Page 1

IP-420

INPUT INSTRUCTION MANUAL

Page 2

CONTENTS

1. START AND END OF THE BODY INPUT MODE ................................................ 1

1-1. Move to the body input mode ............................................................................................. 1

1-2. Return to the normal sewing mode ................................................................................... 4

2. BASIC OPERATION AND DISPLAY ....................................................................5

2-1. Common button ................................................................................................................... 5

2-2. Body input mode standard screen .................................................................................... 6

2-3. Selection of function ......................................................................................................... 10

2-4. Input the numeric value .................................................................................................... 11

2-5. Specifying the position ..................................................................................................... 12

3. EXAMPLE OF OPERATING PROCEDURE ....................................................... 14

3-1. Pattern input ...................................................................................................................... 14

3-2. Trial sewing ........................................................................................................................ 17

3-3. Modication of the pattern ............................................................................................... 18

3-4. Pattern writing ................................................................................................................... 21

3-5. Pattern reading .................................................................................................................. 22

4. INPUT OF PATTERN ..........................................................................................23

4-1. Ordinary sewing ................................................................................................................ 23

(1) Jump feed (020) ............................................................................................................................... 23

(2) Linear ordinary sewing (023) ...........................................................................................................25

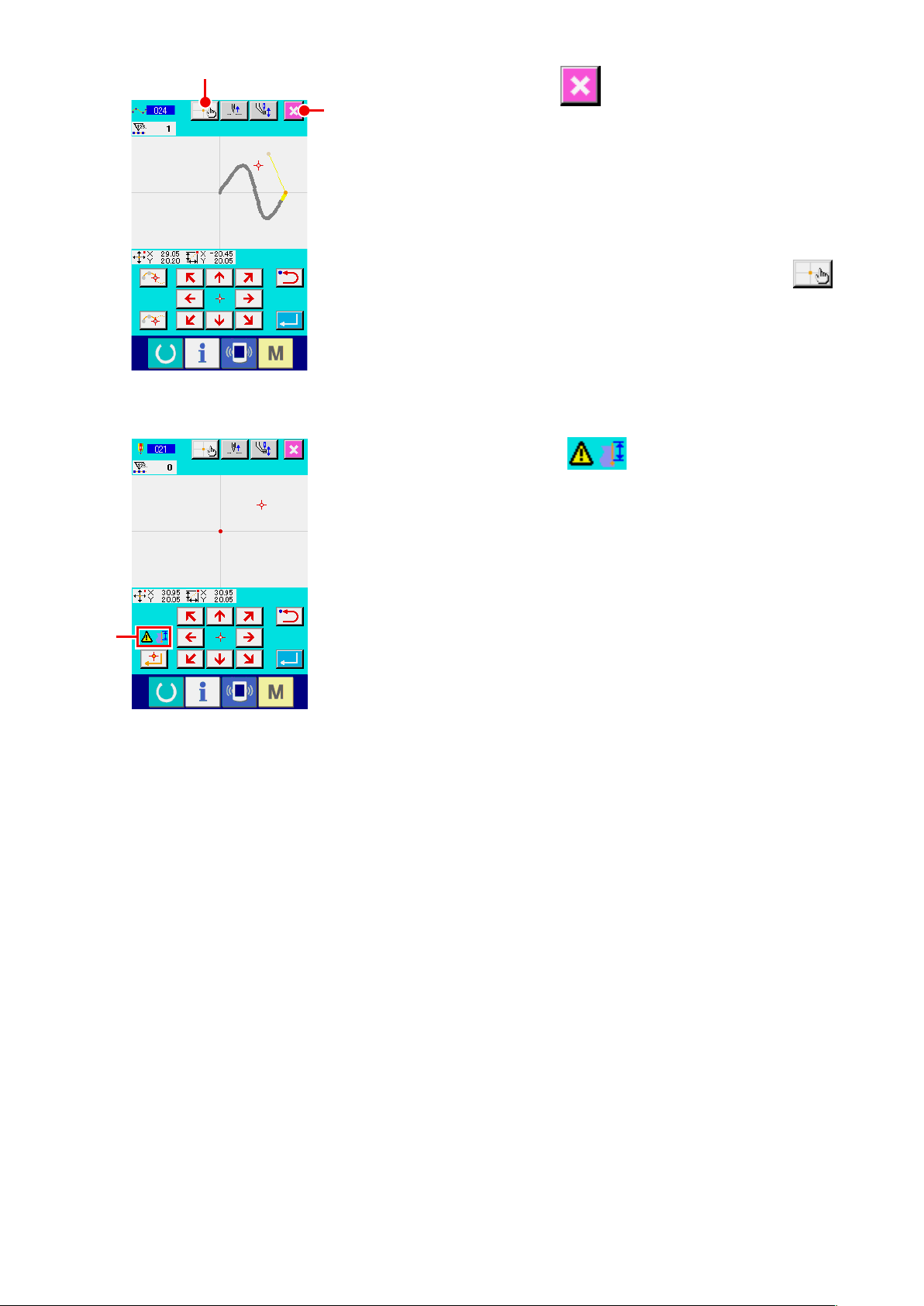

(3) Spline ordinary sewing (024) ...........................................................................................................27

(4) Arc ordinary sewing (025) ................................................................................................................29

(5) Circle ordinary sewing (026) .......................................................................................................... 30

(6) Point sewing (021) ........................................................................................................................... 31

(7) Ordinary sewing (022)......................................................................................................................32

4-2. Zigzag sewing (030 to 033) ............................................................................................... 33

4-3. Offset sewing (034 to 037) ................................................................................................ 35

4-4. Double sewing ................................................................................................................... 37

(1) Double orderly sewing (040 to 043) ................................................................................................. 37

(2) Double reverse sewing (044 to 047) ................................................................................................ 39

(3) Overlapped reverse sewing (050 to 053) ......................................................................................... 40

4-5. Machine control command ............................................................................................... 42

(1) Thread trimming (001) .....................................................................................................................42

(2) The 2nd origin (002) .........................................................................................................................42

(3) Stop (003) ........................................................................................................................................ 43

(4) One revolution of sewing machine (006) .........................................................................................44

(5) Mark 1 and mark 2 (008, 009)..........................................................................................................45

(6) Thread tension controller No. 3 (007) .............................................................................................45

(7) Delay (010) ......................................................................................................................................46

(8) External input (011) .......................................................................................................................... 46

(9) External output (012) .......................................................................................................................47

i

Page 3

(10) Enlargement/reduction reference point (004) ................................................................................48

(11) Inversion point (005) ...................................................................................................................... 49

(12) Thread tension setting (014) .......................................................................................................... 50

(13) Intermediate presser height setting (018) ...................................................................................... 51

(14) Area Classication (016) ................................................................................................................52

(15) Sewing machine stop (019) ...........................................................................................................53

(16) Machine control command deletion (059) ...................................................................................... 54

(17) Sewing speed (092) ....................................................................................................................... 54

4-6. Automatic back-tack (064) ................................................................................................ 55

4-7. Condensation sewing (065) .............................................................................................. 56

4-8. Overlapped sewing (066) .................................................................................................. 57

4-9. Breakpoint (spline and ordinary sewing) ........................................................................ 58

5. MODIFICATION OF THE PATTERN ................................................................... 61

5-1. Point modication ............................................................................................................. 61

(1) Point deletion (070 and 074) ............................................................................................................ 61

(2) Point move (071 and 075)................................................................................................................63

(3) Point adding (076)............................................................................................................................65

5-2. Vertex modication ........................................................................................................... 67

(1) Vertex deletion (072 and 077) ..........................................................................................................67

(2) Vertex move (073 and 078).............................................................................................................. 68

5-3. Element deletion (063) ...................................................................................................... 69

5-4. Jump feed speed change (060) ........................................................................................ 70

5-5. Sewing speed section change (061) ................................................................................ 71

5-6. Sewing pitch change (062) ............................................................................................... 72

5-7. Symmetry ........................................................................................................................... 73

(1) X-axis symmetry (082) ..................................................................................................................... 73

(2) Y-axis symmetry (083) ..................................................................................................................... 73

(3) Point symmetry (084) ....................................................................................................................... 74

(4) Y symmetry pattern inversion orderly sewing (098) ......................................................................... 74

5-8. Shape point modication .................................................................................................. 75

(1) Shape point adding (135).................................................................................................................75

(2) Shape point move (136)...................................................................................................................77

(3) Shape point deletion (137) ............................................................................................................... 78

6. PATTERN OPERATION ...................................................................................... 80

6-1. Pattern copy (086) ............................................................................................................. 80

6-2. Pattern move (085) ............................................................................................................ 81

6-3. Pattern erase (087) ............................................................................................................ 82

6-4. Pattern reading .................................................................................................................. 83

(1) Read the pattern data ...................................................................................................................... 83

(2) Set the enlargement/reduction ratio ................................................................................................. 85

(3) Set the kind of reading data ............................................................................................................. 87

6-5. Pattern writing ................................................................................................................... 89

(1) Write the pattern data ......................................................................................................................89

ii

Page 4

7. FORMATTING MEDIA (090) ............................................................................... 90

8. TRIAL SEWING ..................................................................................................91

8-1. Preparing the trial sewing ................................................................................................. 91

8-2. Performing the trial sewing .............................................................................................. 93

9. SETTING FUNCTION .........................................................................................95

9-1. Comment input .................................................................................................................. 95

9-2. Clamp inversion setting (091) .......................................................................................... 96

9-3. Thread tension reference value setting (113) ................................................................. 96

9-4. Intermediate presser height reference value setting (115) ............................................ 97

10. SELECTING ENDING PROCEDURE (110) ...................................................... 98

11. ALLOCATING FUNCTIONS TO F1 THROUGH F5 BUTTONS (112) .............. 99

12.

DISPLAYING DETAILED INFORMATION ON THE SET VALUE (093) ................ 101

13. DISPLAYING DETAILED INFORMATION ON THE CURRENT NEEDLE

POSITION ....................................................................................................... 103

14. PERFORMING SETTING OF DISPLAY ......................................................... 105

15. ELEMENT FORWARD/BACKWARD (130 and 131) ...................................... 109

16. DIRECT INSTRUCTIONS BY TOUCHING THE SCREEN ............................. 110

16-1. Coordinate direct instructions ..................................................................................... 110

16-2. Needle entry/shape points direct instructions ........................................................... 112

17. PERFORMING SETTING OF THE MEMORY SWITCH DATA ....................... 113

17-1. Setting of the memory switch data is performed ....................................................... 113

17-2. Change over the display language .............................................................................. 114

17-3. Changing the display color of the current point ........................................................ 115

17-4. Setting the zigzag sewing output method ................................................................... 116

18. SELECTING THE FUNCTION CODE TO BE DISPLAYED ............................ 117

19. FUNCTION CODE LIST .................................................................................. 118

20. SETTING RANGE LIST ..................................................................................126

21. BACKUP .........................................................................................................130

22. ERROR CODE LIST .......................................................................................131

23. MESSAGE LIST .............................................................................................. 134

iii

Page 5

1. START AND END OF THE BODY INPUT MODE

1-1. Move to the body input mode

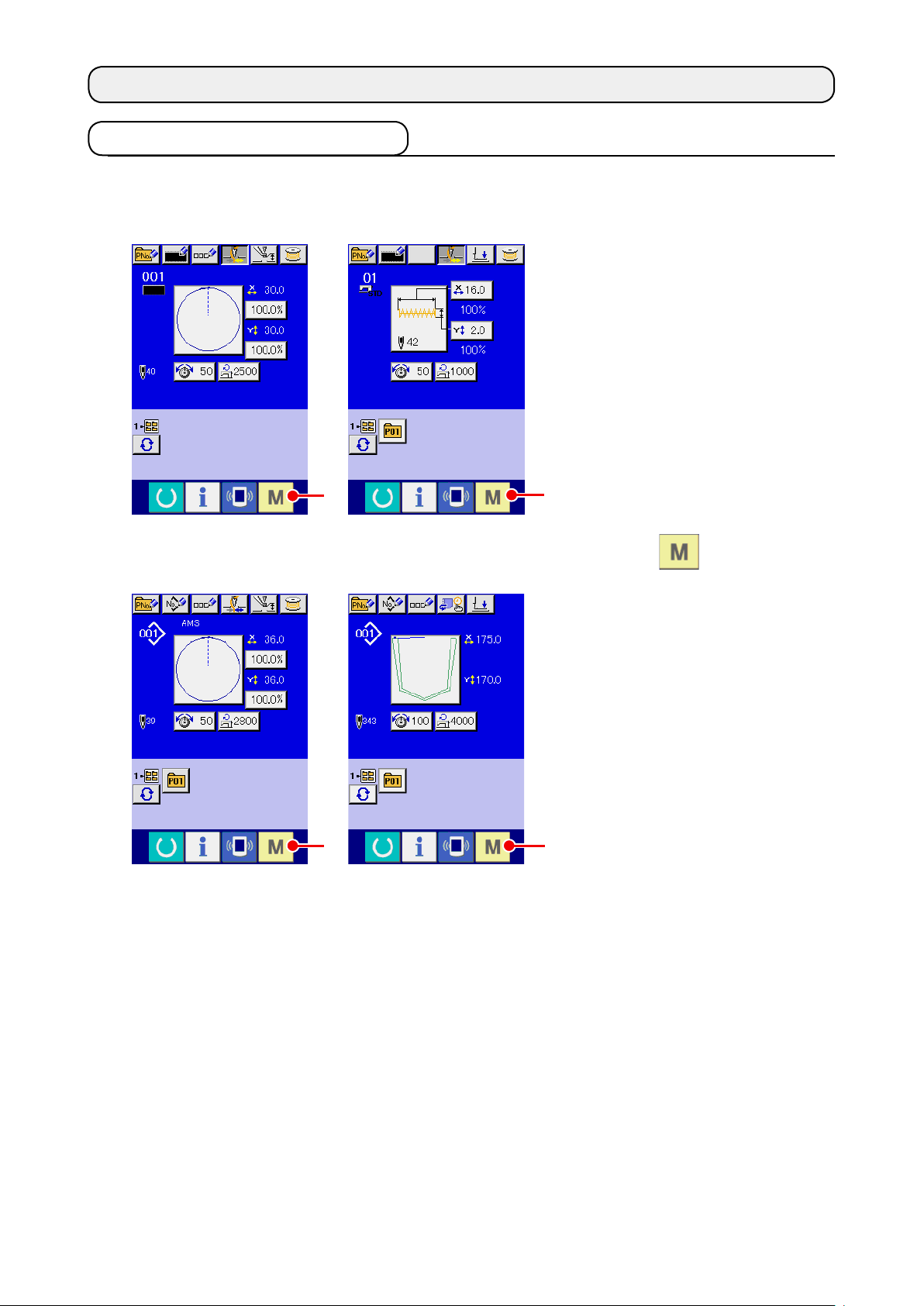

<Data input screen>

①

When the power switch is

②

In order to move from the

A

AMS-E series LK-1900B series

A

Turn ON the power switch.

turned ON, the data input

screen of the normal sewing

mode is displayed after

the welcome screen was

displayed.

Display the mode screen.

normal sewing mode to the

body input mode, press MODE

button A to display

AMS-EN series

A

the mode screen in the state

that the data input screen of

the normal sewing screen is

displayed.

A

AP series

– 1 –

Page 6

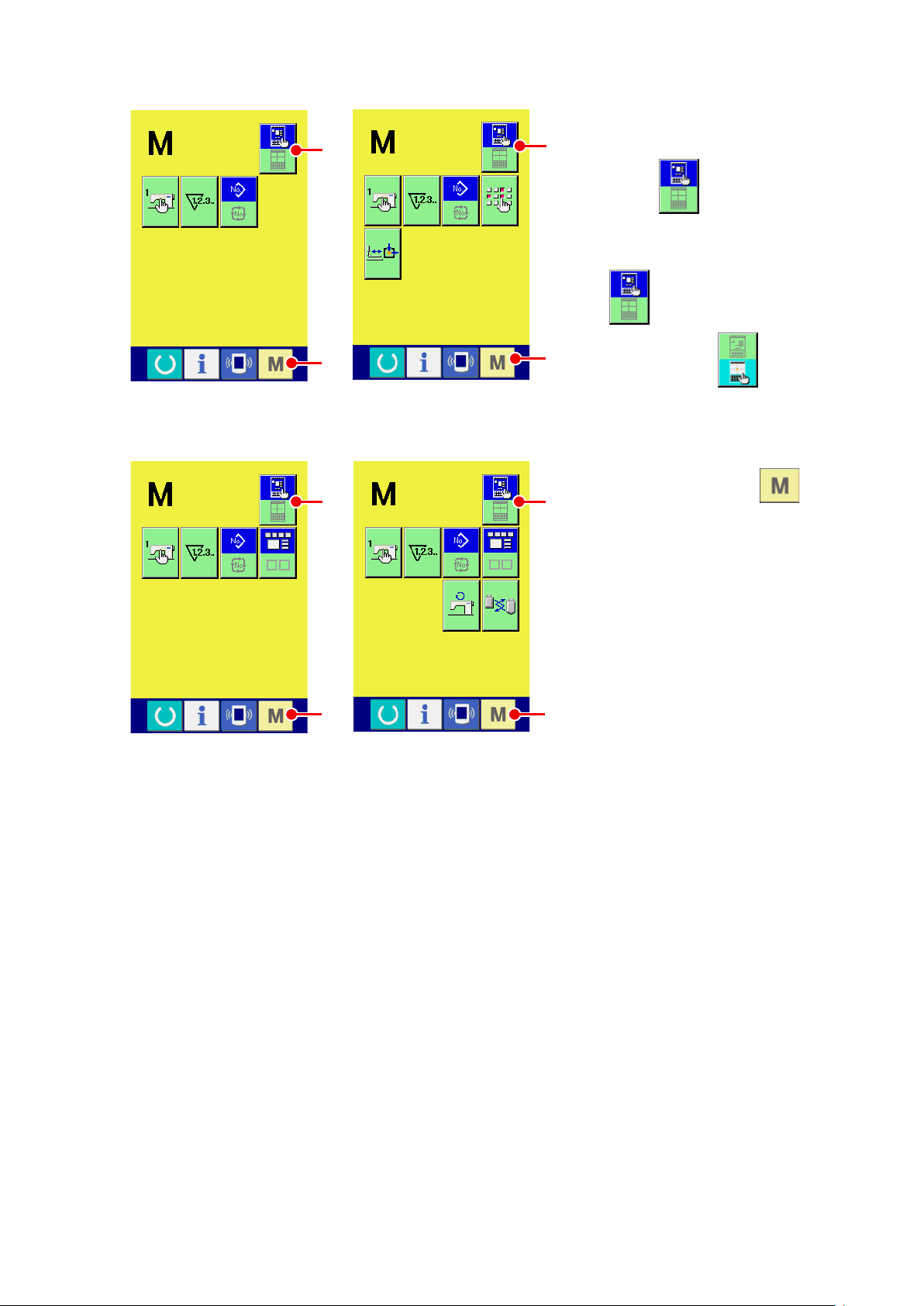

<Mode screen>

B

Select the body input mode.

③

Press MODE SELECTION

B

button B to change over

the display from the normal

sewing mode selection state

to the body input mode

C

AMS-E series

B

C

AMS-EN series AP series

LK-1900B series

C

selection state .

Move to the body input

④

mode.

When MODE button C

B

is pressed in the state that the

body input mode is selected,

the mode moves to the body

input mode, and the backup

data use conrmation screen is

displayed.

* For LK-1900B series, the

standard screen is directly

C

displayed.

– 2 –

Page 7

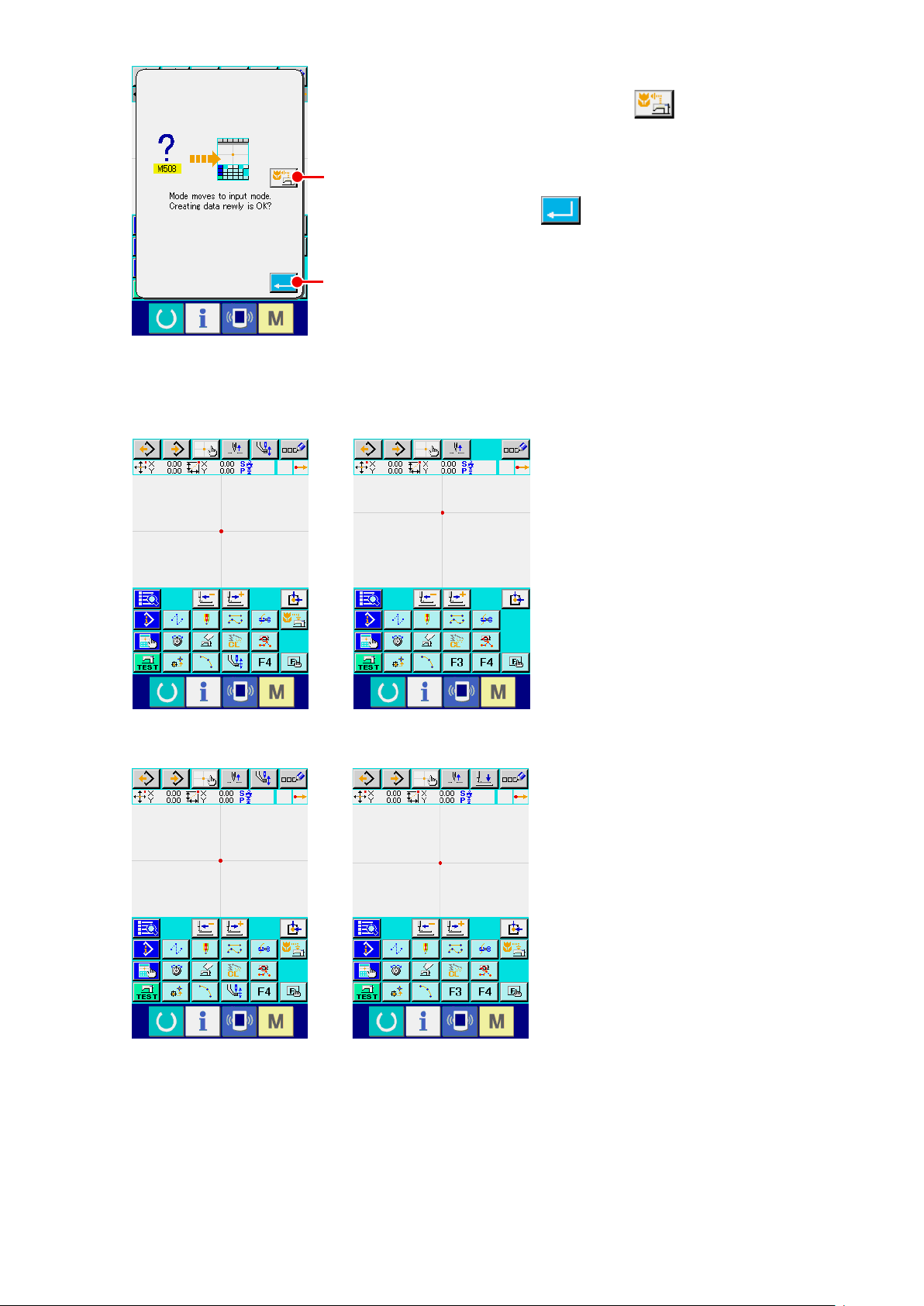

<Standard screen>

Select the sewing data use.

⑤

When SEWING DATA USE button D is pressed, the

body input mode standard screen is displayed in the state that

the backup data is used.

D

When ENTER button E is pressed, new creation can be

performed.

E

AMS-E series LK-1900B series

AMS-EN series AP series

– 3 –

Page 8

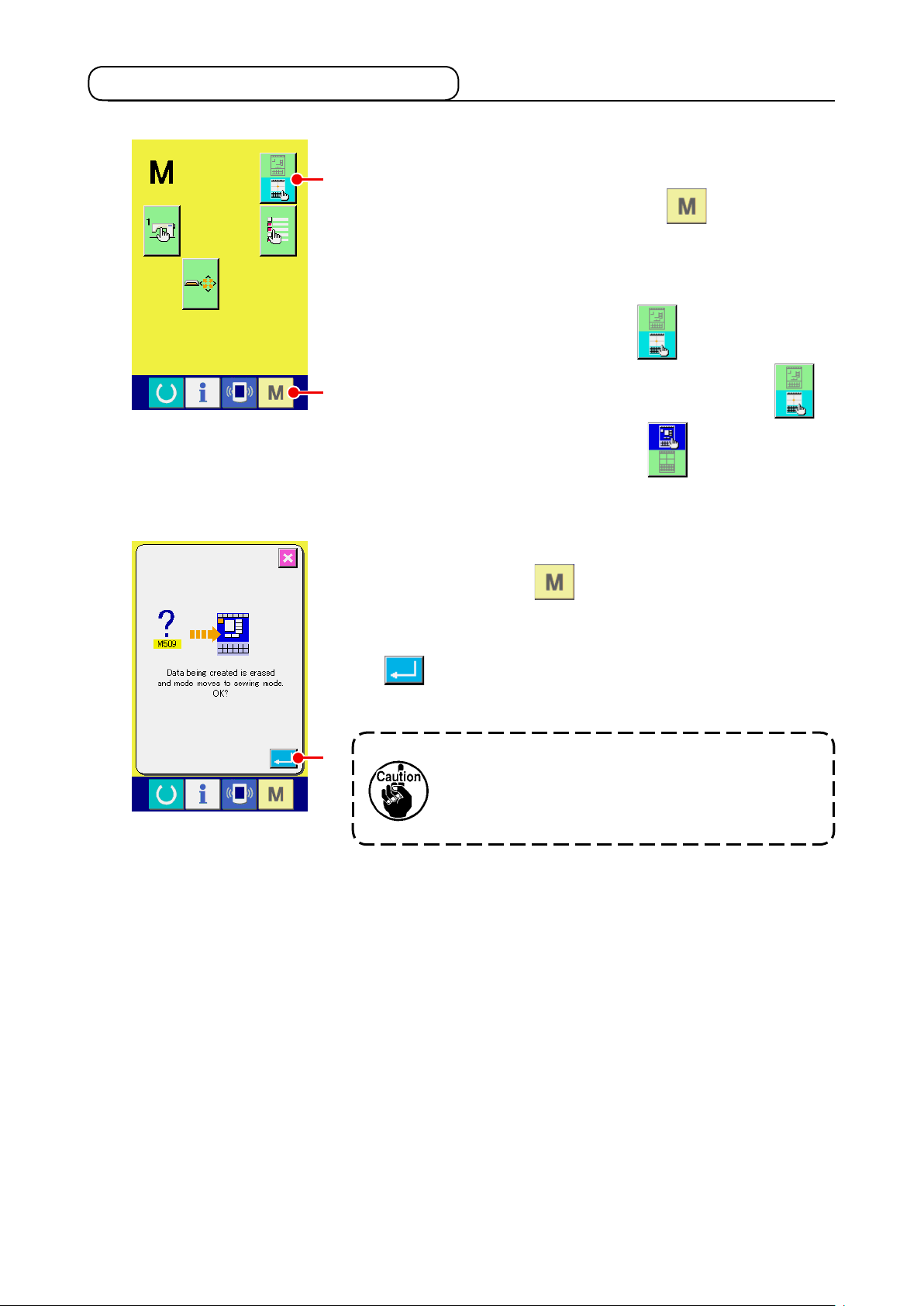

1-2. Return to the normal sewing mode

Display the mode screen.

①

In order to return from the body input mode to the normal

A

sewing mode, press MODE button in the 6tandard

screen to display the mode screen.

Select the normal sewing mode.

②

Press MODE SELECTION button A, and change over

<Mode screen>

B

the display from body input mode selection state to

normal sewing mode selection state .

Change over to the normal sewing mode.

③

When MODE button B is pressed in the state that the

normal sewing mode is selected, the sewing mode move

conrmation screen is displayed. Here, when ENTER button

C is pressed, the data input screen of the normal

sewing mode is displayed.

When the mode moves to the normal sewing

C

mode, the data during creating is erased.

When the data is necessary, perform writing

before moving.

– 4 –

Page 9

2. BASIC OPERATION AND DISPLAY

Explanation is given for the operation and the display which are common to the body input mode.

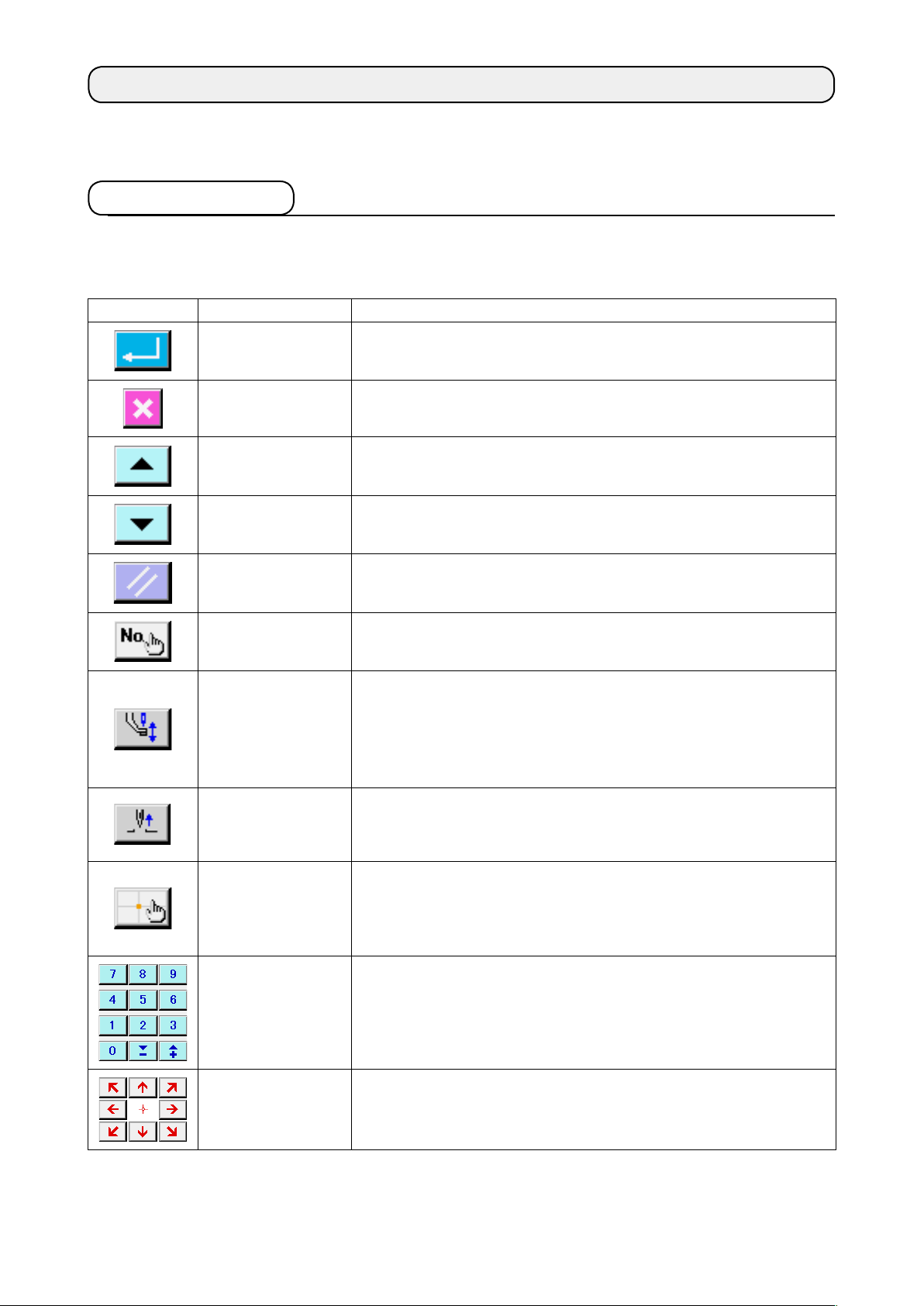

2-1. Common button

Buttons that perform common operation in the respective screens of the body input mode are as shown

in the list below.

Button Name of button Description

ENTER button Executes the selected function.

In case of the data change screen, the changed data is determined.

CANCEL button Closes pop-up screen.

In case of the data change screen, the data being changed is destroyed.

UP SCROLL button Scrolls the button or display upward.

DOWN SCROLL

button

RESET button Performs the release of error.

NUMERAL INPUT

button

INTERMEDIATE

PRESSER UP/

DOWN button

UP POSITION (UP

DEAD POINT)

RETURN button

COORDINATE

DIRECT

INSTRUCTIONS

button

Scrolls the button or display downward.

Ten-key screen is displayed, and input of numeral can be performed.

Every time this button is pressed, intermediate presser is moved to the

position of up ⇒ medium ⇒ down.

Medium position :

Down position : Input position of intermediate presser command

For LK-1900B series, this screen is not displayed.

*

Returns needle position to UP position (upper dead point).

(Return position depends on the setting of the sewing machine.)

Coordinate direct instructions screen is displayed.

Refer to

→

p.110

"16. DIRECT INSTRUCTIONS BY TOUCHING THE SCREEN"

.

Maximum position of the setting of the sewing machine

TEN key Numeral corresponding to the pressed key is inputted. + and - buttons can

increase or decrease the inputted numeric value.

MOVE key The specied position can be moved to the direction corresponding to the

pressed move key.

– 5 –

Page 10

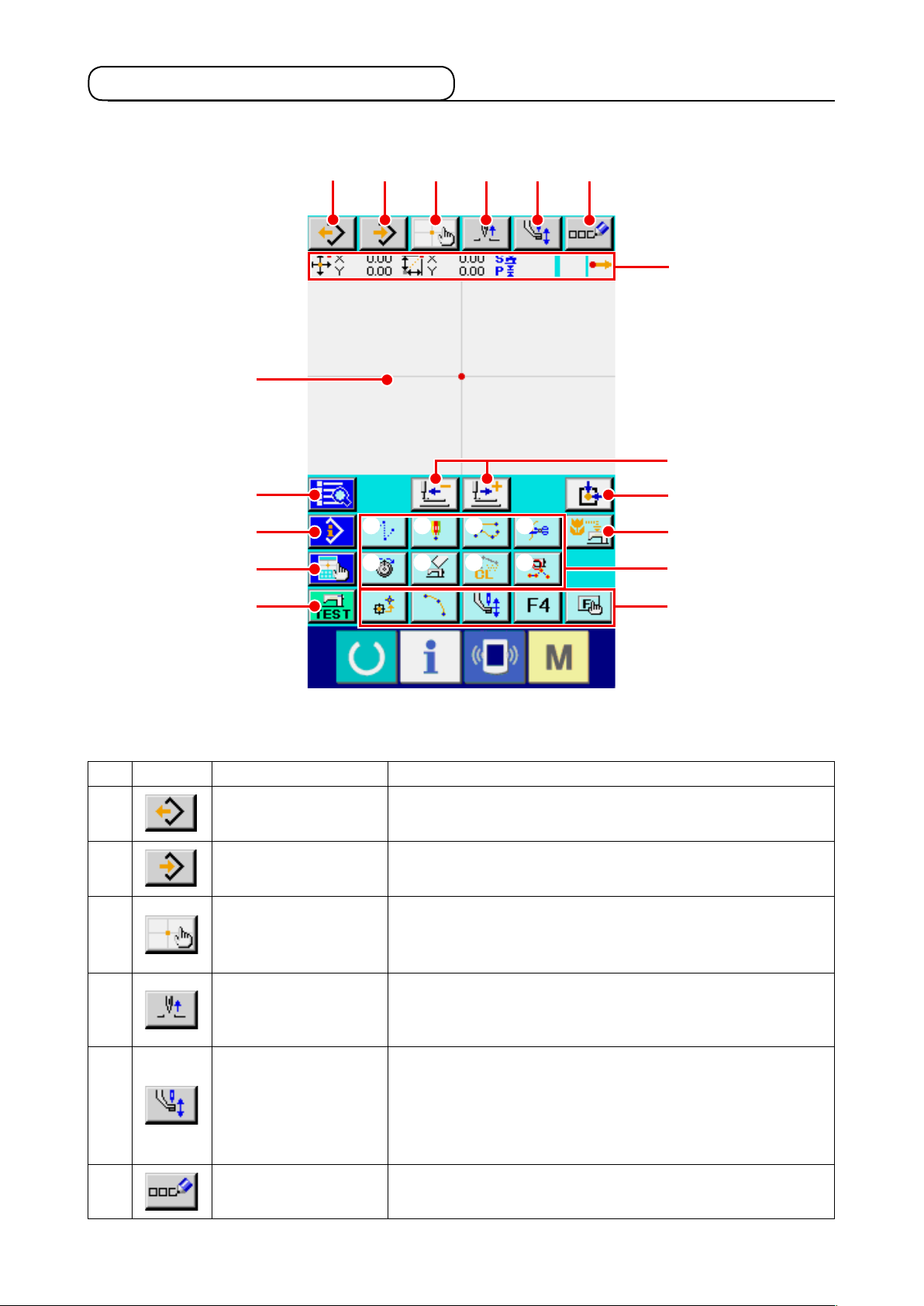

2-2. Body input mode standard screen

The standard screen of the body input mode is as shown below.

P

G

H

I

J

A

B C D E F

① ② ③ ④

⑤ ⑥ ⑦

⑧

Q

K

L

M

N

O

Buttons of the body input mode standard screen are as shown in the list below.

Button Name of button Description

A

B

C

D

E

F

PATTERN READ button Pattern reading screen is displayed.

Refer to

→

PATTERN WRITE button Pattern writing screen is displayed.

Refer to

→

COORDINATE DIRECT

INSTRUCTIONS button

UP POSITION (UP

DEAD POINT) RETURN

button

INTERMEDIATE

PRESSER UP/DOWN

button

COMMENT INPUT

button

Coordinate direct instructions screen is displayed.

Refer to

→

p.112

Returns needle position to UP position (upper dead point).

(Return position depends on the setting of the sewing machine.)

Every time this button is pressed, intermediate presser is moved to

the position of up ⇒ medium ⇒ down.

For LK-1900B series, this screen is not displayed.

*

Comment input screen is displayed.

Refer to

→

"6-4. Pattern reading" p.83

"6-5. Pattern writing" p.89

"16-2. Needle entry/shape points direct instructions"

.

Medium position :

Down position

"9-1. Comment input" p.95

Maximum position of the setting of the sewing machine

:

Input position of intermediate presser command

.

.

.

– 6 –

Page 11

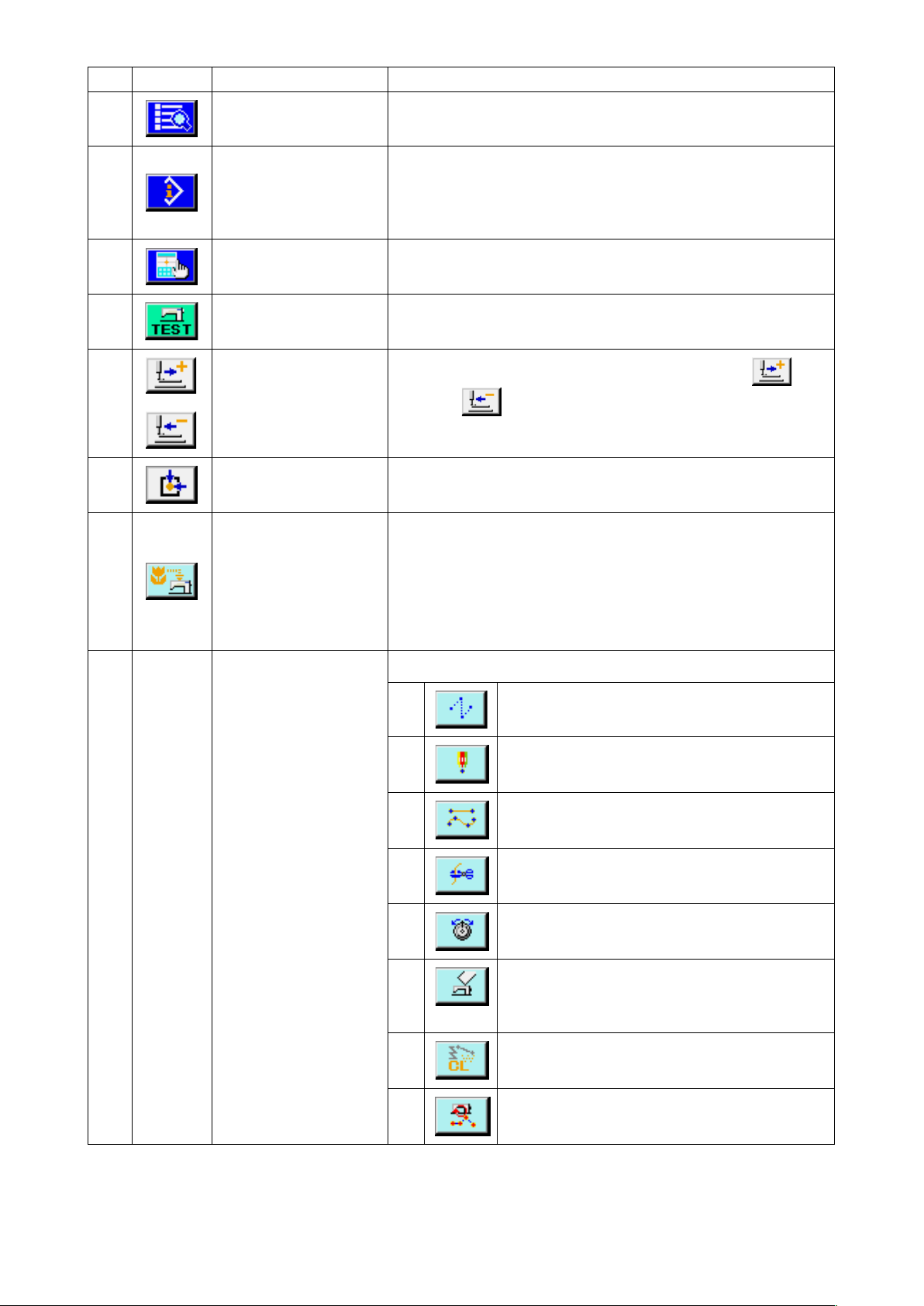

Button Name of button Description

G

H

I

J

K

L

M

CODE LIST button Code list screen is displayed.

Refer to

→

CONTENTS DISPLAY

button

DISPLAY SETTING

button

TRIAL SEWING button Trial sewing screen is displayed.

FEED FORWARD/

BACKWARD button

RETURN TO ORIGIN

button

BACKUP button Performs backup of pattern data to sewing machine.

Contents display screen is displayed, and detailed information on the

present needle position is displayed.

Refer to

→

CURRENT NEEDLE POSITION" p.103

Display setting screen is displayed.

Refer to

→

Refer to

→

Moves the present needle position by one stitch (forward and

backward

when holding pressing a xed number of stitches.

Returns present needle position to the origin.

(Caution : Overwriting is performed on the present pattern data.

When the pattern data is selected from the media in the normal

sewing mode or the users' pattern is being edited, the data will

disappear.)

For LK-1900B series, this screen is not displayed.

*

"2-3. Selection of function" p.10

"13. DISPLAYING DETAILED INFORMATION ON THE

"14. PERFORMING SETTING OF DISPLAY" p.105

"8. TRIAL SEWING" p.91

). The mode becomes the continuous move mode

.

.

.

.

N

FUNCTION button Function allocated to the button can be directly called.

①

②

③

④

⑤

⑥

⑦

⑧

Executes jump feed (

p.23

).

Executes point sewing(

(021)" p.31

Executes normal sewing

(022)" p.32

Executes thread trimming

(001)" p.42

Executes thread tension setting (

tension setting (014)" p.50

Executes machine control command deletion (

(16) Machine control command deletion (059)"

p.54

Executes element deletion (

deletion (063)" p.69

Executes sewing speed section change (

Sewing speed section change (061)" p.71

).

).

).

).

"4-1.(1) Jump feed (020)"

"4-5.(6) Point sewing

"4-1.(7) Ordinary sewing

(

"4-5.(1) Thread trimming

(

"4-5.(12) Thread

).

"5-3. Element

).

"4-5.

"5-5.

).

– 7 –

Page 12

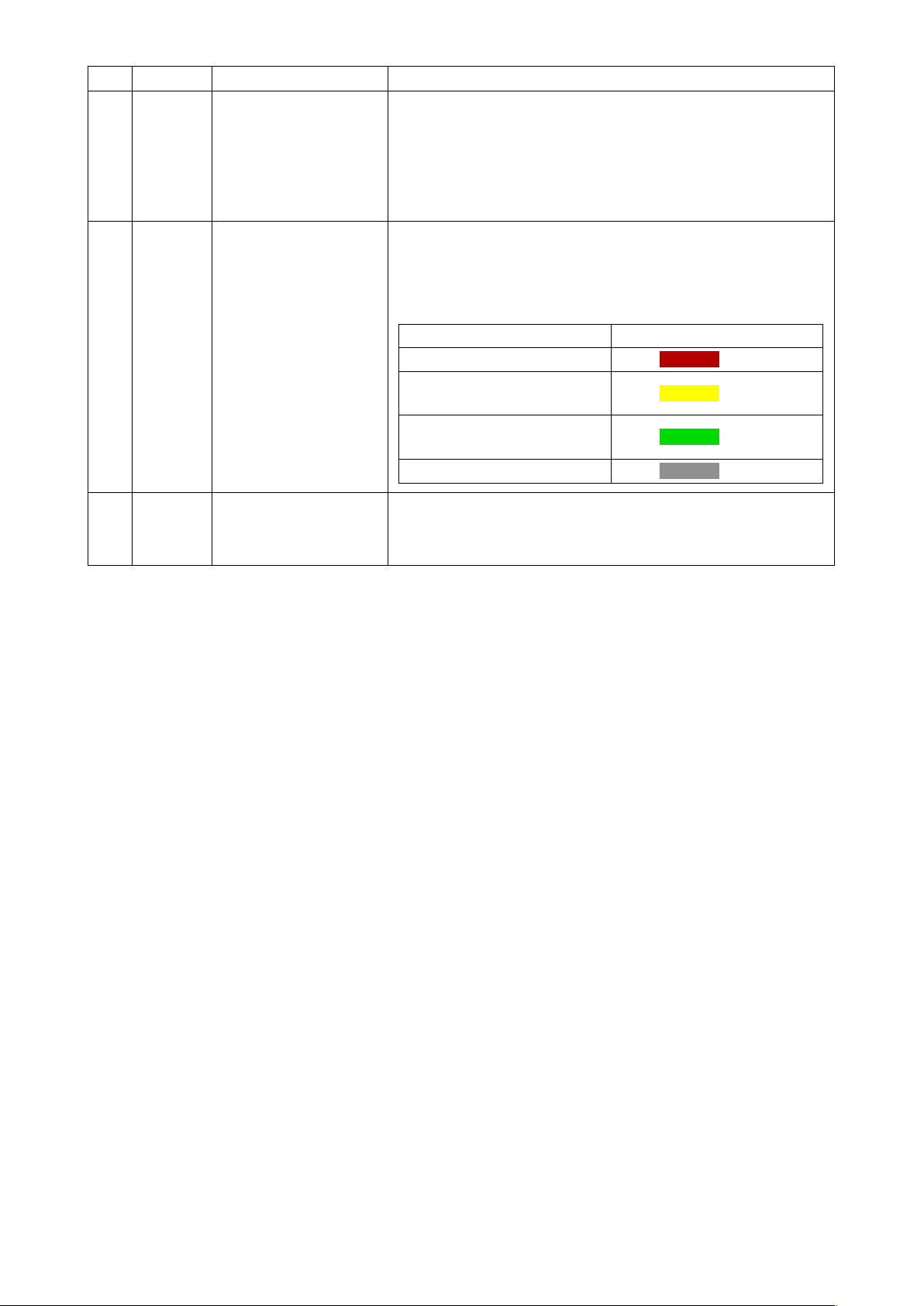

Button Name of button Description

O

P

Q

F button The function you desire can be allocated to each button by means

of function selection and setting (function code 112), and this button

can be used as the function button. When the function is allocated,

pictograph showing the allocated function is displayed.

"11. ALLOCATING FUNCTIONS TO F1 THROUGH F5

.

Kind of point Display color

Current point

sewing start

sewing end

Others

Red

:

Yellow

:

Yellow-green

:

Gray

:

PATTERN DISPLAY

REGION

PRESENT NEEDLE

POSITION

INFORMATION display

Refer to

→

BUTTONS (112)" p.99

Part where pattern is displayed. When pressing down this button,

screen scrolls so that the point becomes the center position of the

display. Screen does not scroll when the outside of sewing area is

pressed.

3 stitches in the direction of

3 stitches in the direction of

Part where information on the present needle position is displayed.

Contents of the display is shown below.

– 8 –

Page 13

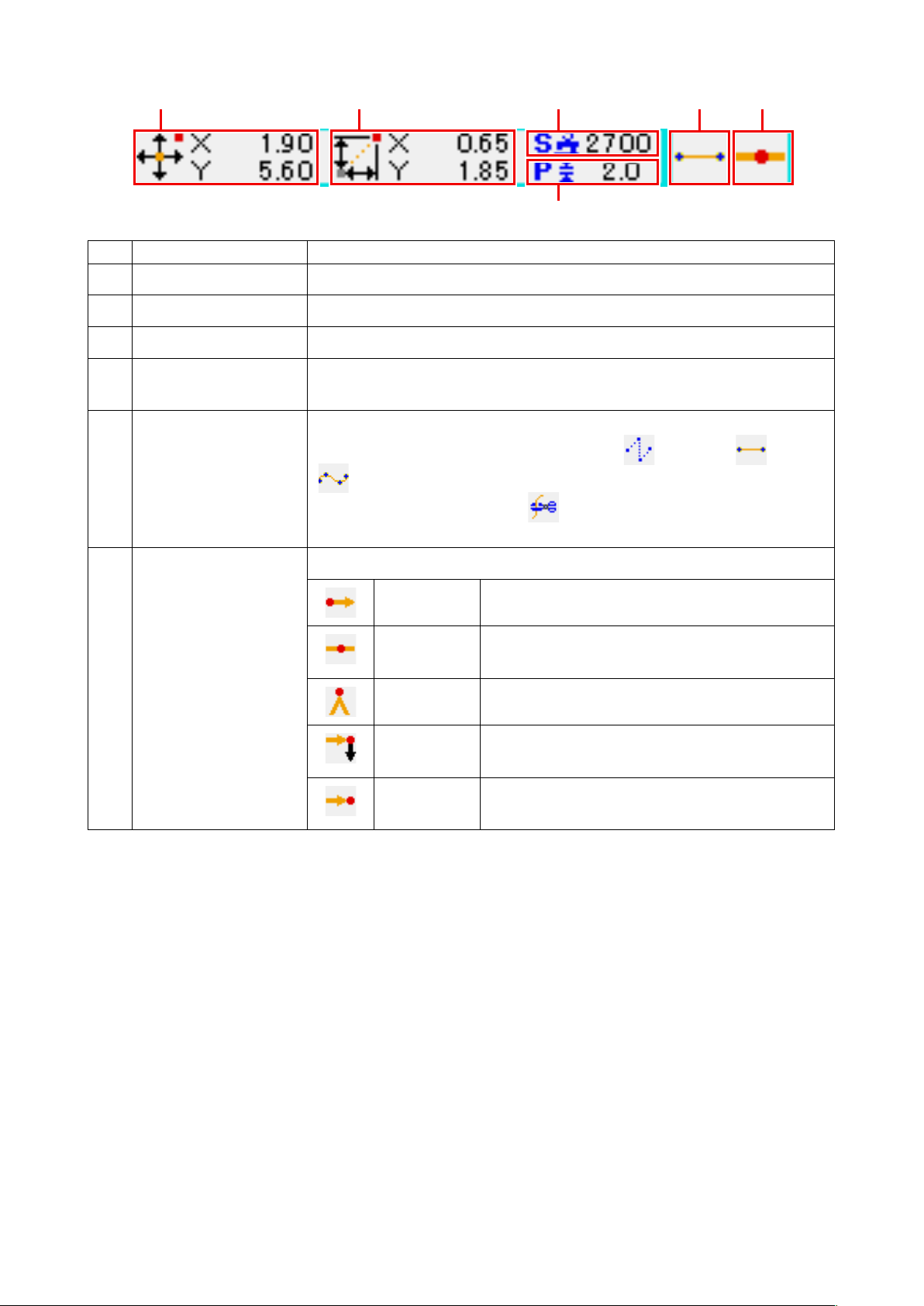

❶

❷

❺ ❻❸

❹

Item Description

Absolute coordinate Absolute coordinate from the origin of the present needle position is displayed.

❶

Relative coordinate Relative coordinate of the present needle position is displayed.

❷

Speed Sewing speed or jump feed speed of the present point is displayed.

❸

Pitch Stitch length of the present element is displayed. (When performing reading after

❹

enlarging/reducing, the value before enlarging/reducing is displayed.)

Kind of element

❺

Kind of needle entry Kind regarding needle entry position is displayed.

❻

The section of present needle position information display can display the comment of pattern by the display setting

"14. PERFORMING SETTING OF DISPLAY" p.105

(

Kind of element of present element is displayed. In case of sewing data, pictograph

in accordance with the kind of element ( jump feed , broken line , spline

, etc. ) is displayed. In case of machine control command, kind of machine

control command (thread trimming , etc. ) is displayed with pictograph.

(For the other pictographs, refer to

Top of pattern Top position (origin) of pattern is displayed.

Midway of

element

Top Top of broken line is displayed.

End of

element

End of

pattern

) as well.

"19. FUNCTION CODE LIST" p.118

Point of midway in element (not the top nor end of

element) is displayed.

End position of element is displayed.

The last position of pattern is displayed.

.)

– 9 –

Page 14

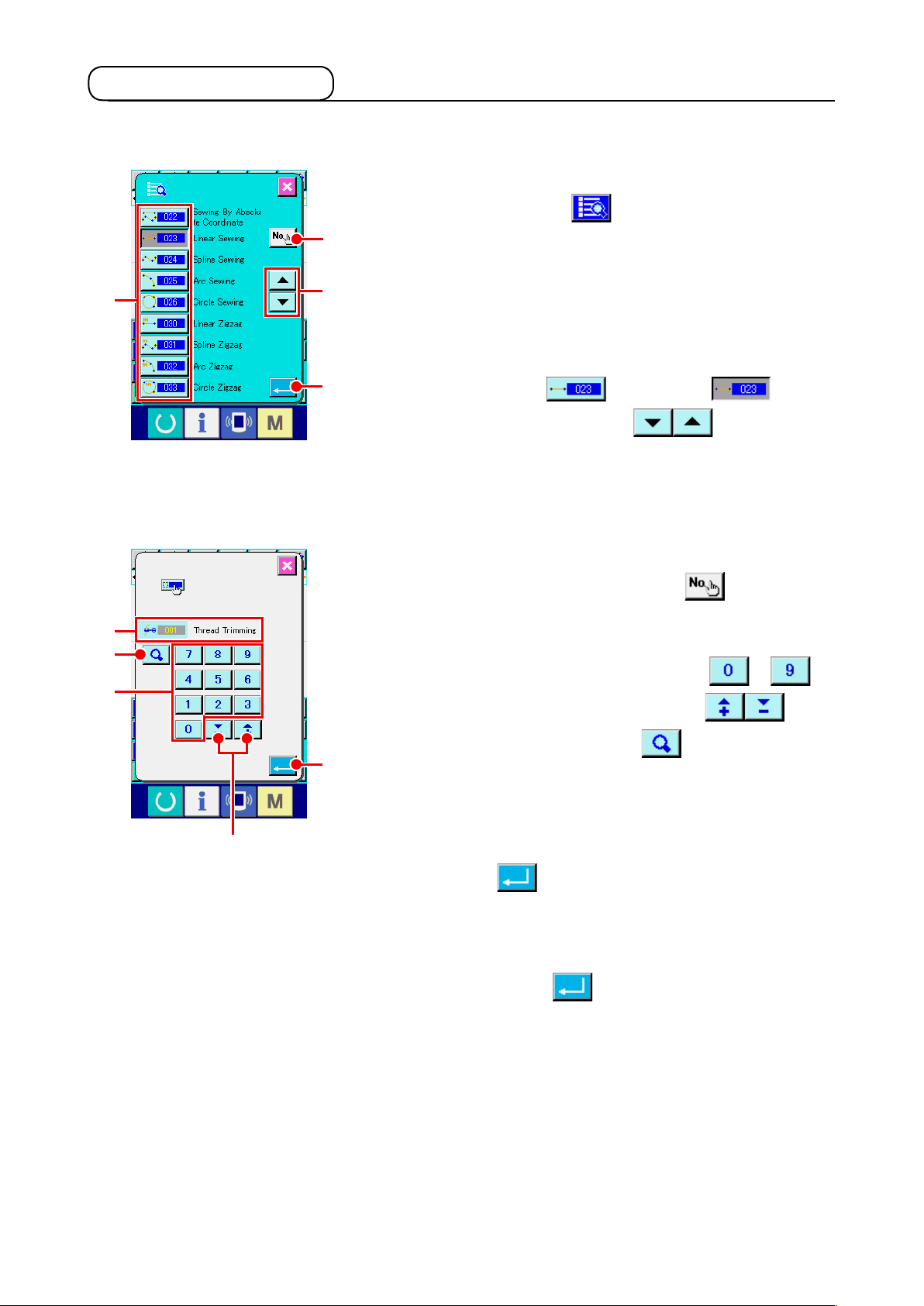

2-3. Selection of function

Procedure of the function selection of the body input mode is given below.

Display the code list screen.

①

When CODE LIST button is pressed in the standard

A

H

G

E

<Code list screen>

C

screen of the body input mode, the code list screen is

displayed.

B

Select the function.

②

Press the calling button of the function you desire to execute

from among the function calling button list A. The selected

D

function calling button is changed to .

When UP/DOWN SCROLL button B is pressed,

the display of function calling button list A is changed over in

order.

Direct input the function code.

③

When FUNCTION CODE INPUT button C is pressed,

the function code input screen is displayed and the function

code can be direct inputted.

Direct input the function code with TEN KEYS to E,

or select the function code with + or - button F.

F

When CONFIRMATION button G is pressed, the

I

information on the function corresponding to the inputted

function code is displayed in the function name display column

.

H

When the function code you desire to execute is inputted and

ENTER button I is pressed, the screen returns to the

function code list screen with inputted function selected.

Execute the function.

④

When ENTER button D is pressed with the function

calling button of the function you desire to execute selected,

setting screen of the function is displayed.

For the respective setting screens, refer to the items of the

respective functions.

– 10 –

Page 15

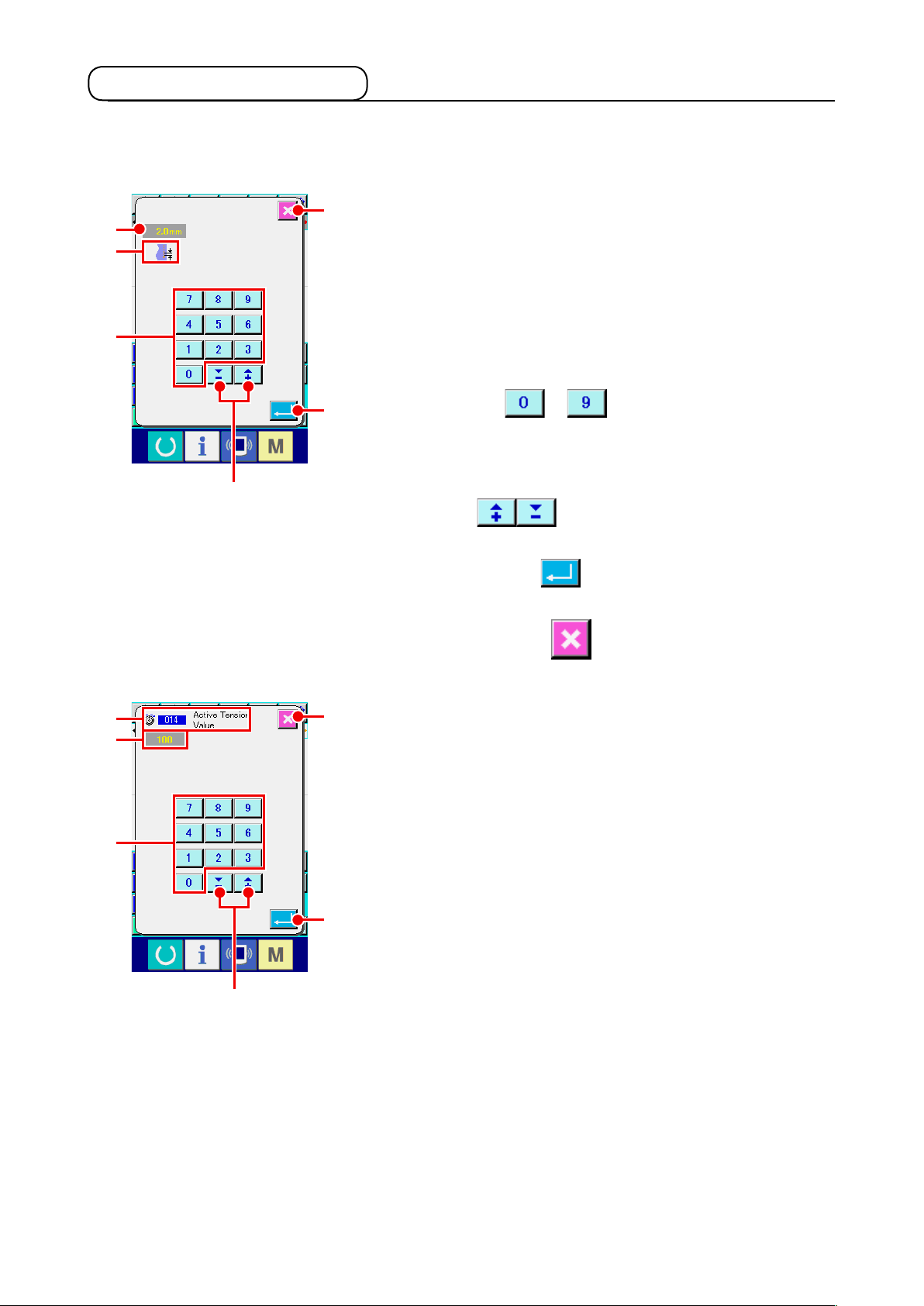

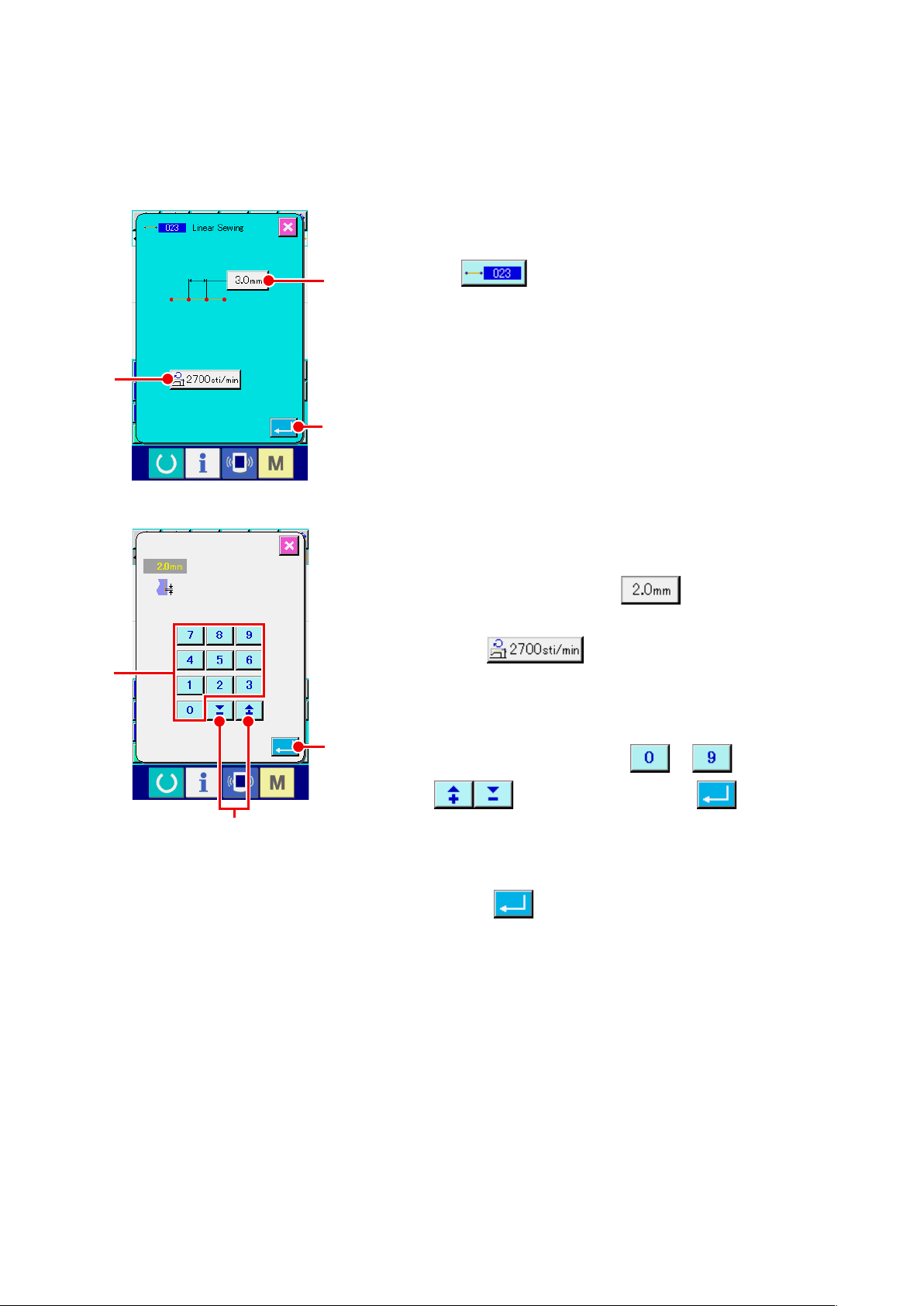

2-4. Input the numeric value

Common numeric value input procedure at the time of creating the pattern data is given below.

Input the setting item.

①

F

C

D

The gure on the right-hand side is the screen which is

displayed when inputting the set value of setting item of the

function.

A

G

C

B

[Example : Change of stitch length]

Kind of setting item to be inputted is displayed at D and the

input value is displayed at C.

When TEN KEY to A is pressed, the numeral of

E

the pressed ten key is inserted to the 1st digit of C, and the

previous input values are moved up by one digit each.

In addition, the input value can be increased or decreased with

+ or - button B. Changeable unit depends on the

kind of setting item.

When ENTER button E is pressed, the input value is

determined and the screen moves.

When CANCEL button F is pressed, the input value is

destroyed and the screen moves.

F

A

B

Input the machine control command parameter.

②

The gure on the left-hand side is the screen which is

displayed when inputting the parameter of machine control

command.

Inputting procedure is the same as that of inputting the set

value of the setting item. At G the function code to perform the

E

input of parameter and the function name are displayed.

– 11 –

Page 16

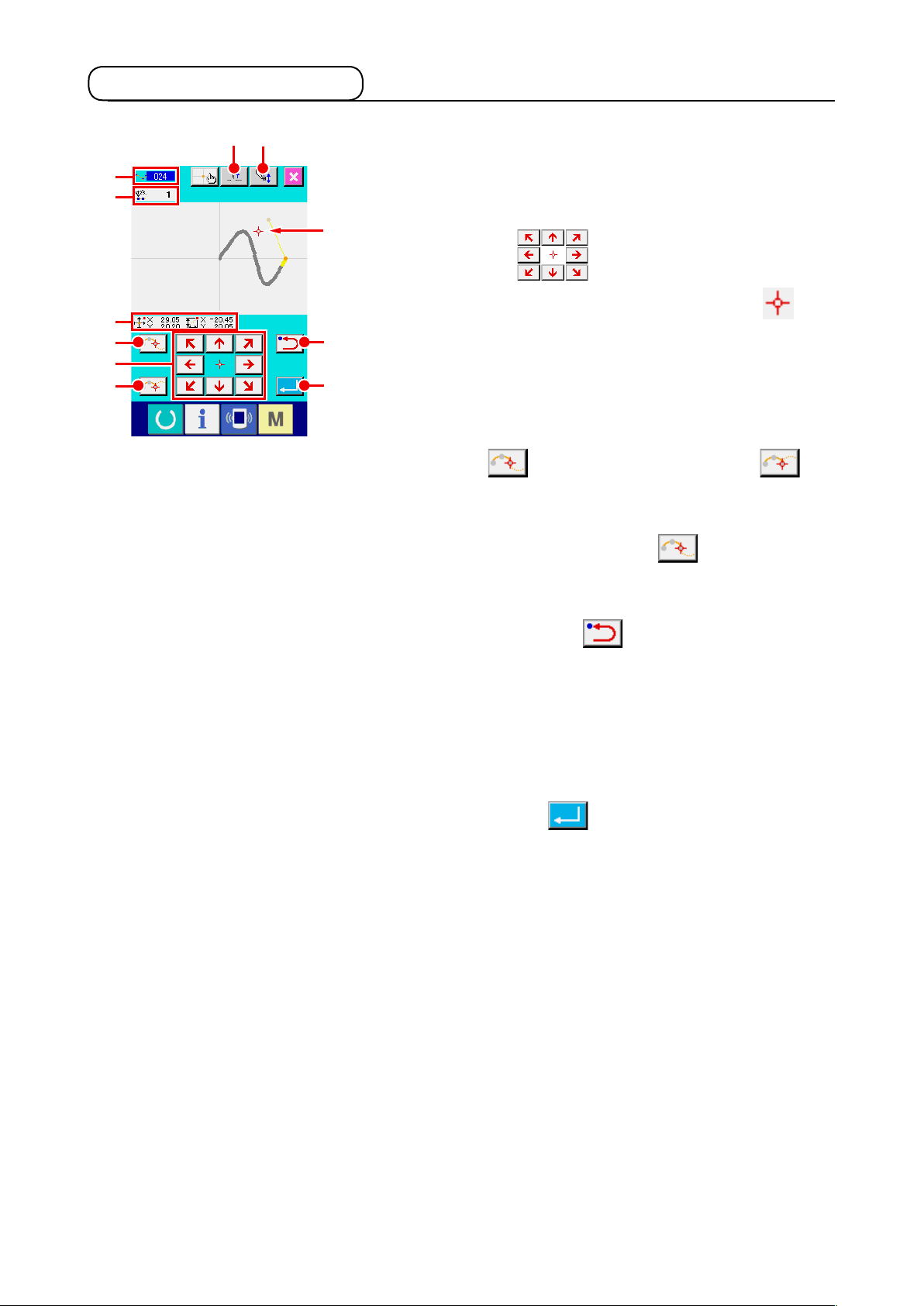

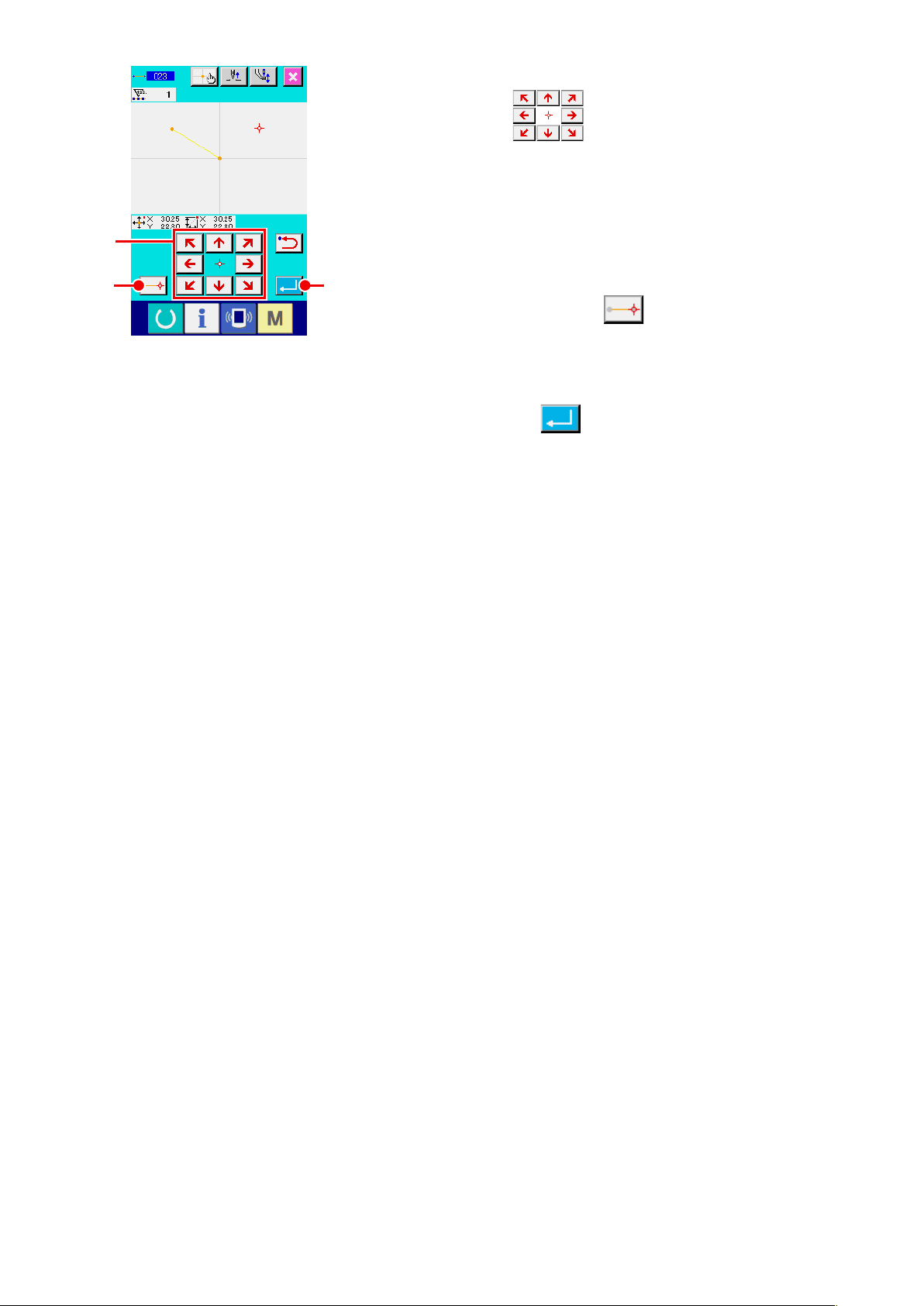

2-5. Specifying the position

J

K

L

B

A

C

HG

The gure on the right-hand side is the position specifying screen

which is displayed when specifying the position at the setting of

function. The selected function code is displayed at J.

M

Press MOVE key A.

①

The presser and the present needle position display

move in the pressed direction, and the coordinate value

D

M

display L is updated. While MOVE key is held pressed,

E

the presser moves in the pressed direction, and when it is

detached, the move of presser stops.

When the presser moves to the target position and PASSING

POINT button B or DECIDING POINT button

is pressed, the position is inputted as the shape point

C

or the needle entry point. At K the number of input points

is displayed. PASSING POINT button B may not be

displayed according to the selected function.

Press BACKWARD button D after moving with MOVE

②

key.

The position returns to the preceeding determined position.

When it is pressed immediately after the determination of input

position, one point of the determined input points is cancelled

and the position returns to the input point before one point.

Press ENTER button E.

③

The outer presser automatically returns to the position where

input was started, traces the element which was operated and

created at the input point inputted until then, moves to the last

of the element, and the data is inserted.

(With/without trace can be selected. For the details, refer to

"10. SELECTING ENDING PROCEDURE (110)" p.98

.)

– 12 –

Page 17

F

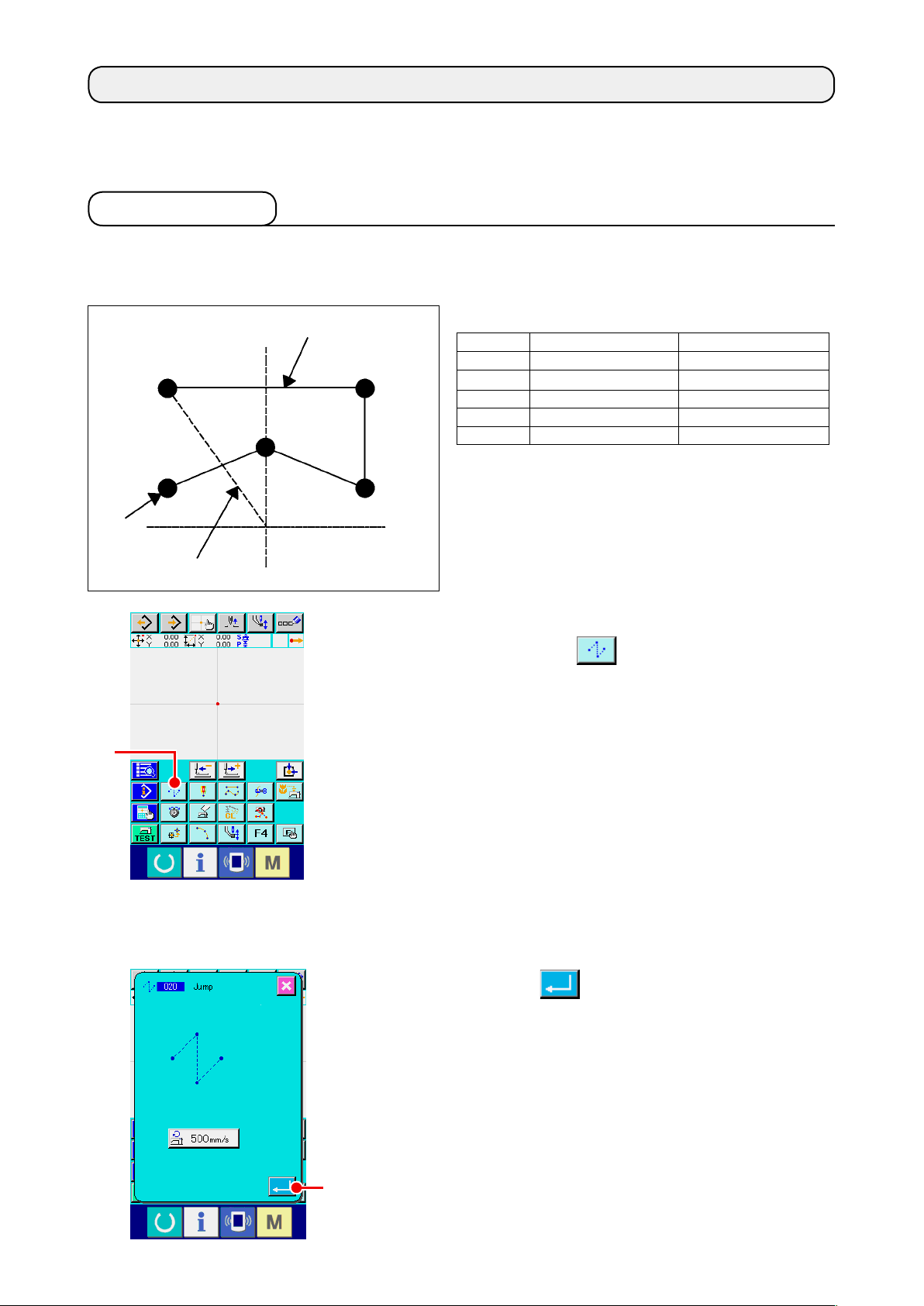

Press CANCEL button I.

④

I

The data during inputting is destroyed, and the screen returns

to the standard screen.

By pressing ENTER button at inputting of the last point,

pressing down of the deciding point button can be omitted.

Press COORDINATE DIRECT INSTRUCTIONS button

⑤

.

F

The coordinate direct instructions screen (

direct instructions" p.110

) is displayed, and the coordinate

"16-1. Coordinate

can be direct specied.

At N warning pictograph is displayed when setting

possible range is exceeded or the like.

N

– 13 –

Page 18

3. EXAMPLE OF OPERATING PROCEDURE

A series of operating procedure up to trial sewing is given below. For the details, refer to the respective

items.

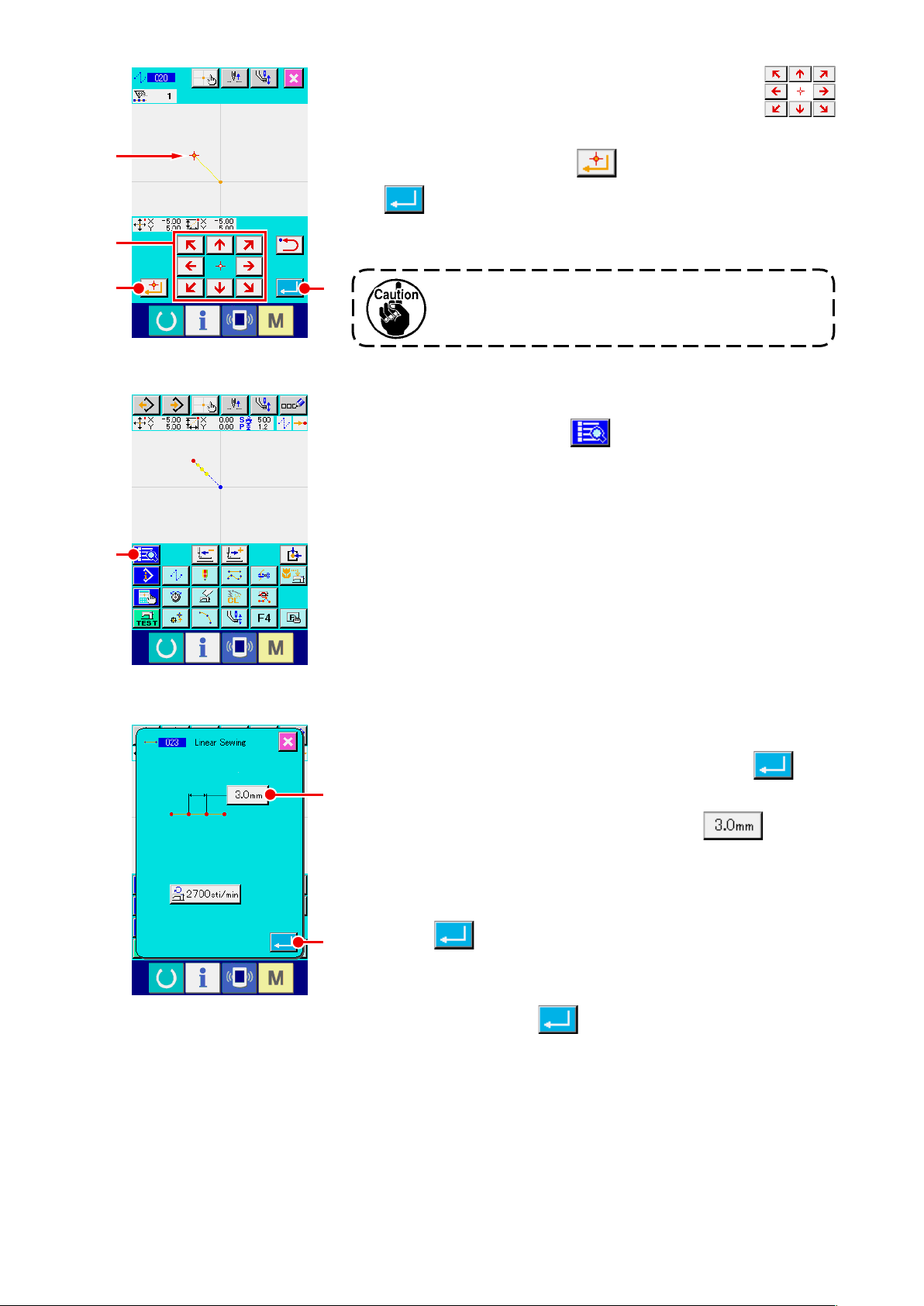

3-1. Pattern input

Create the pattern below using the input function.

Thread

trimming

A

Linear line (pitch 3 mm)

❶

❷

❹

❺ ❸

Origin

Jump feed

Input of jump feed

①

Press JUMP FEED button A in the standard screen to

[Input point]

X(mm) Y(mm)

❶

❷

❸

❹

❺

−5.0 5.0

5.0 5.0

5.0 1.0

0.0 3.0

−5.0 1.0

display the jump feed setting screen.

<Standard screen>

Press ENTER button B in the jump feed setting screen

to display the jump feed position specifying screen.

B

– 14 –

Page 19

❶

C

Move the needle position up to ❶ using MOVE key

in the jump feed position specifying screen, press

C

DECIDING POINT button D, and press ENTER button

E.

D

F

E

At this time, the presser moves. So, be careful.

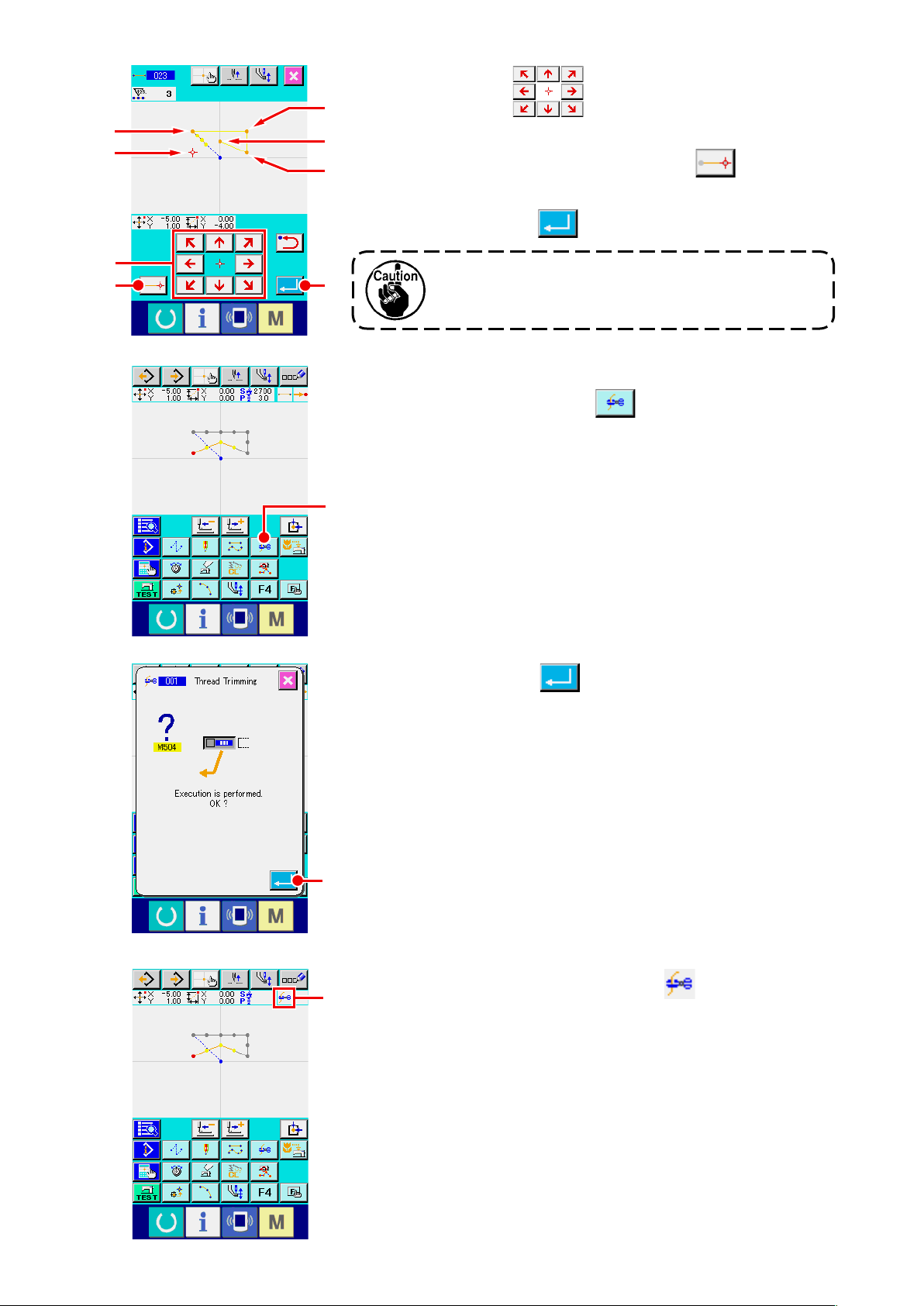

Input of the linear ordinary sewing

②

Press CODE LIST button F in the standard screen to

display the code list screen.

Select the linear ordinary sewing (function code 023) in the

function code list screen, and press ENTER button .

G

Press STITCH LENGTH SETTING button G in the

linear ordinary sewing setting screen to display the stitch

length setting screen.

Press TEN key in the order of “3” and “0”, and press ENTER

H

button in the stitch length setting screen.

Return to the linear ordinary sewing setting screen, confirm

that the display of stitch length setting button is “3.0 mm”, and

press ENTER button H.

– 15 –

Page 20

❶

❺

I

J

Press MOVE key I in the linear ordinary sewing

❷

❹

❸

position specifying screen, move the needle position from ❶

to ❷, and press DECIDING POINT button J.

Repeat this operation to input up to the position of ❺, and

press ENTER button K.

K

At this time, the presser moves. So, be careful.

Input of thread trimming

③

Press THREAD TRIM button L in the standard screen

to display the thread trimming conrmation screen.

L

Press ENTER button M and input thread trimming to the

position of ❺.

M

The standard screen is displayed, and is displayed at N.

N

With the aforementioned operation, a pattern as shown in the

gure on the left-hand side is created.

– 16 –

Page 21

3-2. Trial sewing

The shape or the like of the pattern created by using the input function or readout data is conrmed with

the trial sewing.

Screen and setting possible item of trial sewing change in accordance with machine models.

Description below is the example regarding AMS-210EN.

Before performing the trial sewing, it is necessary to register the setting of the

height of intermediate presser and that of the thread tension.

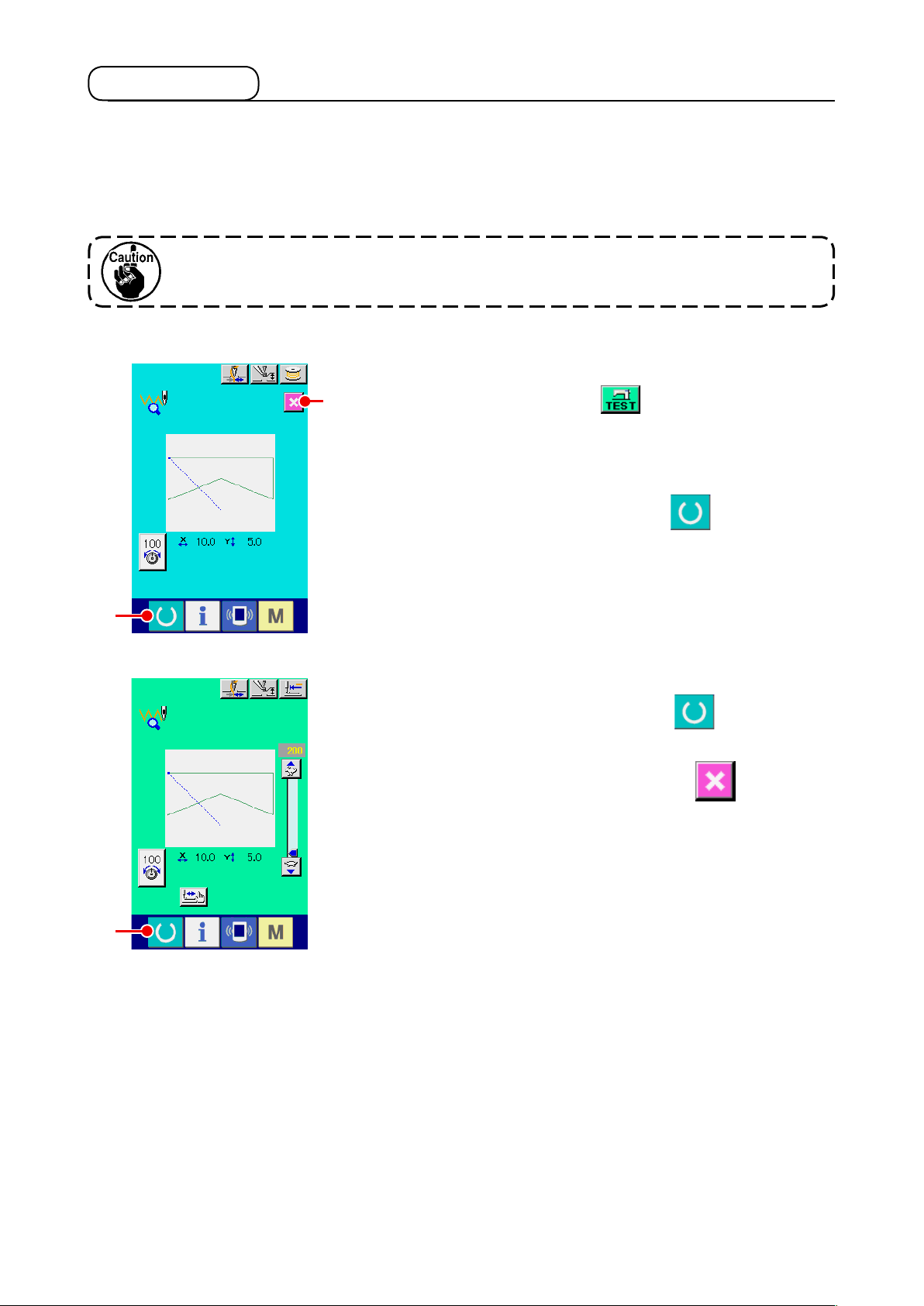

Display the trial sewing preparation screen.

①

Press TRIAL SEWING button in the standard screen to

B

display the trial sewing preparation screen.

Display the trial sewing screen.

②

When SEWING PREPARATION button A is pressed,

A

C

the trial sewing screen is displayed. Perform the normal

sewing machine operation in this screen and the trial sewing

of pattern data can be performed.

Return to creation of pattern.

③

When SEWING PREPARATION button C is pressed in

the trial sewing screen, the screen returns to the trial sewing

preparation screen. When CANCEL button B is pressed

here, the screen returns to the body input mode standard

screen.

– 17 –

Page 22

3-3. Modication of the pattern

Modify the pattern data which has been created in

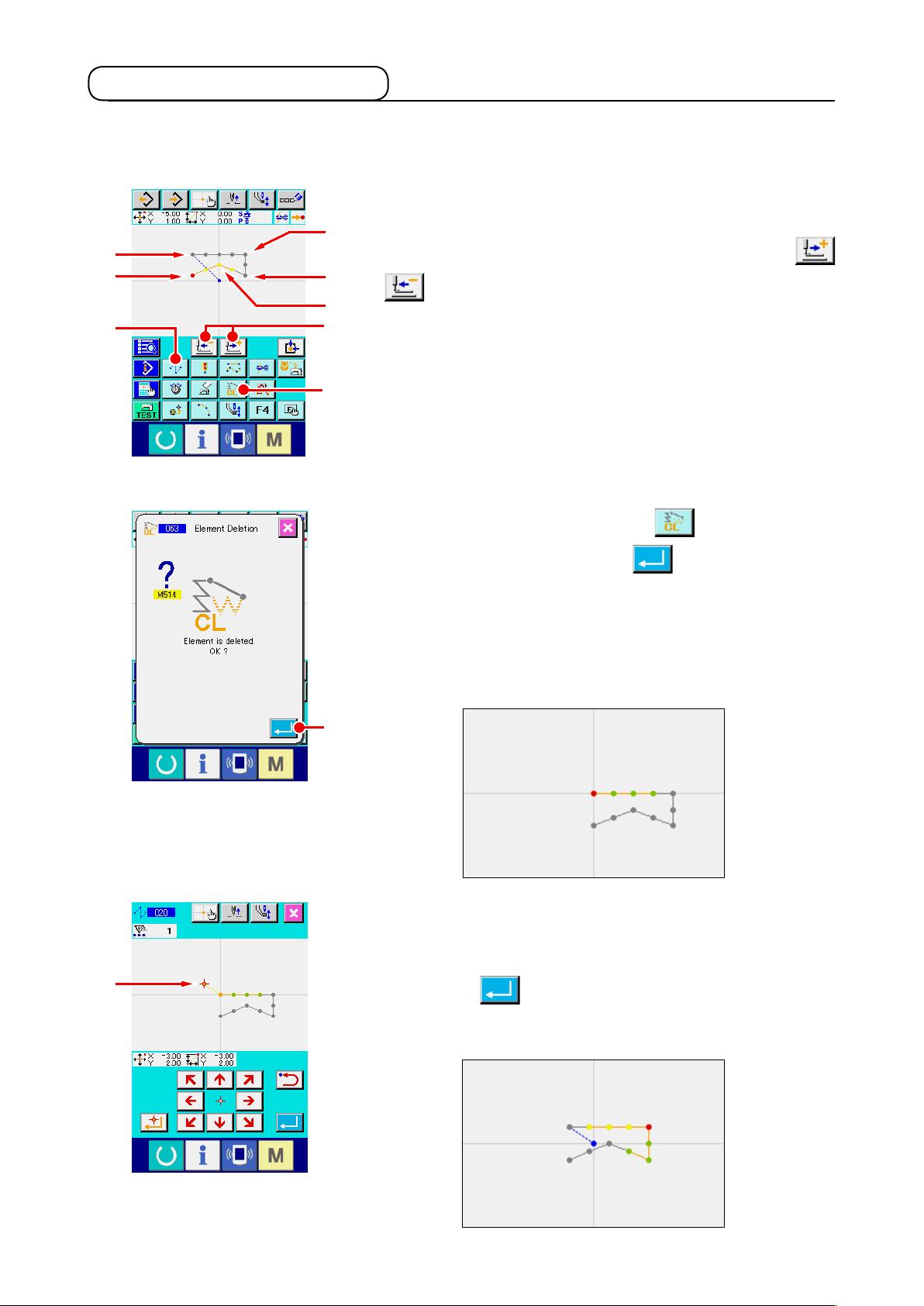

Deletion of element

①

Move the needle position on the way of the jump feed section

❷

❶

❺

E

❸

❹

A

B

<Standard screen>

up to ❶ using FEED FORWARD/BACKWARD buttons

A.

Press ELEMENT DELETION button B in the standard

screen, and press ENTER button C in the conrmation

"3-1. Pattern input" p.14

.

D

screen.

Jump feed up to ❶ is deleted, and the needle position returns

to the origin.

At this time, linear sewing from ❶ through ❺ is in the state of

starting from the origin.

C

Insertion of jump feed

②

Select the jump feed function E on the standard screen. Move

the needle position to D on the position specifying screen.

Press button C.

It can be visually checked that a jump is inserted and the

relative movement of the needle position is caused.

– 18 –

Page 23

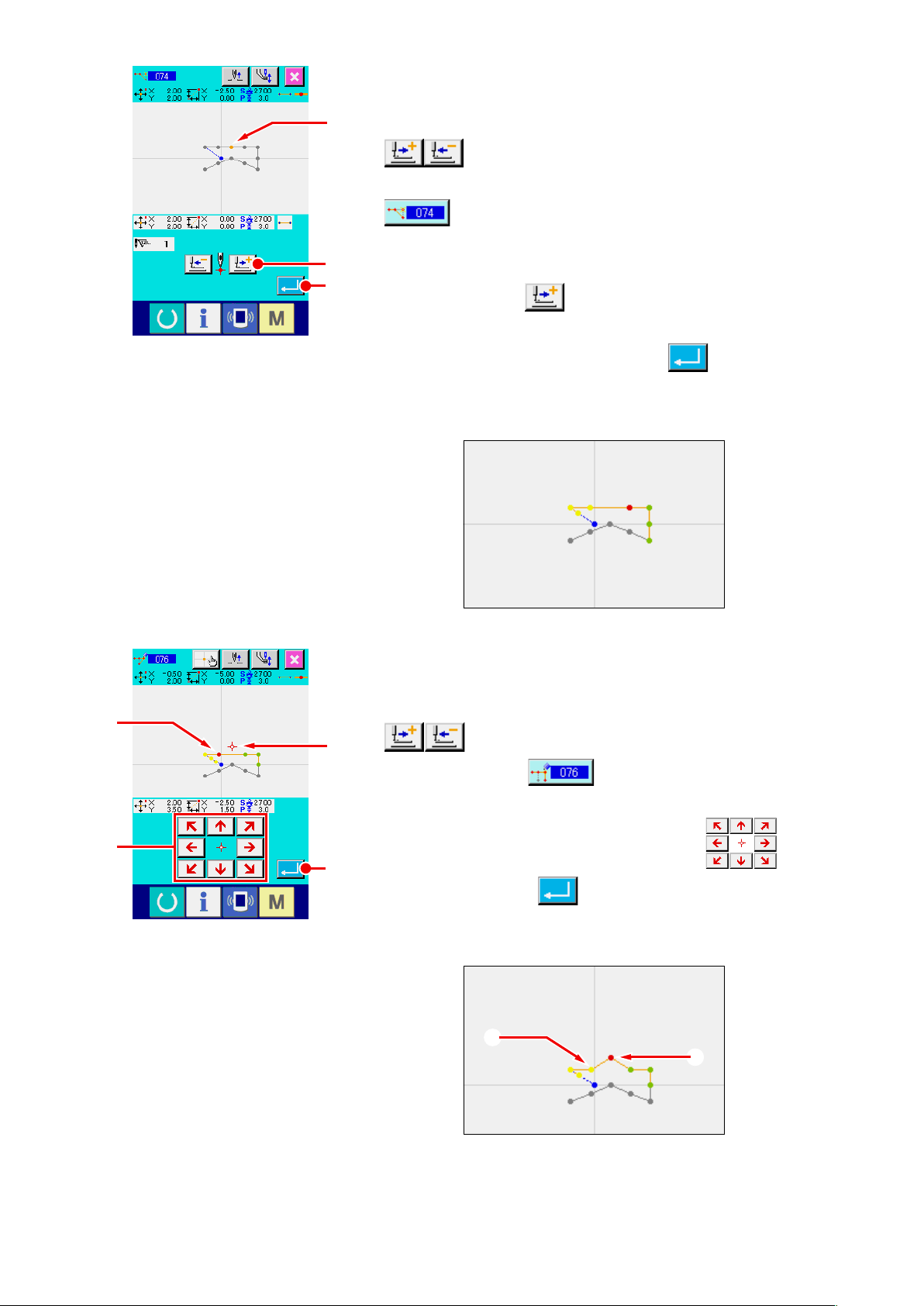

Deletion of point

③

Move the needle position up to the position of E in the

E

standard screen using FEED FORWARD/BACKWARD buttons

A.

Select ABSOLUTE POINT DELETION (function code 074)

from the function code list to display the range

specifying screen.

F

In case of deleting plural needle entry points, press FEED

G

FORWARD button F to move the needle position, and

specify the section of the points to be deleted. Here, specify

point E only, and press ENTER button G.

It is conrmed that point E has been deleted as shown in the

gure below.

H

J

Addition of point

④

Move the needle position up to the position of H in the

standard screen using FEED FORWARD/BACKWARD buttons

I

A, and select ABSOLUTE POINT ADDITION

(function code 076) .

Move the needle position up to the adding point I in the

position specifying screen using MOVE key J, and

K

press ENTER button K.

The needle entry point is added as shown in the gure below.

H

I

– 19 –

Page 24

L

N

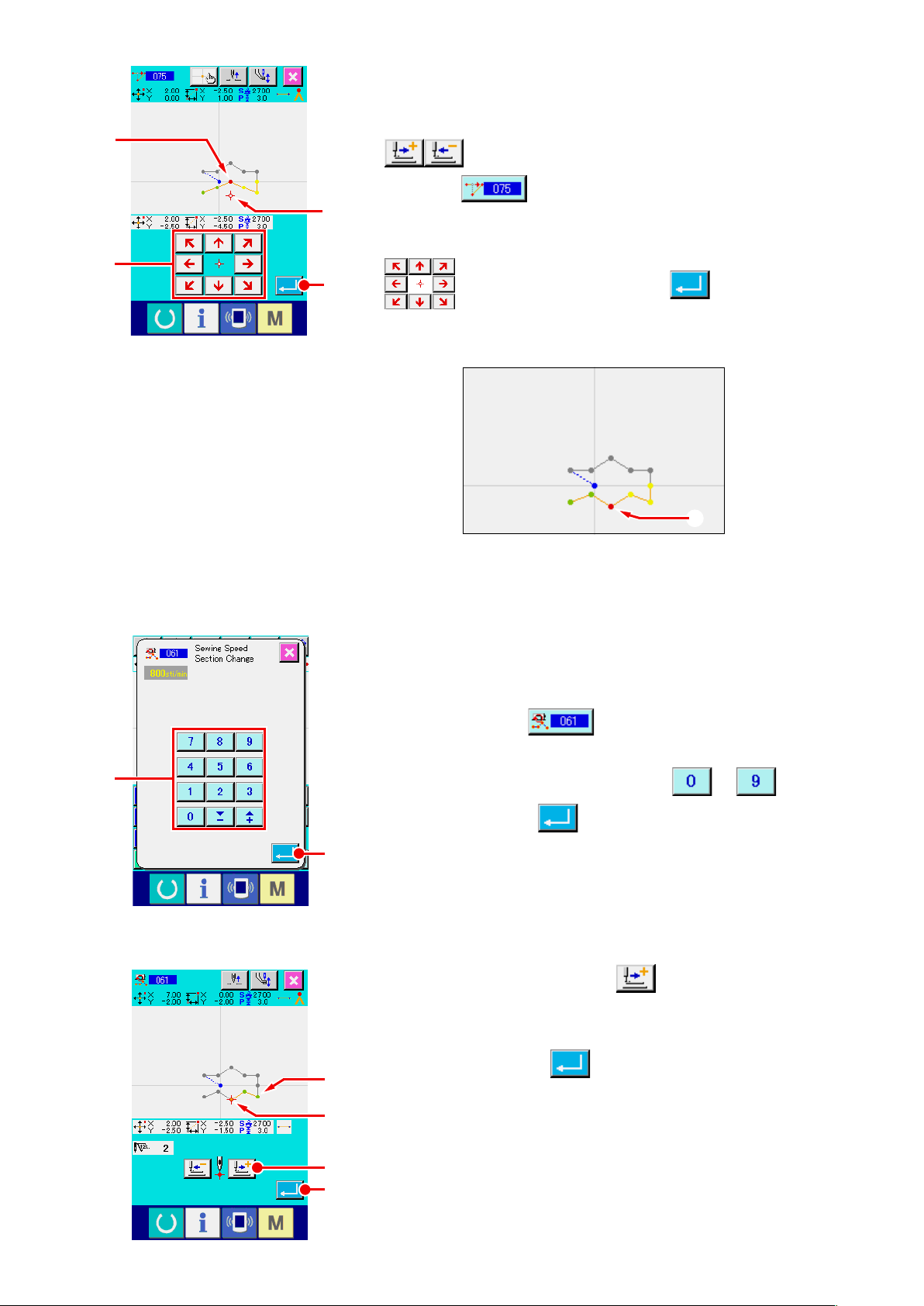

Move of point

⑤

Move the needle position up to the position of L in the

standard screen using FEE FORWARD/BACKWARD buttons

A, and select ABSOLUTE POINT MOVE (function

code 075) .

M

Move the needle position up to the position M of the moving

point in the position specifying screen using MOVE key

O

N, and press ENTER button O.

The needle entry point moves as shown in the gure below.

M

P

Change of speed

⑥

After moving the needle position up to the position of ❸ in the

standard screen, select SEWING SPEED SECTION CHANGE

(function code 061) .

Input the changing speed (example here is 800 rpm) in the

set value input screen using TEN keys to P, and

press ENTER button Q.

Q

Press FEED FORWARD button R in the position

specifying screen, and move the needle position up to section

you desire to change the speed.

M

When ENTER button S is pressed, the speed of the

❸

specified section is changed, and the screen returns to the

M

standard screen.

R

S

– 20 –

Page 25

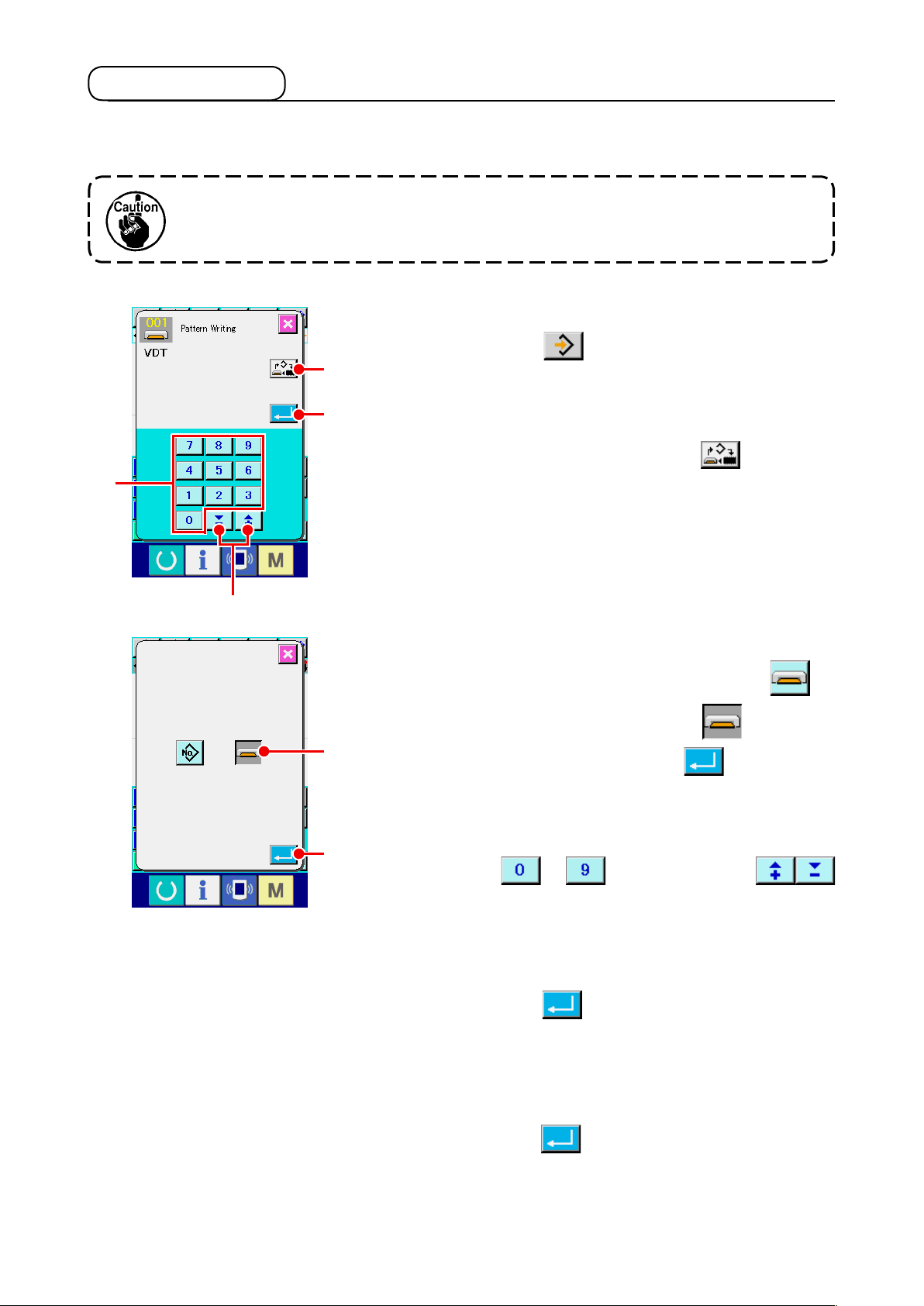

3-4. Pattern writing

The created pattern is written to the media.

Use the media which has been formatted with IP-420.

Display the pattern writing screen.

①

Press WRITE button in the standard screen to display

A

the pattern writing screen.

C

D

B

Select the object media selection screen.

②

Press OBJECT MEDIA SELECTION button A to display

the object media selection screen.

Select the object media.

③

Select the media of writing object. Here select MEDIA E.

The selected media is changed in color . When the

E

media is selected, press ENTER button F to return to

the pattern writing screen.

Select pattern No.

④

F

Press TEN key to C, or + or - button

in the pattern writing screen to specify the pattern No. which

D

is open next.

Write pattern.

⑤

When ENTER button B is pressed, writing to the media

is started. When writing is ended, the standard screen is

displayed.

When a pattern exists in the pattern No. of the specied writing

destination, the overwriting conrmation screen is displayed.

When ENTER button is pressed there, writing is started.

– 21 –

Page 26

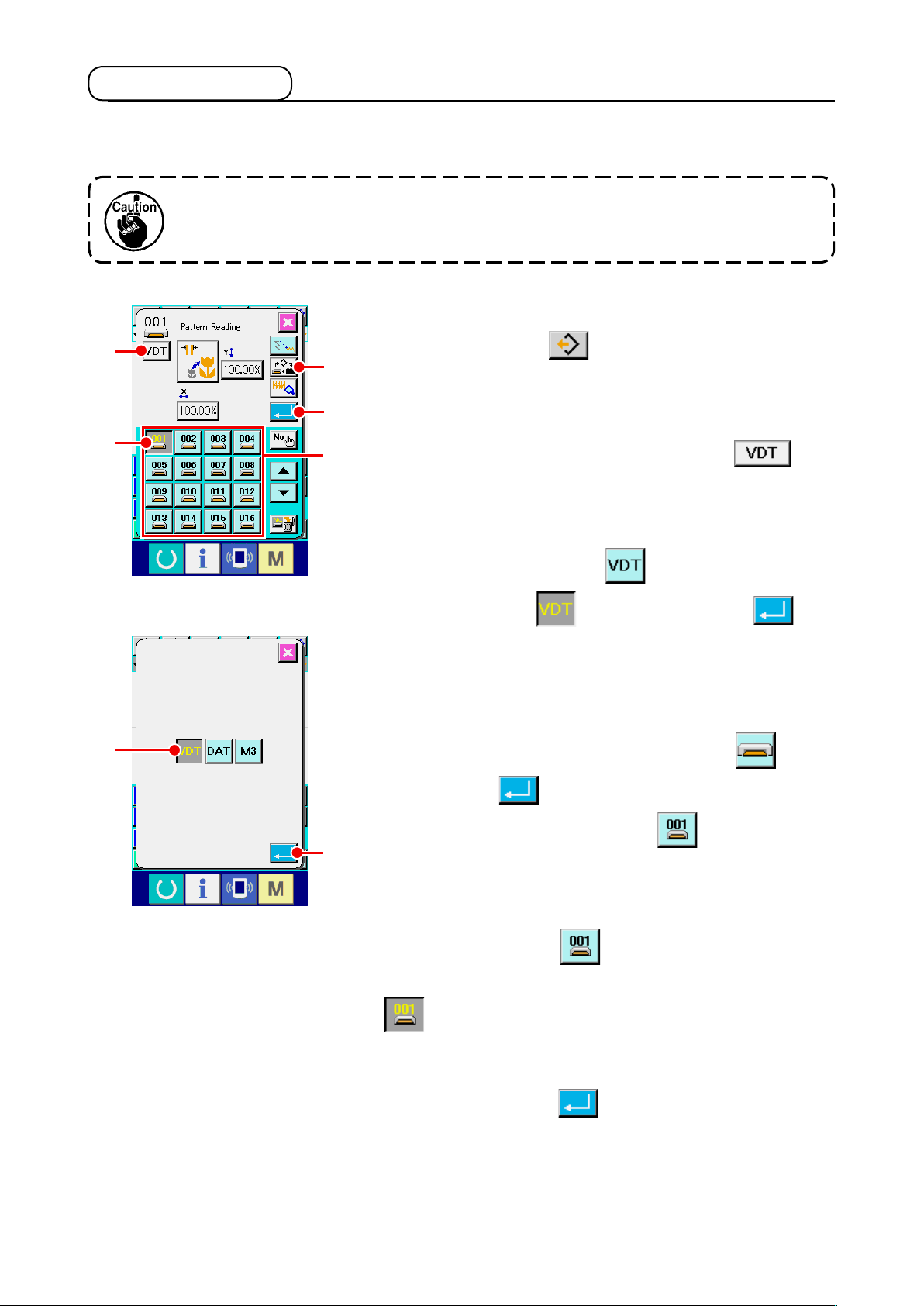

3-5. Pattern reading

Pattern data written to the media is read in.

Use the media which has been formatted with IP-420.

Display the pattern reading screen.

①

C

D

F

Press READ button to display the pattern reading

A

B

E

screen.

Display the pattern kind selection screen.

②

Press PATTERN KIND SELECTION button C to

display the pattern kind selection screen.

Select the pattern kind.

③

Here select VECTOR DATA F. The selected button

is changed in color .When ENTER button G is

pressed, the screen returns to the pattern reading screen.

Select the object media.

④

Press OBJECT MEDIA SELECTION button A to display the

object media selection screen. Select MEDIA , press

ENTER button , and the screen returns to the pattern

reading screen. PATTERN button D of the pattern

G

existing in the part of E is displayed.

Select the pattern.

⑤

Press PATTERN button D of the pattern No. you desire

to read in. The selected pattern button is changed in color

.

Read the pattern.

⑥

When ENTER button B is pressed, reading of the

pattern is started. When the reading of pattern is ended, the

standard screen is displayed.

– 22 –

Page 27

4. INPUT OF PATTERN

4-1. Ordinary sewing

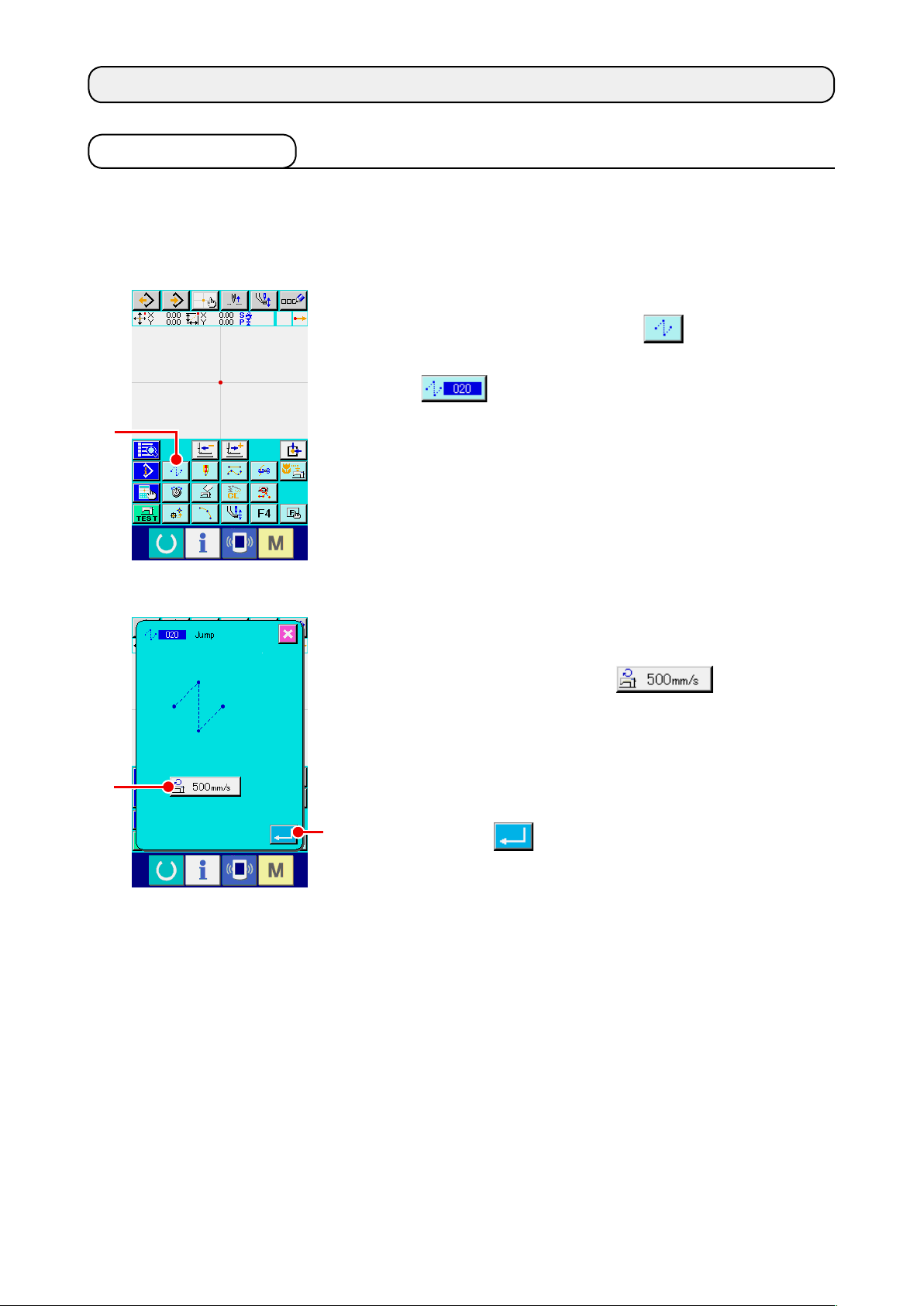

(1) Jump feed (020)

This is used when moving the presser to the specied position without driving the sewing machine.

Display the jump feed setting screen.

①

When pressing JUMP FEED button A in the standard

screen or selecting and executing JUMP FEED (function code

020) in the code list screen, the jump feed setting

A

B

screen is displayed.

Set the jump feed.

②

Present jump feed speed set value is displayed at JUMP

FEED SPEED SETTING button B in the jump

feed setting screen.

When changing the jump feed speed, press the jump feed

speed setting button, and the jump feed speed input screen is

displayed.

After setting or when it is not necessary to change, press

C

ENTER button C, and the coordinate input screen is

displayed.

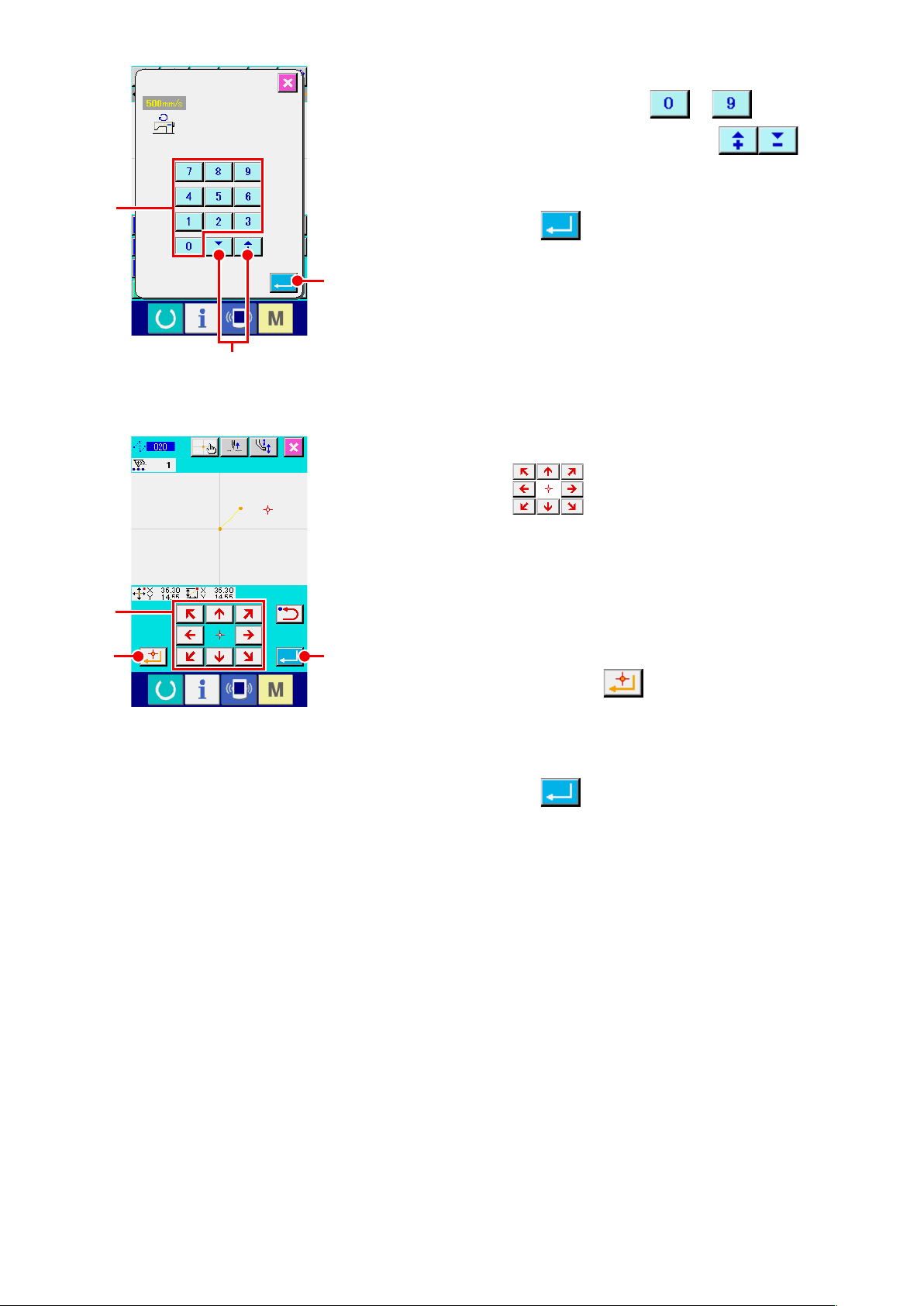

– 23 –

Page 28

D

E

Set the jump feed speed.

③

Direct input the value with TEN keys to D or

increase/decrease the value with + or - button E

in the jump feed speed input screen, and set the jump feed

speed.

When ENTER button F is pressed, the input value

becomes effective, and the screen returns to the jump feed

F

setting screen.

Move the needle position.

④

Press MOVE key G in the coordinate input screen,

G

H

and the needle position moves in the specied direction. While

MOVE key is held pressed, the needle position continuously

moves.

Input the coordinate.

⑤

When the needle position has moved to the specied position

I

and DECIDING POINT button H is pressed, the position

is inputted as the shape point (passing point).

End the setting of jump feed.

⑥

When ENTER button I is pressed, the set data is

inputted, and the screen returns to the standard screen.

It is possible to input by repeating the operation of steps ④

and ⑤ as well.

– 24 –

Page 29

(2) Linear ordinary sewing (023)

When one point is specied, the straight line connecting the point and the needle position is inputted as

the specied stitch length.

Display the linear ordinary sewing setting screen.

①

Select and execute LINEAR ORDINARY SEWING (function

B

D

A

code 023) in the code list screen, and the linear

ordinary sewing setting screen is displayed.

C

Set the linear ordinary sewing.

②

The set value of the present stitch length is displayed at

STITCH LENGTH INPUT button A and the set value

of the present sewing speed is displayed at SEWING SPEED

INPUT button B in the linear ordinary sewing

setting screen.

When the button of the item you desire to change the setting

the input screen of the set value is displayed. Set the value

F

in the input screen with TEN keys to D, or + or -

E

button E, press ENTER button F and the

input value is determined. Then the screen returns to the linear

ordinary sewing setting screen.

After setting, or when it is not necessary to change, press

ENTER button C in the linear ordinary sewing setting

screen, and the coordinate input screen is displayed.

– 25 –

Page 30

Move the needle position.

③

Press MOVE key G in the coordinate input screen,

and the needle position moves in the specied direction. While

MOVE key is held pressed, the needle position continuously

moves.

G

Input the coordinate.

④

When the needle position has moved to the specied position

IH

and DECIDING POINT button H is pressed, the position

is inputted as the shape point (passing point).

End the setting of linear ordinary sewing.

⑤

When ENTER button I is pressed, the set data is

inputted, and the screen returns to the standard screen.

It is possible to input by repeating the operation of steps ③

and ④ as well.

– 26 –

Page 31

(3) Spline ordinary sewing (024)

It is possible to simply input the smooth curve using the spline ordinary sewing.

Display the spline ordinary sewing setting screen.

①

When selecting and executing SPLINE ORDINARY SEWING

B

A

(function code 024) in the code list screen, the spline

ordinary sewing setting screen is displayed.

Set the spline ordinary sewing.

②

The set value of present stitch length is displayed at STITCH

LENGTH INPUT button A, and the set value of

C

present sewing speed is displayed at SEWING SPEED INPUT

button B in the spline ordinary setting screen.

When the button of the item you desire to change the setting is

pressed, the input screen of the set value is displayed. Setting

procedure of stitch length and sewing speed is the same as

that of the linear ordinary sewing.

After setting or when it is not necessary to change, press

ENTER button C, and the coordinate input screen is

displayed.

Move the needle position.

③

E

D

F

Press MOVE key D in the coordinate input screen,

and the needle position moves in the specied direction.

Input the coordinate.

④

When the needle position has moved to the specied position,

press PASSING POINT button E, and the position is

G

inputted as the shape point (passing point).

Or, press DECIDING POINT button F, and the position

is inputted as the breakpoint.

For the breakpoint, refer to

ordinary sewing)" p.58

End the setting of spline ordinary sewing.

⑤

"4-9. Breakpoint (spline and

.

When ENTER button G is pressed, the set date is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

It is possible to input by repeating the operation of steps ③

and ④ as well.

– 27 –

Page 32

1. In order to input the smooth shape of spline

ordinary sewing, the neat curve can be

obtained when selecting the input point

following the procedure below.

1) Select the top of input curve as the input

point. (❺ and ❾)

2) Making the points selected in step 1)

the center, select the points which are

separated a little before and after the

points in step 1). (❹, ❻, ❽, and )

3) Further, select the center of the section

having loose bulge as the input points. (❸,

, and )

❼

4)

Select the points near both ends and the

last point as the input points. (❷, , and )

❺

❹

❸

❷

❶

Input the input points selected by the steps above

❼

❽

❻

❾

in order. Also, be careful of the points below.

•

Take rather many input points at the sharp

curve and rather few ones at the gentle curve.

• Take 3 input points per curve at least.

2. Ellipse can be inputted using the spline

ordinary sewing.

1) Take the joint of the curve at the gentle

section of the curve.

2) Take the input points so as to be

symmetrical if possible.

– 28 –

Page 33

(4) Arc ordinary sewing (025)

When two points are specied, the arc connecting the points and the needle position is inputted as

the specied stitch length. Sewing direction is in the order of the specied points, and either clockwise

direction or counterclockwise one can be inputted.

Display the arc ordinary sewing setting screen.

①

When selecting and executing ARC ORDINARY SEWING

B

A

(function code 025) in the code list screen, the arc

ordinary sewing setting screen is displayed.

Perform setting of the arc ordinary sewing.

②

The set value of present stitch length is displayed at STITCH

LENGTH INPUT button A, and the set value of

C

present sewing speed is displayed at SEWING SPEED INPUT

button B in the arc ordinary sewing setting

screen.

When the button of the item you desire to change is pressed,

the input screen of the set value is displayed. Setting

procedure of stitch length and sewing speed is the same as

that of the linear ordinary sewing.

After setting or when it is not necessary to change, press

ENTER button C, and the coordinate input screen is

displayed.

D

E

Move the needle position.

③

Press MOVE key D in the coordinate input screen,

and the needle position moves in the specied direction.

Input the coordinate.

④

When the needle has moved to the specied position, press

DECIDING POINT button E, and the position is inputted

F

as the shape point (passing point).

Repeat the operation of the steps of ③ and ④ to input two

points. Two input points are necessary as the number of input

points. Also, it is not possible to input more than 3 points.

End setting of the arc ordinary sewing.

⑤

When ENTER button F is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

– 29 –

Page 34

(5) Circle ordinary sewing (026)

When two points are specied, the circle connecting the points and the needle position is inputted as

the stitch length. Stitch direction is in the order of the specied points, and either clockwise direction or

counterclockwise one can be inputted.

Display the circle ordinary sewing setting screen.

①

When selecting and executing CIRCLE ORDINARY SEWING

B

A

(function code 026) in the code list screen, the circle

ordinary sewing setting screen is displayed.

Perform setting of the circle ordinary sewing.

②

The set value of present stitch length is displayed at STITCH

LENGTH INPUT button A, and the set value of

C

present sewing speed is displayed at SEWING SPEED INPUT

button B in the circle ordinary sewing setting

screen.

When the button of the item you desire to change is pressed,

the input screen of the set value is displayed. Setting

procedure of stitch length and sewing speed is the same as

that of the linear ordinary sewing.

After setting, or when it is not necessary to change, press

ENTER button C, and the coordinate input screen is

displayed.

D

E

Move the needle position.

③

Press MOVE key D in the coordinate input screen,

and the needle position moves in the specied direction.

Input the position.

④

When the needle position has moved to the specied position,

press DECIDING POINT button E, and the position is

F

inputted as the shape point.

Repeat the operation of the steps of ③ and ④ to input two

points. Two input points are necessary as the number of input

points. Also, it is not possible to input more than 3 points.

End setting of the circle ordinary sewing.

⑤

When ENTER button F is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

– 30 –

Page 35

(6) Point sewing (021)

This function is used when direct inputting the needle entry point one stitch by one stitch.

Display the point sewing setting screen.

①

Press POINT SEWING button in the standard screen,

or select and execute POINT SEWING (function code 021)

in the code list screen, the point sewing setting

screen is displayed.

B

Perform setting of the point sewing.

②

The set value of present sewing speed is displayed at

C

SEWING PEED INPUT button B in the point

sewing setting screen.

When SEWING SPEED INPUT button is pressed, the sewing

speed input screen is displayed. Setting procedure of the

sewing speed is the same as that of the linear ordinary

sewing.

After setting, or when it is not necessary to change, press

ENTER button C, and the coordinate input screen is

displayed.

Move the needle position.

③

Press MOVE key D in the coordinate input screen,

and the needle position moves in the specied direction.

D

E

Input the coordinate.

④

When the needle position has moved to the specied position,

press DECIDING POINT button E, and the position is

F

inputted as the shape point.

It is possible to input by repeating the operation of steps ③

and ④ as well.

End setting of the point sewing.

⑤

When ENTER button F is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

– 31 –

Page 36

(7) Ordinary sewing (022)

This function can input the linear ordinary sewing and the spline ordinary sewing.

Display the ordinary sewing setting screen.

①

Press ORDINARY SEWING button in the standard

B

A

screen, or select and execute ORDINARY SEWING (function

code 022) in the code list screen, and the ordinary

sewing setting screen is displayed.

Perform setting of the ordinary sewing.

②

The stitch length can be set with STITCH LENGTH INPUT

C

button A, and the sewing speed can be set with

SEWING SPEED INPUT button B in the

ordinary sewing setting screen.

When the button of the item you desire to change is pressed,

the input screen of the set value is displayed. Setting

procedure of the stitch length and the sewing speed is the

same as that of the linear ordinary sewing.

When ENTER button C is pressed, the coordinate input

screen is displayed.

Specify the position.

③

❸

❹

E

D

F

Press MOVE key D in the coordinate input screen,

❷

❶

and the needle position moves in the specied direction. When

DECIDING POINT button F is pressed, the shape point

of the linear ordinary sewing is inputted. When PASSING

POINT button E is pressed, the shape point of the

G

spline ordinary sewing is inputted.

(Refer to

p.58

End setting of the ordinary sewing.

④

"4-9. Breakpoint (spline and ordinary sewing)"

.)

When ENTER button G is pressed, the set data is

inputted, and the screen returns to the standard screen.

For example, when ❶, ❸ and ❹ are inputted with DECIDING

POINT button, and ❷ is inputted with PASSING POINT button,

a pattern as shown in the gure below is created.

❷

– 32 –

❸

❶

❹

Page 37

4-2. Zigzag sewing (030 to 033)

This function is the input function to create the needle entry point of zigzag in the lateral direction in

terms of the input reference line. It is convenient to perform inputting of zigzag sewing of wappen or the

like.

There are 4 kinds of zigzag sewings below.

• Linear zigzag sewing (function code 030)

• Spline zigzag sewing (function code 031)

• Arc zigzag sewing (function code 032)

• Circle zigzag sewing (function code 033)

Display the linear zigzag sewing setting screen.

①

When LINEAR ZIGZAG SEWING (function code 030)

E

D

C

A

is selected and executed in the code list screen, the

linear zigzag sewing setting screen is displayed.

B

G

Perform setting of the linear zigzag sewing.

②

F

The set value of present zigzag pitch is displayed at ZIGZAG

PITCH INPUT button A, the set value of present

H

zigzag width is displayed at ZIGZAG WIDTH INPUT button

B, and the set value of present sewing speed is

displayed at SEWING SPEED INPUT button C

in the linear zigzag sewing setting screen.

When the button of the item you desire to change is pressed,

the input screen of the set value is displayed. Setting

procedure in the input screen of each item is the same as that

of the linear ordinary sewing.

When the button for the item setting of which is to be changed

is pressed, the corresponding set value input screen is

displayed. The procedure for inputting a set value on the

corresponding item input screen is similar to that for the linear

ordinary sewing.

The position and direction to start zigzag sewing can be

selected using START DIRECTION button

F

or

. The button which is displayed in reverse

G

D

,

video represents the currently selected position and direction

to start zigzag sewing.

After setting, or when it is not necessary to change, press

ENTER button H, and the coordinate input screen is

displayed.

– 33 –

E

,

Page 38

I

J

Move the needle position.

③

When MOVE key I in the coordinate input screen

is pressed, the needle position moves in the specied

direction.

Input the coordinate.

④

When the needle position has moved to the specied position

K

and DECIDING POINT button J is pressed, the position

is inputted as the shape point (passing point).

It is possible to input by repeating the steps of ③ and ④ as

well.

End setting of the linear zigzag sewing.

⑤

When ENTER button K is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

Setting procedure of the zigzag sewing of other shapes is the

same as that of the linear zigzag sewing.

Coordinate inputting procedure of the respective sewings is

the same as that of the ordinary sewing.

Zigzag sewing starting method list

No. Button

1

2

3

4

Type of direction to

start sewing

Leftward of the

center of stitch base

line

Rightward of the

center of stitch base

line

Leftward of the end

of stitch base line

Rightward of the end

of stitch base line

Description Example

Sewing is started from the left side toward

the direction of travel with the stitch base line

set at the center of zigzag width. Stitches are

produced in the zigzag form.

Sewing is started from the right side toward

the direction of travel with the stitch base line

set at the center of zigzag width. Stitches are

produced in the zigzag form.

Sewing is started from the left side with the

stitch base line set at the right end of zigzag

width toward the direction of travel.

Sewing is started from the right side with the

stitch base line set at the left end of zigzag width

toward the direction of travel.

– 34 –

Page 39

4-3. Offset sewing (034 to 037)

This is an input function to create the needle entry point which is separated an optional xed distance

in terms of the input reference line. It is convenient when inputting the needle entry point taking the

periphery of small thing as the reference when attaching the small things or the like.

There are 4 kinds of the offset sewings below.

• Linear offset sewing (function code 034)

• Spline offset sewing (function code 035)

• Arc offset sewing (function code 036)

• Circle offset sewing (function code 037)

Display the linear offset sewing setting screen.

①

When selecting and executing LINEAR OFFSET SEWING

D

C

A

(function code 034) in the code list screen, the linear

offset sewing setting screen is displayed.

B

E

Perform setting of the linear offset sewing.

②

The set value of present stitch length is displayed at STITCH

LENGTH INPUT button A, the set value of present offset

F

width is displayed at OFFSET WIDTH INPUT button B,

and the set value of present sewing speed is displayed at SEWING

SPEED INPUT button C in the linear offset sewing

screen.

When the button of the item you desire to change is pressed,

the set value is displayed in the input screen. Setting

procedure of the respective items in the input screen is the

same as that of the linear ordinary sewing.

Creation direction of the offset sewing can be specied with

CREATION DIRECTION buttons D and E. Button

or which is changed in color is the creation direction

which is selected now.

When CREATION DIRECTION, LEFT button D is pressed,

the offset sewing is created on the left side in terms of the

progressing direction and when CREATION DIRECTION, RIGHT

button E is pressed, the offset sewing is created on the right

side in terms of the progressing direction.

After setting, or when it is not necessary to change, press ENTER

button F, and the coordinate input screen is displayed.

– 35 –

Page 40

Move the needle position.

③

Press MOVE key G in the coordinate input screen,

and the needle position moves in the specied direction.

Input the coordinate.

④

When the needle position has move to the specied position,

G

H

❶

❹

❶'

press DECIDING POINT button H, and the position is

I

inputted as the shape point (passing point).

It is possible to input by repeating the steps of ③ and ④ as

well.

End setting of the linear offset sewing.

⑤

When ENTER button I is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

Setting procedure of the offset sewing of other shapes is the

same as that of the linear offset sewing.

Inputting procedure of the coordinate of the respective sewings

is the same as that of the ordinary sewing.

1. Start the shape as shown in the left-hand

gure from the position of ❶, and input in

❷

the order of

❷→❸→❹→❶

. Then the pattern

as shown in the broken line is created.

When starting not the corner of polygon as ❶

but starting from the side as ❶’, a neat offset

❸

sewing can be created.

2. Input a shape that one line is formed from the

start point to the end point of input.

3. In case of arc or circle, when the width is

made larger than the radius of circle, the

pattern which is against expectation is

created. So, be careful.

– 36 –

Page 41

4-4. Double sewing

This is an input function to create the needle entry point to the point which is separated an optional xed

distance in terms of the input reference line.

(1) Double orderly sewing (040 to 043)

Create the sewing so that the sewing composed with the input points and that of the offset gure are in

the same direction. There are 4 kinds of double orderly sewings below.

• Linear double orderly sewing (function code 040)

• Spline double orderly sewing (function code 041)

• Arc double orderly sewing (function code 042)

• Circle double orderly sewing (function code 043)

Display the linear double orderly sewing setting screen.

①

When selecting and executing LINEAR DOUBLE ORDERLY

D

C

A

SEWING (function code 040) in the code list screen,

the linear double orderly sewing setting screen is displayed.

B

E

Perform setting of the linear double orderly sewing.

②

The set value of present stitch length is displayed at STITCH

LENGTH INPUT button A, the set value of present

F

double sewing width is displayed at DOUBLE SEWING WIDTH

INPUT button B , and the set value of present

sewing speed is displayed at SEWING SPEED INPUT button

C in the linear double orderly sewing setting screen.

When the button of the item you desire to change is pressed,

the input screen of the set value is displayed. Setting

procedure in the input screen of the respective items is the

same as that of the linear ordinary sewing.

Creating direction of the double sewing can be specied

with CREATING DIRECTION buttons D and

. Button or which is changed in color is the

E

creating direction which is selected now. When CREATION

DIRECTION, LEFT button D is pressed, the double

sewing is created on the left-hand side in terms of the

progressing direction, and CREATING DIRECTION, RIGHT

E is pressed, the double gure is created on the right-

hand side in terms of the progressing direction.

After setting, or when it is not necessary to change, press ENTER

button F, and the coordinate input screen is displayed.

– 37 –

Page 42

Move the needle position.

③

Press MOVE key G in the coordinate screen, and

the needle position moves in the specied direction.

Input the coordinate.

④

When the needle position has moved to the specied position

G

H

and DECIDING POINT button H is pressed, the position

I

is inputted as the shape point (passing point).

It is possible to input by repeating the steps of ③ and ④ as

well.

End setting of the linear double orderly sewing.

⑤

When ENTER button I is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

Setting procedure of the double orderly sewings of other

shapes is the same as that of the linear double orderly sewing.

Coordinate inputting procedure of the respective sewings is

the same as that of the ordinary sewing.

In case of arc or circle, when the width is made

larger than the radius of circle, the pattern which

is against expectation is created. So, be careful.

– 38 –

Page 43

(2) Double reverse sewing (044 to 047)

Create the sewing so that the sewing composed at the input point and that of the offset gure are in the

reverse direction.

There are 4 kinds of the double reverse sewings below.

• Linear double reverse sewing (function code 044)

• Spline double reverse sewing (function code 045)

• Arc double reverse sewing (function code 046)

• Circle double reverse sewing (function code 047)

Display the linear double reverse sewing setting screen.

①

When selecting and executing LINEAR DOUBLE REVERSE

SEWING (function code 044) in the code list screen,

the linear double reverse sewing setting screen is displayed.

Setting procedure of the double reverse sewing is the same as

that of the double orderly sewing.

Difference between orderly sewing and reverse

sewing

❸

❶

Sewing in case of orderly sewing

❸

❶

Sewing in case of reverse sewing

is inputting point, and ❸ is the last point.

❶

❷

❷

In case of arc or circle, when the width is made

larger than the radius of circle, the pattern which

is against expectation is created. So, be careful.

– 39 –

Page 44

(3) Overlapped reverse sewing (050 to 053)

Sewing of the gure composed at the input point and that which returns it reversely are created.

There are four different types of overlapped reverse sewing as described below:

• Linear overlapped reverse sewing (function code 050)

• Spline overlapped reverse sewing (function code 051)

• Arc overlapped reverse sewing (function code 052)

• Circle overlapped reverse sewing (function code 053)

Displaying the linear overlapped reverse sewing setting

①

screen

When selecting and executing LINEAR OVERLAPPED

A

REVERSE SEWING (function code 050) on the

code list screen, the linear overlapped reverse sewing setting

screen is displayed.

B

Performing setting of the linear overlapped reverse

②

C

sewing

On the linear overlapped reverse sewing setting screen,

the current set value of stitch length is indicated on STITCH

LENGTH INPUT button A and the current set value

of speed of stitch is indicated on SPEED OF STITCH INPUT

button B.

When the button of the item you desire to change is pressed,

the input screen of the set value is displayed. Setting

procedure of stitch length and sewing speed is the same as

that of the linear ordinary sewing.

After setting, or when it is not necessary to change, press

ENTER button C, and the coordinate input screen is

displayed.

– 40 –

Page 45

Move the needle position.

③

Press MOVE key D in the coordinate input screen,

and the needle position moves in the specied direction.

Input the coordinate.

④

When the needle position has moved to the specied position,

D

E

and DECIDING POINT button E is pressed, the position

F

is inputted as the shape point (passing point).

It is possible to input by repeating the steps of ③ and ④ as

well.

End setting of the linear reverse sewing.

⑤

When ENTER button F is pressed, the set data is

inputted, and the screen returns to the standard screen.

DECIDING POINT button of the last point can be omitted.

Setting procedure of the reverse sewings of other shapes is

the same as that of the linear reverse sewing.

– 41 –

Page 46

4-5. Machine control command

Machine control command inputs various control commands to the present point.

(1) Thread trimming (001)

Thread trimming can be optionally performed on the way of pattern data.

Select thread trimming.

①

When selecting and executing THREAD TRIMMING (function

code 001) in the code list screen, the left-hand

screen is displayed.

Input thread trimming.

②

When ENTER button A is pressed in the left-hand

screen, thread trimming is inputted, and the screen returns to

A

the standard screen.

(2) The 2nd origin (002)

This function can set the 2nd origin between the origin and the sewing start point, and specify the

needle position before the start of sewing motion. 2nd origin can be set only on the way of jump feed.

Set the present needle position to one point on the pattern

①

of jump feed.

Select the 2nd origin.

②

When selecting and executing 2ND ORIGIN (function code 002)

in the code list screen, the left-hand screen is displayed.

Input the 2nd origin.

③

A

When ENTER button A is pressed in the right-hand

screen, the 2nd origin is inputted, and the screen returns to

the standard screen.

2nd origin

When 2nd origin is set at ❸ of the jump feed section in the

left-hand gure, the feed stops at ❸ after jump feed of ❶ → ❷

❺

, then the sewing machine performs the cycle operation

→ ❸

of ❸ through ❾.

❷

❶

❽

❸

❹

❾

❼

Origin

This function has to set the present needle

❻

position to one point on the pattern of jump feed

beforehand. When enlarging or reducing the

pattern, the route from the origin to the 2nd origin

is not enlarged or reduced.

– 42 –

Page 47

(3) Stop (003)

This function inputs the Stop command.

①

When selecting and executing STOP (function code 003)

Select the Stop.

in the code list screen, the left-hand screen is

B

C

displayed.

Specify the stop state.

②

The presser state at the time of stop is displayed at PRESSER

STATE SETTING button B, and the needle position

A

at the time of stop is displayed at NEEDLE POSITION

SETTING button C.

To specify the state, press the buttons of PRESSERSTATE

SETTING button B and of NEEDLE POSITION

SETTING button C, and display the setting screen.

Input the Stop.

③

When ENTER button A is pressed in the left-hand

D

screen, the stop is inputted with the set contents, and the

screen returns to the standard screen.

When performing stop after thread trimming,

input in the order of thread trimming and stop.

Perform setting of the presser state.

④

When PRESSER STATE SETTING button B is

pressed, the presser state setting screen is displayed.

The presser position at the time of stop can be selected from D.

The selected button is changed in color. When ENTER button

E is pressed, the selected contents are inputted, and

the screen returns to the stop setting screen.

E

Button display Stop position

Presser lifting position

Presser lowering position

– 43 –

Page 48

Perform setting of the needle position.

⑤

When NEEDLE POSITION SETTING button C is

F

C

pressed, the needle position setting screen is displayed.

The needle position at the time of stop can be selected from F.

The selected button is changed in color. When ENTER button

G is pressed, the selected contents are inputted, and

the screen returns to the stop screen.

Button display Stop position

Upper dead point

UP position

DOWN position

UP position error will be produced at the time of

G

sewing when the needle position is set to DOWN

position at the end of sewing or before jump feed.

Needle stop instructions become invalid when

the sewing machine is in the stop state, and the

needle position does not change.

(4) One revolution of sewing machine (006)

This function inputs one revolution of sewing machine command.

Select one revolution of sewing machine.

①

When selecting and executing ONE REVOLUTION OF

SEWING MACHINE (function code 006) in the code

list screen, the left-hand screen is displayed.

Input one revolution of sewing machine.

②

When ENTER button A is pressed in the left-hand

screen, one revolution of sewing machine is inputted, and the

A

screen returns to the standard screen.

This function, combined with jump feed, is used

for basting or the like.

– 44 –

Page 49

(5) Mark 1 and mark 2 (008, 009)

These functions put marks in the pattern.

Select mark 1 and mark 2.

①

When selecting and executing MARK 1 (function code 008)

Input the mark 1.

②

When ENTER button A is pressed in the left-hand

A

For the operation of the sewing machine in terms

and MARK 2 (function code 009) in the

code list screen, the left-hand screen is displayed.

screen, the mark 1 is inputted, and the screen returns to the

standard screen.

of mark 1 and mark 2, refer to the Engineer's

Manual.

(6) Thread tension controller No. 3 (007)

This function inputs the thread tension controller No. 3 command.

Select the thread tension controller No. 3.

①

When selecting and executing THREAD TENSION

CONTROLLER NO. 3 (function code 007) in the

code list screen, the left-hand screen is displayed.