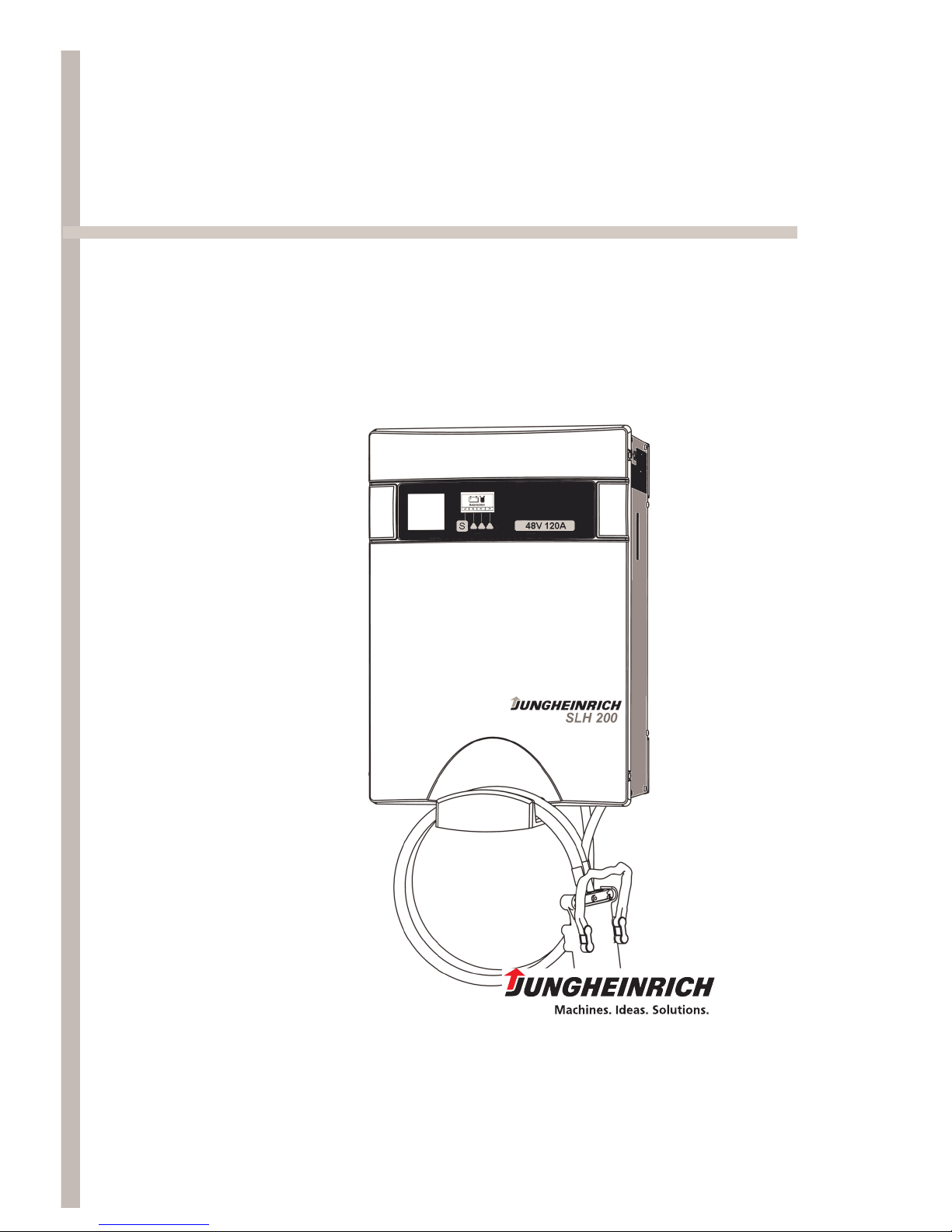

Page 1

4156 EN

SLH 200

10.04 -

Operating Instructions

50452174

01.08

G

Page 2

Contents

2/30 4156 EN

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

D-22047 Hamburg-Germany

Tel.: +49 (0) 40/6948-0

www.jungheinrich.com

Page 3

Contents

3/30 4156 EN

Index

1

General ...........................................................................................................................4

1.1

Purpose of Operating Instructions...........................................................................................4

2

Safety..............................................................................................................................4

2.1

General ......................................................................................................................................4

2.2

Decal and Symbol Notices........................................................................................................4

2.3

Personnel Qualification.............................................................................................................5

2.3.1 Commercial Use................................................................................................................5

2.4

Correct use and application......................................................................................................5

2.5

Assembly and Installation Safety Instructions ........................................................................6

2.6

Operating Safety Instructions...................................................................................................7

2.7

Troubleshooting and Repairs Safety Instructions...................................................................7

3

Product Specifications ..................................................................................................7

3.1

Product Functional Description................................................................................................7

3.2

Model Description.....................................................................................................................8

3.3

Accessory Functional Description...........................................................................................8

3.3.1 Charger.............................................................................................................................8

3.4

Residual Risk.............................................................................................................................8

3.5

Protective Mechanisms.............................................................................................................9

3.6

Charger Labelling and Decals.................................................................................................10

4

Transport, Handling and Storage................................................................................10

5

Assembly / Installation / Commissioning...................................................................10

5.1

Delivery scope.........................................................................................................................10

5.2

Site Requirements...................................................................................................................11

5.3

Mains Connection and Mains Fuses.......................................................................................11

5.4

Assembly and Installation.......................................................................................................12

5.5

Commissioning the charger for the first time and operational testing.................................12

6

Operation......................................................................................................................12

6.1

Operating and Display Function.............................................................................................13

6.1.1 Charge Status Light.........................................................................................................14

6.1.2 Soft keys.........................................................................................................................15

6.1.3 Graphic display and menu structure.................................................................................16

6.1.4 Adjustable parameters.....................................................................................................17

6.1.5 Function – Battery Maintenance.......................................................................................17

6.1.6 Function – Measured values............................................................................................18

6.1.7 Graphic Display Information.............................................................................................18

6.1.8 Parameters – Consumption data......................................................................................18

6.1.9 Parameters - Statistics.....................................................................................................19

6.2

Charger Mains Connection.....................................................................................................19

6.3

Battery Connection.................................................................................................................19

6.4

Charging automatic start........................................................................................................20

6.5

Interrupting a charge...............................................................................................................21

6.6

Charging automatic end..........................................................................................................21

6.7

Readings..................................................................................................................................22

6.8

Status messages.....................................................................................................................23

6.9

Faults and Error Messages.....................................................................................................24

6.10 Switching off the charger........................................................................................................25

7

Maintenance.................................................................................................................25

7.1

Cleaning, Inspection and Maintenance..................................................................................25

7.2

Changing the charging program.............................................................................................26

7.3

Spare parts..............................................................................................................................26

8

Disposal........................................................................................................................26

9

Appendix.......................................................................................................................27

9.1

Dimension and Projection Drawings (not to scale) ...............................................................27

9.2

Specifications..........................................................................................................................28

9.3

Model table..............................................................................................................................28

9.4

Charging programs.................................................................................................................29

9.5

Spare parts catalog.................................................................................................................30

Page 4

General

4/30 4156 EN

1 General

1.1 Purpose of Operating Instructions

The aim of the present operating instructions is to ensure the correct and safe operation

of the SLH 200 charger. The SLH 200 will hereafter be referred to as the charger.

The operating instructions must always be available and stored in the vicinity of the

charger. The operating instructions must be read and applied by anyone involved in

operating the charger, including shipping, assembly and installation, operation,

maintenance and disassembly work.

For commercial use, the relevant work safety guidelines, standards and regulations of the

place or country of operation must be observed alongside the present operating

instructions.

For further information beyond the scope of the operating instructions, please consult

with the manufacturer's specialist technicians.

All documentation is copyright protected. The transfer or reproduction of

documentation, including excerpts, as well as the assessment and dissemination of its

content are prohibited unless expressly permitted.

2 Safety

2.1 General

The operating instructions are a major component of the charger.

The owner shall ensure that the operating instructions are permanently in the vicinity of

the charger, and that operating personnel shall be notified of these guidelines.

The owner shall add further instructions regarding national accident prevention and

environmental protection regulations to the operating instructions, including information

on supervisory and reporting obligations, taking into account particular company

practices e.g. in terms of work organization, work processes and the personnel

employed.

Apart from the operating instructions and the current accident prevention regulations in

force in the country and place of use, generally recognised technical regulations for safe

and proper use shall be observed.

2.2 Decal and Symbol Notices

This charger has been produced in accordance with generally accepted principles and

state-of-the-art technology. To ensure sufficient levels of safety for personnel, additional

safety instructions are issued. Sufficient safety when handling the charger is only

provided when these instructions are observed.

From time to time it is necessary to emphasize specific instructions. These sections have

different meanings:

Page 5

Safety

5/30 4156 EN

Z

ZZ

Z

Note

Notes contain additional information to ensure safe and efficient handling of the

charger.

M

MM

M

Attention

This warning indicates possible damage that could be caused by failing to take

precautionary measures or improper use.

Observe all warnings and measures needed to prevent damage from occuring to the

charger and other articles. Be particularly vigilant.

F

FF

F

Danger

This warning indicates possible damage that could be caused to persons, by failing to

take precautionary measures or improper use.

Observe all warnings and measures required to prevent injuring yourself or other

people. Be particularly vigilant.

2.3 Personnel Qualification

Only qualified technicians should operate the charger. The levels of responsibility for

personnel operating and installing/repairing the charger should be clearly separated.

Qualified technicians in the sense of these basic instructions are people responsible for

assembly, installation, commissioning, operation, maintenance, de-commissioning and

disassembly, and who are suitably qualified to carry out their role.

The charger may only be installed, commissioned for the first time, repaired and

disassembled by qualified and authorized electrical engineers.

With trained electrical engineers it is assumed that they will observe and comply with

current regulations of the local energy supply company as well as the industry work

safety guidelines (e.g. BGV A2) an d all regulations governing the safe and proper use

of the charger (e.g. DIN VDE 0100 and IEC 60664 or DIN VDE 0110).

The manufacturer does not accept liability for any damage or loss of business arising

from the failure to comply with these operating instructions.

2.3.1 Commercial Use

If the charger is used in a commercial environment, the following also applies:

− The operator must undergo special instruction or training on how to charge lead acid

accumulators and how to operate them.

− Only authorised personnel may operate the charger.

2.4 Correct use and application

The SLH 200 charger is designed to charge lead acid accumulators. Depending on the

preset charging program, only wet cell batteries designed for the charger program or

suitably sealed, maintenance-free traction batteries should be charged. The charger is

unsuitable for all other accumulators and non-rechargeable batteries.

If required by the owner, the charger can be fitted with a range of different connectors.

The owner is therefore obliged,

− only to use connectors with the suitable fuse rating for the charger,

− to avoid connecting unsuitable battery types.

Page 6

Safety

6/30 4156 EN

The latter could be achieved for example by colour-coding or mechanically coding the

connector.

Always observe and comply with the battery manufacturer’s instructions.

If the charger has a charging program which has been modified, the owner is obliged to

permanently advise of the suitable battery type on the housing exterior.

To ensure proper use, observe and comply with the details on the location site (see

sections 2.5 and 5.2), the data plate and the specifications (see Appendix).

F

FF

F

Risk of injury

Serious damage to personnel and property could arise from:

-

improper use or incorrect operation,

-

unauthorised opening of the charger,

-

incorrect installation or improper service or repair work.

All instructions regarding the correct use, residual risk, installation, operation and

maintenance contained in these operating instructions must therefore be noted and

observed.

The charger must only be used for the purposes foreseen in the present operating

instructions and the technical description and only with the accessories or components

recommended and approved by the manufacturer.

Any other use beyond the scope of the above is not appropriate. The owner or user of the

charger shall be liable for any damage arising from the above.

The charger shall only be commissioned in accordance with electromagnetic

compatibility guidelines (89/336/EC).

2.5 Assembly and Installation Safety Instructions

Before installing the charger, check that all the components have been supplied against

the delivery notes. If anything is missing, immediately contact the manufacturer.

The place of operation must be weather-proof and dry.

The ambient temperature at the site must not fall below 0°C or exceed 40°C. Avoid the

build-up of heat within the charger, e.g. through heat sources or by blocking the air

vents.

The location site must be sufficiently ventilated to distribute (reduce) charging gases

which may arise (acid fog, electrolytic gas) and prevent the build-up of explosive gas

mixtures.

The site must not contain excessive dust. Avoid the occurrence of conductive dust (soot,

metal).

No liquid must enter the inside of the charger.

The distance between the charger and inflammable materials must be at least 2.5m

horizontally. It is forbidden to store inflammable materials, e.g. in shelves, or to use

inflammable materials above the charger. There must be at least a 5.00m gap between

fire and explosive-hazardous areas.

The charger must be protected against overload or stress. In particular, no components

must be damaged during transport and when being handled. Avoid contact with

electronic components.

The charger contains electrostatic endangered components which can easily be damaged

through improper handling. Electrical components must not be physically damaged or

destroyed.

Page 7

Product Specifications

7/30 4156 EN

Electrical installation (wire cross sections, fuses, earth leads) must be performed in

accordance with current regulations.

Prior to electrical installation, the performance data on the data plate must be checked

against the performance data of the supply connections. The charger must be protected

against excessive shock-hazard voltages through a mains fuse connected in series.

Observe the mains connection values indicated on the data plate (voltage and

frequency).

2.6 Operating Safety Instructions

The charger must only be used when in technically good working order and when used

in accordance with the present operating instructions with attention paid to the safety

and hazard risks. Any faults that could affect safety must be removed immediately.

The data plate specifications regarding the appropriate battery voltage must be checked

and complied with prior to connecting the charger cable. The charger leads must be

connected to the correct battery terminals.

When connecting the battery, route the charging leads so that they cannot be tripped

over and that charging cannot be interrupted by unplugging the charging lead. If an

ongoing charge is interrupted by removing the charging lead, this may produce sparks

which could result in fire or explosions.

If the charger or the operating pattern of the charger is changed in a way that could

affect safety, shut down the charger and notify the relevant department of the fault.

2.7 Troubleshooting and Repairs Safety Instructions

Contact the manufacturer prior to opening the housing for maintenance and repair

purposes.

Prior to carrying out maintenance or repair work, always disconnect the charger from the

mains.

After switching off the charger, wait for at least five minutes before opening the panels

and housing.

No changes or modifications may be made to the charger which could affect safety

without obtaining the manufacturer’s approval. This also applies to the assembly and

setting of safety mechanisms. In particular make sure that no safety, leakage or air

distances are reduced.

Spare parts used must meet the technical requirements specified by the manufacturer.

This requirement is always met by original manufacturer’s spare parts.

3 Product Specifications

3.1 Product Functional Description

The SLH 200 charger is designed to charge lead acid accumulators. Depending on the

preset charging program, wet cell batteries or sealed, maintenance-free traction batteries

can be charged.

The charger has an adjustable, high-frequency power part, a micro-processor controlled

charging electronics system and a control/display panel with buttons and a charge status

light, as well as a graphic enhanced LCD display. The charging program for the

respective battery type is factory-set to the customer’s requirements.

Page 8

Product Specifications

8/30 4156 EN

The various charger assemblies are installed in a secure steel sheet housing with a plastic

front panel. The charger is equipped with a mains cable and connector (optional for

threephase models) for connection to the mains.

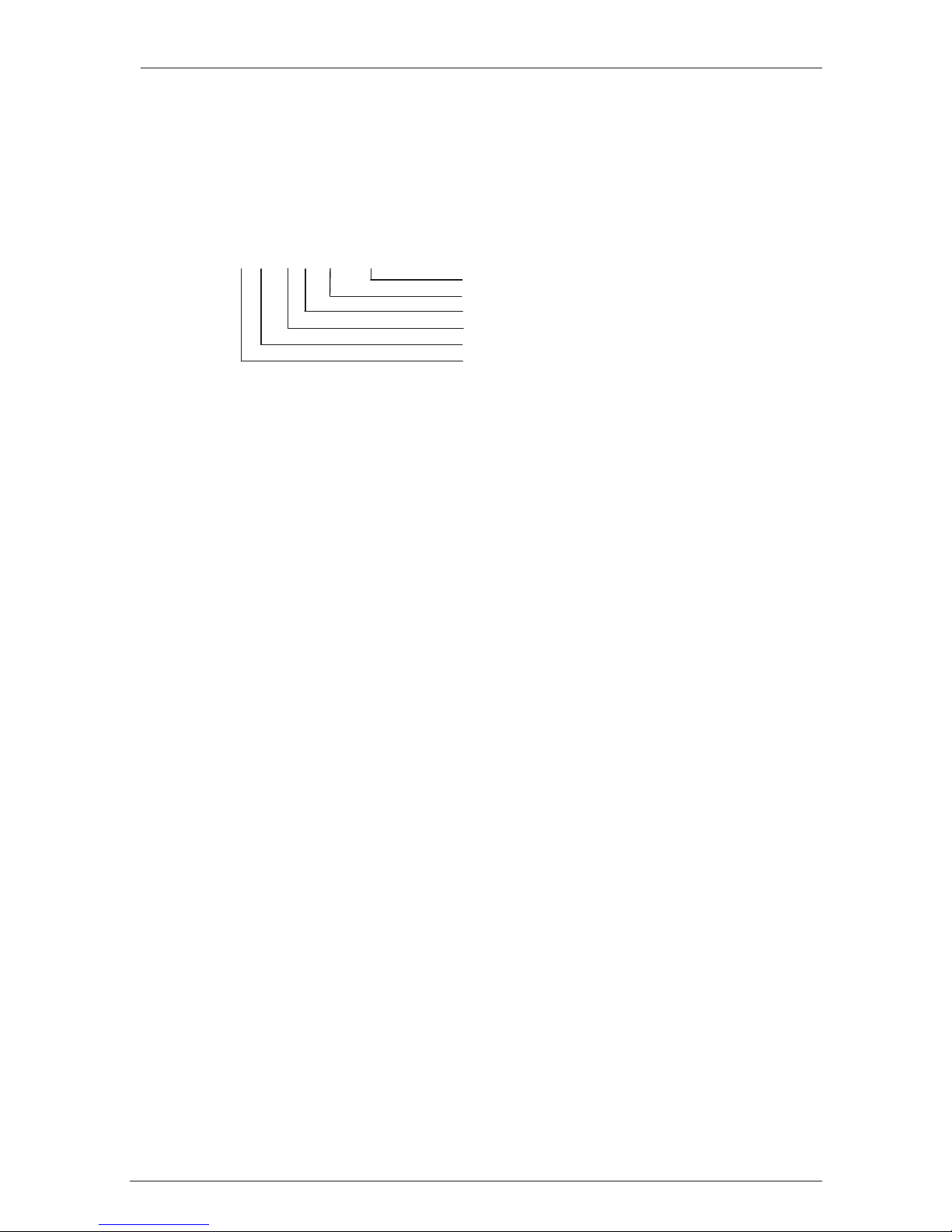

3.2 Model Description

The SLH 200 charger is available in different options. The following is a typical model

description (e.g. for a 24 volt, 120 amp charger).

Type E 230 G 24/120 B-SLH200

Model description – SLH 200

Output rated current

Output rated voltage

Output current type ‘G’ – DC

Input rated voltage

Input current type ‘E’ – Single phase AC current

For the exact technical specifications refer to the data plate on the charger and the

technical specifications attached.

3.3 Accessory Functional Description

3.3.1 Charger

Various battery connectors can be used depending on the battery type. The charger can

therefore be supplied with or without a charging lead, as required. Refer to the attached

delivery notes.

3.4 Residual Risk

F

FF

F

Warning: Hazardous Electrical Voltage!

The charger is an electric component conducting voltages and currents that are

hazardous to people.

The charger must therefore only be operated by trained technicians.

The charger must therefore only be opened, repaired and disassembled where

necessary by qualified electrical engineers.

The mains supply and a battery contact where necessary must be disconnected

before carrying out any work on the charger.

F

FF

F

Explosion hazard

When a battery is charged, potentially explosive gases can escape.

The charger must therefore only be operated in well ventilated rooms.

Never remove the battery connection while charging. This could produce sparks

which could ignite the charging gases (electrolytic gas).

F

FF

F

Danger of getting caught on charging leads

A removed charging lead could cause people to trip over it and run the risk of

interrupting a charge.

People can get caught on removed, loose cables, trip over them and pull the charging

lead out of the battery during charging. The sparks this produces could ignite the

charging gases and as a result cause a fire or trigger an explosion.

When connecting the battery always route the charging lead so that nobody can trip

over it. After charging, place the charging lead carefully on its bracket.

Page 9

Product Specifications

9/30 4156 EN

M

MM

M

Attention

Connecting an incorrect battery to the charger can result in damage to the charger

and battery: The battery could gas, decoct or even explode.

Always check that the charger is set for your battery type. If in doubt, contact the

relevant experts.

M

MM

M

Attention

Corrosive acid gases can be produced when a battery is being charged. Acid gases

can cause short circuits in electrical equipment (risk of burning) and can corrode

components.

Therefore always position batteries next to charging stations in such a way that any

acid gases arising can be freely distributed (reduced) on site and can dissipate.

3.5 Protective Mechanisms

The charger has been designed and constructed in accordance with state-of-the-art

technology. If used properly, it therefore poses no danger to the health and safety of

those operating it or third parties.

All live assemblies are fitted with housings and panels that can only be undone with

tools. All cables and connectors are appropriately screened / earthed. The charger has an

IP 21 protection class.

All electric and electronic components bear the CE mark; all necessary isolating

distances have been observed. All circuits are fitted with primary and secondary fuses

with defined current rating and activation characteristics.

All metallic components are earthed via an earth lead system.

The charger is fitted with an automatic cutout function as soon as the preset maximum

charge status of the battery is reached. This avoids overloading and excessive release of

explosive gases.

Page 10

Transport, Handling and Storage

10/30 4156 EN

3.6 Charger Labelling and Decals

Data plate

Attached to the side of the housing.

Item Description Item Description

1 Series

6 Input

2 Type

7 No. of cells/type

3 Serial no.

8 Protection class

4 Year of

manufacture

9 Output

5 Fuse

10 Factory setting

Baureihe

Line

Typ

Type

Serien-Nr.

Serial-No.

Baujahr

Year of manufacture

Sicherung

Fuse

Eingang

Input

Zellenzahl/Typ

Number of cells/type

Schutzart

Protection class

Ausgang

Output

Batteriekapazität

Battery Capacity

Hersteller

Manufacturer

Jungheinrich AG, D-22047 Hamburg, Germany

öJUNGHEINRICH

e

2

1

3 4

5

6

7

8

9

10

Operating instructions notice

Attached to the top of the housing cover.

48 V - 120 A

Model performance plate

Attached to the front of the housing.

(Example: 48 volt / 120 amp)

4 Transport, Handling and Storage

The charger is supplied in a cardboard box.

Note the instructions on the cardboard box during transport, handling and storage.

Protect against the weather Fragile Top

5 Assembly / Installation / Commissioning

5.1 Delivery scope

The supply consists of the following (minimum) parts:

− Charger and preset charging program,

− the connected mains and battery cables,

− the operating instructions,

− a notice (attached to the charger),

− the delivery note.

Depending on the customer’s requirements, the delivery scope and the charger version

may deviate from this. The enclosed delivery papers (as well as the order confirmation)

contain additional technical specifications.

• Check the delivery immediately to make sure it is complete and undamaged.

• Check the delivery note and the data plate to make sure they agree.

Page 11

Assembly / Installation / Commissioning

11/30 4156 EN

• If anything is missing contact the manufacturer and the shipping company

immediately.

• Check the charger for any loose screw connections etc. If necessary, retighten these

connections.

5.2 Site Requirements

Only use the charger in closed, frost-free and well ventilated rooms with ambient

temperatures of up to 40°C. Select an assembly site where the ventilation slots will not

be covered and the flow of cool air will not be affected. Do not assemble the charger

near radiators or other sources of heat.

Naked flames and smoking in battery rooms are prohibited.

There must be no flammable materials or spark-producing liquids within a 2.5 metre

radius of the charging station.

When assembling, note also that:

− no harmful gases, e.g. acid gases,

− no conductive dusts, such as soot or metallic dust,

− no excessive amounts of non-conductive dust and

− no fluids

may enter the inside of the charger.

When attaching the charger to the wall in an FWG 3 or FWG 6 housing, use the

enclosed wall attachment material (4 off S10 dowels, 4 off M6x60 screws). The drilling

plan is attached.

For chargers in the FDG 12 housing, make sure when assembling that there is sufficient

ventilation, lateral clearance of at least 50cm to the next model and at least 30cm to any

neighbouring walls.

It must be possible to connect to the mains and battery within a cable reach of 3m.

5.3 Mains Connection and Mains Fuses

F

FF

F

Warning: Hazardous Electrical Voltage!

The charger is an electric component conducting voltages and currents that are

hazardous to people.

The charger must therefore only be operated by trained technicians.

The charger must therefore only be opened, repaired and disassembled where

necessary by qualified electrical engineers.

You will require a mains connection at the intended operation site to operate the charger.

The mains voltage and frequency must match the specifications on the data plate. The

mains connection must be properly earthed.

Protect the charger from excessive shock-hazard voltages in accordance with the local

energy supplier’s regulations.

Page 12

Operation

12/30 4156 EN

• Arrange the mains fuses in series in accordance with the following table:

Rated current Mains rating Comment

0 to 6 A 6 A gL

>6 to 10 A 10 A gL

>10 to 16 A 16 A gL

>16 to 18 A 20 A gL

>18 to 23 A 25 A gL

>23 to 32 A 35 A gL

gL safety fuses or safety devices with B or

C characteristics can be used.

Table 1: Mains current and Mains Fuse Rating

5.4 Assembly and Installation

The following requirements must be met in order to assemble the charger:

a mains socket must be within reach,

there must be a surface next to the charger to place the battery on.

For exact details, refer to the technical specifications attached.

5.5 Commissioning the charger for the first time and operational testing

After assembling and installing the charger correctly, it must be commissioned for the

first time for a functional test.

The charger is already factory-set. However, before using it for the first time, check that

the charger is correctly set for the battery you wish to charge. For parameter checking,

see Section 6.1.3.

After commissioning the charger for the first time, it must be labelled on the outside

clearly, permanently and legibly with the details of the permissible battery type.

M

MM

M

Attention

Connecting a non-authorised battery to the charger may result in material damage to

the battery and charger, and consequently to the truck.

The owner and responsible service personnel must eliminate any possibility of

confusion for the truck driver when connecting truck batteries.

• Note the respective battery type on the front of the housing – depending on the

charging lead and the pre-set charging program installed.

• Also note any subsequent modifications to the charging program on the front of the

housing.

• Also note if the actual rated current (In) is set to a lower value than the one indicated

on the data plate.

6 Operation

F

FF

F

Warning: Hazardous Electrical Voltage!

The charger is an electric component conducting voltages and currents that are

hazardous to people.

The charger must therefore only be operated by trained technicians.

The charger must therefore only be opened, repaired and disassembled where

necessary by qualified electrical engineers.

Page 13

Operation

13/30 4156 EN

For a trained operator, battery charging generally includes the following stages:

− Check that the charger and battery type match,

− Connect the charger to the mains if necessary

− Connect the battery,

− (charging starts and ends automatically,)

− Disconnect the battery,

The following sections describe the various operating stages in more detail. Read them

carefully before using the charger for the first time.

6.1 Operating and Display Function

The front of the charger contains the operating and display unit with the charge status

light and the graphic display with soft keys:

12345

Figure 1: Operating and Display Field

1 Charge status light 3 Stop/Start switch – Soft key 1

2 Graphic display 4 Soft keys 2 – 4

5 Charger performance specification plate, e.g. 48 volts – 120 amps

Page 14

Operation

14/30 4156 EN

6.1.1 Charge Status Light

The charge status light shows, in conjunction with the graphic display, the current

operating status and the charging status.

Colour Meaning Explanation

Yellow

Charge

Lights up during the (main) charging phase

Orange

Charge

Lights up during the ährend der re-charging phase

Green

Charge end

Lights up when charging is complete

Red

Fault

Lights up if there is an equipment fault or incorrect

operation:

− Battery disconnected during charging

− Power module faulty

− Max. charging time or discharge rate

exceeded

−

Overvoltage / low voltage cutout

Off

Ready

Charge status light out

No charge, no error (e.g. display after system re-start or

before using the charger for the first time)

Table 2: Charge Status Light

As well as the continually lit displays of the charge status light, some operating

conditions are displayed as a flashing sequence of various colours (1 second rhythm).

The following list shows the various flashing sequences and their meaning. As well as

the flashing sequence, the graphic display shows the respective messages in text form.

Flashing sequence

Meaning Explanation

Yellow

►

Off

Charge start

Start of a new charging sequence

Red

►

Green

Charge end/

fault

Charge complete / pump error or faulty

power module

Yellow

►

Red

Charge/fault

(Main) charge / pump error or faulty

power module

Orange

►

Red

Charge/fault

Recharge / pump error or faulty power

module

Page 15

Operation

15/30 4156 EN

Flashing sequence

Meaning Explanation

Orange

►

Off

Charge

break

Charge break (depends on set charging

program)

Orange

►

Red

►

Off

Charge

break / fault

Charge break / pump error or faulty power

module

Yellow

►

G

reen

Conservation

charge

Conservation or compensation charge

running

Red Yellow

Green

►

►

Conservation

charge / fault

Conservation or compensation charge /

pump error or faulty power module

Table 3: Flashing sequences

6.1.2 Soft keys

There are four keys below the graphic display, known as the soft keys.

Figure 2: Soft keys

The layout and function of the various keys is shown as a symbol in the bottom line of

the graphic display. The following table explains the significance of the symbols:

Symbol Meaning Explanation

X

Cancel

During charge: Charging stopped

(“S” key only)

In the menu control: Change from one menu level to the

one below it

(changes are not accepted)

Confirm

During charge: Charging continues

(“S” key only)

In the menu control: Select the next highest menu level or

confirm a changed setting

Cursor left Controls the display cursor to the left

Cursor right Controls the display cursor to the rights

Cursor up /

increase value

Controls the display cursor up, increases the value of the

displayed setting

Cursor down /

decrease value

Controls the display cursor down, decreases the value of

the displayed setting

Table 4: Soft key meaning

Page 16

Operation

16/30 4156 EN

6.1.3 Graphic display and menu structure

The graphic display gives information on the charger and the charge status in symbol

form and/or as text. The charger can be operated or changes made to the charger setting

in conjunction with the soft keys below.

The following graphic shows the menu structure:

Battery-info

>

Battery nominal volt.

Battery capacity

Charging program

Basic setting

>

Language

>

German

English

French

Italian

others*)

Time

>

Time setting

Date setting

Display

>

Lighting intensity

Contrast

Release information

Functions

>

Switch-on delay

Battery service

>

Deep discharge-start

Equalisation once

Equalisation perman.

Measured values

>

No. of measured values

Configurate...

>

1. Measured value

:

5. Measured value

History

>

End of charge data

>

Data set 1

:

Data set 10

Power consumption

>

Recharged kWh

>

Last cycle

Total

Statistics

>

No. of charge cycles

No. of charge finished

No. of forced switch over

No. of safety switch off

No. of pump failures

*) Indication only if an additional language has been loaded

Figure 3: Menu structure

Page 17

Operation

17/30 4156 EN

6.1.4 Adjustable parameters

Settings can be made and parameter values changed within the menu. An overview of

the various setting ranges and default values is given in the following table:

Menu item

Default value

Setting range

Language

German

German

English

French

Italian

others*

Time

00:00

00:00 - 23:59

Date

01.01.2000

01.01.2000 - 31.12.2099

Lightning intesity

70 %

0 - 100 %

Contrast

100 %

0 - 100 %

Switch-on delay

0 Min.

0 - 999 Min.

Battery service

--

Deep discharge-start

Equalisation once

Equalisation perman.

No. of measured values

5

1 – 5

1. Measured value ..

5. Measured value

Charging voltage

Charging voltage [V]

Charging current

Charging current [A]

Charging voltage [V/Z]

Charging voltage [V/Z]

Charging current [%]

Charging current [%]

Charged Ah

Charged Ah [Ah]

Battery temperature [°C]

Charging time [h]

Date

Time

Status of modules

* * Indication only if an additional language has been loaded

Table 5: einstellbare Parameter

6.1.5 Function – Battery Maintenance

Deep discharge-start:

If the message “Check battery voltage" appears in the graphic display after the battery is

connected, this means the battery voltage is insufficient to start charging. In this case a

depletion start can be performed. Select the Deep discharge start function in menu item

Functions>Battery service and confirm with OK. The charger starts in deep discharge

start mode and charges until there is sufficient battery voltage to start normal charging.

M

MM

M

Attention

Before activating depletion start, check that the charger is preset for the battery to be charged (voltage,

capacity, type).

Page 18

Operation

18/30 4156 EN

Equalisation once/perman.:

If a compensation charge is to be carried out after the normal charge, the equalisation

charge function must be activated prior to charging. Select the Equalisation once

function in menu item Functions>Battery service and confirm with OK. When the

Equalisation once function is activated, a compensation charge is then carried out after

the next charge. If the Equalisation perman. function is activated, a compensation

charge is performed after every charge.

Z

ZZ

Z

Note

The compensation charge starts 24 hours after the start of the normal charge.

For some charging programs a compensation charge is included as standard. In this

case the compensation charge cannot be activated.

6.1.6 Function – Measured values

The Measured values function allows you to set how many and which measured values

are displayed in the graphic display during charging. See also Table 5.

6.1.7 Graphic Display Information

Information on the default settings of the charger and charging end data can also be

taken from the graphic display, see following table:

Menu item

Information

Sample value

Battery-info

Battery nominal volt.

80V

Battery capacity

200 Ah

Charging program

LP2 (E)PzS

Basic setting

Release information

SLH 200

V1.3 605676.03

History

End of charge data

Voltage: 2,7 V/Z

Current: 10,2 A

Charged Ah: 250,0 Ah

Charging time: 08:00 h

Time: 12:00

Date: 01.07.2004

Error messages

Power consumption

Last cycle 20 kWh

Total 100 kWh

Statistics

No. of charge cycles

No. of charge finished

No. of forced switch over

No. of safety switch off

No. of pump failures

Table 6: Graphic Display Information

6.1.8 Parameters – Consumption data

The History>Power consumption menu item shows how many kWh were taken from the

mains in the last charge and overall.

Page 19

Operation

19/30 4156 EN

Z

ZZ

Z

Note

The kWh meter is not calibrated and is therefore not permissible for accounting

purposes.

6.1.9 Parameters - Statistics

The History>Statistics menu item allows the values of the internal event meter to be

called up. They are as follows:

Display information Explanation

No. of charge cycles Number of charges started

No. of charge finished Number of correctly completed charges

No. of forced switch over Number of compulsory changes made

No. of safety switch off Number of safety cut-outs due to charge time exceeded

No. of pump failures Number of pump failures (pressure contact not applied)

6.2 Charger Mains Connection

The charger is fitted with a mains cable and lead for the power supply.

• Connect the charger to the mains circuit by inserting the connector in the socket.

The charger logo will then appear in the graphic display for approx. 3 seconds. The

nominal data is then collated, and “Collect nominal data” appears in the graphic display.

The charger then changes back to the standard display:

80V/35A

V1.0 605676.00

Waiting for:

- Battery

Figure 4: Standard alternating display (e.g. for an 80 volts / 35 amp charger)

6.3 Battery Connection

M

MM

M

Danger

The battery contains sulphuric acid which is highly corrosive. The floating metalic

parts of a battery are always live. Do not open the battery housing and do not touch

any non-insulated metal parts.

For this reason, work on batteries or battery systems must only be carried out:

-

by trained personnel and

-

with regard to the battery manufacturer’s operating instructions.

Corrosive acid gases can be produced when a battery is being charged. Acid gases

can cause short circuits in electrical equipment (risk of burning) and can corrode

components.

-

Therefore always position batteries next to charging stations in such a way that

any acid gases arising can be freely distributed (reduced) on site and can

dissipate.

Page 20

Operation

20/30 4156 EN

F

FF

F

Explosion hazard

Connecting an incorrect battery to the charger can result in damage to the charger

and battery: The battery could gas, decoct or even explode.

Always check that the charger is set for your battery type. If in doubt, contact the

relevant service department of the manufacturer.

We shall now describe how to connect the battery with a charging lead. Please note that

charging automatically begins when the battery is connected.

Connect the battery as follows:

• Route the charging lead in such a way that nobody can trip over it and interrupt the

charging.

• Connect the charging lead to the respective socket of the battery cable.

Automatic charging begins.

6.4 Charging automatic start

Charging starts automatically if

− the charger is connected to the mains,

− the battery terminals are connected correctly to the charger,

− the battery voltage is at least 1.6 volts/cell,

− the On/Off switch has not been pressed.

At the start of charging, the charger performs a self test. During this time the message

“Start new charging” appears in the graphic display.

Start

new charging!

i

Figure 5: Charge start shown in graphic display

At the end of the starting process, the preset readings are cyclically shown in the graphic

display. For reading details, refer to Section 6.7.

Page 21

Operation

21/30 4156 EN

Charging voltage V/C

2,0 V/Z

Charging voltage

80 V

Charging current

35 A

Charging current %

100 %

Recharged Ah

110 Ah

Figure 6: Standard reading display during charging

6.5 Interrupting a charge

The charger should not be interrupted during charging. However, external influences

may necessitate interruption of the process. Note however:

F

FF

F

Explosion hazard

Risk of serious damage to persons and property if the battery is disconnected during

charging. The sparks produced could ignite gases which form during charging.

Always press the ‘S’ key first, if you have to interrupt the charge.

Then disconnect the charging lead from the battery.

Charging is interrupted when you press the ‘S’ key at the front of the panel (see also

Section 6.1.2).

• Press the ‘S’ key once. The charging status light goes out.

Charging is continued when you press the ‘S’ key again.

• Press the ‘S’ key again. The charging status light is lit yellow or orange, depending

on the charge status.

Z

ZZ

Z

Note

In normal operation, charging should not end before the automatic cutout. Premature

cutout will result in a depletion charge. This reduces the available battery capacity.

6.6 Charging automatic end

Charging automatically ends when the charging program is finished, i.e. the battery is

fully charged. The charge status light is then lit green. You can now use the battery. The

graphic display now shows “Charge over”, alternating with the charge end voltage data

(battery voltage in volts/cell), current (charge end current in A) and overall Ah (charged

capacity in Ah).

Page 22

Operation

22/30 4156 EN

End of charge data

Voltage: 2,7 V/Z

Current: 10,5 A

Recharged Ah: 120,00 Ah

Charging

finished!

Figure 7: Alternating charge end display (RH picture: sample values)

6.7 Readings

As described in Section 6.1.4, certain readings can be displayed before, during and after

the charge. The number of readings can be set from 1 to 5. For the various charger

conditions the readings have the following significance:

Reading

Charger condition

Value displayed

Charge voltage*

Charge, conservation charge

Charge voltage

Recharge interval

Battery voltage

Charge end, conservation charge interval

Charge end voltage

Charge current* Charge, recharge interval, conservation

charge

Charge current

Charge end, conservation charge interval

Charge end current

Charge voltage

[V/C]

Charge, conservation charge

Charge voltage [V/C]

Recharge interval

Battery voltage [V/C]

Charge end, conservation charge interval

Charge end voltage [V/C]

Charge current %

(of charge rated

current)

Charge, recharge interval, conservation

charge

Charge current [%]

Conservation charge interval

Charge end current %

Ah total*

Charge, recharge interval

Current Ah total

Charge end, conservation charge interval

Charge end Ah total

Battery

temperature

Charge, recharge interval, conservation

charge

Current temperature

Charge end, conservation charge interval

Charge end temperature

Charge time* Charge, recharge interval, conservation

charge

Current charge time

Charge end, conservation charge interval

Overall charge time

Date Charge, recharge interval, conservation

charge

Current date

Charge end, conservation charge interval

Charge end date

Time* Charge, recharge interval, conservation

charge

Current time

Charge end, conservation charge interval

Charge end time

Module status

All charging phases

Decimal value, display for

charger service only

*Default values

Page 23

Operation

23/30 4156 EN

6.8 Status messages

Status messages are shown via the graphic display and some are also shown via the

charge status light.

Graphic display

message

Charge Status

Light

Cause Effect

Gree

n

Charge

complete

alternating with

Charge end data

voltage: ... V/C

current: ... A

Ah total: ... Ah

Charging completed

properly.

Off

Charge ended by

user

Charging cancelled

prematurely by user

Battery not fully

charged

Red

Battery

disconnected during

charging

Battery disconnected

without pressing the ‘S’

key

Operating error! See

6.5

Battery not fully

charged

Orange

Compulsory change

Re-charge!

Display during

charge

The max. permissible

main charge time has

been exceeded.

Safety function!

See also section 6.9

Red

Mains failure

Display during mains

failure

Mains failure

Charge time is

extended!

Table 7: Status messages

Page 24

Operation

24/30 4156 EN

6.9 Faults and Error Messages

The charger reports faults via the graphic display and the charging status light. The

following table gives an overview of the various fault causes and how to rectify them.

Graphic display

message

Charge

Status Light

Cause Remedy

Red

Max. charge time

exceeded

Charge complete

Max. charge

capacity exceeded

Charge complete

The max. permissible

charge time has been

exceeded.

The max. permissible

charge capacity has

been exceeded.

Safety cutout

Battery capacity too great

for charger

Battery faulty

Notify battery service

department

Red

Deviation

I max!

Charge complete

Too much current from

power part. Control

system damaged.

Charger error

Notify service

department

Red

Battery

disconnected during

charging

Battery disconnected

without pressing the ‘S’

key.

Operating error

Press ‘S’ key before

disconnecting the battery,

see 6.5.

Check charging lead

contacts.

Display works

normally

Compulsory change

Re-charge!

The max. permissible

main charge time has

been exceeded.

Safety function!

Battery capacity too great

for charger

Notify battery service

department

Red

Mains failure

Mains disconnected

Display during

mains failure

Mains failure

Mains fuse faulty

Check / replace mains

fuse

Display works

normally

Deviation

I min!

Charge current less than

controller specification

Notify service

department

Note: the charger does not

cut out.

Red

Overvoltage cutout

Overvoltage

Check battery

voltage

Output voltage greater

than 3.0 volts/cell

Notify service

department

Red

Low voltage cutout

Low voltage

Check battery

voltage

Output voltage less than

minimum cell voltage..

Wrong battery connected.

Battery depleted. Activate

depletion charge start.

Notify battery service

department

Red

Module failure

Module failure 1,2...n

Display flashes

alternately with

current charge

status, see 6.1.1.

Power module failure

Notify service

department

Page 25

Maintenance

25/30 4156 EN

Graphic display

message

Charge

Status Light

Cause Remedy

Red

Pump error

Pressure drop

Display flashes

alternately with

current charge

status, see 6.1.1.

Pressure switch on pump

does not close.

Red

Overtemperature

Temperature error.

Power part

overtemperature.

Check ventilation slots.

Allow the power part to

cool.

Notify service

department

Red

Table 8: Faults and Error Messages

6.10 Switching off the charger

The charger is energised via the mains cable. Disconnect the charger from the mains if:

− the charger is not permanently required,

− the charger electronic system is to be reset to the start status (reset), e.g. if a fault is

displayed.

7 Maintenance

F

FF

F

Warning: Hazardous Electrical Voltage!

The charger is an electric component conducting voltages and currents that are

hazardous to people.

The charger must therefore only be installed, opened, repaired and disassembled

where necessary by qualified electrical engineers.

The mains supply and a battery contact where necessary must be disconnected

before carrying out any work on the charger.

7.1 Cleaning, Inspection and Maintenance

The charger is maintenance-free and will operate trouble-free if used correctly.

• Dust or dirt on the charger can be removed with a dry cloth.

Check at least monthly that

• the mains connection is undamaged,

• the housing is undamaged,

• the charging lead insulation is undamaged,

• the charging lead plug is undamaged,

• the additional earth conductor in three-phase devices is undamaged

• all screw connections are tight.

If any faults are detected, immediately put the charger out of service; all faults must be

immediately rectified by specialist technicians.

Page 26

Disposal

26/30 4156 EN

If the housing has to be opened for maintenance and repairs, contact the charger

manufacturer.

7.2 Changing the charging program

The charging program is factory set (see Appendix). If the charging program has to be

changed, please contact the manufacturer.

7.3 Spare parts

Should you require spare parts, contact the manufacturer, stating the charger data

contained on the data plate.

8 Disposal

If the charger is to be finally decommissioned, all relevant laws and regulations

concerning disposal at the time must be adhered to.

For further information contact the specialist disposal companies or the local authorities.

M

MM

M

Attention

Electronic waste contains a wide range of plastic, metal and heavy metal components

which pose a high hazard risk to the environment. Electronic waste should therefore

be collected and disposed of separately from household or trade waste.

Electronic waste must be dealt with by your company’s disposal department who will

arrange to have it removed by special disposal companies.

Dispose of the charger's packaging separately. Paper, cardboard and plastic should be

recycled.

Page 27

Appendix

27/30 4156 EN

9 Appendix

9.1 Dimension and Projection Drawings (not to scale)

4

4

3

3

9

2

2

7

8

2

7

8

3

9

2

5

6

0

7

8

0

4

5

8

4

5

2

FWG 3

*(FWG 3T)

FWG 6

*(FWG 6T)

FSG 12

4

2

8

*

4

2

8

*

Figure 8: Dimension drawings (*housing depth for T version)

328,5

334,8

328,5

450

6,5

1

2

,

5

1

1

,

5

FWG 3

FWG 6

Figure 9: Drill diagrams

Dimensions (mm) Housing type

Height Width Depth

FWG 3

443 392 278

FWG 3 T

443 392 428

FWG 6

560 392 278

FWG 6 T

560 392 428

FSG 12

780 458 452

S 22

1093 553 410

Table 9: Dimensions

Page 28

Appendix

28/30 4156 EN

9.2 Specifications

Series SLH 200

Model no.

See data plate

Battery type

Wet cell or maintenance-free battery

Characteristic curve

See section 6.4.1

Temperature range

0 to 40 °C

Input rated frequency

47.5 – 63 Hz

Protection class

IP 21 in accordance with EN 60529

Housing

See appendix ‘Dimension and Projection Drawings’

Standards

73/23/EWG – Low voltage guideline

89/336/EWG – EMC guideline

EN 60335-2-29 – Safety

EN 61558 – Transformers

EN 60146 – Semi-conductor power converters

EN 61000-6-2 and EN 61000-6-3 – EMC

EN 61000-3-2 – Mains feedback

EN 61000-3-3 – Voltage fluctuations and flickering

EN 61000-4-4 – Burst and surge

9.3 Model table

The charger model can be clearly identified from the model description in the data plate.

Out- Model type Housing Weight Out Mains Mains Min. Mains Mains plug Charge power

put- put current voltage mains cable cable consumption

voltage current fuse

[V] [kg] [A] [A] [V] [A] [mm²] [mm²] kVA

E230 G 24/ 20 B-SLH200 FWG 3*) 22 20 2,3 230 6 3 x 1,5 Schuko 16 0,5

E230 G 24/ 25 B-SLH200 FWG 3*) 22 25 3 230 6 3 x 1,5 Schuko 16 0,7

E230 G 24/ 35 B-SLH200 FWG 3*) 22 35 4 230 6 3 x 1,5 Schuko 16 0,9

E230 G 24/ 50 B-SLH200 FWG 3*) 22 50 6 230 6 3 x 1,5 Schuko 16 1,4

E230 G 24/ 65 B-SLH200 FWG 3*) 22 65 8 230 10 3 x 1,5 Schuko 16 1,8

E230 G 24/ 85 B-SLH200 FWG 3*) 22 85 10 230 16 3 x 1,5 Schuko 16 2,3

E230 G 24/100 B-SLH200 FWG 3*) 22 100 12 230 16 3 x 1,5 Schuko 25 2,8

E230 G 24/120 B-SLH200 FWG 3*) 22 120 14 230 16 3 x 1,5 Schuko 25 3,2

D400 G 24/150 B-SLH200 FWG 6*) 36 150 6,5 3 x 400 10 5 x 2,5 CEE 16 35 4,5

D400 G 24/170 B-SLH200 FWG 6*) 36 170 7,5 3 x 400 10 5 x 2,5 CEE 16 50 5,2

D400 G 24/190 B-SLH200 S 22 61 190 11 3 x 400 16 5 x 2,5 CEE 16 50 7,6

E230 G 48/ 35 B-SLH200 FWG 3*) 22 35 8 230 10 3 x 1,5 Schuko 16 1,8

E230 G 48/ 50 B-SLH200 FWG 3*) 22 50 11,6 230 16 3 x 1,5 Schuko 16 2,7

E230 G 48/ 65 B-SLH200 FWG 3*) 22 65 15 230 16 3 x 1,5 Schuko 16 3,5

D400 G 48/ 85 B-SLH200 FWG 6*) 36 85 7,5 3 x 400 10 5 x 2,5 CEE 16 16 5,2

D400 G 48/100 B-SLH200 FWG 6*) 36 100 8,8 3 x 400 10 5 x 2,5 CEE 16 25 6,1

D400 G 48/120 B-SLH200 FWG 6*) 36 120 10,3 3 x 400 16 5 x 2,5 CEE 16 25 7,1

D400 G 48/150 B-SLH200 FSG 12 71 150 12,5 3 x 400 16 5 x 2,5 CEE 16 35 8,6

D400 G 48/170 B-SLH200 FSG 12 71 170 14,5 3 x 400 16 5 x 2,5 CEE 16 50 10,0

D400 G 80/ 50 B-SLH200 FWG 6*) 36 50 7,8 3 x 400 10 5 x 2,5 CEE 16 16 5,4

D400 G 80/ 65 B-SLH200 FWG 6*) 36 65 9,6 3 x 400 16 5 x 2,5 CEE 16 16 6,6

D400 G 80/ 85 B-SLH200 FWG 6*) 36 85 12 3 x 400 16 5 x 2,5 CEE 16 16 8,3

D400 G 80/100 B-SLH200 FSG 12 71 100 14,3 3 x 400 16 5 x 2,5 CEE 16 25 9,9

D400 G 80/120 B-SLH200 FSG 12 71 120 17 3 x 400 20 5 x 2,5 CEE 32 25 11,7

D400 G 80/150 B-SLH200 FSG 12 71 150 21 3 x 400 25 5 x 4 CEE 32 35 14,5

D400 G 80/170 B-SLH200 S 22 96 170 25 3 x 400 35 5 x 6 CEE 32 50 17,3

*) FWG 3T bzw. FWG 6T bei Option Spezialfilter

80

24

48

Table 10: Model table

Page 29

Appendix

29/30 4156 EN

9.4 Charging programs

The charging program (CP) is factory set. If the charging program has to be changed,

please contact the manufacturer. If, when you connect the battery the graphic display

shows “No CP set”, there is no valid charging program and no battery capacity preset. In

this case you should contact the manufacturer.

DC (E)PzS Puls (E)PzV

WF 200 plus WF 200 plus Champion Evolution

volt.

LP 3 LP 4 LP 5 LP5 LP 7 LP 8

7 - 8,5h 9 - 11,5h 12 - 14h 7 - 8,5h 12 - 14h 8 - 10h 10 - 12h 12h 12 - 14h

[V]

Cap. (Ah) Cap. (Ah) Cap. (Ah) Cap. (Ah) Cap. (Ah) Cap. (Ah) Cap. (Ah) Cap. (Ah) Cap. (Ah)

90 - 120 130 - 150 170 - 220 110 - 140 120 - 150 80 - 110 110 - 130 130 - 170 90 - 120

110 - 150 160 - 190 210 - 280 140 - 190 150 - 185 100 - 140 140 - 170 160 - 210 110 - 150

150 - 210 220 - 270 290 - 390 190 - 260 190 - 260 140 - 195 195 - 230 225 - 290 150 - 210

210 - 290 310 - 390 420 - 560 260 - 360 270 - 370 200 - 280 280 - 330 320 - 420 210 - 300

300 - 380 410 - 500 540 - 720 350 - 460 380 - 480 260 - 360 360 - 430 420 - 540 300 - 380

390 - 500 530 - 650 710 - 940 460 - 610 490 - 630 340 - 470 470 - 560 550 - 710 380 - 500

460 - 590 630 - 770 830 - 1110 540 - 710 605 - 740 400 - 560 560 - 670 645 - 830 450 - 580

550 - 710 750 - 920 1000 - 1330 650 - 860 730 - 890 480 - 675 675 - 800 775 - 1200 540 - 700

680 - 880 940 - 1150 - 810 - 1070 900 - 1110 600 - 840 840 - 1000 970 - 1250 680 - 880

770 - 1000 1060 - 1310 - 920 - 1210 1030 - 1260 680 - 940 940 - 1130 1095 - 1420 775 - 1000

860 - 1120 - - 1030 - 1360 - 750 - 1050 1050 - 1270 1225 - 1580 -

150 - 210 220 - 270 290 - 390 190 - 260 190 - 260 140 - 195 195 - 230 225 - 290 150 - 210

210 - 290 310 - 390 420 - 560 260 - 360 270 - 370 200 - 280 280 - 330 320 - 420 210 - 300

300 - 380 410 - 500 540 - 720 350 - 460 380 - 480 260 - 360 360 - 430 420 - 540 300 - 380

390 - 500 530 - 650 710 - 940 460 - 610 490 - 630 340 - 470 470 - 560 550 - 710 380 - 500

460 - 590 630 - 770 830 - 1110 540 - 710 605 - 740 400 - 560 560 - 670 645 - 830 450 - 580

550 - 710 750 - 920 1000 - 1330 650 - 860 730 - 890 480 - 675 675 - 800 775 - 1200 540 - 700

680 - 880 940 - 1150 - 810 - 1070 900 - 1110 600 - 840 840 - 1000 970 - 1250 680 - 880

770 - 1000 1060 - 1310 - 920 - 1210 1030 - 1260 680 - 940 940 - 1130 1095 - 1420 775 - 1000

210 - 290 310 - 390 420 - 560 260 - 360 (**) 200 - 280 280 - 330 320 - 420 (**)

300 - 380 410 - 500 540 - 720 350 - 460 (**) 260 - 360 360 - 430 420 - 540 (**)

390 - 500 530 - 650 710 - 940 460 - 610 (**) 340 - 470 470 - 560 550 - 710 (**)

460 - 590 630 - 770 830 - 1110 540 - 710 (**) 400 - 560 560 - 670 645 - 830 (**)

550 - 710 750 - 920 1000 - 1330 650 - 860 (**) 480 - 675 675 - 800 775 - 1200 (**)

680 - 880 940 - 1150 - 810 - 1070 (**) 600 - 840 840 - 1000 970 - 1250 (**)

770 - 1000 1060 - 1310 - 920 - 1210 (**) 680 - 940 940 - 1130 1095 - 1420 (**)

(*) 1.5h less recharge time with EC

(**) Higher battery capacities and 80 V applications on request.

24

48

80

D 400 G 80/150 B-SLH200

D 400 G 80/170 B-SLH200

D 400 G 80/ 65 B-SLH200

D 400 G 80/ 85 B-SLH200

D 400 G 48/ 85 B-SLH200

D 400 G 48/100 B-SLH200

D 400 G 80/100 B-SLH200

D 400 G 80/120 B-SLH200

D 400 G 48/120 B-SLH200

D 400 G 48/150 B-SLH200

D 400 G 48/170 B-SLH200

D 400 G 80/ 50 B-SLH200

D 400 G 24/190 B-SLH200

E 230 G 48/ 35 B-SLH200

E 230 G 48/ 50 B-SLH200

E 230 G 48/ 65 B-SLH200

E 230 G 24/100 B-SLH200

E 230 G 24/120 B-SLH200

D 400 G 24/150 B-SLH200

D 400 G 24/170 B-SLH200

E 230 G 24/ 35 B-SLH200

E 230 G 24/ 50 B-SLH200

E 230 G 24/ 65 B-SLH200

E 230 G 24/ 85 B-SLH200

Charge time without EC (*)

E 230 G 24/ 20 B-SLH200

E 230 G 24/ 25 B-SLH200

(E)PzS

LP 2

Charger type

Charge program:

Table 11: Charging programs

Page 30

Appendix

30/30 4156 EN

9.5 Spare parts catalog

Loading...

Loading...