Page 1

R

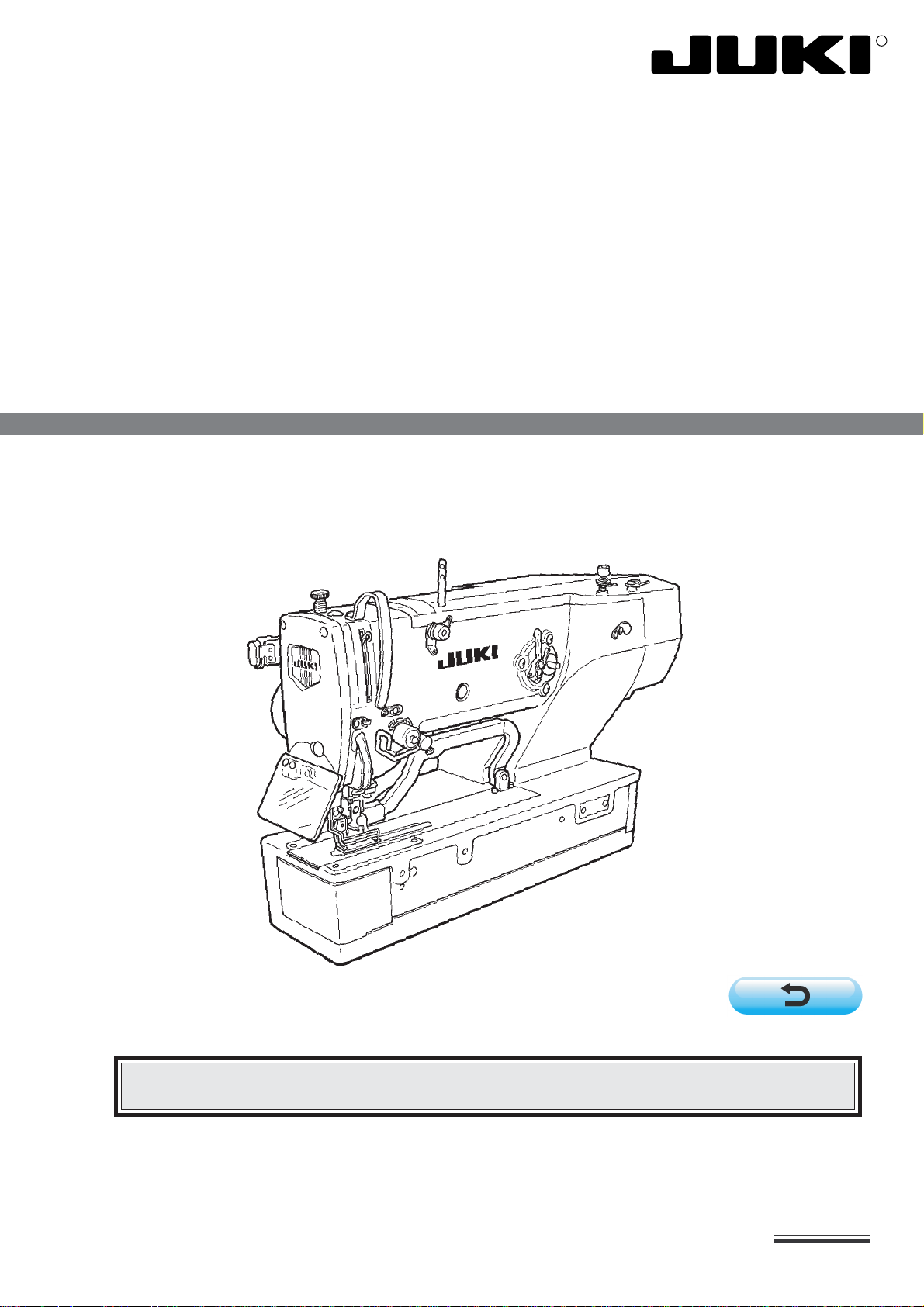

Computer-controlled, High-speed,

Lockstitch Buttonholing Machine

LBH-1790

INSTRUCTION MANUAL

NOTE : Read safety instructions carefully and understand them before using.

Retain this Instruction Manual for future reference.

E-No.03

40012734

Page 2

R

MARKETING & SALES H.Q.

8-2-1, KOKURYO-CHO,

CHOFU-SHI, TOKYO 182-8655, JAPAN

PHONE : (81)3-3480-2357 • 2358

FAX : (81)3-3430-4909 • 4914

Copyright C

2003-2006

JUKI CORPORATION

All rights reserved throughout the world.

Please do not hesitate to contact our distributors or agents in your area for further information when necessary.

* The description covered in this instruction manual is subject to change for improvement of the

commodity without notice.

06 · 09 Printed in Japan (E)

Page 3

IMPORTANT SAFETY INSTRUCTIONS

Putting sewing systems into operation is prohibited until it has been ascertained that the sewing systems in which these

sewing machines will be built into, have conformed with the safety regulations in your country.

Technical service for those sewing systems is also prohibited.

1. Observe the basic safety measures, including, but not limited to the following ones, whenever you use the machine.

2. Read all the instructions, including, but not limited to this Instruction Manual before you use the machine.

In addition, keep this Instruction Manual so that you may read it at anytime when necessary.

3. Use the machine after it has been ascertained that it conforms with safety rules/standards valid in your country.

4. All safety devices must be in position when the machine is ready for work or in operation.

The operation without the specified safety devices is not allowed.

5. This machine shall be operated by appropriately-trained operators.

6. For your personal protection, we recommend that you wear safety glasses.

7. For the following, turn off the power switch or disconnect the power plug of the machine from the receptacle.

7-1 For threading needle(s), looper, spreader etc. and replacing bobbin.

7-2

For replacing part(s) of needle, presser foot, throat plate, looper, spreader, feed dog, needle guard, folder, cloth guide etc.

7-3 For repair work.

7-4 When leaving the working place or when the working place is unattended.

7-5 When using clutch motors without applying brake, it has to be waited until the motor stopped totally.

8. If you should allow oil, grease, etc. used with the machine and devices to come in contact with your eyes or skin or

swallow any of such liquid by mistake, immediately wash the contacted areas and consult a medical doctor.

9. Tampering with the live parts and devices, regardless of whether the machine is powered, is prohibited.

10. Repair, remodeling and adjustment works must only be done by appropriately trained technicians or specially skilled

personnel. Only spare parts designated by JUKI can be used for repairs.

11. General maintenance and inspection works have to be done by appropriately trained personnel.

12. Repair and maintenance works of electrical components shall be conducted by qualified electric technicians or under the

audit and guidance of specially skilled personnel.

Whenever you find a failure of any of electrical components, immediately stop the machine.

13. Before making repair and maintenance works on the machine equipped with pneumatic parts such as an air cylinder, the

air compressor has to be detached from the machine and the compressed air supply has to be cut off. Existing residual

air pressure after disconnecting the air compressor from the machine has to be expelled. Exceptions to this are only

adjustments and performance checks done by appropriately trained technicians or specially skilled personnel.

14. Periodically clean the machine throughout the period of use.

15. Grounding the machine is always necessary for the normal operation of the machine. The machine has to be operated in

an environment that is free from strong noise sources such as high-frequency welder.

16. An appropriate power plug has to be attached to the machine by electric technicians. Power plug has to be connected to

a grounded receptacle.

17. The machine is only allowed to be used for the purpose intended. Other used are not allowed.

18. Remodel or modify the machine in accordance with the safety rules/standards while taking all the effective safety measures.

JUKI assumes no responsibility for damage caused by remodeling or modification of the machine.

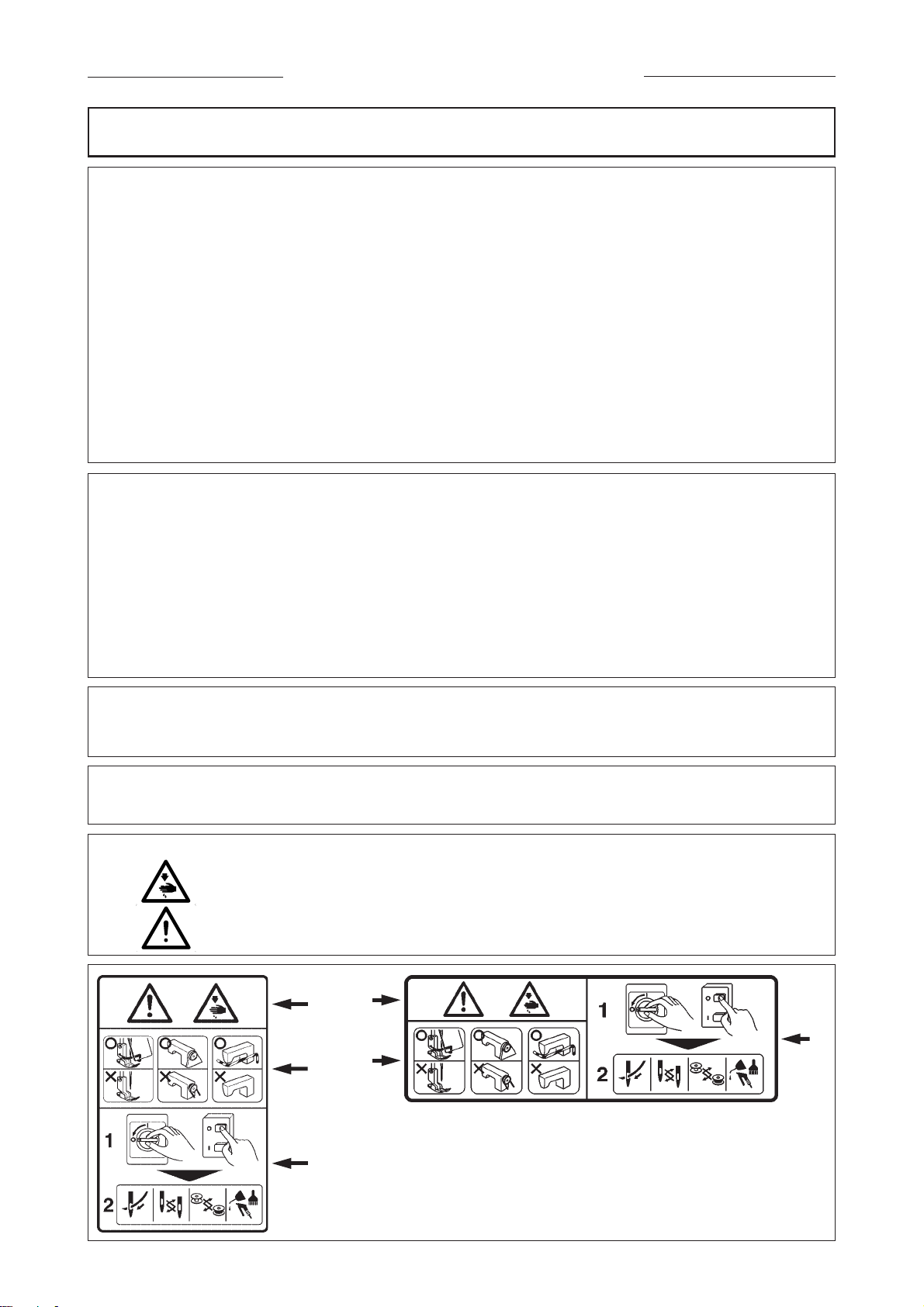

19. Warning hints are marked with the two shown symbols.

Danger of injury to operator or service staff

Items requiring special attention

1

1

3

2

2

1 • There is the possibility that slight to serious injury or death may be caused.

• There is the possibility that injury may be caused by touching moving part.

3

2 • To perform sewing work with safety guard.

• To perform sewing work with safety cover.

• To perform sewing work with safety protection device.

3 • Turn OFF the power and perform “threading”, “replacement of bobbin or

needle”, “cleaning”, “adjustment” and “lubrication”.

i

Page 4

FOR SAFE OPERATION

1. To prevent possible accidents due to electric shocks, neither open the cover of

motor electrical box nor touch the component(s) inside the electrical box.

2. Make sure of the needle entry after changing the pattern. Should the pattern protrude

from the work clamp check, needle interferes with the work clamp check resulting in

the danger of occurrence of needle breakage or the like. In addition, check that the

work clamp check which has been set corresponds to that which has been installed

on the sewing machine.

1. In case nothing is displayed in the operation panel even when the power switch is

turned ON, turn OFF the power switch and check the power voltage and phase.

2. To avoid personal injury, never put your fingers under the thread take-up lever, cloth

presser, cloth cutting knife, or needle when you turn the power switch ON or operate

the sewing machine.

3. To protect against possible accidents due to abrupt startup of the machine, turn

OFF the power switch before tilting the machine head or removing the motor cover.

4. To avoid personal injury, never bring your fingers, hair or clothing close to V belt,

cloth cutting knife or motor during operation, and never place anything on any of

these parts.

5. To avoid personal injury, never operate the machine with the motor cover, eye

protection cover, or any other safety devices removed.

6. To avoid personal injury, be careful never to allow your fingers to go inside the

machine when tilting or raising the machine head.

7. To prevent possible accidents due to electric shocks or damaged electrical

component(s), always turn OFF the power switch before connecting or disconnecting

the power plug.

8. During thunder and lightning storms, stop your work and disconnect the power

from the outlet to ensure safety and prevent possible accidents due to damaged

electrical component(s).

9. If the machine is suddenly moved from a cold place to a warm place, dew

condensation may result. If this occurs, be sure to confirm that there are no potentially

dangerous water drops in the machine before turning it on in order to prevent possible

accidents due to damaged electrical component(s).

10. In the event of a power failure, be sure to turn OFF the power to the machine to

protect against damaged electrical components.

11. This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

ii

Page 5

CONTENTS

蠢 . IMPORTANT SAFETY INSTRUCTIONS ....................................................................... 1

蠡 . SPECIFICATIONS ......................................................................................................... 1

1. Subclass ................................................................................................................................................1

2. Specifications........................................................................................................................................ 1

3. Standard sewing shape list.................................................................................................................. 2

4. Configuration ........................................................................................................................................ 3

蠱 . INSTALLATION ............................................................................................................. 4

蠶 . PREPARATION BEFORE OPERATION ..................................................................... 12

1. Lubrioation ..........................................................................................................................................12

2. Inserting the needle ............................................................................................................................ 12

3. Threading the needle-thread.............................................................................................................. 13

4. Threading the bobbin case ................................................................................................................13

5. Adjusting the bobbin thread tension ................................................................................................14

6. Installation of bobbin case................................................................................................................. 14

7. Installing the knife .............................................................................................................................. 15

蠹 . OPERATION OF THE SEWING MACHINE ................................................................. 16

1. Explanation of the operation panel switch .......................................................................................16

2. Basic operation of the sewing machine ........................................................................................... 18

3. How to use the pedal .......................................................................................................................... 18

4. Input of the presser type .................................................................................................................... 20

5. Performing pattern selection ............................................................................................................. 21

6. Changing needle thread tension .......................................................................................................22

7. Performing re-sewing ......................................................................................................................... 23

8. Winding bobbin thread .......................................................................................................................24

9. Using the counter ............................................................................................................................... 25

10. Using the initial value pattern ............................................................................................................26

11. Changing sewing data ........................................................................................................................27

12. Method of setting sewing data with/without edit .............................................................................28

13. Sewing data list ...................................................................................................................................29

14. Copying sewing pattern .....................................................................................................................35

15. Using pattern register key.................................................................................................................. 36

16. Using parameter register key ............................................................................................................ 37

17. Performing continuous stitching .......................................................................................................38

18. Performing cycle stitching .................................................................................................................40

19. Explanation of plural motions of knife.............................................................................................. 42

20. Method of changing memory switch data ........................................................................................43

21. Memory switch data list ..................................................................................................................... 44

蠧 . MAINTENANCE .......................................................................................................... 48

1. Adjusting the needle-to-hook relation ..............................................................................................48

2. Adjusting the needle thread trimmer ................................................................................................49

3. Adjusting the presser bar pressure ..................................................................................................50

4. Adjustment of the bobbin presser unit .............................................................................................50

5. Thread tension ....................................................................................................................................52

6. Cleaning the filter................................................................................................................................ 52

7. Replacing the fuse .............................................................................................................................. 52

蠻 . GAUGE COMPONENTS ............................................................................................. 53

1. Cloth cutting knife .............................................................................................................................. 53

2. Throat plate ......................................................................................................................................... 53

3. Presser .................................................................................................................................................53

衄 . ERROR CODE LIST .................................................................................................... 54

衂 . TROUBLES AND CORRECTIVE MEASURES ........................................................... 57

衒 . DRAWING OF THE TABLE ......................................................................................... 59

衙 . INITIAL VALUE DATA FOR EACH SHAPE TABLE .................................................... 60

iii

Page 6

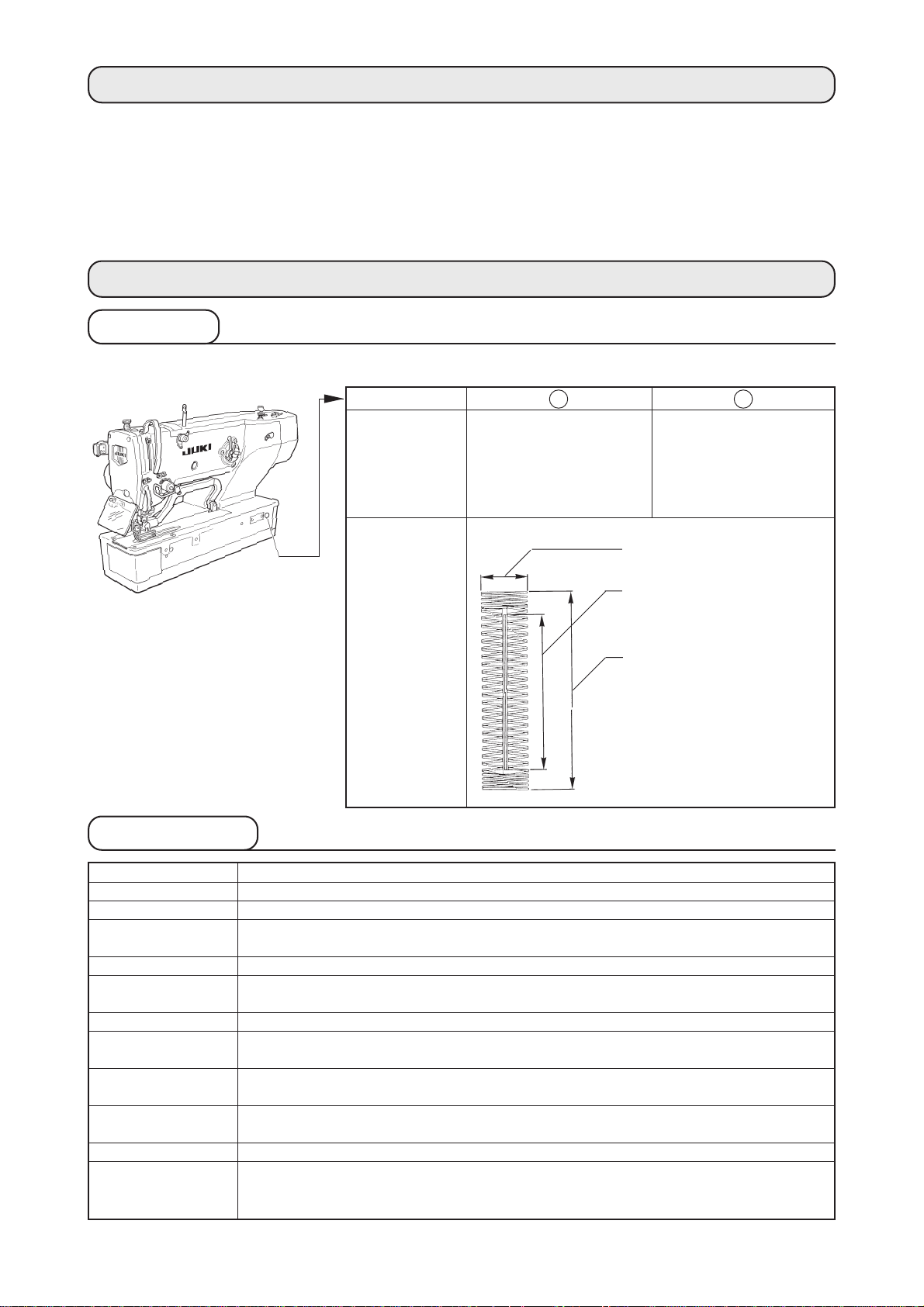

1.

IMPORTANT SAFETY INSTRUCTIONS

1) Never operate the machine unless the oiling tank has been properly lubricated.

2) Be sure to remove any dust from the hook or bobbin thread cutting knife section at the end of the day,

and check the amount of oil remaining.

3) Be sure to return the activating pedal to the home position after the machine has started to run.

4) A safety switch is installed so that this sewing machine can not be operated in the state that the machine

head is tilted. When operating this sewing machine, turn the power switch ON after setting the sewing

machine to the bed base properly.

2. SPECIFICATIONS

1. Subclass

Computer-controlled, high-speed, lockstitch buttonholing machine, LBH-1790, has the subclass machines below.

2. Specifications

Subclass

Major

application

Buttonholing

size

S

Buttonholing of cloth

such as men’s shirts,

blouses, work uniforms,

ladies' wear, etc.

Standard : Max. 5 mm

Special type part : Max. 10 mm

Knife size used :

6.4 to 31.8 mm (1/4' to 1-1/4')

Buttonholing sewing length

Standard : Max. 41 mm

Special type part : Max. 120 mm

K

Buttonholing of knits

such as knitted

underwear, sweaters,

cardigans, jersey, etc.

Sewing speed

Needle

Hook

Needle rocking drive

method

Feed drive method

Presser lifting drive

method

Lift of presser foot

Cloth cutting knife

drive method

Standard sewing

shape

Number of patterns

stored in memory

Motor used

Noise

Standard speed : 3,600 rpm (Max. : 4,200 rpm) (Max. : 3,300 rpm when dry hook is used)

DPX5 #11J to #14J

DP type full-rotary hook

Drive by stepping motor

Drive by stepping motor

Drive by stepping motor

14 mm (Optional setting available) Max. : 17 mm (At the time of needle up by reverse run)

By double-acting solenoid drive

30 kinds

99 patterns

Single phase 220/230/240 V, 3-phase 200 to 240 V, 1000 VA

Workplace-related noise at sewing speed

n = 4,000 min

Noise measurement according to DIN 45635-48-A-1.

–1

: LPA

≦ 83 dB(A)

− 1 −

Page 7

3. Standard sewing shape list

(1) Square type

PANEL

DISPLAY

(7) Eyelet square type

PANEL

DISPLAY

(13) Semilunar square

type

(2) Round type

PANEL

DISPLAY

(8) Eyelet radial type

PANEL

DISPLAY

(14) Semilunar straight

bar-tacking type

(3) Radial square type

PANEL

DISPLAY

(9) Eyelet straight bar-

tacking type

PANEL

DISPLAY

(15) Semilunar taper bar-

tacking type

(4) Radial type

PANEL

DISPLAY

(10) Eyelet taper bar-

tacking type

PANEL

DISPLAY

(16) Eyelet semilunar

type

(5) Radial straight bar-

tacking type

PANEL

DISPLAY

(11) Semilunar type

PANEL

DISPLAY

(17) Eyelet round type

(6) Radial taper bar-tacking

type

PANEL

DISPLAY

(12) Round square type

PANEL

DISPLAY

(18) Square radial type

PANEL

DISPLAY

(19) Square semilunar

type

PANEL

DISPLAY

(25) Semilunar radial type

PANEL

DISPLAY

PANEL

DISPLAY

(20) Square round type

PANEL

DISPLAY

(26) Semilunar round

type

PANEL

DISPLAY

PANEL

DISPLAY

(21) Square straight bar-

tacking type

PANEL

DISPLAY

PANEL

DISPLAY

(22) Square taper bar-

tacking type

PANEL

DISPLAY

PANEL

DISPLAY

(23) Radial semilunar

type

PANEL

DISPLAY

(24) Radial round type

PANEL

DISPLAY

PANEL

DISPLAY

(27) Bar-tacking (28) Bar-tacking, right cut (29) Bar-tacking, left cut (30) Bar-tacking, center cut

PANEL

DISPLAY

PANEL

DISPLAY

PANEL

DISPLAY

PANEL

DISPLAY

− 2 −

Page 8

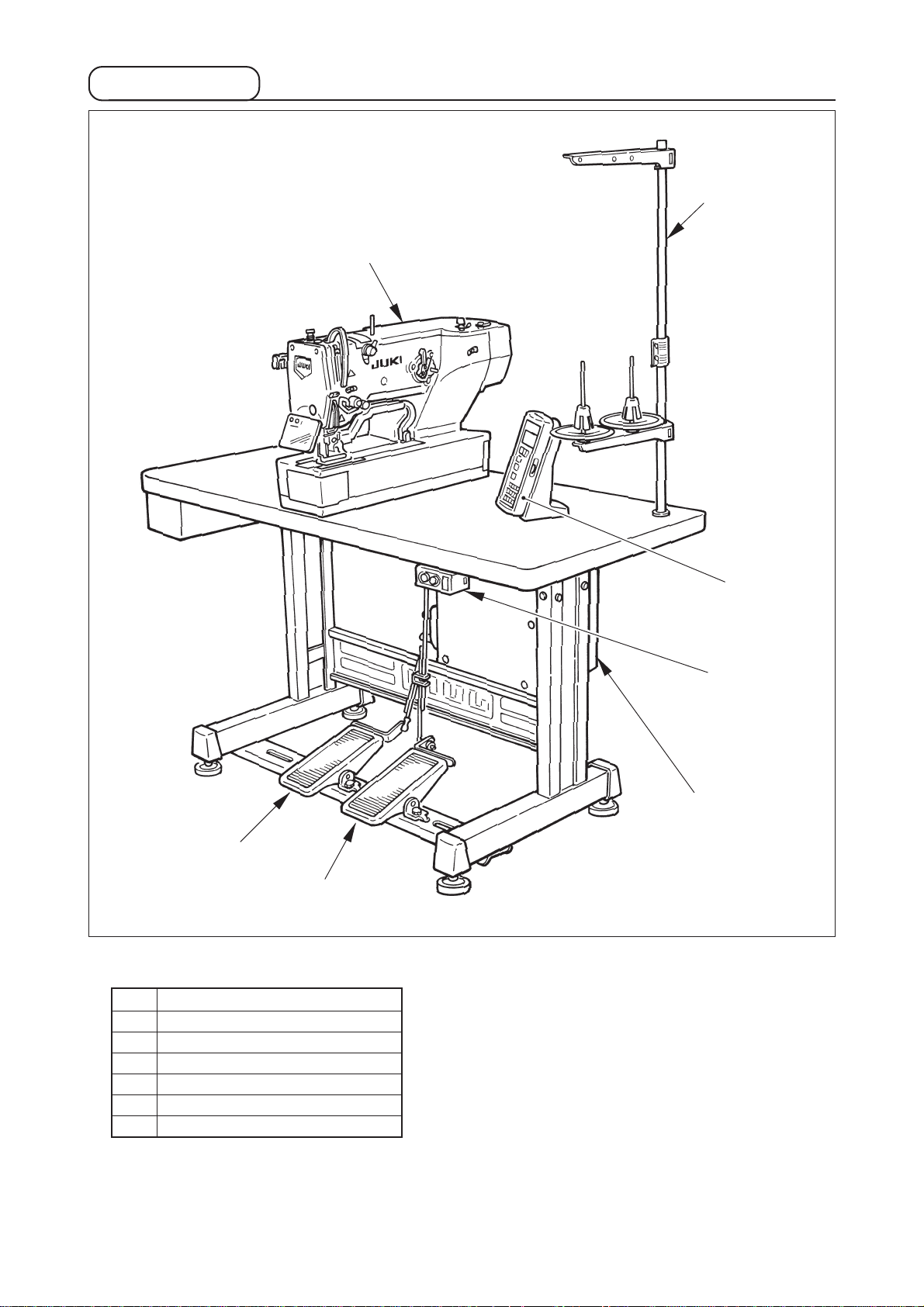

4. Configuration

u

w

t

y

LBH-1790consists of the following components.

q Power ON/OFF switch

w Machine head (LBH-1790)

e Operation panel

r Control box (MC-601)

t Presser lifting pedal

y Starting pedal

u Thread stand device

e

q

r

− 3 −

Page 9

3. INSTALLATION

WARNING :

To prevent possible accidents caused by the fall of the sewing machine, perform the work by two persons

or more when the machine is moved.

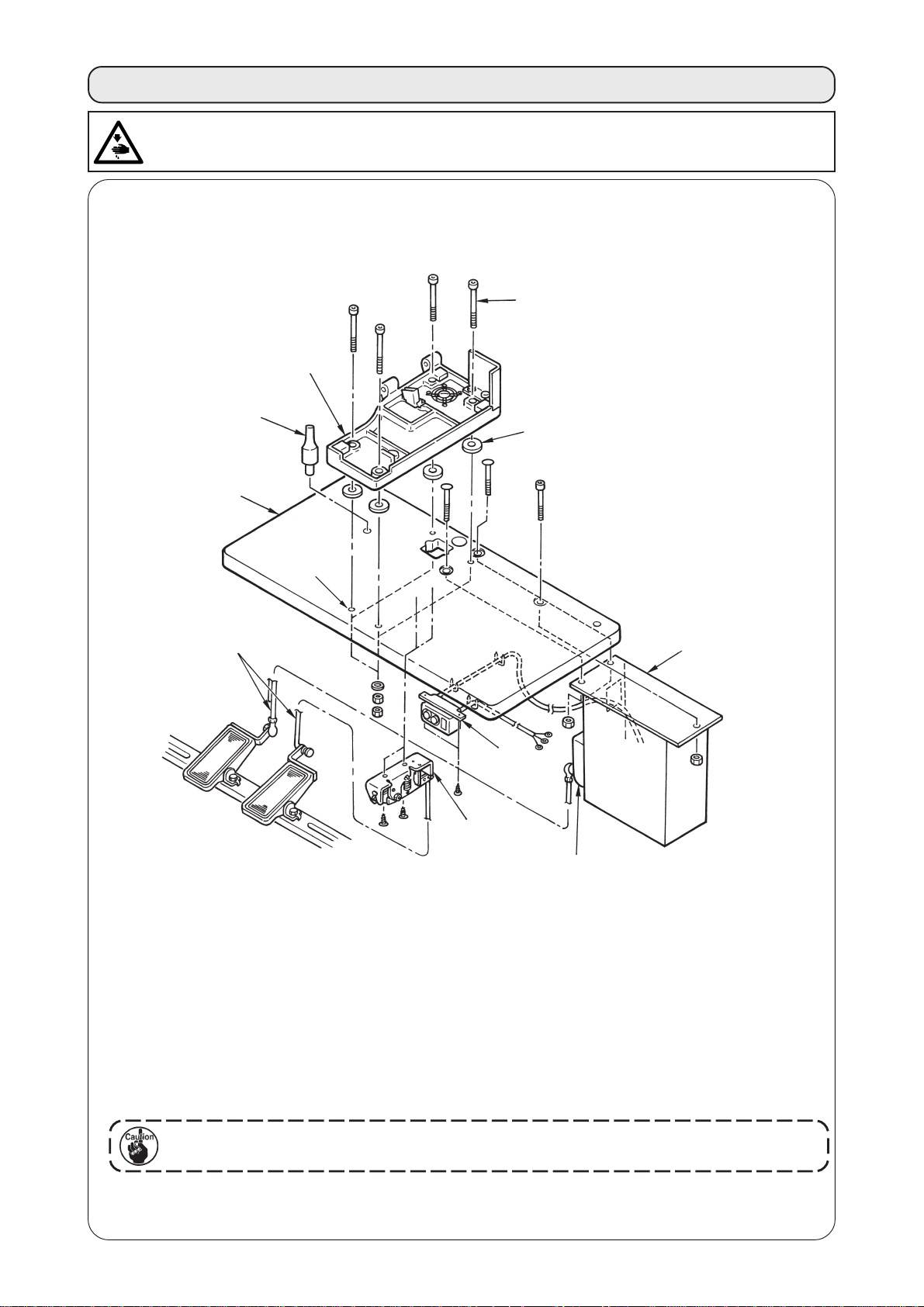

(1) Set-up of the table

r

!1

q

i

u

t

y

w

e

o

!0

1) Securely install control box w and power switch e on table q.

2) Securely fix the respective power cables of power switch e.

3) Pass four bed base fixed screws !1 through bed base r.

4) Set rubber cushions t to holes y (4 places) for fixing bed base and fix bed base r.

5) Fix head support bar u on table q.

6) After placing the sewing machine main unit on bed base r, connect pedal (right side) to pedal switch

o, and pedal (left side) to pedal sensor !0 respectively with connecting rods i which have been

supplied as accessories.

Adjust the positions of the pedals so that connecting rods i and control box w do not

come in contact with each other.

− 4 −

Page 10

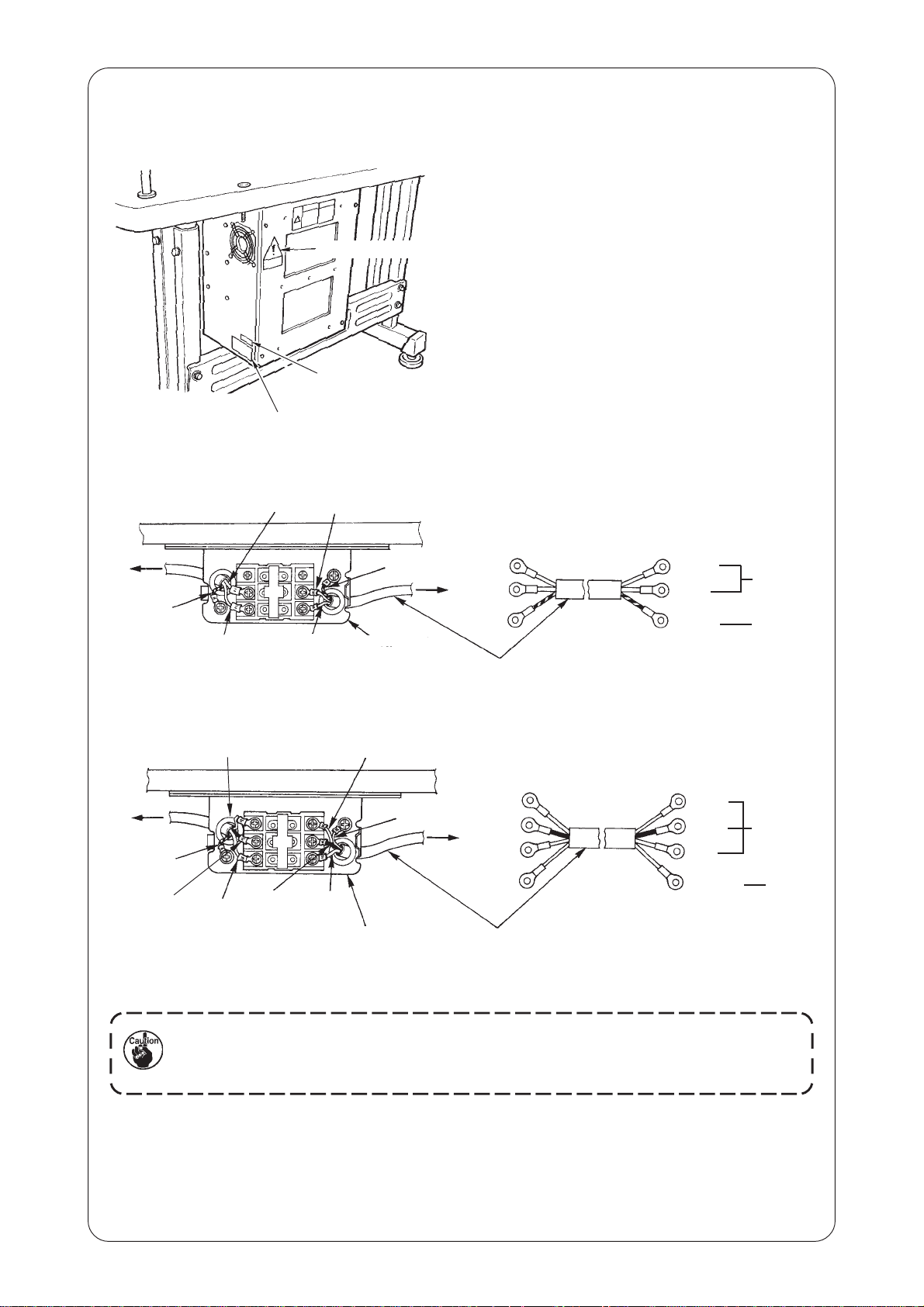

(2) Connecting the power source cord

• Voltage specifications

Power source specifications are indicated on the

voltage indication seal. (3-phase type only)

For other type machines, power source specifications

are indicated on the voltage caution seal and the

rating label.

Voltage caution seal

Voltage indication seal (3-phase type only)

Rating label

• Connecting single phase 200V, 220V, 230V and 240V

Light blue

Table

Control box

Green/Yellow

Brown

Light blue

Brown

Green/Yellow

Power switch

Connect the cord in accordance with the

specifications.

Plug

Power source cord

Brown

Light

blue

Green/

Yellow

AC200 V

AC220 V

AC230 V

AC240 V

GND

• Connecting three phase 200V, 220V and 240V

Table

Control box

Green/Yellow

Black

White

Red

Black

White

Green /

Yellow

Red

Power switch

1. Never use under the wrong voltage and phase.

2. When changing the voltage, refer to the item of "Changing the voltage of 100 /

200V".

Plug

Power source cord

White

Black

Red

Green /

Yellow

AC200 V

AC220 V

AC240 V

GND

− 5 −

Page 11

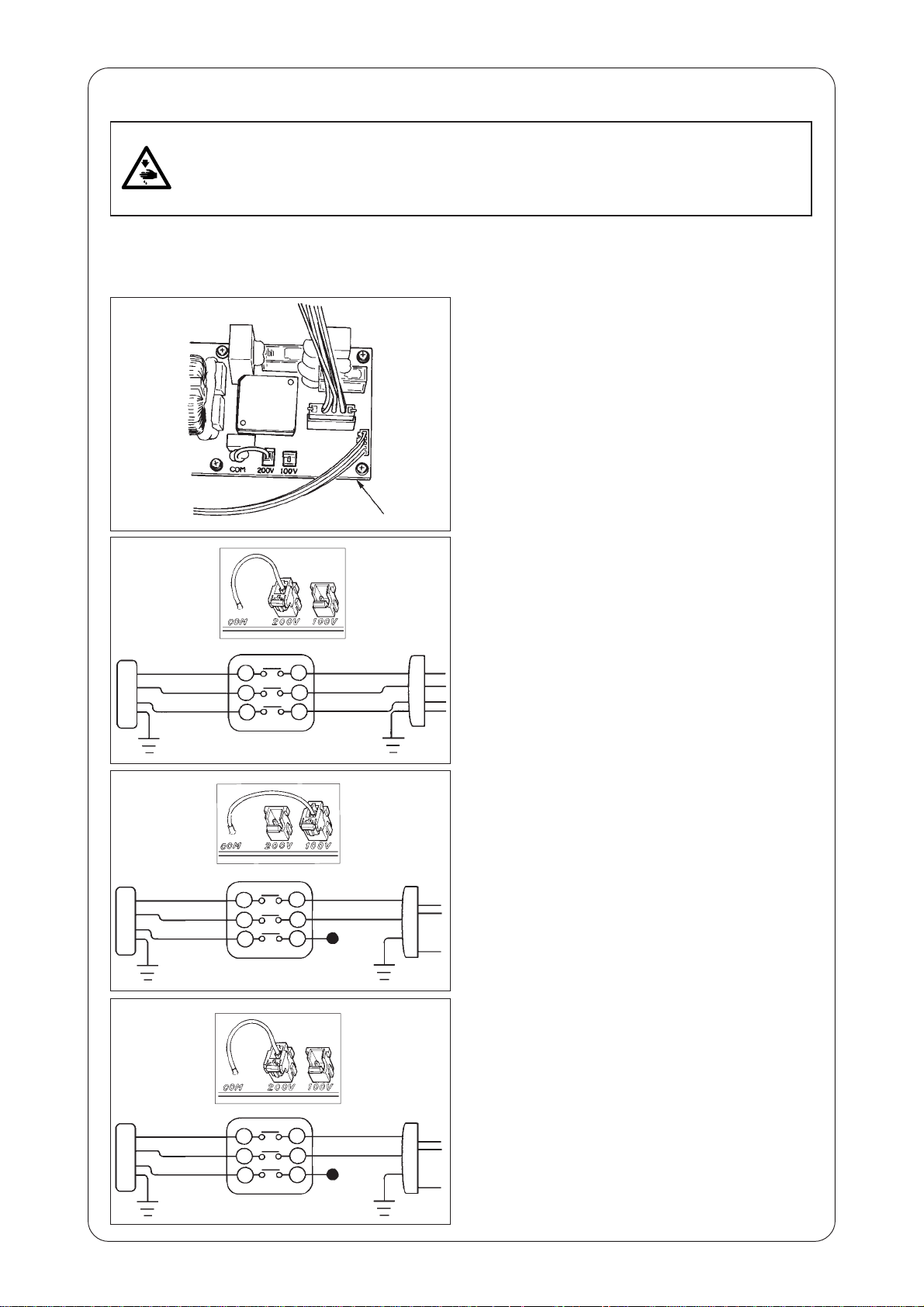

(3) Changing the voltage of 100 / 200V

WARNING :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or

more. To prevent accidents caused by unaccustomed work or electric shock, request the electric

expert or engineer of our dealers when adjusting the electrical components.

It is adaptable to the voltage of single phase 100V to 120V/3-phase 200V to 240V by changing the

voltage changeover connector mounted on FLT p.c.b.

(Caution) When the changing procedure is wrong, the control box will be broken. So, be very

careful.

Changing procedure of the changeover connector

1. Turn OFF the power source with the power

switch after confirming that the sewing machine

has stopped.

2. Draw out the power cord from the power plug

socket after confirming that the power switch is

turned OFF. Then wait for five minutes or more.

3. Remove the front cover.

4. Remove four screws fixing the rear cover of the

control box and slowly open the rear cover.

A. In case of using with 3-phase 200V to 240V

1

A

• Changing the changeover connector

Connect to 200V the 100/200V changeover

connector of FLT p.c.b. 1 located on the side

of the Box Side of the control box.

• Connect the crimp style terminal of AC input cord

to the power plug as shown in the figure.

B

C

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

(Plug side)

(Plug side)

(Plug side)

B. In case of using with single phase 100V to 120V

• Changing the changeover connector

Connect to 100V the 100/200V changeover

connector of FLT p.c.b. 1 located on the side

of the Box Side of the control box.

• Connect the crimp style terminal of AC input cord

to the power plug as shown in the figure.

(Caution) Securely perform the insulation

treatment to the red terminal which

is not used with insulation tape or

the like.

(When the insulation is insufficient,

there is a danger of electric shock or

leakage current.)

C. In case of using with single phase 200V to 240V

• Changing the changeover connector

Connect to 200V the 100/200V changeover

connector of FLT p.c.b. 1 located on the side

of the Box Side of the control box.

• Connect the crimp style terminal of AC input cord

to the power plug as shown in the figure.

(Caution) Securely perform the insulation

treatment to the red terminal which is

not used with insulation tape or the

like.

(When the insulation is insufficient,

there is a danger of electric shock or

leakage current.)

5. Check that the change has been performed without

fail before closing the rear cover.

6. Be careful that the cord is not pinched between

the rear cover and the control box main unit. Close

the rear cover while pressing the lower side of rear

cover, and tighten four screws.

− 6 −

Page 12

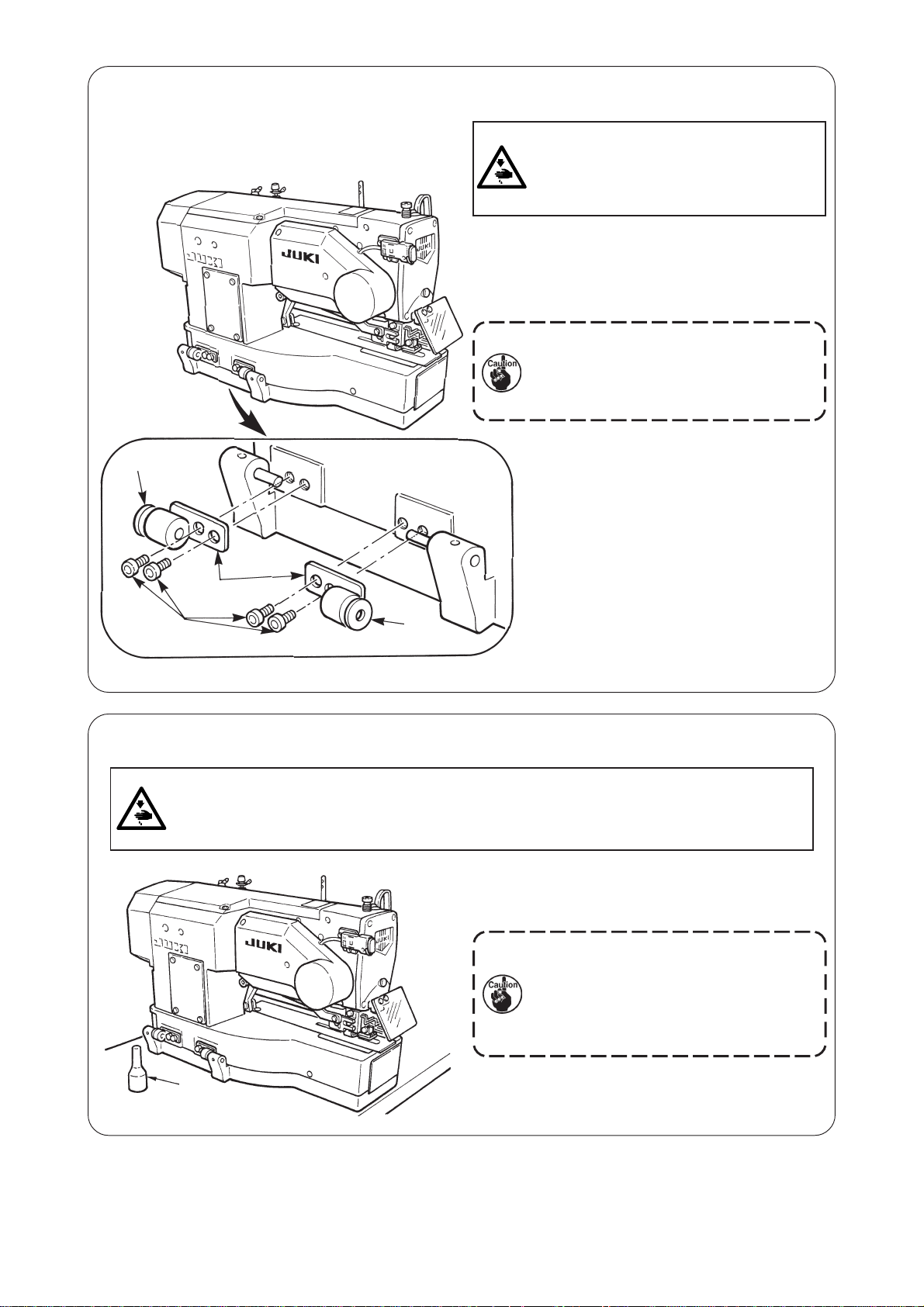

(4) Installing the sewing machine main unit

1) Place hinge plates q and shaft bearings w-1

w-1 (rubber)

WARNING :

To prevent possible accidents caused by the

fall of the sewing machine, perform the work

by two persons or more when the machine

is moved.

(rubber) and w-2 (metal) in two places on the

head base and fix the hinge plates to the machine

head with setscrews e in two places.

When the rubber hinge and metal fitting

hinge are installed in reverse order, it is

dangerous since the sewing machine

shakes when it is tilted. So, be careful.

q

e

w-2

(metal)

(5) Tilting the sewing machine head

WARNING :

When tilting/raising the sewing machine head, perform the work so as not to allow your fingers to

be caught in the machine. In addition, to avoid possible accidents caused by abrupt start of the

machine, turn OFF the power to the machine before starting the work.

When tilting the sewing machine head, tilt quietly the

sewing machine until head support bar q comes in

contact with it.

1. Make sure that sewing machine head

support bar q is placed on the table

before tilting the sewing machine.

2. To protect fall-down, be sure to tilt the

sewing machine in a level place.

q

− 7 −

Page 13

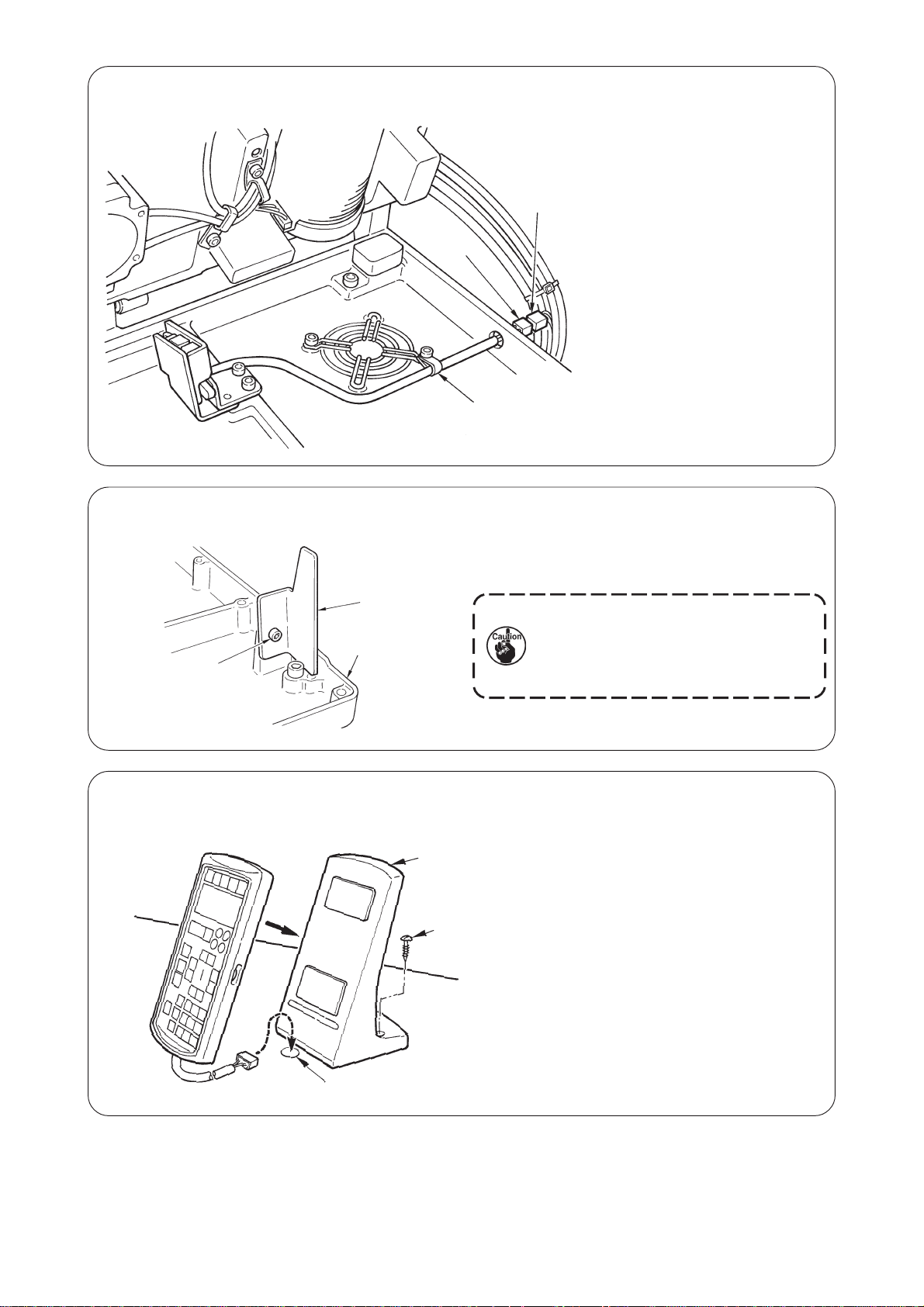

(6) Connecting the safety switch connector

w

q

Cord clamp

(7) Installing the hook oil shield plate

1) Connect safety switch connector q

with connector w located on the

machine head side.

q

e

w

(8) Installing the operation panel

q

Install hook oil shield plate q onto bed base e with

setscrew w.

Fix the sewing machine so that it does

not come in contact with hook oil shield

plate q when raising/tilting the sewing

machine.

Fix operation panel attaching plate q on the table

with woodscrew w and pass the cable through hole

e in the table.

w

e

− 8 −

Page 14

(9) Connecting the cords

Perform the connection of the cords as shown in the figure below.

CN14

Sewing machine head

CN16

CN34

MAIN circuit

board

SDC circuit board

CN16

SDC circuit

CN14

CN44

CN14

q

board

CN42

CN37

CN38

CN39

CN41

Cord

clamp A

CN16

CN37

CN38

CN42

CN39

Operation panel

CN41

CN34

Electric bobbin winding device (optional)

CN44

1) Pass 4 cords (CN38, 39, 41, and 42) connecting

to the right side among the cords connecting to

MAIN circuit board through cord clamp A as shown

in the figure, and connect them to the respective

connectors. Connect CN37 to the connector

without passing through cord clamp A.

In addition, when using the electric bobbin winding

device (optional), similarly pass the cord of the

bobbin winding device through the cord clamp and

connect it to CN44.

2) Directly connect the cord from the operation panel

connecting to the left side of MAIN circuit board

to CN34.

3) Connect the cords connecting to SDC circuit board

directly to CN14 and CN16.

4) Fix the earth wire with the setscrew q.

− 9 −

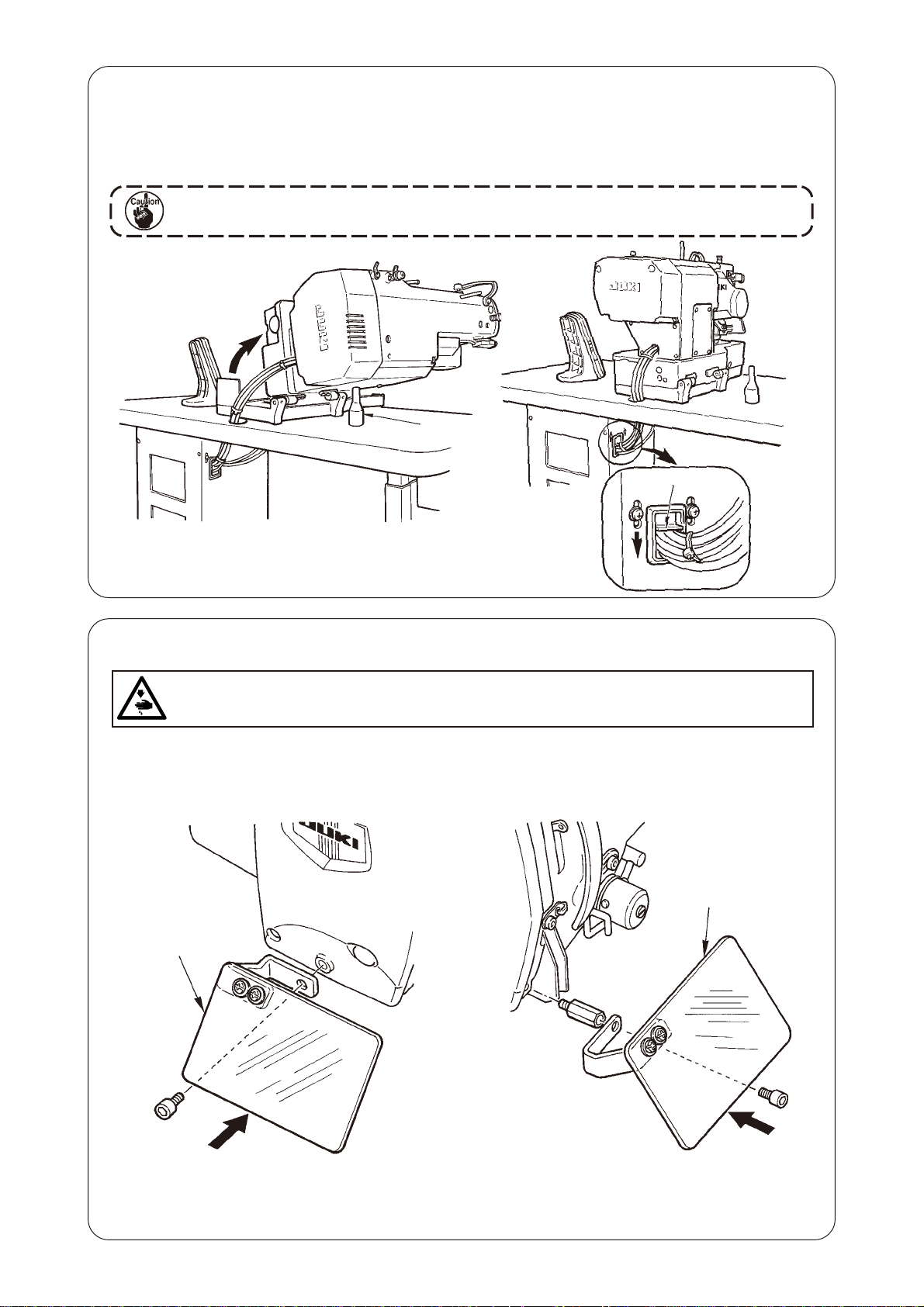

Page 15

(10) Managing the cord

1) Slowly tilting the sewing machine, check that the cords are not forcibly pulled.

2) Fix the cords with cord setting plate 1 as shown in the figure.

When you tilt the sewing machine, make sure that the sewing machine head support

bar 2 is placed on the table.

2

1

(11) Installing the eye protection cover

WARNING :

Be sure to attach this cover to protect the eyes from the disperse of needle breakage.

Be sure to install and use eye protection cover 1 and use the sewing machine.

When placed longitudinally When placed horizontally

1

1

Operator

Operator

− 10 −

Page 16

(12) Fixing the temporary stop switch

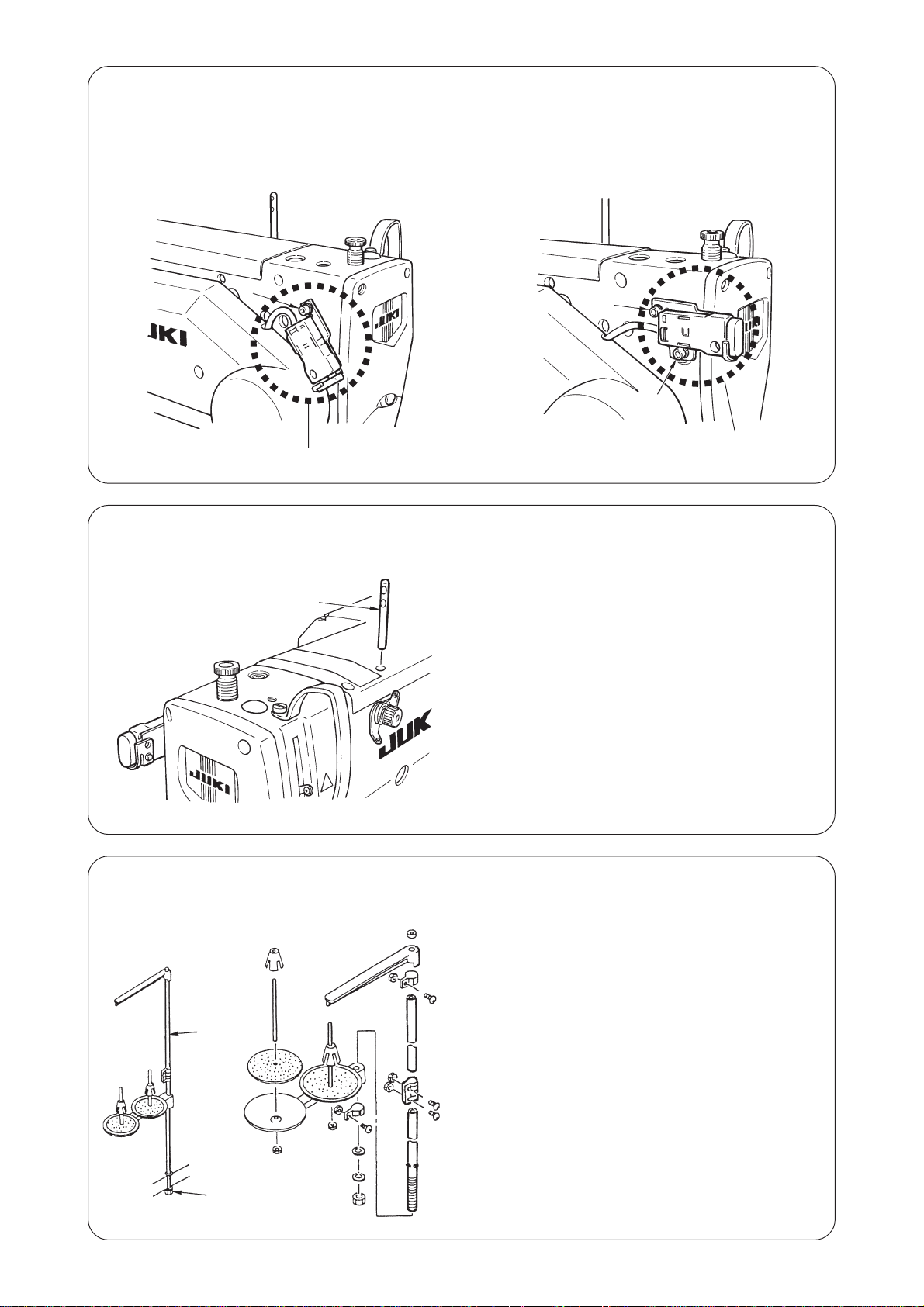

The temporary stop switch has been in the state as shown in figure A at the time of delivery.

Loosen setscrew q and set the switch in the state as shown in figure B, and fix it with setscrew q together

with setscrew w supplied with the machine.

q

q

\

w

B

A

(13) Thread guide rod

Thread guide rod

(14) Installing the thread stand

w

Securely fit the thread guide rod so that two side holes

in the thread guide rod face the thread guide.

1) Assemble the thread stand, and set it in the hole

in the top right corner of the machine table.

2) Tighten locknut q to fix the thread stand.

3) When ceiling wiring is possible, pass the power

cable through spool rest rod w.

q

− 11 −

Page 17

4. PREPARATION BEFORE OPERATION

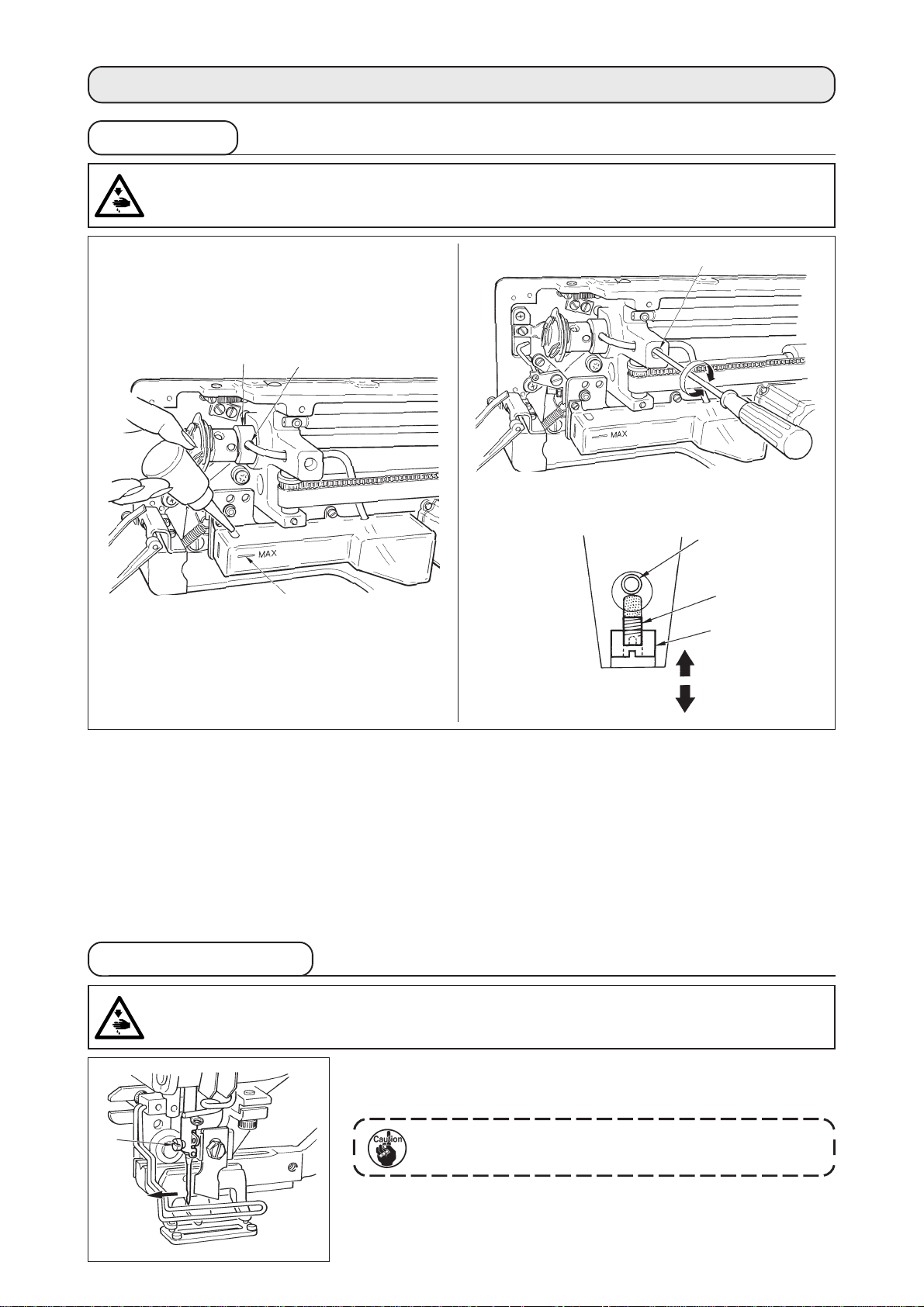

1. Lubrioation

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

w

e

r

q

t

Detailed diagram of oil amount adjusting section

Oil pipe

e

w

Decrease

Oil amount

Increase

1) Lubricating oil to oiling tank

○

Fill the oiling tank with New Defrix Oil No.1 up to the level indicated by “MAX” q.

2) Adjusting the lubrication for the sewing hook

○

Adjust the amount of oil supplied to the sewing hook by loosening lock nut w and turning oil amount

adjusting screw e.

○

Amount of supplied oil is reduced when turning the screws e clockwise.

○

Fix the screw with lock nut w after adjusting the lubrication for the sewing hook.

○

When you first operate your sewing machine after set-up or after an extended period of disuse, remove

the bobbin case and apply a few drops of oil to the hook race. In addition, apply a few drops oil from oiling

hole r in hook driving shaft front metal t to soak the inside felt in oil.

2. Inserting the needle

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

q

A

Hold needle with its recessed part facing toward the operator side A,

insert the needle fully into the needle clamping hole, and tighten needle

setscrew q. Use a DPx5-(#11J, #14J).

When attaching the needle, turn OFF the power to the

motor.

− 12 −

Page 18

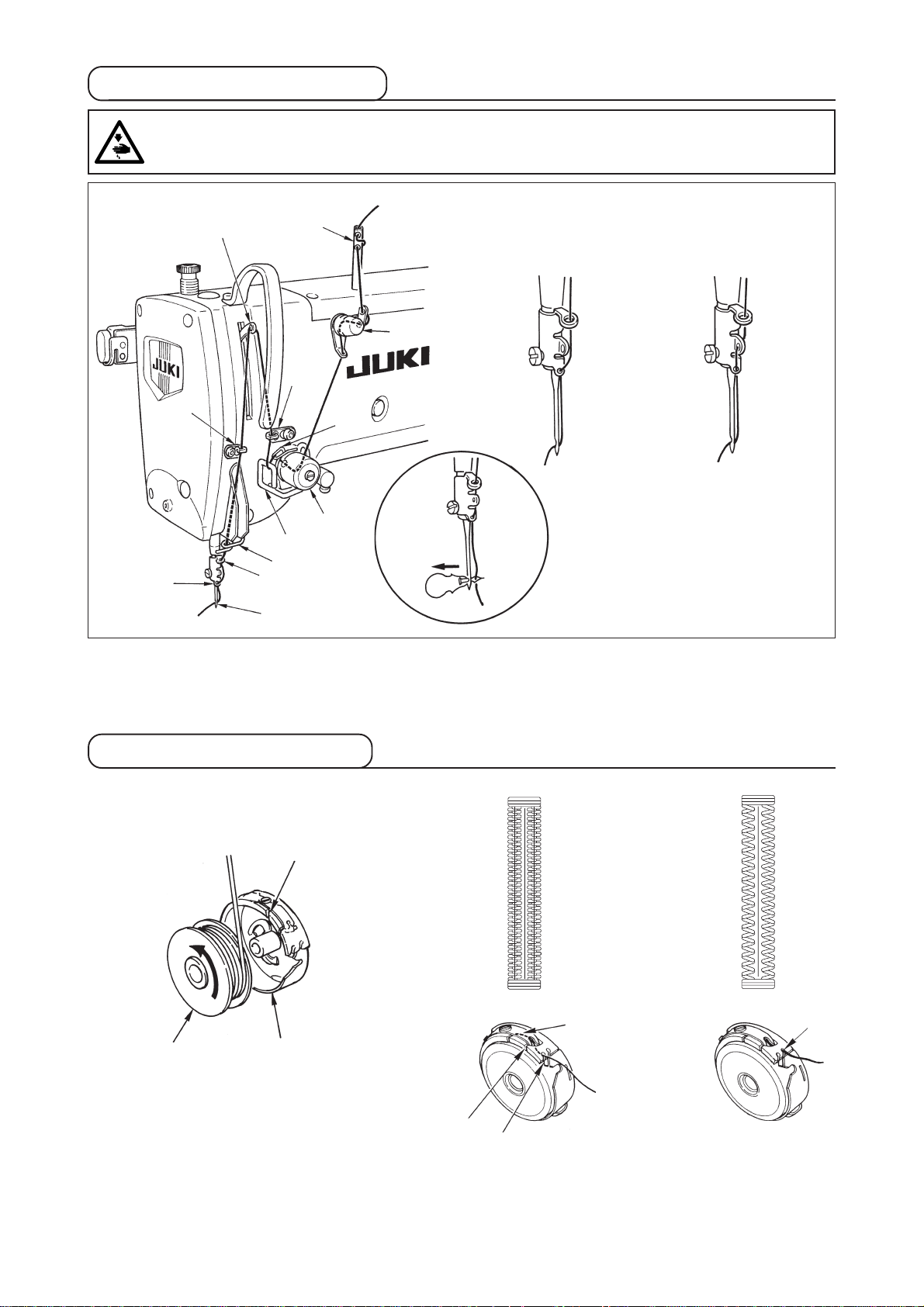

3. Threading the needle-thread

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

!2

o

t

y

q

e

r

w

Cotton thread, spun thread

Synthetic filament thread

!1

u

i

!0

Pass the needle thread in the order q to !2 as shown in the figures.

The threading can be done easily by using the needle threader supplied with the machine.

Change the thread guide threading method according to the thread to be used.

4. Threading the bobbin case

Whip stitchPurl stitch

q

w

Bobbin

Rotating direction of bobbin and threading

1) Fit the bobbin so that it rotates in the direction of the arrow.

2) Pass the thread through thread slit q, then through under the tension spring w, again through thread

slit e, and pull the thread from r.

3) Threading at r for purl stitching is different from that for whip stitching. So, be careful.

Bobbin case

e

r

r

− 13 −

Page 19

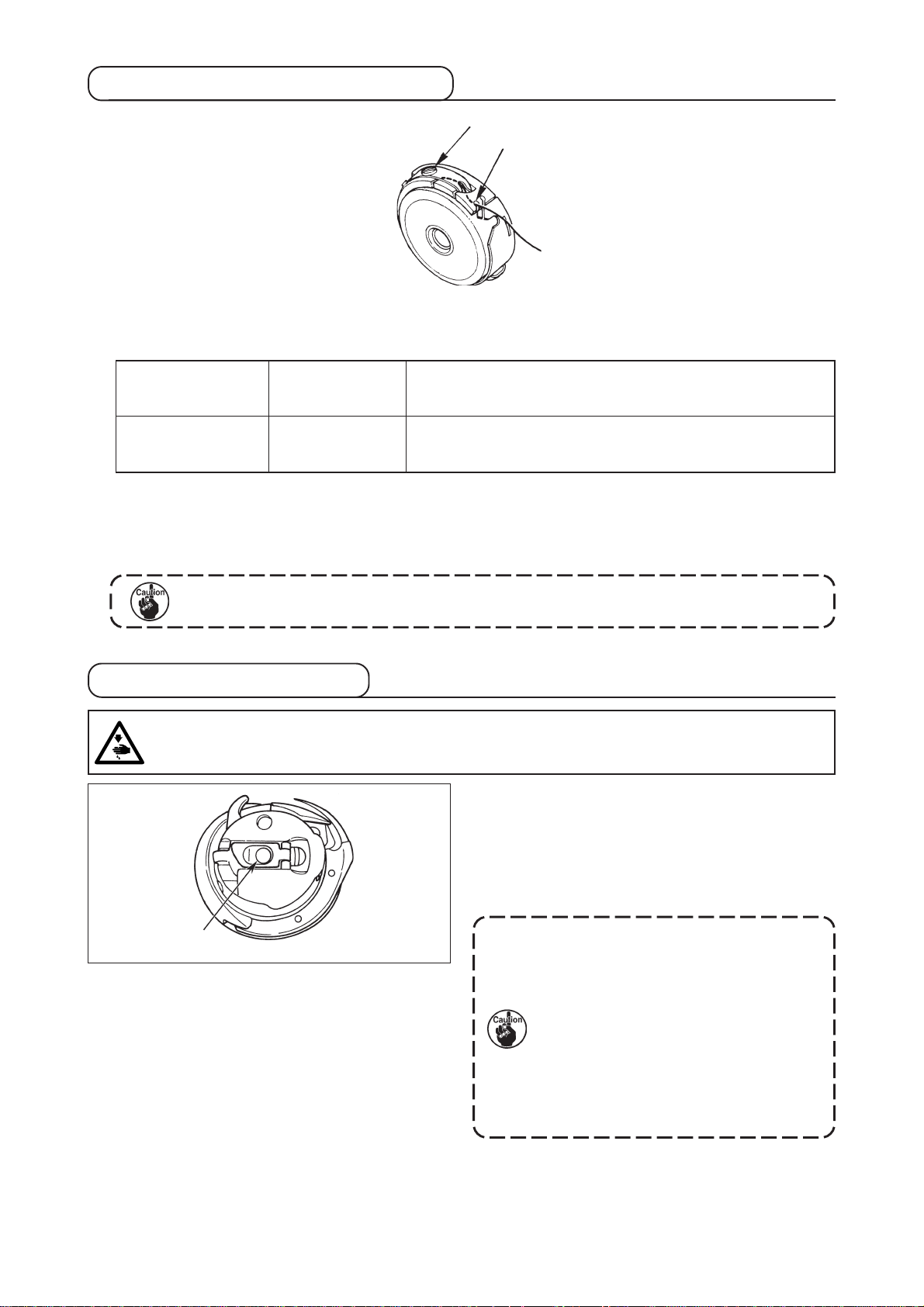

5. Adjusting the bobbin thread tension

w

q

Adjust the bobbin thread tension as given below when the bobbin thread is pulled up at the position where

thread slit q of bobbin case comes up.

To such an extent that bobbin case quietly comes down when holding

Purl stitch

Whip stitch

Turning tension adjust screw w clockwise will increase bobbin thread tension, and turning it counterclockwise

will decrease the tension.

Adjust the bobbin thread tension to lower for synthetic filament thread, and to higher for spun thread. The

thread tension is higher by approximately 0.05N when the bobbin case is set to the hook since idle-prevention

spring is provided.

0.05 to 0.15N

0.15 to 0.3N

thread end coming from bobbin case and shaking it quietly up and

down.

To such an extent that bobbin case barely comes down when holding

thread end coming from bobbin case and shaking it somewhat

strongly.

When bobbin thread tension is adjusted, check the needle thread tension setting of the

memory switch. (See P.44.)

6. Installation of bobbin case

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

q

1) Lift up and hold bobbin case latch lever between

two fingers.

2) Push the bobbin case into the hook so that it is

supported by the hook shaft q and then snap in

the latch lever.

Press the bobbin case until the predetermined

position is reached, and it will click.

1. If the bobbin case is out of the

predetermined position, it can jump

out from the hook to cause the needle

thread to tangle on the hook shaft.

Check to be sure that the bobbin case

is properly installed in the correct

position.

2. There is a difference in the shape of

bobbin case between the standard

hook and the dry one. They have

nothing in common with each other.

− 14 −

Page 20

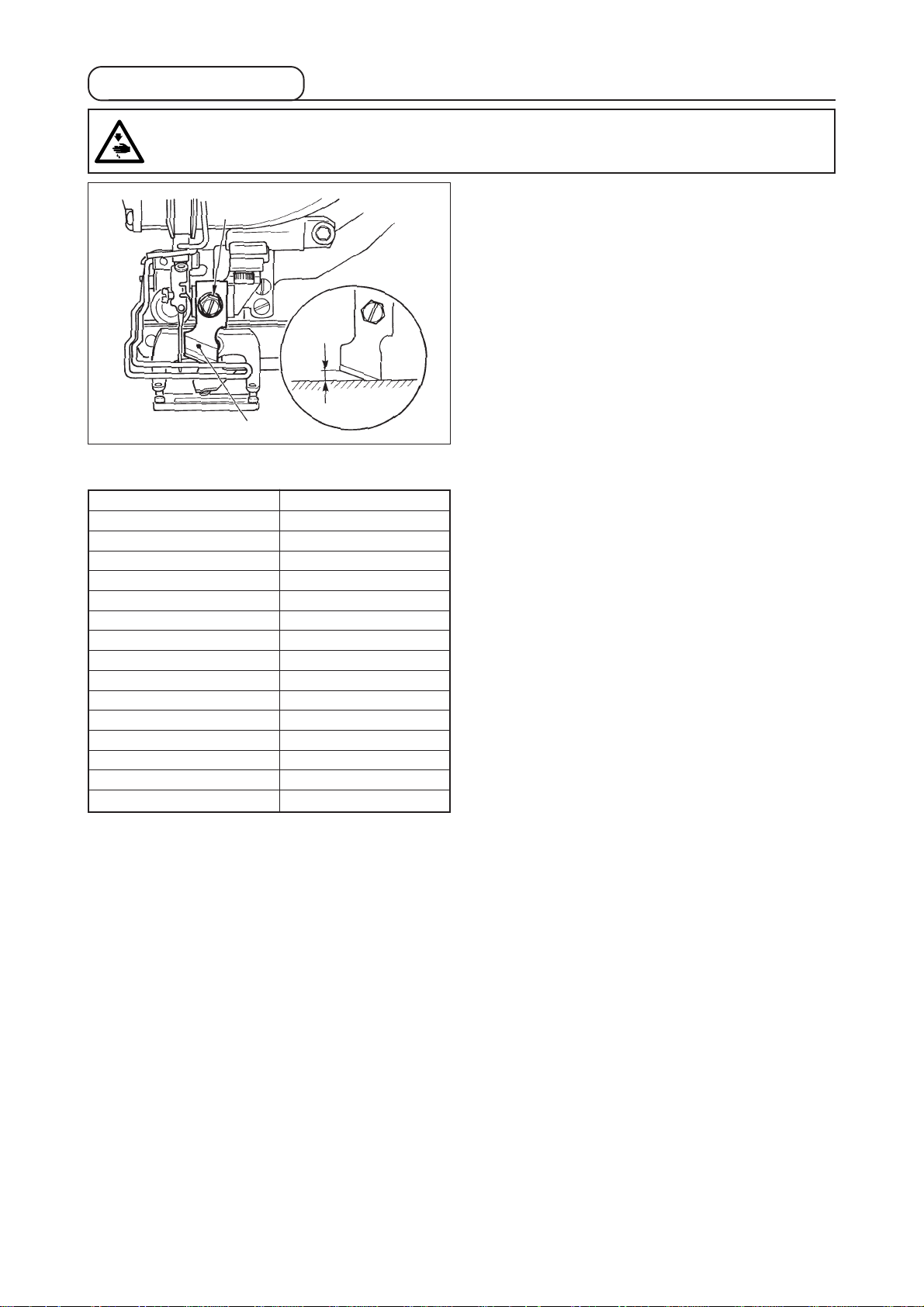

7. Installing the knife

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

w

1 to 2 mm

q

Inch → mm CONVERSION TABLE

Knife size Indication of mm

1/4 6.40

3/8 9.50

7/16 11.10

1/2 12.70

9/16 14.30

5/8 15.90

11/16 17.50

3/4 19.10

13/16 20.60

7/8 22.20

1 25.40

1 1/8 28.60

1 1/4 31.80

1 3/8 34.90

1 1/2 38.10

When replacing the knife with a new one, perform as

follows.

1) Knife q can be easily removed together with the

washer when removing knife retaining screw w.

2) Adjust so that the knife, when lowered the knife

bar by hand, is spaced 1 to 2 mm away from the

top surface of the throat plate as illustrated in the

sketch. Then, be sure to place the washer and

tighten the knife retaining screw.

When the cloth cutting knife you have is indicated in

inch, set the cloth cutting length (knife size) in mm using

the inch → mm conversion table. (See P.29.)

− 15 −

Page 21

5. OPERATION OF THE SEWING MACHINE

1. Explanation of the operation panel switch

q

!6

u

i

o

w

e

r

t

y

!0

!1

!7

!8

!9

!2

!3

!4

!5

@3

@4

There are 3 states below according to back-light colors.

Blue : Input mode .......... Data change is possible.

Green : Sewing mode .... Sewing possible state

Yellow : Error state ........ Some error occurs.

@5

@6

@0

@1

@2

@7

@8

#0

@9

− 16 −

Page 22

No.

q

NAME

LCD display

FUNCTION

Various data such as pattern No.,

shape, etc. are displayed.

No.

!6

OVEREDGING

WIDTH key

NAME

FUNCTION

This key selects overedging width

display.

w

READY key

e

RESET key

r

MODE key

t

PRESSER key

y

WINDER key

u

PATTERN NO. key

i

DATA key

Press this key when starting sewing.

Every time this key is pressed, change-

over of sewing ready set state and data

set state can be performed.

Press this key when releasing error,

travelling the feed mechanism to its

initial position, counter resetting, etc.

Press this key when changing data of

the memory switches.

This key lifts or lowers the presser. When

the presser goes up, the needle bar travels

to the origin and when it comes down, the

needle bar travels to the right.

This key is pressed when performing

bobbin winding.

This key selects pattern No. display.

This key selects data display.

!7

BAR-TACKING

WIDTH, LEFT key

!8

BAR-TACKING

WIDTH, RIGHT

key

!9

CLOTH CUT

LENGTH key

@0

CLEARANCE key

@1

KNIFE GROOVE

WIDTH, RIGHT

key

@2

KNIFE GROOVE

WIDTH, LEFT key

@3

COPY key

This key selects left side of bar-tacking

width compensation display.

This key selects right side of bar-tacking

width compensation display.

This key selects cloth cut length display.

This key selects clearance display.

This key selects knife groove width,

right compensation display.

This key selects knife groove width, left

compensation display.

Press this key when copying pattern.

o

COUNTER key

!0

ITEM SELECTION

key

!1

DATA CHANGE

key

!2

SHAPE key

!3

THREAD TENSION AT

PARALLEL SECTION key

!4

THREAD TENSION AT

BAR-TACKING SECTION

key

Thus key selects counter display.

This key selects pattern No., data No.,

etc.

This key changes various data.

This key selects shape display.

This key selects thread tension at

parallel section display.

This key selects thread tension at bar-

tacking section display.

@4

PRESSER

SELECTION key

@5

FORWARD key

@6

BACKWARD key

@7

PATTERN

REGISTRATION key

@8

PARAMETER

REGISTRATION key

@9

Speed variable

resister

This key selects presser type.

This key makes the feed mechanism

travel forward stitch by stitch.

This key makes the feed mechanism

travel backward stitch by stitch.

This is a short cut key that pattern registration

is available. Registration of shortcut to setting

display of an optional pattern is possible.

For the setting procedure, see P.36.

This is a short cut key that parameter registration

is available. Registration of shortcut to setting

display of an optional pattern, sewing

parameter or adjustment data is possible. For

the setting procedure, see P.37.

Speed increases when this is lifted

upward and decreases when this is

lowered downward.

!5

PITCH key

This key selects pitch of parallel

section.

− 17 −

#0

LCDadjustment

variable rsistor

Light and shade of LCD display can be

adjusted.

Page 23

2. Basic operation of the sewing machine

1) Turn ON the power switch.

First, check that presser type A which has been

set is the same as that of the presser actually

mounted. For checking and setting procedures,

refer to 4. Inputting the presser type.

2) Select the pattern No. you desire to sew.

When the power is turned ON, the pattern No. B

which is selected at present flashes on and off.

When you desire to change it, press ITEM

SELECTION key !0 and select the No. you

desire to sew. When you purchase the sewing

machine, pattern No. 1 to 10 described in

11.Changing sewing data have been registered.

Select the pattern No. you sesire to sew from among

these numbers. (The No. with which the pattern

has not been registered is not displayed.)

B

w

q

A

3) Set the sewing machine to sewing possible state.

Press READY key w and the back-light of LCD display q changes from blue color to green color, and

sewing is possible.

!0

4) Start sewing.

Set the sewing product to the presser portion, and operate the pedal to start the sewing machine, and

sewing starts. When you purchase the sewing machine, 2-pedal type has been set. However, pedal operating

procedure can be selected from among three ones. Select the operating procedure you desire and use the

sewing machine. → 3. How to use the pedal

3. How to use the pedal

This sewing machine can be used by selecting the pedal operating procedure from among 3 types below.

Select the operating procedure you desire for working efficiency and use the sewing machine.

(1) Setting procedure of the pedal type

1) Call the pedal type setting parameter.

Press MODE key r for as long as three

seconds in the state of the input mode and memory

switch (level 2) edit screen A is displayed. When

the pedal type selection parameter is not

displayed, press ITEM SELECTION key !0

to select the pedal type.

r

A

2) Select the pedal type

Press DATA CHANGE key !1 and the picture

is changed as shown in the illustration below. Select

the pedal type B you desire.

2-pedal

(Without intermediate position)

1-pedal

B

!0 !1

1-pedal

(With intermediate position)

− 18 −

Page 24

(2) Explanation of pedal motion

2-pedal type

Initial position

Presser : Intermediate position w

or Sewing position e

1) Setting of sewing product

(Presser goes up as high as the

pedal toe down amount of the left

side pedal.)

2) Start of Sewing

(Sewing starts when the right side

pedal is depressed.)

3) End of sewing

(Presser automatically goes up to

Intermediate position w.)

1-pedal

(Without intermediate position)

Initial position

Presser : Maximum position q

1) Setting of sewing product

2) Confirmation of setting of

sewing product

(Presser comes down to Cloth

setting position e when the first

step of the right side pedal is

depressed.)

3) Start of sewing

(Sewing starts when the second

step of the right side pedal is

depressed.)

4) End of sewing

(Presser automatically goes up to

Maximum position q)

1-pedal

(With intermediate position)

Initial position

Presser : Maximum position q

1) Setting of sewing product

2) Confirmation of setting

of sewing product

(Presser comes down to

Intermedite position w when the

first step of the right side pedal is

depressed.)

3)

Confirmation of start of sewing

(Presser comes down to Cloth

setting position e when the second

step of the right side pedal is

depressed.)

4) Start of sewing

(Sewing starts when the third step

of the right side pedal is depressed.)

5) End of sewing

(Presser automatically goes up to

Maximum position q.)

* Height of the respective positions of q to e

described on the left side can be set or changed by

the memory switches.

Cloth

q

w

e

→ 20. Method of changing memory switch data

• Pedal switch setting

Attach or remove the screw shown in the figure according to the setting of the memory switch.

• 2-pedal type

• 1-pedal (Without intermediate position)

Remove the screw.

• 1-pedal (With intermediate position)

Attach the screw.

− 19 −

Page 25

4. Input of the presser type

(1) Setting procedure of the presser type

1) Call the presser type setting parameter.

Press PRESSER SELECTION key @4

memory switch (level 1) edit screen A is displayed.

and

2) Select the presser type.

Press DATA CHANGE key !1 , and the

picture is changed as shown in the illustration

below. Set the presser type B actually mounted on

the sewing machine referring to Table of presser

type below.

Type 1 Type 2 Type 3 Type 5 *

@4

(2) Table of presser type

Set the number in the frame of engraved part number of presser to the type of presser.

Type

Part No. of presser foot

A

B

!1

Type 1

Type 2

Type 3

Type 5 *

B151177 1 000 *

B151177 2 000 *

B151177 3 000 *

–

* Set type 5 when using the presser other than

type 1 to 3. Change Presser size width

and Presser size length of the memory

switch (level 1) to adjust to the presser to be

used.

→ Refer to 20. Method of changing memory

switch data.

* When using type 5 with stitch width of 6 mm or

more and 41 mm or more in length, it is

necessary to replace components such as

presser arm, feed plate, etc.

− 20 −

Page 26

5. Performing pattern selection

(1) Selection from the pattern selection screen

1) Set the mode to the input mode.

When the back-light of LCD display q shows the

input mode in blue color, it is possible to change

the pattern. When the back-light shows the sewing

mode in green color, press READY key w

change over to the input mode.

2) Call the pattern selection screen.

Press PATTERN No. key u , and pattern

selection screen A is displayed.

Pattern No. B which is selected at present flashes

on and off.

3) Select the pattern.

Press ITEM SELECTION key !0 , and the

patterns which have been registered are changed

over in order and displayed. Here, select the No.

you desire to sew.

to

w

q

B

u

!0

A

(2) Selection by means of the register key

This sewing machine can register the pattern No. you desire with the register switch. When the pattern is

registered once, pattern selection can be performed by pressing only the switch.

/ Refer to 15. Using pattern register key.

− 21 −

Page 27

6. Changing needle thread tension

Needle thread tension can be changed while performing trial sewing since the data related to the needle

thread tension can be set by the sewing mode as well.

1) Call thread tension at parallel section

setting data.

Press THREAD TENSION AT PARALLEL

SECTION key !3 , and sewing data edit screen

A is displayed.

B

A

1), 2)

2) Change thread tension at parallel

section.

Press DATA CHANGE key !1

B goes up or comes down and the thread tension

can be changed. The relation between the finish of

sewing and the set value is as shown in the

illustration below. Set the value referring to the

illustration.

, and set value

3) Call thread tension at bar-tacking

section setting data.

Press THREAD TENSION OF BAR-TACKING

SECTION key !4 , and sewing data edit screen

C is displayed.

4) Changing the needle thread tension at

bar-tacking section

Press DATA CHANGE key !1

D goes up or comes down and the thread trension

can be changed. The relation between the finish of

sewing and the set value is as shown in table below.

Set the value referring to the table.

* For the tension other than that at parallel section

and bar-tacking section, refer to 11. Changing

sewing data and 20. Method of changinf

memory switch data.

, and set value

D

C

3), 4)

!1

!3

!4

Set value of tension at q parallel section and w bar-tacking section

Set value on panel

Initial value

Purl stitch

Whip stitch

q Tension at parallel

section

w Bar-tacking tension

q Tension at parallel

section

w Bar-tacking tension

Crest is lowered.

Thread tension

is decreased.

Thread tension

is decreased.

Thread tension

is decreased.

120

35

60

60

Crest is raised.

Thread tension is

increased.

Thread tension is

increased.

Thread tension is

increased.

For the eyelet radial shape, set the bar-tacking tension first to approximately 120 and make the balance of

stitches.

Purl stitch and Whip stitch

Purl stitch

Whip stitch

Whip stitch

Purl stitch

When applying higher tension to the needle thread to permit it to pass straight

through fabric, the purl stitch is formed by the bobbin thread which is pulled over

from both sides to the center line.

Whip stitch

The whip stitch is formed in zigzag showing the needle thread only on top of

fabric, and the bobbin thread on the bottom.

− 22 −

Page 28

7. Performing re-sewing

When stop switch A is pressed during sewing

operation, the sewing machine interrupts sewing

and stops. At this time, error display screen B is

displayed to inform that the stop switch is pressed.

To continue performing sewing from some

point in sewing

Sewing motion stop status

Error display screen B is displayed.

A

B

Error No. Error pictograph

e

1) Release the error.

Press RESET key e to release the error. Then

step motion screen C is displayed.

2) Return the presser.

Press BACKWARD key @6 and the presser

returns stitch by stitch.

Press FORWARD key @5 and the presser

advances stitch by stitch. Return the presser to the

re-sewing position.

3) Start sewing again.

Depress the right side pedal and sewing starts

again.

To perform re-sewing from the start

Sewing motion stop status

Error display screen B is displayed.

1) Release the error.

Press RESET key e to release the error. Then

step motion screen C is displayed.

E

D

@5

@6

* Existing number of stitches/total number of stitches

are displayed in section D.

* Existing sewing command is displayed in section E.

Kinds of commands are :

Sewing

command

Jump feed

command

C

2) Return the presser to the sewing product

setting position.

Press again RESET key e and the presser

returns to the sewing product setting position.

3) Perform again the sewing work from the

start.

− 23 −

Thread trimmer

command

Knife command

Page 29

8. Winding bobbin thread

(1) Winding the bobbin

1) Set the bobbin .

Fit a bobbin fully onto the bobbin winder shaft. Take

the thread from the spool and pass it through the

guides in the numerical order as shown in the figure,

and wind the end of the thread several times around

the bobbin. Then push the bobbin winder trip latch

q in the direction of the arrow mark.

2) Set the mode to the bobbin winding mode.

Press WINDER key y from either input status

or sewing status to enter the bobbin winding mode,

and bobbin winding screen C is displayed.

q

B

A

3) Start bobbin winding.

Depress the right-hand side pedal, and the sewing

machine rotates and starts winding bobbin thread.

4) Stop the sewing machine.

Once the bobbin is wound with the predetermined

amount of thread, bobbin thread guide q is

released. Press WINDER key y or depress

the right-hand side pedal to stop the sewing

machine. Then remove the bobbin and cut bobbin

thread with thread trimmer retaining plate r.

• Press WINDER key y , and the sewing

machine stops and returns to the normal mode.

• Depress the right-hand side pedal and the sewing

machine stops while the bobbin thread winding

mode stays as it is. Use this way when winding

bobbin thread around plural bobbins.

(2) Adjusting the amount to be wound on

w

r

e

y

C

a bobbin

To adjust the winding amount of the bobbin thread,

loosen the setscrew w and move the bobbin winder

adjusting plate e to the direction of A or B. Then,

tighten the setscrew w.

To the direction of A : Decrease

To the direction of B : Increase

− 24 −

Page 30

9. Using the counter

(1) Setting procedure of the counter value

w

e

D

1) Call counter setting screen.

Press COUNTER key o under the input mode,

and counter screen A is displayed. Then setting is

possible. Setting of the counter value can be

performed only with the input mode (back-light of

LCD display q is blue). In case of the sewing mode

(back-light of LCD display q is green), press

READY key w to set the mode to the input

mode.

B

q

2) Selection of kinds of counters

Press ITEM SELECTION key !0 to make

pictograph B showing the kind of counter flash on

and off. Press DATA CHANGE key !1 , and

select the counter you desire from among the kinds

of counters below.

o

!1!0

3) Change of counter set value

Press ITEM SELECTION key !0 to make counter set value C flash on and off.Press DATA CHANGE

key !1 and input the set value until count-up is reached.

4) Change of existing counter value

Press ITEM SELECTION key !0 to make existing counter value D flash on and off.

Press RESET key e and the value on the way of counting can be cleared.

In addition, it is possible to edit the numerical value with DATA CHANGE key !1 .

C

A

(2) Kind of counter

q Sewing UP counter

Every time the sewing of one shape is performed, the existing value is counted up.

When the existing value is equal to the set value, count-up screen is displayed.

w Sewing DOWN counter

Every time the sewing of one shape is performed, the existing value is counted down.

When the existing value is reached to "0", count-up screen is displayed.

e No. of pcs. UP counter

Every time one cycle or one continuous stitching is performed, the existing value is counted up.

When the existing value is equal to the set value, count-up screen is displayed.

r No. of pcs. DOWN counter

Every time one cycle or one continuous stitching is performed, the existing value is counted down.

When the existing value is reached to "0", count-up screen is displayed.

t Counter not used

(3) Count-up releasing procedure

When count-up condition is reached during sewing

work, the whole count-up screen E flashes on and

off. Press RESET key e to reset the counter,

and the mode returns to the sewing mode. Then

the counter starts counting again.

− 25 −

E

Page 31

10. Using the initial value pattern

This sewing machine has the initial value to perform the optimum sewing for the sewing shapes (30 shapes).

/ Refer to -. INITIAL VALUE DATA FOR EACH SHAPE TABLE.

When creating sewing data newly, it is convenient to create it by copying the initial value pattern.

1) Set the mode to the input mode.

When the back-light of LCD display q shows input

mode in blue color, it is possible to change the

pattern. When the back-light shows the sewing

mode in green color, Press READY key w to

change over to the input mode.

2) Call initial value pattern.

Press PATTERN NO. key u , and pattern

selection screen A is displayed.

Pattern No. B which is selected at present flashes

on and off on the display. Press ITEM SELECTION

key !0 to select initial value pattern .

3) Select shape.

Press SHAPE key !2 , and shape selection

screen C is displayed. Shape D which is selected

at present flashes on and off on the display. Select

shape D to sew with DATA CHANGE key !1

. It is possible to select the shape from among

12 shapes at the time of your purchase. However,

it is possible to select the shape from among

maximum 30 shapes by increasing the shape

selection level (K04).

/ Refer to 20. Method of changing memory

switch data.

4) Perform trial sewing.

Press READY key w to set the mode to the

sewing mode (back-light of LCD display q is

green). Then it is possible to perform sewing and

the selected shape can be sewn.

* Initial value pattern can edit the needle thread

tension data only. However, it returns to the initial

value when changing the shape or performing

re-call of the pattern. So, be careful.

q

u

B

A

C

w

!2

D

!0 !1

2)

3)

5) Copy initial value pattern.

Copy the pattern which has been selected and

confirmed through the steps above to the normal

pattern and use it.

Copying procedure / Refer to 14. copying sewing

pattern.

− 26 −

Page 32

11. Changing sewing data

(1) Initial sewing data at the time of your purchase

Patterns from 1 to 10 have been already registered at the time of your purchase. Initial values of the square

type, the cloth cutting length of which only is different from each other, have been inputted in the sewing

data. / Refer to -. INITIAL VALUE DATA FOR EACH SHAPE TABLE.

Pattern No. Cloth cutting length

1 6.40mm (1/4”)

2 9.50mm (3/8”)

3 11.1mm (7/16”)

4 12.7mm (1/2”)

5 14.30mm (9/16”)

6 15.90mm (5/8”)

7 17.50mm (11/16”)

8 19.10mm (3/4”)

9 22.20mm (7/8”)

10 25.40mm (1”)

(2) Changing procedure of sewing data

1) Set the mode to the input mode.

When the back-light of LCD display q shows the

input mode in blue color, it is possible to change

the sewing mode.

When the back-light of shows the sewing mode in

green color, press READY key w to change

over to the input mode.

Pattern which is

selected at

present

w

Pictograph showing

data item

2) Call sewing data edit screen.

Press DATA key i , and sewing data edit

screen A of the pattern No. which is selected at

present is displayed.

3) Select sewing data to be changed.

Press ITEM SELECTION key !0 , and select

the data item you desire to change.

Data item which is not used according to the shape

and data item which is set without function are

skipped and not displayed. So, be careful.

/ Refer to 12. Method of setting sewing data

with/without edit

Data item No.

i!0 !1

4) Change data.

For the sewing data, there are data item which changes numerical value and that which selects pictograph.

No. such as is attached to the data item which changes numerical value. Increase or decrease the

set value with DATA CHANGE key !1 to change the value.

No. such as is attached to the data item which selects pictograph. Pictograph can be selected with

DATA CHANGE key !1 .

/ For the details of sewing data, refer to 13. Sewing data table.

A

q

− 27 −

Page 33

12. Method of setting sewing data with/without edit

This sewing machine has been set so as not to be capable of editing sewing data items which are less

frequently used at the time of your purchase. When you desire to set the data more closely in accordance

with the sewing products, set the sewing data item to the edit possible state and use the machine.

For the setting of sewing data with/without edit, when S52, right parallel section tension is set to without edit,

sewing is performed with the data of S51 left parallel section tension. When S56, 2nd bar-tacking tension is

set to without edit, sewing is performed with the data of S55, 1st bar-tacking section.

When the sewing data items other than the above ones are set to without edit, the data to be referred are the

initial value data.

1) Set the mode to the input mode.

When the back-light of LCD display q shows the

input mode in blue color, it is possible to set. When

the back-light shows the sewing mode in green

color, press READY key w to change over to

the input mode.

2) Call sewing data with/without edit

changeover screen.

Press DATA key i for as long as three

seconds, and data with/without edit changeover

screen A or B is displayed.

3) Select sewing data you desire to change

over.

Press ITEM SELECTION key !0 , and

select sewing data item C you desire to change

over.

At this time, changeover possible item only can be

selected.

A

B

we

(With edit)

(Without edit)

C

4) Changeover of with/without edit

Press DATA CHANGE key !1 , and

pictograph display C of sewing data repeats

reverse/non-reverse.

Non-reverse display : With edit

Reverse display : Without edit

Return to step 3), and plural sewing data items can

be changed over.

5) Save data which have been set.

Press READY key w

of being changed over can be saved. After two

seconds, the screen returns to the former one.

Press RESET key e

to the former one without saving the data.

, and the data in the state

, and the screen returns

q

i

!0

!1

− 28 −

Page 34

13. Sewing data list

☆ Sewing data are those that can be inputted to 99 patterns from pattern 1 to 99 and can be inputted to

each pattern. The sewing machine has been set in the state that the data which is necessary to set

“With/without edit” cannot be selected at the time of your purchase. Change over the function to “With

edit” if necessary for the use. / Refer to 12. Method of setting sewing data with/without edit.

No.

S01

Sewing shape

This item selects the shape from among the sewing shapes of 30

different kinds which the sewing machine has.

–

* Only 12 kinds of standard sewing shapes can be selected at the

time of your purchase. When increasing the kinds of shapes,

perform setting of K04 Sewing shape selection level of memory

switch data. / Refer to 21. Memory switch list.

S02

Cloth cut length

This item sets the length of cloth that is cut by cloth

cutting knife. However, in case of bar-tack shape (Nos.

27, 28, 29, and 30 of S01), sewing length is set.

By making effective U19 Function of plural motions of cloth

cutting knife of memory switch data, make the plural motions of

knife by the knife size set in the item U18 Cloth cutting knife

size, and the sewing product is cut. / Refer to 21. Memory switch

list.

S03

Knife groove width, right

This item sets the clearance between cloth cutting

knife and right parallel section.

Item

Refer to 2-3. Standard sewing

shape list.

Setting range

1 to 30

3.0 to 120.0

-2.00 to 2.00

Edit unit

1

0.1mm

0.05mm

Remarks

–

–

–

S04

Knife groove width , left

This item sets the clearance between cloth cutting

knife and left parallel section.

S05

Overedging width, left

This item sets the overedging width of left parallel

section.

S06

Ratio of right and left shapes

This item sets enlargement/reduction ratio of right side

shape making the knife position as the center.

S07

Pitch at parallel section

This item sets sewing pitch of left and right parallel

sections.

S08

2nd bar-tacking length

This item sets length of bar-tacking on the front side.

Bottom

of square

type

S09

1st bar-tacking length

This item sets length of bar-tacking on the rear side.

Top of square

type

Bottom of

straight bartacking

Bottom of

taper

-2.00 to 2.00

0.10 to 5.00

50 to 150

0.200 to 2.500

0.2 to 5.0

0.2 to 5.0

0.05mm

0.05mm

1%

0.025mm

0.1mm

0.1mm

–

–

–

–

–

–

* 1 : Displayed according to the shape

* 2 : Displayed when it is set to with edit. Refer to 12. Method of setting sewing data with/without edit.

* 3 : Displayed when the function is selected.

− 29 −

Page 35

No.

Compensation of bar-tacking width, right

S10

Item

This item adjusts right side outer shape of bar-tacking

section in terms of overedging section.

Top of

square

type

Compensation of bar-tacking width, left

S11

Bottom of

square type

This item adjusts left side outer shape of bar-tacking

section in terms of overedging section.

Top of

square

type

Taper bar-tacking offset, left

S12

Bottom of

square type

This item sets length to form bar-tacking section of

taper bar-tacking shape.

Taper bar-tacking offset, right

S13

This item sets length to form bar-tacking section of

taper bar-tacking shape.

Eyelet shape length

S14

This item sets upper side length from center of eyelet

of eyelet shape.

Bottom of

straight bartacking

Bottom of

straight bartacking

Setting range

-1.00 to 1.00

-1.00 to 1.00

0.00 to 3.00

0.00 to 3.00

1.0 to 10.0

Edit unit

0.05mm

0.05mm

0.05mm

0.05mm

0.1mm

Remarks

–

–

*1

*1

*1

Number of stitches of eyelet shape

S15

This item sets number of stitches in the upper 90˚ of

eyelet shape.

Eyelet width

S16

This item sets crossuise size of the inside of eyelet

shape. Actual needle entry point is the dimension to

which S04 Knife groove width, left is added.

Eyelet length

S17

This item sets lengthwise size of the inside of eyelet

shape.

Round type shape length

S18

This item sets upper length from the center of round

type shape.

Top of

round

type

Bottom

of round

type

Number of stitches of radial shape

S19

Top of

Radial

type

Bottom

of radial

type

Bottom of

semilunar

type

This item sets number of stitches in the upper 90˚ of

radial shape.

Top of

semilunar

type

1 to 8

1.0 to 10.0

1.0 to 10.0

1.0 to 5.0

1 to 8

1

0.1mm

0.1mm

0.1mm

1

*1

*1

*1

*1

*1

Reinforcement of radial shape

S20

This item sets with/without reinforcement stitching of radial shape.

: With : Without

Pitch at bar-tacking section

S21

This item sets sewing pitch of bar-tacking section.

Top of

square

type

Bottom

of square

type

Top of

round

type

Bottom of

round

type

Top of

semilunar

type

Bottom of

semilunar

type

Bottom of

straight

bar-tacking

− 30 −

Bottom of

taper bar-

tacking

–

0.200 to 2.500

–

0.025mm

*1, *2

–

Page 36

NO.

S22

1st clearance

This item sets the clearance between 1st bar-tacking

and knife groove. This item is applied to all shapes.

S23

2nd clearance

This item sets the clearance between 2nd bar-tacking

and knife groove.This item is applied to all shapes.

S31

Single/double stitching

This item selects single or double stitching.

Single

stitching

S32

Double stitching cross selection

This item selects overlapping stitching or cross stitching at the

needle entry of parallel section when setting double stitching.

: Double stitching

S33

Compensation of double stitching width

This item sets amount to narrow overedging width of

1st cycle when setting double stitching.

Item

Double

stitching

: Cross stitching

Setting range

0.0 to 4.0

0.0 to 4.0

–

–

0.0 to 2.0

Edit unit

0.1mm

0.1mm

–

–

0.1mm

Remarks

–

–

–

*3

*3

S34

Number of times of basting

This item sets number of times of basting.

: Without basting

S35

Basting pitch

This item sets pitch at the time of performing basting.

S36

Rolling length of basting

This item sets rolling length of needle thread when

performing basting.

S37

Rolling pitch of basting

This item sets rolling pitch of needle thread when

performing basting.

S38

Rolling width of basting

This item sets rolling width of needle thread when

performing basting.

S39

Lengthwise compensation of needle entry of

basting

This item sets the amount to move needle entry position

back and forth when performing basting more than two

cycles.

: With basting

(Setting of number of times)

0 to 9

1.0 to 5.0

2.0 to 20.0

0.2 to 5.0

0.0 to 4.0

0.0 to 2.5

1 time

0.1mm

0.1mm

0.1mm

0.1mm

0.1mm

–

*3

*3

*3

*3

*2, *3

S40

Crosswise compensation of needle entry of

basting

This item sets the amount to move needle entry position

to the right or left when performing basting more than

two cycles.

S41

Compensation of left side position of basting

This item sets the amount to move the sewing reference

position of basting from the center of left overedging to

the right or left.

− 31 −

0.0 to 1.0

-2.0 to 2.0

0.1mm

0.1mm

*3

*2, *3

Page 37

NO.

S42

Compensation of right side position of

Item

basting

This item sets the amount to move the sewing

reference position of basting from the center of right

overedging to the right or left.

S44

Speed setting of basting

This item sets speed of basting.

S45

Sewing together function

This item selects the function when performing sewing together

first.

Setting range

-2.0 to 2.0

400 to 4200

–

Edit unit

0.1mm

100rpm

–

Remarks

*2, *3

*3

–

: Without sewing

together

When "With sewing together" is selected :

Sewing is performed in the order of sewing together / basting /

normal sewing.

S46

Width of sewing together

This item sets sewing width when performing sewing

together.

S47

Pitch of sewing together

This item sets sewing pitch when performing sewing

together.

S51

Left parallel section tension

This item sets needle thread tension at left parallel

section.

S52

Right parallel section tension

This item sets needle thread tension at right parallel

section.

S53

Left parallel section tension (1st cycle of

: With sewing

together

double stitching)

This item sets needle thread tension at left parallel

section of 1st cycle at the time of double stitching.

1.0 to 10.0

0.2 to 5.0

0 to 200

0 to 200

0 to 200

0.1mm

0.1mm

1

1

1

*2, *3

*2, *3

–

*2

*2, *3

S54

Right parallel section tension (1st cycle of

double stitching)

This item sets needle thread tension at right parallel

section of 1st cycle at the time of double stitching.

S55

Tension at 1st bar-tacking section

This item sets needle thread tension at 1st bar-tacking

section.

S56

Tension at 2nd bar-tacking section

This item sets needle thread tension at 2nd bar-tacking

section.

S57

Setting of needle thread tension at the start

of sewing

This item sets needle thread tension of tie stitching at

the start of sewing.

S58

Setting of needle thread tension of basting

This item sets needle thread tension of basting.

− 32 −

0 to 200

0 to 200

0 to 200

0 to 200

0 to 200

1

1

1

1

1

*2, *3

–

*2

–

*3

Page 38

NO.

S59

ACT timing adjustment at the start of 1st bar-

Item

tacking

This item adjusts needle thread tension output start

timing at 1st bar-tacking section.

S60

ACT timing adjustment at the start of right

overedging

This item adjusts needle thread tension output start

timing at right overedging section.

S61

ACT timing adjustment at the start of 2nd

bar-tacking

This item adjusts needle thread tension output start

timing at 2nd bar-tacking section.

S62

Number of stitches of tie stitching at the start

of sewing

This item sets number of stitches of tie stitching at

the start of sewing.

S63

Sewing pitch of tie stitching at the start of

sewing

This item sets sewing pitch pf tie stitching at the start

of sewing.

Setting range

-5 to 5

-5 to 5

-5 to 5

0 to 8

0.00 to 0.70

Edit unit

1 stitch

1 stitch

1 stitch

1 stitch

0.05mm

Remarks

*2

*2

*2

–

*2

S64

Tie stitching width at the start of sewing

This item sets tie stitching width at the start of sewing.

S65

Lengthwise compensation of tie stitching at

the start of sewing

This item sets start position of tie stitching in

lengthwise direction at the start of sewing.

S66

Crosswise compensation of tie stitching at

the start of sewing

This item sets start position of tie stitching in crosswise

direction at the start of sewing.

S67

Tie stitching width at the end of sewing

This item sets tie stitching width at the end of sewing.

S68

Number of stitches of tie stitching at the end

of sewing

This item sets number of stitches of tie stitching at

the end of sewing.

S69

Lengthwise compensation of tie stitching at

the end of sewing

This item sets start position of tie stitching in

lengthwise direction at the end of sewing.

0.0 to 3.0

0.0 to 5.0

0.0 to 2.0

0.1 to 1.5

0 to 8

0.0 to 5.0

0.1mm

0.1mm

0.1mm

0.1mm