Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

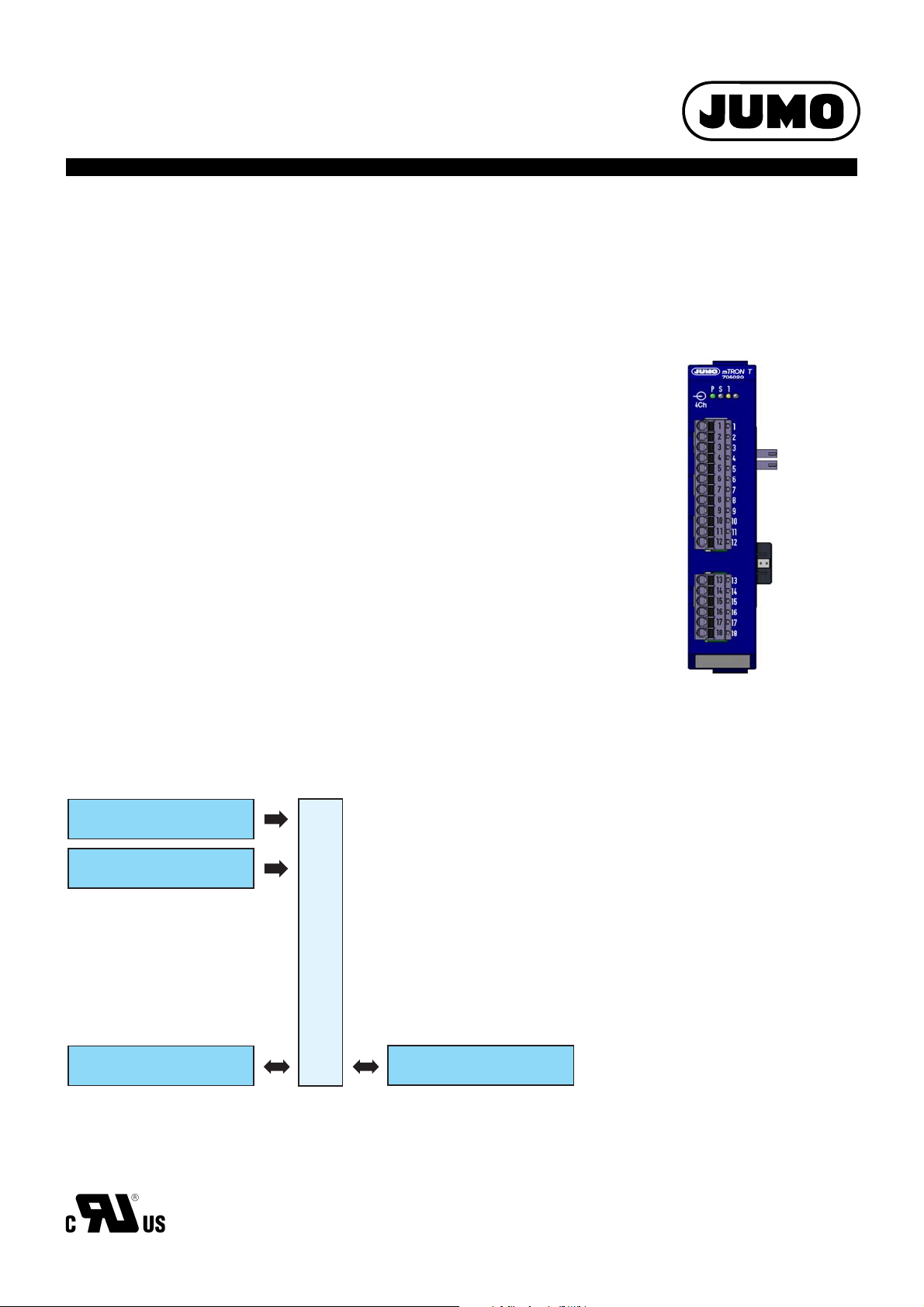

4 universal analog inputs

electrically isolated

1 digital input

(DC 0/24 V)

705020

Voltage supply

System bus

Data Sheet 705020

JUMO mTRON T

Measuring, Control, and Automation System

Analog input module 4-channel

Brief description

The analog input module 4-channel is equipped with four universal analog inputs that are electrically isolated from each other for thermocouples, RTD temperature probes, resistance transmitters, resistance/potentiometers, or standard signals (current or voltage) as well as one digital

input (DC 0/24 V). The digitized input values/states are available in the system for f urther processing.

LEDs are used to indicate applied voltage supply, the module operating status, as well as the

logical status of the digital input.

A setup program can be used to comfortably configure the analog input module.

For service work, the module insert can be easily pulled out of the case at the front. The case

including the bus PCB remains mounted on the DIN rail.

Page 1/10

Block diagram

Approval/approval marks (see “Technical data”)

Type 705020/...

Features

• Four high-quality, universal analog inputs

for thermocouples, RTD temperature

probes, resistance transmitters, resistance/

potentiometers, or standard signals

• All analog inputs are electrically isolated

from each other

• Customer-specific linearization (up to 45

pairs of values or polynomial up to the 4th

order)

• Limit value monitoring

• One digital input DC 0/24 V

• Automatic configuration after the module

insert has been exchanged (Plug and Play)

• Connection of the inputs at the front

• Removable terminal strips with Push-In

technology

• Quick wiring of operating voltage and system bus due to easy module connection

2013-05-07/00529109

Page 2

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Description

Limit value monitoring

For each analog input, two separate alarms

(min/max alarm) can be activated; each alarm

has its own limit value. Alarm type, event text,

collective alarm, alarm suppression, and

alarm delay are configurable.

Analog inputs

The four analog inputs are universal measuring inputs for RTD temperature probes, thermocouples, resistance transmitters,

resistance/potentiometers, and standard signals (current, voltage). Linearizations for over

20 common measuring probes (RTD temperature probes, thermocouples) are saved. A

measured value offset or a fine adjustment

can be carried out to compensate for plantspecific deviations. Due to the measuring circuit monitoring, a measuring range that is too

high or too low, probe/cable break, and probe/

cable short circuit are detected – depending

on the measuring element type – so that the

system is switched to an operational safe status in the event of an error.

Data Sheet 705020 Page 2/10

Customer-specific linearization

A customer-specific linearization is also possible. The required linearization curve can be

entered in the setup program using up to 45

pairs of values or a formula (polynomial up to

the 4th order).

Digital input

In addition, a digital input DC 0/24 V is available. The signal status can be used in the system in a flexible manner.

2013-05-07/00529109

Page 3

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 3/10

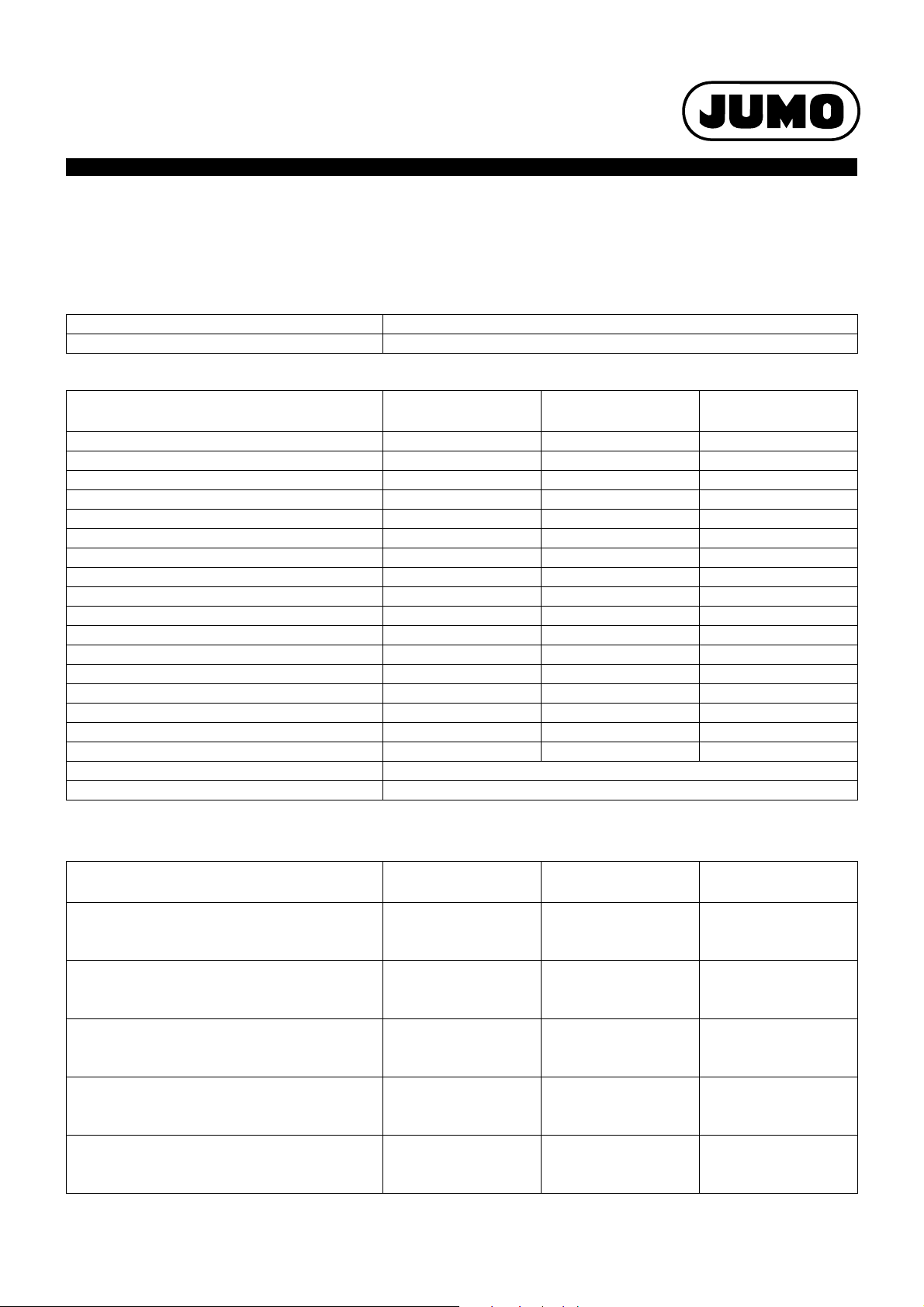

Technical data

Analog inputs

General information

Number 4

A/D converter Dynamic resolution up to 16 bit

Thermocouples

a

Designation Standard Measuring range Measuring accuracy

Fe-CuNi “L” -200 to +900 °C 0.1 % from -100 °C 300 ppm/K

Fe-CuNi “J” DIN EN 60584 -200 to +1200°C 0.1 % from -100 °C 300 ppm/K

Cu-CuNi “U” -200 to +600 °C 0.1 % from -130 °C 300 ppm/K

Cu-CuNi “T” DIN EN 60584 -200 to +400 °C 0.1 % from -150 °C 300 ppm/K

NiCr-Ni “K” DIN EN 60584 -200 to +1372 °C 0.1 % from -80 °C 300 ppm/K

NiCr-CuNi „E“ DIN EN 60584 -200 to +1000 °C 0.1 % from -80 °C 300 ppm/K

NiCrSi-NiSi “N” DIN EN 60584 -100 to +1300 °C 0.1 % from -80 °C 300 ppm/K

Pt10Rh-Pt “S” DINEN 60584 -50 to 1768 °C 0.15 % from 20 °C 300 ppm/K

Pt13Rh-Pt “R” DIN EN 60584 -50 to 1768 °C 0.15 % from 20 °C 300 ppm/K

Pt30Rh-Pt6Rh “B” DIN EN 60584 0 to 1820 °C 0.15 % from 400 °C 300 ppm/K

W5Re-W26Re „C“ 0 to 2320 °C 0.15 % from 500 °C 300 ppm/K

W3Re-W25Re “D” 0 to 2495 °C 0.15 % from 500 °C 300 ppm/K

W3Re-W26Re 0 to 2400 °C 0.15 % from 500 °C 300 ppm/K

Chromel-Copel GOST 8.585-2001 -200 to +800 °C 0.15 % from -80 °C 300 ppm/K

Chromel-Alumel GOST 8.585-2001 -200 to +1372 °C 0.10 % from -80 °C 300 ppm/K

PLII (Platinel II) 0 to 1395 °C 0.10 % from -80 °C 300 ppm/K

Linear 0 to 75 mV 0.1 % 300 ppm/K

Cold junction Pt100 internal

Cold junction accuracy 1 K

a

The accuracy values refer to the maximum measuring range. Smaller measuring ranges lead to reduced linearization accuracy.

Ambient

temperature influence

RTD temperature probe

Designation Standard Measuring range Measuring accuracy

Pt100 DIN EN 60751 -200 to +850 °C 50 ppm/K

2-wire circuit 0.15 %

3-wire/4-wire circuit 0.05 %

Pt500 DIN EN 60751 -200 to +850 °C 50 ppm/K

2-wire circuit 0.30 %

3-wire/4-wire circuit 0.15 %

Pt1000 DIN EN 60751 -200 to +850 °C 50 ppm/K

2-wire circuit 0.20 %

3-wire/4-wire circuit 0.08 %

Ni 100 DIN 43760 -60 to +250 °C 50 ppm/K

2-wire circuit 0.36 %

3-wire/4-wire circuit 0.24 %

Pt100 JIS 1604 -200 to +650 °C 50 ppm/K

2-wire circuit 0.20 %

3-wire/4-wire circuit 0.06 %

2013-05-07/00529109

a

Ambient

temperature influence

Page 4

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 4/10

Designation Standard Measuring range Measuring accuracy

a

Ambient

temperature influence

Pt50 GOST 6651-94 -200 to +1100 °C 50 ppm/K

2-wire circuit 0.30 %

3-wire/4-wire circuit 0.06 %

Pt100 GOST 6651-94 -200 to +850 °C 50 ppm/K

2-wire circuit 0.15 %

3-wire/4-wire circuit 0.05 %

Cu50 GOST 6651-94 -50 to +200 °C 200 ppm/K

2-wire circuit 0.80 %

3-wire/4-wire circuit 0.60 %

Cu100 GOST 6651-94 -50 to +200 °C 200 ppm/K

2-wire circuit 0.80 %

3-wire/4-wire circuit 0.50 %

KTY11-6 -50 to +150 °C 50 ppm/K

2-wire circuit 1%

3-wire/4-wire circuit 0.24 %

Sensor lead resistance Max. 30 per lead with a 3-wire and 4-wire circuit

Max. 10 per lead with a 2-wire circuit

Measuring current Pt100 approx. 250 A, Pt500, and Pt1000 approx. 100 A; not constant

Lead compensation Not required for 3-wire and 4-wire circuit. For a 2-wire circuit, the lead resistance can

be compensated in the software by correcting the process value.

a

The accuracy values refer to the maximum measuring range. Smaller measuring ranges lead to reduced linearization accuracy.

Standard signals

Designation Measuring range Measuring accuracy

Voltage 0.05 % 100 ppm/K

Input resistance R

Input resistance R

> 500 k DC 0(2) to 10 V

E

> 100 k DC0to1V

E

Current (voltage drop 2V) DC0(4)to20mA 0.05 % 100 ppm/K

Resistance transmitter min. 100 , max. 4 k4 100 ppm/K

Resistance/potentiometer 400

400 to 4 k

a

The accuracy values refer to the maximum measuring range. Smaller measuring ranges lead to reduced linearization accuracy.

0.4

4

a

Ambient

temperature influence

50 ppm/K

50 ppm/K

Measuring circuit monitoring

In the event of an error the digitized output values move to a defined status.

Measuring element Out of range Probe/cable short circuit Probe/cable break

Thermocouple Is detected Is not detected Is detected

RTD temperature probe Is detected Is detected Is detected

Voltage

2 to 10 V Is detected Is detected Is detected

0 to 10 V Is detected Is not detected Is not detected

0 to 1 V Is detected Is not detected Is not detected

Current

4 to 20 mA Is detected Is detected Is detected

0 to 20 mA Is detected Is not detected Is not detected

Resistance transmitter Is detected Is not detected Is detected

Resistance/potentiometer Is detected Is detected Is detected

2013-05-07/00529109

Page 5

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 5/10

Digital input

Number 1

Input signal DC 0/24 V

(PLC level; logical “0” = -3 to +5 V; logical “1” = +15 to +30 V)

Electrical data

Voltage supply

Connection Lateral (feed via base unit or router module)

Voltage DC 24 V +25/-20 %

Residual ripple 5 %

Current consumption 130 mA (at DC 19.2 V)

Power consumption 3 W

Inputs (terminals 1 to 18)

Connection At the front (removable terminal strips with Push-In technology)

Conductor cross section on terminals 1 to 18

Wire or strand without ferrule Min. 0.14 mm

Strand with ferrule Without plastic collar: Min. 0.25 mm2, max. 1.5 mm

With plastic collar: Min. 0.25 mm2, max. 0.5 mm

Stripping length on terminals 1 to 18 9 mm

Electrical safety Acc. to DIN EN 61010-1

Overvoltage category III, pollution degree 2

Electromagnetic compatibility Acc. to DIN EN 61326-1

Interference emission Class A – only for industrial use –

Interference immunity Industrial requirements

2

, max. 1.5 mm

2

2

2

Case and ambient conditions

Case type Plastic case for DIN rail mounting in the control cabinet (indoor use); DIN rail acc. to

Dimensions (W × H × D) 22.5 m × 103.6 m × 101.5 m (without connection elements)

Weight Approx. 140 g

Protection rating IP 20, acc. to DIN EN 60529

Ambient temperature range -20 to +55 °C

Storage temperature range -40 to +70 °C

Resistance to climatic conditions Relative humidity 90 % annual average without condensation (climatic class 3K3

Site altitude Up to 2000 m above sea level

Mechanical ambient conditions

a

Test conditions are listed in the System Descripton B 705000.8.

a

DIN EN 60715, 35 mm x 7.5 mm x 1 mm

acc. to DIN EN 60721-3-3 with extended temperature and humidity range)

Classification acc. to DIN EN 60721-3-3, table 6, class 3M2

Approval/approval marks

Approval mark Testing agency Certificate/certification

number

c UL us Underwriters Laboratories E201387 UL 61010-1 (3. Ed.),

Inspection basis Valid for

all types

CAN/CSA-22.2

No. 61010-1 (3. Ed.)

2013-05-07/00529109

Page 6

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Display and connection elements

(1)

(2)

(3)

(4)

(5)

(7)

(6)

Analog input 4

Digital input

»

AC 30 V

DC 50 V

AC 30 V

DC 50 V

Analog input 3

Analog input 2

Analog input 1

»

AC 30 V

DC 50 V

»

AC 30 V

DC 50 V

»

AC 30 V

DC 50 V

Voltage supply Out

Side system bus In

Side system bus Out

Voltage supply In

Data Sheet 705020 Page 6/10

(1) Status displays (LED)

P = Voltage supply

S = Status

1 = Digital input

(LED is lit: Active)

(2) Analog input 1 to 3

(3) Voltage supply Out, DC 24 V

(4) Side system bus Out

(5) Analog input 4;

digital input

(6) Side system bus In

(7) Voltage supply In, DC 24 V

Electrical isolation

2013-05-07/00529109

Page 7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 7/10

U

+

-

x

U

+

-

x

I

+

-

x

E

S

A

Connection diagram

The connection diagram included in the data sheet provides initial information about the connection options. Only use the installation instructions

or the operating manual for the electrical connection. The know-how and the correct tec hnical implementation of the safety warnings/instructions

contained in these documents are the prerequisite for the installation, electrical connection, and initial start as well as for the safety during operation.

Analog inputs

Connection Input Terminals Symbol and terminal designation

Thermocouple 1

RTD temperature probe

2-wire circuit

RTD temperature probe

3-wire circuit

RTD temperature probe

4-wire circuit

2 and 3

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

6 and 7

10 and 11

14 and 15

2 and 4

6 and 8

10 and 12

14 and 16

2 to 4

6 to 8

10 to 12

14 to 16

1 to 4

5 to 8

9 to 12

13 to 16

2, 6, 10, 14

3, 7, 11, 15

2, 6, 10, 14

4, 8, 12, 16

2, 6, 10, 14

3, 7, 11, 15

4, 8, 12, 16

1, 5, 9, 13

2, 6, 10, 14

3, 7, 11, 15

4, 8, 12, 16

Voltage DC 0(2) to 10 V 1

Voltage DC 0 to 1 V 1

Current DC 0(4) to 20 mA 1

Resistance transmitter

A = Start

E = End

S = Slider

Resistance/potentiometer

2-wire circuit

1 and 2

2

3

4

5 and 6

9 and 10

13 and 14

2 and 3

2

3

4

6 and 7

10 and 11

14 and 15

3 and 4

2

3

4

1

2

3

4

1

2

3

4

7 and 8

11 and 12

15 and 16

2 to 4

6 to 8

10 to 12

14 to 16

2 and 4

6 and 8

10 and 12

14 and 16

1, 5, 9, 13

2, 6, 10, 14

2, 6, 10, 14

3, 7, 11, 15

3, 7, 11, 15

4, 8, 12, 16

2, 6, 10, 14

3, 7, 11, 15

4, 8, 12, 16

2, 6, 10, 14

4, 8, 12, 16

Resistance/potentiometer

3-wire circuit

1

2

3

4

2013-05-07/00529109

2 to 4

6 to 8

10 to 12

14 to 16

2, 6, 10, 14

3, 7, 11, 15

4, 8, 12, 16

Page 8

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 8/10

U

+

-

x

Connection Input Terminals Symbol and terminal designation

Resistance/potentiometer

4-wire circuit

1

2

3

4

1 to 4

5 to 8

9 to 12

13 to 16

Digital input

Connection Input Terminals Symbol and terminal designation

Digital input DC 0/24 V 1 17 and 18 17

1, 5, 9, 13

2, 6, 10, 14

3, 7, 11, 15

4, 8, 12, 16

18

2013-05-07/00529109

Page 9

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 9/10

22.5

103.6

6.6

101

94.5

101.5

14.5

Dimensions

Module overview

Base units

• Central processing unit

Data sheet 705001

Input/output modules

• Multichannel controller module

Data sheet 705010

• Relay module 4-channel

Data sheet 705015

• Analog input module 4-channel

Data sheet 705020

• Analog input module 8-channel

Data sheet 705021

• Digital input/output module 12-channel

Data sheet 705030

Special modules

• Router module

Data sheet 705040

Operating, visualization,

recording

• Multifunction panel 840

Data sheet 705060

Power supply units

• 705090/05-33

Data sheet 705090

• 705090/10-33

Data sheet 705090

2013-05-07/00529109

Page 10

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 705020 Page 10/10

Order details

(1) Basic type

705020 Analog input module 4-channel

(2) Voltage supply

36 DC 24 V +25/-20 %

(1) (2)

Order code /

Order example 705020 / 36

Scope of delivery

1 analog input module, 4-channel

1 Installation Instructions B 705020.4

General accessories

Article Part no.

JUMO mTRON T system manual, English 00575577

MiniDVD with setup program (full version), programming software CODESYS V3, and detailed documenta-

tion; incl. USB cable

PC Evaluation Software PCA3000 00431882

Release automatic print for PC Evaluation Software PCA3000 00505548

PCA Communication Software PCC 00431879

Plant Visualization Software JUMO SVS3000: See data sheet 700755 USB cable A-plug mini-B-plug 3 m 00506265

00569494

2013-05-07/00529109

Loading...

Loading...