Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

DGRL

97/23/EG

Data Sheet 603070

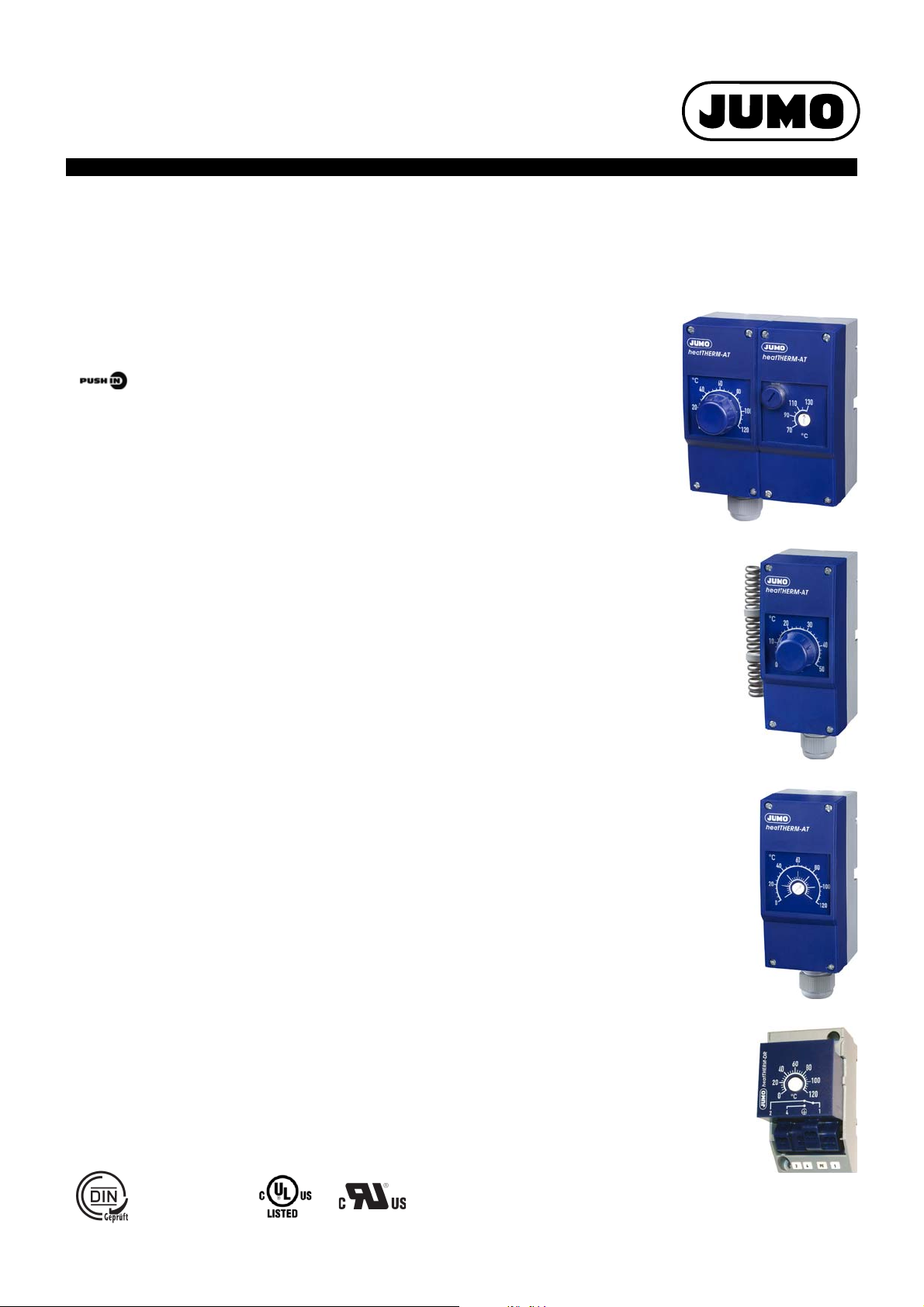

JUMO heatTHERM-AT and JUMO heatTHERM-DR

Type 603070, Surface-Mounted or Room Thermostat Versions

Special features

• -connection technology - reduced installation time by 50 %

• Stable switching point position due to ambient temperature compensation (standard)

• Max. switching capacity 16 A, 230 V

• Tested according to DIN EN 14597

• Operating life at least 250,000 switching cycles for TR and TW

• Switching point deviation during the entire operating life of up to ± 5%

• Protection type max. IP 54

• UL approval (extra code 061)

Page 1/15

Brief description

High application flexibility and the latest connection technology are the essential equipment

features of this new thermostat series.

The thermostat case is suitable for all common installation types such as wall mounting, immersion sleeve, and contact fastening. It can be used universally and reduces the variant range because different mounting types must no longer be taken into account.

The JUMO heatTHERM-DR (type 7+8) type is a specific variation with a special housing bottom

section for DIN rail or wall mounting. As a result, easy mounting on mounting rails TH35 according to DIN EN 60715 (e.g. in control cabinets) is possible. This variant considerably reduces the

mounting time. The flue gas automatic reset temperature limiter JUMO heatTHERM-AT locks

the gas/oil vessel that is connected in parallel with the wood vessel to a chimney.

For these international innovative surface-mounted thermostats with "Push-In

nology, the connection wires are only inserted into the terminal point up to the stop - that's it!

No tool is required for connecting the wire or strand with a ferrule and the wiring becomes safer.

In this manner, the costs and time required for connection are considerably reduced compared

to the conventional screw terminal.

The "Push-In

installation costs can be reduced further because a load contactor is no longer required.

Available are temperature controllers (TR), temperature monitors (TW), safety temperature monitors (STW), safety temperature limiters (STB) as single or double thermostats, and flue gas temperature monitors (ATW).

Approvals according to DIN EN 14597, DGRL, and UL indicate the high quality standards for

this product series.

®

" terminal technology allows direct switching of loads up to 16 A at 230 V AC. The

®

" terminal tech-

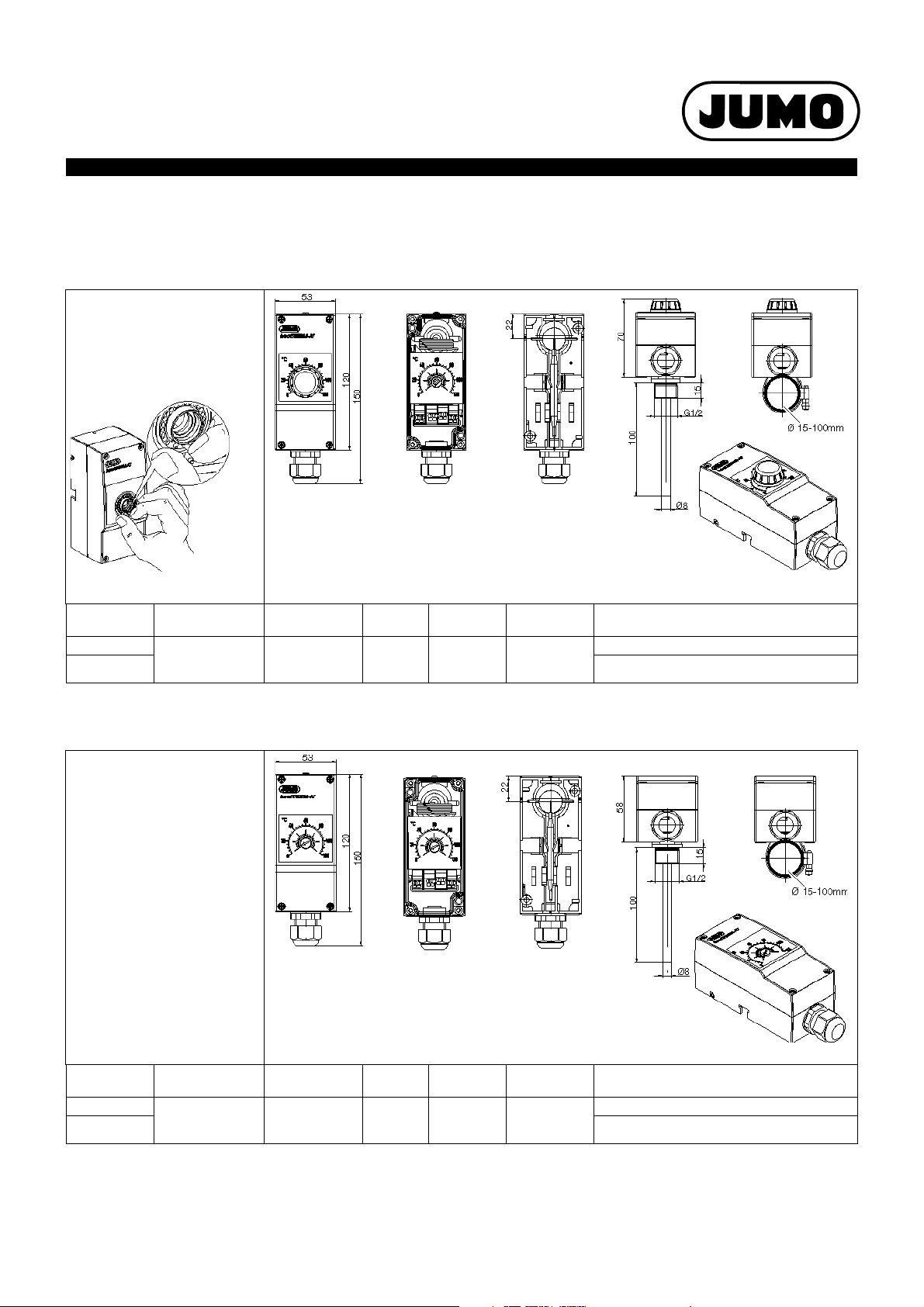

Type 603070/0170 (TR/STB)

Type 603070/0001 (TR)

Approvals/approval marks (see "Technical Data")

2013-03-15/00485234

Design type 5+6* Design type 7+8*

* Only with extra code 061

Type 603070/ 0002 (TW)

Type 603070/0002 (TW)

Page 2

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Technical data

Switching function

Data Sheet 603070 Page 2/15

Temperature controller TR /

temperature monitor TW

If the temperature on the temperature probe exceeds the setpoint value, the microswitch is activated by the

transmission mechanics and the electrical circuit is opened or closed.

If the temperature falls below the selected setpoint value (by the amount of the switching differential), the

microswitch is reset to its initial position.

Safety temperature monitor

STW

If the temperature on the temperature probe exceeds the setpoint value, the snap-action switch is activated

and the electrical circuit is opened or closed. If the temperature falls below the selected setpoint value (by the

amount of the switching differential), the snap-action switch is reset to its initial position.

If the probe has cooled down to a temperature below approx. -20 °C the same electrical circuit opens - however it closes again when the temperature rises.

If the measuring system is destroyed (i.e. if the expansion fluid emerges) the pressure in the diaphragm drops

and permanently opens the electrical circuit.

Safety temperature limiter

STB

If the temperature on the temperature probe exceeds the switching point, the snap-action switch is activated,

the electrical circuit is opened or closed, and the snap-action switch is mechanically locked.

The unlocking difference depends on the control range. Exact values are available from the respective types.

They are also available upon request. If the temperature falls below the selected setpoint value (by the amount

of the unlocking difference) then the snap-action switch can be manually unlocked again.

If the probe has cooled down to a temperature below approx. -20 °C the electrical circuit opens - however it

closes again when the temperature rises.

If the measuring system is destroyed (i.e. if the expansion fluid emerges) the pressure in the diaphragm drops

and permanently opens the electrical circuit. Unlocking is no longer possible.

Temperature compensation

When the ambient temperature on the switching head and the capillary deviates — from the calibration ambient temperature of +22 °C — a switching point offset occurs. This switching point offset is reduced to a minimum due to the temperature compensation.

2013-03-15/00485234

Page 3

Data Sheet 603070 Page 3/15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Technical data

Case

Type 5 + 6 Type 7 + 8

Case Case bottom section: PA (reinforced)

Color: Silver-gray RAL 7001 (for TZ 061 black)

Case lid: ABS with inspection glass (PMMA)

Color: cobalt-blue RAL 5013 (for TZ 061 light-gray,

RAL 7035)

Setpoint adjustment

TR Switching point can be adjusted externally with the

rotary knob.

TW, STW, STB, ATW Switching point can be adjusted with a screwdriver

once the case lid has been removed. The set switching point can be checked through the inspection

glass.

Protection type IP 54 according to EN 60 529 IP 20 according to EN 60 529

Cable inlet Cable gland M20 x 1.5,

for cable-∅ 6-12 mm

Capillary ∅ 1.5 mm - min. bending radius of the capillary 5 mm - material: copper (Cu) or stainless steel (CrNi, 1.4301)

Case fastening Pipe mounting with clamping belt for pipe diameter

15-100 mm, thermowell mounting, wall mounting

Weight Approx. 0.2 kg

- -

Switching point can adjusted with a screwdriver.

Cable connection directly on terminals

Wall mounting, DIN rail installation TH35 according to

DIN EN 60715

Electrical data

Electric contact Snap-action switch with single-pole changeover contact

Switching capacity TR / TW / STW / ATW STB

On the N/C contact (contact deck 1-2):

AC 230 V +10 %, 16 (2.5) A, cos ϕ =1(0.6),

DC 230 V +10 %, 0.25 A

On the N/O contact (contact deck 1-4):

AC 230 V +10 %, 6.3 (2.5) A, cos ϕ =1(0.6),

DC 230 V +10 %, 0.25 A

Electrical connection contact (plug-type terminal)

"Push-In®" terminal technology: patented connection technology by Weidmüller GmbH & Co. KG, Detmold, Germany

Connection cross section 0.75 to 2.5 mm

2

fine wired (single-wire, fine wired with ferrule)

Switching reliability To ensure the greatest possible switching reliability, we recommend a minimum load of:

AC / DC = 24 V, 100 mA for silver contacts

AC / DC = 10 V, 5 mA for gold-plated contacts (TZ 702)

On the N/C contact (contact deck 1-2):

AC 230 V +10 %, 16 (2.5) A, cos ϕ = 1 (0.6),

DC 230 V +10 %, 0.25 A

On the signal contact (contact deck 1-4):

AC 230 V +10 %, 2 (04) A, cos ϕ =1(0.6),

DC 230 V +10 %, 0.25 A

2013-03-15/00485234

Page 4

Data Sheet 603070 Page 4/15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Operating data

Switching point accuracy TR, TW STW, STB with a setting range of:

+20 °C to +80 °C +70 °C to +130 °C

Switching differential

2.5%

In the upper third of

In the

"first half"

(+20 °C to +50 °C)

In the

"second half"

(+50 °C to +80 °C)

In the

"first half"

(+70 °C to +100 °C)

In the

"second half"

(+100 °C to +130 °C)

+0/-8 K +0/-5 K +0/-12 K +0/-5 K

the scale ± 3 %,

at scale

beginning ± 6 %

Temperature compensation When the ambient temperature on the switching head and the capillary deviates — from the calibration ambi-

ent temperature of +22 °C — a switching point offset of approx. -0.1 K/K occurs

(switching point change referring to the ambient temperature change, measured at limit value +120 °C permanently set and capillary length 2,000 mm).

This switching point offset is reduced to a minimum due to the standard temperature compensation.

Limit value temperatures For transport and storage: -30 °C to +50 °C

During use: max. +80 °C, for TZ 061 UL approval max. +65 °C

(type 7 max. 55 °C; type 6+8 max. +50 °C)

For pipe mounting: max. pipe temperature +120 °C

Rated position According to DIN 16257, rated position 0 to rated position 90 (different rated positions upon request)

Approvals/approval marks

Approval marks Inspection

authority

DIN DIN CERTCO TR1191, TW1192,

Certificates/certification

number

Inspection basis Va lid for

DIN EN 14597 JUMO heatTHERM-AT/-DR

STW(STB)1193, STB1194,

ATW1218

DIN TÜV Süd

(German

DIN EN ISO 13849-1 B

= 250,000* JUMO heatTHERM-AT/-DR

10d

Technical

Inspection

Agency)

DGRL TÜV Süd

(German

IS-TAF-MUC 07113377017 Pressure Equipment Directive

97/23/EC

Technical

Inspection

Agency)

UL UL Germany E 66358 UL 873 JUMO heatTHERM-DR

* For further details see: Safety manual JUMO heatTHERM (-AT), (-DR) 602031, 603070.

Contact rating check conducted at 16 A, 230 V, resistive load.

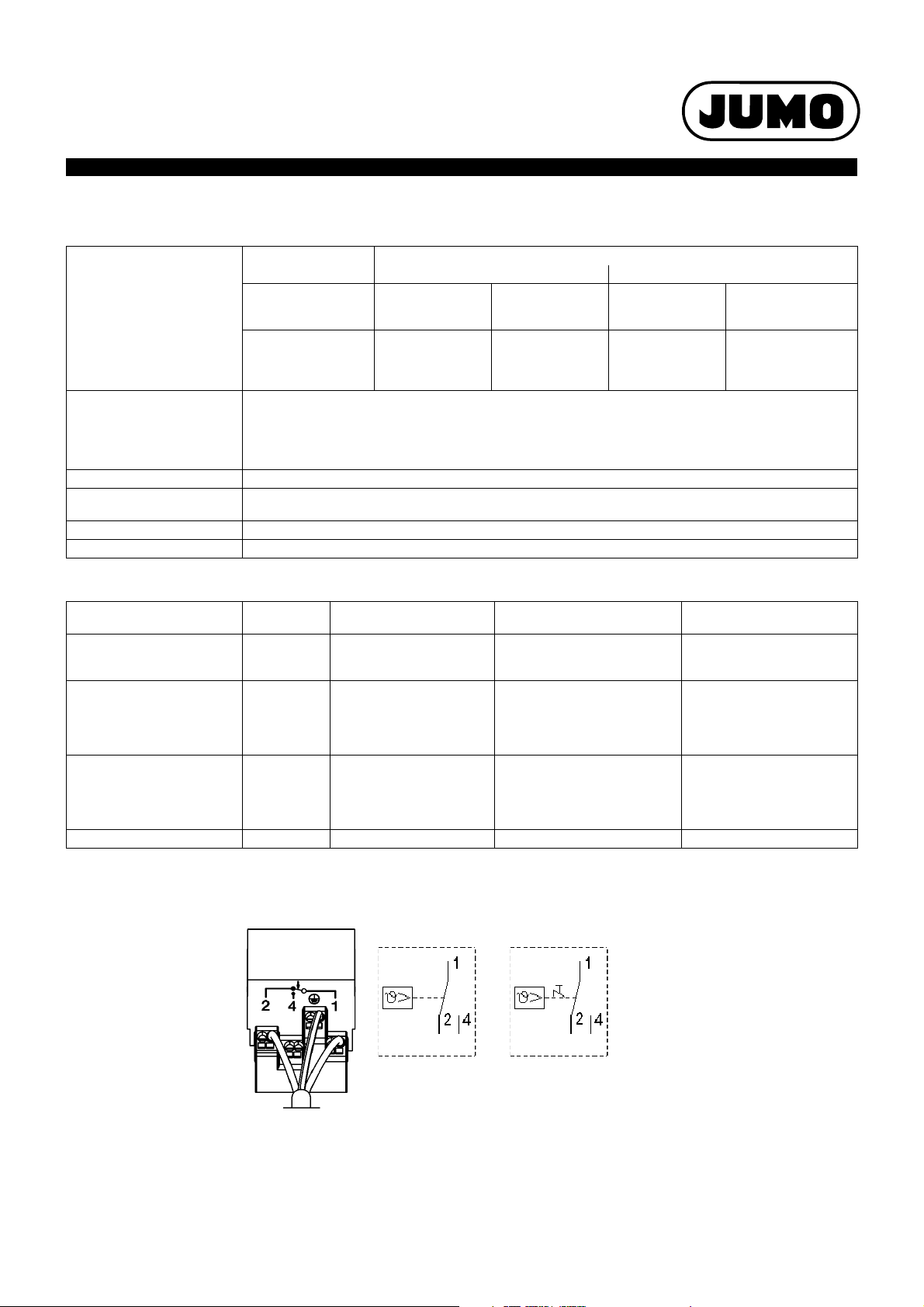

Wiring diagrams

TR, TW, STW STB

according to type

STW and STB

2013-03-15/00485234

Page 5

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Devices in stock: JUMO heatTHERM-AT

Temperature controller TR, type 5

Type 603070/0001

•Protection type IP 54

• Compensation of the ambient temperature

• Individual limitation of the control

range

a

Data Sheet 603070 Page 5/15

Part no. Type Control range °CCapillary mmProbe−∅

(d) × L mm

60003185 JUMO

60003186 Thermowell U 4, brass nickel-plated

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

heatTHERM-AT/

0001

0 to +120 2000 6 × 87 Approx. 3 K

Switching

differential

Process connection

With internal capillary and contact probe

Temperature monitor TW

Type 603070/0002

•Protection type IP 54

• Compensation of the ambient tem-

perature

• Switching value check through in-

spection window in the case lid

a

Part no. Type Control range °CCapillary mmProbe−∅

(d) × L mm

60003187 JUMO

60003188 Thermowell U 4, brass nickel-plated

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

2013-03-15/00485234

heatTHERM-AT/

0002

0 to +120 2000 6 × 87 Approx. 3 K

Switching

Process connection

differential

With internal capillary and contact probe

Page 6

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

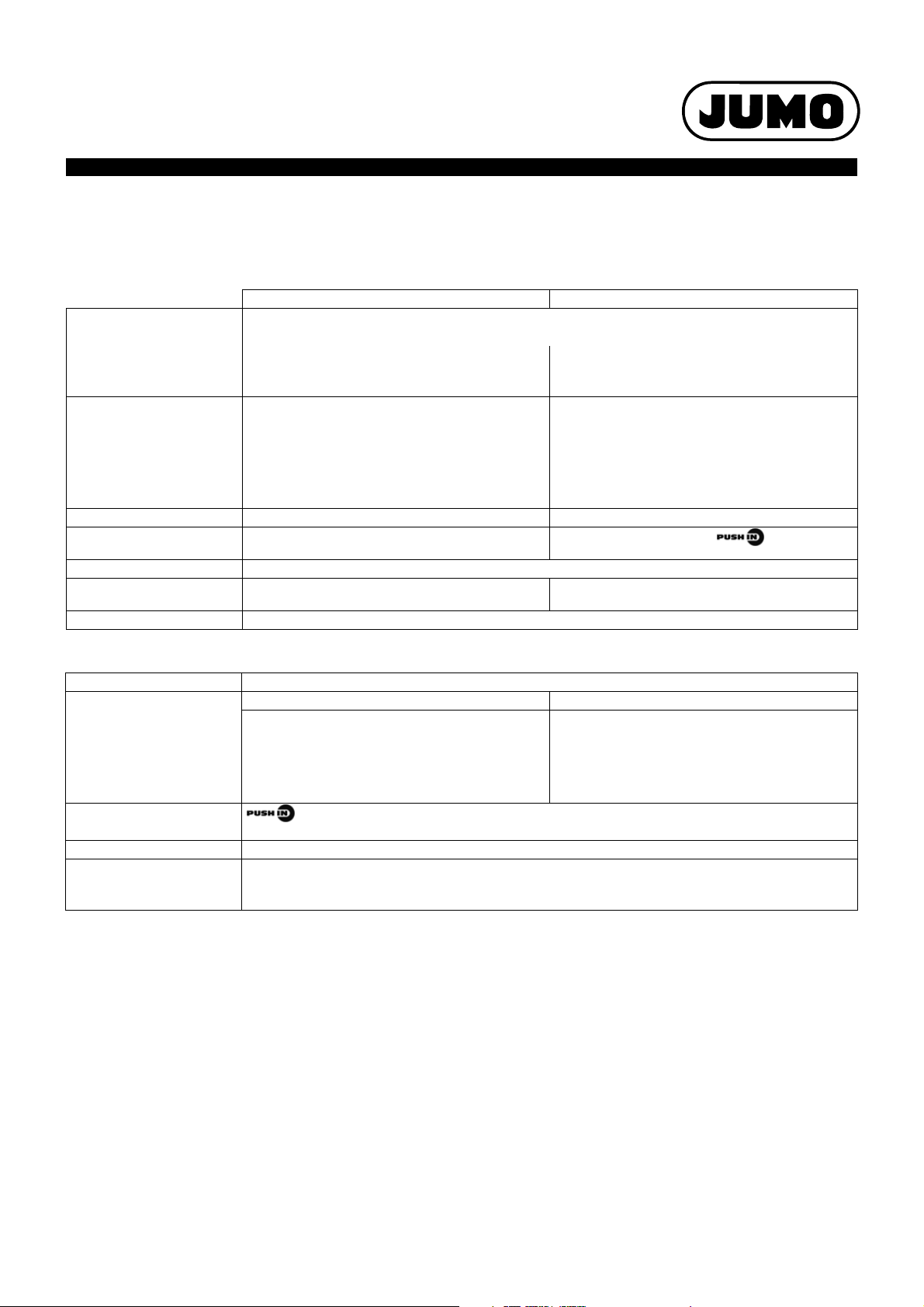

Devices in stock: JUMO heatTHERM-AT

Safety temperature monitor STW, type 5

Type 603070/0020

•Protection type IP 54

• Switching value check through inspection window in the case lid

• Compensation of the ambient temperature

• Subsequent sealing

of the case lid is possible

• Capillary break protection

a

Data Sheet 603070 Page 6/15

Part no. Type Control range °CCapillary mmProbe−∅

(d) × L mm

60003229 JUMO

60003189

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

heatTHERM-AT/

0020

+20 to +80

+70 to +130

2000 6 x 60 Approx. 10 K

Switching

differential

Process connection

With internal capillary and contact probe

Thermowell U 4, brass nickel-plated

Safety temperature limiter STB, type 5

Type 603070/0070

•Protection type IP 54

• Switching value check through in-

spection window in the case lid

• External acknowledgement

of the switching point is possible

•Compensation

of the ambient temperature

• Subsequent sealing

of the case lid is possible

• Capillary break protection

Part no. Type Control range °CCapillary mmProbe−∅

60003230 JUMO

60003190 Thermowell U 4, brass nickel-plated

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

a

heatTHERM-AT/

0070

(d) × L mm

difference

+70 to +130 2000 6 x 60 Approx. 10 K

Unlocking

Process connection

With internal capillary and contact probe

2013-03-15/00485234

Page 7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Devices in stock: JUMO heatTHERM-AT

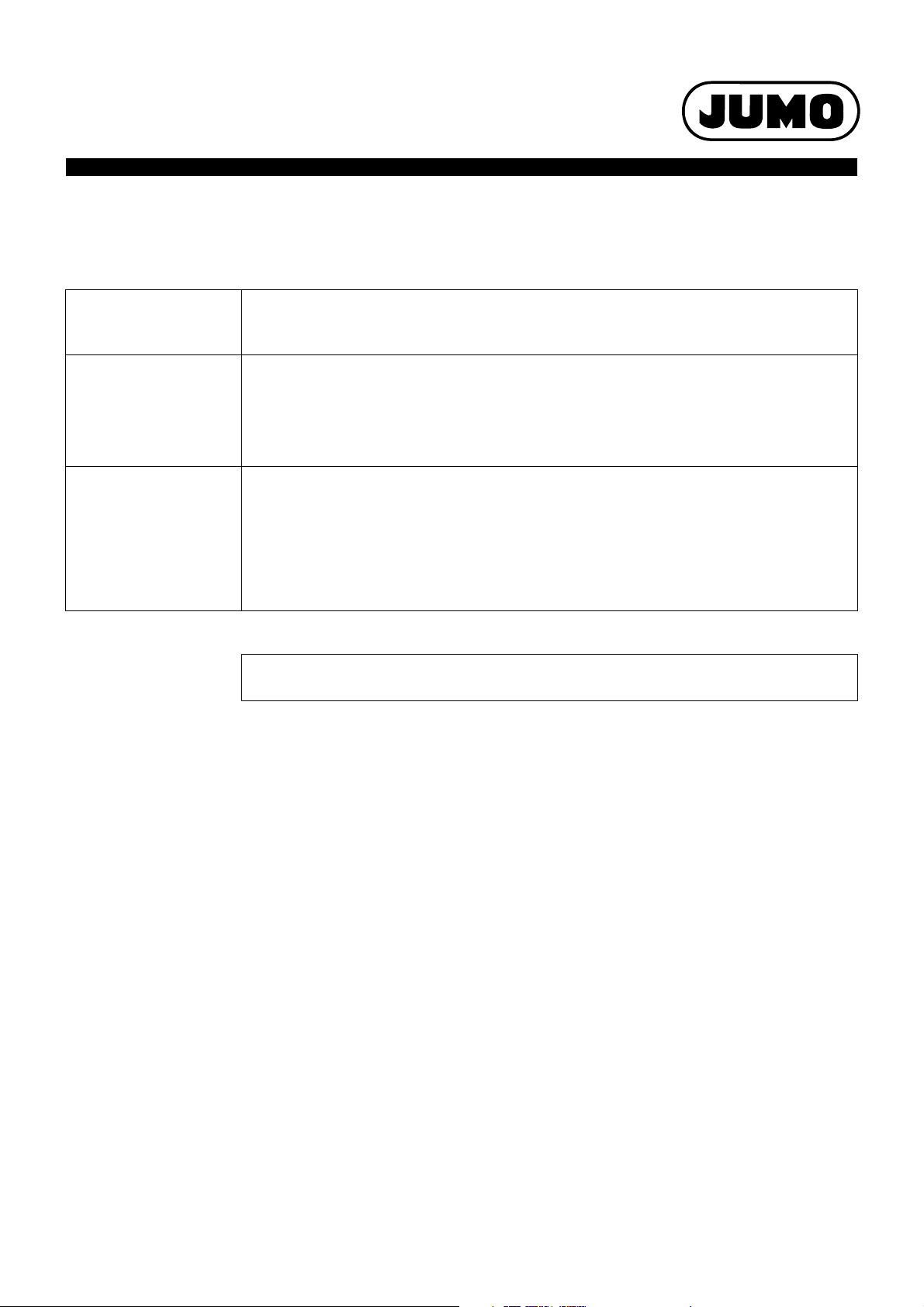

Room thermostat temperature controller TR, type 6

Type 603070/0001

•Protection type IP 54

• Wall mounting

• Individual limitation

of the control range

a

Data Sheet 603070 Page 7/15

Part no. Type Control range °CCapillary mmProbe−∅

(d) × L mm

60003191 JUMO

60003192

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

heatTHERM-AT/

0001

-10 to +40

0 to +50

- - - - 1.5 - 2 K Spiral probe

Switching

differential

Process connection

Room thermostat temperature limiter TW, type 6

Type 603070/0002

•Protection type IP 54

• Wall mounting

• Switching value check through in-

spection window in the case lid

Part no. Type Control range °CCapillary mmProbe−∅

60003193 JUMO

60003194

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

a

heatTHERM-AT/

0002

-10 to +40

0 to +50

(d) × L mm

Switching

differential

Process connection

- - - - 1.5 - 2 K Spiral probe

2013-03-15/00485234

Page 8

Data Sheet 603070 Page 8/15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Devices in stock: JUMO heatTHERM-AT

Temperature controller / safety temperature monitor TR/STW, type 5

Type 603070/0120

•Protection type IP 54

• Switching value check through inspection window in the case lid

• Compensation of the ambient temperature

• Capillary break protection for STW

a

Part no. Type Control range °C Capillary mmProbe−∅

(d) × L mm

60003195

JUMO

heatTHERM-AT/

60003231

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

0120

TR: 0 to +120

STW: 70 to +130 6 x 60 Approx. 10 K

TR: 0 to +120 6 × 87 Approx. 3 K

2000

STW: 70 to +130 6 x 60 Approx. 10 K

6 × 87 Approx. 3 K

Switching

differential

Process connection

With internal capillary and contact probe

Thermowell; brass nickel-plated

Temperature controller / safety temperature limiter TR/STB, type 5

Type 603070/0170

•Protection type IP 54

• Switching value check through inspection window in the case lid

• Compensation of the ambient temperature

• Capillary break protection for STW

a

Part no. Type Control range °C Capillary mmProbe−∅

(d) × L mm

60003196

JUMO

heatTHERM-AT/

60003232

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

2013-03-15/00485234

0170

TR: 0 to +120

STB: 70 to +130 6 x 60 Approx. 10 K

TR: 0 to +120 6 × 87 Approx. 3 K

2000

STB: 70 to +130 6 x 60 Approx. 10 K

6 × 87 Approx. 3 K

Switching differential/

unlocking difference

Process connection

With internal capillary and

contact probe

Thermowell; brass nickelplated

Page 9

Data Sheet 603070 Page 9/15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Devices in stock: JUMO heatTHERM-AT

Room thermostat temperature monitor / temperature monitor TW/TW, type 6

Type 603070/0202

•Protection type IP 54

• Wall mounting

• Switching value control through inspection window in the case lid

a

Part no. Type Control range °C Capillary mmProbe−∅

(d) × L mm

60003212 JUMO

60003213

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

heatTHERM-AT/

0202

-10 to +40

0 to +50

- - - - 1.5 - 2 K Spiral probe

Switching

differential

Process connection

Flue gas temperature monitor with mounting sleeve, design 5

Type 603070/0020

• Switching value check through in-

spection window in the case lid

• Max. allowable probe temperature

+600 °C

• Approval as ATW with capillary

break protection according to

DIN EN 14597

• Time constant t0.632 ≤ 45 sec. in

flue gas

a

Part no. Type Control range °C Capillary mmProbe−∅

(d) × L mm

Switching

differential

Process connection

JUMO

60003390

heatTHERM-AT/

+20 to +280 - - 6 mm Approx. 18 K Intermediate piece with mounting flange

0020

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

2013-03-15/00485234

Page 10

Data Sheet 603070 Page 10/15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Devices in stock: JUMO heatTHERM-DR

Thermostat for DIN rail installation TH35, according to DIN EN 60715, type 7

Type 603070/....-

•Protection type IP 20

• DIN rail installation TH35

• Easy to assemble and user friendly

a

Part no. Type Control range °CCapillary mmProbe−∅

(d) × L mm

Switching

differential

Process connection

Temperature monitor TW

60003283 603070/0002 0 to +120

60003284 603070/0002 0 to +200 6 x 78 Approx. 5 K

2000

60003285 603070/0002 +50 to +300 6 x 66 Approx. 6 K

6 × 87 Approx. 3K

With capillary and

contact probe

Safety temperature monitor STW

60003286 603070/0020

+70 to +130 2000 6 x 60 Approx. 10 K

With capillary and

contact probe

Unlocking

Safety temperature limiter STB

60003287 603070/0070 +70 to +130

60003299 603070/0070

60003300 603070/0070

a

Further design versions (control range, switching differential, process connection) upon request - minimum order quantity 100 pieces. Thermowells page 15.

+20 to +150 6 × 63

2000

+50 to +300 6 × 63

6 x 60 Approx. 10K

difference

In the upper third approx. 15 K

At the scale beginning approx. 30 K

In the upper third approx. 25 K

At the scale beginning approx. 45 K

With capillary and

contact probe

2013-03-15/00485234

Page 11

Data Sheet 603070 Page 11/15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

JUMO heatTHERM-DR

Thermostat for DIN rail installation TH35, according to DIN EN 60715, type 8

Type 603070/0002-8

•Protection type IP 20

• DIN rail installation TH35

• Easy to assemble and user friendly

a

Fastening hole ( 1 )

= ∅ 4.5 mm

a

Upon request - minimum order quantity 100 pieces.

2013-03-15/00485234

Page 12

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details

Surface-mounted thermostat JUMO heatTHERM, type 603070

Order code (1) Basic type

603070 JUMO heatTHERM with single-pole snap-action switch

(2) Basic type extension

0001 Temperature controller (TR)

0002 Temperature monitor (TW)

0020 Safety temperature monitor (STW) or flue gas temperature monitor (ATW)

0070 Safety temperature limiter (STB)

0120 Temperature controller / safety temperature monitor (TR/STW)

0170 Temperature controller / safety temperature limiter (TR/STB)

0202 Temperature monitor / temperature monitor (TW/TW)

(3) Type

5 Surface-mounted thermostat,

with thermowell, flange sleeve, capillary, or as contact probe

Data Sheet 603070 Page 12/15

Minimum purchase order 100 pieces

6 Room thermostat

with spiral probe

7 DIN rail thermostat,

with capillary

8 DIN rail thermostat,

with spiral probe

(4) Control range / limit value range 1 [°C]

016 -10 to +40 TR, TW

021 0 to +50 TR, TW

026 0 to +120 TR, TW

028 0 to +200 TR, TW, STB

040 +20 to +80 STW

043 +20 to +150 TR, TW, STB

064 +50 to +300 TR, TW, STB With thermowell, select process connection 76

671 +70 to +130 STW, STB

384 +20 to +280 ATW Only with process connection 80

Further control ranges / limit value ranges up to 350 °C upon request (up to +500 °C without approval)

(5) Control range / limit value range 2 [°C]

000 Single thermostat

016 -10 to +40 TR, TW Adjustable

021 0 to +50 TR, TW Adjustable

671 +70 to +130 STW, STB Adjustable

Further control ranges / limit value ranges up to 350 °C upon request (up to +500 °C without approval)

2013-03-15/00485234

Page 13

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details

Surface-mounted thermostat JUMO heatTHERM, type 603070

Order code (6) Switching differential 1

00 Without switching differential (STB)

25 2.5 % of the scale range

70 7 % of the scale range

(7) Switching differential 2

00 Without switching differential (STB)

25 2.5 % of the scale range

70 7 % of the scale range

(8) Capillary length 1

0 0 mm only for room thermostat

2000 2000 mm

Special length upon request

(9) Capillary length 2

0 0 mm only for room thermostat

2000 2000 mm

Special length upon request

Data Sheet 603070 Page 13/15

(10) Material of capillary 1

00 Without capillary

20 CrNi Stainless

steel

40 Cu Copper

(11) Material of capillary 2

00 Without capillary Single thermostat

20 CrNi Stainless

steel

40 Cu Copper

(12) Process connection

10 Plain cylindrical probe / con-

tact probe

15 Spiral probe

80

a

Intermediate piece with

mounting flange

76

b

Intermediate piece

a

Only control ranges +20 to +280 °C (ATW) selectable.

b

For process connection 76, select sheath according to data sheet 606710, screw-in sheath "20" U with thread G1/2 made of stainless steel (CrNi).

2013-03-15/00485234

Page 14

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Order details

Surface-mounted thermostat JUMO heatTHERM, type 603070

Order code (13) Diameter 1

6 ∅ 6 mm

17 ∅ 17 mm Spiral probe for room thermostat (with process connection 15)

(14) Diameter 2

00 Single thermostat

6 ∅ 6 mm

17 ∅ 17 mm Spiral probe for room thermostat (with process connection 15)

(15) Probe material 1

20 CrNi Stainless steel

40 Cu Copper

(16) Probe material 2

00 Single thermostat

20 CrNi Stainless steel

40 Cu Copper

Data Sheet 603070 Page 14/15

(17) Capillary insulation

00 No protective tube

13 PVC tube, black

(18) Insulation length (from case)

0No protective hose

460 460 mm

Special length upon request

(19) Extra codes

a

000 Without extra codes

061 With UL approval

402 Case protection type IP54

702 Snap-action switch, gold-plated

749 Setting range with 250 angular degrees (only STB/STW)

758 Tightening band for contact probe

a

List extra codes in sequence, separated by commas.

Order code

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14) (15) (16) (17) (18) (19)

6073070 / - - - - - - - - - - - - - - - - / , . . .

Order example

a

603070 / 0001 - 5 - 021 - 671 - 70 - 00 - 2000 - 00 - 40 - 00 - 10 - 6 - 00 - 20 - 20 - 00 - 0 / 000

a

List extra codes in sequence, separated by commas.

, . . .

2013-03-15/00485234

Page 15

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Accessories

(according to product group 606710)

Data Sheet 603070 Page 15/15

Thermowell set Thermowell with sealing collar Clamp for

strain relief

Suitable for

1 probe

Part no. Type Abbrevia-

tion

60003177 Thermowell

28 G 1/2 8 × 100 mm

Connection

∅ sleeve × fitting length EL Material Pressure loading

for JUMO

60003171 8 x 200 mm

heatTHERM,

1 probe

60003172 8 × 100 mm

60003173 8 x 200 mm

Thermowell set Thermowell with sealing collar Clamp for

strain relief

Suitable for

2 probes

Part no. Type Abbrevia-

tion

60003178 Thermowell

60003204 2 x 8 x 150 mm

60003174 2 x 8 x 200 mm

for JUMO

heatTHERM,

2 probes

29 G 1/2 2 × 8 × 100 mm

Connection

∅ sleeve × fitting length EL Material Pressure loading

Plate for

surface-mounted

thermostat

Brass/

nickel-plated

Stainless steel /

1.4571

Plate for

surface-mounted

thermostat

Brass /

nickel-plated

Screw for

surface-mounted

thermostat

capacity at +150 °C

48 bar60003203 8 x 150 mm

88 bar60003205 8 x 150 mm

Screw for

surface-mounted

thermostat

capacity at +150 °C

48 bar

Thermowell set Thermowell with sealing collar Pressure

spring

Clamp for

strain relief

Plate for

surface-mounted

thermostat

Suitable for

2 probes

Part no. Type Abbrevia-

tion

60003175 Thermowell

60003206 15 x 150 mm

60003176 15 x 200 mm

for JUMO

heatTHERM,

2 probes

49 G 1/2 15 × 100 mm

Connection

∅ sleeve × fitting length EL Material Pressure loading

Stainless steel /

1.4571

Adapter piece for thermowell Material

Part no.

00507273

Steel / nickelplated

2013-03-15/00485234

Screw for

surface-mounted

thermostat

capacity at +150 °C

48 bar

Loading...

Loading...