Page 1

Innovative work station for

relaxed and safe operation

Powerful 3-phase AC

drive motor for maximum

performance

ShockProtect to protect the

operator, truck and load

SmartPilot electric tiller

steering for precise

and easy steering

Curve Control for added

safety when cornering

Folding stand-on

platform (optional)

ERE 225

Electric powered pallet truck (2,500 kg)

The ERE 225 is the perfect truck for

high-performance loading and unloading

of HGVs as well as the rapid transport of

heavy loads over longer distances. Due

to the higher speeds, in comparison with

normal pedestrian trucks, goods can

be handled or transported particularly

eciently.

The workstation is optimally configured

to suit the needs of the operator:

• Innovative control concept for equally

safe travel forward or reverse.

• Extra-high sides to the operator compartment ensure exceptional operator

protection.

• A variety of storage options as well

as a height-adjustable tiller (optional)

ensures ergonomic and fatigue-free

operation of the truck across the entire

shift.

The truck also oers safety and driving

comfort in every situation:

• In addition to the soft suspension of

the stand-on platform, the entire drive

system is cushioned with ShockProtect

suspension.

• ShockProtect ensures that the standon platform is cushioned against

impacts. The advantage: Reduces

stress on the operator’s spinal column.

Considerably less impact on the frame

and all technical components of the

ERE 225.

• Maximum safety is guaranteed, especially during demanding situations

or when frequent journeys are made in

reverse, by the enclosed sides and fixed

stand-on platform.

• The maximum speed of the truck is

automatically reduced when cornering,

depending on the steering angle

(Curve Control).

Up to 465 Ah high-performance batteries

are available for really demanding applications. For multi-shift operations, the

ERE 225 is available with lateral battery

exchange (optional). If the truck is to be

used in very confined spaces, a version

with a folding platform is available

(optional).

Page 2

ERE 225

ERE 225

Fixed platform

ERE 225

Foldable platform

Page 3

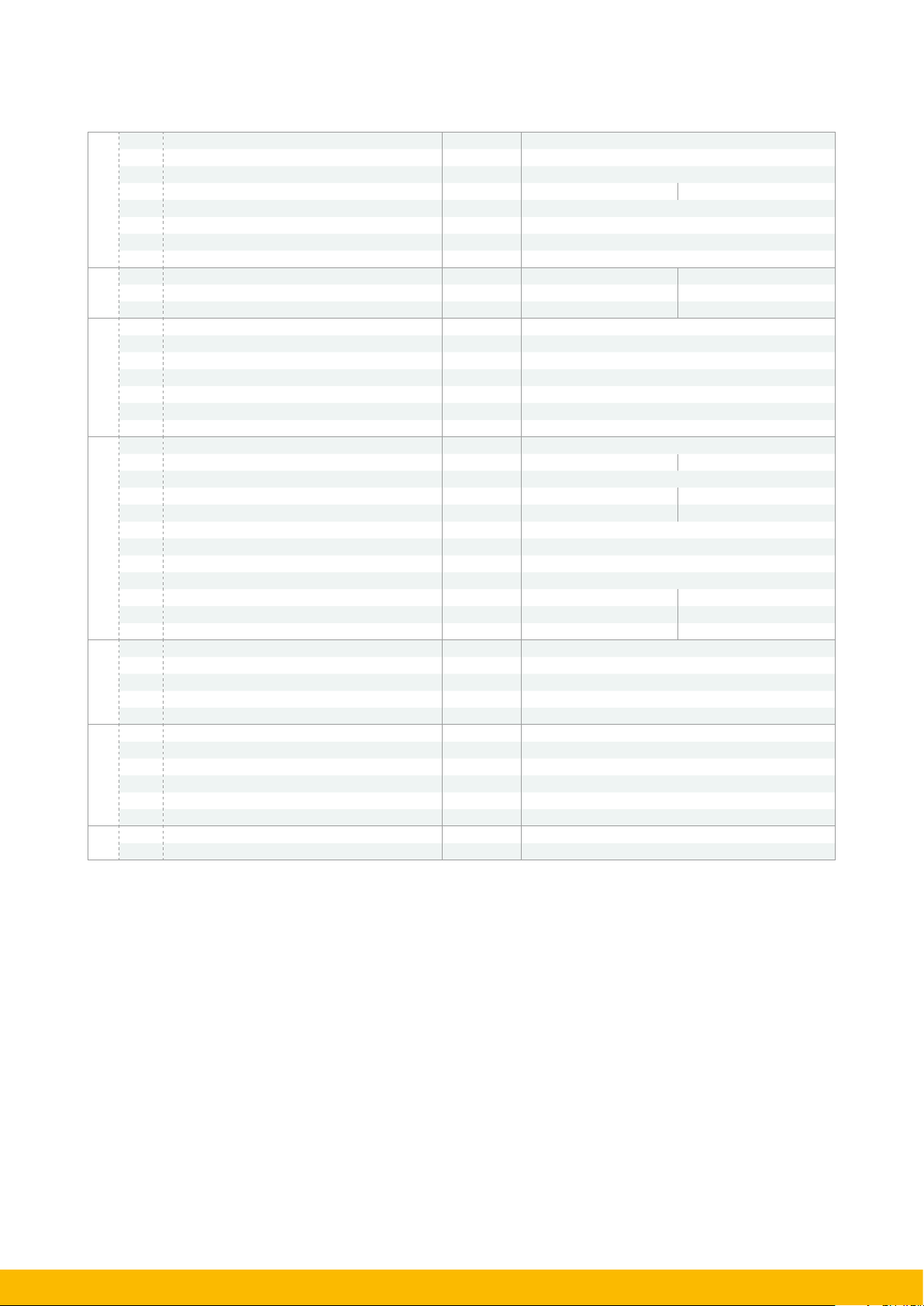

Issue: 05/2011

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ERE 225

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation stand-on stand-on/pedestrian

1.5 Load capacity/rated load Q t 2.5

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 911

1.9 Wheelbase y mm 1484

2.1.1 Net weight incl. battery (see row 6.5) kg 850 792

2.2 Axle load, w. load, front / rear kg 2090 / 1260 2187 / 1105

2.3 Axle load, w.o. load, front / rear kg 150 / 770 158 / 634

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 77

3.3 Tyre size, at rear mm Ø 85 x 110 / Ø 85 x 85

3.4 Additional wheels (dimensions) mm Ø 140 x 57

3.5 Wheels, number front/rear (× = driven wheels) 1x +2/2 or 4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 513

10

mm 338 / 368 / 498

11

4.4 Lift h3 mm 122

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l2 mm 1247

mm 1267 1158 / 1414

14

mm 85

13

mm 2397

1

6)

6)

4.21 Total width b1/b2 mm 770

4.22 Fork dimensions s/e/l mm 55 / 172 / 1150

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m2 mm 30

Basic dimensions

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2699

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2749

4.35 Turning radius W

mm 540

5

3)5)6)

3)5)6)

mm 2260

a

4)5)6)

5.1 Travel speed, w. / w.o. load km/h 9.5 / 12.5

5.2 Lift speed, w. / w.o. load m/s 0.05 / 0.06

5.3 Lower speed, w. / w.o. load m/s 0.055 / 0.04

data

5.8 Max. gradeability, laden/unladen % 8 / 16

Performance

5.10 Service brake electric

6.1 Drive motor rating S2 60 min. kW 2.8

6.2 Lift motor rating at S3 10% kW 2.2

6.3 Battery according to DIN 43531/35/36 A,B,C, no B

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 375

Electrics

6.5 Battery weight kg 288

6.6 Energy consumption according to VDI cycle kWh/h 0.59

8.1 Type of drive control AC SpeedControl

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 66

Misc.

4)

4)6)

1)

1986

834

2253

2300

1812

6)

6)

3)5)6)

2)5)6)

1)

additional dimensions available

2)

Diagonal according to VDI: + 204 mm

3)

Diagonal in accordance with VDI: + 368 mm

4)

Load section lowered: 55 mm

5)

With platform folded down: + 384 mm

6)

With side battery removal: + 72.5 mm

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may result in

different values.

Page 4

Benefit from the advantages

Travel in drive direction with the

ERE 225

ERE 225 with foldable stand-on

platform

Powerful 3-phase AC drive motor and

intelligent electronic controller

Progressive drive technology and control

electronics (SpeedControl) ensure safe

and energy saving operation with adjustment to every application:

• The speed set by the accelerator is

maintained in every travel situation –

even during climbing and descending

gradients and slopes.

• The ERE 225 is protected against

unintended rollback on ramps by automatic brake activation.

• Energy is returned to the battery during

speed reduction using regenerative

braking.

Safer and more ergonomic operator

compartment

The workplace is adjusted to fit operator

and application requirements:

• New operator position: when travelling

with the forks trailing, the operator can

stand sideways and hold themselves

steady with one hand on the tiller, and

the other on the fixed platform handle,

therefore maintaining full control of

the vehicle at all times.

• The operator compartment is symmetrically arranged for easy operation

by both right-handed and left-handed

operators.

• Various storage areas for operator paperwork, clipboard etc.

Comfortable workplace

Foldable stand-on platform (optional)

• A choice of options pedestrian/ride-on

operation.

• Reduced travel speeds; ride-on, when

side protection/support arms are

foldedin (6 km/h) and in pedestrian

operation (4 km/h).

• Minimum working area requirement.

Optimum handling characteristics

• Sprung and cushioned support

wheels connected via the torsion bar

ProTracLink system, ensure safe handling in all situations.

• Jungheinrich ShockProtect: protection

for operator, truck and load through

additional suppression/suspension

of the drive train. The suspension

minimises shocks to the operator and

chassis.

Information at all times

Comprehensive control instrumentation

gives the operator information at a

glance at all times:

• CanDis information display (optional)

with additional hourmeter and service

code storage.

Ergonomic steering

The newly developed tiller head is easily

adjustable to the ergonomic needs of the

operator.

• Clear colour coded buttons with

abrasion resistent symbols for intuitive

operation.

• Comfortable and well arranged operator compartment.

• Contactless sensor system protected in

accordance with OP 65.

• Rocker switch for intuitive and safe

operation of hydraulic functions.

• Height-adjustable tiller head (optional).

Reduced maintenance

• Easy access to all components through

an easily removable one-piece motor

cover.

• Activation of maximum travel speed

only by suitably raised forks ensures

a reliable reduction in wear under the

forks (optional).

Longer times in operation

Battery capacities with up to 465 Ah

ensure longer times in operation:

• Battery compartment L: 3 EPzS 375 Ah.

• Battery compartment L high: 3 EPzS

465 Ah.

• Side battery replacement (optional)

for fast battery change in multi-shift

applications.

Additional equipment

• Entry rollers.

• Load protection frame.

• Cold store application.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ERE 225_042014_en_UK_000

Loading...

Loading...