Page 1

DFG/TFG 16 - 50 A/B/C-K

03.01 -

Operating instructions

50045345

12.03

G

Page 2

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

f

Used before safety instructions which must be observed to avoid danger to

personnel.

m

Used before notices which must be observed to avoid material damage.

A

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

0108.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter. Each chapter

starts with page 1. The page identification consists of a chapter letter and a page

number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing

the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following

graphics:

f

Used before safety instructions which must be observed to avoid danger to

personnel.

m

Used before notices which must be observed to avoid material damage.

A

Used before notices and explanations.

t Used to indicate standard equipment.

o Used to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the truck. No guarantee of

particular features of the truck should therefore be inferred from the present operating

instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Telephone: +49 (0) 40/6948-0

www.jungheinrich.com

Page 3

0108.GB

0108.GB

Page 4

1203.GB

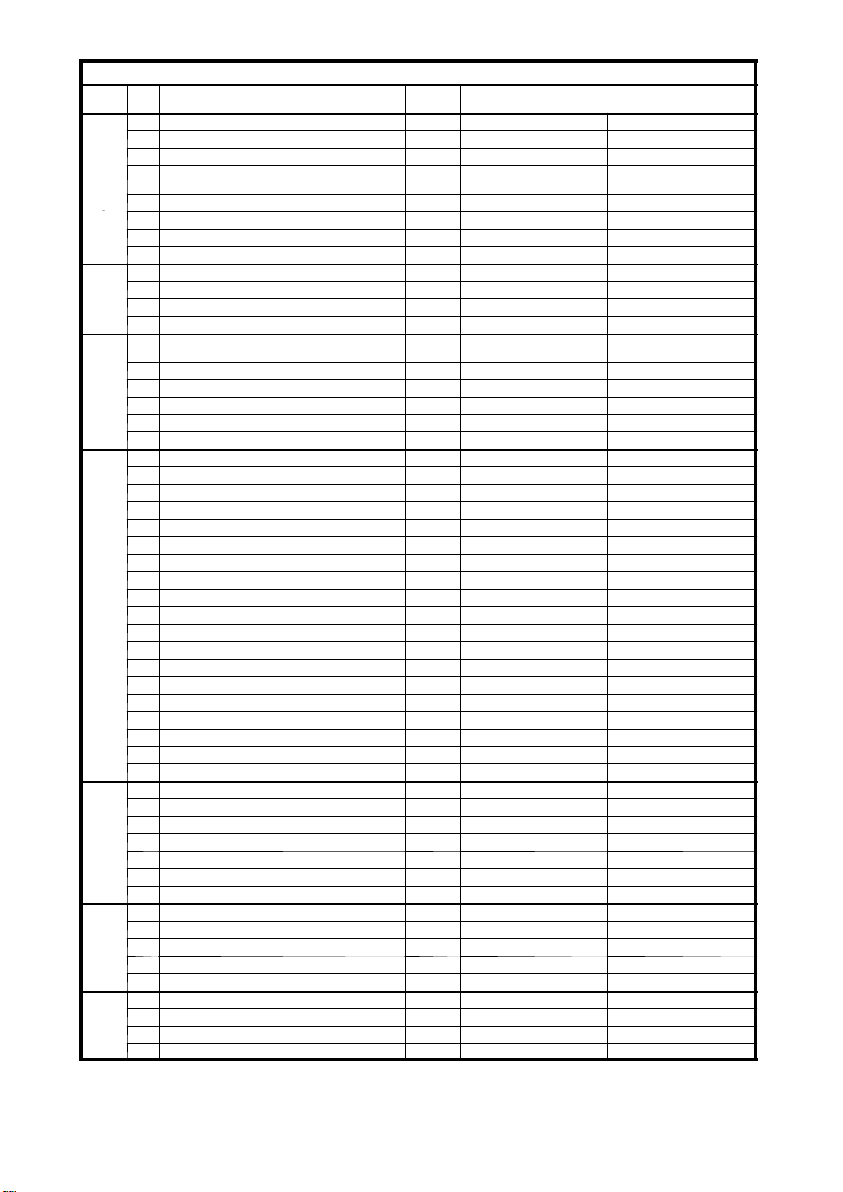

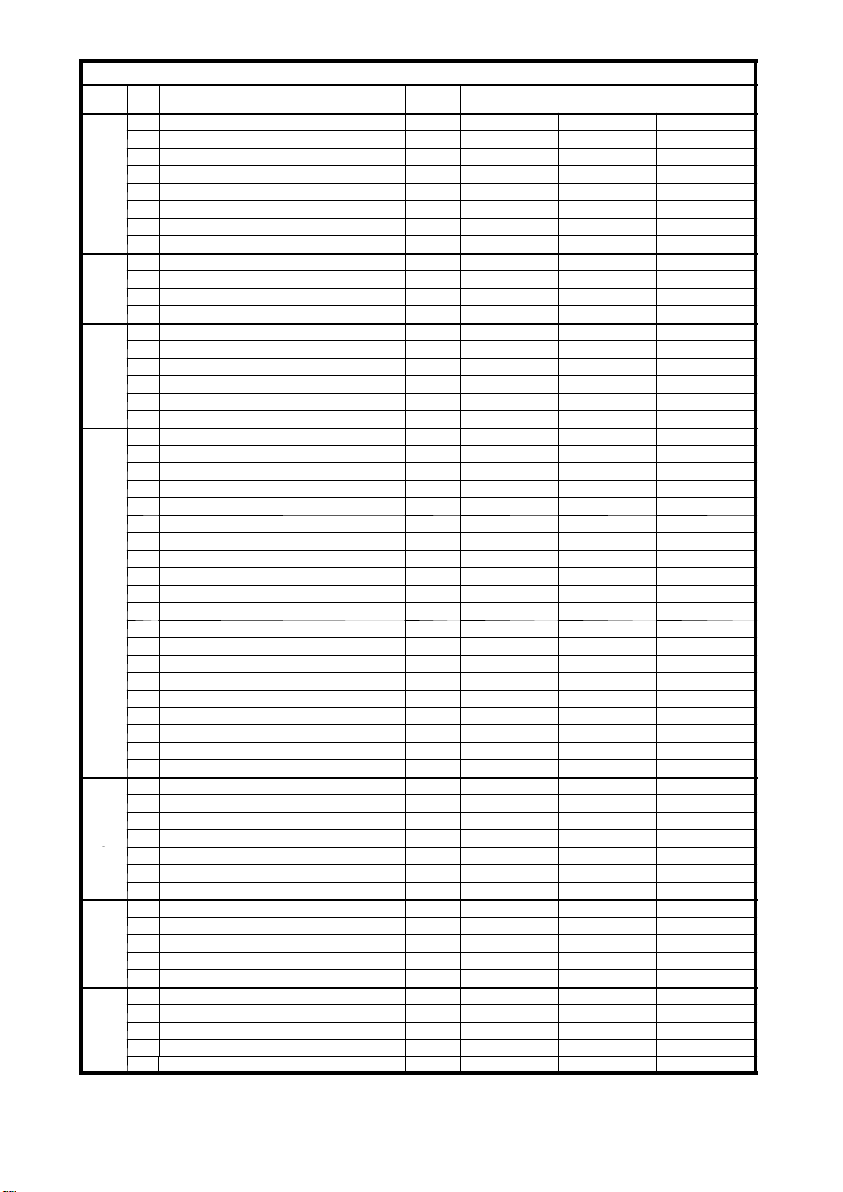

Contents

A Correct Use and Application of the Truck

B Description of Truck

1 Description of Use B 1...................................................

2 Description of Assemblies and Function B 2................................

2.1 Truck B3..............................................................

2.2 Mast B4...............................................................

2.3 Changes in operational requirements B 4..................................

2.4 Safety devices B 4......................................................

3 Technical Data -- Standard Equipment B 5..................................

3.1 Data tables -- DFG/TFG 16/20 AK B 14.....................................

3.2 Data tables -- DFG/TFG 20--30 BK B 16.....................................

3.3 Data tables -- DFG/TFG 40--50 CK B 19.....................................

4 Labels and Plates B 23...................................................

4.1 Truck Rating Plate B 24...................................................

4.2 Load diagrams B 25......................................................

C Transportation and Commissioning

1 Transportation C 1......................................................

2 Commissioning C 4......................................................

D Truck Refuelling

1 Safety Conditions for Handling Diesel Fuel and Liquid Petroleum Gas D 1......

2 Filling with Diesel Fuel D 2...............................................

3 Changing the Gas Bottle D 3.............................................

4 Trucks fitted with Twin--Gas Bottles D 5....................................

E Operation

1 Safety Regulations Governing the Operation of the Forklift Truck E 1..........

2 Description of Drivers Controls and Display Elements E 3....................

3 Checks and Activities Before Daily Use E 11.................................

4 Using the Truck E 17.....................................................

4.1 Start Process TFG E 19...................................................

4.2 Start Process DFG E 20..................................................

4.3 Fault Displays during Operation E 22.......................................

5 Operation of the Forklift Truck E 24.........................................

5.1 Safety regulations applicable when operating the truck E 24...................

5.2 Driving E26.............................................................

5.3 Steering E 28............................................................

5.4 Braking E 28.............................................................

5.5 Operating the Mast and Attachments E 30...................................

5.6 Picking Up, Transporting and Setting

Down Load Units E 32....................................................

5.7 Instructions for the use of restraint belts E 39................................

5.8 Parking the Truck Safely E 41..............................................

5.9 Engine housing and service covers E 42....................................

5.10 Towing E44.............................................................

5.11 Towing Trailers E 44......................................................

5.12 Trailer loads E 45........................................................

6 Fault Locating Operations E 46............................................

1203.GB

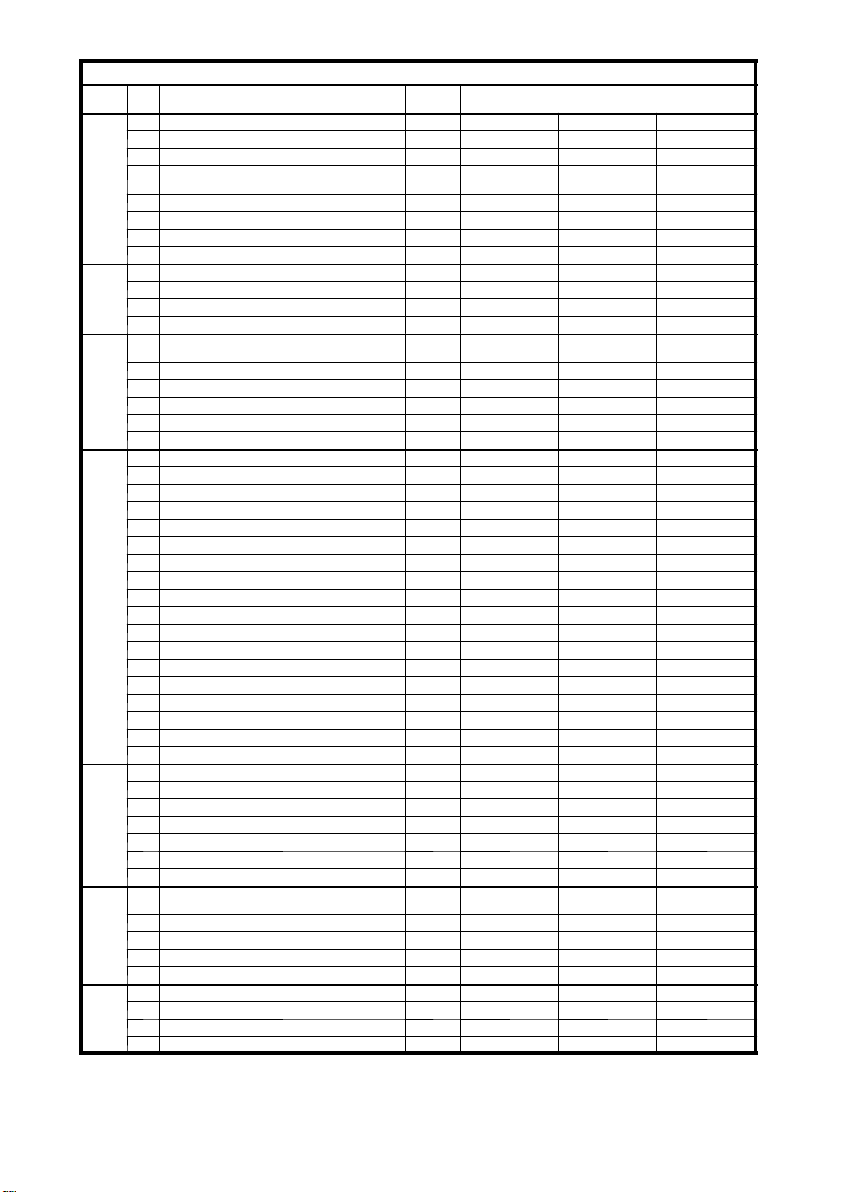

Contents

A Correct Use and Application of the Truck

B Description of Truck

1 Description of Use B 1...................................................

2 Description of Assemblies and Function B 2................................

2.1 Truck B3..............................................................

2.2 Mast B4...............................................................

2.3 Changes in operational requirements B 4..................................

2.4 Safety devices B 4......................................................

3 Technical Data -- Standard Equipment B 5..................................

3.1 Data tables -- DFG/TFG 16/20 AK B 14.....................................

3.2 Data tables -- DFG/TFG 20--30 BK B 16.....................................

3.3 Data tables -- DFG/TFG 40--50 CK B 19.....................................

4 Labels and Plates B 23...................................................

4.1 Truck Rating Plate B 24...................................................

4.2 Load diagrams B 25......................................................

C Transportation and Commissioning

1 Transportation C 1......................................................

2 Commissioning C 4......................................................

D Truck Refuelling

1 Safety Conditions for Handling Diesel Fuel and Liquid Petroleum Gas D 1......

2 Filling with Diesel Fuel D 2...............................................

3 Changing the Gas Bottle D 3.............................................

4 Trucks fitted with Twin--Gas Bottles D 5....................................

E Operation

1 Safety Regulations Governing the Operation of the Forklift Truck E 1..........

2 Description of Drivers Controls and Display Elements E 3....................

3 Checks and Activities Before Daily Use E 11.................................

4 Using the Truck E 17.....................................................

4.1 Start Process TFG E 19...................................................

4.2 Start Process DFG E 20..................................................

4.3 Fault Displays during Operation E 22.......................................

5 Operation of the Forklift Truck E 24.........................................

5.1 Safety regulations applicable when operating the truck E 24...................

5.2 Driving E26.............................................................

5.3 Steering E 28............................................................

5.4 Braking E 28.............................................................

5.5 Operating the Mast and Attachments E 30...................................

5.6 Picking Up, Transporting and Setting

Down Load Units E 32....................................................

5.7 Instructions for the use of restraint belts E 39................................

5.8 Parking the Truck Safely E 41..............................................

5.9 Engine housing and service covers E 42....................................

5.10 Towing E44.............................................................

5.11 Towing Trailers E 44......................................................

5.12 Trailer loads E 45........................................................

6 Fault Locating Operations E 46............................................

Page 5

1203.GB

F Truck Maintenance

1 Operational Safety and Environmental Protection F 1........................

2 Safety Regulations Applicable to Truck Maintenance F 1.....................

3 Servicing and Inspection F 2.............................................

4 Maintenance Check-list DFG/TFG F 3.....................................

5 Maintenance Check-list DFG F 5..........................................

6 Maintenance Check-list TFG F 6..........................................

7 Coolant Specification F 7................................................

8 Lubricant Specifications F 9..............................................

9 Fuel specification -- DFG F 13.............................................

10 Lubrication Chart F 14....................................................

10.1 Lubrication Diagram -- DFG/TFG 16--30 AK/BK F 15..........................

10.2 Lubrication Diagram -- DFG/TFG 40--50 CK F 16.............................

11 Description of Maintenance and Repair Work F 17...........................

11.1 Preparing the Truck for Maintenance and Repair Work F 17...................

11.2 Engine Maintenance TFG 16/20 AK F 17...................................

11.3 Engine Maintenance DFG 16/20 AK F 20...................................

11.4 Engine Maintenance TFG 20--30 BK F 23..................................

11.5 Engine Maintenance DFG 20--30 BK F 25..................................

11.6 Engine Maintenance TFG 40--50 CK F 28..................................

11.7 Engine Maintenance DFG 40--50 CK F 30..................................

11.8 Check Coolant Concentration F 33.........................................

11.9 Clean/Change Air Filter Cartridge F 34......................................

11.10 Transmission unit -- DFG/TFG 16/20 AK F 35................................

11.11 Transmission unit -- DFG/TFG 20--30 BK F 36...............................

11.12 Transmission unit -- DFG/TFG 40--50 CK F 37...............................

11.1 3 Br a k e s F38.............................................................

11.14 Change Wheels F 40.....................................................

11.15 Hydraulic System F 41....................................................

11.16 Electrical System F 42....................................................

12 Exhaust System F 45.....................................................

13 Decommissioning F 45...................................................

14 Inspection F 46..........................................................

14.1 Safety checks to be performed at regular intervals and following any

untoward incidents (D: Accident prevention check according to BGV D27) F 47

15 Storage F 48............................................................

16 Disposal F 52............................................................

Appendix for Diesel Engine Exhaust Gas Filter -- STX Type 1

.........

1 Introduction 1.........................................................

2 Regeneration 1.......................................................

1203.GB

F Truck Maintenance

1 Operational Safety and Environmental Protection F 1........................

2 Safety Regulations Applicable to Truck Maintenance F 1.....................

3 Servicing and Inspection F 2.............................................

4 Maintenance Check-list DFG/TFG F 3.....................................

5 Maintenance Check-list DFG F 5..........................................

6 Maintenance Check-list TFG F 6..........................................

7 Coolant Specification F 7................................................

8 Lubricant Specifications F 9..............................................

9 Fuel specification -- DFG F 13.............................................

10 Lubrication Chart F 14....................................................

10.1 Lubrication Diagram -- DFG/TFG 16--30 AK/BK F 15..........................

10.2 Lubrication Diagram -- DFG/TFG 40--50 CK F 16.............................

11 Description of Maintenance and Repair Work F 17...........................

11.1 Preparing the Truck for Maintenance and Repair Work F 17...................

11.2 Engine Maintenance TFG 16/20 AK F 17...................................

11.3 Engine Maintenance DFG 16/20 AK F 20...................................

11.4 Engine Maintenance TFG 20--30 BK F 23..................................

11.5 Engine Maintenance DFG 20--30 BK F 25..................................

11.6 Engine Maintenance TFG 40--50 CK F 28..................................

11.7 Engine Maintenance DFG 40--50 CK F 30..................................

11.8 Check Coolant Concentration F 33.........................................

11.9 Clean/Change Air Filter Cartridge F 34......................................

11.10 Transmission unit -- DFG/TFG 16/20 AK F 35................................

11.11 Transmission unit -- DFG/TFG 20--30 BK F 36...............................

11.12 Transmission unit -- DFG/TFG 40--50 CK F 37...............................

11.1 3 Br a k e s F38.............................................................

11.14 Change Wheels F 40.....................................................

11.15 Hydraulic System F 41....................................................

11.16 Electrical System F 42....................................................

12 Exhaust System F 45.....................................................

13 Decommissioning F 45...................................................

14 Inspection F 46..........................................................

14.1 Safety checks to be performed at regular intervals and following any

untoward incidents (D: Accident prevention check according to BGV D27) F 47

15 Storage F 48............................................................

16 Disposal F 52............................................................

Appendix for Diesel Engine Exhaust Gas Filter -- STX Type 1

.........

1 Introduction 1.........................................................

2 Regeneration 1.......................................................

Page 6

A1

1203.GB

A Correct Use and Application of the

Truck

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) is

included in the scope of delivery for this truck. The guidelines are part of these

operating instructions and must always be heeded. National regulations are fully

applicable.

The forklift truck described in these operating instructions is a truck that is suitable for

lifting and transporting loads. It must be used, operated and maintained according to

the information in these operating instructions. Any other uses are outside the design

envelope and can lead to injury to persons or damage to equipment and property.

Above all, overloading caused by excessively heavy or unbalanced loads must be

avoided. The max. admissible load to be picked up can be seen from the identification

plate or load diagram label shown on the truck. The fork--lift truck must not be operated

in spaces subject to fire or explosion hazards, or in spaces where corrosive or very

dusty atmospheres prevail.

Duties of the user: User within the meaning of these operating instructions is any

natural person or legal person who either uses the fork--lift truck himself, or on whose

behalf it is used. In special cases (e.g. leasing or renting), the user is considered the

person, who, in accordance with existing contractual agreements between the owner

and the user of the fork--lift truck, is charged with the observance of the operating

duties.

The user m ust ensure that the truck is not abused and only used within its design limits

and that all danger to life and limb of the operator, or third parties, is avoided. In addition

to this, it must be ensured that the relevant accident prevention regulations and other

safety--related provisions, as well as the operating, servicing and maintenance

guidelines, are observed. The user must also ensure that all persons operating the

truck have read and understood these operating instructions.

If these Operating Instructions are not observed the warranty becomes void. The same

applies if improper work is carried out on the device by the customer and/or third parties

without permission of our Customer Service.

Mounting of attachments: T he mounting or installation of any attachments which will

interfere with, or supplement, the functions of the truck is permitted only after written

approval by the m anufacturer has been obtained. If necessary, the approval of local

authorities has to be obtained. Any approval obtained from local authorities does not,

however, make the approval by the manufacturer unnecessary.

Trailing and slipp in g loads: The truck may only be used for trailing or slipping loads

for which the truck has been approved.

A

A1

1203.GB

A Correct Use and Application of the

Truck

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) is

included in the scope of delivery for this truck. The guidelines are part of these

operating instructions and must always be heeded. National regulations are fully

applicable.

The forklift truck described in these operating instructions is a truck that is suitable for

lifting and transporting loads. It must be used, operated and maintained according to

the information in these operating instructions. Any other uses are outside the design

envelope and can lead to injury to persons or damage to equipment and property.

Above all, overloading caused by excessively heavy or unbalanced loads must be

avoided. The max. admissible load to be picked up can be seen from the identification

plate or load diagram label shown on the truck. The fork--lift truck must not be operated

in spaces subject to fire or explosion hazards, or in spaces where corrosive or very

dusty atmospheres prevail.

Duties of the user: User within the meaning of these operating instructions is any

natural person or legal person who either uses the fork--lift truck himself, or on whose

behalf it is used. In special cases (e.g. leasing or renting), the user is considered the

person, who, in accordance with existing contractual agreements between the owner

and the user of the fork--lift truck, is charged with the observance of the operating

duties.

The user m ust ensure that the truck is not abused and only used within its design limits

and that all danger to life and limb of the operator, or third parties, is avoided. In addition

to this, it must be ensured that the relevant accident prevention regulations and other

safety--related provisions, as well as the operating, servicing and maintenance

guidelines, are observed. The user must also ensure that all persons operating the

truck have read and understood these operating instructions.

If these Operating Instructions are not observed the warranty becomes void. The same

applies if improper work is carried out on the device by the customer and/or third parties

without permission of our Customer Service.

Mounting of attachments: T he mounting or installation of any attachments which will

interfere with, or supplement, the functions of the truck is permitted only after written

approval by the m anufacturer has been obtained. If necessary, the approval of local

authorities has to be obtained. Any approval obtained from local authorities does not,

however, make the approval by the manufacturer unnecessary.

Trailing and slipp in g loads: The truck may only be used for trailing or slipping loads

for which the truck has been approved.

A

Page 7

Page 8

B1

1203.GB

B Description of Truck

1 Description of Use

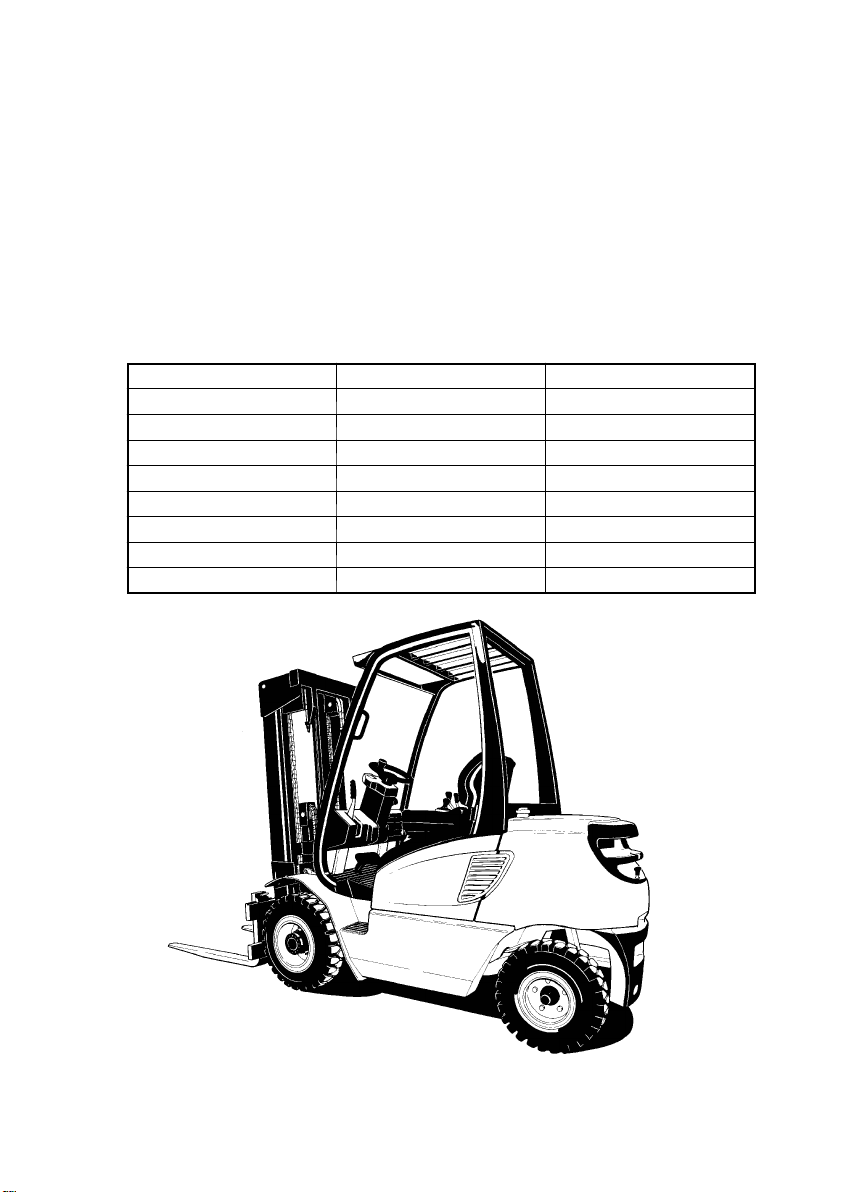

Forklift trucks to series DFG/TFG are driver’s cab forklifts with 4 wheel construction and

combustion engine. Trucks to series DFG have diesel engines, trucks of series TFG a

liquid petroleum gas engine.

The DFG/TFG 16-- 50 AK/BK/CK has a hydrodynamic drive. A combined creep/brake

pedal allows rapid lifting during creep running.

The load--bearing capacity depends on type. The type description indicates the

maximum permitted load. A DFG/TFG 16 can lift, transport and stack loads up to 1600

kg, and a DFG/TFG 20 loads up to 2000 kg.

Model

Load Capacity (kg) Wheel Base (mm)

DFG/TFG 16 A 1600 1400

DFG/TFG 20 A 2000 1400

DFG/TFG 20 B 2000 1685

DFG/TFG 25 B 2500 1685

DFG/TFG 30 B 3000 1685

DFG/TFG 40 C 4000 1985

DFG/TFG 45 C 4500 1985

DFG/TFG 50 C 5000 1985

B1

1203.GB

B Description of Truck

1 Description of Use

Forklift trucks to series DFG/TFG are driver’s cab forklifts with 4 wheel construction and

combustion engine. Trucks to series DFG have diesel engines, trucks of series TFG a

liquid petroleum gas engine.

The DFG/TFG 16-- 50 AK/BK/CK has a hydrodynamic drive. A combined creep/brake

pedal allows rapid lifting during creep running.

The load--bearing capacity depends on type. The type description indicates the

maximum permitted load. A DFG/TFG 16 can lift, transport and stack loads up to 1600

kg, and a DFG/TFG 20 loads up to 2000 kg.

Model

Load Capacity (kg) Wheel Base (mm)

DFG/TFG 16 A 1600 1400

DFG/TFG 20 A 2000 1400

DFG/TFG 20 B 2000 1685

DFG/TFG 25 B 2500 1685

DFG/TFG 30 B 3000 1685

DFG/TFG 40 C 4000 1985

DFG/TFG 45 C 4500 1985

DFG/TFG 50 C 5000 1985

Page 9

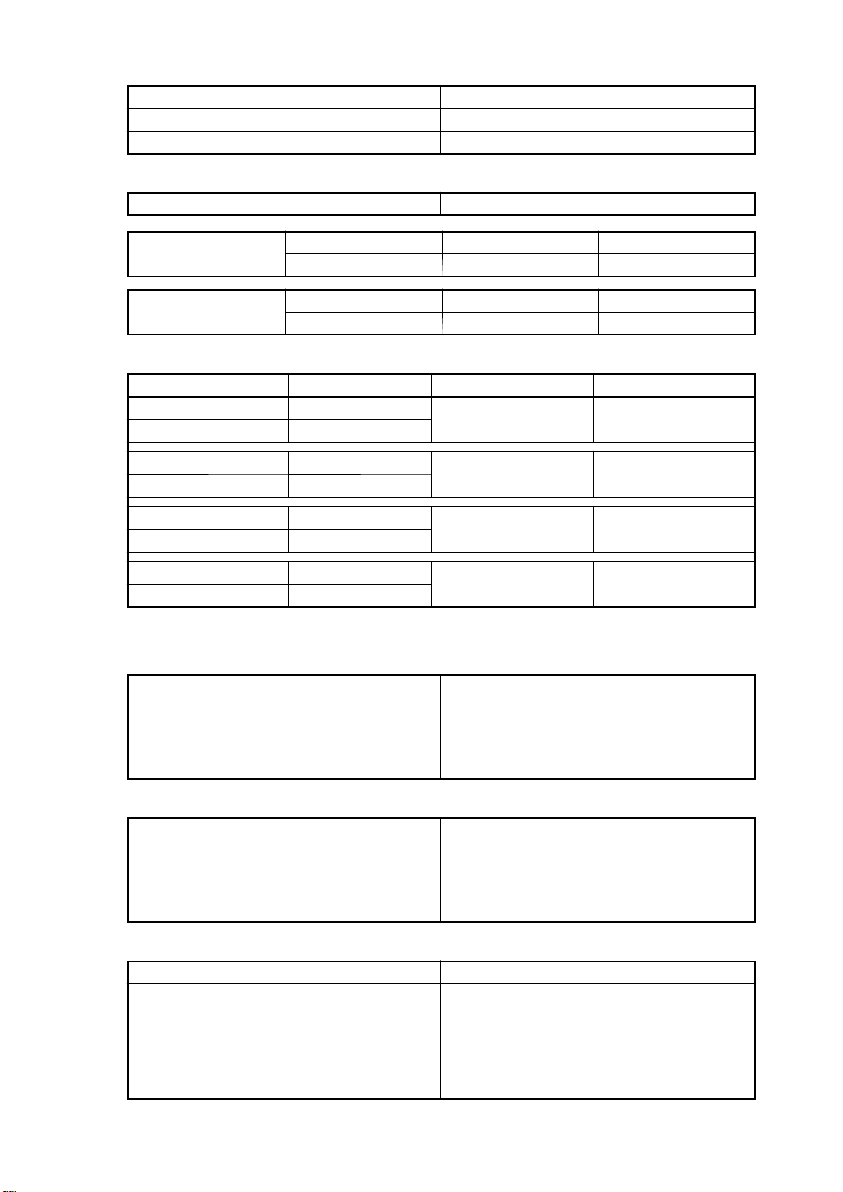

B2

1203.GB

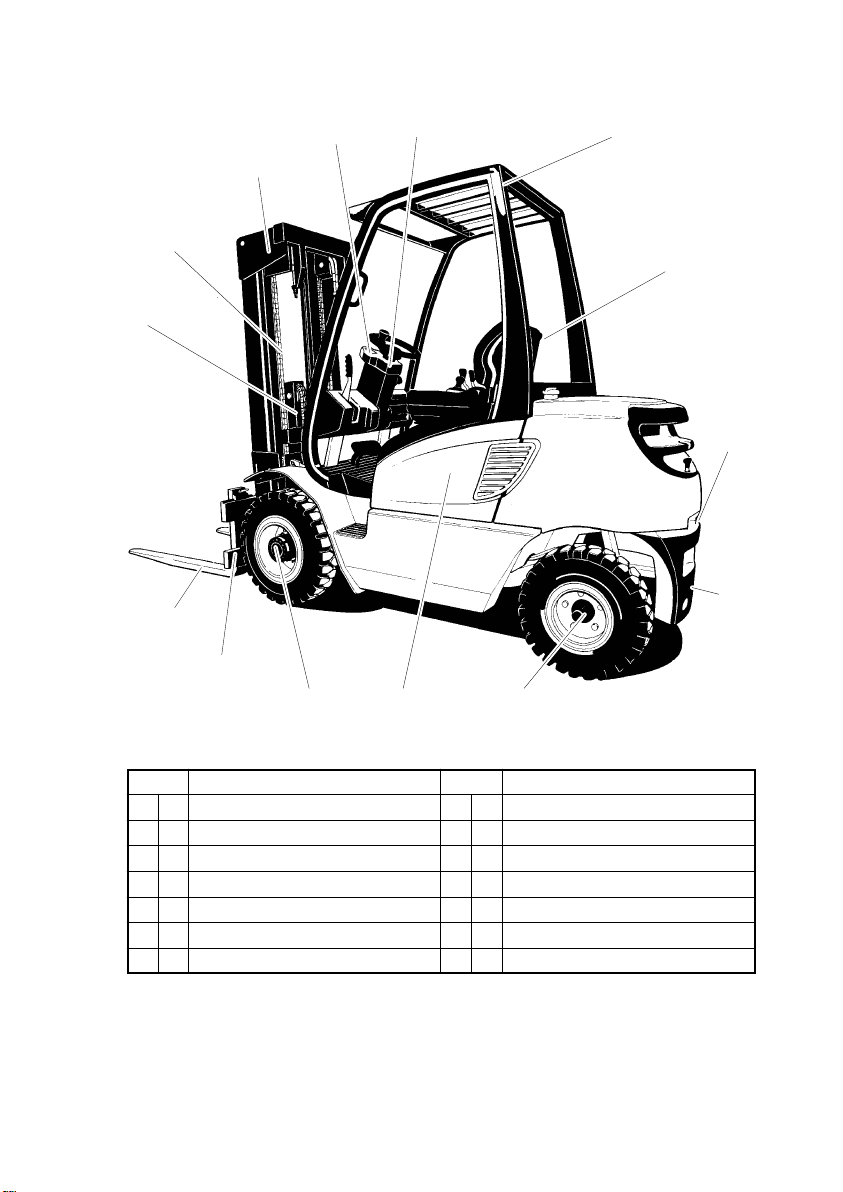

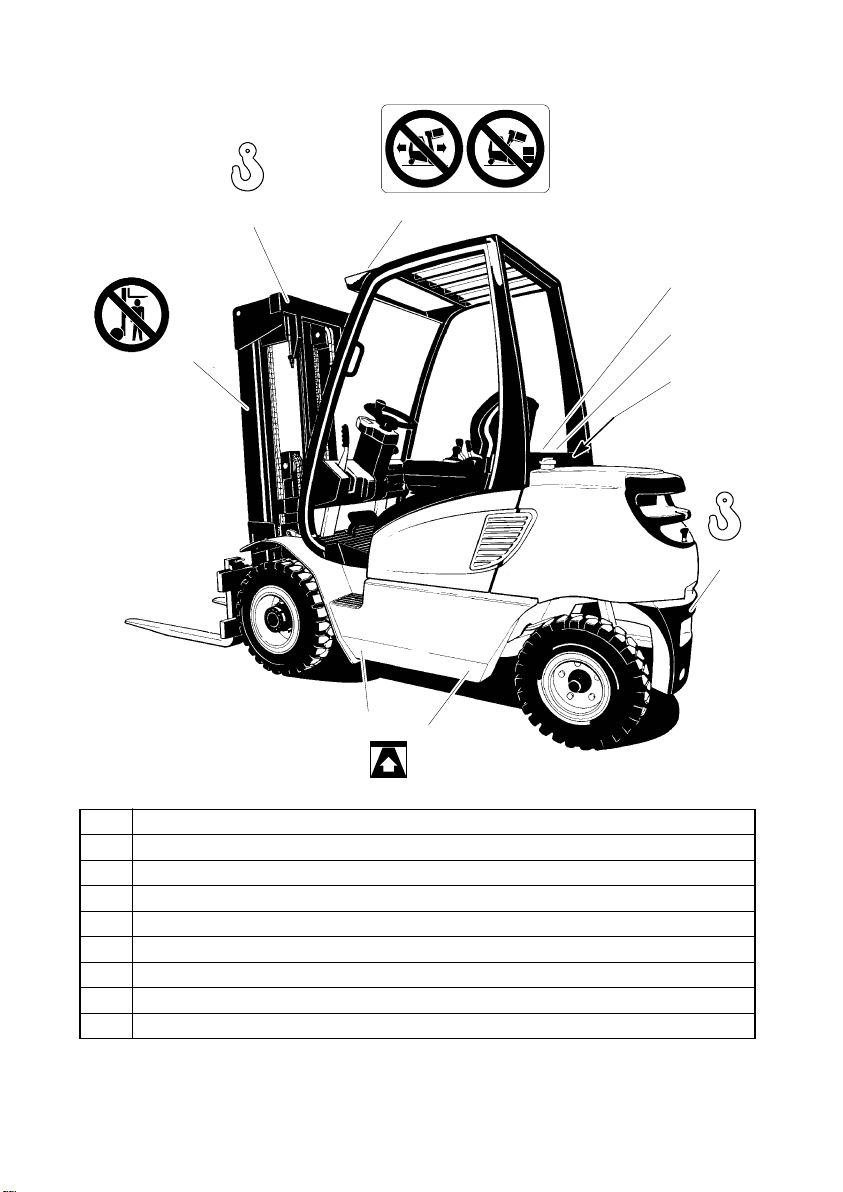

2 Description of Assemblies and Function

1

2

3

4

5

6

7

8

9

101112

13

14

Item Description Item Description

1 F Lift cylinder 8 F Towing coupling

2 F Lift chain 9 F Counterweight

3 F Mast assembly 10 F Steer axle

4 F Instrument panel 11 F Engine cover

5 F Steering column 12 F Drive axle

6 F Driver’s loadguard 13 F Carriage

7 F Driver’s seat 14 F Fork

B2

1203.GB

2 Description of Assemblies and Function

1

2

3

4

5

6

7

8

9

101112

13

14

Item Description Item Description

1 F Lift cylinder 8 F Towing coupling

2 F Lift chain 9 F Counterweight

3 F Mast assembly 10 F Steer axle

4 F Instrument panel 11 F Engine cover

5 F Steering column 12 F Drive axle

6 F Driver’s loadguard 13 F Carriage

7 F Driver’s seat 14 F Fork

Page 10

B3

1203.GB

2.1 Truck

Frame and Superstructure: A stable, torsionally rigid frame in which the equipment

and controls are installed protected, gives the truck a high static safety. The driver’s cab

is spring--mounted to dampen vibrations and noise.

A wide--opening top and two side panels on the engine cover (11) allow easy

maintenance and service. The hydraulic oil tank is side integrated into the frame on the

right and the fuel tank for the DFG series on the opposite side. The gas bottles for the

TFG series are attached to the counterweight (9) in a holder. The vertical free--standing

exhaust pipe which opens high above the machine prevents the transmission of

vibration and sound waves and the penetration of exhaust gases into the driver ’s cab.

Driver’s Cab: Non--slip steps and a handle on the roof pillar ensure easy entrance and

exit. The driver is protected by the roof (6). On the driver’s seat (7), the seat cushioning

and position are adjustable, and on the steering column (5) the angle of the steering

wheel can be modified. Simple operation by ergonomically arranged controls and a

virtually vibration--free driver’s cab means that minimum load is exerted on the driver.

The control and warning displays on the instrument panel (4) allow monitoring of the

systems during operation. As a result, the safety standard is very high.

The driver’s overhead guard m ust be checked prior to starting the truck for cracks, and

if damaged, must be repaired or replaced.

Engine: A silent water--cooled engine with high power and low fuel consumption. The

DFG series are fitted with diesel engines with very clean combustion under all

operating conditions and with low soot output. In the TFG series, liquid petroleum gas

engines are fitted with a very low residual exhaust value.

Drive: A load gearbox with gear oil cooler and torque converter is flanged directly onto

the engine. This transfers the power to the drive axle (12).

The direction lever on the operating console selects forwards/reverse or neutral.

Steering: Hydrostatic steering with a steering cylinder integrated into the steering axle

(10). The steering axle is fully floating in the frame to ensure good ground holding even

on uneven surfaces.

Brakes: The creep/brake pedal operates two hydraulic drum brakes acting on the drive

wheels. The drum brakes adjust automatically for wear. The parking brake acts

mechanically via Bowden cables on the drum brakes when the parking brake lever is

operated.

Wheels: All wheels are within the truck contour. The tyres are either pneumatic or

super--elastic tyres.

Hydraulic System: The hydraulic system gear pump is driven by the engine via the

secondary take--off from the load gears. The pump speed and hence the transport

volume is controlled by the engine speed via the accelerator pedal.

The hydraulic functions are controlled by the control lever via a multiple control valve.

Electrical System: 12 Volt system with starter battery and 3--phase alternator with

integral regulator. The starting repeat block prevents incorrect operation during

starting and a safety circuit allows the engine to start only when the direction lever is in

neutral. For diesel engines, a fast preglow system is fitted, whereas LPG engines have

a contactless electronic ignition system for fast easy starting of the engine. The engine

is turned off using the ignition/starter switch.

f

B3

1203.GB

2.1 Truck

Frame and Superstructure: A stable, torsionally rigid frame in which the equipment

and controls are installed protected, gives the truck a high static safety. The driver’s cab

is spring--mounted to dampen vibrations and noise.

A wide--opening top and two side panels on the engine cover (11) allow easy

maintenance and service. The hydraulic oil tank is side integrated into the frame on the

right and the fuel tank for the DFG series on the opposite side. The gas bottles for the

TFG series are attached to the counterweight (9) in a holder. The vertical free--standing

exhaust pipe which opens high above the machine prevents the transmission of

vibration and sound waves and the penetration of exhaust gases into the driver ’s cab.

Driver’s Cab: Non--slip steps and a handle on the roof pillar ensure easy entrance and

exit. The driver is protected by the roof (6). On the driver’s seat (7), the seat cushioning

and position are adjustable, and on the steering column (5) the angle of the steering

wheel can be modified. Simple operation by ergonomically arranged controls and a

virtually vibration--free driver’s cab means that minimum load is exerted on the driver.

The control and warning displays on the instrument panel (4) allow monitoring of the

systems during operation. As a result, the safety standard is very high.

The driver’s overhead guard m ust be checked prior to starting the truck for cracks, and

if damaged, must be repaired or replaced.

Engine: A silent water--cooled engine with high power and low fuel consumption. The

DFG series are fitted with diesel engines with very clean combustion under all

operating conditions and with low soot output. In the TFG series, liquid petroleum gas

engines are fitted with a very low residual exhaust value.

Drive: A load gearbox with gear oil cooler and torque converter is flanged directly onto

the engine. This transfers the power to the drive axle (12).

The direction lever on the operating console selects forwards/reverse or neutral.

Steering: Hydrostatic steering with a steering cylinder integrated into the steering axle

(10). The steering axle is fully floating in the frame to ensure good ground holding even

on uneven surfaces.

Brakes: The creep/brake pedal operates two hydraulic drum brakes acting on the drive

wheels. The drum brakes adjust automatically for wear. The parking brake acts

mechanically via Bowden cables on the drum brakes when the parking brake lever is

operated.

Wheels: All wheels are within the truck contour. The tyres are either pneumatic or

super--elastic tyres.

Hydraulic System: The hydraulic system gear pump is driven by the engine via the

secondary take--off from the load gears. The pump speed and hence the transport

volume is controlled by the engine speed via the accelerator pedal.

The hydraulic functions are controlled by the control lever via a multiple control valve.

Electrical System: 12 Volt system with starter battery and 3--phase alternator with

integral regulator. The starting repeat block prevents incorrect operation during

starting and a safety circuit allows the engine to start only when the direction lever is in

neutral. For diesel engines, a fast preglow system is fitted, whereas LPG engines have

a contactless electronic ignition system for fast easy starting of the engine. The engine

is turned off using the ignition/starter switch.

f

Page 11

B4

1203.GB

2.2 Mast

Mast: The trucks are fitted with tilting telescopic clear--view masts. Lifting cylinders ( 1)

arranged behind the profile of the mast (3) raise the inner mast. The load chains (2) with

pulley deflection raise the carriage (13) at the same time. The fork (14) is adjustably

mounted on the carriage. Adjustable side r ollers and sliders absorb the lateral pressure

on the carriage from an unbalanced load.

In the double telescopic mast (ZT), lift is achieved b y extending the inner mast only. For

double twin--lift masts (ZZ) and triple twin--lift masts (DZ), first the carriage with load

chains is raised via a short centrally--mounted cylinder and thus the first lift is possible

without altering the truck height (special clearance lift). Only then is the inner mast

extended.

Attachments: Mechanical and hydraulic attachments can be fitted (optional

equipment).

2.3 Changes in operational requirements

Should the operation of your frontlift change so that additional features such as lights,

cab or auxiliary hydraulics, sideshift etc. are requir ed, only officially approved

attachments or ancillary equipment may be used. Consult your nearest Depot or

Distributor for advice regarding any changes in operating or load handling procedures,

which would necessitate alterations to the truck or ancillary equipment.

Under no circumstances should any unauthorised addition or modification be made to

the truck, mast or attachment as originally supplied.

IMPORTANT

If the frontlift is modified or used with attachments other than those originally supplied,

new rating plates must be affixed in the cab and in the European Economic Area (EEA)

countries the truck must be re-certified for conformity to the Machinery Directive

98/37/EEC as amended.

2.4 Safety devices

In addition to the driver ’s overhead guard , the battery isolation switch and key operated

ignition switch are classed as safety devices.

Battery isolation switch: The battery is connected and the truck is ready to run when

the battery isolation switch is raised. The battery is isolated when the battery isolation

switch is in the depressed position.

Key operated ignition switch: The removal of an ignition key by an authorized driver

upon leaving the truck, will prevent the truck from being operated by any unauthorized

person. The driver may not give the ignition key to another person without

authorization.

B4

1203.GB

2.2 Mast

Mast: The trucks are fitted with tilting telescopic clear--view masts. Lifting cylinders ( 1)

arranged behind the profile of the mast (3) raise the inner mast. The load chains (2) with

pulley deflection raise the carriage (13) at the same time. The fork (14) is adjustably

mounted on the carriage. Adjustable side r ollers and sliders absorb the lateral pressure

on the carriage from an unbalanced load.

In the double telescopic mast (ZT), lift is achieved b y extending the inner mast only. For

double twin--lift masts (ZZ) and triple twin--lift masts (DZ), first the carriage with load

chains is raised via a short centrally--mounted cylinder and thus the first lift is possible

without altering the truck height (special clearance lift). Only then is the inner mast

extended.

Attachments: Mechanical and hydraulic attachments can be fitted (optional

equipment).

2.3 Changes in operational requirements

Should the operation of your frontlift change so that additional features such as lights,

cab or auxiliary hydraulics, sideshift etc. are requir ed, only officially approved

attachments or ancillary equipment may be used. Consult your nearest Depot or

Distributor for advice regarding any changes in operating or load handling procedures,

which would necessitate alterations to the truck or ancillary equipment.

Under no circumstances should any unauthorised addition or modification be made to

the truck, mast or attachment as originally supplied.

IMPORTANT

If the frontlift is modified or used with attachments other than those originally supplied,

new rating plates must be affixed in the cab and in the European Economic Area (EEA)

countries the truck must be re-certified for conformity to the Machinery Directive

98/37/EEC as amended.

2.4 Safety devices

In addition to the driver ’s overhead guard , the battery isolation switch and key operated

ignition switch are classed as safety devices.

Battery isolation switch: The battery is connected and the truck is ready to run when

the battery isolation switch is raised. The battery is isolated when the battery isolation

switch is in the depressed position.

Key operated ignition switch: The removal of an ignition key by an authorized driver

upon leaving the truck, will prevent the truck from being operated by any unauthorized

person. The driver may not give the ignition key to another person without

authorization.

Page 12

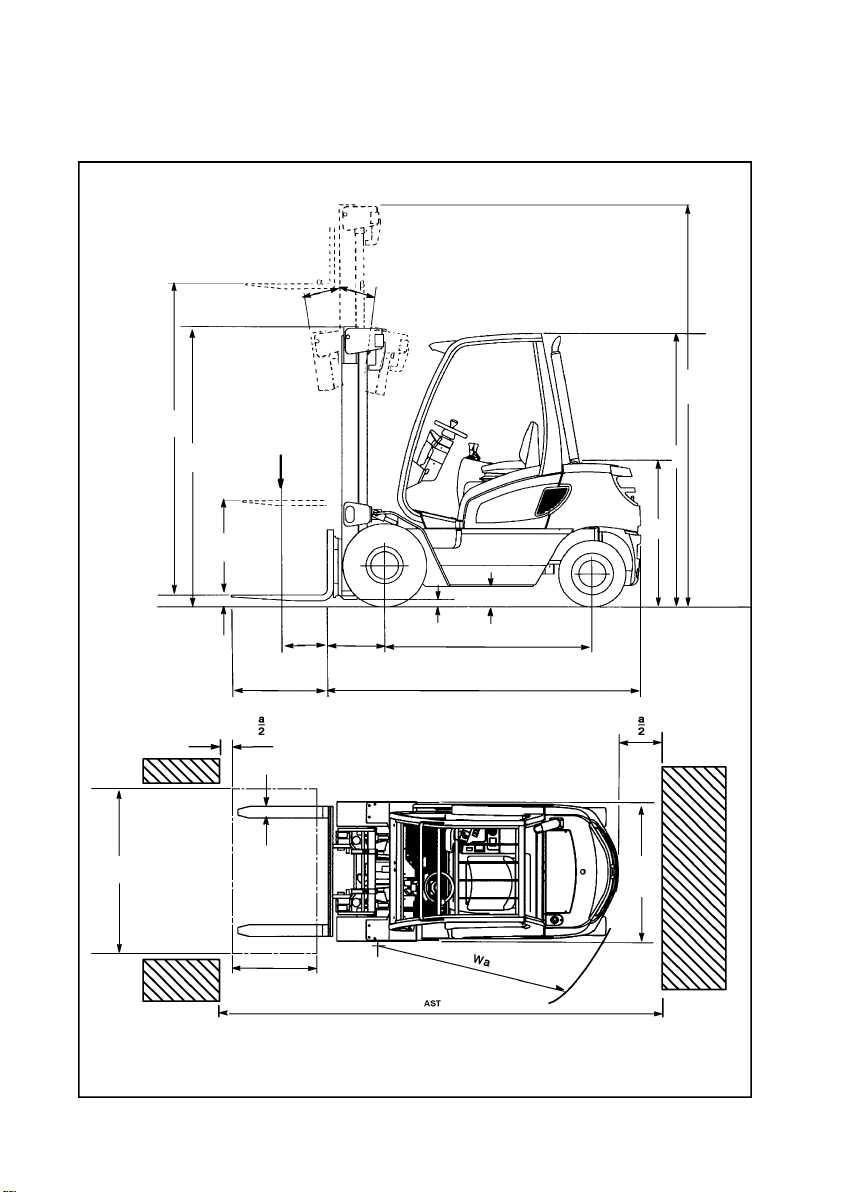

B5

1203.GB

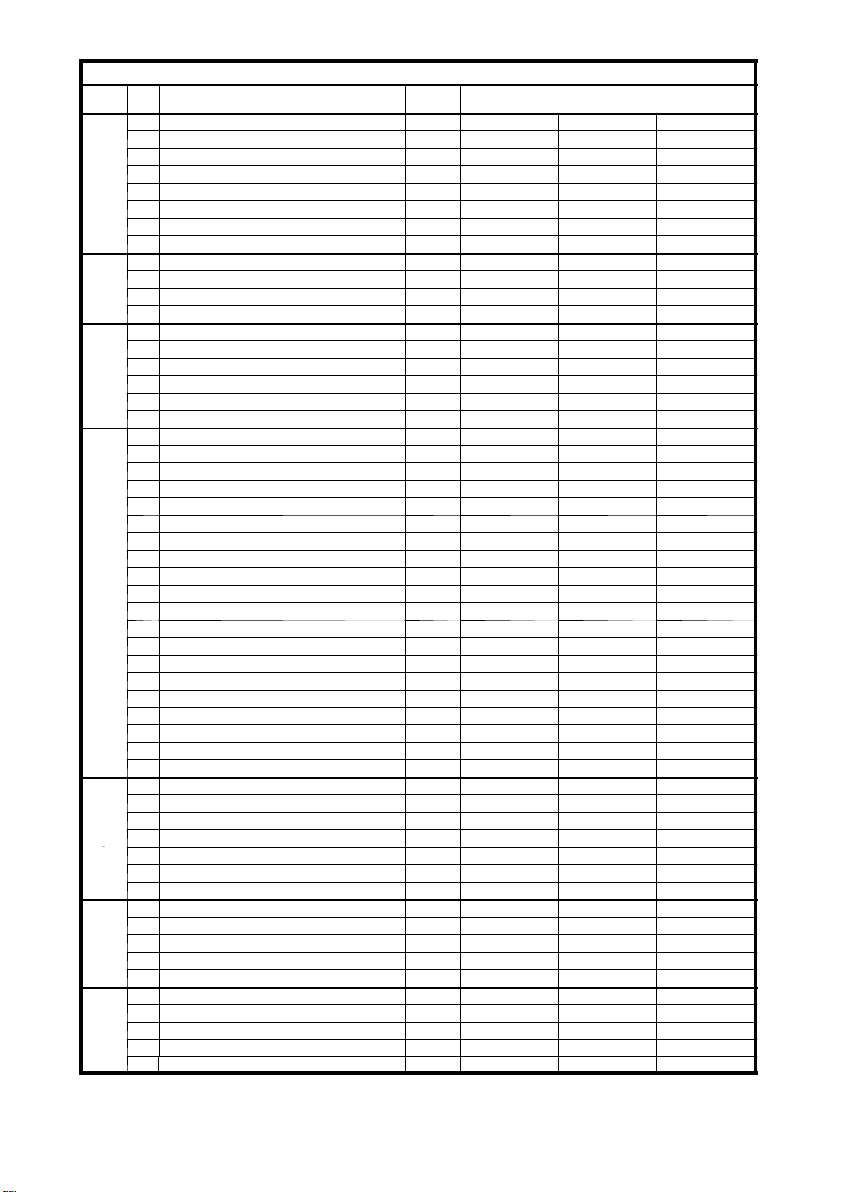

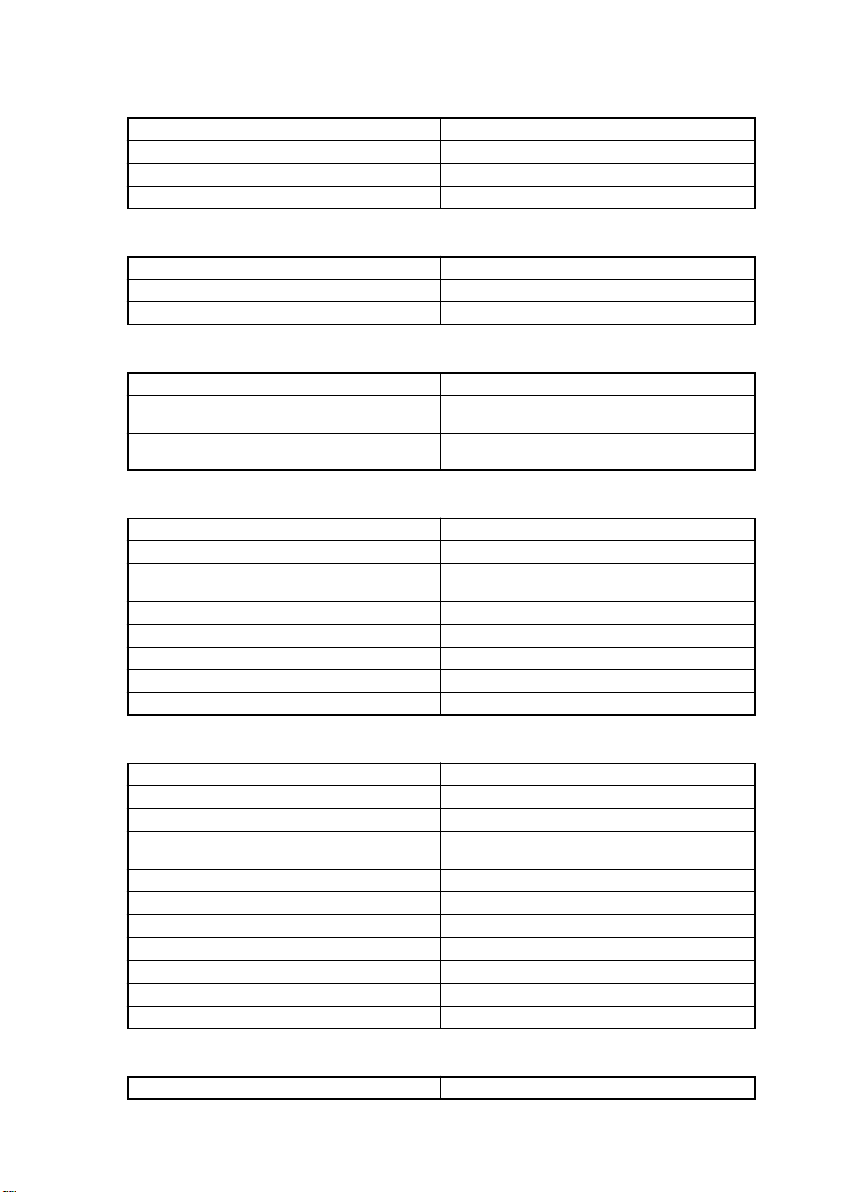

3 Technical Data -- Standard Equipment

Data to VDI 2198, subject to technical alterations and supplements

h

4

h

6

h

7

h

3

h

1

h

2

S

lL

2

y

xC

Q

m

1

m

2

B

d

e

b

A

B5

1203.GB

3 Technical Data -- Standard Equipment

Data to VDI 2198, subject to technical alterations and supplements

h

4

h

6

h

7

h

3

h

1

h

2

S

lL

2

y

xC

Q

m

1

m

2

B

d

e

b

A

Page 13

B6

1203.GB

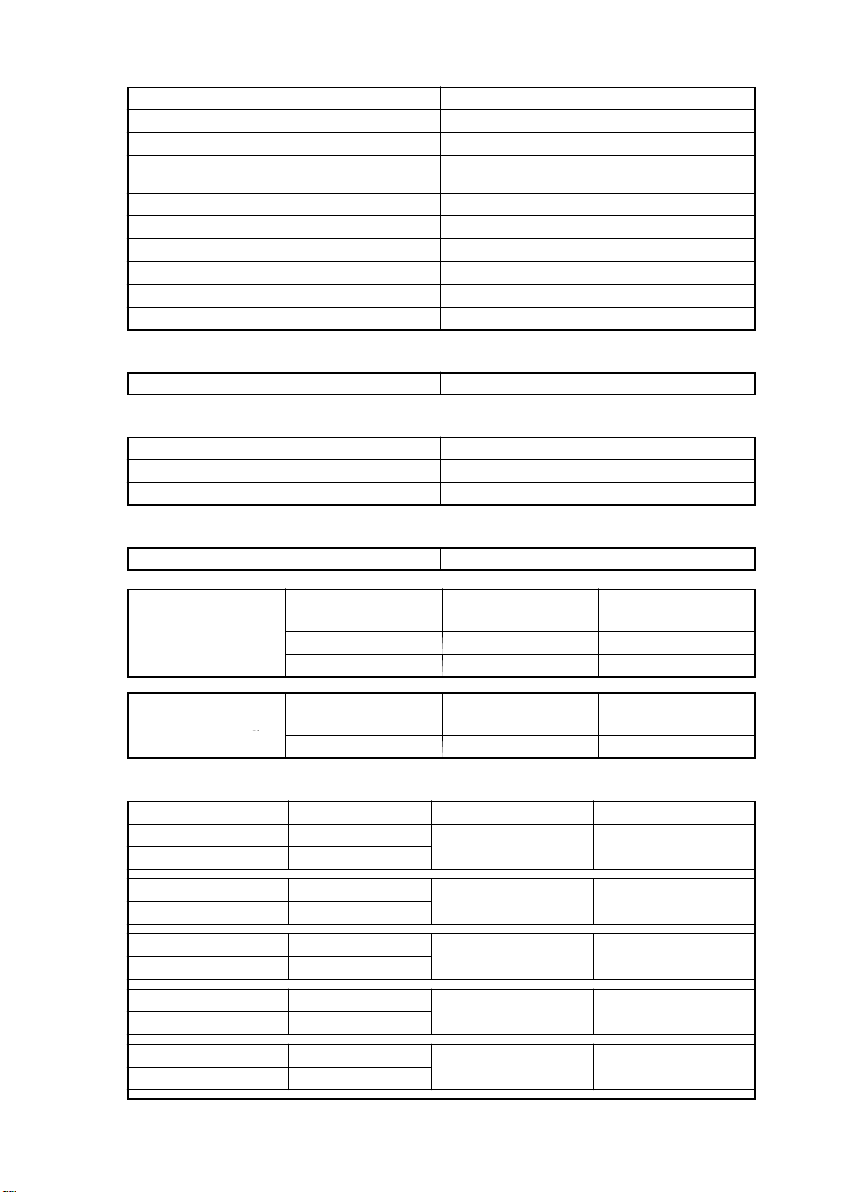

Specification sheet for lift trucks DFG 16/20 AK

No. Description

Code

(Unit)

AX-J

1. Manufacturer Jungheinrich Jungheinrich

1.2 Model Name DFG 16 AK DFG 20 AK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated

ecifi

1.5 Load Capacity Q(t) 1,6 2,0

Sp

e

1.6 Load Centre c(mm) 500 500

S

1.8 Load Distance x(mm) 395 395

1.9 Wheel Base y( mm) 1400 1400

2.1 Weight--unladen (kg) 3020 3270

ht

2.2 Axle Loading laden, front/rear (kg) 4000/620 4600/670

ei

g

2.3 Axle Loading unladen, front/rear (kg) 1320/1700 1240/2030

W

Longitudinal stabilit y 1,66 1,59

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L)/SE(L)

ssi

s

3.2 Tyre Size: front 6.50--10 (14PR) 6.50-- 10 (14PR)

Ch

a

3.3 Tyre Size: rear 18x7--8 (16PR) 18x7--8 (16PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 895 895

W

3.7 Track width, rear b11(mm) 870 ( offset) 870 (offset)

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/10 7/10

4.2 Mast Height, lowered h1(mm) 2080 2080

4.3 Free Lift h2(mm) 100 100

4.4 Lift Height h3(mm) 3090 3090

4.5 Height of extended mast h4(mm) 3670 3670

4.7 Height of overhead guard (Cabin) h6(mm) 2130 2130

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1005/1065 1005/1065

4.12 Coupling height h10(mm) 375/545 375/545

ons

4.19 Ov erall Length l1(mm) 3245 3300

nsi

o

4.20 Length to Fork Fac e l2(mm) 2245 2300

ime

n

4.21 Over all Width b1/b2(mm) 1070 1070

Di

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A

4.24 Fork C arriage width / outs ide fork s b3(mm) 1000/849 1000/849

4.31 Ground Clearanc e laden under mas t m1(mm) 115 11 5

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 135 135

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3570 3615

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 3770 3815

4.35 Turning Radius Wa(mm) 1975 2020

5.1 Travel Speed laden/unladen (km/h) 18,7/19,0 18,4/18,7

5.2 Lifting Speed laden/unladen (m/s) 0,61/0,65 0,60/0,65

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,56/0,48 0,57/0,48

rma

5.5 Draw-bar -pull laden/unladen (kN) 12,7/9,0 12,6/8,2

rfo

r

5.7 Gradeability laden/unladen (%) 26/23 23/21

Pe

5.9 Acceleration time, laden/unladen s 5,0/4,5 5,1/4,4

5.10 Service brake type mech./hydr. mech./hydr.

7.1 Engine Manufacturer/Model 404C.22 404C.22

e

7.2 Engine Output to ISO 1585 (kw) 34,1 34,1

gin

e

7.3 Rated Rotation (1/min) 2400 2400

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/2216 4/2216

max. torque Nm/rpm 143/1800 135/1900

8.1 Type of Drive Control hydrodyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160

th

e

8.3 Oil flow for attachments l/min 45 45

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80

B6

1203.GB

Specification sheet for lift trucks DFG 16/20 AK

No. Description

Code

(Unit)

AX-J

1. Manufacturer Jungheinrich Jungheinrich

1.2 Model Name DFG 16 AK DFG 20 AK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated

ecifi

1.5 Load Capacity Q(t) 1,6 2,0

Sp

e

1.6 Load Centre c(mm) 500 500

S

1.8 Load Distance x(mm) 395 395

1.9 Wheel Base y( mm) 1400 1400

2.1 Weight--unladen (kg) 3020 3270

ht

2.2 Axle Loading laden, front/rear (kg) 4000/620 4600/670

ei

g

2.3 Axle Loading unladen, front/rear (kg) 1320/1700 1240/2030

W

Longitudinal stabilit y 1,66 1,59

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L)/SE(L)

ssi

s

3.2 Tyre Size: front 6.50--10 (14PR) 6.50-- 10 (14PR)

Ch

a

3.3 Tyre Size: rear 18x7--8 (16PR) 18x7--8 (16PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 895 895

W

3.7 Track width, rear b11(mm) 870 ( offset) 870 (offset)

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/10 7/10

4.2 Mast Height, lowered h1(mm) 2080 2080

4.3 Free Lift h2(mm) 100 100

4.4 Lift Height h3(mm) 3090 3090

4.5 Height of extended mast h4(mm) 3670 3670

4.7 Height of overhead guard (Cabin) h6(mm) 2130 2130

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1005/1065 1005/1065

4.12 Coupling height h10(mm) 375/545 375/545

ons

4.19 Ov erall Length l1(mm) 3245 3300

nsi

o

4.20 Length to Fork Fac e l2(mm) 2245 2300

ime

n

4.21 Over all Width b1/b2(mm) 1070 1070

Di

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A

4.24 Fork C arriage width / outs ide fork s b3(mm) 1000/849 1000/849

4.31 Ground Clearanc e laden under mas t m1(mm) 115 11 5

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 135 135

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3570 3615

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 3770 3815

4.35 Turning Radius Wa(mm) 1975 2020

5.1 Travel Speed laden/unladen (km/h) 18,7/19,0 18,4/18,7

5.2 Lifting Speed laden/unladen (m/s) 0,61/0,65 0,60/0,65

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,56/0,48 0,57/0,48

rma

5.5 Draw-bar -pull laden/unladen (kN) 12,7/9,0 12,6/8,2

rfo

r

5.7 Gradeability laden/unladen (%) 26/23 23/21

Pe

5.9 Acceleration time, laden/unladen s 5,0/4,5 5,1/4,4

5.10 Service brake type mech./hydr. mech./hydr.

7.1 Engine Manufacturer/Model 404C.22 404C.22

e

7.2 Engine Output to ISO 1585 (kw) 34,1 34,1

gin

e

7.3 Rated Rotation (1/min) 2400 2400

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/2216 4/2216

max. torque Nm/rpm 143/1800 135/1900

8.1 Type of Drive Control hydrodyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160

th

e

8.3 Oil flow for attachments l/min 45 45

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80

Page 14

B7

1203.GB

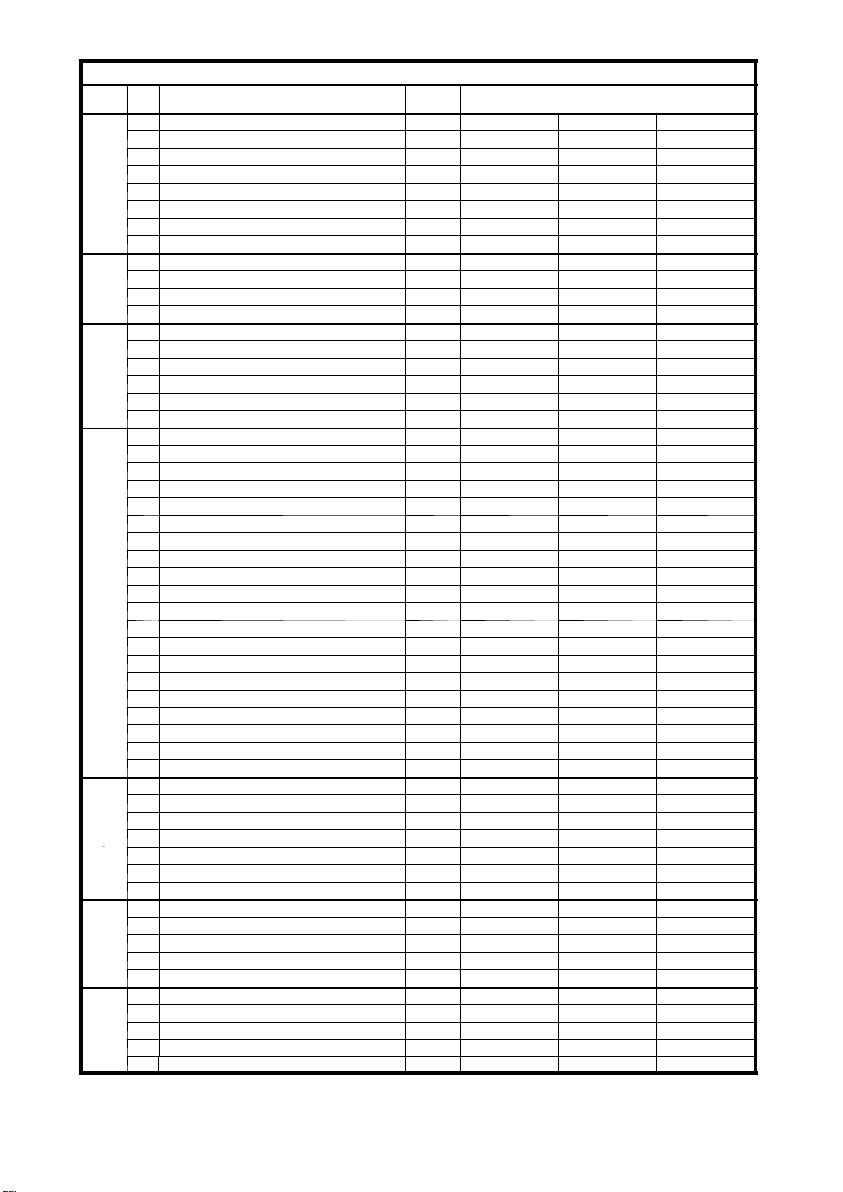

Specification sheet for lift trucks TFG 16/20 AK

No. Description

Code

(Unit)

AX-J

1. Manufacturer Jungheinrich Jungheinrich

1.2 Model Name TFG 16 AK TFG 20 AK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other LPG LPG

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated

ecifi

1.5 Load Capacity Q(t) 1,6 2,0

Sp

e

1.6 Load Centre c(mm) 500 500

S

1.8 Load Distance x(mm) 395 395

1.9 Wheel Base y( mm) 1400 1400

2.1 Weight--unladen (kg) 3000 3250

ht

2.2 Axle Loading laden, front/rear (kg) 4030/570 4630/620

ei

g

2.3 Axle Loading unladen, front/rear (kg) 1270/1730 1190/2060

W

Longitudinal stabilit y 1,69 1,61

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L)/SE(L)

ssi

s

3.2 Tyre Size: front 6.50--10 (14PR) 6.50-- 10 (14PR)

Ch

a

3.3 Tyre Size: rear 18x7--8 (16PR) 18x7--8 (16PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 895 895

W

3.7 Track width, rear b11(mm) 870 ( offset) 870 (offset)

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/10 7/10

4.2 Mast Height, lowered h1(mm) 2080 2080

4.3 Free Lift h2(mm) 100 100

4.4 Lift Height h3(mm) 3090 3090

4.5 Height of extended mast h4(mm) 3670 3670

4.7 Height of overhead guard (Cabin) h6(mm) 2130 2130

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1005/1065 1005/1065

4.12 Coupling height h10(mm) 375/545 375/545

ons

4.19 Ov erall Length l1(mm) 3245 3300

nsi

o

4.20 Length to Fork Fac e l2(mm) 2245 2300

ime

n

4.21 Over all Width b1/b2(mm) 1070 1070

Di

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A

4.24 Fork C arriage width / outs ide fork s b3(mm) 1000/849 1000/849

4.31 Ground Clearanc e laden under mas t m1(mm) 115 11 5

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 135 135

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3570 3615

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 3770 3815

4.35 Turning Radius Wa(mm) 1975 2020

5.1 Travel Speed laden/unladen (km/h) 18,5/19,5 18/19

5.2 Lifting Speed laden/unladen (m/s) 0,56/0,65 0,55/0,65

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,56/0,48 0,57/0,48

rma

5.5 Draw-bar -pull laden/unladen (kN) 10,1/8,6 9,8/7,8

rfo

r

5.7 Gradeability laden/unladen (%) 24/22 22/20

Pe

5.9 Acceleration time, laden/unladen s 5,2/4,6 5,4/4,7

5.10 Service brake type mech./hydr. mech./hydr.

7.1 Engine Manufacturer/Model FE FE

e

7.2 Engine Output to ISO 1585 (kw) 26,0 26,0

gin

e

7.3 Rated Rotation (1/min) 2400 2400

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/1988 4/1988

max. torque Nm/rpm 120/1600 120/1600

8.1 Type of Drive Control hydrodyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160

th

e

8.3 Oil flow for attachments l/min 45 45

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80

B7

1203.GB

Specification sheet for lift trucks TFG 16/20 AK

No. Description

Code

(Unit)

AX-J

1. Manufacturer Jungheinrich Jungheinrich

1.2 Model Name TFG 16 AK TFG 20 AK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other LPG LPG

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated

ecifi

1.5 Load Capacity Q(t) 1,6 2,0

Sp

e

1.6 Load Centre c(mm) 500 500

S

1.8 Load Distance x(mm) 395 395

1.9 Wheel Base y( mm) 1400 1400

2.1 Weight--unladen (kg) 3000 3250

ht

2.2 Axle Loading laden, front/rear (kg) 4030/570 4630/620

ei

g

2.3 Axle Loading unladen, front/rear (kg) 1270/1730 1190/2060

W

Longitudinal stabilit y 1,69 1,61

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L)/SE(L)

ssi

s

3.2 Tyre Size: front 6.50--10 (14PR) 6.50-- 10 (14PR)

Ch

a

3.3 Tyre Size: rear 18x7--8 (16PR) 18x7--8 (16PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 895 895

W

3.7 Track width, rear b11(mm) 870 ( offset) 870 (offset)

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/10 7/10

4.2 Mast Height, lowered h1(mm) 2080 2080

4.3 Free Lift h2(mm) 100 100

4.4 Lift Height h3(mm) 3090 3090

4.5 Height of extended mast h4(mm) 3670 3670

4.7 Height of overhead guard (Cabin) h6(mm) 2130 2130

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1005/1065 1005/1065

4.12 Coupling height h10(mm) 375/545 375/545

ons

4.19 Ov erall Length l1(mm) 3245 3300

nsi

o

4.20 Length to Fork Fac e l2(mm) 2245 2300

ime

n

4.21 Over all Width b1/b2(mm) 1070 1070

Di

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A

4.24 Fork C arriage width / outs ide fork s b3(mm) 1000/849 1000/849

4.31 Ground Clearanc e laden under mas t m1(mm) 115 11 5

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 135 135

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3570 3615

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 3770 3815

4.35 Turning Radius Wa(mm) 1975 2020

5.1 Travel Speed laden/unladen (km/h) 18,5/19,5 18/19

5.2 Lifting Speed laden/unladen (m/s) 0,56/0,65 0,55/0,65

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,56/0,48 0,57/0,48

rma

5.5 Draw-bar -pull laden/unladen (kN) 10,1/8,6 9,8/7,8

rfo

r

5.7 Gradeability laden/unladen (%) 24/22 22/20

Pe

5.9 Acceleration time, laden/unladen s 5,2/4,6 5,4/4,7

5.10 Service brake type mech./hydr. mech./hydr.

7.1 Engine Manufacturer/Model FE FE

e

7.2 Engine Output to ISO 1585 (kw) 26,0 26,0

gin

e

7.3 Rated Rotation (1/min) 2400 2400

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/1988 4/1988

max. torque Nm/rpm 120/1600 120/1600

8.1 Type of Drive Control hydrodyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160

th

e

8.3 Oil flow for attachments l/min 45 45

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80

Page 15

B8

1203.GB

Specification sheet for lift trucks DFG 20--30 BK

No. Description

Code

(Unit)

BX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name DFG 20 BK DFG 25 BK DFG 30 BK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel Diesel

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated Seated

ecifi

1.5 Load Capacity Q(t) 2,0 2,5 3,0

Sp

e

1.6 Load Centre c(mm) 500 500 500

S

1.8 Load Distance x(mm) 450 450 480

1.9 Wheel Base y( mm) 1685 1685 1685

2.1 Weight--unladen (kg) 3760 4190 4540

ht

2.2 Axle Loading laden, front/rear (kg) 5220/540 5820/870 6680/860

ei

g

2.3 Axle Loading unladen, front/rear (kg) 2000/1760 1840/2350 1850/2690

W

Longitudinal stabilit y 1,54 1,65 1,48

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssi

s

3.2 Tyre Size: front 7.00--12 (12PR) 7.00--12 (12PR) 27x10- -12 (14PR)

Ch

a

3.3 Tyre Size: rear 6.50--10 (10PR) 6.50--10 (10PR) 6.50 --10 (10PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 990 990 1045

W

3.7 Track width, rear b11(mm) 938 (offset) 938 (offset) 938

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 6/6 6/6 6/6

4.2 Mast Height, lowered h1(mm) 2300 2300 2300

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3300 3300 3300

4.5 Height of extended mast h4(mm) 3896 3896 3896

4.7 Height of overhead guard (Cabin) h6(mm) 2220 2220 2220

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1095/1065 1095/1065 1095/1065

ns

4.12 Coupling height h10(mm) 440/615 440/615 440/615

sio

n

4.19 Ov erall Length l1(mm) 3515 3525 3640

en

s

4.20 Length to Fork Fac e l2(mm) 2515 2525 2640

Di

m

4.21 Over all Width b1/b2(mm) 1170 1170 1285

D

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000 50/125/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A ISO 3A

4.31 Ground Clearanc e laden under mas t m1(mm) 125 125 125

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 132 132 142

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3925 3935 4050

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 4125 4135 4250

4.35 Turning Radius Wa(mm) 2265 2275 2360

5.1 Travel Speed laden/unladen (km/h) 18,7/18,9 18,5/18,7 18,6/18,8

5.2 Lifting Speed laden/unladen (m/s) 0,56/0,60 0,56/0,60 0,55/0,60

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,53/0,55 0,53/0,55 0,55/0,52

rma

5.5 Draw-bar -pull laden/unladen (kN) 16,9/11,8 16,7/10,8 16,6/12,2

rfo

r

5.7 Gradeability laden/unladen (%) 31/31 26/25 22/27

Pe

5.9 Acceleration time, laden/unladen s 5,0/4,6 5,12/4,50 5,5/4,7

5.10 Service brake type mech./hydr. mech./hydr. mech./hy dr.

7.1 Engine Manufacturer/Model

704.30/704.26

(12.03 an later )

704.30/704.26

(12.03 an later )

704.30/704.26

(12.03 an later )

ne

7.2 Engine Output to ISO 1585 (kw) 40 40 40

ngi

n

7.3 Rated Rotation (1/min) 2100 2100 2100

E

n

7.4 Nº of Cylinders/Dis placement (/cm#) 4/2955 4/2955 4/2955

max. torque Nm/rpm 190/1600 190/1600 190/1600

8.1 Type of Drive Control hydrodyn. hydr odyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160 160

th

e

8.3 Oil flow for attachments l/min 60 60 60

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80 <80

B8

1203.GB

Specification sheet for lift trucks DFG 20--30 BK

No. Description

Code

(Unit)

BX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name DFG 20 BK DFG 25 BK DFG 30 BK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel Diesel

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated Seated

ecifi

1.5 Load Capacity Q(t) 2,0 2,5 3,0

Sp

e

1.6 Load Centre c(mm) 500 500 500

S

1.8 Load Distance x(mm) 450 450 480

1.9 Wheel Base y( mm) 1685 1685 1685

2.1 Weight--unladen (kg) 3760 4190 4540

ht

2.2 Axle Loading laden, front/rear (kg) 5220/540 5820/870 6680/860

ei

g

2.3 Axle Loading unladen, front/rear (kg) 2000/1760 1840/2350 1850/2690

W

Longitudinal stabilit y 1,54 1,65 1,48

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssi

s

3.2 Tyre Size: front 7.00--12 (12PR) 7.00--12 (12PR) 27x10- -12 (14PR)

Ch

a

3.3 Tyre Size: rear 6.50--10 (10PR) 6.50--10 (10PR) 6.50 --10 (10PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 990 990 1045

W

3.7 Track width, rear b11(mm) 938 (offset) 938 (offset) 938

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 6/6 6/6 6/6

4.2 Mast Height, lowered h1(mm) 2300 2300 2300

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3300 3300 3300

4.5 Height of extended mast h4(mm) 3896 3896 3896

4.7 Height of overhead guard (Cabin) h6(mm) 2220 2220 2220

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1095/1065 1095/1065 1095/1065

ns

4.12 Coupling height h10(mm) 440/615 440/615 440/615

sio

n

4.19 Ov erall Length l1(mm) 3515 3525 3640

en

s

4.20 Length to Fork Fac e l2(mm) 2515 2525 2640

Di

m

4.21 Over all Width b1/b2(mm) 1170 1170 1285

D

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000 50/125/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A ISO 3A

4.31 Ground Clearanc e laden under mas t m1(mm) 125 125 125

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 132 132 142

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3925 3935 4050

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 4125 4135 4250

4.35 Turning Radius Wa(mm) 2265 2275 2360

5.1 Travel Speed laden/unladen (km/h) 18,7/18,9 18,5/18,7 18,6/18,8

5.2 Lifting Speed laden/unladen (m/s) 0,56/0,60 0,56/0,60 0,55/0,60

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,53/0,55 0,53/0,55 0,55/0,52

rma

5.5 Draw-bar -pull laden/unladen (kN) 16,9/11,8 16,7/10,8 16,6/12,2

rfo

r

5.7 Gradeability laden/unladen (%) 31/31 26/25 22/27

Pe

5.9 Acceleration time, laden/unladen s 5,0/4,6 5,12/4,50 5,5/4,7

5.10 Service brake type mech./hydr. mech./hydr. mech./hy dr.

7.1 Engine Manufacturer/Model

704.30/704.26

(12.03 an later )

704.30/704.26

(12.03 an later )

704.30/704.26

(12.03 an later )

ne

7.2 Engine Output to ISO 1585 (kw) 40 40 40

ngi

n

7.3 Rated Rotation (1/min) 2100 2100 2100

E

n

7.4 Nº of Cylinders/Dis placement (/cm#) 4/2955 4/2955 4/2955

max. torque Nm/rpm 190/1600 190/1600 190/1600

8.1 Type of Drive Control hydrodyn. hydr odyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160 160

th

e

8.3 Oil flow for attachments l/min 60 60 60

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80 <80

Page 16

B9

1203.GB

Specification sheet for lift trucks TFG 20 --30 BK

No. Description

Code

(Unit)

BX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name TFG 20 BK TFG 25 BK TFG 30 BK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other LPG LPG LPG

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated Seated

ecifi

1.5 Load Capacity Q(t) 2,0 2,5 3,0

Sp

e

1.6 Load Centre c(mm) 500 500 500

S

1.8 Load Distance x(mm) 450 450 480

1.9 Wheel Base y( mm) 1685 1685 1685

2.1 Weight--unladen (kg) 3730 4160 4510

ht

2.2 Axle Loading laden, front/rear (kg) 5200/530 5800/860 6660/850

ei

g

2.3 Axle Loading unladen, front/rear (kg) 1980/1750 1820/2340 1830/2680

W

Longitudinal stabilit y 1,54 1,65 1,48

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssi

s

3.2 Tyre Size: front 7.00--12 (12PR) 7.00--12 (12PR) 27x10- -12 (14PR)

Ch

a

3.3 Tyre Size: rear 6.50--10 (10PR) 6.50--10 (10PR) 6.50 --10 (10PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 990 990 1045

W

3.7 Track width, rear b11(mm) 938 (offset) 938 (offset) 938

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 6/6 6/6 6/6

4.2 Mast Height, lowered h1(mm) 2300 2300 2300

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3300 3300 3300

4.5 Height of extended mast h4(mm) 3896 3896 3896

4.7 Height of overhead guard (Cabin) h6(mm) 2220 2220 2220

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1095/1065 1095/1065 1095/1065

ns

4.12 Coupling height h10(mm) 440/615 440/615 440/615

sio

n

4.19 Ov erall Length l1(mm) 3515 3525 3640

en

s

4.20 Length to Fork Fac e l2(mm) 2515 2525 2640

Di

m

4.21 Over all Width b1/b2(mm) 1170 1170 1285

D

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000 50/125/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A ISO 3A

4.31 Ground Clearanc e laden under mas t m1(mm) 125 125 125

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 132 132 142

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3925 3935 4050

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 4125 4135 4250

4.35 Turning Radius Wa(mm) 2265 2275 2360

5.1 Travel Speed laden/unladen (km/h) 18,7/18,9 18,5/18,7 18,6/18,8

5.2 Lifting Speed laden/unladen (m/s) 0,56/0,60 0,56/0,60 0,55/0,60

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,53/0,55 0,53/0,55 0,55/0,52

rma

5.5 Draw-bar -pull laden/unladen (kN) 16,4/11,7 16,2/10,8 16,1/12,1

rfo

r

5.7 Gradeability laden/unladen (%) 30/31 26/25 22/27

Pe

5.9 Acceleration time, laden/unladen s 5,15/4,80 5,31/4,50 6,3/5,3

5.10 Service brake type mech.hydr. mech.hydr. mech.hydr.

7.1 Engine Manufacturer/Model 3.0 L4 3.0 L4 3.0 L4

e

7.2 Engine Output to ISO 1585 (kw) 44 44 44

gin

e

7.3 Rated Rotation (1/min) 2200 2200 2200

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/2966 4/2966 4/2966

max. torque Nm/rpm 196/1600 196/1600 196/1600

8.1 Type of Drive Control hydrodyn. hydr odyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160 160

th

e

8.3 Oil flow for attachments l/min 60 60 60

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80 <80

B9

1203.GB

Specification sheet for lift trucks TFG 20 --30 BK

No. Description

Code

(Unit)

BX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name TFG 20 BK TFG 25 BK TFG 30 BK

n

1.3 Drive: Electric, Diesel, Gas olene, LPG , other LPG LPG LPG

icatio

n

1.4

Steering: H and, Pedes trian, Standing, Seated, Order

Picking

Seated Seated Seated

ecifi

1.5 Load Capacity Q(t) 2,0 2,5 3,0

Sp

e

1.6 Load Centre c(mm) 500 500 500

S

1.8 Load Distance x(mm) 450 450 480

1.9 Wheel Base y( mm) 1685 1685 1685

2.1 Weight--unladen (kg) 3730 4160 4510

ht

2.2 Axle Loading laden, front/rear (kg) 5200/530 5800/860 6660/850

ei

g

2.3 Axle Loading unladen, front/rear (kg) 1980/1750 1820/2340 1830/2680

W

Longitudinal stabilit y 1,54 1,65 1,48

is

3.1

Tyre type: Cus hion, Super Elastic , Pneumatic,

Polyurethan

SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssi

s

3.2 Tyre Size: front 7.00--12 (12PR) 7.00--12 (12PR) 27x10- -12 (14PR)

Ch

a

3.3 Tyre Size: rear 6.50--10 (10PR) 6.50--10 (10PR) 6.50 --10 (10PR)

els/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

he

e

3.6 Track width, front b10(mm) 990 990 1045

W

3.7 Track width, rear b11(mm) 938 (offset) 938 (offset) 938

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 6/6 6/6 6/6

4.2 Mast Height, lowered h1(mm) 2300 2300 2300

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3300 3300 3300

4.5 Height of extended mast h4(mm) 3896 3896 3896

4.7 Height of overhead guard (Cabin) h6(mm) 2220 2220 2220

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1095/1065 1095/1065 1095/1065

ns

4.12 Coupling height h10(mm) 440/615 440/615 440/615

sio

n

4.19 Ov erall Length l1(mm) 3515 3525 3640

en

s

4.20 Length to Fork Fac e l2(mm) 2515 2525 2640

Di

m

4.21 Over all Width b1/b2(mm) 1170 1170 1285

D

4.22 Fork Dimension s/e/l(mm) 40/100/1000 40/100/1000 50/125/1000

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 2A ISO 2A ISO 3A

4.31 Ground Clearanc e laden under mas t m1(mm) 125 125 125

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 132 132 142

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 3925 3935 4050

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 4125 4135 4250

4.35 Turning Radius Wa(mm) 2265 2275 2360

5.1 Travel Speed laden/unladen (km/h) 18,7/18,9 18,5/18,7 18,6/18,8

5.2 Lifting Speed laden/unladen (m/s) 0,56/0,60 0,56/0,60 0,55/0,60

nc

e

5.3 Lowering Speed laden/unladen (m/s) 0,53/0,55 0,53/0,55 0,55/0,52

rma

5.5 Draw-bar -pull laden/unladen (kN) 16,4/11,7 16,2/10,8 16,1/12,1

rfo

r

5.7 Gradeability laden/unladen (%) 30/31 26/25 22/27

Pe

5.9 Acceleration time, laden/unladen s 5,15/4,80 5,31/4,50 6,3/5,3

5.10 Service brake type mech.hydr. mech.hydr. mech.hydr.

7.1 Engine Manufacturer/Model 3.0 L4 3.0 L4 3.0 L4

e

7.2 Engine Output to ISO 1585 (kw) 44 44 44

gin

e

7.3 Rated Rotation (1/min) 2200 2200 2200

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/2966 4/2966 4/2966

max. torque Nm/rpm 196/1600 196/1600 196/1600

8.1 Type of Drive Control hydrodyn. hydr odyn. hydrodyn.

rs

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160 160

th

e

8.3 Oil flow for attachments l/min 60 60 60

O

8.4 Noise Level at Operator ’s Ear dB(A) <80 <80 <80

Page 17

B10

1203.GB

Specification sheet for lift trucks DFG 40--50 CK

No. Description

Code

(Unit)

CX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name DFG 40 CK DFG 45 CK DFG 50 CK

on

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel Diesel

ati

o

1.4 Steering: Hand, Pedestrian, Standing, Seated Seated Seated Seated

cifi

c

1.5 Load Capacity Q(t) 4,0 4,5 5,0

pe

c

1.6 Load Centre c(mm) 500 500 600

S

1.8 Load Distance x(mm) 564 564 579

1.9 Wheel Base y( mm) 1985 1985 1985

2.1 Weight--unladen (kg) 6140 6540 7080

ht

2.2 Axle Loading laden, front/rear (kg) 9100/1040 9980/1060 10700/1380

ei

g

2.3 Axle Loading unladen, front/rear (kg) 2860/3280 2980/3560 2840/4240

W

Longitudinal stabilit y

3.1 Tyre type: Cushion, Super Elastic, Pneu., Polyurethan SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssis

3.2 Tyre Size: front 8.25--15 (18PR) 8.25--15 (18PR) 3.00--15 (18PR)

ha

s

3.3 Tyre Size: rear 7.00--12 (12PR) 7.00--12 (12PR) 7.00 --12 (12PR)

ls/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

hee

l

3.6 Track width, front b10(mm) 1165 1165 1165

W

h

3.7 Track width, rear b11(mm) 1163 1163 1163

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/11 7/11 7/11

4.2 Mast Height, lowered h1(mm) 2540 2540 2540

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3500 3500 3500

4.5 Height of extended mast h4(mm) 4200 4200 4350

4.7 Height of overhead guard (Cabin) h6(mm) 2350 2350 2350

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1225 1225 1225

4.12 Coupling height h10(mm) 535/700 535/700 535/700

s

4.19 Ov erall Length l1(mm) 4140 4140 4240

sio

n

4.20 Length to Fork Fac e l2(mm) 2990 2990 2990

en

s

4.21 Over all Width b1/b2(mm) 1400 1400 1400

Di

m

4.22 Fork Dimension s/e/l(mm) 50/125/1150 50/125/1150 60/150/1150

D

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 3A ISO 3A ISO 4A

4.24 Fork Carriage Width b

3

1260 1260 1260

4.31 Ground Clearanc e laden under mas t m1(mm) 190 190 190

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 230 230 230

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 4440 4440 4555

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 4640 4640 4755

4.35 Turning Radius Wa(mm) 2650 2650 2750

4.36 Smalles t Distance to Piv ot Point b

13

900 900 900

5.1 Travel Speed laden/unladen (km/h) 24,5/25,4 23,5/24,8 22,3/24,3

5.2 Lifting Speed laden/unladen (m/s) 0,52/0,55 0,51/0,55 0,50/0,55

nce

5.3 Lowering Speed laden/unladen (m/s) 0,52/0,38 0,52/0,38 0,52/0,38

rma

n

5.5 Draw-bar -pull laden/unladen (kN) 34,00/16,50 34,00/16,5 34,00/16,5

rfo

r

5.7 Gradeability laden/unladen (%) 33,5/26,8 30,7/25,2 28/23,3

Pe

r

5.9 Acceleration time, laden/unladen s 4,8/4,7 4,9/4,8 6,0/5,6

5.10 Service brake type mech./hydr. mech./hydr. mech./hy dr.

7.1 Engine Manufacturer/Model 1004.4 2 1004.4 2 1004.4 2

e

7.2 Engine Output to ISO 1585 (kw) 60 60 60

gin

e

7.3 Rated Rotation (1/min) 2200 2200 2200

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/4230 4/4230 4/4230

max. torque Nm/rpm

8.1 Type of Drive Control hydrodyn. hydr odyn. hydrodyn.

s

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160 160

her

s

8.3 Oil flow for attachments l/min 30 30 30

Ot

h

8.4 Noise Level at Operator ’s Ear dB(A) 78 78 78

8.5 Trailer C oupling Type / DIN Type 15170 / ty pe h 15170 / type h 15170 / type h

B10

1203.GB

Specification sheet for lift trucks DFG 40--50 CK

No. Description

Code

(Unit)

CX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name DFG 40 CK DFG 45 CK DFG 50 CK

on

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel Diesel

ati

o

1.4 Steering: Hand, Pedestrian, Standing, Seated Seated Seated Seated

cifi

c

1.5 Load Capacity Q(t) 4,0 4,5 5,0

pe

c

1.6 Load Centre c(mm) 500 500 600

S

1.8 Load Distance x(mm) 564 564 579

1.9 Wheel Base y( mm) 1985 1985 1985

2.1 Weight--unladen (kg) 6140 6540 7080

ht

2.2 Axle Loading laden, front/rear (kg) 9100/1040 9980/1060 10700/1380

ei

g

2.3 Axle Loading unladen, front/rear (kg) 2860/3280 2980/3560 2840/4240

W

Longitudinal stabilit y

3.1 Tyre type: Cushion, Super Elastic, Pneu., Polyurethan SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssis

3.2 Tyre Size: front 8.25--15 (18PR) 8.25--15 (18PR) 3.00--15 (18PR)

ha

s

3.3 Tyre Size: rear 7.00--12 (12PR) 7.00--12 (12PR) 7.00 --12 (12PR)

ls/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

hee

l

3.6 Track width, front b10(mm) 1165 1165 1165

W

h

3.7 Track width, rear b11(mm) 1163 1163 1163

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/11 7/11 7/11

4.2 Mast Height, lowered h1(mm) 2540 2540 2540

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3500 3500 3500

4.5 Height of extended mast h4(mm) 4200 4200 4350

4.7 Height of overhead guard (Cabin) h6(mm) 2350 2350 2350

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1225 1225 1225

4.12 Coupling height h10(mm) 535/700 535/700 535/700

s

4.19 Ov erall Length l1(mm) 4140 4140 4240

sio

n

4.20 Length to Fork Fac e l2(mm) 2990 2990 2990

en

s

4.21 Over all Width b1/b2(mm) 1400 1400 1400

Di

m

4.22 Fork Dimension s/e/l(mm) 50/125/1150 50/125/1150 60/150/1150

D

4.23 Carriage DIN 15173, ISO 2328, Class/F orm A,B ISO 3A ISO 3A ISO 4A

4.24 Fork Carriage Width b

3

1260 1260 1260

4.31 Ground Clearanc e laden under mas t m1(mm) 190 190 190

4.32 Ground Clearanc e at the c entre of Wheel Base m2(mm) 230 230 230

4.33 Aisle width with pallet 1000x1200 transverse Ast(mm) 4440 4440 4555

4.34 Aisle width with pallet 800x1200 Pallet longitudinal Ast(mm) 4640 4640 4755

4.35 Turning Radius Wa(mm) 2650 2650 2750

4.36 Smalles t Distance to Piv ot Point b

13

900 900 900

5.1 Travel Speed laden/unladen (km/h) 24,5/25,4 23,5/24,8 22,3/24,3

5.2 Lifting Speed laden/unladen (m/s) 0,52/0,55 0,51/0,55 0,50/0,55

nce

5.3 Lowering Speed laden/unladen (m/s) 0,52/0,38 0,52/0,38 0,52/0,38

rma

n

5.5 Draw-bar -pull laden/unladen (kN) 34,00/16,50 34,00/16,5 34,00/16,5

rfo

r

5.7 Gradeability laden/unladen (%) 33,5/26,8 30,7/25,2 28/23,3

Pe

r

5.9 Acceleration time, laden/unladen s 4,8/4,7 4,9/4,8 6,0/5,6

5.10 Service brake type mech./hydr. mech./hydr. mech./hy dr.

7.1 Engine Manufacturer/Model 1004.4 2 1004.4 2 1004.4 2

e

7.2 Engine Output to ISO 1585 (kw) 60 60 60

gin

e

7.3 Rated Rotation (1/min) 2200 2200 2200

En

g

7.4 Nº of Cylinders/Dis placement (/cm#) 4/4230 4/4230 4/4230

max. torque Nm/rpm

8.1 Type of Drive Control hydrodyn. hydr odyn. hydrodyn.

s

8.2 Hydraulic Oil Press ure for Attachments (bar) 160 160 160

her

s

8.3 Oil flow for attachments l/min 30 30 30

Ot

h

8.4 Noise Level at Operator ’s Ear dB(A) 78 78 78

8.5 Trailer C oupling Type / DIN Type 15170 / ty pe h 15170 / type h 15170 / type h

Page 18

B11

1203.GB

Specification sheet for lift trucks DFG 40--50 CK (09/03 an d later)

No. Description

Code

(Unit)

CX-J

1. Manufacturer Jungheinrich Jungheinrich Jungheinrich

1.2 Model Name DFG 40 CK DFG 45 CK DFG 50 CK

on

1.3 Drive: Electric, Diesel, Gas olene, LPG , other Diesel Diesel Diesel

ati

o

1.4 Steering: Hand, Pedestrian, Standing, Seated Seated Seated Seated

cifi

c

1.5 Load Capacity Q(t) 4,0 4,5 5,0

pe

c

1.6 Load Centre c(mm) 500 500 600

S

1.8 Load Distance x(mm) 564 564 579

1.9 Wheel Base y( mm) 1985 1985 1985

2.1 Weight--unladen (kg) 6279 6669 7434

ht

2.2 Axle Loading laden, front/rear (kg) 8954/1325 9869/1300 10762/1673

ei

g

2.3 Axle Loading unladen, front/rear (kg) 2810/3469 2937/3732 2795/4639

W

Longitudinal stabilit y

3.1 Tyre type: Cushion, Super Elastic, Pneu., Polyurethan SE(L)/SE(L) SE(L) /SE(L) SE(L)/SE( L)

ssis

3.2 Tyre Size: front 3.00--15 (18PR) 3.00--15 (18PR) 3.00--15 (18PR)

ha

s

3.3 Tyre Size: rear 28 x 9 -- 15 28 x 9 -- 15 28 x 9 -- 15

ls/

C

3.5 Wheels, Numbers front/rear (x=traction) 2x/2 2x/2 2x/2

hee

l

3.6 Track width, front b10(mm) 1180 1180 1170

W

h

3.7 Track width, rear b11(mm) 1160 1160 1160

4.1 Tilt of Mast/Carriage, forward/backw ard Grad. 7/11 7/11 7/11

4.2 Mast Height, lowered h1(mm) 2540 2540 2540

4.3 Free Lift h2(mm) 150 150 150

4.4 Lift Height h3(mm) 3500 3500 3500

4.5 Height of extended mast h4(mm) 4200 4200 4350

4.7 Height of overhead guard (Cabin) h6(mm) 2370 2370 2370

4.8 Seat Height / Head clearance (SIP 100mm) h7(mm) 1255/1010 1255/1010 1255/1010

4.12 Coupling height h10(mm) 535/700 535/700 535/700

s

4.19 Ov erall Length l1(mm) 4145 4145 4260

sio

n

4.20 Length to Fork Fac e l2(mm) 2995 2995 3110

en

s

4.21 Over all Width b1/b2(mm) 1450 1450 1450

Di

m

4.22 Fork Dimension s/e/l(mm) 50/125/1150 50/125/1150 60/150/1150

D