Page 1

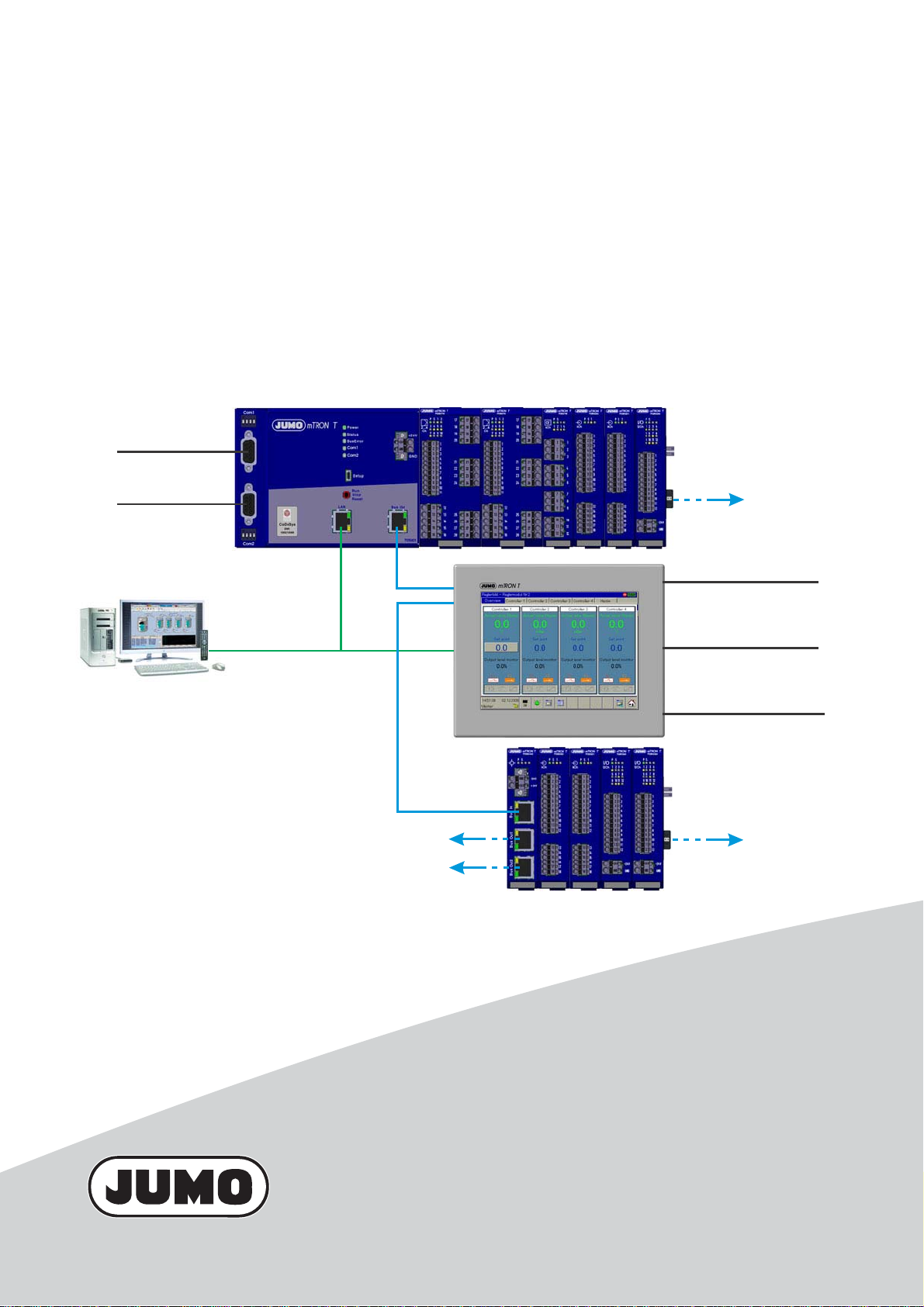

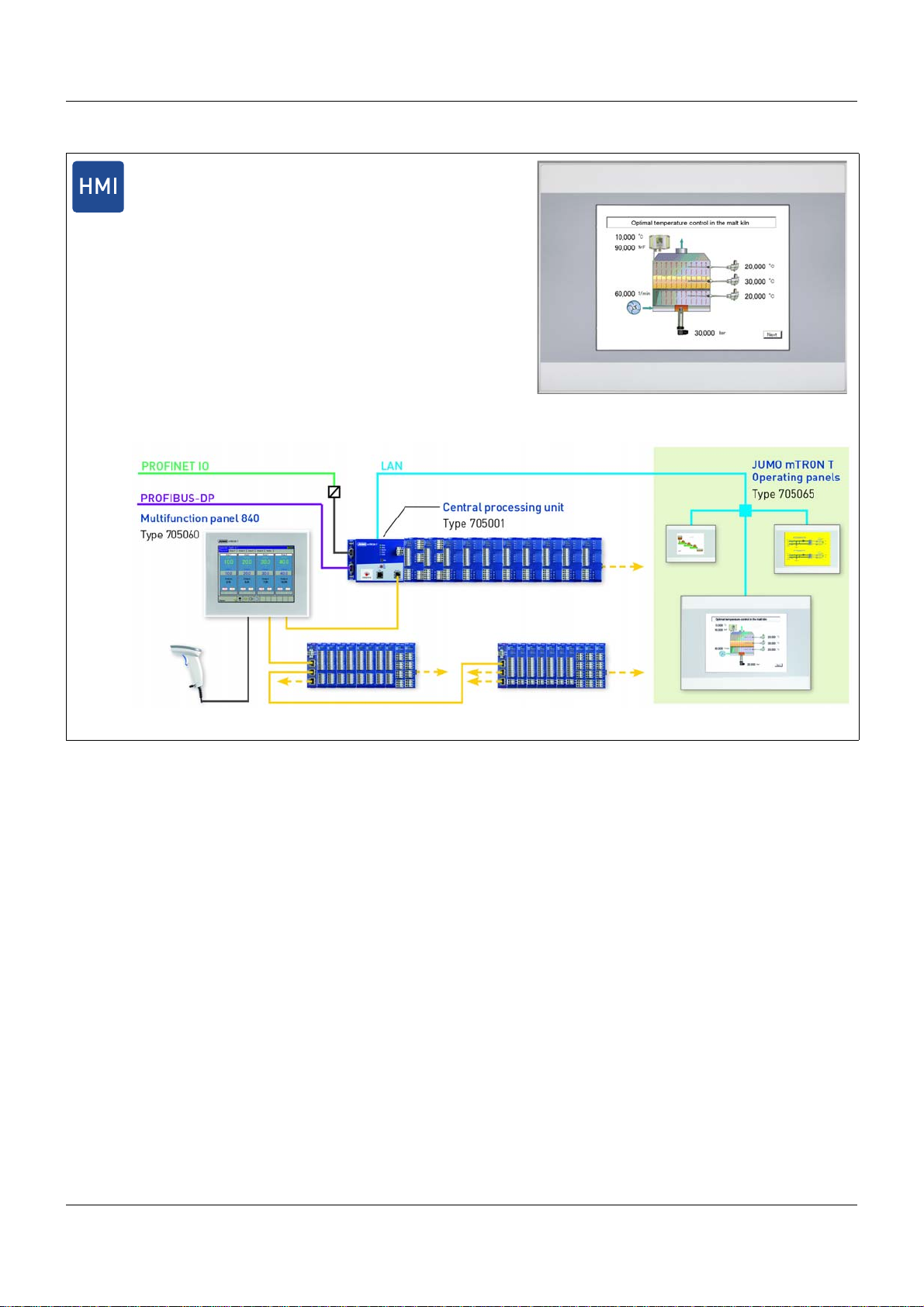

JUMO mTRON T

- Web browser

- Setup program

- PC Evaluation Software PCA3000

- PCA Communication Software PCC

- Plant Visualization Software SVS3000

- Programming system CODESYS

LAN

Com2

RS422/485 or RS232,

Modbus master/slave

or

PROFIBUS-DP slave

System bus

Com1

RS422/485 or RS232,

Modbus master/slave

Com1

Com2

USB

RS422/485 or RS232,

Modbus master/slave,

connection for bar code scanner

RS422/485 or RS232,

Modbus master/slave,

connection for bar code scanner

Host and device

max. 100 m

max. 100 m

Measuring, Control, and Automation System

System Description

B 705000.8

2014-05-06/00575652

Page 2

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.1 Structure of this system description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 The JUMO mTRON T measuring, control, and automation system . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.3 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.4 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2.5 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.6 Operating, visualization, recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.7 Power supply units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.8 PC programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.3 Content of the technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3.1 Device documentation in printed form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3.2 Device documentation in the form of PDF files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3.3 Documentation for optional software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.4 Device documentation on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3.5 Training documents on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.4 Available technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4.2 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4.3 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4.4 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4.5 Operating, visualization, recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4.6 Power supply units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.1 Warning symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Note signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Acceptance of goods, storage, and transport . . . . . . . . . . . . . . . . . . . . . . . . .25

3.1 Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Notes on storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 Returning goods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.1 Accompanying letter for repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.2 Protection against electrostatic discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Identifying the device version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.1 Nameplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3

Page 4

Contents

4.3.1 General accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.2 Central processing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.3 Controller module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.1 General information on installation/dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Module sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.1 System with centralized module assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.2 System with decentralized module assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3 Installation/dismounting on DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.1 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3.2 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.3 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.4 Mounting in a panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4.1 Multifunction panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5 Replacing module inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5.1 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5.2 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.1 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2 Electrical isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.3 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.4 Current load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.5 System bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7 Startup and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

7.1 Setup program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.2 Multifunction panel 840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8.1 General technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.1 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.2 Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.3 Protection type according to DIN EN 60529 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.4 Protection rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.5 EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.6 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.1.7 Ambient requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.8 Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.9 Climatic tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.10 Mechanical tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4

Page 5

Contents

8.2 System expansion (system version 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.3 Training courses/seminars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5

Page 6

Contents

6

Page 7

1.1 Structure of this system description

This system description, which is also a component of the system manual (accessories), describes features that relate to the overall measuring, control, and automation system or are

equally applicable for all modules.

The complete scope of information for each module is contained in the downloadable operating

manuals.

NOTE!

The user should follow the individual sections of this system description step for step to gain

an overview of the measuring, control, and automation system and the available technical

documentation.

Content of the individual sections

Section Explanation

1 Introduction • Initial information on the measuring, control, and automation sys-

tem

• Find out how the technical documentation is structured

1 Introduction

2 Safety information • Symbols and types of figures used and their meanings

3 Receipt of goods, storage,

and transport

4 Identifying the

device version

5 Installation • Correctly fitting or installing the devices, taking into conside ratio n

6 Electrical connection • Safely connecting the devices, taking into consideration the "in-

7 Startup and

configuration

• Checking the delivery for damage and completeness

• Notes on storage and transport

• Handling the packaging material

• Notes on disposal

• Detecting which device version is indicated by the specifications

on the nameplate

the prevailing climatic conditions at the installation location

stallation notes"

• Starting up and configuring the system using the setup program

(overview).

• Configuring and operating the system using the multi function p anel (overview).

NOTE!

All additional information is module-specific and is contained in the respective index divider

of the system manual and in the downloadable operating manuals.

7

Page 8

1 Introduction

- Web browser

- Setup program

- PC Evaluation Software PCA3000

- PCA Communication Software PCC

- Plant Visualization Software SVS3000

- Programming system CODESYS

LAN

Com2

RS422/485 or RS232,

Modbus master/slave

or

PROFIBUS-DP slave

System bus

Com1

RS422/485 or RS232,

Modbus master/slave

Com1

Com2

USB

RS422/485 or RS232,

Modbus master/slave,

connection for bar code scanner

RS422/485 or RS232,

Modbus master/slave,

connection for bar code scanner

Host and device

max. 100 m

max. 100 m

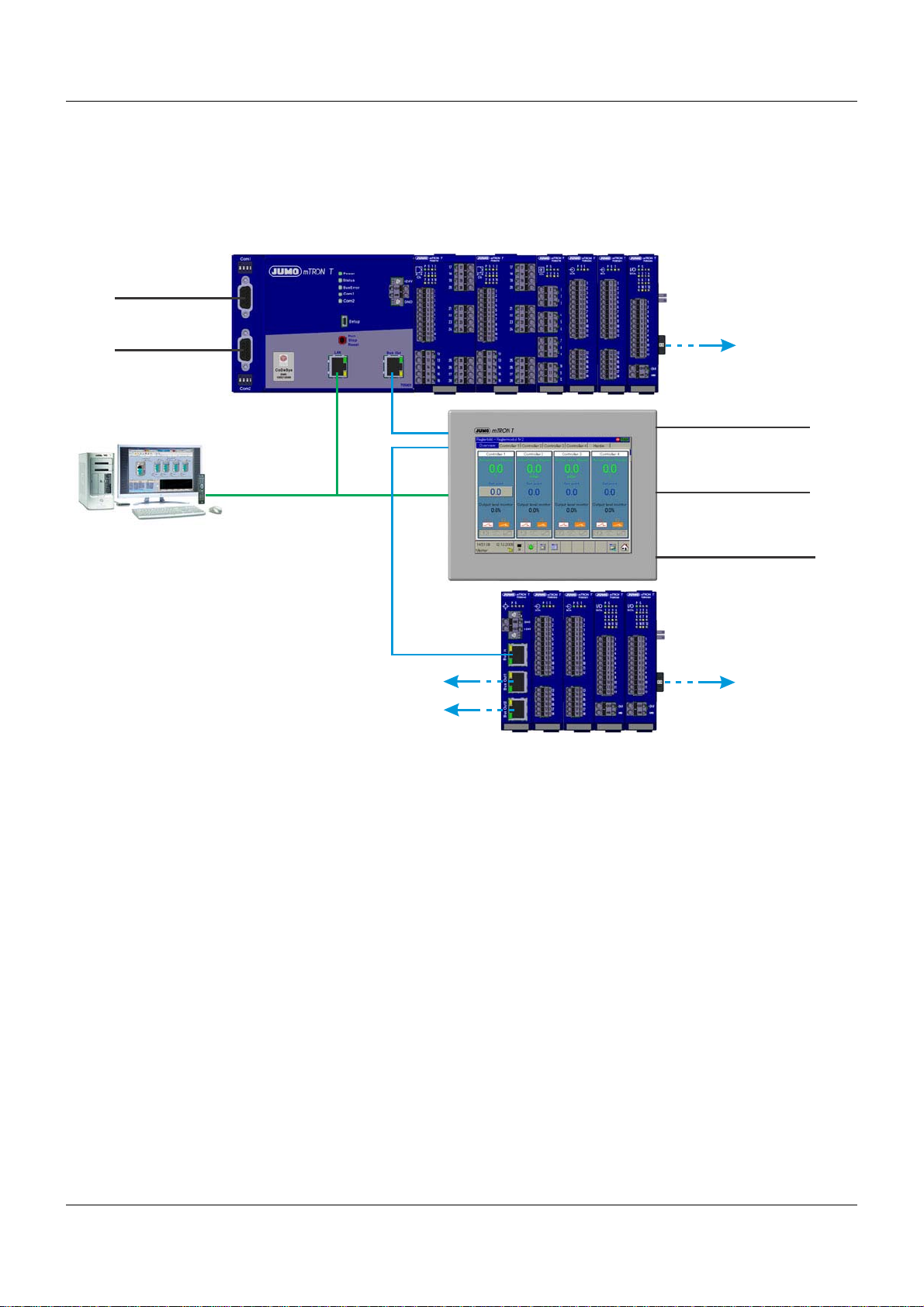

1.2 The JUMO mTRON T measuring, control, and automation system

1.2.1 Overview

1.2.2 Brief description

The modular measuring, control, and automation system is suitable for the precise detection,

regulation, control, and recording. Special features of the system are the easy operation and

the corresponding software components, the high measuring accuracy and regulation quality

8

as well as the sturdy and service-friendly mechanical system.

An application consists of a base unit (central processing unit), a maximum of 30 input/output

modules (multichannel controller module, analog input module 4-channel, analog input mod ule

8-channel, digital input/output module 12-channel), and if necessary the multifunction p anel, up

to four operating panels, and router modules for distributed module arrangement. For userfriendly all-in-one solutions, various PC programs are available.

Automation solutions for small and medium size machine lines are possible due to the integration of an optional PLC including programming system according to IEC 61131-3.

The base unit is equipped with a sturdy metal case; the router module and the input and output

modules are equipped with a plastic case. All these devices can be fitted on a 35 mm DIN rail.

The multifunction panel with TFT touch screen has a metal case with decor foil and is intended

for mounting into a panel cut-out.

The system operates at a voltage of DC 24 V. The supply of operating voltage is only requ ired

at the base unit (central processing unit), at the router module, and at the multifunction panel.

Page 9

1.2.3 Base units

• The base unit, up to 30 input/output modules, and up to 30 router modules can be used to

build a compact and economic central or decentral measuring, control, and automation system (visualization and operation either with the multifunction panel or the plant visualization

software JUMO SVS3000).

• The base unit s cont ain the process image of the application. Furthermore, all configuration

and parameter data of the system are stored in these modules (except for the multifunction

panel). As a result, individual input/output modules can be replaced with Plug and Play.

• All base units operate at a voltage supply of DC 24 V.

• The setup program or the multifunction panel ca n be used to comfortab ly configure and pa-

rameterize the base units.

• LEDs are used to indicate the voltage supply as well as the operating status of a module

and of the interfaces.

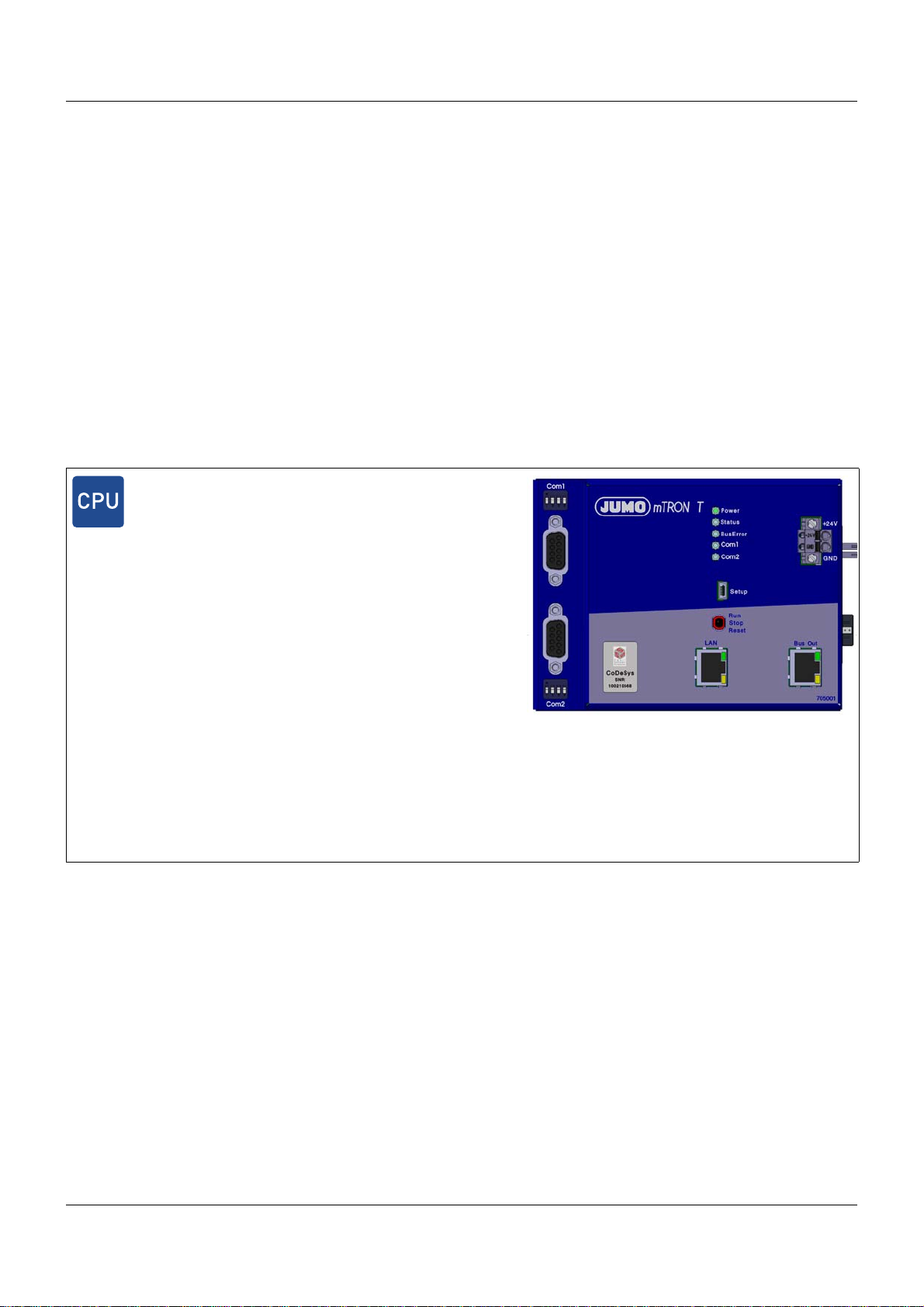

Central processing unit

• The central processing unit is the basis for the maximum extension of the system

• Nine program generators (option)

• 64 limit values are monitored

• An integrated PLC acc. to IEC 61131-3 (option)

• Math and logic function (option) for all connected multichannel

controller modules

• Two interfaces for field bus applications; optional:

- RS232, Modbus RTU as master or slave

- RS422/485 Modbus RTU as master or slave

- PROFIBUS-DP as slave (as of system version 02)

• One USB device interface (setup)

• System bus connection at the front (Bus Out)

• A LAN interface (Ethernet) for HTTP and Modbus/TCP as

master and slave

• Integrated web server

• E-mail transmission

• The central processing unit operates at a voltage supply of

DC 24 V and supplies the connected input/output modules

• Dimensions (W x H x D): 135 mm x 101 mm x 67.1 mm

(without connection elements)

For further information: Refer to data sheet 705001

1 Introduction

Additional base units in preparation.

9

Page 10

1 Introduction

1.2.4 Input/output modules

• The modules are equipped with removable terminal strips with Push-In technology for the

electrical connection.

• All input/output modules operate at a voltage supply of DC 24 V.

• The setup program, the multifunction p anel or the optional PLC can be used to comfort ably

configure and parameterize the modules.

• LEDs are used to indicate the voltage supply as well as the operating status of a module

and the input/output statuses.

• For service work (replacemen t) or adding option al boards, the module insert can be easily

pulled out of the case at the front.

Multichannel controller module

• 2-channel PID controller with relay output or logic output

to control solid-state relays

• Up to 4 PID controller channels can be activated (cascadable)

• Two universal analog inputs, two digital inputs

(DC 0/24 V) and two digital outputs (relay or logic DC 0/15 V)

• Supported measuring probes: Thermocouples, RTD temperature probes, resistance transmitters, resistance/potentiometers, or standard signals (current or voltage)

• The analog inputs are electrically isolated from each other

• Three option slots for the extension of up to four

universal analog inputs, eight digital inputs,

three analog outputs, or eight digital outputs

• Su pported controller types: Two-state controller, three-state

controller, modulating controller, continuous controller, or continuous controller with integrated actuator controller

• Customer-specific linearization possible by using a formula

• Limit value monitoring

• Four formulae for math and logic functions (option)

• One counting input up to 10 kHz

• The module operates independently (configurable) which

means the control task is carried out even if the base unit or

the higher-ranking system malfunctions

• If the controller is replaced during service work the new controller (identical type) is automatically configured

• Dimensions (W x H x D): 45 mm x 103.6 mm x 101.5 mm

(without connection elements)

For further information: Refer to data sheet 705010

10

Page 11

Relay module 4-channel

• Four relay outputs controlled via the system bus by digital signals

• Each relay is equipped with a changeover contact

AC 230 V / 3 A

• Separate terminal strip per relay output

• Automatic configuration after the module insert has been exchanged during service work

• Dimensions (W x H x D): 22.5 mm x 103.6 mm x 101.5 mm

(without connection elements)

For further information: Refer to data sheet 705015

Analog input module 4-channel

• Four universal analog inputs

• Supported measuring probes: Thermocouples, RTD temperature probes, resistance transmitters, resistance/potentiometers or standard signals (current or voltage)

• The analog inputs are electrically isolated from each other

• Customer-specific linearization possible by using a formula or

up to 45 pairs of values

• Limit value monitoring

• Automatic configuration after the module insert has been exchanged during service work

• A digital input (DC 0/24 V) is also provided

• Dimensions (W x H x D): 22.5 mm x 103.6 mm x 101.5 mm

(without connection elements)

1 Introduction

For further information: Refer to data sheet 705020

Analog input module 8-channel

• Eight analog inputs for RTD temperature probes Pt100, Pt500

or Pt1000 in 2-wire circuit

• The analog inputs are not electrically isolated from each other

• Limit value monitoring

• Automatic configuration after the module insert has been exchanged during service work

• A digital input (DC 0/24 V) is also provided

• Dimensions (W x H x D): 22.5 mm x 103.6 mm x 101.5 mm

(without connection elements)

For further information: Refer to data sheet 705021

11

Page 12

1 Introduction

Digital input/output module 12-channel

• 12 channels which can be respectively configured as digital inputs (DC 0/24 V) or as digital outputs (DC 0/24 V, 500 mA)

• Supply of external voltage through terminal at the front

• Automatic configuration after the module insert has been exchanged during service work

• Dimensions (W x H x D): 22.5 mm x 103.6 mm x 101.5 mm

(without connection elements)

For further information: Refer to data sheet 705030

1.2.5 Special modules

Router module

• The router module distributes the input/output modules to

several DIN rails/control cabinets (decentralized arrangement)

• It uses the system bus to link modules to the base unit or the

multifunction panel

• Up to 100 m distance between two router modules or between

a router module and the base unit or the multifunction panel

• Up to 30 router modules are possible

• The router module operates at a voltage supply of DC 24 V and

supplies the connected input/output modules

• No configuration of the router module required

• For applications such as Hot Connect, for example, the address of the router module can be set by rotary coding switches

• Three RJ45 system bus connections at the front

(1 × Bus In, 2 × Bus Out), electrically isolated

• Dimensions (W x H x D): 22.5 mm x 103.6 mm x 101.5 mm

(without connection elements)

For further information: Refer to data sheet 705040

12

Page 13

1.2.6 Operating, visualization, recording

Multifunction panel 840

• Touchscreen with front made of aluminum incl. design foil

(IP67)

• TFT color monitor 21.3 cm (8.4”),

resolution 640 x 480 pixels, 256 colors, with LED backlight

• As an interface between man and machine it allows an optimal

and clearly-arranged view of the process statuses and parameters of the system

• Display (in real time) and operation of controller screen, process screen, program editor, and recording function (option)

• Configuration of all connected modules

• Setpoint values and batch texts are directly entered on the

screen

• Data archiving and evaluation with PC

• The multifunction panel operates at a voltage supply of

DC 24 V

• A setup program can be used to comfortably configure the

multifunction panel

• Two interfaces for field bus applications; optional:

- RS232, Modbus RTU as master or slave

- RS422/485, Modbus RTU as master or slave

• One USB device interface (setup)

• Two USB host interfaces (memory stick)

• Two system bus connections (Bus In and Bus Out)

• A LAN interface (Ethernet) for HTTP and Modbus/TCP as

master and slave

• Integrated web server

• E-mail transmission

• Connection possibility for barcode scanner

• Dimensions (W x H x D): 235mm x 195mm x 58mm

For further information: Refer to data sheet 705060

1 Introduction

13

Page 14

1 Introduction

Operating panels 350, 570, 1040

• TFT color display (64k colors) with resistiv-touch technology

• Display sizes 8.9 cm (3.5''), 14.5 cm (5.7''), and 26.4 cm

(10.4'')

• Display resolutions 320 × 240 pixels and 640 × 480 pixels

• Different case materials (plastics, metal)

• Protection type IP65 (at the front)

• Voltage supply DC 24 V

• Ethernet interface (RJ45) for connection to the system

• Up to four operating panels per central processing unit (PLC

option required)

• Specific process screens for operating the system

• Direct access to PLC variables

System structure:

For further information: Refer to data sheet 705065

14

Page 15

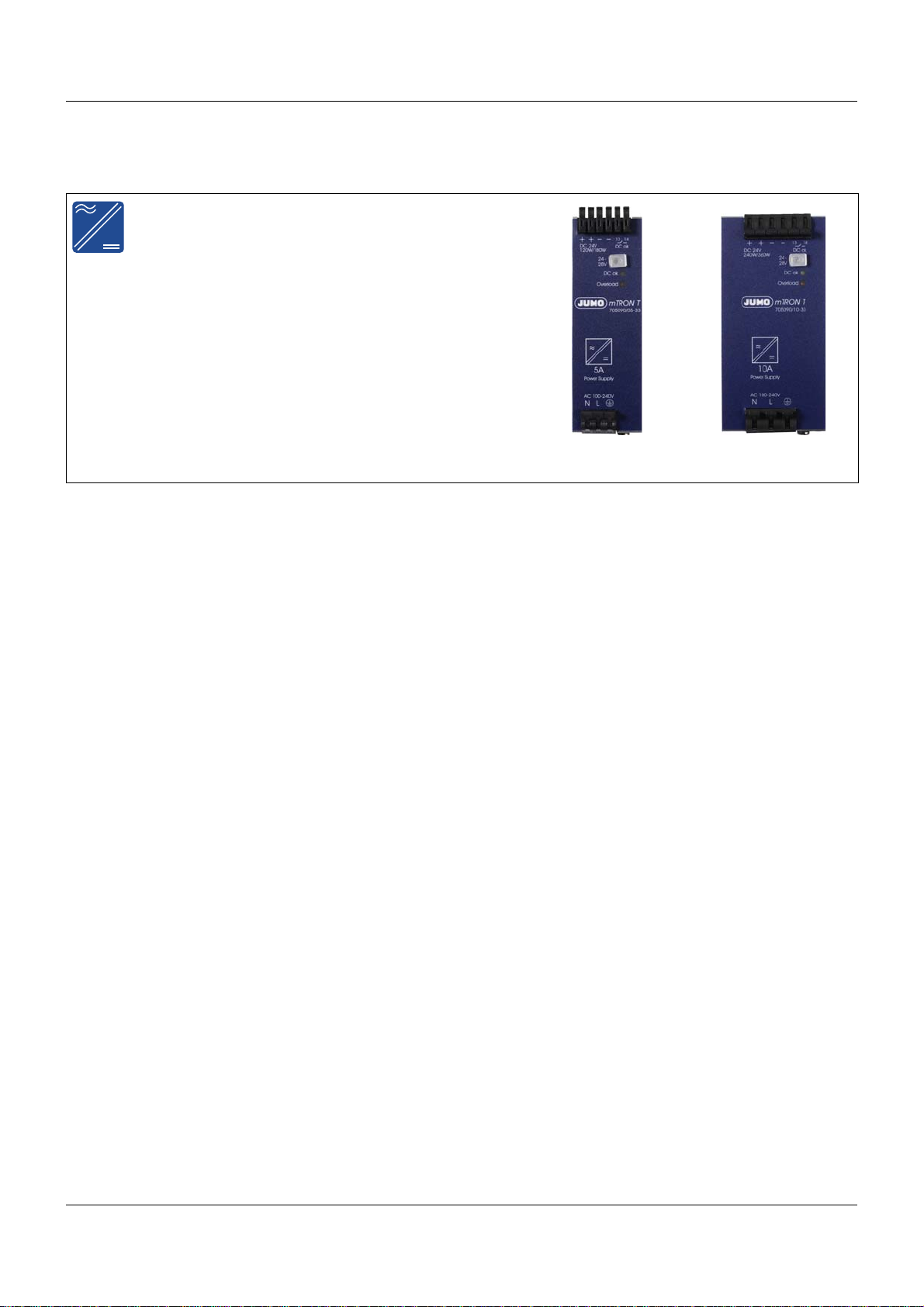

1.2.7 Power supply units

Power supply units 705090/...

• Voltage supply AC 100 V... 240 V

• 150 % peak load capability (for typical 4 s)

• M inimum current inrush

• Floating DC-OK relay contact

• Efficiency up to 93.5 %

• Active power factor correction (PFC)

• Active filter against mains transients

• Quick connection due to spring-cage terminals

• Dimensions (WxHxD):

705090/05-33: 40 mm x 130.5 mm x 121.5 mm

705090/10-33: 60 mm x 130.5 mm x 121.5 mm

For further information: Refer to data sheet 705090

1 Introduction

15

Page 16

1 Introduction

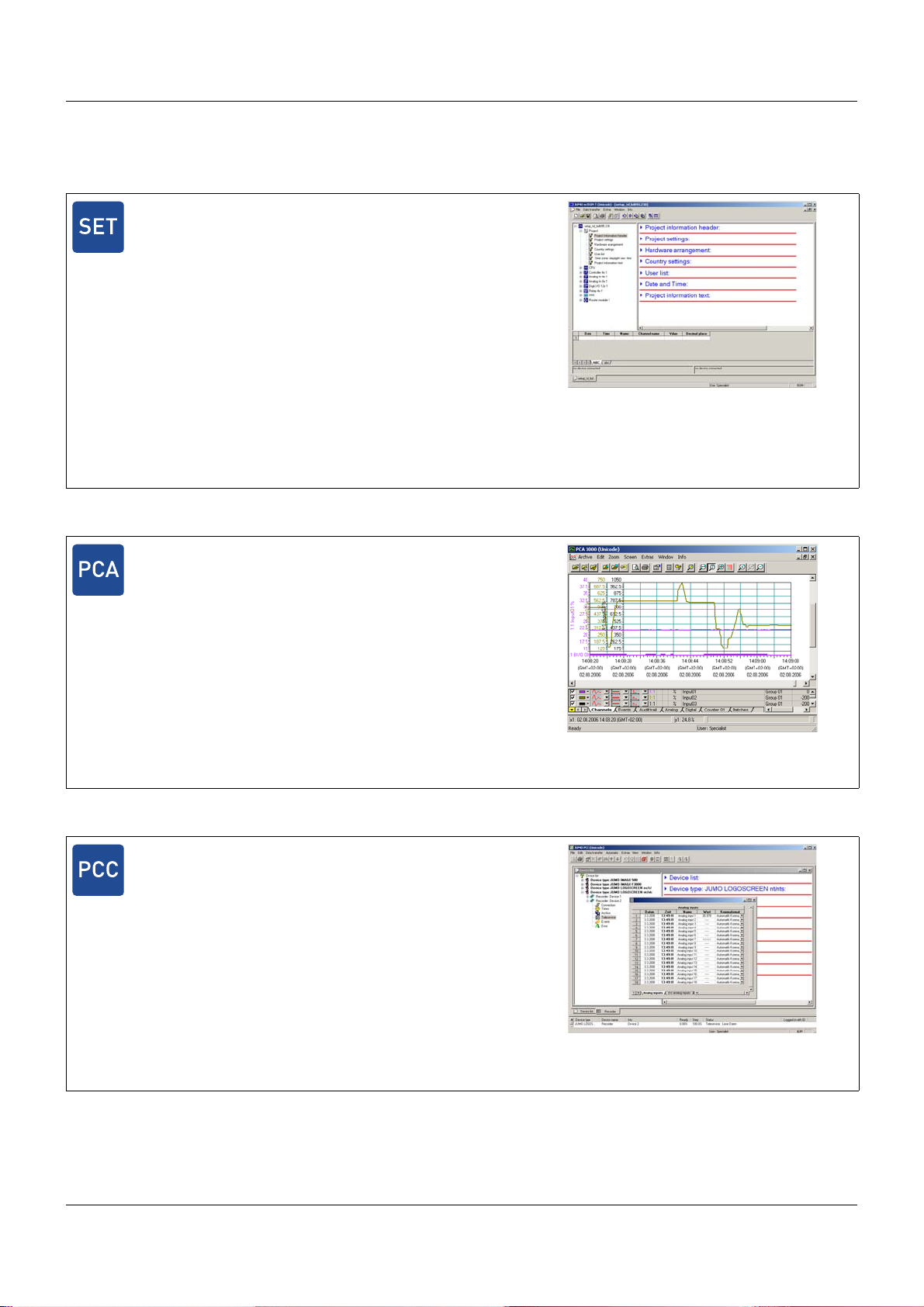

1.2.8 PC programs

Setup program

Setup program for project planning and configuration of the entire

measuring, control, and automation system

A complete PLC can be activated as an option.

The setup program is distinguished by:

• User-friendly configuration, parameterization, and startup of

the base units, the input/output modules, and the multifunction

panel

• Automatic import of the hardware configuration into the PLC

programming software CODESYS

• Program editor

• Process screen editor

The project file contains all data that is relevant for the configuration, parameterization, and visualization. The file also contains the

controller programs and, if applicable, the customer-specific PLC

code.

For further information: Refer to operating manual 705000.6

PC Evaluation Software PCA3000

Professional evaluation software to manage, archive, visualize and

evaluate process data (measuring data, batch data, messages, ...)

The process data can be imported via USB memory stick or provided by the software PCC.

• Data memory: Clearly arranged and easy backup and archiving of all process data in a data file

• Data backup: Archive data can directly be imported from CD/

DVD and then displayed

• Data export: Data export to HTML level or ASCII text file

(for evaluation in Excel) or customer-specific forms

• Communication: The communication software PCC optimally

adapted to PCA3000 can be used to comfortably import data

via an interface or a modem

For further information: Refer to operating manual 709701.0

PCA Communication Software PCC

The communication software PCC optimally adapted to PCA3000

can be used to comfortably import data via an interface or modem.

• Data memory: Clearly-arranged, easy backup and archiving of

all process data in a data file

• Teleservice function (display of the process data)

For further information: Refer to operating manual 709702.0

16

Page 17

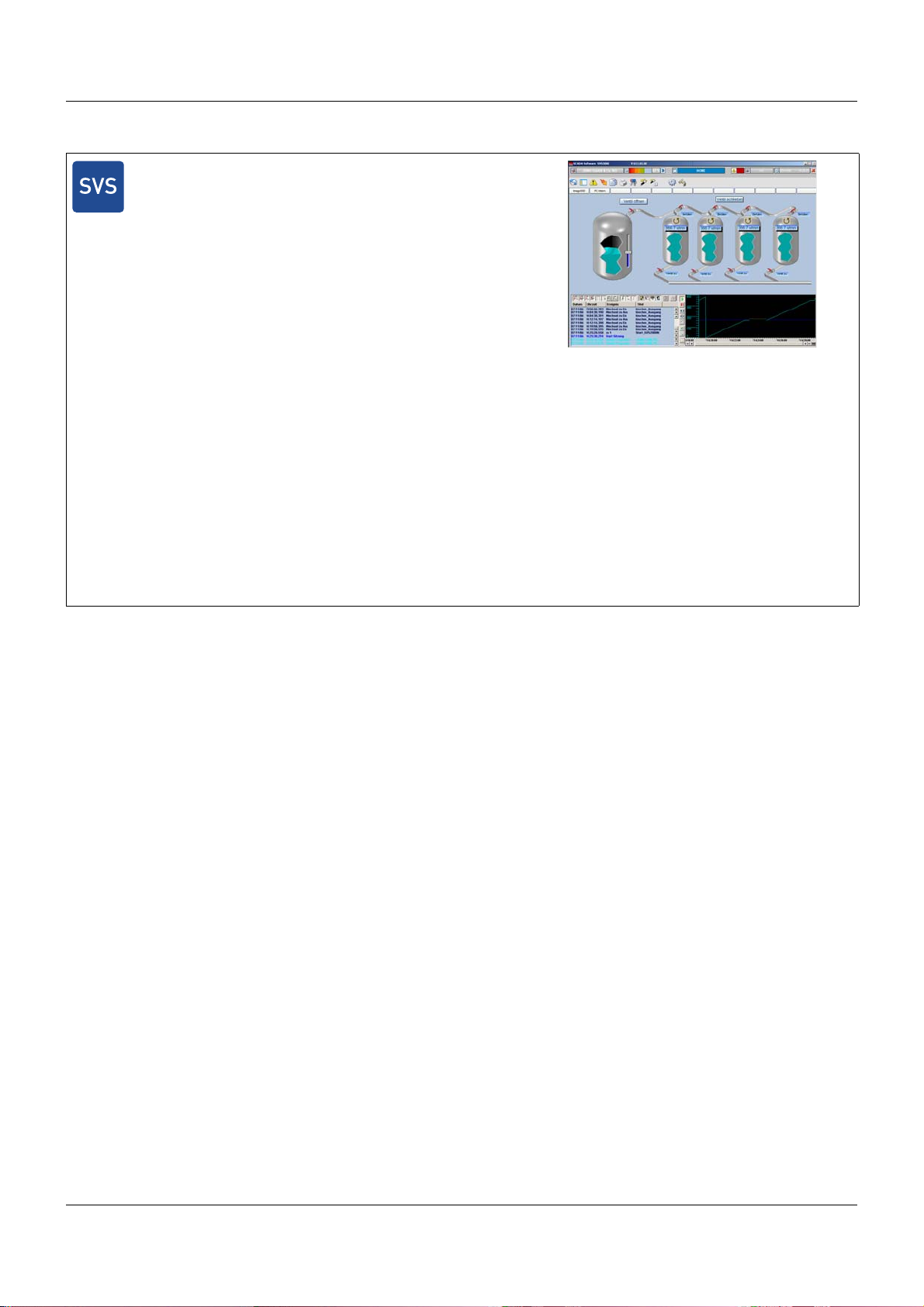

Plant Visualization Software JUMO SVS3000

Plant Visualization Software for online visualization, batch reporting and operation of the measuring, control and automation system

with a networked PC

This software ensures quick familiarity and easy creation of applications. The user is able to quickly configure an individual application according to his/her requirements due to the prepared masks

(process, group, trend screens).

• Easy and quick application creation

• Extensive library with predefined graphical elements

• System operation via group masks

• Extensive do cumentation function with continuous and batch

related evaluation

• Search function for date/time, plant, and batch criteria to be

defined

• Automatic print and data export

• Recipe function

• Quick and easy commissioning/startup due to installation

menu

• Alarm and event list

• Pa ssword protected

• History and real time trend

• Networ k compatible

• Connection of bar code scanner

• Remote alerting (optional)

For further information: Refer to data sheet 700755

1 Introduction

17

Page 18

1 Introduction

1.3 Content of the technical documentation

The documentation for the measuring, control, and automation system is intended for plant

manufacturers and users with specialist training. It has a modular structure and comprises different sections.

1.3.1 Device documentation in printed form

B 7050XX.4

Installation instructions

A hard copy of the installation instructions is included in the scope of delivery of every modu le.

The installation instructions describe the installation of the device and the connection of the

supply and signal cables. They also contain the order details and a list of technical data.

The scope of delivery for a power supply unit includes a hard copy of the operating instructions.

These include information on installation and electrical connection.

B 705000.0

System manual

A hard copy of the system manual can be provided as an accessory subject to charge.

The system manual describes the scope of services of the measuring, control, and automation

system and provides all information for project design and startup.

Index divider 1 "System description" summarizes the information applicable to all modules.

Module-specific descriptions in the following sections complement the specifications stated

here.

Index divider 2 "Setup program" describes the project design of the overall system.

1.3.2 Device documentation in the form of PDF files

The device documentation files specified below are saved as PDF files on the DVD contained

in the scope of delivery of a base unit.

T 705000

Data sheet

The data sheet provides general information on the measuring, control, an d automation system

and forms the basis for plant planning and purchase decisions.

T 7050XX

Data sheet

The data sheets of the individual modules provide spe cific information, order det ails, and technical data.

B 7050XX.0

Operating manual

The operating manuals of the individual modules contain all information on installation, electrical connection, startup, operation, and – if required – parameterization and configuration.

18

Page 19

B 7050XX.2.0

Interface description (Modbus interface)

It provides information on communication with other devices or superordinate systems using

the Modbus protocol (Modbus RTU, Modbus TCP).

B 7050XX.4

Installation instructions

The installation instructions describe the installation of the device and the connection of the

supply and signal cables. The instructions also contain a list of the technical data.

B 7050XX.5.X

Operating manual (application)

The operating manual describes the use of a certain application (e. g. PLC application).

1.3.3 Documentation for optional software

The manuals specified below are available on the Internet as PDF files. They also form part of

the scope of delivery of the respective software.

1 Introduction

B 705000.6

B 709701.0

B 709702.0

B 700755.0

Setup program

The manual describes the function of the setup program.

PC evaluation software PCA3000

The operating manual describes the operation and the features of the PC evaluation sof tware.

The PC evaluation software helps to visualize and evaluate the recorded process data (measurement data, batch data, messages, etc.).

PCA communication software PCC

The operating manual describes the operation and the features of the PCA communication

software. The PCA communication software is responsible for the data transfer from a device

or system to a PC or to a network.

Plant visualization software SVS3000

The operating manual describes the operation and features of the plant visualization software.

The plant visualization software is responsible for networking interface-ready process devices

with a PC.

19

Page 20

1 Introduction

1.3.4 Device documentation on the Internet

All documents are available for download on the Internet at www.jumo.net.

Download procedure:

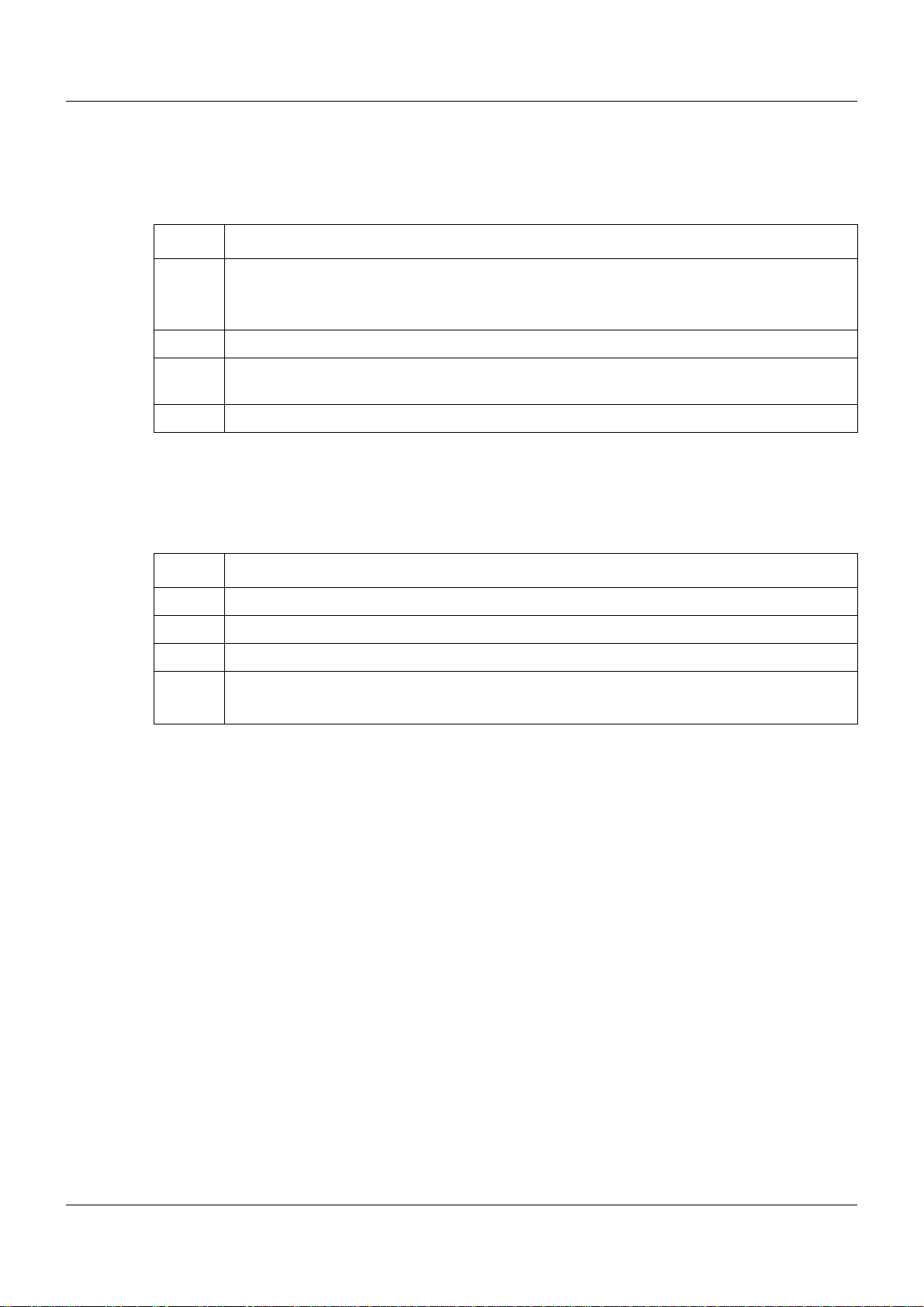

Step Action

1 On the JUMO website, enter the number of th e relevant pro duct group in the sea rch field at

the top right (e.g. 705001 for the central processing unit) and st art the search.

The search results are listed.

2 Select product (click the link).

3 In the "Documentation" dropdown list, select the desired documentation in the required

national language (click the link).

4 +++++Open the PDF document or save it as a file.

1.3.5 Training documents on the Internet

Training documents (eLearning courses) on various topics are available at www.jumo.net.

Procedure:

Step Action

1 On the JUMO website, navigate to the "Support/Services" area.

2 In the "Information & Training" menu on the left-hand side, select "eLearning courses".

3 Click the link "Review of our eLearning courses".

4 Select the desired eLearning course from the overview (click the link).

The presentation starts.

20

Page 21

1.4 Available technical documentation

The documents specified below are available for the measuring, control, and automation system.

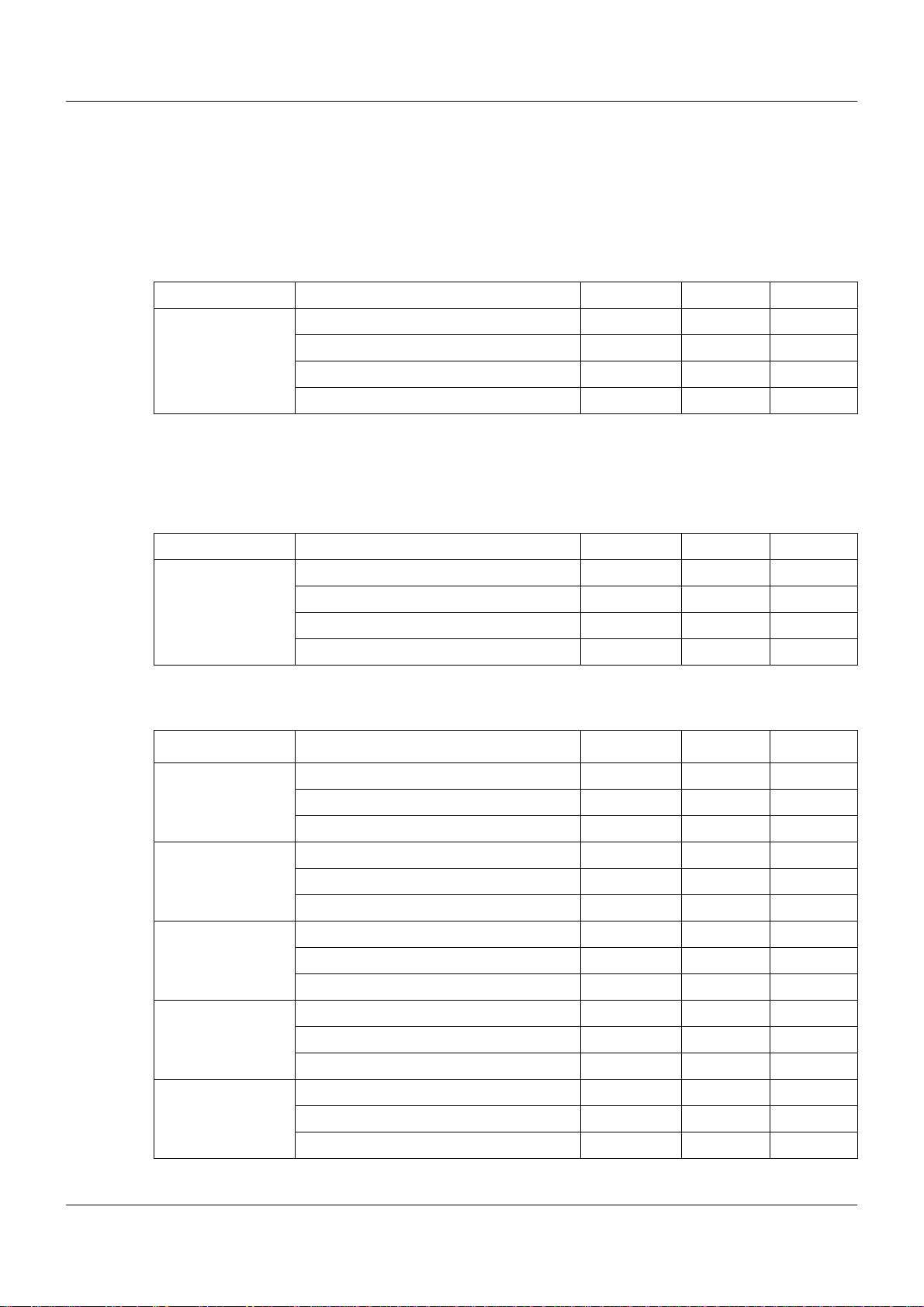

1.4.1 General information

Product Type of documentation No. Printed PDF file

Measuring,

control, and

automation system

1

Accessory subject to charge

2

Includes an overview of the purpose and content of all documents

1.4.2 Base units

Data sheet T 705000 - X

System manual

Setup program manual B 705000.6 - X

System description

1

2

1 Introduction

B 705000.0 X -

B 705000.8 - X

Product Type of documentation No. Printed PDF file

Central

processing unit

Data sheet T 705001 - X

Operating manual B 705001.0 - X

Modbus interface description B 705001.2.0 - X

Installation instructions B 705001.4 X X

1.4.3 Input/output modules

Product Type of documentation No. Printed PDF file

Multichannel

controller module

Relay module

4-channel

Analog

input module

4-channel

Data sheet T 705010 - X

Operating manual B 705010.0 - X

Installation instructions X X

Data sheet T 705015 - X

Operating manual B 705015.0 - X

Installation instructions B 705015.4 X X

Data sheet T 705020 - X

Operating manual B 705020.0 - X

Installation instructions B 705020.4 X X

Analog

input module

8-channel

Digital input/

output module

12-channel

Data sheet T 705021 - X

Operating manual B 705021.0 - X

Installation instructions B 705021.4 X X

Data sheet T 705030 - X

Operating manual B 705030.0 - X

Installation instructions B 705030.4 X X

21

Page 22

1 Introduction

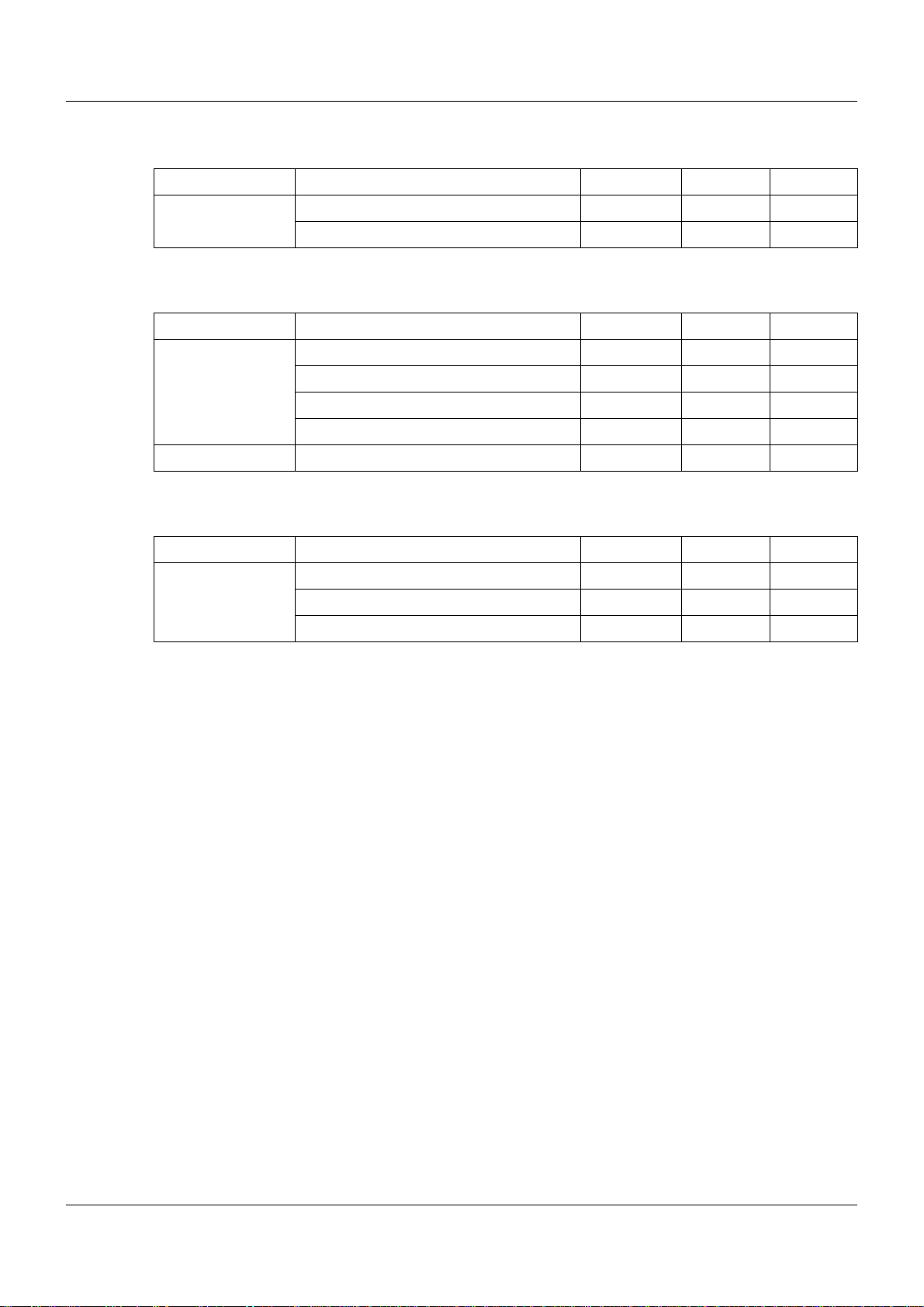

1.4.4 Special modules

Product Type of documentation No. Printed PDF file

Router module Data sheet T 705040 - X

Installation instructions B 705040.4 X X

1.4.5 Operating, visualization, recording

Product Type of documentation No. Printed PDF file

Multifunction

panel 840

Operating panels Data sheet T 705065 - X

Data sheet T 705060 - X

Operating manual B 705060.0 - X

Modbus interface description B 705060.2.0 - X

Installation instructions B 705060.4 X X

1.4.6 Power supply units

Product Type of documentation No. Printed PDF file

24 V power supply

units

Data sheet T 705090 - X

Operating instructions QS5.241 X Operating instructions QS10.241 X -

22

Page 23

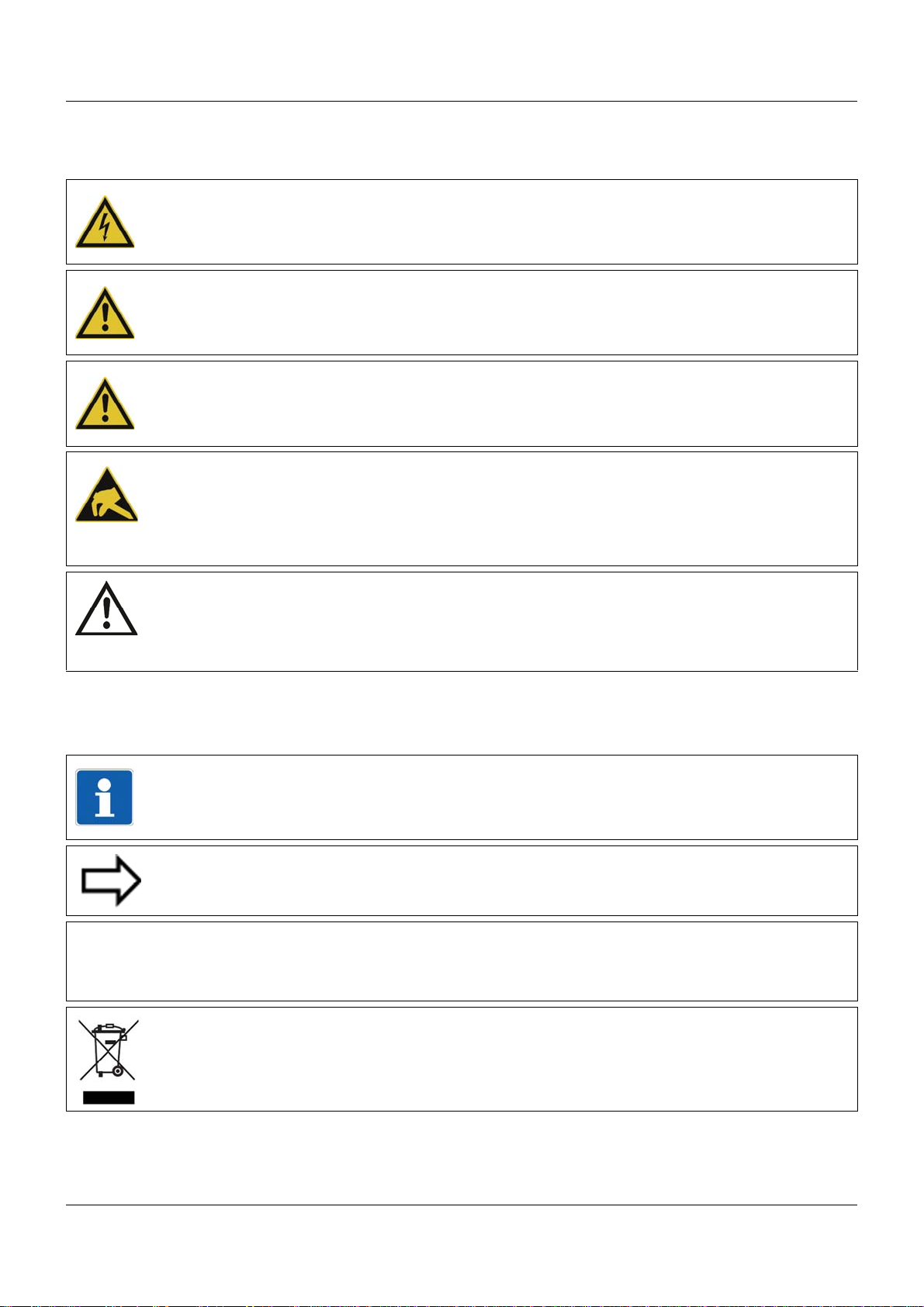

2.1 Warning symbols

&

DANGER!

This symbol indicates that personal injury caused by electrical shock may occur if the respective precautionary measures are not carried out.

WARNING!

This symbol in connection with the signal word indicates that personal injury may occur if the

respective precautionary measures are not carried out.

CAUTION!

This symbol in connection with the signal word indicates that damage to assets or data loss

will occur if the respective precautionary measures are not taken.

CAUTION!

This symbol indicates that components could be destroyed by electrostatic discharge

(ESD = Electro Static Discharge) if the respective cautionary measures are not taken.

Only use the ESD packages intended for this purpose to return device inserts, assembly

groups, or assembly components.

2 Safety information

READ DOCUMENTATION!

This symbol – placed on the device – indicates that the associated device documentation

has to be observed. This is necessary to recognize the kind of the potential hazards as

well as the measures to avoid them.

2.2 Note signs

NOTE!

This symbol refers to important information about the product, its handling, or additional

use.

REFERENCE!

This symbol refers to further information in other sections, chapters, or manuals.

FURTHER INFORMATION!

This symbol is used in the tables and refers to further information in connection with the

table.

DISPOSAL!

This device and the batteries (if installed) must not be disposed in the garbage can after

use! Please ensure that they are disposed properly and in an environmentally friendly

manner.

23

Page 24

2 Safety information

2.3 Intended use

The modules described are intended for measuring, control, an d automation t asks in an ind ustrial environment, as described in the technical data. Oth er uses or uses beyond th ose defined

are not viewed as intended uses.

The modules are built according to the relevant standards and directives as well as the applicable safety regulations. Nevertheless, incorrect use may lead to bodily injury or property damage.

To avoid danger, the modules may only be used:

• For the intended use

• When in good order and condition

• When taking into account the technical documentation provided

Even if a module is used correctly and according to the intended use, it may still cause appli-

cation-related dangers (e.g. due to missing safety devices or incorrect settings).

2.4 Qualification of personnel

This document contains the necessary information for the intended use of the modules to which

it relates.

It is intended for technically qualified personnel who have received special training and have

the appropriate knowledge in the field of automation technology (measuring, process, and control technology).

The appropriate level of knowledge and the technically fault-free implementation of the safety

information and warnings contained in the technical documentation provided are prerequisites

for risk-free mounting, installation, and startup as well as for ensuring safety when operating

the described modules. Only qualified personnel have the required specialist knowledge to correctly interpret and implement the safety information and warnings contained in this document

in specific situations.

24

Page 25

3 Acceptance of goods, storage, and transport

3.1 Checking the delivery

• Ensure that the packaging and contents are not damaged

• Check that the delivery is complete using the delivery papers and the order details

• Inform the supplier immediately if there is any damage

• Store damaged parts until clarification is received from the supplier

3.2 Notes on storage and transport

• Store the module in a dry and clean environment. Observe the admissible ambient conditions (see "Technical data")

• The transport of the module is to be shockproof

• The original packaging provides optimum protection for storage and transport

3.3 Returning goods

In the event of repair, please return the module in a clean and complete state.

Use the original packaging to return goods.

3.3.1 Accompanying letter for repair

Please include the completed accompanying letter for repair when returning goods.

Do not forget to state the following:

• Description of the application and

• Description of the error that has occurred

The accompanying letter for repair can be downloaded online from the manufacturer's website

(use the search function if necessary).

3.3.2 Protection against electrostatic discharge (ESD)

(ESD = electrostatic discharge)

To prevent damage from ESD, electronic modules or components must be handled, packaged,

and stored in an ESD-protected environment. Measures against electrostatic discharge and

electrical fields are described in DIN EN 61340-5-1 and DIN EN 6 1340-5-2 "Protection of electronic devices from electrostatic phenomena".

When returning electronic modules or components, please note the following:

• Sensitive components must only be packaged in an ESD-protected environment. Workspaces such as this divert electrostatic charges to ground in a controlled manner and prevent static charges due to friction capacities.

• Only use packaging for ESD-sensitive modules/components. These must consist of conductive plastics.

No liability can be assumed for damage caused by ESD.

25

Page 26

3 Acceptance of goods, storage, and transport

CAUTION!

Electrostatic charges occur in non-ESD protected environments.

Electrostatic discharges can damage modules or components.

For transport purposes, use only the ESD packaging provided.

3.4 Disposal

Disposing of the device

DISPOSAL!

Devices and/or replaced parts should not be placed in the refuse bin at the end of their service life as they consist of materials that can be recycled by specialist recycling plants.

Dispose of the device and the packaging material in a proper and environmentally friendly

manner.

For this purpose, observe the country-specific laws and regulations for waste treatment a nd

disposal.

Disposing of the packaging material

The entire packaging material (cardboard packaging, inserts, plastic film, and plastic bags) is

fully recyclable.

26

Page 27

4.1 Nameplates

(A) (B)

The position and content of the nameplates is explained below using the example of the multichannel controller module 705010.

Position

The nameplate (B) is affixed to the module case.

Additional nameplates with reduced information are located on the module insert (A) and inside

the module case (C; not shown). This duplicate identification marking via nameplates (A) and

(C) is important when replacing a module insert or retrofitting optional modules.

4 Identifying the device version

Content

The nameplates contain important information. This includes:

Device type

Compare the specifications on the nameplate with the order.

Identify the supplied device version using the order details of the respective module.

Part no. (TN)

The part no. clearly identifies an article in the catalog. It is important for communication

between the customer and the sales department.

Description Designation on the name-

plate

Device type (A + B + C) Typ 705010/18-113-36

Part no. (A + B + C) TN 00XXXXXX

Fabrication number (A + B + C) F-Nr 0070033801211010006

Voltage supply (B) - DC 24 V +25/-20 %

Example

27

Page 28

4 Identifying the device version

Fabrication no. (F-Nr)

Among other things, the fabrication number contains the date of production (year/week).

Example: F-Nr = 0070033801211010006

The figures concerned are in positions 12, 13, 14, and 15 (from the left).

The device was therefore produced in the 1st calendar week of 2011.

28

Page 29

4.2 Scope of delivery

1x module in the ordered version

1x cover for system bus (for central processing unit and router module)

2x end brackets for DIN rail (for central processing unit and router module)

1x installation instructions B 7050xx.4

1x mini-DVD with setup program (demo version), programming software CODESYS V3, and

detailed documentation on the central processing unit

If you have any questions, please contact the supplier!

4.3 Accessories

The following articles are subject to charge and must be ordered separately:

4.3.1 General accessories

4 Identifying the device version

Article Part no.

JUMO mTRON T system manual, English 00575577

MiniDVD with setup program (full version), programming sof tware CODESYS V3, a nd

detailed documentation; incl. USB cable

PC Evaluation Software PCA3000 00431882

Release automatic print for PC Evaluation Software PCA3000 00505548

PCA Communication Software PCC 00431879

Plant Visualization Software JUMO SVS3000: See data sheet 700755 USB cable A-plug mini-B-plug 3 m 00506265

4.3.2 Central processing unit

Accessories

Article Part no.

Interface modules (expansion boards):

RS232 Modbus RTU 00569505

RS422/485 Modbus RTU 00569506

PROFIBUS-DP (slave; as of system version 02 and as of the central processing unit‘s

production date 27/2013 (calendar week))

Extra codes (activations):

00569494

00569507

Math/logic module (activation for all connected controller modules) 00569509

PLC according to IEC 61131-3 (CODESYS V3) 00569510

Program generator 1 to 9 00569511

Program generator 1 to 9 with process steps (as of system version 02) 00606498

29

Page 30

4 Identifying the device version

4.3.3 Controller module

Accessories

Article Part no.

Modules for option slots (expansion boards):

Analog input 00569497

Relay (changeover contact) 00569498

2 relays (N/O contacts with common pole) 00569499

Analog output 00569500

2 digital inputs 00569501

Solid-state relay 1 A 00569502

2 open-collector outputs 00569503

30

Page 31

5 Installation

5.1 General information on installation/dismounting

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

Prior to the installation/dismounting of these modules or the removal of the module insert, the

load circuits are to be disconnected from the voltage and the terminal strips are to be removed from the module. This work must only be performed by qualified personnel.

WARNING!

The modules must never be installed in areas with an explosion hazard.

There is the risk of an explosion.

The entire system must only be used outside of areas with an explosion hazard.

Mounting site

All modules have protection type IP20 and are only intended for use in fireproof con trol cabinets

or switch boxes. The mounting site should be virtually vibration-free. Electromagnetic fields

caused by equipment such as motors or transformers should be avoided.

Multifunction panel 840 has protection type IP67 at the front and is intended for installation in

a panel cut-out. The rear has protection type IP20.

Climatic conditions

The ambient temperature and the relative humidity at the mounting site must correspond to the

technical data. Aggressive gases and vapors have a negative ef fect on the operating life of the

modules. The mounting site must be free from dust, powder, and other suspended matter so

that the cooling slots do not become blocked.

DIN rail

All modules are mounted on a DIN rail according to DIN EN 60715 (35 mm × 7.5 mm × 1 mm).

For reasons of stability, the spacing of the fastening screws for the DIN rail should not exceed

200 mm. The minimum distances for the modules that are specified in the module-specific installation or operating instructions must be observed.

Installation position

The DIN rail should be mounted horizontally so that all modules are arranged vertically. Otherwise the admissible ambient temperature range will be restricted.

Space requirement

The modules require the minimum distances shown in the following figure for the purpose of

installation/dismounting and for future maintenance or replacement. In the event of shorter distances the minimum bending radius of the cables, the performance of the electrical inst allation,

and the clear arrangement of the plant are no longer guaranteed.

Installation instructions of the individual modules

31

Page 32

5 Installation

5.2 Module sequence

5.2.1 System with centralized module assignment

Example: Central processing unit with input/output modules

The central processing unit (A) is required for this purpose. It contains all configuration, parameter, and pro cess data of the entire system and the customer-specific PLC a pplication (if applicable). All modules are mounted to the right; the sequence is at the user's discretion. They are

snapped on to the DIN rail and moved to the left against the central processing unit or the previous module until the plug connections for the voltage supply and the system bus are connected. Any distance between two modules is not allowed.

A maximum of 30 input/output modules can be managed by one central processing unit.

Cover

Once all modules are installed the cover (B) must be positioned on the DIN rail from the right

and moved to the left against the final module (B1). It protects the contacts of the final module

against touching and contamination.

The cover is included in the scope of delivery of the central processing unit and therefore does

not need to be ordered separately.

End brackets

The final mechanical element of the DIN rail is formed by an end bracket (C) on each side. The

right end bracket is positioned on the DIN rail from the outside, moved to the left against the

cover (C2), and fastened with a screwdriver (C3). The left end bracket is mounted according to

the same principle following the installation of the central processing unit.

The end brackets are included in the scope of delive ry of the central processing unit and therefore do not need to be ordered separately.

32

Page 33

5.2.2 System with decentralized module assignment

Example: Modules on multiple DIN rails

5 Installation

A router module (A) is required for the construction of a decentralized measuring, control, and

automation system. This is the case, for example, if not all modules fit on a DIN rail, or if modules must be mounted at a distance of more than 100 m from the central processing unit or an

upstream router module.

Cover

Once all modules are installed, the cover (B) must be positioned on the DIN rail from the right

and moved to the left against the final module (B1). It protects the contacts of the final module

against touching and contamination.

The strand with the router module is provided with a cover in the same manner.

The cover is included in the scope of delivery of the central processing unit and the router mod-

ule. It therefore does not need to be ordered separately.

End brackets

The final mechanical element of the DIN rail is formed by an end bracket (C) on each side. The

right end bracket is positioned on the DIN rail from the outside, moved to the left against the

cover (C2), and fastened with a screwdriver (C3). The left end bracket is mounted according to

the same principle following the installation of the central processing unit.

The strand with the router module is provided with end brackets in the same manner.

The end brackets are included in the scope of delivery of the central processing unit and the

router module and therefore do not need to be ordered separately.

NOTE!

Therefore, the arrangement of modules on various DIN rails may also be required in order to

differentiate between optional and mandatory modules (see setup program manual

B 705000.6, Section "System bus": Alias device address).

33

Page 34

5 Installation

5.3 Installation/dismounting on DIN rail

All modules in the system are intended for installation on a DIN rail according to DIN EN 60715

(35mm×7.5mm×1mm).

The following must always be installed on the left, at the start of the DIN rail:

• A central processing unit or

• A router module

These modules connect the input/output modules to the voltage supply and the system bus.

NOTE!

To determine the required minimum width of the DIN rail, the widths of the individual modules

are to be added (see technical data of the modules in the respective data sheet or the

module-specific installation instructions).

The widths of the cover (17.5 mm) and both end brackets (each 9.5 mm) should also be

taken into consideration: 17.5 mm + 2 × 9.5 mm = 36.5 mm.

34

Page 35

5 Installation

(A)

(A2)

(A1)

(B)

(B3)

(B4)

5.3.1 Base units

Installation of a base unit, using the example of a central processing unit 705001

Installing the end brackets

Procedure:

Step Activity

1 Mount the central processing unit (A) on the DIN rail from below and press upward (A1).

2 Pivot the central processing unit (A) toward the rear until it snaps into place (A2).

3 Position the end bracket (B) on the DIN rail and move to the right against the central pro-

cessing unit (B3). Fasten the end bracket using a screwdriver (B4).

35

Page 36

5 Installation

(A) (C) (D)

(C3)

(D2)

(B)

(B4) (B4)

(B)

(A)

(E1)

(E)

(A6)

(A5)

Dismounting a base unit, using the example of a central processing unit 705001

Removing the central processing unit from the DIN rail

36

Procedure:

Step Activity

1 Remove the connection cables if required (Setup, LAN, Bus Out).

2 If required, use a screwdriver to release the wired terminal (E) of the central processing unit

(A) and pull off toward the front (E1).

3 Fully release the end bracket (D) using a screwdriver (D2), press upward from below, pivot

toward the front, and remove from the DIN rail.

Note: The end bracket does not need to be removed from the DIN rail if there is sufficient

space to the side to move it at least 10 mm to the right.

Page 37

5 Installation

Step Activity

4 Move the cover (C) to the right (C3) until the sid e co ntacts of the neighb or ing modu le are

exposed. Then release the cover at the bottom using a screwdriver, press upward, and

remove from the DIN rail.

Note: The cover does not need to be removed from the DIN rail if there is sufficient space

to the side to move it at least 10 mm to the right.

5 Move the modules (B) on the right next to the central processing unit (A) to the right (B4)

until the side contacts of the central processing unit are exposed.

➥ These modules are isolated from the voltage supply and the system bus.

6 Press the central processing unit (A) upward from underneath (A5), pivot off the DIN rail

toward the front (A6), and remove.

37

Page 38

5 Installation

(A) (A1)

(A2)

(D)

(C5) (D6)

(D7)

(C)(A)

(B4)(A3)

(B)

5.3.2 Input/output modules

In a sequence at the user's discretion, input/output modules can be arranged to the right next

to a base unit or a router module.

Installation, using the example of a multichannel controller module 705010

Example installation

Procedure:

Step Activity

1 Mount the multichannel controller module (A) in the DIN rail from above (A1).

2 Pivot the multichannel controller module (A) downward until it snaps into place (A2).

3 Move the multichannel controller module (A) to the left against the previous module (A3)

until the plug connections for the voltage supply and the system bus are connected.

38

4 Position additional modules (B) and move to the left against the previous module (B4).

5 After the final module, position the cover (C) on th e DIN rail and move to the lef t against the

module (C5).

Page 39

5 Installation

Step Activity

6 After attaching the cover, position the end bracket (D) on the DIN rail and move to the left

against the cover (D6).

7 Fasten the end bracket (D) using a screwdriver (D7). For this purpose, ensure that the end

bracket and the cover are positioned flush against the final module.

39

Page 40

5 Installation

(C2)

(D1)

(A4) (B3)

(C) (D)

(A) (B)

(A)

(F)

(E)

(E5)

(F7)

(A6)

(A8)

Dismounting, using the example of a multichannel controller module 705010

Removing the multichannel controller module from the DIN rail

40

Procedure:

Step Activity

1 Fully release the end bracket (D) using a screwdriver (D1), press upward from below, pivot

2 Move the cover (C) to the right (C2) until the sid e co ntacts of the neighb or ing modu le are

toward the front, and remove from the DIN rail.

Note: The end bracket does not need to be removed from the DIN rail if there is sufficient

space to the side to move it at least 20 mm to the right.

exposed. Then release the cover at the bottom using a screwdriver, press upward, and

remove from the DIN rail.

Note: The cover does not need to be removed from the DIN rail if there is sufficient space

to the side to move it at least 20 mm to the right.

Page 41

5 Installation

Step Activity

3 Move the modules (B) on the right next to the multichannel controller module that is to be

replaced (A) a minimum of 20 mm to the right (B3).

➥ These modules are isolated from the voltage supply and the system bus.

4 Move the multichannel controller module (A) to the right (A4) until the side contacts of the

neighboring module (here: central processing unit) – on the left, next to the multichannel

controller module that is to be replaced – are exposed.

➥ The multichannel controller module is isolated from the voltage supply and the system

bus. This is a prerequisite for the dismounting of the multichannel controller module.

5 If required, pull off the wired terminals (E) of the multichannel controller module (A) toward

the front (E5).

6 Insert a suitable screwdriver (F) into the unlocking slot of the multichannel controller mod-

ule (A6) and press upward (F7).

7 Pivot the multichannel controller module (A) upward off the DIN rail (A8) and remove it.

41

Page 42

5 Installation

(A1)

(A2)

(B)

(A)

(B3)

(B4)

(A)

5.3.3 Special modules

Installation, using the example of a router module 705040

Procedure:

Step Activity

1 Mount the router module (A) in the DIN rail from above (A1).

2 Pivot the router module (A) downward until it snaps into place (A2).

3 Position the end bracket (B) on the DIN rail and move to th e right against the router module

(B3).

4 Fasten the end bracket (B) using a screwdriver (B4). For this purpose, ensure that the end

bracket is positioned flush against the router module.

42

Page 43

Dismounting, using the example of a router module 705040

(A)(B)

(A3)

(B2)

(A)

(C)

(D)

(D1)

(C5)

(A4)

(A6)

Removing the router module from the DIN rail

5 Installation

Procedure:

Step Activity

1 Remove the connection cables if required (Bus In, Bus Out1, Bus Out2).

2 If required, use a screwdriver to release the wired terminal (D) of the router module (A) and

3 Fully release the end bracket (B) using a screwdriver (B2), press upward from below, pivot

➥ The router module, all modules on the right next to the router module, and, where appli-

cable, additional devices connected via Bus Out1 or Bus Out2 (router modules, multifunction panel) are isolated from the system bus.

pull off toward the front (D1).

➥ The connection to the voltage supply is isolated.

toward the front, and remove from the DIN rail.

Note: The end bracket does not need to be removed from the DIN rail if there is sufficient

space to the side to move it at least 10 mm to the left.

43

Page 44

5 Installation

Step Activity

4 Move the router module (A) to the left (A3) until the side contacts on the right side of the

5 Insert a suitable screwdriver (C) into the unlocking slot of the router module (A4) and press

6 Pivot the router module (A) upward off the DIN rail (A6) and remove it.

router module are exposed.

upward (C5).

44

Page 45

5.4 Mounting in a panel

(A)

(B)

(B2)

(A1)

(C)

(C)

(C3)

(C3)

(D)

(D4)

(C)

(C)

(C)

(C)

(C)

(C)

(C3)

(C3)

(C3)

(C3)

(C3)

(C3)

(B2)

(B)

5.4.1 Multifunction panel

Mounting a multifunction panel 840 (705060)

5 Installation

Procedure:

Step Activity

1 Insert the device (A) into the panel cut-out (A1) fr om the fron t until the two side spr ing balls

(B) click into place (B2). The spring balls facilitate the mounting, but do not replace the fastening elements (step 2).

2 Insert the fastening elements (C) into the recesses of the case (C3) and use a screwdriver

(D) to evenly clamp them against the rear side of the panel with a torque of 0.5 Nm (D4).

NOTE!

The provided template is to be used to create the panel cut-out. This is the only way to guarantee optimum positioning of the multifunction panel.

45

Page 46

5 Installation

(A)

(E)

(B) (D)

(G)

(C)

(F)

(F)

(F)

5.5 Replacing module inserts

5.5.1 Input/output modules

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

The load circuits are to be disconnected from the voltage supply prior to removing the wired

terminal strips. This work must only be performed by qualified personnel.

Replacement of a module insert, using the example of a multichannel controller module 705010

46

For service purposes (or when retrofitting options for the multichannel controller module), the

case (D) can remain in the system; only the module insert (B) is replaced. For this purpose, the

system does not need to be isolated from the voltage supply (hot swapping).

The system will detect a module insert of the same type that has been replaced and will automatically reconfigure it. Retrofitted functions for the multichannel controller module (exp ansion

slots) must be configured using the setup program or the multifunction panel.

The new module insert also has a new nameplate (G), which will dif fer from the old one at le ast

with regard to the fabrication number, and is no longer identical to nameplates (E) and (C) on

the case (D).

Therefore, in the event of replacement, the module insert will be supplied along with a new

nameplate that will be affixed to the case (D) in place of the old nameplate (C). This means that

the specifications of nameplates (G) and (C) once again correspond to one another.

Page 47

CAUTION!

Only module inserts of the same type may be used for the replacement.

Otherwise, the function of the system may be affected.

The module inserts can be clearly identified using the nameplate.

CAUTION!

With the multichannel controller module 705010, a new modu le insert may contain retrofitted

inputs or outputs that have not yet been configured.

This can lead to unintended behavior, particularly at the outputs and the actuators connected

to them.

Prior to using the retrofitted inputs or outputs, ensure that these have been configured correctly.

Removing the module insert

Step Activity

1 Disconnect load circuits from the relay or solid state relay outputs.

2 Pull off the wired terminal strips (A) toward the front.

5 Installation

3 Press the old module insert (B) toge ther on the gro oved surfaces at the to p and bottom and

remove from the case (D).

4 For the multichannel controller module, also remove the modules (F) of th e expansion slot s

from the case (D) toward the front, if required.

Mounting the module insert

Step Activity

1 Affix the new nameplate in place of the old nameplate (C) in the case.

2 For the multichannel controller module, also insert the modules (F) of the expansion slots

into the case (D), if required.

3 Hold the new module insert (B) at the grooved surfaces on the top and bottom and insert

them into the case (D). For this purpose, ensure that the board of the module insert slides

into the guide rails of the case. For the multichannel controller module, also ensure that the

modules (F) of the expansion slots slide in the guide rails of the module insert.

4 Reattach the wired terminal strips (A).

NOTE!

When mounting the module insert, ensure that the snap holders (under the grooved surfaces)

audibly snap into place.

NOTE!

The availability of the system can be increased through the storage of module inserts and

modules for expansion slots.

47

Page 48

5 Installation

(A)

(E)

(B) (D)

(F)

(C)

5.5.2 Special modules

Replacing the module insert of a router module 705040

For service purposes, the case (D) can remain in the system; only the module insert (B) is replaced. Thanks to the hot connect functionality of the router module, this can even be performed during operation with the corresponding configuration (alias device address).

The new module insert also has a new nameplate (F), which differs from the old one at least

with regard to the fabrication number and is no longer identical to nameplates (E) and (C) on

the case (D).

Therefore, in the event of replacement, the module insert will be supplied along with a new

nameplate that will be affixed to the case (D) in place of the old nameplate (C). This means that

the specifications of nameplates (F) and (C) once again correspond to one another.

Removing the module insert

Step Activity

1 Pull off the connection cables if required (Bus In, Bus Out1, Bus Out2).

2 Pull off the wired terminal strip (A) toward the front.

3 Press the old module insert (B) toge ther on the gro oved surfaces at the to p and bottom and

remove from the case (D).

48

Page 49

Mounting the module insert

Step Activity

1 Affix the new nameplate in place of the old nameplate (C) in the case.

2 Hold the new module insert (B) at the grooved surfaces on the top and bottom and insert

them into the case (D). For this purpose, ensure that the board of the module insert slides

into the guide rails of the case.

3 Reattach the wired terminal strip (A).

4 Reconnect the connection cables if required (Bus In, Bus Out1, Bus Out2).

NOTE!

When mounting the module insert, ensure that the snap holders (under the grooved surfaces)

audibly snap into place.

NOTE!

The availability of the system can be increased through the storage of module inserts.

5 Installation

49

Page 50

5 Installation

50

Page 51

6.1 Installation notes

NOTE!

These installation notes apply for the entire measuring, control, and automation system and,

on some occasions, are only applicable for a specific module.

The respective connection diagram shows the context.

Requirements for the personnel

• Work o n the modules must only be carried out to the extent described and, like the electrical

connection, only by qualified personnel.

• Before plugging and unplugging connection cables ensure that the person performing the

work is electrostatically discharged (e.g. by touching grounded metallic parts).

Cables, shielding, and grounding

• When selecting the cable material, when insta lling, and when performing the electrical connection of the module, the regulations of DIN VDE 0100 "Erection of power installations with

rated voltages up to 1000 V" and the respective national regulations (e.g. on the basis of

IEC 60364) are to be observed.

• Certain cables must be heat resistant up to at least 80 °C at maximum load. The relevant

instructions in the connection diagram of the affected modules must be observed.

• Route input, output, and supply cables separately and not parallel to one another.

• Only use shielded and twisted probe and interface cables. Do not route the lines close to

current-carrying components or cables.

• For temperature probes, ground the shielding on one side in the control cabinet.

• Do not perform loopthroug hs on the grounding cables, but route the cables individua lly to a

shared grounding point in the control cabinet; in doing so, ensure that the cables are as

short as possible.

Ensure that the equipotential bonding is correct.

6 Electrical connection

Electrical safety

• Isolate power supply units from the voltage supply on the primary side if there is a risk of

touching parts with dangerous electrical voltage (e.g. 230 V) in the course of work.

• The fuse rating of the power supply units on the primary sid e should not exceed a value of

10 A (inert).

• With modules with relay or solid state relay outputs, the load circuits can be operated with

a dangerous electrical voltage (e.g. 230 V). Disconnect load circuits from the voltage supply

during installation/dismounting and electrical connection.

• In order to prevent the destruction of the relay or solid st ate relay output s in the event of an

external short circuit in the load circuit, the load circuit should be fused to the maximum admissible output current.

• The modules are not suitable for installation in areas with an explosion hazard.

• In addition to a faulty inst allation, incorrectly set values on the module could also imp air the

correct function of the following process. Therefore, ensure that safety devices independent

of the module (e.g. overpressure valves or temperature limiters/monitors) are available and

that it is only possible for qualified personnel to define settings. Please observe the corresponding safety regulations in this context.

51

Page 52

6 Electrical connection

References to other information

• The electromagnetic compatibility meets the standards and regulations cited in the technical data.

• The USB device interface and volt age supply in the central processing unit 705001 a re not

electrically isolated. In general, please observe the specifications regarding electrical isolation.

52

Page 53

6.2 Electrical isolation

Central processing unit 705001

USB device

System bus Out 1

Ethernet

Com 1

Com 2

System bus

24 V

AC 1500 V

~

~

AC 1500 V

~

~

AC 30, DC 50 V

~

~

AC 30, DC 50 V

~

~

Multichannel controller module 705010

Analog input 1

AC 3800 V

Option 1

Option 2

Option 3

Analog input 2

Relay output 3

Relay output 4

Digital input 1 to 2

AC 30 V, DC 50 V

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

Options for the multichannel

controller module 705010

Analog input 3

Digital output 3

Input/output modules

Base units

AC 30 V, DC 50 V

AC 3800 V

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

Digital output 4

~

~

AC 30 V, DC 50 V

Analog input 4

Digital input 7 to 8

Digital input 5 to 6

Analog output 3

Analog output 1

...

Relay output 10

Relay output 5

...

Open-collector output 9 to 10

Open-collector output 5 to 6

Solid state relay output 10

Solid state relay output 5

~

~

AC 3800 V

~

~

AC 800 V (peak)

~

~

AC 30 V, DC 50 V

Relay module 4-channel 705015

Relay output 1

AC 3800 V

~

~

~

~

Relay output 4

Digital input 9 to 10

Analog output 2

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

~

~

AC 3800 V

~

~

~

~

AC 30 V, DC 50 V

~

~

AC 30 V, DC 50 V

AC 800 V (peak)

AC 3800 V

...

Open-collector output 7 to 8

6 Electrical connection

53

Page 54

6 Electrical connection

Analog input module 4-channel 705020

~

~

Digital input

AC 30 V, DC 50 V

Analog input module 8-channel 705021

~

~

~

~

Router module 705040

System bus In AC 500 V

~

~

System bus Out 1

AC 500 V

~

~

System bus

24 V

Voltage supply

Power supply units 24 V 705090

DC 24 V

3800 V

AC 230 V

~

~

SELV DIN EN 50178

...

Analog input 1

Analog input 4

Special modules

Multifunction panel 840 705060

Operating, visualization, recording

Com 1

Com 2

USB host

USB device

Ethernet

System bus In

AC 30, DC 50 V

~

~

AC 1500 V

~

~

AC 1500 V

~

~

AC 30 V, DC 50 V

Digital input/output module 12-channel 705030

~

~

Digital input/output 1 to 12

AC 30 V, DC 50 V

System bus Out 2

AC 500 V

~

~

System bus Out

AC 1500 V

~

~

AC 30, DC 50 V

~

~

AC 30, DC 50 V

~

~

AC 30, DC 50 V

~

~

~

~

AC 30 V, DC 50 V

AC 30 V, DC 50 V

Digital input

Analog input 1 to 8

~

~

AC 30 V, DC 50 V

54

Page 55

6 Electrical connection

Setup

LAN Bus Out