Page 1

ENGLISH

LBH-1790 / IP-310

INSTRUCTION MANUAL

Page 2

CONTENTS

1. NAME OF EACH SECTION OF THE OPERATION PANEL ............................................4

1-1 Body ..........................................................................................................................4

1-2 Buttons to be used in common ..............................................................................6

2. BASIC OPERATION OF THE SEWING MACHINE .........................................................7

3. LCD DISPLAY SECTION AT THE TIME OF INDEPENDENT SEWING .........................9

3-1 Data input screen ....................................................................................................9

3-2 Sewing screen .......................................................................................................12

4. HOW TO USE THE PEDAL ...........................................................................................15

4-1 Setting procedure of the pedal type ....................................................................15

4-2 Explanation of pedal motion ................................................................................17

5. INPUTTING THE PRESSER TYPE ...............................................................................18

5-1 Setting procedure of the presser type.................................................................18

5-2 Table of presser type .............................................................................................19

6. PERFORMING PATTERN NO. SELECTION .................................................................20

6-1 Selection from the data input screen ..................................................................20

6-2 Selection by means of DIRECT button ................................................................21

7. NAMING THE PATTERN ...............................................................................................22

8. PERFORMING SEWING SHAPE SELECTION .............................................................23

9. CHANGING NEEDLE THREAD TENSION ...................................................................25

10. PERFORMING RE-SEWING .......................................................................................27

10-1 To continue performing sewing from some point in sewing ...........................28

10-2 To perform sewing from the start ......................................................................28

11. WINDING BOBBIN THREAD .......................................................................................29

12. USING COUNTER .......................................................................................................30

12-1 Setting procedure of the counter .......................................................................30

12-2 Count-up releasing procedure ...........................................................................33

13. PERFORMING NEW REGISTRATION OF THE PATTERN ........................................34

14. SEWING SHAPE LIST .................................................................................................36

15. CHANGING SEWING DATA ........................................................................................37

15-1 Initial sewing data at the time of your purchase ..............................................37

15-2 Changing procedure of sewing data .................................................................38

15-3 Sewing data list ...................................................................................................40

16. SETTING PROCEDURE OF SEWING DATA WITH/WITHOUT EDIT .........................50

17. COPYING SEWING PATTERN ....................................................................................51

18. REGISTERING THE PATTERN TO DIRECT BUTTON ...............................................53

18-1 How to register ....................................................................................................53

18-2 Register state at the time of your purchase......................................................54

19. REGISTERING SEWING DATA TO CUSTOMIZE BUTTON .......................................55

19-1 How to register ....................................................................................................55

– 1 –

Page 3

– 2 –

19-2 Register state at the time of your purchase......................................................56

20. CHANGING SEWING MODE .......................................................................................57

21. LCD DISPLAY SECTION AT THE TIME OF CONTINUOUS STITCHING ..................58

21-1 Data input screen ................................................................................................58

21-2 Sewing screen .....................................................................................................60

22. PERFORMING CONTINUOUS STITCHING ................................................................63

22-1 Selection of the continuous stitching data ....................................................... 63

22-2 Editing procedure of the continuous stitching data ........................................64

23. LCD DISPLAY SECTION AT THE TIME OF CYCLE STITCHING ..............................67

23-1 Data input screen ................................................................................................67

23-2 Sewing screen .....................................................................................................69

24. PERFORMING CYCLE STITCHING ............................................................................72

24-1 Selection of the cycle data .................................................................................72

24-2 Editing procedure of the cycle data...................................................................73

25. PERFORMING CHANGE OF DISPLAY OF SEWING PRODUCT ..............................75

26. CHANGING MEMORY SWITCH DATA .......................................................................77

26-1 Changing procedure of memory switch data ...................................................77

26-2 Memory switch data list ......................................................................................79

27. EXPLANATION OF PLURAL MOTIONS OF KNIFE ...................................................86

28. ERROR CODE LIST ....................................................................................................89

29. USING COMMUNICATION FUNCTION ......................................................................98

29-1 Handling possible data .......................................................................................98

29-2 Performing communication by using the media ............................................100

29-3 Performing communication by using RS-232C ..............................................103

29-4 Take-in of the data .............................................................................................104

30. INFORMATION FUNCTION .......................................................................................107

30-1 Observing the maintenance and inspection information ..............................108

30-2 Inputting the inspection time ...........................................................................111

30-3 Releasing procedure of the warning ............................................................... 113

30-4 Observing the production control information ............................................... 114

30-4-1 When displaying from the information screen ..................................................... 114

30-4-2 When displaying from the sewing screen ............................................................ 116

30-5 Performing setting of the production control information ............................117

30-6 Observing the working measurement information ........................................121

31. TRIAL SEWING FUNCTION ......................................................................................125

31-1 Performing trial sewing.....................................................................................125

31-2 Vector parameter list .........................................................................................128

31-3 Thread tension value display color list ...........................................................129

32. PERFORMING KEY LOCK ........................................................................................130

33. DISPLAYING VERSION INFORMATION ...................................................................132

34. USING CHECK PROGRAM .......................................................................................133

34-1 Displaying the check program screen.............................................................133

Page 4

34-2 Performing needle thread trimmer origin adjustment ...................................135

34-3 Performing bobbin thread trimmer origin adjustment ...................................136

34-4 Performing sensor check .................................................................................137

34-5 Performing LCD check ......................................................................................139

34-6 Performing touch panel compensation ...........................................................140

35. COMMUNICATION SCREEN OF MAINTENANCE PERSONNEL LEVEL ...............143

35-1 Data which are possible to be handled ...........................................................143

35-2 Displaying maintenance personnel level ........................................................144

36. INFORMATION SCREEN OF THE MAINTENANCE PERSONNEL LEVEL .............145

36-1 Display of error record ......................................................................................145

36-2 Display of the cumulative working information ..............................................147

– 3 –

Page 5

– 4 –

1. NAME OF EACH SECTION OF THE OPERATION PANEL

1-1 Body

( Front ) ( Right side )

!0

6

1

9

8

7

5432

Page 6

1

Touch panel • LCD display section

2

3

4

5

6

MEDIA slot

7

CONNECTOR for RS-232C communication

8

VARIABLE RESISTOR for adjusting contrast

READY key

INFORMATION key

COMMUNICATION key

MODE key

Changeover of the data input screen and the sewing

→

screen can be performed.

Changeover of the data input screen and the

→

information screen can be performed.

Changeover of the data input screen and the

→

communication screen can be performed.

Changeover of the data input screen and the mode

→

changeover screen which performs various detail

settings can be performed.

MEDIA slot (use it with lid closed.)

→

Contrast of the screen can be adjusted. Adjust it as

→

of colored LCD screen

9

CONNECTOR for external input

!0

MEDIA take-out lever

you like.

– 5 –

Page 7

– 6 –

1-2 Buttons to be used in common

The buttons which perform common operations in each screen of IP-310 are as follows :

CANCEL button

ENTER button

UP SCROLL button

DOWN SCROLL button

RESET button

NUMERAL INPUT button

SEWING DATA DISPLAY button

This button closes the pop-up screen. In case of the

→

data change screen, the data being changed can be

cancelled.

This button determines the changed data.

→

This button scrolls the button or the display in the

→

upward direction.

This button scrolls the button or the display in the

→

downward direction.

This button performs the release of error.

→

This button displays ten keys and input of numerals

→

can be performed.

This button displays the sewing data list

→

corresponding to the pattern No. being selected.

CHARACTER INPUT button

PRESSER DOWN button

BOBBIN WINDER button

Refer to

→

This button displays the character input screen.

→

Refer to

→

This button lowers the presser and displays the

→

presser down screen. To raise the presser, press

PRESSER UP button displayed in the presser down

screen.

This button performs bobbin thread winding.

→

Refer to

→

15. CHANGING SEWING DATA, p.37

7. NAMING THE PATTERN, p.22

11. WINDING BOBBIN THREAD, p.29

.

.

.

Page 8

2. BASIC OPERATION OF THE SEWING MACHINE

Turn ON the power switch.

1

First, check that the presser type (A)

which has been set is the same as that of the

presser actually mounted. For checking and

B

setting procedures, refer to

PRESSER TYPE, p.18

Select the pattern No. you desire to sew.

2

When the power is turned ON, the data input

screen is displayed. Pattern No. button (B)

which is selected at present is displayed in the

upper section of the screen. Press the button to

select the pattern No. For selecting procedure

of the pattern No., refer to

PATTERN NO. SELECTION, p.20

When you purchase the sewing machine, Pattern

Nos. 1 to 10 described in

data at the time of your purchase have been

registered, p.37

Select the pattern No. you desire to sew from

among these numbers. (The No. to which the

pattern has not been registered is not displayed.)

.

5. INPUTTING THE

.

6. PERFORMING

.

15-1. Initial sewing

C

※ Forthedetailedexplanationofthisscreen,see

3. LCD DISPLAY SECTION AT THE TIME OF

INDEPENDENT SEWING, p.9

.

A

– 7 –

Page 9

– 8 –

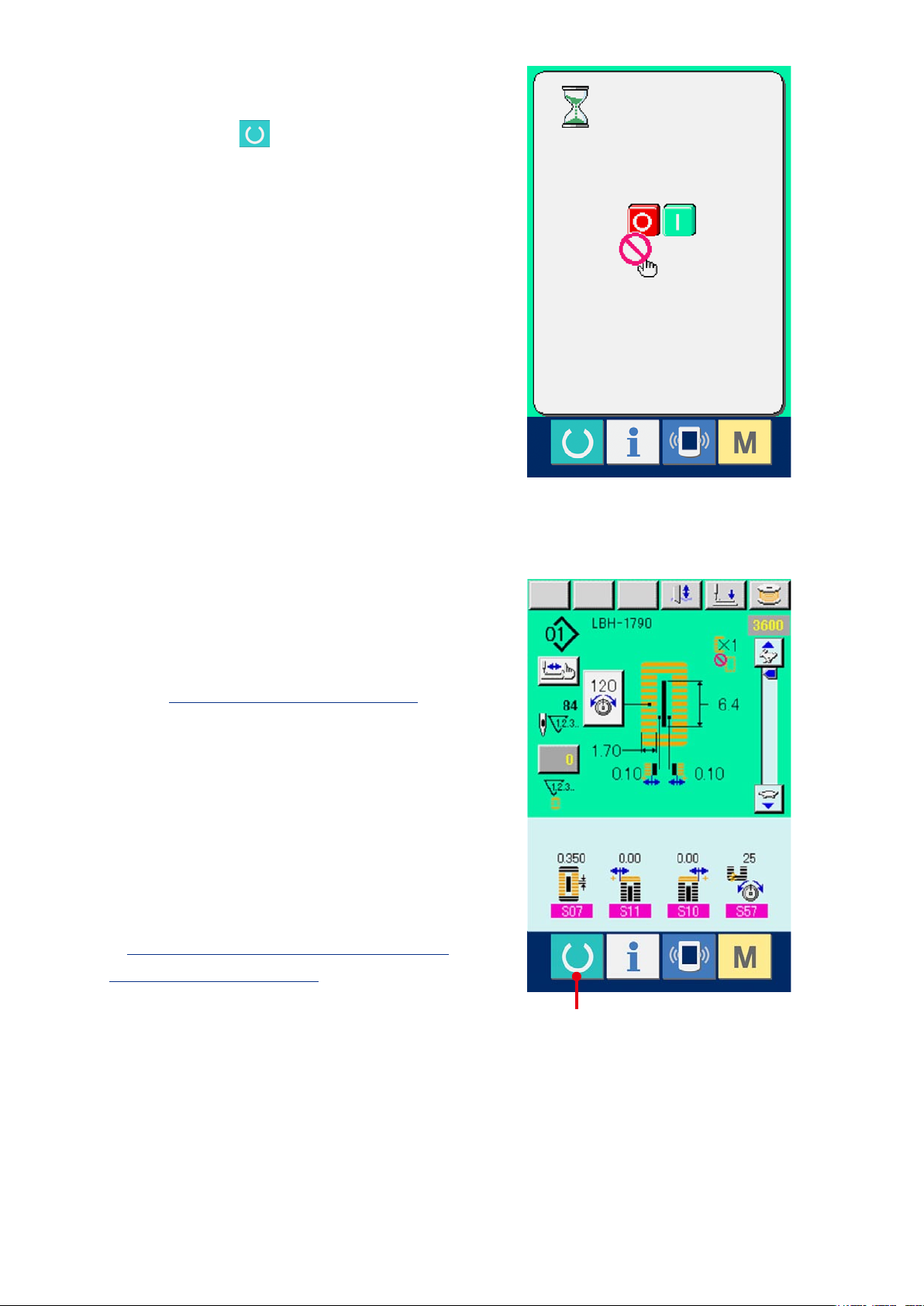

Set the sewing machine to sewing possible

3

state.

Press READY key (C), and POWER OFF

PROHIBITION screen is displayed. Make

preparations for sewing while this screen is

displayed. When the sewing is in a possible state,

the back-light of LCD display changes to green

color.

Start sewing.

4

Set the sewing product to the presser portion,

operate the pedal to start the sewing machine,

and sewing starts.

Refer to

→

4. HOW TO USE THE PEDAL, p.15

.

※ Forthedetailedexplanationofthisscreen,refer

to

3. LCD DISPLAY SECTION AT THE TIME OF

INDEPENDENT SEWING, p.9

.

C

Page 10

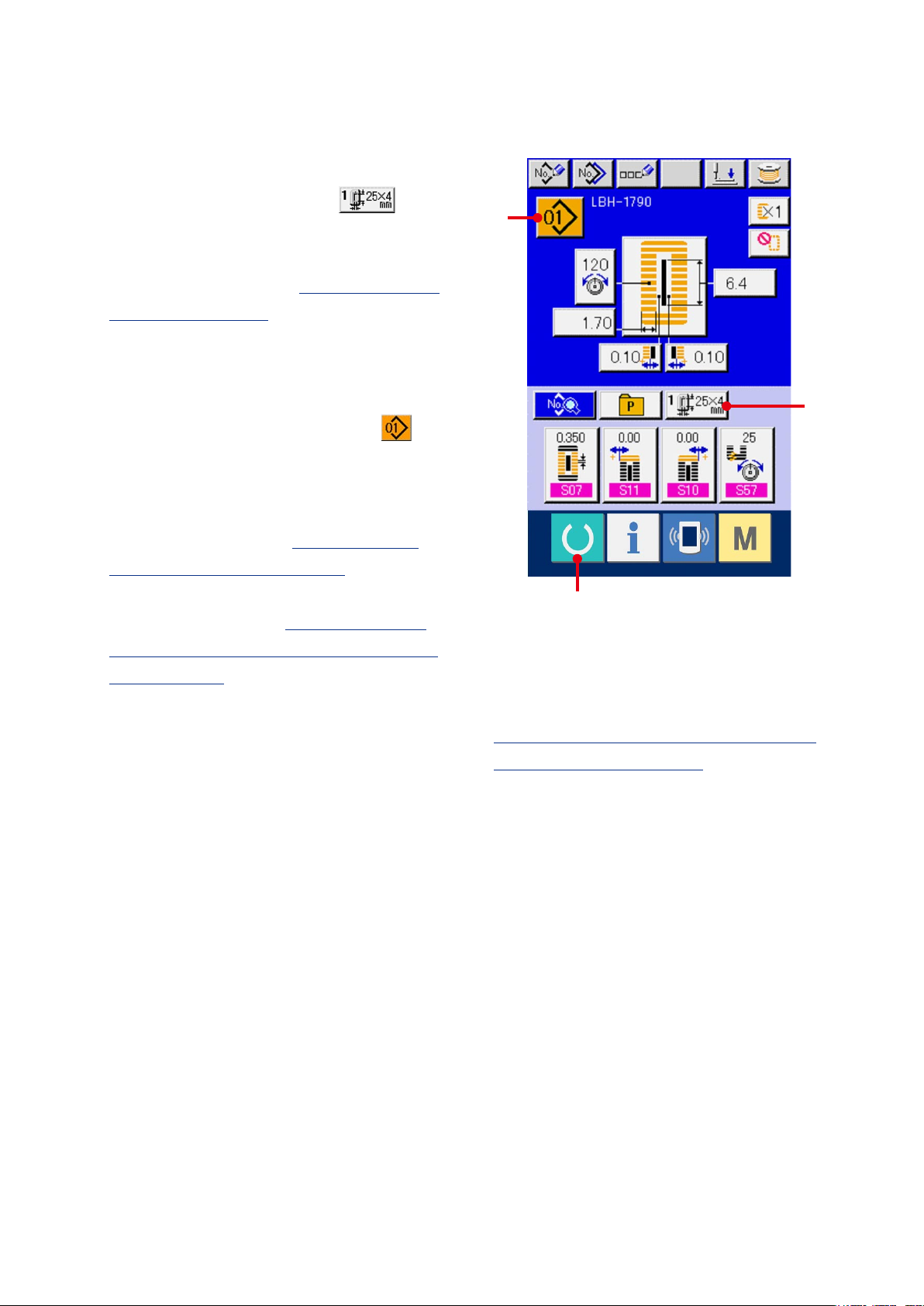

3. LCD DISPLAY SECTION AT THE TIME OF INDEPENDENT SEWING

3-1 Data input screen

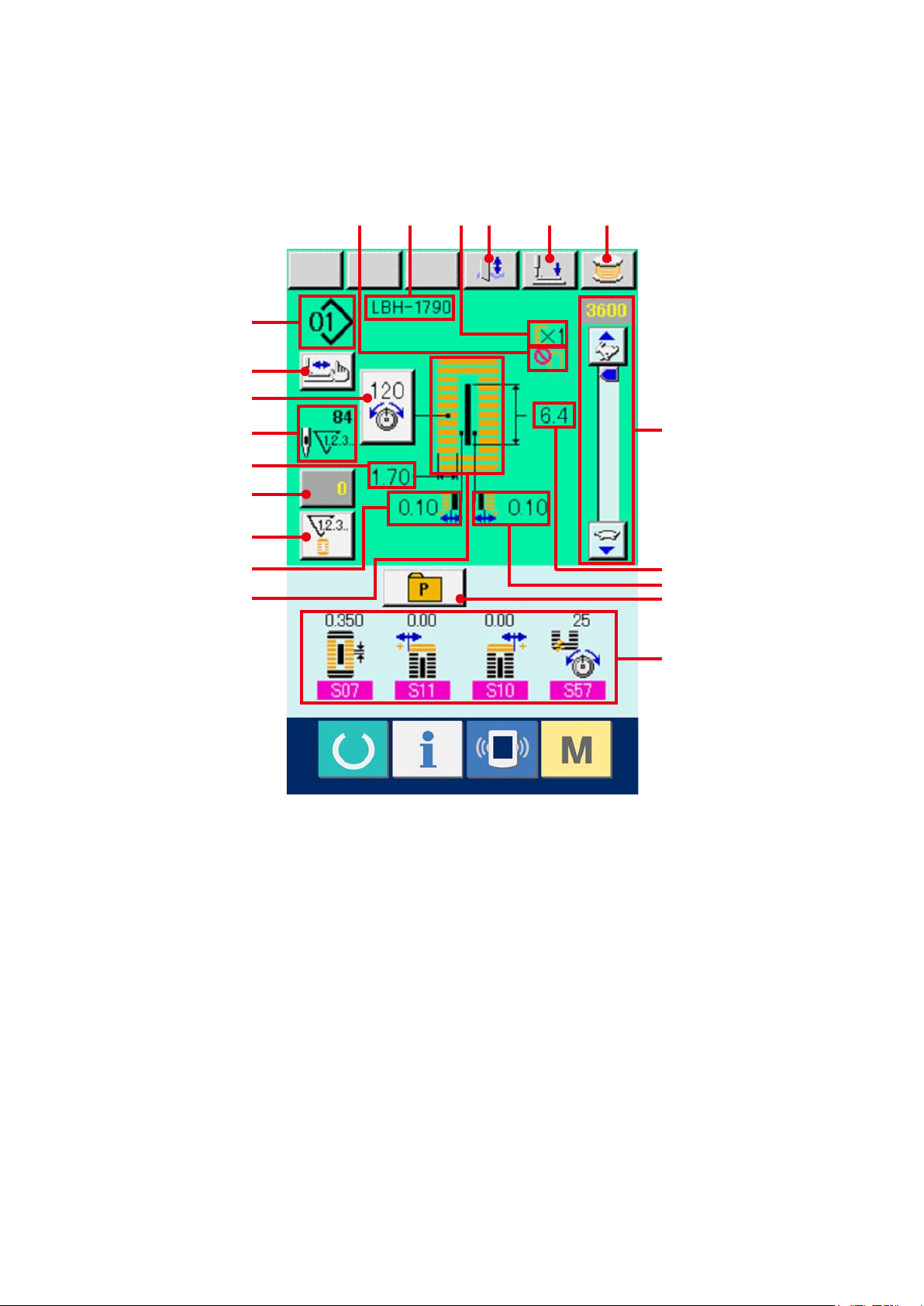

A B C D E F

G

H

I

J

K

L

M

N

O

P

Q

R

S

– 9 –

Page 11

– 10 –

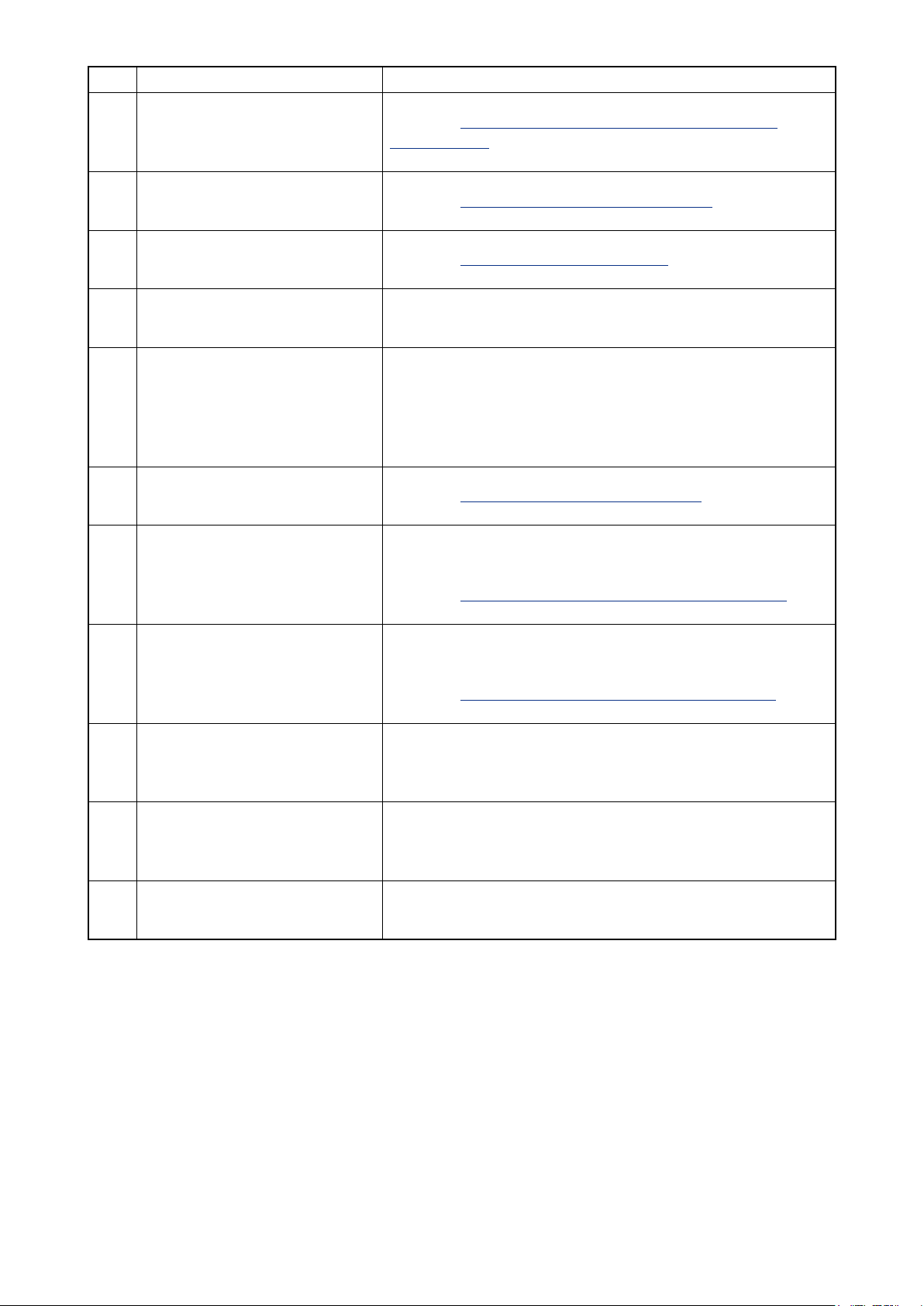

Button and display Description

A PATTERN NEW REGISTER button

Pattern No. new register screen is displayed.

Refer to

→

PATTERN, p.34

13. PERFORMING NEW REGISTER OF SEWING

.

B PATTERN COPY button

C PATTERN NAME SETTING button

D PATTERN NAME display Name which has been inputted to the sewing pattern being selected is

E PRESSER DOWN button Presser down screen is displayed and the needle moves to the right

F BOBBIN WINDER button

G PATTERN SELECTION button

Sewing data copy screen is displayed.

Refer to

→

Sewing pattern name input screen is displayed.

Refer to

→

displayed.

side. To raise the presser, press the presser up button displayd in the

presser down screen.

When performing threading in this state, turn OFF the power before

*

performing.

Bobbin thread can be wound.

Refer to

→

Pattern No. being selected at present is displayed on this button

and when the button is pressed, the pattern No. change screen is

displayed.

Refer to

→

17. COPYING SEWING PATTERN, p.51

7. NAMING THE PATTERN, p.22

11. WINDING BOBBIN THREAD, p.29

6. PERFORMING PATTERN NO. SELECTION, p.20

.

.

.

.

H NEEDLE THREAD TENSION

SETTING button

I OVEREDGING WIDTH, LEFT

SETTING button

J KNIFE GROOVE WIDTH, LEFT

SETTING button

K DIRECT SELECTION button When this button is pressed, the screen of pattern No. list registered to

Needle thread tension value which is set to the pattern data being

selected at present is displayed on this button and when the button is

pressed, the needle thread tension change screen is displayed.

Refer to

→

Overedging width, left which is set to the pattern data being selected at

present is displayed on this button and when the button is pressed, the

overedging width, left change screen is displayed.

Knife groove width, left which is set to the pattern data being selected

at present is displayed on this button and when the button is pressed,

the knife groove width, left change screen is displayed.

the direct selection button is displayed.

9. CHANGING NEEDLE THREAD TENSION, p.25

.

Page 12

Button and display Description

L SEWING DATA CHANGE button Sewing data list screen is displayed.

Refer to

→

15. CHANGING SEWING DATA, p.37

.

M WITH/WITHOUT DOUBLE

STITCHING SETTING button

N NUMBER OF TIMES OF BASTING

SETTING button

O CLOTH CUTTING LENGTH

SETTING button

P SEWING SHAPE SELECTION button Sewing shape which is set to the pattern data being selected at

Q KNIFE GROOVE WIDTH, RIGHT

SETTING button

R PRESSER TYPE SELECTION button Presser type being selected at present is displayed on this button

With/without double stitching which is set to the pattern data being

selected at present is displayed on this button and when the button is

pressed the with/without double stitching change screen is displayed.

Number of times of basting which is set to the pattern data being

selected at present is displayed on this button and when the button is

pressed, the number of times of basting change screen is displayed.

Cloth cutting length which is set to the pattern data being selected at

present is displayed on this button and when the button is pressed, the

cloth cutting length change screen is displayed.

present is displayed on this button and when the button is pressed, the

sewing shape change screen is displayed.

Refer to

→

Knife groove width, right which is set to the pattern data being selected

at present is displayed on this button and when the button is pressed,

the knife groove width, right change screen is displayed.

and when the button is pressed, the presser type change screen is

displayed.

Refer to

→

8. PERFORMING SEWING SHAPE SELECTION, p.23

5. INPUTTING PRESSER TYPE, p.18

.

.

S CUSTOMIZE button Sewing data which are more frequently used can be laid out to four

buttons. When this button is pressed, the laid-out sewing data change

screen is displayed.

Refer to

→

BUTTON, p.55

19. REGISTERING SEWING DATA TO CUSTOMIZE

.

– 11 –

Page 13

– 12 –

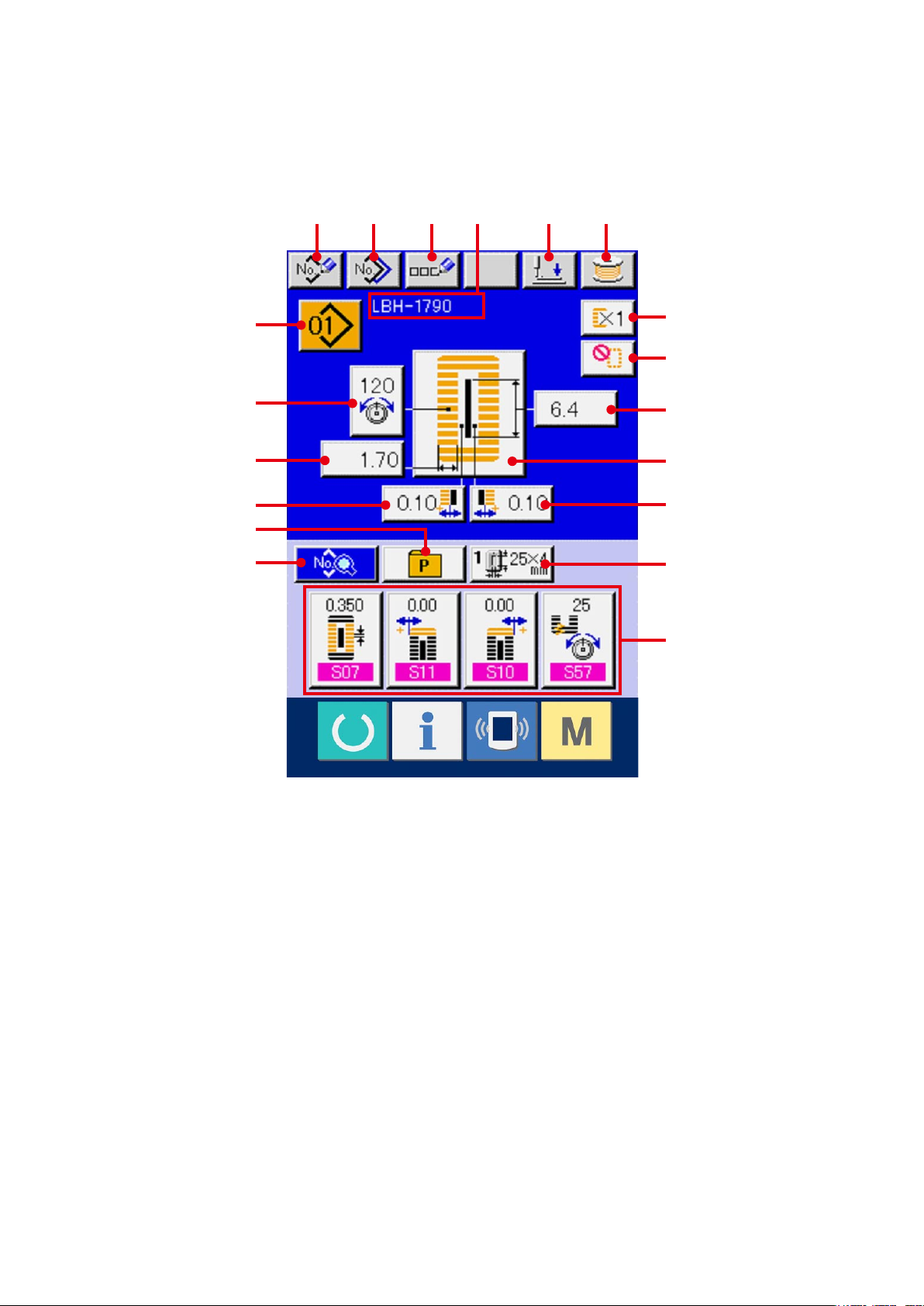

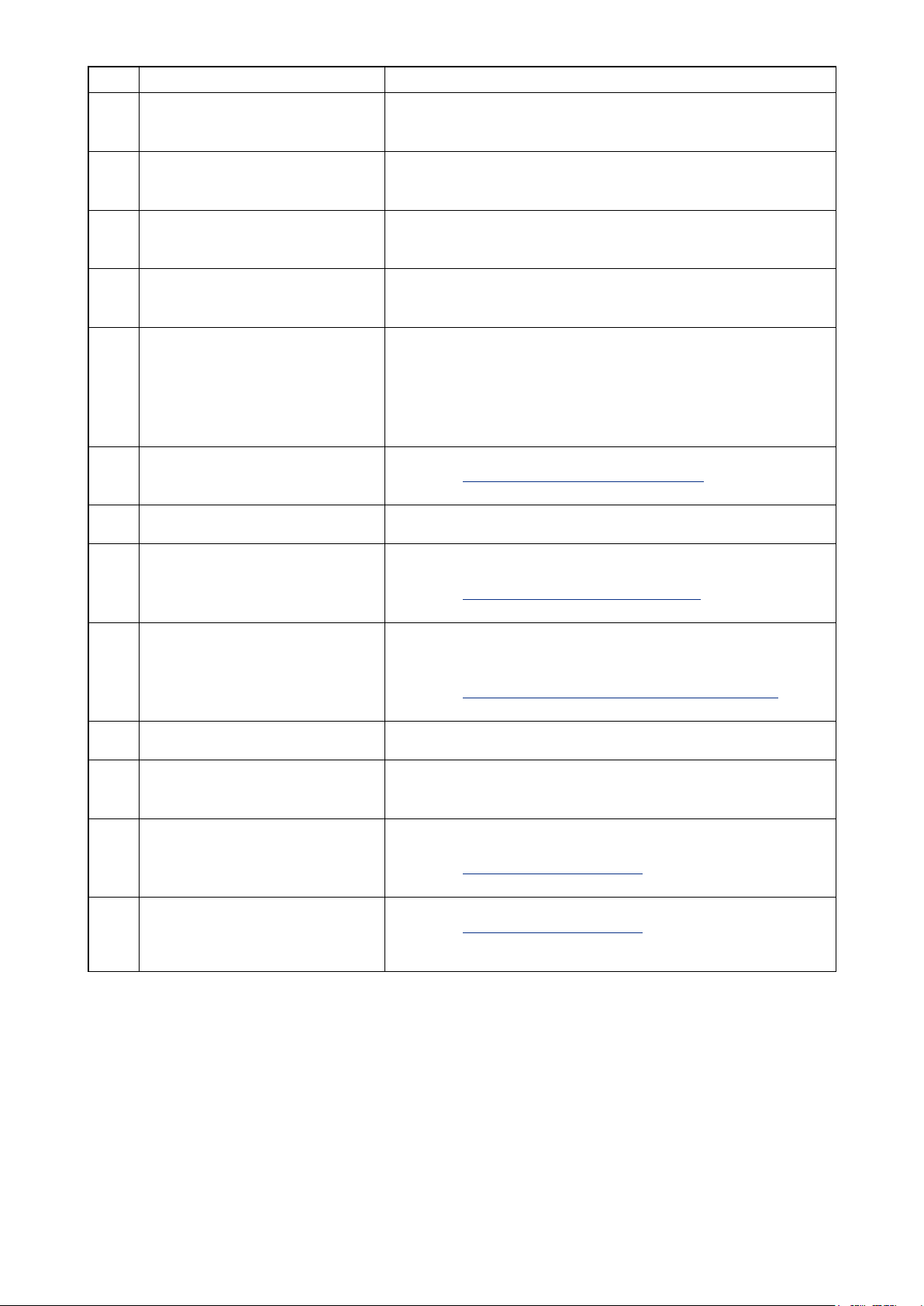

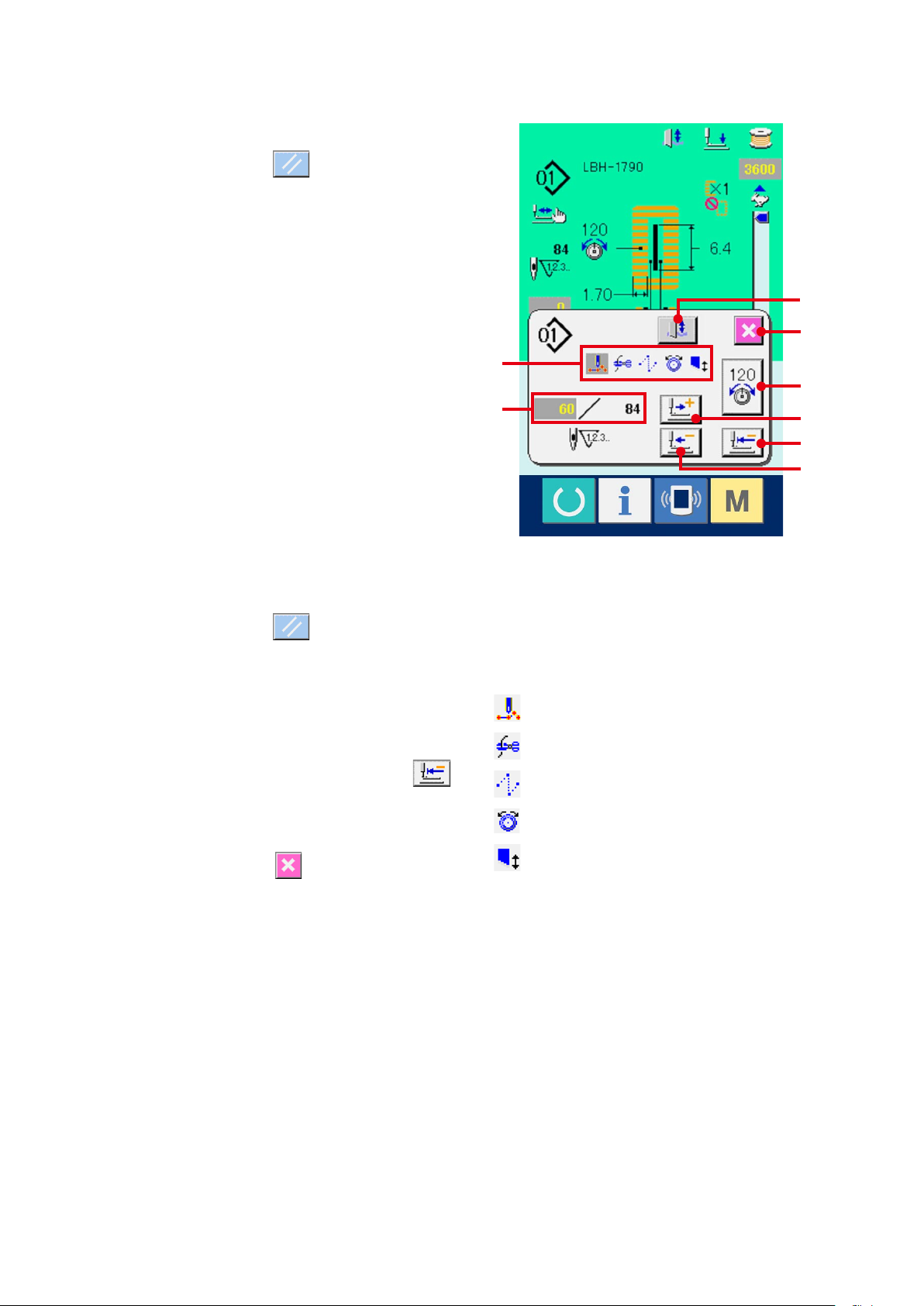

3-2 Sewing screen

G

H

J

K

L1

L2

M

N

A B C E F

I

D

O

P

Q

R

S

Page 14

Button and display Description

A NUMBER OF TIMES OF BASTING

display

B PATTERN NAME display Pattern name which is set to the pattern data during sewing is

Number of times of basting which is set to the pattern data during

sewing is displayed.

displayed.

C WITH/WITHOUT DOUBLE

STITCHING display

D KNIFE CANCEL button Every time this button is pressed, dropping of knife and non-dropping

E PRESSRER DOWN button Presser can be lowered and the knife down screen is displayed.

F BOBBIN WINDER button

G PATTERN NO. display Pattern No. during sewing is displayed.

H STEP STITCHING button

I NEEDLE THREAD TENSION button

With/without double stitching which is set to the pattern data during

sewing is displayed.

of knife can be changed over alternately.

To raise the presser, press the presser up button displayed in the

presser down screen.

When performing threading in this state, turn OFF the power before

*

performing.

Bobbin thread can be wound.

Refer to

→

When this button is pressed, the screen of step stitching to check

needle entry point and to perform re-sewing is displayed.

Refer to

→

Needle thread tension which is set to the pattern data during sewing is

displayed, and when this button is pressed, the needle thread tension

change screen is displayed.

Refer to

→

11. WINDING BOBBIN THREAD, p.29

10. PERFORMING RE-SEWING, p.27

9. CHANGING NEEDLE THREAD TENSION, p.25

.

.

.

J NUMBER OF TOTAL STITCHES

display

K OVEREDGING WIDTH, LEFT display Overedging width, left which is set to the pattern during sewing is

L1 COUNTER VALUE CHANGE button

L2 COUNTER CHANGE OVER button

Number of total stitches of the pattern data during sewing is displayed.

displayed.

Existing counter value is displayed on this button. When the button is

pressed, the counter value change screen is displayed.

Refer to

→

Display of sewing counter/No. of pcs. counter can be changed over.

Refer to

→

12. USING COUNTER, p. 30

12. USING COUNTER, p. 30

.

.

– 13 –

Page 15

– 14 –

Button and display Description

M KNIFE GROOVE WIDTH, LEFT

display

N SEWING SHAPE display Sewing shape of the pattern data during sewing is displayed.

O SPEED variable resistor Number of rotation of sewing machine can be changed.

P CLOTH CUTTING LENGTH display Cloth cutting length which is set to the pattern data during sewing is

Knife groove width, left which is set to the pattern during sewing is

displayed.

displayed.

Q KNIFE GROOVE WIDTH, RIGHT

display

R DIRECT SELECTION button When this button is pressed, the screen of pattern No. list registered

Knife groove width, right which is set to the pattern during sewing is

displayed.

to the direct selection button is displayed.Pattern No. during sewing is

displayed.

※ Atthetimeofyourpurchase,thebuttonissettonon-displaysetting.

When you desire to make it display, set K18

Display/non-display

setting of direct button to the display state.

Refer to

→

S CUSTOMIZE display Sewing data value which is laid out to the customize button is

displayed.

26. CHANGING MEMORY SWITCH DATA, p.77

.

Page 16

4. HOW TO USE THE PEDAL

This sewing machine can be used by selecting the pedal operating procedure from among 3 types described

later.Selecttheoperatingprocedureyoudesireforworkingefciencyandusethesewingmachine.

4-1 Setting procedure of the pedal type

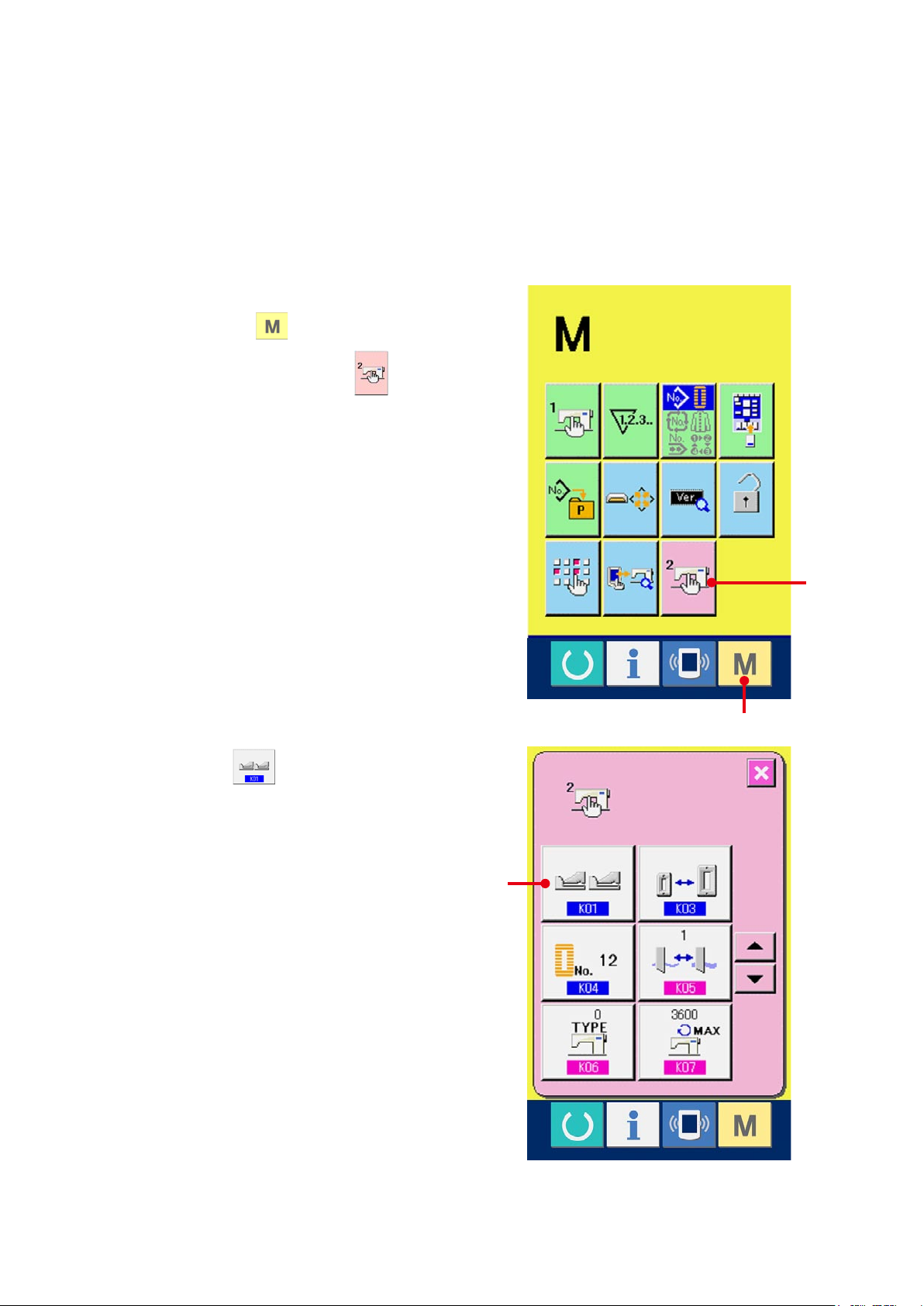

Call the pedal type setting parameter.

1

Hold pressing switch (A) for 6 seconds

and memory switch (level 2) button (B) is

displayed on the screen. When this button is

pressed, the memory switch (level 2) list screen

is displayed.

Press button K01 (C) of the pedal type

selection parameter on the memory switch (level

2) list screen and the pedal type change screen is

displayed.

B

A

C

– 15 –

Page 17

– 16 –

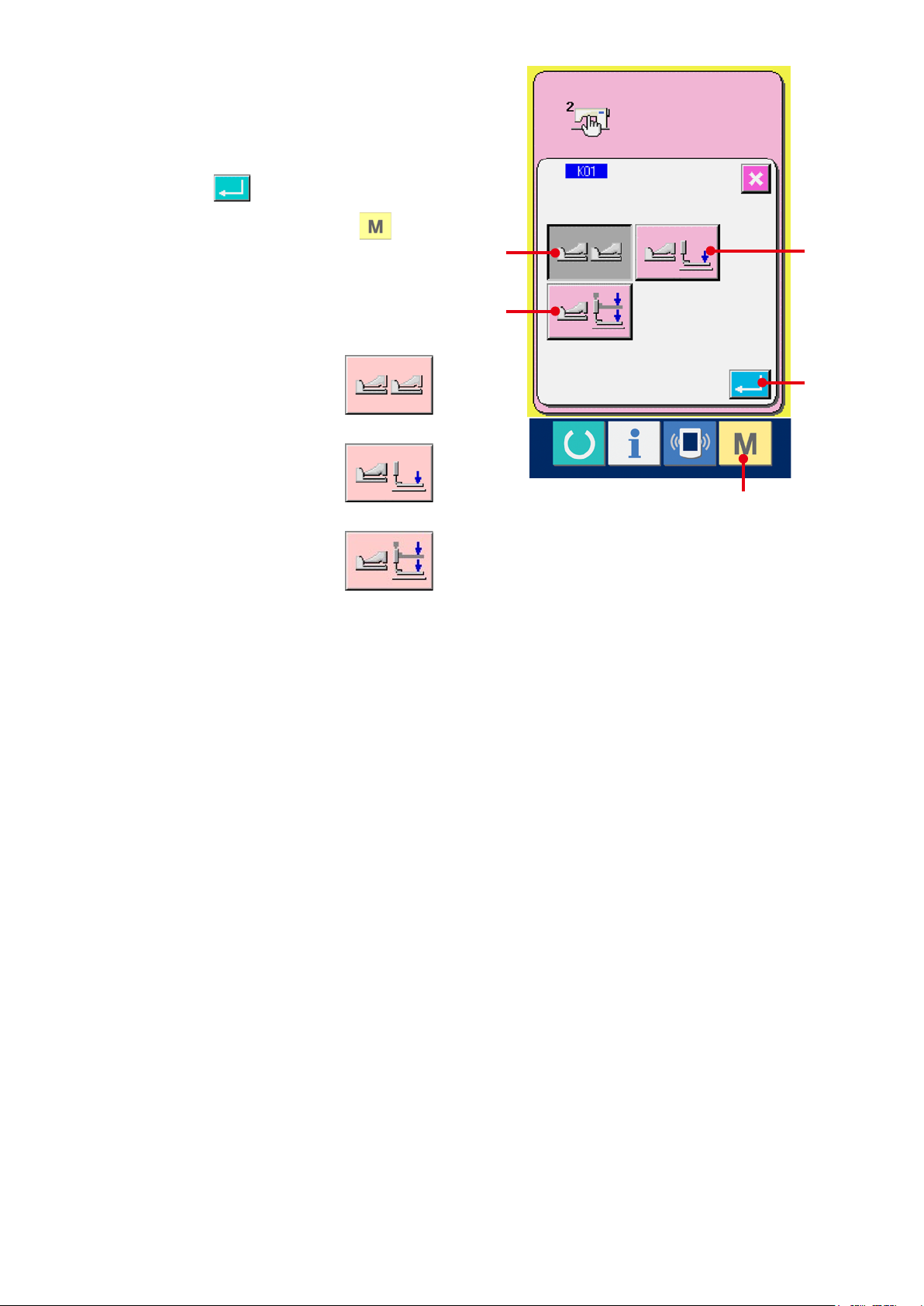

Select the pedal type.

2

Three kinds of pedal type buttons (D to F) are

displayed on the pedal type change screen.

Select the pedal type you desire and press

ENTER button (G). Close the pop-up

and display screen 1. When switch (A) is

pressed further, the screen returns to the data

edit screen.

D

F

E

D : 2-pedal

1-pedal (Without intermediate

E :

position)

1-pedal (With intermediate

F :

position)

G

A

Page 18

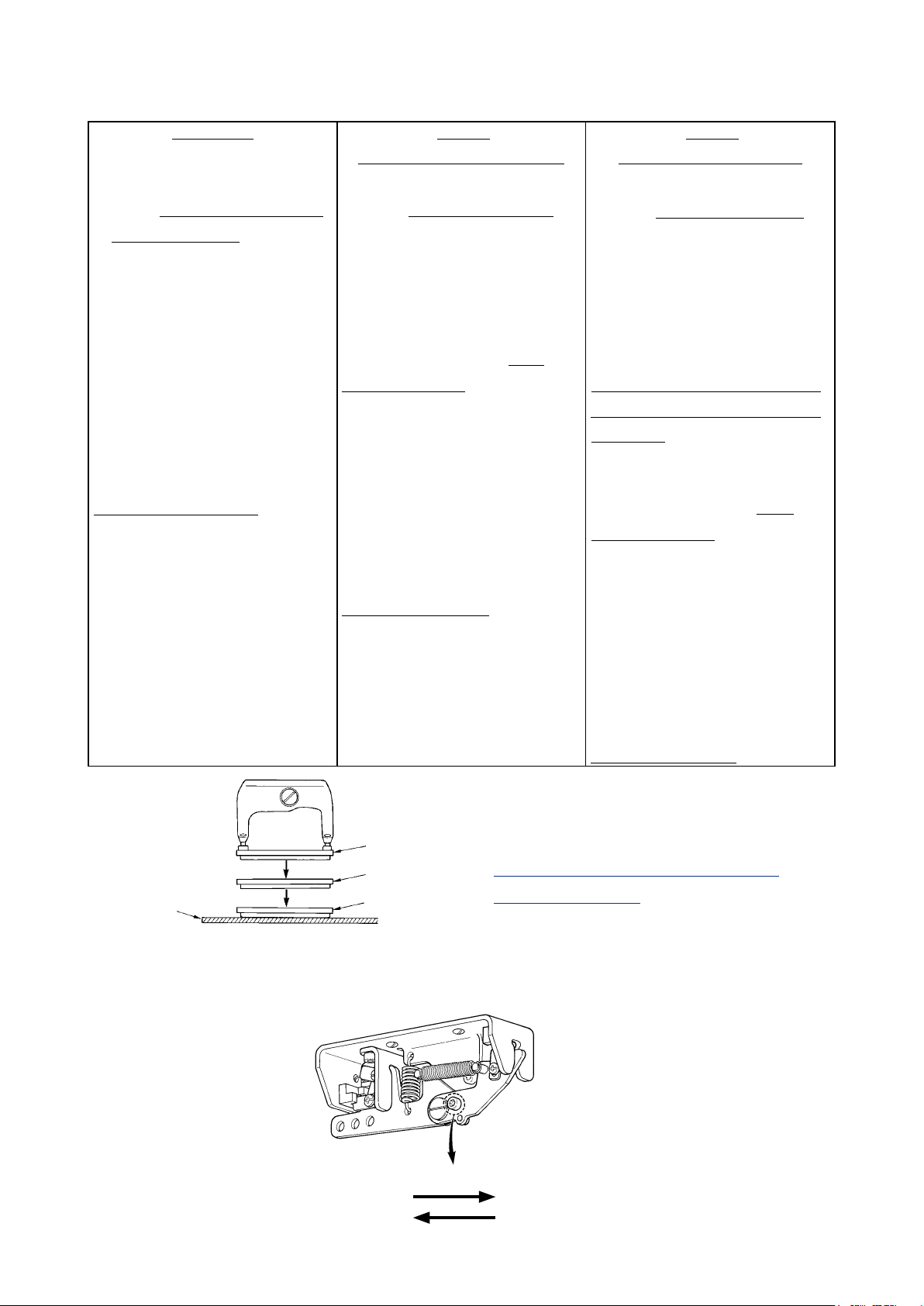

4-2 Explanation of pedal motion

2-pedal type

INITIAL POSITION

Presser : Intermediate position

or Sewing position

3

2

1) SETTING OF SEWING

PRODUCT

Presser goes up as high as the

pedal toe down amount of the left

side pedal.

2) START OF SEWING

Sewing starts when the right side

pedal is depressed.

3) END OF SEWING

Presser automatically goes up to

Intermediate position 2.

1-pedal

(Without intermediate position)

INITIAL POSITION

Presser : Maximum position

1

1) SETTING OF SEWING

PRODUCT

2) CONFIRMATION OF SETTING

OF SEWING PRODUCT

Presser comes down to Cloth

setting position 3whentherst

step of the right side pedal is

depressed.

3) START OF SEWING

Sewing starts when the second

step of the right side pedal is

depressed.

4) END OF SEWING

Presser automatically goes up to

Maximum position 1.

1-pedal

(With intermediate position)

INITIAL POSITION

Presser : Maximum position

1

1) SETTING OF SEWING

PRODUCT

2) CONFIRMATION OF SETTING

OF SEWING PRODUCT

Presser comes down to

Intermediate position 2 when the

rststepoftherightsidepedalis

depressed.

3) CONFIRMATION OF START

OF SEWING

Presser comes down to Cloth

setting position 3 when the

second step of the right side pedal

is depressed.

4) START OF SEWING

Sewing starts when the third

step of the right side pedal is

depressed.

5) END OF SEWING

Presser automatically goes up to

Maximum position 1.

※ Heightoftherespectivepositionsof1 to 3

described on the left side can be set or changed

by the memory switches.

26. METHOD OF CHANGING MEMORY

→

SWITCH DATA, p.77

.

Cloth

Pedal switch setting

●

1

2

3

Attachorremovethescrewshowninthegureaccordingtothesettingofthememoryswitch.

2-pedal type

1-pedal (Without intermediate position)

Remove the screw.

Attach the screw.

1-pedal (With intermediate position)

– 17 –

Page 19

– 18 –

5. INPUTTING THE PRESSER TYPE

5-1 Setting procedure of the presser type

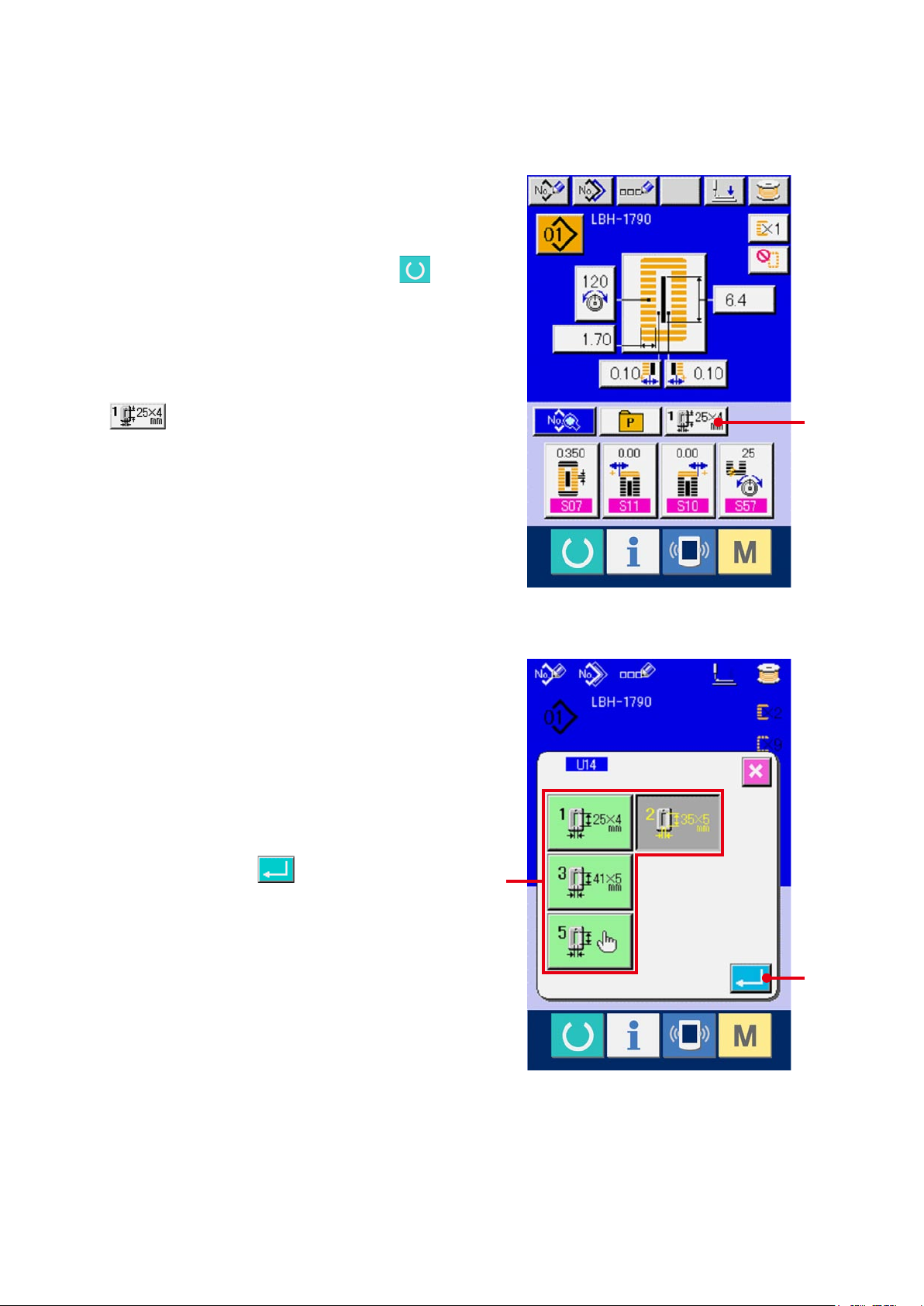

Display the data input screen.

1

Only in case of the data input screen (blue), the

contents of setting can be changed. In case of the

sewing screen (green), press READY key

and display the data input screen.

Call the presser type selection screen.

2

Press PRESSER TYPE SELECTION button

(A) and the presser type selection screen

is displayed.

Select the presser type.

3

Press button (B) of the presser type mounted

on the sewing machine. The button pressed is

shown in reverse video. Set the presser type

referring to Table of presser type described later.

Determine the presser type.

4

A

Press ENTER button (C) and the presser

type change screen is closed. Then the change

hasbeennished.

B

C

Page 20

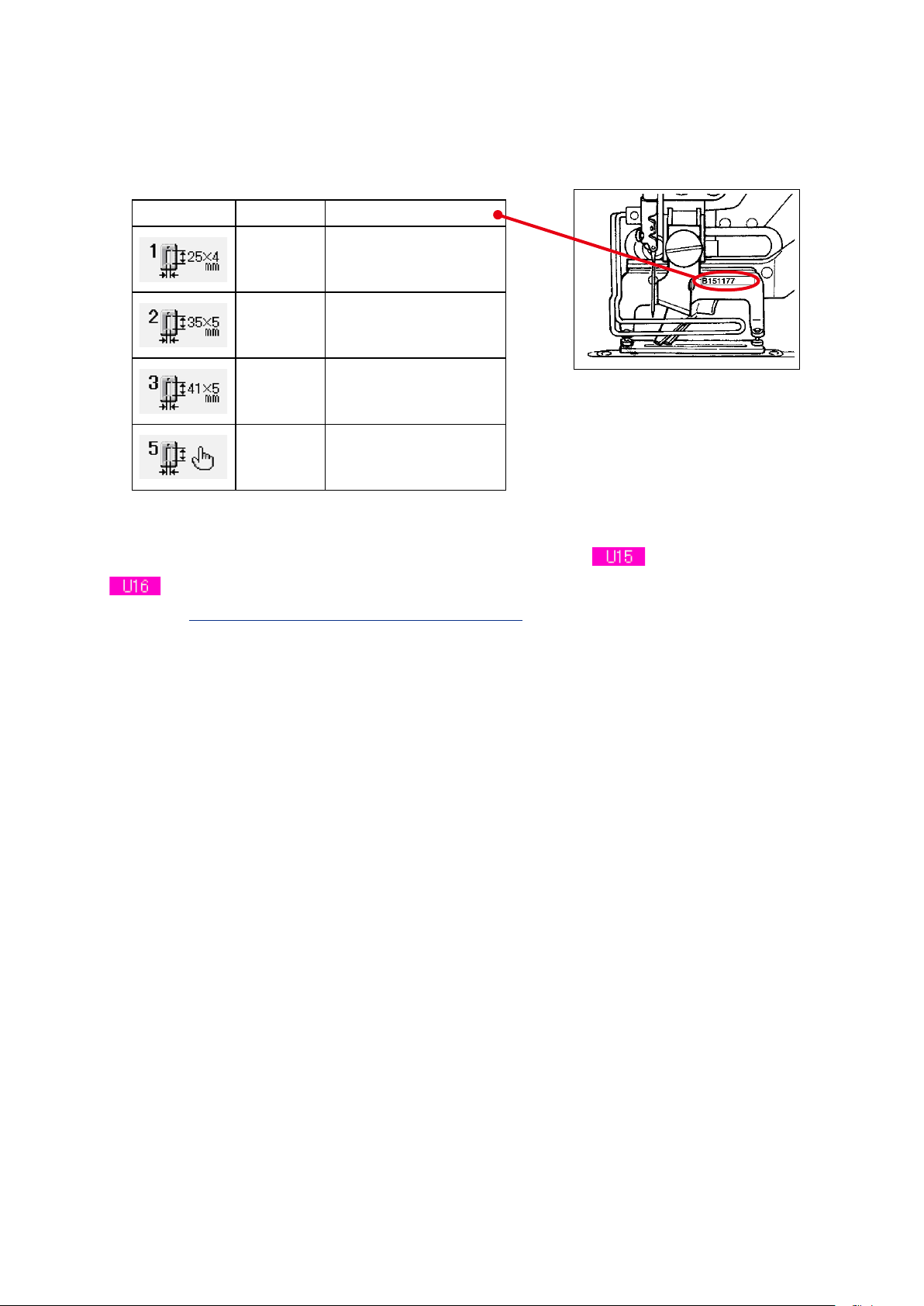

5-2 Table of presser type

Make the number in the frame of engraved part number of presser foot correspond to the type of presser.

Type Part No. of presser foot

Type 1

Type 2

Type 3

Type 5 -

B 1 5 1 1 7 7 1 0 0 0 *

B 1 5 1 1 7 7 2 0 0 0 *

B 1 5 1 1 7 7 3 0 0 0 *

※ Settype5whenusingthepresserfoototherthantype1to3.Change Presser size width and

Presser size length of the memory switch (level 1) to adjust to the presser to be used.

Refer to

→

26. CHANGING MEMORY SWITCH DATA, p.77

.

※ Whenusingtype5withstitchwidthof6mmormoreand41mmormoreinlength,itisnecessaryto

replace components such as presser arm, feed plate, etc.

– 19 –

Page 21

– 20 –

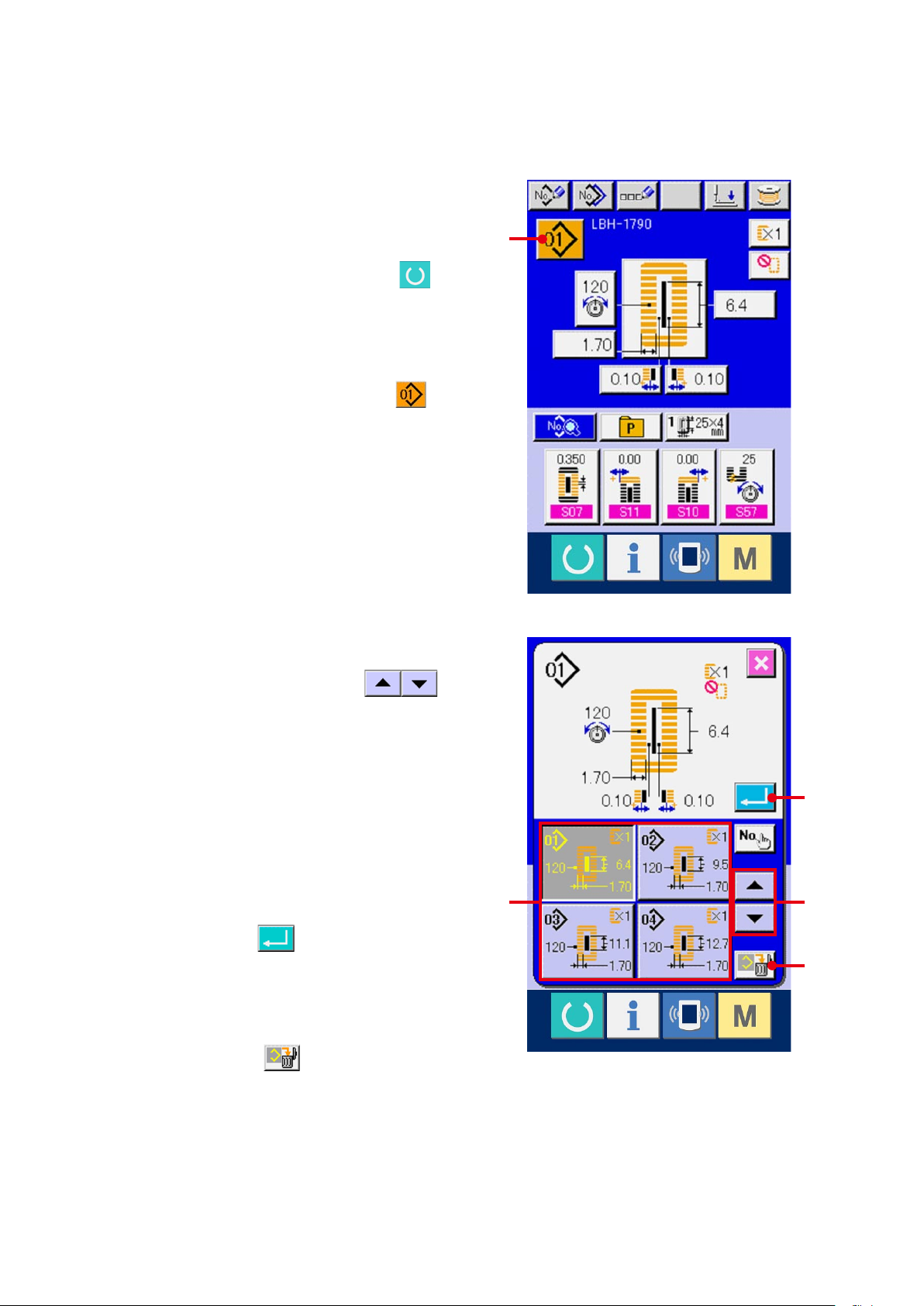

6. PERFORMING PATTERN NO. SELECTION

6-1 Selection from the data input screen

Display the data input screen.

1

Only in case of the data input screen (blue), the

contents of setting can be changed. In case of the

sewing screen (green), press READY key

and display the data input screen.

Call the PATTERN NO. SELECTION screen.

2

Press PATTERN NO. SELECTION button (A)

and the pattern No. selection screen is displayed.

Pattern No. which is selected at present and the

contents are displayed in the upper part of the

screen and the list of the pattern No. buttons

A

which have been registered is displayed in the

lower part.

Select the pattern No.

3

When UP or DOWN SCROLL button

(B) is pressed, the pattern No. buttons (C) which

have been registered are changed over in order.

The contents of the sewing data inputted in the

pattern No. are displayed in the button. Here,

press the pattern No. button (C) you desire to

select.

Determine the pattern No.

4

Press ENTER button (D), and the pattern

No. selection screen is closed. Then the selection

D

BC

E

hasbeennished.

※ Whenyoudesiretodeletetheregisteredpattern,

press DELETE button (E).

However, the pattern which is registered to

continuous stitching and cycle stitching cannot be

deleted.

Page 22

6-2 Selection by means of DIRECT button

This sewing machine can register the pattern No. you desire to DIRECT button.

When the pattern has been registered, the pattern selection can be simply performed only by pressing the

button.

Refer to

→

Display the direct button selection screen.

1

Press DIRECT button (A) in the data

input screen (blue) and display the DIRECT

button selection screen.

※ Whenthedisplayisselectedwiththedisplay/non-

display of the direct button of the memory switch

(level 2) DIRECT button can be used

even in the sewing screen.

Refer to

→

DATA, p.77

18. REGISTERING THE PATTERN TO DIRECT BUTTON, p.53

26. CHANGING MEMORY SWITCH

.

.

A

Select the pattern No.

2

The pattern Nos. which have been registered

to DIRECT button can be selected. Press the

PATTERN NO. button (B) you desire to select

and the direct button selection screen is closed.

Then the selected pattern No. is displayed.

B

– 21 –

Page 23

– 22 –

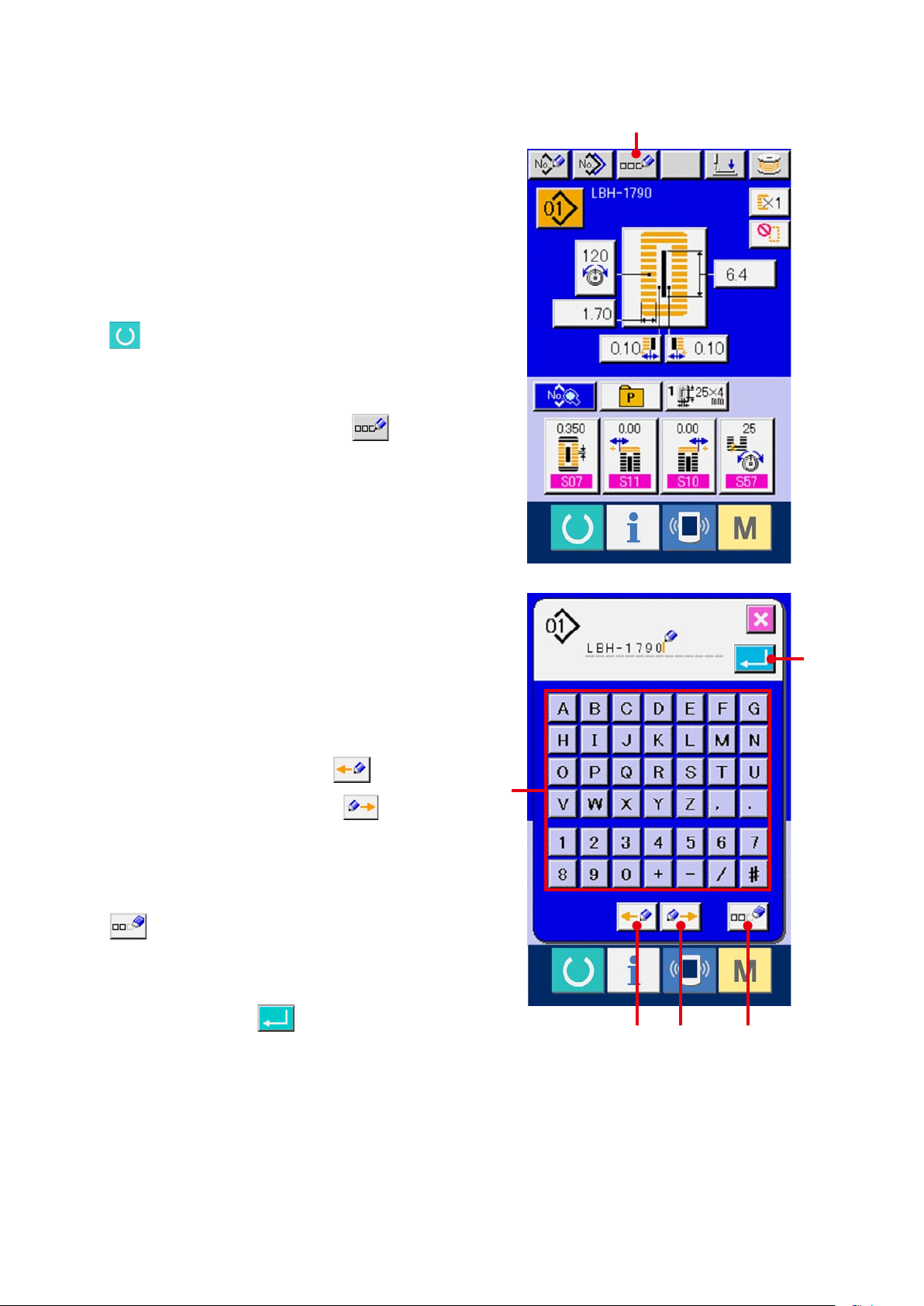

7. NAMING THE PATTERN

As many as 14 characters can be inputted to the

patterns respectively.

Display the data input screen.

1

Only in case of the data input screen (blue), input

of the pattern name can be performed. In case of

the sewing screen (green), press READY switch

and display the data input screen (blue).

Call the character input screen.

2

Press CHARACTER INPUT button (A) and

the character input screen is displayed.

A

Input the character.

3

Press the character button (B) you desire to input,

and input of the character can be performed.

Characters (A to Z and 0 to 9) and symbols (+, -, /,

#, ...) can be inputted. As many as 14 characters

can be inputted. The cursor can travel with

CURSOR LEFT TRAVEL button (C) and

CURSOR RIGHT TRAVEL button (D).

When you desire to delete the inputted character,

adjust the cursor to the position of the character

you desire to delete and press DELETE button

(E).

Finish inputting the character.

4

Press ENTER button (F) and inputting the

characterisnished.Afterthenish,theinputted

F

B

C D E

character is displayed in the upper part of the

data input screen (blue).

Page 24

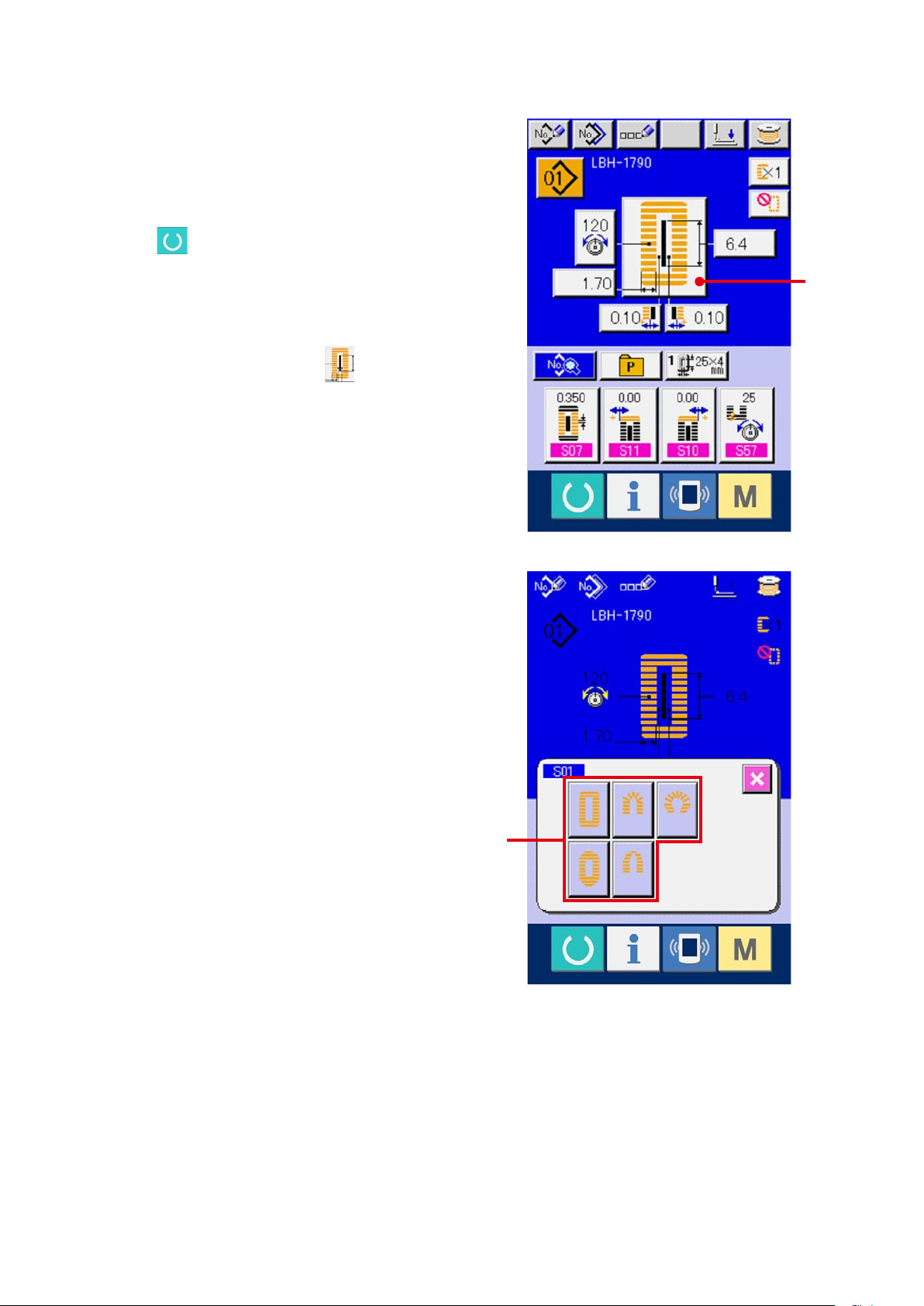

8. PERFORMING SEWING SHAPE SELECTION

Display the data input screen.

1

Only in case of the data input screen (blue), the

selection of sewing shape can be performed. In

case of the sewing screen (green), press READY

switch and display the data input screen

(blue).

Call the sewing shape selection screen.

2

Press SEWING SHAPE button (A) and the

sewing shape selection screen is displayed.

Select the 1st bar-tacking section.

3

Select the shape you desire to sew from among

5 kinds of the 1st bar-tacking shape buttons

(B). When it is selected, the total sewing shape

in which the selected 1st bar-tacking is used is

displayed.

A

– 23 –

B

Page 25

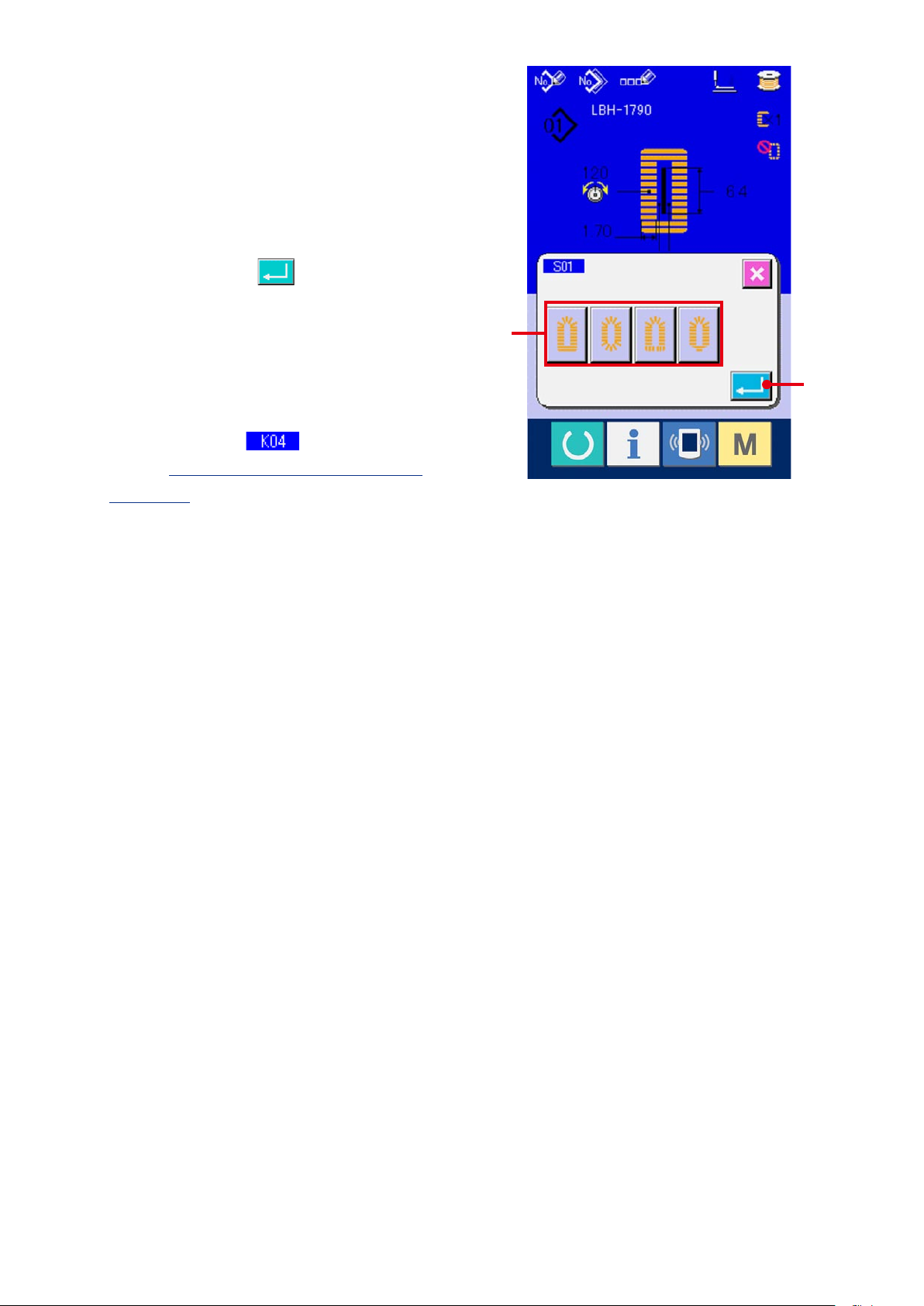

– 24 –

Select the sewing shape.

4

Select SEWING SHAPE button (C) you desire to

sew.

Finish the sewing shape selection.

5

Press ENTER button (D)tonishthe

shape selection and the selected sewing shape is

displayed in the data input screen (blue).

Note) The number of sewing shapes to be

displayed changes according to the level selected

in the sewing shape selection level of memory

DIP switch (level 2) .

Refer to

→

DATA, p.77

26. CHANGING MEMORY SWITCH

.

C

D

Page 26

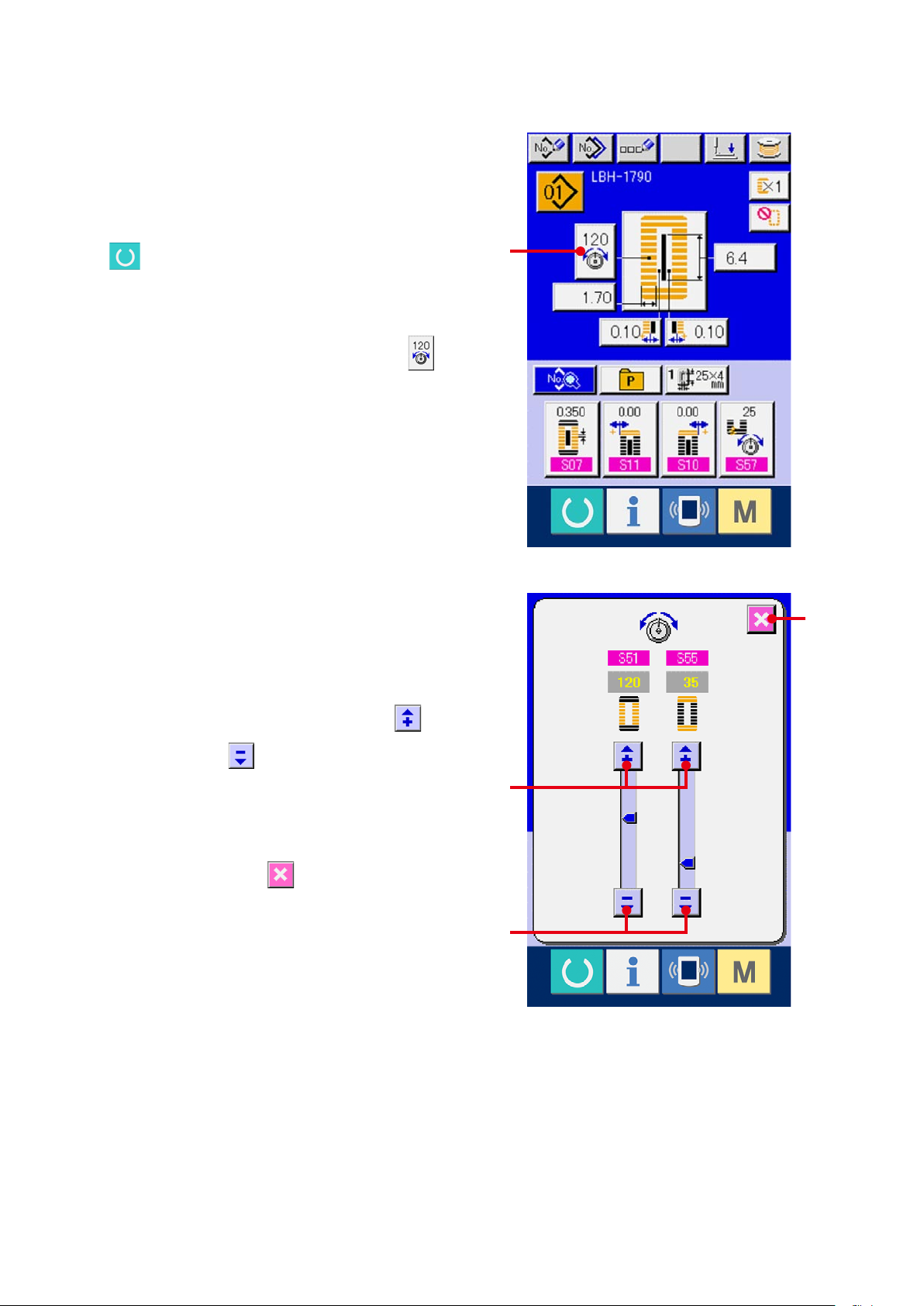

9. CHANGING NEEDLE THREAD TENSION

Display the data input screen.

1

Only in case of the data input screen (blue),

needle thread tension can be changed. In case of

the sewing screen (green), press READY switch

and display the data input screen (blue).

Call the needle thread tension change screen.

2

Press NEEDLE THREAD TENSION button

(A) and the needle thread tension change screen

is displayed.

Change the needle thread tension.

3

Needle thread tension at the parallel section and

that at the bar-tacking section can be changed in

the needle thread tension change screen.

A

D

Change the tension value with UP button (B)

or DOWN button (C) corresponding to the

respective sections.

Finish the change of needle thread tension.

4

Press CANCEL button (D) and the needle

thread tension change screen is closed. Then the

changehasbeennished.

B

C

– 25 –

Page 27

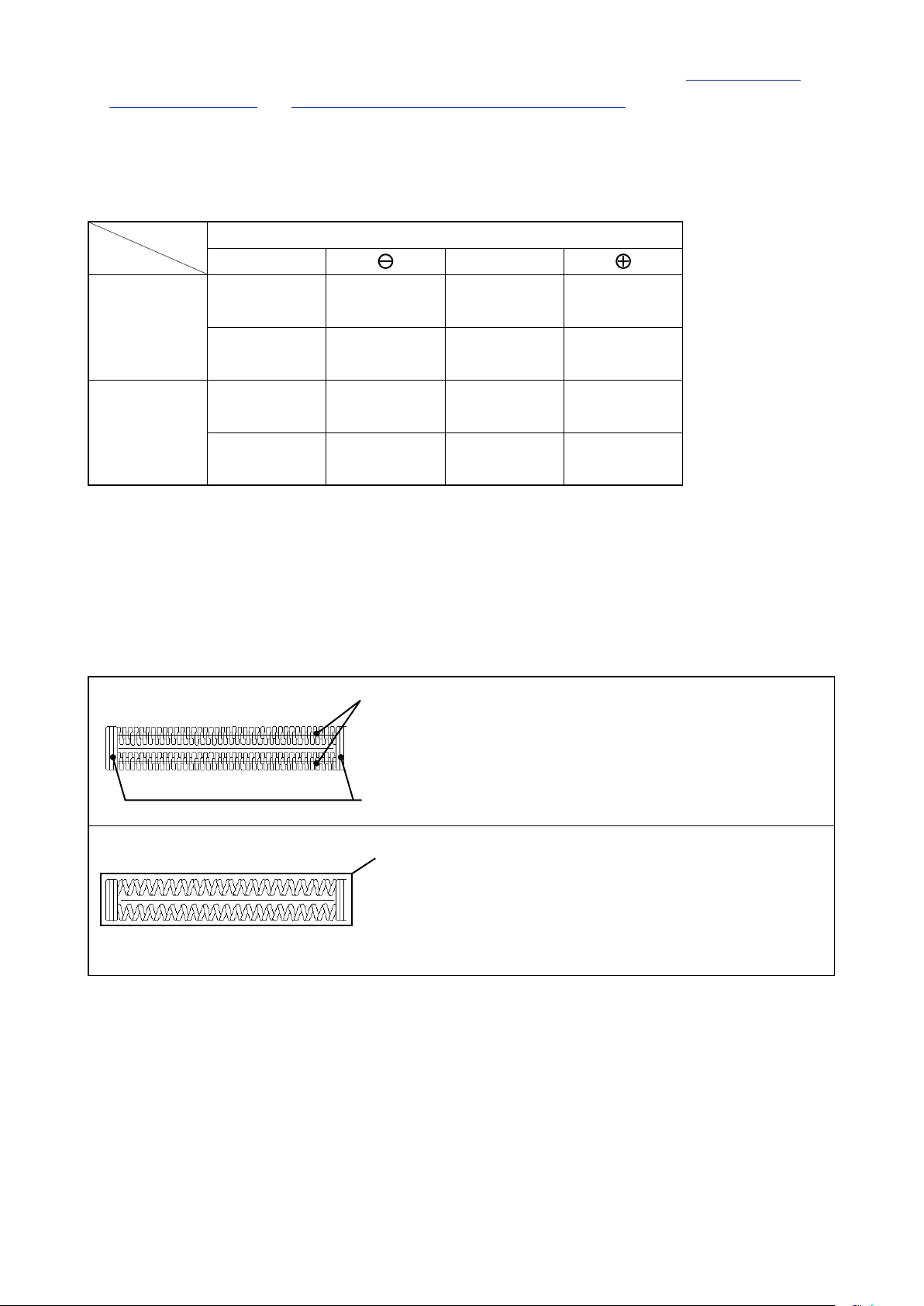

※ Forthetensionotherthanthatatparallelsectionandatbar-tackingsection,referto

15. CHANGING

SEWING DATA, p.37

and

26. CHANGING MEMORY SWITCH DATA, p.77

Set value of tension at 1 parallel section and 2 bar-tacking section

Set value on panel

Initial value

Parallel

Purl stitch

Whip stitch

1

section tension

Bar-tacking

2

tension

Parallel

1

section tension

Bar-tacking

2

tension

Crest is lowered. 120 Crest is raised.

Thread tension

is decreased.

Thread tension

is decreased.

Thread tension

is decreased.

35

60

60

Thread tension

is increased.

Thread tension

is increased.

Thread tension

is increased.

.

In case of the radial

eyelet shape, set

the bar-tacking

tensionrstto

approximately 120

and make the

balance of stitches.

Purl stitch and Whip stitch

Purl stitch

Whip stitch

Whip stitch

Purl stitch

When applying higher tension to the needle thread to

permit it to pass straight through fabric, the purl stitch is

formed by the bobbin thread which is pulled over from

both sides to the center line.

Whip stitch

The whip stitch is formed in zigzag showing the needle

thread only on top of fabric, and the bobbin thread on the

bottom.

– 26 –

Page 28

10. PERFORMING RE-SEWING

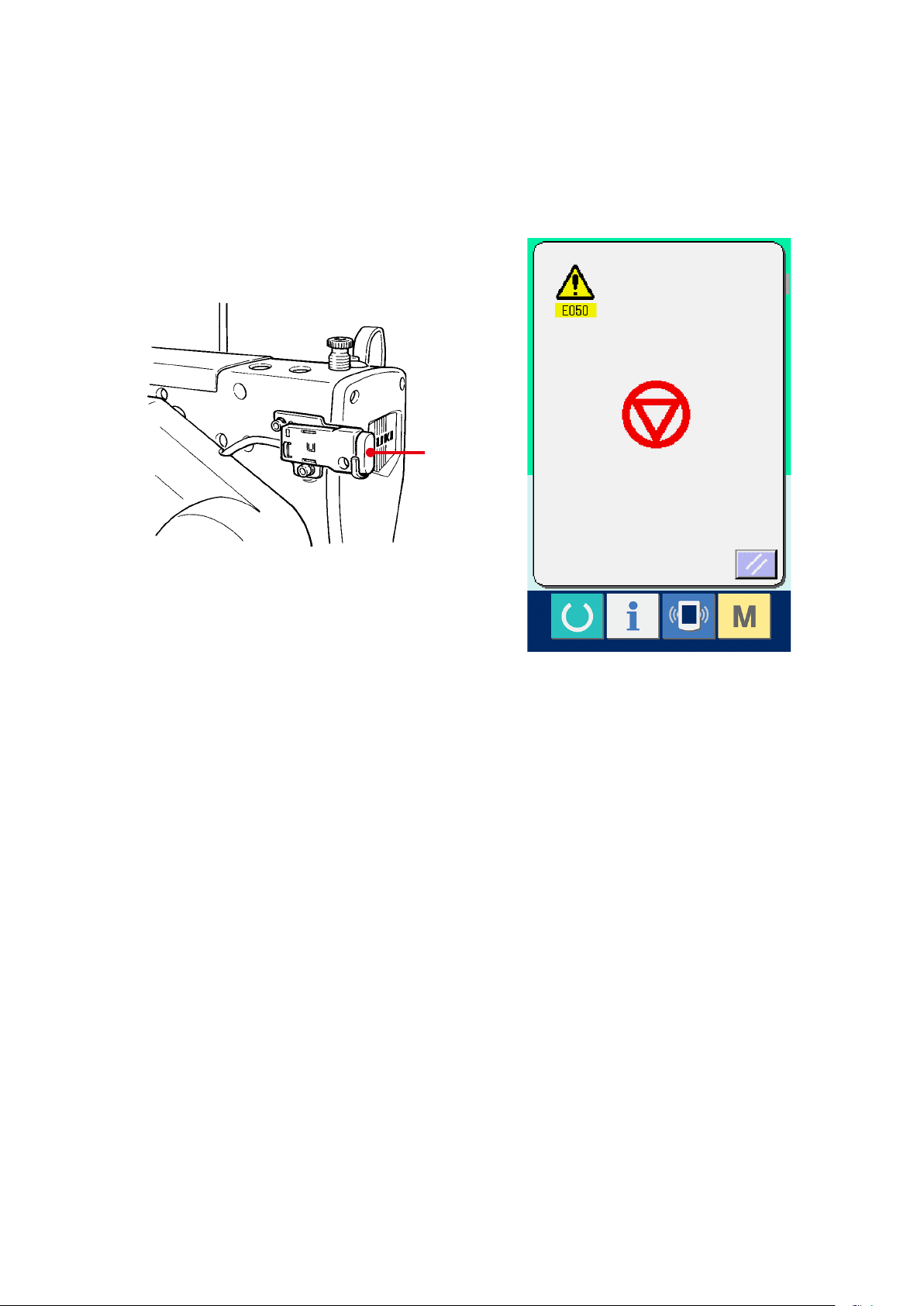

When STOP switch (A) is pressed during sewing, the sewing machine interrupts sewing and stops. At this

time, the error screen is displayed to inform that the STOP switch is pressed.

A

– 27 –

Page 29

– 28 –

10-1 To continue performing sewing from some point in sewing

Release the error.

1

Press RESET button (B) to release the

error. Then the step motion screen is displayed.

Return the presser.

2

Press BACKWARD button (C), and the presser

returns stitch by stitch.

Pre ss FORWA RD key (D), and the pres ser

J

I

advances stitch by stitch. Return the presser to

the re-sewing position.

Start sewing again.

3

Depress the right side pedal and sewing starts

again

.

10-2 To perform sewing from the start

Release the error.

1

Press RESET button (B) to release the

error. Then the step motion screen is displayed.

Return the sewing product to the setting

2

position.

Press INITIAL POSITION TRAVEL button

(E) and the presser returns to the sewing product

setting position (start position).

Press CANCEL button (I) to close the pop-

F

G

※ Theexistingsewingcommandsareshown

in reverse video in section (F). The kinds of

commands are 5 kinds below.

: Sewing command

: Thread trimming command

: Jump feed

: Thread tension

: Knife drive

H

D

E

C

up and the presser returns to the sewing product

setting position (start position).

Start the sewing.

3

When the right pedal is depressed, sewing starts

again.

※ In case of thecontinuous stitching, (E) moves

to the sewing start position of the shape during

sewing and when it is pressed subsequently, it

moves to the sewing start position of the previous

shape.

※ Theexistingnumberofstitches/numberoftotal

stitches are displayed in section (G).

※ Threadtensionvalueisdisplayedinsection(H).

When thread tension command is inputted in the

needle entry point by means of the external input

device, the button is displayed and thread tension

can be changed.

※ Knifecanbecancelledwith(J).

Page 30

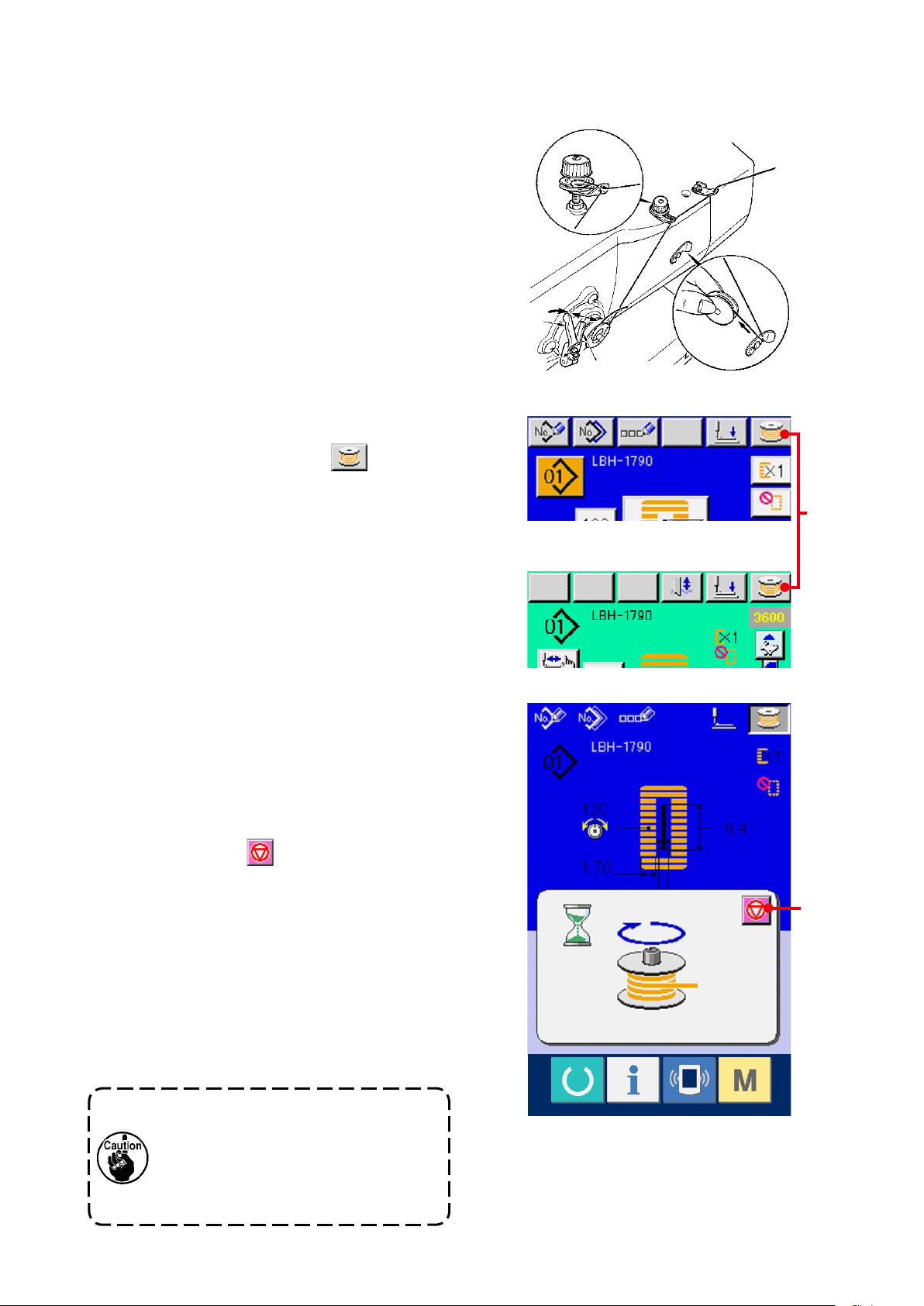

11. WINDING BOBBIN THREAD

Set the bobbin.

1

Fit a bobbin fully onto the bobbin winder shaft.

Then push the bobbin thread guide in the

direction of the arrow mark.

Display the bobbin winding screen.

2

Press BOBBIN WINDER button (A) in the

data input screen (blue) or the sewing screen

(green) and the bobbin winding screen is

A

displayed.

Start bobbin winding.

3

Depress the start pedal, and the sewing machine

rotates and starts winding bobbin thread.

Stop the sewing machine.

4

Press STOP button (B) and the sewing

machine stops and returns to the normal mode.

Or, depress the start pedal twice during winding

bobbin and the sewing machine stops while the

bobbin thread winding mode stays as it is.

Depress the start pedal again and the bobbin

B

winding starts again. Use this way when winding

bobbin thread around plural bobbins.

When winding the bobbin thread in

the state that sewing is not performed,

remove the needle thread from the

thread path of thread take-up and

remove the bobbin from the hook.

– 29 –

Page 31

– 30 –

12. USING COUNTER

12-1 Setting procedure of the counter

Display the counter setting screen.

1

Press switch and the COUNTER SETTING

button (A) is displayed on the screen. When

this button is pressed, the counter setting screen

is displayed.

Selection of kinds of counters

2

This sewing machine has two kinds of counters,i.

e., sewing counter and No. of pcs. counter.

A

Press SEWING COUNTER KIND SELECTION

button (B) or NO. OF PCS. KIND

SELECTION button (C) to display the counter

kind selection screen. The kinds of the respective

counters can be set separately.

D

B

E

C

F

G

Page 32

[ Sewing counter ]

UP counter :

Every time the sewing of one shape is performed,

the existing value is counted up. When the existing

value is equal to the set value, the count-up screen

is displayed.

DOWN counter :

Every time the sewing of one shape is performed,

th e existin g value is cou nted down . Whe n the

existing value is reached to "0", the count-up screen

is displayed.

Counter not used

[ No. of pcs. counter ]

UP counter :

Every time one cycle or one continuous stitching is

performed, the existing value is counted up. When

the existing value is equal to the set value, the count-

up screen is displayed.

DOWN counter :

Every time one cycle or one continuous stitching

is performed, the existing value is counted down.

When the existing value is reached to "0", the count-

up screen is displayed.

Counter not used

– 31 –

Page 33

– 32 –

Change of counter set value

3

In case of the sewing counter, press button

(F) and in case of the No. of pcs. counter, press

button (G) and the set value input screen is

displayed.

Here, input the set value. (See p.30.)

Change of counter existing value

4

In case of the sewing counter, press button

(D) and in case of the No. of pcs. counter, press

button (E) and the existing value input screen

is displayed.

Here, input the existing value. (See p.30.)

Page 34

12-2 Count-up releasing procedure

When count-up condition is reached during sewing

work, the count-up screen is displayed and the

buzzer beeps.Press CLEAR button (H) to reset

the counter and the screen returns to the sewing

screen. Then the counter starts counting again.

H

– 33 –

Page 35

– 34 –

13. PERFORMING NEW REGISTRATION OF THE PATTERN

Display the data input screen.

1

Only in case of the data input screen (blue), new

registration of the pattern can be performed. In

case of the sewing screen (green), press READY

switch and display the data input screen

(blue).

Call the pattern new registration screen.

2

Press NEW REGISTRATION button (A) and

the pattern new registration screen is displayed.

Input the pattern No.

3

Input the pattern No. you desire to newly register

A

with the ten keys (B). When the pattern No.

which has been already registered is inputted,

the sewing shape which has been registered is

displayed in the upper part of the screen. Select

the pattern No. which is not displayed and has

not been registered. New registration to the

pattern No. which has been already registered is

prohibited.

It is possible to retrieve the pattern No. which has

not been registered with the - • + button

(C • D).

Determine pattern No.

4

Press ENTER button (E) to determine

the pattern NO. to be newly registered and the

screen of 1st bar-tacking shape list is displayed.

E

B

C D

Page 36

Select the 1st bar-tacking shape.

5

Select the shape you desire to sew from among 5

kinds of the 1st bar-tacking shape buttons (F).

When it is selected, the total sewing shape

in which the 1st bar-tacking shape is used is

displayed.

F

Select the sewing shape.

6

Select SEWING SHAPE button (G) you desire to

sew.

Finish the selection of sewing shape.

7

Press ENTER button (H)tonishthe

selection of the shape. Then the sewing shape

which has been selected is displayed in the data

input screen (blue). The initial value of sewing

data is inputted according to the selected sewing

shape.

Note) Number of sewing shapes to be displayed

changes according to the level selected in the

sewing shape selection level of memory DIP

switch (level 2) .

G

H

Refer to

→

DATA, p.77

26. CHANGING MEMORY SWITCH

.

– 35 –

Page 37

– 36 –

14. SEWING SHAPE LIST

1) Square type 2) Round type 3) Radial square type 4) Radial type 5) Radial straight bartacking type

6) Rad ial taper bar-

tacking type

11) Semilunar type 12) Round square

16) Eyelet semilunar

type

7) Eyelet square type 8) Eyelet radial type 9) Eyelet straight bar-

type

17) Eyelet round type 18) Square radial

13) Semilunar square

type

type

tacking type

14) Semilunar

straight bartacking type

19) Square semilunar

type

10) Eyelet taper bartacking type

15) Semilunar taper

bar-tacking type

20) Square round

type

21) Square straight

bar-tacking type

26) Semilunar round

type

22) Square taper bartacking type

27) Bar-tacking 28) Bar-tacking, right

23) Radial semilunar

type

cut

24) Radial round type 25) Semilunar radial

type

29) Bar-tacking, left

cut

30) Bar-tacking,

center cut

Page 38

15. CHANGING SEWING DATA

15-1 Initial sewing data at the time of your purchase

Patterns from 1 to 10 have been already registered at the time of your purchase. The initial values of the

square type shape which are different in the cloth cutting length only have been inputted in the sewing data.

For the initial values of the square type shape, refer to “13. INITIAL VALUE DATA FOR EACH SHAPE

→

TABLE” in the Instruction Manual supplied with the device.

Pattern No. Cloth cutting length

1 6.40 mm (1/4")

2 9.50 mm (3/8")

3 11.10 mm (7/16")

4 12.70 mm (1/2")

5 14.30 mm (9/16")

6 15.90 mm (5/8")

7 17.50 mm (11/16")

8 19.10 mm (3/4")

9 22.20 mm (7/8")

10 25.40 mm (1")

– 37 –

Page 39

– 38 –

15-2 Changing procedure of sewing data

Display the data input screen.

1

Only in case of the data input screen (blue),

change of the sewing data can be performed.

In case of the sewing screen (green), press

READY switch and display the data input

screen (blue).

Call the sewing data screen.

2

Press SEWING DATA button (A) and the

sewing data screen is displayed.

Select the sewing data to be changed.

3

Press UP/DOWN SCROLL button (B)

and select SEWING DATA ITEM button (C) you

desire to change. Data item not used according

to the shape and data item which is set to without

function are not displayed. So, be careful.

Refer to

→

SEWING DATA WITH/WITHOUT EDIT, p.50

16. SETTING PROCEDURE OF

.

A

C

B

Page 40

Change the data.

4

For the sewing data, there are the data item to

change the numeral and data item to select the

pictograph. No. in pink color such as is

put on the data item to change the numeral and

the set value can be changed with the +/- button

which is displayed in the change screen. No.

in blue color such as is put on the data

item to select the pictograph and the pictograph

which is displayed in the change screen can be

selected.For the details of the sewing data, refer

to

15-3 Sewing data list, p.40

.

– 39 –

Page 41

– 40 –

15-3 Sewing data list

Sewing data are those that can be inputted to 99 patterns from pattern 1 to 99 and can be inputted to

each pattern.

The sewing machine has been set in the state that the data which is necessary to set "With/ without edit"

cannot be set at the time of your purchase. Change over the function to "With edit" if necessary for use.

Refer to

→

No. Item Setting range Edit unit Remarks

16. SETTING PROCEDURE OF SEWING DATA WITH/WITHOUT EDIT, p.50

Sewing shape

This item selects the shape from among the sewing shapes

of 30 different kinds which the sewing machine has.

Refer to

→

※Only12kindsofstandardsewingshapescanbeselected

at the time of your purchase. When increasing the kinds

of shapes, perform setting of K04 Sewing shape selection

level of memory switch data.

Refer to

→

Cloth cut length

This item sets the length of cloth that is cut by

cloth cutting knife. However, in case of bartack shape (Nos. 27, 28, 29 and 30 of S01),

sewing length is set.

By making effective Function of plural motions of

cloth cutting knife of memory switch data, make the plural

motions of knife by the knife size set in the item

Cloth cutting knife size, and the sewing product is cut.

Refer to

→

Knife groove width, right

This item sets the clearance between cloth

cutting knife and right parallel section.

14. SEWING SHAPE LIST, p.36

1 〜 30

26-2 Memory switch list, p.79

26-2 Memory switch data list, p.79

.

.

.

1 to 30 1 ---

3.0 to 120.0 0.1mm ---

-2.00 to 2.00 0.05mm ---

.

(Remarks)

※1:Displayedaccordingtotheshape.

※2:Displayedwhenitissettowithedit.

Refer to

16. SETTING PROCEDURE OF SEWING DATA WITH/WITHOUT EDIT, p.50

※3:Displayedwhenthefunctionisselected.

.

Page 42

No. Item Setting range Edit unit Remarks

Knife groove width, left

-2.00 to 2.00 0.05mm --This item sets the clearance between cloth

cutting knife and left parallel section.

Overedging width, left

0.10 to 5.00 0.05mm --This item sets the overedging width of left

parallel section.

Ratio of right and left shapes

50 to 150 1% --This item sets enlargement/reduction ratio of

right side shape making the knife position as

the center.

Pitch at parallel section

This item sets sewing pitch of left and right

0.200 to

2.500

0.025mm ---

parallel sections.

2nd bar-tacking length

0.2 to 5.0 0.1mm --This item sets length of bar-tacking on the front

side.

Square

type,

bottom

Straight

bar-tack,

bottom

Flow,

bottom

1st bar-tacking length

This item sets length of bar-tacking on the rear

side.

Square

type, top

Compensation of bar-tacking width, right

This item adjusts left side outer shape of bartacking section in terms of overedging section.

Both 1st and 2nd bar-tacking can be

compensated.

Straight

bar-tack,

bottom

Square

type, top

Square

type,

bottom

Compensation of bar-tacking width, left

This item adjusts left side outer shape of bartacking in terms of overedging section.

0.2 to 5.0 0.1mm ---

-1.00 to 1.00 0.05mm ---

-1.00 to 1.00 0.05mm ---

– 41 –

Page 43

– 42 –

No. Item Setting range Edit unit Remarks

Flow bar-tacking offset, left

0.00 to 3.00 0.05mm ※1

This item sets length to form bar-tacking

sectionofowbar-tackingshape.

Flow bar-tacking offset, right

0.00 to 3.00 0.05mm ※1

This item sets length to form bar-tacking

sectionofowbar-tackingshape.

Eyelet shape length

1.0 to 10.0 1 ※1

This item sets upper side length from center of

eyelet of eyelet shape.

Number of stitches of eyelet shape

1 to 8 0.1mm ※1

This item sets number of stitches in the upper

90゚ofeyeletshape.

Eyelet width

1.0 to 10.0 0.1mm ※1

This item sets crosswise size of the inside of

eyelet shape.

Actual needle entry point is the dimension to

which S04 Knife groove width, left is added.

Eyelet length

1.0 to 10.0 0.1mm ※1

This item sets lengthwise size of the inside of

eyelet shape.

Round type shape length

1.0 to 5.0 0.1mm ※1

This item sets upper side length from the

center of round type shape.

Round

type, top

Radial, top Semilunar,

top

Round

type,

bottom

Radial,

bottom

Semilunar,

bottom

Number of stitches of radial shape

This item sets number of stitches in the upper

90° of radial shape.

1 to 8 1 ※1

Page 44

No. Item Setting range Edit unit Remarks

Reinforcement of radial shape

--- --- ※1,※2

This item sets with / without reinforcement

stitching

of radial shape.

: With : Without

Pitch at bar-tacking section

This item sets sewing pitch of bar-tacking

section.

Square

type, top

Square

type,

bottom

Round

type,

top

Round

type,

bottom

Semilunar,

top

Semilunar,

bottom

Straight

bar-tack,

bottom

1st clearance

This item sets the clearance between 1st

bar-tacking and knife groove. This item is

applied to all shapes.

2nd clearance

This item sets the clearance between 2nd

bar-tacking and knife groove. This item is

applied to all shapes.

Single/double stitching

This item selects single or double stitching.

: Single stitching :

Flow,

bottom

Double stitching

0.100 to

0.025mm ---

2.500

0.0 to 4.0 0.1mm ---

0.0 to 4.0 0.1mm ---

--- --- ---

– 43 –

Page 45

– 44 –

No. Item Setting range Edit unit Remarks

Double stitching cross selection

This item selects overlapped stitching or cross stitching at

the needle entry of parallel section when setting double

stitching.

--- --- ※3

: Overlapped

stitching

Compensation of double stitching

width

This item sets amount to narrow

overedging width of 1st cycle when

setting double stitching.

Number of times of basting

This item sets number of times of basting.

: Without

basting

Basting pitch

This item sets pitch at the time of

performing basting.

Rolling length of basting

This item sets rolling length of needle

thread when performing basting.

Rolling pitch of basting

This item sets rolling pitch of needle

thread when performing basting.

: Cross stitching

0.0 to 2.0 0.1mm ※3

0 to 9 1 ※3

: 1 to 9 times

1.0 to 5.0 0.1mm ※3

2.0 to 20.0 0.1mm ※3

0.2 to 5.0 0.1mm ※3

Rolling width of basting

This item sets rolling width of needle

thread when performing basting.

Lengthwise compensation of needle

entry of basting

This item sets the amount to move

needle entry position back and forth when

performing basting more than two cycles.

0.0 to 4.0 0.1mm ※3

0.0 to 2.5 0.1mm ※2,※3

Page 46

No. Item Setting range Edit unit Remarks

Crosswise compensation of needle

entry of basting

This item sets the amount to move needle

entry position to the right or left when

performing basting more than two cycles.

Compensation of left side position of

basting

This item sets the amount to move the

sewing reference position of basting from

the center of left overedging to the right or

left.

Compensation of right side position of

basting

This item sets the amount to move the

sewing reference position of basting from

the center of right overedging to the right

or left.

Speed setting of basting

This item sets speed of basting.

0.1 to 1.0 0.1mm ※3

-2.0 to 2.0 0.1mm ※2,※3

-2.0 to 2.0 0.1mm ※2,※3

400 to 4200 100rpm ※3

– 45 –

Page 47

No. Item Setting range Edit unit Remarks

Left parallel section tension

This item sets needle thread tension at

left parallel section.

Right parallel section tension

This item sets needle thread tension at

right parallel section.

Left parallel section tension (1st cycle

of double stitching)

This item sets needle thread tension at

left parallel section of 1st cycle at the time

of double stitching.

Right parallel section tension (1st

cycle of double stitching)

This item sets needle thread tension at

right parallel section of 1st cycle at the

time of double stitching.

Tension at 1st bar-tacking section

This item sets needle thread tension at

1st bar-tacking section.

Tension at 2nd bar-tacking section

This item sets needle thread tension at

2nd bar-tacking section.

0 to 200 1 ---

0 to 200 1 ※2

0 to 200 1 ※2,※3

0 to 200 1 ※2,※3

0 to 200 1 ---

0 to 200 1 ※2

Setting of needle thread tension at the

start of sewing

This item sets needle thread tension of tie

stitching at the start of sewing.

Setting of needle thread tension of

basting

This item sets needle thread tension of

basting.

0 to 200 1 ---

0 to 200 1 ※3

– 46 –

Page 48

No. Item Setting range Edit unit Remarks

ACT timing adjustment at the start of

1st bar-tacking

This item adjusts needle thread tension

output start timing at 1st bar-tacking

section.

ACT timing adjustment at the start of

right overedging

This item adjusts needle thread tension

output start timing at right overedging

section.

ACT timing adjustment at the start of

2nd bar-tacking

This item adjusts needle thread tension

output start timing at 2nd bar-tacking

section.

Number of stitches of tie stitching at

the start of sewing

This item sets number of stitches of tie

stitching at the start of sewing.

Sewing pitch of tie stitching at the start

of sewing

This item sets sewing pitch of tie stitching

at the start of sewing.

Tie stitching width at the start of

sewing

This item sets tie stitching width at the

start of sewing.

Lengthwise compensation of tie

stitching at the start of sewing

This item sets start position of tie stitching

in lengthwise direction at the start of

sewing.

Crosswise compensation of tie

stitching at the start of sewing

This item sets start position of tie stitching

in crosswise direction at the start of

sewing.

-5 to 5 1 stitch ※2

-5 to 5 1 stitch ※2

-5 to 5 1 stitch ※2

0 to 8 1 stitch ---

0.00 to 0.70 0.05mm ※2

0.0 to 3.0 0.1mm ---

0.0 to 5.0 0.1mm ※2

0.0 to 2.0 0.1mm ※2

– 47 –

Page 49

– 48 –

No. Item Setting range Edit unit Remarks

Tie stitching width at the end of sewing

This item sets tie stitching width at the

end of sewing.

Number of stitches of tie stitching at

the end of sewing

This item sets number of stitches of tie

stitching at the end of sewing.

Lengthwise compensation of tie

stitching at the end of sewing

This item sets start position of tie stitching

in lengthwise direction at the end of

sewing.

Crosswise compensation of tie

stitching at the end of sewing

This item sets start position of tie stitching

in crosswise direction at the end of

sewing.

Knife motion

This item sets "With/without motion" of normal cloth cutting

knife.

0.1 to 1.5 0.1mm ---

0 to 8 1 stitch ---

0.0 to 5.0 0.1mm ※2

0.0 to 2.0 0.1mm ※2

--- --- ---

: Normal knife

motion Off

Knife motion at 1st cycle of double stitching

This item sets "With/without motion" of cloth cutting knife at

1st cycle when double stitching is performed.

: Normal knife

motion Off

Maximum speed limitation

This item sets max. number of revolutions

of the sewing machine. The maximum

value of data edit is equal to the number

of revolutions of K07 Maximum speed

limitation of the memory switch data.

Refer to

→

list, p.79

26-2 Memory switch data

.

: Normal knife

motion ON

: Normal knife

motion ON

--- --- ※2,※3

400 to 4200 100rpm ---

Page 50

No. Item Setting range Edit unit Remarks

Pitch of going

This item sets sewing pitch of going side

of bar-tacking shape (Shape Nos. 27, 28,

29 and 30 of S01).

Width of going

This item sets width of going side of

bar-tacking shape (Shape Nos. 27, 28, 29

and 30 of S01).

Pitch of returning

This item sets sewing pitch of retuning

side of bar-tacking shape (Shape Nos.

27, 28, 29 and 30 of S01).

Width of returning

This item sets width of returning side of

bar-tacking shape (Shape Nos. 27, 28,

29 and 30 of S01).

0.200 to

2.500

0.10 to 10.00 0.05mm ---

0.200 to

2.500

0.10 to 10.00 0.05mm ---

0.025mm ---

0.025mm ---

– 49 –

Page 51

– 50 –

16. SETTING PROCEDURE OF SEWING DATA WITH/WITHOUT EDIT

Display the sewing data with/without edit

1

setting screen.

When continuing pressing switch for three

seconds, the sewing data with/without edit setting

button (A) is displayed on the screen.When

this button is pressed, the sewing data with/

without edit setting screen is displayed.

A

Select the sewing data with/without edit.

2

The list of data item buttons (B) which are

possible to set the data with/without edit among

the sewing data is displayed. When the button is

pressed, reverse display/normal display changes

over alternately.

When you desire to set "With edit", set the

reverse display.When you desire to set "Without

edit", set the normal display.

: Without edit

: With edit

Determine the sewing data with/without edit.

3

B

C

When ENTER button (C) is pressed, the

state of with/without edit of the sewing data item

which has been set is determined.

Page 52

17. COPYING SEWING PATTERN

The sewing data of the pattern No. which has been

already registered can be copied to the pattern No.

which has not been registered. Overwriting copy

of the pattern is prohibited. When you desire to

overwrite, perform it after erasing the pattern once.

Refer to

→

SELECTION, p.20

Display the data input screen.

1

Only in case of the data input screen (blue),

copying is possible. In case of the sewing screen

(green), press READY switch and display

the data input screen (blue).

6. PERFORMING PATTERN NO.

.

A

Call the pattern copy screen.

2

When pattern copy button (A) is pressed,

the pattern copy (copy source selection) screen is

displayed.

Select the pattern No. of copy source.

3

Select the pattern No. of copy source from the list

of pattern buttons (B).

Then press copy destination input button

(C) and the copy destination input screen is

displayed.

C

B

– 51 –

Page 53

– 52 –

Input the pattern No. of copy destination.

4

Input the pattern No. of copy destination with ten

keys (D). It is possible to retrieve the pattern No.

which is not used with - and + buttons

(E • F).

Start copying.

5

Press ENTER button (G) and copying

starts.

Pattern No. which has been copied in the

selected state returns to the pattern copy (copy

source selection) screen after approximately two

seconds.

※1 Cycledataandcontinuousstitchingdatacan

be copied by the same method.

※2 Whendeletionisperformedincasethe

remaining pattern No. which has been

registered is one, pattern deletion error (Error

code 402) is displayed.

※3 Whentryingtoperformcopyingtothepattern

D

G

E F

No. which has been already registered,

copy disapproval error (Error code 401) is

displayed.

Page 54

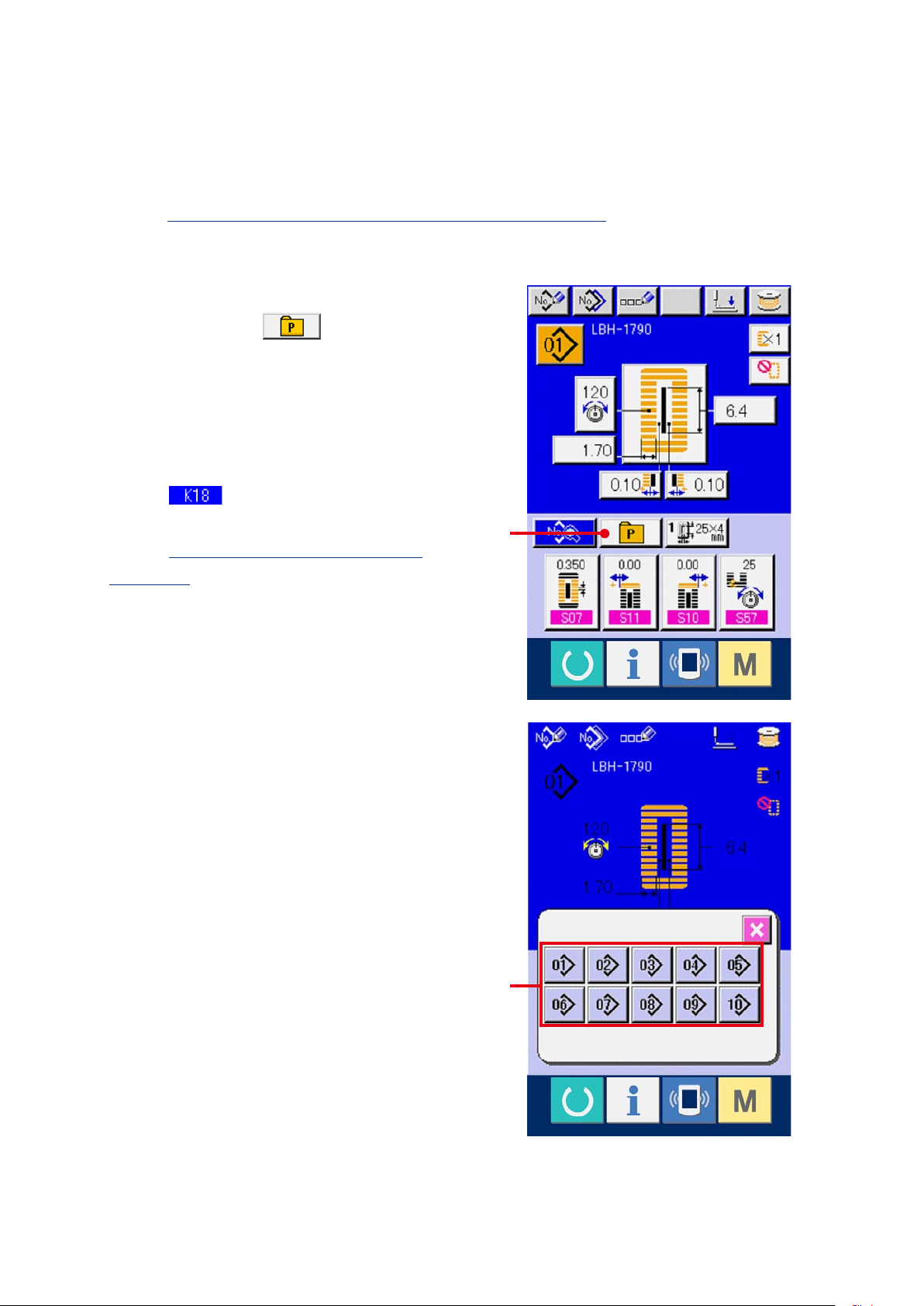

18. REGISTERING THE PATTERN TO DIRECT BUTTON

Register the pattern Nos. which are frequently used with the direct buttons for use.

Once the patterns are registered, the pattern selection can be performed with ease by pressing only the

button.

18-1 How to register

Display the direct pattern register screen.

1

When switch is pressed, direct pattern

register button (A) is displayed on the screen.

When this button is pressed, the direct pattern

register screen is displayed.

Select the button to be registered.

2

Direct patterns can be registered up to 10

patterns.

10 direct buttons (B) are displayed on the screen.

When the button located on the position you

desire to register is pressed, the pattern No. list

screen is displayed.

A

B

– 53 –

Page 55

– 54 –

Select the pattern No. to be registered.

3

Select the pattern No. you desire to register

from among pattern No. buttons (C). When the

selected button is pressed twice, the selection is

released.

Register the direct pattern.

4

When ENTER button (D) is pressed, the

registerofdirectpatternisnishedandthedirect

pattern No. register screen is displayed.

The registered pattern No. is displayed on the

direct button.

C

18-2 Register state at the time of your purchase

Pattern Nos. 1 to 10 have been registered at the time of your purchase.

D

Page 56

19. REGISTERING SEWING DATA TO CUSTOMIZE BUTTON

Register parameters which are frequently used to CUSTOMIZE button and use them.

Screen of the change of parameters which have been registered can be displayed by pressing only

CUSTOMIZE button in the data input screen.

19-1 How to register

Display the customize pattern register screen.

1

When switch is pressed, the customize

pattern register button (A) is displayed on the

screen.

When this button is pressed, the customize

pattern register screen is displayed.

Select the button to be registered.

2

The customize buttons can be registered up to

four buttons. Four costomize register buttons (B)

are displayed on the screen. When the button

located on the position you desire to register is

A

pressed, the sewing data list screen is displayed.

B

– 55 –

Page 57

– 56 –

Select the sewing data to be registered.

3

Select the sewing data you desire to register with

the sewing data buttons (C). When the selected

button is pressed twice, the selection is released.

Register to the customize button.

4

When ENTER button (D) is pressed,

registertothecustomizebuttonisnishedand

the customize button register screen is displayed.

The registered sewing data is displayed on the

customize button.

C

19-2 Register state at the time of your purchase

The following items have been registered in order at the time of your purchase.

Pitch at parallel section

Compensation of bar-tacking width, left

D

Compensation of bar-tacking width, right

Setting of needle thread tension at the start of sewing

Page 58

20. CHANGING SEWING MODE

Display the sewing mode selection screen.

1

When switch is pressed, the sewing mode

selection button (A) is displayed on the

screen. When this button is pressed, the sewing

mode selection screen is displayed.

※ Imageofthebuttonofthesewingmodeselection

button changes according to the sewing mode

which is selected at present.

When independent sewing is selected :

When cycle stitching is selected :

When continuous stitching is selected :

A

Select the sewing mode.

2

Select the sewing mode you desire to sew.

Independent sewing button (B) :

Cycle stitching button (C) :

Continuous stitching button (D) :

Determine the sewing mode.

3

When ENTER button (E) is pressed,

changeofthesewingmodeisnished.When

switch is pressed, the data input screen of

the selected sewing mode is displayed.

B

C

D

E

– 57 –

Page 59

– 58 –

21. LCD DISPLAY SECTION AT THE TIME OF CONTINUOUS STITCHING

This sewing machine can perform the continuous stitching that continuously sew the plural sewing

pattern data without lifting the presser.

It is possible to install a long presser of as long as 120 mm size and to automatically sew up to as many

as 6 shapes in the presser.

Inaddition,itispossibletoregisterasmanyas20data.Registerorcopythedatatolltheneedforuse.

Refer to

→

PATTERN, p.51

13. PERFORMING NEW REGISTRATION OF PATTERN, p.34

.

and

17. COPYING SEWING

※ Itisnecessarytochangethecomponentsfromthestateatthetimeofyourpurchaseaccordingto

the setting conditions.

21-1 Data input screen

A B C D E F

G

H

I

L

J

K

Page 60

Button and display Description

A CONTINUOUS STITCHING DATA

NEW REGISTER button

Continuous stitching data new register screen is displayed.

B CONTINUOUS STITCHING DATA

COPY button

C DATA NAME INPUT button

D DATA NAME display Name inputted in continuous stitching data No. which is being

E PRESSER DOWN button Presser down screen is displayed and the needle moves to the right

F BOBBIN WINDER button

G CONTINUOUS STITCHING

DATA NO. SELECTION button

H SEWING ORDER Sewing order of continuous stitching data which have been inputted is

Continuous stitching data copy screen is displayed.

Continuous stitching data name input screen is displayed.

Refer to

→

selected is displayed.

side. To raise the presser, press the presser up button displayd in the

presser down screen.

When performing threading in this state, turn OFF the power before

*

performing.

Bobbin thread can be wound.

Refer to

→

Continuous stitching data No. which is being selected at present is

displayed in the button. When it is pressed, continuous stitching data

No. selection screen is displayed.

displayed.

7. NAMING THE PATTERN, p.22

11. WINDING BOBBIN THREAD, p.29

.

.

I FEED AMOUNT INPUT button Cloth feed amount before sewing is displayed.

When the button is pressed, feed amount input screen is displayed.

J PATTERN NO. SELECTION

button

K SEWING DATA EDIT button Sewing data information such as pattern No., shape, cloth cutting

L ALL DELETE button Contents inputted to continuous stitching data which is being selected

Pattern No. which has been inputted is displayed.

When the button is pressed, pattern No. list screen is displayed and

pattern No. selection can be performed.

length, etc. which have been inputted is displayed

are deleted.

※ Number of patterns only to which buttons H to K and displays have been inputted is displayed.

– 59 –

Page 61

– 60 –

21-2 Sewing screen

A B C D

E

O

F

G

H

I

P

J

K1

K2

Q

L

M

N

R

Page 62

Button and display Description

A CONTINUOUS STITCHING DATA

NAME display

B KNIFE CANCEL button Every time the button is pressed, dropping/non-dropping knife is

C PRESSER DOWN button Presser can be lowered and the knife down screen is displayed.

Name inputted to continuous stitching data during sewing is displayed.

changed over alternately.

To raise the presser, press the presser up button displayed in the

presser down screen.

When performing threading in this state, turn OFF the power before

*

performing.

D BOBBIN WINER button

E CONTINUOUS STITCHING

PATTERN NO. display

F WITH/WITHOUT DOUBLE

STITCHING display

G NUMBER OF TIMES OF BASTING

display

H STEP STITCHING button

I NEEDLE THREAD TENSION

CHANGE button display

J NUMBER OF TOTAL STITCHES

display

K1 COUNTER VALUE CHANGE button

Bobbin thread can be wound.

Refer to

→

Continuous stitching data No. during sewing is displayed.

With/without double stitching which is set to the pattern data during

sewing is displayed.

Number of times of basting which is set to the pattern data during

sewing is displayed.

When the button is pressed, the step stitching screen to check the

needle entry point and to perform re-sewing is displayed.

Refer to

→

Needle thread tension which is set to the pattern data during sewing is

displayed.

Number of total stitches of the continuous stitching data during sewing

is displayed.

Existing counter value is displayed on this button. When the button is

pressed, the counter value change screen is displayed.

Refer to

→

11. WINDING BOBBIN THREAD, p.29

10. PERFORMING RE-SEWING, p.27

12. USING COUNTER, p. 30

.

.

.

K2 COUNTER CHANGE OVER button

L OVEREDGING WIDTH, LEFT button Overedging width, left which is set to the pattern data during sewing is

M KNIFE GROOVE WIDTH, LEFT

display

N SEWING SHAPE display Sewing shape during sewing is displayed.

Display of sewing counter/No. of pcs. counter can be changed over.

Refer to

→

displayed.

Knife groove width, left which is set to the pattern data during sewing

is displayed.

12. USING COUNTER, p. 30

.

– 61 –

Page 63

– 62 –

Button and display Description

O PATTERN NO. display Pattern No. inputted to continuous stitching data during sewing is

displayed. Pattern NO. being sewn at present is displayed in reverse

video.

P SPEED variable resistor Number of rotation of sewing machine can be changed. The number

of rotation which is set is displayed.

Q CLOTH CUTTING LENGTH display Cloth cutting length which is set to the pattern data during sewing is

displayed.

R KNIFE GROOVE WIDTH, RIGHT

display

Knife groove width, right which is set to the pattern data during sewing

is displayed.

Page 64

22. PERFORMING CONTINUOUS STITCHING

First, change the sewing mode to the continuous stitching before performing setting.

Refer to

→

20. CHANGING SEWING MODE, p.57

.

22-1 Selection of the continuous stitching data

Display the data input screen.

1

Only in case of the data input screen (light blue),

it is possible to select continuous stitching data

No. In case of the sewing screen (green), press

READY switch and display the data input

screen (light blue).

Call the continuous stitching data No.

2

selection screen.

When continuous stitching data No. selection

button (A) is pressed, the continuous

stitching data No. selection screen is displayed.

A

Continuous stitching data No. selected at present

and the contents are displayed in the upper part

of the screen and other continuous stitching

data No. buttons which have been registered are

displayed in the lower part of the screen.

Select the continuous stitching data No.

3

When UP/DOWN SCROOL button

is pressed, the registered continuous stitching

data No. buttons change over in order. Contents

registered to the continuous stitching data

are displayed in the buttons. Here, press the

continuous stitching data button (B) you desire to

select.

Determine the continuous stitching data No.

4

C

B

When ENTER button (C) is pressed, the

continuous stitching data No. selection screen is

closedandtheselectionhasbeennished.

– 63 –

Page 65

– 64 –

22-2 Editing procedure of the continuous stitching data

Display the data input screen.

1

Only in case of the data input screen (light blue),

it is possible to change the continuous stitching

data. In case of the sewing screen (green), press

READY switch and display the data input

screen (light blue).

After the screen is displayed, select the