Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Data Sheet 605041

Explosion protected surface-mounting thermostat

ATH-Ex type series

Special features

• compact case (75x110x56mm)

• 5 A contact rating

• can be fitted directly in zone 1, 2, 21 and 22

• Temperature can be set in zone 1, 2, 21 and 22

• Control ranges from -20°C to +500°C

o

m

e

d

l i

s

b

i

e

g

n

p

h

s

a

d

e

Page 1/6

u

o

t

Brief description

Explosion protected surface-mounting thermostats of the ATH-Ex type series control and

monitor thermal processes and can be directly used in explosive areas - Zone 1 and Zone 21.

The devices are available as temperature monitors TW and fail-safe temperature monitors STW.

The thermostats operate according to the fluid or gas expansion principle. The electrical

switching element is a pressure-resistant encapsulated microswitch.

Design as per DIN EN 14597:

TW Temperature monitor

STW Fail-safe temperature monitor

Ex identification

II 2G Ex ed IIC T6 for explosive gas atmosphere

II 2D Ex tD A21 IP65 T80°C for explosive dust atmosphere

ATH- Ex -. .

Explosion protection

Device group II, category 2,

II 2G

equipment for explosive gas atmosphere

Device group II, category 2,

II 2D

equipment for explosive dust atmosphere

Approval/approval marks (see Technical Data)

2012-03-01/00073252

DGRL

Page 2

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Technical data

Switching function

Data Sheet 605041 Page 2/6

Temperature monitor TW

and fail-safe proof temperature monitor STW

If the temperature exceeds the setpoint value set on the temperature

probe, the microswitch will be tripped by the transmission mechanics

and the current circuit opened or closed.

The microswitch is reset to its original status once the setpoint value

set is gone below (by the hysteresis).

Self-monitoring

for the fail-safe temperature monitor STW

If the measuring system is destroyed, i.e. if the expansion fluid

emerges, the pressure in the STW diaphragm drops and permanently

opens the current circuit. Unlocking is no longer possible.

If the probe has cooled down to a temperature within the control

range table, e.g. below -20°C, the current circuit is also opened. The

STW is automatically restarted.

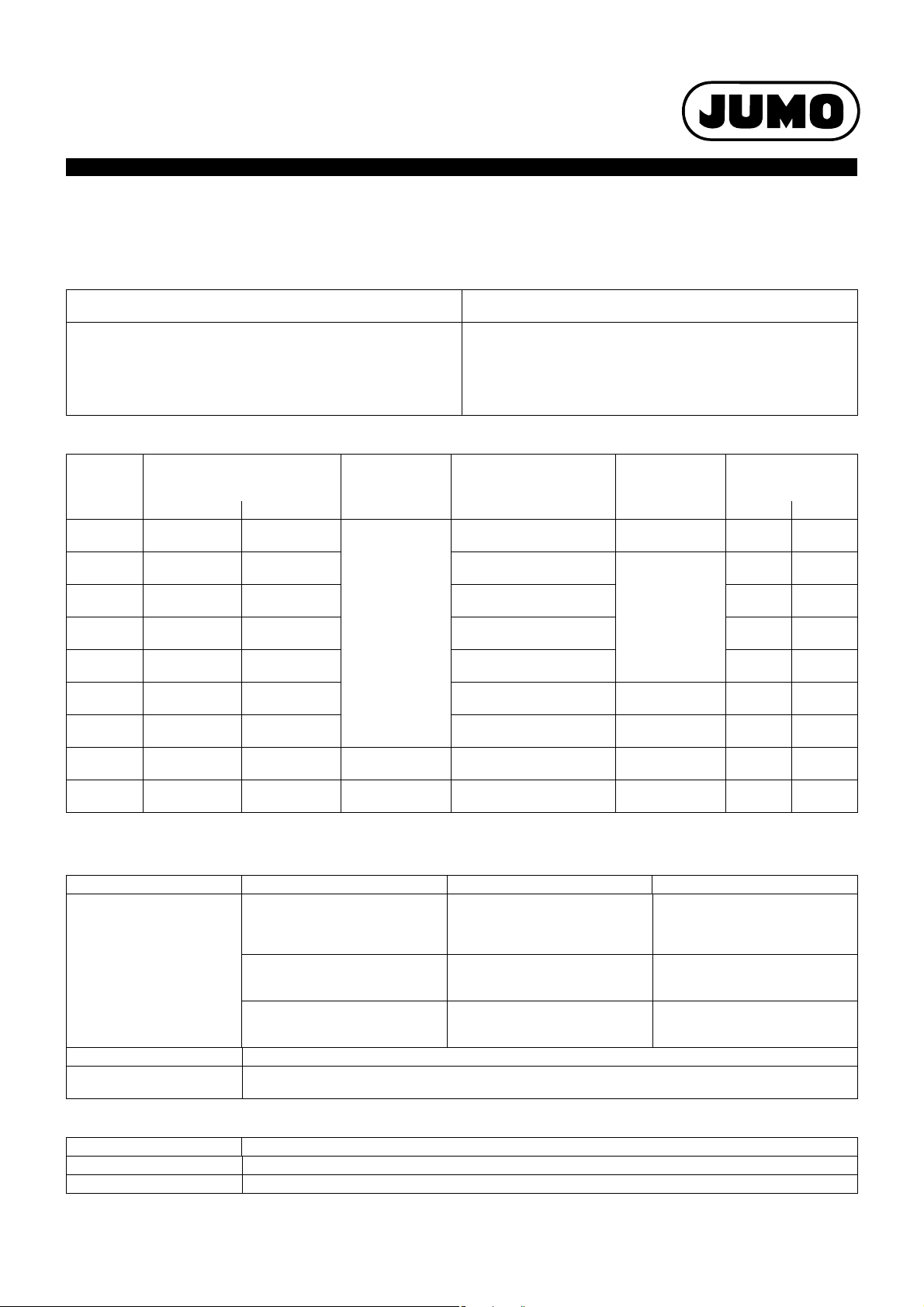

Control ranges and probe table

Control

range

Switching point accuracy in the

upper third of the scale range

a

capillary length

maximum

maximum probe

temperature as per

DIN EN 14597

STW opens at

probe

temperature

Probe length "L"

with "d“ = 6 mm

in °C TW STW in mm in °C below °C TW STW

-20...+50

0...+50

0...+100

+40...+120

+50...+200

+80...+250

+50...+300

+20...+400

+20...+500

a.

Offset of the switching point accuracy to a different scale range is possible upon customer request.

+0 K

-3 K

+0 K

-2 K

+0 K

-4 K

+0 K

-3 K

+0 K

-6 K

+0 K

-7 K

+0 K

-10 K

+0 K

-15 K

+0 K

-19 K

+0 K

-3.5 K

+0 K

-2.5 K

+0 K

-5 K

+0 K

-4 K

+0 K

-8 K

+0 K

-8.5 K

+0 K

-12.5 K

+0 K

-19 K

+0 K

-24 K

+60 -30 153 132

+60

202 172

+115 117 102

-10

5000

+140 135 117

+230 107 94

+300 -20 90 78

+345 -30 67 60

1000 +460 -30 - - 202

2000 +550 -30 237 149

Capillary and temperature probe

Type End of scale Capillary ∅ 1.5 mm Temperature probe

ATH-Ex-.. up to 200°C Copper (Cu)

Material No. 2.0090

electrically tin-plated

Copper (Cu)

Material No. 2.0090

hard soldered,

electrically tin-plated

up to 300°C Stainless steel (CrNi)

Material No. 1.4571

Stainless steel (CrNi)

Material No. 1.4571,

welded

up to 500°C Stainless steel (CrNi)

Material No. 1.4571

Stainless steel (CrNi)

Material No. 1.4571,

welded

capillary length standard 1000 mm, maximum 5000 mm

min. bending radius of

5mm

capillary

Electrical data

Switching element pressure-resistant encapsulated microswitch with change-over contact

maximum contact rating AC 230 V +10%, 5 A, cos

Electrical connection Screw-connection in a case, suitable for a cable cross section up to 2.5 mm

2012-03-01/00073252

ϕ ≥ 0.9

2

Page 3

Data Sheet 605041 Page 3/6

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Operating data

Hysteresis in % from the

control / limit value range

Ranges with scale limit value ≤ 350 °C

Switching

Rated value Possible process

function

value

Ranges with scale limit value > 350°C

Switching

Rated value Possible process

function

TW 3 3-5 TW 5 5-9

STW 5 5-7 STW 6 6-11

Ambient temperature

influence referring to the

control / limit value range

When the ambient temperature on the case deviates from the calibration ambient temperature 22°C

a switching point offset occurs.

Higher ambient temperatures = lower switching point

Lower ambient temperature = higher switching point

Panel-mounting thermostats with scale limit value

< 200°C ≥ 200°C ≤ 350°C > 350°C ≤ 500°C

TW STW (STB) TW STW (STB) TW STW (STB)

Influence on the switch head

0.08%/K 0,17 %/K 0,06%/K 0,13%/K 0,14%/K 0,12%/K

Influence on the capillary per meter

0,047%/K 0,054%/K 0,09%/K 0,11 %/K 0,04%/K 0,03 %/K

Permissible storage

-50...+50°C

temperature

admissible ambient

temperature during use

Temperature class with scale limit value capillary line Switch head

T 6 max. +50°C +50 °C

< 200°C -40°C -20°C

min.

≥ 200°C ≤ 350°C -20°C -20°C

> 350°C ≤ 500°C -40°C -20°C

Rated position (NL) as per DIN 16 257, NL 0 ... NL 90 (different NL on request)

value

Case

Material Polyester case, glass-fibre enforced, black

Limit value setting The limit value can be adjusted once the case lid has been removed on the set point value setter.

Protection class EN 60 529-IP 65

Cable inlet Ex cable screw connection M 20 x 1.5, sealing area 6-12 mm

Switch head fastening by 4 screws once the case lid is removed

Weight approx. 1.32 lb

Process connection

ATH-Ex.. type series

with capillary

a

plain cylindrical probe 10 (standard)

Sheath 20 (on request)

Screw-in sleeve with screw-in spigot G 1/2 form A as per DIN 3852/2

and clamping piece with fastening screw to fix the probe

Material of sheath 20 up to+150°C CuZn as standard, over +150°C CrNi as standard

Fitting length S Standard lengths: 100, 120, 150, 200 or 300 mm (different lengths on request)

Immersion tube ∅ D = 8 mm

a.

For different process connections and sheaths, see data sheet 606710 (only 21, 22, 60 and 65).

Note

Physical and toxic features of the expansion means, which could emerge in the event of a measuring system break.

Control range

with scale limit value

< 200°C

Hazardous

reactions

no

Fire and explosion hazard harmful to

Ignition

Explosion

temperature

+355°C 0.6-8V%

limit

water

Ye s Ye s

Information about toxicology

irritant hazardous to

health

a

toxic

no≥ 200°C ≤ 350°C +490°C - -

> 350°C ≤ 500°C no no no no no

a.

There is currently no statement by the health authority concerning hazards to health in the event of short-term exposure and low concentration, e.g. measuring

system break.

2012-03-01/00073252

Page 4

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Approval/approval marks

1

42

14 2

(1)

(2)

98

45

Ø 4,5

110

29

L

d

75

56

Data Sheet 605041 Page 4/6

Types Switching

function

ATH -E x- 2 TW

ATH-Ex-20 STW 97/23/EC STW: STW(STB) 76707

Ignition protection type Ex ed IIC T6

Ex General regulations European standard EN 60079-0 VDE 0170 / 0171 Part 1

e increased safety European standard EN 60079-7 VDE 0170 / 0171 Part 6

d pressure-resistant

encapsulation

IIC Gas group

T6 Temperature class

IP 65 T 80°C Use in combustible dust European standard EN 61241-0

IP 65 Protection class as per EN 60529-IP65

T 80°C max. admissible surface temperature (use in combustible dust)

ATEX approval DGRL approvals DIN approvals

PTB 03 ATEX 1167

European standard EN 60079-1

European standard EN 61241-1

- TW: TW 76607

VDE 0170 / 0171 Part 5

VDE 0170 / 0171 Part 15-1-1

Connection diagram

ATH -Ex -..

ATH-Ex-2, ATH-Ex-20

Dimensions

ATH -Ex -..

(1) = Ex cable screw-connection

M20x1.5x6-12

(2) = Ex cable screw connection

For different process

connections and sheaths, refer

to data sheet 606710

(only 20, 21, 22, 60 and 65)

2012-03-01/00073252

Page 5

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Stock versions

Data Sheet 605041 Page 5/6

Part no. Type Control range °C Measuring system

Capillary mm Probe ø×length mm

material

60001242 ATH-Ex-2 –20...+50

6×153

60001243 ATH-Ex-2 0...+50 6×202

60001244 ATH-Ex-2 +40...+120 6×135

60001246 ATH-Ex-2 +50...+300 6×67

CrNi 2000

60001247 ATH-Ex-20 +40...+120 6×117

60001248 ATH-Ex-20 +50...+300 6×60

Order details

Explosion protected surface-mounting thermostat, type series ATH -E x-..

Order

code ( 1 ) Basic type

605041 Surface-mounting thermostat for explosive areas, type series ATH-Ex

( 2 ) Basic type extensions

02 ATH-Ex-2 Temperature monitor TW

20 ATH-Ex-20 Fail-safe temperature monitor STW

( 3 ) Control/limit value ranges °C

014 -20...+50

021 0...+50

025 0...+100

056 +40...+120

062 +50...+200

080 +80...+250

064 +50...+300

045 +20...+400

046 +20...+500

( 4 ) Capillary length

1000 1,000 mm

2000 2,000 mm

3000 3,000 mm

4000 4,000 mm

5000 5,000 mm

. . . . (special length, specifications in plain text in mm)

( 5 ) Capillary material

20 CrNi Stainless steel (1.4571)

40 Cu Copper tin-plated (only possible up to 200°C)

( 6 ) Process connection (PC)

10 plain cylindrical probe (standard)

20 Screw-in sleeve

( 7 ) Thread of process connection

00 without thread (process connection 10)

13 External thread G 1/2

2012-03-01/00073252

Page 6

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

( 8 ) Material of process connection

00 only with process connection 10

46 CuZn (brass up to 150°C)

20 CrNi (Stainless steel 1.4571)

( 9 ) Fitting length "S“ (immersion tube length)

000 ATH-Ex-.. without sheath

100 100mm

120 120mm

150 150mm

200 200mm

300 300mm

400 400mm

( 10 ) Diameter "D" (immersion tube diameter)

00 ATH-Ex-.. without sheath

88 mm

( 11 ) Diameter "d" (probe diameter)

66 mm

Data Sheet 605041 Page 6/6

( 12 ) Extra codes

000 no extra code

Order code

( 1 ) ( 2 ) ( 3 ) ( 4 ) ( 5 ) ( 6 ) ( 7 ) ( 8 ) ( 9 ) ( 10 ) ( 11 ) ( 12 )

605041 /---------/,. . .

Order example

605041 / 20 - 062 - 2000 - 40 - 10 - 00 - 00 - 000 - 00 - 6 / 000 , . . .

2012-03-01/00073252

Loading...

Loading...