Page 1

Lockstitch machine with a long arm and a thread trimmer

J-350QVP

INSTRUCTION MANUAL

EN

Attention :

Congratulations on your purchase of a JUKI sewing machine.

Please be sure to read this Instruction Manual before operating the sewing machine

to ensure safe operation. Please be sure to keep the Instruction Manual so that you

can read it whenever necessary.

JUKI website: http://www.juki.com

Page 2

"IMPORTANT SAFETY INSTRUCTIONS"

When using an electrical appliance, basic safety precautions should always be followed, including the

following: Read all instructions before using this sewing machine.

"DANGER

1. An appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electric outlet immediately after using and before cleaning.

____

"WARNING

1. Do not allow this appliance to be used as a toy. Close attention is necessary when this appliance

is used by or near children. This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the appliance

in a safe way and understand the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

2. Use this appliance only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the appliance to the nearest authorized

dealer or service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the sewing machine and foot controller free from the accumulation of lint, dust and loose cloth.

5. Keep ngers away from all moving parts. Special care is required around the sewing machine

needle.

6. Always use the proper throat plate. The wrong plate can cause the needle to break.

7. Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deect the needle causing it to break.

9. Switch the sewing machine off ("O") when making any adjustments in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot and the like.

10. Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other user servicing adjustments mentioned in the instruction manual.

11. Never drop or insert any object into any opening.

12. Do not use outdoors.

13. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

14. To disconnect, turn all controls to the off ("0") position, then remove plug from outlet.

15. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

16. Turn OFF the power switch before insertion/removal of any cords and any plugs.

17. Basically, the machine should be disconnected from the electricity supply when not in use.

18. If the power cord of this appliance is damaged, it must be replaced with a special cord byyour

nearest authorized dealer or service center.

To reduce the risk of electric shock:

____

To reduce the risk of burns, re, electric shock, or injury to persons:

"

"

"SAVE THESE INSTRUCTIONS"

This sewing machine is intended for household use only.

Use the stitch regulator made by the Grace Company.

Stitch regulator can be used on the following machine model-number.

Sewing machine model number Stitch regulator model number

J-350QVP Sure Stitch for JUKI J-350

In order to use your machine safely, be sure to read the Instruction Manual for the Sure Stitch for

JUKI J-350QVP provided by Grace Company for how to install the machine on the frame, how to connect the stitch regulator and how to operate the machine.

– 1 –

Page 3

Congratulations on your purchase of a JUKI sewing machine.

Please be sure to read safety precautions in "To use the sewing machine safely" in the Instruction

Manual before use to fully understand the functions and operating procedures of the sewing machine so as to use the sewing machine for a long time.

After you have read the Instruction Manual, please be sure to keep it together with the warranty so

that you can read it whenever necessary.

To use the sewing machine safely

Marks and pictographs included in the Instruction Manual and shown on the sewing machine are

used so as to ensure safe operation of the sewing machine and to prevent possible risk of injury to

the user and other people.

Warning marks are used for different purposes as described below.

WARNING

ATTENTION

Pictographs mean the following:

Danger

warning which

is not specied

Prohibited

matter which is

not specied

Generally

required

behavior

WARNING

For the combination of the material and the thread and needle, in particular, refer to the explanation

table in "Replacement of the needle".

If the needle or thread does not match the material used such as in the case that an extra heavyweight material (e.g., denim) is sewn with a thin needle (#11 or higher), the needle can break resulting in an unexpected personal injury.

Indicates that there is a possible risk of death or serious injury if this

mark is ignored and the sewing machine is used in a wrong manner.

Indicates the operation, etc. which can cause a possible risk of personal

injury and/or physical damage if this mark is ignored and the sewing machine is used in a wrong manner.

There is a risk

of electrical

shock

Disassembly/

alteration is

prohibited

Disconnect the

power plug

There is a risk

of re

Do not place

ngers under

the needle

There is a

risk of injury

to hands, etc.

Do not pour

oil, etc.

Other precautions

●

● Do not put the sewing machine

under the direct

sunlight or

in ahumid

place.

Be aware that the following state can take place since the sewing machine incorporates semi-conductor electronic parts and precise electronic circuits.

● Be sure to use the sewing machine in

the temperature range

from 5ºC to 40ºC.

If the temperature is exces-

sively low, the machine can

fail to operate normally.

Do not wipe the sewing machine with solvent such as thinner.

When the sewing machine is soiled, put

a small quantity of neutral detergent on a

piece of soft cloth and carefully wipe off the

sewing machine with it.

* The operating temperature of the sewing machine

is between 5ºC and 40ºC. Do not use the sewing

machine under the direct sunlight, near the burning

things such as a stove and candle, or in a humid

place. By so doing, the temperature in the interior

portion of the sewing machine can rise or the coating of the power cord can melt, causing re or electrical shock.

– 2 –

Page 4

HOW TO CARRY THE SEWING MACHINE

A

CAUTION

How to take out the sewing machine

CAUTION

If you pull up the sewing machine by holding presser regulating screw

section A, the sewing machine can break.

In addition, be aware that the presser regulating screw can break if a

physical impact is given to it.

Pull out the sewing machine from the cutout of styrene foam by holding

the main body of the arm.

Turn OFF the power switch. Always must be disconnected plug from socket-outlet.

How to hold the sewing machine

CAUTION

1. Never hold the handwheel since it rotates.

2. Always must be handle the sewing machine with two persons or

more since the sewing machine weighs 26 kg or more.

3. Do not hold the sewing machine by placing hands near the needle

bar and the presser bar to avoid the risk of injury.

Carry the sewing machine while holding the machine arm with two per-

sons as shown in the gure.

– 3 –

Page 5

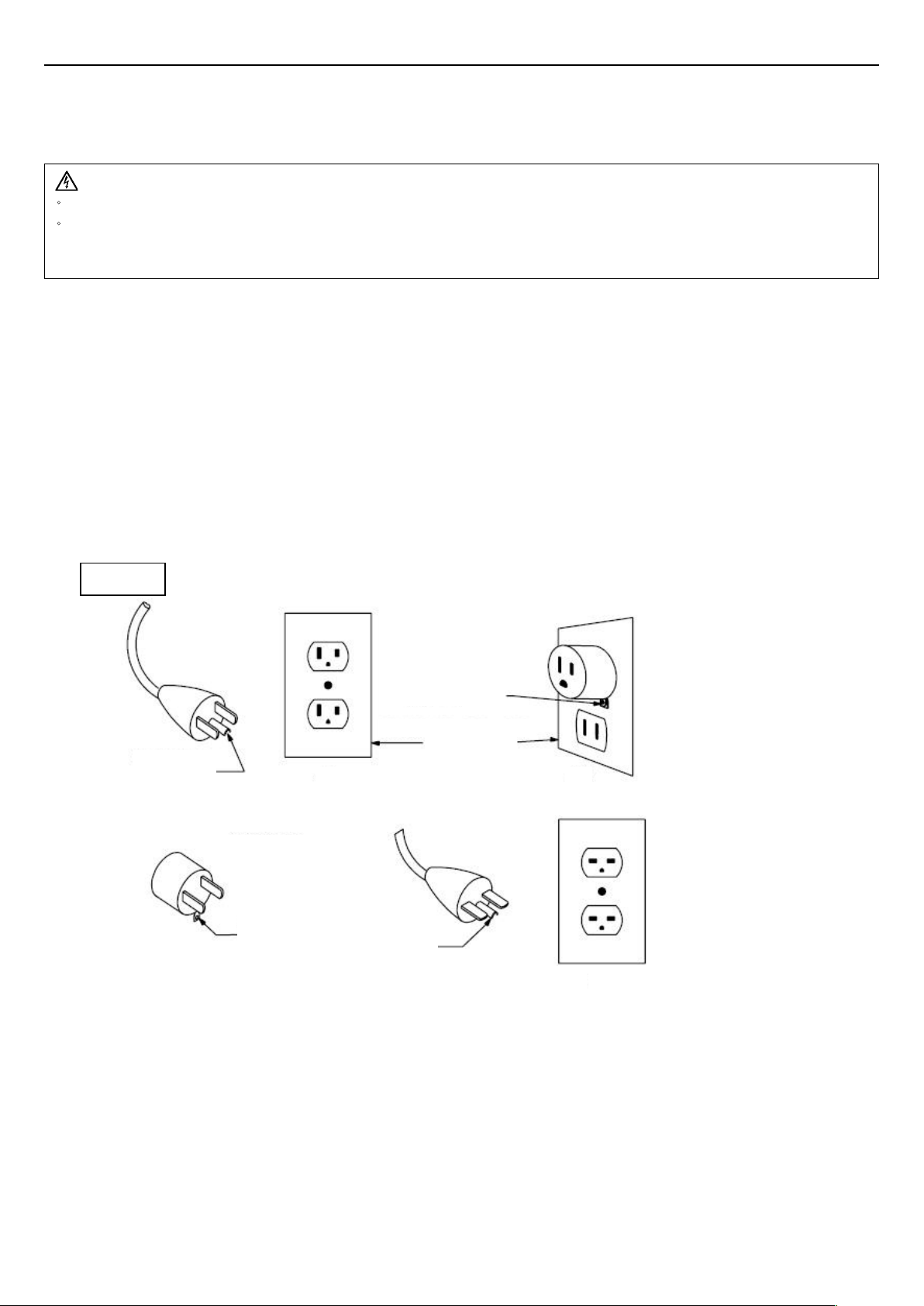

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of malfunction or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This product is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER

Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

・

The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-

・

grounding conductor. If repair or replacement of the cord or plug is necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualied electrician or serviceman if the grounding instructions are not completely understood, or if in doubt

as to whether the product is properly grounded.

Do not modify the plug provided with the product. if it will not t the outlet, have a proper outlet installed by a qualied

electrician.

This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the plug illustrated in sketch

A

in Figure 1. A temporary adaptor, which looks like the adaptor illustrated in sketches B and C, may be used to connect

this plug to a 2-pole receptacle as shown in sketch B if a properly grounded outlet is not available. The temporary adaptor

should be used only until a properly grounded outlet can be installed by a qualied electrician. The green colored rigid ear,

lug, and the like, extending from the adaptor must be connected to a permanent ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be held in place by the metal screw.

Figure 1

Grounding

pin

(C)

Adapter

Grounding

means

(A)

Metal

screw

Cover of

grounded

outlet box

(B)

Grounding

pin

(D)

– 4 –

Page 6

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ...................................................1-2

HOW TO CARRY THE SEWING MACHINE ...............................................3

GROUNDING INSTRUCTIONS ...................................................................4

Specications ...............................................................................................6

Accessories ..................................................................................................6

Principal Parts ..............................................................................................7

Name and Function of each component..................................................8-12

Winding the bobbin ................................................................................13-16

Attaching the needle ................................................................................... 16

Threading the machine ............................................................................... 17

Adjusting the thread tension ..................................................................18-19

Presser foot lifting lever .............................................................................. 19

Setup and operation ..............................................................................20-27

Maintenance ............................................................................................... 28

Maintenance and lubrication..................................................................28-29

Troubles and Corrective Measures ............................................................30

– 5 –

Page 7

Specications

Description Specication

Sewing speed Max. 2,200 sti/min

Needle bar stroke 35 mm

Lift of presser foot 4.5 mm

Needle GB 134R

Lubricating oil New Defrix Oil No.1

Dimensions of sewing machine 22.2W x 46.0H x 73.0L (cm)

Weight of sewing machine 26 kg

Rated power supply / Power consumption AC100V-AC240V/1.2A-0.8A, 50/60Hz

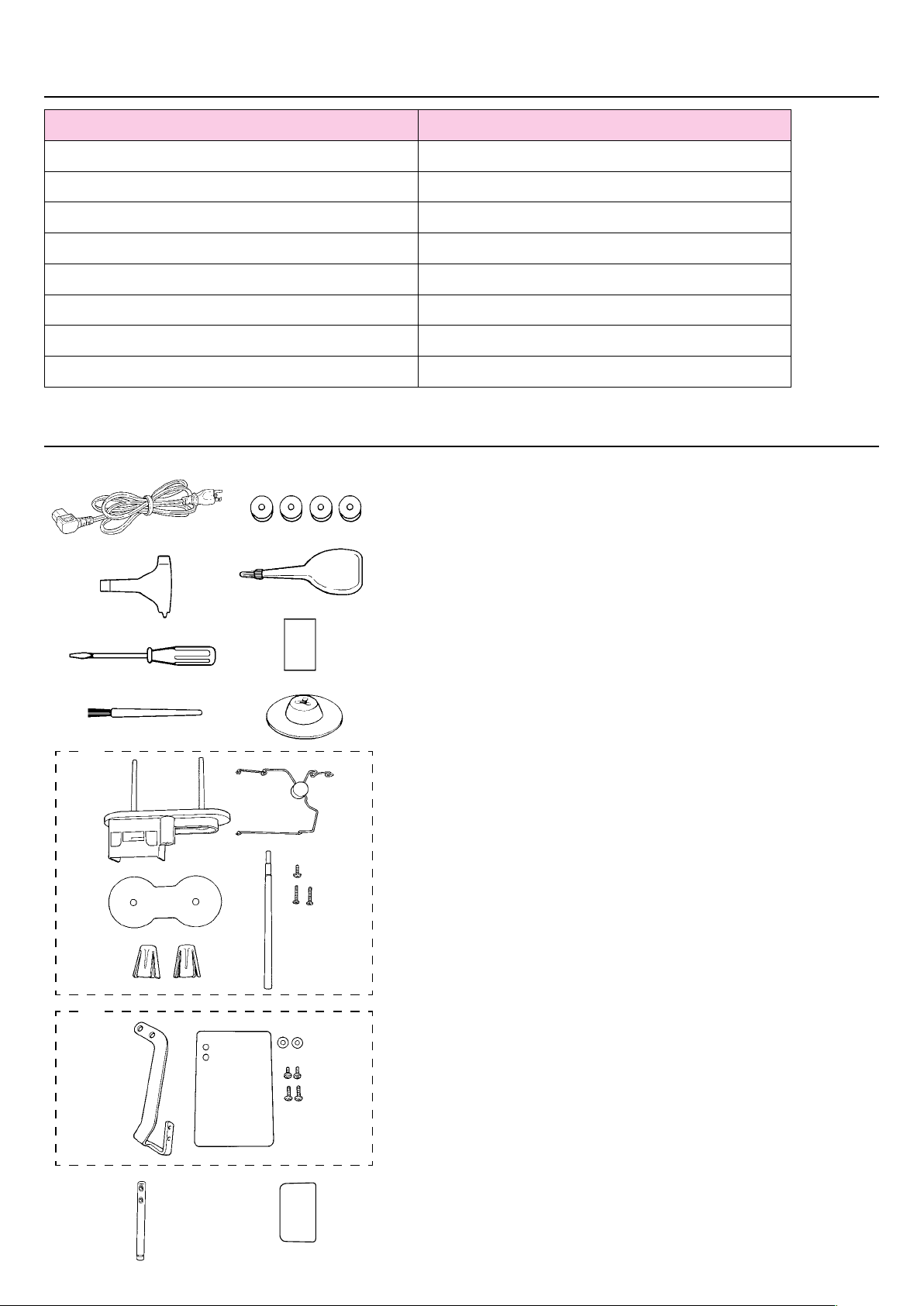

Accessories

1

2

5

6

7

3

4

8

9

1. Power cord

2. Exclusive screwdriver

3. Screwdriver (medium)

4. Cleaning brush

5. Bobbins (4pcs.)

6. Oilcan

7. Needles (GB 134R #18)

8. Spool cap

9. Thread stand components

(Spool holder disk, thread stand thread guide, bobbin winderspool

holder disk, bobbin winder seat, bobbin winder side anchors(two

pieces), setscrew (large), setscrews (small) (two pieces))

10. Eye protection cover components

(Safety plate, safety plate mounting plate, washers (two

pieces),setscrews (large) (two pieces), setscrews (small) (two

pieces))

11. Thread guide pin

12. Blind seal (Spare)

10

11 12

– 6 –

Page 8

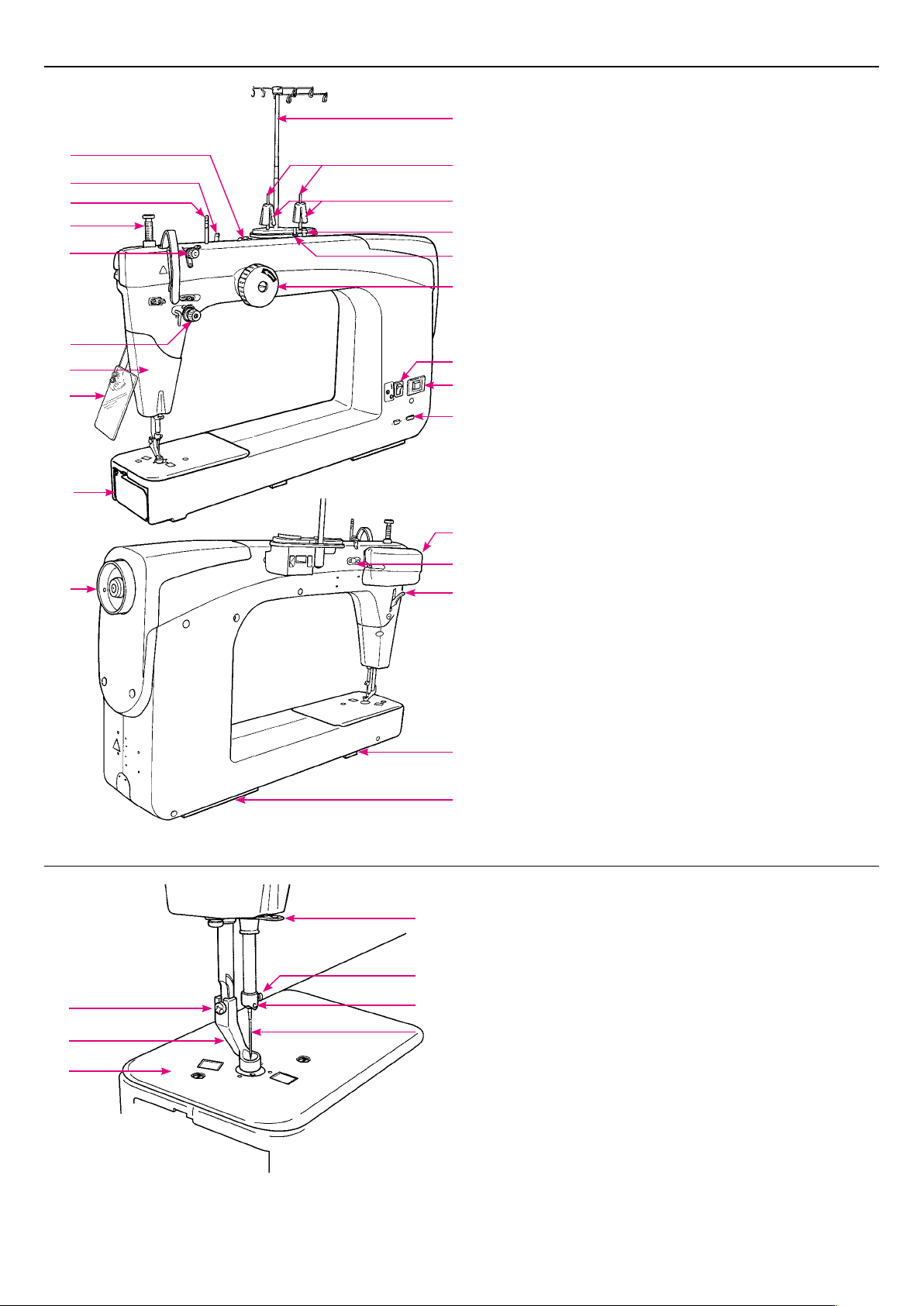

Principal Parts

1

2

15

3

17

4

5

16

22

18

7

8

9

10

11

6

12

13

20

19

21

14

1. Thread trimmer retaining plate

2. Thread guide base

3. Presser foot pressure regulator

4. Thread tension dial

5. Lamp (built-in type)

6. Hand pulley

7. Bobbin winder

8. Spool holder disk

9. Bobbin winder side anchor

10. Bobbin presser

11. Bobbin winding shaft

12. Power switch

13. Inlet of electric power cord

14. Presser foot lifting lever

15. Thread guide pin

16. Eye protection cover

17. Tension controller No. 1

18. Hand wheel

19. Presser regulator cover

20. Stitch regulator connection connector

21. Panel junction cable connection connector

22. Hook cover

23. Connecting plate (large)

24. Connecting plate (small)

24

23

1. Screw in the presser foot

2. Presser foot

7

3. Throat plate

4. Needle clamp

4

5. Needle bar thread hook

6. Needle

1

2

5

7. Needle bar thread guide

6

3

– 7 –

Page 9

Name and Function of each component

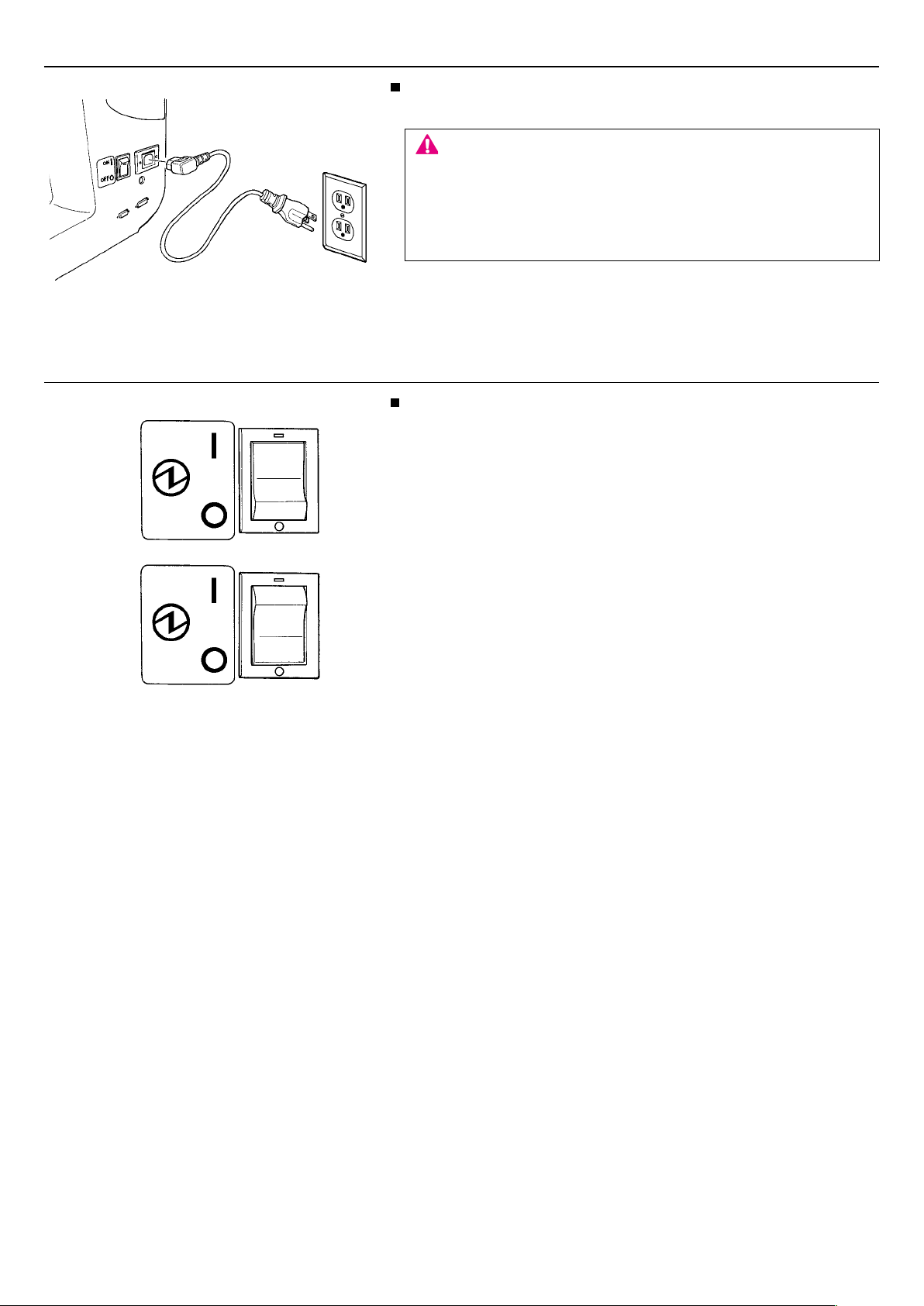

Power cord

Insert the electric power cord plug into the corresponding inlet.

CAUTION

Turn OFF the power switch before insertion/removal of any cords

and any plugs.

Perform these following steps before you are not using your sewing

machine.

1. Turn OFF the power switch.

2. Remove the power plug from the wall outlet.

Power switch

Turn ON the machine, set the power switch to ”I”.

Turn OFF the machine, set the power switch to ”O”.

ON

OFF

– 8 –

Page 10

❻

❺

❹

❸

❷

❶

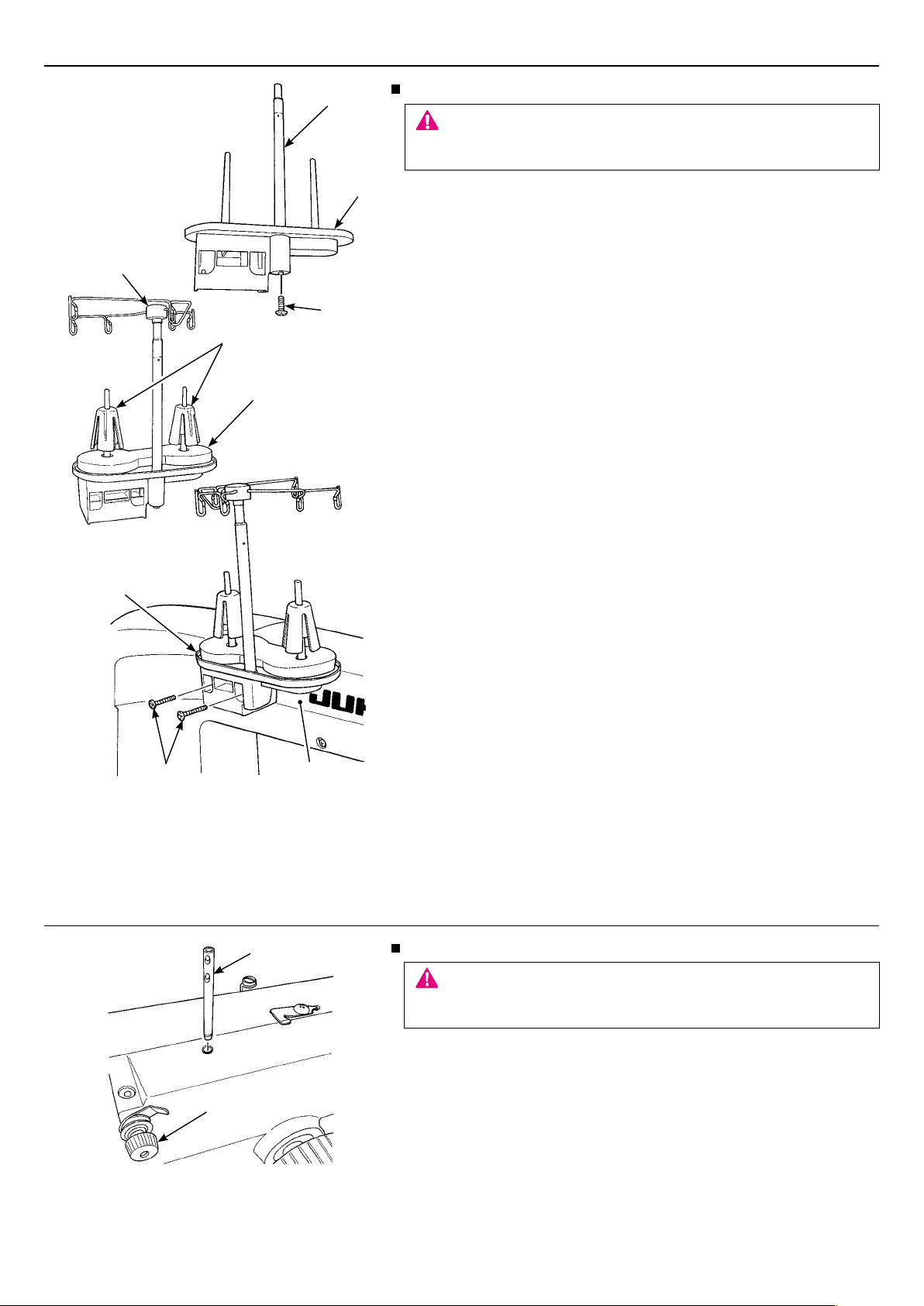

Installing the thread stand

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

1. Insert bobbin winder spool holder disk ❷ into spool holder ❶. Fix

the former with setscrew ❸.

2. Set bobbin winder seat ❹ and two anti-vibration cones ❺ on

spool holder ❶.

3. Set thread stand thread guide ❻ on the top of bobbin winder

spool holder disk ❷.

4. Install thread stand ❼ on frame ❾ with two setscrews ❽.

❼

❽

❶

❾

Installing the thread guide

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

❷

Insert thread guide pin ❶ into the frame with the holes in the pin faced

to tension controller No. 1 ❷. Pat the top of the thread guide pin with

the handle of screwdriver to prevent the pin from slipping off easily.

– 9 –

Page 11

❸

❷

❶

Panel cord binding procedure

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

Remove two setscrews from the presser regulator cover.

❶

Remove the presser regulator cover.

Arrange the panel cord as illustrated in the gure. Then, secure

❷

the cable with a cable clip band.

It is necessary to place the panel cord at a position where the cord

does not come in contact with the mechanical parts.

Align the notch in the cover with the panel cord.

❸

Fix the presser regulator cover with the setscrews.

❹

❺

❻

❶

❹

❷

❸

❹

Installing the eye protection cover

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

DANGER

Be sure to install the eye protection cover since the cover protects

eyes from being injured by a fragment of a broken needle.

1. Place eye protection cover ❷ and washer ❸ in the written order

on eye protection cover mounting plate ❶ and x them with set-

screw ❹.

2. Install eye protection cover mounting plate ❶ on frame ❻ with

two setscrews ❺.

– 10 –

Page 12

Decrease

Diminution

Disminuye

❷

❸

Minimum clearance between the throat plate

and the presser foot: 0.5 mm (at the time of

shipment)

Increase

Augmentation

Aumenta

❶

Presser foot pressure regulator and its indicator

CAUTION

Turn OFF the power switch.

Turning the presser foot pressure regulator adjusts the pressure of

the presser foot.

Adjusting the presser foot height

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

If the sewing machine does not smoothly run because of the material

thickness, it is necessary to change the presser foot height.

Bring needle bar ❶ to the lowest point end. Loosen setscrew ❷ and

adjust the height of presser foot ❸. The minimum clearance be-

tween the throat plate and the presser foot has been factory-adjusted

to 0.5 mm at the time of shipment.

* Adjust the presser foot height so that an approximately 0.5

mm clearance is provided between the material and the

presser foot sole.

CAUTION

If the upper position of the presser foot is too high, stitches cannot

be formed.

– 11 –

Page 13

Stoke is

increased

Stroke is

decreased

❶

❷

❶

❸

Upper position:

Stroke is 1.8 to 3.5

mm

Lower position:

Stroke is 3.5 to 5

mm

Adjusting the presser foot stroke

It is possible to adjust the presser foot

stroke.

Remove presser regulator cover.

Loosen nut ❶. Shift block ❷ upward

to increase the stroke, or downward to

decrease it.

To increase the stroke more, change the

position of setscrew ❸ of the link arm to

the lower position (stroke: 3.5 to 5 mm).

The setscrew has been factory-set at

the upper position (stroke: 1.8 to 3.5

mm) at the time of shipment.

After the completion of the adjustment,

install the presser regulator cover which

you have removed before the adjust-

ment.

CAUTION

When the stroke is changed, the

clearance between the presser foot and

the throat plate will change. Re-adjust

the presser foot height to a value

which matches the material thickness.

❶

❷

CAUTION

Turn OFF the power switch.

Always must be disconnected plug

from socket-outlet.

Handwheel

CAUTION

Keep hand away from the handwheel while the sewing machine is

running.

Push and turn the Hand pulley to turn the main shaft.

❶

Red marker dot (A) is in the front side: It is used as the marker dot

❷

at the time of lubricating.

A

– 12 –

Page 14

Winding the bobbin

spool cap

in place

❸

Thread stand

thread guide

❺

Bobbin winder

side anchor

Spool holder

disk

Thread guide base

❹

Bobbin winder

❶

Positioning latches

❷

Bobbin presser

Bobbin winding shaft

Thread trimmer retaining plate

1

Installing the thread guide.

CAUTION

Turn OFF the power switch.

Raise the bobbin winder fully, turning slightly until the positioning latches engage.

❶

Set the large spool over the bobbin winder side anchor

❷

Set the household-type thread onto the spool holder disk and then insert a spool cap in place.

❸

To set a large-diameter spool, set the bobbin winder side anchor upside down to stabilize the spool.

❹

Pass the thread coming from the spool on the thread guide pin (rod) just above the spool.

❺

.

– 13 –

Page 15

2

3

Hook cover

CAUTION

Keep hand away from the handwheel while the sewing machine is running.

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

Take out the bobbin case.

Bring up the needle. Take out the bobbin case.

Take out the bobbin from the bobbin case.

Snap in the latch to let the bobbin come out of the bobbin case.

4

5

❷

❶

Thread the thread guide base.

Installing the bobbin.

Wind thread on the bobbin clockwise by several turns.

❶

Place the bobbin on the bobbin winding shaft.

❷

Press the bobbin presser.

❸

Thread is automatically wound on the bobbin.

❸

– 14 –

Page 16

6

Upon completion of winding the bobbin.

Return the bobbin presser to its home position. Take out the bobbin.

Trim the thread with the thread cutting knife.

7

Thread passage

Thread tension

spring

5cm

* The bobbin should run clockwise.

Loading the bobbin into the bobbin case

Snap in the bobbin case latch, and put the bobbin into the bobbin case so that

the bobbin runs clockwise.

Passing the thread through the slit of the bobbin case, continue passing it under

the thread tension spring, and pull out the thread open end about 5cm from the

bobbin case.

.

8

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

Set the bobbin in the sewing machine.

Insert the bobbin case fully into the hook, and close the bobbin case latch.

– 15 –

Page 17

Adjusting the thread guide base

Good

Thread unevenly wound around the bobbin would badly affect the bobbin thread tension.

Thicker toward downside

Loosen the screw of the thread

guide base to make adjust-

ment.

Loosens

Move up

Thicker toward upside Move down

Attaching the needle

Attaching the needle

CAUTION

Turn OFF the power switch.

1. Turn OFF the power switch.

2. Lower the presser foot.

3. Move the needle bar up to the highest position of its

stroke.

4. Holding a needle with its long groove faced to the

left, insert the needle into the needle bar until it will

go no further. Then, tighten the needle clamp screw.

Tightens

Needle with

a round shank

Needle clamp screw

Tightens

Loosens

Scarf

Checking the needle

Flat plate

Parallel

Due to the position of the machine in both the frame and sit

down table, the scarf goes to the back and the groove to the

front.

Check the needle for its straightness occasionally. Any defective needle

would cause needle breakage, stitch skipping, thread breakage or

damage to materials.

– 16 –

Page 18

Threading the machine

CAUTION

Thread take-up

❽

❾

❼

❺

❻

Turn OFF the power switch before threading or passing thread.

❶

❷

❸

❹

* Bring the thread take-up ❼ to the upper end of its stroke.

Then, pass the thread through it.

1

2

❽

❼

❺

❻

❹

❶

❷

Pass the thread through

the thread guide ❶.

Thread the machine head

in numerical order, ❷ to

.

❽

❸

Thread tension disk

3

Pass the thread through

the thread guides ❾ and

.

❾

Thread the needle .

Pass the thread through the clearance

between the two thread tension disks.

– 17 –

Page 19

Adjusting the thread tension

CAUTION

Turn OFF the power switch before taking out the bobbin case or replacing the needle.

· Adjusting the bobbin case

Tension adjusting

screw

·

Proper thread tension

Improperly adjusted thread tension may cause

puckering on materials, inferior stitches, or

thread breakage.

Increase

Decrease

Needle thread

As a measure of the thread tension applied by the bobbin case, when

a bobbin (Cotton TEX40) is loaded in the bobbin case, the bobbin

should slowly drop by its own weight as illustrated in the gure.

* Adjust the needle thread tension in accordance with the bobbin

thread tension.

* The bobbin case for the J-350QVP is an exclusive JUKI part. Please

consult the JUKI dealers when you purchase it.

The needle thread tension is too low

Needle thread

Thread tension dial

Bobbin thread

Increase the needle

thread tension.

Center of the

material

Bobbin thread

The needle thread tension is too high

Needle thread

Bobbin thread

Decrease the needle

thread tension.

– 18 –

Page 20

Tension controller No. 1

When tension nut No. 1 ❶ is turned to the right A, the remaining length

of thread after thread trimming is shortened. When it is turned to the left B,

❶

B

A

the remaining length of thread is lengthened.

*

Be sure to carry out back tacking by several stitches at the beginning of sewing.

Tabulated relationship between material, thread and needle

Material Thread Needle

A&E

Cotton broadcloth *2 + felt

Cotton broadcloth *2 + felt

* Be sure to check the relationship between the material and the needle or thread by carrying out trial stitching on a waste

piece of the cloth to be sewn.

* Decrease the sewing speed when using frictional thread such as the metallic thread.

* Depending on the type of thread and the direction of the stitch, the thread may not be cut by the automatic thread cutting

device of the sewing machine.

In that case, please trim the thread after stitching 2 to 3 needles from the back side of the fabric to the front side.

Signature Machine Quilting Thread (cotton)

TEX40

YLI

Machine Quilting Thread (cotton)

TEX40

#18

#18

Presser foot lifting lever

❷

❶

❷

❶

Presser foot lifting lever

The presser foot can be up or down position by using the presser

foot lifting lever.

Lowered position .......

❶

Upper position ...........The position of the presser foot during

❷

* Be careful that the presser foot and the needle should not interfere

when the needle is in down position and the presser foot is raised

to the extra lift position.

Presser foot should be lowered when sewing.

placement/removal of a sewing product on/

from the sewing machine.

– 19 –

Page 21

Setup and operation

Basic Operating Procedures

Stand-up type

Sit-down type

Select the operation usage on the LCD screen operation panel

The J-350QVP is installed with JUKI SMART STITCH.

Select the standing-use type by pressing button, or the

sitting-use type by pressing button.

Furthermore, the maximum sewing speed and ON/OFF of the

automatic thread trimming at the end of sewing can be set on the

operation panel.

For details,

please refer to the "Stitch Regulator User Manual".

[ JUKI SMART STITCH ]

This is the function for remaining the stitch length at the preset value by means of the sensor which reads the movement of

the material. ( Hereinafter referred to as "JSS". )

* Refer to the following for

the TL-2200QVP.

* Quilt sandwiches should cover both sensors which are built in at throat

plate.

* Precision of sensors may be lowered, depending on the materials to be

quilted.

Sensor

Sensor

– 20 –

Page 22

<1. Stand-up type>

Setting the maximum Sewing Speed

①

You can set the maximum sewing speed in 5% increments.

Setting the Stitch Mode

②

・ Cruise Stitch Mode

When you press the "start button" on the right handlebar, the

machine will sew at the minimum sewing speed that has been

set.

When you move the sewing machine by the handles, the

machine will sew automatically with a sewing speed so that

the set "Stitch per Inch" (SPI) can be maintained.

If you do not operate the sewing machine for a certain

*

period of time, the sewing machine will automatically stop

sewing.

Baste Stitch Mode

・

When you press the "start button" on the right handlebar and

move the sewing machine by the handles, it will sew with the

stitch length that has been set.

If you do not operate the sewing machine for a certain

*

period of time, the sewing machine will automatically stop

sewing.

Precise Stitch Mode

・

When you press the start button on right handle bar, green

light at JSS will indicate machine is on.

When you begin to move the machine the needle will move

creating a continuous even stitch. When you move the sewing

machine by the handles, the machine will automatically sew a

constant stitch length according to the distance moved.

If you do not operate the sewing machine for a certain

*

period of time, the sewing machine will automatically stop

sewing.

– 21 –

Page 23

Manual Stitch Mode

・

When you press the "start button" on the right handlebar, the

machine will sew at the sewing speed that has been set.

* Non-regulated mode. JSS does not function.

Trimming Thread

③

When you press this button, Upper and lower threads are

trimmed automatically.

Auto Thread Trimming

④

When the sewing machine is stopped, the automatic thread

trimmer is engaged trimming both upper and lower threads.

* Start sewing.

In a "stand-up" setup, you can stitch by moving the machine.

If the material sags, the sewing machine will fail to form

*

stitches at regular intervals.

Set the material between the quilting frames so that it is

adequately tensed.

– 22 –

Page 24

When you press the "start button" on the right handlebar, the

sewing machine will start sewing according to your settings.

When you press the "start button" again, the sewing machine will

stop sewing.

CAUTION

Don’t put any heavy objects on the quilting frame and don’t put

・

a load heavier than normal sewing.

Be careful of surrounding people and objects since you move

・

the machine and sew.

If you move the assembled quilting frame, some parts may be

・

damaged or bent.

When moving the quilting frame, disassemble it, and then reas-

semble it correctly after it has been delivered.

* Use the screwdriver included with the sewing machine to re-

move any hazardous sharp shavings from the disassembled

quilting frame and other components, as there is a risk of injury

from such hazardous sharp points.

❸

❶

❷

❹

❻

❺

The following functions can be assigned to the left button using the

custom switch/pedal switch.

Thread trimmer ........................

❶

Needle travel up/down

❷

............ Needle is moved by a half stitch

Thread trimming is carried out

(i.e., needle goes up or comes down)

(Initial setting)

One stitch

❸

(without thread trimming)........ One stitch is sewn

One stitch Thread trimmer .....One stitch is sewn. Then, thread

❹

trimming is carried out.

Two stitch Thread trimmer ...... Two stitches are sewn. Then,

❺

thread trimming is carried out.

Three stitch Thread trimmer ... Three stitches are sewn. Then,

❻

thread trimming is carried out.

– 23 –

Page 25

<2. Sit-down type>

Setting the maximum Sewing Speed

①

You can set the maximum sewing speed in 5% increments.

Setting the Stitch Mode

②

Cruise Stitch Mode

・

When you depress the foot controller, the machine will sew at

the minimum sewing speed that has been set.

When you move the material, the machine will sew

automatically with a sewing speed so that the set "Stitch per

Inch" (SPI) can be maintained.

Baste Stitch Mode

・

When you depress the foot controller and move the material,

the machine will form stitches with the stitch pitch that has

been set.

・ Precise Stitch Mode

When you press the foot control, the green light at JSS will

indicate machine is on.

When you begin to move the fabric the needle will move

creating a continuous even stitch.

Manual Stitch Mode

・

When you depress the foot controller, the machine will sew at

the sewing speed that has been set.

* Non-regulated mode. JSS does not function.

– 24 –

Page 26

Trimming Thread

③

When you press this button, threads are trimmed automatically.

Auto Thread Trimming

④

When the sewing machine is stopped, the automatic thread

trimmer operates.

B

A

Operation and needle up/down operation

⑤

When you press part A of the foot controller (pedal), the sewing

machine will start sewing.

The sewing machine sews at a faster speed according to the

amount that part A is pressed.

When you release your foot from part A, the machine will stop.

When you get your foot off of A section, the sewing machine

stops running. When you place your foot on B section, the

needle moves up and down.

* Start sewing.

While pressing the foot controller (pedal), move the fabric to form

stitches.

CAUTION

* While sewing, don’t pull or push the fabric with force, as it will

cause the needle to break or cause injuries.

The following function can be assigned to the operation step that

is activated by depressing the foot controller to B side, using the

custom switch/pedal switch.

❸

❶

❷

❹

❻

❺

Thread trimmer

❶

Needle travel up/down

❷

....................... Thread trimming is carried out

............

Needle is moved by a half stitch

(i.e., needle goes up or comes down)

One stitch

❸

(Initial setting)

(without thread trimming)........ One stitch is sewn

One stitch Thread trimmer .....One stitch is sewn. Then, thread

❹

trimming is carried out.

Two stitch Thread trimmer ...... Two stitches are sewn. Then,

❺

thread trimming is carried out.

Three stitch Thread trimmer ... Three stitches are sewn. Then,

❻

thread trimming is carried out.

– 25 –

Page 27

・ Setting the Foot Pedal

When you depress the pedal, the sewing machine runs. When

you release the pedal, the sewing machine stops.

・ Kick ON/OFF function

Using the on/off function.

Depress and release pedal to activate JSS.

Depress and release pedal again to deactivate JSS.

In the case the sewing machine is held in the stop state

*

for a while after having set the KICK to the ON state, the

KICK will be automatically turned OFF.

When the JSS is in the ON state, the automatic thread

*

trimmer and pedal switch will not operate.

<Common settings for the stand-up type and sit-down type>

・ Calculator function

Simple calculation is possible.

– 26 –

Page 28

・ Bobbin Estimate Setting function

Details of the bobbin estimate can be set.

1) Inputting the bobbin thread length

● In the case of inputting a rough amount

Find the rough amount of thread you use in the table shown

below according to the type and thickness of the thread.

Then, set that thread amount.

2) Inputting the bobbin thread amount at the time of reset

Assume the estimate of thread wound on the bobbin with

respect to the thread amount that is fully wound of the

bobbin. Then, input the percentage of the thread amount of

fully-wound bobbin.

(Thread amount of fully-wound bobbin is assumed to be 100

%.)

The bobbin estimate counter (in %) is displayed on the bobbin

estimate counter icon.

If the estimate of thread becomes 20 % or less, the percentage is

displayed in red on the bobbin estimate counter icon.

When using the bobbin estimate counter, see the table given

below for the amount of thread of a fully wound bobbin.

The thread amount varies depending on the type of

*

thread. Use the table for rough indication.

J-350QVP Bobbin estimate counter (Rough indication) (Reference)

Thread amount of a fully-wound bobbin

This is the amount of thread fully wound on a bobbin when the bobbin estimate counter is used.

The thread amount varies depending on the type of thread. Use the table for rough indication.

*

Name Material m Yard

A&E

1

Signature Machine Quilting Thread

TEX40

YLI

2

Machine Quilting Thread

TEX40

FLORIAN

3

Quilting THREAD

TEX40

SUPERIOR

4

THREADS KING TUT

TEX40

cairo quilt

5

TEX35(#50)

Ⅰ

Cotton 55 60

Cotton 45 49

Cotton 45 49

Cotton 45 49

Cotton 55 60

MACHINE QUITING &CRAFTS

6

Multicolor MERCERIZED COTTON

TEX50

SULKY

7

Premium 30wt. Lighter

glide

8

No.40

Cotton 50 55

Cotton 55 60

Polyester 90 98

– 27 –

Page 29

Maintenance

❹

❷

❶

Replacing the blind seal

CAUTION

Turn OFF the power switch.

Always must be disconnected plug from socket-outlet.

1. Remove two setscrews ❷ and ❸ from LED cover ❶. Then, the

LED cover can be lowered.

2. Rip off the stained blind seal. Put new blind seal ❹ in place.

❸

Maintenance and lubrication

CAUTION

Always must be disconnected plug from socket-outlet before cleaning or lubricating the sewing machine.

Cleaning the hook

Turn OFF the power switch. Remove the needle.

Loosen the screws to remove the throat plate.

Then clean up the hook components using a cleaning brush.

– 28 –

Page 30

Cleaning the sensor

Sensor

Sensor

Lubricating the machine

CAUTION

Avoid the use of alcohol, benzene, thinner, etc. for cleaning the

sensor.

Wipe the lens surface clean with a piece of soft dry cloth approxi-

mately once a day.

1

Bring the red marker dot to the right front.

CAUTION

1. If oil gets in eyes, immediately rinse the oil

out with water. If you swallow oil by mistake,

immediately consult a medical doctor.

2. Keep this machine away from children.

3. Waste oil disposal is legally obliged. Dispose of

the waste oil according to the relevant legislation.

2

The sewing machine can be lubricated in two different methods. Select one of the two methods for lubrication.

1

1. Apply one or two drops of oil to the hole indicated by the arrow.

1. Lubricate the machine after removing the bobbin case.

2

2. Apply one or two drops of oil to the arrowed sections shown in the gure.

Use the machine oil (New Defrix Oil No.1 or similar) supplied with the machine.

After the lubrication, turn the handwheel by hand to allow the oil to spread in the whole hook.

For daily use, lubricate the sewing machine once a day.

After unpacking or after the sewing machine remained unused for an extended period of time, apply a larger quantity

of oil (ve to seven drops) than usual. If the quantity of oil is excessive, oil can drop on the material. Take care not to

apply an excessive quantity of oil to the needle bar and the hook section.

After the lubrication, carry out trial stitching without exceptions.

After the lubrication, wipe off the oil remaining on the throat plate surface.

Take care to keep the oil off of the sensor portion.

If the lens is stained with oil, wipe off the oil of the lens with a piece of soft cloth.

CAUTION

Avoid the use of alcohol, benzene, thinner, etc. for cleaning the sensor.

– 29 –

Page 31

Troubles and Corrective Measures

If sewing difculties occur, make sure the instructions are correctly followed. If a problem still exists, the reminders below

help to solve it.

If the sensor fails, the error message will be displayed.

(Error message indicates which sensor has failed.)

If the error message is displayed, please contact your distributor.

Troubles Case Corrective measures Page

Stitches are

skipped.

Needle thread

breaks.

The bobbin thread

breaks.

The needle

breaks.

Stitches are puckered.

Stitch performance is bad.

The rotation noise

is too heavy or

too high.

The handwheel

does not rotate

smoothly or does

not turn.

The sewing

machine cannot

perform sewing at

the beginning of

sewing.

1. The needle is bent or the needle point is

blunted.

2. The needle has not been attached to the

needle bar properly.

1. The machine head has been threaded

incorrectly.

2. The needle thread tension is too high or

low.

3. The needle is bent or the needle point is

blunted.

4. The needle is not suited to the thread

used.

1. The bobbin thread tension is too high.

2. The rubbing of the bobbin case spring

has produced a slot.

3. Scratches on the needle hole in the throat

plate.

1. The needle is bent or has been installed

improperly.

2. The needle hits the throat plate or the

presser foot.

1. The tension of the needle thread is not

balanced with that of the bobbin thread.

2. When the combination of the needle and

the thread is improper.

3. The needle is too thick for the material.

1. The tension of the needle thread is not

balanced with that of the bobbin thread.

1. Thread wastes accumulate in the hook.

1. The thread is entangled and caught in the

hook.

1. Remaining length of thread is shorter.

2. Back tacking has not been carried out.

Replace the needle.

・

Attach the needle properly to the nee-

・

dle bar.

Correct the threading.

・

Properly adjust the thread tension.

・

Replace the needle.

・

Replace the needle by the one suited

・

to the thread used.

Decrease the tension.

・

Replace the bobbin case.

・

Replace the throat plate.

・

Replace or correctly attach the needle.

・

Correctly position the needle, throat

・

plate, or presser foot.

Balance the tension.

・

Properly correct the combination of

・

needle and the thread.

Replace the needle by the one suited

・

to the material.

Balance the tensions. 19

・

Clean up the sewing machine. 28

・

Lubricate the hook, strongly turn the

・

handwheel clockwise and counterclockwise several times, then remove

the thread caught in the hook.

Loosen the tension controller No. 1

・

(turn to the left) to increase the remaining length of thread after automatic

thread trimming.

Draw thread through the needle eyelet

・

to adjust the remaining length of thread

to approximately 5 cm.

B

e sure to carry out back tacking by

・

several stitches at the beginning of

sewing.

16

16

17

18

16

16

18

-

-

16

-

18

19

16

-

19

-

19

– 30 –

Page 32

2-11-1,TSURUMAKI,TAMA-SHI,

TOKYO,206-8551,JAPAN

PHONE

FAX

: (81)42-357-2341

: (81)42-357-2379

Copyright © 2018 JUKI CORPORATION.

• All rights reserved throughout the world.

000918

Loading...

Loading...