Page 1

JUMO mTRON T

Measuring, Control, and Automation System

Central Processing Unit

B 705001.0

Operating Manual

2014-08-27/00575582

Page 2

Page 3

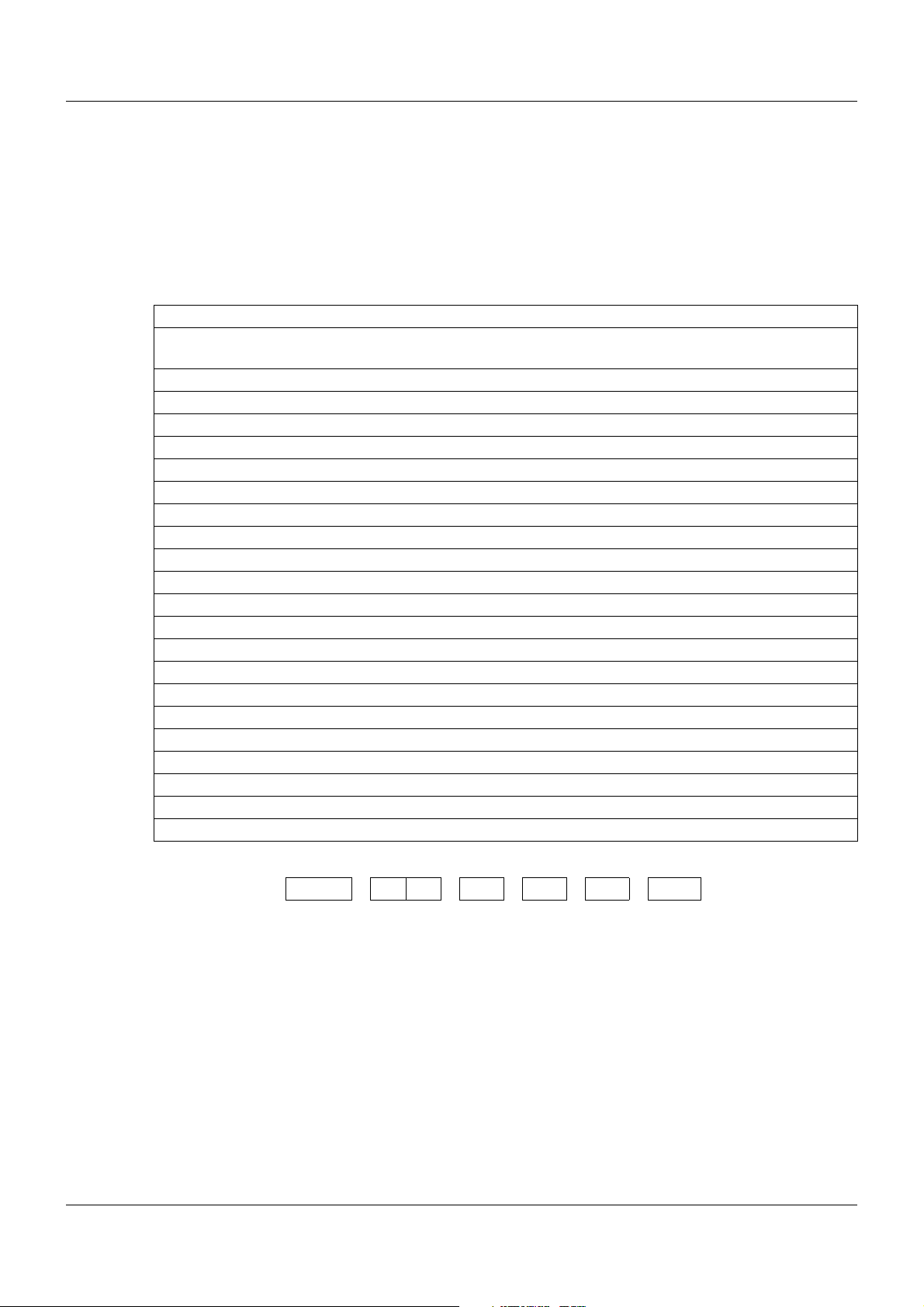

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.1 Available technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.2 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.3 Input/output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.4 Special modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.5 Operating, visualization, recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.6 Power supply units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 Warning symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 Note signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2.4 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Acceptance of goods, storage, and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Notes on storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.3 Returning goods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Identifying the device version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.2 Order details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.3 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.5 General accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5 System version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.1 General information on installation/dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Installation/dismounting on DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

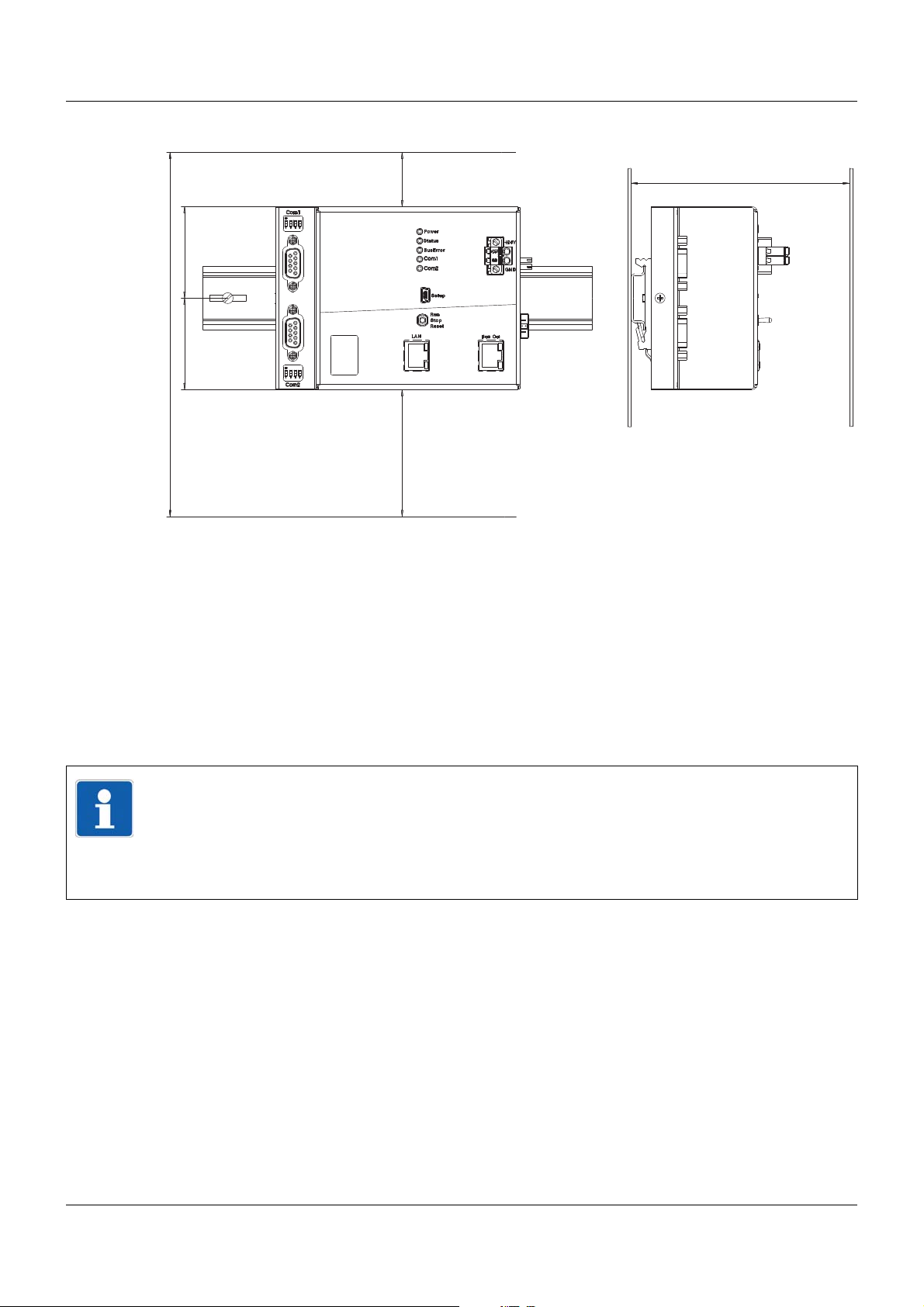

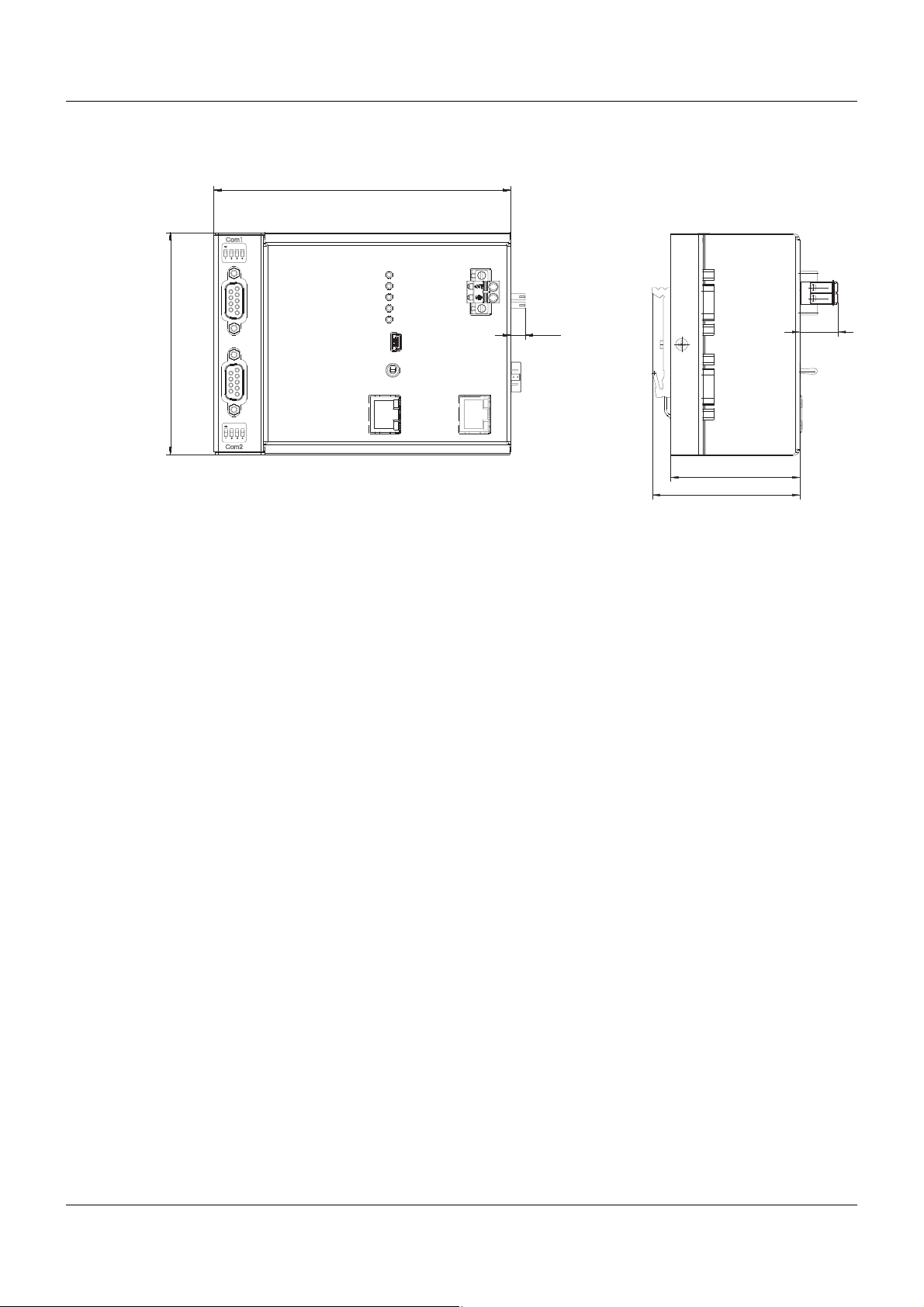

3.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.1 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

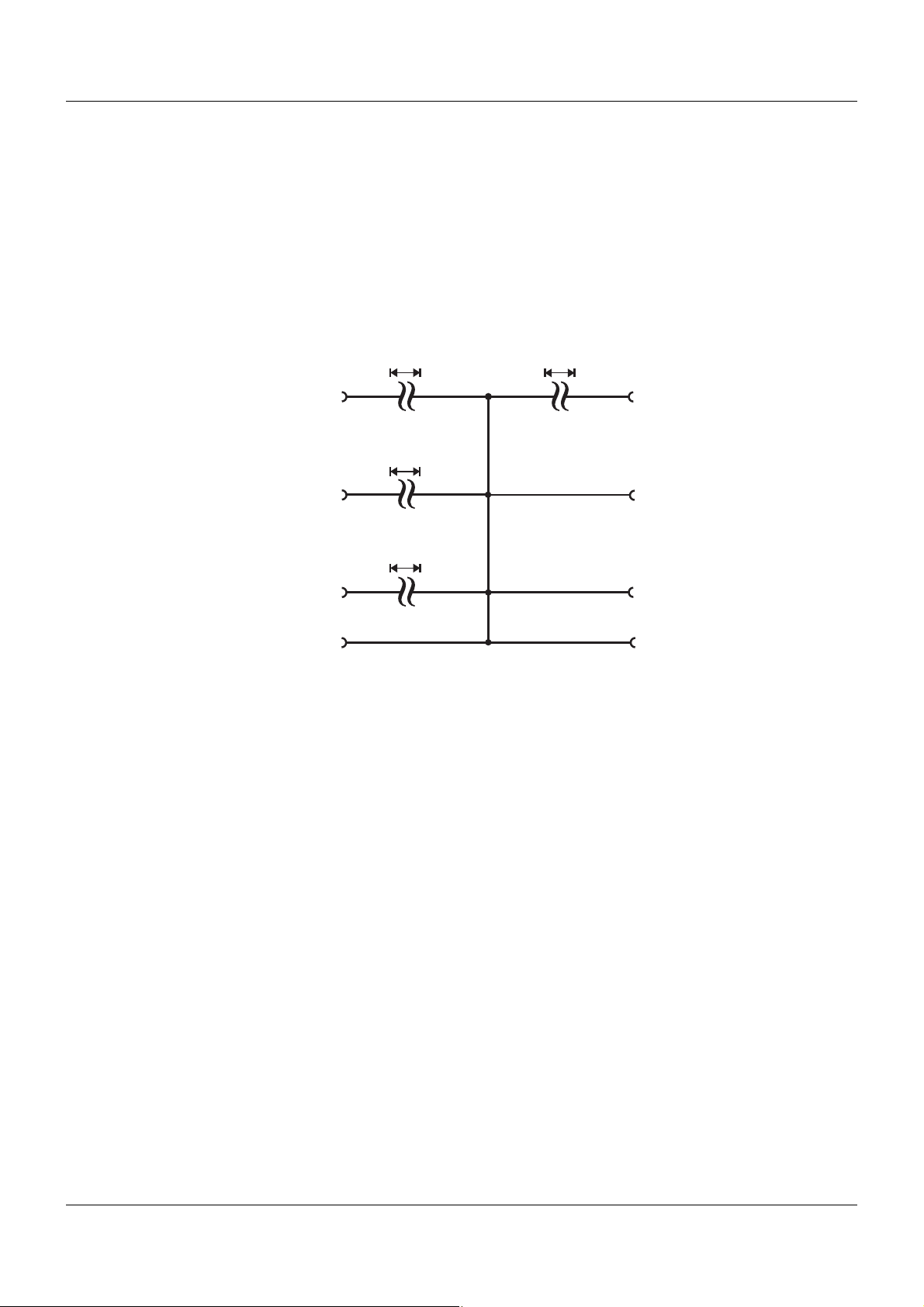

4.2 Electrical isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

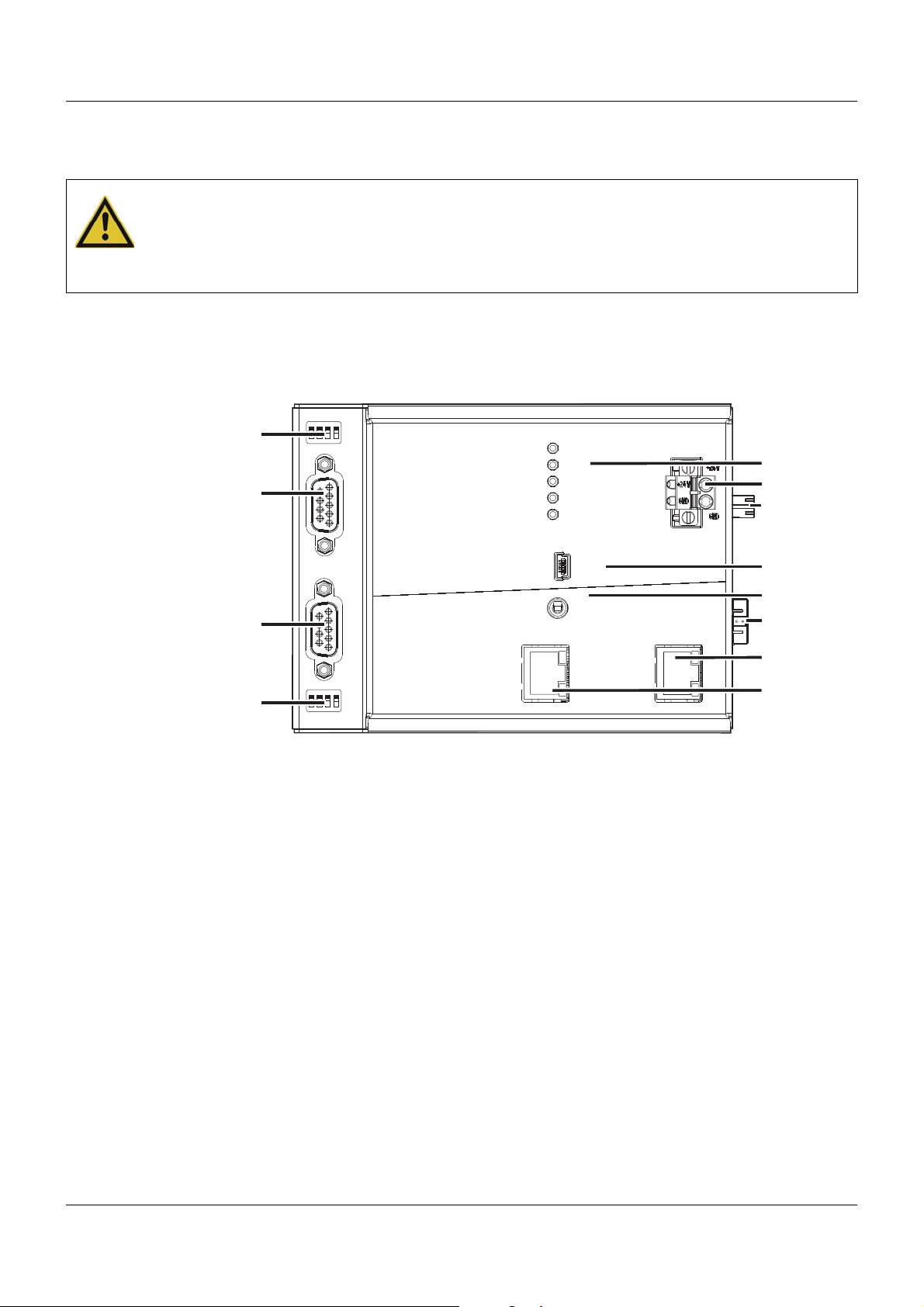

4.3 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 Display, operating, and connection elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.2 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3.3 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3

Page 4

Contents

4.3.4 Terminating resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 Functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.1 Display, operating, and connection elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 System states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3 System switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 LED displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.1 Display modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.2 System states and errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.5 Operation on the multifunction panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.1 Program generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.1 Selectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1.1 Analog selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1.2 Digital selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Device data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.2.1 Setup info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.3 Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.1 Analog variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.2 Integer variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.3 Digital variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.3.4 Text variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.4 Limit value monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.4.1 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.4.2 Alarm and hysteresis functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.5 Binary links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.6 Modbus/TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.7 Serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.7.1 Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.8 PROFIBUS (version 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.9 Web server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.10 PLC configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.11 Program generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.11.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.11.2 Setpoint limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.11.3 Basic status setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.11.4 Manual mode setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.11.5 Setpoint specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.11.6 Names of operating contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.11.7 Tolerance band monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.11.8 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.11.9 Process screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4

Page 5

Contents

7 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

7.1 PLC parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8 Configuration – in setup program only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

8.1 E-mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.1.1 E-mail server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.2 Modbus frames for reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.3 Modbus frames for writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.4 Analog PLC output texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.5 Integer PLC output texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.6 Digital PLC output texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.7 Texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

9 Program editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

9.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

9.2 Program schema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.3 Program simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9.4 Process steps (as of version 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

9.5 License dependance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

9.5.1 "Program editor" license . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10 Online parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

10.1 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.2 System bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

10.3 Enabling of extra codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.4 Resetting the user list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

10.5 Date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

10.6 Calibrate / test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.6.1 LED test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.6.2 Switch test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.6.3 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

10.6.4 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

11 Retrofitting interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

12 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

12.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

12.1.1 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

12.1.2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

12.1.3 Case and ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

12.1.4 Approval/approval marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

12.2 Cycle time, sampling rate, and shut-down time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

5

Page 6

Contents

12.3 Resources for customer specific PLC programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6

Page 7

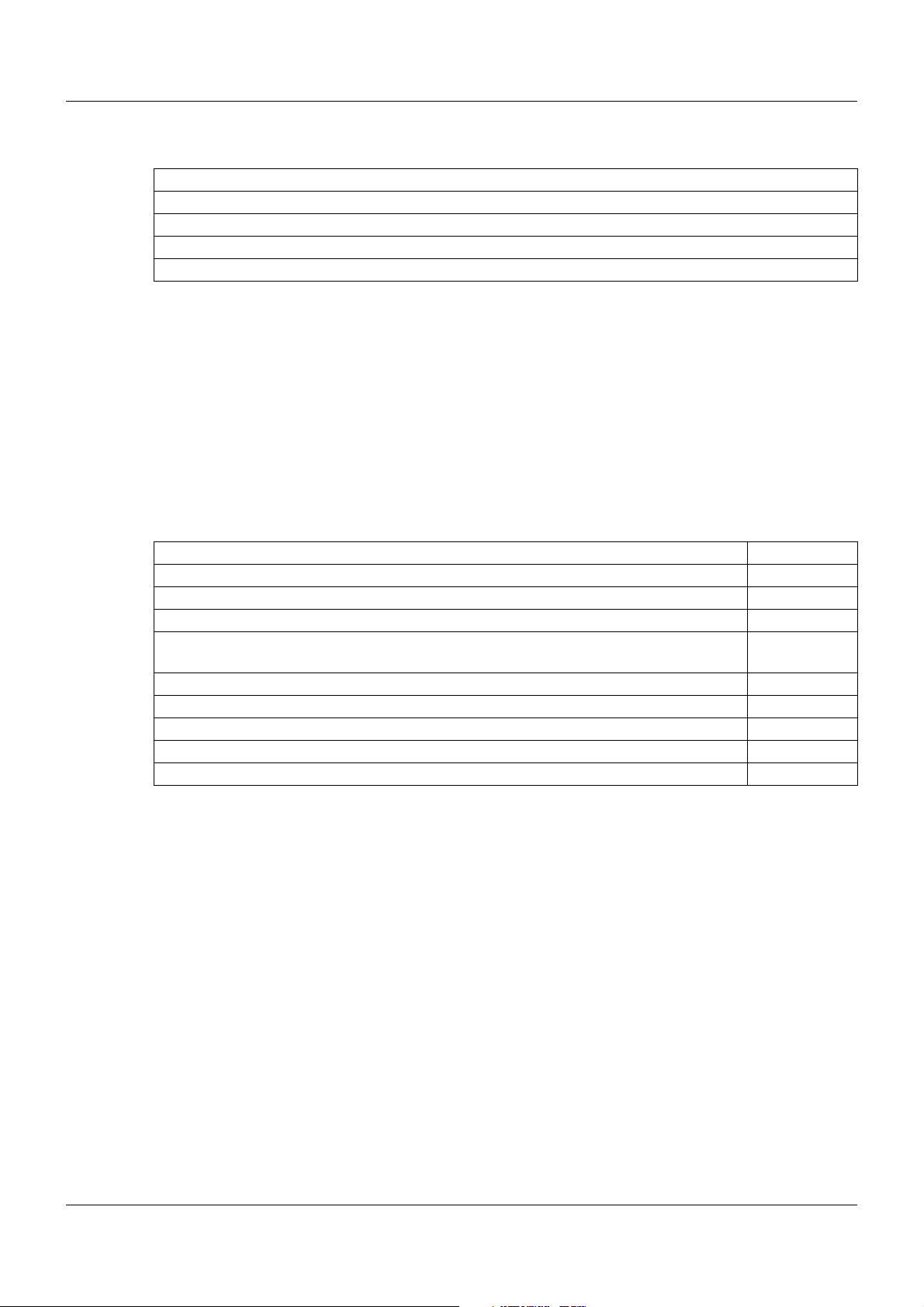

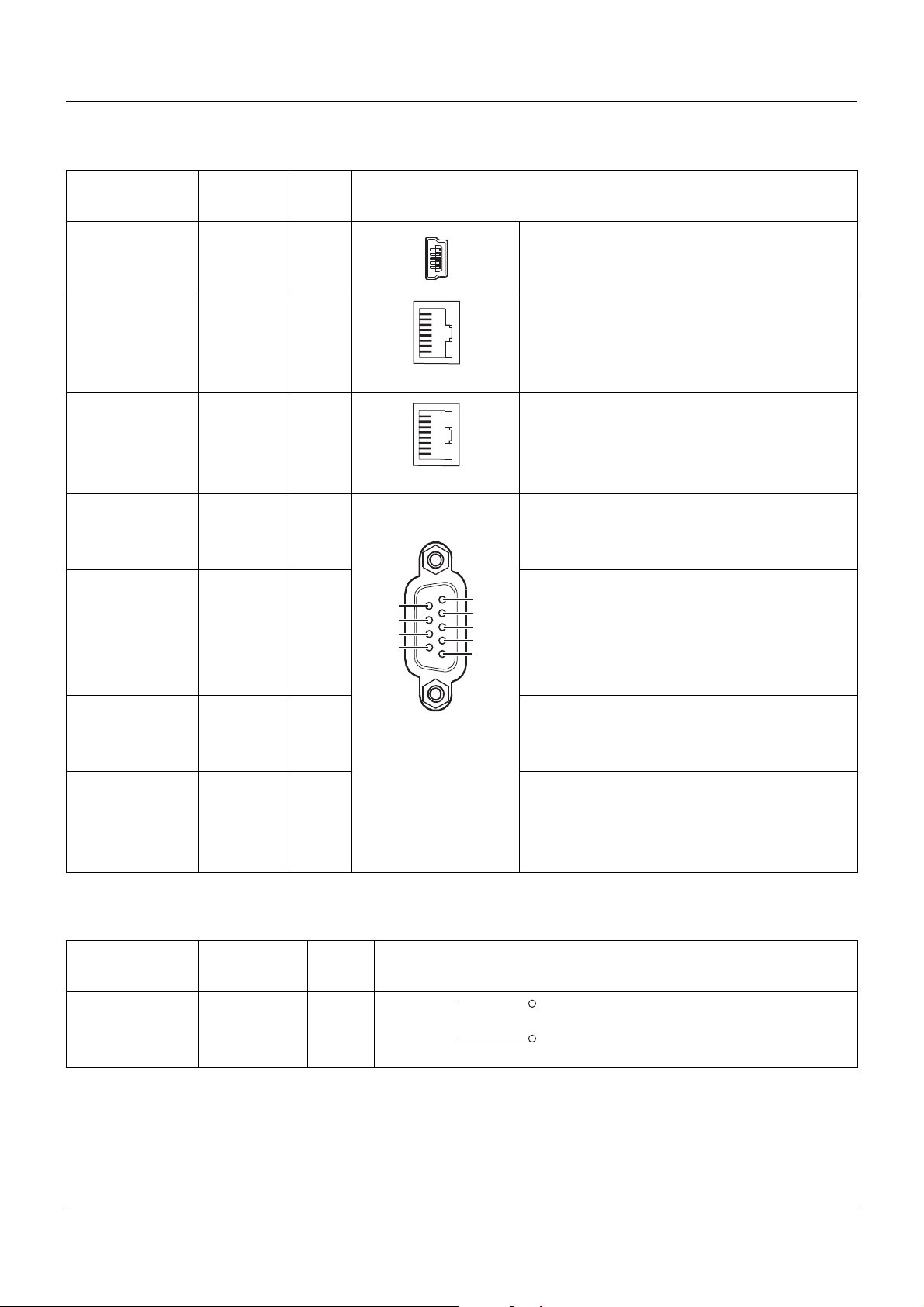

1.1 Available technical documentation

The documents specified below are available for the measuring, control, and automation system.

1.1.1 General information

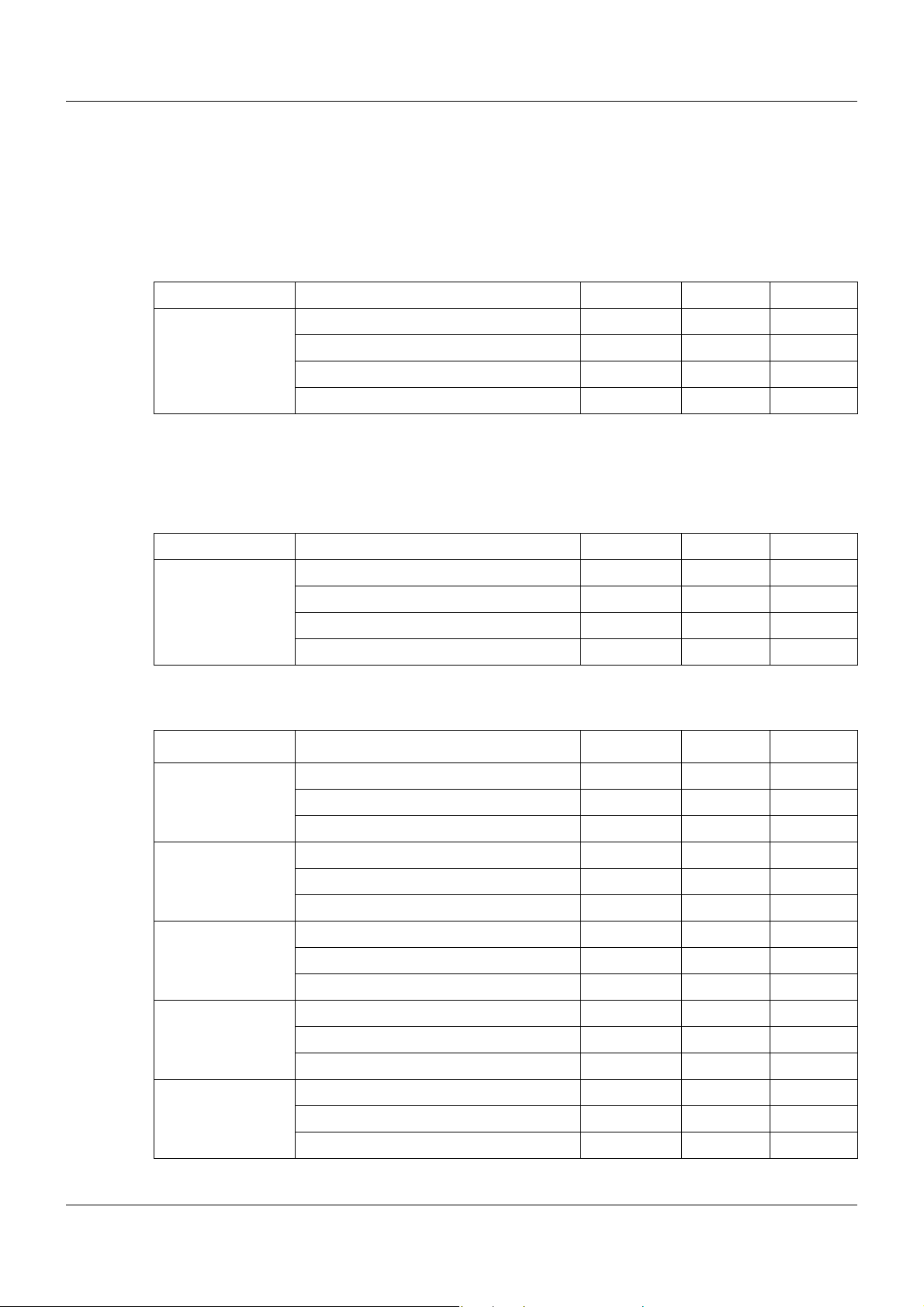

Product Type of documentation No. Printed PDF file

Measuring,

control, and

automation system

1

Accessory subject to charge

2

Includes an overview of the purpose and content of all documents

1.1.2 Base units

Data sheet T 705000 - X

System manual

Setup program manual B 705000.6 - X

System description

1

2

1 Introduction

B 705000.0 X -

B 705000.8 - X

Product Type of documentation No. Printed PDF file

Central

processing unit

Data sheet T 705001 - X

Operating manual B 705001.0 - X

Modbus interface description B 705001.2.0 - X

Installation instructions B 705001.4 X X

1.1.3 Input/output modules

Product Type of documentation No. Printed PDF file

Multichannel

controller module

Relay module

4-channel

Analog

input module

4-channel

Data sheet T 705010 - X

Operating manual B 705010.0 - X

Installation instructions X X

Data sheet T 705015 - X

Operating manual B 705015.0 - X

Installation instructions B 705015.4 X X

Data sheet T 705020 - X

Operating manual B 705020.0 - X

Installation instructions B 705020.4 X X

Analog

input module

8-channel

Digital input/

output module

12-channel

Data sheet T 705021 - X

Operating manual B 705021.0 - X

Installation instructions B 705021.4 X X

Data sheet T 705030 - X

Operating manual B 705030.0 - X

Installation instructions B 705030.4 X X

7

Page 8

1 Introduction

1.1.4 Special modules

Product Type of documentation No. Printed PDF file

Router module Data sheet T 705040 - X

Installation instructions B 705040.4 X X

1.1.5 Operating, visualization, recording

Product Type of documentation No. Printed PDF file

Multifunction

panel 840

Operating panels Data sheet T 705065 - X

Data sheet T 705060 - X

Operating manual B 705060.0 - X

Modbus interface description B 705060.2.0 - X

Installation instructions B 705060.4 X X

1.1.6 Power supply units

Product Type of documentation No. Printed PDF file

24 V power supply

units

Data sheet T 705090 - X

Operating instructions QS5.241 X Operating instructions QS10.241 X -

8

Page 9

1.2 Safety information

&

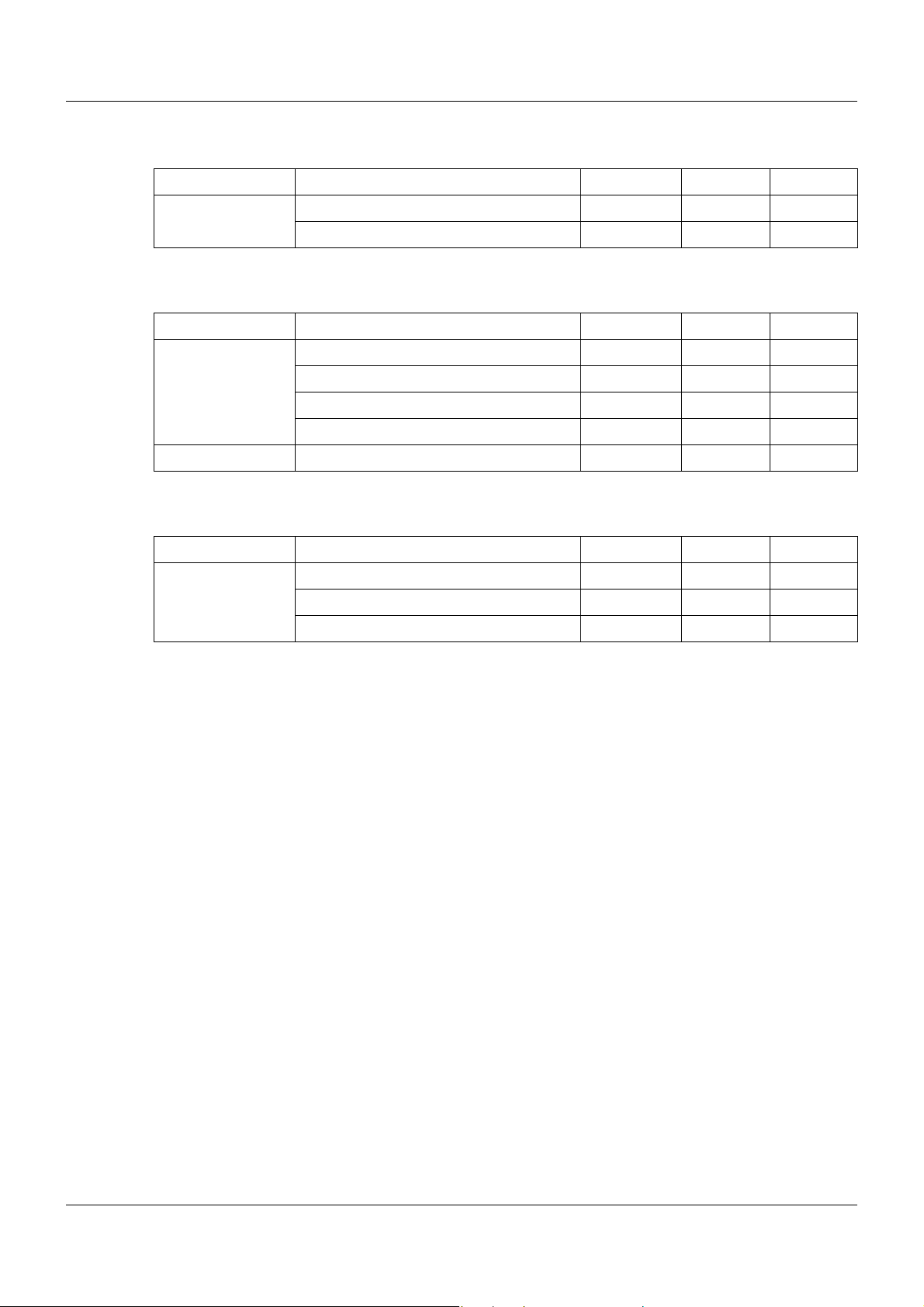

1.2.1 Warning symbols

DANGER!

This symbol indicates that personal injury caused by electrical shock may occur if the respective precautionary measures are not carried out.

WARNING!

This symbol in connection with the signal word indicates that personal injury may occur if the

respective precautionary measures are not carried out.

CAUTION!

This symbol in connection with the signal word indicates that damage to assets or data loss

will occur if the respective precautionary measures are not taken.

CAUTION!

This symbol indicates that components could be destroyed by electrostatic discharge

(ESD = Electro Static Discharge) if the respective cautionary measures are not taken.

Only use the ESD packages intended for this purpose to return device inserts, assembly

groups, or assembly components.

1 Introduction

READ DOCUMENTATION!

This symbol – placed on the device – indicates that the associated device documentation

has to be observed. This is necessary to recognize the kind of the potential hazards as

well as the measures to avoid them.

1.2.2 Note signs

NOTE!

This symbol refers to important information about the product, its handling, or additional

use.

REFERENCE!

This symbol refers to further information in other sections, chapters, or manuals.

FURTHER INFORMATION!

This symbol is used in the tables and refers to further information in connection with the

table.

DISPOSAL!

This device and the batteries (if installed) must not be disposed in the garbage can after

use! Please ensure that they are disposed properly and in an environmentally friendly

manner.

9

Page 10

1 Introduction

1.2.3 Intended use

The modules described are intended for measuring, control, an d automation t asks in an ind ustrial environment, as described in the technical data. Oth er uses or uses beyond th ose defined

are not viewed as intended uses.

The modules are built according to the relevant standards and directives as well as the applicable safety regulations. Nevertheless, incorrect use may lead to bodily injury or property damage.

To avoid danger, the modules may only be used:

• For the intended use

• When in good order and condition

• When taking into account the technical documentation provided

Even if a module is used correctly and according to the intended use, it may still cause appli-

cation-related dangers (e.g. due to missing safety devices or incorrect settings).

1.2.4 Qualification of personnel

This document contains the necessary information for the intended use of the modules to which

it relates.

It is intended for technically qualified personnel who have received special training and have

the appropriate knowledge in the field of automation technology (measuring, process, and control technology).

The appropriate level of knowledge and the technically fault-free implementation of the safety

information and warnings contained in the technical documentation provided are prerequisites

for risk-free mounting, installation, and startup as well as for ensuring safety when operating

the described modules. Only qualified personnel have the required specialist knowledge to correctly interpret and implement the safety information and warnings contained in this document

in specific situations.

10

Page 11

1.3 Acceptance of goods, storage, and transport

1.3.1 Checking the delivery

• Ensure that the packaging and contents are not damaged

• Check that the delivery is complete using the delivery papers and the order details

• Inform the supplier immediately if there is any damage

• Store damaged parts until clarification is received from the supplier

1.3.2 Notes on storage and transport

• Store the module in a dry and clean environment. Observe the admissible ambient conditions (see "Technical data")

• The transport of the module is to be shockproof

• The original packaging provides optimum protection for storage and transport

1.3.3 Returning goods

In the event of repair, please return the module in a clean and complete state.

Use the original packaging to return goods.

1 Introduction

Accompanying letter for repair

Please include the completed accompanying letter for repair when returning goods.

Do not forget to state the following:

• Description of the application and

• Description of the error that has occurred

The accompanying letter for repair can be downloaded online from the manufacturer's website

(use the search function if necessary).

Protection against electrostatic discharge (ESD)

(ESD = electrostatic discharge)

To prevent damage from ESD, electronic modules or components must be handled, packaged,

and stored in an ESD-protected environment. Measures against electrostatic discharge and

electrical fields are described in DIN EN 61340-5-1 and DIN EN 6 1340-5-2 "Protection of electronic devices from electrostatic phenomena".

When returning electronic modules or components, please note the following:

• Sensitive components must only be packaged in an ESD-protected environment. Workspaces such as this divert electrostatic charges to ground in a controlled manner and prevent static charges due to friction capacities.

• Only use packaging for ESD-sensitive modules/components. These must consist of conductive plastics.

No liability can be assumed for damage caused by ESD.

11

Page 12

1 Introduction

CAUTION!

Electrostatic charges occur in non-ESD protected environments.

Electrostatic discharges can damage modules or components.

For transport purposes, use only the ESD packaging provided.

1.3.4 Disposal

Disposing of the device

DISPOSAL!

Devices and/or replaced parts should not be placed in the refuse bin at the end of their service life as they consist of materials that can be recycled by specialist recycling plants.

Dispose of the device and the packaging material in a proper and environmentally friendly

manner.

For this purpose, observe the country-specific laws and regulations for waste treatment a nd

disposal.

Disposing of the packaging material

The entire packaging material (cardboard packaging, inserts, plastic film, and plastic bags) is

fully recyclable.

12

Page 13

1.4 Identifying the device version

(A)

1.4.1 Nameplate

Position

The nameplate (A) is affixed to the module case.

1 Introduction

Contents

It contains important information. This includes:

Device type

Compare the specifications on the nameplate with the order.

Identify the supplied device version using the order details of the respective module.

Part no. (TN)

The part no. clearly identifies an article in the catalog. It is important for communication

between the customer and the sales department.

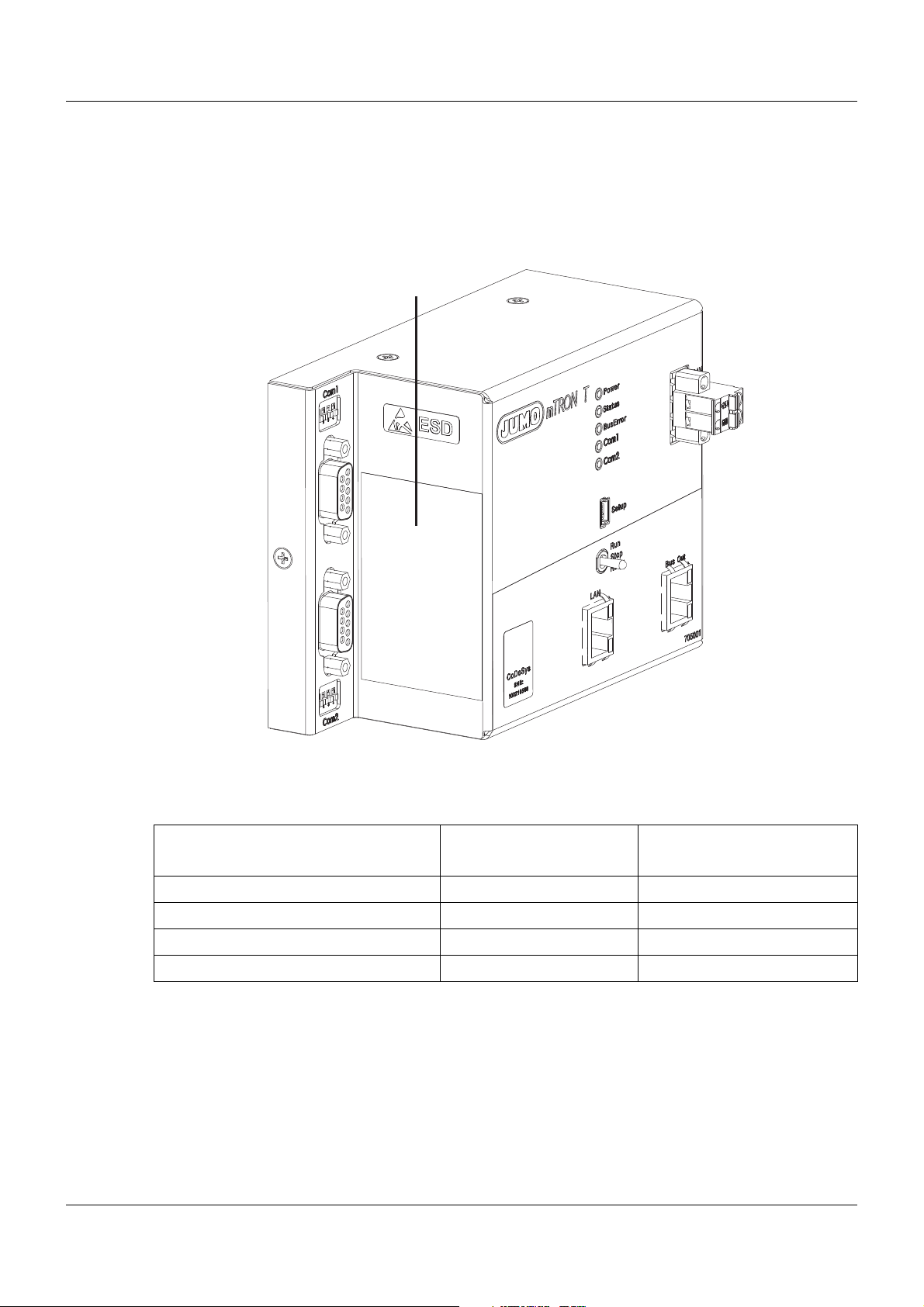

Description Designation on the name-

plate

Device type Type 705001/08-51-54-36/000

Part no. TN 00XXXXXX

Fabrication number F-Nr 0070033801211010006

Voltage supply - DC 24 V -20/+25 %

Example

13

Page 14

1 Introduction

Fabrication no. (F-Nr)

Among other things, the fabrication number contains the date of production (year/week).

Example: F-Nr = 0070033801211010006

The figures concerned are in positions 12, 13, 14, and 15 (from the left).

The device was therefore produced in the 1st calendar week of 2011.

1.4.2 Order details

(1) Basic type

705001 Central processing unit (1x Ethernet (RJ45), 1x system bus (RJ45), 1x system bus (E-

Bus), monitoring of 64 limit values)

(2) Basic type extension

0 Standard

(3) Version

8 With factory settings

(4) Interface Com1

00 Not used

51 RS232 Modbus RTU

54 RS422/485 Modbus RTU

(5) Interface Com2

00 Not used

51 RS232 Modbus RTU

54 RS422/485 Modbus RTU

64 PROFIBUS-DP (slave; as of system version 02)

(6) Voltage supply

36 DC 24 V +25/-20 %

(7) Extra codes

000 Without extra code

214 Math/logic function (activation for all connected controller modules)

224 PLC acc. to IEC 61131-3 (CODESYS V3)

225 Program generator 1 to 9

228 Program generator 1 to 9 with process steps (as of system version 02)

14

(1) (2) (3) (4) (5) (6) (7)

Order code /---/,...

Order example 705001 / 0 8 - 00 - 00 - 36 / 214

1

List extra codes in sequence, separated by a comma.

1

Page 15

1.4.3 Delivery package

1 central processing unit in the ordered version

1 cover for system bus

2 screw-on end clamps for DIN rail

1 Installation Instructions B 705001.4

Setup program with program editor JUMO mTRON T (30-day trial version, on MiniDVD)

Content of the Mini-DVD:

• Setup program with program editor JUMO mTRON T (30-day trial version)

• CODESYS programming software (free version)

• CODESYS Repository Package - Operating panels (free version)

• GSD file JUMO mTRON T - CPU (free version)

• PC Evaluation Software PCA3000 (30-day trial version)

• PCA Communication Software PCC (30-day trial version)

• Documentation in PDF format

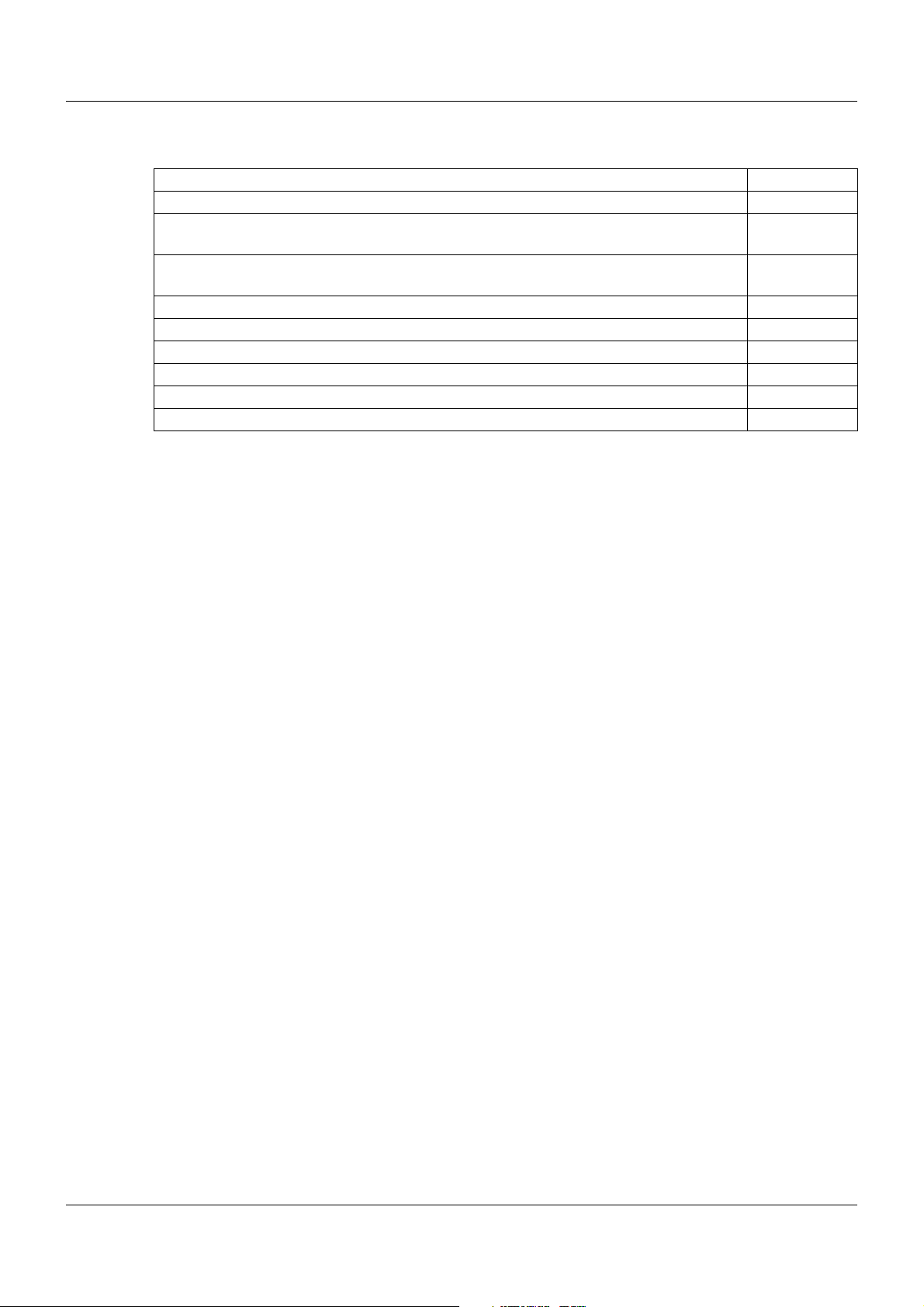

1.4.4 Accessories

1 Introduction

Article Part no.

Interface modules (expansion boards):

RS232 Modbus RTU 00569505

RS422/485 Modbus RTU 00569506

PROFIBUS-DP (slave; as of system version 02 and as of the central processing unit‘s

production date 27/2013 (calendar week))

Extra codes (activations):

Math/logic module (activation for all connected controller modules) 00569509

PLC according to IEC 61131-3 (CODESYS V3) 00569510

Program generator 1 to 9 00569511

Program generator 1 to 9 with process steps (as of system version 02) 00606498

00569507

15

Page 16

1 Introduction

1.4.5 General accessories

Article Part no.

JUMO mTRON T system manual, English 00575577

Setup program with program editor JUMO mTRON T (on MiniDVD), incl. USB cable

(A-plug to mini-B-plug, 3 m)

Program editor JUMO mTRON T (on MiniDVD), incl. USB cable (A-plug to mini-B-

plug, 3 m)

PCA3000/PCC JUMO software package 00431884

PC Evaluation Software PCA3000 00431882

Release automatic print for PC Evaluation Software PCA3000 00505548

PCA Communication Software PCC 00431879

Plant Visualization Software JUMO SVS3000: See data sheet 700755 USB cable A-plug mini-B-plug 3 m 00506265

Content of the Mini-DVD:

• Setup program with program editor JUMO mTRON T in case of part no. 00569494

• Program editor JUMO mTRON T in case of part no. 00622333

• CODESYS programming software (free version)

• CODESYS Repository Package - Operating panels (free version)

• GSD file JUMO mTRON T - CPU (free version)

• PC Evaluation Software PCA3000 (30-day trial version)

• PCA Communication Software PCC (30-day trial version)

• Documentation in PDF format

00569494

00622333

1.5 System version

The system version of the measuring, control, and automation system is determined by the

compatibility index of the base unit.

Example composition of a version number for the central processing unit: 248.xx.yy

248 = basic version, xx = compatibility index (system version), yy = current version

In the current document, descriptions that apply only for a particular system version are labeled

accordingly (e.g. "version 02").

16

Page 17

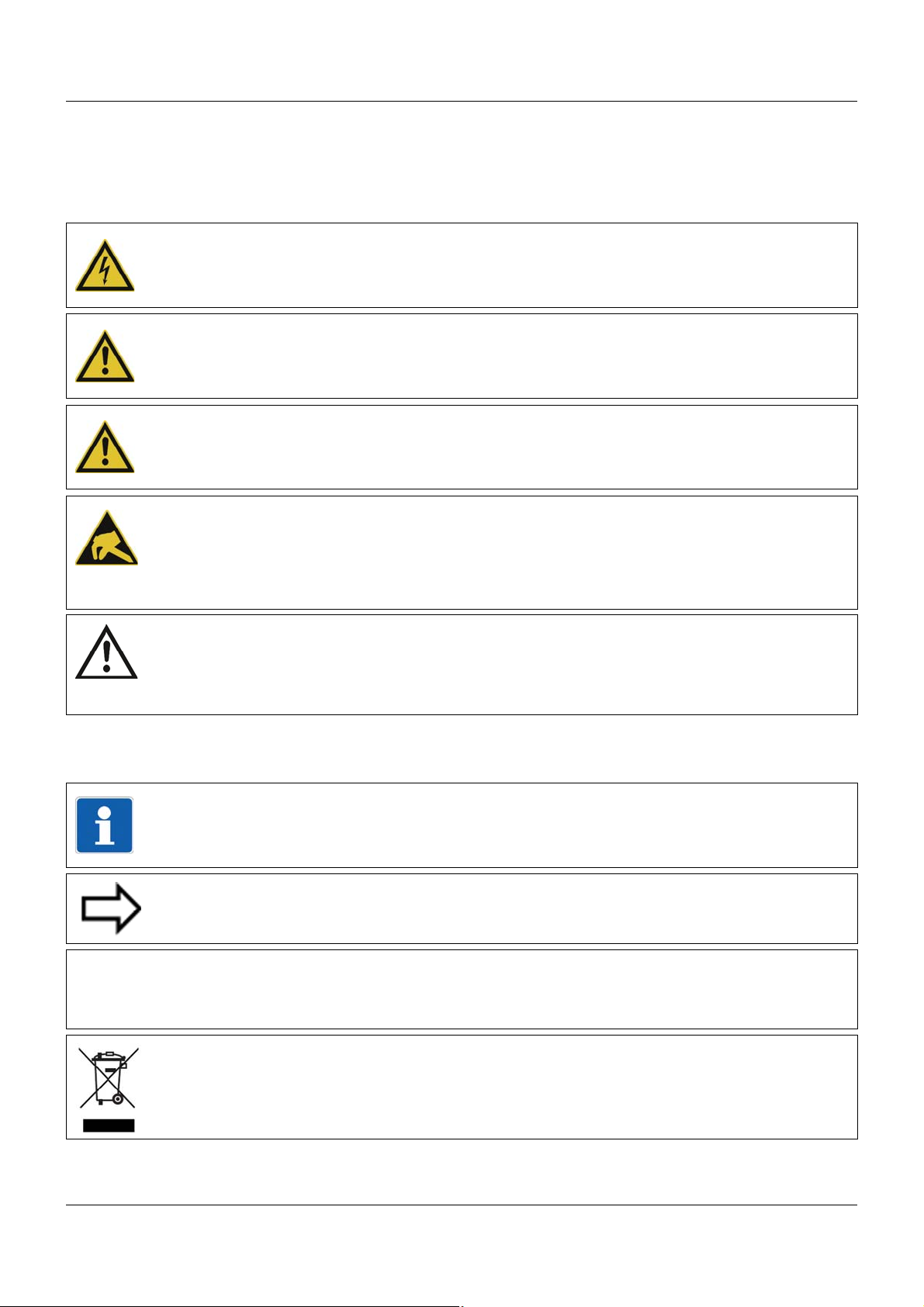

2.1 Brief description

Com1

RS232 (Modbus RTU) or

RS422/485 (Modbus RTU)

705001

Voltage supply Out

System bus

Com2

RS232 (Modbus RTU) or

RS422/485 (Modbus RTU) or

PROFIBUS-DP slave

USB (device)

For setup program

Bus Out

To permit connection to a

multifunction panel or

router module

LAN

Mainly for use of the

integrated web server

or the setup program

Switch / push-button

Run, Stop, or Reset

Voltage supply In

(at the front)

The central processing unit is the heart of the system. It contains the process image of the application and manages the configuration and parameter data of the complete system (except

for the multifunction panel).

For individual control tasks nine program generators (option) are available and 64 limit values

can be monitored.

LEDs are used to indicate applied voltage su pply, the operating status of the PLC, system malfunctions, as well as the communication through interfaces.

A USB device interface (setup), a LAN connection (Ethernet), and two system bus connections

are available as standard. Up to two interfaces can be optionally equipped for fieldbus applica tions.

The central processing unit, the input/output modules connected laterally, and modules integrated by a router are comfortably configured and parameterized with the setup program.

A PLC according to IEC 61131-3 can be released as an option. A switch is available to toggle

the system operating status (Run, Stop, and Reset).

2.2 Block diagram

2 Description

17

Page 18

2 Description

18

Page 19

3 Installation

3.1 General information on installation/dismounting

DANGER!

With multichannel controller module 705010 and relay module 705015, the load circuits from

relay or solid state relay outputs can be operated with a dangerous electrical voltage (e.g.

230 V).

There is a risk of electric shock.

Prior to the installation/dismounting of these modules or the removal of the module insert, the

load circuits are to be disconnected from the voltage and the terminal strips are to be removed from the module. This work must only be performed by qualified personnel.

WARNING!

The modules must never be installed in areas with an explosion hazard.

There is the risk of an explosion.

The entire system must only be used outside of areas with an explosion hazard.

Mounting site

All modules have protection type IP20 and are only intended for use in fireproof con trol cabinets

or switch boxes. The mounting site should be virtually vibration-free. Electromagnetic fields

caused by equipment such as motors or transformers should be avoided.

Multifunction panel 840 has protection type IP67 at the front and is intended for installation in

a panel cut-out. The rear has protection type IP20.

Climatic conditions

The ambient temperature and the relative humidity at the mounting site must correspond to the

technical data. Aggressive gases and vapors have a negative ef fect on the operating life of the

modules. The mounting site must be free from dust, powder, and other suspended matter so

that the cooling slots do not become blocked.

DIN rail

All modules are mounted on a DIN rail according to DIN EN 60715 (35 mm × 7.5 mm × 1 mm).

For reasons of stability, the spacing of the fastening screws for the DIN rail should not exceed

200 mm. The minimum distances for the modules that are specified in the module-specific installation or operating instructions must be observed.

Installation position

The DIN rail should be mounted horizontally so that all modules are arranged vertically. Otherwise the admissible ambient temperature range will be restricted.

Space requirement

The modules require the minimum distances shown in the following figure for the purpose of

installation/dismounting and for future maintenance or replacement. In the event of shorter distances the minimum bending radius of the cables, the performance of the electrical inst allation,

and the clear arrangement of the plant are no longer guaranteed.

19

Page 20

3 Installation

120

201

50.5

30

70

50.5

Minimum distances

3.2 Installation/dismounting on DIN rail

All modules in the system are intended for installation on a DIN rail according to DIN EN 60715

(35 mm × 7.5 mm × 1 mm).

The following must always be installed on the left, at the start of the DIN rail:

• A central processing unit or

• A router module

These modules connect the input/output modules to the voltage supply and the system bus.

NOTE!

To determine the required minimum width of the DIN rail, the widths of the individual modules

are to be added (see technical data of the modules in the respective data sheet or the

module-specific installation instructions).

The widths of the cover (17.5 mm) and both end brackets (each 9.5 mm) should also be

taken into consideration: 17.5 mm + 2 × 9.5 mm = 36.5 mm.

20

Page 21

3 Installation

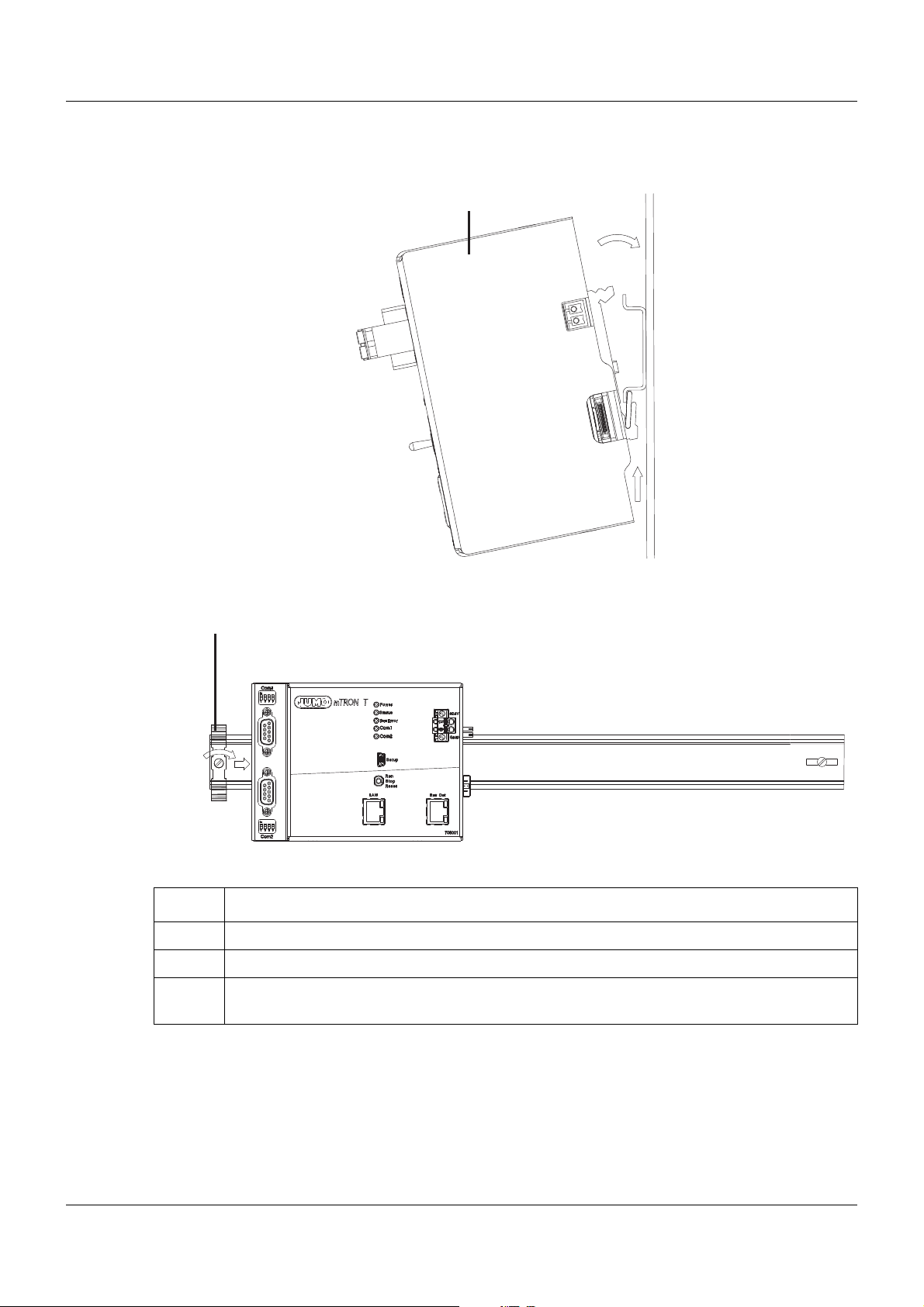

(A)

(A2)

(A1)

(B)

(B3)

(B4)

3.2.1 Base units

Installation of a base unit, using the example of a central processing unit 705001

Installing the end brackets

Procedure:

Step Activity

1 Mount the central processing unit (A) on the DIN rail from below and press upward (A1).

2 Pivot the central processing unit (A) toward the rear until it snaps into place (A2).

3 Position the end bracket (B) on the DIN rail and move to the right against the central pro-

cessing unit (B3). Fasten the end bracket using a screwdriver (B4).

21

Page 22

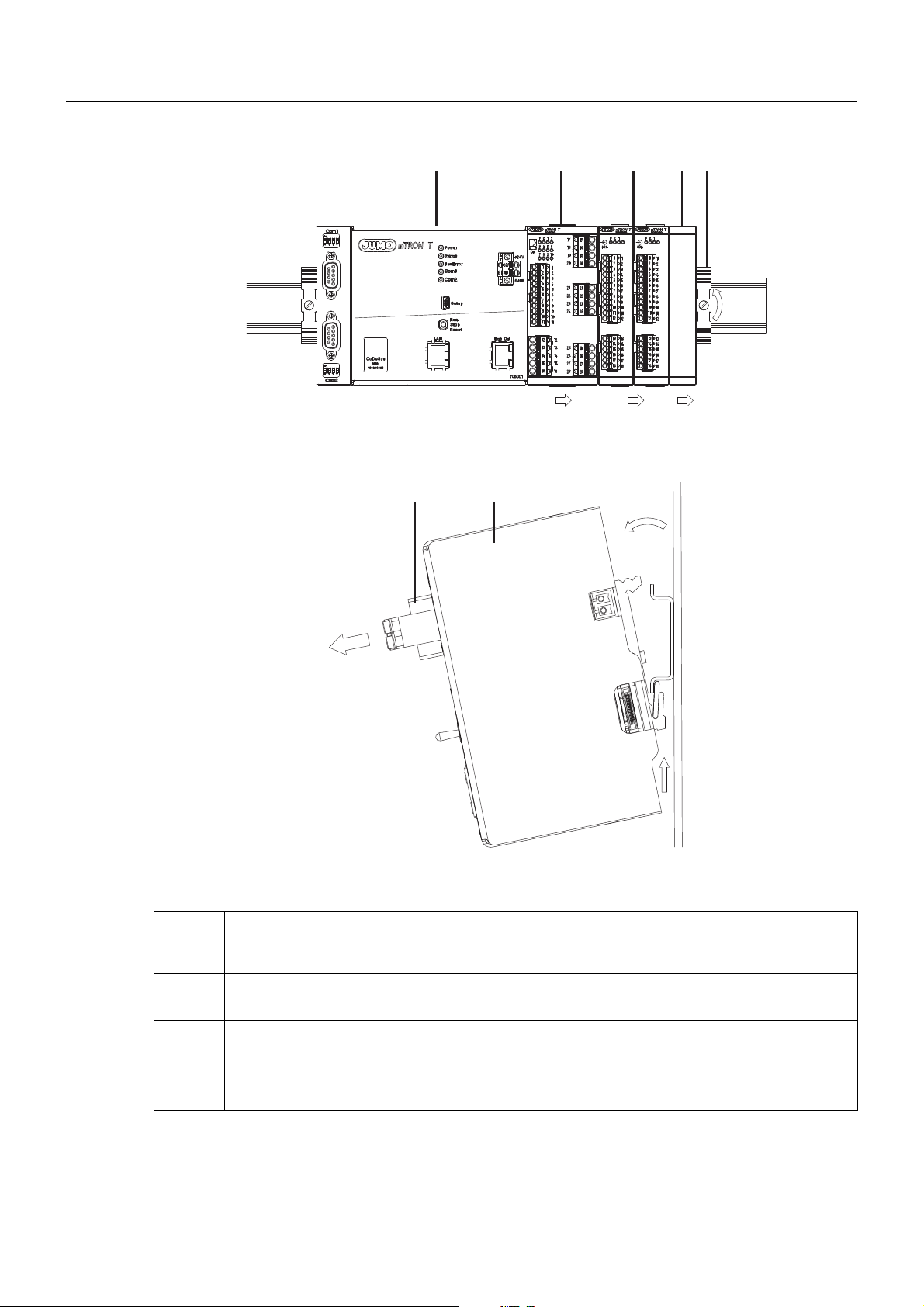

3 Installation

(A) (C) (D)

(C3)

(D2)

(B)

(B4) (B4)

(B)

(A)

(E1)

(E)

(A6)

(A5)

Dismounting a base unit, using the example of a central processing unit 705001

Removing the central processing unit from the DIN rail

22

Procedure:

Step Activity

1 Remove the connection cables if required (Setup, LAN, Bus Out).

2 If required, use a screwdriver to release the wired terminal (E) of the central processing unit

(A) and pull off toward the front (E1).

3 Fully release the end bracket (D) using a screwdriver (D2), press upward from below, pivot

toward the front, and remove from the DIN rail.

Note: The end bracket does not need to be removed from the DIN rail if there is sufficient

space to the side to move it at least 10 mm to the right.

Page 23

3 Installation

Step Activity

4 Move the cover (C) to the right (C3) until the sid e contacts of the neighb or ing mo du le are

exposed. Then release the cover at the bottom using a screwdriver, press upward, and

remove from the DIN rail.

Note: The cover does not need to be removed from the DIN rail if there is sufficient space

to the side to move it at least 10 mm to the right.

5 Move the modules (B) on the right next to the central processing unit (A) to the right (B4)

until the side contacts of the central processing unit are exposed.

➥ These modules are isolated from the voltage supply and the system bus.

6 Press the central processing unit (A) upward from underneath (A5), pivot off the DIN rail

toward the front (A6), and remove.

23

Page 24

3 Installation

6,6

135

101

58.7

67.1

17.4

3.3 Dimensions

24

Page 25

4.1 Installation notes

NOTE!

These installation notes apply for the entire measuring, control, and automation system and,

on some occasions, are only applicable for a specific module.

The respective connection diagram shows the context.

Requirements for the personnel

• Work on the modules must only be carried out to the extent described and, like the electrical

connection, only by qualified personnel.

• Before plugging and unplugging connection cables ensure that the person performing the

work is electrostatically discharged (e.g. by touching grounded metallic parts).

Cables, shielding, and grounding

• When selecting the cable material, when installing, and when performing the electrical connection of the module, the regulations of DIN VDE 0100 "Erection of power installations with

rated voltages up to 1000 V" and the respective national regulations (e.g. on the basis of

IEC 60364) are to be observed.

• Certain cables must be heat resistant up to at least 80 °C at maximum load. The relevant

instructions in the connection diagram of the affected modules must be observed.

• Route input, output, and supply cables separately and not parallel to one another.

• Only use shielded and twisted probe and interface cables. Do not route the lines close to

current-carrying components or cables.

• For temperature probes, ground the shielding on one side in the control cabinet.

• Do not perform loopthroughs on the grounding cables, but route the cables individually to a

shared grounding point in the control cabinet; in doing so, ensure that the cables are as

short as possible.

Ensure that the equipotential bonding is correct.

4 Electrical connection

Electrical safety

• Isolate power supply units from the voltage supply on the primary side if there is a risk of

touching parts with dangerous electrical voltage (e.g. 230 V) in the course of work.

• The fuse rating of the power supply units on the primary side should not exceed a value of

10 A (inert).

• With modules with relay or solid state relay outputs, the load circuits can be operated with

a dangerous electrical voltage (e.g. 230 V). Disconnect load circuits from the voltage supply

during installation/dismounting and electrical connection.

• In order to prevent the destruction of the relay or solid state relay outputs in the event of an

external short circuit in the load circuit, the load circuit should be fused to the maximum admissible output current.

• The modules are not suitable for installation in areas with an explosion hazard.

• In addition to a faulty installation, incorrectly set values on the module could also impair the

correct function of the following process. Therefore, ensure that safety devices independent

of the module (e.g. overpressure valves or temperature limiters/monitors) are available and

that it is only possible for qualified personnel to define settings. Please observe the corresponding safety regulations in this context.

25

Page 26

4 Electrical connection

Interface Com1

System bus Out

Side system bus Out

DC 1500 V

USB device interface

(setup)

Interface Com2

LAN

DC 1500 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

Voltage supply Out

Voltage supply In

References to other information

• The electromagnetic compatibility meets the standards and regulations cited in the technical data.

• The USB device interface and voltage supply in the central processing unit 705001 are not

electrically isolated. In general, please observe the specifications regarding electrical isolation.

4.2 Electrical isolation

26

Page 27

4 Electrical connection

Setup

LAN Bus Out

Run

Stop

Reset

Power

Status

Bus Error

Com1

Com2

Com2

2

1

3

4

ON

2

1

3

4

ON

Com1

(1)

(2)

(3)

(4)

(11)

(5)

(7)

(8)

(10)

(6)

(9)

(12)

4.3 Connection diagram

CAUTION!

At maximum load, the temperature at the "+24 V" and "GND" terminals (Voltage supply In)

may exceed 60 °C.

As a result the insulation of the cable may be damaged.

The cable must be heat resistant up to at least 80 °C.

4.3.1 Display, operating, and connection elements

This overview shows the position of the display, operating, and connection elements. The assignment to individual functions is illustrated in the following sections.

(1) Status displays (LED)

(2) Voltage supply In, DC 24 V

(3) Vo ltage supply Out, DC 24 V

(4) USB device interface (Setup)

(5) Switch/button for Run, Stop, or Reset

(6) Side system bus Out

(7) System bus Out

(8) LAN interface

(9) Com2 terminating resistors

(10) Com2 interface

(1 1) Com1 interface

(12) Com1 terminating resistors

27

Page 28

4 Electrical connection

8

1

8

1

6

7

8

9

2

3

4

5

1

U

+

-

x

4.3.2 Interfaces

Connection Designa-

tion

Number

Connection element

USB device Setup (4)

System bus Out Bus Out (7) 1 TX+

2 TX3 RX+

6 RX-

Ethernet LAN (8) 1 TX+

2 TX3 RX+

6 RX-

Serial interface

(RS232), option

Com1,

Com2

(11),

(10)

2 RxD

3 TxD

5 GND

Serial interface

(RS422), option

Com1,

Com2

(11),

(10)

3 TxD+

4 RxD+

5 GND

8 TxD9 RxD-

Serial interface

(RS485), option

Com1,

Com2

(11),

(10)

3 TxD+/RxD+

5 GND

8 TxD-/RxD-

Transmit data +

Transmit data Receive data +

Receive data -

Transmit data +

Transmit data Receive data +

Receive data Receive data

Transmit data

Ground

Transmit data +

Receive data +

Ground

Transmit data Receive data Transmit/Receive data +

Ground

Transmit/Receive data -

PROFIBUS-DP,

option (as of system version 02)

Com2 (10) 8 RxD/TxD-N (A)

3 RxD/TxD-P (B)

6 VP (+5 V)

5 DGND

Transmit/Receive data Transmit/Receive data +

Voltage supply +

Data ground

4.3.3 Voltage supply

Connection Designation Num-

ber

Voltage supply In +24 V and

(2) +24 V

GND

28

Symbol and terminal designation

GND

Page 29

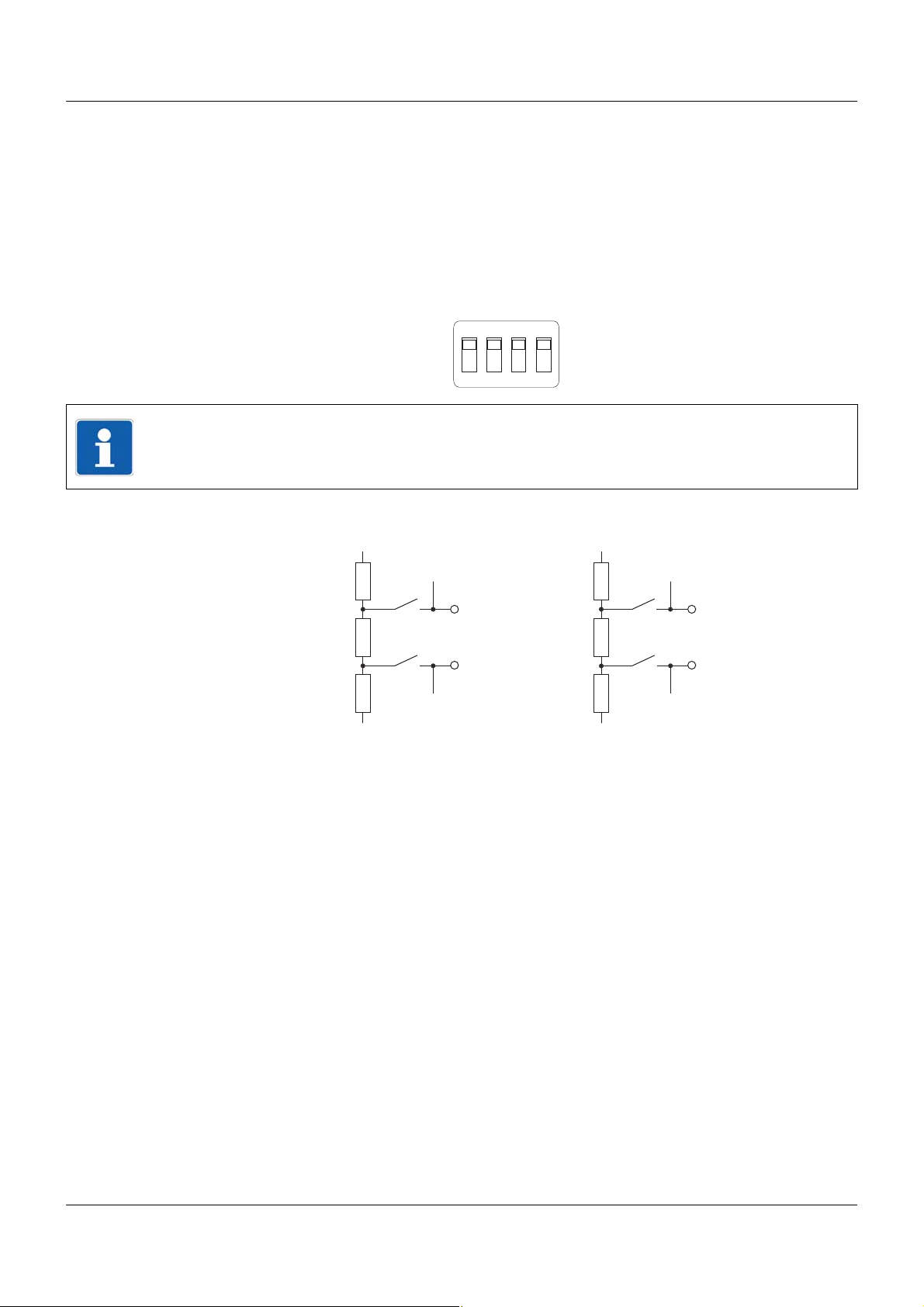

4.3.4 Terminating resistors

2

1

3

4

ON

332 ?

120 ?

332 ?

GND

+5 V

4

9

332 ?

120 ?

332 ?

GND

+5 V

3

4

3

8

1

2

The internal terminating resistors for the Com1 and Com2 interfaces are only relevant for

RS422/485.

The terminating resistors are deactivated by default. To activate them, DIP switches 1 to 4 for

the relevant interface must be pushed upward using a suitable tool such as a ballpoint pen (ON

position).

The following figure shows the position of the DIP switches when the terminating resistors are

activated.

NOTE!

To ensure fault-free operation, terminating resistors are required at the start and end of an

RS422/485 transmission path.

Internal terminating resistors

4 Electrical connection

29

Page 30

4 Electrical connection

4.4 Functional check

Once the electrical connection is complete, the following points must be checked:

1) Voltage supply

2) LED function

3) Errors during initialization

Voltage supply

If Then

"Power" LED (green) is lit The central processing unit is supplied with volt-

"Power" LED is not lit The central processing unit is not supplied with

age.

voltage, or the electrical function of the LED is

faulty.

Remedy:

• Check voltage supply to "+24 V" and "GND"

terminals of the central processing unit.

• Check power supply unit and connection between power supply unit and central processing unit.

If the "Power" LED does not light up, despite a

voltage supply being present, the central processing unit must be replaced.

LED function

When the voltage supply is connected, the LEDs on the central processing unit are tested automatically.

(If a voltage supply is present, the "Power" LED is permanently lit in green.)

If Then

The following LEDs light up in red simultaneously for approx. two seconds:

Status

BusError

Com1

Com2

One of the listed LEDs does not light up The central processing unit must be replaced.

After the test of the red LEDs, the following LEDs

light up in green simultaneously for approx. two

seconds:

Status

Com1

Com2

One of the listed LEDs does not light up The central processing unit must be replaced.

The electrical function of the LEDs is in order.

The electrical function of the LEDs is in order.

30

Page 31

Errors during initialization

If Then

4 Electrical connection

Startup

After the LED test,

the "Status" LED lights up in red and

the "BusError" LED does not light up

After the LED test,

the "Status" LED flashes red and

the "BusError" LED does not light up

There is an internal error and the central processing unit must be replaced.

The internal buffer battery is dead and must be

replaced.

For buffer battery replacement, please contact

the device manufacturer or plant installer.

The checks described above complete the process of installation and electrical connection. For

startup, use the additional documentation (operating manual or system manual).

The "Introduction" section of this document contains an overview of all documentation for the

measuring, control, and automation system.

31

Page 32

4 Electrical connection

32

Page 33

5.1 Display, operating, and connection elements

Setup

LAN Bus Out

Run

Stop

Reset

Power

Status

Bus Error

Com1

Com2

Com2

2

1

3

4

ON

2

1

3

4

ON

Com1

(1)

(2)

(3)

(4)

(11)

(5)

(7)

(8)

(10)

(6)

(9)

(12)

This overview shows the position of the display, operating, and connection elements.

5 Operation

(1) Status displays (LED)

(2) Voltage supply In, DC 24 V

(3) Vo ltage supply Out, DC 24 V

(4) USB device interface (Setup)

(5) Switch/button for Run, Stop, or Reset

(6) Side system bus Out

(7) System bus Out

(8) LAN interface

(9) Com2 terminating resistors

(10) Com2 interface

(1 1) Com1 interface

(12) Com1 terminating resistors

33

Page 34

5 Operation

5.2 System states

The following characteristics indicate the various system states:

"Run" system state

• To achieve this state, use the system switch (Run) or the setup program;

if there is an error in a mandatory module, the system does not enter the "Run" state.

Requirement: the system must not be in the "Init" state.

• Input values are adopted by the system; outputs are actuated (are active).

• Interfaces (Com1 and Com2) are active.

• The system switch, setup program, or PLC can be used for changeover to "Stop".

• The setup program can be used to transfer the configuration; here the user can make the

adjustment whether the system is set to the safe "Stop" state beforehand.

• Software update is possible, but the system is set to "Stop" automatically.

"Stop" system state

• To achieve this state, use the system switch (Stop), setup program, or PLC.

Requirement: the system must not be in the "Init" state.

• Input values are adopted by the system; outputs are switched off (inactive).

• Modules are in safe state (except independent controller modules).

• Interfaces (Com1 and Com2) are active.

• The setup program can be used for changeover to "Run", provided this is not prevented by

the "Stop" switch setting.

• The setup program can be used to transfer the configuration.

• Recording function continues to run, default values are used in part.

• Software update is possible.

• Three-step controller in manual mode: control element can still be operated, provided communication with the multifunction panel is available.

"Init" system state

• To achieve this state, use the system switch ("Origin" reset).

• Outputs are switched off (inactive).

• Modules are in safe state (except independent controller modules).

• Interfaces (Com1 and Com2) are active.

• Changeover to "Run" and "Stop" is not possible using the setup program or PLC.

• System startup must be performed with the setup program.

• Recording function continues to run; analog inputs of the multifunction panel are set to default values.

• PLC program and all internal PLC memory areas are deleted; PLC is set to original state.

"Calibration mode" system state

• Activation in setup program using the "Calibrate / test" function (online parameter) for the

relevant module

• The entire system enters calibration mode.

• PLC in "Stop" state; system bus in "Run" state (outputs are actuated)

34

Page 35

5.3 System switch

The central processing unit switch (Run/S top/Reset) allows the various system states to be set.

However, the system state does not just depend on the switch position; it also depends on in-

ternal errors, which may prevent changeover to another state. For example, an error may result

in a system start being blocked, even though the switch is set to "Run".

Error states are indicated by the "Status" and "BusError" LEDs.

Chapter 5.4 "LED displays", page 38

The setup program or a Web browser is used for diagnostics and, if necessary, also for trou-

bleshooting.

"Run" switch position

The system enters the "Run" state, provided there are no internal errors that prevent this.

Chapter 5.2 "System states", page 34

During changeover from the "S top" st ate to the "Run" st ate, an event message is issued (plant

"Run").

"Stop" switch position

The system enters the "Stop" state.

Chapter 5.2 "System states", page 34

During changeover from the "Run" state to the "Stop" state, an event message is issued (plant

"Stop").

5 Operation

NOTE!

In the "Stop" state it is not possible to set the PLC to the "Start" state using the CoDeSys

programming system.

"Reset" switch position (button function)

This switch position triggers three different functions. Starting from the "Stop" position, the

switch must be pushed down in a specific sequence (button function) and held. If the relevant

sequence and the required times are not observed, the entire sequence must be repeated. During a sequence, LEDs signal the end of the time periods and successful completion of the sequence.

The following diagrams show the time sequence for the switch position (Reset, Stop) and the

signaling from the "Status" (S) and "BusError" (BE) LEDs. See also:

Chapter 5.4.1 "Display modes", page 39

When the switch is pushed to the "Reset" position, both LEDs switch off. When the first thresh-

old in the sequence is reached (2 s), the "Status" (S) LED lights up in red. When the second

threshold is reached (10 s or 2 s if pushed again in "Origin" reset), the "BusError" (BE) LED

lights up in red. This allows you to see when the switch can be released.

If the sequence was completed successfully, the relevant reset is triggered. Both LEDs flash

for approx. 2.5 seconds as confirmation. If the sequence was incorrect, a reset is not triggered

and the LEDs resume the state that they were in before the start of the sequence.

NOTE!

The following reset sequences – except "origin" reset – can be performed only after basic initialization of the system.

35

Page 36

5 Operation

2 s < t < 10 s

t > 3 s

Reset

Stop

S

BE

t > 2 s t > 3 s

S

BE

t > 3 s

t > 2 s

t > 10 s

10 s < t < 15 s

Reset

"Warm" reset:

The "warm" reset is initialized by holding the switch in the "Reset" position between 2 s and

10 s.

The PLC performs a warm start, which means that the retain area is retained (see CoDeSys

documentation on warm start of PLC).

The retain variables of external inputs (interfaces) are also retained.

An event message is issued (warm start reset).

"Cold" reset:

The "cold" reset is initialized by holding the switch in the "Reset" position for at least 10 s.

A "cold" reset resets the system bus (master restarts, data of the modules on the bus is read

in again).

The PLC performs a cold start, which means that the retain area is deleted (see CoDeSys documentation on cold start of PLC).

The retain variables of external inputs (interfaces) are reset.

An event message is issued (cold start reset).

36

Page 37

5 Operation

2 s < t < 10 s

0,25 s < t < 3 s

2 s < t < 10 s

t > 3 s

Reset

Stop

Reset

Stop

S

BE

t > 2 s t > 2 s t > 3 s

"Origin" reset:

The "origin" reset is initialized by holding the switch in the "Reset" position between 2 s and

10 s, briefly releasing it (between 0.25 s and 3 s), and then holding it in the "Reset" position

again between 2 s and 10 s.

An "origin" reset resets the system bus (master starts again, dat a of the mod ules on the bus is

read in again) and deletes the bus configuration.

The PLC performs a full reset, which means that the PLC program and the retain area are deleted (see CoDeSys documentation on origin (full) reset of PLC).

The retain variables of external inputs (interfaces) are reset.

The system enters "Init" state.

Chapter 5.2 "System states", page 34

An event message is issued (origin reset).

NOTE!

A "origin" reset is also possible during the basic initialization of the system. For this purpose,

after switching on the system, the switch must be held in the "Reset" position until the reset

sequence starts (observe the LEDs). This makes it possible, for example, to delete a faulty

PLC program that would otherwise block the start of the system.

CAUTION!

An "origin" reset deletes the entire configuration.

The system can no longer be started in the "Run" switch position.

To operate the system again, the configuration – incl. PLC program and bus configuration –

must be loaded into the central processing unit with the setup program.

37

Page 38

5 Operation

5.4 LED displays

"Power" LED

If the central processing unit is being supplied with voltage, the LED is lit permane ntly in green.

"Status" LED

This LED indicates the system state and – in combination with the "BusError" LED – errors in

the system. Possible displays are listed in the "System states and errors" section.

Chapter 5.4.2 "System states and errors", page 40

"BusError" LED

This LED indicates problems relating to the system bus and the modules that are connected to

the central processing unit.

In combination with the "Status" LED, it also indicates errors in the system. Possible displays

are listed in the "System states and errors" section. Diagnostics requires the setup program or

a Web browser.

"Com1" and "Com2" LEDs

These LEDs indicate the status of the relevant interface. The display depends on the system

version.

Version 01:

• LED off: Interface module is not equipped

• LED flashes green and red: Error (defective interface, wrong setting. or wrong connection)

• LED flashes green: Communication is active

Version 02:

• LED off: Interface module is not equipped

• LED is lit green: Interface module is equipped, no communication

• LED flashes green: Communication is active

• LED flashes red: Communication error

- for Modbus master: Slave does not answer.

- for Modbus slave: Timeout detected (master does not answer).

- for PROFIBUS (Com2): External communication to the master is disrupted.

• LED is lit red, only for PROFIBUS (Com2): Internal error

For diagnostics in the event of an error, the setup program or a web browser is required.

38

Page 39

5.4.1 Display modes

The following table lists all the states that the "Status" (red/green) and "BusError" (red) LEDs

can display.

5 Operation

Display mode Description Green sym-

bol

--- LED state not relevant --- --Off LED off

On LED on (permanently lit)

Flickering LED flickers (50 ms on, 50 ms off)

Single flickering LED flashes briefly (50 ms on, 200 ms off)

Blinking LED flashes (200 ms on, 200 ms off)

Single flash LED flashes once (200 ms on, 1000 ms off)

Double flash LED flashes twice (on/off/on for 200 ms each

time, 1000 ms off)

Triple flash LED flashes three times (on/off/on/off/on for

200 ms each time, 1000 ms off)

Quadruple flash LED flashes four times (on/off/on/off/on/off/on for

200 ms each time, 1000 ms off)

Blinking red/green LED flashes red and green (200 ms red, 200 ms

green)

Red symbol

39

Page 40

5 Operation

5.4.2 System states and errors

The following table lists all the system states and errors that are indicated by the "Status" and

"BusError" LEDs. In most cases, further diagnostics must be performed with the setup program.

Category "Status"

LED

Start error Internal error (1st boot-

Start er ror/

operation

Start error Buffer battery dead (sys-

Start error Various errors when start-

Start er ror Error in topology

"BusError"

LED

Meaning Diagnos-

loader)

Internal error (2nd boot-

loader)

No firmware (2nd boot-

loader)

Internal error Setup pro-

tem start only possible with

"cold" reset)

ing the system bus (e.g. no

memory, initialization error,

error when reading the bus

configuration)

Bus configuration not available.

If the "Com1" and "Com2"

LEDs also light up red, the

input voltage is too low

(< 19 V).

Bus configuration does not

correspond to the actual

state.

Target state of hardware

configurator does not correspond to the actual state.

Recommended action

tics with

LED Replace central pro-

cessing unit.

Perform restart, read

gram

LED Replace buffer battery.

Setup program or

Web

browser

Setup program or

Web

browser

out error.

After several restart

attempts with an internal

error:

replace central processing unit.

Re-transfer configuration with the setup program.

Check that all (mandatory) modules are present and correctly

connected; check LED

display of modules; if

necessary, re-transfer

configuration with the

setup program.

40

Page 41

5 Operation

Category "Status"

LED

Start er ror Incompatible module on

"BusError"

LED

Meaning Diagnos-

system bus

No firmware present in

module

Incorrect (incompatible)

hardware (actual/target)

Incorrect (incompatible)

hardware VdN (actual/target)

Incorrect (incompatible)

software in module (actual/

target)

Incorrect (incompatible)

software in module (incompatible with central processing unit)

Incorrect (incompatible)

software in module (incompatible with hardware)

Incorrect (incompatible)

software VdN in module

(actual/target)

Optional board 1 incorrect

(actual/target)

Optional board 2 incorrect

(actual/target)

Optional board 3 incorrect

(actual/target)

tics with

Setup program or

Web

browser

Recommended action

Use the setup program

to determine which

module is incompatible;

replace module, or load,

replace, or remove

optional board.

Perform firmware

update, observe versioning.

Manual for setup

program

B 705000.6

Operation --- Calibration mode LED/setup

program

Operation --- DHCP error (no IP

address)

Battery pre-warning/bat-

tery dead (after "cold"

reset, see "Buffer battery

dead" start error)

PLC program not available. Re-transfer configura-

Operation --- System in "Run" (OP) state

– no error

Operation --- System in "Stop" (INIT)

state – no error, only in

start phase

Operation --- System in "Stop" (PREOP)

state – no error, only in

start phase

LED/setup

program

LED

LED

LED

Buffer battery is dead or

almost dead;

replace buffer battery.

tion with the setup program.

41

Page 42

5 Operation

Category "Status"

LED

Operation --- System in "Stop"

Operation --- Error in a mandatory mod-

Operation --- Error in an optional module LED/setup

Operation --- Module error (central pro-

"BusError"

LED

Meaning Diagnos-

tics with

LED

(SAFEOP) state – no error

LED/setup

ule

cessing unit performs bus

scan)

program,

Web

browser, or

multifunction panel

program,

Web

browser, or

multifunction panel

LED None (modules that are

Recommended action

Check that all mandatory modules are present and correctly

connected; check function of modules, replace

affected module if necessary.

Check that all optional

modules are present

and correctly connected; check function

of modules, replace

affected module if necessary.

still located on the system bus are started

automatically).

42

Page 43

5.5 Operation on the multifunction panel

(2)

(3)

(4)

(1)

The basic steps for operation and visualization are described in the operating manual of the

multifunction panel (B 705060.0).

This operating manual describes how to operate the program generator.

Multifunction panel – "Controller" button

5 Operation

(1) "Controller" button (operation) (2) "Controller" menu (opened with the "Con-

troller" button)

(3) Operate program generator; opens the

generator screen

To operate the program generators, select the "Program generator" entry (3).

(4) Operate multichannel controller module;

opens the controller screen

Operating manual for multichannel con-

troller module (B 705010.0)

43

Page 44

5 Operation

5.5.1 Program generator

Program generator operation (option) covers the following settings and functions:

• Selecting a program

• Specifying the program section and delay time for program start

• Starting and stopping the program

• Changing the program temporarily

• Changing to manual mode and setting the setpoint values and operating contacts

• Displaying setpoint values, operating contacts, program names and sections, tolerance

band signal, and running times

NOTE!

The channel and setpoint value of the program generator must be assigned to the input signal (setpoint value) of the relevant controller channel in the controller module NV connecting

list.

Generator screen – overview of the nine program generators

44

This overview shows the following information for all activated program generators:

• Function: program generator (or current program) or fixed-setpoint generator

• Current program section of first program channel

• Remaining running time of program

To select a program generator, touch the relevant box. Program generators shown on a gray

background are switched off and cannot be selected. The colors of the background and foreground – except for gray – can be configured for each program generator (central processing

unit).

The "Start/Stop" and "Info" tabs always relate to the selected program generator.

If only one program generator is switched on, the Start/Stop screen of the relevant program

generator is displayed in place of the overview.

Page 45

5 Operation

(1)

(5)

(2)

(3)

(4)

Generator screen – Start/Stop screen for the selected program generator (basic status)

(1) Program name (2) Program generator is in basic status (pro-

gram is not running)

(3) "Start" button; opens the Start/Stop screen (4) Changeover to manual mode

(5) Change the setpoint values (incl. tolerance

band) and operating contacts for basic status

(For description, see manual mode)

Setpoint values, tolerance band, and operating contacts for basic status can be configured.

45

Page 46

5 Operation

(3)

(1)

(4)

(5)

(6)

(7)

(2)

(8)

Generator screen – Start/Stop screen after "Start" button has been pushed

(1) Program start

Starts the selected program.

(3) Cancel dialog without applying the entries

(return to basic status)

(5) Program section that is used for the start of

the program generator

(Only for program start)

(7) Remaining time in program section

(Only for program start)

If 00:00:00 is set, the program starts when

the relevant program section starts. If

00:10:00 is set (example), the program

starts 10 minutes before the end of the program section.

(2) Apply entries without program start (return

to basic status)

(4) Program selection

All programs that were assigned to the rele-

vant program generator in the program edi-

tor are available for selection here.

(6) Delay of program start

(Not for program start = time or start with

time)

(8) Start tim e (date and time)

(Only for program start = time or start with

time)

46

Page 47

Generator screen – program running

(9)

(8)

(11)

(1)

(3)

(4)

(5)

(7)

(6)

(10)

(2)

5 Operation

(1) Program name and number of current pro-

gram section in channel 1

(3) Switch position of operating contacts (4) Remaining running time of program

(5) Skip to next program section of channel 1

(carried out for channel 2 and 3 at same

time if present)

(7) Skip to previous program section of chan-

nel 1 (carried out for channel 2 and 3 at

same time if present)

(9) Temporary change to program with pro-

gram editor

(11) "Program running" display

(2) Current setpoint value of program genera-

tor (here: setpoint value 1 of channel 1)

(6) Abort program

(8) Pause program

(10) Running time of program that has elapsed

The appearance of (2), (3), (4), and (10) can be configured: selection of the signals (or of running time) and the color, assignment of name and unit.

NOTE!

Temporary changes to setpoint values on the multifunction panel are only displayed on the

generator screen for running programs. If the program is paused, temporary changes are applied, but not displayed. The changes do not take effect and are not shown on th e generator

screen until the program continues to run.

47

Page 48

5 Operation

(1)

(2)

(3)

(4)

(1)

(2)

(5)

Generator screen – program paused

(1) "Program paused" display (2) Continue program

Generator screen – Start/Stop image of selected program generator in manual mode

(1) Time display (not relevant in manual mode) (2) Changeover to basic status

(3) Change the setpoint values (incl. tolerance

band) and operating contacts for manual

mode

(5) Manual mode is active

(4) Time display (not relevant in manual mode)

Setpoint values, tolerance band, and operating contacts for manual mode can be configured.

48

Page 49

Generator screen – program channel selection in manual mode

(1)

(2)

(3)

(4)

This screen appears when the button (3) for changing the setpoint values and operating contacts is pushed.

5 Operation

Generator screen – setting the setpoint values and operating contacts in manual mode

(1) Setpoint value 1 to 4 in selected program

channel 1

(3) 16 operating contacts in the selected pro-

gram channel 1 (contact 1 = right)

(2) Upper limit of the tolerance band (for set-

point value 1)

(4) Lower limit of the tolerance band (for set-

point value 1)

49

Page 50

5 Operation

(1)

(2)

(3)

(4)

(5)

(6)

Generator screen – information about the selected program generator

(1) Setpoint values (2) Operating contacts

(3) Tolerance band signal of setpoint value 1 (4) Runtimes

(5) Switch to next program channel (if avail-

able)

16 operating contacts can be defined in each of the three program channels (maximum three

program channels). These are linked with OR, so that 16 operating contacts are available for

each program generator.

(6) Current program section

Operating with barcode scanner

Operating the program generator is also possible by reading barcodes; the following functions

are supported:

• Program selection (program number 1 to 99)

• Program start

• Program stop

The corresponding barcodes can be found in the operating manual of multifunction panel 840

(B 705060.0).

50

Page 51

NOTE!

The parameters described in this section can be configured either with the setup program, or

on the multifunction panel (exception: setup info in the device data).

6.1 Selectors

The selectors contain all analog and digital signals that are available for configuration in the

central processing unit.

These are, firstly , the central processing unit (CPU) signals. This relates to internal signals (incl.

PLC) and variables. The values of the variables are read in via an interface, such as Com1.

Chapter 6.3 "Variables", page 60

Chapter 8.2 "Modbus frames for reading", page 114

Secondly , they are signals originating from the input/output modules (incl. multichannel controller module) and multifunction panel.

6.1.1 Analog selector

6 Configuration

The following table lists all analog signals.

Category Signal Description

Inactive No signal selected

Central processing unit

Analog variables Analog variable 1 to 64 Analog variable 1 to 64 (via interface)

Program

generator 1 to

Program

generator 9

Channel 1 SP1 to Channel 3 SP1 Setpoint value 1 of program channel 1 to 3

Channel 1 SP2 to Channel 3 SP2 Setpoint value 2 of program channel 1 to 3

Channel 1 SP2 to Channel 3 SP2 Setpoint value 3 of program channel 1 to 3

Channel 1 SP4 to Channel 3 SP4 Setpoint value 4 of program channel 1 to 3

PLC Analog output 13 to 16 Signal of PLC analog output 13 to 16

Analog PLC output block 10 to

block 18

PLC Analog output 1 to 16 Signal of PLC analog output 1 to 16

51

Page 52

6 Configuration

Category Signal Description

Multichannel controller module

Controller C01ActualValue to

C04ActualValue

C01Setpoint to C04Setpoint Setpoint value of contro ller channel 1 to 4

C01OutpLevelMon to

C04OutpLevelMon

Analog inputs AI01 to AI04 Measured value of analog input 1 to 4

Mathematics Math01 to Math04 Result of math function 1 to 4

HW counter HWCounter Counter reading of hardware counter

Setpoint value SP01RampValue to

SP04RampValue

Analog input module 4-channel

Actual value of controller channel 1 to 4

Output level (display value) of controller

module 1 to 4

Ramp end value of ramp function 1 to 4

(if ramp function switched on)

or

Active setpoint value (external setpoint value +

setpoint value) of setpoint function 1 to 4

(if ramp function switched off)

Analog inputs AI01 to AI04 Measured value of analog input 1 to 4

Analog input module 8-channel

Analog inputs AI01 to AI08 Measured value of analog input 1 to 4

Multifunction panel 840

System bus

analog inputs

Process image Current process image Number of current process image on the dis-

Counter/Int 1 to Counter/Int 27 Current value of counter or integrator

Counter/Int clo 1 to

Counter/Int clo 27

Value of counter or integrator in most recent

closed measuring period

play of the multifunction panel

0 = process image 1, 1 = process image 2 etc.

(-1 = no active process image)

52

Page 53

6.1.2 Digital selector

The following table lists all digital signals.