Page 1

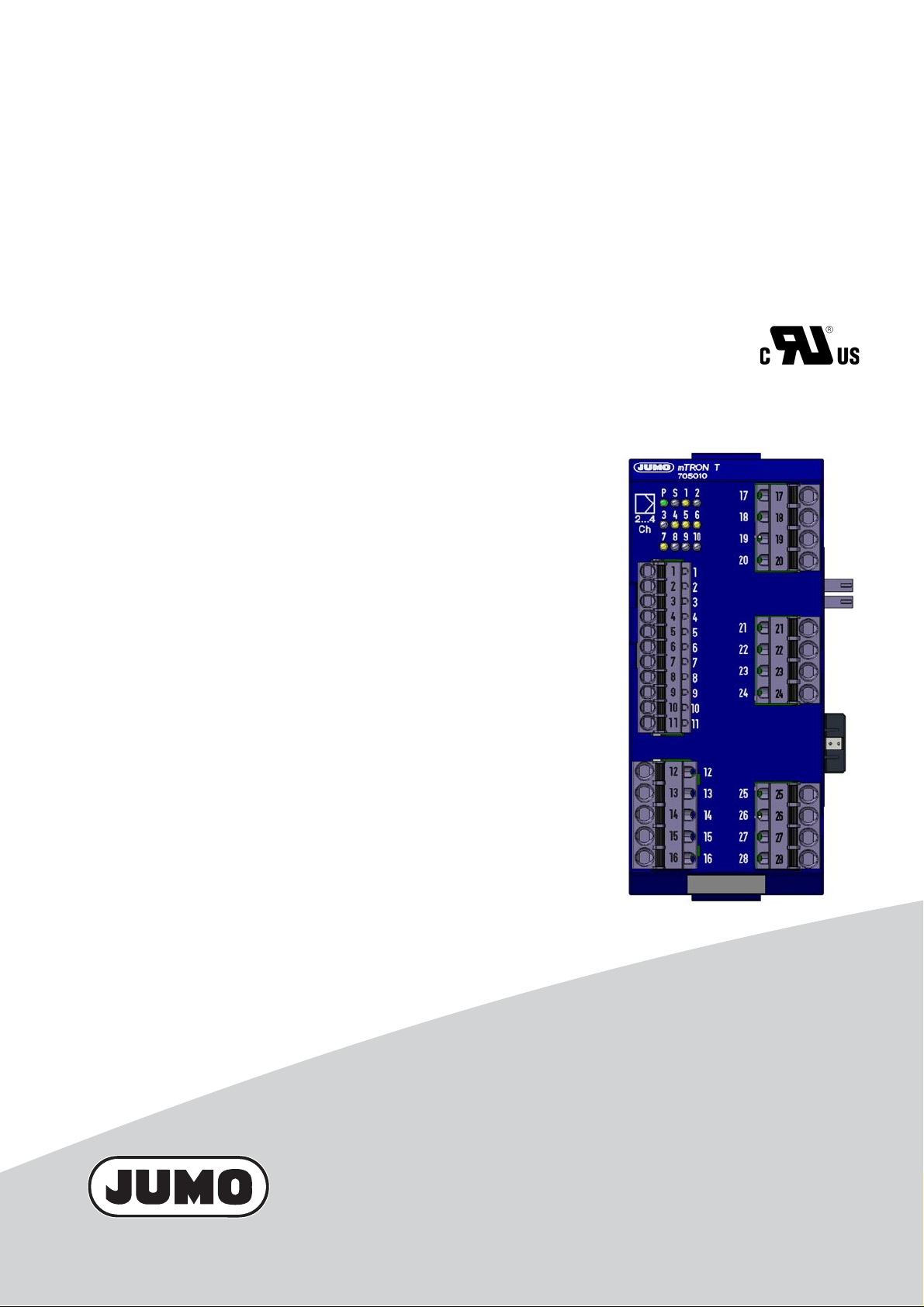

JUMO mTRON T

Measuring, Control, and Automation System

Multichannel Controller Module

B 705010.0

Operating Manual

2013-06-19/00575595

Page 2

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.1 Available technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.2 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.3 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.4 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.5 Operating, visualization, recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.6 Power supply units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 Warning symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 Note signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2.4 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Acceptance of goods, storage, and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Notes on storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.3 Returning goods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Identifying the device version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.1 Nameplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.2 Order details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.5 General accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.1 General information on installation/dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Installation/dismounting on DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Replacing module inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.1 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.1 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2 Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3.1 Display and connection elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.2 Overview of inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3

Page 4

Contents

4.3.3 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.3.4 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.5 Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.6 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4 Connection examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4.1 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4.2 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5 Functional test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.1 Display and connection elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 LED displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.1 Display modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.2 System states and errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3 Operation on the multifunction panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.1 Multichannel controller module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.1 Analog selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Digital selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 "Independent controller" operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.4 Device data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.5 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.5.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.5.2 Fine adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.6 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.6.1 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.7 HW Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.7.1 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.8 Binary linkings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.9 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.9.1 Controller (features) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.9.2 Controller input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.9.3 Self-optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.9.4 K-Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.9.5 Controller collective alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.10 Setpoint values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.10.1 Ramp function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.11 Limit value monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.11.1 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.11.2 Alarm and hysteresis functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.12 Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.13 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.14 NV connecting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.14.1 Analog signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4

Page 5

Contents

6.14.2 Digital signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.14.3 Analog signals (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.14.4 Digital signals (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.14.5 Replacement values (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

7.1 Controller parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.2 Controller types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8 Configuration – in setup program only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

8.1 Customer-specific linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.1.1 Grid points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

8.1.2 Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

8.2 Math/Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

9 Online parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

9.1 Calibrate / test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

9.1.1 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

9.1.2 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

9.1.3 Digital input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

9.1.4 Digital output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.1.5 Internal Pt100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

9.1.6 LED test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

9.1.7 Calibration constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

9.1.8 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

10 Retrofitting inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

11.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

11.1.1 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

11.1.2 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.1.3 Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

11.1.4 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

11.1.5 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11.1.6 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11.1.7 Case and ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

11.1.8 Approval/approval marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

5

Page 6

Contents

6

Page 7

1.1 Available technical documentation

The documents specified below are available for the measuring, control, and automation system.

1.1.1 General information

Product Type of documentation No. Printed PDF file

Measuring,

control, and

automation system

1

Accessory subject to charge

2

Includes an overview of the purpose and content of all documents

1.1.2 Base units

Data sheet T 705000 - X

System manual

Setup program manual B 705000.6 - X

System description

1

2

1 Introduction

B 705000.0 X -

B 705000.8 - X

Product Type of documentation No. Printed PDF file

Central

processing unit

Data sheet T 705001 - X

Operating manual B 705001.0 - X

Modbus interface description B 705001.2.0 - X

Installation instructions B 705001.4 X X

1.1.3 Input/output modules

Product Type of documentation No. Printed PDF file

Multichannel

controller module

Relay module

4-channel

Analog

input module

4-channel

Data sheet T 705010 - X

Operating manual B 705010.0 - X

Installation instructions X X

Data sheet T 705015 - X

Operating manual B 705015.0 - X

Installation instructions B 705015.4 X X

Data sheet T 705020 - X

Operating manual B 705020.0 - X

Installation instructions B 705020.4 X X

Analog

input module

8-channel

Digital input/

output module

12-channel

Data sheet T 705021 - X

Operating manual B 705021.0 - X

Installation instructions B 705021.4 X X

Data sheet T 705030 - X

Operating manual B 705030.0 - X

Installation instructions B 705030.4 X X

7

Page 8

1 Introduction

1.1.4 Special modules

Product Type of documentation No. Printed PDF file

Router module Data sheet T 705040 - X

Installation instructions B 705040.4 X X

1.1.5 Operating, visualization, recording

Product Type of documentation No. Printed PDF file

Multifunction

panel 840

Data sheet T 705060 - X

Operating manual B 705060.0 - X

Modbus interface description B 705060.2.0 - X

Installation instructions B 705060.4 X X

1.1.6 Power supply units

Product Type of documentation No. Printed PDF file

24 V power supply

units

Data sheet T 705090 - X

Operating instructions QS5.241 X Operating instructions QS10.241 X -

8

Page 9

1.2 Safety information

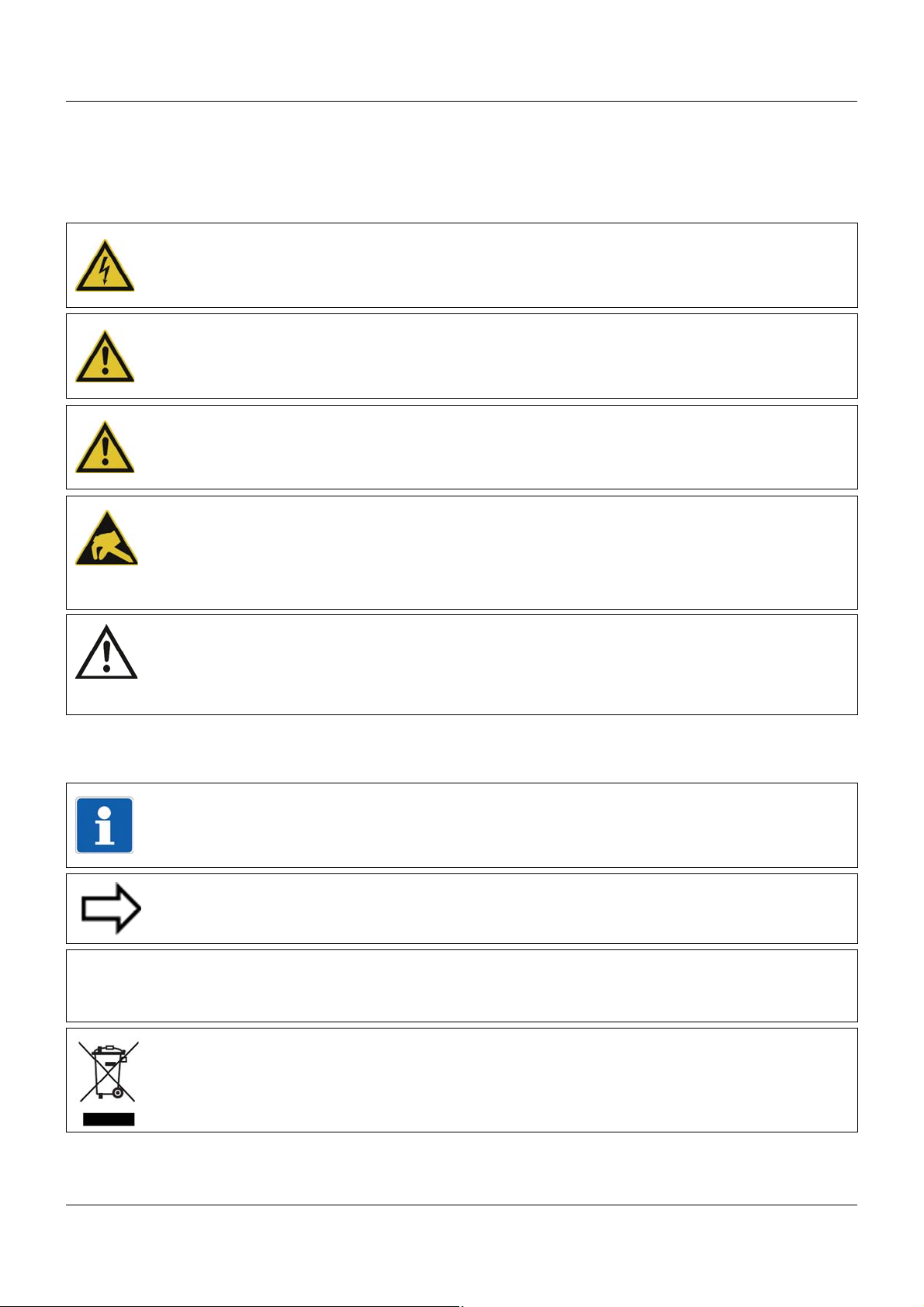

&

1.2.1 Warning symbols

DANGER!

This symbol indicates that injury to persons caused by electrical shock may occur, if the

respective protective measures are not carried out.

WARNING!

This symbol in connection with the signal word indicates that injury of persons may occur,

if the respective protective measures are not carried out.

CAUTION!

This symbol in combination with the signal word indicates that damage to assets or data

loss will occur if suitable precautions are not taken.

CAUTION!

This sign indicates that components could be destroyed by electrostatic discharge

(ESD = Electro Static Discharge), if the respective cautionary measures are not taken.

Only use the ESD packages intended for this purpose to return device inserts, assembly

groups or assembly components.

1 Introduction

READ DOCUMENTATION!

This symbol – placed on the device – indicates that the associated device documentation

has to be observed. This is necessary to recognize the kind of the potential hazards as

well as to take the measures to avoid them.

1.2.2 Note signs

TIP!

This symbol refers to important information about the product or its handling or additional

use.

REFERENCE!

This symbol refers to further information in other sections, chapters, or manuals.

FURTHER INFORMATION!

This sign is used in the tables and refers to further information in connection with the table.

DISPOSAL!

This device and, if installed, the batteries must not be disposed of in the garbage can after

use! Please ensure that they are disposed of properly and in an environmentally friendly

manner.

9

Page 10

1 Introduction

1.2.3 Intended use

The modules described are intended for measuring, control, an d automation t asks in an ind ustrial environment, as described in the technical data. Oth er uses or uses beyond th ose defined

are not viewed as intended uses.

The modules are built according to the relevant standards and directives as well as the applicable safety regulations. Nevertheless, incorrect use may lead to bodily injury or property damage.

To avoid danger, the modules may only be used:

• For the intended use

• When in good order and condition

• When taking into account the technical documentation provided

Even if a module is used correctly and according to the intended use, it may still cause appli-

cation-related dangers (e.g. due to missing safety devices or incorrect settings).

1.2.4 Qualification of personnel

This document contains the necessary information for the intended use of the modules to which

it relates.

It is intended for technically qualified personnel who have received special training and have

the appropriate knowledge in the field of automation technology (measuring, process, and control technology).

The appropriate level of knowledge and the technically fault-free implementation of the safety

information and warnings contained in the technical documentation provided are prerequisites

for risk-free mounting, installation, and startup as well as for ensuring safety when operating

the described modules. Only qualified personnel have the required specialist knowledge to correctly interpret and implement the safety information and warnings contained in this document

in specific situations.

10

Page 11

1.3 Acceptance of goods, storage, and transport

1.3.1 Checking the delivery

• Ensure that the packaging and contents are not damaged

• Check that the delivery is complete using the delivery papers and the order details

• Inform the supplier immediately if there is any damage

• Store damaged parts until clarification is received from the supplier

1.3.2 Notes on storage and transport

• Store the module in a dry and clean environment. Observe the admissible ambient conditions (see "Technical data")

• The transport of the module is to be shockproof

• The original packaging provides optimum protection for storage and transport

1.3.3 Returning goods

In the event of repair, please return the module in a clean and complete state.

Use the original packaging to return goods.

1 Introduction

Accompanying letter for repair

Please include the completed accompanying letter for repair when returning goods.

Do not forget to state the following:

• Description of the application and

• Description of the error that has occurred

The accompanying letter for repair can be downloaded online from the manufacturer's website

(use the search function if necessary).

Protection against electrostatic discharge (ESD)

(ESD = electrostatic discharge)

To prevent damage from ESD, electronic modules or components must be handled, packaged,

and stored in an ESD-protected environment. Measures against electrostatic discharge and

electrical fields are described in DIN EN 61340-5-1 and DIN EN 6 1340-5-2 "Protection of electronic devices from electrostatic phenomena".

When returning electronic modules or components, please note the following:

• Sensitive components must only be packaged in an ESD-protected environment. Workspaces such as this divert electrostatic charges to ground in a controlled manner and prevent static charges due to friction capacities.

• Only use packaging for ESD-sensitive modules/components. These must consist of conductive plastics.

No liability can be assumed for damage caused by ESD.

11

Page 12

1 Introduction

CAUTION!

Electrostatic charges occur in non-ESD protected environments.

Electrostatic discharges can damage modules or components.

For transport purposes, use only the ESD packaging provided.

1.3.4 Disposal

Disposing of the device

DISPOSAL!

Devices and/or replaced parts should not be placed in the refuse bin at the end of their service life as they consist of materials that can be recycled by specialist recycling plants.

Dispose of the device and the packaging material in a proper and environmentally friendly

manner.

For this purpose, observe the country-specific laws and regulations for waste treatment a nd

disposal.

Disposing of the packaging material

The entire packaging material (cardboard packaging, inserts, plastic film, and plastic bags) is

fully recyclable.

12

Page 13

1.4 Identifying the device version

(A) (B)

1.4.1 Nameplates

Position

The nameplate (B) is affixed to the module case.

Additional nameplates with reduced information are located on the module insert (A) and inside

the module case (C; not shown). This duplicate identification marking via nameplates (A) and

(C) is important when replacing a module insert or retrofitting optional modules.

1 Introduction

Content

The nameplates contain important information. This includes:

Device type

Compare the specifications on the nameplate with the order.

Identify the supplied device version using the order details of the respective module.

Part no. (TN)

The part no. clearly identifies an article in the catalog. It is important for communication between the customer and the sales department.

Description Designation on the name-

plate

Device type (A + B + C) Typ 705010/18-113-36

Part no. (A + B + C) TN 00XXXXXX

Fabrication number (A + B + C) F-Nr 0070033801211010006

Voltage supply (B) - DC 24 V +25/-20 %

Example

13

Page 14

1 Introduction

Fabrication no. (F-Nr)

Among other things, the fabrication number contains the date of production (year/week).

Example: F-Nr = 0070033801211010006

The figures concerned are in positions 12, 13, 14, and 15 (from the left).

The device was therefore produced in the 1st calendar week of 2011.

Identifying the optional modules

The device type (Typ) also contains information about factory-fitted optional modules (in the

example above – 705010/18-113-36 – this is string 113). The optional modules can be identified by the order details.

This chapter contains additional information to identify optional modules:

Chapter 10 "Retrofitting inputs/outputs", page 137

TIP!

The information on the nameplates must also be considered when replacing the module insert

(Chapter 3.3 "Replacing module inserts", page 24).

14

Page 15

1.4.2 Order details

(1) Basic type

705010 Multichannel controller module, 2x universal input, 2x digital input, 2x relay output

(2) Basic type extension

1 2 relays (N/O contact)

2 2 logic outputs 0/15 V

(3) Version

8 With factory settings

(4) Option slot 1

0 Not used

1 Analog input 2

2 Relay (changeover contact)

3 2 relays (N/O contacts with common pole)

4 Analog output

5 2 digital inputs

6 Solid-state relay 1 A

7 2 open-collector outputs

(5) Option slot 2

0 Not used

1 Analog input 2

2 Relay (changeover contact)

3 2 relays (N/O contacts with common pole)

4 Analog output

5 2 digital inputs

6 Solid-state relay 1 A

7 2 open-collector outputs

(6) Option slot 3

0 Not used

2 Relay (changeover contact)

3 2 relays (N/O contacts with common pole)

4 Analog output

5 2 digital inputs

6 Solid-state relay 1 A

7 2 open-collector outputs

(7) Voltage supply

36 DC 24 V +25/-20 %

1 Introduction

(1) (2) (3) (4) (5) (6) (7)

Order code /- -

Order example 705010 / 1 8 - 0 0 0 - 36

15

Page 16

1 Introduction

1.4.3 Scope of delivery

1 multichannel controller module in the ordered version

1 Installation instructions B 705010.4

1.4.4 Accessories

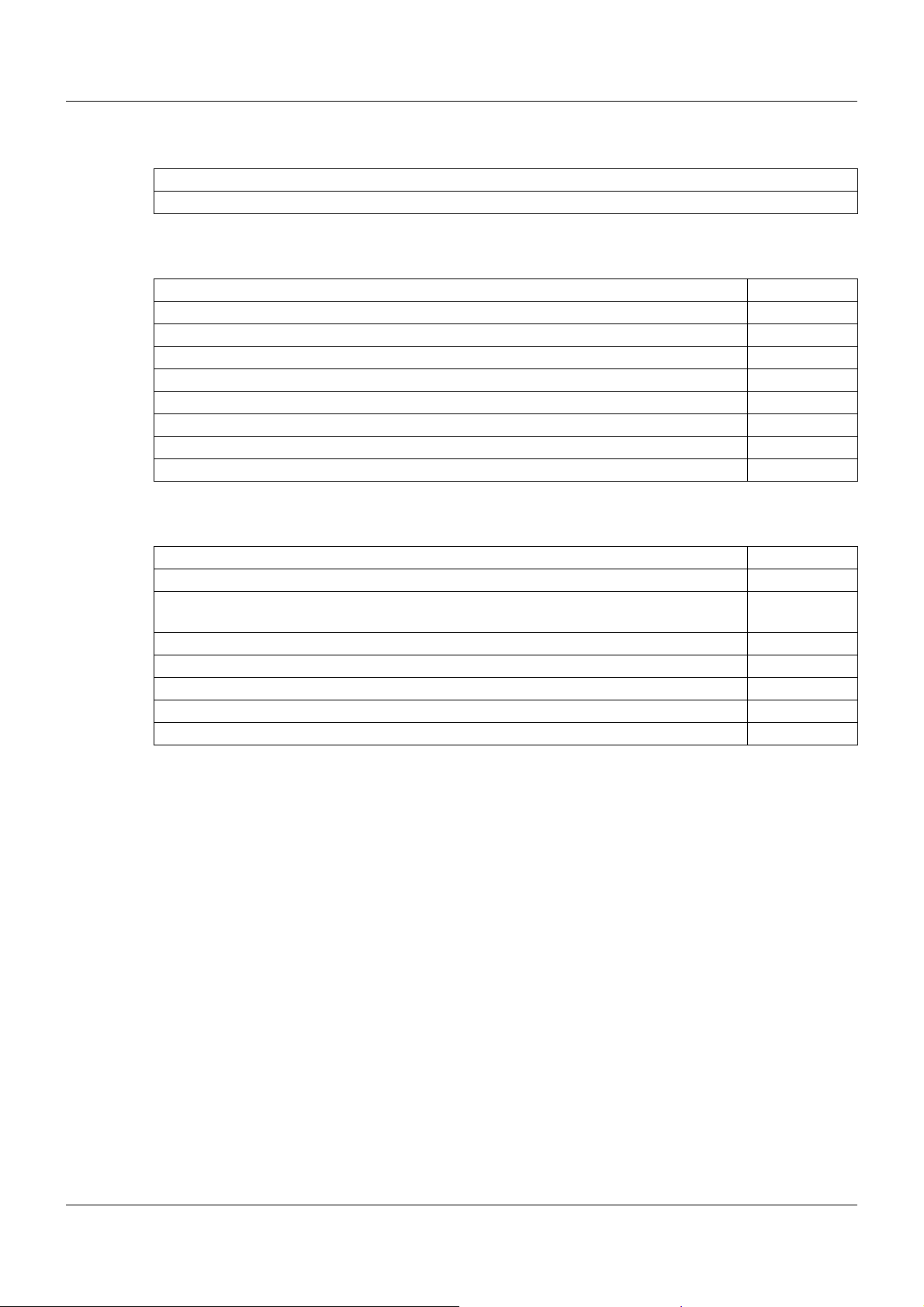

Article Part no.

Modules for option slots (expansion boards):

Analog input 00569497

Relay (changeover contact) 00569498

2 relays (N/O contacts with common pole) 00569499

Analog output 00569500

2 digital inputs 00569501

Solid-state relay 1 A 00569502

2 open-collector outputs 00569503

1.4.5 General accessories

Article Part no.

JUMO mTRON T system manual, English 00575577

MiniDVD with setup program (full version), programming sof tware CODESYS V3, a nd

detailed documentation; incl. USB cable

PC Evaluation Software PCA3000 00431882

Release automatic print for PC Evaluation Software PCA3000 00505548

PCA Communication Software PCC 00431879

Plant Visualization Software JUMO SVS3000: See data sheet 700755 USB cable A-plug mini-B-plug 3 m 00506265

00569494

16

Page 17

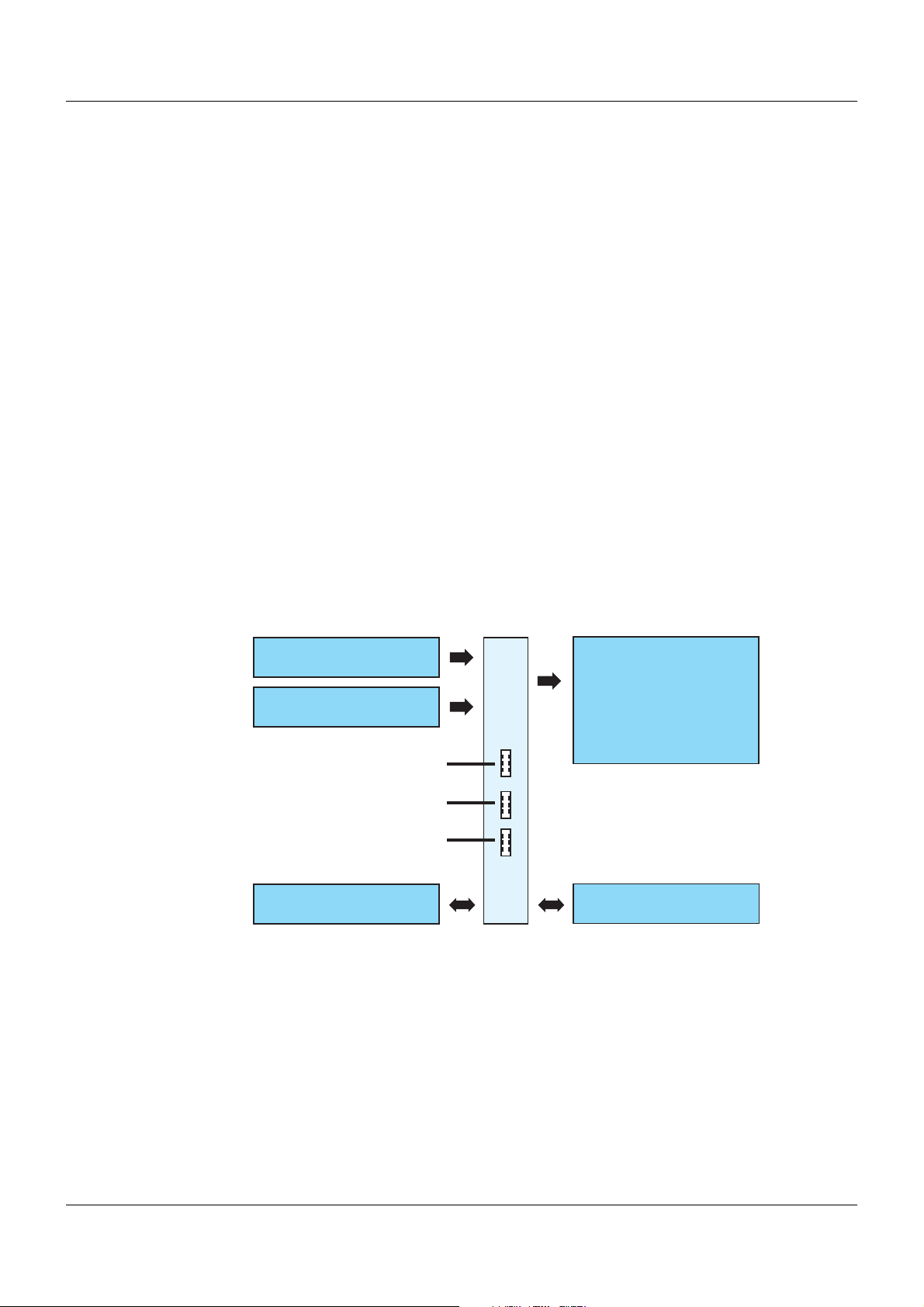

2.1 Brief description

2 universal analog inputs

Option 1

2 digital inputs

(DC 0/24 V)

2 digital outputs:

Relay

Logic

(N/O)

or

(DC 0/15 V,

to control an external

solid-state relay)

705010

Option 2

Option 3

Voltage supply

System bus

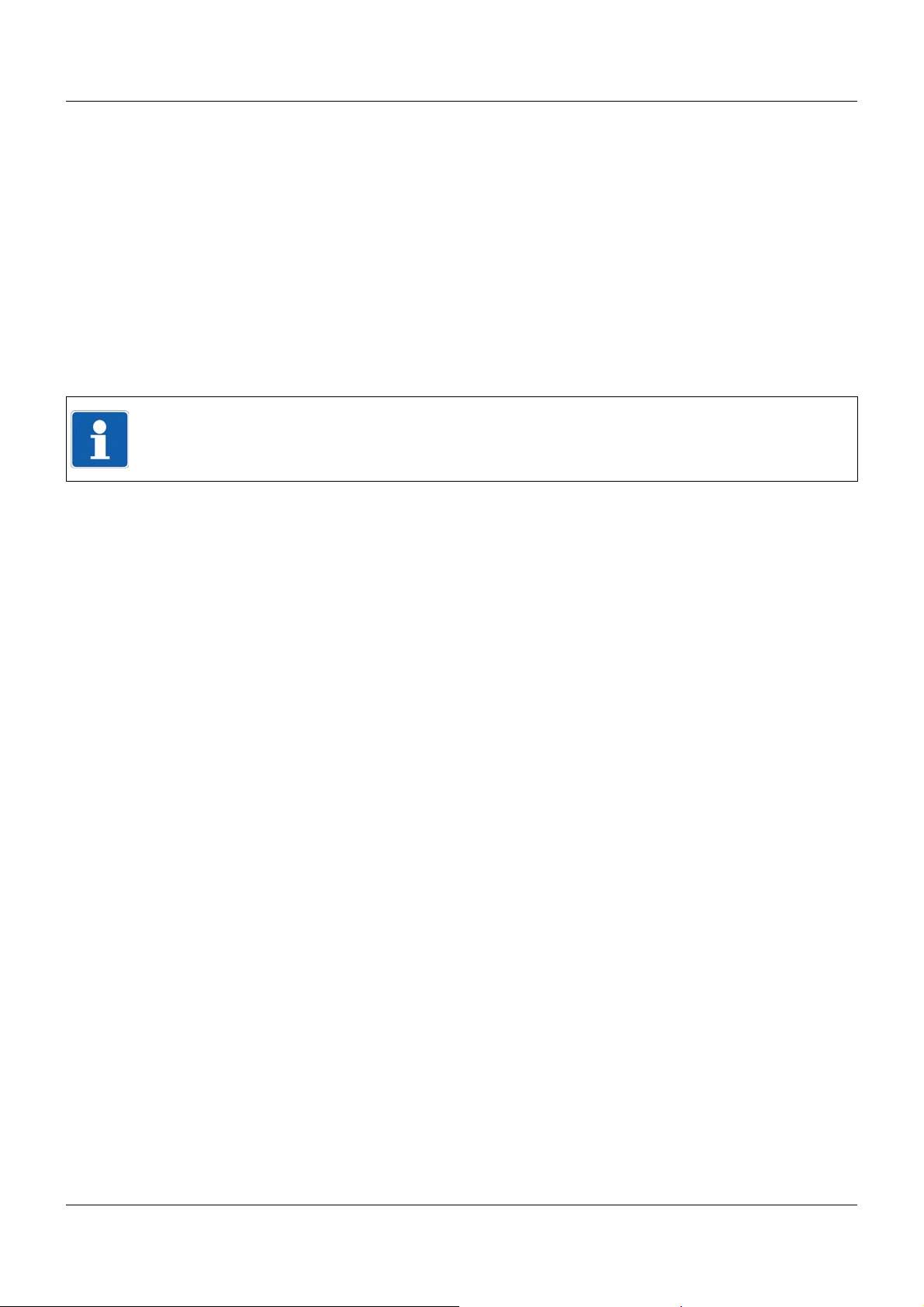

The multichannel controller module supports up to four PID controller channels (cascadable).

In the standard version, two high-quality universal analog inputs for thermocouples, RTD temperature probes, resistance transmitters, resistance/potentiometers, and standard signals are

available. Two digital inputs (DC 0/24 V) and two digital outputs as a relay with N/O contact

(AC 230 V / 3 A) or as a logic output (DC 0/15 V) are also available as part of the standard version. Due to the three option slots (option 1, 2, and 3), the module can be extended up to four

universal analog inputs, eight digital inputs, three analog outputs, or eight digital outputs.

The digitized input values/states are available in the system for further processing. The digital

and the analog outputs can be actuated by t he system (via the connection list or directly by the

PLC) or directly by the module.

The module operates independently , even if the central processing unit fails or the higher-ranking system malfunctions. This behavior can be configured.

LEDs are used to indicate applied voltage supply, the module operating status, as well as the

status of the digital inputs/outputs.

For expansion of the inputs/outputs or for service work, the module insert can be easily pulled

out of the case at the front. The case including the bus PCB remains mounted on the DIN rail.

A setup program allows the user to comfortably configure and parameterize the multichannel

controller module.

2 Description

2.2 Block diagram

17

Page 18

2 Description

18

Page 19

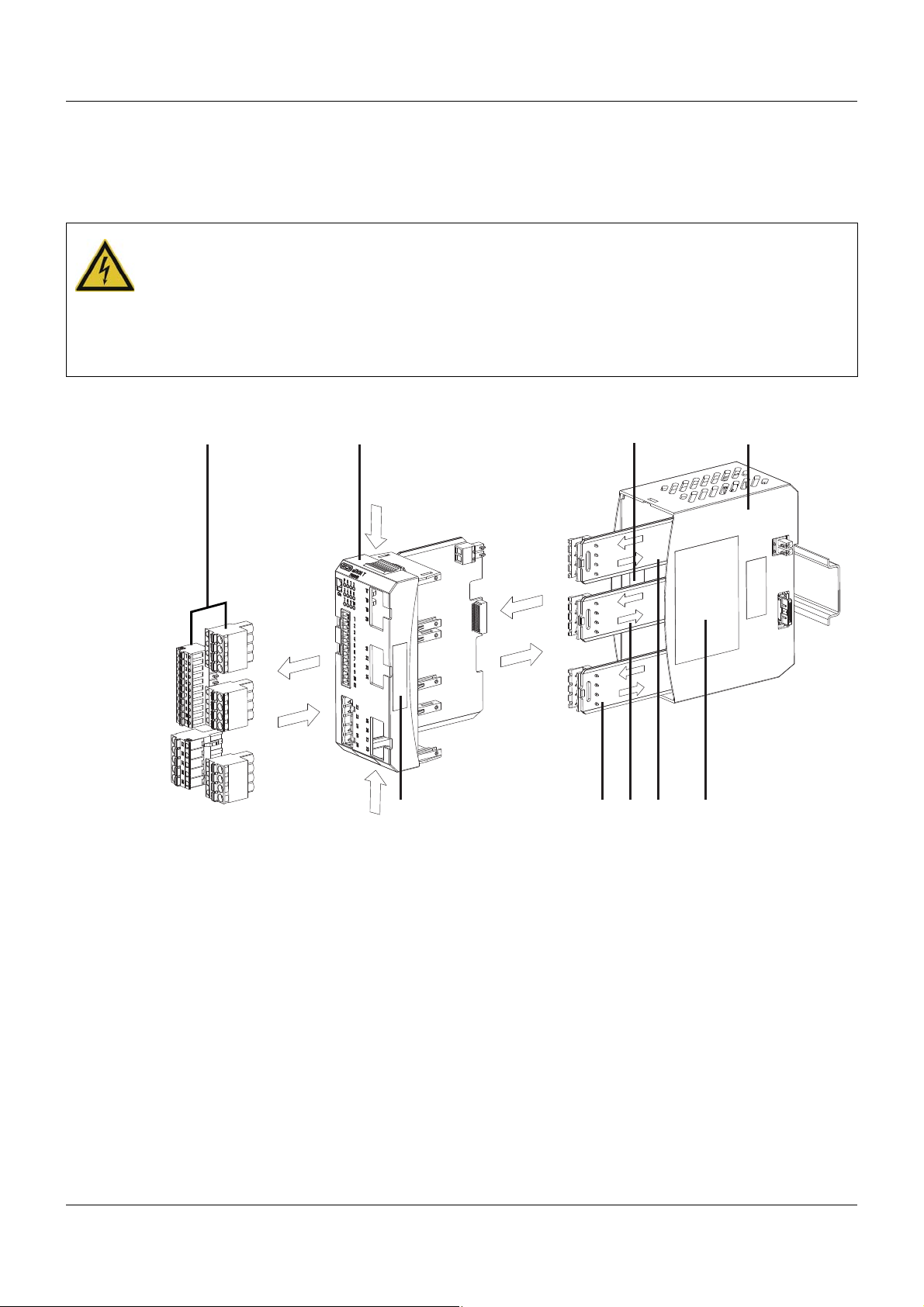

3 Installation

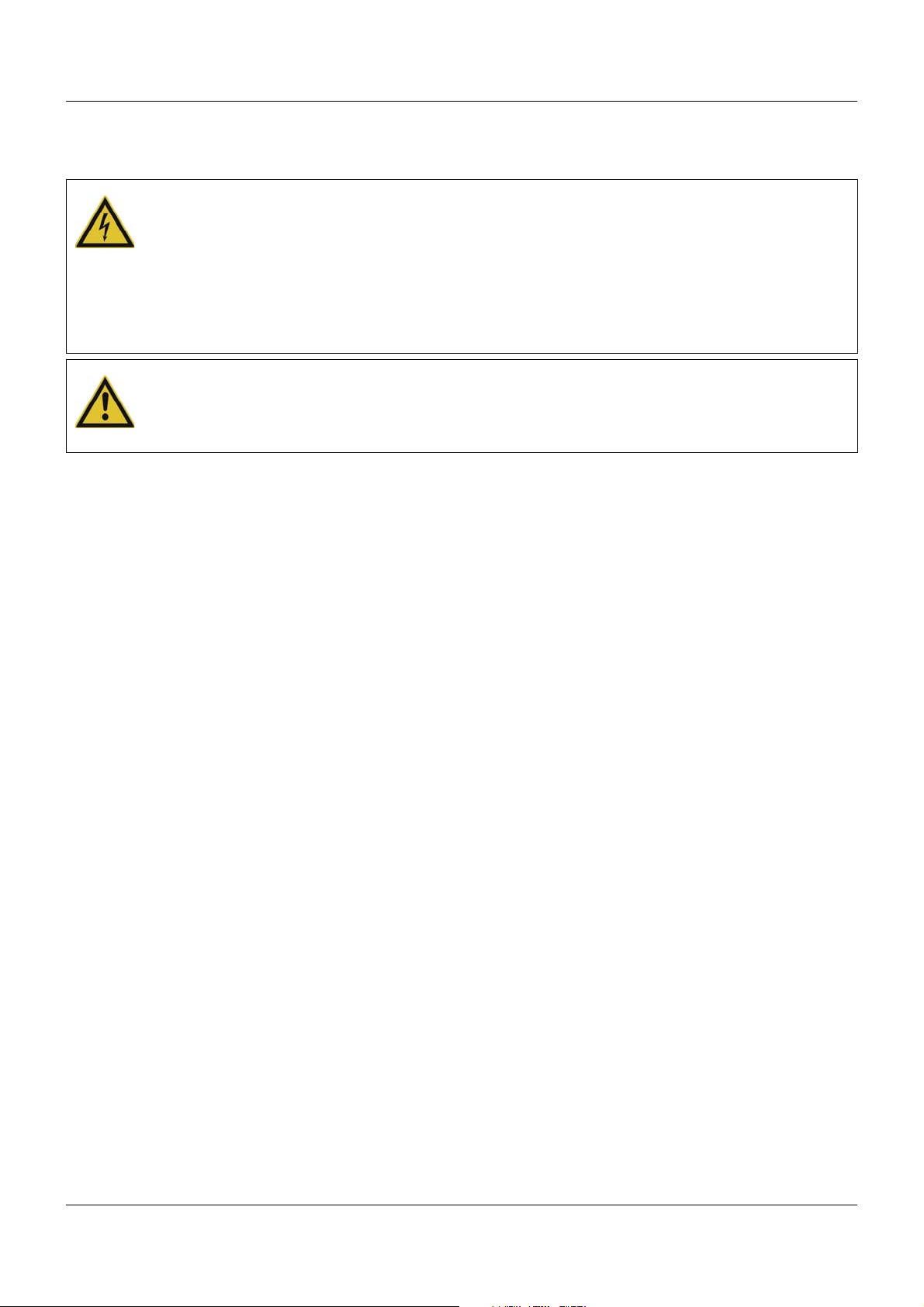

3.1 General information on installation/dismounting

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

Prior to the installation/dismounting of these modules or the removal of the module insert, the

load circuits are to be disconnected from the voltage and the terminal strips are to be removed from the module. This work must only be performed by qualified personnel.

WARNING!

The modules must never be installed in areas with an explosion hazard.

There is the risk of an explosion.

The entire system must only be used outside of areas with an explosion hazard.

Mounting site

All modules have protection type IP20 and are only intended for use in fireproof con trol cabinets

or switch boxes. The mounting site should be virtually vibration-free. Electromagnetic fields

caused by equipment such as motors or transformers should be avoided.

Multifunction panel 840 has protection type IP67 at the front and is intended for installation in

a panel cut-out. The rear has protection type IP20.

Climatic conditions

The ambient temperature and the relative humidity at the mounting site must correspond to the

technical data. Aggressive gases and vapors have a negative ef fect on the operating life of the

modules. The mounting site must be free from dust, powder, and other suspended matter so

that the cooling slots do not become blocked.

DIN rail

All modules are mounted on a DIN rail according to DIN EN 60715 (35 mm × 7.5 mm × 1 mm).

For reasons of stability, the spacing of the fastening screws for the DIN rail should not exceed

200 mm. The minimum distances for the modules that are specified in the module-specific installation or operating instructions must be observed.

Installation position

The DIN rail should be mounted horizontally so that all modules are arranged vertically. Otherwise the admissible ambient temperature range will be restricted.

Space requirement

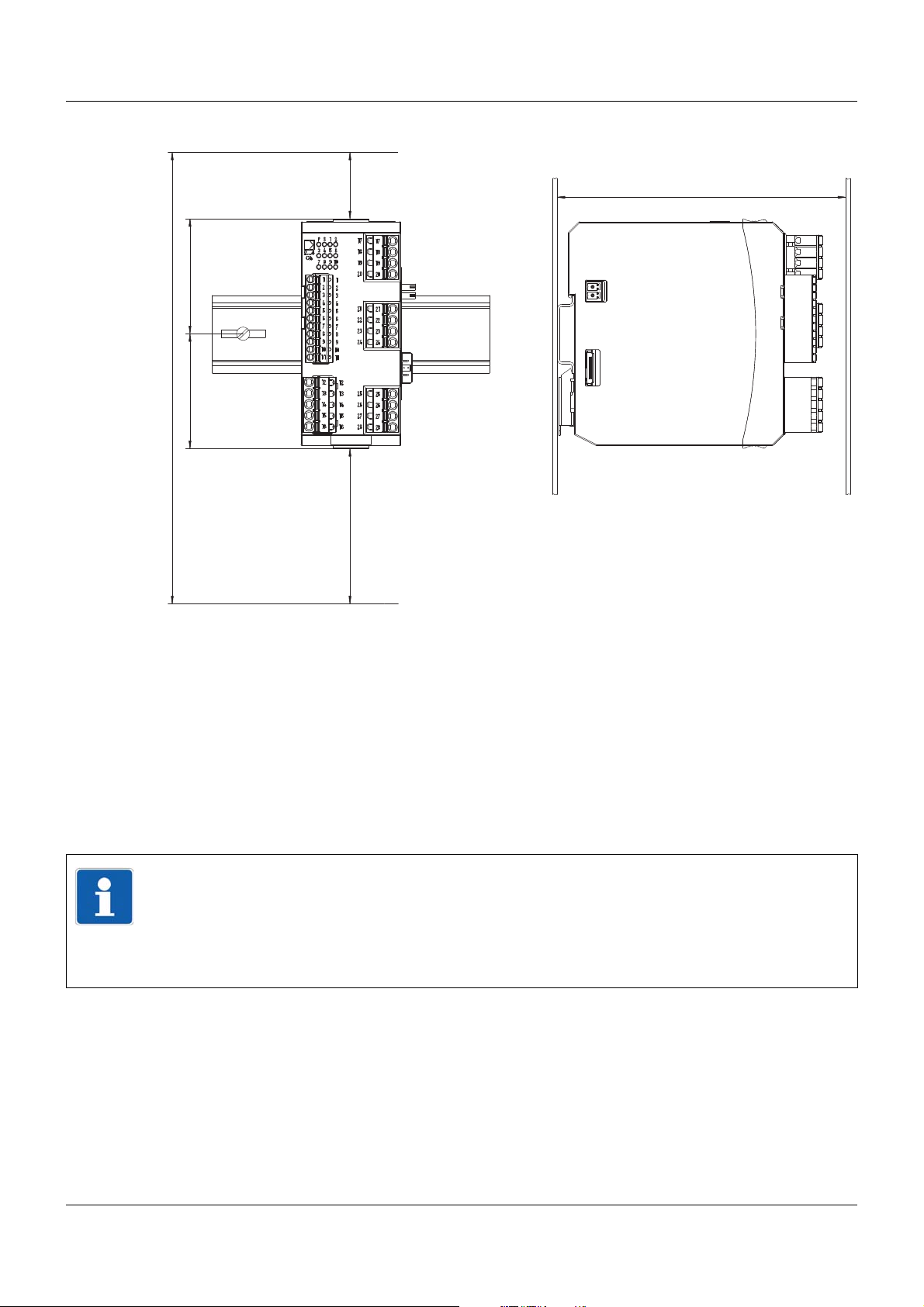

The modules require the minimum distances shown in the following figure for the purpose of

installation/dismounting and for future maintenance or replacement. In the event of shorter distances the minimum bending radius of the cables, the performance of the electrical inst allation,

and the clear arrangement of the plant are no longer guaranteed.

19

Page 20

3 Installation

130

203.6

51.8

30

70

51.8

Minimum distances

3.2 Installation/dismounting on DIN rail

All modules in the system are intended for installation on a DIN rail according to DIN EN 60715

(35mm×7.5mm×1mm).

The following must always be installed on the left, at the start of the DIN rail:

• A central processing unit or

• A router module

These modules connect the input/output modules to the voltage supply and the system bus.

TIP!

To determine the required minimum width of the DIN rail, the widths of the individual modules

are to be added (see technical data of the modules in the respective data sheet or the module-specific installation instructions).

The widths of the cover (17.5 mm) and both end brackets (each 9.5 mm) should also be taken into consideration: 17.5 mm + 2 × 9.5 mm = 36.5 mm.

3.2.1 Input/output modules

In a sequence at the user's discretion, input/output modules can be arranged to the right next

to a base unit or a router module.

20

Page 21

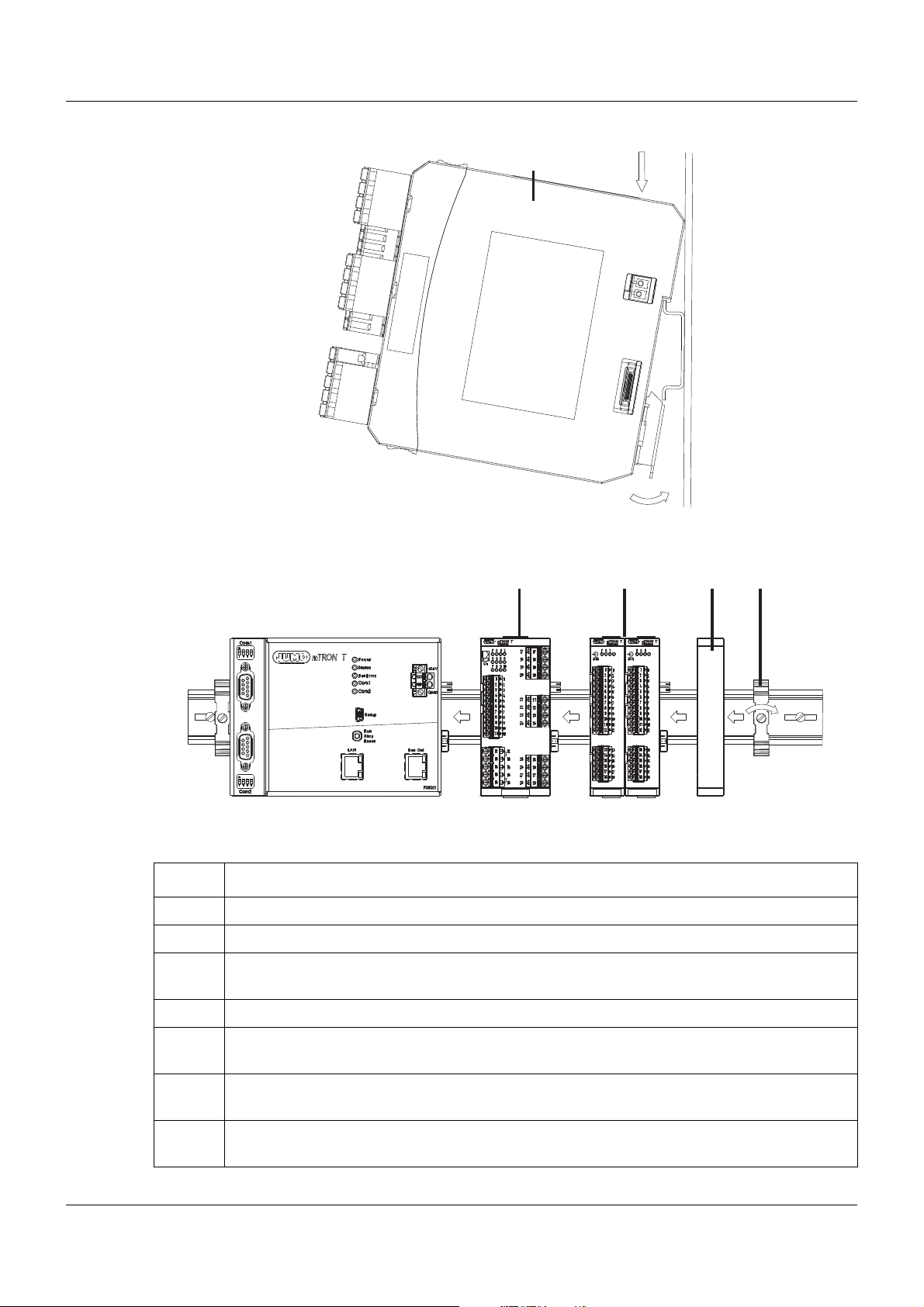

Installation, using the example of a multichannel controller module 705010

(A) (A1)

(A2)

(D)

(C5) (D6)

(D7)

(C)(A)

(B4)(A3)

(B)

3 Installation

Example installation

Procedure:

Step Activity

1 Mount the multichannel controller module (A) in the DIN rail from above (A1).

2 Pivot the multichannel controller module (A) downward until it snaps into place (A2).

3 Move the multichannel controller module (A) to the left against the previous module (A3)

until the plug connections for the voltage supply and the system bus are connected.

4 Position additional modules (B) and move to the left against the previous module (B4).

5 Aft er the final module, position the cover (C) on the DIN rail and move to the left a gainst the

module (C5).

6 After attaching the cover, positio n th e en d br ac ke t (D) on the DIN rail and mov e to th e left

against the cover (D6).

7 Fasten the end br acket ( D) using a screwdrive r (D7). For this purpose, ensure that the end

bracket and the cover are positioned flush against the final module.

21

Page 22

3 Installation

(C2)

(D1)

(A4) (B3)

(C) (D)

(A) (B)

(A)

(F)

(E)

(E5)

(F7)

(A6)

(A8)

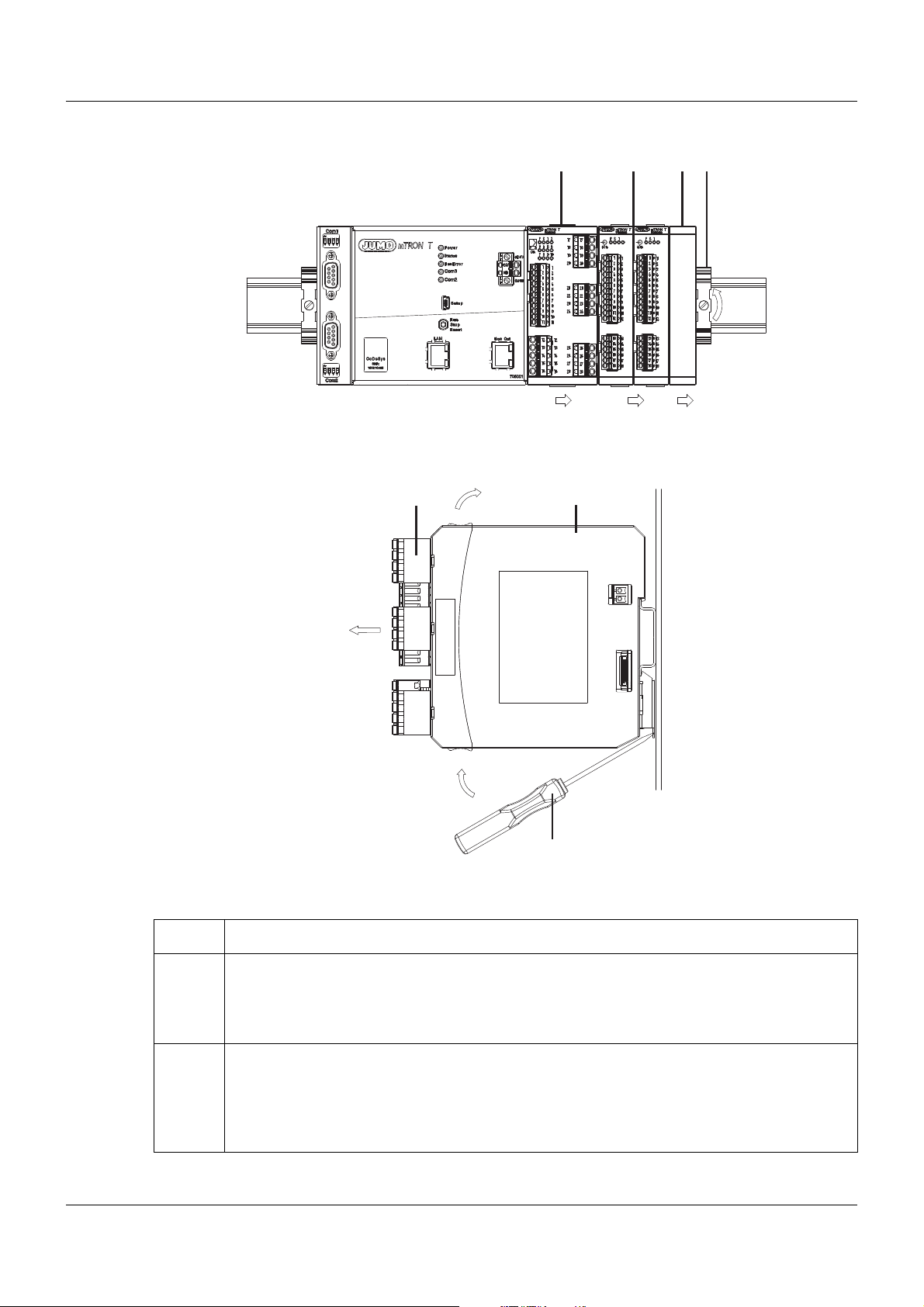

Dismounting, using the example of a multichannel controller module 705010

Removing the multichannel controller module from the DIN rail

22

Procedure:

Step Activity

1 Fully release the end bracket (D) using a screwdriver (D1) , press upward from below, pivot

2 Move the cover (C) to the right (C2) until the side contacts of the neighboring module are

toward the front, and remove from the DIN rail.

Note: The end bracket does not need to be removed from the DIN rail if there is sufficient

space to the side to move it at least 20 mm to the right.

exposed. Then release the cover at the bottom using a screwdriver, press upward, and

remove from the DIN rail.

Note: The cover does not need to be removed from the DIN rail if there is sufficient space

to the side to move it at least 20 mm to the right.

Page 23

3 Installation

Step Activity

3 Move the modules (B) on the right next to the multichannel controller module that is to be

replaced (A) a minimum of 20 mm to the right (B3).

➥ These modules are isolated from the voltage supply and the system bus.

4 Move the multichannel controller module (A) to the right (A4) until the side contacts of the

neighboring module (here: central processing unit) – on the left, next to the multichannel

controller module that is to be replaced – are exposed.

➥ The multichannel controller module is isolated from the voltage supply and the system

bus. This is a prerequisite for the dismounting of the multichannel controller module.

5 If required, pull off the wired terminals (E) of the multichannel controller module (A) toward

the front (E5).

6 Insert a suitable screwdriver (F) into the unlocking slot of the multichannel controller mod-

ule (A6) and press upward (F7).

7 Pivot the multichannel controller module (A) upward off the DIN rail (A8) and remove it.

23

Page 24

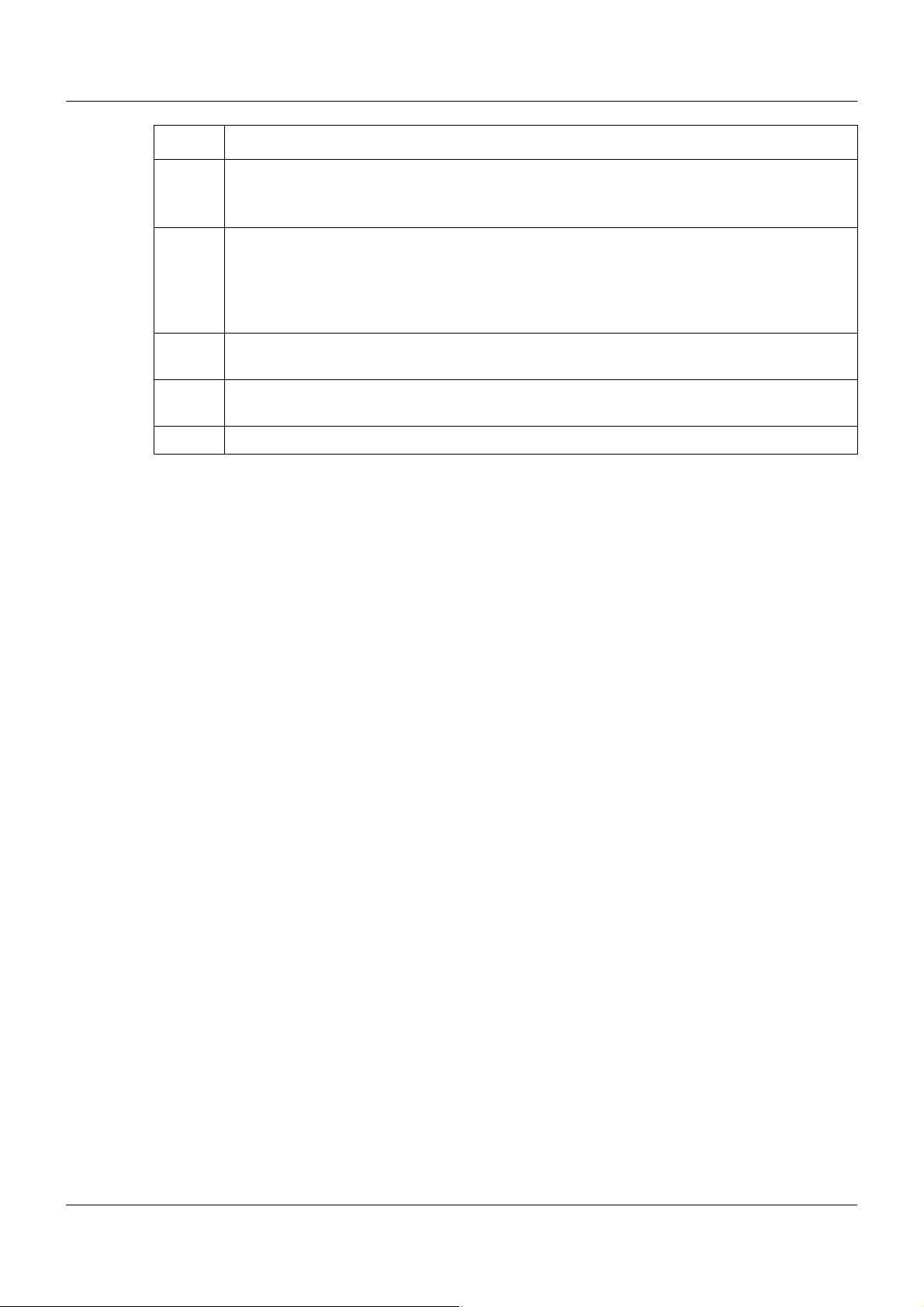

3 Installation

(A)

(E)

(B) (D)

(G)

(C)

(F)

(F)

(F)

3.3 Replacing module inserts

3.3.1 Input/output modules

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

The load circuits are to be disconnected from the voltage supply prior to removing the wired

terminal strips. This work must only be performed by qualified personnel.

Replacement of a module insert, using the example of a multichannel controller module 705010

24

For service purposes (or when retrofitting options for the multichannel controller module), the

case (D) can remain in the system; only the module insert (B) is replaced. For this purpose, the

system does not need to be isolated from the voltage supply (hot swapping).

The system will detect a module insert of the same type that has been replaced and will automatically reconfigure it. Retrofitted functions for the multichannel controller module (exp ansion

slots) must be configured using the setup program or the multifunction panel.

The new module insert also has a new nameplate (G), which will dif fer from the old one at le ast

with regard to the fabrication number, and is no longer identical to nameplates (E) and (C) on

the case (D).

Therefore, in the event of replacement, the module insert will be supplied along with a new

nameplate that will be affixed to the case (D) in place of the old nameplate (C). This means that

the specifications of nameplates (G) and (C) once again correspond to one another.

Page 25

CAUTION!

Only module inserts of the same type may be used for the replacement.

Otherwise, the function of the system may be affected.

The module inserts can be clearly identified using the nameplate.

CAUTION!

With the multichannel controller module 705010, a new modu le insert may contain retrofitted

inputs or outputs that have not yet been configured.

This can lead to unintended behavior, particularly at the outputs and the actuators connected

to them.

Prior to using the retrofitted inputs or outputs, ensure that these have been configured correctly.

Removing the module insert

Step Activity

1 Disconnect load circuits from the relay or solid state relay outputs.

2 Pull off the wir ed terminal strips (A) toward the front.

3 Installation

3 Press the old module inse rt (B) together o n the grooved surface s at the top and bottom and

remove from the case (D).

4 For the multichannel co ntroller module, also remove the modules (F) of the exp ansion slots

from the case (D) toward the front, if required.

Mounting the module insert

Step Activity

1 Affix the new nameplate in place of the old nameplate (C) in the case.

2 For the multichannel controller module, also insert the modules (F) of the expansion slots

into the case (D), if required.

3 Hold the new module insert (B) at the grooved surfaces on the top and bottom and insert

them into the case (D). For this purpose, ensure that the board of the module insert slides

into the guide rails of the case. For the multichannel controller module, also ensure that the

modules (F) of the expansion slots slide in the guide rails of the module insert.

4 Reattach the wired terminal strips (A).

TIP!

When mounting the module insert, ensure that the snap holders (under the grooved surfaces)

audibly snap into place.

TIP!

The availability of the system can be increased through the storage of module inserts and

modules for expansion slots.

25

Page 26

3 Installation

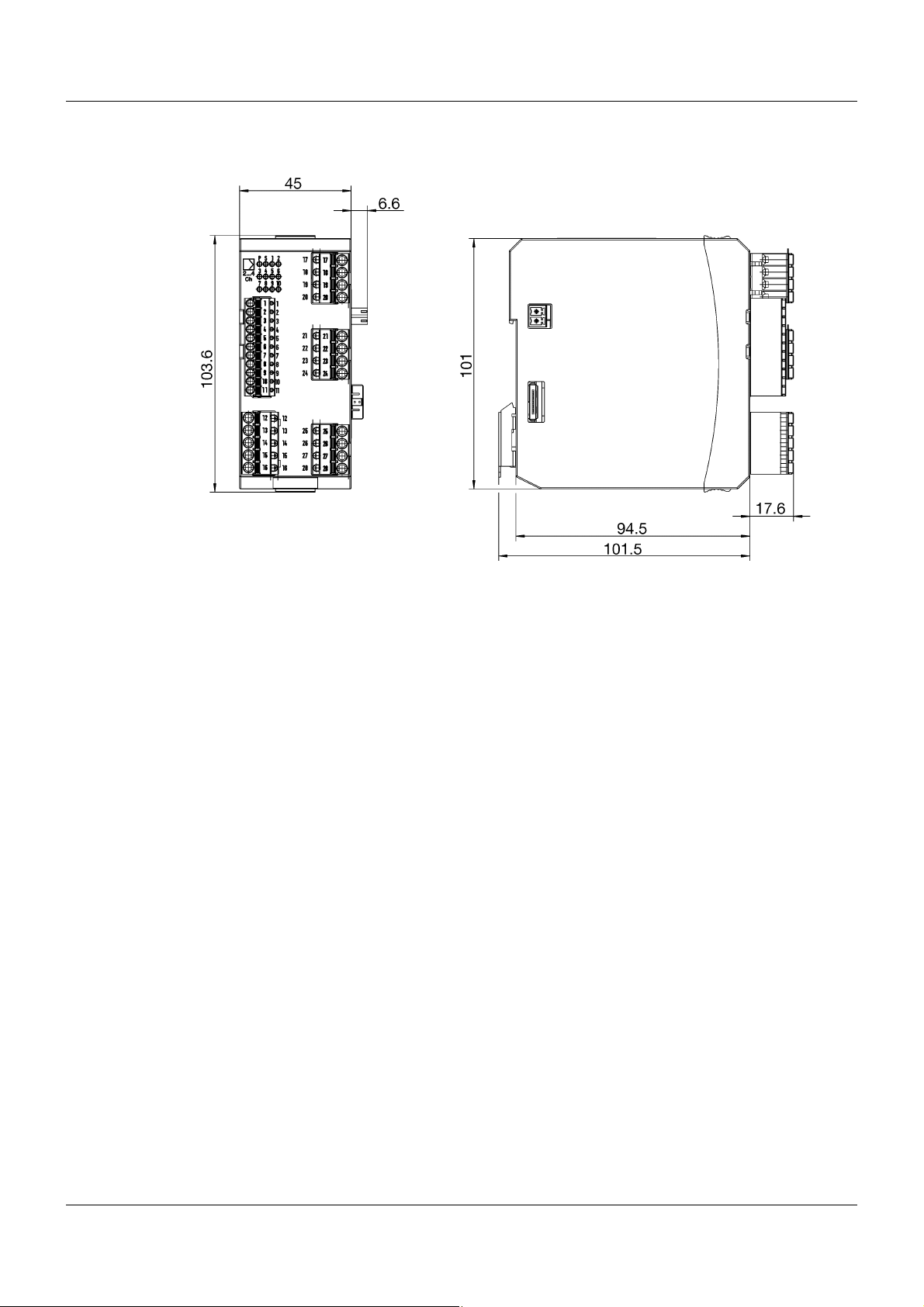

3.4 Dimensions

26

Page 27

4.1 Installation notes

TIP!

These installation notes apply for the entire measuring, control, and automation system and,

on some occasions, are only applicable for a specific module.

The respective connection diagram shows the context.

Qualification of personnel

• Work on the modules must only be carried out to the extent described and, like the electrical

connection, only by qualified personnel.

Cables, shielding, and grounding

• When selecting the cable material, when installing, and when performing the electrical connection of the module, the regulations of DIN VDE 0100 "Erection of power installations with

rated voltages up to 1000 V" and the respective national regulations (e.g. on the basis of

IEC 60364) are to be observed.

• Certain cables must be heat resistant up to at least 80 °C at maximum load. The relevant

instructions in the connection diagram of the affected modules must be observed.

• Route input, output, and supply cables separately and not parallel to one another.

• Only use shielded and twisted probe and interface cables. Do not route the lines close to

current-carrying components or cables.

• For temperature probes, ground the shielding on one side in the control cabinet.

• Do not perform loopthroughs on the grounding cables, but route the cables individually to a

shared grounding point in the control cabinet; in doing so, ensure that the cables are as

short as possible.

Ensure that the equipotential bonding is correct.

4 Electrical connection

Electrical safety

• Isolate power supply units from the voltage supply on the primary side if there is a risk of

touching parts with dangerous electrical voltage (e.g. 230 V) in the course of work.

• The fuse rating of the power supply units on the primary side should not exceed a value of

10 A (inert).

• With modules with relay or solid state relay outputs, the load circuits can be operated with

a dangerous electrical voltage (e.g. 230 V). Disconnect load circuits from the voltage supply

during installation/dismounting and electrical connection.

• In order to prevent the destruction of the relay or solid state relay outputs in the event of an

external short circuit in the load circuit, the load circuit should be fused to the maximum admissible output current.

• The modules are not suitable for installation in areas with an explosion hazard.

• In addition to a faulty installation, incorrectly set values on the module could also impair the

correct function of the following process. Therefore, ensure that safety devices independent

of the module (e.g. overpressure valves or temperature limiters/monitors) are available and

that it is only possible for qualified personnel to define settings. Please observe the corresponding safety regulations in this context.

27

Page 28

4 Electrical connection

References to other information

• The electromagnetic compatibility meets the standards and regulations cited in the technical data.

• The USB device interface and voltage supply in the central processing unit 705001 are not

electrically isolated. In general, please observe the specifications regarding electrical isolation.

28

Page 29

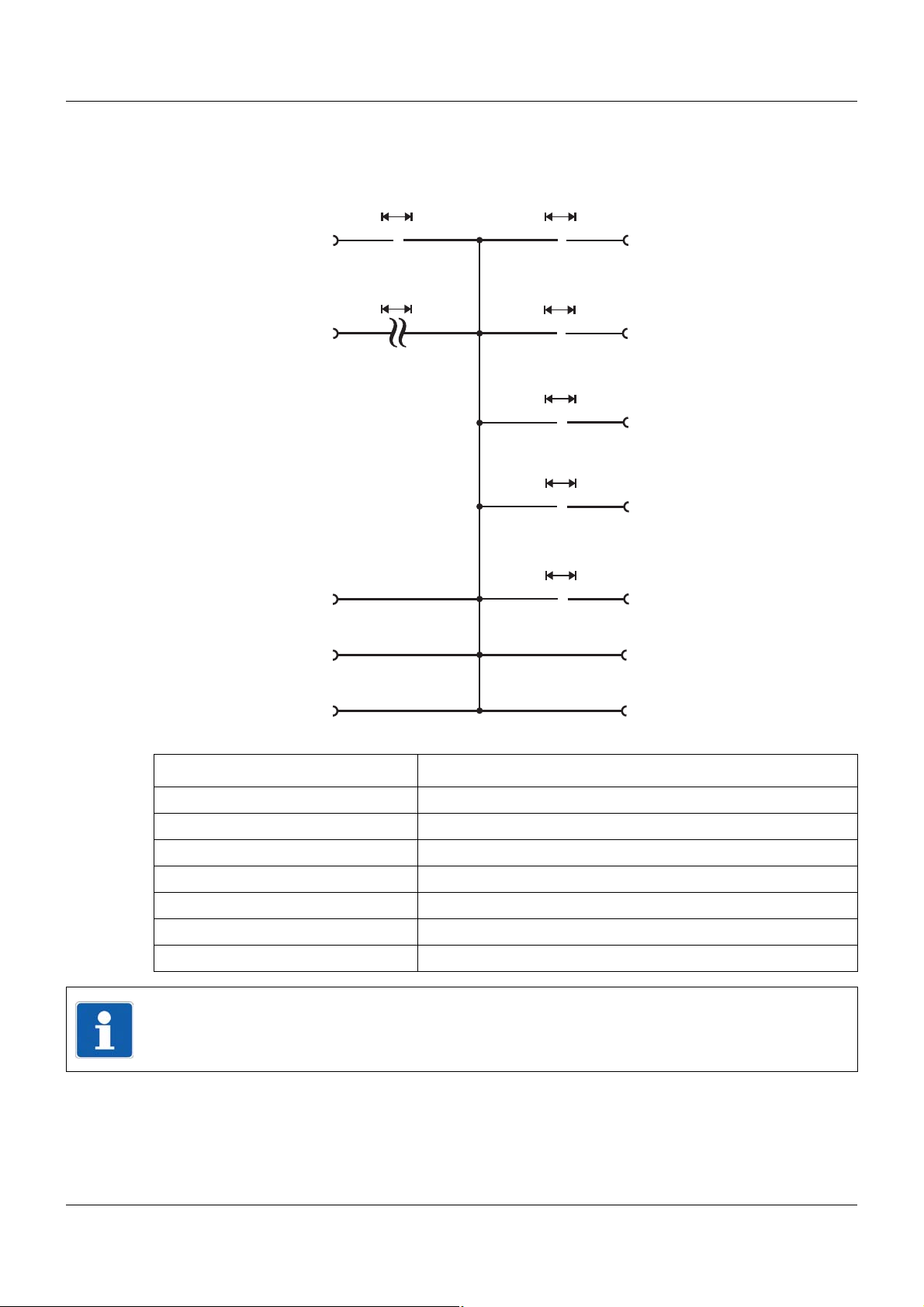

4.2 Galvanic isolation

Open-collector outputs

»

Analog inputs

Digital inputs

DC 0/24 V

Solid-state relay outputs

»

800 V (peak)

System bus

Logic outputs

DC 0/15 V

»

»

AC 30 V

DC 50 V

Voltage supply

DC 24 V

Relay outputs

»

AC 3800 V

Analog outputs

»

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

Voltage supply Out

Side system bus In

Side system bus Out

Voltage supply In

4 Electrical connection

Inputs/outputs Galvanically isolated from each other

Relay outputs Yes

Logic outputs DC 0/15 V Yes

Solid state relay outputs Yes

Open-collector outputs Outputs of different expansion slots

Analog outputs Yes

Digital inputs DC 0/24 V Inputs of different modules (motherboard, expansion slots)

Analog inputs Yes

TIP!

Signals to digital inputs belonging to one module (motherboard or expansion slot) must have

the same ground reference to avoid undefined signal levels.

29

Page 30

4 Electrical connection

4.3 Connection diagram

CAUTION!

At maximum load, the temperature may exceed 60 °C at the terminals.

As a result the insulation of the cable may be damaged.

The cable must be heat resistant up to at least 80 °C.

CAUTION!

The controller module configuration does not necessarily correspond to the intended application during initial startup (e.g. "Independent controller" operating mode active).

This may result in undefined plant behavior.

Therefore, where possible during startup, no actuators should be connected and load current

circuits should be isolated. The plant installer is essentially responsible for the startup process.

30

Page 31

4.3.1 Display and connection elements

4 Electrical connection

(1) Terminal strip expansion slot 1

(2) Voltage supply Out, DC 24 V

(3) Terminal strip expansion slot 2

(4) Side system bus Out

(5) Terminal strip expansion slot 3

(6) Terminal strip digital outputs 3, 4

(7) Side system bus In

(8) Terminal strip analog inputs 1, 2

and digital inputs 1, 2

(9) Voltage supply In, DC 24 V

(10) Status displays (LED):

P = Voltage supply and operating mode

S = Status

1 to 10 = Digital inputs/outputs (LED is lit: active)

31

Page 32

4 Electrical connection

4.3.2 Overview of inputs and outputs

This overview shows the position of the inputs and outputs in relation to the terminal strip s. The

assignment to the individual terminals is described in the following sections.

Standard version

(1) Analog input 1

Analog input 2

Digital input 1

Digital input 2

(2) Digital output 3

Digital output 4

(3) Analog input 3 Digital input 5 Analog output 1 Digital output 5

(4) Analog input 4 Digital input 7 Analog output 2 Digital output 7

(5) Digital input 9 Analog output 3 Digital output 9

Optional

Digital input 6 Digital output 6

Digital input 8 Digital output 8

Digital input 10 Digital output 10

32

Page 33

4 Electrical connection

U

+

-

x

U

+

-

x

I

+

-

x

E

S

A

4.3.3 Analog inputs

Input 1, 2: Standard version; input 3, 4: Option

Connection Input Terminals Symbol and terminal designation

Thermocouple 1

RTD temperature probe

2-wire circuit

RTD temperature probe

3-wire circuit

RTD temperature probe

4-wire circuit

Voltage DC 0(2) to 10 V 1

Voltage DC 0 to 1 V 1

2 and 3

2

3

4

1

2

3

4

6 and 7

18 and 19

22 and 23

2 and 4

6 and 8

18 and 20

22 and 24

2, 6, 18, 22

3, 7, 19, 23

2, 6, 18, 22

4, 8, 20, 24

1

2

3

4

2 to 4

6 to 8

18 to 20

22 to 24

2, 6, 18, 22

3, 7, 19, 23

4, 8, 20, 24

1

2

3

4

1 to 4

5 to 8

17 to 20

21 to 24

1, 5, 17, 21

2, 6, 18, 22

3, 7, 19, 23

4, 8, 20, 24

1 and 2

2

3

4

5 and 6

17 and 18

21 and 22

2 and 3

2

3

4

6 and 7

18 and 19

22 and 23

1, 5, 17, 21

2, 6, 18, 22

2, 6, 18, 22

3, 7, 19, 23

Current DC 0(4) to 20 mA,

Heater current AC 0 to 50 mA12

Resistance transmitter

A = Start

E = End

3 and 4

7 and 8

3

4

1

2

3

4

19 and 20

23 and 24

2 to 4

6 to 8

18 to 20

22 to 24

3, 7, 19, 23

4, 8, 20, 24

2, 6, 18, 22

3, 7, 19, 23

4, 8, 20, 24

S = Slider

Resistance/potentiometer

2-wire circuit

1

2

3

4

2 and 4

6 and 8

18 and 20

22 and 24

2, 6, 18, 22

4, 8, 20, 24

33

Page 34

4 Electrical connection

+

-

+

U

x

U

x

+

-

+

U

x

U

x

+

-

xIx

U

,

Connection Input Terminals Symbol and terminal designation

Resistance/potentiometer

3-wire circuit

1

2

3

4

2 to 4

6 to 8

18 to 20

22 to 24

2, 6, 18, 22

3, 7, 19, 23

4, 8, 20, 24

Resistance/potentiometer

4-wire circuit

1

2

3

4

1 to 4

5 to 8

17 to 20

21 to 24

1, 5, 17, 21

2, 6, 18, 22

3, 7, 19, 23

4, 8, 20, 24

4.3.4 Digital inputs

Connection Input Terminals Symbol and terminal designation

Digital input DC 0/24 V,

standard version

(Input 1: Counting input)

Digital input DC 0/24 V,

optional

Terminals 19 and 20, 23 and

24 as well as 27 and 28 are

internally linked.

1

2

5

6

7

8

9

10

9 and 11

10 and 11

17 and 19

18 and 20

21 and 23

22 and 24

25 and 27

26 and 28

9

10

11

17, 21, 25

18, 22, 26

19, 23, 27

20, 24, 28

4.3.5 Analog outputs

Connection Output Terminals Symbol and terminal designation

Analog output

DC 0/2 to 10 V or

DC 0/4 to 20 mA

1

2

3

(configurable),

optional

34

18 and 19

22 and 23

26 and 27

18, 22, 26

19, 23, 27

Page 35

4 Electrical connection

U

+

-

x

E

C

E

C

4.3.6 Digital outputs

Standard version

In the standard version the controller module is equipped with relay or logic output s (see “Order

details”).

Connection Output Terminals Symbol and terminal designation

Relay output (N/O) 3

4

12 and 13

15 and 16

12, 15

13, 16

Logic output DC 0/15 V 3

4

12 and 13

15 and 16

12, 15

13, 16

The digital output numbering starts with 3. T his allows the direct assignment to the LEDs of the

digital outputs (LED 3 to 10).

Optional

Connection Output Terminals Symbol and terminal designation

Relay output (changeover

contact)

Relay output (N/O) 5

5

7

9

6

7

8

9

10

17 to 19

21 to 23

25 to 27

17 and 18

18 and 19

21 and 22

22 and 23

25 and 26

26 and 27

17, 21, 25

18, 22, 26

19, 23, 27

17, 21, 25

18, 22, 26

19, 23, 27

Solid-state relay 5

Open-collector output

C = Collector

E = Emitter

7

9

5

6

7

8

9

10

18 and 19

22 and 23

26 and 27

17 and 18

17 and 19

21 and 22

21 and 23

25 and 26

25 and 27

18, 22, 26

19, 23, 27

17, 21, 25

18, 22, 26

19, 23, 27

35

Page 36

4 Electrical connection

I

+

-

x

+

-

LN

p

I

I

+

-

x

+

+

-

L

N

p

I

-

+

I

+

-

x

+

+

-

L

N

p

I

-

4.4 Connection examples

This chapter provides some examples to illustrate the connection of the inputs and outputs of

the module.

TIP!

Details for the load of the inputs and outputs are given in the "Technical data" and the information for the galvanic isolation (electric strenght). This information has to be observed when

connecting. In addition, the notes in the instructions of the connected external device must be

observed (if applicable).

4.4.1 Analog inputs

The following table shows examples of the connection of a transmitter with current output (standard signal) to an analog input of the multichannel controller module. The examples – with the

exception of the 2-wire transmitter – also generally apply to a transmitter with voltage output;

in this case, however, the different terminal designations must be considered.

Input Symbol and

terminal designation

Current DC 0(4) to 20 mA 3, 7, 19, 23

4, 8, 20, 24

Current DC 0(4) to 20 mA 3, 7, 19, 23

4, 8, 20, 24

Current DC 4 to 20 mA 3, 7, 19, 23

4, 8, 20, 24

Example of external wiring

4-wire transmitter

3-wire transmitter with external

power supply

36

2-wire transmitter with external

power supply

Page 37

4 Electrical connection

I

x

I

I

U

+

-

x

+

-

L

N

N

L

N

N

L

N

E

C

E

C

R

R

The following table shows an example of the connection of a current transformer for he ater current monitoring to an analog input of the multichannel controller module.

Input Symbol and

Heater current AC 0 to 50 mA 3, 7, 19, 23

4.4.2 Digital outputs

The following table shows examples how to use the differrent digital outputs of the multichannel

controller module.

Output Symbol and

Logic output DC 0/15 V 12, 15

Relay output (changeover

contact)

Example of external wiring

terminal designation

4, 8, 20, 24

Current transformer AC/AC

Example of external wiring

terminal designation

13, 16

External solid-state relay

17, 21, 25

18, 22, 26

19, 23, 27

Relay output (N/O) 17, 21, 25

18, 22, 26

19, 23, 27

Solid-state relay 18, 22, 26

19, 23, 27

Open-collector output

17, 21, 25

18, 22, 26

C = Collector

E = Emitter

19, 23, 27

37

Page 38

4 Electrical connection

4.5 Functional test

The voltage supply must be tested on completion of the electrical connection:

Signal Meaning

The "P" LED (Power, gr een or orange) is lit The module is being supplied with voltage

The "P" LED (Power, gr een or orange) is not lit The module is not supplied with voltage or there

through the side contacts.

is a problem with the electrical function of the

LED.

Remedy:

• Check the voltage supply to the side cont act s

of the preceding module (top contact +24 V,

bottom contact GND).

• Check voltage supply at the "+24 V" and

"GND" terminals of the base unit or router

module.

• Check power supply unit and connection between the power supply unit and the base unit

or router module.

If the "Power" LED does not light up despite a

voltage supply being present, the module insert

or – if the bus board inside the case is faulty – the

entire module must be replaced.

Startup

The check described above completes the process of installation and electrical connection. For

startup, use the additional documentation (operating manual or system manual).

The "Introduction" section of this document contains an overview of all documentation for the

measuring, control, and automation system.

38

Page 39

5.1 Display and connection elements

This overview shows the position of the display and connection elements.

5 Operation

(1) Expansion slot 1:

- Analog input 3

- Digital inputs/outputs 5, 6

- Analog output 1

(3) Expansion slot 2:

- Analog input 4

- Digital inputs/outputs 7, 8

- Analog output 2

(5) Expansion slot 3:

- Digital inputs/outputs 9, 10

- Analog output 3

(7) Side system bus In (8) Analog inputs 1, 2

(9) Voltage supply In, DC 24 V (10) LEDs:

(2) Voltage supply Out, DC 24 V

(4) Side system bus Out

(6) Digital outputs 3, 4

and digital inputs 1, 2

P = Voltage supply and operating mode

S = Status

1 to 10 = Digital inputs/outputs 1 to 10

39

Page 40

5 Operation

5.2 LED displays

"P" LED (Power)

The LED is permanently lit in green or blue if the module is being supplied with voltage.

It also indicates the operating mode of the controller module:

Green: Normal operation

Blue: Independent operation

"S" LED (Status)

This LED indicates the status of the module. Diagnostics requires the setup program or a Web

browser as appropriate.

LEDs "1" to "10"

The LEDs indicate the status of the relevant digital input or output.

LED lights up yellow = digital input or output is active

5.2.1 Display modes

The following table lists all possible states of the "S" LED (Status).

Display mode Description Green sym-

bol

--- LED state not relevant --- --Off LED off

On LED on (permanently lit)

Flickering LED flickers (50 ms on, 50 ms off)

Single flickering LED flashes briefly (50 ms on, 200 ms off)

Blinking LED flashes (200 ms on, 200 ms off)

Single flash LED flashes once (200 ms on, 1000 ms off)

Double flash L ED flashes twice (on/off/on for 200 ms each

time, 1000 ms off)

Triple flash LED flashes three times (on/off/on/off/on for

200 ms each time, 1000 ms off)

Quadruple flash LED flashes four times (on/off/on/off/on/off/on for

200 ms each time, 1000 ms off)

Blinking red/green LED flashes red and green (200 ms red, 200 ms

green)

Red symbol

On green/

Single flickering red

40

LED lights up green, flashes red (50 ms red)

Page 41

5.2.2 System states and errors

The following table lists all the system states and errors that are indicated b y the "S" LED (Status). In most cases, further diagnostics must be performed with the setup program.

5 Operation

Category "S" LED

(Status)

Start error Module error (hardware does not

Start error Internal error (bootloader)

Start er ror No firmware LED Replace module

Start er ror Incorrect optional board 1, 2, 3

Bus status No connection to central processing

Bus status System in "Stop" (INIT) state – no

Bus status System in "Stop" (PREOP) state – no

Operation

(Priority 1)

Operation

(Priority 2)

Operation

(Priority 3)

Operation

(Priority 3)

Meaning Diagnos-

tics with

LED Replace module

start up)

LED Replace module

V arious errors during startup (e.g. no

memory, initialization error)

LED Check optional board and

(actual/target)

LED Check whether the central pro-

unit

LED

error, only in start phase

LED

error, only in start phase

Calibration mode LED/setup

program

Collective alarm (incl. out of range) LED/setup

program

System in "Stop" (SAFEOP) state –

no error

System in "Run" (OP) state – no

error

LED

LED

Recommended action

replace, load, or remove as

required; replace module if

necessary

cessing unit is running; check

cabling and topology

41

Page 42

5 Operation

(2)

(4)

(3)

(1)

5.3 Operation on the multifunction panel

The basic steps for operation and visualization are described in the operating manual of the

multifunction panel (B 705060.0).

This operating manual describes how to operate the controller channels of the multichannel

controller module (controller module).

Operation of the program generator and configuration of the program editor are covere d in the

operating manual for the central processing unit (B 705001.0).

Multifunction panel – "Controller" button

(1) "Controller" button (operation) (2) "Controller" menu (opened with the "Con-

troller" button)

(3) Operate multichannel controller module;

opens the controller screen

To operate the controller channels of the multichannel controller module, select the "Controller

4x ..." entry . If multiple multichannel controller modules are ava ilable, they will be arranged one

below the other and assigned different numbers. Th e multichannel controller module in this example has been assigned the number 1.

(4) Operate program generator; opens the

generator screen

Operating manual for central process-

ing unit (B 705001.0)

42

Page 43

5.3.1 Multichannel controller module

Operation of the multichannel controller module includes the following settings and functions:

• Setpoint value entry

• Display of actual value, setpoint value, output level, switch setting of outputs, self-optimization, manual mode, and ramp function

• Start of self-optimization

• Changeover to manual mode

• In manual mode: Specification of output level or actuator opening and closing

• Display of inputs and outputs (hardware) of the multichannel controller module

Controller screen – overview of controller channels 1 to 4 (controller 1 to 4)

5 Operation

This screen provides an overview of all controller channels that are switched on:

• Actual value

• Setpoint value (display or input field; depends on the configuration and user rights)

• Output level

• Switch setting for outputs of the controller channel (K1, K2)

• Self-optimization, manual mode, ramp function (active/not active)

Controller channel 4 is switched on in this example; the actual value and setpoint value have

not yet been configured.

To select a particular controller channel, select the relevant tab at the top of the window. If a

controller channel is switched off, a gray area appea rs in the overview and the t ab is not ava ilable. If only one controller channel is switched on, the controller screen for that particular controller channel is displayed instead of this overview.

Select the tab on the right to open an overview screen with the inputs and outputs of the multichannel controller module.

43

Page 44

5 Operation

(8)

(1)

(7)

(6)

(5)

(2)

(3)

(4)

(3)

(1)

(2)

Controller screen – controller channel 1: Two-state controller in automatic mode

(1) Switch setting of output 1 (K1)

and 2 (K2) of the controller channel

(3) Changeover to manual mode (4) Self-optimization start/stop

(5) Display of output level (bar graph) (6) Display of output level (percent)

(7) Input field for setpoint value or setpoint

value display (depends on configuration)

(2) Display of self-optimization, manual mode,

ramp function (from left to right)

(8) Display of actual value

Controller screen – controller channel 2: Two-state controller in manual mode

44

(1) Manual mode is active (2) Changeover to automatic mode

(3) Input field for output level

Page 45

Controller screen – controller channel 3: Modulating controller in manual mode

(1)

(2)

(1) Open actuator (2) Close actuator

5 Operation

TIP!

If the modulating controller is in manual mode, the actuator can also be opened and closed

in the "Stop" system state.

TIP!

If the output level feedback of the position controller is "out of range", the current position of

the actuator can no longer be determined. In this case, the actuator can be operated with buttons (1) and (2), as for the three-step controller. The commands "Open actuator" or "Close

actuator" are issued for as long as the relevant button is held.

45

Page 46

5 Operation

Controller screen – overview of the inputs and outputs of the multichannel controller module

This screen provides an overview of the inputs and outputs o f the multichannel controller module:

• Measured value of analog inputs (including display of measuring range overflow and underflow)

• Signal of analog outputs (optional)

• Switching status of digital inputs and outputs

Information about controller channels 1 to 4 is also displayed:

• Number of the active parameter block

• Number of the active setpoint value (when using the setpoint value function)

46

Page 47

TIP!

The parameters described in this section can be configured either with the setup program or

with the multifunction panel (exception: Device data and replacement values).

6.1 Analog selector

The analog selector contains all analog signals that are available in the multichannel controller

module for configuration.

The following table lists all analog signals. The entry in the "Type" column indicates the source

of the signal:

• Internal only: Internal signal that is only available inside the multichannel controller module.

• Internal: Internal signal of the multichannel controller module (including signals of analog

inputs)

The signal is also transmitted to the base unit via the system bus, to allow it to be used by

other modules.

• External: External input (NV_...) that must be linked in the NV connecting list to a signal

from another module (see Chapter 6.14 "NV connecting list", page 105).

The signal name "NV_..." indicates the intended use; in principle, the signal can also be

used for other purposes.

6 Configuration

Category Signal Type Description

Inactive No signal selected

Further signals Samp ling Ra te Internal

only

Controller NV_C01ActualValue to

NV_C04ActualValue

NV_C01Setpoint to

NV_C04Setpointt

C01OutpLevelMon to

C04OutpLevelMon

C01OutpLevel1 to

C04OutpLevel1

C01OutpLevel2 to

C04OutpLevel2

C01Diff to C04Diff Internal Difference between setpoint value

External Actual value for controller channel

External Setpoint value for controller chan-

Internal Output level (display value) of

Internal Output level at first controller out-

Internal Ou tput level on second controller

Sampling rate of controller

module

1 to 4

nel 1 to 4

controller channel 1 to 4

put (continuous) of controller

channel 1 to 4

output (continuous) of controller

channel 1 to 4

and actual value of controller

channel 1 to 4

47

Page 48

6 Configuration

Category Signal Type Description

Setpoints NV_SP01Ext to NV_SP04Ext External External setpoint value for set-

point value function 1 to 4

SP01RampOutput to

SP04RampOutput

SP01Active to SP04Active Internal Active setpoint value (external

SP01Setpoint1 to SP04Setpoint1 Internal Setpoint value 1 (fixed setpoint

SP01Setpoint2 to SP04Setpoint2 Internal Setpoint value 2 (fixed setpoint

SP01Setpoint3 to SP04Setpoint3 Internal Setpoint value 3 (fixed setpoint

SP01Setpoint4 to SP04Setpoint4 Internal Setpoint value 4 (fixed setpoint

Analog inputs AI01 to AI04 Internal Measured value of analog input 1

Mathematics Math01 to Math04 Internal Result of math function 1 to 4

NV_M01Flag to NV_M04Flag External Any analog value 1 to 4

Hardware counter

NVAnalogOutputs

HWCounter Internal Counter reading of hardware

NV_AO01 to NV_AO03 External Signal for controlling analog out-

Internal Current setpoint value of ramp

function 1 to 4

setpoint value + setpoint value) of

setpoint value function 1 to 4

value or correction value) of setpoint value function 1 to 4

value or correction value) of setpoint value function 1 to 4

value or correction value) of setpoint value function 1 to 4

value or correction value) of setpoint value function 1 to 4

to 4

(freely available)

counter

put 1 to 3

48

Page 49

6.2 Digital selector

The digital selector contains all digital signals that are available in the multichannel controller

module for configuration.

The following table lists all digital signals. The entry in the "Type" column indicates the source

of the signal:

• Internal only: Internal signal that is only available inside the multichannel controller module.

• Internal: Internal signal of the multichannel controller module (including signals of digital inputs).

The signal is also transmitted to the base unit via the system bus, to allow it to be used by

other modules.

• External: External input (NV_...) that must be linked in the NV connecting list to a signal

from another module (see Chapter 6.14 "NV connecting list", page 105).

The signal name "NV_..." indicates the intended use; in principle, the signal can also be

used for other purposes.

Category Signal Type Description

Inactive No signal selected

Further signals Master No tCo n ne cte d Internal

Controller C01ContrLoopMonit to

C04ContrLoopMonit

only

Internal

only

6 Configuration

No connection to the base unit via

the system bus (controller module

operates independently)

Alarm signal of control loop monitoring of controller channel 1 to 4

C01OutpLevelMonit to

C04OutpLevelMonit

C01ManualMode to

C04ManualMode

C01TuneActive to C04TuneActive Internal Self-optimization active for con-

C01Output1 to C04Output1 Internal Switch position of first controller

C01Output2 to C04Output2 Internal Switch position of second control-

C01CollAlarm to C04CollAlarm Internal Collective alarm of controller

Internal

only

Internal Manual mode active on controller

Alarm signal of output level monitoring of controller channel 1 to 4

channel 1 to 4

troller channel 1 to 4

output of controller channel 1 to 4

ler output of controller channel 1

to 4

channel 1 to 4 (configurable with

signals from the digital selector)

49

Page 50

6 Configuration

?

?

Category Signal Type Description

Controller

(continued)

Setpoints SP01RampTolBa n d to

Analog inputs AI01Alarm1 to AI04Alarm1 Internal Alarm signal 1 of analog input 1 to

Digital inputs DI01, DI02, DI05 to DI10 Internal Signal of digital input 1, 2, 5 to 10

NV_C01TuneStart to

NV_C04TuneStart

NV_C01TuneStop to

NV_C04TuneStop

NV_C01ParamSet to

NV_C04ParamSet

NV_C01ManualMode to

NV_C04ManualMode

NV_C01Stop to NV_C04Stop External Switch off controller channel 1 to

SP04RampTolBand

NV_SP01Changeover1 to

NV_SP04Changeover1

NV_SP01Changeover2 to

NV_SP04Changeover2

AI01Alarm2 to AI04Alarm2 Internal Alarm signal 2 of analog input 1 to

External Start self-optimization for control-

ler channel 1 to 4

External Abort self-optimization for control-

ler channel 1 to 4

External Changeover from parameter

block 1 to parameter block 2 for

controller channel 1 to 4

External Changeover to manual mode for

controller channel 1 to 4

4

Internal Alarm signal of tolerance band

monitoring of ramp function 1 to 4

External Bit 0 of setpoint changeover of

setpoint value function 1 to 4

External Bit 1 of setpoint changeover of

setpoint value function 1 to 4

4

4

NVDigitalOutputs NV_DO03 to NV_DO10 External Signal for controlling digital output

Limit monitoring LI01 to LI04 Internal Output signal of limit value moni-

Mathematics Logic01 to Logic04 Internal Result of logic function 1 to 4

Signal rejections NV_SR01 to NV_SR08 External Signal for activating signal sup-

Alarm CollectiveAlarm Internal Controller module collective alarm

HW counter HWCounterSignal Internal Signal of hardware counter in "fill"

Digital links DigitalLink01 to DigitalLink04 Internal Result of binary linking 1 to 4

Digital inputs

If the HW counter is activated, the signal of digital input 1 is inactive.

NV_LI01Confirmation to

NV_LI04Confirmation

3 to 10

toring 1 to 4

External Signal to acknowledge the output

signal of limit value monitoring 1

to 4

pression of digital input 1, 2, 5 to

10

operating mode (as switch-off signal when threshold value

reached)

50

Page 51

Alarm

6 Configuration

The collective alarm of the controller module is made up of all functions for which the "Collective

alarm" alarm type has been activated, along with the controller channel collective alarms (collective alarm 1 to 4).

51

Page 52

6 Configuration

6.3 "Independent controller" operating mode

The controller module can be configured for independent operation. This enables it to continue

to operate if communication fails between the controller module and the central processing

unit.

Chapter 6.4 "Device data", page 54

Principle

If the "Independent controller" operating mode is enabled, the controller module can continue to perform control tasks with the remaining resources if communication fails (all internal

functions continue to run).

Otherwise, if the "Independent controller" operating mode is not enabled, the controller

channels and outputs of the controller module switch off if communication fails.