Page 1

SERVICE MANUAL

CD RECEIVER

MA471<Rev.005>20117SERVICE MANUAL

KW-XG56TU, KW-XR411E, KW-XR411EU,

KW-XR411EY, KW-XR414UI, KW-XR416DU,

KW-XR416DUH, KW-XR416DUN,

KW-XR416SUN, KW-XR416U, KW-XR416UH,

KW-XR416UN, KW-XR416UP, KW-XR416UT,

KW-XR417EE, KW-XR418J

only KW-XR418

except

COPYRIGHT © 2011 Victor Company of Japan, Limited

KW-XR411/KW-XR417

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

for KW-XR411/KW-XR417

COPYRIGHT © 2011 Victor Company of Japan, Limited

No.MA471<Rev.005>

2011/7

Page 2

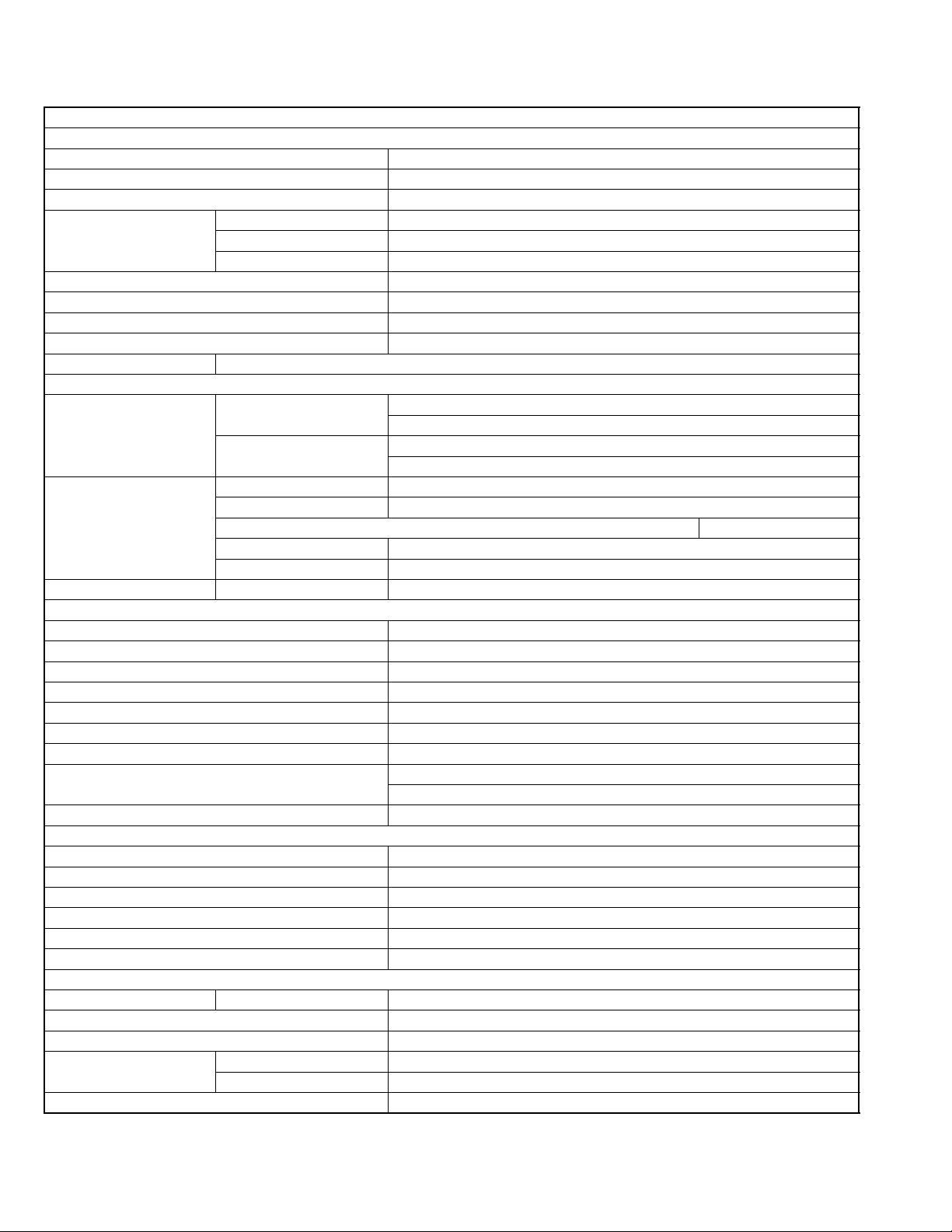

SPECIFICATION

KW-XR418

AUDIO AMPLIFIER SECTION

Power Output 20 W RMS × 4 Channels at 4 Ω and < 1% THD+N

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz) Q1.0, Q1.25, Q1.5, Q2.0

Middle ±12 dB (0.5 kHz, 1.0 kHz, 1.5 kHz, 2.5 kHz) Q0.75, Q1.0, Q1.25

Treble ±12 dB (10.0 kHz, 12.5 kHz, 15.0 kHz, 17.5 kHz) Q (Fixed)

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal USB input terminal, AUX (auxiliary) input jack, Antenna input, Steering wheel remote input

TUNER SECTION

Frequency Range FM 87.5 MHz to 107.9 MHz (with channel interval set to 100 kHz or 200 kHz)

87.5 MHz to 108.0 MHz (with channel interval set to 50 kHz)

AM 530 kHz to 1 710 kHz (with channel interval set to 10 kHz)

531 kHz to 1 602 kHz (with channel interval set to 9 kHz)

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format MPEG1/2 Audio Layer 3

Max. Bit Rate: 320 kbps

WMA (Windows Media

USB SECTION

USB Standard USB 1.1, USB 2.0

Data Transfer Rate (Full Speed) Max. 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA

Max. Current DC 5 V 500 mA

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 111 mm × 160 mm (7-3/16" × 4-3/8" × 6-5/16")

Mass (approx.) 1.8 kg(3.9 lbs) (excluding accessories)

Designs & specifications are subject to change without notice.

® Audio) Decoding Format Max. Bit Rate: 320 kbps

Panel Size (approx.) 188 mm × 117 mm × 23 mm (7-7/16" × 4-5/8" × 5/16")

1-2 (No.MA471<Rev.005>)

Page 3

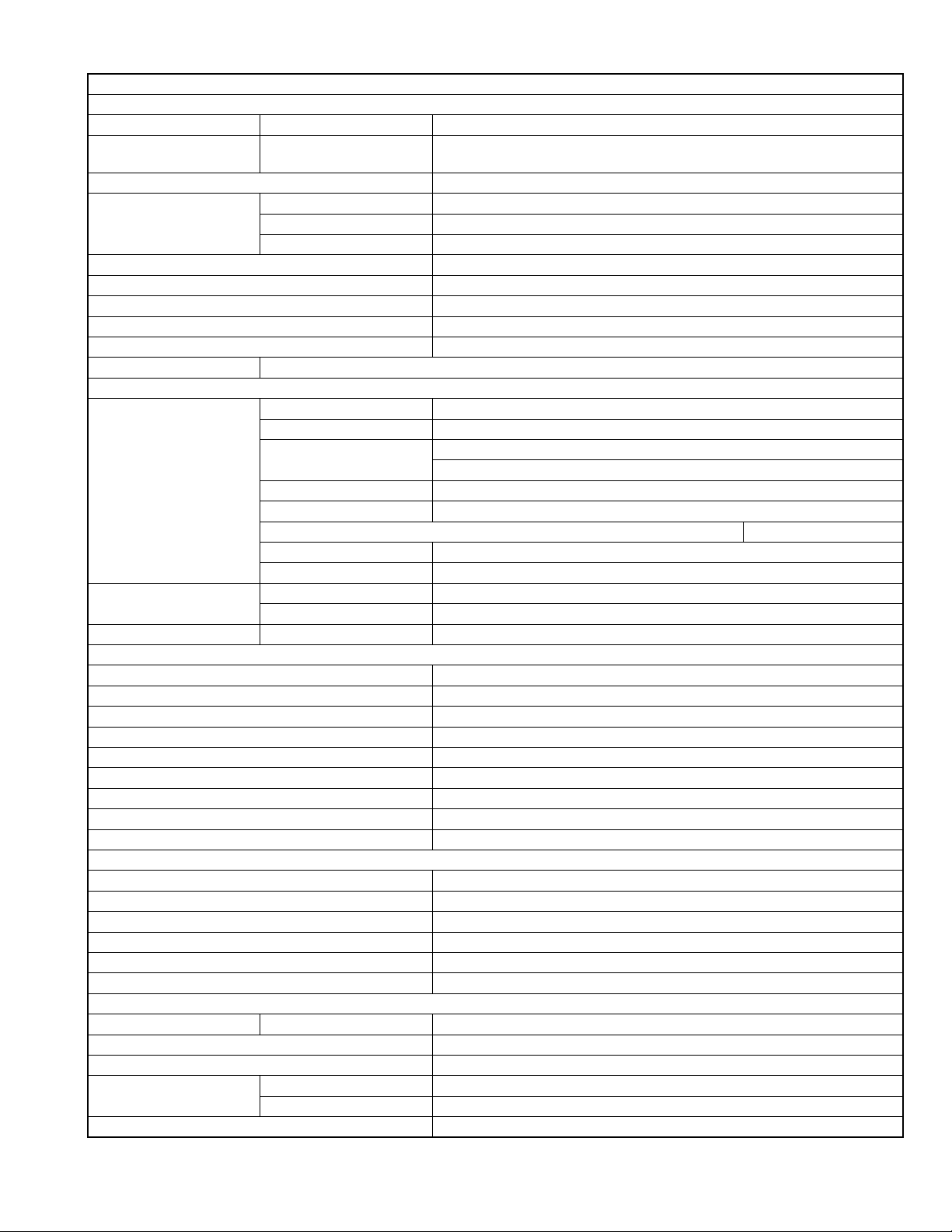

KW-XR411/KW-XR417

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz) Q1.0, Q1.25, Q1.5, Q2.0

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal AUX (auxiliary) input jack, USB input terminal, Aerial input, Steering wheel remote input

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

MW Tuner Sensitivity 20 µV

LW Tuner Sensitivity 50 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media

USB SECTION

USB Standard USB 1.1, USB 2.0

Data Transfer Rate (Full Speed) Max. 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA

Max. Current DC 5 V 500 mA

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D):

(approx.)

Mass 1.8 kg (excluding accessories)

Designs & specifications are subject to change without notice.

Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 1% total har-

monic distortion.

Middle ±12 dB (0.5 kHz, 1.0 kHz, 1.5 kHz, 2.5 kHz) Q0.75, Q1.0, Q1.25

Treble ±12 dB (10.0 kHz, 12.5 kHz, 15.0 kHz, 17.5 kHz) Q (Fixed)

FM-LO (KW-XR417) 65.0 MHz to 74.0 MHz

AM MW: 522 kHz to 1 620 kHz

LW: 144 kHz to 279 kHz

Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

Selectivity 40 dB

® Audio) Decoding Format Max. Bit Rate: 320 kbps

Installation Size 182 mm × 111 mm × 160 mm

Panel Size 188 mm × 117 mm × 23 mm

(No.MA471<Rev.005>)1-3

Page 4

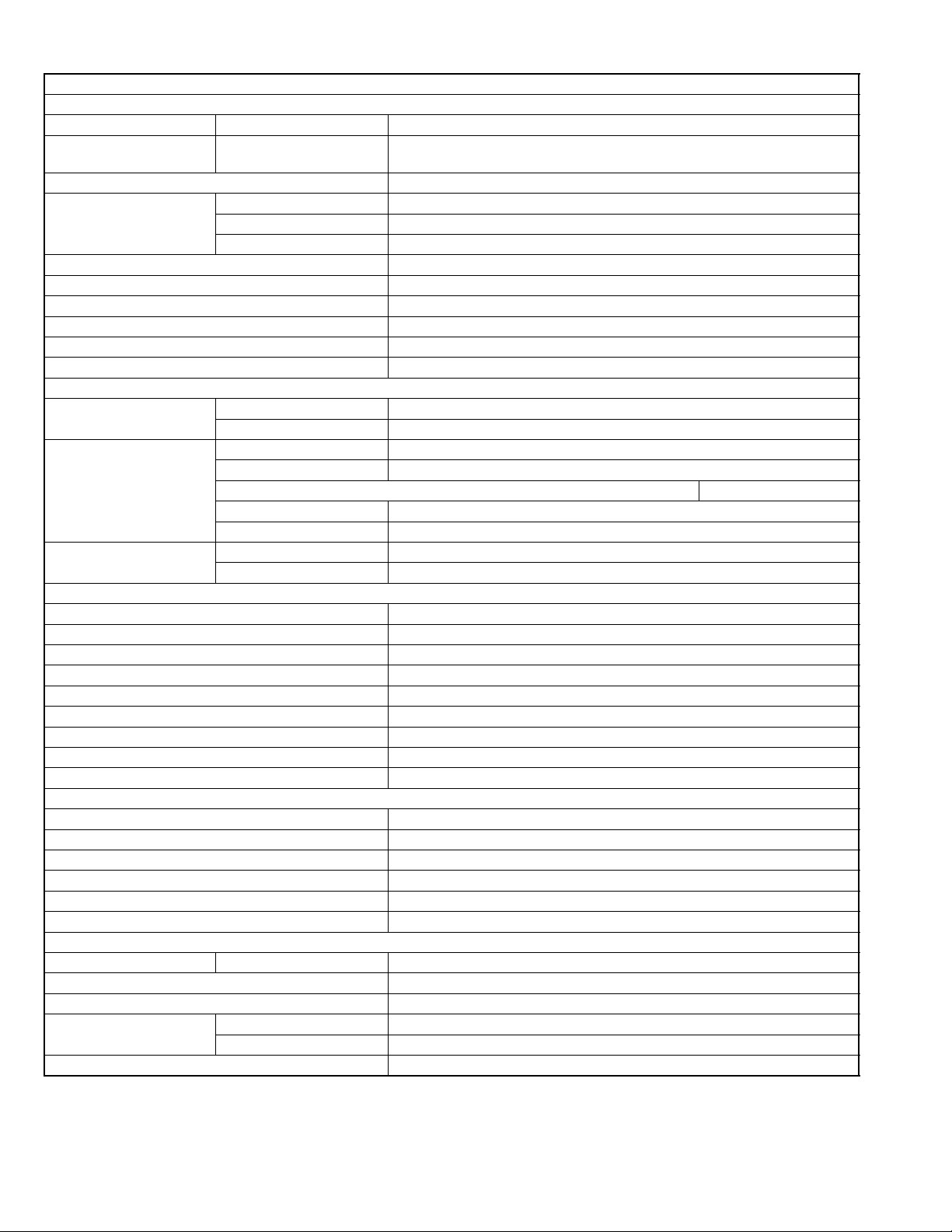

KW-XR416/KW-XR414/KW-XG56TU

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz) Q1.0, Q1.25, Q1.5, Q2.0

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 5.0 V/20 kΩ load (full scale)

Subwoofer-Out Level/Impedance 5.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal AUX (auxiliary) input jack, USB input terminal, Antenna input

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity 20 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media

USB SECTION

USB Standard USB 1.1, USB 2.0

Data Transfer Rate (Full Speed) Max. 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA

Max. Current DC 5 V 500 mA

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D):

(approx.)

Mass 1.4 kg (excluding accessories)

Designs & specifications are subject to change without notice.

Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 1% total har-

monic distortion.

Middle ±12 dB (0.5 kHz, 1.0 kHz, 1.5 kHz, 2.5 kHz) Q0.75, Q1.0, Q1.25

Treble ±12 dB (10.0 kHz, 12.5 kHz, 15.0 kHz, 17.5 kHz) Q (Fixed)

AM 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

Selectivity 40 dB

® Audio) Decoding Format Max. Bit Rate: 320 kbps

Installation Size 178 mm × 100 mm × 160 mm

Panel Size 184 mm × 112 mm × 23 mm

1-4 (No.MA471<Rev.005>)

Page 5

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

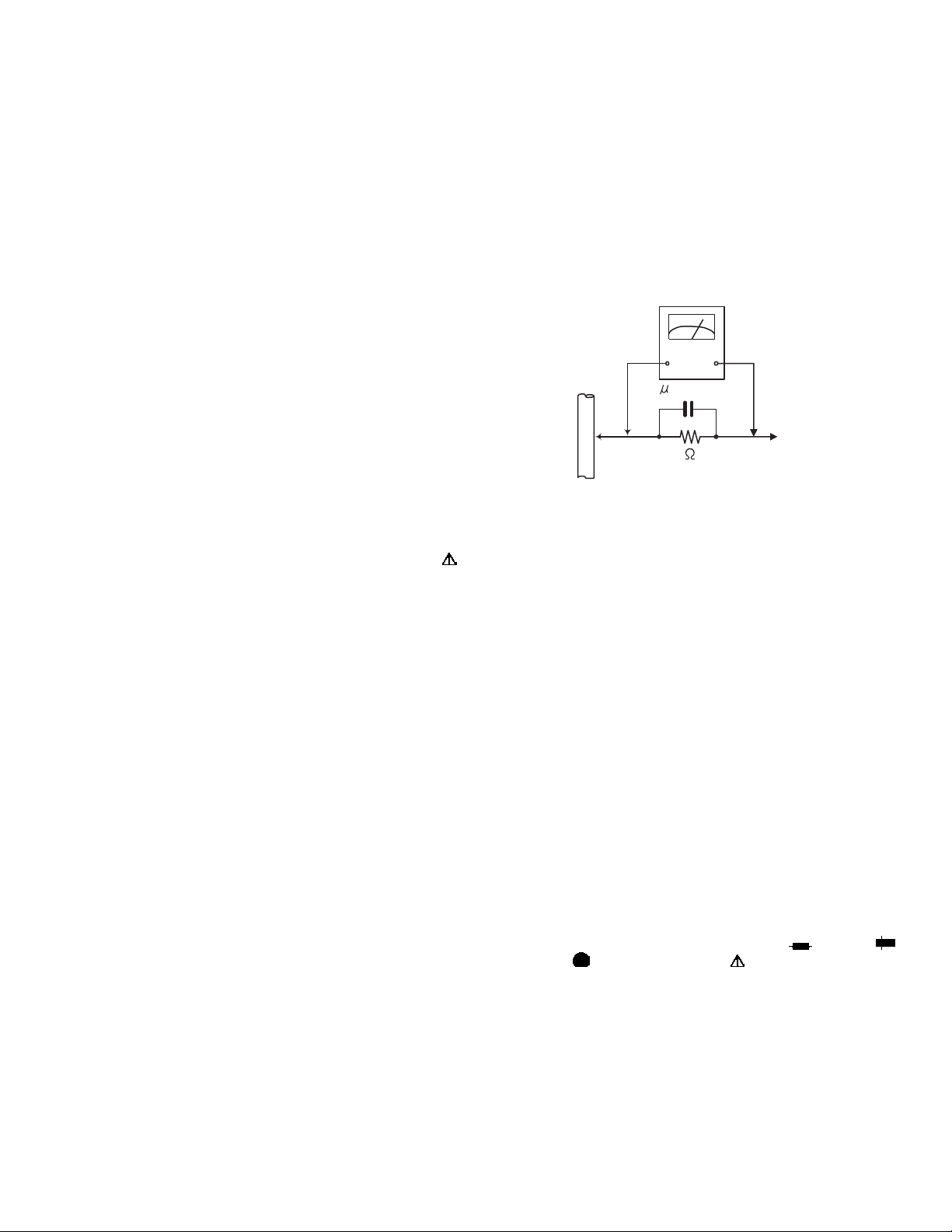

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MA471<Rev.005>)1-5

Page 6

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

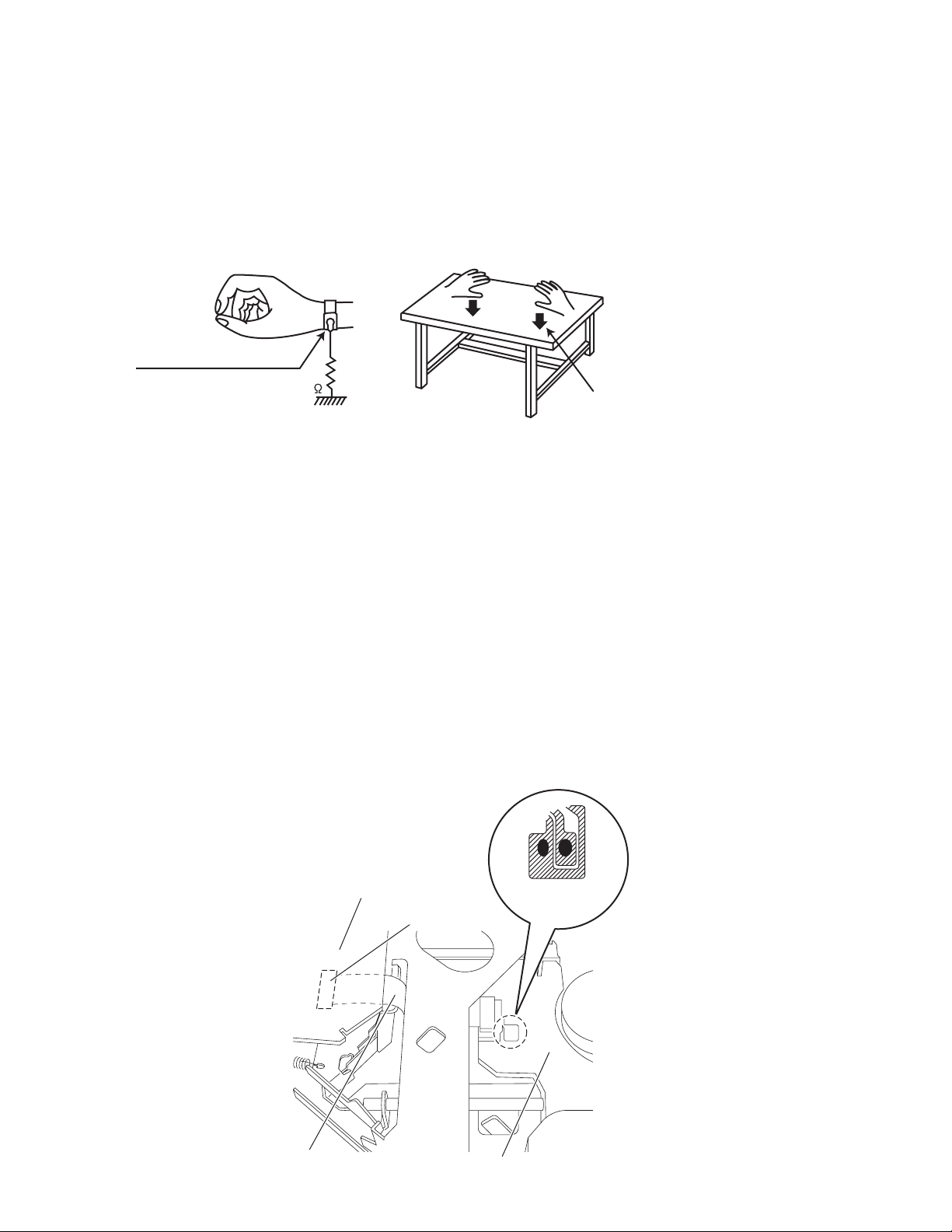

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connector on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

1-6 (No.MA471<Rev.005>)

Mechanism control board

CN102

Flexible wire

Short land section

Pickup

Page 7

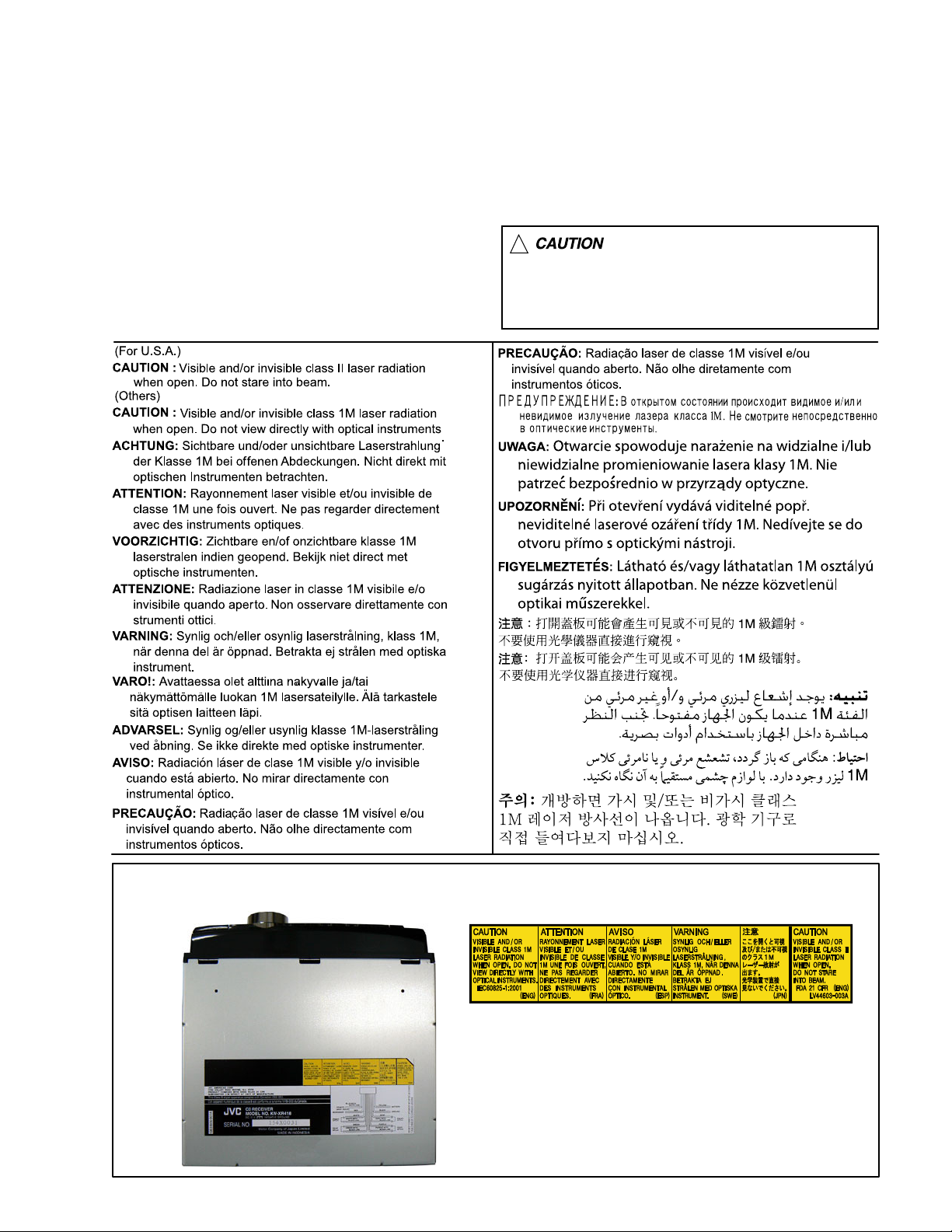

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MA471<Rev.005>)1-7

Page 8

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-8 (No.MA471<Rev.005>)

Page 9

SECTION 3

DISASSEMBLY

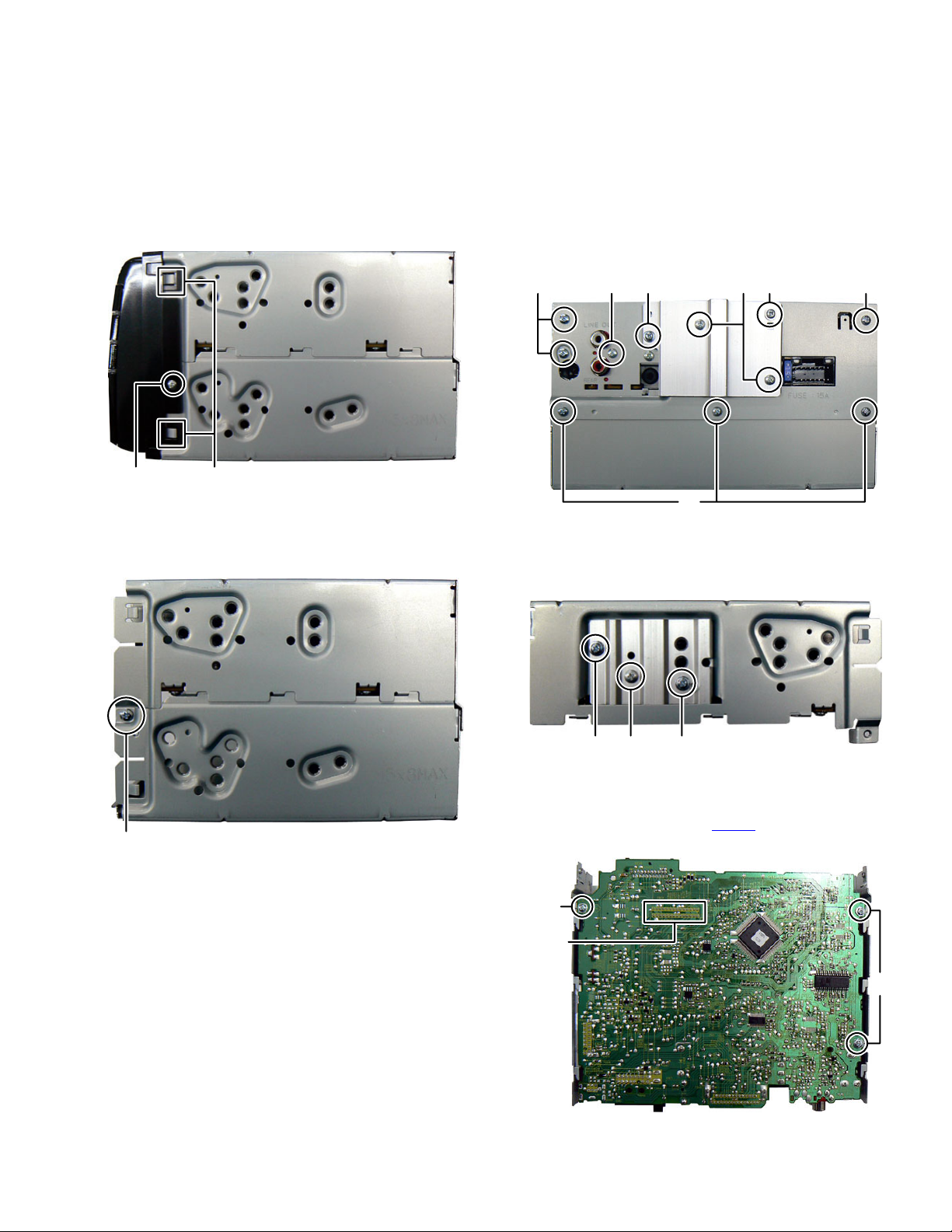

3.1 Main body (Used model: KW-XR418)

3.1.1 Removing the Front panel (See Fig.1)

(1) Remove the two screws A attaching the both side of the

Front panel.

(2) Disengage four hooks a engaged both side of the Front

panel.

A hook a

Fig.1

3.1.2 Removing the Bottom chassis (See Fig.2, 3)

(1) Remove the two screws B attaching the both side of the

Bottom chassis. (See Fig.2)

(2) Remove the three screws C attaching the Bottom chassis.

(See Fig.3)

(3) Remove the two screws D and two screws E attaching the

Heat sink. (See Fig.3)

(4) Remove the three screws F and one screw G attaching the

Rear bracket. (See Fig.3)

DDEFFG

C

Fig.3

3.1.3 Removing the Main board (See Fig.4, 5)

(1) Remove the two screws H and one screw J attaching the

Side plate. (See Fig.4)

B

Fig.2

HHJ

Fig.4

(2) Remove the three screws K attaching the Main board. (See

Fig.5)

(3) Disconnect B-B connector CN501

nected the CD mechanism and Main board. (See Fig.5)

of the Main board con-

K

CN501

K

Fig.5

(No.MA471<Rev.005>)1-9

Page 10

3.1.4 Removing the CD mechanism (See Fig.6)

(1) Remove the three screws L attaching the CD mechanism.

3.1.5 Removing the Switch board (See Fig.7)

(1) Remove the Volume knob.

(2) Remove the sixteen screws M attaching the Switch board.

L

L

Fig.6

3.2 CD MECHANISM assembly section

• Remove the CD MECHANISM assembly from the main body.

Removing the MECHANISM CONTROL BOARD

3.2.1

assembly (See Fig.

(1)

From the bottom side of CD MECHANISM assembly,

remove the solders from the soldered sections (

c

) on the MECHANISM CONTROL BOARD assembly.

1

(See Fig.

(2) Remove the three screws A attaching the MECHANISM

CONTROL BOARD assembly. (See Fig.1.)

.)

a

b

1

and 2)

Mechanism

control board

a, b

CN102

and

M

M

M

Fig.7

(3) Solder the short land sections on the pickup. (See Fig.2.)

Caution:

• Solder the short land sections on the pickup before

disconnecting the flexible wire from the connector

CN102 on the MECHANISM CONTROL BOARD as-

sembly.

If the card wire is disconnected without attaching

solder, the pickup may be destroyed by static

electricity. (See Fig.2.)

•

When attaching the MECHANISM CONTROL

BOARD assembly, remove the solders from the

short land sections after connecting the flexible

wire to the connector CN102

CONTROL BOARD assembly.

on the MECHANISM

A

1-10 (No.MA471<Rev.005>)

A

Fig.1

Mechanism control board

CN102

A

c

Flexible wire

Fig.2

Short land section

Pickup

Page 11

3.2.2 Removing the top cover (See Fig.3 to 5)

• Remove the MECHANISM CONTROL BOARD assembly.

(1) From the front side of the CD MECHANISM assembly,

change the hook position of the two roller springs. (See

Fig.3.)

Top cover

B

Roller spring Roller spring

Fig.3

(2) From the side of the CD MECHANISM assembly, remove

the six screws B attaching the top cover. (See Fig.3 and 4.)

Top cover

(3) Take out the top cover in an upward direction. (See Fig.5.)

Top cover

Fig.5

3.2.3 Removing the roller (See Fig.6)

• Remove the MECHANISM CONTROL BOARD assembly and

top cover.

(1) From the bottom side of the top cover, remove the screw C

attaching the gear holder.

(2) Remove the R.holder assembly from disc plate, and then

take out the roller from R.holder assembly in the direction

of the arrow.

Reference:

When attaching the R.ACT gear (2) and R.ACT gear (3),

apply grease to the section d of R.holder assembly.

B

Fig.4

B

Gear holder

Roller gear

R.ACT gear(3)

R.ACT gear(2)

Top cover

C

d

R.holder assembly

Fig.6

Roller coller

Washer

Roller

Disc plate

(No.MA471<Rev.005>)1-11

Page 12

3.2.4 Removing the PHOTO BOARD assembly (See Fig.7

and 8)

• Remove the MECHANISM CONTROL BOARD assembly and

top cover.

From the bottom side of the top cover, release the

(1)

projection

7

Fig.

(2) Take out the disc plate in the direction of the arrow. (See

Fig.7.)

e

from the notch of the disc plate. (See

.)

e

e

(3) From the reverse side of the disc plate, remove the screw

D attaching the PHOTO BOARD assembly. (See Fig.8.)

D

Photo board

Disc plate

Fig.8

Top cover

Fig.7

3.2.5 Removing the mechanism section (See Fig.9 and 10)

• Remove the MECHANISM CONTROL BOARD assembly and

top cover.

From the top side of the CD MECHANISM assembly,

(1)

remove the two screws

assembly. (See Fig.

(2) Remove the two roller springs on the top side of the mecha

frame. (See Fig.9.)

(3) Remove the four SUS springs on the top side of the mecha

frame. (See Fig.9.)

Mechanism section

SUS

spring

E

attaching the loading motor

9

.)

Mecha frame

Disc plate

SUS

spring

(4) Remove the link spring on the top side of the mecha frame.

(See Fig.10.)

(5) Release section f of the three dampers from the mecha

frame. (See Fig.10.)

Reference:

When attaching the roller spring and SUS spring, keep

direction before remove.

Move the slide cam (R) assembly in the direction of the

(6)

arrow, and then take out the mechanism section in an

upward direction. (See Fig.

Reference:

When attaching the mechanism section, apply grease to

the section g. (See Fig.10.)

F

10.)

Cam cover

SUS

spring

1-12 (No.MA471<Rev.005>)

Roller spring

Loading motor assembly

Fig.9

SUS

spring

E

Mecha frame

Fig.10

Page 13

3.2.6 Removing the slide cam (L) (See Fig.11 to 13)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover and mechanism section.

(1) From the top side of the mecha frame, remove the screw F

attaching the cam cover. (See Fig.11.)

Take out the cam cover from mecha frame in an upward

(2)

11

F

.)

Cam cover

direction. (See Fig.

Reference:

When attaching the slide cam (L), apply grease to the

section h. (See Fig.13.)

h

Slide cam(L)

h

h

h

Mecha frame

Fig.11

(3) Take out the slide cam (L) in the direction of the arrow.

(See Fig.12.)

Slide cam(L)

Slide cam(L)

h

h

Fig.13

3.2.7 Removing the F.lock lever and slide cam (R) (See

Fig.14 and 15)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover and mechanism section.

(1) From the top side of the mecha frame, take out the slide

cam (R) assembly in an upward direction. (See Fig.14.)

(2) Rotate the F.lock lever in the direction of the arrow 1, and

then take out the direction of the arrow 2. (See Fig.14.)

h

F.lock lever

h

2

h

h

Slide cam(R) assembly

1

h

Fig.12

Mecha frame

Mecha frame

h

h

Fig.14

Link arm

(No.MA471<Rev.005>)1-13

h

Page 14

Reference:

When attaching the slide cam (R) assembly, the f.lock

lever and the link arm apply grease to the section

14

(See Fig.

and 15.)

h

Slide cam(R) assembly

h

h

h

h

h

h

Slide cam(R) assembly

Fig.15

3.2.8 Removing the damper (See Fig.16)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover and mechanism section.

From the mechanism section, pull out the three dampers in the

direction of the arrow.

Reference:

Before inserting the shaft to the dampers, apply IPA to the

pocket j of damper.

3.2.9 Removing the clamper assembly (See Fig.17)

• Remove the MECHANISM CONTROL BOARD assembly, top

.

cover and mechanism section.

(1) From the top side of the mechanism section, release the

clamper spring.

(2) Move the clamper assembly in the direction of the arrow,

and then release the joints (k and m).

Take out the clamper assembly from the T.M chassis

(3)

assembly.

Clamper assembly

Clamper spring

k

T.M. chassis assembly

m

Fig.17

Damper (Brown)

j

Damper (Gray)

j

Damper (Brown)

j

Fig.16

1-14 (No.MA471<Rev.005>)

Page 15

3.2.10 Removing the feed motor (See Fig.18 and 19)

r

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section and clamper assembly.

(1) From the bottom side of the T.M chassis assembly, remove

the two screws G attaching the feed motor assembly. (See

Fig.18.)

G

Feed motor assembly

Switch board

p

n

Trigger arm

3.2.11 Removing the SWITCH BOARD assembly (See

Fig.18)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section, clamper assembly and feed motor

assembly.

From the bottom side of the T.M chassis assembly, take out

the SWITCH BOARD assembly in an upward direction from

T.M chassis assembly.

3.2.12 Removing the loading motor (See Fig.20)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section and clamper assembly.

(1) From the right side of the L.M base assembly, remove the

two screws J attaching the loading motor.

(2) Take out the loading motor in the direction of the arrow

from the L.M base assembly.

Reference:

When attaching the loading motor, apply grease to the

section r.

F.wheel gear

T.M. chassis assembly

Fig.18

(2)

Remove the two screws H attaching the feed motor to

19

f.motor holder. (See Fig.

Reference:

When attaching the f. wheel gear, trigger arm and feed

motor, apply grease to the sections (n, p and q). (See

Fig.18 and 19.)

Feed motor

F.worm gear

.)

Comp. spring

J

L.M. base assembly

L.worm gear

Loading moto

r

Fig.20

q

H

F.motor holder

Fig.19

(No.MA471<Rev.005>)1-15

Page 16

3.2.13 Removing the pickup assembly (See Fig.21 to 22)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section, clamper assembly and feed motor

assembly.

Caution:

• Do not touch section u on the pickup assembly. (See Fig.21

and 22.)

(1) From the bottom side of the T.M chassis assembly, move

the pickup assembly in the direction of the arrow from the

T.M chassis assembly. (See Fig.21.)

(2) Pull out the main shaft. (See Fig.21.)

t

Pick up assembly

u

Main shaft

3.2.14 Removing the spindle motor (See Fig.23 and 24)

Remove the MECHANISM CONTROL BOARD assembly,

•

top cover, mechanism section, clamper assembly, feed motor

assembly and pickup assembly.

(1) From the top side of the T.M chassis assembly, remove the

CD T.table assembly from the spindle motor. (See Fig.23.)

(2) Remove the two screws L attaching the spindle motor.

(See Fig.23.)

(3) Take out the spindle motor from the bottom side of the T.M

chassis assembly. (See Fig.23.)

LL

CD T.table assembly

s

T.M. chassis assembly

Fig.21

(3) Remove the screw K attaching the pickup to the rack plate.

(See Fig.22.)

K

Rack plate

u

T.M.chassis assembly

Spindle motor

Fig.23

Reference:

When attaching the CD T.table assembly to the spindle

motor shaft, apply loctite 460 to inside the CD T.table

24

assembly. (See Fig.

CD T.table assembly

Spindle motor

.)

Loctite

Fig.24

Pick up

Reference:

When attaching the loading motor, apply grease to the

sections s and t. (See Fig.21.)

1-16 (No.MA471<Rev.005>)

Fig.22

Page 17

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc

(4) Extension cable : EXTCD004-28P

4.2 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K ohm (2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.5 How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

4.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.4 Dummy load

Exclusive dummy load should be used for AM,and FM.

For FM dummy load, there is a loss of 6dB between SSG output

and antenna input.

The loss of 6dB need not be considered sincedirect reading of

figures are applied in this working standard.

Extension cable

EXTCD004-28P

(No.MA471<Rev.005>)1-17

Page 18

4.6 SERVICE MODE

Operating key: [MENU] → [DOWN] (3 sec)

Navigation key : Press [SEL] in any main display item to select that option.

Volume Knob Turn: forward and backward selection

INT ALL Initialize all data to factory shipment state.

Note : A disc is inserted, and it is displayed only at the time of CD function.

RUNNING MODE 1 CD6 module running mode 1 (Only factory use)

MODE 2 CD6 module running mode 2 (Only factory use)

CHECK MODE

CD ERROR

NORMAL PLAY Disc operation & playback. (playback from starting position)

CURENT ##** Laser Electric Current Value

##: Initial value **: Current value

JITTER #### Jitter Value

Note: Pressing "FF" or "REW" key to switch between

current value and jitter value display.

OUT TRK OFF Tracking off at CD outermost lap.

INN TRK OFF Tracking off at CD innermost lap.

CD LASER ON CD Laser Illumination and electric current.

CURENT ##** Laser Electric Current Value

##: Initial value **: Current value

JITTER #### Jitter Value

Note: Pressing "FF" or "REW" key to switch between

current value and jitter value display.

STOP Disc stop, LD(Laser) OFF

Display the CD Error past record stored in EEPROM.

TOTAL-****: Total error count

E#xxyyyy : Latest 3 errors recorded. #: countor xx: error code yyyy: detailed error code

0#xxyyyy : The first 5 errors recorded. #: countor xx: error code yyyy: detailed error code

Note: Shifting among the above items is done by using "FF" or "REW" key.

CLR CDERROR

TSUBUYAKI

DC OK

1-18 (No.MA471<Rev.005>)

Clear CD Error history from EEPROM.

Only engineer use

DC offset error information

*See " DC offset error information " for details.

Page 19

4.7 DC OFFSET ERROR INFORMATION

4.7.1 Display indication

DC OK

DC ERROR

VOL

push

BACK

DC 1 ERROR

VOL

knob

VOL

push

BACK

CLR DC1 VOL push to confirmDC 1 OK

DC 2 X

VOL

push

BACK

4.7.2 DC offset error distinction.

(1) DC ERROR 1

When improper connection or other DC offset errors are detected.

"PROTECT" blinks to the display.

It is possible to return even times how many by reset.

(2) DC ERROR 2

When the DC offset error is detected due to the trouble of the capacitor.

• The number of times that detected in the case of less than 3 times.

"PROTECT" blinks to the display.

It is possible to return to the 3rd times by reset.

• When the detected number becomes 4 times.

"PROTECT" lights to the display.

It is fixed that trouble occurs internally, and reset doesn't return either.

( Operation other than the Power on/off, Eject, Reset, and Service mode are prohibited with "PROTECT" lit.

4.7.3 Error content confirmation.

Whether it turns on power and the "PROTECT" display appears are confirmed.

(1) When the "PROTECT" display appears.

The content of the DC offset error is confirmed in the Service mode.

* Because it takes DC offset protection, the following is displayed.

"DC ERROR"

(1-1) When "DC1 ERROR" is displayed. (DC ERROR1)

•Forecast cause

It comes in contact with improper connection or GND of the speaker wiring.

It is confirmed that there is no improper connection of the speaker wiring and pushes reset.

•When "PROTECT" is not displayed, it is unquestionable.

The error data of EEPROM, it deletes it. (CLR DC1)

•When "PROTECT" is still displayed.

The DC offset has been generated by the reasons other than the improper connection.

Forecast cause: Power AMP is broken.

After parts are exchanged, reset is confirmed pushing again.

(1-2) When "DC2 X" is displayed. (DC ERROR2)

* As for X, the detected number is displayed. (0-4)

* When X is 0, it is unquestionable because the DC offset has never been detected.

When leak of capacitor is detected, it is displayed.

It is confirmed that there is no problem in the capacitor and deletes the error data of EEPROM. (CLR DC2)

It is confirmed that reset is pushed and "PROTECT" is not displayed.

CLR DC2 VOL push to confirm

After above-mentioned (1-1) and (1-2) are executed, the conect of the DC offset error is confirmed in the Service mode.

If the part displayed as "DC ERROR" becomes "DC OK", it is unquestionable.

(2) When the "PROTECT" display doesn't appear.

The content of the DC offset error is confirmed in the Service mode.

(2-1) When "DC OK" is displayed, it is unquestionable because the DC offset has not been detected in the past.

(2-2) When "DC ERROR" is displayed, the confirmation similar to (1-1) and (1-2) is done because there is a history that detected

the DC offset error in the past.

(No.MA471<Rev.005>)1-19

Page 20

4.8 TUNER SERVICE MODE

Key operation (FM and AM mode)

Enter service mode: [SEL] → [MENU] (3 sec)

Exit service mode: press [ENTER] (SEL) key.

Go to next item: press [DISP] key

Back to previous item: press [BACK] key

VER=#*** MICON version display

# indicates destination: J=USA, U=OTHERS (eg. ASIA), R=EUROPE, E=EASTERN EUROPE

*** indicates version No.

CD6V#### CD module version display.

######## Tuner device and version identification display

Display :TOM V3 for TOMIC V3 tuner.

Display: ATOM V5 for ATOMIC V5 tuner.

TINJ= ## Tuner injection indicator

"##" indicates current tuner injection.

FOR RDS ONLY

PI =#### PI display of receiving station, "####" indicates PI code.

PTY=## PTY display of receiving station (00~29), "##" indicates PTY code.

TP=#TA=* TP, TA display of receiving station

"#" indicates TP ON/OFF: 1=ON; 0=OFF;

"*" indicates TA ON/OFF: 1=ON; 0=OFF.

MS=#DI=* M/S, DI display of receiving station

"#" indicates M/S ON/OFF: 1=ON; 0=OFF;

"*" indicates DI ON/OFF: 1=ON; 0=OFF.

AF=#### Display the contents of AF memory (by scrolling) "####" indicate AF frequencies.

LEV= ##H Field strength indicator.

U&W= ##H Adjacent and Multi path noise level indicator.

IFC= ##H IF COUNTER result indicator.

IFBW= # FM IF filter bandwidth indicator.

RFAGC=## FM RF AGC resulting attenuation.

IFAGC=## FM IF AGC resulting attenuation.

##** CLOCK display of receiving station (Original DISP key operation)

######## FOR RDS ONLY

PS NAME display of receiving station (Original DISP key operation)

##### FREQUENCY display of receiving station (Original DISP key operation)

1-20 (No.MA471<Rev.005>)

Page 21

4.9 ERROR CODE

4.9.1 Mechanical Error Detail Codes

Condition Details Error code Detailed code

LOADING Error Error without SW change in LOAD when time-out is done

B1 time out When there is no change in the state of the switch from the state

with DISC forward.

C1 time out When there is no change in the state of the switch from the state

that DISC is drawn in a half.

B2 time out When there is no change in the state of the switch from the state

that DISC is in the interior.

EJECT Error Error without SW change in EJECT when time-out is done.

B1 time out When there is no change in the state of the switch from the state

that DISC is in the interior.

C2 time out When there is no change in the state of the switch from the state

that DISC is drawn in a half.

B2 time out When there is no change in the state of the switch in EJECT from

initial LOAD ERROR.

FORCE EJECT Error Transition to Force EJECT waiting or Force EJECT transition from

error Error by abnormal SW.

E1 FORCE EJECT ERROR When detect abnormal SW from the state of NO DISC 01 0041

E2 FORCE EJECT ERROR When detect abnormal SW from the state with DISC forward in

LOAD.

E3 FORCE EJECT ERROR When detect abnormal SW from the initial state. 01 0043

E5 FORCE EJECT ERROR When detect abnormal SW from the state that half DISC is drawn

in LOAD and EJECT.

E7 FORCE EJECT ERROR When detect abnormal SW from the atate that DISC is in the inte-

rior in LOAD and EJECT.

E8 FORCE EJECT ERROR When receive Force EJECT key after it makes an error from Force

EJECT.

E9 FORCE EJECT ERROR When receive Force EJECT key after it makes an error from LOAD

error or EJECT error.

Error in Running mode

Case 1 When DISC was extracted or fall in EJECT END and EJECT

START.

Case 2 When DISC is pushed in EJECT END. 09 0032

09 0011

09 0012

09 0015

01 0023

01 0026

01 0027

01 0042

01 0045

01 0047

01 0048

01 0049

09 0031

4.9.2 Disc error code

Condition Details Error code Detailed code

TOC READING Error When it hasn't completed CD TOC reading. 84 0059

1'st track access Error It doesn't end even if the first track access passes 30sec after the

TOC reading ends in the running mode.

Last track access Error It doesn't end even if the last track access passes 30sec after the

first track ends in the running mode.

NODISC judgement It be judged NODISC. 80 0090

NO DISC with start failure Not possible to start. 80 0091

Stopped with no playback When it was stopped in playback in the running mode. 80 0093

Logical format NG Analysis of logical format is impossible or it does not correspond

to logical formats.

80 0060

80 0061

80 0094

(No.MA471<Rev.005>)1-21

Page 22

5.1 16 PIN CORD DIAGRAM (For KW-XR418)

SECTION 5

TROUBLESHOOTING

1

16

2

8

BK

YL

RD

GN

8

7

6

5

4

3

2

1

GN

GN/BK

VI/BK

VI

NC

BL/WH

RD

BK

WH

WH/BK

GY/BK

GY

NC

NC

NC

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

Black

Red

Blue

White

VI

GN

GY

YL

Violet

Green

Gray

Yellow

7

5

6

9

10

12

11

3

WH

GN/BK

VI

VI/BK

WH/BK

GY

GY/BK

BL/WH

1-22 (No.MA471<Rev.005>)

Page 23

5.2 16 PIN CORD DIAGRAM (For KW-XR411, KW-XR417)

GN

VI

NC

RD

BK

WH

WH/BK

GY/BK

GY

BR

NC

NC

YL

9

10

11

12

13

14

15

16

8

7

6

5

4

3

2

1

GN/BK

VI/BK

BL/WH

BK

RD

BL

WH

VI

Black

Red

Blue

White

Violet

GN

GY

BR

YL

Green

Gray

Brown

Yellow

BR

YL

NC

BK

2

4

6

8

NC

1

NC

3

BL/WH

5

RD

7

16

13

10

12

2

1

3

8

7

5

6

9

RD

YL

BK

BL/WH

BR

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

RD

RD

YL

7

4

8

5

2

7

8

1

2

5

6

3

GY/BK

11

4

VI/BK

GY/BK

WH/BK

GN/BK

2

4

6

8

VI

1

GY

3

WH

5

GN

7

(No.MA471<Rev.005>)1-23

Page 24

5.3 16 PIN CORD DIAGRAM (For KW-XR416, KW-XR416D, KW-XR414)

1

16

4

3

8

7

6

5

4

3

2

1

BK

YL

BL

BL/WH

GN

GN/BK

VI/BK

VI

BL

BL/WH

RD

BK

WH

WH/BK

GY/BK

GY

NC

NC

NC

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

Black

Red

Blue

White

VI

GN

GY

YL

Violet

Green

Gray

Yellow

2

8

7

5

6

9

10

12

11

RD

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

1-24 (No.MA471<Rev.005>)

Page 25

5.4 16 PIN CORD DIAGRAM (For KW-XG56T)

8

7

6

5

4

3

2

1

WH

WH / BK

GY / BK

GY

NC

NC

NC

YL

YL

1

GY

5

GY / BK

6

WH / BK

7

GN

GN / BK

VI / BK

VI

BL

BL / WH

RD

BK

16

15

14

13

12

11

10

BK

GY

WH

YL

9

YL

1

GY

4

Black

Gray

White

Yellow

5

6

7

8

9

10

GN

VI

BL

RD

NC

NC

BL

BK

WH / BK

GY / BK

Green

Violet

Blue

Red

RD

WH

YL

GY

1

2

3

4

GY / BK

10

WH / BK

9

WH

8

BK

9

RD

10

BL

12

GN

16

VI

13

GN / BK

15

VI / BK

14

BL / WH

11

WH

3

BK

8

RD

2

BL

7

GN

1

VI

2

GN / BK

3

VI / BK

6

3

GN / BK

4

5

6

NC

NC

VI / BK

GN

VI

1

2

(No.MA471<Rev.005>)1-25

Page 26

5.5 16 PIN CORD DIAGRAM (For KW-XR416SUN)

8

7

6

5

4

3

2

1

GN

GN/BK

VI/BK

VI

BL

BL/WH

RD

BK

1

16

2

WH

WH/BK

GY/BK

BK

YL

RD

GY

NC

NC

NC

YL

9

10

11

12

13

14

15

16

BK

RD

BL

VI

GN

WH

GY

YL

Black

Red

Blue

Violet

Green

White

Gray

Yellow

20

19

18

17

16

15

14

13

12

11

BK

NC

WH/BK

GY/BK

GN/BK

VI/BK

NC

NC

NC

NC

20

10

YL

10

NC

9

8

WH

7

GY

6

GN

5

VI

NC

4

3

NC

RD

2

BL/WH

2

1

4

3

9

10

8

7

5

6

12

BL

BL / WH

WH

WH / BK

GN

GN / BK

VI

VI / BK

GY

9

1

8

18

6

16

5

15

7

11

1-26 (No.MA471<Rev.005>)

GY / BK

17

Page 27

(No.MA471<Rev.005>)1-27

Page 28

Victor Company of Japan, Limited

J&K Car Electronics Corporation 2967-3, Ishikawa-machi, Hachioji-shi, Tokyo, 192-8525, Japan

(No.MA471<Rev.005>)

Printed in Japan

VSE

Loading...

Loading...