Page 1

SERVICE MANUAL

CD RECEIVER

MA387<Rev.003>20089SERVICE MANUAL

KD-BT11J, KD-BT11E, KD-BT11EX,

KD-BT11EY, KD-BT11EU, KD-BT11EE,

KD-BT11U, KD-BT11UT, KD-BT19UR,

KD-BT12E, KD-BT12EX

for J/U/UT/UR

for

E/EX/EY/EU/EE

COPYRIGHT © 2008 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

for EE

for J/UR

COPYRIGHT © 2008 Victor Company of Japan, Limited

No.MA387<Rev.003>

2008/9

Page 2

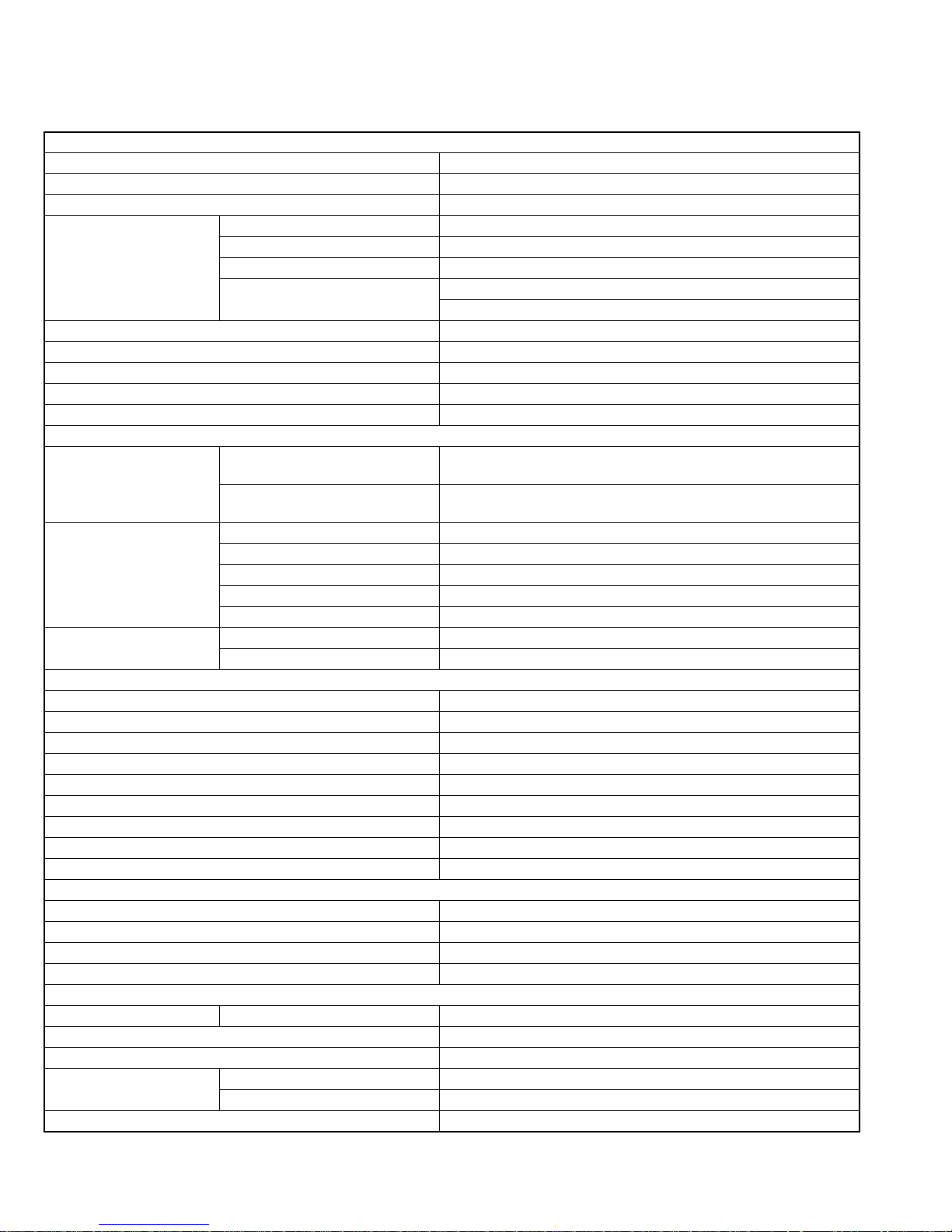

SPECIFICATION

J / UR

AUDIO AMPLIFIER SECTION

Power Output 20 W RMS × 4 Channels at 4 Ω and < or = 1% THD+N

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz)

Mid-range ±12 dB (500 Hz, 1.0 kHz, 1.5 kHz, 2.5 kHz)

Treble ±12 dB (10.0 kHz 12.5 kHz 15.0 kHz 17.5 kHz)

Q Bass: Q1.0, Q1.25, Q 1.5, Q2.0

Mid-range: Q0.5, Q0.75, Q1.0, Q1.25

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Subwoofer-Out Level/Impedance 2.5 V /20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal CD changer jack AUX (auxiliary) input jack Antenna input

TUNER SECTION

Frequency Range FM

AM with channel interval set to 10 kHz: 530 kHz to 1 710 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz)

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

Version Bluetooth 1.2 certified

Power Class Class 2 Radio (possible distance 10 m)

Service Area 10 m

Profile HFP 1.5, OPP 1.1, A2DP 1.2, AVRCP 1.3

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D)

(approx.)

Mass 1.3 kg (2.9 lbs) (excluding accessories)

Design and specifications are subject to change without notice.

Installation Size

Panel Size 188 mm × 58 mm × 6 mm (7-7/16” × 2-5/16” × 1/4”)

with channel inter val set to 100 k Hz or 200 kH z: 87.5 MH z to 107.9 MH z

with channel interval set to 50 kHz: 87.5 MHz to 108.0 MHz

with channel interval set to 9 kHz: 531 kHz to 1 602 kHz

65 dB

BLUETOOTH

GENERAL

182 mm × 52 mm × 160 mm (7-3/16” × 2-1/16” × 6-5/16”)

1-2 (No.MA387<Rev.003>)

Page 3

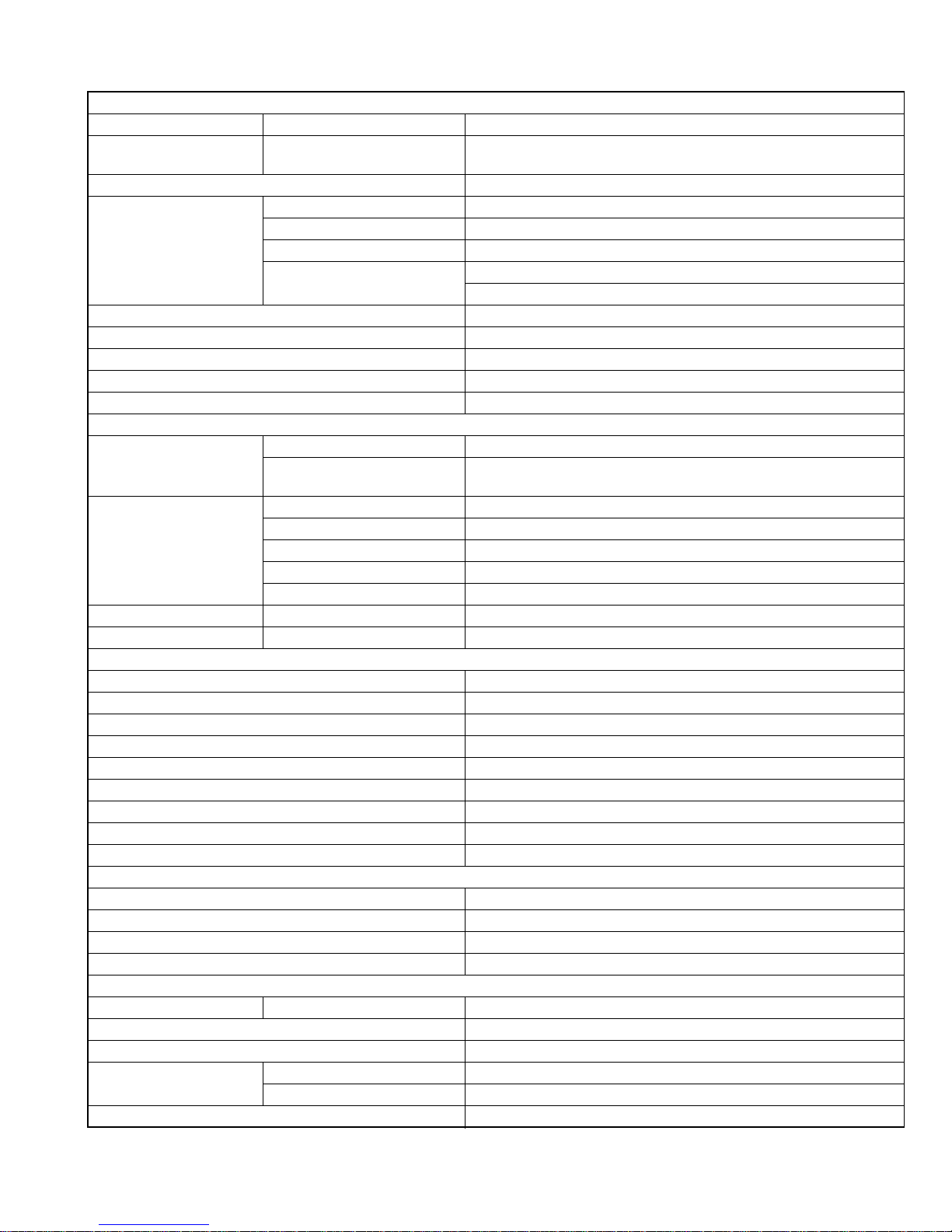

E/EX/EY/EU

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Front/Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz)

Mid-range ±12 dB (500 Hz, 1.0 kHz, 1.5 kHz, 2.5 kHz)

Treble ±12 dB (10.0 kHz 12.5 kHz 15.0 kHz 17.5 kHz)

Q Bass: Q1.0, Q1.25, Q 1.5, Q2.0

Mid-range: Q0.5, Q0.75, Q1.0, Q1.25

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 80 dB

Line-Out/Subwoofer-O ut Level/Impedance 2.5 V /20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal

CD changer jack Steering wheel remote input AUX (auxiliary) input jack Aerial input

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM MW: 522 kHz to 1 620 kHz

LW: 144 kHz to 279 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Sel ectivity (400 kHz )

65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

MW Tuner Sensitivity/Selectivity 20 µV/35 dB

LW Tuner Sensitivity 50 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

BLUETOOTH

Version Bluetooth 1.2 certified

Power Class Class 2 Radio (possible distance 10 m)

Service Area 10 m

Profile HFP 1.5, OPP 1.1, A2DP 1.2, AVRCP 1.3

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negat ive ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

Installation Size 182 mm × 52 mm × 160 mm

Panel Size 188 mm × 58 mm × 13 mm

Mass 1.3 kg (excluding accessor ies)

Design and specifications are subject to change without notice.

(No.MA387<Rev.003>)1-3

Page 4

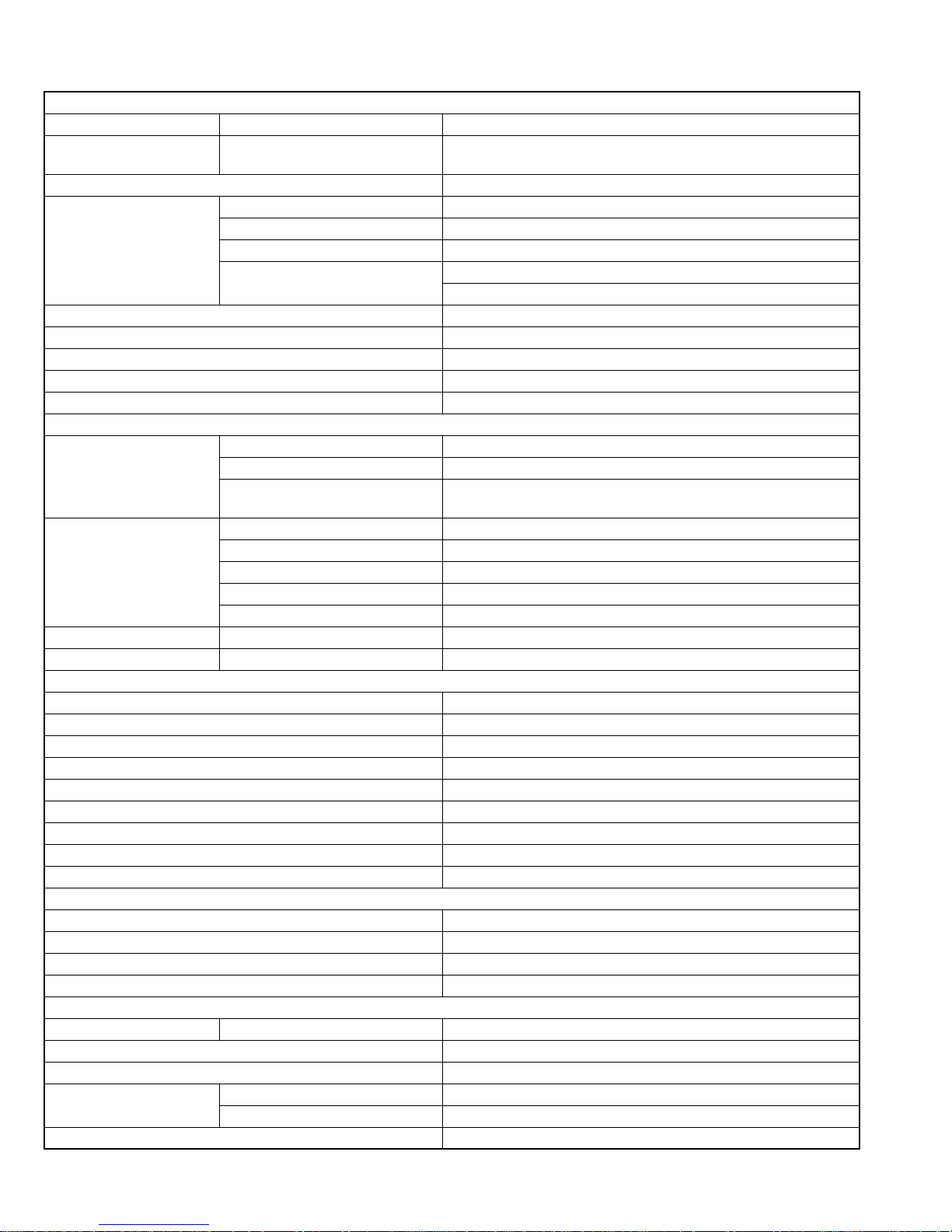

EE

AUDIO AMPLIFIER SECTION

Maximum Power Ou tput Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Front/Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 H z at no more than 0.8%

total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz)

Mid-range ±12 dB (500 Hz, 1.0 kHz, 1.5 kHz, 2.5 kHz)

Treble ±12 dB (10.0 kHz 12.5 kHz 15 .0 kHz 17.5 kHz)

Q Bass: Q1.0, Q1.25, Q 1.5, Q2.0

Mid-range: Q0.5, Q0.75, Q1.0, Q1.25

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 80 dB

Line-Out/Subwoofer-Out Level/Impedance 2.5 V /20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal AUX (auxiliary) input jack, Aerial input

TUNER SECTION

Frequency Range FM1/FM2 87.5 MHz to 108.0 MHz

FM3 65.00 MHz to 74.00 MHZ

AM MW: 522 kHz to 1 620 kHz

LW: 144 kHz to 279 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channe l Selec tivity (40 0 kHz )

65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

MW Tuner Sensitivity/Selectivity 20 µV/35 dB

LW Tuner Sensitivity: 50 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

BLUETOOTH

Version Bluetooth 1.2 certified

Power Class Class 2 Radio (possible distance 10 m)

Service Area 10 m

Profile HFP 1.5, OPP 1.1, A2DP 1.2, AVRCP 1.3

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

Installation Size 182 mm × 52 mm × 160 mm

Panel Size 188 mm × 58 mm × 13 mm

Mass 1.3 kg (exclu ding accessories)

Design and specifications are subject to change without notice.

1-4 (No.MA387<Rev.003>)

Page 5

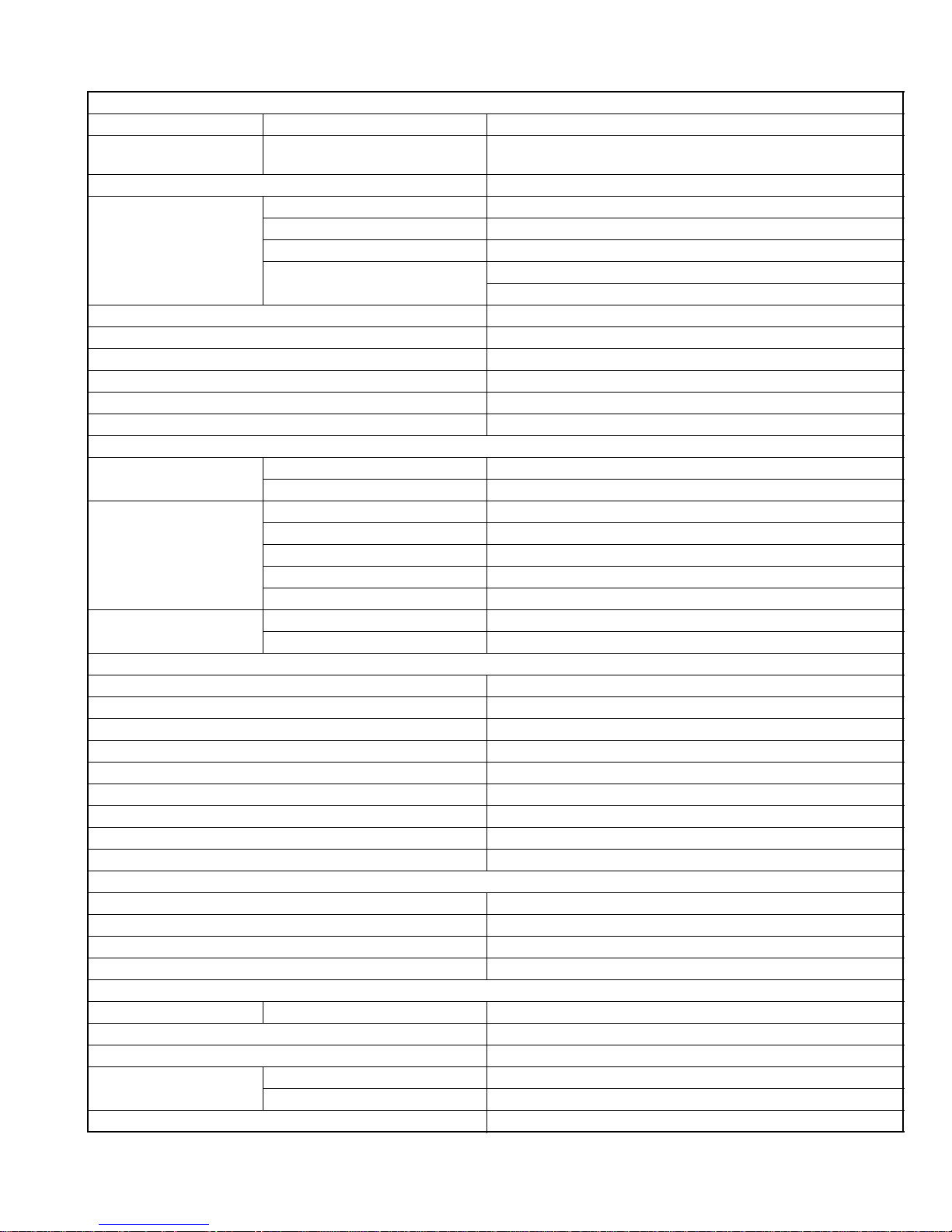

U/UT

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Front/Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz)

Mid-range ±12 dB (500 Hz, 1.0 kHz, 1.5 kHz, 2.5 kHz)

Treble ±12 dB (10.0 kHz 12.5 kHz 15.0 kHz 17.5 kHz)

Q Bass: Q1.0, Q1.25, Q 1.5, Q2.0

Mid-range: Q0.5, Q0.75, Q1.0, Q1.25

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 80 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Subwoofer-Out Level/Impedance 2.5 V /20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminal CD changer jack AUX (auxiliary) input jack Antenna input

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz)

65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

BLUETOOTH

Version Bluetooth 1.2 certified

Power Class Class 2 Radio (possible distance 10 m)

Service Area 10 m

Profile HFP 1.5, OPP 1.1, A2DP 1.2, AVRCP 1.3

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative groun d

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

Installation Size 182 mm × 52 mm × 160 mm

Panel Size 188 mm × 58 mm × 6 mm

Mass 1.3 kg (excluding accessories)

Design and specifications are subject to change without notice.

(No.MA387<Rev.003>)1-5

Page 6

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-6 (No.MA387<Rev.003>)

Page 7

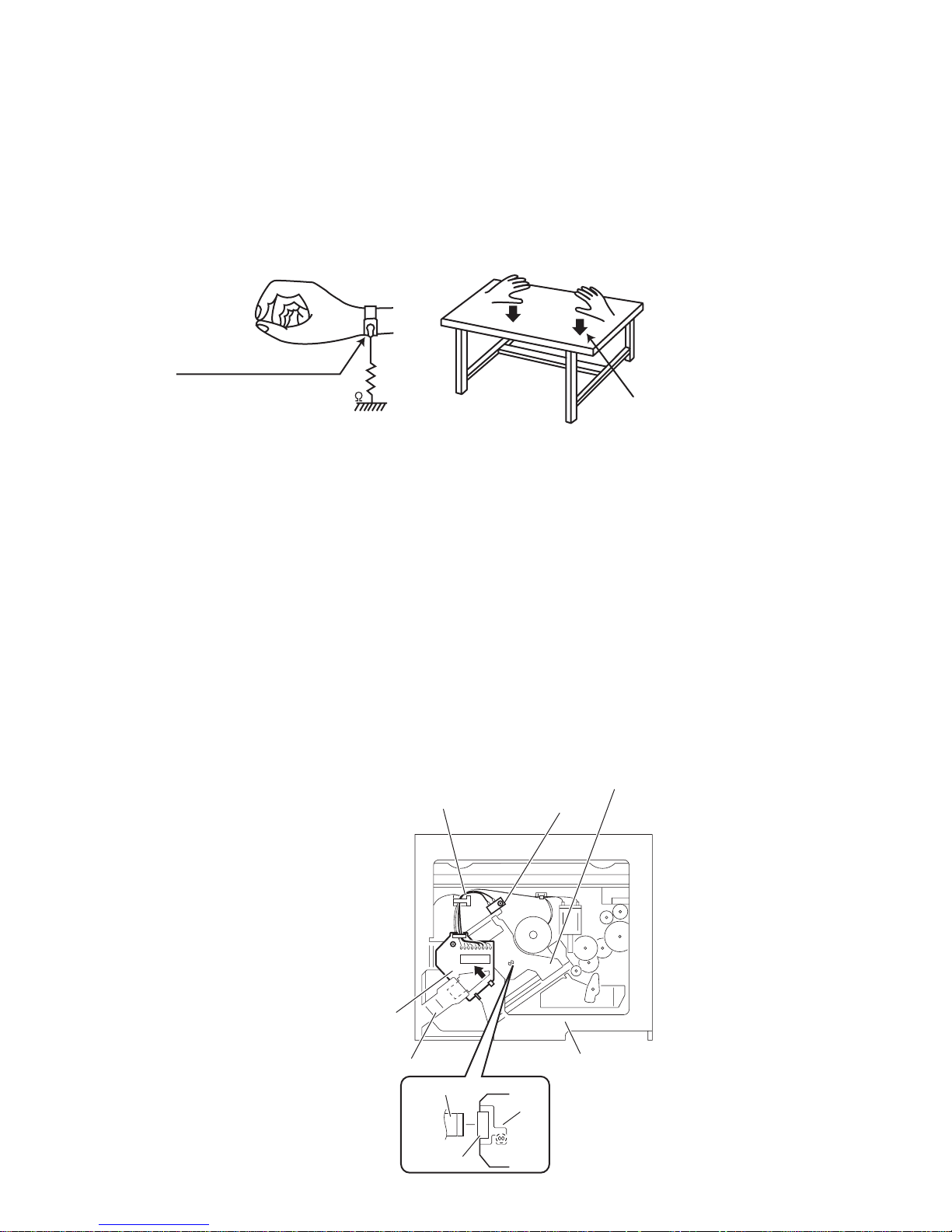

1.2 Preventing static electricity

Electrostatic discharge (ESD), w hi ch occurs w hen sta tic ele ct ricit y sto red i n the bod y, fa bric , etc. is discharged, ca n de stroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to che ck the con dition of th e laser dio de in the opt ical pick up. The tes ter's internal power so urce can ea sily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nip pers, etc. afte r replacing th e optical pi ckup. For speci fic details, refe r to the

replacement procedure in th e t ext . R em ove the anti-static pin w he n re pla cing the traverse unit. Be c arefu l not to tak e to o l on g a

time when attaching it to the connector .

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

Pickup

Wires

Push switch

Base board

Frame

Flexible wire

Connector

CD mechanism

assembly

Pickup

(No.MA387<Rev.003>)1-7

Page 8

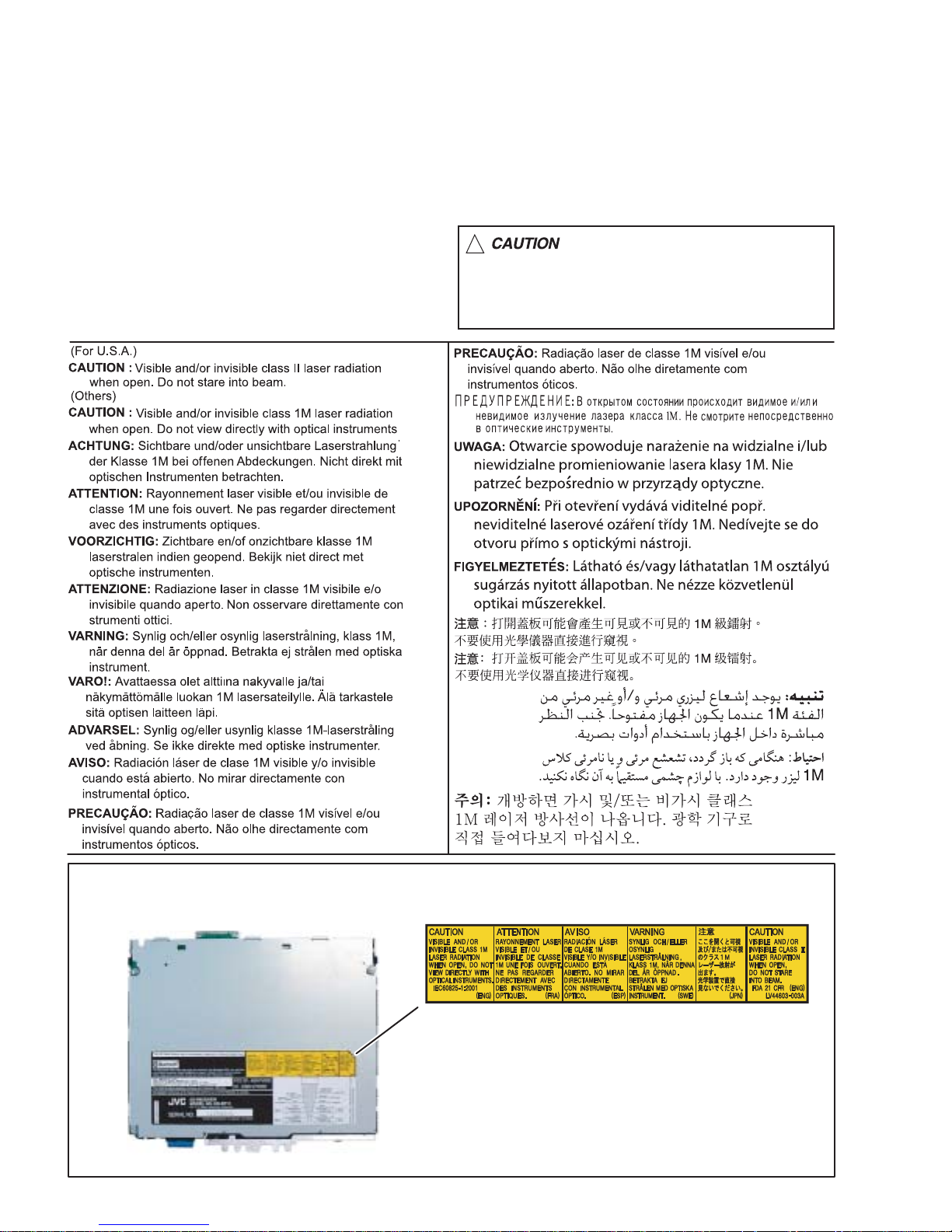

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-8 (No.MA387<Rev.003>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

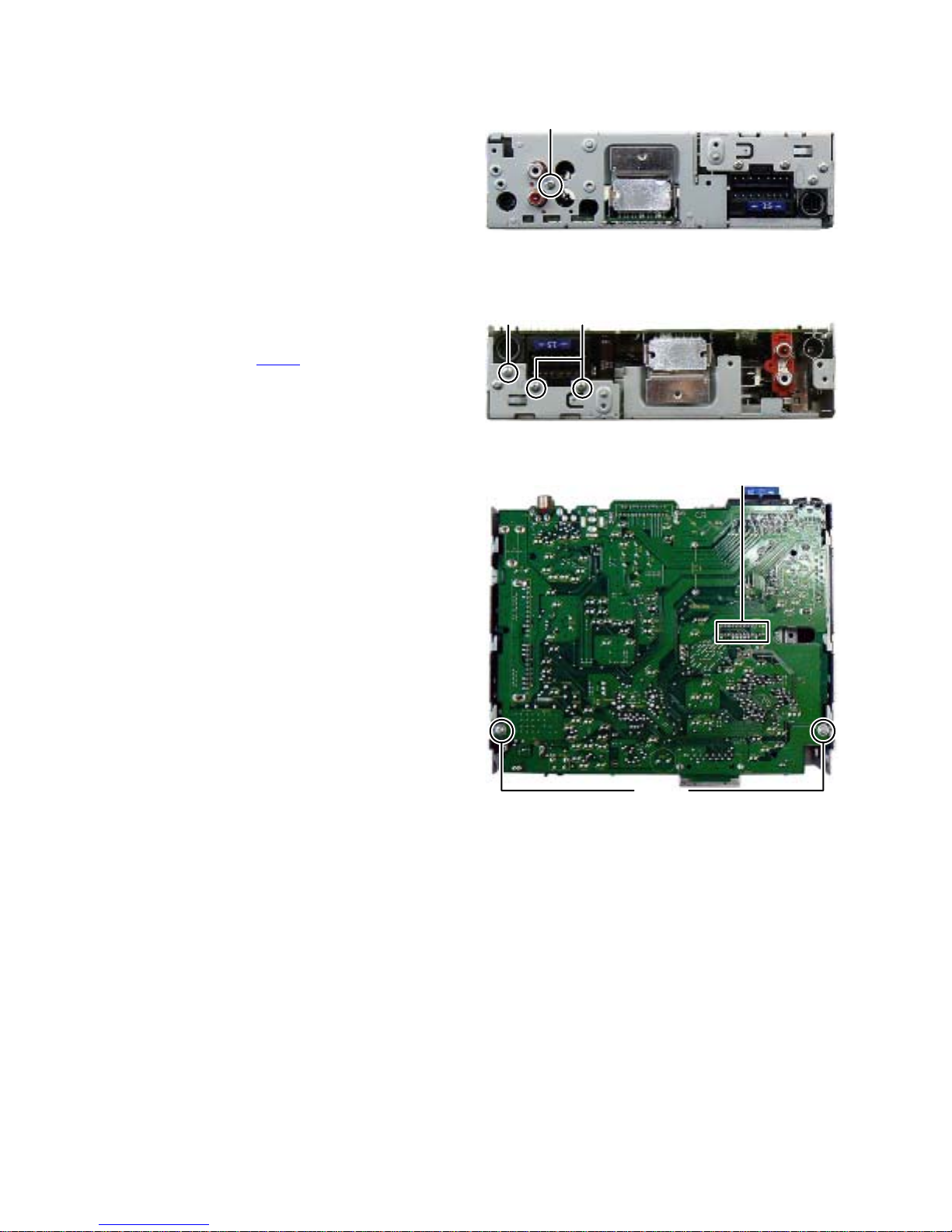

3.1 Main body

3.1.1 Removing the FRONT CHASSIS assembly (See Fig.1)

(1) Disengage the four hooks a engaged the both side of the

FRONT CHASSIS assembly.

hook

a

Fig.1

3.1.2 Removing the HEAT SINK (See Fig.2, 3)

(1) Remove the three screws A and the two screws B attaching

the HEAT SINK. (See Fig.2)

(2) Remove the two screws C and the one screw D attaching

the HEAT SINK. (See Fig.3)

A

B

Fig.2

D

C

Fig.3

(No.MA387<Rev.003>)1-9

Page 10

3.1.3 Removing the BOTTOM COVER (See Fig.4)

(1) Remove the one screw E attaching the BOTTOM COVER.

(2) Slide the BOTTOM COVER to backward.

3.1.4 Removing the MAIN BOARD assembly (See Fig.5, 6)

(1) Remove the two screws F and the one screw G attaching

the MAIN BOARD assembly. (See Fig.5)

(2) Remove the two screws H attaching the MAIN BOARD assembly.

(See Fig.6)

(3) Disconnect the connector CN501

BOARD assembly and CD MECHANISM assembly. (Se e

Fig.6)

connected to MAIN

E

Fig.4

FG

Fig.5

CN501

1-10 (No.MA387<Rev.003>)

H

Fig.6

Page 11

3.1.5 Removing the CD MECHANISM assembly (See Fig.7)

(1) Remove the three screws J attaching the CD MECHANISM

assembly.

3.1.6 Removing the SWITCH BOARD assembly (See Fig.8)

(1) Remove the VOLUME KNOB.

(2) Remove the four screws K attaching the REAR COVER.

(3) Disengage the nine hooks b engage d the REAR COVER.

Fig.7

hook

J

J

b

K

Fig.8

hook

K

b

(No.MA387<Rev.003>)1-11

Page 12

3.2 CD mechanism assembly

A

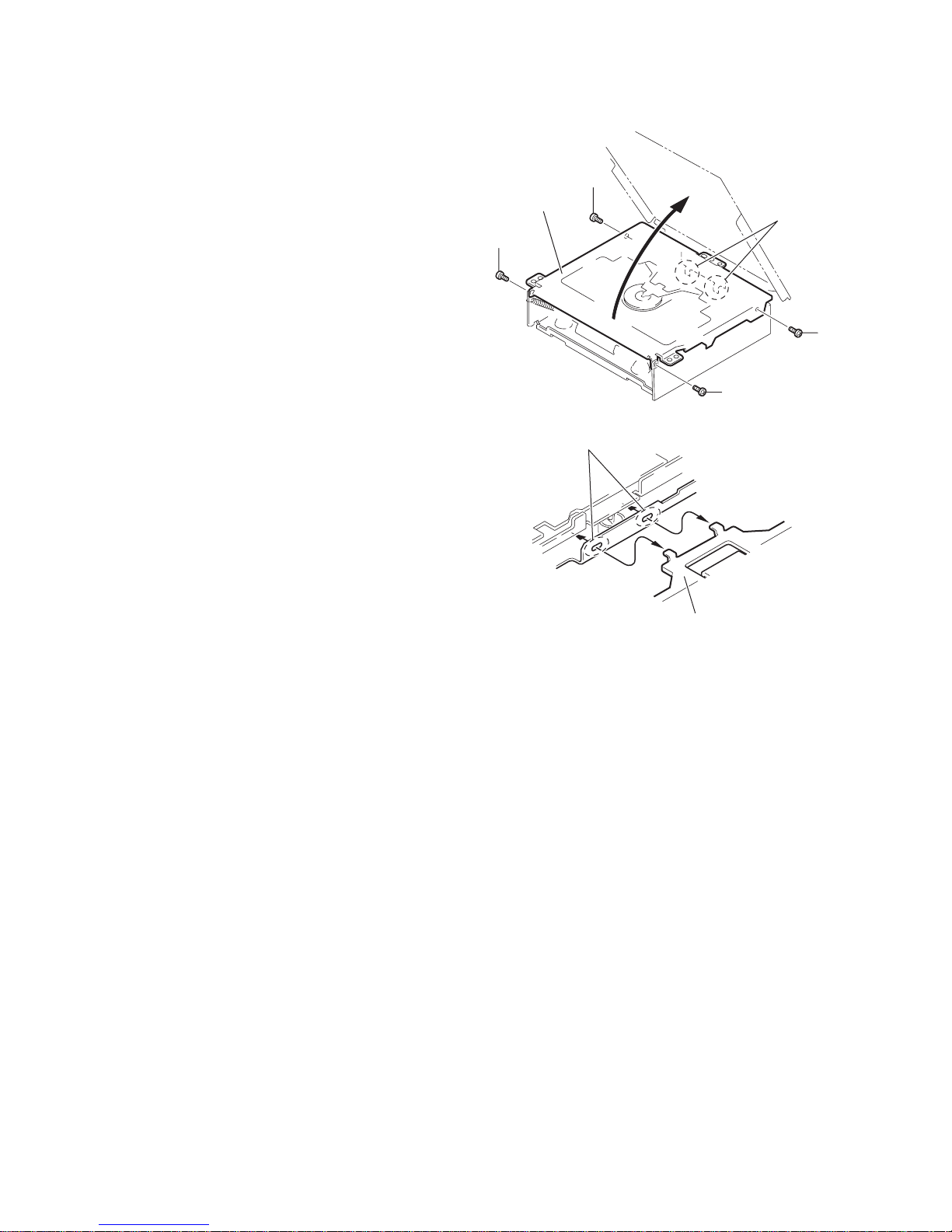

3.2.1 Removing the top cover

(See Figs.1 and 2)

(1) From the both side of the CD mechanism assembly, re-

move the four screws A attaching the top cover. (See

Fig.1.)

(2) Lift the front side of the top cover and move the top cover

backward to release the two joints a. (See Figs.1 and 2.)

Top cover

A

a

A

A

Fig.1

a

Top cover

Fig.2

1-12 (No.MA387<Rev.003>)

Page 13

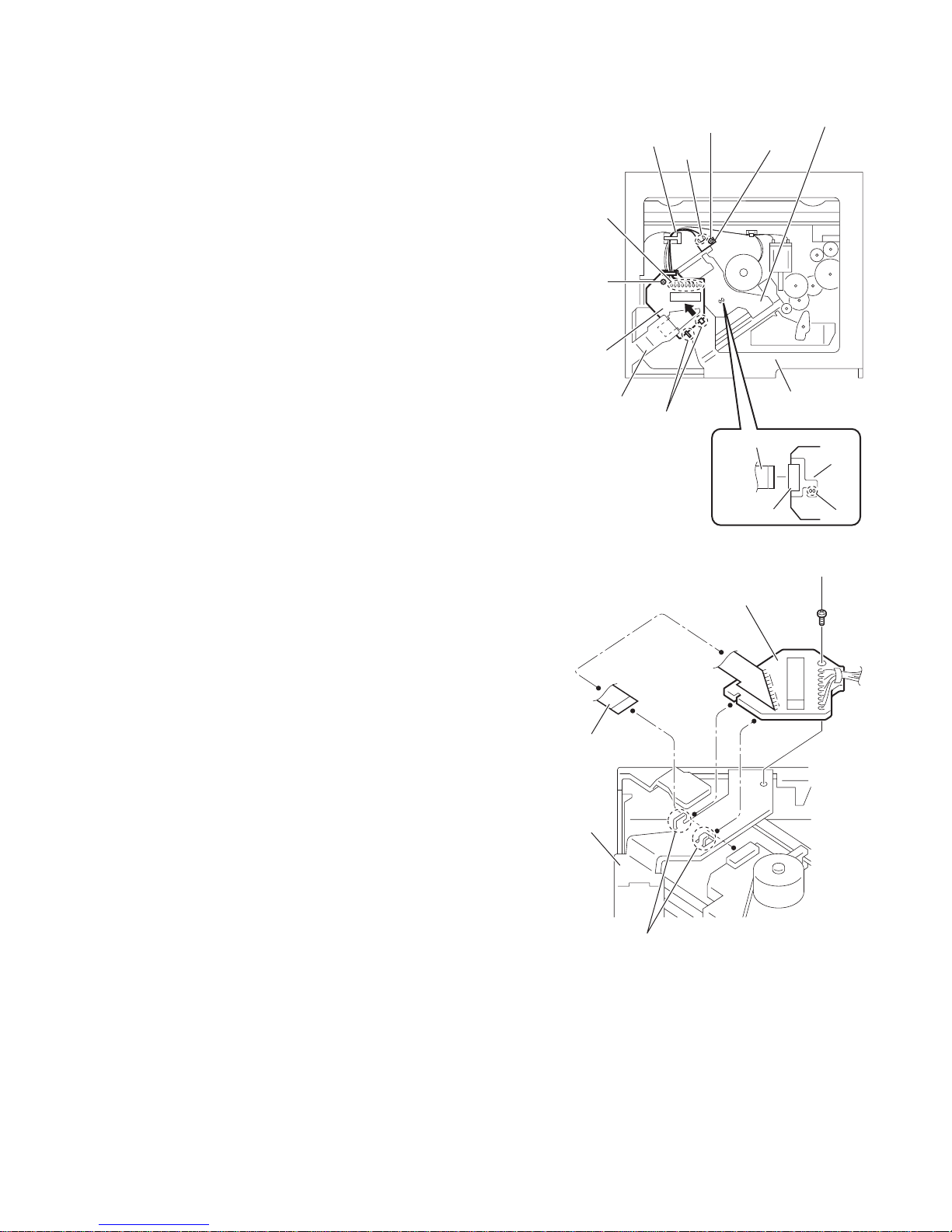

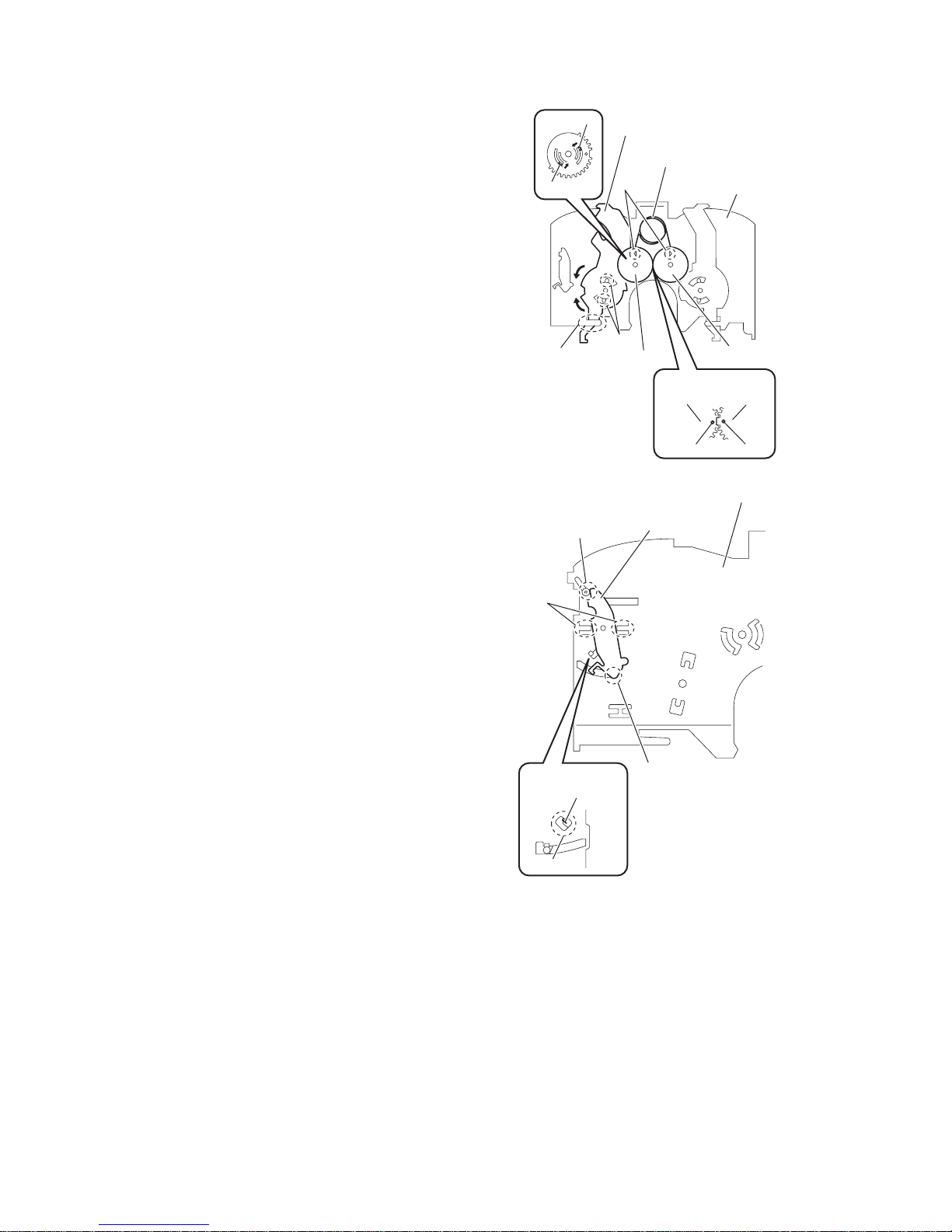

3.2.2 Removing the push switch

(See Figs.3)

(1) From the bottom side of the CD mechanism assembly, re-

move the screw B attaching the push switch.

(2) Take out the push switch from the CD mechanism assem-

bly.

Reference:

Remove the wires fro m solder ed sections b of the push sw itch

as required.

3.2.3 Removing the base board

(See Figs.3 and 4)

Caution:

Solder the short land c before the f lexib le wire is disc onnec ted

from the connector on the pic ku p. If the f lex ible wire is disconnected without applying solder, the pickup may be destroyed

by static electricity. (See Fig.3.)

(1) From the bottom side of the CD mechanism assembly, re-

move the scre w C attaching the base board. (See Figs.3

and 4.)

(2) Solder the short land c on the pickup. (See Fig.3.)

(3) Disconnect the flexible wire fr om the conne ctor on the pic k-

up. (See Fig.3.)

(4) Remove the base board from the joints d of the fram e in the

direction of the arrow. (See Figs.3 and 4.)

Reference:

Remove the wires from the soldered sections e on the base

board as required. (See Fig.3.)

Caution:

When reattaching the base board, be sure to remove solder

from the short land c after connecting the flexible wire. (See

Fig.3.)

e

C

Base board

Frame

Wires

B

b

d

Push switch

Flexible wire

Connector

Fig.3

Pickup

CD mechanism

assembly

Pickup

c

C

Base board

Flexible wire

Frame

d

Fig.4

(No.MA387<Rev.003>)1-13

Page 14

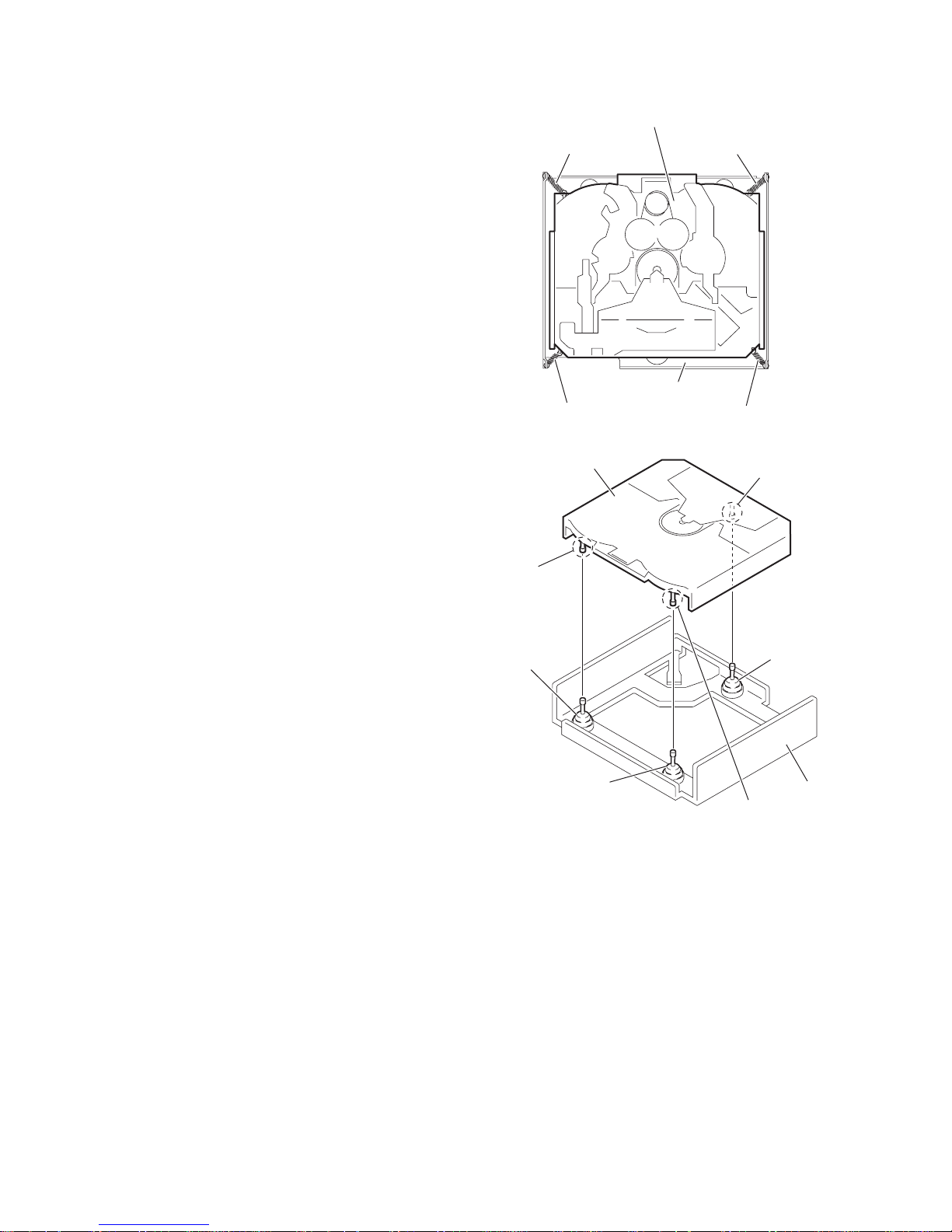

3.2.4 Removing the chassis unit

(See Figs.5 and 6)

• Remove the top cover and base board.

(1) From the top side of the CD mec hanism a ssembly, r emove

the front suspension springs and rear suspension springs

attaching the chassis unit to the frame. (See Fig.5.)

(2) Remove the chassis unit from the da mpers on the f rame in

an upward direction. (See Fig.6.)

Note:

• Pay attention to misuse and loss of each spring. (See Fi g.5.)

• When reassembling, make sure that the three shafts on the

underside of the chassis unit are inserted to the dampers

certainly. (See Fig.6.)

Chassis unit

Front suspension spring

Front suspension spring

Frame

Rear suspension spring Rear suspension spring

Fig.5

Chassis unit

Shaft

Shaft

Damper F

Damper F

Damper R

Frame

Shaft

Fig.6

1-14 (No.MA387<Rev.003>)

Page 15

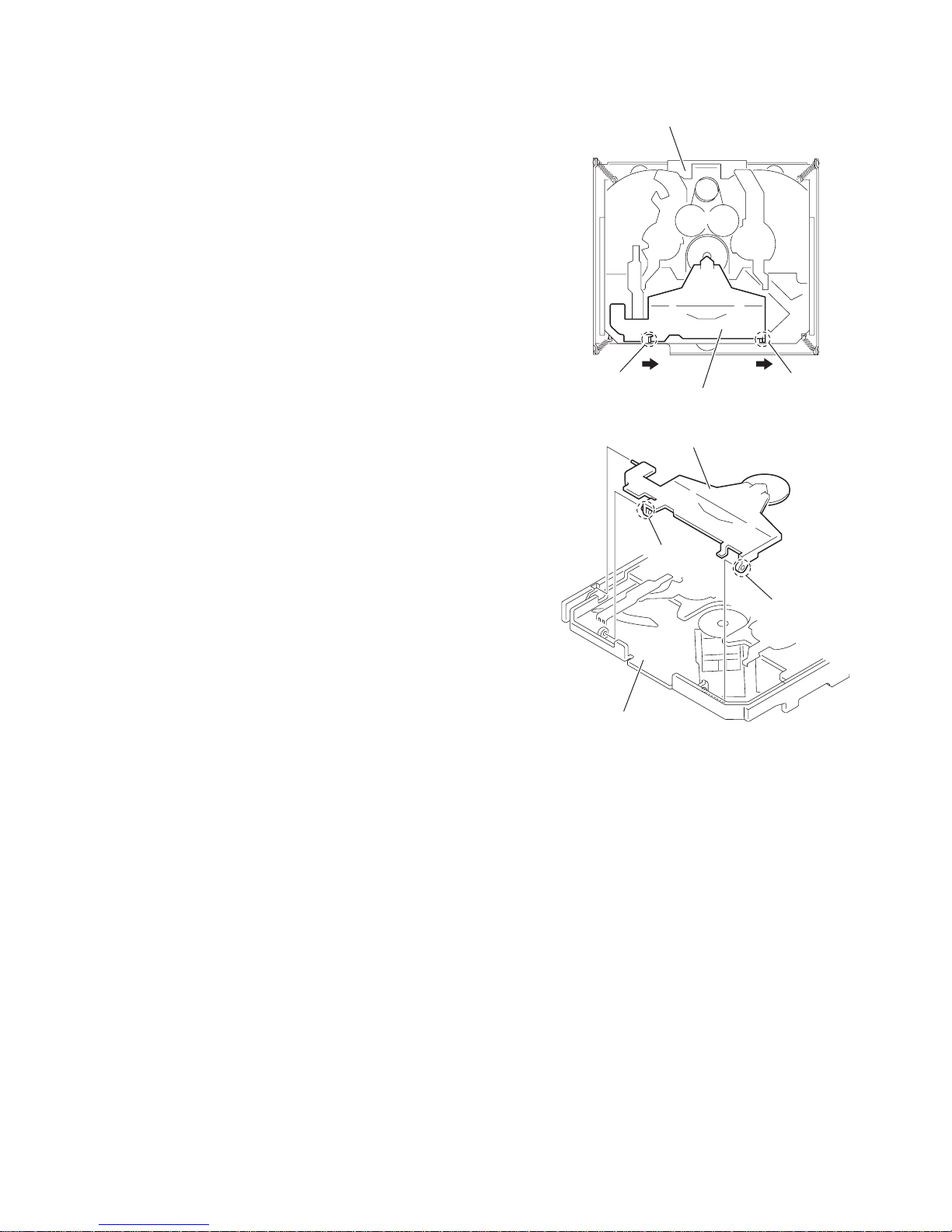

3.2.5 Removing the clamper assembly

(See Figs.7 and 8)

• Remove the top cover.

Move the clamper assembly in the direction of the arrow to release the joints f from the chassis unit.

Chassis unit

f

Clamper assembly

Clamper assembly

Chassis unit

f

Fig.7

f

f

Fig.8

(No.MA387<Rev.003>)1-15

Page 16

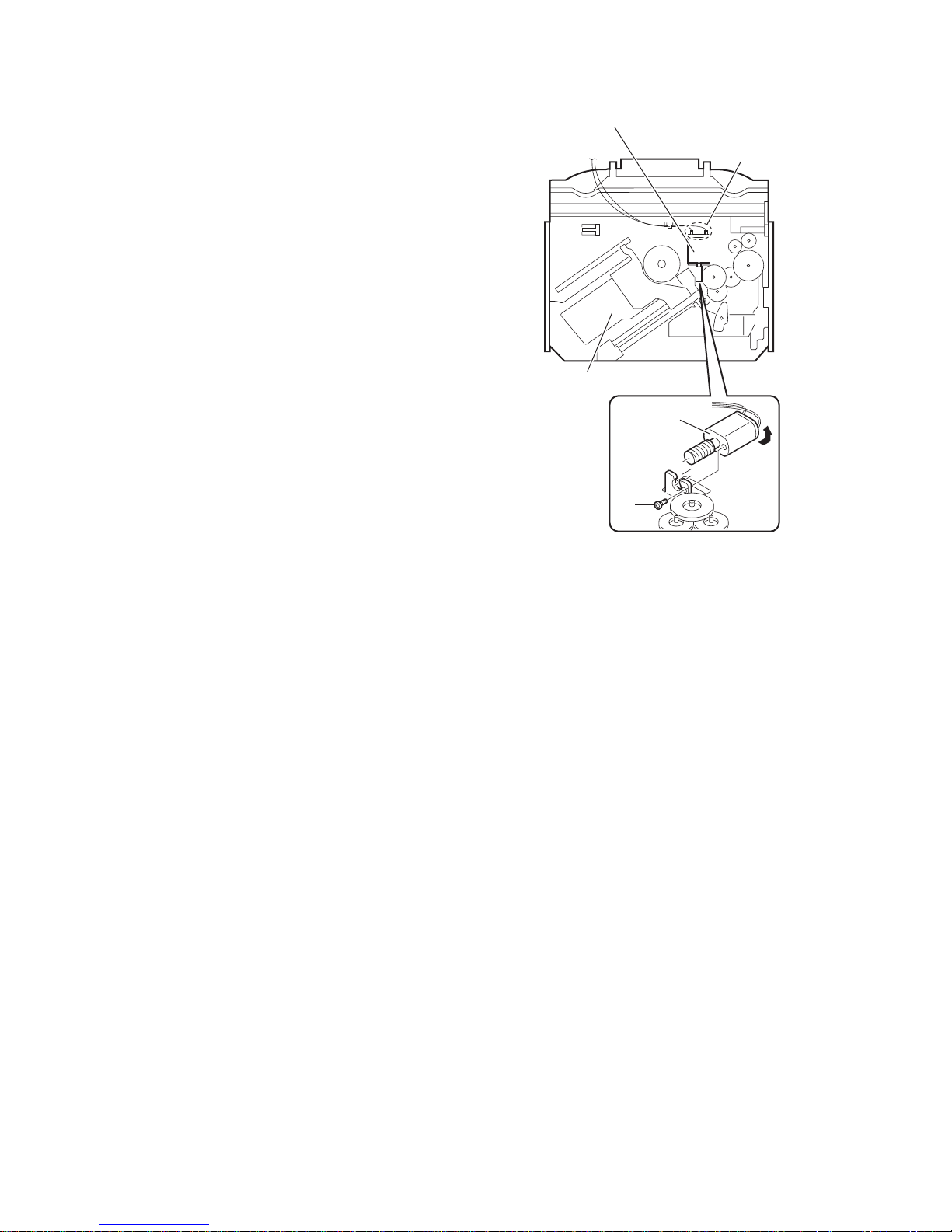

3.2.6 Removing the loading/feed motor assembly

(See Fig.9)

• Remove the top cover, base board and cha ss is unit.

From the bottom side of the chassis unit, remove the screw D

and take out the loading/feed motor assembly in the direction of

the arrow.

Reference:

Remove the wires from th e sold ered sec tions g of the lo ading /

feed motor assembly as required.

Loading/feed motor assembly

g

Chassis unit

Loading/feed

motor

assembly

D

Fig.9

1-16 (No.MA387<Rev.003>)

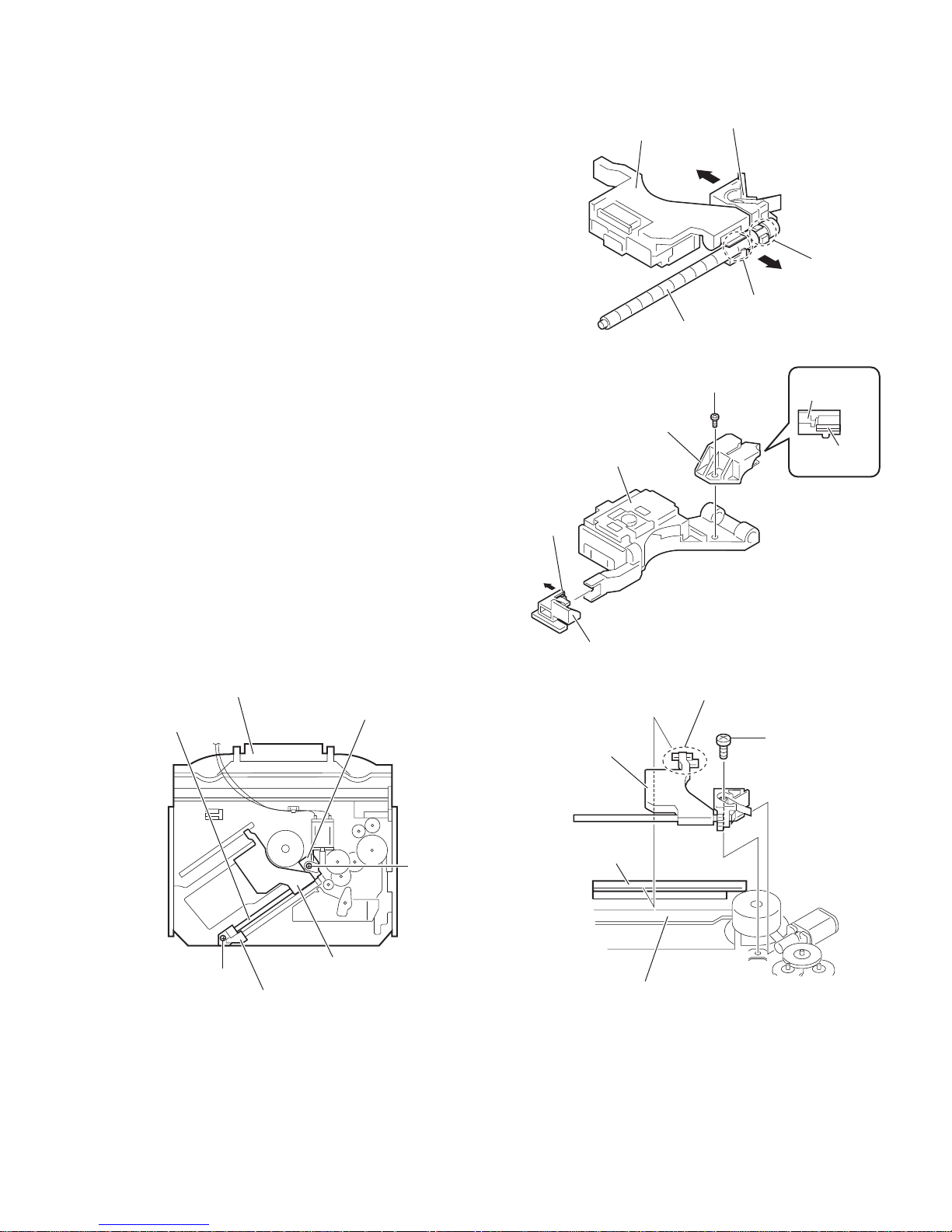

Page 17

3.2.7 Removing the pickup

(See Figs.10 to 12)

• Remove the top cover, base board and chassis unit.

(1) From the bottom side of the chassis unit, remove the screw

E attaching the pu. shaf t ho lder B an d pull the pu . shaft out

of the pu. shaft holder A. (See Fig.10.)

(2) Remove the screw F attaching the pu. sh aft hol der A. (See

Fig.10.)

(3) Take out the pickup with pu. shaft holder A an d feed s crew

assembly from the chassis unit. (See Fig.11.)

(4) Remove the section h of the pu. shaft holder A in th e direc-

tion of the arrow. (See Fig.11.)

(5) Remove the feed screw assembly from the section j of the

pickup in the direction of the arrow. (See Fig.11.)

(6) Remove the screw G attaching the feed screw holder to the

pickup. (See Fig.12.)

Reference:

Remove the feed nut spring from the feed screw holder

as required. (See Fig.12.)

(7) Release th e c law k in the direction of the arrow to remove

the feed sub holder. (See Fig.12.)

Pickup

Feed screw assembly

Feed screw holder

Pu. shaft holder A

Fig.11

G

h

j

Feed screw

holder

3.2.8 Reattachi ng the picku p

(See Figs.10 to 13)

(1) Reattach the feed sub holder to the pickup. (See Fig.12.)

(2) Reattach the feed screw holder to the pickup using the

screw G. (See Fig.12.)

(3) Reattach the feed screw assembly and pu. shaft holder A

to the pickup as before. (See Fig.11.)

(4) Set the section m of the pickup to the rail of the chas sis unit

at first and attach the pickup to the chassis unit with the

screw F as before. (See Figs.10 and 13.)

(5) Attach the pu. shaft to the pickup as before. (See Fig.10.)

(6) Attach the pu. shaft holder B to the chassis unit with the

screw E as before. (See Fig.10.)

Chassis unit

Pu. shaft holder A

Pu. shaft

F

Pickup

k

Feed sub holder

Pickup

Rail

Feed nut

spring

Fig.12

m

F

Pickup

E

Pu. shaft holder B

Fig.10

Chassis unit

Fig.13

(No.MA387<Rev.003>)1-17

Page 18

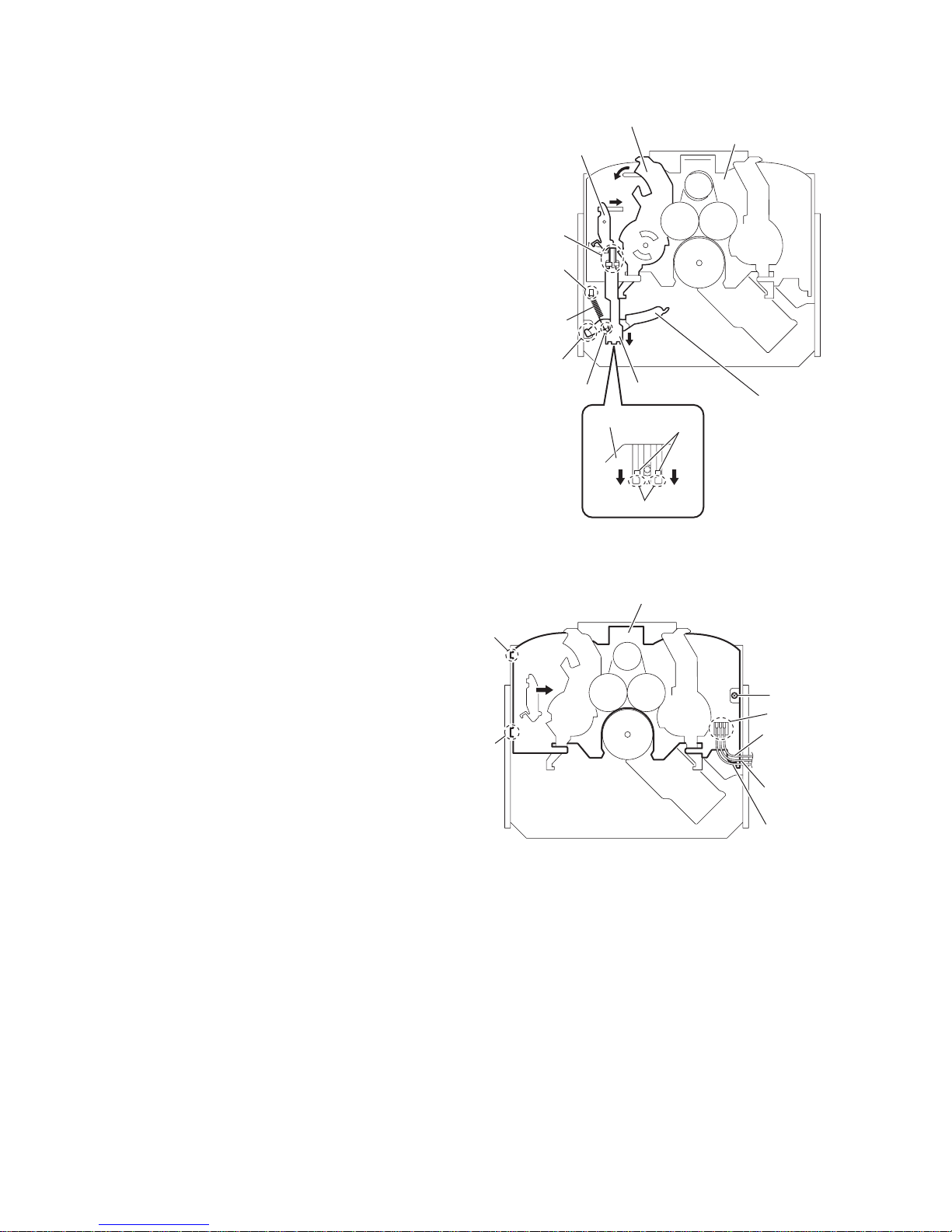

3.2.9 Removing the trigger arm

(See Fig.14)

• Remove the top cover, base board, chassis unit and clamper

assembly.

(1) From the top side of the chassis unit, remove the trigger

arm spring from the sections (n, p).

(2) From the bottom side of the chassis unit, release the claws

q of the trigger arm base in the directio n o f the arrow to remove them from the sections r of the chassis unit to the

other side.

Note:

When releasing the claws q, t ake care n ot to break th em.

(3) From the top side of the chassis unit, move the select arm

R and select lock arm in the direction of the arrow to remove the trigger arm base from the section s in the direction of the arrow.

(4) Remove the trigger arm from the section t.

3.2.10 Removing the top plate assembly

(See Fig.15)

• Remove the top cover, base board, chassis unit, clamper as-

sembly and trigger arm.

(1) Remove the screw H attaching the top plate assembly.

(2) Move the top plate assembly in the d irection of the arr ow to

release the joints (u, v).

Reference:

Remove the wires from the soldered sections w of the top plate

assembly as required.

Note:

When reassembling, solder the wires as before.

Select lock arm

Trigger arm

spring

u

v

Select arm R

s

n

t

p

Chassis unit

Top plate assembly

Chassis unit

Trigger arm base

Trigger arm

q

r

Fig.14

H

w

Wire(Red)

1-18 (No.MA387<Rev.003>)

Wire(White)

Wire(Brown)

Fig.15

Page 19

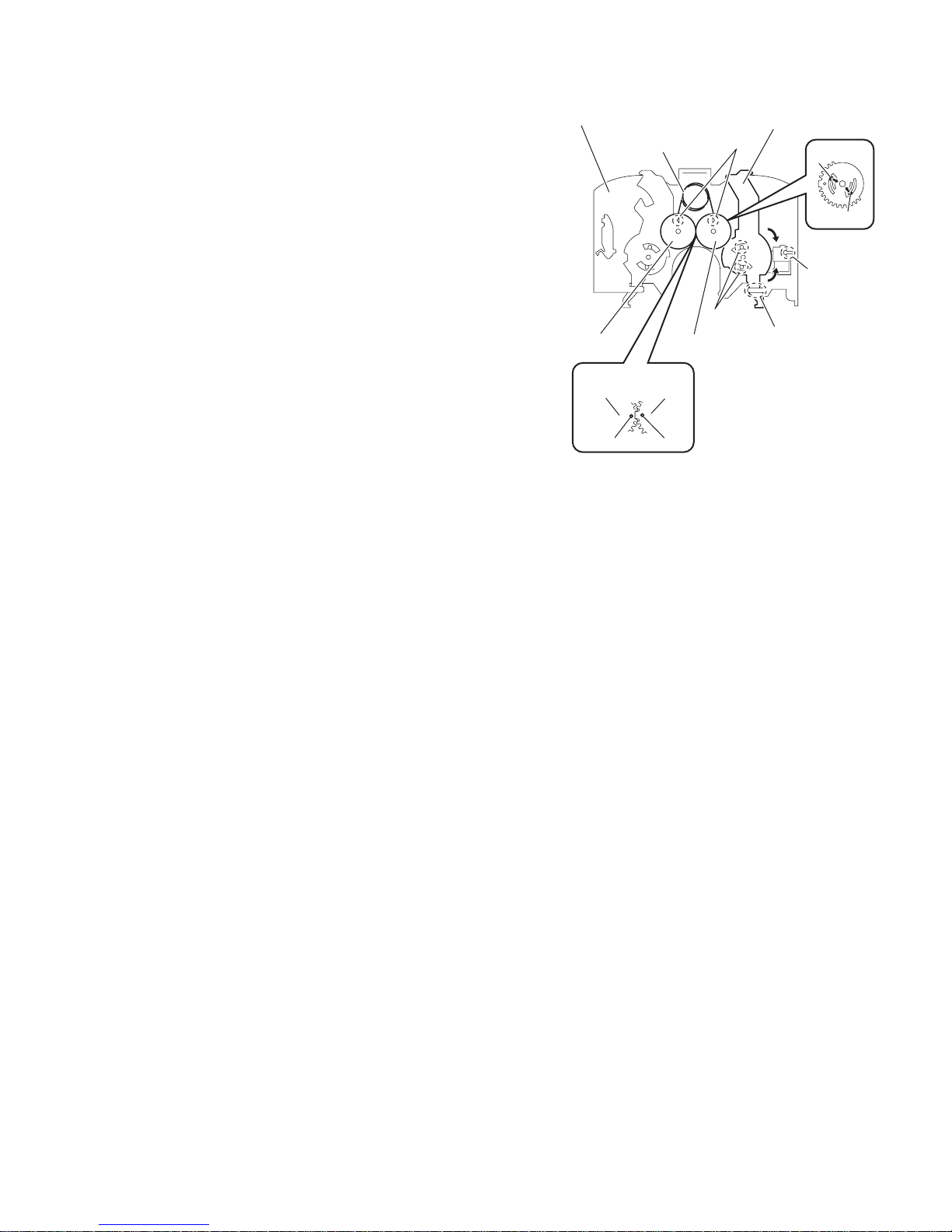

3.2.11 Removing the mode switch

(See Fig.16)

• Remove the top cover, base board, chassis unit, clamper as-

sembly, trigger arm and top plate assembly.

(1) From the top side of the top plate assembly, remove the

link gear spring from the sections x of the link gear L and

link gear R.

(2) Remove the link gear L in an upward direction whi le releas-

ing the claws y of the link gear L in the direction of the arrow.

(3) Move the mode switch in the direction of t he arrow 1 to re -

move the sections z of the top plate assembly.

(4) Move the mode switch in the direction of the arrow 2 and

remove the mode switch from the sections (aa, ab).

Note:

When reattaching the link gear L, attach it after aligning the

hole ac of the link gear L to the hole ac of the link gear R.

Reference:

When reassembling, reverse the above removing procedure.

Top plate assembly

Link gear spring

Link gear R

Link

gear R

ac ac

Link gear L

Link

gear L

aa

Fig.16

Mode switch

x

1

2

z

y

y

ab

(No.MA387<Rev.003>)1-19

Page 20

3.2.12 Removing the select arm R and select lock arm

(See Figs.17 and 18)

• Remove the top cover, base board, chassis unit, clamper as-

sembly, trigger arm and top plate asse mbly.

(1) From the top side of the top plate assembly, remove the

link gear spring from the sections ad of the link gear L and

link gear R. (See Fig.17.)

(2) Remove the link gear R in an upward direction while releas-

ing the claws ae of the lin k gear R in the dire ction of the a rrow. (See Fig.17.)

(3) Move the select arm R in the direction of the arrow 1 to re-

move the sections af of the top plate assembly. (See

Fig.17.)

(4) Move the select arm R in the direction of the arrow 2 and

remove the select arm R from the sections ag. (See

Fig.17.)

(5) From the bottom side of the top plate assembly, remove

the select lock arm spring from the section ah. (See

Fig.18.)

(6) From the top side of the top plate assembly, remove the

section aj of the select lock arm from the top plate assembly at first and remove the sections (ak, am) of th e sele ct

lock arm from the top plate assembly. (See Fig.18.)

Note:

• When removing the select lock arm spring, be careful not to

lose it. (See Fig 18.)

• When reattaching the link gear R, attach it after ali gn ing the

hole an of the link gear R to the hole an of the link gear L.

(See Fig.17.)

Reference:

When reassembling, reverse the above removing procedure.

ak

ae

1

2

af

ae

Select arm R

ad

ag

Link gear R

Select lock arm

aj

Link gear spring

Top plate assembly

Link gear L

Link

gear R

an an

Fig.17

Top plate assembly

Link

gear L

1-20 (No.MA387<Rev.003>)

Select lock

arm spring

ah

am

Fig.18

Page 21

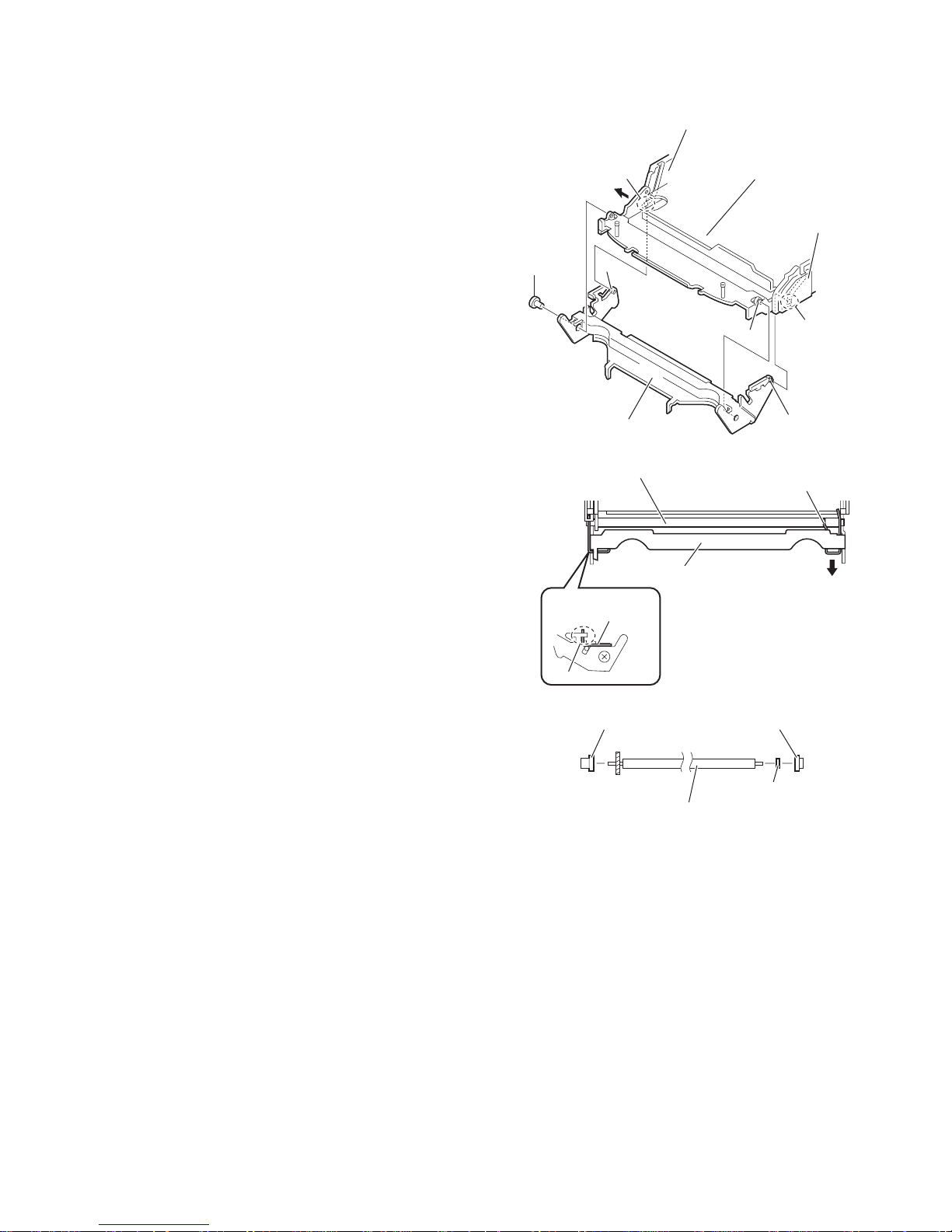

3.2.13 Removing the loading roller assembly

(See Figs.19 to 21)

• Remove the top cover, base board, chassis unit, clamper as-

sembly and top plate assembly.

(1) From the left side of the chassis unit, remove the screw J

attaching the lock arm assembly. (See Fig.19.)

(2) Remove the projection ap of the lock arm assembly from

the joint aq while opening the cam plate R in the direction

of the arrow. (See Fig.19.)

(3) Remove the lock arm assembly from the projection ar of

the chassis unit. (See Fig.19.)

(4) Remove the projection as of the lock arm assembly from

the joint at of the cam plate L assembly. (See Fig.19.)

(5) From the right side of the lock arm assembly, remove the

loading roller spring L from the section au. (See Fig.20.)

(6) From the top side of the lock arm assembly, remove the

loading roller spring R in the direction of the arrow and remove the loading roller assembly. (See Fig.20.)

(7) Remove the roller guide R, HL washer and roller guide L

from the both ends of the loading roller assembly. (See

Fig.21.)

aq

J

ap

Lock arm assembly

Loading roller assembly

Cam plate R

Fig.19

Chassis unit

Cam plate L assembly

ar

Loading roller spring R

at

as

Lock arm assembly

Loading roller

spring L

au

Fig.20

Roller guide L Roller guide R

HL washer

Loading roller assembly

Fig.21

(No.MA387<Rev.003>)1-21

Page 22

3.2.14 Removing the loading gear 1, loading gear 2, loading gear 3 and feed gear 1

(See Fig.22)

• Remove the top cover, base board and cha ss is unit.

(1) From the bottom side of the chassis unit, pull out the load-

ing gear 1.

(2) Take out the loading gear 2.

(3) Pull out the loading gear 3.

(4) Pull out the feed gear 1.

3.2.15 Removing the loading gear 4, loading gear 5 and

loading gear 6

(See Fig.22)

• Remove the top cover, base board and cha ss is unit.

(1) From the bottom side of the chassis unit, remove the screw

K attaching the loading gear bracket.

(2) Take out the loading gear bracket and remove the loading

gear 5 and loading gear 6 from the loading gear bracket.

(3) Pull out the loading gear 4.

Loading gear bracket

Loading gear 3

Feed gear 2

Loading gear 6

Loading gear

bracket

Loading gear 4

Loading gear 1

Loading

gear 5

K

3.2.16 Removing the change gear 2, change gear 3A and

change gear 3B

(See Figs.22 and 23)

• Remove the top cover, base board and cha ss is unit.

(1) From the bottom side of the chassis unit, pull out the load-

ing gear 1. (See Fig.22.)

(2) Pull out the change gear 2. (See Fig.22.)

(3) Pull out the change arm. (See Fig.22.)

(4) Move the change gear plate rivet assembly in the direction

of the arrow 2 to remove the se ction av of the change gear

plate rivet assembly fro m the chass is unit whil e moving the

change lock lever in the direction of the arrow 1. (See

Fig.23.)

(5) Pull out the change gear 3A and change gear 3B from the

change gear plate rivet assembly. (See Fig.23.)

3.2.17 Removing the cam plate L assembly

(See Fig.24)

• Remove the top cover, base board, chassis unit, clamper as-

sembly, top plate assembly and loading roller assembly.

(1) From the left side of the chassis unit, slide the cam plate L

assembly in the direction of the arrow.

(2) Remove the cam plate L asse mb ly from th e slo ts aw of the

chassis unit.

Feed gear 1

Chassis unit

Fig.22

Change gear plate rivet assembly

Change gear 3B

1

Chassis unit

Change lock lever

Fig.23

Chassis unit

Change arm

Change gear plate

rivet assembly

2

av

Loading gear 2

Change

gear 3A

Change gear 3B

Change gear 3A

aw

1-22 (No.MA387<Rev.003>)

aw

Cam plate L assembly

Fig.24

Page 23

3.2.18 Removing the cam plate R

(See Fig.25)

• Remove the top cover, base board, chassis unit, clamper as-

sembly, top plate assembly and loading roller assembly.

From the right side of the chassis unit, remove the cam plate R

from the slots ax of the chassis unit.

Reference:

When a slide hook rivet assembly and a trigger rack spring

have come off from the chassis unit, attach them before at-

taching the cam plate R.

3.2.19 Removing the trigger rack plate

(See Figs.25 and 26)

• Remove the top cover, base board, chassis unit, clamper as-

sembly, top plate assembly, loading roller assembly and cam

plate R.

(1) Remove the slide hook rivet assembly and trigger rack

spring from the chassis unit. (See Fig.25.)

(2) From the bottom side of the chassis unit, pull out the load-

ing gear 1. (See Fig.26.)

(3) Remove the trigger control spring from the sections (ay,

az). (See Fig.26.)

(4) Take out the trigger rack plate from the chassis unit. (See

Fig.26.)

Reference:

When attaching the trigger rack plate, insert the projection a'

of the chassis unit in the slot b' on the bottom side of the trig ger

rack plate as before. (See Fig.26.)

Chassis unit

ax

Cam plate R

b'

Trigger rack spring

Slide hook rivet assembly

ax

Fig.25

Trigger control spring

az

a'

Trigger

rack plate

Trigger rack plate

Loading gear 1

ay

Chassis unit

Fig.26

(No.MA387<Rev.003>)1-23

Page 24

3.2.20 Removing the spindle motor assembly

(See Figs.27 and 28)

• Remove the top cover, base board, chassis unit and clamper

assembly.

(1) From the top side of the chassis unit, turn the turn table

from side to side and remove the two screws M attaching

the spindle motor assembly through the hole of th e turn table. (See Fig.27.)

(2) From the bottom si de of the ch assis unit , turn the ch ange

gear 2 in the direct ion of the arrow 2 while pulling the trigger

arm in the direction of the arrow 1 and let the pickup move

in the direction of the arrow 3. (See Fig.28.)

(3) Slide the spindle motor assembly in the direction of the ar-

row and take out it in an upward d irec tio n from the cha ss is

unit. (See Fig.28.)

Reference:

Remove the wires fro m the soldered sections c' on th e base

board and remove them from the se ction s (d', e') on the chas -

sis unit as required.

Chassis unit

Wire(black)

Wire(red)

M

Fig.27

Spindle motor assembly

d'

Turn table

e'

Change gear 2

c'

Base board

3

Pickup

2

1

Trigger arm

Chassis unit

Fig.28

1-24 (No.MA387<Rev.003>)

Page 25

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC :CTS-1000

(6) Extension cable for check

EXTSH002-22P x 1

4.2 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K.(2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.5 How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink an d rear brac ket ont o the pow er amplifi er IC and regulato r IC resp ectivel y, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

4.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.4 Dummy load

Exclusive dummy load should be used for AM,and FM.

For FM dummy load, there i s a l oss of 6dB b etw ee n SSG out put

and antenna input.

The loss of 6dB need not be considered sincedirect reading of

figures are applied in this working standard.

Extension cable

EXTSH002-22P

(No.MA387<Rev.003>)1-25

Page 26

5.1 16 PIN CORD DIAGRAM (for KD-BT11J)

SECTION 5

TROUBLESHOOTING

BK

RD

BL

WH

OR

Black

Red

Blue

White

Orange

8

7

6

5

4

3

2

1

BK

8

BK

RD

NC

BL/WH

WH

GN

VI

GY

GN

VI

GY

YL

YL

OR/WH

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

Green

Violet

Gray

Yellow

16

15

14

13

12

11

10

9

16

7

15

5

3

11

2

10

4

12

1

YL

RD

OR/WH

BL/WH

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

9

1-26 (No.MA387<Rev.003>)

Page 27

5.2 16 PIN CORD DIAGRAM (for KD-BT11E,EX,EY,EU,EE, KD-BT19UR,KD-BT12E,EX)

8

7

6

5

4

3

2

1

BL/WH

BK

RD

NC

WH

GN

VI

GY

7 RD

16 YL

15 OR/WH

8 BK

5 BL/WH

YL

OR/WH

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

16

15

14

13

12

11

10

9

MEMORY

ACC

ILL

GND

REMOTE

BK

RD

BL

Black

Red

Blue

WH White

OR

Orange

GN

VI

GY

YL

Green

Violet

Gray

Yellow

RD

1

3

5

7

NC

NC

BL/WH

RD

RD 7

YL 4

NC

YL

OR/WH

BK

6

8

5

2

4

6

8

3 GN

11 GN/BK

2 VI

10 VI/BK

4 WH

12 WH/BK

1 GY

9 GY/BK

RR

FR

FL

RL

Rear Right

Front Right

Front Left

Rear Left

RL+

RL-

RR+

RR-

FL+

FL-

FR+

FR-

REMOTE

ACC

MEMORY

GND

ILL

Remote out

ACC Line

Memory Backup Battery+

Ground

Illuminations Control

7

8

1

2

5

6

3

4

VI

1

GY

3

WH

5

GN

7

VI/BK

GY/BK

WH/BK

GN/BK

2

4

6

8

(No.MA387<Rev.003>)1-27

Page 28

5.3 16 PIN CORD DIAGRAM (for KD-BT11U,UT)

BK

RD

BL

WH

Black

Red

Blue

White

8

7

6

5

4

3

2

1

BK

RD

BL

BL/WH

WH

GN

VI

GY

GN

VI

GY

YL

OR

YL

OR/WH

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

Green

Violet

Gray

Yellow

Orange

16

15

14

13

12

11

10

9

8

16

7

15

3

11

10

4

12

2

1

9

5

BK

YL

RD

OR / WH

GN

GN / BK

VI

VI / BK

WH

WH / BK

GY

GY / BK

BL / WH

BL

6

1-28 (No.MA387<Rev.003>)

Page 29

(No.MA387<Rev.003>)1-29

Page 30

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA387<Rev.003>)

Printed in Japan

VPT

Page 31

REVISION INFORMATION

CD RECEIVER

KD-BT11J, KD-BT11E, KD-BT11EX,

KD-BT11EY, KD-BT11EU, KD-BT11EE,

KD-BT11U, KD-BT11UT, KD-BT19UR

■ OVERVIEW

Add KD-BT19UR

■ DETAILS

COVER SECTION

Title Line No.MA387<Rev.001> No.MA387<Rev.002> Description

Revision Rev.001 Rev.002

Issue Date 2008/01 2008/06

Model No. KD-BT11E,

Cover Illustration ILLUSTRATION(ma387_0001.png) ILLUSTRATION(ma387_0001.png)

SPECIFICATION 1 J J / UR

KD-BT11EE,

KD-BT11EU,

KD-BT11EX,

KD-BT11EY,

KD-BT11J,

KD-BT11U,

KD-BT11UT

SECTION 5 TROUBLESHOOTING

Title Line No.MA387<Rev.001> No.MA387<Rev.002> Description

5.2 16 PIN CORD

DIAGRAM (for KDBT11E,EX,EY,EU,EE,

KD-BT19UR)

T 5.2 16 PIN CORD DIAGRAM (for KD-

BT11E,EX,EY,EU,EE)

KD-BT11E,

KD-BT11EE,

KD-BT11EU,

KD-BT11EX,

KD-BT11EY,

KD-BT11J,

KD-BT11U,

KD-BT11UT,

KD-BT19UR

5.2 16 PIN CORD DIAGRAM (for KDBT11E,EX,EY,EU,EE, KD-BT19UR)

COPYRIGHT © 2008 Victor Company of Japan, Limited

MA387-R002

2008/06

Page 32

STANDARD SCHEMATIC DIAGRAMS

Description of Major ICs

Diagram Name No.MA387<Rev.001> No.MA387<Rev.002> Description

Menu - IC201: NAU0004-003

NAU0004-003.xml

PARTS LIST

MODEL No. LIST

Model No. No.MA387<Rev.002>

KD-BT11E 02

KD-BT11EE 06

KD-BT11EU 05

KD-BT11EX 03

KD-BT11EY 04

KD-BT11J 01

KD-BT11U 07

KD-BT11UT 08

KD-BT19UR 09

Geneeal assembly [M1]

Symbol or

!

M1 24 ------------ GE32864-012A F.PANEL HI ASSY (Addition) 1 09

M1 25 ------------ GE32866-021A FINDER ASSY (Addition) 1 09

M1 30 ------------ GE32817-006A DETACH BTN (Addition) 1 09

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

Main board [01]

Symbol or

!

! 01 IC201 ------------ NAU0004-003 RF MODULE (Addition) 1 09

01 D1 ------------ MA111-X SI DIODE (Addition) 1 09

01 D2 ------------ MA111-X SI DIODE (Addition) 1 09

01 D201 ------------ MA8056/M/-X Z DIODE (Addition) 1 09

01 D202 ------------ MA8056/M/-X Z DIODE (Addition) 1 09

01 D203 ------------ MA8056/M/-X Z DIODE (Addition) 1 09

01 D204 ------------ MA8056/M/-X Z DIODE (Addition) 1 09

01 D301 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D302 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D303 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D304 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D341 ------------ MA111-X SI DIODE (Addition) 1 09

01 D351 ------------ MA111-X SI DIODE (Addition) 1 09

01 D714 ------------ MA8056/M/-X Z DIODE (Addition) 1 09

01 D720 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D721 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D722 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D723 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

01 D782 ------------ MA111-X SI DIODE (Addition) 1 09

01 D784 ------------ MA8110/M/-X Z DIODE (Addition) 1 09

01 C732 ------------ NCJA0JK-474W-R C CAPACITOR (Addition) 1 09

01 L1 ------------ NQL10A3-4N7X COIL (Addition) 1 09

01 CN1 ------------ NNZ0196-001X COAXIAL JACK (Addition) 1 09

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

Switch board [02]

Symbol or

!

02 D663 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

02 D664 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

02 D665 ------------ MA8062/M/-X Z DIODE (Addition) 1 09

02 R656 ------------ NRS181J-181X MG RESISTOR (Addition) 1 09

02 R664 ------------ NRSA63J-102X MG RESISTOR (Addition) 1 09

02 R670 ------------ NRSA63J-102X MG RESISTOR (Addition) 1 09

02 R672 ------------ NRSA63J-102X MG RESISTOR (Addition) 1 09

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

2 (MA387-R002)

Page 33

Packing and accessories [M3]

Symbol or

!

M3 A9 ------------ GE20235-002A TRIM PLATE (Addition) 1 09

M3 P8 ------------ GE40218-095A MIRAMA SHEET (Addition) 1 09

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

(MA387-R002) 3

Page 34

Victor Company of Japan, Limited

Mobile Entertainment Business Group Mobile Entertainment Category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(MA387-R002)

Printed in Japan

No.MA387<Rev.001> VPT

Page 35

REVISION INFORMATION

CD RECEIVER

KD-BT11J, KD-BT11E, KD-BT11EX,

KD-BT11EY, KD-BT11EU, KD-BT11EE,

KD-BT11U, KD-BT11UT, KD-BT19UR,

KD-BT12E, KD-BT12EX

■ OVERVIEW

Add KD-BT12E and KD-BT12EX.

■ DETAILS

COVER SECTION

Title Line No.MA387<Rev.002> No.MA387<Rev.003> Description

Revision Rev.002 Rev.003

Issue Date 2008/06 2008/09

Model No. KD-BT11E,

KD-BT11EE,

KD-BT11EU,

KD-BT11EX,

KD-BT11EY,

KD-BT11J,

KD-BT11U,

KD-BT11UT,

KD-BT19UR

Cover Illustration ILLUSTRATION(ma387_0001.png) ILLUSTRATION(ma387_0001.png)

Category Mobile Entertainment Business Group

Mobile Entertainment Category

0 COVER 1 Lead free solder used in the board

2 Lead free solder used in the board

(material : Sn-Ag-Cu, melting point : 219

Centigrade)

3 Lead free solder used in the board

(material : Sn-Cu, melting point : 230

Centigrade)

COPYRIGHT © 2008 Victor Company of Japan, Limited

KD-BT11E,

KD-BT11EE,

KD-BT11EU,

KD-BT11EX,

KD-BT11EY,

KD-BT11J,

KD-BT11U,

KD-BT11UT,

KD-BT12E,

KD-BT12EX,

KD-BT19UR

Mobile Entertainment Division

(material : Sn-Ag-Cu, melting point : 219

Centigrade)

Lead free solder used in the board

(material : Sn-Cu, melting point : 230

Centigrade)

-

MA387-R003

2008/09

Page 36

SECTION 5 TROUBLESHOOTING

Title Line No.MA387<Rev.002> No.MA387<Rev.003> Description

5.2 16 PIN CORD

DIAGRAM (for KDBT11E,EX,EY,EU,EE,

KD-BT19UR,KDBT12E,EX)

T 5.2 16 PIN CORD DIAGRAM (for KD-

BT11E,EX,EY,EU,EE, KD-BT19UR)

5.2 16 PIN CORD DIAGRAM (for KDBT11E,EX,EY,EU,EE, KD-BT19UR,KD-

BT12E,EX)

STANDARD SCHEMATIC DIAGRAMS

Schematic Diagram

Diagram Name No.MA387<Rev.002> No.MA387<Rev.003> Description

Menu LCD & Key control section LCD and Key control section

Description of Major ICs

Diagram Name No.MA387<Rev.002> No.MA387<Rev.003> Description

Menu - IC701: UPD78F1167GC1AF

UPD78F1167GC1AF.xml

2 (MA387-R003)

Page 37

PARTS LIST

MODEL No. LIST

Model No. No.MA387<Rev.003>

KD-BT11E 02

KD-BT11EE 06

KD-BT11EU 05

KD-BT11EX 03

KD-BT11EY 04

KD-BT11J 01

KD-BT11U 07

KD-BT11UT 08

KD-BT12E 0A

KD-BT12EX 0B

KD-BT19UR 09

General assembly [M1]

Symbol or

!

M1 24 ------------ GE32864-011A F.PANEL HI ASSY (Addition) 1 0A,0B

M1 25 ------------ GE33246-018A FINDER ASSY (Addition) 1 0A,0B

M1 26 ------------ GE32812-018A TEL BUTTON (Addition) 1 0A,0B

M1 30 ------------ GE32817-001A DETACH BTN (Addition) 1 0A,0B

M1 47 ------------ GE33582-001A NAME PLATE (Addition) 1 0A,0B

<Rev.002> <Rev.003>

Electrical parts list Main board [01]

Symbol or

!

! 01 IC701 ------------ UPD78F1167GC1AF IC(PROGRAMED) (Addition) 1 0A,0B

<Rev.002> <Rev.003>

Part No.

Part No.

Part Name Description Qty Models

Part Name Description Qty Models

Packing and accessories [M3]

Symbol or

!

M3 A1 ------------ GET0508-002B INST BOOK (Addition) 1 0A

M3 A1 ------------ GET0508-004B INST BOOK (Addition) 1 0B

M3 A2 ------------ GET0508-009B INST.MANUAL (Addition) 1 0A

M3 A2 ------------ GET0508-011B INST.MANUAL (Addition) 1 0B

M3 A3 ------------ GET0508-008B INST.MANUAL (Addition) 1 0A

M3 A3 ------------ GET0508-010B INST.MANUAL (Addition) 1 0B

M3 A4 ------------ ------------ WARRANTY CARD (Addition) 1 0A,0B

M3 A19 ------------ GET0508-001B INST BOOK (Addition) 1 0A

M3 A19 ------------ GET0508-003B INST BOOK (Addition) 1 0B

M3 A20 ------------ GET0551-005A EC DOC SHEET (Addition) 1 0A,0B

M3 P1 ------------ GE33583-001A CARTON (Addition) 1 0A,0B

<Rev.002> <Rev.003>

Part No.

Part Name Description Qty Models

(MA387-R003) 3

Page 38

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(MA387-R003)

Printed in Japan

No.MA387<Rev.002> VPT

Page 39

PARTS LIST

KD-BT11J,KD-BT11E,KD-BT11EX

KD-BT11EY,KD-BT11EU,KD-BT11EE

KD-BT11U,KD-BT11UT,KD-BT19UR

KD-BT12E,KD-BT12EX

* All printed circuit boards and its assemblies are not available as service parts.

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD mechanism assembly and parts list (Block No.MB)

Electrical parts list (Block No.01~02)

Packing materials and accessories parts list (Block No.M3)

MA387PAR<Rev.003>

3- 2

3- 6

3-11

3-18

3-1

Page 40

Exploded view of general assembly and parts list

Block No.

Only 11UT ver.

64

14

13

5

1

a

c

e

a

e

b

A

6

Except

11EE ver.

15

12

19

18

MMM1

16

Only

11EE ver.

15

40

6

37

35

62

24

30

26

31

38

32

6

36

29

28

33

25

41

Only

11EE

12E,12EX ver.

65

27

34

42

Switch board

21

20

17

42

43

46

48

45

39

3-2

Page 41

M

50

b

52

c

Main board

51

f

7

7

22

11E,11EX,11EY

11EU,12E,12EX ver.

d

g

57

60

55

f

56

63

54

59

58

g

61

53

48

42

46

43

17

44

49

Only 11J ver.

47

A

23

8

4

2

d

11

3

47

9

8

10

Only

11J,11EE,11U,

11UT,19UR ver.

2

The parts without symbol number are not service.

3-3

Page 42

General Assembly

Block No. [M][1][M][M]

Symbol No. Part No. Part Name Description Local

1 GE10216-003A TOP CHASSIS 11J,11E,11EX,11EY,11EU,11U,11UT,19UR,12E,12EX

1 GE10216-006A TOP CHASSIS 11EE

2 GE32823-002A HEAT SINK 11J,11EE,11U,11UT,19UR

2 GE32823-001A HEAT SINK 11E,11EX,11EY,11EU,12E,12EX

3 GE20228-001A BOTTOM COVER

4 GE32830-002A INSULATOR

5 GE40395-001A SIDE PANEL

6 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x3)

7 GE40377-002A SCREW (x2)

8 GE40377-001A SCREW (x3)

9 QYSDST2610ZA TAP SCREW M2.6 x 10mm

10 QYSDST2610ZA TAP SCREW M2.6 x 10mm

11 QYSDSF2606ZA TAP SCREW M2.6 x 6mm

12 QYSDSF2606ZA TAP SCREW M2.6 x 6mm(x2)

13 GE40377-002A SCREW (x2)

14 QYSDST2608ZA TAP SCREW M2.6 x 8mm

15 QYSDST2604ZA TAP SCREW M2.6 x 4mm

16 QYSDST2606ZA TAP SCREW M2.6 x 6mm 11J,11E,11EX,11EY,11EU,11U,11UT,19UR,12E,12EX

17 GE10215-001A FRONT CHASSIS

18 GE32350-002A LOCK LEVER

19 GE40368-002A TORSION SPRING

20 GE32810-001A RELEASE LEVER

21 GE30999-004A COMP.SPRING

22 GE40400-001A BLIND

23 GE40417-001A DUST FILTER

24 GE32864-013A F.PANEL HI ASSY 11J

24 GE32864-014A F.PANEL HI ASSY 11E,11EX,11EY,11EU

24 GE32864-015A F.PANEL HI ASSY 11EE

24 GE32864-008A F.PANEL HI ASSY 11U,11UT

24 GE32864-012A F.PANEL HI ASSY 19UR

24 GE32864-011A F.PANEL HI ASSY 12E,12EX

25 GE32866-008A FINDER ASSY 11J

25 GE32866-009A FINDER ASSY 11E,11EX,11EY,11EU

25 GE32866-016A FINDER ASSY 11EE

25 GE32866-010A FINDER ASSY 11U,11UT

25 GE32866-021A FINDER ASSY 19UR

25 GE33246-018A FINDER ASSY 12E,12EX

26 GE32812-009A TEL BUTTON 11J,11E,11EX,11EY,11EU,11EE,11U,11UT,19UR

26 GE32812-018A TEL BUTTON 12E,12EX

27 GE32814-001A BAND EQ BTN

28 GE32815-001A PUSH BTN

29 GE32816-001A POWER BTN 11J,19UR

29 GE32816-002A POWER BTN 11E,11EX,11EY,11EU,11U,11UT,12E,12EX

29 GE32816-003A POWER BTN 11EE

30 GE32817-008A DETACH BTN 11J

30 GE32817-009A DETACH BTN 11E,11EX,11EY,11EU

30 GE32817-007A DETACH BTN 11EE

30 GE32817-005A DETACH BTN 11U,11UT

30 GE32817-006A DETACH BTN 19UR

30 GE32817-001A DETACH BTN 12E,12EX

31 GE30999-006A COMP.SPRING

32 GE32818-001A EJECT BTN

33 GE32824-001A SRC BTN 11J,19UR

33 GE32824-002A SRC BTN 11E,11EX,11EY,11EU,11U,11UT,12E,12EX

33 GE32824-003A SRC BTN 11EE

34 GE20227-001A PRESET BTN 11J,11E,11EX,11EY,11EU,11U,11UT,19UR

34 GE20233-001A PRESET BTN 11EE,12E,12EX

35 GE40218-083A SHEET

36 GE40399-001A NAVI BTN ASSY 11J,19UR

36 GE40399-002A NAVI BTN ASSY 11E,11EX,11EY,11EU,11U,11UT,12E,12EX

36 GE40399-004A NAVI BTN ASSY 11EE

37 FSYH4036-069 SHEET

38 GE40347-001A JVC BADGE

39 GE40398-001A VOL KNOB ASSY 11J,19UR

39 GE40398-002A VOL KNOB ASSY 11E,11EX,11EY,11EU,11EE,11U,11UT,12E,12EX

40 GE40127-005A KNOB SPRING

41 GE10214-001A REAR COVER

42 VKZ4777-010 MINI SCREW (x4)

43 GE32819-001A LCD LENS

44 GE32820-001A LENS CASE

45 GE32821-001A LCD CASE

46 GE40397-002A LIGHTING SHEET

47 GE32987-005A NAME PLATE 11J

47 GE32996-002A NAME PLATE 11E,11EX,11EY,11EU

3-4

Page 43

Symbol No. Part No. Part Name Description Local

47 GE32999-002A NAME PLATE 11EE

47 GE32990-001A NAME PLATE 11U,11UT

47 GE33582-001A NAME PLATE 12E,12EX

48 QLD0518-001 LCD MODULE

49 QNZ0950-001 RUBBER CONNECTO

50 QMFZ063-150-J1 FUSE 15A

51 GE40354-001A IC BRACKET

52 GE40396-002A REG BRACKET

53 GE33092-001A BT TUNER BKT

54 GE33093-001A MIC HOLDERT

55 GE40418-001A STATIC SHIELDER

56 QYSDST2004ZA TAP SCREW M2 x 4mm

57 QYSDST2004ZA TAP SCREW M2 x 4mm(x2)

58 LV44615-002A SCREW

59 QAM1059-001 COAXIAL CABLE

60 QAN0090-001 MICROPHONE

61 LVA10808-01AD BT ANT 11J,11E,11EX,11EY,11EU,11EE,11U,11UT,12E,12EX

62 GE30854-001A LED HOLDER

63 GE40424-001A OE HOLDING BKT 11E,11EX,11EY,11EU,12E,12EX

64 GE31574-083A UT LABEL 11UT

65 FSYH4036-069 SHEET (x2) 11EE,12E,12EX

3-5

Page 44

CD mechanism assembly and parts list

TN2007-1026

120

Block No.

M

M

B

M

42

A

124

44

52

127

15

33

24

102

36

50

62

51

123

25

26

10

63

14

13

16

112

122

4

120

48

47

12

20

27

79

105

101

43

61

11

35

125

B

64

99

104

45

11

46

106

21

111

121

12

49

59

A

B

80

32

28

86

23

93

87

81

78

130

76

3-6

74

75

71

64

62

a

126

63

a

72

100

120

110

89

1

120

120

92

124

58

77

108

91

90

22

88

2

The parts without symbol number are not service.

3

Page 45

CD mechanism

Symbol No. Part No. Part Name Description Local

1 30350101T FRAME

2 30350103T DAMPER F (x2)

3 30350104T DAMPER R

4 30350107T TOP COVER

10 30320513T CLAMPER SUB SPG

11 30350505T FRONT SUS SPG (x2)

12 30350506T REAR SUS SPRING (x2)

13 30350508T FEED NUT SPP

14 30350509T FEED SCREW HLDR

15 30350525T PU SHAFT HLDR B

16 30350528T LOCK LEVER

20 30350529T LOCK PLATE

21 30350581T CHANGE GEAR2

22 30350582T CHANGE GEAR 3A

23 30350583T CHANGE GEAR 3B

24 30350535T FEED SUB HOLDER

25 30350536T PU SHAFT HLDR A

26 30350539T FD THRUST SPP

27 30350542T CHANGE ARM

28 30350580T FEED GEAR 1

32 30350554T LOCK LEVER SP

33 30350555T PU SHAFT

35 64010418T PUSH SW P389-01

36 69011629T PICK UP OPTIMA-727AD

42 30350801T TOP PLATE

43 30350802T SELECT ARM R

44 30350803T MODE SWICH

45 30350806T SELECT LOCK ARM

46 30350807T SPRING

47 30350808T TRIGGER ARM

48 30350809T TRG ARM BASE

49 30350810T TRIGGER ARM SPR

50 30350811T LINK GEAR L

51 30350812T LINK GEAR R

52 30350813T LINK GEAR SPR

58 19501403T WIRE CLUMPER

59 30321013T WIRE CLAMPER

61 30351001T WIRE CLAMPER

62 30351008T MODE SW WIRE

63 30351003T REST SW WIRE

64 30351004T LD WIRE

71 30321137T LDG ROLLER (x2)

72 30321143T COLLAR SCREW

74 30351101T LOCK ARM

75 30351102T LD ROLLER SPR R

76 30351103T LD ROLLER SPR L

77 30351105T ROLLER GUIDE R

78 30351106T ROLLER GUIDE L

79 30351116T CAM PLATE R (N)

80 30351111T TR CONTROL SPR

81 30351113T SPRING

86 30351122T LOADING GEAR 1

87 30351123T LOADING GEAR 2

88 30351128T LOADING GEAR 3

89 30351129T LOADING GEAR 4

90 30351140T LOADING GEAR 5

91 30351131T LOADING GEAR 6

92 30351133T LD GEAR BRACKET

93 30351135T PLATE

99 303505309T MORTER ASSY

100 303505302T SPINDLE MOTOR

101 303505303T CLAMPER ASSY

102 303505304T FEED SCREW ASSY

104 303505501T CHASSIS RIVET

105 303505502T CLAMPER ARM RVT

106 303505503T RIVET ASSY

108 303510304T BASE BOARD ASSY

110 303511301T ROLLER SHAFT

111 303511302T CAM PLATE L

112 303511501T SLIDE HOOK RVT

120 9P0420037T SCREW (x5)

121 9C0117187T SCREW (x2)

122 9C0120207T SCREW

123 9C4517506T SCREW

Block No. [M][B][M][M]

3-7

Page 46

Symbol No. Part No. Part Name Description Local

124 9P0420047T SCREW (x2)

125 9P0420067T SCREW

126 9P0420087T SCREW

127 9C0420257T SCREW

130 9W0513060T HL WASHER

3-8

Page 47

Grease point 1/2

grease

TNG-87

TN-4456

TNS-925R

GP-501MK

back side

1

4

back side

back side

two sides

104

101

44

43

74

3-9

Page 48

Grease point 2/2

T

grease

TNG-87

TN-4456

TNS-925R

G-322

102

111

26

out side

33

106

79

27

25

16

90

92

99

105

3-10

50

93

back side

TR CONTROL SPR

side

CHF LOCK PL

51

Page 49

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

IC71 LC72725KM-X IC 11E,11EX,11E

IC161 TDA7719-X IC

IC201 NAU0004-001 RF MODULE 11J,11E,11EX,

IC201 NAU0004-003 RF MODULE 19UR,12E,12

IC202 NJM4565V-X IC

IC203 NJM4565V-X IC

IC205 BD33KA5FP-X REGULATOR IC

IC301 TB2926AHQ IC

IC501 LA6242H-X IC

IC541 TC94A70FG-005A IC

IC571 NJM2878F4-15-X IC

IC581 NJM4580M-X IC

IC701 UPD78F1167GC1R IC(PROGRAMED) 11J,11U,11UT

IC701 UPD78F1167GC1S IC(PROGRAMED) 11E,11EX,11E

IC701 UPD78F1167GC1AF IC(PROGRAMED) 12E,12EX

IC771 S-24CS16A0I-G-X IC 11E,11EX,11E

IC801 TC7WT241FU-X IC 11J,11E,11EX,

IC802 TC7WT241FU-X IC 11J,11E,11EX,

IC901 AN34001A REGULATOR IC

Q1 RT1N141C-X DIGI TRANSISTOR

Q1 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q252 RT1P141C-X DIGI TRANSISTOR

Q252 or UN2111-X TRANSISTOR 11J,11E,11EX,

Q322 IMX9-W PAIR TRANSISTOR

Q502 2SA1705/ST/-T TRANSISTOR

Q571 2SA1708/ST/-T TRANSISTOR

Q581 2SA1365/F/-X TRANSISTOR

Q582 RT1N141C-X DIGI TRANSISTOR

Q582 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q711 RT1P141C-X DIGI TRANSISTOR

Q711 or UN2111-X TRANSISTOR 11J,11E,11EX,

Q712 RT1N141C-X DIGI TRANSISTOR

Q712 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q781 RT1P141C-X DIGI TRANSISTOR

Q781 or UN2111-X TRANSISTOR 11J,11E,11EX,

Q782 DTC143TKA-X DIGI TRANSISTOR

Q784 RT1P141C-X DIGI TRANSISTOR

Q784 or UN2111-X TRANSISTOR 11J,11E,11EX,

Q881 RT1N141C-X DIGI TRANSISTOR

Part No. Part Name Description Local

Y,11EU,11EE,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT

EX

Y, 11 E U , 11 E E

Y,11EU,11EE,

12E,12EX

11EY, 11EU,11

U,11UT,19UR,

12E,12EX

11EY, 11EU,11

U,11UT,19UR,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

11EY, 11EU,11

EE ,11U ,11UT,

12E,12EX

Symbol No.

Q881 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q902 RT1N141C-X DIGI TRANSISTOR

Q902 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q933 2SA1365/F/-X TRANSISTOR

Q934 RT1N141C-X DIGI TRANSISTOR

Q934 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q976 RT1N141C-X DIGI TRANSISTOR

Q976 or UN2211-X TRANSISTOR 11J,11E,11EX,

Q977 ISA1530AC1/R/-X TRANSISTOR

Q977 or 2SB709A/R/-X TRANSISTOR 11J,11U

Q977 or 2SB709A/QR/-X TRANSISTOR 11E,11EX,11E

D1 1SS355W-X DIODE 11J,11E,11EX,

D1 or MA111-X SI DIODE 11J,11E,11EX,

D1 MA111-X SI DIODE 19UR

D2 1SS355W-X DIODE 11J,11E,11EX,

D2 or MA111-X SI DIODE 11J,11E,11EX,

D2 MA111-X SI DIODE 19UR

D201 UDZW5.6B-X Z DIODE 11J,11E,11EX,

D201 or MA8056/M/-X Z DIODE 11J,11E,11EX,

D201 MA8056/M/-X Z DIODE 19UR

D202 UDZW5.6B-X Z DIODE 11J,11E,11EX,

D202 or MA8056/M/-X Z DIODE 11J,11E,11EX,

D202 MA8056/M/-X Z DIODE 19UR

D203 UDZW5.6B-X Z DIODE 11J,11E,11EX,

D203 or MA8056/M/-X Z DIODE 11J,11E,11EX,

D203 MA8056/M/-X Z DIODE 19UR

D204 UDZW5.6B-X Z DIODE 11J,11E,11EX,

D204 or MA8056/M/-X Z DIODE 11J,11E,11EX,

D204 MA8056/M/-X Z DIODE 19UR

Part No. Part Name Description Local

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

Y,11EU,11EE,

11UT,12E,12E

X

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

11EY, 11EU,11

EE ,11U ,11U T,

12E,12EX

3-11

Page 50

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

D301 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D301 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D301 MA8062/M/-X Z DIODE 19UR

D302 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D302 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D302 MA8062/M/-X Z DIODE 19UR

D303 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D303 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D303 MA8062/M/-X Z DIODE 19UR

D304 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D304 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D304 MA8062/M/-X Z DIODE 19UR

D341 1SS355W-X DIODE 11J,11E,11EX,

D341 or MA111-X SI DIODE 11J,11E,11EX,

D341 MA111-X SI DIODE 19UR

D351 1SS355W-X DIODE 11J,11E,11EX,

D351 or MA111-X SI DIODE 11J,11E,11EX,

D351 MA111-X SI DIODE 19UR

D501 1A3G-T1 SI DIODE

D712 UDZW6.2B-X Z DIODE 11E,11EX,11E

D712 or MA8062/M/-X Z DIODE 11E,11EX,11E

D714 UDZW5.6B-X Z DIODE 11J,11E,11EX,

D714 or MA8056/M/-X Z DIODE 11J,11E,11EX,

D714 MA8056/M/-X Z DIODE 19UR

D720 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D720 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D720 MA8062/M/-X Z DIODE 19UR

D721 UDZW6.2B-X Z DIODE 11J,11E,11EX,

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

Y, 11 EU , 1 2E , 1

2EX

Y, 11 EU , 1 2E , 1

2EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

D721 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D721 MA8062/M/-X Z DIODE 19UR

D722 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D722 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D722 MA8062/M/-X Z DIODE 19UR

D723 UDZW6.2B-X Z DIODE 11J,11E,11EX,

D723 or MA8062/M/-X Z DIODE 11J,11E,11EX,

D723 MA8062/M/-X Z DIODE 19UR

D782 1SS355W-X DIODE 11J,11E,11EX,

D782 or MA111-X SI DIODE 11J,11E,11EX,

D782 MA111-X SI DIODE 19UR

D783 MC2836-X DIODE

D783 or MA152WA-X DIODE 11J,11E,11EX,

D784 UDZW11B-X Z DIODE 11J,11E,11EX,

D784 or MA8110/M/-X Z DIODE 11J,11E,11EX,

D784 MA8110/M/-X Z DIODE 19UR

D851 MA22D23-X SB DIODE 11U,11UT

D851 or CRS03-W SB DIODE 11U,11UT

D851 or RB160M-30-X SB DIODE 11U,11UT

D852 MA22D39-X SB DIODE 11U,11UT

D901 1N5401-F64 SI DIODE

D901 or 1N5401-TU-15 SI DIODE 11J,11E,11EX,

D903 GS1J-X DIODE 11E,11EX,11E

D971 MA22D23-X SB DIODE

D971 or CRS03-W SB DIODE 11J,11E,11EX,

D971 or RB160M-30-X SB DIODE 11J,11E,11EX,

D972 MA22D39-X SB DIODE

C3 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C5 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C6 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C7 NCBA0JK-224W C CAPACITOR 0.22uF 6.3V K

C21 QEKJ1AM-227Z E CAPACITOR 220uF 10V M

C22 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C71 NDCA1HJ-561W C CAPACITOR 560pF 50V J 11E,11EX,11E

C72 NCBA1CK-223W C CAPACITOR 0.022uF 16V K 11E,11EX,11E

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

Y,11EU,12E,1

2EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

11E Y,11E U,11

EE,11U,11UT,

12E,12EX

Y, 11 EU , 11 EE ,

12E,12EX

Y, 11 EU , 11 EE ,

12E,12EX

3-12

Page 51

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C73 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M 11E,11EX,11E

C74 NDCA1HJ-330W C CAPACITOR 33pF 50V J 11E,11EX,11E

C75 NDCA1HJ-330W C CAPACITOR 33pF 50V J 11E,11EX,11E

C76 NCBA1CK-103W C CAPACITOR 0.01uF 16V K 11E,11EX,11E

C77 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M 11E,11EX,11E

C78 NCBA1CK-103W C CAPACITOR 0.01uF 16V K 11E,11EX,11E

C81 QTE1H57-105Z E CAPACITOR 1uF 50V

C91 QTE1H57-105Z E CAPACITOR 1uF 50V

C160 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C161 QTE1H57-105Z E CAPACITOR 1uF 50V

C162 QTE1H64-225Z E CAPACITOR 2.2uF 50V

C163 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C164 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C165 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C166 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C167 NCBA1EK-472W C CAPACITOR 4700pF 25V K

C168 QTE1A57-107Z E CAPACITOR 100uF 10V

C169 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C170 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C171 QTE1H57-105Z E CAPACITOR 1uF 50V

C172 QTE1H64-225Z E CAPACITOR 2.2uF 50V

C173 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C176 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C177 QTE1C57-106Z E CAPACITOR 10uF 16V

C201 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C202 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C203 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C204 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C205 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C206 NDCA1HJ-220W C CAPACITOR 22pF 50V J

C207 NCBA1AK-333W C CAPACITOR 0.033uF 10V K

C208 NDCA1HJ-391W C CAPACITOR 390pF 50V J

C212 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C213 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C215 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C216 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C217 NDCA1HJ-121W C CAPACITOR 120pF 50V J

C218 NDCA1HJ-121W C CAPACITOR 120pF 50V J

C219 NDCA1HJ-121W C CAPACITOR 120pF 50V J

C220 NDCA1HJ-121W C CAPACITOR 120pF 50V J

C230 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C231 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C240 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C241 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C243 NCBA1AK-333W C CAPACITOR 0.033uF 10V K

C251 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C252 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C253 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C254 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C255 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C256 NDCA1HJ-391W C CAPACITOR 390pF 50V J

C260 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C301 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C302 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C303 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C304 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C307 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C311 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C312 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C313 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C314 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C315 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C316 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C317 QTE1C57-476Z E CAPACITOR 47uF 16V

C318 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C319 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C320 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C321 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

Y,11EU,11EE,

12E,12EX

Y,11EU,11EE,

12E,12EX

Y,11EU,11EE,

12E,12EX

Y,11EU,11EE,

12E,12EX

Y,11EU,11EE,

12E,12EX

Y,11EU,11EE,

12E,12EX

C326 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C385 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C386 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C501 NBE41AM-476X TA E CAPACITOR 47uF 10V M

C502 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C503 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C504 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C505 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C506 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C511 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C512 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C513 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C514 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C515 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C516 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C517 NDCA1HJ-121W C CAPACITOR 120pF 50V J

C518 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C519 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C521 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C522 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C523 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C524 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C525 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C526 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C527 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C528 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C529 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C531 NCBA1HK-102W C CAPACITOR 1000pF 50V K

C532 NCBA1HK-271W C CAPACITOR 270pF 50V K

C533 NCBA1HK-271W C CAPACITOR 270pF 50V K

C534 NCBA1AK-273W C CAPACITOR 0.027uF 10V K

C535 NCBA1CK-183W C CAPACITOR 0.018uF 16V K

C536 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C537 NCBA1HK-222W C CAPACITOR 2200pF 50V K

C538 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C541 NCBA1AK-333W C CAPACITOR 0.033uF 10V K

C542 NCBA1AK-333W C CAPACITOR 0.033uF 10V K

C543 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C544 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C545 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C546 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C547 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C548 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C549 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C550 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C551 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C552 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C554 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C555 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C556 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C557 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C558 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C559 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C560 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C561 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C562 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C563 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C564 NDCA1HJ-680W C CAPACITOR 68pF 50V J

C565 NCBA1CK-153W C CAPACITOR 0.015uF 16V K

C566 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C567 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C568 NCBA1EK-472W C CAPACITOR 4700pF 25V K

C569 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C570 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C571 NCBA1CK-153W C CAPACITOR 0.015uF 16V K

C572 NDCA1HJ-470W C CAPACITOR 47pF 50V J

C573 NCBA1AK-333W C CAPACITOR 0.033uF 10V K

C574 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C575 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C576 NCBA1EK-562W C CAPACITOR 5600pF 25V K

C578 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C580 QTE1E57-475Z E CAPACITOR 4.7uF 25V

C582 NDCA1HJ-151W C CAPACITOR 150pF 50V J

C583 QTE0J57-476Z E CAPACITOR 47uF 6.3V

C584 NCBA1HK-821W C CAPACITOR 820pF 50V K

C590 QTE1E57-475Z E CAPACITOR 4.7uF 25V

C592 NDCA1HJ-151W C CAPACITOR 150pF 50V J

C593 QTE0J57-476Z E CAPACITOR 47uF 6.3V

3-13

Page 52

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C594 NCBA1HK-821W C CAPACITOR 820pF 50V K

C596 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C597 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C701 NDCA1HJ-220W C CAPACITOR 22pF 50V J

C702 NDCA1HJ-270W C CAPACITOR 27pF 50V J

C705 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C706 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C707 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C708 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C709 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C711 QERF0JM-337Z E CAPACITOR 330uF 6.3V M

C712 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C713 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C714 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C715 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C716 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C717 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C718 NDCA1HJ-101W C CAPACITOR 100pF 50V J 11E,11EX,11E

C722 NCB31HK-681X C CAPACITOR 680pF 50V K