JUMO 605041 User Manual

ATH-Ex

(shown with cover removed)

Explosion-protected surface-mounting Thermostat for

potentially explosive gas atmospheres Zone 1

and potentially explosive dust atmospheres Zone 21

B 605041.0

Operating Instructions

2012-10-19/00347683

Please read these Operating Instructions before commissioning the instrument.

Keep the manual in a place that is accessible to all users at all times. Please

assist us to improve these operating instructions, where necessary. Your suggestions will be appreciated.

Phone +49 661 6003-0

Fax +49 661 6003-607

All necessary settings and, where appropriate, alterations inside the instrument

are described in these operating instructions. If any difficulties should still arise

during commissioning, you are asked not to carry out any unauthorized manipulations on the unit. You could endanger your rights under the instrument warranty! Please contact the nearest subsidiary or the head office in such a case.

Contents

Page

1 Introduction ............................................................................... 4

1.1 Typographical conventions ...................................................................... 4

1.1.1 Warning signs .............................................................................................. 4

1.1.2 Note signs ................................................................................................... 4

1.2 Application ................................................................................................. 5

1.3 Marking ...................................................................................................... 5

1.4 Safety notes ............................................................................................... 5

2 Instrument identification .......................................................... 6

2.1 Nameplate .................................................................................................. 6

2.2 Type designation ....................................................................................... 6

3 Mounting .................................................................................... 7

3.1 Dimensions ................................................................................................ 7

3.2 Opening the surface-mounting thermostat ............................................ 8

3.3 Securing the surface-mounting thermostat ........................................... 8

3.4 Capillary / temperature probe / pocket ................................................... 8

3.4.1 General ........................................................................................................ 8

3.4.2 Approved probes and protection tubes (pockets) ...................................... 9

3.5 Permissible operating conditions at the pocket .................................. 10

3.5.1 Probe mountings 20, 22 and 23 ................................................................ 10

3.5.2 Probe mountings 10, 21, 60, 65 ................................................................ 13

3.6 Mounting the probe ................................................................................. 13

4 Installation ............................................................................... 14

4.1 Regulations and notes ............................................................................ 14

4.2 Electrical connection .............................................................................. 15

4.3 Connection diagrams ............................................................................. 15

5 Settings .................................................................................... 16

5.1 Limit setting ............................................................................................. 16

5.2 Self-monitoring ........................................................................................ 16

5.2.1 Response to a fracture in the measuring system ..................................... 16

5.2.2 Response to low temperature ................................................................... 16

6 Instrument description ........................................................... 17

6.1 Technical data ......................................................................................... 17

7 Appendix .................................................................................. 20

1 Introduction

1.1 Typographical conventions

1.1.1 Warning signs

Danger

This sign is used when there may be injury to personnel if the instructions are

ignored or not followed correctly!

Caution

This sign is used when there may be damage to equipment if the instructions

are ignored or not followed correctly!

1.1.2 Note signs

Note

This sign is used when your special attention is drawn to a remark.

Reference

This sign refers to further information in other chapters or sections.

1

abc

✱ Action

Footnote

Footnotes are remarks that refer to specific points in the text. Footnotes

consist of two parts:

A marker in the text and in the footnote text.

The markers in the text are arranged as continuous superscript numbers.

The footnote text (in smaller typeface) is placed at the bottom of the page and

starts with a superscript number.

This sign indicates that an action to be performed is described.

The individual steps are marked by this asterisk, e. g.

✱ Select setpoint

4

1.2 Application

Depending on the version, the explosion-protected surface-mounting thermostat, type ATH-Ex, can be used as

■ TW temperature monitor

■ STW fail-safe temperature monitor

in areas with an explosion hazard caused by gases, vapors or mists, Zone 1,

or in areas with combustible dust or dust/air mixtures, Zone 21.

If this surface-mounting thermostat is used inside the hazardous area, the

relevant regulations for mounting and operating equipment in such an area

must be observed.

Cutting through or kinking the capillary of surface-mounting thermostat,

type ATH-Ex, will result in permanent instrument failure!

1.3 Marking

1 Introduction

II 2G Ex ed IIC T6 for potentially explosive gas atmospheres

II 2D Ex tD A21 IP65 T80°C for potentially explosive dust atmospheres

Test certificate: PTB 03 ATEX 1167

CE marking and No. of notified body: CE 0044

.

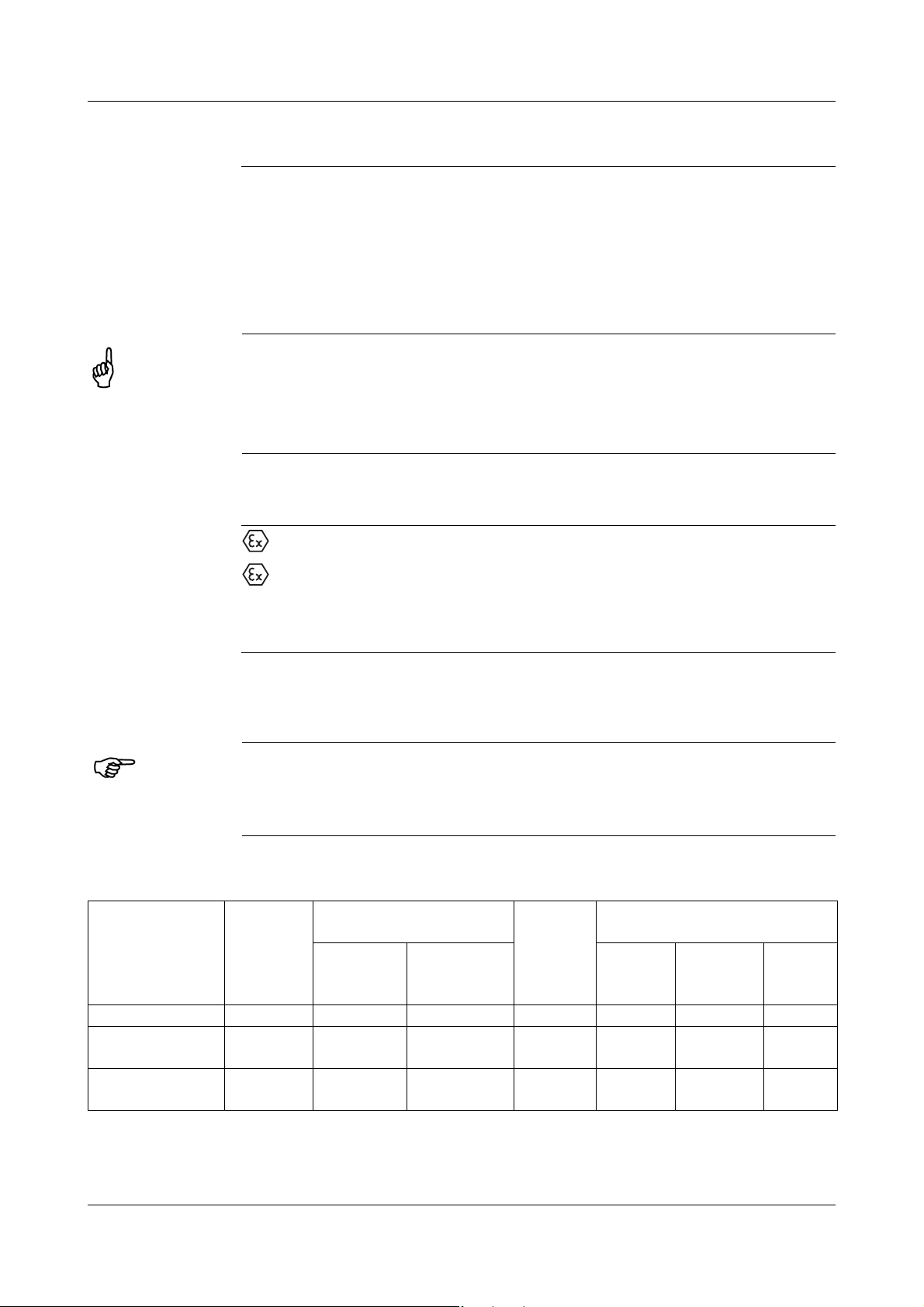

1.4 Safety notes

Filling liquid may escape in the event of a measuring system fracture. At present there is no restrictive statement from the health authorities concerning any

danger to health over short periods and at low concentrations, e.g. after a

fracture of the measuring system.

Physical and toxicological properties of the substances that may escape in the

event of a system fracture:

End of scale°CDangerous

reaction

< +200 – +355 0.6 — 8 X X X –

≥ +200

≤ +350

>+350

≤ +500

– +490 – – X X X –

–– – ––––

– = no; X = yes

Fire/explosion

hazard

Ignition

temp.

°C

Explosion

limit

% v/v

Water

contam-

ination

Toxicological data

irritant danger

to health

toxic

5

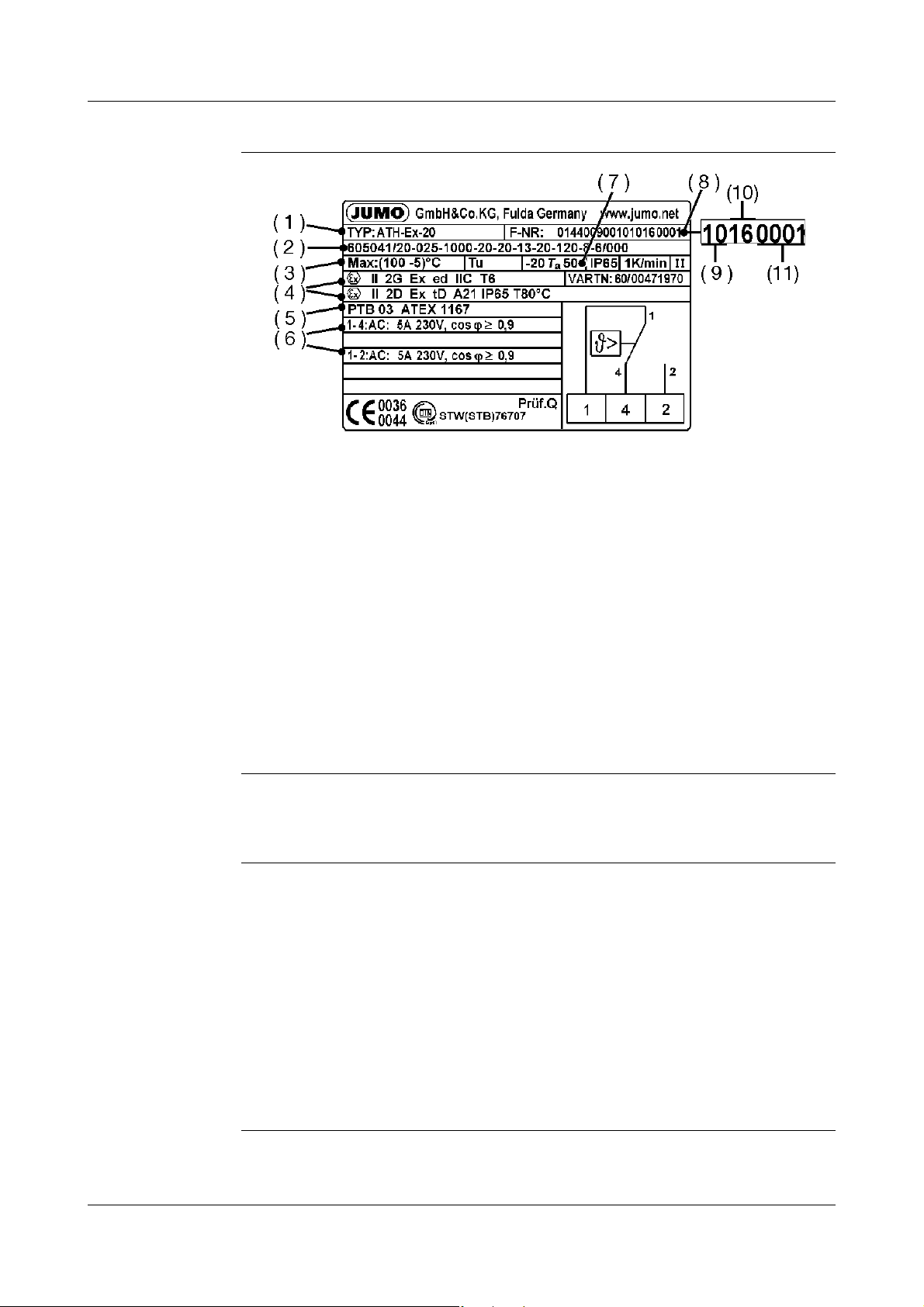

2 Instrument identification

2.1 Nameplate

( 1 ) Type ➈ Chapter 2.2 “Type designation”, page 6

( 2 ) Type code

( 3 ) Control range or limiting value range / ambient temperature

at which this thermostat has been calibrated (option)

( 4 ) Ex-marking

( 5 ) Testing laboratory / Test certificate

( 6 ) Breaking capacicty

( 7 ) Permissible ambient temperature

( 8 ) Fabrication number

( 9 ) Date of manufacture

( 10 Week of manufacture

( 11 ) Device number

2.2 Type designation

ATH- Ex -. .

ATH surface-mounting thermostat (with capillary)

ATH- Ex marking for explosion-protected version

ATH- Ex -. . code number for the function:

2 = temperature monitor (TW)

with changeover contact.

Limit adjustable within the housing.

20 = fail-safe temperature monitor (STW)

with changeover contact.

Limit adjustable within the housing.

6

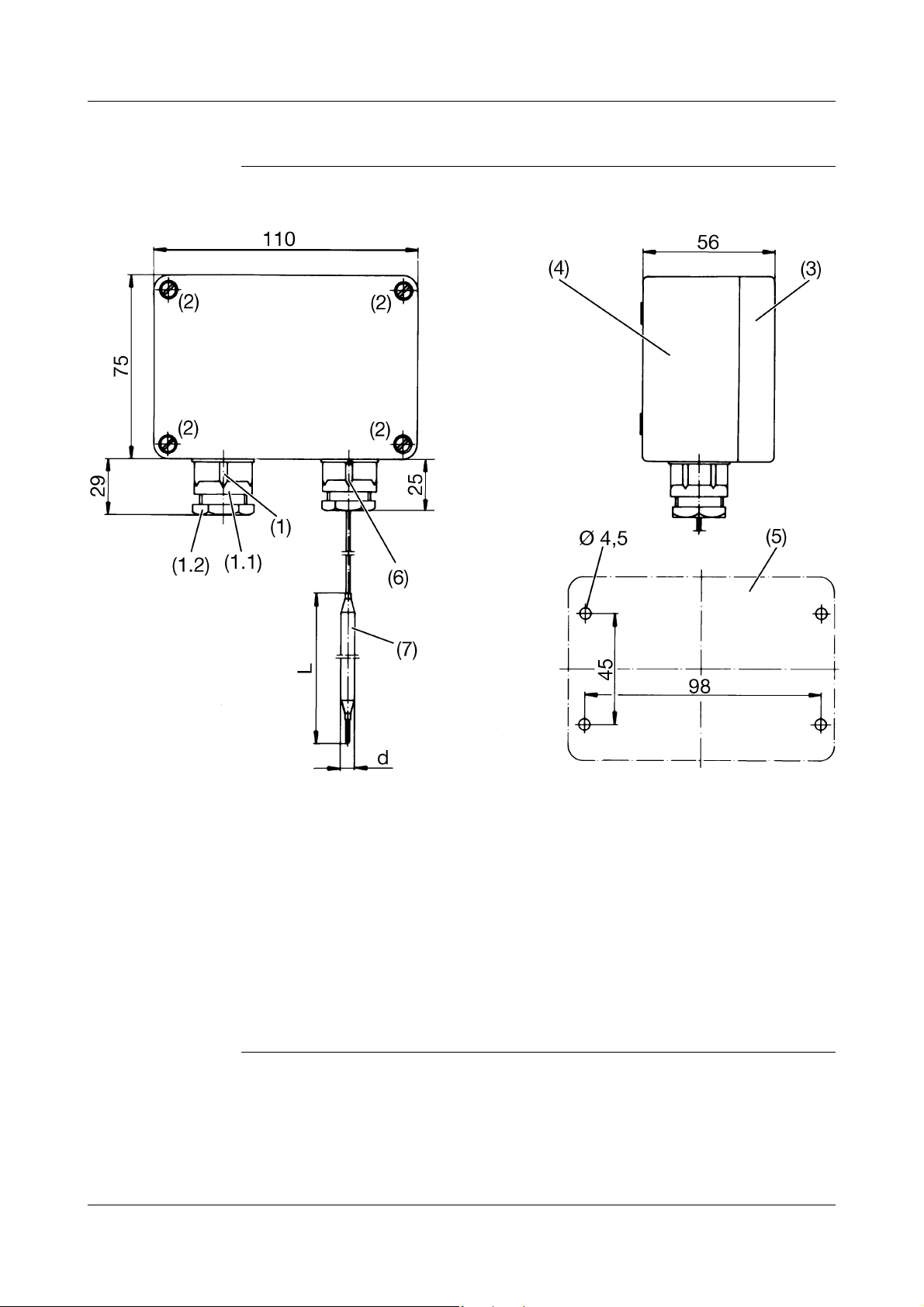

3.1 Dimensions

3 Mounting

(1) Ex cable gland M 20 x 1.5 x 6-12

(1.1) Screw-in thread. Tightening torque: 3.75 Nm

(1.2) Compression screw. Tightening torque: for cable dia.06mm=3.5Nm

Tightening torque: for cable dia. 12 mm = 2.5 Nm

(2) Cover screws (2 are lead-sealable)

(3) Cover

(4) Housing bottom

(5) Drilling diagram

(6) Ex cable gland for sealing the capillary exit

(7) Temperature probe

7

3 Mounting

3.2 Opening the surface-mounting thermostat

✱ Unscrew the 4 cover screws (2)

✱ Remove cover (3) with seal (not visible)

Make sure that the seal is seated correctly when reassembling!

3.3 Securing the surface-mounting thermostat

Mounting

position

to DIN 16257, NL 0 — NL 90 (other NL on request)

✱ Drill fixing holes according to the drilling diagram.

✱ Use the 4 screws to secure the housing bottom.

3.4 Capillary / temperature probe / pocket

3.4.1 General

Cutting through or kinking the capillary of the surface-mounting thermostats

will result in permanent failure of the instrument!

Minimum permissible bending radius of the capillary is 5 mm.

The temperature probe must be installed in a JUMO pocket, otherwise the

approval of the thermostat becomes invalid.

The temperature probe must completely immersed in the medium to be measured.

To ensure their overall accuracy of response, the thermostats must only be

used together with the pockets supplied by the factory (diameter D=8, 10 or

15 mm).

Pockets with diameter D=10 mm may only be fitted with probes with diameter

d=8 mm.

Only 2 or 3 probes may be fitted into a common pocket (probe mounting “10”,

diameter d=6 mm), and only pockets 15 x 0.75 mm may be used. When fitting

2 probes into a common pocket, the factory-supplied spring clip must be fitted in the pocket.

For operation in air, probe mounting “10” (without pocket) must be chosen.

8

Loading...

Loading...