Page 1

49783200303

KS-F345

SERVICE MANUAL

CASSETTE RECEIVER

KS-F345

Area Suffix

EE ---- Russian Federation

S.BASS

SEL

D

ISP

FM

A

M

SSM

EX

SCMMO

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3 Adjustment method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.49783

2003/03

Page 2

KS-F345

1.1 Safety Precautions

SECTION 1

Important Safety Precautions

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2 (No.49783)

Page 3

SECTION 2

Disassembly method

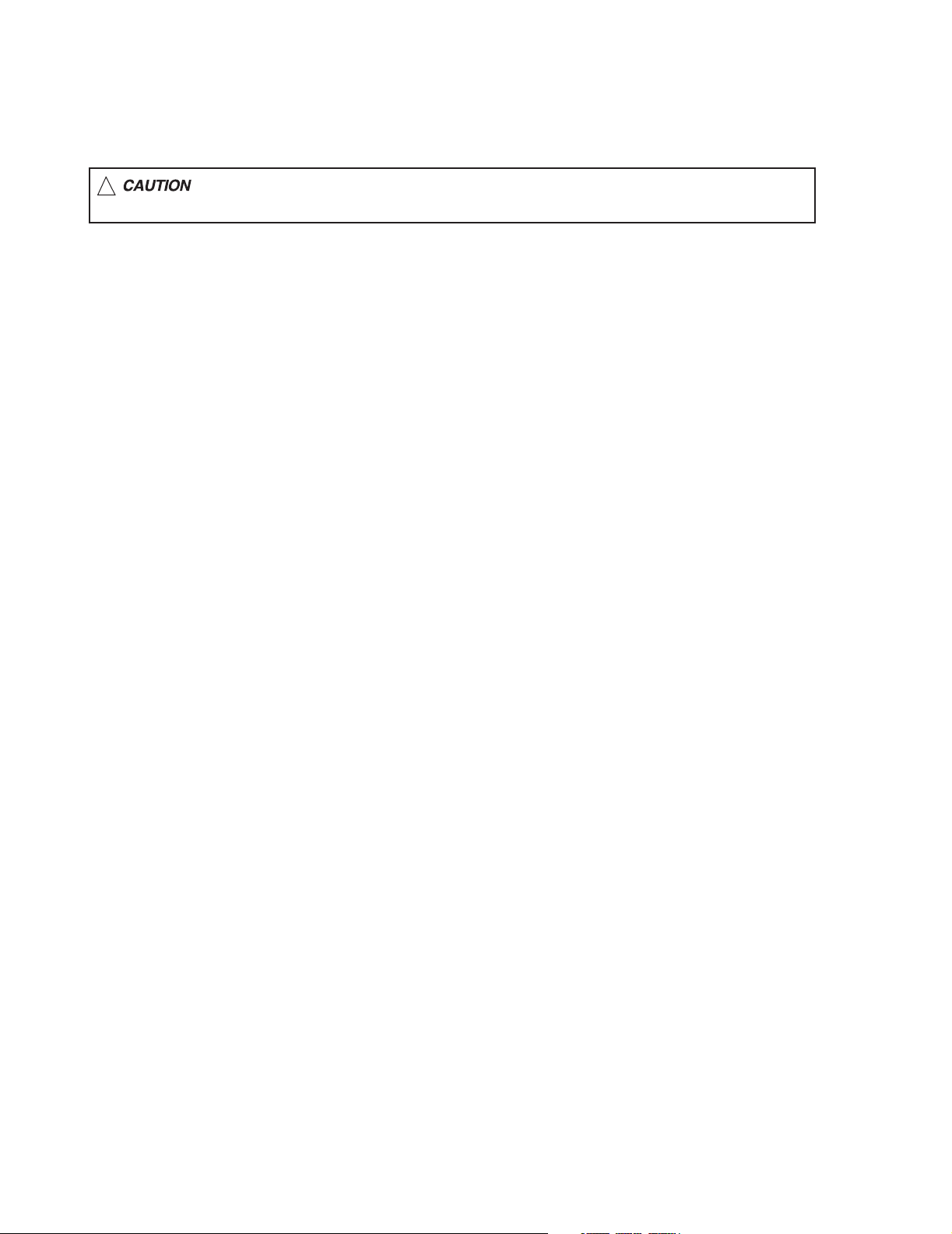

2.1 Main body

2.1.1 Removing the front panel assembly

(See Fig.1)

(1) Press the release button and remove the front panel as-

sembly.

2.1.2 Removing the bottom cover

(See Fig.2)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Turn the body upside down.

(2) Insert a screwdriver under the joints to release the two

joints a on the left side, the two joints b on the right side and

the joint c on the back of the body, then remove the bottom

cover from the body.

CAUTION:

When releasing the joint c using a screwdriver, do not

damage the main board.

KS-F345

Front panel assembly

Release button

Fig.1

Bottom cover

Joint b

Joint a

2.1.3 Removing the front chassis

(See Fig.3)

• Prior to performing the following procedure, remove the front

panel assembly and bottom cover.

(1) Remove the screw A on each side of the body.

(2) Release the two joints d and two joints e on the sides, then

remove the front chassis toward the front.

Joint a

Joint c

Fig.2

Joint d Joint e

A

Joint d

Front chassis

Fig.3

Joint e

Joint b

(No.49783)1-3

Page 4

KS-F345

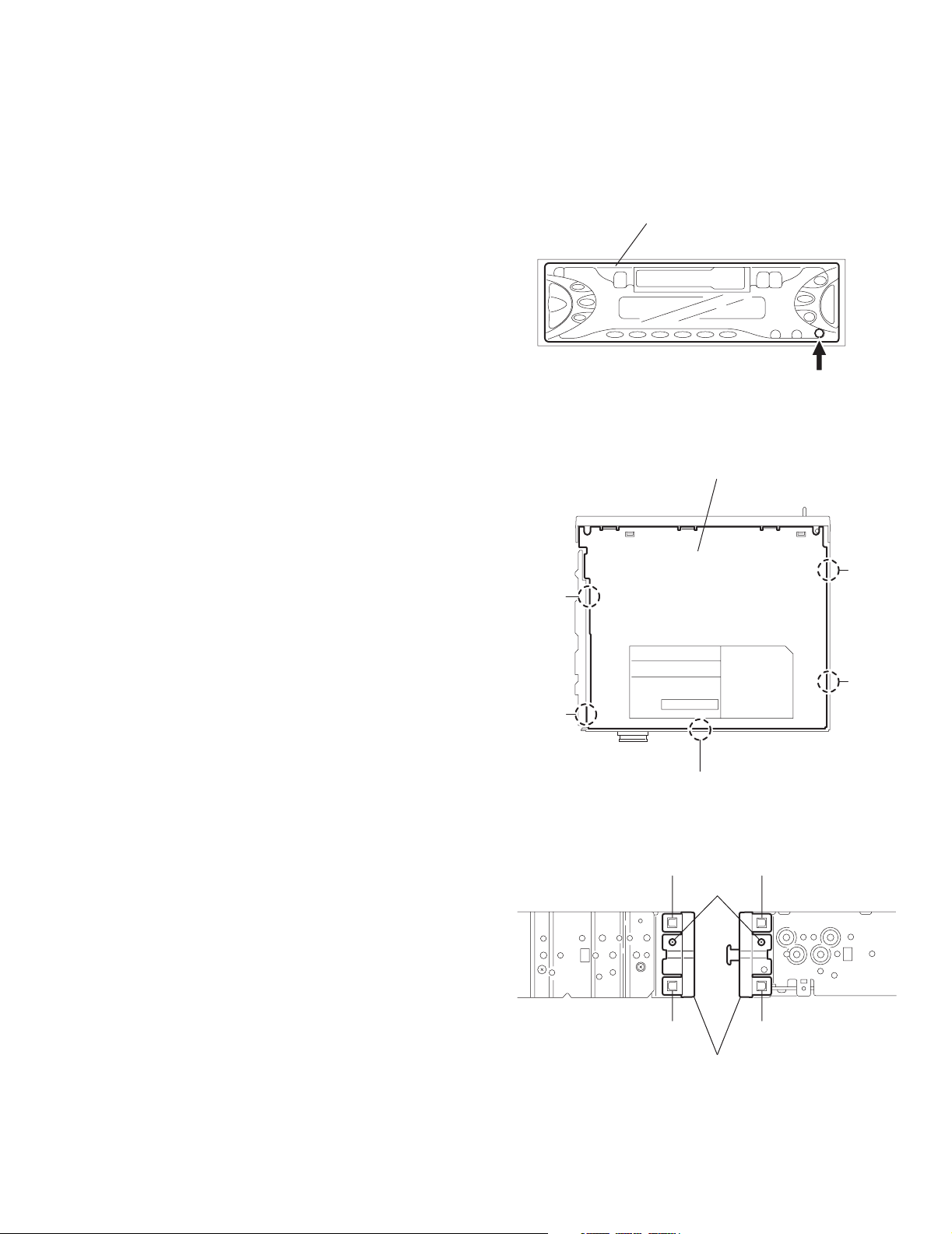

2.1.4 Removing the heat sink

(See Fig.4)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the two screws B and two screws C attaching the

heat sink on the left side of the body, and remove the heat

sink.

2.1.5 Removing the rear panel

(See Fig.5 )

• Prior to performing the following procedure, remove the front

panel assembly and bottom cover.

(1) Remove the two screws D, one screw E and three screws

F attaching the rear panel on the back of the body.

CB C

Heat sink

Fig.4

D

FF

2.1.6 Removing the main board

(See Fig.6)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink and

rear panel.

(1) Remove the two screws G attaching the main board on the

top chassis.

(2) Disconnect the two connectors CN901 and CN721 on the

main board from the cassette mechanism assembly.

E

G

CN721

D

Fig.5

Main board

G

CN901

Fig.6

1-4 (No.49783)

Page 5

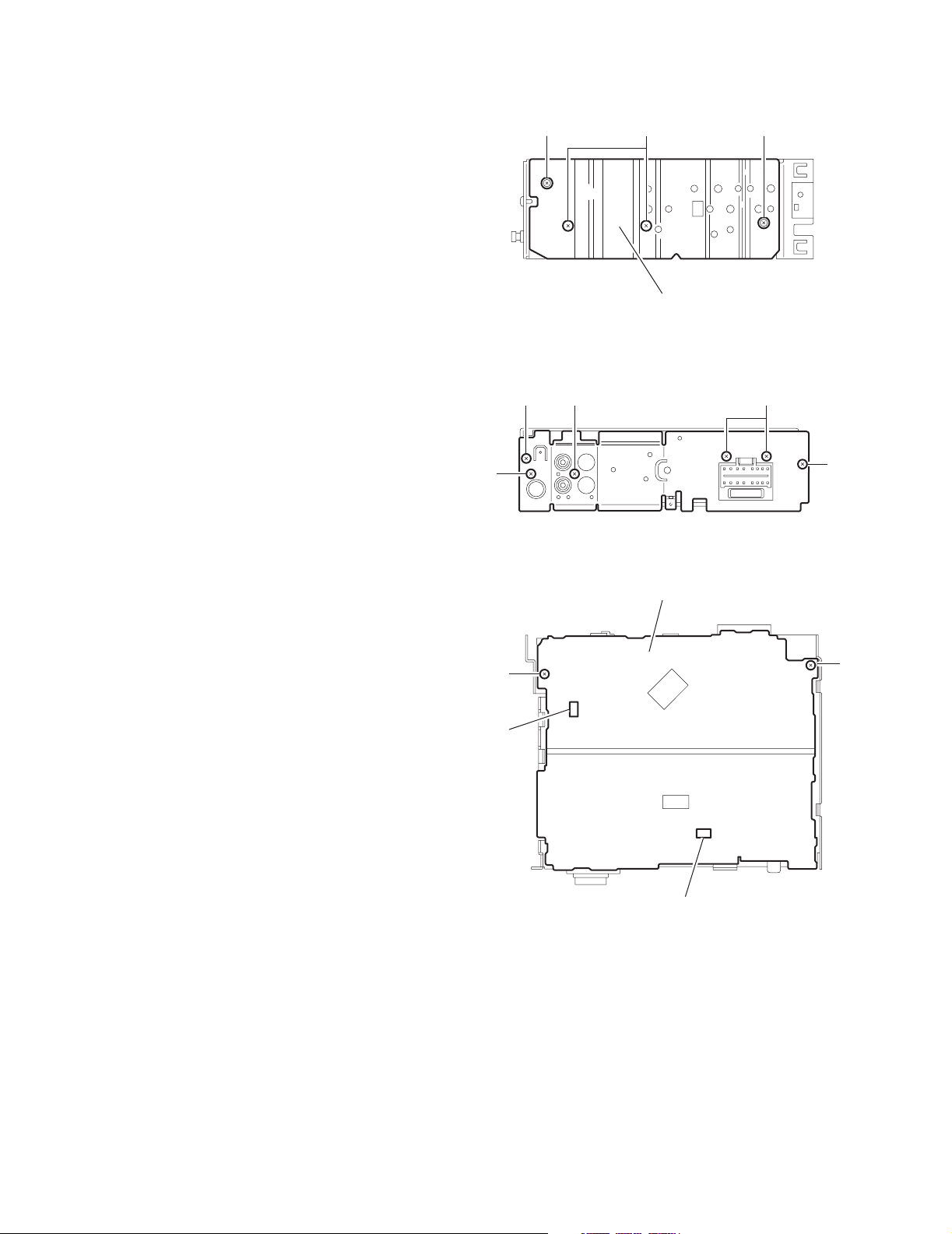

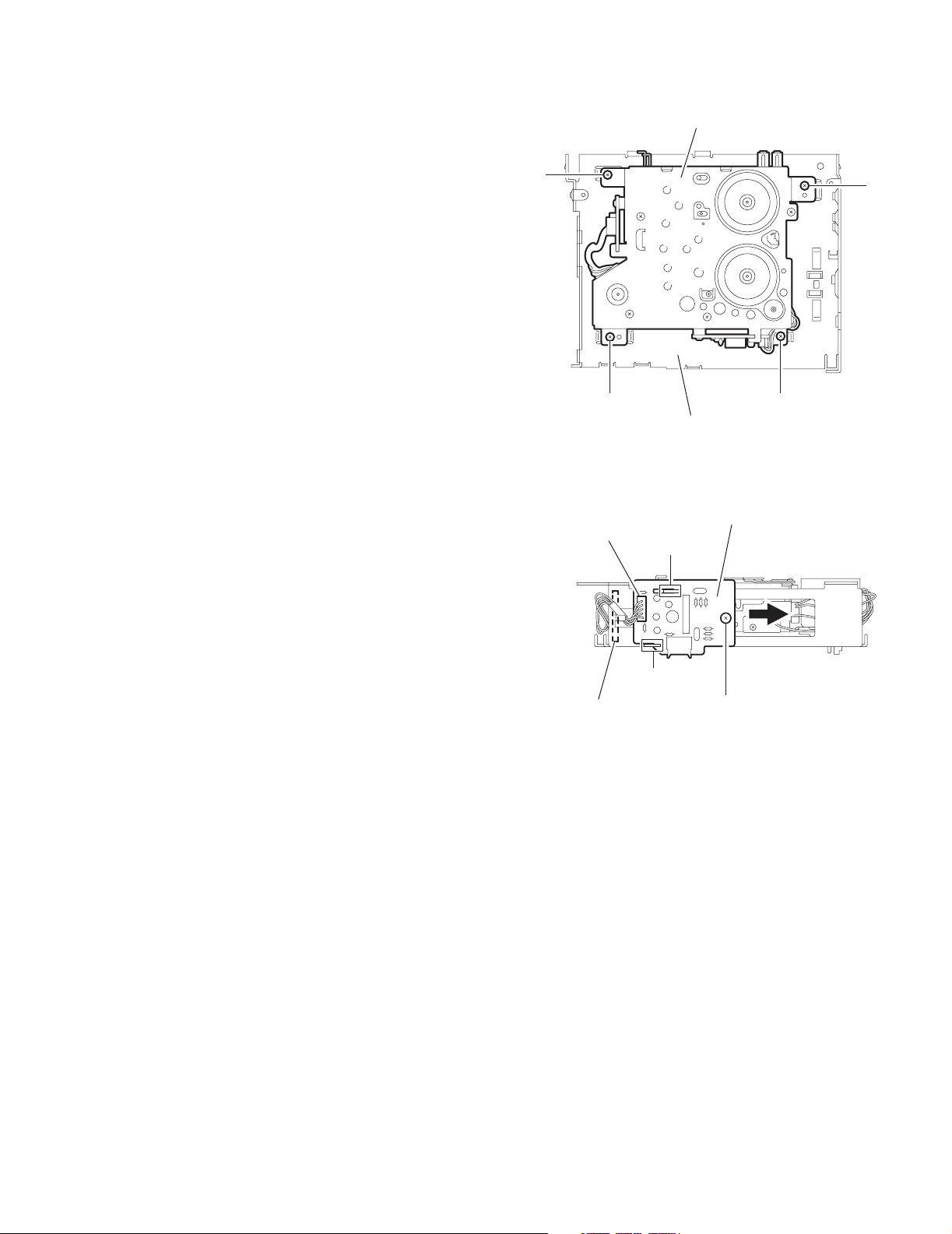

2.1.7 Removing the cassette mechanism assembly

(See Fig.7)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink, rear

panel and main board.

(1) Remove the four screws H attaching the cassette mecha-

nism assembly from the top chassis.

H

KS-F345

Cassette mechanism assembly

H

2.1.8 Removing the head amplifier board

(See Fig.8)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink, rear

panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from CJ901 on the head amplifier

board.

(2) Remove the one screw J attaching the head amplifier

board.

(3) Move the head amplifier board in the direction of the arrow

to release the two joints f, the head amplifier board can be

removed.

H

CJ901

joint f

To head relay board

H

Top chassis

Fig.7

Head amplifier board

joint f

J

Fig.8

(No.49783)1-5

Page 6

KS-F345

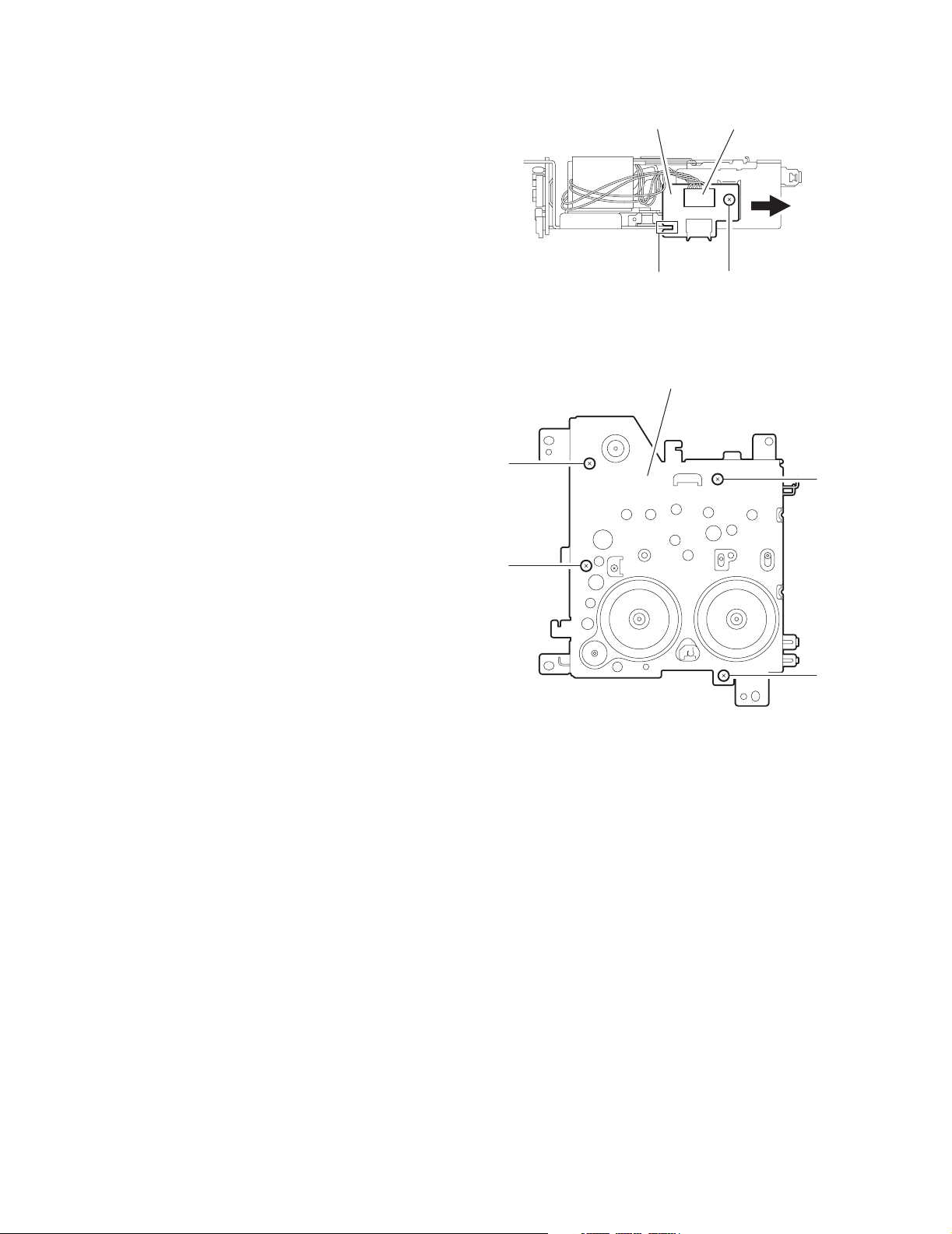

2.1.9 Removing the relay board

(See Fig.9)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink, rear

panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from CP722 on the relay board.

(2) Remove the one screw K attaching the relay board.

(3) Move the relay board in the direction of the arrow to release

the joint g, the relay board can be removed.

Relay board

CP722

2.1.10 Removing the mecha bracket

(See Fig.10)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink, rear

panel, main board, cassette mechanism assembly, head amplifier board and relay board.

(1) Remove the four screws L attaching the mecha bracket.

joint g

Fig.9

Mecha bracket

K

L

L

L

L

Fig.10

1-6 (No.49783)

Page 7

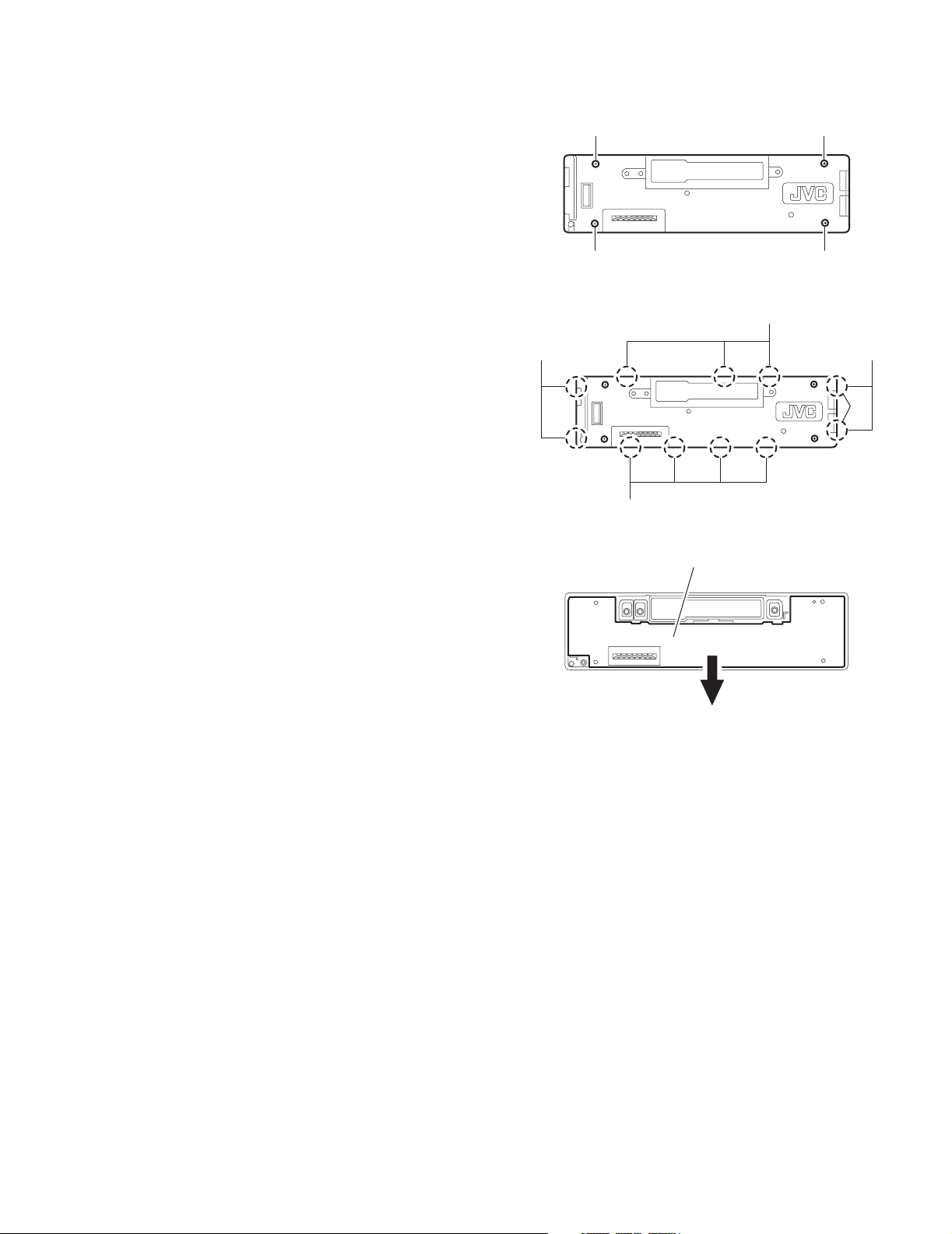

2.1.11 Removing the switch (LCD & key) board

(See Fig.11~13)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the four screws M attaching the rear cover on the

back of the front panel assembly.

(2) Release the eleven joints h, the front panel and the rear

cover become separate.

(3) Remove the switch board from the rear cover.

M

M

M M

Fig.11

Joint h

KS-F345

Joint h

Joint h

Joint h

Fig.12

Switch (LCD & Key) board

Fig.13

(No.49783)1-7

Page 8

KS-F345

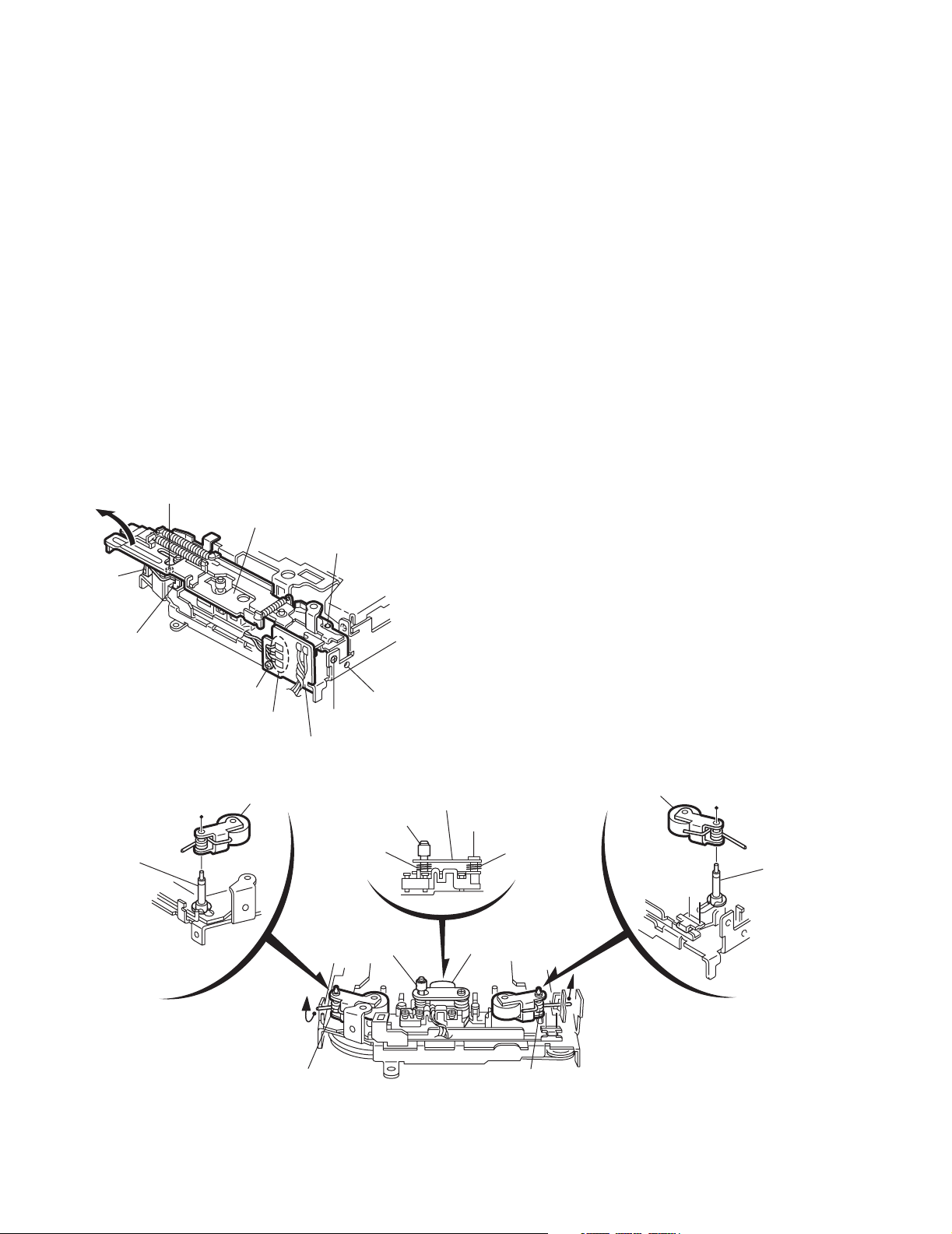

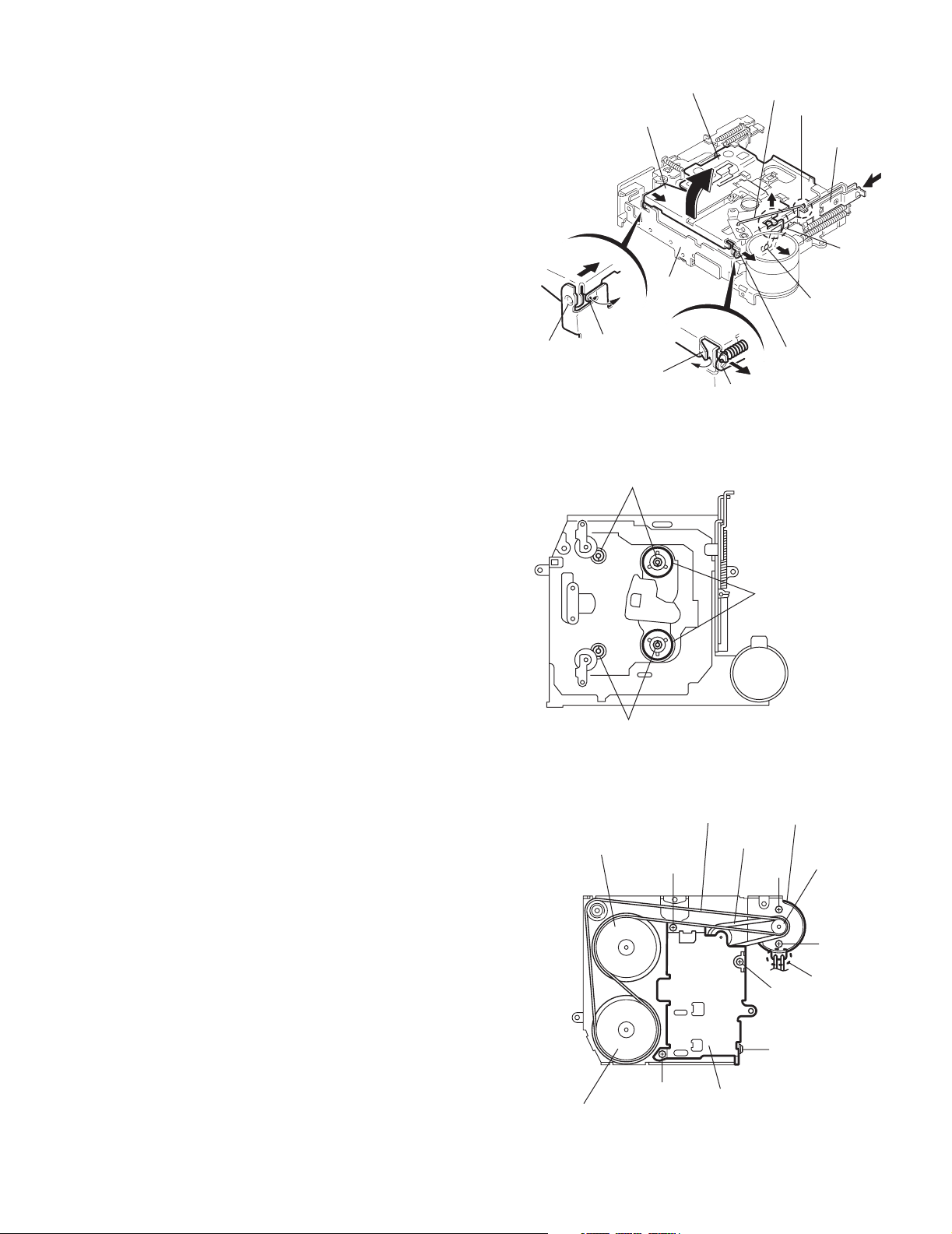

2.2 Cassette mechanism assembly

• Prior to performing the following procedures, remove the head

amplifier board, the relay board and the mechanism bracket.

2.2.1 Removing the direction switch board

(See Fig.1)

(1) Unsolder the three wires a on the direction switch board.

(2) Remove the one screw A attaching the direction switch

board.

2.2.2 Removing the FF / REW lever assembly

(See Fig.1)

(1) Remove the screw B attaching the FF / REW lever assem-

bly on the back of the cassette mechanism assembly.

(2) Remove the screw C on the upper side of the FF / REW

lever assembly.

(3) Lift and pull forward the FF / REW lever assembly to disen-

gage the joints b, c, d and e.

2.2.3 Reattaching the FF / REW lever assembly

(See Fig.1)

(1) Reattach the FF / REW lever assembly to the joint c on the

back of the chassis.

(2) Reattach the pinch-roller shaft e, the change lever d and

the return link e to the chassis.

C

FF / REW lever assembly

Joint c

2.2.4 Removing the playback head

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the screw D attaching the playback head.

(2) Remove the C washer and pull out the FF roller.

(3) Remove the S support plate, the A arm spring (a) and (b),

the playback head.

ATTENTION:

The A arm spring (a) differs from the A arm spring (b).

2.2.5 Removing the pinch-roller (R) and (F) assembly

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the P arm spring (f) in the pinch-roller (F) assem-

bly from the chassis.

(2) Remove the P arm spring (r) in the pinch-roller (R) assem-

bly from the chassis.

(3) Draw out the pinch roller (F) and (R) assembly from the

shaft.

ATTENTION:

The P arm spring (f) differs from the P arm spring (r).

ATTENTION:

The pinch roller (F) assembly differs from the pinch roller (R)

assembly.

Joint e

Joint d

A

Soldering a

Direction switch board

Fig.1

Pinch-roller (R) assembly

Shaft

Remove the P arm spring (r)

from the chassis.

Joint b

B

C washer

A arm spring (b)

FF roller

S support plate

D

Playback head

Pinch-roller (F) assembly

A arm spring (a)

Shaft

Remove the P arm spring (f)

from the chassis.

1-8 (No.49783)

P arm spring (r)

P arm spring (f)

Fig.2

Page 9

KS-F345

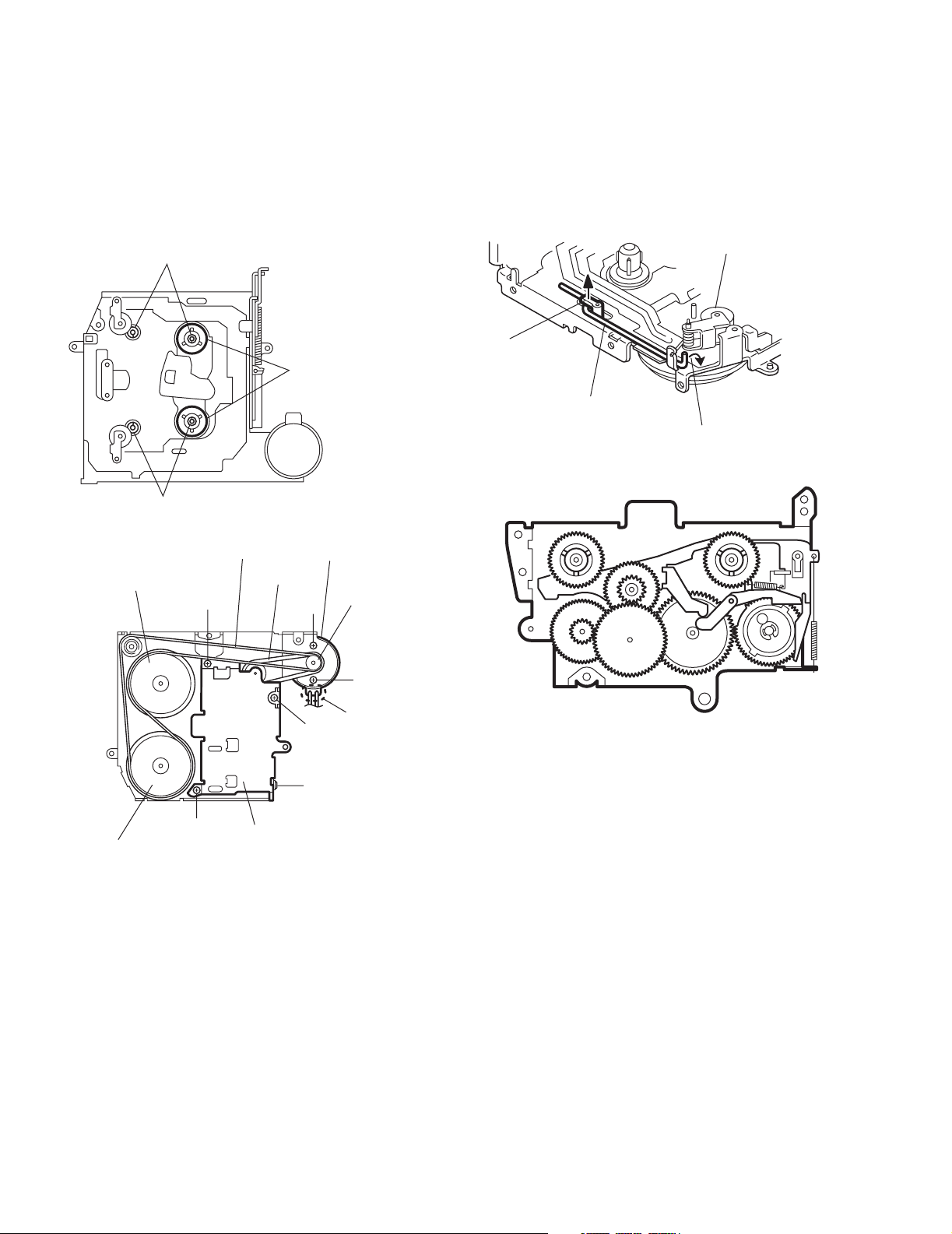

2.2.6 Removing the cassette hanger / cassette holder

(See Fig.3)

• Prior to performing the following procedure, remove the FF /

REW lever assembly.

(1) From the rear of the unit, bend the two tabs f outwards and

disengage the two joints g in the direction of the arrow.

(2) Push the eject lever and remove the cassette holder from

the playback head. Disengage the two joints h of the cassette hanger / cassette holder and the eject lever in the direction of the arrow.

(3) Lift the cassette hanger / cassette holder and disengage

the joint i of the return link and the eject lever.

2.2.7 Removing the reel disc assembly

(See Fig.4)

• Prior to performing the following procedure, remove the FF /

REW lever assembly and the cassette hanger / cassette holder.

(1) Remove the C washer and pull out reel disc assembly.

ATTENTION:

Replace with a new C washer when reattaching.

Joint g

Cassette holder

Cassette hanger

Chassis

Tab f

Tab f

C washer

Return link

Joint i

Eject lever

Joint h

Joint h

Joint g

Fig.3

2.2.8 Removing the motor assembly

(See Fig.5)

(1) Unsolder the two wires j on the motor assembly.

(2) Turn over the cassette mechanism assembly and remove

the main belt and the sub-belt from the motor pulley.

ATTENTION:

The main belt can now be removed.

(3) Remove the two screws G attaching the motor assembly.

C washer

Flywheel (BF)

Fig.4

Main-belt

E

Reel disc assembly

Motor assembly

Sub-belt

G

E

Motor pulley

G

Soldering j

Flywheel (BR)

Reel base assembly

E

Fig.5

F

(No.49783)1-9

Page 10

KS-F345

2.2.9 Removing the Flywheel (BF) and (BR) assembly

(See Fig.4 and 5)

• Prior to performing the following procedure, remove the cas-

sette hanger / cassette holder.

(1) From the upper side of the cassette mechanism assembly,

remove the C washer from each shaft of the flywheel (BF)

and (BR).

(2) Turn over the cassette mechanism assembly and remove

the main belt. Pull out the flywheel (BF) and (BR) downward respectively.

C washer

Reel disc assembly

C washer

Fig.4

Main-belt

Motor assembly

2.2.10 Removing the reel base assembly

(See Fig.5 and 6)

(1) Raise the part k of the reel base assembly slightly and re-

move the selector link (B) on the front side of the cassette

mechanism assembly by turning it as shown in Fig.6.

(2) Remove the three screws E and the one screw F on the

underside of the cassette mechanism assembly.

ATTENTION:

The reel base assembly is not repairable. Handle with care.

Pinch-roller (R) assembly

k

Selector link (B).

Turn the selector link (B).

Fig.6

Inside of the reel base assembly

Flywheel (BF)

Flywheel (BR)

Sub-belt

E

Reel base assembly

E

Fig.5

G

E

F

Motor pulley

G

Soldering j

Fig.7

1-10 (No.49783)

Page 11

KS-F345

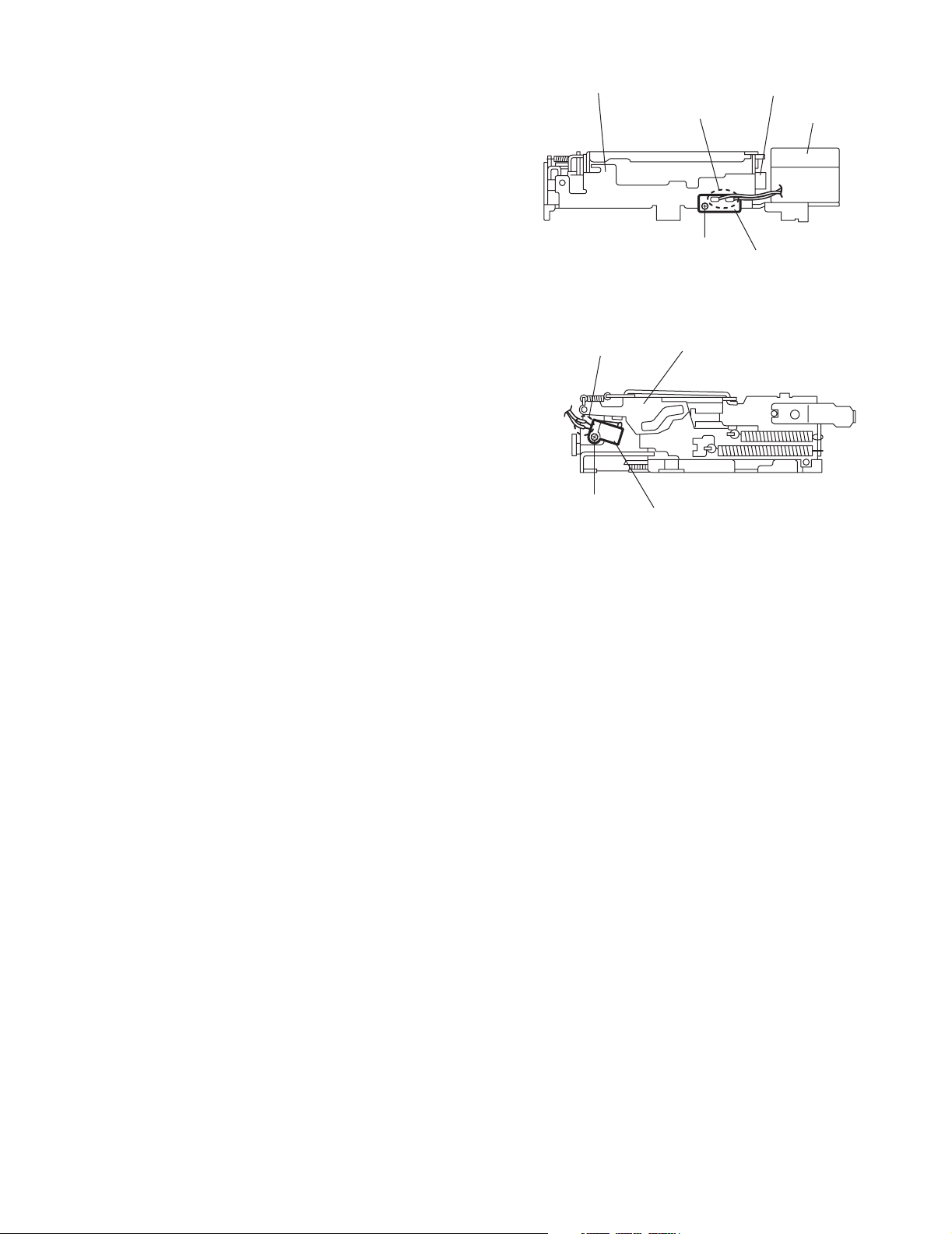

2.2.11 Removing the mute switch board

(See Fig.8)

(1) Unsolder the two wires l on the mute switch board on the

back of the cassette mechanism assembly.

(2) Remove the screw H attaching the mute switch board.

2.2.12 Removing the power switch

(See Fig.9)

• Prior to performing the following procedure, remove the motor

assembly.

(1) Unsolder the two wires m on the power switch on the side

of the cassette mechanism assembly.

(2) Remove the screw I attaching the power switch.

Cassette mechanism assembly

Soldering l

H

Fig.8

Soldering m

I

Cassette mechanism assembly

Power switch

Fig.9

Rower switch

Motor assembly

Mute switch board

(No.49783)1-11

Page 12

KS-F345

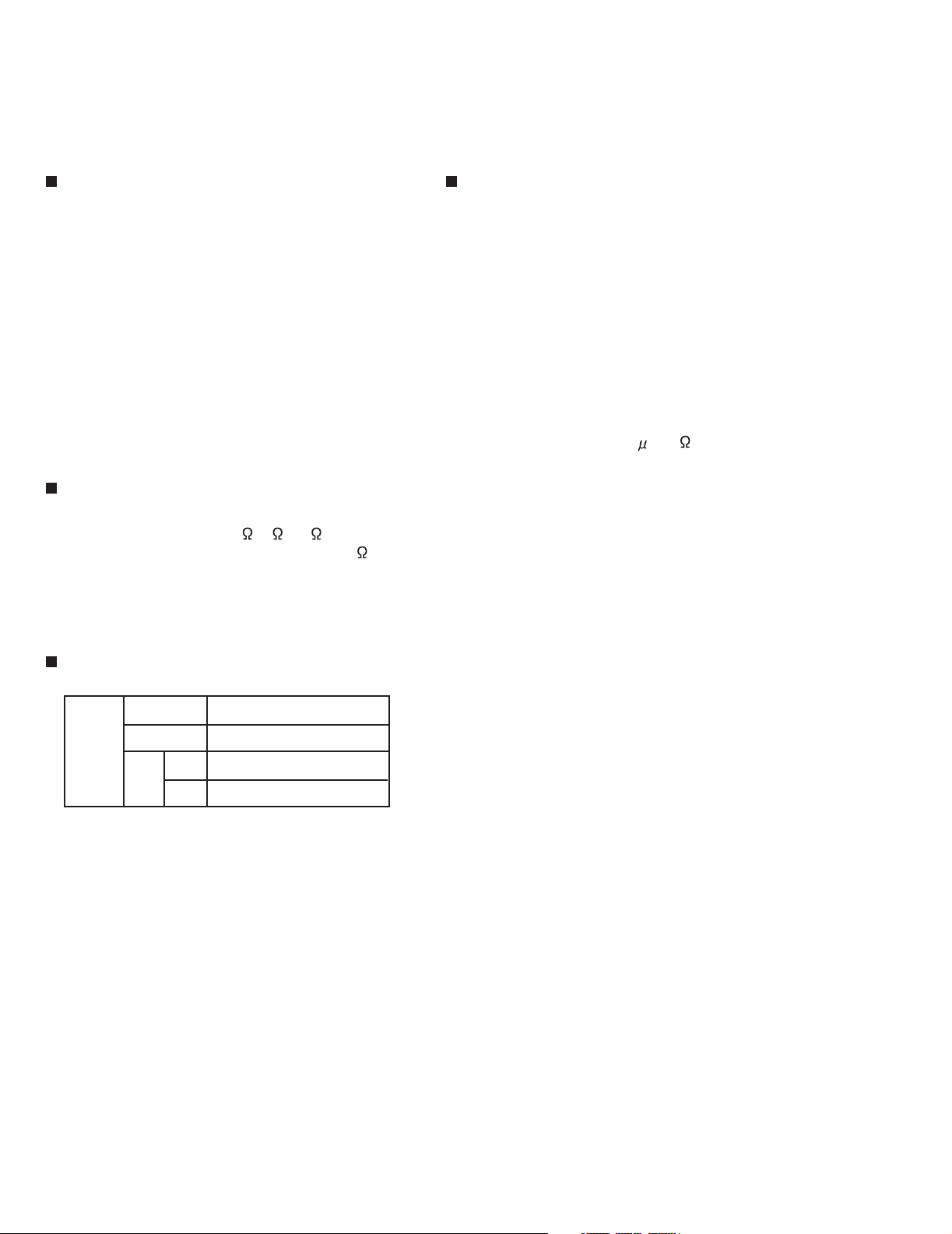

3.1 Adjustment method

Test instruments reqired for adjustment Standard volume position

1. Digital oscilloscoe(100MHz)

2. Frequency counter meter

3. Electric voltmeter

4. Wow & flutter meter

5. Test tapes

VT724.......................for DOLBY level measurement

VT739............For playback frequency measurement

VT712....For wow flutter & tape speed measurement

VT703.....................For head azimuth measurement

6. Torque gauge...................Cassette type for CTG-N

(Mechanism adjustment)

SECTION 3

Adjustment

Balance and Bass, Treble volume, Fader

: Center(Indication"0")

Loudness, Dolby NR, Sound, Cruise : Off

Volume position is about 2V at speaker output with

following conditions, Playback the test tape VT721.

AM mode 999kHz/62dB, INT/400Hz, 30%

modulation signal on recieving.

FM mono mode 97.9MHz/66dB, INT/400Hz, 22.5kHz

deviation pilot off mono

FM stereo mode 1kHz, 67.5kHz dev.pilot 7.5kHz dev

Output level 0dB (1 V,50 /open terminal)

Measuring conditions(Amplifier section)

Power supply voltage.............. DC14.4V(11V to 16V allowance)

Load impedance............ 4 (4 to 8 allowance)

Line out level/Impedance..............1.0V/20k load (250 nWb/m)

Frequency band

87.5 MHz to 108.0 MHz

65.0 MHz to 74.0 MHz

522 kHz to 1620 kHz

MW

144 kHz to 279 kHz

LW

Band

FM1/FM2

FM3

AM

1-12 (No.49783)

Page 13

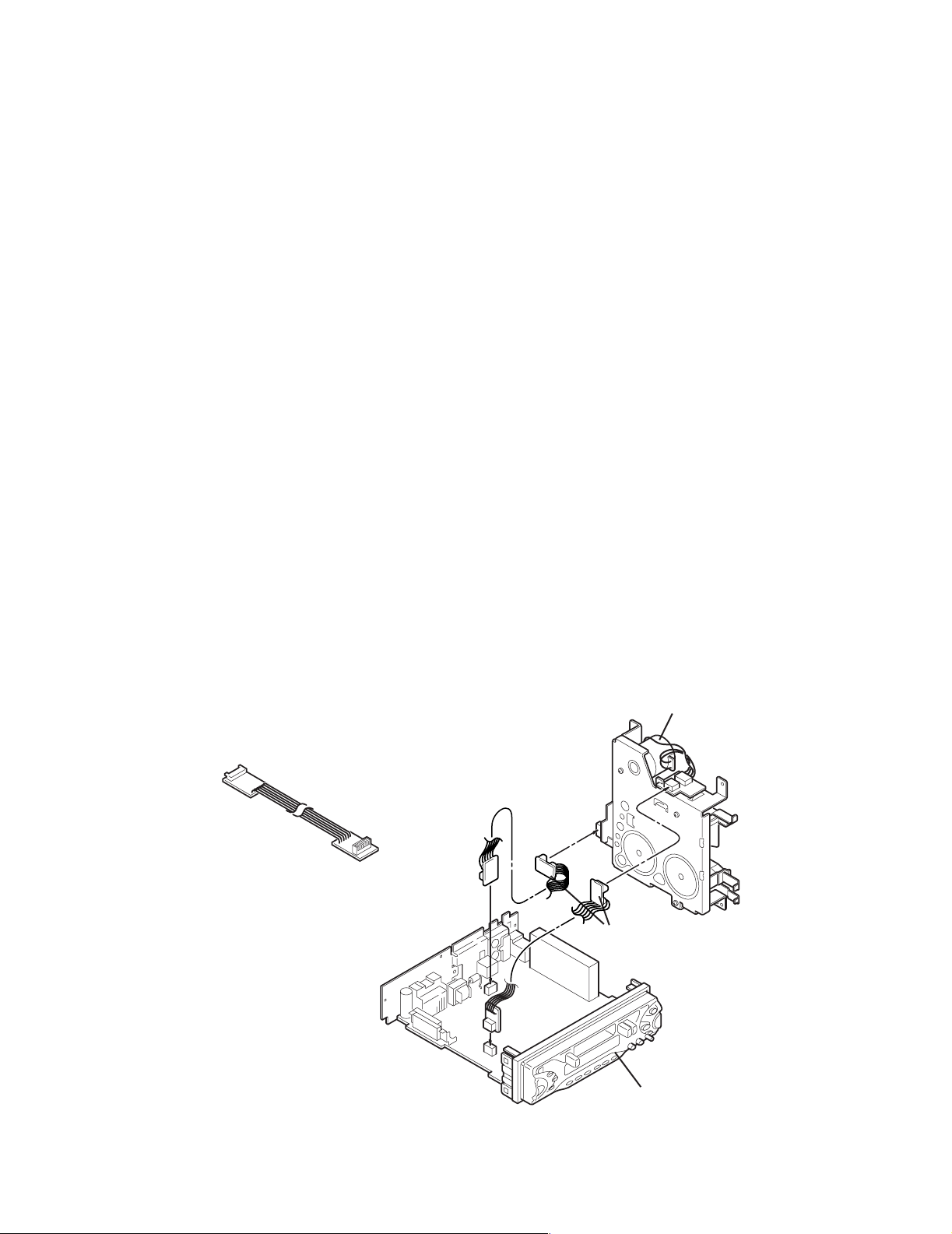

Information for using a car audio service jig

1. For 1995 and 1996, we're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

2. As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the

mechanism assembly after disassembly.

3. Extension cord : EXTKSRT002-6P ( 6 pin extension cord ) For connection between mechanism assembly

and main board.

4. Check for mechanism driving section such as motor ,etc..

Disassembly method

1. Remove the front panel assembly.

2. Remove the bottom cover.

3. Remove the front chassis.

4. Remove the two screws D of the rear panel. (Refer to Disassembly method.)

5. Remove the heat sink.

6. Reattach the heat sink with two screws B. (Refer to Disassembly method.)

7. Install the front chassis and front panel assmbly.

8. Confirm that current is being carried by connecting an extension cord jig.

Note

Available to connect to the CJ701 connector when installing the front panel.

KS-F345

CAUTION :

Be sure to attach a heat sink on the power amplifier IC of a main board when supplying the power.

If voltage is applied without attaching the heat sink, the power amplifier IC will be destroyed by heat.

Cassette mechanism

EXTKSRT002-6P

Extension cord

: EXTKSRT002-6P

Main board

Front panel assembly

(No.49783)1-13

Page 14

KS-F345

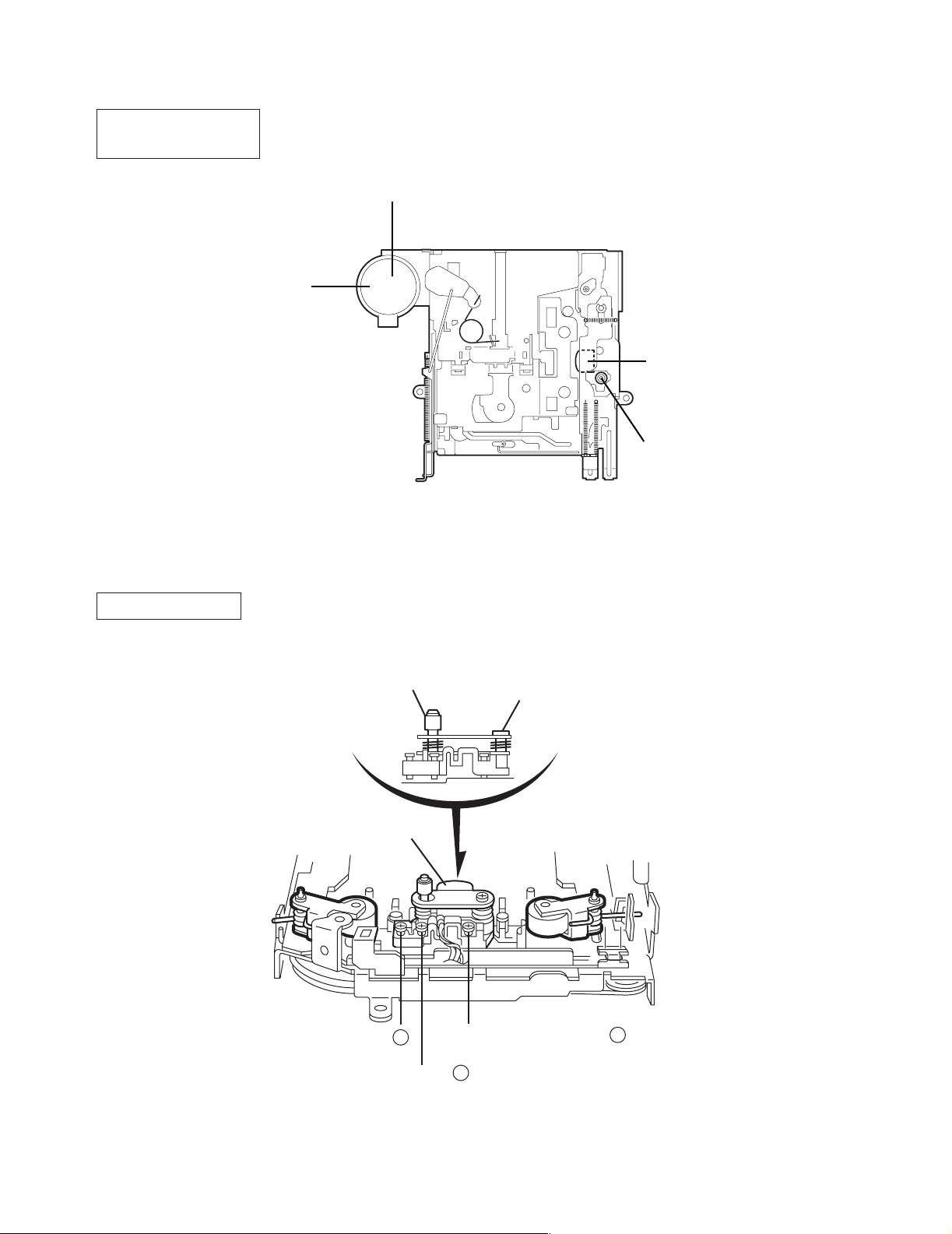

Arrangement of adjusting & test points

Cassette mechanism

(Surface)

Motor assembly

Tape speed adjust

Playback head

Azimuth screw

Head section view

Head azimuth screw

Playback head

Height adjusting screw

c

Fixed screw

Height adjusting screw

a

1-14 (No.49783)

Height adjusting screw

b

Page 15

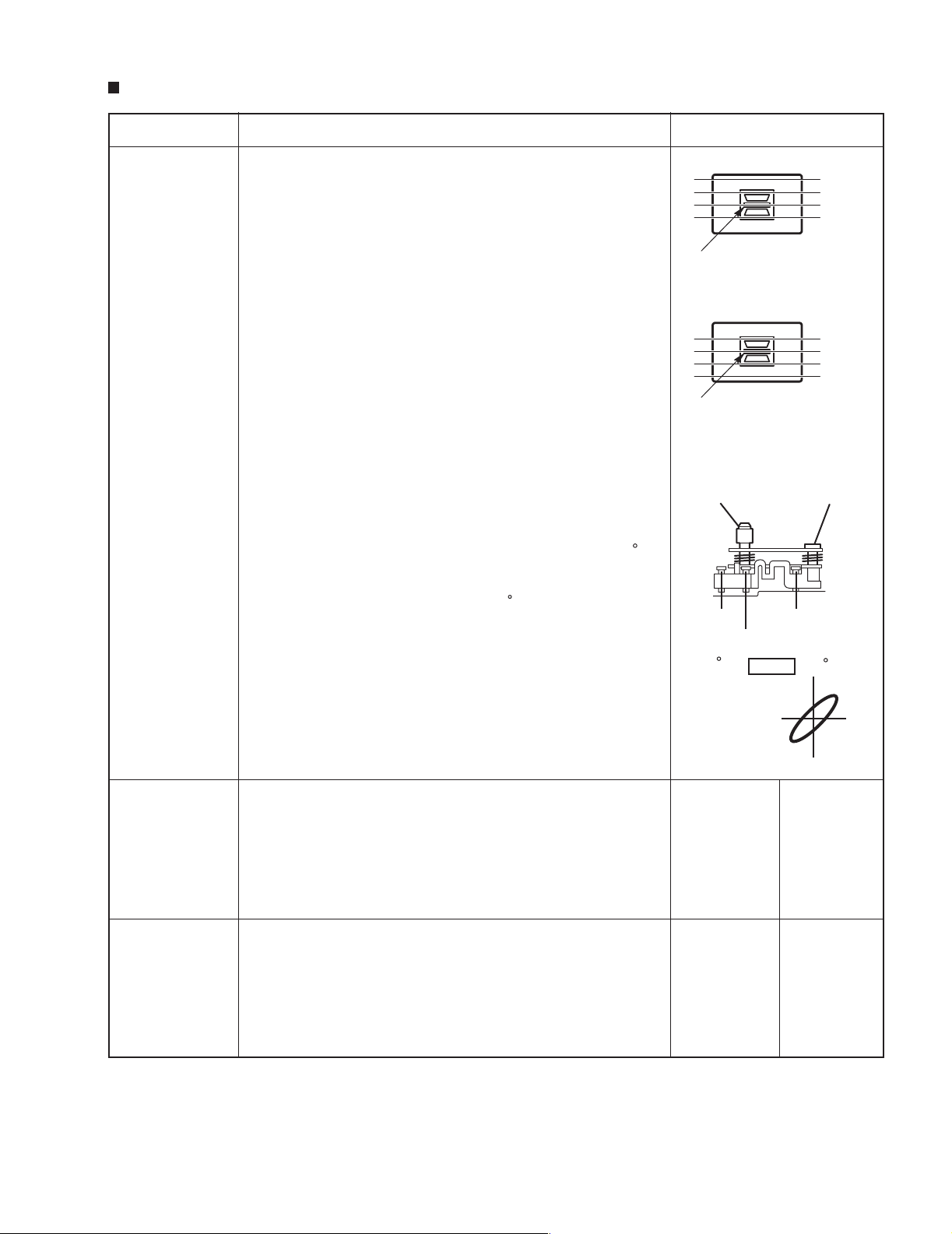

Mechanism adjustment section

Item Adjusting & Confirmation Methods Adjust Std. Value

1.Head azimuth

"Head Height Adjustment"

Note

Adjust the azimuth directly. When you adjust the height using a mirror tape, remove the cassette housing from the

mechanism chassis.

After installing the cassette housing, perform the azimuth

adjustment.

Head shield

KS-F345

A Line

1.Load the mirror tape ( SCC-1659 ). Adjust with height

adjustment screw (a) and azimuth adjustment screw (b) so

that line "A" of the mirror tape runs in the center between

Lch and Rch in the reverse play mode.

2.After switching from REV to FWD then to REV, check that

the head position set in procedure "1" is not changed.

*If the position has shifted, adjust again and check.

3.Adjust the azimuth screw (b) so that line "B" of the mirror

tape runs in the center between Lch and Rch in the forward

play mode.

"Head Azimuth Adjustment"

1.Load the test tape ( VT724: 1kHz ) and play it back in the

reverse play mode. set the Rch output level to maximum.

2.Load the test tape ( VT703: 10kHz ) and play it back in the

forward play mode. Adjust the Rch and Lch output levels

to maximum, with azimuth adjustment screw (b).

In this case, the phase difference should be within 45 .

3.Engage the reverse mode and adjust the output level to

maximum, with azimuth adjustment screw (c).

*The phase diff

erence should be 45 or more.

4.When switching between forward and reverse modes, the

difference between channels should be within 3dB.

*Between FWD Lch and Rch, REV Lch and Rch.

5.When the test tape ( VT721 : 315Hz ) is played back, the

level difference between channels should be within 1.5dB.

The head is at low position

during FWD.

B Line

Head shield

The head is at height position

during REV.

Head azimuth

screw

screw (c)

screw (b)

0

Phase

Fixed screw

screw (a)

45

2.Tape Speed and

Wow & Flutter

3.Playback

Frequency

response

1.Check to see if the reading of the frequency counter & Wow

flutter meter is within 2940-3090 Hz( FWD/REV ), and less

than 0.35% ( JIS RMS ).

2.In case of out of specification, adjust the motor with a builtin volume resistor.

1.Play the test tape ( VT724 : 1kHz ) back and set the volume

position at 2V.

2.Play the test tape ( VT739 )back and confirm 0

+

3dB at1kHz/

-

8kHz and -4+2dB at 1kHz/125Hz.

3.When 8kHz is out of specification, it will be necessary to

readjust the azimuth.

Built-in

volume resistor

Tape Speed

2940-3090Hz

Wow&Flutter

Less than

0.35%

(JIS RMS)

Speaker out

1kHz/8kHz

+

: 0dB 3dB,

-

125Hz/1kHz

: -4dB+2dB,

(No.49783)1-15

Page 16

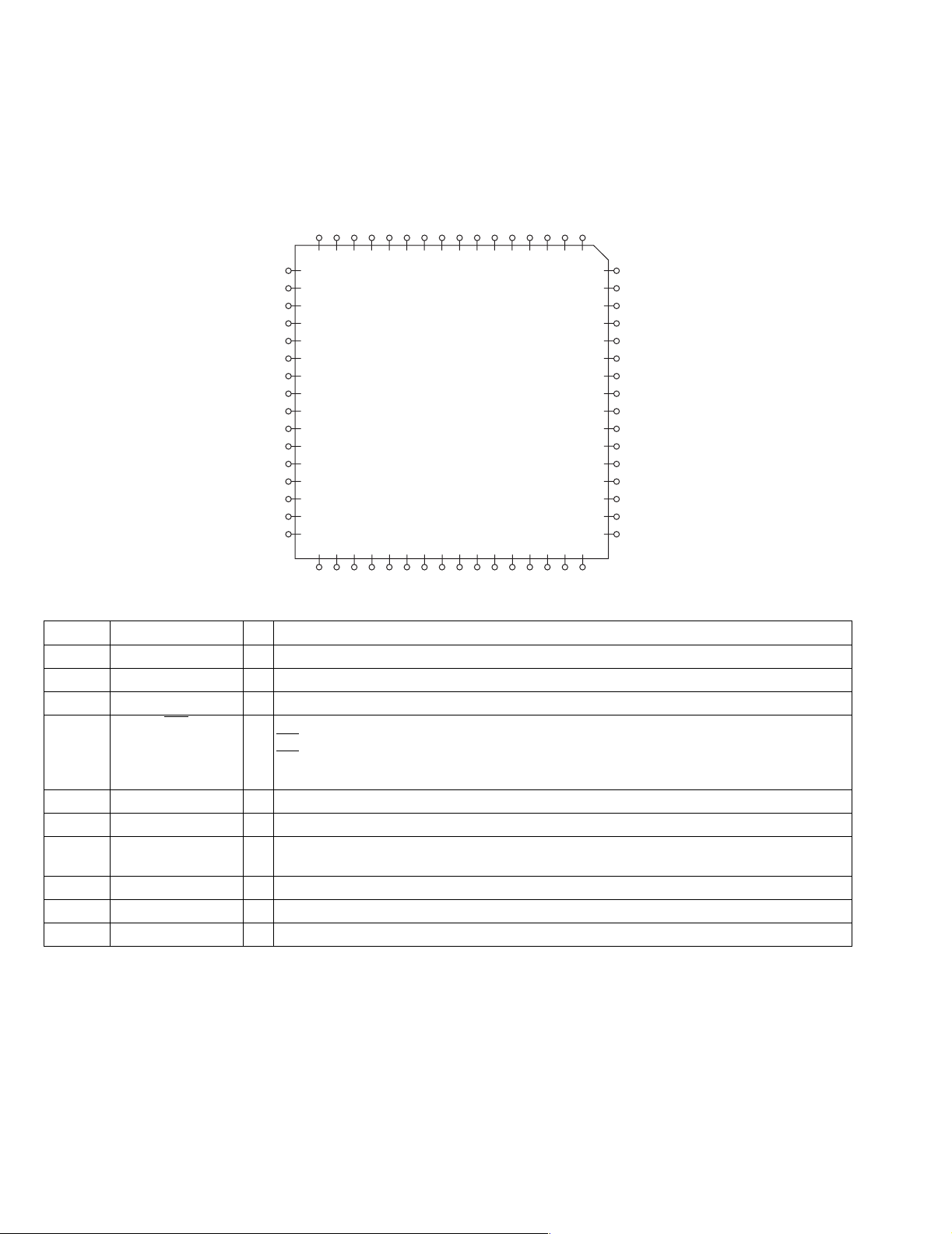

KS-F345

4.1 LC75823W (IC651) : LCD driver

• Pin Layout & Symbol

S8

S9

S10

S11

S12

S13

S14

S15

S16

SECTION 4

Description of major ICs

DATA

CLOCKCEOSC

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

Vss

INH

VDD

COM3

COM2

COM1

S52

S51

S50

S49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

• Pin function

S32

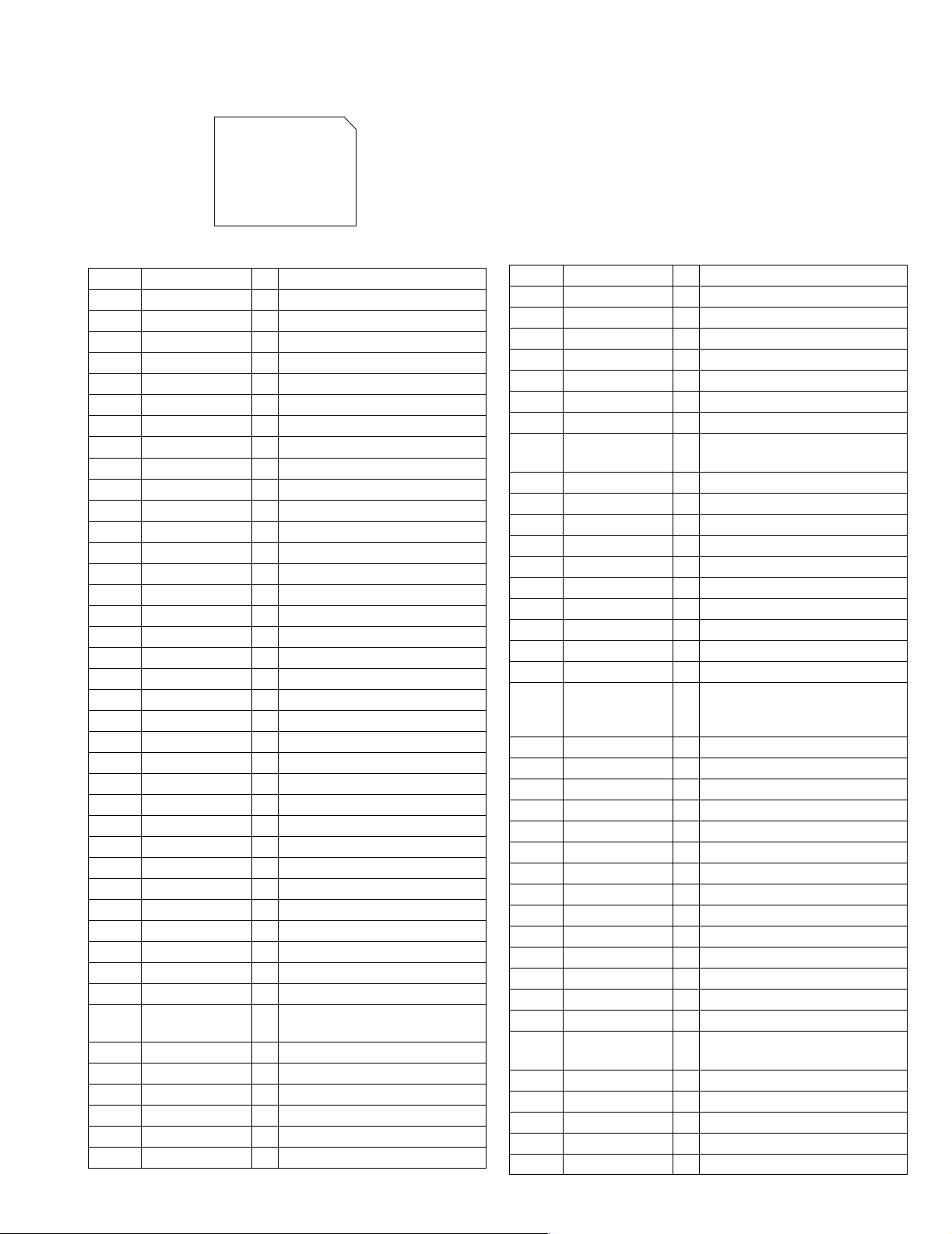

Pin No. Symbol I/O Functions

1 to 7 -- Non connect

8 to 52 S8 to S52 O Common driver output pins. The frame frequency is given by : t0=(fosc/384)Hz.

53 S53 to S55 -- Power supply connection. Provide a voltage of between 4.5 and 6.0V.

57 INH

I Display turning off input pin.

="L" (Vss) ----- off (S1 to S52, COM1 to COM3="L"

INT

INT="H" (VDD)----- on

Serial data can be transferred in display off mode.

58, 59 Non connect

60 Vss -- Power supply connection. Connect to GND.

61 OSC I/O Oscillator connection.

An oscillator circuit is formed by connecting an external resistor and capacitor at this pin.

62 CE I Serial data interface connection to the controller. CE : Chip enable

63 CLOCK I Serial data interface connection to the controller. CL : Sync clock

64 DATA I Serial data interface connection to the controller. DI : Transfer data

1-16 (No.49783)

Page 17

4.2 LC72362N-9B40 (IC701) : Micon

•Pin layout

24 - 1

25

-

KS-F345

80

-

40

64

41 - 64

• Pin functions

Pin No. Symbol I/O Function

1 XIN I Crystal oscillator

2GND-To GND

3 J BUS SI I Bus serial data input from CP751

4 J BUS SO O Bus serial data output to CP751

5 J BUS SCK O Bus serial clock output to CP751

6 J BUS I/O SEL O BUS I/O switch signal output

7 NC - Non connect

8 LCD SO O Serial data output to IC651

9 LCD SCK O Serial clock output to IC651

10 LCD CE O Chip enable output to IC651

11 NC - Non connect

12 E.VOL SO O Serial data output

13 E.VOL SCK O Serial clock output

14 CE O Non connect

15 TUNER ILLUM - Non connect

16 TAPE ILLUM - Non connect

17 CD ILLUM - Non connect

18 DIMMEROUT - Non connect

19 NC - Non connect

20 NC - Non connect

21 NC - Non connect

22 NC - Non connect

23 NC - Non connect

24 NC - Non connect

25 KS1 - Non connect

26 KS0 O Initializing output port

27 K3 I Initializing input port

28 K2 I Initializing input port

29 K1 - Non connect

30 K0 I Initializing input port

31 Vdd - Power supply

32 TEST I Test iput

33 NC - Non connect

34 SEEK/STOP O Output the "If signal request"

35 MONO O Monaural and stereo change

over output

36 R/T - Non connect

37 NC - Non connect

38 POWER CNT O Power control output

39 NC - Power supply

40 NC - Non connect

41 IF CONT - IFC control

Pin No. Symbol I/O Function

42 NC - Non connect

43 NC - Non connect

44 NC - Non connect

45 NC - Non connect

46 NC - Non connect

47 NC - Non connect

48 TAPE IN I H:RADIO L:TAPE

49 F/R SENCE I FORWARD/REVERSE switch

detector

50 TAPE MUTE I DIR.FF/REW.MUTE

51 SD/ST I Station detector and ST input

52 NC - Non connect

53 DETACH I Detection of Front Panel

54 NC - Non connect

55 J BUS INT - Non connect

56 REMOCON - TO GND

57 FM/AM I Change over the FM/AM iuput

58 DOLBY - Non connect

59 NC - Non connect

60 MUTE - The mute time is controlled by

the connected capacitor when

changing over the FM/AM

61 MEMORY DET I Memory detector input

62 LEVEL METER I Non connect

63 SMETER I Signal meter input

64 KEY 2 I Momentary key input

65 KEY 1 I Momentary key input

66 KEY 0 I Momentary key input

67 ACCDET I ACC DET

68 SENS - To GND

69 NC - Non connect

70 FM/AM IF COUNT - AM/FM Frequency detection

71 NC - Non connect

72 NC - Non connect

73 Vdd - Power supply

74 AM OSC - Non connect

75 FM OSC I Input the local oscillator signal of

FM

76 Vss - Connect to GND

77 NC O Non connect

78 EO O PLL Error signal output

79 TEST 1 - To GND

80 XOUT O Crystal oscillator

(No.49783)1-17

Page 18

KS-F345

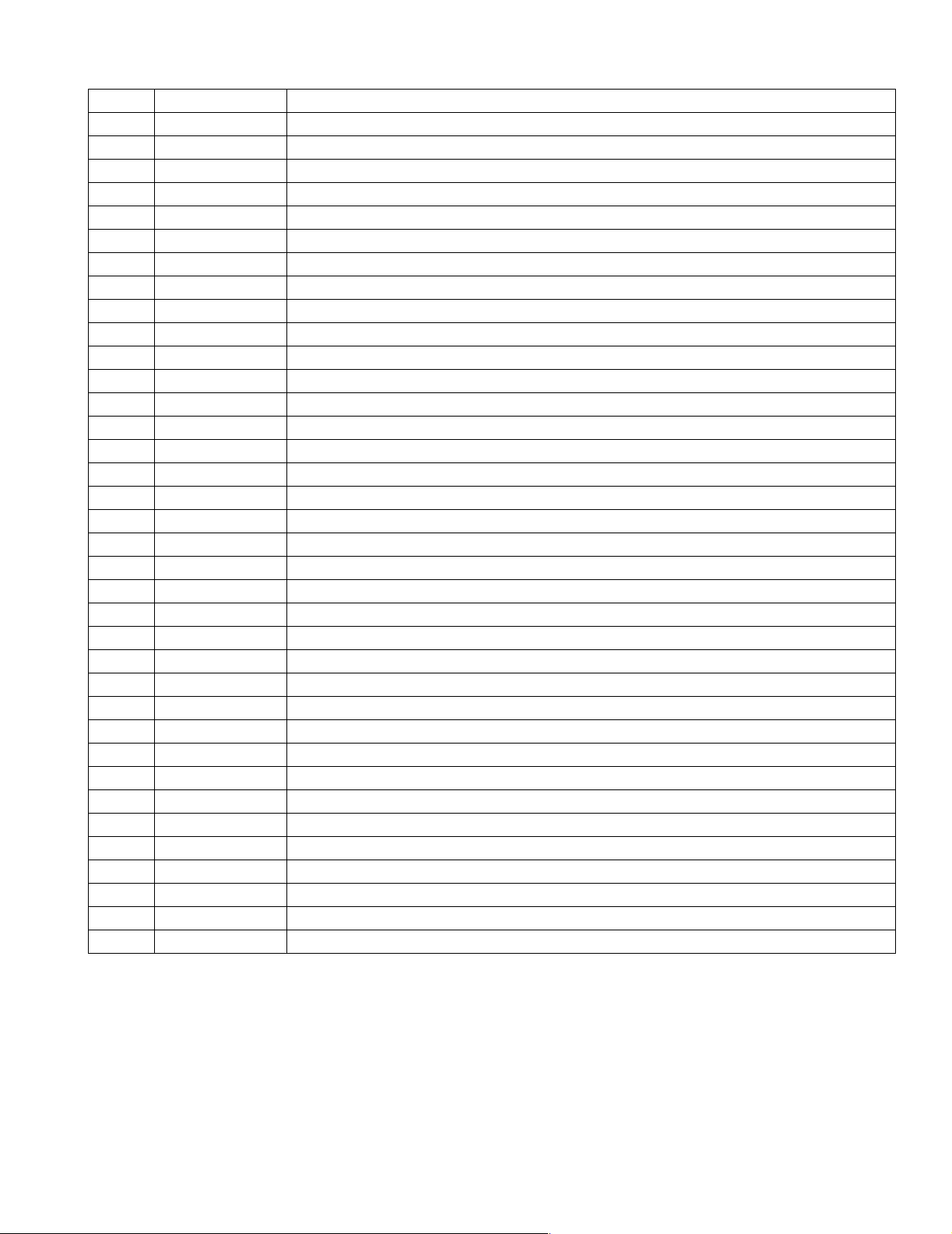

4.3 LC75421M-X (IC931): E. volume

• Pin layout

36 ~ 19

1 ~ 18

• Block diagram

10

3

2

4

5

6

7

8

9

36

1

CCB

INTERFACE

35

34

33

32

31

30

29

28

11

12

13

14

15

16

LVref

CONTROL

17

CIRCUIT

18

LOGIC

CIRCUIT

19

CIRCUIT

CONTROL

RVref

222120

23

27

26

25

24

1-18 (No.49783)

Page 19

• Pin functions

Pin No Symbol Function

1 DI Serial data input terminal for control

2 CE Chip enable terminal

3 VSS GND

4 LROUT Rear Lch fader output terminal

5 LFOUT Front Lch fader output terminal

6 LFIN Front Lch input terminal

7 LOUT C & R connection terminal for super bass band

8 LSB C & R connection terminal for super bass band

9 LBASS2 C & R connection terminal for bass band

10 LBASS1 C & R connection terminal for bass band

11 LTRE Capacitor connection terminal for treble band filter

12 LIN Lch input terminal

13 LSELO Input selector output terminal

14 L5 input signal terminal

15 L4 input signal terminal

16 L3 input signal terminal

17 L2 input signal terminal

18 L1 input signal terminal

19 Vref Power supply for analog GND

20 R1 input signal terminal

21 R2 input signal terminal

22 R3 input signal terminal

23 R4 input signal terminal

24 R5 input signal terminal

25 RSELO Input selector output terminal

26 RIN Rch input terminal

27 RTRE Capacitor connection terminal for treble band filter

28 RBASS1 C & R connection terminal for bass band filter

29 RBASS2 C & R connection terminal for bass band filter

30 RSB C & R connection terminal for super bass band filter

31 ROUT C & R connection terminal for super bass band filter

32 RFIN Rch input terminal

33 RFOUT Front Rch fader output terminal

34 RROUT Rear Rch fader output terminal

35 VDD Power supply terminal

36 CL Serial clock output terminal for control

KS-F345

(No.49783)1-19

Page 20

KS-F345

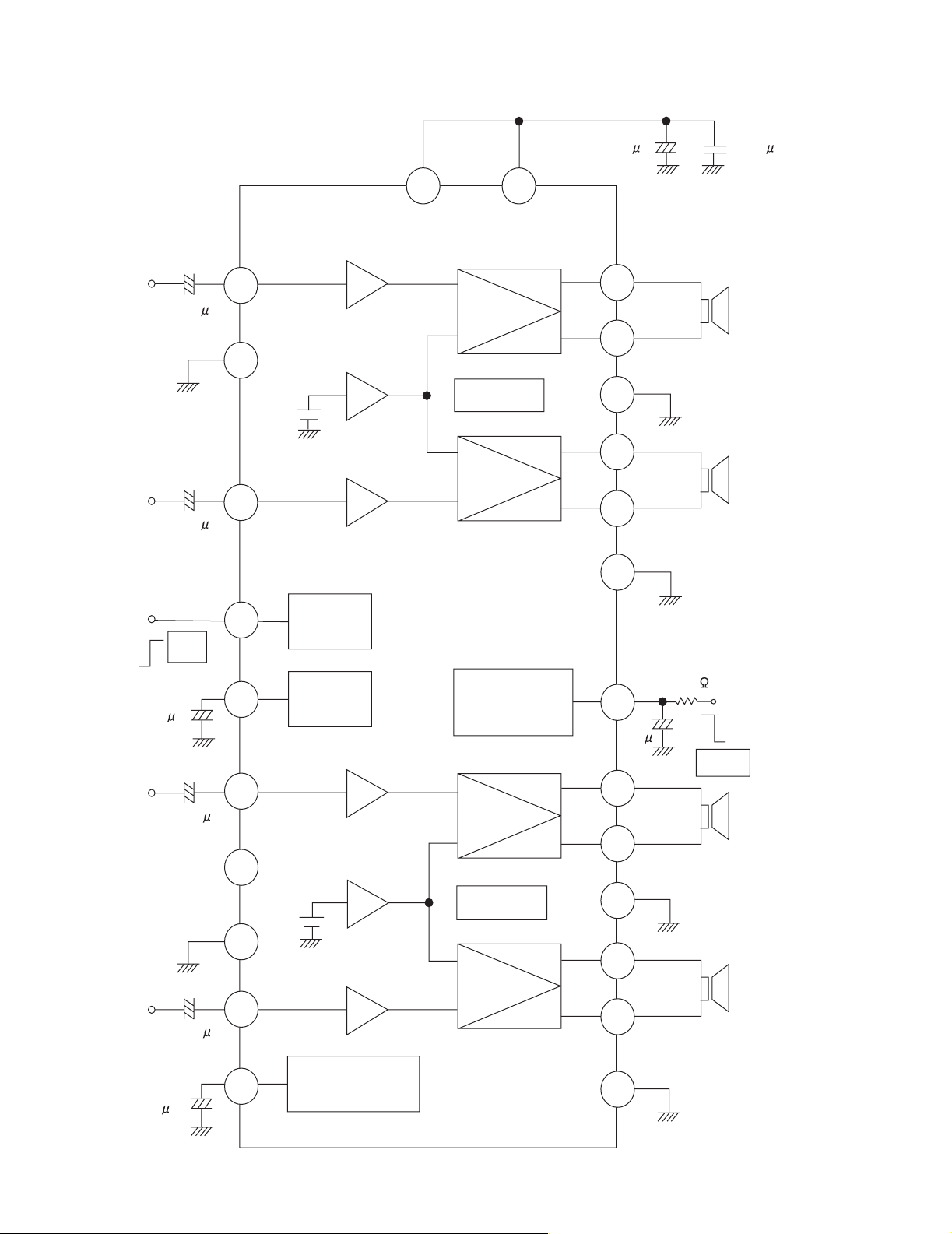

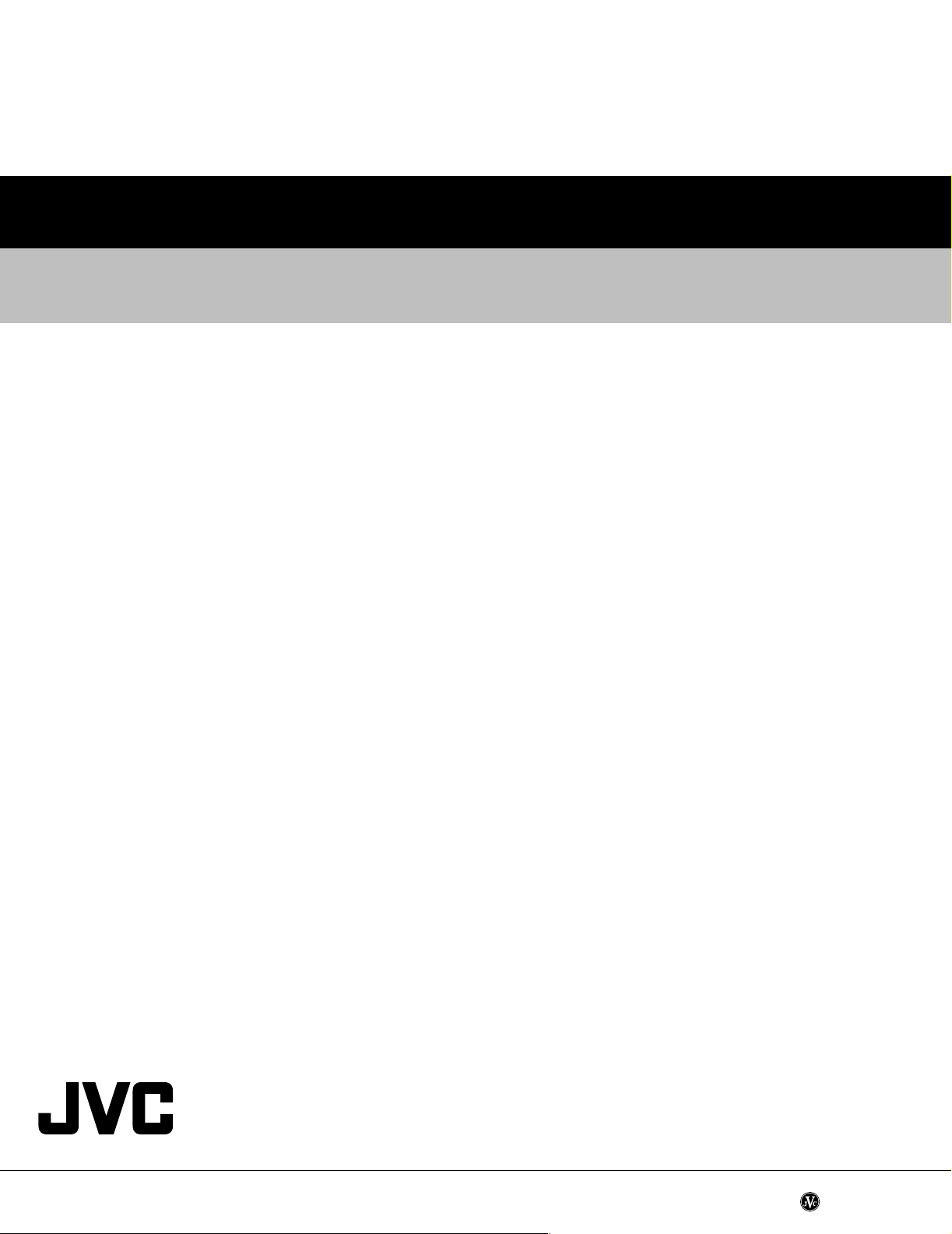

4.4 LA4743K (IC981) : Power amp.

• Block diagram

IN 1

TAB

IN 2

+

0.22 F

+

0.22 F

11

1

12

Vcc 1/2 Vcc 3/4

6 20

-

+

Protective

circuit

-

+

2200 F 0.022 F

+

9

7

+

OUT 1+

OUT 1-

PWR GND1

8

+

OUT 2+

5

-

OUT 2-

3

PWR GND2

2

ST BY

R.F

47 F

IN 3

PRE GND

IN 4

+5V

ST ON

+

0.22 F

N.C

+

0.22 F

4

Stand by

Switch

Mute

10

+

Ripple

Filter

Mute

22

circuit

3.3 F

+

15

-

+

-

17

19

10K

+

OUT 3+

OUT 3-

Low Level

Mute ON

25

18

21

23

PWR GND3

OUT 4+

OUT 4-

13

14

Protective

circuit

-

+

+

-

ON TIME C

1-20 (No.49783)

22 F

Muting &

16

+

ON Time Control

Circuit

PWR GND4

24

Page 21

• Terminal layout

TAB

GND

FR-

STDBY

FR+

VP1

RR-

GND

RR+

RIPPLE

INRF

INRR

SGND

FLIN

RLIN

DNTIME

RL+

GND

RL-

VP3

FL+

MUTE

FL-

GND

NC

• Pin function

Pin No. Symbol Function

1 TAB Header of IC

2 GND Power GND

3 FR- Outpur(-) for front Rch

4 STDBY Stand by input

5 FR+ Output (+) for front Rch

6 VP1 Power input

7 RR- Output (-) for rear Rch

8 GND Power GND

9 RR+ Output (+) for rear Rch

10 RIPPLE Ripple filter

11 RRIN Rear Rch input

12 FRIN Front Rch input

14 FLIN Front Lch input

15 RLIN Rear Lch input

16 ONTIME Power on time control

17 RL+ Output (+) for rear Lch

18 GND Power GND

19 RL- Output (-) for rear Lch

20 VP3 Power input

21 FL+ Output (+) for front

22 MUTE Muting control input

23 FL- Output (-) for front

24 GND Power GND

25 NC Non connection

KS-F345

(No.49783)1-21

Page 22

KS-F345

4.5 AN80T05LF (IC781) : Regulator

• Pin layout & Block diagram

Reference Voltage

Thermal

Protection

ASO & Peak

Current Protection

Pre

Drive

Pre

Drive

AMP

Out

AMP

Out

Pre

Drive

123456789101112

ILL

MODE2 MODE1 STB VDD

10V

5.6V

AMP VCC ANT COM

8.7VAM8.7VFM8.7V

• Pin function

Pin No. Symbol Function

1 ILL 10V power supply for illumination.

2 MODE2 When 5V is input,becomes AM. and the antenna output is turned on.

3 MODE1 When 5V is input,becomes AM. and the output of FM is switched.

4 STB When 5V is input outputs to ILL,COM and AMP. It is 0V usually.

5 VDD 5.6V power supply.

6 AMP Power supply supply to remote amplifier

7 VCC Back up. connects with ACC with it.

8 ANT Power supply supply to auto antenna.

9 COM 8.7V power supply.

10 AM The power supply of 8.7V to AM.

11 FM The power supply of 8.7V to FM.

12 GND Ground

Pre

Drive

Pre

Drive

GND

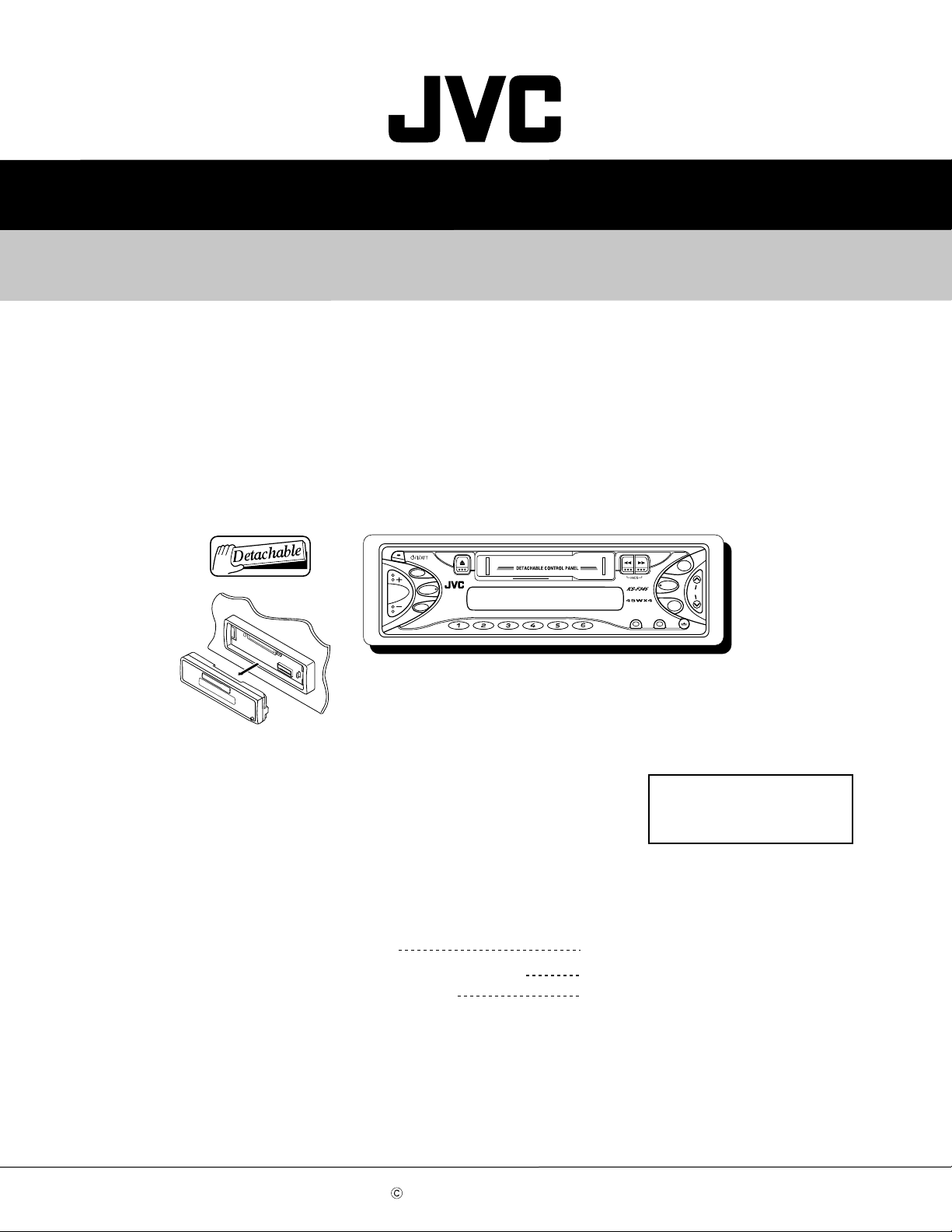

4.6 UPC1228HA (IC901) : Head amp

• Pin layout & Block diagram • Pin function

Pin No. Symbol

1 Input 1

AMP1 AMP2

2 Negatice feed back 1

3 Output 1

4 Power supply; +Vcc

1

2345678

5 Ground

6 Output 2

7 Negative feed back 2

8 Input 2

1-22 (No.49783)

Page 23

KS-F345

(No.49783)1-23

Page 24

KS-F345

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49783)

Printed in Japan

200303WPC

Page 25

SCHEMATIC DIAGRAMS

CASSETTE RECEIVER

KS-F345

CD-ROM No.SML200303

KS-F345

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

S.BASS

FM

SEL

DISP

AM

SSM

EX

SCMMO

Area Suffix

EE ---- Russian Federation

2-1

2-2

2-5,6

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

No.49783SCH

2003/03

Page 26

KS-F345

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 27

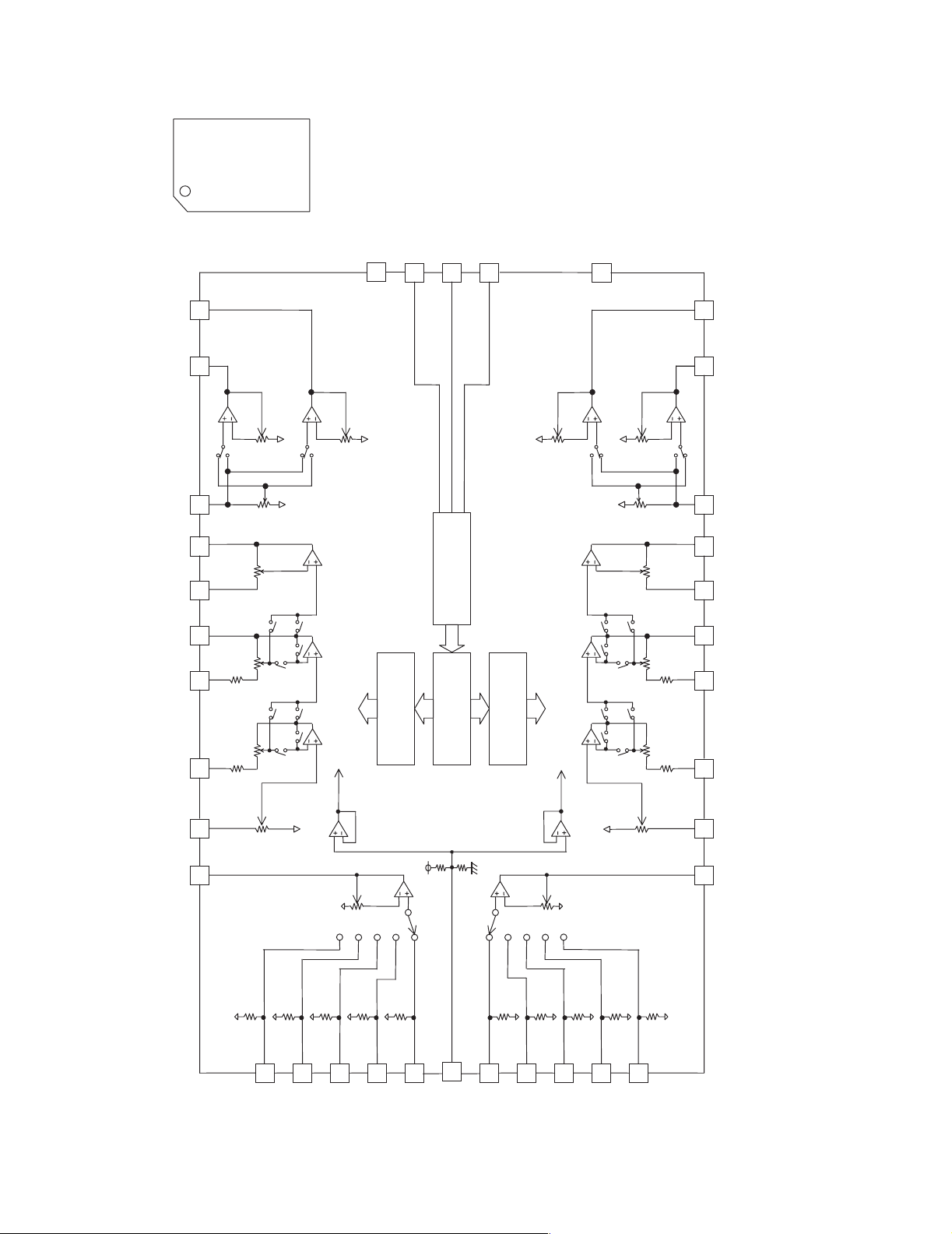

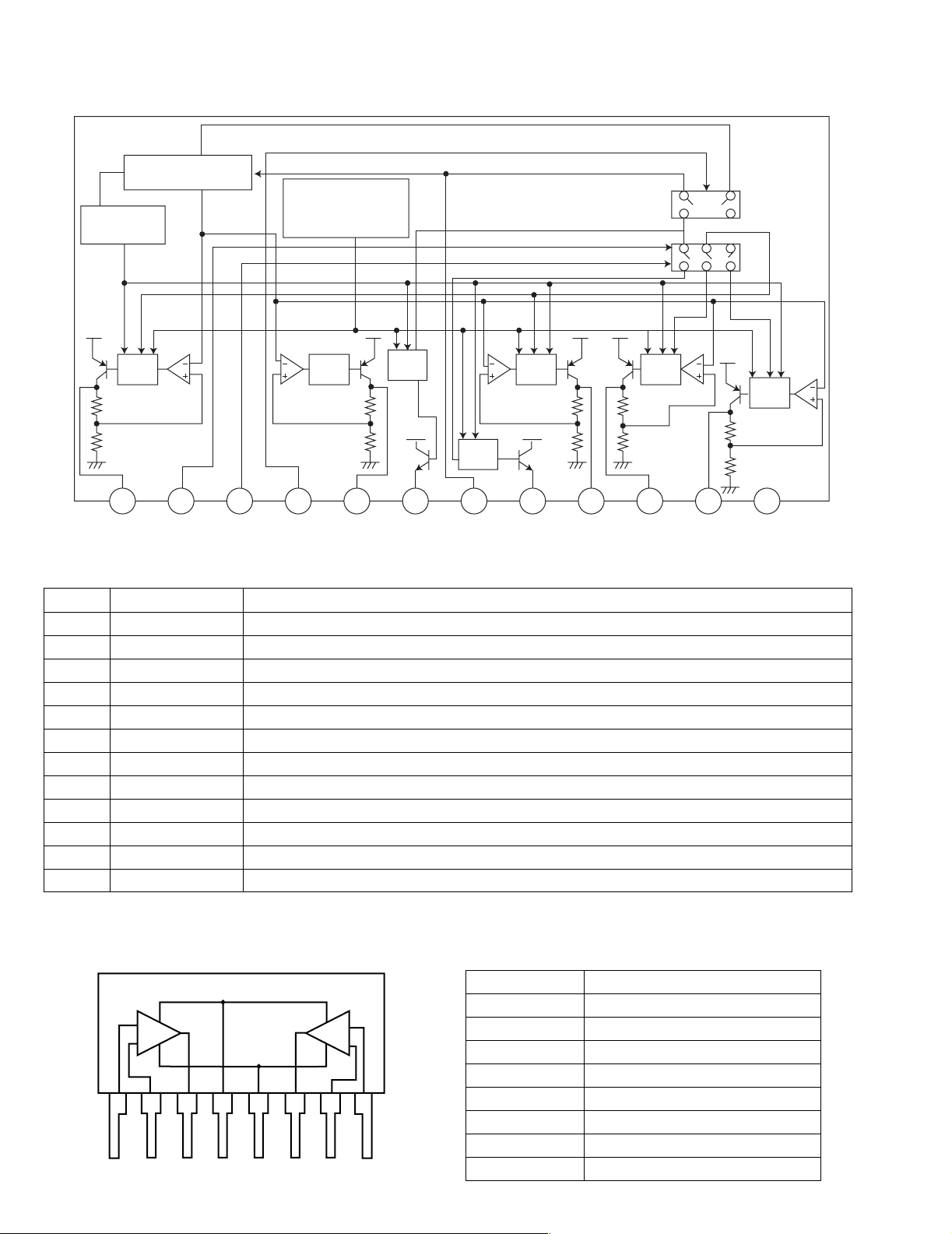

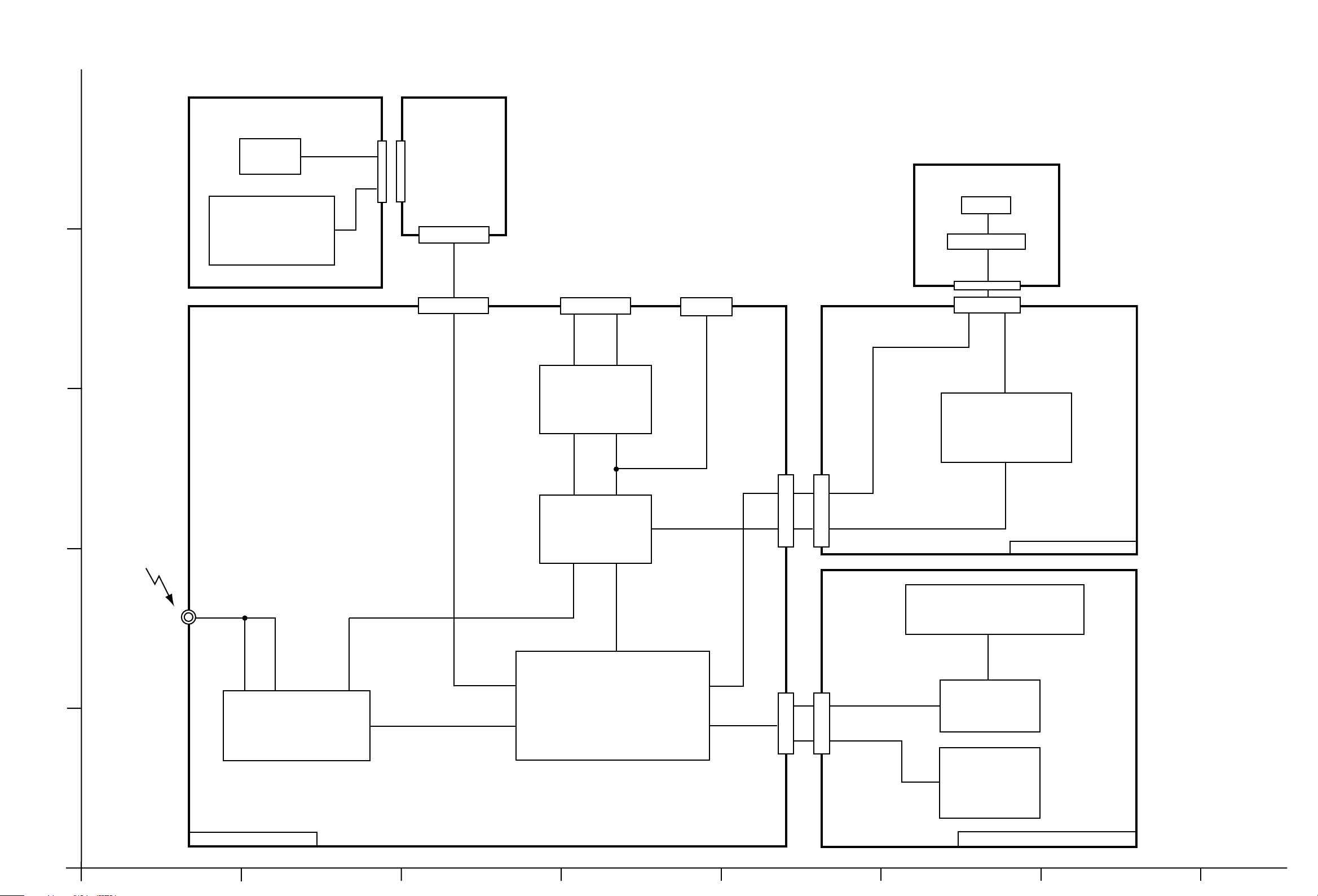

Block diagram

5

4

DIRECTION BOARD

MAIN

MOTOR

MUTE SWITCH

TAPE/RADIO SW

CP722

RELAY

BOARD

CP721

CN721

TO

SPEAKER

CONNECTOR

CP981

LINE REAR OUT

CJ921

KS-F345

HEAD

PROG-SW

CJ901

Lch Front

Lch Rear

Lch Rear

Lch

Rear OUT

F/R

LCH

IC981

POWER AMP.

IC901

HEAD AMPLIFIER

Lch RearLch Front

3

IC931

E.VOLUME

TAPE L

CN901

CP901

ANT

2

J1

FM

AM

TAPE IN

PROG

TUNER L

CE

DATA

CLK

IC701

TU1

AM/FM TUNER PACK

SEEK/STOP, MONO,

SD/ST, S METER,

FM OSC, EO, BAND

SYSTEM CONTROL MICON

F/R

CJ701

DATA

CLOCK

CE

KEY0 - 2

CP701

LCH

HEAD AMP SECTION

LCD1

S3 - S47

COM1 - COM3

IC651

LCD DRIVER

KEY

S601 - S606

1

S608 - S612

S614 - S621

MAIN AMP SECTION

LCD & KEY CONTROL SECTION

AB CD E F G

2-1

Page 28

Standard schematic diagrams

Main amp section

5

4

To

LCD & Key control

section CP701

J1

QNZ0009-001

C772

2.2/50

C773

0.001

Q772

KTC3199/GL/-T

R774

1.5K

R773

1K

Q771

KTC3199/GL/-T

R772

Q3

R771

4.7K

10K

D792

MTZJ9.1C-T2

C771

D771

1SS119-041

220/10

R17

2.2K

R6

D791

2SA1706/ST/-TKTA1267/YG/-T

10K

1SS119-041

R1

R2

R3

L1

4.7uH

Q1

R5

Q2

KRC102M-T

10

1K

1K

1K

TU1

D1

1SS119-041

10K

R4

TU-9V

BAND

QAU0221-001

D2

1SS119-041

220/10

EO

C786

0.1/50

C3

KS-F345

1SS119-041

D973

10/16

0.022

0.022

0.1/50

0.022

C2

C5

0

B69

IFC/C

FM.OSC

10K

C6

C7

C4

R9

R10

10k

0.01

C11

Q4

KRC102M-T

SK/ST

0.1/50

C8

470

470

R51

0.01

C15

R52

5.6k

S.METER

C131

R61

1/50

1/50

C231

R14

8.2k

R15

Q5

22k

KRC102M-T

MONO

SO/ST

MUTE

C9

0.01

R62

5.6k

IF.C

D990

MTZJ11B-T2

C972

KS-F345

Q972

KRA102M-T

C988

220/10

47/16

Q989

KRA102M-T

ACC.MUTE

MUTE2

D161

1SS119-041

D261

1SS119-041

CJ921

R163

LRO

820

R165

2.2K

R265

2.2K

820

R263

RRO

QNN0519-001

R164

100

2SD2144S/VW/-T2SD2144S/VW/-T

Q261 Q161

R264

100

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

TUNER SIGNAL

TAPE SIGNAL

FRONT SIGNAL

REAR SIGNAL

CJ701

VMC0334-001

3

To

Head amp

section CP721

CN721

QGB1214J1-06S

2

To

Head amp

section CP901

CN901

QGB1214J1-06S

1

R719

R718

R720

L783

47uH

3.3K

3.3K

3.3K

D705

D704

D711

MTZJ6.2B-T2

MTZJ6.2B-T2

MTZJ6.2B-T2

R704

R705

D786

1A3G-T1

D706

D707

MTZJ6.2B-T2

MTZJ6.2B-T2

D718

1SS119-041

10K

KTC3199/GL/-T

47K

R715

C709

C710

D708

D709

0.1

MTZJ6.2B-T2

MTZJ6.2B-T2

Q701

2.2k

0.47/50

LCD.SO

LCD.SCK

LCD.CE

DETACH

TAPE14V

TAPEIN

TAPE.L

TAPE.R

KEY2

KEY1

KEY0

PROG

5V

14V

CE

R5V

D713

1SS119-041

TAPEIN

F/R

IC701

LC72362N-9B40

SD/ST

PROG

R727

SK/ST

MONO

9V

F/R

47K

47K

R725

47K

R708

R702

47K

47K

R703

47K

R707

IFC/C

CL

DI

R724

DETACH

4.7K

LCD.CE

LCD.SCK

BAND

TUL

LCD.SO

TUR

MUTE

MEM.DET

S.METER

KEY2

R710

R709

R712

C706

C12

0.01

270P

4.7K

4.7K

4.7k

5V

X701

QAX0406-001Z

D716

1SS119-041

4.7k

4.7k

R714

R713

C702

22P

C701

27P

FM.OSC

47K

R726

100/6.3

0.22

KRC102M-T

C703

IF.C

KEY0

KEY1

C704

Q783

TUR

TAPE.L

EO

TAPE.R

9V

C705

10/16

TAPE14V

14V

MEM.DET

R5V

5V

TU-9V

Q784

2SA1706/ST/-T

R786

1K

C232

1/50

C132

1/50

L782

47uH

R785

C934

22/16

RB721Q-40-T2

47K

TUL

R792

6.8

D961

Q789

C943

1/50

L781

47uH

KRA102M-T

R789

R790

470K

C933

100K

C134

0.082

C942

0.0015

0.0015

1/50

C234

R795

47K

R796

IC931

LC75421M-X

0.082

C235

R232 R132

Q782

1SS119-041

D781

18K

C783

C135

0.082

C236

7.5k 7.5k

2SA1706/ST/-T

1K

R784

Q781

KRC102M-T

R990

2200/6.3

R131

C137

C136

0.15

0.082

C237

R783

Q987

KRA102M-T

10K

KRC102M-T

3.9k

0.15

0.15

R231

47K

C784

D782

1SS119-041

Q988

C150

C940

C941

C238

3.9k

R931

1/50

1/50

0.15

220/10

C781

10/16

2.2/50

C250

2.2/50

C160

2.2/50

2.2/50

C260

10

C785

10/16

IC781

AN80T05LF

C987

10/16

CE

R941

3.3k

100/10

C931

1A3G-T1

D784

R985

DI

4.7k

R722

3.3K

C707

LRO

R721

C932

0.01

R999

RRO

0.1

C138

L981

D785

1A3G-T1

47k

R993

27K

C976

0.22

R992

27K

R997

47k

R991

27K

R994

27K

R996

47k

C981

2200/16

D981

IN5401-TM

R787

QQR1367-001

R797

12K

2.4K

R788

C977

0.22

C975

0.22

C995

470P

C994

470P

C974

0.22

LRO-

LRO+

C992

0.1

C997

C985

470P

4.7/25

C996

C983

470P

0.1

R998

C986

47k

22/16

C982

47/16

C989

10/16

R973

4.7K

C991

0.1

RRO-

RRO+

RFO+

RRO+

LRO+

LFO+

RFO-

C984

10/16

ACC.MUTE

RRO-

LRO-

LFO-

100

CL

3.3K

0.1

RFO+

LFO+

C993

0.1

RFO-

R972

2.7K

C990

0.1

IC981

LA4743K

Q971

KRC102M-T

MUTE2

D974

1SS119-041

QNZ0611-001

CP981

QAM0089-001

QMFZ047-150-T

LFO-

2-2

HAB C DE FG

Page 29

KS-F345

LCD & Key control section

5

SW3

SW4

SW5

SW7

SW8

SW9

SW10

SW11

SW12

SW13

SW14

SW15

SW16

SW17

SW18

SW19

SW20

SW21

SW22

SW23

SW24

SW25

SW26

SW27

SW28

SW29

SW30

SW31

SW32

SW33

SW34

SW35

COM1

COM2

COM3

INH

OSC

CE

CLOCK

DATA

S47

SW36

SW37

S46

S3

4

VMC0335-001

CP701

5V

14V

REMOCON

DATA

CLOCK

CE

KEY1

KEY2

R5V

KEY0

SW6

3

D655

10k

R655

10k

R656

10k

R654

MA152WK-X

D654

MA152WK-X

MA152WA-X

D653

R653

180K

D652

MA152WA-X

C651

R651

1.5k

R652

4.7/6.3

0.01

C653

680p

C652

47k

SW38

S45

S4

SW39

S44

S5

SW40

SW41

S43

IC651

LC75823W

S6

S7

SW42

S42

SW43

S41

S8

SW44

SW45

SW46

SW47

COM1

COM2

COM3

S39

S40

S38

S37

S35

S34

S33

S36

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

S13

S12

S11

S10

S9

S16

S15

S14

2

R649

D613

D619

D620

1.5k

R648

D616

820

820

R647

R646

D617

D618

D614

D615

D610

820

620

R645

560

R644

R643

D611

R601

680

S601

R607

680

S608

R613 R614 R615

680 560

S615

D606

R638

D602

D601

D603

R637

820

R636

1.5k

R635

820

820

10K

R657

D657

MA152WK-X

IC652

RPM6938-SV4

C654

4.7/6.3

47

R658

PL601

QLL0151-001

PL603

QLL0151-001

D612

D607

820

R642

D608

R641

820

1.8k

R640

D604

D605

1k

820

R639

S609

S602

S616

R608

R602

560

560

S617

S603

S610

R603

R609

680

680

680

R604 R605

910

S604

R610 R611

910 1.2k

S611

R616

910 1.2k

S618

S605

1.2k

S612

S619

R617

S614

S620

S606

R618

1.5k

S621

1

AB CD E F G

2-3

Page 30

KS-F345

KS-F345

Head amp section

5

CJ901

QGA2002C1-05

4

IC901

UPC1228HA

R101

R104

330k

15k

C105

C104

C103

100p

C102

0.01

100

R103

C101

47/6.3

CP901

QGB1214K1-06S

0.47/50

TAPE SIGNAL

820p

C203

R204

330k

C201

C202

820p

100p

0.47/50

R203

C204

C205

100

47/6.3

R201

0.01

15k

C901

100/10

100

R901

To

Main amp section

CN901

3

CP722

QGA2002F1-06

2

CP721

To

Main amp section

CN721

QGB1214K1-06S

1

2-4

HAB C DE FG

Page 31

Printed circuit boards

Main board

KS-F345

5

L981

CJ921

D981

R718

C14

R715

D708

C232

C13

R719

R709

C934

D709

C709

R702

R703

R792

CP751

C942

R710

CN901

C943

C231

R726

C705

C933

D716

C710

C131

R61 R62

C134

C233

R707

IC701

C704

C703

D786

C12

D771

C10

J1

C771

R771

Q771

R773

C773

R772

TU1

4

L1

D2

D1

3

D704

R2

C11

R14

R3

C2

C3

C5

C4

D792

C6

C7

R10

C15

Q5

D705

C786

D711

D706

R712

R15

C1

Q4

R1

Q772

D791

R713

C133

C772

R774

R7

R52

R51

Q1

R6

R4

Q3

R5

Q2

R17

R9

C8

R714

R725

L782

CJ701

R724

R708

C9

C706

D707

R720

C132

C135

C234

C701

C702

C136

C235

R232

X701

Q261

R971

C137

C707

C236

R131

R761

D261

C940

C238

C237

R265

IC931

R763

C260

D974

R132

C138

R231

Q971

R727

R757

C941

C150

C250

D701

R760

R722

Q161

C751

R721

R931

R165

R972

R752

R941

R263

D961

D713

R759

R756

C160

R785

D714

R163

D161

R789

Q784

C985

D715

R164

L781

R762

C931

Q972

IC751

R996

R994

R758

R999

Q987

Q988

C990

C932

C996

R264

R751

CP981

R998

Q789

R990

R755

R993

D781

D782

R790

R753

C991

R997

R795

R796

R788

C997

R992

C994

C972

R991

L783

R754

R764

D973

C785

C992

C784

R786

Q782

C975

C974

Q989

R783

C977

C976

R973

C995

R784

D990

R704

Q701

IC781

C993

C982

R787

C989

R705

C984

C988

D718

D785

CN721

R797

Q783

C986

D784

C981

R985

C987

C983

IC981

Q781

C783

C781

2

1

AB C

2-5

Page 32

KS-F345

Front board

D601

S620

D608

D605

R616

R615

D604

S621

S619

R611

R618

R617

S614

D606

S618

D602

D603

S601

D619

S602

D620

S603

R603

R602

5

S604

S605

D618

D616

S608

IC652

D617

LCD1

S606

D613

S609

D614

R608

S610

R609

D615

S611

D610

R610

S612

D611

S615

D612

R613

S616

D607

S617

4

Forward side

Reverse side

R654

R655

R656

IC651

R644

R645

D657

PL601

R657

R605

R604

R607

IC652

R601

R649

R648

R647

C654

R646

R658

R635

R653

R642

R636

R637

R651

R643

C652

R614

R639

R638

C651

D655

R640 R641

D654

R652

CP701

C653

D652

D653

PL603

3

2-6

Mecha board

2

(Head amplifier board) (Relay board)

C203

R204

R201

C105

R101

R104

C103

IC901

C205

R103

R203

C104

R901

C901

C102

C204

CP901

C202

C101

C201

CJ901

CP721

CP722

1

AB CD

Page 33

< MEMO >

KS-F345

Page 34

KS-F345

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49783SCH)

Printed in Japan

2003/03

Page 35

PARTS LIST

[ KS-F345 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

KS-F345

EE --------- Russian Federation

- Contents -

Exploded view of general assembly and parts list (Block No.M1) --------------------- 3-2

Cassette mechanism assembly and parts list (Block No.MP) -------------------------- 3-4

Electrical parts list (Block No.01~03) ---------------------------------------------------------- 3-8

Packing materials and accessories parts list (Block No.M3,M5) ---------------------- 3-12

No. 49783 3-1

Page 36

KS-F345

Exploded view of general assmbly and parts list

54

14

56

57

53

Block No.

M

M

1

M

B

A

Main board

24

11

49

15

20

15

23

19

17

44

43

22

21

44

10

47

50

45

48

LCD1

46

55

14

52

51

9

13

16

13

A

7

B

2

3

18

17

8

5

38

4

1

4

12

6

12

4

37-3

12

34

4

36

30

Front board

33

27

40

25

29

37-2

35

28

42

39

37-1

26

32

41

31

3-2

5

Page 37

Exploded view of general

Assembly and parts list

Block No. [M][1][M][M]

Symbol No.

1 ------------ CDS-363 MECHA

2 VKL7821-001 EJECT LEVER

3 QYSPSPT2625Z SCREW 2.6mm x 2.5mm

4 QYSDSP2604Z SCREW 2.6mm x 4mm(x4)

5 QYSDST2605Z SCREW 2.6mm x 5mm(x2)

6 GE20134-001A MECHA BKT

7 GE10043-011A TOP CHASIS

8 GE40135-001A EARTH PLATE

9 GE30568-006A HEAT SINK

10 GE30393-001A BOTTOM COVER

11 FSMA3004-203 INSULATOR

12 QYSDST2604Z SCREW 2.6mm x 4mm(x4)

13 FSKZ4005-001 SCREW (x2)

14 QYSDST2604Z SCREW 2.6mm x 4mm(x2)

15 QYSDST2606Z SCREW 2.6mm x 6mm(x2)

16 QYSDST2612Z SCREW 2.6mm x 12mm(x2)

17 QYSDST2004M MINI SCREW 2mm x 4mm(x2)

18 GE10053-001A FRONT CHASSIS

19 GE30583-001A LOCK LEVER

20 FSKW4005-003 TORSION SPRING

21 FSXP3026-002 RLS KNOB

22 FSKW3002-004 COMP. SPRING

23 FSJC3014-002 CASSETTE LID

24 VKW4947-002 DOOR SPRING

25 GE10051-001A FRONT PANEL

26 GE30584-007A FINDER ASSY

27 FSJK3014-001 LIGHT LENS

28 GE20119-001A PRESET BUTTON

29 FSYH4036-077 SHEET

30 GE30304-001A POWER BUTTON

31 GE20131-021A D.FUNC BUTTON

32 GE30307-001A SND FTN BUTTON

33 FSYH4036-032 SHEET

34 GE20130-031A PUSH BUTTON

35 GE20120-002A UP/DOWN BUTTON

36 GE20118-002A +/- BUTTON

37 FSXP4007-00A BUTTON ASS'Y

38 FSKW3002-003 COMP. SPRING

39 FSKW3002-003 COMP. SPRING

40 FSKW3002-003 COMP. SPRING

41 GE30306-001A DETACH BUTTON

42 FSKW3002-012 COMP.SPRING

43 GE10052-001A REAR COVER

44 VKZ4777-001 MINI SCREW (x4)

45 FSJK3033-001 LCD LENS

46 GE30309-002A LCD CASE

47 FSKS3020-003 LENS CASE

48 FSYH4075-003 LIGHTING SHEET

49 GE30645-001A NAME PLATE

50 QNZ0440-001 LCD CONNECTOR

51 GE40136-001A IC BRACKET

52 QMFZ047-150-T FUSE 15A

53 GE30382-015A REAR BRACKET

54 QYSDST2606Z SCREW 2.6mm x 6mm

55 QYSDSF2606Z SCREW 2.6mm x 6mm(x2)

56 QYSDST2606Z SCREW 2.6mm x 6mm

37-1 FSXP3066-001 FF BUTTON

37-2 FSXP3067-001 REW BUTTON

37-3 FSXP3065-001 EJECT BUTTON

LCD1 QLD0249-001 LCD MODULE

Part No. Part Name Description Local

KS-F345

3-3

Page 38

KS-F345

Cassette mechanism assembly and parts list

81

109

24

66

72

30

CDS-363SJ1

89

120

107

53

23

69

96

123

31

121

68

47

Block No.

19

61

61

M

M

P

M

109

20

73

109

42

40

44

63

54

70

12

38

79

78

39

106

37

49

35

41

21

32

7

77

107

10

117

100

116

1

97

82

57

106

2

105

109

119

45

46

48

50

93

114

26

3

87

115

106

86

109

65

71

122

67

85

25

58

94

110

117

83

76

95

107

118

8

22

62

5

6

101

3-4

107

43

15

9

16

4

117

74

80

Page 39

Cassette mechanism

Block No. [M][P][M][M]

Symbol No.

1 X-0363-1001S MAIN CHASSIS AS

2 X-0363-1002S HEAD PLATE ASSY

3 X-0363-1004S FR CONV ARM (A)

4 X-0363-6001S REEL BASE ASSY

5 X-0363-6007S LEVER BRKT ASSY

6 X-0363-6003S TU GEAR ARM ASS

7 X-0363-6004S PINCH ARM(R) AS

8 X-0363-6005S PINCH ARM(F) AS

9 X-0363-6006S DETECTOR CAM AS (x2)

10 X-0363-2005S REEL SPINDLE AS (x2)

12 X-0036-1019S EJ.CAM LOCK ASY

15 1-0363-6010S FLYWHEEL ASSY F

16 1-0363-6011S FLYWHEEL ASSY R

19 1-0036-1065S FF LEVER(JVC)

20 1-0036-1066S REW LEVER(JVC)

21 1-0036-1007S EJECT LEVER

22 1-0036-1013S LOCK ARM

23 1-0036-1015S SPG SUPPORT PLT

24 1-0036-1018S CENTER PLATE

25 1-0036-1023S CHANGE LEVER(B)

26 1-0036-1026S FR ARM(B)

30 1-0138-1002S CASSETTE HANGER

31 1-0138-1006S ADJUSTER SHIN(X

32 1-0138-1010S CASSETTE HOLDER

35 1-0363-1003S EJECT CAM

37 1-0036-2001S IDLE GEAR

38 1-0036-2003S REDUCT.GEAR(B)

39 1-0036-2004S REDUCT.GEAR(A)

40 1-0036-2007-5S RATCHET

41 1-0036-2009S SENSOR ARM

42 1-0036-2010S SELECTOR GEAR

43 1-0036-2014S DETECTOR GEAR

44 1-0038-2014S GEAR LOCK ARM

45 1-0038-2018S TAPE GUIDE

46 1-0363-2006S ADJUSTER LINK B

47 1-0138-2005-3S ADJUSTER ARM(B)

48 1-0036-2005S PULLEY GEAR

49 1-0032-2007S TAPE HOOKER

50 1-0058-2021-5S IDLE PULLEY(A)

53 1-0363-3018S FF ROLLER

54 1-0036-3018S COLLER

57 1-0363-3007S HP ROLLER(A)

58 1-0363-3011S PROGRAM ROLLER

61 1-0036-4001S FF/REW LEVER SP

62 1-0036-4002S LOCK LEVER SPG

63 1-0036-4003S GEAR LOCK ARM S

65 1-0036-4006S HEAD PLATE SPG

66 1-0036-4007S EJ.CAM LOCK SPG

67 1-0036-4008S PROGRAM ARM SPG

68 1-0036-4010S ADJUST ARM SP(A

69 1-0036-4011S ADJUST ARM SP(B

70 1-0036-4015S DASH SPG

71 1-0036-4017S CHANGING ARM SP

72 1-0036-4023S CENTER PLT SP(B

73 1-0038-4014S RATCHET SPG

74 1-0138-4001S BACK TEMSION SP

76 1-0363-4003S PINCH ARM SPG F

77 1-0363-4004S PINCH ARM SPG R

78 1-0363-4005S EJECT LEVER SPG

79 1-0036-4005S EJECT CAM SPG

80 1-0036-5020S MAIN BELT(AL)

81 1-0363-5007S RETURN LINK

82 1-0036-5001S SUB BELT

83 1-0363-5003S SELECTOR LINK B

85 1-0036-7002S WIRE(A)

86 1-0036-7003S WIRE(B)

87 1-0036-7073S WIRE(AL)

89 X-0363-7006S MOTOR ASSY

93 1-0363-7001S MUTE SW

94 1-0363-7002S SLIDE SW

95 1-0363-7008S SLIDE SW PWB

96 1-0036-7016S HEAD

97 1-0363-7005S POWER SW

100 1-0036-7089S 6P WIRE ASY(JVC

Part No. Part Name Description Local

Symbol No.

101 1-0036-7088S 5P WIRE ASY(JVC

105 2-1816-0032-E8S MYLAR WASHER(S) (x2)

106 2-1812-0030-D2S PSW-S (x3)

107 1-0036-5024S PSW(REEL) (x5)

109 2-1712-0050-16S E RING (x5)

110 2-1712-5060-16S E RING

114 1-0363-7015S MUTE SW PWB

115 2-1331-7040-C2S SCREW S

116 2-1331-7060-C2S SCREW S

117 2-1382-0030-C2S SCREW B (x5)

118 2-1332-0040-C1S SCREW S

119 2-1032-0070-C2S SCREW (x2)

120 2-1032-0025-C2S SCREW (x2)

121 2-1012-0040-C2S SCREW

122 2-1012-0030-F2S SCREW

123 1-0138-5002S AZIMUTH SCREW (x3)

Part No. Part Name Description Local

KS-F345

3-5

Page 40

KS-F345

Grease point 1/2

Grease

FL-942

SW-902

SW-522B

FG-84M

C68

CFD-409

1

Reverse side

A

24

3-6

2

72

Page 41

Grease point 2/2

KS-F345

19

20

5

35

30

12

3

38

16

39

42

37

43

4

15

3-7

Page 42

KS-F345

Electrical parts list

Main board

Block No. [0][1][0][0]

Symbol No.

IC701 LC72362N-9B40 IC

IC781 AN80T05LF IC

IC931 LC75421M-X IC

IC981 LA4743K POWER IC

Q1 2SA1706/ST/-T TRANSISTOR

Q2 KRC102M-T D.TR.I.M

Q3 KTA1267/YG/-T TRANSISTOR

Q4 KRC102M-T D.TR.I.M

Q5 KRC102M-T D.TR.I.M

Q161 2SD2144S/VW/-T TRANSISTOR

Q261 2SD2144S/VW/-T TRANSISTOR

Q701 KTC3199/GL/-T TR I/M

Q771 KTC3199/GL/-T TR I/M

Q772 KTC3199/GL/-T TR I/M

Q781 KRC102M-T D.TR.I.M

Q782 2SA1706/ST/-T TRANSISTOR

Q783 KRC102M-T D.TR.I.M

Q784 2SA1706/ST/-T TRANSISTOR

Q789 KRA102M-T D.TR.I.M

Q971 KRC102M-T D.TR.I.M

Q972 KRA102M-T D.TR.I.M

Q987 KRA102M-T D.TR.I.M

Q988 KRC102M-T D.TR.I.M

Q989 KRA102M-T D.TR.I.M

D1 1SS119-041 DIODE I/M

D2 1SS119-041 DIODE I/M

D161 1SS119-041 DIODE I/M

D261 1SS119-041 DIODE I/M

D704 MTZJ6.2B-T2 Z DIODE

D705 MTZJ6.2B-T2 Z DIODE

D706 MTZJ6.2B-T2 Z DIODE

D707 MTZJ6.2B-T2 Z DIODE

D708 MTZJ6.2B-T2 Z DIODE

D709 MTZJ6.2B-T2 Z DIODE

D711 MTZJ6.2B-T2 Z DIODE

D713 1SS119-041 DIODE I/M

D716 1SS119-041 DIODE I/M

D718 1SS119-041 DIODE I/M

D771 MTZJ9.1C-T2 Z.DIODE I M

D781 1SS119-041 DIODE I/M

D782 1SS119-041 DIODE I/M

D784 1A3G-T1 SI DIODE

D785 1A3G-T1 SI DIODE

D786 1A3G-T1 SI DIODE

D791 1SS119-041 DIODE I/M

D792 1SS119-041 DIODE I/M

D961 RB721Q-40-T2 DIODE

D973 1SS119-041 DIODE I/M

D974 1SS119-041 DIODE I/M

D981 1N5401-TM SI DIODE

D990 MTZJ11B-T2 Z DIODE

C2 QDX11EK-223Z C CAPACIT OR 0.022uF 25V K

C3 QEKJ1HM-104Z E CAPACIT OR 0.1uF 50V M

C4 QEKJ1HM-104Z E CAPACIT OR 0.1uF 50V M

C5 QEKJ1CM-106Z E CAPACIT OR 10uF 16V M

C6 QDX11EK-223Z C CAPACIT OR 0.022uF 25V K

C7 QDX11EK-223Z C CAPACIT OR 0.022uF 25V K

C8 QERF1HM-104Z E CAPACITOR 0.1uF 50V M

C9 QDYB1CM-103Y C CAPACITOR 0.01uF 16V M

C11 QDYB1CM-103Y C CAPACITOR 0.01uF 16V M

C12 QCBB1HK-271Y C CAPACITOR 270pF 50V K

C15 QDYB1CM-103Y C CAPACITOR 0.01uF 16V M

C131 QERF1HM-105Z E CAPACITOR 1uF 50V M

C132 QERF1HM-105Z E CAPACITOR 1uF 50V M

C134 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C135 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C136 QFVD1HJ-154Z MF CAPACITOR 0.15uF 50V J

C137 QFVD1HJ-154Z MF CAPACITOR 0.15uF 50V J

C138 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

Part No. Part Name Description Local

Symbol No.

C150 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C160 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C231 QERF1HM-105Z E CAPACITOR 1uF 50V M

C232 QERF1HM-105Z E CAPACITOR 1uF 50V M

C234 QFLK1HJ-152Z M CAPACITOR 1500pF 50V J

C235 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C236 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C237 QFVD1HJ-154Z MF CAPACITOR 0.15uF 50V J

C238 QFVD1HJ-154Z MF CAPACITOR 0.15uF 50V J

C250 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C260 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C701 QDUB1HJ-270Y C CAPACITOR 27pF 50V J

C702 QDCB1HJ-220Y C CAPACITOR 22pF 50V J

C703 QERF0JM-107Z E CAPACITOR 100uF 6.3V M

C704 QFVD1HJ-224Z MF CAPACITOR 0.22uF 50V J

C705 QERF1CM-106Z E CAPACITOR 10uF 16V M

C706 QDYB1CM-103Y C CAPACITOR 0.01uF 16V M

C707 QFV61HJ-103Z MF CAPACITOR 0.01uF 50V J

C709 QERF1HM-474Z E CAPACITOR 0.47uF 50V M

C710 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C771 QERF1AM-227Z E CAPACITOR 220uF 10V M

C772 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C773 QDGB1HK-102Y C CAPACITOR 1000pF 50V K

C781 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C783 QETN0JM-228Z E CAPACITOR 2200uF 6.3V M

C784 QERF1AM-227Z E CAPACITOR 220uF 10V M

C785 QERF1CM-106Z E CAPACITOR 10uF 16V M

C786 QERF1AM-227Z E CAPACITOR 220uF 10V M

C931 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

C932 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C933 QERF1HM-105Z E CAPACITOR 1uF 50V M

C934 QERF1CM-226Z E CAPACITOR 22uF 16V M

C940 QERF1HM-105Z E CAPACITOR 1uF 50V M

C941 QERF1HM-105Z E CAPACITOR 1uF 50V M

C942 QFLK1HJ-152Z M CAPACITOR 1500pF 50V J

C943 QERF1HM-105Z E CAPACITOR 1uF 50V M

C972 QERF1AM-227Z E CAPACITOR 220uF 10V M

C974 QFVD1HJ-224Z MF CAPACITOR 0.22uF 50V J

C975 QFVD1HJ-224Z MF CAPACITOR 0.22uF 50V J

C976 QFVD1HJ-224Z MF CAPACITOR 0.22uF 50V J

C977 QFVD1HJ-224Z MF CAPACITOR 0.22uF 50V J

C981 QEZ0615-228 E CAPACITOR 2200uF

C982 QERF1CM-476Z E CAPACITOR 47uF 16V M

C983 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C984 QERF1CM-106Z E CAPACITOR 10uF 16V M

C985 QERF1EM-475Z E CAPACITOR 4.7uF 25V M

C986 QERF1CM-226Z E CAPACITOR 22uF 16V M

C987 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C988 QERF1CM-476Z E CAPACITOR 47uF 16V M

C989 QERF1CM-106Z E CAPACITOR 10uF 16V M

C990 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C991 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C992 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C993 QCFB1HZ-104Y C CAPACITOR 0.1uF 50V Z

C994 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C995 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C996 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C997 QCBB1HK-471Y C CAPACITOR 470pF 50V K

R1 QRE141J-100Y C RESISTOR 10Ω 1/4W J

R2 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R3 QRE141J-102Y C RESISTOR 1k

R4 QRE141J-103Y C RESISTOR 10k

R5 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R6 QRE141J-103Y C RESISTOR 10k

R9 QRE141J-103Y C RESISTOR 10k

R10 QRE141J-103Y C RESISTOR 10k

R14 QRE141J-822Y C RESISTOR 8.2k

R15 QRE141J-223Y C RESISTOR 22kΩ 1/4W J

R17 QRE141J-222Y C RESISTOR 2.2k

R51 QRE141J-471Y C RESISTOR 470

R52 QRE141J-562Y C RESISTOR 5.6kΩ 1/4W J

R61 QRE141J-471Y C RESISTOR 470

R62 QRE141J-562Y C RESISTOR 5.6k

R131 QRE141J-392Y C RESISTOR 3.9kΩ 1/4W J

R132 QRE141J-752Y C RESISTOR 7.5k

Part No. Part Name Description Local

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

3-8

Page 43

Symbol No.

R163 QRE141J-821Y C RESISTOR 820Ω 1/4W J

R164 QRE141J-101Y C RESISTOR 100Ω 1/4W J

R165 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R231 QRE141J-392Y C RESISTOR 3.9kΩ 1/4W J

R232 QRE141J-752Y C RESISTOR 7.5kΩ 1/4W J

R263 QRE141J-821Y C RESISTOR 820

R264 QRE141J-101Y C RESISTOR 100

R265 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R702 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R703 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R704 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R705 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R707 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R708 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R709 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R710 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R712 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R713 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R714 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R715 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R718 QRE141J-332Y C RESISTOR 3.3k

R719 QRE141J-332Y C RESISTOR 3.3k

R720 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R721 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R722 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R724 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R725 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R726 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R727 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R771 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R772 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R773 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R774 QRE141J-152Y C RESISTOR 1.5kΩ 1/4W J

R783 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R784 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R785 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R786 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R787 QRE141J-101Y C RESISTOR 100Ω 1/4W J

R788 QRE141J-242Y C RESISTOR 2.4kΩ 1/4W J

R789 QRE141J-104Y C RESISTOR 100kΩ 1/4W J

R790 QRE141J-474Y C RESISTOR 470kΩ 1/4W J

R792 QRE141J-6R8Y C RESISTOR 6.8Ω 1/4W J

R795 QRE141J-183Y C RESISTOR 18kΩ 1/4W J

R796 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R797 QRE141J-123Y C RESISTOR 12kΩ 1/4W J

R931 QRE141J-100Y C RESISTOR 10Ω 1/4W J

R941 QRE141J-332Y C RESISTOR 3.3kΩ 1/4W J

R972 QRE141J-272Y C RESISTOR 2.7kΩ 1/4W J

R973 QRE141J-472Y C RESISTOR 4.7kΩ 1/4W J

R985 QRE141J-472Y C RESISTOR 4.7k

R990 QRE141J-103Y C RESISTOR 10kΩ 1/4W J

R991 QRE141J-273Y C RESISTOR 27k

R992 QRE141J-273Y C RESISTOR 27k

R993 QRE141J-273Y C RESISTOR 27kΩ 1/4W J

R994 QRE141J-273Y C RESISTOR 27k

R996 QRE141J-473Y C RESISTOR 47k

R997 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

R998 QRE141J-473Y C RESISTOR 47k

R999 QRE141J-473Y C RESISTOR 47kΩ 1/4W J

L1 QQL231K-4R7Y INDUCTOR I/M 4.7uH K

L781 QQL231K-470Y INDUCTOR I/M 47uH K

L782 QQL231K-470Y INDUCTOR I/M 47uH K

L783 QQL231K-470Y INDUCTOR I/M 47uH K

L981 QQR1367-001 CHOKE COIL

CN721 QGB1214J1-06S CONNECTOR B-B (1-6)

CN901 QGB1214J1-06S CONNECTOR B-B (1-6)

CP981 QNZ0611-001 16P CONNECTOR

J1 QNZ0009-001 CAR ANT JACK

TU1 QAU0221-001 TUNER

X701 QAX0406-001Z CRYSTAL

CJ701 VMC0334-001 CONNECTOR

CJ921 QNN0519-001 PIN JACK

Part No. Part Name Description Local

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Mecha control board

Block No. [0][2][0][0]

Symbol No.

IC901 UPC1228HA I.C.

C101 QDGB1HK-821Y C CAPACITOR 820pF 50V K

C102 QEKJ1HM-474Z E CAPACITOR 0.47uF 50V M

C103 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C104 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C105 QFV61HJ-103Z MF CAPACITOR 0.01uF 50V J

C201 QDGB1HK-821Y C CAPACITOR 820pF 50V K

C202 QERF1HM-474Z E CAPACITOR 0.47uF 50V M

C203 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C204 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C205 QFV61HJ-103Z MF CAPACITOR 0.01uF 50V J

C901 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

R101 QRE141J-153Y C RESISTOR 15kΩ 1/4W J

R103 QRE141J-101Y C RESISTOR 100Ω 1/4W J

R104 QRE141J-334Y C RESISTOR 330k

R201 QRE141J-153Y C RESISTOR 15k

R203 QRE141J-101Y C RESISTOR 100Ω 1/4W J

R204 QRE141J-334Y C RESISTOR 330kΩ 1/4W J

R901 QRE141J-101Y C RESISTOR 100Ω 1/4W J

CP721 QGB1214K1-06S CONNECTOR B-B (1-6)

CP722 QGA2002F1-06 CONNECTOR W-B (1-6)

CP901 QGB1214K1-06S CONNECTOR B-B (1-6)

CJ901 QGA2002C1-05 CONNECTOR W-B (1-5)

Part No. Part Name Description Local

Ω

1/4W J

Ω

1/4W J

Front board

Block No. [0][3][0][0]

Symbol No.

IC651 LC75823W IC

D601 SML-310LT/MN/-X LED

D602 LNJ308G81/1-3/X LED

D603 LNJ308G81/1-3/X LED

D604 LNJ308G81/1-3/X LED

D605 LNJ308G81/1-3/X LED

D606 LNJ308G81/1-3/X LED

D607 LNJ308G81/1-3/X LED

D608 LNJ308G81/1-3/X LED

D610 LNJ308G81/1-3/X LED

D611 LNJ308G81/1-3/X LED

D612 LNJ308G81/1-3/X LED

D613 LNJ308G81/1-3/X LED

D614 LNJ308G81/1-3/X LED

D615 LNJ308G81/1-3/X LED

D616 LNJ308G81/1-3/X LED

D617 LNJ308G81/1-3/X LED

D618 LNJ308G81/1-3/X LED

D619 LNJ308G81/1-3/X LED

D620 LNJ308G81/1-3/X LED

C651 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C652 NBE20JM-475X TA E CAPACITOR 4.7uF 6.3V M

C653 NCB31HK-681X C CAPACITOR 680pF 50V K

R601 NRSA63J-681X MG RESISTOR 680

R602 NRSA63J-561X MG RESISTOR 560

R603 NRSA63J-681X MG RESISTOR 680

R604 NRSA63J-911X MG RESISTOR 910

R605 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R607 NRSA63J-681X MG RESISTOR 680

R608 NRSA63J-561X MG RESISTOR 560

R609 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R610 NRSA63J-911X MG RESISTOR 910

R611 NRSA63J-122X MG RESISTOR 1.2k

R613 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R614 NRSA63J-561X MG RESISTOR 560

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

KS-F345

3-9

Page 44

KS-F345

Symbol No.

R615 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R616 NRSA63J-911X MG RESISTOR 910Ω 1/16W J

R617 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R618 NRSA63J-152X MG RESISTOR 1.5kΩ 1/16W J

R635 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R636 NRSA02J-821X MG RESISTOR 820

R637 NRSA02J-152X MG RESISTOR 1.5k

R638 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R639 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R640 NRSA02J-102X MG RESISTOR 1kΩ 1/10W J

R641 NRSA02J-182X MG RESISTOR 1.8kΩ 1/10W J

R642 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R643 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R644 NRSA02J-561X MG RESISTOR 560Ω 1/10W J

R645 NRSA02J-621X MG RESISTOR 620Ω 1/10W J

R646 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R647 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R648 NRSA02J-821X MG RESISTOR 820Ω 1/10W J

R649 NRSA02J-152X MG RESISTOR 1.5kΩ 1/10W J

R651 NRSA02J-152X MG RESISTOR 1.5kΩ 1/10W J

R652 NRSA02J-473X MG RESISTOR 47k

R653 NRSA02J-184X MG RESISTOR 180k

R654 NRSA02J-103X MG RESISTOR 10kΩ 1/10W J

R655 NRSA02J-103X MG RESISTOR 10kΩ 1/10W J

R656 NRSA02J-103X MG RESISTOR 10kΩ 1/10W J

CP701 VMC0335-001 PANEL CONNECTOR

PL601 QLL0151-001 LAMP

PL603 QLL0151-001 LAMP

S601 NSW0124-001X TACT SW

S602 NSW0124-001X TACT SW

S603 NSW0124-001X TACT SW

S604 NSW0124-001X TACT SW

S605 NSW0124-001X TACT SW

S606 NSW0124-001X TACT SW

S608 NSW0124-001X TACT SW

S609 NSW0124-001X TACT SW

S610 NSW0124-001X TACT SW

S611 NSW0124-001X TACT SW

S612 NSW0124-001X TACT SW

S614 NSW0124-001X TACT SW

S615 NSW0124-001X TACT SW

S616 NSW0124-001X TACT SW

S617 NSW0124-001X TACT SW

S618 NSW0124-001X TACT SW

S619 NSW0124-001X TACT SW

S620 NSW0124-001X TACT SW

S621 NSW0124-001X TACT SW

Part No. Part Name Description Local

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

3-10

Page 45

<MEMO>

KS-F345

3-11

Page 46

KS-F345

Packing materials and accessories parts list

P5

Block No.

Block No.

M

M

M

M

M

M

3

5

P6

P7

A12

A3

P6

A14

A13

P2

KIT : A6~A10

P1

A1,A2,A4,A5

P3

P4

A11

3-12

Page 47

KS-F345

Packing

Block No. [M][3][M][M]

Symbol No.

P1 FSPG4002-001 POLY BAG

P2 QPA00801205 POLY BAG 8cm x 12cm

P3 QPA01003003 POLY BAG 10cm x 30cm

P4 FSYH4036-068 SHEET

P5 GE30646-001A CARTON

P6 GE10047-001A EPS CUSHION (x2)

P7 QPC03004315P POLY BAG 30cm x 43cm

Part No. Part Name Description Local

Accessories

Block No. [M][5][M][M

Symbol No.

A1 GET0112-001B INST BOOK ENG RUS

A2 GET0112-002A INSTALL MANUAL ENG RUS

A3 LV40978-001A CAUTION SHEET

A4 BT-54013-5 WARRANTY CARD

A5 VND3046-001 SERIAL TICKET

A6 VKZ4027-202 PLUG NUT

A7 VKH4871-001SS MOUNT BOLT

A8 VKZ4328-001 LOCK NUT

A9 WNS5000Z WASHER

A10 GE40130-001A HOOK (x2)

A11 FSJB3002-30C HARD CASE

A12 GE20137-003A MOUNTING SLEEVE

A13 GE20135-001A TRIM PLATE

A14 QAM0089-001 16P CORD ASSY

KIT KSFX480K-SCREW1 SCREW PARTS KIT A6~A10

Part No. Part Name Description Local

3-13

Page 48

CASSETTE RECEIVER

РЕСИВЕР С ПРОИГРЫВАТЕЛЕМ КОМПАКТ-ДИСКОВ

KS-F345

ENGLISH

РУCCKИЙ

For installation and

connections, refer to

the separate manual.

Указания по

установке и

выполнению

соединений

приводятся в

отдельной

инструкции.

S.BASS

SEL

DISP

В соответствии с Законом Российской Федерации “О защите прав

потребителей” срок службы (годности) данного товара “по истечении

которого он может представлять опасность для жизни, здоровья

потребителя, причинять вред его имуществу или окружающей среде”

составляет семь (7) лет со дня производства. Этот срок является

временем, в течение которого потребитель данного товара может

безопасно им пользоваться при условии соблюдения инструкции по

эксплуатации данного товара, проводя необходимое обслуживание,

включающее замену расходных материалов и/или соответствующее

ремонтное обеспечение в специализированном сервисном центре.

Дополнительные косметические материалы к данному товару,

поставляемые вместе с ним, могут храниться в течение двух (2) лет со дня

его производства.

Срок службы (годности), кроме срока хранения дополнительных

косметических материалов, упомянутых в предыдущих двух пунктах, не

затрагивает никаких других прав потребителя, в частности, гарантийного

свидетельства JVC, которое он может получить в соответствии с законом

о правах потребителя или других законов, связанных с ним.

FM

AM

SSM

EX

SCMMO

INSTRUCTIONS

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

GET0112-001A

[EE]

Page 49

Благодарим Вас за приобретение изделия JVC. Перед тем, как приступать к эксплуатации,

пожалуйста, внимательно прочитайте все инструкции с тем, чтобы полностью изучить и

обеспечить оптимальную работу этого устройства.

СОДЕРЖАНИЕ

Как перенастроить Ваше устройство ... 2

РАСПОЛОЖЕНИЕ КНОПОК........ 3

Панель управления ................................. 3

ОСНОВНЫЕ ОПЕРАЦИИ ............. 4

Включение ............................................... 4

Установка часов ..................................... 5

ОПЕРАЦИИ С

РУCCKИЙ

РАДИОПРИЕМНИКОМ ............... 6

Прослушивание радио ............................ 6

Сохранение радиостанций в памяти ..... 7

Настройка на запрограммированную

радиостанцию ....................................... 8

ОПЕРАЦИИ С МАГНИТОФОНОМ ....

Прослушивание кассеты ........................ 9

НАСТРОЙКА ЗВУКА .................... 10

Настройка звука ..................................... 10

Включение или отключение функции

ультрабасов .......................................... 10

Выбор запрограммированных

режимов звучания ................................ 11

Сохранение в памяти Ваших

собственных настроек звука .............. 11

ОТСОЕДИНЕНИЕ ПАНЕЛИ

УПРАВЛЕНИЯ ............................. 12

ВЫЯВЛЕНИЕ НЕИСПРАВНОСТЕЙ ...

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ ...

9

ТЕХНИЧЕСКИЕ

ХАРАКТЕРИСТИКИ.................... 15

13

14

Как перенастроить Ваше устройство

Одновременно нажмите кнопки SEL (выбор) и (резервный/включено/аттенюатор)

и удерживайте нажатыми более 2 секунд.

В результате этого встроенный микрокомпьютер будет перенастроен.

(резервный/включение/аттенюатор)

S.BASS

SEL

DISP

SEL (выбор)

Примечание:

Ваши запрограммированные настройки—такие как запрограммированные каналы или настройки

звука—также сотрутся.

ПЕРЕД ТЕМ, КАК ПРИСТУПАТЬ К ЭКСПЛУАТАЦИИ

*Для Вашей безопасности....

•

Не повышайте слишком сильно громкость, поскольку в

результате этого заглушаются внешние звуки, что

делает опасным управление автомобилем.

•

Остановите автомобиль перед тем, как выполнять

любые сложные операции.

2

*Температура внутри автомобиля....

Если Вы припарковали Ваш автомобиль на

длительное время в жаркую или холодную погоду,

перед тем, как включать это устройство,