Page 1

SERVICE MANUAL

MICRO COMPONENT SYSTEM

MB50520066

UX-G70J,UX-G70C,UX-G70B,

UX-G70E,UX-G70EN,

UX-G70EV,UX-G70EE

SUPER VIDEO

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

COPYRIGHT © 2006 Victor Company of Japan, Limited

CA-UXG70

TABLE OF CONTENTS

SP-UXG70SP-UXG70

No.MB505

2006/6

Page 2

SPECIFICATION

Amplifier section Output Power Northern america 120 W per channel, min. RMS, driven into 6 Ω at 1kHz with no more than 10% total

harmonic distortion. (for northern america)

Europe 160 W (80 W+80 W) at 6

Audio Input LINE IN 500 mV/49 k

250 mV/49 k

125 mV/49 k

GAME IN (northern america) 500 mV/49 k

TV SOUND IN 500 mV/49 kΩ

Audio Output LINE OUT 1.0 Vrms (3 kΩ) (at "L.OUT LVL1")

SUBWOOFER OUT 260 mVrms/3.9 k

HEADPHONES OUT 17 mW/32 Ω

Digital output DVD OPTICAL DIGITAL OUT -21 dBm to -15 dBm (660 nm ±30 nm)

USB input USB AUDIO

Video Output Color system NTSC (interlaced/progressive) for northern america

VIDEO (composite) 1 V(p-p)/75

S-VIDEO Y (luminance) : 1 V(p-p)/75 Ω

RGB 0.7 V(p-p)/75

COMPONENT (Y) : 1 V(p-p)/75

Speaker impedance 6

Headphone impedance 16 Ω - 1 kΩ

Tuner section FM tuning range 87.5 MHz - 108.0 MHz

AM tuning range 530 kHz - 1 710 kHz for northern america

Disc player section Playable disc DVD Video/DVD Audio/CD/VCD/SVCD

Dynamic range 80 dB

Horizontal resolution 500 lines

Wow and flutter Immeasurable

General Power requirement AC 120 V , 60 Hz for northern america

Power consumption 90 W (at operation) for northern america

Dimensions (approx.)(W/H/D) 175 mm

Speakers Speaker units Tweeter 1.5 cm (5/8 inch) dome

Squawker 4 cm (1-5/8 inch) cone

Woofer 13.5 cm (5-3/8 inch) cone

Impedance 6

Dimensions (approx.) (W/H/D) 166 mm × 250 mm × 232 mm (6-9/16 inch × 9-7/8 inch × 9-3/16 inch)

Mass (approx.) 2.8 kg (6.2 lbs) each

500 mVrms (1.5 k

PAL (interlaced/progressive) for europe

C (chrominance, burst) : 0.286 V(p-p)/75 Ω for northern america

C (chrominance, burst) : 0.3 V(p-p)/75

(PB/PR) : 0.75 V(p-p)/75 Ω for northern america

(PB/PR) : 0.7 V(p-p)/75

Ω - 16 Ω

522 kHz - 1 629 kHz fro europe

CD-R/CD-RW (CD/SVCD/VCD/MP3/WMA/JPEG format)

DVD-R/-RW (DVD-VR/DVD Video/MP3/WMA/JPEG format)

+R/+RW (DVD Video format)

DVD-ROM (DVD Video format)

AC 230 V , 50 Hz for europe

95 W (at operation) for europe

14 W (at standby)

1.0 W (at standby display OFF mode)

Ω

Ω (at "L.IN LVL1")

Ω (at "L.IN LVL2")

Ω (at "L.IN LVL3")

Ω

Ω

Ω for europe

Ω

× 250 mm × 411 mm (6-9/10 inch × 9-7/8 inch × 16-1/5 inch)

Ω (10% THD) for europe

Ω) (at "L.OUT LVL2")

Ω

Ω for europe

Ω for europe

× 1

× 1

× 1

Design and specifications are subject to change without notice.

1-2 (No.MB505)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB505)1-3

Page 4

1.5 Safety Precautions (U.K only)

(1) This design of this product contains special hardware and many circuits and components specially for safety purposes. For con-

tinued protection, no changes should be made to the original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those used in the original circuits.

(2) Any unauthorised design alterations or additions will void the manufacturer's guarantee; furthermore the manufacturer cannot

accept responsibility for personal injury or property damage resulting therefrom.

(3) Essential safety critical components are identified by ( ) on the Parts List and by shading on the schematics, and must never

be replaced by parts other than those listed in the manual. Please note however that many electrical and mechanical parts in

the product have special safety related characteristics. These characteristics are often not evident from visual inspection. Parts

other than specified by the manufacturer may not have the same safety characteristics as the recommended replacement parts

shown in the Parts List of the Service Manual and may create shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be separated from live parts,

high temperature parts, moving parts and/or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

1.5.1 Warning

(1) Service should be performed by qualified personnel only.

(2) This equipment has been designed and manufactured to meet international safety standards.

(3) It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(4) Repairs must be made in accordance with the relevant safety standards.

(5) It is essential that safety critical components are replaced by approved parts.

(6) If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-4 (No.MB505)

Page 5

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.7 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.8 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connecto on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

Short land section

Connector

Card wire

DVD pickup

DVD changer mechanism assembly

(No.MB505)1-5

Page 6

1.9 Importance administering point on the safety

D9044

D9047

D9043

Q9044

IC901

B9105

D9048

C9041

B9301

B9302

B9300

B9104

HS902

C9045

B9106

D9040

B9501

B9600

B9502

D9025

B9202

D9024

D9023

C9022

CN901

HS901

R9046

R9045

C9042

D9042

R9044

FT913

D9004

D9003

C9003

C9024

B9204

C9004

C9023

C9025

C9021

D9022

D9014

D9021

B9900

D9046

D9045

Q9043

FT914

B9203

D9002

D9001

C9005

C9014

D9012

D9011

D9013

B9303

B9205

C9012

R9031

D9031

B9101

RY901

B9102

B9103

C9043

C9044

C9002

FT907

C9001

FT905

C9015

FT909

C9011

FT911

C9013

R9033

R9032

D9032

Q9031

C9031

T9000

FT908

FT906

FT910

FT912

CN903

B9100

B9700

LF901

FT903

FT904

C9052

C9051

B9305

B9304

CN906

R9050

EP901

B9201

B9200

CN904

FT901

FT902

B9500

B9950

CN905

S9001

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F9001 : 6.3A 125V

F9002 : 6.3A 125V

F9003 : 3.15A 125V

F9004 : 3.15A 125V

F9006 : 2.5A 125V

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

^

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

F9001 : 6.3A 125V

F9002 : 6.3A 125V

F9003 : 3.15A 125V

F9004 : 3.15A 125V

F9006 : 2.5A 125V

1-6 (No.MB505)

Page 7

1.10 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MB505)1-7

Page 8

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-8 (No.MB505)

Page 9

SECTION 3

A

DISASSEMBLY

3.1 Main body

3.1.1 Removing the side panel

(Fig.1, 2)

(1) Remove the six screws A attaching the side panel. (See

Fig.1)

(2) Remove the four screws B attaching the side panel. (See

Fig.2)

3.1.2 Removing the top cover

(Fig.1, 3)

(1) Remove the one screw C attaching the top cover. (See

Fig.1)

(2) Remove the two screws D attaching the top cover. (See

Fig.3)

C G

B

G

Fig.1

B

Fig.2

D

A

Fig.3

(No.MB505)1-9

Page 10

3.1.3 Removing the front panel

(Fig.4 to 6)

(1) Disconnect the card wire from the connector CN359

on the regulator board. (See the Fig.4)

CN360

(2) Disconnect the card wire from the connector CN760 on the

main board. (See Fig.4)

(3) Disconnect the connector wire from the connector CN713

on the main board. (See Fig.4)

(4) Disconnect the connector wire from the connector CN405

on the video board. (See Fig.4)

(5) Remove the two screws E and two screws F attaching the

front panel. (See Fig.5)

(6) Remove the hook a. (See Fig.5)

(7) Remove the hook b and then removing the front panel.

(See Fig.6)

and

CN360

E

CN359

Fig.4

CN706CN713CN405

Fig.5

hook b

hook a

F

3.1.4 Removing the rear cover

(Fig.1)

(1) Remove the two screws G attaching the rear cover.

1-10 (No.MB505)

Fig.6

Page 11

3.1.5 Removing the video board

(Fig.7, 8)

(1) Disconnect the card wire from the connector CN401

on the video board. (See Fig.7)

CN402

(2) Remove the three screws H attaching the video board.

(See Fig.8)

3.1.6 Removing the tuner pack

(Fig.8, 9)

(1) Disconnect the card wire from the connector CN712

main board. (See Fig.9)

(2) Remove the two screws J attaching the tuner pack. (See

Fig.8)

3.1.7 Removing the fan

(Fig.8, 9)

(1) Disconnect the connector wire from the connector CN708

on the main board. (See Fig.9)

(2) Remove the two screws K attaching the fan. (See Fig.8)

on the

and

CN401

CN402

Fig.7

H

J

H

CN712

K

Fig.8

CN708

Fig.9

(No.MB505)1-11

Page 12

3.1.8 Removing the rear panel

(Fig.10, 11)

(1) Remove the eight screws L attaching the rear panel. (See

Fig.10)

(2) Remove the rear panel from the hook c. (See Fig.11)

L

L

L

L

Fig.10

1-12 (No.MB505)

hook c

Fig.11

Page 13

3.1.9 Removing the transformer board

(Fig.12)

(1) Disconnect the connector wire from the connector CN903

on the transformer board.

(2) Remove the one screw M attaching the transformer board.

(3) Disconnect the connector CN901

board and then removing the transformer board with power

cord.

connecting the regulator

3.1.10 Removing the main board

(Fig.13)

(1) Disconnect the card wire from the connector CN703

main board.

(2) Remove the one screw N attaching the main board.

(3) Disconnect the main board from the connector CN701

connecting the regulator board.

CN702

3.1.11 Removing the amplifier board

(Fig.14)

(1) Disconnect the amplifier board from the connector CN353

and CN354.

on the

and

CN904

CN703

M

Fig.12

CN702

Fig.13

CN903 CN901

CN701

N

CN354

CN353

Fig.14

(No.MB505)1-13

Page 14

3.1.12 Removing the regulator board

(Fig.15)

(1) Disconnect the connector wire from the connector CN361

on the regulator board.

(2) Remove the four screws P attaching the regulator board.

(3) Disconnect the card wire from the connector CN356

P

.

CN361

3.1.13 Removing the power transformer

(Fig.16)

(1) Remove the four screws Q attaching the power transform-

er.

P

CN356

Fig.15

Q

1-14 (No.MB505)

Q

Fig.16

Page 15

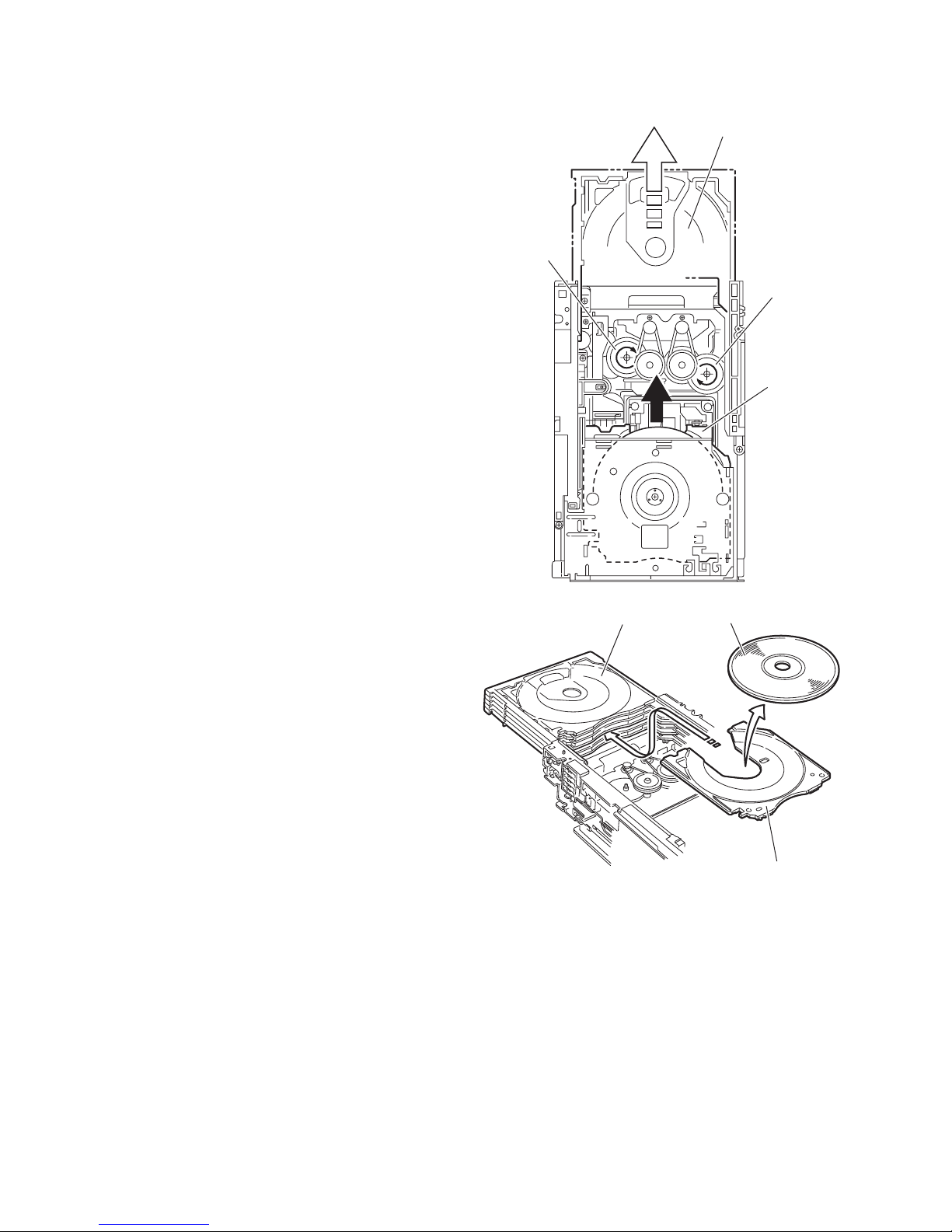

3.1.14 Removing the DVD changer mechanism assembly

(Fig.17 to 19)

(1) Remove the four screws R attaching the main chassis.

(See Fig.17)

(2) Remove the two screws S and two screws T attaching the

DVD changer mechanism assembly. (See Fig.18, 19)

R

R

Fig.17

T

s

Fig.18

Fig.19

(No.MB505)1-15

Page 16

3.1.15 Removing the USB board

(Fig.20)

(1) Remove the three screws U attaching the USB board.

3.1.16 Removing the FL board

(Fig.21)

(1) Remove the four screws V attaching the FL board.

(2) Disconnect the card wire from the connector CN100

FL board.

on the

U

Fig.20

V

3.1.17 Removing the switch board

(Fig.22)

(1) Remove the volume knob.

(2) Remove the twelve screws W attaching the switch board.

CN100

W

Fig.21

W

W

Fig.22

V

W

1-16 (No.MB505)

Page 17

3.2 DVD changer mechanism assembly section

Remove the DVD changer mechanism assembly from the main body. (See "Removing the DVD changer mechanism assembly".)

3.2.1 Removing the tray assemblies

(See Figs.1 to 5)

(1) From the top side of the main body, remove the two screws

A from the top cover and release the two joints a on the

both sides of the DVD changer mechanism assembly. (See

Figs.1 and 2.)

(2) Remove the two rods from the top cover and remove the

top cover from the lifter assembly. (See Figs.1 and 2.)

(3) Remove the open det. lever on the left side of the DVD

changer mechanism assembly. (See Fig.3.)

(4) From the right side of the DVD changer mechanism as-

sembly, draw out the tray assemblies toward the front while

pushing the part b of the side (R) assembly. (See Figs.4

and 5.)

Note:

The tray can be locked if all tray assemblies are attached.

(5) From the topside of the DVD changer mechanism assem-

bly, move the stopper tabs c in the direction of the arrow

and release them. Pull out the tray assemblies from the

DVD changer mechanism assembly. (See Fig. 5.)

Note:

Remove the tray assembly from top tray 5 in order.

Reference:

When reattaching the tray assembly, or when removing the

disc remaining inside, refer to another section "3.3.15 Taking

out the disc in the play mode".

A

a

Lifter assembly

Fig.1

Rods

Top cover

A

a

Rods

Top cover

a

a

Lifter assembly

Fig.2

(No.MB505)1-17

Page 18

Fig.3

r

Open det. leve

Tray assemblies

c

b

Side(R) assembly

Fig.4

Tray assembly

Fig.5

1-18 (No.MB505)

Page 19

3.2.2 Removing the DVD servo board

(See Figs.6 to 8)

Caution:

Solder the short land sections d on the DVD pickup before disconnecting the card wire extending from the DVD pickup. If

you do not follow this instruction, the DVD pickup may be damaged.

(1) From the topside of the DVD changer mechanism assem-

bly, solder the short land sections d on the DVD pick up.

(See Fig.6.)

(2) From the bottom side of the DVD changer mechanism as-

sembly, disconnect the card wire from the connectors

(CN201

Reference:

(3) Disconnect the wires from the connectors (CN452

on the DVD servo board. (See Fig.7.)

(4) Remove the two screws B attaching the DVD servo board.

(See Fig.7.)

(5) From the reverse side of the DVD servo board, release the

lock of the connector CN101

and disconnect the card wire. (See Fig.8.)

Caution:

Unsolder the solders from the short land sections d after reassembling. (See Fig.6.)

3.2.3 Removing the switch board

(1) From the bottom side of the DVD changer mechanism as-

sembly, remove the screw C attaching the switch board on

the DVD changer mechanism assembly.

(2) Disconnect the wires from the connectors (CN452

on the DVD servo board.

(3) Release the wires from the section f and remove the switch

board.

(4) Release the wires from the sections g and remove the

switch board.

Reference:

When reassembling, pass the wires through the sections (f, g)

as before.

, CN451) on the DVD servo board. (See Fig.7.)

When connecting the card wire to the connector CN451

pass it through the sections e on the DVD traverse

mechanism assembly. (See Fig.7.)

, CN453)

in the direction of the arrow

(See Fig.7)

, CN453)

d

,

DVD changer mechanism assembly

Fig.6

DVD changer mechanism assembly

e

CN451

DVD pickup

CN453

f

g

Switch board

B

C

CN201

DVD servo board

DVD traverse mechanism assembly

DVD servo board

B

Fig.7

CN452

CN101

Lock

Fig.8

(No.MB505)1-19

Page 20

3.2.4 Removing the motor board

(See Figs.9 and 10)

(1) From the top side of the DVD changer mechanism assem-

bly, remove the two belts from the motor pulleys. (See

Fig.9.)

Note:

Take care not to attach grease on the belt.

(2) Remove the two screws D attaching the motors to the load-

er assembly. (See Fig.9.)

(3) From the bottom side of the DVD changer mechanism as-

sembly, remove the two screws E. (See Fig.10.)

(4) Disconnect the connector CN2

tray switch board and remove the motor board. (See

Fig.10.)

(5) Disconnect the card wire from the connector CN1

forward side of the motor board. (See Fig.10.)

Note:

When connecting the card wire, let the card wire through the

slots h of the motor board. (See Fig.10.)

Reference:

You need not to remove the tray assemblies, and in such case,

move it.

3.2.5 Removing the motor

(See Fig. 10)

• Remove the motor board.

(1) From the reverse side of the motor board, unsolder the four

soldered sections i on the motor board.

(2) From the forward side of the motor board, remove the mo-

tors.

on the motor board from the

on the

Belt

D

Motor Motor

Motor pulleys

Belt

D

Loader assembly

Fig.9

Motors

Motor board

i

Tray switch

board

E

CN2

CN1

h

DVD changer mechanism assembly

Fig.10

Motors

Motor board

E

1-20 (No.MB505)

Page 21

3.2.6 Removing the DVD traverse mechanism assembly

(See Fig.11)

• Remove the tray assemblies and DVD servo board.

(1) From the bottom side of the DVD changer mechanism as-

sembly, remove the three screws F attaching the DVD

traverse mechanism assembly.

(2) Remove the wires from the section j.

(3) Take out the DVD traverse mechanism assembly from the

DVD changer mechanism assembly.

DVD changer mechanism assembly

F

j

F

F

DVD traverse mechanism assembly

Fig.11

(No.MB505)1-21

Page 22

3.2.7 Removing the DVD pickup

(See Figs.12 to 14)

• Remove the tray assemblies, DVD servo board and DVD

traverse mechanism assembly.

(1) From the top side of the DVD traverse mechanism assem-

bly, release the lock of the connector on the DVD pickup

and disconnect the card wire in the direction of the arrow.

(See Fig.12.)

(2) Turn the screw shaft gear in the direction of the arrow 1 to

move the DVD pickup in the direction of the arrow 2. (See

Fig.12.)

(3) Remove the screw G attaching the feed bracket and re-

move the feed bracket from the sections k. (See Fig.12.)

(4) Release the claw m of the thrust spring in the direction of

the arrow and remove the thrust spring. (See Fig.12.)

(5) Remove the guide shaft from the sections (n, p) on the

C.TM chassis. (See Fig.13.)

(6) Remove the section q of the DVD pickup. (See Fig.13.)

(7) Remove the two screws H attaching the rack arm spring

and rack arm. (See Fig.14.)

(8) Pull the guide shaft from the DVD pickup in the direction of

the arrow. (See Fig.14.)

3.2.8 Attaching the DVD pickup

(See Figs.12 to 14)

(1) Attach the guide shaft to the DVD pickup and attach the

rack arm spring and rack arm with the screws H. (See

Fig.14.)

(2) Attach the section q of the DVD pickup to the C.TM chassis

first and attach the guide shaft to the sections (n, p). (See

Fig.13.)

Reference:

When attaching the guide shaft to the section p, attach it

under the rod spring. (See Fig.13.)

(3) Attach the thrust spring and feed bracket with the screw G.

(See Fig.12.)

(4) Turn the screw shaft gear in the direction of the arrow 1 to

move the DVD pickup in the direction of the arrow 2. (See

Fig.15.)

(5) Connect the card wire to the connector on the DVD pickup.

(See Fig.15.)

DVD traverse mechanism assembly

Thrust spring

Connector

Screw shaft gear

DVD pickup

Fig.12

DVD pickup

1

k

Thrust spring

q

Feed bracket

2

G

m

1-22 (No.MB505)

p

Rod spring

n

Guide shaft

C.TM chassis

Fig.13

Page 23

Guide shaft

DVD pickup

Rack arm

H

Rack arm spring

Fig.14

Connector

DVD pickup

222

Screw shaft gear

Fig.15

1

(No.MB505)1-23

Page 24

3.2.9 Removing the spindle motor board

(See Figs.16 and 17)

• Remove the tray assemblies, DVD servo board and DVD

traverse mechanism assembly.

(1) From the top side of the DVD traverse mechanism assem-

bly, remove the wires from the soldered sections r on the

spindle motor board. (See Fig.16.)

(2) From the bottom side of the DVD traverse mechanism as-

sembly, remove the three screws J attaching the spindle

motor board. (See Fig.17.)

Reference:

When attaching the spindle motor board, let the card wire

through the hole s on the C.TM chassis. (See Fig.17.)

DVD traverse mechanism assembly

Spindle motor board

r

Fig.16

DVD traverse mechanism assembly

s

J

C.TM chassis

Fig.17

1-24 (No.MB505)

Page 25

3.2.10 Removing the feed motor

(See Figs.18 and 19)

• Remove the tray assemblies and DVD traverse mechanism

assembly.

(1) From the top side of the DVD traverse mechanism assem-

bly, remove the screw K attaching the feed bracket and remove the feed bracket from the sections t. (See Fig.18.)

(2) Release the claw u of the thrust spring in the direction of

the arrow and remove the thrust spring. (See Fig.18.)

(3) Remove the screw shaft from the section v and remove it

in the direction of the arrow. (See Fig.19.)

(4) Remove the middle gear. (See Fig.19.)

(5) Remove the screw L attaching the feed motor to the C.TM

chassis. (See Fig.19.)

(6) Remove the wires from the soldered sections w on the

spindle motor board. (See Fig.19.)

(7) Take out the feed motor from the motor base.

Reference:

After attaching the feed motor, pass the wires through the sections x on the C.TM chassis as before. (See Fig.19.)

Feed bracket

Thrust spring

K

t

Thrust spring

Spindle motor board

w

x

Fig.18

Middle gear

v

Screw shaft

u

C.TM chassis

L

Fig.19

(No.MB505)1-25

Page 26

3.2.11 Removing the side (L) and tray switch board

(See Figs.20 to 22)

• Remove the tray assemblies.

(1) From the topside of the DVD changer mechanism assem-

bly, remove the two screws M attaching the side (L). (See

Fig.20.)

(2) From the left side of the DVD changer mechanism assem-

bly, disconnect the connector CN3

from the motor board and detach the side (L) in an upward

direction. (See Fig.21.)

(3) Remove the screw N attaching the tray switch board to the

side (L). (See Fig.22.)

(4) Release the joint tab y of the side (L) in the direction of the

arrow 1 and release the joint tab z while removing the tray

switch board in the direction of the arrow 2. (See Fig.22.)

on the tray switch board

SIde(L)

M

M

DVD changer mechanism assembly

Fig.20

M

Side(L)

M

CN3

Tray switch board

Motor board

Side(L)

Fig.21

y

1

1-26 (No.MB505)

2

z

Tray switch board

N

Fig.22

Page 27

3.2.12 Removing the side (R) assembly

(See Fig.23 to 27)

• Remove the tray assemblies and DVD servo board.

(1) From the inside of the side (R) assembly, release the two

tabs aa of the gear cover and remove the gear cover outward. (See Figs.23 and 24.)

(2) From the right side of the DVD changer mechanism as-

sembly, remove the elevator spring attached to the hook

ab of the loader assembly. (See Figs.24 and 25.)

(3) From the top side of the DVD changer mechanism assem-

bly, turn the gear 1 clockwise to move the elevator cam

rearward. (See Fig.25.)

(4) Move the two slots ac and joint ad of the elevator cam and

remove the elevator cam outward. (See Fig.25.)

(5) Remove the three screws P and detaches the side (R) as-

sembly upward. (See Figs.26 and 27.)

Note:

When reattaching the side (R) assembly, make sure to fit the

shaft (part ae) into the slot of the select lever. (See Fig.26.)

Side(R) assembly

aa

P

Elevator spring

ac

Fig.25

P

ae

ab

Elevator cam

acad

Select lever

Side(R) assembly

Gear cover

Loader assembly

P

Fig.23

Elevator spring

Gear 1

Side(R) assembly

Fig.26

P

ab

P

Fig.24

Side(R) assembly

Fig.27

(No.MB505)1-27

Page 28

3.2.13 Removing the lifter assembly

(See Figs.28 to 32)

• Remove the tray assemblies, DVD servo board, side (L) and

side (R) assembly.

(1) (1) From the top side of the DVD changer mechanism as-

sembly, turn the gear 1 clockwise to move the lifter assembly upward. (See Figs.28 and 29.)

(2) Turn the gear 2 clockwise to move the hook toward the

front until it stops. (See Figs.28 and 29.)

(3) Move the hook stopper in the direction of the arrow 2 while

pushing the tab af of the hook stopper to unlock it in the direction of the arrow 1 and release four joints ag to detach

from the rack holder. (See Fig.30.)

(4) Release the rod (L) from part ah. (See Fig.30.)

(5) Turn the gear 1 clockwise again to move the lifter assembly

upward. (See Fig.31.)

(6) Remove the lifter assembly from the DVD changer mecha-

nism assembly upward at the positions ai where the four

pins on the both sides of the lifter assembly fit to the notch-

es of the loader assembly. (See Fig.31.)

(7) Move the lifter assembly in the direction of the arrow and

release it from the hook. (See Fig.32.)

Hook stopper

Gear 2

Gear 1

ag

Rack holder

af

Hook

ag

1

ag

Hook stopper

Fig.30

Lifter assembly

ag

2

Rod(L)

ai

ah

ai

Hook

Gear 2

Lifter assembly

Fig.28

Gear 1

Lifter assembly

Gear 1

ai

Loader assembly

Fig.31

Lifter assembly

ai

Hook stopper

Hook

Fig.29

1-28 (No.MB505)

Hook

Fig.32

Page 29

3.2.14 Removing the sensor board and SV resistor

(See Fig.33)

• Remove the tray assemblies, side (L), side (R) assembly and

lifter assembly.

(1) Remove the solders from the soldered sections aj on the

sensor board and remove the wires.

(2) Remove the two screws Q and take out the sensor board

with the SV resistor.

Reference:

• Remove the soldered section ap on the sensor board as required.

• When reassembling, pass the wires through the slot ak of

the sensor board as before.

Note:

When reattaching the SV. resister, fit the projection am on the

bottom of the SV. resister into slot an of the sensor slider.

Sensor board

Q

ap

Q

ak

aj

SV resistor

am

an

SV resistor

Slider

Fig.33

(No.MB505)1-29

Page 30

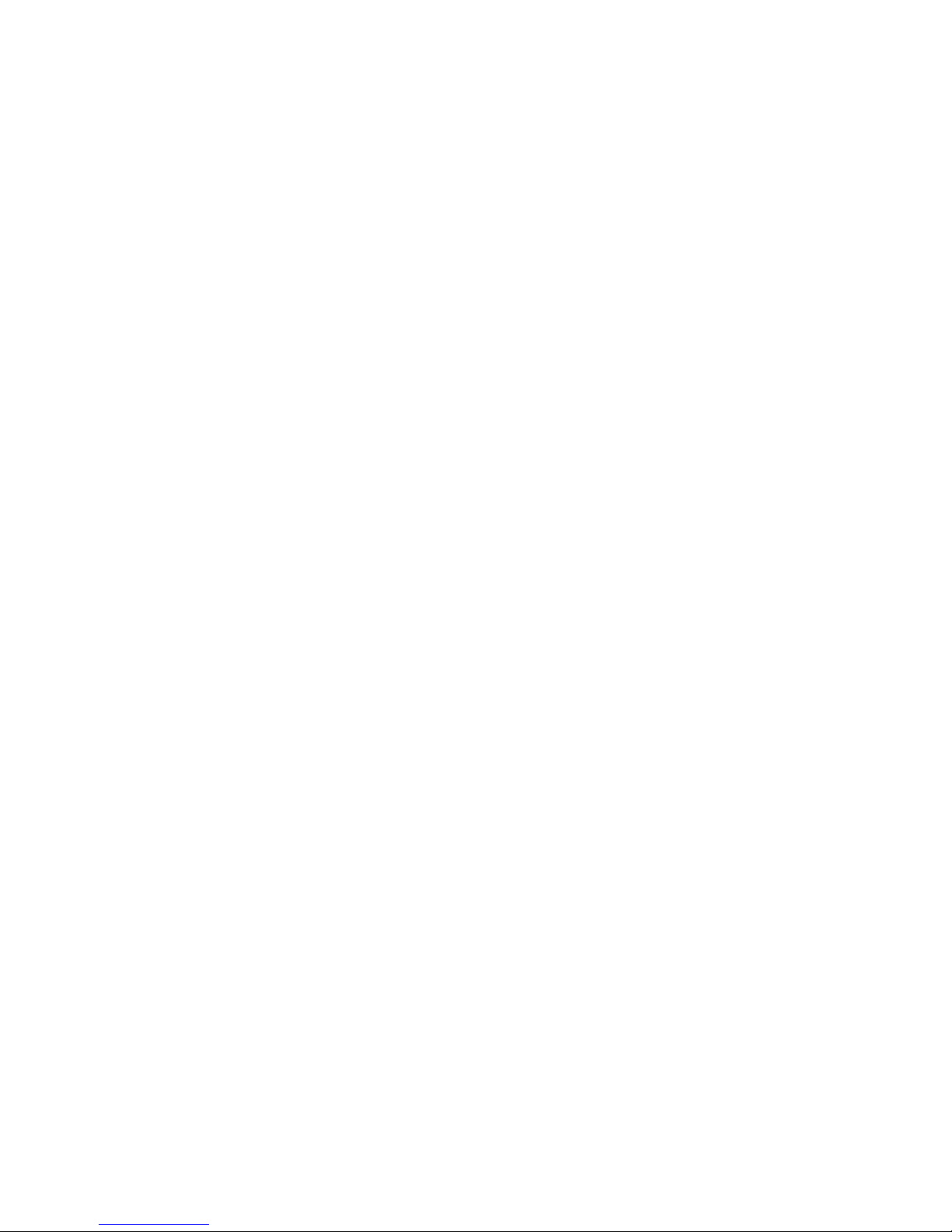

3.2.15 Taking out the disc in the play mode

(See Fig.34 to 37)

Reference:

Refer to "3.3.1 Removing the tray assemblies".

(1) From the top side of the DVD changer mechanism assem-

bly, remove the top cover.

(2) Unlock the tray assemblies and draw out the tray assem-

blies toward the front.

(3) From the top side of the DVD changer mechanism assem-

bly, turn the gear 1 clockwise to move the lifter assembly

upward. (See Fig.34.)

(4) Turn the gear 2 clockwise to move the sub tray remaining

inside the lifter assembly toward the front, then pull out.

(See Fig.34.)

(5) Take out the disc on the sub tray. (See Fig.35.)

(6) After clearing away the disc, insert the sub tray into the

main tray. (See Fig.36.)

Note:

When reattaching the sub tray, move the tray stopper on

the bottom of the main tray in the direction of the arrow

to lock the sub tray certainly. (See Figs.36 and 37.)

(7) Push the tray assembly toward the DVD changer mecha-

nism assembly and reattach.

Tray assembly

Gear 2

Gear 1

Sub tray

Fig.34

Tray assembly

Fig.35

Disc

Sub tray

1-30 (No.MB505)

Page 31

Tray stopper

r

Main tray

Sub tray

Fig.36

Tray stoppe

Fig.37

(No.MB505)1-31

Page 32

SECTION 4

ADJUSTMENT

4.1 ATTENTION IN SERVICE OF DVD SECTION

(1) When pickup, Flash ROM ,DVD module board were changed, initialize EEPROM by all means.

(2) When full initialization was excuted, excute learning with a DVD test disc by all means.

Test disc : VT-501, VT-502

Learning method : It is adjusted automatically by normal playback of a DVD disc.

4.2 Test mode

Item Operation Managemant

Tray lock STOP [key] + DISC 1 EJECT

(Only during Stanby Mode)

Cold start [Remocon key]

STANDBY/ON + ENTER + 10

CLOCK

FAST FORWARDING

FAN ON/OFF Setting STOP [key] + DISC 2 EJECT

VOLUME LARGE

STEP CHANGE

MICON VERSION

DISPLAY

FL ALL SEGMENT

and TEMPERATURE

DATA

DVD test mode STOP [key] + EJECT 5[key]

[Remocon key]

STANDBY/ON + ENTER + 2

(During STANDBY MODE)

[Remocon Key]

STANDBY/ON + ENTER + 1

[Remocon Key]

STANDBY/ON + ENTER + 9

[Remocon Key]

STANDBY/ON + ENTER + >=10

(Hold during AC In)

Loader-Mehca is locked.

EJECT processing isn't done by pushing EJECT key at tray

lock state.

Then display to LOCKED/UNLOCKED.

EJECT 1 is pushed, pushing STOP again, tray lock is off.

Back up to tray locked ON/OFF.

Cold start processing.

After cold start is activated, FL temporary display

COLD' for 2 seconds. Then return to previous display.

To activate cold start AC OFF system, then AC ON again.

Fast Forward Clock (Increase clock counter speed)

Can only be activated after SYSTEM Clock is set

To exit this TEST mode, AC OFF the system, then AC ON

again.

Toggle between FAN switch ON and OFF.

( FANCTRL : L -> H TOGGLE )

This test mode is only effective during STANDBY MODE.

Need to set POUTREG to H when FANCTRL is H.

Test mode exit when system STANDBY -> P.ON

VOLUME CHANGE

VOLUME STEP MAX(40)

-> VOLUME STEP CENTER(20) TOGGLE

Normal Operation TEST mode.

System returns to normal operation after performing VOLUME

CHANGE.

TEMPORARY DISPLAY FOR MICON VERSION (5SEC)

After 5 seconds, return to previous display.

Each key press will toggle temporary display for the following:

SYSCON VERSION -> DVD LSI (BE) VERSION) and DVD

MECHA VERSION

* DVD LSI (BE & FE) VERSION CAN ONLY BEEN DISPLAY

DURING

SYSTEM POWER ON IN DVD MODE (WHEN DVD LSI P.ON)

* IF THERE IS NO INFORMATION FEEDBACK, SYS-CON

WILL DISPLAY

"WAIT" BLINKING 0.5SEC ON & OFF

Actual FL display SYSCOM version "012417-R**" or

"030227-R**"

FL ALL SEGMENT ON (NO BLINK)

Each key press will toggle between FL ALL SEGMENT, TEMP

decimal data and DVD THERMISTOR Temperature data.

Enters DVD-TEST mode.

DVD-TEST mode specification based on DVD-MODULE spec.

To exit DVD-TEST mode, AC OFF the system, then AC ON

again.

For Region Rewrite and DVD-AUDIO Device Key Writing,

refer to Region Rewrite and Device Key Writing section below

for exit procedure.

1-32 (No.MB505)

Page 33

Item Operation Managemant

DVD initialize >>| [key] during DVD test mode DVD module initialized.

FL 8 Segments will display 'INIT' after initialize.

" T xxy v0 " <- " T xxy vw "

Display will return to DVD Test Mode Area display.

( " T xxy vw " )

Press Power key to exit this TEST mode.

To exit this TEST mode, AC OFF the system, then AC ON

again.

DVD region confirm

mode

STOP [key] + EJECT 5[key]

(Hold during AC In)

FL display " T E*0 " (E=Euro) Region*

FL display " T E2 0 " (E=Euro) Region 2

or " TJC10 " (JC=USA/CANADA)Region 1

Tuner test mode [Remocon key]

Standby + enter + 0

eg: V U2 9K " VE 9K " Euro or " VJC 10K " (USA/CANADA)

V: version

U2: A/UF/UN/US

9K: AM STEP SETTING

SAFETY MODE check

by WHAT

STOP + LINE [key]

In standby [after safety trigger]

(A) If safety-cassette deck trigger, FL show : " ACM SAFETY "

(B) If /protect trigger, FL show : "AMP SAFETY"

(C) If /safety-reg trigger, FL show : "REG SAFETY"

(D) If flock trigger, FL show : "FAN SAFETY"

(E) If DVD temperature trigger, FL show : "DVD-SAFETY"

POWER KEY PRESSED to exit

*Note:

1. Other than Device Key Writing & DVD Region Re-write case, other test mode can be exit

by pressing POWER KEY on SET.

2. During any other Test Mode, when POWER KEY is pressed, wait until "POFF OK" displayed

(with Backlight LED off) meaning that DVD Test mode is successfully exit.

3. "POFF OK" Display will be indicated for 5sec only, then it will return to Standby Mode Display

4. After "POFF OK" dsiplay, system is now go back to normal operation mode.

4.3 Other test mode's operation

1. To enter DVD TEST mode,

a. AC POWER OFF

b. Press and hold STOP+DVD5 EJECT/CLOSE keys.

c. AC POWER ON while holding STOP+DVD5 EJECT/CLOSE keys.

d. Sys-con will send the following commands:

(INIT Command, TEST MODE Start)

(MODE STATE REPORT Command, DELIVERY INFO)

(STATUS REQUEST, DESTINATION AND REGION INFO)

(DESTINATION INFO, DESTINATION NUMBER, REGION INFO).

e. DVD Mecha will start in TEST MODE, FL will display:

Txxyvw

xx is the received DESTINATION information. Display as follows:

xx = JC/1U/D/E/2U/3U/UB/UT/4U/UY/EE/UF

y = region number

v = study state information from MECHA-CON (Display Byte3 when Byte7 is "0x09")

w = initialization state from MECHA-CON (Display Byte4 when Byte7 is "0x09".Display blank when Byte4 is "0xFF". )

2. To extie DVD TEST mode,

a. During TEST MODE (except for Device Key write & DVD Region Re-write), press POWER KEY

and wait until "POFF OK" is displayed for 5sec, then system goes into Standby Mode & Backlight LED is off

This means that System now successfully exit the DVD Test Mode & back to normal mode

b. To exit TEST mode for Device Key Write & DVD Region Re-write, first AC OFF,

then AC ON again to return to normal state.

(No.MB505)1-33

Page 34

3. EEPROM INITIALIZATION

(1) NORMAL INITIALIZE

a. During DVD TEST MODE, Press >>| key on remote control to start NORMAL EEPROM INITIALIZATION.

b. Sys-con will send the following command:

c. Mecha will feedback the following information after finish INITIALIZATION:

Status: Byte 0 = 0x00 (NORMAL), Byte 7 = 0x09, Byte 4 = initialization state

d. When received status, FL will display:

Txxyvw

w = initialization state from MECHA-CON (Display Byte4 when Byte7 is "0x09".Display blank when Byte4 is "0xFF". )

(2) FULL INITIALIZE

a. During DVD TEST MODE, STOP key on set 2 seconds control to start FULL EEPROM INITIALIZATION.

b. Sys-con will send the following command:

c. Mecha will feedback the following information after finish INITIALIZATION:

Status: Byte 0 = 0x00 (NORMAL), Byte 7 = 0x09, Byte 4 = initialization state

d. When received status, FL will display:

Txxyvw

w = initialization state from MECHA-CON (Display Byte4 when Byte7 is "0x09".Display blank when Byte4 is "0xFF". )

4. DEVICE KEY CHECKSUM DISPLAY

a. During DESTINATION INFO display screen (1), press MENU key to enter DEVICE KEY CHECKSUM display

(TEST MODE, MODE STATE, CHECK MODE)

(DEVICE KEY CHECKSUM)

FL will display (Example):

XXXXXX X DISPLAY BOTH CPPM AND CPRMX

5. DVD CHECK MODES

a. Press MENU key again to enter CHECK MODE.

(TEST MODE, MODE STATE, CHECK MODE)

FL Display:

HCEKC

Press '1' key on REMOTE CONTROL to START PLAYBACK.

FL Display:

ALPYABKC

Press '2' key on REMOTE CONTROL to perform SEARCH TNO+1

FL Display:

BOW B E (2 seconds)L

Status: 00(NORMAL) XX XX cc cc jj jj

ccccjj j cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

j

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

Press '3' key on REMOTE CONTROL to perform SEARCH TNO-1

FL Display:

HCEKC

Press '4' key on REMOTE CONTROL to light up CD_LD and display laser current.

FL Display:

LDC D R (2 seconds)

LS

Status: 00(NORMAL) XX XX cc cc jj jj

ccccjj j cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

j

Press '5' key on REMOTE CONTROL to light up DVD_LD and display laser current.

1-34 (No.MB505)

(Static)

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

Page 35

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

Press '6' key on REMOTE CONTROL to enter DVD x 2 JITTER MEASUREMENT MODE

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

Press '7' key on REMOTE CONTROL to view EEPROM (MECHA) content in -1 address step.

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

Press '8' key on REMOTE CONTROL to view EEPROM (MECHA) content in +1 address step.

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

LDC D R (2 seconds)

ccccjj j cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

LS

j

(Static)

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

TIJ X (2 seconds)

1

ccccjjjj

(Static)

cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

PEE B D (2 seconds)

ccccjjjj

W

(Static)

cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

PEE F D (2 seconds)

ccccjjjj

W

(Static)

Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

Press '9' key on REMOTE CONTROL to perform SEARCH DVD_SL DESIGNATED POSITION and

JITTER MEASUREMENT

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

Press '10' key on REMOTE CONTROL to perform SEARCH DVD_DL PARALLEL DISC DESIGNATED

POSITION and JITTER MEASUREMENT

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

Press '0' key on REMOTE CONTROL to perform monitor output.

FL Display:

Status: 00(NORMAL) XX XX cc cc jj jj

MPET (2 seconds)

ccccjjjj

(Static)

D-DLVD (2 seconds)

ccccjjjj

(Static)

NIT ROOM (2 seconds)

ccccjjjj

(Static)

cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

Press '>=10' key to INITIALIZE EEPROM (MECHA)

FL Display:

ITNI (2 seconds)

Press PLAY key on REMOTE CONTROL to start PLAYING and obtain LASER CURRENT and JITTER value.

(No.MB505)1-35

Page 36

FL Display:

RJ TISL (2 seconds)

Status: 00(NORMAL) XX XX cc cc jj jj

ccccjjjj

(Static)

cccc: Byte 0 = 0x00, Byte 7 = 0x00, Byte 3,4 ¨DISPLAY

jjjj: Byte 0 = 0x00, Byte 7 = 0x00, Byte 5,6 ¨DISPLAY

Press STOP key on REMOTE CONTROL to stop JITTER measurement.

FL display remains.

FFFF FFFF

(Static)

b. During CHECK mode, at any time press MENU key to exit CHECK mode and return to starting screen of DVD

TEST MODE.

* During TEST mode,at press POWER key send POWER OFF command to MECHA-CON and if poweroff permit

flag is 1, display "POFF OK"

FF KOOP

1-36 (No.MB505)

Page 37

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB505)1-37

Page 38

Victor Company of Japan, Limited

Audio/Video Systems Category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB505)

Printed in Japan

VPT

Loading...

Loading...