Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 605055

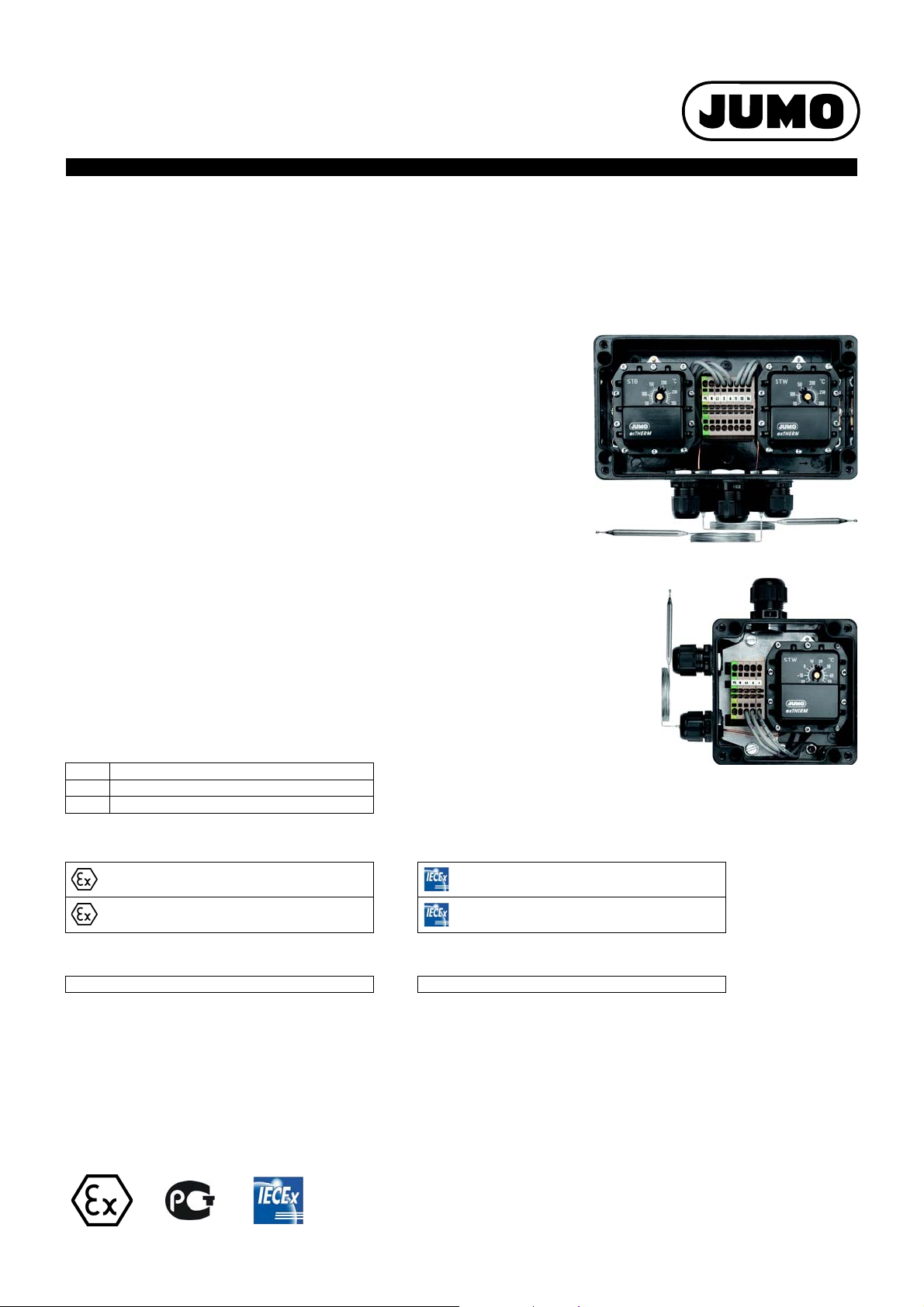

JUMO exTHERM-AT

Type 605055, Explosion-proof surface-mounted thermostat

for zones 1, 2, 21, and 22

Special features

• Single thermostat and double thermostat with capillary or rigid thermowell

• Switching capacity up to 25 A

• Admissible ambient temperatures -55 °C to +70 °C

• Thermowell for use in zone 0 available as an accessory

• Quick and safer electrical connection through Push-In

• Stable switching points through standard ambient temperature compensation

Brief description

The explosion-proof surface-mounted thermostats of the JUMO exTHERM series are built to

monitor and control temperatures in potentially explosive areas. The use in environments with

gas and steam is permitted (zones 1 and 2); use in environments with conductive dust (zones

21 and 22) is also permitted.

®

terminal technology

JUMO exTHERM-AT double thermostat

Page 1/9

The JUMO exTHERM-AT is available as temperature monitor TW, safety temperature monitor

(STW), and safety temperature limiter (STB). The thermostats work according to the liquid expansion or gas expansion principle. The electrical switching element is a pressure-resistant encapsulated thermostat with a snap-action switch. Stable switching points when ambient

temperatures fluctuate are made possible by the standard ambient temperature compensation.

The thermostats of the JUMO exTHERM-AT series are RoHS conform and cadmium free.

Ver sion according to DIN EN 14597:

TW Temperature monitor

STW Safety temperature monitor

STB Safety temperature limiter

ATEX identification IECEx identification

II 2G Ex d e IIC T4/T5/T6 Gb

For explosive gas atmosphere

II 2D Ex tb IIIC T85 °C/T100°C/T130°C Db

For explosive dust atmosphere

2G Ex d e IIC T4/T5/T6 Gb

For explosive gas atmosphere

2D Ex tb IIIC T85 °C/T100 °C/T130°C Db

For explosive dust atmosphere

ATEX confirmation IECEx confirmation

EPS 11 ATEX 1 354 IECEx EPS 13.0046

JUMO exTHERM-AT single thermostat

Approvals/approval marks (see "Technical data")

*

2014-07-15/00576368

* Available with

extra code (TZ 372)

Page 2

Data Sheet 605055 Page 2/9

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Technical data

Switching function

Temperature monitor TW and safety temperature monitor STW

If the temperature on the temperature probe

exceeds the setpoint value, the microswitch is

activated by the transmission mechanics and

the electrical circuit is opened or closed.

If the temperature falls below the selected setpoint value (by the amount of the switching

differential), the microswitch is reset to its initial position.

Temperature compensation

When the ambient temperature on the switching head and the capillary deviates – from the calibration ambient temperature of +22 °C – a switching point offset occurs. This switching point offset is reduced to a minimum due to the temperature compensation.

Case

Material Polyester case, glass fiber reinforced, black (option: stainless steel)

Protection type EN 60529 - IP66 (polyester case), pollution level 2, IP 66 with extra code 861

Setpoint

value adjustment

Switching

head fastening

Weight Approx. 1200 g single thermostat / approx. 2000 g double thermostat

Cable inlet Ex cable gland M20 × 1.5, sealing area 6 to 13 mm

Restart lock for the safety

temperature limiter STB

If the temperature on the temperature probe

exceeds the set limit value, the electrical circuit is opened and the microswitch is mechanically locked.

The microswitch can be manually unlocked

once the dangerous temperature of the setpoint value drops by approx. 20 % of the scale

range.

With screwdriver (once the case lid has been removed)

Using four screws (once the case lid has been removed)

and Ex cable gland M25 × 1.5, sealing area 7 to 17 mm

Self-monitoring for the safety temperature

monitor STW and safety temperature limiter

STB

If the measuring system is destroyed (i.e. if the

expansion fluid escapes) the pressure in the

membrane of the STB and STW drops and

permanently opens the electrical circuit.

Unlocking is then no longer possible.

If the probe has cooled down to a temperature

below approx. 40 °C the electrical circuit also

opens – however it automatically closes again

when the temperature rises.

Process connection

JUMO exTHERM-AT

with capillary

Plain cylindrical probe (standard), rigid thermowell, spiral probe for room thermostat version

Accessories

JUMO exTHERM-AT Multi-section standard thermowells made out of CrNi for use in zones 1, 2, 21, 22 (see data sheet 606710)

Multi-section thermowells made out of CrNi for use in zone separation 0/1, 20/21 (see new data sheet 605057)

Operating data

Medium ambient

temperature influence

deviates from the calibration ambient temperature of +22 °C, a switching point offset occurs.

When the ambient temperature on the switching head and/or the capillary

Higher ambient temperature = lower switching point

Lower ambient temperature = higher switching point

Admissible storage

temperature / admissible ambient tempera-

-40 °C, optionally -55 °C to +70 °C (referring to T4)

ture when in use

Max.

probe temperature

+15 % of the limit value / max. adjustment value or 25 K

Rated position (NL) According to DIN 16257, NL 0 to NL 90

2014-07-15/00576368

Page 3

Data Sheet 605055 Page 3/9

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Electrical data

Max. switching capacity Selectable on the N/C contact (contact deck 1-2):

AC 400 V +10 %, 16 A

AC 230 V +10 %, 16 (2.5) A, cos ϕ = 1 (0.6)*

AC 230 V +10 %, 25 (4) A, cos ϕ =1(0.6)

DC 230 V +10 %, 0.25 A

Selectable on the N/O contact (contact deck 1-4):

TW, STW STB

AC 400 V +10 %, 6.3 A

AC 230 V +10 %, 6.3 (2.5) A, cos ϕ = 1 (0.6)*

AC 230 V +10 %, 2 (0.4) A, cos ϕ =1(0.6)

DC 230 V +10 %, 0.25 A

AC 400V +10%, 2A

AC 230 V +10 %, 2 (0.4) A, cos ϕ =1(0.6)*

AC 230 V +10 %, 2 (0.4) A, cos ϕ =1(0.6)

AC 230 V +10 %, 0.25 A

Snap-action switch, gold-plated AC / DC = 24 V, 0.1 mA

Min. switching capacity To ensure the greatest possible switching reliability we recommend a minimum load of:

AC / DC = 24 V, 100 mA for silver contacts

AC / DC = 10 V, 5 mA for gold-plated contacts

Capillary and temperature probe

Type Capillary∅ 1.5 mm Temperature probe

JUMO exTHERM-AT Stainless steel (CrNi) 1.4571 Stainless steel (CrNi) 1.4571, welded

Capillary length Max. 5000 mm

Capillary bending radius

≥ 5mm

* standard

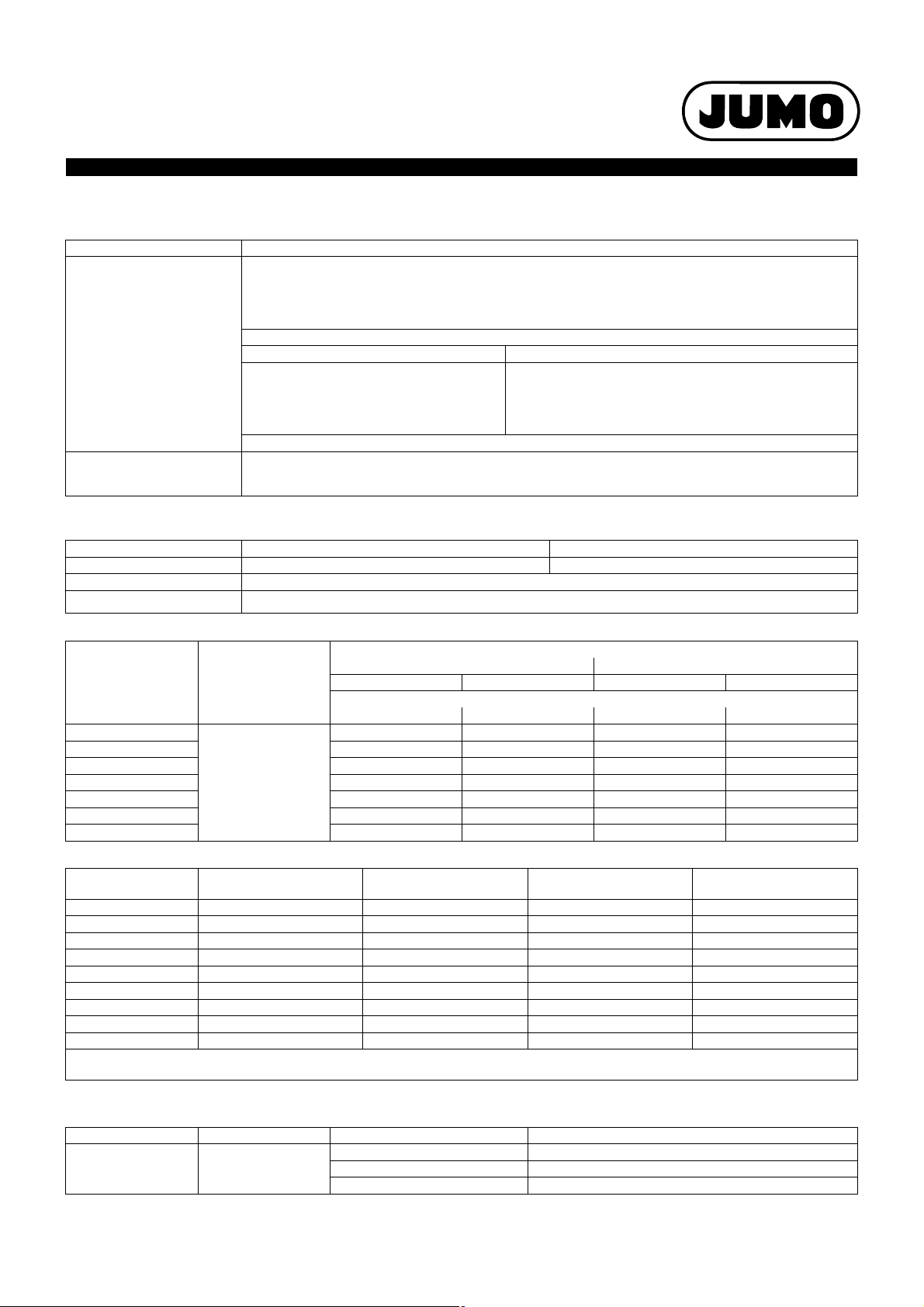

Control ranges and probe table

Control range Max.

capillary length

For "d" = 4 mm For "d" = 6 mm

Probe length "L"

TW STW, STB TW STW, STB

Hysteresis

In °C In mm Approx. 2.5 % Approx. 7 % Approx. 2.5 % Approx. 7 %

-20 to +50

- - - - 138 81

0 to +120 203 113 90 58

0 to +200 154 87 72 48

+130 to +190 - - - - 115 70

5000

+50 to +300 135 78 65 - +20 to +500 - - - - 278 - -

+140 to +500 - - - - - - 126

Switching point tolerance in the middle section of the scale

Control range

in °C

TW

in K

STW upward adjustment

in K

STW downward adjustment

in K

STB

in K

-20 to +40 +2/-2 - - - - - -

-20 to +50 +3/-3 +0/-5 +5/-0 +0/-5

0 to +100 +5/-5 +0/-10 +10/-0 +0/-10

0 to +120 +5/-5 +0/-10 +10/-0 +0/-10

+130 to +190 +8/-8 +0/-16 +16/-0 +0/-16

0 to +200 +8/-8 +0/-16 +16/-0 +0/-16

+50 to +300 +12/-12 +0/-24 +24/-0 +0/-24

+20 to +500 +22/-22 - - - - - -

+140 to +500 +22/-22 +0/-44 +44/-0 +0/-44

Temperature monitors (TW) and safety temperature monitors (STW) are adjusted ascendingly in the middle section of the scale as standard

procedure. Safety temperature limiters (STB) are adjusted in the upper section of the scale. Special adjustments are possible upon request.

Approvals/approval marks

JUMO exTHERM-AT Switching function Certificates/test confirmations Tests

TW EPS 11 ATEX 1 354 ATEX

STW IECEx EPS 13.0046 IECEx TZ 372

STB POCC DE.ME92.B02680 GOST

2014-07-15/00576368

Page 4

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Wiring diagrams

122

120

34

L

37

90

106

82

6,3

Ø

d

M25x1,5

M20x1,5

JUMO exTHERM-AT

Dimensions

JUMO exTHERM-AT

(Examples)

Single thermostat

Data Sheet 605055 Page 4/9

= upward adjustment

= downward adjustment

TW / STW STB STB TW STW

2014-07-15/00576368

Page 5

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Dimensions

220

120

L

d

90

34

37

6,3

Ø

82

204

M20x1,5

M25x1,5

45

27

39

90

24

122

38

120

≈ 31

56

≈ 34

≈ 93

M16x1.5

M20x1.5

Ø 56

JUMO exTHERM-AT

(Examples)

Double thermostat

Data Sheet 605055 Page 5/9

Room thermostat

2014-07-15/00576368

Page 6

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Dimensions

28

45

122

120

37~

34~

12

35

90

147~

S

D

G

L1

M 25 x 1,5

M 20 x 1,5

JUMO exTHERM-AT

(Examples)

Thermostat with rigid thermowell (process connection

74)

Thermowells can be ordered

separately according to data

sheet 605057 (with Exapproval) or data

sheet 606710 (standard)

Data Sheet 605055 Page 6/9

Thermostat with sleeve and

heat sink, limit value > 150 °C

2014-07-15/00576368

Page 7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Dimensions

45

47

90

150~

16

G3/4

16Ø

S

220

120

37~

34~

4040

M20x1,5

M20x1,5

M25x1,5

JUMO exTHERM-AT

(Examples)

Double thermostat with sleeve

(process connection 74)

Thermowells can be ordered

separately according to data

sheet 605057 (with Ex approval) or data sheet 606710

(standard)

Data Sheet 605055 Page 7/9

Double thermostat

with sleeve and heat sink, limit

value > 150 to 300 °C

2014-07-15/00576368

Page 8

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details

Explosion-proof panel-mounted thermostat JUMO exTHERM-AT

Order code (1) Basic type

605055 Surface-mounted thermostat JUMO exTHERM-AT for potentially explosive areas

(2) Basic type extensions

0002 Temperature monitor (TW)

0020 Safety temperature monitor (STW)

0070 Safety temperature limiter (STB)

0270 Temperature monitor (TW) / safety temperature limiter (STB)

2070 Safety temperature monitor (STW) / safety temperature limiter (STB)

(3) Design type

5 Surface-mounted thermostat

6 Room thermostat

(4) Case

4 Polyester case black (standard)

6 Stainless steel case

(5) Control ranges / limit value ranges 1 in °C

013 -20 to +40 (only room thermostat)

014 -20 to +50

026 0 to +120

028 0 to +200

046 +20 to +500 (only TW)

064 +50 to +300

539 +140 to +500 (only STW and STB)

532 +130 to +190

(6) Control ranges / limit value ranges 2 in °C

000 (only single thermostat)

013 -20 to +40 (only room thermostat)

014 -20 to +50

026 0 to +120

028 0 to +200

046 +20 to +500 (only TW)

064 +50 to +300

539 +140 to +500 (only STW and STB)

532 +130 to +190

(7) Switching capacity

11 AC / DC = 24 V, 100 mA (gold-plated snap-action switch)

21 AC 230 V +10 %, 16 (2.5) A, cos ϕ =1(0.6) (standard)

41 AC 400 V +10 %, 16 A

25 AC 230 V +10 %, 25 (4) A, cos ϕ =1(0.6)

(8) Operating temperatures in °C

340 -55 to +40 T6 (+70 °C T4) (+50 °C T4 at 25 A)

467 -40 to +40 T6 (standard) (+70 °C T4) (+50 °C T4 at 25 A)

(9) Switching differential 1

00 Without switching differential (STB)

25 Approx. 2.5 % (TW)

70 Approx. 7 % (TW, STW)

(10) Switching differential 2

00 Without switching differential (STB) and for single thermostat

25 Approx. 2.5 % (TW)

70 Approx. 7 % (TW, STW)

Data Sheet 605055 Page 8/9

2014-07-15/00576368

Page 9

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

(11) Capillary length 1

0 0 mm design type 6, rigid thermowell

1000 1000 mm

3000 3000 mm

. . . . (Special length, specifications in plain text, 1000 mm increments)

(12) Capillary length 2

0 0 mm (only design type 6 and for single thermostat)

1000 1000 mm

3000 3000 mm

. . . . (Special length, specifications in plain text, 1000 mm increments)

(13) Capillary material

20 Stainless steel (CrNi)

(14) Process connection (PC)

10 Plain cylindrical probe

15 Spiral probe

74 Mounting adaptor

(thermowells can be ordered separately according to data sheet 605057

(with Ex-approval) or data sheet 606710 (standard)

(15) Diameter 1 "d" (single thermostat)

4 Ø 4mm

6 Ø 6mm

56 Ø 56 mm

(16) Diameter 2 "d" (double thermostat)

0 Without

4 Ø 4mm

6 Ø 6mm

(17) Insertion length "S"

0 Without thermowell

200 200 mm

300 300 mm

(18) Extra codes

000 Without extra code

372 IECEx Approvals (extra code 861 not available)

861 IP66 (extra code 861 not available)

Data Sheet 605055 Page 9/9

Order code:

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14) (15) (16) (17) (18)

605055 / . . . . - . - . - . . . - . . . - . . - . . - . . - . . - . . . . - . . . . - . . - . . - . . - . . - . . . / . . . , . . .

Order example:

605055 / 2070 - 5 - 4 - 028 - 064 - 21 - 467 - 25 - 00 - 1000 - 1000 - 20 - 10 - 4 - 4 - 200 / 000 , . . .

Stock versions

Part no. Type Control range °C Measuring system

material

60003365 605055/20 (STW) -20 to +50

60003366 605055/02 (TW) -20 to +40 - - Spiral probe

60003367 605055/20 (STW) 0 to +120 1000 mm 6 x 58 mm

60003368 605055/20 (STW) +50 to +300 1000 mm 4 x 78 mm

60003369 605055/2070 (STW/STB)

0 to +200 (STW)

+50 to +300 (STB) 4 x 78 mm (STB)

CrNi

60003391 605055/20 (STW) 0 to +200 1000 mm 6 x 48 mm

60003395 605055/0070 (STB) 0 to +200 1000 mm 6 x 48 mm

60003401 605055/0002 (TW) 0 to +200 1000 mm 6 x 154 mm

2014-07-15/00576368

Capillary length Probes

1000 mm 6 x 81 mm

1000 mm

4 x 87 mm (STW)

Loading...

Loading...