Page 1

SERVICE MANUAL

CASSETTE RECEIVER

MA094B20053

KS-F185,KS-F185S,KS-F185G

KS-F185

Area suffix

UH ---------------------- Thailand

UN --------------------- Indonesia

U -------------------- Other Areas

KS-F185S

Area suffix

UN --------------------- Indonesia

KS-F185G

Area suffix

UN --------------------- Indonesia

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA094B

2005/3

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 45 W per channel

Rear 45 W per channel

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±10 dB at 100 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 1.0 V/20 kΩ load (250 nWb/m)

Frequency Range FM 87.5 MHz to 108.0 MHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

[AM Tuner] Sensitivity 20 µV

Wow & Flutter 0.15% (WRMS)

Fast-Wind Time 190 sec. (C-60)

Frequency Response 50 Hz to 14 000 Hz (Normal tape)

Signal-to-Noise Ratio 52 dB

Stereo Separation 40 dB

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0ºC to +40ºC

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 150 mm

Mass (approx.) 1.3 kg (excluding accessories)

Front 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than

0.8% total harmonic distortion.

Rear 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than

0.8% total harmonic distortion.

Treble ±10 dB at 10 kHz

TUNER SECTION

AM 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 2.0 dB

Selectivity 35 dB

CASSETTE DECK SECTION

GENERAL

Panel Size (approx.) 188 mm × 58 mm × 11 mm

Design and specifications are subject to change without notice.

1-2 (No.MA094B)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

(No.MA094B)1-3

Page 4

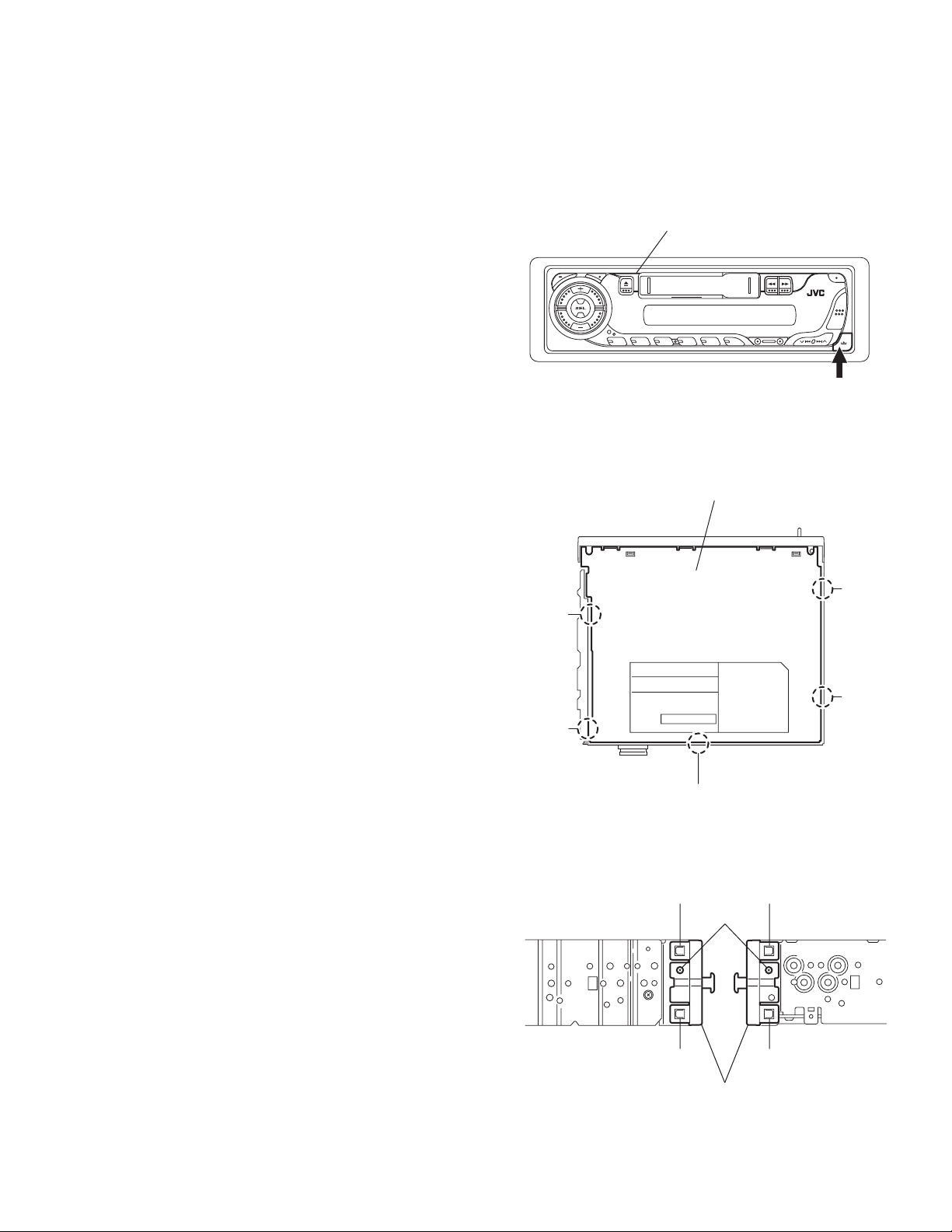

2.1 HOW TO IDENTIFY MODELS

2.1.1 NAME PLATE

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

Discernment sign

1-4 (No.MA094B)

Page 5

SECTION 3

DISASSEMBLY

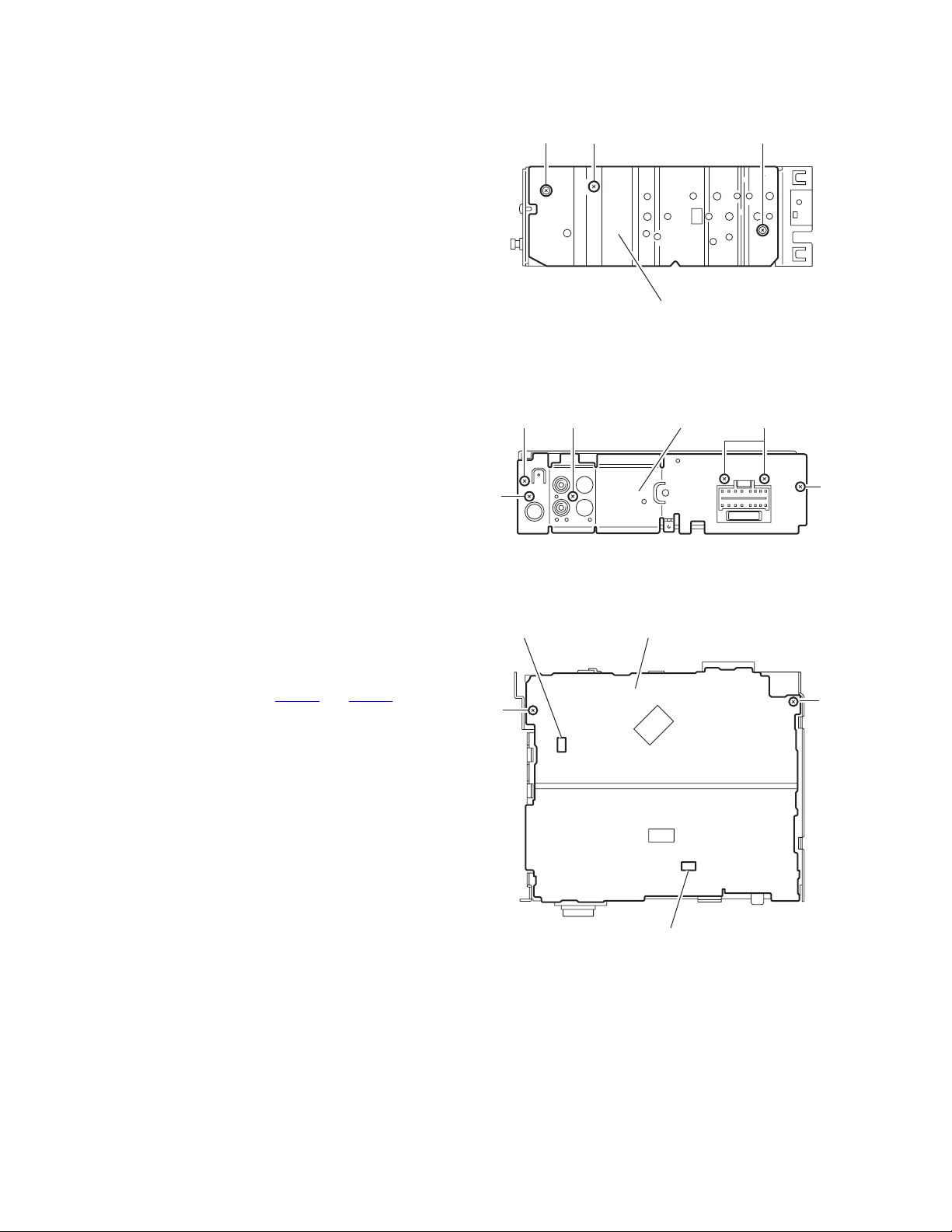

3.1 Main body

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button and remove the front panel assem-

bly.

3.1.2 Removing the bottom cover

(See Fig.2)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Turn the body upside down.

(2) Insert a screwdriver under the joints to release the two

joints a on the left side, the two joints b on the right side and

the joint c on the back of the body, then remove the bottom

cover from the body.

CAUTION:

When releasing the joints using a screwdriver, do not damage

the board.

Joint a

Front panel assembly

Fig.1

Bottom cover

Detach button

Joint

b

3.1.3 Removing the front chassis assembly

(See Fig.3)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) Remove the two screws A on each side of the body.

(2) Release the two joints d and the two joints e on the sides,

then remove the front chassis assembly toward the front.

Joint a

Joint c

Fig.2

Joint d Joint e

A

Joint d

Front chassis assembly

Fig.3

Joint e

Joint b

(No.MA094B)1-5

Page 6

3.1.4 Removing the heat sink

(See Fig.4)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the screw B and two screws C attaching the heat

sink on the left side of the body, and remove the heat sink.

3.1.5 Removing the rear panel

(See Fig.5)

• Prior to performing the following procedure, remove the front

panel assembly and bottom cover.

(1) Remove the two screws D , screw E and three screws F at-

taching the rear panel on the back of the body.

D

C

F

B

Heat sink

Fig.4

Rear panel

C

F

3.1.6 Removing the main board

(See Fig.6)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink and rear panel.

(1) Remove the two screws G attaching the main board on the

top chassis.

(2) Disconnect the two connectors (CN901

main board from the cassette mechanism assembly.

and CN721) on the

E

CN721

G

D

Fig.5

Main board

G

CN901

1-6 (No.MA094B)

Fig.6

Page 7

3.1.7 Removing the cassette mechanism assembly

(See Fig.7)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel and main board.

(1) Remove the four screws H attaching the cassette mecha-

nism assembly from the top chassis.

H

Cassette mechanism assembly

H

3.1.8 Removing the head amplifier board

(See Fig.8)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from CJ901 on the head amplifier

board.

(2) Remove the one screw J attaching the head amplifier

board.

(3) Move the head amplifier board in the direction of the arrow

to release the two joints f, the head amplifier board can be

removed.

3.1.9 Removing the relay board

(See Fig.9)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from CP722

(2) Remove the one screw K attaching the relay board.

(3) Move the relay board in the direction of the arrow to release

the joint g, the relay board can be removed.

on the relay board.

H

CJ901

Joint f

To head relay board

Top chassis

Fig.7

Head amplifier board

Joint f

J

Fig.8

Relay board

H

CP722

Joint g

Fig.9

K

(No.MA094B)1-7

Page 8

3.1.10 Removing the mecha bracket

(See Fig.10)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel, main board, cassette mechanism assembly,

head amplifier board and relay board.

(1) Remove the four screws L attaching the mecha bracket.

Mecha bracket

3.1.11 Removing the front board

(See Fig.11 to 13)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Remove the four screws M attaching the rear cover on the

back of the front panel assembly. (See Fig.11)

(2) Release the nine joints h, the front panel and the rear cover

become separate. (See Fig.12)

(3) Remove the front board from the rear cover. (See Fig.13)

Caution:

Take care not to lose the springs.

L

L

Fig.10

M Front panel assembly

M

M M

L

L

Joint h

Fig.11

Joint h

Joint h

Fig.12

Front board

Fig.13

1-8 (No.MA094B)

Page 9

3.2 Cassette mechanism assembly

• Prior to performing the following procedures, remove the head

amplifier board, the relay board and the mechanism bracket.

3.2.1 Removing the direction switch board

(See Fig.1)

(1) Unsolder the three wires a on the direction switch board.

(2) Remove the one screw A attaching the direction switch

board.

3.2.2 Removing the FF / REW lever assembly

(See Fig.1)

(1) Remove the screw B attaching the FF / REW lever assem-

bly on the back of the cassette mechanism assembly.

(2) Remove the screw C on the upper side of the FF / REW

lever assembly.

(3) Lift and pull forward the FF / REW lever assembly to disen-

gage the joints b, c, d and e.

3.2.3 Reattaching the FF / REW lever assembly

(See Fig.1)

(1) Reattach the FF / REW lever assembly to the joint c on the

back of the chassis.

(2) Reattach the pinch-roller shaft e, the change lever d and

the return link e to the chassis.

C

FF / REW lever assembly

Joint c

3.2.4 Removing the playback head

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the screw D attaching the playback head.

(2) Remove the C washer and pull out the FF roller.

(3) Remove the S support plate, the A arm spring (a) and (b),

the playback head.

ATTENTION:

The A arm spring (a) differs from the A arm spring (b).

3.2.5 Removing the pinch-roller (R) and (F) assembly

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the P arm spring (f) in the pinch-roller (F) assem-

bly from the chassis.

(2) Remove the P arm spring (r) in the pinch-roller (R) assem-

bly from the chassis.

(3) Draw out the pinch roller (F) and (R) assembly from the

shaft.

ATTENTION:

The P arm spring (f) differs from the P arm spring (r).

ATTENTION:

The pinch roller (F) assembly differs from the pinch roller (R)

assembly.

Joint e

Joint d

A

Soldering a

Direction switch board

Fig.1

Pinch-roller (R) assembly

Shaft

Remove the P arm spring (r)

from the chassis.

Joint b

B

C washer

A arm spring (b)

FF roller

S support plate

D

Playback head

Pinch-roller (F) assembly

A arm spring (a)

Shaft

Remove the P arm spring (f)

from the chassis.

P arm spring (r)

P arm spring (f)

Fig.2

(No.MA094B)1-9

Page 10

3.2.6 Removing the cassette hanger / cassette holder

(See Fig.3)

• Prior to performing the following procedure, remove the FF /

REW lever assembly.

(1) From the rear of the unit, bend the two tabs f outwards and

disengage the two joints g in the direction of the arrow.

(2) Push the eject lever and remove the cassette holder from

the playback head. Disengage the two joints h of the cassette hanger / cassette holder and the eject lever in the direction of the arrow.

(3) Lift the cassette hanger / cassette holder and disengage

the joint i of the return link and the eject lever.

Cassette holder

Cassette hanger

Chassis

Return link

Joint i

Eject lever

Joint h

Joint h

3.2.7 Removing the reel disc assembly

(See Fig.4)

• Prior to performing the following procedure, remove the FF /

REW lever assembly and the cassette hanger / cassette holder.

(1) Remove the C washer and pull out reel disc assembly.

ATTENTION:

Replace with a new C washer when reattaching.

3.2.8 Removing the motor assembly

(See Fig.5)

(1) Unsolder the two wires j on the motor assembly.

(2) Turn over the cassette mechanism assembly and remove

the main belt and the sub-belt from the motor pulley.

ATTENTION:

The main belt can now be removed.

(3) Remove the two screws G attaching the motor assembly.

Joint g

Flywheel (BF)

Tab f

C washer

C washer

Tab f

Fig.3

Fig.4

Main-belt

E

Joint g

Reel disc assembly

Motor assembly

Sub-belt

G

Motor pulley

1-10 (No.MA094B)

Flywheel (BR)

Reel base assembly

E

Fig.5

G

Soldering j

E

F

Page 11

3.2.9 Removing the Flywheel (BF) and (BR) assembly

(See Fig.4 and 5)

• Prior to performing the following procedure, remove the cas-

sette hanger / cassette holder.

(1) From the upper side of the cassette mechanism assembly,

remove the C washer from each shaft of the flywheel (BF)

and (BR).

(2) Turn over the cassette mechanism assembly and remove

the main belt. Pull out the flywheel (BF) and (BR) downward respectively.

C washer

Reel disc assembly

C washer

Fig.4

Main-belt

Motor assembly

3.2.10 Removing the reel base assembly

(See Fig.5 and 6)

(1) Raise the part k of the reel base assembly slightly and re-

move the selector link (B) on the front side of the cassette

mechanism assembly by turning it as shown in Fig.6.

(2) Remove the three screws E and the one screw F on the

underside of the cassette mechanism assembly.

ATTENTION:

The reel base assembly is not repairable. Handle with care.

Pinch-roller (R) assembly

k

Selector link (B).

Turn the selector link (B).

Fig.6

Inside of the reel base assembly

Flywheel (BF)

Flywheel (BR)

Sub-belt

E

Reel base assembly

E

Fig.5

Motor pulley

G

E

F

G

Soldering j

Fig.7

(No.MA094B)1-11

Page 12

3.2.11 Removing the mute switch board (See Fig.8)

(1) Unsolder the two wires l on the mute switch board on the

back of the cassette mechanism assembly.

(2) Remove the screw H attaching the mute switch board.

3.2.12 Removing the power switch

(See Fig.9)

• Prior to performing the following procedure, remove the motor

assembly.

(1) Unsolder the two wires m on the power switch on the side

of the cassette mechanism assembly.

(2) Remove the screw I attaching the power switch.

Cassette mechanism assembly

Soldering l

H

Fig.8

Soldering m

I

Cassette mechanism assembly

Power switch

Fig.9

Rower switch

Motor assembly

Mute switch board

1-12 (No.MA094B)

Page 13

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Frequency counter meter

(3) Electric voltmeter

(4) Wow & flutter meter

(5) Test tapes

VT724 : For DOLBY level measurement

VT739 : For playback frequency measurement

VT712 : For wow flutter & tape speed measurement

VT703 : For head azimuth measurement

(6) Torque gauge : Cassette type for CTG-N (Mechanism adjustment)

Standard volume position

Balance and Bass, Treble volume, Fader : Center (Indication "0")

Loudness, Dolby NR, Sound, Cruise : Off

Volume position is about 2V at speaker output with following conditions, Playback the test tape VT721.

AM mode 999kHz/62dB, INT/400Hz, 30% modulation signal on receiving.

FM mono mode 97.9MHz/66dB, INT/400Hz, 22.5kHz deviation pilot off mono

FM stereo mode 1kHz, 67.5kHz dev. pilot 7.5kHz dev.

Output level 0dB (1µV,50Ω/open terminal)

Measuring conditions (Amplifier section)

Power supply voltage : DC14.4V (11V to 16V)

Load impedance : 4 Ω (4 Ω to 8 Ω allowance)

Line out : 1.0V/20kΩload (250 nWb/m)

(No.MA094B)1-13

Page 14

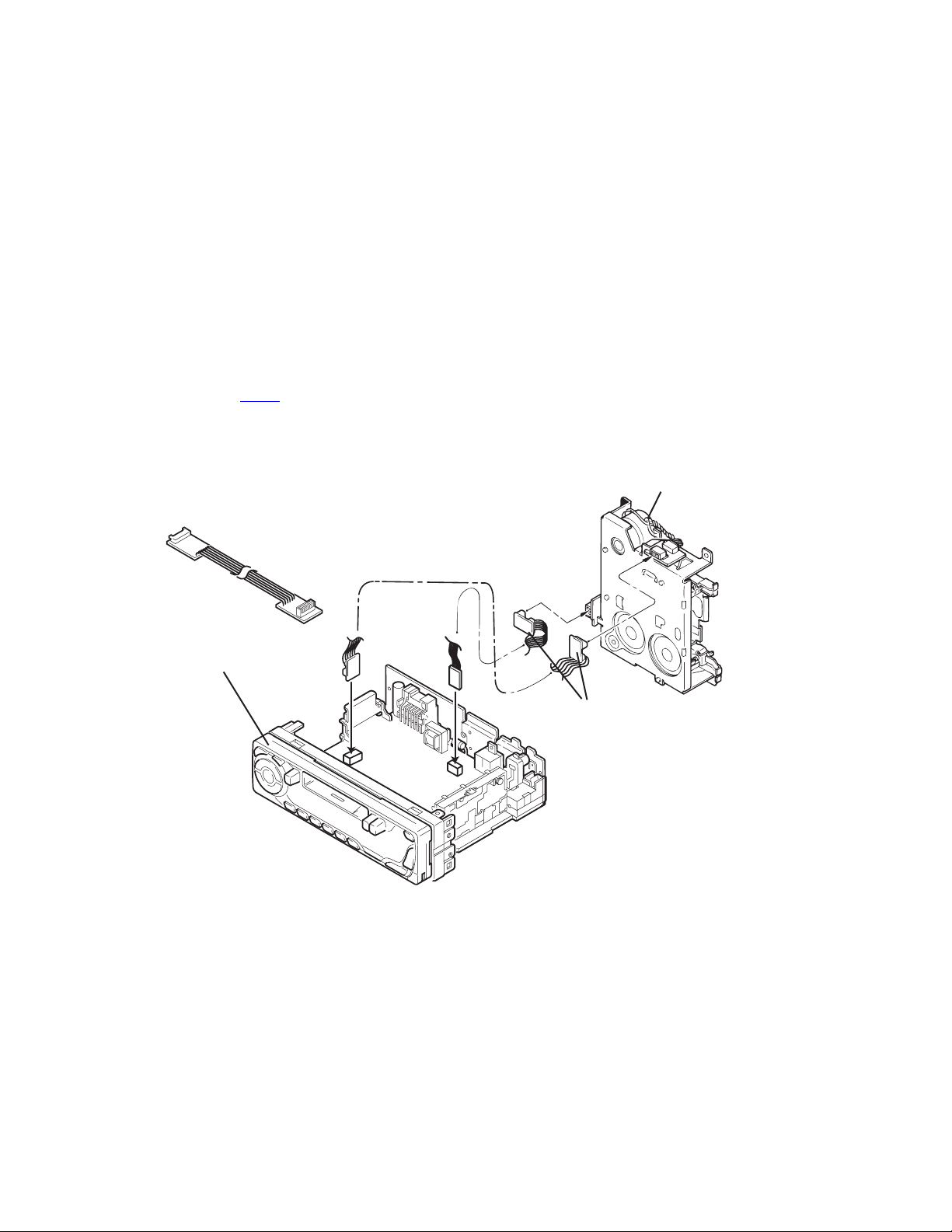

Information for using a car audio service jig

(1) We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

(2) As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the mechanism assembly

after disassembly.

(3) Extension cord : EXTKSRT002-6P ( 6 pin extension cord ) For connection between mechanism assembly3. Extension cord :

EXTKSRT002-6P ( 6 pin extension cord ) For connection between mechanism assembly and main board.

(4) Check for mechanism driving section such as motor ,etc.

Disassembly method

(1) Remove the front panel assembly.

(2) Remove the bottom cover.

(3) Remove the front chassis assembly.

(4) Remove the heat sink.

(5) Remove the main board.

(6) Reattach the heat sink with the screw B. (Refer to Disassembly method.)

(7) Reattach the front panel assembly.

(8) Confirm that current is being carried by connecting an extension cord jig.

NOTE:

Available to connect to the CJ701

CAUTION :

Be sure to attach the heat sink on the power amplifier IC of a main board when supplying the power.

If voltage is applied without attaching the heat sink, the power amplifier IC will be destroyed by heat.

connector when installing the front panel.

Cassette mechanism

EXTKSRT002-6P

Front Panel assembly

Extension cord

: EXTKSRT002-6P

Main board

1-14 (No.MA094B)

Page 15

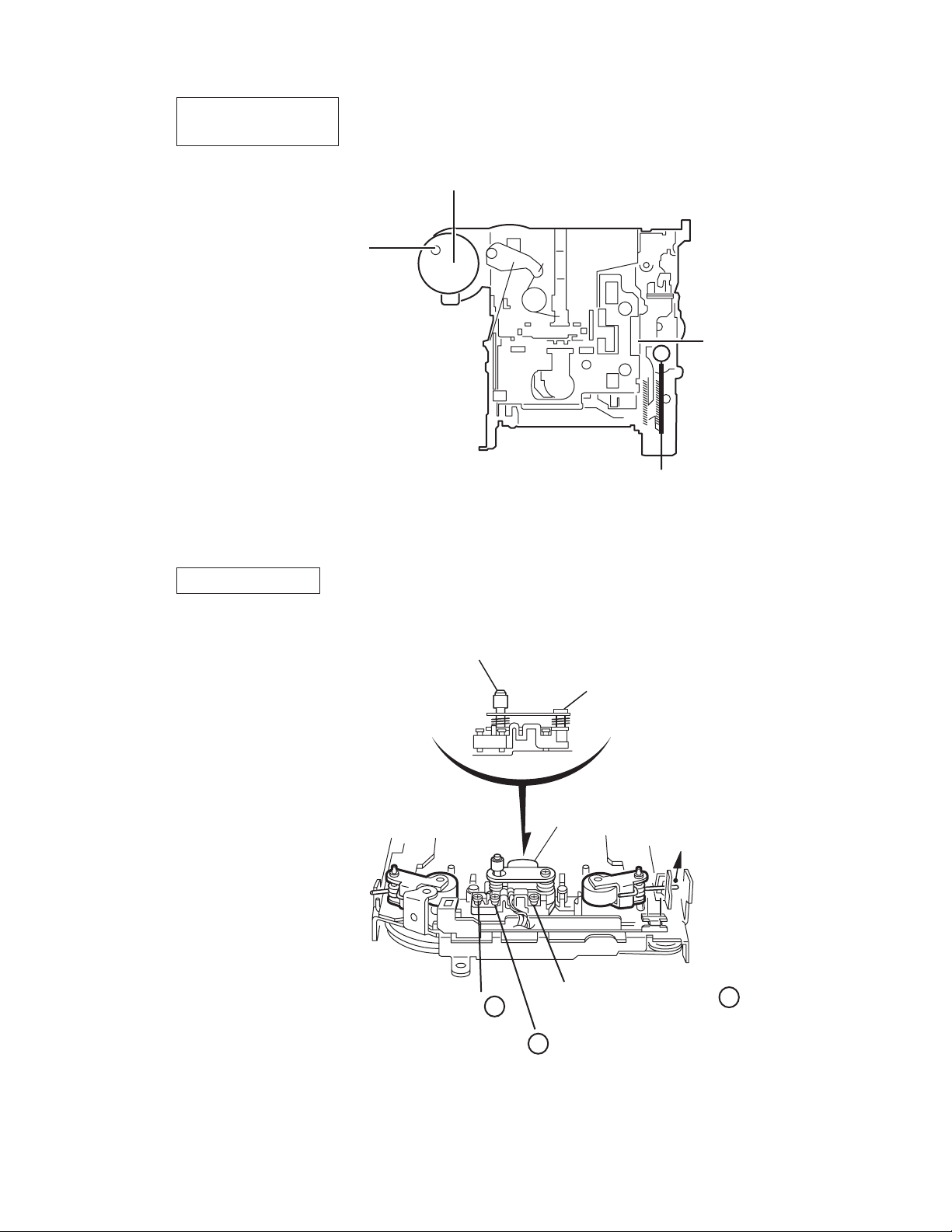

4.2 Arrangement of Adjusting & Test points

Cassette mechanism

(Surface)

Tape speed adjust

Motor assembly

Playback head

Azimuth screw

Head section view

Head azimuth screw

Height adjusting screw c

Fixed screw

Playback head

Height adjusting screw a

Height adjusting screw b

(No.MA094B)1-15

Page 16

Item

Conditions

Adjustment and Confirmation methods

S.Values Adjust

Head

1.

azimuth

adjustment

Test tape:

SCC-1659

VT703 (10kHz)

Test tape:

VT724 (1kHz)

VT703 (10kHz)

VT721 (315Hz)

Head height adjustment

Adjust the azimuth directly. When you

adjust the height using a mirror tape,

remove the cassette housing from the

mechanism chassis.

After installing thecassette housing,

perform the azimuth adjustment.

Load the SCC-1659 mirror tape. Adjust with

1.

height adjustment screw A and azimuth

adjustment screw B so that line A of the

mirror tape runs in the center between Lch

and Rch in the reverse play mode.

After switching from REV to FWD then to

2.

REV, check that the head position set in

procedure 1 is not changed. (If the position

has shifted, adjust again and check.)

Adjust with azimuth adjustment screw B so

3.

that line B of the mirror tape runs in the

center between Lch and Rch in the forward

play mode.

Head azimuth adjustment

Load VT724 (1kHz) and play it back in

1.

the reverse play mode.

Set the Rch output level to max.

Load VT703 (10kHz) and play it back in

2.

the forward play mode. Adjust the Rch

and Lch output levels to max, with

azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

Engage the reverse mode and adjust the

3.

output level to max, with azimuth

adjustment screw C.

(The phase difference should be 45 or

more.)

When switching between forward and

4.

reverse modes, the difference between

channels should be within 3dB. (Between

FWD L and R, REV L and R.)

A line

Head shield

The head is at low position

during.

B line

Head shield

The head is at High position

during REV.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

HEIGHT Adj A

phase

2.

Tape speed

and wow

flutter

confirmation

3.

Play back

frequency

response

confirmation

1-16 (No.MA094B)

When VT721 (315Hz) is played back,

5.

the level difference between channels

should be within 1.5dB.

Test tape: VT712

(3kHz)

Test tape: VT724

(1kHz)

VT739

(63Hz / 1kHz / 10kHz)

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

Check to see if the reading of the F, counter /

1.

wow flutter meter is within 3015Hz to 3045Hz

(FWD/ REV), and less than 0.35% (JIS RMS).

In case of out of specification, adjust the

2.

motor with a built-in volume resistor.

Play test tape VT724, and set the volume

1.

position at 2V.

Play test tape VT739 and confirm.

2.

1kHz / 10kHz: -1 3dB,

1kHz / 63Hz: 0 3dB,

When 10kHz is out of specification, it will be

3.

necessary to read adjust the azimuth.

Tape speed:

3015Hz

to 3045Hz

Wow

flutter: less

than 0.35%

Speaker out

1kHz / 63Hz

: 0 3dB

1kHz / 10kHz

: -1 3dB

Built-in volume

resistor

Page 17

5.1 16 PIN CORD DIAGRAM

SECTION 5

TROUBLESHOOTING

8

7

6

5

4

3

2

1

BK

RD

NC

BL/WH

WH

GN

VI

GY

WH/BK

GN/BK

GY/BK

16 YL

8 BK

7 RD ACC

5 BL/WH REMOTE

4 WH

12 WH/BK

3 GN

11 GN/BK RL-

2 VI RR+

10 VI/BK

1 GY FR+

YL

NC

NC

NC

VI/BK

16

15

14

13

12

11

10

9

MEMORY

GND

FL+

FL-

RL+

RR-

BK

RD

BL

WH

Black

Red

Blue

White

GN

VI

GY

YL

Green

Violet

Gray

Yellow

9 GY/BK

RR

FR

FL

RL

Rear Right

Front Right

Front Left

Rear Left

FR-

REMOTE

ACC

MEMORY

GND

Remote out

ACC Line

Memory Backup Battery +

Ground

(No.MA094B)1-17

Page 18

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA094B)

Printed in Japan

VPT

Page 19

PARTS LIST

[ KS-F185 ] [ KS-F185S ]

[ KS-F185G ]

* All printed circuit boards and its assemblies are not available as service parts.

KS-F185

Area suffix

UH ---------------------- Thailand

UN --------------------- Indonesia

U -------------------- Other Areas

KS-F185S

Area suffix

UN --------------------- Indonesia

KS-F185G

Area suffix

UN --------------------- Indonesia

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Cassette mechanism assembly and parts list (Block No.MP)

Electrical parts list (Block No.01~03) (F185_UH,UN,U) (F185S/F185G_UN)

Electrical parts list (Block No.04~06) (F185_UH3,UN3,U3)

Packing materials and accessories parts list (Block No.M3)

3-2

3-5

3-10

3-12

3-16

MA094B

3-1

Page 20

Exploded view of general assembly and parts list

Block No.

1

A

M

M

1

M

13

11

14

B

10

2

13

5

4

5

12

12

12

5

5

15

40

41

Switch board

3-2

24

23

25

26

22

28

32

30

27

31

31

29

34

31

51

33

36

41

52

35

44

45

49

37

42

39

38

Page 21

M

M

8

56

6

9

3

54

57

8

6

59

B

58

53

A

55

Main board

19

21

18

20

7

17

7

16

4

4

15

49

45

44

47

43

50

46

48

3-3

Page 22

General Assembly

Symbol No. Part No. Part Name Description Local

1 GE10043-012A TOP CHASSIS

2 GE40135-001A EARTH PLATE

3 GE30938-003A SIDE PANEL

4 QYSDST2004ZA TAP SCREW M2 x 4mm(x2)

5 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x4 )

6 GE40235-001A SCREW (x2)

7 QYSDST2606ZA TAP SCREW M2.6 x 6mm(x2 )

8 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x2 )

9 QYSDST2610Z A TAP SCREW M2.6 x 10mm

10 VKL7821-002 EJECT LEVER

11 QYSPSPT2625ZA SCREW M2.6 x 2.5mm

12 QYSDSP2604ZA SCREW M2.6 x 4mm(x4)

13 QYSDST2605ZA TAP SCREW M2.6 x 5mm(x2)

14 GE20134-002A MEC HA BKT

15 GE10095-001A FR O NT CHASSIS

16 GE31033-001A LO C K LEVER

17 FSKW4005-003 TORSION SPRING

18 GE40202-005A COMPRESSION SPRING

19 GE31034-001A RLS KNOB

20 FSJC3014-002 CASSETTE LID

21 VKW4947-002 DOOR SPRING

22 GE10093-003A FRONT PANEL F185GUN

22 GE10093-002A FRONT PANEL F185SUN

22 GE10093-001A FRONT PANEL

23 GE31353-007A FINDER ASSY F185GUN

23 GE31353-006A FINDER ASSY F185SUN

23 GE31353-005A FINDER ASSY

24 GE31044-001A POWER BUTTON

25 GE31345-001A PLUS MINUS BTN

26 GE31346-001A SEL BUTTON

27 GE31347-001A SCM BTN

28 FSXP3065-0 02 EJECT BUT TON

29 FSXP3066-001 FF BUTTON

30 FSXP3067-001 REW BUTTON

31 FSKW3002-003 COMP.SPRING (x3)

32 FSJK3014-001 LIGHT LENS

33 GE20161-001A PRESET BUTTON

34 FSYH4036-031 SHEET

35 GE31024-006A UP/DOWN BTN

36 GE31028-003A SSM BTN

37 GE31025-003A SEARCH BTN

38 GE31032-007A DETACH BTN F185GUN

38 GE31032-006A DETACH BTN F185SUN

38 GE31032-005A DETACH BTN

39 GE40202-003A COMPRESSION SPRING

40 GE10094-001A REAR COVER

41 VKZ4777-010 MINI SCREW (x4)

42 GE31348-001A LCD CASE

43 GE31349-001A LENS CASE

44 GE31350-001A LCD LENS

45 GE40232-001A LIGHTING SHEET

46 GE30393-002A BOTTOM COVER

47 FSMA3004-203 INSU LATOR

48 GE31317-001A NAME PLATE F185GUN

48 GE31314-001A NAME PLATE F185SUN

48 GE31311-004A NAME PLA TE F185U

48 GE31311-005A NAME PLA TE F185U3

48 GE31311-001A NAME PLATE F185UH,F185UN

48 GE31311-003A NAME PLA TE F185UH3,F185UN3

49 QLD0333-001 LCD MODULE

50 QNZ0440-001 LCD CONNECTOR

51 QLL0033-003 LAMP

52 QLL0033-003 LAMP

53 QMFZ047-150-T FUSE 15A

54 GE30912-017A REAR BRACKET

55 QYSDST2606Z A TAP SCREW M2.6 x 6mm

56 QYSDSF2606ZA TAP SCREW M2.6 x 6mm(x2)

57 QYSDSF2606Z A TAP SCREW M2.6 x 6mm

58 GE40172-004A IC BRACKET

59 GE40240-001A REG IC BRACKET

F185U,F185 U3,F185UH,F185UH3,F185UN

,F185UN3

F185U,F185 U3,F185UH,F185UH3,F185UN

,F185UN3

F185U,F185 U3,F185UH,F185UH3,F185UN

,F185UN3

Block No. [M][1][M][M]

3-4

Page 23

Cassette mechanism assembly and parts list

CDS-363SJ2

Block No.

M

M

M

P

30

12

81

66

109

78

72

49

24

21

32

89

100

120

116

97

57

106

2

105

109

119

45

46

123

107

53

23

69

31

93

114

121

68

47

109

115

65

71

67

61

61

25

58

110

19

76

83

107

118

8

109

20

22

62

6

73

109

42

107

43

40

44

54

70

63

79

35

117

38

4

117

39

106

37

41

7

77

107

10

50

82

48

26

9

74

87

106

86

122

94

95

101

117

85

80

3-5

Page 24

Cassette mechanism

Symbol No. Part No. Part Name Description Local

2 X-0363-10 02S HEAD PLATE ASSY

4 X-0363-6001S REEL BASE ASSY

6 X-0363-6003S TU GEAR ARM ASSY

7 X-0363-6004S PINCH ARM(R) ASSY

8 X-0363-6005S PINCH ARM(F) ASSY

9 X-0363-6006S DETECTOR CAM ASSY (x2)

10 X-0363-2005S REEL SPINDLE ASSY (x2)

12 X-0036 -1 019S EJ.CA M LO CK ASY

19 1-0036-1065S FF LEVER(JVC)

20 1-0036-1066S REW LEVER(JVC)

21 1-0036-1007S EJECT LEVER

22 1-0036-1013S LOCK ARM

23 1-0036-1015S SPG SUPPORT PLT

24 1-0036-1018S CENTER PLATE

25 1-0036-1023S CHANGE LEVER(B)

26 1-0036-1026S FR ARM(B)

30 1-0138-1002S CASSETTE HANGER

31 1-0138-1006S ADJUSTER SHIN(X

32 1-0138-1010S CASSETTE HOLDER

35 1-0363-1003S EJECT CAM

37 1-0036-2001S IDLE GEAR

38 1-0036-2003S REDUCT.GEAR(B)

39 1-0036-2004S REDUCT.GEAR(A)

40 1-0036-2007-5S RATCHET

41 1-0036-2009S SENSOR ARM

42 1-0036-2010S SELECTOR GEAR

43 1-0036-2014S DETECTOR GEAR

44 1-0038-2014S GEAR LOCK ARM

45 1-0038-2018S TAPE GUIDE

46 1-0363 -2 006S ADJUSTER LIN K B

47 1-0138-2005-3S ADJUSTER ARM(B)

48 1-0036-2005S PULLEY GEAR

49 1-0032-2007S TAPE HOOKER

50 1-0058-2021-5S IDLE PULLEY(A)

53 1-0363-3018S FF ROLLER

54 1-0036-3018S COLLER

57 1-0363-3007S HP ROLLER(A)

58 1-0363-3011S PROGRAM ROLLER

61 1-0036-4001S FF/REW LEVER SP

62 1-0036-4002S LOCK LEVER SPG

63 1-0036-4003S GEAR LOCK ARM S

65 1-0036-4006S HEAD PLATE SPG

66 1-0036-4007S EJ.CA M LO CK SPG

67 1-0036-4008S PROGRAM ARM SPG

68 1-0036-4010S ADJUST ARM SP(A

69 1-0036-4011S ADJUST ARM SP(B

70 1-0036-4015S DASH SPG

71 1-0036-4017S CHANGING ARM SP

72 1-0036-4023S CENTER PLT SP(B

73 1-0038-4014S RATCHET SPG

74 1-0138-4001S BACK TEMSION SP

76 1-0363 -4 003S PINCH ARM SPG F

77 1-0363 -4 004S PINCH ARM SPG R

78 1-0363 -4 005S EJECT LEVE R SPG

79 1-0036 -4 005S EJECT CAM SPG

80 1-0036-5020S MAIN BELT(AL)

81 1-0363-5007S RETURN LINK

82 1-0036-5001S SUB BELT

83 1-0363-5003S SEL EC TO R LI N K B

85 1-0036-7002S WIRE(A)

86 1-0036-7003S WIRE(B)

87 1-0036-7073S WIRE(AL)

89 X-0363-7006S MOTOR ASSY

93 1-0363-7001S MUTE SW

94 1-0036-7007-1S SLIDE SW

95 1-0363-7008S SLIDE SW PWB

97 1-0036-7034S POWER SW

100 1-0036-7089S 6P WIRE ASY(JVC

101 1-0036-7088S 5P WIRE ASY(JVC

105 2-1816-0032-E8S MYLAR WASHER(S) (x2)

106 2-1812-0030-D2S PSW-S (x3)

107 1-0036-5024S PSW(REEL) (x5)

109 2-1712- 0050-16S E RING (x5)

1 10 2-1712-5060-16S E RING

Block No. [M][P ] [M][M]

3-6

Page 25

Symbol No. Part No. Part Name Descript i on Local

114 1-0363-7015S MUTE SWITCH BOARD

115 2-1331-7040-C2S SCREW S

116 2-1331-7060-C2S SCREW S

117 2-1382-0030-C2S SCREW B (x5)

118 2-1332-0040-C1S SCREW S

119 2-1032-0070-C2S SCREW (x2)

120 2-1032-0025-C2S SCREW (x2)

121 2-1012-0040-C2S SCREW

122 2-1012-0030-F2S SCREW

123 1-0138-5002S AZIMUTH SCREW (x3)

3-7

Page 26

Grease point 1/2

Grease

FL-942

SW-902

SW-522B

FG-84M

C68

EP-56

1

Reverse side

A

24

2

72

3-8

Page 27

Grease point 2/2

19

20

5

35

30

12

3

38

16

39

42

37

43

4

15

3-9

Page 28

Electrical parts list

Main board

Symbol No.

Part No. Part Name Description Local

(F185_UH,UN,U) (F185S/F185G_UN)

Block No. [0] [1 ]

Symbol No.

IC701 LC72362N-9C64 IC

IC781 AN80T05LF IC

IC931 PT2319-L-X IC

IC981 LA4743K POWER IC

Q1 2SA1706/ST/-T TRANSISTOR

Q2 KRC102M-T DIGI TRANSISTOR

Q3 KTA1267/YG/-T TRANSISTOR

Q4 KRC102M-T DIGI TRANSISTOR

Q5 KRC102M-T DIGI TRANSISTOR

Q161 2SD2144S/VW/-T TRANSISTOR

Q261 2SD2144S/VW/-T TRANSISTOR

Q701 KTC3199/GL/-T TRANSISTOR

Q771 KTC3199/GL/-T TRANSISTOR

Q772 KTC3199/GL/-T TRANSISTOR

Q781 KRC1 02 M - T DIGI TRANSISTOR

Q782 2SA1706/ST/-T TRANSISTOR

Q783 KRC1 02 M - T DIGI TRANSISTOR

Q784 2SA1706/ST/-T TRANSISTOR

Q789 KRA102M-T DIGI TRANSISTOR

Q971 KRC1 02 M - T DIGI TRANSISTOR

Q972 KRA102M-T DIGI TRANSISTOR

Q987 KRA102M-T DIGI TRANSISTOR

Q988 KRC1 02 M - T DIGI TRANSISTOR

Q989 KRA102M-T DIGI TRANSISTOR

D1 1SS119-041-T2 DIODE

D2 1SS119-041-T2 DIODE

D3 1SS119-041-T2 DIODE

D4 1SS119-041-T2 DIODE

D161 1SS119-041-T2 DIODE

D261 1SS119-041-T2 DIODE

D704 MTZJ6.2B-T2 Z DIODE

D705 MTZJ6.2B-T2 Z DIODE

D706 MTZJ6.2B-T2 Z DIODE

D707 MTZJ6.2B-T2 Z DIODE

D708 MTZJ6.2B-T2 Z DIODE

D709 MTZJ6.2B-T2 Z DIODE

D711 MTZJ6.2B-T2 Z DIODE

D713 1SS119-041-T2 DIODE

D714 1SS119-041-T2 DIODE

D716 1SS119-041-T2 DIODE

D718 1SS119-041-T2 DIODE

D771 MTZJ9.1C-T 2 Z DI O DE

D781 1SS119-041-T2 DIODE

D782 1SS119-041-T2 DIODE

D784 1A3G-T1 SI DIODE

D785 1A3G-T1 SI DIODE

D786 1A3G-T1 SI DIODE

D791 1SS119-041-T2 DIODE

D792 1SS119-041-T2 DIODE

D961 RB721Q-40-T2 DIODE

D973 1SS119-041-T2 DIODE

D974 1SS119-041-T2 DIODE

D981 1N5401-TM SI DIODE

D990 MTZJ11B-T2 Z DIODE

C2 QDX11EK-223Z C CAPACITOR 0.022uF 25V K

C3 Q EKJ 1HM-104Z E CAPACITOR 0.1uF 50V M

C4 Q EKJ 1HM-104Z E CAPACITOR 0.1uF 50V M

C5 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C6 QDX11EK-223Z C CAPACITOR 0.022uF 25V K

C7 QDX11EK-223Z C CAPACITOR 0.022uF 25V K

C8 QERF1H M-104 Z E CAPACITOR 0.1uF 50V M

C9 QDYB1CM-103Y C CAPACITOR 0.01uF 16V M

C11 Q CBB1HK-331Y C CAPACITOR 330pF 50V K

C12 Q CBB1HK-271Y C CAPACITOR 270pF 50V K

C15 Q DYB1CM-103Y C CAPACITOR 0.01uF 16V M

C131 QERF1HM-105Z E CAPACITOR 1uF 50V M

C132 QERF1HM-105Z E CAPACITOR 1uF 50V M

Part No. Part Name Description Local

C134 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C135 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C136 QFV61HJ-154Z MF CAPACITOR 0.15uF 50V J

C137 QFV61HJ-154Z MF CAPACITOR 0.15uF 50V J

C138 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C150 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C160 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C231 QERF1HM-105Z E CAPACITOR 1uF 50V M

C232 QERF1HM-105Z E CAPACITOR 1uF 50V M

C234 QFLA1HJ-152Z M CAPACITOR 1500pF 50V J

C235 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C236 QFV61HJ-823Z MF CAPACITOR 0.082uF 50V J

C237 QFV61HJ-154Z MF CAPACITOR 0.15uF 50V J

C238 QFV61HJ-154Z MF CAPACITOR 0.15uF 50V J

C250 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C260 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C701 QDUB1HJ-270Y C CAPACITOR 27pF 50V J

C702 QDCB1HJ-220Y C CAPACITOR 22pF 50V J

C703 QERF0JM-107Z E CAPACITOR 100uF 6.3V M

C704 QFV61HJ-224Z MF CAPACITOR 0.22uF 50V J

C705 QERF1CM-106Z E CAPACITOR 10uF 16V M

C706 QDYB1CM-103Y C CAPACITOR 0.01u F 16V M

C707 QFV61HJ-103Z MF CAPACITOR 0.01uF 50V J

C708 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C709 QERF1HM-474Z E CAPACITOR 0.47uF 50V M

C710 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C771 QERF1AM-227Z E CAPACITOR 220uF 10V M

C772 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C773 QDGB1HK-102Y C CAPACITOR 1000pF 50V K

C781 QERF1CM-106Z E CAPACITOR 10uF 16V M

C783 QETN0JM-228Z E CAPACITOR 2200uF 6.3V M

C784 QERF1AM-227Z E CAPACITOR 220uF 10V M

C785 QERF1CM-106Z E CAPACITOR 10uF 16V M

C786 QERF1AM-227Z E CAPACITOR 220uF 10V M

C931 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

C932 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C933 QERF1HM-105Z E CAPACITOR 1uF 50V M

C934 QERF1CM-226Z E CAPACITOR 22uF 16V M

C940 QERF1HM-105Z E CAPACITOR 1uF 50V M

C941 QERF1HM-105Z E CAPACITOR 1uF 50V M

C942 QFLA1HJ-152Z M C APACITOR 1500pF 50V J

C943 QERF1HM-105Z E CAPACITOR 1uF 50V M

C972 QERF1AM-227Z E CAPACITOR 220uF 10V M

C974 QFV61HJ-224Z MF CAPACITOR 0.22uF 50V J

C975 QFV61HJ-224Z MF CAPACITOR 0.22uF 50V J

C976 QFV61HJ-224Z MF CAPACITOR 0.22uF 50V J

C977 QFV61HJ-224Z MF CAPACITOR 0.22uF 50V J

C981 QEZ0645-228 E CAPACITOR 2200uF

C982 QERF1CM-476Z E CAPACITOR 47uF 16V M

C983 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C984 QERF1CM-106Z E CAPACITOR 10uF 16V M

C985 QERF1EM-475Z E CAPACITOR 4.7uF 25V M

C986 QERF1CM-226Z E CAPACITOR 22uF 16V M

C987 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C988 QERF1CM-476Z E CAPACITOR 47uF 16V M

C989 QERF1CM-106Z E CAPACITOR 10uF 16V M

C990 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C991 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C992 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C993 QCFB1HZ-104Y C CAPACI TOR 0.1uF 50V Z

C994 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C995 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C996 QCBB1HK-471Y C CAPACITOR 470pF 50V K

C997 QCBB1HK-471Y C CAPACITOR 470pF 50V K

Ω

R1 QRE141J-100Y C RESISTOR 10

R2 QRE141J-102Y C RESISTOR 1k

R3 QRE141J-102Y C RESISTOR 1k

R4 QRE141J-103Y C RESISTOR 10k

R5 QRE141J-102Y C RESISTOR 1k

R6 QRE141J-103Y C RESISTOR 10k

R9 QRE141J-103Y C RESISTOR 10k

R10 QRE141J-103Y C RESISTOR 10k

R14 QRE141J-822Y C RESISTOR 8.2k

R15 QRE141J-223Y C RESISTOR 22k

R16 QRE141J-104Y C RESISTOR 100k

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

3-10

Page 29

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R17 QRE141J-222Y C RESISTOR 2.2kΩ 1/4W J

R51 QRE141J-391Y C RESISTOR 390

R52 QRE141J-512Y C RESISTOR 5.1k

R61 QRE141J-391Y C RESISTOR 390

R62 QRE141J-512Y C RESISTOR 5.1k

R131 QRE141J-392Y C RESISTOR 3.9k

R132 QRE141J-752Y C RESISTOR 7.5k

R163 QRE141J-102Y C RESISTOR 1k

R164 QRE141J-101Y C RESISTOR 100

R165 QRE141J-222Y C RESISTOR 2.2k

R231 QRE141J-392Y C RESISTOR 3.9k

R232 QRE141J-752Y C RESISTOR 7.5k

R263 QRE141J-102Y C RESISTOR 1k

R264 QRE141J-101Y C RESISTOR 100

R265 QRE141J-222Y C RESISTOR 2.2k

R702 QRE141J-473Y C RESISTOR 47k

R703 QRE141J-473Y C RESISTOR 47k

R704 QRE141J-103Y C RESISTOR 10k

R705 QRE141J-473Y C RESISTOR 47k

R707 QRE141J-473Y C RESISTOR 47k

R708 QRE141J-473Y C RESISTOR 47k

R709 QRE141J-472Y C RESISTOR 4.7k

R710 QRE141J-472Y C RESISTOR 4.7k

R711 QRE141J-224Y C RESISTOR 220k

R712 QRE141J-472Y C RESISTOR 4.7k

R713 QRE141J-472Y C RESISTOR 4.7k

R714 QRE141J-472Y C RESISTOR 4.7k

R715 QRE141J-222Y C RESISTOR 2.2k

R718 QRE141J-332Y C RESISTOR 3.3k

R719 QRE141J-332Y C RESISTOR 3.3k

R720 QRE141J-332Y C RESISTOR 3.3k

R721 QRE141J-332Y C RESISTOR 3.3k

R722 QRE141J-332Y C RESISTOR 3.3k

R724 QRE141J-472Y C RESISTOR 4.7k

R725 QRE141J-473Y C RESISTOR 47k

R726 QRE141J-473Y C RESISTOR 47k

R727 QRE141J-473Y C RESISTOR 47k

R728 QRE141J-103Y C RESISTOR 10k

R771 QRE141J-472Y C RESISTOR 4.7k

R772 QRE141J-103Y C RESISTOR 10k

R773 QRE141J-102Y C RESISTOR 1k

R774 QRE141J-152Y C RESISTOR 1.5k

R783 QRE141J-473Y C RESISTOR 47k

R784 QRE141J-102Y C RESISTOR 1k

R785 QRE141J-473Y C RESISTOR 47k

R786 QRE141J-102Y C RESISTOR 1k

R787 QRE141J-101Y C RESISTOR 100

R788 QRE141J-242Y C RESISTOR 2.4k

R789 QRE141J-1 04Y C RESISTOR 100k

R790 QRE141J-4 74Y C RESISTOR 470k

R792 QRE141J-6 R8Y C RES IS TO R 6.8

R795 QRE141J-183Y C RESISTOR 18k

R796 QRE141J-473Y C RESISTOR 47k

R797 QRE141J-123Y C RESISTOR 12k

R931 QRE141J-100Y C RESISTOR 10

R941 QRE141J-332Y C RESISTOR 3.3k

R972 QRE141J-272Y C RESISTOR 2.7k

R973 QRE141J-472Y C RESISTOR 4.7k

R985 QRE141J-472Y C RESISTOR 4.7k

R990 QRE141J-103Y C RESISTOR 10k

R991 QRE141J-273Y C RESISTOR 27k

R992 QRE141J-273Y C RESISTOR 27k

R993 QRE141J-273Y C RESISTOR 27k

R994 QRE141J-273Y C RESISTOR 27k

R996 QRE141J-473Y C RESISTOR 47k

R997 QRE141J-473Y C RESISTOR 47k

R998 QRE141J-473Y C RESISTOR 47k

R999 QRE141J-473Y C RESISTOR 47k

L1 QQL231K-4R7Y INDUCTOR I/M 4.7uH K

L781 QQL231K-470Y INDUCTOR I/M 47uH K

L782 QQL231K-470Y INDUCTOR I/M 47uH K

L783 QQL231K-470Y INDUCTOR I/M 47uH K

L981 QQR1367-001 CHOKE COIL

CJ701 VMC0334-001 CONNECTOR

CJ921 QNN0519-001 PIN JACK

CN721 QGB1214J1 -0 6S CO NNECTOR B-B (1-6)

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

CN901 QGB1214J1-06S CONNECTOR B-B (1-6)

CP981 QNZ0611-001 16P CONNECTOR

J1 QNB0100-002 CAR ANT JACK

TU1 QAU0311-001 TUNER

X701 QAX0406-001Z CRYSTAL 4.500MHz

Switch board

(F185_UH,UN,U) (F185S/F185G_UN)

Block No. [0] [2 ]

Symbol No.

IC651 LC75823W IC

D601 SML-310LT/MN/-X LED

D602 LNJ308G81/1-3/X LED

D603 LNJ308G81/1-3/X LED

D604 LNJ308G81/1-3/X LED

D605 LNJ308G81/1-3/X LED

D606 LNJ308G81/1-3/X LED

D607 LNJ308G81/1-3/X LED

D608 LNJ308G81/1-3/X LED

D609 LNJ308G81/1-3/X LED

D610 LNJ308G81/1-3/X LED

D611 LNJ308G81/1-3/X LED

D612 LNJ308G81/1-3/X LED

D613 LNJ308G81/1-3/X LED

D614 LNJ308G81/1-3/X LED

D615 LNJ308G81/1-3/X LED

D616 LNJ308G81/1-3/X LED

D617 LNJ308G81/1-3/X LED

D618 LNJ308G81/1-3/X LED

D619 LNJ308G81/1-3/X LED

D654 UDZS5.1B-X Z DIODE

C651 NCB31CK-105X C CAPACITOR 1uF 16V K

C652 NBE20JM-475X TA E CAPACITOR 4.7uF 6.3V M

C653 NCB31HK-681X C CAPACITOR 680pF 50V K

R601 NRSA63J-681X MG RESISTOR 680

R602 NRSA63J-561X MG RESISTOR 560

R603 NRSA63J-681X MG RESISTOR 680

R604 NRSA63J-911X MG RESISTOR 910

R605 NRSA63J-681X MG RESISTOR 680

R606 NRSA63J-561X MG RESISTOR 560

R607 NRSA63J-681X MG RESISTOR 680

R608 NRSA63J-911X MG RESISTOR 910

R609 NRSA63J-122X MG RESISTOR 1.2k

R610 NRSA63J-152X MG RESISTOR 1.5k

R611 NRSA63J-222X MG RESISTOR 2.2k

R612 NRSA63J-681X MG RESISTOR 680

R613 NRSA63J-561X MG RESISTOR 560

R614 NRSA63J-681X MG RESISTOR 680

R615 NRSA63J-911X MG RESISTOR 910

R635 NRS181J-221X MG RESISTOR 220

R636 NRSA02J-122X MG RESISTOR 1.2k

R637 NRSA02J-122X MG RESISTOR 1.2k

R638 NRSA02J-821X MG RESISTOR 820

R639 NRSA02J-821X MG RESISTOR 820

R640 NRSA02J-431X MG RESISTOR 430

R642 NRSA02J-271X MG RESISTOR 270

R644 NRSA02J-271X MG RESISTOR 270

R646 NRSA02J-821X MG RESISTOR 820

R647 NRSA02J-821X MG RESISTOR 820

R648 NRSA02J-431X MG RESISTOR 430

R650 NRSA02J-431X MG RESISTOR 430

R652 NRSA02J-122X MG RESISTOR 1.2k

R653 NRSA02J-122X MG RESISTOR 1.2k

R654 NRSA02J-152X MG RESISTOR 1.5k

R655 NRSA02J-473X MG RESISTOR 47k

R657 NRSA02J-184X MG RESISTOR 180k

R661 NRSA63J-103X MG RESISTOR 10k

R662 NRSA63J-103X MG RESISTOR 10k

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/8W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

3-11

Page 30

Symbol No.

R663 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

CP701 VMC0335-001 PANEL CONNECTOR

S601 NSW 0124-001X TACT SW

S602 NSW 0124-001X TACT SW

S603 NSW 0124-001X TACT SW

S604 NSW 0124-001X TACT SW

S605 NSW 0124-001X TACT SW

S606 NSW 0124-001X TACT SW

S607 NSW 0124-001X TACT SW

S608 NSW 0124-001X TACT SW

S609 NSW 0124-001X TACT SW

S610 NSW 0124-001X TACT SW

S611 NSW 0 124-001X TACT SW

S612 NSW 0124-001X TACT SW

S613 NSW 0124-001X TACT SW

S614 NSW 0124-001X TACT SW

S615 NSW 0124-001X TACT SW

S616 NSW 0124-001X TACT SW

S617 NSW 0124-001X TACT SW

S618 NSW 0124-001X TACT SW

Part No. Part Name Description Local

Mechanism control board

(F185_UH,UN,U) (F185S/F185G_UN)

Block No. [0] [3 ]

Symbol No.

IC901 U PC1228HA IC

C101 QDGB1HK-821Y C CAPACITOR 820pF 50V K

C102 QEKJ1HM-474Z E CAPACITOR 0.47uF 50V M

C103 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C104 QEKJ0JM-47 6Z E CAPACITOR 47uF 6.3V M

C105 QFV61HJ- 10 3Z MF CAPACITOR 0.01uF 50V J

C201 QDGB1HK-821Y C CAPACITOR 820pF 50V K

C202 QERF1HM-474Z E CAPACITOR 0.47uF 50V M

C203 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C204 QEKJ0JM-47 6Z E CAPACITOR 47uF 6.3V M

C205 QFV61HJ- 10 3Z MF CAPACITOR 0.01uF 50V J

C901 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

R101 QRE141J-153Y C RESISTOR 15k

R103 QRE141J-101Y C RESISTOR 100

R104 QRE141J-334Y C RESISTOR 330k

R201 QRE141J-153Y C RESISTOR 15k

R203 QRE141J-101Y C RESISTOR 100

R204 QRE141J-334Y C RESISTOR 330k

R901 QRE141J-101Y C RESISTOR 100

CJ901 Q GA2 002C 1-05 CONNECTOR W-B (1-5)

CP721 QGB1214K1-06S CONNECTOR B-B (1-6)

CP722 QGA2002F1-06 CONNECTOR W-B (1-6)

CP901 QGB1214K1-06S CONNECTOR B-B (1-6)

Part No. Part Name Description Local

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Main board (F185_UH3,UN3,U3)

Block No. [0][ 4 ]

Symbol No.

IC701 UPD178078GF-708 IC

IC902 KIA7810API IC

IC911 TEA6320T-X IC

IC941 LA4743K POWER IC

IC961 AN80T05LF IC

Q2 UN2211-X TRANSISTOR

Q7 2SC3661-X TRANSISTOR

Q8 KRC101S-X TRANSISTOR

Q10 2SC3661-X T RANSISTOR

Q11 2SC2412K/R/-X TRANSISTOR

Q12 2SC2412K/R/-X TRANSISTOR

Q131 2SC2412K/R/-X TRANSISTOR

Q231 2SC2412K/R/-X TRANSISTOR

Q701 2SC2412K/R/-X TRANSISTOR

Q953 UN2211-X TRANSISTOR

Q959 UN2211-X TRANSISTOR

Q960 2SA1037AK/RS/-X TRANSISTOR

Q961 2SA1037AK/RS/-X TRANSISTOR

Q962 2SB1322/RS/-T TRANSISTOR

Q963 2SA1037AK/RS/-X TRANSISTOR

Q964 UN2211-X TRANSISTOR

Q965 UN2211-X TRANSISTOR

Q966 UN2211-X TRANSISTOR

Q967 2SA1037AK/RS/-X TRANSISTOR

Q978 UN2211-X TRANSISTOR

Q979 UN2111-X TRANSISTOR

Q981 UN2111-X TRANSISTOR

D1 1SS355-X SI DIODE

D2 1SS355-X SI DIODE

D6 UDZS9.1B-X Z DIODE

D30 1SS355-X SI DIODE

D744 NRS181J-0R0X MG RESISTOR 0

D751 UDZS6.2B-X Z DIODE

D752 UDZS6.2B-X Z DIODE

D753 UDZS6.2B-X Z DIODE

D754 UDZS6.2B-X Z DIODE

D755 UDZS6.2B-X Z DIODE

D756 UDZS6.2B-X Z DIODE

D757 UDZS6.2B-X Z DIODE

D776 1SS355-X SI DIODE

D931 1SS355-X SI DIODE

D932 1SS355-X SI DIODE

D961 1N5401-F64 DIODE

D963 1SS355-X SI DIODE

D964 1SS355-X SI DIODE

D965 RB160M-30-X SB DIOD E

D966 RB160M-30-X SB DIOD E

D977 1SS355-X SI DIODE

D978 UDZS11B- X Z DIODE

D982 1SS355-X SI DIODE

D984 1SS355-X SI DIODE

C1 QEKJ1HM-104Z E CAPACITOR 0.1uF 50V M

C2 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C3 QERF1AM-227Z E CAPACITOR 220uF 10V M

C4 QERF1AM-227Z E CAPACITOR 220uF 10V M

C6 NCB3 1EK-563X C CAPACITOR 0.056uF 25V K

C7 NCB3 1EK-123X C CAPACITOR 0.012uF 25V K

C8 QERF1AM-107Z E CAPACITOR 100uF 10V M

C9 QERF1AM-227Z E CAPACITOR 220uF 10V M

C17 NCS31HJ -15 1X C CAPACITOR 150pF 50V J

C18 QERF1HM-474Z E CAPACITOR 0.47uF 50V M

C20 NCS31HJ-102X C CAPACITOR 1000pF 50V J

C21 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C24 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C31 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C112 QERF1HM-105Z E CAPACITOR 1uF 50V M

C113 NCB31HK-822X C CAPACITOR 8200pF 50V K

C114 NCB21CK-104X C CAPACITOR 0.1uF 16V K

C1 15 QERF1HM-22 4Z E CAPACITOR 0.22uF 50V M

C116 NCB31EK-333X C CAPACITOR 0.033u F 25 V K

C117 NCB31EK-123X C CAPACITOR 0.012u F 25 V K

Part No. Part Name Description Local

Ω

1/8W J

3-12

Page 31

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C118 QERF1HM-105Z E CAPACITOR 1uF 50V M

C119 QERF1HM-105Z E CAPACITOR 1uF 50V M

C143 NCS31HJ-391X C CAPACITOR 390p F 5 0V J

C144 NCS31HJ-391X C CAPACITOR 390p F 5 0V J

C153 QERF1HM-10 5Z E CAPACITOR 1uF 50V M

C154 NCB31HK-183X C CAPACITOR 0.018uF 50V K

C212 QERF1HM-10 5Z E CAPACITOR 1uF 50V M

C213 NCB31HK-822X C CAPACITOR 8200pF 50V K

C214 NCB21CK-104X C CAPACITOR 0.1uF 16V K

C215 QERF1HM-22 4Z E CAPACITOR 0.22uF 50V M

C216 NCB31EK-333X C CAPACITOR 0.033uF 25V K

C217 NCB31EK-123X C CAPACITOR 0.012uF 25V K

C218 QERF1HM-10 5Z E CAPACITOR 1uF 50V M

C219 QERF1HM-10 5Z E CAPACITOR 1uF 50V M

C243 NCS31HJ-391X C CAPACITOR 390p F 5 0V J

C244 NCS31HJ-391X C CAPACITOR 390p F 5 0V J

C253 QERF1HM-10 5Z E CAPACITOR 1uF 50V M

C254 NCB31HK-183X C CAPACITOR 0.018uF 50V K

C701 NDC31HJ-270X C CAPACITOR 27pF 50 V J

C702 NDC31HJ-270X C CAPACITOR 27pF 50 V J

C703 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C704 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C705 NCB31HK-102X C CAPACITOR 1000pF 50V K

C707 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C708 QERF1AM-227Z E CAPACITOR 220uF 10V M

C709 QERF0JM-107Z E CAPACITOR 100uF 6.3V M

C710 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C711 NCB21CK-224X C CAPACITOR 0.22uF 16V K

C712 NCB21HK-104X C CAPACITOR 0.1uF 50V K

C713 NRSA02J-0R0X MG RESISTOR 0

C902 QFV11HJ-334AZ MF CAPACITOR 3.34F 50V J

C903 QFV61HJ-104Z MF CAPA CITOR 0.1uF 50V J

C911 QERF1CM-476Z E CAPACITOR 47uF 16V M

C912 QERF1CM-107Z E CAPACITOR 100uF 16V M

C913 QERF1CM-107Z E CAPACITOR 100uF 16V M

C932 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C941 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C942 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C943 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C945 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C946 QERF1CM-22 6Z E CAPACITOR 22uF 16V M

C947 QFVD1HJ-22 4Z MF CAPACITOR 0.22uF 50V J

C948 QFVD1HJ-22 4Z MF CAPACITOR 0.22uF 50V J

C949 QFVD1HJ-22 4Z MF CAPACITOR 0.22uF 50V J

C950 QFVD1HJ-22 4Z MF CAPACITOR 0.22uF 50V J

C951 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C952 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C953 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C954 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C961 QEZ0645-228 E CAPACITOR 2200uF

C962 QERF1CM-10 6Z E CAPACITOR 10uF 16V M

C963 QERF1CM-10 6Z E CAPACITOR 10uF 16V M

C964 QERF1AM-227Z E CAPACITOR 220uF 10V M

C965 QERF1AM-227Z E CAPACITOR 220uF 10V M

C966 QERF1CM-10 6Z E CAPACITOR 10uF 16V M

C967 QERF1CM-10 6Z E CAPACITOR 10uF 16V M

C968 QERF1CM-10 6Z E CAPACITOR 10uF 16V M

C969 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C970 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C971 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C977 QERF1AM-227Z E CAPACITOR 220uF 10V M

C978 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C979 QERF1CM-47 6Z E CAPACITOR 47uF 16V M

C981 QERF1CM-107Z E CAPACITOR 100uF 16V M

C982 QERF1CM-10 6Z E CAPACITOR 10uF 16V M

C984 QERF1AM-227Z E CAPACITOR 220uF 10V M

R1 NRSA63J-150X MG RESISTOR 15

R2 NRSA63J-150X MG RESISTOR 15

R6 NRSA63J-100X MG RESISTOR 10

R9 NRSA63J-102X MG RESISTOR 1k

R10 N RSA63J-392X MG RESISTOR 3.9k

R12 N RSA63J-102X MG RESISTOR 1k

R14 N RSA63J-471X MG RESISTOR 47 0

R24 N RSA63J-102X MG RESISTOR 1k

R25 N RSA63J-102X MG RESISTOR 1k

R26 N RSA63J-103X MG RESISTOR 10 k

R27 N RSA63J-102X MG RESISTOR 1k

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

R29 NRS181J-1 52 X MG RESISTOR 1.5kΩ 1/8W J

R32 NRSA63 J-101X MG RESISTOR 100

R35 NRSA63 J-822X MG RESISTOR 8.2k

R36 NRSA63 J-223X MG RESISTOR 22k

R37 NRSA63 J-104X MG RESISTOR 100k

R112 NRSA63J-223X MG RESISTOR 22k

R113 NRSA63J-272X MG RESISTOR 2.7k

R114 NRSA63J-272X MG RESISTOR 2.7k

R132 NRSA63J-222X MG RESISTOR 2.2k

R135 NRSA63J-101X MG RESISTOR 100

R136 NRSA63J-102X MG RESISTOR 1k

R141 NRSA63J-273X MG RESISTOR 27k

R142 NRSA63J-273X MG RESISTOR 27k

R143 NRSA63J-473X MG RESISTOR 47k

R144 NRSA63J-473X MG RESISTOR 47k

R151 NRSA63J-302X MG RESISTOR 3k

R152 NRSA63J-103X MG RESISTOR 10k

R212 NRSA63J-223X MG RESISTOR 22k

R213 NRSA63J-272X MG RESISTOR 2.7k

R214 NRSA63J-272X MG RESISTOR 2.7k

R232 NRSA63J-222X MG RESISTOR 2.2k

R235 NRSA63J-101X MG RESISTOR 100

R236 NRSA63J-102X MG RESISTOR 1k

R241 NRSA63J-273X MG RESISTOR 27k

R242 NRSA63J-273X MG RESISTOR 27k

R243 NRSA63J-473X MG RESISTOR 47k

R244 NRSA63J-473X MG RESISTOR 47k

R251 NRSA63J-302X MG RESISTOR 3k

R252 NRSA63J-103X MG RESISTOR 10k

R701 NRS181J-271X MG RESISTOR 270

R702 NRSA63J-0R0X MG RESISTOR 0

R703 NRS181J-0R0X MG RESISTOR 0

R704 NRSA63J-0R0X MG RESISTOR 0

R705 NRSA63J-103X MG RESISTOR 10k

R707 NRSA63J-473X MG RESISTOR 47k

R708 NRSA63J-104X MG RESISTOR 100k

R709 NRSA63J-104X MG RESISTOR 100k

R710 NRSA63J-473X MG RESISTOR 47k

R711 NRSA63J-391X MG RESISTOR 390

R712 NRS181J-0R0X MG RESISTOR 0

R713 NRSA63J-103X MG RESISTOR 10k

R715 NRSA63D-103X MG RES ISTOR 10k

R716 NRSA63D-103X MG RES ISTOR 10k

R717 NRSA63D-103X MG RES ISTOR 10k

R718 NRSA63D-472X MG RES ISTOR 4.7k

R719 NRSA63D-472X MG RES ISTOR 4.7k

R720 NRSA63D-472X MG RES ISTOR 4.7k

R724 NRSA63J-472X MG RESISTOR 4.7k

R725 NRSA63J-472X MG RESISTOR 4.7k

R726 NRSA63J-472X MG RESISTOR 4.7k

R728 NRSA63J-103X MG RESISTOR 10k

R729 NRSA63J-472X MG RESISTOR 4.7k

R730 NRSA63J-472X MG RESISTOR 4.7k

R731 NRSA63J-472X MG RESISTOR 4.7k

R732 NRSA63J-473X MG RESISTOR 47k

R733 NRS181J-473X MG RESISTOR 47k

R734 NRS181J-103X MG RESISTOR 10k

R736 NRSA63J-103X MG RESISTOR 10k

R737 NRSA63J-473X MG RESISTOR 47k

R738 NRSA63J-473X MG RESISTOR 47k

R740 NRSA63J-473X MG RESISTOR 47k

R743 NRSA63J-473X MG RESISTOR 47k

R744 NRSA63J-473X MG RESISTOR 47k

R746 NRSA63J-473X MG RESISTOR 47k

R747 NRSA63J-473X MG RESISTOR 47k

R748 NRSA63J-103X MG RESISTOR 10k

R750 NRSA63J-473X MG RESISTOR 47k

R776 NRSA63J-473X MG RESISTOR 47k

R778 NRSA63J-473X MG RESISTOR 47k

R779 NRSA63J-473X MG RESISTOR 47k

R911 NRSA63J-271X MG RESISTOR 270

R912 NRSA63J-271X MG RESISTOR 270

R913 NRSA63J-100X MG RESISTOR 10

R941 NRSA63J-473X MG RESISTOR 47k

R959 NRSA63J-222X MG RESISTOR 2.2k

R960 NRSA63J-273X MG RESISTOR 27k

R961 QRE141J-470Y C RESISTOR 47

R962 NRSA63J-682X MG RESISTOR 6.8k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/8W J

Ω

1/16W J

Ω

1/8W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/8W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/8W J

Ω

1/8W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/16W J

3-13

Page 32

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R963 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R966 NRSA63J-473X MG RESISTOR 47k

R967 NRSA63J-222X MG RESISTOR 2.2k

R969 NRS181J-222X MG R ESISTOR 2.2k

R970 NRSA63J-473X MG RESISTOR 47k

R971 NRS181J-222X MG R ESISTOR 2.2k

R972 NRS181J-222X MG R ESISTOR 2.2k

R974 NRSA63J-123X MG RESISTOR 12k

R975 NRSA63J-243X MG RESISTOR 24k

R977 NRSA63J-181X MG RESISTOR 180

R979 NRSA63J-473X MG RESISTOR 47k

L1 QQL231K-4R 7Y INDUC TO R I/ M 4.7uH K

L701 Q Q L231K-470Y INDUCTOR I/M 47uH K

L702 Q Q L231K-470Y INDUCTOR I/M 47uH K

L961 Q Q R 1366-001 CH O KE COIL

CJ701 VMC0334-001 CONNECTOR

CN901 QGB1214J1-06S CONNECTOR B-B (1-6)

CN902 QGB1214J1-06S CONNECTOR B-B (1-6)

CP981 QNZ0611-001 16P CONNECTOR

J1 QNB0100-002 CAR ANT JACK

J931 QNN0519-001 PIN JACK

TU1 QAU0281-001 TUNE R PACK

X701 QAX0 406-001Z CRYSTAL 4.500MHz

Ω

1/16W J

Ω

1/16W J

Ω

1/8W J

Ω

1/16W J

Ω

1/8W J

Ω

1/8W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Switch board (F185_UH3,UN3,U3)

Block No. [0] [5 ]

Symbol No.

IC651 PT6523LQ-L L C D DRIVER

D601 SML-310LT/MN/-X LED

D602 LNJ308G81/1-3/X LED

D603 LNJ308G81/1-3/X LED

D604 LNJ308G81/1-3/X LED

D605 LNJ308G81/1-3/X LED

D606 LNJ308G81/1-3/X LED

D607 LNJ308G81/1-3/X LED

D608 LNJ308G81/1-3/X LED

D609 LNJ308G81/1-3/X LED

D610 LNJ308G81/1-3/X LED

D611 LNJ308G81/1-3/X LED

D612 LNJ308G81/1-3/X LED

D613 LNJ308G81/1-3/X LED

D614 LNJ308G81/1-3/X LED

D615 LNJ308G81/1-3/X LED

D616 LNJ308G81/1-3/X LED

D617 LNJ308G81/1-3/X LED

D618 LNJ308G81/1-3/X LED

D619 LNJ308G81/1-3/X LED

D654 UDZS5.1B- X Z DIODE

C651 NCB31CK-105X C CAPACITOR 1uF 16V K

C652 NBE20JM- 47 5X TA E CAPACITOR 4. 7uF 6.3V M

C653 NCB31HK-68 1X C CAPACITOR 68 0p F 50 V K

R601 NRSA63J-681X MG RESISTOR 680

R602 NRSA63J-561X MG RESISTOR 560

R603 NRSA63J-681X MG RESISTOR 680

R604 NRSA63J-911X MG RESISTOR 910

R605 NRSA63J-681X MG RESISTOR 680

R606 NRSA63J-561X MG RESISTOR 560

R607 NRSA63J-681X MG RESISTOR 680

R608 NRSA63J-911X MG RESISTOR 910

R609 NRSA63J-122X MG RESISTOR 1.2k

R610 NRSA63J-152X MG RESISTOR 1.5k

R611 NRSA63J-222X MG RESISTOR 2.2k

R612 NRSA63J-681X MG RESISTOR 680

R613 NRSA63J-561X MG RESISTOR 560

R614 NRSA63J-681X MG RESISTOR 680

R615 NRSA63J-911X MG RESISTOR 910

R635 NRS181J-221X MG R ESISTOR 220

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/8W J

R636 NRSA02J-122X MG RESISTOR 1.2kΩ 1/10W J

R637 NRSA02J-122X MG RESISTOR 1.2k

R638 NRSA02J-821X MG RESISTOR 820

R639 NRSA02J-821X MG RESISTOR 820

R640 NRSA02J-431X MG RESISTOR 430

R642 NRSA02J-271X MG RESISTOR 270

R644 NRSA02J-271X MG RESISTOR 270

R646 NRSA02J-821X MG RESISTOR 820

R647 NRSA02J-821X MG RESISTOR 820

R648 NRSA02J-431X MG RESISTOR 430

R650 NRSA02J-431X MG RESISTOR 430

R652 NRSA02J-122X MG RESISTOR 1.2k

R653 NRSA02J-122X MG RESISTOR 1.2k

R654 NRSA02J-152X MG RESISTOR 1.5k

R655 NRSA02J-473X MG RESISTOR 47k

R657 NRSA02J-184X MG RESISTOR 180k

R661 NRSA63J-103X MG RESISTOR 10k

R662 NRSA63J-103X MG RESISTOR 10k

R663 NRSA63J-103X MG RESISTOR 10k

CP701 VMC0335-001 PANEL CONNECTOR

S601 NSW0124-001X TACT SW

S602 NSW0124-001X TACT SW

S603 NSW0124-001X TACT SW

S604 NSW0124-001X TACT SW

S605 NSW0124-001X TACT SW

S606 NSW0124-001X TACT SW

S607 NSW0124-001X TACT SW

S608 NSW0124-001X TACT SW

S609 NSW0124-001X TACT SW

S610 NSW0124-001X TACT SW

S611 NSW0124-001X TACT SW

S612 NSW0124-001X TACT SW

S613 NSW0124-001X TACT SW

S614 NSW0124-001X TACT SW

S615 NSW0124-001X TACT SW

S616 NSW0124-001X TACT SW

S617 NSW0124-001X TACT SW

S618 NSW0124-001X TACT SW

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Mechanism control board

(F185_UH3,UN3,U3)

Block No. [0][ 6 ]

Symbol No.

IC901 UPC1228HA IC

C101 QDGB1HK-821Y C CAPACITOR 820pF 50V K

C102 QEKJ1HM-474Z E CAP AC ITOR 0.47uF 50V M

C103 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C104 QEKJ0JM-476Z E C APACITOR 47uF 6.3V M

C105 QFV61HJ-103Z MF CAPACITOR 0.01uF 50V J

C201 QDGB1HK-821Y C CAPACITOR 820pF 50V K

C202 QERF1HM-474Z E CAPACITOR 0.47uF 50V M

C203 QCBB1HK-101Y C CAPACITOR 100pF 50V K

C204 QEKJ0JM-476Z E C APACITOR 47uF 6.3V M

C205 QFV61HJ-103Z MF CAPACITOR 0.01uF 50V J

C901 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

R101 QRE141J-153Y C RESISTOR 15k

R103 QRE141J-101Y C RESISTOR 100

R104 QRE141J-334Y C RESISTOR 330k

R201 QRE141J-153Y C RESISTOR 15k

R203 QRE141J-101Y C RESISTOR 100

R204 QRE141J-334Y C RESISTOR 330k

R901 QRE141J-101Y C RESISTOR 100

CJ901 QGA2002C1-05 CONNECTOR W-B (1-5)

CP721 QGB12 14K1-06S CONNEC TOR B-B (1-6)

CP722 QGA2002F1-06 CONNECTOR W-B (1-6)

CP901 QGB12 14K1-06S CONNEC TOR B-B (1-6)

Part No. Part Name Description Local

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

3-14

Page 33

<MEMO>

3-15

Page 34

Packing materials and accessories parts list

Block No.

3

M

M

M

P1

P7

F185UN, F185UN3,

F185SUN,

F185GUN

A3

P3

A1 A6

F185U,F185U3

F185UH,F185UH3

P7

P2

P3

A1 A4

A5 A6

P3

A1 A5

KIT: A8A7

P4

A10A9 A11

A2

P6

A13

P5

A12

3-16

Page 35

Packing and Accessories

Block No. [M][3][M][M]

Symbol No. Part No. Part Name Descript i on Local

A 1 GET0225-001A INST BOOK F185U,F185U3,F185UH,F1 85 U H3

A 1 GET0225-003A INST BOOK F185GUN,F1 85SUN,F185U N, F185UN3

A 2 GE20137-003A MOUNTING SLEEVE

A 3 GE20135-006A TRIM PLATE F185GUN

A 3 GE20135-003A TRIM PLATE F185SUN

A 3 GE20135-004A TRIM PLATE

A 4 GET0225-002A INST BOOK CHI (TAIWAN) ARA PER F185U,F185U3

A 5 GET0225-004A INSTALL MANUAL F185UH3,F1 85U3

A 5 GET0225-004A INSTALL MANUAL F185UH,F185U

A 6 GET0225-005A INSTALL MANUAL F185U,F185U3

A 6 GET0225-006A INSTALL MANUAL F185GUN,F1 85SUN,F185U N, F185UN3

A 7 VKZ4027-202 PLUG NUT

A 8 VKH4871-003 MOUNT BO LT

A 9 VKZ4328-003 LOCK NUT

A 10 QYWWS53A008 ZA WASHER 0mm/5.3mm x

A 11 GE40130-00 2A HOOK (x2)

A 12 FSJB3002-0 0C HARD CA SE

A 13 QAM0013-007 16P CORD ASSY

KIT SRW-385U SCREW PARTS KIT A7 A8 A9 A10 A11 F185UH

P 1 GE31318-001A CARTON F185GUN

P 1 GE31315-001A CARTON F185SUN

P 1 GE31312-001A CARTON

P 2 QPC03004315P POLY BAG 30cm x 43cm

P 3 FSPG4002-001 POLY BAG

P 4 QPA00801205 POLY BAG 8cm x 12cm

P 5 FSYH4036-068 SHEET

P 6 QPA01003003 POLY BAG 10cm x 30cm

P 7 GE10070-003A EPS CUSHION

F185U,F185U3,F185UH,F185UH3,F185UN

,F185UN3

F185U,F185U3,F185UH,F185UH3,F185UN

,F185UN3

3-17

Page 36

SCHEMATIC DIAGRAMS

CASSETTE RECEIVER

KS-F185,KS-F185S

KS-F185G

CD-ROM No.SML200503

UH ---------------------- Thailand

UN --------------------- Indonesia

U -------------------- Other Areas

UN --------------------- Indonesia

KS-F185

Area suffix

KS-F185S

Area suffix

Contents

Block diagram (For UH,UN,U version)

Standard schematic diagrams (For UH,UN,U version)

Block diagram (For UH3,UN3,U3 version)

Standard schematic diagrams (For UH3,UN3,U3 version)

Printed circuit boards

KS-F185G

Area suffix

UN --------------------- Indonesia

2-1

2-2

2-5

2-6

2-9 to 11

COPYRIGHT 2005 Victor Company of Japan, Limited.

No.MA094BSCH

2005/3

Page 37

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 38

Block diagram

(For UH, UN, U version)

ANT

Mechanism control board

MAIN

MOTOR

MUTE SW

TAPE/RADIO SW

Main amplifier section

J1

Relay board

CP722

CP721

CN721 CP981 CJ921

TO

SPEAKER

CONNECTOR

LFO+,LFO-

RFO+,RFO-

POWER AMP

IC981

LRO+,LRORRO+,RRO-

LINE

REAR OUT

LRO

RRO

Head amplifier section

IC901

HEAD AMP

HEAD

PROG.SW.

CJ901

LCH

RCH

F/R

L1

FM

AM

TU1

FM/AM TUNER PACK

SK/ST

MONO

SD/ST

S.METER

FM.OSC

EO

BAND

IFC/C

IF.C

TAPEIN

PROG

IC701

MICON

TUL, TUR

LCD.SO

LCD.SCK

LCD.CE

KEY0 to KEY2

DETACH

LFO

RFO

IC931

E.VOL

DI

CL

CE

LRO

RRO

TAPE.L, TAPE.R

F/R

CN901

CJ701

CP901

LCH

RCH

LCD & Key control section

DATA

CLOCK

CP701

CE

KEY0 to KEY2

LCD1

S3 to S47

COM1 to COM3

IC651

LCD DRIVER

S601 to S618

KEY

2-1

Page 39

Standard schematic diagrams

Main amplifier section

J1

QNB0100-002

L1

4.7u

10

R1

1K

R2

1K

R3

D1

1SS119-041

R774

To CP701

(SHEET 3)

CN721

QGB1214J1-06S

To CP721

(SHEET 2)

To CP901

(SHEET 2)

CJ701

VMC0334-001

CN901

QGB1214J1-06S

R719

R718

R720

D711

C713

0.1

MTZJ6.2B-T2

C772

2.2/50

KTC3199/GL/-T

3.3K

3.3K

3.3K

D705

D704

D706

MTZJ6.2B-T2

MTZJ6.2B-T2

MTZJ6.2B-T2

R704

R705

C773

0.001

Q772

D707

C714

0.1

MTZJ6.2B-T2

D718

1SS119-041

10K

47K

R715

C709

1.5K

R773

1K

Q771

KTC3199/GL/-T

C710

D708

D709

0.1

MTZJ6.2B-T2

MTZJ6.2B-T2

Q701

KTC3199/GL/-T

2.2k

0.47/50

1A3G-T1

C715

0.1

L783

47u

D786

LCD.SO

LCD.SCK

LCD.CE

DETACH

TAPE14V

TAPEIN

TAPE.L

TAPE.R

R772

10K

ACC5V

KEY2

KEY1

KEY0

PROG

F/R

C771

220/10

R771

D771

Q3

4.7K

MTZJ9.1C-T2

1SS119-041

D792

Q1

2SA1706/ST/-TKTA1267/YG/-T

10K

R6

1K

R5

D791

1SS119-041

R17

2.2K

Q2

KRC102M-T

BAND

1SS119-041

1SS119-041

1SS119-041

SK/ST

MONO

(For UH, UN, U version)

TU1

QAU0311-001

10/16

R725

R702

R703

R707

R708

0.022

C2

C10

C708

0.1/50

C4

C5

R10

B69

FM.OSC

IFC/C

IC701

LC72362N-9C64

0.1

47K

47K

47K

47K

47K

IFC/C

C6

10k

0.33

C11

Q4

KRC102M-T

10K

R9

SK/ST

C7

D4

D3

R14

8.2k

1SS119-041

R15

22k

R16

1SS119-041

SSM

TAPEIN

SD/ST

F/R

PROG

D701

D714

D715

D713

10K

R4

TU-9V

D2

EO

1SS119-041

0.1/50

C3

1SS119-041

C786

220/10

R727

47K

Q5

KRC102M-T

MONO

CE

CL

SSM

10k

R928R711

220k

SD/ST

DETACH

0.1/50

C8

R724

0.01

C15

DI

4.7K

R52

S.METER

LCD.CE

LCD.SCK

BUS.INT

R51

1/50

C131

LCD.SO

BAND

Q989

KRA102M-T

C133

1/50

C233

L781

Q789

KRA102M-T

1SS119-041

1SS119-041

C943

1/50

1/50

47u

R789

R790

470K

ACC.MUTE

MUTE2

D161

D261

SI/SO

C933

100K

SCK

R796

C134

0.082

C942

0.0015

C234

1SS119-041

R795

18K

47K

LRO

RRO

CD.RCH

C783

C135

C235

R232 R132

Q782

D781

2200/6.3

R163

1K

R165

2.2K

R265

2.2K

R263

CP751

QNZ0095-001

14V

0.082

0.15

C136

C236

7.5k 7.5k

2SA1706/ST/-T

1K

R784

Q781

KRC102M-T

KRA102M-T

10K

R990

1K

SCK

3.9k

R131

0.15

C137

C237

47K

R783

Q987

KRC102M-T

SI/SO

C150

1/50

C940

C941

C238

R231

R931

C784

220/10

D782

1SS119-041

Q988

2SD2144S/VW/-T2SD2144S/VW/-T

Q261 Q161

CD.LCH

2.2/50

C250

C781

10/16

10

QNN0519-001

R164

100

R264

100

2.2/50

C160

R941

C260

C785

10/16

IC781

AN80T05LF

C987

10/16

CJ921

CE

3.3k

100/10

C931

D784

1A3G-T1

R985

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

47k

R722

3.3K

C707

LRO

R721

C932

0.01

R999

CL

RRO

R993

C977

27K

0.22

C997

470P

1A3G-T1

0.22

C976

R992

27K

R997

47k

R991

27K

R994

27K

R996

47k

C981

2200/16

D981

1N5401-TM

R787

QQR1367-001

R797

12K

R788

2.4K

C975

0.22

C995

470P

C994

470P

C974

0.22

C996

470P

R998

47k

100

C984

10/16

3.3K

0.1

0.1

C138

L981

D785

C985

4.7/25

C983

0.1

C986

22/16

C982

47/16

C989

10/16

R973

4.7K

ACC.MUTE

C992

0.1

C991

LRO+

0.1

RRO+

RRO-

RFO+

RRO+

LRO+

LFO+

RFO-

RRO-

LRO-

LFO-

DI

4.7k

LRO-

RFO+

LFO+

C993

0.1

RFO-

R972

2.7K

C990

0.1

LFO-

IC981

LA4743K

Q971

KRC102M-T

MUTE2

D974

1SS119-041

CP981

QNZ0611-001

QAM0013-007

SHEET 1

Q972

10K

D990

MEM.DET

MTZJ11B-T2

C972

100

R759

1K

1K

R753

47K

TAPE.L

TAPE.R

Q784

2SA1706/ST/-T

R786

1K

KRA102M-T

220/10

R755

R754

TUR

C705

10/16

R756

100

330K

CD.RCH

C132

1/50

C232

1/50

R757

47K

R758

100

R785

L782

47u

47K

C934

22/16

RB721Q-40-T2

47K

C988

47/16

CD.LCH

IC931

PT2319-X

TUL

C13

R792

6.8

D961

1SS119-041

D973

MUTE

C9

0.01

BUS.INT

BUS.SCK

R61

1/50

R62

C231