Page 1

SERVICE MANUAL

MA479<Rev.002>20112SERVICE MANUAL

KD-A525J, KD-BTP50J, KD-BTP52U,

KD-R520J, KD-R521E, KD-R521EU,

KD-R521EY, KD-R524UI, KD-R525U,

KD-R525UH, KD-R525UN, KD-R526U,

KD-R526UH, KD-R526UN, KD-R526UT,

CD RECEIVER

KD-R528J

For

KD-R526/KD-BTP52

KD-R525

KD-R528/KD-A525/KD-BTP50

For

KD-R520

For KD-R521

COPYRIGHT © 2011 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

KD-R521/KD-R526/KD-BTP52

For

KD-R525

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

COPYRIGHT © 2011 Victor Company of Japan, Limited

No.MA479<Rev.002>

2011/2

Page 2

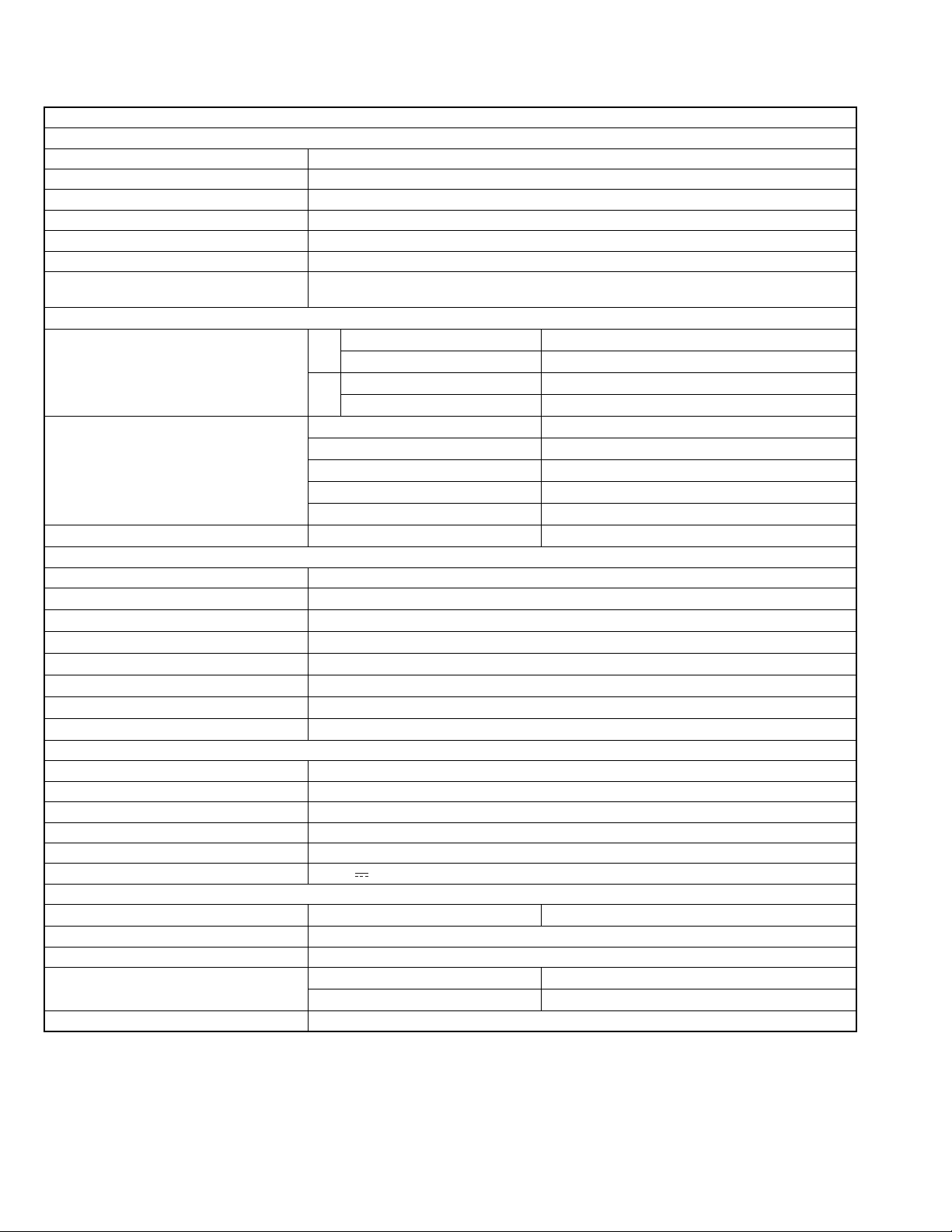

SPECIFICATION

KD-A525, KD-BTP50, KD-R520, KD-R528

AUDIO AMPLIFIER SECTION

Power Output

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance

Frequency Response

Line-Out or Subwoofer-Out Level/Impedance

Output Impedance

Other Terminal USB input terminal, Front auxiliary input jack, Rear auxiliary/Bluetooth adapter input jack, Antenna

TUNER SECTION

Frequency Range FM with channel interval set to 200 kHz

FM Tuner Usable Sensitivity

AM Tuner Sensitivity/Selectivity

CD PLAYER SECTION

Type Compact disc player

Signal Detection System

Number of Channels

Frequency Response

Signal-to-Noise Ratio

Wow and Flutter

MP3 Decoding Format (MPEG1/2 Audio Layer 3)

WMA (Windows Media® Audio) Decoding Format

USB SECTION

USB Standard USB 1.1, USB 2.0

Data Transfer Rate (Full Speed) Max. 12 Mbps

Compatible Device Mass Storage Class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA

Max. Current DC 5 V 500 mA

General

Power Requirement Operating Voltage

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D):(approx.)

Mass 1.2 kg (2.7 lbs) (excluding accessories)

20 W RMS × 4 Channels at 4 Ω and ≤ 1% THD+N

4 Ω (4 Ω to 8 Ω allowance)

40 Hz to 20 000 Hz

2.5 V/20 kΩ load (full scale)

1 K

Ω

terminal

87.9 MHz to 107.9 MHz

with channel interval set to 50 kHz

AM with channel interval set to 10 kHz

with channel interval set to 9 kHz

50 dB Quieting Sensitivity

Alternate Channel Selectivity(400 kHz)

Frequency Response

Stereo Separation

Non-contact optical pickup (semiconductor laser)

2 channels (stereo)

5 Hz to 20 000 Hz

98 dB

Less than measurable limit

Max. Bit Rate: 320 kbps

Max. Bit Rate: 192 kbps

Installation Size

Panel Size

87.5 MHz to 108.0 MHz

530 kHz to 1 700 kHz

531 kHz to 1 611 kHz

9.3 dBf (0.8 µV/75

16.3 dBf (1.8 µV/75

65 dB

40 Hz to 15 000 Hz

40 dB

20 µV/40 dB

DC 14.4 V (11 V to 16 V allowance)

182 mm × 52 mm × 159 mm (7-3/16’’ × 2-1/16’’ × 6-5/16’’)

188 mm × 59 mm × 9 mm (7-7/16’’ × 2-3/8’’ × 3/8’’)

Ω

)

Ω

)

• Subject to change without notice.

• If a kit is necessary for your car, consult your telephone directory for the nearest car audio speciality shop.

• Microsoft and Windows Media are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries.

1-2 (No.MA479<Rev.002>)

Page 3

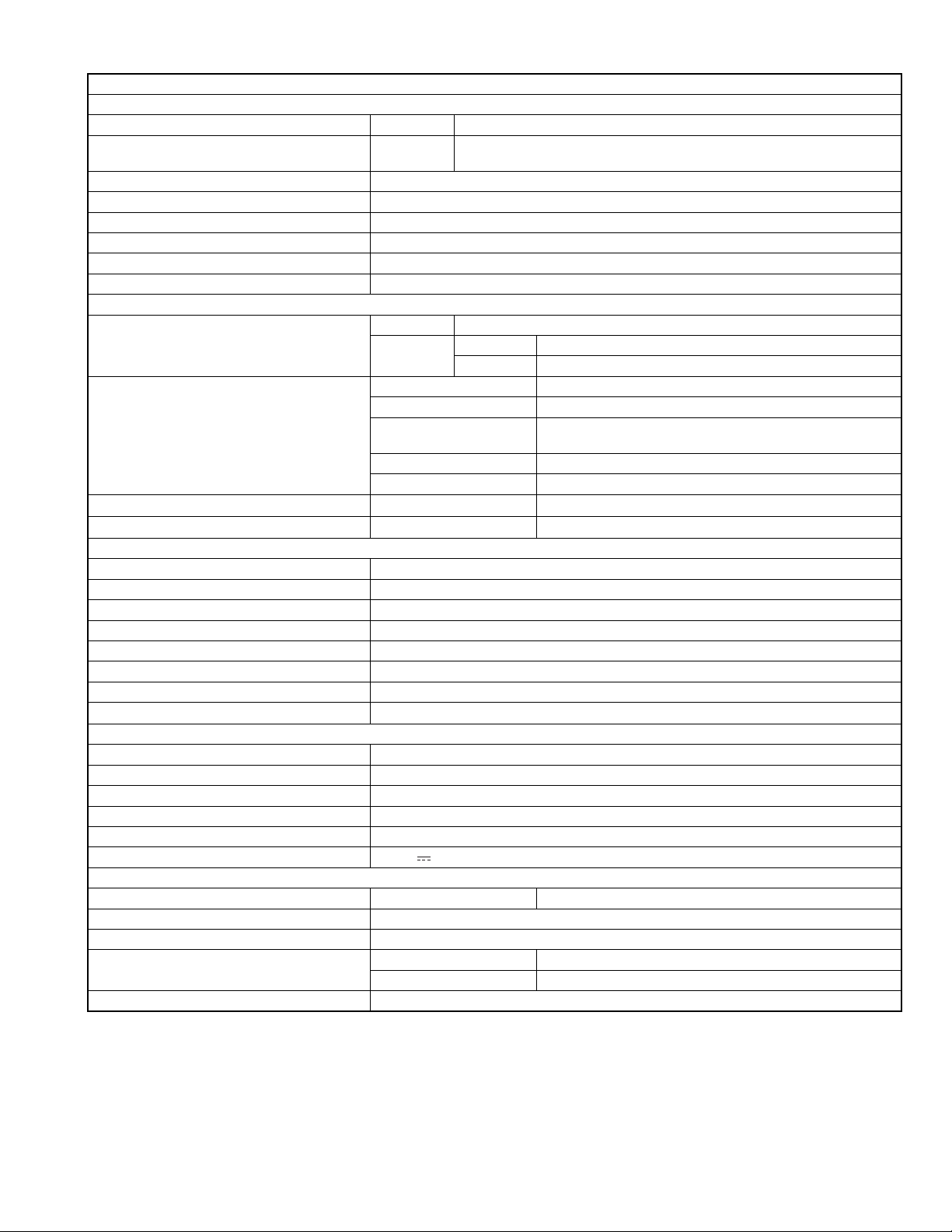

KD-R521

AUDIO AMPLIFIER SECTION

Maximum Power Output

Continuous Power Output (RMS)

Load Impedance

Frequency Response

Signal-to-Noise Ratio 70 dB

Line-Out or Subwoofer-Out Level/Impedance

Output Impedance ≤

Other Terminal

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner

MW Tuner

LW Tuner

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

®

WMA (Windows Media

USB SECTION

USB Standard USB 1.1, USB 2.0

Data Transfer Rate (Full Speed) Max. 12 Mbps

Compatible Device Mass Storage Class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA

Max. Current DC 5 V 500 mA

General

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D):(approx.) Installation Size 182 mm × 52 mm × 159 mm

Mass 1.2 kg (excluding accessories)

Audio) Decoding Format

Front/Rear

Front/Rear 20 W per channel into 4 Ω,40 Hz to 20 000 Hz at no more than 1% total harmonic dis-

4 Ω (4 Ω to 8 Ω allowance)

40 Hz to 20 000 Hz

2.5 V/20 kΩ load (full scale)

600

Ω

USB input terminal, Front auxiliary input jack, Rear auxiliary/Bluetooth adapter input jack, Aerial input

AM MW 531 kHz to 1 611 kHz

Usable Sensitivity 9.3 dBf (0.8 µV/75

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75

Alternate Channel Selectivity

(400 kHz)

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

Sensitivity/Selectivity 20 µV/40 dB

Sensitivity 50 Mv

Max. Bit Rate: 192 kbps

Panel Size 188 mm × 59 mm × 9 mm

50 W per channel

tortion.

LW 153 kHz to 279 kHz

65 dB

Ω

)

Ω

)

• Subject to change without notice.

• Microsoft and Windows Media are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries.

• KD-R521:‘’Made for iPod,’’ and ‘’Made for iPhone’’ mean that an electronic accessory has been designed to connect specifically to

iPod, or iPhone, respectively, and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory

with iPod, or iPhone may affect wireless performance.

• iPhone, iPod, iPod classic, iPod nano, and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries.

(No.MA479<Rev.002>)1-3

Page 4

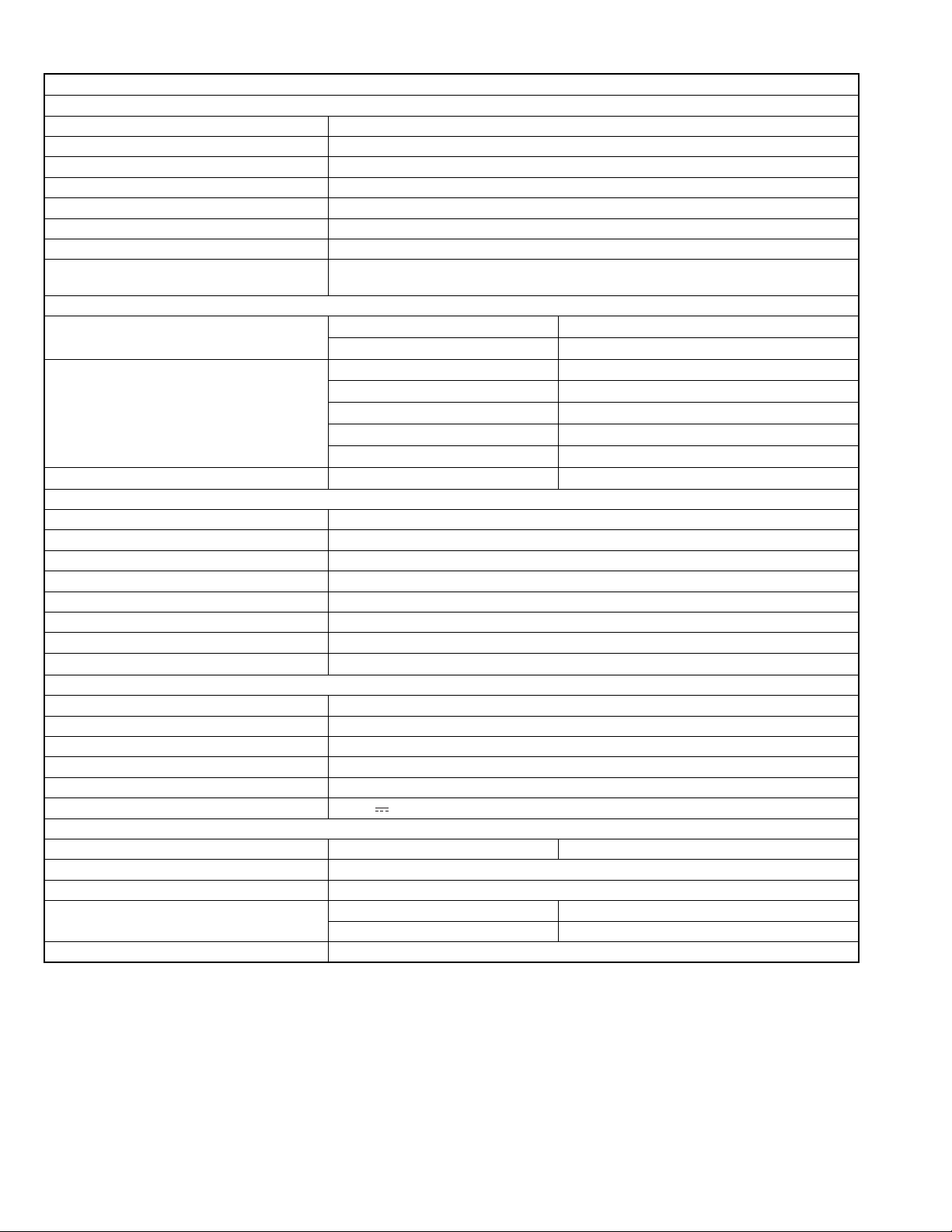

KD-BTP52, KD-R524, KD-R525, KD-R526

AUDIO AMPLIFIER SECTION

Maximum Power Output 50 W per channel

Ω

Continuous Power Output (RMS) 20 W per channel into 4

Signal-to-Noise Ratio 70 dB

Load Impedance

Frequency Response

Line-Out or Subwoofer-Out Level/Impedance

Output Impedance

Other Terminal

TUNER SECTION

Frequency Range FM

FM Tuner

AM Tuner Sensitivity/Selectivity

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

®

WMA (Windows Media

USB SECTION

USB Standard USB 1.1, USB 2.0

Data Transfer Rate (Full Speed) Max. 12 Mbps

Compatible Device Mass Storage Class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA

Max. Current DC 5 V 500 mA

General

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D):(approx.) Installation Size 182 mm × 52 mm × 159 mm

Mass 1.2 kg (excluding accessories)

Audio) Decoding Format Max. Bit Rate: 192 kbps

4 Ω (4 Ω to 8 Ω allowance)

40 Hz to 20 000 Hz

2.5 V/20 kΩ load (full scale)

1 k

Ω

USB input terminal, Front auxiliary input jack, Rear auxiliary/Bluetooth adapter input jack, Antenna terminal

AM

Usable Sensitivity 9.3 dBf (0.8 µV/75

50 dB Quieting Sensitivity

Alternate Channel Selectivity(400 kHz)

Frequency Response

Stereo Separation

Panel Size 188 mm × 59 mm × 9 mm

,40 Hz to 20 000 Hz at no more than 1% total harmonic distortion.

87.5 MHz to 108.0 MHz

531 kHz to 1 611 kHz

Ω

)

16.3 dBf (1.8 µV/75

65 dB

40 Hz to 15 000 Hz

40 dB

20 µV/40 dB

Ω

)

• Subject to change without notice.

• Microsoft and Windows Media are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries.

• KD-R524:‘’Made for iPod,’’ and ‘’Made for iPhone’’ mean that an electronic accessory has been designed to connect specifically to

iPod, or iPhone, respectively, and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory

with iPod, or iPhone may affect wireless performance.

• iPhone, iPod, iPod classic, iPod nano, and iPod touch are trademarks of Apple Inc., registered in the U.S. and other countries.

1-4 (No.MA479<Rev.002>)

Page 5

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

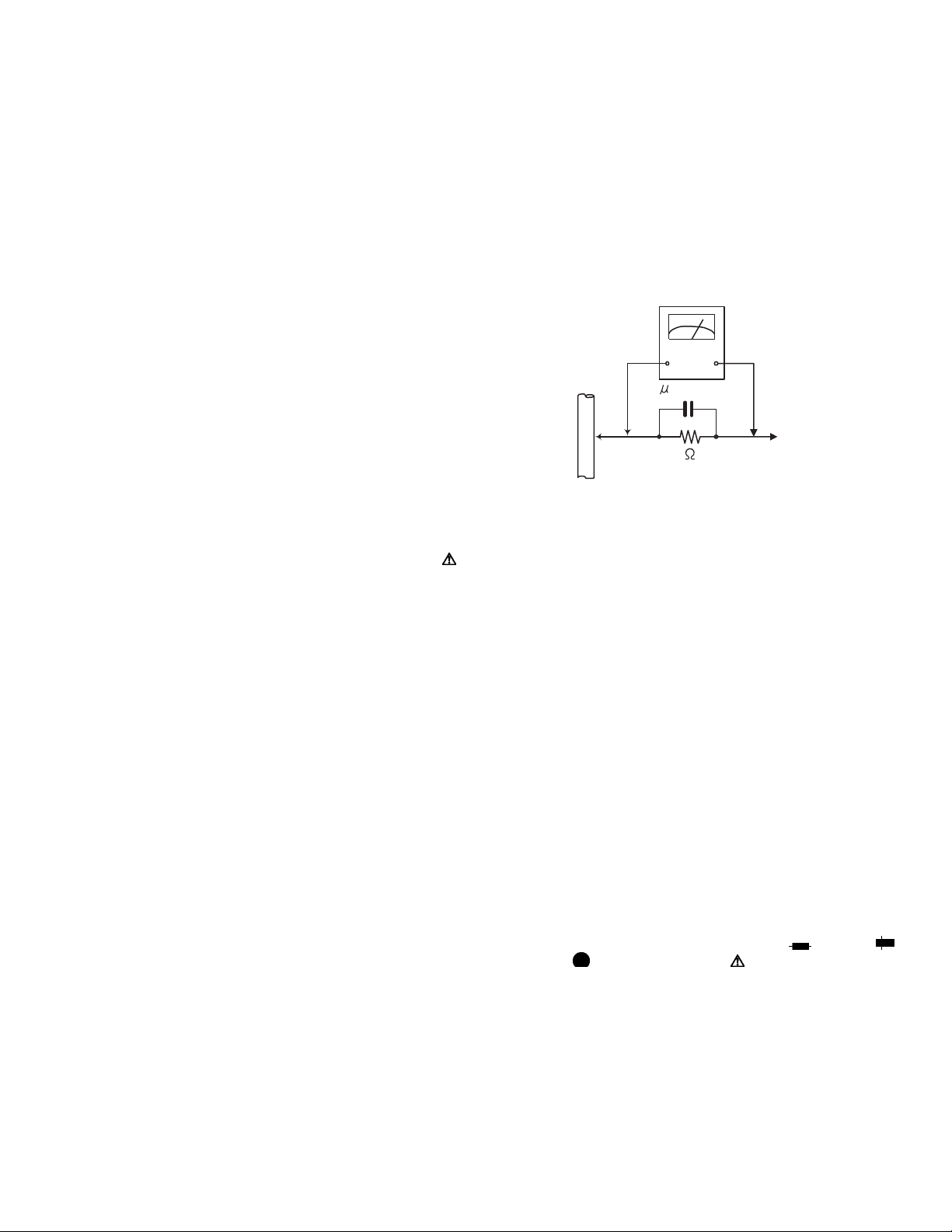

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MA479<Rev.002>)1-5

Page 6

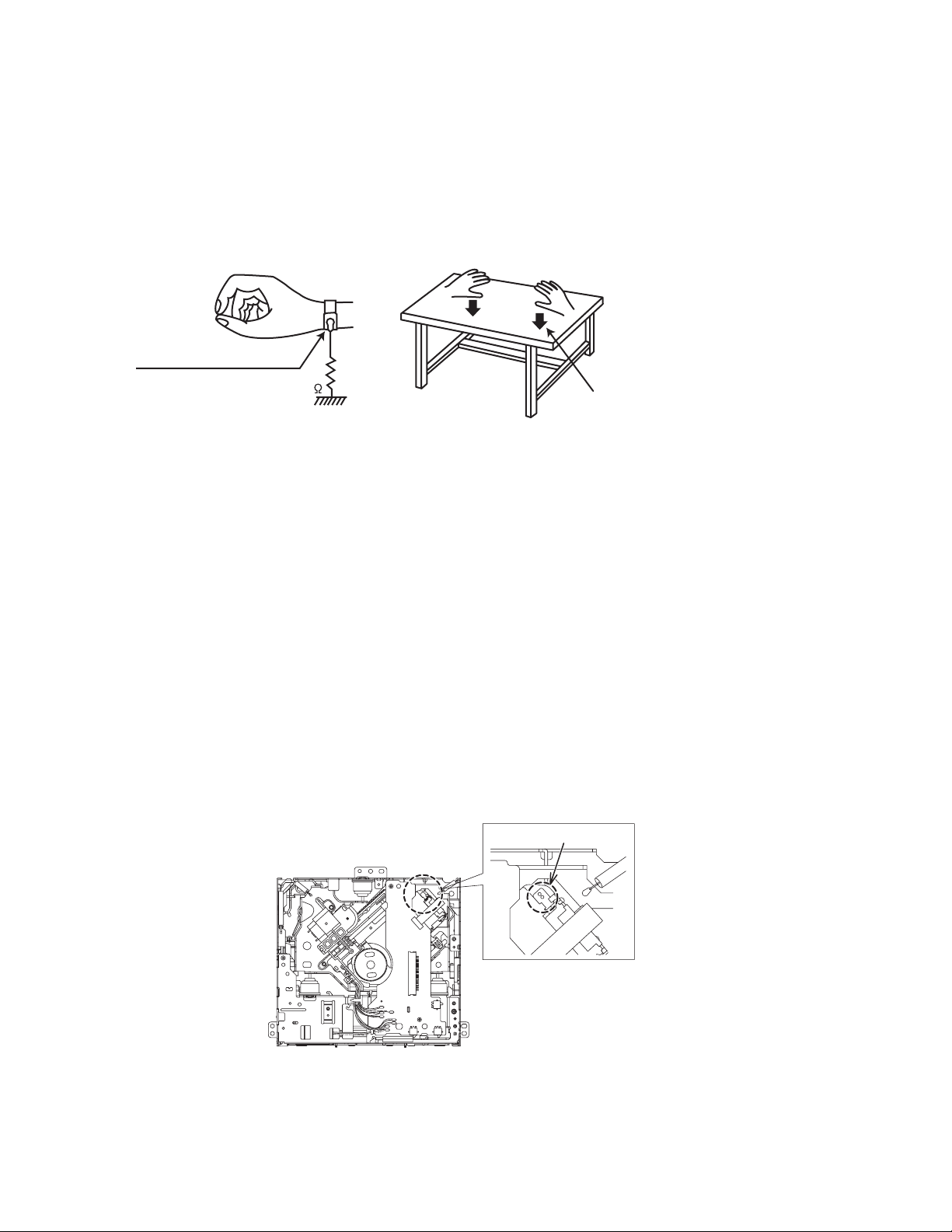

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connector on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

SOLDER

1-6 (No.MA479<Rev.002>)

Page 7

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MA479<Rev.002>)1-7

Page 8

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

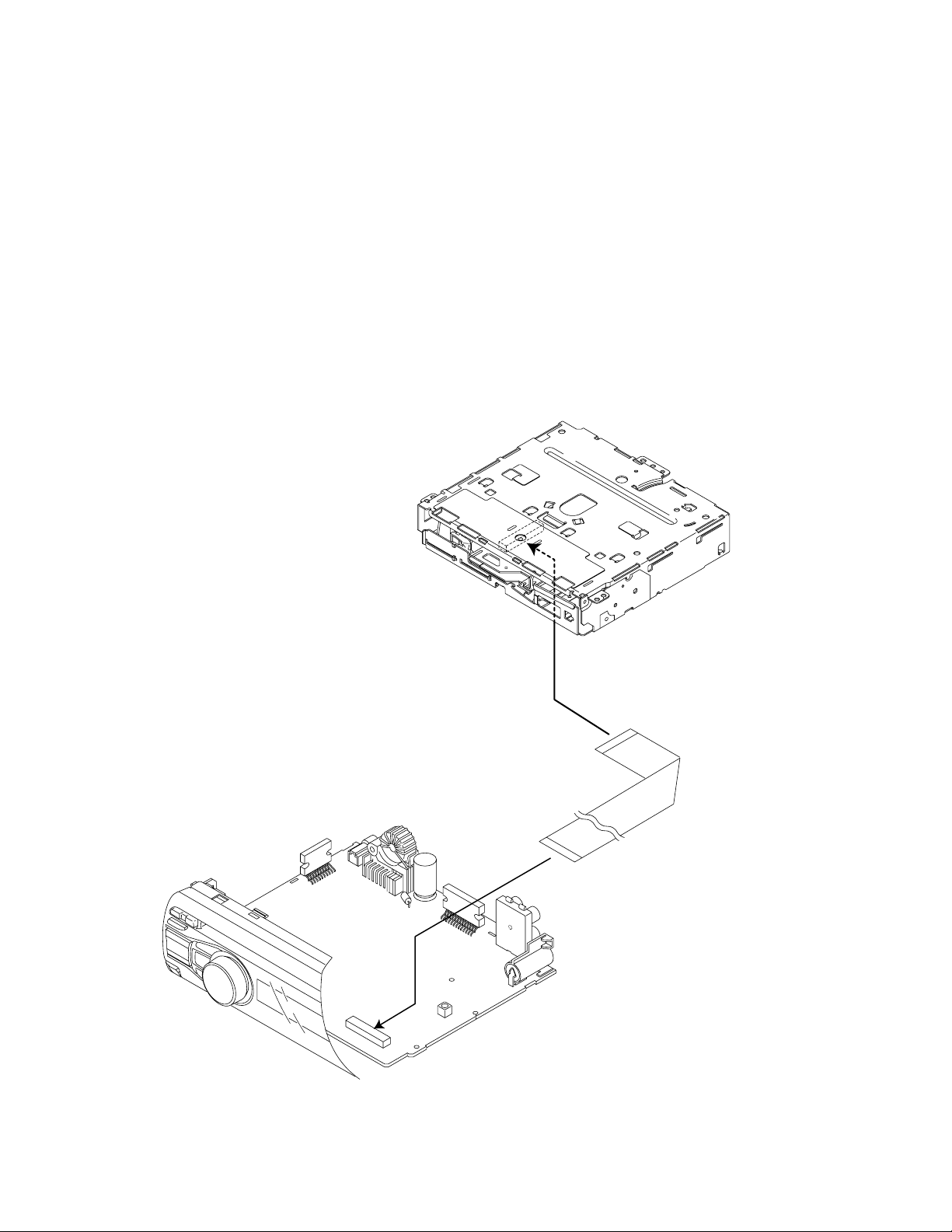

2.1 KD-BTP50J and KD-BTP52U

The KD-BTP50J and the KD-BTP52U are packaged products of a CD RECEIVER and a BLUETOOTH ADAPTER.

Model CD RECEIVER BLUETOOTH ADAPTER

KD-BTP50J KD-R520 KS-BTA100

KD-BTP52U KD-R525 KS-BTA100

SECTION 3

DISASSEMBLY

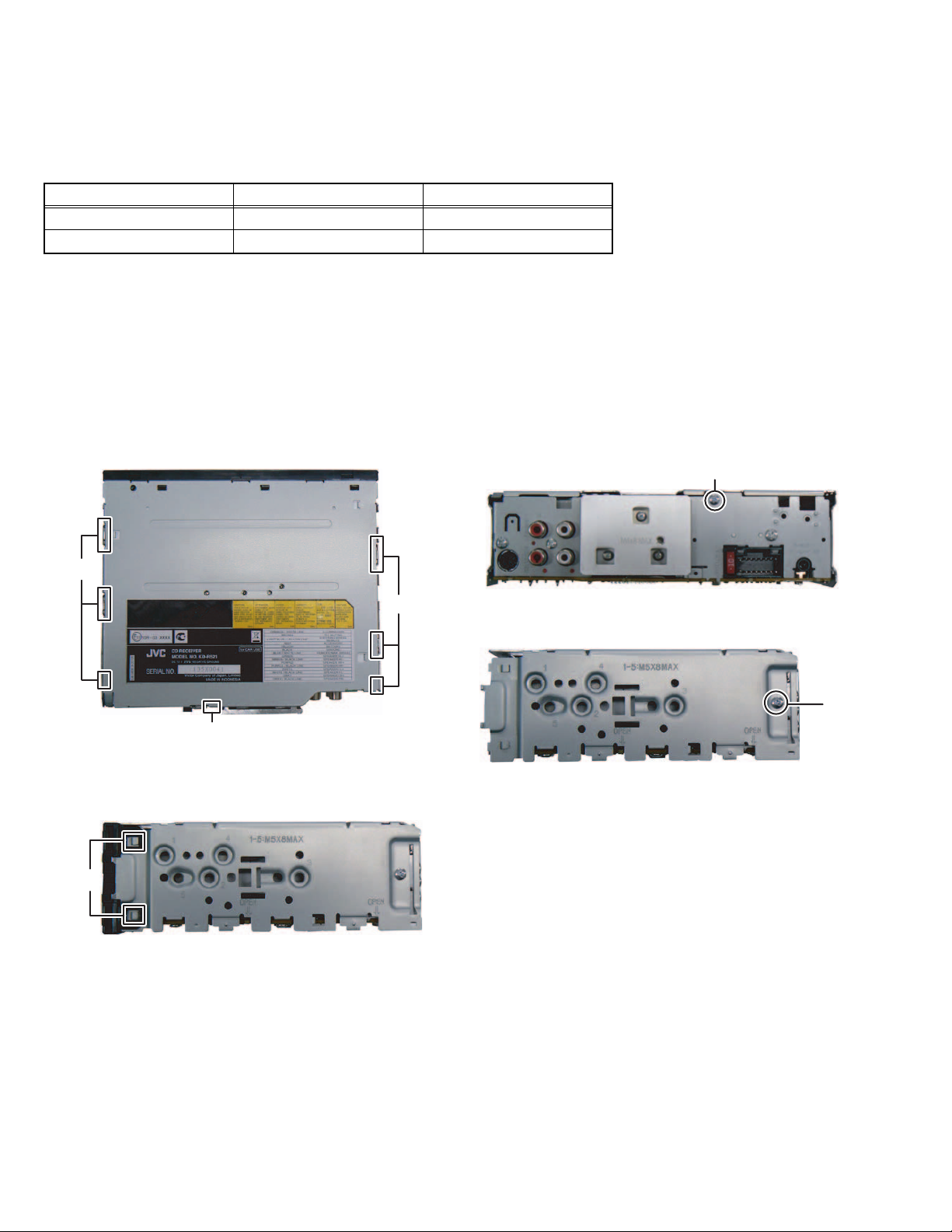

3.1 Main body (Used model: KD-R521)

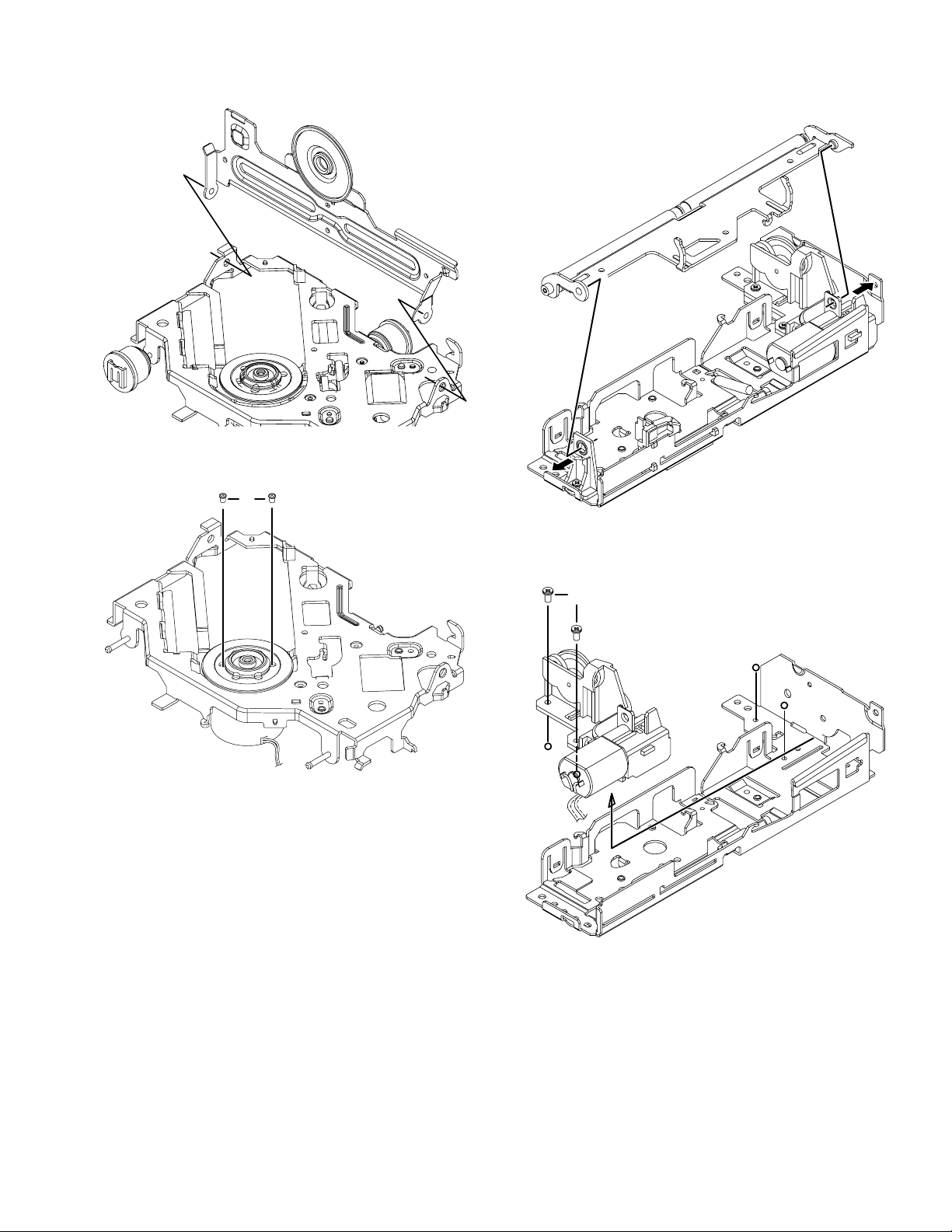

3.1.1 Removing the Bottom chassis (See Fig.1)

(1) Disengage the seven hooks a engaging the Bottom chas-

sis.

(2) Slide the Bottom chassis backward to remove it.

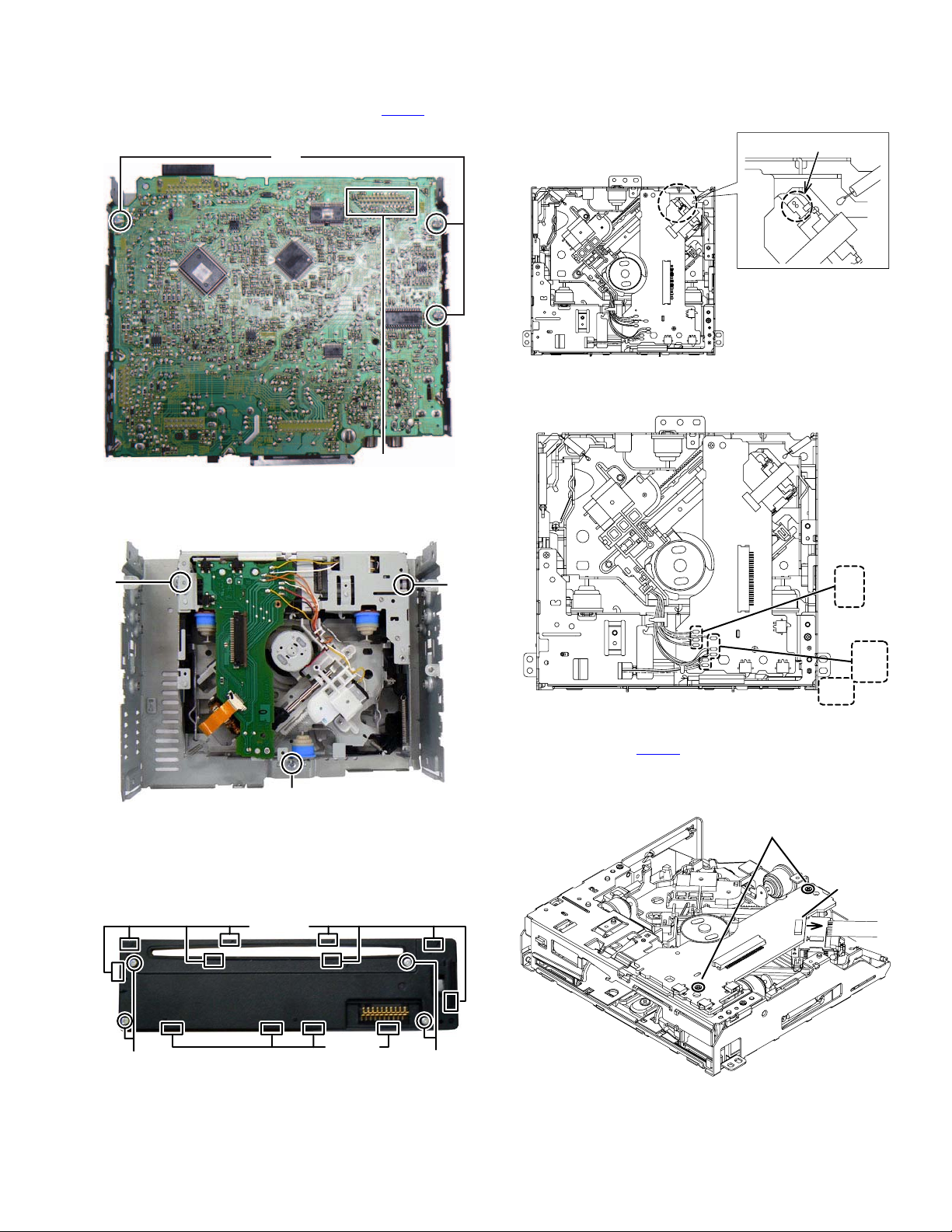

3.1.3 Removing the Main board (See Fig.3, 4 and 5)

(1) Remove the one screw A attaching the Rear Bracket. (See

Fig.3)

A

hook a

hook a

hook a

Fig.1

3.1.2 Removing the Front chassis (See Fig.2)

(1) Disengage the four hooks b engaging both sides of the

Front chassis.

hook b

Fig.2

Fig.3

(2) Remove the two screws B attaching both sides of the Top

chassis. (See Fig.4)

B

Fig.4

1-8 (No.MA479<Rev.002>)

Page 9

(3) Remove the three screws C attaching the Main board. (See

Fig.5)

(4) Disconnect the board to board connector CN502

connect-

ing the Main board and the CD mechanism. (See Fig.5)

C

CN502

Fig.5

3.1.4 Removing the CD mechanism (See Fig.6)

(1) Remove the three screws D attaching the CD mechanism.

3.2 CD mechanism assembly section

3.2.1 Removing the Mecha control board

(1) Solder the short land on the pickup. (See Fig. 1)

SOLDER

Fig.1

(2) Remove the eight wires from the Mecha control board.

(See Fig.2)

D

D

Fig.6

3.1.5 Removing the Switch board (See Fig.7)

(1) Remove the Volume knob.

(2) Remove the four screws E attaching the Rear cover.

(3) Disengage the twelve hooks c engaging the Rear cover.

hook c

D

BLACK

RED

WHITE

YELLOW

ORANGE

ORANGE

WHITE

YELLOW

Fig.2

(3) Disconnect the flexible wire from the pickup connected to

the connector CN102

on the Mecha control board. (See

Fig.3)

(4) Remove the two screws A attaching the Mecha control

board. (See Fig.3)

A

CN102

hook c

EE

Fig.7

Fig.3

(No.MA479<Rev.002>)1-9

Page 10

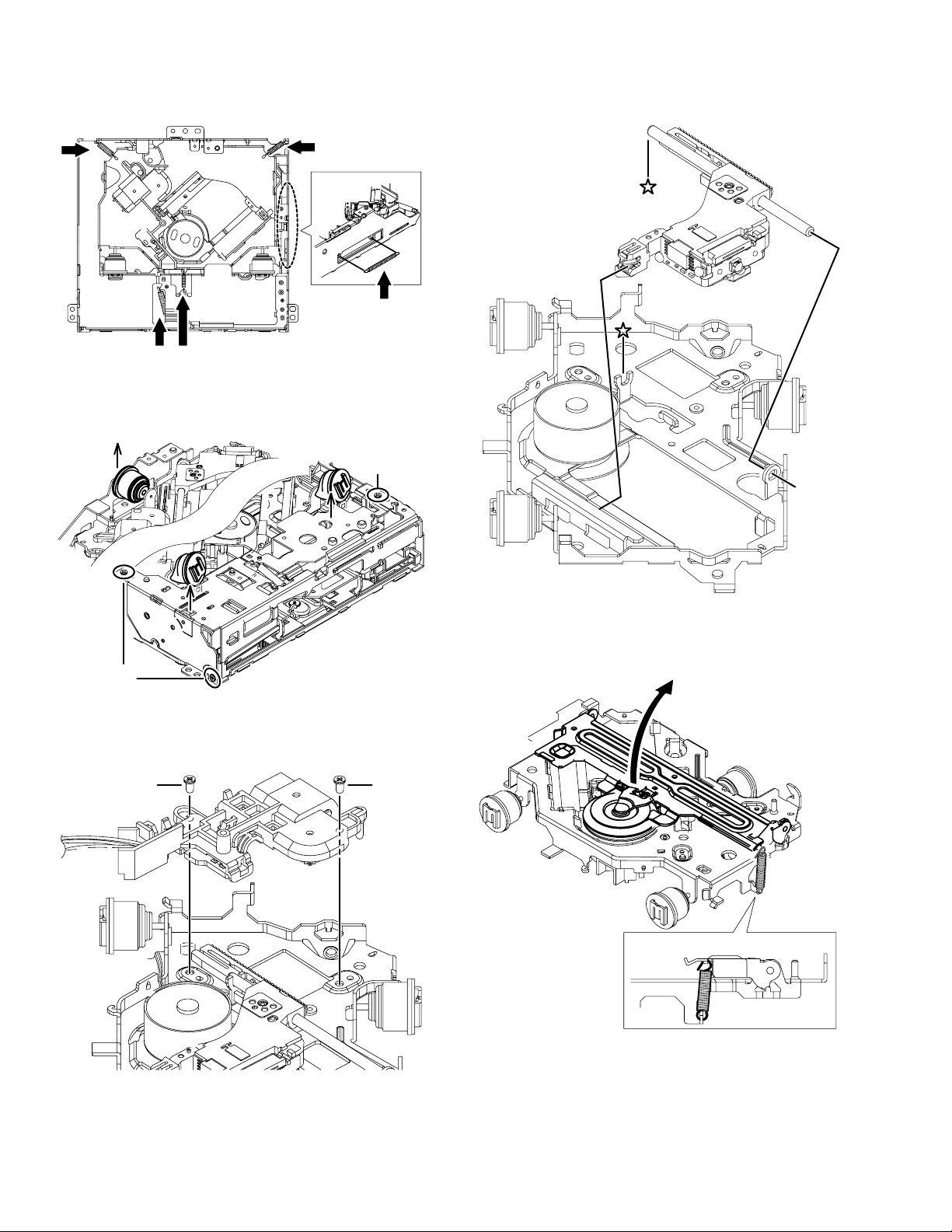

3.2.2 Removing the Traverse mechanism (See Fig.4, 5)

(1) Remove the five springs from the traverse mechanism.

(See Fig.4)

Fig.4

(2) Remove the three screws B attaching the bottom frame as-

sembly. (See Fig.5)

(3) Remove the three dumpers from the bottom frame assem-

bly. (See Fig.5)

B

(2) Remove the shaft from the TM base. (See Fig.7)

(3) Disengage the hook a on the pickup from the TM base.

(See Fig.7)

shaft

B

Fig.5

3.2.3 Removing the Pickup (See Fig.6, 7)

(1) Remove the two screws C attaching the feed bracket as-

sembly. (See Fig.6)

CC

Fig.7

3.2.4 Removing the Spindle motor (See Fig.8. 9)

(1) Remove the HC CL. Spring from the HC CL. base and the

TM base, and then lift up the HC CL. base. (See Fig.8)

HC CL. spring

[ SIDE VIEW ]

Fig.8

1-10 (No.MA479<Rev.002>)

Fig.6

Page 11

(2) Remove the HC CL. base from th holes on the TM base.

(See Fig.9)

Fig.9

(3) Remove the two screws D attaching the spindle motor.

(See Fig.10)

D

3.2.5 Removing the Loading motor

(1) Remove the roller arm assembly from the bottom frame as-

sembly. (See Fig.11)

Fig.11

(2) Remove the two screws E attaching the loading motor as-

sembly, and then remove the loading motor assembly in

the direction of the arrow. (See Fig.12)

Fig.10

E

Fig.12

(No.MA479<Rev.002>)1-11

Page 12

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc

4.2 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K ohm (2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.5 4.5 How to connect the cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively,

before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

4.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.4 Dummy load

Exclusive dummy load should be used for AM,and FM.

For FM dummy load, there is a loss of 6dB between SSG output

and antenna input.

The loss of 6dB need not be considered sincedirect reading of

figures are applied in this working standard.

1-12 (No.MA479<Rev.002>)

Original cable

Page 13

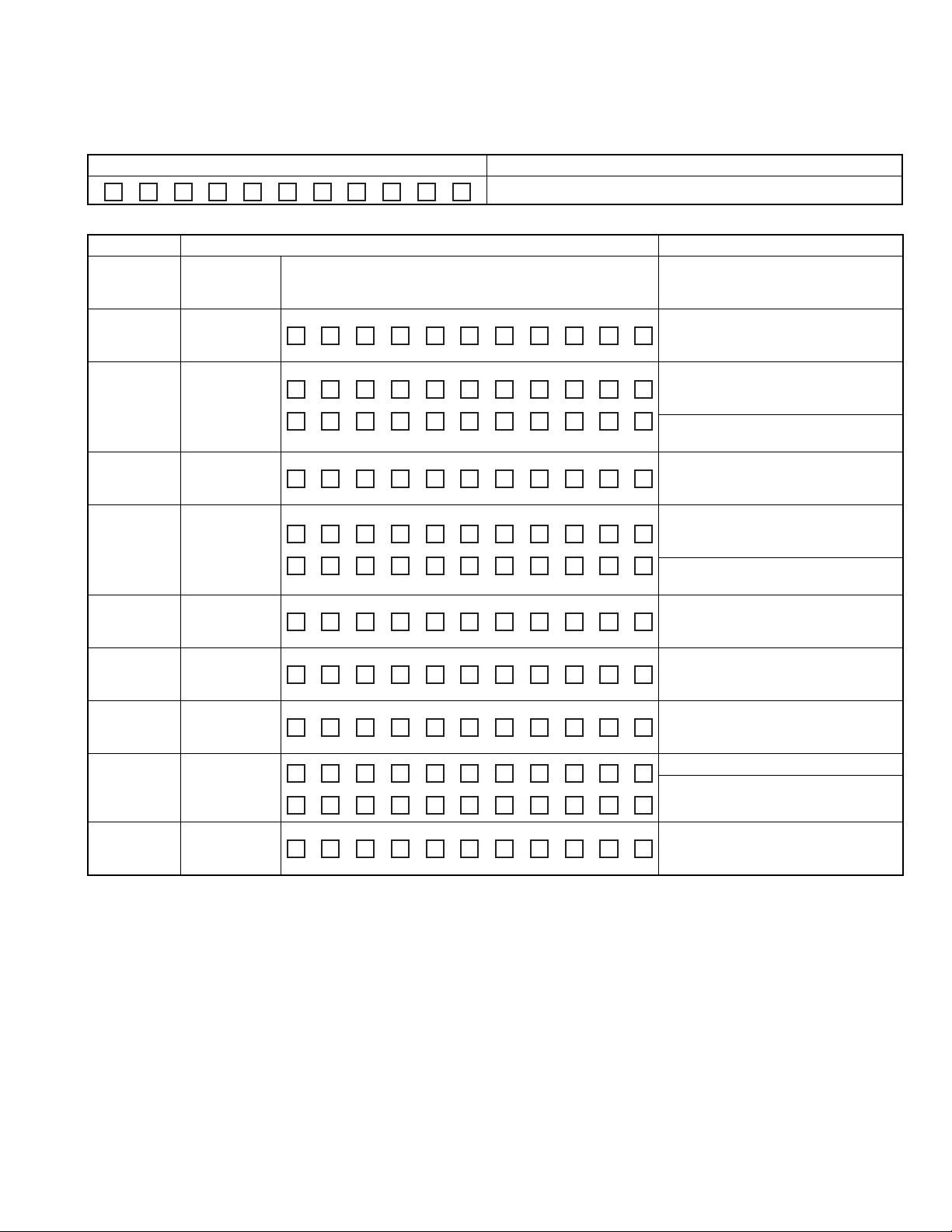

4.6 Service mode

Operating Key : [MENU] → [DOWN] (7sec)

4.6.1 Mode content

Syscon shall display the information after entering this mode. The operation shown below shall be workable.

Display content Detail

S R V T E S T

The display is released when another operation is executed.

4.6.2 Common operation mode for all sources.

Operation Display content Detail

EQ CD error

information

display mode

MENU Syscon

UP Syscon

UP Power ON

DOWN Disc

DOWN Disc

BRIGHTNESS Disc eject

BRIGHTNESS

I<< Force

I<< Force Power

version

display

version

display

duration

clear

operation

duration

display

operation

duration clear

number of

times

Disc eject

number of

times clear

Power OFF

information

display

OFF

information clear

Transit CD error information display mode

S Y S #

@ @ @

P O N T M 0 H X X

P O N T M 0 X X X X

P O N T M 0 H 0 0

C D T M 0 H X X

C D T M X X X X X

C D T M 0 H 0 0

E J C N T X X X X X

E J C N T 0 H 0 0

P O F F - - -

P O F F P N L

P O F F - - -

# = Display of destination.

J = USA, R = EUROPE, E = EASTERN-EUROPE

U = OTHERS(eq. ASIS), @@@ = Syscon version

00~50 are displayed in " X X ".

For less than 1 hour, the display is indicated

per 10 minutes.

00001~10922 are displayed in " X X X X X ".

MAX 10922 (hours).

Clear Power ON duration by pressing for 2

seconds when Power ON duration is displayed.

00~50 are displayed in " X X ".

For less than 1 hour, the display is indicated

per 10minutes.

00001~10922 are displayed in " X X X X X ".

MAX 10922 (hours).

Clear Disc operation duration by pressing

for 2 seconds when it is displated (Only the

displayed media is cleared).

Display Disc Eject number of times.

MAX 65535 (times)

Clear Disc Eject number of times by pressing for 2 seconds when it is displayed.

No force Power OFF

Force Power OFF due to Syscon-Panel

commnication error.

Clear force Power OFF information by

pressing for 2 seconds when it is displayed.

(No.MA479<Rev.002>)1-13

Page 14

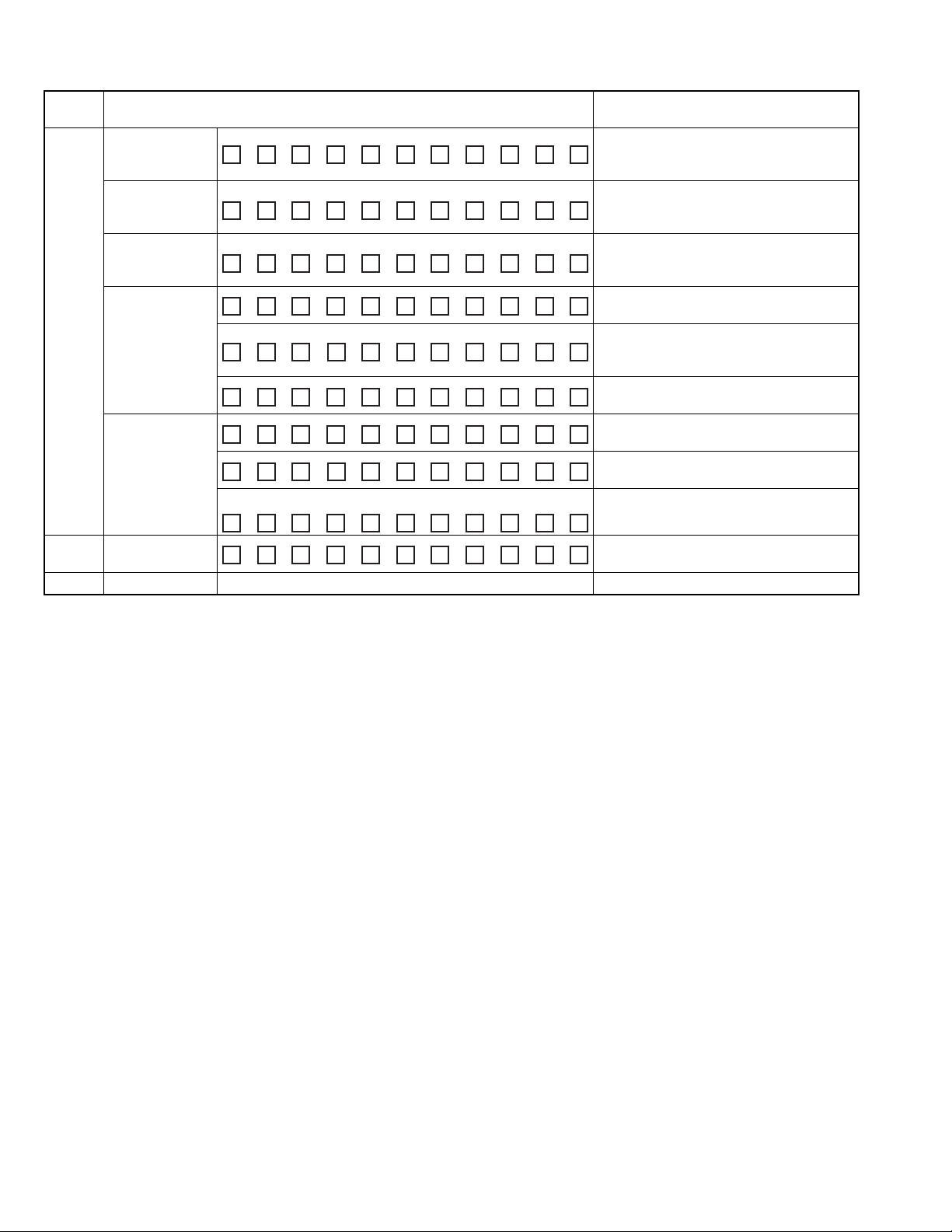

4.6.3 CD error information display mode

Operation

Move

between

DISP

(Forward

search)

i t e m w i t h

I<< / >>I

EQ CD error

EQ Mode release CD error information display mode release Back to default status, All lights on

Display content Detail

CD

mecha error log

display

CD

load error

informationdisplay

CD

load error

informationdisplay

CD

time code

error count

informationdisplay

(count skip)

CD

time code error

count information

display

(no count update)

informationclear

M E C H E R #AXX

L O A D E R # X X

E J E C T E R # X X

C N T L O S E

C D D A XX

C D R O M X X

C N T S T A Y

C D D A XX

CD error information all clear

C D R O M X X

M E C H A E R 1 - -

Mecha error history 1,2,3 (latest)

# = History No. (1,2,3)

X X : number of errors, " -- " when there is none.

Load error switch 1,2

# = History No. (1,2)

X X : number of errors, " -- " when there is none.

Eject error switch 1,2,3,4

# = History No. (1,2,3,4)

X X : number of errors, " -- " when there is none.

CD time code error count information (count updated) mode display

CD-DA error count numbers

X X : numbers of errors and " -- " when there is

none

CD-ROM (compressed file) error count numbers

X X : numbers of errors and " -- " when there is none

CD time code error count information (count not

updated) mode display

CD-DA error count numbers

X X : numbers of errors and " -- " when there is none

CD-ROM (compressed file) error count numbers

X X : numbers of errors and " -- " when there is none

Clear CD error information by pressing for 2

seconds when it is displayed.

1-14 (No.MA479<Rev.002>)

Page 15

4.7 Service information clear mode

* The receiver is connected with the DC power supply (with the power supply turned off).

Operating Key : [BACK] → [POWER] → [DC power supply turned ON]

Mode content

After entering this mode, Syscom shall clear the information stored for service an output to the display.

Display content Detail

D A T A C L R O K

D A T A C L R N G

When normal end

When error end

4.7.1 The following table shows the data that is cleared.

Information for data clearing Detail

CD mecha information CD mecha log display

CD load error information display

CD eject error information display

CD time code error count information display (count skip)

CD time code error count information display (no count update)

Service information Power ON duration display

CD operation duration display

CD eject number of times display

Force power OFF information display

DC error information DC error 1 display (wrong connection and other detection

information in detectiong duration)

DC error 2 display (capacitor leakage detection number

information)

4.8 DC error information mode

* The receiver is connected with the DC power supply (with the power supply turned off).

Operating Key : [MENU] → [UP] → [DC power supply turned ON]

4.8.1 Mode content

Syscon shall display the following after entering this mode. The operation shown below shall be workable.

Display content Detail

D C E R R

D C O K

When DC error is detected (in case that one of capacitor

leakage, wrong connection or other detection is found).

When DC error is not detected (in case that none of capacitor

leakage, wrong connection or other detection is found).

4.8.2 Mode operation specification

Operation Display content Detail

UP DC ERR1

display

UP DC ERR1

clear

DOWN DC ERR2

display

DOWN DC ERR2

clear

D C 1 E R R

D C 1 O K

D C 1 O K

D C 2 4

D C 2 0

When wrong connection & DC error in other detection

duration is detected.

When wrong connection & DC error in other detection

duration is not detected.

Clear detection information when wrong connection & DC error in other detection duration is displayed.(Clear data flash)

Display detecting number of times in capacitor leakage

detection duration (0~4)

Clear number of times for detection information in capacitor leakage detection duration.(Clear data flash)

(No.MA479<Rev.002>)1-15

Page 16

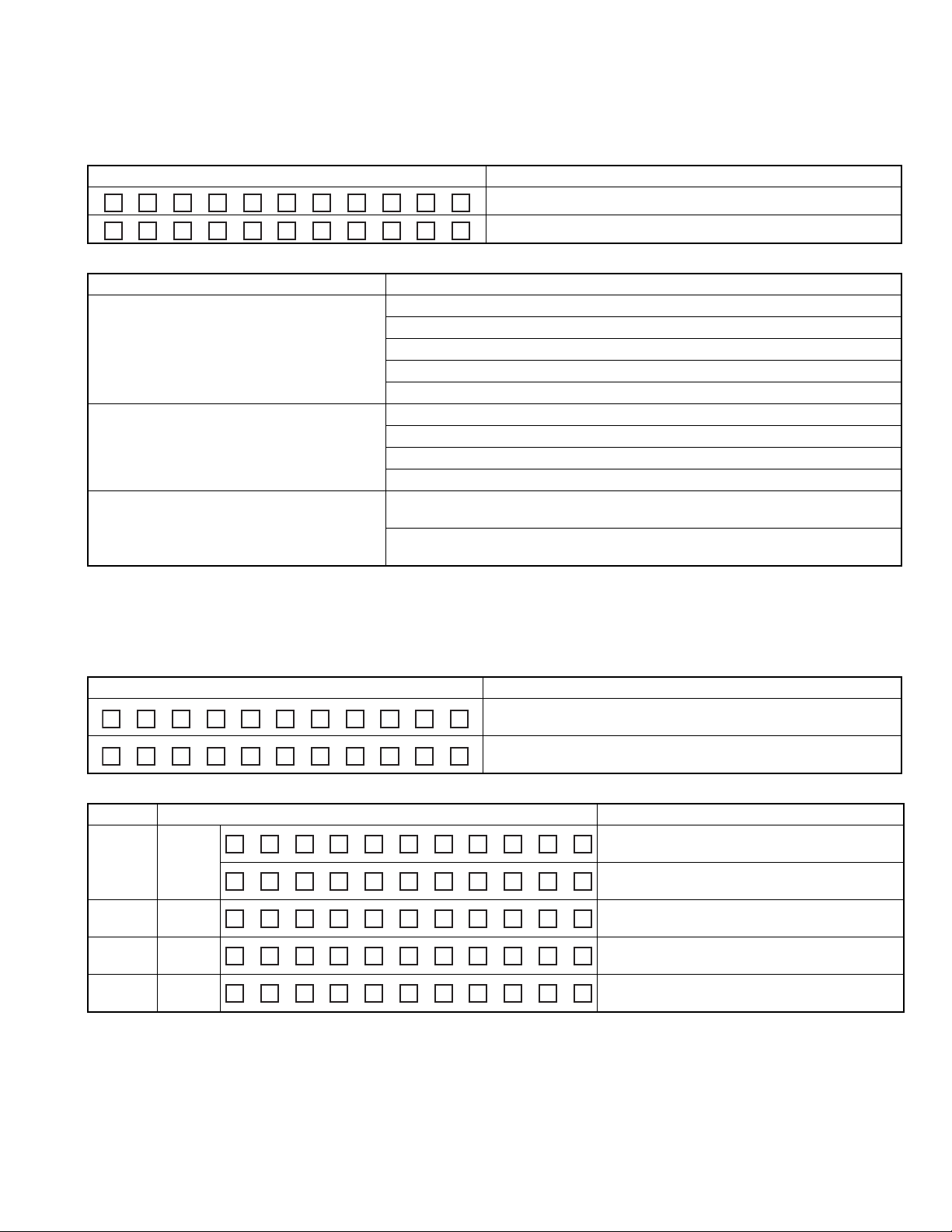

5.1 16PIN CORD DIAGRAM

5.1.1 For KD-A525,KD-R528

SECTION 5

TROUBLESHOOTING

1

16

2

9

10

12

11

8

7

6

5

3

2

1

BK

YL

RD

GN

GN / BK

VI

VI / BK

WH

WH/BK

GY/BK

NC

BL/WH

RD

BK

GN

GN/BK

VI/BK

VIGY

LB/YL

BR

OR/WH

YL

10

11

12

134

14

15

16

9

GN

VI

LB

YL

BR

OR

Green

Violet

Light Blue

Yellow

Brown

Orange

White

WH

BK

Black

GY

Gray

BL Blue

Red

RD

15

13

3

14

8

7

5

6

OR / WH

LB / YL

BL / WH

BR

WH

WH / BK

GY

GY / BK

1-16 (No.MA479<Rev.002>)

Page 17

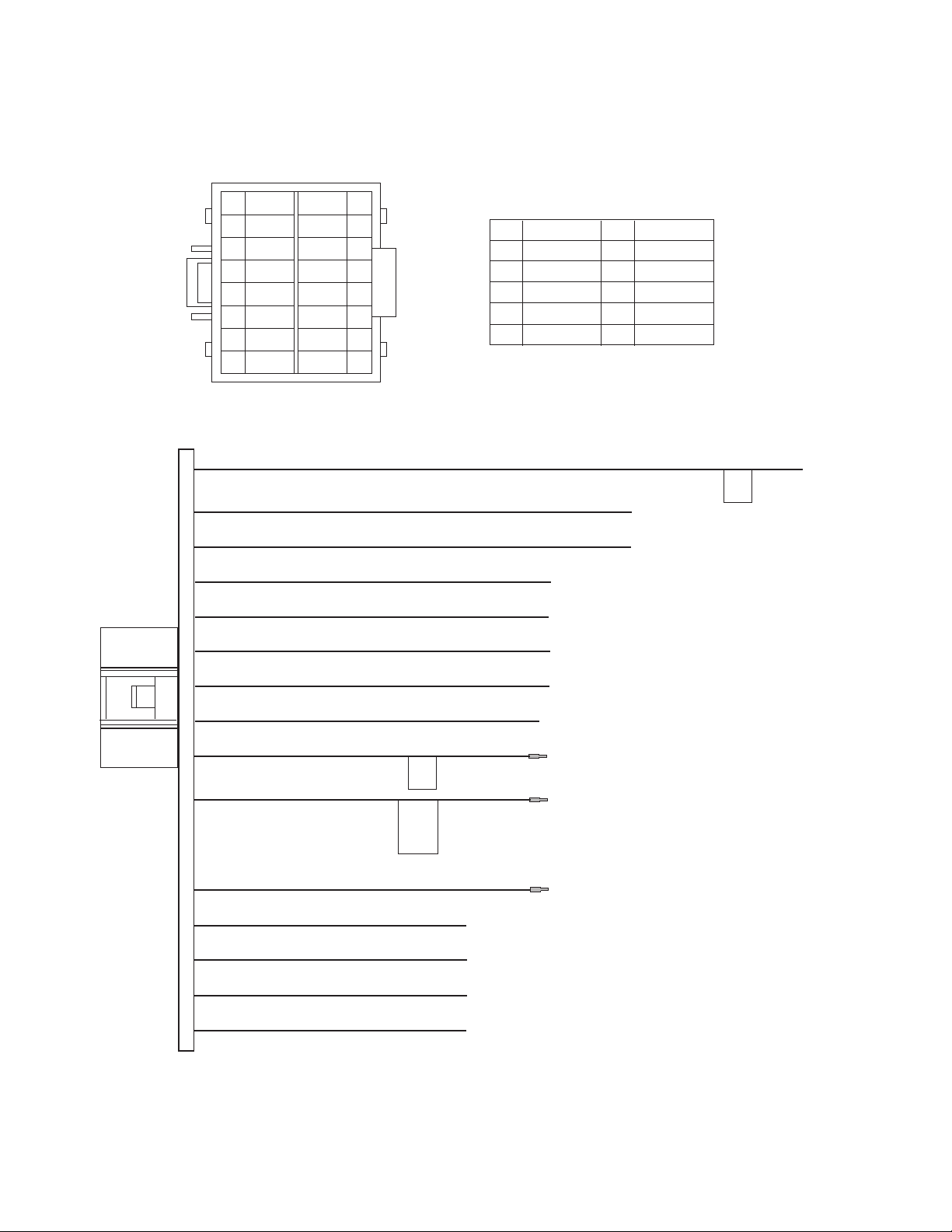

5.1.2 For KD-BTP50, KD-R520

1

16

2

9

10

8

7

6

5

3

2

1

BK

YL

RD

GN

GN / BK

WH

WH/BK

GY/BK

NC

BL/WH

RD

BK

GN

GN/BK

VI/BK

VIGY

NC

BR

OR/WH

YL

10

11

12

134

14

15

16

9

BK

RD

BL

WH

GY

Black

Red

Blue

White

Gray

GN

Green

VI

Violet

BR Brown

OrangeOR

Yellow

YL

12

11

15

3

14

8

7

5

6

VI

VI / BK

OR / WH

BL / WH

BR

WH

WH / BK

GY

GY / BK

(No.MA479<Rev.002>)1-17

Page 18

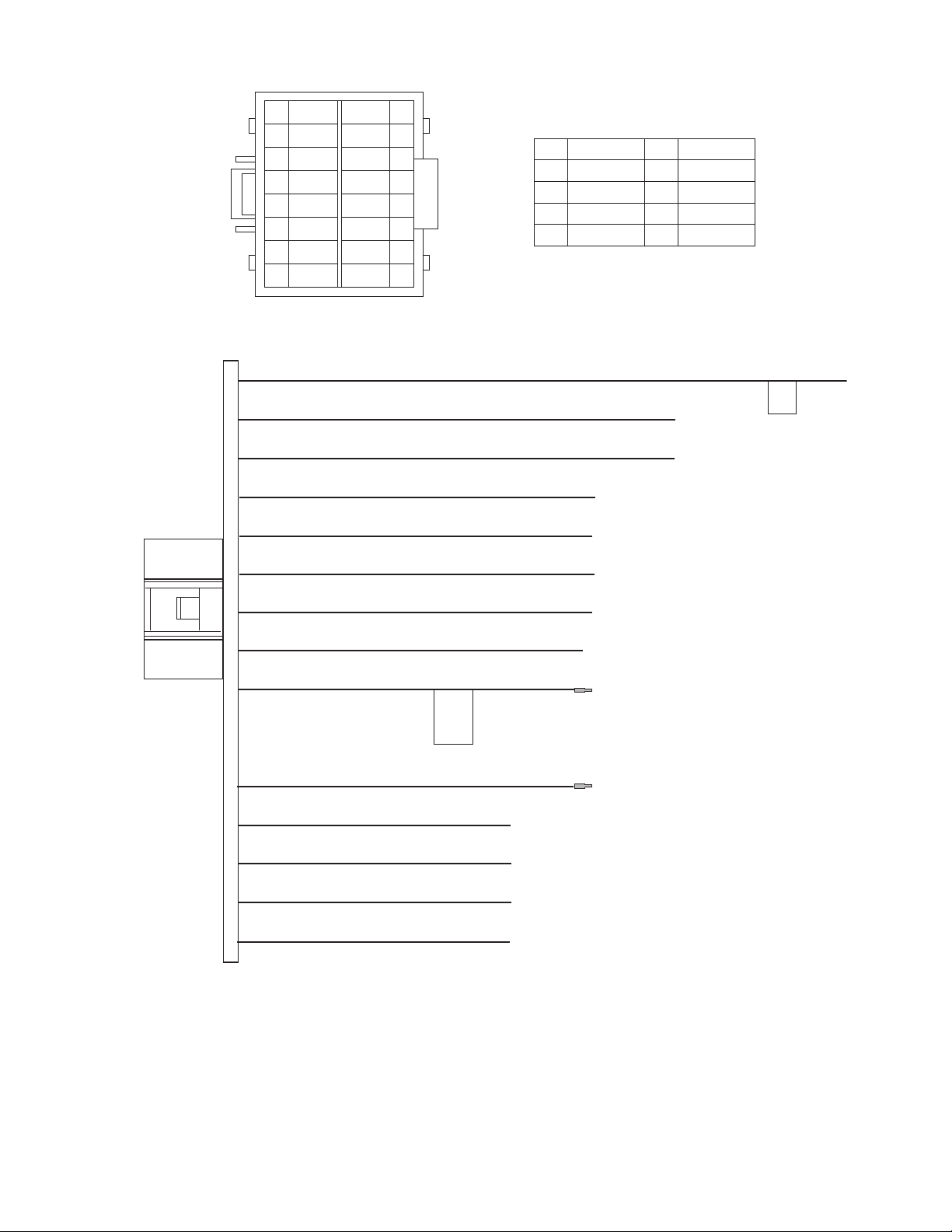

5.1.3 For KD-R521

8

7

6

5

4

3

WH

WH/BK

GY/BK

GY

NC

BL/WH

GN

GN/BK

VI/BK

VI

LB/YL

BR

10

11

12

13

14

White

WH

Black

BK

GY

BL

RD

Gray

Blue

Red

9

GN

VI

LB

YL

BR

OR

Green

Violet

Light Blue

Yellow

Brown

Orange

2

16

1

14

15

3

9

10

12

11

8

7

5

6

13

2

1

RD 1

YL 1

BK

BR

OR / WH

BL / WH

GN

GN / BK

VI

VI / BK

WH

WH / BK

GY

GY / BK

LB / YL

RD1

BK

OR/WH

YL1

15

16

1

VI

3

GY

5

WH

7

GN

2

4

6

8

VI/BK

GY/BK

WH/BK

GN/BK

RD 3

9

NC

10

11

13

BL/WH

RD2

15 16

NC

12

14

BR

YL2

OR/WH

BK

RD 2

15

YL 2

12

16

10

14

13

7

8

1

2

5

6

3

4

1-18 (No.MA479<Rev.002>)

Page 19

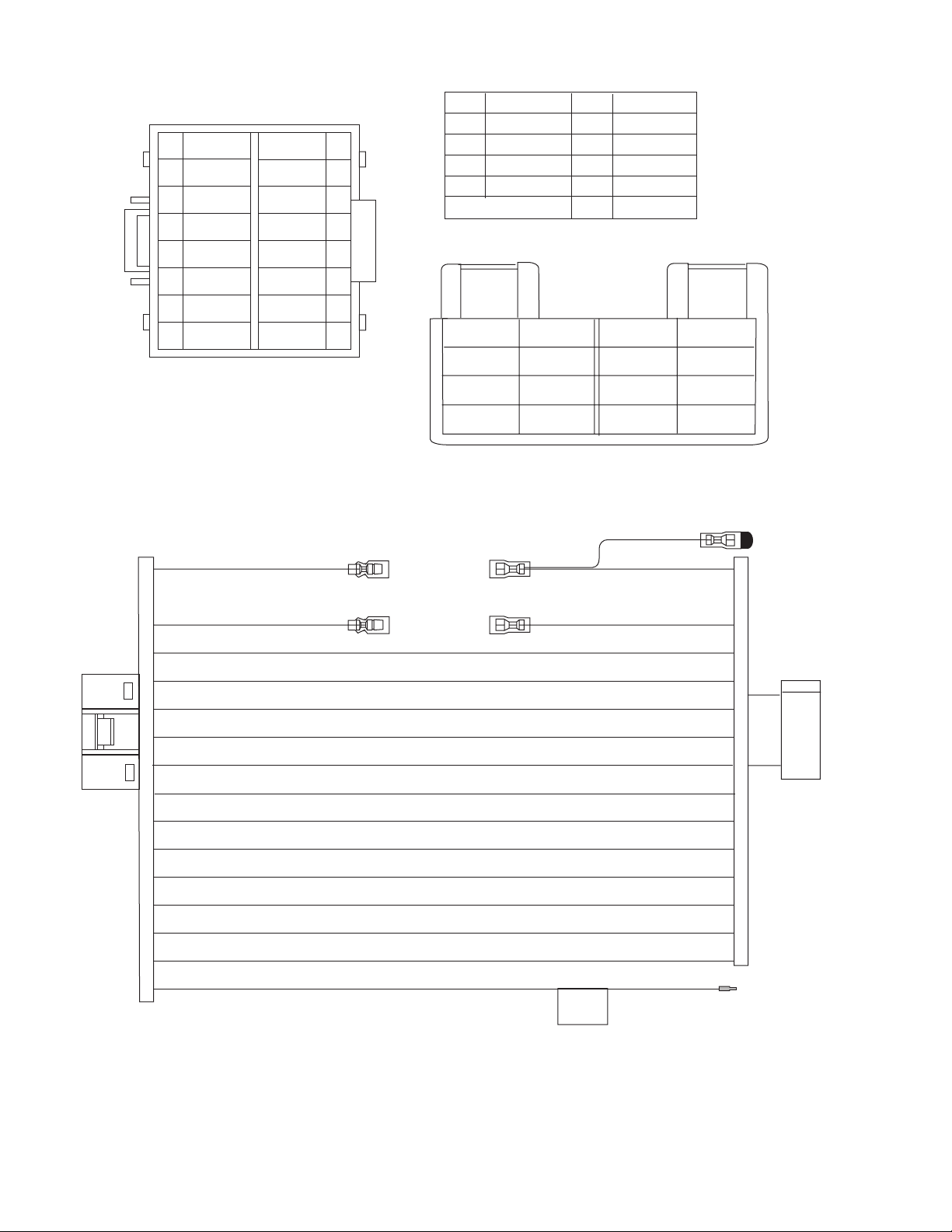

5.1.4 For KD-R524, KD-BTP52, KD-R525, KD-R526

1

16

2

9

10

12

11

8

7

6

5

3

2

1

BK

YL

RD

GN

GN / BK

VI

VI / BK

WH

WH/BK

GY/BK

BL

BL/WH

RD

BK

GN

GN/BK

VI/BK

VIGY

LB/YL

BR

OR/WH

YL

10

11

12

134

14

15

16

9

GN

VI

LB

YL

BR

OR

Green

Violet

Light Blue

Yellow

Brown

Orange

White

WH

BK

Black

GY

Gray

BL Blue

Red

RD

15

13

4

3

14

8

7

5

6

OR / WH

LB / YL

BL

BL / WH

BR

WH

WH / BK

GY

GY / BK

(No.MA479<Rev.002>)1-19

Page 20

Victor Company of Japan, Limited

Mobile Entertainment Division 2967-3, Ishikawa-machi, Hachioji-shi, Tokyo, 192-8525, Japan

(No.MA479<Rev.002>)

Printed in Japan

VSE

Page 21

SCHEMATIC DIAGRAMS

23

CD RECEIVER

KD-A525J KD-BTP50J KD-BTP52U

KD-R520J KD-R521E KD-R521EU

KD-R521EY KD-R524UI KD-R525U

KD-R525UH KD-R525UN KD-R526U

KD-R526UH KD-R526UN KD-R526UT

KD-R528J

(No.MA479<Rev.002>)1/

Page 22

■ PRECAUTIONS ON SCHEMATIC DIAGRAMS

z Due to the improvement in performance, some part numbers shown in the circuit diagrams

may not agree with those indicated in the Parts List.

z The parts numbers, values and rated voltage etc. in the Schematic Diagrams are for

reference only.

z Since the circuit diagrams are standard ones, the circuits and circuit constants may be

subject to change for improvement without any notice.

■ PRECAUTIONS ON PARTS LIST

z

The parts identified by the symbol are critical for safety. Whenever replacing these parts, be sure to

use specified ones to secure the safety.

z

The parts not indicated in this Parts List and those which are filled with lines --- in the Parts No.

columns will not be supplied.

z

P.W. BOARD Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No.

columns will be supplied.

z

When ordering chips, screws etc., place bulk orders (unit of tens) whenever possible to improve

shipping efficiency.

z

There are cases where the actual implemented parts in the sets and the service parts are different.

When ordering parts, make sure to refer to the Parts List.

■

PRECAUTIONS ON SERVICE

Certain parts of the power circuits and the GNDs differ according to the models. Care must be

taken for the following points as the differences are indicated separately in the LIVE GND ( ) and

the ISOLATED (NEUTRAL) GND ( ).

1. Do not touch the LIVE GND, or do not touch the LIVE GND and the ISOLATED (NEUTRAL)

GND at the same time. It may cause an electric shock.

Before pulling out the chassis or other parts, make sure to pull out the power cord from the

wall outlet first.

2. Do not short circuit between the LIVE GND and ISOLATED (NEUTRAL) GND, or never

measure the LIVE GND and ISOLATED (NEUTRAL) GND at the same time using measuring

instruments (oscilloscope, etc.). It may blow fuses or damage other parts.

■ DEVIATION TOLERANCE RANGE

DEVIATION TOLERANCE RANGE

F G J K M N R H Z P

± 1% ± 2% ± 5% ±10% ±20% ±30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

23

(No.MA479<Rev.002>)2/

Page 23

Q981

Q971Q970

BU/SURGE DET

Q952Q951

SW3.3 CCT

Q881

ILMI

Q782

MUTE CONTROL

Q781

Q780

LINE MUTE

Q701

PAN3.3V SW

Q634

Q632

LED

DRIVER

Q631

Q627

5V REG.

Q540

Q341

Q321

Q251

A525J only

DC-DC USB5V

& HSS

IC981

IC931

3.3V REG.

IC901

REGULATOR

IC771

EPROM

IC702

RESET

CPU

IC701

REMOCON

IC681

LCD

DRIVER

IC661

RGB

DRIVER

IC601

IC580

CD LPF

RF AMP

IC540

IC532

REG.

IC531 1.5V REG.

IC530 3.3V REG.

BTL DRIVER

IC501

POWER

AMP.

IC301

E.VOLUME

IC161

IC80

IPOD CP

FM/AM TUNER

IC1

CJ601

LCD&Key section

Main section

CD section

LCD1 (U / UN / UH / UT / UI / 528J)

DI1 (A525J / R520J / E / EU / EY / BTP50J)

S2 to S51 (U / UN / UH / UT / UI / 528J)

S1 to 50 (A525J / R520J / E / EU / EY / BTP50J)

RROUT

RLOUT

RL/SUBL, RR/SUBR

FLOUT, FROUT

RSTCP

SCKCP

SDACP

REAR /

FRONT,

LINE OUT

WOOFER

SUB-

REAR,

FRONT,

U / UN / UT / UH / UI only

only

A525J

A525J only

except A525J

except R520J

A525J / R520J / E / EU / EY / BTP50J only

U / UN / UH / UT / UI / 528J only

RGB LIGHTING

D623, D625

CN603

S701

,

,

,

D780

D781

,

,

J120

USB5V

VDD3.3V

USB5V

10V

D+, D-

3.3V

VDD3.3V

,

ANTENNA

ANT OUT

OE

LED4

LED5

LED6

LED7

LED0

LED1

LED2

P1

P2

P3

REMOTE

ILL

TEL MUTE

DC_ERR

FAUX-L, FAUX-R

D891

TELMUTE

VREF

D+, D-

AUX-L, AUX-R

KEY1

PON_CD

3.3V

1.5V

VDD5V

VDD5V

1.5V

(IC540

VDDM1)

D782

REAR

AUX IN

SUB-

WOOFER

LINE OUT

X540

16.934MHz

X1

4MHz

X701

12MHz

SP+/-

FEED+/-

LOAD+/-

FOCUS+/-

TRK+/-

FWD, REV, DRVMUTE

BTL_DMO, BTL_FMO

BTL_FOO, BTL_TRO

MUTE

AMP_MUTE

MUTE

CD PICK UP

VF1, VF2, VT1, VT2

MD, LD, Vc (VREF)

TRK+/-

FOCUS+/-

FOCUS & TRACKING

COIL

PICK UP

CN502

SW1

SW2

SW3

LED

D630 to D632

BACK LIGHT LED

X702

32.768kHz

AMP_STBY

STBY

PON_PANEL

Subboard

CTRL1, CTRL2

MEMORY

USBPON, FREQ_SEL

MEMORY

MEMORY

EXT

ACC_OUT

ACC_IN

SW5V, VDD5V,

CD8V, A9V, ILM10V

LED

JS601

ENCODER

CD.L, CD.R

CD.L, CD.R

CD.L

CD.R

CN701

SDATU

SCLTU

J321

CN901

SPK

BATTERY

J1

ANT

FL+/-

FR+/-

RL+/-

RR+/-

RAUX-L

RAUX-R

TU.L

TU.R

EACH BLOCK

FAUX-L

FAUX-R

J601

PSW, SW1, SW2, SW3

CMDREQ, CMDSO, CMDSI

CMDBUCK, CMDCCE

CDRESET, SRAMSTB, CDMUTE

BSIF_REQ, GATE

LRCK, BCK, DATA

VF1, VF2

VT1, VT2

CD_MD, LD

RGB LIGHTING

D624

REMOCON

LCD DISPLAY

COM1 to 4

OE REMOTE

REMOCON

REMOCON

VOL1

VOL2

KEY0

KEY1

LCDCE

LCDCL

LCDDA

RGBCL

RGBCL

LCDDA

LCDDA

LCDCE

LCDCLK

VOL1, VOL2

KEY0

S601 to S611

KEY MATRIX

REST (PSW)

SW1

REST SW

LOAD+/-

FEED+/-

LOAD MOTOR

FEED MOTOR

SP+/-

SW1, SW2, SW3

DETECT SW

SPINDLE MOTOR

USB

AUX

INPUT

CN102

CN101

E_MUTE

OFFSET

AC-GND

BU_DET

RESET

BEEP

DIMMER_IN

TELMUTE

D651

D631 to D633, D635 to D645

D653, D654

SW5V

SW3.3V

VDD3.3V

5V

10V

VDD5V

Block diagram

created date:2011-03-04No.MA479

23

(No.MA479<Rev.002>)3/

Page 24

DZ2J062/M/-XDZ2J062/M/-X

NIL

NIL 1k ohm1k ohm

D704

R777

0 ohm

47/16

22/16

0 ohm

*

*

*

*

Tuner

Out

Line

*

*

NIL

NIL

10/50

330 ohm

NILC727

OTHERS

NIL

KD-R527EE* REMARK

R330

C330

B314

27p

2.24V1.81V 2.24V 2.24V 1.02V 1.81V

0V1.47V0.58V 0V1.02V0.58V

STAGE2

STAGE1

STAGE

VOLTAGE

L10

Tuner

R9

22k ohm

27k ohm

27k ohm

OE REMOTE

R785

0 ohm

QAM1344-001

NIL 10pC28

NQL103J-10NX

POWER CORD ASSY QAM1345-001QAM1330-001 QAM1329-001

NIL

NIL

*

42 6

5

31

654321

-Rear-L/Sub-L- - - Rear-R/Sub-R

-Rear-R/Sub-RFront-L Front-R

Rear-L/Sub-L

-

Front-RRear-R Sub-RSub-LFront-LRear-L

***

*

QEKJ1CM-476Z-S

100p

100pNILC316~319

!

MAINGND

(3.3V)

(3.3V)

(3.3V)

(3.3V)

(3.3V)

(3.3V)

(0V)

(0V)

(0V)

(0V)

3.3V

(0V)

3.3V

3.3V

(3.3V)

3.3V

(7.9V)

0V

14.4V

( )

( )

( )

*

NO USED FOR KD-R527EE

*

*

*

*

*

*

J321MODELS* REMARK

1 pair

2 pairs

3 pairs

R527EE

R626U,R621E,A625J,R628J

R526U,R525U,R524UI,R528J,R620J

QNN0864-001

QNN0866-001

QNN0868-001

NIL

NIL

0 ohm

NIL

NIL

NIL

0.047

100 ohm

NQL553J-27NJ

0.1

68 ohm47 ohm

0.1

NQL553J-27NJ

100 ohm

0.047

MFI341S213-XMFI341S213-X

C178

C166

L161

R82

C80

IC80

R527EE

R620 SERIESR52X

* REMARK

iPOD

33k ohm

39k ohm

15k ohm

33k ohm

22k ohm

27k ohm

R527EE

R621E Series

TDA7851A

TB2926CHQ

QEKJ1CM-226Z-S

NIL

NIL

0 ohm

0 ohm

0 ohm

NIL

NIL

KD-R620 SERIESKD-R52X* REMARK

C309

R303

Power IC

R304

R307

R306

IC301

*

*

*

*

*

*

FOR U VERSION ONLY

*

10k

VDD5V

3.3V

3.3V

RT1P241C-X

RT1N441C-X

47k

47k

22k

47k

22k

RT1P144C-X

RT1N241C-X

10k

RT1N141C-X

22k

10k

22k

*

*

*

0V

0V

0V

3.3V

0V

3.3V

0V

3.3V

3.3V

0V

3.3V

3.3V

R628J

R525U Series

R526U Series

QMFZ064-100-J1

SETTING

R528J

0V

0.7V

3.3V

3.3V

0V

3.3V3.3V

0V

15k ohm

39k ohm

8.2k ohm

27k ohm

22k ohm

47k ohm

NIL

33k ohm

15k ohm

NIL

R626U Series

0V

0V

2.9V

0V

0V

0.6V

3.3V

3.3V

3.3V

4V4V4V

4V4V4V

14.3V

3.3V

1.6V

0V

14.3V

4.9V

4.9V

4.9V

14.3V

4.4V

1.2V

8.6V

0V

1.2V

9.8V

3.3V 3.3V

2.6V

0V

0V

4.9V

4.6V4.6V

3.3V0V

0V

3.3V

3.3V

0V

0V

0V

0.6V 0.6V

0.6V0.6V

0.6V

0.8V

0.8V

3.3V

5.1V 10V

14.4V

0V

0V

3.3V

3.3V

3.3V

0V

0V

1.5V

3.3V

0V

0V

0V

0V

1.5V

3.3V

0V

0V

3.3V

1.48V

*

*

2.6V

3.3V

3.3V

0V

(3.3V)

3.3V

3.3V

3.3V

3.3V

3.3V

1V

1.6V

0V

3.3V

3.3V

0V

(3.3V)0V3.3V

0V

0V

0V

3.3V

3.3V

3.3V

3.3V

3.3V

(3.3V)

0V

3.3V

2.5V

3.3V

3.3V

0V

0V

0V

0V

3.3V

0V0V0V0V0V

0V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V0V3.3V

3.3V

(1/8W)

D102,D112:DZ2J068/M/-X

!

* MODELS

8.2k ohm

22k ohm

27k ohm

15k ohm

33k ohm

33k ohm

15k ohm

47k ohm

A625J

R620J

R524UI

R767

R765

R766

R764

STAGE

D120,D121,D130,D131:DZ2J062/M/-X

L703:NQR0502-001X

(1/8W)

QEZ0937-278

FOR U VERSION ONLY

*

*

*

*

NOT USED

VOUT

/OC EN

GND

VIN

*

1/8W

(1/8W)

F901

FOR R626U.R621E,A625J, R628J ONLY

0V 0V

0V 0V

C301-C304:QTE1C66-474Z

FRONT AUX

C305-C308:NCB21CK-474X-A

!

USE ONLY

(FOR st ONLY)

DETAIL DEBUGGING

GND

BTLGND

IPOD CP CIRCUIT

DC-DC USB5V & HSS

EPROM

0V

3.3V

REAR AUX

0V

0V 0V

0V

LINE MUTE

POWER IC MUTE

BU DET SURGE DET

ILMI

TEL MUTE

ANT

ACC IN

REMOTE OUT

OE REMOTE

TEL MUTE

ILL

4V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

3.3V

1.5V

1.5V

3.0V

6.8V

6.8V

(1/10W)

(1/10W)

!

!

!

QTE1V67-475Z

QTE1V67-475Z

3.3V

3.3V

3.3V0V8.6V

0.0V

0.0V

3.3V

3.3V

E.VOLUME

3.5V

5V

2.0V

1.8V

2.9V

4.2V

8.5V

8.5V

0V

(1/8W)

(1/4W)

2.2V

4.5V

NOTES

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE(V)

ALL CAPACITANCE VALUES ARE IN uF(P=pF)

ALL RESISTANCE VALUES ARE IN OHM.

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR.

ALL RESISTORS ARE 1/16W 5% METAL GLAZE RESISTOR.

UNLESS OTHERWISE SPECIFIED.2.

CONDITION---FM MODE. AM MODE ( )CD MODE.

1. VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER WITHOUT INPUT SIGNAL

0V

REAR LEFT(+)

0V

FRONT LEFT(+)

FRONT RIGHT(+)

0V

5.6V

REAR RIGHT(+)

REAR LEFT(-)

FRONT LEFT(-)

FRONT RIGHT(-)

REAR RIGHT(-)

ACC

REMOTE/P-con

MEMORY

0V

0V

7.1V

0V

0V

* POWER CORD ASS'Y

0V

ANTENNA

FUSE 10A

8.5V

7.1V

0V

7.0V

14.4V

3.6V

3.3V

3.9V

3.3V

3.3V

0V6.2V

6.2V

3.2V

3.5V

0.4V

3.8V

7.0V

3.8V

7.0V

7.1V

7.1V

7.2V

7.2V

7.2V

7.2V

7.2V

7.2V

7.2V

7.1V

0V

8.5V

3.1V

3.1V

0V

0V

0V

0V

1.4V

0V

REGULATOR

LINE OUT

0V

CPU

(1/10W)

(1/10W)

TOMIC

POWER AMP.

TUNER

FM/AM

COMPONENTS IN () INDICATE NOT USE.3.

(1/10W)

4MHz

ANT

TUNER

CD

(1/8W)

RESET

MAIN PWB: GEB10301A

REMOCON

USBPON

SDATU

S.GND

LCDCL

D-

D+

RL/SUBL

FROUT

SDATU

SCLTU

VDD3.3V

USBPON

RAUX-L

RAUX-G

RAUX-R

FAUX-G

SCLTU

SDATU

REV

FWD

LCDDA

KEY0

D-

D+

OC

RROUT

RLOUT

FLOUT

BU_DET

RESET

A9V

HC1-2

PSW

SW3.3V

FAUX-R

FAUX-L

HC1-2

FR-

OFFSET

CD8V

PON_PANEL

RROUT

FROUT

FLOUT

RLOUT

OC

FREQ_SEL

CMDREQ

SDACP

SCKCP

BSIF_REQ

GATE

CMDBUCK

CMDSI

CMDSO

CMDCCE

RR/SUBR

RROUT

RLOUT

DIMMER_IN

RGBCLK

KEY1

RAUX-R

RAUX-G

RAUX-L

RL/SUBL

RR/SUBR

SCKCP

SDACP

RSTCP

DRVMUTE

CDRESET

PON_CD

SW3

SW2

SW1

PSW

AMP_STBY

OFFSET2

PON_PANEL

RESET

VOL1

OFFSET2

BEEP

FL+

RL-

RL+

FL-

FR+

RR+

RR-

MUTE

LCDDA

LCDCE

RGBCLK

DIMMER_IN

BU_DET

TELMUTE

VOL2

CDMUTE

SRAMSTB

AMP_MUTE

LCDCE

REMOCON

KEY1

KEY0

SW3

VOL2

VOL1

SW2

SW1

DRVMUTE

REV

FWD

CDMUTE

SRAMSTB

CDRESET

CMDCCE

CMDBUCK

CMDSI

CMDSO

LRCK

BCK

GATE

DATA

BSIF_REQ

CMDREQ

PON_CD

CD.L

CD.R

RSTCP

TELMUTE

SCLTU

BU_DETDATA

BCK

LRCK

LCDCL

FREQ_SEL

DC_ERR

FAUX-R

FAUX-L

FAUX-G

MUTE

E_MUTE

AMP_MUTE

AMP_STBY

CD.R

CD.L

TU.R

TU.L

OFFSETDC_ERR

BEEP

RL-

FL-

FR-

RR-

RL+

FL+

FR+

RR+

E_MUTE

TU.L

TU.R

MAINGND

MAINGND

!

sure to use the specified one.

When replacing those parts make

Parts are safety assurance parts.!

X702

QAX0401-001

X701

QAX0957-001Z

X1

QAX0952-001Z

TP12

TEST3

TEST1

TEST2

TRCLK

TP10

SDA

SCL

TRDA0

TP9

TP15

SN

TRDA2

TP7

TRDA1

TP8

TRDA3

TP6

RST

GND

VDD

SWDIO

TP2

SWCLK

TP1

TH301

S701

QSW0648-001Z

R777

R745

100

R780

47k

R167 2.2k

R790

27

R789

27

R4

4.7k

R349

4.7k

R6

220

R7

220

R343 0

R786

10K

R762 4.7k

R784

10K

R783

100K

R353 0

R723

47k

R763

4.7k

R764

R765

R168

0

R373

0

R112

470

R341

22k

R351

22k

R722

47k

R165

100

R163

100

R766

R302

47k

R781

330

R493

15

R310

10

B314

R987

R746

47k

R11

0

R963

R720

47K

R965

0

R767

270

R962

R759

47k

R785

R758 3.3k

R778

270

R893

12k

R891

10k

R782

820

R721

1M

R779

270

R161

10k

R162 0

R8

47

R770 4.7k

R7714.7k

R772 4.7k

R100

0

R102

0

R110

0

R904

R3240R334

0

R253

330

R347

4.7k

R252

4.7k

R305

R773

4.7k

R258

180

R256

22k

R257

180

R907

270K

R908

4.7k

R909

27k

R251

4.7k

R254

330

R255

22k

R738

2.2k

R737

910

R732

4.7k

R894

0

R952

330

R951

1K

R774

4.7k

R757

3.3k

0.5%

R985

130K

R756

47k

R892

68k

R881

27k

R974

47k

R973

20k

R971

10k

R131

47K

R972

10k

R121

47K

R970

47k

R332

180

R320

330

R357

4.7k

R322

180

R111

47K

R101

47K

R321

22k

R331

22k

R330

330

R307

R5 47

R743

47k

R742 47k

R306

R304

R718 47k

R303

R358

4.7k

R323

0

R333

0

R702

100

R754

3.3k

R724

4.7k

R703

910

R132

470

R704

R706

910

R725

47k

R726 47k

R753

3.3k

R747

24k

R701

4.7k

R775

15k

OPEN

R883

R776

15k

R342

180

R3

R1 680k

R352

180

R9

R751

22k

R2 680k

R750

3.3k

R10

R976

68k

R350

330

R975

47k

R901

10k

R752

R787

R788

R906

4.7k

R851

4.7k

R882

4.7k

R941 4.7k

R981

180K

R749

3.3k

150kR983

33K

R982

R988 0

R744 47k

0.5%

R986

75k

R739

10k

R961

0

R903

R769

R768

47k

R712

910

R922

0

R902

R736

47k

R741 10k

R740 10k

R735

47k

R731

47k

R730

47k

R82

100

C178

R340

330

R728 47k

R715

100

R713

100

R708

100

R727

47k

Q981

RT1N441C-X

Q881

RT1N141C-X

Q952

RT1N441C-X

Q781

RT1N241C-X

Q780

RT1P241C-X

Q782

RT1P241C-X

Q701

RT1P144C-X

2SC1623A/5-6/-X

Q971

2SC1623A/5-6/-X

Q970

Q951

2SA812A/5-6/-X

L7

4.7

L702

4.7u

L701

4.7u

L901

QQR1884-001

L6

560u

L981

22

L10

L2

1.8u

L8

4.7u

L1

0.47u

L9

0.47u

L3

0.27u

L161

L982

L5

560u

NQR0251-002X

L12

NQR0007-002X

R130

L102

NQR0251-002X

L11

NQR0499-001X

L101

NQR0007-002X

R120

NQR0499-001X

L983

NQR0502-001X

L985

NQR0007-002X

R122

L703

KEY0100

KEY199

KEY2 (STBY)98

STAGE 197

STAGE 296

TEL MUTE95

AVCC394

ENC293

RGB_CLK92

NO USE91

NO USE90

/NMI89

D-88

D+87

DVSS86

DVCC385

X284

CVSS83

X182

CVCC381

XT280XT1

79

REGVCC3

78

OC (HIGH SIDE SW)

77

PON (HIGH SIDE SW)

76

SCL CP

75

SDA CP

74

BSIF-REQ

73

CP RESET

72

SCL TU EVOL EEPROM

71

SDA TU EVOL EEPROM

70

CMD_REQ

69

DRVMUTE

68

GATE

67

REV

66

FWD

65

SWCLK

64

SWDIO

63

DVSS

62

DVCC3

61

BU_DET(PS2)

60

CMD_BUCK

59

CMD_SI

58

CMD_SO

57

CMD_CCE

56

CD-RST

55

CD-MUTE

54

PON_CD

53

SRAMSTB

52

SW3 (LOAD END)

51

SW2 (EJECT END)

50

SW1 49

PSW(RST SW) 48

AMP MUTE 47

RCA MUTE 46

NO USE 45

HC1_2 44

NO USE 43

AMP STBY 42

DIMMER 41

IPOD SELECT 40

PNO_FL 39

NO USE 38

NO USE 37

DVSS 36

DVCC3 35

NO USE 34

DC OFFSET DET 33

PON_PANEL 32

REG1-1 31

NC30NC29NC28NC27NC26NC25NC24NC23REG1-322DATA21BCK20LRCK19REG2-218REC2-117REMO16DVSS15ACC DET(PS1)14LCD_CL13NC12LCD_DA11REG1-210VFD_CE9FERQ_SEL8BEEP7MODE6/RESET5VREFH4AVSS3ENC12DC OFFSET DET

1

IC701

JCV8019

AMRFIN

1

AMRFDEC

2

FMRFIN23FMRFIN14GNDRF5VCC6AMRFAGC7LOUT8ROUT9AGND10AMIFAGC211MPXIN12MPXOUT13RSSI14TEST15XTAL

16

DGND

17

SCL

18

SDA

19

VREF

20

VREG

21

VCC

22

GNDRF

23

VCO

24

PLL1

25

PLLREF

26

PLL2

27

AMSELIN128AMSELIN2

29

AMIFAGC1

30

AMSELOUT1

31

AMSELOUT2

32

IC1

TEF6614TV1S4-X

SE1L1SE1R2SE2L3SE2R4SE3L5SE3R6QD3L7QD3G8QD3R9QE4L10QE4LO11QE4RO12QE4R13CREF

14

GND

15

SWR

16

SWL

17

OUTRF

18

OUTRR

19

OUTLR

20

OUTLF

21

WINTC

22

MUTE

23

VDD

24

SCL

25

SDA

26

DC_ERR

27

WIN_IN

28

IC161

TDA7718N-X

TAB/NC

1

OFFSET/TAB

2

GND

3

OUTRR-

4

STBY

5

OUTRR+

6

VCC1/2

7

OUTFR-

8

GND

9

OUTFR+

10

RIPPLE

11

INFR

12

INRR

13

PRE-GND

14

INRL

15

INFL

16

AC-GND

17

OUTFL+

18

GND

19

OUTFL-

20

VCC3/4

21

OUTRL+

22

MUTE

23

OUTRL-

24

GND

25

CD/OFFSET

26

TAB/NC

27

IC301

EXT15ANT OUT14SW5V13VDD5V12ACCOUT11ACC IN10GND9CTRL18VCC7CTRL26AUDIO OUT5AUDIO F4CD OUT3ILM F2ILM OUT

1

IC901

LV5680P

SW

1

EN

2

COMP

3

FB4GND

5

FREQ

6

VIN

7

BST

8

MP2562DS-X

IC981

MODE1

1

NC

2

nRST

3

VCC4VSS

5

SCL

6

SDA

7

MODE0

8

MFI341S2313-X

IC80

A0

1

A1

2

A2

3

GND4SDA

5

SCL

6

WPIN

7

VDD

8

IC771

R1EX24002ASAA-X

654

3 2 1

Q321

IMX9-W

654

3 2 1

Q251

IMX9-W

654

3 2 1

Q341

IMX9-W

5 4

321

OPEN

IC961

VDD

4

RST

3

GND2NC

1

IC702

XC6120N282NG-X

VIN

4

VOUT3GND

2

CTRL

1

IC931

XC6213B332NG-X

8 7

6 4

321

QQR1872-001

L4

D321

BAW56-TP-X

-

D781

BAW56-TP-X

-

D341

BAW56-TP-X

-

D783

BAW56-TP-X

-

D780

BAW56-TP-X

-

D251

BAW56-TP-X

-

D891

MC2836-X

D131

D704

D121

D113

D123 D132

D112

DZ2J068/M/-X

D971

DZ2J068/M/-X

D970

D719

D720

D111

D101

D130

D120

D110

D100

D102

D1

D2

D301

D851

MBRX130-TP-X

D941

MBRX130-TP-X

D901

1N5401-BPC04

D942

MBRX130-TP-X

D852

MBRX130-TP-X

D902

MBRX130-TP-X

D981

DB22306-X

D782

RKS801KF-X

D982

RKS801KF-X

D983

C168

C330 10/50

C881

22/16

C350

10/50

C904

47/16

C962

100/6.3

C320

10/50

C252

10/50

C704

100/16

C162 4.7/35

C251 10/50

C907

330/6.3

C911

C906 100/16

C903

47/16

QEKJ1AM-107Z-S

C172

100/10

C340

10/50

C910

10/25

C901

2700/16

C24

100/16

C932

330/6.3

C913 330/6.3

C25

C174 4.7/35

QERF1CM-106Z-E

C310 10/16

C963

QEKJ1CM-106Z-S

C160

10/16

C309

0.47/16

C303

N

0.47/16

C301N

0.47/16

C304

N

0.47/16

C302N

C909

C891

0.1

10

C908

C724

18p

C725

18p

C984

0.1

C989

10

C177

1

C703

0.01

C902

0.47

C988

C368

C722

10

C726

10

C987

C122

1

C990 0.1

C727

27P

C933

0.1

C931

0.1

C254

100p

C941

0.1

C316

C317

C318

C319

C728

0.01

C729

4700P

C730

4700P

C914 4700p

C6

6P

C1

1000P

C954

0.1

C912 0.1

C2 7p

470p

C26

2p

C27

C253

100p

C706

0.1

C120

C131

1

C130

C351

100p

C731

0.1

C732

C8

0.1

C733 10

C28

C29

C341

100p

C321

100p

C121

1

C111

1

C102

1

C101

1

C110 C100

C308

0.47

C331

100p

C307

0.47

C306

0.47

C712

0.1

C713

0.1

C714

0.1

C715

0.1

C305

0.47

NCB21AK-105X-A

C313

1

C132

0.1

C171 1

C170 1

C169 1

C80

0.047

C985 10

C983

150p

10

C981

C982

C708

0.1

C711

0.1

C311

C716 0.1

C723

0.047

C705 0.1

C5

15p

C314

1

C173

1

C166

0.1

C315

1

C312

C702

10p

C21

0.1

C161

1

C4

0.22

C701

10p

C10

1

C19 0.1

C13 1

C851

C15

0.1

C16

0.01

C942

C18

0.01

C12

0.01

C11

0.01

C17 0.1

C23 0.1

C905

0.1

C7

27P

C14

0.22

C22

0.1

C717

0.1

C718 0.47

C112

0.1

C20

12p

C3

1000P

G

3

R

2

L

1

J120

QNS0307-001

J321

QNB0190-001

J1

KEY1 20

KEY0 19

USB5V 18

USB5V 17

D- 16

D+ 15

USBGND 14

LCDDA 13

LCDCE 12

LCDCL 11

VOL2 10

VOL1 9

RGBCL 8

REMOCON 7

10V 6

3.3V 5

D-GND 4

AUX-G 3

AUX-R 2

AUX-L 1

QGZ1102J1-20

CN701

18171615141312111098765432

1

CN901

QNZ0607-001

<Main section 1 (Except KD-BTP50J,52U)>

(Except KD-BTP50J,52U)

To Main section 2

CN601

(A525J,520J,521E,521EU,521EY)

To LCD & Key section

CN601

526UH,526UN,526UT,528J)

(524UI,525U,525UH,525UN,526U,

To LCD & Key section

ANT

SPK BATTERY

created date:2011-03-04No.MA479

23

(No.MA479<Rev.002>)4/

Page 25

0V

3.3V

1.5V

3.3V

3.3V

3.3V

1.6V

1.6V

1.6V

0V

1.6V

1.6V

1.6V

1.6V

1.6V

1.6V

1.6V

3.3V

1.5V

1.6V

VDD5V

1.9V

2.4V

3.0V

1.5V

3.3V

0V

0V

0V

4.6V

4.6V

4.6V

4.6V

1.6V

1.4V

1.6V

0.9V

3.3V

0V

3.3V

2.5V

0V0V3.3V

0V

0V

2.5V

0V

0V

1.7V

3.3V

3.3V

1.4V

1.5V

3.3V

1.5V

0V

0V

0V

0V

0V

3.3V

3.3V

0V

0V

1.7V

0V

1.6V

1.9V

1.6V

3.3V

1.9V

1.6V

0V

1.6V

0V0V0V0V0V0V0V

0V

1.5V

1.6V

0V

1.6V

1.9V

1.9V

1.8V

1.9V

1.9V

1.6V

0V

2.2V

0V

0V

1.6V

1.3V

1.6V

1.6V

3.3V

1.6V

1.6V

1.3V

4.8V

0V

4.5V

1.6V1.6V

1.6V

1.6V

7.2V

3.0V

3.2V

3.2V

3.4V

3.2V

3.0V

3.2V

3.5V

0V

0V

7.2V

0V

!

!

MAIN PWB: GEB10301A

-

4.2V

4.2V

+

4.2V

0v

4.2V

4.2V

8.5V

VCC

4.2V

GND

-

+

CD LPF

BTLGND

LASER DIODE CIRCUIT

16.9344MHz

CD.L

VT2

DSPL

MAINGND

VREF

DRVMUTE

HC1-2

HC1-2

S.GND

A9V

CD.R

DSPL

DSPR

FOCUS-

FOCUS+

VREF

VT1

BTL_FOO

VF1

CD8V

TRK+

TRK-

FOCUS+

FOCUS-

FEED+

FEED-

SP-

SP+

LOAD-

BTL_TRO

LOAD+

PON_CDD1.5V

BTL_FMO

BTL_DMO

FWD

REV

TRK+

FEED+

LOAD+

LOAD-

PSW

SW3

VREF

SW2

SP+

SP-

FEED-

CD_MD

SW1

VF2

TRK-

SW3

CD_MD

PSW

SW2

SW1

DRVMUTE

REV

FWD

BTL_FOO

BTL_TRO

BTL_FMO

BTL_DMO

CDMUTE

VT1

VT2

VF2

VF1

VREF

SRAMSTB

CDMUTE

SRAMSTB

CDRESET

CDRESET

CMDCCE

CMDBUCK

CMDSI

CMDSO

CMDCCE

CMDBUCK

CMDSO

CMDSI

LRCK

BCK

GATE

DATA

BSIF_REQ

CMDREQ

CMDREQ

BSIF_REQ

GATE

DATA

BCK

LRCK

PON_CD

DSPR

sure to use the specified one.

When replacing those parts make

Parts are safety assurance parts.!

3 2 1

X540

QAX0929-001Z

R549

1K

R529

R557

470

R599

47k

R591

0

R555

4.7

R542

R554

4.7

R596

R593

20k

R556

0

R588

220K

R584 10k

R563

100

R586

0

R580

0

R531

R532

R533

R562

100

R564

100

R577

10K

R576

10K

R520

10k

R561

100

R560

100

R518

100

R559

100

R517

8.2k

R565 10K

R516

8.2k

R510

8.2k

R566 10K

R513

0

R567 100

R507

11K

R509

0

R568 100

R515

0

R514

8.2k

R569 100

R504

51k

R508

0

R545

2.2M

R519

68k

R501

33k

R572 100K

R571 10K

R583 10k

R530

0

R512

0

R570 100

R574

15K

R573

330K

R511

0

R540

220

R506

6.8K

R502

100

R541

0

R589 10k

R528

R503

100

R558

1M

R590 10k

R582

220k

R579

10k

R585

0

R551 0

R595

R587

47K

R581 47k

R598 47k

R552 0

R592

20k

R553 47K

R547 4.7

R597

10k

R594 10

R543

0

R534

10K

R546

R505

22K

R544

R548 100K

R550

4.7K

R575

3.3k

Q540

2SA2188/F/-X

NQR0502-001X

L562

NQR0502-001X

L531

NQR0502-001X

L561

NQR0502-001X

L563

NQR0502-001X

L564

NQR0502-001X

L565

VCoF 80

PVREF 79

LPFo

78

LPFN

77

TMAX

76

PDo 75

VDDM1

74

/SRAMSTB 73

VSS-1

72

VDD-1 71

TEST 70

/RST 69

MS

68

/CCE 67

BUCK 66

BUS3 65

BUS2 64

BUS1 63

BUS0 62

VDD3

61

Pio7

60

Pio6

59

Pio5

58

Pio4

57

Pio3

56

Pio2

55

Pio1

54

Pio0

53

VSS-2

52

VDD1-2

51

XVDD3

50

Xo

49

Xi

48

XVSS3

47

DVSS3L

46

Lo

45

DVDD3L

44

DVDD3R

43

Ro

42

DVSS3R

41

CDMoN340

Pio14/CDMoN239

Pio13/CDMoN138

Pio12/CDMoN0/FGiN37

Pio1136

Pio1035

Pio934

Pio833

VDD1-332

DMo31

FMoS30

FMo29

VSS-328

TRo27

Foo26

AVDD325

TEi24

RFRP23

RFZi22

FSMoNiT21

LDo

20

MDi

19

AVSS3

18

VRo

17

TNi

16

TPi

15

FPi1

14

FPi2

13

FNi1

12

FNi2

11

RVSS3

10

RFo

9

AGCi

8

DCoFC

7

RFEQo

6

RFRPI

5

RFI

4

SLCO

3

RVDD3

2

VCOI

1

JCV8022

IC540

38

GND

37

GND

36

S-GND

35

VCONT

34

MUTE1

33

MUTE234

32

VIN4-

31

VIN4

30

VREF-IN

29

VREF-OUT

28

REG-OUT

27

REG-IN

26

VIN+OP

25

VIN-OP

24

VO-OP

23

VIN3

22

VIN3-

21

VIN2

20

VIN2-

19

VIN2+

18

VIN117VIN1-16VIN1+15VCCS14VCCP113VO1+12VO1-11VO2+10VO2-

9

VO3-8VO3+7VO4-6VO4+5VLO+4VLO-3VCC22REV1FWD

LA6565-X

IC501

1234

5 6 7 8

NJM4565E-X

IC580

VIN

4

VOUT3GND

2

CTRL

1

IC531

XC6213B152NG-X

VIN

4

VOUT3GND

2

CTRL

1

IC532

XC6213B152NG-X

VIN

4

VOUT3GND

2

CTRL

1

IC530

XC6213B332NG-X

RKS801KF-X

D540

D502

GS1J-LTP-X

D503

QERF1EM-475Z-E

C586

4.7/25

QEKJ0JM-467Z-S

C590

47/6.3

QEKJ0JM-467Z-S

C591

47/6.3

QERF1EM-475Z-E

C584

4.7/25

C514

100/10

C596

4700p

C508

C509

C510

C552

0.033

C553 4700p

C554 390P

C555 680P

C556 0.068

C557 0.047

C516

0.1

C515

C550 10

C551

0.1

C504

0.1

C535

0.1

C534

0.1

C546 1

C548 68p

C549

0.1

C547

0.015

C545 0.1

C544 3300p

C543

0.01

C541 2200p

C540 0.1

C531

0.1

C530

1

C532

1

C572

0.015

C574 0.01

C573

0.1

C571

47p

C569

0.1

C567 1

C533

0.1

C511

470p

470P

C512

C518

C507

C517

C506

C505

C501

C513

0.1/50

C503

0.1

C575

C576

1500p

C592

C585

68p

C570

0.1

C563

C560

C582

C593

C561 10

C562 10

C565

0.1

C564

0.1

C559

0.1

C542 0.1

C568

0.1

C566

0.1

C558

0.1

C595

68p

C587

68p

C588

0.1

C583

C594

68p

TRK-

26

TRK+

25

FOCUS+

24

FOCUS-

23

GND

22

LD

21

GND

20

SPINDLE-

19

SPINDLE+

18

FEED-

17

FEED+

16

LOAD+

15

LOAD-

14

HC1_2

13

GND

12

MD

11

VREF

10

VT1

9

PSW

8

VT2

7

SW1

6

VF2

5

SW2

4

D3.3V

3

SW3

2

VF1

1

CN502

QGF1040F1-26

<Main section 2 (Except KD-BTP50J,52U)>

(Except KD-BTP50J,52U)

To Main section 1

CN101

To CD section

created date:2011-03-04No.MA479

23

(No.MA479<Rev.002>)5/

Page 26

BTP52U Series

BTP52U Series

BTP52U Series

DZ2J062/M/-XDZ2J062/M/-X

NIL

NIL 1k ohm1k ohm

D704

R777

0 ohm

47/16

22/16

0 ohm

*

*

*

*

Tuner

Out

Line

*

*

NIL

NIL

10/50

330 ohm

NILC727

OTHERS

NIL

KD-R527EE* REMARK

R330

C330

B314

27p

2.24V1.81V 2.24V 2.24V 1.02V 1.81V

0V1.47V0.58V 0V1.02V0.58V

STAGE2

STAGE1

STAGE

VOLTAGE

L10

Tuner

R9

22k ohm

27k ohm

27k ohm

OE REMOTE

R785

0 ohm

QAM1344-001

NIL 10pC28

NQL103J-10NX

POWER CORD ASSY QAM1345-001QAM1330-001 QAM1329-001

NIL

NIL

*

42 6

5

31

654321

-Rear-L/Sub-L- - - Rear-R/Sub-R

-Rear-R/Sub-RFront-L Front-R

Rear-L/Sub-L

-

Front-RRear-R Sub-RSub-LFront-LRear-L

***

*

QEKJ1CM-476Z-S

100p

100pNILC316~319

!

( )( )

MAINGND

(3.3V)

(3.3V)

(3.3V)

(3.3V)

(3.3V)

(3.3V)

(0V)

(0V)

(0V)

(0V)

3.3V

(0V)

3.3V

3.3V

(3.3V)

3.3V

(7.9V)

0V

14.4V

( )

( )

( )

*

NO USED FOR KD-R527EE

*

*

*

*

*

*

J321MODELS* REMARK

1 pair

2 pairs

3 pairs

R527EE

R626U,R621E,A625J,R628J

R526U,R525U,R524UI,R528J,R620J

QNN0864-001

QNN0866-001

QNN0868-001

NIL

NIL

0 ohm

NIL

NIL

NIL

0.047

100 ohm

NQL553J-27NJ

0.1

68 ohm47 ohm

0.1

NQL553J-27NJ

100 ohm

0.047