Page 1

SERVICE MANUAL

CD RECEIVER

4985820035

KD-S845

D

45Wx4

7

10

8

9

KD-S845

11

12

RPT

N

BA

TUNER

RND

SCM

Area Suffix

U ------- Other Areas

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.49858

2003/5

Page 2

1.1 Safety Precautions

SECTION 1

Important Safety Precautions

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2 (No.49858)

Page 3

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conducti ve sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Grou nd yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before insta llation, both sides of the lase r diode on the replacement o ptical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CDpickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

Short-circuit point

Pickup

Pickup

(No.49858)1-3

Page 4

SECTION 2

Disassembly method

2.1 Main body

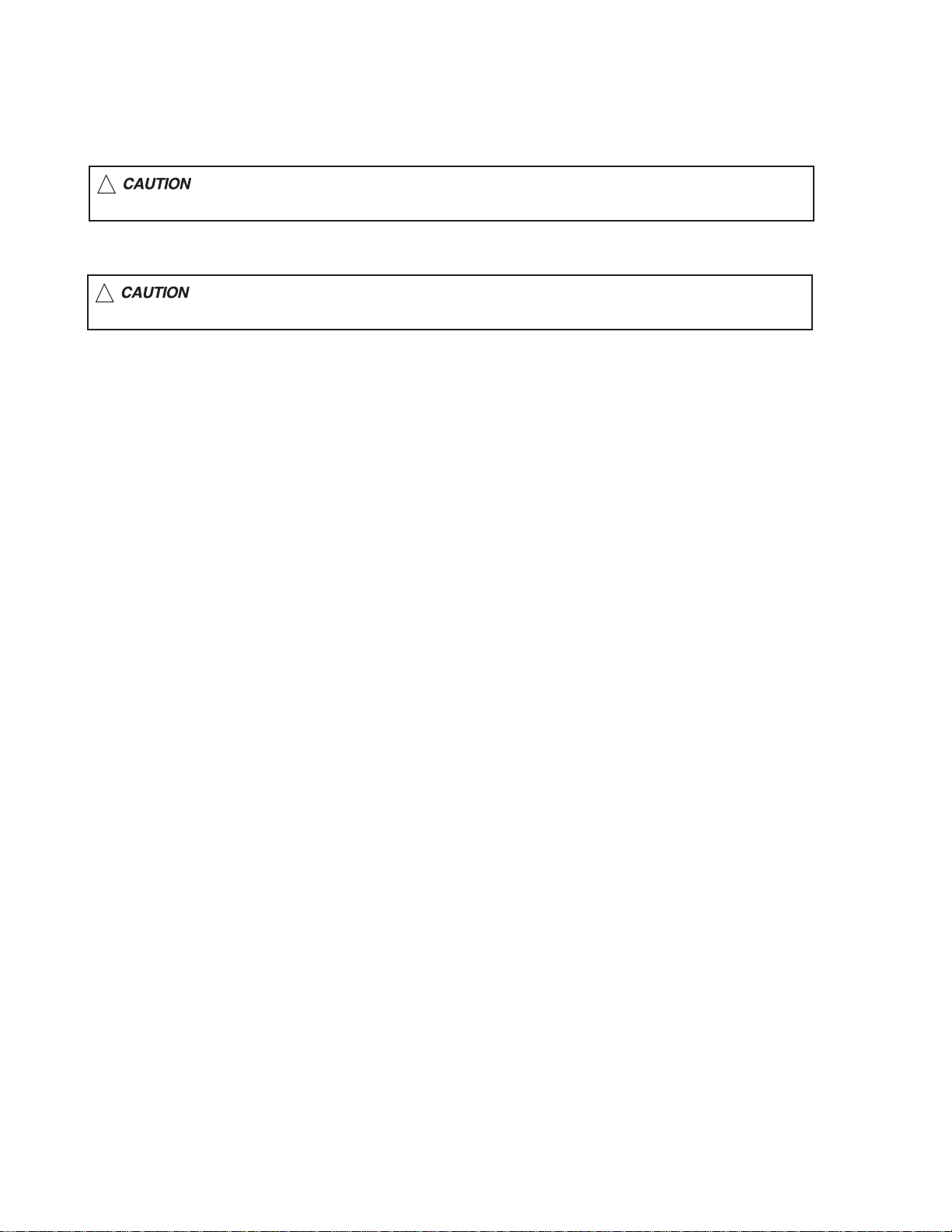

2.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button in the lower left part of the front

panel and remove the front panel assembly in the direction

of the arrow.

2.1.2 Removing the front chassis assembly

(See Figs.2 to 3)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Release the two joints a and two joints b on both sides of

the main body.

(2) Release the two joints c on the bottom side of the main

body and remove the front chassis assembly in the direction of the arrow.

Front panel assembly

Joint

a

Fig.1

Eject button

Joint

b

Joint

a

Front chassis assembly

Joint c Joint c

Fig.2

Front chassis assembly

Fig.3

Joint

b

1-4 (No.49858)

Page 5

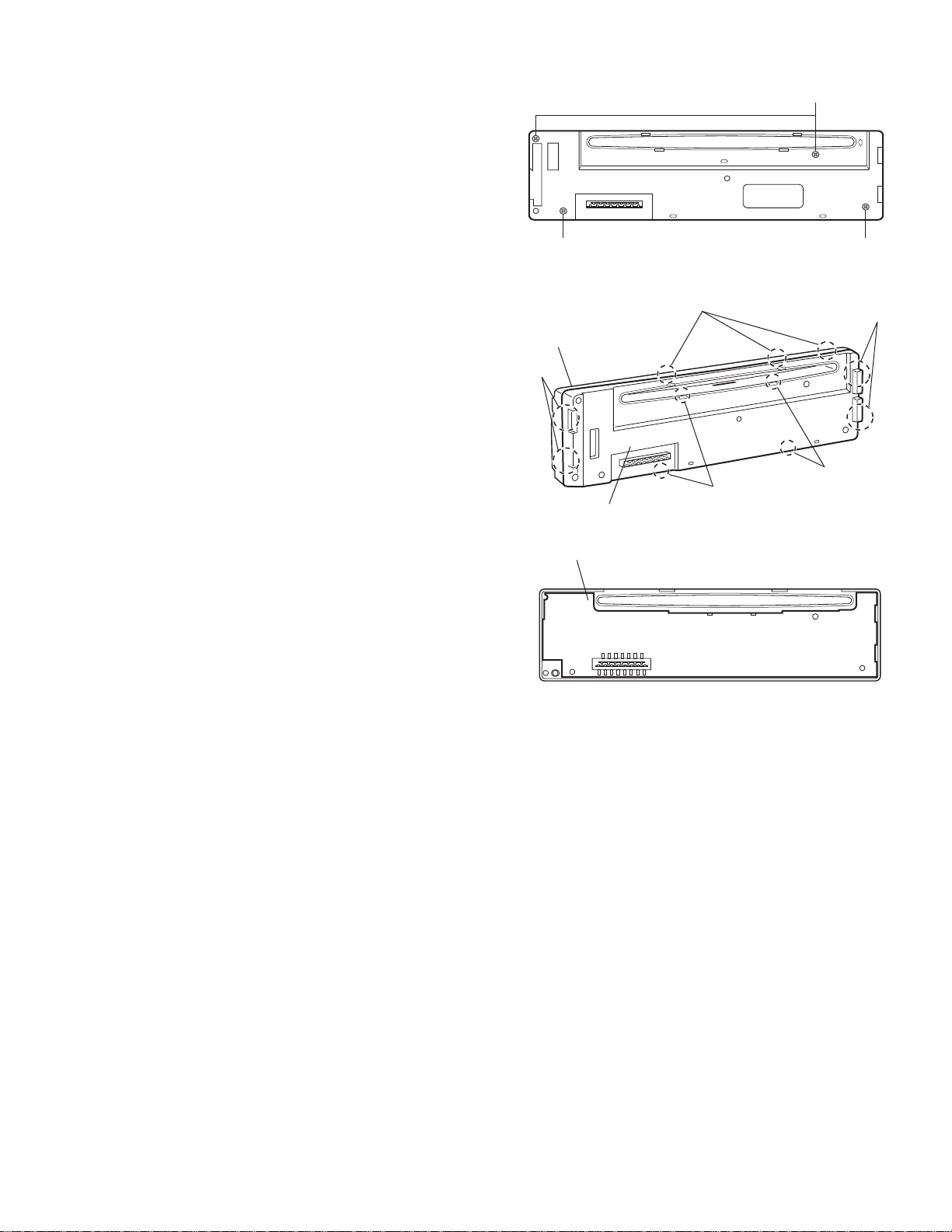

2.1.3 Removing the heat sink

(See Fig.4)

(1) Remove the three screws A on the left side of the main

body.

2.1.4 Removing the bottom cover

(See Figs.5 and 6)

• Prior to performing the following procedure, remove the front

panel assembly, front chassis assembly and heat sink.

(1) Turn over the main body and relea se the two joints d, two

joints e and joint f.

CAUTION:

Do not damage the main board when releasing the joint f using

a screwdriver. (See Figs.5 and 6)

A

Joint d

Joint f

Rear panel

Bottom cover

Heat sink

Fig.4

Fig.5

A

Bottom cover

Joint e

Joint e

Joint d

Joint f

Rear panel

Fig.6

(No.49858)1-5

Page 6

2.1.5 Removing the rear bracket

(See Fig.7)

• Prior to performing the following procedure, remove the front

panel assembly, front chassis assembly, heat sink and bottom

cover.

(1) Remo v e the one screws B, for screws C and three screws

D on the back side of the main body.

(2) Remove the rear bracket.

CC

Rear bracket

2.1.6 Removing the main board

(See Fig.8)

• Prior to performing the following procedure, remove the front

panel assembly, front chassis assembly, heat sink, bottom

cover and rear bracket

(1) Remove the two screws E attaching the main board.

(2) Disconnect the connector CN501 and remove the main

board.

2.1.7 Removing the CD mechanism assembly

(See Fig. 9)

• Prior to performing the following procedure, remove the front

panel assembly, front chassis assembly, heat sink, bottom

cover, rear bracket, main board and CD mecha board.

(1) Remove the three screws F.

F

B

E

Top chassis

DD

Fig.7

Main board assembly

E

CN501

Fig.8

CD mechanism section

F

1-6 (No.49858)

F

Fig.9

Page 7

2.1.8 Removing the front board

(See Figs. 10 to 12)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the fo ur screws G on the back side of the front

panel assembly.

(2) Release the ten joints g.

(3) Take out the front board.

G

GG

Fig.10

Front panel

Joint g

Rear cover

Front board

Joint g

Joint g

Fig.11

Fig.12

Joint g

Joint g

(No.49858)1-7

Page 8

2.2 CD mechanism section

2.2.1 Removing the CD mechanism control board

(See Fig.1 and 2)

(1) Unsolde r the part a and b on the CD mechanism control

board.

(2) Remove the stator fixing the CD mechanism control board

and the damper bracket (To remove the stator smoothly,

pick up the center part).

(3) Remove the screw A attaching the CD mechanism control

board.

(4) Re move the CD mechanism control board in the direction

of the arrow while releasing it from the two damper bracket

slots d and the front bracket slot e.

(5) Disco nnect the flexible wire from connector on the pickup

unit.

ATTENTION:

Turn the FD gear in the direction of the arrow to move the entire pickup unit to the appropriate position where the flexible

wire of the CD mechanism unit can be disconnected easily.(Refer to Fig.2)

CD mechanism assembly

D

h

Front bracket

Pickup unit

Damper bracket

D

A

Fig.1

e

b

Flexible wire

a

h

c

D

d

CD mechanism

control board

FD gear

Shift the lock

Fig.2

1-8 (No.49858)

Page 9

2.2.2 Removing the loading motor

(See Fig.3 to 5)

• Rrior to performing the following procedure, remove the CD

mechanism control board.

(1) Remove the two springs f attaching the CD mechanism as-

sembly and the front bracket.

(2) Remove the two screws B and the front bracket while pull-

ing the flame outward.

(3) Remove the belt and the screw C from the loading motor.

CD mechanism control board

f

f

B

Loading motor

Pull outward Pull outward

Flame

Loading motor

Front bracket

Fig.3

Front bracket

Fig.4

C

Fig.5

Belt

(No.49858)1-9

Page 10

2.2.3 Removing the CD mechanism assembly

(See Fig.1, 6 to 9)

• Prior to performing the following procedure, remove the CD

mechanism control board and the front bracket (loading motor).

(1) Remove the three screws D and the damper bracket.

(2) Raise the both sides fix arms and move the fix plates in the

direction of the arrow to place the four shafts g as shown in

Fig.8 and 9.

(3) Remove the CD mechanism assembly and the two springs

h attaching the flame.

(4) Remove the two screws E and both sides rear damper

brackets from the dampers. Detach the CD mechanism assembly from the left side to the right side.

ATTENTION:

The CD mechanism assembly can be removed if only the rear

damper bracket on the left side is removed.

CD mechanism

D

Flame

Fix plate (L)

assembly

h

D

Rear damper bracket

Fig.6

Fig.7

Damper bracket

D

D

E

h

Fix arm (L)

g

Fix arm (R)

Damper

g

Fig.8

Rear damper bracket

E

Fix plate(R)

g

Fig.9

Fig.9

Damper

g

1-10 (No.49858)

Page 11

2.2.4 Removing the feed motor assembly

(See Fig.10)

• Prior to performing the following procedure, remove the CD

mechanism control board, the front bracket (loading motor)

and the CD mechanism assembly.

(1) Remove the two screws F and the feed motor assembly.

Feed motor assembly

F

FD screw

Part i

Part j

Pickup unit

2.2.5 Removing the pickup unit

(See Fig.10 and 11)

• Prior to performing the following procedure, remove the CD

mechanism control board, the front bracket (loading motor),

the CD mechanism assembly and the feed motor assembly.

(1) Detach the FD gear part of the pickup unit upward. Then re-

move the pickup unit while pulling out the part i of the FD

screw.

ATTENTION:

When reattaching the pickup unit, reattach the part j of

the pickup unit, then the part i of the FD screw.

(2) Remove th e screw G attaching the nut push spring plate

and the pickup mount nut from the pickup unit. Pull out the

FD screw.

2.2.6 Removing the spindle motor

(See Fig.12 and 13)

• Prior to performing the following procedure, remove the CD

mechanism control board, the front bracket (loading motor),

the CD mechanism assembly and the feed motor assembly.

(1) Turn up the CD mechanism assembly and remove the two

springs k on both sides of the clamper arms. Open the

clamper arm upward.

(2) Turn the turn table, and remove the two screws H and the

spindle motor.

FD gear

Nut push spring plate

FD screw

Spindle motor

Pickup unit

Fig.10

G

Pickup mount nut

Pickup unit

Fig.11

H

H

k

Fig.12

k

Fig.13

(No.49858)1-11

Page 12

3.1 Adjustment method

SECTION 3

Adjustment

Test instruments required for adjustment

1. Digital oscilloscope (100MHz)

2. AM Standard signal generator

3. FM Standard signal generator

4. Stereo modulator

5. Electric voltmeter

6. Digital tester

7. Tracking offset meter

8. Test Disc JVC :CTS-1000

9. Extension cable for check

EXTGS004-26P 1

Standard measuring conditions

Power supply voltage DC14.4V(10.5~16V)

Load impedance 4 (2 Speakers connection)

Line oout impeadance 20k

Output Level Line out 2.0V (Vol. MAX)

How to connect the extension cable for adjusting

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

BBE : OFF

Frequency Band

FM 87.5MHz to 108.0MHz

AM

Dummy load

Exclusive dummy load should be used for AM, and FM. For

FM dummy load, there is a loss of 6dB between SSG output

and antenna input. The loss of 6dB need not be considered

since direct reading of figures are applied in this working

standard.

531 kHz to 1602 kHz

1-12 (No.49858)

EXTGS004-26P

Page 13

3.2 Flow of functional operation unit TOC read

When the pickup correctly moves

v

to the inner area of the disc

Power ON

Set Function CD

When the laser diode correctly

emits

Microprocessor

commands

FMO

TC9490FA "40"

FEED MOTOR

+TERMINAL

IC501 "7"

REST SW

When correctly focused

FOO

TA2157 "15"

Focus Servo Loop ON

$83

$82

$81

3.3V

Hi-Z

0V

6V

4V

2V

OFF

ON

Pickup feed to the inner area

2.2V

RF signal eye-pattern

remains closed

Disc inserted

YES

Laser emitted

Focus search

Disc rotates

Tracking loop closed

YES

Microprocessor

commands

SEL

TC9490FA"38"

LD

CN601"1"

"No disc"

display

When the disc correctly rotates

Microprocessor

commands

DMO

TC9490FA "41"

$84 $86 $ A200

$84

3.3V

0V

4V

0V

3.3V

2.2V

0V

RF signal eye-pattern

opens

TOC read out

Jump to the first track

Play

Spindle

motor(-)

IC501 "4"

Acceleration Servo CLV

Tracking Servo Loop ON

RF signal

6V

3.2

2V

Rough

Servo

0.5 Sec 0.5 Sec

Rough Servo Mode

CLV Servo Mode

(Program Area)

CLV Servo Mode

(Lead-In Area;

Digital :0)

(No.49858)1-13

Page 14

PARTS LIST

[ KD-S845 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

KD-S845

U --------------------- Other Areas

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD mechanism assembly and parts list (Block No.MB)

Electrical parts list (Block No.01~02)

Packing materials and accessories parts list (Block No.M3)

3-2

3-4

3-6

3-12

No. 49858 3-1

Page 15

KD-S845

Exploded view of general assembly and parts list

Block No.

8

54

55

56

8

56

8

49

51

3

7

10

7

50

A

52

53

Main board

B

C

5

48

9

13

16

9

12

11

36

35

15

14

36

57

4

39

45

M

38

41

40

44

37

M

1

M

42

43

3-2

31

A

28

26

Front

board

19

27

24

21

17

20

34

25

2

B

1

6

29

6

47

46

6

30

23

22

33

32

18

Page 16

General assembly

Block No. [M][1][M][M]

Symbol No.

1 ------------ CD MECHA

2 FSJC1029-401 TOP CHASSIS

3 FSMH3001-202 SIDE PANEL

4 FSKM3011-002 BOTTOM COVER

5 FSMA3004-203 INSULATOR

6 QYSDST2604Z SCREW 2.6mm x 4mm(x3)

7 FSKZ4005-001 SCREW (x2)

8 QYSDST2604Z SCREW 2.6mm x 4mm(x3)

9 QYSDST2606Z SCREW 2.6mm x 6mm(x2)

10 FSKZ4005-001 S CR EW

11 FSJC2013-014 FRONT CHASSIS

12 FSKS3010-001 LOCK LEVER

13 FSKW4005-003 TORSION SPRING

14 FSXP3026-002 RLS KNOB

15 FSKW3002-015 COMP.SPRING

16 FSPK3009-002 BLIND

17 GE10003-003A FRONT PANEL

18 GE30111-034A FINDER ASSY

19 GE20104-004A PRESET BUTTON

20 FSYH4036-069 SHEET (x2)

21 GE30105-002B POWER BUTTON

22 GE30109-002A EJECT BUTTON

23 GE20110-010C D.FUNC.BUTTO N

24 GE30112-001A PUSH BUTTON(2)

25 GE40102-001A REMOTE LENS

26 GE30366-001A SEL BUTTON

27 FSYH4036-032 SHEET

28 GE30546-004A KNOB

29 GE30104-002A RIM LENS

30 GE20109-002C UP/DOWN BUTTON

31 GE30106-001A SND FUNC BUTTON

32 FSXP3055-001 DETACH BUTTON

33 FSKW3002-012 COMP.SPRING

34 GE30117-001A LIGHT LENS

35 GE10004-004B REAR COVER

36 VKZ4777-001 MINI SCREW (x4)

37 GE30276-001A LCD CASE

38 FSJK3025-001 LCD LENS

39 FSKS3019-001 LENS CASE

40 FSYH4074-001 LIGHTING SHEET

41 FSYH4071-001 LIGHTING SHEET

42 GE30939-001A NAME PLATE

43 LV41843-001A LASER CAUTION

44 QLD0225-001 LCD MODULE

45 QNZ0442-001 LCD CONNECTOR

46 QYSDST2004Z SCREW 2mm x 4mm

47 LV40847-002A SPACER

48 VMA4652-001SS SHIELD PLATE

49 QMFZ047-150-T FUSE 15A

50 FSKM3010-020 REAR BRACKET

51 FSKL4024-001 IC BRACKET

52 GE40107-002A HEAT SINK

53 GE40103-002A REG BRACKET

54 QYSDST2606Z SCREW 2.6mm x 6mm

55 QYSDSF3006Z SCREW 3mm x 6mm

56 QYSDST2606Z SCREW 2.6mm x 6mm(x3)

57 GE30854-001A LED HOLDER

Part No. Part Name Description Local

KD-S845

3-3

Page 17

KD-S845

CD mechanism assembly and parts list

Grease

G-31SA

G-31SA(Bottom side)

RX-405

102

23

Block No.

TN-CCD1001Z-138S

M

49

M

B

M

12

90

91

b

113

14

70

3

80

101

16

71

86

1

102

23

101

101

101

15

113

100

7

20

62

67

42

62

64

a

b

c

68

d

110

61

72

41

50

10

9

13

2

4

100

7

6

19

18

8

48

43

65

66

11

105

103

135

17

5

134

3-4

88

93

102

c

62

79

22

133

101

82

81

117

22

108

89

92

49

116

84

107

36

131

56

107

d

107

33

106

49

d

130

29

38

108

32

40

39

106

132

a

104

51

63

107

57

Page 18

CD mechanism

Block No. [M][B][M][M]

Symbol No.

1 30310101T FRAME

2 30310103T DANPER PIN (x2)

3 30310107T UPPER PL

4 30310108T SEL STOP PL

5 30310142T SEL ARM (L)L

6 30310143T SEL ARM (R)L

7 30310145T S ARM SPRING(L) (x2)

8 30310112T TRIG LV R

9 30310155T TRIG PL(Z)

10 30310115T TRIG PL SPRING

11 30310116T TRIG ARM

12 30310134T FIX ARM (L)B

13 30310159T FIX ARM (R)Z

14 30310150T FIX PL (L)Z

15 30310156T FIX PL (R) Z

16 30310138T LDG GR (6)B

17 30310122T LDG GR (6)SP

18 30310148T S.L ARM(N)

19 30310125T S.L ARM SPRING

20 30310149T REAR DAM BKT(Z)

22 30310151T HUNG UP SP (FZ) (x2)

23 30310129T HUNG UP SP (R) (x2)

29 30300510T PU GEAR(B)

32 30310544T F.M.BASE(Z)

33 30310547T FD GR BLK(Z)

36 30310546T PU GUIDE(Z)

38 30310533T THRUST SPR(M)

39 30310577T PU M NUT(Z-S)

40 30310512T NUT PUSH SPR PL

41 30310558T CLP ARM(Z)

42 30310514T CLP ARM SPRING

43 30310552T CLAMPER(Z)

48 30310557T CLAMPER PLATE(Z

49 30310524T DAMPER (J) (x3)

50 30310525T CLP ARM SPR (L)

51 30310545T F SCREW GUIDE(Z

56 64180405T DET SW

57 QAL0230-001 C.D PICK (SONY)

61 30311035T FPC HOLDER(Z)

62 19501403T WIRE CLUMPER (x4)

63 30311045T PICK UP FPC(Z-S

64 30311044T CONNECT.PCB(Z-S

65 30311038T WIRE (5P-Z)

66 30311039T WIRE (LD-Z)

67 30311040T WIRE (FD-Z)

68 30311041T WIRE (RS-Z)

70 64180402T DET SW (x2)

71 64180403T DET SW (x2)

72 68150242T CONNECTOR

79 30311105T SOPPORT PL

80 30311138T GR MT BLK(N)

81 30311109T LDG GR (2)

82 30311110T LDG GR (3)

84 30311112T LDG GR (5)

86 30311136T LDG ROLLER (x2)

88 30311118T L.P SP (L)

89 30311119T L.P SP (R)

90 30311123T SW PCB

91 30311124T SW ACTR

92 30311129T LDG BELT

93 30311140T FRONT BRKT (J)

100 9C0620503T C B TAP SCREW (x2)

101 9C2020401T C SCREW TS.G (x5)

102 9C4320403T C B TAP SCREW (x4)

103 9C0117223T SCREW (x2)

104 9C0917703T C TAP SCREW S3

105 9C0320201T C TAP SCREW S3

106 9C4920013T C TAP SCREW S3 (x2)

107 9C4920603T C TAP SCREW B3 (x4)

108 9P0220031T TAMS SCREW (x2)

110 9C0420253 C TAP SCREW

113 9W0330276 NW BLUE (x2)

116 9W0725030T LUMILAR W

117 9W0640030T WASHER

Part No. Part Name Description Local

Symbol No.

130 303105310T FEED MO ASSY

131 303105311T SPINDLE MO ASSY

132 303105312T FEED SCREW ASSY

133 303111301T LDG MOTOR ASSY

134 303111302T RDG RLR SFT ASY

135 303105502T T.T.BASE ASSY

Part No. Part Name Description Local

KD-S845

3-5

Page 19

KD-S845

Electrical parts list

Main board

Symbol No.

IC31 TB2118F-X PLL IC

IC161 TEA6320T-X IC

IC301 LA4743K POWER IC

IC401 TC94A02F-005 IC

IC451 K6R1008VDTI10-X SRAM IC

IC461 NJU7241F25-X IC

IC471 NJU7241F33-X IC

IC501 LA6574H-X BTL DRIVER

IC521 TA2147F-X IC

IC541 TC9490FA IC

IC581 NJM4565M-WE IC

IC701

IC702 IC-PST600M/G/-W IC

IC901 AN80T07 IC

Q1 2SD601A/R/-X TRANSISTOR

Q2 2SD601A/R/-X TRANSISTOR

Q3 UN2111-X TRANSISTOR

Q5 2SB709A/R/-X TRANSISTOR

Q6 2SB815/7/-X TRANSISTOR

Q7 UN2211-X TRANSISTOR

Q31 UN2211-X TRANSISTOR

Q241 2SD601A/R/-X TRANSISTOR

Q321 2SD1781K/QR/-X TRANSISTOR

Q331 2SD1781K/QR/-X TRANSISTOR

Q341 2SD1781K/QR/-X TRANSISTOR

Q351 2SD1781K/QR/-X TRANSISTOR

Q430 UN2211-X TRANSISTOR

Q440 UN2211-X TRANSISTOR

Q501 2SB1322/RS/-T TRANSISTOR

Q521 2SB1241/QR/-T TRANSISTOR

Q541 UN2111-X TRANSISTOR

Q542 UN2211-X TRANSISTOR

Q781 UN2111-X TRANSISTOR

Q782 UN2211-X TRANSISTOR

Q784 UN2111-X TRANSISTOR

Q976 UN2211-X TRANSISTOR

Q977 2SA1037AK/RS/-X TRANSISTOR

Q981 2SD601A/R/-X TRANSISTOR

D1 1SS133-T1 SI DIODE

D2 1SS133-T1 SI DIODE

D4 1SS355-X SI DIODE

D5 1SS355-X SI DIODE

D240 1SS355-X SI DIODE

D241 1SS355-X SI DIODE

D242 1SS133-T1 SI DIODE

D243 1SS133-T1 SI DIODE

D321 1SS355-X SI DIODE

D331 1SS355-X SI DIODE

D341 1SS355-X SI DIODE

D351 1SS355-X SI DIODE

D501 1A3G-T1 SI DIODE

D701 UDZS6.2B-X Z DIODE

D702 UDZS6.2B-X Z DIODE

D703 UDZS6.2B-X Z DIODE

D704 UDZS6.2B-X Z DIODE

D705 UDZS6.2B-X Z DIODE

D706 UDZS6.2B-X Z DIODE

D707 UDZS6.2B-X Z DIODE

D708 UDZS6.2B-X Z DIODE

D709 UDZS6.2B-X Z DIODE

D710 1SS355-X SI DIODE

D712 UDZS6.2B-X Z DIODE

D781 1SS133-T1 SI DIODE

D782 1SS133-T1 SI DIODE

D784 UDZS11B-X Z DIODE

D851 RB160M-30-X SB DIODE

D852 RB160M-30-X SB DIODE

D901 1N5401-TU-15 DIODE

D902 1SS355-X SI DIODE

D971 RB160M-30-X SB DIODE

Part No. Part Name Description Local

UPD784215AGC184

IC

Block No. [0][1][0][0]

Symbol No.

D972 RB160M-30-X SB DIODE

D981 1SS355-X SI DIODE

D982 1SS355-X SI DIODE

C1 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C2 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C3 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C4 QERF1AM-227Z E CAPACITOR 220uF 10V M

C5 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C6 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C10 QERF1CM-106Z E CAPACITOR 10uF 16V M

C11 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C31 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

C32 NDC31HJ-470X C CAPACITOR 47pF 50V J

C33 QERF0JM-476Z E CAPACITOR 47uF 6.3V M

C34 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C35 NDC31HJ-100X C CAPACITOR 10pF 50V J

C36 NDC31HJ-7R0X C CAPACITOR 7pF 50V J

C37 NDC31HJ-100X C CAPACITOR 10pF 50V J

C38 NCB31HK-102X C CAPACITOR 1000pF 50V K

C39 NCB31HK-102X C CAPACITOR 1000pF 50V K

C40 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C41 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C42 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C43 QFV61HJ-473Z MF CAPACITOR 0.047uF 50V J

C44 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C45 NCB31HK-272X C CAPACITOR 2700pF 50V K

C46 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C47 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C48 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C49 NCB31HK-102X C CAPACITOR 1000pF 50V K

C50 NCS31HJ-101X C CAPACITOR 100pF 50V J

C51 NCS31HJ-331X C CAPACITOR 330pF 50V J

C81 QERF1HM-105Z E CAPACITOR 1uF 50V M

C82 NCB31HK-562X C CAPACITOR 5600pF 50V K

C84 NCB31HK-183X C CAPACITOR 0.018uF 50V K

C91 QERF1HM-105Z E CAPACITOR 1uF 50V M

C92 NCB31HK-562X C CAPACITOR 5600pF 50V K

C94 NCB31HK-183X C CAPACITOR 0.018uF 50V K

C161 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C162 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C164 NCB31HK-822X C CAPACITOR 8200pF 50V K

C165 NCB21CK-154X C CAPACITOR 0.15uF 16V K

C166 NCB21CK-224X C CAPACITOR 0.22uF 16V K

C167 NCB31EK-333X C CAPACIT O R 0.033uF 25V K

C168 NCB31HK-562X C CAPACITOR 5600pF 50V K

C169 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C170 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C171 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C172 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C174 NCB31HK-822X C CAPACITOR 8200pF 50V K

C175 NCB21CK-154X C CAPACITOR 0.15uF 16V K

C176 NCB21CK-224X C CAPACITOR 0.22uF 16V K

C177 NCB31EK-333X C CAPACIT O R 0.033uF 25V K

C178 NCB31HK-562X C CAPACITOR 5600pF 50V K

C179 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C180 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C191 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C192 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

C193 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

C194 NCB31EK-823X C CAPACIT O R 0.082uF 25V K

C241 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C242 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C243 NCB31EK-473X C CAPACIT O R 0.047uF 25V K

C244 QEKJ1HM-224Z E CAPACITOR 0.22uF 50V M

C301 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C302 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C303 NCS31HJ-391X C CAPACITOR 390pF 50V J

C304 NCS31HJ-391X C CAPACITOR 390pF 50V J

C311 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C312 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C313 NCS31HJ-391X C CAPACITOR 390pF 50V J

C314 NCS31HJ-391X C CAPACITOR 390pF 50V J

C315 QERF1EM-475Z E CAPACITOR 4.7uF 25V M

Part No. Part Name Description Local

3-6

Page 20

Symbol No.

Part No. Part Name Description Local

Symbol No.

KD-S845

Part No. Part Name Description Local

C316 QERF1EM-475Z E CAPACITOR 4.7uF 25V M

C317 QERF1CM-476Z E CAPACITOR 47uF 16V M

C318 QEKJ1CM-226Z E CAPA CITOR 22uF 16V M

C319 NCB31EK-223X C CAPACIT O R 0.022uF 25V K

C320 NCB31EK-223X C CAPACIT O R 0.022uF 25V K

C321 NCB31EK-473X C CAPACIT O R 0.047uF 25V K

C322 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C323 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C324 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C325 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C341 NCB31EK-473X C CAPACIT O R 0.047uF 25V K

C403 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C404 QERF1AM-107Z E CAPACITOR 100uF 10V M

C405 QERF1AM-107Z E CAPACITOR 100uF 10V M

C406 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C407 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C408 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C409 QERF1AM-107Z E CAPACITOR 100uF 10V M

C410 QERF1AM-107Z E CAPACITOR 100uF 10V M

C411 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C412 NCB31AK-334X C CAPACIT O R 0.33uF 10V K

C413 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C414 QERF1AM-107Z E CAPACITOR 100uF 10V M

C416 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C418 QERF1AM-107Z E CAPACITOR 100uF 10V M

C419 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C420 NDC31HJ-220X C CAPACITOR 22pF 50V J

C421 NDC31HJ-220X C CAPACITOR 22pF 50V J

C422 NCB31EK-273X C CAPACIT O R 0.027uF 25V K

C423 NCB31HK-221X C CAPACITOR 220pF 50V K

C424 NCB31EK-223X C CAPACIT O R 0.022uF 25V K

C430 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C440 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C451 QERF1AM-107Z E CAPACITOR 100uF 10V M

C452 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C453 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C454 NCS31HJ-102X C CAPACITOR 1000pF 50V J

C461 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C462 QERF0JM-107Z E CAPACITOR 100uF 6.3V M

C463 QERF0JM-107Z E CAPACITOR 100uF 6.3V M

C464 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C471 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C472 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C473 QEKJ0JM-227Z E CAPACITOR 220uF 6.3V M

C474 QEKJ0JM-227Z E CAPACITOR 220uF 6.3V M

C501 QERF1AM-227Z E CAPACITOR 220uF 10V M

C502 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C503 QEDJ1AM-476Z E CAPA CITOR 47uF 10V M

C521 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C522 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C523 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C524 QERF1AM-107Z E CAPACITOR 100uF 10V M

C525 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C526 QERF1AM-107Z E CAPACITOR 100uF 10V M

C527 NCB31HK-682X C CAPACITOR 6800pF 50V K

C528 NDC31HJ-5R0X C CAPACITOR 5pF 50V J

C529 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C530 QERF1AM-107Z E CAPACITOR 100uF 10V M

C531 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C532 NCB31EK-104X C CAPACIT O R 0.1uF 25V K

C533 NDC31HJ-680X C CAPACITOR 68pF 50V J

C541 QERF1AM-107Z E CAPACITOR 100uF 10V M

C542 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C543 QEKJ1HM-105Z E CAPA CITOR 1uF 50V M

C544 QERF1AM-107Z E CAPACITOR 100uF 10V M

C545 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C546 NDC31HJ-470X C CAPACITOR 47pF 50V J

C547 NCB31HK-153X C CAPACITOR 0.015uF 50V K

C548 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C549 NCB31HK-272X C CAPACITOR 2700pF 50V K

C550 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C551 NCB31EK-333X C CAPACIT O R 0.033uF 25V K

C552 NCB31EK-333X C CAPACIT O R 0.033uF 25V K

C553 NCB31EK-473X C CAPACIT O R 0.047uF 25V K

C554 NCB31EK-473X C CAPACIT O R 0.047uF 25V K

C555 NCB31EK-473X C CAPACIT O R 0.047uF 25V K

C556 NCB31HK-471X C CAPACITOR 470pF 50V K

C557 NCB31HK-471X C CAPACITOR 470pF 50V K

C558 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C559 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C560 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C561 QERF1AM-107Z E CAPACITOR 100uF 10V M

C562 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C565 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C566 QERF1AM-107Z E CAPACITOR 100uF 10V M

C567 NCS31HJ-101X C CAPACITOR 100pF 50V J

C568 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C569 QERF1AM-107Z E CAPACITOR 100uF 10V M

C570 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C571 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C581 NCS31HJ-561X C CAPACITOR 560pF 50V J

C582 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C583 QEKJ0JM-476Z E CAPA CITOR 47uF 6.3V M

C584 NCS31HJ-560X C CAPACITOR 56pF 50V J

C591 NCS31HJ-561X C CAPACITOR 560pF 50V J

C592 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C593 QEKJ0JM-476Z E CAPA CITOR 47uF 6.3V M

C594 NCS31HJ-560X C CAPACITOR 56pF 50V J

C595 QEKJ1AM-107Z E CAPACITOR 100uF 10V M

C596 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C701 NDC31HJ-220X C CAPACITOR 22pF 50V J

C702 NDC31HJ-270X C CAPACITOR 27pF 50V J

C703 NDC31HJ-270X C CAPACITOR 27pF 50V J

C704 NDC31HJ-8R0X C CAPACITOR 8pF 50V J

C705 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C706 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C707 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C708 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C709 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C710 QERF0JM-476Z E CAPACITOR 47uF 6.3V M

C711 QERF1AM-227Z E CAPACITOR 220uF 10V M

C712 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C713 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C716 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C717 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C718 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C781 QERF0JM-476Z E CAPACITOR 47uF 6.3V M

C782 NCB31EK-823X C CAPACITOR 0.082uF 25V K

C784 QERF1CM-107Z E CAPACITOR 100uF 16V M

C851 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C852 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C901 QEZ0645-228 E CAPACITOR 2200uF

C902 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C903 QERF1CM-476Z E CAPACITOR 47uF 16V M

C904 QERF1CM-106Z E CAPACITOR 10uF 16V M

C905 QERF1CM-476Z E CAPACITOR 47uF 16V M

C906 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C907 QERF1AM-227Z E CAPACITOR 220uF 10V M

C908 QERF1AM-227Z E CAPACITOR 220uF 10V M

C909 QERF1AM-227Z E CAPACITOR 220uF 10V M

C910 QERF1CM-476Z E CAPACITOR 47uF 16V M

C911 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C912 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C913 QERF1CM-106Z E CAPACITOR 10uF 16V M

C914 QERF1CM-107Z E CAPACITOR 100uF 16V M

C915 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C918 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C919 QERF1CM-106Z E CAPACITOR 10uF 16V M

C920 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C961 NCS31HJ-101X C CAPACITOR 100pF 50V J

C962 NCS31HJ-101X C CAPACITOR 100pF 50V J

C963 NCS31HJ-101X C CAPACITOR 100pF 50V J

C964 NCS31HJ-101X C CAPACITOR 100pF 50V J

C965 NCS31HJ-101X C CAPACITOR 100pF 50V J

C966 NCS31HJ-101X C CAPACITOR 100pF 50V J

C967 NCS31HJ-101X C CAPACITOR 100pF 50V J

C968 NCS31HJ-101X C CAPACITOR 100pF 50V J

C971 NCB31EK-104X C CAPACITOR 0.1uF 25V K

R1 NRS181J-120X MG RESISTOR 12Ω 1/8W J

R2 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R3 NRSA63J-472X MG RESISTOR 4.7k

R4 NRSA63J-332X MG RESISTOR 3.3k

R5 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R6 NRSA63J-473X MG RESISTOR 47k

R7 NRSA63J-472X MG RESISTOR 4.7k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-7

Page 21

KD-S845

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R9 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R10 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R31 NRS181J-100X MG RESISTOR 10Ω 1/8W J

R32 NRSA63J-622X MG RESISTOR 6.2kΩ 1/16W J

R33 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R34 NRSA63J-222X MG RESISTOR 2.2k

R35 NRSA63J-222X MG RESISTOR 2.2k

R36 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R37 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R38 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R39 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R40 NRSA63J-393X MG RESISTOR 39kΩ 1/16W J

R41 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R42 NRS181J-100X MG RESISTOR 10Ω 1/8W J

R43 NRSA63J-471X MG RESISTOR 470Ω 1/16W J

R44 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R51 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R81 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R82 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R91 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R92 NRSA63J-472X MG RESISTOR 4.7k

R161 NRSA63J-224X MG RESISTOR 220k

R162 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R163 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R164 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R165 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R171 NRSA63J-224X MG RESISTOR 220kΩ 1/16W J

R172 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R173 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R174 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R175 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R181 NRSA63J-271X MG RESISTOR 270Ω 1/16W J

R182 NRSA63J-271X MG RESISTOR 270Ω 1/16W J

R241 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R242 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R243 NRSA63J-184X MG RESISTOR 180kΩ 1/16W J

R244 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R245 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R246 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R247 NRSA63J-563X MG RESISTOR 56kΩ 1/16W J

R301 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R302 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R311 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R312 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R321 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R322 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R323 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R331 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R332 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R333 NRSA63J-101X MG RESISTOR 100

R341 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R342 NRSA63J-821X MG RESISTOR 820

R343 NRSA63J-101X MG RESISTOR 100

R351 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R352 NRSA63J-821X MG RESISTOR 820

R353 NRSA63J-101X MG RESISTOR 100

R402 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R404 NRSA63J-103X MG RESISTOR 10k

R408 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R409 NRSA63J-331X MG RESISTOR 330

R410 NRSA63J-331X MG RESISTOR 330

R411 NRSA63J-225X MG RESISTOR 2.2MΩ 1/16W J

R412 NRSA63J-0R0X MG RESISTOR 0

R420 NRSA63J-221X MG RESISTOR 220

R421 NRSA63J-471X MG RESISTOR 470Ω 1/16W J

R422 NRSA63J-223X MG RESISTOR 22k

R423 NRSA63J-473X MG RESISTOR 47k

R424 NRSA63J-221X MG RESISTOR 220

R425 NRSA63J-471X MG RESISTOR 470

R426 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R427 NRSA63J-471X MG RESISTOR 470

R430 NRSA63J-102X MG RESISTOR 1k

R440 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R451 NRSA63J-103X MG RESISTOR 10k

R501 NRSA63J-682X MG RESISTOR 6.8k

R502 NRSA63J-682X MG RESISTOR 6.8kΩ 1/16W J

R503 NRSA63J-562X MG RESISTOR 5.6k

R504 NRSA63J-103X MG RESISTOR 10k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

R506 NRSA63J-822X MG RESISTOR 8.2kΩ 1/16W J

R507 NRSA63J-203X MG RESISTOR 20kΩ 1/16W J

R521 NRSA63J-823X MG RESISTOR 82kΩ 1/16W J

R522 NRSA63J-823X MG RESISTOR 82kΩ 1/16W J

R523 NRSA63J-823X MG RESISTOR 82kΩ 1/16W J

R524 NRSA63J-823X MG RESISTOR 82k

R525 NRSA63J-154X MG RESISTOR 150k

R526 NRSA63J-154X MG RESISTOR 150kΩ 1/16W J

R527 NRSA02J-220X MG RESISTOR 22Ω 1/10W J

R528 NRSA02J-220X MG RESISTOR 22Ω 1/10W J

R529 NRSA63J-823X MG RESISTOR 82kΩ 1/16W J

R530 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R531 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R532 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R533 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R534 NRSA63J-202X MG RESISTOR 2kΩ 1/16W J

R535 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R536 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R537 NRSA63J-273X MG RESISTOR 27kΩ 1/16W J

R541 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R542 NRSA63J-472X MG RESISTOR 4.7k

R543 NRSA63J-472X MG RESISTOR 4.7k

R544 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R545 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R546 NRSA63J-562X MG RESISTOR 5.6kΩ 1/16W J

R547 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R548 NRSA63J-155X MG RESISTOR 1.5MΩ 1/16W J

R549 NRSA63J-474X MG RESISTOR 470kΩ 1/16W J

R550 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R551 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R552 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R553 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R554 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R555 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R556 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R557 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R558 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R559 NRSA63J-105X MG RESISTOR 1MΩ 1/16W J

R570 NRSA63J-331X MG RESISTOR 330Ω 1/16W J

R571 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R572 NRSA63J-331X MG RESISTOR 330Ω 1/16W J

R573 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R574 NRSA63J-331X MG RESISTOR 330Ω 1/16W J

R575 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R581 NRSA63J-203X MG RESISTOR 20kΩ 1/16W J

R582 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R583 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R584 NRSA63J-563X MG RESISTOR 56kΩ 1/16W J

R585 NRSA63J-183X MG RESISTOR 18kΩ 1/16W J

R586 NRSA63J-152X MG RESISTOR 1.5k

R587 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R591 NRSA63J-203X MG RESISTOR 20k

R592 NRSA63J-223X MG RESISTOR 22k

R593 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R594 NRSA63J-563X MG RESISTOR 56k

R595 NRSA63J-183X MG RESISTOR 18k

R596 NRSA63J-152X MG RESISTOR 1.5kΩ 1/16W J

R597 NRSA63J-0R0X MG RESISTOR 0

R701 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R702 NRSA63J-0R0X MG RESISTOR 0

R703 NRSA63J-0R0X MG RESISTOR 0

R704 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R705 NRSA63J-473X MG RESISTOR 47k

R706 NRSA63J-473X MG RESISTOR 47k

R707 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R708 NRSA63J-332X MG RESISTOR 3.3k

R709 NRSA63J-473X MG RESISTOR 47k

R710 NRSA63J-0R0X MG RESISTOR 0

R711 NRSA63J-0R0X MG RESISTOR 0

R712 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R713 NRSA63J-0R0X MG RESISTOR 0

R714 NRSA63J-473X MG RESISTOR 47k

R715 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R716 NRSA63J-0R0X MG RESISTOR 0

R719 NRSA63J-0R0X MG RESISTOR 0

R720 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R721 NRSA63J-102X MG RESISTOR 1k

R722 NRSA63J-103X MG RESISTOR 10k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-8

Page 22

Symbol No.

R723 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R725 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R726 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R728 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R729 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R734 NRSA63J-222X MG RESISTOR 2.2k

R735 NRSA63J-222X MG RESISTOR 2.2k

R736 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R741 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R742 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R743 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R744 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R745 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R746 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R747 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R748 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R749 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R750 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R751 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R752 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R753 NRSA63J-473X MG RESISTOR 47k

R754 NRSA63J-821X MG RESISTOR 820

R755 NRSA63J-106X MG RESISTOR 10MΩ 1/16W J

R756 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R757 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R758 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R760 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R763 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R765 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R766 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R767 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R783 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R784 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R851 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R901 QRE142J-102X C RESISTOR 1kΩ 1/4W J

R902 NRSA02J-912X MG RESISTOR 9.1kΩ 1/10W J

R903 NRSA02J-472X MG RESISTOR 4.7kΩ 1/10W J

R971 NRS181J-222X MG RESISTOR 2.2kΩ 1/8W J

R972 NRS181J-222X MG RESISTOR 2.2kΩ 1/8W J

R976 NRSA02J-273X MG RESISTOR 27kΩ 1/10W J

R977 NRSA02J-123X MG RESISTOR 12kΩ 1/10W J

R981 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

RA451 NRZ0014-103X NET RESISTOR 10k

RA452 NRZ0014-103X NET RESISTOR 10k

RA453 NRZ0014-103X NET RESISTOR 10k

RA454 NRZ0014-103X NET RESISTOR 10k

RA455 NRZ0014-103X NET RESISTOR 10k

RA456 NRZ0014-103X NET RESISTOR 10k

RA457 NRZ0014-103X NET RESISTOR 10k

L1 QQL244J-4R7Z INDUCTIOR 4.7uH J

L401 NQL114K-470X INDUCITOR 47uH K

L402 NQL114K-470X INDUCITOR 47uH K

L403 NQL114K-470X INDUCITOR 47uH K

L541 NQL114K-470X INDUCITOR 47uH K

L542 NQL114K-470X INDUCITOR 47uH K

L543 NQL114K-470X INDUCITOR 47uH K

L544 NQL114K-470X INDUCITOR 47uH K

L701 NQL114K-470X INDUCITOR 47uH K

L901 QQR0703-001 CHOKE COIL

CN601 QGB2027M1-26S CONNECTOR B-B (1-26)

CN701 VMC0334-001 CONNECTOR

CN901 QNZ0002-001 16P CONNECTOR

J1 QNB0100-002 CAR ANT JACK

J321 QNN0175-001 PIN JACK

TU1 QAU0291-001 TUNER

X31 QAX0616-001Z CRYSTAL 10.250MHz

X401 QAX0413-001Z CRYSTAL 16.9344MHz

X701 QAX0617-001Z CRYSTAL 12.500MHz

X702 QAX0401-001 CRYSTAL 32.768KHz

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Front board

Block No. [0][2][0][0]

Symbol No.

IC601 LC75823W IC

IC602 RPM6938-SV4 REMOCON RCV

D601 SML-310VT/JK/-X LED

D602 SML-310VT/JK/-X LED

D603 SML-310VT/JK/-X LED

D604 SML-310VT/JK/-X LED

D605 SML-310VT/JK/-X LED

D606 SML-310VT/JK/-X LED

D607 SML-310VT/JK/-X LED

D608 SML-310VT/JK/-X LED

D609 SML-310VT/JK/-X LED

D610 SML-310VT/JK/-X LED

D611 SML-310VT/JK/-X LED

D613 SML-310VT/JK/-X LED

D614 SML-310VT/JK/-X LED

D615 SML-310VT/JK/-X LED

D616 SML-310VT/JK/-X LED

D617 SML-310VT/JK/-X LED

D618 LT1F67AF-W LED

D619 SML-310VT/JK/-X LED

D620 SML-310VT/JK/-X LED

D621 SML-310VT/JK/-X LED

D622 SML-310VT/JK/-X LED

D623 SML-310VT/JK/-X LED

D624 SML-310VT/JK/-X LED

D625 SML-310LT/MN/-X LED

D641 UDZS5.1B-X Z DIODE

D642 1SS355-X SI DIODE

D643 1SS355-X SI DIODE

D644 NSPW310BS/BRS/ LED

D645 NSPW310BS/BRS/ LED

D646 UDZS6.2B-X Z DIODE

C601 NCB31HK-223X C CAPACITOR 0.022uF 50V K

C602 NCS31HJ-681X C CAPACITOR 680pF 50V J

C603 NBE20JM-106X TA E CAPACITOR 10uF 6.3V M

C611 NCB31HK-123X C CAPACITOR 0.012uF 50V K

C612 NBE20JM-475X TA E CAPA CITOR 4. 7uF 6.3V M

R601 NRSA63J-182X MG RESISTOR 1.8kΩ 1/16W J

R602 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R603 NRSA63J-182X MG RESISTOR 1.8kΩ 1/16W J

R604 NRSA63J-272X MG RESISTOR 2.7kΩ 1/16W J

R605 NRSA63J-392X MG RESISTOR 3.9kΩ 1/16W J

R606 NRSA63J-821X MG RESISTOR 820

R607 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R608 NRSA63J-122X MG RESISTOR 1.2k

R609 NRSA63J-182X MG RESISTOR 1.8k

R610 NRSA63J-272X MG RESISTOR 2.7kΩ 1/16W J

R611 NRSA63J-392X MG RESISTOR 3.9k

R612 NRSA63J-821X MG RESISTOR 820

R613 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R614 NRSA63J-122X MG RESISTOR 1.2k

R615 NRSA63J-182X MG RESISTOR 1.8kΩ 1/16W J

R616 NRSA63J-272X MG RESISTOR 2.7k

R631 NRSA63J-821X MG RESISTOR 820

R632 NRSA63J-182X MG RESISTOR 1.8kΩ 1/16W J

R633 NRSA63J-182X MG RESISTOR 1.8k

R634 NRSA63J-182X MG RESISTOR 1.8k

R635 NRSA63J-182X MG RESISTOR 1.8kΩ 1/16W J

R636 NRSA63J-182X MG RESISTOR 1.8k

R637 NRSA63J-182X MG RESISTOR 1.8k

R638 NRSA63J-511X MG RESISTOR 510

R639 NRSA63J-511X MG RESISTOR 510

R640 NRSA63J-511X MG RESISTOR 510Ω 1/16W J

R641 NRSA63J-511X MG RESISTOR 510

R642 NRSA63J-821X MG RESISTOR 820

R643 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R644 NRSA63J-182X MG RESISTOR 1.8k

R645 NRSA63J-182X MG RESISTOR 1.8k

R646 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R647 NRSA63J-821X MG RESISTOR 820

R648 NRSA63J-681X MG RESISTOR 680

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

KD-S845

3-9

Page 23

KD-S845

Symbol No.

R649 NRSA63J-821X MG RESISTOR 820Ω 1/16W J

R651 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R652 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R653 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R654 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R655 NRSA63J-103X MG RESISTOR 10k

R656 NRSA63J-103X MG RESISTOR 10k

R657 NRSA63J-513X MG RESISTOR 51kΩ 1/16W J

R658 NRSA63J-184X MG RESISTOR 180kΩ 1/16W J

R659 NRS181J-391X MG RESISTOR 390Ω 1/8W J

R660 NRS181J-391X MG RESISTOR 390Ω 1/8W J

R661 NRS181J-103X MG RESISTOR 10kΩ 1/8W J

R662 NRSA63J-471X MG RESISTOR 470Ω 1/16W J

R681 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

CJ601 VMC0335-001 PANEL CONNECTOR

JS690 QSW0793-001 ROTARY ENCODER

S601 NSW0124-001X TACT SW

S602 NSW0124-001X TACT SW

S603 NSW0124-001X TACT SW

S604 NSW0124-001X TACT SW

S605 NSW0124-001X TACT SW

S606 NSW0124-001X TACT SW

S607 NSW0124-001X TACT SW

S608 NSW0124-001X TACT SW

S609 NSW0124-001X TACT SW

S610 NSW0124-001X TACT SW

S611 NSW0124-001X TACT SW

S612 NSW0124-001X TACT SW

S613 NSW0124-001X TACT SW

S614 NSW0124-001X TACT SW

S615 NSW0124-001X TACT SW

S616 NSW0124-001X TACT SW

S617 NSW0124-001X TACT SW

S618 NSW0124-001X TACT SW

S619 NSW0124-001X TACT SW

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

3-10

Page 24

<MEMO>

KD-S845

3-11

Page 25

KD-S845

Packing materials and accessories parts list

Block No.

P1

A1

A2 A3

P7

M

3

M

M

P6

P7

P5

A10

A11

KIT

A12

P2

: A7A8 A4A5A6

P3

3-12

P4

A9

Page 26

Packing and accessories

Block No. [M][3][M][M]

Symbol No.

A 1 GET0163-001A INST BOOK ENG CHI CHI(TAIWAN)ARA

A 2 GET0163-002A INSTALL MANUAL ENG CHI CHI(TAIWAN)ARA

A 3 LVT0918-001A MP3 SHEET

A 4 VKZ4027-202 PLUG NUT

A 5 VKH4871-001SS MOUNT BOLT

A 6 VKZ4328-001 LOCK NUT

A 7 WNS5000Z WASHER

A 8 FSKL4010-002 HOOK (x2)

A 9 FSJB3001-30C HARD CASE

A 10 FSKM2004-202

A 11 FSJD2034-005 TRIM PLATE

A 12 QAM0390-001 16P CORD

KIT

P 1 FSPG4002-001 POLY BAG

P 2 QPA00801205 POLY BAG 8cm x 12cm

P 3 QPA01003003 POLY BAG 10cm x 30cm

P 4 FSYH4036-068 SHEET

P 5 QPC03004315P POLY BAG 30cm x 43cm

P 6 GE30940-001A CARTON

P 7 GE10036-001A PAPER CUSHION (x2)

Part No. Part Name Description Local

MOUNTING SLEEVE

KDGS717K-SCREW1

SCREW PARTS KIT

A4 to A8

KD-S845

3-13

Loading...

Loading...