Page 1

SERVICE MANUAL

CD RECEIVER

KD-S821R

KD-S821R

Contents

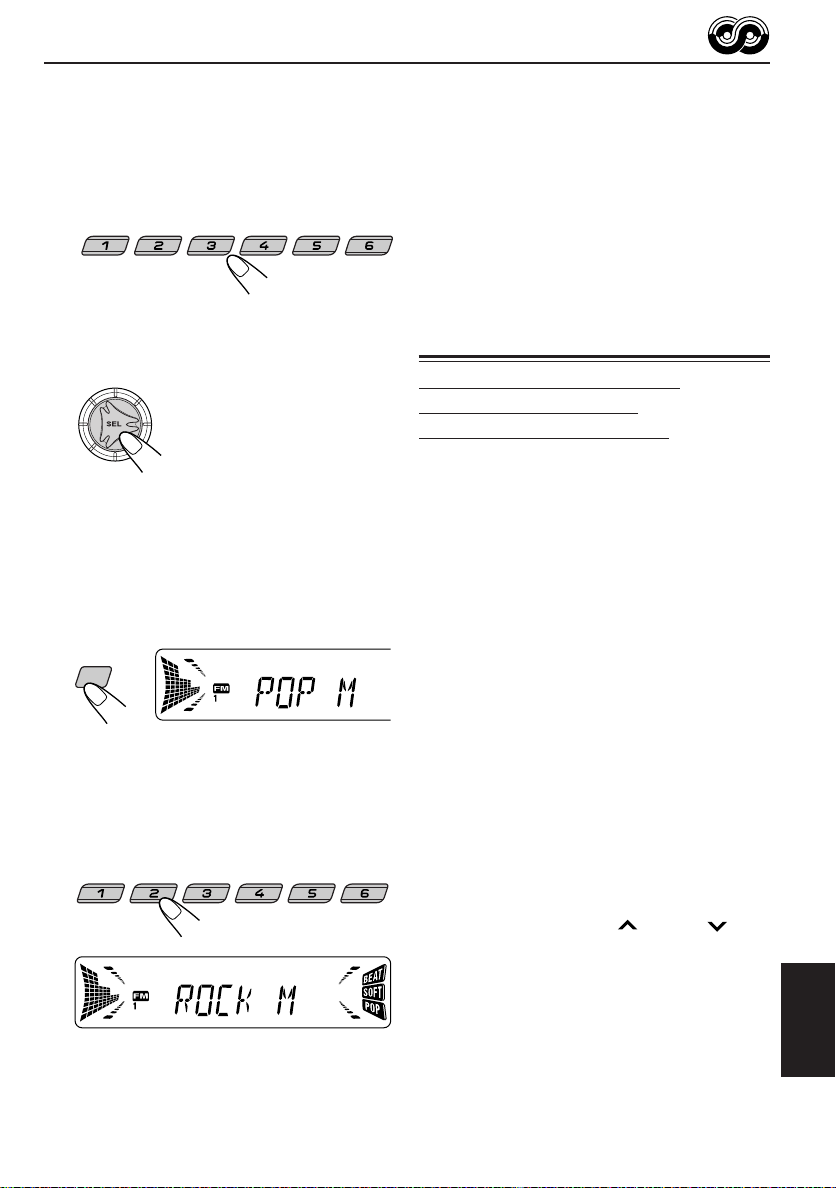

DISP

MO

RND

7

45Wx4

89

10

KD-S821R

12

RDS

11

TP PTY SCM

COMPACT

DIGITAL AUDIO

Area Suffix

E -------- Continental Europe

EX ------ Central Europe

Safety precaution

Preventing static electricity

Disassembly method

Adjustment method

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

1-2

1-3

1-4

1-11

Flow of functional

operation unit TOC read

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

2-1

2-3

2-3

2-6

No.49679

Feb. 2002

Page 2

KD-S821R

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

KD-S821R

Preventing static electricity

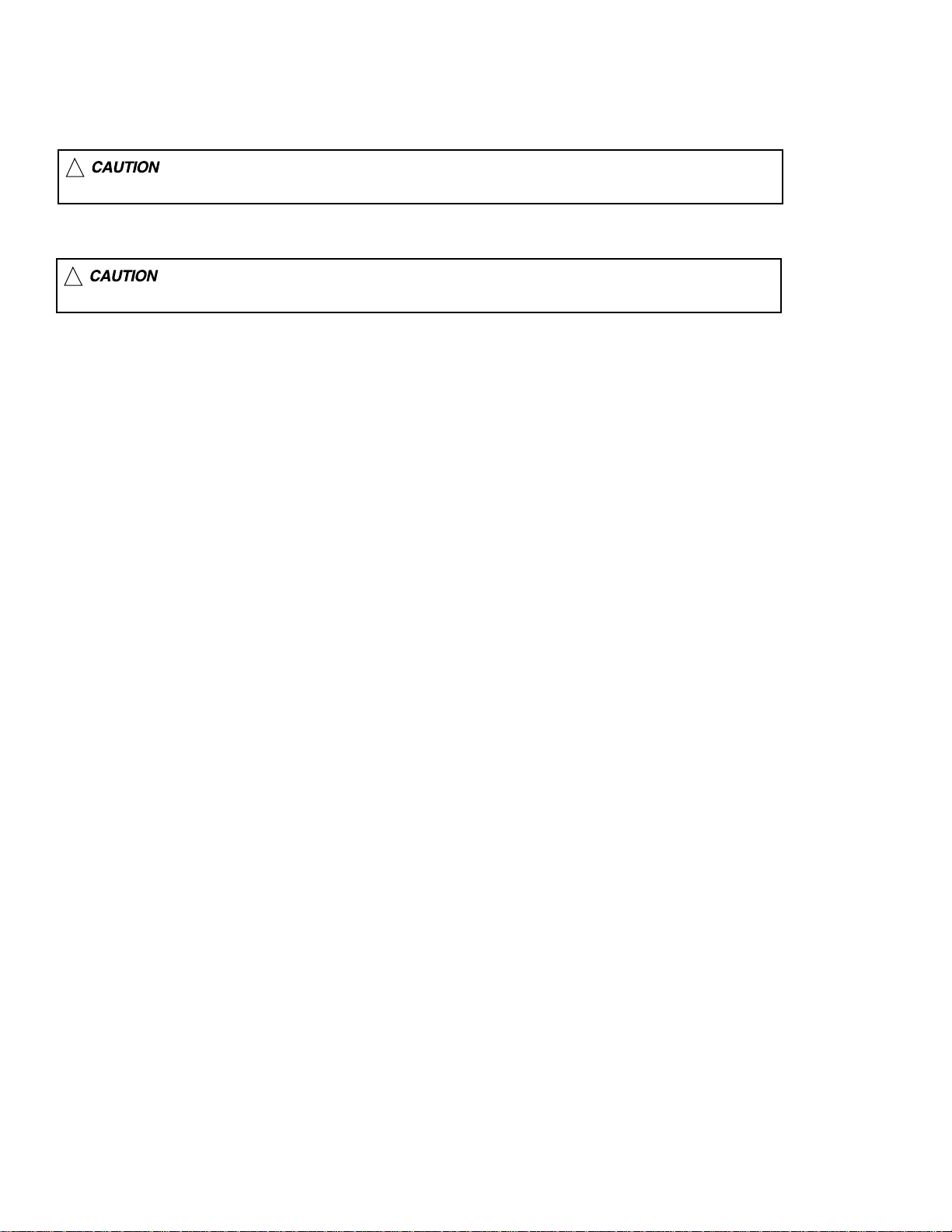

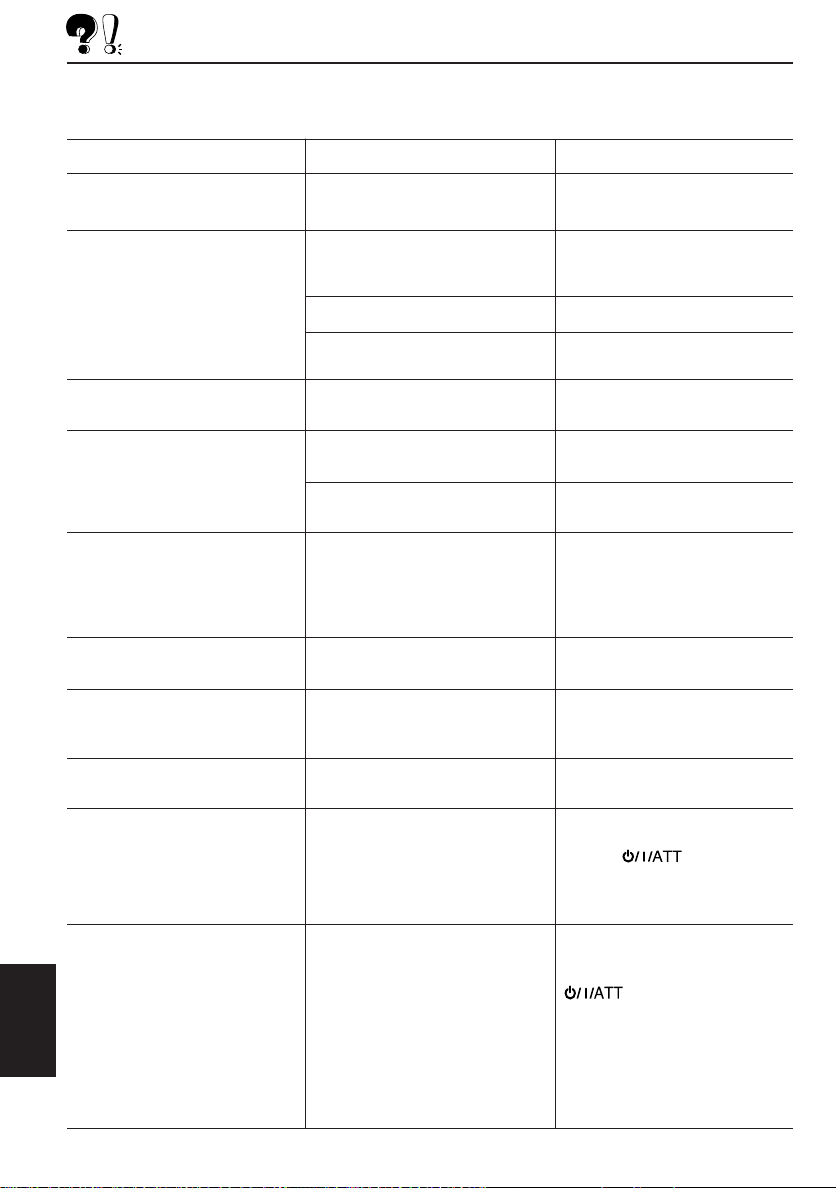

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

(conductive sheet) or iron plate

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

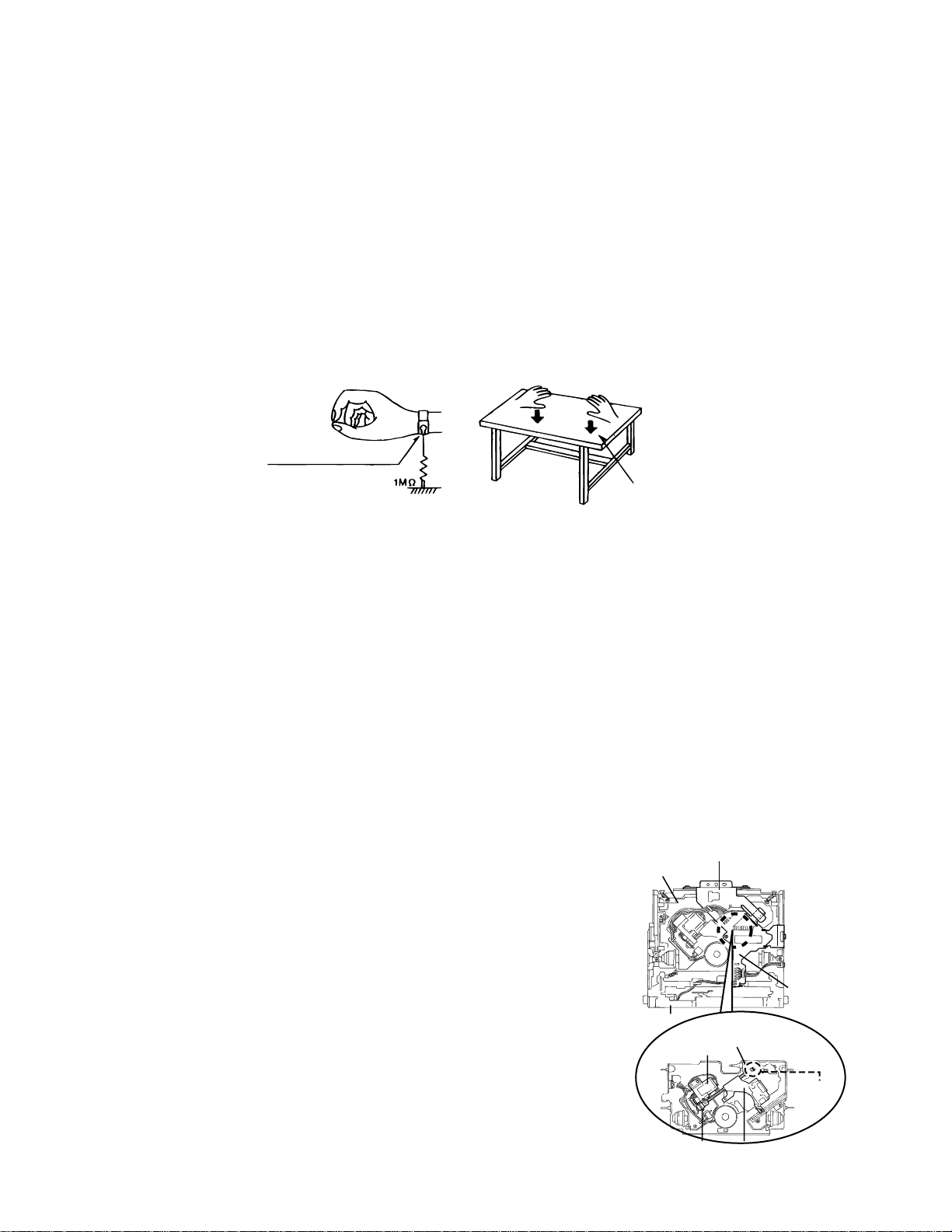

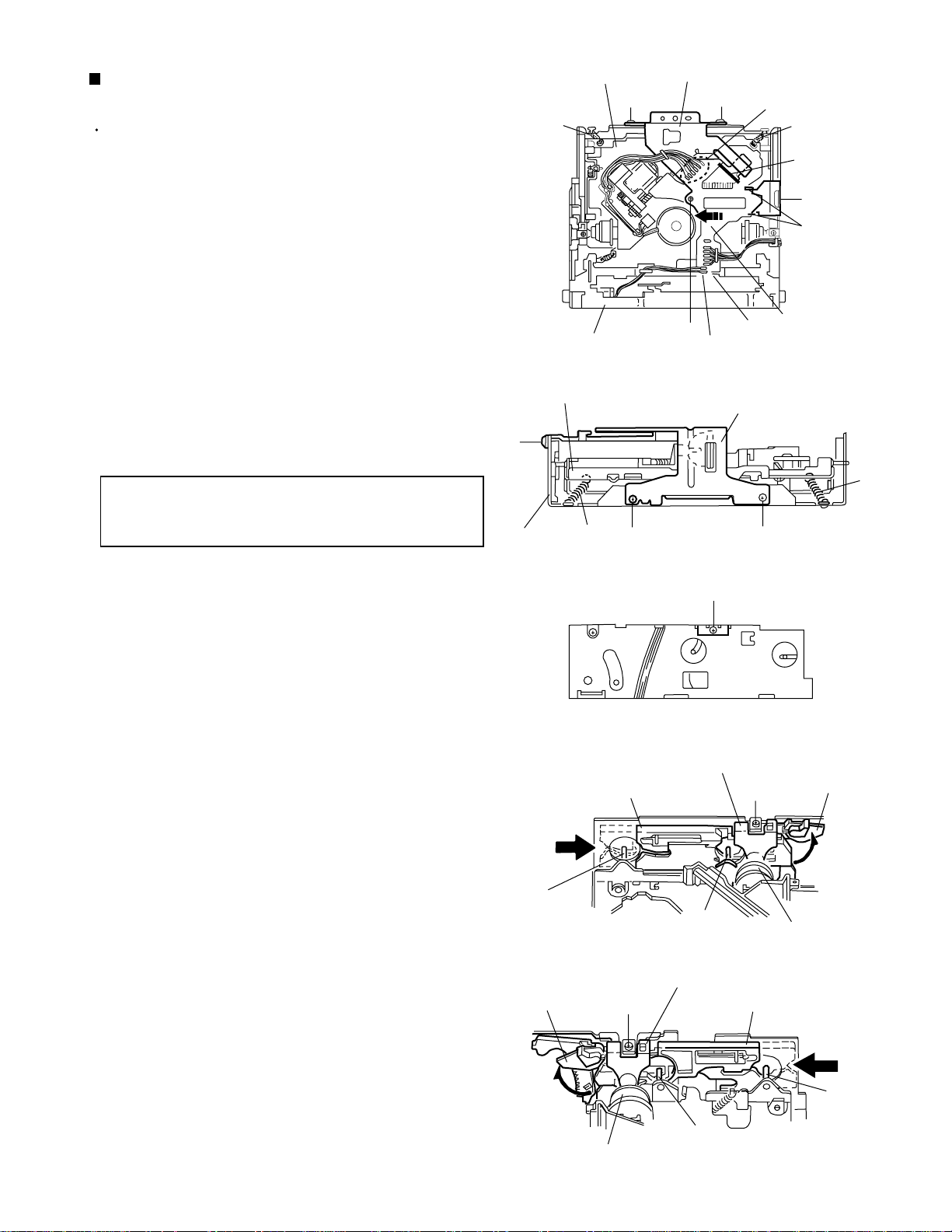

CD mechanism ass’y

Damper bracket

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the substrate.

1.Solder is put up before the card wire is removed from connector on

the CD substrate as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

Front bracket

Feed motor ass’y

FD screw

CD mechanism

control board

Soldering

FD gear

Pickup unit

1-3

Page 4

KD-S821R

Disassembly method

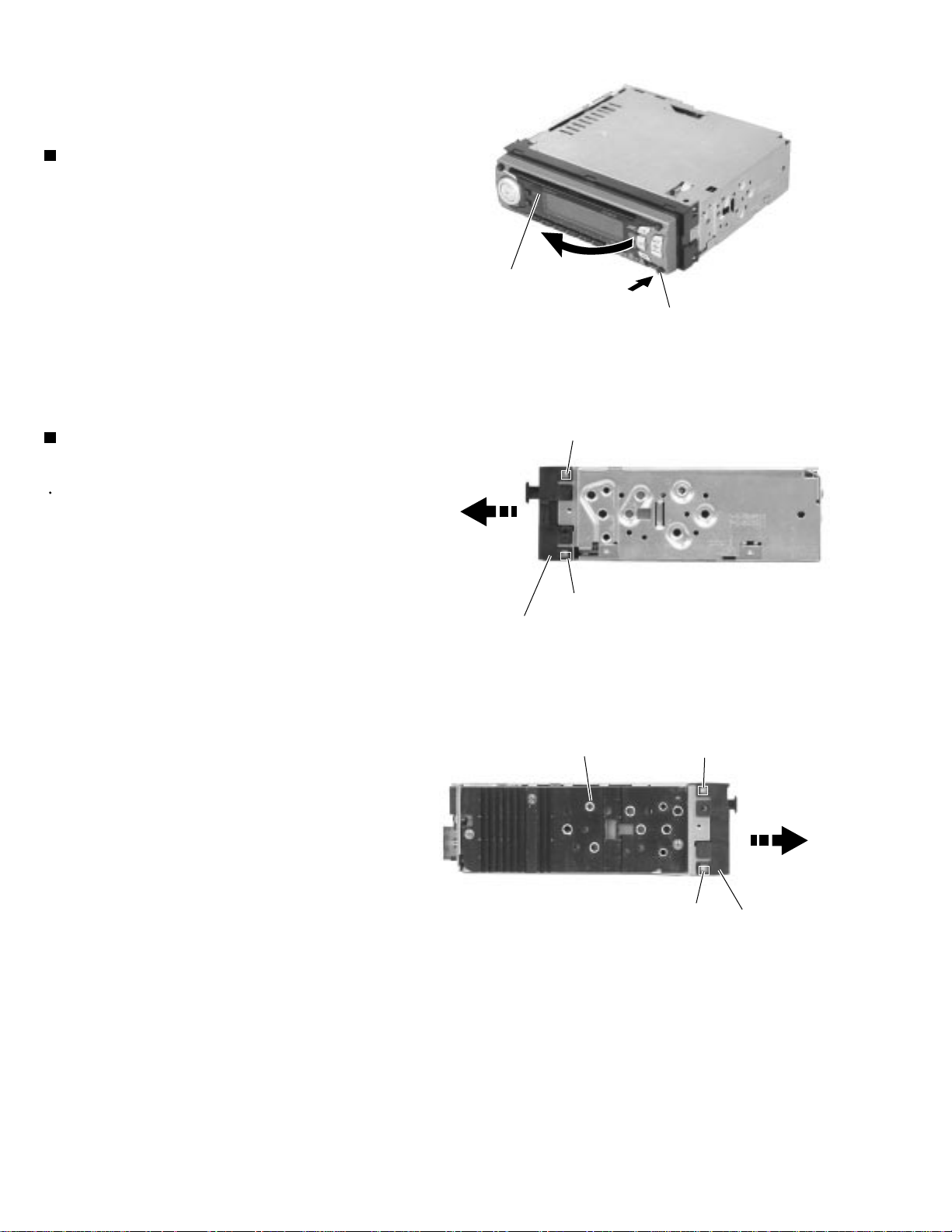

<Main body>

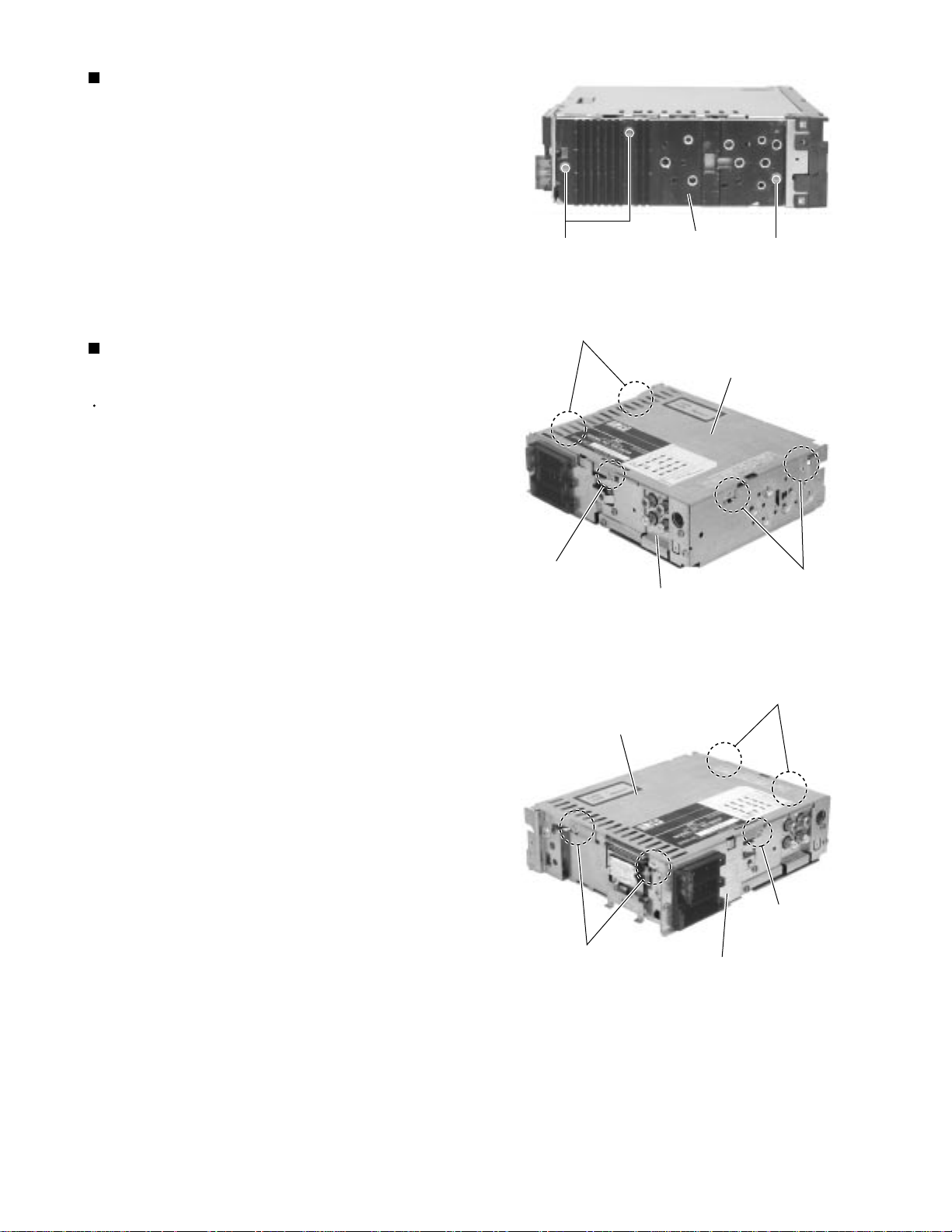

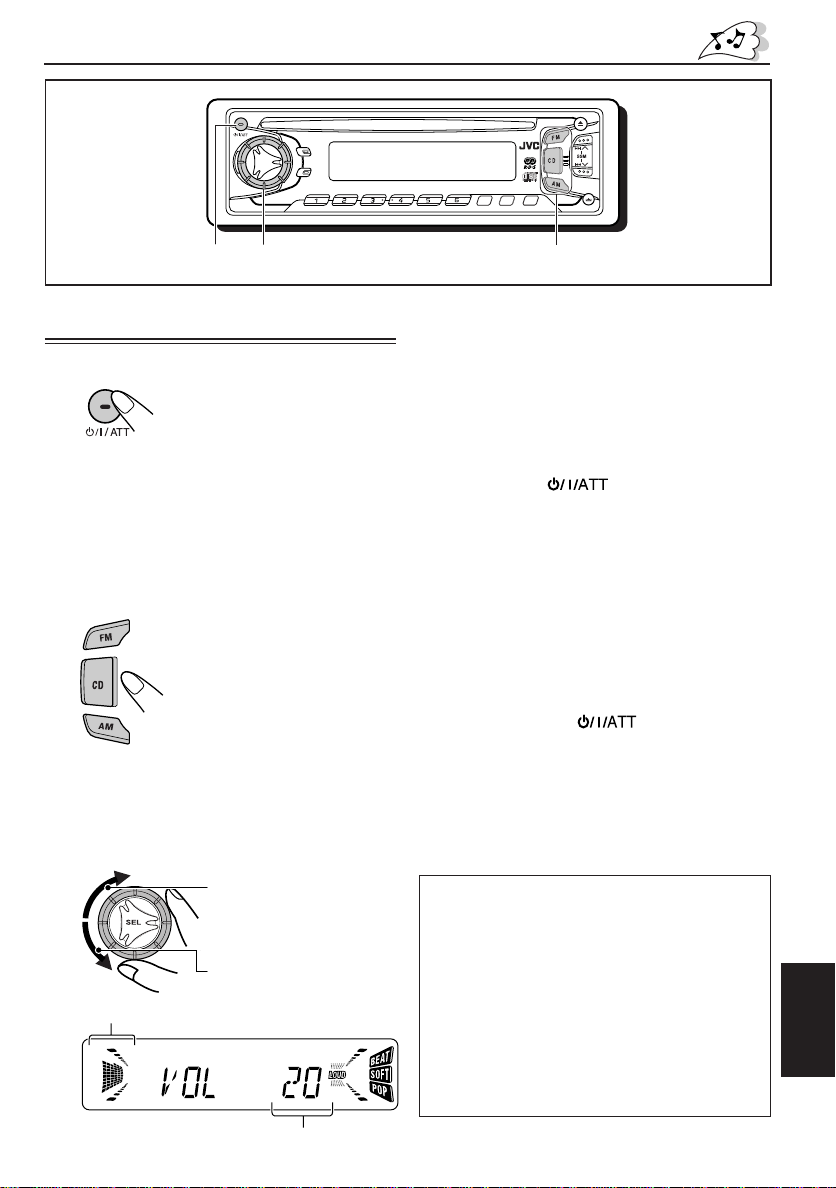

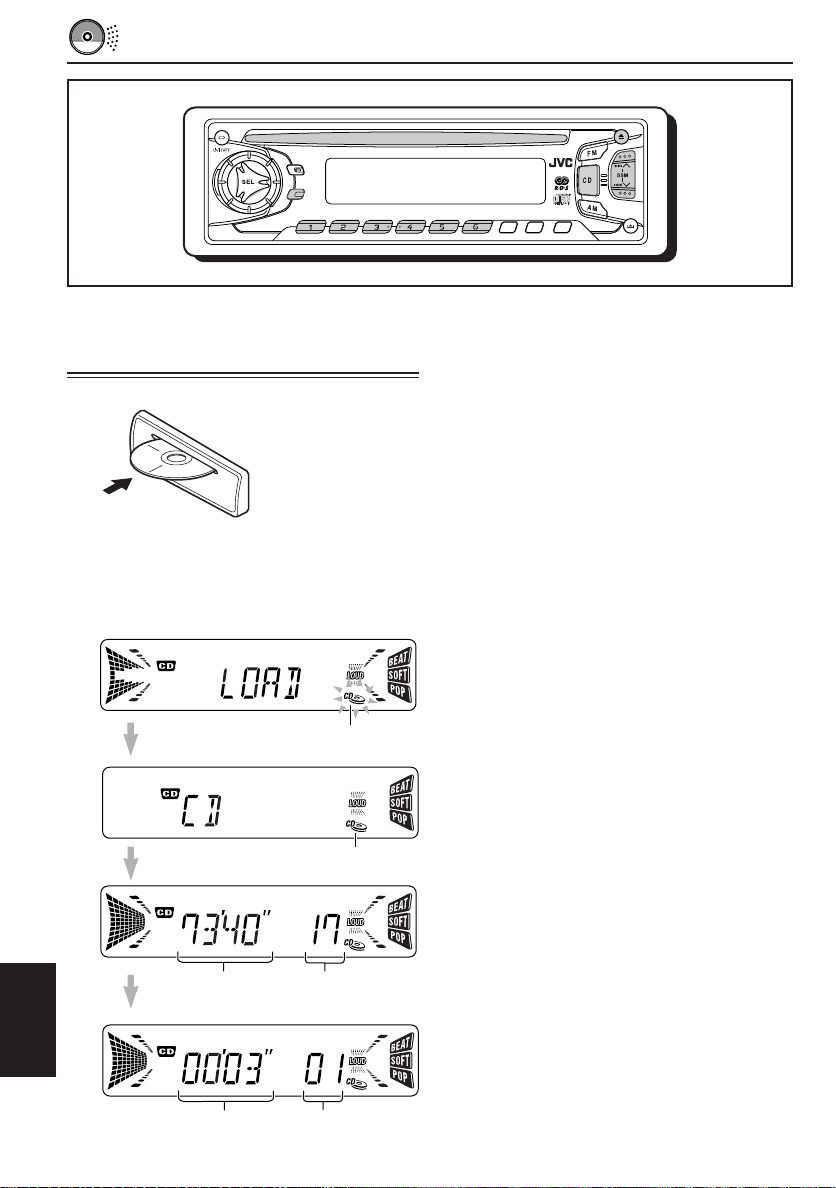

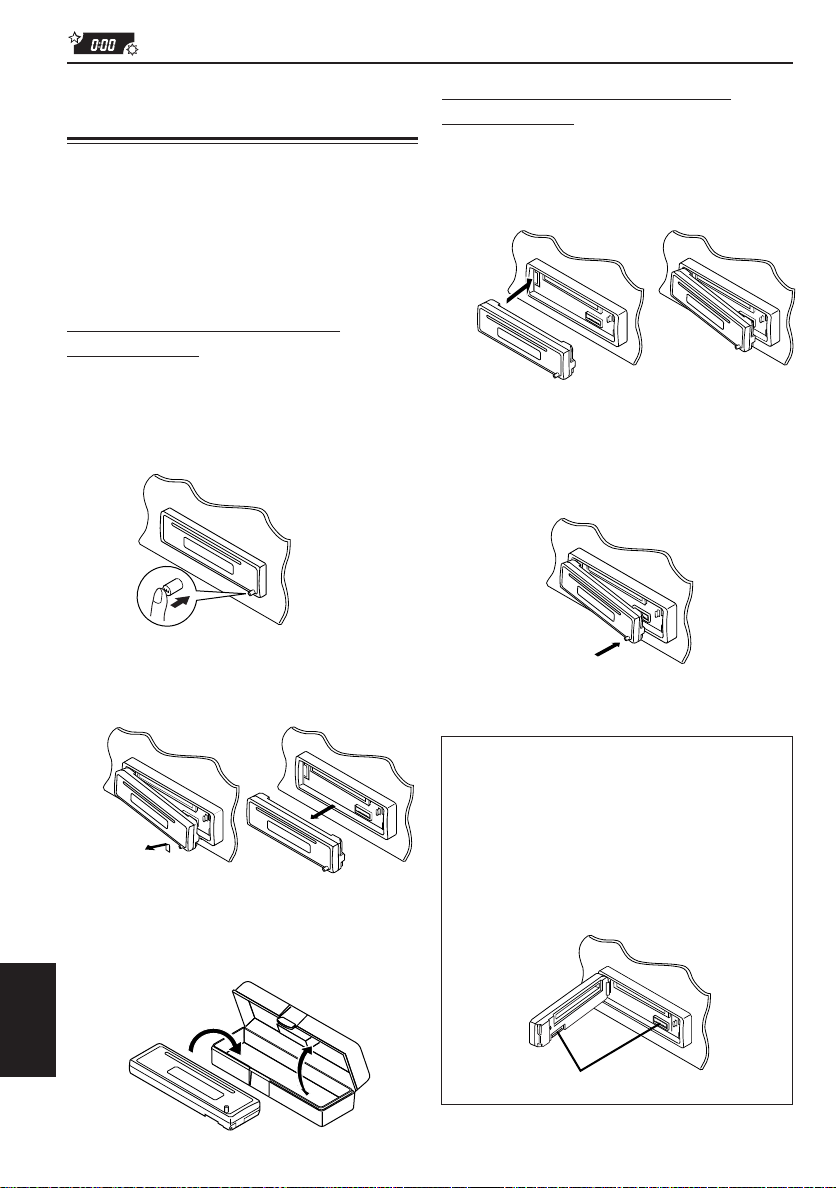

Removing the front panel assembly

(See Fig.1)

1.

Press the eject button in the lower right part of the

front panel. Remove the front panel assembly from

the body.

Front panel assembly

Eject button

Fig.1

Removing the front chassis assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Release the four joint tabs a on both sides of the

front chassis assembly and remove the front chassis

assembly toward the front.

Tab a

Tab a

Front chassis assembly

Heat sink

Fig.2

Tab a

1-4

Fig.3

Tab a

Front chassis

assembly

Page 5

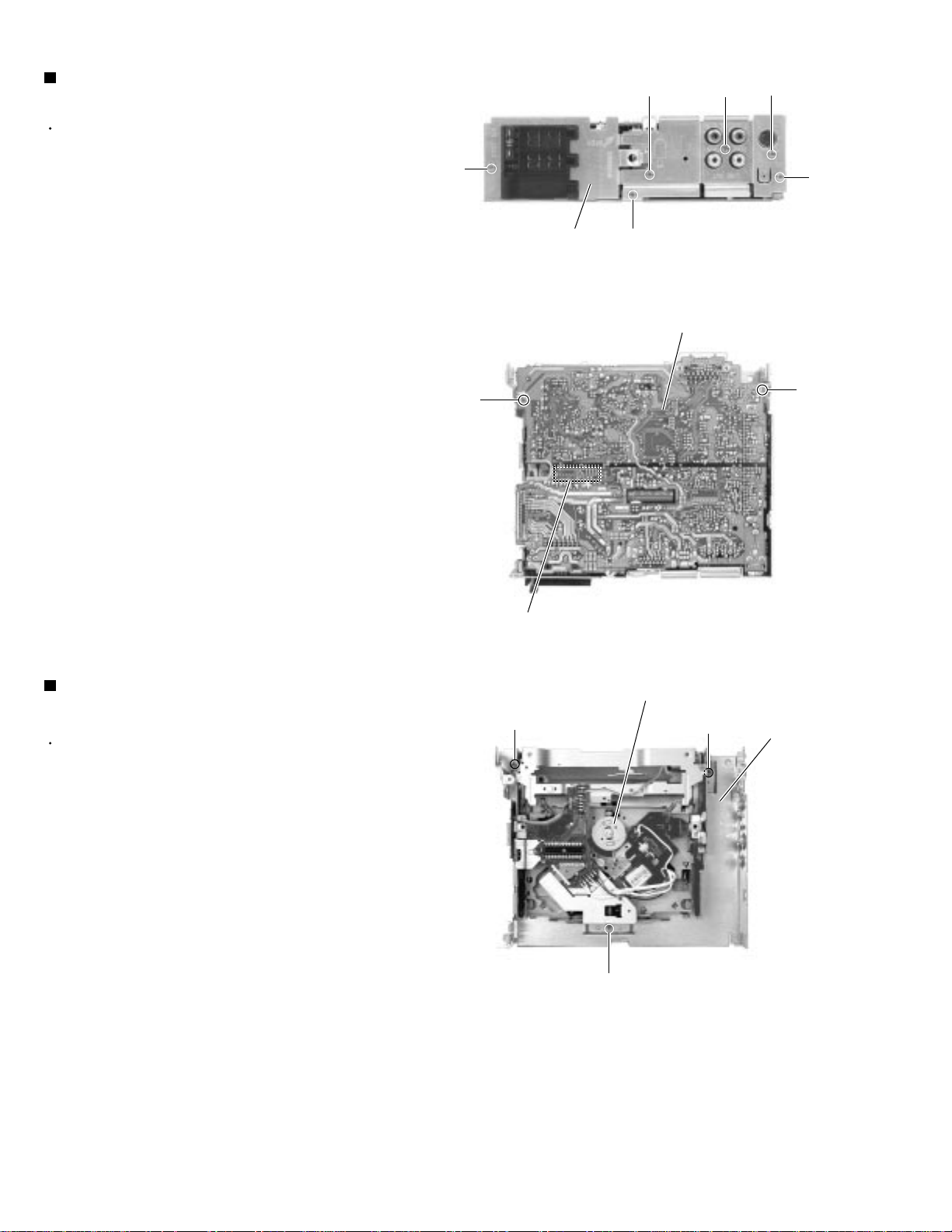

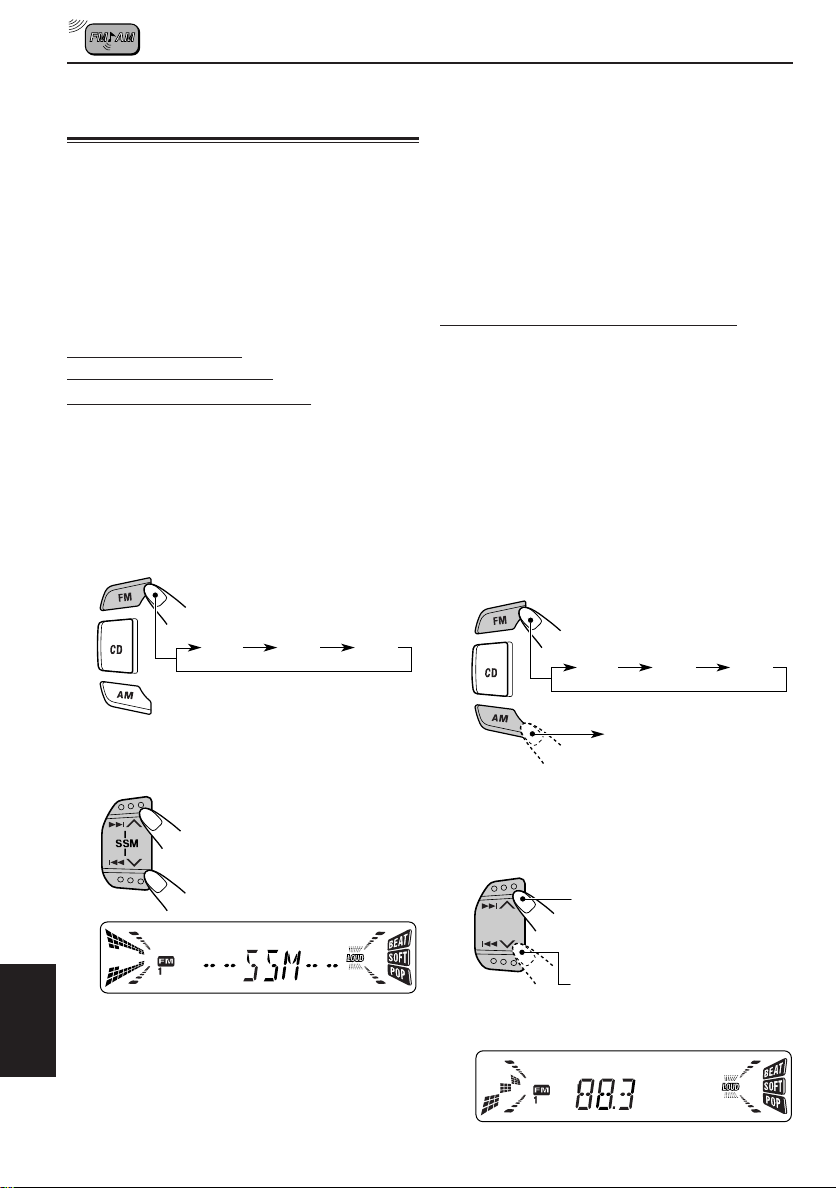

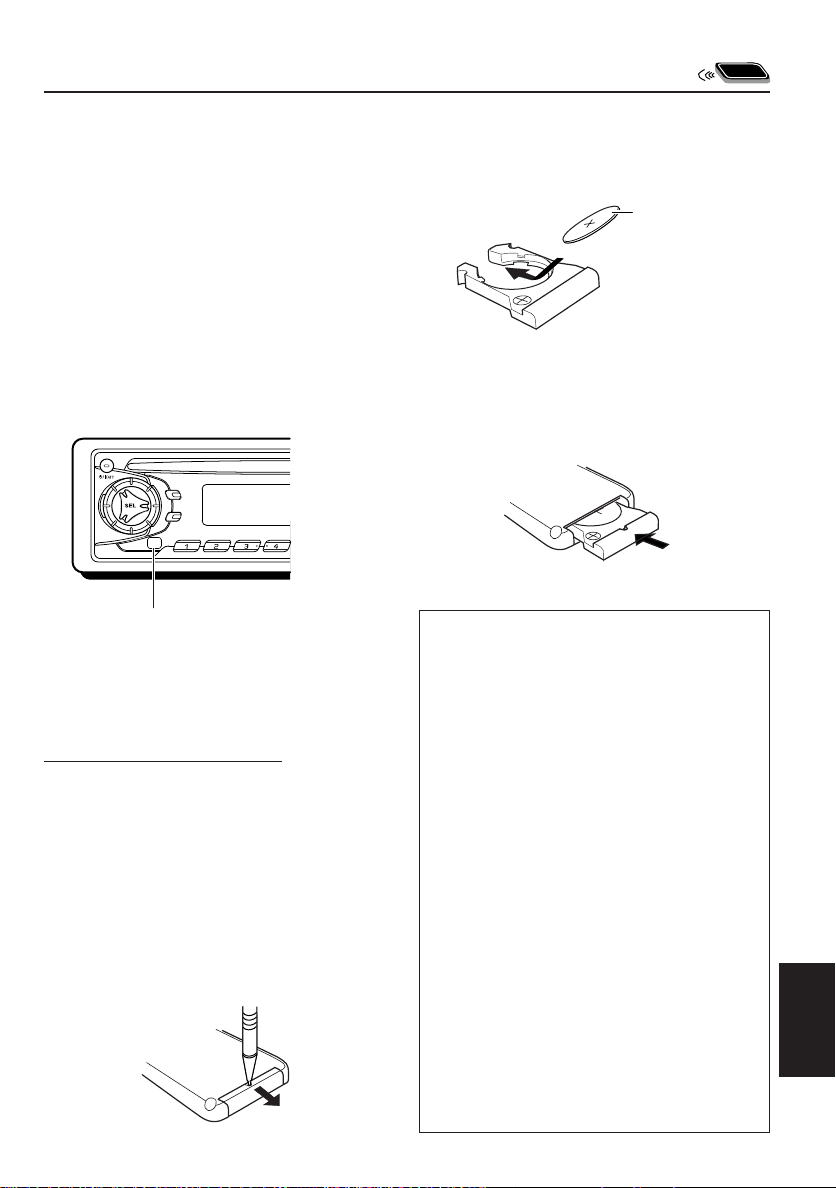

Removing the heat sink (See Fig.4)

1.

Remove the three screws A on the left side of the

body.

KD-S821R

Removing the bottom cover

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly

and the heat sink.

1.

Turn over the body and unjoint the five joints b with

the bottom cover and the body using a screwdriver.

A

Joints b

Joint b

Heat sink

Fig.4

Rear panel

Fig.5

A

Bottom cover

Joints b

Bottom cover

Joints b

Joints b

Joint b

Rear panel

Fig.6

1-5

Page 6

KD-S821R

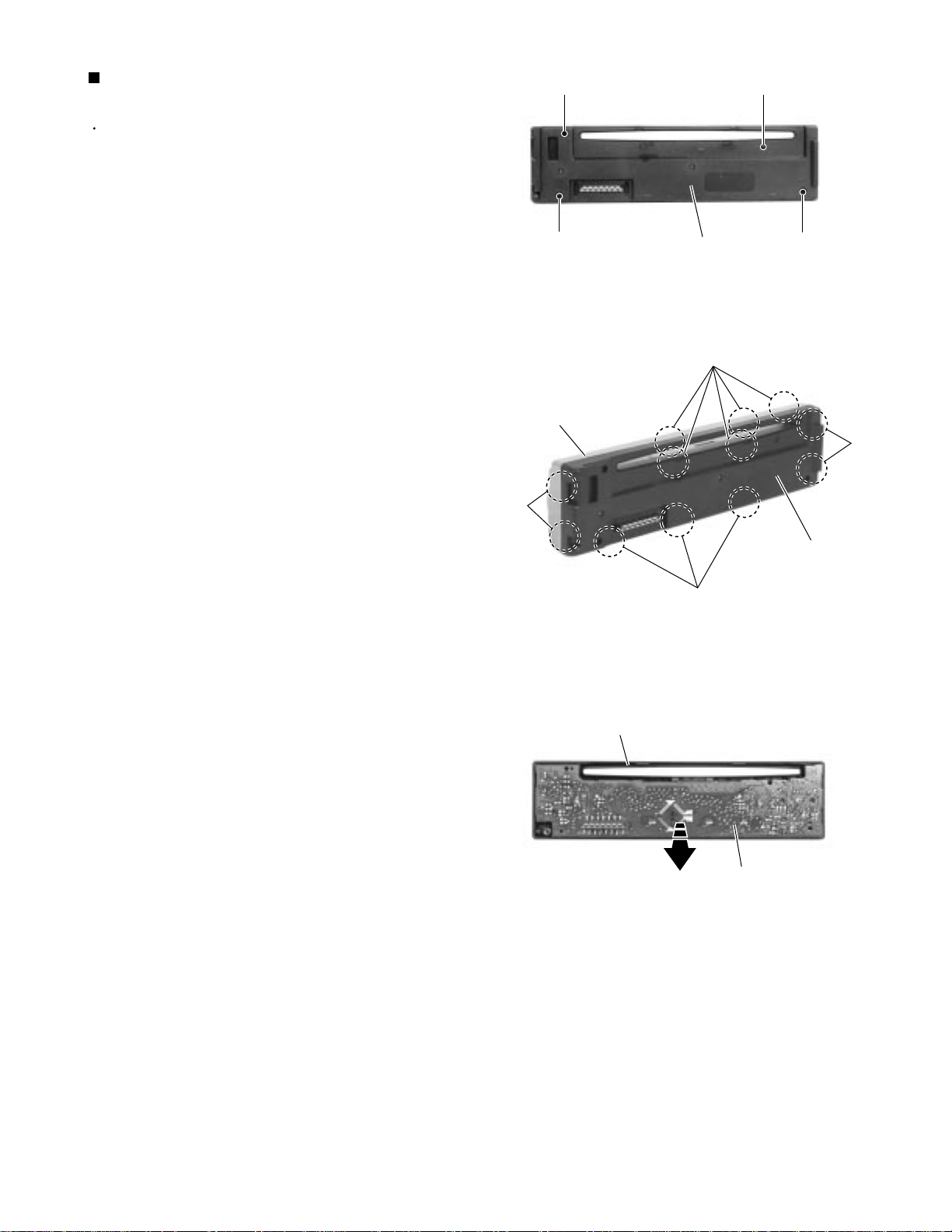

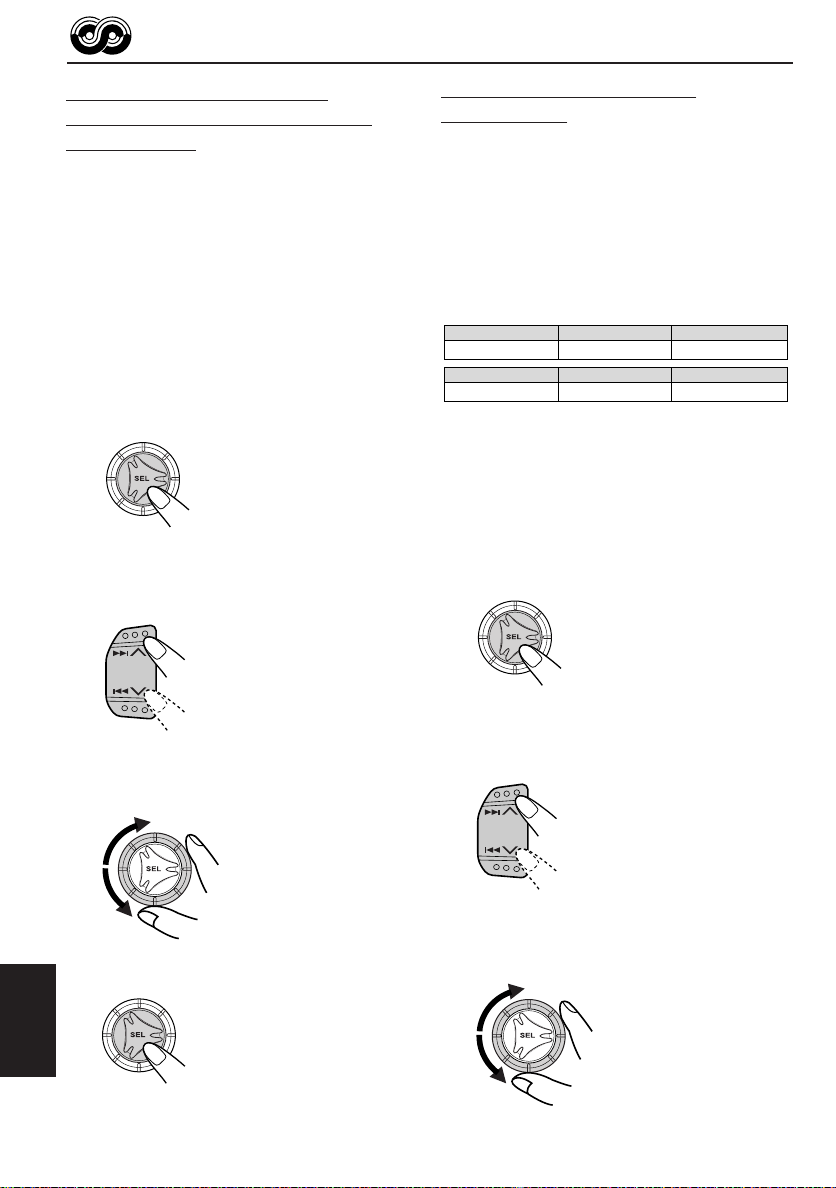

Removing the main board

(See Fig.7 and 8)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink and the bottom cover.

1.

Remove the screw B, the two screws C and the

three screws D attaching the rear bracket on the

back of the body. Remove the rear panel.

2.

Remove the two screws E attaching the main board

on the bottom of the body. Disconnect connector

CN501 on the main board in the direction of the

arrow.

D

E

Rear panel

C

D

Fig.7

Main board

B

C

D

E

Removing the CD mechanism section

(See Fig.9)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink, the bottom cover and the main board.

1.

Remove the three screws F attaching the CD

mechanism section on the back of the top chassis.

CN501

F

Fig.8

CD mechanism section

F

Fig.9

F

Top chassis

1-6

Page 7

KD-S821R

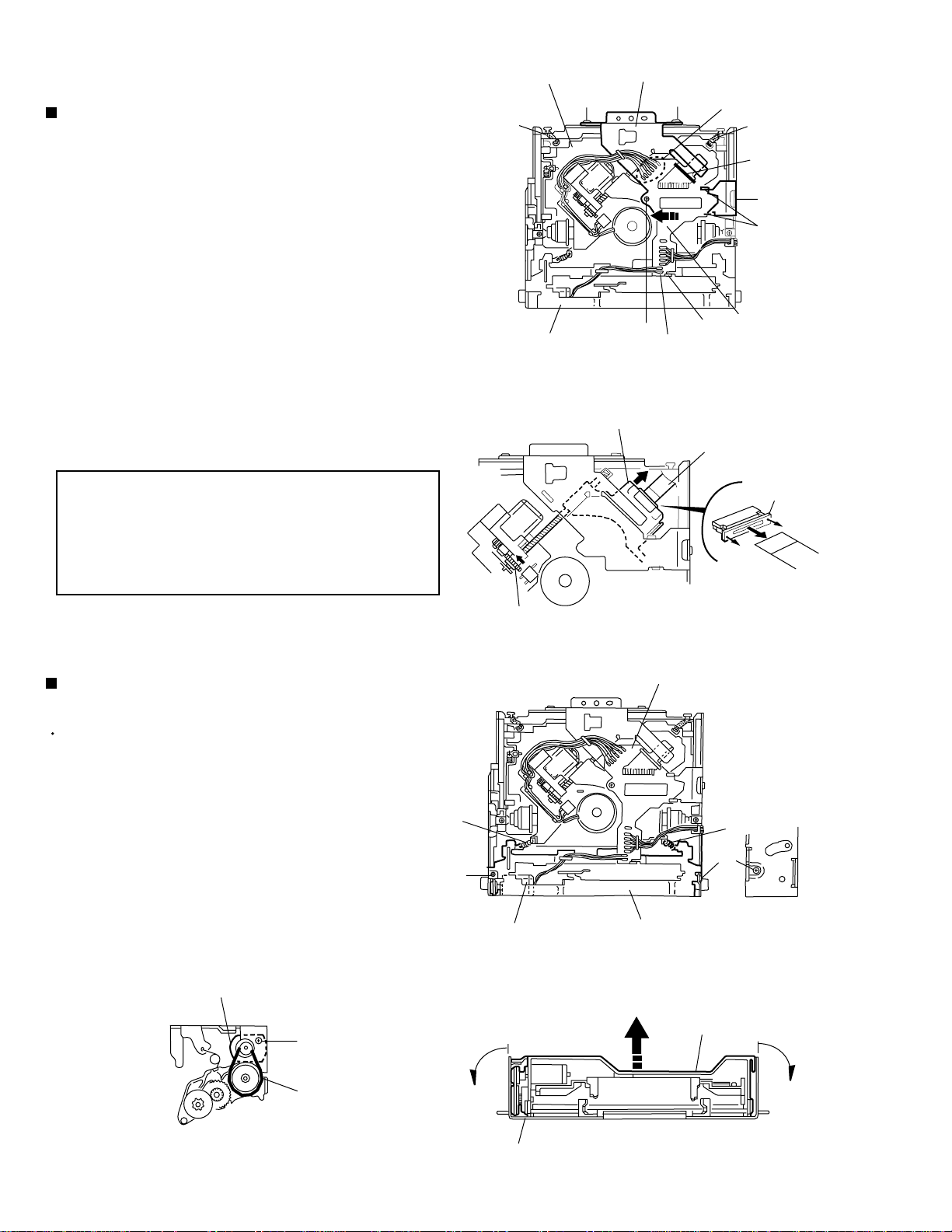

Removing the control switch board

(See Fig.10 to 12)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Remove the four screws G attaching the rear cover

on the back of the front panel assembly.

2.

Unjoint the twelve joints c with the front panel and

the rear cover.

3.

Remove the control switch board on the back of the

front panel.

Joints c

G

G

Front panel

Rear cover

Fig.10

Joints c

G

G

Joints c

Front panel

Rear cover

Joints c

Fig.11

Control switch board

Fig.12

1-7

Page 8

KD-S821R

<CD mechanism section>

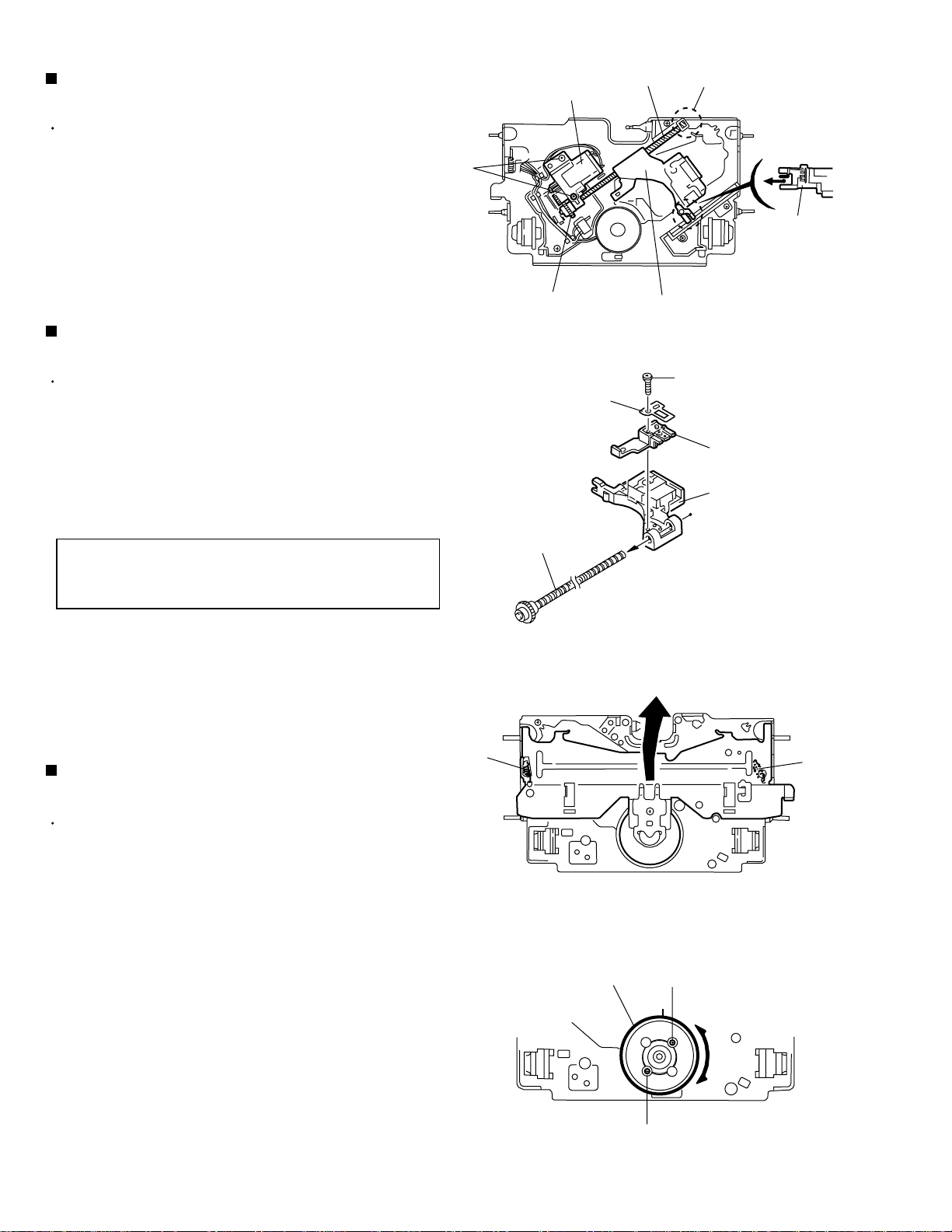

Removing the CD mechanism control

board (See Fig.1 and 2)

1.

Unsolder the part a and b on the CD mechanism

control board.

2.

Remove the stator fixing the CD mechanism control

board and the damper bracket (To remove the stator

smoothly, pick up the center part).

3.

Remove the screw A attaching the CD mechanism

control board.

4.

Remove the CD mechanism control board in the

direction of the arrow while releasing it from the two

damper bracket slots d and the front bracket slot e.

5.

Disconnect the flexible wire from connector on the

pickup unit.

ATTENTION:

Turn the FD gear in the direction of the

arrow to move the entire pickup unit to

the appropriate position where the

flexible wire of the CD mechanism unit

can be disconnected easily.

(Refer to Fig.2)

CD mechanism assembly

D

h

Front bracket

Pickup unit

Damper bracket

D

A

Fig.1

e

b

Flexible wire

a

h

c

D

d

CD mechanism

control board

Shift the lock

Removing the loading motor

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the CD mechanism control board.

1.

Remove the two springs f attaching the CD

mechanism assembly and the front bracket.

2.

Remove the two screws B and the front bracket

while pulling the flame outward.

3.

Remove the belt and the screw C from the loading

motor.

Loading motor

C

f

B

Loading motor

Pull outward

FD gear

Fig.2

CD mechanism control board

f

B

Front bracket

Fig.3

Front bracket

Pull outward

1-8

Fig.5

Belt

Flame

Fig.4

Page 9

KD-S821R

Removing the CD mechanism assembly

(See Fig.1, 6 to 9)

Prior to performing the following procedure, remove

the CD mechanism control board and the front

bracket (loading motor).

1.

Remove the three screws D and the damper

bracket.

2.

Raise the both sides fix arms and move the fix plates

in the direction of the arrow to place the four shafts g

as shown in Fig.8 and 9.

3.

Remove the CD mechanism assembly and the two

springs h attaching the flame.

4.

Remove the two screws E and both sides rear

damper brackets from the dampers. Detach the CD

mechanism assembly from the left side to the right

side.

ATTENTION:

The CD mechanism assembly can be

removed if only the rear damper

bracket on the left side is removed.

CD mechanism

h

Front bracket

CD mechanism

D

Flame

assembly

D

assembly

h

D

Damper bracket

D

A

Fig.5

e

b

Damper bracket

D

Fig.6

a

h

c

D

d

CD mechanism

control board

h

Fix plate (L)

g

Fix arm (R)

D

Fig.7

Rear damper bracket

g

Fig.8

Rear damper bracket

E

Fix plate(R)

E

Fix arm (L)

Damper

Damper

g

g

Fig.9

1-9

Page 10

KD-S821R

Removing the feed motor assembly

(See Fig.10)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism assembly.

1.

Remove the two screws F and the feed motor

assembly.

Removing the pickup unit

(See Fig.10 and 11)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Detach the FD gear part of the pickup unit upward.

Then remove the pickup unit while pulling out the

part i of the FD screw.

Feed motor assembly

F

FD gear

Nut push spring plate

FD screw

Pickup unit

Fig.10

Part i

Part j

Pickup unit

G

Pickup mount nut

Pickup unit

ATTENTION:

2.

Remove the screw G attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

When reattaching the pickup unit,

reattach the part j of the pickup unit,

then the part i of the FD screw.

Removing the spindle motor

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Turn up the CD mechanism assembly and remove

the two springs k on both sides of the clamper arms.

Open the clamper arm upward.

2.

Turn the turn table, and remove the two screws H

and the spindle motor.

k

FD screw

Spindle motor

Fig.11

k

Fig.12

H

1-10

H

Fig.13

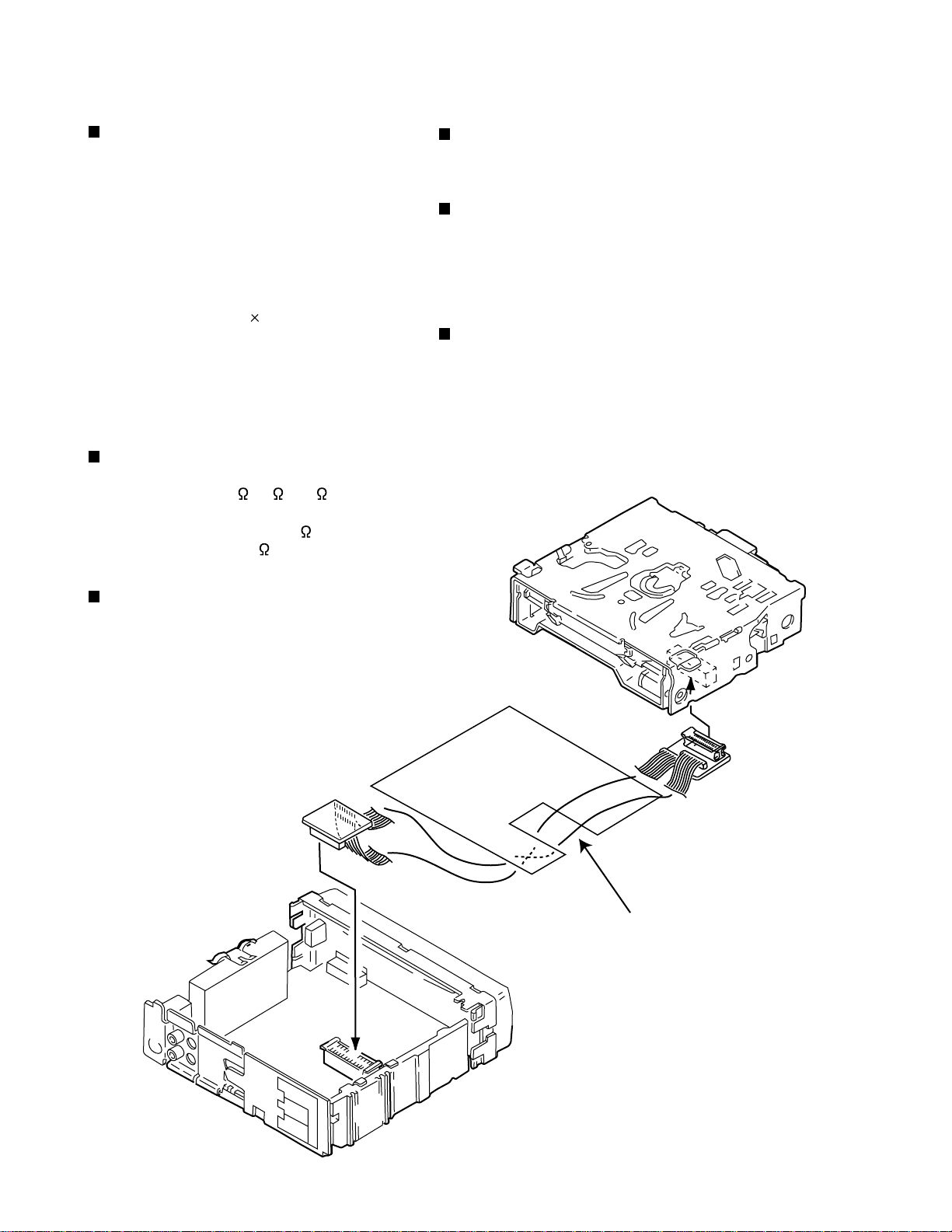

Page 11

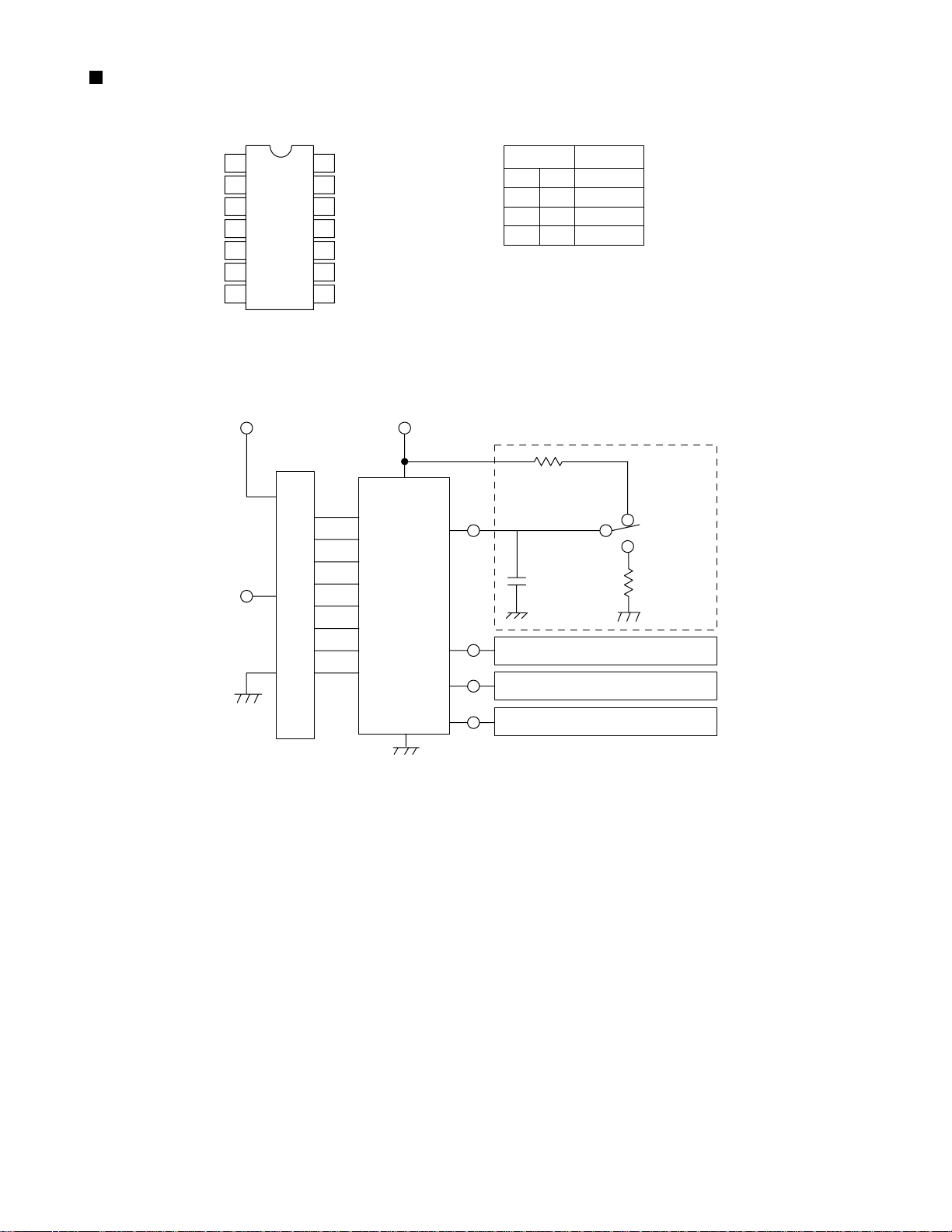

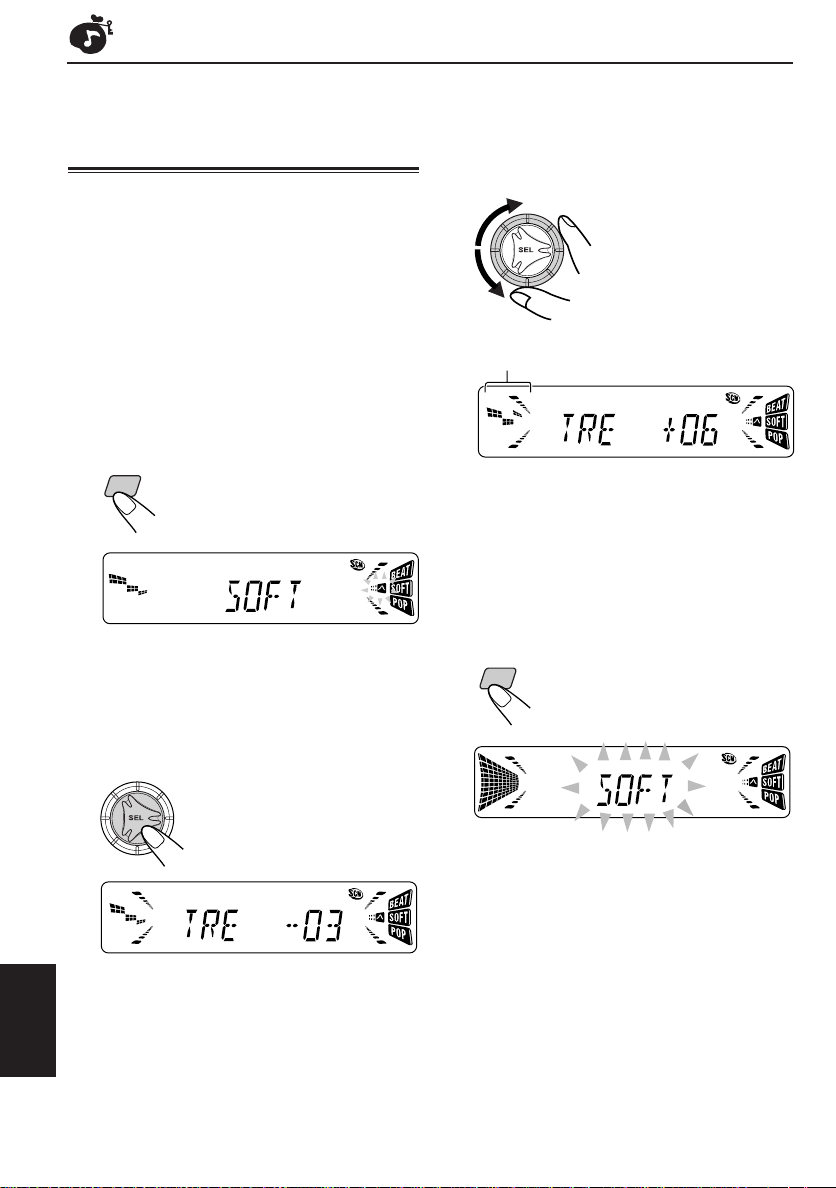

Adjustment method

KD-S821R

Test instruments required for adjustment

1. Digital oscilloscope (100MHz)

2. AM Standard signal generator

3. FM Standard signal generator

4. Stereo modulator

5. Electric voltmeter

6. Digital tester

7. Tracking offset meter

8. Test Disc JVC :CTS-1000

9. Extension cable for check

EXTGS004-26P 1

Standard measuring conditions

Power supply voltage: DC14.4V(11V to 16V allowance)

Load impedance: 4 (4 to 8 allowance)

Line-Out Level/Impedance:

2.0V/20k load(full scall)

Output Impedance: 1k

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

BBE : OFF

Frequency Band

FM 87.5MHz ~ 108.0MHz

MW 522kHz ~ 1620 kHz

LW 144kHz ~ 279kHz

Dummy load

Exclusive dummy load should be used for AM,and FM. For

FM dummy load,there is a loss of 6dB between SSG output

and antenna input.The loss of 6dB need not be considered

since direct reading of figures are applied in this working

standard.

How to connect the extension cable for adjusting

EXTGS004-26P

1-11

Page 12

KD-S821R

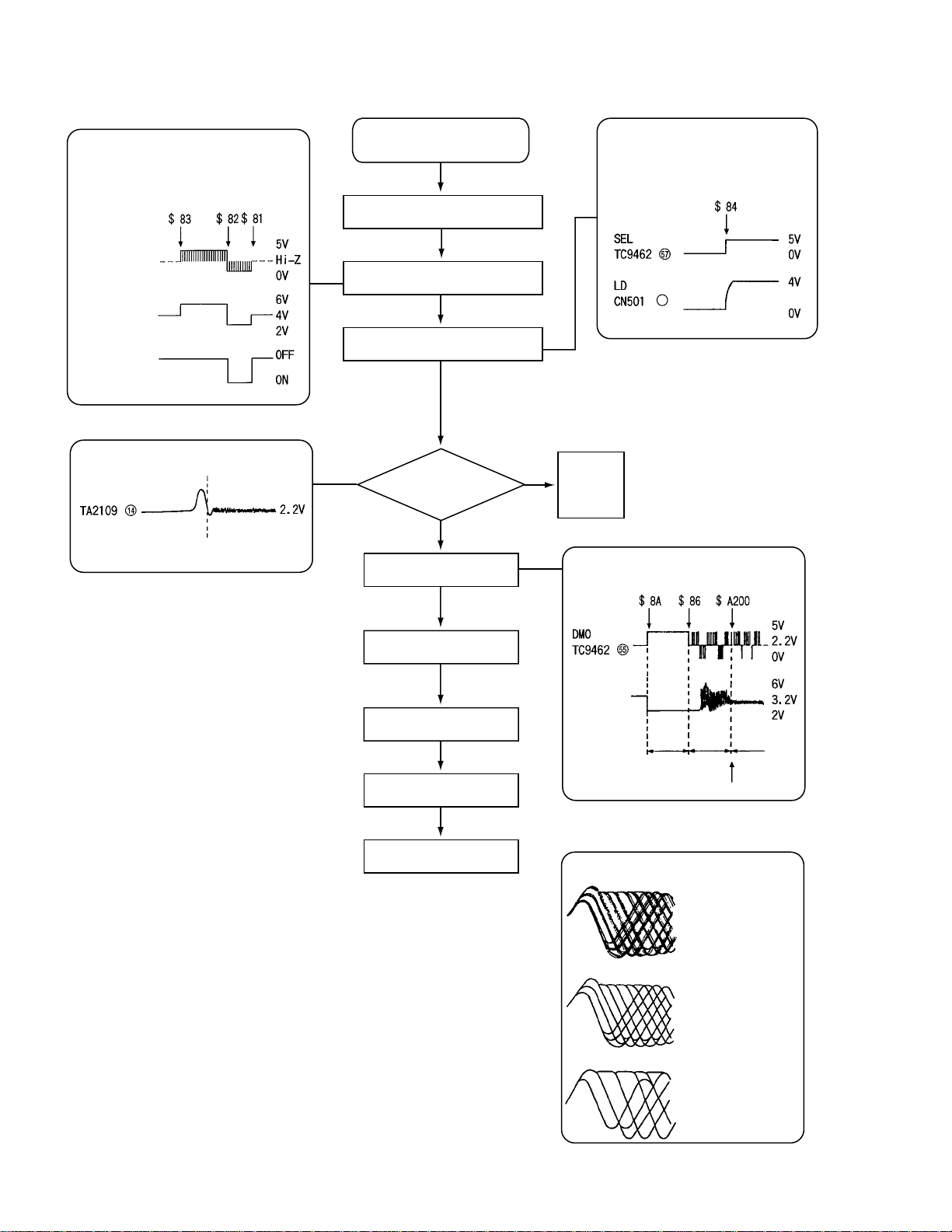

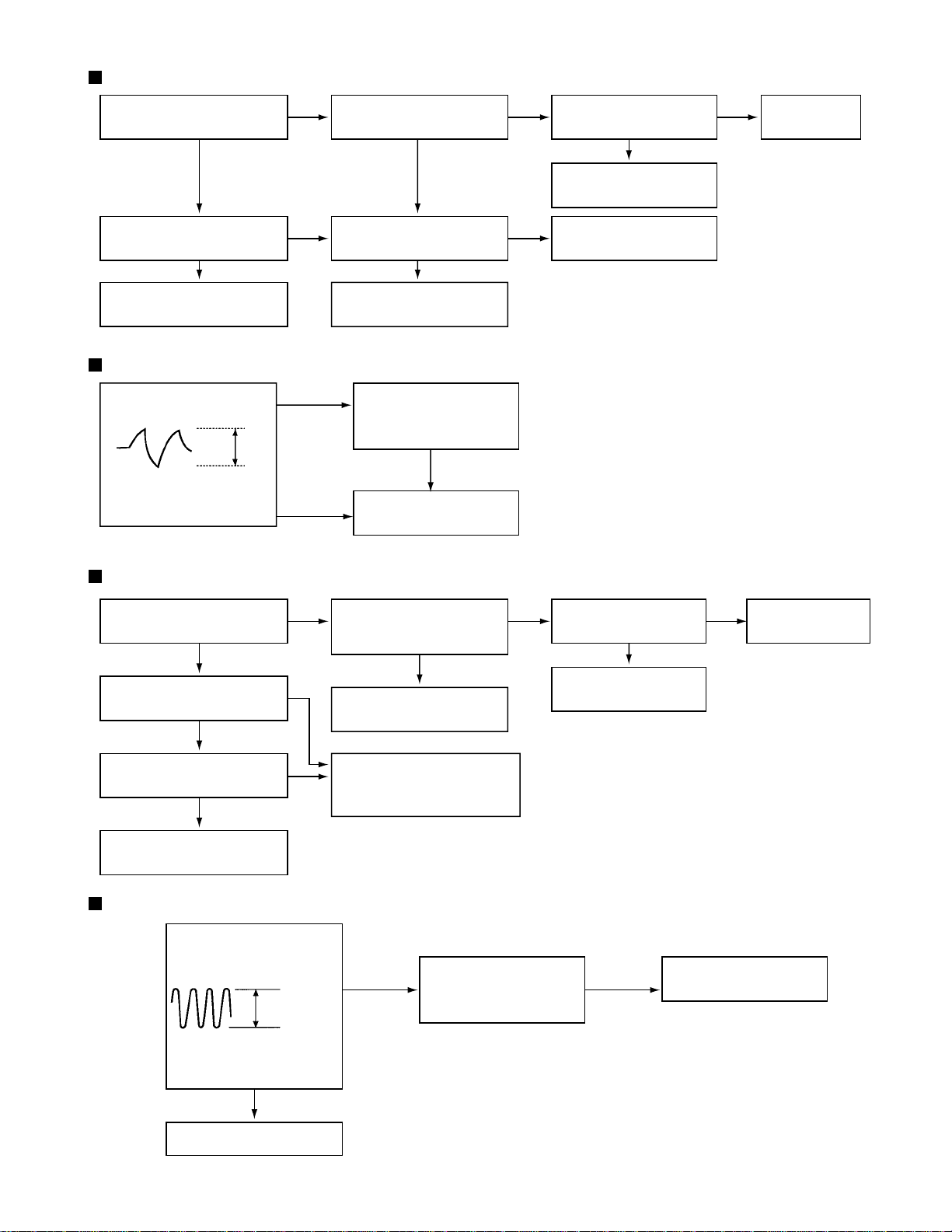

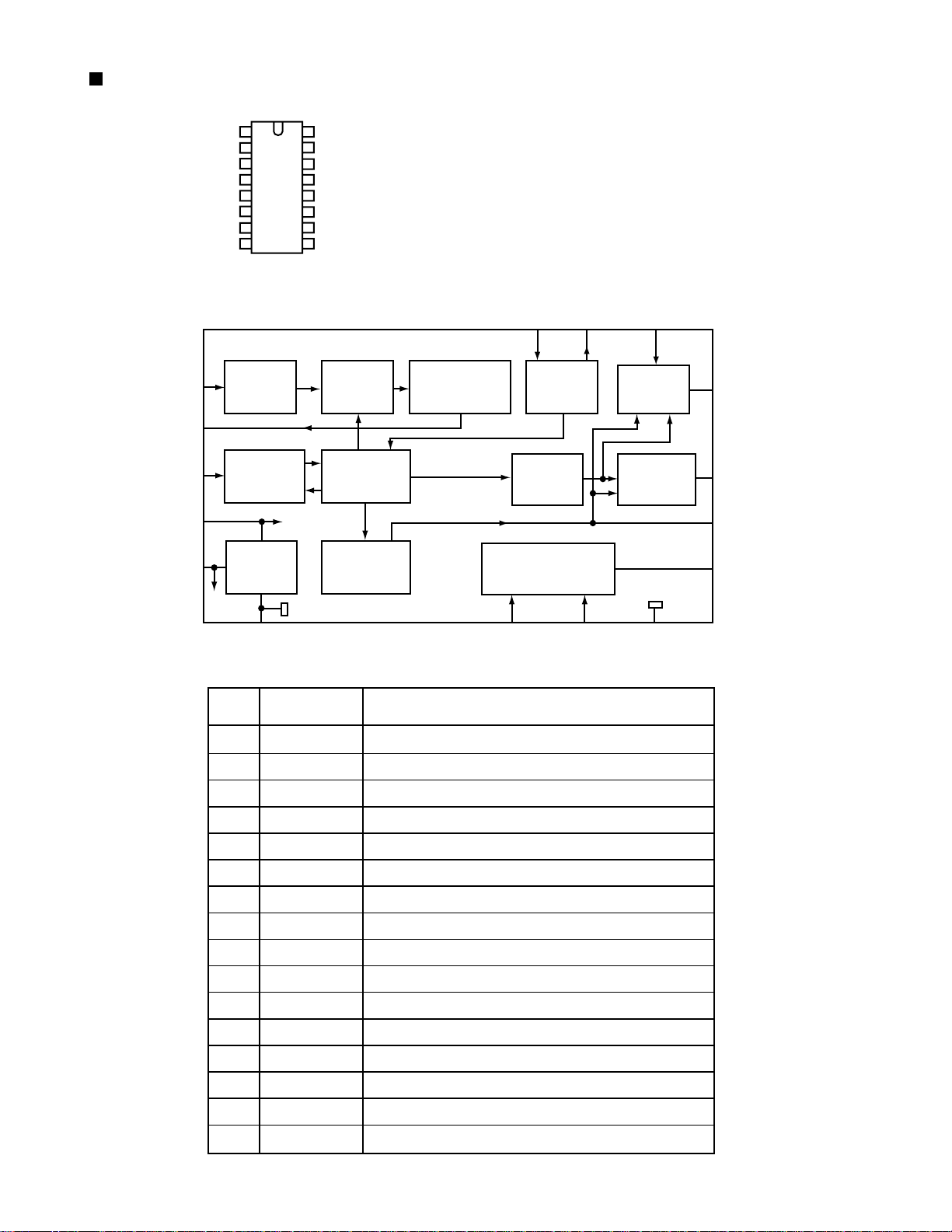

Flow of functional operation until TOC read

Power ON

• When the pickup correctly moves

to the inner area of the disc

Set Function to CD

• When the laser diode correctly

emits

Microprocessor

commands

FMO

TC9462 "53"

FEED MOTOR

+TERMINAL

TERMINAL

IC501 "10"

REST SW

• When correctly focused

FEO

Focus Servo Loop ON

Disc inserted

Pickup feed to the inner area

Laser emitted

Focus search

Disc rotates

RF signal eye-pattern

remains closed

Tracking loop closed

RF signal eye-pattern

opens

TOC readout

YES

YES

Microprocessor

commands

1

"No disc"

display

• When the disc correctly rotates

Microprocessor

commands

Spindle

motor (-)

IC501 "7"

AccelerationAcceleration

0.5 Sec

Rough

Servo

0.5 Sec

Servo CLV

1-12

Jump to the first track

Play

Tracking Servo Loop ON

• RF signal

Rough Servo Mode

CLV Servo Mode

(ProgramArea)

CLV Servo Mode

(Lead-In Area;

Digital: 0)

Page 13

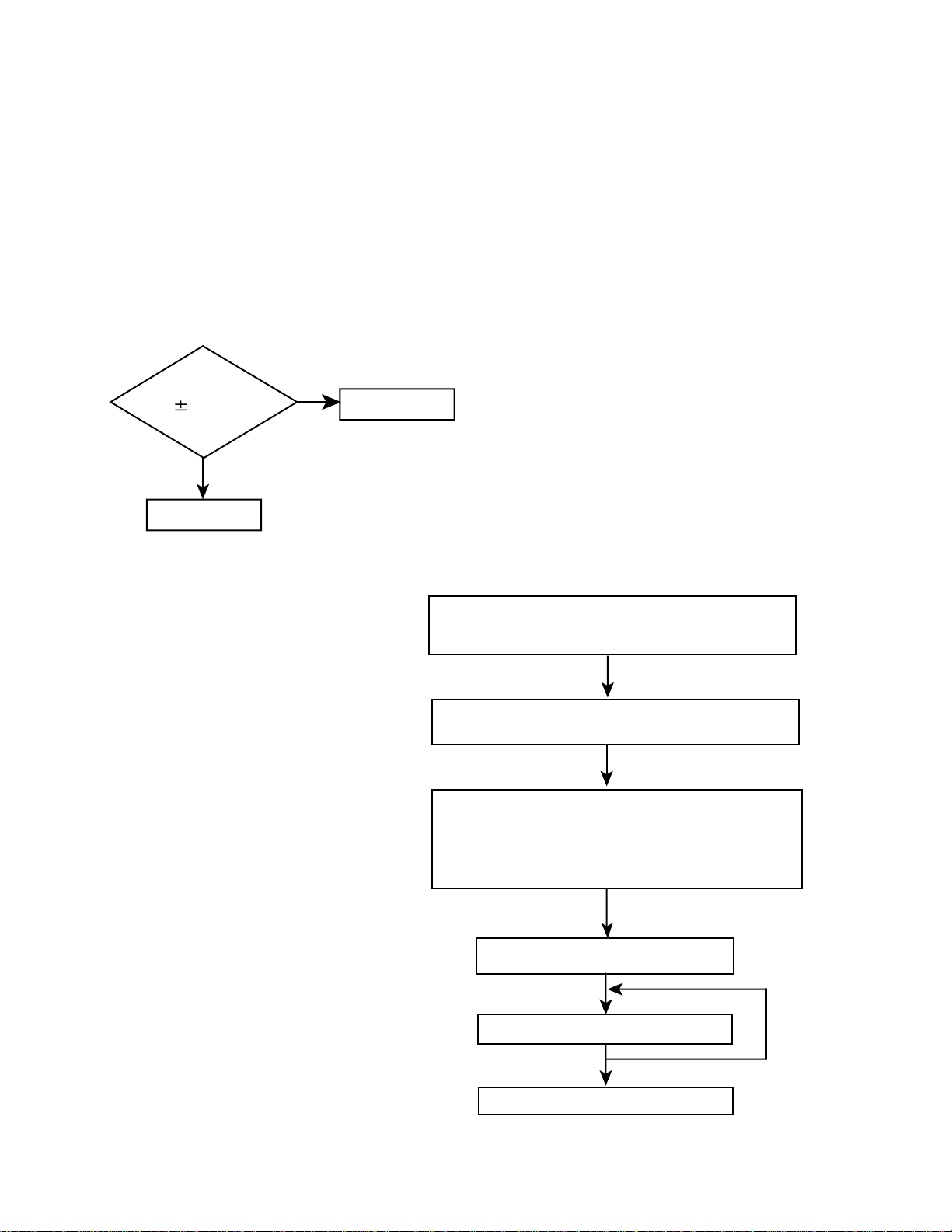

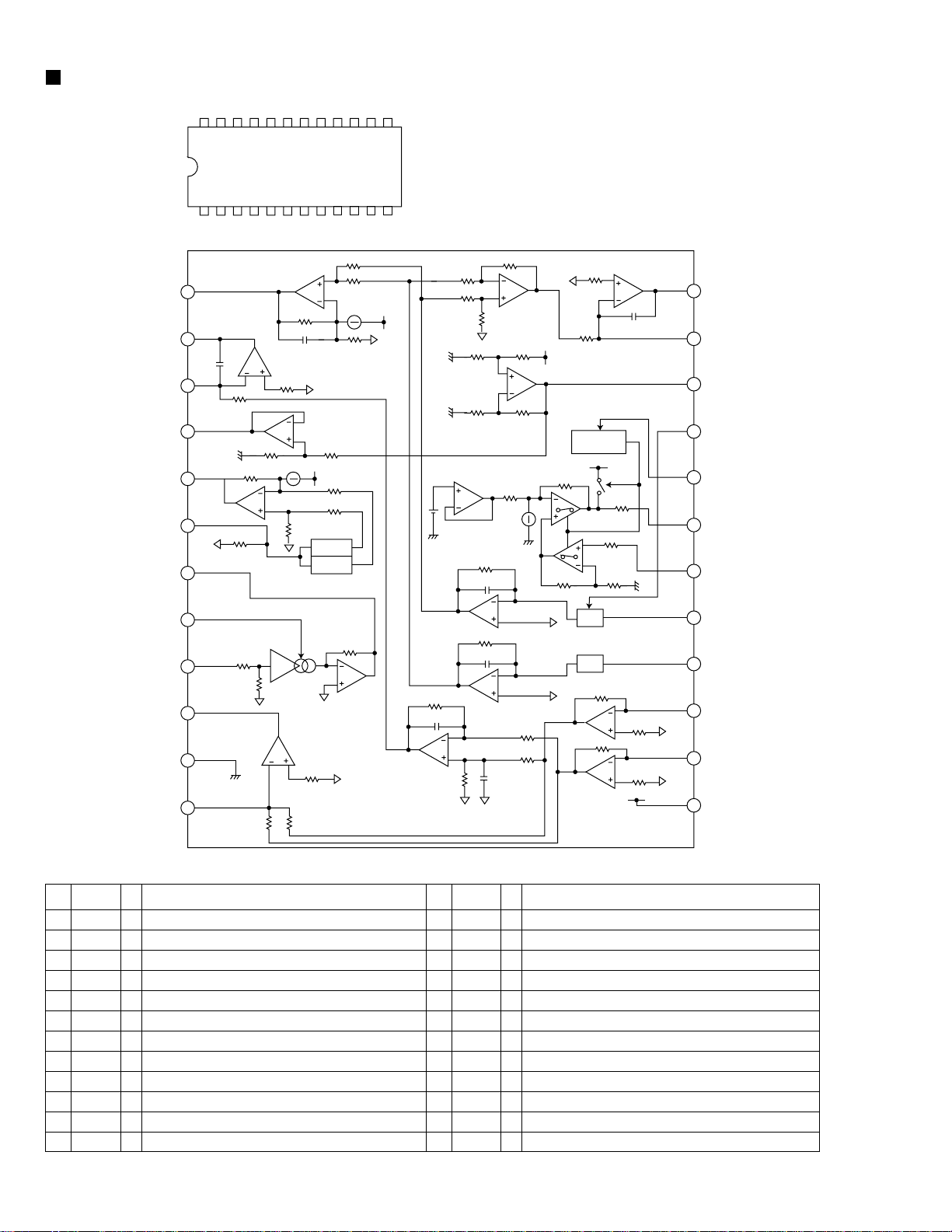

Feed Section

Is the voltage output at

IC541 pin "53" 5V or 0V?

YES

Is 4V present at both

sides of the feed motor?

YES

NO

Is the wiring for IC541

(90) ~ (100) correct?

NO

Is 6V or 2V present at

IC501 "10" and "11"?

NO

YES

YES

Is 5V present at IC501

pin "20"?

YES

Check the vicinity of

IC541.

Check the feed motor

connection wiring.

NONO

KD-S821R

Check CD 9V

and 5V.

Check the feed motor.

Focus Section

When the lens is

moving:

4V

Does the S-search

waveform appear at

IC501 pins "6" and "7"?

Spindle Section

Is the disk rotated?

YES

Does the RF signal

appear at TP1?

YES

Is the RF waveform at TP1

distorted?

YES

Check IC501.

NO

YES

NO

NO

NO

Check the circuits in

the vicinity of IC501

pins "14" ~ "18".

Check the pickup and

its connections.

Is 4V present at IC501

pins "8" and "9" ?

Check the spindle motor

and its wiring.

Check the circuits in the

vicinity of IC521 "2" ~ "7",

"18"~"24" or the pickup

YES

YES

NO NO

Is 4V present at IC541

pin "55" ?

YES

Check the vicinity of

IC501.

Check IC521 and

IC541.

Proceed to the Tracking

section

Tracking Section

When the disc is rotated

at first:

Is the tracking error signal

output at IC521 "12"?

Check IC521.

Approx. 1.2 V

YES

Check the circuit in the

vicinity of IC521 pins

"2" ~ "12".

YESYES

Check the pickup and

its connections.

1-13

Page 14

KD-S821R

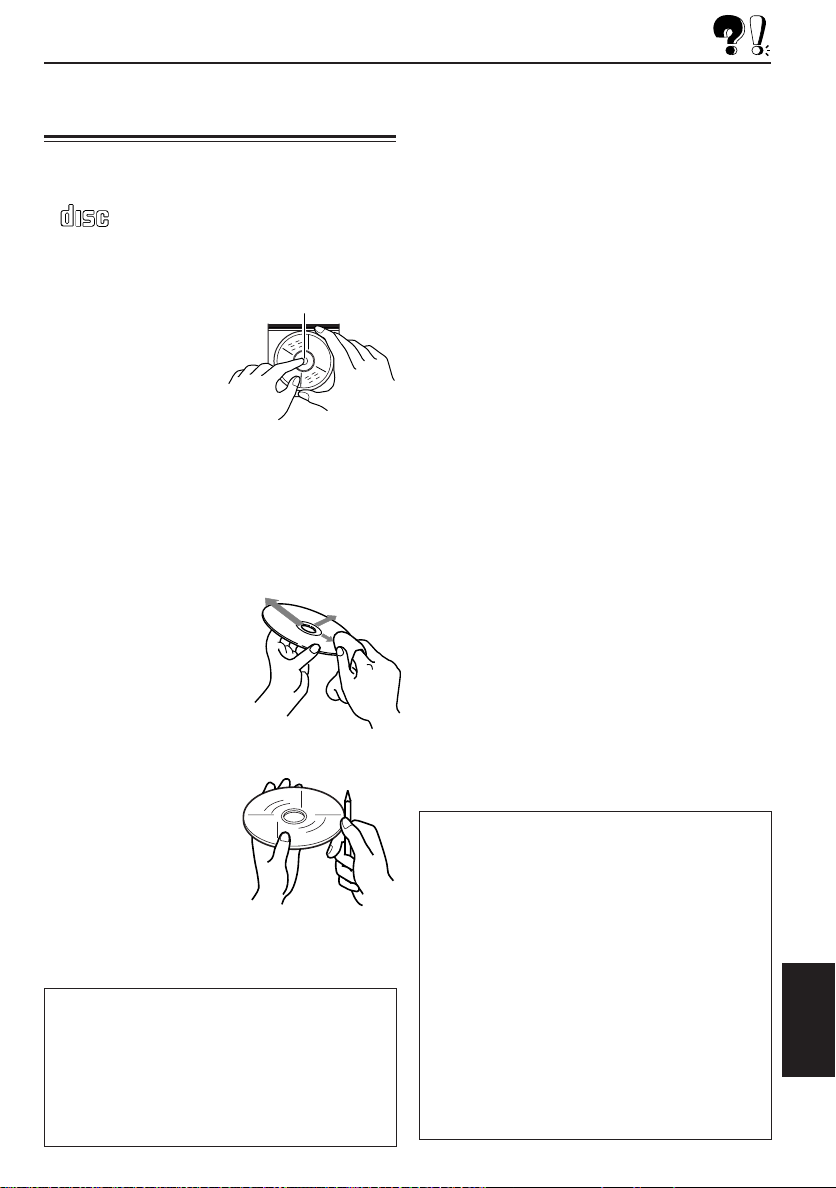

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will be low.

Is RF output

1.0 0.35Vp-p?

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

1-14

Play a disc.

Check the eye-pattern at TP1.

Finish.

Page 15

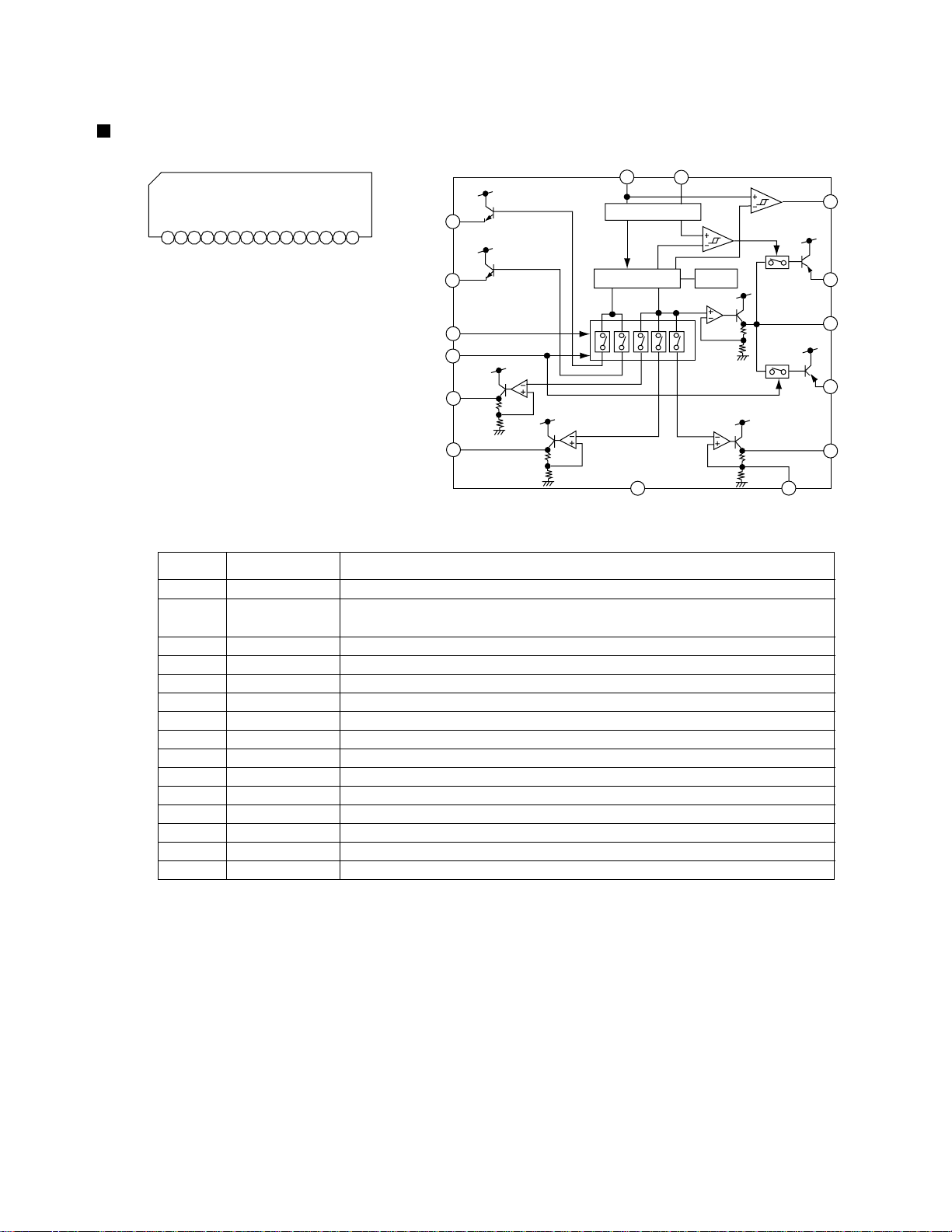

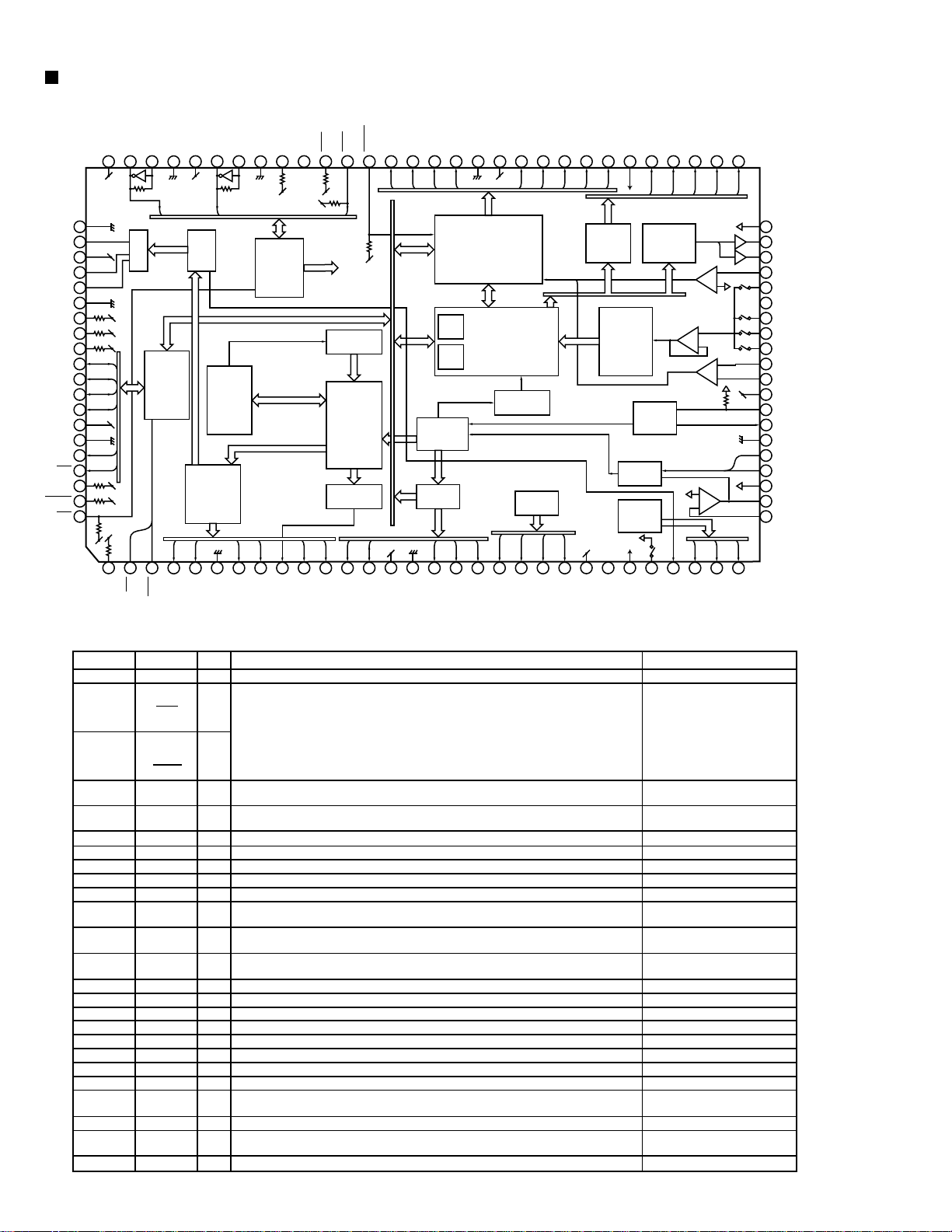

Description of major ICs

HA13164A (IC961) : Regurator

1.Pin layout

REMOTE

ANT

ACC.IN

VDD5V

SW5V

ACC5V

ANT CTRL

MEMORY.IN

BATT DET9VCTRL

CD 8VAJ10V

1 2 3 4 5 6 7 8 9 101112131415

GND

2.Block daiagram

2

8

Surge Protector

3

KD-S821R

9

1

7

11

12

10

3.Pin function

Pin No. Symbol Function

1

2

REMOTE

ANT

Output voltage is VCC-1V.When M or H level applied to CTRL pin.

Output voltage is VCC-1V.When M or H level to CTRL pin and H

level to ANT-CTRL.

3

4

5

6

7

8

9

10

11

12

13

14

15

ACC.IN

VDD5V

SW5V

ACC5V

ANT CTRL

MEMORY.IN

BATT DET

9V

CTRL

CD 8V

AJ

10V

GND

Connected to ACC.

Regular 5.7V.

Output voltage is 5V when M or H level applied to CTRL pin.

Output for ACC detector.

L:ANT output OFF, H:ANT output ON

Connected to VCC.

Low battery detect.

Output voltage is 9V When M or H level applie to CTRL pin.

L:BIAS OFF, M:BIAS ON, H:CD ON

Output voltage is 8V when H level applied to CTRL pin.

Adjustment pin for ILM output voltage.

Output voltage is 10V when M or H level applied to CTRL pin.

Connected to GND.

BIAS TSD

15

6

4

5

14

13

1-15

Page 16

KD-S821R

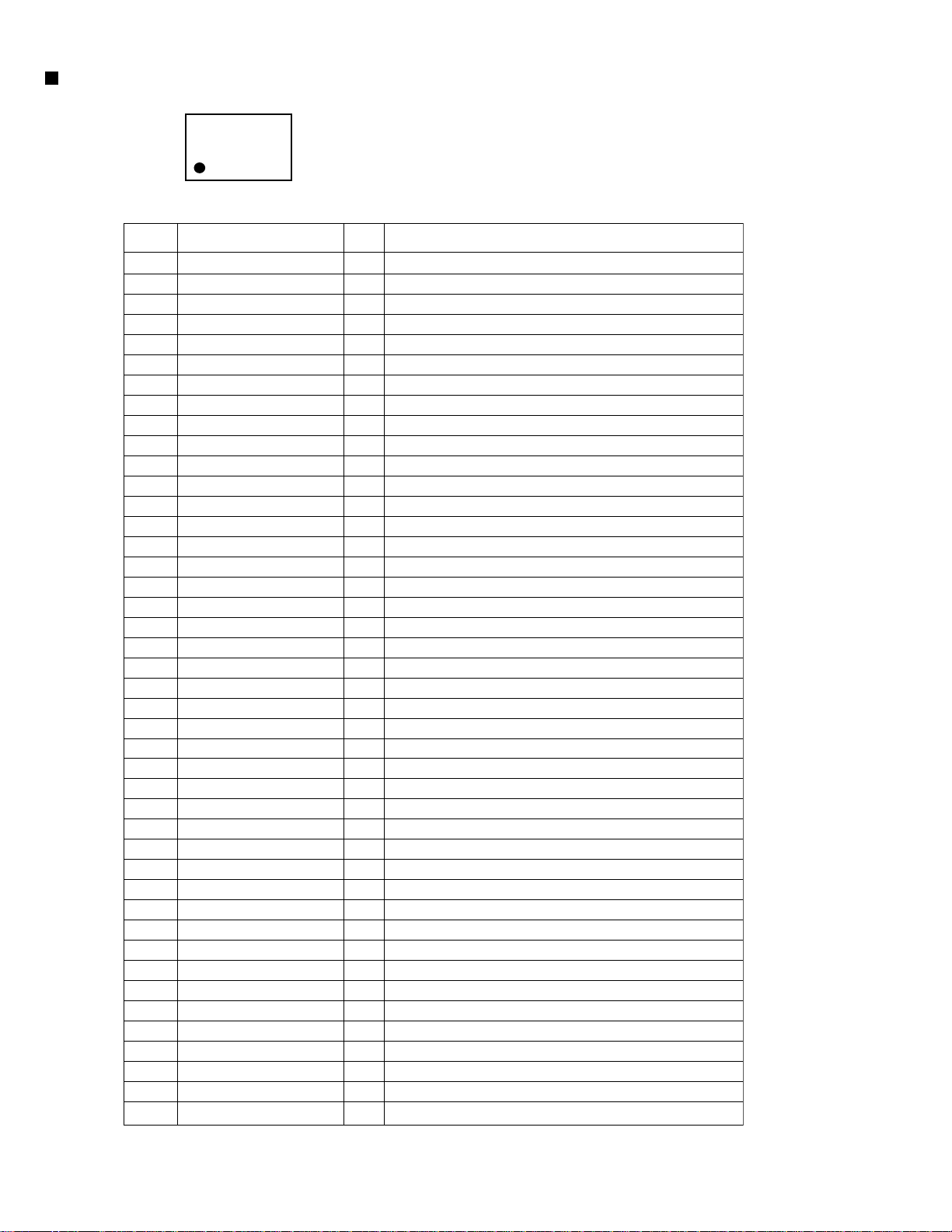

UPD178078GF-558 (IC701) : System CPU

81

~

NC

BUSINT

BUSSI

BUSSO

JBUS-SCK

NC

I2CDAI

I2CDAO

I2CCLK

NC

LCDDA

LCDSCK

BUSI/O

NC

LCODE

SW2

SW3

SW4

RESTSW

ENC1

ENC2

KEY0

KEY1

KEY2

LEVEL

AVDD

SM

SQ

NC

AVSS

REGCPU

VDD

REGOSC

X2

X1

GND0

SD/ST

GND2

NC

IFC

VDDPLL

OSC

NC

80 ~ 51

50

~

31

1 ~ 30

1.Pin layout

100

2.Pin function (1/2)

Pin

NO.

1

2

3

4

5

6,7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30,31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

I/OSymbol FUNCTION

-

No use

I

JVC bus communication line

I

JVC bus communication line

O

JVC bus communication line

O

JVC bus communication line

-

No use

I

Serial data input

O

Serial data output

O

Serial clock output

-

No use

O

LCD driver serial data output

O

Serial data for LCD

O

JVC bus output select

-

No use

O

LCD driver communication line

I

CD mech switch

I

CD mech switch

I

CD mech switch

I

Traverse mech rest switch

I

Encoder input

I

Encoder input

I

Key input

I

Key input

I

Key input

I

Audio level input

-

Power supply

I

Signal level meter input

-

Signal level meter input

-

No use

-

Connect to GND

-

Connect to GND with capacitor

-

Power supply

-

Connect to GND with capacitor

-

System clock

I

System clock

-

Connect to GND

I

Station detector & Stereo indicator

-

Connect to GND

-

No use

I

IF count input

-

---

I

FM,AM osc input

-

No use

1-16

Page 17

KD-S821R

2.Pin function (2/2)

Pin

NO.

46

GNDPLL

47

AMEO

48

FMEO

49

IC(VPP)

50

RESET

51

SW1

52

REMOCON

53

NC

54

TEL-MUTE

55

POWER

56

CDON

57

MUTE

58

STAGE 1

59

BUZZER

60

STAGE 2

61~68

89~98

100

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

99

NC

LM0

LM1

BUCK

CCE

BUS0

BUS1

BUS2

BUS3

RST

PS1

PS2

DETACH

RDSSCK

GND1

MONO

SEEK/STP

FM/AM

AFCK

RDSDA

PLLMONITOR

NC

VDDPORT

GNDPORT

I/OSymbol FUNCTION

-

---

O

PLL error output for AM

O

PLL error output for FM

-

Setting to write for flash

I

System reset

I

CD mech switch

I

Remocon input

-

No use

-

No use

O

Power control

O

CD power control

O

Mute control

-

No use

-

No use

-

No use

-

No use

O

CD mech driver control

O

CD mech driver control

O

CD LSI communication line

O

CD LSI communication line

I/O

I/O

I/O

I/O

CD LSI communication line

CD LSI communication line

CD LSI communication line

CD LSI communication line

O

CD LSI communication line

I

ACC detection input

I

Memory detection

I

Detach detection

-

No use

-

Connect to GND

O

Mono by force

O

Switching SEEK & STOP

O

Band switch

-

No use

O

Antena regulator control signal

-

No use

-

Non connection

-

Vdd

-

Connect to GND

UPD178078GF-558

1-17

Page 18

KD-S821R

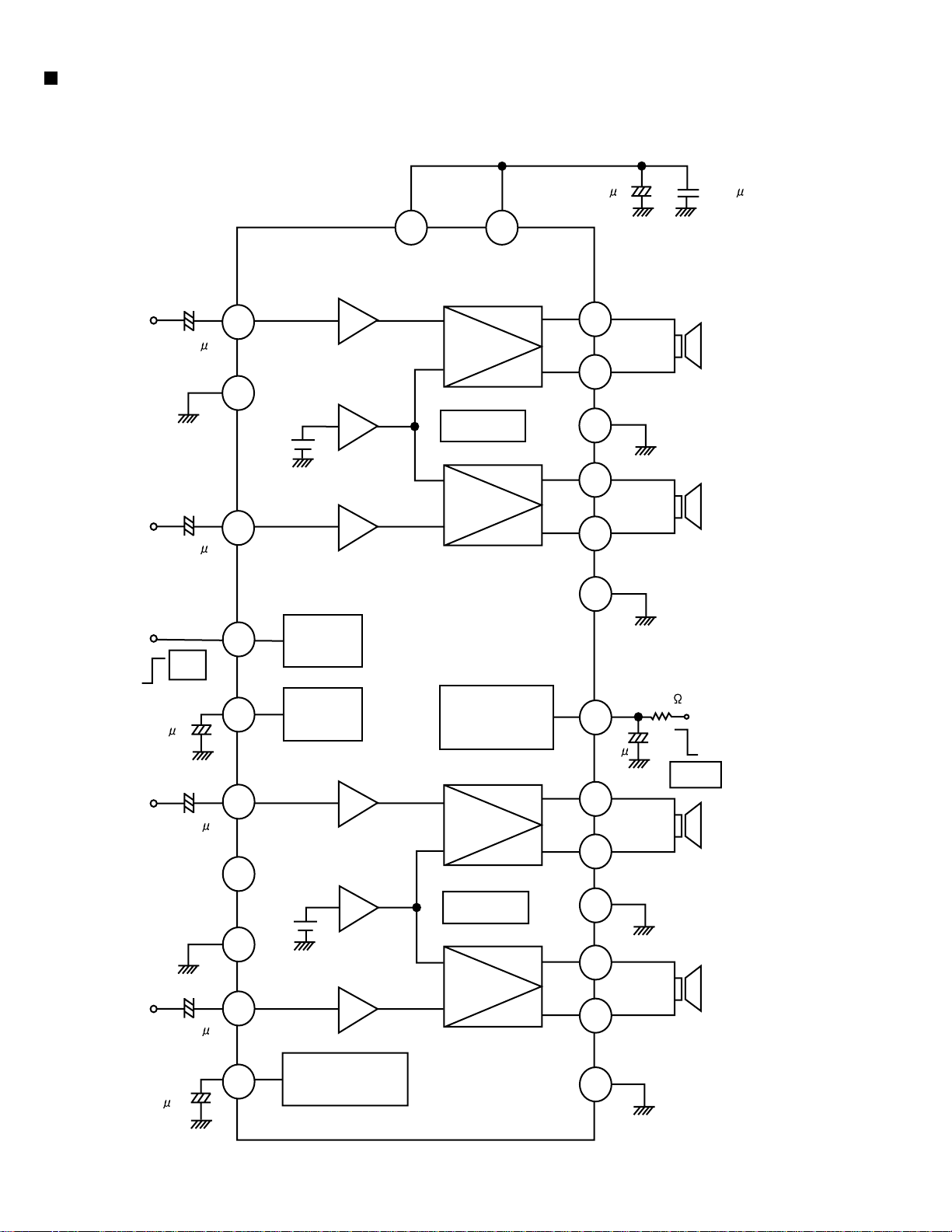

LA4743K(IC301):Power amp

1.Block diagram

IN 1

TAB

IN 2

ST BY

R.F

47 F

IN 3

PRE GND

+

0.22 F

+

0.22 F

+5V

ST ON

+

0.22 F

N.C

+

Vcc 1/2 Vcc 3/4

2200 F 0.022 F

6 20

11

+

-

+

-

9

7

OUT 1+

OUT 1-

1

PWR GND1

8

OUT 2+

5

OUT 2-

3

PWR GND2

12

Protective

circuit

-

+

+

-

2

4

Stand by

Switch

Mute

3.3 F

OUT 3+

OUT 3-

10K

+

Low Level

Mute ON

10

+

Ripple

Filter

Mute

circuit

22

+

15

-

+

-

17

19

25

18

21

PWR GND3

OUT 4+

13

Protective

circuit

+

-

1-18

IN 4

0.22 F

ON TIME C

22 F

+

14

Muting &

16

+

ON Time Control

Circuit

+

23

24

OUT 4-

PWR GND4

Page 19

2.Terminal layout

KD-S821R

3.Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SymbolPin No. Function

TAB

GND

OUTRRSTBY

OUTRR+

VCC1/2

OUTRFGND

OUTRF+

RIPPLE

INRF

INRR

SGND

INLR

INLF

ONTIME

OUTLF+

GND

OUTLFVCC3/4

OUTLR+

MUTE

OUTLRGND

NC

Header of IC

Power GND

Outpur(-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

Front Lch input

Rear Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front

Muting control input

Output (-) for front

Power GND

Non connection

LA4743K

1-19

Page 20

KD-S821R

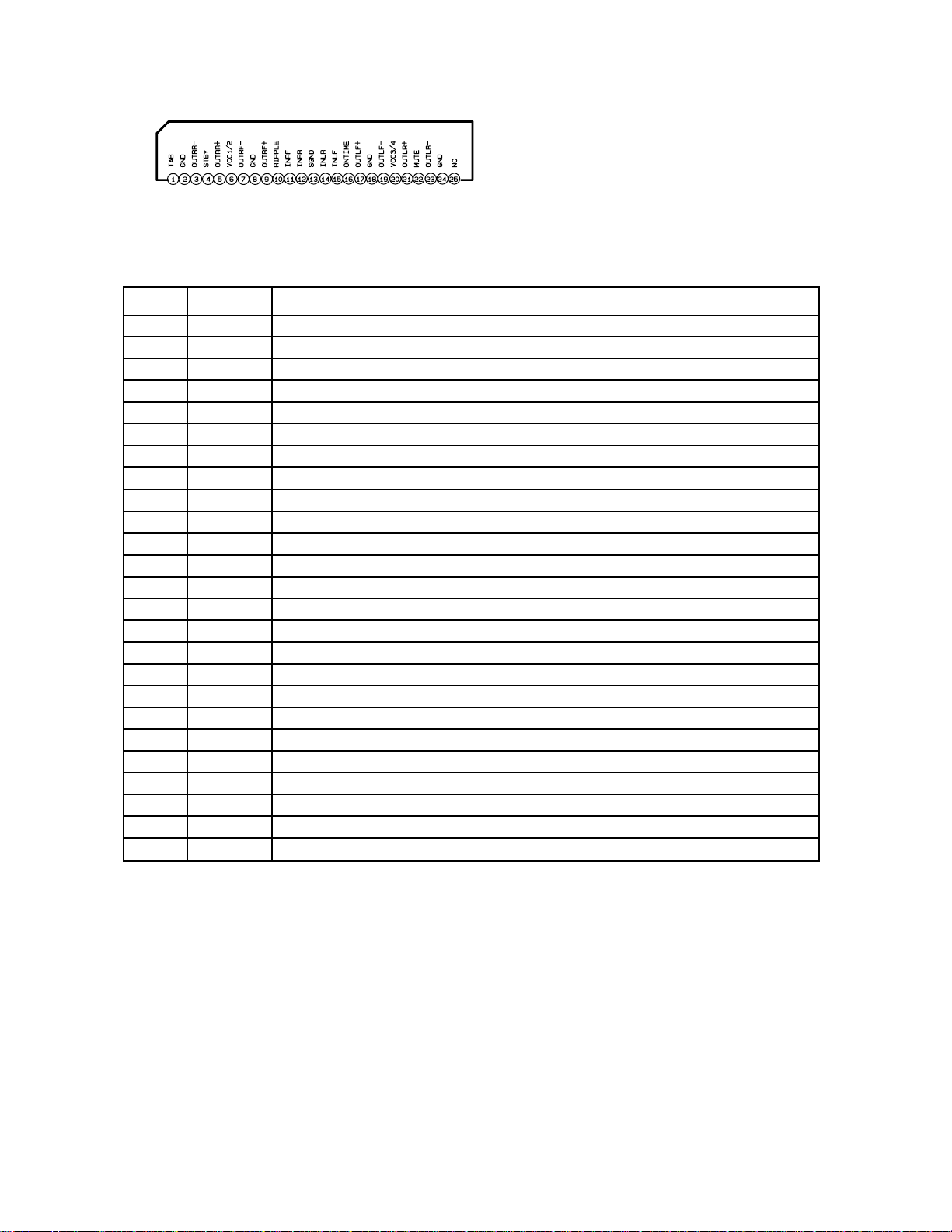

LA6567H-X(IC501):BTL driver

1.Pin layout & blockdiagram

VCC2

V05-

V05+

V04+

V04-

V03+

V03-

FR

1

2

3

4

5

6

7

FR

CH 3,4,5

Power supply

CH5

CH4

CH3

Thermal shutdown

Output control

Level shiftLevel shiftLevel shiftLevel shift

Input

22K 11K

Signal system power supply

28

27

26

25

24

23

22

FR

REV

FWD

S-GND

VCONT

VIN4

VIN4G

VCC-S

FR

V02+

V02-

V01+

V01-

VCC1

VIN1

VIN1G

8

9

10

11

12

13

14

CH2

CH1

CH1,2

Power supply

11K

22K

5VREG(PNPTr

The outside putting)

22K

11K

22K

11K

21

20

19

18

17

16

15

VREF-IN

REG-OUT

REG-IN

VIN3G

VIN3

VIN2G

VIN2

1-20

Page 21

KD-S821R

2. Pin function

Pin no. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

VCC2

V05V05+

V04+

V04V03+

V03V02+

V02V01+

V01-

VCC1

VIN1

VIN1G

VIN2

VIN2G

VIN3

VIN3G

REG-IN

REG-OUT

VREF-IN

VCC-S

VIN4G

VIN4

VCONT

S-GND

FWD

LA6567H-X(2/2)

Function

CH3,4,5 Power supply( It is short with VCC1,VCC-S)

Loading output(-)

Loading terminal (+)

CH4 Output terminal(+)

CH4 Output terminal(-)

CH3 Output terminal(+)

CH3 Output terminal(-)

CH2 Output terminal(+)

CH2 Output terminal(-)

CH1 Output terminal(+)

CH1 Output terminal(-)

CH1,2(BTL) Power supply(It is short with VCC-S,VCC2)

CH1 Input terminal

CH1 Input terminal(For gain adjustment)

CH2 Input terminal

CH2 Input terminal(For gain adjustment)

CH3 Input terminal

CH3 Input terminal(For gain adjustment)

Regulator terminal(Outside putting PNP base)

Regulator terminal(Outside putting PNP collector)

Standard voltage input terminal

Signal system power supply(It is short with VCC1,VCC2)

CH4 Input terminal(For gain adjustment)

CH4 Input terminal

5CH(VLO) Output voltage set terminal

Signal system GND

5CH(VLO)Signal output switch terminal(FWD),Input of logic of loading part

28

REV

5CH(VLO)Signal output switch terminal(REV),

Input of logic of loading part

Frame(FR)at the center becomes system GND.

Please be short-circuited on the outside and use the terminal of the power supply system

and three teminals of VCC-S, VCC1,VCC2.

1-21

Page 22

KD-S821R

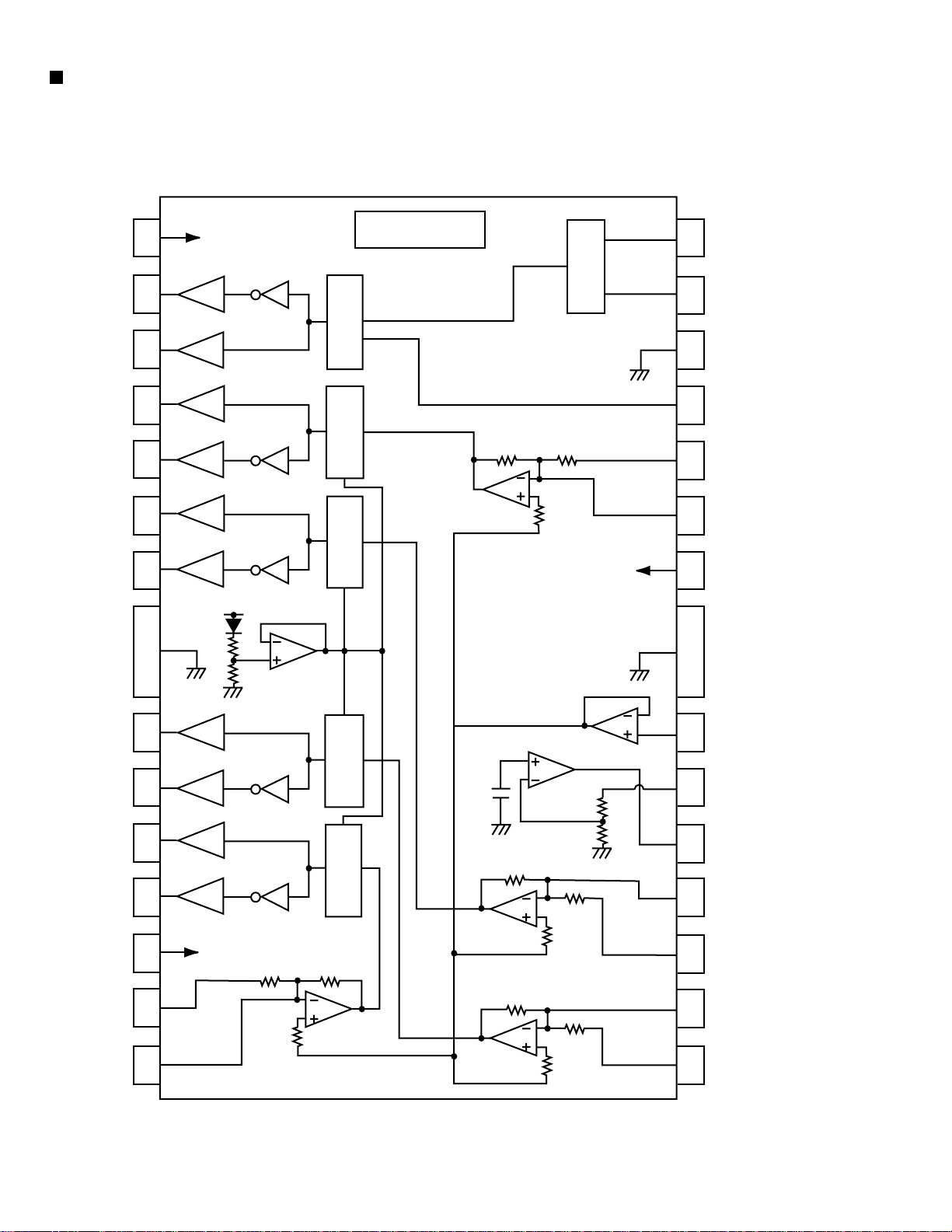

TC9462F(IC541): DSP & DAC

1.Pin layout & Block Diagram

RST

DD

XV

80

79

81DV

SR

82RO

83DV

DD

84DVR

85LO

86DV

SL

87TEST1

88TEST2

89TEST3

90BUS0

91BUS1

92BUS2

93BUS3

94V

DD

95V

SS

96BUCK

97CCE

98TEST4

99TSMOD

100

1 2 3

TEST0

XO78XI

LPF

HSO

Micon

interface

UHSO

SS

XV

77

4 5

EMPH

DD

V

75

76

1bit

DAC

PXO

SS

PXI

V

74

73

Clock

generator

Correction

circuit

Audio out

circuit

6

7 8 9 10 11 12 13

SS

V

BCK

LRCK

AOUT

72

TESIO1

DOUT

71

TESIN

MBOV

DACT

69

70

Address circuit

16KRAM

Digital out

IPF

CKSE

SBOK

DMOUT

68

CLCK

IO3

IO265IO164IO063V

67

66

ROM

Automatic adjustment

RAM

Synchronous

guarantee

EFM decode

Sub code

decoder

14 15

16 17 18 19 20 21 22

SS

DD

V

V

DATA

SFSY

SS

DD

V

62

Servo

control

Digital equalizer

circuit

CLV servo

SBSY

SPCK

FLGD60FLGC59FLGB58FLGA57SEL562V

61

PWM D/A

A/D

Status

23 24 25

DD

COFS

MONIT

V

TESIO0

SPDA

REF

DMO54FVO53FMO52TEBC51RFGC

55

Data

slicer

VCO

PLL

TMAX

26

27 28

REF

ZDET

HSSW

P2V

+

-

+

-

PDO

+

-

+

-

29

TMAXS

30

TMAX

50 V

REF

49 TRO

48 FOO

TEZI

47

46 TEI

45 TSIN

44 SBAD

43 FEI

42 RFRP

41 RFZI

40 RFCT

39 AV

DD

38 RFI

37 SLCO

36 AV

SS

35 VCOF

34 VCOREF

33 PV

REF

32 LPFO

31 LPFN

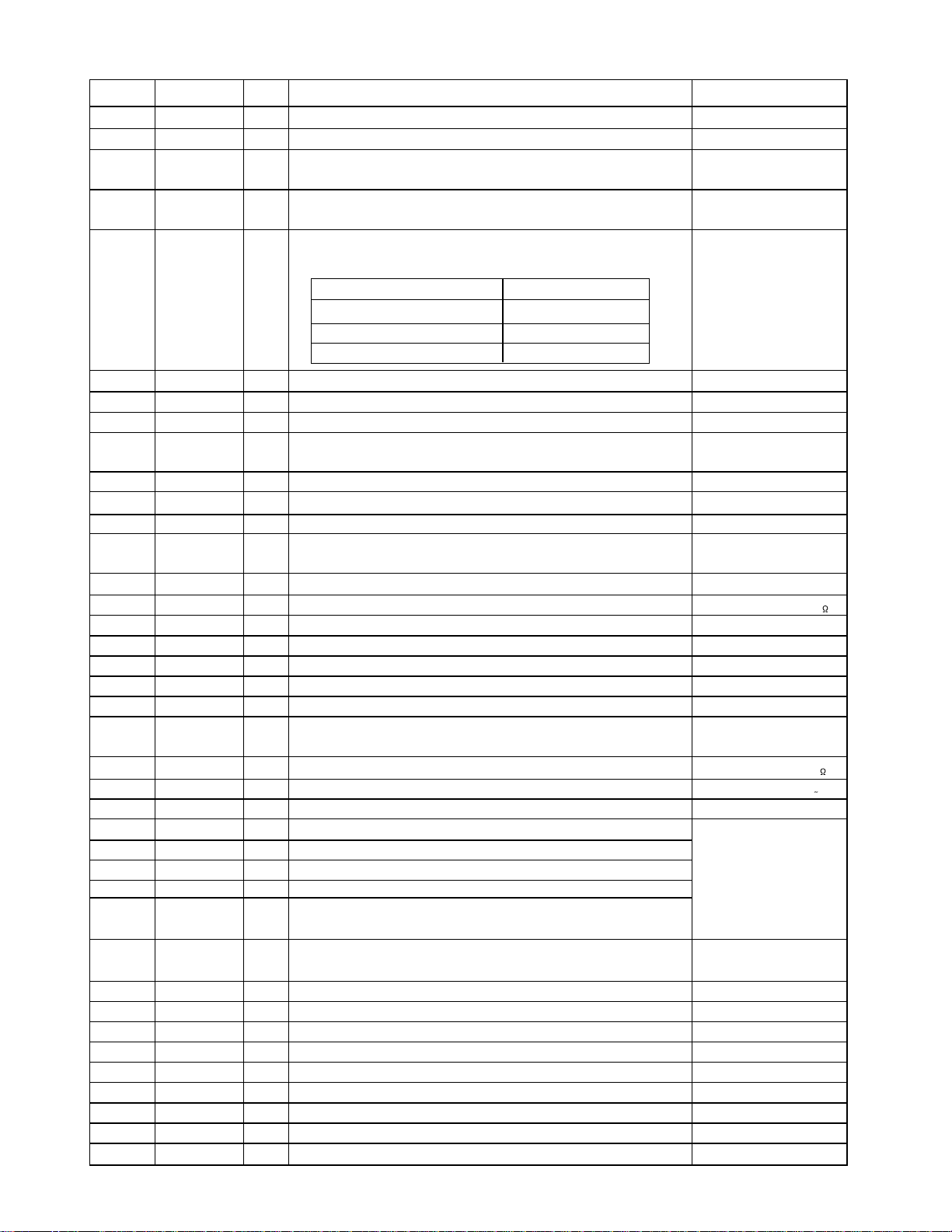

2.Pin function

PIN No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25 P2V

SYMBOL

TEST0

HSO

UHSO

EMPH

LRCK

V

SS

BCK

AOUT

DOUT

MBOV

IPF

SBOK

CLCK

V

DD

V

SS

DATA

SFSY

SBSY

SPCK

SADA

COFS

MONIT

V

DD

TESIO0--I

REF

I/O

FUNCTIONAL DESCRIPTION

-

Non connected

Non connected

-

-

Non connected

Non connected

Digital GND terminal.

--

-

Non connected

Non connected

Non connected

Non connected

Non connected

-

Non connected

Non connected

-

--

Digital power supply voltage terminal.

--

Digital GND terminal.

-

Non connected

Non connected

-

-

Non connected

Non connected

Non connected

Non connected

-

-

Non connected

Digital power supply voltage terminal.

Test input/output terminal.Normally,keep at "L" level.

The terminal that inputted the clock for read of text data by command.

--

PLL double reference voltage supply terminal.

REMARKS

With pull-up resistor.

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

1-22

Page 23

Pin No.

26

27

28

29

30

Symbol

HSSW

ZDET

PDO

TMAXS

TMAX

I/O

Non connected

Non connected

Phase difference signal output terminal of EFM

O

Function Remarks

signal and PLCK signal.

TMAX detection result output terminal. Selected by

O

command bit (TMPS)

TMAX detection result output terminal. Selected by

O

command bit (TMPS)

DIFFERENCE RESULT TMAX OUTPUT

Longer than fixed freq. "P2VREF"

Shorter than fixed freq. "VSS"

Within the fixed freq. "Hiz"

KD-S821R

TC9462F(2/3)

-

-

3-state output.

(P2VREF,PVREF,VSS)

3-state output.

(P2VREF,PVREF,VSS)

3-state output.

(P2VREF,HiZ,VSS)

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58~61

62

63

64~67

68

69

70

LPFN

LPFO

PVREF

VCOREF

VCOF

AVSS

SLCO

RFI

AVDD

RFCT

RFZI

RFRP

FEI

SBAD

TSIN

TEI

TEZI

FOO

TRO

VREF

RFGC

TEBC

FMO

FVO

DMO

2VREF

SEL

FLGA~D

VDD

VSS

IO0~3

DMOUT

CKSE

DACT

LPF amplifier inverting terminal for PLL.

I

LPF amplifier output terminal for PLL.

O

PLL reference voltage supply terminal.

VCO center frequency reference level terminal. Normally,

I

keep at "PVREF" level.

VCO filter terminal.

O

Analog GND terminal.

Data slice level output terminal.

O

RF signal input terminal.

I

Analog power supply voltage terminal.

-

RFRP signal center level input terminal

I

RFRP zero cross input terminal

I

RF ripple signal input terminal

I

Focus error signal input terminal

I

Sub-beam adder signal input terminal

I

Test input terminal Normally, keep at "vref" level

I

Tracking error signal input terminal. Take in at tracking

I

servo ON.

Tracking error zero cross input terminal

I

Focus servo equalizer output terminal

O

Tracking servo equalizer output terminal

O

Analog reference voltage supply terminal

RF amplitude adjustment control signal output terminal

O

Tracking balance control signal output terminal

O

Feed equalizer output terminal

O

Speed error signal or feed search equalizer output

O

terminal

Disk equalizer output terminal

O

DSP, Synchronize to PXO)

Analog double reference voltage supply terminal

APC circuit ON/OFF indication signal output terminal

O

Non connected

Digital power supply voltage terminal

Digital GND terminal

Non connected

Non connected

Non connected

Non connected

-

(PWM carrier=88.2kHz for

Analog input.

Analog output.

-

-

Analog output.

Analog output.

Analog input.

(Zin:selected by command)

Analog input(Zin : 50k )

Analog input.

Analog input.

Analog input.

Analog input.

Analog input.

Analog input.

Analog input(Zin :10k )

Analog output.(2VREF AVSS)

3-state PWM signal

output.

(2VREF,VREF,VSS)

(PWM carrier

=88.2kHz)

3-state output.

(2VREF,VREF,VSS)

-

-

-

-

-

-

-

-

-

1-23

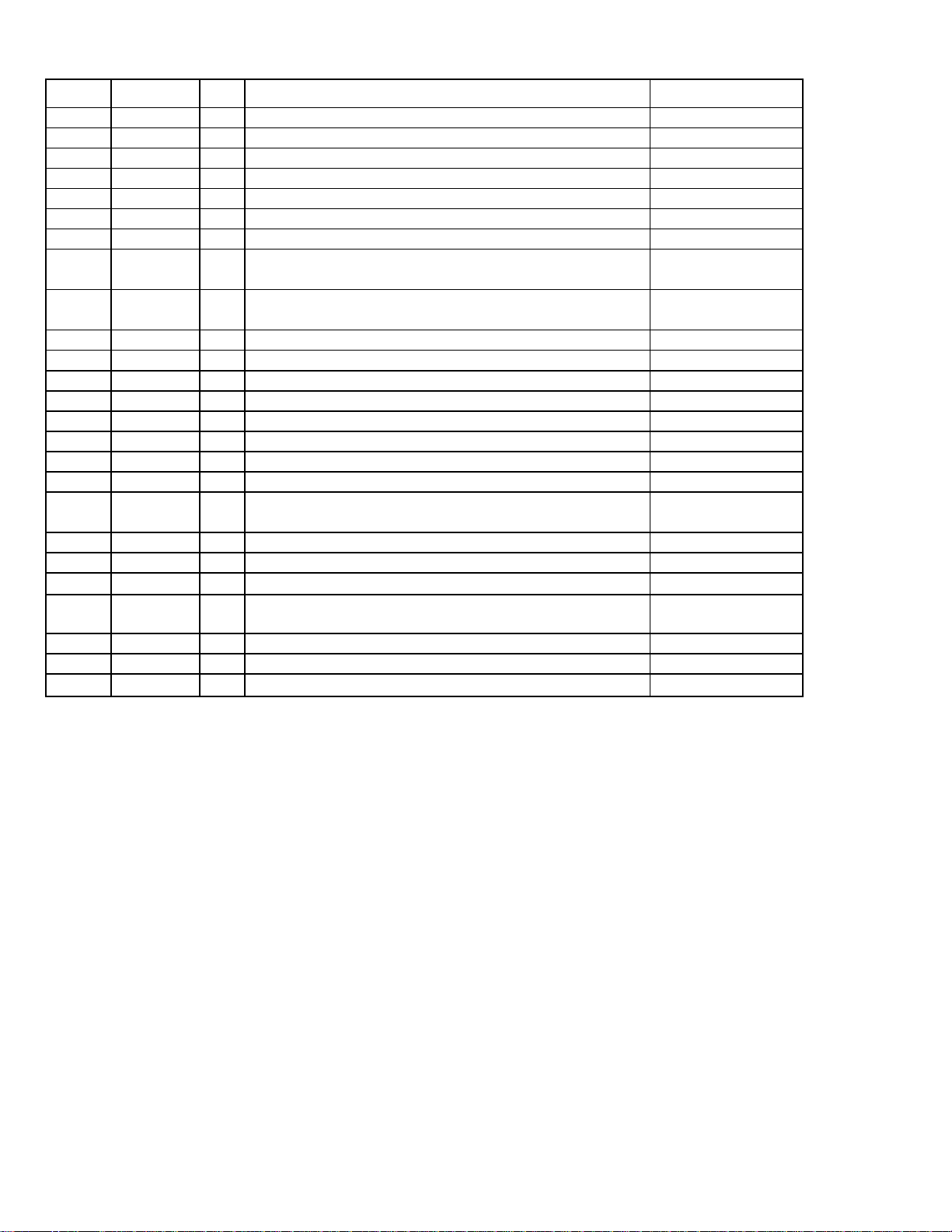

Page 24

KD-S821R

Pin No.

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87~89

90~93

94

95

96

97

98

99

100

Symbol

TESIN

TESIO1

VSS

PXI

PXO

VDD

XVSS

XI

XO

XVDD

DVSR

RO

DVDD

DVR

LO

DVSL

TEST1~3

BUS0~3

VDD

VSS

BUCK

CCE

TEST4

TSMOD

RST

I/O

Test input terminal, Normally, keep at "L" level

I

Test input/output terminal. Normally, keep at "L" level

I

Digital GND terminal

Crystal oscillator connecting input terminal for DSP

I

Crystal oscillator connecting output terminal for DSP

O

Digital power supply voltage terminal

Oscillator GND terminal for system clock

Crystal oscillator connecting input terminal for system

I

clock

Crystal oscillator connecting output terminal for system

O

clock

Oscillator power supply voltage terminal for system clock

Analog GND terminal for DA converter (Rch)

R channel data forward output terminal

O

Analog supply voltage terminal for DA converter

Reference voltage terminal for DA converter

L channel data forward output terminal

O

Analog GND terminal for DA converter (Lch)

Non connected

Micon interface data input/output terminal

I/O

Digital power supply voltage terminal

Digital GND terminal

Micon interface clock input terminal

I

Command and data sending/receiving chip enable signal

I

input terminal

Non connecetd

Non connected

Reset signal input terminal. Reset at "L" level

I

Function Remarks

TC9462F(3/3)

Analog input.

Analog input.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Schmit input.

With pull-up resistor.

-

Schmit input.

Schmit input.

With pull-up resistor.

-

-

1-24

Page 25

SAA6579T-X(IC71):RDS detecter

1.Pin layout

SCOUT

2.Block diagram

QUAL

DATA

Vref

MUX

vdd

GND

CIN

1

2

3

4

5

6

7

8

CLK

16

T57

15

OSCO

14

OSCI

13

vdd

12

GND

11

TEST

10

MODE

9

KD-S821R

121413

3.Pin function

4

8

7

CLOCKED

COMPARATOR

5

3

REFERENCE

VOLT AGE

Pin No.

1

2

3

4

ANTIALIASING

FILTER

6 11

Symbol

VP1

QUAL

DATA

Vref

MUX

57 kHz

BAND PASS

(8th ORDER)

COSTAS LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGERATION

AND SYNC

RECONSTRUCTION

FILTER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

OSCILLATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

910

Description

Quality indication output

RDS data output

Reference voltage output (0.5VDDA)

Multiplex signal input

QUALITY BIT

GENERATOR

DIFFERENTIAL

DECODER

1

2

15

15

5

6

7

8

9

10

11

12

13

14

15

16

vdd

GND

CIN

SCOUT

MODE

TEST

GND

vdd

OSCI

OSCO

T57

CLK

+5V supply voltage for analog part

Ground for analog part (0V)

Sub carrier input to comparator

Sub carrier output of reconstruction filter

Oscillator mode / test control input

Test enable input

Ground for digital part (0V)

+5V supply voltage for digital part

Oscillator input

Oscillator output

57 kHz clock signal output

RDS clock output

1-25

Page 26

KD-S821R

TA2109F-X (IC521) : RF amp.

1. Pin layout

24 13

112

2. Block diagram

SBAD

13

FEO

14

10pF

FEN

15

VRO

16

RFRP

17

RFIS

18

RFGO

19

10k ohm

21k ohm

20k ohm

20k ohm

50k ohm

36pF

7.96k ohm

50uA

20k ohm

15k ohm 30k ohm

15k ohm

20uA

10k ohm

21k ohm

12k ohm

12k ohm

PEAK

BOTTOM

10k ohm

10k ohm

30k ohm

21k ohm 29k ohm

24k ohm 24k ohm

180k ohm

1.74k ohm

20pF

65uA

47k ohm

SW3

13k ohm

7.67k ohm

10k ohm

3 STATE

DET.

SW2

680 ohm

2.12k ohm

20pF

SW1

LDC

1k ohm

TEO

TEN

2VRO

TEB

SEL

LDO

MDI

12

11

10

9

8

7

6

3. Pin function

Pin

SymbolI/O

No.

Vcc

FNI

FPI

TPI

TNI

MDI

SEL

TEB

TEN

I

I

I

I

I

O

I

I

O

I

O

10

11

12

1

2

3

4

5

6

7

8

9

LDO

2VRO

TEO

RFGC

20

AGCI

21

re=130 ohm

RFO

22

GND

23

RFN

24

23.5k ohm

3.3k ohm

12k ohm

1.53k ohm

3.3k ohm

Pin function

Power supply input terminal

Main beam I-V amp input terminal

Main beam I-V amp input terminal

Sub beam I-v input terminal

Sub beam I-V input terminal

Monitor photo diode amp input terminal

Laser diode amp output terminal

Laser diode control signal input terminal

T. error balance adj. signal input terminal

Reference voltage output terminal

TE amp negative input terminal

TE error signal output terminal

180k ohm

40pF

180k ohm

Pin

No.

13

14

15

16

17

18

19

20

21

22

23

24

180k ohm

20pF

60k ohm

60k ohm

40pF

SymbolI/O

SBAD

RFRP

RFGO

RFGC

FEO

FEN

VRO

RFIS

AGCI

RFO

GND

RFN

O

O

I

O

O

I

O

I

I

O

-

I

TNI

TPI

FPI

FNI

Vcc

5

4

3

2

1

I-I

I-I

20k ohm

20k ohm

20k ohm

20k ohm

Pin function

Sub beam adder signal output terminal

Focus error signal output terminal

FE amp negative input terminal

Reference voltage (VREF) output terminal

Track count signal output terminal

RFRP detect circuit input terminal

RF gain signal output terminal

RF amplitude adj. control signal input terminal

RF signal amplitude adj. amp input terminal

RF signal output terminal

Ground terminal

RF amp negative input terminal

1-26

Page 27

HD74HC126FP-X (IC771) : Buffer

KD-S821R

1.Terminal layout

1C

1

1A

2

3

1Y

4

2C

5

2A

6

2Y

GND

2.Block diagram

7

Input

3Y

14

3A

13

12

3C

11

4Y

10

4A

9

4C

8

Vcc

Vcc Vcc

1A

2A

3A

4A

1C

2C

3C

See Function Table

4C

3.Pin function

Output

1Y

Output

2Y

Output

3Y

Output

4Y

Input Output

C

A

L

X

H

L

H

H

Note:

1k

CL

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

Y

Z

H

L

H : High

L : Low

X : H and L

Z : H.L.X

S1

1k

1-27

Page 28

KD-S821R

LC75823W (IC601) : LCD driver

1. Pin Layout & Symbol

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

DICLCE

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

S17

S18

S19

OSC

S20

S21

S22

S23

S24

S25

COM3

COM2

S26

S27

COM1

S28

S29

S30

S50

S31

S49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

S32

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

2. Pin Function

Pin No.

1 to 50

51 to 52

53 to 55

COM1 to COM3

56 to 60

61

62

63

64

Symbol

S1 to S50

OSC

CE

CLK

DATA

I/O

O

Segment output pins used to display data transferred

Function

by serial data input.

--

Non connected

O

Common driver output pins. The frame frequency is given

by : t0=(fosc/384)Hz.

--

Non connected

Oscillator connection.

I/O

An oscillator circuit is formed by connecting an external

resistor and capacitor at this pin.

Serial data CE : Chip enable

interface connection

I

to the controller. CL : Sync clock

DI : Transfer data

1-28

Page 29

TEA6320T-X (IC161) : E.volume

KD-S821R

1.Pin layout

SDA

1

GND

TL

B2L

B1L

IVL

ILL

QSL

IMD

INTUL

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

OUTLR

OUTLF

INCDCHL

INCDL

3.Pin functions

Pin

Symbol

No.

CD-CH

TAPE

TUNER

I/O

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

2.Block diagram

SCL

VCC

OUTRR

OUTRF

TR

B2R

B1R

IVR

ILR

QSR

Vref

INCDCHR

CAP

INTUR

INCDR

21

31

2

19

16

15

13

11

14

22

20

18

17

Functions Functions

10 8 9 7 6

POWER

SUPPLY

SOURCE

SELECTOR

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

Pin

No.

Symbol

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

I/O

5

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

12

MUTE

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SDA

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

INCDCHL

IMO

INTUL

Serial data input/output.

I/O

Ground.

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor left channel or

-

output to an external equalizer.

Bass control capacitor left channel.

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

Not used

Input C left source.

I

Not used

Input B left source.

I

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

INCDR

INTUR

CAP

INCDCHR

Vref

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

Vcc

I

Input A right source.

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

-

Supply voltage.

16

INCDL

Input A left source.

I

32

SCL

I

Serial clock input.

1-29

Page 30

KD-S821R

RPM6938-SV4(IC602) : Remote sensor

AMP

I/V

conversion

PD

magnetic shield

BPF

fo

trimming

circuit

NJM4565M-WE (IC581) : CD L.P.F

AGC

Detector

Vcc

Comp

Vcc

22k

Rout

GND

A OUTPUT

-

A INPUT

+

A INPUT

V

+

1

2

3

-

4

8

V

B OUTPUT

7

-

B INPUT

6

5

+

B INPUT

1-30

Page 31

PARTS LIST

[ KD-S821R ]

* All printed circuit boards and its assemblies are not available as service parts.

KD-S821R

Area suffix

E ----------- Continental Europe

EX --------------- Central Europe

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD mechanism assembly and parts list (Block No.MB)

Electrical parts list (Block No.01~02)

Packing materials and accessories parts list (Block No.M3,M5)

3- 2

3- 4

3- 7

3-12

3-1

Page 32

KD-S821R

Exploded view of general assembly and parts list

Block No.

M

M

1

M

8

49

51

45

50

8

8

47

48

43

46

Main board

3

7

10

16

5

44

9

13

9

12

11

35

15

34

4

42

40

37

39

55

41

36

14

7

2

6

35

56

30

Front

1

6

27

6

board

54

19

28

26

25

23

20

33

24

17

29

22

21

38

32

31

18

3-2

Page 33

KD-S821R

Parts list (General assembly)

Block No. M1MM

Item

A

1 -----------2 FSJC1029-404

3 FSMH3001-202

4 FSKM3011-002

5 FSMA3004-203

6 QYSDST2604Z

7 FSKZ4005-001

8 QYSDST2604Z

9 QYSDST2606Z

10 FSKZ4005-001

11 FSJC2013-013

12 FSKS3010-001

13 FSKW4005-003

14 FSXP3026-002

15 FSKW3002-015

16 FSPK3009-002

17 GE10003-001A

18 GE30111-016A

19 GE20104-002A

20 GE30105-002B

21 GE30109-002A

22 GE20110-004C

23 GE30112-001A

24 GE40102-001A

25 GE30366-001A

26 FSYH4036-032

27 GE30546-001A

28 GE30104-001A

29 GE20109-001C

30 GE30106-003A

31 FSXP3055-001

32 FSKW3002-012

33 GE30117-001A

34 GE10004-001B

35 VKZ4777-001

36 QLD0216-001

37 QNZ0442-001

38 GE30276-001A

39 FSJK3025-001

40 FSKS3019-001

41 FSYH4074-001

42 GE30323-002A

43 QMFZ047-150-T

44 VMA4652-001SS

45 FSKM3012-015

46 FSKL4024-001

47 GE40104-002B

48 GE40103-001A

49 QYSDST2606Z

50 QYSDST2606Z

51 QYSDSF3006Z

54 FSYH4036-069

55 FSYH4071-001

56 FSKS3016-002

Parts number Parts name Area

CD MECHA

TOP CHASSIS

SIDE PANEL

BOTTOM COVER

INSULATOR

SCREW

SCREW

SCREW

SCREW

SCREW

FRONT CHASSIS

LOCK LEVER

TORSION SPRING

RLS KNOB

COMP.SPRING

BLIND

FRONT PANEL

FINDER ASSY

PRESET BUTTON

POWER BUTTON

EJECT BUTTON

D.FUNCT BUTTON

PUSH BUTTON

REMOTE LENS

SEL BUTTON

SHEET

KNOB

RIM LENS

UP DOWN BUTTON

SND FUNC BUTTON

DETACH BUTTON

COMP. SPRING

LIGHT LENS

REAR COVER

MINI SCREW

LCD MODULE

RUBBER CONNE

LCD CASE

LCD LENS

LENS CASE

LIGHTING SHEET

NAME PLATE

FUSE

EARTH PLATE

REAR BRACKET

POWER IC BKT

HEAT SINK

REGULATOR BKT

SCREW

SCREW

SCREW

SHEET

LIGHTING SHEET

LED HOLDER

Q'ty

1

1

1

1

1

3

CHASSIS+MECHA BKT

2

CHASSIS+SIDE PANEL

3

CHASSIS+REAR BKT

2

CHASSIS+MAIN PWB

1

SIDE PANEL+IC BKT

1

1

1

FOR LOCK LEVEL

1

1

1

1

1

1

1

1

1

FM/CD/AM

1

1

1

1

FOR SEL BUTTON

1

1

1

1

1

1

FOR DETACH BUTTON

1

1

4

FRONT+REAR

1

1

1

1

1

1

1

1

1

1

1

1

1

1

FOR ANT

1

16P & TR BRACK

1

LINE OUT

2

1

1

Description

3-3

Page 34

KD-S821R

CD mechanism assembly and parts list

Grease

G-31SA

G-31SA(Bottom side)

RX-405

101

14

17

12

16

70

b

90

91

5

71

15

100

7

TN-CCD1001Z-136J

Block No.

M

M

B

M

102

23

102

1

23

101

49

101

101

20

10

9

11

105

65

66

62

13

2

4

100

7

6

8

64

b

a

62

68

d

110

67

c

61

72

113

88

93

3

80

86

102

22

79

c

113

133

134

82

22

81

117

19

92

18

135

49

116

103

84

107

43

36

48

131

56

d

d

107

49

130

50

32

38

52

41

39

109

42

a

104

51

63

40

107

57

3-4

62

101

108

89

107

33

106

29

132

106

108

Page 35

KD-S821R

Parts list (CD mechanism)

Block No. MBMM

Item

A

1 30310101T

2 30310103T

3 30310107T

4 30310108T

5 30310142T

6 30310143T

7 30310145T

8 30310112T

9 30310155T

10 30310115T

11 30310116T

12 30310134T

13 30310159T

14 30310150T

15 30310156T

16 30310138T

17 30310122T

18 30310148T

19 30310125T

20 30310149T

22 30310151T

23 30310129T

29 30300510T

32 30310544T

33 30310547T

36 30310546T

38 30310533T

39 30310548T

40 30310512T

41 30310558T

42 30310514T

43 30310552T

48 30310557T

49 30310524T

50 30310525T

51 30310545T

52 30310556T

56 64180405T

57 OPTIMA-720L1

61 30311035T

62 19501403T

63 30311037T

64 30311036T

65 30311038T

66 30311039T

67 30311040T

68 30311041T

70 64180402T

Parts number Parts name Area

FRAME

DANPER PIN

UPPER PLATE

SEL STOP PLATE

SEL ARM (L)L

SEL ARM (R)L

S ARM SPRING(L)

TRIG LEVER

TRIG PL(Z)

TRIG PL SPRING

TRIG ARM

FIX ARM (L)B

FIX ARM (R)Z

FIX PL (L)Z

FIX PL (R) Z

LDG GR (6)B

LDG GEAR (6)SP

S.L ARM(N)

S.L ARM SPRING

REAR DAM BKT(Z)

HUNG UP SP (FZ)

HUNG UP SP (R)

PU GEAR(B)

F.M.BASE(Z)

FD GR BLK(Z)

PU GUIDE(Z)

THRUST SPR(M)

PU M NUT(Z)

NUT PUSH SPR PL

CLP ARM(Z)

CLP ARM SPRING

CLAMPER(Z)

CLAMPER PLATE(Z

DAMPER (J)

CLP ARM SPR (L)

F SCREW GUIDE(Z

PU G.SP PLT(Z)

DET SW

C.D PICK (CAR)

FPC HOLDER(Z)

WIRE CLAMPER

PICK UP FPC(Z)

CONNECT.PCB(Z-J

WIRE (5P-Z)

WIRE (LD-Z)

WIRE (FD-Z)

WIRE (RS-Z)

DET SWITCH

Q'ty

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

ESE11SF4

1

1

3

1

1

1

1

1

1

2

ESE22MH1

Description

3-5

Page 36

KD-S821R

Parts list (CD mechanism)

Item

A

71 64180403T

72 68150232T

79 30311105T

80 30311138T

81 30311109T

82 30311110T

84 30311112T

86 30311136T

88 30311118T

89 30311119T

90 30311123T

91 30311124T

92 30311129T

93 30311140T

100 9C0620503T

101 9C2020401T

102 9C4320403T

103 9C0117223T

104 9C0917703T

105 9C0320201T

106 9C4920013T

107 9C4920603T

108 9P0220031T

109 9C0314203T

110 9C0420253

113 9W0330276

116 9W0725030T

117 9W0640030T

130 303105310T

131 303105311T

132 303105312T

133 303111301T

134 303111302T

135 303105502T

Parts number Parts name Area

DET SWITCH

CONNECTOR

SOPPORT PLATE

GR MT BLK(N)

LDG GEAR (2)

LDG GEAR (3)

LDG GEAR (5)

LDG ROLLER

L.P SPRING (L)

L.P SPRING (R)

SW PCB

SW ACTUATOR

LDG BELT

FRONT BRKT (J)

C B TAP SCREW

C SCREW TS.G

C B TAP SCREW

SCREW

C TAP SCREW S3

C TAP SCREW S3

C TAP SCREW S3

C TAP SCREW B3

TAMS SCREW

C TAP SCREW

C TAP SCREW

NW BLUE

LUMILAR W

WASHER

FEED MO ASSY

SPINDLE MO ASSY

FEED SCREW ASSY

LDG MOTOR ASSY

RDG RLR SFT ASY

T.T.BASE ASSY

Q'ty

2

1

1

1

1

1

1

2

1

1

1

1

1

1

2

5

4

2

1

1

2

4

2

1

1

2

1

1

1

1

1

1

1

1

Block No. MBMM

Description

ESE22MH3

TKC-W26X-C1

M2X5

M2X4

M2X4

M1.7X2.2

M1.7X7

M2X2

M2X10

M2X6

M2X3

M1.4X2

M2X2.5

2.9X5X0.3

2.3X9.8X0.25

1.4X3.2X0.4

3-6

Page 37

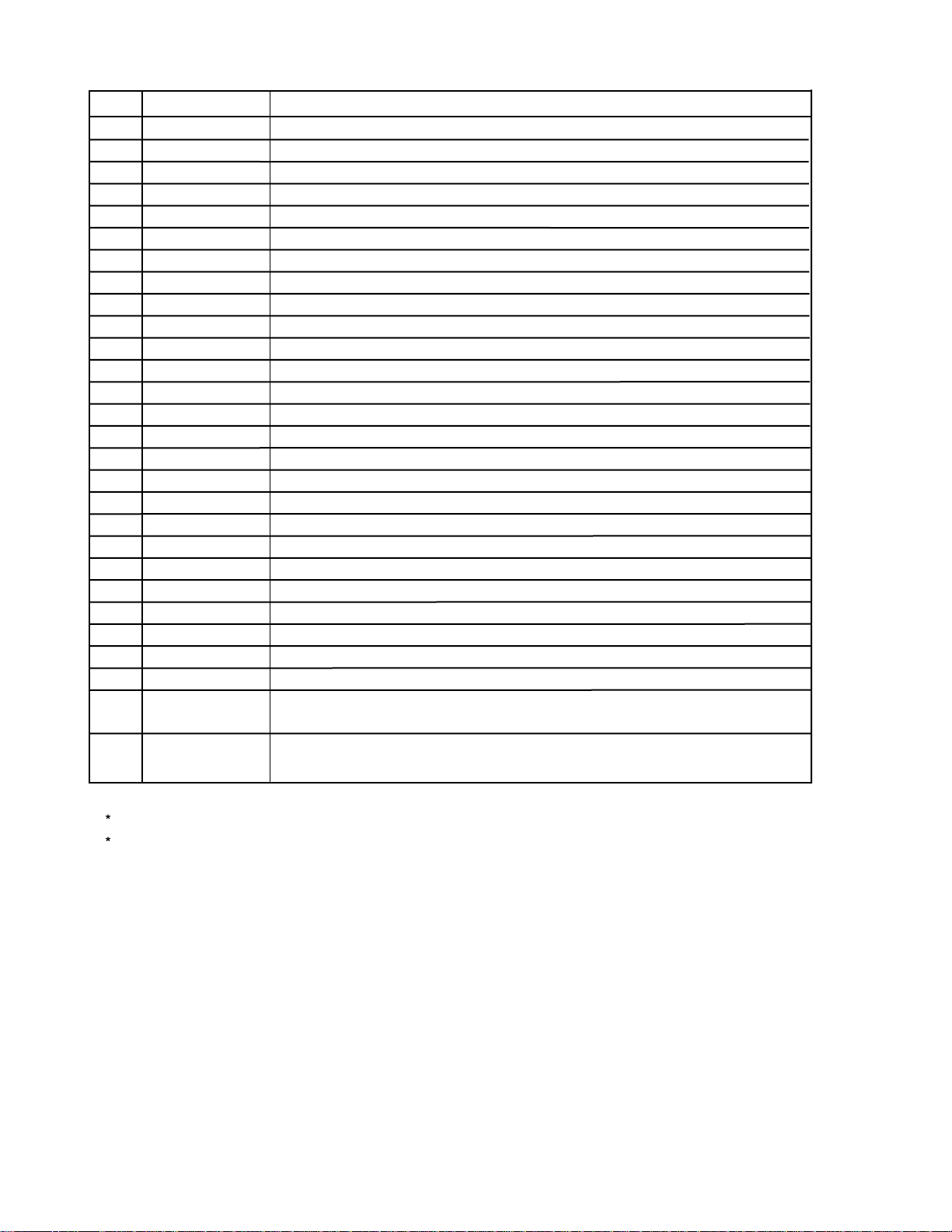

KD-S821R

Electrical parts list (Main board)

Item

A

C 1 NDC31HJ-5R0X C CAPACITOR

C 2 NDC31HJ-100X C CAPACITOR

C 3 QERF1HM-104Z E CAPACITOR .10MF 20% 50V

C 4 NCS31HJ-221X C CAPACITOR

C 5 QERF1HM-474Z E CAPACITOR .47MF 20% 50V

C 6 NCB31EK-473X C CAPACITOR

C 7 NDC31HJ-101X C CAPACITOR

C 9 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 10 NCB31HK-102X C CAPACITOR

C 31 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 32 NCB31HK-102X C CAPACITOR

C 41 NCB31EK-333X C CAPACITOR

C 42 NCB31HK-822X C CAPACITOR

C 43 QERF1CM-107Z E CAPACITOR 100MF 20% 16V

C 51 QERF1HM-474Z E CAPACITOR .47MF 20% 50V

C 52 NCB31HK-472X C CAPACITOR

C 53 NCB31EK-104X C CAPACITOR

C 54 NCB31EK-103X C CAPACITOR

C 55 NCB31HK-331X C CAPACITOR

C 71 NDC31HJ-820X C CAPACITOR

C 72 NDC31HJ-470X C CAPACITOR

C 73 NCB31HK-103X C CAPACITOR

C 74 QERF1AM-476Z E CAPACITOR 47MF 20% 10V

C 75 NDC31HJ-561X C CAPACITOR

C 76 QEKJ1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 77 NCB31EK-223X C CAPACITOR

C 161 QEKJ1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 162 NCB31HK-822X C CAPACITOR

C 163 NCB31AK-154X C CAPACITOR

C 164 QEKJ1HM-224Z E CAPACITOR .22MF 20% 50V

C 165 NCB31EK-333X C CAPACITOR

C 166 NCB31HK-562X C CAPACITOR

C 167 QEKJ1HM-475Z E CAPACITOR 4.7MF 20% 50V

C 168 QEKJ1HM-475Z E CAPACITOR 4.7MF 20% 50V

C 169 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 171 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 172 NCB31HK-183X C CAPACITOR

C 173 NCB31EK-104X C CAPACITOR

C 181 QEKJ1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 182 NCB31HK-822X C CAPACITOR

C 183 NCB31AK-154X C CAPACITOR

C 184 QEKJ1HM-224Z E CAPACITOR .22MF 20% 50V

C 185 NCB31EK-333X C CAPACITOR

C 186 NCB31HK-562X C CAPACITOR

C 187 QERF1HM-475Z E CAPACITOR 4.7MF 20% 50V

C 188 QERF1HM-475Z E CAPACITOR 4.7MF 20% 50V

C 189 QEKJ1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 191 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 192 NCB31HK-183X C CAPACITOR

C 241 NCB21HK-153X C CAPACITOR

C 242 NCB31EK-473X C CAPACITOR

C 243 QEKJ1CM-226Z E CAPACITOR 22MF 20% 16V

C 244 QEKJ1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 309 QEKJ1CM-107Z E CAPACITOR 100MF 20% 16V

C 310 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 311 NCB31EK-473X C CAPACITOR

C 312 NCB31EK-473X C CAPACITOR

C 313 NCB31HK-223X C CAPACITOR

C 315 NCB31HK-223X C CAPACITOR

C 316 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 317 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 321 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 322 NCS31HJ-391X C CAPACITOR

Parts number Parts name Ar

Block No. 01

Remarks

Item

A

C 331 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 332 NCS31HJ-391X C CAPACITOR

C 341 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 342 NCS31HJ-391X C CAPACITOR

C 351 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 352 NCS31HJ-391X C CAPACITOR

C 391 NCB31EK-104X C CAPACITOR

C 392 NCB31EK-104X C CAPACITOR

C 393 NCB31EK-104X C CAPACITOR

C 394 NCB31EK-104X C CAPACITOR

C 501 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 502 NCB31HK-103X C CAPACITOR

C 503 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 521 NCB31HK-103X C CAPACITOR

C 522 NCB31HK-103X C CAPACITOR

C 523 NCB31EK-103X C CAPACITOR

C 524 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 525 NCB31HK-103X C CAPACITOR

C 526 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 527 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 528 NDC31HJ-101X C CAPACITOR

C 529 NCB31HK-103X C CAPACITOR

C 530 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 531 NCB31EK-104X C CAPACITOR

C 532 NCB31EK-104X C CAPACITOR

C 533 NDC21HJ-560X C CAPACITOR

C 541 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 542 NCB31HK-103X C CAPACITOR

C 543 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 544 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 545 NCB31HK-103X C CAPACITOR

C 546 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 547 NDC31HJ-470X C CAPACITOR

C 548 NCB31HK-153X C CAPACITOR

C 549 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 550 NCB31HK-103X C CAPACITOR

C 551 NCB31HK-272X C CAPACITOR

C 552 NCB31HK-103X C CAPACITOR

C 553 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 554 NCB31HK-103X C CAPACITOR

C 555 NCB31EK-333X C CAPACITOR

C 556 NCB31HK-332X C CAPACITOR

C 557 NDC31HJ-561X C CAPACITOR

C 558 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 559 NCB31EK-473X C CAPACITOR

C 560 NCB31EK-473X C CAPACITOR

C 561 NCB31EK-473X C CAPACITOR

C 562 NCB31EK-473X C CAPACITOR

C 563 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 564 NCB31HK-103X C CAPACITOR

C 565 NCB31HK-103X C CAPACITOR

C 566 NDC31HJ-100X C CAPACITOR

C 567 NDC31HJ-100X C CAPACITOR

C 568 NCB31HK-103X C CAPACITOR

C 569 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 570 NDC31HJ-101X C CAPACITOR

C 571 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 572 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 573 NCB31HK-103X C CAPACITOR

C 581 NCS31HJ-821X C CAPACITOR

C 582 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 583 QEKJ0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 584 NCS31HJ-121X C CAPACITOR

Parts number Parts name

Remarks

3-7

Page 38

KD-S821R

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list (Main board)

Item

A

C 591 NCS31HJ-821X C CAPACITOR

C 592 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 593 QEKJ0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 594 NCS31HJ-121X C CAPACITOR

C 595 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 701 NDC31HJ-220X C CAPACITOR

C 702 NDC31HJ-220X C CAPACITOR

C 703 NCB31EK-104X C CAPACITOR

C 704 NCB31EK-104X C CAPACITOR

C 706 QEKJ0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 707 NCB31HK-103X C CAPACITOR

C 708 QERF0JM-107Z E CAPACITOR 100MF 20% 6.3V

C 713 NCB31HK-471X C CAPACITOR

C 718 NCB31HK-103X C CAPACITOR

C 719 NCB31EK-104X C CAPACITOR

C 720 NCB31EK-104X C CAPACITOR

C 721 NCB31EK-104X C CAPACITOR

C 770 NCB31HK-103X C CAPACITOR

C 776 NCB31HK-103X C CAPACITOR

C 781 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 782 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 783 NCB31EK-823X C CAPACITOR

C 891 NCB31EK-473X C CAPACITOR

C 901 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 902 NCB31EK-104X C CAPACITOR

C 903 QEKJ1CM-226Z E CAPACITOR 22MF 20% 16V

C 904 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 905 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 907 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 908 QEZ0338-228 E CAPACITOR 2200MF

C 909 NCB31EK-104X C CAPACITOR

C 911 QERF1AM-476Z E CAPACITOR 47MF 20% 10V

C 912 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 913 QEKJ1CM-107Z E CAPACITOR 100MF 20% 16V

C 914 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 915 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 933 NCB31EK-103X C CAPACITOR

CN501 QGB2027M1-26S CONNECTOR

CP601 VMC0334-001 CONNECTOR F.PANEL CONN.

CP961 QNZ0112-001 CAR CONNECTOR

D 1 1SS133-T1 SI DIODE

D 2 1SS133-T1 SI DIODE

D 3 1SS355-X DIODE

D 4 1SS355-X DIODE

D 161 1SS355-X DIODE

D 162 1SS355-X DIODE

D 182 1SS355-X DIODE

D 241 1SS133-T1 SI DIODE

D 242 1SS133-T1 SI DIODE

D 321 1SS355-X DIODE

D 331 1SS355-X DIODE

D 341 1SS355-X DIODE

D 351 1SS355-X DIODE

D 501 DSK10C-T1 DIODE

D 701 UDZS5.6B-X Z DIODE

D 702 UDZS5.6B-X Z DIODE

D 703 UDZS5.6B-X Z DIODE

D 704 UDZS5.6B-X Z DIODE

D 705 UDZS5.6B-X Z DIODE

D 706 UDZS5.6B-X Z DIODE

D 707 UDZS5.6B-X Z DIODE

D 781 1SS355-X DIODE

D 782 1SS133-T1 SI DIODE

Parts number Parts name Ar

Block No. 01

Remarks

Item

A

D 784 UDZ11B-X Z DIODE

D 891 1SS355-X DIODE

D 892 1SS355-X DIODE

D 901 1SS355-X DIODE

D 910 CRS03-W SB DIODE

D 911 1N5401-TU-15 DIODE

D 912 CRS03-W SB DIODE

IC 71 SAA6579T-X IC

IC161 TEA6320T-X IC

IC301 LA4743K IC

IC501 LA6567H-X IC

IC521 TA2109F-X IC

IC541 TC9462F IC

IC581 NJM4565M-WE IC

IC701 UPD178078GF-558 IC

IC961 HA13164A IC

J 1 QNB0100-002 ANT TERMINAL

J 301 QNN0175-001 PIN JACK

J 302 QUY360-300F FORMED BUS WIRE

L 1 QQL244J-4R7Z INDUCTOR

L 541 QQL244J-4R7Z INDUCTOR

L 542 QQL244J-4R7Z INDUCTOR

L 701 QQL244J-4R7Z INDUCTOR

L 961 QQR0703-001 CHOKE COIL

R 1 NRSA63J-8R2X MG RESISTOR

R 2 NRSA63J-102X MG RESISTOR

R 3 NRSA63J-102X MG RESISTOR

R 4 NRSA63J-223X MG RESISTOR

R 5 NRSA63J-472X MG RESISTOR

R 6 NRSA63J-473X MG RESISTOR

R 7 NRSA63J-472X MG RESISTOR

R 8 NRSA63J-473X MG RESISTOR

Parts number Parts name

1 UN2211-X TRANSISTOR

2 2SD601A/R/-X TRANSISTOR

3 UN2111-X TRANSISTOR

4 2SB709A/R/-X TRANSISTOR

5 2SB815/7/-X TRANSISTOR

7 UN2211-X TRANSISTOR

31 2SD601A/R/-X TRANSISTOR

32 2SD601A/R/-X TRANSISTOR

41 2SD601A/R/-X TRANSISTOR

42 2SC3661-X TRANSISTOR

43 UN2211-X TRANSISTOR

51 2SD601A/R/-X TRANSISTOR

52 2SD601A/R/-X TRANSISTOR

53 UN2211-X TRANSISTOR

161 2SD601A/R/-X TRANSISTOR

162 UN2111-X TRANSISTOR

174 UN2111-X TRANSISTOR

181 2SD601A/R/-X TRANSISTOR

241 2SD601A/R/-X TRANSISTOR

321 2SD1048/6-7/-X TRANSISTOR

331 2SD1048/6-7/-X TRANSISTOR

341 2SD1048/6-7/-X TRANSISTOR

351 2SD1048/6-7/-X TRANSISTOR

501 2SB1322/RS/-T TRANSISTOR

521 2SB1322/RS/-T TRANSISTOR

781 UN2111-X TRANSISTOR

782 UN2211-X TRANSISTOR

783 UN2111-X TRANSISTOR

891 UN2211-X TRANSISTOR

976 UN2211-X TRANSISTOR

977 2SB709A/R/-X TRANSISTOR

Remarks

3-8

Page 39

KD-S821R

Electrical parts list (Main board)

Item

A

R 9 NRSA63J-332X MG RESISTOR

R 10 NRS181J-8R2X MG RESISTOR

R 31 NRSA63J-102X MG RESISTOR

R 32 NRSA63J-103X MG RESISTOR

R 33 NRSA63J-152X MG RESISTOR

R 41 NRSA63J-332X MG RESISTOR

R 42 NRSA63J-102X MG RESISTOR

R 43 NRSA63J-102X MG RESISTOR

R 44 NRS181J-330X MG RESISTOR

R 51 NRSA63J-471X MG RESISTOR

R 52 NRSA63J-153X MG RESISTOR

R 53 NRSA63J-103X MG RESISTOR

R 54 NRSA63J-103X MG RESISTOR

R 55 NRSA63J-222X MG RESISTOR

R 56 NRSA63J-473X MG RESISTOR

R 57 NRSA63J-473X MG RESISTOR

R 58 NRSA63J-473X MG RESISTOR

R 71 NRSA63J-222X MG RESISTOR

R 72 NRSA63J-222X MG RESISTOR

R 73 NRSA63J-222X MG RESISTOR

R 161 NRSA63J-224X MG RESISTOR

R 162 NRSA63J-223X MG RESISTOR

R 163 NRSA63J-222X MG RESISTOR

R 164 NRSA63J-332X MG RESISTOR

R 165 NRSA63J-473X MG RESISTOR

R 166 NRSA63J-473X MG RESISTOR

R 167 NRSA63J-103X MG RESISTOR

R 168 NRSA63J-223X MG RESISTOR

R 169 NRSA63J-472X MG RESISTOR

R 170 NRSA63J-472X MG RESISTOR

R 181 NRSA63J-224X MG RESISTOR

R 182 NRSA63J-223X MG RESISTOR

R 183 NRSA63J-222X MG RESISTOR

R 184 NRSA63J-332X MG RESISTOR

R 185 NRSA63J-473X MG RESISTOR

R 186 NRSA63J-473X MG RESISTOR

R 187 NRSA63J-103X MG RESISTOR

R 188 NRSA63J-223X MG RESISTOR

R 241 NRSA63J-224X MG RESISTOR

R 242 NRSA63J-102X MG RESISTOR

R 243 NRSA63J-101X MG RESISTOR

R 244 NRSA63J-123X MG RESISTOR

R 245 NRSA63J-184X MG RESISTOR

R 246 NRSA63J-223X MG RESISTOR

R 247 NRSA63J-473X MG RESISTOR

R 310 NRSA63J-472X MG RESISTOR

R 321 NRSA63J-273X MG RESISTOR

R 322 NRSA63J-821X MG RESISTOR

R 323 NRSA63J-222X MG RESISTOR

R 324 NRSA63J-101X MG RESISTOR

R 331 NRSA63J-273X MG RESISTOR

R 332 NRSA63J-821X MG RESISTOR

R 333 NRSA63J-222X MG RESISTOR

R 334 NRSA63J-101X MG RESISTOR

R 341 NRSA63J-273X MG RESISTOR

R 342 NRSA63J-102X MG RESISTOR

R 343 NRSA63J-222X MG RESISTOR

R 344 NRSA63J-101X MG RESISTOR

R 351 NRSA63J-273X MG RESISTOR

R 352 NRSA63J-102X MG RESISTOR

R 353 NRSA63J-222X MG RESISTOR

R 354 NRSA63J-101X MG RESISTOR

R 501 NRSA63J-822X MG RESISTOR

Parts number Parts name Ar

Block No. 01

Remarks

Item

A

R 502 NRSA63J-562X MG RESISTOR

R 503 NRSA63J-242X MG RESISTOR

R 504 NRSA63J-203X MG RESISTOR

R 506 NRS181J-0R0X MG RESISTOR

R 507 NRS181J-822X MG RESISTOR

R 508 NRS181J-203X MG REGISTOR

R 521 NRSA63J-473X MG RESISTOR

R 522 NRSA63J-473X MG RESISTOR

R 523 NRSA63J-473X MG RESISTOR

R 524 NRSA63J-473X MG RESISTOR

R 525 NRSA63J-104X MG RESISTOR

R 526 NRSA63J-104X MG RESISTOR

R 527 NRSA02J-220X MG RESISTOR

R 528 NRSA02J-220X MG RESISTOR

R 529 NRSA63J-273X MG RESISTOR

R 530 NRSA63J-473X MG RESISTOR

R 531 NRSA63J-222X MG RESISTOR

R 532 NRSA63J-153X MG RESISTOR

R 533 NRSA63J-682X MG RESISTOR

R 534 NRSA63J-473X MG RESISTOR

R 541 NRSA63J-472X MG RESISTOR

R 542 NRSA63J-472X MG RESISTOR

R 543 NRSA63J-472X MG RESISTOR

R 544 NRSA63J-472X MG RESISTOR

R 545 NRSA63J-103X MG RESISTOR

R 546 NRSA63J-103X MG RESISTOR

R 547 NRSA63J-473X MG RESISTOR

R 548 NRSA63J-683X MG RESISTOR

R 549 NRSA63J-474X MG RESISTOR

R 550 NRSA63J-333X MG RESISTOR

R 551 NRSA63J-103X MG RESISTOR

R 552 NRSA63J-152X MG RESISTOR

R 553 NRSA63J-153X MG RESISTOR

R 554 NRSA63J-332X MG RESISTOR

R 555 NRSA63J-332X MG RESISTOR

R 556 NRSA63J-682X MG RESISTOR

R 557 NRSA63J-152X MG RESISTOR

R 558 NRS181J-101X MG RESISTOR

R 581 NRSA63J-243X MG RESISTOR

R 582 NRSA63J-223X MG RESISTOR

R 583 NRSA63J-223X MG RESISTOR

R 584 NRSA63J-333X MG RESISTOR

R 585 NRSA63J-123X MG RESISTOR

R 586 NRSA63J-152X MG RESISTOR

R 591 NRSA63J-243X MG RESISTOR

R 592 NRSA63J-223X MG RESISTOR

R 593 NRSA63J-223X MG RESISTOR

R 594 NRSA63J-333X MG RESISTOR

R 595 NRSA63J-123X MG RESISTOR

R 596 NRSA63J-152X MG RESISTOR