Page 1

Robust tow tractor with sprung

wheels for external operations

Comfortable travel for

both indoor and outdoor

applications

High energy eciency levels

due to maintenance-free

3-phase AC drive motor

Dierent cab versions

EZS 6250

Electric tow tractor (25,000 kg)

The Jungheinrich EZS 6250 is a versatile

and economic tow tractor for towing

trailers up to 25,000 kg. The ability to

couple several trailers together allows

loading characteristics to be varied and

provides for the flexibility required in

material-handling operations.

The coupling is visible from the operator’s sitting position, and is easily

accessible. The semi-automatic remote

release (optional) allows the coupling

and decoupling of trailers without the

operator having to leave the vehicle,

saving both time and money. Another of

the vehicle’s advantages is that the EZS

6250 is available with many dierent tow

couplings to allow it to fit every trailer

type.

High performance is ensured with the

three-phase-technology drive motor.

The advantages: quick acceleration

and high top speed. At the same time,

significant energy savings, longer operation time and minimum maintenance

requirements are realised due to the

omission of the carbon brushes. This

performance is achieved through the

optimal cohesion of drive motor and

drive controller with the added benefit of

regenerative braking.

Due to its very tight turning circle, the

EZS eortlessly handles tight spaces

with flying colours. The sprung wheels

oer high travel comfort and safety even

over uneven flooring. Other highlights

include the variation of available cabin

types, hydraulic steering and regenerative braking. The sprung loaded wheels

oer both travel comfort and safety. The

automatically activating parking brake

reduces roll-back on slopes.

Page 2

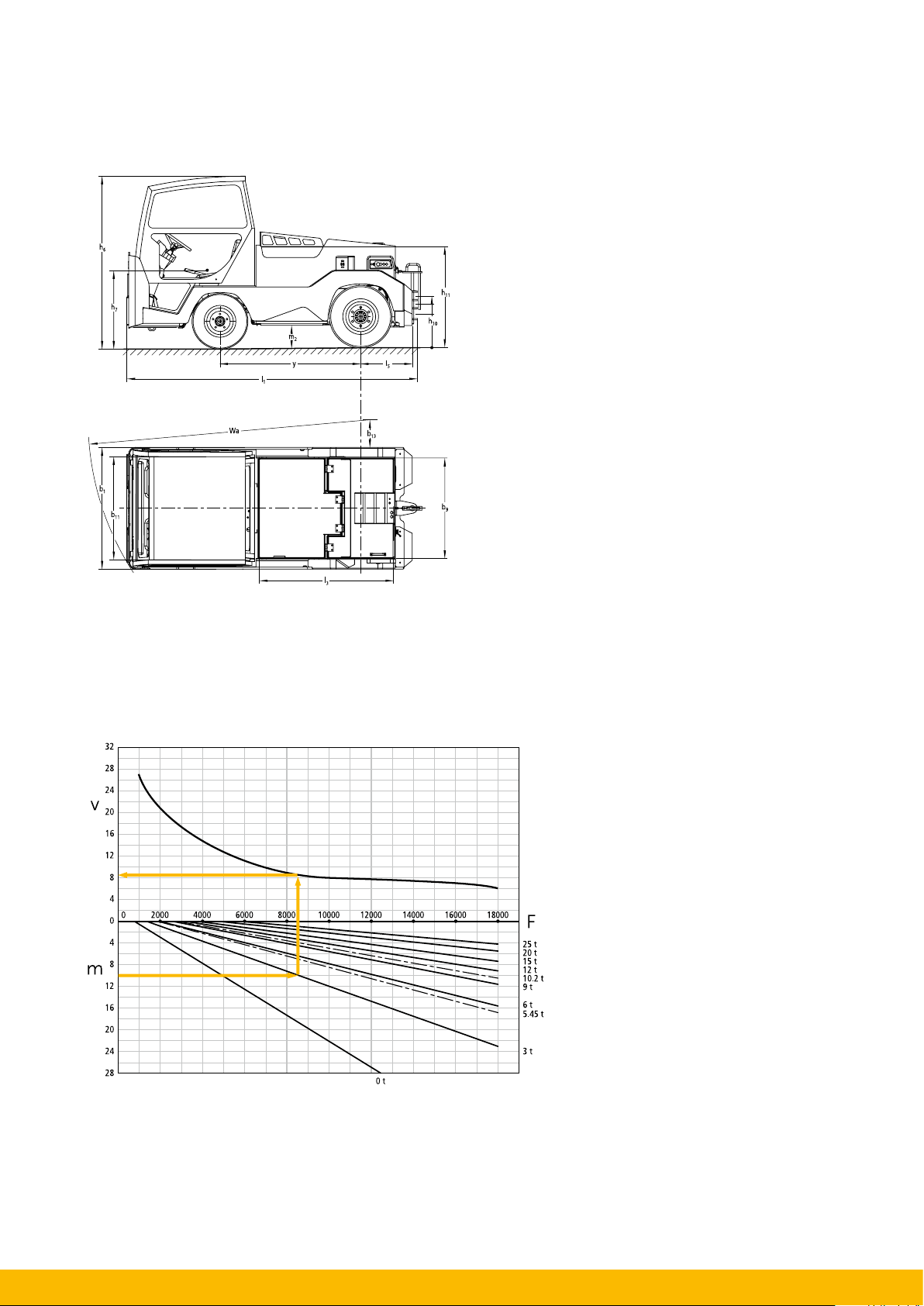

EZS 6250

Pulling ability

v=speed [km/h], m=incline [%], F=drawbar pull [N]

The reading example:

The EZS 6250 runs with 3 tonne load on a 10

continue upgrade %. This requires the EZS

8500 N tractive eort and is about 8,5 km/h

reach.

Note:

For EZS 6250 over 5000 N no continuous

operation possible.

Gradients / gradient greater than 4 % is the

use of braked trailers recommended!

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EZS 6250

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 25

1.7 Rated tractive power F N 5000

Identification

1.9 Wheelbase y mm 1540

2.1.1 Net weight incl. battery (see row 6.5) kg 4250

2.3 Axle load, w.o. load, front / rear kg 1925 / 2325

Weights

3.1 Tyres Lu, SE

3.2 Tyre size, at front mm 6.50-10

3.3 Tyre size, at rear mm 7.00-12

3.5 Wheels, number front/rear (× = driven wheels) 2 / 2x

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

4.2.1 Total height h15 mm

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.16 loading area length l3 mm 1400

4.18 loading area width b

4.19 Overall length l

4.21 Total width b

Basic dimensions

4.32 Floor clearance centre wheelbase m

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed, w. / w.o. load km/h 10 / 26

5.5 Drawbar pull w. / w.o. load N 5000

5.6 Max. drawbar pull, laden/unladen N 18000

5.7 Gradeability laden/unladen % - / -

data

5.8 Max. gradeability, laden/unladen % - / -

Performance

5.10 Service brake hydraulic

6.1 Drive motor rating S2 60 min. kW 23.0

6.4 Battery voltage/nominal capacity K5 V/Ah 80 / 620

trics

Elec-

6.5 Battery weight kg 1558

8.1 Type of drive control AC

8.5 Trailer coupling, model/type DIN Stufenkupplung

Misc.

8.6 Steering hydraulic

mm 1140

10

mm 1140

11

mm 1900

6

mm 790

7

mm 375

10

mm 850

9

mm 3180

1

mm 1330

1/b2

mm 150

2

mm 3150

a

mm 590

13

Issue: 11/2009

1)

2)

2)

1)

375 / 480 / 570 mm

2)

See diagram

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Different couplings available

(optional)

Inching buttons for simple coupling and decoupling

Innovative 3-phase AC technology

Three-phase AC technology motors

oer you more power and performance while, at the same time, reducing

operating costs. Make the most of these

advantages:

• High degree of eciency with excellent energy management.

• Powerful acceleration.

• High top speed, even when laden.

• Rapid change in direction of travel

• No carbon brushes – maintenancefree drive motor.

Comfortable and safe operation

The truck’s controls ensure comfortable and safe operation with adjustable

options to suit every application:

• The speed set by the accelerator is

automatically maintained under all

travel conditions including on gradients

/ descents.

• Regenerative braking with energy recovery when slowing down.

• Safe starting and stopping, also on

slopes with the electric parking brake

(that automatically engages when

stationary and automatically releases

when starting).

Multi-stage coupling for different

trailer coupling

• Adjustable steering column and seat

for optimal sitting position.

• Hydraulic steering: Easy to operate, no

kickback.

Optimal ergonomics

• Ergonomic controls for comfortable

operation.

• Highly visible and accessible coupling

from the driver’s position.

• Fast, easy coupling / decoupling of

trailers with semi-automatic remote

unlocking from the operator position

(optional).

• Various couplings available for dierent

trailer types.

• Inching buttons for simple coupling

and decoupling.

• CSE non marking tyres (optional).

• Many surfaces / compartments for

operator materials, pens, papers, etc.

Robust construction for the hardest

applications

• Frames from 8 mm high-quality sheet

steel.

• Extra high chassis apron on the front

bodywork.

Long operating times

Energy-saving 3-phase AC technology

and high battery capacity ensure long

operating times.

• Standard version: 80 V/620 Ah.

• Exchangeable with batteries from the

Jungheinrich EFG 425 electric 4-wheel

fork lift.

Always informed

Comprehensive display and setting instruments always allow a complete overview of system operations:

• Information regarding battery discharge status, operation hours, speed

and fault diagnostics.

Supplementary equipment.

An extensive array of supplementary

equipment allows the individual adjustment of the vehicle to your application.

• Various couplings.

• Remote coupling release.

• Built-in battery charging socket

mounted on the tow tractor.

• Dierent cabin equipment.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EZS 6250_012014_en_UK_000

Loading...

Loading...