Page 1

SERVICE MANUAL

CD RECEIVER

4983920035

KD-LH3105

Area Suffix

U ------- Other Areas

TABLE OF CONTENTS

1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.49839

2003/5

Page 2

SPECIFICATION

AUDIO AMPLIFIER

SECTION

TUNER SECTION Frequency Range FM 87.5 MHz to 108.0 MHz

CD PLAYER SECTION Type Compact disc player

GENERAL Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power

Output (RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4 kHz, 6 kHz, 12 kHz

Level ±10 dB

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-In Level/Impedance 1.5 V/20 kΩ load

Line-Out Level/Impedance 4.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/

Impedance

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

[AM Tuner] Sensitivity 20 µV

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 decoding format MPEG1/2 Audio Layer 3

Max. Bit Rate 320 Kbps

Grounding System Negative ground

Allowable Operating

Temperature

Dimensions

(W × H × D)

2.0 V/20 kΩ load (full scale)

AM 531 kHz to 1 602 kHz

50 dB Quieting

Sensitivity

Alternate Channel

Selectivity (400 kHz)

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

Selectivity 35 dB

0°C to +40°C

Installation Size

(approx.)

Panel Size (approx.) 188 mm × 58 mm × 12 mm

Mass (approx.) 1.4 kg (excluding accessories)

Front 19 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than

0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz

to 20 000 Hz at no more than

0.8% total harmonic distortion.

16.3 dBf (1.8 µV/75 Ω)

65 dB

182 mm × 52 mm × 150 mm

Design and specifications are subject to change without notice.

1-2 (No.49839)

Page 3

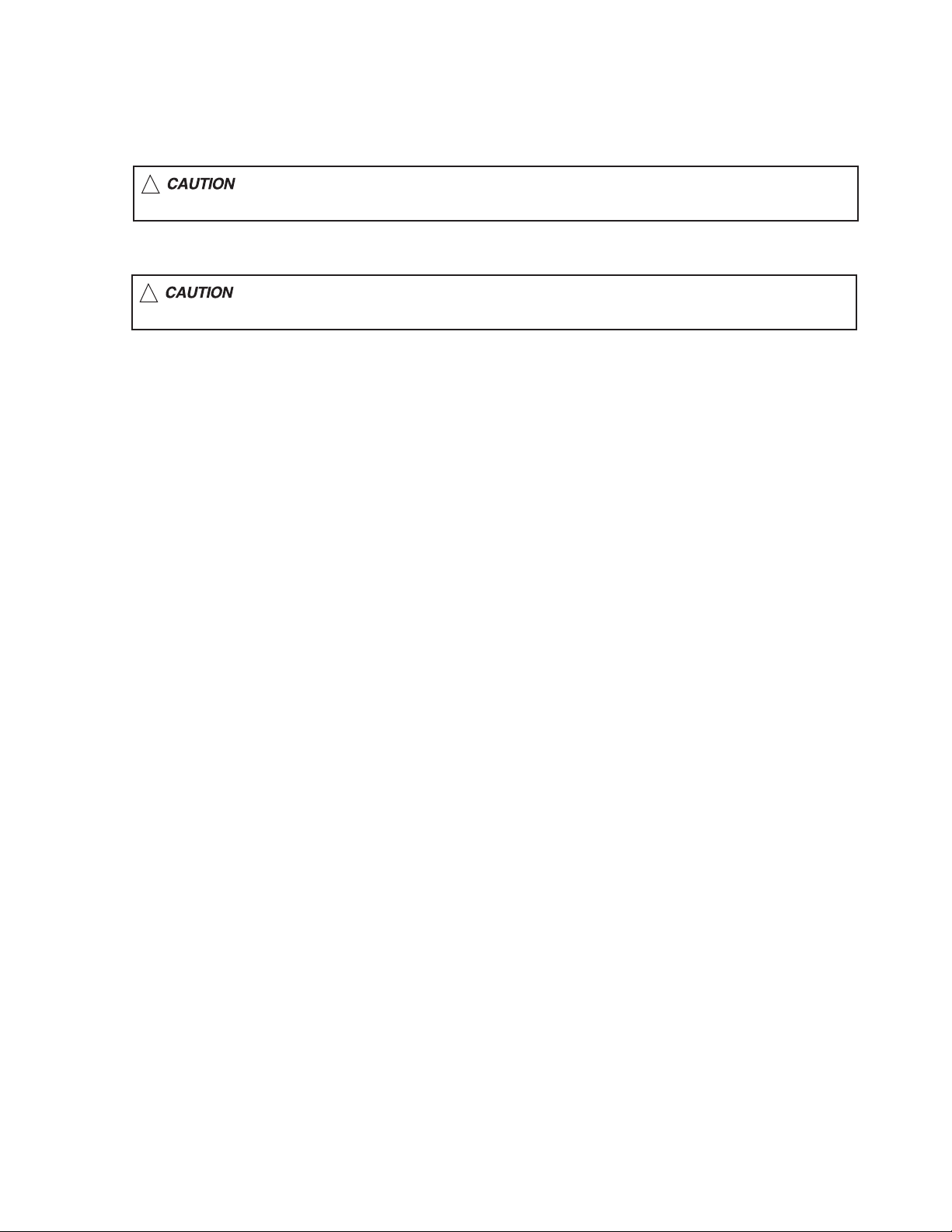

1.1 Safety Precautions

SECTION 1

Precautions

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.49839)1-3

Page 4

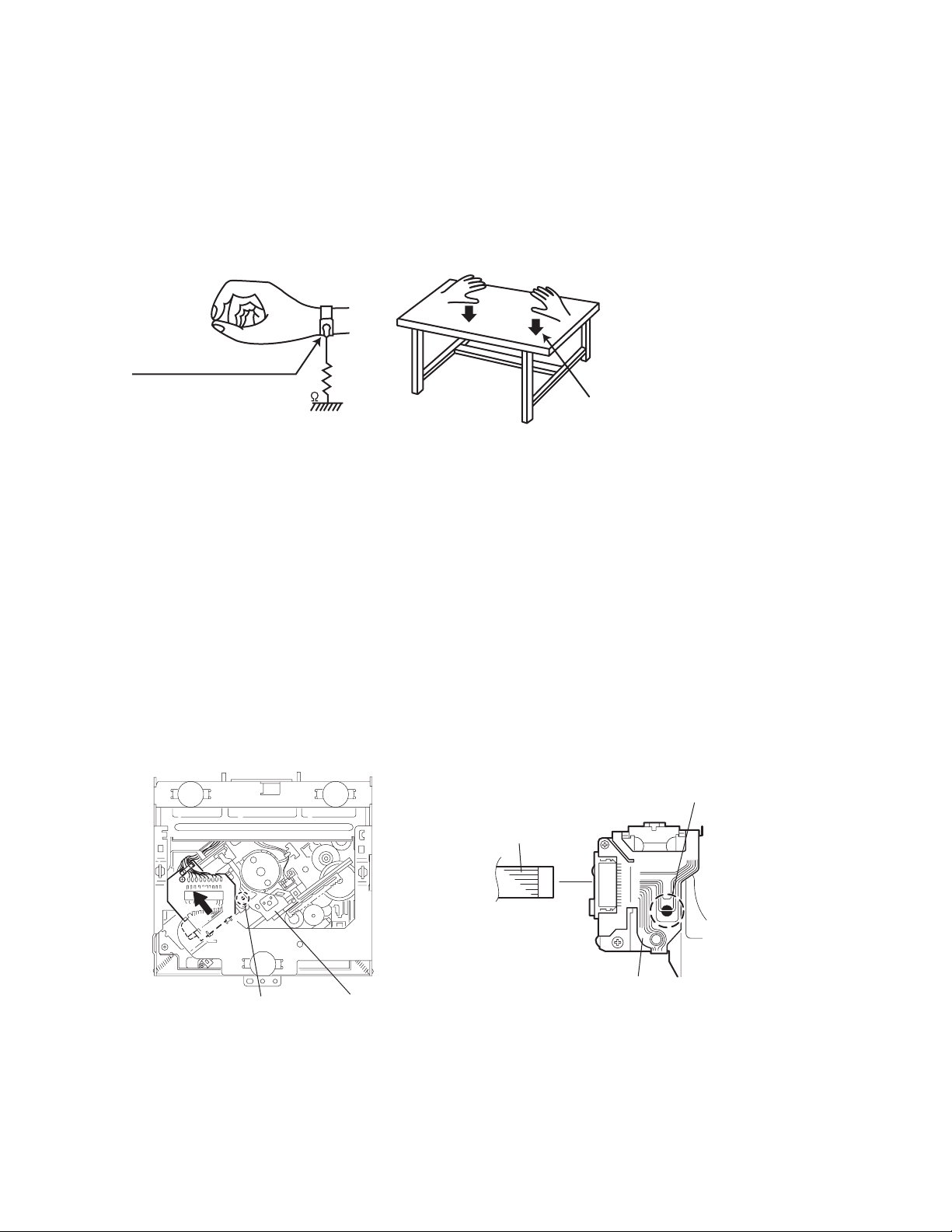

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CDpickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.49839)

Short-circuit point

Pickup

Pickup

Page 5

SECTION 2

Disassembly method

2.1 Main body

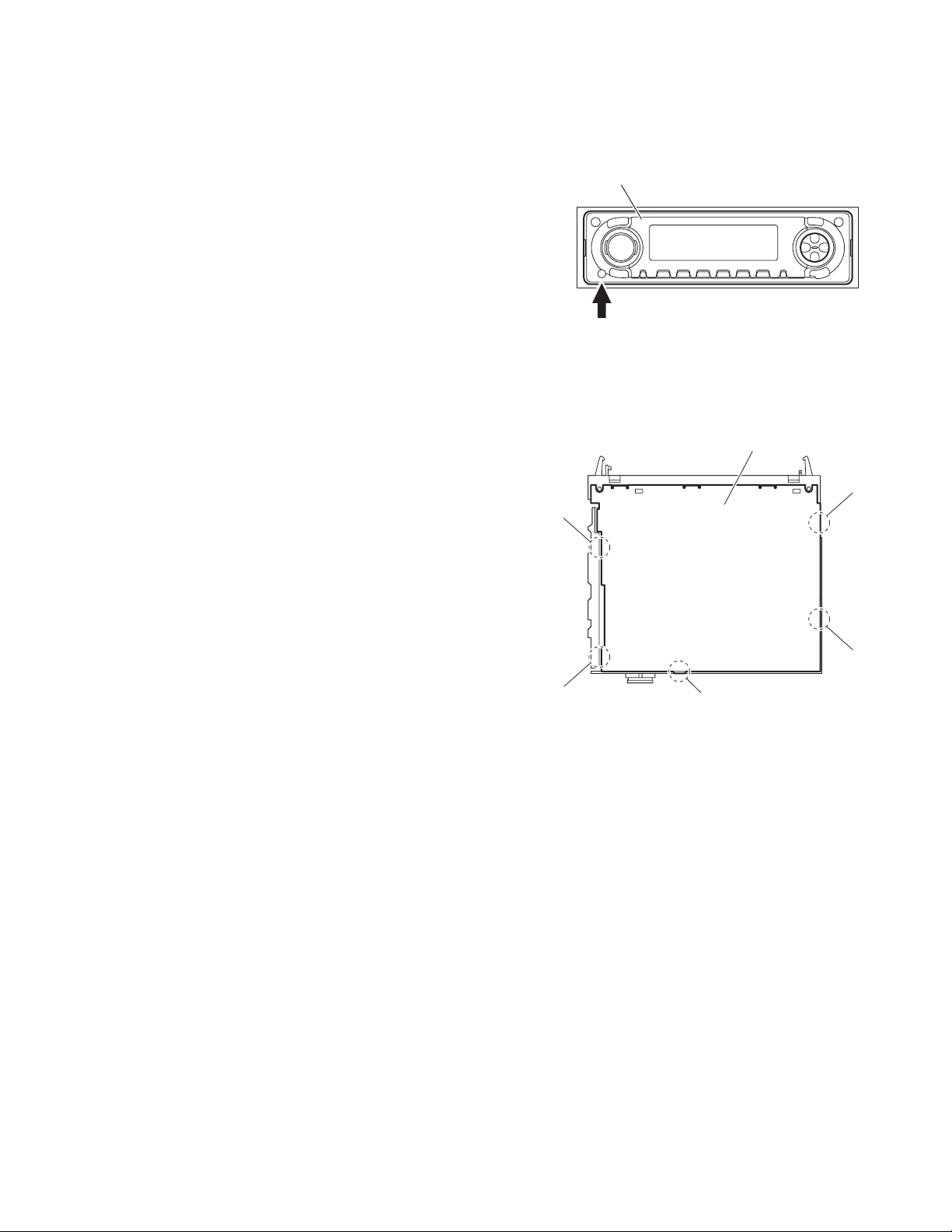

2.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button in the lower left part of the front

panel assembly and remove the front panel assembly.

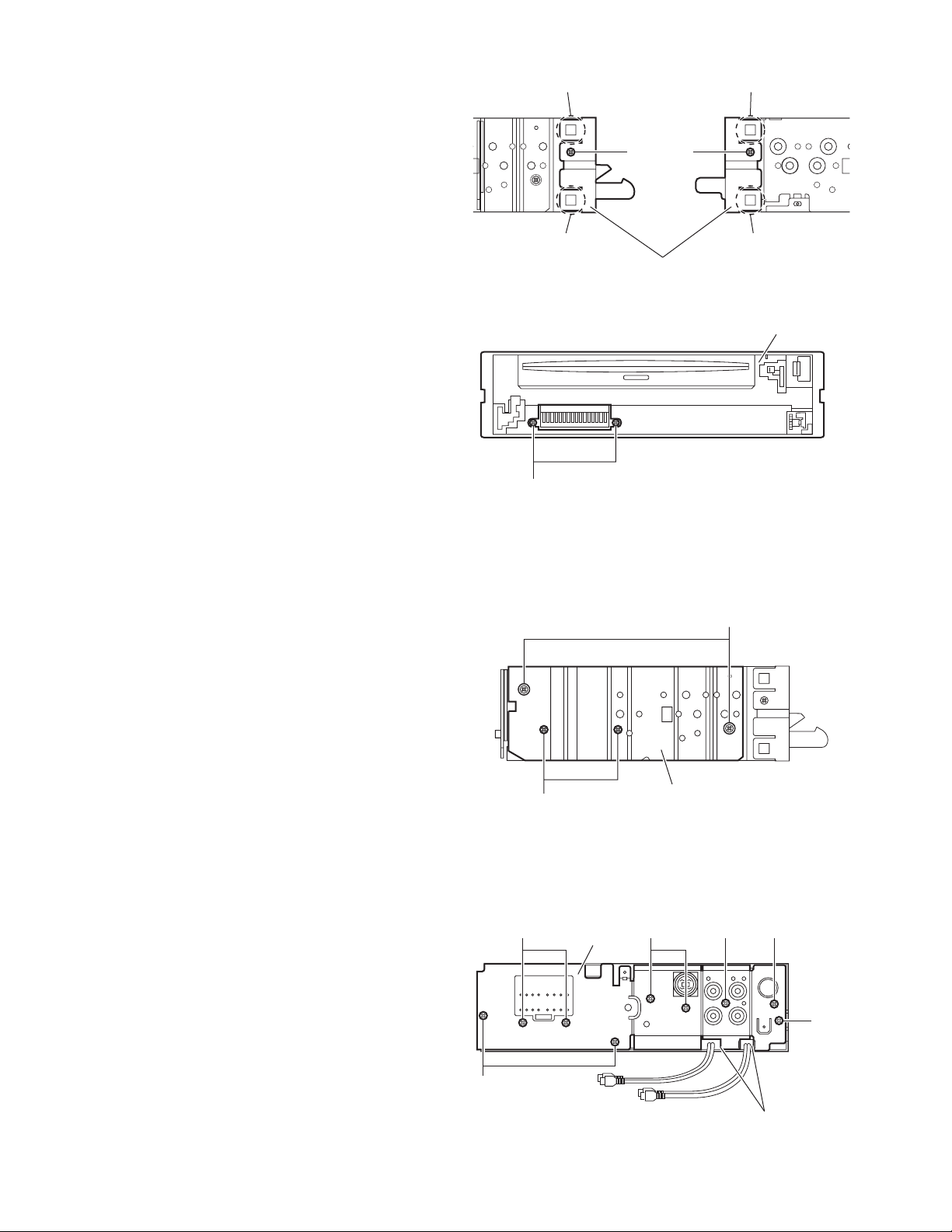

2.1.2 Removing the bottom cover

(See Fig.2)

• Prior to performing the following procedure, remove the front

panel assembly as required.

(1) Turn over the main body and release the two joints a, two

joints b and joint c.

Caution:

Do not damage the main board when releasing the joints using

a screwdriver.

Front panel assembly

Detach button

Fig.1

Bottom cover

Joint b

Joint a

Joint a

Joint b

Joint c

Fig.2

(No.49839)1-5

Page 6

2.1.3 Removing the front chassis assembly

(See Figs.3 and 4)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) Remove the two screws A on the both sides of the main

body. (See Fig.3.)

(2) Remove the two screws B on the front side of the main

body. (See Fig.4.)

(3) Release the two joints d and two joints e on the both sides

of the main body. (See Fig.3.)

B

Joint d

A

Joint d

Front chassis assembly

Joint e

A

Joint e

Fig.3

Front chassis assembly

Fig.4

2.1.4 Removing the heat sink

(See Fig.5)

• Prior to performing the following procedure, remove the front

panel assembly as required.

(1) Remove the two screws C and two screws D on the left

side of the main body.

2.1.5 Removing the rear bracket

(See Fig.6)

• Prior to performing the following procedures, remove the bot-

tom cover.

(1) Remove the three screws E, three screws F and three

screws G on the back side of the main body.

(2) Remove the rear bracket.

Reference:

During reassembly, before fixing the rear bracket onto the

main body, insert the SUB WOOFER cable and LINE IN cable

into the slots.

C

D

Heat sink

Fig.5

FG

Rear bracket

G

F

E

1-6 (No.49839)

E

Insert SUB WOOFER cable and

LINE IN cable into the slots.

Fig.6

Page 7

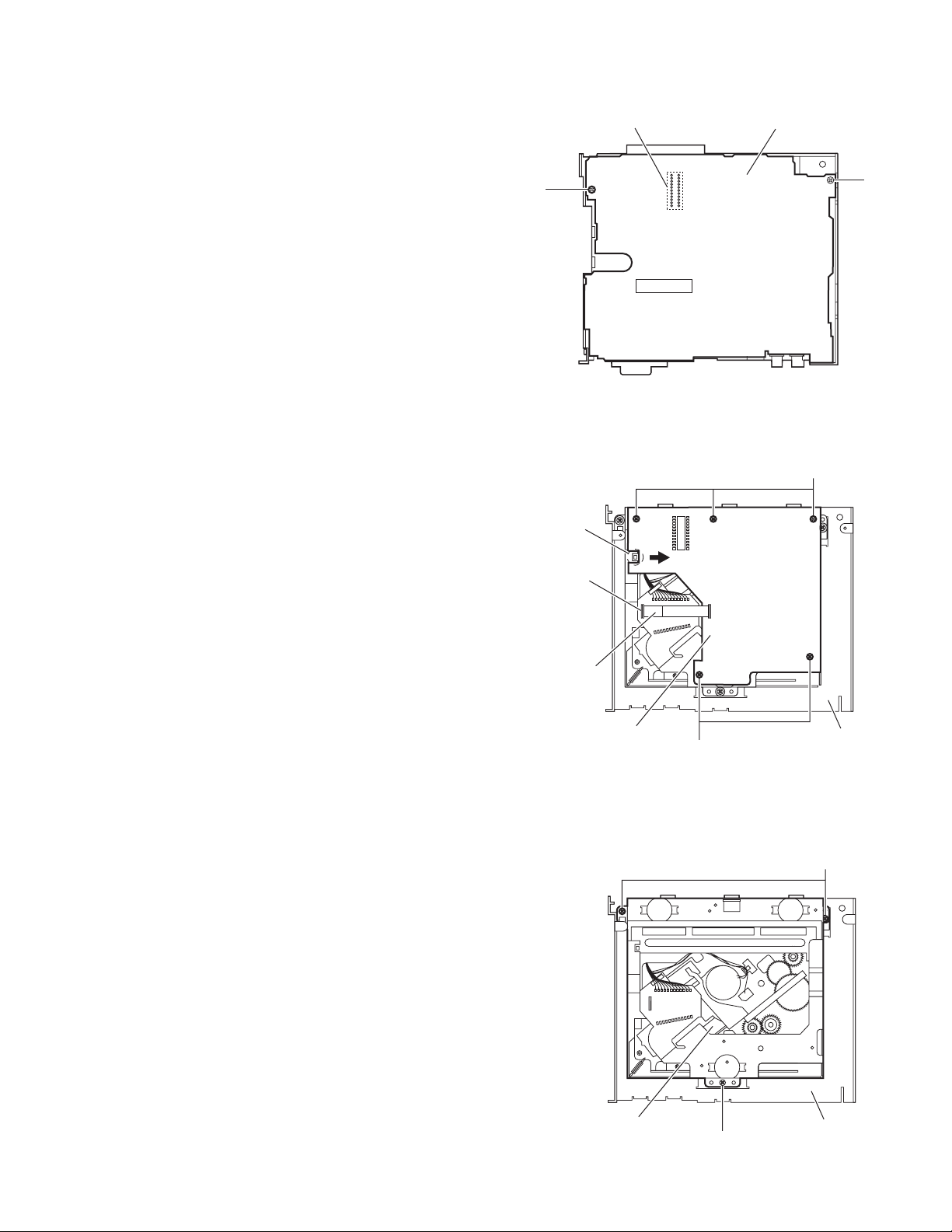

2.1.6 Removing the main board

(See Fig.7)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink and rear bracket.

(1) Remove the two screws H attaching the main board.

(2) Disconnect the connector CN601 and remove the main

board in an upward direction.

2.1.7 Removing the mecha control board

(See Fig.8)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear bracket and main board.

(1) Remove the five screws J attaching the mecha control

board.

(2) Disconnect the card wire from the mecha connector.

(3) Move the mecha control board in the direction of the arrow

to release it from the joint f.

H

Joint f

Mecha

connector

CN601

Main board

H

Fig.7

J

2.1.8 Removing the CD mechanism assembly

(See Fig.9)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear bracket, main board and mecha control board.

(1) Remove the three screws K attaching the CD mechanism

assembly to the top chassis.

Card wire

Mecha control board

CD mechanism assembly

Top chassis

J

Fig.8

K

Top chassis

K

Fig.9

(No.49839)1-7

Page 8

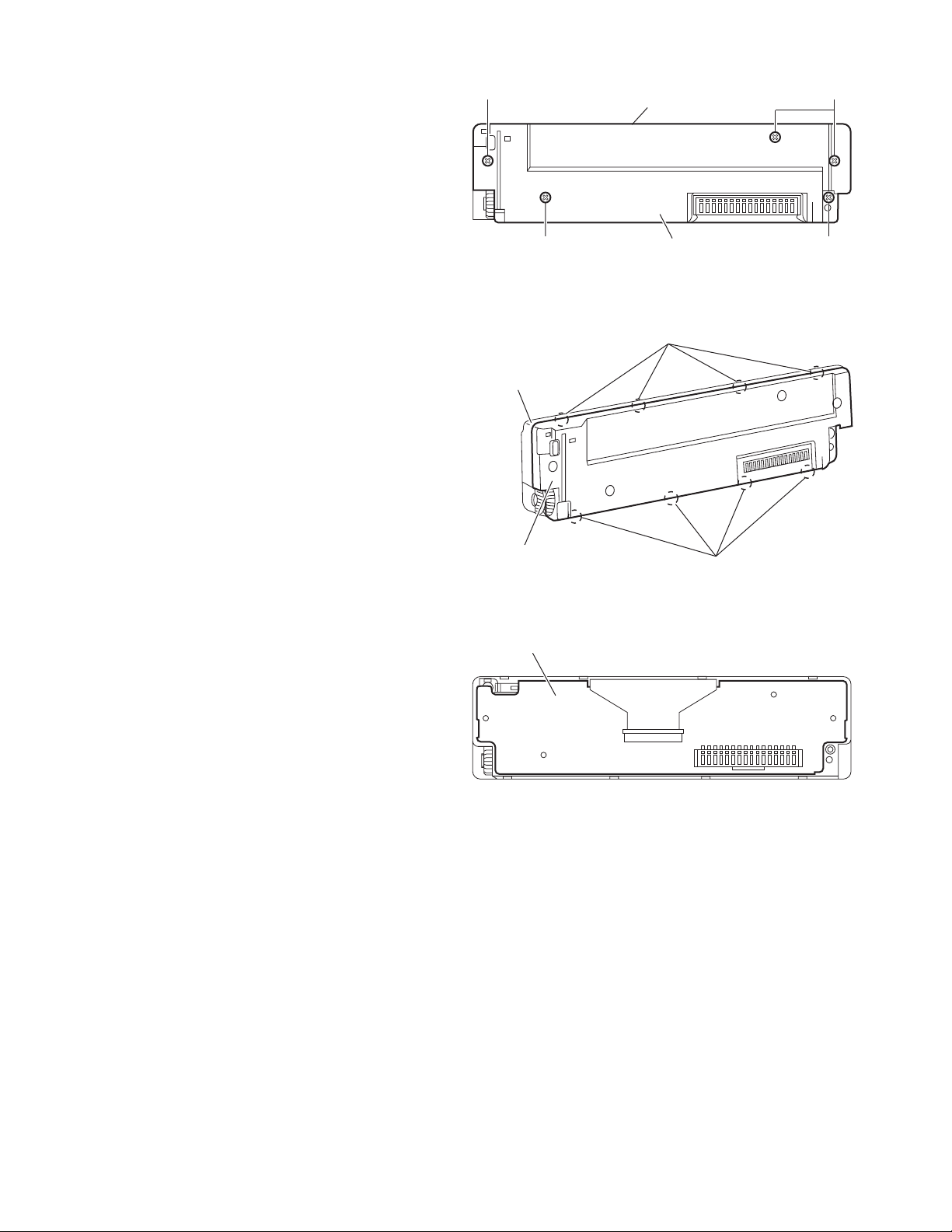

2.1.9 Removing the front board

(See Figs.10 to 12)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Remove the five screws L attaching the rear cover on the

back side of the front panel assembly. (See Fig.10.)

(2) Release the eight joints g, remove the rear cover from the

front panel assembly. (See Fig.11.)

(3) Take out the front board. (See Fig.12.)

L

Front panel assembly

L

L

Front panel assembly

Rear cover

Front board

Rear cover

Fig.10

g

Joint

Fig.11

L

Joint g

1-8 (No.49839)

Fig.12

Page 9

2.2 CD Mechanism section

A

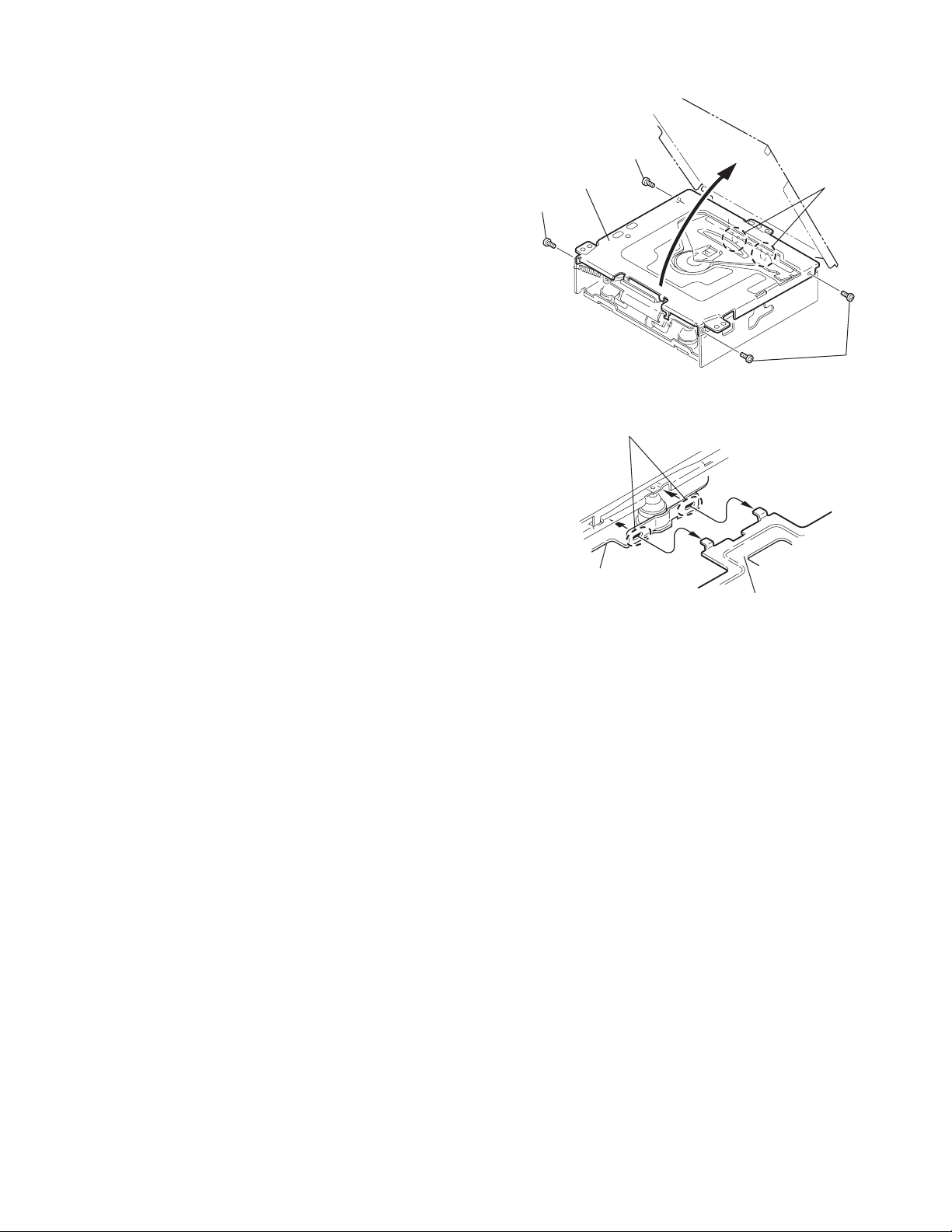

2.2.1 Removing the top cover

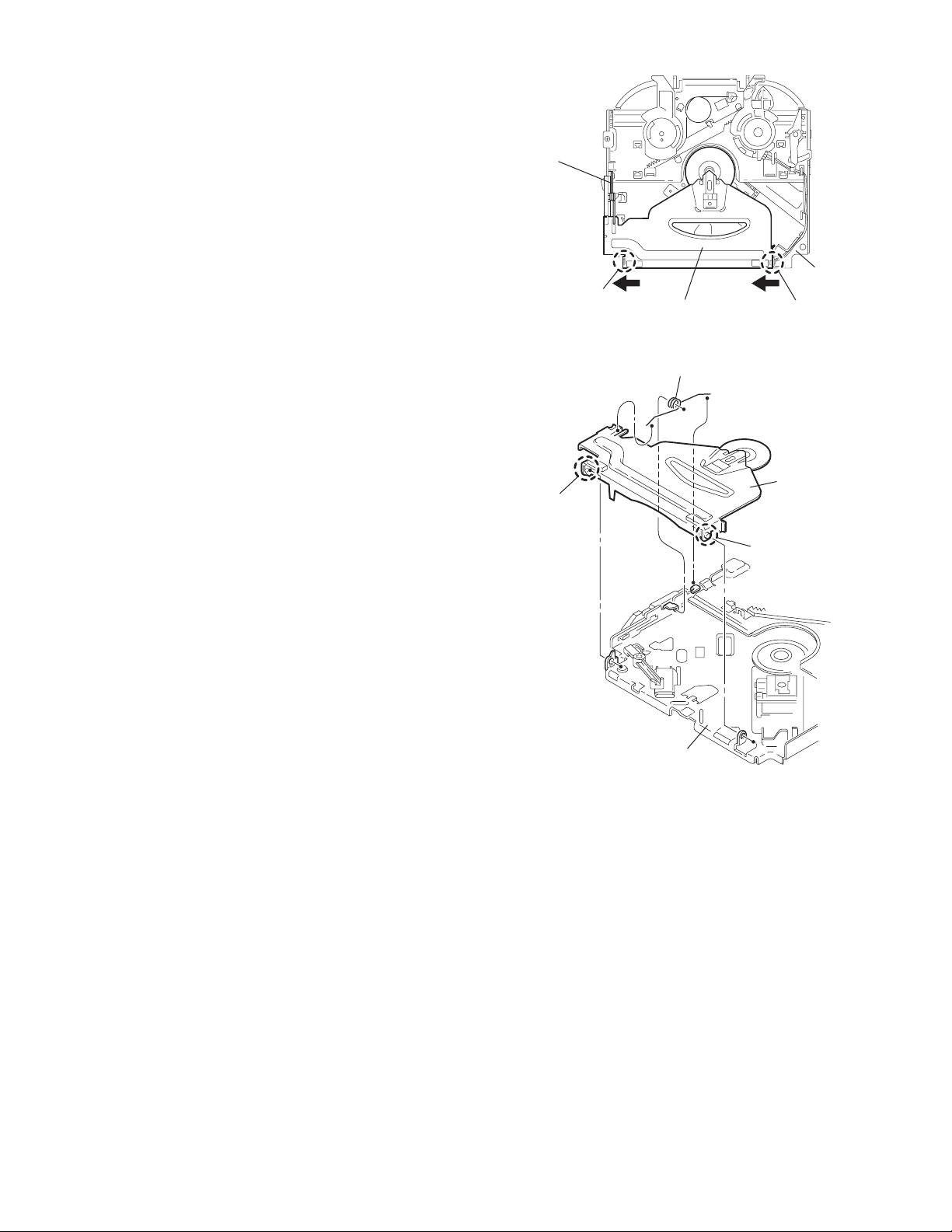

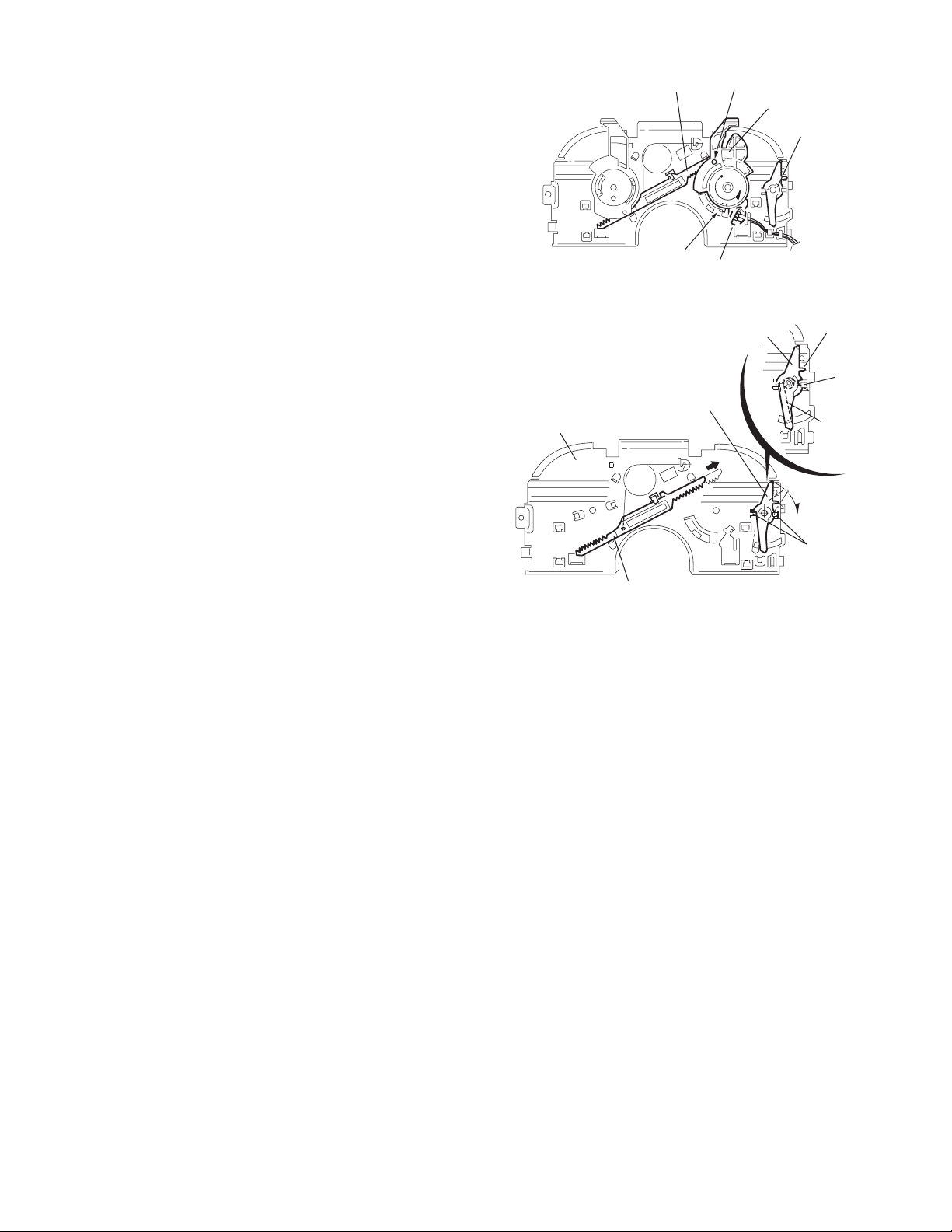

(See Figs.1 and 2)

(1) Remove the four screws A on the both side of the body.

(2) Lift the front side of the top cover and move the top cover

backward to release the two joints a.

Top cover

Joints a

A

Joints a

A

Fig.1

Fig.2

Top cover

(No.49839)1-9

Page 10

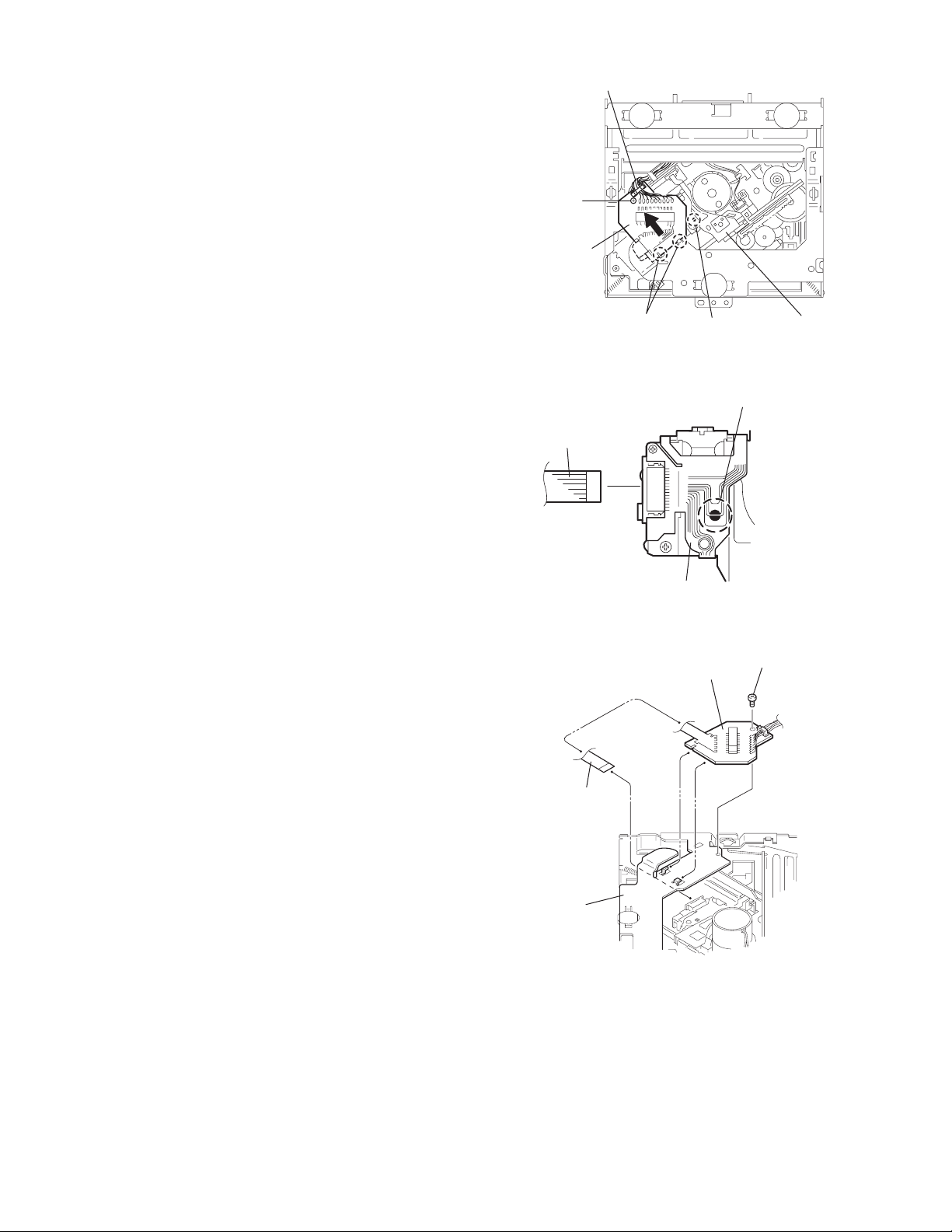

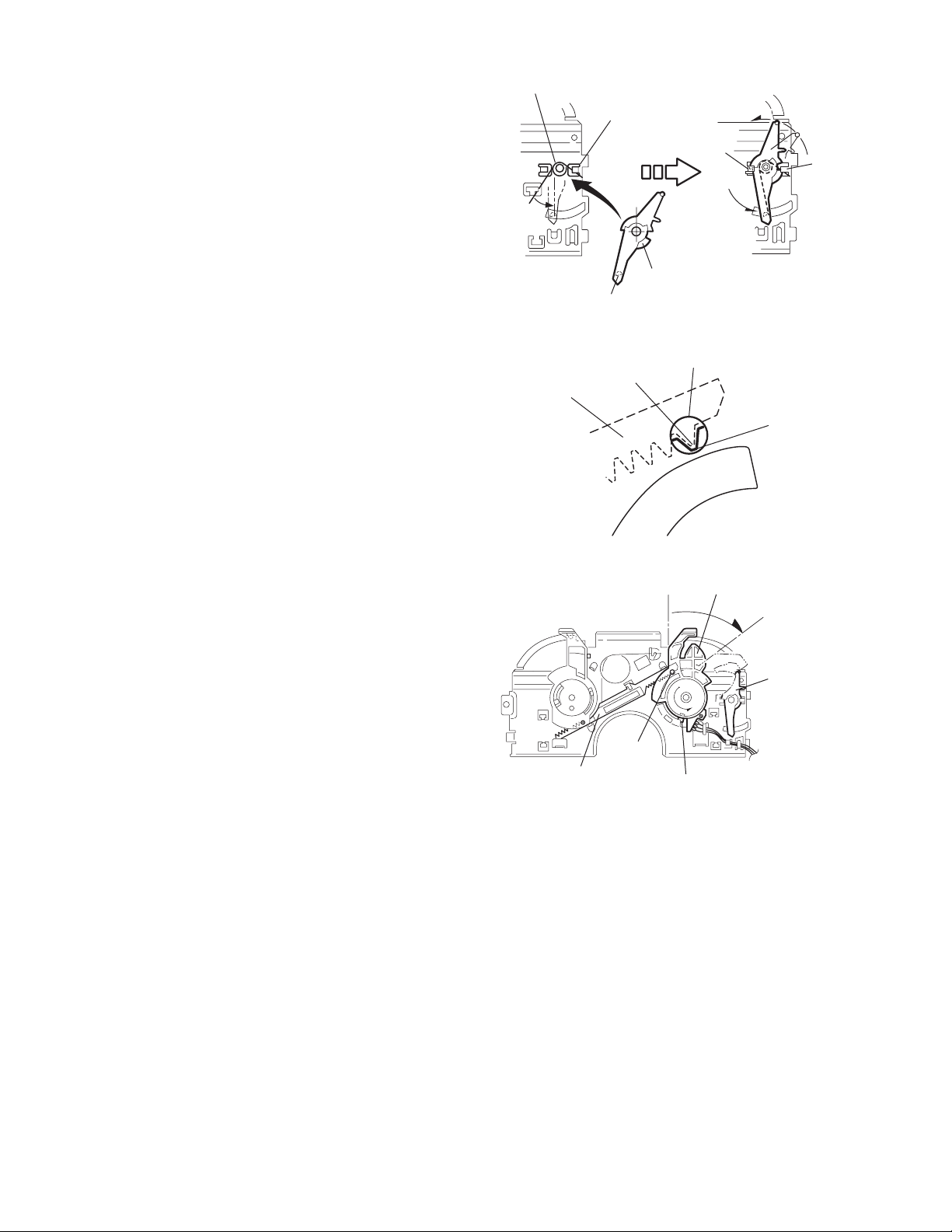

2.2.2 Removing the connector board

(See Figs.3 to 5)

CAUTION:

Before disconnecting the flexible wire from the pickup, solder

the short-circuit point on the pickup. No observance of this instruction may cause damage of the pickup.

(1) Remove the screw B fixing the connector board.

(2) Solder the short-circuit point on the pickup.

(3) Disconnect the flexible wire from the pickup.

(4) Move the connector board in the direction of the arrow to

release the two joints b.

(5) Unsolder the wires on the connector board if necessary.

CAUTION:

Unsolder the short-circuit point after reassembling.

B

Connector board

Flexible wire

Wires

Joints b

Short-circuit point

Fig.3

Short-circuit point

(Soldering)

Pickup

Flexible wire

Frame

Pickup

Fig.4

B

Connector board

Fig.5

1-10 (No.49839)

Page 11

2.2.3 Removing the DET switch

(See Figs.6 and 7)

(1) Extend the two tabs c of the feed sw. holder and pull out

the switch.

(2) Unsolder the DET switch wire if necessary.

DET

switch

Connector

board

Pickup

Fig.6

DET switch

Tab c

Tab c

DET switch wire

Feed sw. holder

Fig.7

(No.49839)1-11

Page 12

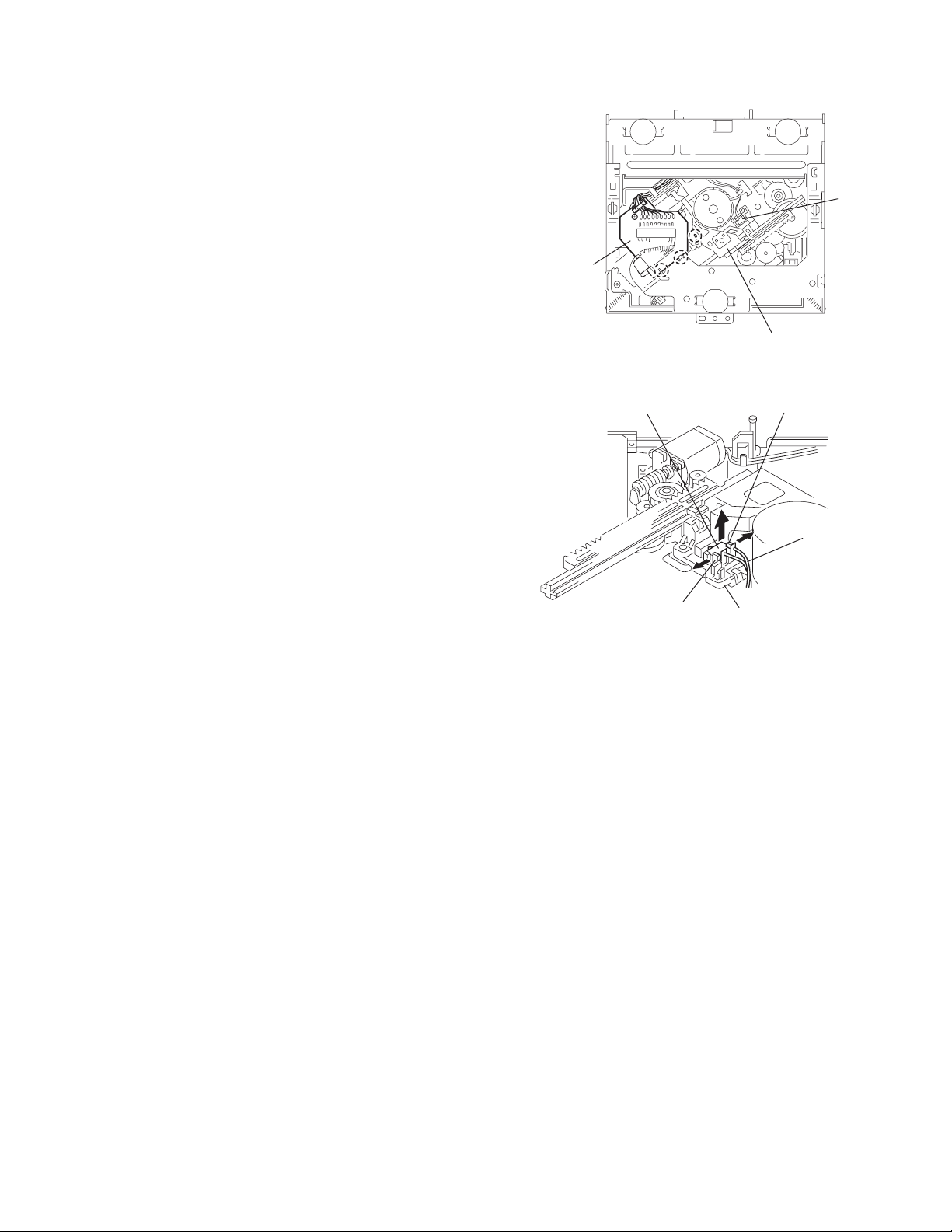

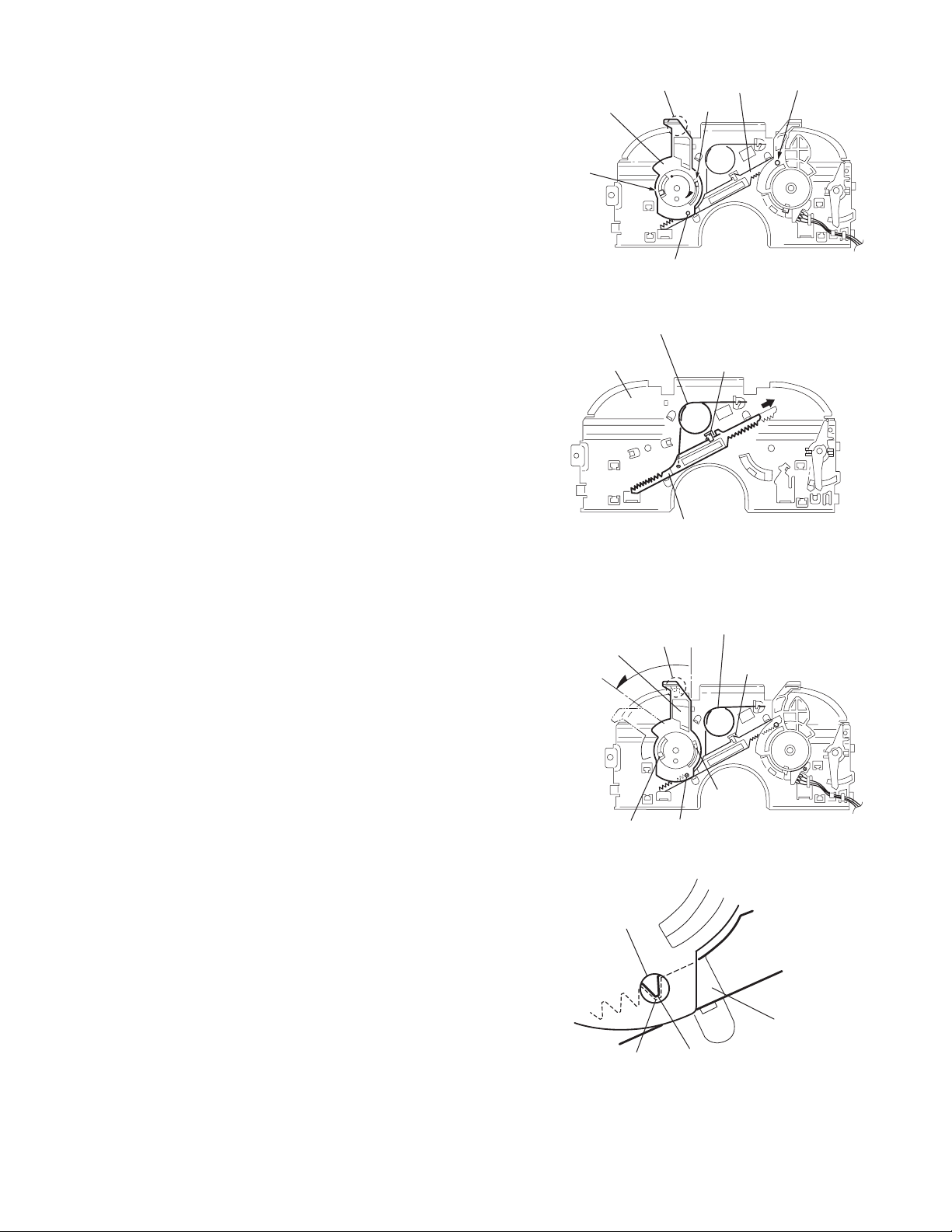

2.2.4 Removing the chassis unit

r

(See Figs.8 and 9)

• Prior to performing the following procedure, remove the top

cover and connector board.

(1) Remove the two suspension springs (L) and (R) attaching

the chassis unit to the frame.

CAUTION:

• The shape of the suspension spring (L) and (R) are different. Handle them with care.

• When reassembling, make sure that the three shafts

on the underside of the chassis unit are inserted to the

dampers certainly.

Suspension spring (R)

Chassis unit

Suspension spring (L)

Frame

Suspension spring (R)

Chassis unit

Shafts

Damper

Damper

Suspension spring (L)

Fig.8

Shaft

Dampe

Frame

Fig.9

1-12 (No.49839)

Page 13

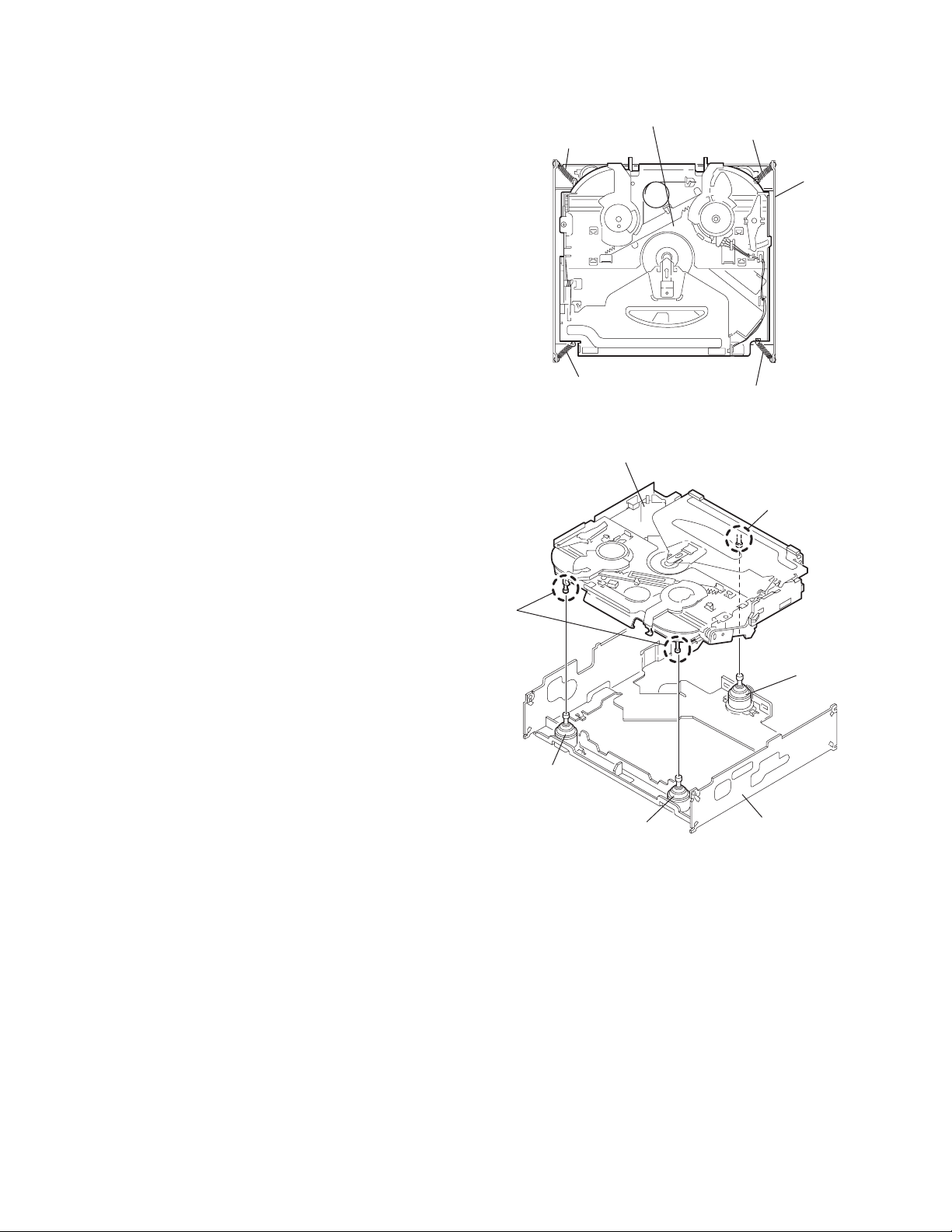

2.2.5 Removing the clamper assembly

(See Figs.10 and 11)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the clamper arm spring.

(2) Move the clamper assembly in the direction of the arrow to

release the two joints d.

Clamper arm

spring

Joint d

Joint d

Clamper assembly

Fig.10

Clamper arm spring

Chassis rivet

assembly

Joint d

Clamper assembly

Chassis rivet assembly

Joint d

Fig.11

(No.49839)1-13

Page 14

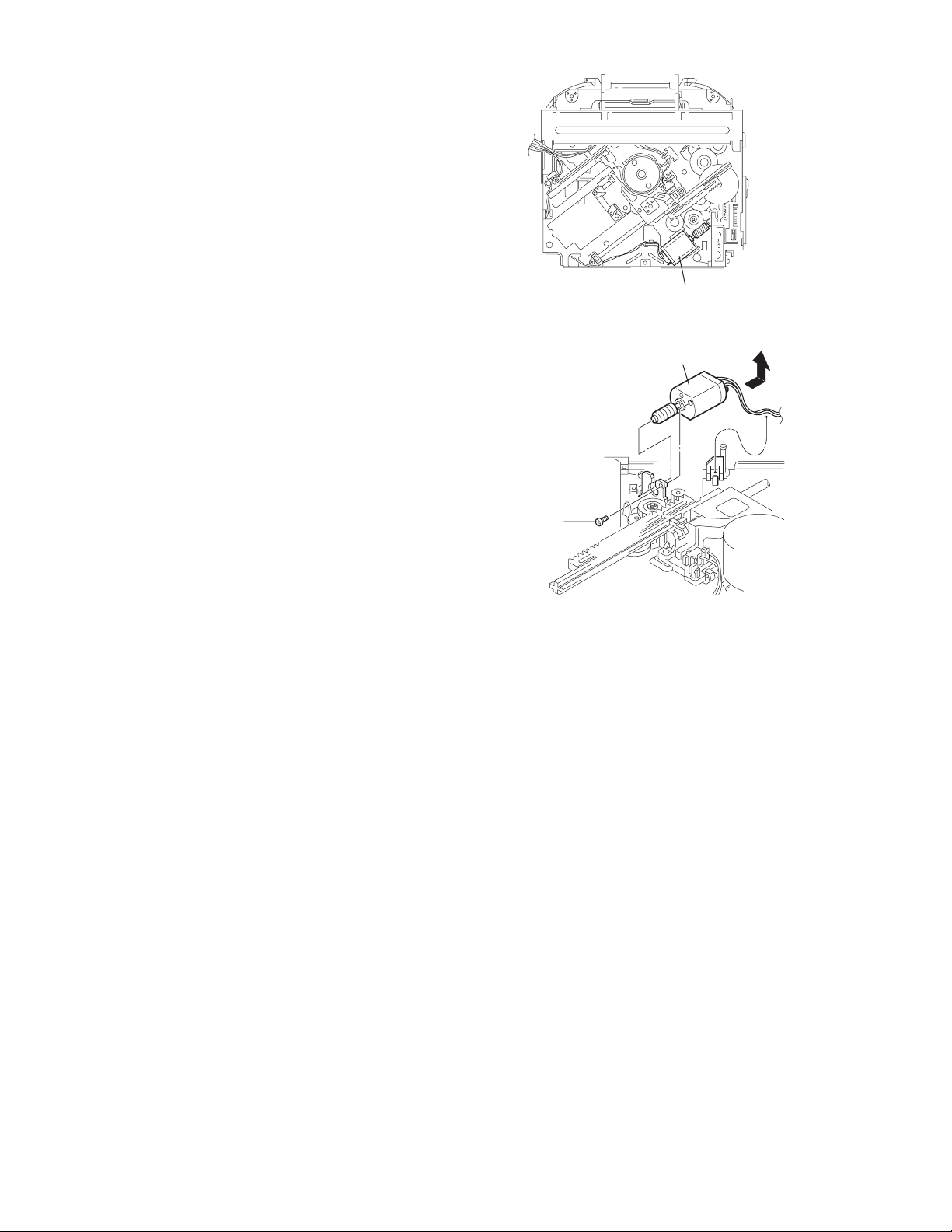

2.2.6 Removing the loading / feed motor assembly

(See Figs.12 and 13)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw C and move the loading / feed motor as-

sembly in the direction of the arrow to remove it from the

chassis rivet assembly.

(2) Disconnect the wire from the loading / feed motor assembly

if necessary.

CAUTION:

When reassembling, connect the wire from the loading /

feed motor assembly to the flame as shown in Fig.12.

Loading / feed motor assembly

Fig.12

Loading / feed motor assembly

C

Fig.13

1-14 (No.49839)

Page 15

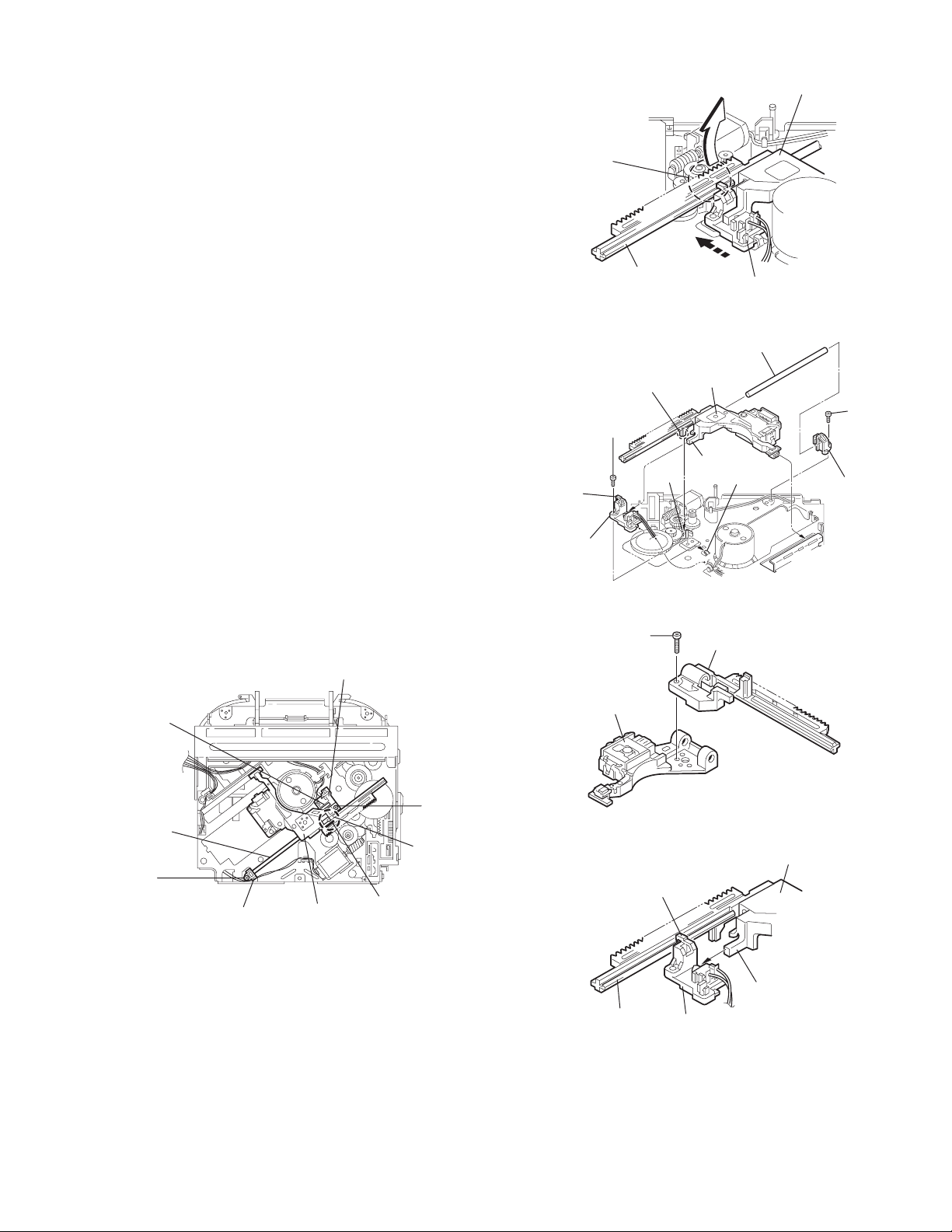

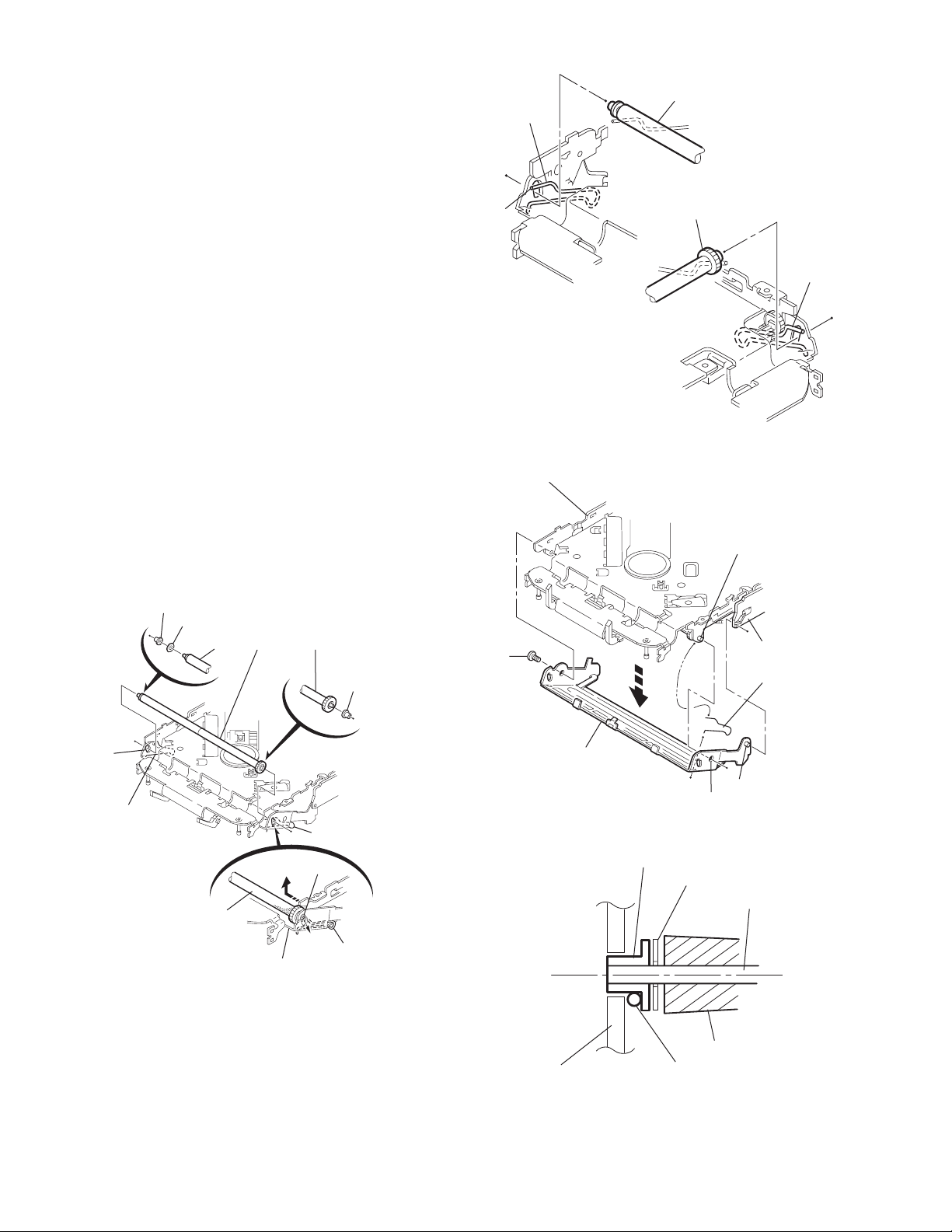

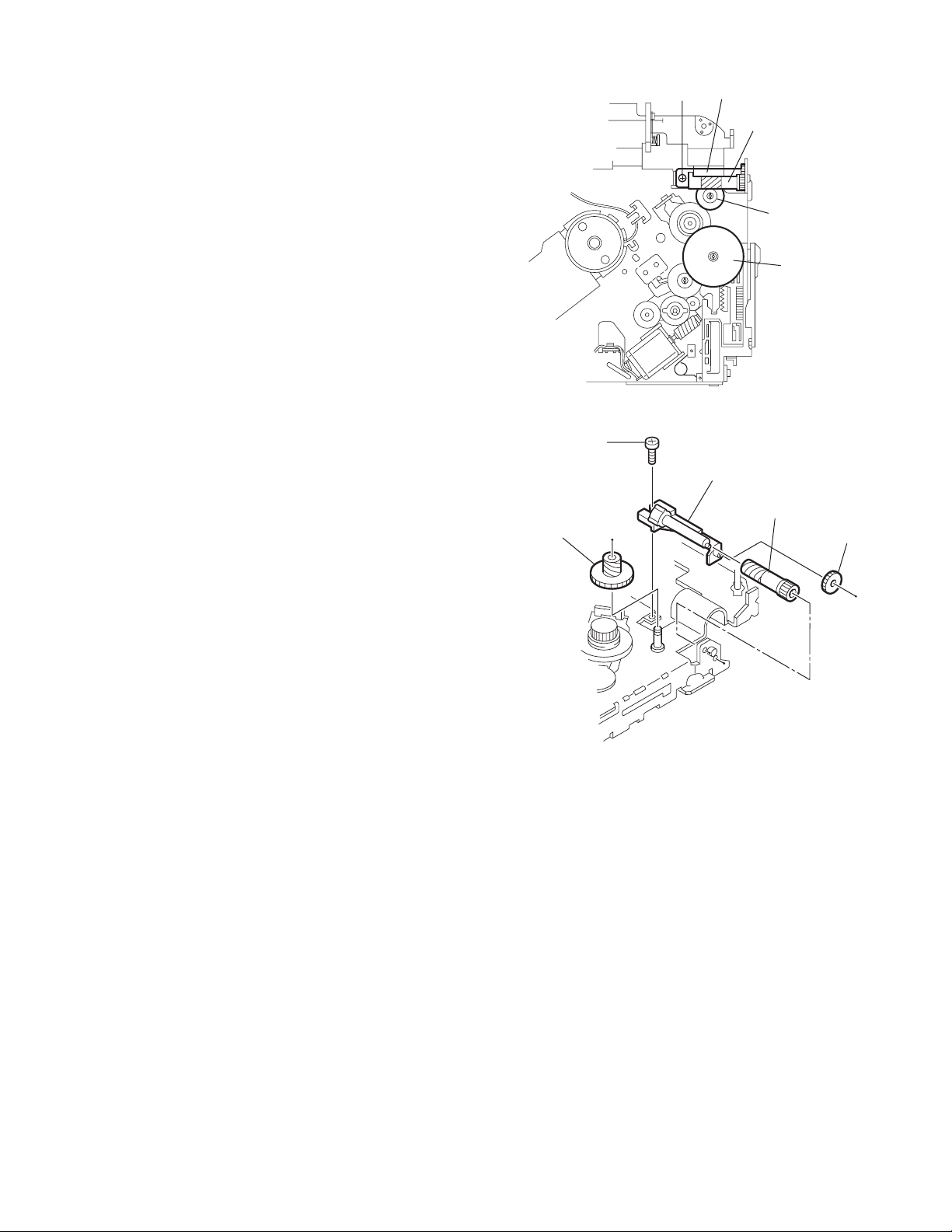

2.2.7 Removing the pickup unit

r

(See Figs.14 to 18)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw D and pull out the pu. shaft holder from

the pu. shaft.

(2) Remove the screw E attaching the feed sw. holder.

(3) Move the part e of the pickup unit upward with the pu. shaft

and the feed sw. holder, then release the joint f of the feed

sw. holder in the direction of the arrow. The joint g of the

pickup unit and the feed rack is released, and the feed sw.

holder comes off.

(4) Remove the pu. shaft from the pickup unit.

(5) Remove the screw F attaching the feed rack to the pickup

unit.

Part e

Feed rack

Pickup unit

Feed sw. holder

Fig.15

2.2.8 Reattaching the pickup unit

(See Figs.14 to 17)

(1) Reattach the feed rack to the pickup unit using the screw F.

(2) Reattach the feed sw. holder to the feed rack while setting

the joint g to the slot of the feed rack and setting the joint f

of the feed rack to the switch of the feed sw. holder correctly.

(3) As the feed sw. holder is temporarily attached to the pickup

unit, set to the gear of the joint g and to the bending part of

the chassis (joint h) at a time.

CAUTION:

Make sure that the part i on the underside of the feed

rack is certainly inserted to the slot j of the change lock

lever.

(4) Reattach the feed sw. holder using the screw E.

(5) Reattach the pu. shaft to the pickup unit. Reattach the pu.

shaft holder to the pu. shaft using the screw D.

Feed sw. holder

Joint f

Joint g

Feed sw. holder

Pickup unit

E

Part i

Slot j

F

Pu. shaft

Pickup unit

Joint f

Joint h

Fig.16

Feed rack

D

Pu. shaft holde

Pu. shaft

D

Pu. shaft holder

Pickup unit

Fig.14

Part e

E

Joint g

Feed rack

Fig.17

Pickup unit

Joint g

Joint f

Feed sw. holder

Fig.18

(No.49839)1-15

Page 16

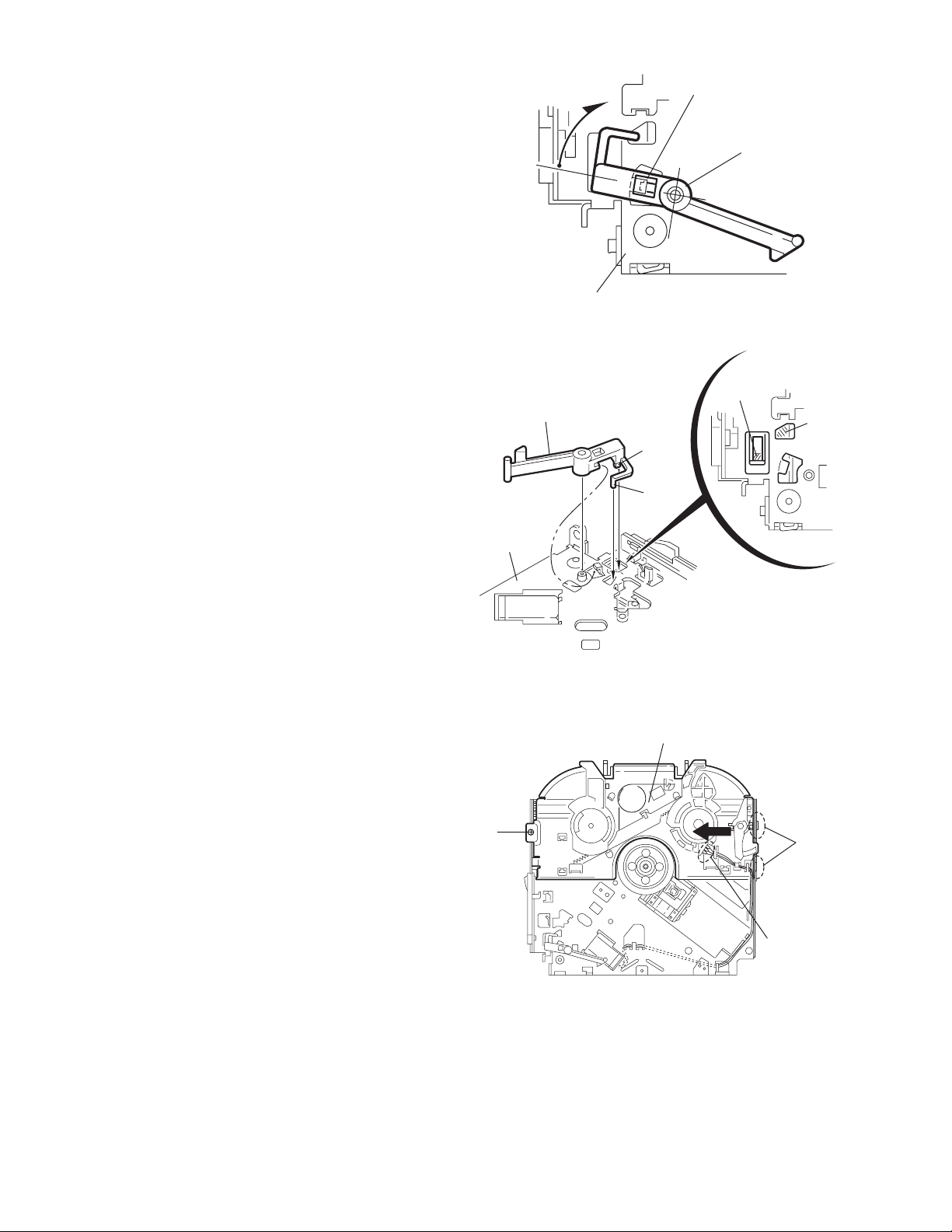

2.2.9 Removing the trigger arm

r

(See Figs.19 and 20)

• Prior to performing the following procedure, remove the top

cover, connector board and clamper unit.

(1) Turn the trigger arm in the direction of the arrow to release

the joint k and pull out upward.

CAUTION:

When reassembling, insert the part m and n of the trigger

arm into the part p and q at the slot of the chassis rivet

assembly respectively and join the joint k at a time.

Chassis rivet assembly

Trigger arm

Chassis

rivet

assembly

Joint k

Trigger arm

Fig.19

Part p

Part q

Part m

Part n

2.2.10 Removing the top plate assembly

(See Fig.21)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit, and clamper assembly.

(1) Remove the screw H.

(2) Move the top plate assembly in the direction of the arrow to

release the two joints r.

(3) Unsolder the wire marked s if necessary.

H

Fig.20

Top plate assembly

Joints

s

Fig.21

1-16 (No.49839)

Page 17

2.2.11 Removing the mode sw. / select lock arm

(See Figs.22 and 23)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the mode sw. to release from the link plate (joint t)

and turn in the direction of the arrow to release the joint u.

(2) Unsolder the wire of the mode sw. marked s if necessary.

(3) Turn the select lock arm in the direction of the arrow to re-

lease the two joints v.

(4) The select lock arm spring comes off the select lock arm at

the same time.

Link plate

Joint u

Fig.22

Joint t

Mode sw.

Select lock arm

s

Top plate

Select lock arm

Link plate

Select lock arm

Fig.23

Top plate

Hook w

Select lock

arm spring

Joints v

(No.49839)1-17

Page 18

2.2.12 Reassembling the mode sw. / select lock arm

(See Figs.24 to 26)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the select lock arm spring to the top plate and set

the shorter end of the select lock arm spring to the hook w

on the top plate.

(2) Set the other longer end of the select lock arm spring to the

boss x on the underside of the select lock arm, and join the

select lock arm to the slots (joint v). Turn the select lock

arm as shown in the figure.

(3) Reattach the mode sw. while setting the part t to the first

peak of the link plate gear, and join the joint u.

CAUTION:

When reattaching the mode sw., check if the points y and

z are correctly fitted and if each part operates properly.

Select lock arm spring

Hook w

Joint v

Joint v

Select lock arm

Boss x

Fig.24

Joint t

Point y

Link plate

Point z

Link plate

Fig.25

Mode sw.

Select

lock arm

Joint t

Joint u

Fig.26

1-18 (No.49839)

Page 19

2.2.13 Removing the select arm R / link plate

(See Figs.27 and 28)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the select arm R to release from the link plate

(joint a') and turn as shown in the figure to release the two

joints b' and joint c'.

(2) Move the link plate in the direction of the arrow to release

the joint d'. Remove the link plate spring at the same time.

REFERENCE:

Before removing the link plate, remove the mode sw..

Select arm R

Joint b'

Link plate spring

Joint c'

Joint a'

Link plate

Joint b'

Fig.27

Joint r

2.2.14 Reattaching the Select arm R / link plate

(See Figs.29 and 30)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the link plate spring.

(2) Reattach the link plate to the link plate spring while joining

them at joint d'.

(3) Reattach the joint a' of the select arm R to the first peak of

the link plate while joining the two joints b' with the slots.

Then turn the select arm R as shown in the figure. The top

plate is joined to the joint c'.

CAUTION:

When reattaching the select arm R, check if the points e'

and f' are correctly fitted and if each part operates properly.

Top plate

Select arm R

Joint b'

Joint d'

Link plate

Fig.28

Link plate spring

Joint c'

Joint d'

Joint b'

Joint a'

Fig.29

Joint a'

Point e'

Link plate

Point f'

Fig.30

(No.49839)1-19

Page 20

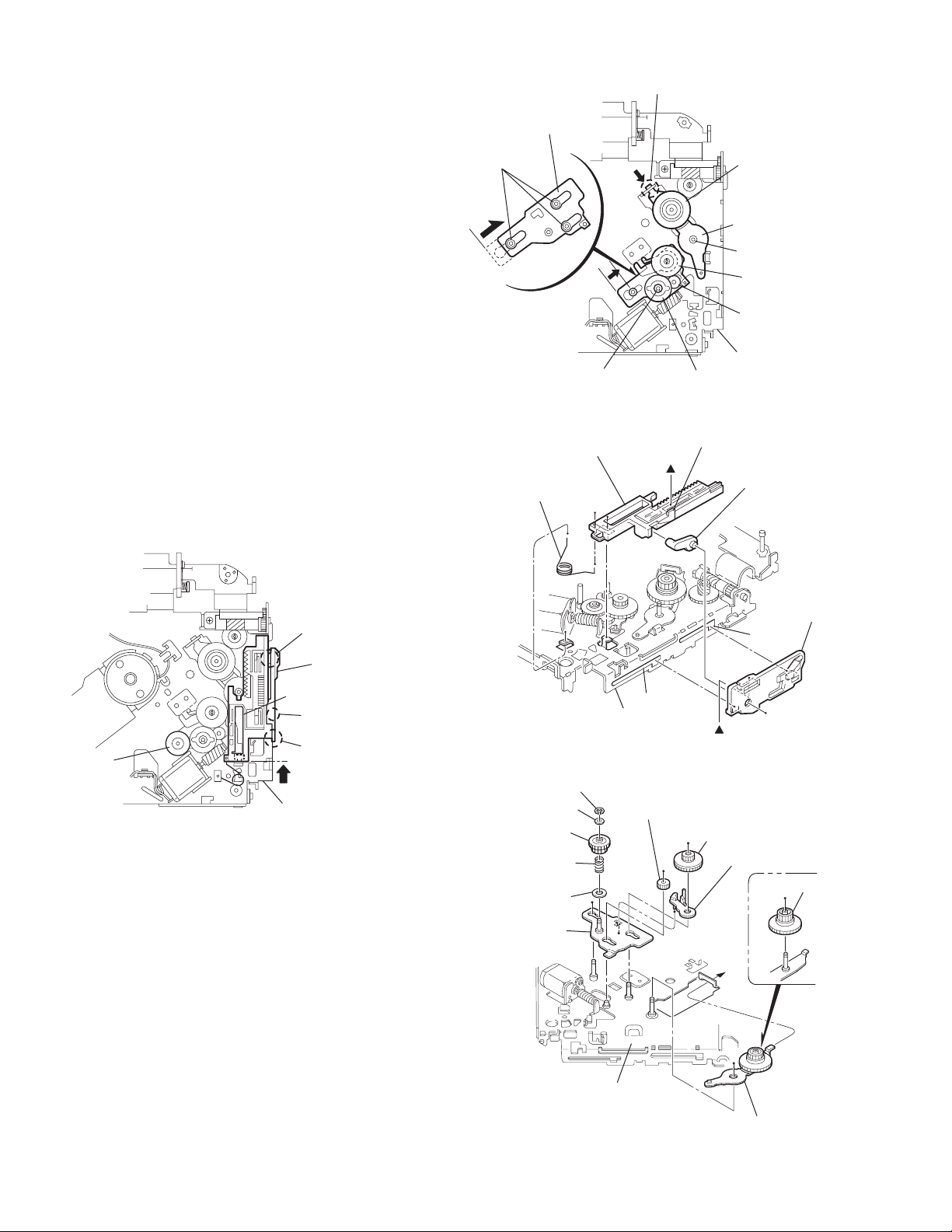

2.2.15 Removing the loading roller assembly

(See Figs.31 to 33)

• Prior to performing the following procedure, remove the

clamper assembly and top plate assembly.

(1) Push inward the loading roller assembly on the gear side

and detach it upward from the slot of the joint g' of the lock

arm rivet assembly.

(2) Detach the loading roller assembly from the slot of the joint

h' of the lock arm rivet assembly.

Roller guide

spring

Part k'

Loading roller assembly

Loading roller assembly

The roller guide comes off the gear section of the loading

roller assembly.

Remove the roller guide and the HL washer from the shaft

of the loading roller assembly.

(3) Remove the screw J attaching the lock arm rivet assembly.

(4) Push the shaft at the joint i' of the lock arm rivet assembly

inward to release the lock arm rivet assembly from the slot

of the L side plate.

(5) Extend the lock arm rivet assembly outward and release

the joint j' from the boss of the chassis rivet assembly. The

roller guide springs on both sides come off at the same

time.

CAUTION:

When reassembling, reattach the left and right roller

guide springs to the lock arm rivet assembly before reattaching the lock arm rivet assembly to the chassis rivet

assembly. Make sure to fit the part k' of the roller guide

spring inside of the roller guide. (Refer to Fig.34.)

Roller guide

HL washer

Loading roller assembly

Roller guide

Chassis rivet assembly

J

Roller guide

spring

Fig.32

Boss

L side plate

Roller guide spring

Joint h'

Roller guide spring

Loading roller assembly

1-20 (No.49839)

Joint g'

Lock arm rivet assembly

Fig.31

Roller guide spring

Roller guide spring

Lock arm rivet assembly

Lock arm rivet assembly

Joint j'

Joint i'

Fig.33

Roller guide

HL washer

Roller shaft assembly

Loading roller

Roller guide spring

Fig.34

Page 21

2.2.16 Removing the loading gear 5, 6 and 7

(See Figs.35 and 36)

• Prior to performing the following procedure, remove the top

cover, chassis unit, pickup unit and top plate assembly.

(1) Remove the screw K attaching the loading gear bracket.

The loading gear 6 and 7 come off the loading gear bracket.

(2) Pull out the loading gear 5.

K

Loading gear 5

Loading gear bracket

K

Loading gear 6

Loading gear 5

Loading gear 3

Fig.35

Loading gear bracket

Loading gear 6

Loading gear 7

Fig.36

(No.49839)1-21

Page 22

2.2.17 Removing the gears

(See Figs.37 to 40)

• Prior to performing the following procedure, remove the top

cover, chassis unit, top plate assembly and pickup unit.

• Pull out the loading gear 3. (See Fig.35.)

(1) Pull out the feed gear.

(2) Move the loading plate assembly in the direction of the ar-

row to release the L side plate from the two slots m' of the

chassis rivet assembly. (See Fig.37.)

(3) Detach the loading plate assembly upward from the chas-

sis rivet assembly while releasing the joint n'. Remove the

slide hook and loading plate spring from the loading plate

assembly.

(4) Pull out the loading gear 2 and remove the change lock le-

ver.

(5) Remove the E ring and washer attaching the change gear

2.

(6) The change gear 2, change gear spring and adjusting

washer come off.

(7) Remove the loading gear 1.

(8) Move the change plate rivet assembly in the direction of the

arrow to release from the three shafts of the chassis rivet

assembly upward. (See Fig.38.)

(9) Detach the loading gear plate rivet assembly from the shaft

of the chassis rivet assembly upward while releasing the

joint p'. (See Figs.38 and 40.)

(10) Pull out the loading gear 4.

Change plate

rivet assembly

Shafts

E ring

Loading plate assembly

Loading plate spring

Joint p'

Loading gear 4

Loading gear plate

rivet assembly

Shaft

Loading gear 2

Loading gear 1

Chassis rivet assembly

Change gear 2

Fig.38

Joint n'

Slide hook

Feed gear

Fig.37

Slot m'

L side plate

Loading plate assembly

Joint n'

Slot m'

Chassis rivet assembly

Chassis rivet assembly

E ring

Washer

Change gear 2

Change gear

spring

Adjusting

washer

Change plate

rivet assembly

L side plate

Slot m'

Slot m'

Fig.39

Loading gear 1

Loading gear 2

Change lock lever

Loading gear 4

1-22 (No.49839)

Chassis rivet assembly

Loading gear plate rivet

assembly

Fig.40

Page 23

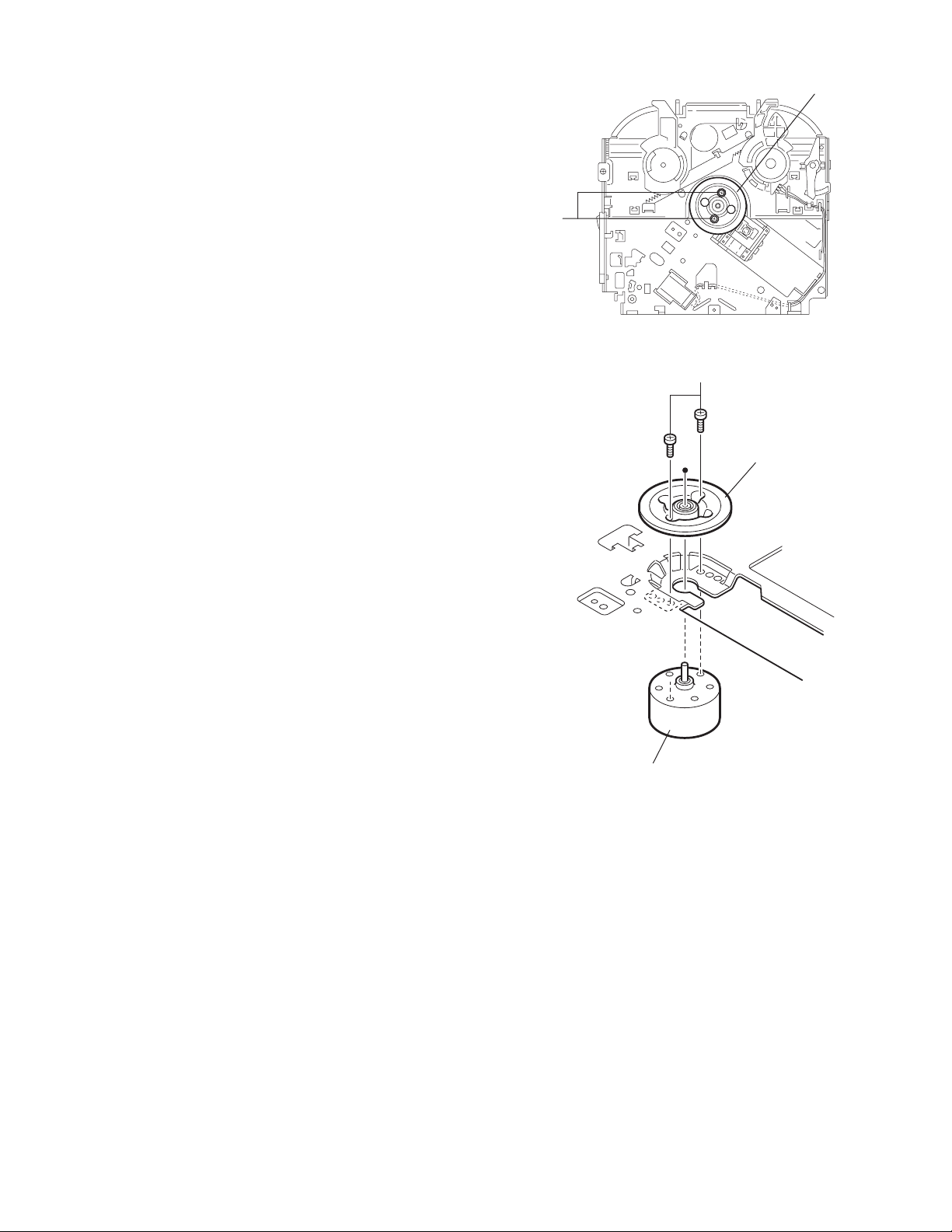

2.2.18 Removing the turn table / spindle motor

(See Figs.41 and 42)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit and clamper assembly.

(1) Remove the two screws L attaching the spindle motor as-

sembly through the slot of the turn table on top of the body.

(2) Unsolder the wire on the connector board if necessary.

Turn table

L

Fig.41

L

Turn table

Spindle motor

Fig.42

(No.49839)1-23

Page 24

SECTION 3

Adjustment

3.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) AM Standard signal generator

(3) FM Standard signal generator

(4) Stereo modulator

(5) Electric voltmeter

(6) Digital tester

(7) Tracking offset meter

(8) Test Disc JVC :CTS-1000

(9) Extension cable for check

EXTSH002-22P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

Frequency Band

FM 87.5MHz to 107.9MHz

(with channel interval set to 200kHz)

87.5MHz to 108.0MHz

(with channel interval set to 50kHz)

AM 530kHz to 1710kHz

(with channel interval set to 10kHz)

531kHz to 1602kHz

(with channel interval set to 9kHz)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

The cardboard is cut in a suitable size.

uses for the insulation stand of mechanism.

Heat sink

(Attach the heat sink

using the two screws.)

Front chassis assembly

(Attach the front chassis assembly using the two screws.)

Extension cable

EXTSH002-22P

Rear bracket

(Attach the rear bracket

using the screw.)

1-24 (No.49839)

Page 25

3.2 Troubleshooting

Feed section

Is the voltage output at

IC621 pin "40" 5V or 0V?

Is 4V present at both

sides of the feed motor?

YES

YES

NO YES NO

Is the wiring for IC621

pin "40"?

NO

Is 3.3V present at IC681

pin "6"?

YES

Check the vicinity of

Check CD 8V

and 5V.

IC621.

NO

Is 6V or 2V present at

IC681 "16" and "17"?

YES

Check the feed motor

connection wiring.

NO

Check the feed motor.

Focus section

When the lens is

moving:

4V

Does the S-search

waveform appear at

IC681 pins "13" and "14"?

Spindle section

Is the disk rotated?

YES

Does the RF signal

appear at IC601 pin "19"?

YES

Is the RF waveform at

IC601 pin "19" distorted?

YES

Proceed to the Tracking

section

Check IC681.

NO

Check the circuits in

the vicinity of IC681

pins "13","14"and"1".

YES

Check the pickup and

its connections

NO

Is 4V present at IC681

pins "15" and "16"?

Check the spindle motor

and its wiring

NO

Check the circuits in the

vicinity of IC601 pin "19"

NO

or the pickup

YES

YES

NO

Is 4V present at IC621

pins "41" ?

Check the vicinity of

IC681.

NO

YES

Check the circuits in

the vicinity of IC621

or IC621

Tracking section

When the disc is rotated

at first:

Is the tracking error signal

output at IC601 "11"?

Check IC621.

Approx. 1.2V

YES

YES YES

Check the circuit in the

vicinity of IC601 pins

"2" to "7".

Check the pickup and

its connections

(No.49839)1-25

Page 26

3.3 Flow of functional operation unit TOC read

When the pickup correctly moves

to the inner area of the disc

$82

Microprocessor

commands

FMO

TC94A14FA "40"

FEED MOTOR

+TERMINAL

IC681 "17"

REST SW

When correctly focused

FEO

TA2157 "15"

$83

$81

Focus Servo Loop ONo

v

3.3V

Hi-Z

0V

6V

4V

2V

OFF

ON

Pickup feed to the inner area

2.2V

RF signal eye-pattern

remains closed

RF signal eye-pattern

opens

Power ON

Set Function CD

Disc inserted

YES

Laser emitted

Focus search

Disc rotates

n

Tracking loop closed

TOC read out

YES

When the laser diode correctly

emits

Microprocessor

commands

SEL

TC94A14FA "38"

LD

CN601 "10"

"No disc"

display

When the disc correctly rotates

Microprocessor

commands

DMO

TC94A14FA "41"

Spindle

motor(-)

IC681 "16"

$84 $86 $ A200

Acceleration Servo CLV

0.5 Sec 0.5 Sec

$84

Rough

Servo

3.3V

0V

4V

0V

3.3V

2.2V

0V

6V

3.2

2V

1-26 (No.49839)

Jump to the first track

Play

Tracking Servo Loop ON

RF signal

Rough Servo Modev

CLV Servo Mode

(Program Area)

CLV Servo Mode

(Lead-In Area;

Digital :0)

Page 27

3.4 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

3.5 Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at RF test point.

Finish.

(No.49839)1-27

Page 28

Description of major ICs

+

-

+

-

-

+

+

-

-

-

+

+

4.1 BA3220FV-X (IC301,IC281) : Line out amp

• Pin layout

SECTION 4

• Block diagram

14

8

3220

17

CL-

14

LGND

13

OUTL OUTR RGND

1112

10

CR-

9

CR+

8

REFL

REFR

FILTER

1

2

Vcc

3

INL

4

NFLCL+

56

FIL

NFR

7

INR

1-28 (No.49839)

Page 29

4.2 BA5830FP-X (IC681) : Power driver

• Pin Layout

22232425262728 15161718192021

BIAS

Pre Vcc

-

+

-

+

+

-

+

-

-

+

• Pin function

Pin No. Symbol Function

1 OPIN2(-) CH2 Pre OP amplifier invert input

2 OPOUT2 CH2 Pre OP amplifier output

3 OPIN1(-) CH1 Pre OP amplifier invert input

4 OPOUT1 CH1 Pre OP amplifier output

5 REG-B Connect to external Tr Base

6 REG(+) Regulator terminal of output feedback

7 PreGND Pre Block and Regulator GND

8 MUTE Mute terminal

9 PowGND Power Block GND

10 PowVcc1 CH1, 2 Power Block Vcc

11 VO1(-) Driver CH1 negative output

12 VO1(+) Driver CH1 positive output

13 VO2(-) Driver CH2 negative output

14 VO2(+) Driver CH2 positive output

10k

L

-

H

+

1.65V

20k

10k

2.4V

20k

-

+

+

-

10k

PreGND

7654321 141312111098

CH4 CH3

10k 10k 10k 10k

-

20k

10k

10k

LD/SLED

CONTROL

H

L

10k

-

+

+

-

10k

MUTE

CONTROL

Pow

GND

Pow

GND

Pow

Vcc2

Pow

Vcc1

+

Level shifter

Level shifter

+

-

+

10k 10k 10k 10k

T.S.D

10k

-

+

10k

CH1

10k

-

+

Level shifter

Level shifter

+

10k

-

10k

-

10k

CH2

T.S.D : thermal shutdown

Unit of resistance : [ ]

Pin No. Symbol Function

15 VO3(+) Driver CH3 positive output

16 VO3(-) Driver CH3 negative output

17 VO4(+) Driver CH4 positive output

18 VO4(-) Driver CH4 negative output

19 PowVcc2 CH3, 4 Power Block VCC

20 PowGND Power Block GND

21 CNT Control terminal

22 LDIN Loading input

23 OPOUTSL SLED Pre OP amplifier output

24 OPINSL(-) SLED Pre OP amplifier invert input

25 OPOUT3 CH3 Pre OP amplifier output

26 OPIN3(-) CH3 Pre OP amplifier invert input

27 BIAS BIAS input

28 PreVcc Pre-Block VCC

-

+

10k

-

+

10k

NOTE:

When PIN2,4,22,25 is high ("H"), the positive output pin of the driver is high ("H") and the negative output pin is low ("L").

When PIN23 is high ("H"), the positive output pin of CH4 is low ("L") and negative output pin is high ("H").

(No.49839)1-29

Page 30

4.3 BR24L16F-W-X (IC703) : EEPROM

A

• Pin layout • Pin function

VCC WP SCL SDA

Symbol I/O Function

VCC - Power supply.

GND - GND

A0,A1,A2 I No use connect to GND.

SCL I Serial clock input.

SDA I/O Serial data I/O of slave and ward address.

A0 A1 A2 GND

WP I Write protect terminal.

• Block diagram

A0 1

11bit

A1 2

A2 3

GND 4

High voltage osc circuit

Address

decoder

Control circuit

4.4 BU4066BCFV-X (IC131) : Quad analog switch

• Pin layout & Block diagram

VDD C1 C4 I/O4 I/O3O/I4 O/I3

14 13 12 11 810 9

16kbit EEPROM allay

11bit

START

Slave Ward

Address resister

Power supply

voltage det.

STOP

ACK

8bit

Data

resister

8 Vcc

7 WP

6 SCL

5 SD

1-30 (No.49839)

1234 756

I/O1 O/I1 O/I2 I/O2 VssC2 C3

Page 31

4.5 HA13164A (IC901) : Regulator

• Terminal layout

123456789101112131415

• Block diagram

ANT OUT

EXT OUT

ANT CTRL

CTRL

CD OUT

AUDIO OUT

C3

0.1u

C4

0.1u

C5

0.1u

C6

10u

2

1

7

11

12

10

VCC ACC

8

Surge Protector

BIAS TSD

15

3

TAB

C1

100u

C2

0.1u

13

ILM AJGND GND

+B

ACC

BATT.DET OUT

9

COMPOUT

6

VDD OUT

4

SW5VOUT

5

ILMOUT

14

R1

C7

0.1u

C8

0.1u

UNIT R:

C:F

note1) TAB (header of IC)

connected to GND

• Pin function

Pin No. Symbol Function

1 EXTOUT Output voltage is VCC-1 V when M or H level applied to CTRL pin.

2 ANTOUT Output voltage is VCC-1 V when M or H level to CTRL pin and H level to ANT-CTRL.

3 ACCIN Connected to ACC.

4 VDDOUT Regular 5.7V.

5 SW5VOUT Output voltage is 5V when M or H level applied to CTRL pin.

6 COMPOUT Output for ACC detector.

7 ANT CTRL L:ANT output OFF H:ANT output ON

8 VCC Connected to VCC.

9 BATT DET Low battery detect.

10 AUDIO OUT Output voltage is 9V when M or H level applied to CTRL pin.

11 CTRL L:BIAS OFF M:BIAS ON H:CD ON

12 CD OUT Output voltage is 8V when H level applied to CTRL pin.

13 ILM AJ Adjustment pin for ILM output voltage.

14 ILM OUT Output voltage is 10V when M or H level applied to CTRL pin.

15 GND Connected to GND.

(No.49839)1-31

Page 32

4.6 HD74HC126FP-X (IC781) : Buffer

• Pin layout • Pin function

Input Output

CA Y

LX Z

HL H

HH L

Note:

H:High level

L:Low level

X:Irrelevant

Z:Off(High-impedance)

State a 3-state input

• Block diagram

1C

1A

1Y

2C

2A

2Y

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

VCC

4C

4A

4Y

3C

3A

3Y

Vcc Vcc

1k

Input

Note:

CL includes probe and jig capacitance

See Function Table

1A

2A

3A

4A

1C

2C

3C

4C

1Y

2Y

3Y

4Y

Output

Output

Output

Output

S1

CL

1k

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

1-32 (No.49839)

Page 33

4.7 HD74HCT126T-X : (IC503) Buffer

• Pin arrangement • Pin function

Input Output

1C

1A

1Y

2C

2A

2Y

GND

• Block diagram

1

2

3

4

5

6

7

14

13

12

11

10

Vcc

4C

4A

4Y

3C

9

3A

8

3Y

CA Y

LX Z

HL L

HH H

H : High level

L : Low level

X : Irrelevant

Z : Off (Hhigh-impedance)state of a 3-stage output

1A

1C

2A

2C

3A

3C

4A

1Y

2Y

3Y

4Y

4C

(No.49839)1-33

Page 34

4.8 IC-PST3424U-X (IC803) : Reset

T

• Pin layout

VOUT

VDD

• Block diagram

1

2

VDD

43VSS

NC

2

Vref

3

VSS

• Pin function

No. Pin Name Function

1 Vout Reset Signal Output PIN

2 VDD VDD PIN / Voltage Detect PIN

3 NC Non connect

4 VSS VSS PIN

+

-

1 VOU

4.9 IC-PST9333U-X (IC702) : Regulator

• Pin layout • Block diagram

NC 1

GND 2

• Pin function

Pin No. Symbol Function

1 NC Non connect

2 GND GND terminal

3 VOUT Reset signal output terminal

4 Vcc Vcc terminal/Voltage detect terminal

4 Vcc

3 VOUT

Vcc 4

NC 1

3 VOUT

2 GND

1-34 (No.49839)

Page 35

4.10 RPM6938-SV4 (IC805) : Remote control receiver

• Pin diagram

1 2 3

• Block diagram

AMP

I/V

conversion

PD

magnetic shield

BPF

fo

trimming

circuit

4.11 TDA7404D-X (IC911):Car radio signal processor

• Terminal layout

1

14

28

15

AGC

Detector

Vcc

Comp

Vcc

22k

Rout

GND

• Block diagram

MIX

Gain/Auto Zero

Input Multiplexer

Mono/Beep

Mixing Stage

Beep

Supply

Loudness

Volume

Soft Mute

Digital Control I C-Bus

Treble

2

Bass

Mono Fader

Mono Fader

Mono Fader

Mono Fader

Mono Fader

Mono Fader

Zero Cross

(No.49839)1-35

Page 36

4.12 LH28F160BJHET92 (IC802) : 16M flash memory

A

• Pin Layout

• Block Diagram

A15 1

14 2

A

13 3

A

A

12 4

11 5

A

A

10 6

9 7

A

A

8 8

19 9

A

NC 10

WE# 11

RP# 12

V

CCW 13

WP# 14

RY/BY# 15

A

18 16

A

17 17

7 18

A

A

6 19

A

5 20

A

4 21

A

3 22

A

2 23

A1 24

Output

buffer

48-LEAD TSOP

STANDARD PINOUT

12mm x 20mm

TOP VIEW

DQ0 to DQ15

Input

buffer

48

47

46

44

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

16

A

BYTE#

GND

DQ

15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

VCC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

GND

CE#

A0

-1-A19

Input

buffer

Address

latch

Address

counter

Y

decoder

X

decoder

Output

Multiplexer

Boot block 0

Boot block 1

Parameter block 0

Parameter block 1

Parameter block 2

ID code

register

Status

register

comparator

Y gate

Main block 0

Parameter block 3

Parameter block 4

Parameter block 5

Data

32k word

(64k byte)

Main block

x 31

Main block 1

register

Command

interface

Data

machine

Main block 29

Main block 30

user

Write

state

I/O logic

Write/Erase

voltage

selecter

VCC

BYTE#

CE#

WE#

OE#

RP#

WP#

RY/BY#

VCCW

VCC

GND

1-36 (No.49839)

Page 37

• Pin function

Pin No. Symbol I/O Function

1 to 8 A15 to A8 I Address input for memory address

9 A19 I Address input for memory address

10 NC - Non connection

11 WE# I Write enable

12 RP# I Reset

13 VCCW - Power supply for write/erase

14 WP# I Write protect

15 RY/BY# O Ready/Busy

16,17 A18,A17 I Address input for memory address

18 to 25 A7 to A0 I Address input for memory address

26 CE# I Chip enable

27 GND - Ground

28 OE# I Output enable

29 DQ0 I/O Data input/output

30 DQ8 I/O Data input/output

31 DQ1 I/O Data input/output

32 DQ9 I/O Data input/output

Pin No. Symbol I/O Function

33 DQ2 I/O Data input/output

34 DQ10 I/O Data input/output

35 DQ3 I/O Data input/output

36 DQ11 I/O Data input/output

37 VCC - Power supply

38 DQ4 I/O Data input/output

39 DQ12 I/O Data input/output

40 DQ5 I/O Data input/output

41 DQ13 I/O Data input/output

42 DQ6 I/O Data input/output

43 DQ14 I/O Data input/output

44 DQ7 I/O Data input/output

45 DQ15 I/O Data input/output

A-1 I Address input for memory address

46 GND - Ground

47 BYTE# I Byte enable

48 A16 I Address input for memory address

(No.49839)1-37

Page 38

4.13 MN102H60KCG (IC801) : LCD display sub CPU

• Pin Layout

100 76

1

75

25

26 50

51

• Pin function

Pin No. Symbol I/O Function

1 RES O LCD reset output

2 RE O Read enable output for extension memory

3 WE O Write enable output for extension memory

4 VccWCNT O Writing voltage control for external ROM

5 RY/BY I Read/Busy input for extension memory

6 CS1 O Chip select1 output for extension memory

7NCONot use

8 SWLED4 O SW_LED flashing output 4 for [PRESET1-6] key LED

9 SWLED5 O SW_LED flashing output 5 for [SEEKUP]+[SEEKDOWN] key LED

10 SWLED6 O SW_LED flashing output 6 for [DISCUP]+[DISCDOWN] key LED

11 NC O Not use

12 /WORD I Bus width setting for extension memory (H: 8-bit width)

13 to 16 A0 to A3 O Extension memory output 0 to 3

17 VDD - Power supply

18 NC O Base clock output

19 GND - Ground

20 XI I Connect to ground

21 NC O Not connect

22 VDD - Power supply

23 OSCI I Crystal connecting terminal (25MHz)

24 OSCO O Crystal connecting terminal (25MHz)

25 MODE I Mode setting input, pull up (H: memory extension mode)

26 to 33 A4 to A11 O Extension memory output 4 to 11

34 AVDD - Analog power supply

35 to 42 A12 to A19 O Extension memory output 12 to 19

43 VREF- - Analog reference power supply, connect to ground

44 A20 O Extension memory output 20

45 Thermal I Thermal fuse input

46 ANA I Audio level input for spectrum analyzer

47 WDOUT O Watch dog timer over flow output (H: over flow)

48 PON O Power on output

49 RD O LCD read strobe output

50 LCDCLK O LCD driver clock output (300kHz)

51 WR O LCD write strobe output

52,53 NC - Not use

54 VREF+ - Analog reference power supply, connect to AVDD

55 RS O LCD regist select output

56 CS O LCD chip select output

1-38 (No.49839)

Page 39

Pin No. Symbol I/O Function

57 NC O Not use

58 VOL1 I Rotary encoder input 1

59 VOL2 I Rotary encoder input 2

60 NC - Not use

61 AGND - Analog ground

62 to 65 KEY0 to KEY3 I Key 0 to 3 input AD terminal

66 VDD - Power supply

67 SWLED0 O SW_LED flashing output 0 for [VOL] key LED

68 SWLED1 O SW_LED flashing output 1 for [SEL] key LED

69 SWLED2 O SW_LED flashing output 2 for [DISP] key LED

70 DISPCLK I Serial communication clock input

71 DISPDATA I Displaying data input (Serial)

72 KEYDATA O Key code data output (Serial)

73 SIFDA I/O On board serial writing data input/output, pull up

74 SIFCK I On board serial writing clock input, pull up

75 NMI I NMI (H fix)

76 DISPCE I Chip enable input for serial communication

77 - Ground

78 PSAVE2 I POWER SAVE2 (Memory power supply off) detecting input

79 NC - Not use

80 KEY_IN I Key interrupt input

81 ADSEP I Address data separate/common mode setting terminal

H: separate mode

82 RESET I Reset input (L: reset)

83 VDD - Power supply terminal

84 to 91 D0 to D7 I Extension memory input 0 to 7

92 GND - Ground

93 to 100 P10 to P17 I LCD data bus input/output 0 to 7

(No.49839)1-39

Page 40

4.14 M62449FP-X (IC912) : Equalizer

DATA

LATCH

DGND

OUT2

F5R2

F5O2

F5I2

F4R2

F4O2

F4I2

F3R2

F3O2

2

3

4

10

1

5

6

7

8

9

11

12

GE5

GE4

GE3

MICON

INTERFACE

12K 12K

12K

12K

GE5

GE4

GE3

42

41

40

39

38

37

36

3534

33

32

31

CLK

AVSS

DVDD

OUT1

F5R1

F5O1

F5I1

F4R1

F4O1

F4I1

F3R1

F3O1

F3I2

F2R2

F2O2

F2I2

F1R2

F1O2

F1I2

IN2

REFIN

13

14

15

16

17

18

20

19

21

GE2

2K

SBK

GE1

AVS S

40K

70K

CH2

40K

CH1

AVD D

70K

GE1

GE2

2K

68K

3029

28

27

2625

24

23

22

F3I1

F2R1

F2O1

F2I1

F1R1

F1O1

F1I1

IN1

AVDD

1-40 (No.49839)

Page 41

4.15 NJM2360AM-X (IC921) : DC-DC convertor

•Pin layout

1. Cs

1

2

3

4

• Block diagram

8

7

6

5

2. Es

3. C

4. GND

5. INV

6. Vcc

7. S

8. C

T

IN

I

D

Switch

collector

Switch

emitter

Timing

capacitor

1

Q

1

2

3

4GND

4.16 NJM4565V-X (IC132, IC572) : Dual ope amp

• Terminal layout & Pin function

1

A

2

-

3

4

Q

V

1.25V

+

2

REF

B

-

QS

R

C OSC

T

+

Ipk

COMP

+

-

Driver

8

collector

Ipk sense

7

+

6

V

Comparator

5

reversal input

1

8

7

6

AOUTPUT

2

A-INPUT

3

A+INPUT

4

V

5

B+INPUT

6

B-INPUT

7

B OUTPUT

8

V

5

(No.49839)1-41

Page 42

4.17 NJU7241F25-X (IC651) : Regulator

T

• Pin layout

GND 1

5 STB

VIN 2

VOUT 3

• Block diagram

4 NC

VIN 2

STB 5

Vref

GND 1

4.18 NJU7241F33-X (IC504, IC804) : Voltage regulator

Short protect

3 VOU

1 GND

1

2

3

5

4

PIN FUNCTION

1. GND

IN

2. V

3. VOUT

4. +NC

5. STB

1-42 (No.49839)

Page 43

4.19 PCM1716E-X (IC571) : D/A converter

O

•Pin layout

28 15

114

• Block diagram

BCK

LBCK

DATA

ML/llS

MC/DM1

MD/DM0

CS/WO

MODE

MUTE

RST

Serial

Input

I/F

Mode

Control

I/F

8X Oversampling

Digital Filter

with

Function Controller

SCK

BPZ-Cont

Crystal OSC

XTI XTO CLKO Vcc1 VccAGND1 DGND

• Pin function

Pin

Symbol I/O Function

No.

1 LRCK I LRCK clock input

2 DATA I Serial audio data input

3 BCK I Bit clock input for serial audio data

4 CLKO O Buffered output of system clock

5 XTI I Oscillator input / External clock input

6 XTO O Oscillator output

7 DGND - Digital ground

8 VDD - Digital power +5V

9 VDD2R - Analog power +5V

10 AGND2R - Analog ground

11 EXTR O Rch common pin of analog output amp

12 NC - Non connection

13 VOUTR O Rch analog voltage output of audio signal

14 AGND1 - Analog ground

15 Vcc1 - Analog power +5V

Mult-level

Delta-Sigma

Modulator

Pin

Vcc2L

DAC

DAC

Power Supply

Symbol I/O Function

AGND2L

Open drain

Vcc2R

AGND2R

Low-pass

Filter

Low-pass

Filter

VoutL

EXTL

VoutR

EXTR

ZER

No.

16 VOUTL O Lch analog voltage output of audio signal

17 NC - Non connection

18 EXTL O Lch common pin of analog output amp

19 AGND2L - Analog ground

20 Vcc2L - Analog power +5V

21 ZERO O Zero data flag

22 RST I Reset

23 CS/IWO I Chip select / Input format selection

24 MODE I Mode control select

25 MUTE I Mute control

26 MD/DM0 I Mode control, Data /

De-emphasis selection 1

27 MC/DM1 I Mode control, BCK /

De-emphasis selection 2

28 ML/IIS I Mode control, WDCK /

Input format selection

(No.49839)1-43

Page 44

4.20 TA2157FN-X (IC601):RF amp

• Terminal layout

24 ~ 13

1 ~ 12

• Block diagram

13

14

15

16

17

18

19

20

21

10pF

40k30k

20k 20k

20k

20k

15k

50 A

12k

12k

BOTTOM

PEAK

20k

20k

20k

PEAK

1.3V

40k

240k

15pF

240k

15pF

40k

50k

2k

20k

50k

14k

K

1

15k

x0.5

x2

x0.5

x2

1k

2k

1.75k

10pF

12

11

10

9

8

7

6

5

4

PIN

VCTRLPIN

1-44 (No.49839)

180k

40pF

22

23

24

SEL

(APC SW)

180k

40pF

3k

3k

TEB

(TE BAL)

60k

60k

RFGC

(AGC Gian)

VCC APC ON -50% +12dB

HiZ APC ON 0% +6dB

GND

APC OFF

(LDO=H)

50% 0dB

94k

94k

22k

22k

3

2

1

TEB

(TE BAL)

Normal mode

(0dB)

Normal mode

(0dB)

CD-RW mode

(+12dB)

Page 45

• Pin function

Pin No. Symbol I/O Function

1 VCC - 3.3V power supply pin

2 FNI I Main-beam amp input pin

3 FPI I Main-beam amp input pin

4 TPI I Sub-beam amp input pin

5 TNI I Sub-beam amp input pin

6 MDI I Monitor photo diode amp input pin

7 LDO O Laser diode amp output pin

8 SEL I APC circuit ON/OFF control signal, laser diode (LDO) control signal input

or bottom/peak detection frequency change pin.

SEL

GND

Hiz

VCC

9 TEB I Tracking error balance adjustment signal input pin

Adjusts TE signal balance by eliminating carrier component from PWM signal (3-state output,

PWM carrier = 88.2kHz) output from TC94A14F/FA

TEBC pin using RC-LPF and inputting DC.

TEBC input voltage:GND~VCC

10 TEN I Tracking error signal generation amp negative-phase input pin

11 TEO O Tracking error signal generation amp output pin.

Combining TEO signal RFRP signal with TC94A14F/FA configures tracking search system.

12 RFDC O RF signal peak detection output pin

13 GVSW I AGC/FE/TE amp gain change pin

APC

circuit

LDO

OFF Connected VCC through 1k resistor

ON

Control signal output

ON Control signal output

GVSW Mode

GND

Hiz

CD-RW

Normal

VCC

14 VRO O Reference voltage (VRO) output pin

*VRO=1/2VCC When VCC=3.3V

15 FEO O Focus error signal generation amp output pin

16 FEN I Focus error signal generation amp negative-phase input pin

17 RFRP O Signal amp output pin for track count

Combining RFRP signal and TEO signal with TC94A14F/FA configures tracking search system.

18

19

20

21 AGCIN I RF signal amplitude adjustment amp input pin

22 RFO O RF signal generation amp output pin

23 RFI I RF signal generation amp input pin

24 GND - GND pin

REIS

RFGO

RFGC

I

OIRF signal amplitude adjustment amp output pin

RF amplitude adjustment control signal input pin

Adjusts RF signal amplitude by eliminating carrier component from PWM signal (3-state output,

PWM carrier=88.2kHz)output fromTC94A14F/14FA *RFGC pin using RC-LPF and inputting DC.

*RFGC input voltage:GND~VCC

(No.49839)1-45

Page 46

4.21 TC94A14FA (IC621) : DSP & DAC

• Terminal layout & block daiagram

48 47 46 45 44 43 42 41 40 39

38 37 36 35 34 33

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

LPF

generator

Micro-

controller

interface

Clock

1-bit

DAC

Correction

Audio out

circuit

circuit

Address

circuit

16 k

RAM

Digital

output

PWM

Servo

control

ROM

RAM

CLV servo

Synchronous

guarantee

EFM

decoder

Sub code

decoder

Digital equalizer

automatic

adjustment circuit

A/D

Data

slicer

VCO

PLL

TMAX

D/A

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

64

17

161514131211101 2 3 4 5 6 7 8 9

• Pin function

Pin

Symbol I/O Descroption

No

1 BCK O Bit clock output pin.32fs48fsor 64fs selectable by command.

2 LRCK O L/R channel clock output pin."L" for L channel and "H" for R channel.

Output polarity can be inverted by command.

3 AOUT O Audio data output pin. MSB-first or LSB-first selectable by command.

4 DOUT O Digital data output pin.Outputs up to double-speed playback.

5 IPF O Correction flag output pin. When set to "H" AOUT output cannot be corrected by C2 correction processing.

6V

DD3

7V

SS3

- Digital 3.3V power supply voltage pin.

- Digital GND pin.

8 SBOK O Subcode Q data CRCC result output pin. "H" level when result is OK.

9 CLCK O Subcode P-W data read I/O pin. I/O polarity selectable by command.

10 DATA O Subcode P-W data output pin.

11 SFSY O Playback frame sync signal output pin.

12 SBSY O Subcode block sync signal output pin. "H" level at S1 when subcode sync is detected.

13 HSO

14 UHSO

15 PV

I/O General-purpose input / output pins.Input port at reset.

- PLL-only 3.3V power supply voltage pin.

DD3

16 PDO O EFM and PLCK phase difference signal output pin.

1-46 (No.49839)

Page 47

Pin

Symbol I/O Descroption

No

17 TMAX O TMAX detection result output pin.

TMAX Detection Result

Longer than fixed period

Within fixed period

Shorter than fixed period

TMAX Output

DD3"

"PV

"HiZ"

"AV

SS3"

18 LPFN I Inverted input pin for PLL LPF amp.

19 LPFO O Output pin for PLL LPF amp.

20 PVREF - PLL-only VREF pin.

21 VCOF O VCO filter pin.

22 AV

- Analog GND pin.

SS3

23 SLCO O DAC output pin for data slice level generation.

24 RFI I RF signal input pin. Zin selectable by command.

25 AV

- Analog 3.3V power supply voltage pin.

DD3

26 RFCT I RFRP signal center level input pin.

27 RFZI I RFRP signal zero-cross input pin.

28 RFRP I RF ripple signal input pin.

29 FEI I Focus error signal input pin.

30 SBAD I Sub-beam adder signal input pin.

31 TEI I Tracking error input pin. Inputs when tracking servo is on.

32 TEZI I Tracking error signal zero-cross input pin.

33 FOO O Focus equalizer output pin.

34 TRO O Tracking equalizer output pin.

35 VREF - Analog reference power supply voltage pin.

36 RFGC O RF amplitude adjustment control signal output pin.

37 TEBC O Tracking balance control signal output pin.

38 SEL O APC circuit ON/OFF signal output pin. At laser on, high impedance with UHS="L",

H output with UHS="H".

39 AV

- Analog 3.3V power supply voltage pin.

DD3

40 FMO O Feed equalizer output pin.

41 DMO O Disc equalizer output pin.

42 V

43 V

SS3

DD3

- Digital GND pin.

- Digital 3.3V power supply voltage pin.

44 TESIN I Test input pin. Normally, fixed to "L".

45 XV

- System clock oscillator GND pin.

SS3

46 XI I System clock oscillator input pin.

47 XO O System clock oscillator output pin.

48 XV

49 DV

SS3

- System clock oscillator 3.3V power supply voltage pin.

DD3

R - DA converter GND pin.

50 RO O R-channel data forward output pin.

51 DV

- DA converter 3.3V power supply pin.

DD3

52 DVR - Reference voltage pin.

53 LO O L-channel data forward output pin.

54 DV

L - DA converter GND pin.

SS3

55 ZDET O 1 bit DA converter zero detection flag output pin.

56 V

SS5

- Microcontroller interface GND pin.

57 BUS0

58 BUS1

I/O Microcontroller interface data I/O pins.59 BUS2

60 BUS3

61 BUCK I Microcontroller interface clock input pin.

62 /CCE I Microcontroller interface chip enable signal input pin.At "L", BUS0 to BUS3 are active.

63 /RST I Reset signal input pin. At reset, "L".

64 V

DD5

- Microcontroller interface 5V power supply pin.

(No.49839)1-47

Page 48

4.22 TC94A20F-008 (IC652) : Audio digital processor with DAC and SRAM

• Pin layout & Block diagram

Po1/A4

Po0/A3

TXo

TESTP

VSSR

32

VRARRoVDAR

31

30

29

28

27

26

VDALLoVRAL

25

24

23

VSSL

VSS

STANDBY

VDD

22

21

20

19

18

/LRCKiB/A2

17

Po2/A5

Po3/A6

VDDT

Po4/A7

Po5/A8

Po6/A9

Po7

VSS

IRQ/REQ/A10R

VDDM(SRAM)

Fi0/ /OE

33

register

C-Pointer

register

Y-Pointer

register

X-Pointer

Bus

DAC

Switch

register

34

35

36

General

Output Port

37

38

39

40

41

Flag

42

43

DIT

2sets

Address Calc.

ERAM

CROM

2k word

*7

4k word

YRAM

4k word

Y0 - Y1 - Y2

X0 - X1 - X2

DAC

AX AY

MX MY MZ

MAC ALU

A3

round & limit

A2

Audio. I/F

round & limit

A0 A1

BCKiB/A1

16

SDi1/A0

15

LRCKiA

14

BCKiA

13

SDi0

12

LRCKo

11

BCKo

10

9

SDo

87

VDDT

MiACK/A11R

6

/MiCK/SCL

Fi1/ /CAS

VSSM(SRAM)

Pi0/io0

Pi1/io1

VSS

Timer

44

4546

Interrupt

Control

I-Bus

SRAM I/F

47

48

49

Pi2/io2

General

Input Port

50

Pi3/io3

XRAM

4k word

SRAM I/F

51

52

VDD

Pi4/CLCK/io4

53

Pi5/DATA/io5

X-Bus

1Mbit

54

SRAM

Y-B us

I/F

SubQ

55

56

VSSP

Fi2/SBSY/io7

PRAM

256word

57

PDo

Program

PROM

VC0

58

VCoi

Control

4k*3

=12kword

59

VDDP

40bit

Timing

Generator

60

Decoder

Instruction

61

VDDX

543

MiDiO/SDA

Microcom. I/F

/MiLP/ /RAS

/MiCS/ /WE

2

MiMD

1

/RESET

62

63

Xi

64

Xo

VSSX

TSTiN/SFSY/io6

CKi/CKo/Po6/SBOK

1-48 (No.49839)

Page 49

• Pin function

Pin No. Symbol I/O Function

1 /RESET I Hard reset input (H:Operation L: Reset)

2 MiMD I Mode select input for MCU interface (H:IIC L:Serial)

3 /MiCS I Chip select input for MCU interface

/WE O Write-enable for external DRAM

4 /MiLP I Latch pulse input for MCU interface

/RAS O Low address strobe for external DRAM

5 MiDio I/O Data input and output for MCU interface (IIC:SDA)

6 /MiCK I Clock input for MCU interface (IIC:SCL)

7 MiACK O Acknowledge output for MCU interface

A11R O Address output-11 for external DRAM

8 VDDT - Power supply for digital circuit (3.3V)

9 SDo O Data output

10 BCKo O Bit clock output

11 LRCKo O LR clock output

12 SDi0 I Data input-0

13 BCKiA I Bit clock input-A

14 LRCKiA I LR clock input-A

15 SDi1 I Data input-1 (Address output-5 for external SRAM)

A0 O Address output-1 for external DRAM

16 BCKiB I Bit clock input-B

A1 O External DRAM address output-1

17 LRCKiB I LR clock input-B (Enable signal output for external SRAM)

A2 O Address-2 for external DRAM

18 VDD - Power supply for digital circuit (2.5V)

19 STANBY I Control input for stand-by mode (H:STB,L:Normal)

20 VSS - Ground for digital circuit

21 VSSL - Ground for DAC Lch

22 VRAL - Reference voltage for DAC Lch

23 LO O DAC Lch output

24 VDAL - Power supply for DAC Lch (2.5V)

25 VDAR - Power supply for DAC Rch (2.5V)

26 RO O DAC Rch output

27 VRAR - Reference voltage for DAC Rch

28 VSSR - Ground for DAC Rch

29 TESTP I Test terminal (H:Test mode L:Normal)

30 TXO O SPDIF output

31 Po0 O General output port-0

A3 O Address-3 for external DRAM

32 Po1 O General output port-1

A4 O Address-4 for external DRAM

33 Po2 O General output port-2

A5 O Address-5 for external DRAM

34 Po3 O General output port-3

A6 O Address-6 for external DRAM

35 VDDT - Power supply for digital circuit (3.3V)

36 Po4 O General output port-4

A7 O Address-7 for external DRAM

37 Po5 O General output port-5 (Address output-7 for external SRAM)

A8 O Address-8 for external DRAM

38 Po6 O General output port-6 (Address output-6 for external SRAM)

A9 O Address-9 for external DRAM

39 Po7 O General output port-7

40 VSS - Ground for digital circuit

41 IRQ/REQ I/O Interruption input (BS I/F:REQ output)

A11R O Address-11 for external DRAM

42 VDDM - Power supply for built-in 1Mbit SRAM (2.5V)

43 Fi0 I Flag input-0

/OE O Enable output for external up DRAM

44 Fi1 I Flag input-1

/CAS O Column address strobe for external DRAM

45 VSSM - Ground for built-in 1Mbit SRAM

(No.49839)1-49

Page 50

4.23 TMP91CW12AF4R31 (IC501) : CPU

• Pin Layout

75 51

76 50

100 26

125

• Pin function

Pin No Symbol I/O Function

1 VREFL - Connect to ground

2 AVSS - Connect to ground

3 AVCC - Connect to 3.3V

4 CDON O CD power supply (3.3V) control

5 CDREQ O CD mechanism power supply request

6 CDMUTE O ICD mute

7 MP3RESET O CD MP3 reset

8 MP3STB O CD MP3 standby (H: Standby)

9 to 11 NC - Not connect

12 SW2 I CD mechanism SW2

13 REST I CD mechanism rest SW

14 to 17 NC - Not connect

18 LCDCE/SO O Chip enable to LCD driver (Not connect)

19 LCDDA/SI O Data to LCD driver (Not connect)

20 LCDCK O Clock to LCD driver (Not connect)

21 BUSS0 I JVC BUS data

22 BUSSI O JVC BUS data

23 BUSSCK I/O JVC BUS clock

24 AM0 Pull up to 3.3V

25 DVCC - Connect to 3.3V

26 X2 Crystal oscillator (24.576MHz)

27 DVSS - Connect to ground

28 X1 Crystal oscillator (24.576MHz)

29 AM1 Pull up to 3.3V

30 RESET I Reset

31,32 NC - Not connect

33 EMU0 - Not connect

34 EMU1 - Not connect

35 B.DET I Back up power supply detection (H: STOP mode)

36 SW1 I CD mechanism SW1

37 P.DET I Main power off detection (H: HALT mode)

38 to 42 NC - Not connect

43 ALE - Not connect

44 BUS3 I/O CD DSP data3

45 BUS2 I/O CD DSP data2

46 BUS1 I/O CD DSP data1

47 BUS0 I/O CD DSP data0

48 BUCK O Clock to CD DSP data

1-50 (No.49839)

Page 51

Pin No Symbol I/O Function

49 CCE O CD DSP chip enable

50 DSPRESET O CD DSP reset

51 NC Not connect

52 DISCSEL I 8cm DISC mode (L)

53 DACSEL I DAC mode (H)

54 WMASEL I WMA mode (H)

55 TESTMODE I LCD/AD key/Remocon invalidity selection (L)

56 RWSEL O CD-RW switching (RW:L)

57 LD/FE O LOADING/FEED switching (H:LD,L:FE)

58 LOAD O Loading (L:Loading,H:Eject)

59 /BUSIO O JVC BUS input/output control (Inverting output)

60 BUSIO O JVC BUS input/output control

61 NC - Not connect

62 DVSS - Connect to ground

63 NMI I Connect to P.DET

64 DVCC - Connect to 3.3V

65 DACML O DAC mode control latch

66 DACMC O DAC mode control BCk

67 DACMD O DAC mode control data

68 DACCS O DAC chip select

69 to 77 NC - Not connect

78 BOOT

79 NC - Not connect

80 8VDET I CD mechanism power supply detection (L: 8V exist)

81 MP3REQ I CD MP3 request

82,83 NC - Not connect

84 MP3DI I CD MP3 data

85 MP3CK O Clock for CD MP3 data

86 BUSINT I Interrupt for JVC BUS transmission start

87,88 NC - Not connect

89 DVCC - Connect to 3.3V

90 NC - Not connect

91 DVSS - Connect to ground

92 KEY0 I Key input0 (8-bits A/D input)

93 KEY1 I Key input1 (8-bits A/D input)

94 TEMP I detecting signal for high temperture

95 IOP I IOP measuring signal of pick

96 to 99 NC - Not connect

100 VREFH - Connect to 3.3V

(No.49839)1-51

Page 52

4.24 UPD784217AGC205 (IC701) : CPU

• Pin Layout

75 51

76 50

100 26

125

• Pin function

Pin No Symbol I/O Function

1 to 7 NC - Not use

8 ANT CONT - Antenna remote control

9 VDD - Power supply

10 X2 -

11 X1 -

12 VSS - Ground

13 XT2 -

14 XT1 -

15 RESET I System reset

16 REMOCON I Remocon input

17 BUS-INT I J-BUS INT

18 PS2 I Power save2, H means STOP mode

19 CD-REQ I CD REQ INPUT

20 RDS-SCK I Not use

21 STEERING REMOCON I Steering remocon input

22 KEY DATA I KEY DATA

23 AVDD - A/D converter power supply

24 AVREF0 - A/D reference voltage

25 VOL1 I Volume encoder pulse input 1

26 VOL2 I Volume encoder pulse input 2

27 to 29 NC - Not use

30 MRC I MRC input

31 SQ I Not use, pull down

32 SM I S.METER input

33 AVSS - Ground

34 NC - Not use

35 STAGE3 I Feature selection, pull up

36 AVREF -

37 BUS-SI I J-BUS data input

38 BUS-SO O J-BUS data output

39 BUS-SCK I/O J-BUS clock input/output

40 BUS-I/O O J-BUS I/O selection output:H, input:L

41 DISP DA O DISPLAY DATA output

42 DISP SCK O DISPLAY SCK

43 DISP CE O DISPLAY CE

44 BUZZER O Buzzer output

45 E2PROM-DI I I2C data input

46 E2PROM-DO O I2C data output

47 E2PROM-CLK O I2C clock output

48 OPEN I DOOR OPEN SW

1-52 (No.49839)

Page 53

Pin No Symbol I/O Function

49 DETACH I Detach detect input; H means detaching

50 NC - Not use

51 to 53 NC - Not use

54 EQ-CLK O Clock output for e-EQ IC

55 EQ-DA O Data output for e-EQ IC

56 EQ-LA O Latch output for e-EQ IC

57 to 59 NC - Not use

60 RDS DA I Not use

61 SD/ST I Station detector or stereo indicator input;

H means a station is there, L means the program is stereo.

62 AFCK O Not use

63 SEEK/STOP O Auto seek and stop selecting output;

H means seeking, L means receiving.

64 CF SEL O Wide & Narrow

65 FM/AM O FM,AM band selecting output; H=FM, L=AM

66 PLL-CE O CE output for PLL IC

67 PLL-DO O Data output for PLL IC

68 PLL-CLK O Clock output for PLL IC

69 PLL-DI I Data input from PLL IC

70 TEL-MUTING I Telephone muting detection input;

Active level can be selected H or L in PSM

71 DIM-OUT O Dimmer detector output

72 VSS - Ground

73 DIM-IN I Dimmer detector input L=dimmer on

74 PS1 I Power save1 L=ACC off

75 POWER O Power on/off control output H=power on

76 CD-ON - Not use

77 MUTING O Muting output L=muting on

78 CD MUTING I CD mute input L=mute on

79 CD RESET O CD reset control out H=reset on

80 LINE SEL I Feature selection

H: line input (U57:not support), L: support

81 VDD - Power supply

82 NC - Not use

83 VOL-DA O Data output for e-vol IC

84 VOL-CLK O Clock output for e-vol IC

85 WOOFER SEL I Feature selection H:support L:Not support

86 SUB MUTING O Muting control output for subwoofer

87 LPF1 O LPF control1

88 LPF2 O LPF control2

89 STAGE2 I Feature selection H: R or Do L: J or U

90 STAGE1 I Feature selection H: R or U L: J or Do

91 to 93 NC - Not use

94 TEST For rewriting flash memory

95 to 100 NC - Not use

(No.49839)1-53

Page 54

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY MOBILE ENTERTAINMENT CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49839)

Printed in Japan

WPC

Page 55

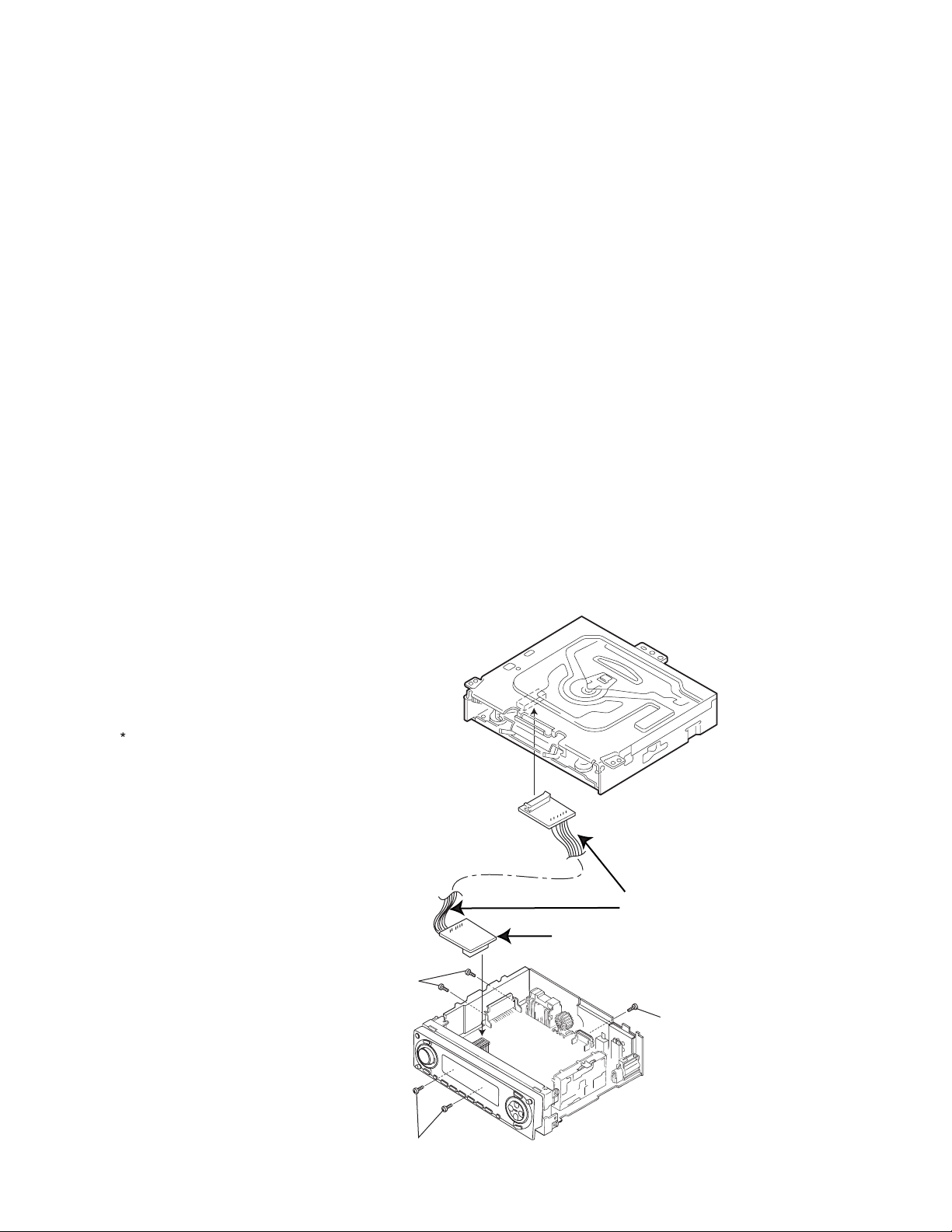

PARTS LIST

[ KD-LH3105 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

KD-LH3105

U --------------------- Other Areas

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD mechanism assembly and parts list (Block No.MB)

Electrical parts list (Block No.01~03)

Packing materials and accessories parts list (Block No.M3)

3-2

3-4

3-6

3-14

No. 49839 3-1

Page 56

KD-LH3105

Exploded view of general assembly and parts list

Block No.

M

M

1

M

10

75

79

72

77

10

80

78

76

10

82

81 74

4

8

11

8

71

A

Main board

B

9

29

19

73

28

21

27

24

18

73

25

30

9

22

23

20

6

5

17

31

53

15

16

53

83

61

58

66

60

57

64

59

65

67

68

LCD1

C

3-2

43

62

C

38

55

42

49

54

35

40

45

33

44

37

39

46

48

51

50

54

36

41

56

47

34

26

32

15

A

7

2

3

1

B

69

70

14

7

13

12

7

53

52

Front board

Sub board

13

63

83

13

Page 57

General assembly

Block No. [M][1][M][M]

Symbol No.Part No. Part Name Description Local

1 ------------ CD MECHA

2 GE10043-210A TOP CHASSIS

3 GE40135-001A EARTH PLATE

4 GE30938-003A HEAT SINK