Page 1

Model KE-750 / KE-760

SET -UP GUIDE

&

MAIN UNIT UNPACKING GUIDE

(Main Unit Packing Guide)

JUKI CORPORATION

ELECTRONIC ASSEMBLY &

TEST SYSTEMS DIVISION

SMT TRAINING CENTER

Page 2

SET - UP GUIDE

Page 3

Table of Contents

1. Basic Configuration and Name of Each Part ............................................................1

2. How to Install the Main Unit.....................................................................................2

3. Adjusting the Transport Height and Leveling the Machine.......................................4

4. Demounting the Head Unit Fixing Parts....................................................................7

5. Connecting the Air Tubes........................................................................................8

6. Connecting the Power Codes..................................................................................9

7. Attaching the Supplied Parts..................................................................................10

8. Interface with External Equipment.......................................................................... 14

9. Attaching the Matrix Tray Changer (MTC) ............................................................ 18

10. Checking the Machine Before Turning on the Power.............................................24

11. Adjusting the Height of the Replacement Table (Optional)...................................25

Page 4

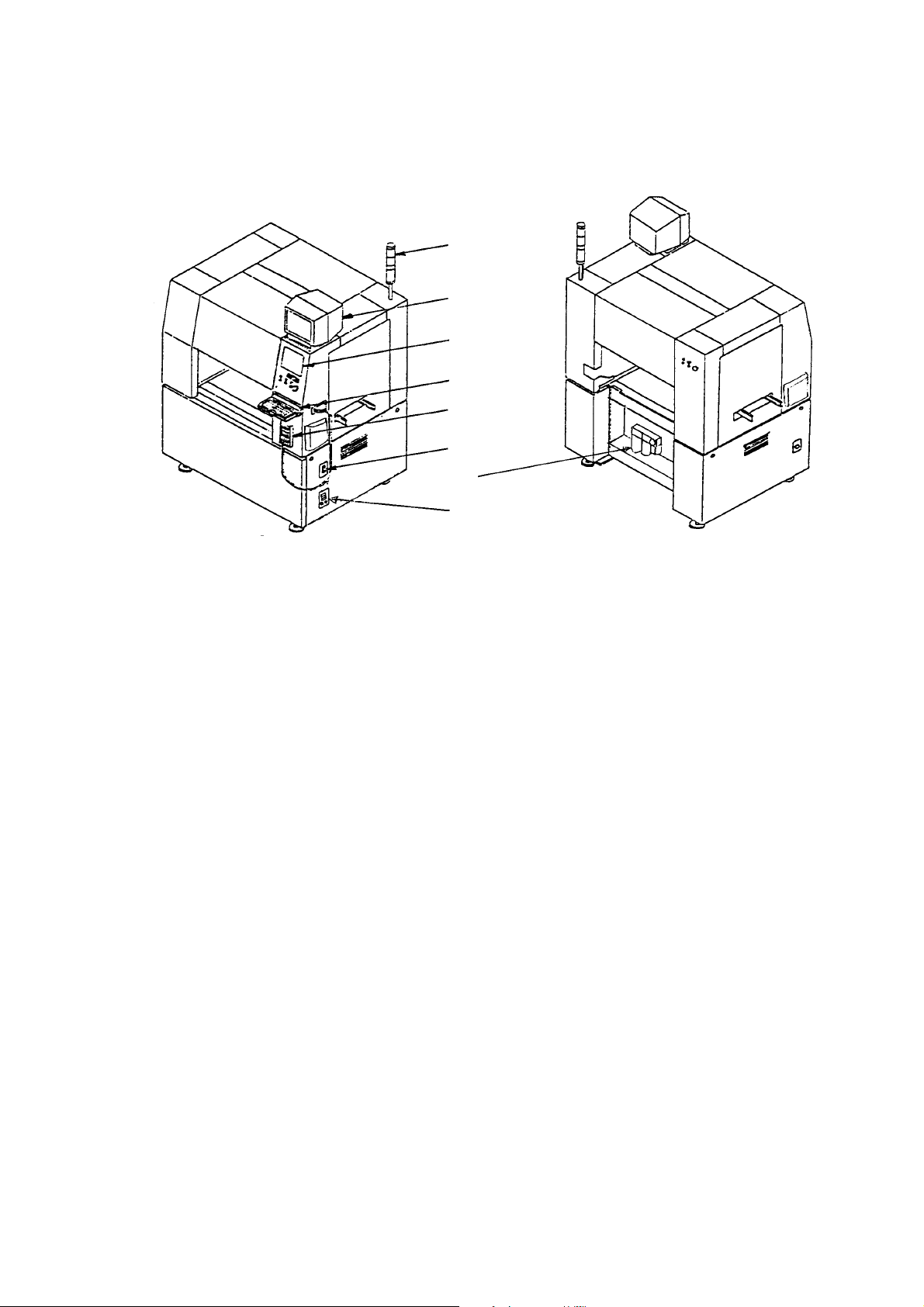

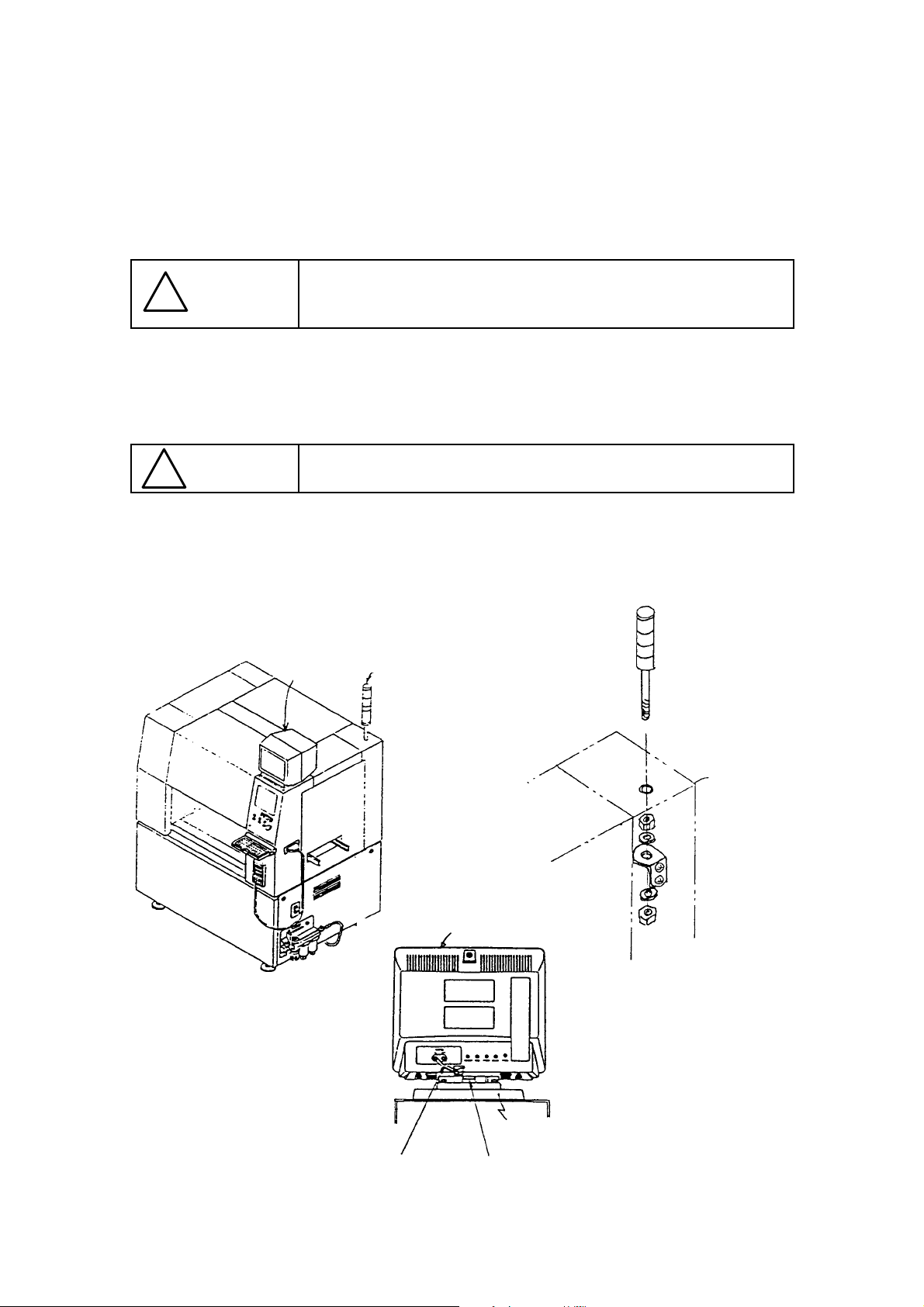

1. Basic Configuration and Name of Each Part

t

w

e

y

r

q

u

i

Figure 1.1 Figure 1.2

1. Breaker 5. Signal light

2. Vision monitor 6. Keyboard

3. Liquid crystal display 7. Filter regulator

4. HOD (Handheld Operating Device) unit 8. Interface panel

- 1 -

Page 5

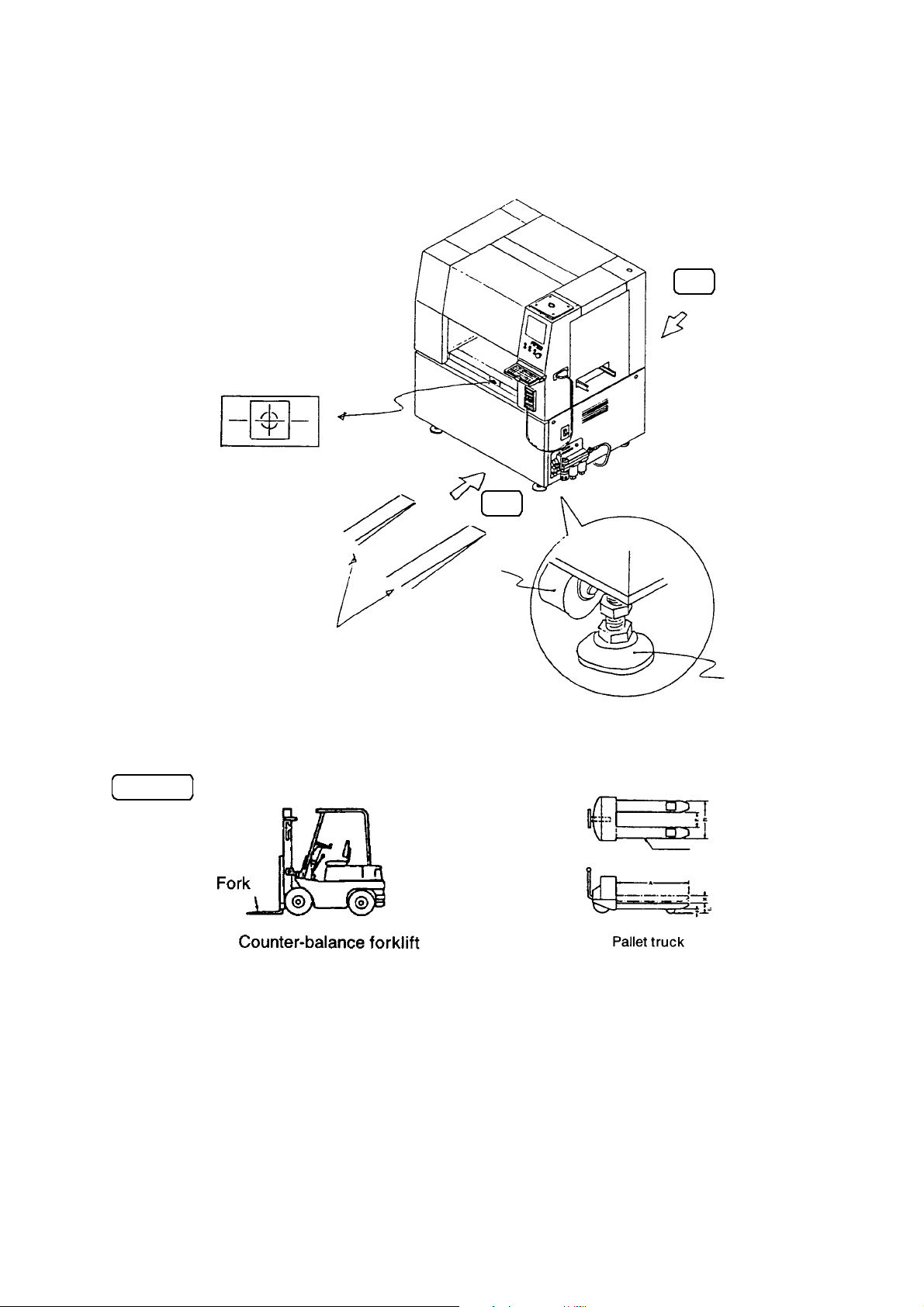

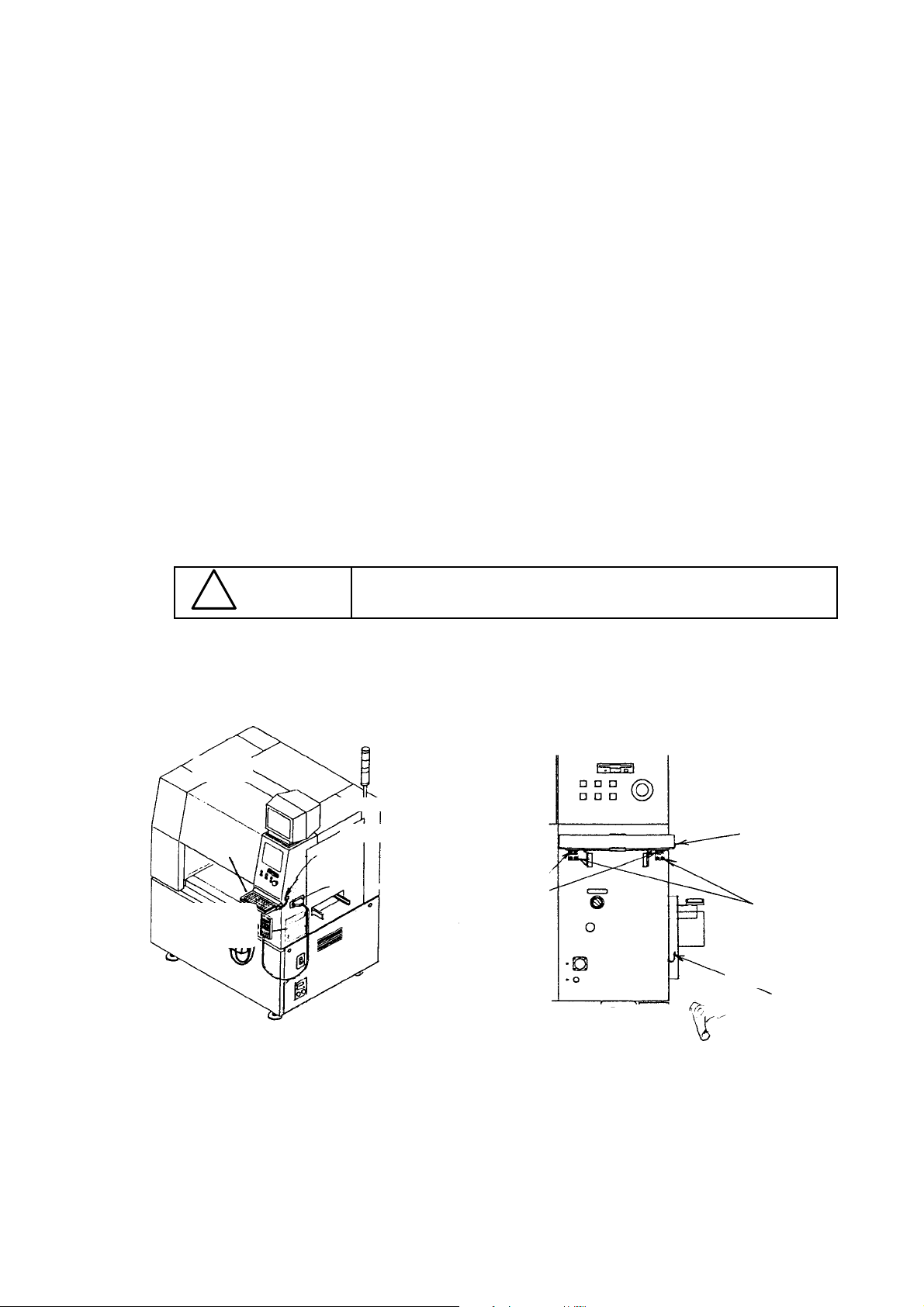

2 . How to Install the Main Unit

Center mark

Rear

Front

Example

o

Fork of the forklift

(finger of the pallet truck)

!0

Figure 2.1

Counter-balance forklift

Figure 2.2 Figure 2.3

- 2 -

Page 6

(1) Lift the adjuster !0 to bring the casters o into contact with the floor before

installing or moving the main unit.

(2) When using a forklift to mov e the main unit, be sure to put the fork under the

bottom of the main unit from the front side, then lift and mov e it after the fork

protrudes enough from the rear of the main unit. (Follow this instruction also

when you use a pallet truck to move the machine.)

(1) Make sure of the center mark when moving the machine with a

CAUTION

!

forklift (pallet truck).

(2) Do not use a forklift (pallet truck) to move the machine with a vision

monitor w and signal light t attached.

- 3 -

Page 7

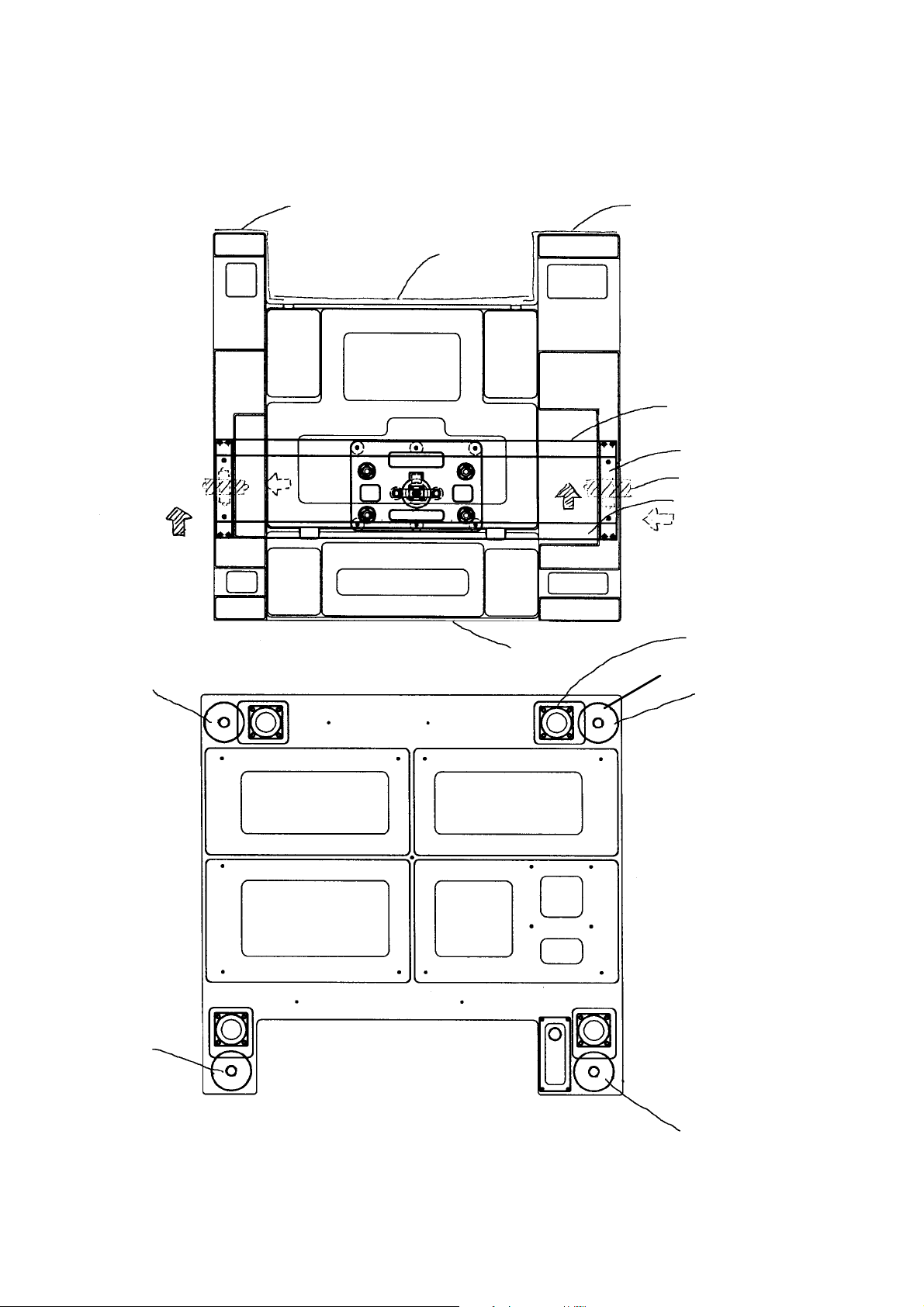

3 . Adjusting the Transport Height and Leveling the Machine

e

Cover RBL

Cover RBC

Cover FB

Figure 3.1 (Viewing from the top of unit.)

Cover RBR

Base bar R

Base bar B

Level vial

Base bar F

Caster

r

Adjuster

w

Figure 3.2 (Viewing from the bottom of unit.)

- 4 -

q

Page 8

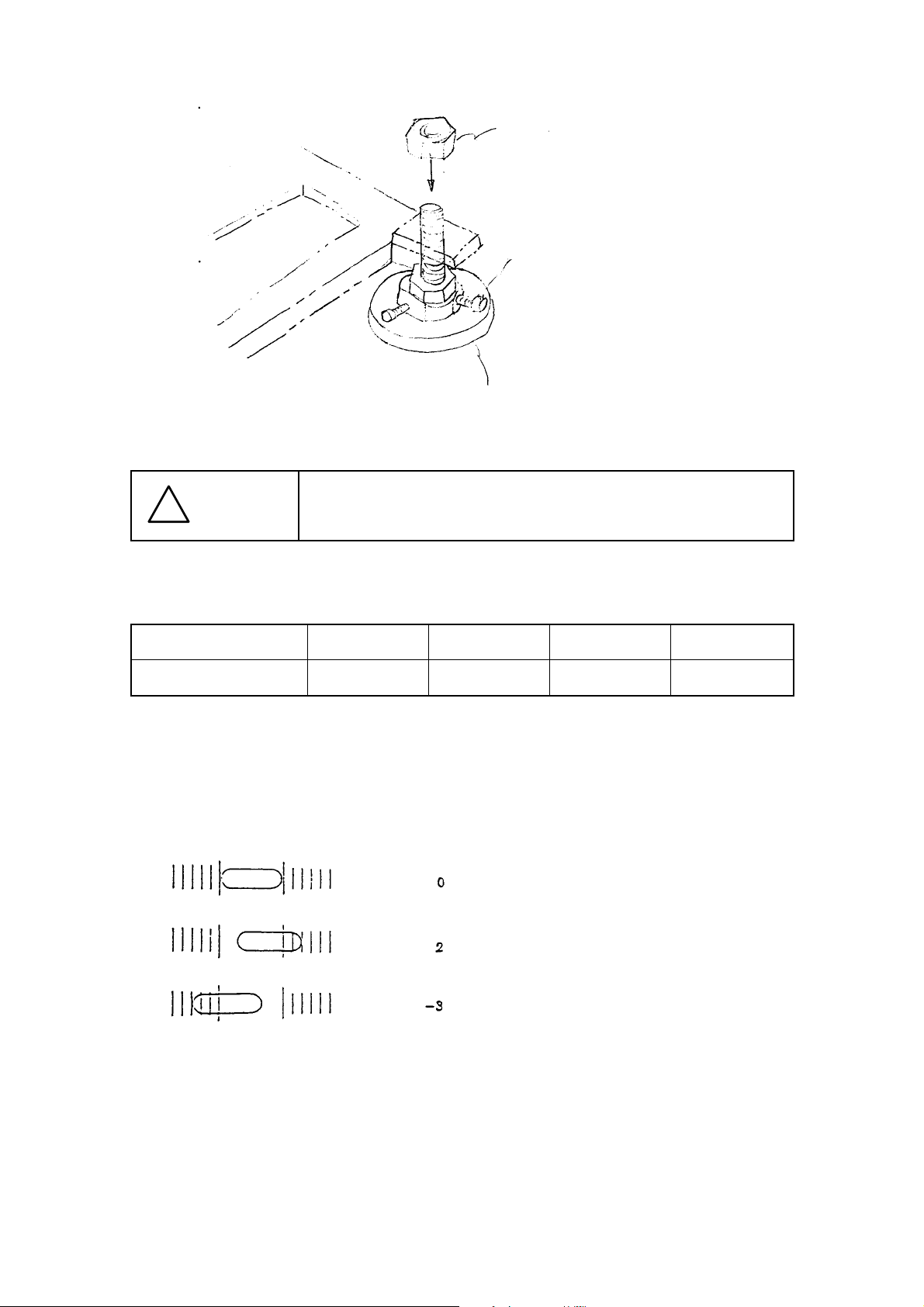

(1) Adjustment procedure

1) Detach the cover FB, cover RBC, cover RBR and cover RBL.

2) Loosen three hexagonal screws of adjuster. (Make sure that the adjuster moves

freely.)

3) Lift the adjuster in the order of q, e , w , r, q ,... as shown in Figure 3.2. You can

easily lift the main unit.

4) Leveling the main unit in the front and rear directions.

Put the level vial on the point indicated as a dotted line, and adjust the adjusters q

and w or e and r to set the level vial within – 1 division of the scale specified on

the supplied level setting table.

5) Leveling the main unit in the left and right directions.

Put the level vial on the point indicated as an actual line, adjust the adjusters q and

r or w and e to set the level vial within – 1 division of the scale specified on the

supplied level setting table.

6) Repeat Steps 4) and 5) to set the level vial on the base bar B within – division of

the scale specified on the supplied level setting table.

7) Lock the adjust nut.

Make sure that the level vial is set within – 1 di vision of the scale specified on the

supplied level setting table while being in lock.

8) Tighten three hexagonal screws of adjuster

.

- 5 -

Page 9

Base room inside

CAUTION

!

Adjust nut

Hexagonal screw

Adjust foot

The right scales of the level vial are + (plus) and the left ones are ( m inus ) w hen vi ew ed fr om t he a r r ow m a r k of the l ev el v i a l a s si gnm ent

figure.

Level setting table

Setting position A B C D

Setting value

Note: In case of the level vial (0.05/1 scale)

The scales (setting value) of the level vial

- 6 -

Page 10

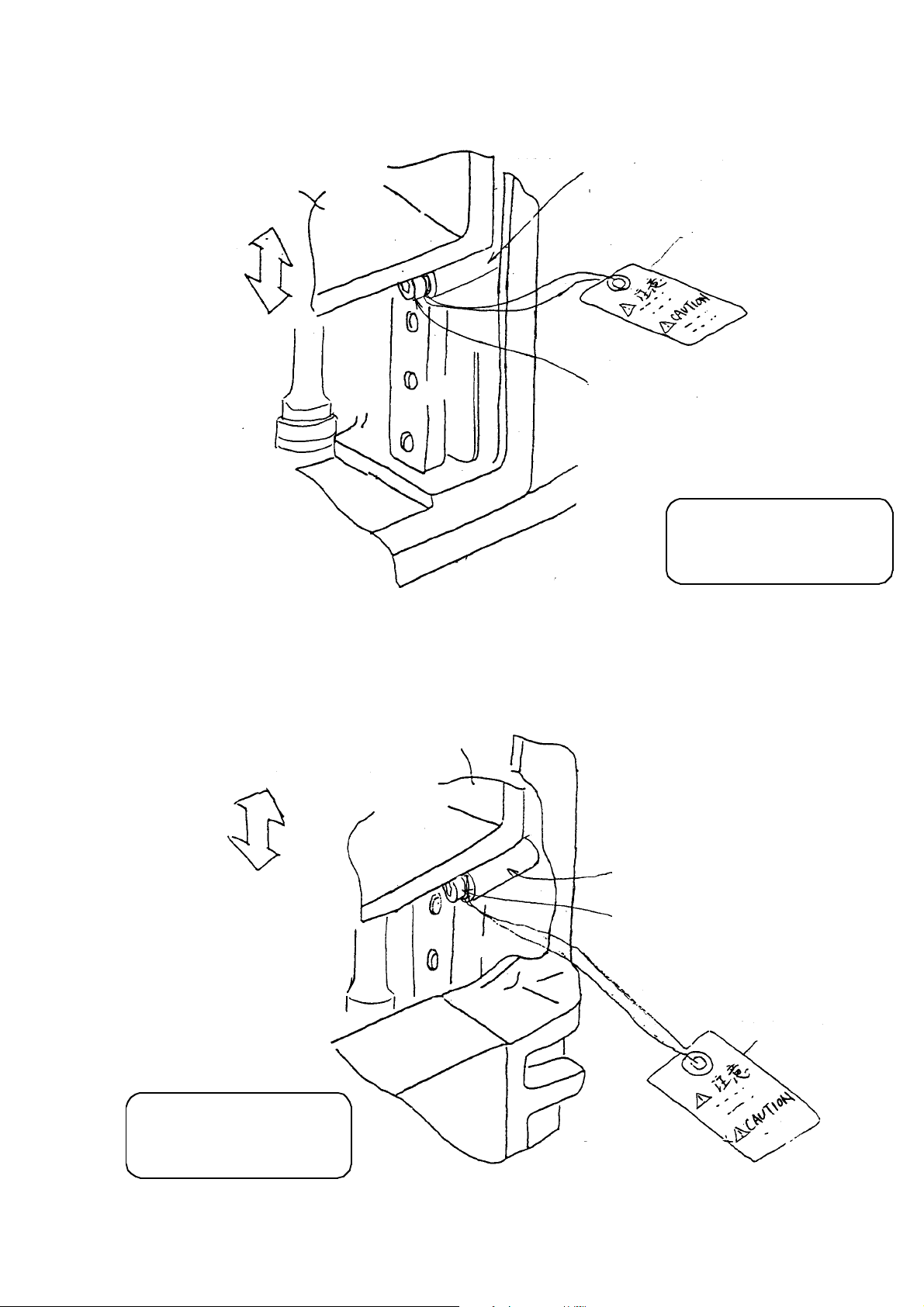

4. Demounting the Head Unit Fixing Parts

Z-axis slide bracket

KE-750

Spacer

HX00334000C

Set-up caution tag

Shammy cap

SL6042542TN

❋ As for the model KE-750,

remove the fixing parts

to detach three heads.

(1) Remove the shammy cap screw to detach the spacer.

(2) Make sure that the Z-axis slide bracket smoothly moves vertically.

Z-axis slide bracket

Spacer

HX00334000C

Shammy cap

SL6042542TN

Set-up caution tag

❋ As for the model KE-760,

remove the fixing parts

to detach two heads.

KE-760

- 7 -

Page 11

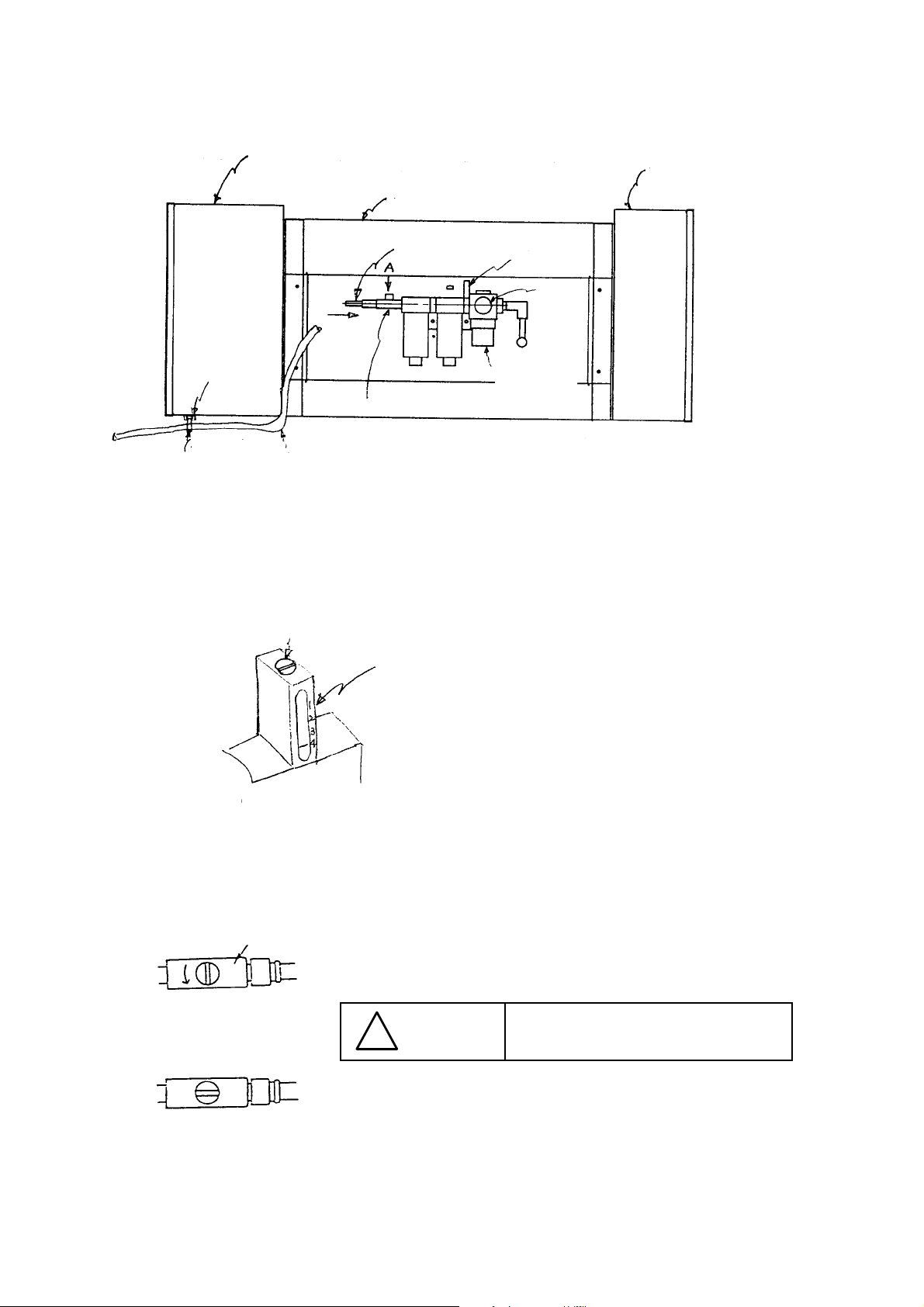

5. Connecting the Air Tubes

Fixing base

Tie-up band

Cover RBR

Fixing base

connect

Cover RBC

Piping at factory side

Hand valve

Pressure

switch

Pressure

gauge

Pressure

adjustment

knob

Cover RBL

1) Connect the air tube (¿.12), piped at the factory side, to the hand valve.

2) Adjust the pressure adjustment knob to 5 kgf/cm

3) Make sure that the pressure switch is set to 4 kgf/cm

2

.

2

.

(Use the (-) screw driver to adjust the pressure switch.)

4) Fix the air tub e, p ip ed at the factory s ide, at the fixing b as e w ith t he tie-up b and.

(It should not interfere in the replacement table.)

A view direction drawing

Hand valve

(a) Close

Pressure switch (Pressure detection cable assembly)

Be sure to use dried ai r through the

CAUTION

!

drier to supply compressed air.

(b) Open

- 8 -

Page 12

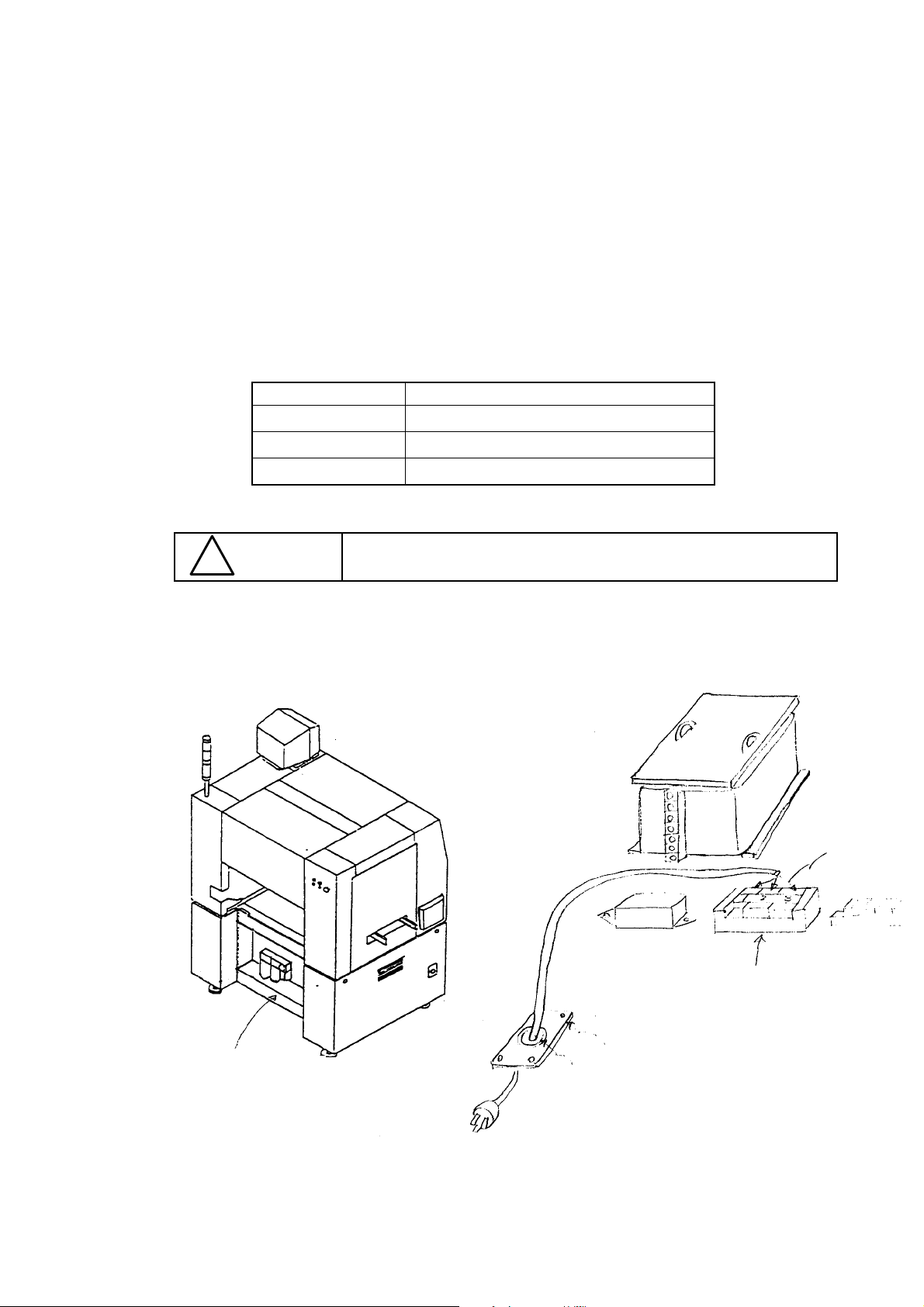

6. Connecting the Power Code

(1) Remove the cover RBC located on the rear of the main unit.

(2) Insert the power code inside the main unit via a groummet with a film after passing it

through a mouth guard as shown in Figure 6.2.

2-1 Be sure to install the insulation cover on the terminal plate after connecting the

power code to the terminal plate.

(3) Connect each terminal of the power code to the terminal plate of the power unit.

3-1 You can connect the black line to the No. 2 plate and the white line to the No. 1

plate because the alternate current is supplied.

Table 6.1

Color of the line Number of the terminal plate

Black (white 1

White (black) 2

Green 3

CAUTION

!

Make sure that the plugs of the power supply side has been

assembled before connecting the power code to the main unit.

Ground

Terminal plate

Cover RBC

Figure 6.1 Main unit (rear side)

Figure 6.2

Mouth guard

Grommet with a film

- 9 -

Page 13

7. Attaching Other Supplied Parts

(1) Signal Light

a) Insert the signal light through the upper hole of the cover RUR.

b) Locate the supplied nuts and washers as indicated in Figure 7.2, then fix them on

the bracket. Connect the connector to the bracket.

After installing the signal light, adjust its height so that the distance

CAUTION

!

(2) Vision Monitor

a) Insert the power code of the vision monitor from the hole in the middle of the monitor

base to the main unit, then fix the top of the vision monitor on the monitor base.

from the floor to the upper surface of the signal light can be 2,000 mm

(2,050 mm if installing the machine abroad).

CAUTION

!

b ) Pull out the image monitor cab le from the rear of the monitor top , then connect it to

the VIDEO IN jack.

c) Connect the power code connector to the power relay cable at the rear side of the

panel computer.

Make sure that the protruded part of the monitor top is hooked over

the knob of the monitor base.

Vision

monitor

Signal light

Cover RUR

Figure 7.1

Image monitor cable

- 10 -

Monitor base

Knob

Figure 7.2

Figure 7.3

Page 14

(3) Keyboard Bracket Assembly

a) Fix the keyboard connecting plate of the keyboard bracket ass embl y on the main

unit with four stopper screws as shown in Figure 7.5.

b) Connect the keyboard cable to the keyboard connector located in the hole on the

right side of the cover FUR.

(4) HOD (Handheld Operating Device)

a) Connect the HOD cable to the HOD connector located on the right side of the

main unit.

(5) Hand knob

a) Hook the hand knob over the handle hook located on the front right of the main

unit.

(6 ) Feeder relay cable

Connect the feeder relay cable and air tube from the connector bracket to the

connectors on the main unit cover (Perform this operation for the front and rear

sides).

! CAUTION

Keyboard

bracket

assembly

Connector

bracket

The connector bracket is already fixed on the replacement table

(optional).

Keyboard connector

HOD connector

Keyboard

connecting

Hand knob

Keyboard

bracket

assemblyplate

Stopper

screws (four)

(SM0040601SC)

Handle hook

Figure 7.4

Figure 7.5

- 11 -

Page 15

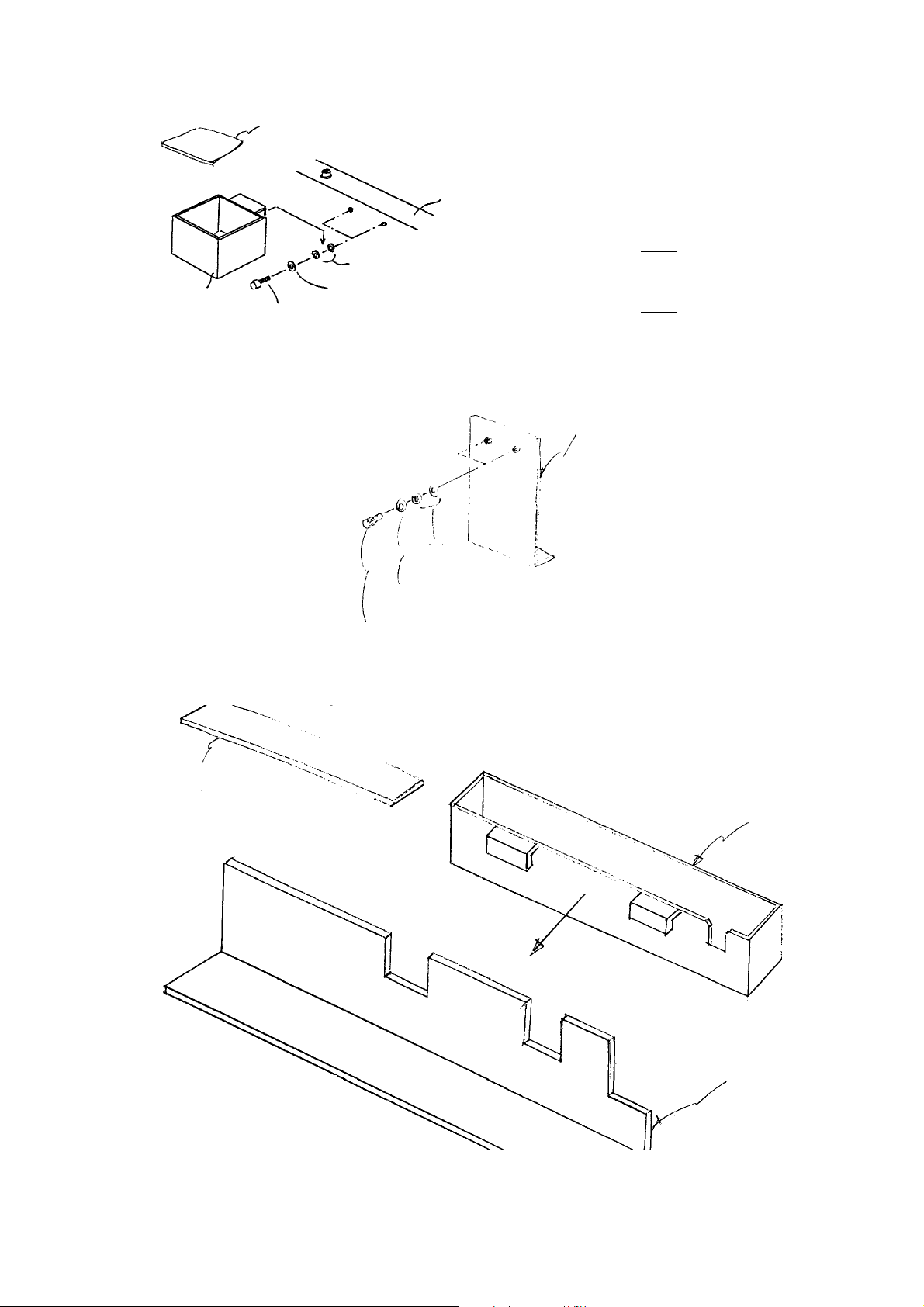

x

Chip box

E2801721000

Figure 7.1

Chip cushion

E2802721000

Washer (small circle) WP03020500SC

Washer (large) WP0330516SC

Hexagonal screw SM6030602TN

✴ Hook the U-shaped groove of the chip bo

over the washer (small circle).

Rail plate FR/FL

2 x 2 positions

Chip box stay

Washer (large)

WP0330516SC

Hexagonal screw

SM6030602TN

Washer (small circle)

WP03020500SC

Figure 7.2

Chip box L

E2803723000

Figure 7.3

ATC support angle

E3424725000

- 12 -

Page 16

(7) Chip Box Assembly

<Front reference>

a) Hook the U-shaped groove over the washer fixed on the rail plate FR and the chip

b ox s tay with a hexagonal screw as s how n in Figure 7.1. Hook the chip b ox L

over the ATC support angle as shown in Figure 7.3.

<Far end reference>

a) Hook the U-shaped groove over the washer fixed on the rail plate FL and the chip

b ox s tay with a hex agonal screw as s how n in Figure 7.2 Hook the chip b ox L

over the ATC support angle as shown in Figure 7.3.

- 13 -

Page 17

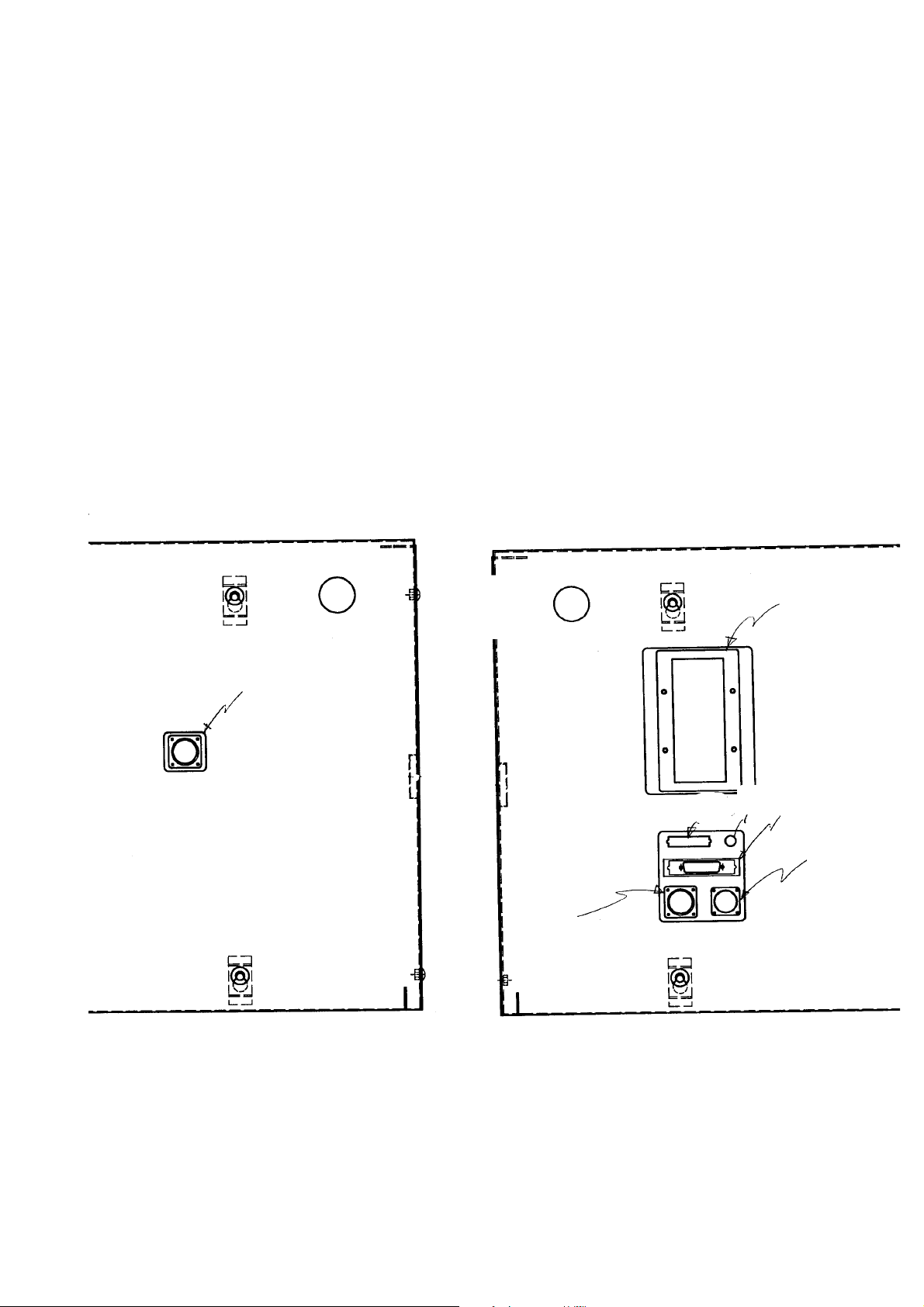

8 . Interface with External Equipment

1) q is the READY OUT (IN) connector (14-pin) to be connected to external equipment

when you use the machine as inline. The pin assignment is different depending on

the board transport direction; left to right or right to left as indi cated in Table 1-4-1

and Table 1-4-2 .

2) w is the connector (50-pin) for the signal from/to an optional matrix tray changer.

3) e is the power connector (10-pin) (AC 100 V) for an optional matrix tray changer.

4) r is the printer connector (D-Sub, 25-pin) and conforms to the Centronics standard.

q

q

w

Light

Breaker

r

e

Figure 8.1 Front left side of the main unit Figure8.2 Front right side of the main unit

- 14 -

Page 18

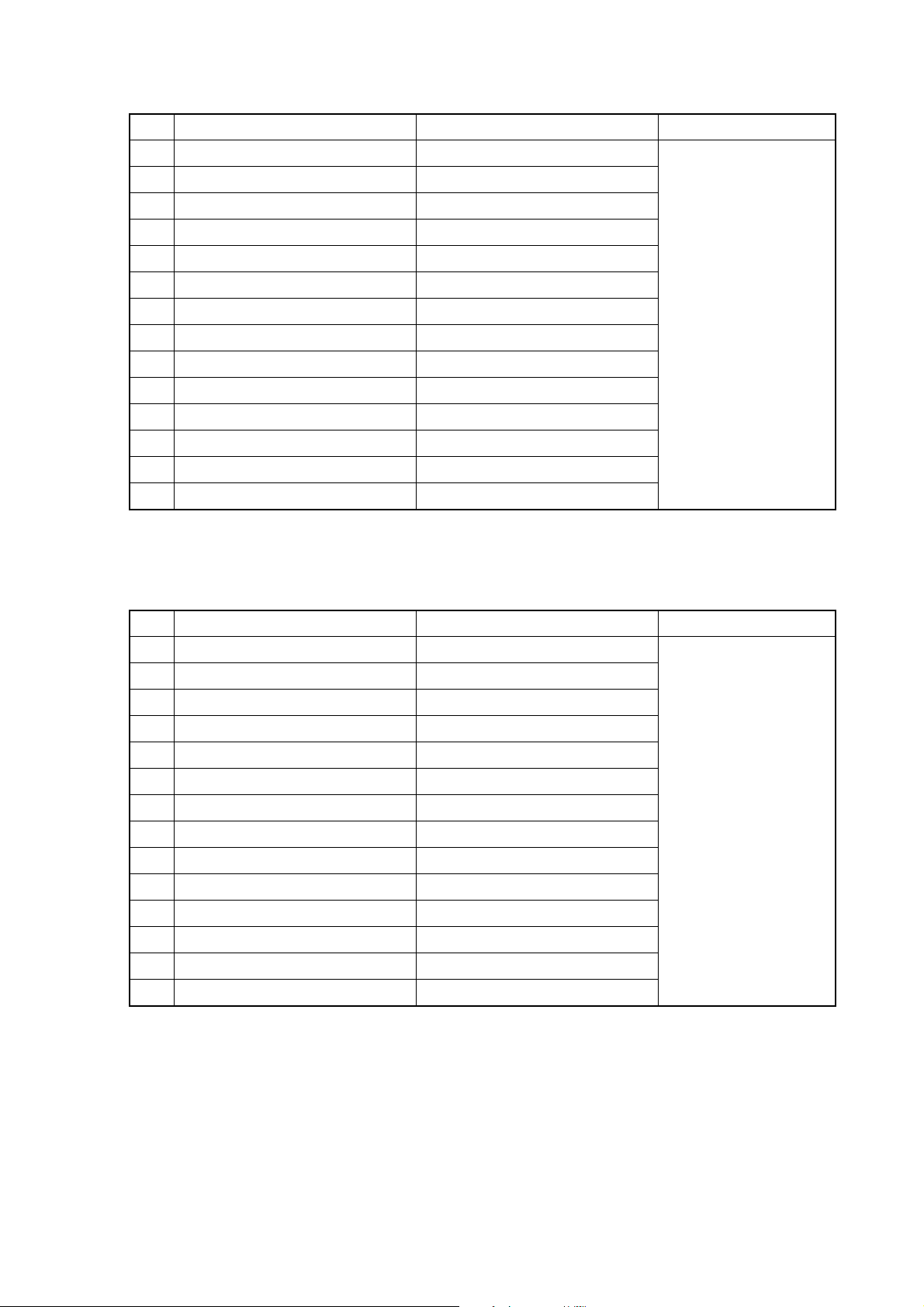

Signal (left to right) Signal (right to left) Connctor type

1 READY OUT+ READY IN+

2 READY OUT- READY IN- (GND)

3 BOARD AVAILABLE 1 BOARD AVAILABLE 3

4 BOARD AVAILABLE 2 BOARD AVAILABLE 4

5NC NC

6NC NC

7NC NC

8NC NC

9NC NC

10 NC NC

11 NC NC

12 NC NC

13 NC NC

14 NC NC

Table 8.1 Connectors on the front left side of the main unit

AMP

206043-1

(Connectors of the

cable are 206044-1)

Signal (left to right) Signal (right to left) Connctor type

1 READY IN+ READY OUT+

2 READY IN- (GND) READY OUT-

3 BOARD AVAILABLE 3 BOARD AVAILABLE 1

4 BOARD AVAILABLE 4 BOARD AVAILABLE 2

5NC NC

6NC NC

7NC NC

8NC NC

9NC NC

10 NC NC

11 NC NC

12 NC NC

13 NC NC

14 NC NC

Table 8.2 Connectors on the front right side of the main unit

AMP

206043-1

(Connectors of the

cable are 206044-1)

- 15 -

Page 19

The interface circuit diagram of the READY OUT (IN) and BOARD AVAILABLE connectors is

indicated in Figure 8.3. These connectors conform to the SMEMA standard.

READY OUT 1

READY OUT 2

+24 V

15 KΩ

BOARD AVAILABLE 2

BOARD AVAILABLE 1

+24 V

15 KΩ

READY IN

Figure8.3

GND

BOARD AVAILABLE 3

BOARD AVAILABLE 4

- 16 -

Page 20

Signal Connector type

1 -Strobe

2D0

3D1

4D2

5D3

6D4

7D5

8D6

9D7

10 -ACK

11 BUSY D-SUB 25-pin, FEMALE

12 PE

13 SLCT

14 -AUTO FEED XT

15 -ERROR

16 -INIT

17 -SLCT IN

18 GND

19 GND

20 GND

21 GND

22 GND

23 GND

24 GND

25 GND

Table 8.3 Pin assignment of the printer connector

- 17 -

Page 21

9. Attaching the Matrix Tray Changer (MTC)

Figure 9.1

54

Placer MTC entrance to be inserted

Placer MTC entrance to be inserted

Figure 9.2

Adjuster

rubber

- 18 -

Shuttle fitting bracket

Adjuster retainer

Adjuster spacer

Page 22

(1) Rear placement set-up (TR4NE)

S et the MT C so t hat the gap is within 54 mm as shown in Figure 9.1. Attach the

adjuster rubber and adjuster spacer at the position where the adjuster retainer can be

attached at the adjuster part, and tighten the lock nut with adjusting its height with the

adjuster. Then fix it with the adjuster retainer.

Be sure to set the MTC so that the gap between the machine unit and

CAUTION

!

the M T C uni t ( TR 4N E) is 54 m m or l ess ; other w i s e, the head m a y not

move to the pick position.

- 19 -

Page 23

Figure 9.3

* (104 or less)

Conveyor fixing screw

(long hole:6 portions)

Figure 9.4

Adjust screw

- 20 -

Page 24

(2) Horizontal placement set-up (related drawing) TR3NE

Set the MTC so that the gap is within 104 mm as shown in Figure 9.3 after detaching

the shuttle. Adjust its height with the adjust screw. Attach the shuttle after set-up.

Be sure to set the MTC so that the gap between the machine unit and the MTC

CAUTION

!

unit (TR3NE) is 104 mm or less; otherwise, the head may not move to the pick

position.

- 21 -

Page 25

Cover SBR

SMEMA

q

Breaker

Light

Printer connector

Interface panel

w

q MTC signal connector

w MTC power connector

MTC air supply opening

e

Cover RBR

Figure 9.3

Cover RBC

Filter regulator

Cover RBL

Figure 9.4

- 22 -

Page 26

Connect the MTC power connector and signal connector to the interface panel on the front

right side of the main unit as shown in Figure 9.3, then connect the air tube to the MTC air

joint on the rear side of the main unit.

CAUTION

!

Use two cables and an air tube supplied with the MTC.

- 23 -

Page 27

10. Checking the Machine Before Tuning on the Power

Check to see if:

q The machine is leveled.

w The height of the board transport rail satisfies the specifications.

e The lock nut of the adjuster is fixed.

r Air is supplied normally.

t The power code is connected properly, and its voltage is appropriate.

y The supplied parts are attached properly.

u The machine is connected to external equipment properly.

i Each unit operates smoothly. Check the following parts manually:

1) Y-axis: Hold both edges of the X axis with both hands and move the X axis from

the front to the rear and vice versa smoothly.

2) X-axis: Hold the head bracket, and mov e it from left to right and v ice versa

smoothly.

3) Head: Move the Z-axis and -axis with your hands smoothly.

- 24 -

Page 28

11. Adjusting the Height of the Replacement Table (Optional)

Perform the height adjustment for the replacement table after leveling the main unit.

Do not fall down the replacement table sideways while changing the

CAUTION

!

(1) Adjusting the Caster Plate Fixing Position

You can set the height of the replacement table in two step s depending on the

manner the caster plate is fixed.

Adjust the height according to that of the board transport track.

caster plate fixing position; otherwise, the trolley handle may be

damaged.

Caster plate

Upper

Trolley frame

Fixing screwplate

Figure 11.1

Lower

Figure 11.2

Board transport height Caster plate fixing position

880 to 900 mm Upper (See the upper figure.)

900 to 920 mm Lower (See the lower figure.)

Add 50 mm if the machine is for ZEVA.

The cas ter plate is already fix ed on the low er p osition ( indicated in the Figure 11.2)

when the replacement table is installed.

- 25 -

Page 29

CAUTION

!

When the gap between the bank location pin B and the bottom of the bank

support is less than 7mm as shown in Figure 11.3, fix the caster plate at the

upper position.

Bank support

7 mm

Bank location pin B

Figure 11.3

- 26 -

Page 30

Adding the trolley spacer (E2738721000) (For height adjustment)

Adjust the height of the replacement table with the trolley spacer as shown in Figure 11.4 if an

inconvenience occurs due to a slanting floor or a low replacement table.

Height adjustment tap (M6)

Trolley spacer

Fixing screw

Trolley

E2738721000

Caster plate

Figure 11.4

1. Loosen the fixing screws.

2. Ins ert the M6 screw into the height adjust ment tap , then turn the M6 screw until the

space between the caster plate and the trolley is made.

3. Insert the required pieces of the trolley spacer into the space.

4. Remove the adjustment screw, then tighten the fixing screw.

CAUTION

!

When the caster plate is fixed at the upper

position, insert the trolley spacer into the

space between the trolley and the fixing

screw, and then fix them as shown in

Figure 11.5.

Trolley

Caster plate

Fixing screw

- 27 -

Trolley spacer

Figure 11.5

Page 31

(2) Adjusting the Bank Stopper Fixing Position

S et the b ank stop p er in up p er, middle, or low er p os ition according to the b oard

transport height.

Bank stopper

Roller guide

Figure 11.6

Board transport height Bank stopper fixing position

894 to 900 Lower

914 to 920 mm

887 to 893 Middle

907 to 913 mm

880 to 886 Upper

900 to 906 mm

(Add 50 mm when the machine is for ZEVA.)

The position of the bank stopper above is just an example. Attach the

CAUTION

!

bank stopper where the trolley stopper plate touches more of the

bank stopper. The left fixing position may be different from the right

fixing position depending on the floor where the machine is installed.

Bank stopper

Trolley stopper plate

Figure 11.7

- 28 -

Page 32

MAIN UNIT UNPACKING GUIDE

(Main Unit Packing Guide)

Page 33

Table of Contents

1. Head Unit .................................................................................................................1

2. X-Y Unit....................................................................................................................3

3. Board Transport Unit................................................................................................5

4. ATC (Auto Tool Changer) Unit ................................................................................8

5. VCS (Vision Centering System) Unit ......................................................................9

6. CAL Block..............................................................................................................10

7. HOD (Handled Operating Device) Bo x ................................................................11

8. Vision Monitor.........................................................................................................11

9. Signal Light.............................................................................................................12

10. Keyboard Bracket Assembly.................................................................................13

11. Feeder Relay Cable of the Connector Bracket......................................................14

12. Safety Cover .........................................................................................................15

13. Filter Regulator (Air Assembly)...............................................................................16

14. Replacement Table (Optional).............................................................................. 17

List of Supplied Parts to Be Packed ......................................................................20

15. Hand disk...............................................................................................................24

Page 34

-

1. Head Unit

1-1. Fixing the Z-Axis

Z-axis slide bracket

Spacer HX00334000C

Set-up caution tag

Shammy cap

SL6042542TN

(1) Attach the spacer as

indicated in Figure 1.1 to

prevent the Z-axis slide

b racket from moving up

or down.

(2) Make sure that the head

unit is stable after

attaching the spacer

even though y ou move

it in the direction

indicated with the arrow

mark.

Z-axis slide bracket

Figure 1.1

Spacer HX00334000C

Shammy cap

SL6042542TN

CAUTION

!

Attach the set-up caution

tag onto the shammy cap for

each head respectively.

Set-up caution tag

Figure 1.2

- 1

Page 35

-

1-2. Head Main Unit (KE-750, KE-760)

Drier

Figure 1.3

1. Put the drier into the bottom of the OCC as indicated in Figure 1.3.

2. Wrap the bott om of the head w ith a p iece of anticorrosiv e pap er, then p as te a tap e

over the anticorrosive paper.

3. Wrap the head completely with the air cap, then fix them with an adhesive tape.

Anticorrosive

paper

- 2

Page 36

-

2. X-Y Unit

(1) Fixing the Y-axis Rail (Fixing the X-axis Frame Assembly)

q Move the whole X-axis frame completely to the front of the machine, then push it

against the stopper rubber located on the front side.

w Fix the safety cover stoppers (E1348700000) on two taps (right and left) located

on the linear guide of the Y-axis frame with the M5 x 20 screws from the rear side.

Adjust the eccentricity of the stopper to push the Y-axis frame against the rubber

on the front, then fix it.

e Attach the set-up caution tag onto the fixing part.

M5 x 20 screw

(SM6052002TN)

Tap E1348700000

X-axis Unit

Set-up caution tag

Figure 2.1

- 3

Page 37

-

2) Fixing the X-axis Rail (Fixing the Head Bracket)

q Move the head bracket (whole head unit) on the X-axis to the left side of the unit.

w Move the head b racket (whole head unit) comp letely to the left s ide to pus h it

against the rubber stopper. Then, fix the X-axis stopper at two M3 taps located

on the b ottom of the X- axis frame w ith the s hammy cap S L6030842TN from the

bottom.

e Attach the set-up caution tag onto the X-axis stopper.

2 x ( M3 x l8) + (M3 Spring washer)

(SL6030842TN = Shammy cap)

Figure 2.2

X-axis stopper

(E5001715000)

- 4

Page 38

-

3. Board Transport Unit

(1) Supplied Parts to Be Packed

Pack the following three items together with other supplied parts into the

E5353700000 packing carton box (See theList of Supplied Parts to Be Packed).

Remove them from the board transport unit to pack them.

(Note that the hand knob is to be used to change the board transport rail width.)

Supplied parts:

E20217150A0 Back up pin M assembly 8

E2206700000 Hand knob 1

E2801725000 Chip box assembly 2

Screw shaft

U plate

Chip box

assembly (two)

Hand knob

Back up pin M assembly (eight)

Figure3.1

- 5

Page 39

-

(2) How to Pack

a. Packing the Center part

1) Roll up the air cap which is to be crashed easil y when the board width is set

to the minimum value (30 mm), then put it into the center part.

2) Adjust the board transport width to the minimum value (30 mm), and paste

filament tapes approximately in the middle of the screw shaft and the guide

shaft (two positions) (see Figures 1-1 and 2-1).

300

Rail plate M

Air cap

Filament tapes (two positions)

Rail plate F

Move these plates until the board

transport width becomes the

minimum value (30 mm).

Figure2.1

CAUTION

!

b. Right And Left Edges

1) Put air cap which can be crashed easily into the protruded parts from the main

unit.

2) Wrap the air cap around the protruded parts as indicated in Figure 2-2.

Make sure that the rail plate (black part) receives no load. If the rail

plate is deformed, the machine cannot operate normally.

*Note that the air cap should n o t

touch any sensor.

Filament tapes

q

CAUTION

!

w

Figure3.2

Make sure that the rail plate (black part) receives no load. If the rail

plate is deformed, the machine cannot operate.

e

- 6

Page 40

-

c. BU plate

Fix the BU plate with filament tapes (four positions).

ilament tapes (four positions)

Fix the BU plate so that it

can be kept stable.

BU plate

Figure3.3

- 7

Page 41

-

4. ATC(Auto Tool Changer) Unit

p

q Fix the nozzle on the ATC unit.

w Align the hole of the ATC b as e w ith that of the s lide plate, then p ut t he tie-up b elt

through these holes. Tighten the tie-up belt. Make sure that the slide plate is fixed

and all nozzle cannot be removed.

e Cover the nozzle with air cap so that it cannot move, then paste adhesive tapes over

the air cap to fix them.

Nozzle

Air ca

Slide plate

ATC base

Figure4.1

Tie-up belt

Hole

- 8

Page 42

-

5. VCS (Vision Centering System)Unit

q Cover the whole unit completely with air cap.

w Paste an adhesive tape on the air cap at the bottom of the light base.

Air cap

Light base

Figure5.1

Adhesive

tape

- 9

Page 43

-

6 . CAL Block

q Cover the upper part of the CA block with air cap to protect the upper surface of the

CAL plate, then fix the air cap with an adhesive tape.

Air cap

Tape

CAL plate

Figure 6.1

w Put the CAL p iece A and the C AL p iece B into viny l sacks s ep arately. W rap

these vinyl sacks with air cap, then pack them in the carton box where the other

supplied parts are packed.

Vinyl sack

Air cap

Figure 6.2

❇ The CAL piece B is supplied with only the KE740 or FM740 model.

- 10

Page 44

-

7. HOD (Handheld Operating Device) Box

See the HOD box packing assembly (E53027000A0) to pack the HOD box.

8. Vision Monitor

Repack only the monitor in the carton box which the manufacturer specified.

q Do not disassemble the stand part from the mounter main unit.

w Put air cap in the carton box when there is any gap in the

CAUTION

!

carton box after repacking the monitor.

e Paste an adhesive tape whose width is 50 mm over the

carton box after repacking the monitor to close the carton

box.

Figure 8.1

Monitor

Stand part

Carton

Figure 8.2

- 11

Page 45

-

9. Signal Light

Rep ack the patrol light cab le ass emb ly (E94417150A0) in the carton box w hich the

manufacturer specified.

Carton

CAUTION

!

Pack the nuts and washers (supplied) in the same carton box also.

Patrol light

cable assembly

Figure 9.1

- 12

Page 46

-

10. Keyboard Bracket Assembly

(1) Disconnect the keyboard connection cable from the main unit.

(2) Remove four stopper screws fixing the keyboard attachment plate, then the keyboard

bracket assembly from the main unit.

(3) Pus h dow n the keyboard s tands L and R ins ide, w rap the w hole keyb oard b racket

assembly with air cap completely, and pack it in the same carton box where the other

supplied parts are packed.

Keyboard connection cable

Keyboard

attachment plate

Figure 10.1 Figure 10.2

- 13

Keyboard stand L

Stopper

screws

Keyboard stand R

Page 47

-

11. Feeder Relay Cable of the Connector Bracket (Supplied)

Fix the feeder relay cable and air tube on the connector bracket with a filament tape.

CAUTION

!

Fix the air tube so that it cannot be damaged at all.

Feeder relay cable

Filament

tape

Figure 11.1

Connector

bracket

Cover FB

The front of the connector bracket is fixed on the cover FB , and the rear is fix ed on the

cover RBC.

CAUTION

!

The connector bracket is already fixed on the replacement table

(optional).

- 14

Page 48

-

12. Safety Cover

Fix the safety cover with a filament tape so that it cannot be opened.

Safety cover

Filament tape

Figure 12.1

- 15

Page 49

-

13. Filter Regulator (Air Assembly)

1. Remove the air tube, piped at the factory side.

2. Do not remove this unit if exporting the machine abroad because this model differs from

the former models, such as KE-710/720 and KE-730/740.

CAUTION

!

Cover RBR

Turn off the air of the main unit before following the instructions

above.

Cover RBL

Cover RBC

Piping at factory side

remove

Figure 13.1

- 16

Page 50

-

14. Replacement Table (Optional)

(1) Fixing the Feeder Bank and the Floor Trolley

Fix the feeder bank and the side pole of the floor trolley with the P.P band.

P.P band

Figure 14.1

Feeder band

Floor trolley

(2) Fixing the Trolley Handle (Right and Left)

Fix the slider and the trolley handle by wrapping them with a filament tape.

Hook the tie-up belt over the stopper screw to keep the trolley handle stable.

Stopper screw

Tie-up belt

Filament tape

Slider

Trolley handle

Figure 14.2

- 17

Page 51

-

(3) Fixing the Feeder Relay Cable

Fix the feeder relay cable and the air tub e on the connector b racket with a filament

tape.

Feeder relay

cable

Connector

Filament tape

Figure 14.3

bracket

!

CAUTION

Take care not to damage the air tube at all.

- 18

Page 52

-

(4) Wrap the whole unit with air cap completely.

Air cap

Trolley

Floor

Feeder bank

trolley

Connec t or

brac ket

Feeder

relay

cable

Figure 14.4

- 19

Page 53

-

KE-750 List of the Supplied Parts to Be Packed

Pack the following supplied parts in the E5010715000 carton box.

Part No . Part Name Quantity

E94507000A0 Power cable assembly 1

E9690715000 Light 1

E53027000A0 HOD Box packing assembly 1

E6953861B00 Content label 2

MDFRX1001L0 New deflexed oil No. 1 1

J1067000000 Oil feeder 1

B91212200A0 Oil feeder 1

MGREAS400G0 Grease 1

J106600000B Hexagonal wrench 2 mm 1

J106600000C Hexagonal wrench 2.5 mm 1

J106600000D Hexagonal wrench 3 mm 1

J106600000E Hexagonal wrench 4 mm 1

J1080000000 Ball screwdriver 1

MAI17002000 Cross-headed screw driver (No.1) 1

E0120K750A0 Operating Instructions (KE750 Japanese) 1

E5001715000 X-axis stopper 1

SL603842TN 5001 Shammy Cap 2

NM6030001SC 5001 hexagonal nut 2

!

1)

!

!

!

E1348700000 Safety cover stopper 2

SM6052002TN 1348 hexagonal-hole-headed screw 2

E5010715000 Supplied carton box 1

E28017250A0 Chip box assembly 2

E5002721000 Packing box for keyboard 3

Op erating In structions ( K E750 Engl i sh) f o r a fo r e i gn count r y ( ZEVA ) 1

E20217150A0 Back up pin M assembly 8

E2206700000 Hand knob 1

E13417210A0 Keyboard bracket assembly 1

E36217210A0 CAL piece assembly (730) 1

E29007250A0 Air set (ø4, ø6, ø10 excluding any tube) 1

2)

E9613721000 Hard disk 1

)

5

E1014725000 Adjust nut 30 4

6)

HX003630000 Tie-up belt 1

- 20

Page 54

-

CAUTION

abels

!

1) Select parts to be packed depending on th e user.

2) This part is fixed on the main unit for Japan. Do not pack it in the carton

box. (Remove it from the main unit and pack it in the carton box if the

machine is to be exported abroad.)

3) Put air cap so that there cannot be any gap inside the carton box.

4) Paste the content labels on the outside of the carton box (two

positions)

PARTS NO. KE750 or FP750

PARTS NAME ACCESSORY

L

5) Remove the adjust nut 30 from the main unit, then pack it into the

supplied carton box.

6) The tie-up belt is used to fix the air tube which is piped at the factory

side.

* Refer to page 8 in the Set-up Guide.

- 21

Page 55

-

KE-760 List of the Supplied Parts to Be Packed

Pack the following supplied parts in the E5010715000 carton box.

Part No . Part Name Quantity

E94507000A0 Power cable assembly 1

E9690715000 Light 1

E53027000A0 HOD Box packing assembly 1

E6953861B00 Content label 2

MDFRX1001L0 New deflexed oil No. 1 1

J1067000000 Oil feeder 1

B91212200A0 Oil feeder 1

MGREAS400G0 Grease 1

J106600000B Hexagonal wrench 2 mm 1

J106600000C Hexagonal wrench 2.5 mm 1

J106600000D Hexagonal wrench 3 mm 1

J106600000E Hexagonal wrench 4 mm 1

J1080000000 Ball screwdriver

MAI17001000 Cross-headed screw driver (No.1) 1

E0120K760A0 Operating Instructions (KE760 Japanese) 1

E5001715000 X-axis stopper 1

SL603842TN 5001 Shammy Cap 2

NM6030001SC 5001 hexagonal nut 2

E1348700000 Safety cover stopper 2

!

1)

!

!

!

SM6052002TN 1348 hexagonal-hole-headed screw 2

E5010715000 Supplied carton box 1

E28017250A0 Chip box assembly 2

E28037250A0 Chip box L assembly 3

E5002721000 Packing box for keyboard 3

Opera ting Instr uctions ( KE760 Engli sh) for a f or ei gn country ( ZEVA) 1

E20217150A0 Back up pin Assembly 8

E2206700000 Hand knob 1

E13417210A0 Keyboard bracket assembly 1

E36417210A0 CAL piece set (740) 1

E29007150A0 Air set (ø4, ø6, ø10 excluding any tube) 1

2)

E9613721000 Hard disk 1

)

5

E1014725000 Adjust nut 30 4

6)

HX003630000 Tie-up belt 1

- 22

Page 56

-

CAUTION

abels

!

1) Select parts to be packed depending on the user.

2) This part is fixed on the main unit for Japan. Do not pack it in the carton

box. (Remove it from the main unit and pack it in the carton box if the

machine is to be exported abroad.)

3) Put air cap so that there cannot be any gap inside the carton box.

4) Paste the content labels on the outside of the carton box (two

positions)

PARTS NO. KE760 or FP760

PARTS NAME ACCESSORY

L

5) Remove the adjust nut 30 from the main unit, then pack it into the

supplied carton box.

6) The tie-up belt is used to fix the air tube which is piped at the factory

side.

Refer to page 8 in the Set-up Guide.

- 23

Page 57

-

15. Hard Disk

p

The hard disk should be detached and transported with packed separately.

q Remove the hard disk from the main unit.

B e s ure to s p ecify the model numb er of the machine from w hich the hard dis k is

removed.

w Wrap the hard disk with an anti-static air cap.

Double

40 cm or more

20 cm or more

e Fix the air cap with a cellophane adhesive tape so as not to spread.

r Place the hard disk into the supplied box.

1. Take care that the hard disk is stable in the supplied box.

CAUTION

!

2. Place the supplied screws in the sack, then fix the sack on the air ca

wrapping the hard disk with a cellophane adhesive tape.

- 24

Page 58

Revision Date

00 1997. 07

● Specifications are subject to be changed without notice.

– 1 –

Page 59

ELECTRONIC ASSEMBLY &

TEST SYSTEM DIVISION

8-2-1, KOKURYO-CHO, CHOFU-CITY, TOKYO 182, JAPAN

PHONE: 03-3480-3330 FAX: 03-3488-1971

TELEX: 03-242-4343 JUKI J

Sales agent

Loading...

Loading...