Page 1

SERVICE MANUAL

YA787<Rev.002>20108SERVICE MANUAL

MULTI FORMAT LCD MONITOR

DT-R17L4D/CAT,

DT-R17L4D

DT-R17L4D

/EAT,

/UAT

BASIC CHASSIS

X1

COPYRIGHT © 2010 Victor Company of Japan, Limited

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.YA787<Rev.002>

2010/8

Page 2

SPECIFICATION

Items Contents

Dimension (W × H × D) 43.0 cm × 31.41 cm × 18.1 cm (17" × 12-3/8" × 7-1/4") [with the stand]

43.0 cm × 30.9 cm × 10.2 cm (17" × 12-1/4" × 4-1/8") [without stand]

Mass 8.0 kg (17.6 lbs) [with the stand]

6.5 kg (14.3 lbs) [without stand]

Power Requirements AC120 V / AC220 V - AC240 V, 50 Hz / 60 Hz

Rated Input Current 1.2 A (AC120 V) / 0.8 A (AC220 V - AC240 V)

Operating conditions Operating temperature: 5°C - 35°C (41°F - 95°F)

Operating humidity: 20% - 80% (non-condensing)

(Slightly variable depending on ambient conditions for installation.)

Aspect Ratio 16 : 9 (Wide format)

Effective Screen Dimensions Width: 37.29 cm (14-3/4”), Height: 20.97 cm (8-3/8”)

Display Pixels Horizontal 1366 × Vertical 768 (WXGA)

Display Colors 16,777,216 colors (256 colors for each of RGB)

Compliant video signal format

Speaker 3cm × 4cm oval type × 2, 8 Ω

Audio Power Output 1 W + 1 W (8 Ω)

VIDEO Input BNC connector × 1, 1 V (p-p) / 75 Ω (negative sync provided)

DVI-D (HDCP) Input DVI-D 3-row 24-pin connector × 1 (compatible with DDC2B)

E. AUDIO HD/

SD SDI

[IN-1/2]

AUDIO Input RCA pin jack connector × 2, 500 mV (rms) / high impedance

REMOTE RS-232C D-sub 2-row 9-pin connector × 1 (for external serial control)

COMPOSITE NTSC, PAL, BW(50Hz/60Hz)

SDI ( DIGI TAL) 480/60i, 480/59.94i, 576/50i, 720/60p, 720/59.94p, 720/50p, 720/30p, 720/2 9.97p, 720/25p, 720/24p,

720/23.98p, 1035/60i, 1035/59.94i, 1080/60i, 1080/59.94i, 1080/50i, 1080/30p, 1080/29.97p, 1080/

25p, 1080/24p, 1080/23.98p, 1080/30psF, 1080/29.97psF, 1080/24psF, 1080/23.98psF, 1080/60p,

1080/50p, 1080/25psF

DVI PC (DIGITAL)

Output BNC connector × 1, 1 V (p-p) / 75 Ω

Output BNC connector × 1 (compatible with EMBEDDED AUDIO signals)

Format HD SDI: BTA S-004C, SMPTE292M

Output RCA pin jack connector × 2, 500 mV (rms) / 600 Ω

RS-485 input/output RJ-45 8-pin connector × 2 (for external serial control)

MAKE/TRIGGER

VGA60, WVGA60, SVGA60, XGA60, WXGA(1280), WXGA+60, SXGA60, WSXGA+60, UXGA60,

WUXGA60, 720/60p, 1080/60p, 720/50p, 1080/50p

*Input and Output are Bridge Connection (Automatic termination)

*Input and Output are Bridge Connection (Automatic termination)

[Digital video signal (8bit × 3), single-link (3 data channels) connection]

<Available computer signal>

Horizontal: 31.469 kHz - 75.000 kHz, Vertical: 48 Hz - 65 Hz

Input BNC connector × 2 (compatible with EMBEDDED AUDIO signals)

SD SDI: ITU-R BT.656:525/625, SMPTE259M:525

EMBEDDED AUDIO: SMPTE299M, SMPTE272M

RJ-45 8-pin connector × 1 (for external parallel control)

Design and specifications are subject to change without notice.

1-2 (No.YA787<Rev.002>)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE: ( ) side

GND, the ISOLATED (NEUTRAL): ( ) side GND and

EARTH: ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(6) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

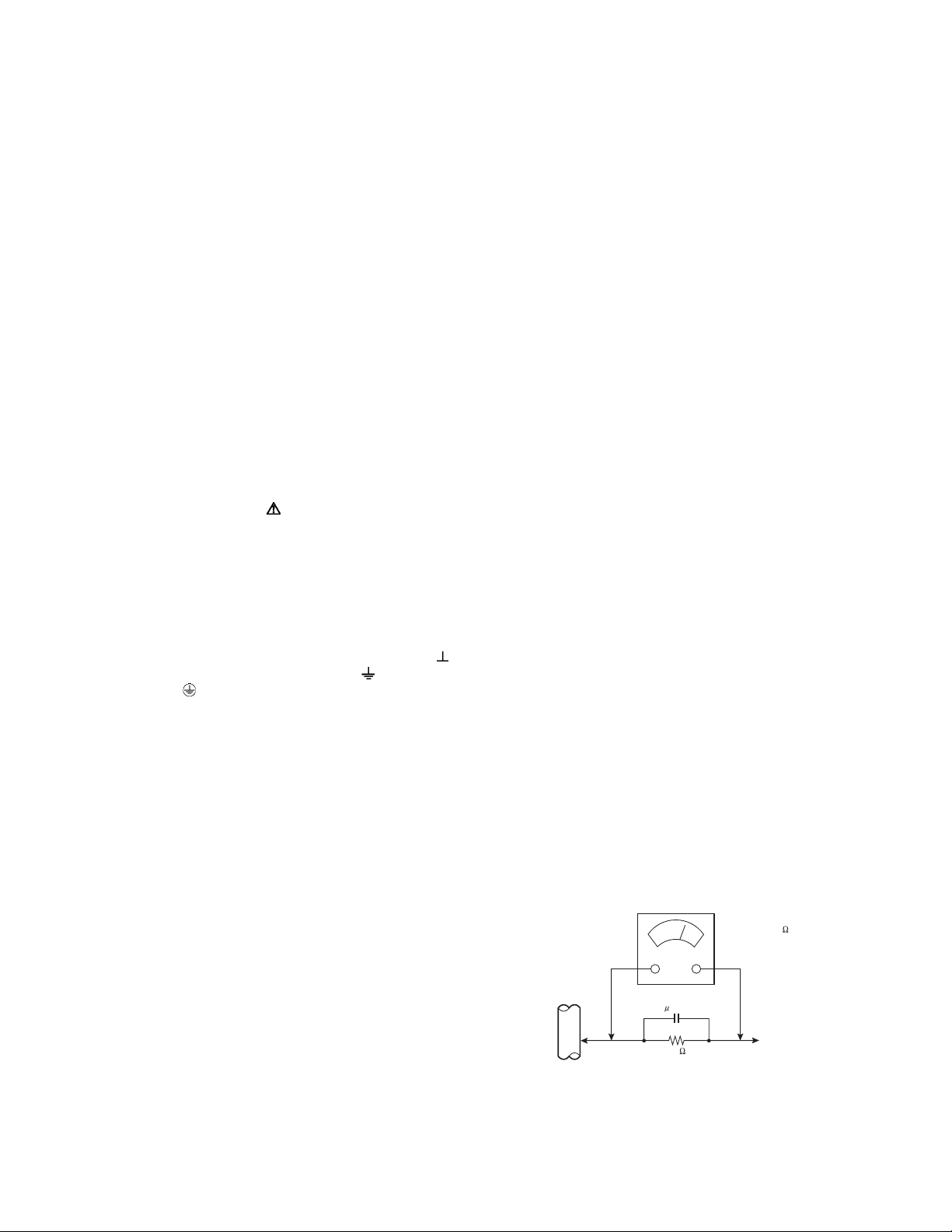

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

GOOD EARTH GROUND

1500 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TAL PAR T

(No.YA787<Rev.002>)1-3

Page 4

1.2 SAFETY PRECAUTIONS [FOR UK]

(1) The design of this product contains special hardware and

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the product have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessary be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the Parts List in the Service

Manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the Parts List of

Service Manual may cause shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubing’s, barriers and the like to be separated from

live parts, high temperature parts, moving parts and / or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

WARNING

(1) The equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are

replaced by approved parts.

(5) If mains voltage selector is provided, check setting for

local voltage.

1.3 HANDLING LCD PANEL

1.3.1 PRECAUTION FOR TRANSPORTATION

When transporting the display unit, pressure exerted on the

internal LCD (Liquid Crystal Display) panel due to improper

handing (such as tossing and dropping) may cause damages

even when the unit is carefully packed. To prevent accidents

from occurring during transportation, pay careful attention prior

to delivery such as through exchanging the handing instructions

to transporters.

Ensure that the following requirements are met during

transportation, as the LCD panel of this unit is made of glass and

therefore fragile.

(1) Avoid vibrations and impacts

The unit may be broken if it is toppled sideways even when

properly packed. Ensure that the unit is carried by at least

2 persons and pay careful attention not to exert any

vibration or impact on it.

(2) Do not place equipment lay a LCD panel on its side.

A LCD panel should always be placed upright during both

transportation and safekeeping. Don't lay it on its side. The

panel of a LCD panel is very fragile to the impact in the

horizontal direction.

When a car carries a LCD panel, load it on board the car in

parallel with the moving direction of the car. Don't lay

several LCD panels one on top another.

During safekeeping, don't lay more than two LCD panels

one on top another even if they are kept upright.

1.3.2 OPTICAL FILTER (FRONT FILTER)

Avoid placing the unit under direct sunlight over a prolonged

period of time. This may cause the optical filter to deteriorate in

quality and color.

Clean the filter surface by wiping it softly lightly with outing

flannels a soft and lightly fuzz cloth (such a flannel).

Do not use solvents such as benzene or thinner to wipe the filter

surface. This may cause the filter to deteriorate in quality or the

coating on the surface to come off.

As the filter surface is fragile. Do not scratch or hit it with hard

materials.

1.3.3 NOTES PRECAUTIONS FOR REPLACEMENT OF

EXTERIOR PARTS

Take note of the following when replacing exterior parts (back

REAR COVER, FRONT PANEL, OPTICAL FILTER):

Do not exert pressure on the front of the LCD panel (glass

surface).

Pay careful attention not to scratch or stain the front of the LCD

panel (surface) with hands.

When replacing exterior parts, the front of the LCD panel should

be placed facing downward. Place a met, etc. underneath to

avoid causing scratched to the front surface.

However, never use materials that are too soft (such as blanket

cloth). If replacement is made with the LCD panel surface facing

downward and in contact with the blanket, pressure may be

exerted on the LCD panel, thus causing damages to it.

1-4 (No.YA787<Rev.002>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

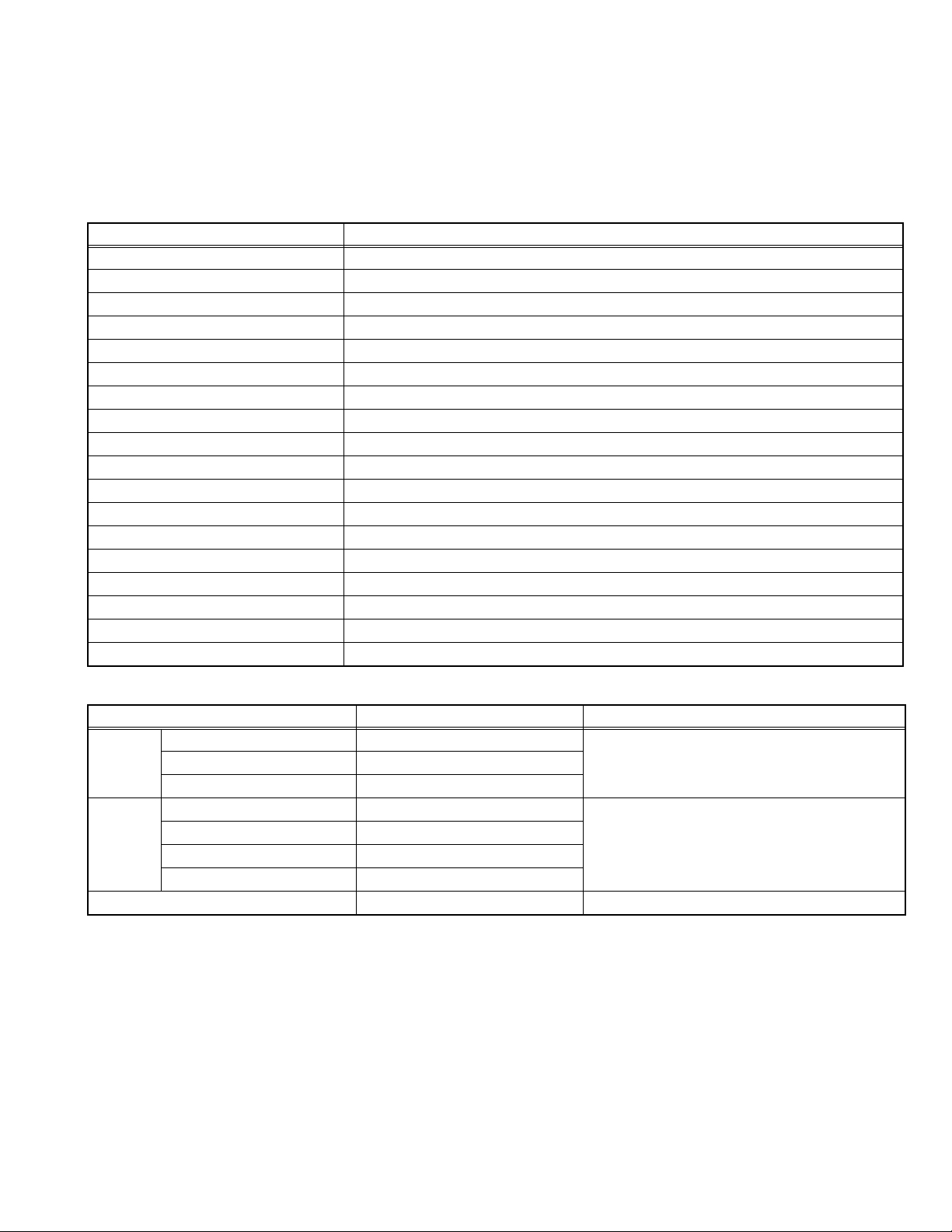

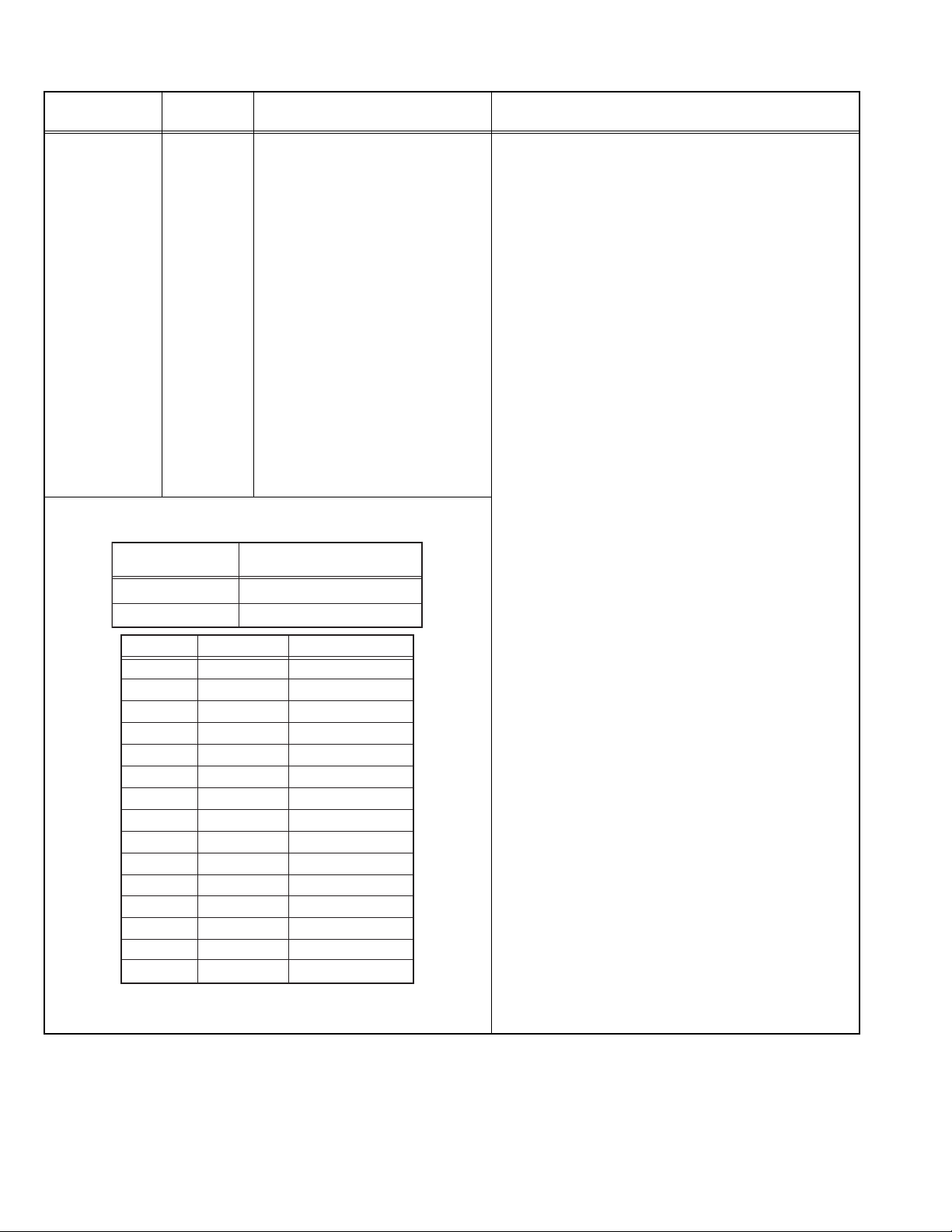

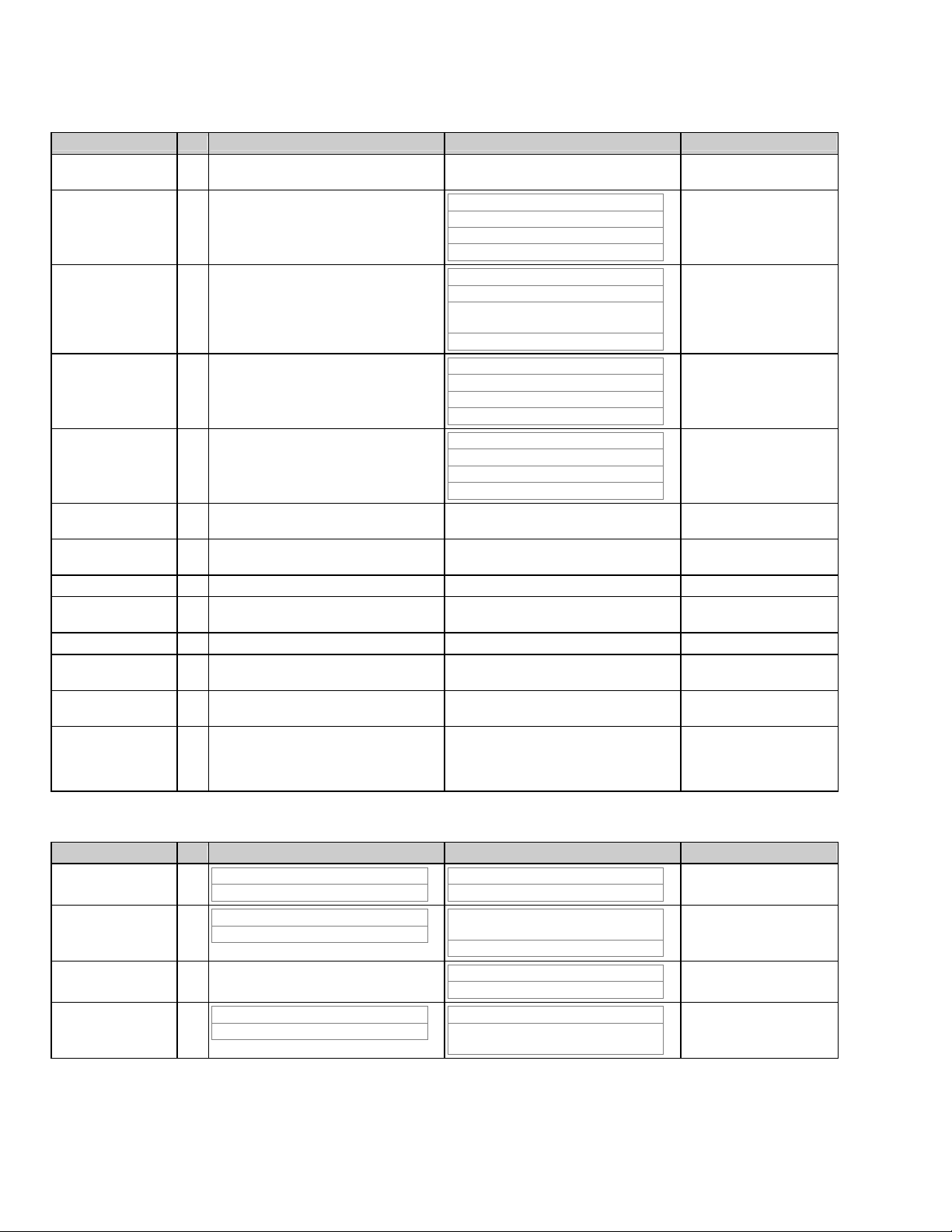

2.1 MAIN DIFFERENCE LIST

Item DT-R17L4D/CAT DT-R17L4D/EAT DT-R17L4D/UAT

POWER CORD CHINESE TYPE (3 Pin) EU TYPE (3 Pin)

UK TYPE (3 Pin)

INLET PWB FV-8081A-H2 FV-8080A-H2 FV-8080A-H2

POWER PWB FV-9038A-H2 FV-9037A-H2 FV-9037A-H2

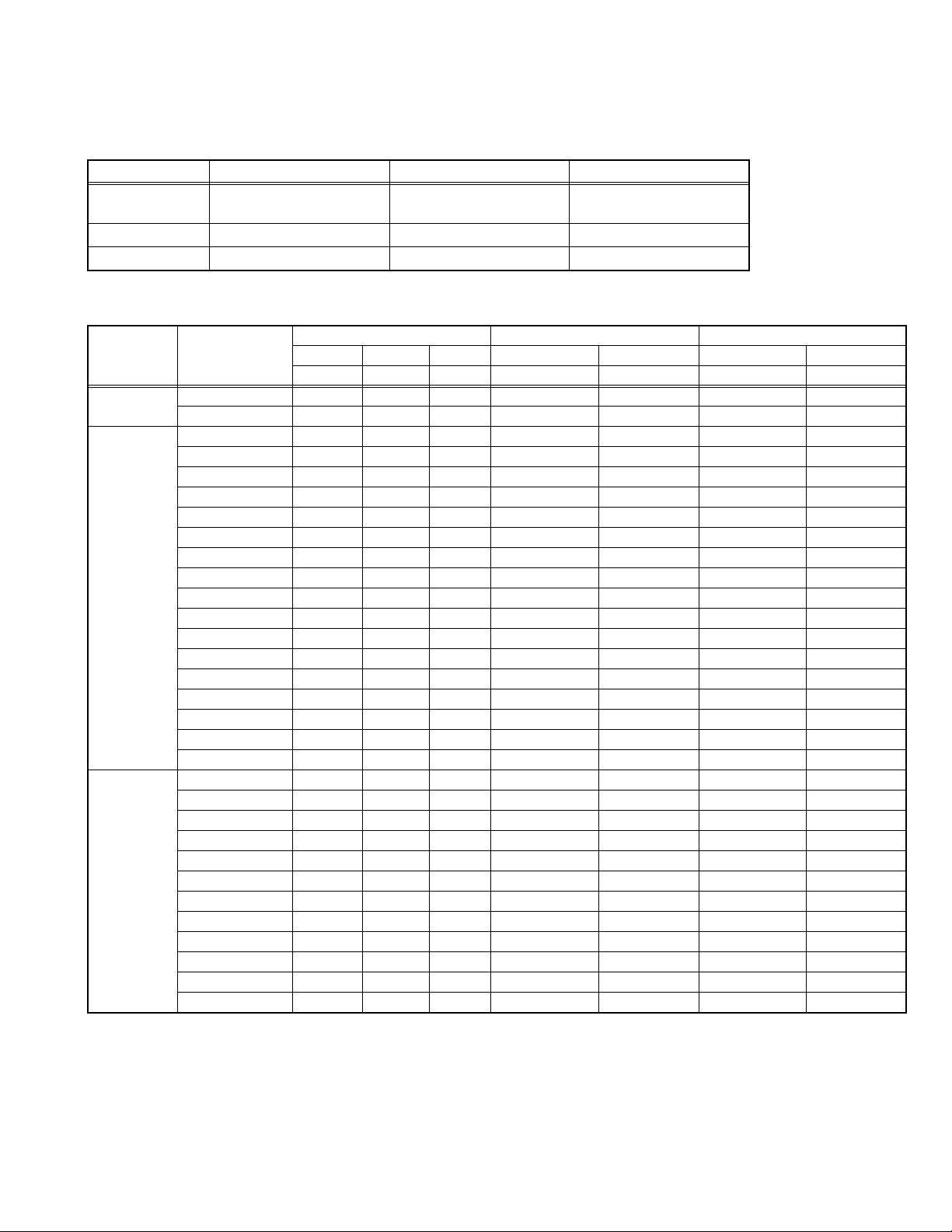

2.2 TIMING SPECIFICATION

Frequency Total area Effective area

Classification Signal name

VIDEO NTSC, BW/60 59.94 15.734 ---- 858 525 720 483

PAL 50.00 15.625 ---- 864 625 720 576

SDI 480/60i 59.94 15.734 13.500 858 525 720 483

576/50i 50.00 15.625 13.500 864 625 720 576

720/60p 60.00 45.000 74.250 1650 750 1280 720

720/50p 50.00 37.500 74.250 1980 750 1280 720

720/30p 30.00 22.500 74.250 3300 750 1280 720

720/25p 25.00 18.750 74.250 3960 750 1280 720

720/24p 24.00 18.000 74.250 4125 750 1280 720

1035/60i 60.00 33.750 74.250 2200 1125 1920 1035

1080/60i 60.00 33.750 74.250 2200 1125 1920 1080

1080/50i 50.00 28.125 74.250 2640 1125 1920 1080

1080/30p 30.00 33.750 74.250 2200 1125 1920 1080

1080/25p 25.00 28.125 74.250 2640 1125 1920 1080

1080/24p 24.00 27.000 74.250 2750 1125 1920 1080

1080/24psF 48.00 27.000 74.250 2750 1125 1920 1080

1080/30psF 60.00 33.750 74.250 2200 1125 1920 1080

1080/60p 60.00 67.500 148.500 2200 1125 1920 1080

1080/60p 50.00 56.250 148.500 2640 1125 1920 1080

DVI(COMPO/RGB)

480/60p 59.94 31.469 27.000 858 525 720 483

576/50p 50.00 31.250 27.000 864 625 720 576

640*480/60p 59.94 31.469 25.175 800 525 640 480

720/60p 60.00 45.000 74.250 1650 750 1280 720

720/50p 50.00 37.500 74.250 1980 750 1280 720

1080/60i 60.00 33.750 74.250 2200 1125 1920 1080

1080/50i 50.00 28.125 74.250 2640 1125 1920 1080

1080/60p 60.00 67.500 148.500 2200 1125 1920 1080

1080/50p 50.00 56.250 148.500 2640 1125 1920 1080

1080/30p 30.00 33.750 74.250 2200 1125 1920 1080

1080/25p 25.00 28.125 74.250 2640 1125 1920 1080

1080/24p 24.00 27.000 74.250 2750 1125 1920 1080

Vertical

Hz kHz MHz pixel/line line/frame pixel/line line/frame

Horizontal Dot clock Number of pixels Number of lines Number of pixels Number of lines

US TYPE (3 Pin)

(No.YA787<Rev.002>)1-5

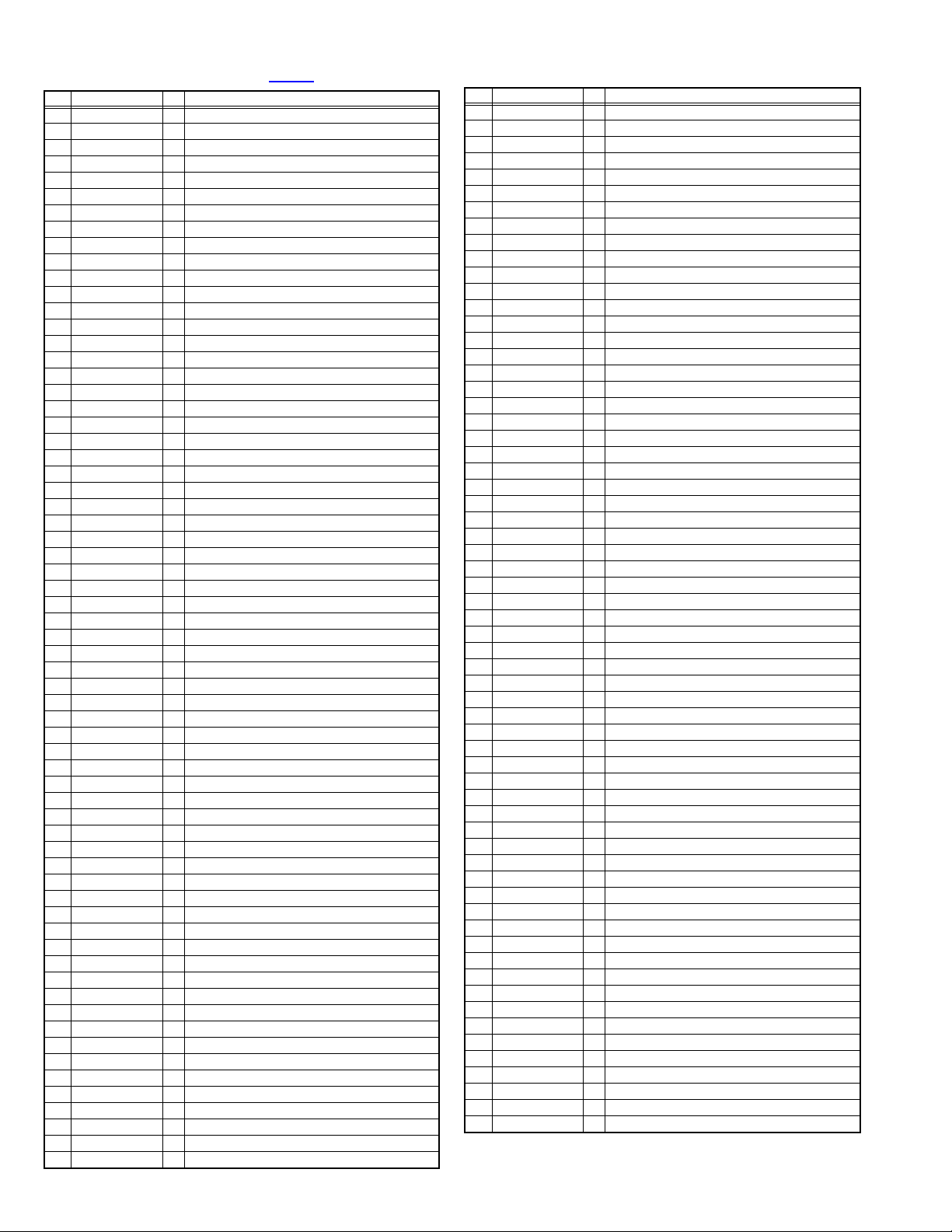

Page 6

Frequency Total area Effective area

Classification Signal name

Vertical

Horizontal Dot clock Number of pixels Number of lines Number of pixels Number of lines

Hz kHz MHz pixel/line line/frame pixel/line line/frame

DVI(PC) 720/60p 60.00 45.000 74.250 1650 750 1280 720

1080/60p 60.00 67.500 148.500 2200 1125 1920 1080

VGA/60 59.940 31.469 25.175 800 525 640 480

Wide VGA 59.941 31.469 33.546 1066 525 852 480

SVGA 60.317 37.879 40.000 1056 628 800 600

XGA 60.004 48.363 65.000 1344 806 1024 768

WideXGA(1280) 60.000 47.760 79.998 1675 796 1280 768

Wide XGA+ 59.999 55.919 106.470 1904 932 1440 900

SXGA 60.020 63.981 108.000 1688 1066 1280 1024

UXGA 60.000 75.000 162.000 2160 1250 1600 1200

WUXGA 59.950 74.038 154.000 2080 1235 1920 1200

The dot clock of the analog video signal is the internal sampling frequency.

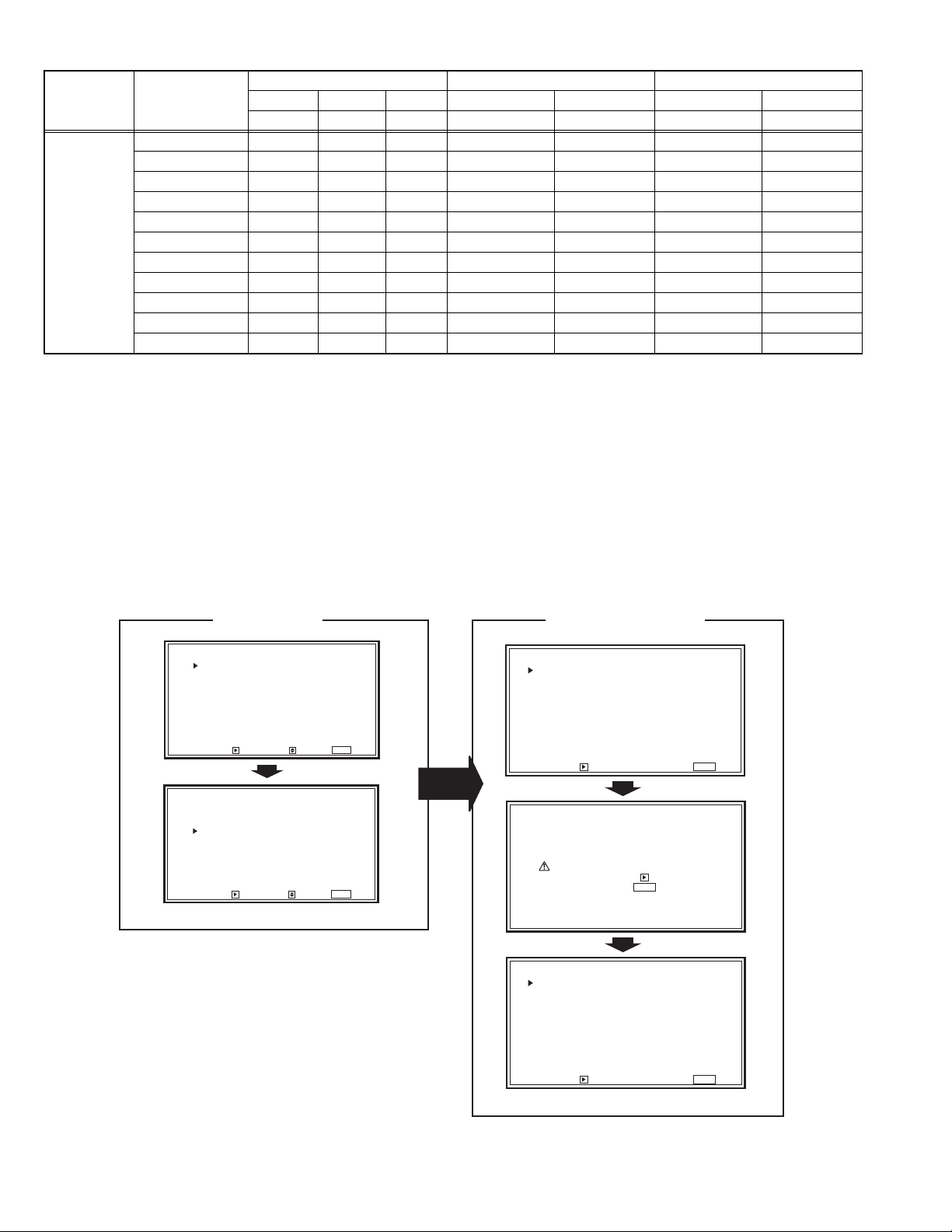

2.3 HOUR METER FUNCTION

This model is equipped with an "HOUR METER" function that

displays elapsed time on operating time of the set.

Elapsed time can be checked at the "HOUR METER BLOCK" in

the SERVICE MODE.

Also you can reset elapsed time to zero if needed.

Elapsed time count 1 hour. Maximum elapsed time is 65535

hour.

HOW TO RESET ELAPSED TIME

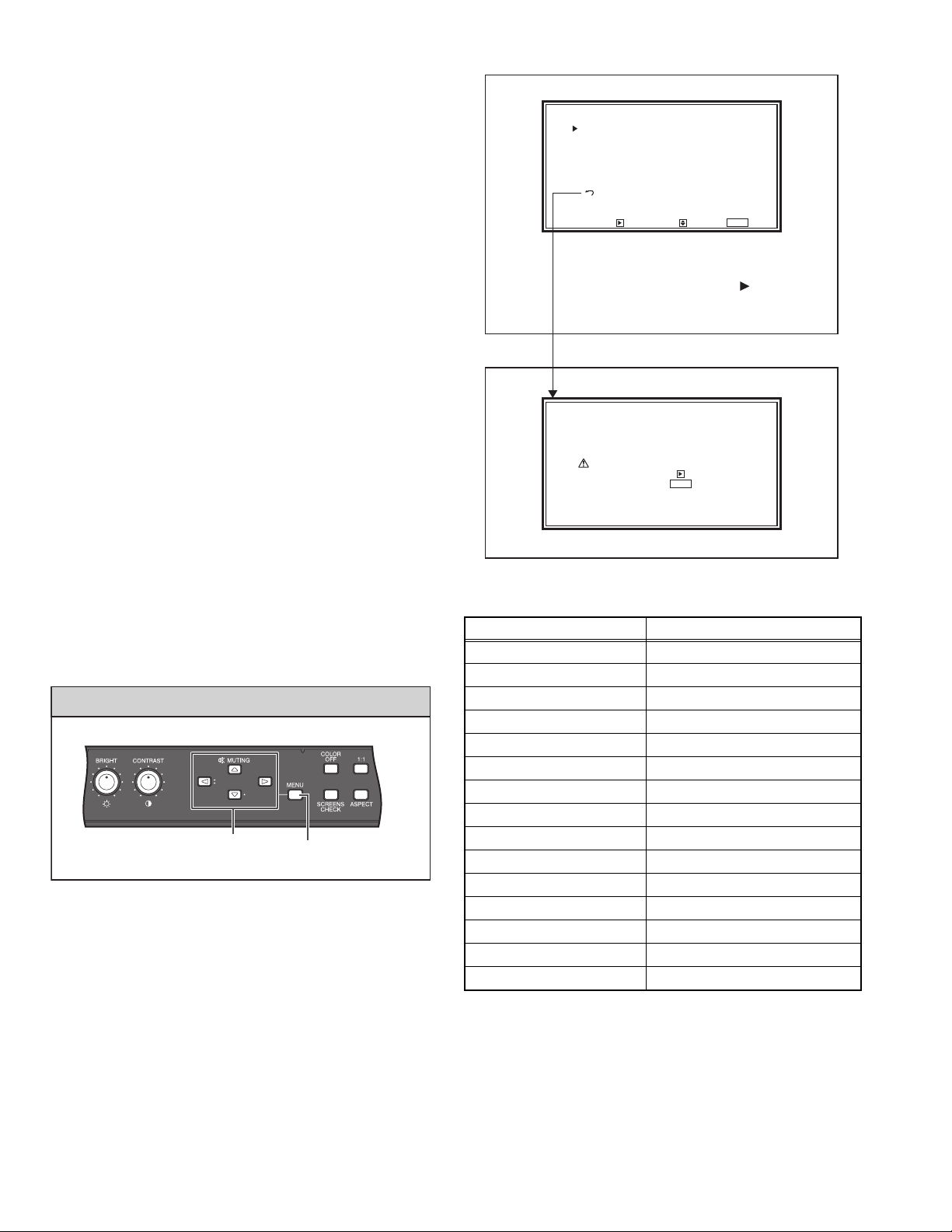

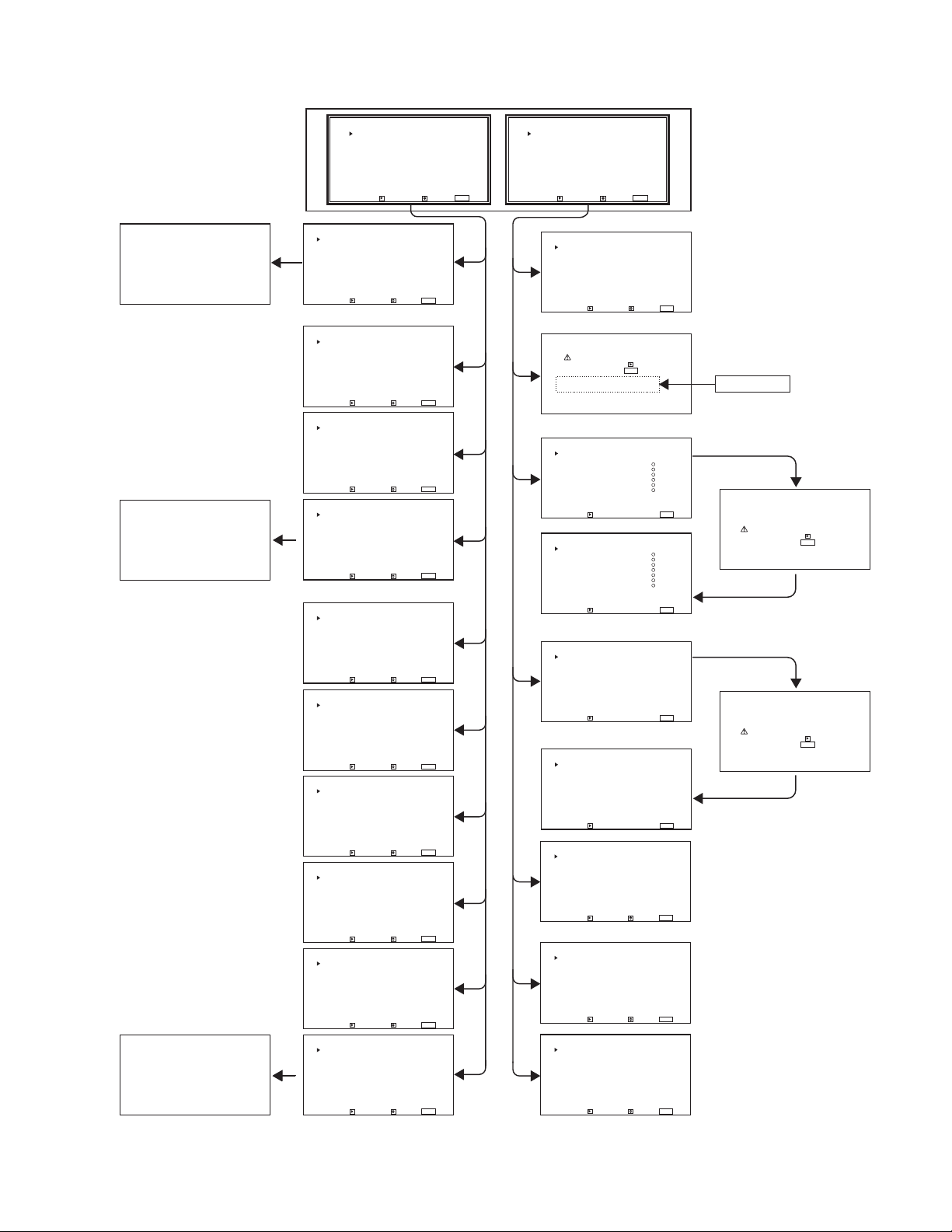

(1) Enter the SERVICE MODE (Fig.1).(See the page for

HOW TO ENTER THE SERVICE MODE)

(2) Press [] key, and select "HOUR METER BLOCK" in

the second page (2/2) of SERVICE MODE (Fig.2).

(3) Press [] key, and display "HOUR METER BLOCK"

screen (Fig.3).

(4) While the "HOUR METER BLOCK" is displayed, press

[] key and it will display "RESET HOUR METER"

(Fig.4).

(5) Press [] key and reset the HOUR METER (Fig.5).

SERVICE MODE

<SERVICE MENU> (1/2)

WHITE BALANCE BLOCK

DECODER BLOCK

SYNC BLOCK

SIGNAL BLOCK

ADC BLOCK

HDMI BLOCK

FORMAT BLOCK

DISPLAY BLOCK

ENHANCE BLOCK

CPU BLOCK

ENTER : SELECT : EXIT :

<SERVICE MENU> (2/2)

DEVICE INITIAL VALUE

UPDATE CPU PROGRAM

DIAGNOSIS BLOCK

HOUR METER BLOCK

FIRM WARE VERSION

WAVE FORM BLOCK 1

WAVE FORM BLOCK 2

ENTER : SELECT : EXIT :

MENU

MENU

Fig.1

Fig.2

HOUR METER BLOCK

<HOUR METER BLOCK>

RESET

HOUR METER (x1h): 12345

ENTER : EXIT :

<RESET HOUR METER>

Are you sure?

"YES" then key.

"NO" then key.

MENU

MENU

Fig.3

Fig.4

1-6 (No.YA787<Rev.002>)

<HOUR METER BLOCK>

RESET

HOUR METER (x1h): 00000

ENTER : EXIT :

MENU

Fig.5

Page 7

2.4 TECHNICAL INFORMATION

2.4.1 LCD PANEL

This unit uses the flat type panel LCD (Liquid Crystal Display) panel that occupies as little space as possible, instead of the

conventional CRT (Cathode Ray Tube), as a display unit.

Since the unit has the two polarizing filter that are at right angles to each other, the unit adopts "normally black" mode, where light

does not pass through the polarizing filter and the screen is black when no voltage is applied to the liquid crystals.

2.4.1.1 SPECIFICATIONS

The following table shows the specifications of this unit.

Item Specifications

Maximum dimensions (W × H × D) 413.0 mm × 252.0 mm × 43.6 mm

Weight 2.1 kg

Effective screen size Width: 372.9 mm, Height: 209.7 mm

Aspect ratio 16 : 9

Drive device / system a-Si-TFT, active matrix system

Resolution Horizontally 1366 × Vertically 768 × RGB <WXGA> / 3147264 dots in total

Pixel pitch (pixel size) H: 0.091 mm, V: 0.273 mm

Displayed color 16777216 colors / 256 colors for R, G, and B

Brightness 350 cd/m

2

Contrast ratio 900 : 1

Response time 17 ms

View angle Horizontally: 178°, Vertically: 178°

Surface polarizer Anti-glare type, 3H hard coat

Color filter Vertical stripe

Backlight Cold cathode fluorescent lamp × 8

Power supply voltage in LCD 12 V

Power supply voltage in INVERTER 24 V

Panel interface system LVDS (Low Voltage Differential Signaling)

2.4.1.2 PIXEL FAULT SPECIFICATION

Fault Criteria for number of faulted cell Screen display

Bright dot random 0 All black screen

two dots adjacent 0

three dots adjacent or more 0

Dark dot random 5 or less in all colors Red, green and blue level 100% on entire screen

two dots adjacent 1 or less in all colors

three dots adjacent or more 0

total 5 or less in all colors

Any pixel fault 5 or less in all colors ---

(No.YA787<Rev.002>)1-7

Page 8

2.4.2 MAIN CPU PIN FUNCTION [IC1703

Pin Pin name I/O Function

1 P33/SC3.3AC O For Scaler(IC1401) power

2 P32/D1.2AC O For Scaler(IC1401) power

3 P31/DDS1.2AC O For Scaler(IC1401) power

4 P30/D1.2PLAC O For Scaler(IC1401) power

5 P67/SY_VI I Video sync input detection [Detect = L]

6 P68/TE_STB O

7

P65/SCK2/TE_RST

8 P64/PWDA O Not used

9 P63/PWAD O Not used

10 P62/DSP_RST O Not used

11 P61/AMUTE2 O Audio output muting [Muting = H]

12 P60/AMUTE1 O Audio muting [Muting = H]

13 VSS - GND

14 P90/REMOTE I Remote control

15 P91/DIMMER O Brightness control for front panel LED [Low = H]

16 VCC - 3.3V power supply

17 P92/PW_LED_G O Power LED (green) control [On = H]

18 P93/PW_LED_R O Power LED (red) control [On = H]

19 P94/INP_LEDD O Front panel LED (FVI) control [On = H]

20 P95/INP_LEDE O Front panel LED (Video) control [On = H]

21 P96 O Not used

22 P97/INP_LEDF O Front panel LED (SDI-2) control [On = H]

23 MO0/ND0 I CPU mode select [H Fixed]

24 MO1/MD1 I CPU mode select

25 MO2/MD2 I CPU mode select

26 FWE I For on-board writing to flash memory of CPU

27 NMI I Not used [L Fixed]

28 RESET I Reset for CPU [Reset = L]

29 VSS - GND

30 VCL - For outside capacitor

31 VCC - 3.3V power supply

32 EXTAL - System clock oscillation (crystal)

33 XTAL - System clock oscillation (crystal)

34 VSS - GND

35 ETMS/PC*4 I For Emulator

36 ETCK/PC*5 I For Emulator

37 /STBY I Not used [H Fixed]

38 ETDI/PC*6 I For Emulator

39 /ETRST I For Emulator

40 ETDO/PC*7 O For Emulator

41 P50/SCK0/TICS O Not used

42

P51/TxD0/TxD_485

43

P52/RxD0/RxD_485

44 P53/SCK1/TSCK O

45

P54/TxD1/TxD_232

46

P55/RxD1/RxD_232

47 P56 O Not used

48 P57/SYS_ON O System standby power control [On = H]

49

P40/IRQ0/DC5V_DET

50

P41/IRQ1/DC1R2_DET

51

P42/IRQ2/AC.DET

52

P43/IRQ3/PO.ALARM

53 VSS - GND

54 AVSS/Vss - GND

55 P70/AN0/KEY_1 I Key scan data for control button

56 P71/AN1/KEY_2 I Key scan data for control button

57 P72/AN2/KEY_3 I Key scan data for control button

58 P73/AN3/KEY_4 I Key scan data for control button

59 P74/AN4/KEY_5 I Key scan data for control button

60 P75/AN5 I Not used

61 P76/AN6 I Not used

62

P77/AN7/GF9351 BOOT

63

P00/AN8 VOL_CONT

64

P01/AN9 VOL_BRIG

65

P02/AN10 VOL_CHRO

Standby mode for Sync separator(IC2107) [Standby = L]

O Reset for Sync separator(IC2107) [Reset = L]

O Data transmission for RS-485 external control

I Data receive for RS-485 external control

Clock for on-board writing to flash memory of CPU

O Data transmission for RS-232C external control

I Data receive for RS-232C external control

I D5V power detection [Detect = H]

I D1.2V power detection [Detect = L]

I AC power detection [On = L]

I Error detection for Power Supply Unit [Error = L]

I Not used

I Volume data for Contrast

I Volume data for Bright

I Volume data for Chroma

: DIGITAL PWB ASS'Y]

Pin Pin name I/O Function

66

P03/AN11 VOL_PHAS

67

P04/AN12 VOL_AUDIO

68

P05/AN13/H_BUSY

69

P06/AN14/EXOUT

70 P07/AN15/BUSY I Initialization end detection for Scaler (IC1401)

71 AVCC/Vcc - 3.3V power supply

72 Avref/Vcc - 3.3V fixed

73 PA44/IRQ4/SOS I Error detection for Inverter [Error = H]

74 P45/FPGA_VD I V.sync from FPGA (IC1307)

75

P45/IRQ6/FPGA_VD

76

P47/IRQ7/S_Vsync

77

P80/VSYNC_0/DVI_RST

78

P81/HSYNC_0/HDMI_DET

79

P82/CSYNC_1/HD5V_DET

80

P83/VSYNC_1/ DDC_WP

81

P84/HSYNC_1/DDC_MIC

82

P85/CSYNC_0/DDC-HP

83 VCC - 3.3V power supply

84

PB6/VSYNC0/Vsync

85 PB7/DVI_INT I DVI interruption

86 VSS - GND

87 BAT_LED_R O Not used

88 BAT_LED_G O Not used

89 P85 O Not used

90 P84 O Not used

91 PA7/G_TAL O Tally LED (green) control [On = H]

92 PA6/VS_ERROR I V.sync from FPGA (IC1601)

93 PA5/R_TAL O Tally LED (red) control [On = H]

94 PA4/TXD_EN2 O Control for data transmission enable [On = H]

95 PA3/TXD_EN1 O Control for data transmission enable [On = H]

96 PA2/SERIAL_2 O RS-232C/RS-485 select

97 PA1/SERIAL_1 O RS-232C/RS-485 select

98 PA0/ID_SET O

99 P83/SDA1 I/O

100 P82/SCL1 O

101 P81/SDA0 I/O Data for Inter IC (serial) bus: E2PROM(IC1702) etc.

102 P80/SCL0 O

103 SCL2 O

104 SDA2 I/O

105 SCL3 O

106 SDA3 I/O

107 P27/GPIO_A2 O Control for PROM of Scaler(IC1401)

108 P26 O Not used

109 P25/CC_RST O Not used

110 P24/SC_RST O Reset for Scaler(IC1401) [Reset = L]

111 P23/CS O Chip select for Scaler(IC1401) [Select = L]

112 P22/SCK O Clock for Scaler(IC1401)

113 P21/SI O Data transmission for Scaler(IC1401)

114 P20/SO I Data receive for Scaler(IC1401)

115 VCC - 3.3V power supply

116

P17/PW7/CNF_W

117 P16/PW6 O Reset for Digital caption (DCC)

118 VSS - GND

119

P15/PW5/TC_RST

120

P14/PW4/AD_RST

121

P13/PW3/CNF_PROG

122

P12/PW2/CNF_DONE

P11/PW1/FPGA_RST

123

124

P10/PW0/LCD_PWM

125

P37/D15/OPTION3

126

P36/D13/OPTION2

127

P35/D13/OPTION1

128 P34/D12 VMUTE O Picture muting [Muting = L]

I Volume data for Phase

I Volume data for Volume (audio)

I

Communication permission detection for Scaler (IC1401)

I Interrupt for Scaler(IC1401)

O Not used

I H.sync from FPGA (IC1307)

O Reset for DVI receiver [Reset = L]

I DVI sync detection [Detect = H]

I DVI 5V power detection [Detect = L]

O Programming control for EDID ROM

O Inter IC (serial) bus select for DVI

O DVI hot plug control [On = H]

I V.sync from FPGA(IC1307)

ID set control for serial communication [ID set = H]

Data for Inter IC (serial) bus: Sync separator(IC2107)

Clock for Inter IC (serial) bus: Sync separator(IC2107)

Clock for Inter IC (serial) bus: E2PROM(IC1702) etc.

Clock for Inter IC (serial) bus: FPGA(IC1307/IC1601) etc.

Data for Inter IC (serial) bus: FPGA(IC1307/IC1601) etc.

Clock for Inter IC (serial) bus: Video decoder(IC1205) etc.

Data for Inter IC (serial) bus: Video decoder(IC1205) etc.

O Not used

O Reset for Video decoder (IC1205) [Reset = L]

O Reset for Video A-D converter (IC1202) [Reset = L]

I For FPGA (IC1307/IC1601) configuration

I For FPGA (IC1307/IC1601) configuration

O Reset for FPGA (IC1307/IC1601) [Reset = L]

O Brightness control for Backlight

O For optional FPGA (IC1601) control

O For optional FPGA (IC1601) control

O For optional FPGA (IC1601) control

1-8 (No.YA787<Rev.002>)

Page 9

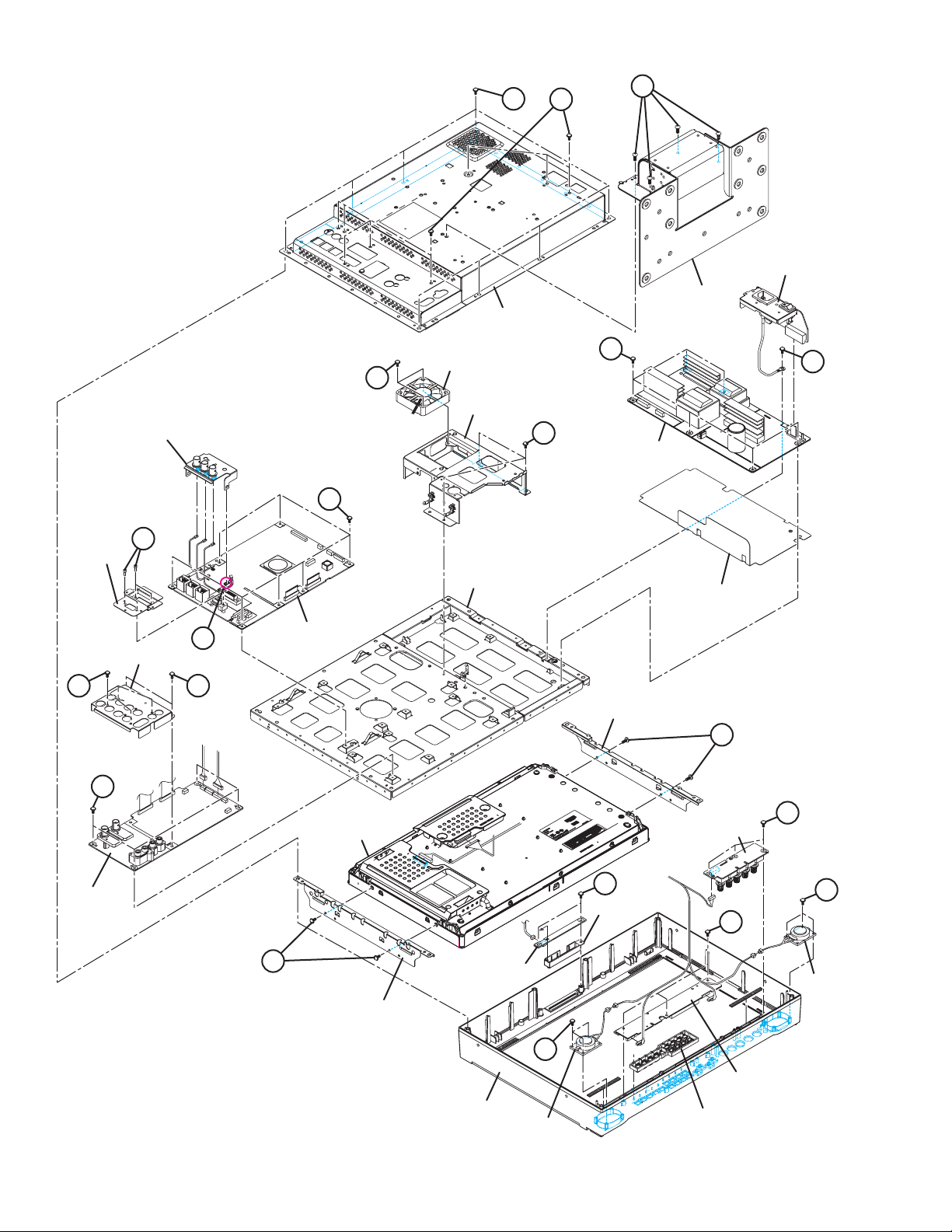

SECTION 3

DISASSEMBLY

3.1 CAUTION AT DISASSEMBLY

• Make sure that the power cord is disconnected from the outlet.

• Pay special attention not to break or damage the parts.

• Make sure that there is no bent or stain on the connectors before inserting, and firmly insert the connectors.

• Be sure to reattach the wire clamps removed during the procedure to the original positions. (Attaching the wire clamps in wrong

positions may affect the performance.)

REFERENCE:

When removing each board, remove the connector if necessary. The operation is easier if you write down the connection points

(connector numbers) of the connector. For connection of each board, refer to the "WIRING DIAGRAM" of the Standard Circuit

Diagram.

3.2 DISASSEMBLY PROCEDURE [MAIN UNIT]

3.2.1 REMOVING THE STAND (Fig.3-1)

(1) Remove the 4 screws [A].

(2) Remove the STAND.

3.2.2 REMOVING THE REAR COVER (Fig.3-1)

(1) Remove the 8 screws [B] and 8 screws [C].

(2) Remove the REAR COVER.

3.2.3 REMOVING THE COOLING FAN (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 2 screws [D].

(2) Remove the COOLING FAN.

3.2.4 REMOVING THE INLET PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 1 screw [G].

(2) Remove the INLET PWB.

3.2.5 REMOVING THE POWER PWB (Fig.1)

• Remove the REAR COVER.

• Remove the INLET PWB.

(1) Remove the 3 screws [H].

(2) Remove the FAN BRACKET.

(3) Remove the 6 screws [J].

(4) Remove the POWER PWB.

3.2.6 REMOVING THE DIGITAL PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 1 clip [a].

(2) Remove the SDI SHIELD.

(3) Remove the 4 screws [K].

(4) Remove the DVI BRACKET.

(5) Remove the 7 screws [L].

(6) Remove the DIGITAL PWB.

3.2.7 REMOVING THE ANALOG PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 4 screws [M] and 2 screws [N].

(2) Remove the TERMINAL BRACKET.

(3) Remove the 4 screws [P].

(4) Remove the ANALOG PWB.

3.2.8 REMOVING THE VOLUME PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the REAR BASE.

(2) Remove the 3 screws [R].

(3) Remove the VOLUME PWB.

3.2.9 REMOVING THE SWITCH PWB/PUSH KNOB (Fig.3-1)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the 3 screws [S].

(2) Remove the SWITCH PWB.

(3) Remove the PUSH KNOB.

3.2.10 REMOVING THE SPEAKER (Fig.3-1)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the 6 screws [T].

(2) Remove the SPEAKER(L/R).

3.2.11 REMOVING THE TALLY PWB (Fig.3-1)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the 2 screws [U].

(2) Remove the TALLY PWB with the TALLY LENS.

(3) Remove the TALLY LENS from the TALLY PWB.

3.2.12 REMOVING THE LCD PANEL UNIT (Fig.3-1)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the LCD PANEL UNIT with the SIDE BRACKET.

(2) Remove the 4 screws [V].

(3) Remove the SIDE BRACKET(L/R).

(No.YA787<Rev.002>)1-9

Page 10

B

REAR COVER

C

A

INLET PWB

STAND

SDI SHIELD

DVI

BRACKET

TERMINAL BRACKET

K

M

P

J

COOLING FAN

G

D

FAN BRACKET

H

POWER PWB

L

REAR BASE

a

DIGITAL PWB

INSULATOR

N

SIDE BRACKET

V

R

LCD PANEL UNIT

VOLUME PWB

ANALOG PWB

1-10 (No.YA787<Rev.002>)

U

TALLY LENS

T

S

V

SIDE BRACKET

TALLY PWB

SPEAKER

T

SWITCH PWB

FRONT PANEL

SPEAKER

PUSH KNOB

Fig.3-1

Page 11

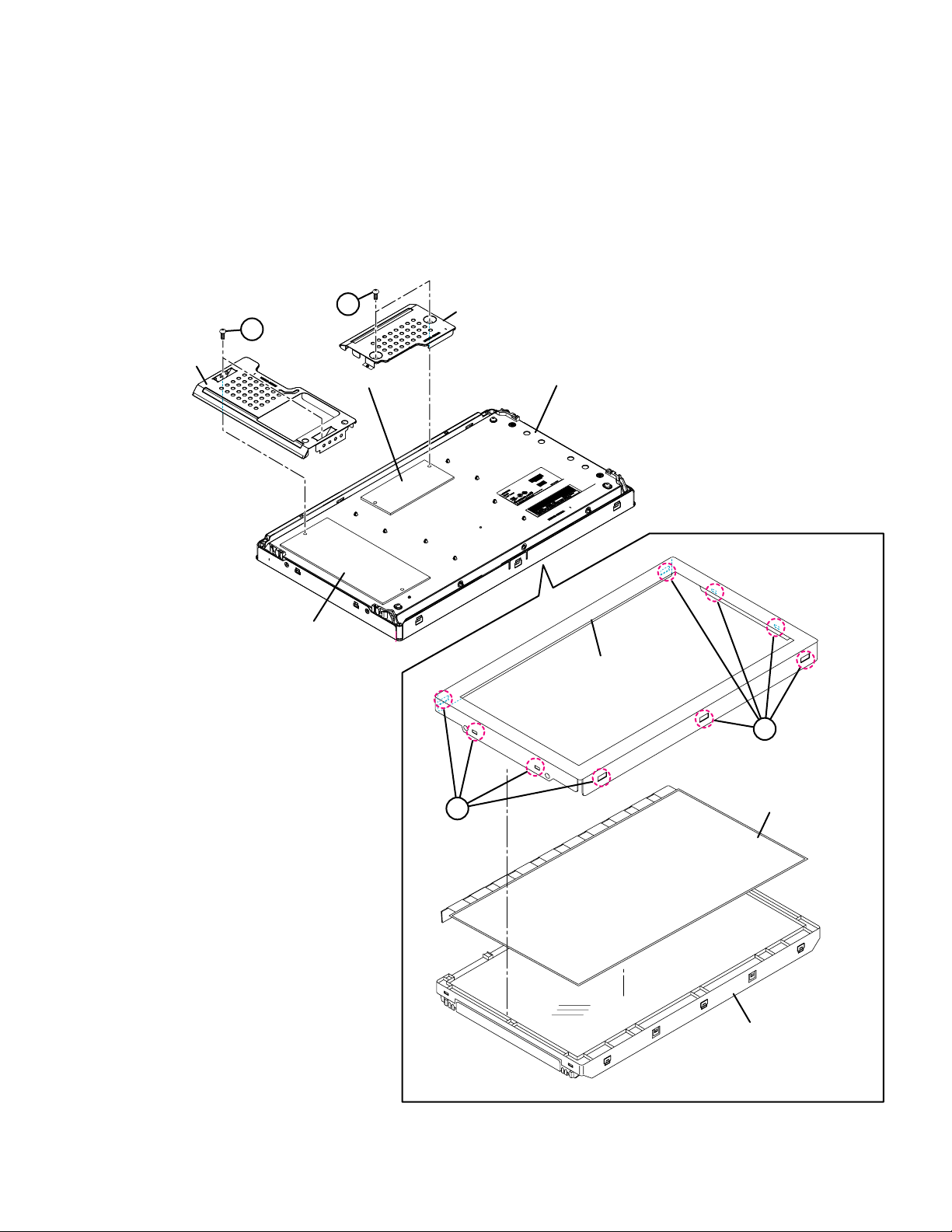

3.3 DISASSEMBLY PROCEDURE [LCD PANEL UNIT]

3.3.1 REMOVING THE LCD CONTROL PWB (Fig.3-2)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the 2 screws [A].

(2) Remove the LCD CONTROL PWB COVER.

(3) Remove the LCD CONTROL PWB.

3.3.2 REMOVING THE INVERTER PWB (Fig.3-2)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the 2 screws [B].

(2) Remove the INVERTER PWB COVER.

(3) Remove the INVERTER PWB.

3.3.3 REMOVING THE BACK LIGHT UNIT (Fig.3-2)

• Remove the REAR COVER.

• Remove the REAR BASE.

(1) Remove the 9 hooks [a].

(2) Remove the PANEL FRAME and LCD PANEL.

INVERTER PWB

COVER

B

LCD CONTROL PWB

INVERTER PWB

A

LCD CONTROL PWB

COVER

LCD PANEL UNIT

PANEL FRAME

a

a

LCD PANEL

BACK LIGHT UNIT

Fig.3-2

(No.YA787<Rev.002>)1-11

Page 12

3.4 REPLACEMENT OF MEMORY ICs

This model uses memory IC. In the memory IC is memorized

data for correctly operating the video and drive circuits.

When replacing the memory IC, be sure to use IC written with the

initial values of data.

3.4.1 PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power plug from the

wall outlet.

(2) Replace IC

Be sure to use memory IC written with the initial data

values.

(3) Power on

Connect the power plug into the wall outlet and turn the

power on.

3.4.2 PROCEDURE FOR SET-UP MENU

(1) Press the [] key and [] key on the front panel

simultaneously.

(2) The SET-UP MENU screen (Fig. 3-3) is displayed.

(3) Check the setting value of the SET-UP MENU table. (Refer

to the next page.)

(4) If the value is different, select the setting item with the []

/ [] key, and set the correct value with the [] / [] key.

(5) Press the [MENU] key, and return to the normal screen.

<SET-UP MENU>

FUNCTION SETTING

PICTURE SUB ADJ.

SIZE/POSI. ADJ.

WHITE BALANCE SET.

REMOTE SETTING

INFORMATION

CONTROL LOCK :OFF

DVI INPUT SEL.:AUTO

all reset

ENTER : SELECT : EXIT :

MENU

SET-UP MENU screen

Select “all reset” and press the [ ] key,

the [all reset] screen is displayed.

Fig.3-3

<all reset>

Are you sure?

"YES" then key.

"NO" then key.

[all reset] screen

MENU

3.4.3 PROCEDURE FOR ALL RESET

(1) The SET-UP MENU is displayed.

(2) Select "all reset" with the [] / [] key and press the []

key.

(3) The all reset screen is displayed (Fig.3-4).

(4) Press the [] key to reset all the standard settings.

FRONT PANEL BUTTON POSITION

FUNCTION

(///)

MENU

Fig.3-4

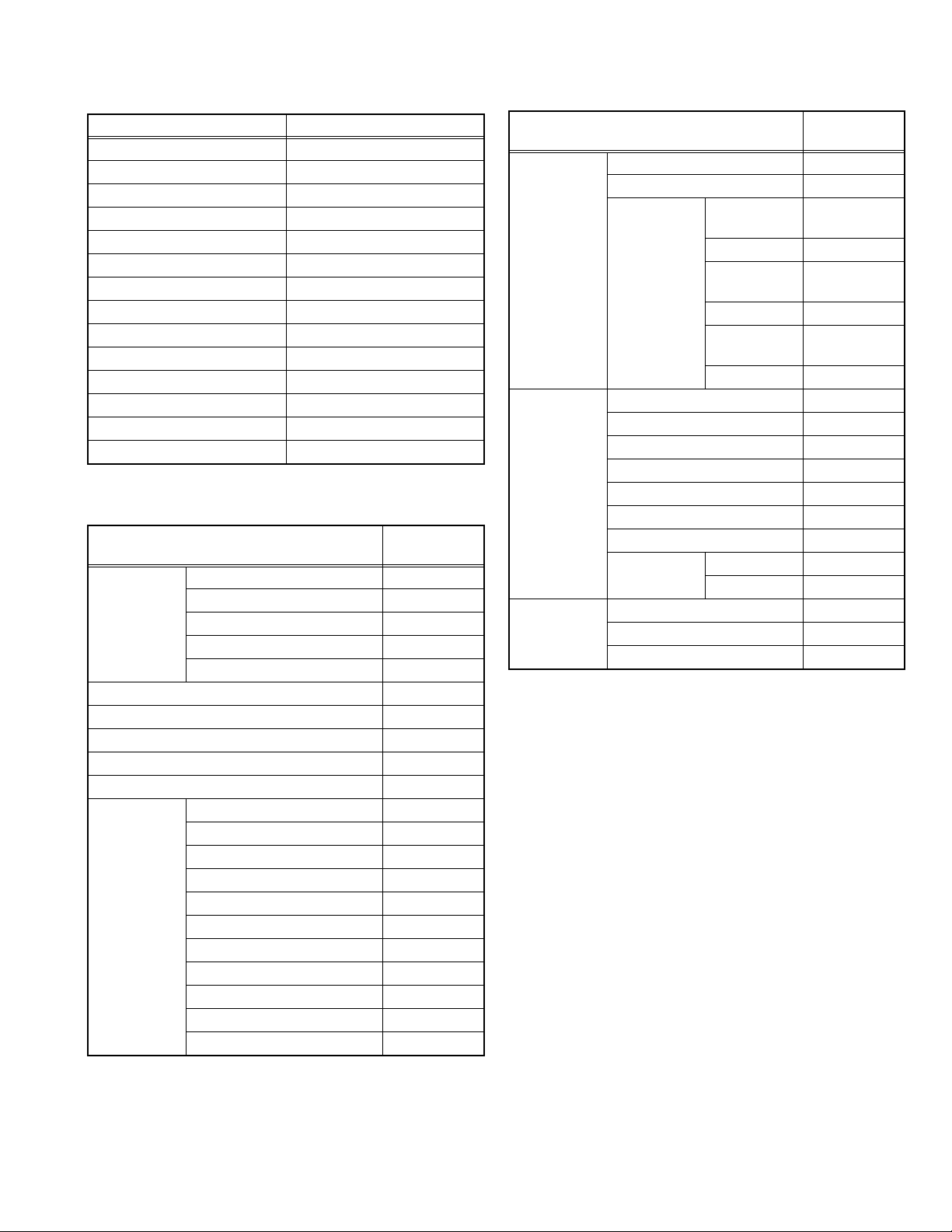

3.4.4 SERVICE SETTING ITEMS

Setting item Contents

WHITE BALANCE BLOCK White balance adjustment

DECODER BLOCK Video decoder adjustment

SYNC BLOCK Sync. circuit adjustment

SIGNAL BLOCK Signal circuit adjustment

ADC BLOCK Video A-D converter adjustment

HDMI BLOCK HDMI/DVI circuit adjustment

FORMAT BLOCK Video format adjustment

DISPLAY BLOCK Display size/position adjustment

ENHANCE BLOCK Enhance circuit adjustment

CPU BLOCK Setting of CPU

DEVICE INITIAL VALUE Initial setting of devices

UPDATE CPU PROGRAM Update of CPU program

DIAGNOSIS BLOCK Diagnosis function

HOUR METER BLOCK Hour meter function

FIRM WARE VERSION Version of firmware

1-12 (No.YA787<Rev.002>)

Page 13

3.4.5 SETTINGS OF FACTORY SHIPMENT

3.4.5.1 FRONT PANEL OPERATION

Setting item Setting position

POWER switch (REAR) Off

STNAD-BY switch (FRONT) Off

CONTRAST knob Center

BRIGHT knob Center

CHROMA knob Center

PHASE knob Center

VOLUME knob Min

COLOR OFF Off

AREA MARKER Off

SAFETY MARKER Off

T.C. (TIME CODE) Off

1 : 1 Off

SCREENS CHECK Off

INPUT SELECT SDI 1

3.4.5.2 MENU OPERATION

(1) MAIN MENU

Setting item

PICTURE

FUNCTION

BACK LIGHT 00

AUTO ASPECT (DT-R17L4D/EAT) OFF

MANUAL ASPECT (DT-R17L4D/EAT) 4 : 3

ASPECT (Other models) 4 : 3

SD4:3 SIZE NORMAL

MARKER AREA MARKER OFF

APERTURE FREQ. OFF

APERTURE LEVEL 01

CTI OFF

LTI OFF

I/P MODE NORMAL

MARKER ASPECT 4 : 3

SAFETY MARKER OFF

SAFETY AREA 80%

FRAME OFF

CENTER MARKER OFF

LINE BRIGHTNESS HIGH

R-AREA MARKER OFF

R-MARKER ASPECT 4 : 3

R-SAFETY MARKER OFF

R-SAFETY AREA 80%

Setting

position

AUDIO

SETTING

SCOPE

SETTING

SYNC

FUNCTION

Setting item

BALANCE 00

E.AUDIO GROUP 1G

LEVEL

METER

SETTING

GAIN 0

SIZE NORMAL

POSITION 1

TRANSPARENT OFF

AUTO OFF ON

WAVE DISPLAY Y

WAVE FILTER FLAT

WAVE OVER

LEVEL

NO SYNC ACTION OFF

DELAY TIME 30 sec.

LOW LATENCY OFF

LEVEL

METER ch

BAR TYPE 3COLORS

REFERENCE

LEVEL

OVER LEVEL -10dB

BAR

BRIGHTNESS

PEAK HOLD OFF

MARKING OFF

LEVEL 75

Setting

position

OFF

-20dB

HIGH

(No.YA787<Rev.002>)1-13

Page 14

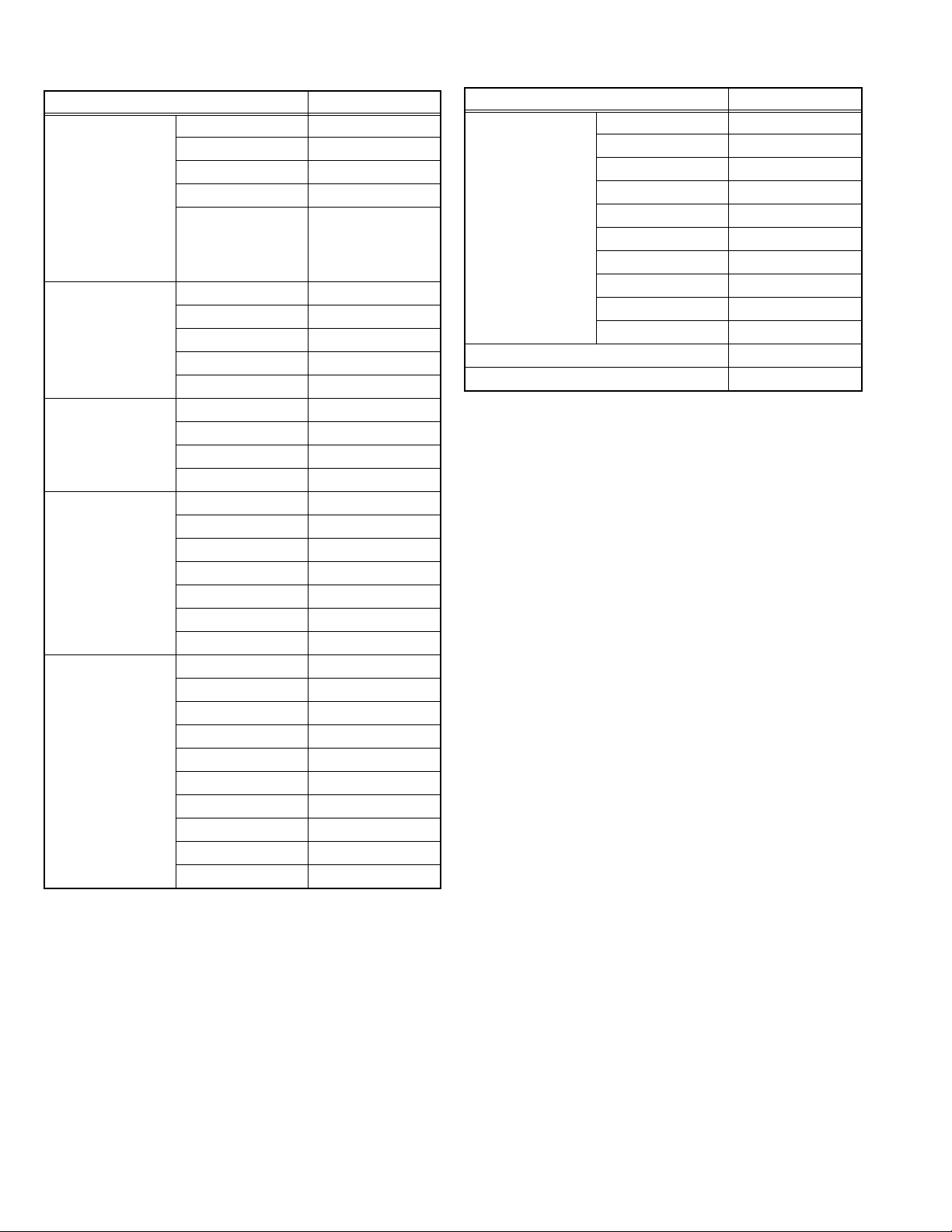

(2) SETUP MENU

Setting item Setting position

FUNCTION

SETTING

PICTURE SUB

ADJ.

SIZE/POSI. ADJ. H SIZE 000

WHITE BALANCE

SET.

REMOTE SETTING SERIAL TYPE RS232C

sub menu POSI. LOWER1

COLOR SYSTEM AUTO

TALLY SELECT GREEN

DIMMER NORMAL

COMPONENT

PHASE

CONTRAST 00

BRIGHT 00

CHROMA 00

PHASE 00

NTSC SETUP 00

H POSITION 000

V SIZE 000

V POSITION 000

COLOR TEMP. 6500K

R DRIVE 000

G DRIVE 000

B DRIVE 000

R CUT OFF 000

G CUT OFF 000

B CUT OFF 000

PARALLEL TYPE MAKE

PIN 1 ---

PIN 2 ---

PIN 3 ---

PIN 4 ---

PIN 5 ---

PIN 6 TALLY

PIN 7 ENABLE

PIN 8 GND

DISABLE (DTR17L4D/EAT)

ENABLE (Other

models)

Setting item Setting position

IMFOMATION POSITION UPPER

SOURCE ID OFF

CHARACTER SET. ---

STATUS DISPLAY AUTO

TIME CODE VITC

CRC ERROR OFF

SUB HOUR METER 00000H

MODEL DT-R17L4D

VERSION A

HOUR METER 00000H

CONTROL LOCK OFF

DVI INPUT SEL AUTO

1-14 (No.YA787<Rev.002>)

Page 15

3.5 REPLACEMENT OF CHIP COMPONENT

3.5.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.5.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.5.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE:

After removing the part, remove remaining solder from the

pattern.

A

B

C

(4) Then solder leads B and C.

A

B

C

(No.YA787<Rev.002>)1-15

Page 16

SECTION 4

ADJUSTMENT

4.1 BEFORE ADJUSTMENT

(1) The setting (adjustment) using the MENU as on screen

display is made on the basis of the initial setting

values. The setting values which adjust the screen to

the optimum condition can be different from the initial

setting values.

(2) Make sure that connection is correctly made to AC power

source.

(3) Turn on the power of the monitor and measuring

instrument for warming up for at least 30 minutes before

starting adjustment.

(4) If the input signal is not specified, use the most appropriate

signal for adjustment.

(5) Never touch parts (such as variable resistors, transformers

and condensers) or setting items/values not shown in the

adjustment items of this service adjustment.

4.2 MEASURING INSTRUMENT AND TOOLS

• Color analyzer (color temperature meter)

• Signal generator

- Gray scale pattern (1% step) or Whole black pattern (0%

brightness): XGA1024 × 768 dots (H fr 48.4kHz, V fr 60Hz)

Fig.1

Fig.2

Please don’t touch!

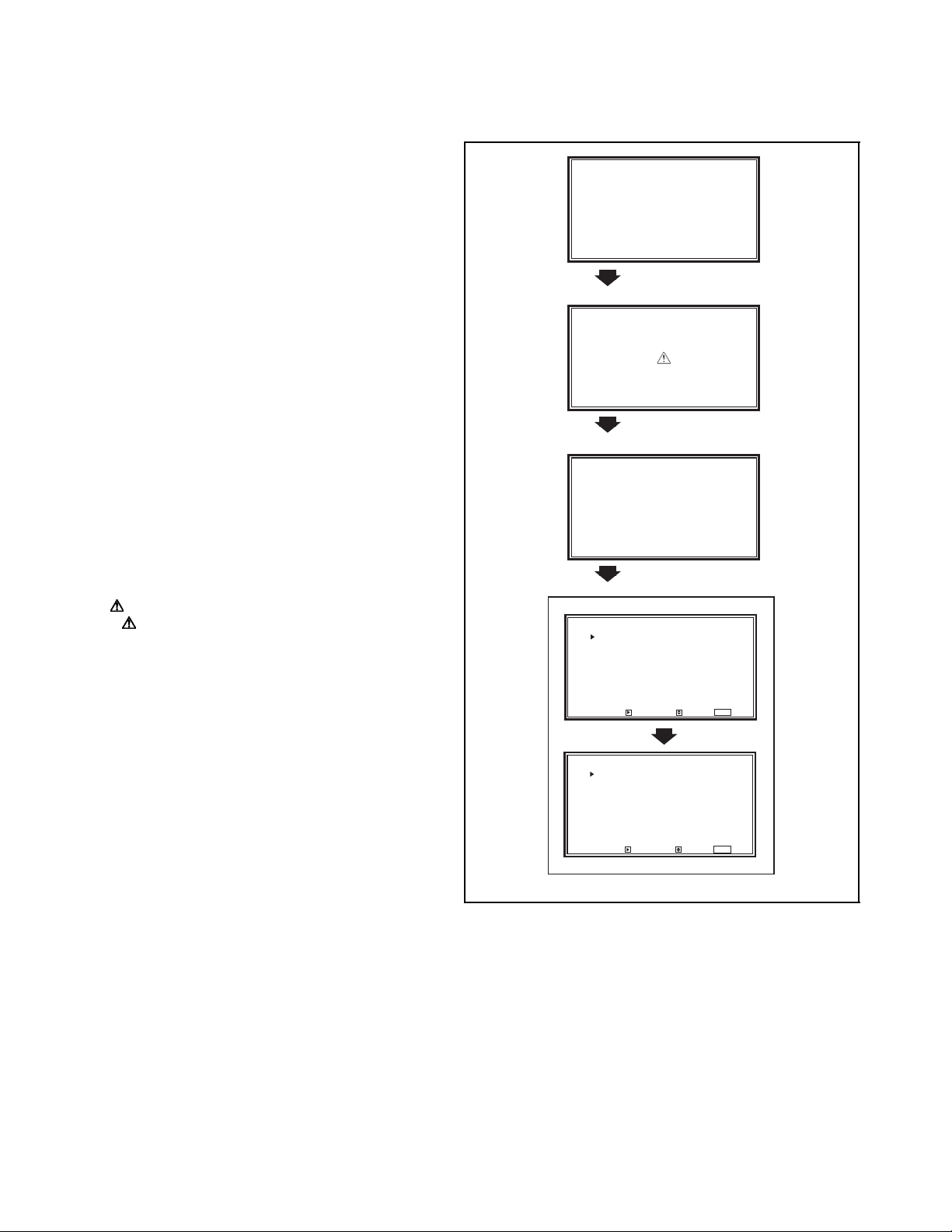

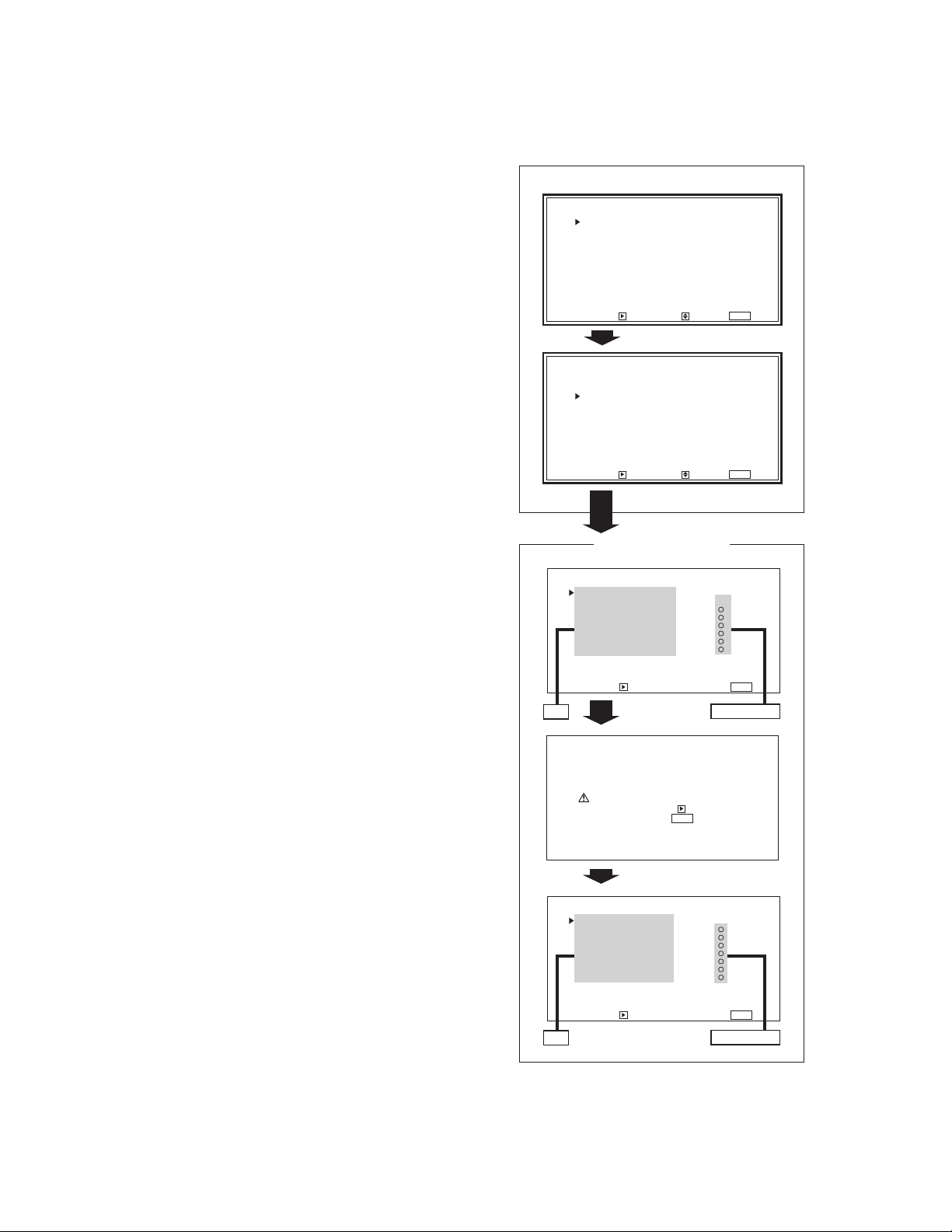

4.3 PROCEDURE FOR SERVICE MODE

4.3.1 HOW TO ENTER THE SERVICE MODE

(1) Press the [MENU] key and [] key simultaneously (Fig. 1).

(2) The " " mark is displayed at the center of the screen (Fig. 2).

(3) While " " mark is displayed, press the [] key and [] key

simultaneously.

(4) The word "Please don't touch!" (Fig.3) is displayed on the

screen center.

(5) While the word "Please don't touch!" is displayed, press the

[] key.

(6) The SERVICE MODE menu is displayed as shown in Fig. 4.

4.3.2 SELECT & ADJUSTMENT OF SERVICE MODE ITEM

While the SERVICE MODE menu is displayed.

(1) Press the [] / [] key to change the setting item.

(2) After selecting the item, press the [] key.

(3) The adjustment menu mode is displayed.

(4) Press the [] / [] key to change the setting value.

(5) Press the [MENU] key to display the original menu.

(6) Perform in the same manner for other SERVICE MODE

items.

Note:

When the adjustment is made at SERVICE MODE, the

changed data is memorized in a memory simultaneously with

the change.

4.3.3 HOW TO EXIT THE SERVICE MODE

Press the [MENU] key to exit the SERVICE MODE.

Fig.3

<SERVICE MENU> (1/2)

WHITE BALANCE BLOCK

DECODER BLOCK

SYNC BLOCK

SIGNAL BLOCK

ADC BLOCK

HDMI BLOCK

FORMAT BLOCK

DISPLAY BLOCK

ENHANCE BLOCK

CPU BLOCK

ENTER : SELECT : EXIT :

<SERVICE MENU> (2/2)

DEVICE INITIAL VALUE

UPDATE CPU PROGRAM

DIAGNOSIS BLOCK

HOUR METER BLOCK

FIRM WARE VERSION

ENTER : SELECT : EXIT :

Fig.4

MENU

MENU

1-16 (No.YA787<Rev.002>)

Page 17

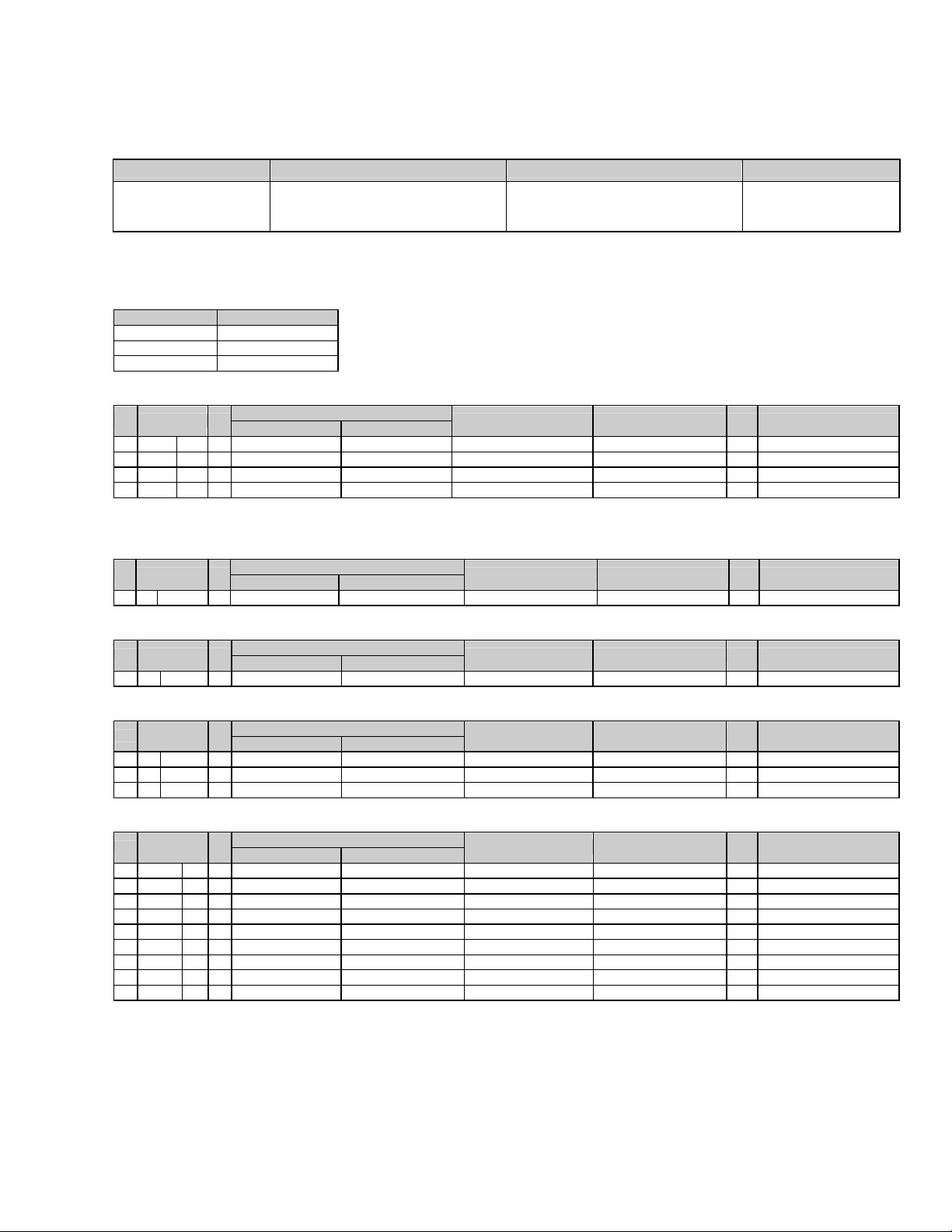

4.4 COMPOSITION OF A SERVICE MENU SCREEN

<SERVICE MENU> (1/2)

WHITE BALANCE BLOCK

DECODER BLOCK

SYNC BLOCK

SIGNAL BLOCK

ADC BLOCK

HDMI BLOCK

FORMAT BLOCK

DISPLAY BLOCK

ENHANCE BLOCK

CPU BLOCK

ENTER : SELECT : EXIT :

MAIN MENU

MENU

<SERVICE MENU> (2/2)

DEVICE INITIAL VALUE

UPDATE CPU PROGRAM

DIAGNOSIS BLOCK

HOUR METER BLOCK

FIRM WARE VERSION

ENTER : SELECT : EXIT :

MENU

WAA 001 255

WHITE BALANCE BLOCK

adjustment item screen

SAA 001 000

SIGNAL BLOCK

adjustment item screen

CAA 001 000

<WHITE BALANCE BLOCK>

WAA

WAB

WAC

WAD

WAE

WAF

WAG

WAH

WAI

WAJ

ENTER : SELECT : EXIT :

WHITE BALANCE BLOCK

adjustment item select screen

<DECODER BLOCK>

VAA

VAB

VAC

VAD

VAE

VAF

VAG

VAH

VAI

VAJ

ENTER : SELECT : EXIT :

<SYNC BLOCK>

YAA

YAB

YAC

YAD

YAE

YAF

YAG

YAH

YAI

YAJ

ENTER : SELECT : EXIT :

<SIGNAL BLOCK>

SAA

SAB

SAC

SAD

SAE

SAF

SAG

SAH

SAI

SAJ

ENTER : SELECT : EXIT :

SIGNAL BLOCK

adjustment item select screen

<ADC BLOCK>

AAA

AAB

AAC

AAD

AAE

AAF

AAG

AAH

AAI

AAJ

ENTER : SELECT : EXIT :

<HDMI BLOCK>

HAA

HAB

HAC

HAD

HAE

HAF

ENTER : SELECT : EXIT :

<FORMAT BLOCK>

FAA

FAB

FAC

FAD

FAE

FAF

FAG

FAH

FAI

FAJ

ENTER : SELECT : EXIT :

<DISPLAY BLOCK>

DAA

DAB

DAC

DAD

DAE

DAF

DAG

DAH

DAI

DAJ

ENTER : SELECT : EXIT :

<ENHANCE BLOCK>

EAA

EAB

EAC

EAD

EAE

EAF

EAG

EAH

EAI

EAJ

ENTER : SELECT : EXIT :

<CPU BLOCK>

CAA:MENU DATA

CAB:SIGNAL RANGE

CAC:SIZE/POSI. DATA

CAD:FREQUENCY DATA

CAE:SYSTEM CONSTANT

CAF:TEMP. SENSOR DATA

CAG:TEST MODE

CAH:LTI/CTI

CAI:IP MODE

CAJ:COLORIMETLY

ENTER : SELECT : EXIT :

CPU BLOCK adjustment item select screenCPU BLOCK adjustment item screen

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

<DEVICE INITIAL VALUE>

IA:TC90A92(VIDEO DEC.)

IB:ISL98001(A/D CONV.)

IC:TE8200PF(SYNC SEPA)

ID:SM5302A(LPF)

IE:ANX9021(DVI RECEIV.)

IF:GF9351(SCALER)

IG:FPGA FRONTEND 1

IF:FPGA BACKEND 1

IJ:TAP0172(POWER AMP)

ENTER : SELECT : EXIT :

<UPDATE CPU PROGRAM>

Are you sure?

"YES" then key.

"NO" then key.

Necessity!: PC,cable

& terminal software

CURRENT Ver.

***********

<DIAGNOSIS BLOCK>

CLEAR

I2C MAIN PB :X3

I2C ANALOG PB :

I2C SWITCH PB :

INVERTER :

POWER :

FAN :

TEMP. SENSOR :

ENTER : EXIT :

<DIAGNOSIS BLOCK>

CLEAR

I2C MAIN PB :

I2C ANALOG PB :

I2C SWITCH PB :

INVERTER :

POWER :

FAN :

TEMP. SENSOR :

ENTER : EXIT :

<HOUR METER BLOCK>

RESET

HOUR METER (x1h): 12345

ENTER : EXIT :

<HOUR METER BLOCK>

RESET

HOUR METER (x1h): 00000

ENTER : EXIT :

<FIRM WARE VERSION>

MICON :********

E2PROM :********

FPGA FRONT :********

FPGA BACK :********

SCALER :********

DCC MICON :********

ENTER : SELECT : EXIT :

<WAVE FORM BLOCK 1>

MAA

MAB

MAC

MAD

MAE

MAF

MAG

MAH

MAI

MAJ

ENTER : SELECT : EXIT :

<WAVE FORM BLOCK 2>

NAA

NAB

NAC

NAD

NAE

NAF

NAG

NAH

NAI

NAJ

ENTER : SELECT : EXIT :

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

Flashing 0.5 sec.

DIAGNOSIS BLOCK

<CLEAR>

Are you sure?

"YES" then key.

"NO" then key.

<RESET HOUR METER>

Are you sure?

"YES" then key.

"NO" then key.

MENU

MENU

(No.YA787<Rev.002>)1-17

Page 18

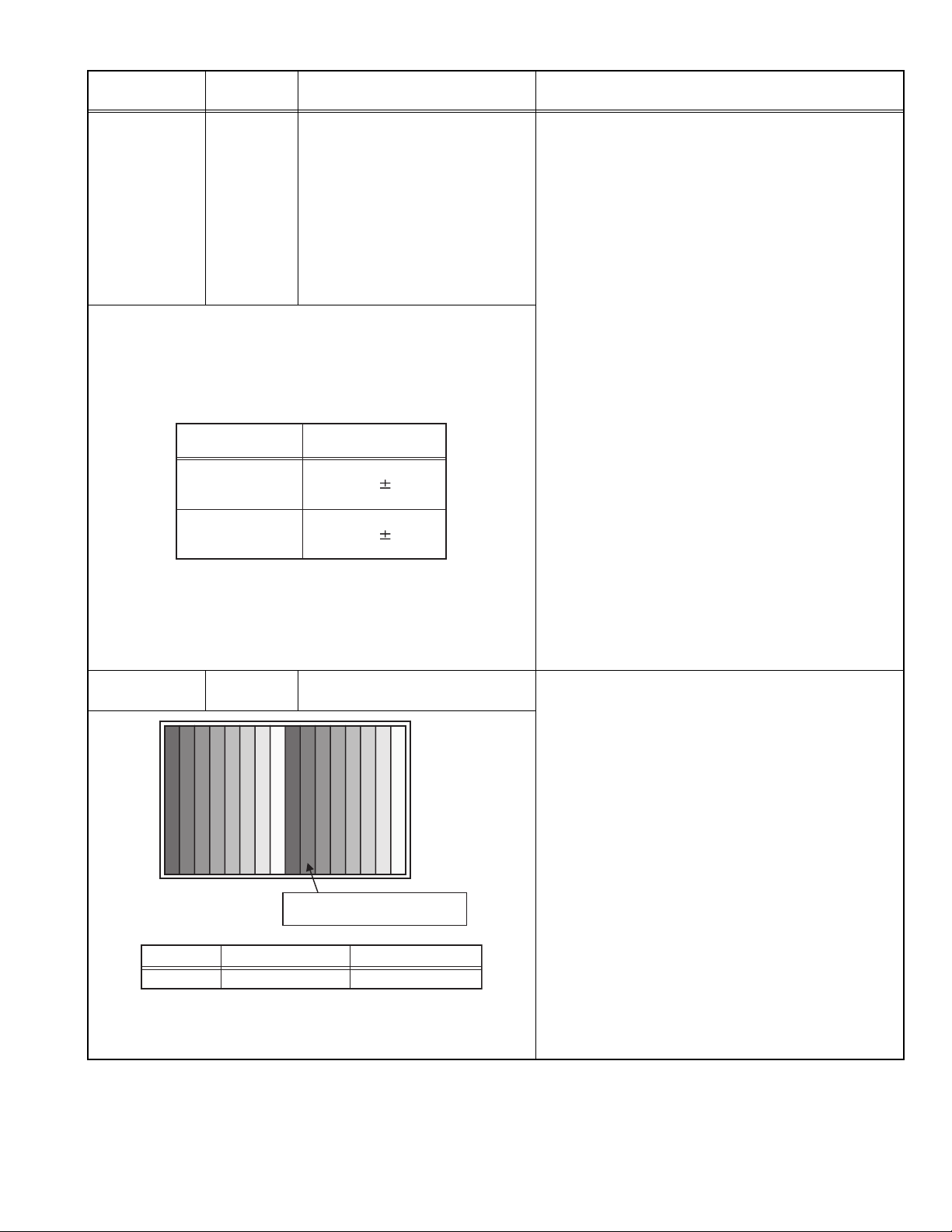

4.5 ADJUSTMENT PROCEDURE

item

WHITE

BALANCE

Measuring

instrument

Color

analyzer

COLOR TEMP.

9300K

6500K

Setting No.

IAG 086

IAG 087

IAG 088

WAA 001

WAA 002

WAA 003

WAA 004

WAA 005

WAA 006

WAB 001

WAB 002

WAB 003

WAB 004

WAB 005

WAB 006

[IG: FPGA FRONTEND 1]

IAG 086: GAMMA PATERN

IAG 087: GAMMA_LEVEL[9:8]

IAG 088: GAMMA_LEVEL[7:0]

[WHITE BALANCE BLOCK]

(Color temperature: 9300K)

WAA 001: G DRIVE

WAA 002: B DRIVE

WAA 003: R DRIVE

WAA 004: G CUT OFF

WAA 005: B CUT OFF

WAA 006: R CUT OFF

(Color temperature: 6500K)

WAB 001: G DRIVE

WAB 002: B DRIVE

WAB 003: R DRIVE

WAB 004: G CUT OFF

WAB 005: B CUT OFF

WAB 006: R CUT OFF

Colour temperature

adjustment point

X=0.283, Y=0.297

X=0.313, Y=0.329

Setting item

Initial setting value

GAMMA PATERN

GAMMA_LEVEL[9:8]

GAMMA_LEVEL[7:0]

G DRIVE

B DRIVE

R DRIVE

G CUT OFF

B CUT OFF

R CUT OFF

G DRIVE

B DRIVE

R DRIVE

G CUT OFF

B CUT OFF

R CUT OFF

Adjustment part Description

• Keep the set running for 15 minutes or longer. If you turn

the set on again, wait for 5 minutes or longer before

starting the adjustment.

• Set other items in MAIN MENU and SET-UP MENU to

the initial state.

(1) Set INPUT SELECT to "SDI 1".

(2) Set COLOR TEMP. to "9300K" in WHITE BALANCE

SET. of SET-UP MENU.

(3) Enter SERVICE MODE.

(4) Select "DEVICE INITIAL VALUE".

(5) Select "IG: FPGA FRONTEND 1".

(6) Set <IAG 086> to 001, <IAG 087> to 002, and <IAG

088> to 204 to display the internal 70% white signal.

(7) Select "WHITE BALANCE BLOCK".

(8) Select "WAA".

(9) Adjust <WAA 001>, <WAA 002>, and <WAA 003> by

using the color analyzer so that the values at the color

temperature adjustment point match the values on

the left table. Set one or more of <WAA 01>, <WAA

02>, and <WAA 03> to "255".

(10) Select "IG: FPGA FRONTEND 1" again.

(11) Set <IAG 087> to 001, and <IAG 088> to 050 to dis-

play the internal 30% white signal.

(12) Select "WHITE BALANCE BLOCK".

(13) Select "WAA".

(14) Adjust <WAA 004>, <WAA 005>, and <WAA 006> by

using the color analyzer so that the values at the color

temperature adjustment point match the values on

the left table. Set one or more of <WAA 004>, <WAA

005>, and <WAA 006> to "255".

000

000

000

255

255

255

000

000

000

255

255

255

000

000

000

(15) Set COLOR TEMP. to "6500K" in WHITE BALANCE

SET. of SET-UP MENU.

(16) Repeat the procedures from (3) to (7).

(17) Select "WAB".

(18) Adjust <WAB 001>, <WAB 002>, and <WAB 003> by

using the color analyzer so that the values at the color

temperature adjustment point match the values on

the left table. Set one or more of <WAB 01>, <WAB

02>, and <WAB 03> to "255".

(19) Repeat the procedures from (10) to (12).

(20) Select "WAB".

(21) Adjust <WAB 004>, <WAB 005>, and <WAB 006> by

using the color analyzer so that the values at the color

temperature adjustment point match the values on

the left table. Set one or more of <WAB 004>, <WAB

005>, and <WAB 006> to "255".

(22) Select "IG: FPGA FRONTEND 1".

(23) Reset the values <IAG 086>, <IAG 087>, and <IAG

088> to the initial setting values.

NOTE:

• With this adjustment mode, the changed data is written

in the MEMORY instantly.

1-18 (No.YA787<Rev.002>)

Page 19

item

Measuring

instrument

LUMINANCE Color

analyzer

COLOR TEMP.

9300K 170 20

6500K 170 20

BRIGHTNESS Signal gener-

ator

Setting No.

SAA13

Setting item

BRIGHT OFFSET

Adjustment part Description

[IG: FPGA FRONTEND 1]

IAG 86: GAMMA PATERN

IAG 87: GAMMA_LEVEL[9:8]

IAG 88: GAMMA_LEVEL[7:0]

[CPU BLOCK]

(Color temperature: 9300K)

CAB 058: BACK LIGHT OFFSET

(Color temperature: 6500K)

CAB 059: BACK LIGHT OFFSET

Luminance(cd/m2)

[SIGNAL BLOCK]

SAA 013: BRIGHT OFFSET

123456701 2345670

Adjust so that 1% black

shines slightly on the screen.

Initial setting value

000

• Keep the set running for 15 minutes or longer. If you turn

the set on again, wait for 5 minutes or longer before

starting the adjustment.

• Confirm the white balance adjustment are finished.

• Set other items in MAIN MENU and SET-UP MENU to

the initial state.

(1) Set COLOR TEMP. to "9300K" in WHITE BALANCE

SET. of SET-UP MENU.

(2) Enter SERVICE MODE.

(3) Select "DEVICE INITIAL VALUE".

(4) Select "IG: FPGA FRONTEND 1".

(5) Set <IAG 086> to 001, <IAG 087> to 003, and <IAG

088> to 255 to display the internal test pattern.

(6) Select "CPU BLOCK".

(7) Select "CAB".

(8) Adjust <CAB 058> by using the color analyzer so that

the values at the color temperature adjustment point

match the values on the left table.

(9) Set COLOR TEMP. to "6500K" in WHITE BALANCE

SET. of SET-UP MENU.

(10) Enter SERVICE MODE again.

(11) Select "CPU BLOCK".

(12) Select "CAB".

(13) Adjust <CAB 059> by using the color analyzer so that

the values at the color temperature adjustment point

match the values on the left table.

(14) Select "IG: FPGA FRONTEND 1".

(15) Reset the values <IAG 086>, <IAG 087>, and <IAG

088> to the initial setting values.

NOTE:

• With this adjustment mode, the changed data is written

in the MEMORY instantly.

• Confirm that white balance/Luminance adjustment are

finished.

• Set other items in MAIN MENU and SET-UP MENU to

the initial state.

(1) Set INPUT SELECT to "DVI".

(2) Set COLOR TEMP. to "9300K" in WHITE BALANCE

SET. of SET-UP MENU.

(3) Input an XGA-60 gray scale pattern (1% step) signal

or a whole black signal (0% brightness) from DVI ter-

minal.

(4) Enter SERVICE MODE.

(5) Select "SIGNAL BLOCK".

(6) Select "SAA".

(7) In case of a gray scale pattern (1% step), adjust <SAA

013> so that 1% black slightly shines and 0% black

does not shine on the screen.

In case of a whole black signal (0% brightness), ad-

just <SAA 013> so that the whole screen does not

shine.

NOTE:

• With this adjustment mode, the changed data is written

in the MEMORY instantly.

(No.YA787<Rev.002>)1-19

Page 20

SECTION 5

TROUBLESHOOTING

5.1 SELF-DIAGNOSIS FUNCTION

5.1.1 OUTLINE

This model has a "Self-diagnosis function" which checks the

operation state of the circuits and temperature inside the set, and

informs us of a failure and memorize it when a failure occurs.

Diagnosis is performed when the power is turned on, and

information input to the main microcomputer is monitored at all

time.

The diagnosis is displayed on the screen and LED flashing.

Failure detection is based on input state of I

control lines connected to the main microcomputer.

5.1.2 ENTERING SELF-DIAGNOSIS BLOCK

(1) Enter the SERVICE MODE. (Fig. 1)

(2) Select DIAGNOSIS BLOCK in the second page (2/2) and

press the [] key. (Fig. 2)

(3) DIAGNOSIS BLOCK screen is displayed.

2

C bus and various

SERVICE MENU

<SERVICE MENU> (1/2)

WHITE BALANCE BLOCK

DECODER BLOCK

SYNC BLOCK

SIGNAL BLOCK

ADC BLOCK

HDMI BLOCK

FORMAT BLOCK

DISPLAY BLOCK

ENHANCE BLOCK

CPU BLOCK

ENTER : SELECT : EXIT :

Fig.1

<SERVICE MENU> (2/2)

DEVICE INITIAL VALUE

UPDATE CPU PROGRAM

DIAGNOSIS BLOCK

HOUR METER BLOCK

FIRM WARE VERSION

MENU

5.1.3 EXIT FROM SELF-DIAGNOSIS BLOCK

(1) To return to the SERVICE MODE screen, press the

[MENU] key.

5.1.4 CREAR OF ITEMS IN DIAGNOSIS

(1) Enter the SERVICE MODE. (Fig. 1)

(2) Select DIAGNOSIS BLOCK in the second page (2/2) and

press the [] key. (Fig. 2)

(3) DIAGNOSIS BLOCK screen is displayed. (Fig. 3)

(4) To delete an error, select "CLEAR" and press the [] key.

(Fig. 4)

(5) Then, items in DIAGNOSIS is initialized, and all items are

displayed as "O". (Fig. 5)

5.1.5 POINTS TO NOTE WHEN USING THE SELF-DIAGNOSIS

FEATURE

Failure history can be counted up to 9 times for each item. When

the number exceeds 9, the display will remain as 9. Failure

history will be stored in the memory unless it has been deleted.

In addition to circuit failures (abnormal operation), the following

cases may also be diagnosed as abnormal and displayed and

counted as "X".

(1) Temporary defective transmissions across circuits due to

pulse interruptions

(2) Misalignment in the on/off timing of power for I

2

C bus (Vcc)

when turning on/off the power.

If a failure is expected to reoccur, clear (reset) the failure history

to make the unit record the new diagnosis results.

ENTER : SELECT : EXIT :

DIAGNOSIS BLOCK

<DIAGNOSIS BLOCK>

CLEAR

I2C MAIN PB :X3

I2C ANALOG PB :

I2C SWITCH PB :

INVERTER :

POWER :

FAN :

TEMP. SENSOR :

ENTER : EXIT :

Item

<CLEAR>

Are you sure?

"YES" then key.

"NO" then key.

<DIAGNOSIS BLOCK>

CLEAR

I2C MAIN PB :

I2C ANALOG PB :

I2C SWITCH PB :

INVERTER :

POWER :

FAN :

TEMP. SENSOR :

Fig.2

Fig.3

Fig.4

MENU

MENU

Failure history

MENU

1-20 (No.YA787<Rev.002>)

ENTER : EXIT :

Item

Fig.5

MENU

Failure history

Page 21

5.1.6 DETAILS

Type of error Indication Description of detection Countermeasure

2

Communication error in main

memory, video decoder etc on

the DIGITAL PWB

I2C MAIN PB An I

C communication error is

detected in case that the normal

communication cannot be done

by trying three times.

2

Communication error in sync

separator, audio selector etc on

the ANALOG PWB

I2C ANALOG PB An I

C communication error is

detected in case that the normal

communication cannot be done

by trying three times.

2

Communication error in LED

driver on the SW PWB

I2C SWITCH PB An I

C communication error is

detected in case that the normal

communication cannot be done

by trying three times.

Error in INVERTER UNIT INVERTER An alarm signal from INVERTER

circuit continuously detected for

about 2.4 seconds leads repeated restart four times.

Error in POWER PWB POWER An alarm signal from POWER

SUPPLY UNIT is continuously

detected for about 5 seconds.

Error in COOLING FAN FAN An error is detected when the

COOLING FAN stops for 0.8

seconds.

<Excluding the below cases>

• 7 seconds after the power on

• Controlled stop

Temperature rise in DIGITAL

PWB

TEMP. SENSOR A temperature sensor on

DIGITAL PWB detects an error,

the temperature continuously

exceeds 81°C for 60 seconds.

Memorize the number of error

times in the main memory (up to

nine times).

Flash LED for self-diagnosis

indication.

Memorize the number of error

times in the main memory (up to

nine times).

Memorize the number of error

times in the main memory (up to

nine times).

Memorize the number of error

times in the main memory (up to

nine times), and turn the power

off forcibly.

Flash LED for self-diagnosis

indication.

Memorize the number of error

times in the main memory (up to

nine times), and turn the power

off forcibly.

Flash LED for self-diagnosis

indication.

Memorize the number of error

times in the main memory (up to

nine times), and turn the power

off forcibly.

Flash LED for self-diagnosis

indication.

Memorize the number of error

times in the main memory (up to

nine times), and turn the power

off forcibly.

Flash LEDs for self-diagnosis

indication.

5.1.7 INDICATION OF SELF DIAGNOSIS BY USING LED

Flashing LEDs located on the front panel indicate the result of self-diagnosis.

SELF-DIAGNOSIS AND FLASHING LED (z=Blinking, O=Lighting)

Flashing LED

Diagnosis

Priority Indication

SDI-2 DVI VIDEO

Error in POWER PWB z 1 Notes:

Error in INVERTER UNIT z 3

Communication error in DIGITAL PWB z 5

• Indication color: Green

• Flashing interval: 0.25 second

• When two or more errors are detected at

Abnormal temperature rise in DIGITAL PWB zz 2

Error in COOLING FAN zz4

• All LEDs are lighted while various data are

MAIN CPU writing error zzz-

During MAIN CPU writing O O O -

the same time, errors are displayed one

after another, according to the order of

priority.

written in the main memory.

(No.YA787<Rev.002>)1-21

Page 22

Victor Company of Japan, Limited

Business Solution Division 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YA787<Rev.002>)

Printed in Japan

VSE

Page 23

REVISION INFORMATION

MULTI FORMAT LCD MONITOR

DT-R17L4D/CAT, DT-R17L4D/EAT,

DT-R17L4D

/UAT

■ OVERVIEW

Due to additional destinations, the following models are added.

<Additional models>

DT-R17L4D/CAT

DT-R17L4D/UAT

■ DETAILS

COVER SECTION

Title Line No.YA787<Rev.001> No.YA787<Rev.002> Description

Revision Rev.001 Rev.002

Issue Date 2010/07 2010/08

Model No. DT-R17L4D/EAT DT-R17L4D/CAT,

DT-R17L4D/EAT,

DT-R17L4D/UAT

<Additional models>

DT-R17L4D/CAT

DT-R17L4D/UAT

COPYRIGHT © 2010 Victor Company of Japan, Limited

YA787-R002

2010/08

Page 24

SECTION 2 SPECIFIC SERVICE INSTRUCTIONS

Title Line No.YA787<Rev.001> No.YA787<Rev.002> Description

2.1 MAIN

DIFFERENCE LIST

2 -

3 -

4 -

5 -

2.2 TIMING

SPECIFICATION

2.3 HOUR METER

FUNCTION

11 ILLUSTRATION(ya787_2002.png) ILLUSTRATION(ya787_2002.png) XML Structure

2.4 TECHNICAL

INFORMATION

2.4.1 LCD PANEL T 2.3.1 LCD PANEL 2.4.1 LCD PANEL

2.4.1.1

SPECIFICATIONS

2.4.1.2 PIXEL FAULT

SPECIFICATION

2.4.2 MAIN CPU PIN

FUNCTION [IC1703:

DIGITAL PWB

ASS'Y]

T - 2.1 MAIN DIFFERENCE LIST

Item

DT-R17L4D/CAT

DT-R17L4D/EAT

DT-R17L4D/UAT

POWER CORD

CHINESE TYPE (3 Pin)

EU TYPE (3 Pin)

UK TYPE (3 Pin)

US TYPE (3 Pin)

INLET PWB

FV-8081A-H2

FV-8080A-H2

FV-8080A-H2

POWER PWB

FV-9038A-H2

FV-9037A-H2

FV-9037A-H2

T 2.1 TIMING SPECIFICATION 2.2 TIMING SPECIFICATION

T 2.2 HOUR METER FUNCTION 2.3 HOUR METER FUNCTION

T 2.3 TECHNICAL INFORMATION 2.4 TECHNICAL INFORMATION

T 2.3.1.1 SPECIFICATIONS 2.4.1.1 SPECIFICATIONS

T 2.3.1.2 PIXEL FAULT SPECIFICATION 2.4.1.2 PIXEL FAULT SPECIFICATION

T 2.3.2 MAIN CPU PIN FUNCTION

[IC1703: DIGITAL PWB ASS'Y]

2.4.2 MAIN CPU PIN FUNCTION

[IC1703: DIGITAL PWB ASS'Y]

SECTION 3 DISASSEMBLY

Title Line No.YA787<Rev.001> No.YA787<Rev.002> Description

3.4.5.2 MENU

OPERATION

11

12 -

53

10

AUTO ASPECT

OFF

MANUAL ASPECT

4 : 3

COMPONENT PHASE

DISABLE

2 (YA787-R002)

AUTO ASPECT (DT-R17L4D/EAT)

OFF

MANUAL ASPECT (DT-

R17L4D/EAT)

4 : 3

ASPECT (Other models)

4 : 3

COMPONENT PHASE

DISABLE (DT-R17L4D/EAT)

ENABLE (Other models)

Page 25

STANDARD SCHEMATIC DIAGRAMS

Exploded View

Diagram Name No.YA787<Rev.001> No.YA787<Rev.002> Description

Menu - USING P.W. BOARD <Additional models>

DT-R17L4D/CAT

DT-R17L4D/UAT

PARTS LIST

MODEL No. LIST

Model No. No.YA787<Rev.002>

DT-R17L4D/CAT 01

DT-R17L4D/EAT 02

DT-R17L4D/UAT 03

EXPLODED VIEW [M1MM]

Symbol or

!

M1MM 68 ------------ LC34798-001A-H SHIELD COVER (Addition) 1 01

! M1MM PW2 ------------ FV-1080A-H2 DIGITAL PWB (Addition) 1 01,03

! M1MM PW4 ------------ FV-9038A-H2 POWER PWB (Addition) 1 01

! M1MM PW5 ------------ FV-8081A-H2 INLET PWB (Addition) 1 01

<Rev.001> <Rev.002>

PRINTED WIRING BOARD

DIGITAL P.W. BOARD ASS´Y [10]

Symbol or

!

10 IC1702 ------------ M24256BWMN6R17C IC (Addition) 1 01,03

<Rev.001> <Rev.002>

Part No.

Part No.

Part Name Description Qty Models

Part Name Description Qty Models

INLET P.W. BOARD ASS´Y [80]

Symbol or

!

! 80 C8902 ------------ QFZ9084-474 MPP CAPACITOR (Addition) 1 01

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

POWER P.W. BOARD ASS´Y [90]

Symbol or

!

90 D9508 ------------ KDZ7.5B-X Z DIODE (Addition) 1 01

90 R9508 ------------ QRT039J-R27 MF RESISTOR (Addition) 1 01

90 R9509 ------------ QRT039J-R27 MF RESISTOR (Addition) 1 01

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

PACKING [M4MM]

Symbol or

!

! M4MM A1 ------------ QMPS210-200-JC POWER CORD (Addition) 1 01

! M4MM A1 ------------ QMPE450-244-JC POWER CORD (Addition) 1 03

! M4MM A3 ------------ LCT2650-001A-H INST BOOK (Addition) 1 01

! M4MM A3 ------------ LCT2646-001A-H INST BOOK (Addition) 1 03

M4MM P3 ------------ LC31100-001A-H CORNER PIECE (Addition) 8 01

M4MM P4 ------------ LC11194-062A-H PACKING CASE (Addition) 1 01

M4MM P5 ------------ QZW0334-001 RECYCLE MARK (Addition) 1 01

M4MM P6 ------------ QZW0346-001 RECYCLE MARK (Addition) 4 01

M4MM P7 ------------ LY35839-001A LABEL (Addition) 1 01

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

(YA787-R002) 3

Page 26

Victor Company of Japan, Limited

Business Solution Division 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(YA787-R002)

Printed in Japan

No.YA787<Rev.001> VSE

Page 27

PARTS LIST

26

MULTI FORMAT LCD MONITOR

DT-R17L4D/EAT

(No.YA787<Rev.001>)1/

Page 28

■ PRECAUTIONS ON SCHEMATIC DIAGRAMS

z Due to the improvement in performance, some part numbers shown in the circuit diagrams

may not agree with those indicated in the Parts List.

z The parts numbers, values and rated voltage etc. in the Schematic Diagrams are for

reference only.

z Since the circuit diagrams are standard ones, the circuits and circuit constants may be

subject to change for improvement without any notice.

■ PRECAUTIONS ON PARTS LIST

z

The parts identified by the symbol are critical for safety. Whenever replacing these parts, be sure to

use specified ones to secure the safety.

z

The parts not indicated in this Parts List and those which are filled with lines --- in the Parts No.

columns will not be supplied.

z

P.W. BOARD Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No.

columns will be supplied.

z

When ordering chips, screws etc., place bulk orders (unit of tens) whenever possible to improve

shipping efficiency.

z

There are cases where the actual implemented parts in the sets and the service parts are different.

When ordering parts, make sure to refer to the Parts List.

■

PRECAUTIONS ON SERVICE

Certain parts of the power circuits and the GNDs differ according to the models. Care must be

taken for the following points as the differences are indicated separately in the LIVE GND ( ) and

the ISOLATED (NEUTRAL) GND ( ).

1. Do not touch the LIVE GND, or do not touch the LIVE GND and the ISOLATED (NEUTRAL)

GND at the same time. It may cause an electric shock.

Before pulling out the chassis or other parts, make sure to pull out the power cord from the

wall outlet first.

2. Do not short circuit between the LIVE GND and ISOLATED (NEUTRAL) GND, or never

measure the LIVE GND and ISOLATED (NEUTRAL) GND at the same time using measuring

instruments (oscilloscope, etc.). It may blow fuses or damage other parts.

■ DEVIATION TOLERANCE RANGE

DEVIATION TOLERANCE RANGE

F G J K M N R H Z P

± 1% ± 2% ± 5% ±10% ±20% ±30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

26

(No.YA787<Rev.001>)2/

Page 29

WR6

WR5

WR4

WR3

WR2

WR1

S7

S6

S5

S5

S4

S3

S2

S1

PW7

PW6

PW5

PW4

PW3

PW2

PW1

LV1

67

66

65

65

65

65

64

63

62

61

60

60

59

58

57

56

55

54

53

52

51

9

8

3C

3B

3A

32

21

16

10

10

5

5

3

2

1

!

!

!

!

!

!

!

COVER

LCD CONTROL PWB

COVER

INVERTER PWB

LCD PANEL UNIT

PANEL FRAME

LCD PANEL

!

!

!

!

!

!

!

!

!

LCD PANEL UNIT

RATING LABEL

EXPLODED VIEW

created date:2010-07-13No.YA787

26

(No.YA787<Rev.001>)3/

Page 30

MODEL MARK

26

DT-R17L4D/EAT

Safe Symbol No. Parts No. Parts Name Description QTY Local

EXPLODED VIEW <M1MM>

LV1 WJW0131-001A-E DIGITAL(LVDS) CABLE DIGITAL PWB CN1LVD-LCD

WR1 WJZ0303-001A-E WIRE VOLUME PWB CN8VOLWR2 QUQL05-5004AA-E FFC WIRE ANALOG PWB-DIGITAL PWB 2

WR3 QJJ064-041414-E WIRE ANALOG PWB CN211VWR4 QJJ064-092229-E WIRE ANALOG PWB CN2PWCWR5 WJZ0362-001A-E WIRE LCD PANEL UNIT-POWER

WR6 QJJ064-032213-E WIRE TALLY PWB CN80TA-DIGITAL

S1 LC42784-002A SCREW 1

S2 QYSBSF4016MA TAP SCREW M4 x 16mm 8

S3 LC42784-002A SCREW 8

S4 LC43100-001A ASSY SCREW 4

S5 LC43100-001A ASSY SCREW 6

S6 QNB0081-001 HEX SCREW 2

S7 QNB0037-001 CONNECTOR

! 1 LC13769-002A-H REAR COVER 1

! 2 LC13764-001B-H FRONT PANEL 1

! 3 QLD0648-001-JMT LCD PANEL UNIT Inc.3A-3C(LC170WXN-SAA1-

! 3A 6871L-1316A LCD CONTROL PWB 1

! 3B 6632L-0483A INVERTER PWB 1

! 3C 6900L-0222A BACK LIGHT UNIT 1

5 QAS0484-003 SPEAKER 2

8 LC34117-001A-C TERMINAL BRACKET 1

! 9 LC34757-001A-H REAR BASE 1

10 LC22779-001A-H SIDE BRACKET 2

16 LC13806-001A-H STAND BASE 1

21 LC22492-001A PUSH KNOB 1

32 LC33642-001A TALLY LENS 1

51 LC42552-002A BLANK PLATE 1

52 LC34823-001A-H SPONGE SPACER 2

53 LC43321-001A-H STAND FOOT 6

54 LC34438-001A-C SDI SHIELD 1

55 QNZ0472-002 BNC CONNECTOR 3

56 LC43129-001A GUARD 3

57 QAM0275-010 COAXIAL CABLE 3

58 LC34710-001A-H DVI BRACKET 1

! 59 QAR0412-002 COOLING FAN 1

60 QZW0156-002 WIRE CLAMP 3

61 LC22781-001A-H FAN BRACKET 1

! 62 LC34695-001A-H PWB INSULATOR 1

63 CM46758-A06 VOLUME KNOB 5

ACCESSORY

PANEL UNIT

DIGITAL PWB CN10FC

DIGITAL PWB CN111V

POWER PWB CN9PWC

PWB CN9PNL

PWB CN10TA

411)

1

1

1

1

1

1

2

1

64 CM48149-A01 JVC MARK 1

65 LC34473-004A-H STICK SHEET 4

66 LC22852-001A-H CONTROL SHEET 1

67 LP41241-007A SPACER 1

! PW1 FV-2034A-H2 ANALOG PWB 1

! PW2 FV-1078A-H2 DIGITAL PWB 1

! PW3 FV-8069A-H2 TALLY PWB 1

! PW4 FV-9037A-H2 POWER PWB 1

! PW5 FV-8080A-H2 INLET PWB 1

! PW6 FV-8067A-H2 VOLUME PWB 1

! PW7 FV-8077A-H2 SWITCH PWB 1

PRINTED WIRING BOARD DIGITAL P.W. BOARD ASS´Y <10>

IC1203 MM1572FN-X IC 1

IC1204 MM3141FN-X IC 1

IC1205 TC90A92AFG IC 1

IC1301 MM1561JF-X IC 1

IC1302 MM1563DF-X IC 1

IC1303 BU2373FV-X IC 1

IC1305 GS1574ACNE3 IC 1

IC1306 GS1559-CBE2 IC 1

IC1307 XC3S12E4FGG320C IC 1

IC1308 PCM1723E-X IC 1

IC1309 MM1701CH-X IC 1

IC1310 PQ050DNA1Z-X IC 1

IC1311 PQ033DNA1Z-X IC 1

IC1401 GF9351-165CBE2 IC 1

IC1501 H5DU2562GTR-J3C IC 1

IC1502 H5DU2562GTR-J3C IC 1

IC1503 H5DU2562GTR-J3C IC 1

IC1504 H5DU2562GTR-J3C IC 1

IC1505 H5DU2562GTR-J3C IC 1

IC1506 LP2996MR-X IC 1

IC1508 39VF400A70EKD01 IC(MICRO C ROM) 1

IC1509 TC74LCX08FT-F-X IC 1

IC1601 XC3S12E4FGG320C IC 1

IC1602 M25P80-VMN6PR17 IC (SERVICE) 1

IC1603 TC74VHCT574AFTX IC 1

IC1604 M35075-065FP-X IC 1

IC1605 TC74LCX574FTF-X IC 1

IC1606 THC63LVD1023B IC 1

IC1607 PQ033DNA1Z-X IC 1

IC1701 MM3286DF-X IC 1

IC1702 M24256BWMN6R17E IC (SERVICE) 1

IC1703 HD64F2437FVR17 IC(MCU) (SERVICE) 1

(No.YA787<Rev.001>)4/

Page 31

MODEL MARK

26

DT-R17L4D/EAT

Safe Symbol No. Parts No. Parts Name Description QTY Local

IC1705 IC-PST8428U-W IC 1

IC1706 TC74HC4053AFT-X IC(DIGITAL) 1

IC1801 M62320GP1-X IC 1

IC1802 TC7MB3244FK-X IC 1

IC1803 MAX1481EUB-X IC 1

IC1804 MAX1481EUB-X IC 1

IC1806 MAX3232ECD-X IC 1

IC1808 BD9781HFP-W IC 1

IC1809 R1161D122B-X IC 1

IC1810 R1161D122B-X IC 1

IC1811 TC7WH157FU-X IC 1

IC1812 TC7WH157FU-X IC 1

IC1813 TC7WH157FU-X IC 1

IC1814 TC7WH157FU-X IC 1

IC1815 TC7WH157FU-X IC 1

IC1816 TC74VHC00FT-X IC 1

Q1204 2SC3928A/QR/-X TRANSISTOR 1

Q1301 2SC3928A/QR/-X TRANSISTOR 1

Q1302 2SC3928A/QR/-X TRANSISTOR 1

Q1701 2SC3928A/QR/-X TRANSISTOR 1

Q1702 2SC2411K/QR/-X TRANSISTOR 1

Q1703 2SC2411K/QR/-X TRANSISTOR 1

Q1803 2SC3928A/QR/-X TRANSISTOR 1

Q1804 RT1N441C-X TRANSISTOR 1

Q1805 RT1N441C-X TRANSISTOR 1

Q1806 RT1N441C-X TRANSISTOR 1

Q1807 RT1N441C-X TRANSISTOR 1

Q1808 RT1N441C-X TRANSISTOR 1

Q1809 RT1N441C-X TRANSISTOR 1

Q1810 RT1N441C-X TRANSISTOR 1

D1302 SML-210MT-X LED (DRY) Green(For design) 1

D1305 HSU119-X SI DIODE 1

D1306 HSU119-X SI DIODE 1

D1701 RKZ5.6B2KG-X Z DIODE 1

D1702 RKZ5.6B2KG-X Z DIODE 1

D1813 HSU119-X SI DIODE 1

D1822 HSU119-X SI DIODE 1

D1823 RKZ4.3B2KG-X Z DIODE 1

D1824 RKZ3.0B2KG-X Z DIODE 1

D1825 CMS05-W SB DIODE 1

D1826 RKZ5.6B2KG-X Z DIODE 1

D1827 HSU119-X SI DIODE 1

D1828 HSU119-X SI DIODE 1

C1170 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1171 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1172 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1173 NCJ41CM-226X-U C CAPACITOR 22uF 16V M 1

C1174 NCJ41CM-226X-U C CAPACITOR 22uF 16V M 1

C1247 NEHT0JM-107X E CAPACITOR 100uF 6.3V M 1

C1248 NCB31CK-105X C CAPACITOR 1uF 16V K 1

C1249 NCB31CK-105X C CAPACITOR 1uF 16V K 1

C1250 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1251 NEHT0JM-107X E CAPACITOR 100uF 6.3V M 1

C1252 NCB31CK-105X C CAPACITOR 1uF 16V K 1

C1253 NCB11AK-106X C CAPACITOR 10uF 10V K 1

C1254 NCB31CK-105X C CAPACITOR 1uF 16V K 1

C1255 NCB11AK-106X C CAPACITOR 10uF 10V K 1

C1256 NDC31HJ-390X C CAPACITOR 39pF 50V J 1

C1257 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1258 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1259 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1260 NCB31CK-105X C CAPACITOR 1uF 16V K 1

C1261 NDC31HJ-121X C CAPACITOR 120pF 50V J 1

C1262 NCB31CK-104X C CAPACITOR 0.1uF 16V 1

C1263 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1264 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1265 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1266 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1267 NCB31CK-104X C CAPACITOR 0.1uF 16V 1

C1268 NCB31CK-104X C CAPACITOR 0.1uF 16V 1

C1269 NCB11AK-106X C CAPACITOR 10uF 10V K 1

C1270 NCB31CK-104X C CAPACITOR 0.1uF 16V 1

C1271 NCB31CK-104X C CAPACITOR 0.1uF 16V 1

C1272 NCB31CK-104X C CAPACITOR 0.1uF 16V 1

C1273 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1

C1274 NCB31HK-103X C CAPACITOR 0.01uF 50V K 1