Page 1

2014-05-01

/00564764

(translation of the German

Operating Manual

original manual)

B 701150.0

according to DIN EN 14597

safety temperature monitor

JUMO safetyM STB/STW

Safety temperature limiter,

Page 2

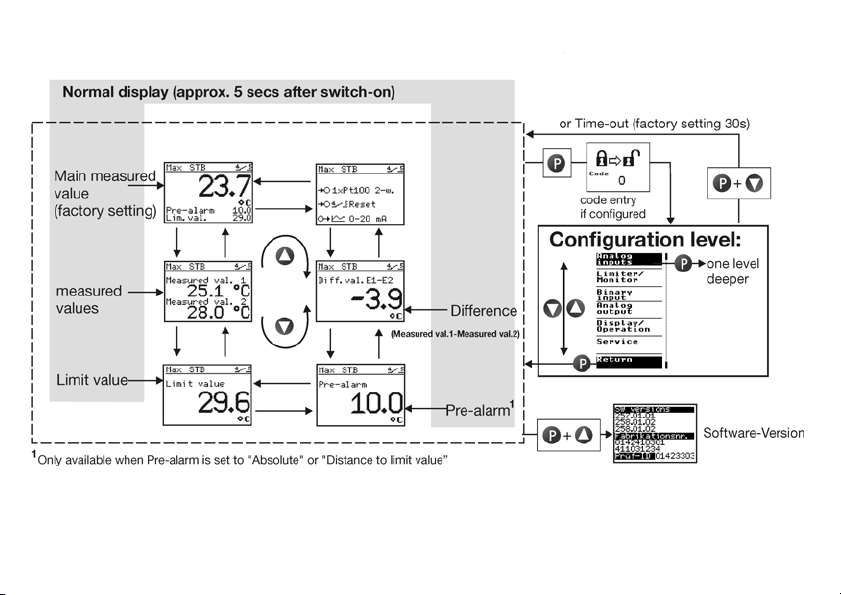

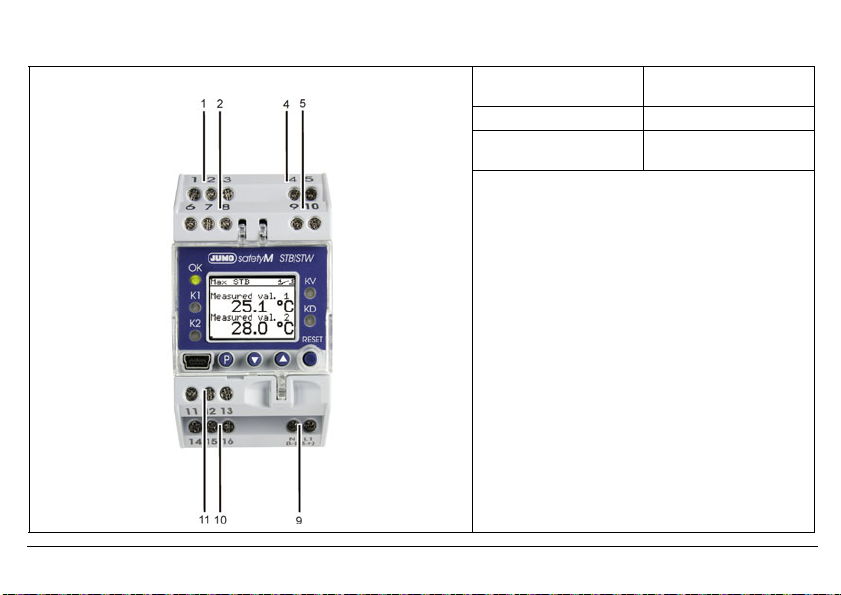

Operating overview

Page 3

Operating overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Safety temperature monitor (STW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.2 Safety temperature limiter (STB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.3 Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2 Identifying the device version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.2 Device software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3 Serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.4 Service addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.2 Installation location, DIN rail installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3 Close mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.4 Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.5 Electrical isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.6 Use of the setup interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Installation notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5 Commissioning the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 Display and operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.2 Setting the display after switch-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Inhalt

Page 4

Inhalt

5.3 Selecting and editing parameters (plausibility inquiry for input values) . . . . . . . . . . . . . . . . . . . . . . . . .29

5.4 Aborting edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.5 Alarm acknowledgement using the Reset key (only for temperature limiters STB) . . . . . . . . . . . . . . . .30

5.6 Alarm acknowledgement via binary input (only for temperature limiters STB). . . . . . . . . . . . . . . . . . . .30

5.7 Lead sealing the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6 Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.2 Safety temperature monitor (STW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.2.1 Safe operating status STW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.3 Safety temperature limiter (STB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.3.1 Safe operating status STB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4 Relevant standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.5 Validity of the Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.6 Connection possibilities of the sensors (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.7 Standards and definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.7.1 Terms and abbreviations acc. to DIN EN 14597 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.7.2 Terms and abbreviations acc. to DIN EN 61 508 and DIN EN 61 511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.8 Safety instrumented parameters related to the temperature monitoring unit . . . . . . . . . . . . . . . . . . . .41

6.8.1 Failure rates and SFF for 701150...23 (AC 230 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.8.2 Failure rates and SFF for 701150...25 (AC/DC 24 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.9 Determining the Safety Integrity Level (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.9.1 Safety integrity of the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.9.2 Safety-relevant system properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.10 Determining the achieved Performance Level PL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Page 5

6.10.1 Terms and abbreviations acc. to DIN EN ISO 13849 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.11 Connection possibilities of the sensors (PL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.11.1 Calculations DIN EN ISO 13849-1 Performance Level - low voltage 230 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

6.11.2 Calculations DIN EN ISO 13849-1 Performance Level - extra low voltage (ELV) 24 V . . . . . . . . . . . . . . . . . . . . . . . . .53

6.11.3 Contribution to risk minimization through the control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.12 Evaluating the achieved Performance Level PL and the relationship to the SIL . . . . . . . . . . . . . . . . . .56

6.13 Other applicable device documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.14 Behavior during operation and in case of malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.15 Regular tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.15.1 Recommended tests for temperature probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.16 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

7 Configuration level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.1 Navigation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

7.2 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

7.2.1 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

7.2.2 Sensor type 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

7.2.3 Offset 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.2.4 Lead wire resistance 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.2.5 Filter time 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.2.6 Scaling start 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.2.7 Scaling end 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.2.8 Sensor type 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

7.2.9 Offset 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

7.2.10 Lead wire resistance 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Inhalt

Page 6

Inhalt

7.2.11 Filter time 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.2.12 Scaling start 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

7.2.13 Scaling end 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

7.3 Limiter/monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

7.3.1 Device function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

7.3.2 Switching behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

7.3.3 Limit value, hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

7.3.4 Pre-alarm function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

7.3.5 Pre-alarm, hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

7.3.6 Limit value difference, hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

7.3.7 Setting range min. (formerly ALHI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.3.8 Setting range max. (formerly ALLO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

7.4 Binary input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

7.4.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

7.5 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.5.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.5.2 Signal type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.5.3 Scaling start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.5.4 Scaling end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.5.5 Error signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

7.5.6 Behavior when leaving the scaling range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

7.6 Display/operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

7.6.1 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

7.6.2 Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

7.6.3 Decimal place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Page 7

7.6.4 Normal display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

7.6.5 Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

7.6.6 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

7.6.7 Time-out light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

7.6.8 Time-out operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.6.9 Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

7.7 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

7.7.1 Limit switching cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

7.7.2 Current switching cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

7.7.3 Operating hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.1 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

8.2 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

8.3 Binary input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

8.4 Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

8.5 Measuring circuit monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

8.6 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

8.7 Test voltages according to EN 60730, part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

8.8 Electrical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

8.9 Environmental influences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

8.10 Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

8.11 Approvals/approval marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

8.12 Probes for the operating medium air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

8.13 Probes for the operating medium water and oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Inhalt

Page 8

Inhalt

8.14 Probes for the operating medium water, oil and air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

9 Setup program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.1 Minimum hardware and software prerequisites: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

9.2 Displaying the device software version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

9.3 Forgotten the code? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

9.4 Special function: thermocouple reverse polarity protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

10 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

11 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

12 What to do, if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

13 Information for devices with extra code 062 GL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

13.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

13.2 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

13.3 Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

14 Output behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Page 9

Page 10

2014-05-01

1 Brief description

10

1 Brief description

The safety temperature limiter (STB) and the safety temperature monitor (STW) are used to reliably detect and avert hazards

that could cause injuries, are harmful to the environment or cause destruction of production plants and produced goods, at an

early stage.

Its primary task is to reliably monitor thermal processes and switch the systems to an operationally safe status in the event of

malfunctions.

The measured value at the analog input can be recorded by various probes or standard signals.

The limit value overrange is indicated by the installed LEDs K1 and K2 (red) for each channel, and the installed relay "Alarm"

switches the system to an operationally safe status (alarm range).

The high standards of DIN EN 61508 and DIN EN ISO 13849 are met by a device design, the 1oo2D structure of which ensures

reliable detection of errors and, thus, can also be used for applications according to the new Machinery Directive 2006/42/EC.

1.1 Safety temperature monitor (STW)

The STW is a safety component according to Machinery Directive, which, when activated, resets automatically if the probe

temperature has gone below / exceeded the limit value by an amount equal to the hysteresis. Possible settings: monitoring for

limit value overrange or underrange.

v Chapter 7.3.2 "Switching behavior"

1.2 Safety temperature limiter (STB)

The STB is a safety component according to Machinery Directive that is permanently locked after response. Manual reset using

the key is only possible once the probe temperature has gone below / exceeded the limit value by an amount equal to the

hysteresis. Possible settings: monitoring for limit value overrange or underrange.

v Chapter 7.3.2 "Switching behavior"

The transparent cover can be lead sealed to prevent unauthorized operation.

However, the key remains accessible.

Page 11

1.3 Safety information

H

A

V

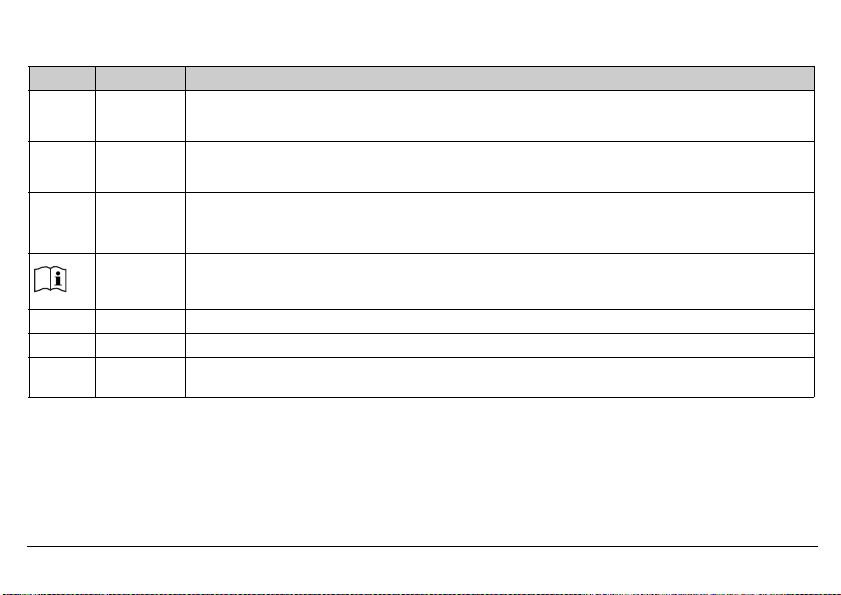

Symbol Meaning Explanation

Note This symbol is used to draw your attention to important information.

Caution This symbol is used when there is a risk of damage to equipment or data if the instructions are ig-

Danger This symbol is used when there is a risk of injury to persons if the instructions are ignored or not

Read This text contains important information and must always be read before work is continued. Han-

v Reference This symbol refers to further information in other manuals, chapters or sections.

1

abc

*

2014-05-01

Footnote Footnotes are remarks referring to specific points in the text marked with a superscript number.

Instructions

for action

nored or not followed correctly.

followed correctly.

dling the device in any way that is not described in the Operating Manual or that is expressly forbidden will jeopardize your warranty rights.

This symbol indicates that an action to be performed is described. The individual steps are marked

by an asterisk.

1 Brief description

11

Page 12

2014-05-01

A

Voltage supply AC 110 to 240 V:

Voltage supply AC/DC20 to 30 V:

Switching behavior

2 Identifying the device version

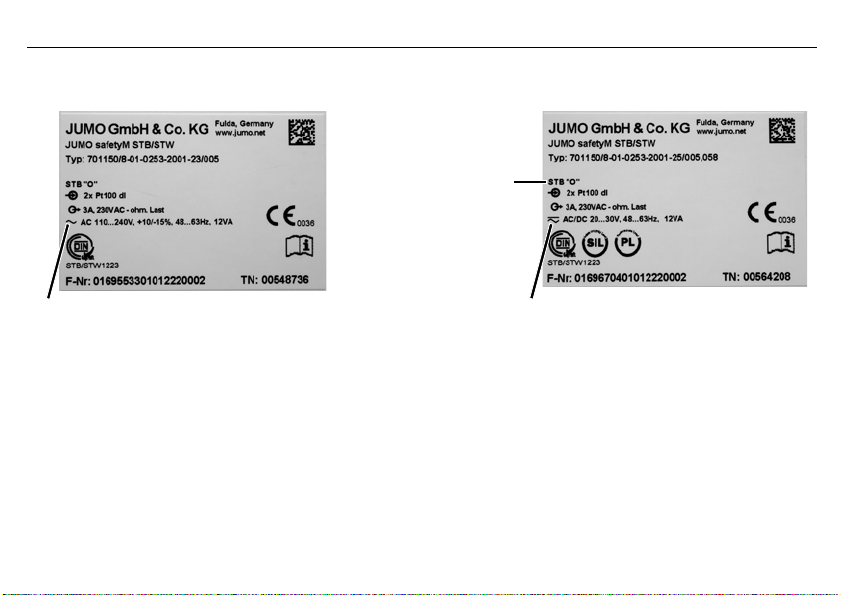

The type plate is affixed to the side of the device.

The voltage supply must correspond to the voltage given on the type plate!

2 Identifying the device version

12

Page 13

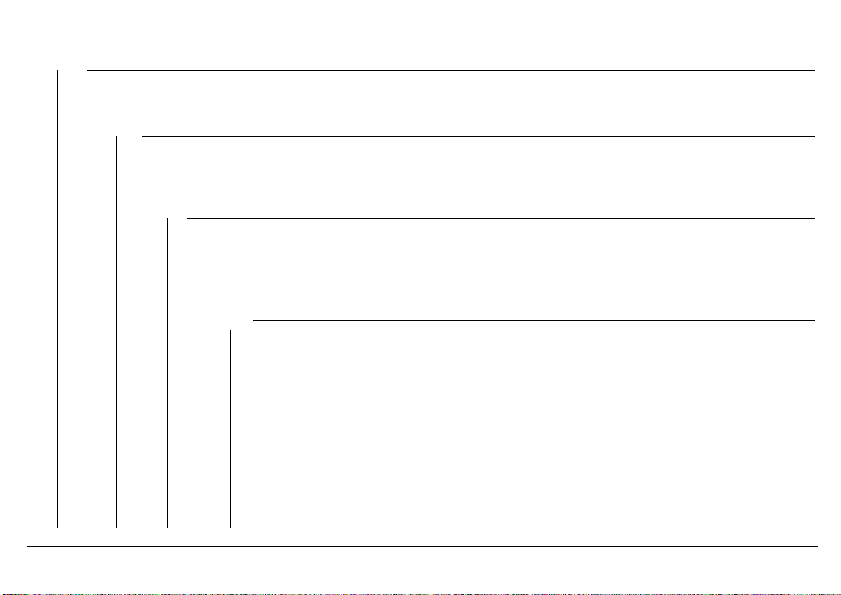

Basic type

701150 Safety temperature limiters (STB) / monitors (STW) according to DIN EN 14597

Ver sion

8 Factory setting

9 Configured according to customer specifications

01 German (factory setting)

02 English

03 French

0251 Safety temperature monitor max. alarm (inverse, N/C contact)

0252 Safety temperature monitor min. alarm (direct, N/O contact)

0253 Safety temperature limiter max. alarm (inverse, N/C contact)

0254 Safety temperature limiter min. alarm (direct, N/O contact)

1003 1x Pt100 in 2-wire circuit

2001 2x Pt100 in 3-wire circuit (ex-factory)

2003 2x Pt100 in 2-wire circuit

2006 2x Pt1000 in 3-wire circuit

2037 2x W3Re-W25Re "D"

2039 2x Cu-CuNi "T"

2040 2x Fe-CuNi "J"

2041 2x Cu-CuNi "U"

2042 2x Fe-CuNi "L"

2043 2x NiCr-Ni "K"

Language

Switching behavior

Measuring input1 (programmable)

2014-05-01

2 Identifying the device version

13

Page 14

2014-05-01

2044 2x Pt10Rh-Pt "S"

2045 2x Pt13Rh-Pt "R"

2046 2x Pt30Rh-Pt6Rh "B"

2048 2x NiCrSi-NiSi "N"

1053 1x 4 to 20 mA

2053 2x 4 to 20 mA

23 AC 110 to 240 V +10 % /-15 %, 48 to 63 Hz

25 20 to 30 V AC/DC, 48 to 63 Hz

701150 / 8 - 01 - 0253 - 2001 - 23 / 005 , 062

1. The first number on the measuring input means single probe "1“ or double probe "2“

2 Identifying the device version

Voltage supply

Analog output (configurable)

001 0 to 20 mA

005 4 to 20 mA (ex-factory)

040 0 to 10 V

070 2 to 10 V

Extra code

2.1 Scope of delivery

-JUMO safetyM STB/STW in the version ordered

- Operating Manual B701150.0

058 SIL and PL approval

062 GL approval

14

Page 15

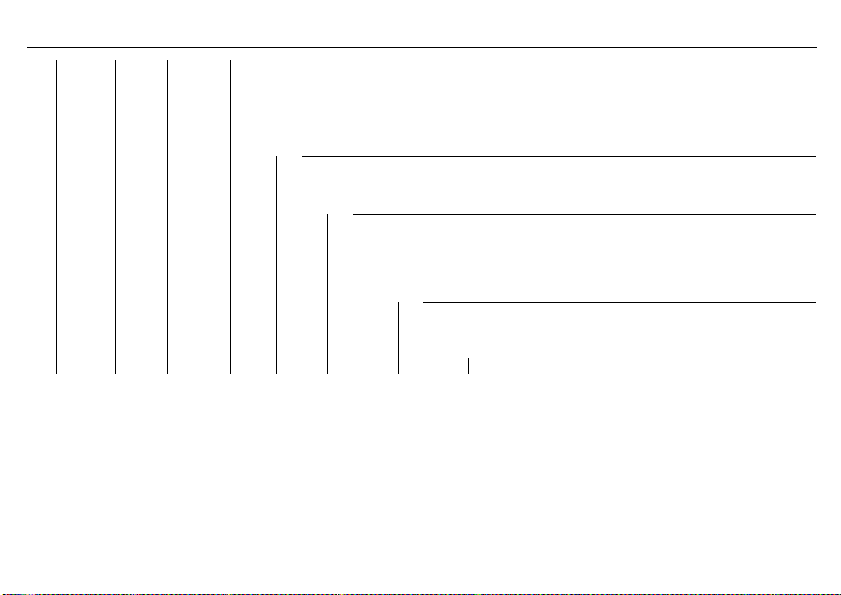

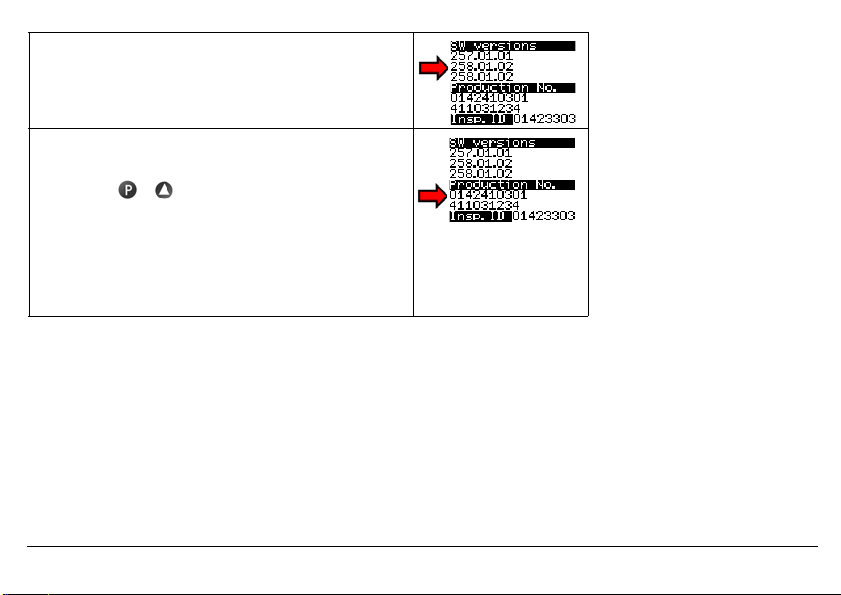

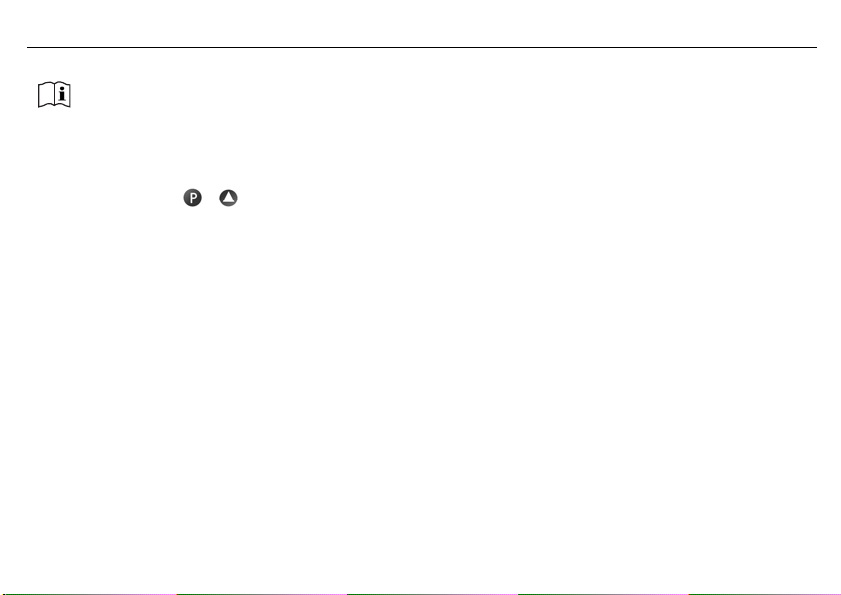

2.2 Device software versions

Diagnosis module version: 257.01.01

Analog channel 1 version: 258.01.02

Analog channel 2 version: 258.01.02

2.3 Serial number

The serial number is indicated on the device.

h Press the + keys

Construction:

The first 8 digits specify the serial number: 01424103

Digit 9 and 10 the production plant in Fulda: 01

Digit 11 (second line) the hardware version: 4

Digit 12 and 13 the year: 2011

Digit 14 and 15 the calendar week: 03

Digit 16 to 19 consecutive numbers: 1234

2.4 Service addresses

Phone support in Germany:

Telephone:+49 661 6003-9135

Fax: +49 661 6003-881899

Email: service@jumo.net

2014-05-01

Austria:

Telephone:+43 1 610610

Fax: +43 1 6106140

Email: info@jumo.at

Switzerland:

Telephone:+41 44 928 24 44

Fax: +41 44 928 24 48

Email: info@jumo.ch

2 Identifying the device version

15

Page 16

2014-05-01

A

2 Identifying the device version

This operating manual is a translation of the German original manual.

It is valid for the following hardware and software versions:

Diagnosis module from version: 257.01.01

Analog channel 1 from version: 258.01.02

Analog channel 2 from version: 258.01.02

Hardware version: 0

16

h Press the + keys

Keep the operating manual in a place accessible to all users at all times.

All necessary settings are described in this Operating Manual.

Handling the device in any way that is not described in the Operating Manual or that is expressly forbidden will

jeopardize your warranty rights and may disable the safety function.

It is forbidden to access the inside of the device!

Repairs may only be performed by JUMO at the head office in Fulda.

Please contact the nearest subsidiary or the head office should you encounter any problems.

Page 17

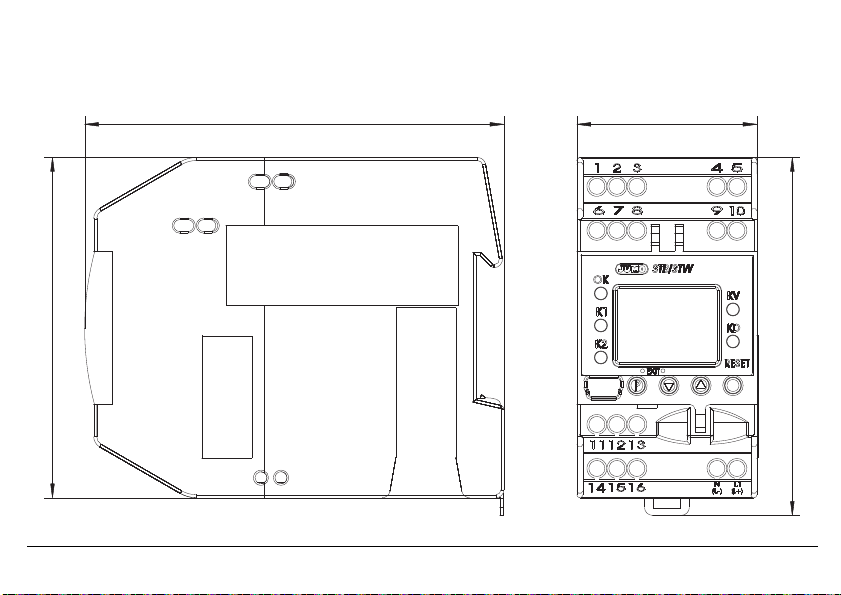

3 Installation

45

89 4,

85

104 8,

3.1 Dimensions

2014-05-01

3 Installation

17

Page 18

2014-05-01

V

3.2 Installation location, DIN rail installation

The device is not suitable for use in potentially explosive atmospheres.

The device is hooked into a 35 mm DIN rail (EN 60715) from the front and

pushed down to engage.

The ambient conditions at the installation site must meet the requirements

v

specified in the technical data.

Chapter 8 "Technical data"

As far as possible, the installation site should be vibration-free to prevent the screw-connections from working loose.

a

The installation site should be free from aggressive media, e.g. acids and lyes, and, if possible, free from dust, flour or

a

other suspended matter in order to prevent the cooling slots from becoming clogged.

3.3 Close mounting

Observe a minimum spacing of 20 mm from the top and bottom.

a

1. To allow the release slot to be accessed with a screwdriver from below.

2. To allow the device to be swiveled up and unhooked from the DIN rail for removal.

Several devices may be mounted side by side without a gap.

a

3 Installation

18

Page 19

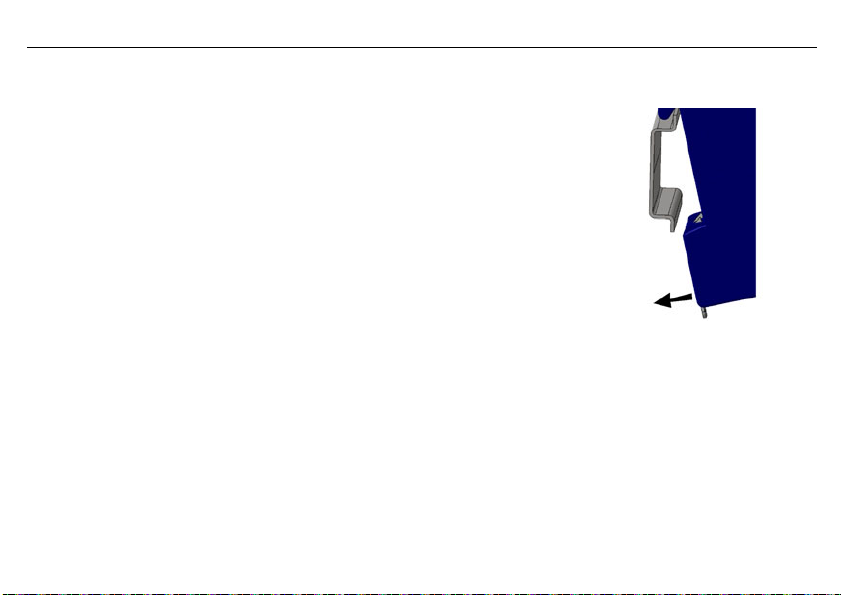

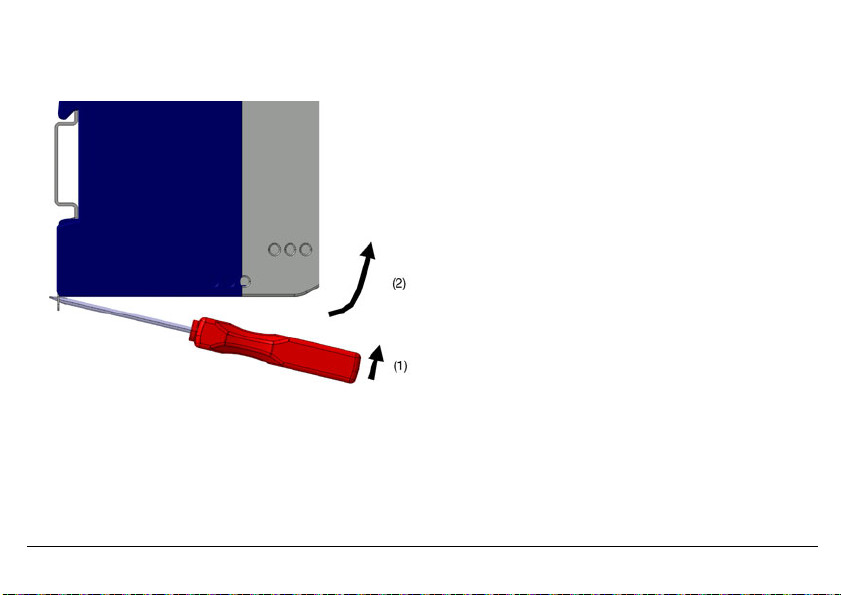

3.4 Dismantling

h Insert a screwdriver into the release lug from below and lift up (1).

h Simultaneously swivel the screwdriver and case up out of the DIN rail (2).

2014-05-01

3 Installation

19

Page 20

2014-05-01

»

3700 V AC

»

3700 V AC

(1)

(2)

(4)

(3)

(5)

(8)

(6)

(7)

»

3700 V AC

50 V DC

»

3.5 Electrical isolation

3 Installation

20

(1) Analog inputs

(3) Binary input

(5) Setup interface

(6) Display

(7) Analog output

3.6 Use of the setup interface

- The setup interface USB is only designed for service use for a limited period, e.g. for transmitting setup data and during

- It is not suitable for operation in a fixed installation for an unlimited period as the monitoring function is switched off during

(8) Power supply

commissioning.

data transmission with the setup program.

(2) Relay output "Alarm"

(4) Relay output "Pre-alarm"

Page 21

4 Electrical connection

V

4.1 Installation notes

Check that the safety temperature limiter is correctly installed for its application (temperature measurement) and is oper-

a

ated within the admissible system parameters.

The device is designed for installation in switch cabinets, machines/plants or systems.

a

Ensure that the customer's fuse rating does not exceed 20 A.

Isolate the device at all poles prior to starting service or repair work.

a

All incoming and outgoing lines without a connection to the power supply network must be laid with shielded and

a

twisted lines. Connect the screen on the device side to ground.

Do not run input and output lines close to current-carrying components or cables.

a

Do not connect any additional consumers to the screw terminals for the device power supply.

a

The choice of cable, the installation and the electrical connection of the device must conform to the requirements of VDE

a

0100 "Regulations on the Installation of Power Circuits with Nominal Voltages below 1000 V" or the appropriate local

regulations.

Protect the relay circuit by suitable measures.

a

The maximum contact rating is 230 V/3 A (ohmic load).

The electromagnetic compatibility conforms to the standards and regulations cited in the technical data.

a

v Chapter 8 "Technical data"

During commissioning we recommend carrying out a trial run of the system until temperature switch-off at the set limit.

a

Only allow qualified electricians to carry out the electrical connection and the configuration settings until commissioning.

2014-05-01

4 Electrical connection

21

Page 22

2014-05-01

A

4 Electrical connection

The approval according to DIN EN 14597 is only valid when the correct probe with DIN approval is set in the configuration level and also connected.

The limit value to be monitored must be within the admissible temperature range of the DIN probe.

v Chapter 8.12 "Probes for the operating medium air"

v Chapter 8.13 "Probes for the operating medium water and oil"

The monitoring function is deactivated during data transmission using the setup program.

v Chapter 12 "What to do, if ..."

22

Page 23

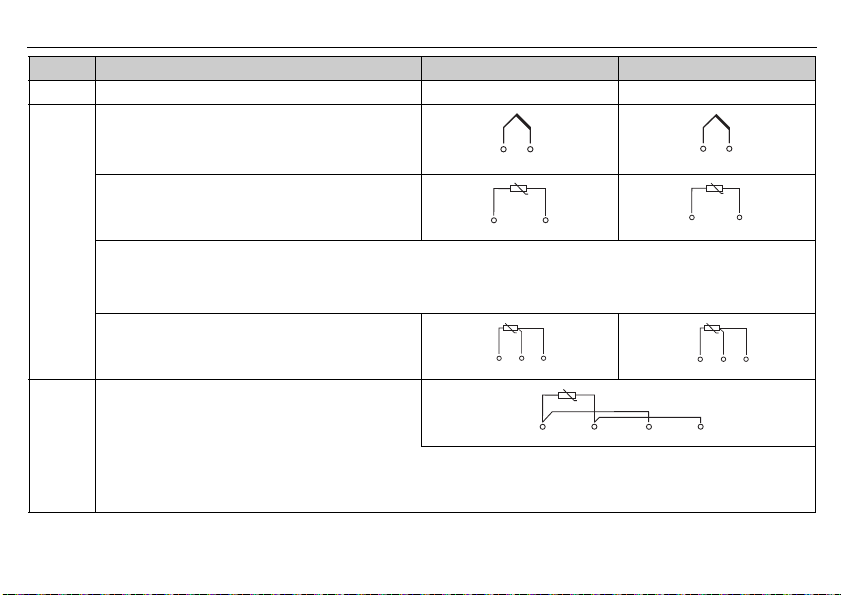

4.2 Connection diagram

Connection is carried out via screw terminals. Lead Admissible cross sec-

1 wire

fine-strand,

with core-end ferrule

2014-05-01

4 Electrical connection

tion

≤ 2.5 mm

≤ 1.5 mm

2

2

23

Page 24

2014-05-01

V

+

–

2

3

+

–

7

8

J

13

J

68

A

Enter the lead resistance for RTD temperature probes in two-wire circuit when using greater line

lengths.

v Setup program: edit => analog inputs

123

J

678

J

J

13 68

4 Electrical connection

Legend Remark Screw terminals Screw terminals

1, 2 Analog input1 (E1) Analog input2 (E2)

Thermocouple/

double thermocouple

RTD temperature probe Pt100/Pt1000 in

2-wire circuit

RTD temperature probe Pt100/Pt1000

in three-wire circuit

RTD temperature probe Pt100 in

two-wire circuit, individual probe for both analog

inputs

Caution:

When only one probe (SIL2) is connected, the temperature limitation device

is reduced from SIL3 to SIL2. However, the internal 2-channel structure (1oo2D) in the device is still retained.

Both channels measure the same probe due to the simplified external circuit.

24

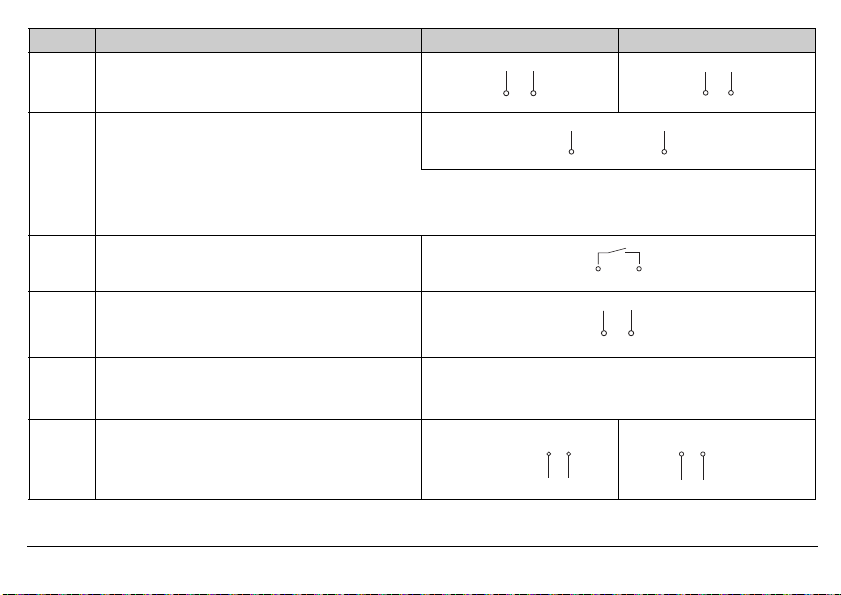

Page 25

V

V

Legend Remark Screw terminals Screw terminals

2

3

+

–

I

x

7

8

+

–

I

x

+

–

I

x

4

5

Ground

9

10

+

–

Ix,U

x

L1 N

L1 N

L+ L-

L+ L-

4 to 20 mA

4 to 20 mA for both analog inputs

Caution:

When only one probe (SIL2) is connected, the temperature limitation device

is reduced from SIL3 to SIL2. However, the internal 2-channel structure (1oo2D) in the device is still retained.

Both channels measure the same current signal due to the simplified external circuit.

4 Binary input

Connection to a potential-free contact

5 Analog output:

0 to 20 mA

4 to 20 mA (ex-factory)

0(2) to 10V

Caution

The analog output is not part of the safety func-

tion!

9 Voltage supply

2014-05-01

according to rating plate

AC:

L1 Line conductor

N Neutral

4 Electrical connection

DC:

(L+)

(L-)

25

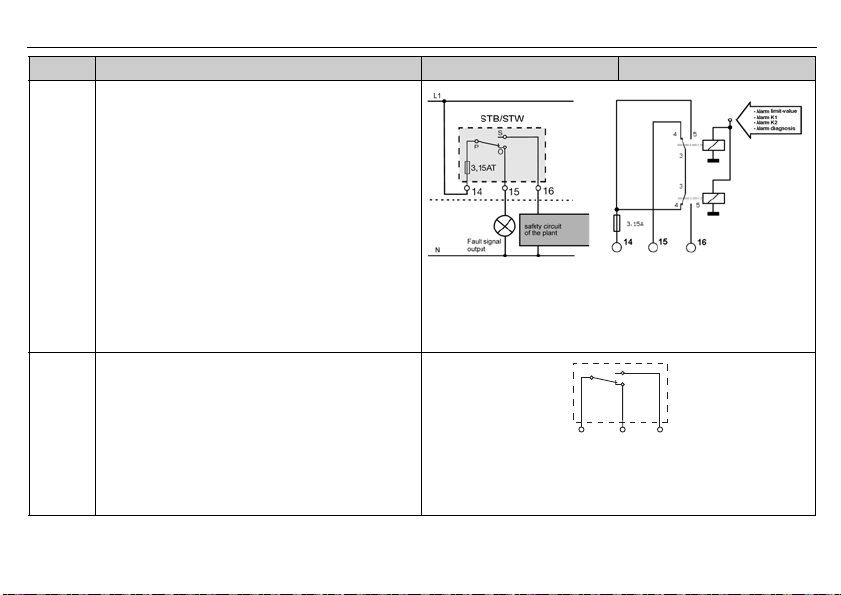

Page 26

2014-05-01

V

Internal

circuitry

S

P

11

12 13

Ö

Legend Remark Screw terminals Screw terminals

10 Relay output "Alarm" (current-free state)

Relay (changeover contact element) with fuse cutout

4 Electrical connection

26

11 Relay output for pre-alarm (KV)

Changeover contact

Caution

The pre-alarm relay output is not part of the

safety function!

Page 27

5 Commissioning the device

H

(1) (2) (3)

(4)

(5)

(6)

(7)

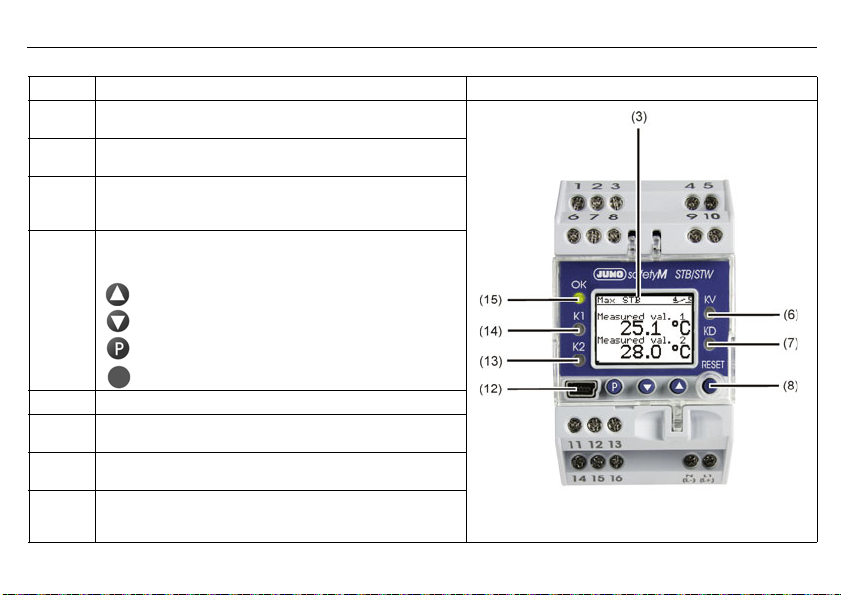

5.1 Display and operating elements

h Connect the voltage supply - a test routine will start during which all LEDS will flash and the display with background light-

ing will indicate white pixels for 2 seconds and black pixels for 2 seconds.

Once the test routine has been completed, the device will indicate the main measured value (factory set).

v If an alarm or error message appears, refer to Chapter 10 "Alarm messages".

5.2 Setting the display after switch-on

v Chapter 7.6.4 "Normal display"

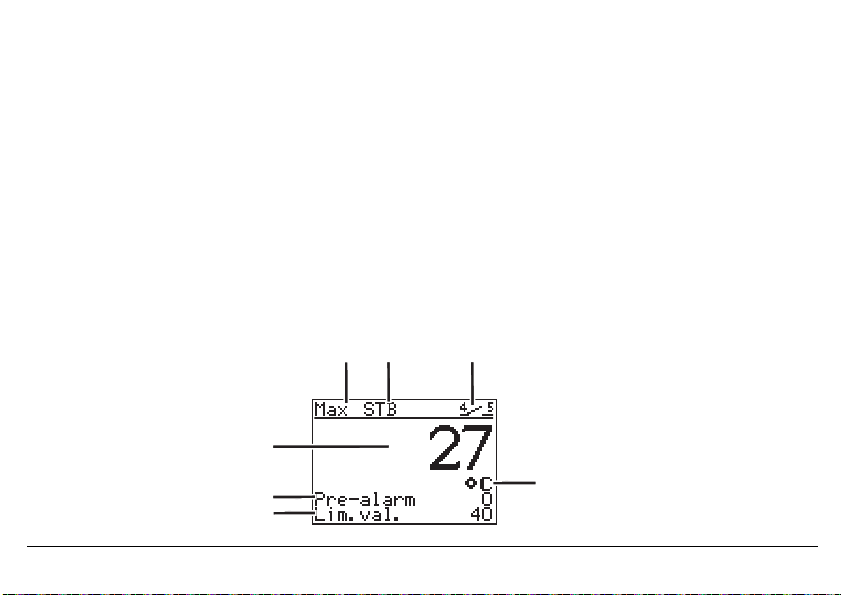

The screen is factory set to show the main measured value in German. The example shows the screen layout of a safety temperature limiter monitoring a maximum value of 29.6°C with a pre-alarm set to 9.9°C.

If the main measured value is within the hysteresis during "Power ON", the relay outputs "Pre-alarm" and "Alarm"

are deactivated.

1 Switching behavior 2 Device function

3 Binary input

7 Main measured value

6 Pre-alarm 4 Temperature unit

5 Limit value

2014-05-01

5 Commissioning the device

27

Page 28

2014-05-01

Legend Remark

3LCD display

6 LED KV (yellow)

7 LED KD (yellow)

8Keys

12 Setup interface

13 LED K2 (red)

14 LED K1 (red)

15 LED OK

Black and white with background lighting 96 x 64 pixels

Is lit if the pre-alarm was triggered.

Is lit if the diagnosis processor has switched off a component.

(Can only be operated when the transparent hood is folded up)

Increase value / previous parameter

Reduce value / next parameter

Programming

RESET

Is lit for all errors.

Is lit for all errors.

Green: OK range

OFF: Error occurred

5 Commissioning the device

28

Page 29

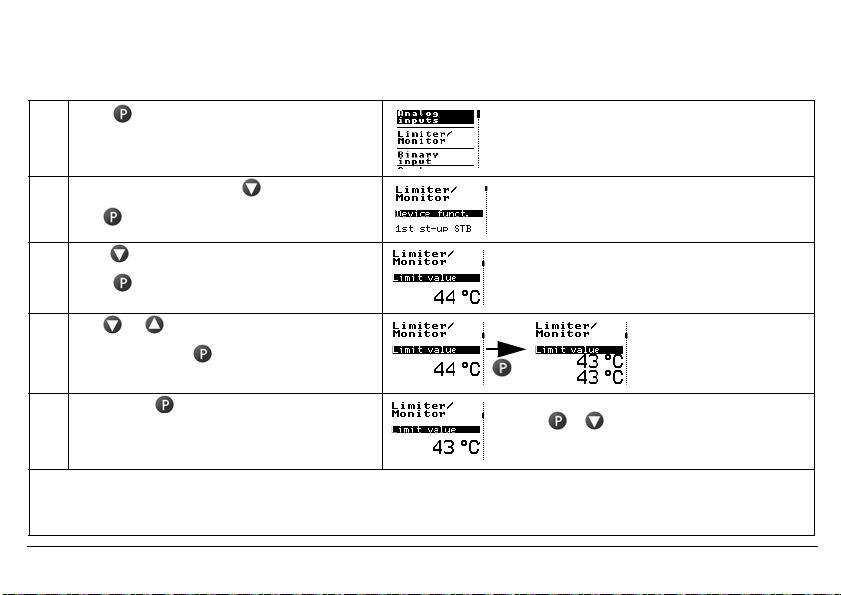

5.3 Selecting and editing parameters (plausibility inquiry for input values)

The values are displayed in the standard display.

Carry out steps 1 to 4 to edit a value, e.g. in this case, the limit value

1 Press The first menu item "Analog inputs" has a black

2 Select limiter/monitor with

Use to change to the submenu

3 Press 2x until the limit value appears

Press (limit value flashes)

background. The vertical line on the right shows

the current position.

4 Use or to set the desired value

Acknowledge with

(limit value is shown in duplicate)

5 Briefly press to confirm the value.

The value is applied and saved.

If no key is pressed, the device automatically returns to the standard display after 30 seconds (timeout) and the value

H

is not saved. The length of the timeout is configurable.

Use + to return to the standard display

or menu topic "Back" or

return automatically after a timeout

Limit value flashes in duplicate on the display as a

control.

v see operating overview on the first inner page of this manual.

2014-05-01

5 Commissioning the device

29

Page 30

2014-05-01

5 Commissioning the device

30

5.4 Aborting edit

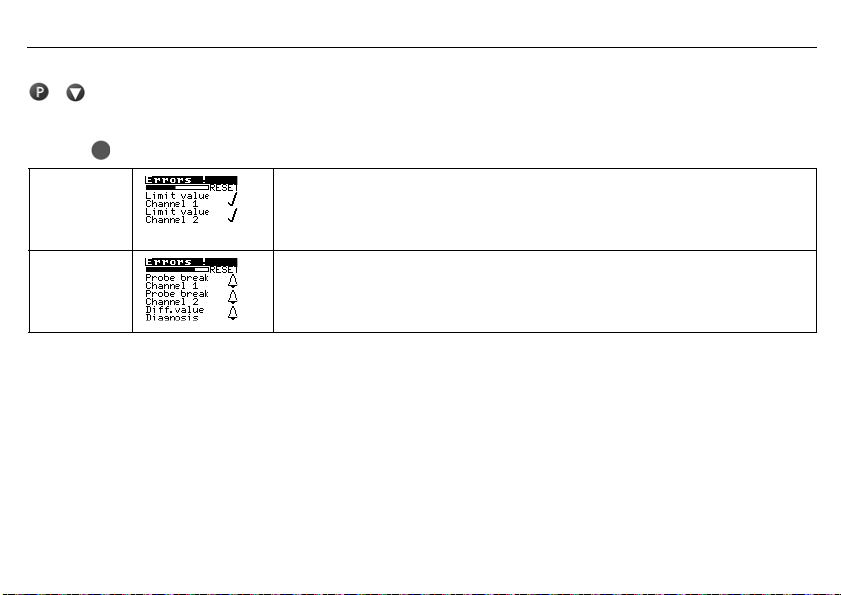

+ are used to abort editing and retain the previous value.

5.5 Alarm acknowledgement using the Reset key (only for temperature limiters STB)

h Press key and hold down

Ticks appear

after the errors

A bell is

shown after

the error.

The alarm is no longer pending and is acknowledged as soon as the time bar has finished (3 seconds).

The alarm condition is still pending and cannot be acknowledged.

5.6 Alarm acknowledgement via binary input (only for temperature limiters STB)

The binary input can be configured so that, for example, alarms can be unlocked via a potential-free contact.

The function only reacts to the switching flank from the "open" to the "closed" state.

The contact then behaves in the same way as the "Reset" button.

v Chapter 7.4.1 "Function"

Page 31

5.7 Lead sealing the device

The device settings must not change under operating conditions.

A lead-sealed, transparent cover must therefore be placed over it to prevent unintentional or unauthorized adjustment.

Two holes are provided to the left and right of the transparent cover through which wire

can be guided for lead sealing to connect the cover to the housing. The wire ends are

secured with the lead seal.

2014-05-01

5 Commissioning the device

31

Page 32

2014-05-01

6 Safety Manual

32

6 Safety Manual

6.1 Brief description

The safety temperature limiter (STB) and safety temperature monitor (STW) enable early and reliable detection of risks which

could potentially result in personal injuries, environmental damage, or destruction of the production plant and production materials.

Its task is to reliably monitor process variables such as temperature or pressure and to switch the plants to an operationally

safe status in the event of malfunctions.

The measured value at the analog input can be recorded by various probes or standard signals.

Even when using double sensors (1oo2) only one physical measuring point is monitored at the measuring point.

Limit value exceedance is indicated by the installed LED K1 and K2 (red) for each channel and the integrated alarm relay

switches the system to safe operating status (alarm range).

The SIL3 requirements of DIN EN 61508 or PLe DIN EN ISO 13849 are met by a device concept that has a 1oo2D structure

which ensures reliable detection of errors.

6.2 Safety temperature monitor (STW)

The safety temperature monitor is a device that is automatically reset when activated once the sensor temperature has fallen

below or risen above the set limit value by an amount equal to the switching differential. Possible settings: monitoring for limit

value overrange or underrange.

Mode of operations:

- Minimum requirements: 2B, 2K, 2P

- Additional requirements: 2N, 2D

6.2.1 Safe operating status STW

The safe status is when the relay output alarm between terminals 14 and 16 is switched off (closed-circuit principle).

Page 33

6.3 Safety temperature limiter (STB)

The safety temperature limiter is a device that is permanently locked after responding.

Manual reset using the key is possible once the probe temperature has fallen below / has exceeded the limit value by the

amount of the switching differential. Possible settings: monitoring for overrange or underrange.

Mode of operations:

- Minimum requirements: 2B, 2J, 2V, 2K, 2P and adjustable with special tools

- Additional requirements: 2N, 2F, 2D

6.3.1 Safe operating status STB

The safe status is when the relay output alarm between terminals 14 and 16 is switched off (closed-circuit principle).

This status is maintained until manual unlocking is performed in the valid range of the device.

The transparent, sealable protective cover prevents unauthorized operation.

The key for manual unlocking can be accessed with the aid of a tool.

6.4 Relevant standards

Failure of the devices could affect the safety of persons and/or the safety of the environment.

Certification to IEC 61 508 is provided because of the worldwide use of these systems.

The temperature monitoring unit type 701150 with extra code "058" meets the requirements

- For safety function to SIL3 according to DIN EN 61 508 parts 1 to 7:

Functional Safety - Safety Related Electrical /Electronic / Programmable Electronic Systems

- DIN EN 61 511 Parts 1 to 3:

Functional Safety - Safety-Related Systems for the Process Industry

- DIN EN 14 597:2005-12:

Temperature Regulation Equipment and Temperature Limiter for Heat-Generating Systems

- DIN EN 60 730-2-9:

2014-05-01

6 Safety Manual

33

Page 34

2014-05-01

Automatic Electrical Control and Regulating Devices for Household Use and Similar Applications Parts 2-9: Special Requirements for Temperature-Dependent Control and Regulating Devices

- EN 61 326

- DIN EN ISO 13849-1 PLe

- UL 60730-2-9

- According to the Pressure Equipment Directive

6 Safety Manual

6.5 Validity of the Safety Manual

34

H

The evaluation described in this Safety Manual in terms of functional safety and display of certificates applies to

the specified versions of temperature monitoring units including sensor versions.

Specifications that do not take the sensor system into consideration is identified as such.

6.6 Connection possibilities of the sensors (SIL)

The JUMO safetyM STB/STW 701150 evaluation device structure is basically identical. Various possibilities to connect the

sensors are available. These possibilities are listed in the following table along with the achievable SIL level:

Page 35

Variant Connected sensors

1 1 × Pt100 in 2-wire circuit

1a 2x Pt100/1000 2-wire circuit 1oo2 1oo2D SIL3

2 2x Pt100/1000 3-wire circuit 1oo2 1oo2D SIL3

3 2x thermocouple 1oo2 1oo2D SIL3

4 1x Pt100/1000

5 STB/STW 701150 without

Important information:

Variants 1 to 4 were evaluated with JUMO probes according to data sheets 901006 and 902006. For variant 5 no sensor system was taken into account. In this case, the user selects the sensor system. For this reason, the user is responsible for evaluating the achievable SIL.

If the used SIL-capable sensor consists of hardware and software (e.g. transmitter), the maximum SIL that can be achieved –

irrespective of the architecture – is the one according to which the sensor software was developed (so, for example, if the sensor software has SIL2, the max. achievable SIL is 2).

individual sensor

2-wire and 3-wire circuit

1x thermocouple

sensor system 1oo2D architecture.

No probe or use 4 to 20 mA

(means that the sensor is not

taken into account for the calculation).

Sensor

system

architecture

1oo1 1oo2D SIL2

1oo2 1oo2D SIL3

Sensors connected by the

system user

Architecture

acc. to connection 1oo1

or 1oo2

Logic

architectureAchievable SIL

1oo2D SIL of the used

sensor (HW only)

SIL1 SIL1 SIL2

SIL2 SIL2 SIL3

SIL3 SIL3 SIL3

Max. achievable

SIL of the system

with 1oo1 sensor

system architecture

Max. achievable

SIL of the system with 1oo2

sensor system

architecture

2014-05-01

6 Safety Manual

35

Page 36

2014-05-01

The possibility to connect passive sensors such as double thermocouples, Pt100 sensors, or Pt1000 sensors means that the

sensors do not necessarily require a SIL qualification. In this case, the specification of the failure rates for the passive sensors

is sufficient for the SIL qualification of the overall system. The user of the system must always determine the PFD

PFH value of the overall safety chain to evaluate the achieved SIL

Requirements regarding proof-check interval and lifetime apply only in terms of functional safety.

Requirements as specified by DIN EN 14 597 are defined in the Operating Manual B 701150 and are independent of the re-

quirements of this Safety Manual.

Temperature probe

Admissible measuring ranges must be observed for devices with approval according to DIN EN 14 597 and SIL certification. If

other temperature probes than those described by JUMO data sheets 901006 and 902006 are used, their registration and suitability for use must be verified.

6 Safety Manual

36

and/or

avg

Page 37

6.7 Standards and definitions

6.7.1 Terms and abbreviations acc. to DIN EN 14597

Abbreviation Explanation

Type 2 Mode of operation for which the manufacturing variation and migration of the operating value, operat-

Type B Micro disconnection in operation, corresponding contact disconnection at at least one pole to

Type D A free trip mechanism that also cannot be closed temporarily for as long as the error persists.

Type F (STB) A mode of operation in which, after the RS has been installed, it can only be reset with the aid of a tool.

Type J (STB) A free trip mechanism with contacts that cannot be prevented from opening and which may not func-

Type K A probe mode of operation in which a probe break or a disconnection between the probe head and the

Type N A mode of operation in which the operating value does not increase as a result of a leak in the probe or

Type V (STB) A lockout that can only be reactivated through a manual reset.

Type P A mode of operation that is effective following a specified test through a change in temperature, as

ing duration, or operating procedure has been checked.

provide functional reliability.

tion as an automatically resetting RS if the means of resetting is held in the "Reset" or "On" position.

switching head does not cause the operating value to increase.

in the parts that connect the probe and switching head. This mode is intended for use with electrical error models.

specified in 17.101 of DIN EN 60730-2-9.

2014-05-01

6 Safety Manual

37

Page 38

2014-05-01

6 Safety Manual

38

6.7.2 Terms and abbreviations acc. to DIN EN 61 508 and DIN EN 61 511.

Name Description

Actuator Part of a safety-related system that intervenes in the process to achieve a safe state.

EUC EUC (equipment under control)

E / E / PE Electrical/electronic/programmable electronic (E/E/EP):

Failure End of the ability of a functional unit to perform a required function.

Diagnostic coverage Partial reduction in the probability of dangerous hardware failures due to the use of

Errors A non-normal condition that can cause a reduction or the loss of the ability of a

Functional safety A part of overall safety related to the EUC and EUC control system that depends on the

Functional unit Unit consisting of hardware or software or both that is suitable for performing a

Dangerous failure A failure with the potential of placing the safety-related system in a dangerous state or a

Safe failure A failure without the potential of placing the safety-related system in a dangerous state

Hazard Potential source of damage

Security Absence of unjustifiable risks

Equipment, machine, apparatus, or system used for manufacturing, shaping materials,

for transport, medical purposes, or other activities.

based on electrical (E) and/or electronic (E) and/or programmable electronic (PE)

technology

automatic diagnostic tests.

functional unit to perform a required function.

correct function of the E/E/EP safety-relevant system, safety-relevant systems of other

technology, and external equipment for risk reduction.

specified task.

state without functional capability.

or state without functional capability.

Page 39

Name Description

Safety function A function that is performed by an E / E / PE safety-related system, safety-related

Safety integrity The probability that a safety-related system will perform the required safety function

Safety Integrity Level (SIL) One of four discrete levels for specifying the requirement for safety integrity of the

Safety-related system A system that

Safety Instrument System (SIS) Safety instrumented system to perform one or more safety-related functions. A SIS

λ Failure rate per hour

Lambda:

Lambda dangerous:

Δangerous Δetect: λ

Lambda

Δangerous Υndetect: λ

Lambda

λ

Lambda:

λ

Lambda:

λ

D

S

SD

system based on some other technology, or external equipment for reducing risk with

the goal of achieving or maintaining a safe state for the EUC taking into consideration a

specified dangerous event.

under all specified conditions within a specified period of time according to

requirements.

safety functions assigned to the E/E/PE safety related system. Safety Integrity Level 4

represents the highest level of safety integrity, while Safety Integrity Level 1 represents

the lowest.

- performs necessary safety functions that are required to reach or maintain a safe state

for the EUC and

- is designed by itself or with other E / E / PE safety-related systems of other

technology or external equipment for risk reduction to achieve the necessary safety

integrity for the required safety functions.

consists of sensor(s), logic system, and actuator(s).

Rate of dangerous failures per hour

Rate of detected dangerous failures per hour

DD

Rate of undetected dangerous failures per hour

DU

Rate of safe failures per hour

Rate of detected safe failures per hour

2014-05-01

6 Safety Manual

39

Page 40

2014-05-01

Name Description

Lambda:

λ

SU

BPCS Basic Process Control System

DC Diagnostic Coverage

FIT Failures In Time (1x10

HFT Hardware Fault Tolerance

PFD Probability of Failure on Demand

PFD

avg

MooN Architecture with M from N channels

MTBF Mean Time Between Failures

MTTR Mean Time To Repair

SFF Safe Failure Fraction

SIL Safety Integrity Level

Rate of undetected safe failures per hour

-9

per h)

Average Probability of Failure on Demand

6 Safety Manual

40

Page 41

6.8 Safety instrumented parameters related to the temperature monitoring unit

The following parameters were calculated by means of an FMEDA component under the following conditions:

- Error models corresponding to requirements of DIN EN 61508 for conformity with SIL2 or SIL3

- Failure rate of components according to the RDF 2000 UTE C 80-810 standard and SN 29500

- Sensors were combined as a subsystem in the following five variants:

6.8.1 Failure rates and SFF for 701150...23 (AC 230 V)

λ

Variant

[Fit]

s

1 865.21 306.24 32.31 96 % 4.56 e

1a 865.21 306.24 32.31 96 % 1.05 e

2 868.17 303.28 32.31 96 % 1.05 e

3 881.62 326.78 33.62 96 % 1.03 e

4 887.68 343.82 35.52 96 % 1.22 e

5 881.02 313.43 35.57 96 % 1.04 e

λ

[Fit]

dd

λ

[Fit]

dd

SFF PFH (1/h)

PFD

avg

-9

-9

-9

-9

-9

-9

2.02 e

4.57 e

4.57 e

4.49 e

5.30 e

4.48 e

-4

-5

-5

-5

-5

-5

Important information:

Variants 1 to 4 were evaluated with JUMO probes according to data sheets 901006 and 902006.

For variant 5 no sensor system was taken into account.

In this case, the user selects the sensor system.

2014-05-01

6 Safety Manual

41

Page 42

2014-05-01

6.8.2 Failure rates and SFF for 701150...25 (AC/DC 24 V)

6 Safety Manual

42

Variant

λ

[Fit]

s

λ

[Fit]

dd

λ

[Fit]

dd

SFF

1 799.3 306.32 33.61 96 % 6.59 e-92.91 e

1a 799.3 306.32 33.61 96 % 3.07 e-91.35 e

2 802.26 303.36 33.61 96 % 3.07 e-91.35 e

3 827.25 324.71 37.91 96 % 3.13 e-91.37 e

4 833.31 341.75 39.81 96 % 3.23 e-91.41 e

5 818.96 323.07 36.26 96 % 3.05 e-91.33 e

PFH (1/h)

PFD

avg

-4

-4

-4

-4

-4

-4

Important information:

Variants 1 to 4 were evaluated with JUMO probes according to data sheets 901006 and 902006.

For variant 5 no sensor system was taken into account.

In this case, the user selects the sensor system.

The PFH and PFD

thermore, the calculation was based on a lifetime of 10 years (T

ing to the tables of DIN EN 61508 for sensor systems and logic.

values were calculated with the assumption that the time to restore the system is 8 h (MTTR = 72 h). Fur-

avg

= 10 y). The Common Cause Factor was determined accord-

1

Page 43

6.9 Determining the Safety Integrity Level (SIL)

The achievable Safety Integrity Level is determined by the following safety-related parameters:

- Average probability of dangerous failures of a safety function on demand (PFD

- Hardware Fault Tolerance (HFT) and

- Safe Failure Fraction (SFF).

The specific safety-related parameters for the 701150 measuring system may be found in the table of the "Safety-related parameters" chapter.

The following table shows how the "Safety Integrity Level" (SIL) depends on the "average probability of dangerous failures of a

safety function of the entire safety-related system" (PFD

ered, i. e. the demand rate for the safety-related system averages once a year.

) according to DIN EN 61 508. The "low demand mode" is consid-

avg

Table High Demand PFH

Safety Integrity Level

(SIL)

4

3 ≥10

2 ≥10

1 ≥10

Operating mode with high demand rate

PFH (high demand mode)

≥10

-9

-8

-7

-6

to <10

to <10

to <10

to <10

-8

-7

-6

-5

avg

),

2014-05-01

6 Safety Manual

43

Page 44

2014-05-01

Table Low Demand PFD

Safety Integrity Level

(SIL)

4

3 ≥10

2 ≥10

1 ≥10

Operating mode with low demand rate

(low demand mode)

PFD

av

-5

≥10

-4

-3

-2

to <10

to <10

to <10

to <10

-4

-3

-2

-1

6 Safety Manual

44

The sensor, logic unit, and actuator together form a safety-related system that performs a safety function. The "average probability of dangerous failures of the entire safety-related system" (PFD

tuator subsystems according to the following diagram.

Typical subdivision of the "average probability of dangerous failures of a safety function on demand" (PFD

The specifications related to functional safety in this Safety Manual include sensor systems (resistance temperature sensors,

thermocouples), logic unit (701150), and (as signal contact) the relay output in the 701150 system.

) is usually divided up into the sensor, logic unit, and ac-

avg

) into subsystems

avg

The actuator (for example a power contactor) is system-related and must be taken into consideration separately according to

the standard for the safety loop.

Page 45

6.9.1 Safety integrity of the hardware

According to DIN EN 61 508, a distinction must be made between systems of type A and systems of type B.

A subsystem can be considered to be type A if, for the components required to achieve the safety function,

- the failure behavior of all components used is sufficiently defined; and

- the behavior of the subsystem can be fully determined under failure conditions; and

- reliable failure data from experience in the field exists for the subsystem to show that the assumed failure rates for detected

and undetected dangerous failures are achieved.

A subsystem can be considered to be type B if, for the components required to achieve the safety function,

- the failure behavior of at least one of the components used is not sufficiently defined; or

- the behavior of the subsystem cannot be fully determined under failure conditions; or

- no sufficiently reliable failure data from experience in the field exists for the subsystem to support the utilized failure rates

for detected and undetected dangerous failures.

The 701150 temperature monitoring unit corresponds to a type B system.

The following table shows the achievable Safety Integrity Level (SIL) in dependency on the proportion of non-dangerous failures (SFF) and the hardware fault tolerance (HFT) for safety-related type B subsystems.

For 701150 the following table applies:

Safe Failure Fraction (SFF) Hardware fault tolerance (HFT) for type B

012

<60 % Not allowed SIL1 SIL2

60 to <90 % SIL1 SIL2 SIL3

90 to <99% SIL2 SIL3 SIL4

≥99 % SIL3 SIL4 SIL4

2014-05-01

6 Safety Manual

45

Page 46

2014-05-01

6 Safety Manual

46

6.9.2 Safety-relevant system properties

Device versions differ in the following architectures:

The evaluation unit from 701150 in STW, STB versions is implemented as 1oo2D architecture.

The types with an individual sensor are executed in one-channel sensor systems (1oo1).

These are monitored:

- Probe break in the sensor system subsystem

- Probe short circuit in the sensor system subsystem

- Random hardware failure in one channel

The variants with two sensors are consistently structured with two channels.

The two subsystems have to be galvanically isolated from each other.

These are monitored:

- Probe break sensor system subsystem

- Probe short circuit in the sensor system subsystem

- Reverse polarity of the probes

- Random hardware failure in one channel

Systems have a lifetime of ten years.

The proof check for SIL2 and SIL3 certified systems is also ten years.

If the temperature is above/below the permissible limits, the system switches to the safe state without delay. Premature switch-

ing is admissible if a malfunction is detected.

Page 47

Safety feature Requirement / comment

SIL

The sensor system is included in the

SIL evaluation.

Operating mode concerning

safety function

SIL2 SIL3

Operating mode with lower and higher demand rate possible on a customer-specific

basis

Safety-critical inputs Temperature sensor inputs 4 to 20 mA current loop

Safety-relevant inputs Setup and parameterization

Safety-critical output Alarm contact limit value

Subsystem type Type B

Safety architecture (logic unit JUMO

STB/STW 701150)

Safety architecture (sensor system) SIL2

Hardware error tolerance (logic unit

JUMO STB/STW 70.1150)

Hardware error tolerance (sensor system)

Proportion of safe errors SIL2 sensor system HFT=0: 90 % to < 99 % SIL3 sensor system HFT=1:

CCF Calculation according to DIN EN 61508 Part 7 Appendix D and/or DIN EN ISO 13849-

Average failure probability of a safety

function on demand (overall system)

1oo2D

1oo1

SIL3

1oo2

HFT=1

SIL2: HFT=0 SIL3: HFT=1

90 % to <99 %

1 Table F.1 min. 65 %

SIL2:

Low demand: PFD

High demand: PFH < 10

avg

< 10

-2

-6

SIL3:

Low demand: PFD

High demand: PFH < 10

avg

< 10

-7

-3

Interval for repeat test No repeat test

2014-05-01

6 Safety Manual

47

Page 48

2014-05-01

H

Safety feature Requirement / comment

Planned operating duration 10 years

Architecture according to DIN EN ISO

13849-1

MTTF

-DC

according to DIN EN

d

ISO 13849-1 table K.1

Mode of operation and software

class according to DIN EN 14597

avg

Sensor system, one-channel: Cat. 2 Sensor system, two-channel: Cat. 3

PL d: ≥ 62 years DC

JUMO STB/STW 701150 possesses the following mode of operations

2B, 2D, 2F, 2K, 2J, 2V, 2N, 2P software class C

avg

6 Safety Manual

≥ 60 % PL e: ≥ 62 years DC

avg

48

≥ 90 %

6.10 Determining the achieved Performance Level PL

The following safety-related parameters are required to determine the Performance Level of components/devices:

As further parameters to be observed, operational aspects such as the demand rate and/or the test rate of the safety function

can also influence the resulting PL.

Excerpt from DIN EN ISO 13849-1:2008-12

This excerpt contains references to the complete standard DIN EN ISO 13849-1:2008-12, which are therefore not

reproduced in this chapter.

6.10.1 Terms and abbreviations acc. to DIN EN ISO 13849

Formula symbol or

abbreviation

PL (a, b, c, d, e) Description for the Performance Level Table 3

Description Definition

or location

Page 49

Formula symbol or

abbreviation

Description Definition

or location

AOPD Active Opto-Electronic Protective Device (e.g. light barrier) Appendix H

B, 1, 2, 3, 4 Description for the categories Table 7

B

Number of cycles in which a dangerous failure occurred in 10 % of a random

10d

sample of the observed pneumatic or electromechanical components that are

subject to wear (mean time to dangerous failure)

Appendix C

Cat. Category 3.1.2

CC Current converter Appendix I

CCF Common Cause Failure 3.1.6

DC Diagnostic Coverage 3.1.26

DC

avg

Average diagnostic coverage E.2

F, F1, F2 Frequency and/or duration of the exposure to danger A.2.2

FB Function block 4.6.3

FVL Programming language with unlimited language range 3.1.35

FMEA Failure Modes and Effects Analysis 7.2

I, I1, I2 Input device, e.g. sensor 6.2

i, j Index for counting Appendix D

I/O Inputs/outputs Table E.1

i

, i

ab

bc

Fasteners Image 4

K1A, K1B Contactors Appendix I

L, L1, L2 Logic 6.2

LVL Programming language with limited language range 3.1.34

2014-05-01

6 Safety Manual

49

Page 50

2014-05-01

6 Safety Manual

50

Formula symbol or

abbreviation

Description Definition

or location

M Motor Appendix I

MTTF Mean Time To Failure Appendix C

MTTF

MTTF

n, N, N

N

low

c

d

Mean time to critical failure 3.1.25

Mean time to dangerous failure

Number of units 6.3, D.1

Number of SRP/CS with PL

in an SRP/CS combination 6.3

low

O, O1, O2, OTE Output device, e.g. drive unit 6.2

P, P1, P2 Possibility of avoiding the danger A.2.3

PES Programmable electronic system 3.1.22

PL Performance Level 3.1.23

PLC Programmable Logic Controller Appendix I

PL

PL

r

low

f

a

Lowest Performance Level of a SRP/CS in an SRP/CS combination 6.3

Required Performance Level 3.1.24

Demand rate 3.1.30

RS Rotary encoder Appendix I

S, S1, S2 Severity of violation A.2.1

SW1A, SW1B, SW1 Position switch Appendix I

SIL Safety Integrity Level Table 4

SK (Cat.) Category (B, 1, 2, 3, 4), structure as basis to achieve a certain PL

SRASW Safety-Related Application Software 4.6.3

Page 51

Formula symbol or

abbreviation

SRESW Safety-Related Embedded Software 4.6.2

SRP Safety-Related Part General

SRP/CS Safety-Related Part of (a) Control System(s) 3.1.1

Sub-PL/Sub-SIL PL or SIL at subsystem level. A subsystem a system that – based on a subtask –

TE Test facilities 6.2

T

M

T

Functional life, designated Mission Time

M

T

10d-value

Description Definition

already adequately performs a safety function (for example, an input module that

reliably records the inputs).

Functional life 3.1.28

Reference value for a preventative exchange (10 % of the B10d value). At this val-

ue, a dangerous failure has already occurred for approx. 63 % of all components.

In this case, the standard DIN EN ISO 13849-1:12006 recommends replacement.

or location

6.11 Connection possibilities of the sensors (PL)

The JUMO safetyM STB/STW 701150 evaluation device structure is basically identical.

Various possibilities to connect the sensors are available. These possibilities are listed in the following table along with the

achievable PL level:

2014-05-01

6 Safety Manual

51

Page 52

2014-05-01

6 Safety Manual

52

Variant Connected sensors

1 1 × Pt100 in 2-wire circuit

1a 2x Pt100/1000 2-wire circuit 1oo2 1oo2D PLe

2 2x Pt100/1000 3-wire circuit 1oo2 1oo2D PLe

3 2x thermocouple 1oo2 1oo2D PLe

4 1x Pt100/1000

5 STB/STW 701150 without

Important information:

Variants 1 to 4 were evaluated with JUMO probes according to data sheets 901006 and 902006. For variant 5 no sensor system was taken into account. In this case, the user selects the sensor system. For this reason, the user is responsible for evaluating the achievable PL.

individual sensor

2-wire and 3-wire circuit

1x thermocouple

sensor system 1oo2D architecture.

No probe or use 4 to 20 mA.

(means that the sensor is not

taken into account for the calculation).

Sensor

system

architecture

1oo1 1oo2D PLd

1oo2 1oo2D PLe

Sensors connected by the

system user

Architecture

acc. to connection 1oo1

or 1oo2

Logic

architectureAchievable PL

1oo2D PL of the used

sensor

PLb PLd PLe

PLc PLd PLe

PLd PLd PLe

PLe PLe PLe

Max. achievable

PL of the system

with 1oo1 sensor

system architecture

≥ 90 %

DC

701150

Max. achievable

PL of the system

with 1oo2 sensor system architecture

≥ 90

DC

701150

%

Page 53

6.11.1 Calculations DIN EN ISO 13849-1 Performance Level - low voltage 230 V

Variant

MTTF

d

1 100 years

1a 100 years

2 100 years

3 100 years

4 100 years

5 100 years

3

(337 years) 90 % 80 PLd

3

(337 years) 90 % 80 PLe

3

(340 years) 90 % 80 PLe

3

(317 years) 91 % 80 PLe

3

(313 years) 91 % 80 PLe

3

(327 years) 91 % 80 See above table

DC

avg

CCF PL

6.11.2 Calculations DIN EN ISO 13849-1 Performance Level - extra low voltage (ELV) 24 V

Variant

1 100 years

1a 100 years

2 100 years

3 100 years

4 100 years

MTTF

d

3

(336 years) 90 % 80 PLd

3

(336 years) 90 % 80 PLe

3

(339 years) 90 % 80 PLe

3

(315 years) 90 % 80 PLe

3

(311 years) 90 % 80 PLe

5 100 years3 (318 years) 90 % 80 See above table

2014-05-01

DC

avg

CCF PL

3. The MTTFd value of a partial system must be

limited to 100 years according to the DIN EN

ISO 13849-1 requirements.

6 Safety Manual

53

Page 54

2014-05-01

6 Safety Manual

54

6.11.3 Contribution to risk minimization through the control system

The objective of compliance with the overall draft procedure for the machine is to achieve the safety objectives (see 4.1). The

draft of the SRP/CS to provide the required risk minimization is an integral part of the overall draft procedure for the machine.

The SRP/CS provides the safety function(s) with a PL that achieves the required risk minimization. Through the provision of

safety functions, either as an inherently safe part of the construction or as the control of a protective guard or protective device,

the design of the SRP/CS is part of the risk minimization strategy. This is an iterative process and is depicted in images 1 and

3.

The features of each safety function (see section 5) and the required Performance Level must be described and documented in

the specification of the safety requirements.

In this part of DIN EN ISO 13849, the Performance Levels are defined in the form of the probability of a dangerous failure per

hour. Five Performance Levels (a to e) are specified with defined areas of the probability of a dangerous failure per hour (see table).

Performance Level (PL) Average probability

a ≥ 10

b ≥ 3 Þ 10-6 to < 10

c ≥ 10-6 to < 3 × 10

d ≥ 10-7 to < 10

e ≥ 10-8 to < 10

of a dangerous failure per hour 1/h

-5

-4

to < 10

-5

-6

-6

-7

NOTE: in addition to the average probability of a dangerous failure per hour, further measures are required to achieve the PL.

Page 55

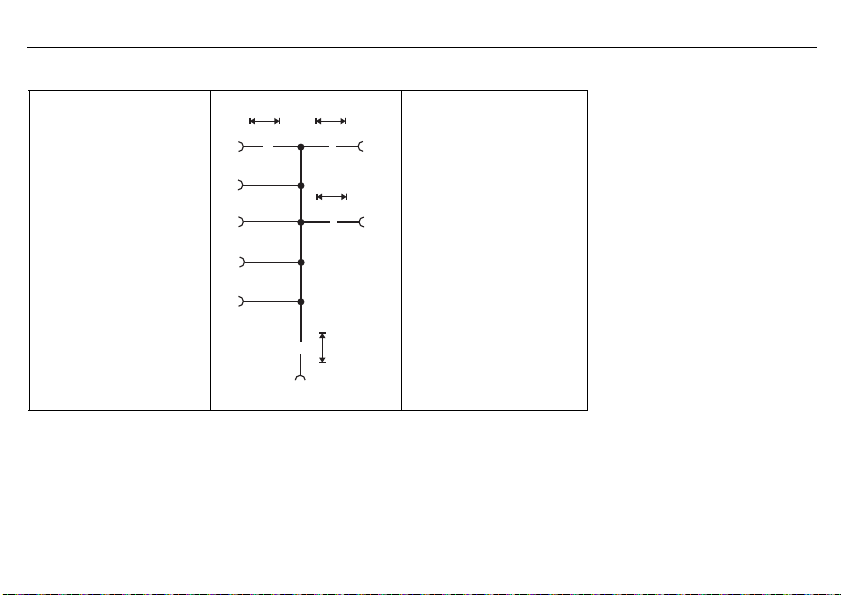

Schematic representation of a combination of safety-related parts of controls for processing a typical safety function

1 2

SRP/CS

a

SRP/CS

b

SRP/CS

c

ILO

i

ab

i

bc

I Input

L Logic

OOutput

1 Start event, e.g. manual actuation of a button, opening of a protective guard,

interruption of the beam of an AOPD

2 Drive unit of the machine, e.g. motor brake

2014-05-01

6 Safety Manual

55

Page 56

2014-05-01

6 Safety Manual

56

6.12 Evaluating the achieved Performance Level PL and the relationship to the SIL

For application in this part of DIN EN ISO 13849, the capability of safety-related parts to perform a safety function is expressed

through the determination of a Performance Level.

The PL must be assessed for each selected SRP/CS and/or SRP/CS combination that performs a safety function. The PL of

the SRP/CS must be determined by assessing the following aspects:

- The MTTF

- The DC (see Appendix E)

- The CCF (see Appendix F)

- The structure (see section 6)

- The behavior of the safety function under failure conditions (see section 6)

- Safety-related software (see 4.6 and Appendix J)

- Systematic failures (see Appendix G)

- The capability to perform a safety function under predictable ambient conditions

value of individual components (see Appendices C and D)

c

The following diagram depicts the procedure for selecting the categories in combination with MTTF

DC

to achieve the required PL for each safety function.

avg

for each channel and the

d

Page 57

Relationship between the categories DC

PL Performance Level

1MTTF

2MTTF

3MTTF

of each channel = low

d

of each channel = medium

d

of each channel = high

d

, MTTFd of each channel and PL

avg

2014-05-01

6 Safety Manual

57

Page 58

2014-05-01

The diagram above shows the different possible combinations for assessing the category with DC

of each channel (bars). The bars in the diagram show the three MTTFd areas of each channel (low, medium and high)

MTTF

d

that can be selected to achieve the required PL.

Before the simplified procedure from the diagram shown is applied (which shows the results of different Markov models on the

basis of intended architectures from section 6), the category of the SRP/CS and the DC

must have been determined (see section 6 and Appendices C to E).

For categories 2, 3, and 4, sufficient measures against failures due to combined failures must be fulfilled (see Appendix F). Taking these parameters into account, the diagram represents a graphical procedure for determining the PL achieved by the SRP/

CS. The combination of category (including failures due to combined failures) and DC

lected in image 5. In accordance with the MTTF

column must be selected.

The vertical position of these areas determines the achieved PL, which can be read off the vertical axis. If the area covers two

or three possible PLs, the achieved PL is specified in table 7. To select the exact PL on the basis of the precise value of the

of each channel, see Appendix K.

MTTF

d

of each channel, one of the three differently hatched areas of the applicable

d

6 Safety Manual

(horizontal axis) and the

avg

and the MTTFd of each channel

avg

determines which column must be se-

avg

58

Page 59

6.13 Other applicable device documentation

For temperature monitoring unit 701150 the measures, values, and requirements specified in this Operating Manual regarding

installation, electrical connection, function, and startup must be observed.

6.14 Behavior during operation and in case of malfunction

Behavior during operation and in case of a malfunction is described in the Operating Manual.

A functional test must be performed after startup, repair in the safety system, or a change in safety-related parameters.

If an error is detected during a functional test, measures must be taken to once again ensure the functional capability of the