Page 1

JUMO LOGOSCREEN fd

Secure Data Management and

FDA-Compliant Measured Data Recording

B 706585.4

Installation Instructions

2013-10-23/00586157

Page 2

Page 3

Contents

1 Introduction 5

1.1 Preface .......................................................................................................... 5

1.2 Arrangement of the documentation ........................................................... 6

1.3 Typographical conventions ......................................................................... 9

2 Identifying the instrument version 11

2.1 Nameplate ................................................................................................... 11

2.2 Order details ............................................................................................... 12

2.3 Standard accessories ................................................................................ 13

2.4 Accessories ................................................................................................ 13

3 Installation 15

3.1 Installation site and climatic conditions .................................................. 15

3.2 Dimensions ................................................................................................. 15

3.3 Mounting in a panel .................................................................................... 16

4 Electrical connection 17

4.1 Installation notes ........................................................................................ 17

4.2 Procedure .................................................................................................... 18

4.3 Overview of the electrical isolation .......................................................... 19

4.4 Connection diagram .................................................................................. 20

4.5 Connection examples concerning binary inputs/outputs ...................... 26

5 Functional test 29

6 Technical data (extract from data sheet) 31

6.1 Analog inputs .............................................................................................. 31

Page 4

Contents

6.2 Binary inputs/outputs (option) .................................................................. 34

6.3 Outputs ........................................................................................................ 34

6.4 Interfaces .................................................................................................... 34

6.5 Screen ......................................................................................................... 35

6.6 Electrical data ............................................................................................. 35

6.7 Environmental influences .......................................................................... 36

6.8 Housing ....................................................................................................... 36

6.9 Approvals/marks of conformity ................................................................ 36

7 Glossary 37

Page 5

1.1 Preface

E

B

1 Introduction

Please read these Operating Instructions before commissioning the

instrument. Keep the manual in a place that is accessible to all users at all

times.

Please assist us to improve this operating manual, where necessary.

Your comments will be appreciated.

If any difficulties should arise during commissioning, you are asked

not to carry out any manipulations that could endanger your rights

under the instrument warranty!

Please contact the nearest subsidiary or the head office in such a

case.

When returning modules, assemblies or components, the

regulations of EN 61340-5-1 and EN 61340-5-2 “Protection of

electronic devices from electrostatic phenomena” must be

observed. Use only the appropriate ESD packaging for transport.

Please note that we cannot accept any liability for damage caused

by ESD.

ESD=electrostatic discharge

5

Page 6

1 Introduction

1.2 Arrangement of the documentation

The documentation for this instrument is addressed to equipment

manufacturers (OEMs) and users with appropriate technical expertise. It

consists of the following parts:

Instrument documentation in printed form

B 706585.1 Operating Instructions

The operating instructions are an extract from the operating manual and cover

the basic operation of the paperless recorder.

B 706585.4(.1) Installation Instructions

The installation instructions describe the installation of the recorder and the

connection of the supply and signal cables. The instructions also contain a list

of the technical data.

B 706585.4 Installation instructions for recorders with die-cast zinc front

B 706585.4.1 Installation instructions for recorders with stainless steel front

Instrument documentation in the form of PDF files

The “Instrument documentation in the form of PDF files” is on the CD that is

included in the delivery.

B 706585.0 Operating Manual

It contains information about commissioning, operation, parameterization and

configuration on the instrument.

B 706585.1 Operating Instructions

The operating instructions are an extract from the operating manual and cover

the basic operation of the paperless recorder.

B 706585.2.0 Interface Description (serial interfaces)

This provides information on the communication (RS232/RS485) with

supervisory systems.

Interface Description (Ethernet interface)

This provides information on the connection of a paperless recorder to a

company-internal network. This description is integrated into B 706585.2.0.

B 706585.2.3 Interface Description (PROFIBUS-DP interface)

This provides information on the connection of a paperless recorder to a

PROFIBUS-DP system.

6

Page 7

B 706585.4(.1) Installation Instructions

The installation instructions describe the installation of the recorder and the

connection of the supply and signal cables. The instructions also contain a list

of the technical data.

B 706585.4 Installation instructions for recorders with die-cast zinc front

B 706585.4.1 Installation instructions for recorders with stainless steel front

B 706585.6 Setup Program

The manual describes the function of the setup program. The setup program is

available as an option.

T 706585 Data Sheet

The data sheet contains general information, the order details and the

technical data.

B 709701.0 PC Evaluation software PCA3000

The operating manual describes the operation and the features of the PC

evaluation software.

1 Introduction

PCA3000 serves to visualize and evaluate process data (measurement data,

batch data, messages, instrument audit trails, ...). The process data can be

read in via the CompactFlash memory card, or made available through the

PCC software.

B 709702.0 PCA Communications software PCC

The operating manual describes the operation and the features of the PCA

Communications software.

PCC is responsible for the data transfer from the recorder to a PC, or to a

network.

B 709703.0 PC Security Manager Software PCS

The operating manual describes the operation and the features of the PC

Security Manager software.

The PCS ensures that only authorized persons can gain access to the system

components (instrument, PC software) and use electronic signatures on

electronic documents.

The configuration of the Security Manager can only be performed by the

system administrator.

7

Page 8

1 Introduction

B 709704.0 PC Audit Trail Manager Software PCAT

The operating manual describes the operation and the features of the PC audit

trail manager software.

PCAT documents actions performed in the PC software components, which

lead to modifications of files, user lists (rights files), device lists etc. The

different message types are: “Information”, “Warnings” and “Errors”.

Audit trail records cannot be modified.

Device audit trail data are not shown in PCAT, only in PCA3000.

Internet

All documents are available for downloading at www.jumo.net

8

Page 9

1.3 Typographical conventions

V

E

Warning signs

The signs for Danger and Caution are used in this manual under the following

conditions:

Danger

This symbol is used when there may be danger to personnel if the

instructions are ignored or not followed correctly!

Caution

This symbol is used when there may be damage to equipment or data if the

instructions are ignored or not followed correctly!

Caution

This symbol is used where special care is required when handling

components liable to damage through electrostatic discharge.

1 Introduction

Note signs

h

Note

This symbol is used when your special attention is drawn to a remark.

Reference

This symbol refers to further information in other manuals, chapters or

sections.

Action instruction

This symbol indicates that an action to be performed is described.

The individual steps are marked by this asterisk, e.g.

h Rotate control knob

h Press control knob

9

Page 10

1 Introduction

10

Page 11

2 Identifying the instrument version

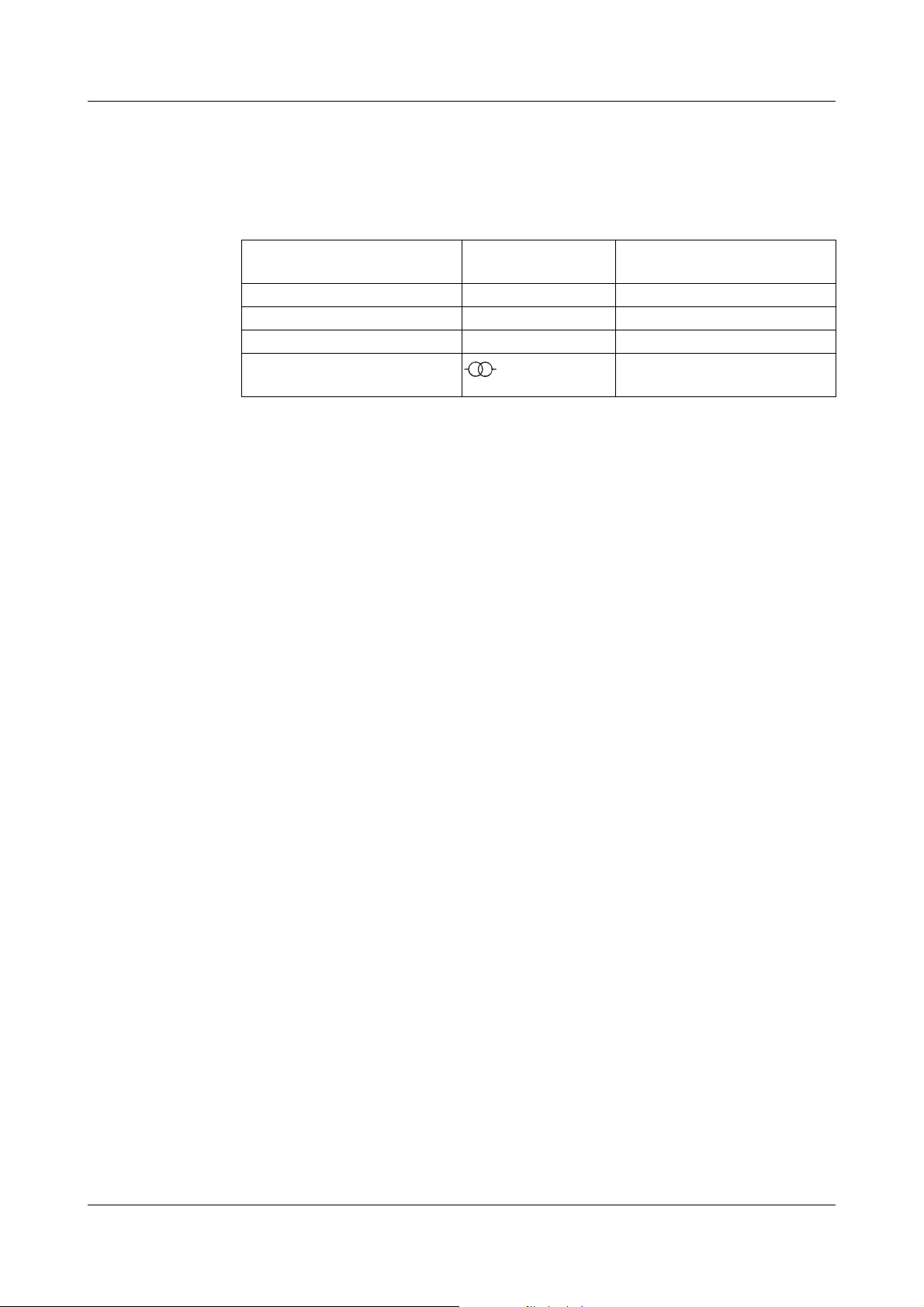

2.1 Nameplate

Position The nameplate is glued onto the paperless recorder.

Contents It contains important information, such as:

Description Designation on

the nameplate

Device type Typ 706585/18-321-33/020

Part no. TN 00xxxxxx

Serial no. F-Nr 0022969000013050006

Supply voltage AC 110 — 240 V

Typ Please check the type supplied against your order document. Refer to

Chapter 2.2 “Order details” for identification of the type.

TN The part no. provides an unambiguous definition of an article from the catalog.

It is used in communication between the sales department and the customer.

F-Nr The serial number (F-Nr) indicates the production date (year/week). The figures

concerned are in positions 12, 13, 14, 15.

Example:

F-Nr 0022969000013050006

This shows that the paperless recorder was manufactured in 2013, week 5.

Example

+10/-15%, 48—63Hz

11

Page 12

2 Identifying the instrument version

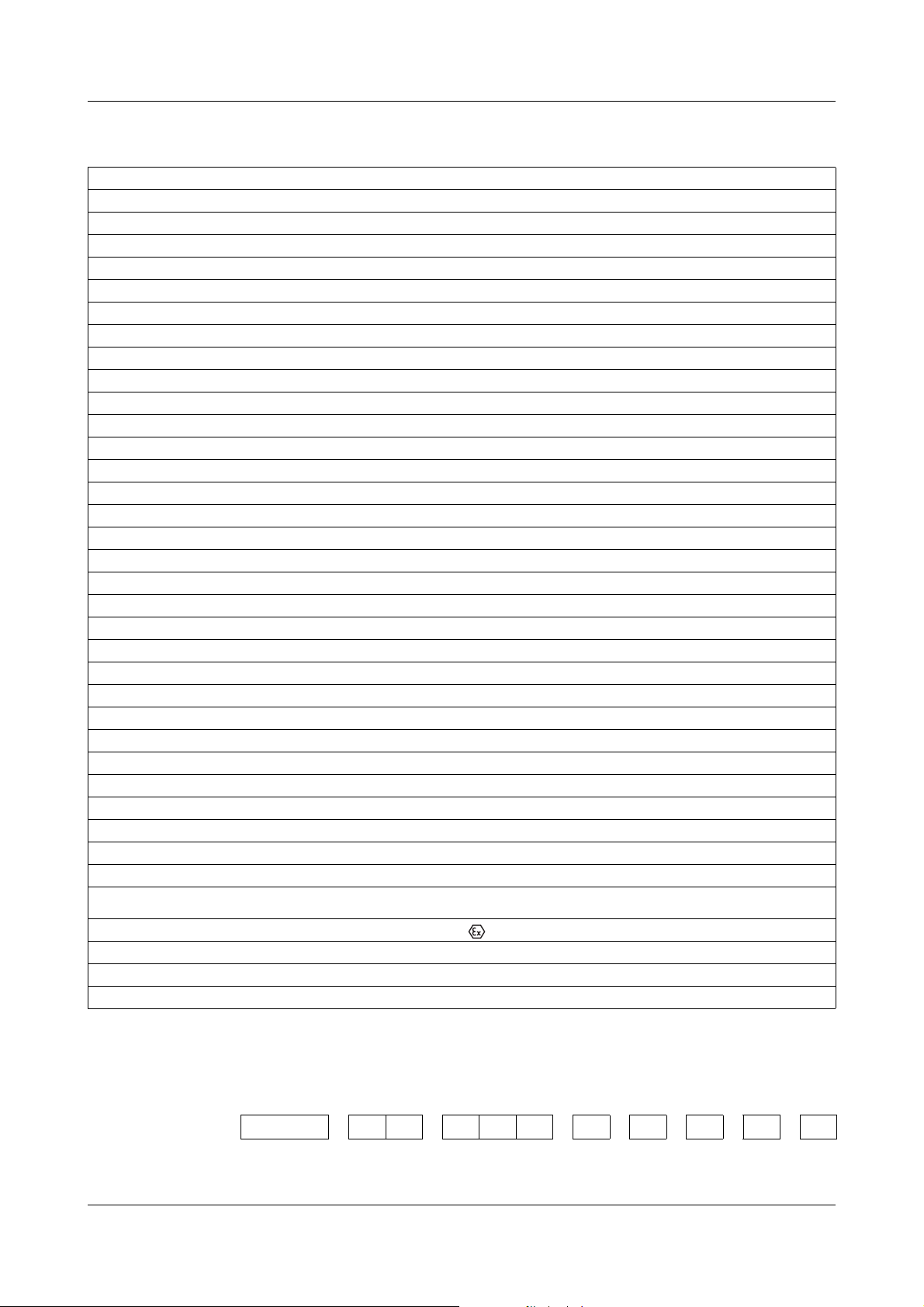

2.2 Order details

(1) Basic type

706585 LOGOSCREEN fd

(2) Basic type extension

0 No software package

1 With software package (setup program, PCA3000, PCC, PCS, PCAT, USB cable)

(3) Language / Setup

8 Factory setting (German/English)

9 Set to customer specification

(4) Module slot 1

0Not used

2 3 analog inputs and 8 binary inputs/outputs

3 6 analog inputs

(5) Module slot 2

0Not used

2 3 analog inputs and 8 binary inputs/outputs

3 6 analog inputs

(6) Module slot 3

0Not used

1 6 relay outputs

2 3 analog inputs and 8 binary inputs/outputs

3 6 analog inputs

(7) Voltage supply

25 AC/DC 20 to 30 V, 48 to 63 Hz

33 AC 100 to 240 V +10/-15 %, 48 to 63 Hz

(8) Extra codes memory

020 Lithium battery for memory buffering (ex-factory)

021 Storage capacitor

(9) Extra codes

.Not used

260 Math and logic module

(10) Extra codes housing

.Not used

350 Universal carrying case TG-35

444 Stainless steel front with touchpad

(11) Extra codes

. Without extra codes

267 PROFIBUS-DP interface

a

This extra code is available in combination with voltage supply AC 100 to 240 V, not with low supply voltage.

UL and ATEX approvals not applicable. The protection type in the carrying case corresponds to IP20, outside IP20D.

a

Order code (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

Order example 706585 / - - / , , ,

List extra codes in sequence, separated by commas.

12

Page 13

2 Identifying the instrument version

2.3 Standard accessories

• 1 Installation Instructions B 706585.4

• 1 Operating Instructions B 706585.1

• 4 mounting brackets

•1 panel seal

• 1 CD with detailed operating instructions and supplementary

documentation (see Chapter 1.2 “Arrangement of the documentation”)

2.4 Accessories

• Software package (setup program, PCA3000, PCC, PCS, PCAT)

• CompactFlash memory cards

• USB memory sticks

• USB cable

13

Page 14

2 Identifying the instrument version

14

Page 15

3.1 Installation site and climatic conditions

193

10

21

144

144

The installation site should be as free as possible from vibration.

Electromagnetic fields, such as those caused by motors, transformers,

frequency converter etc. should be avoided as far as possible.

The ambient temperature at the site can be 0 to 50 °C, at a relative humidity of

75 %, no condensation.

v Chapter 4.1 “Installation notes”

3.2 Dimensions

Recorder with

zinc diecast

front

3 Installation

Panel cut-out

15

Page 16

3 Installation

Panel seal

3.3 Mounting in a panel

h Fit panel seal (IP65 seal).

h Insert the paperless recorder from the front into the panel cut-out.

h From behind the panel, hook the four mounting brackets into the grooves

on the sides of the housing and tighten them evenly up against the back of

the panel.

16

Page 17

4.1 Installation notes

• The device is designed for installation in electrical cabinets, machines, or

systems. External fuse protection and shut-off must be provided for the

device. The fuse must not exceed 20 A.

An instrument fuse is already built into the device itself (depending on the

device design).

AC/DC20—30V, 48—63Hz: fuse 2.5A slow-blow

AC 100 — 240 V +10/-15 %, 48 — 63 Hz: fuse 1.25 A slow-blow

• The choice of cable, the installation and the electrical connection must

conform to the requirements of VDE 0100 “Regulations on the Installation

of Power Circuits with Nominal Voltages below 1000 V” or the appropriate

local regulations.

• Work inside the instrument must only be carried out to the extent

described and, like the electrical connection, only by qualified personnel.

• For service and repair work the device must be disconnected from the

power supply (all poles).

• To generate the operating voltage of 20 ... 30 V for Extra Low Voltage

(ELV), the maximum nominal voltage of an external power supply must

not exceed 240 V (line-to-line and line-to-neutral). If the external nominal

voltage is greater than 240 V, an Safety Extra Low Voltage (SELV) power

supply must be used. For line-to-line supply of the external power supply,

the power supply must have all-pole fuse protection. The fuse must shut

off both connections.

4 Electrical connection

• Run input, output and supply cables separately and not parallel to one

another.

• In EMC disturbed environments, all input and output cables without

connection to the mains supply must be arranged as twisted and

screened cables. Earth the screen on the instrument side to the earth

potential.

• Ground the instrument at the PE terminal of the supply voltage connector

to the protective earth conductor. This cable must have the same crosssection as that used for the supply cables. Earthing cables must be wired

in a star configuration to a common earth point that is connected to the

protective earth conductor of the electrical supply.

• Do not connect any additional loads to the supply terminals of the

instrument.

• The device is not suitable for use in areas with an explosion hazard (Ex

areas).

• Electromagnetic compatibility (EMC) conforms to the standards and

regulations cited in the technical data.

v Chapter 6 “Technical data (extract from data sheet)”

• Inductive loads close to the instrument, such as contactors or solenoid

valves, should have RC modules fitted for interference suppression.

17

Page 18

4 Electrical connection

Module slot 3 (top)

Relay card

}

Module slot 2 (middle)

6 analog channels or

3 analog channels and

8 binary inputs/outputs

}

Module slot 1 (bottom)

6 analog channels or

3 analog channels and

8 binary inputs/outputs

}

21

22

23

31

32

33

41

42

43

51

52

53

61

62

63

71

72

73

123

4

10 11

12

1

2

3

4

5

6

9

8

7

B12

B 9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

+

U

U

+

-

-

--

in

out

U

U

out

U

U

in

33

44

11

22

12341234123

4

12341234123

4

12341234123

4

8.

9.

11.

10.

14.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

Connector number

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B 9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

123

4

123

4

123

4

9

8

7

123

4

10 11

123

4

123

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

}

Module slot 2 (middle)

6 analog channels or

3 analog channels and

8 binary inputs/outputs

}

Module slot 1 (bottom)

6 analog channels or

3 analog channels and

8 binary inputs/outputs

}

Connector number

Module slot 3 (top)

6 analog channels or

3 analog channels and

8 binary inputs/outputs

4.2 Procedure

h Make the electrical connection as per Chapter 4.4 “Connection diagram”.

h Apply strain relief for the connecting cables, if necessary.

Instrument

variant 1

Instrument

variant 2

18

Page 19

Connector

Binary

inputs/outputs

Ethernet

interface

Relay

contacts

Test voltage

contacts to

relay coil

2.3kV AC

Test voltage

AC supply: 2.3kV/50Hz

AC/DC supply: 2.3kV/50Hz

RS232 for

barcode reader

Supply

AC or AC/DC

Serial interface

RS232 / RS485

CompactFlash

memory card

USB

interfaces

Analog input 1 — 18

summary

4 Electrical connection

Connector/slot Function

1 Relay output

2 RS232 for barcode reader

3 PROFIBUS-DP

4 Supply voltage

5 USB host interface

6Ethernet

7 RS232 and RS485

8 Analog input

9 Analog input or binary inputs/outputs

10 Analog input

11 Analog input or binary inputs/outputs

12 Analog input

13 Analog input or binary inputs/outputs

14 Relay card (for instrument variant 1)

15 USB device interface

4.3 Overview of the electrical isolation

19

Page 20

4 Electrical connection

V

3.

2.

1.

12

13

11

PE

N

L1

(L+)

(L-)

4.

PE

N

L1

(L+)

(L-)

4.

L1 N

L1 N

PE

PE

21

22

23

31

32

33

414243

51

52

53

61

62

63

71

72

73

123

4

10 11

12

1

2

3

4

5

6

9

8

7

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

+

U

U

+

-

-

--

in

out

U

U

out

U

U

in

33

44

11

22

12341234123412341234123

4

12341234123

4

8.

9.

11.

10.

14.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

123

4

10 11

12

1

2

3

4

5

6

9

8

7

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

+

U

U

+

-

-

--

in

out

U

U

out

U

U

in

33

44

11

22

12341234123412341234123

4

12341234123

4

8.

9.

11.

10.

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

2134

+

–

2134

2134

2134

2134

ESA

2134

2134

2134

4.4 Connection diagram

The electrical connection must only

be carried out by specialist personnel.

Back panel v Chapter 4.2 “Procedure”

Connections

Terminal assignment Connector Diagram

Supply

voltage

Supply voltage

as on nameplate

Analog inputs Thermocouple

RTD temperature probe

2-wire circuit

RTD temperature probe

3-wire circuit

RTD temperature probe

4-wire circuit

Connector 4

L1 (L+)

N (L-)

PE

Connectors

8 to 11

(input 1—12)

for instrument

variant 1

20

Resistance transmitter

E = end

S = slider

A = start

Potentiometer in

2-wire circuit

or

connectors

8 to 13

(input 1—18)

for instrument

variant 2

Potentiometer in

3-wire circuit

Potentiometer in

4-wire circuit

Page 21

4 Electrical connection

21

22

23

31

32

33

414243

51

52

53

61

62

63

71

72

73

123

4

10 11

12

1

2

3

4

5

6

9

8

7

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

+

U

U

+

-

-

--

in

out

U

U

out

U

U

in

33

44

11

22

12341234123412341234123

4

12341234123

4

8.

9.

11.

10.

14.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

123

4

10 11

12

1

2

3

4

5

6

9

8

7

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

+

U

U

+

-

-

--

in

out

U

U

out

U

U

in

33

44

11

22

12341234123412341234123

4

12341234123

4

8.

9.

11.

10.

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

Terminal assignment Connector Diagram

Analog inputs Voltage input 0 — 1 V Connectors

8 to 11

(input 1—12)

Voltage input 0 — 10 V

Current input

for instrument

variant 1

or

connectors

8 to 13

(input 1—18)

for instrument

variant 2

21

Page 22

4 Electrical connection

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

-

-

in

out

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

9.

B2

B3

B4

B5

B6

B7

B8

+

-+

B1

-

UinU

out

+-

24V external

supply voltage

Load

B1

B2

B3

B4

B5

B6

B7

B8

Uin+

Uin-

Uout+

Uout-

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

B12

B9

B10

B11

B13

B14

B15

B16

U

+

+

U

-

-

in

out

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

11.

B10

B11

B12

B13

B14

B15

B16

+

-+

B9

-

UinU

out

B9

B10

B11

B12

B13

B14

B15

B16

Uin+

Uin-

Uout+

Uout-

Terminal assignment Connector Diagram

Binary inputs/

outputs

H The configuration in the instrument or in the setup program

defines whether it is a binary input or binary output.

B1 ... B8

voltage-controlled

LOW = -3 to +5 V DC

HIGH = 12 to 30 V DC

B1 Binary input/output 1

B2 Binary input/output 2

B3 Binary input/output 3

B4 Binary input/output 4

B5 Binary input/output 5

B6 Binary input/output 6

B7 Binary input/output 7

B8 Binary input/output 8

U

+external supply

in

voltage

U

- ground

in

++24V (60mA) internal

U

out

supply voltage

U

- ground

out

Connector 9

only for modules

with 3 analog

inputs

Example:

Connecting a load to

binary output 4 (B4)

and a solid-state

relay to binary

output 3 (B3) requires

an external supply

voltage.

Diagram of the

connector:

B9 ... B16

Connector 11

only for modules

voltage-controlled

LOW = -3 to +5 V DC

HIGH = 12 to 30 V DC

B9 Binary input/output 9

B10 Binary input/output 10

with 3 analog

inputs

Example:

Binary input 12 (B12)

is operated from the

internal supply

voltage.

B11 Binary input/output 11

B12 Binary input/output 12

B13 Binary input/output 13

B14 Binary input/output 14

Diagram of the

connector:

B15 Binary input/output 15

B16 Binary input/output 16

+external supply

U

in

voltage

- ground

U

in

U

++24V (60mA) internal

out

supply voltage

- ground

U

out

22

Page 23

4 Electrical connection

13

14

15

16

17

18

4

3

2

1

B20

B17

B18

B19

B21

B22

B23

B24

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

U

U

U

+

+

U

U

+

+

U

-

-

-

-

-

-

in

out

in

out

in

out

1

2

3

4

1

2

3

4

1

2

3

4

9

8

7

1

2

3

4

10 11

1

2

3

4

1

2

3

4

12

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

1

2

3

4

1

2

3

4

1

5

4

2

3

4

6

11

22

33

44

1

2

3

4

11

22

33

44

12.

13.

11.

9.

8.

10.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

16

17

18

B20

B17

B18

B19

B21

B22

B23

B24

U

+

+

U

-

-

in

out

1

2

3

4

11

22

33

44

13.

B18

B19

B20

B21

B22

B23

B24

+

-+

B17

-

UinU

out

B17

B18

B19

B20

B21

B22

B23

B24

Uin+

Uin-

Uout+

Uout-

3.

2.

1.

12

13

11

PE

N

L1

(L+)

(L-)

4.

1.

12

13

11

1312

11

21

22

23

31

32

33

41

42

43

51

52

53

61

62

63

71

72

73

123

4

10 11

12

1

2

3

4

5

6

9

8

7

B12

B9

B10

B11

B13

B14

B15

B16

B4

B1

B2

B3

B5

B6

B7

B8

+

+

+

U

U

+

-

-

--

in

out

U

U

out

U

U

in

33

44

11

22

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

12341234123

4

8.

9.

11.

10.

14.

3.

2.

1.

12

13

11

5.

6.

7.

PE

N

L1

(L+)

(L-)

4.

15.

21

22

23

31

32

33

41

42

43

51

52

53

61

62

63

71

72

73

14.

2322

21

3332

31

4342

41

5352

51

6362

61

7372

71

Terminal assignment Connector Diagram

Binary inputs/

B17 ... B24

outputs

voltage-controlled

LOW = -3 to +5 V DC

HIGH = 12 to 30 V DC

B17 Binary input/output 17

B18 Binary input/output 18

B19 Binary input/output 19

B20 Binary input/output 20

B21 Binary input/output 21

B22 Binary input/output 22

B23 Binary input/output 23

B24 Binary input/output 24

U

+external supply

in

voltage

U

- ground

in

++24V (60mA) internal

U

out

supply voltage

U

- ground

out

Relay outputs Relay 1 - alarm

changeover (SPDT)

Connector 13

only for

instrument

variant 2

and on modules

with 3 analog

inputs

Connector 1

Example:

Binary input 20 (B20)

is operated from the

internal supply

voltage.

Diagram of the

connector:

Relay 2

changeover (SPDT)

Relay 3

changeover (SPDT)

Relay 4

changeover (SPDT)

Relay 5

changeover (SPDT)

Relay 6

changeover (SPDT)

Relay 7

changeover (SPDT)

Connector 14

only for

instrument

variant 1

23

Page 24

4 Electrical connection

3.

2.

1.

12

13

11

PE

N

L1

(L+)

(L-)

4.

2.

2

1

3

4

5

6

7

8

9

3.

2.

1.

12

13

11

PE

N

L1

(L+)

(L-)

4.

3.

2

1

3

4

5

6

7

8

9

5.

6.

7.

15.

5.

5.

6.

7.

15.

6.

8

1

5.

6.

7.

15.

7.

2

1

3

4

5

6

7

8

9

Terminal assignment Connector Diagram

Interfaces RS232C for barcode reader

9-pin SUB-D socket connector

2 RxD receive data

3 TxD transmit data

5 GND ground

PROFIBUS-DP

9-pin SUB-D socket connector

(extra code)

3 RxD/TxD-P B conductor

Receive/transmit data

positive

5 DGND

Data transmission ground

6 VP supply voltage positive

8 RxD/TxD-N A conductor

Receive/transmit data

negative

USB host interface

for memory sticks

The recorder without stainless

steel front also has a USB host

interface on the front panel,

connected in parallel. The two

interfaces cannot both be

operated at the same time.

Connector 2

Connector 3

Connector 5

Ethernet

RJ45 socket connector

1 TX+ transmit data +

2 TX- transmit data 3RX+ receive data +

6RX+ receive data -

RS232C

9-pin SUB-D socket connector

(switchable to RS485)

2 RxD receive data

3 TxD transmit data

5 GND ground

Connector 6

Connector 7

24

Page 25

4 Electrical connection

5.

6.

7.

15.

7.

2

1

3

4

5

6

7

8

9

5.

6.

7.

15.

15.

Terminal assignment Connector Diagram

RS485

9-pin SUB-D socket connector

(switchable to RS232)

3TxD+/RxD+

Transmit/receive data +

5 GND ground

8TxD-/RxD-

Transmit/receive data -

USB device interface

for connecting a PC

The recorder without stainless

steel front also has a USB

device interface on the front

panel, connected in parallel.

The two interfaces cannot both

be operated at the same time.

Connector 7

Connector 15

25

Page 26

4 Electrical connection

paperless

recorder

paperless

recorder

4.5 Connection examples concerning binary inputs/outputs

Binary inputs Triggering via external relays and external supply voltage:

Triggering via external relays and internal supply voltage:

26

Page 27

4 Electrical connection

paperless

recorder

paperless

recorder

Triggering via external opto-coupler and internal supply voltage:

Triggering via external switches (potential-free) and internal supply voltage:

27

Page 28

4 Electrical connection

paperless

recorder

paperless

recorder

Binary outputs Triggering of external relays via external supply voltage:

Triggering of external relays via internal supply voltage:

By triggering the external relays via the internal supply voltage the total

current must not exceed 60 mA.

28

Page 29

Start-up screen

5 Functional test

After the paperless recorder has been installed and wired up, it can be

commissioned. After applying or switching on the supply voltage, the start-up

screen will appear for a short time.

The visualization will start automatically after the initialization phase.

Visualization

Further steps

The paperless recorder is now in the recording phase.

The recorder can be configured by an authorized person, either by

using the control knob (rotating and pressing) or with the help of

the PC setup program.

Further information about configuration can be found in the

Operating Manual B 706585.0.

Finally, make another check that the connection, configuration and

function of the recorder are all correct.

29

Page 30

5 Functional test

30

Page 31

6 Technical data (extract from data sheet)

6.1 Analog inputs

Thermocouple

Designation Measuring range Accuracy

Fe-CuNi L DIN 43710

Fe-CuNi J EN 60584

Cu-CuNi U DIN 43710

Cu-CuNi T EN 60584

NiCr-Ni K EN 60584

NiCr-CuNi E EN 60584

NiCrSi-NiSi N EN 60584

Pt10Rh-Pt S EN 60584

Pt13Rh-Pt R EN 60584

Pt30Rh-Pt6Rh B EN 60584

W3Re/W25Re D

W5Re/W26Re C

W3Re/W26Re

Chromel-copel GOST R 8.585-2001

Chromel-alumel GOST R 8.585-2001

PLII (Platinel II)

Shortest span Type L, J, U, T, K, E, N, chromel-alumel, PLII: 100 °C

Range start/end freely programmable within the limits, in 0.1 °C steps

Cold junction Pt100 internal or thermostat external constant

Cold junction accuracy (internal) ±1 °C

Cold junction temperature (external) -50 to +150 °C adjustable

Sampling cycle Channel 1 to 18: 125 ms in total

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10.0 sec

Electrical isolation see “Electrical data” on page 35 and

Resolution > 14 bit

Features also programmable in °F

a

The linearization accuracy refers to the maximum measuring range. The linearization accuracy is reduced

with short spans.

-200 to +900 °C

-200 to +1200 °C

-200 to +600 °C

-270 to +400 °C

-200 to +1372 °C

-200 to +1000 °C

-100 to +1300 °C

0 to 1768 °C

0 to 1768 °C

0 to 1820 °C

0 to 2495 °C

0 to 2320 °C

0 to 2400 °C

-200 to +800 °C

-200 to +1372 °C

0 to 1395 °C

Type S, R, B, D, C, W3Re/W26Re, chromel-copel: 500 °C

“Overview of the electrical isolation” on page 19

±0.1 %

±0.1 % from -100 °C

±0.1 % from -150 °C

±0.1 % from -150 °C

±0.1 % from -80 °C

±0.1 % from -80 °C

±0.1 % from -80 °C

±0.15 %

±0.15 %

±0.15 % from 400 °C

±0.15 % from 500 °C

±0.15 % from 500 °C

±0.15 % from 500 °C

±0.15 % from -80 °C

±0.1 % from -80 °C

±0.15 %

a

RTD temperature probe

Designation Connection

circuit

Pt100 EN 60751

(TC = 3.85*10

Pt100 JIS 1604

(TC = 3.917*10

Pt100 GOST 6651-94 A.1

(TC = 3.91*10

Pt500 EN 60751

(TC = 3.85*10

Pt1000 EN 60751

(TC = 3.85*10

-3

1/°C)

-3

-3

1/°C)

-3

1/°C)

-3

1/°C)

1/°C)

2-/3-wire

2-/3-wire

4-wire

2-/3-wire

2-/3-wire

4-wire

2-/3-wire, 4-wire

2-/3-wire, 4-wire

2-/3-wire, 4-wire

2-/3-wire, 4-wire

2-/3-wire

2-/3-wire

4-wire

Measuring range AccuracyaMeasurement

current

-200 to +100 °C

-200 to +850 °C

-200 to +850 °C

-200 to +100 °C

-200 to +650 °C

-200 to +650 °C

-200 to +100 °C

-200 to +850 °C

-200 to +100 °C

-200 to +850 °C

-200 to +100 °C

-200 to +850 °C

-200 to +850 °C

±0.5 °C

±0.8 °C

±0.5 °C

±0.5 °C

±0.8 °C

±0.5 °C

±0.5 °C

±0.8 °C

±0.5 °C

±0.9 °C

±0.5 °C

±0.8 °C

±0.5 °C

250 µA

250 µA

250 µA

250 µA

250 µA

250 µA

250 µA

250 µA

100 µA

100 µA

100 µA

100 µA

100 µA

31

Page 32

6 Technical data (extract from data sheet)

Designation Connection

circuit

Ni100 DIN 43760

(TC = 6.18*10

Pt50 ST RGW 1057 1985

(TC = 3.91*10

Cu50

(TC = 4.26*10

Cu100 GOST 6651-94 A.4

(TC = 4.26*10

Connection circuit 2-, 3-, or 4-wire circuit

Shortest span 15 °C

Sensor lead resistance max. 30 per conductor for 3-wire/4-wire circuit

Range start/end freely programmable within the limits, in 0.1 °C steps

Sampling cycle Channel 1 to 18: 125 ms in total

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10 sec

Electrical isolation see “Electrical data” on page 35 and

Resolution > 14 bit

Features also programmable in °F

a

The linearization accuracy refers to the maximum measuring range. The linearization accuracy is reduced

with short spans.

-3

1/°C)

-3

1/°C)

-3

1/°C)

-3

1/°C)

2-/3-wire, 4-wire -60 to +180 °C ±0.4 °C

2-/3-wire

2-/3-wire

4-wire

4-wire

2-/3-wire

2-/3-wire

4-wire

4-wire

2-/3-wire

2-/3-wire

4-wire

4-wire

max. 10 per conductor for 2-wire circuit

“Overview of the electrical isolation” on page 19

Measuring range AccuracyaMeasurement

current

250 µA

-200 to +100 °C

-200 to +1100 °C

-200 to +100 °C

-200 to +1100 °C

-50to+100°C

-50to+200°C

-50to+100°C

-50to+200°C

-50to+100°C

-50to+200°C

-50to+100°C

-50to+200°C

±0.5 °C

±0.9 °C

±0.5 °C

±0.6 °C

±0.5 °C

±0.9 °C

±0.5 °C

±0.7 °C

±0.5 °C

±0.9 °C

±0.5 °C

±0.6 °C

250 µA

250 µA

250 µA

250 µA

250 µA

250 µA

250 µA

250µA

250 µA

250 µA

250 µA

250 µA

Resistance transmitter and potentiometer

Designation Measuring range Accuracy

Resistance transmitter up to 4000 ±4 100 µA

Potentiometer

to 4000

Connection circuit resistance transmitter: 3-wire circuit

potentiometer: 2-/3-/4-wire circuit

Shortest span 60

Sensor lead resistance max. 30 per conductor for 4-wire circuit

max. 10 per conductor for 2-/3-wire circuit

Resistance values freely programmable within the limits, in 0.1 steps

Sampling cycle Channel 1 to 18: 125 ms in total

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10.0 sec

Electrical isolation see “Electrical data” on page 35 and

“Overview of the electrical isolation” on page 19

Resolution > 14 bit

a

The linearization accuracy refers to the maximum measuring range. The linearization accuracy is reduced

with short spans.

±400 m

±4

a

Measurement

current

250 µA

100 µA

32

Page 33

6 Technical data (extract from data sheet)

Input for DC voltage, DC current

Basic range Accuracy

-12 to +112 mV

-10 to +210 mV

-1.5 to +11.5 V

-0.12 to +1.12 V

-1.2 to +1.2 V

-11.2 to +11.2 V

±100 V

±240 V

±6 mV

±1 mV

±2 mV

±12 mV

Shortest span 5 mV

Range start/end freely programmable within the limits in 0.01 mV steps

-1.3 to +22 mA

-22 to +22 mA

±20 A

±44 A

Shortest span 0.5mA

Range start/end freely programmable within the limits in 0.01 mA steps

Overrange/underrange according to NAMUR NE 43

Sampling cycle Channel 1 to 18: 125 ms in total

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10.0 sec

Electrical isolation see “Electrical data” on page 35 and

“Overview of the electrical isolation” on page 19

Resolution >14 bit

a

The linearization accuracy refers to the maximum measuring range. The linearization accuracy is reduced

with short spans.

a

Input resistance

R

1M

E

R

470 k

E

R

470 k

E

R

470 k

E

R

470 k

E

R

470 k

E

burden voltage 3V

burden voltage 3V

Transducer short circuit/break

Short-circuit

a

Thermocouple not detected detected

RTD temperature probe detected detected

Resistance transmitter not detected detected

Potentiometer not detected detected

Voltage ±210 mV not detected detected

Voltage > ±210 mV not detected not detected

Current not detected not detected

a

Programmable reaction of device, e.g. triggering alarm

Break

a

33

Page 34

6 Technical data (extract from data sheet)

6.2 Binary inputs/outputs (option)

Input or output configurable as input or output

Number 8, 16 or 24, depending on the device version,

to DIN VDE 0411, Part 500; max. 25 Hz, max. 32 V

Input

• level logic "0": -3 to +5 V (input current max. ±1 mA),

logic "1": 12 to 30 V (2.5 mA input current 5mA)

• counting frequency 8Hz

High-speed input the first two binary inputs of each module (B1, B2, B9, B10, B17, B18),

if the module is not fitted with relays or 6 analog inputs

• task count function, e.g. for flow measurement

• counting frequency 10 kHz

Output

• type open-collector output, switches relative to positive voltage

• level logic "0": transistor is inhibited

(max. permissible voltage across switching transistor 30 V,

max. leakage current 0.1 mA)

logic "1": transistor is switched on

(max. voltage across switching transistor 1.6 V, max. current 50 mA)

• sampling cycle at least 1 sec (1 Hz)

6.3 Outputs

1 relay (ex-factory) changeover (SPDT), 3 A, 230 V AC

6 relays (option) changeover (SPDT), 3 A, 230 V AC

a

With resistive load.

b

It is not permissible to mix SELV circuits and supply circuits.

a

a, b

6.4 Interfaces

RS232/RS485 (connector 7) Qty. 1, switchable between RS232 and RS485

• protocol Modbus master, Modbus slave and barcode reader

• baud rate 9600, 19200, 38400

• modem can be connected

•connector SUB-D

• external inputs via the Modbus master/slave function, 24 analog and 24 binary

RS232 for barcode reader

(connector 2)

• protocol Modbus master, Modbus slave and barcode reader

• baud rate 9600, 19200, 38400

•connector SUB-D

• external inputs via the Modbus master/slave function, 24 analog and 24 binary

Ethernet (connector 6)

• quantity max. 1

• protocols TCP, IP, HTTP, DHCP, SMTP, ModbusTCP

• baud rate 10 Mbits/sec, 100 Mbits/sec

•connector RJ45

• data format HTML

Qty. 1

34

Page 35

6 Technical data (extract from data sheet)

USB host (connector 5)

• quantity 2 (or 1 with stainless steel front),

connector 5 and front connector (not with stainless steel front); no

parallel operation

• use for connecting a memory stick

• max. current 100 mA

USB device (connector 15)

• quantity 2 (or 1 with stainless steel front), connector 15 and front connector

(not with stainless steel front); no parallel operation)

• use for connecting to the (master) computer

6.5 Screen

Resolution/size 320 × 240 pixels/5.5"

Type/number of colors TFT color screen/256 colors

Screen refresh rate > 150 Hz

Brightness setting adjustable on instrument

Screen saver (switch-off) through waiting time or control signal

6.6 Electrical data

Supply voltage (switch-mode PSU) AC 100 to 240V +10/-15%, 48 - 63Hz or

AC/DC 20 to 30V, 48 - 63Hz (ELV)

Electrical safety to EN 61010, Part 1, August 2002

overvoltage category II, pollution degree 2

Protection class I terminal for PE conductor

Test voltages (type test)

• mains supply circuit to meas.

circuit

• mains supply circuit to housing

(protective conductor)

• measuring current circuits to

measuring current circuit and

housing 500 V/50 Hz, 1 min

• electrical isolation between

analog inputs up to 30 V AC and 50 V DC

Supply voltage error < 0.1 % of range span

Power consumption approx. 40 VA

Data backup CompactFlash memory card

Electrical connection

• mains supply and relays at rear through pluggable screw terminals, 5.08 mm raster,

• analog and binary inputs at rear through pluggable screw terminals, 3.81 mm raster,

with AC supply: 2.3 kV/50 Hz, 1 min,

with AC/DC supply: 2.3 kV/50 Hz, 1 min

with AC supply: 2.3 kV/50 Hz, 1 min,

with AC/DC supply: 2.3 kV/50 Hz, 1 min

max. conductor cross-section 2.5 mm

max. conductor cross-section 1.5 mm

2

or 2× 1.5 mm2 with ferrules

2

35

Page 36

6 Technical data (extract from data sheet)

6.7 Environmental influences

Ambient temperature range 0 to +50 °C

Ambient temperature effect 0.03 %/°C

Storage temperature range -20 to +60 °C

Climatic conditions 75 % relative humidity, no condensation

EMC EN 61326-1

• interference emission Class A - only for industrial use -

• immunity to interference to industrial requirements

6.8 Housing

Housing front zinc die-casting, optionally in stainless steel (extra code)

Housing type housing for flush-panel mounting to IEC 61554, in stainless steel

Bezel size 144 mm × 144 mm to IEC 61554

Depth behind panel 193 mm (incl. terminals)

Panel cut-out 138

Panel thickness 2 to 40 mm

Housing mounting in panel to DIN 43834

Operating position unrestricted, but taking into account the viewing angle of the screen,

Enclosure protection to EN 60529 Category 2, front IP65, rear IP20

Weight approx. 3.5 kg

+1.0

mm × 138

horizontally ±65°, vertically +40° to -65°

+1.0

mm to IEC 61554

6.9 Approvals/marks of conformity

Mark of conformity Testing

laboratory

c UL us Underwriters

Laboratories

II 2G Ex px IIC

II 2D Ex px IIIC IP65

electrosuisse SEV 08 ATEX 0155 U EN 60079-0:2009

Certificates/

certification

numbers

E 201387 UL 61010-1

Test basis valid for

the flush-mounted

CAN/CSAC22.2 No. 61010-1

EN 60079-2:2007

EN 61241-4:2006

instrument; not in

conjunction with extra

code 350

the flush-mounted

instrument; only in

conjunction with

extra code 444 and

without extra code

350

36

Page 37

A

Accessories 13

B

Back panel 20

C

Climatic conditions 15

Commissioning 5

CompactFlash 7

Connection diagram 20

D

Dimensions 15

Documentation, arrangement of 6

7 Glossary

E

Electrical connection 17

Electrostatic discharge (ESD) 5

F

Functional test 29

I

Installation 15

Installation notes 17

Installation site 15

Instrument documentation in printed form 6

Instrument documentation in the form of PDF files 6

Instrument version, identification of 11

Introduction 5

M

Mounting 16

N

Note signs 9

37

Page 38

7 Glossary

O

Order details 12

P

Panel mounting 16

R

Returning 5

S

Standard accessories 13

Start-up screen 29

T

Technical data 31

Typographical conventions 9

V

Views 15

Visualization level 29

W

Warning signs 9

Warranty 5

38

Page 39

Page 40

JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc.

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO House

Temple Bank, Riverway

Harlow - Essex CM20 2DY, UK

Phone: +44 1279 63 55 33

Fax: +44 1279 63 52 62

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Loading...

Loading...