente de servicio.

PASO 2: Presione ’’TEST’’ (PRUEBA) y,

después, presione ’’RESET" (REINICIO)

para asegurarse de que la conexión a la

toma de energía eléctrica es correcta.

Nota: El aspecto actual del interruptor de

circuito de avería por puesta a tierra puede

ser distinto al de la ilustración.

2

1

27

Page 28

Español

!

Conexión a la red de agua/

Aspiración de agua

Conexión a la red de agua

¡Atención!

Observar estrictamente las normas y

disposiciones de la empresa local de

abastecimiento de agua. Según la normativa

alemana DIN 1988, la limpiadora de alta

presión no puede acoplarse a la red pública

de abastecimiento de agua potable, a fin de

evitar que los detergentes y agentes químicos

puedan acceder y contaminar el agua

potable. Un acoplamiento de breve duración

a través de un dispositivo de bloqueo antiretorno (Nº de pedido 6.412-578), sin

embargo, está permitido.

Verificar si la conexión a la red de agua

cumple con los valores detallados en las

Características Técnicas del aparato.

Acoplar la manguera de alimentación de

agua (no incluida en el equipo de serie del

aparato) a la toma de agua del aparato y a

la conexión de la red de agua (grifo).

Abrir la alimentación de agua (grifo).

Aspirar agua de un recipiente abierto

Empalmar la manguera de aspiración con

filtro (Nº de pedido 4.440-238) a la toma de

agua del aparato.

Purgar el aire del aparato antes de ponerlo

en marcha

Para evacuar el aire del aparato,

desenroscar la boquilla, haciendo

funcionar el aparato hasta que el agua

salga sin burbujas.

Desconectar el aparato y volver a enroscar

la boquilla.

Manejo del aparato

¡Peligro!

En caso de trabajar con el aparato en

gasolineras, estaciones de servicio o en otras

áreas o zonas de peligro, deberán

observarse estrictamente las instrucciones

y normas de seguridad nacionales vigentes.

¡Atención!

Por razones de la protección del medio

ambiente, la limpieza de motores sólo se

puede ejecutar en aquellos lugares que

dispongan de un separador de aceite.

¡Atención!

La limpieza de animales sólo se podrá

realizar con el chorro de baja presión en

abanico (véase el apartado «Ajustar el tipo de

chorro»).

Funcionamiento con alta presión

El aparato está equipado con un presostato.

El motor sólo se pone en marcha en caso de

oprimir la palanca (gatillo) de accionamiento

de la pistola.

Colocar el interruptor de conexión y

desconexión del aparato en la posición «I».

El indicador luminoso se ilumina en verde.

Desbloquear la pistola y oprimir el gatillo.

Ajustar (+/–) gradualmente la presión de

trabajo y el caudal del agua girando a dicho

efecto el mando para la regulación de la

presión y el caudal de agua.

Trabajando la máquina con el mínimo

caudal de agua, el calor irradiado por el

motor calienta el agua aprox. 15 °C.

Ajustar el tipo de chorro

La palanca de accionamiento (gatillo) de la

pistola tiene que estar sin oprimir («pistola

cerrada»).

Girar el cuerpo de la boquilla hasta que el

símbolo correspondiente al tipo de chorro

coincida con la marca de referencia.

Seleccionar el chorro concentrado de alta

presión o de abanico conmutando de un

chorro a otro sin accionar mandos ni

pulsadores:

Tan sólo hay que girar la lanza orientada

en ángulo de 45° hacia abajo, hacia la

izquierda o derecha.

Significado de los símbolos:

Chorro concentrado de alta

presión (0°), para la eliminación

de la suciedad resistente

y fuertemente adherida.

Chorro de alta presión en

abanico (25°) para eliminar la

suciedad que está cubriendo

grandes superficies

Chorro de baja presión en

abanico para agregar

detergente (CHEM), permite

trabajar con detergente o con

escasa presión

28

Page 29

Español

!

Funcionamiento con detergente

¡Atención!

Sólo deberán emplearse aquellos

productos que han sido homologados y

autorizados por el Fabricante. Los

detergentes inapropiados pueden causar

daños en las limpiadoras de alta presión y en

los objetos a limpiar. Obsérvense

estrictamente las instrucciones y consejos de

dosificación que incorporan las etiquetas de

las envolturas de los detergentes. En interés

de la protección del medio ambiente

recomendamos hacer un uso muy moderado

de los detergentes.

Los detergentes y agentes conservantes de

Kärcher han sido desarrollados

específicamente para el aparato y la tarea de

limpieza concreta, garantizando así el

funcionamiento correcto de la limpiadora.

Consulte a este respecto a su Distribuidor

o solicite nuestro catálogo general o folletos

informativos sobre detergentes.

Llenar el depósito del detergente.

Colocar la boquilla en la posición .

Colocar la válvula dosificadora en la

posición correspondiente a la dosificación

deseada.

Dosificación de detergente con el caudal

máximo:

Posición de la válvula

dosificadora

Para lograr unos resultados óptimos en la

limpieza, aconsejamos proceder según el

siguiente método:

Separar la suciedad pulverizando

moderadamente el detergente con el

chorro de baja presión sobre la superficie a

limpiar seca; dejar que actúe durante un

cierto tiempo, sin que llegue a secarse

sobre la superficie.

Eliminar la suciedad con el chorro de agua

de alta presión.

Tras concluir la tarea de limpieza, colocar

la válvula dosificadora del detergente en la

posición «0», conectar el aparato durante

un minuto y enjuagarlo con agua limpia.

1357

0,5%2,5%5,0%7,0

%

Interrumpir el funcionamiento

del aparato

Soltar el gatillo de la pistola. El aparato se

desconecta. Al oprimir nuevamente el

gatillo, el aparato se pone en marcha.

Tiempo de disposición de

funcionamiento

Al abrir la pistola en el tiempo de disposición

de funcionamiento se pone en marcha el

aparato. El indicador luminoso se ilumina en

verde.

Si la pistola se mantiene cerrada durante 30

minutos, se finaliza el tiempo de disposición

de funcionamiento. El indicador luminoso

parpadea en verde.

Restablecer el tiempo de

disposición de funcionamiento.

Desconectar el interruptor del aparato.

Esperar brevemente.

Volver a conectar el aparato.

El aparato puede ser ajustado a

funcionamiento continuo por el Servicio

Técnico Postventa Oficial.

Desconectar el aparato

Colocar el interruptor de conexión y

desconexión del aparato en la posición

«0». Retirar el enchufe del aparato de la

toma de corriente.

Cerrar la alimentación de agua (grifo).

Oprimir el gatillo de la pistola, hasta

evacuar completamente la presión del

interior del aparato.

Oprimir la palanca de bloqueo de la pistola

hacia delante para asegurar el gatillo

contra accionamiento fortuito.

¡Peligro!

Peligro de escaldadura por agua

caliente. El agua residual contenida en el

aparato desconectado puede calentarse. Al

desacoplar el tubo flexible de la admisión de

agua, el agua calentada puede salir

disparada y causar quemaduras por

escaldadura. Desacoplar el tubo flexible

recién cuando el aparato se haya enfriado.

29

Page 30

Español

!

Transporte del aparato

Para transportar el aparato por trayectos

largos, sujetar el aparato por el asa

y arrastrar el aparato tras de sí.

En caso de transportar el aparato en

posición horizontal, evacuar previamente

el depósito del detergente.

Guardar el aparato

Colocar la pistola en el soporte

correspondiente.

Enrollar la manguera de alta presión y

colgarla del soporte

o

Enrollar el cable de conexión en torno al

soporte.

Protección antiheladas

¡Atención!

¡Las heladas dañan el aparato si no

está completamente vacío de agua! Guardar

la máquina en un recinto protegido contra

heladas (provisto de calefacción).

Si no se puede guardar el aparato en un lugar

protegido contra heladas:

Vaciar el depósito del detergente. (Si fuera

necesario, véanse los Trabajos de cuidado

y mantenimiento)

Evacuar el agua y enjuagar el aparato con

anticongelante.

Dejar marchar en seco el aparato como

máximo 1 minuto.

Emplear anticongelante habitual en el

comercio para automóviles a base de

glicol.

Observar las prescripciones de manejo del

fabricante del anticongelante.

Trabajos de cuidado y

mantenimiento

¡Peligro!

Antes de ejecutar cualquier trabajo de

cuidado o mantenimiento del aparato, extraer

el cable de conexión del mismo de la toma de

corriente.

¡Atención!

El aceite usado que se origina al

efectuar un cambio de aceite

eliminarse o entregarse en los puntos oficiales

de recogida de aceites usados.

deberá

Inspección de seguridad /

Contrato de mantenimiento

En su Distribuidor puede Vd. pedir un

contrato para inspecciones de seguridad

regulares o de mantenimiento. Consulte

a su Distribuidor al respecto.

Antes de cada puesta en

marcha del aparato

Verificar si el cable de conexión presenta

huellas de daños o desperfectos (¡Peligro

de descargas eléctricas!). Los cables de

conexión que estuvieran defectuosos

deberán sustituirse inmediatamente.

Encargar dicho trabajo a un técnico

especialista del Servicio Técnico

Postventa Oficial o a un electricista

autorizado.

Verificar el estado de la manguera de alta

presión (¡existe peligro de que pueda

estallar!). Cambiarla inmediatamente si

está dañada.

Verificar la estanqueidad de la bomba.

Unas fugas del orden de tres gotas por

minuto son admisibles. En caso de

comprobarse fugas mayores, avisar al

Servicio Técnico Postventa.

Semanalmente

Verificar el nivel del aceite en el depósito.

De presentar el aceite un aspecto lechoso

(agua en el aceite), avisar inmediatamente

al Servicio Técnico Postventa.

Limpiar el filtro fino.

– Dejar el aparato sin presión.

– Desenroscar el tornillo de sujeción del

capó. Retirar el capó.

– Destornillar la tapa con el filtro.

– Limpiar el filtro con agua limpia o con

aire comprimido.

– Volver a montar el aparato en el orden

inverso.

Limpiar el filtro en la manguera de

aspiración del detergente.

30

Page 31

Español

!

Anualmente o cada 500 horas

de funcionamiento

Cambiar el aceite

– Las cantidades y clases de aceite

figuran en las Características Técnicas.

– Soltar el tornillo de sujeción y retirar el

capó. Extraer el tornillo de vaciado del

aceite situado en el frontal de la carcasa

del motor.

– Evacuar el aceite recogiéndolo en un

recipiente apropiado.

– Enroscar el tornillo de vaciado del

aceite.

– Poner lentamente aceite en el depósito.

Prestar atención a que desaparezcan

las burbujas de aire.

En caso necesario

Vaciar y limpiar el depósito del detergente.

– Retirar la tapa del depósito de

detergente con la manguera de

aspiración.

– Colocar el aparato sobre la parte

posterior.

– Vaciar y limpiar el depósito del

detergente.

Localización de averías

¡Peligro!

Antes de efectuar cualquier reparación

del aparato, hay que desconectarlo y

desenchufarlo de la red eléctrica. Los

trabajos de verificación o reparación que

fuera necesario efectuar en las piezas y

componentes eléctricos de la máquina sólo

deberán ser ejecutados por personal

especializado del Servicio Técnico Postventa

Oficial.

Avisar el Servicio Técnico Postventa en caso

de averías no descritas en este capítulo, en

caso de duda, así como en casos en donde

se indique explícitamente.

Indicador luminoso

El indicador luminoso indica estados de

funcionamiento (verde) y averías (rojo).

Restablecimiento:

Desconectar el interruptor del aparato.

Esperar brevemente.

Volver a conectar el aparato.

Indicador de estado de funcionamiento

Luz verde continua:

– El aparato está listo para el

funcionamiento.

1 parpadeo de la luz verde:

– La disposición de funcionamiento se

termina tras 30 minutos.

– El aparato se ha desconectado tras 30

minutos de servicio continuo (seguridad

en caso de manguera de alta presión

rota).

Indicación de averías

1 parpadeo de la luz roja:

– Inestanqueidades en el lado de alta

presión. Controlar la estanqueidad de la

manguera de alta presión, de las

uniones de manguera y de la pistola.

2 parpadeos de la luz roja:

– Motor demasiado caliente. Desconectar

el interruptor del aparato. Dejar que se

enfríe el aparato. Volver a conectar el

aparato.

3 parpadeos de la luz roja:

– Avería en la alimentación de corriente.

Comprobar la conexión a la red.

Verificar los fusibles.

4 parpadeos de la luz roja:

– Consumo de corriente demasiado alto.

Avisar al Servicio Técnico Postventa.

El aparato no se pone en

marcha

El tiempo de disposición de

funcionamiento se ha terminado. El

indicador luminoso parpadea en verde.

Desconectar y volver a conectar el

aparato.

Verificar si el cable de conexión a la red

eléctrica presenta huellas de daños

o desperfectos.

En caso de constatar una avería en los

circuitos o sistemas eléctricos del aparato,

avisar al Servicio Técnico Postventa.

31

Page 32

Español

El aparato no coge presión

Colocar la boquilla en la posición de «alta

presión».

Limpiar la boquilla o sustituirla, según el

caso.

Limpiar el filtro fino, sustituirlo en caso

necesario.

Purgar el aire del aparato (véase el

capítulo «Puesta en marcha del aparato»).

Verificar el caudal y la presión del agua

suministrada al aparato (véanse al

respecto las Características Técnicas).

Verificar si las tuberías de alimentación

que conducen a la bomba presentan

inestanqueidades u obstrucciones.

En caso necesario, consultar con el

Servicio Técnico Postventa.

Inestanqueidades en la bomba

Unas fugas del orden de tres gotas por

minuto son admisibles. En caso de

comprobarse fugas mayores, avisar al

Servicio Técnico Postventa.

Golpes de pistón en la bomba

Verificar la estanqueidad de todas tuberías

de alimentación, así como las del circuito

del detergente.

Purgar el aire del aparato (véase el

capítulo «Puesta en marcha del aparato»).

Limpiar el filtro fino.

En caso necesario, consultar con el

Servicio Técnico Postventa.

Repuestos

En las páginas finales de estas Instrucciones

figura la lista de los repuestos más usuales.

Garantía

En cada país rigen las condiciones de

garantía establecidas por las

correspondientes Sociedades Distribuidoras.

Las perturbaciones y averías de su aparato

serán subsanadas de modo gratuito dentro

del plazo de garantía en la medida en que las