Page 1

Corrosion-proof and

resistant to acids and salts

Lubrication nipple on

all moving parts for

long service life

Electric lift (AMX I10e)

Glass bead blasted surfaces

for straightforward cleaning

Robust and reliable

AMX I10/I10p/I10e/I10ep

Stainless steel scissor lift hand pallet truck (1,000 kg)

The Inox versions of the AMX I10 / I10e

scissor lift hand pallet trucks are ideal

for transporting goods in areas where

absolute hygiene is required. The advantages of the stainless steel range

come to the fore in damp and harsh

environments.

Individually adaptable to the application

at hand, it is possible to choose from a

number of dierent versions. Jungheinrich’s decades of experience in stainless

steel hand pallet trucks are reflected

today in its completely reliable and

robust trucks.

In meat or fish processing, the chemical

or pharmaceuticals sectors, scissor lift

hand pallet trucks oer the right solution.

Page 2

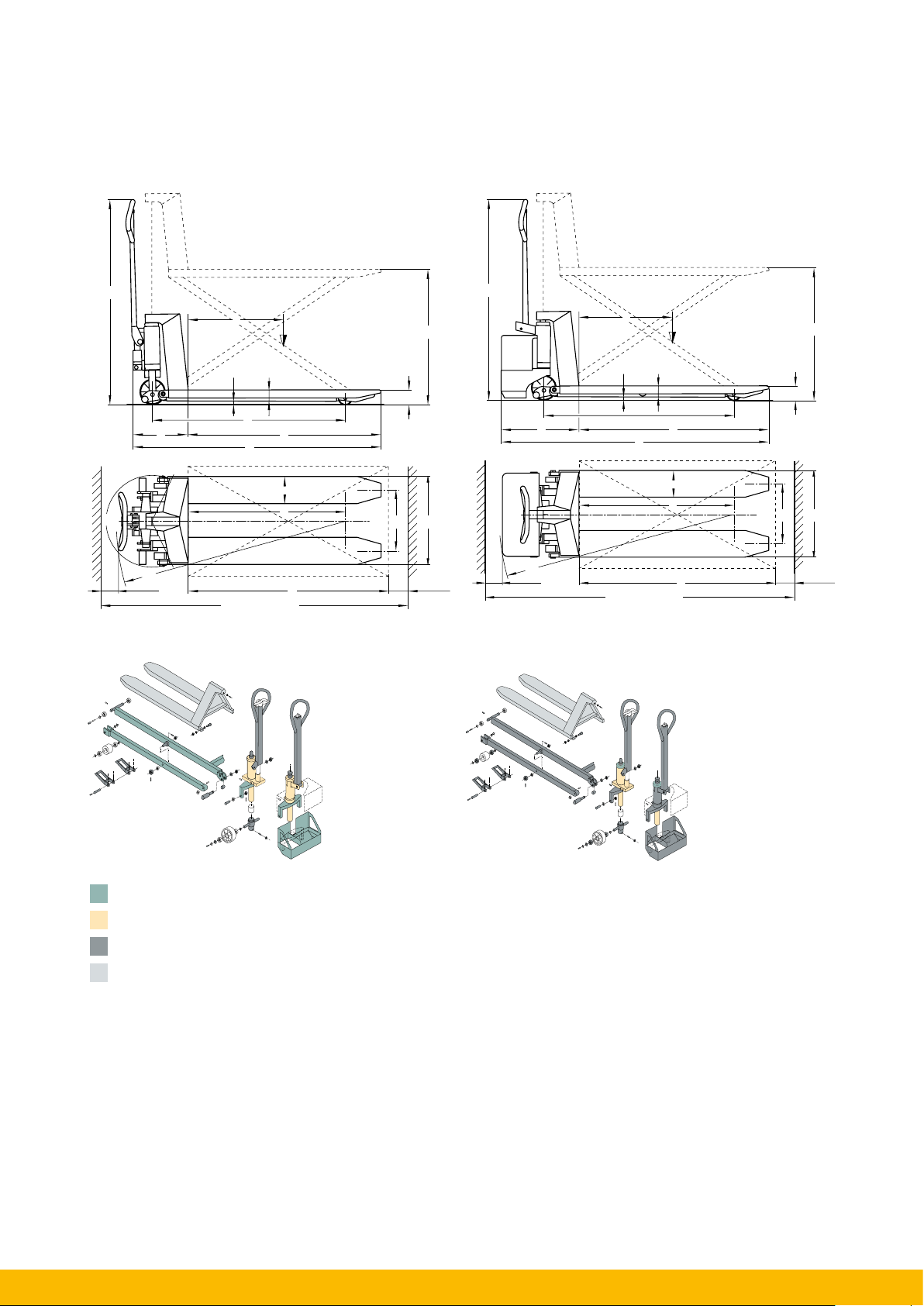

AMX I10/I10p/I10e/I10ep

0

a/2 = 100

Ast = Wa + l

6

– x + a

AMX I10/ I10p

h

14

c

Q

sm

2

l

2

230ϒ

Wa

a/2 = 100 a/2 = 10

y

l

l

1

e

x

Ast = Wa + l6– x + a

l

6

h

13

b11b1/b

AMX I10e/ I10ep

h

14

h

3

l

2

Q

sm

2

l

l

1

e

x

c

5

2

Wa

l

a/2 = 100

6

h

13

b11b1/b

h

3

5

AMX I10/I10e

Right tiller gure is for the E model

Electro plating

Chromite coating

Stainless steel (AISI 303/304)

Acid resistant stainless steel (AISI 316)

AMX I10p/I10ep

I

Right tiller gure is for the E model

I

Page 3

Issue: 06/2011

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model AMX I10 AMX I10p AMX I10e AMX I10ep

1.3 Drive manual manual Electrics Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation hand

1.5 Load capacity/rated load Q t 1

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 925

1.9 Wheelbase y mm 1140

2.1 Service weight kg 108 108 140 140

2.2 Axle load, w. load, front / rear kg 750 / 358 750 / 358 753 / 357 753 / 387

2.3 Axle load, w.o. load, front / rear kg 38 / 70 38 / 70 40 / 100 40 / 100

Weights

3.1 Tyres N;V

3.2 Tyre size, at front mm Ø 150x45

3.3 Tyre size, at rear mm Ø 80x60

3.5 Wheels, number front/rear (× = driven wheels) 2/2

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

4.4 Lift h3 mm 710

4.9 Height of tiller in drive position min. / max. h

4.14 Standing height raised h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 50 / 163 / 1140

4.25 Width over forks b

Basic dimensions

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 1770 1770 1830 1830

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 1830 1830 1890 1890

4.35 Turning radius W

5.3 Lower speed, w. / w.o. load m/s 0.15 / 0.09 0.15 / 0.09 0.08 / 0.05 0.08 / 0.05

mm 145

10

mm 440

11

mm 1195

14

mm 800

12

mm 90

13

mm 1480 1480 1580 1580

1

mm 340 340 440 440

2

mm 540

1/b2

mm 540

5

mm 28

2

mm 1355 1355 1415 1415

a

Perform-

ance data

6.4 Battery voltage/nominal capacity K5 V/Ah 12 / 60 12 / 60

6.5 Battery weight kg 20 20

trics

Elec-

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

AMX I 10 controls Enclosed fork tips AMX I10e control

Easy handling

• Smooth controls for both left and

right-handed operators.

• Special lowering valve for sensitive,

controlled load lowering.

• Short front end dimension (340 mm)

ensures safe operation even in confined spaces.

• Skids on the fork tips allow for easy

pallet handling.

Optimum hygiene

• The enclosed fork tips ensure that no

dirt sprays up from the fork rollers onto

the load during travel.

• Freely accessible or fully enclosed

cavities allow for eective cleaning

with no “hiding places for bacteria”.

• Grease nipples on critical moving parts.

• Food grade lubricant (class H1 and H2).

Lift height:

Extra standing legs oer good stability up

to a height of 800 mm.

Eortless lifting and lowering

• Option of manual hydraulic (AMX I10)

or electro-hydraulic (AMX I10e) with 1.1

kW lift motor.

• Integrated pump unit with reservoir.

• Sensitive lowering with hand lever.

The lowering valve is incorporated in

the pump unit. The hydraulic system

is protected against overloading by a

pressure relief valve.

Forks

Robust, torsion-resistant construction

with closed fork tips.

Maintenance-free battery and builtin charger (AMX I10e)

• Built-in electronically controlled

battery charger.

• Charging possible at any 240-V mains

socket.

• Maintenance-free 60 Ah battery.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_AMX I10/I10p/I10e/I10ep_042014_en_UK_000

Loading...

Loading...