Page 1

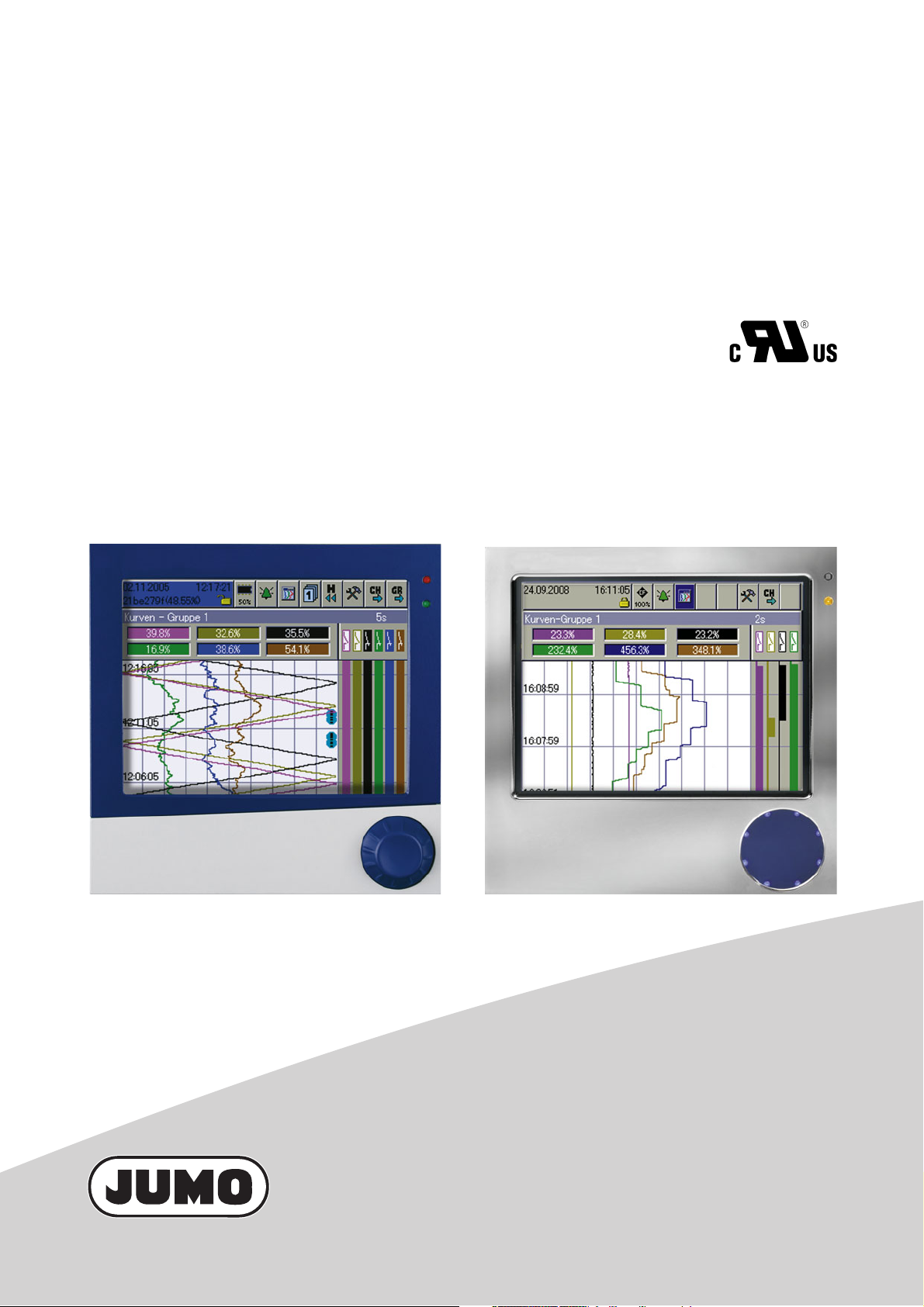

JUMO LOGOSCREEN nt

Paperless recorder with TFT display,

CompactFlash card, and

USB interfaces

B 706581.0

Operating Manual

2014-05-22/00504660

Page 2

Menu structure of the paperless recorder

v Chapter 8 "Device Manager"

v Chapter 7 "Memory Manager"

v Chapter 6 "Alarm and Event Lists"

v Chapter 4 "Visualization"

v Chapter 5 "Memory Presentation (History)"

New device functions

The device software version 187.03.xx is replaced by version 187.04.xx. The following additional functions are available with the new version:

- additional horizontal recorder image; applicable for curve presentation, for binary presentation, for display of a closed batch, and for memory presentation

- Expansion of the external inputs from 24 to 54

- Expansion of the external texts from 9 to 27

- Time synchronization through SNTP

-New web server

- Modbus slave monitoring (timeout monitoring)

The device software can be checked in the menu Device manager

sion

SW version.

Device info Ver-

Page 3

Contents

1 Introduction 9

1.1 Preface ........................................................................................................ 9

1.2 Arrangement of the Documentation ...................................................... 10

1.3 Typographical Conventions .................................................................... 12

2 Instrument Description 15

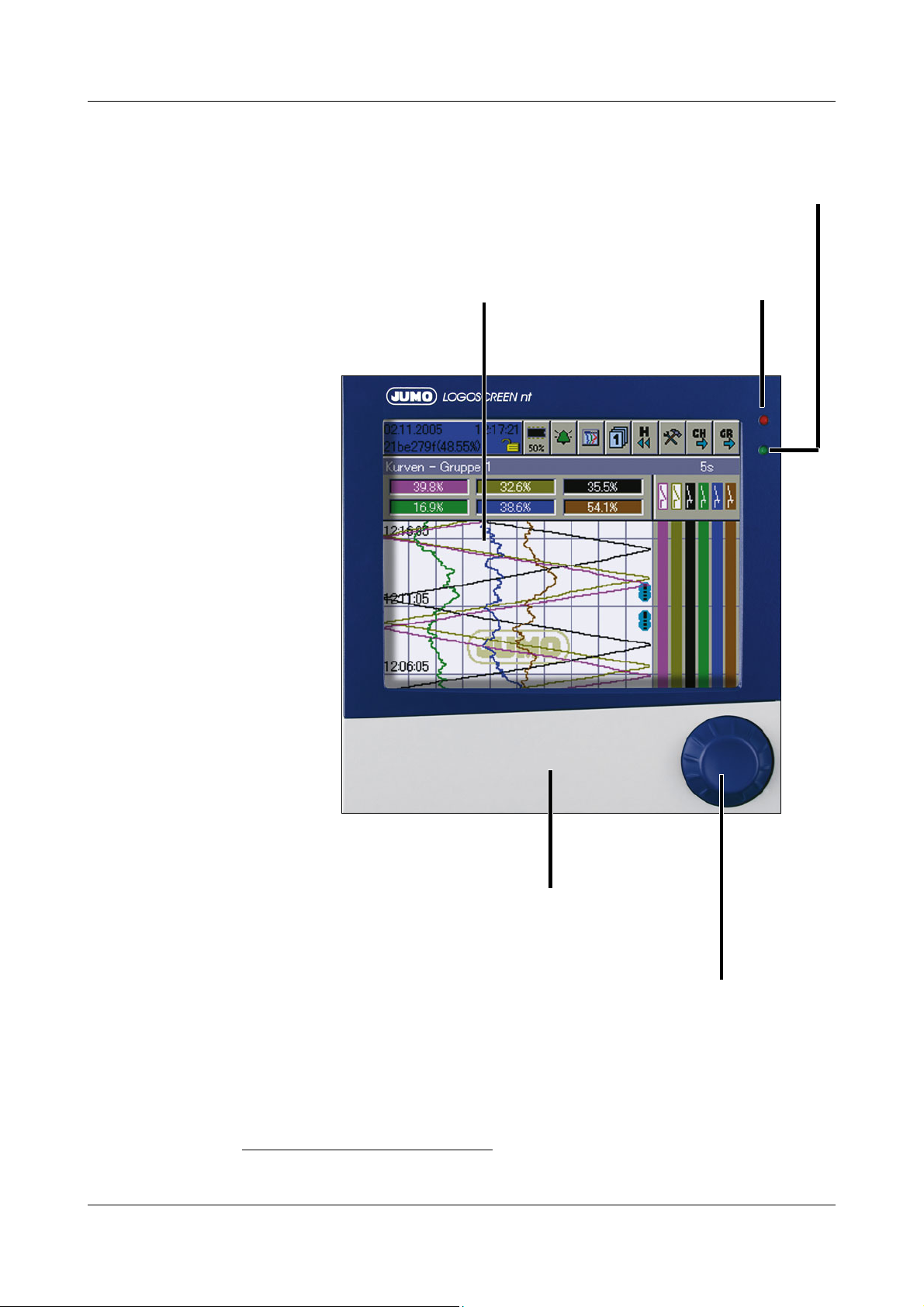

2.1 Displays and Controls ............................................................................. 17

2.2 Analog Inputs ........................................................................................... 20

2.3 Binary Inputs/Outputs ............................................................................. 21

2.4 Relay Outputs ........................................................................................... 22

2.5 Counter/Integrators ................................................................................. 22

2.5.1 Counter ...................................................................................................... 23

2.5.2 Integrators .................................................................................................. 23

2.5.3 Operating time counter .............................................................................. 24

2.5.4 High-speed counters ................................................................................. 24

2.5.5 Flow rate quantity ...................................................................................... 24

2.5.6 Recording period of the counts ................................................................. 25

2.5.7 Reset counters ........................................................................................... 26

2.5.8 Response to setting the time ..................................................................... 26

2.5.9 Response to instrument reconfiguration .................................................... 27

2.5.10 Response to reconfiguration of the counters on the instrument ............... 27

2.5.11 Response to reconfiguration of counters with setup program .................. 27

2.6 Math/Logic Module .................................................................................. 28

2.7 Binary Signals ........................................................................................... 31

2.8 Operating Modes ..................................................................................... 35

2.8.1 Normal, Timed, and Event Mode ............................................................... 35

2.8.2 Eco mode ................................................................................................... 36

2.9 Data Storage ............................................................................................ 38

2.10 Reading out Data ..................................................................................... 40

2.11 Archiving and Evaluating Data ................................................................

41

3 Operating Principle 43

3.1 Operating Principle and Graphic Elements ........................................... 43

3.2 Operating Example .................................................................................. 48

Page 4

Contents

3.3 Group and Plant Management (Batches) ............................................... 50

4 Visualization 53

4.1 Activating the Operator Level ................................................................. 53

4.2 Overview of Header Lines ....................................................................... 54

4.3 Curve Presentation .................................................................................. 55

4.3.1 Vertical presentation .................................................................................. 55

4.3.2 Horizontal presentation .............................................................................. 56

4.4 Bar Graph Presentation ........................................................................... 57

4.5 Text Picture Presentation ........................................................................ 58

4.6 Process Image Presentation ................................................................... 59

4.7 Binary diagram presentation .................................................................. 59

4.7.1 Vertical presentation .................................................................................. 60

4.7.2 Horizontal presentation .............................................................................. 60

4.8 Reports ..................................................................................................... 61

4.9 Batches/Plants ......................................................................................... 62

4.9.1 Current Batches ......................................................................................... 62

4.9.2 Completed Batches ................................................................................... 64

4.9.3 Batch Control with Barcode Reader .......................................................... 65

4.10 Counters and Integrators ........................................................................ 68

4.11 Comment Entry ........................................................................................ 69

5 Memory Presentation (History) 71

5.1 Vertical presentation ................................................................................ 72

5.2 Horizontal presentation ........................................................................... 74

6 Alarm and Event Lists 75

6.1 Call from One of the Visualization Modes ............................................. 76

6.2 Call from the Memory Presentation ....................................................... 78

6.3 Symbols .................................................................................................... 78

7 Memory Manager 79

8 Device Manager 83

Page 5

Contents

8.1 Close Device Manager ............................................................................ 84

8.2 Log-in and Log-out .................................................................................. 84

8.3 Device information ................................................................................... 86

8.4 Device Audit Trail ..................................................................................... 91

8.5 Configuration ............................................................................................ 92

8.6 Parameterization ...................................................................................... 92

8.7 Service ...................................................................................................... 93

9 Parameterization 95

9.1 Fine calibration ......................................................................................... 96

9.2 Counters/integrators ............................................................................... 98

9.3 Date and time ........................................................................................... 98

9.4 Batches/plants ......................................................................................... 99

10 Configuration - General 101

11 Configuration - Device Data 103

12 Configuration - Screen 105

12.1 Brightness … Show text image ........................................................... 105

12.2 Show process image … Bar code -> current batch ........................... 106

13 Configuration - Analog Inputs 109

13.1 Sensor … Offset ..................................................................................... 109

13.2 Filter Constant … Unit ........................................................................... 110

13.3 Comma format … Alarm Configuration ............................................... 112

13.4 Alarm configuration ............................................................................... 113

13.4.1 Status … Alarm text 2 .............................................................................. 113

13.4.2 Alarm rejection ......................................................................................... 114

Page 6

Contents

14 Configuration - Binary Inputs/Outputs 115

14.1 Function … Alarm Configuration .......................................................... 115

14.2 Alarm Configuration .............................................................................. 116

15 Configuration - Relay 119

16 Configuration - External Analog Inputs 121

16.1 Range Start … Alarm Configuration .................................................... 121

16.2 Alarm configuration ............................................................................... 122

16.2.1 Status … Alarm text 2 .............................................................................. 122

16.2.2 Alarm rejection ......................................................................................... 124

17 Configuration - External Binary Inputs 125

17.1 Channel Name … Alarm Configuration ................................................ 125

17.2 Alarm Configuration .............................................................................. 127

18 Configuration - Groups 129

18.1 Parameter ............................................................................................... 130

18.2 Analog Channels .................................................................................... 131

18.3 Binary Channels ..................................................................................... 134

18.4 Counters/Integrators ............................................................................. 134

18.5 Diagram View ......................................................................................... 135

18.6 Normal Operation .................................................................................. 137

18.7 Event Mode ............................................................................................. 139

18.8 Timed Mode ............................................................................................ 140

19 Configuration Report 141

19.1 Total … Period ........................................................................................ 141

19.2 External … Out of range ........................................................................ 143

20 Configuration - Limit Monitoring 145

20.1 Function … Alarm Configuration .......................................................... 145

Page 7

Contents

20.2 Alarm Configuration .............................................................................. 147

21 Configuration - Counters/Integrators 149

21.1 General Setting ...................................................................................... 149

21.2 Function … Specific Setting ................................................................. 151

21.3 Input Signal … Decimal Place ............................................................... 153

21.4 Range Start … Alarm Configuration .................................................... 155

21.5 Alarm Configuration .............................................................................. 156

22 Configuration - Interface 159

22.1 Ethernet .................................................................................................. 160

22.2 RS232/RS485 .......................................................................................... 162

22.2.1 General .................................................................................................... 162

22.2.2 Modbus master ........................................................................................ 164

22.3 RS232 for Barcode Reader ................................................................... 166

22.4 Modbus/TCP .......................................................................................... 167

23 Configuration – Batches/Plants 169

23.1 General Information on Batches .......................................................... 169

23.2 General Plant Parameters ..................................................................... 171

23.3 Plant 1 — 3 .............................................................................................. 172

23.3.1 General .................................................................................................... 172

23.3.2 Lines 1—10 .............................................................................................. 174

23.4 Final Remarks ........................................................................................ 177

24 Configuration - Date and Time 179

24.1 Time Synch. … Daylight Saving Time .................................................. 179

24.2 Start Daylight Saving ............................................................................. 181

24.3 End Daylight Saving ............................................................................... 182

25 Configuration - Time server (SNTP) 183

25.1 General information about SNTP ......................................................... 183

25.2 Synchronize with server ... period ........................................................ 184

Page 8

Contents

26 Configuration - Undocumented Parameters 185

27 Entering text and values 187

27.1 Text entry ................................................................................................ 187

27.1.1 Entering characters .................................................................................. 187

27.1.2 Insert spaces ........................................................................................... 189

27.1.3 Delete character ....................................................................................... 189

27.1.4 Move cursor ............................................................................................. 189

27.1.5 Enter text from text list ............................................................................. 189

27.1.6 Finish entry .............................................................................................. 189

27.1.7 Reject entry .............................................................................................. 190

27.2 Entry via selection field ......................................................................... 190

27.3 Entering values ....................................................................................... 191

27.3.1 Whole numbers (integers) ........................................................................ 191

27.3.2 Real numbers (floating point) ................................................................... 192

28 Web server 193

28.1 General .................................................................................................... 194

28.2 Online Visualization (All Visualizations Except Batches) .................... 197

28.3 Three freely programmable HTML pages ............................................ 199

28.4 Online Visualization of Current Batch Reports ................................... 200

28.5 QuadView ................................................................................................ 201

28.6 General information ............................................................................... 204

28.7 Online visualization (all visualizations other than batches) ............... 206

28.8 Online visualization of the current batch reports ............................... 207

28.9 QuadView ................................................................................................ 208

29 Appendix 211

29.1 Bar code ................................................................................................. 211

29.1.1 Batch control ........................................................................................... 211

29.1.2 Batch texts ............................................................................................... 212

30 Index 215

Page 9

1.1 Preface

E

B

1 Introduction

Please read this manual before commissioning the instrument. Keep the

instructions in a place which is accessible to all users at all times.

Please assist us in improving these instructions where necessary.

Your comments will be appreciated.

If any difficulties should arise during commissioning, you are asked

not to carry out any manipulations that could endanger your rights

under the instrument warranty!

Please contact the nearest subsidiary or the head office in such a

case.

When returning modules, assemblies or components, the

regulations of EN 61340-5-1 and EN 61340-5-2 “Protection of

electronic devices from electrostatic phenomena” must be

observed. Use only the appropriate ESD packaging for transport.

Please note that we cannot accept any liability for damage caused

by ESD.

ESD = Electro Static Discharge

9

Page 10

1 Introduction

1.2 Arrangement of the Documentation

The documentation for this instrument is addressed to equipment

manufacturers (OEMs) and users with appropriate technical expertise. It

consists of the following parts:

Instrument documentation in printed form

B 706581.1 Operating instructions

The operating instructions are an extract from the operating manual and cover

the basic operation of the paperless recorder.

B 706581.4(.1) Installation instructions

The installation instructions describe the installation of the recorder and the

connection of the supply and signal cables. The instructions also contain a list

of the technical data.

B 706581.4 Installation instructions for recorder with zinc die-cast panel

B 706581.4.1 Installation instructions for recorder with stainless steel panel

Instrument documentation in the form of PDF files

The “Instrument documentation in the form of PDF files” is on the CD that is

included in the delivery.

B 706581.0 Operating manual

It contains information about commissioning, operation and parameterization

on the instrument, as well as about the setup program (available as an option).

B 706581.1 Operating instructions

The operating instructions are an extract from the operating manual and cover

the basic operation of the paperless recorder.

B 706581.2.0 Interface description (serial interfaces)

This provides information on communication (RS 232/RS 485) with

supervisory systems.

Interface description (Ethernet interface)

This provides information on the connection of a paperless recorder to a

company-internal network. This description is integrated into B 706581.2.0.

B 706581.2.3 Interface description (PROFIBUS-DP interface)

10

This provides information on the connection of a paperless recorder to a

PROFIBUS-DP system.

Page 11

B 706581.4(.1) Installation instructions

The installation instructions describe the installation of the recorder and the

connection of the supply and signal cables. The instructions also contain a list

of the technical data.

B 706581.4 Installation instructions for recorder with zinc die-cast panel

B 706581.4.1 Installation instructions for recorder with stainless steel panel

B 706581.6 Setup program

These instructions describe the functions of the setup program. The setup

program is available as an accessory.

T 706581 Data sheet

The data sheet contains general information, the order details and, technical

data.

B 709701.0 PC evaluation software PCA3000

The operating manual describes the operation and the features of the PC

evaluation software.

1 Introduction

The PC evaluation software serves to visualize and evaluate process data

(measurement data, batch data, messages ...). The process data can be read

in via the CompactFlash memory card, or made available through the PCC

software.

B 709702.0 PCA communications software PCC

The operating manual describes the operation and features of the PCA

Communications software.

The PCA Communications software is responsible for the data transfer from

the paperless recorder to a PC, or across a network.

Internet

All documents are available for

downloading at www.jumo.net

h Start the product search on the home page.

h Enter 706581 and start the search.

h Select the paperless recorder.

h Select the download section.

h Download the PDF file.

11

Page 12

1 Introduction

V

E

1.3 Typographical Conventions

Warning signs

The signs for Danger and Caution are used in this manual under the following

conditions:

Danger

This symbol is used when there may be danger to personnel if the

instructions are ignored or not followed correctly!

Warning

This symbol is used when there may be damage to equipment or data if the

instructions are ignored or not followed correctly!

Warning

This symbol is used where special care is required when handling

components liable to damage through electrostatic discharge.

Note signs

h

Note

This symbol is used when your special attention is drawn to a remark.

Reference

This symbol refers to further information in other manuals, chapters or

sections.

Action instruction

This symbol indicates that an action to be performed is described.

The individual steps are marked by this asterisk, e.g.

h Rotate control knob

h Press control knob

12

Page 13

Presentation modes

Screen texts

1 Introduction

Program

manager

Edit

Device data

Texts that are displayed in the setup program are indicated by italic script.

Menu items

Menu items in the setup and instrument software referred to in this operating

manual are shown in italics. Menu name, menu item and submenu item are

separated from each other by “

”.

13

Page 14

1 Introduction

14

Page 15

2 Instrument Description

Setup program

PC Eval. software (PCA3000)

PCA Communications software

Software

Internal channels

18x math channels

18x logic channels

27x counters / integrators

Inputs/outputs

0…18 analog inputs max.

0…24 binary inputs/outputs max.

(maximum of 3 module slots,

can be fitted with 6 analog inputs

or 3 analog inputs

and 8 binary inputs/outputs)

Display/operation

JUMO LOGOSCREEN nt

Power supply

Display

Operation

5.5" TFT color display,

320 x 240 pixels,

256 colors

control knob or touchpad

(left, right, press)

additionally

up to 54 analog inputs and

up to 54 binary inputs

Inputs via interface

1 relay (standard)

additionally

6 relays (option)

Relay outputs

AC 100...240V +10/-15%,

48...63Hz

AC/DC 20...30V, 48...63Hz

Interface

as standard

1x RS232/RS485

option

1x PROFIBUS-DP

1x Ethernet 10/100 Mbits/sec

4x USB interfaces

1x RS232 (barcode reader)

internal memory

256 Mbytes

external memory

CompactFlash card and

USB memory stick

Meas. data memory

The connection diagram is described in the Installation

Instructions B 706581.4(.1). When the paperless recorder is

delivered, a printed version of the installation instructions is

included.

B 706581.4 Installation instructions for recorder

B 706581.4.1 Installation instructions for recorder

with zinc die-cast panel

with stainless steel panel

15

Page 16

2 Instrument Description

II 2G Ex px IIC

II 2D Ex px IIIC IP65

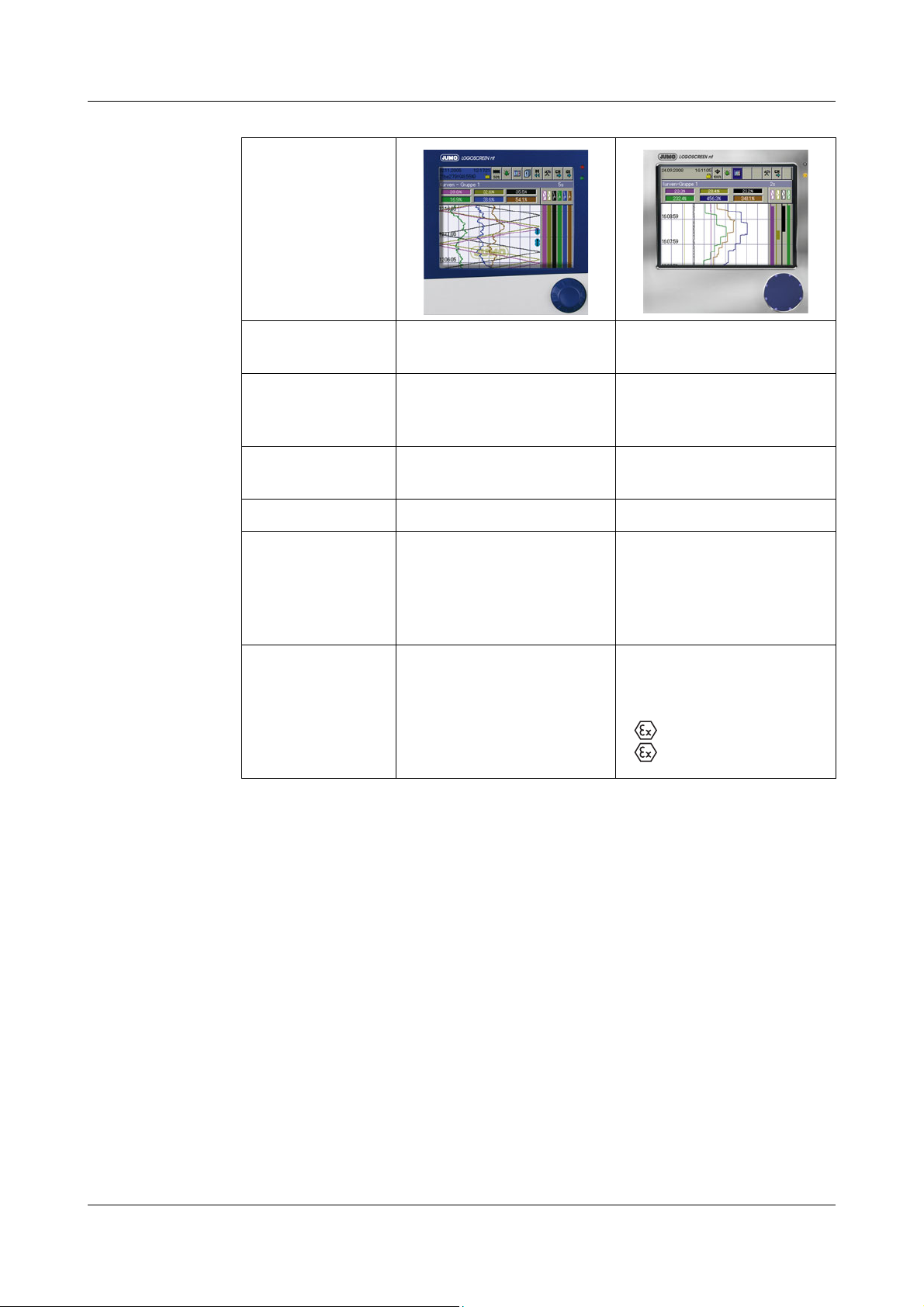

Device

features

Front panel Zinc die-cast with lid Stainless steel

(enclosed)

Interfaces

locatesd on

front panel

External memory CF-card located on front

Operation Control knob Touchpad

Interfaces

located on

device‘s rear

Special features Tested acc. to KTA 3505 EC type-examination

2x USB None

None

panel, maximum 4 GB

2x USB,

1x RS232/RS485,

1x RS232,

1x Ethernet,

1x PROFIBUS-DP (option)

2x USB,

1x RS232/RS485,

1x RS232,

1x Ethernet,

1x PROFIBUS-DP (option)

Ex label

16

Page 17

2.1 Displays and Controls

Power LED (green)

is on continuously as soon as power is applied.

Status LED (red)

is on continuously

if an alarm is present.

Cover

for the CompactFlash

®

slot

1

and the setup plug connection

Control knob

The control knob is used to configure and operate the

paperless recorder. It can be rotated in both clockwise

and anti-clockwise directions, and pressed.

TFT color display

320 x 240 pixels, 256 colors

Recorder with

zinc die-cast

panel

2 Instrument Description

1.

CompactFlash® is a registered trademark of the SanDisk Corporation.

17

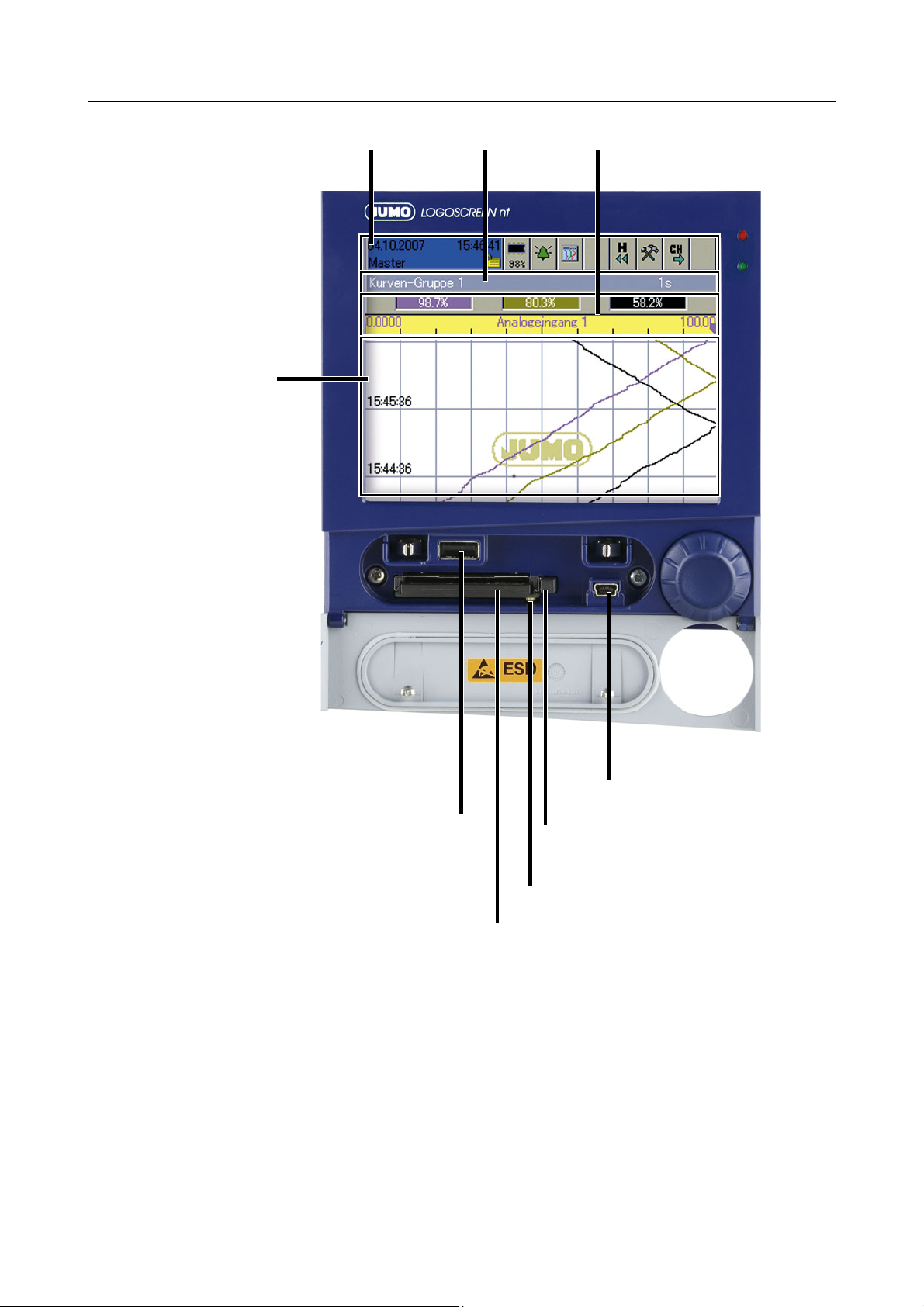

Page 18

2 Instrument Description

USB host

for data exchange

(measurement data,

configuration data,

user lists) between the

recorder and the PC

USB device

for communication with the

setup program or PCC

Header Status &

title bar

Ejector for the CompactFlash

memory card

Numerical

measurement display

Visualization window

(diagram)

CompactFlash slot

for data exchange

(measurement data, configuration

data, user lists) between the

recorder and the PC

Signal LED

Light is on during access to the

CompactFlash memory card.

Recorder with

zinc die-cast

panel

18

A

H

The CompactFlash memory card must not be removed during

access (signal LED is on).

The USB interfaces are not designed for continuous use.

The life of the background illumination can be prolonged by

using the parameter “Screen off”.

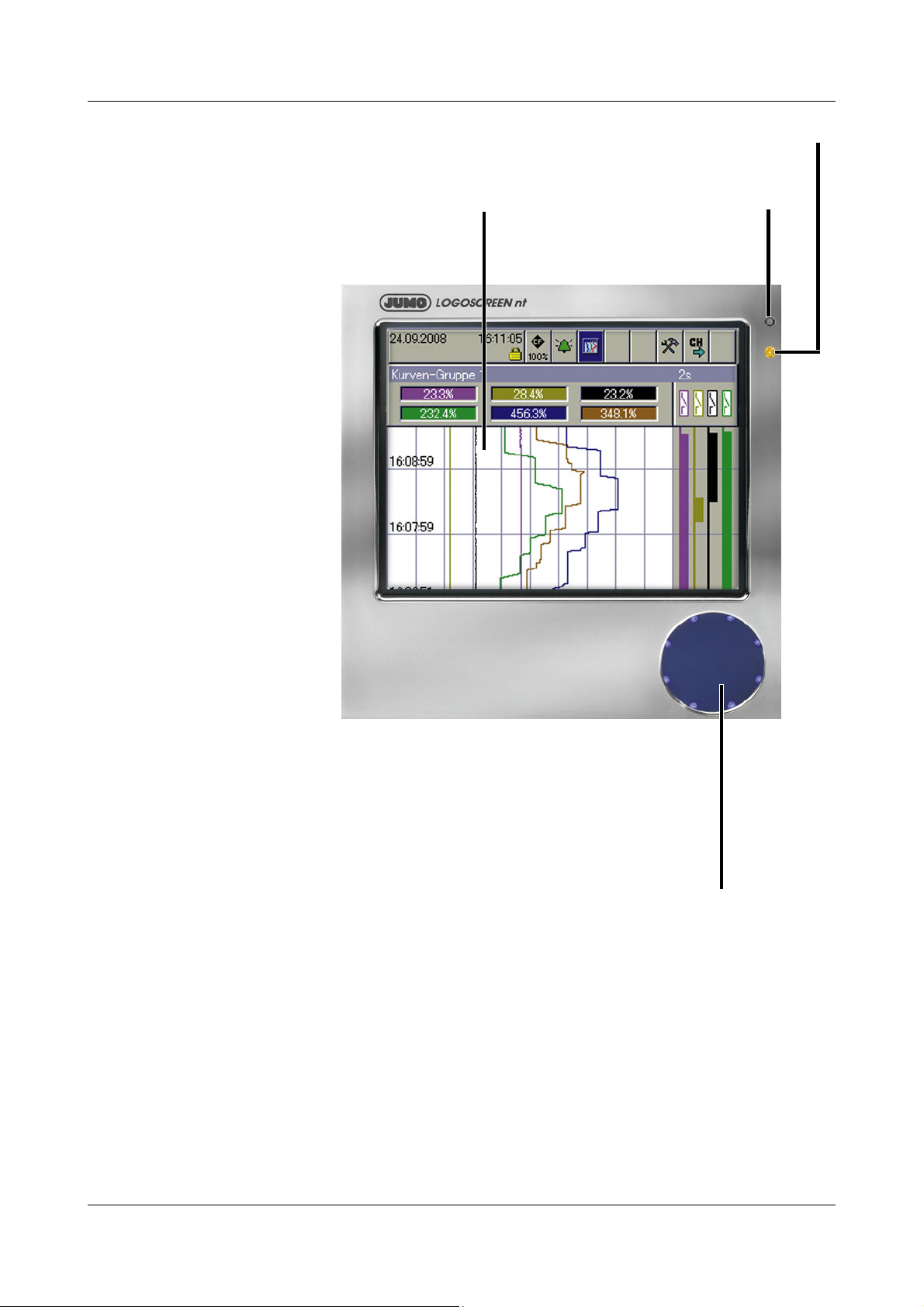

Page 19

Recorder with

Power LED (green)

is on continuously as soon as power is applied.

Status LED (red)

is on continuously

if an alarm is present.

To uc h pa d

The touchpad is used to configure and operate the

recorder. A circular motion with a finger at the outer

edge has the same effect as the turning of the con-

trol knob. Tapping the middle of the touchpad has

the same effect as when the control knob is pressed.

TFT color display

320 x 240 pixels, 256 colors

stainless steel

panel

2 Instrument Description

All descriptions of the control knob in this operating manual also apply to the

touchpad.

For recorders with a stainless steel panel (extra code 444) the

A

CompactFlash memory card is not available as external memory.

The measured data can be saved through one of the interfaces or

through a USB flash drive (on the rear side).

No interfaces at the front panel are available.

The installation instructions from B 706581.4.1 are to be heeded

and complied with.

19

Page 20

2 Instrument Description

2.2 Analog Inputs

Internal

analog inputs

External

analog inputs

The paperless recorder can be equipped with 0 to 18 analog inputs. During

configuration, they are designated Analog input 1 — 18.

There are two ways of finding out the exact number of analog inputs that have

been integrated:

- Check the type code on the nameplate against the type designation. Please

refer to the Installation Instructions B 706581.4 for an explanation of the

nameplate and type designation.

- Read the information on the instrument, in the menu Device manager

Device info Hardw.

In addition to the internal analog inputs, external analog inputs can also be

connected to the recorder.

External analog inputs can be connected to the recorder via three different

interfaces. When configuring the external analog inputs, these are designated

External analog input 1 — 54.

Serial interface RS232/RS485 (Modbus)

The measured values of the external inputs can be transmitted to the recorder

via these two serial interfaces. The paperless recorder can be operated either

as a Modbus slave or as a Modbus master.

Further information on using the serial interface can be found in the Interface

Description B 706581.2.0.

Ethernet interface

Further information on using the serial interface can be found in the Interface

Description B 706581.2.0.

PROFIBUS-DP

This requires the extra code PROFIBUS-DP interface.

Further information on using the PROFIBUS-DP interface can be found in the

Interface Description B 706581.2.3.

20

Page 21

2.3 Binary Inputs/Outputs

2 Instrument Description

Internal

binary inputs/

outputs

External

binary inputs

The recorder can be equipped with 0, 8, 16 or 24 binary inputs/outputs. During

configuration, they are designated Binary input/output 1 — 24. The function

(input or output) can be configured.

There are two ways of finding out the exact number of binary inputs/outputs

that have been implemented:

- Check the type code on the nameplate against the type designation. Please

refer to the Installation Instructions B 706581.4 for an explanation of the

nameplate and type designation.

- Read the information on the instrument, in the menu Device manager

Device info Hardw.

In addition to the internal binary inputs/outputs, external binary inputs can also

be connected to the recorder.

Only external binary inputs are supported, but no external binary

outputs.

External binary inputs can be connected to the recorder via three different

interfaces. When configuring the external binary inputs, they are designated

External binary input 1 — 54.

Serial interface RS232/RS485 (Modbus)

The states of the external inputs can be transmitted to the recorder via these

two interfaces. The paperless recorder can be operated either as a Modbus

slave or as a Modbus master.

Further information on using the serial interface can be found in the Interface

Description B 706581.2.0.

Ethernet interface

Further information on using the serial interface can be found in the Interface

Description B 706581.2.0.

PROFIBUS-DP

This requires the extra code PROFIBUS-DP interface.

Further information on using the PROFIBUS-DP interface can be found in the

Interface Description B 706581.2.3.

21

Page 22

2 Instrument Description

2.4 Relay Outputs

A maximum of 7 relays (1 as standard, 6 as an extra) is available to signal, for

instance, alarms or limit infringements. The action can be configured as break

(SPST-NC) or make (SPST-NO) contact.

There are two ways of finding out whether the 6 additional relays are available:

- Check the type code on the nameplate against the type designation. Please

refer to the Installation Instructions B 706581.4 for an explanation of the

nameplate and type designation.

- Read the information on the instrument, in the menu Device manager

Device info Hardw.

2.5 Counter/Integrators

These are not electrical measurement inputs (hardware), but channels which

are calculated by the paperless recorder (software).

22

The terms counter and integrators encompass the following elements:

-Counter

- Integrators

- Operating time counter

- High-speed counter (hardware counter)

- Flow rate quantity

Page 23

2.5.1 Counter

Counter inputs - Binary inputs

-Alarms

-Errors

-...

v Chapter 2.7 "Binary Signals"

2 Instrument Description

Counting

frequency

Weighting Counted pulses are weighted by multiplying them by a factor. A down counter

8Hz max.

can be implemented by entering a negative weighting

(e.g. weighting factor -1).

2.5.2 Integrators

Integrator

inputs

Integrator

time base

Weighting Integrators are weighted by multiplying them by a factor. Negative integration

Weighting

example

- Analog inputs

- sec, min, hr and day

can be implemented by entering a negative weighting (e.g. a weighting factor

of -1).

-Flow rate

- Input signal of 0 … 20mA

corresponds to a flow rate of 0 … 1000 liters/sec

Minimum size

of the input

signal

-Time base 1sec

- Weighting 0.001 (conversion from liters to m³)

- Display of the integration value (flow rate quantity) in m³

This type of flow measurement is based on an analog input. Fast

binary inputs offer another possibility (high-speed counters).

v Chapter 2.5.5 "Flow rate quantity"

Entering a threshold (amount of the threshold value) has the effect that

integration takes place only when the value has been exceeded. No

integration will occur on falling below this value. The advantage of integration

with a threshold value larger than 0 is that possible noise from a transducer

can be suppressed in this way.

23

Page 24

2 Instrument Description

2.5.3 Operating time counter

The operating time counter will count how long a selected binary input or one

of the binary signals is closed. The time can be displayed in sec, min, hr and

days.

2.5.4 High-speed counters

Counter inputs The first two binary inputs of each module (B1, B2, B9, B10, B17, B18) can be

counted. Binary inputs are available if the module is fitted with 3 analog inputs

and 8 binary inputs.

Counting

frequency

Weighting Counted pulses can be weighted (by multiplying them by a factor). A down

Max. 10kHz

counter can be implemented by entering a negative weighting (e.g. weighting

factor -1).

2.5.5 Flow rate quantity

This makes used of the options of existing counter function to determine flow

rate quantities with the high-speed counters over the assigned time intervals

(the "pulses within the time base" are multiplied by the "weighting").

The flow rate quantity only appears on the paperless recorder.

It is not saved.

Counter inputs The first two binary inputs of each module (high-speed counters B1, B2, B9,

B10, B17, B18) can be used to measure the flow rate quantity (pulse counting).

Binary inputs are available if the module is fitted with 3 analog inputs and 8

binary inputs.

Time base sec, min, hr and day

The time base defines the duration for which pulses will be counted (gate time)

and the display interval of the flow rate quantity.

Counting

frequency

Weighting Counting pulses can be weighted (by multiplying them by a factor). A down

Max. 10kHz

counter can be implemented by entering a negative weighting (e.g. weighting

factor -1).

24

Page 25

2.5.6 Recording period of the counts

For all counters, integrators, operating time counters, and high-speed

counters, the counters are concluded and the counter states are stored and

restarted after an adjustable amount of time (recording time period). The

counter states of the most recently completed recording period can be

numerically displayed.

The following counter/integrator types are possible:

-Periodic

In addition, the time period (from 1 min to 12 hrs)must be selected in the

parameter Configuration

Period.

-External

In this case, the counter/integrator is updated only when the selected

control signal is active (e.g. binary input is closed). When the control signal

is deactivated (e.g. binary input is opened), the counter/integrator value is

saved and reset to 0.

-Daily

2 Instrument Description

Counters/Integrators General settings

- Weekly

-Monthly

-Yearly

-Total

-Daily (start — end)

In addition, the time period must be selected through the two parameters

Configuration

Configuration

counter/integrator will then only be updated from the start time. When the

end time has been reached, the counter/integrator value is saved and then

reset to 0.

Counters/Integrators General settings Start and

Counters/Integrators General settings End. The

25

Page 26

2 Instrument Description

2.5.7 Reset counters

Periodic reset There is a recording time period for each counter, integrator, operating time

counter and high-speed counter. At the end of this period, the current data

(value and time) are saved and the value reset to 0. Then the next time period

is recorded.

The overall and annual counters/integrators are an exception. These are saved

whenever any count/integration has been completed, but not reset to 0. This

means that they can be evaluated in the evaluation software PCA3000 as well.

External reset A control signal can be configured for all counters, integrators, operating time

counters and high-speed counters. The signal generates a reset of the counter

states to 0 without previous values being saved. The period for the summation

will be restarted at this point. This means that after the test run of an

installation, for instance, the recording can be freshly started; the test run

values that are not required are eliminated.

v Chapter 21.1 "General Setting"

v Chapter 21.3 "Input Signal … Decimal Place"

Reset from

control knob

The parameterization menu makes it possible to set counter states to a

specific value. The preconditions is that a user is logged in to the device.

When the value is entered after editing, a message with the new and the old

count value is entered in the event list.

The time period for the counter/integrator summation will not be restarted. The

previous counter/integrator values will also not be saved.

If you wish to save the previous counter/integrator values, you

must execute the function “Save all + update CF.” in the menu for

the memory manager.

In this way, the recording can be freshly started for individual counters/

integrators, e.g. after the test run of an installation; the test run values that are

not required will be eliminated in the process.

2.5.8 Response to setting the time

When the time is set, all counter states are completed and saved and, value is

reset to 0, and the recording period is restarted.

26

Page 27

2 Instrument Description

2.5.9 Response to instrument reconfiguration

When the instrument is reconfigured, the current counter/integrator recording

periods remain unaffected. The counter/integrator values will not be reset to 0

and the recording period will not be restarted.

The values can be deliberately reset, via the “Parameterization”

menu.

2.5.10 Response to reconfiguration of the counters on the instrument

If a counter/integrator on the instrument is reconfigured, then only the affected

counter/integrator will be concluded, saved, reset to 0 and have the recording

period restarted.

If anything is changed through reconfiguration in the menu Configuration

Counters/integrators General settings, then all counters/integrators are

concluded, saved, the values reset to 0, and the recording period is restarted.

2.5.11 Response to reconfiguration of counters with setup program

If a counter/integrator is reconfigured, the setup program will conclude and

save all counter states and reset the value to 0 and the recording period is

restarted.

27

Page 28

2 Instrument Description

2.6 Math/Logic Module

The math and logic module is available as an extra. Like the counters/

integrators, the math and logic module are channels that are not available as

hardware but are calculated by the instrument software.

The math and logic module consists of two parts:

- the math module for calculating analog values and

- the logic module for linking Boolean values (0 or 1).

Math module The math module provides 18 measurement inputs for calculating new

“virtual” channels.

For the calculated channels, separate math channels are provided in addition

to the internal analog inputs. In configuration, you have to activate the required

math channel in the group configuration and thus assign it to a group.

Configuration

Setupprogram How a math channel is formed is determined through the setup program.

As variables for the formulae, the following may be available:

- Analog inputs

- Binary inputs

- Counters/integrators

-Alarms

-Errors

If counter/integrator values are used for calculation, then please note that their

accuracy is reduced, since, in this case, two different data formats will have to

be used for calculation. Counters/integrators are calculated in double-float

format (8 bytes per value), whereas the math module employs a single-float

format (4 bytes per value) according to the IEEE 754 standard. Nevertheless, it

is possible to include these values in the math module.

➔

Group x➔Analog channels ➔Channel x = Math x

28

Page 29

2 Instrument Description

The following fixed functions are available:

-difference

-ratio

- relative humidity

- moving average

For the moving average, the reference channel has to be entered (in most

cases, the analog input) and the time (in minutes). They will be used to

calculate the moving average.

The following operators and functions are available for formulas: +, -, *, /, (, ),

SQRT(), MIN(), MAX(), SIN(), COS(), TAN(), **, EXP(),

ABS(), INT(), FRC(), LOG(), LN().

On going above or falling below the scalable values, the math channel is

treated as for “out-of-range”.

Formulas are entered in the PC, in the setup program. It is not possible to edit

math formulas on the instrument.

Further information can be obtained from the instructions on the

setup program (B 706581.6).

Logic module Up to 18 channels are available for the logic channels.

As is the case with all the other binary signals, the calculated digital (Boolean)

values can be used for different functions:

- recording in event traces,

- as a control signal for display switch-off,

- clock time synchronization,

- operating time counter,

- externally controlled counters/integrators

- counter/integr. reset

- event mode,

- for output to a relay and

- as count input for a counter.

29

Page 30

2 Instrument Description

Following are some of the variables available for formulas:

- Binary inputs

- Logic channels

-Alarms

-Errors

These functions can be used for formulas:

-! (NOT)

-& (AND)

-| (OR)

-^ (XOR)

- / (rising edge)

- \ (falling edge)

-( (open bracket)

-) (close bracket)

Further information can be obtained from the instructions on the

setup program (B 706581.6).

30

Page 31

2 Instrument Description

2.7 Binary Signals

Binary signals are used by the recorder, forexample to

-operate a relay,

- activate the Event operating mode,

- start external reports and

- start batch reports.

Binary signals are made visible as binary traces or switch symbols and can be

used as a basis for counters. The binary inputs (internal and external) are

binary signals.

Binary I/O The switching states of the internal binary inputs/outputs are indicated by the

binary signals. Depending on the instrument hardware level, 0, 8, 16 or 24

binary inputs/outputs are available.

v Chapter 14 "Configuration - Binary Inputs/Outputs"

Binary I/O alarm If the alarm configuration of an internal binary input/output is active, the

switching state is indicated through the corresponding binary signal.

v Chapter 14.2 "Alarm Configuration"

Relays The switching states of the internal relays (1 or 7) are indicated by the binary

signals.

Limits (limit

monitoring)

Limit alarms If the alarm configuration of a limit monitoring is active, the alarm is indicated

Logic With the binary signals the results of the logical operations (logic 1 to 18) are

The result of the limit monitoring (limit 1 — 9) is indicated through the binary

signals.

v Chapter 20 "Configuration - Limit Monitoring"

through the corresponding binary signal.

v Chapter 20.2 "Alarm Configuration"

rendered.

The math and logic module are available as extra codes. A configuration of the

module is only possible with the setup program.

Further information can be found in the instructions to the setup

program (B 706581.6).

Logic alarms If the alarm configuration in the logic module is active then the alarm is ren-

dered through the corresponding binary signal.

Batch The binary signals are used to indicate whether the corresponding batch

report for plant 1 — 3 is active, i.e. whether a batch report is currently being

run.

31

Page 32

2 Instrument Description

Ext. binary input Binary signals are used to indicate the switching states of the external binary

inputs. Up to 54 external binary inputs are available.

v Chapter 17 "Configuration - External Binary Inputs"

Alarms, ext.

binary input

Alarms, analog

inputs

Math

alarms

Alarms,

counters/integr.

Group alarms The binary signals are used to indicate whether an infringement of the

If the alarm configuration of an external binary input is active, the switching

state is indicated through the corresponding binary signal.

v Chapter 17.2 "Alarm Configuration"

The alarm monitoring states of the internal analog inputs are indicated by the

binary signals. Depending on the instrument hardware level, up to 18 internal

analog inputs are available. There are two binary alarm signals for each analog

input.

v Chapter 13 "Configuration - Analog Inputs"

If the alarm configuration in the math module is active then the alarm is rendered through the corresponding binary signal.

The alarm monitoring states of the counters/integrators are indicated by the

binary signals. 27 counters/integrators are available. There are two binary

alarm signals for each counter/integrator.

tolerance band is present within a group, or whether there is an alarm for an

analog or binary channel. The individual channel alarms are OR-linked.

Infringement of tolerance band, group 1 — 9

Alarms, ext.

Analoginputs

There are two binary signals for each group:

- Alarm1 TL Group 1 — 9 = positive tolerance band infringement on a

channel and

- Alarm2 TL Group 1 — 9 = negative tolerance band infringement on a

channel and

v Chapter 18.2 "Analog Channels"

Alarm group 1 — 9

There is a binary signal for each group:

- Alarm Group 1 — 9 = alarm for an analog or binary channel in the

corresponding group.

v Chapter 13.4 "Alarm configuration"

The alarm monitoring states of the external analog inputs are indicated by the

binary signals. 54 external analog inputs are available. There are two binary

alarm signals for each external analog input.

v Chapter 13 "Configuration - Analog Inputs"

32

Page 33

2 Instrument Description

Collective alarm The term "Collective alarm" encompasses the following listed signals:

Signal Description

Device alarm The signal is formed from an OR link of all alarm

configurations (e.g. alarm configuration of analog inputs and

binary inputs and outputs) and the PROFIBUS

communication error signal.

Mem.al.

Read CF

CF card full The signal is activated when the memory space of a CF card

Mem.al.

interface

Login The signal is activated as soon as a user is logged in to

Error The signal “Error” (also referred to as system error) is

The signal is activated when the device-internal memory

space available for data readout via CF card has fallen below

the selected threshold value.

v Chapter 2.10 "Reading out Data"

(Mem.al. = memory alarm)

that has been inserted (external memory) has fallen below the

selected threshold value.

v Chapter 2.10 "Reading out Data"

The signal is activated when the device-internal memory

space available for data readout via interface has fallen

below the selected threshold value.

v Chapter 2.10 "Reading out Data"

(Mem.al. = memory alarm)

instrument.

v Chapter 8.2 "Log-in and Log-out"

activated when:

- the CF card is faulty or full,

- the device battery is empty,

- the internal memory is faulty or

- a p.c.b in the device has not been calibrated.

Reserve 1 Currently not used.

Fieldbus

error

Reserve 2 Currently not used.

CF card

inserted

CF card

removed

The signal is activated when an error occurs during

communication via PROFIBUS.

The signal is activated when a CF card is inserted in the

instrument.

The signal is activated when a CF card is removed from the

instrument.

33

Page 34

2 Instrument Description

Signal Description

Slave timeout

COM1

Slave TO

COM1 inv.

Slave timeout

COM2

Slave TO

COM1 inv.

Slave timeout

TCP

The signal is activated when timeout monitoring of the

RS232/RS485 interface is active and no Modbus slave communication takes place.

v Chapter 22.2 "RS232/RS485"

v See "Activate replacement value" on Page 122.

v See "Activate replacement value" on Page 126.

Inverse behavior of the "Slave timeout COM1" signal.

The signal is activated when timeout monitoring of the

"RS232 for barcode readers" interface is active and no Modbus slave communication takes place.

v Chapter 22.3 "RS232 for Barcode Reader"

v See "Activate replacement value" on Page 122.

v See "Activate replacement value" on Page 126.

Inverse behavior of the "Slave timeout COM2" signal.

The signal is activated when timeout monitoring of the Ethernet interface is active and no Modbus slave communication

takes place.

v Chapter 22.4 "Modbus/TCP"

v See "Activate replacement value" on Page 122.

v See "Activate replacement value" on Page 126.

Slave TO

TCP inv.

Math With the binary signals the results of the math operations are rendered. If the

result of the math (analog value) = 0 then the corresponding binary signal is

also "0". The leaving the configured math range limits is also rated as "0".

The math and logic module are available as extra codes. A configuration of the

module is only possible with the setup program.

Inverse behavior of the "Slave timeout TCP" signal.

Further information can be found in the instructions to the setup

program (B 706581.6).

34

Page 35

2.8 Operating Modes

2.8.1 Normal, Timed, and Event Mode

The operating modes are used to determine the cycle in which measurement

data are stored.

2 Instrument Description

3 operating

modes

Stored value The "Stored value" parameter determines what is stored: average, minimum,

Storage cycle The "Storage cycle" parameter determines the interval between two stored

The instrument has 3 operating modes:

- Normal operation

-Timed mode

-Event mode

The following settings can, among others, be made for each of the three

operating modes:

-Stored value

- Storage cycle (memory rate)

maximum or momentary value between two storage cycles, or the peak value

(envelope). With the "Peak value setting, the minimum and maximum value of

the last storage cycle will be saved.

Another option for the stored value is "Eco mode". This is a special storage

possibility, which is described separately in Chapter 2.8.2.

values. The diagram speed corresponds to the storage cycle, which means

that with a storage cycle of 5sec, for example, the stored value is entered in

the diagram every 5sec.

Normal

operation

Timed mode For timed mode, a period of time can be defined (up to 24 hrs) within which a

Event mode Event mode is activated by a control signal that is assigned to an event or

Priority The respective priorities of the operating modes are allocated as follows:

If the instrument is not in timed or event mode, normal operation is active.

specific stored value and a specific storage cycle are active.

alarm. Event mode can be used, for example, to shorten the storage cycle

when an alarm is present.

Operating mode Priority

Normal

operation

Timed mode Medium

Event mode High

Low

35

Page 36

2 Instrument Description

t1 t1

Tolerance band

t1 = storage through “Min. storage cycle” (forced storage).

The tolerance band is specified

with regard to the unit of the

analog channels (e.g. ± 1 °C).

Active

operating mode

2.8.2 Eco mode

The active operating mode is shown in the diagram by different symbols

behind the current display for the diagram speed:

Operating mode Symbol

Normal

operation

Timed mode

Event mode

The parameters for Eco mode are set in the menu for normal operation.

However, Eco mode can be used for all three operating modes.

In Eco mode, the momentary values (current values) are recorded in a

predefined minimum storage cycle (independent of the tolerance band).

36

Page 37

2 Instrument Description

10s

10s

10s

10s

10s

10s 10s 10s

t

t1

t2

t3

t4

10s

t6

t5

t1 = storage through “Min. storage cycle” (forced storage) and

application of a new tolerance band.

t2 = no storage, since the measurement is again within the tolerance

at the end of the storage cycle (10sec).

t3 = storage and application of a new tolerance band, since the

measurement has gone outside the tolerance band at the end of

the storage cycle.

t4 = storage and application of a new tolerance band, since the

measurement has gone outside the tolerance band at the end of

the storage cycle.

t5 = storage through “Min. storage cycle” (forced storage) and

application of a new tolerance band.

t6 = no storage, since the measurement is again within the tolerance

at the end of the storage cycle (10 sec).

If the measurements go outside the tolerance band, and the new

measurement, which is outside the tolerance band, is present for at least the

duration of the storage cycle that was set in the active operating mode, then it

is acquired and stored and a new tolerance band is applied.

Going outside the tolerance band is not necessarily recorded. If

the measurements return inside the tolerance band within the

storage cycle (t2), then there will be no recording and “Min. storage

cycle” is still active.

37

Page 38

2 Instrument Description

A/D 2

A/D 1

CPU

(SRAM)

20

kB

20

kB

20

kB

20

kB

20

kB

Internal

memory

Analog inputs

External

CompactFlash

memory card

2.9 Data Storage

Operating

principle

Data recording Measurements are acquired continuously in a 125msec sampling cycle. Based

on these measurements, reports are compiled and limits checked. The

measurements are transferred to the main memory of the instrument,

according to the programmable storage cycle and stored value (maximum,

minimum, average, Min&Max, momentary value or economy mode).

The paperless recorder saves the data according to groups, and the input can

be assigned to several groups (up to 9).

Main memory

(SRAM)

Internal

memory

CompactFlash

memory card

(external)

The data stored in the SRAM are regularly copied to the internal memory in

20 kbyte blocks.

When a block in main memory has been filled, it is copied to the internal

memory. Internal memory has a capacity of max 256 Mbytes. Every write

action is monitored, so that any errors in saving data can be immediately

identified. The instrument monitors the capacity of the internal memory and

activates one of the “memory alarm” signals when the capacity has fallen

below the configurable residual capacity level. These signals can be used,

forinstance, to operate the alarm relay.

This is written to as a ring memory, i.e. when the memory is full, the oldest data

will automatically be overwritten by new data.

The data from the internal memory can be shown as a history presentation on

the recorder. The size of the history memory can be configured.

If an external CompactFlash memory card (Industrial Grade) is inserted into

the paperless recorder, memory blocks are automatically written to the CF

card.

The instrument monitors the capacity of the CompactFlash card and activates

the “Memory alarm (CF card)” signal if the level falls below a configurable

residual capacity. This signals can be used, for instance, to operate a relay

(warning signal “Swap CF card”).

38

For recorders with a stainless steel panel (extra code 444) the CompactFlash

memory card is not available as external memory. The measured data can be

saved through one of the interfaces or through a USB flash drive (on the rear

side).

Page 39

2 Instrument Description

Data security The data are stored in coded form in a proprietary format. This ensures a high

level of data security. If the CompactFlash card is removed from the

instrument, no data will be lost immediately, as these data are still stored in the

internal memory. A loss of data will only occur if, after the CompactFlash card

has been removed, internal memory is completely rewritten as well, and no

data have been read out through the interface.

If the paperless recorder is disconnected from the supply, then:

- RAM and clock time are buffered by a lithium battery (ex-factory) for at least

10 years, with a storage capacitor for at least 2 days (ambient

temperature

-40 to +45°C),

- Measurement and configuration data in the backup memory will not be lost.

Storage cycle Different storage cycles, ranging from 125msec to 32000sec can be

configured for normal, event and timed mode under “Configuration”.

The storage cycle determines the time intervals at which the measurements

are stored.

Stored value Under this parameter, separate configurations are made for normal, event and

timed mode, to decide which value is to be stored (average, momentary,

minimum, maximum, peak values or Eco mode).

Recording

format

Recording

duration

Optimization of

recording

duration

Data are recorded encoded in a proprietary format.

The recording duration depends on various factors:

- number of analog channels and event traces being recorded

- Storage cycle (memory rate)

- number of events in the event list

The recording duration can be optimized by process-oriented selection of the

storage cycle and stored value.

In normal operation (no error, no alarm, etc.) a storage cycle that is as long as

possible (e.g. 60sec, 180sec, etc.) should be selected, depending on the

particular application.

In the event of an alarm or error, the storage cycle can be shortened via event

mode, with the effect that the measurement data are recorded with a high time

resolution.

39

Page 40

2 Instrument Description

2.10 Reading out Data

In addition to automatic read-out via the CompactFlash memory card,

measurement data can also be read out through one of the interfaces (RS232,

RS485, USB device, Ethernet) and with a memory stick (USB host).

The options for reading a CF card/memory stick and interface work in a

parallel manner. For this reason, there are also two “binary signals”, which

indicate when the available storage space has fallen below a certain

configurable value.

Memory alarm The limit for alarms can be set by the parameter

Memory alarm in the configuration level.

The parameter

to determine which storage space indication should be shown in the status

bar. The “binary signals” for storage space detection function independently of

this parameter.

Binary Signals “Mem.al. CF readout”

If this signal is set, this means that no data have been fetched via the CF card

or USB memory stick for a prolonged period, and the available capacity of the

internal memory has fallen below the configured level (this only applies if the

parameter

card").

“Mem.al. interface”

If this signal is set, this means that no data have been fetched via the interface

for a prolonged period, and the available capacity of the internal memory has

fallen below the configured level (this only applies if the parameter

Configuration ➔ Device data ➔ Data readout via... is set to “Interface”).

“CF card full”

If this signal is set, it means that not enough space is available on the CF card.

The PCA3000 program can help here. Data can be read into PCA3000, and

then saved to the hard disk or on a network, thus freeing up space on the CF

card. Alternatively, you can use a new CF card.

Configuration ➔ Device data ➔ Data readout via... can be used

Configuration ➔ Device data ➔ Data readout via ... is set to "CF

Configuration ➔ Device data ➔

Difference

between

CF card and

USB stick

40

v See "Binary Signals" on Page 31.

The signal is not operated in reference to a full USB memory stick.

Unlike CF cards, data are not automatically stored on an inserted USB

memory stick.

Page 41

2 Instrument Description

Initial

commissioning

Production phase 1 Conversion /

optimization

Production phase 2

t (time)

Process data

(e.g. Temp. in °C)

Readout via

interface

Use the PCA Communications software PCC to read out measurement data

via the serial or USB device or Ethernet interface.

Use the same archive (in the PC) for reading out data via the

interface as for a readout via the CF card. This saves having to put

together data from different files at a later date.

v Please refer to the Operating Manual B 709702.0 for further information.

2.11 Archiving and Evaluating Data

Life-cycle data

management

The integrated life-cycle data management allows users to save all the

process data from the system that is being monitored in an archive file on their

PCs or a server system.

The recovery of configuration-dependent plant/system data, which may be

required for commissioning, maintenance or optimization during the life-cycle

of a plant or system, is enabled by the associated PC Evaluation software

PCA3000 in a dialog window.

41

Page 42

2 Instrument Description

Open archive

Evaluation

software

PCA3000

42

v Please refer to the Operating Manual B 709701.0 for further information.

Page 43

3 Operating Principle

Function is activated when the

control knob is pressed.

Fixed functions Variable functions

with changing symbols

3.1 Operating Principle and Graphic Elements

Header

The functions of the paperless recorder are selected in the header. The

selected function is indicated by a blue background.

Recorder with control knob

- Function selection by rotating the control knob (to right or left).

- Function is activated by pressing the control knob.

Recorder with touchpad (stainless steel front panel)

- Function selection through a circular motion with a finger at the outer edge

of the touchpad (when activating the circular motion, two of the eight LEDs

in the touchpad are on).

- Function selection by tapping the middle of the touchpad (all LEDs in the

touchpad are on).

The symbols (for the variable functions) vary according to the function that is

currently active.

The following diagram shows the header for normal display when the vertical

diagram (curve display) has been selected.

43

Page 44

3 Operating Principle

Group

step-on

Channel

step-on

Numerical

measurement display

(diagram view)

Memory presentation / history

(visualization of the data in

internal memory)

Operator level

(visualization of current data)

Group selection

Device

manager

Memory manager

Alarm and event lists

Device manager v Chapter 8

Memory manager v Chapter 7

Alarm and event lists v Chapter 6

Operator level (visualization) v Chapter 4

Group selection v See "Group selection" on Page 55.

Memory presentation (History) v Chapter 5

Numerical measurement display v See "Numerical measurement display

Channel step-on v See "Channel step-on" on Page 61.

Group step-on v See "Group step-on" on Page 61.

v See "Numerical measurement display"

(diagram view)" on Page 46.

on Page 56.

44

Page 45

3 Operating Principle

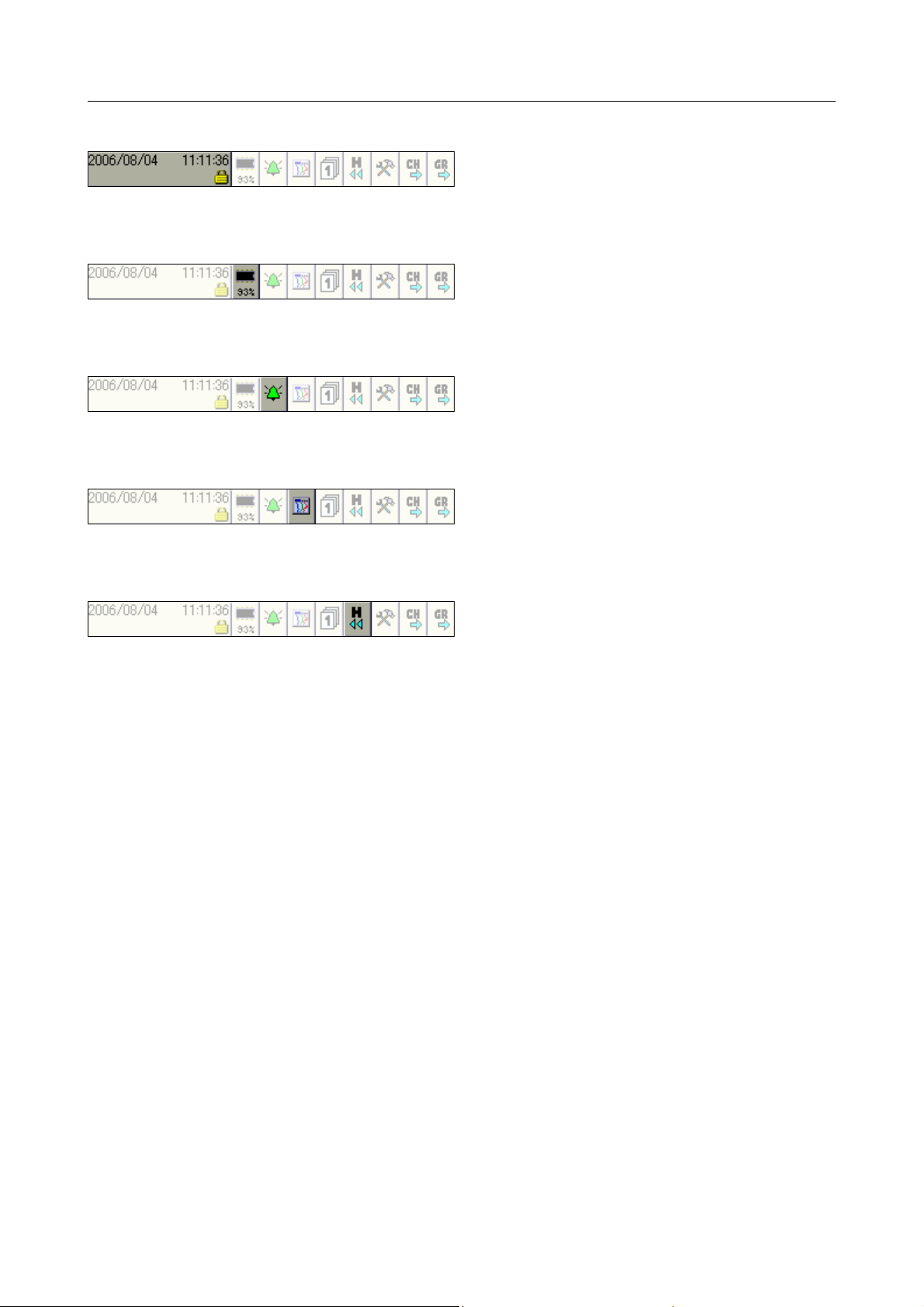

Sampling rate and operating mode

= normal mode

= event mode

= timed mode

If the text is shown in red, this indicates

an error message.

Data are currently being read by the PCA

Communications software PCC.

Data are currently being transferred to the

CF card.

Caution: Do not remove CF card!

Status

and title bar

This line (bar) shows alarm and error messages, as well as general information,

and information about the active representation mode (e.g. sampling rate). It is

automatically blanked out by the system, if necessary.

45

Page 46

3 Operating Principle

An alarm for a channel is shown in red

(HIGH alarm) or orange (LOW alarm). The

colors can be configured in the setup

program.

Numerical

measurement

display

(diagram

view)

The numerical measurement display is available for the presentation modes:

- Curves,

- history (of the curve presentation) and

- digital diagram

available.

In the curve presentation, the numerical display can be switched on or off.

This switching on or off also applies to the history presentation.

If the numerical measurement display is switched on in the history (of the

curve presentation), you can switch between MIN and MAX display. Whether

or not MIN and MAX values are both available at the same time, depends on

the settings for the group operating mode.

In the binary presentation, the diagram header can be switched on and off.

46

Page 47

Visualization

Symbols for data acquisition:

Comment has been entered

Event occurred

Alarm is no longer present

Alarm has been signaled

window

(diagram)

3 Operating Principle

In the visualization window, the measurement data are shown in graphical

form. Alarms are indicated by a red or orange color for the curve (can be

configured in the setup program).

Communication with the operator (device configuration, checking alarm and

event lists etc.) also takes place via the visualization window.

47

Page 48

3 Operating Principle

3.2 Operating Example

Start The normal display is active.

Operation

h Select the operator level by rotating the control knob.

h Activate the operator level by pressing the control knob.

48

Page 49

h Select the operator level by rotating the control knob.

h Activate the bar graph presentation by pressing the control knob.

Result The bar graph presentation starts.

3 Operating Principle

49

Page 50

3 Operating Principle

Plant number Group Plant (batch)

01…9None

11…91

21…3

4…6

7…9

1

2

Not assigned

31…3

4…6

7…9

1

2

3

3.3 Group and Plant Management (Batches)

Within the recorder, all analog inputs, binary inputs, counters and integrators,

are collected together into groups. A maximum of nine groups is available as a

total. Each group can consist of a maximum of 6 analog inputs, 6 binary inputs

(or outputs), and 4 counters/integrators.

The visualization and storage of the analog inputs and binary inputs (outputs)

is always made on a group basis.

If plants (batches) are used, the groups have fixed assignments to the plants

(batches).

50

Page 51

3 Operating Principle

Batch for plant Main group

11

24

37

In order for a batch to be usable, its main group must be active

(status = “Display” or “Display, save”) and at least one analog

channel in the group must be assigned.

The number of plants is configured through the parameter Device manager

Configuration

plants.

Batches/plants

Gen. plant parameters

Number of

51

Page 52

3 Operating Principle

52

Page 53

4.1 Activating the Operator Level

Operator level

The type of visualization (curve presentation, bar graph etc.) is selected at the

operator level. Note that the appearance of the operator level can be

influenced by the configuration.

h Select the operator level by rotating the control knob.

h Activate the operator level by pressing the control knob.

You can alter the visualization after activating the operator level.

4 Visualization

The functions in the header line will change, depending on the visualization.

The following types of visualization are available:

Curves v Chapter 4.3

Bar graph v Chapter 4.4

Tex t pi cture v Chapter 4.5

Process image v Chapter 4.6

Binary v Chapter 4.7

Report v Chapter 4.8

Batch v Chapter 4.9

Counters/integrators v Chapter 4.10

Comment entry v Chapter 4.11

53

Page 54

4 Visualization

4.2 Overview of Header Lines

Curve

presentation

(diagram)

Bar graph

presentation

Tex t pic t ure

presentation

Process image

presentation

Binary

presentation

Reports

Batches

(current)

Batches

(completed)

Counters and

integrators

Comment entry The comment entry does not have its own header. The current header will

remain when this function is activated. The comment that has been entered is

placed in the event list.

The first four functions in the header are identical for all

visualizations. These are supervisory functions (see "Header" on

page 43).

54

Differences only arise in the last five functions.

Page 55

4.3 Curve Presentation

Group selection

Memory presentation

Numerical measurement display

(diagram view)

Channel step-on

Group step-on

Sampling rate

and

oper. mode:

=

Normal mode

=

Event mode

=

Timed mode

An alarm (Alarm 1 or Alarm 2) is

indicated by an orange or a red background. The

colors can be configured in the setup program.

An alarm (Alarm 1 or Alarm 2) is

indicated by a red or orange curve color.

The colors can be configured in the

setup program.

For this type of display one distinguishes between vertical and horizontal presentation. Only one of the two presentation types can be active for all groups.

4 Visualization

v Configuration

v Configuration

4.3.1 Vertical presentation

In the display, signals are continuously displayed on the screen running from

top to bottom.

Screen Show diagrams

Screen Diagram display

Group selection You can use this function to directly select and display any one of the groups.

55

Page 56

4 Visualization

Programmable

alarm limits

Group number

Memory

presentation

Numerical

measurement

display

Channel

step-on

Group

step-on

This function starts the presentation of the data that are available in the history

memory.

v Chapter 5 "Memory Presentation (History)"

This function is used to switch the numerical measurement display (diagram

header) and binary traces on or off, as well as to activate the envelope display.

This function activates the scaling display. Repeated activation steps through

the scaling for the channels within the group, and then blanks it out again.

Unlike “Group selection”, where any group can be selected, this function is

used to select the groups one after another.

4.3.2 Horizontal presentation

In the display, signals are continuously displayed on the screen running from

right to left.

The same functions as for the vertical presentation apply.

56

Page 57

4.4 Bar Graph Presentation

Configurable

alarm limits

An alarm (Alarm 1 or Alarm 2) is indicated by

an orange or red background. The colors

can be configured in the setup program.

In this visualization mode, the analog inputs are presented both numerically

and in bar graph form. In addition to the analog channels, the digital inputs can

also be visualized at the bottom of the display.

4 Visualization

If only digital channels are to be presented, then Chapter 4.7 "Binary diagram

presentation" is recommended.

57

Page 58

4 Visualization

Channel description

Channel name

Changeover to

1-channel

presentation

An alarm (Alarm 1 or Alarm 2) is

indicated by an orange or red background.

The colors can be configured in the setup

program.

Channel description

Channel name

Changeover to group

presentation

Programmable

alarm limits

4.5 Text Picture Presentation

In the presentation, the analog channels are presented numerically, together

with the channel name and the channel description. In addition to the analog

channels, the digital inputs can also be visualized at the right-hand edge of the

display.

Group

presentation

1-channel

presentation

58

Page 59

4.6 Process Image Presentation