Page 1

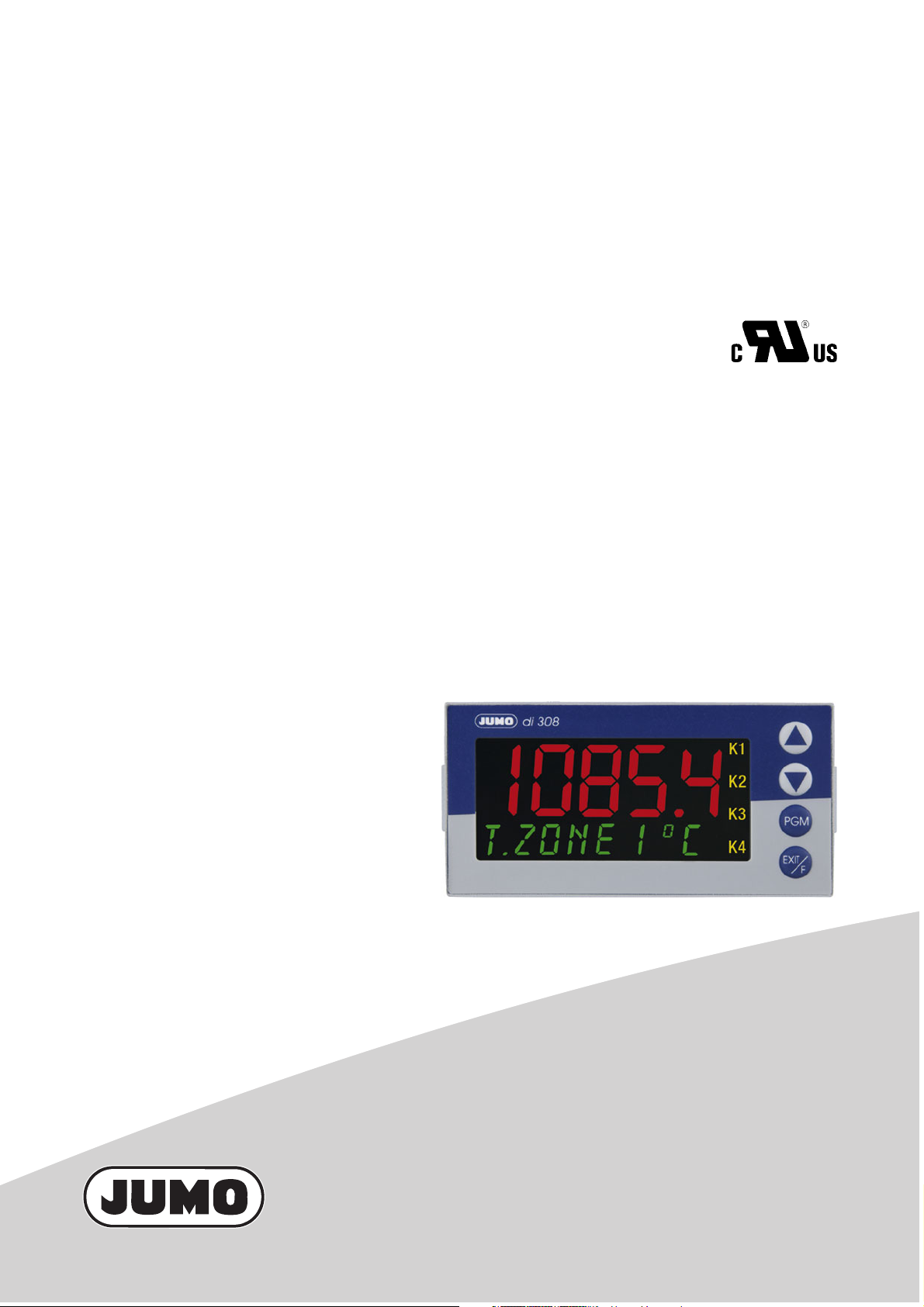

JUMO di 308

Digital Indicator

B 70.1550.0

Operating Manual

2010-04-28/00485282

Page 2

Please read this operating manual before commissioning

E

)

*

the instrument. Keep the manual in a place accessible to all

users at all times. Your comments are appreciated and may

assist us in improving this manual.

All necessary settings are described in this operating

manual. Manipulations not described in the manual or

expressly forbidden will jeopardise your warranty rights.

Please contact the nearest subsidiary or the head office,

should you encounter problems

The manual is valid from instrument software version

217.01.01

It appears by simultaneously pressing the P and i keys

(four-digit display; example: 01.01).

When accessing the inner parts of the unit and returning

.

modules, assemblies or components, please observe the

regulations according to EN 61340-5-1 and EN 61340-5-2

„Protection of electrostatic sensitive devices“. Only use

ESD packaging for transport.

Please note that we cannot accept any liability for damage

caused by ESD.

ESD=Electro Static Discharge

Page 3

Content

1 Introduction 7

1.1 Description ............................................................... 7

1.2 Typographical conventions ..................................... 9

2 Identifying the instrument version 11

2.1 Type designation .................................................... 11

2.2 Scope of delivery ................................................... 13

2.3 Accessories ............................................................ 13

3 Mounting 15

3.1 Mounting site and climatic conditions ................ 15

3.2 Dimensions ............................................................ 15

3.3 Fitting in position ................................................... 15

3.4 Removing the plug-in module .............................. 16

4 Electrical connection 17

4.1 Installation notes ................................................... 17

4.2 Electrical isolation ................................................. 19

4.3 Connection diagram .............................................. 20

4.4 Termination resistor for the RS422/485 interface 25

4.5 Connection of the PROFIBUS-DP connector ..... 26

Page 4

Content

5 Operation 27

5.1 Displays and controls ............................................ 27

5.2 Level concept ......................................................... 28

5.3 Level inhibit ............................................................ 29

5.4 Entries and operator prompting ........................... 30

6 Operator level 31

7 Configuration 33

7.1 Analog inputs „INPUT“ .......................................... 35

7.2 Limit comparators „LIMITCOM“ .......................... 42

7.3 Outputs „OUTPUT“ ................................................ 51

7.4 Binary functions „BINFUNCT“ .............................. 54

7.5 Display / Operation „DISPLAY“ ............................ 56

7.6 Interfaces „INTERFCE“ ......................................... 60

8 Extra codes 63

8.1 Math and logic module ......................................... 63

8.2 Difference, humidity or ratio calculation ............. 64

Page 5

Content

9 Retrofitting of modules 65

10 Appendix 67

10.1 Technical data ........................................................ 67

10.2 Alarm messages .................................................... 72

11 Index 73

Page 6

Content

Page 7

1 Introduction

1.1 Description

The digital indicator shows temperatures in °C or °F

and standard signals in plain text.

Inputs/outputs The standard instrument is equipped with an analog

input, two binary inputs, two relay outputs, two logic

outputs as well as a voltage supply for two-wire

transmitters.

Optional

modules

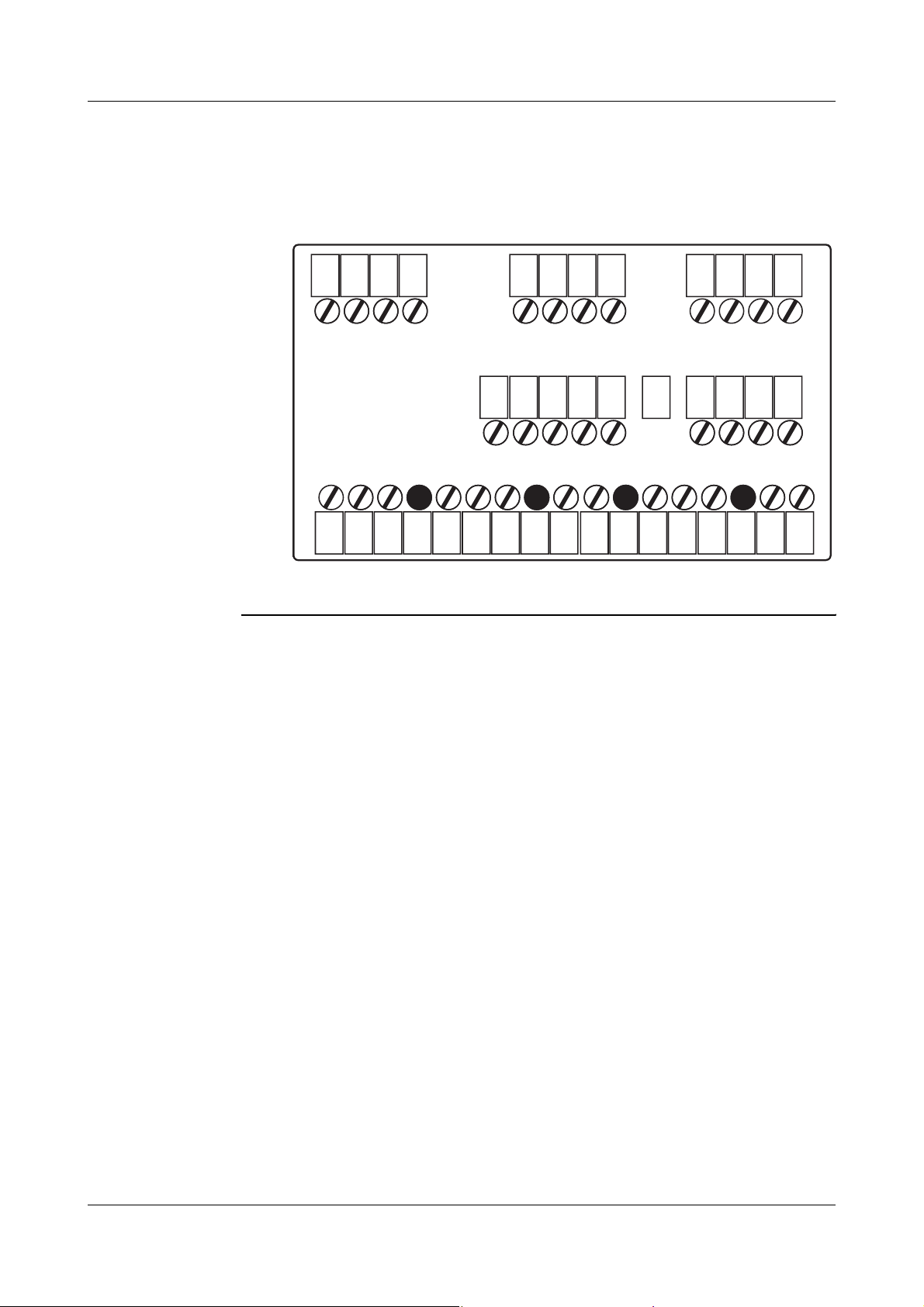

Displays The high-contrast, multi-colour LCD display for

Three extension slots can be equipped with additional

inputs and outputs as well as interfaces.

process value/text and operator prompting contains a

five-digit 7-segment display (showing the value or

parameter setting) and an eight-digit 16-segment

display with colour change (value, parameter name,

channel name, process/alarm text as max. 24

character ticker or pseudo bargraph). Four additional

switch position indicators are available for binary

outputs (relay or logic).

Operation The instrument is operated and configured by four

keys; an optional setup program for a PC is available.

The user-friendly setup program provides additional

configuration possibilities (e.g. math and logic

Special

functions

functions, display texts).

The instrument offers 4 configurable limit

comparators and an optional math and logic module

(two virtual channels).

Extensive binary functions are available for the

assignment of functions to the signals of limit

comparators, logic and binary inputs.

7

Page 8

1 Introduction

Special

functions

(continued)

The computation results of both math functions can

be used for the different analog parameters (e.g. as

value shown in the display).

Instruments with a second (optional) analog input

allow the computation of differential, humidity or ratio

computations by means of default formulas.

Probes 10 types of probes (RTD temperature probe,

thermocouple, resistance transmitter, standard

signals) and more than 20 linearisations are available

for analog input configuration. Customer-specific

linearisation with 10 interpolation points or by the

entry of the polynomial coefficients is possible.

Interface and

electrical

connection

An optional interface (RS422/485 or PROFIBUS-DP)

can be used for integration of the instrument in a data

network.

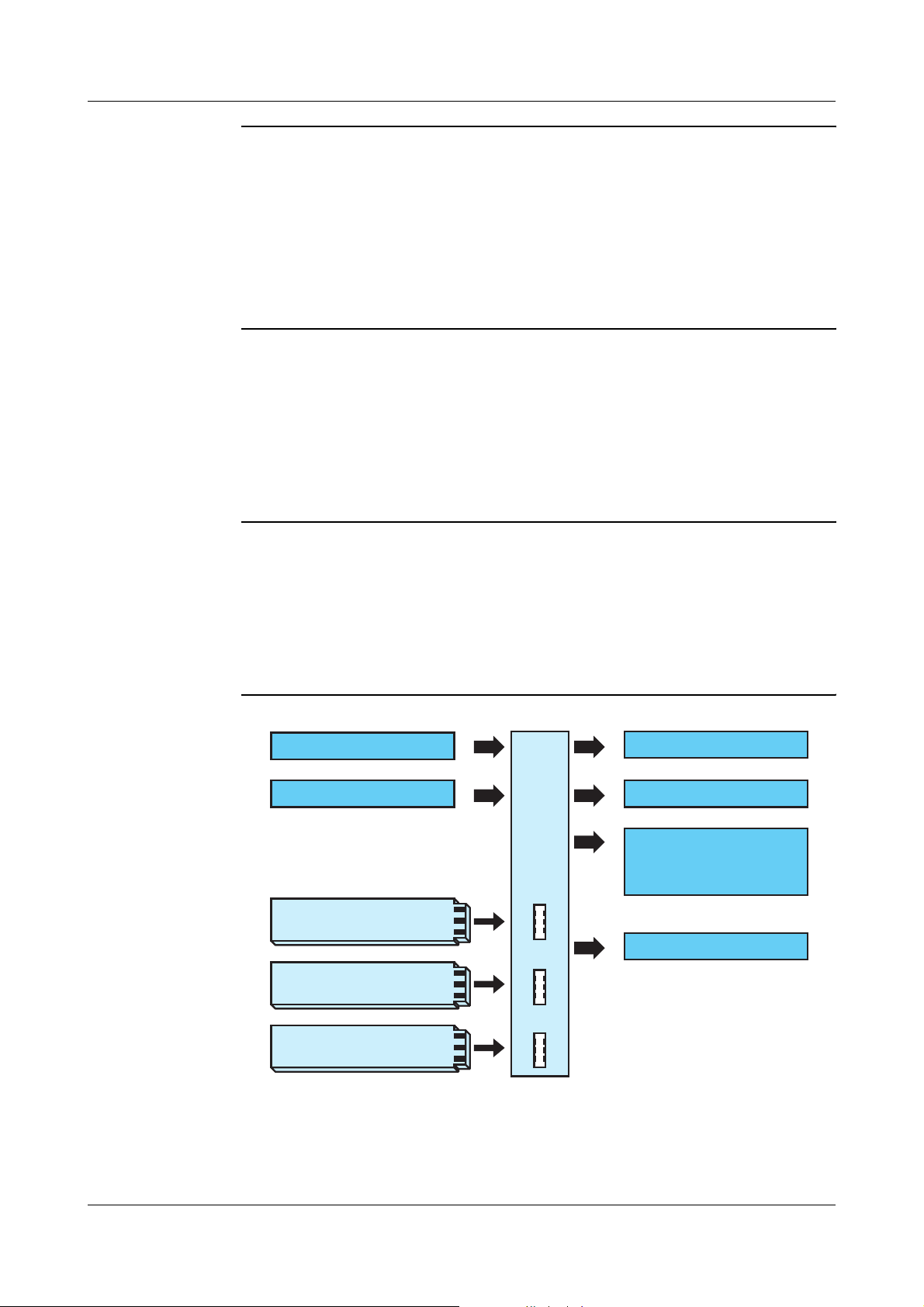

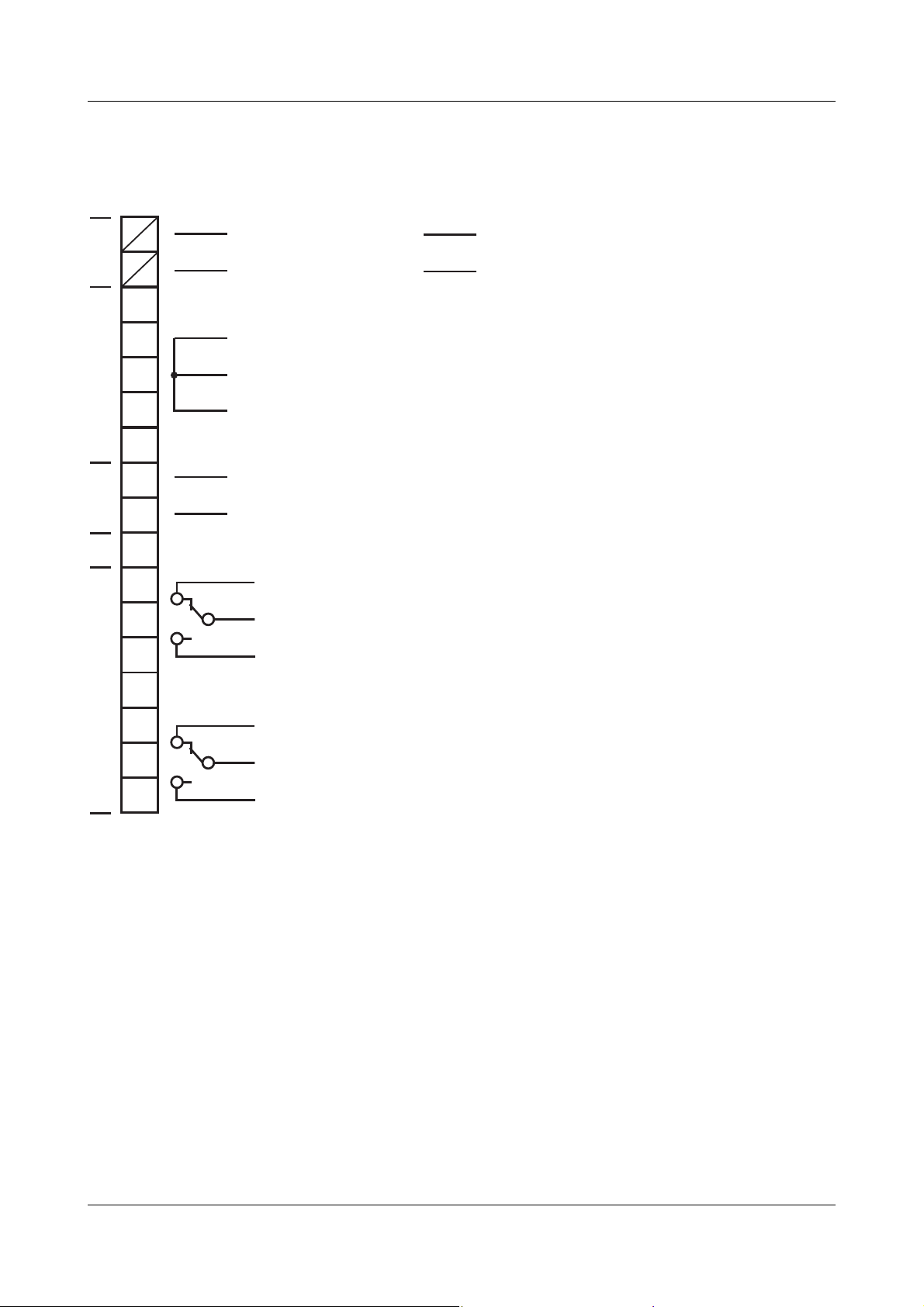

Block

structure

The electrical connection is made at the back of the

instrument by means of screw terminals.

Analog input

2 binary inputs

Option 1

Option 2

Option 3

2 relays (change-over)

2 logic outputs

Voltage supply for

2-wire transmitters

Setup interface

8

Page 9

1.2 Typographical conventions

1 Introduction

Warning

signs

V

*

E

Danger

Caution

Caution

This symbol is used when there may

be danger to personnel if the

instructions are ignored or not

followed correctly!

This symbol is used when there may

be damage to equipment or data if

the instructions are ignored or not

followed correctly!

This symbol is used where special

precautionary measures are required

when handling components liable to

damage through electrostatic

discharge.

Note

signs

H

v

h

Note

Reference

Action

instruction

This symbol is used to draw your

special attention to a remark.

This symbol refers to further

information in other operating

manuals, chapters or sections.

This symbol refers to a description of

an action to be performed.

The individual steps are marked by

this asterisk, e.g.:

EXIT

hPress

EXIT

F

F

9

Page 10

1 Introduction

Representation

Menu items

Blinking

display

Text referring to the setup program is

shown in italics, for example:

„Display/Operation“.

S

E

NS

O

R

10

Page 11

2 Identifying the instrument version

2.1 Type designation

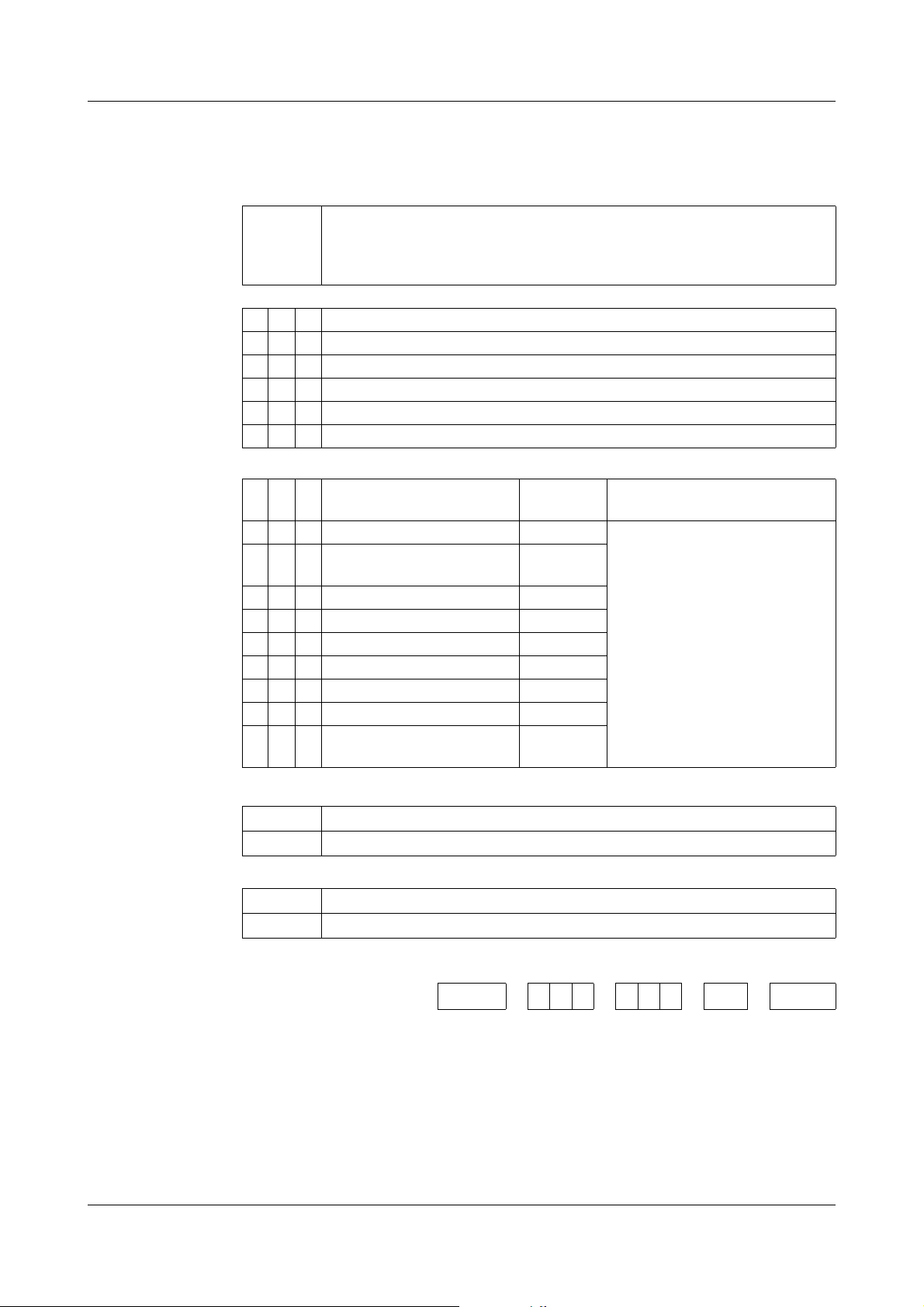

(1) Basic type

701550 Digital Indicator

incl. 1 analog input, 2 binary inputs, 2 relay outputs,

2 logic outputs and 1 setup interface,

Front dimension 96mm x 48mm

(2) Basic type extensions

1 Basic type

Version

8 Standard with factory settings

9 Programming to customer specification

Logic outputs (2 are available as standard)

10/12V

(3) Option slots

1. 2. 3. Option slot Max.

0 0 0 not assigned

111Analog input 2

(universal) 1

2 2 2 Relay (change-over) 2

3 3 3 2 relays (n.o. make) 2

444Analog output 2

5 5 5 2 binary inputs 2

6 6 6 Solid state relay 1A 2

7 7 7 RS422/485 interface 1

8 8 8 PROFIBUS-DP

interface 1

number

Please note:

The position of the

options (slot 1, 2 or 3) is

freely assignable,

however, the max.

number must not be

exceeded.

(4) Voltage supply

23 AC 110—240V -15/+10%, 48—63Hz

25 AC/DC 20—30V, 48—63Hz

(5) Extra codes

000 none

214 Math and logic module

(1) (2) (3) (4) (5)

Ordering code:

Ordering example:

701550 / 1 8 1 – 1 4 0 – 2 3 / 0 0 0

/––/

11

Page 12

2 Identifying the instrument version

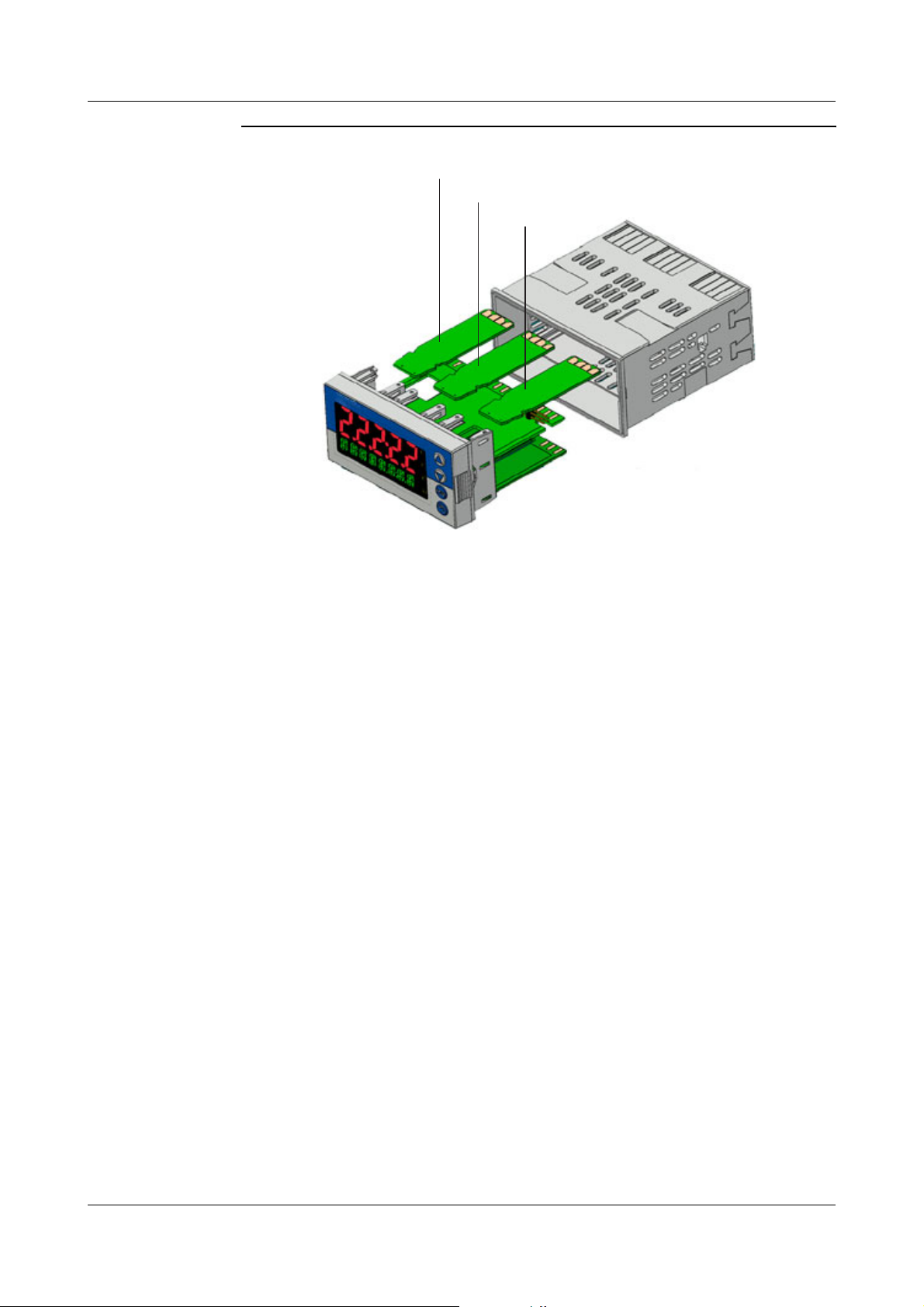

View of

option slots

1

2

3

12

Page 13

2 Identifying the instrument version

2.2 Scope of delivery

- Display instrument

- Seal

- Mounting brackets

- Operating Manual B70.1550.0 in DIN A6 format

2.3 Accessories

Mini-CD Mini-CD with demo setup program and PDF

documents (operating manual and further

documentation)

Sales No.: 70/00448699

PC interface PC interface with TTL/RS232 converter and adapter

(socket connector) for setup program

Sales No.: 70/00350260

USB interface PC interface with USB/TTL converter, adapter (socket

connector) and adapter (pins)

Sales No.: 70/00456352

Setup

program

Setup program with startup function (recording and

visualisation measuring data)

Sales No.: 70/00493223

13

Page 14

2 Identifying the instrument version

Setup

program

(continued)

Required hardware:

- PC Pentium IV or compatible

- 256MB RAM, 100MB free fixed disk memory

-CD ROM drive

- free serial or USB interface

Required software:

Microsoft

1

Windows 2000/XP/Vista

14

1. Microsoft is a registered trademark of Microsoft Corporation

Page 15

3.1 Mounting site and climatic conditions

The conditions at the mounting site must meet the

requirements specified in the technical data. The

ambient temperature at the mounting site can range

from 0...55°C with a maximum relative humidity of

≤ 90%.

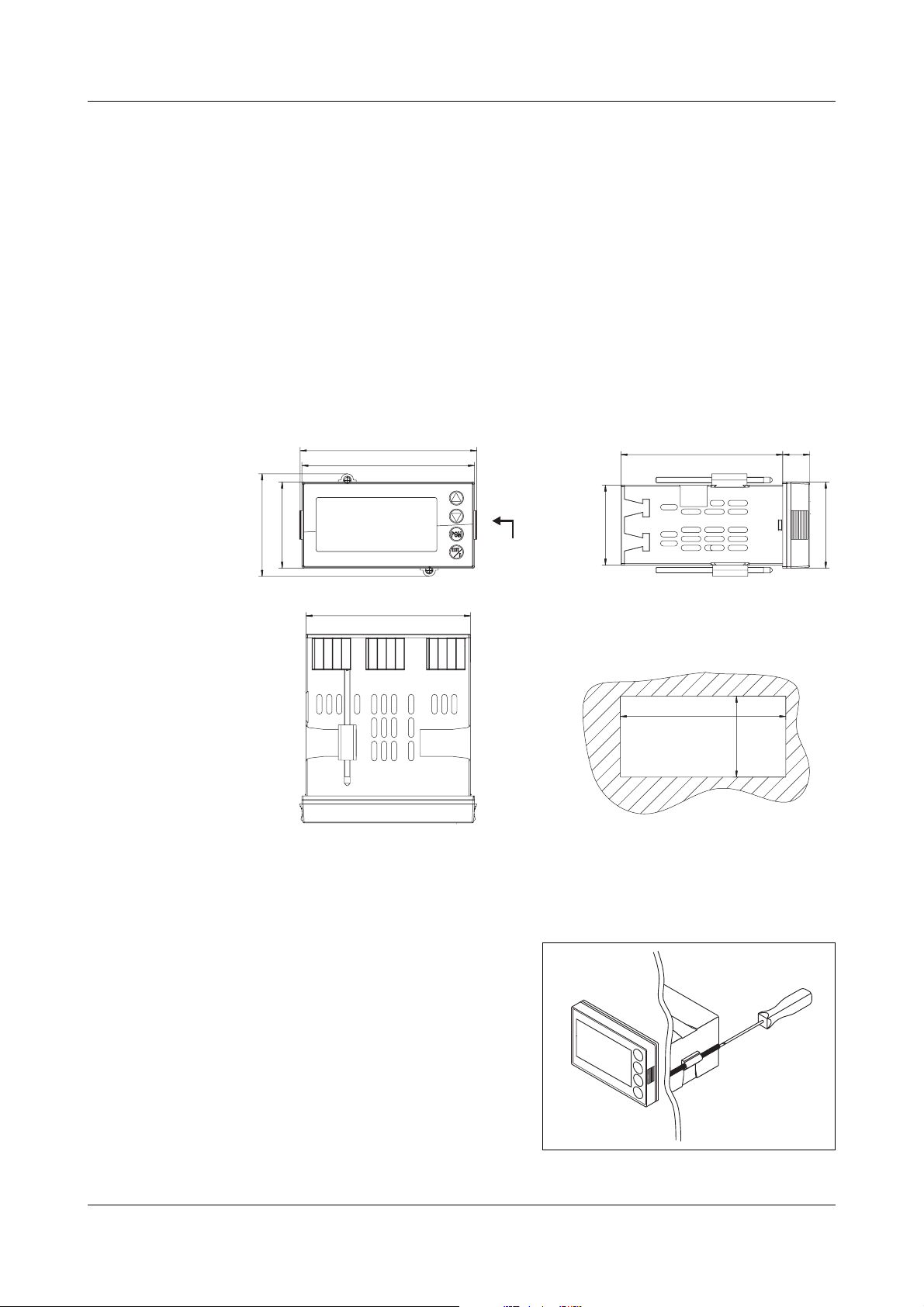

3.2 Dimensions

3 Mounting

48

57.1

99

96

91.5

PC interface adapter

44.5

Panel cut-out

92

90

+0.8

15

48

+0.8

45

3.3 Fitting in position

hPlace the supplied seal

on the instrument body.

hInsert the instrument

from the front into the

panel cut-out.

hFrom the panel rear,

slide the mounting

15

Page 16

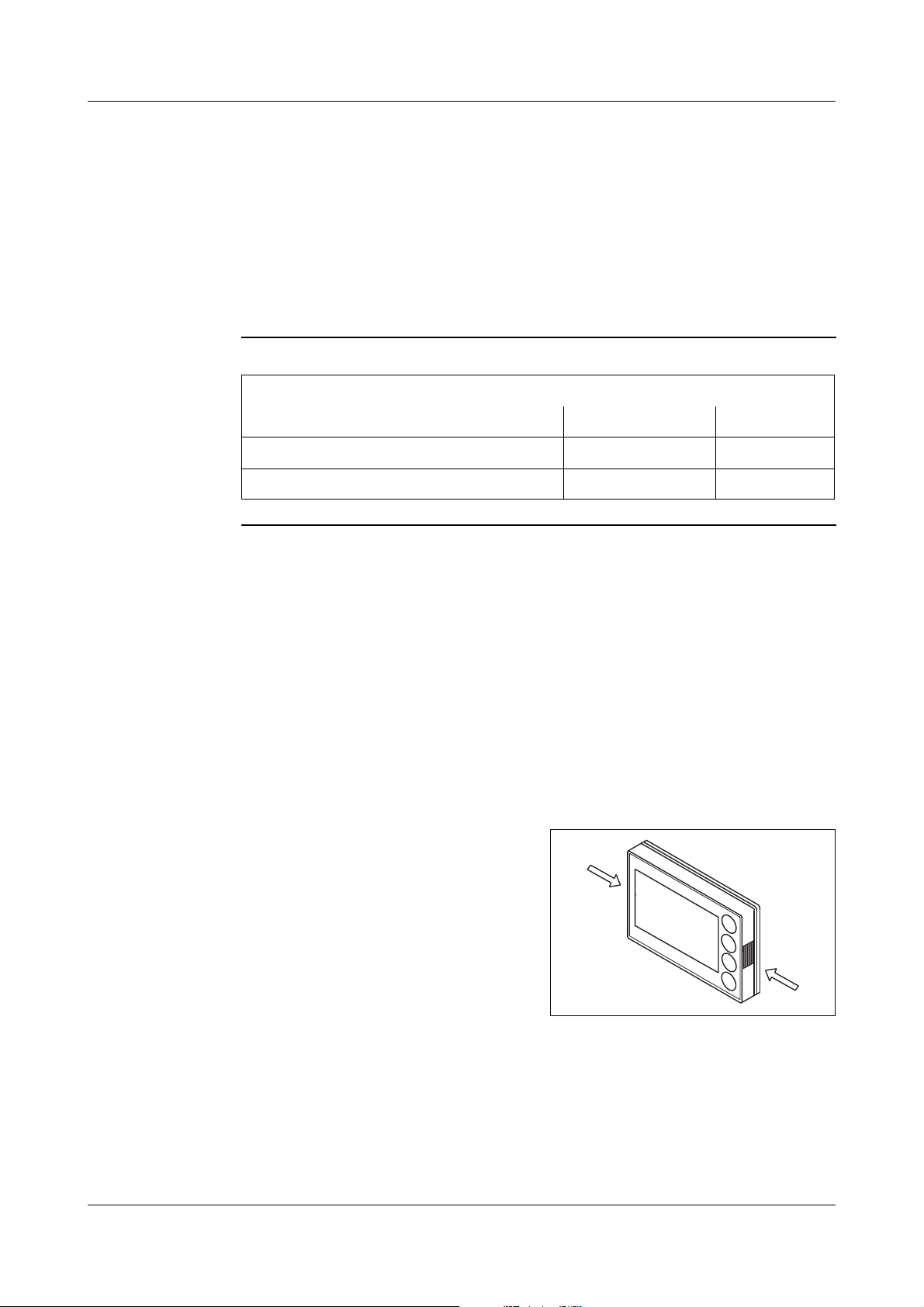

3 Mounting

brackets into the guides on the sides of the

housing.

The flat faces of the mounting brackets must make

contact with the housing.

hPlace the mounting brackets against the panel rear,

and tighten them evenly with a screwdriver.

Mounting

controllers

back-to-back/

next to each

other

Minimum spacing of panel cut-outs

without setup plug 30mm 11mm

with setup plug (arrow) 65mm 11mm

Care of the

front panel

The front panel can be cleaned with commercial

detergents and cleaning agents. It has a limited

resistance to organic solvents (e.g. methylated spirits,

white spirit, P1, xylol, etc.). Do not use high-pressure

cleaning equipment.

3.4 Removing the plug-in module

The plug-in module can be removed from its housing

for servicing.

horizontal vertical

16

hPress together the

knurled surfaces on the

front panel (left and

right), and pull out the

plug-in module.

H

When re-inserting the plug-in module, ensure

that the latches (beneath the knurled areas)

engage.

Page 17

4.1 Installation notes

- The choice of cable, the installation and the

electrical connection of the instrument must

conform to the requirements of VDE 0100

"Regulations on the Installation of Power Circuits

with Nominal Voltages below 1000V" or the

appropriate local regulations.

- The electrical connection must only be carried out

by qualified personnel.

- The instrument shall be operated by mains

protected with a branch circuitry overcurrent

protection device not more than 20 Amps.

For servicing/repairing a Disconnecting Device shall

4 Electrical connection

be provided to disconnect all conductors.

- The load circuit must be fused for the maximum

relay current, in order to prevent the output relay

contacts becoming welded in the event of a short

circuit occurring at that point.

- Electromagnetic compatibility conforms to the

standards and regulations cited in the technical

data.

vChapter 10.1 „Technical data“

- Run input, output and supply cables separately and

not parallel to one another.

- Sensor and interface cables should be shielded

cables with twisted conductors. Do not run cables

close to current-carrying components or cables.

Ground the shielding on one side.

- Do not connect any additional loads to the supply

terminals of the instrument.

17

Page 18

4 Electrical connection

- The instrument is not suitable for use in areas with

an explosion hazard (Ex areas).

.

Only allow qualified personnel to

V

carry out the electrical connection.

Identify the instrument version by

H

means of the type code.

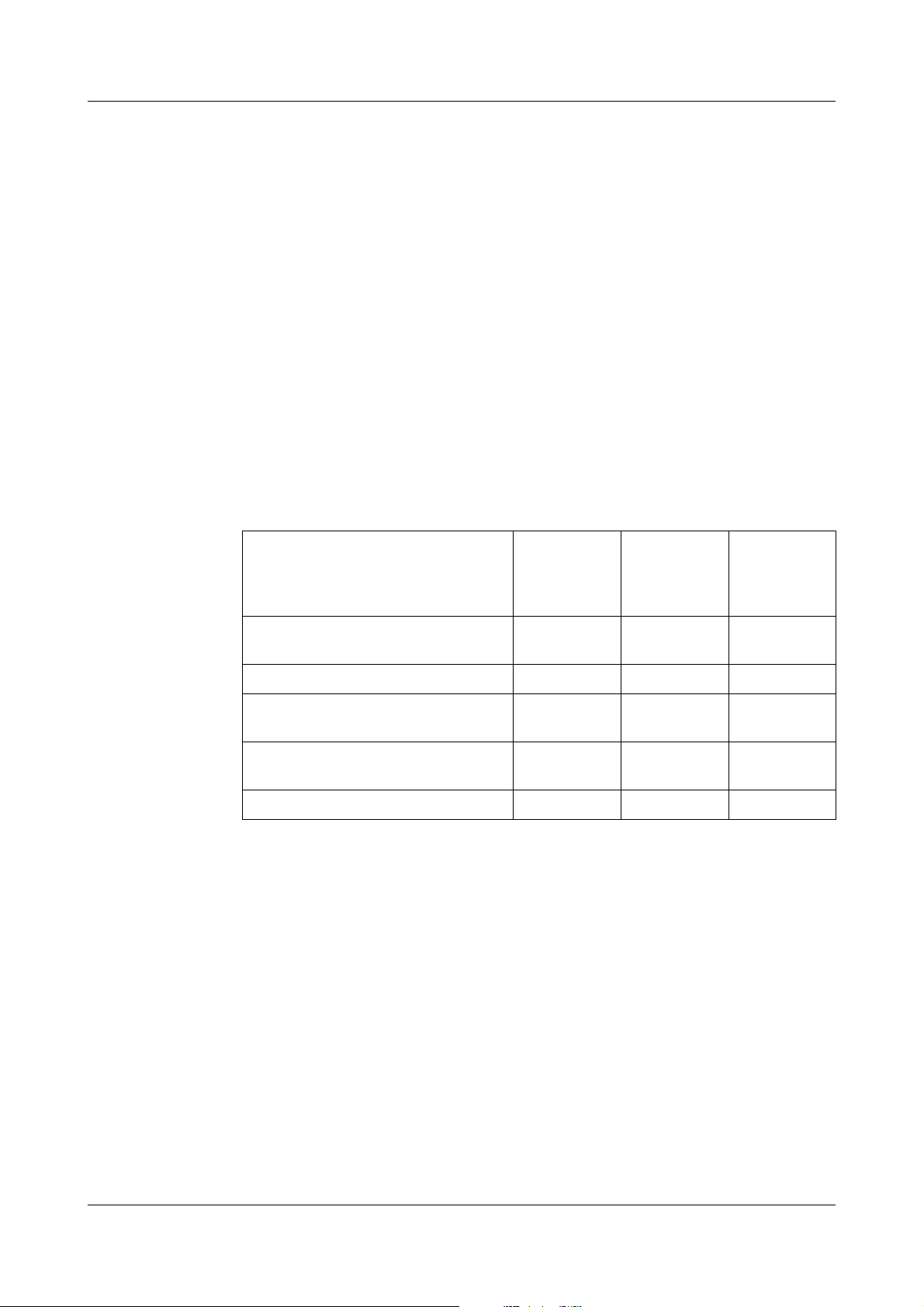

Installation information on conductor cross

sections and core ferrules

Without core-end ferrule

Core-end ferrule without lip

Core end ferrule with lip

up to 1.5mm

Core end ferrule with lip

above 1.5mm

Twin ferrule with lip

2

2

Minimum

crosssection

0.34mm

0.25mm

0.25mm

1.5mm

0.25mm

2

2

2

2

2

Maximum

crosssection

2.5mm

2.5mm

1.5mm

2.5mm

1.5mm

2

2

2

2

2

Min.

length of

core-end

ferrule

10mm

(stripped)

10mm

10mm

12mm

12mm

18

Page 19

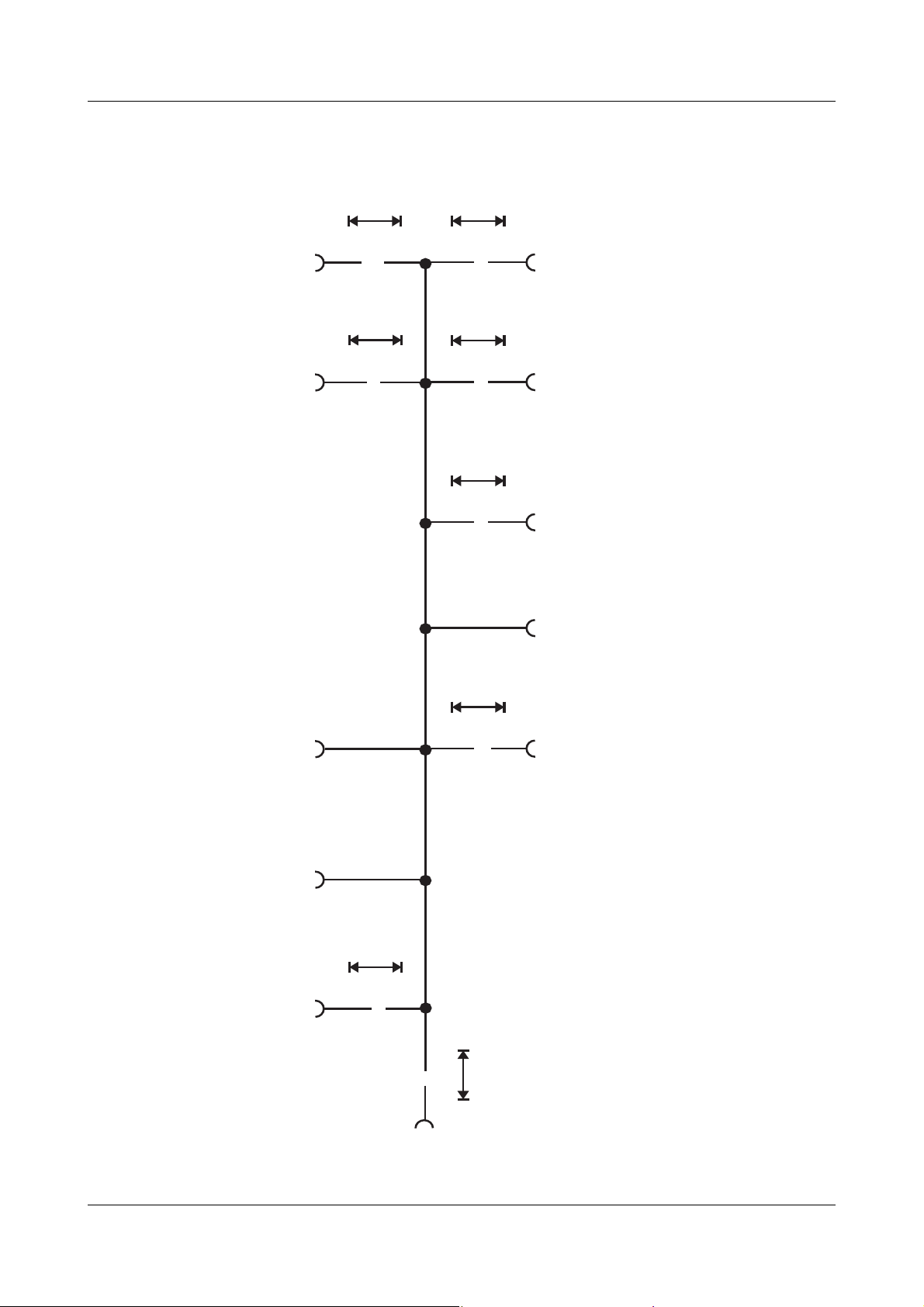

4.2 Electrical isolation

30 V AC

50 V DC

4 Electrical connection

3800 V AC

Input 1

»

30 V AC

50 V DC

Input 2 Solid-state relay outputs

3800 V AC

»

30 V AC

50 V DC

Relay outputs

»

»

Analog outputs

»

Logic outputs

30 V AC

50 V DC

Binary inputs

Setup

interface

RS422/485

PROFIBUS-DP

30 V AC

50 V DC

»

Voltage supply

»

3800 V AC

Voltage supply

for 2-wire transmitters

»

19

Page 20

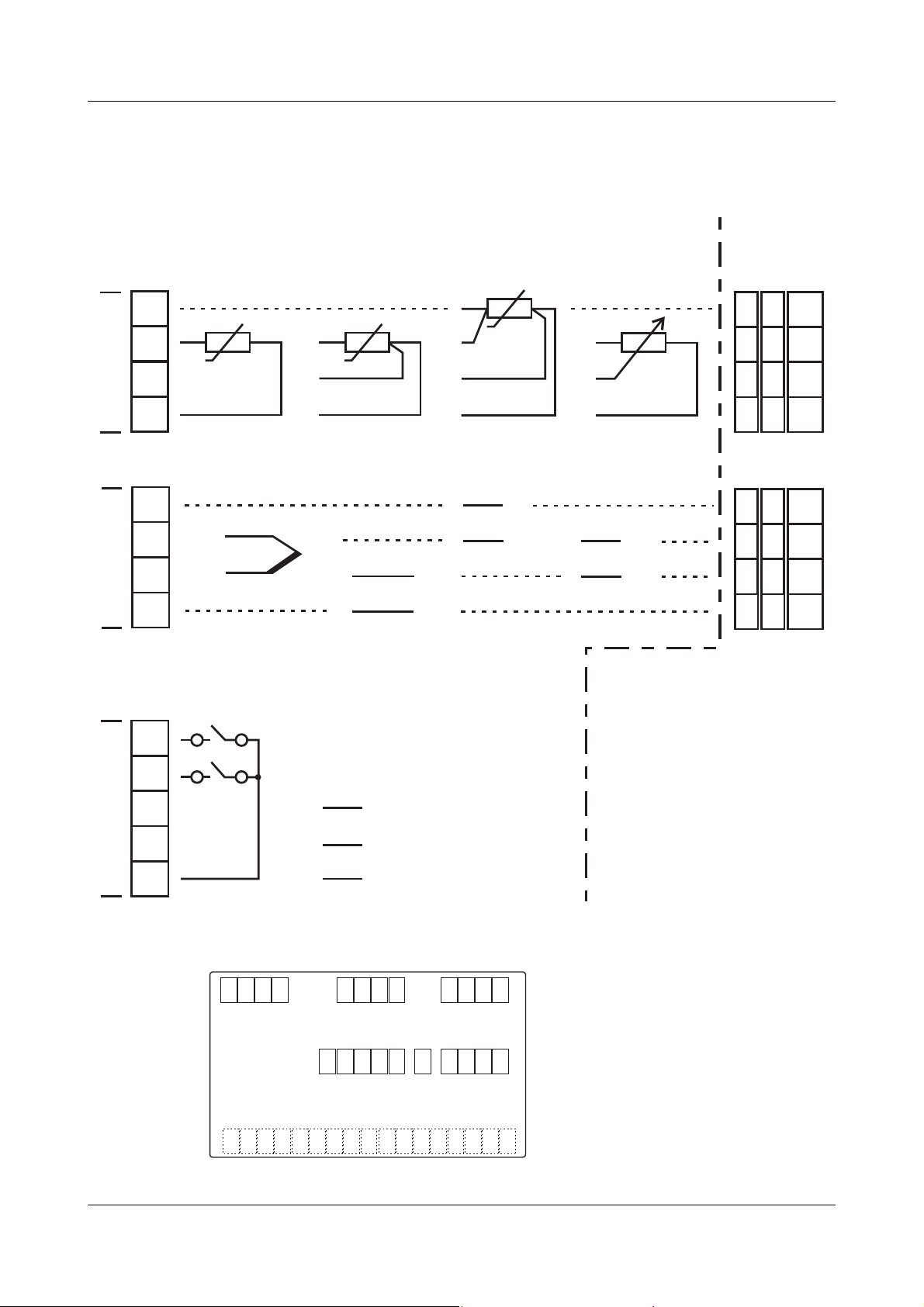

4 Electrical connection

4.3 Connection diagram

Terminal strips on the back of the instrument:

Option 1Option 2Option 3

Terminal strip 1

(Option slots)

Terminal strip 2

Terminal strip 3

Connection

diagram in the

setup

program

12

17

16

15

5

6

7

10

11

8

6

7

8

9

8

9

6

9

12

13

4

3

3

4

4

5

2

2

N(L+)

1

1

L1(L+)

10

11

The setup program includes a graphic connection

diagram subject to updates depending on the

configuration or equipment.

It also allows the preparation of a list of connections

containing the hardware equipment and configuration

of the connections.

Connection diagram and list of connections can be

printed out.

vSetup program (Extras -> Connection diagram; or

via Toolbar „IN/OUT“)

20

Page 21

4 Electrical connection

Assignment of terminal strip 3:

Voltage supply and binary outputs 1+2

L1

L+

N

L-

Supply

4

5

6

8

=

U

9

11

12

13

U

L1

AC 110—240V AC/DC 20—30V

N

+

=

15.8—15.2V /

30—50mA

-

Ö

230V/3A

P

S

Voltage supply

for 2-wire transmitters

(No-load voltage approx. 25V)

Binary output 1

L+

L-

Relays

15

16

17

Ö

P

S

230V/3A

Binary output 2

21

Page 22

4 Electrical connection

Assignment of terminal strip 2:

Analog input 1, binary inputs 1+2, and binary outputs 3+4

Terminal strip 2

RTD temp.

probe

1

2

3

input 1

Analog

4

1

2

input 1

Analog

3

4

Thermocouple

RTD temp.

probe

Current Voltage

+

-

- /

I

x

Terminal

RTD temp.

probe

0(2)—10V

+

U

x

-

+

~

I

~

x

Resistance

transmitter

E

S

A

Voltage

0—1V

+

U

x

-

-

strip 1*

5

1

6

2

3

4

1

2

3

4

7

8

5

6

7

8

10

11

12

10

11

12

9

9

Binary input

1+2

6

7

1

2

8

Binary

9

10

Position of terminal strip 1 and 2 (on the back of the instrument):

Terminal strip 1

Terminal strip 2

Terminal strip 3

GND

10

11

12

Option 3

15

16

17

Binary output

3+4

(logic 12V)

13

12

10

8

9

11

9

3 (+)

4 (+)

GND (-)

5

6

7

6

7

8

8

9

4

Option 1Option 2

4

5

6

1

2

3

1

2

3

N(L+)

4

L1(L+)

* Assignment of

terminal strip 1

for analog input 2

(see also next page)

22

Page 23

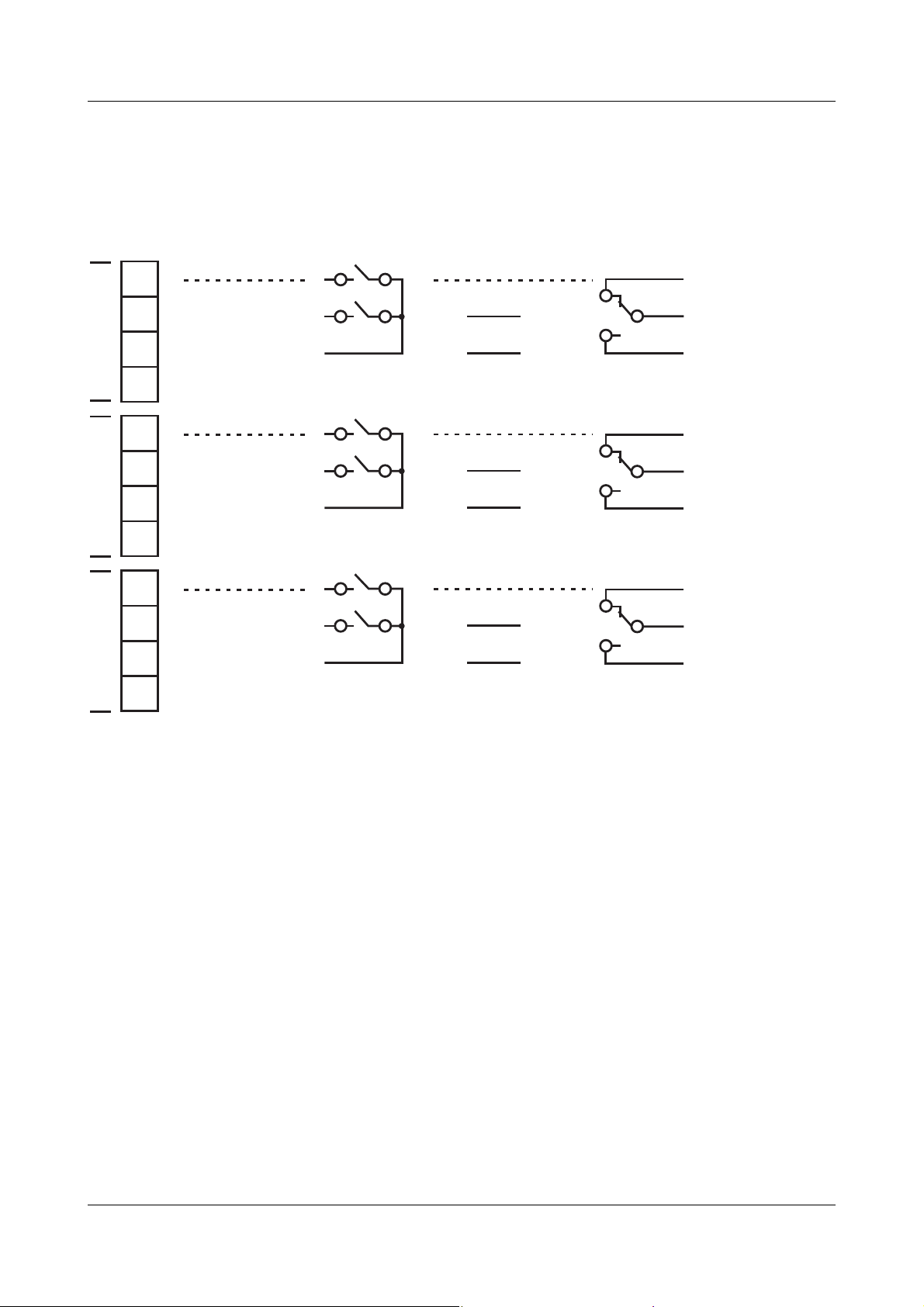

4 Electrical connection

Assignment of terminal strip 1 (option boards):

Inputs, outputs and interfaces

1

2

3

Option 1

4

5

6

7

Option 2

8

9

10

11

Option 3

12

Analog

input

Analog input 2

Connection as

analog input 1

Analog input 2

Connection as

analog input 1

Analog input 2

Connection as

analog input 1

2 binary

inputs

Binary

input 3+4

Binary

input 5+6

Binary

input 7+8

3

4

GND

5

6

GND

7

8

GND

Analog

output

U

/ I

x

Analog

output 5

Ux/ I

Analog

output 6

Ux/ I

Analog

output 7

Relay

(change-over)

Ö

+

x

-

Binary

output 5

+

x

-

Binary

output 6

+

x

-

Binary

output 7

P

S

Ö

P

S

Ö

P

S

H

H

The maximum number of option boards has to be taken into

account (see Chapter 2.1 „Type designation“).

Note numbering of the outputs (see

„OUTPUT““

).

Chapter 7.3 „Outputs

23

Page 24

4 Electrical connection

Assignment of terminal strip 1 (option boards) - continued:

Inputs, outputs and interfaces

1

2

3

Option 1

4

5

6

7

Option 2

8

9

10

11

Option 3

12

2 Relays

(n.o. make)

Binary

output 5+8

Binary

output 6+9

Binary

output 7+10

Solid-state

relay

5

8

6

9

7

10

Binary

output 5

Binary

output 6

Binary

output 7

PROFIBUS

VP (+5 V)

RxD/TxD-P (B)

RxD/TxD-N (A)

DGND

VP (+5 V)

RxD/TxD-P (B)

RxD/TxD-N (A)

DGND

VP (+5 V)

RxD/TxD-P (B)

RxD/TxD-N (A)

DGND

RS422

RxD +

RxD TxD +

TxD -

RxD +

RxD TxD +

TxD -

RxD +

RxD TxD +

TxD -

RS485

RxD/

TxD +

RxD/

TxD -

RxD/

TxD +

RxD/

TxD -

RxD/

TxD +

RxD/

TxD -

H

H

24

The maximum number of option boards has to be taken into

account (see Chapter 2.1 „Type designation“).

Note numbering of the outputs (see

„OUTPUT““

).

Chapter 7.3 „Outputs

Page 25

4 Electrical connection

4.4 Termination resistor for the RS422/485 interface

Setting

resistors

To ensure fault-free operation of several instruments

in a line structure, their internal termination resistors

must be activated at the start and end

.

hPull plug-in module out towards the front by

pressing on the knurled areas

hUsing a suitable aid (e.g. ballpoint pen), press all the

white switches into the same direction

Bus

h Push all 5 switches down

termination

active

No

h Push all 5 switches up

bus

termination

(ex-factory)

hRe-insert the module into the housing

Check hPress the P + i keys

When checking the software version and the

termination resistors activated, an additional decimal

point appears behind the version number (top

display).

Example of

active:

inactive:

version number 01.01

01.01.

01.01

:

25

Page 26

4 Electrical connection

4.5 Connection of the PROFIBUS-DP connector

Mounting the

adapter

Assignment of

the 9 pole

D-Sub socket

hIdentify option slot with the PROFIBUS-DP

interface by means of the type code (in the case of

pre-configured instruments)

2

1

3

1

In this example, the

PROFIBUS-DP

interface is in

option slot 1.

Pin at

D-Sub

socket

2

3

1

2

3

4

4

5

6

Pin at terminal

strip 1: Signal

(Example for

option slot 1)

6

7

Designation

L1(L+)

N(L+)

4

5

6

8

6 1: VP Voltage supply,

positive

3 2: RxD/TxD-P Receive/Transmit

data, positive

8 3: RxD/TxD-N Receive/Transmit

data, negative

5 4: DGND Ground

To fit the D-Sub adapter, open the black housing

*

of the adapter board; otherwise the connection

screws in the instrument back are not

accessible.

It is important to note that the adapter is fitted in

the position shown above to ensure correct pin

assignment.

26

Page 27

5.1 Displays and controls

(1)

5 Operation

(4)

(2)

(3)

(1) 7-segment display (measured value display)

five-digit, red; decimal place is configurable

(automatic adjustment on display overflow)

(2) 16-segment display (24 character ticker,

parameter name, level symbols)

eight-digit, green or red;

decimal place configurable

(3) Indication

yellow; for four switch positions of max. four

outputs (display lit = ON)

(4) Keys

The displays are configurable.

vChapter 7.5 „Display / Operation „DISPLAY““

27

Page 28

5 Operation

5.2 Level concept

The parameters for instrument setting are organised

at different levels.

Normal display

EXIT

F

> 2 sec

or time-out

Navigation principle

EXIT

F

i

d

P

P

USER

OPERATOR

CONFIG

1. USER only

1

visible if user data

is configured (setup program)

P

P

P

i

d

Time-out

H

If no key is pressed for 180 secs the instrument

changes back to normal display!

vChapter 6 „Operator level“

User level

Up to eight freely chosen

parameters

Operator level

Process data

Configuration level

- INPUT (analog inputs)

- LIMITCOM (limit comparators)

- OUTPUT (outputs)

- BINFUNCT (binary functions)

- DISPLAY (display)

- INTERFCE (interfaces)

User data

„USER“

vChapter 7 „Configuration“

vSetup program (Display/Operation -> Operation ->

Operation time-out)

The setup program allows the display and editing up

to 8 freely chosen parameters at this level.

vSetup program (Display/Operation -> User data ->

Parameters 1...8)

The user can assign a symbol for the representation

of each parameter. Otherwise, the default symbol will

appear. All letters and numbers that can be presented

by a 16 segment display are permissible.

28

Page 29

5.3 Level inhibit

Access to the individual levels can be prevented.

Code Configuration level

0enabled

1 inhibited

5 Operation

hEnter code by pressing

P and d (simultaneously

for > 5sec).

hChange code by pressing

hEnter code by pressing

P (display blinks!)

i and d. Ex-factory: all

levels enabled.

EXIT

hReturn to normal display by pressing or

EXIT

F

F

automatically after approx. 180 secs

The configuration level can also be inhibited via the

binary function.

vChapter 7.4 „Binary functions „BINFUNCT““

29

Page 30

5 Operation

5.4 Entries and operator prompting

When entries are made within the levels, the

parameter symbol appears in the lower display.

Select

P

id/

NS

R

O

S

E

hSelect parameter by pressing

hChange to the entry mode by pressing

Alter

E

S

R

O

NS

i or d.

i

d

P (lower

display blinks!)

hAlter value by pressing i and d

The value alters dynamically for as long as the key

is kept pressed.

hAssign the value by pressing

P or automatically

after 2 secs

or

EXIT

hCancel the entry with .

EXIT

F

F

The value will be assigned.

To enter digits after the decimal point, the value

H

of system point must be set accordingly (see

page 57).

For the display of measurement values of the

analog inputs, the digits after the decimal point

can be set separately (see page 38).

30

Page 31

Access

6 Operator level

Normal display

EXIT

F

> 2 sec

P

or time-out

Navigation principle

EXIT

F

i

d

P

USER

1

d

P

OPERATOR

1. USER only visible

if user data is configured

(setup program)

Operator level

Process data

31

Page 32

6 Operator level

Process data Process data is shown in the operator level in

accordance with the configuration.

Symbol Meaning

INPUT1 Measured value of analog input 1

INPUT2 Measured value of analog input 2 (only if

available)

MIN INP1 Minimum value for analog input 1

(only if function is activated)

MAX INP1 Maximum value for analog input 1

(only if function is activated)

HOLD1 Hold value for analog input 1

(only if function is activated)

MIN INP2 Minimum value for analog input 2

(only if analog input 2 is available and

function activated)

MAX INP2 Maximum value for analog input 2

(only if analog input 2 is available and

function activated)

HOLD2 Hold value for analog input 2

(only if analog input 2 is available and

function activated)

MATHE1 Calculated result of mathematical formula 1

(only if mathematics module is available or

if analog output 2 is available as a

prerequisite for function „Humidity“,

„Difference“ or „Ratio“)

MATHE2 Calculated result of mathematical formula 2

(Same conditions as with MATHE1)

32

Page 33

Access

7 Configuration

Normal display

EXIT

> 2 sec

F

or time-out

Navigation principle

EXIT

F

i

d

H

Levels can be inhibited

P

P

vChapter 5.3 „Level inhibit“

USER

OPERATOR

CONFIG

1. USER only visible

1

d

d

P

- INPUT (analog inputs)

- LIMITCOM (limit comparators)

- OUTPUT (outputs)

- BINFUNCT (binary functions)

- DISPLAY (display)

- INTERFCE (interfaces)

if user data is configured

(setup program)

Configuration level

H

H

Parameters are not displayed if the equipment

level does not permit the function assigned to the

parameter. Example: Analog output 2 cannot be

configured if no second analog output is

implemented in the instrument.

Some parameters can only be programmed

through the set-up program. In the following

tables, these are marked in the „Parameter“

column with „(Setup)“.

33

Page 34

7 Configuration

Analog

selector

With some parameters, you can choose from a series

of analog values. To provide you with an overview,

this selection is listed below.

Value Description

0

deactivated

1

analog input 1

2

analog input 2

3

(reserved)

4

(reserved)

5

math 1

6

math 2

7

(reserved)

8

(reserved)

9

(reserved)

10

(reserved)

11

analog marker

12

minimum value input 1

13

minimum value input 2

14

(reserved)

15

(reserved)

16

maximal value input 1

17

maximal value input 2

18

(reserved)

19

(reserved)

20

hold value input 1

21

hold value input 2

22

(reserved)

23

(reserved)

24

any analog value

25

internal Pt100

26

sampling cycle time

34

Page 35

7.1 Analog inputs „INPUT“

7 Configuration

Configuration

Analog inputs

Limit

comparators

Outputs

Binary

functions

Display /

Operation

Interfaces

Sensor type

Depending on the instrument version, up to two

analog inputs are available.

➔ INPUT1 (analog input 1) ➔

➔ INPUT2 (analog input 2) ➔

Parameter Value/

Selection

SENSOR 0

Description

No function

1

RTD temperature probe in 3-wire circuit

2

RTD temperature probe in 2-wire circuit

3

RTD temperature probe in 4-wire circuit

4

Thermocouple

5

Resistance transmitter

7

0…20mA

8

4 ... 20mA

9

0…10V

10

2…10V

11

0 ... 1V

Factory set on analog input 2: no function

Factory settings are shown

bold

.

35

Page 36

7 Configuration

➔ INPUT1 (analog input 1) ➔

➔ INPUT2 (analog input 2) ➔

Linearization

Parameter Value/

Selection

LINEAR 0

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Description

Linear

1

Pt100 DIN

2

Pt500 DIN

3

Pt1000 DIN

4

KTY11-6

5

Pt100 GOST

6

Pt 50 GOST

7

Cu100

8

Cu50

9

Chromel-Copel

W5Re-W26Re C

W3Re-W25Re D

NiCr-Con E

Cu-Con T

Fe-Con J

Cu-Con U

Fe-Con L

NiCr-Ni K

Pt10Rh-Pt S

Pt13Rh-Pt R

Pt30Rh-Pt6Rh B

NiCrSi-NiSi N

W3Re-W26Re

Customised linearization

Measurement

offset

OFFSET -19999…

0

…

99999

For customised linearization, a maximum of 10

knee points can be implemented, or a 4th order

polynomial function programmed

the setup program)

For the „KTY11-6“ linearization, the resistance

Ω

is 2k

program and with 2-wire circuit)

The measurement offset is used to correct a

measured value by a certain amount upward or

downward. Examples:

Measured displayed

value offset value

294.7 +0.3 295.0

295.3 - 0.3 295.0

To enter digits after the decimal point, the value

of system point must be set accordingly (see

page 57).

Special case: „2-wire circuit“

If the input is connected to an RTD temperature

probe in 2-wire circuit, then the lead resistance

is set in ohms here.

at 25°C

.

(setting only through the setup

(only through

.

36

Factory settings are shown

bold

.

Page 37

➔ INPUT1 (analog input 1) ➔

➔ INPUT2 (analog input 2) ➔

7 Configuration

Scale low point

Scale high point

Filter time

constant

Parameter Value/

Selection

SCAL-LOW -19999…

0

…

99999

SCAL-HI -19999…

100

…

99999

FILTER 0.0…

0.6

…

100.0

Description

On transducers with standard signal and on

resistance potentiometers, a display value is

assigned to the physical signal (scaling).

Example: 0—20mA 0—1500°C.

The range of the physical signal can be 20 %

wider or narrower without generating an out-ofrange signal.

With a standard signal and customised

linearization, the display range coincides with

the linearization range (range of the x values).

For the above example this means:

Start x = 0, End x = 20, in order that the display

range goes from 0 to 1500 °C.

If the range of the x values is smaller, the display range is reduced accordingly.

To adjust the digital input filter

(time in seconds; 0.0 sec = filter off).

63% of the alterations are acquired after 2x

filter time constant (2nd order filter) at a filter

time step change.

When the filter time constant is large:

- high damping of interference signals

- slow reaction of the process value display

to process value changes

- low limit frequency (low-pass filter)

Fine adjustment

begin value

Fine adjustment

end value

FINEADJB -19999…

0

…

99999

FINEADJE -19999…

1

…

99999

Factory settings are shown

These parameters are factory-

(Activation in the setup program > Non

documented parameters; please contact the

manufacturer.)

These values cannot be accepted by

another instrument.

A

If these values have been altered by

mistake, this setting has to be canceled

using the procedure described under

„Customised fine tuning“.

See description on page 39.

bold

.

deactivated

.

37

Page 38

7 Configuration

➔ INPUT1 (analog input 1) ➔

➔ INPUT2 (analog input 2) ➔

Decimal point

Correction

value KTY at

25°C

Parameter Value/

Selection

DECPOINT 0

(Setup) 0…

2000

…

4000

Factory settings are shown

Description

no digit after the decimal point

1

one digit after the decimal point

2

two digits after the decimal point

3

three digits after the decimal point

7

System point

This setting is only valid for the display of

measurement value of analog input 1 or 2!

(Adjustment in the setup program under

Display/Operation -> Display -> Channel name)

Resistance in ohms at 25°C/77°F for

„KTY 11-6“ linearisation

Adjustment only possible in the setup program:

-> Analog inputs -> Analog input 1 or 2

bold

.

Temperature

unit

Temperature unit

Mains

frequency

Mains frequency

Sampling cycle

time

Sampling cycle

time

➔ INPUT (analog inputs general) ➔

Parameter Value/

Selection

UNIT

FREQUENC

CYCLE-t

Factory settings are shown

Description

01deg. Celsius

deg. Fahrenheit

Unit for temperature values

0150Hz

60Hz

Adaptation of the conversion time of the input

circuitry to the supply frequency

0

50ms

1

90ms

2

150ms

3

250ms

bold

.

38

Page 39

7 Configuration

Customised

fine adjustment

The customised fine adjustment is used to correct the

values displayed by the instrument. This may be

necessary, for example, after a system validation, if

the displayed values no longer coincide with the

actual values at the point where the measurement is

taken.

Using a reference measuring instrument, two

measured values are determined which should be as

far apart as possible (start value, end value). Ensure

that the measuring conditions are stable. Enter the

reference value found as the start value (FINEADJB)

or end value (FINEADJE) on the instrument to be

tuned.

Example The temperature inside an oven is measured with an

RTD temperature probe and displayed on an

instrument. The reading on the instrument deviates

from the actual temperature as a result of the sensor

temperature drifting. At 20°C the instrument reads

15°C, at 80°C it shows 70°C (exaggerated example

for better understanding).

Sensor

15°C / 70°C

20°C / 80°C

20°C / 80°C

Oven

Display on the instrument

Reference measuring instrument

39

Page 40

7 Configuration

Procedure:

hStep 1: The measurement carried out with the

reference measuring instrument shows a constant

oven temperature of 20°C.

hStep 2: Enter value 20 as start value (FINEADJB) at

the instrument.

hStep 3: The oven temperature is increased to 80°C,

the temperature is still controlled by a

reference measuring instrument.

The temperature must remain constant.

hStep 4: Enter the value 80 as end value

(FINEADJE) at the instrument.

The following diagram shows the changes in the

characteristic curve caused by the fine adjustment

(point of intersection with the x axis as well as ascent)

Display

(Instrument)

80

70

After fine

adjustment

Before fine

adjustment

20

15

Measurement

(Reference)

40

20 80

Page 41

7 Configuration

Special case:

Offset

Repeated

fine adjustment

If the deviation between measured value and

displayed value at the low and high measuring point

is identical, an offset correction is sufficient (ascent

remains unchanged). In this case, fine adjustment is

not required.

vMeasured value correction (offset), page 36

Reset the fine adjustment prior to repeating it. For this

purpose, program start value (FINEADJB) and end

value (FINEADJE) are given the same value. This

automatically sets the start value to 0 and the end

value to 1.

Always check the start value and the end value

*

prior to starting fine adjustment.

Reset the fine adjustment, if they deviate from

the factory-set values 0 (FINEADJB) and 1

(FINEADJE).

41

Page 42

7 Configuration

7.2 Limit comparators „LIMITCOM“

Configuration

Analog inputs

Limit

comparators

Outputs

Binary

functions

Display /

Operation

Interfaces

Limit

comparator

functions

Hysteresis

function

Limit comparators (threshold monitors, limit contacts)

can be used to monitor an input variable (process

value for the limit comparator) against a fixed limit

value or another variable w (setpoint value for the limit

comparator). When a limit value is exceeded, a signal

can be output or an internal controller function

initiated.

4 limit comparators are available.

Limit comparators can have different switching

functions (lk1 to lk8). The switching differential HySt

(HYSTERES) can be set and is, in all cases,

symmetrical in relation to the limit value.

The hysteresis function (symmetrical, asymmetrical)

defines the ranging of the switching differential

around the limit value (adjustment in the setup

program).

42

Page 43

7 Configuration

Limit value AL

relative to

setpoint

value w

lk1 symmetrical

asymmetrical, left asymmetrical, right

The limit comparator functions lk1 to lk6 monitor the

input variable for a limit value AL (LIMVALUE) to be set,

the absolute value depending on setpoint value w.

ON

AL

HySt

w

Measurement

lk2 symmetrical

asymmetrical, left asymmetrical, right

ON

HySt

AL

w

Measurement

43

Page 44

7 Configuration

lk3 symmetrical

asymmetrical, left asymmetrical, right

ON

HySt

AL

Measurement

w

lk4 symmetrical

asymmetrical, left asymmetrical, right

ON

HySt

AL

Measurement

w

44

Page 45

lk5 symmetrical

7 Configuration

ON

AL

HySt

asymmetrical, left asymmetrical, right

lk6 symmetrical

ON

w

w

Measurement

AL

HySt

Measurement

asymmetrical, left asymmetrical, right

Example of a

variable

setpoint value

The measurement is monitored (analog input 1). The

setpoint value w default value is manually entered via

a potentiometer connected to analog input 2. For this,

analog input 2 is selected as setpoint value

(LCSETVAL).

45

Page 46

7 Configuration

Fixed limit

value AL

lk7 symmetrical

asymmetrical, left asymmetrical, right

In the case of the limit comparator functions lk7 and

lk8, the measurement is monitored with respect to a

fixed limit value AL (LIMVALUE).

ON

HySt

Measurement

AL

lk8 symmetrical

asymmetrical, left asymmetrical, right

ON

HySt

Measurement

AL

46

Page 47

➔ LIMITC 1 (limit comparator 1) ➔

➔ LIMITC 2 (limit comparator 2) ➔

➔ LIMITC 3 (limit comparator 3) ➔

➔ LIMITC 4 (limit comparator 4) ➔

7 Configuration

Function

Limit value

Hysteresis

Fixed limit

comparator

setpoint value

Parameter Value/

Selection

FUNCTION

LIMVALUE -19999…

0

…

99999

HYSTERES 0…1…

99999

FIXLCVAL -19999…

0

…

99999

Description

0

no function

1

lk1

2

lk2

3

lk3

4

lk4

5

lk5

6

lk6

7

lk7

8

lk8

Limit value to be monitored

(see limit comparator functions lk1...lk8:

limit value AL)

Switching differential in respect to the limit

value

(see limit comparator functions lk1...lk8:

hysteresis HySt)

A fixed setpoint value can be set for the

limit comparator (lk1...lk6).

The limit comparator setpoint value

LCSETVAL must be deactivated for the

fixed setpoint value to be active.

Action/

Range response

Switch-on delay

Switch-off delay

ACT-RESP

ON DELAY0…9999 Delays the switch-on edge by a definable

OFFDELAY0…9999 Delays the switch-off edge by a definable

Factory settings are shown

0

absolute/off

1

relative/off

2

absolute/on

3

relative/on

Defines the switching action of the limit

comparator and the switch status for an

overrange or underrange (signal at „Out of

Range“).

See description on page 49.

time period (time in seconds).

time period (time in seconds).

bold

.

47

Page 48

7 Configuration

➔ LIMITC 1 (limit comparator 1) ➔

➔ LIMITC 2 (limit comparator 2) ➔

➔ LIMITC 3 (limit comparator 3) ➔

➔ LIMITC 4 (limit comparator 4) ➔

Acknowledgement

Pulse time

Limit

comparator

actual value

Limit

comparator

setpoint value

Parameter Value/

Selection

ACKNOWL

PULSE-t

0

…9999 The limit comparator resets automatically

LCACTVAL (analog

selector)

Analog

input 1

LCSETVAL (analog

selector)

deactivated

Description

0

no acknowledgement

1

acknowledgement only possible with the

limit comparator inactive

2

acknowledgement always possible

For setting with acknowledgement, the limit

comparator is latching, which means, it

remains „ON“ even when the switch-on

condition is no longer present.

The limit comparator must be reset by

pressing the

EXIT

( d + ) keys or a binary signal.

EXIT

F

F

after an adjustable time period (time in

seconds).

Input variable for limit comparator

(see limit comparator functions lk1...lk8:

Measurement)

v „Analog selector“, page 34

Setpoint value for limit comparator

(see limit comparator functions lk1...lk6:

setpoint value w)

v „Analog selector“, page 34

Hysteresis

function

(Setup)

When LCSETVAL is deactivated, parameter

FIXLCVAL can be used to enter a fixed

default setpoint value.

symmetrical

Switching differential ranging around the

limit value

asymmetrical

left

Adjustment only possible in the setup

program:

asymmetrical

-> Limit comparators -> 1 ... 4

right

Factory settings are shown

bold

.

48

Page 49

7 Configuration

Switching

action

Switching action means: limit comparator reaction to

a limit value or setpoint value change as well as to

Power ON.

„absolute“ switching action:

At the time of the change, the limit comparator reacts

according to its function.

„relative“ switching action:

Following Power ON, the limit comparator remains in

its „OFF“ switch position, even if the process value is

within the switch-on range.

If the setpoint value or the limit value is altered while

the limit comparator is in its „OFF“ position, which

leads to the actual value now being in the switch-on

range, the limit comparator still remains in the „OFF“

switch position.

The limit comparator will only resume operation

according to its function when the process value is

outside of the switch-on range. In other words: it

remains „OFF“ until the process value has again

reached the switch-on range.

See the following example:

49

Page 50

7 Configuration

Example of the

switching

action

„relative“:

Monitoring the actual value x with function lk4,

change of setpoint value w

→w

1

2

a) Start situation:

Limit comparator „OFF“, as actual value x not in the

switch-on range (grey area).

AL

ON

OFF

w= x

1

b) Situation at the time of the setpoint value change:

Limit comparator remains „OFF“, although the actual

value is now in the switch-on range.

AL

ON

OFF

w

x

2

c) Actual value has left the switch-on range:

Limit comparator operates according to its function

again, which means it remains „OFF“ until the actual

value has reached the switch-on range again.

AL

ON

50

OFF

w= x

2

Page 51

7.3 Outputs „OUTPUT“

7 Configuration

Configuration

Analog inputs

Limit

comparators

Outputs

Binary

functions

Display /

Operation

Interfaces

Numbering of

the outputs

Configuration of the instrument outputs is subdivided

into analog outputs (OUTANALG; max. 2) and binary

outputs (OUTLOGIC; max. 10). Binary outputs are

relays, solid-state relays and logic outputs. Display

and numbering of the outputs depends on the

assignment of the option slots.

The switching states of the binary outputs 1...4 are

shown in the display (K1…K4).

Standard for all instrument versions:

(Binary) output 1 = relay

(Binary) output 2 = relay

(Binary) output 3 = logic output

(Binary) output 4 = logic output

Extended numbering of the option slots:

Option

slot

Plug-in

board with

1 analog

output

Plug-in

board with

1 binary

output

(relay or

Plug-in

board with

2 binary

outputs

(2 relays)

solid-state

relay)

Option 1Output 5 Output 5 Output 5+8

Option 2Output 6 Output 6 Output 6+9

Option 3Output 7 Output 7 Output 7+10

51

Page 52

7 Configuration

➔ OUTLOGIC (binary outputs) ➔

Binary

output 1

...

Binary

output 10

Inversion

Parameter Value/

Selection

OUTPUT 1

...

OUTPUT10

(Setup) active

inactive

Description

0

no function

1

Binary input 1

2

Binary input 2

3

Binary input 3

4

Binary input 4

5

Binary input 5

6

Binary input 6

7

Binary input 7

8

Binary input 8

9

Limit comparator 1

10

Limit comparator 2

11

Limit comparator 3

12

Limit comparator 4

13

Logic formula 1

14

Logic formula 2

15

Binary marker

16

(reserved)

17

(reserved)

18

(reserved)

Function inverted

Function not inverted

Inversion also affects function „Deactivated“,

i. e. the output is always activated!

Adjustment only possible in the setup program:

-> Outputs -> Binary outputs

Factory settings are shown

bold

.

52

Page 53

7 Configuration

➔ OUTANALG (analog outputs) ➔ Output 5 ➔

➔ Output 6 ➔

➔ Output 7 ➔

Parameter Value/

Selection

Function FUNCTION

Type of signal SIGNAL

Range error RANG ERR0…101 Output signal (in % of the value range) for

Scale low point SCAL-LOW

Scale high point

SCAL-HI -19999…

(analog

selector)

deactivated

-19999…

0

…

99999

100

…

99999

Description

Function of the output

v „Analog selector“, page 34

0

0...10V

1

2...10V

2

0...20mA

3

4...20mA

Physical output signal

an overrange or underrange.

101=last output signal

A value range of the output variable is

assigned to a physical output signal. The

ex-factory setting corresponds to an output

variable with a value range of 0...100.

Example:

Via an analog output (0 … 20mA), a

temperature ranging between 150 … 500°C

is to be output.

i.e.: 150 … 500°C 0…20mA

Scale low point: 150 / Scale high point: 500

Offset

(Setup) -19999…

0

…

99999

Factory settings are shown

The offset is used to correct the output

signal by a certain amount upwards or

downwards.

Examples:

Original Output

value Offset value

294.7 +0.3 295.0

295.3 - 0.3 295.0

To enter digits after the decimal point, the

value of system point must be set

accordingly (see page 57).

Adjustment only possible in the setup

program:

-> Outputs -> Analog outputs

bold

.

53

Page 54

7 Configuration

7.4 Binary functions „BINFUNCT“

Configuration

Analog inputs

Limit

comparators

Outputs

Binary

functions

Display /

Operation

Interfaces

Switching

action

Binary signals of binary inputs, limit comparators and

logics can be assigned functions.

Potential-free contact

ON

Switch-on

edge

OFF

or switching pulse

ON - contact closed

OFF - contact open

t

The following binary functions react to switch-on

edges:

- Acknowledge limit comparator

- Reset min/max value

- Tare function

- Reset tare function

- Go to the next scroll parameter

All remaining binary functions react to switch-on or

switch-off states.

54

Page 55

7 Configuration

Binary input 1

...

Binary input 8

Limit

comparator 1

...

Limit

comparator 4

Logic 1

Logic 2

Parameter Value/

Selection

B-FUNCT1

B-FUNCT8

LCFUNCT1

LCFUNCT4

L-FUNCT1

L-FUNCT2

Description

0

no function

1

Key inhibit

2

Level inhibit

3

Display off (keys inactive)

4

Acknowledge limit comparator

5

Hold function

6

Reset min/max value

7

Tare function

8

Reset tare function

9

Tex t disp la y

10

Go to the next scroll parameter

11

Colour change

Level inhibit:

The configuration level is inhibited.

Tare function:

The tare function is used to zero the display

value of the analog inputs and values (math)

derived from these inputs. The function is reset

after Power ON.

Further

functions via

setup program

Text display:

With the binary function active, a configurable

text appears on the lower display: This text can

be uniquely defined

program)

Factory settings are shown

.

(only through the setup

bold

.

Several binary functions can be combined with each

other in the setup program. The text display can be

configured as an information or as an alarm text (with

colour change).

No information or alarm texts are shown when

*

the instrument is in the USER, OPERATOR or

CONFIGURATION level.

55

Page 56

7 Configuration

7.5 Display / Operation „DISPLAY“

Configuration

Analog inputs

Limit

comparators

Outputs

Binary

functions

Display /

Operation

Interfaces

Display 1

(upper display)

Display 2

(lower display)

The values to be shown, the type of presentation (e.g.

text, pseudo bargraph) and the display settings (e.g.

colour, brightness) can be configured under this menu

item.

Furthermore, start delay after Power ON, operation

time-out, level inhibit and function key assignment

can be defined here.

Parameter Value/

Selection

DISPLAY1 (analog

selector)

Analog

input 1

DISPLAY2 (analog

selector)

deactivated

Description

Display value for the upper display

v „Analog selector“, page 34

Display value for the lower display

v „Analog selector“, page 34

Display type

(lower display)

Display colour

(lower display)

DISPTYPE

COLOUR

0

Value

1

Channel name

2

Process display text

3

Unit and value display

4

Pseudo bargraph display

Channel name (max. 8 characters), process

display text (max. 24 characters), unit (max. 2

characters) as well as bargraph scaling can

only be entered through the setup program.

For better legibility we recommend the

exclusive use of capitals, numbers as well as

the following special characters:

° % / \ ( ) + - < > _ | ,

Enter a space at the end of text comprising

more than 8 and less than 24 characters.

01green

red

Factory settings are shown

bold

.

56

Page 57

7 Configuration

Ticker time

(ticker)

Decimal point

(system point)

Parameter Value/

Selection

TICKER-t

DECPOINT

Description

0

100ms (fast ticker)

1

200ms

2

300ms

3

400ms

4

500ms

5

600ms

6

700ms

7

800ms

8

900ms

9

1000ms

10

1100ms (slow ticker)

0

no digit after the decimal point

1

one digit after the decimal point

2

two digits after the decimal point

3

three digits after the decimal point

If the value to be displayed cannot be shown

including the programmed decimal point, the

number of digits after the decimal point are

automatically reduced. If subsequently the

measured value contains less digits, the

reading appears with the decimal point as

programmed.

Brightness

Time-out

Start

delay time

Min/max mode

Hold

(Value)

BRIGNESS0…5 (bright) 0...5 (dark)

TIMEOUT 0…

START-t

MIN-MAX

(Setup)

180

…

255

0

…3600 Start delay time in seconds after Power ON

active

not

active

Time period in seconds, after which the

instrument automatically returns to normal

display if no key is pressed.

0

Min/max mode inactive

1

Min/max mode active for analog input 1

2

Min/max mode active for analog input 2

3

Min/max mode active for analog input 1 and 2

Hold mode for analog input 1 or 2

With the hold mode active, the current

measurement can be saved with function key

„F“ or the binary function. The saved value

can be shown in display 1 or 2 as well as in

the scroll mode.

Adjustment only possible in the setup

program:

-> Display/Operation -> Display -> Min-Max/

Hold

Factory settings are shown

bold

.

57

Page 58

7 Configuration

Scroll time

Function key

„F“

Parameter Value/

Selection

SCROLL-t

F-KEY

0

…255 Scroll mode change-over time in seconds;

Description

0 = scroll mode inactive

255 = scroll mode stop

With the scroll mode active, keys

i and d can be used to select the next or

the previous scroll parameter. If the scroll

mode was stopped, further actions are only

possible with this key.

Adjustment of the scroll parameters only

possible in the setup program:

-> Display/Operation -> Display > Scroll mode

The parameter names are shown in the lower

display.

Example:

INPUT1 = Channel name, analog input 1

MIN INP1 = Min. value, analog input 1

MAX INP1 = Max. value, analog input 1

HOLD1 = Hold value, analog input 1

0

no function

1

Apply hold value

2

Tare function

3

Reset tare function

4

Reset min.-max value

5

Scroll mode stop

6

LK acknowledgement

Level

inhibit

(Setup)

Keep the function key pressed for at least 2

seconds to ensure that the function will be

performed.

none

Configuration level

Factory settings are shown

Access to the configuration level can be

inhibited. The setting is independent of binary

function „Level inhibit“.

Setting in the setup program:

-> Display/Operation -> Operation

See also Chapter 5.3 „Level inhibit“.

bold

.

58

Page 59

7 Configuration

Bargraph

scaling

Channel name

Parameter Value/

Selection

(Setup) -19999

... 0 ...

+99999

-19999

...

100

+99999

(Setup)

INPUT1

INPUT2

MATHE1

MATHE2

xxxx

xxx.x

xx.xx

x.xxx

System

point

Description

Scaling start

Scaling end

...

Adjustment only possible in the setup

program:

-> Display/Operation -> Display > Lower

display

Channel name for analog input 1

Channel name for analog input 2

Channel name for math 1

Channel name for math 2

no digit after the decimal point

one digit after the decimal point

two digits after the decimal point

three digits after the decimal point

Digit after the decimal point as system

point

User data

Individual channel names (max. 8 characters)

can be allocated for the analog inputs and

math functions.

The decimal point of the values of the analog

inputs can be defined different to that of the

system point.

Adjustment only possible in the setup

program:

-> Display/Operation -> Display > Channel

name

(The setting at the instrument is made in the

menu for analog input, parameter

„DECPOINT“.)

(Setup) A maximum of eight parameters from the

configuration level can be defined to be

available in the user level of the instrument.

The parameter name (max. 8 characters) can

be user-defined. Without a user-defined entry,

the name programmed in the instrument will

appear.

Adjustment only possible in the setup

program:

-> Display/Operation -> User data

Factory settings are shown

bold

.

59

Page 60

7 Configuration

7.6 Interfaces „INTERFCE“

Configuration

Analog inputs

Limit

comparators

Outputs

Binary

functions

Display /

Operation

Interfaces

Protocol PROTOCOL

Baud rate

The interface parameters for the RS422/485 or

PROFIBUS-DP interface have to be configured in

order to communicate with PCs, bus systems and

peripheral devices.

➔ RS422485 (Modbus) ➔

Parameter Value/

BAUD RATE

Selection

Description

01Modbus

Modbus integer

0

9600 bps

1

19200 bps

2

38400 bps

Data

format

Device address

Min. response

time

DFORMAT

ADDRESS 0…1…

255

(Setup)

0

…500 Time period in milli-seconds that elapses

Factory settings are shown

0

8 data bits, 1 stop bit, no parity

1

8 data bits, 1 stop bit, odd parity

2

8 data bits, 1 stop bit, even parity

3

8 data bits, 2 stop bits, no parity

Address in data network

between the request of a device in the data

network and the response of the display

instrument.

Adjustment only possible in the setup

program:

-> Interfaces -> RS422/RS485

bold

.

60

Page 61

➔ PROFIBUS (PROFIBUS-DP) ➔

7 Configuration

Parameter Value/

Protocol PROTOCOL

Device address ADDRESS

Analog marker

(analog value)

Binary marker

(binary value)

ANA-VAL

BIN-VAL

For further information, please refer to the

v

separate interface descriptions:

- B70.1550.2.0 (Modbus)

Description

Selection

0

Intel

1

Motorola

2

Intel integer

0…

125

…

Address in data network

255

-19999…

0

…

99999

0

…255 Binary value

Factory settings are shown

Analog value

bold

.

- B70.1550.2.3 (PROFIBUS-DP)

61

Page 62

7 Configuration

62

Page 63

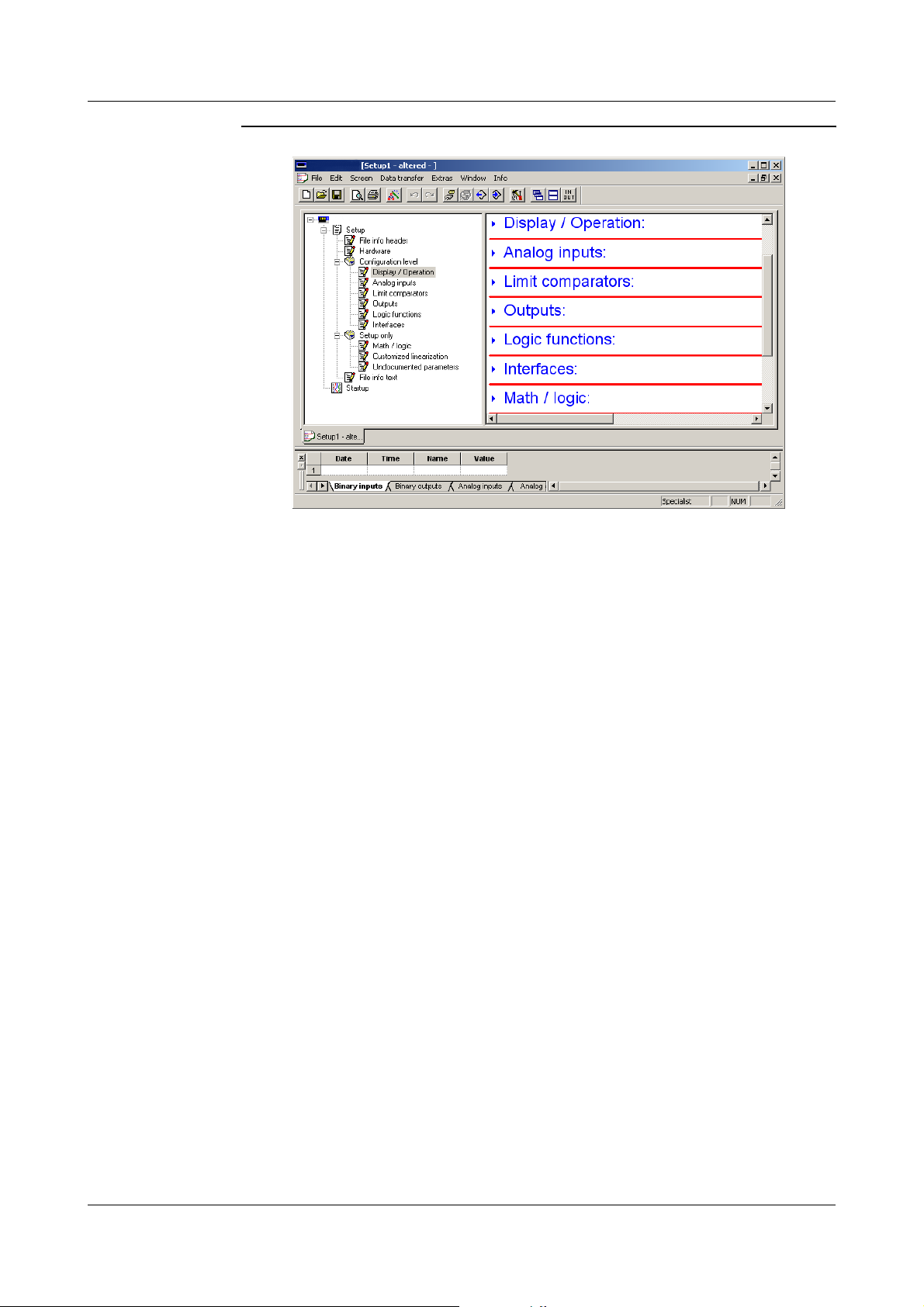

8.1 Math and logic module

Prerequisite: The „Math“ extra code must be enabled.

vSetup program (Extras -> Enable extra codes)

The Setup program can be used to carry out two

mathematical calculations or logical combinations of

various signals and process variables from the

controller. The formula is created by means of a

formula editor.

vSetup program (Math/Logic)

With math formulae, the calculated result is presented

through the two signals „Math 1“ and „Math 2“ of the

analog selector. With logic formulae, the result of the

8 Extra codes

Entering

formulae

logical combinations is available through the signals

„Logic 1“ and „Logic 2“ of the binary selector when

configuring the binary functions.

vChapter 7.4 „Binary functions „BINFUNCT““

- The string of characters in the formula consists of

ASCII characters. It can have a maximum length of

60 characters.

- The formula can only be entered in the setup

program.

- Formulae can be freely entered according to the

standard mathematical rules.

- In the string of characters of the formula, spaces

can be inserted as required. Spaces are not

permitted within function designations, variables

names and constants.

63

Page 64

8 Extra codes

8.2 Difference, humidity or ratio calculation

The controller can be configured through the Setup

program such that a difference, humidity or ratio

calculation is carried out by means of a default

formula. Analog input 2 must be available. The

functions need not be enabled.

vSetup program (Math/Logic)

Difference The difference of the measurements is formed from

analog input 1 (E1) and analog input 2 (E2).

Difference: E1-E2

Humidity The relative humidity is determined by means of a

psychrometric humidity sensor, through the

mathematical combination of the wet bulb and dry

bulb temperature.

Relative humidity: (E1, E2)

E1 - dry bulb temperature via analog input 1

E2 - wet bulb temperature via analog input 2

Ratio The math module forms the ratio of the

measurements from analog input (E1) and analog

input 2 (E2).

Ratio: E1/E2

Result The result is under „Math 1“ or „Math 2“ and can be

used as analog value for various parameters.

64

vAnalog selector, Page 34

Page 65

Safety notes

A

9 Retrofitting of modules

Only qualified personnel are permitted to carry

out module retrofits.

Removing the

controller

module

Identifying the

module

E

Risk of damage to the modules by electrostatic

discharge. For this reason, avoid electrostatic

charge during fitting and removal. Carry out

retrofitting on a grounded workbench.

hPress together the knurled

surfaces on the front panel (left

and right), and pull out the

controller module.

hIdentify the module by the sales number pasted on

the packaging

Modules Code Sales

No.

View of boards

Analog input 2 1 70/00442785

1 relay

(changeover)

2 relays

(make, N/O)

1 analog output 4 70/00442788

2 binary inputs 5 70/00442789

2 70/00442786

3 70/00442787

65

Page 66

9 Retrofitting of modules

Retrofitting of

modules

Modules Code Sales

No.

1 solid-state relay

230V/1A

Interface

RS422/485

PROFIBUS-DP 8 70/00442791

6 70/00442790

7 70/00442782

hSelect slot for the option

1

2

3

View of boards

66

hPush the module into the slot until the plug

connector engages

hPush the module into the housing until the lugs

engage in their slots

Page 67

10.1 Technical data

Thermocouple input

10 Appendix

Designation Measuring range Measuring

accuracy

Fe-Con „L“

Fe-Con „J“

Cu-Con „U“

Cu-Con „T“

NiCr-Ni „K“

NiCr-Con „E“

NiCrSi-NiSi „N“

Pt10Rh-Pt „S“

Pt13Rh-Pt „R“

Pt30Rh-Pt6Rh „B“

W5Re-W26Re „C“

W3Re-W25Re „D“

W3Re-W26Re

Chromel-Copel

Cold junction Pt 100 internal

1

incl. measuring accuracy at the cold junction

2

in the range from 300…1820°C

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

GOST R

8.585-2001

-200 to +900°C

-200 to +1200°C

-200 to +600°C

-200 to +400°C

-200 to +1372°C

-200 to +1000°C

-100 to +1300°C

0 to +1768°C

0 to +1768°C

0 to +1820°C

0 to +2320°C

0 to +2495°C

0 to +2400°C

-200 to +800°C

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

≤

0.25%

RTD temperature probe input

2

1,3

Ambient

temperature

error

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

100ppm/K

Designation Connection

circuit

Pt100 DIN EN

60751

Pt500 DIN EN

60751

Pt1000 DIN EN

60751

Pt50 GOST

6651-94

Pt100 GOST

6651-94

Cu50 GOST

6651-94

Cu100 GOST

6651-94

KTY11-6 2-wire -50 to +150°C

3

The accuracy refers to the max. measurement range span. The linearization accuracy is

reduced with short spans.

2-wire/3-wire/

4-wire

2-wire/3-wire/

4-wire

2-wire/3-wire/

4-wire

2-wire/3-wire/

4-wire

2-wire/3-wire/

4-wire

2-wire/3-wire/

4-wire

2-wire/3-wire/

4-wire

Measuring

range

-200 to +850°C

-200 to +850°C

-200 to +850°C

-200 to +850°C

-200 to +850°C

-50 to +200°C

-50 to +200°C

Measuring

accuracy

3-/4wire

≤

0.05%≤ 0.4% 50ppm/K

≤

0.2%

≤

0.1%

≤

0.1%

≤

0.05%≤ 0.4% 50ppm/K

≤

0.2%

≤

0.1%

−≤

3

2wire

≤

0.4% 100ppm/K

≤

0.2% 50ppm/K

≤

0.8% 50ppm/K

≤

1.6% 50ppm/K

≤

0.8% 50ppm/K

2.0% 50ppm/K

Ambient

temperature error

67

Page 68

10 Appendix

RTD temperature probe input (continued)

Sensor lead

resistance

Measuring current approx. 250µA

Lead compensation Not required for 3-wire and 4-wire circuit. For a 2-wire circuit, the

max. 30Ω per lead for 3-wire/4-wire circuit

lead resistance can be compensated in the software by correcting

the actual value.

Standard signals input

Designation Measuring range Measuring

accuracy

Voltage 0(2)—10V

0—1V

Input resistance RIN > 100k

Current 0(4)—20mA

Voltage drop ≤ 1.5V

Resistance transmitter min. 100Ω, max. 4k

3

The accuracy refers to the max. measurement range span. The linearization accuracy is

reduced with short spans.

Ω±

Ω

≤

0.05%

≤

0.05%

≤

0.05% 100ppm/K

4

Ω

Ambient

3

temperature

error

100ppm/K

100ppm/K

100ppm/K

Binary inputs

Floating contacts open = inactive; short-circuited to GND = active

Measuring circuit monitoring

In the event of a fault, the outputs change to defined statuses (configurable).

Sensor Measuring overrange /

underrange

Thermocouple • - •

RTD temperature probe • • •

Voltage 2—10V

0—10V

0—1V

Current 4—20mA

0—20mA

Resistance transmitter - - •

• = detected - = not detected

•

•

•

•

•

Probe or lead

short-circuit

•

-

-

•

-

Probe or lead

break

•

-

-

•

-

68

Page 69

10 Appendix

Outputs

Relay (change-over)

Contact rating

Contact life

Relay (changeover

(option))

Contact rating

Contact life

Relay (n.o. make (option))

Contact rating

Contact life

Logic output 0/12V / 25mA max. (sum of all output currents)

Solid-state relay (option)

Contact rating

Protection circuitry

Voltage (option)

Output signals

Load resistance

Accuracy

Current (option)

Output signals

Load resistance

Accuracy

Voltage supply for

2-wire transmitter

350,000 operations at rated load/750,000 operations at 1A

100,000 operations at rated load/350,000 operations at 3A

350,000 operations at rated load/900,000 operations at 1A

15.8—15.2V / 30—50mA (no-load voltage approx. 25V)

5A at 230VAC resistive load

8A at 230VAC resistive load

3A at 230VAC resistive load

1A at 230V

Varistor

0—10V / 2—10V

R

0—20mA / 4—20mA

R

electrically isolated, not stabilised

Load

≤

Load

≤

≥

500

0.5%

≤ 500

0.5%

Ω

Ω

A/D converter

Resolution dynamic up to 16 Bit

Sampling cycle time 50ms, 90ms, 150ms, 250ms (configurable)

Display

Type LCD with background lighting

Display 1 7-segment display, 18mm high, 5 digits, color: red

Function of display 1 measurement display and parameter setting

Display 2 16-segment display, 7mm high, 8 digits, color: red/green

(switchable)

Function of display 2 24-character running text display (alarms), display of

measurements or parameter names

Display 3 4 switching status indicators (K1 to K4), 3mm high

69

Page 70

10 Appendix

Electrical data

Supply voltage (switchmode PSU)

Electrical safety acc. to EN 61010, part 1

Power consumption max. 13VA

Data backup EEPROM

Electrical connection at the back via screw terminals,

Installation information on conductor cross-sections

and core-end ferrules

Without

core-end ferrule

Core-end ferrule

without lip

Core end ferrule

with lip

up to 1.5mm2

Core end ferrule

with lip

above 1.5mm2

AC 110—240V -15/+10%, 48—63Hz

AC/DC 20—30V, 48—63Hz

Overvoltage category III, pollution degree 2

conductor cross section up to max. 2.5mm2

with core-end ferrule (length: 10mm)

min.

crosssection

0.34mm22.5mm210mm

0.25mm 2.5mm210mm

0.25mm21.5mm210mm

1.5mm

max.

crosssection

2

2.5mm212mm

Min. length of

core-end

ferrule

(stripped)

Electromagnetic

compatibility

Interference emission

Interference immunity

Twin ferrule with

lip

meeting industrial requirements

0.25mm21.5mm212mm

EN 61326-1

Class B

70

Page 71

10 Appendix

Housing

Housing type Plastic housing for panel mounting acc. to IEC 61554

Depth behind panel 90mm

Ambient/storage

temperature range

Climatic conditions rel. humidity ≤ 90% annual average, no condensation