Page 1

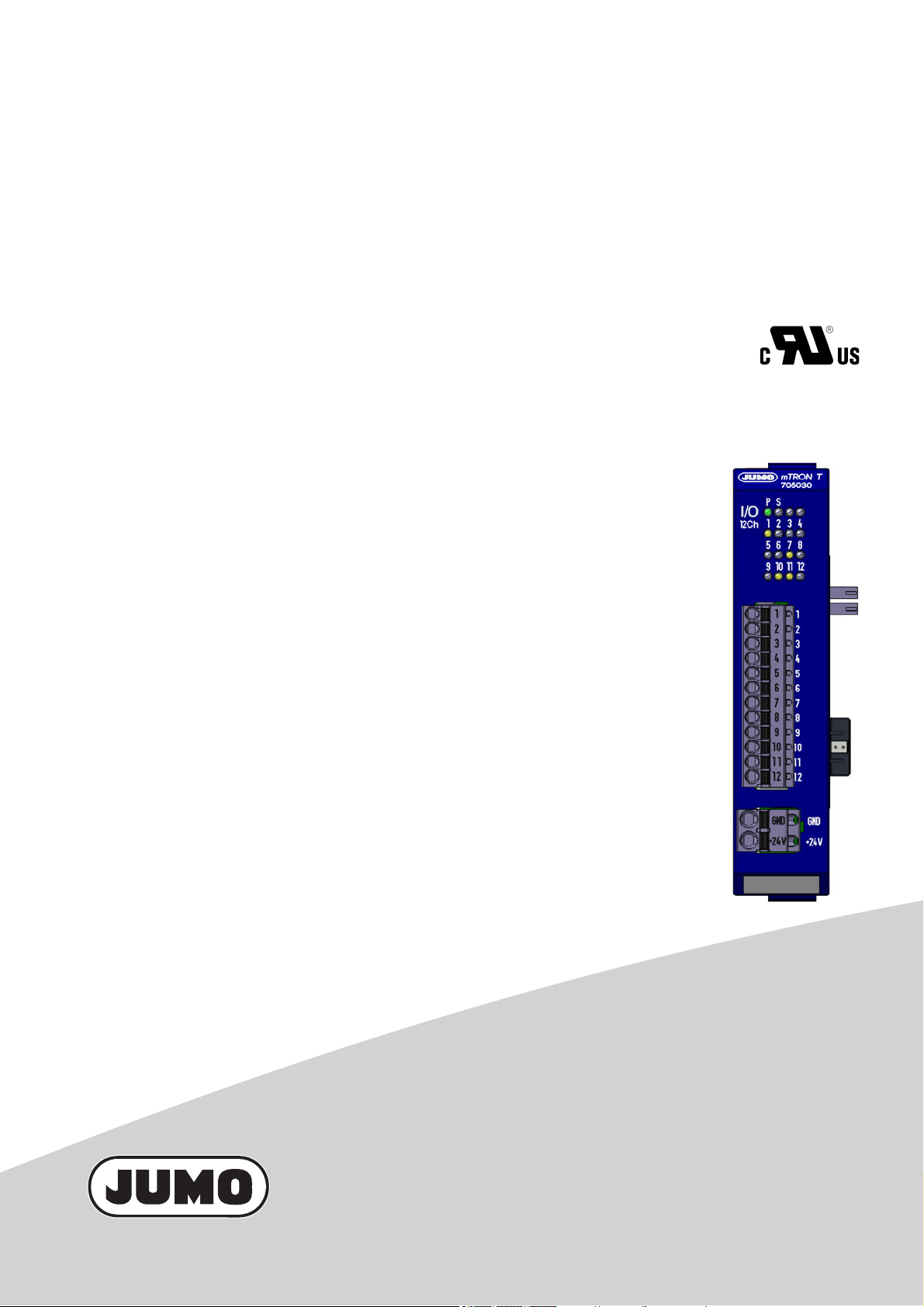

JUMO mTRON T

Measuring, Control, and Automation System

Digital Input/Output Module 12-Channel

B 705030.0

Operating Manual

2014-01-20/00575632

Page 2

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Available technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.2 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.3 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.4 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.5 Operating, visualization, recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.6 Power supply units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Warning symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Note signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.4 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Acceptance of goods, storage, and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Notes on storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 Returning goods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Identifying the Device Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.1 Nameplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.2 Order details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.4 General accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.1 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1 General information on installation/dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Installation/dismounting on DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Replacing module inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3.1 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.1 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Electrical isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.1 Display and connection elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3.2 Digital input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.3 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3

Page 4

Contents

4.4 Functional test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.1 Display and connection elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 LED displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.1 Display modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.2 System states and errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.1 Digital inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1.1 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 NV connecting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.1 Digital signals (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.2 Replacement values (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Online parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.1 Calibrate / test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.1 Digital output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.2 Digital input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1.3 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1.1 Digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1.2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1.3 Case and ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.1.4 Approval/approval marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4

Page 5

1.1 Available technical documentation

The documents specified below are available for the measuring, control, and automation system.

1.1.1 General information

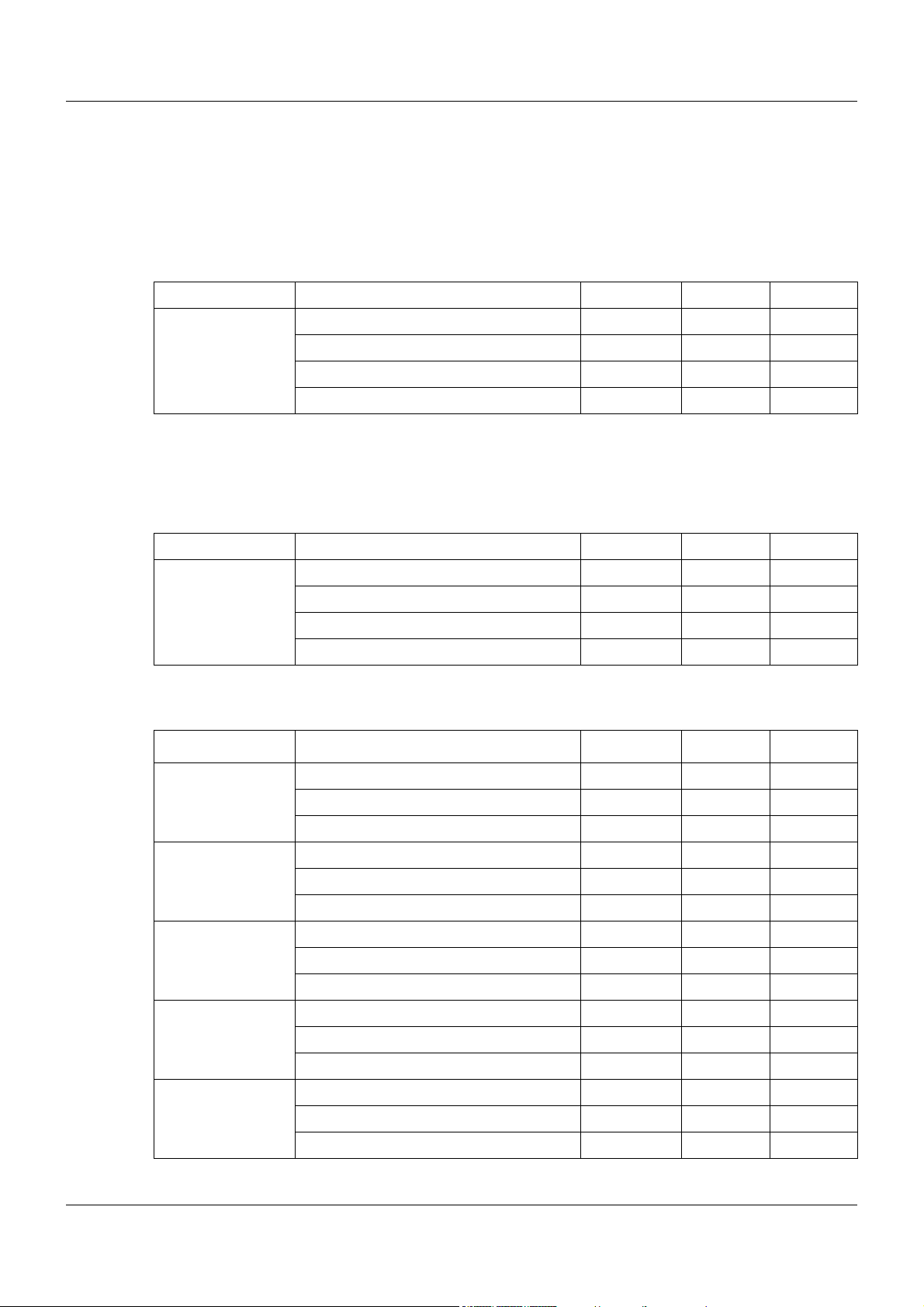

Product Type of documentation No. Printed PDF file

Measuring,

control, and

automation system

1

Accessory subject to charge

2

Includes an overview of the purpose and content of all documents

1.1.2 Base units

Data sheet T 705000 - X

System manual

Setup program manual B 705000.6 - X

System description

1

2

1 Introduction

B 705000.0 X -

B 705000.8 - X

Product Type of documentation No. Printed PDF file

Central

processing unit

Data sheet T 705001 - X

Operating manual B 705001.0 - X

Modbus interface description B 705001.2.0 - X

Installation instructions B 705001.4 X X

1.1.3 Input/output modules

Product Type of documentation No. Printed PDF file

Multichannel

controller module

Relay module

4-channel

Analog

input module

4-channel

Data sheet T 705010 - X

Operating manual B 705010.0 - X

Installation instructions B 705010.4 X X

Data sheet T 705015 - X

Operating manual B 705015.0 - X

Installation instructions B 705015.4 X X

Data sheet T 705020 - X

Operating manual B 705020.0 - X

Installation instructions B 705020.4 X X

Analog

input module

8-channel

Digital input/

output module

12-channel

Data sheet T 705021 - X

Operating manual B 705021.0 - X

Installation instructions B 705021.4 X X

Data sheet T 705030 - X

Operating manual B 705030.0 - X

Installation instructions B 705030.4 X X

5

Page 6

1 Introduction

1.1.4 Special modules

Product Type of documentation No. Printed PDF file

Router module Data sheet T 705040 - X

Installation instructions B 705040.4 X X

1.1.5 Operating, visualization, recording

Product Type of documentation No. Printed PDF file

Multifunction

panel 840

Data sheet T 705060 - X

Operating manual B 705060.0 - X

Modbus interface description B 705060.2.0 - X

Installation instructions B 705060.4 X X

1.1.6 Power supply units

Product Type of documentation No. Printed PDF file

24 V power supply

units

Data sheet T 705090 - X

Operating instructions QS5.241 X -

Operating instructions QS10.241 X -

6

Page 7

1.2 Safety information

&

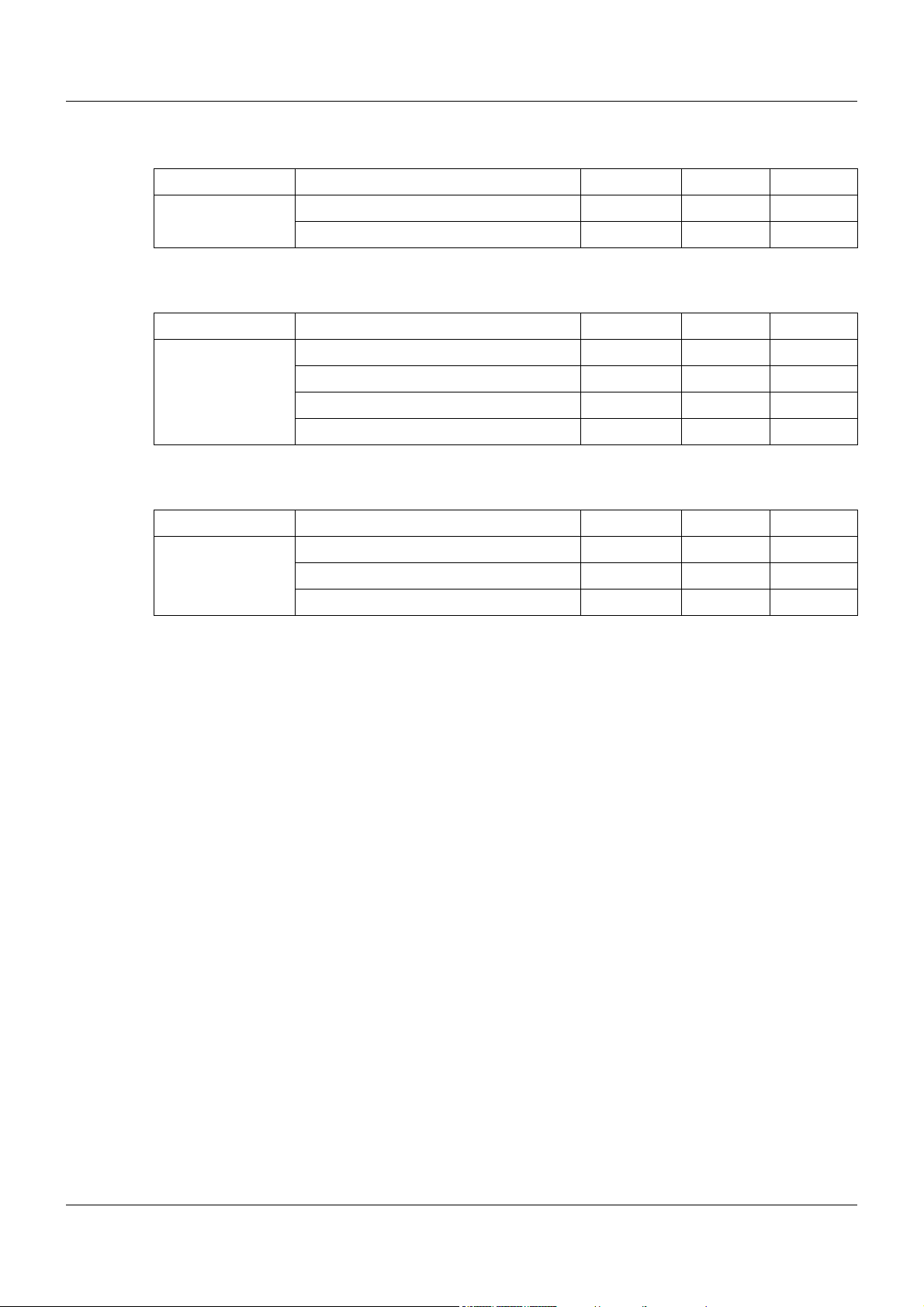

1.2.1 Warning symbols

DANGER!

This symbol indicates that personal injury caused by electrical shock may occur if the re-

spective precautionary measures are not carried out.

WARNING!

This symbol in connection with the signal word indicates that personal injury may occur if the

respective precautionary measures are not carried out.

CAUTION!

This symbol in connection with the signal word indicates that damage to assets or data loss

will occur if the respective precautionary measures are not taken.

CAUTION!

This symbol indicates that components could be destroyed by electrostatic discharge

(ESD = Electro Static Discharge) if the respective cautionary measures are not taken.

Only use the ESD packages intended for this purpose to return device inserts, assembly

groups, or assembly components.

1 Introduction

READ DOCUMENTATION!

This symbol – placed on the device – indicates that the associated device documentation

has to be observed. This is necessary to recognize the kind of the potential hazards as

well as the measures to avoid them.

1.2.2 Note signs

NOTE!

This symbol refers to important information about the product, its handling, or additional

use.

REFERENCE!

This symbol refers to further information in other sections, chapters, or manuals.

FURTHER INFORMATION!

This symbol is used in the tables and refers to further information in connection with the

table.

DISPOSAL!

This device and the batteries (if installed) must not be disposed in the garbage can after

use! Please ensure that they are disposed properly and in an environmentally friendly

manner.

7

Page 8

1 Introduction

1.2.3 Intended use

The modules described are intended for measuring, control, and automation tasks in an industrial environment, as described in the technical data. Other uses or uses beyond those defined

are not viewed as intended uses.

The modules are built according to the relevant standards and directives as well as the applicable safety regulations. Nevertheless, incorrect use may lead to bodily injury or property damage.

To avoid danger, the modules may only be used:

• For the intended use

• When in good order and condition

• When taking into account the technical documentation provided

Even if a module is used correctly and according to the intended use, it may still cause application-related dangers (e.g. due to missing safety devices or incorrect settings).

1.2.4 Qualification of personnel

This document contains the necessary information for the intended use of the modules to which

it relates.

It is intended for technically qualified personnel who have received special training and have

the appropriate knowledge in the field of automation technology (measuring, process, and control technology).

The appropriate level of knowledge and the technically fault-free implementation of the safety

information and warnings contained in the technical documentation provided are prerequisites

for risk-free mounting, installation, and startup as well as for ensuring safety when operating

the described modules. Only qualified personnel have the required specialist knowledge to correctly interpret and implement the safety information and warnings contained in this document

in specific situations.

8

Page 9

1.3 Acceptance of goods, storage, and transport

1.3.1 Checking the delivery

• Ensure that the packaging and contents are not damaged

• Check that the delivery is complete using the delivery papers and the order details

• Inform the supplier immediately if there is any damage

• Store damaged parts until clarification is received from the supplier

1.3.2 Notes on storage and transport

• Store the module in a dry and clean environment. Observe the admissible ambient conditions (see "Technical data")

• The transport of the module is to be shockproof

• The original packaging provides optimum protection for storage and transport

1.3.3 Returning goods

In the event of repair, please return the module in a clean and complete state.

Use the original packaging to return goods.

1 Introduction

Accompanying letter for repair

Please include the completed accompanying letter for repair when returning goods.

Do not forget to state the following:

• Description of the application and

• Description of the error that has occurred

The accompanying letter for repair can be downloaded online from the manufacturer's website

(use the search function if necessary).

Protection against electrostatic discharge (ESD)

(ESD = electrostatic discharge)

To prevent damage from ESD, electronic modules or components must be handled, packaged,

and stored in an ESD-protected environment. Measures against electrostatic discharge and

electrical fields are described in DIN EN 61340-5-1 and DIN EN 61340-5-2 "Protection of electronic devices from electrostatic phenomena".

When returning electronic modules or components, please note the following:

• Sensitive components must only be packaged in an ESD-protected environment. Workspaces such as this divert electrostatic charges to ground in a controlled manner and prevent static charges due to friction capacities.

• Only use packaging for ESD-sensitive modules/components. These must consist of conductive plastics.

No liability can be assumed for damage caused by ESD.

9

Page 10

1 Introduction

CAUTION!

Electrostatic charges occur in non-ESD protected environments.

Electrostatic discharges can damage modules or components.

For transport purposes, use only the ESD packaging provided.

1.3.4 Disposal

Disposing of the device

DISPOSAL!

Devices and/or replaced parts should not be placed in the refuse bin at the end of their service life as they consist of materials that can be recycled by specialist recycling plants.

Dispose of the device and the packaging material in a proper and environmentally friendly

manner.

For this purpose, observe the country-specific laws and regulations for waste treatment and

disposal.

Disposing of the packaging material

The entire packaging material (cardboard packaging, inserts, plastic film, and plastic bags) is

fully recyclable.

10

Page 11

1.4 Identifying the Device Version

(B)

(A)

1.4.1 Nameplates

Position

The nameplate (B) is affixed to the module case.

An additional nameplate with reduced information is located on the module insert (A). This

duplicate identification is important when replacing a module insert or retrofitting optional modules.

1 Introduction

Contents

It contains important information. This includes:

Device type

Compare the specifications on the nameplate with the order.

Identify the supplied device version using the order details of the respective module.

Part no. (TN)

The part no. clearly identifies an article in the catalog. It is important for communication

between the customer and the sales department.

Description Designation on the name-

plate

Device type (A + B) Typ 705030/36

Part no. (B) TN 00XXXXXX

Fabrication number (A + B) F-Nr 0070033801211010006

Voltage supply (B) - DC 24 V +25/-20 %

Example

11

Page 12

1 Introduction

Fabrication no. (F-Nr)

Among other things, the fabrication number contains the date of production (year/week).

Example: F-Nr = 0070033801211010006

The figures concerned are in positions 12, 13, 14, and 15 (from the left).

The device was therefore produced in the 1st calendar week of 2011.

1.4.2 Order details

(1) Basic type

705030 Digital input/output module 12-channel

(2) Voltage supply

36 DC 24 V +25/-20 %

(1) (2)

Order code /

Order example 705030 / 36

1.4.3 Scope of delivery

1 digital input/output module, 12-channel

1 Installation Instructions B 705030.4

1.4.4 General accessories

Article Part no.

JUMO mTRON T system manual, English 00575577

MiniDVD with setup program (full version), programming software CODESYS V3, and

detailed documentation; incl. USB cable

PC Evaluation Software PCA3000 00431882

Release automatic print for PC Evaluation Software PCA3000 00505548

PCA Communication Software PCC 00431879

Plant Visualization Software JUMO SVS3000: See data sheet 700755 -

USB cable A-plug mini-B-plug 3 m 00506265

00569494

12

Page 13

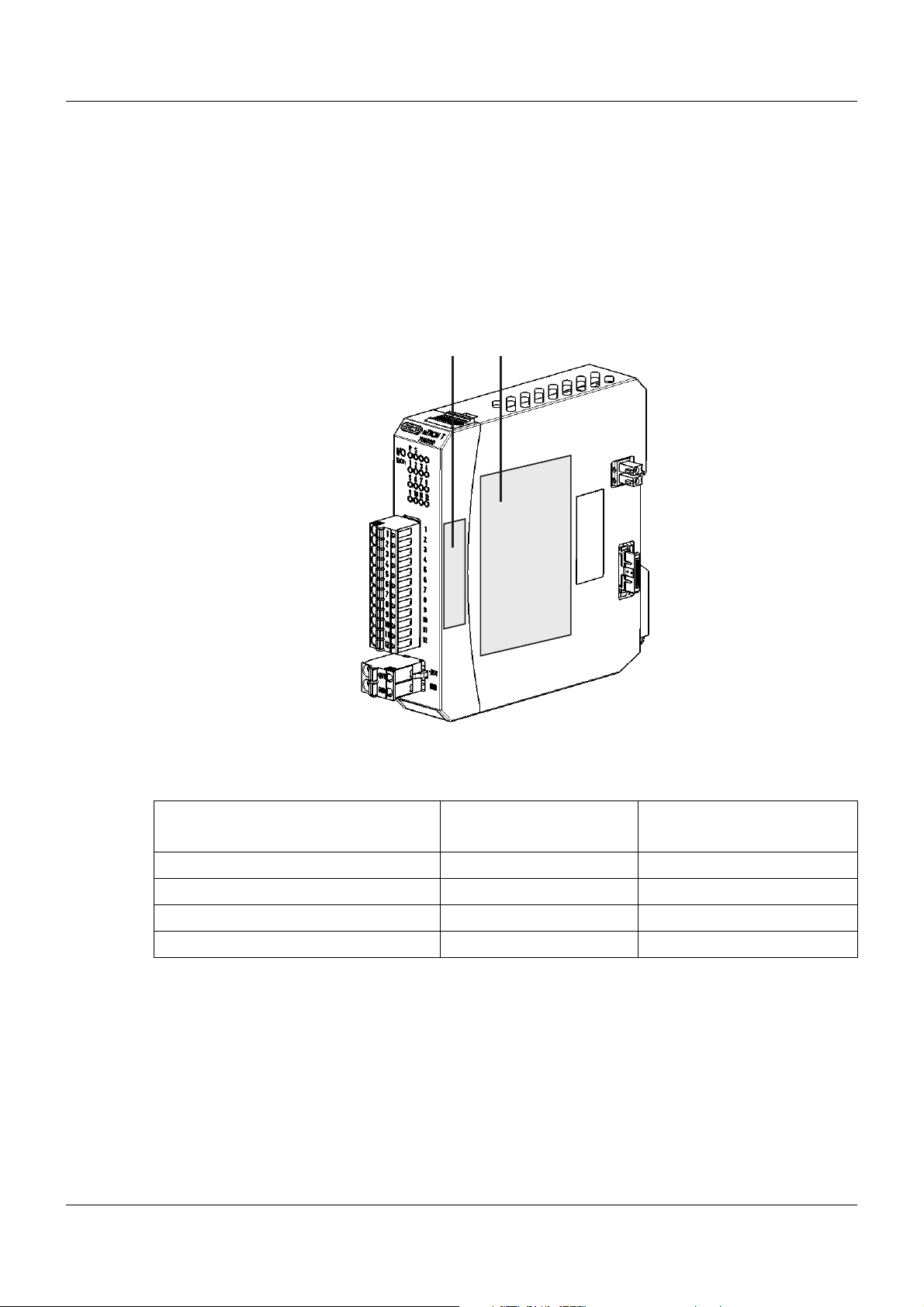

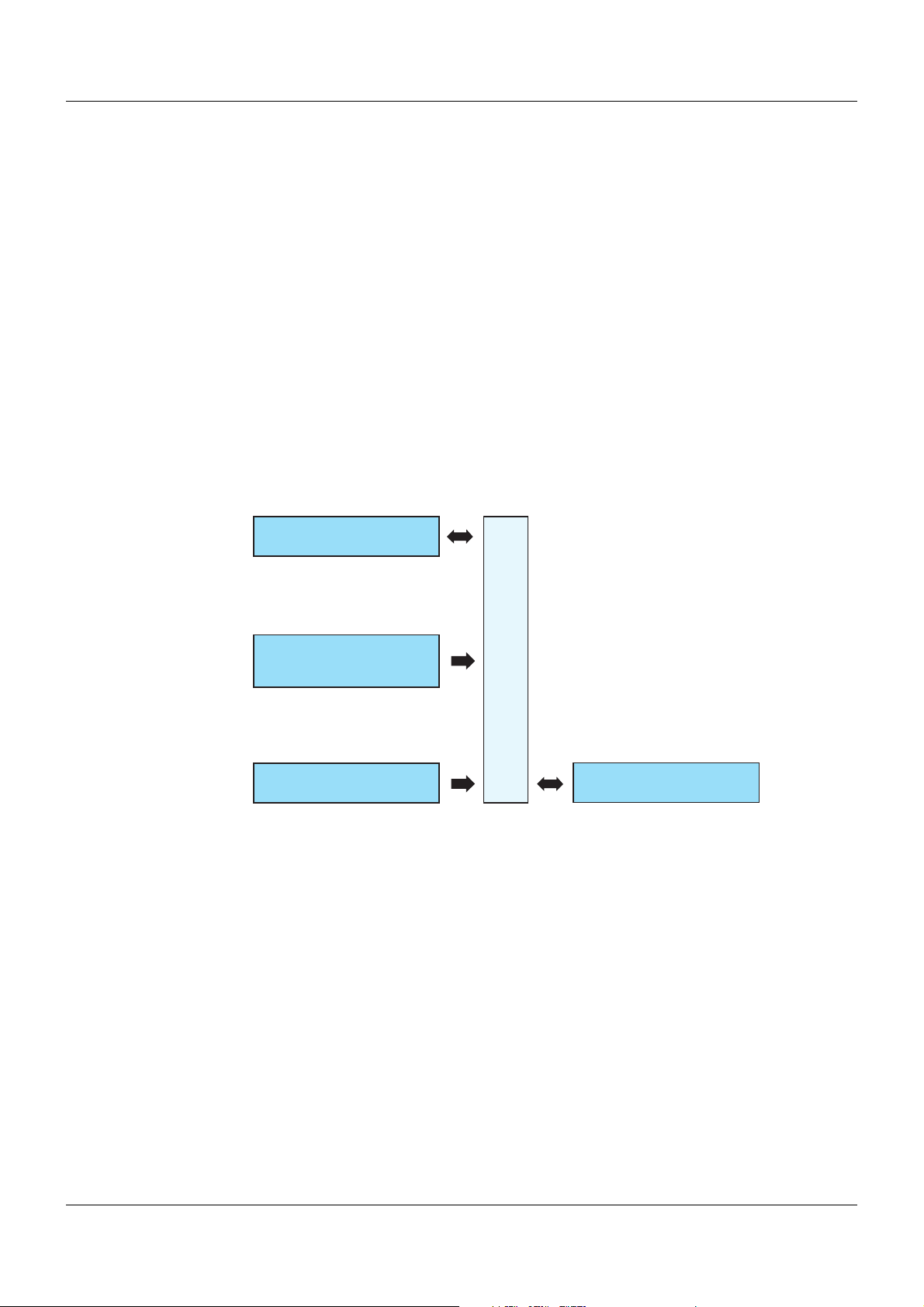

2.1 Brief description

12 Digitalein- oder -ausgänge

(DC 0/24 V) frei konfigurierbar

705030

Spannungsversorgung

Systembus

Externe

Spannungsversorgung

für digitale Ein-/Ausgänge

The module is equipped with 12 channels which can optionally be configured as digital inputs

or digital outputs.

The digitized input states are available in the system for further processing. The digital outputs

are actuated via the system bus by digital signals (assignment via the connection list or directly

by the PLC).

The load current of up to 6 A (12 × max. 500 mA) must be provided via the terminals +24V/

GND at the front.

LEDs are used to indicate applied voltage supply, the module operating status, as well as the

digital input/output status.

A setup program can be used to comfortably configure the digital input/output module.

For service work, the module insert can be easily pulled out of the case at the front. The case

including the bus PCB remains mounted on the DIN rail.

2.2 Block diagram

2 Description

13

Page 14

2 Description

14

Page 15

3.1 General information on installation/dismounting

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

Prior to the installation/dismounting of these modules or the removal of the module insert, the

load circuits are to be disconnected from the voltage and the terminal strips are to be removed from the module. This work must only be performed by qualified personnel.

WARNING!

The modules must never be installed in areas with an explosion hazard.

There is the risk of an explosion.

The entire system must only be used outside of areas with an explosion hazard.

Mounting site

All modules have protection type IP20 and are only intended for use in fireproof control cabinets

or switch boxes. The mounting site should be virtually vibration-free. Electromagnetic fields

caused by equipment such as motors or transformers should be avoided.

Multifunction panel 840 has protection type IP67 at the front and is intended for installation in

a panel cut-out. The rear has protection type IP20.

3 Mounting

Climatic conditions

The ambient temperature and the relative humidity at the mounting site must correspond to the

technical data. Aggressive gases and vapors have a negative effect on the operating life of the

modules. The mounting site must be free from dust, powder, and other suspended matter so

that the cooling slots do not become blocked.

DIN rail

All modules are mounted on a DIN rail according to DIN EN 60715 (35 mm × 7.5 mm × 1 mm).

For reasons of stability, the spacing of the fastening screws for the DIN rail should not exceed

200 mm. The minimum distances for the modules that are specified in the module-specific installation or operating instructions must be observed.

Installation position

The DIN rail should be mounted horizontally so that all modules are arranged vertically. Otherwise the admissible ambient temperature range will be restricted.

Space requirement

The modules require the minimum distances shown in the following figure for the purpose of

installation/dismounting and for future maintenance or replacement. In the event of shorter distances the minimum bending radius of the cables, the performance of the electrical installation,

and the clear arrangement of the plant are no longer guaranteed.

15

Page 16

3 Mounting

130

203.6

51.8

30

70

51.8

Minimum distances

3.2 Installation/dismounting on DIN rail

All modules in the system are intended for installation on a DIN rail according to DIN EN 60715

(35mm×7.5mm×1mm).

The following must always be installed on the left, at the start of the DIN rail:

• A central processing unit or

• A router module

These modules connect the input/output modules to the voltage supply and the system bus.

NOTE!

To determine the required minimum width of the DIN rail, the widths of the individual modules

are to be added (see technical data of the modules in the respective data sheet or the

module-specific installation instructions).

The widths of the cover (17.5 mm) and both end brackets (each 9.5 mm) should also be

taken into consideration: 17.5 mm + 2 × 9.5 mm = 36.5 mm.

3.2.1 Input/output modules

In a sequence at the user's discretion, input/output modules can be arranged to the right next

to a base unit or a router module.

16

Page 17

Installation, using the example of a multichannel controller module 705010

(A) (A1)

(A2)

(D)

(C5) (D6)

(D7)

(C)(A)

(B4)(A3)

(B)

3 Mounting

Example installation

Procedure:

Step Activity

1 Mount the multichannel controller module (A) in the DIN rail from above (A1).

2 Pivot the multichannel controller module (A) downward until it snaps into place (A2).

3 Move the multichannel controller module (A) to the left against the previous module (A3)

until the plug connections for the voltage supply and the system bus are connected.

4 Position additional modules (B) and move to the left against the previous module (B4).

5 After the final module, position the cover (C) on the DIN rail and move to the left against the

module (C5).

6 After attaching the cover, position the end bracket (D) on the DIN rail and move to the left

against the cover (D6).

7 Fasten the end bracket (D) using a screwdriver (D7). For this purpose, ensure that the end

bracket and the cover are positioned flush against the final module.

17

Page 18

3 Mounting

(C2)

(D1)

(A4) (B3)

(C) (D)

(A) (B)

(A)

(F)

(E)

(E5)

(F7)

(A6)

(A8)

Dismounting, using the example of a multichannel controller module 705010

Removing the multichannel controller module from the DIN rail

18

Procedure:

Step Activity

1 Fully release the end bracket (D) using a screwdriver (D1), press upward from below, pivot

2 Move the cover (C) to the right (C2) until the side contacts of the neighboring module are

toward the front, and remove from the DIN rail.

Note: The end bracket does not need to be removed from the DIN rail if there is sufficient

space to the side to move it at least 20 mm to the right.

exposed. Then release the cover at the bottom using a screwdriver, press upward, and

remove from the DIN rail.

Note: The cover does not need to be removed from the DIN rail if there is sufficient space

to the side to move it at least 20 mm to the right.

Page 19

3 Mounting

Step Activity

3 Move the modules (B) on the right next to the multichannel controller module that is to be

replaced (A) a minimum of 20 mm to the right (B3).

➥ These modules are isolated from the voltage supply and the system bus.

4 Move the multichannel controller module (A) to the right (A4) until the side contacts of the

neighboring module (here: central processing unit) – on the left, next to the multichannel

controller module that is to be replaced – are exposed.

➥ The multichannel controller module is isolated from the voltage supply and the system

bus. This is a prerequisite for the dismounting of the multichannel controller module.

5 If required, pull off the wired terminals (E) of the multichannel controller module (A) toward

the front (E5).

6 Insert a suitable screwdriver (F) into the unlocking slot of the multichannel controller mod-

ule (A6) and press upward (F7).

7 Pivot the multichannel controller module (A) upward off the DIN rail (A8) and remove it.

19

Page 20

3 Mounting

(A)

(E)

(B) (D)

(G)

(C)

(F)

(F)

(F)

3.3 Replacing module inserts

3.3.1 Input/output modules

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

The load circuits are to be disconnected from the voltage supply prior to removing the wired

terminal strips. This work must only be performed by qualified personnel.

Replacement of a module insert, using the example of a multichannel controller module 705010

20

For service purposes (or when retrofitting options for the multichannel controller module), the

case (D) can remain in the system; only the module insert (B) is replaced. For this purpose, the

system does not need to be isolated from the voltage supply (hot swapping).

The system will detect a module insert of the same type that has been replaced and will automatically reconfigure it. Retrofitted functions for the multichannel controller module (expansion

slots) must be configured using the setup program or the multifunction panel.

The new module insert also has a new nameplate (G), which will differ from the old one at least

with regard to the fabrication number, and is no longer identical to nameplates (E) and (C) on

the case (D).

Therefore, in the event of replacement, the module insert will be supplied along with a new

nameplate that will be affixed to the case (D) in place of the old nameplate (C). This means that

the specifications of nameplates (G) and (C) once again correspond to one another.

Page 21

CAUTION!

Only module inserts of the same type may be used for the replacement.

Otherwise, the function of the system may be affected.

The module inserts can be clearly identified using the nameplate.

CAUTION!

With the multichannel controller module 705010, a new module insert may contain retrofitted

inputs or outputs that have not yet been configured.

This can lead to unintended behavior, particularly at the outputs and the actuators connected

to them.

Prior to using the retrofitted inputs or outputs, ensure that these have been configured correctly.

Removing the module insert

Step Activity

1 Disconnect load circuits from the relay or solid state relay outputs.

2 Pull off the wired terminal strips (A) toward the front.

3 Mounting

3 Press the old module insert (B) together on the grooved surfaces at the top and bottom and

remove from the case (D).

4 For the multichannel controller module, also remove the modules (F) of the expansion slots

from the case (D) toward the front, if required.

Mounting the module insert

Step Activity

1 Affix the new nameplate in place of the old nameplate (C) in the case.

2 For the multichannel controller module, also insert the modules (F) of the expansion slots

into the case (D), if required.

3 Hold the new module insert (B) at the grooved surfaces on the top and bottom and insert

them into the case (D). For this purpose, ensure that the board of the module insert slides

into the guide rails of the case. For the multichannel controller module, also ensure that the

modules (F) of the expansion slots slide in the guide rails of the module insert.

4 Reattach the wired terminal strips (A).

NOTE!

When mounting the module insert, ensure that the snap holders (under the grooved surfaces)

audibly snap into place.

NOTE!

The availability of the system can be increased through the storage of module inserts and

modules for expansion slots.

21

Page 22

3 Mounting

22.5

103.6

6.6

101

94.5

101.5

17.6

3.4 Dimensions

22

Page 23

4.1 Installation notes

NOTE!

These installation notes apply for the entire measuring, control, and automation system and,

on some occasions, are only applicable for a specific module.

The respective connection diagram shows the context.

Requirements for the personnel

• Work on the modules must only be carried out to the extent described and, like the electrical

connection, only by qualified personnel.

• Before plugging and unplugging connection cables ensure that the person performing the

work is electrostatically discharged (e.g. by touching grounded metallic parts).

Cables, shielding, and grounding

• When selecting the cable material, when installing, and when performing the electrical connection of the module, the regulations of DIN VDE 0100 "Erection of power installations with

rated voltages up to 1000 V" and the respective national regulations (e.g. on the basis of

IEC 60364) are to be observed.

• Certain cables must be heat resistant up to at least 80 °C at maximum load. The relevant

instructions in the connection diagram of the affected modules must be observed.

• Route input, output, and supply cables separately and not parallel to one another.

• Only use shielded and twisted probe and interface cables. Do not route the lines close to

current-carrying components or cables.

• For temperature probes, ground the shielding on one side in the control cabinet.

• Do not perform loopthroughs on the grounding cables, but route the cables individually to a

shared grounding point in the control cabinet; in doing so, ensure that the cables are as

short as possible.

Ensure that the equipotential bonding is correct.

4 Electrical connection

Electrical safety

• Isolate power supply units from the voltage supply on the primary side if there is a risk of

touching parts with dangerous electrical voltage (e.g. 230 V) in the course of work.

• The fuse rating of the power supply units on the primary side should not exceed a value of

10 A (inert).

• With modules with relay or solid state relay outputs, the load circuits can be operated with

a dangerous electrical voltage (e.g. 230 V). Disconnect load circuits from the voltage supply

during installation/dismounting and electrical connection.

• In order to prevent the destruction of the relay or solid state relay outputs in the event of an

external short circuit in the load circuit, the load circuit should be fused to the maximum admissible output current.

• The modules are not suitable for installation in areas with an explosion hazard.

• In addition to a faulty installation, incorrectly set values on the module could also impair the

correct function of the following process. Therefore, ensure that safety devices independent

of the module (e.g. overpressure valves or temperature limiters/monitors) are available and

that it is only possible for qualified personnel to define settings. Please observe the corresponding safety regulations in this context.

23

Page 24

4 Electrical connection

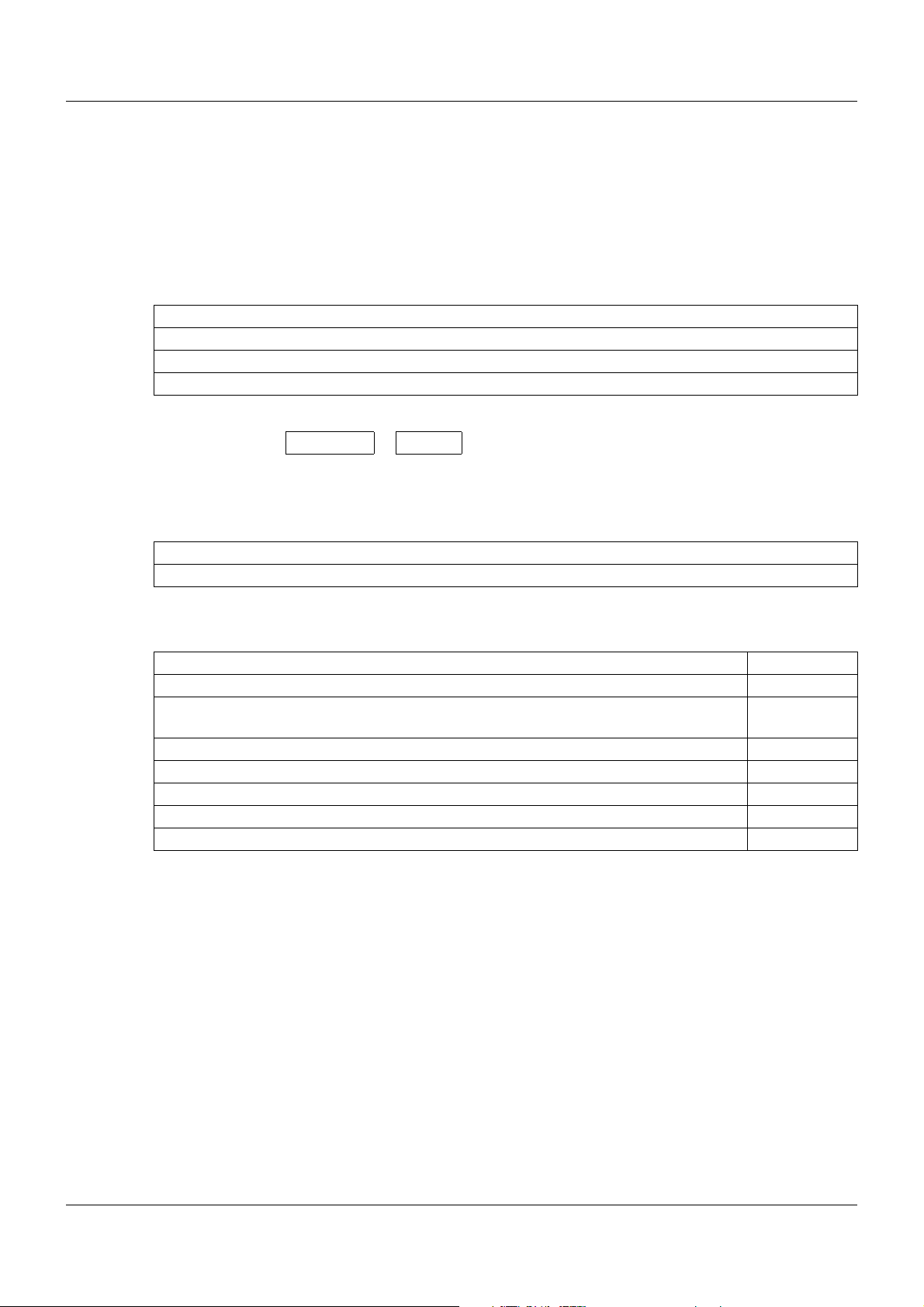

AC 30 V

DC 50 V

»

External voltage supply DC 24 V

via terminal at the front

Voltage supply Out

Side

system bus In

Side system bus Out

Voltage

supply In

Digital inputs

Digital outputs

or

12

1

.

.

.

References to other information

• The electromagnetic compatibility meets the standards and regulations cited in the technical data.

• The USB device interface and voltage supply in the central processing unit 705001 are not

electrically isolated. In general, please observe the specifications regarding electrical isolation.

4.2 Electrical isolation

4.3 Connection diagram

NOTE!

The external voltage supply for the digital input/output module 12-channel and the voltage supply for controlling the digital inputs of this module must be switched on/off with a common disconnecting device (common electrical circuit).

CAUTION!

At maximum load, the temperature may exceed 60 °C at the terminals.

As a result the insulation of the cable may be damaged.

The cable must be heat resistant up to at least 80 °C.

CAUTION!

Connecting the external voltage supply DC 24 V via the terminals at the front

(terminals “GND“ and “+24V“):

Ensure that the polarity is correct!

CAUTION!

The voltage of the digital outputs depends on the external voltage supply.

In case of undervoltage, no voltage is provided at the digital outputs.

Observe the technical data for the external voltage supply!

24

Page 25

CAUTION!

(1)

(2)

(3)

(4)

(5)

(7)

(6)

Signals to the several digital inputs must have the same ground reference.

Otherwise undefined signal levels can occur.

Ground reference via terminal “GND“ required!

4.3.1 Display and connection elements

4 Electrical connection

(1) Status displays (LED)

P = Voltage supply

S = Status

1 to 12 = Digital input/output

(LED is lit: Active)

(2) Voltage supply Out, DC 24 V

(3) Digital inputs/outputs

(4) Side system bus Out

(5) External voltage supply

DC 24 V

(6) Side system bus In

(7) Voltage supply In, DC 24 V

25

Page 26

4 Electrical connection

U

+

-

x

U

+

-

x

4.3.2 Digital input

The connection depends on the configuration (input or output).

Connection Input Terminals Symbol and terminal designation

Apply signal DC 0/24 V to terminals 1to12

Ground reference via GND terminal required!

Or:

Switch DC 24 V from terminal

+24V to terminals 1to12 via

floating contact.

External voltage supply

DC 24 V via terminals +24 V

and GND required!

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

1 and GND

2 and GND

3 and GND

4 and GND

5 and GND

6 and GND

7 and GND

8 and GND

9 and GND

10 and GND

11 and GND

12 and GND

1and+24V

2and+24V

3and+24V

4and+24V

5and+24V

6and+24V

7and+24V

8and+24V

9and+24V

10 and +24 V

11 and + 2 4 V

12 and +24 V

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12

GND

+24 V

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12

4.3.3 Digital outputs

The connection depends on the configuration (input or output).

Connection Output Terminals Symbol and terminal designation

Output signal:

DC 0/24 V / maximum 500 mA

External voltage supply

DC 24 V via terminals +24 V

and GND required!

1

2

3

4

5

6

7

8

9

10

11

12

1andGND

2andGND

3andGND

4andGND

5andGND

6andGND

7andGND

8andGND

9andGND

10 and GND

11 and G ND

12 and GND

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12

GND

26

Page 27

4.4 Functional test

The voltage supply must be tested on completion of the electrical connection:

Signal Meaning

LED "P" (Power, green) is lit The module is being supplied with voltage

LED "P" (Power, green) is not lit The module is not supplied with voltage or there

4 Electrical connection

through the side contacts.

is a problem with the electrical function of the

LED.

Remedy:

• Check the voltage supply to the side contacts

of the preceding module (top contact +24 V,

bottom contact GND).

• Check voltage supply at the "+24 V" and

"GND" terminals of the base unit or router

module.

• Check power supply unit and connection between the power supply unit and the base unit

or router module.

If the "Power" LED does not light up despite a

voltage supply being present, the module insert

or – if the bus board inside the case is faulty – the

entire module must be replaced.

Startup

The check described above completes the process of installation and electrical connection. For

startup, use the additional documentation (operating manual or system manual).

The "Introduction" section of this document contains an overview of all documentation for the

measuring, control, and automation system.

27

Page 28

4 Electrical connection

28

Page 29

5.1 Display and connection elements

(1)

(2)

(3)

(4)

(5)

(7)

(6)

5 Operation

(1) Status displays (LED)

P = Voltage supply

S = Status

1 to 12 = Digital input/output

(LED is lit: Active)

(2) Voltage supply Out, DC 24 V

(3) Digital inputs/outputs

(4) Side system bus Out

(5) External voltage supply

DC 24 V

(6) Side system bus In

(7) Voltage supply In, DC 24 V

29

Page 30

5 Operation

5.2 LED displays

"P" LED (Power)

The LED is permanently lit in green if the module is being supplied with voltage.

"S" LED (Status)

This LED indicates the status of the module. Diagnostics requires the setup program or a Web

browser as appropriate.

LEDs "1" to "12"

The LEDs indicate the status of the relevant digital input or output.

• LED is not lit = input or output is inactive (Low level)

• LED is lit (yellow) = input or output is active (High level)

5.2.1 Display modes

The following table lists all possible states of the "S" LED (Status).

Display mode Description Green sym-

bol

--- LED state not relevant --- ---

Off LED off

On LED on (permanently lit)

Flickering LED flickers (50 ms on, 50 ms off)

Single flickering LED flashes briefly (50 ms on, 200 ms off)

Blinking LED flashes (200 ms on, 200 ms off)

Single flash LED flashes once (200 ms on, 1000 ms off)

Double flash LED flashes twice (on/off/on for 200 ms each

time, 1000 ms off)

Triple flash LED flashes three times (on/off/on/off/on for

200 ms each time, 1000 ms off)

Quadruple flash LED flashes four times (on/off/on/off/on/off/on for

200 ms each time, 1000 ms off)

Blinking red/green LED flashes red and green (200 ms red, 200 ms

green)

On green/

Single flickering red

LED lights up green, flashes red (50 ms red)

Red symbol

30

Page 31

5.2.2 System states and errors

The following table lists all the system states and errors that are indicated by the "S" LED (Status). In most cases, further diagnostics must be performed with the setup program.

5 Operation

Category "S" LED

(Status)

Bus status No connection to central processing

Bus status System in "Stop" (INIT) state – no

Bus status System in "Stop" (PREOP) state – no

Operation

(Priority 3)

Operation

(Priority 3)

Meaning Diagnos-

unit

error, only in start phase

error, only in start phase

System in "Stop" (SAFEOP) state –

no error

System in "Run" (OP) state – no

error

Recommended action

tics with

LED Check whether the central pro-

cessing unit is running; check

cabling and topology

LED

LED

LED

LED

31

Page 32

5 Operation

32

Page 33

NOTE!

?

The parameters described in this section can be configured either with the setup program or

with the multifunction panel.

6.1 Digital inputs/outputs

The digital input/output module has 12 channels, each of which can be configured as digital

input or digital output.

The digital outputs are actuated by assigned external inputs (NV_DO01 to NV_DO12).

Assigned external inputs (NV_SR01 to NV_SR12) are also used to suppress the signals of the

digital inputs.

Chapter 6.2 "NV connecting list", page 36

Setup dialog

6 Configuration

Parameters

Parameters Selection/settings Description

Function Input The relevant channel is configured as

input.

Output The relevant channel is configured as

output.

Inverting Inverting of the input signal or the output signal (depending on the configuration of

the channel)

Normal Not inverted

Inverse Inverted

Level at suppression

TAG number 7 characters Identification marking (documentation in

Input signal level during active signal suppression

Inactive Low level (0)

Active High level (1)

PLC)

33

Page 34

6 Configuration

Level at suppression

When signal suppression is active, the input signal and the inverting parameter are irrelevant.

In this case, a fixed signal with a configurable level is issued (to the system bus).

Status after change of configuration

Modified parameters are incorporated immediately.

Behavior after power on

After power on, all channels of the digital input/output module are initially configured as input.

When the initialization phase is over and valid values of the external input signals are available,

the outputs are activated (according to the configuration).

34

Page 35

6.1.1 Alarm

?

Signal monitoring can be activated for each digital input.

Setup dialog

Parameters

Parameters Selection/settings Description

Alarm type The alarm type is not set by default.

6 Configuration

Collective alarm Alarm results in collective alarm of the

module.

Event text

Event Alarm results in an entry (event text) in

the event list.

Alarm active at High (1) Alarm at high level (1)

Low (0) Alarm at low level (0)

Event text Use default text or select other text from

the list.

Text that is entered in the event list for

an alarm (if Alarm type = "Event").

Setup program: Selection of text from a list

Click the "..." button to open a list with the text numbers and the associated texts. The texts can

be edited.

Multifunction panel: Selection of text using the text number

The setup program is required to view and edit the texts.

35

Page 36

6 Configuration

6.2 NV connecting list

The NV connecting list is used to link external inputs (NV_...) of the digital input/output module

to signals from other modules via the system bus.

A comprehensive list with the module signals is included in the following chapter:

Chapter 6.2.1 "Digital signals (overview)", page 37

Further information about the signals can be found in the operating manual for the relevant

module.

Replacement values are available in the event that these signals are not available (connection

to base unit interrupted or system in "Stop" state).

Chapter 6.2.2 "Replacement values (overview)", page 42

NOTE!

There is no NV connecting list in the input/output module configuration menu on the multifunction panel. Instead, a central NV connecting list is available in the configuration menu of

the base unit (CPU).

Setup dialog

Parameters

36

Parameters Selection/settings Description

Digital signal /

Valu e

...\NV_SR01

(Example)

Select input to be connected. List of external inputs of the module

If a connection has already been configured, the module and its signal are displayed in the "Value" column.

This is the previously selected external input.

Select the module and – in the selector

next to it on the right – the signal to connect to the external input.

List of modules in the system and the

relevant signals

Page 37

Parameters Selection/settings Description

?

6 Configuration

Replacement

value

Replacement value for the relevant signal (The selection On/Off is active if a signal

is assigned to the external input.)

Off Low level (0)

On High level (1)

Replacement value

The replacement value is used if the relevant signal is not available (connection to base unit

interrupted or system in "Stop" state).

Status after change of configuration

The connections are available immediately.

Behavior after power on

The connections are available immediately after system initialization.

6.2.1 Digital signals (overview)

The following table contains all signals that are available in the NV connecting list for connection to the external inputs (NV_...) of the digital input/output module.

Category Signal Description

Inactive No signal selected

Central processing unit

Digital variables Digital variable 1 to 64 Digital variable 1 to 64 (via interface)

37

Page 38

6 Configuration

Category Signal Description

Program

generator 1 to

Program

generator 9

Operating contact 1 to 16 Operating contact 1 to 16 of program channels

(in the three program channels, operating contacts with the same name are linked with OR)

Mode: Basic status Status: Program is not running (basic status)

Mode: Automatic Status: Program is running (automatic mode,

no delay time or program end time)

Mode: Automatic 1 Status: Program is running (automatic mode,

incl. delay time and program end time)

Mode: Standstill Status: Program stopped during automatic

mode (time base stopped)

Mode: Delay Status: Program start delayed (delay time

runs)

Mode: Program end Status: Program ends (program end time runs,

corresponds to length of end signal)

Mode: Manual Status: Manual mode

Tolerance band channel 1 to 3 Tolerance band signal of program channel 1 to

3

PLC Binary output 27 to 32 Signal of PLC digital output 27 to 32

Limit monitoring Limit monitoring 1 to 64 Output signal of limit value monitoring 1 to 64

Binary linking Binary linking 1 to 8 Result of binary linking 1 to 8

PLC Binary output 9 to 32 Signal of PLC digital output 9 to 32

Binary PLC output block 13 to

block 18

Alarm analog

variables

Alarm integer

variables

PLC Binary output 1 to 32 Signal of PLC digital output 1 to 32

Alarm1 ExAI1 to Alarm1 ExAI64 Alarm signal 1 of analog variable 1 to 64

Alarm2 ExAI1 to Alarm2ExAI64 Alarm signal 2 of analog variable 1 to 64

Alarm1 ExInt1 to Alarm1 ExInt64 Alarm signal 1 of integer variable 1 to 64

Alarm2 ExInt1 to Alarm2ExInt64 Alarm signal 2 of integer variable 1 to 64

38

Page 39

Category Signal Description

6 Configuration

Alarms/

Faults

CAlarm/Fault System collective alarm or system fault (cen-

tral processing unit and modules)

CAlarm/Fault ackn. System collective alarm or system fault with

acknowledgement

Signal remains active until acknowledgement.

CAlarm device System collective alarm (central processing

unit and modules)

CAlarm ackn. System collective alarm with acknowledge-

ment

Signal remains active until acknowledgement.

Fault System fault (central processing unit and mod-

ules)

Fault ackn. System fault with acknowledgement

Signal remains active until acknowledgement.

CAlarm Basis Central processing unit collective alarm

System Run System state (Run = 1, Stop = 0)

Reserve 1 (Reserved for future use.)

Fieldbus error Error at fieldbus interface

System error mandatory Error in a mandatory module

System error optional Error in an optional module

No PLC No PLC program available

Battery empty Battery alarm (central processing unit buffer

battery is dead and must be replaced)

Notify service department!

Attention: RAM memory content is deleted!

Battery low Battery pre-warning (central processing unit

buffer battery can be replaced within 4 weeks

without data loss)

Notify service department!

39

Page 40

6 Configuration

Category Signal Description

Multichannel controller module

Controller C01ManualMode to

C04ManualMode

C01TuneActive to C04TuneActive Self-optimization active for controller module

C01Output1 to C04Output1 Switch position of first controller output of con-

C01Output2 to C04Output2 Switch position of second controller output of

C01CollAlarm to C04CollAlarm Collective alarm of controller channel 1 to 4

Setpoint SP01RampTolBand to

SP04RampTolBand

SP01Changeover1 to

SP04Changeover1

SP01Changeover2 to

SP04Changeover2

Manual mode active for controller channel

1to4

1to4

troller channel 1 to 4

controller channel 1 to 4

(can be configured with signals from the digital

selector)

Alarm signal of tolerance band monitoring of

ramp function 1 to 4

Bit 0 of setpoint changeover of setpoint value

function 1 to 4

Bit 1 of setpoint changeover of setpoint value

function 1 to 4

Analog inputs AI01Alarm1 to AI04Alarm1 Alarm signal 1 of analog input 1 to 4

AI01Alarm2 to AI04Alarm2 Alarm signal 2 of analog input 1 to 4

Digital inputs DI01, DI02, DI05 to DI10 Signal of digital input 1, 2, 5 to 10

If the HW counter is activated, the signal of

digital input 1 is inactive.

Limit monitoring LI01 to LI04 Output signal of limit value monitoring 1 to 4

Mathematics Logic01 to Logic04 Result of logic function 1 to 4

Miscellaneous CollectiveAlarm Controller module collective alarm

HWCounterSignal Signal of hardware counter in "fill" operating

mode (as shut-down signal when threshold

value reached)

40

Page 41

6 Configuration

Category Signal Description

Analog input module 4-channel

Analog inputs AI01Alarm1 to AI04Alarm1 Alarm signal 1 of analog input 1 to 4

AI01Alarm2 to AI04Alarm2 Alarm signal 2 of analog input 1 to 4

Digital inputs DI01 Signal of digital input

Alarm CollectiveAlarm Module collective alarm

Analog input module 8-channel

Analog inputs AI01Alarm1 to AI08Alarm1 Alarm signal 1 of analog input 1 to 8

AI01Alarm2 to AI08Alarm2 Alarm signal 2 of analog input 1 to 8

Digital inputs DI01 Signal of digital input

Alarm CollectiveAlarm Module collective alarm

Digital input/output module 12-channel

Digital inputs DI01 to DI12 Signal of digital input 1 to 12

Alarm CollectiveAlarm Module collective alarm

Multifunction panel 840

System bus

digital inputs

Alarm batch 1 to

Alarm batch 9

CollectiveAlarm Collective alarm of multifunction panel (pro-

Fault Fault in multifunction panel (independent of

Batch 1 active to Batch 9 active Signal for active batch 1 to 9

Push button 1 to

Push button 18

Collective alarm of batch 1 to 9 (process values)

cess values)

process values)

Status of push button 1 to 18 in process screen

41

Page 42

6 Configuration

6.2.2 Replacement values (overview)

The following table contains the replacement values with their factory settings. Replacement

values can only be configured in the setup program.

Digital signals

Category Signal Factory

setting

Signal suppression

Signal suppression 1 to 9

NV_SR01 to NV_SR09

Off Signal for activating signal sup-

Description

pression

42

Page 43

NOTE!

An active connection between the setup program and the central processing unit is required

to configure the parameters described in this section.

7.1 Calibrate / test

CAUTION!

Incorrect settings may result in inadmissible changes to values.

This can have negative effects on the system function.

This function must be used only by (or under the instruction of) a service technician of the

device manufacturer.

7.1.1 Digital output

Setup dialog

7 Online parameters

Parameters

Parameters Selection/settings Description

BinaryIO 1

to

BinaryIO 12

Set all Click the "Set all" button. All digital outputs change to active state

Delete all Click the "Delete all" button. All digital outputs change to inactive

Select digital output (activate checkbox).

You can select multiple outputs simultaneously.

The selected digital output changes to

active state (High level).

(High level).

state (Low level).

43

Page 44

7 Online parameters

7.1.2 Digital input

Setup dialog

Parameters

Parameters Selection/settings Description

Read out Click the "Read out" button. The current status of the digital inputs is

read out. Active inputs are marked with

a check mark.

Read out permanently

Click the "Read out permanently" button The current status of the digital inputs is

read out permanently (until the user

aborts). Active inputs are marked with a

check mark.

44

Page 45

7.1.3 Versions

Setup dialog

7 Online parameters

This dialog displays the module versions.

45

Page 46

7 Online parameters

46

Page 47

8.1 Technical data

8.1.1 Digital inputs and outputs

Number 12

Digital inputs

Input signal DC 0/24 V

(PLC level; logical ”0“ = -3 to +5 V; logical ”1“ = +15 to +30 V)

Current Max. 5 mA per input

Digital outputs

Output signal DC 0/24 V (depending on external voltage supply)

Current Max. 500 mA per output, short-circuit proof

8.1.2 Electrical data

Voltage supply For module electronics

Connection Lateral (feed via base unit or router module)

Voltage DC24V+25/-20%

Residual ripple 5 %

External voltage supply For digital inputs/outputs

Connection At the front

Voltage DC24V+25/-20%SELV

Current Max. 6 A

Current consumption 90 mA (module electronics only; at DC 19.2 V)

Power consumption 2 W (module electronics only)

Inputs or outputs (terminals 1 to 12) and exter-

nal voltage supply (2-pole terminal GND/

+24 V)

Conductor cross section on terminals 1 to 12

Wire or strand without ferrule Min. 0.14 mm

Strand with ferrule Without plastic collar: Min. 0.25 mm2, max. 1.5 mm

Strand with ferrule With plastic collar: Min. 0.25 mm2, max. 0.5 mm

Stripping length on terminals 1 to 12 9 mm

Conductor cross section on terminals GND

and +24 V

Wire or strand without ferrule Min. 1.5 mm

Strand with ferrule Min. 1.5 mm2, max. 2.5 mm

2× strand with twin ferrule

with plastic collar

Stripping length on terminals GND and +24 V 10 mm

Electrical safety Acc. to DIN EN 61010-1

Electromagnetic compatibility Acc. to DIN EN 61326-1

Interference emission Class A – only for industrial use –

Interference immunity Industrial requirements

At the front (removable terminal strips with Push-In technology)

2

, max. 1.5 mm

2

, max. 2.5 mm

1.5 mm

Overvoltage category III, pollution degree 2

2

2

2

2

8 Appendix

2

2

47

Page 48

8 Appendix

8.1.3 Case and ambient conditions

Case type Plastic case for DIN rail mounting in the control cabinet (indoor

use); DIN rail acc. to DIN EN 60715, 35 mm x 7.5 mm x 1 mm

Dimensions (W x H x D) 22.5 mm x 103.6 mm x 101.5 mm (without connection elements)

Weight Approx. 130 g

Protection type IP20, acc. to DIN EN 60529

Ambient temperature range -20 to +55 °C

Storage temperature range -40 to +70 °C

Resistance to climatic conditions Relative humidity ≤ 90 % annual average without condensation

(climatic class 3K3 acc. to DIN EN 60721-3-3 with extended tem-

perature and humidity range)

Site altitude Up to 2000 m above sea level

Mechanical ambient conditions

1

Test conditions are listed in the System Descripton B 705000.8.

8.1.4 Approval/approval marks

1

Classification acc. to DIN EN 60721-3-3, table 6, class 3M2

Approval mark Testing agency Certificate/certifica-

tion number

c UL us Underwriters Laborato-

ries

E201387 UL 61010-1 (3. Ed.),

Inspection basis Valid for

all types

CAN/CSA-22.2

No. 61010-1 (3. Ed.)

48

Page 49

Page 50

JUMO GmbH & Co. KG

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow - Essex CM20 2DY, UK

Phone: +44 1279 63 55 33

Fax: +44 1279 63 52 62

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Loading...

Loading...