Page 1

22019200310

SERVICE MANUAL

AUDIO/VIDEO CONTROL RECEIVER

RX-DP20VSL

DVD

AUDIO

LEARN

TRANSMIT

TV/DBS

VCR 1

LEARN

DVD

DVD MULTI

CD

PHONO

CDR

TAPE/MD

VCR 1 VCR 2

EXT 7.1CH

FM/AMVIDEOTV/DBS

ANALOG/DIGITAL

EFFECT

INPUT

123

LIVENESS

SOUND

456

TEST

7

/P

89

STANDBY

STANDBY/ON

MASTER VOLUME

CC CONVERTER

RX-DP20V

AUDIO/VIDEO CONTROL RECEIVER

PHONES

DIMMER

DOOR

UP

DOOR

DOWN

VIDEO LÑAUDIOÑR

S-VIDEODIGITAL

VIDEO

CC CONVERTER

10

RETURN

THX

EX/ES/7.1

SLEEP DIMMER

/ REW

PLAY

PTY SEARCH

PTY PTY

REC

CHANNEL

TV VOL

SETUP

MENU

TEXT

DISPLAY

DVD

MENU

RM-SRXDP20R

A/V CONTROL RECEIVER

FM MODE

DSP SURR/DSPSURROUND

ANALOG DIRECT

STOP PAUSE

TV/VIDEO

MUTING

SET

LIGHT

REMOTE CONTROL

+

100

+

100

OFF

TV

CATV/

DBS

FF/

TA/NEWS/INFODISPLAY MODE

VOLUME

ADJUST

MENU

EXIT

Area Suffix

B ------------------------------ U.K.

E ---------- Continental Europe

EN ----------- Northern Europe

EV ------------- Eastern Europe

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.22019

2003/10

Page 2

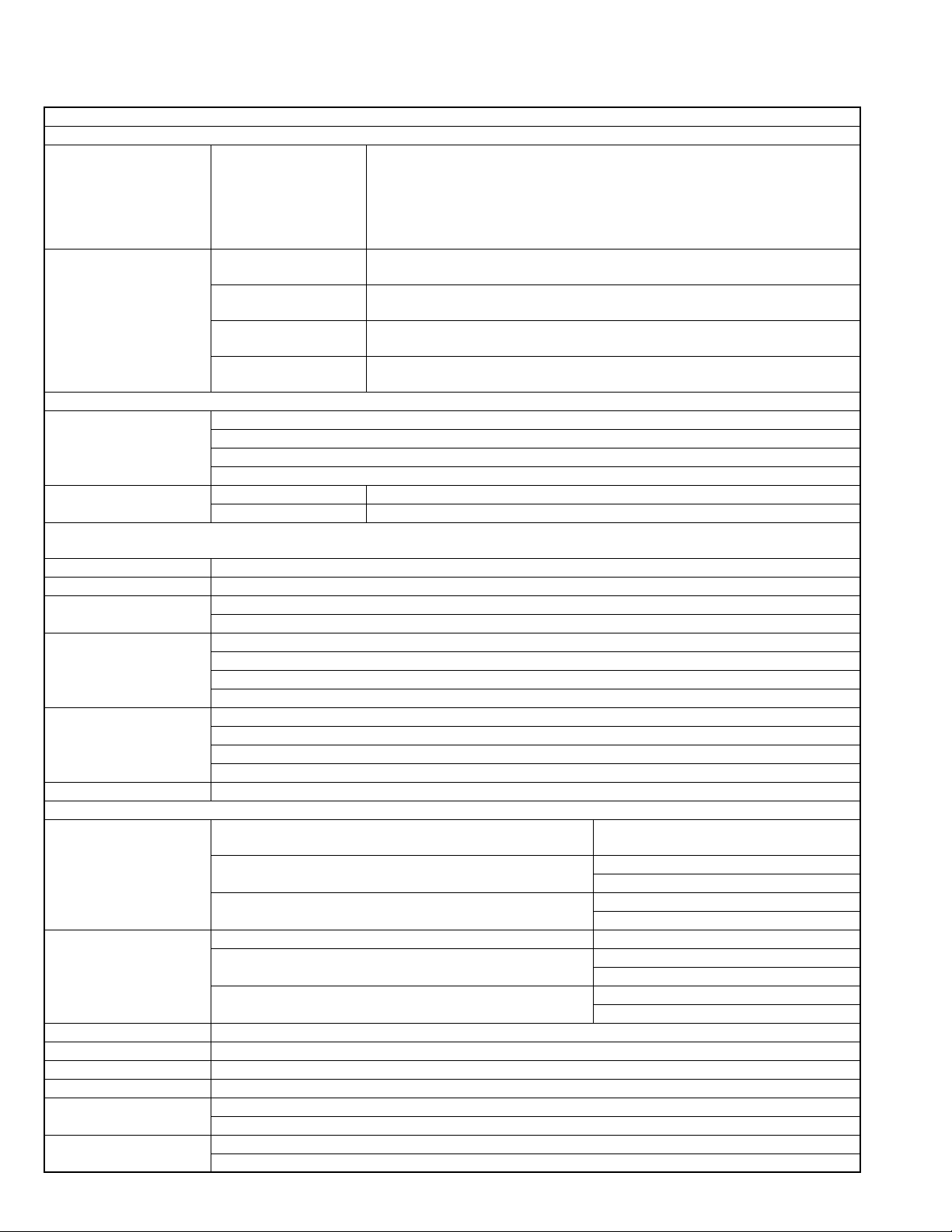

SPECIFICATION

Amplifier

Output Power

At Stereo operation

(Analog Direct On)

At Surround operation

(Analog Direct On)

Audio

Audio Input Sensitivity

/Impedance (1 kHz)

Audio Input (DIGITAL IN)* Coaxial 1(DVD), 2(CD), 3(TV/DBS):0.5 V(p-p)/75 Ω

* Corresponding to Linear PCM, Dolby Digital, and DTS Digital Surround (with sampling frequency - 32 kHz, 44.1 kHz, 48 kHz)

Front channels 120 W per channel, min. RMS, driven into 8 Ω, 20 Hz to 20 kHz with no more

than 0.02% total harmonic distortion.

120 W per channel, min. RMS, driven into 4 Ω, 20 Hz to 20 kHz with no more

than 0.07% total harmonic distortion.

130 W per channel, min. RMS, driven into 8 Ω at 1 kHz, with no more than 0.8%

total harmonic distortion. (IEC 268-3/DIN)

Front channels 120 W per channel, min. RMS, driven into 8 Ω, 20 Hz to 20 kHz with no more

than 0.02% total harmonic distortion.

Center channel 120 W, min. RMS, driven into 8 Ω, 20 Hz to 20 kHz with no more than 0.02%

total harmonic distortion.

Surround channels 120 W per channel, min. RMS, driven into 8 Ω, 20 Hz to 20 kHz with no more

than 0.02% total harmonic distortion.

Surround back channels 120 W per channel, min. RMS, driven into 8 Ω, 20 Hz to 20 kHz with no more

than 0.02% total harmonic distortion.

PHONO IN (MC):0.25 mV/100 Ω

PHONO IN (MM):2.5 mV/47 kΩ

CD IN, CDR IN, TAPE/MD IN, EXT 7.1CH IN:200 mV/47 kΩ

DVD IN, VCR 1 IN, VCR 2 IN, TV SOUND/DBS IN, VIDEO:200 mV/47 kΩ

Optical 4(CDR), 5(MD), 6(VCR1):-21 dBm to -15 dBm (660 nm ±30 nm)

Audio Output Level PREOUT:1 V

Recording Output Level TAPE/MD OUT, CDR OUT, VCR 1 OUT, VCR 2 OUT:200 mV

Digital output

Optical:DIGITAL OUT

Signal-to-Noise Ratio

('66 IHF/'78 IHF)

(Analog Direct On)

Frequency Response

(8 Ω)

RIAA Phono Equalization ±1.0 dB (20 Hz to 20 kHz)

Video

Video Input Sensitivity

/Impedance

Video Output Level Composite video:VCR 1 OUT,VCR 2 OUT,MONITOR OUT 1 V(p-p)/75 Ω

Synchronization Negative

Signal-to-Noise Ratio 45 dB

Tuning Range 87.5 MHz to 108.0 MHz

Usable Sensitivity Monaural:17.0 dBf (1.95 µV/75 Ω)

50 dB Quieting Sensitivity Monaural:21.3 dBf (3.2 µV/75 Ω)

Signal-to-Noise Ratio

(IHF-A weighted)

Signal wave length:660 nm

Output level:-21 dBm to -15 dBm

PHONO IN (MC):60 dB/72 dB (at REC OUT)

PHONO IN (MM):72 dB/80 dB (at REC OUT)

CD IN, CDR IN, TAPE/MD IN, EXT 7.1CH IN:92 dB/80 dB

:92 dB/80 dBDVD IN, VCR 1 IN, VCR 2 IN, TV SOUND/DBS IN, VIDEO

PHONO IN (MC) :20 Hz to 20 kHz (±1 dB)

PHONO IN (MM):20 Hz to 20 kHz (±1 dB)

CD IN, CDR IN, TAPE/MD IN, EXT 7.1CH IN:10 Hz to 100 kHz (+1 dB, -3 dB)

DVD IN, VCR 1 IN, VCR 2 IN, TV SOUND/DBS IN, VIDEO:10 Hz to 100 kHz (+1 dB, -3 dB)

Composite video:

DVD IN, VCR 1 IN, VCR 2 IN, TV SOUND/DBS IN, VIDEO

S-video:

DVD IN, VCR 1 IN, VCR 2 IN, TV SOUND/DBS IN, VIDEO

Component:1 IN (DVD), 2 IN,3 IN (Y: luminance):1 V(p-p)/75 Ω

S-video:VCR 1 OUT, VCR 2 OUT, MONITOR OUT (Y: luminance):1 V(p-p)/75Ω

Component:MONITOR OUT (Y: luminance):1 V(p-p)/75 Ω

Stereo:41.3 dBf (31.5 µV/75 Ω)

Monaural:78 dB at 85 dBf

Stereo:73 dB at 85 dBf

1 V(p-p)/75 Ω

(Y: luminance)1 V(p-p)/75Ω

(C: chrominance, burst)0.286 V(p-p)/75 Ω

(PB, PR):0.7 V(p-p)/75 Ω

(C: chrominance, burst):0.286 V(p-p)/75 Ω

(PB, PR): 0.7 V(p-p)/75 Ω

1-2 (No.22019)

Page 3

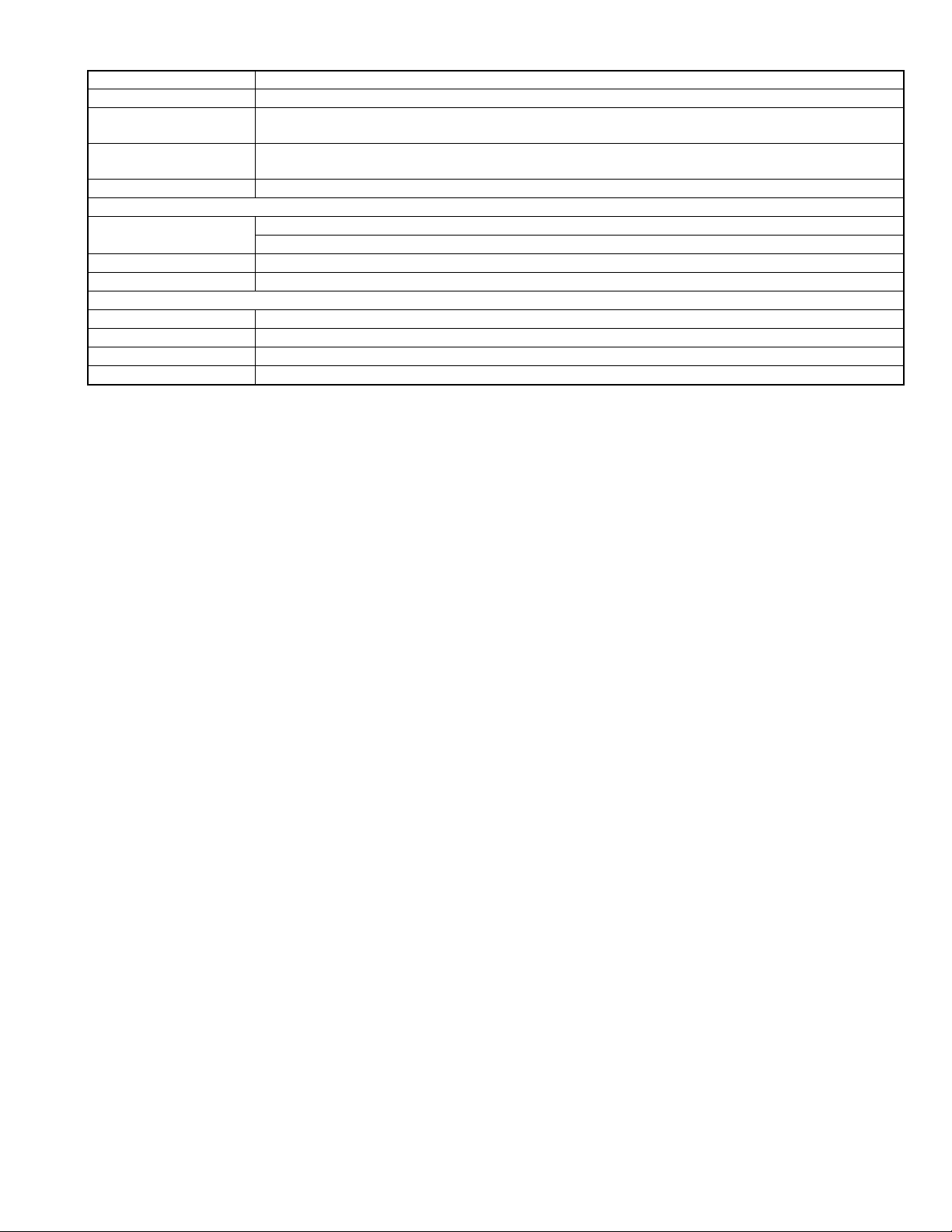

Total Harmonic Distortion Monaural:0.4% at 1 kHz

Stereo:0.6% at 1 kHz

Stereo Separation at REC

OUT

Alternate Channel Selectivity

Frequency Response 30 Hz to 15 kHz (+0.5 dB, -3 dB)

Tuning Range MW:522 kHz to 1 629 kHz

Usable Sensitivity Loop antenna: 400 µV/m

Signal-to-Noise Ratio 50 dB (100 mV/m)

Power Requirements AC 230V~, 50 Hz

Power Consumption 600 W/690 VA (at operation), 2.7 watts (in standby mode)

Dimensions (W × H × D) 445 mm × 177 mm × 475 mm

Mass 24 kg

Designs & specifications are subject to change without notice.

35 dB at 1 kHz

60 dB (±400 kHz)

AM (MW/LW) tuner

LW:144 kHz to 288 kHz

General

(No.22019)1-3

Page 4

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the origin al lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

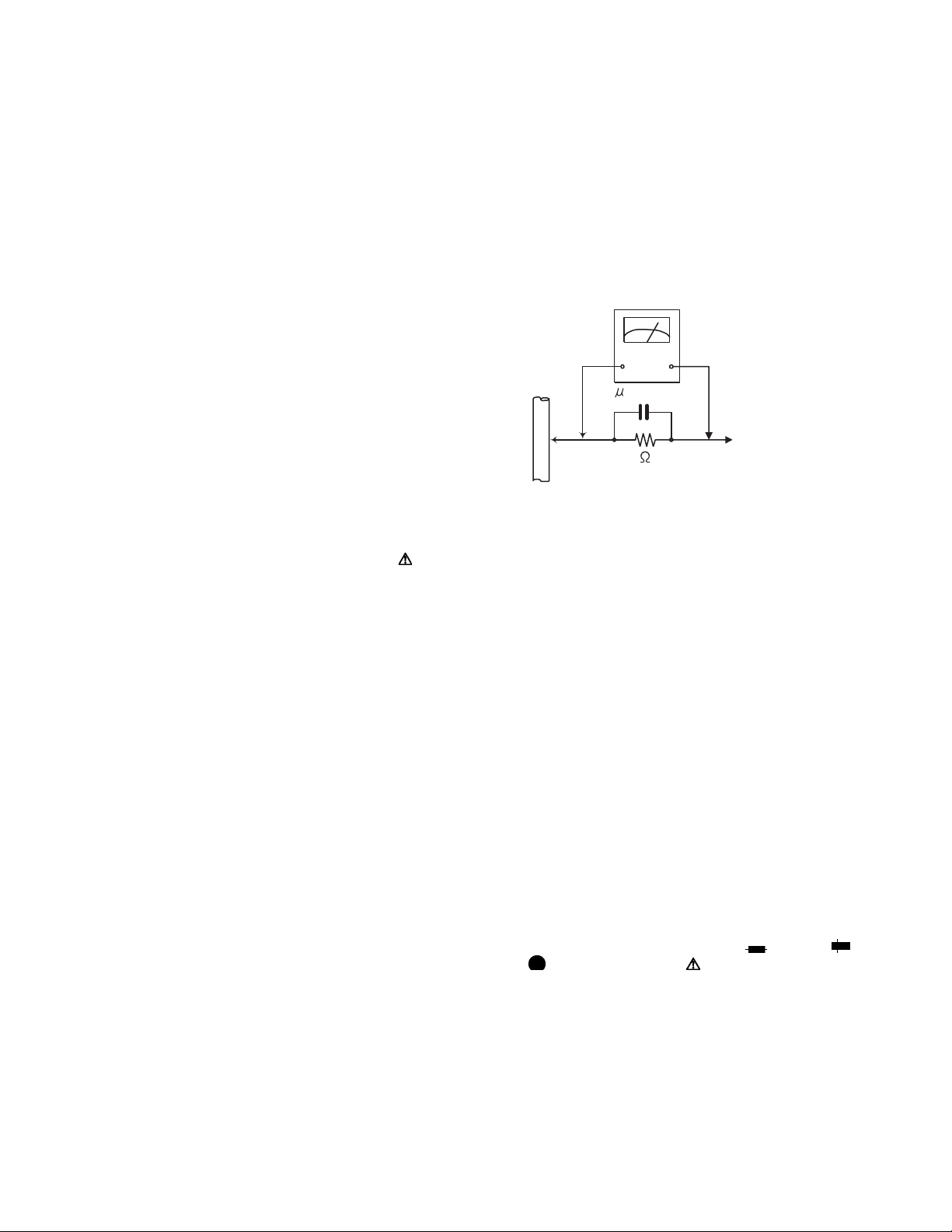

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

1-4 (No.22019)

Page 5

1.5 Safety Precautions (U.K only)

(1) This design of this product contains special hardware and many circuits and components specially for safety purposes. For con-

tinued protection, no changes should be made to the original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those used in the original circuits.

(2) Any unauthorised design alterations or additions will void t he manufacturer's guarantee; furthermore the manufacturer cannot

accept responsibility for personal injury or property damage resulting therefrom.

(3) Essential safety critical components are identified by ( ) on the Parts List and by shading on the schematics, and must never

be replaced by parts other than those listed in the manual. Please not e however that many electrical and mechanical parts in

the product have special safety related characteristics. These characteristics are often not evident from visual inspection. Parts

other than specified by the manufacturer may not have the same safety characteristics as the recommended replacement parts

shown in the Parts List of the Service Manual and may create shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be separated from live parts,

high temperature parts, moving parts and/or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it shoul d be confirmed that they have been returned to

normal, after re-assembling.

1.5.1 Warning

(1) Service should be performed by qualified personnel only.

(2) This equipment has been designed and manufactured to meet international safety standards.

(3) It is the legal responsibility of the repairer to ensure that these safety standard s are maintained.

(4) Repairs must be made in accordance with the relevant safety standards.

(5) It is essential that safety critical components are replaced by approved parts.

(6) If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

(No.22019)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.22019)

Page 7

SECTION 3

A

DISASSEMBLY

3.1 Main body section

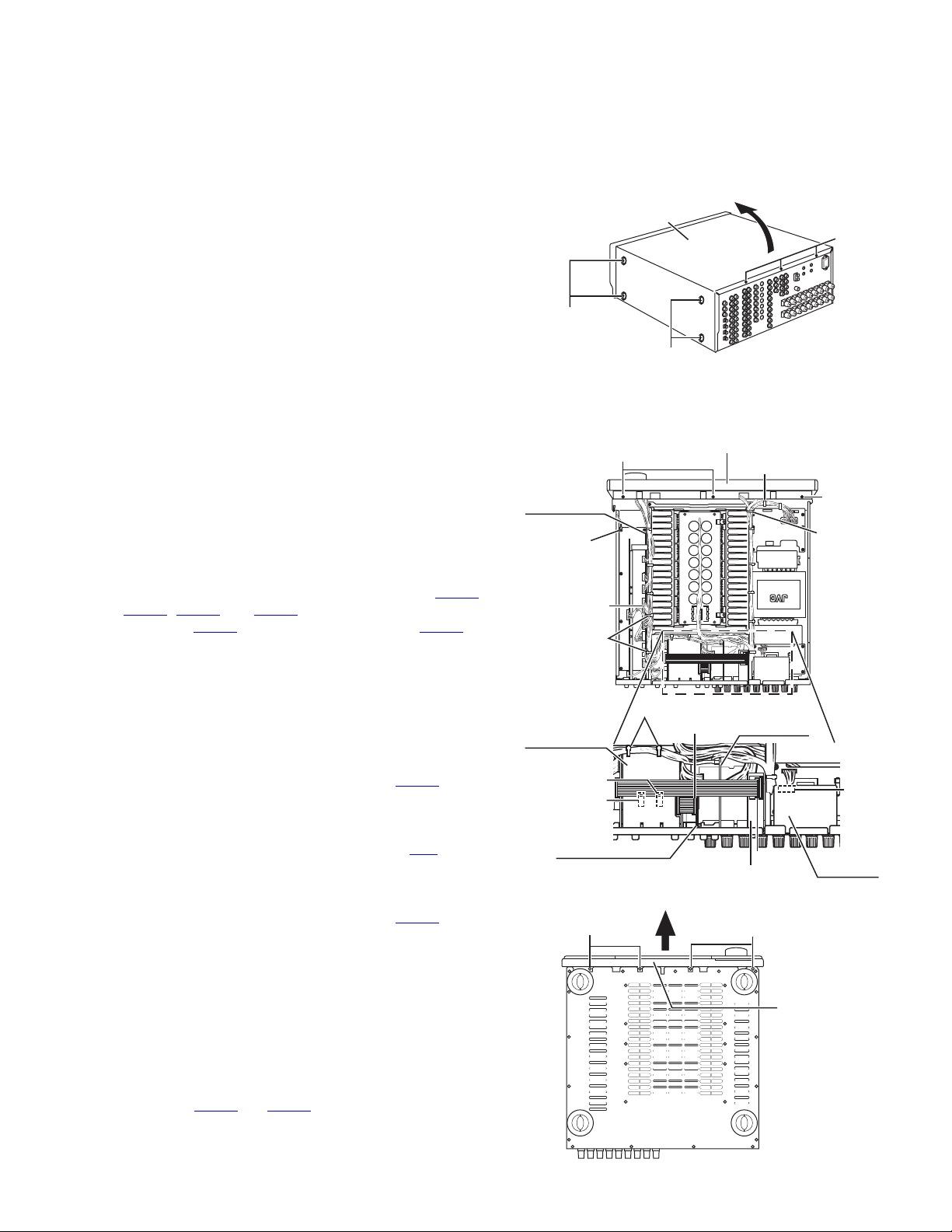

3.1.1 Removing the top cover

(See Fig.1)

(1) Remove the eight screws A attaching the top cover on both

sides of the body.

(2) Remove the three screws B on back of the body.

(3) Remove the top cover from behind in the direction of the

arrow while pulling both sides outward.

3.1.2 Removing the front panel assembly

(See Fig.2 and 3)

• Prior to performing the following procedure, remove the top

cover.

(1) Cut off the tie band 1 fixing the harness.

(2) Remove the screw a, and remove the lug wire.

(3) Remove the three screws C attaching the front panel

assembly.

(4) Remove the four screws D attaching the front panel

assembly on bottom of the body. Detach the front panel

assembly toward the front.

(5) Disconnect the harness from the connector CN971

CN977, CN983 a nd CN985 on the system control board

(see fig.5), CN973 on the front AV in board and CN373 on

the front DIGITAL in board (see 2-3.Front panel assembly

section/ fig.2).

Top cover

B

(both sides)

A

(both sides)

Fig.1

C

Audio signal

1 board

a

(fixing the

lug wire)

,

CN201

Tie band 3

Front panel assembly

Tie band 1

C

Harness

band

3.1.3 Removing the V compo 2 board & tuner unit & compu

link board

(See Fig.2 and 4)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the harness from the connecto r CN581

V compo 2 board.

Remove the two screws E' attaching the V compo 2 board

to the rear panel.

(2) Disconnect the card wire from th e connector CN1

tuner unit.

Remove the two screws E'' attaching the tuner unit to the

rear panel.

(3) Disconnect the harness from the connecto r CN301

compu link board.

Remove the two screws E''' attaching the compu link board

to the rear panel.

3.1.4 Removing the Y/C separator board

(See Fig.2)

• Prior to performing the following procedure, remove the top

cover.

(1) Cut off the tie band 2 fixing the harness.

(2) Draw out up the Y/C separator board , disconnecting the

connectors CN481

and CN482 on the Y/C separator board.

on the

on the

on the

Y/C separator

board

CN482

CN481

V compo 2 board

D

Tie band 2

CN581

Fig.2

Audio 7.1ch

in board

CN1

Tuner unit

D

Compu

link board

Front panel

assembly

CN301

Fig.3

(No.22019)1-7

Page 8

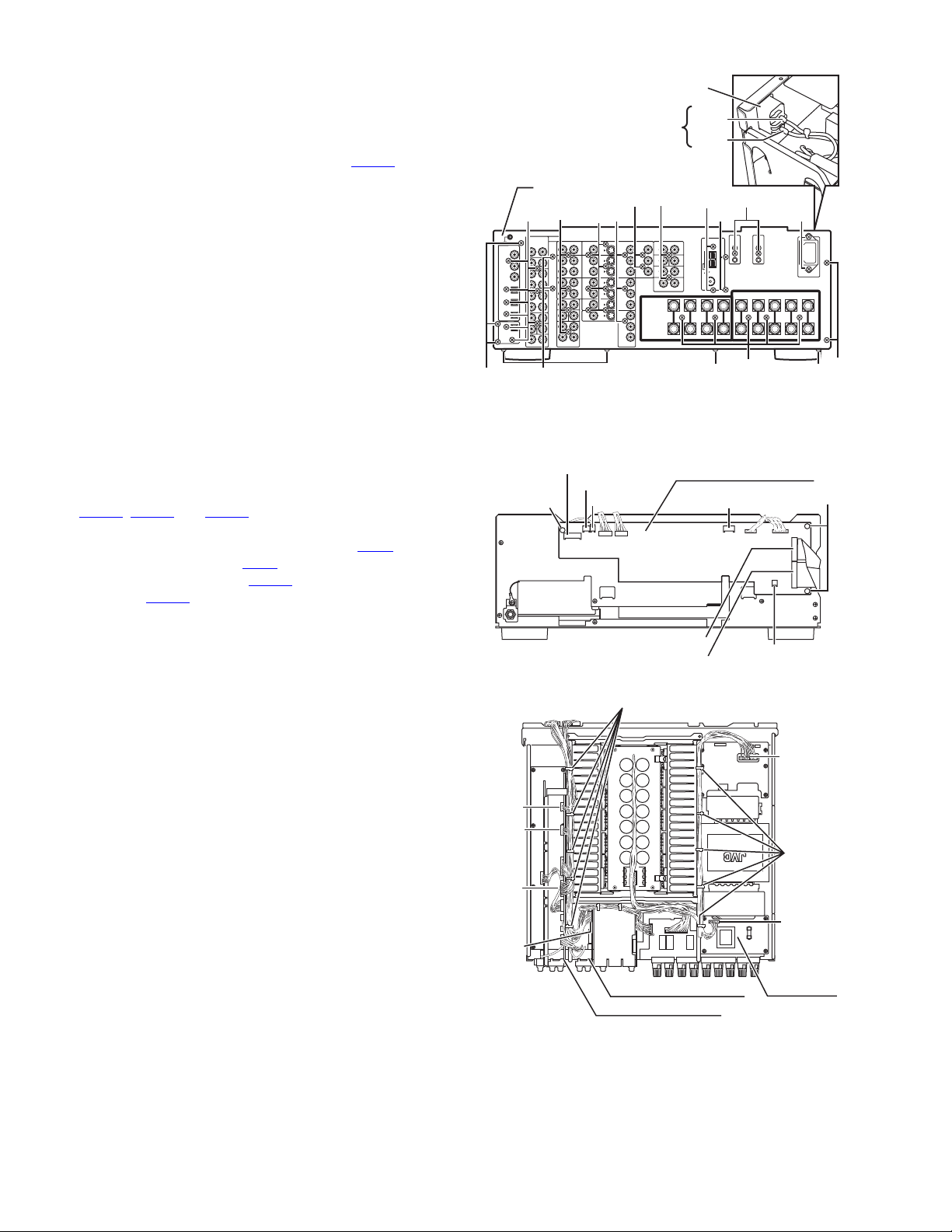

3.1.5 Removing the audio 7.1ch in board

(See Fig.2 and 4)

• Prior to performing the following procedure, remove the top

cover.

(1) Cut off the tie band 2 & 3 fixing the harness.

(2) Disconnect the harness from the con nector CN201

audio signal 1 board.

(3) Remove the two screws E'''' attaching the audio 7.1ch in

board to the rear panel.

3.1.6 Removing the rear panel

(See Fig.4)

• Prior to performing the following procedure, remove the top

cover.

(1) Unsolder the two solder parts on the AC inlet.

(2) Remove the thirty-eight screws E & E' & E'' & E''' & E''''

attaching each board to the rear panel.

(3) Remove the thirteen screws F attaching the rear panel on

the back of the body and bottom.

3.1.7 Removing the system control board

(See Fig.5 and 6)

• Prior to performing the following procedure, remove the top

cover and front panel assembly.

(1) Disconnect the card wires and harness from the connector

, CN964 and CN981 on the system control board.

CN963

(2) Cut off the tie bands fixing the harness.

(3) Disconnect the harness from the connector CN45

power supply 2 board and CN25 on the power/ fuse board.

(4) Disconnect the connector CN324 on the audio signal 2

board and CN234

(5) Remove the three plastic rivet.

on the audio signal 1 board.

on the

on the

Rear panel

E

FF

CN983

CN977

Plastic rivet

Solder part

E

EE

CN981

AC inlet

Black

Red

E''''E'

E''

F

F

Fig.4

System control board

CN985

E'''

E

Plastic rivet

E

F

F

CN234

CN224

CN203

CN324

CN963

CN964

Fig.5

Tie band

Audio signal 2 board

Audio signal 1 board

Fig.6

CN971

CN45

(on power

supply 2

)

board

Tie band

CN25

Power/ fuse

board

1-8 (No.22019)

Page 9

3.1.8 Removing the DSP board & shield cover

(See Fig.7)

• Prior to performing the following procedure, remove the top

cover, rear panel and front panel assembly.

(1) Disconnect the connector CN631

(2) Disconnect the connector CN203

on the DSP board.

on the audio signal 1

board.

And cut off the tie bands fixing the harness.

(3) Removing the two plastic rivet, and disconnect the

connector CN633

, CN643 and CN635 on the DSP board.

(4) Removing the screw G attaching the shield cover and

remove the shield cover.

Top view

G

Shield cover

CN631

CN203

Audio signal

1 board

DSP board

3.1.9 Removing the audio signal 1 board

(See Fig.8)

• Prior to performing the following procedure, remove the top

cover, rear panel and DSP board.

(1) Disconnect the harness from the connector CN202

, CN234, CN224, CN207 and CN223 on the audio

CN204

signal 1 board.

(2) Remove the plastic rivet.

(3) Disconnect the connector CN205

, CN221 and CN206 on

the audio signal 1 board.

,

Plastic rivet

CN204

CN202

CN633

CN205

CN643

CN234

CN221

Plastic rivet

Fig.7

CN224

CN206

Fig.8

CN635

CN207

CN223

Audio signal 1 board

(No.22019)1-9

Page 10

3.1.10 Removing the audio signal 2 board & video board & S video board

T

(See Fig.9 to 11)

• Prior to performing the following procedure, remove the top

cover, rear panel, Y/C separator board, DSP board and audio

Input base board

signal 1 board.

(1) Disconnect the harness from the con nector CN973

on the

front AV in board (see 2-3.Front panel assembly section/

fig.2).

(2) Disconnect the harness from the con nector CN324

on the

audio signal 2 board.

(3) Remove the audio signal 2 board from the connector CN15

and CN6 on the input base board.

(4) Remove the video board fro m the connector CN7

on the

input base board.

(5) Remove the S video board from the connector CN8

input base board.

on the

Audio signal 2 board

3.1.11 Removing the V compo 1 board

(See Fig.9 to 11)

• Prior to performing the following procedure, remove the top

cover and rear panel.

(1) Remove the V compo 1 board from the connector CN9

on

Connection between the Input base board and each board.

CN15/CN6

the input base board.

Video board

CN7

CN8

CN9

CN324

FRONT

V compo 1 board

S video board

Fig.9

Audio signal 2 board (CN325/CN321)

Video board (CN401)

S video board (CN451)

V compo 1 board (CN501)

Fig.10

Input base board

FRON

CN15

CN6

CN7

CN8

CN9

Fig.11

1-10 (No.22019)

Page 11

3.1.12 Removing the input base board

(See Fig.12)

• Prior to performing the following procedure, remove the top

cover, rear panel, DSP board, audio signal 1 board, audio

signal 2 board, video board, S video board and V compo 1

board.

(1) Disconnect the harness from the connector CN62

on the

power supply 1 board and CN44 on the power supply 2

board.

And cut off the tie bands fixing the harness.

(2) Disconnect the harness from the connector CN

743 on the

speaker board.

(3) Disconnect the card wire from the connector CN1

, CN2

and the harness from the connector CN11 on the input

base board.

(4) Remove the seven screws H attaching the input base

board.

3.1.13 Removing the speaker board

(See Fig.12)

• Prior to performing the following procedure, remove the top

cover and rear panel.

(1) Disconnect the harness from the connector CN741

, CN742

and CN743 on the speaker board.

H

CN1

CN2

CN11

H

Input base board

CN743

Power supply

1 board

CN741

CN62

CN44

(on the power

supply 2 board)

CN742

3.1.14 Removing the power supply 1 board

(See Fig.13)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the harness from the connector CN61

, CN64 and CN65 on the power supply 1 board.

CN63

, CN62,

(2) Disconnect the harness from the connector CN44 and

CN45 on the power supply 2 board.

(3) Remove the six screws I attaching the power supply 1

board.

Speaker board

Fig.12

CN63

CN65

CN62

II

CN61

CN64

(fixing the

lug wire)

Power supply 1 board

CN44/CN45

(on the power

supply 2 board)

Fig.13

(No.22019)1-11

Page 12

3.1.15 Removing the power transformer 1 with the power supply 2 board

(See Fig.14)

• Prior to performing the following procedure, remove the top

cover and power supply 1 board.

(1) Disconnect the harness from the connector CN46 and

on the power supply 2 board.

CN47

(2) Remove the two screws J attaching the power transformer

1.

3.1.16 Removing the thermal SW 1 board

(See Fig.14)

• Prior to performing the following procedure, remove the top

cover and power supply 1 board.

(1) Remove the screw K attaching the thermal SW 1 board.

3.1.17 Removing the power transformer 2

(See Fig.15 and 16)

• Prior to performing the following procedure, remove the top

cover and power supply 1 board.

(1) Disconnect the harness from the con nector CN701

power amp. board.

(2) Unsolder the solder points PW82

PW83(E/EN ver.) on the power trans board.

(3) Remove the four screws L attaching the power transformer

2.

and PW81(B ver.) /

on the

Thermal SW

FRONT

CN47

1 board

K

Power supply 2 board

CN46

J

Power

transformer 1

Fig.14

Power amp. board

CN701

Power trans

3.1.18 Removing the power transformer 3 with the power supply 3 board

(See Fig.17)

• Prior to performing the following procedure, remove the top

cover, power supply 1 board, power transformer 1 and power

transformer 2.

(1) Disconnect the harness from the connector CN41

power supply 3 board.

(2) Remove the two screws M attaching the power transformer

3.

on the

board

L

Fig.15

PW81(B ver.)

PW83(E/EN ver.)

PW82

L

Power

transformer 2

Fig.16

Power supply 3 board

CN41

1-12 (No.22019)

Power

transformer 3

M

Fig.17

Page 13

3.1.19 Removing the power/ fuse board

(See Fig.18)

• Prior to performing the following procedure, remove the top

cover, rear panel, power supply 1 board and power

transformer 2.

(1) Disconnect the harness from the connector CN25

power/ fuse board.

(2) Remove the four screws N attaching the power/ fuse

board.

(3) Unsolder the solder points PW21

on the power/ fuse board.

3.1.20 Removing the head phone board

(See Fig.19 and 20)

• Prior to performing the following procedures, remove the top

cover and front panel assembly.

(1) Disconnect the harnesses from the connector CN981

the system control board (see fig.5) and CN738 on the

power amp. board.

(2) Removing the nut O fixing the head phone board.

(3) Removing the screw P attaching the lug wire and bra cket.

, PW22, PW23 and PW24

on the

on

CN25

N

Lug wire

P

N

PW23 (red)

PW21 (blue)

PW24 (white)

N

PW22 (brown)

Power/ fuse board

Fig.18

Bracket

O

CN738

Barrier

Q

(Front side)

Head phone board

Fig.19

Q

Power

amp.

assembly

Power amp.

board

R

Fig.20

(No.22019)1-13

Page 14

3.1.21 Removing the power amp. assembly

(See Fig.20 and 21)

• Prior to performing the following procedures, remove the top

cover, rear panel, front panel assembly, system control board,

DSP board, audio signal 1 board, audio signal 2 board, video

board, S video board, V compo 1 board and speaker board.

(1) Remove the three screws Q fixing the barriers, and remove

the tow barriers.

(2) Remove the eight screws R attaching the power amp.

assembly.

(3) Pull up the power amp. assembly.

(Rear side)

R

Fig.21

1-14 (No.22019)

Page 15

3.2 Power amp. assembly section

3.2.1 Removing the relay board & Rch amp. board & Lch amp. board & Cch amp. board & SL/SRch amp. board

(See Fig.1 to 3)

• Prior to performing the following procedure, remove the power

amp. assembly.

(1) Disconnect the harness from the two connectors on each

thermal compensation board (top side).

(2) Remove the two screws A attaching the relay board.

(3) Disconnect the harness from the five connectors on each

top side

Connector

(on the thermal

compensation

board)

thermal compensation board (bottom side).

(4) Pull up each amp. boa rd of Lch, Cch, SL/SRch and Rch

from the power amp. board with the relay board.

(5) Remove each amp. board from the connector CN721

, CN781 and CN761 on the relay board.

CN821

,

Fig.1

Lch amp. board

Cch amp. board

Relay board

bottom side

A

CN713

CN813

CN773

CN753

Connector

(on the thermal

compensation

board)

Power amp. board

Cch amp. board

Lch amp. board

A

Fig.2

CN721 CN821

CN781

CN712

CN812

CN772

CN752

Connector

(on the thermal

compensation

board)

SL/SRch amp. board

Rch amp. board

SL/SRch amp. board

Rch amp. board

CN761

Relay board

Fig.3

(No.22019)1-15

Page 16

3.2.2 Removing the thermal SW 2 board

(See Fig.4)

• Prior to performing the following procedure, remove the power

amp. assembly, relay board and each amp. board of Lch, Cch,

SL/SRch, Rch.

(1) Remove the screw B attaching the thermal SW 2 board.

3.2.3 Removing the heat sink

(See Fig.4 to 6)

• Prior to performing the following procedure, remove the power

amp. assembly, relay board and each amp. board of Lch, Cch,

SL/SRch, Rch.

(1) Remove the eight screws C attaching the heat sink on the

both sides of the power amp. assembly.

(2) Remove the eight screws D attaching the power ICs (top

side).

(3) Remove the twenty screws D attaching the power ICs

(bottom side).

top side

Heat sink

Heat sink

Power ICs

C (both sides)

Fig.4

bottom side

B

Thermal SW 2 board

bottom side

Heat sink

Fig.5

DD

DD

Fig.6

1-16 (No.22019)

Page 17

3.3 Front panel assembly section

3.3.1 Removing the FL display board & front AV in board

(See Fig.1 and 2)

• Prior to performing the following procedure, remove the top

cover and front panel assembly.

(1) Pull out the volume knob on the front side of the front panel

assembly and remove the nut attaching the FL display

board.

(2) Remove the three screws A attaching the front AV in board

and remove the front AV in board.

(3) Remove the nine screws B attaching the FL display bo ard

on the back of the front panel assembly.

(4) Disconnect the harness from the connector CN969

and CN982 on the FL display board.

, CN975

Operation switch panel

Door

B

Front panel assembly

Volume knob

Fig.1

FL display board

B

Nut

CN969

CN975

CN973

3.3.2 Removing the power switch board & front DIGITAL in board & motor assembly

(See Fig.3)

• Prior to performing the following procedure, remove the front

panel assembly and FL display board.

(1) Remove the four screws C attaching the power switch

board and remove the power switch board.

(2) Remove the screw D attaching the front DIGITAL in board

and remove the front DIGITAL in board.

(3) Remove the three screws E attaching the motor assembly

on the back of the front panel assembly.

(4) Remove the belt and the two screws a attaching the motor.

Front DIGITAL

A

in board

CN373

Front AV in board

D

CN373

CN982

B

Fig.2

Power switch board

FF

Door

Fig.3

C

E

Belt

Motor assembly

a

(No.22019)1-17

Page 18

3.3.3 Removing the door input board

(See Fig.3 and 4)

• Prior to performing the following procedure, remove the front

panel assembly and FL display board.

(1) Remove the four screws F attaching the door and remove

the door from the front panel assembly.

(2) Remove the six screws G attaching the door input board.

G

Door input board

Door

Fig.4

1-18 (No.22019)

Page 19

SECTION 4

ADJUSTMENT

4.1 Adjustment of idling current

Measuring point Alignment point Measuring condition

Lch B903

Rch B911

Cch B907 & B908 VR801

SLch B907 & B908 VR771

SRch B909 & B910 VR772

SBLch B901 & B902 VR702

SBRch B913 & B914 VR752

Attention:

This adjustment does not obtain a correct adjustment value immediately after the amplifier is used (state that an internal temperature

has risen).

Please adjust immediately after using the amplifier after turning off the power supply of the amplifier and falling an internal temperature.

Adjustment method

(1) Prior to turning the power ON, fully turn the adjusting resistor (VR701

terclockwise direction and connect the DC voltmeter to the measur ing terminal (B901-B902, B903-B904, B905-B906, B907-

B908, B909-B910, B911-B912, B913-B914).

(2) Adjust the resistor so that the measured value becomes 2.0mV just after the power sup ply is turned on.

(3) Adjust the resistor so that the measured value becomes 2.5mV mo re than 60 seconds after the power supply is turned on.

(4) After stability is 1.0-4.0mV.

& B904 VR701 No load and No signal.Rated li n e vo ltage

& B912 VR751

SURROUND : OFF

Room temperature : 20~25ºC

, VR702, VR751, VR752, VR771, VR772, VR801) coun-

Refer to following page "Idling Current graph".

* It is not abnormal though the idling current might not become 0mA even if it is finish ed to turn variable resistance ( VR701

, VR752, VR771, VR772, VR801) in the direction of counterclockwise.

VR751

B901, B902 (SBLch)

B903, B904 (Lch)

VR701 (Lch)

VR702 (SBLch)

B905, B906 (SLch)

VR801 (Cch)

B907, B908 (Cch)

VR771 (SLch)

VR772 (SRch)

B909, B910 (SRch)

VR751 (Rch)

VR752 (SBRch)

B911, B912 (Rch)

, VR702,

B913, B914 (SBRch)

(No.22019)1-19

Page 20

4.2 Idling Current graph (1/2)

4

3.5

3

2.5

2

1.5

1

Voltage at measering point(mV)

0.5

SL ch / SR ch

SL ch

SR ch

0

02468101214

Time(Min)

SBL ch / SBR ch

4

3.5

3

2.5

2

1.5

1

Voltage at measering point(mV)

SBL ch

SBR ch

0.5

0

02468101214

1-20 (No.22019)

Time(Min)

Page 21

4.3 Idling Current graph (2/2)

4

3.5

3

2.5

2

1.5

1

Voltage at measering point(mV)

0.5

L ch / R ch

L ch

R ch

0

02468101214

Time(Min)

C ch

4

3.5

3

2.5

2

1.5

1

Voltage at measering point(mV)

0.5

0

0246

8101214

Time(Min)

(No.22019)1-21

Page 22

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

1-22 (No.22019)

Page 23

(No.22019)1-23

Page 24

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.22019)

Printed in Japan

WPC

Loading...

Loading...