Page 1

Operating Instructions

51105427

DFG/TFG 316s-320s

G

04.08 -

07.08

Page 2

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

F

Used before safety instructions which must be observed to avoid danger to

personnel.

M

Used before notices which must be observed to avoid material damage.

Z

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

Page 3

0108.GB

Page 4

I 1

0708.GB

Table of contents

A Correct Use and Application

B Truck Description

1 Application ........................................................................................... B 1

2 Assemblies and Functional Description .............................................. B 2

2.1 Truck ................................................................................................... B 3

2.2 Load handler ....................................................................................... B 4

3 Standard Version Specifications ......................................................... B 5

3.1 DFG/TFG 316s/320s Specifications .................................................... B 8

4 Identification points and data plates .................................................... B 11

4.1 Truck data plate .................................................................................. B 12

4.2 Truck load chart .................................................................................. B 13

4.3 Attachment load chart ......................................................................... B 14

C Transport and Commissioning

1 Transport ............................................................................................. C 1

2 Lifting by crane .................................................................................... C 1

3 Securing the truck during transport ..................................................... C 2

4 Using the truck for the first time .......................................................... C 3

5 Operating the truck without its own drive system ................................ C 3

D Fuelling the Truck

1 Safety regulations for handling diesel fuel and LPG ........................... D 1

2 Filling with diesel ................................................................................. D 2

3 Replace the LPG bottle ....................................................................... D 3

E Operation

1 Safety Regulations for the Operation of Forklift Trucks ...................... E 1

2 Controls and Displays ......................................................................... E 3

3 Operating the lift and tilt mechanisms (o) .......................................... E 8

4 Twin Pedal Operation (o) ................................................................... E 9

5 Tests and tasks to be performed before starting the truck .................. E 14

6 Starting up the truck ............................................................................ E 19

6.1 Adjusting the driver’s seat ................................................................... E 20

6.2 Adjusting the steering column ............................................................. E 21

6.3 Seat belt .............................................................................................. E 21

7 Starting the truck ................................................................................. E 22

7.1 Starting procedure for the TFG ........................................................... E 23

7.2 Starting procedure for the DFG ........................................................... E 24

7.3 Operating Error Displays ..................................................................... E 26

7.4 Switching off the engine ...................................................................... E 26

Page 5

0708.GB

I 2

8 Industrial Truck Operation ................................................................... E 27

8.1 Safety regulations for truck operation ................................................. E 27

9 Travel .................................................................................................. E 29

9.1 Steering ............................................................................................... E 31

9.2 Brakes ................................................................................................. E 31

10 Mast and Attachment Operation ......................................................... E 33

10.1 Controlling the speed of the lifting device ........................................... E 35

10.2 Lifting, transporting and depositing load units ..................................... E 36

11 Transporting loads .............................................................................. E 39

12 Hazardous situations ........................................................................... E 41

12.1 Parking the truck safely ....................................................................... E 42

13 Engine bonnet and service covers ...................................................... E 43

13.1 Service covers ..................................................................................... E 44

13.2 Towing the truck .................................................................................. E 45

13.3 Towing trailers ..................................................................................... E 45

14 Troubleshooting .................................................................................. E 46

F Truck Maintenance

1 Operational Safety and Environmental Protection .............................. F 1

2 Maintenance Safety Regulations ........................................................ F 1

3 Servicing and Inspection ..................................................................... F 3

4 DFG/TFG maintenance checklist ........................................................ F 4

5 DFG maintenance checklist ................................................................ F 6

6 TFG maintenance checklist ................................................................. F 7

7 Coolant specification ........................................................................... F 8

8 Consumables ...................................................................................... F 9

9 DFG fuel specifications ....................................................................... F 9

10 Lubrication chart .................................................................................. F 10

10.1 Lubrication chart - DFG/TFG ............................................................... F 11

11 Maintenance and repairs ..................................................................... F 12

11.1 Preparing the truck for maintenance and repairs ................................ F 12

11.2 Starting aid .......................................................................................... F 12

11.3 Servicing the engine - TFG 316s/320s ................................................ F 13

11.4 Engine servicing - DFG 316s/320s ..................................................... F 16

11.5 Checking the coolant concentration .................................................... F 19

11.6 Filling the cooling circuit ...................................................................... F 19

11.7 Cleaning/replacing the air filter cartridge ............................................. F 20

11.8 Checking the wheel attachment and air pressure ............................... F 21

11.9 Hydraulic system ................................................................................. F 22

11.10 Electrical system ................................................................................. F 23

11.11 Relay layout ........................................................................................ F 26

12 Exhaust system ................................................................................... F 27

13 Restoring the truck to service after cleaning or repairs ....................... F 27

14 Decommissioning the industrial truck .................................................. F 27

14.1 Prior to decommissioning .................................................................... F 27

14.2 During decommissioning: .................................................................... F 28

Page 6

I 3

0708.GB

14.3 Returning the truck to operation after decommissioning ..................... F 28

15 Periodic safety checks and after unusual events ................................ F 29

16 Final de-commissioning, disposal ....................................................... F 29

17 HUSS FS - MK Series Diesel Particle Filter Operating Instructions .... F 30

17.1 Important General Instructions ............................................................ F 30

17.2 Important safety instructions ............................................................... F 30

17.3 Functional description ......................................................................... F 31

17.4 HUSS Control Operation ..................................................................... F 32

17.5 HUSS Control Operating Instructions ................................................. F 33

17.6 Regeneration ....................................................................................... F 34

17.7 Maintenance ........................................................................................ F 37

Page 7

0708.GB

I 4

Page 8

A 1

03.08.GB

A Correct Use and Application

Z

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are

supplied with the truck. The guidelines form part of these operating instructions and

must be observed. National regulations apply in full.

It must be used, operated and serviced in accordance with the present instructions.

Any other type of use is beyond the scope of application and can result in damage to

personnel, the industrial truck or property. In particular, avoid overloading the truck

with loads which are too heavy or placed on one side. The data plate attached to the

truck or the load chart are binding for the maximum load capacity. The industrial truck

must not be used in fire or explosion endangered areas, or areas threatened by

corrosion or excessive dust.

Proprietor responsibilities: For the purposes of the present operator manual the

“proprietor” is defined as any natural or legal person who either uses the industrial

truck himself, or on whose behalf it is used. In special cases (e.g. leasing or renting)

the proprietor is considered the person who, in accordance with existing contractual

agreements between the owner and user of the industrial truck, is charged with

operational duties.

The proprietor must ensure that the industrial truck is used only for the purpose it is

intended for and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The owner must ensure that all

users have read and understood these operating instructions.

M

Failure to comply with the operating instructions shall invalidate the warranty. The

same applies if improper work is carried out on the truck by the customer or third

parties without the permission of the manufacturer’s customer service department.

Attaching accessories: The mounting or installation of additional equipment which

affects or enhances the performance of the industrial truck requires the written

permission of the manufacturer. In some cases, local authority approval shall be

required.

Approval of the local authorities however does not constitute the manufacturer’s

approval.

Towing trailers

Z

see Chapter E, Section 13.3.

Page 9

03.08.GB

A 2

Page 10

B 1

04.08.GB

B Truck Description

1 Application

The DFG/TFG series trucks are 4-wheel sit-down IC engine forklifts. The DFG series

are diesel engine trucks, while the TFG series are fitted with a petrol engine for LPG

operation.

The DFG/TFG 316-320s is equipped with a hydrostatic drive system. The IC engine

drives a high pressure pump for the hydraulic functions and two hydraulic motors to

drive wheels.

Truck models and maximum capacity.

*) The load charts attached to the truck are binding in terms of capacity

Model Capacity (kg)*) Wheel base (mm)

DFG/TFG 316s 1600 1400

DFG/TFG 320s 2000 1400

Page 11

04.08.GB

B 2

2 Assemblies and Functional Description

Item Description Item Description

1 t Lift cylinder 8 t Trailer coupling

2 t Load chain 9 t Counterweight

3 t Mast 10 t Steering axle

4 t Dashboard 11 t Engine cover

5 t Steering column 12 t Hydrostatic drive axle

6 t Overhead guard 13 t Fork carriage

7 t Driver's seat 14 t Fork

Page 12

B 3

04.08.GB

2.1 Truck

Chassis/Superstructure: A rigid chassis which protects the units and controls,

provides the truck with maximum static safety. The operator position is articulating,

which cushions vibrations and noise.

Maintenance and servicing are made easy through the wide opening cover and the

two side panels of the engine housing (11). The hydraulic oil reservoir is integrated

on the right-hand side and the fuel tank for the DFG series on the opposite side in the

chassis. The LPG bottle for the TFG series is secured to a bracket on the

counterbalance weight (9). The exhaust system and exhaust pipe prevents exhaust

from entering the operator position and reduces exhaust noise.

Operator position: Non-slip steps and a handle on the posts of the overhead guard

provide easy entry and exit. The driver is protected by the overhead guard (6). On the

driver’s seat (7) the seat cushioning and the seat position are adjustable, while the

steering wheel tilt can be set on the steering column (5). Easy operation through

ergonomically arranged controls and a practically vibration-proof cab mean that the

driver is only subjected to minimum stress. The control and warning displays on the

dashboard (4) enable the system to be monitored during operation, thereby ensuring

a very high level of safety.

Engine: Silent, water-cooled engines featuring high performance and low

consumption. In the DFG series diesel engines are used with very clean fuel

combustion under all operating conditions and soot levels below the visibility level.

For the TFG series petrol engines are used with very low residual exhaust levels.

Drive: Both drive wheels are powered by individual hydraulic motors which in turn are

driven by a hydraulic pump. Forward/reverse or neutral can be set with the travel lever

on the control panel.

Steering: Hydrostatic steering with a steering cylinder integrated in the steering axle

(10). The steering axle is fully floating in the chassis to ensure excellent grip even on

non-level surfaces.

Brakes: The truck brakes to a halt via the hydraulic motors, keeping energy

consumption to a minimum. The parking brake is an automatic multi-plate brake.

Hydraulic system: All operations can be performed sensitively, proportionally and

simultaneously.

Hydraulic functions are controlled by the control lever through a multiple control valve.

Page 13

04.08.GB

B 4

Electrical system: 12 volt system with starter battery and AC generator with

integrated controller. A repeat start block prevents incorrect operation during start-up

and a safety switch ensures the engine can only start when the travel direction lever

is in neutral. For diesel motors, a rapid pre-heat system is installed, LPG motors have

a non-contact electronic ignition system for rapid and trouble-free engine starting.

The ignition / start switch is used to stop the engine.

2.2 Load handler

Mast: The aim is to optimise visibility. The maximum strength steel section are

narrow, allowing for good fork visibility in particular with the three-stage mast. The

same standard has been achieved for the fork carriage. The mast and the fork

carriage run on permanently-lubricated and hence maintenance-free angled castors.

Attachments: The trucks can be optionally fitted with mechanical and hydraulic

attachments.

Page 14

B 5

04.08.GB

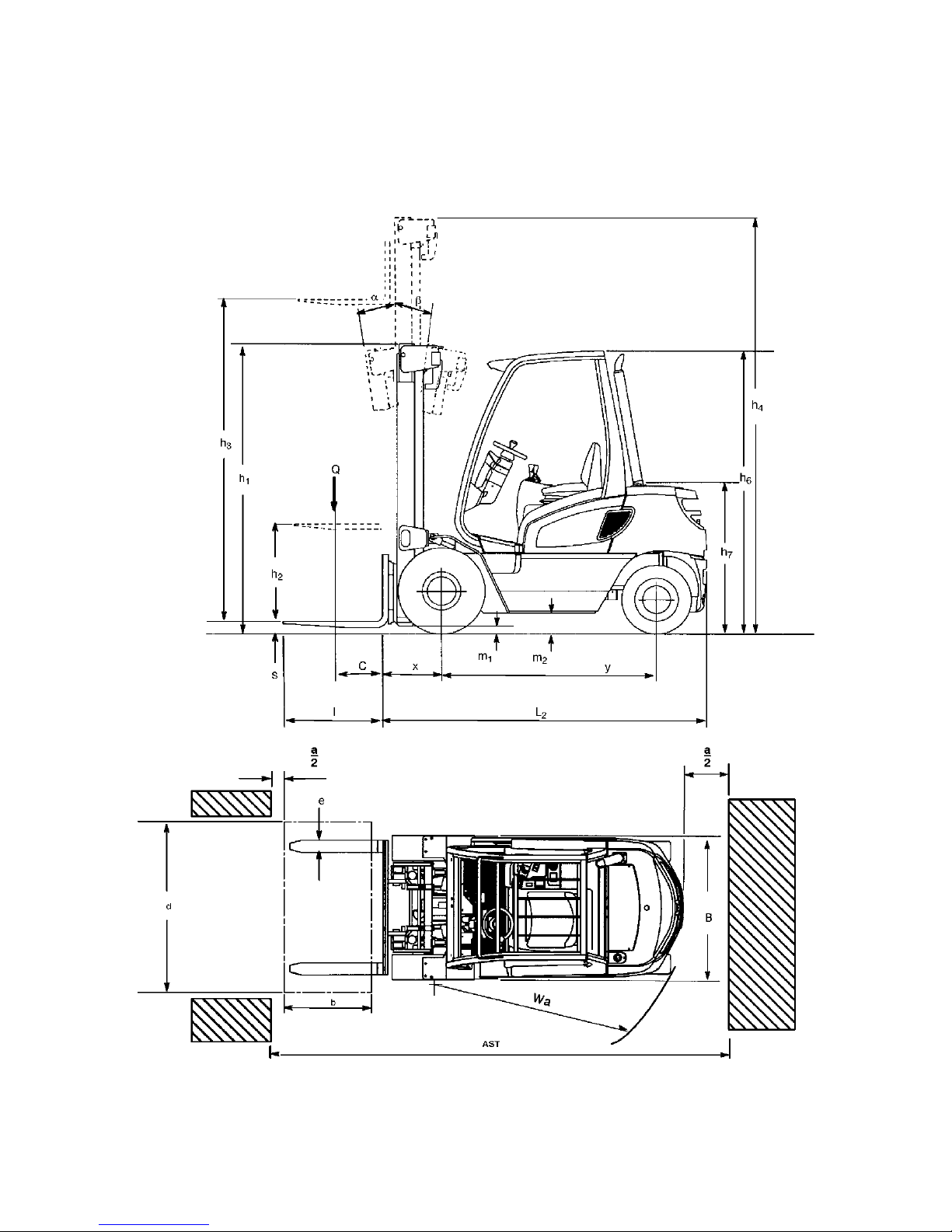

3 Standard Version Specifications

Z

Technical specification details in accordance with VDI 2198. Technical modifications

and additions reserved.

Page 15

04.08.GB

B 6

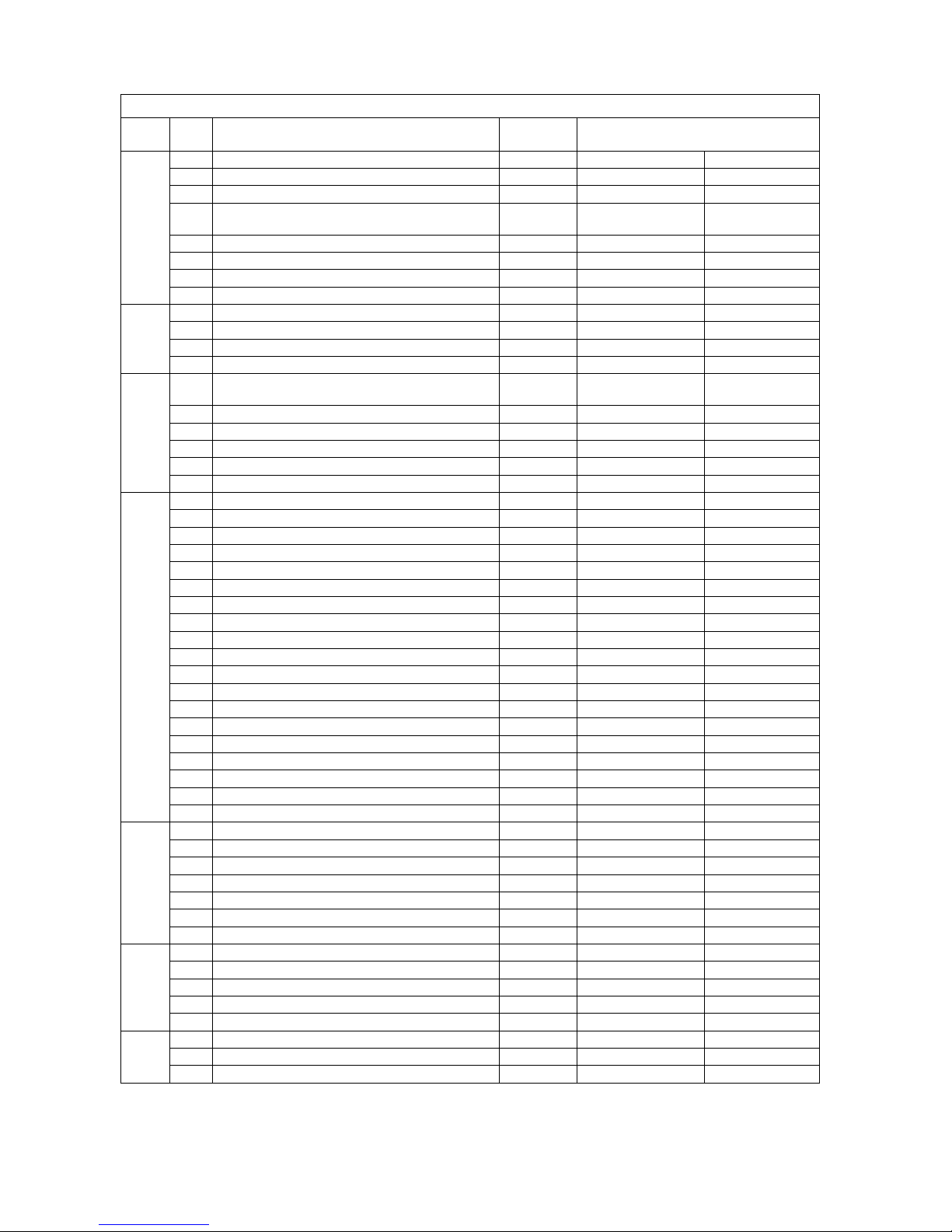

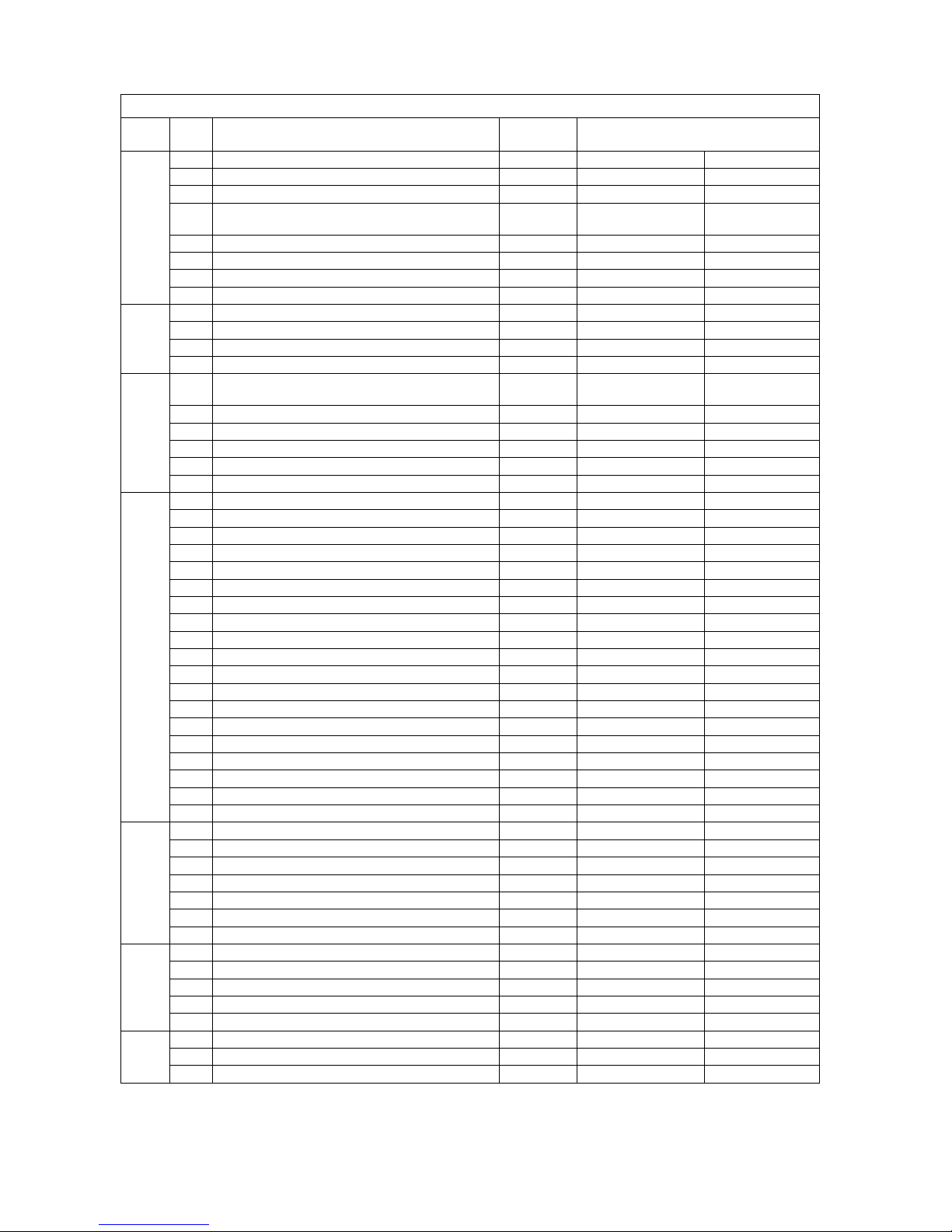

DFG 316s/320s Specification Sheet

No. Description Code

(Unit)

AH-J

Specification

1 Manufacturer Jungheinrich Jungheinrich

1.2 Model DFG 316s DFG 320s

1.3 Drive system: electric, diesel, petrol, LPG, other Diesel Diesel

1.4 Steering: manual, pedestrian truck, stand-up, sit-down,

order picker

Sit-down Sit-down

1.5 Capacity Q(t) 1.6 2.0

1.6 Load centre of gravity c(mm) 500 500

1.8 Load distance x(mm) 395 395

1.9 Wheel base y(mm) 1400 1400

Weight

2:1 Weight - unladen (kg) 3020 3270

2.2 Axle load, laden, front/rear (kg) 4000/620 4600/670

2.3 Axle load, unladen, front/rear (kg) 1320/1700 1240/2030

Longitudinal stability 1.66 1.59

Tyres/chassis

3.1 Tyre type: elastic, super elastic, pneumatic Polyurethane tyres

SE(L)/SE(L) SE(L)/SE(L)

3.2 Tyre size: Front 6.50-10 (14PR) 6.50-10 (14PR)

3.3 Tyre size: rear 18x7-8 (16PR) 18x7-8 (16PR)

3.5 No. of wheels front/rear (x = mechanical pull) 2x/2 2x/2

3.6 Track width, front b

10

(mm) 895 895

3.7 Track width, rear b

11

(mm) 870 (offset) 870 (offset)

Dimensions

4.1 Mast/chassis tilt, front/rear Degrees 7/10 7/10

4.2 Lowered mast height h

1

(mm) 2080 2080

4.3 Free lift h

2

(mm) 100 100

4.4 Lift height h

3

(mm) 3090 3090

4.5 Extended mast height h

4

(mm) 3670 3670

4.7 Overhead guard height (cabin) h

6

(mm) 2130 2130

4.8 Seat height / headroom (SIP 100 mm) h

7

(mm) 1005/1065 1005/1065

4.12 Hitch height h

10

(mm) 375/545 375/545

4.19 Overall length l

1

(mm) 3245 3300

4.20 Length to fork surface l

2

(mm) 2245 2300

4.21 Overall width b

1/b2

(mm) 1070 1070

4.22 Fork dimensions s/e/l(mm) 40/100/1000 40/100/1000

4.23 Carriage DIN 15173, ISO 2328, class/type A,B ISO 2A ISO 2A

4.24 Fork carriage width / outer forks b

3

(mm) 1000/849 1000/849

4.31 Ground clearance laden below mast m

1

(mm) 115 115

4.32 Ground clearance (centre wheelbase) m

2

(mm) 135 135

4.33 Working aisle width for pallets 1000 x 1200 traverse Ast(mm) 3570 3615

4.34 Working aisle width for pallets 800 x 1200 lengthwise Ast(mm) 3770 3815

4.35 Turning radius Wa(mm) 1975 2020

Power

5.1 Travel speed w. / w.o. load (km/h) 18.5/19 18.5/19

5.2 Lift speed w. / w.o. load (m/s) 0.61/0.65 0.60/0.65

5.3 Lower speed w. / w.o. load (m/s) 0.55/0.52 0.55/0.53

5.5 Tow force w. / w.o. load (kN) 16.5/8.4 16.2/7.6

5.7 Gradeability w. / w.o. load (%) 36/28 29/22

5.9 Acceleration time w. / w.o. load s 5.1/4.8 5.3/5.0

5.10 Service brake type Hydrostatic Hydrostatic

Engine

7.1 Engine: Manufacturer/Model 404D.22 404D.22

7.2 Engine output in accordance with ISO 1585 (kw) 34.1 34.1

7.3 Speed (rpm) 2400 2400

7.4 Number of cylinders/capacity ( /cm

3

) 4/2216 4/2216

Max. torque Nm/rpm 143/1800 143/1800

Misc.

8.1 Drive type Hydrostatic Hydrostatic

8.2 Hydraulic oil pressure for attachments (bar) 160 160

8.3 Oil flow for attachments l/min 45 45

Page 16

B 7

04.08.GB

TFG 316s/320s Specification Sheet

No. Description Code

(Unit)

AH-J

Specification

1 Manufacturer Jungheinrich Jungheinrich

1.2 Model TFG 316s TFG 320s

1.3 Drive system: electric, diesel, petrol, LPG, other LPG LPG

1.4 Steering: manual, pedestrian truck, stand-up, sit-down,

order picker

Sit-down Sit-down

1.5 Capacity Q(t) 1.6 2.0

1.6 Load centre of gravity c(mm) 500 500

1.8 Load distance x(mm) 395 395

1.9 Wheel base y(mm) 1400 1400

Weight

2:1 Weight - unladen (kg) 3000 3250

2.2 Axle load, laden, front/rear (kg) 4030/570 4630/620

2.3 Axle load, unladen, front/rear (kg) 1270/1730 1190/2060

Longitudinal stability 1.69 1.61

Tyres/chassis

3.1 Tyre type: elastic, super elastic, pneumatic Polyurethane tyres

SE(L)/SE(L) SE(L)/SE(L)

3.2 Tyre size: Front 6.50-10 (14PR) 6.50-10 (14PR)

3.3 Tyre size: rear 18x7-8 (16PR) 18x7-8 (16PR)

3.5 No. of wheels front/rear (x = mechanical pull) 2x/2 2x / 2

3.6 Track width, front b10(mm) 895 895

3.7 Track width, rear b11(mm) 870 (offset) 870 (offset)

Dimensions

4.1 Mast/chassis tilt, front/rear Degrees 7/10 7/10

4.2 Lowered mast height h

1

(mm) 2080 2080

4.3 Free lift h

2

(mm) 100 100

4.4 Lift height h

3

(mm) 3090 3090

4.5 Extended mast height h

4

(mm) 3670 3670

4.7 Overhead guard height (cabin) h

6

(mm) 2130 2130

4.8 Seat height / headroom (SIP 100 mm) h

7

(mm) 1005/1065 1005/1065

4.12 Hitch height h

10

(mm) 375/545 375/545

4.19 Overall length l

1

(mm) 3245 3300

4.20 Length to fork surface l

2

(mm) 2245 2300

4.21 Overall width b

1/b2

(mm) 1070 1070

4.22 Fork dimensions s/e/l(mm) 40/100/1000 40/100/1000

4.23 Carriage DIN 15173, ISO 2328, class/type A,B ISO 2A ISO 2A

4.24 Fork carriage width / outer forks b

3

(mm) 1000/849 1000/849

4.31 Ground clearance laden below mast m

1

(mm) 115 115

4.32 Ground clearance (centre wheelbase) m

2

(mm) 135 135

4.33 Working aisle width for pallets 1000 x 1200 traverse Ast(mm) 3570 3615

4.34 »Working aisle width for pallets 800 x 1200 lengthwise Ast(mm) 3770 3815

4.35 Turning radius Wa(mm) 1975 2020

Power

5.1 Travel speed w. / w.o. load (km/h) 18.0/18.5 18.0/18.5

5.2 Lift speed w. / w.o. load (m/s) 0.56/0.65 0.55/0.65

5.3 Lower speed w. / w.o. load (m/s) 0.55/0.52 0.55/0.53

5.5 Tow force w. / w.o. load (kN) 14.6/7.4 14.5/7.1

5.7 Gradeability w. / w.o. load (%) 32/25 28/22

5.9 Acceleration time w. / w.o. load s 4.8/4.6 4.9/4.7

5.10 Service brake type Hydrostatic Hydrostatic

Engine

7.1 Engine: Manufacturer/Model FE 2.0 FE 2.0

7.2 Engine output in accordance with ISO 1585 (kw) 26 26

7.3 Revolutions (rpm) 2400 2400

7.4 Number of cylinders/displacement ( /cm

3

) 4/1998 4/1998

Max. torque Nm/rpm 120/1600 120/1600

Misc.

8.1 Drive type Hydrostatic Hydrostatic

8.2 Hydraulic oil pressure for attachments (bar) 160 160

8.3 Oil flow for attachments l/min 45 45

Page 17

04.08.GB

B 8

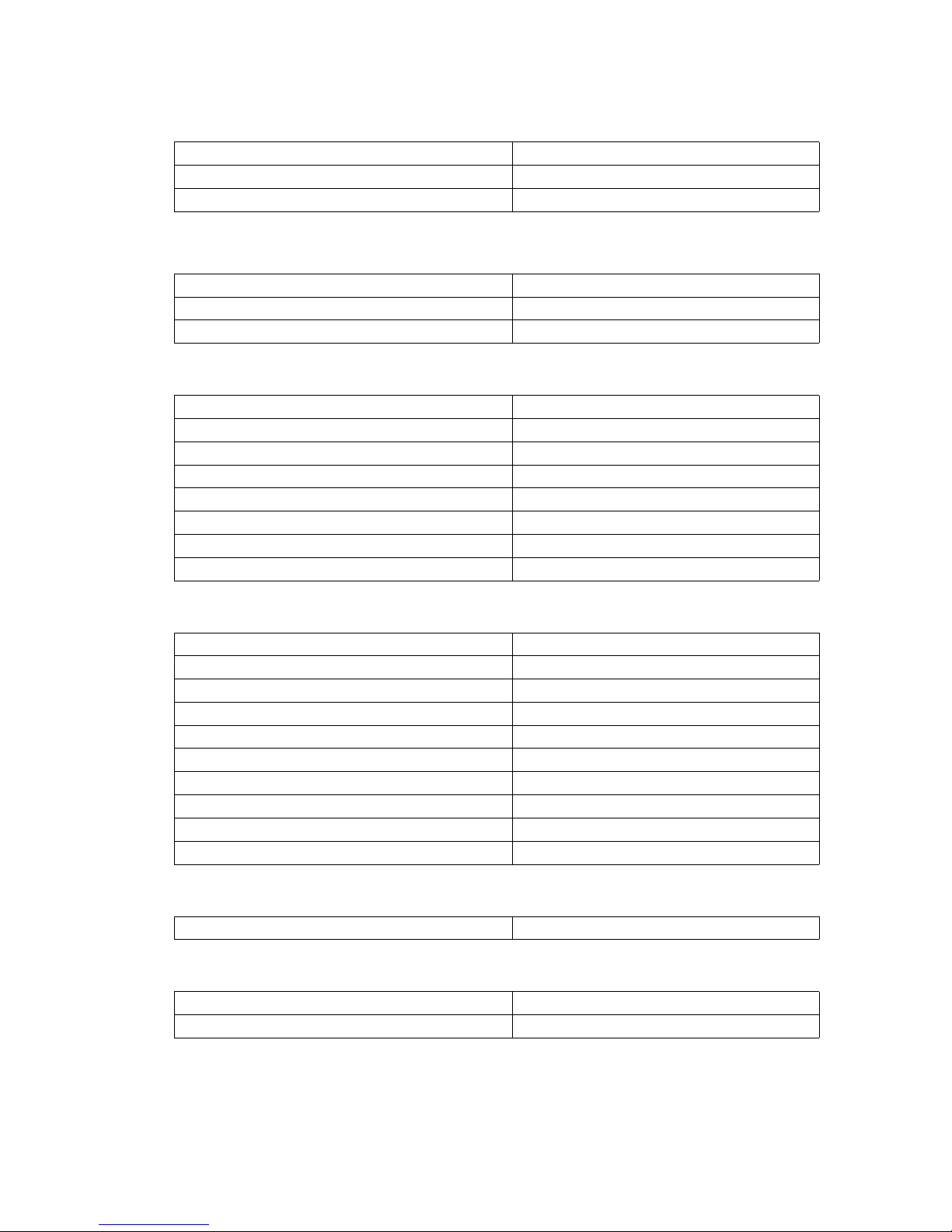

3.1 DFG/TFG 316s/320s Specifications

Steering system

Drive axle

Engine - DFG 316s/320s

Engine - TFG 316s/320s

Air filter

Brake system

MODEL Fully hydrostatic

PUMP As for main hydraulic system

NUMBER OF TURNS STOP TO STOP 5

MODEL Radial piston axle

MODEL ESE 02

LUBRICANT CAPACITY N/A

MODEL 404D.22 four cylinder

IGNITION ORDER 1 3 4 2

CONTROL SPEED 2400 rpm (unladen) / 880 rpm (idle)

VALVE CLEARANCE (inlet/outlet) 0.20mm cold

OIL PRESSURE 4.5 bar @ 2300 rpm

OIL CAPACITY 8.9 litres

FUEL TANK 42 litres

COOLANT CAPACITY 9.0 litres

MODEL FE 2.0 four cylinder

IGNITION ORDER 1 3 4 2

CAPACITY 1998cc

CONTROL SPEED 3100 rpm (unladen) / 830 rpm (idle)

OIL PRESSURE 3.0 bar @ 2300 rpm

SPARK PLUG TYPE NGK BPR 2E or DENSO W9EXR-U

SPARK PLUG ELECTRODE DISTANCE 0.80mm

OIL CAPACITY 4.3 litres

FUEL TANK N/A

COOLANT CAPACITY 9.0 litres

MODEL Cyclopac – dry element

MODEL Multiplate brake

PARKING BRAKE Disc works via a hydraulic pressure system

Page 18

B 9

04.08.GB

Wheels and Tyres

Tires

Z

Permissible tyre types: Only use tyres approved by the lift truck manufacturer, if in

doubt contact your local JH service branch.

Noise Emissions

Vibrations

TYRE SIZE See specifications sheet

TYRE PRESSURE

6.50-10

Model Drive axle - bar Steer axle - bar

DFG/TFG 316s/320s 7.75 9.0

23x9-10 DFG/TFG 316s/320s 9.0 9.0

WHEEL NUT TORQUE Model Drive axle - Nm Steer axle - Nm

DFG/TFG 316s/320s 210 176

APPLICATION AREA TYRE SIZE TYPE MODEL

Drive axle 6.50x10 10PR Pneumatic tyres diagonal DFG/TFG 316s/320s

Steer axle 18x7-8 14PR

Drive axle 6.50x10 Full rubber profile DFG/TFG 316s/320s

Steer axle 18x7-8

Drive axle 23x9x10 18PR Pneumatic tyres diagonal DFG/TFG 316s/320s

Steer axle 18x7-8 14PR

Drive axle 23x9x10 Full rubber profile DFG/TFG 316s/320s

Steer axle 18x7-8

NOISE EMISSION LEVEL in accordance with

EN 12053 as harmonised with ISO 4871.

<80 dB(A)

Cyclopac – dry element

The noise emission level is calculated in

accordance with standard procedures and takes

into account the noise level when travelling,

lifting and when idle. The noise level is

measured at the driver’s ear.

WHOLE BODY VIBRATIONS THROUGH

AVERAGE VALUE in accordance with EN 13059

0.57 m/s

The vibration acceleration acting on the body in

the operating position is, in accordance with

standard procedures, the linearly integrated,

weighted acceleration in the vertical direction. It

is calculated when travelling over bumps at

constant speed.

Page 19

04.08.GB

B 10

Electrical system

Hydraulic system

Conditions of use

Z

For constant use below 0°C it is recommended to fill the hydraulic system with frostresistant oil as indicated by the manufacturer. Special equipment and authorisation

are required if the truck is to be used in cold stores or conditions of extreme

temperature or air humidity fluctuations.

SYSTEM 12 volt negative earth

ELECTROMAGNETIC COMPATIBILITY

(EMC)

Within the following limits in accordance with

“Industrial Truck Electromagnetic Compatibility

(9/95)” product standards:

t interference emission (EN 50081-1)

t resistance (EN 50 082-2)

t electrostatic discharge (EN 61000-4-2)

HYDRAULIC PUMP 1PX series

CONTROL VALVE 5000 series

STEER PRESSURE 106 bar

MAIN PRESSURE 215 bar

TANK CAPACITY 46 litres

HYDRAULIC SYSTEM CAPACITY 51 litres

AMBIENT TEMPERATURE

t during operation -15

°C to +40°C

Page 20

B 11

04.08.GB

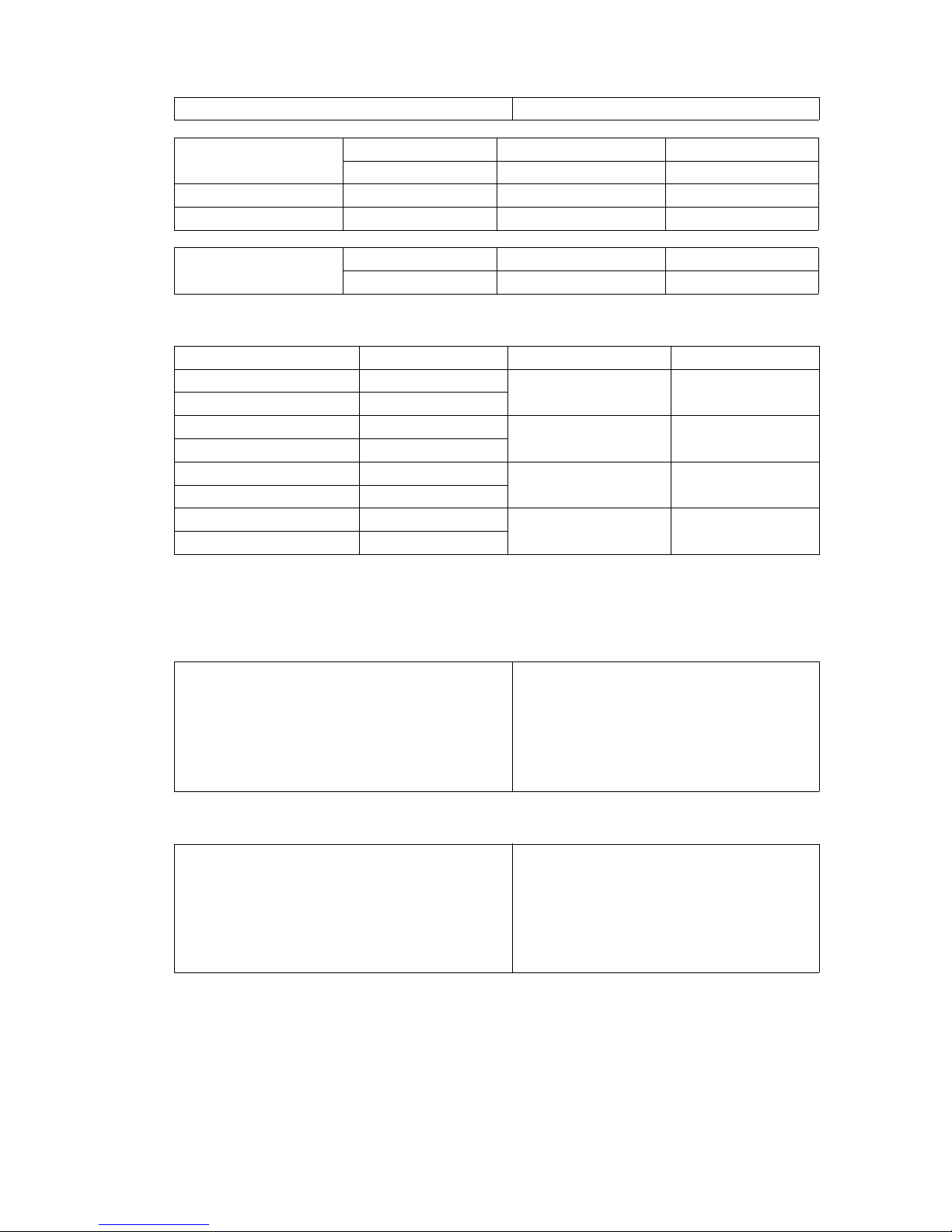

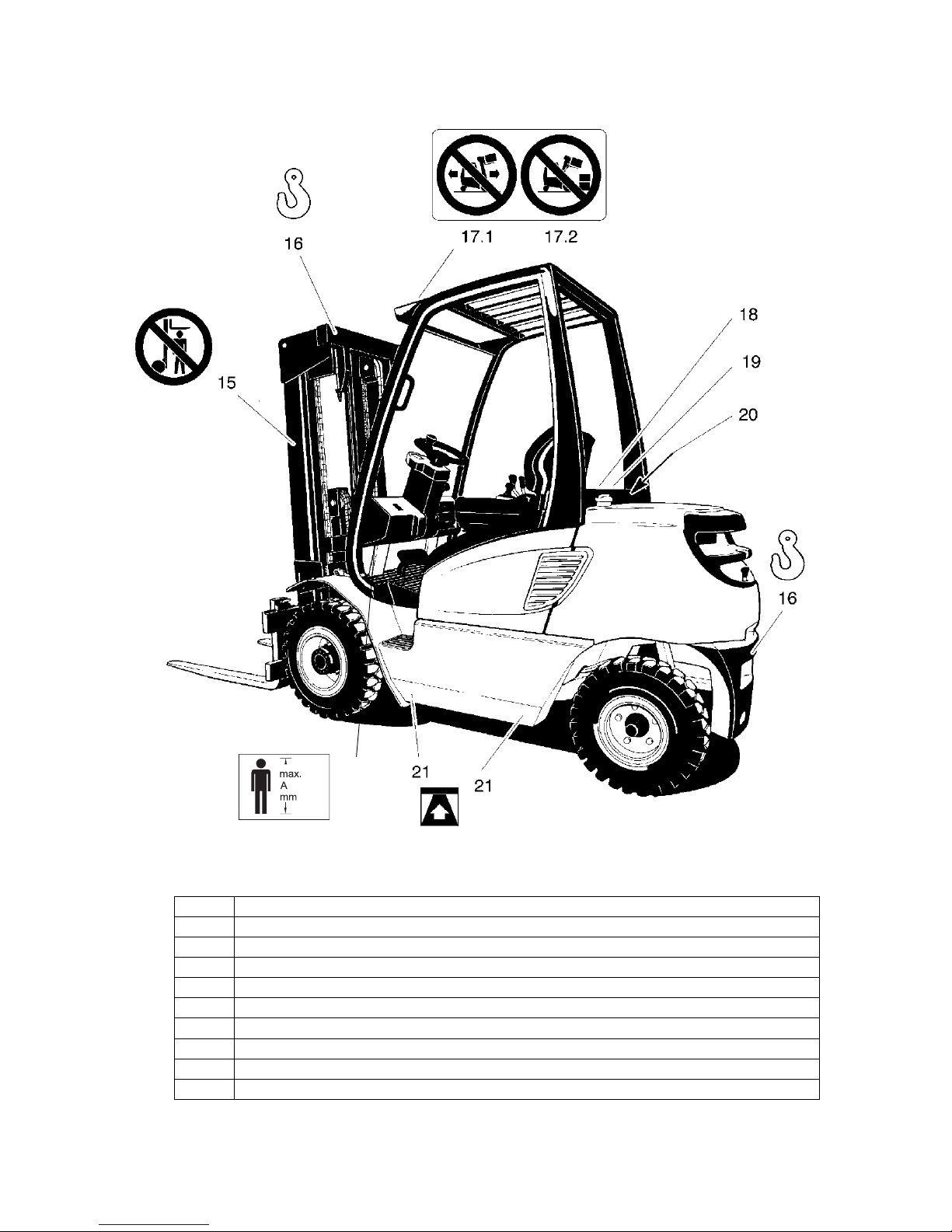

4 Identification points and data plates

Item Description

15 "Do not stand under the load handler" warning

16 Strap points for crane lifting

17.1 “Do not travel with a raised load” warning

17.2 “Do not tilt the mast forward with a raised load” warning

18 Forks, capacity / load centre of gravity / lift height load chart

19 Sideshift, capacity / load centre of gravity / lift height load chart

20 Truck data plate

21 Jack contact points decal

22 “Maximum body size” notice

22

Page 21

04.08.GB

B 12

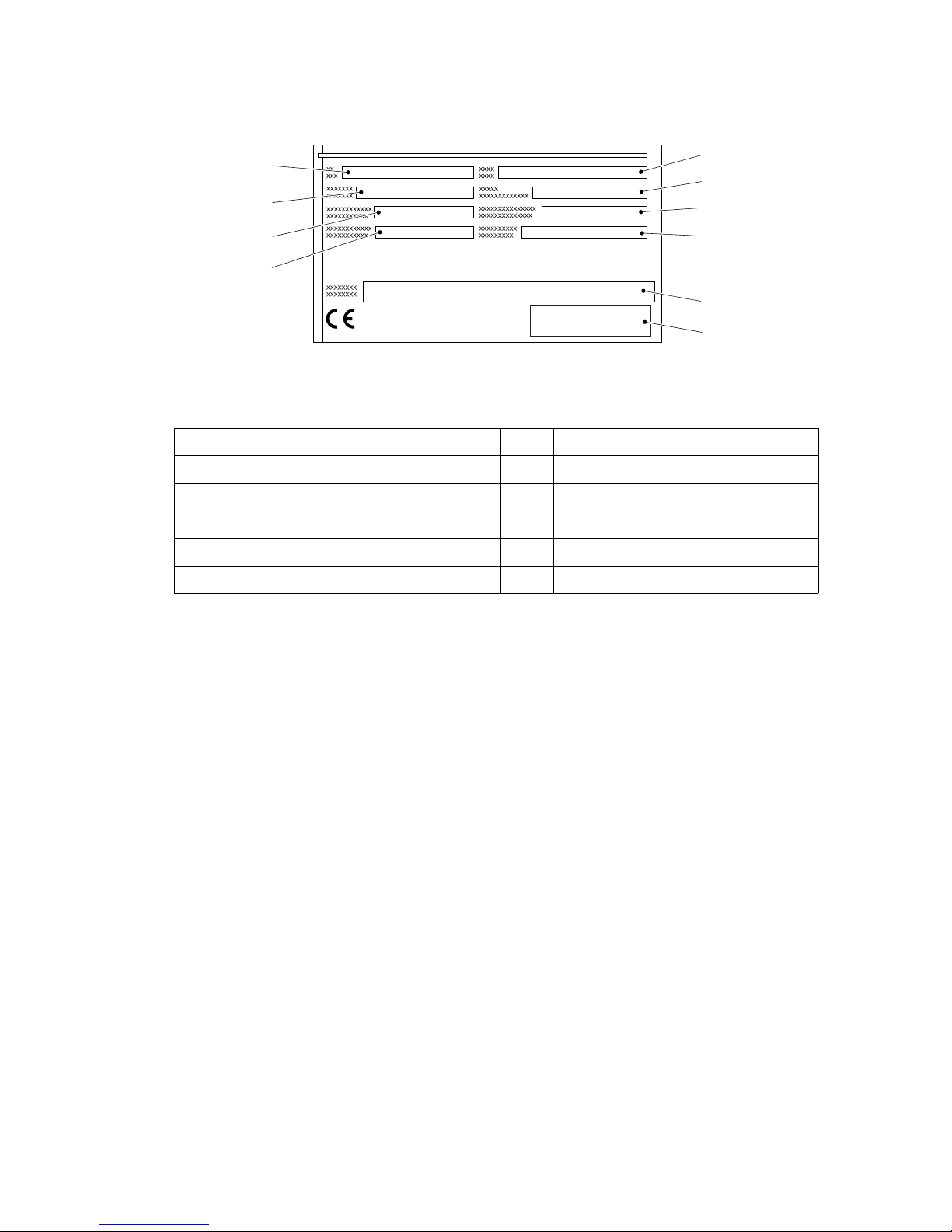

4.1 Truck data plate

Z

For queries regarding the truck or ordering spare parts always quote the truck serial

number (24).

Item Description Item Description

23 Type 28 Manufacturer

24 Serial no. 29 Net weight in kg

25 Rated capacity in kg 30 Load centre of gravity (mm)

26 Rated output (kW) 31 Year of manufacture

27 Manufacturer’s logo 32 Option

23

24

25

26

31

30

27

29

32

28

Page 22

B 13

04.08.GB

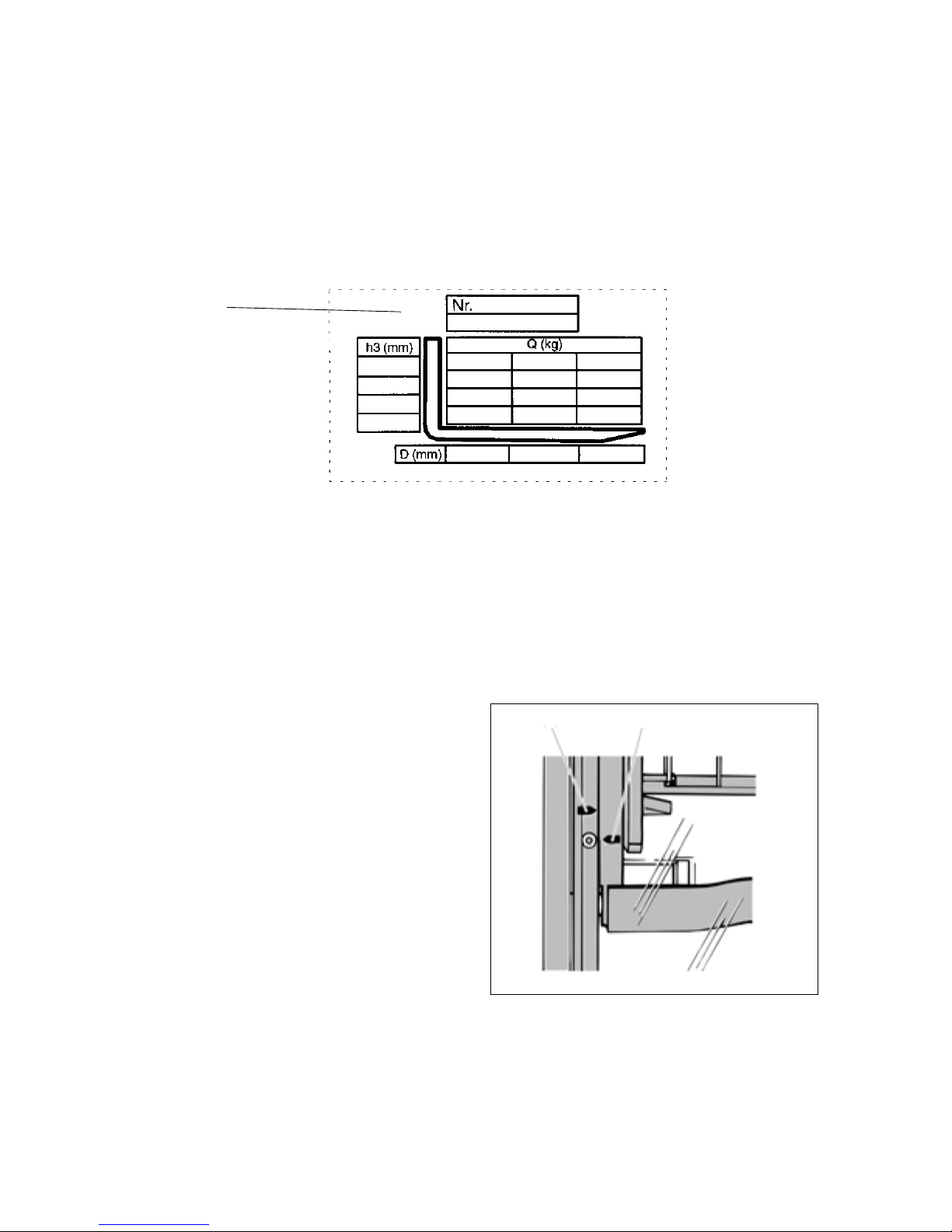

4.2 Truck load chart

The load chart (16) gives the capacity (Q) of the truck in kg with a vertical mast. The

diagram will differ, depending on the height of the mast used. The maximum capacity

is shown as a table with a given load centre of gravity D (in mm) and the required lift

height H (in mm). The truck load chart shows the truck's capacity with new forks (as

supplied). From a fork length of 1300 mm this means a decrease in load. Trucks

supplied without fork tines are given a standard data plate.

The arrow shape markings (38 and 39)

on the inner and outer masts show the

driver when the specified lift limits have

been reached. These arrows are

attached to all masts with a heightdependent capacity rating.

4250

3600

2900

1250 1250

850

500

600 700

1105

1105

850

850

850

600

Example:

16

38 39

Page 23

04.08.GB

B 14

4.3 Attachment load chart

The attachment load chart gives the truck’s capacity Q in combination with the

respective attachment in kg. The serial number specified in the load chart must match

the data plate of the attachment, as the capacity for each truck is specifically indicated

by the manufacturer. It is shown in the same way as the truck’s capacity and can be

determined accordingly.

Z

For loads with a centre of gravity above 500 mm upward, the capacities are reduced

by the difference of the altered centre of gravity.

Page 24

C 1

04.08.GB

C Transport and Commissioning

1 Transport

Transport can be carried out in two different ways, depending on the height of the

mast and the local conditions.

– Vertically, with the mast assembled (for low heights)

– Vertically, with the mast dismantled (for large heights), all hydraulic lines between

the basic truck and the mast separated.

Safety Instructions for Assembly and Commissioning

F

On site assembly of the truck, commissioning and driver instruction may only be

carried out by personnel trained and authorised by the manufacturer.

The hydraulic lines may only be connected to the basic truck / mast interface and the

truck commissioned when the mast has been properly assembled.

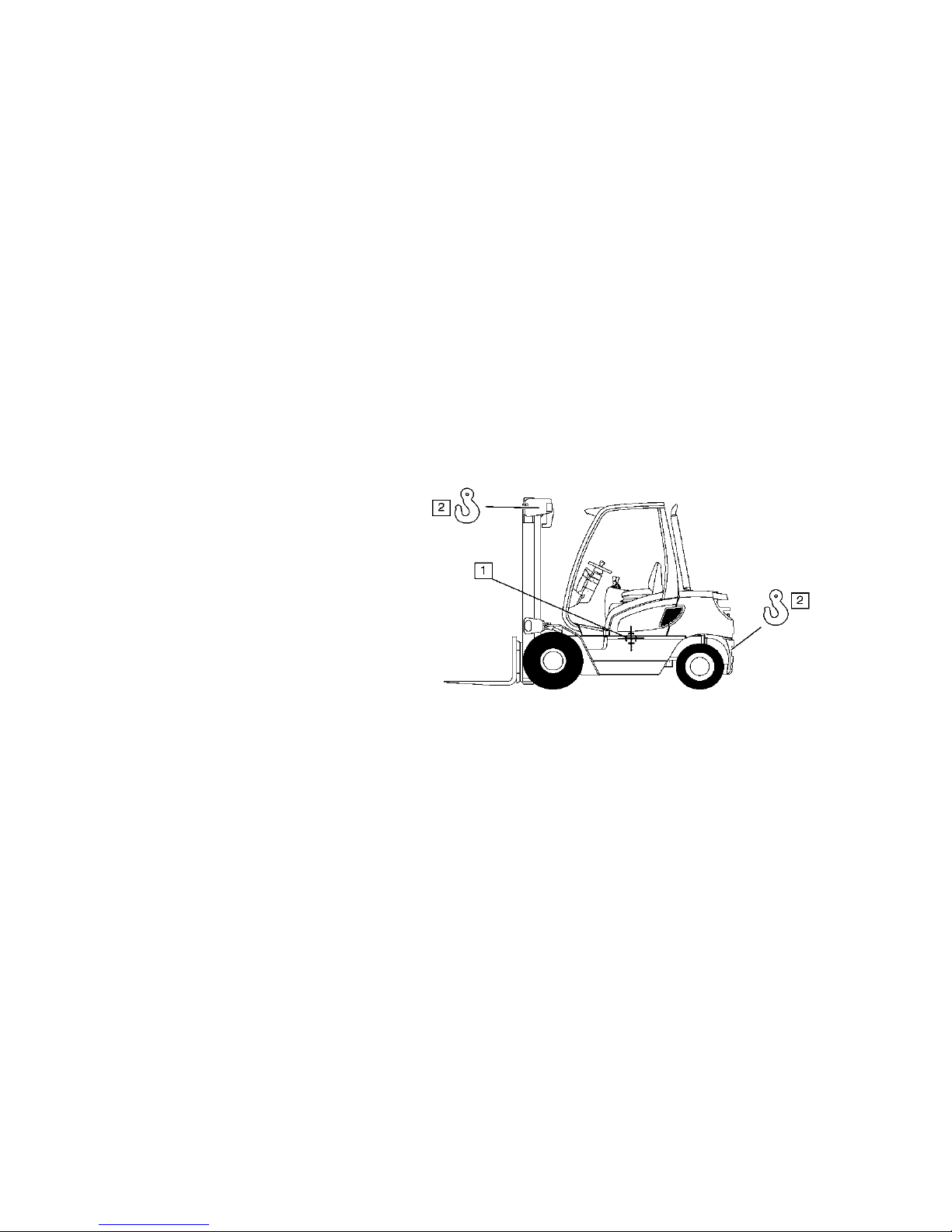

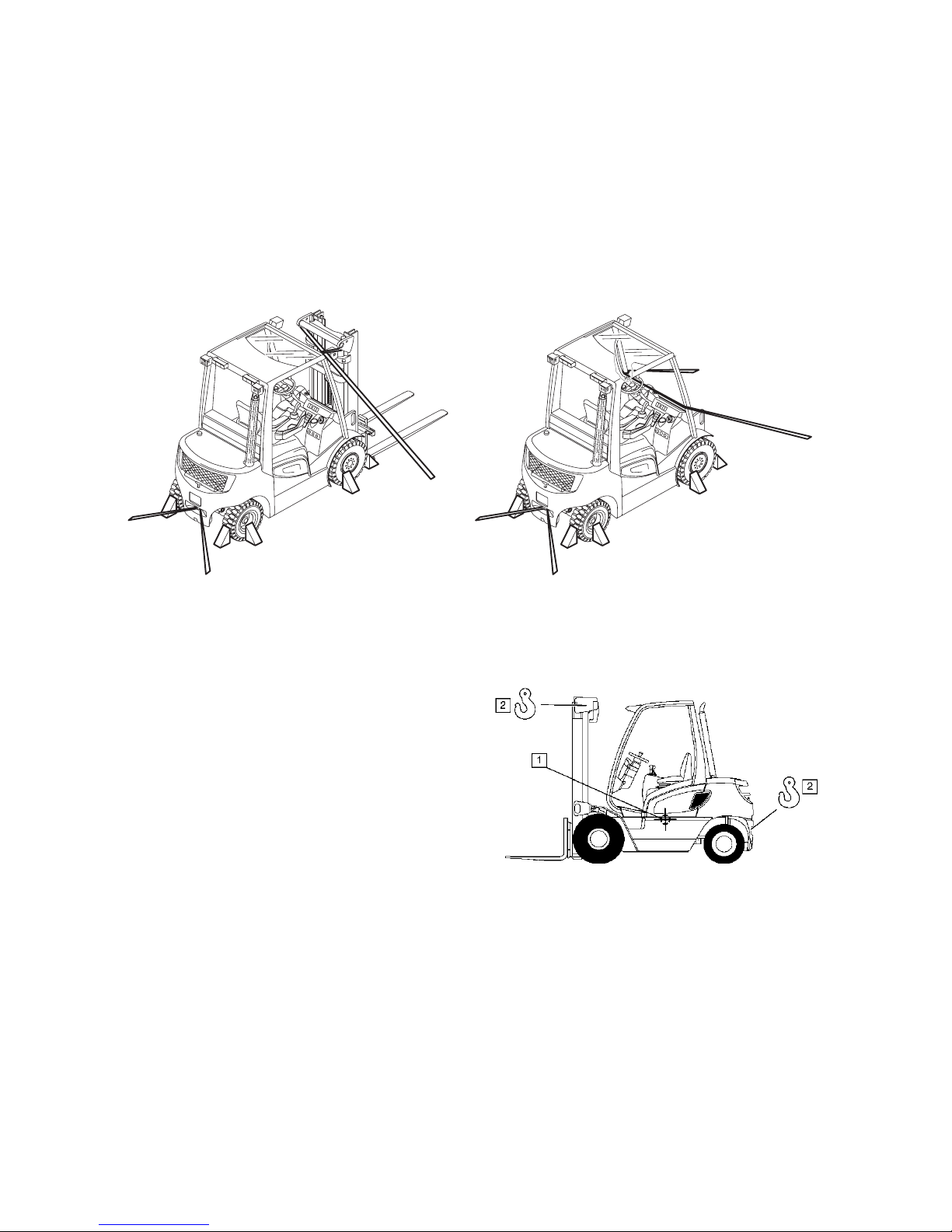

2 Lifting by crane

M

Only use lifting gear with

sufficient capacity (for

transport weight see truck data

plate).

– Parking the truck securely

(see Chapter E).

– Attach the crane slings to the

top cross member of the

mast (1) and the trailer

coupling (2).

M

Only suspend crane belts/chains to the top eye of the counterbalance weight and the

eyes of the upper cross member (mast).

The mast must be tilted back fully.

The crane belt or the chain on the mast must be at least 2m long.

M

Lifting slings should be fastened to the harness in such a way that they do not come

into contact with any attachments or the overhead guard when it is being raised.

Page 25

04.08.GB

C 2

3 Securing the truck during transport

F

The truck must be securely fastened when being transported on a lorry or a trailer.

The lorry / trailer must have fastening rings and a wooden floor.

M

Loading must be carried out by specially trained staff in accordance with

recommendations contained in Guidelines VDI 2700 and VDI 2703. In each case

correct measurements must be made and appropriate safety measures adopted.

– To secure the truck with the mast assembled, use the eyes on the upper cross

member of the mast and the trailer pins.

– If the truck is to be transported without a mast, it must be tied down at the front of

the chassis.

The attached picture shows the

approximate centre of gravity location.

Page 26

C 3

04.08.GB

4 Using the truck for the first time

F

Commissioning and driver instruction must be performed by trained personnel. If

several trucks have been delivered, make sure that always the serial numbers of the

load handlers, masts and basic trucks match each other.

To prepare the truck after delivery or after transport, proceed as follows:

– Make sure the truck’s equipment is complete and in a satisfactory condition.

– Check the engine oil level.

– Hydrostatic drive axle oil level

– Check hydraulic oil level.

– Check battery terminals and acid level.

Start up the truck as indicated.

5 Operating the truck without its own drive system

The brake system is designed so that the multi-plate brakes are automatically

activated when the truck comes to rest. It must therefore be released for towing as

described below.

F

Support the mast and carriage on blocks before working underneath the forklift truck.

Releasing the mechanical brake

Should you need to tow the truck,

observe the following procedure:

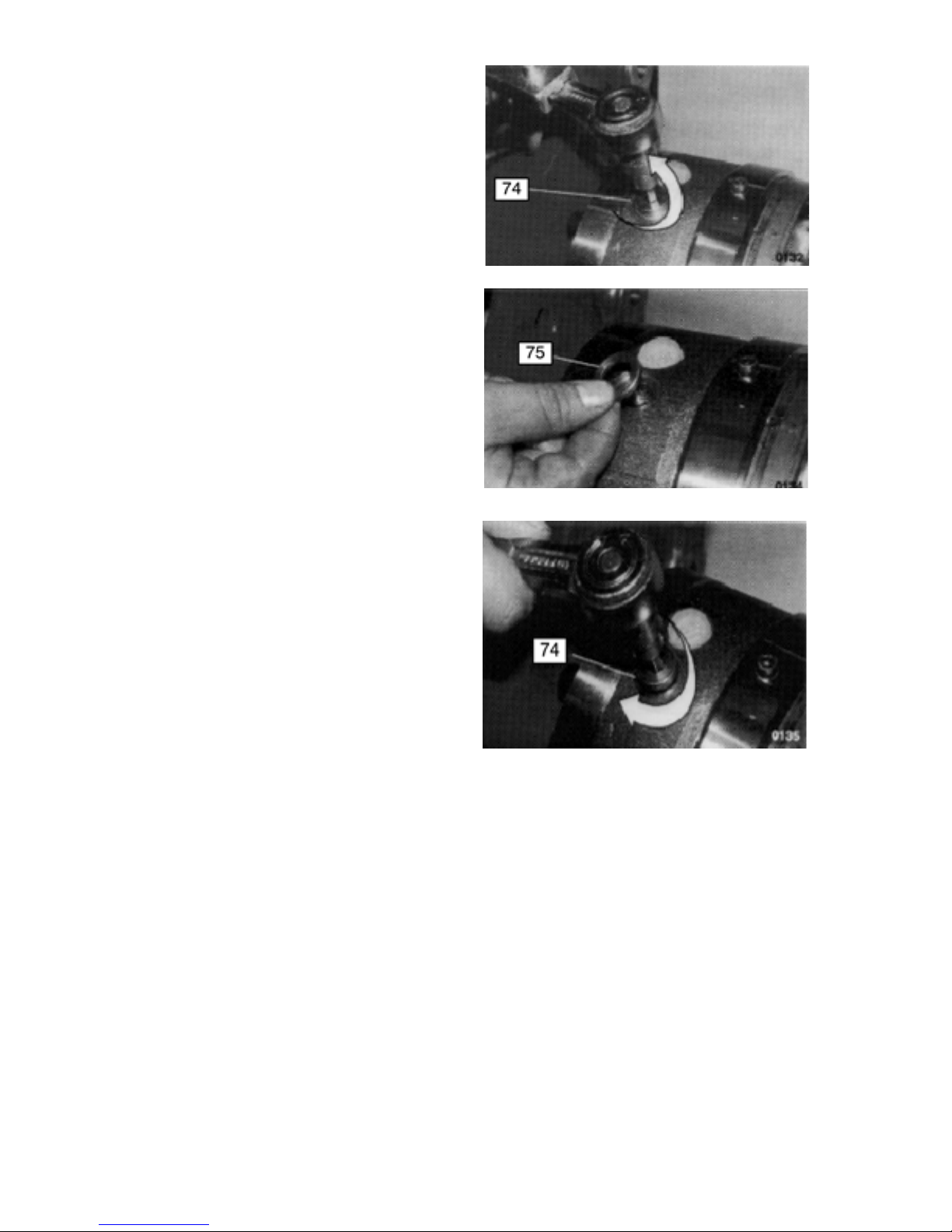

Components

73 Ball

74 Plug

75 Washer

76 O ring

– Plug (74) position

Page 27

04.08.GB

C 4

– Remove the four plugs (74) from the

hydrostatic drive axle.

M

Leave the drive axle housing balls in

place.

– Pull out the washers (75) and

O rings (76).

– Refit the plugs (74) in pairs while

applying a torque of 30 Nm.

– Tow the truck slowly. You may

notice some resistance on the first

quarter turn of the wheels. This

depends on the period of time the

truck has not been in operation.

M

Towing a truck with a decommissioned engine will cause the hydrostatic drive axle to

overheat. To avoid this, the truck must only be towed a short distance at a maximum

speed of 4 km/h.

– After towing the truck it is essential to refit the washers and O rings. Failure to

comply with this instruction will prevent the emergency or parking brakes from

working.

– Remove the plugs (74) and washers (75) and attach new O rings (76). Torque the

plugs to 60 ± 6 Nm.

Page 28

C 5

04.08.GB

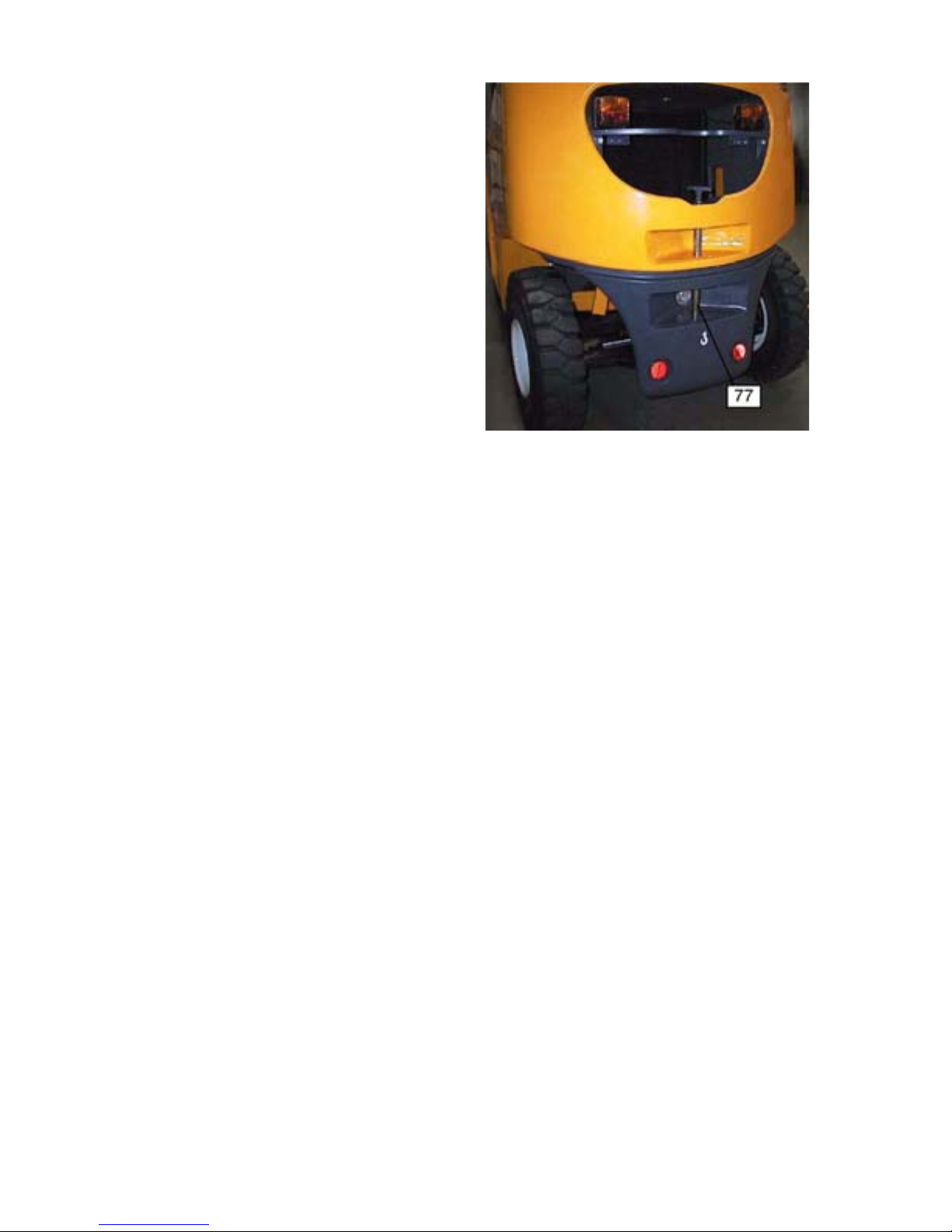

Hitch point

A rigid tow bar must be used to move

a forklift truck.

The tow point of the truck is

indicated (77).

Using the hitch point

– Push the tow pin (78) down and turn

it 90 degrees.

– Pull the tow pin up and insert the tow

eye or tiller of the trailer vehicle into

the opening (79).

– Insert the tow pin, push it down, turn

it 90 degrees and engage it.

F

One person must be seated in the towed truck to steer it. Tow the truck at walking

pace.

Z

As the steering auxiliary unit is not operational, extra effort is required to steer the

truck.

Page 29

04.08.GB

C 6

Page 30

D 1

04.08.GB

D Fuelling the Truck

1 Safety regulations for handling diesel fuel and LPG

Before filling up or replacing the LPG bottle, first park the truck securely (see Chapter E).

Fire protection: When handling fuels and LPG, smoking, naked flames and other

ignition sources are strictly prohibited in the immediate vicinity. Labels indicating the

hazard zone must be positioned where they are clearly visible. It is prohibited to store

flammable materials in this area. Fire equipment in full working order must be

provided within easy reach of the filling area.

F

Use only a carbon dioxide dry fire extinguisher or a carbon dioxide gas extinguisher

to fight LPG fires.

Storage and transport: The diesel and LPG storage and transport devices must

comply with statutory requirements. If there is no filling point available, the fuel must

be stored and transported in clean, approved containers. The contents must be

clearly indicated on the container. Unsealed LPG bottles must be brought

immediately into the open air, stored in well ventilated areas and the supplier must be

notified. Spilled diesel must be set using a suitable agent and disposed of in

accordance with environmental regulations.

Personnel for filling fuel and replacing LPG bottles: Personnel handling LPG

must be have sufficient knowledge of the nature of liquid gases to ensure safe

operation.

Filling up the LPG tank: LPG tanks remain connected to the truck and are filled up

at LPG stations. Always follow the instructions of the tank system and LPG container

manufacturer as well as statutory and local regulations when filling up.

Hose / pipe safety valve

M

Attention: A hose / pipe safety valve must be present when using fluid gas, to prevent

the gas from escaping suddenly if a line fails.

– Use only gas bottles with a hose / pipe safety valve.

– The bottle connection to the truck must have a hose / pipe safety valve (available

from the factory).

The owner must comply with all legal requirements, technical standards and health

and safety regulations applicable to liquid gas.

F

Liquid gas produces frost damage when it comes into contact with bare skin.

Page 31

04.08.GB

D 2

2 Filling with diesel

F

The truck must only be filled at locations

specifically designed for this purpose.

– Park the truck securely before filling

up (see Chapter E).

– Open the cap (1).

– Fill up with clean diesel.

Z

Do not overfill the tank.

Level:

DFG 316s/320s: 42 l

M

Only use DIN 590 diesel with a cetane

rating above 50.

The fuel indicator (2) shows the fuel

level. When the indicator points to the

red area the tank must be filled up.

M

Never allow the fuel tank to run dry. Air

in the fuel system will result in

malfunctions.

– Tighten the cap back on after filling

with fuel.

Page 32

D 3

04.08.GB

3 Replace the LPG bottle

F

The LPG bottle must only be replaced at designated areas by trained and authorised

personnel.

– Park the truck securely before

filling up (see Chapter E).

– Close the shut-off valve (3)

securely.

– Start the engine and allow the

LPG system to run empty in

neutral.

– Unscrew the union nut (4) with

an appropriate key while holding

against the handle (6).

– Remove the hose (5) and

immediately screw the valve cap

onto the empty LPG bottle.

– Slacken the sealing straps (8)

and remove the cover (7).

– Carefully remove the LPG bottle

from the bracket and place it

down securely.

F

Use only 18 kg (29l) LPG

replacement bottles.

– Insert the new LPG bottle in the

bracket and turn it so that the

neck of the shut off valve is

facing down.

– Secure the LPG bottle with the

sealing straps.

– Refit the hose in accordance with

regulations.

– Carefully open the shut off valve

and check the connection is

sealed using a foam-based

agent.

Page 33

04.08.GB

D 4

o Reusable LPG bottles with central filling device

F

Refillable liquid gas bottles contain a

dispensing valve (10), a filling stop valve

(11), a relief valve (12) and a level

display (13). To fill the tank close the

dispensing valve, unscrew the cover of

the filling stop valve and insert the

nozzle of the LPG pump into the filling

port. The filling stop valve automatically

stops the gas from being filled when the

bottle reaches the maximum level. At

filling, screw the lid back on.Observe

any guidelines or regulations on filling

LPG bottles that are attached to the LPG

pump.

Z

Safety notices:

– The tank and the fittings must be checked regularly for physical damage, corrosion

and other damage in accordance with the regulations of the country of use.

– Tank repairs must only be carried out by trained personnel.

o Lift trucks with two LPG bottles

F

A twin LPG bottle container may only be used if the truck is equipped with an

operational reverse camera system and outer mirrors on both sides.

A supply valve is also attached to the unit in addition to the shutoff valves on both gas

bottles. This valve can be used to select from which of the two bottles the gas is to be

taken. The two bottles cannot be used together.

M

Close both shutoff valves on the gas bottles to interrupt the supply of gas.

1110

13

12

Page 34

E 1

04.08.GB

E Operation

1 Safety Regulations for the Operation of Forklift Trucks

Driver authorisation: The forklift truck may only be used by suitably trained

personnel, who have demonstrated to the proprietor or his representative that they

can drive and handle loads and have been authorised to operate the truck by the

proprietor or his representative.

Driver’s rights, obligations and responsibilities: The driver must be: informed of

his rights and duties; trained in the operation of the forklift truck; and familiar with the

contents of these operating instructions. The driver shall be afforded all due rights.

Safety shows must be worn for pedestrian operated trucks.

Unauthorised use of truck: The driver is responsible for the truck during the time it

is in use. He shall prevent unauthorised persons from driving or operating the truck.

Do not carry passengers or lift other people.

Damage and Faults: The supervisor must be immediately informed of any damage

or faults to the forklift truck or attachment. Trucks which are unsafe for operation (e.g.

wheel or brake problems) must not be used until they have been rectified.

Repairs: The driver must not carry out any repairs or alterations to the industrial truck

without the necessary training and authorisation to do so. The driver must never

disable or adjust safety mechanisms or switches.

Hazardous area: A hazardous area is defined as the area in which a person is at risk

due to truck movement, lifting operations, the load handler (e.g. forks or attachments)

or the load itself. This also includes areas which can be reached by falling loads or

lowering operating equipment.

F

Unauthorised persons must be kept away from the hazardous area. Where there is

danger to personnel, warning shall be sounded in good time. If unauthorised

personnel are still within the hazardous area the truck shall be brought to a halt

immediately.

Safety devices and warning signs: Safety devices, warning signs and warning

instructions shall be strictly observed.

M

Trucks with reduced headroom are equipped with a warning sign within the driver's

line of sight. The max. recommended body size indicated on this sign must be

observed.

Page 35

04.08.GB

E 2

Page 36

E 3

04.08.GB

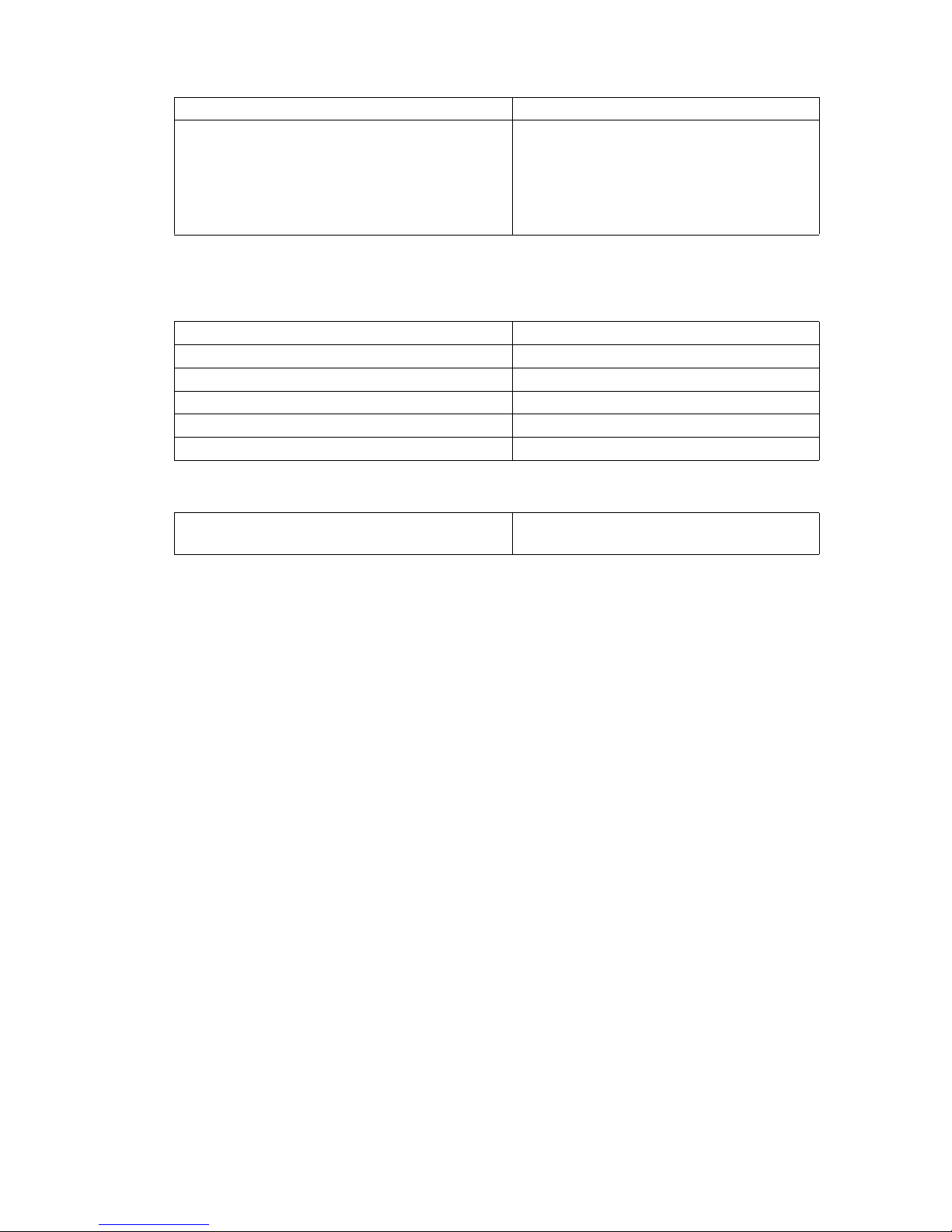

2 Controls and Displays

Item Control /

display item

Function

1 Parking brake

indicator

t When lit, indicates that the parking

brake is applied.

2 Fuel display (DFG) t Indicates how much fuel is left in the

tank.

3 Coolant temperature

indicator

t Indicates the coolant temperature.

4 Neutral position t When lit, indicates that the travel

direction switch is in neutral.

5 o Not used.

6 Hydrostatic drive

indicator

o When lit, indicates that the hydrostatic

drive is faulty.

Slow flashing indicates a minor error

in the hydrostatic drive, such as

accelerator potentiometer, mast lever

or engine actuator.

Rapid flashing indicates a more

serious error in the hydrostatic drive

(truck automatically brakes), such as

the pump potentiometer, brake pedal,

error in 5 volt circuit.

A permanently lit indicator during

travel indicates an error in the engine

speed sensor.

7Light o Indicates that the headlights are on.

8 Engine oil pressure

indicator

t When lit, indicates insufficient engine

lubricant oil pressure.

9 Not used o

10 Not used o

Page 37

04.08.GB

E 4

Page 38

E 5

04.08.GB

Item Control /

display item

Function

11 t Not used.

12 Seat belt indicator o When lit indicates that the seat belt

has not been properly attached.

13 Indicator control light o Shows the indicator status (right/left).

14 Fuel supply

indicator (DFG)

t When lit, indicates the fuel supply is

too low.

15 Time / service hours

display

t Indicates the time or number of

service hours operated.

16 Preheat control light

(DFG)

t Indicates the cold start mechanism is

operating.

17 Charge current

indicator

t When lit, indicates that the battery is

not charged.

18 Steering wheel t Steers truck in desired direction.

19 Set heating/air

connection

o

20 Steering column

adjusting lever

t Adjusts the steering column tilt.

Page 39

04.08.GB

E 6

Page 40

E 7

04.08.GB

Item Control /

display item

Function

21 Heating

o Controls the heating (page E13)

22 Accelerator pedal t Controls the engine speed and / travel and

lift speeds.

23 Raise/lower

control lever

t Raises and lowers the fork carriage. To

raise the fork carriage: pull the lever back.

To lower the fork carriage: push the lever

forward.

24 Mast tilt control

lever

t Tilts the mast forward and back.

To tilt the mast forward: push the lever

forward. To tilt the mast back: pull the lever

back.

25 Switch o Lamps, demister etc.

26 Ignition / starter

switch

t Switches power supply on and off.

Starts and stops the engine. Removing the

ignition key prevents the truck from being

switched on by unauthorised personnel.

27 Main switch /

isolator

(emergency

disconnect)

t Interrupts the main circuit, all electrical

functions are deactivated.

The engine switches off.

The truck brakes suddenly.

This switch should only be used to stop in

an emergency.

In normal circumstances the stopping

instructions listed on page E 25 should be

observed.

28 Warning switch

t Activates a warning sound.

29 Travel direction

lever

t Selects the travel direction.

30 Slow travel /

brake pedal

t 1st zone: controls slow travel.

2nd zone: applies service brake.

31 Parking brake

switch

t Applies / releases parking brake.

To engage, turn switch to position 1. To

release, turn switch to position 0.

32 5 level selector t Each level increases or reduces the

acceleration and brake speeds.

Page 41

04.08.GB

E 8

3 Operating the lift and tilt mechanisms (o)

Symbol Purpose Symbol Purpose

1. Tilt mast forward. 5. Tilt mast back.

2. Raise forks and tilt mast

forward.

6. Lower forks and tilt mast back.

3. Raise forks. 7. Lower forks.

4. Raise forks and tilt mast

back.

8. Lower forks and tilt mast forward.

Main control mechanism

Main control lever

Additional control levers

Page 42

E 9

04.08.GB

4 Twin Pedal Operation (o)

Introduction

This option enables the driver to control the travel direction with two pedals. The

system offers precise speed and direction control through two user-friendly pedals.

Right foot: forward. Left foot: backward.

Twin pedal

Direction / Accelerator Pedals

Pressing the direction pedal increases the engine speed and travel speed. When you

release your foot from the pedal, the truck slows down. Suddenly removing your foot

from the pedal causes the truck to slow down in a controlled manner and then stop.

Brake / slow travel pedal

When the brake / slow travel pedal is used in conjunction with a direction or

accelerator pedal, the speed and direction of the truck are controlled with precision.

Reverse /

accelerator pedal

Brake /

slow travel pedal

Forward /

accelerator pedal

Page 43

04.08.GB

E 10

t Gear shift lever

Z

When the gear shift lever is in the

middle position, the gear is in

neutral.

– To select forward gear, push the

lever forward.

– To select reverse gear, push the

lever back.

Z

The engine will not start when the

gear shift lever is in the forward or

reverse position.

Page 44

E 11

04.08.GB

o Gear selector mounted o the steering column

If your truck is equipped with a

steering column lever, it replaces

the standard gear selector.

Z

When the steering column lever is in

the middle position, the gear is in

neutral.

– To select forward gear, push the

lever forward.

– To select reverse gear, push the

lever back.

Z

The engine cannot start when the

lever is in the forward or reverse

position.

t 5 stage switch for travel mode

The Total Control System (TCS)

can control 36 performance

parameters. This provides a wide

range of setting options. To simplify

the complexity of this, five preprogrammed combinations can be

selected by the switch. The software

parameters have been designed to

correspond to five typical truck

applications. By simply shifting over

the 5 stage switch the truck’s

characteristics can be set to suit the

application at hand.

5 stage

switch

Parking brake

switch

Page 45

04.08.GB

E 12

M

Stop the truck and apply the parking brake. Select the required travel mode.

Z

The travel mode can only be altered when the truck is idle.

F

The truck can only be operated when the travel mode has been set correctly.

Z

The travel characteristics of trucks not fitted with a 5 stage switch are factory-set.

Loading / depositing: maximum performance and

productivity for intensive loading/unloading

operations over short distances and at low heights.

Outdoor operation: fast outdoor duty cycles over

short to medium distances, with medium heights.

Fast-reacting auxiliary hydraulics.

Mixed application: good all-round performance for

mixed operations.

Indoor operation: reduced engine speed. Basic

travel characteristics, high lift speeds. For controlled

working in tight areas.

Safety: reduced performance and exhaust levels

and low fuel consumption. For working with fragile

loads, in pedestrian zones, at night or noise-sensitive

areas.

Page 46

E 13

04.08.GB

o Heating controller

– Turn the thermostat control button (41)

anti-clockwise to reduce the driver's

cab temperature.

– Turn the fan control button (42)

clockwise to control the air flow. To

switch it off, turn the fan control button

to the O position.

– Push the air flow controller (43) as far

down as possible to direct the air flow

to the cabin floor. Push the air flow

controller (43) as far up as possible to

switch off the air flow to the cabin floor.

The air flow to the windscreen is

controlled independently of this lever.

Page 47

04.08.GB

E 14

Horn

– Press the button (25) to sound the

horn.

5 Tests and tasks to be performed before starting the truck

Truck

M

Visually inspect the whole of the truck (especially the wheels and the lifting device)

for obvious signs of damage.

– Test the seat belt (see page E21).

– Make sure the load chains are evenly tensioned.

Checking the engine oil - TFG

– Open the engine bonnet

(see page E 43).

– Remove the oil dipstick (44 / 46

or 48).

– Wipe the dipstick with a lint-free cloth

and put in back fully into its port.

– Remove the dipstick again and

check whether the oil level is

between the MIN and MAX

markings.

– If the oil level is below the centre

point, remove the fuel cap (43) and

add the correct grade of oil to the

engine until the oil level has reached

the MAX mark on the dipstick.

Page 48

E 15

04.08.GB

Checking the engine oil - DFG

– Remove the dipstick (50).

– Wipe the dipstick with a lint-free cloth

and put in back fully into its port.

– Remove the dipstick again and check

whether the oil level is between the

MIN and MAX markings.

– If the oil level is below the centre point,

remove the fuel cap (49) and add the

correct grade of oil to the engine until

the oil level has reached the MAX mark

on the dipstick.

Page 49

04.08.GB

E 16

Checking the hydraulic oil level

If the oil is cold

– Fully extend and retract the mast a

single time.

– Stop the engine.

– Remove the dipstick (53) and wipe it

with a clean cloth. Check the hydraulic

oil level. It should lie between the MIN

and MAX markings on the dipstick. If

necessary, top up to the MIN marking

on the dipstick.

If the oil is hot

– Fully extend and retract the mast a

single time.

– Stop the engine.

– Remove the dipstick (53) and wipe it

with a clean cloth. Check the hydraulic

oil level. It should lie just above the

MAX marking on the dipstick. If

necessary, top up to just above the

MAX marking on the dipstick.

Z

If the engine goes out or does not run

smoothly when the mast is extended,

lower the mast fully.

Page 50

E 17

04.08.GB

Checking the coolant level

– Cheeck the coolant level on the

reservoir (56).

The coolant level should be between

the “MIN” and “MAX” markings.

M

If the coolant is below the MIN

marking, this indicates possible

leakage in the radiator system. In this

case the truck should only be used

once the cause has been removed.

F

If the engine is hot, the radiator

system is pressurised. Slowly open

the reservoir lid until the pressure

has dropped.

When adding the coolant include a

premixed solution of water and antifreeze in the same concentration

levels as for a car.

Bleeding the coolant system

It should be possible to empty the system by opening the drain taps in the radiator

and on the side of the cylinder block. When bleeding the coolant system remove the

reservoir lid. Prevent the truck against authorised use.

Checking the fuel supply - (DFG)

– Set the ignition / starter key (26) to the

“I” position.

– Check the fuel supply on the fuel

gauge (2).

– If necessary, add diesel (see

Chapter D, Section 2).

Page 51

04.08.GB

E 18

Checking the windscreen fluid level

– Make sure there is sufficient

windscreen fluid in the container (1).

Top up if required.

– In winter, use windscreen fluid with

anti-freeze.

Wheels and Tyres

– Check wheels and tyres for wear (see

Chapter F). Measure the tyre pressure

(pneumatic tyres only) (see tyre

pressure table in Chapter B).

1

Page 52

E 19

04.08.GB

6 Starting up the truck

F

Before the truck can be commissioned, operated or a load unit lifted, the driver must

ensure that there is nobody within the hazardous area.

o Trucks with reduced headroom X

M

Failure to observe the recommended

body size can cause stress and

endanger the driver and may lead to

lasting ill health due to an unhealthy

posture and excessive strain on the

driver.

The owner must ensure that truck

operators do not exceed the max. body

size indicated.

In addition the owner must check that

the driver’s used can sit in an upright

position without having to strain.

Page 53

04.08.GB

E 20

6.1 Adjusting the driver’s seat

Z

To achieve optimum seat cushioning, the driver’s seat must be adapted to the driver’s

weight.

Adjusting the seat to the driver's weight:

– Sit on the driver’s seat. When the correct weight adjustment has been made, the

arrow of the driver weight display (59) will be above the calibration line. If the arrow

is facing too far to the left or right, the seat must be adjusted to the driver's weight.

– To do this, move the weight adjustment lever (1) approx. 90° forward.

– To set the seat to a lesser weight, push the weight adjustment lever (1) down.

– To set the seat to a greater weight, push the weight adjustment lever (1) up.

– After adjusting, return the lever to its original position.

To adjust the backrest:

– Sit on the driver’s seat.

– Lift up the backrest adjuster (2) and adjust the backrest tilt.

– Release the backrest tilt adjuster (2) to lock the backrest in position.

To adjust the seat position:

– Pull up the longitudinal adjuster (3) and push the driver’s seat forwards or

backwards to the desired position.

– Engage the longitudinal adjuster (3) in position again.

F

The longitudinal adjuster must be securely located in the desired position. The

driver’s seat setting must not be changed during travel.

59

1

2

3

Page 54

E 21

04.08.GB

6.2 Adjusting the steering column

– Release the steering column adjusting

lever (20) in the direction of the arrow

towards the driver’s seat (L).

– Tilt the steering column (62) forward or

backward as required.

– Push the steering column adjusting

lever in the direction of the arrow (F).

6.3 Seat belt

F

Put on the seat belt each time before starting the industrial truck.

The belt protects against serious injury.

Protect the belt from contamination (e.g. cover it when the truck is idle) and clean it

regularly. Frozen belt locks or pulleys must be thawed out and dried to prevent them

from freezing up again.

Z

The dry temperature of the warm air should not exceed +60 °C.

F

Do not alter the belt setting.

This will increase the risk of malfunctioning.

– Always replace the seat belt after an accident.

– Only original spare parts must be used for retrofits or repairs.

F

Damaged or non-operational belts must only be replaced by contractual dealers or

branches.

– Withdraw the belt completely and check the belt is frayed.

– Check the belt lock and that the belt enters the take up roller mechanism.

Check the cover for damage

Testing the automatic blocking system:

– Park the truck horizontally.

– Jerk the belt outwards.

M

The automatic system should lock the belt in the retractor.

– Open the engine bonnet by approx. 30°.

M

The automatic system should lock the belt in the retractor.

Starting the industrial truck on steep slopes

The automatic blocking system locks the belt in the retractor when the truck is

positioned on a steep slope. This prevents the belt from being pulled out of the

retractor.

Z

Carefully drive the truck off the slope and then put on the belt.

Page 55

04.08.GB

E 22

7 Starting the truck

Before starting the truck.

F

Before starting the truck, inspect the overhead guard for cracks and repair or replace

if damaged.

If the engine has not been run for several weeks or if the oil filter has been changed,

start the engine (see section 4.1 or 4.2) and leave it to run in idle for a few minutes

before starting.

Starting the engine

F

The truck should only be operated from the driver’s seat.

– Set the key switch to the I position.

– Set the travel direction lever to neutral “N”.

Z

The engine can only be started if the travel direction lever is in neutral and the parking

brake switch in the I position.

Key operated ignition

Key settings

Position Function

O=O° Disconnects all main circuits, the

key can be removed.

I=30° All consumers off

II=60° All consumers on

pre-heat Pre-heat

III=90° Start

Page 56

E 23

04.08.GB

7.1 Starting procedure for the TFG

F

Note the safety regulations for handling

liquid gas (see Chapter D, section 1).

– Slowly open the shutoff valve (63) on

the LPG bottle.

– Put the key in the ignition / starter

switch (26).

– Set the ignition / starter key to the “II”

position.

– Press the warning switch (28) and test

the horn.

The charging current (17), engine oil

pressure (8), neutral setting (4) and

parking brake (1) indicators light up.

– Gently apply the accelerator pedal

(22).

– Now move the ignition / starter key to

the “III” position.

M

Only apply the starter for a maximum of

15 seconds without interruption. Before

starting again, wait 30-60 seconds and

reset the ignition / starter switch to 0.

– Release the key as soon as the engine

starts. It automatically reverts to the

“II“ position.

F

When working with LPG trucks always

observe the following safety regulations.

If the truck does not start:

– Close the gas bottle shutoff valve.

– Turn off the ignition / starter O.

– Call for a trained, authorised customer

service engineer.

M

All indicators lights except for neutral

setting (4) and parking brake (1) should

go out as soon as the engine starts. If

not, stop the engine immediately and

rectify the fault.

Page 57

04.08.GB

E 24

7.2 Starting procedure for the DFG

– Put the key in the ignition / starter

switch (26).

– Set the ignition / starter key to the “II”

position.

– Press the warning switch (28) and test

the horn.

– After setting the ignition / starter (26) to

the II position, the charge current (17),

engine oil pressure (8), neutral setting

(4) and parking brake (1) indicators

will light up.

– Keep turning the key slowly until the

pre-heat indicator (16) goes on.

Z

On the DFG 316s/320s models if the bulb

does not go out, turn the ignition key to the

“III” position after approx. 4 seconds.

M

Only apply the starter for a maximum of

15 seconds without interruption. Before

starting again, wait 30-60 seconds and

reset the ignition / starter switch to 0.

– Release the key as soon as the engine

starts. It automatically reverts to the

II position.

M

All indicators lights except for neutral

setting (4) and parking brake (1) should

go out as soon as the engine starts. If

not, stop the engine immediately and

rectify the fault.

Page 58

E 25

04.08.GB

F

Once the engine has started, Carry out a

test run and perform the following

checks:

– Test the parking brake (31) and

service brake (30).

– Test the engine speed with the

accelerator pedal (22) over a range of

speeds while checking the freedom of

movement of the pedal.

– Test the operation of the raise/lower

(23), tilt (24) and if applicable the

attachment hydraulic control

functions.

– Turn the steering wheel (18) as far as

it will go in both directions and test the

steering.

M

Do not run up the engine in idle The

engine soon reaches operating

temperature at a moderate charge

and when the speed alternates.

Only fully charge the engine when

the engine coolant temperature

display (3) shows operating

temperature (indicator horizontal).

The truck is ready for operation

once all the functional controls have

been satisfactorily performed and

operating temperature is reached.

24

23

3

Page 59

04.08.GB

E 26

7.3 Operating Error Displays

When the following indicators are lit:

– Engine oil pressure (8),

– Charge current (17),

– Coolant temperature (3),

– Hydrostatic drive (6),

the engine must be stopped

immediately.

M

The engine should only be started

again once the fault has been

removed.

Z

For troubleshooting procedures, see

section 6.

When the truck is operating check

the fuel display (3) (DFG).

7.4 Switching off the engine

M

Do not switch off the engine from full

charge. Instead, let it run for a short

while to allow the temperature to

compensate.

– Stop the truck.

– Set the travel direction switch (29)

to neutral.

– Apply the parking brake lever (31).

– Set the ignition / starter switch

(26) to “0”.

M

Additional requirements for the

TFG:

Close the shutoff valve (63) on the

LPG bottle.

If the ignition key is set to “0” while

the engine is running, the engine will

continue to run for a short while. This

ensures that the remaining gas in

the lines between the engine and the

automatic shutoff valve of the gas

system is used up.

Page 60

E 27

04.08.GB

8 Industrial Truck Operation

8.1 Safety regulations for truck operation

Travel routes and work areas: Only use lanes and routes specifically designated for

truck traffic. Unauthorised third parties must remain clear of the work area. Loads

must only be stored in places specially designated for this purpose.

Driving conduct: The driver must adapt the travel speed to local conditions. The

truck must be driven at slow speed when negotiating bends or narrow passageways,

when passing through swing doors and at blind spots. The driver must always

observe an adequate braking distance between the forklift truck and the vehicle in

front and must be in control of the truck at all times. Abrupt stopping (except in

emergencies), rapid U turns and overtaking at dangerous or blind spots are not

permitted. Do not lean out or reach beyond the working and operating area.

Travel visibility: The driver must look in the direction of travel and must always have

a clear view of the route ahead. When carrying loads which affect visibility, these must

be stored at the rear of the truck. If this is not possible, a second person must walk in

front of the truck as a lookout.

Negotiating slopes and inclines: Slopes or inclines may only be negotiated if they

are designated traffic routes, are clean and have a non-slip surface and providing

they can be safely negotiated in accordance with the technical specifications of the

truck. The truck must always be driven with the load unit facing uphill. The industrial

truck must not be turned, operated at an angle or parked on inclines or slopes.

Inclines must only be negotiated at slow speed, with the driver ready to brake at any

moment.

Negotiating lifts and docks: Lifts and docks must only be used if they have sufficient

capacity, are suitable for driving on and authorised for truck traffic by the owner. The

driver must satisfy himself of the above before entering these areas. The truck must

enter lifts with the load in front and must take up a position which does not allow it to

come into contact with the walls of the lift shaft. People travelling in the lift with the

forklift truck must only enter the lift after the truck has come to a halt and must exit the

lift before the truck.

Nature of loads to be carried: The operator must make sure that the load is in a

satisfactory condition. Loads must always be positioned safely and carefully. Use

suitable precautions, e.g. a load guard, to prevent parts of the load from tipping or

falling down.

Page 61

04.08.GB

E 28

Towing trailers

(see page E46)

F

Exhaust emissions: The truck must only be operated in well ventilated areas. If the

truck is operated in enclosed areas, this can lead to a build-up of harmful exhaust

emissions, resulting in dizziness, tiredness and even death.

M

The user must comply with legal requirements, technical standards and health and

safety regulations when operating an IC engine powered lift truck in closed rooms.

Page 62

E 29

04.08.GB

9 Travel

F

Adapt the travel speed to the conditions

of the travel lane, the work area and the

load

– Set the travel direction switch (29) to

neutral.

– Raise the fork carriage approx. 200

mm so that the forks are clear of the

ground.

– Tilt the mast fully backward:

– Release the parking brake.

Forward travel

– Set the travel direction switch (29)

forward.

M

In normal operation do not set the

isolator (27) from max. speed to “OFF”.

The truck brakes automatically. (full

braking).

– Slowly apply the accelerator pedal

(22) until you reach the required travel

speed.

Changing direction

– Set the travel direction switch (29) via

neutral to the required direction.

– Slowly apply the accelerator pedal

(22) until you reach the required travel

speed.

Page 63

04.08.GB

E 30

Reversing

F

Make sure you have sufficient space to reverse into.

– Move the travel direction switch (29) backwards.

Accelerating

– Slowly apply the accelerator pedal (22) until the truck starts to move.

– Continue to depress the accelerator. The engine and travel speeds will increase.

Braking

F

The brake pattern depends largely on

the ground conditions. The driver must

take this into consideration when

handling the truck. Brake carefully to

prevent the load from slipping.

Braking

– Take your foot off the accelerator pedal (22). The truck brakes slowly.

– Depress the brake pedal (30) fully to increase the brake force.

Page 64

E 31

04.08.GB

9.1 Steering

F

Very little steering force is required for

the hydrostatic steering, therefore turn

the steering wheel (26) with caution.

9.2 Brakes

Service brake

The parking brake acts on the multi-plate

brakes via a hydraulic pressure system.

This system is fail-safe as the parking

brakes automatically apply in the event

of pressure loss.

– Take your foot off the accelerator

pedal (22).

The truck will brake hydrostatically

depending on the travel program that is

active.

Additional braking can be achieved by

pressing the brake / slow travel pedal (30).

The parking brake is applied during the

last movement of the brake / slow travel

pedal.

Parking brake

The parking brake switch secures the

automatic multi-plate brake in the brake

position.

To apply the parking brake set the switch

(31) to the I position.

To release the parking brake set the

switch (31) to the O position.

Page 65

04.08.GB

E 32

Z

Before leaving the truck apply the parking brake switch and switch off the engine.

An audible warning will sound if the parking brake is not applied.

F

The parking brake will keep the truck with the maximum permissible load, on a clean

concrete surface, at a 15% incline.

Page 66

E 33

04.08.GB

10 Mast and Attachment Operation

F

The control levers must only be operated from the driver’s seat.

The lift mechanism is operated by the control levers on the right-hand side of the

driver's seat.

Lifting/lowering the fork carriage

F

Never reach through the mast!

– Pull the control lever (23) back to raise

the fork carriage.

– Push the control lever (23) forward to

lower the fork carriage.

Tilting the mast forward / backward

F

When tilting the mast back, do not

position any part of your body between

the mast and the front wall.

– Pull the control lever (24) back to tilt

the mast back.

– Push the control lever (24) forward to

tilt the mast forward.

Operating attachments

Attachments are operated via the control

levers (25.26) to the right of control lever

(24) (mast tilt).

F

Note the manufacturer’s operating

instructions and the capacity of the

attachment.

Auxiliary hydraulics ZH1

The auxiliary hydraulics ZH 1 (control lever 25) can be used to control hydraulic

attachments (e.g. sideshift). They are applied by pressing the lever forward or pulling

it back.

1

Page 67

04.08.GB

E 34

Auxiliary hydraulics ZH2 +ZH3

The auxiliary hydraulics ZH2 (e.g. for

fork positioners) are controlled in the

same way as for ZH1 by applying the

control lever (26). You can toggle from

ZH2 to ZH3 with the switch (1).

o Intergrated sideshift ISS

The fork carriage can be moved sideways using the ISS.

– Sideshift left: Push the control lever (25) forward.

– Sideshift right: Pull the control lever (25) back.

F

Note the reduced capacity for sideshift (Chapter B, page 14)

o Integrated fork positioner

The integrated fork positioner allows the distance between the forks to be changed.

– Push the lever (26) to increase the fork spread

– Pull the lever (26) to reduced the fork spread

To synchronise the alignment of the forks, open them as far as the stop and then

close them again.

Other attachments

Z

Always follow the manufacturer’s operating instructions when using other

attachments.

Z

Mark the control levers with symbols to indicate their function.

M

The attachments must have a e mark. The reduced residual capacity must be

re-calculated and indicated on a separate capacity plate.

1

Page 68

E 35

04.08.GB

10.1 Controlling the speed of the lifting device

Moving the control levers (23-26) and

changing the engine speed governs the

operating speed of the hydraulic

cylinders.

When the control levers are released

(23-26) they automatically revert to

neutral and the lifting device remains in

the position it has reached.

M

Always apply the control lever

sensitively, never with a sudden jerk.