Page 1

Printing Recorder

with text printing and

LED dot-matrix display

B 70.6030.0

Operating Manual

2009-06-03/00353037

Page 2

Key functions

e - Paper (chart) fast-forward,

when recording is stopped

(in basic status)

- Abort parameter

entry (Exit)

- Leave the levels

S - Start/Stop

of recording

- Selection of decimal point

position when entering values

- For text entry:

Fast character selection

(jump to “ ”, “0”, “A”, “a”, “°”,

2”

“

, “À”, “à”)

F - Function key for special

functions

(press for at least 4sec)

factory setting:

print the scaling

l, r - Shift cursor left/right

(selecting position)

h, R - Select display:

- Instrument designation,

date & time

- Measurements of the

channels

- System status

- Parameter selection

- Channel selection

- Value selection

from a table of values

- Increment/decrement

present digit

E - Initiate parameter entry

-Confirm entry

- Acknowledge error message

- Activate/de-activate statistical

display (in basic status)

l + r - Activate/de-activate the

display of status/error

messages

h + R - Change to next level

Page 3

Contents

1 Introduction 7

1.1 Preface ......................................................................................................... 7

1.2 Arrangement of the documentation .......................................................... 8

1.2.1 Structure of this operating manual ............................................................... 8

1.3 Typographical conventions ........................................................................ 9

1.3.1 Warning signs ............................................................................................... 9

1.3.2 Note signs ..................................................................................................... 9

1.3.3 Presentation ............................................................................................... 10

2 Instrument description 11

2.1 Display and controls ................................................................................ 11

2.2 Basics of operation ................................................................................... 12

3 Operation and visualisation 23

3.1 Limit monitoring by limit comparators ................................................... 23

3.2 Open-collector outputs ............................................................................ 25

3.3 Different chart speeds (paper feed) ........................................................ 26

3.4 Graphic print-out ...................................................................................... 27

3.4.1 Measurement traces (signal traces) ............................................................ 29

3.4.2 Event traces ................................................................................................ 30

3.5 Text printing ............................................................................................... 31

3.5.1 Printing priorities ......................................................................................... 31

3.5.2 Printing modes ........................................................................................... 34

3.5.3 Queuing during text printing ....................................................................... 35

3.5.4 Limit comparator texts, external text, binary-linked external text .............. 36

3.5.5 Report ......................................................................................................... 38

3.5.6 Switching the chart speed .......................................................................... 41

3.5.7 “Power On” and “Power Off” texts ............................................................. 42

3.5.8 Scaling ........................................................................................................ 43

3.5.9 Time ............................................................................................................ 46

3.5.10 Print out channel numbers ......................................................................... 47

3.5.11 Recording start and stop ............................................................................ 47

3.5.12 Incrementing the two event counters ......................................................... 48

3.5.13 Print test ..................................................................................................... 49

3.5.14 Service print ................................................................................................ 50

Page 4

Contents

3.6 Colour assignment ................................................................................... 51

3.7 Relationship between measurement range and scaling ....................... 52

4 Configuration table 53

4.1 Operating examples ................................................................................. 53

4.2 Table of the configuration parameters ................................................... 55

4.2.1 Operating level (S-level) .............................................................................. 55

4.2.2 Parameter level (P-Level) ............................................................................ 56

4.2.3 Configuration level 1 (C1-level) ................................................................... 57

4.2.4 Configuration level 2 (C2-level) ................................................................... 63

4.2.5 Configuration level 3 (C3-level) ................................................................... 66

5 Identifying the instrument version 69

5.1 Instrument description ............................................................................. 69

5.2 Order details .............................................................................................. 70

6 Installation 71

6.1 Site and climatic conditions .................................................................... 71

6.2 Assembly in a control panel ..................................................................... 71

7 Electrical connection 73

7.1 Installation notes ...................................................................................... 73

7.2 Technical data ........................................................................................... 74

7.3 Connection diagram ................................................................................. 78

7.4 Electrical isolation .................................................................................... 81

8 Starting up 83

8.1 Opening and closing the door ................................................................. 83

8.2 Marking the channel label ........................................................................ 83

8.3 Fitting the print head ................................................................................ 84

9 Consumables 85

9.1 Consumables ............................................................................................ 85

Page 5

Contents

9.2 Removing and replacing the chart cassette .......................................... 86

9.2.1 Changing the roll chart ............................................................................... 88

9.2.2 Changing the fanfold chart ......................................................................... 89

10 Extra codes and accessories 91

10.1 Converting the chart cassette ................................................................. 91

10.2 “8 logic inputs”, “interface for ER8”,

“voltage output” ........................................................................................ 92

10.3 External relay module ER8 ....................................................................... 93

10.4 Setup program .......................................................................................... 95

10.5 Mathematics and logic module ............................................................... 97

10.6 Interface (RS422/RS485) .......................................................................... 98

11 Fault-finding 99

11.1 What to do if … ......................................................................................... 99

12 Appendix 101

12.1 Error messages ....................................................................................... 101

12.2 Hardware fault ......................................................................................... 103

12.3 Status messages .................................................................................... 104

12.4 Character set .......................................................................................... 105

12.5 Summary of the parameters .................................................................. 106

13 Index 109

Page 6

Contents

Page 7

1.1 Preface

E

B

1 Introduction

Please read this Operating Manual before commissioning the instrument.

Keep the operating manual in a place which is accessible to all users at all

times.

Please assist us to improve this manual, where necessary.

Your suggestions will be appreciated.

Phone in Germany (0661) 6003-727

from abroad (+49) 661 6003-0

Fax in Germany (0661) 6003-508

from abroad (+49) 661 6003-607

All the necessary settings are described in this manual. However, if

any problems should arise during start-up, you are asked not to

carry out any unauthorised manipulations. You could endanger

your rights under the warranty!

Please contact the nearest JUMO office or the head office.

When returning modules, assemblies or components, the

regulations of EN 61340-5-1 and EN 61340-5-2 “Protection of

electronic devices from electrostatic phenomena” must be

observed. Use only the appropriate ESD packaging for transport.

Please note that we cannot accept any liability for damage caused

by ESD.

ESD=electrostatic discharge

7

Page 8

1 Introduction

1.2 Arrangement of the documentation

The documentation for this instrument consists of the following parts:

Operating

Manual

B 70.6030.0

Interface

Description

B 70.6030.2

Setup

Program

B 70.6030.3

Online Help The online help is part of the setup program. It is a Windows

This operating manual is always supplied with the instrument. It is addressed

to OEMs (original equipment manufacturers) and users with the appropriate

technical know-how.

In addition to installation and electrical connections, it also includes

information on commissioning, operation, and setting the parameters in the

instrument, on extra codes and accessories.

This manual is supplied with the instrument if the Extra Code “RS422” or

“RS485” was ordered. It provides information about communication with

higher-level (supervisory) systems.

This manual describes the installation of the setup program, and also deals

with special features in the operation of the setup program.

1.2.1 Structure of this operating manual

This operating manual is laid out so that the user is immediately able to get on

with operating and configuring the instrument. To this end, the chapters which

describe procedures which are usually only carried out once, such as

description of the instrument, type designations, assembly and electrical

connections, are placed at the end of the manual.

1

online help.

1. Microsoft and Windows are registered trademarks

of the Microsoft Corporation

8

Page 9

1.3 Typographical conventions

V

E

v

1.3.1 Warning signs

The signs for Danger and Warning are used in this manual under the

following conditions:

Danger

This symbol is used where there may be danger to personnel if the

instructions are disregarded or not followed accurately!

Warning

This symbol is used where there may be danger to equipment or data if the

instructions are disregarded or not followed accurately!

Warning

This symbol is used where special care is required when handling

components which are liable to damage from electrostatic discharge.

1 Introduction

1.3.2 Note signs

Note

This symbol is used when your attention is drawn to a special remark.

Reference

This sign refers to further information in other manuals, chapters or sections.

Footnote

Footnotes are notes which refer to certain points in the text. Footnotes

consist of two parts:

Marking in the text and the footnote text.

The markings in the text are arranged as continuous superscript numbers.

Action

This symbol shows that an action to be performed is described.

The individual steps are designated by the star, for example:

h Press the

abc

h

1

h key

h Confirm with

E

9

Page 10

1 Introduction

1.3.3 Presentation

Keys

h + E

Program

Manager

Edit

Î

instrument data

Keys are shown in a box. Both symbols and texts are possible. If a key has

multiple functions, then the text shown is that which corresponds to the

currently active function.

Screen texts

Texts which are displayed in the setup program are distinguished by italic

script.

Menu items

The menu items in the setup program which are referred to in this manual are

shown in italic script. Menu name, menu item, and sub-menu item are

separated from one another by “

Δ.

10

Page 11

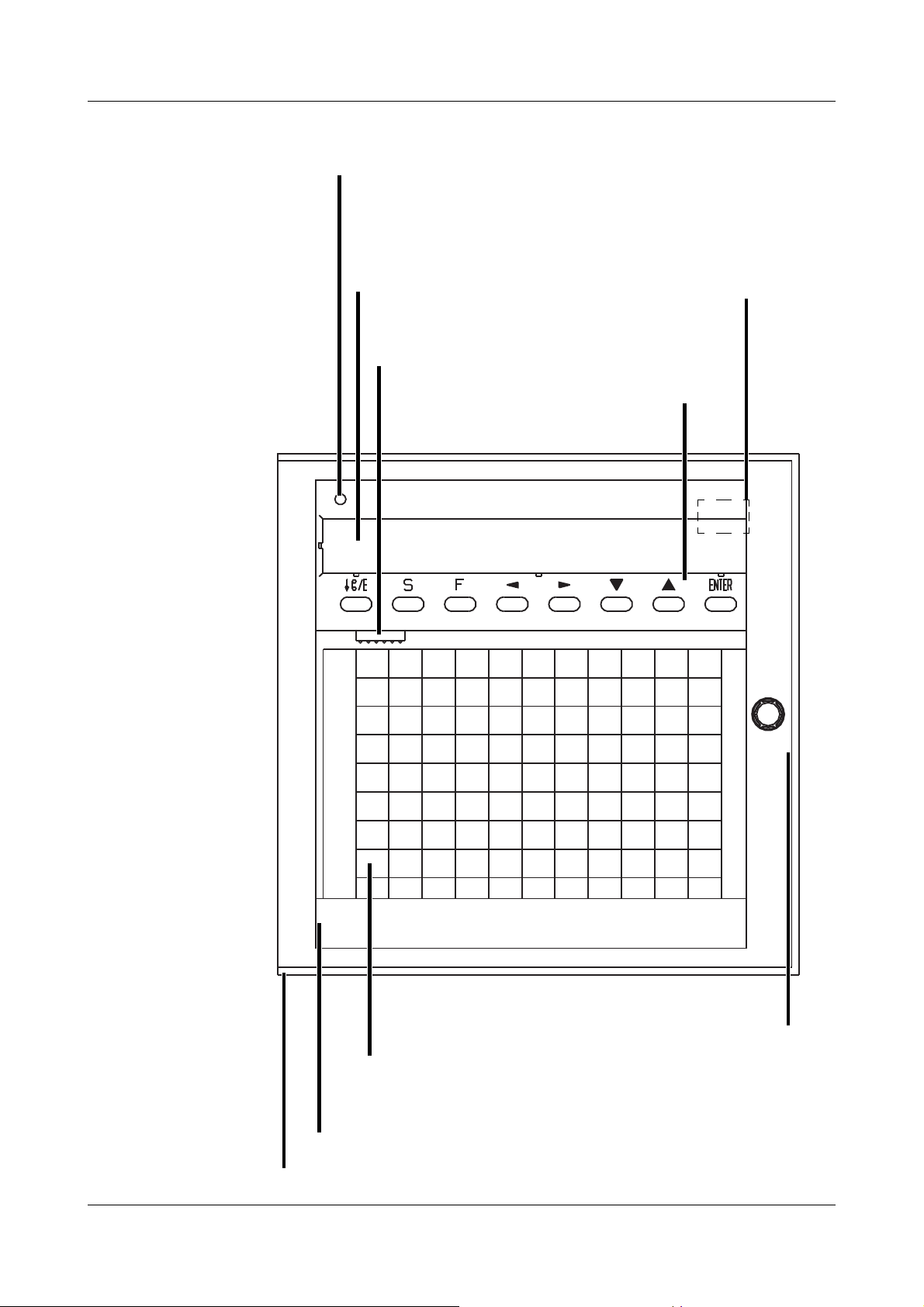

2 Instrument description

Fault signal LED

This lights up as soon as the recording is interrupted by the “end

of chart paper”, “stop” through pressing stop key S , or by an

external stop.

24-character green LED

dot-matrix display

Print head

Keys for

operating und programming

Setup interface

(behind the swing-up

LED dot-matrix)

Panel-mounting housing to IEC 61554 in galvanised steel sheet

Measurement channel label

Here you can enter the channel designation and/or the

corresponding measurement range

Chart paper

Housing door

to open or close

2.1 Display and controls

11

Page 12

2 Instrument description

2.2 Basics of operation

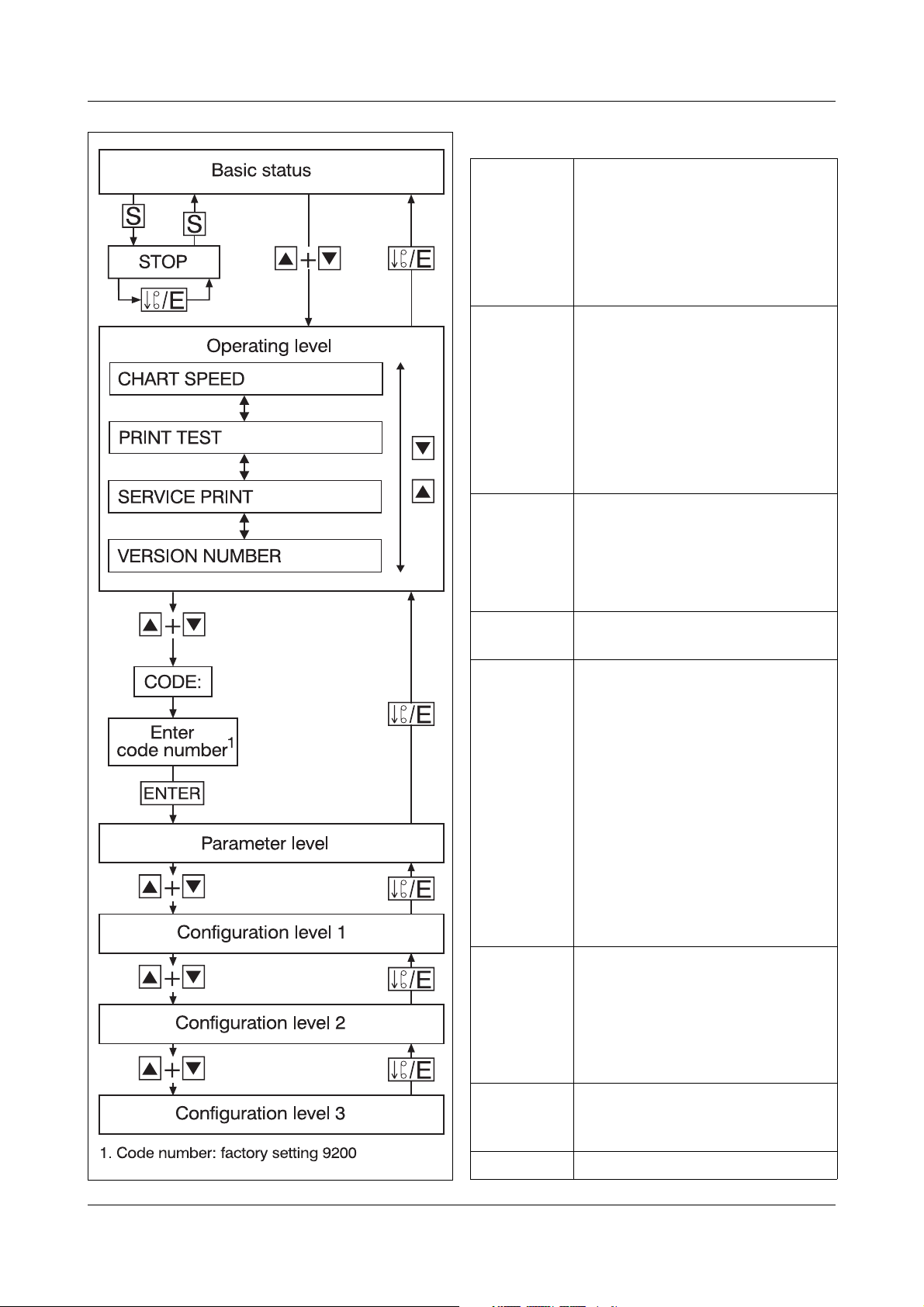

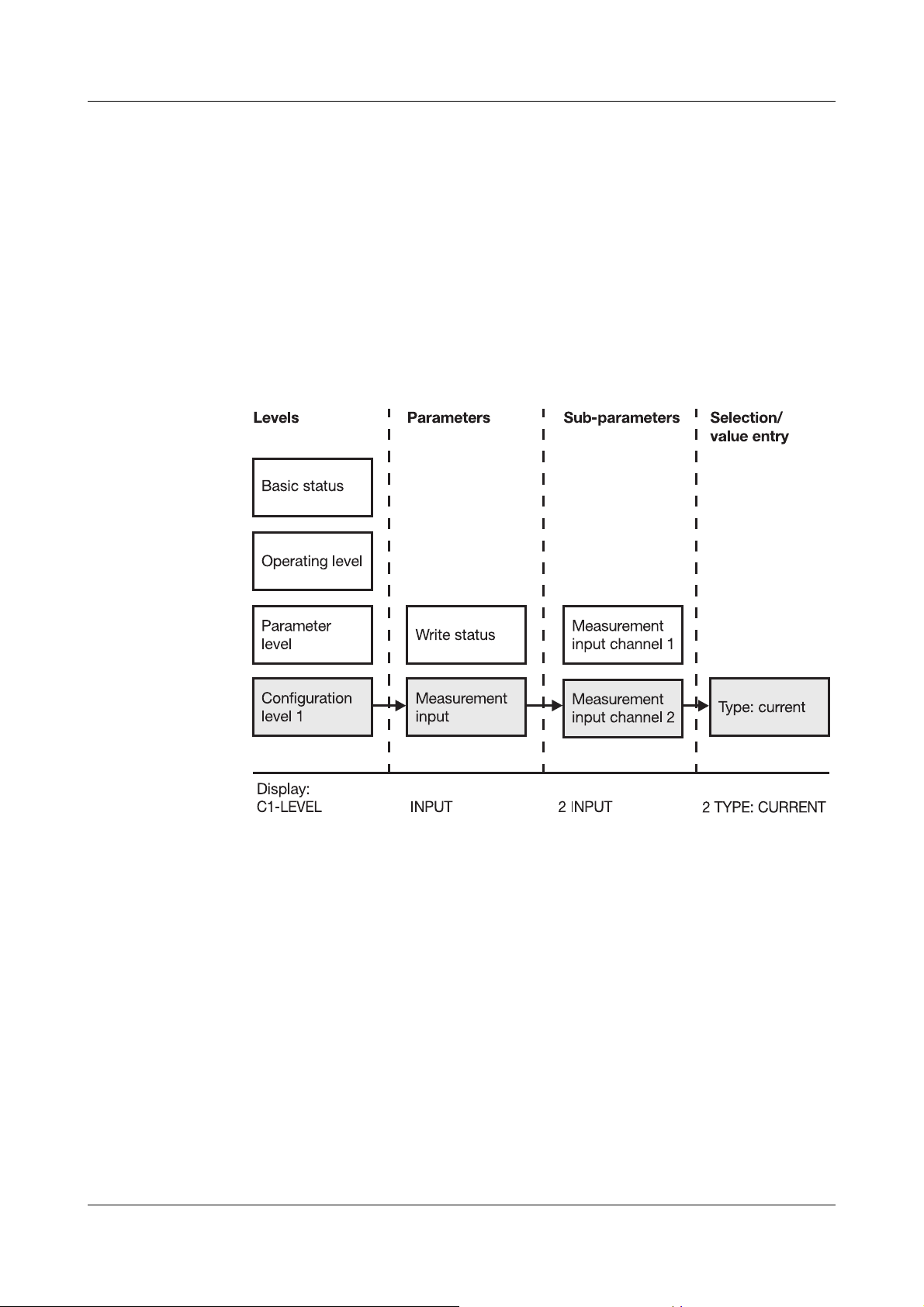

In order to keep the operating and programming of the printing recorder clear

and simple, the individual parameters and functions are divided into several

levels:

- Basic status

- Operating level (S-level)

- Parameter level (P-level)

- Configuration level 1 (C1-level)

- Configuration level 2 (C2-level)

- Configuration level 3 (C3-level)

12

The levels, parameters and sub-parameters are arranged as a tree structure.

Starting from the basic status, it branches out into the individual levels, and

from there further into the corresponding parameters and, if available, subparameters.

If it is necessary to alter a certain parameter, then step through the relevant

level until this parameter is reached.

Pressing E starts the editing process.

If a parameter has several sub-parameters, these can also be accessed by

pressing E.

Page 13

2 Instrument description

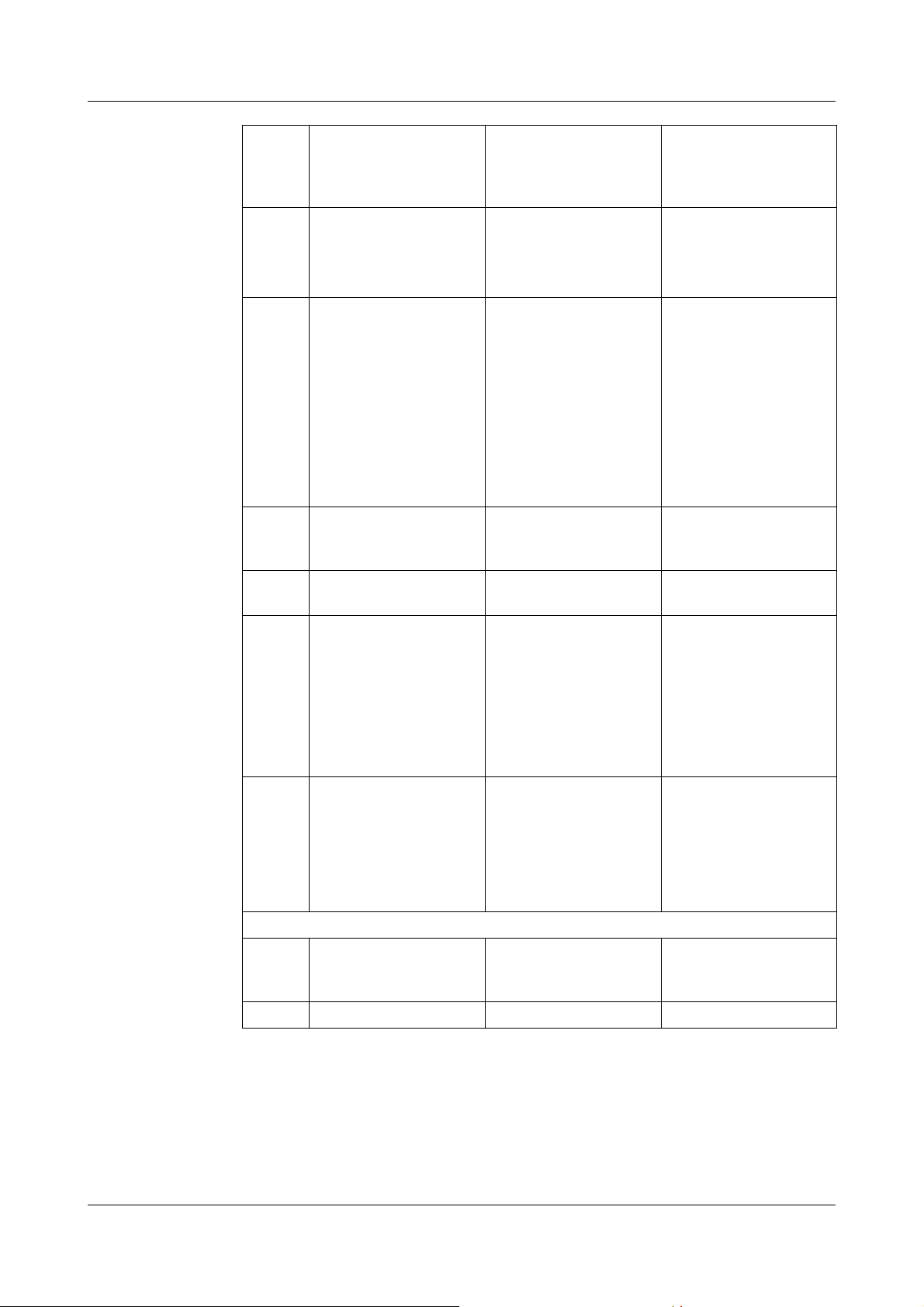

Key

functions

e

S

F

l, r

h, R

Basic status Operating level after correct

code number

in parameter and

configuration levels

Chart fast-forward,

when recording is

stopped

Start/stop

recording mode

Function key

(reserved for

special functions)

----------------- ----------------- Shift cursor to left/right

Select display:

-Instrument

name,

date & time

-Channel

measurements

-System status

1

-Abort parameter

entry

(Exit)

-Leave the level

Start/stop

recording mode

Function key

(reserved for

special functions)

-Select parameter

-Select channel

-Select value

from table

-Enter figures:

Change the

place selection

-Abort parameter

entry

-Leave the level

Step

-for values:

Select the

decimal place

-for texts:

Quick selection

of character:

jump to “ ”, “0”,

“A”“, “a”, “°”, “

“à”

-----------------

(select place)

-Select parameter

-Select channel

-Select value

from table

-Enter text/figures:

Change the

place selection

2”

, “À”,

E

Key combinations

Change-over

between cyclic and

static display

l + r Activate/de-activate the

display of status/error

messages

-Initiate the

parameter entry

-Confirm the

entry

-Acknowledge any

error messages

----------------- -----------------

-Initiate the

parameter entry

-Confirm the

entry

-Acknowledge any

error messages

h + R Change to next level Change to next level Change to next level

1. Press the F key for at least 4 sec in the standard version: print out the

scaling of all the active channels (writing status = ON).

13

Page 14

2 Instrument description

For all alterations to the parameters (sub-parameters):

Confirmation of

parameters

Abort

programming

Error messages

during

programming

Selection A selection consists of a list of several options:

If there are no further sub-parameters available, then E transfers all the

data which belong to the parameter into the memory.

Inside a parameter, programming can be abandoned by pressing the e key.

If the last sub-parameter has not been confirmed, then the data

which were already edited for the parameter will be abandoned.

The old values for the sub-parameters will be retained.

If error messages occur during programming, as a result of erroneous entries,

then these messages must be acknowledged with E before the programming can be taken up again.

Three keys are used to select an option:

h Select the option with the h and R keys

h Confirm the selection with E

14

Page 15

2 Instrument description

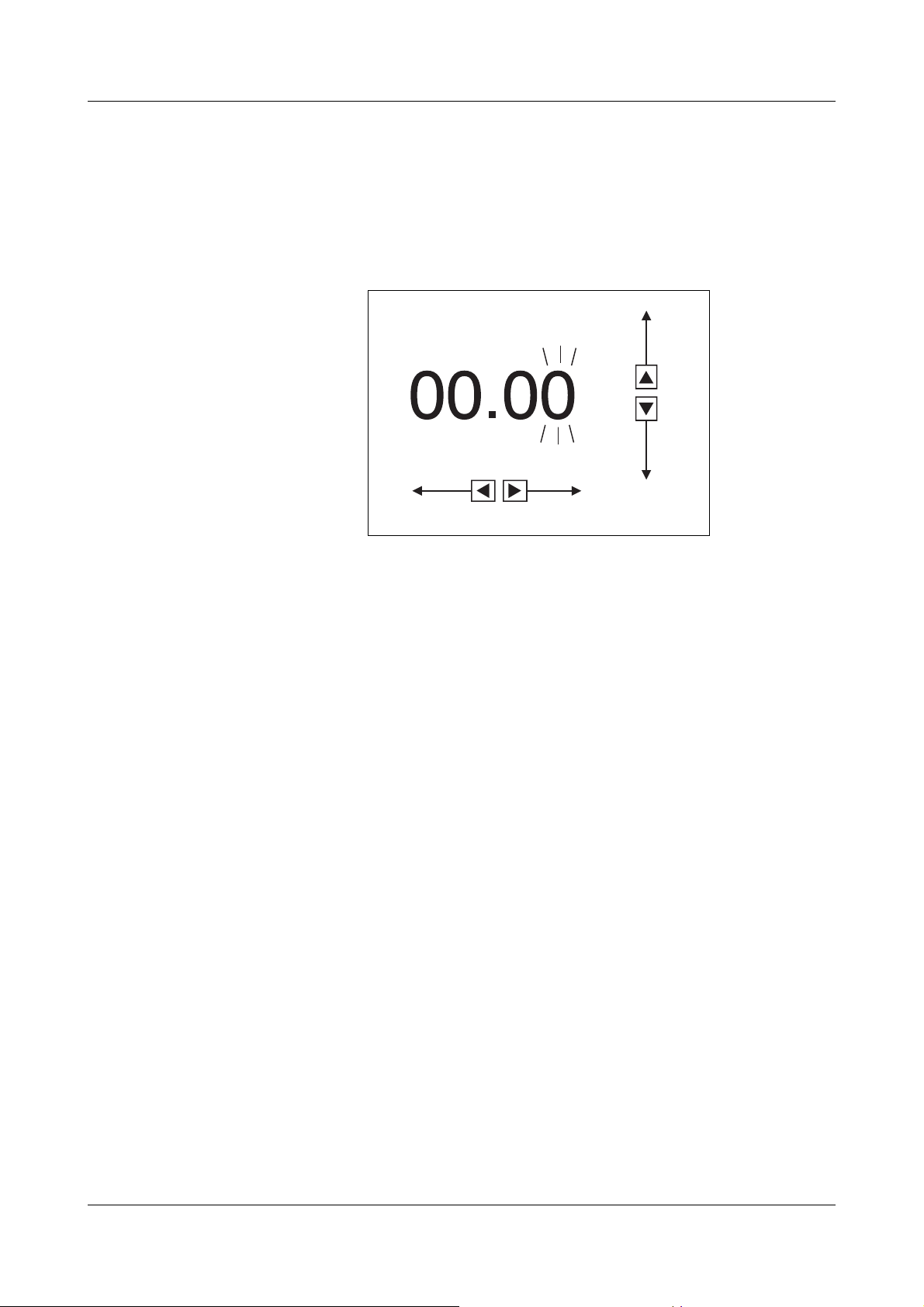

Value/text

entry

Five keys are used to enter values:

h select the position to be altered, using the l and r keys

h increment and decrement the selected position with the h and R keys

h move the decimal point with the S key

h confirm the value entered with E

An erroneous entry will cause an error message in the display

v Section 12.1 “Error messages”

The error message must be acknowledged by E

Afterwards, a new value can be entered.

Five keys are used to enter texts:

h select the character to be entered, using the l and r keys

h select the new character with the h and R keys

(quick character selection with the S key)

h confirm the text entry with E

15

Page 16

2 Instrument description

Key inhibit If the printing recorder is fitted with the extra code “logic inputs”, then it is

possible when a selected logic input is closed, in connection with the parameter Configuration level 3

The following keys or functions can be inhibited in the basic status:

- e chart fast-forward, when the recording mode is stopped

- S start/stop of recording mode

- F function key, to activate scaling print-out

- h + R change from the basic status to the operating level

Even when the keys are inhibited, certain functions are still possible in the ba-

sic status:

- l + r switch error messages on/off

- h , R channel selection

- E switch between cyclic and static display

Key inhibit has no effect as long as the printing recorder is in the basic status

or in one of the configuration levels. On leaving these levels the keys will be inhibited if the logic input is set. It is only possible to call up the operating or

configuration levels again after opening this logic input.

Î Inhibit keys, to inhibit the recorder keys.

16

Page 17

2 Instrument description

Basic status After the supply voltage has been applied, the printing recorder will be initial-

ised and is then in the basic status. Measurements are made, processed, and

recorded.

The 24-character LED dot-matrix display can show:

- instrument designation (name), date and time

(the time can be switched off via the parameter Parameter level

time)

- channel number and measurements (incl. units) of all active channels

(in pairs)

- channel number, name and measurement (incl. units) of all active channels

(sequentially)

- status and error messages

-interface texts

v Section 10.6 “Interface (RS422/RS485)”

- customer-specific texts

The display can be either cyclic or static:

Î Display

Cyclic display

The printing recorder switches automatically to the next display after about

3sec.

Static display

In the basic status, the static display is activated and de-activated with E.

If it is activated, then the present display remains, and is regularly updated.

In the basic status, the information in the display can be changed over with the

h and R keys.

Status and error messages will be identified in plain language by a regularly

flashing display, instead of the present display.

The display of status and error messages can be inhibited, or activated again,

by pressing l + r .

If a measurement is outside the valid range of the A/D converter

(out-of-range), or if a probe break has been detected, then the

character combination “>>>>>>” will appear in place of the value.

The recording can be stopped or re-started with the S key. In the stop status

“STOP” will flash in the LED dot-matrix display.

Using the e key, in the stop status, activates the chart fast-forward.

Pressing the F key for at least 4 sec will restart the scaling print-out.

The operating level can be accessed by pressing the h + R keys simultane-

ously.

17

Page 18

2 Instrument description

Example of the basic status for a 6-channel recorder

BUILDING28 03.11.98 08 : 54 Display instrument name, date and time

hR

1 -5.321m/h 2 +34.67°C Display the first 2 channels in one frame

hR

3 +76.20°C 4 +20.35bar Display the next two channels in one frame

hR

5 +35.08°C 6 +007.4U/m Display the next two channels in one frame

hR

1 CONVEYOR -5.321m/h Display the 6 channels, each in a separate frame

hR

2 MIXER +34.67°C

hR

Operating level

(S-level)

3 MOT7. BEARING +76.20°C

hR

4 PRESSURE +20.35 bar

hR

5 VENT.TEMP. +35.08°C

hR

6 SHAFT +007.4U/m

The operating level can be accessed from the basic status with the aid of the

h + R keys, from the parameter level by using e.

Signal acquisition and processing remain active in this level.

The following parameters can be altered:

- chart speed

-print test

- service print

- version number (display only)

18

It the operating level is active, then signal acquisition, processing

and recording, as well as limit monitoring, will all continue to be

performed.

Page 19

2 Instrument description

Parameter

level (P-level)

The parameter level can be accessed from the operating level with the aid of

the h + R keys, from the configuration level 1 by using e.

The parameter level and configuration levels are protected by a four-figure

code number.

There are two different code numbers:

- Code number for the restricted parameter set (factory setting 9200)

- Code number for the full parameter set (factory setting 9210)

The parameters which belong to the restricted parameter set are defined in the

setup program under Edit

Here, parameters which are not needed for the application, or only have to be

programmed once, can be appropriately marked. They will no longer be displayed on the recorder after the new setup has been transferred.

If one of the two code numbers is entered, then

- signal acquisition and

-recording

will be interrupted.

Furthermore

Î Instrument operation …

- events will no longer be recorded,

- reports will be aborted and reset,

- limits will no longer be monitored,

- the Code for the mathematics module will no longer be applied,

- the fault signal output will be set to fault, and

- all other outputs will remain in their last state.

The parameters can now be programmed.

If the wrong code number is entered, then the recorder will remain

in the normal mode. Signal acquisition, processing and recording

are still active.

The parameters can be looked at, but not programmed.

The code numbers can be altered through the setup program

Î Code numbers …) or on the instrument.

(Edit

v Section 4.2 “Table of the configuration parameters”

If customer-specific code numbers are entered, then the original

JUMO code numbers will be overwritten, and are no longer valid.

19

Page 20

2 Instrument description

If the same figures are used for both code numbers, then these

code numbers will be interpreted as code numbers for the complete parameter set.

The relays in the external relay module ER8 remain in their present

state. They will only be switchable again when the printing recorder has been returned to the operating level or the basic status.

After a valid code number has been entered, the following parameters can be

altered in the parameter level:

- language

- date & time

- summer time

- display brightness

Configuration

level 1 (C1-level)

-display time

Channel-specific parameters can be configured in configuration level 1. This

level can be accessed from the parameter level with the aid of the h + R keys,

or from configuration level 2 by using e.

If a correct code number is entered when calling up the parameter

level, then the signal acquisition and recording will be interrupted

in this level. The parameters can be viewed and altered.

The relays of the external relay module ER8 remain in the present

state. They will only be switchable again when the printing recorder has been returned to the operating level or the basic status.

Configuration level 1 includes the following channel-specific parameters:

-plot status

- signal input

-scaling

20

- channel name (word and number)

- limit comparator

- limit feed

-zoom

- presentation range (offset)

- peak value recording

Page 21

2 Instrument description

Configuration

level 2 (C2-level)

Configuration level 2 can be accessed from configuration level 1 with the aid

of the h + R keys, or from configuration level 3 by using e.

If a correct code number is entered when calling up the parameter

level, then the signal acquisition and recording will be interrupted

in this level. The parameters can be viewed and altered.

The relays of the external relay module ER8 remain in the present

state. They will only be switchable again when the printing recorder has been returned to the operating level or the basic status.

Configuration level 2 includes the following global parameters:

- unit name

-open-collector output

- chart speed in limit operation

- timed operation (feed time)

- print-out of speed change

- print-out of the “power on” text

- print-out of the “power off” text

-scaling print

-time print

- print channel number

-report

-start text

-end text

-presetting

-code number

21

Page 22

2 Instrument description

Configuration

level 3 (C3-level)

Configuration level 3 can be accessed from configuration level 2 with the aid

of the h + R keys.

If a correct code number is entered when calling up the parameter

level, then the signal acquisition and recording will be interrupted

in this level. The parameters can be viewed and altered.

The relays of the external relay module ER8 remain in the present

state. They will only be switchable again when the printing recorder has been returned to the operating level or the basic status.

Configuration level 3 contains parameters which mostly belong to the extra

codes and the mathematics module:

- relay output

1

- mathematical module

- interface

- external text

- text logic links

-external stop

- external speed

-event counter

-external scaling

-external report

- key inhibit

2

1

1

1

1

1

1

1

1

22

- event traces

1. The parameters can only be edited if the extra codes

“logic inputs” and “interface for ER8” have been implemented in the recorder.

2. The parameter can only be edited if the extra code “RS 422”

or “RS 485” has been implemented in the recorder.

Page 23

3 Operation and visualisation

The printing recorder has a large variety of possibilities for presenting the

measurements acquired at the signal inputs on the paper, for monitoring them,

and for control.

The functions are available for:

- limit monitoring through limit comparators

-open-collector outputs

- different chart paper speeds

- graphics printing

- text printing

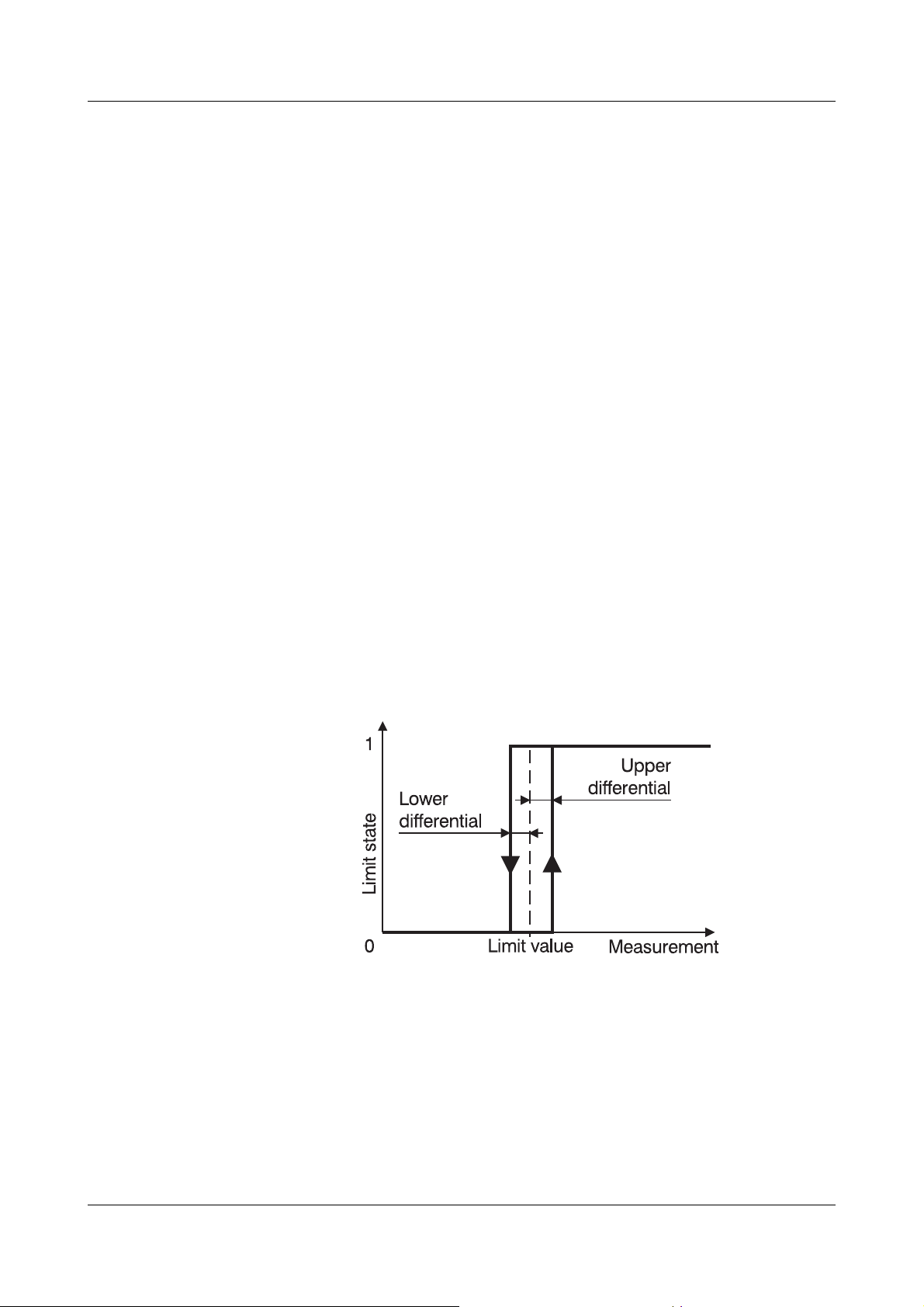

3.1 Limit monitoring by limit comparators

8 limit comparators are available for monitoring limits. They are set up through

the parameter Configuration level 1

rameters can be used to establish the limit values, switching differential (hysteresis) limits, texts, limit comparator functions (lk) and the response to a

probe break.

Î Limit comparator. Appropriate sub-pa-

The texts are printed out when the values go out-of-range or exceed the differential values, as described in the section on text printing.

v Section 3.5.4 “Limit comparator texts, external text, binary-linked external

text”

The limit comparators produce a logical 0 or 1 as output. The sub-parameter

“LK-function” also decides what the result of the limit state is.

LK function: lk7

23

Page 24

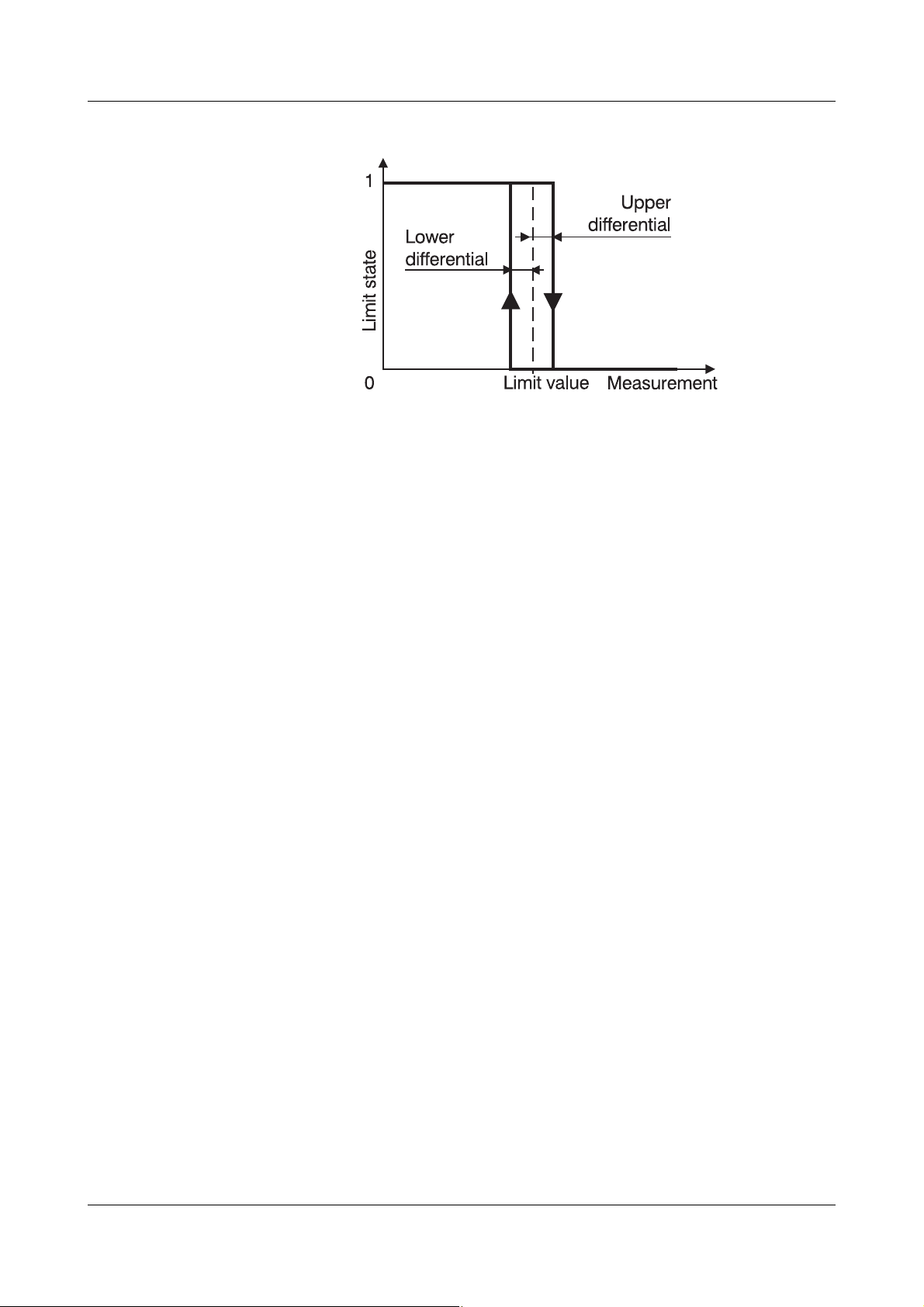

3 Operation and visualisation

LK function: lk8

As well as producing the text print-out, the results from

- limit comparators 1 to 3 can be fed to the open-collector outputs 1 to 3,

and/or

- those from limit comparators 1 to 8 to the relay outputs 1 to 8 (option).

The relay outputs are available as an option (extra code ER8).

v Section 10.3 “External relay module ER8”

The state of the limit comparators can be documented by using

the event traces on the chart paper.

v Section 3.4.2 “Event traces”

The response of the limit comparators to out-of-range measurements or a probe break can be defined with the parameter Config-

uration level 1 ➔ Limit comparator ➔ Probe break.

The limit values can be printed out in the form of limit marks (“l”)

together with the scaling.

v Section 3.5.8 “Scaling”

24

Page 25

3 Operation and visualisation

3.2 Open-collector outputs

The printing recorder is equipped with four open-collector outputs. The outputs 1 to 3 have a fixed assignment to the limit comparators 1 to 3. Output 4 is

used as a fault signal output. The outputs can be activated by using the parameter Configuration level 2

Fault output The fault signal output can be used to indicate a fault. During correct operation

of the printing recorder this output is active. In the event of a fault or disturbance, or if the status in the parameter Configuration level 2

is OFF, it becomes inactive (open).

The following causes will lead to a fault signal:

- Chart paper end

- Power off

- The battery of the recorder is discharged

- No communication with the external relay module ER8

- Fatal errors

Î Open-collector.

Î Open-collector

25

Page 26

3 Operation and visualisation

Differential

(Se - Sa) x (Ze - Za) x 0.01

100

------------------------------------------------------------

=

3.3 Different chart speeds (paper feed)

The printing recorder is equipped with several different chart speeds, so that

the measurements can always be optimally interpreted on the chart.

Normal chart

speed

Limit operation

(limit feed)

External

speed

The chart paper is transported with the speed which is programmed in the parameter Operating level

If the value goes above or below the programmable limits

(Configuration level 1

over to the speed programmed in Configuration level 2

To avoid excessively frequent chart speed changes, a switching

differential (hysteresis) of 0.5% is applied to the switching level.

The switching differential is referred to the scaling and zoom.

Se = scaling end

Sa = scaling start

Ze = zoom end

Za = zoom start

A signal at a logic input (extra code) can be used to switch to a chart paper

speed which is programmed in Configuration level 3

Î Chart speed.

Î Limit feed) then the paper transport will be switched

Î Feed limit.

Î External speed.

Timed

operation

(feed time)

This chart paper speed is valid for a programmable period of time, and is defined by the parameter Configuration level 2

If it is set so that start time = end time, then the timed operation is inactive.

Different priorities apply for the various speeds.

v Section 3.5.6 “Switching the chart speed”

Î Feed time.

26

Page 27

3.4 Graphic print-out

The printing recorder is fitted with a print head which always has 6 colour

pens, regardless of the number of channels. For the 3-channel version the colour sequence is: violet, red, black, violet, red, black. For the 6-channel version

it is: violet, red, black, green, blue, brown. This means that in the 3-channel

version the colours last twice as long. When using the setup program, if colours are assigned to a 3-channel recorder which are not available (green, blue,

brown), they will automatically be replaced (violet, red, black). The printing of

measurements and texts is always made in the same direction (unidirectional

printing).

The time which is needed to print out one line depends on the number of

points which have to be printed in this line. If the maximum number of points

are printed, then about 12 seconds are required for one line.

As the chart speed increases, more and more measurements, and so more

and more lines, have to be printed. So the printer must reduce the time which

it needs to try and print a line as the speed increases. These times can be seen

in the following table.

3 Operation and visualisation

Speed (mm/h) minimum time per line (sec)

5

10

20

60

120

240

300

360

600

720

288

144

72

24

12

9

6

5

4.8

4

Up to a speed of 120mm/h every line can be printed in the time available,

since there are never more than 12 seconds required. At higher speed, if the

time taken to print a line is longer than the value in the table, then the lag is

compensated for by speeding up to the next line.

Example:

At a speed of 300mm/h the printing recorder attempts to print a line every 6

seconds, according to the table. But it needs 9 seconds to print a line. This is

compensated by increasing the speed by 50% for the next line.

The recorder has been so developed that the printed traces are always as visible as possible. For instance, an alternating print of the different colours

avoids a mixing and waste of colour if the measurements are the same.

27

Page 28

3 Operation and visualisation

Example:

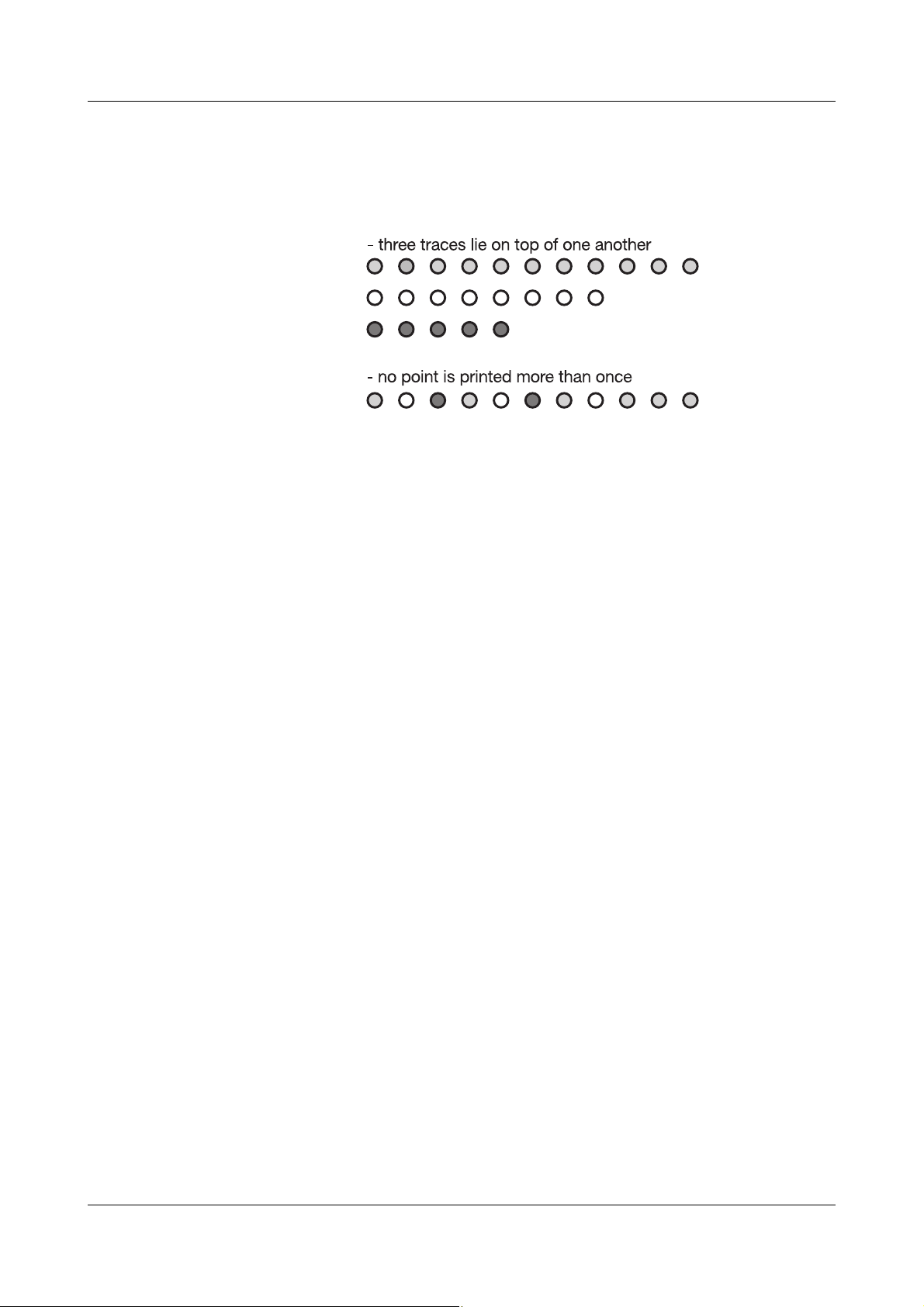

If three traces lie on top of one another, then the alternating print pattern ensures that no point has a multiple print, but that each channel uses one point

at a time, sequentially.

28

Page 29

3 Operation and visualisation

ZOOM-START

Mk - Sa()100 %⋅

Se - Sa

-----------------------------------------=

ZOOM-END

Mg - Sa()100 %⋅

Se - Sa

-----------------------------------------=

ZOOM-START

500m/h 0m/h–()100 %⋅

2000m/h 0m/h–()

----------------------------------------------------------

25 %==

ZOOM END–

1500m/h 0m/h–()100 %⋅

2000m/h 0m/h–()

----------------------------------------------------------------------- 75 %==

3.4.1 Measurement traces (signal traces)

In the factory setting, all the measurement traces are printed over the full chart

width. The parameters “zoom” and ”presentation range” offer the possibility of

altering the print-out.

Zoom

(plot area)

Zoom operation is used to record a section of the complete measurement

range in an enlargement. Zoom operation is activated by the parameter Con-

figuration level 1

The values to be entered for the start (ZOOM-START) and end (ZOOM-END)

are made in %, and can be calculated as follows:

Mk = smallest measurement to be recorded

Mg = largest measurement to be recorded

Sa = scaling start

Se = scaling end

The difference between start and end values must be at least 10%.

Example:

The selected input signal is a voltage in the range 0 — 10V, and the scaling is

set to the range 0 — 2000m/h. The section of the range from 500 — 1500m/h

is to be displayed.

Î Zoom.

Presentation

range (offset)

Peak value recording

This parameter can be used to determine a range of the chart paper on which

the trace will be recorded. Either the complete chart paper width of 100 mm

can be used, or just a portion. In this way it can be arranged that all the channels are presented next to one another (strip recording). The presentation

range is activated by the parameter Configuration level 1

The printing recorder can acquire considerably more values than it can print.

At a chart speed of 20 mm/h, for instance, approximately only every 24th

measurement is recorded on the chart. The peak value recording function can

deal with this situation.

Peak value recording = OFF:

When the peak value recording is switched off, the latest value present at the

instant of printing is recorded on the chart.

Peak value recording = ON:

When the peak value recording is switched on, the minimum and maximum

measurements are stored internally between two lines which are to be printed.

Î Offset.

29

Page 30

3 Operation and visualisation

These minimum and maximum values are printed when peak value recording

is activated. One advantage of the peak value recording is that at least an impression of the measurement trace on the chart can be gained, even at slow

chart speeds and after text printing in the “Interrupt measurement trace”

mode.

The peak value recording can be switched on and off for each channel by using the parameter Configuration level 1

Î Peak value recording.

Colour

assignment

The colours which are used to print the traces can be set with the aid of the

setup program.

In the basic status, for a 3-channel recorder, the colours violet, red and black

are assigned to the channels 1 — 3.

When using a 6-channel recorder, the colours green, blue and brown are also

used, for the additional channels 4 — 6.

3.4.2 Event traces

In addition to the measurement traces, the printing recorder offers the possibility of recording up to 8 event traces. The sources for the events can be the

limit comparators as well as the logic inputs (extra code).

The source selection and trace selection are made by the parameter Configu-

ration level 3

The setup program can be used to select the start position of the event traces

on the chart paper, between 0 and 100%.

If not all the event traces are selected, then a gap will appear at the corresponding positions. This means that every trace has the same spacing from

the defined start position.

Î Event traces.

Colour

assignment

30

In the 6-channel version, the colours violet, red, black, green, blue, brown, violet and red are assigned to the event traces 1 — 8. In the 3-channel version

the colours green, blue, brown are replaced by violet, red, black.

The colours can be changed with the aid of the setup program.

Page 31

3.5 Text printing

As well as the traces of the chart, the recorder can also print text. Text printing

is used to make comments on the traces and for recording events. The characters are printed in dots in a 7 x 9 matrix.

3.5.1 Printing priorities

There are different kinds of text which can have priorities and a printing mode

assigned to them by the setup program. These priorities determine the criteria

for interruption or cancellation when more than one text print is required at the

same time.

For all the following explanations, the rule is:

- Text 1 = text with higher priority

- Text 2 = text with lower priority

If Text 2 is being printed when a request for Text 1 appears, then the printing of

Text 2 is abandoned and Text 1 is printed. The abandoned text will not be continued and not repeated.

3 Operation and visualisation

If a request for Text 2 occurs while Text 1 is being printed, then Text 2 will be

printed out after Text 1 has been printed.

Example:

A report is printed from 12:00 to 12:05 with high priority. At 12:02 a limit is exceeded, so the corresponding text should be printed out. Since printing this

text is not possible at the moment, the text will be printed after the report is

finished.

31

Page 32

3 Operation and visualisation

Time Text-print request the actual text printed is:

12:07

12:06 12:02 Limit exceeded

12:05

12:04

12:03

12:02 Limit exceeded Report

12:01

12:00 Report

If texts with the same priority cannot be printed at once, then the order in

which they will be printed is not determined by the order in which the corresponding events occurred, but is determined by an internal order of precedence in the recorder.

-Start text

- Text on change of chart speed

-Report

- External text

- Binary-linked external text

- Limit comparator texts

- Print event counter

- Customized texts

- External scaling

-Print time

- Cyclic scaling

- Channel numbers

Example:

Although the priorities have been configured to be the same, the time will be

printed before the cyclic scaling.

If the recorder is put into the stop status, or switched off, then all the printing

requests which were already present or which occur during this period will be

cancelled. The print-out of the texts will not be dealt with when the recording

starts again. Exception: A request for the print-out of a report which occurs

during a stop status will not be cancelled. The report will be printed after the

stop is ended. But if a report which was being printed is interrupted by a stop

it will not be continued after the recording has been restarted.

32

Page 33

3 Operation and visualisation

In the following cases, all current request for text printing will be cancelled,

and any fresh ones will be ignored:

- Recorder goes into the stop status

- Recorder is switched off

One exception to this rule is the report.

v Section 3.5.5 “Report”

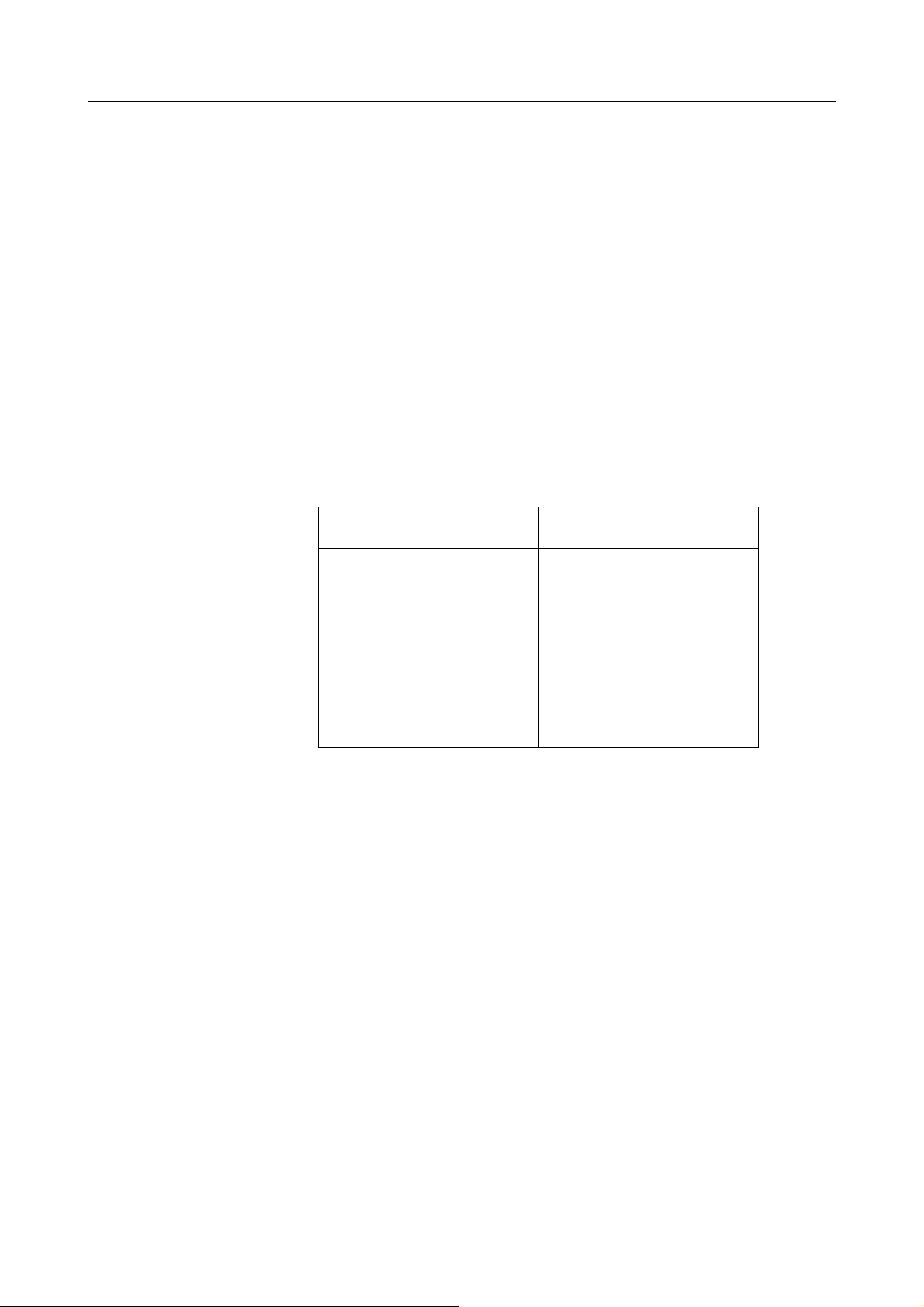

The following fixed priorities have been assigned for stop, service and print

test:

Priority Text

higher

lower

- Stop by S-key, external stop, no chart paper,

configuration by keys or via setup

-Print test

- Service print

- Text print according to the configured priority list

33

Page 34

3 Operation and visualisation

3.5.2 Printing modes

Texts can be printed in two modes:

- by interrupting the measurement trace (Outplot)

- overwrite the measurement trace (Inplot)

Interrupt

measurement

trace

Overwrite

measurement

trace

The text is printed as fast as possible. During the text printing there is no recording of measurements or event traces. The chart paper speed is optimised

for the text printing. It is not the same as the programmed chart speed.

Typically, a time of 10 — 40sec is needed to print a line of text.

Advantages:

-rapid text printing

- other messages are blocked for the shortest possible time

- an optimised chart speed ensures that the text is always perfectly legible

- text printing can also be carried out when the chart speed is programmed

to 0mm/h.

Disadvantages:

- measurements and event traces are not recorded during the text printing

- the chart speed is altered during the text printing. The time correlation is

lost.

The text is printed with the current chart speed. Measurements and event traces are printed at the same time. Text printing is not performed if the chart

speed is 0mm/h. At this chart speed, texts which would be printed in the

“Overwrite measurement trace” mode are not recognised in the priority evaluation.

The time taken to print a line of text will vary, depending on the programmed

chart speed.

Chart speed Time to print 1 text line

5mm/h

20mm/h

120mm/h

Advantages:

- the time correlation is also preserved during text printing

- the recording of measurements and events is not interrupted at any time.

approx. 43min.

approx. 11min.

approx. 2min.

34

Page 35

Disadvantages:

- the text printing can take a very long time

- the printing of other texts is blocked

- text printing is not possible at a chart speed of 0mm/h.

3.5.3 Queuing during text printing

External texts, binary-linked texts, limit comparator texts for going above and

below limit values, as well as event texts, are printed through a queue. This

means that, as long as the queue is not full, complete documentation is assured.

The print queue has:

- 24 entry positions for external texts

- 48 entry positions for binary-linked texts

- 48 entry positions for limit comparator texts

and

3 Operation and visualisation

- 20 entry positions for event texts

If the queue has filled its quota of a particular type, then any further texts of

this types will be lost, until entry positions are free again in the queue.

If a very large number of events need to be recorded, then use either the print mode “Interrupt measurement trace” or a sufficiently

high chart speed, since in this case the entry positions in the

queue will be freed much faster.

35

Page 36

3 Operation and visualisation

3.5.4 Limit comparator texts, external text, binary-linked external text

Limit

comparator

texts

External text

Limit comparator texts can be printed out. To do this, the parameter Configuration level 1

corresponding texts must be entered. Every time that a measurement goes

above or below a limit value, the appropriate text will be printed.

v Section 3.1 “Limit monitoring by limit comparators”

There are eight logic inputs available for external texts.

If a logic input is closed (positive edge triggering) then the corresponding text

will be printed. Opening the logic input has no effect.

Î Limit comparator Î Limtext state must be set to ON and the

Binary-linked

external text

(text logic links)

The function is activated by the parameter Configuration level 3

text.

Extra code “Logic inputs” is required.

If this extra code is not present, then the parameter will not be

displayed.

It is possible to interpret the signals on the first four logic inputs as a binary

number, and to associate a text with each binary number. Up to 16 texts can

be defined in this way.

The text which is assigned to the binary number is printed out after every

change of state of the logic inputs concerned.

Text printing can be switched off individually for each of the 16 texts.

Example:

If the binary number 1001 is present on the logic inputs, then text 9 will be

printed.

If logic input 1 is opened, then the binary number 1000 is present on the logic

inputs, and so text 8 will be printed.

Î External

36

Page 37

3 Operation and visualisation

1. logic input

4. logic input

Binary no. Decimal no. /text

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Activation is carried out by the parameter Configuration level 3 Î Text logic

links.

Extra code “Logic inputs” is required.

If this extra code is not present, then the parameter will not be

displayed.

Colour

assignment

Print-outs of limit comparator texts are made in the colours of the corresponding measurement traces. The colours which are used for printing external and

binary-linked external texts can be selected with the aid of the setup program

(normal setting: black).

General For limit comparator texts, external texts and binary-linked external texts:

As well as the programmed text, the time when the text printing request was

initiated is also output.

The time reference mark “_” will not be printed, since the print-out

through the queue can happen after some delay.

37

Page 38

3 Operation and visualisation

Report no. and recorder designation

Start report (date + time)

till Report end (date + time)

MIN. MAX. AVER. DIM.

Designation ch. 1 min. value 1 max. value 1 average 1 unit

Designation ch. 2 min. value 1 max. value 1 average 1 unit

Designation ch. 3 min. value 1 max. value 1 average 1 unit

Designation ch. 4 min. value 1 max. value 1 average 1 unit

Designation ch. 5 min. value 1 max. value 1 average 1 unit

Designation ch. 6 min. value 1 max. value 1 average 1 unit

3.5.5 Report

The report is used to create statistics about the measurements, referred to a

definable period of time (statistical period).

The minimum, maximum and average values of the measurements are calculated for the statistical period. The result is printed out at the end of the statistical period, in the form of a table.

When selecting the report it is possible to choose between two types of report.

The instance number on the print-out (1 or 2) identifies the type.

The texts “to”, “MIN.”, “MAX.”, “AVER.” and “DIM.” are printed in the language

which has been configured. Only channels which are actually present and

which have the plot status activated are included in the report.

If an overrange or underrange has occurred during the statistical period, then

“--------” will be printed out instead of the minimum, maximum and average

values.

The report is activated through the parameter Configuration level 2

Available selections are: “periodic”, “weekly”, “monthly” or “external” report.

38

Example:

A “periodic report” has been selected, with “report time 17:15 hrs.“ and “interval 2 hrs.”. This means that the first report will be produced at 17:15. Further

reports will be made at 19:15, 21:15 etc.

Please note, that the calculation of the average value is more accurate for the “periodic” report than for all other types of report

(statistical period longer than one day).

Î Report.

Page 39

3 Operation and visualisation

External report The external report is controlled by a selectable logic input. In addition to the

parameter Configuration level 2

which is wanted must be selected through the parameter Configuration level 3

Î External report (e.g. LOG.INPUT 6). The statistical period starts when the

logic input is closed. The report is printed out when the logic input is opened

(negative-edge triggering).

Î Report (EXTERN.CONTACT), the logic input

Colour

assignment

As a result of the expansion to two reports from software version 105.02.XX,

up to two external reports are now available.

When the external report is used, the setting for the parameter

Configuration level 2

or second istance of the report.

Right:

Configuration level 2

Configuration level 3

Wrong:

Configuration level 2

Configuration level 3

The colour which is used to print the instrument designation can be defined

with the aid of the setup program (basic setting: black).

The minimum, maximum and average values are printed in the same colours

as the corresponding measurement traces. The colours for the traces can also

be altered in the setup program.

Î Report must define whether it uses the first

Î 1. Report = EXTERNAL CONTACT

Î 1. External report = Logic inp. 8

Î 2. Report = EXTERNAL CONTACT

Î 1. External report = Logic inp. 8

39

Page 40

3 Operation and visualisation

General For the report:

- If the printing recorder is switched off at the end of the statistical period,

then the print-out will be completely cancelled.

The same applies if the instrument is re-configured from the keys, or if the

setup connector is plugged in.

- If the print-out of a report has been interrupted by a stop, new configuration, setup, print test or service print, then the recording will not be continued after the recording has restarted.

- If the recorder is in the stop status at the time when the print-out should

begin, then the report will be printed after the stop has been removed.

The statistics for the new report will already be compiled from the originally

planned time.

Sample report The recorder is configured with the report type “periodic”, “time: 7:00 hrs.“

and “interval: 24hrs.”. This means than the statistical period ends, and the results are printed, every day at 7.00. The switch-on is on 03.11.98 at 10.30. On

05.11.98 it is in the stop status from 2.00 to 8.30. It is also in the stop status

from 21.00 on 06.11.98 till 08.00 on 10.11.98. At 11.30 on 11.11.98 a different

speed is programmed for the printing recorder, using the setup program on a

PC. At 10.00 on 12.11.98 the instrument is switched off.

The recorder will print out the following reports:

Time of

print-out

04.11.98 7:00 03.11.98 10:30 - 04.11.98 7:00

05.11.98 8:30 04.11.98 7:00 - 05.11.98 7:00

06.11.98 7:00 05.11.98 7:00 - 06.11.98 7:00

10.11.98 8:00 06.11.98 7:00 - 10.11.98 7:00

11.11.98 7:00 10.11.98 7:00 - 11.11.98 7:00

12.11.98 7:00 11.11.98 11:30 - 12.11.98 7:00

The statistical period can be selected from “periodic”, “weekly”, “monthly” or

“external”. If monthly report is selected, it is printed out on the first day of each

month.

Statistical period

40

Page 41

3.5.6 Switching the chart speed

Every change of chart speed is recorded by printing out a line with the time of

the change and the new chart speed, if the parameter “Print chart speed” is

set to ON in Configuration level 2

The style of the line provides information on the type of paper feed which is

used for recording after the change:

3 Operation and visualisation

Î Print speed change.

Normal operation

— — — — —

—-—-—-—-

---------------

Limit operation

External speed (feed)

Timed operation

The individual events have different priorities:

Event Priority

Limit operaton

External speed

Timed operation

Normal operation

higher

lower

The actual chart speed is that set for the event with the highest priority.

41

Page 42

3 Operation and visualisation

Fixing the printing priority applied to the text for Speed changeover affects not only the print-out of the marking at change-over,

but also the change-over itself.

v Section 3.5.1 “Printing priorities”

As long as a text with a higher priority is being printed, a change-

over will not happen if the parameter Configuration level 2

speed change is set to ON. Otherwise, the change-over takes

place at once.

Text printing in the mode “Overwrite measurement trace” can take

a very long time.

v Section 3.5.2 “Printing modes”

v In order not to delay the change-over of the paper speed, the

priorities for texts which are printed in this mode should be lower than the priority for speed/feed change-over.

Î Print

The line which indicates the type of change-over will still be printed, even if the corresponding text cannot be printed.

This is the case if, in the setup program, Text for speed change,

measurement trace: overwrite is configured under Edit

texts in Print mode and a paper feed/speed of 0 mm/h has been

set.

Text printing is relatively quick in the mode “Interrupt measurement

trace”.

v Section 3.5.2 “Printing modes”

In order to avoid text printing in this mode being cancelled by a

change-over of the paper feed, the priority for these texts should

be higher than the priority for paper feed change-over.

3.5.7 “Power On” and “Power Off” texts

The time of “Power On” and “Power Off” can be documented by using this

feature. Both texts are printed in red, with the date and time of the event. The

print-out can be inhibited through the configuration.

Î Print

42

The priority cannot be assigned. It is always higher than that for the texts

which have a configurable priority. Both texts are configured through the parameter Configuration level 2

Î Print “Power off” text.

Î Print “Power on” text and Configuration level 2

Page 43

3.5.8 Scaling

3 Operation and visualisation

The scaling can be printed in two different ways:

cyclic:

for each channel, at a configurable spacing

(Configuration level 2

triggered:

for each channel, when the F-key is pressed for at least 4 sec, or by closing a

logic input

(Configuration level 3

The basic rule is: scaling can only be carried out when the plot status is activated for the corresponding channel.

Î Print scale)

Î External scaling)

Cyclic

scaling print

Selectable spacings:

-approx. 30cm

-approx. 60cm

-approx. 90cm

-switched off

The scaling is printed in the colour selected for the channel. In the bottom line

is the programmed channel designation and the dimensional unit for the

measurements.

If the presentation range of 0 — 100mm has not been altered, then the scale

marks for 0%, 50% and 100% levels will be in the second line. If the presentation range has been restricted, then “I” marks will appear in this line, which

indicate the start and end of the presentation range. The corresponding numerical values will be shown in the next line.

Limit marks (“I”) for the channel concerned will be printed in the top line.

The limit marks are the threshold levels for the limit comparators, which are

programmed with the aid of the parameter Configuration level 1

parator

limit comparators is set up in the parameter Configuration level 1

parator

Î Limit value. The correlation between measurement channels and the

Î Channel.

Î Limit com-

Î Limit com-

The limit marks are only printed if the corresponding limit comparator is active,

i.e.:

- Limit-text state = ON

(Configuration level 1

or

- Open-collector output 1 — 3 = ON

(Configuration level 2

or

- Relay output 1 — 8 = ON

(Configuration level 3

Î Limit comparator Î Limit-text status)

Î Open-collector output Î Status)

Î Relay output Î Status)

43

Page 44

3 Operation and visualisation

Example:

- Channel 3

- Presentation range: 0 — 100mm

- Limit comparator thresholds at 200 and 500°C

Example:

- Channel 2

- Presentation range limited to: 50 — 100mm

- Limit comparator threshold at 300V

44

Page 45

3 Operation and visualisation

Triggered

scaling print

To start the triggered scaling print, the F-key must be pressed for at least 4

seconds.

Alternatively, the triggered scaling print can be initiated by a logic input (extra

code).

The scalings are printed out for all channels with an activated plot status.

The print-out is made up in the same layout as described for “Cyclic scaling

print”.

Example

- three channels have been activated

45

Page 46

3 Operation and visualisation

3.5.9 Time

The print-out is performed cyclically, at a configurable spacing (Configuration

level 2

Selectable spacings:

-approx. 2cm

-approx. 4cm

-approx. 6cm

-not time printing

Î Print time).

The spacings do not depend on the paper feed which has been set up. The

spacings listed above are only approximates, since the print is made at round

values of time.

For every fourth print-out of the time, there will also be produced, alternating

after the time, the actual current chart speed, the programmed instrument

name, or the date.

The date is also normally printed out when the date changes at 00:00 hrs.

To provide a precise time reference on the chart paper, a time reference mark

(“_”) is placed before the text.

46

Page 47

3.5.10 Print out channel numbers

03.11.98 13.20 Recording start

03.11.98 12.34 Recording stop

In order to be able to associate measurements more clearly with a channel, the

channel number can be printed next to the trace, in the channel colour. The

print-out is made cyclically, at a configurable spacing (Configuration level 2

Print channel numbers).

Selectable spacings:

-2cm

-4cm

-6cm

- print switched off

3 Operation and visualisation

Î

3.5.11 Recording start and stop

The start and stop of recording is registered by a configurable start and end

text (Configuration level 2

The text printing can be switched on or off independently for the start and end

texts. The print-out is made together with the time, and always in red.

Both texts will only be printed while the recording is enabled, i.e. the print of

the end text is always made “in arrears”.

Î Start text, Configuration level 2 Î End text).

The start text should always have the highest priority, to ensure

that it is always printed out at the start of recording.

47

Page 48

3 Operation and visualisation

13:22 Charge no. 23

3.5.12 Incrementing the two event counters

The event counter is assigned to a freely selected logic input. Every time the

corresponding logic input is closed, the event counter is incremented. It can

be pre-loaded with a value through the setup program and the keys on the recorder (Configuration level 3

Every time it is incremented, the event is registered by printing the time and

the programmed text, followed by the current state of the counter.

Î Event counter).

The time reference mark “_” will not be printed, since the print-out

may appear after being delayed in the print queue.

v Section 3.5.4 “Limit comparator texts, external text, binary-

linked external text”

If the counter state is larger than 99999, then the number can no

longer be displayed. The print-out will be “ ***** “ for the counter

state.

48

Page 49

3.5.13 Print test

_13.25 03.11.98 Print test

3 Operation and visualisation

The print test can only be initiated from the keys on the printing recorder (Operating level

and the print head.

Î Print test). It is used to test the function of the printing system

The print test carries on until it is stopped by Test print = Off.

Any text prints which have been started will be aborted and not

continued after the print test. This also applies to the statistical report.

All requests for text printing which occur during the print test will

be stored and carried out after the print test.

Six traces will also be printed out for the 3-channel version of the recorder,

since each colour occurs twice. This means that the functioning of all the pens

is tested. In this case, the parameter Configuration level 1

effect.

Î Plot status has no

49

Page 50

3 Operation and visualisation

13.45 03.11.98 SERVICE PRINT

Software version : 105.02.01

Power interrupts : 00012

Operating time [h] : 01234

Event counter 1 : 00000

Event counter 2 : 09000

Temp.-Min. : +20.32

Temp.-Max. : +31.02

3.5.14 Service print

The service print can only be initiated from the keys on the printing recorder

(Operating level

The print-out consists of:

- the current date and time

-the software version

- the number of mains power supply interruptions

- the total operational time of the recorder in hours

- the current state of the two event counters

- the minimum and maximum ambient temperatures of the internal Pt100

cold junction

Î Service print).

50

Any text print-outs which were started will be aborted and not

continued after the service print. This also applies to the statistical

report.

All requests for text printing which occur during the service print

will be stored and carried out after the service print.

If the mathematics/logic module is activated, an “M” will be printed

after the software version.

Page 51

3.6 Colour assignment

With the aid of the setup program you can select the colours which are used

for print-outs.

Selections can be made for:

- Measurement traces

- Event traces

- Instrument name

- External text

- Binary-linked external text

- Even texts, event counters

Texts which are associated with a channel (e.g. scaling, channel

number, limit comparator texts) are printed in the same colour as

the channel concerned. This also applies to the statistical report.

3 Operation and visualisation

The colours are fixed for:

- Start and end text always red

- “Power on” / “Power off” text always red

- Time print alternating

- Print change of feed/speed alternating

1. The colour changes for each print-out. This ensures an even consumption of the coloured inks.

1

1

51

Page 52

3 Operation and visualisation

3.7 Relationship between measurement range and scaling

The printing recorder offers the facility to differentiate between the measurement range for the input signals which are connected and the scaling on the

chart paper.

If the parameter Configuration level 1

is not programmed to linear, X1 or X2, then the selected measurement range is

automatically applied to the scaling. If the characteristic type is linear, X1 or X2

there is no automatic application of the measurement range to the scaling. So

in this case, the scaling should be checked, and altered if necessary (Configu-

ration level 1

Example:

The parameter Measurement input is programmed as a resistance thermome-

ter.

Type: resistance thermometer

Characteristic: Pt100

Connection: 2/3-wire

Dim. unit: °C

Range start: -200°C

Range end: +850°C

Filter: 0.1sec

The measurement range (-200 to +850°C) is automatically applied to the scaling (-200 to +850%).

Example:

The parameter Measurement input is programmed as a current input.

Î Scale).

Î Measurement input Î Characteristic

Ty pe : c ur re nt

Characteristic: linear

Range start: 0mA

Range end: 20mA

Filter: 0.1sec

The measurement range is not applied to the scaling. The parameter Configu-

ration level 1

sional unit).

Unit: l

Start value: 0l

End value: 1000l

Number format: AUTO

Î Scale can be used to alter the scaling (including the dimen-

52

Page 53

4 Configuration table

4.1 Operating examples

Example 1 The date, time and weekday are to be programmed.

l

Key Display Description

5 AMB. TEMP. +35.08°C Recorder is in basic status

h + R Call up operating level

S-LEVEL (now in operating level)

h + R Start code check

CODE: 9200 Enter 9200, by using the l, r, h, R

keys

E Conclude entry of code number

P-LEVEL (now in parameter level)

h Call 1st. parameter of the parameter

level

LANGUAGE

h Call next parameter

DATE & TIME

E Call parameter to be changed

DATE: 03.11.98 Alter date, by using the l, r, h, R

keys

E Confirm date

DAY: MONDAY Alter weekday, using the h, R keys

E Confirm weekday

TIME: 12:00 Change time, using the l, r, h, R

keys

E Confirm time

DATE & TIME Parameter entry is finished

e Leave parameter level

INITIALISATION As long as the display is flashing,

the recorder is being initialised

with the new data

S-LEVEL Recorder is in the operating level again

53

Page 54

4 Configuration table

Example 2 Starting from example 1, the instrument designation is to be changed.

l

Key Display Description

S-LEVEL

h + R Start code check

CODE: 9200 Enter 9200, by using the l, r, h, R

keys

E Conclude entry of code number

P-LEVEL

h + R Call up configuration level 1

C1-LEVEL

h + R Call up configuration level 2

C2-LEVEL

h Call 1st. parameter of this level

UNIT NAME (the name of the instrument)

E Call the parameter to be altered

TEXT: LOGOPRINT 500 Enter the new designation (UNIT

NAME), using the l, r, h, R and S

keys

E Confirm instrument designation

UNIT NAME Parameter entry is finished

e Leave level

C1-LEVEL

e Leave level

P-LEVEL

e Leave level

INITIALISATION As long as the display is flashing,

the recorder is being initialised

with the new data

S-LEVEL Recorder is in the operating level

again

54

e Leave operating level

LOGOPRINT 03.11.98 09:45 Recorder is in basic status again

Page 55

4.2 Table of the configuration parameters

All the parameters for the instrument are presented in the following table. The

parameters are explained in the order in which they appear in the recorder.

The first column of the table shows the path through the levels to the particular

parameter.

The “X” symbol stands for a number which is to be selected (e.g.

channel number 1 — 3 or 1 — 6). This number is shown in the display of the printing recorder for all the sub-parameters.

To preserve a clear layout, the “X” is only shown for the first subparameter in the table.

The settings or selections which are available for the parameter are shown in

the second column.

The third column contains a description of the parameter or the selection options, if the selection or the function of the parameter are not obvious.

4 Configuration table

4.2.1 Operating level (S-level)

Parameter Value/selection Description

Chart speed Operating level

➔ Chart speed

Chart speed: 0, 5, 10, 20, 60, 120, 240,

Print test Operating level

➔ Print test

Print test: OFF, ON

Service print Operating level

➔ Service print

Service print: NO, YES

Version number Operating level

➔ Version number

Version: 105.02.01

Setting the chart paper

speed

300, 360, 600, 720mm/h

Start print test

The print test can be used

to test the functioning of

the printing system

Start service print

The service print provides

information about the software version, no. of mains

power supply interruptions,

total no. of operational

hours of the recorder, the

count states of the event

counters 1 and 2, and the

minimum and maximum

ambient temperatures.

Displays the number of the

software version

55

Page 56

4 Configuration table

4.2.2 Parameter level (P-Level)

Parameter Value/selection Description

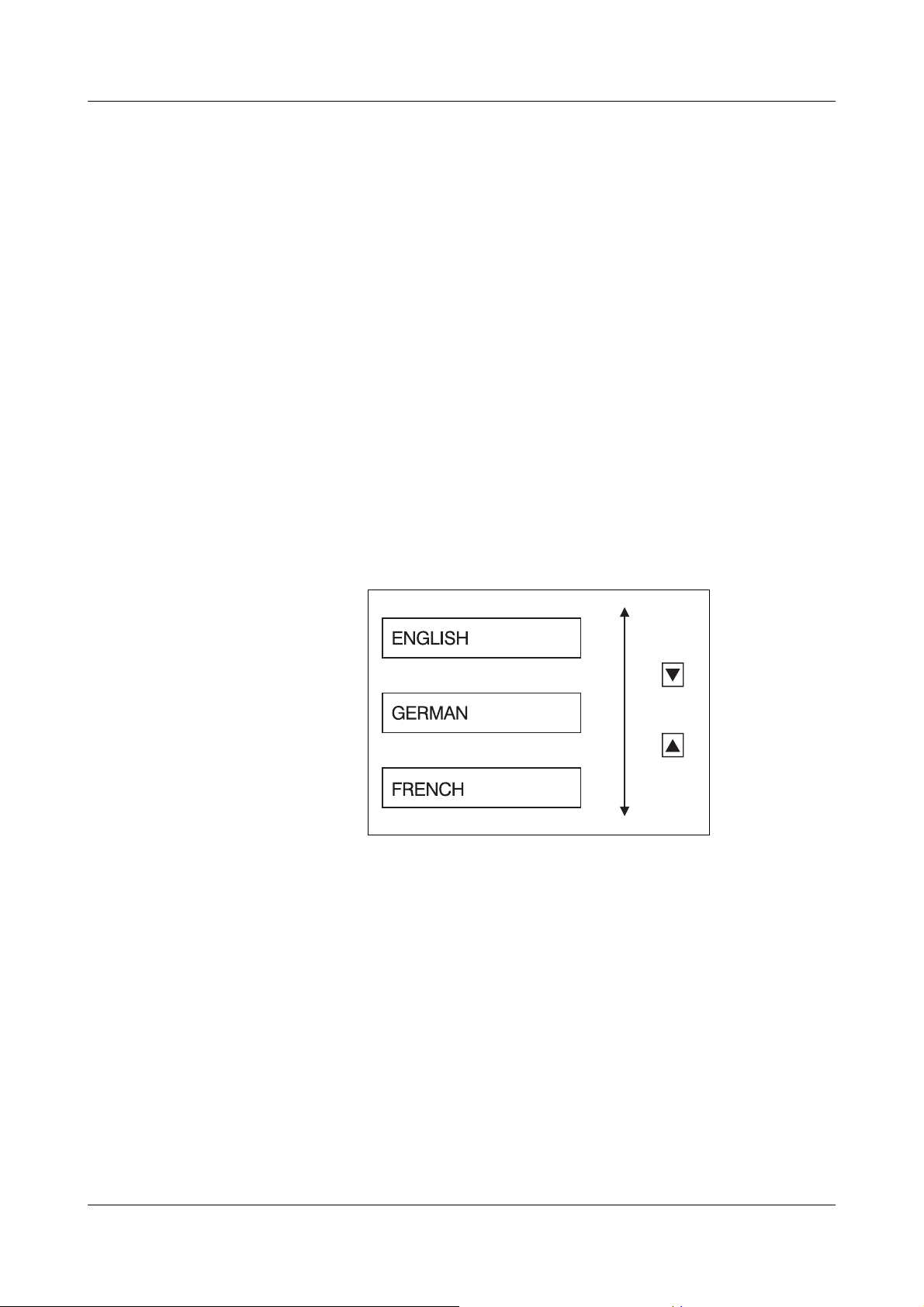

Language Parameter level

➔ Language

Language: ENGLISH

Date & time Parameter level

➔ Date & time

Date:

Weekday:

GERMAN

FRENCH

DD:MM:YY

MONDAY

TUESDAY

WEDNESDAY

THURSDAY

FRIDAY

SATURDAY

SUNDAY

Select language

The language setting

affects all the nonprogrammable texts in the

recorder which can be

displayed or printed out.

Programming the

system clock

The actual time is printed

out for certain events, and

is used as a reference time

for time-dependent events,

such as statistical reports,

timed operation, and summer time.

Time:

Summer time Parameter level

➔ Summer time

Summer time:

Start:

Start:

End:

End:

Display brightness Parameter level

➔ Display

Brightness: 1 — 4

Display time Parameter level

➔ Display time

Display time: ON, OFF

hh:mm

OFF, ON

Enter date:

DD:MM:YY

Enter time:

hh:mm

Enter date:

DD:MM:YY

Enter time:

hh:mm

Entry of the period during

which the system clock of

the recorder will be adjusted to summer time.

The period of summer time

is only valid for the defined

period of time.

It must be freshly programmed each year.

Start and end can only be

entered if the status is set

to ON.

Display brightness

1 = dark

4 = very bright

Select status for display of

time in the basic status

56

Page 57

4.2.3 Configuration level 1 (C1-level)

Parameter Value/selection Description

Plot status Configuration level 1

➔ Plot status

X Plot status 1 — 3 or 1 — 6

Status: ON, OFF

4 Configuration table

Setting for each writing

channel: should the signal

trace be printed on the

chart and appear in the

statistical report or not.

Measurement input Configuration level 1

➔ Measurement input

X Measurement input

Ty pe :

Configuration level 1

➔ Measurement input

Type: Resistance

thermometer

Characteristic: Pt100, Pt100 JIS, Pt500,

Connection: 2/3-wire

Unit:

(dimension)

Range start: -9999 to +9999 Enter start of

Range end: -9999 to +9999

1—3 or 1—6

RES.THERMOMETER

THERMOCOUPLE

POTENTIOMETER

RES. TRANSMITTER

VO LTAG E

CURRENT

SHUNT

Pt1000, Ni100, X1, X2,

4-wire

°C, °F

Measurement span ≥ 15°C

Select the type of probe/

sensor and input signal,

determine the measurement range + filter time

constant for each input

channel.

X1 = customer-specific

linearisation 1

X2 = customer-specific

linearisation 2

(with X1 or X2 : followed

immediately by the entry