LS-2342, 2342-7

INSTRUCTION MANUAL

CONTENTS

1. SPECIFICATIONS ............................................................................................................ 1

2. INSTALLATION

2-1. Attaching the drain container ............................................................................................................3

2-2. Installation of the sewing machine ....................................................................................................3

2-3. Pneumatic components ......................................................................................................................5

2-4. Installing the thread stand .................................................................................................................6

................................................................................................................ 3

3. PREPARATION OF THE SEWING MACHINE ................................................................ 7

3-1. Lubrication ...........................................................................................................................................7

3-2. Attaching the needle ...........................................................................................................................8

3-3. Attaching and removing the bobbin .................................................................................................. 8

3-4. Threading the hook ............................................................................................................................. 9

3-5. Winding a bobbin ................................................................................................................................ 9

3-6. Threading the machine head ...........................................................................................................10

3-7. How to set the model of the machine head .................................................................................... 11

3-8. Adjusting the machine head ............................................................................................................12

4. ADJUSTING THE SEWING MACHINE .........................................................................14

4-1. Adjusting the stitch length ...............................................................................................................14

4-2. Thread tension ..................................................................................................................................15

4-3. Thread take-up spring ......................................................................................................................16

4-4. Adjusting the pressure of the presser foot ..................................................................................... 16

4-5. Needle-to-hook relation .................................................................................................................... 17

4-6. Adjusting the hook needle guard ....................................................................................................18

4-7. Adjusting the bobbin case opener ..................................................................................................18

4-8. Position of the counter knife and adjustment of the knife pressure (LS-2342S-7, 2342H-7) ..... 19

4-9. Adjusting the amount of the alternating vertical movement of the walking foot and the presser

foot .....................................................................................................................................................19

5. OPERATION OF THE SEWING MACHINE ................................................................... 20

5-1. Hand lifter ..........................................................................................................................................20

5-2. Resetting the safety clutch ..............................................................................................................20

5-3. Fixing the feed adjusting dial ...........................................................................................................20

5-4. Normal-/reverse-feed stitch needle entry points alignment at the time of automatic reverse

feed stitching (LS-2342S-7, 2342H-7) ..............................................................................................21

5-5. Operation switches ........................................................................................................................... 22

5-6. Knee switch (LS-2342S-7, 2342H-7) .................................................................................................24

6. SEWING SPEED TABLE ............................................................................................... 27

7. TROUBLES IN SEWING AND CORRECTIVE MEASURES

......................................... 28

i

1. SPECIFICATIONS

No. Item Application

1 Model LS-2342S LS-2342S-7

2 Model name Cylinder-bed, 1-needle, unison-feed,

lockstitch machine

(Standard type)

3 Application Medium- to heavy-weight materials, car seat, furniture

4 Sewing speed Max. 2,500 sti/min (See "6. SEWING SPEED TABLE" p.27.) *1

5 Needle SCHMETZ 134-35

(Nm 100 to Nm 180, Standard : Nm 140)

6 Applicable thread size for sewing #40 to #5

(US : #33 to #138, Europe : 90/3 to 20/3)

7 Applicable thread size to be cut #30 to #5

8 Stitch length Max. 9 mm (forward/reverse feed)

9 Stitch length dial 1-pitch dial 2-pitch dial

10 Presser foot lift Hand lifter : 10 mm, Automatic presser foot lifter : 20 mm

11 Stitch length adjusting mechanism By dial

12 Reverse stitch adjusting method By lever Air cylinder type

13 Thread take-up Link type

14 Needle bar stroke 40 mm

15 Amount of the alternate vertical

movement

16 Hook Full-rotary vertical-axis 1.6-fold hook (Latch type)

17 Feed mechanism Elliptical feed

18 Top and bottom feed actuation

mechanism

19 Thread trimming method Cam-driven scissors type

20 Lubrication Concentrated tank type oil wick lubrication (partially by manual)

21 Lubricating oil JUKI New Defrix Oil No. 2 (equivalent to ISO standard VG32)

22 Tube diameter 72 mm

23 Space under the arm 347 mm × 127 mm

24 Hand wheel size Outer diameter : ø123 mm

25 Motor/Control box SC-922B

26 Machine head weight 61 kg 63 kg

27 Rated power consumption 310VA

28 Noise

- Equivalent continuous emission sound

pressure level (LpA) at the workstation:

A-weighted value of 83.0 dB; (Includes

KpA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 11204 GR2 at 2,500 sti/min.

- Sound power level (LWA);

A-weighted value of 89.5 dB; (Includes

KWA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 3745 GR2 at 2,500 sti/min.

1 mm to 9 mm (Alternate vertical dial adjustment type)

Timing belt

Cylinder-bed, 1-needle, unison-feed,

lockstitch machine with automatic thread

trimmer (Standard type)

#30 to #5

(US : #46 to #138, Europe : 60/3 to 20/3)

(US : #46 to #138, Europe : 60/3 to 20/3)

(with touch-back switch)

- Equivalent continuous emission sound

pressure level (LpA) at the workstation:

A-weighted value of 77.5 dB; (Includes

KpA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 11204 GR2 at 2,500 sti/min.

*1 The speed setting according to the amount of the alternating vertical movement of the walking foot and presser

foot is automatically carried out.

– 1 –

No. Item Application

1 Model LS-2342H LS-2342H-7

2 Model name Cylinder-bed, 1-needle, unison-feed,

lockstitch machine

(Thick-thread type)

3 Application Medium- to heavy-weight materials, car seat, furniture

4 Sewing speed Max. 2,000 sti/min (See "6. SEWING SPEED TABLE" p.27.) *1

5 Needle SCHMETZ 134-35

(Nm 100 to Nm 180, Standard : Nm 180)

6 Applicable thread size for sewing #20 to #0 (US : #69 to #266, Europe : 40/3 to 10/3)

7 Applicable thread size to be cut #20 to #0

8 Stitch length Max. 9 mm (forward/reverse feed)

9 Stitch length dial 1-pitch dial 2-pitch dial

10 Presser foot lift Hand lifter : 10 mm, Automatic presser foot lifter : 20 mm

11 Stitch length adjusting mechanism By dial

12 Reverse stitch adjusting method By lever Air cylinder type

13 Thread take-up Link type

14 Needle bar stroke 40 mm

15 Amount of the alternate vertical

movement

16 Hook Full-rotary vertical-axis 1.6-fold hook (Latch type)

17 Feed mechanism Box feed

18 Top and bottom feed actuation

mechanism

19 Thread trimming method Cam-driven scissors type

20 Lubrication Concentrated tank type oil wick lubrication (partially by manual)

21 Lubricating oil JUKI New Defrix Oil No. 2 (equivalent to ISO standard VG32)

22 Tube diameter 72 mm

23 Space under the arm 347 mm × 127 mm

24 Hand wheel size Outer diameter : ø123 mm

25 Motor/Control box SC-922B

26 Machine head weight 61 kg 63 kg

27 Rated power consumption 310VA

28 Noise

- Equivalent continuous emission sound

pressure level (LpA) at the workstation:

A-weighted value of 83.0 dB; (Includes

KpA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 11204 GR2 at 2,000 sti/min.

- Sound power level (LWA);

A-weighted value of 91.0 dB; (Includes

KWA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 3745 GR2 at 2,000 sti/min.

1 mm to 9 mm (Alternate vertical dial adjustment type)

Timing belt

Cylinder-bed, 1-needle, unison-feed,

lockstitch machine with automatic thread

trimmer (Thick-thread type)

(US : #69 to #266, Europe : 40/3 to 10/3)

(with touch-back switch)

- Equivalent continuous emission sound

pressure level (LpA) at the workstation:

A-weighted value of 78.0 dB; (Includes

KpA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 11204 GR2 at 2,000 sti/min.

*1 The speed setting according to the amount of the alternating vertical movement of the walking foot and presser

foot is automatically carried out.

– 2 –

2. INSTALLATION

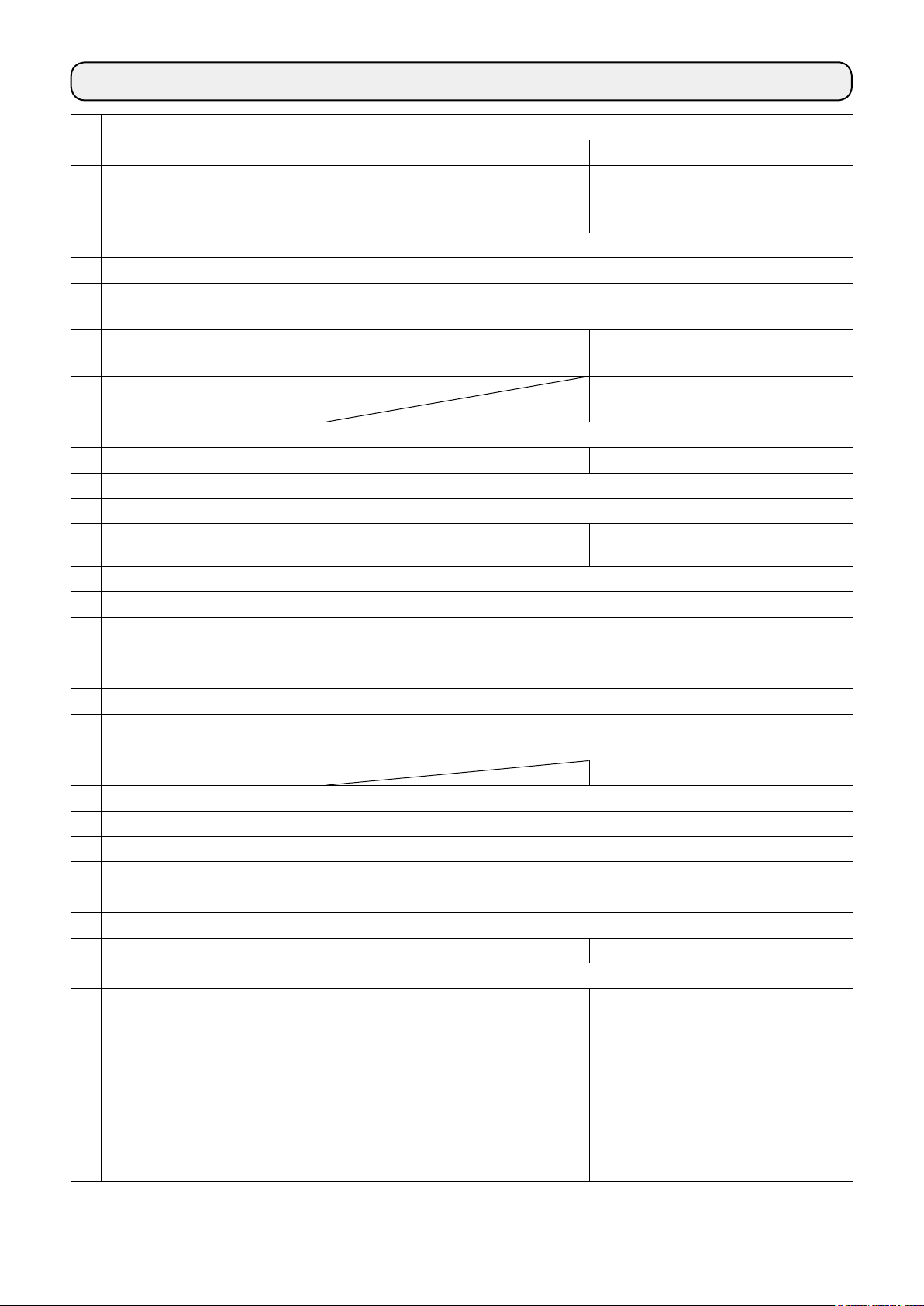

2-1. Attaching the drain container

❷

❸

❶

❹

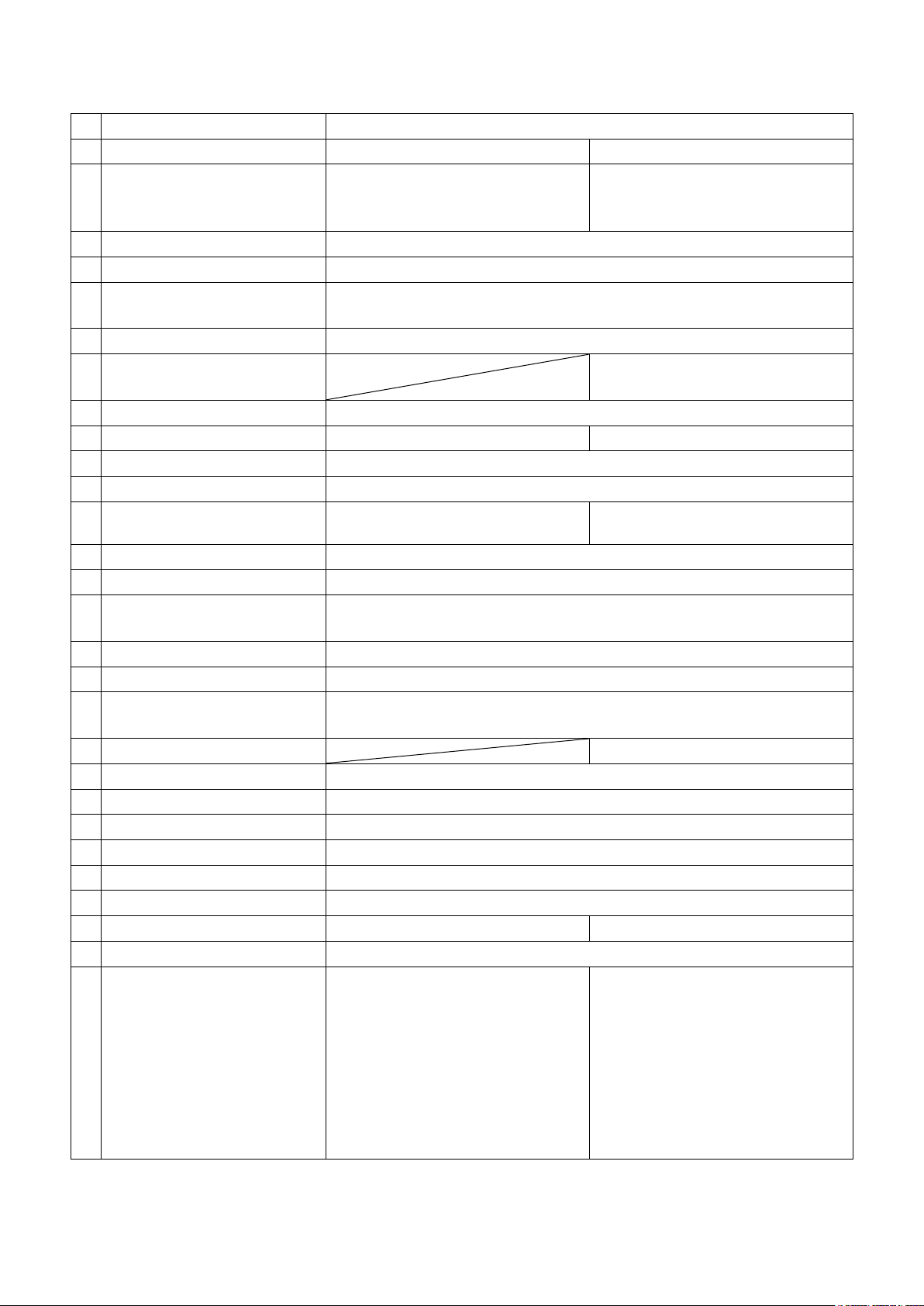

2-2. Installation of the sewing machine

1) Attach oil extractor

machine table, and x it with setscrew ❷ and wash-

er ❸.

2) After xing oil extractor

in the oil extractor.

onto the top surface of the

❶

, screw drain container ❹

❶

❸

❷

1) To prevent possible accidents caused by the full of

the sewing machine, perform the work by two per-

sons or more when the machine is moved.

Loosen bed cover mounting screws

cations) to remove them. Remove bed cover ❷.

Then, carry the sewing machine by holding pulley

cover ❸.

❶

2) Do not put protruding articles such as the screw-

Do not hold the handwheel and the reverse

feed lever.

driver and the like at the location where the sewing

machine is placed.

(three lo-

❶

– 3 –

❺

❻

❹

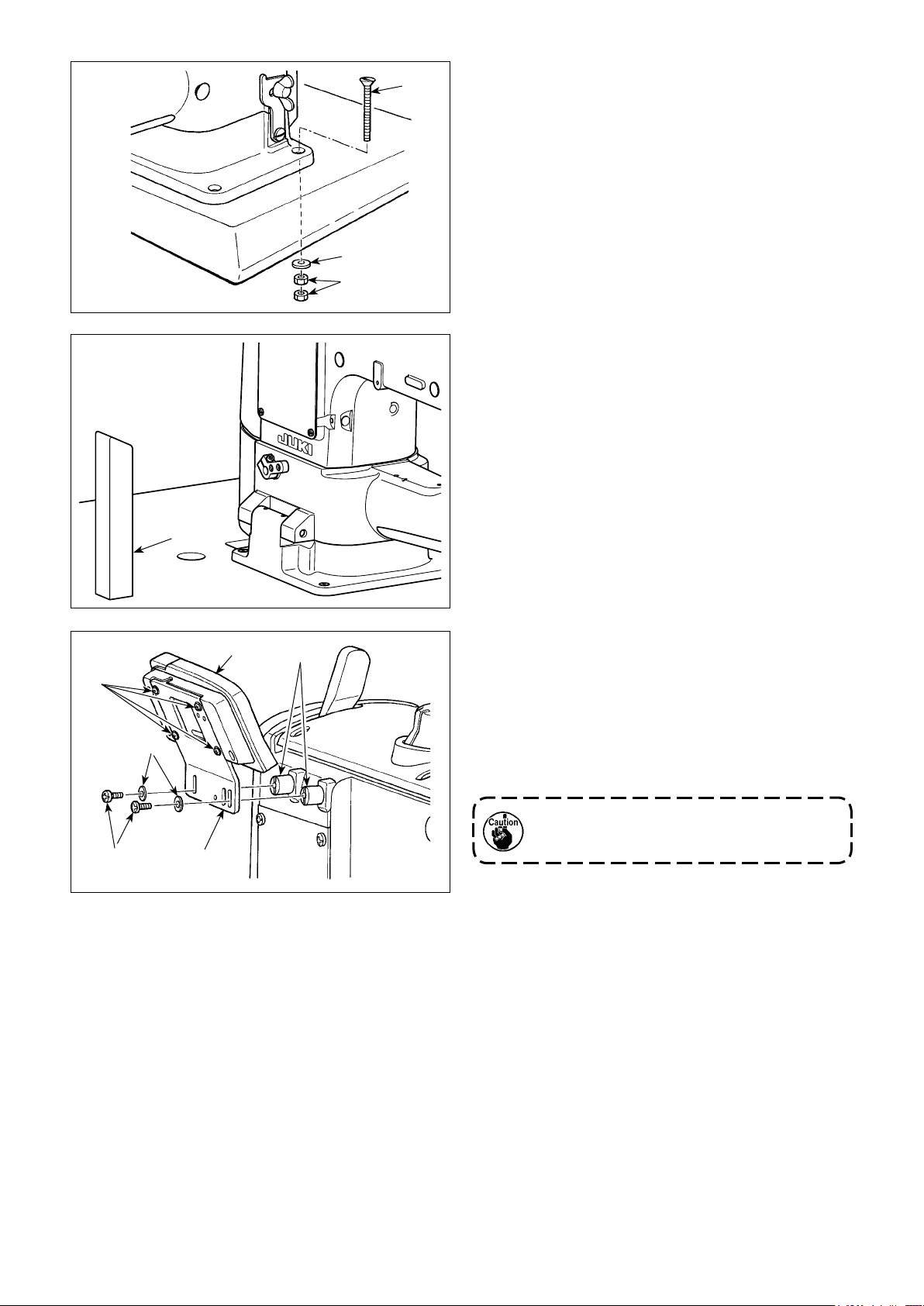

3) Fix the sewing machine in the four places of the ma-

chine table with countersunk screws ❹, washers ❺

and nuts ❻ supplied with the sewing machine.

❼

❾

❽

4) Securely attach head support rod

to the table

❼

until it goes no further.

5) Mount spacers

supplied with the machine head

❽

on the frame.

6) Install bracket

on CP panel ❾ with screws

supplied with the panel.

7) Install bracket

on spacer ❽ with screws sup-

plied with the machine head and washers sup-

plied with the panel.

Do not use the screws supplied the panel

instead of screws supplied with the machine head.

* Accessory screw

supplied with the machine head :

Thread diameter M5; Length 8 mm

– 4 –

2-3. Pneumatic components

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

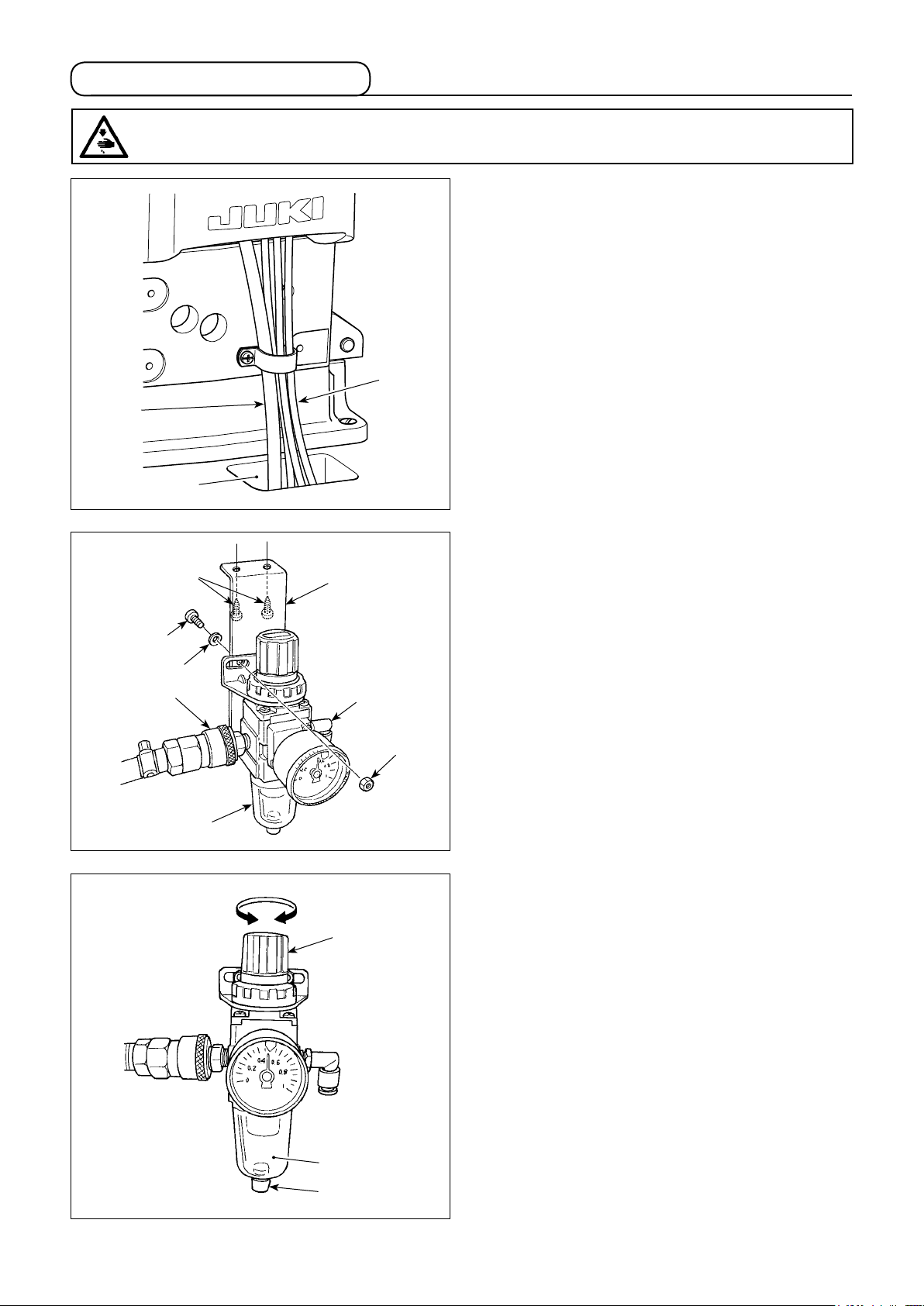

(1) Routing the air tube and cables

Pass the air tube and cables ❶ through hole ❷ in the

table down to the undersurface.

If humidity is high, water may leak from ø8 air tube ❸

for exhaust coming from the sewing machine.

❶

❸

❷

❽

❷

❸

❼

❶

Decrease Increase

❺

❶

❻

❹

(2) Installing the regulator

1) Install regulator (asm.)

screw ❷, spring washer ❸ and nut ❹ which are

supplied with the unit.

2) Install couplings

❻

3) Attach mounting plate

table with accessory screws ❽ supplied with the

plate.

4) Connect ø6 air tube coming from the sewing ma-

chine to coupling ❻.

on mounting plate ❺ with

❶

and ❼ on regulator ❶.

on the undersurface of the

❺

(3) Adjusting the air pressure

1) The operating air pressure is 0.5 to 0.55 MPa.

Adjust the air pressure using air pressure regulating

knob ❶ of the lter regulator.

2) In the case uid accumulation is observed in

tion of the lter regulator, turn drain cock ❷ to drain

the uid.

A

sec-

A

❷

– 5 –

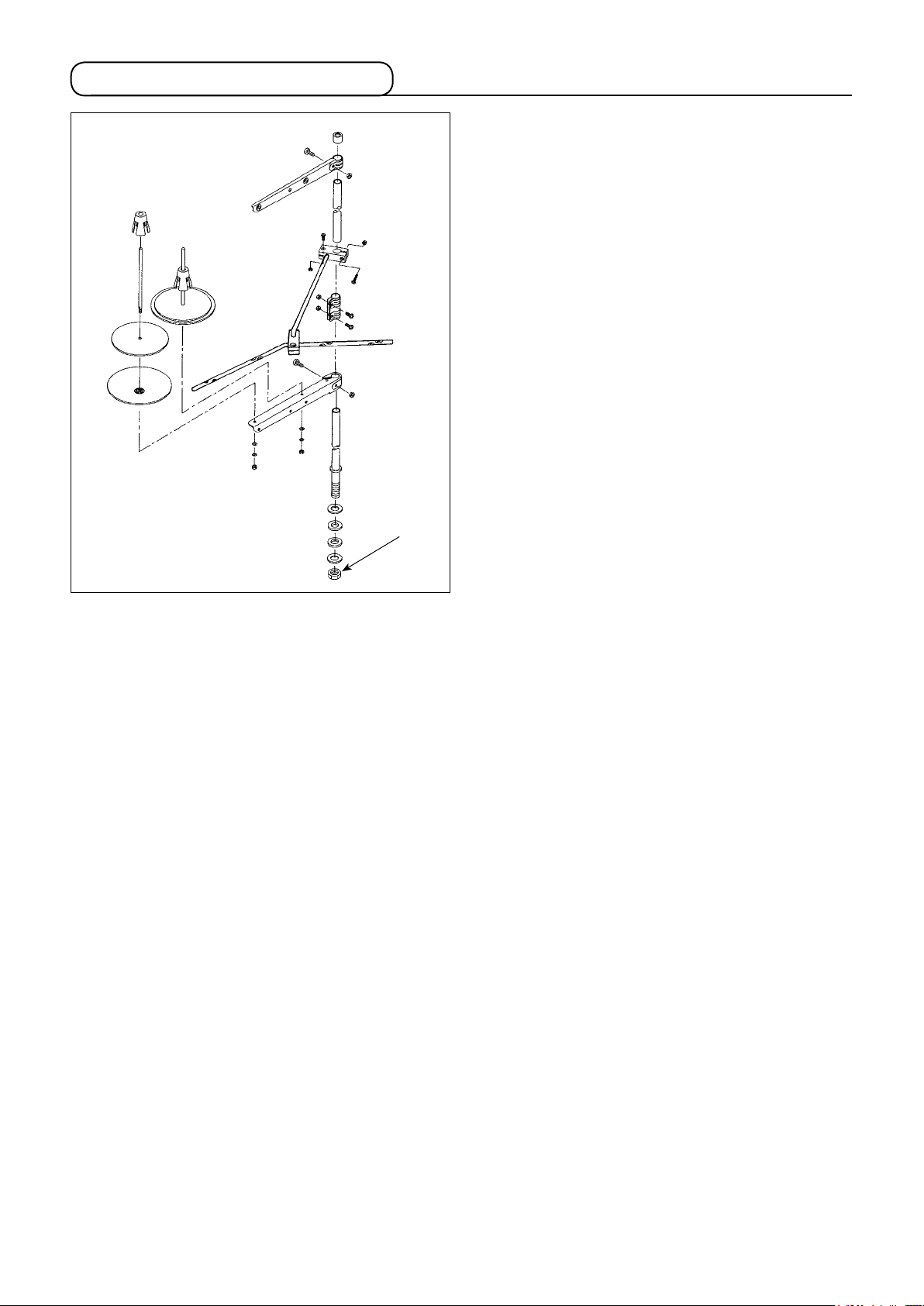

2-4. Installing the thread stand

Assemble the thread stand, set it up on the machine

table using the installation hole in the table and tighten

nut ❶ gently.

❶

– 6 –

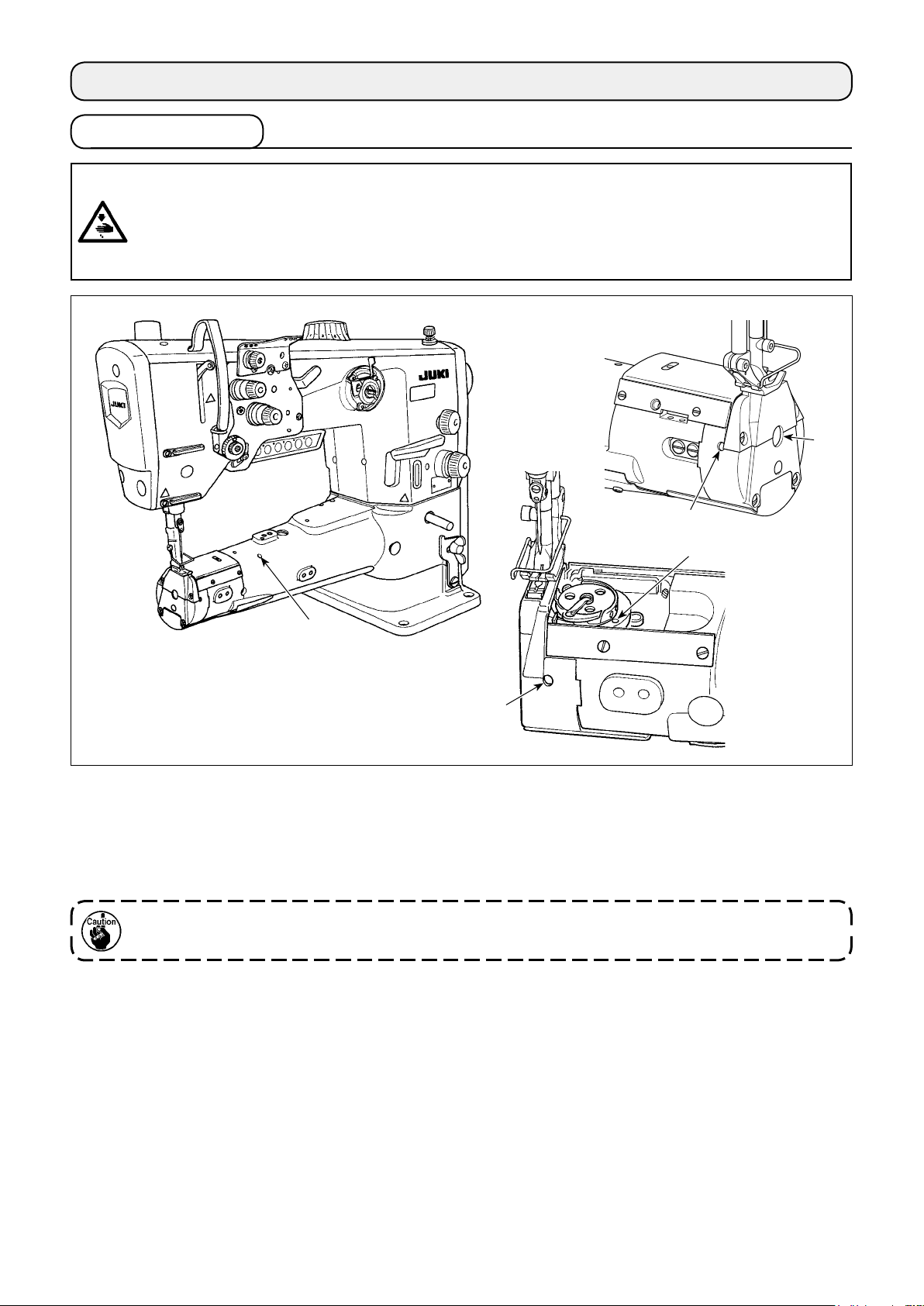

3. PREPARATION OF THE SEWING MACHINE

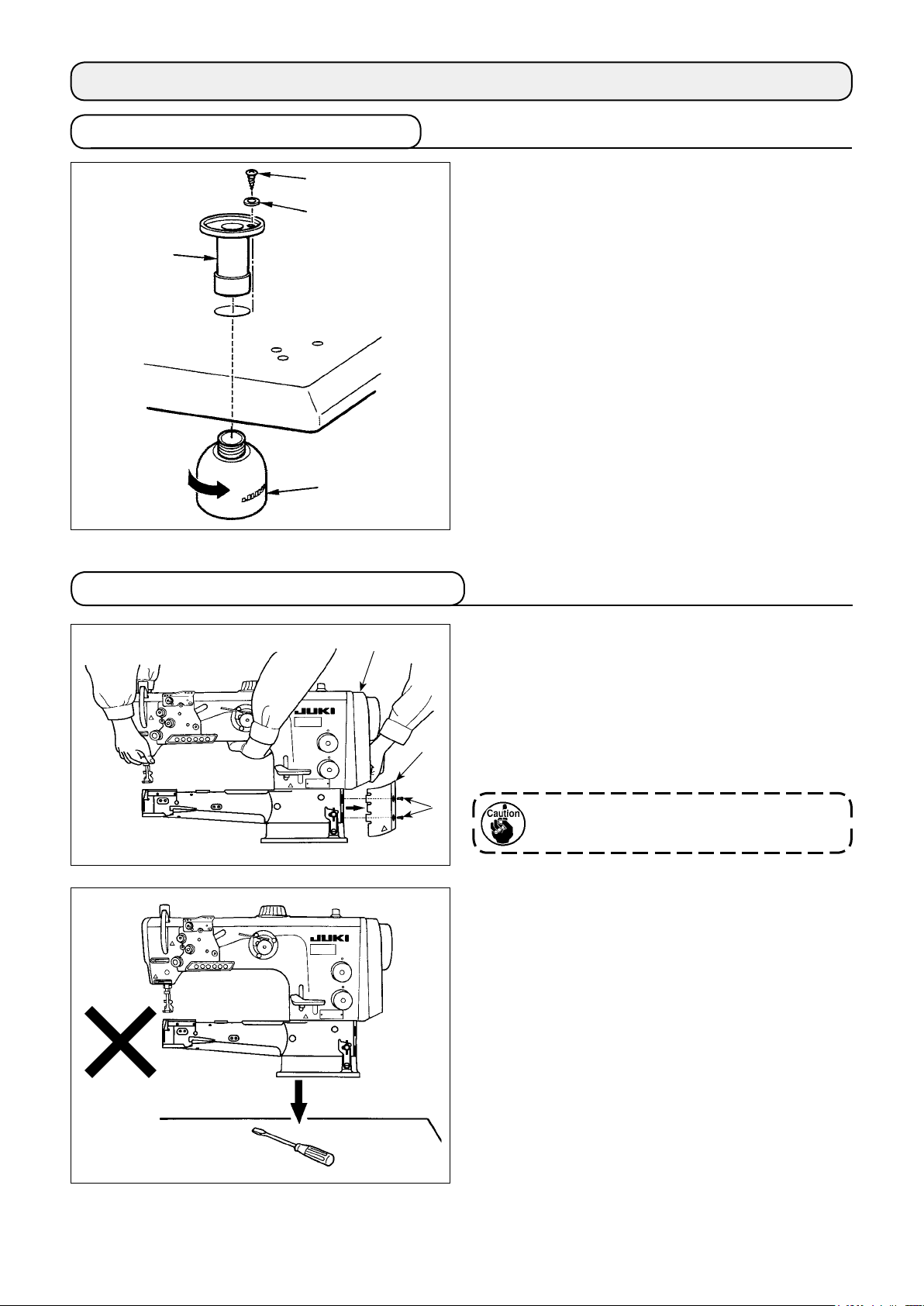

3-1. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent accidents due

to abrupt start of the sewing machine.

2.Topreventtheoccurrenceofaninammationorrash,immediatelywashtherelatedportionsifoiladheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomiting may occur. Put oil in a place where children cannot

reach.

D

A

C

E

B

1) Be sure to lubricate the section indicated with arrows

to D with an adequate amount of oil once a day be-

A

fore starting the operation.

is oil tank. Be sure to add oil to the oil tank approximately once a week.

2)

E

3) Apply appropriate amount of oil to the arrowed sections when you operate the sewing machine for the rst time

after the purchase or after the machine has been left unused for an extended period of time.

If oil is excessively applied to

cally wipe out oil on the throat plate base cover.

A, B, C

and D, oil may drop from the throat plate base cover. Periodi-

– 7 –

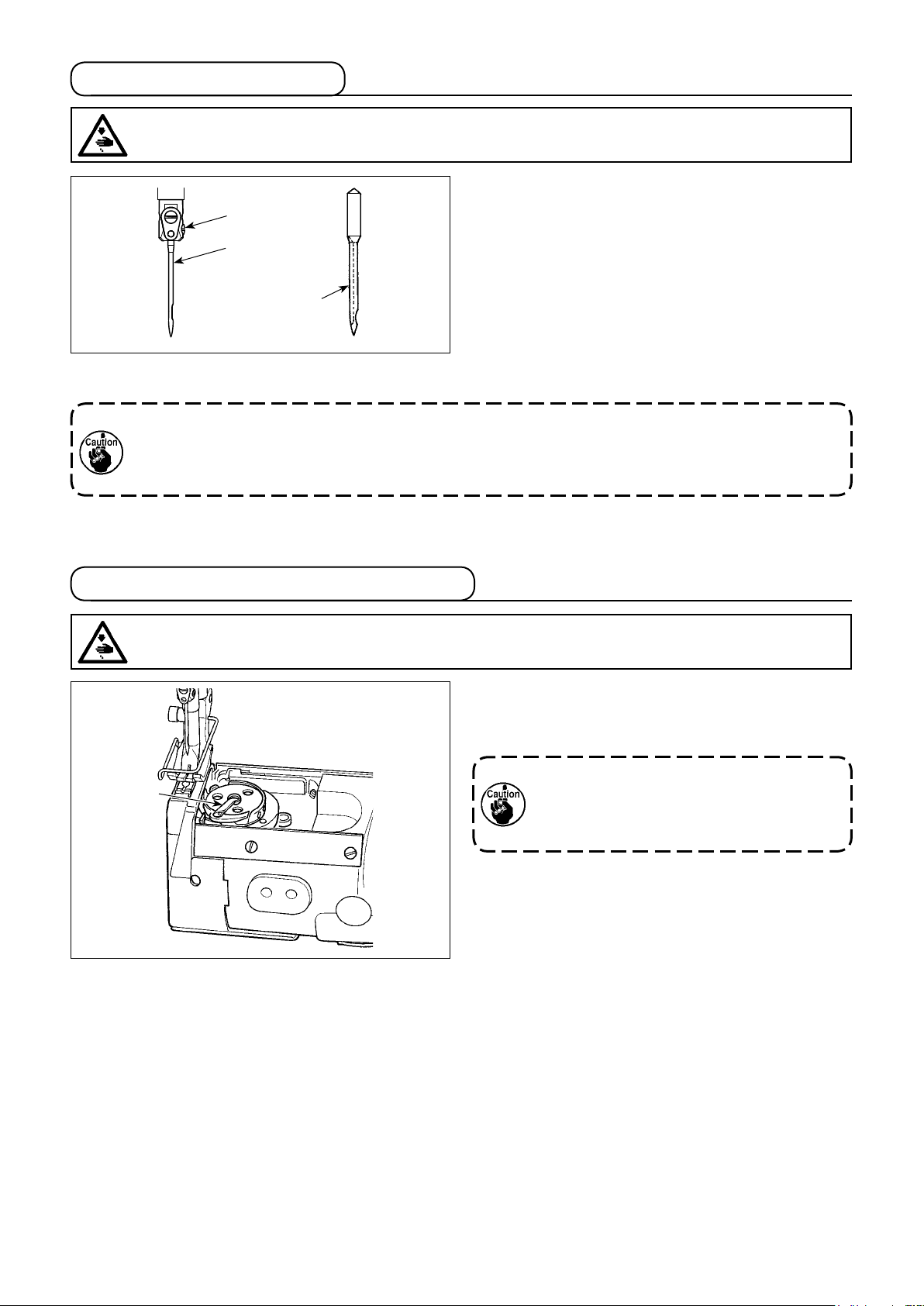

3-2. Attaching the needle

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Use 134-35 needles.

❷

❶

Long groove

When replacing the needle, check the clearance provided between the needle and the blade point

of hook. (Refer to "4-5. Needle-to-hook relation" p.17 and "4-6. Adjusting the hook needle guard"

p.18.)

If there is no clearance, the needle and the hook will be damaged.

1) Turn the handwheel to bring the needle bar to the

highest position of its stroke.

2) Loosen needle clamp screw

. Hold the needle so

❷

that the long groove on needle ❶ faces directly to

the right.

3) Push needle

deep into the needle clamp hole

❶

until it will go no further.

4) Tighten needle clamp screw

rmly.

❷

3-3. Attaching and removing the bobbin

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

1) Lift latch

2) Put the bobbin into the shaft in the hook correctly

and release the latch ❶.

❶

of hook, and take out the bobbin.

❶

Do not make the machine run idle with the

bobbin (bobbin thread). The bobbin thread

is caught in the hook. As a result, the hook

may be damaged.

– 8 –

Loading...

Loading...